Page 1

SEIKI - SEICOS

å10/å18T/å21L

INSTRUCTION MANUAL

OPERATION

40 Edition 1.01 02-2001

NO-0000-1-0211-E-1-02

Hitachi Seiki Deutschland

Werkzeugmaschinen GmbH

Page 2

CONTENTS

1. OUTLINE ......................................................................................... 1 - 1

1-1 Items requiring attention when reading this manual. .........................................................1 - 1

2. SPECIFICATIONS .............................................................................. 2 - 1

3. OPERATION......................................................................................... 3 - 2

I. Basic Machine Operation......................................................................................................3 - 2

1. Manual Operation ..............................................................................................................3 - 3

1-1 Jog Feed.................................................................................................................... 3 - 3

1-2 Manual Reference Point Return................................................................................. 3 - 3

1-3 Rapid traverse ........................................................................................................... 3 - 4

1-4 Manual Handle Feed .................................................................................................. 3 - 5

2. Automatic Operation .........................................................................................................3 - 6

2-1 Automatic Mode......................................................................................................... 3 - 6

2-2 Selecting the Run Program ....................................................................................... 3 - 6

2-3 Stopping the Automatic Operation ............................................................................. 3 - 7

2-4 Dry Run ..................................................................................................................... 3 - 8

2-5 Single Block............................................................................................................... 3 - 8

2-6 Override.....................................................................................................................3 - 8

2-7 Per-program Machining T ime Display Function (Option)........................................... 3 - 9

2-8 Tape Operation (Simple DNC Operation) ................................................................ 3 - 10

2-9 DNC Operation (Optional) ....................................................................................... 3 - 10

2.10 Submemory ............................................................................................................. 3 - 14

3. Operation Related to Safety ............................................................................................3 - 19

3-1 Emergency stop ...................................................................................................... 3 - 19

3-2 Overtravel ................................................................................................................ 3 - 19

4. NC Operation keys.......................................................................................................... 3 - 20

5. Quick Tool Setter (Q Setter) ............................................................................................ 3 - 22

5-1 Outline ..................................................................................................................... 3 - 22

5-2 Operation Method .................................................................................................... 3 - 22

5-3 Tool Nose Point Interlock ......................................................................................... 3 - 25

5-4 Related Parameters ................................................................................................ 3 - 25

5-5 Related Alarms ........................................................................................................ 3 - 26

5-6 Compensation Input Checking................................................................................. 3 - 26

6. Q setter barrier................................................................................................................ 3 - 27

6-1 Outline ..................................................................................................................... 3 - 27

6-2 Description of the function ....................................................................................... 3 - 27

6-3 Precautions ............................................................................................................. 3 - 28

6-4 Related parameters ................................................................................................. 3 - 28

i

Page 3

7. Q Setter Repeat Function ............................................................................................... 3 - 29

7-1 Outline ..................................................................................................................... 3 - 29

7-2 Operation................................................................................................................. 3 - 29

7-3 Working ................................................................................................................... 3 - 30

7-4 Precaution .............................................................................................................. 3 - 33

7-5 Relevant Parameters............................................................................................... 3 - 33

7-6 Relevant Alarms....................................................................................................... 3 - 34

8. Simple Jaw Edge Forming Function ............................................................................... 3 - 34

8-1 Outline ..................................................................................................................... 3 - 34

8-2 Operation................................................................................................................. 3 - 34

8-3 Function Keys.......................................................................................................... 3 - 36

8-4 Jaw Configuration And Machining Conditions .......................................................... 3 - 36

8-5 Precaution ............................................................................................................... 3 - 37

8-6 Relevant Parameters............................................................................................... 3 - 37

8-7 Relevant Alarms....................................................................................................... 3 - 37

8-8 Set V alues for Standard Soft Jaws .......................................................................... 3 - 39

8-9 Operation Of Simple Soft Jaw Forming Function .................................................... 3 - 45

II. Screen Operation............................................................................................................ 3 - 49

1. Screen Layout and Basic Operation ............................................................................... 3 - 50

1-1 Main Display Area .................................................................................................... 3 - 50

1-2 Alarm Display Area .................................................................................................. 3 - 51

1-3 Program Number Display Area................................................................................ 3 - 51

1-4 Key Input Area.......................................................................................................... 3 - 52

1-5 Error Message ......................................................................................................... 3 - 52

1-6 Function Menu ......................................................................................................... 3 - 52

1-7 Tree Chart................................................................................................................ 3 - 53

2. Operation of Overall Screen............................................................................................3 - 55

2-1 Program................................................................................................................... 3 - 56

2-2 Tool Path Plot........................................................................................................... 3 - 57

2-3 Tool Data.................................................................................................................. 3 - 57

2-4 Spindle Dat a ............................................................................................................ 3 - 57

2-5 Feed Speed ............................................................................................................. 3 - 57

2-6 Rotary Tool Speed.................................................................................................... 3 - 57

2-7 Spindle Clamp Speed .............................................................................................. 3 - 57

2-8 Dwell........................................................................................................................ 3 - 57

2-9 Load Meter ............................................................................................................... 3 - 57

2-10 Positional Data ........................................................................................................ 3 - 57

2-11 G Codes .................................................................................................................. 3 - 58

2-12 M codes ................................................................................................................... 3 - 58

2-13 Time Measurement.................................................................................................. 3 - 58

2-14 Date And Time ......................................................................................................... 3 - 59

ii

Page 4

3. Position ...........................................................................................................................3 - 60

3-1 Reloading of Relative Coordinate System ............................................................... 3 - 61

3-2 Command Value Display ......................................................................................... 3 - 61

3-3 Restart (Option)....................................................................................................... 3 - 61

3-4 Floating reference.................................................................................................... 3 - 61

3-5 Set up ...................................................................................................................... 3 - 61

4. Work Coordinates (Offset).............................................................................................. 3 - 64

4-1 Removal Amount ..................................................................................................... 3 - 65

4-2 Machining Reference Point Shift.............................................................................. 3 - 65

4-3 Work Length ............................................................................................................ 3 - 65

4-4 External Work Zero Point Offset .............................................................................. 3 - 65

4-5 Setting of 2nd Reference Point................................................................................ 3 - 66

5. Set (Data)........................................................................................................................3 - 67

5-1 Display and Setting.................................................................................................. 3 - 67

5-2 Number Search ....................................................................................................... 3 - 68

5-3 Eco-eco ................................................................................................................... 3 - 71

6. Macro V ariable.................................................................................................................3 - 72

6-1 Macro V ariable and Dat a Display............................................................................. 3 - 72

6-2 Number Search ....................................................................................................... 3 - 72

7. Plot.................................................................................................................................. 3 - 74

8. Plotting Parameters ........................................................................................................3 - 76

9. Tool (offset) ..................................................................................................................... 3 - 80

9-1 Setting of Offset Value ............................................................................................. 3 - 81

9-2 Tool list..................................................................................................................... 3 - 81

9-3 Setting of T ype......................................................................................................... 3 - 82

9-4 Setting of Name ....................................................................................................... 3 - 83

9-5 Data Clear ............................................................................................................... 3 - 83

9-6 Tool life Management ............................................................................................... 3 - 84

9-7 Number Search ....................................................................................................... 3 - 84

9-8 Double Cutting (Option) ........................................................................................... 3 - 84

10. Alarm Diagnosis.............................................................................................................. 3 - 85

10-1 Alarm History ........................................................................................................... 3 - 86

11. System............................................................................................................................ 3 - 87

11-1 Parameter Setting.................................................................................................... 3 - 87

11-2 Diagnosis................................................................................................................. 3 - 89

11-3 Mechanical Compensation ...................................................................................... 3 - 91

11-4 Position Region ....................................................................................................... 3 - 92

11-5 Software V ersion......................................................................................................3 - 93

11-6 Date and Time ......................................................................................................... 3 - 94

11-7 SLBUS..................................................................................................................... 3 - 95

11-8 System Table........................................................................................................... 3 - 96

1 1-9 F Menu..................................................................................................................... 3 - 96

iii

Page 5

12. Program .........................................................................................................................3 -101

12-1 Operating Key Input Area On Screen...................................................................... 3 -102

12-2 Displaying Program ................................................................................................ 3 -102

12-3 Creating New Program ........................................................................................... 3 -102

12-4 Deleting Program.................................................................................................... 3 -103

12-5 Initialization Of Program Memory............................................................................ 3 -103

12-6 PROGRAM SEARCH ............................................................................................. 3 -103

12-7 Program Copy ........................................................................................................ 3 -104

12-8 Changing Program Number.................................................................................... 3 -104

12-9 Program Editing (Edit Mode or Background Editing) .............................................. 3 -104

12-10Word Search .......................................................................................................... 3 -105

12-11Background Edit (Program Screen Only) ............................................................... 3 -106

12-12Range Assignment Edit Operation (Program Screen Only) ................................... 3 -108

12-13Word Convert (Program Screen Only) ................................................................... 3 -110

12-14Macro Variables .......................................................................................................3 -111

13. Program List .................................................................................................................. 3 -1 1 2

13-1 Program List........................................................................................................... 3 -112

13-2 Program Search ..................................................................................................... 3 -114

13-3 Program Delete ...................................................................................................... 3 -114

13-4 Program Arrangement ............................................................................................ 3 -1 15

13-5 Program Merging .................................................................................................... 3 -115

13-6 Initialization Of Program Memory............................................................................ 3 -115

14. Input / Output.................................................................................................................. 3 -1 16

14-1 Program List........................................................................................................... 3 -117

14-2 Data Setting Table................................................................................................... 3 -118

14-3 Check ..................................................................................................................... 3 -120

14-4 Details Of Setting Data ........................................................................................... 3 -120

14-5 Call Select (Optional).............................................................................................. 3 -122

14-6 Don-Don FD I/O Screen ......................................................................................... 3 -123

15. Input/Output (With PC Card Used) ................................................................................3 -125

15-1 Available PC Cards................................................................................................. 3 -125

15-2 Initial Formatting of PC Card................................................................................... 3 -125

15-3 Starting PC Card Operation.................................................................................... 3 -125

15-4 Ending PC Card Operation..................................................................................... 3 -127

15-5 PC Card Input/Output ............................................................................................. 3 -128

15-6 Operating the PC Card Directory ........................................................................... 3 -131

15-7 Error Messages ...................................................................................................... 3 -136

4. INDIVIDUAL PROGRAMS .................................................................. 4 - 2

I . Tool Life Management .......................................................................................................4 - 2

1. Outline of tool life management ................................................................................. 4 - 2

2. Operation of tool life management function ............................................................... 4 - 2

3. Screen explanations .................................................................................................. 4 - 2

4. Alarm .........................................................................................................................4 - 3

iv

Page 6

5. Spare tool................................................................................................................... 4 - 3

6. Registering and deleting the spare tool...................................................................... 4 - 3

7. Selection order of spare tools .................................................................................... 4 - 4

8. Sample Program ....................................................................................................... 4 - 4

8-1 Details of Tool Life by Times ...................................................................................... 4 - 5

I I . Cutting Monitor ..................................................................................................................4 - 6

1. Outline of Cutting Monitor .......................................................................................... 4 - 6

2. Monitoring Function.................................................................................................... 4 - 6

3. Description of Monitoring Function ............................................................................ 4 - 6

4. Load Settings............................................................................................................. 4 - 8

5. Monitoring Operation.................................................................................................. 4 - 9

6. Load Graph.............................................................................................................. 4 - 10

7. Life Graph ................................................................................................................ 4 - 11

8. Alarms ..................................................................................................................... 4 - 11

9. Sample Program ..................................................................................................... 4 - 12

10. Parameters.............................................................................................................. 4 - 12

10-1 Selection of Monitored Data System (Parameter 8000) .......................................... 4 - 12

10-2 Selection of Initial Setting (Parameter 8001)............................................................ 4 - 12

10-3 Automatic Calculation Parameters (Parameters 8010-8029).................................. 4 - 13

10-4 Timer Parameters (8030-8044) ............................................................................... 4 - 13

10-5 Adaptive Parameters ............................................................................................... 4 - 14

III. Staf ..................................................................................................................................4 - 15

1. Periodic Check ........................................................................................................ 4 - 15

1-1 Periodic Check - Main Screen ................................................................................. 4 - 15

2. Status Display/OK Monitor....................................................................................... 4 - 17

3. Instruction Manual Information ................................................................................. 4 - 18

4. LSSOL diagram (Switch Status).............................................................................. 4 - 19

4-1 Layout Drawing........................................................................................................ 4 - 19

4-2 List........................................................................................................................... 4 - 20

IV. UUP Function.................................................................................................................. 4 - 21

1. General Description ................................................................................................. 4 - 21

1-1 Applicable CNC Models ........................................................................................... 4 - 21

2. Connection of UUP .................................................................................................. 4 - 21

2-1 UUP Specifications.................................................................................................. 4 - 21

2-2 Connecting between the PC and CNC Unit ............................................................. 4 - 21

2-3 Setting the TCP/IP addresses ................................................................................. 4 - 23

2-4 Setting/Referring to the IP Address on the CNC Side .............................................. 4 - 24

2-5 Connecting Materials ............................................................................................... 4 - 28

V. External Measuring Function........................................................................................... 4 - 29

1. Outline........................................................................................................................... 4 - 29

2. Tool Data....................................................................................................................... 4 - 30

3. External Measurement .................................................................................................. 4 - 31

4. Qualitative Compensation............................................................................................. 4 - 32

5. Wear Management ....................................................................................................... 4 - 33

v

Page 7

vi

Page 8

1. OUTLINE

SEICOS-∑10L, ∑16T, ∑18T and ∑21L are products that have integrated the latest device

technology and realized down-sizing with high reliability .

The machine is designed by giving consideration to users standpoint in the operating system as

the man-machine interface, thus offers a most easy-to-operate machine.

This manual contains explanation on the operating method of the following models. As for the

subject of programming, refer to “SEIKI-SEICOS

subjects on alarms and maintenance to “SEIKI-SEICOS

respectively.

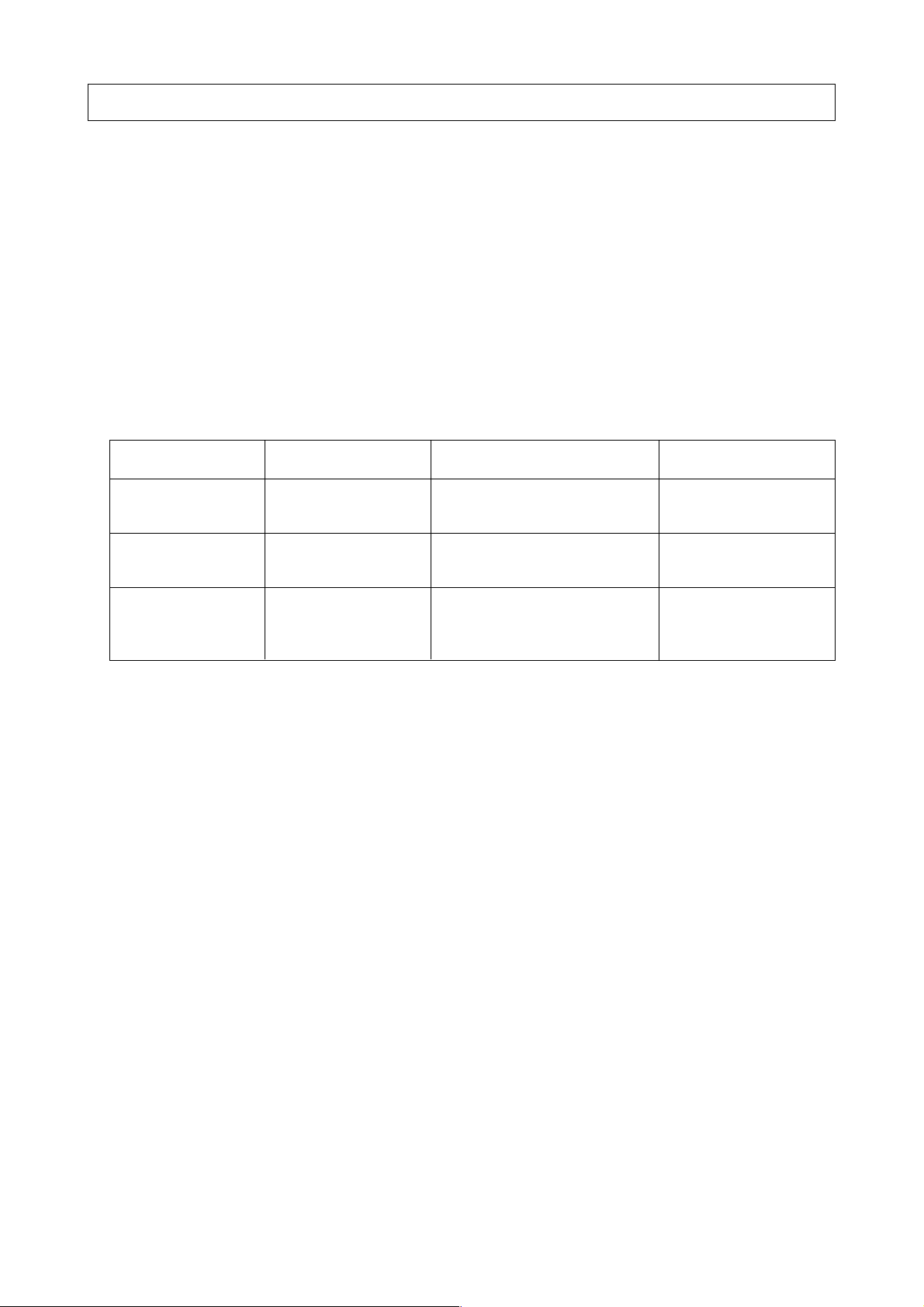

Model Name Abbreviation

SEIKI-SEICOS ∑10L S-∑10L

SEIKI-SEICOS ∑16T S-∑16T

SEIKI-SEICOS ∑18T S-∑18T

SEIKI-SEICOS ∑21L S-∑21L

1-1 Items requiring attention when reading this manual.

∑10L/16T/18T/21L program part” and for

∑10/16/18/21 maintenance part”

(1) In this manual and the reference manual “program part”, explanations are made on all the

functions that are applicable to these NC machines, including optional functions. The option

function selected for adoption are different for each machine. Please confirm the

specification of the machine beforehand, as there may be some functions referred to in the

manual are not usable depending on the machine.

(2) In this manual, those functions not specifically remarked “able” should be understood as

“unable”.

(3) The contents of this manual may be changed without notice to meet a future machine

improvement.

Note) Programs, parameters, macro variables and tool compensation amounts, etc. are stored in

the memory of NC unit. Generally, these dat a are not lost by switching the power ON/

OFF.

Nevertheless, data could be lost inadvertently or by erroneous operation. Also a case

may occur when you are compelled to have valuable date in the memory cleared for

restoring the system from a trouble.

To cope with such an unexpected situation, we suggest that you take note of the important

data and keep them separately . It facilit ates quick restoration of working condition of the

machine by re-entering the data.

Note) When processing a work, do not start the operation suddenly . Make a trial warm-up run

first for fully confirming that the machine acts correctly , then proceed with subsequent

operating procedures.

1 - 1

Page 9

1 - 2

Page 10

2. SPECIFICA TIONS

1. CONTROLLED AXES

1-1 Controlled Axes

The 2 axes, X and Z, are controllable. Optionally , additional axes can be appended. The ∑10L

can control up to 6 axex, including 4 additonal axes, the 3rd through 6the axes. The

control up to 4 axes, including 2 additional axes, the 3rd and 4th axes.

1-2 Simultaneous Controllable Axes

The 2 axes, X and Z, can be controlled simultaneously regardless of rapid traverse or cutting

feed. Table 1-2 shows the configuration of the controlled axes.

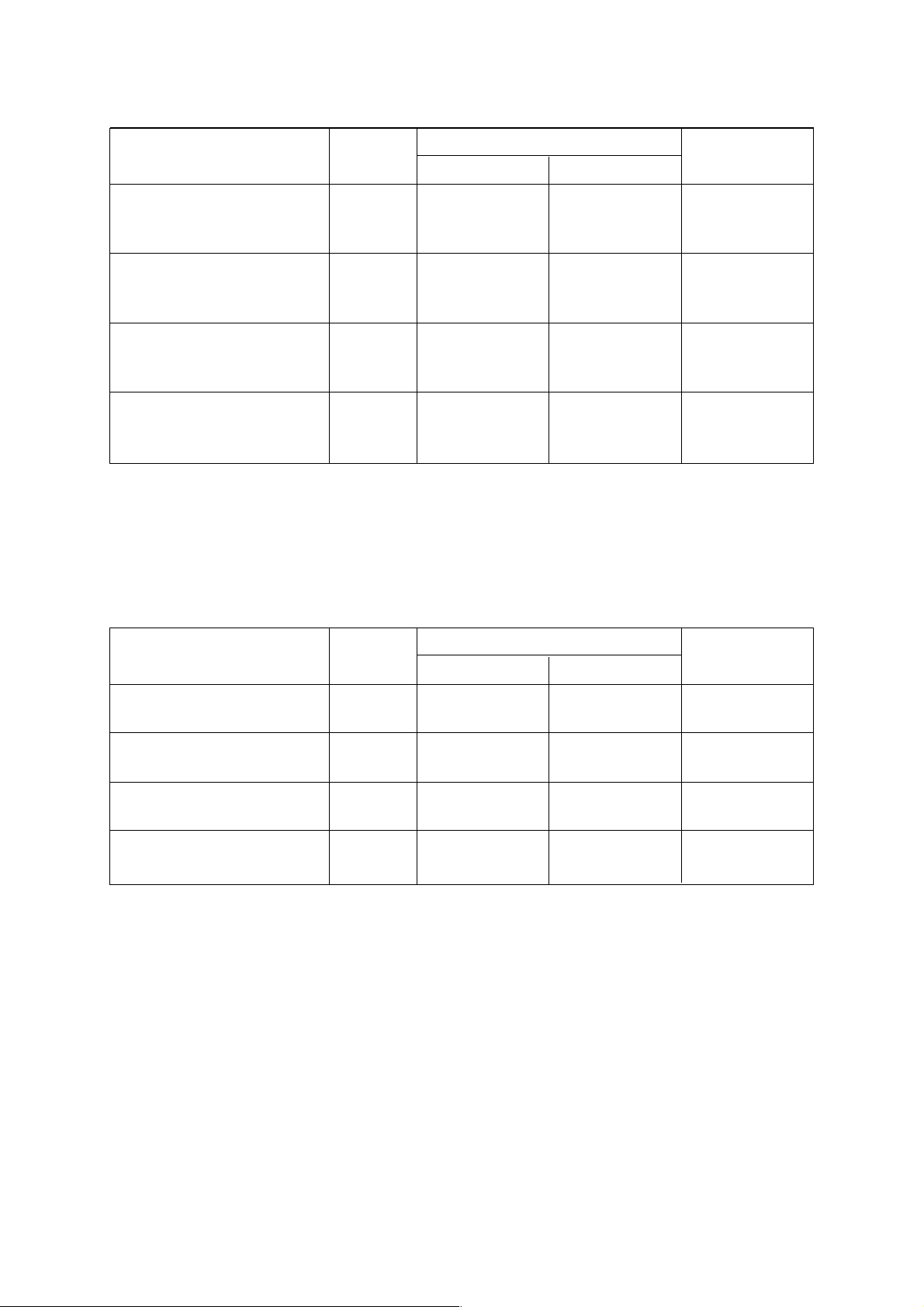

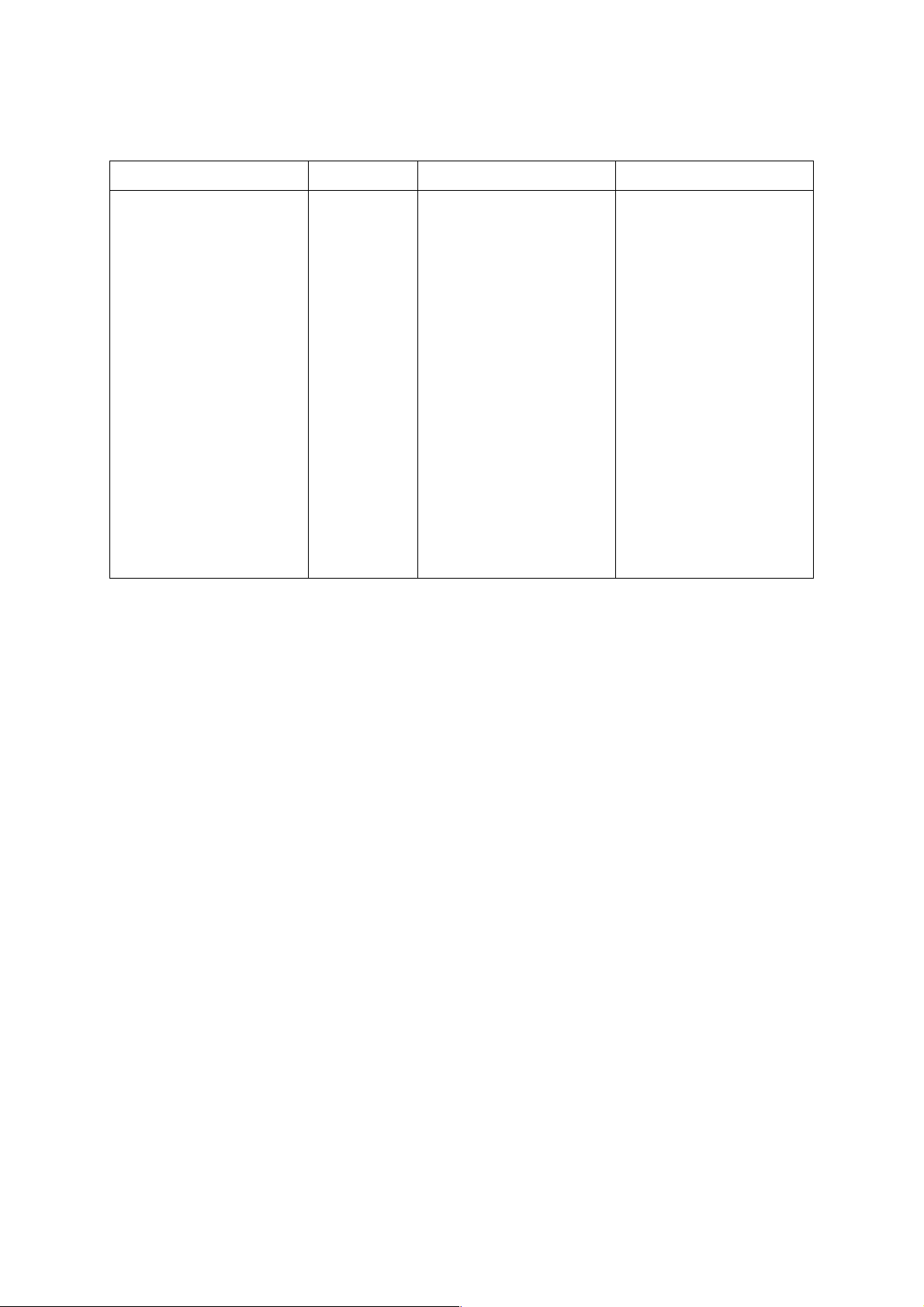

Table 1-2

No. of Axes Axis Name Remarks

Standard 2 axes X, Z

controlled axes

Additional axes ∑10L: 4 axes Select out of Y,

control

∑21L: 2 axes A, B and C

∑21L can

Simultaneous Standard 2 axes + All the axes specified by

controllable axes additional axes the system

(up to 4 axes)

Note 1) The number of controlled axes, and relations between the axis name and axes can be

selected with parameters.

1-3 Increment System

There are two types of increment systems; IS-B and IS-C. You can select either of them by a

parameter. (IS-A is not available for the moment.) Millimeter/inch switching is set with a

parameter. For detailed description of parameters, refer to “Parameters”.

1-4 Maximum Commandable Value

Table 1-4 (next page) shows the increment systems and commandable values.

1-5 10-Time Minimum Setting Unit

The input increment can be made 10 times larger by parameter setting. Table 1-5 (next page)

shows the commandable values.

2 - 1

Page 11

Table 1-4

Linear Axis

Unit Type

Minimum setting unit IS-A 0.01 0.001 0.01

IS-B 0.001 0.0001 0.001

IS-C 0.0001 0.00001 0.0001

Least command increment IS-A 0.01 0.001 0.01

IS-B 0.001 0.0001 0.001

IS-C 0.0001 0.00001 0.0001

Maximum stroke IS-A ±999999.99 ±99999.999 ±999999.99

IS-B ±99999.999 ±9999.9999 ±99999.999

IS-C ±9999.9999 ±999.99999 ±9999.9999

Maximum commandable IS-A ±999999.99 ±99999.999 ±999999.99

value IS-B ±99999.999 ±9999.9999 ±99999.999

IS-C ±9999.9999 ±999.99999 ±9999.9999

[10-Time Minimum setting unit]

For the Types IS-B and IS-C, the minimum setting unit can be made 10 times lartger by

parameter setting.

(mm) (inch)

Table 1-5

Rotary Axis

(deg.)

Linear Axis

Unit Type

Minimum setting unit IS-B 0.01 0.001 0.01

IS-C 0.001 0.0001 0.001

Least command increment IS-B 0.001 0.001 0.001

IS-C 0.0001 0.0001 0.0001

Maximum stroke IS-B ±99999.999 ±99999.999 ±99999.999

IS-C ±9999.9999 ±9999.9999 ±9999.9999

Maximum commandable IS- B ±999999.99 ±99999.999 ±999999.99

value IS-C ±99999.999 ±9999.9999 ±99999.999

Note 1) For the Type IS-A, nothing is changed even if you set the parameter for 10-time minimum

setting unit.

(mm) (inch)

Rotary Axis

(deg.)

1-6 Position Detector

The pulse encoder is provided as a standard position detector . Optionally, the pulse scale or the

Inductosyn detecting function can be selected. When the Inductosyn detecting function is

selected, however , you need a converter which serves as an interface equivalent to the pulse

scale.

Absolute encoder will be installed for adding the optional absolute position detection function.

2 - 2

Page 12

2. INTERPOLATING FUNCTIONS

2-1 Positioning (G00)

Each axis can be fed at a rapid traverse rate independently by specifying G00.

2-2 Linear Interpolation (G01)

Linear interpolation is performed at the feed rate specified by an F-code in a G01 command.

2-3 ANGLE DESIGNATION LINEAR INTERPORATION (G01)

With G01, an angle from Z axis is specified where linear interpolation is commanded.

2-4 Circular Interpolation (G02, G03)

Circular interpolation can be performed arbitrarily at 0 to 360° at the feed rate specified by an Fcode in a G02 or G03 command.

2-5 Radius Designation on Arc (G02, G03)

R can be directly specified as a circular arc radius value, assuming, I, J, and K to be a vector

amount from a start point to the center in circular interpolation.

2-6 Sine Curvilinear Interpolation <Virtual Axis Interpolation> (G07)

Not available with

By performing interpolation without moving one axis within a circular arc plane (hypothetical

axis) in a helical cutting command, sine curvilinear interpolation is performed between the

remaining two axes.

2-7 Helical Cutting......Not available with

Another axis is linearly interpolated synchronously with circular interpolation.

∑∑

∑21L.

∑∑

∑∑

∑21L.

∑∑

2-8 Polar Coordinate Interpolation

A command programmed in the orthogonal coordinate system is converted into a linear axis

move (tool) and rotary axis move (work rotation) to control a profile.

2-9 Cylindrical Interpolation

If a linear axis stroke and rotary axis angle are specified by a program command, the rotary axis

stroke internally specified in terms of angle is converted into a distance on the circumference.

As the distance on the circumference can be regarded a linear axis stroke on the

circumference, linear interpolation and circular interpolation can be performed in combination

with other linear axis.

2 - 3

Page 13

3. THREADING

3-1 THREADING (G32)

With F or E code, a thread lead is directly commanded. With E code, you can assign the

number of thread ridges per inch can be assigned by a parameter .

3-2 MULTIPLE THREADIGN (G32)

Use this to perform multiple thread cutting which has two or more thread ridges in a lead. With

Address Q, command a threading start shift angle. be performed.

3-3 VARIABLE LEAD THREADING

By commanding the increase or decrease amount in lead per one screw thread turning, you can

perform variable lead threading. With Address K, command a lead changing amount.

4. FEED FUNCTION

4-1 RAPID TRAVERSE RATE AND RAPID OVERRIDE

The maximum speed available in the axial direction is 240,000mm/min (IS-B). Further, override

can be applied to rapid traverse by rapid override.

4-2 CUTTING FEED RATE AND FEED OVERRIDE

The maximum feed rate range available for setting is 6~240,000mm/min (IS-B).

Override can be applied, by feed rate override, within a range of 0~200% by every 10%.

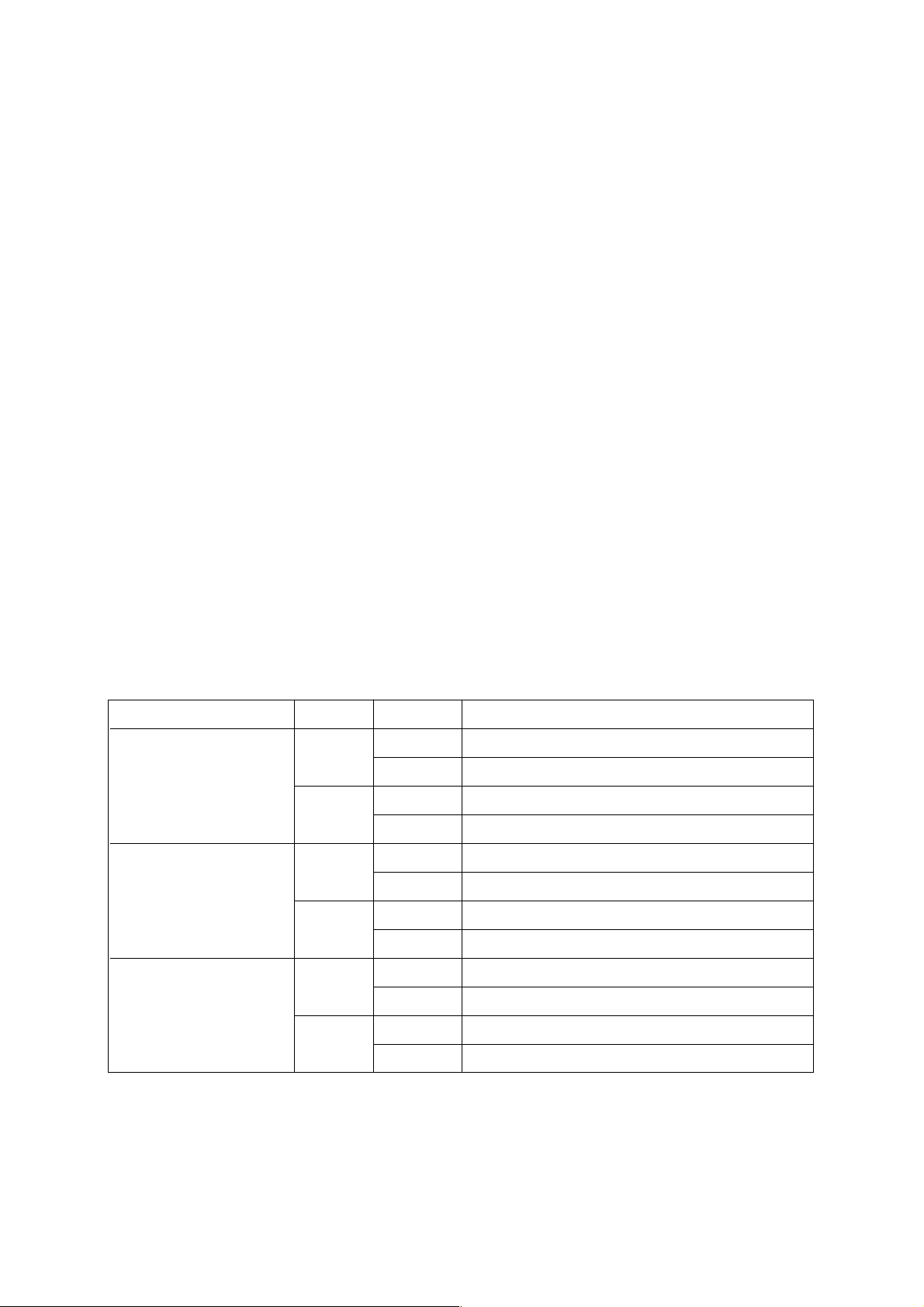

Table 4-2 shows the ranges of feed rate command values:

TYPE F COMMAND RANGE

mm

Feed per minute

(G98)

inch

mm

Feed per revolution

(G99)

inch

mm

Threading

(G32)

inch

F60 F1~F999999 (mm/min)

F61 F0.1~F999999.9 (mm/min)

F51 F0.1~F99999.9 (inch/min)

F52 F0.01~F99999.99 (inch/min)

F32 F0.01~F999.99 (mm/rev)

F33 F0.001~F999.999 (mm/rev)

F23 F0.0001~F99.999 (inch/rev)

F24 F0.001~F99.9999 (inch/rev)

F35 F0.00001~F999.99999 (mm/rev)

F26 F0.000001~F99.999999 (mm/rev)

F26 F0.000001~F99.999999 (inch/rev)

F17 F0.0000001~F9.9999999 (inch/rev)

Note 1) The above types are selected with parameters. (Parameter no. 3401)

Note 2) The maximum cutting feed rate is limited by the cutting feed clamp rate set with a parameter .

Note 3) Address E may be used as the feed rate, where the command value ranges for E and F

are the same.

2 - 4

Page 14

4-3 Override Cancel

A cutting feed override rate can be fixed at 100 % by a signal from the machine.

4-4 Automatic Acceleration/Deceleration

Linear acceleration/deceleration is performed in case of rapid traverse, and exponential function

type acceleration/deceleration is performed in case of cutting feed or jog feed.

4-5 Dwell (G04)

Migration to operation in the next program block can be delayed by a specified time by a G04

command. Use P, X, or U for an address.

4-6 Exact Stop Check (G09)

In the block where G09 is specified, an imposition check is made at the end of block execution.

4-7 Exact Stop Check Mode (G61)/Cutting Mode (G64)

Normally, the G64 mode is effected and the program proceeds to the next block immediately

after interpolation is completed. If G61 is specified, the program will proceed to the next block

after entering imposition at the end point of each block, in the subsequent move command. The

G61 mode is cancelled by specifying G64.

4-8 Automatic Corner Override (G62)...... Not available with

An override is applied automatically to a cutting feed rate at a corner during tool diameter

compensation.

∑∑

∑21L.

∑∑

5. REFERENCE POINT

5-1 Reference Point Return A (G27 to G29)

Reference point return A includes the following:

(1) Manual reference point return.

(2) Reference point return check (G27)

(3) Automatic reference point return (G28)

(4) Return from the reference point (G29)

5-2 Reference Point Return B (G30)

Second reference point return (G30) returns the axes to the position set in a parameter .

5-3 Third/Fourth Reference Point Return (G30)

The axes can be returned to the 3rd/4th reference point preset by a G30 command (P3, P4).

5-4 Floating Reference Point Return (G301) …… Not available with

The axes can be returned to the preset optional point of the machine.

2 - 5

∑∑

∑21L.

∑∑

Page 15

6. COORDINATE SYSTEM

6-1 Tool Nose Coordinate System

At the time of turret indexing or manual zero point return, the tool nose position assuming the

machining reference point to be zero (0) is automatically set in the coordinate system.

6-2 Coordinate System Setting (G50)

An axis command following G50 sets the coordinate system where a current tool coordinate

value will be a specified value.

6-3 Machine Coordinate System Selection (G53)

A tool moves to a position in the machine coordinate system by a G53 command.

6-4 Plane Designation (G17, G18, G19)

A G-code is used to specify the plane where you want to perform circular interpolation, tool

diameter compensation, and so on.

G17: X-Y plane, G18: Z-X plane, G19: Y-Z plane

7. COORDINATES AND DIMENSIONS

7-1 Absolute/Incremental Programming

Absolute/incremental programming is switched by a G-code.

Absolute : X Y Z B C

Incremental : U V W D H

7-2 Decimal Point Input

A decimal point can be input to the command data associated with a distance (angle), speed,

and dwell. A decimal point position is after the millimetric or inch units digit.

The addresses which can use decimal points are X, Y, Z, A, B, C, D, H, U, V, W, I, J, K, R, P, Q,

E, and F.

Depending on conditions applies, however, a decimal point may not be usable.

7-3 Inch/Metric Conversion (G20, G21)

You can select the inch system/metric system as units of input by specifying G20/G21.

• G20: Inch input

• G21: Metric input

2 - 6

Page 16

8. SPINDLE FUNCTIONS

8-1 Spindle Function (8-digit S-code)

By specifying an address S following by up to 8-digit numerical command, you can send out an

analog signal and gear signal corresponding to a binary code signal and spindle motor rpm.

8-2 Spindle Override

An override can be applied from 50 to 150 % in an increment of 10 % by an external signal.

8-3 Constant Surface Speed Control (G96, G97)

With a surface speed directly assigned with S code, this function serves to continuously control

the spindle motor rpm so that the circumferential speed is held constant to changes in tool

position. Command to make this function valid or invalid is performed with G code.

G96: Constant surface speed control is performed.

G97: Constant surface speed control is not performed.

9. TOOL FUNCTIONS

9-1 Tool Function (8-digit T-code)

An 8-digit BCD code signal is sent out by specifying an address T followed by up to 8-digit

numerical command.

When ATC is mounted, use T6 digits. When not, use T4 digits.

Use T code to perform A TC operation, tool rest indexing, setting of a work coordinate system (tip

coordinate system), combined compensation, etc..

9-2 Tool Life Management Function

The tools are sorted into several groups and when the cutting time or integrated cutting times of

a tool in each group reaches the specified life time or cutting times, this function selects the next

tool in the preset order .

Note) For the

∑21L, only a life count by M12 is allowed.

10. MISCELLANEOUS FUNCTIONS

10-1 Miscellaneous Function (8-digit M-code)

The machine can be turned on/off by specifying an address M followed by up to 8-digit numerical

value.

10-2 Second Miscellaneous Function (B-function)

An 8-digit BCD code signal is sent out by an address A, B, or C followed by up to 8-digit

numerical command, based on parameter setting.

10-3 Miscellaneous Function Lock

The M, S, T, and B-function commands are disabled. No signal is sent out to the machine.

2 - 7

Page 17

11. PROGRAM CONSTRUCTION

11-1 Command Tape

8-unit black paper tape (EIA RS-227, ISO 1 154, JIS C6246)

11-2 Tape Format

EIA/ISO (At input: Automatic recognition, At output: Selected by a parameter)

11-3 Input Format

A variable-block, word-address format with decimal point (EIA RS-274C, ISO R1056/R1058) is

used.

11-4 Command Tape Codes

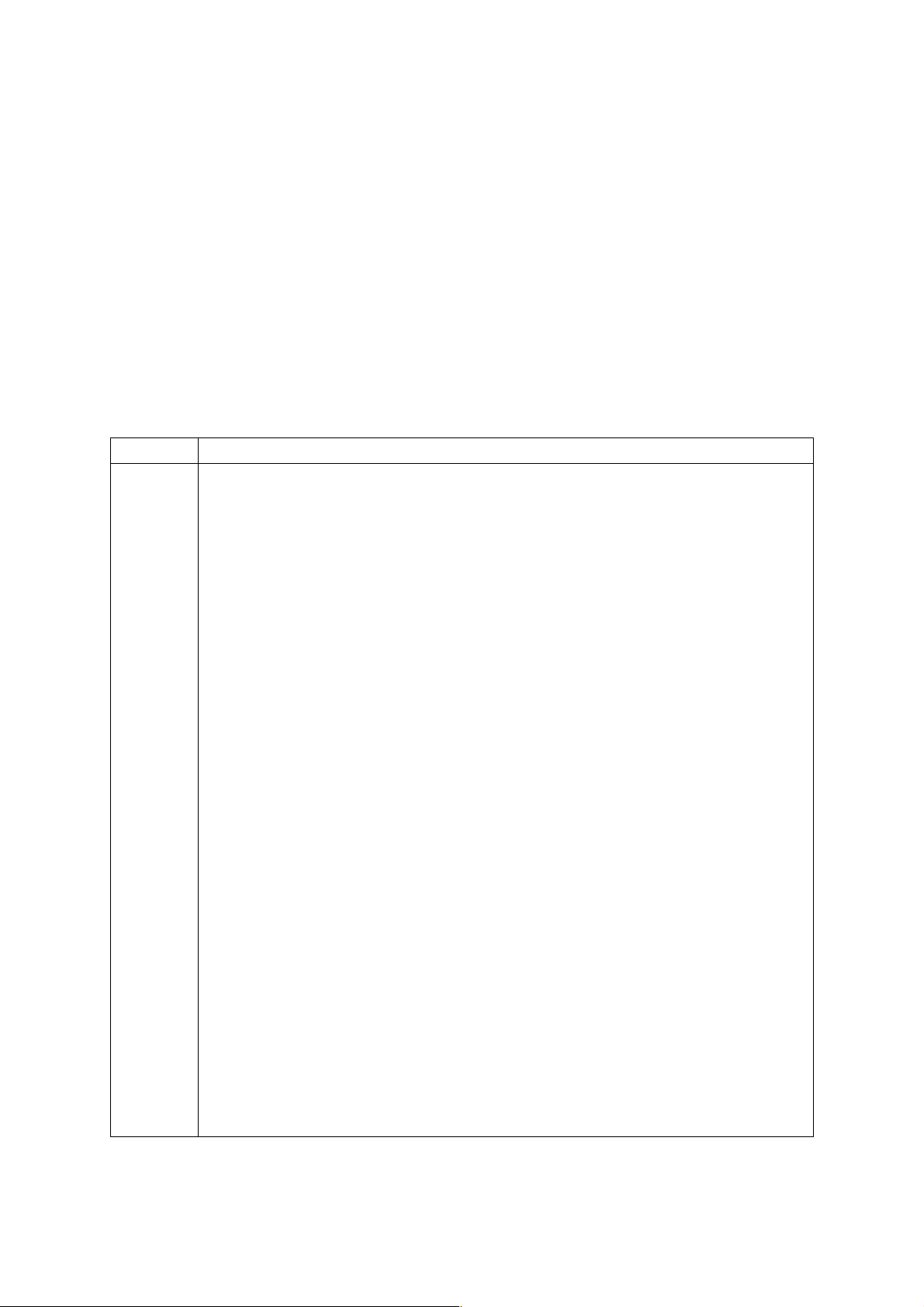

Table 11-4

Address Description

A Additional axis coordinate value

B Additional axis coordinate value, 2nd miscellaneous function

C Additional axis coordinate value

D Incremental coordinate value of B axis

E Feed function (threading)

F Feed functions

G Preparatory functions

H Incremental coordinate value of C axis

I X-axis component of the circular arc center

J Y-axis component of the circular arc center

K Z-axis component of the circular arc center

L Canned cycle times designation, Repeat times in a subprogram call

M Miscellaneous function

N Sequence number

O Program number

P Dwell, Program number in a subprogram call

Q Fixed cycle, Multiple threading starting angle

R Radius command value for circular interpolation, Canned cycle

S Spindle functions

T T ool functions

U Incremental coordinate value of X axis, Dwell

V Incremental coordinate value of Y axis

W Incremental coordinate value of Z axis

X X-axis coordinate value, Dwell

Y Y-axis coordinate value

Z Z-axis coordinate value

2 - 8

Page 18

11-5 Command Words and Command Value Ranges

Table 11-5

Function Address Metric input. Inch Input.

Program number # O 1~99999999 1~99999999

Sequence number # N 1~99999999 1~99999999

Preparatory function G 0~999 0~999

Coordinate value X, Y, Z,

U, V, W, ±99999.999(mm) ±9999.9999(inch)

I, J, K,

Q, R , ±99999.999(deg) ±9999.9999(deg)

A, B, C,

Feed function F See the table 4-2. See the table 4-2.

Spindle function S 0~32767 0~32767

Tool function T

Miscellaneous function M 0~99999999 0~99999999

Dwell P, X, U 0~99999.999(sec) 0~99999.999(sec)

Call program number P 1~99999999 1~99999999

Repeat times L 1~99999999 1~99999999

11-6 Subprogram (M98, M99)

A subprogram can be called in the MEMORY mode. A called subprogram can further call

another subprogram. The subprogram can be called eightfold at maximum.

11-7 Programmable Mirror Image (G501, G511)

A mirror image can be applied to each axis by a program command.

11-8 DIRECT TAP (G842, G843)

You can perform highly accurate tapping at high speed in G842/G843 tap cycles, by fully

synchronizing a rotary tool rotation with the feed of X or Z axis.

11-9 Optional Block Skip

A program block containing a slash code, “/”, in its beginning is ignored by turning on the

OPTIONAL BLOCK SKIP switch provided on the p art of the machine. You can add “/2” through

“/9” (optional block skip 2 through 9) as an option.

11-10 Control-in/-out

“(”: Control-out

“)”: Control-in

This function is used when giving a program name to a program number or giving a comment

halfway a program. All the information between control-out and control-in is ignored within a

significant information section.

2 - 9

Page 19

1 1-11 Command Data Input Methods

(1) MDI (manual data input ) through the keyboard

(2) Inputting from an external input/output device via an RS-232C interface (Reading the NC

tape)

11-12 Internal Data Output Methods

(1) Displaying on the CRT

(2) Outputting to an external input/output device via an RS-232C interface (Punching out the NC

tape)

12. HOW TO FACILITATE PROGRAMMING

12-1 Canned Cycle for Drilling (G80~G89, G831, G841, G861)

Drilling, tapping, and boring cycles can be specified in one program block.

12-2 Fixed Cycle (G90, G92, G94)

The following 3 kinds of fixed cycles can be commanded:

(1) Cutting cycle A (G90) → outside/inside diameter cutting

(2) Threading cycle (G92)

(3) Cutting cycle B (G94) → end face cutting

12-3 Maltipul Fixed Cycle

Several kinds of fixed cycles are prepared beforehand to facilitate a program. With information

of the finished configuration alone being given, the tool passage for rough cutting to the end is

automatically fixed. A fixed cycle for threading is also available. They are divided roughly into the

following three:

Maltipul type fixed cycle A : G70, [(G71, G72) T ype 1], G76

Maltipul type fixed cycle B : A + G73, G74, G75

Maltipul type fixed cycle C : B + [(G71, G72) T ype 2]

12-4 Optional Angle Chamfering Corner R (, C/, R)

Optional angle chamfering or corner R can be inserted automatically by adding [,C] or [,R] to the

end of the program block where linear or circular interpolation is specified.

2 - 10

Page 20

13. TOOL OFFSET FUNCTIONS

13-1 Automatic Tip R Compensation and Cutter Compensation

(1) Automatic Nose R Compensation (G143)

It is normally held at G143 (Automatic Nose R Compensation Valid Mode). Therefore,

without G code not being commanded, tip R compensation is automatically executed.

Nose R is set to tool compensation R and virtual nose points (1~8) to T.

(2) Cutter Compensation (G145 : G40~G42)

With G145 command, Cutter Compensation mode is created.

With G40~G42 commands while in this mode, cutter compensation can be carried out.

A tool diameter is set to tool compensation R and a virtual nose point (9) to T.

13-2 Groove Width Compensation (G150 to G152)

When a grooving tool is used, one virtual tool nose (for example, 3) is used to run the program

to apply compensation. It is also necessary to compensate the other virtual tool nose (for

example, 4) side. When this is done, this function compensates the groove width by specifying

a G-code.

13-3 Addition of T ool Offset s

The number of tool offset pairs can be expanded up to 200.

Expansion of tool offset pairs: 64/99/200 (Up to 99 pairs for the

Note) The number of tool offset pairs, 200, is only allowed when the ATC is attached.

∑21L)

14. ACCURACY COMPENSATING FUNCTIONS

14-1 Backlash Compensation

This function is to compensate the lost motions which the mechanical system has.

A compensation amount can be set as a parameter in the least command increment for each

axis within a range of up to 9999 pulses.

14-2 Stored Pitch Error Compensation

This function is to compensate a pitch error for feed screws. Compensation data is set as a

parameter. The number of compensation positions is 128 for each axis.

2 - 11

Page 21

15. MEASURING FUNCTIONS

15-1 Skip Function

If a skip signal is input from an external device in the midst of an X-, Y-, or Z-command following

G31, the next block will be executed, canceling the rest of this command. A skip signal input

position can be read with a system macro variable.

15-2 Q SETTER

Through simple manual operation with the touch sensor, tool offset volume is automatically

written.

15-3 Q-setter Repeat Function

By measuring the tool with the Q-setter once, automatic measurement with the Q-setter is

activated by simple operation when changing tips.

16. CUSTOM MACRO

16-1 Custom Macro

A function peculiar to the user can be created. There are 100 common variables, but their

number can be optionally extended up to 600.

17. AXIS CONTROL

17-1 Follow-up Function

In case of emergency stop or servo alarm, a machine travel amount is reflected on an NC unit

internal position. For this reason, automatic operation is enabled after resetting the emergency

stop or servo alarm, even if you do not have to perform zero point return.

In case of speed feedback or position feedback alarm, however, an actual machine position and

the NC unit internal position do not match, because the follow-up function does not work

properly .

17-2 Mirror Image

This function can reverse the sign of the travel direction specified by a program command or

MDI command for the X-, Y-, Z-axis, or an additional axis. Make this setting in the Setting

screen.

2 - 12

Page 22

18. MANUAL OPERATION

18-1 Manual Continuous Feed

With the axial feed switch being pressed in Jog mode, manual continuous feed is performed.

Feed rates are as follows:

1 Jog feed

Jog feed rate can be changed over into 24 stages through use of the switch. Speed in 24

stages is set with parameters.

2 Manual rapid

When jog feed is executed as the rapid traverse button being pushed, manual rapid traverse

is available.

18-2 Manual Pulse Generator

The machine is capable of fine feed by means of the pulse generator on the machine operation

panel. One rotation of the pulse generator generates 100 pulses. You can select a scale factor

of x 1, x 10, or x M (M=1 to 100 set in a parameter) by a signal from the machine.

19. AUTOMATIC OPERATION

19-1 DNC Operation

With the optional board being added, DNC operation from the host CPU is made available.

19-2 Program Number Search

An 8-digit program number following O can be searched for from the data in the Program

screen.

19-3 Sequence Number Search

A sequence number can e searched for in the program currently selected from the data in the

Program screen.

19-4 Restart of Program

To restart a program, there are three ways; program restart, block restart, and machining break

point return.

1 Program restart is a function to restart from the block of a specified sequence number.

2 Machining break point return is a function to position a tool to a break point by jog feed.

19-5 Sequence Number Comparison and Stop

If you encounter the block of a preset sequence number during program execution, the machine

stops after executing that block.

19-6 Preread Buffer

In order to avoid discontinuation of the program blocks at the time of cutting due to the

processing time of the NC unit, the preread buffer generally prereads one program block in case

of automatic operation.

2 - 13

Page 23

(1) The preread buffer prereads the different number of program blocks, depending on the

function.

Function No. of pre-reading blocks

Automatic tip R compensation 4 blocks

Multi buffer 12 blocks

Tool diameter compensation 2 to 4 blocks

Others 0 or 1 block

Note 1) In the tool diameter compensation mode, the preread buffer prereads up to 4 blocks if

they contain the blocks free from an axis move command.

Note 2) The following commands suppress the preread buffer.

Example: G28, G30, G31, G53,

G10, G20, G21,

M00, M01, M02, M30

T Command

Note 3) As the automatic tip R compensation is normally held valid (G143 mode), pre-reading of

4 blocks is carried out.

(2) When the SINGLE BLOCK switch is turned on

(State in which automatic tip R compensation is held invalid : G140, G145 mode)

When the SINGLE BLOCK switch is turned on and the program blocks are executed

sequentially by pressing the CYCLE START switch, the preread buffer does not exist.

Because, when the CYCLE START switch is pressed, one program block is taken into the

preread buffer and executed immediately. Therefore, the preread buffer does not exist

during and after execution.

Note 1) Pre-reading is performed when any of the following applies:

(a) In Multi Buffer mode (G251)

(b) Tool radius compensation mode (G41, G42)

(c) When optional angle chamfering corner R is specified (, C/, R)

(d) Thread cutting (G32)

(e) T apping mode (G63)

Note 2) When the SINGLE BLOCK switch is turned from OFF to ON during automatic operation

to stop it, the preread buffer exists.

19-7 Feedhold

All axes can be stopped temporarily. Pressing the CYCLE START button restarts feeding the

axes. Prior to restarting axis feed, you can allow intervention by manual operation in the manual

mode.

2 - 14

Page 24

19-8 External Reset and Reset Signal

The NC unit can be reset from the outside. A reset cancels all the commands and decelerates

the machine to a stop. A reset signal is output to the machine while the RESET button of the

MDI & CRT panel is being pressed, the machine is being reset by an external reset signal, or the

EMERGENCY STOP button is being pressed.

19-9 Data Server

A large-capacity program can be processed at a high speed by means of the Ethernet controller

and the hard disk of the auxiliary storage unit. (For details, see SEIKI-SEICOS

INSTRUCTION MANUAL, NT DOMAIN TYPE)

∑ DATA SERVER

19-10 Scheduler

The program number per work and the number of machining works are managed to operate

different types of works continuously, using the robot or the bar feeder.

(For details, see SCHEDULER AJC FUNCTION INSTRUCTION MANUAL (SEIKI-SEICOS∑))

20. PROGRAM TEST FUNCTIONS

20-1 Machine Lock

In the machine lock mode, the machine does not move, but the position display is updated as if

the machine were moving.

When the machine lock is turned ON→OFF in auto operation, Machine is shifted by the amount

moved by the machine lock.

20-2 Dry Run

If the DRY RUN switch is turned on, the machine operates at a jog feed rate instead of a

programmed cutting feed rate. This function can be also enabled in case of rapid traverse by

parameter setting.

20-3 Single Block

Program commands can be executed block by block.

20-4 Pre-Machining Plotting

In pre-machining plotting, as Machine performs synchronous plotting while in auto running in

machine lock and dry run state, format failures and erroneous coordinate commands, if any, in a

program can be easily detected. When, on start of pre-machining plotting, an interlock signal,

etc. to stop interpolation has been made effective, pre-machining plotting is stopped with the

corresponding command.

2 - 15

Page 25

21. DISPLAY AND SETTING

21-1 Machining End Notice

Input a scheduled program end time. When the machining time reaches the scheduled end

time, a signal is output to an external device.

21-2 Run Hour Display

Machine run hours are displayed in the format of hours:minutes:seconds. Display is made by

each of the functions including the expected ending, working time, cutting time, lap T, and date/

time.

21-3 Work Count Function

The number of machined workpieces can be counted by the M12 command. By setting the

number of workpieces beforehand, a signal is output to the machine when reaching the

prescribed number of workpieces.

22. PART PROGRAM STORAGE & EDITING

22-1 Part Program Storage & Editing

The contents of the NC tape can be stored and edited. Relevant operations include deletion,

alteration, and insertion. Range editing is allowed by expanded part program editing. Use of

backgrounding allows you to edit another program during automatic operation.

Tape storage length : 80, 160, 320, 500 or 1,000 m

Registered programs : 100, 200, 400, 800, or 1,000 programs

Note) For the

320 m and 400 programs, respectively.

∑21L, the maximum part program storage length and registered programs are

22-2 Part Program Comparison

The program registered in the memory is compared with the one in the tape.

23. DIAGNOSTIC FUNCTIONS

23-1 Self Diagnostic Function

This function makes various checks.

The signals exchanged between the machine and NC unit can be confirmed on the screen.

• G contact : From PMC to CNC

• RG contact: From PMC to CNC

• F contact : From CNC to PMC

• RF contact : From CNC to PMC

• X contact : From machine to PMC

• Y contact : From PMC to machine

2 - 16

Page 26

23-2 Alarm Diagnosis

If the CNC has any error, it displays its corresponding alarm number and message.

23-3 Cutting Monitoring Function

This function monitors the cutting load of the spindle and feed axes to prevent abnormal cutting

or defective cutting.

24. DATA INPUT AND OUTPUT

24-1 Input/Output Interface (RS-232C)

This function allows you to output the programs, tool offset amounts, parameters, etc.

memorized in the memory to an external device, and input the data from the external device. A

device equipped with the RS-232C interface is available as an external device.

25. SAFETY FUNCTIONS

25-1 Emergency Stop

An emergency stop cancels all the commands and stops the machine instantaneously.

25-2 Overtravel

When the machine reaches a stroke end, a relevant signal is received, the axies are stopped

instantaneously, and an overtravel alarm is indicated.

25-3 Interlock

There are three kinds of axis interlocks; all axes interlock, individual axis interlock, and axis

directional interlock.

If the interlock is applied while moving the axis, the machine will be decelerated to stop. If an

interlock signal is canceled, the machine will be accelerated to resume operation.

25-4 Stored Stroke Limit 1

Stored stroke limit 1 assumes the out side of the area set by a prameter to be a prohibited area.

25-5 Stored Stroke Limit 2 and 3 (G22, G23)

Use this function when you want to ensure that a tool will not enter a non-cutting area.

Set stored stroke limit-2 with a parameter whether the inside or outside of the set area should be

prohibited. Stored stroke limit-3 assumes the inside of the set area to be a prohibited area.

Use a G-code to enable/disable stored stroke limit-2.

· G22: Enable

· G23: Disable

(Stored stroke limit-3 is enabled regardless of the G-code)

25-6 Stroke Check Before Move …… Not available with

This function checks whether or not specified end point coordinates enter a stored stroke limit

area before a move command in the program block.

2 - 17

∑∑

∑21L.

∑∑

Page 27

26. STATUS OUTPUT

26-1 NC Ready Signal

When the NC unit is turned on and becomes ready to control, this signal is output to the

machine, and when the NC unit is turned off, a signal output to the machine is called off.

26-2 Automatic Operation Running Signal

This is a signal to be output while automatic operation is under way.

26-3 Automatic Operation Stopping Signal

This is a signal to be output while the program is stopping due to feedhold.

26-4 Distribution Complete Signal

This is a signal to be output upon completion of distribution so that the M-, S-, T-, or B-function

can be executed after completing a move command in the block where there were specified.

27. EXTERNAL DATA INPUT

27-1 External Data Input

The data are sent from a machine’s external device to the NC unit to carry out required

operation.

1 External O- or N-number search

2 External tool offset data read

2 - 18

Page 28

3. OPERA TION

I. Basic Machine Operation

II. Screen Operation

3 - 1

Page 29

3. OPERA TION

I. Basic Machine Operation

1. Manual Operation

2. Automatic Operation

3. Operation Related to Safety

4. NC Operation keys

5. Quick Tool Setter (Q Setter)

6. Q Setter Barrier

7. Q Setter Repeat Function

8. Simple Jaw Edge Forming Function

3 - 2

Page 30

1. Manual Operation

The machine can be manually operated by using the switches on the machine operation panel.

1-1 Jog Feed

The machine can be operated continuously by manual operation.

(1) Select the mode selector switch “JOG”.

JOG

(2) Select the jog feed rate.

(3) Select the axis you want to move.

The machine moves in the direction of the selected axis.

Note 1) When multiple axes are selected, those axes move all simult aneously.

Note 2) When the axis has been selected before selecting the JOG mode, the machine does not

move even if the mode is changed to JOG. Select the axis newly.

1-2 Manual Reference Point Return

The machine can be returned to the reference point by manual operation.

(1) Select the mode selector switch “JOG”.

JOG

(2) Select the rapid traverse rate.

3 - 3

Page 31

(3) Select “ZERO RETURN”.

ZERO RETURN

The machine moves at the rapid traverse rate toward the reference point for each axis.

(4) When the machine returns to the reference point, the reference point return lamp gets

illuminated.

Note 1) Once reference point return is completed and the reference point return lamp gets

illuminated, manual reference point return operation cannot be performed again until the

reference point return lamp is turned off.

Note 2) The reference point return lamp goes off in the following cases.

(1) When the machine moved from the reference point.

(2) When an emergency stop resulted and the machine moved.

Note 3) When performing low-speed manual reference point return, do so from the position a

little distant from the reference point.

1-3 Rapid traverse

The machine can be rapid traversed continuously by manual operation.

(1) Select the mode selector switch “JOG”.

JOG

(2) Select an appropriate rapid traverse override.

(3) Select the axis you want to move, and “RAPID” simultaneously. The machine moves in the

direction of the selected axis at the rapid traverse rate.

Note 1) Same as Notes for Jog Feed

3 - 4

Page 32

1-4 Manual Handle Feed

The machine can be finely fed by turning the manual pulse generator .

(1) Select the mode selector switch “HANDLE”.

HANDLE

(2) Select the handle axis.

X Y Z

(3) Select a handle magnification.

1/1 10/1 100/1

(4) Turn the handle.

Clockwise: “+” direction

Counterclockwise: “-“ direction

Note 1) Do not turn the manual pulse generator so quickly. If so done, the machine may not stop

immediately after turning the handle, or the scale and the travel amount may not coincide

with each other.

Note 2) If the magnification “x 100” is selected and the handle is turned very quickly, the machine

moves at a rate close to the rapid traverse rate. If you then stop the machine suddenly,

it may be shocked.

Note 3) In some cases, the mode selector switch “HANDLE” of (1) many not be provided, where

Handle mode is selected by handle axis selection of (2).

3 - 5

Page 33

2. Automatic Operation

2-1 Automatic Mode

(1) Memory operation

(a) Store the program in the memory in advance.

(b) Select the program you want to run.

(c) Select the mode selector switch “AUTO”.

AUTO

(d) Press the CYCLE START button.

CYCLE START Lamp

CYCLE START

Pressing this button stars automatic operation and turns on the CYCLE START lamp.

(2) MDI operation

(a) Select the mode selector switch “MDI”.

MDI

(b) Input the program into the MDI operation buffer memory. The commands for multiple

blocks can be input into the MDI operation buffer memory from the CRT/MDI panel.

The program can be edited in the same manner as editing that stored in the memory.

(c) Press the CYCLE START button. Automatic operation starts and the CYCLE START

lamp gets illuminated.

2-2 Selecting the Run Program

(1) Program No./Sequence No. search

(a) Select the mode selector switch “AUTO”.

(b) Display the Overall screen. (The Program screen will also do.) When any other screen

than the Overall screen is displayed, press the RETURN key several times to display

the Overall screen.

(c) Press the O key in case of program number search, and press the N key in case of the

sequence number search.

(d) Then, enter the program number or sequence number you want to search for, and

press the cursor move key.

(e) A program or sequence number search is executed.

3 - 6

Page 34

(2) Rewind

(a) Select the mode selector switch “EIDT”.

(b) Display the Overall screen. (The Program screen will do.)

(c) Press the RESET key of the NC unit.

(d) Select the mode selector switch “AUTO”.

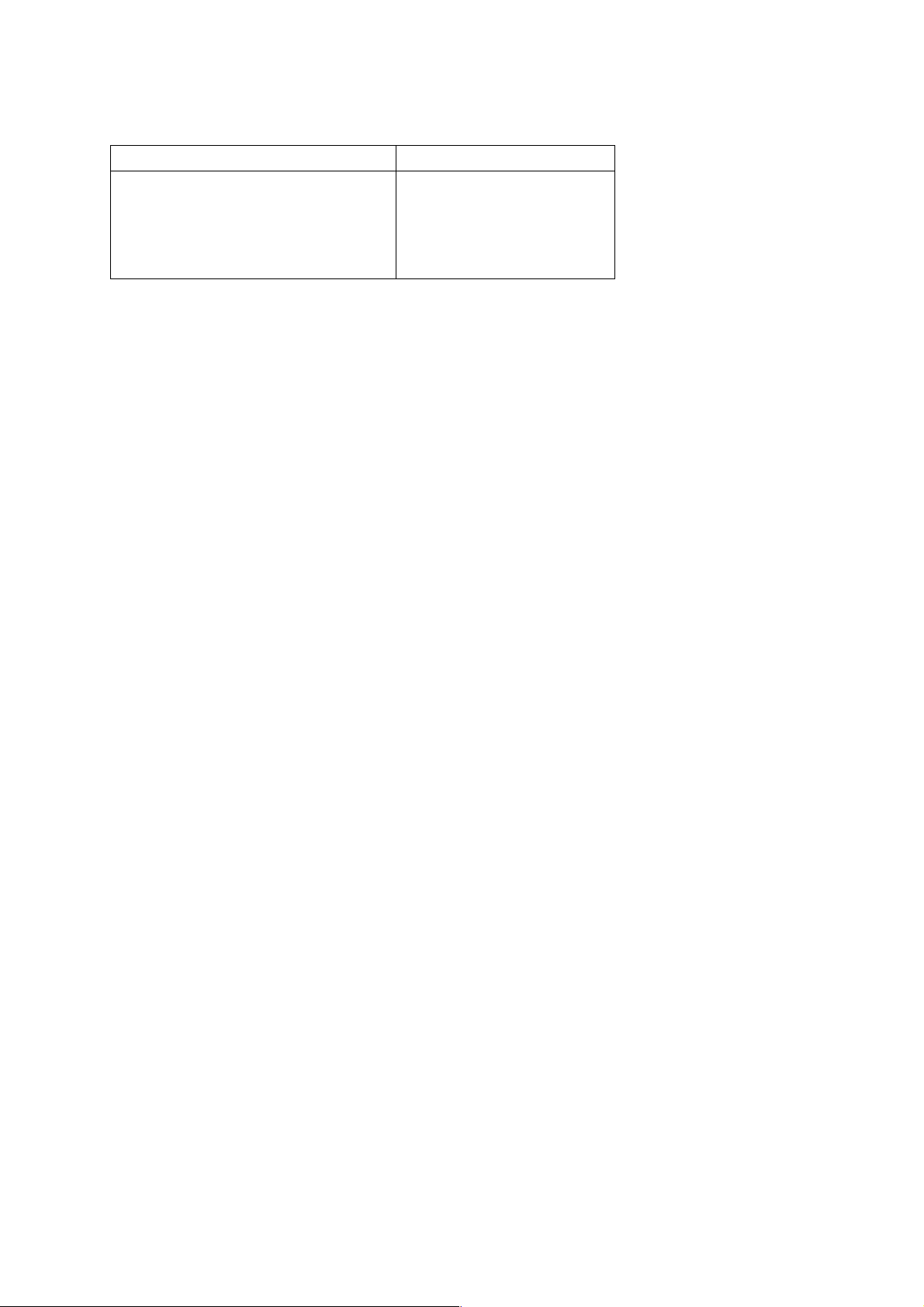

Part Program Storage Length Registered Programs

80 m 100 programs

160 m 100 or 200 programs

320 m 100, 200 or 400 programs

500 m 100, 200, or 400 programs

1000 m 100, 200, 800, or 1,000 programs

(3) Part program storage length and registered programs

Note) For the ∑21L, the maximum part program storage length and registered programs are

320 m and 400 programs, respectively.

2-3 Stopping the Automatic Operation

There are two methods to stop automatic operation; one is to insert a stop instruction (M00, M01,

M02, or M30) in the program in advance at which you want it to stop, and the other is to press the

button (FEEDHOLD or RESET) on the operation panel.

(1) Program stop (M00)

If the block where M00 has been specified is executed, automatic operation stops and

execution does not proceed to the next block. (The CYCLE START lamp remains turned on)

The model information so far is all saved.

Pressing the PROGRAM CYCLE START button restarts automatic operation.

(2) Optional stop (M01)

If the block where M01 has been specified is executed, automatic operation stops and

execution does not proceed to the next block. (The CYCLE START lamp remains turned on)

However, this is true only when the OPTIONAL STOP switch on the machine operation panel

in turned on.

(3) Program end (M02, M30)

(a) Indicates the end of the main program.

(b) Stops automatic operation and places the machine in the reset mode.

(c) Normally, M02 moves the cursor to the next block, and M30 returns the program to its

beginning.

3 - 7

Page 35

2-4 Dry Run

This function enables a dry run speed, ignoring the feed rate specified with the program.

DRY RUN

Normally , dry run is ef fective only during cutting feed.

To make it effective during rapid traverse as well, set “1” in the bit 6 (RDR) of the parameter

1401.

2-5 Single Block

The single block function stops the machine after executing one block. T urn on the SINGLE

BLOCK switch.

ON

OFF

This causes the machine to stop after executing one block. Pressing the PROGRAM CYCLE

ST AR T button stops the machine af ter executing the next block.

Note 1) Even at the middle point of the G28/G29/G30

command, the mach ine stops after executing

one block.

Note 2) The single block stop points in the canned cycle

for drilling are 1 , 2 , and 6 shown in the figure

below.

2-6 Override

For details related to the override function, refer to the instruction manual for the machine.

(1) Feed rate override

With the switch on the machine operation panel, an override of 0 % to 254 % (in an increment

of 1 %) can be applied to feed per minute (G98) and feed per revolution (G99).

(2) Rapid traverse override

The override selected with the switch on the machine operation panel can be applied to the

rapid traverse rate.

(3) Feed rate override cancel

With a signal from the machine side, the feed rate override and automatic rapid traverse

override can be fixed at 100 %.

3 - 8

Page 36

2-7 Per-program Machining Time Display Function (Option)

When you run the program, the programmed machining time is displayed on the machining time

display screen.

Up to 10 main program numbers and machining times can be displayed. If you run more than 10

programs, the oldest programs will be discarded sequentially . However, the machining time of the

same program number will be updated.

The time from the start of reset condition to the next reset condition in the memory operation

mode will be counted. The reset condition at this stage is the condition obtained by pressing the

reset key , external reset signal, M02, M30, etc.

The time counted will be only the time automatic operation is executed, therefore, the machining

time will not be counted during hold and during single block stoppage.

Calculation and display of machining time

1 Select the automatic (memory) operation mode and press the reset key.

2 Select the overall (program) screen and search for the program that calculates the

machining time.

3 Run the program and execute machining.

4 If the reset key is pressed or M02, M30 is executed, the count for machining time will be

terminated.

5 Select the program screen, press F7/Program list and then press F5/Machinig time. The

machining time screen will be displayed.

6 If you repeat the procedures from 1 to 5 the program number and time will be sequentially

displayed on the machining time screen.

3 - 9

Page 37

The maximum number of programs for which the machining time can be displayed is 10. If the

number of programs exceeds 10, the oldest programs will be discarded sequentially. However,

the machining time of the same program number will be updated.

2-8 Tape Operation (Simple DNC Operation)

The machine is directly operated by the program from the paper tape or external device without

using the internal memory of the NC unit. From the tape operation program, you can also call a

subprogram stored in the internal memory of the NC unit.

Note) Be sure to diable DNC operation during tape operation.

1 Select an input device and baud rate in the I/O screen.

(When using the RS-232C of the operation panel, select the RS-232C.)

2 Select the mode selector switch, TAPE.

3 Make setting on the part of the input device to make the system ready.

(Set the paper tape when the reader is used, and make the connected device ready for output

when the RS-232C is used.

4 Press the PROGRAM START button.

→ This reads one block worth of the program from the external device and start tape

operation.

Note) Since an internal processing buffer is provided, the buffer worth of the data are pre-read.

2-9 DNC Operation (Optional)

This, by receiving NC command data from the host CPU, continuously performs machining for

long hours.

NC Unit

3 - 10

Page 38

(1) Interface Between Host CPU and NC Unit

RS232C Interface

Transmittal mode Serial voltage interface (start/stop system)

Baud rate 1200 to 19200 (For details, see Parameters.)

Max. cable length 15 m

Noise resistance Inferior

Start/stop system

As in the following drawing, the start signal and the stop signal come preceding and

following respectively in relation to the information bits.

JD5C (∑10L)/JD28A (∑21L)

(PCR-EV20MDT)

12345678910

12345678910

RD OV DR OV CS OV CD OV +24

RD OV DR OV CS OV CD OV +24

11 12 13 14 15 16 17 18 19 20

11 12 13 14 15 16 17 18 19 20

SD OV ER OV RS OV +24

SD OV ER OV RS OV +24

When no using CS, short-circuit it with RS.

When using DR, short-circuit it with ER.

Be sure to short-circuit CD with ER.

(2) parameter Setting

1 No.0180 I/O channel when a remote buffer is used

Be sure to set 3.

2 No.0181 The specification No. of the I/O unit when a remote buffer is used

Set V alue I/O unit

0 Control code (DC1 to DC4) is used.

4 Control code (DC1 to DC4) is not used.

3 - 11

Page 39

3 No.0182 Baud rates when a remote buffer is used.

Set V alue Baud Rate

The set values 13 to 15 are only useable for RS422.

(3) Operation

1

Push F5/Set to enter Setting screen for other selections.

(bps) (bps)

150

2 100

3110

4 150

5 200

6 300

7 600

8 1200

Set V alue Baud Rate

9 2400

10 4800

1 1 9600

12 19200

13 38400

14 76800

15 86400

2 Set DNC Operation Mode Selection to “YES”.

3

Pushing RETURN to enter Overall screen, select Memory mode.

4 Start the host CPU.

5 Pushing START , start running.

Program transfer into the DNC operation memory is started and, in a few seconds,

running starts.

* Note) Steps 4 and 5 get reversed depending on the transfer conditions of the host

CPU.

3 - 12

Page 40

<Starting Following Sequence No. Search>

You can start operation with the sequence No. having been assigned in the DNC

program.

1 Execute 1 to 4 of the above item.

2

Input, following “ N ”, a sequence No. where operation is to be started.

Push “ ↓ ” key.

3

Program transfer starts into DNC operation memory and searching is started. On

completion of searching, the sequence No. having been found is displayed on the

screen at its beginning. When it has not been found, an alarm takes place.

4 Push START for running. Operation starts with the sequence No. thus having been

found.

3 - 13

Page 41

2.10 Submemory

(Unavailable for

ΣΣ

Σ10)

ΣΣ

2.10.1 Outline

The submemory is a feature to increase the capacity of the program memory by using a storage

*1

medium newly added into the NC unit(normally an ATA flash card

The ATA flash card is called the submemory and the conventional memory(battery backup RAM)

the main memory, respectively. Up to 10 directories can be created in the submemory and one

of them is selected for operation as required.

*1 When a hard disk data server is attached, the submemory also uses a hard disk.

(1) Program storage length

You can select 1,000, 2,000, 4,000, or 10,000 m on the part of the submemory.

The total program storage length equals this length plus the capacity of the main memory.

(Example) When the main memory is 80 m long and the submemory 2,000 m long,

respectively, the total program storage length is 2,080 m long.

(2) Number of programs

Up to 1,000 programs held in one directory plus the main memory

Up to 2,000 programs held in all the directories in the submemory

(Example 1) When no directories are created in the submemory;