Page 1

SEIKI - SEICOS

å10/ 16/18/ 21

INSTRUCTION MANUAL

MAINTENANCE

41 Edition 1.01 11-2000

Hitachi Seiki Deutschland

Werkzeugmaschinen GmbH

Page 2

Page 3

CONTENTS

I-I SEICOS

1. OVERVIEW .........................................................................................................................1 - 3

2. FUNCTIONS AND HANDLING OF CONTROL UNITS......................................................... 1 - 7

3. TROUBLESHOOTING ...................................................................................................... 1 - 24

4. POWER-ON ADJUSTMENT ............................................................................................. 1 - 25

5. DAIL Y MAINTENANCE AND INSPECTION ........................................................................ 1 - 29

I-II SEICOS

1. OVERVIEW ....................................................................................................................... 1 - 33

2. PCB CONNECTORS AND CARD CONFIGURATION ...................................................... 1 - 37

3. TROUBLESHOOTING ...................................................................................................... 1 - 50

4. POWER-ON ADJUSTMENT ............................................................................................. 1 - 51

5. DAIL Y MAINTENANCE AND INSPECTION ........................................................................ 1 - 55

ΣΣ

Σ 10 UNIT ............................................................................. 1 - 2

ΣΣ

ΣΣ

Σ 16/18/21 UNIT................................................................ 1 - 32

ΣΣ

I-III RS-232C INTERFACE SPECIFICATION ....................................... 1 - 62

II. ALARM LIST ....................................................................................... 2 - 1

1. Alarms Related to Program and Operation..........................................................................2 - 2

2. Alarms Related to Absolute Pulse Coder (APC) ................................................................ 2 - 50

3. Alarms Related to Serial Pulse Coder (SPC) ....................................................................2 - 52

4. Alarms Related to Servo....................................................................................................2 - 56

5. Alarms Related to Overtravel............................................................................................. 2 - 67

6. Alarms Related to Overheat...............................................................................................2 - 69

7. Alarms Related to Direct Tap ............................................................................................. 2 - 70

8. Alarms Related to Serial Spindle........................................................................................ 2 - 71

9. System Alarms ..................................................................................................................2 - 73

III. PARAMETERS ................................................................................... 3 - 1

1. DISPLA Y, SETTING, AND OUTPUT OF PARAMETERS...................................................... 3 - 2

2. DESCRIPTION OF P ARAMETERS..................................................................................... 3 - 5

2.1 Parameters Related to Communication (RS-232C) (No. 0100 onward)...................... 3 - 8

2.2 Parameters Related to Axis Control/Input Increment ................................................. 3 - 17

2.3 Parameters Related to Coordinate System ............................................................... 3 - 26

2.4 Parameters Related to Stroke Limit ........................................................................... 3 - 33

2.5 Parameters Related to Chuck Tail Stock Barrier (L-system) ..................................... 3 - 37

2.6 Parameters Related to Feed Rate ............................................................................. 3 - 41

2.7 Parameters Related to Acceleration/Deceleration Control......................................... 3 - 49

2.8 Parameters Related to Servo..................................................................................... 3 - 68

2.9 Parameters Related to DI/DO.................................................................................... 3 - 91

2.10 Parameters Related to CRT/MDI, Display, and Editing ............................................ 3 - 96

i

Page 4

2.11 Parameters Related to Program ............................................................................ 3 - 105

2.12 Parameters Related to Pitch Error Compensation ................................................ 3 - 121

2.13 Parameters Related to Spindle Control.................................................................. 3 - 125

2.14 Parameters Related to Tool Offset......................................................................... 3 - 164

2.15 Parameters Related to Canned Cycle ................................................................... 3 - 172

2.16 Parameters Related to Direct Tap.......................................................................... 3 - 191

2.17 Parameters Related to Custom Macro .................................................................. 3 - 201

2.18 Parameters Related to Skip Function .................................................................... 3 - 209

2.19 Parameters Related to Measurement .................................................................... 3 - 212

2.20 Parameters Related to Graphic Display................................................................. 3 - 226

2.21 Parameters Related to Manual Handle Feed, Manual Handle Interrupt,

and Tool Axis Direction Handle Feed...................................................................... 3 - 232

2.22 Parameters Related to Polygon Machining (L-system Only) ................................. 3 - 235

2.23 Parameters Related to Cutting Monitoring ............................................................. 3 - 239

2.24 Parameters Related to High-speed, High-accuracy Contour Control by RISC ...... 3 - 248

2.25 Other Parameters .................................................................................................. 3 - 255

2.26 Parameters Related to Maintenance...................................................................... 3 - 277

IV. DIAGNOSE4 - 1

1. DIAGNOSE DISPLA Y ..........................................................................................................4 - 2

1.1 Input/Output Signals..................................................................................................... 4 - 3

APPENDIX: BOOT SYSTEM ................................................................. A - 1

1. OVERVIEW ......................................................................................................................... A - 2

1.1 St arting up the BOOT SYSTEM................................................................................... A - 3

1.2 System Files and User Files ........................................................................................ A - 3

2. SCREEN CONFIGURA TION AND OPERATING METHODS ..............................................A - 4

2.1 SYSTEM DA TA LOADING Screen................................................................................ A - 5

2.2 SYSTEM DATA CHECK Screen...................................................................................A - 7

2.3 SYSTEM DATA DELETE Screen................................................................................. A - 8

2.4 SYSTEM DATA SAVE Screen ...................................................................................... A - 9

2.5 SRAM DA TA BACKUP Screen................................................................................... A - 11

2.6 MEMORY CARD FILE DELETE Screen.................................................................... A - 14

2.7 MEMORY CARD FORMAT Function ......................................................................... A - 14

2.8 LOAD BASIC SYSTEM .............................................................................................. A - 1 5

3. ERROR MESSAGES AND REMEDIES ............................................................................ A - 17

ii

Page 5

MAINTENANCE

I-I SEICOS Σ 10 UNIT

I-II SEICOS Σ 16/18/21 UNIT

I-III RS-232C INTERFACE SPECIFICATION

II. ALARMS LIST

III. PARAMETERS

IV. DIAGNOSE

1 - 1

Page 6

I-I SEICOS

1. OVERVIEW

1.1 System Configuration

1.2 Component Units List

2. FUNCTIONS AND HANDLING OF CONTROLLER

2.1 Power Unit

2.2 CPU Board

2.3 Option-1 Board (DNC)

2.4 Option-3 Board (PMC)

2.5 64-bit RISC Board (RISC)

2.6 MMC-IV Board (MMC-TV)

2.7 Liquid Crystal Display (LCD)

2.8 Data Server Board

2.9 List of Units and Print Boards

ΣΣ

Σ 10 UNIT

ΣΣ

3. TROUBLESHOOTING

3.1 Tracking through the ALARM Screen

3.2 Tracking through the Controller’s Monitor

4. POWER-ON ADJUSTMENT

4.1 Power-on Procedure

4.2 System Table

4.3 SLBUS Table

5. DAIL Y MAINTENANCE AND INSPECTION

5.1 Replacing the Battery

1 - 2

Page 7

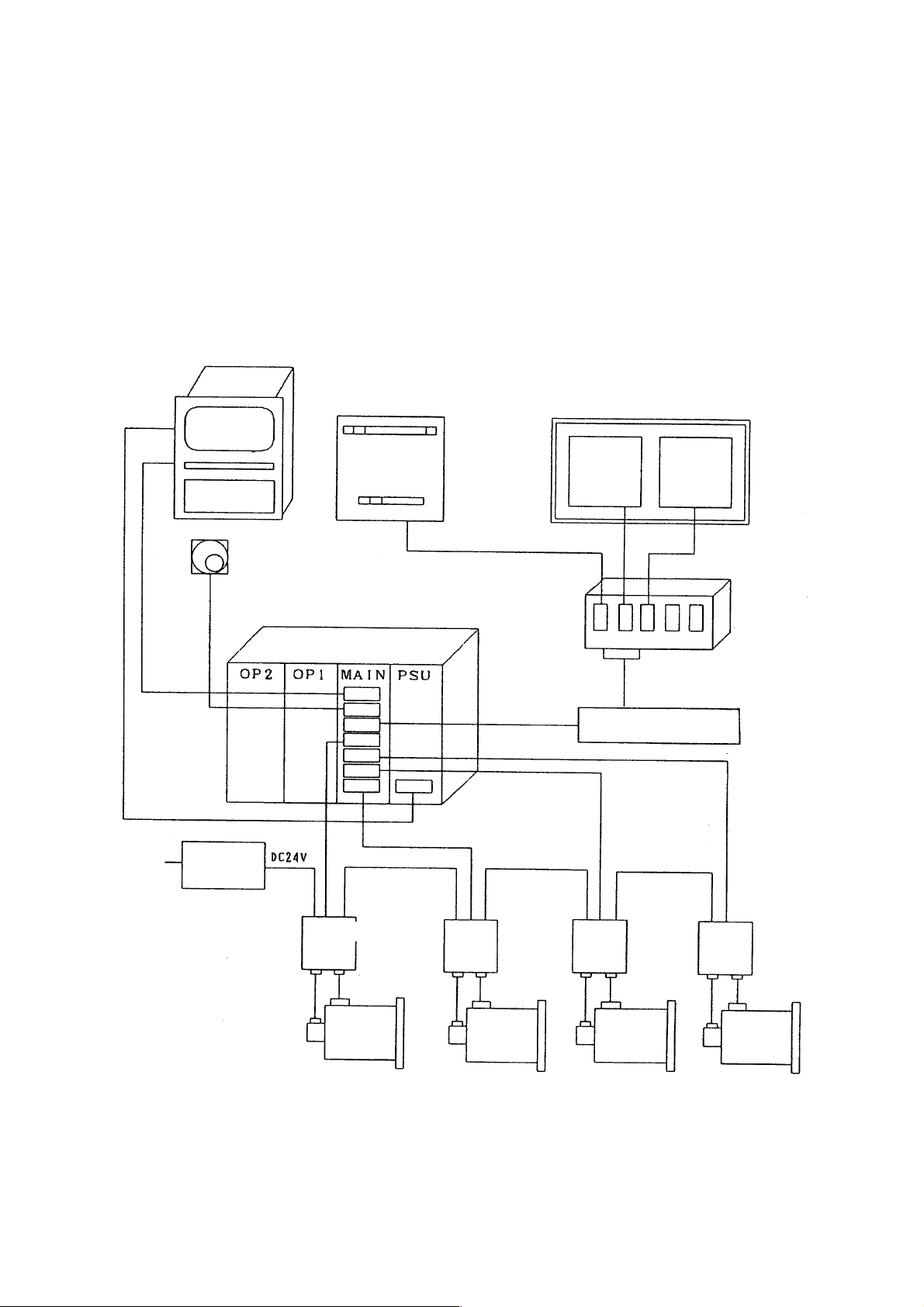

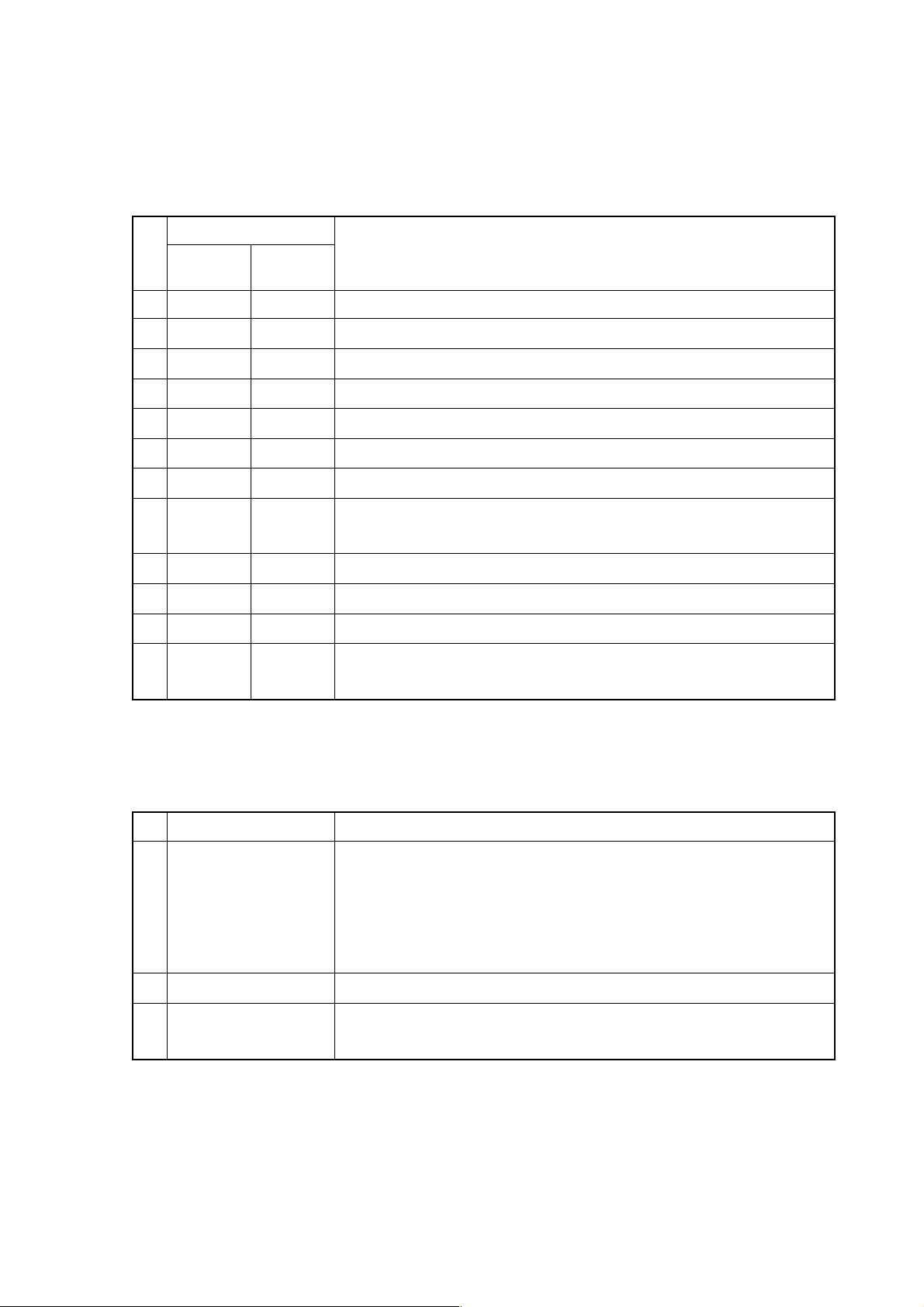

1. OVERVIEW

The SEICOS Σ 10 CNC unit is a compact high-reliability unit provided with up-to-date

device technologies. In the M-system, it enables high-speed, high-accuracy machining by

using 64-bit RISC.

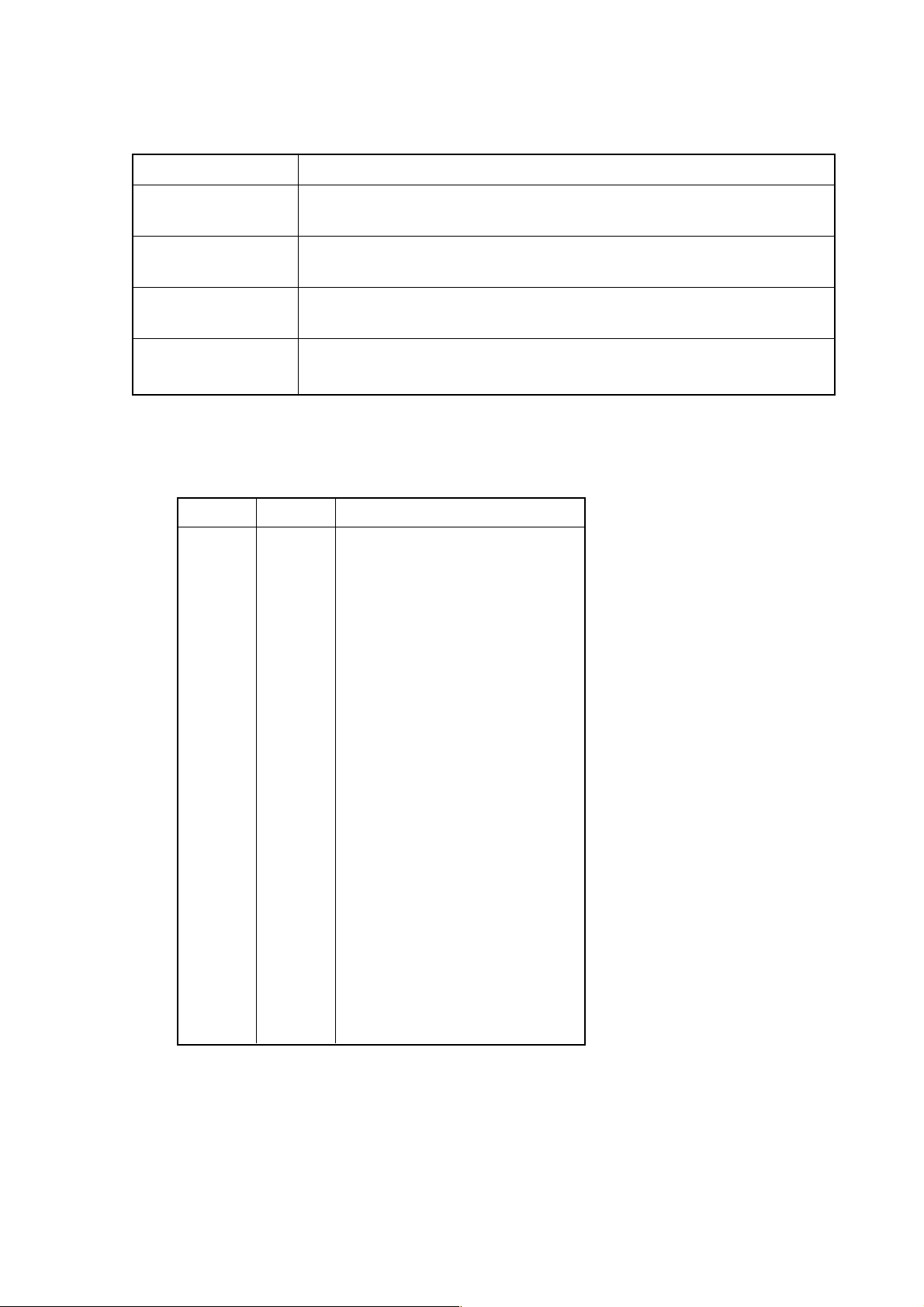

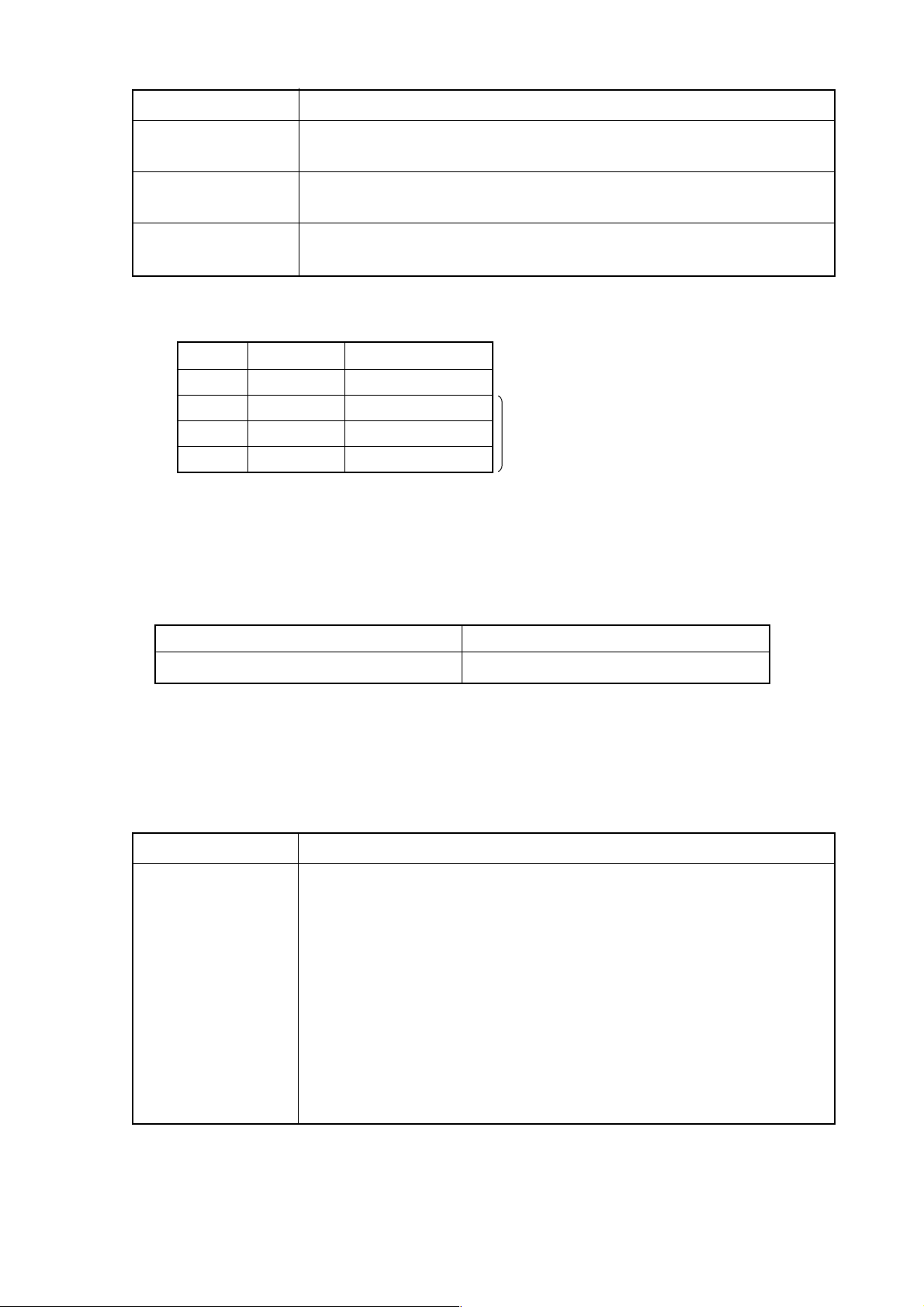

1.1 System Configuration

The following figure shows a system example using the SEICOS Σ 10 CNC unit.

CRT NC Operation Panel

Machine Operation Panel

Manual Pulse Generator

CNC Unit

I/O Slave

SLBUS

Distribution

Board

SLBUS Conversation

Module

200 V AC

Power

Unit

Spindle

Motor

Spindle

Amp.

Servo

Amp.

1 - 3

Servo

Motor

Servo

Amp.

Servo

Motor

Servo

Amp.

Servo

Motor

Page 8

1.2 Component Units List

The following table lists the component units of the controller. A mounting position of

each unit is fixed as shown in the mounting drawing. All the component units are plug-in

type and can be easily replaced.

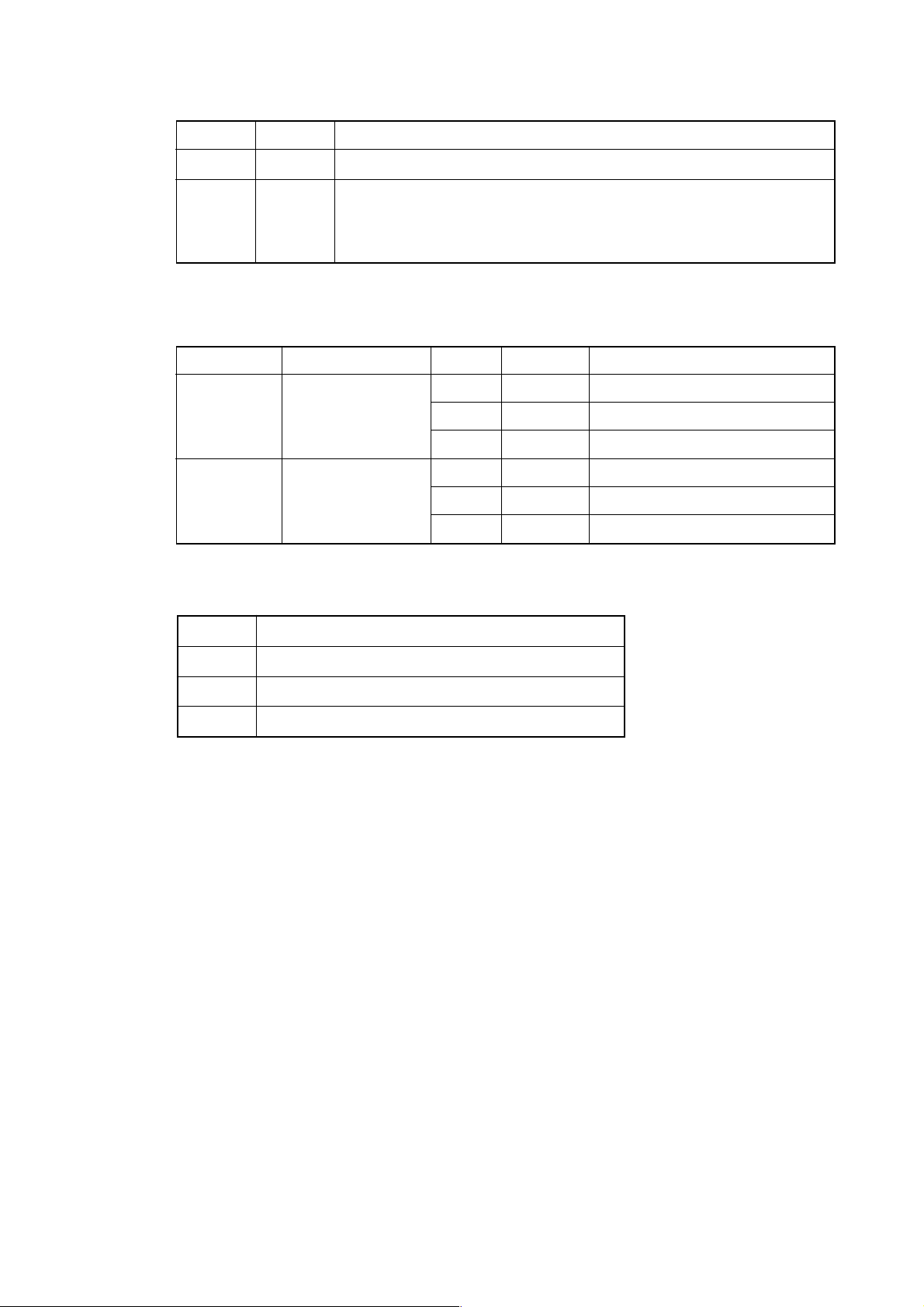

(1) Unit list

Name Symbol Function/Usage

Power unit PSU ON/OFF control

CPU board MAIN Main CPU

PMC board PMC Sequence control

I/O board I/O High-speed skip

RISC board RISC High-accuracy profile control (for M)

DNC board DNC DNC operation

(Note) The PMC board may be called an “option-3 board,” and DNC board an “option-

1 board,” respectively.

1 - 4

Page 9

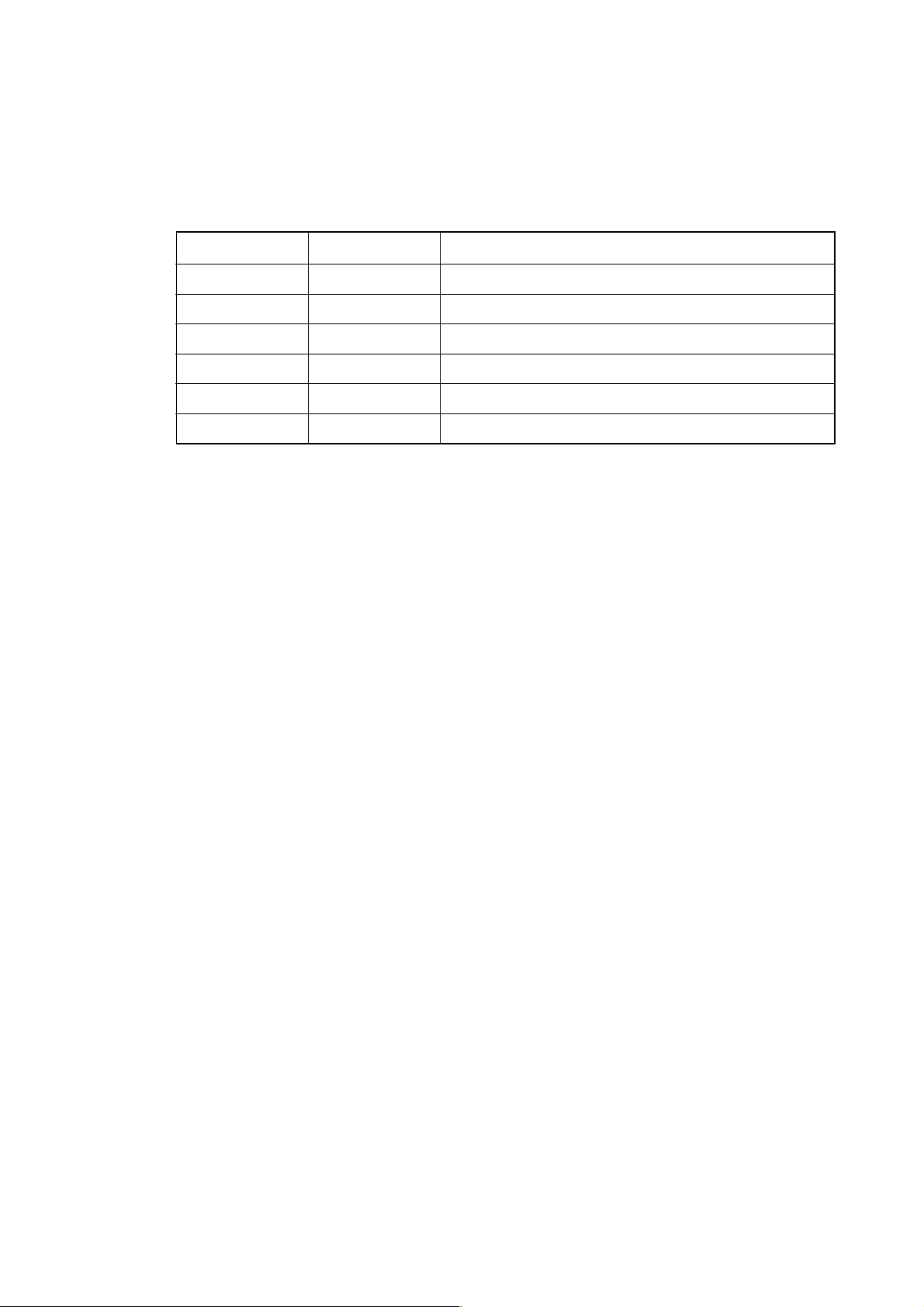

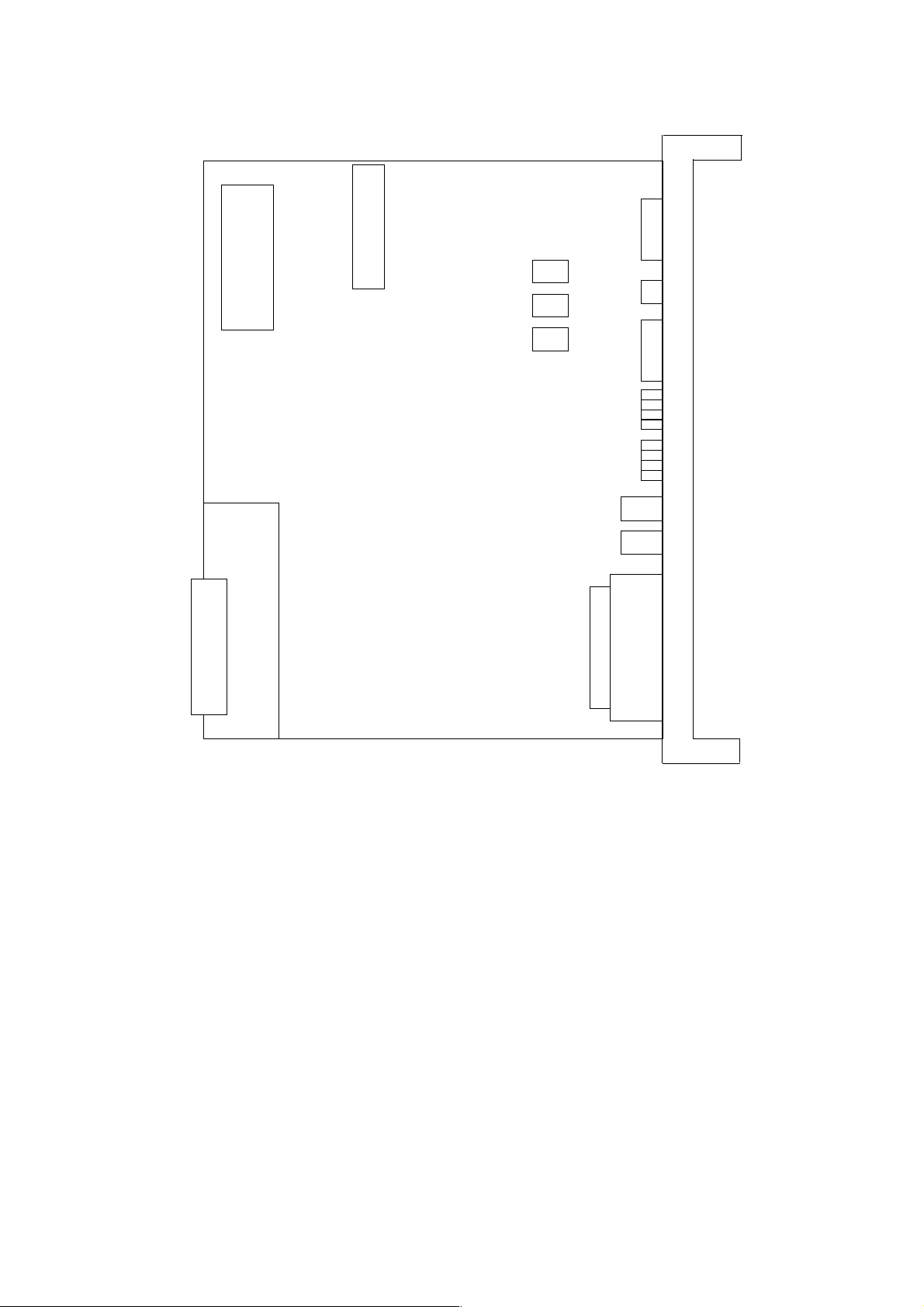

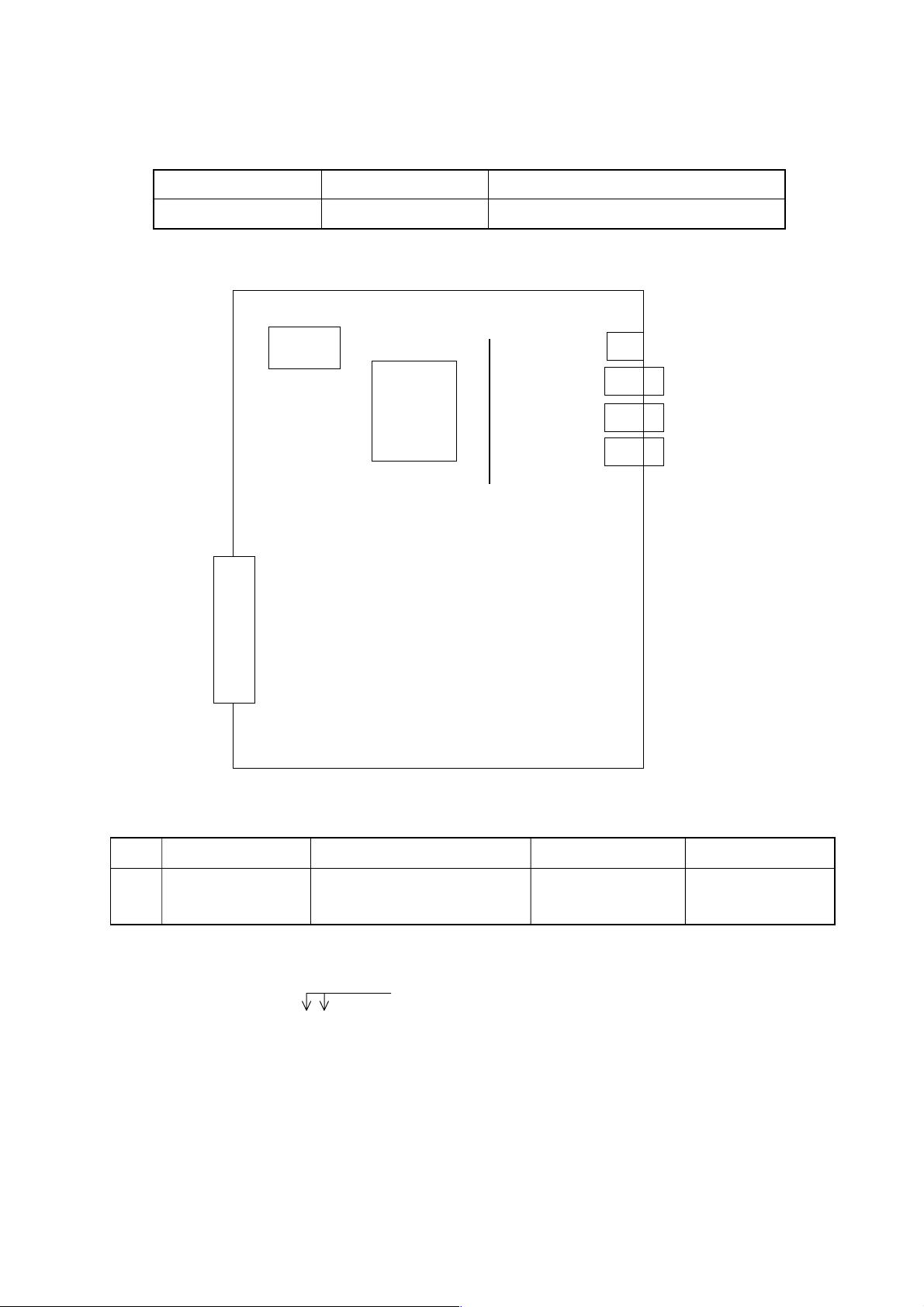

(2) SEICOS Σ 10 unit configuration

DMC

Board

Communication CPU

Remote

Buffer

DNC1

DNC2

Optional

RISC

Board

RISC

CPU

Highaccuracy

Profile

Control

(for M)

I/O

Board

HighSpeed

Skip

PMC

Board

PMC

CPU

PMC-RC3/4

I/O LINK

(Note)

Basic System

CPU

Board

CNC

CPU

Servo 6

Axes,

Spindle

Interface,

CRT,

Keyboard,

RS-232C*2

Memory

Card,

Manual

Handle

PMC-RB5/6

I/O LINK

Power

Unit

ON/OFF

Control

I/O PMC

<

< >

< >

< >

CPU

(Note)

Main

CPU

Power

Source

>

3 Slots

4 Slots

6 Slots

8 Slots

(Note) The PMC board is required when using the “PMC-RC3 or PMC-RC4,” but not

required when using the “PMC-RB5 or PMC-RB6.” [The PMC function is

incorporated in the main CPU board.]

1 - 5

Page 10

(3) SEICOS Σ 10 Multi unit configuration

MMC

Board

MMC-IV

CPU

HDD

FDD

PRT

Keyboard

RS232C

Basic

DMC

Board

Communi-

cation CPU

Remote

Buffer

DNC1

DNC2

(for M)

Highaccuracy

Profile

Control

Optional

RISC

Board

RISC

CPU

I/O

Board

Highspeed

Skip

PMC

Board

PMC

CPU

PMC-RC3/4

I/O LINK

(Note)

Basic System

CPU

Board

CNC

CPU

Servo 6

Axes,

Spindle

Interface,

CRT,

Keyboard,

RS-232C*2,

Memory

Card,

Manual

Handle

PMC-RB5/6

I/O LINK

Gra-

phic

Board

Power

Unit

ON/OFF

Control

I/O PMC

CPU

Main

CPU

Power

Source

(’•)

< >

< >

< >

4 Slots

6 Slots

8 Slots

(Note) The PMC board is required when using the “PMC-RC3 or PMC-RC4,” but not

required when using the “PMC-RB5 or PMC-RB6.” [The PMC function is

incorporated in the main CPU board.]

1 - 6

Page 11

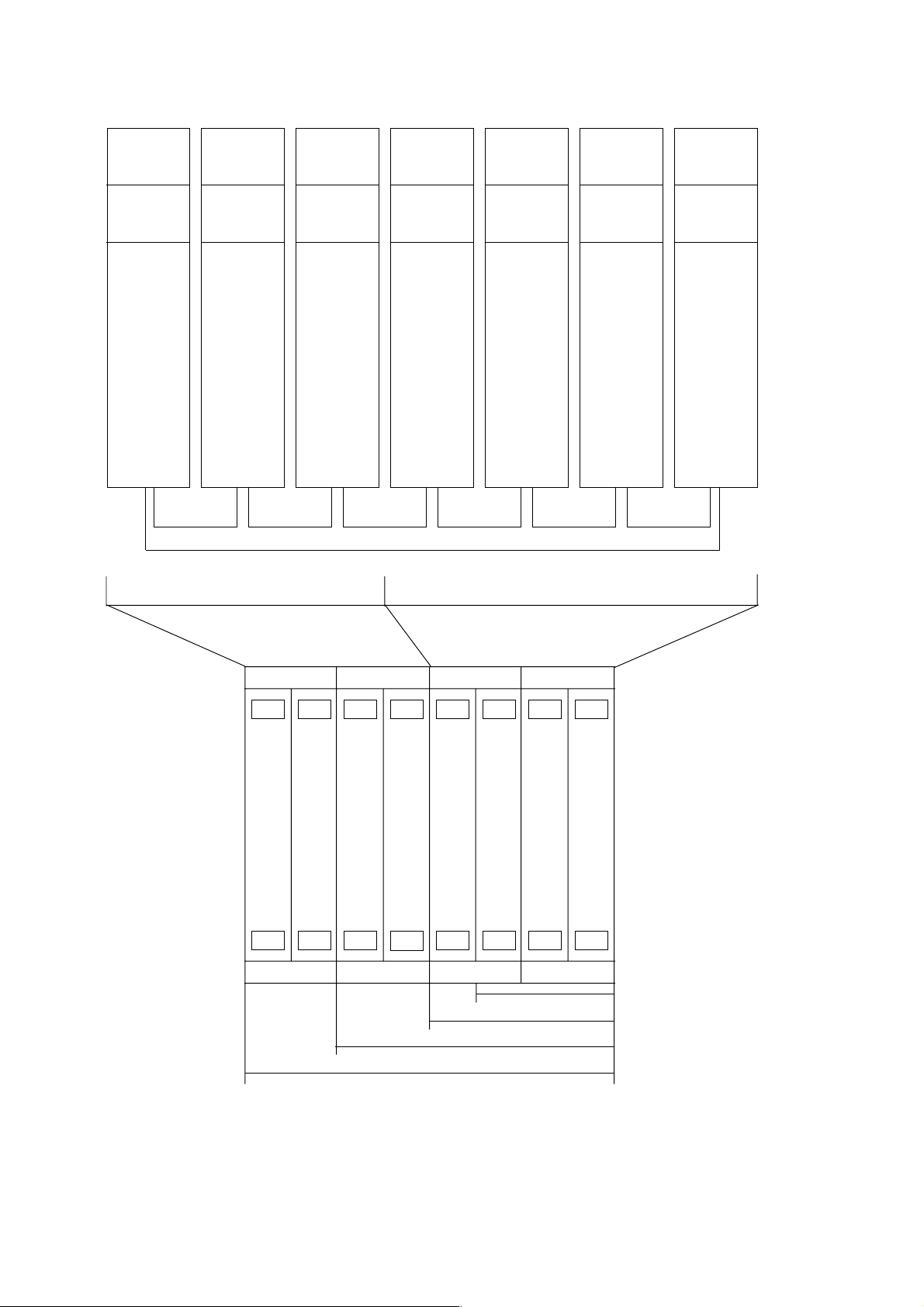

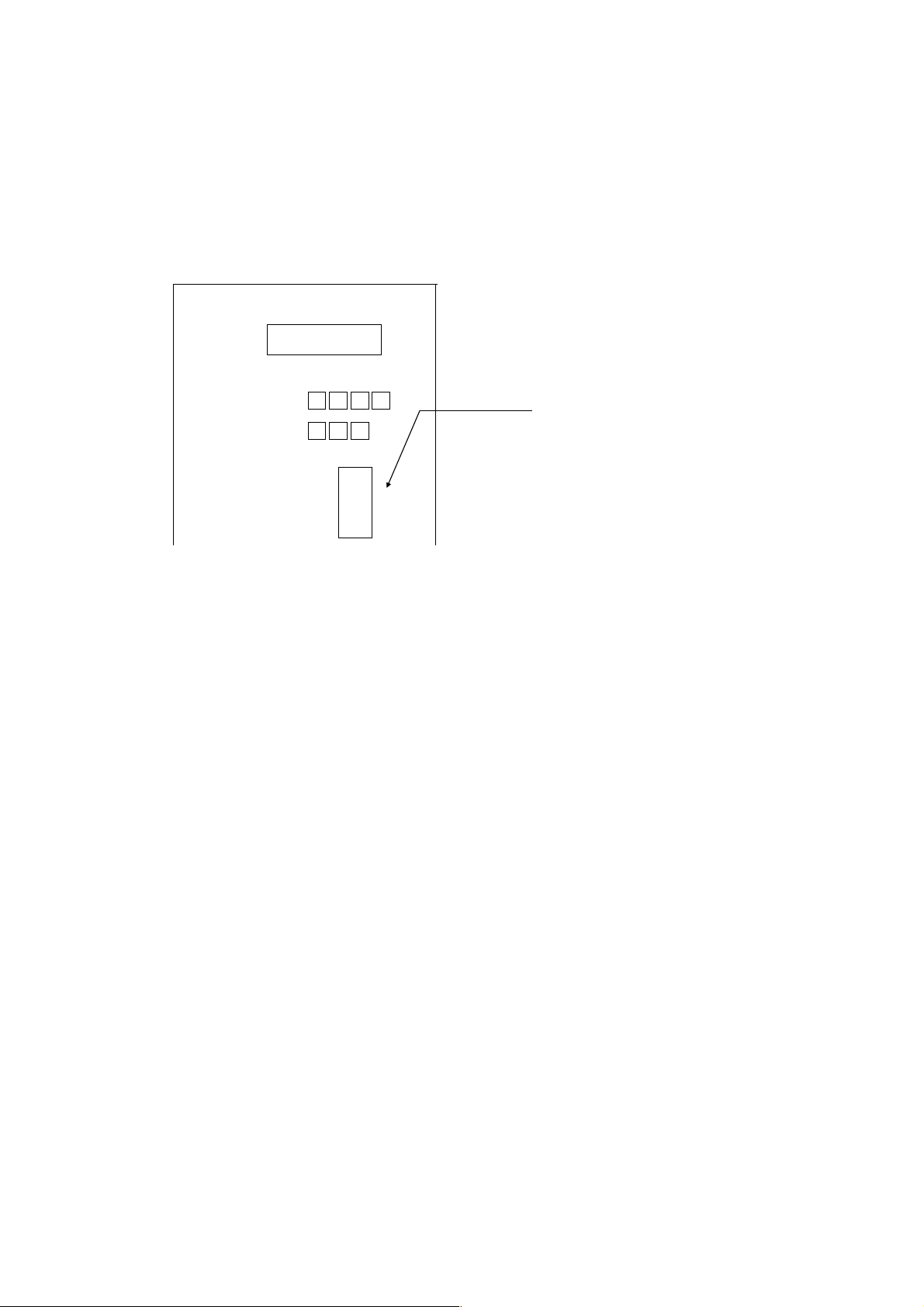

2. FUNCTIONS AND HANDLING OF CONTROL UNITS

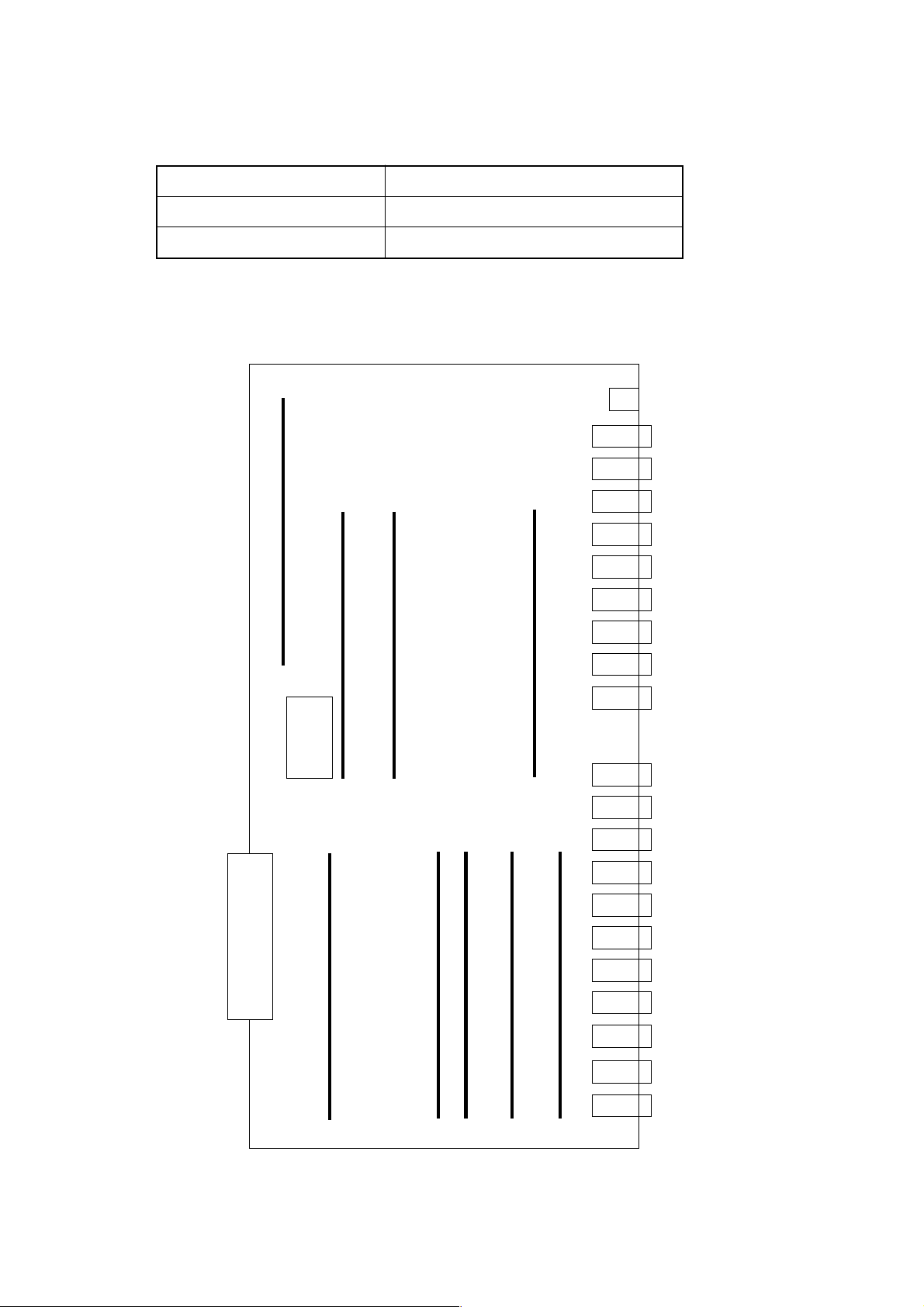

2.1 Power Unit (PSU)

This unit supplies DC power to each control unit.

Name Type

Power Unit AI A16B-1212-0901

Power Unit BI A16B-1212-0871

CP1

(ACIN)

F1

CP2

(ACOUT)

Battery Case

PIL LED

ALM LED

Graphic Board [MULTI Specification Only]

CP5

(24V)

CP3

(ACOUT)

CP4

CONTROL

CP6

(24E)

F3

F4

1 - 7

Page 12

2.1.1 LED Indications

Signal Color Description

PIL Green Illuminated when an input supply voltage is supplied to the CP1.

ALM Red Illuminated when a DC output voltage has an overcurrent/

2.1.2 FUSE

(1) Type

Power Unit Order No. Symbol Ratings Individual No.

AI A02B-0200-K100 F3 3.2A A60L-0001-0075#3.2

BI A02B-0200-K101 F3 5.0A A60L-0001-0075#5.0

overvoltage or drops.

F1 7.5A A60L-0001-0245#GP75

F4 5.0A A60L-0001-0046#5.0

F1 7.5A A60L-0001-0245#GP75

F4 5.0A A60L-0001-0046#5.0

(2) Application

Symbol Application

F1 AC200V input

F3 Indicator

F4 Others

1 - 8

Page 13

2.1.3 SETTING OF GRAPHIC BOARD (A20B-8001-0480)

TM10 B A

TM11 B A

~

ROM

TM16 B A

TM17 B A

TM3 A B

TM2 A B

JA1A

(OUT)

LCD ADJ.

JNA

TM1 A B

JA1B (IN)

HS

PHS

STATUS

ALARM

JNA

TM1~TM3 LCD/CRT switchingA:CRT B: LCD (B:Standard setting)

TM10 ROM switching A: Standard setting

LCD ADJ. Adjustment in VIDEO output level

HS AB Adjustment in NC page HSYNC phase A: Standard setting

012 Adjustment in NC page horizontal position 1: Standard setting

PHS01234 Fine adjustment in NC page HSYNC phase 0: Standard setting

• Perform adjustment with “HS AB” and “PHS 01234” when dots slippage causing

flicker takes place on switching between an MMC page and an NC page. First,

change “PHS 01234” and set it so that no flicker takes place. When adjustment

cannot be made even through this, change “HS AB”.

• Use “HS 012” to adjust by one dot when an MMC and an NC page are not equal in

their horizontal position.

• Adjust luminance blur with “LCD ADJ.” on the main board for the NC page. For the

MMC page, make adjustment with “LCD ADJUST” of the MMC-IV board.

1 - 9

Page 14

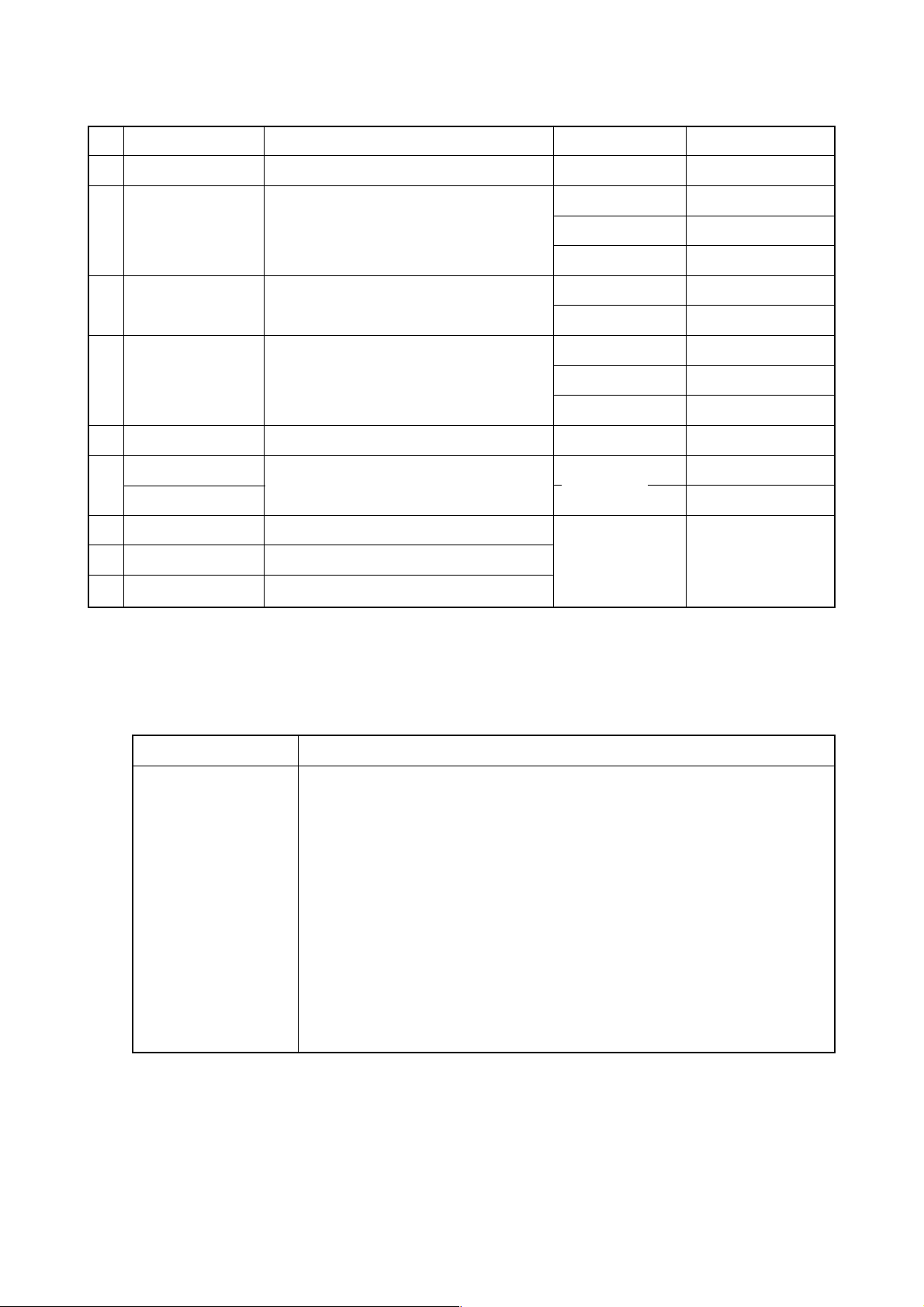

2.2 CPU Board (MAIN)

This is a CNC main CPU board.

Name Type

S-Σ 10M Main CPU Board A16B-3200-0190

S-Σ 10L Main CPU Board A16B-3200-0210

LED

JA1

JA2

JD5A

①

②③

⑩

Boot ROM

⑤⑦⑧

⑥⑨

④

JD5B

JA3

JD1A

JA7A

JA8A

JA4A

JS1A

JS2A

JS3A

JS4A

JS5A

JS6A

JF21

1 - 10

JF22

JF23

JF24

JF26

Page 15

2.2.1 List of Modules

No. Name Function Specification Type

① DRAM module CNC system RAM 8MB A20B-2902-0461

② SRAM module Extension SRAM 256KB A20B-2902-0350

768KB A20B-2902-0351

2.25MB A20B-2902-0352

③ FROM module CNC system, PMC Ladder 8MB A20B-2902-0501

12MB A20B-2902-0500

④ Spindle module Spindle control Serial+Analog A20B-2901-0980

Serial A20B-2901-0981

Analog A20B-2901-0982

⑤ PMC module PMC control With SLC A20B-2902-0480

HSSBC module

⑥

CRTC module Multi (VGA) A20B-2902-0275

⑦ Servo module Servo control 5th and 6th axes

⑧ Servo module Servo control 3rd and 4th axes

⑨ Servo module Servo control 1st and 2nd axes

2.2.2 LED Indications

The STATUS LED is green and the ALARM LED is red.

(1) LED indication change at power-on □: Turned off ■: Turned on

LED Indication Description

BTATUS □□□□ The Power is not turned on.

BTATUS ■■■■ The CPU is not starting after turning on the power.

BTATUS ■□■■ Each processor in the system is waiting for ID.

BTATUS □□■■ ID setting for each processor in the system is completed.

BTATUS ■■□■ Completion of FANUC BUS initialization

BTATUS □■□■ Completion of PMC initialization (1)

BTATUS ■□□■ Completion of setting of hardware configuration information for each

BTATUS ■■■□ Completion of initial run of the PMC ladder (PMC-RB)

BTATUS □■■□ Digital servo initialization wait

BTATUS ■□□□ Initial setting is completed and the system is running normally

CRTC text display control

printed circuit board in the system

Standard A20B-2902-0490

(HSSB)

A20B-2902-0070

A20B-2902-0061

1 - 11

Page 16

(2) LED indications for errors

LED Indication Description

STATUS □■□□

ALARM ■■□

STATUS □■□□

ALARM □■■

STATUS □■□□

ALARM □■□

STATUS ■■■■

ALARM ×■×

2.2.3 Connectors

Symbol Name Description

JA1 CRT CRT video signal

JA2 MDI MDI keyboard

JD5A R232-1 RS-232C serial port

JD5B R232-2 RS-232C serial port

JA3 MPG Manual pulse generator

JD1A IOLINK FANUC I/O link

JA7A SPDL-1 Serial spindle

JA8A A-OUT1 Analog output

JA4A APCBAT APC battery

JS1A SERV01 1st axis servo amplifier

JS2A SERV02 2nd axis servo amplifier

JS3A SERV03 3rd axis servo amplifier

JS4A SERV04 4th axis servo amplifier

JS5A SERV05 5th axis servo amplifier

JS6A SERV06 6th axis servo amplifier

JF21 SCALE1 1st axis scale

JF22 SCALE2 2nd axis scale

JF23 SCALE3 3rd axis scale

JF24 SCALE4 4th axis scale

JA26 SV-CHK Servo check

□: Turned off ■: Turned on ×: Irrelevant

The main CPU board has a RAM parity error or the option-2 board

has a servo alarm or RAM parity.

A servo alarm (watchdog timer alarm) occurred.

Other system alarm occurred.

The system is stopping before the CPU is started.

1 - 12

Page 17

2.3 Option-1 Board (DNC)

This is a DNC operation board.

Name Specification Type

Option-1 Board Remote Buffer A16B-2200-0913

CPU

Communication ROM

JNA

F-BUS

Backplane

Connector

①

LED

JD5C

JD6A

2.3.1 List of Modules

No. Name Function Specification Type

Communication

① Communication control A20B-2901-0361

control module

2.3.2 LED Indications

Indicates the status of the communicating function

STATUS □□□□ (green)

ALARM □□□ (red)

Indication of Communicating Function

□: Turned off ■: Turned on ×: Irrelevant ☆: Blinking

1 - 13

Page 18

LED Indication Description

STATUS ■■■■

ALARM ■□□

STATUS ××□■

ALARM □□□

STATUS ××☆☆

ALARM □□□

2.3.3 Connectors

Symbol Name Description

JD5C R232-3 RS-232C serial port

JD6A R422-1 RS422 serial port

2.4 Option-3 Board (PMC)

This is a sequence control board.

The CPU is not running after turning on the power.

The remote buffer has been initialized and the system is running

normally.

There is an error in communication control of the option-1 board.

Name Specification Type

Option-3 board PMC-RC A16B-3200-0054

LED

JD1A

①

JNA

F-BUS

Backplane

Connector

②

JE5D

JE5E

JE6B

1 - 14

Page 19

2.4.1 List of Modules

No. Name Function Specification Type

① DRAM for PMC

DRAM module

for PMC

② PMC control PMP2 A20B-2901-0960

PMC control

module

2.4.2 LED Indications

Indicates the status of Indicates the status of

the PMC-RC function the CAP-II function

(1) LED indications for the PMC-RC function

A20B-2901-0961

[Not used]

STATUS (green)

ALARM (red)

(a) LED indication change at power-on

□: Turned off ■: Turned on ×: Irrelevant

LED Indication Description

STATUS ■■××

STATUS □□××

STATUS ■■××

STATUS □□××

(b) LED indications for errors

LED Indication Description

STATUS ☆☆××

ALARM □□□

STATUS □☆××

ALARM ■□□

STATUS ☆□××

ALARM □□□

The CPU is not starting after turning on the power.

Waiting for ID setting for each processor in the system

Waiting for completion of initialization of each processor in the

system

Initialization of the PMC-RC function is completed and the system is

running normally.

□: Turned off ■: Turned on ×: Irrelevant ★☆ : Blinking

Other printed circuit board has NMI. (LEDs blinking simultaneously)

Check other printed circuit board for LED indication.

Parity error for the ladder memory or work memory.

Initialize the ladder memory or replace the work RAM module.

A bus error (illegal memory access) occurred.

Replace the option-3 board.

1 - 15

Page 20

LED Indication Description

STATUS ■☆××

ALARM □□□

STATUS ☆■××

ALARM ■□□

STATUS ★☆××

ALARM □□□

2.4.3 Connectors

Symbol Name Description

JD1A IOLINK FANUC I/O LINK

JD5D RS232-4 RS232C

JD5E RS232-5 Unused

JD6B R422-2 Unused

An I/O link has a communication error, etc.

Check a link device or cable.

The PMC control module has a parity error, etc. in it.

Replace the PMC control module.

Checksum error for the system program memory.

The DRAM module for PMC may be defective.

May not be installed

2.5 64-bit RISC Board (RISC) ...... for M

This is a board designed for high-accuracy profile control.

Name Type

64bit RISC board A16B-3200-0150

2.5.1 LED Indications

The STATUS LED is green and ALARM LED is red.

(1) LED indication change at power-on □ : Turned off ■: Turned on

LED Indication Description

STATUS □□□□

STATUS ■■■■

STATUS □□□■

STATUS □□■□

STATUS ■□□□

STATUS ■□□■

STATUS ■□■□

STATUS ■■□□

The power is not turned on.

The RISC CPU is not starting after turning on the power.

The DRAM and SRAM are being tested. (When an error is detected

during a test, this in-test LED indication is held)

The ROM is being tested. (When an error is detected during a test,

this in-test LED indication is held)

Waiting for a request from the main CPU request (1)

Waiting for a request from the main CPU request (2)

Waiting for a request from the main CPU request (3)

Waiting for a request from the main CPU request (4)

1 - 16

Page 21

(2) LED indication while running □: Turned off ■: Turned on

LED Indication Description

STATUS □□□★

STATUS □★□★

STATUS □★★□

STATUS ★□□□

STATUS ★□★★

(3) LED indication for errors □: Turned off ■: Turned on

LED Indication Description

STATUS □□□■

STATUS □□■□

STATUS □□■■

STATUS □■□□

STATUS ■■■□

Waiting for the RISC mode

Waiting for an input of NC statement

Running a command in the RISC mode

Resetting

Override 0 at acceleration/deceleration time before inter-polation

(Waiting for an override change)

An error was detected in testing the DRAM or SRAM on the RISC

board.

An error was detected in testing the ROM module.

A synchronizing signal from the main CPU cannot be detected.

An error was detected in accessing the F-BUS.

System error

(4) ALARM LED indications □ : Turned off ■: Turned on

LED Indication Description

STATUS ■□□

STATUS □■□

STATUS □□■

The RISC CPU is not starting.

SRAM parity

DRAM parity

2.6 MMC-IV BOARD (MMC-IV) ...... Applies only to Multi-Interactive Spec.

This DOS-V personal computer is used in multi-interactive processing. This is a board

designed for high-accuracy profile control.

Name MODEL

MMC-IV BOARD

Note) The conventional and new types of MMC-IV Board are differentiated by use of a

memory card socket.

• Conventional type: With a memory card socket

• New type: Without a memory card socket

A02B-0207-C022 (Conventional type)

A16B-2203-0180 (New type)

2.6.1 SETTING ADJUSTMENT

Since Machine is delivered as having been adjusted prior to shipment, no change is

necessary under normal circumustances.

1 - 17

Page 22

2.6.2 LED DISPLAY

STATUS LED in green color and ALARM LED in red color.

(1) Normal state □ : Turned off ■ : Turned on ×: Irrelevant

LED Indication Description

STATUS □□□□

STATUS ■×××

STATUS ×××■

(2) Abnormal state ■: Turned on ×: Irrelevant

LED Indication Description

STATUS ■××

STATUS ×■×

STATUS ××■

Power OFF state

MMC-IV reset cancelled

HDD access lamp

NMI has occurred in MMC-IV CPU.

Ambient temperature of HDD is either equal to or below 5°C or

equal to or above 55°C.

Parity alarm has occurred in DRAM on the back plane.

2.7 LIQUID CRYSTAL DISPLAY (LCD)

This is a board designed for high-accuracy profile control.

Name SPEC. MODEL

9.5" Monochromatic LCD Without Multi A02B-0222-C110

10.4" Color LCD Without Multi A02B-0222-0150

10.4" Color LCD With Multi A02B-0200-0153

2.7.1 ADJUSTMENT REQUIRED

(1) For A02B-0222-C110 ...... Without Multi Spec./9.5" Monochromatic LCD

VRD 1

DISPLAY, REAR VIEW

1 - 18

Page 23

• VRD1 (Contrast Adjustment)

Through adjustment of VRD1, contrast can be adjusted.

Note

Do not change any setting, volume, etc. other than those mentioned above. A change, if

made in any setting other than the above, results in incorrect screen display.

(2) For A02B-0222-C150 ...... Without Multi Spec./10.4" Color LCD

This display does not include the set pin, volume, etc. for screen adjustment.

Note

Do not change any setting, volume, etc. other than those mentioned above. A change, if

made in any setting other than the above, results in incorrect screen display.

(3) For A02B-0200-C153 ...... With Multi Spec./10.4" Color LCD

T M 1

• • •

SW 1

DISPLAY, REAR VIEW

• TM1 (Flicker Adjustment)

On occurrence of flicker on the screen, change setting of the set pin TM1 into

the other. Normally, flicker can be eliminated in one of these two ways.

• SW1 (Setting of Horizontal Position)

① Use this to shift a display screen horizontally by one dot.

② Use this to set position where all displays are available. There is only one

place for toral display. As it is normally set prior to shipment, no change is

necessary.

Note

Do not change any setting, volume, etc. other than those mentioned above. A change, if

made in any setting other than the above, results in incorrect screen display.

1 - 19

Page 24

2.8 DATA SERVER BOARD

Name MODEL

DATA SERVER BOARD A16B-2202-0630

2.8.1 LED DISPLAY

STATUS LED in green color and ALARM LED in red color.

(1) LED Indications on Supply of Power □ : Turned off ■ : Turned on

No LED 1 2 3 4 DATA SERVER STATE

display

1 STATUS □□□□ Power OFF state

2 STATUS ■■■■ Initial state immediately after supply of power.

3 STATUS □■■■ Main memory test

4 STATUS ■□■■ Ethernet RAM test

5 STATUS □□■■ Common RAM test

6 STATUS ■■□■ Initialization of system area

7 STATUS □■□■ FANUC BUS interrupt test 1

8 STATUS ■□□■ FANUC BUS interrupt test 2

9 STATUS □□□■ FANUC BUS interrupt test 3

10 STATUS ■■■□ FANUC BUS interrupt test 4

11 STATUS □■■□ Initialization of interrupt controller

12 STATUS ■□■□ Initialization BIOS

13 STATUS □□■□ Program loading

14 STATUS ■□□□ Completion of starting of the data server board

When the data server board starts properly, LED display is stopped in “No.14”

state.

Hardware in

checking

Starting of

data serve

software

1 - 20

Page 25

(2) LED Indications on Occurrence of Error (STATUS)

□: Turned off ■: Turned on ×: Irrelevant

“STATUS” LED repeats “LONG” and “SHORT” patterns. The “LONG” pattern is

displayed for a longer time length, while the “SHORT” one for a shorter time

length.

LED DISPLA Y (ST ATUS)

No

LONG

1 2 3 4

1 □□□■ □□■□ Main memory failure. Check the data server board.

2 □□□■ ■□■□ Ethernet RAM failure. Check the data server board.

3 □□□■ □■■□ Common RAM failure. Check the data server board.

4 ■□□■ ×××× An invalid interrupt has been given to CPU.

5 □■□■ ×××× An invalid interrupt has been given to CPU.

6 ■■□■ ×××× An invalid interrupt has been given to CPU.

7 □■■■ ■□□□ A system error has occurred in the data server board.

8 □□■■ ■□□□ A bus error has occurred in FUNUC BUS. Check the data

SHORT

1 2 3 4

server board.

DATA SERVER STATE

9 □□■■ □■□□ A parity error has occurred in the main memory.

10 □□■■ ■■□□ A parity error has occurred in the Ethernet RAM.

11 □□■■ □□■□ A parity error has occurred in the Common RAM.

12 □□■■ ■□■□ “Refresh” to the main memory has ceased for a time longer

than the set length.

(3) LED Display on Occurrence of Error (ALARM)

■: Turned on ×: Irrelevant

No LED DISPLAY 1 2 3 DATA SERVER STATE

1 ALARM ■×× Either a parity error has occurred in any of the main memory,

Ethernet RAM, and Common RAM, or “refresh” to the main

memory has ceased for a time longer than the set length.

Referring to “STATUS” LED NO’s 9 to 12, identify the failure

and replace the part.

2 ALARM ×■× Fuse is gone. Replace a fuse.

3 ALARM ××■ CPU is in Halt or SHUTDOWN state.

Check the board.

1 - 21

Page 26

2.8.2 REPLACEMENT OF FUSE

(1) Check the fuse on the front panel of the data server board for any disconnection.

On occurrence of disconnection, a white marker appears in a small window of the

fuse.

(2) Remove the cause which has disconnected the fuse.

(3) Pulling out the disconnected fuse, insert a new one of the same specification.

STATUS

ALARM

F 1

2.0A

Fuse

Fuse specification: A08B-0048-K101

Capacity:2.0A

Application: For Ethernet supply power

1 - 22

Page 27

2.9 LIST OF UNITS AND PRINT BOARDS

2.9.1 CONTROL UNIT RACK

NAME SPECIFICATIONS TYPE

S-Σ 10L

CONTROL UNIT

RACK

S-Σ 10L

CONTROL UNIT

RACK

2.9.2 POWER UNIT

NAME TYPE

POWER UNIT AI A16B-1212-0901

POWER UNIT BI A16B-1212-0871

2.9.3 CONTROL UNIT P.C.B.

MMC-IV not

provided

MMC-IV

provided

MMC-IV not

provided

MMC-IV

provided

6 slots A02B-0200-C003

8 slots A02B-0200-C004

6 slots A02B-0200-C011

8 slots A02B-0200-C012

4 slots A02B-0129-C002

6 slots A02B-0129-C003

4-slots A02B-0129-C010

6 slots A02B-0129-C011

NAME SPECIFICATIONS TYPE

MAIN CPU BOARD

OPTION 1 BOARD

OPTION 3 BOARD

HIGH-SPEED SKIP

SIGNAL INPUT BOARD

CONTROL UNIT

GRAPHIC BOARD

64-BIT RISC BOARD

DATA SERVER BOARD

MC-IV BOARD

S-Σ 10M

S-Σ 10L

REMOTE BUFFER

PMC-RC

MULTIINTERACTIVE

A16B-3200-0190

A16B-3200-0210

A16B-2200-0913

A16B-3200-0054

A16B-2200-0954

A20B-8001-0480

A16B-3200-0150

A16B-2202-0630

A02B-0207-C022

(Conventional type)

A16B-2203-0180

(New type)

1 - 23

Page 28

3. TROUBLESHOOTING

When a trouble happened, check “when it happened,” “what you were operating,” “what it

was like,” and “how often it happens.”

3.1 T racking through the ALARM Screen

When an alarm happened during operation, an alarm message appears on the top area

of the screen.

For some alarms, the details are displayed on the diagnostic screen. Confirm, then, the

description on the diagnostic screen in the following operation:

[Display Operation of Diagnostic Screen]

While NC “General Screen” is displayed, operate as:

(OPER./MAINTE) → F4 SYSTEM →3 0 (F MENU) INPUT →

△

2 (F_SYSTEM) INPUT → F7 DGNOS

to display the diagnostic screen. Input, then, a number to be referred to and push

F6 NO.SRH . Data for the diagnostic number are displayed. (The page key is

useable to make a change.)

(Note 1) When the diagnostic function does not appear in F7 following “F SYSTEM”

being selected in the above operation, push (RETURN) a few times.

(Note 2) Use ALTER , not (RETURN), for return operation from the

diagnostic screen.

△

3.2 Tracking through the Controller’s Monitor LEDs

Each unit in the controller has monitor LEDs so that you can check for the status of each

unit. For details, see 2. FUNCTIONS AND HANDLING OF CONTROL UNITS.

Each Unit

STATUS

ALARM

1 - 24

Page 29

4. POWER-ON ADJUSTMENT

4.1 Power-on Procedure

①Enter (set) the PMC ladder and others.

②Enter (set) the NC parameters.

③Turn off the power and turn it on again.

(Note) When system software has not been entered into the NC internal memory,

transfer it into the NC internal memory according to the instructions in

[APPENDIX] BOOT SYSTEM, and then, go through the above-mentioned

steps.

4.2 System Table

This CNC unit sets allocations of the data areas such as machining program, tool offset

amount through the "system table."

To display the System Table screen, operate in the following order in the Overall screen:

OPER./MAINTE → F4/SYSTEM → 2 5 (SYSTEM TABLE) → INPUT

△

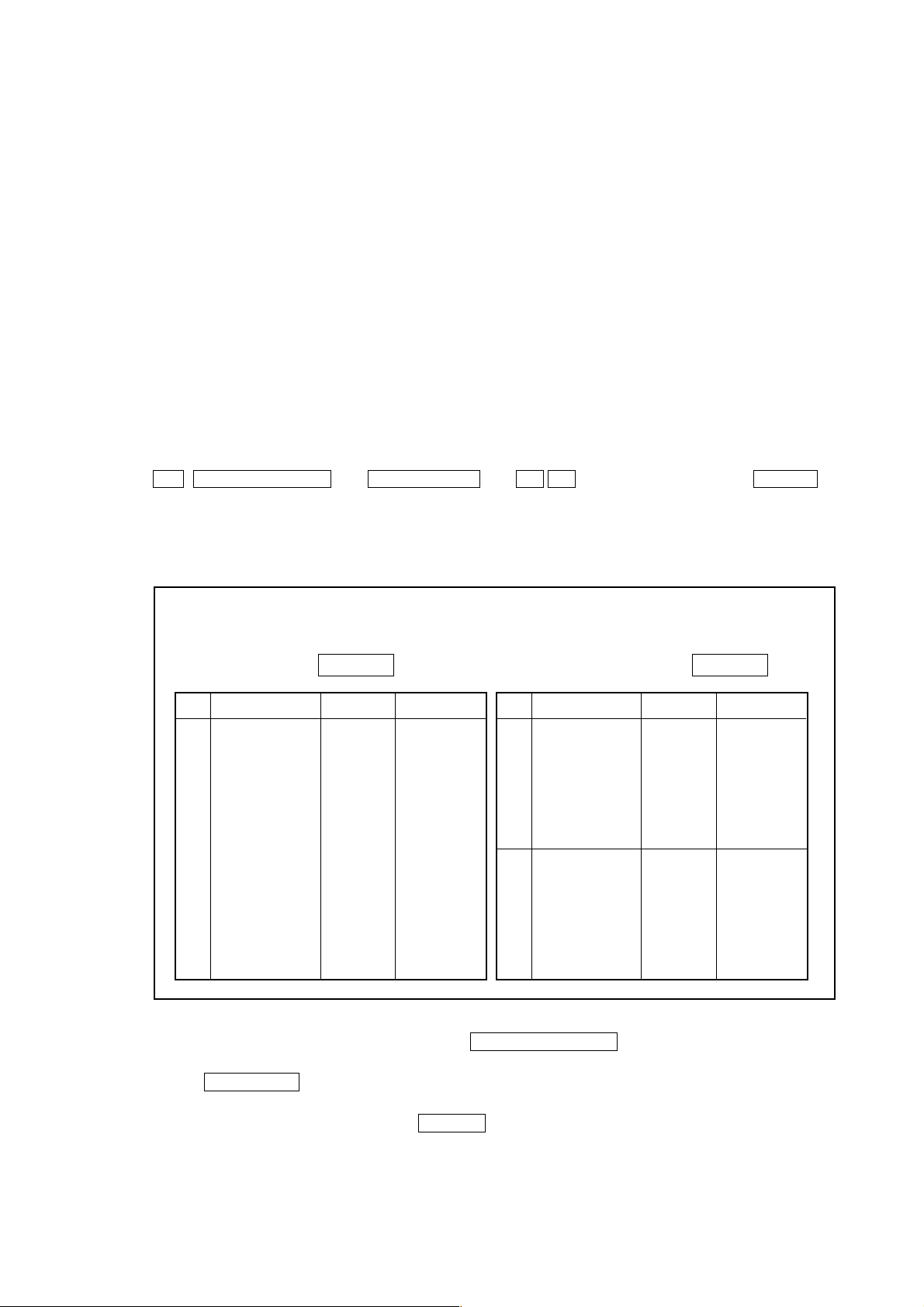

SYSTEM T ABLE

BASIC RAM SIZE 38E40 EXT. RAM SIZE 0

No. TABLE SIZE OFFSET No. TABLE SIZE OFFSET

01 SYSTEM 10000 0 11 0 0

02 TOOL 5000 0 12 0 0

03 SPARE 3900 0 13 0 0

04 MONI 6F00 0 14 0 0

05 PRGRM 13000 0 15 DUMMY 6600 32800

06 0 0 16 0 0

07 0 0 17 0 0

08 0 0 18 0 0

09 0 0 19 0 0

10 0 0 20 0 0

When initially starting up the system, press F5/SYSTEM CLR to initialize the system.

When this is done, the basic RAM capacity and extended RAM capacity are automaticlly set.

Pressing F3/TABLE brings the cursor into the table. In accordance with the names versus

capacities table provided on the next page, set the table names and capacities, using

[Cursor] and [Alphanumeral] plus the INPUT key.

1 - 25

Page 30

(Note 1) The numbers 01 through 15 are the tables for the basic RAM, and 16 through

20 are those for the extended RAM. When the extended RAM capacity is 0

(zero), do not set for the numbers 16 through 20.

(Note 2) Set the capacity in an increment of 100, suffixing a numeral with “H” (indicates

hexadecimal)

(Note 3) If the capacity is entered, the offset for the next table will be automatically set.

Different from the S-III, however, the last table capacity is not adjusted. Set a

dummy table before the last table capacity so that it will be of specified

capacity.

(Note 4) The table number 01 has a fixed table name, “SYSTEM,” and capacity,

“1000H.” For the other tables, you can set any table names in any places.

(Note 5) A standard set value varies from one model to another. When actually setting

it, follow the materials for each model.

(Note 6) When the system table is changed, be sure to turn off and on the power to

make sure that “790 System Table Error” does not occur, and then, start

1 - 26

Page 31

operating the system.

Function Table Spec.

System Data

Tool offset

Tool life

management

Cutting

monitoring

Machining

program

SYSTEM 10000H

TOOL 200 pairs 2800H 5000H

SPARE 200 pairs 2000H

MONI 200 pairs 4800H

PRGRM 1,000m 6F000H

Capacities

Σ 10M Σ 10L

32 pairs 600H C00H

64 pairs C00H 1400H

100 pairs 1400H 2800H

400 pairs 5000H

500 pairs 5E00H

1,000 pairs BC00H

32 pairs B00H

64 pairs F00H

100 pairs 1300H

400 pairs

500 pairs 3900H

1,000 pairs

32 pairs 2800H

64 pairs 2E00H

100 pairs 3500H

400 pairs

500 pairs 6F00H

1,000 pairs

80m A000H

160m 13000H

320m 24000H

500m 37000H

640m 4A000H

1,280m 8B000H

2,000m D5000H

2,560m 10E000H

4,000m 1A1000H

5,120m 200000H

400H

2000H

Remarks

Table No. 01 Fixed

The 100 pairs in the Spec.

column represents;

M-system: 100 pairs

L-system: 99 pairs

The Spec. column

represents the number of

tool offset pairs.

The spec. column

represents the number of

tool offset pairs.

The maximum number of

registerable programs is

irrelevant.

High-precision

contour control

Automatic

program

(Multi-interactive)

HPCC 10000H

3800H

TLFILE

1 - 27

3500H

5100H

6600H

M-system only

NR/TG turning only

NR/TG turning + rotation

CA

Page 32

4.3 SLBUS Table

In order to allocate the addresses for the input signals (X contact) and output signal (Y

contact) on the part of the machine, itis necessary to set ths SLBUS table.

To display the SLBUS TABLE screen, operate as follows in the OVERALL screen.

[ ] (OPRE/MAINTE) → [F4/SYSTEM] → [2][4](SLBUS) → [INPUT]

SLBUS TABLE

△

Lead Ch. Chanels Bytes Address

No. Loc# Type Slave Division

Buffer Size IN OUT IN OUT IN OUT

01 00 0 00 00 00 00 00 00 F0 F0

02 00 0 01 01 02 00 00 10 00 00

03 00 0 00 00 00 00 00 00 00 00

04 00 0 00 00 00 00 00 00 00 00

05 00 0 00 00 00 00 00 00 00 00

06 00 0 00 00 00 00 00 00 00 00

07 00 0 00 00 00 00 00 00 00 00

08 00 0 00 00 00 00 00 00 00 00

09 00 0 00 00 00 00 00 00 00 00

10 00 0 00 00 00 00 00 00 00 00

11 00 0 00 00 0000 0000 0000

12 00 0 00 00 00 00 00 00 00 00

13 00 0 00 00 00 00 00 00 00 00

14 00 0 00 00 00 00 00 00 00 00

15 00 0 00 00 00 00 00 00 00 00

16 00 0 00 00 00 00 00 00 00 00

High

Speed

To alter the set value, press [F9/ALTER]. The message, “DO YOU WANT TO ALTER

? (Y/N),” is messaged. Press [Y]. Aframe cursor appears in the table, allowing you to

alter the set value. Make setting according to the machine specifications.

When you start up the system for the first time, press [F8/CLEAR ALL] to initialize the

data, and then, set each item.

After alteration is completed, press [F9/REFER] to end the setting mode.

1 - 28

Page 33

5. DAILY MAINTENANCE AND INSPECTION

5.1 Replacing the Battery

[WARNING]

Turn on the power for the machine (CNC), press the EMERGENCY STOP switch, and

then, replace the battery. Since this work is carried out with the cabinet left open in the

power-on state, only personnel who has been trained on maintenance and safety

should do it.

When opening the cabinet to replace the battery, do not touch a high-voltage circuit. If

the cover is not in place and you touch there, you will get an electric shock.

5.1.1 CNC Memory Backup Battery

The CNC is provided with batteries for retaining memory to store programs, offset

volumes, parameters, etc. When battery voltage has lowered, “794 BATTERY

ALARM” warning is displayed. On appearance of the warning, change batteries as

soon as possible. Try not to turn off the CNC unit as much as possible until the battery

is replaces.

(1) CNC memory backup battery replacement procedure

① Turn on the power for the machine (CNC). (Note)

② Remove a battery case located on the front panel of the power unit. Hold down

the top of the case and pull it to your side to remove it.

③ Disconnect a connector attached to the battery.

④ Replace the battery and put back the connector.

⑤ Reattach the battery case.

⑥ Turn off the power for the machine (CNC).

CNC Controller

Power Unit

Front Panel

Lithium Battery

Battery Case

A02B-0200-K102 (For Power Sources AI and BI)

A02B-0200-K106 (For Power Sources C)

1 - 29

Page 34

[Note]

Whether the CNC is turned on or off, the battery can be replaced. When replacing it

with the CNC turned off, however, complete replacement within 30 minutes. If the

battery has been removed for 30 minutes or more with the power turned off, the

contents of the CNC memory may be lost. When the contents of the memory are lost

this way, a RAM PARITY system alarm may occur to disable the CNC, even if it is

turned on.

5.1.2 Replacing the Absolute Encoder Battery

When the machine has an absolute encoder such as absolute pulse coder or absolute

linear scale, an absolute encoder battery has been installed in addition to a memory

backup battery.

When an APC alarm no. F307 or no. F308 occurs, replace the battery as soon as

possible. Unless it is replaced, an absolute position will be lost and you will have to

manually operate reference point return again.

(1) Absolute encoder battery replacement procedure (α series servo amplifier

module)

① Turn on the power for the machine (CNC).

② Remove a battery case located on the front of a α series servo amplifier

module (SVM). Hold the top and bottom of the case and pull it to your side.

③ Disconnect a connector attached to the battery.

④ Replace the battery and put back the connector.

⑤ Reattach the battery case.

⑥ Turn off the power for the machine (CNC).

Battery Case

α Series

SVM

Connector CX5X

Connector

1 - 30

Battery

A06B-6073-K001

Page 35

(2) Absolute encoder battery replacement procedure (Separate pulse coder)

① Turn on the power for the machine (CNC).

② Unscrew the battery case and remove the cover.

③ Replace the dry cells in the case. Set two each of dry cells in different

directions.

④ After replacing the dry cells, put back the cover.

⑤ Turn off the power for the machine (CNC).

Screws

Cover

[Note]

Replace the battery with the CNC turned on. If the battery is replaced with the power

turned off, a memorized absolute position will be lost.

1 - 31

Page 36

I-II SEICOS

1. OVERVIEW

1.1 System Configuration

1.2 Hardware Overview

2. PCB CONNECTORS AND CARD CONFIGURATION

2.1 S-Σ 16/18/21 Mother Boards

2.2 Inverter PCBs

2.3 Serial Communication Board (Remote Buffer)/C Language Board

2.4 RISC Board

2.5 Data Server Board

2.6 List of Unit and PCBs

3. TROUBLESHOOTING

3.1 Tracking through the ALARM Screen

ΣΣ

Σ 16/18/21 UNIT

ΣΣ

4. POWER-ON ADJUSTMENT

4.1 Power-on Procedure

4.2 System Table

4.3 SLBUS T able

5. DAILY MAINTENANCE AND INSPECTION

5.1 Replacing the Battery

5.2 Replacing the Fuse for the Control Unit

5.3 Replacing the Fan Motor

5.4 Adjusting the Contrast of the Monochrome Display

1 - 32

Page 37

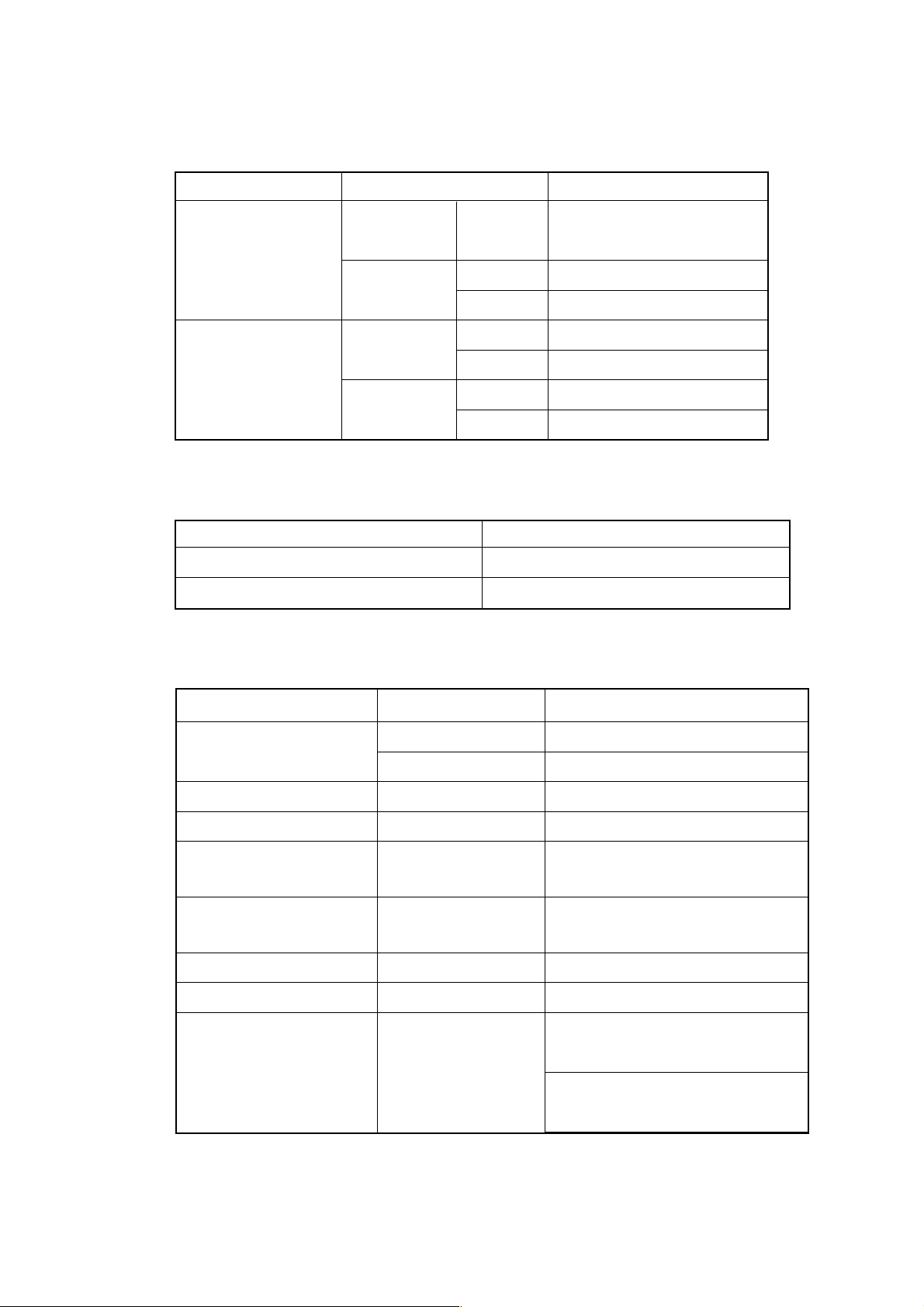

1. OVERVIEW

The SEICOSΣ 16/18/21 CNC system is a more compact high-reliability unit provided with

up-to-date device technology and integrates a display unit and an NC unit.

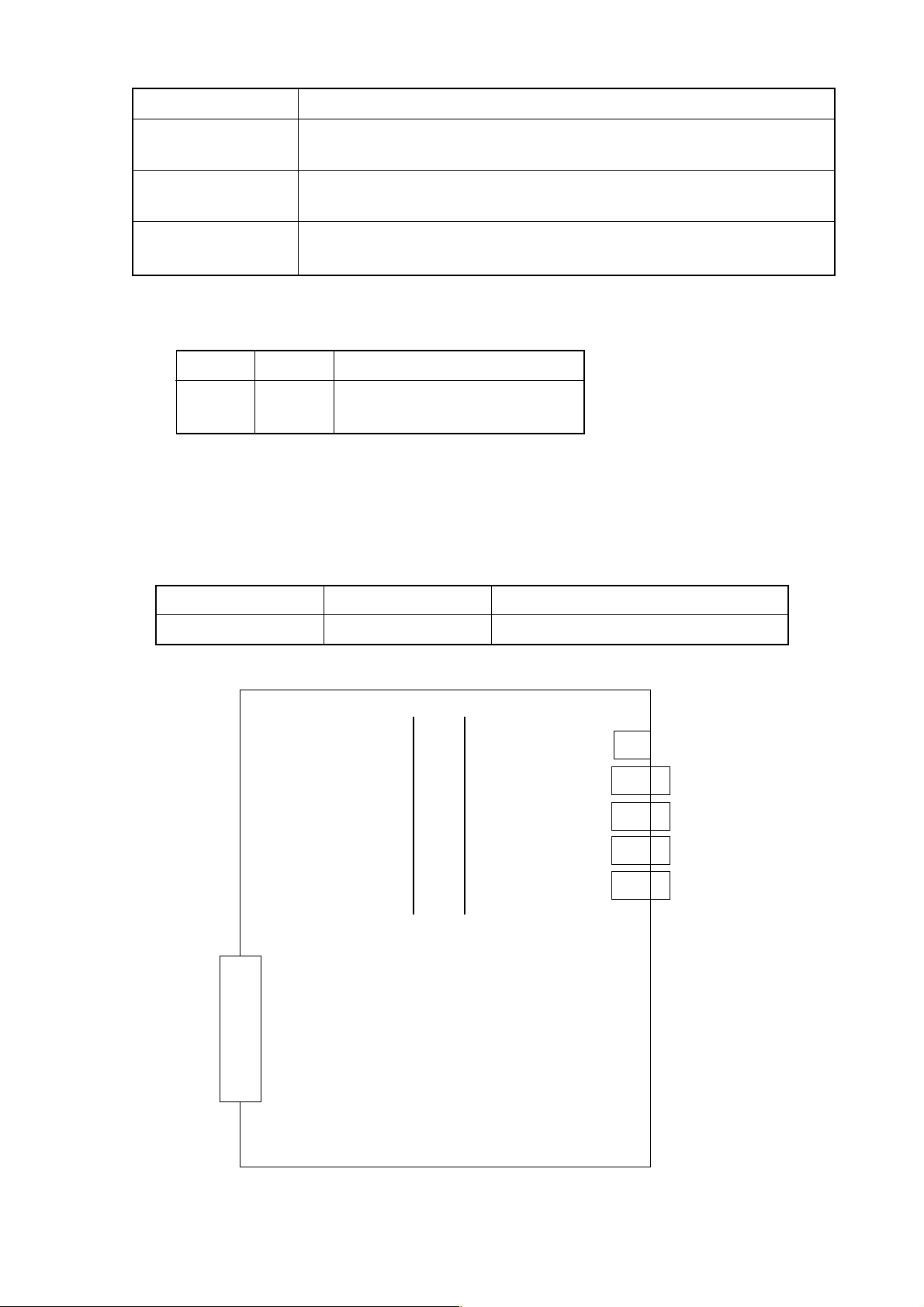

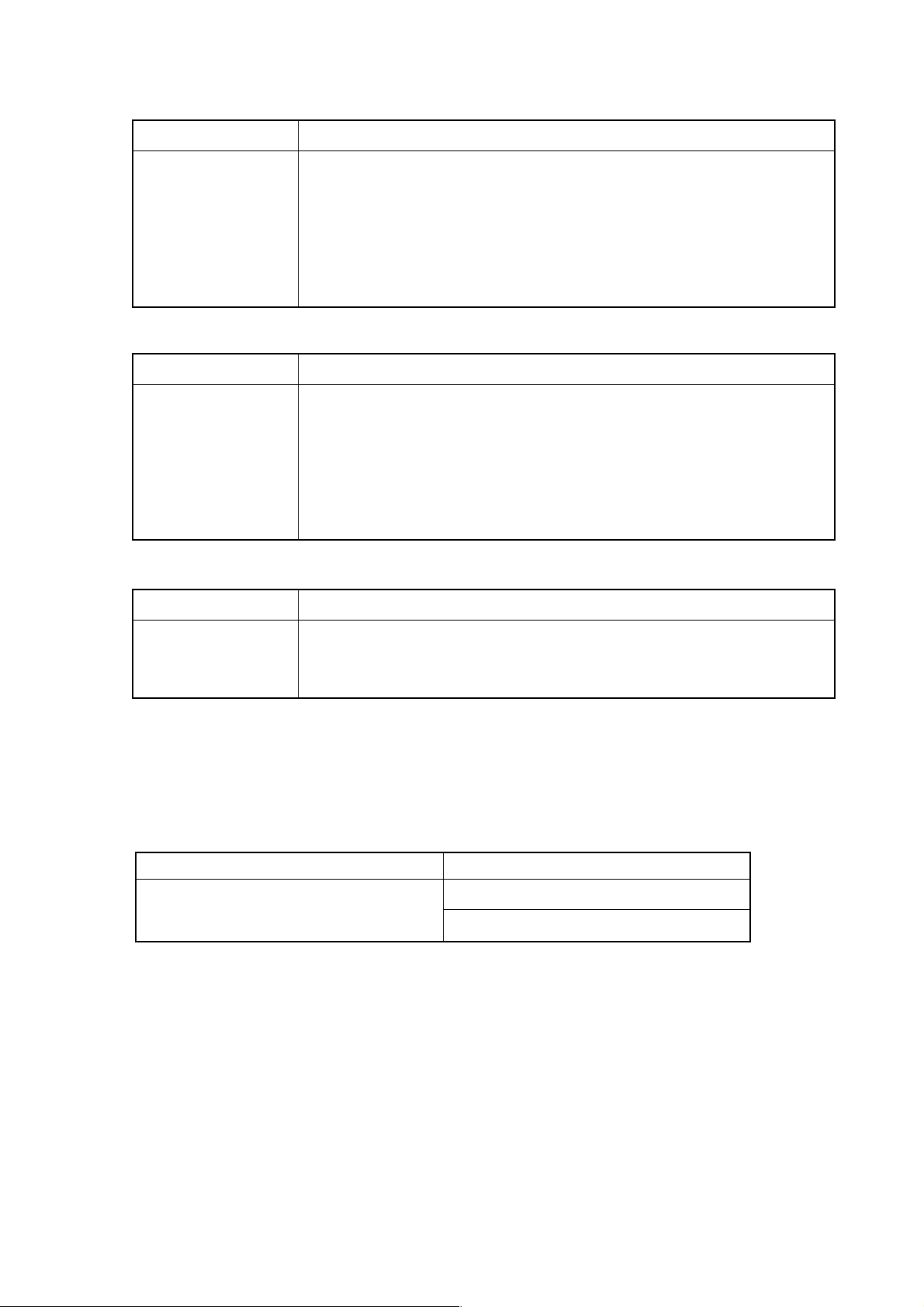

1.1 System Configuration

The following figure shows a system example using the SEICOS Σ 16/18/21 CNC unit.

CONTROL/LCD Unit

Optical Cable

Spindle Amp.

I/O LINK

Servo Amps.

CNC Keyboard

SLBUS

Conversation

Module

SLBUS

SLBUS

Distribution Board

Spindle

Motor

Servo

Motor

Servo

Motor

1 - 33

I/O Slaves

Servo

Motor

Page 38

1.2 Hardware Overview

1

1

1

1

1

1

1

1234567890123456789012345678901212345678901234

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1234567890123456789012345678901212345678901234

1234567890123456789012345678901212345678901234

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1234567890123456789012345678901212345678901234

1234567890123456789012345678901212345678901234

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1234567890123456789012345678901212345678901234

1234567890123456789012345678901212345678901234

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1234567890123456789012345678901212345678901234

1.2.1 SEICOS

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

Serial Communication Board

23456789012345678901234567890121234567890123

Remote Buffer (DNC)

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

(S- ƒ°16M Only)

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

Data Server Board

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

Data Server Function

ΣΣ

Σ 16

ΣΣ

RISC Board

Option

23456789012345678901234567890121234567890

23456789012345678901234567890121234567890

23456789012345678901234567890121234567890

23456789012345678901234567890121234567890

23456789012345678901234567890121234567890

23456789012345678901234567890121234567890

23456789012345678901234567890121234567890

Mother Board

CNC Control CPU

• 2- to 8-axis Control

• Spindle Interface

• LCD/MDI

• I/O Link

• PMC-RB5/-RB6

• Analog Output/

High-speed DI

• RS-232C x 2

• Memory Card Interface

Basic System

Control/LCD Unit

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

C Language Board

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

C Language Function

for PMC

No Option Slots, or 2, 3,

or 4 Slots (Note)

(Note) If there are 3 or 4 slots provided, only the RISC board can be installed in the

2nd slot (center) of the 3 slots and in the 4th slot (farthest from the LCD) of the

4 slots, respectively.

1 - 34

Page 39

1.2.2 SEICOS

2

2

2

2

2

2

2

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

Serial Communication Board

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

Remote Buffer (DNC)

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

Data Server Board

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

ΣΣ

Σ 18

ΣΣ

234567890123456789012345678901212345678901

234567890123456789012345678901212345678901

234567890123456789012345678901212345678901

234567890123456789012345678901212345678901

234567890123456789012345678901212345678901

234567890123456789012345678901212345678901

234567890123456789012345678901212345678901

Mother Board

CNC Control CPU

• 2- to 6-axis Control

• Spindle Interface

• LCD/MDI

• I/O Link

• PMC-RB5/-RB6

• Analog Output/

High-speed DI

• RS-232C x 2

• Memory Card Interface

Basic System

Data Server Function

Option

Control/LCD Unit

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

C Language Board

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

C Language Function

for PMC

No Option Slots, or 2, 4,

or 4 Slots (Note)

(Note) If there are 4 slots provided, the 4th slot (farthest from the LCD) is not

available.

1 - 35

Page 40

1.2.3 SEICOS

1

1

1

1

1

1

1

5

5

5

5

5

5

5

ΣΣ

Σ 21

ΣΣ

23456789012345678901234567890121234567890

23456789012345678901234567890121234567890

23456789012345678901234567890121234567890

23456789012345678901234567890121234567890

23456789012345678901234567890121234567890

23456789012345678901234567890121234567890

23456789012345678901234567890121234567890

Mother Board

CNC Control CPU

• 2- to 4-axis Control

• Spindle Interface

• LCD/MDI

• I/O Link

• PMC-RA5

• Analog Output/

High-speed DI

• RS-232C x 2

• Memory Card Interface

Basic System

234567890123456789012345678901212345678901234

234567890123456789012345678901212345678901234

234567890123456789012345678901212345678901234

234567890123456789012345678901212345678901234

234567890123456789012345678901212345678901234

Serial Communication Board

234567890123456789012345678901212345678901234

234567890123456789012345678901212345678901234

Remote Buffer (DNC)

Option

Control/LCD Unit

No Option Slots, or 2 Slots

1 - 36

Page 41

2. PCB CONNECTORS AND CARD CONFIGURATION

2.1 Mother Boards

2.1.1 Specification

Name Specification

S-Σ 16 Mother Boards A20B-8100-0130

S-Σ 18 Mother Boards A20B-8100-0135

S-Σ 21 Mother Boards A20B-8100-0136

(PMC-RA5)

2.1.2 Connector Applications

Connector No. Application

COP10A Servo motor (FSSB)

CA55 MDI (CNC keyboard)

CA54 Servo check

JD36A RS-232C serial port 1

JD36B RS-232C serial port 2

JA40 Analog output/high-speed DI

JD1A I/O link

JA41 Serial spindle/position coder

CP1B 24 V DC-OUT

CP1A 24 V DC-IN

JNA F-BUS interface

CN8B Video signal interface

MCRD1 PCMCIA (memory card) interface

1 - 37

Page 42

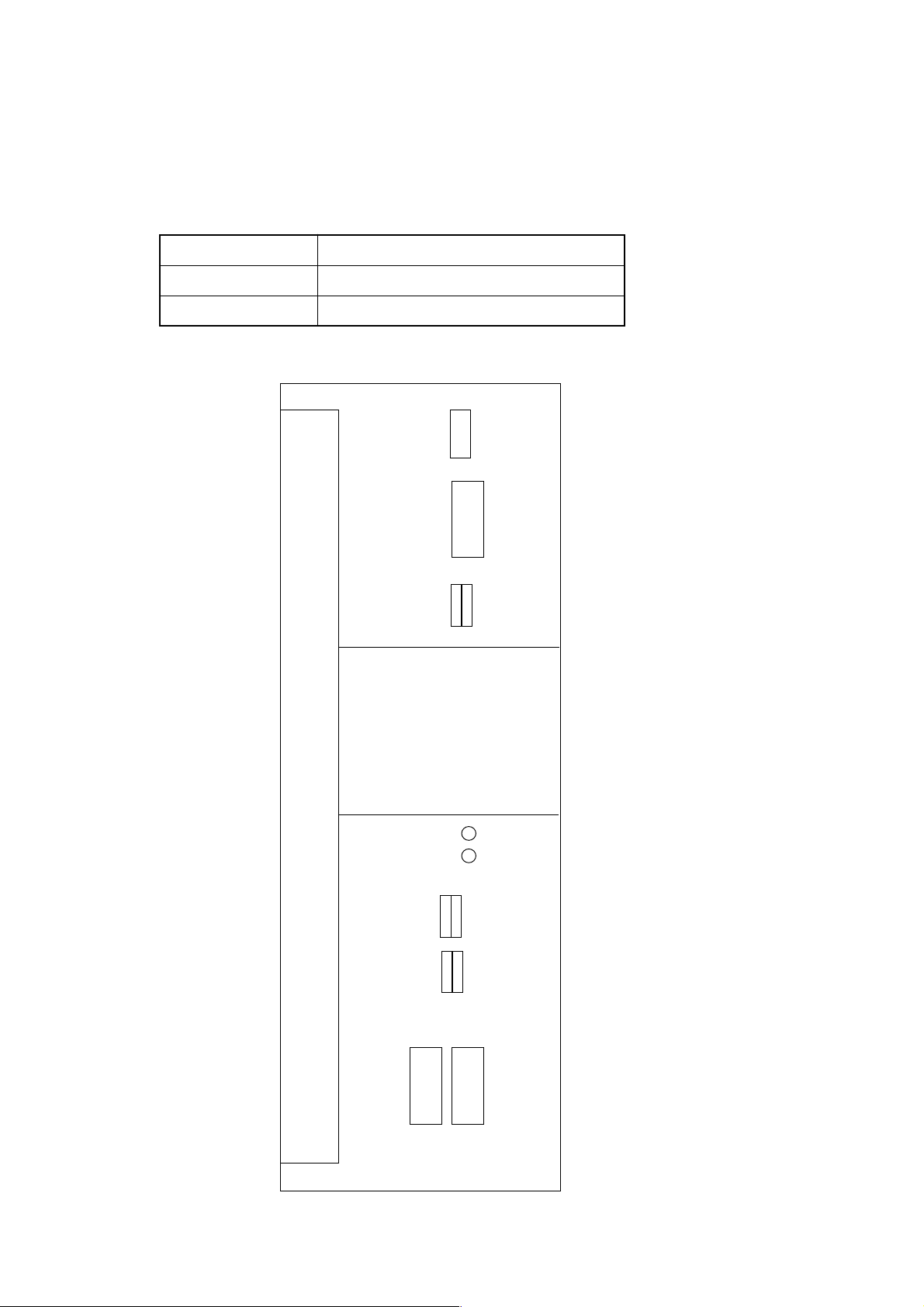

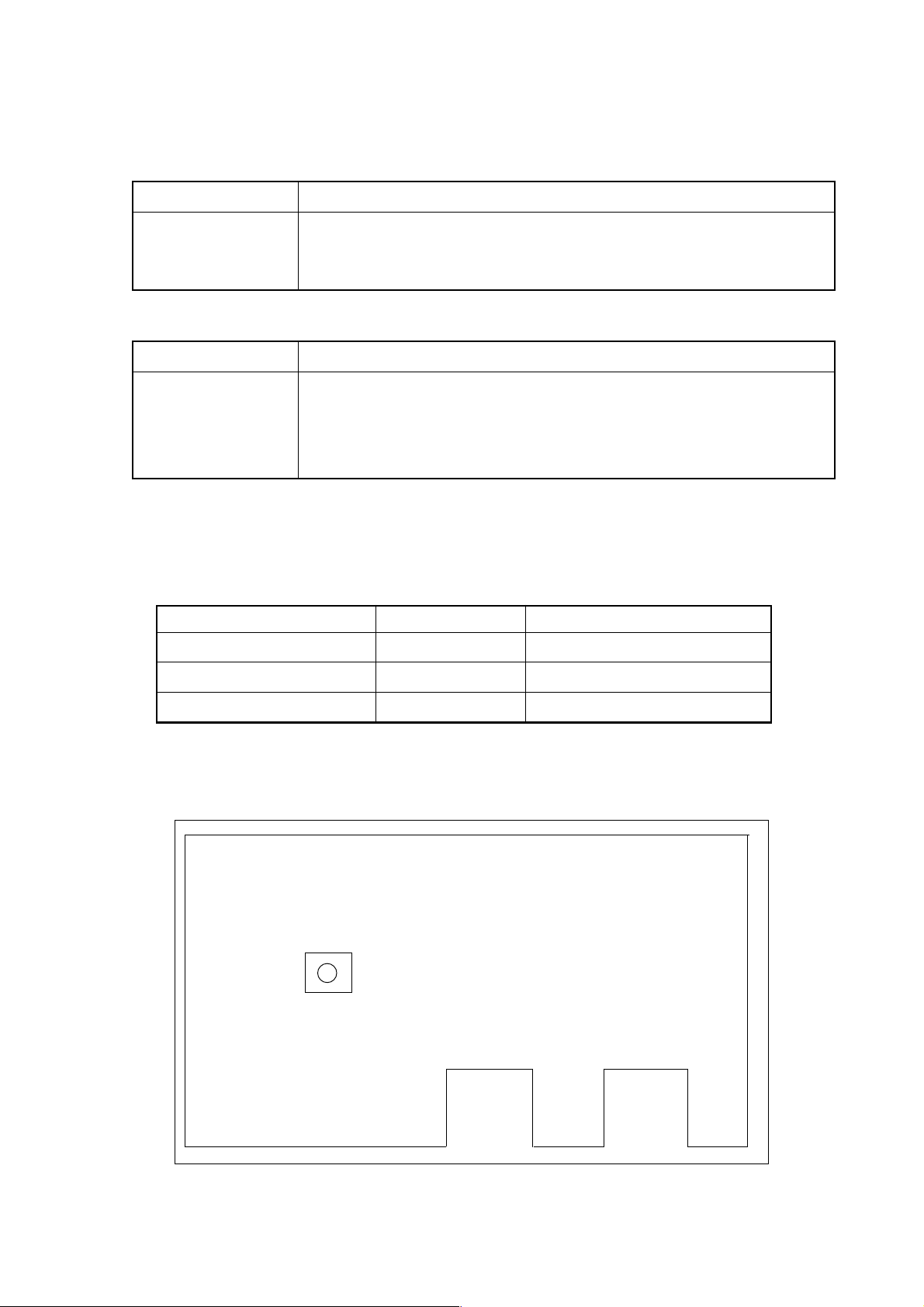

2.1.3 Connector Mounting Positions

(COP10A is a connector located

above the server card)

Inverter PCB

Battery

Rear of Unit

Mother Board

Mother Board

1 - 38

Page 43

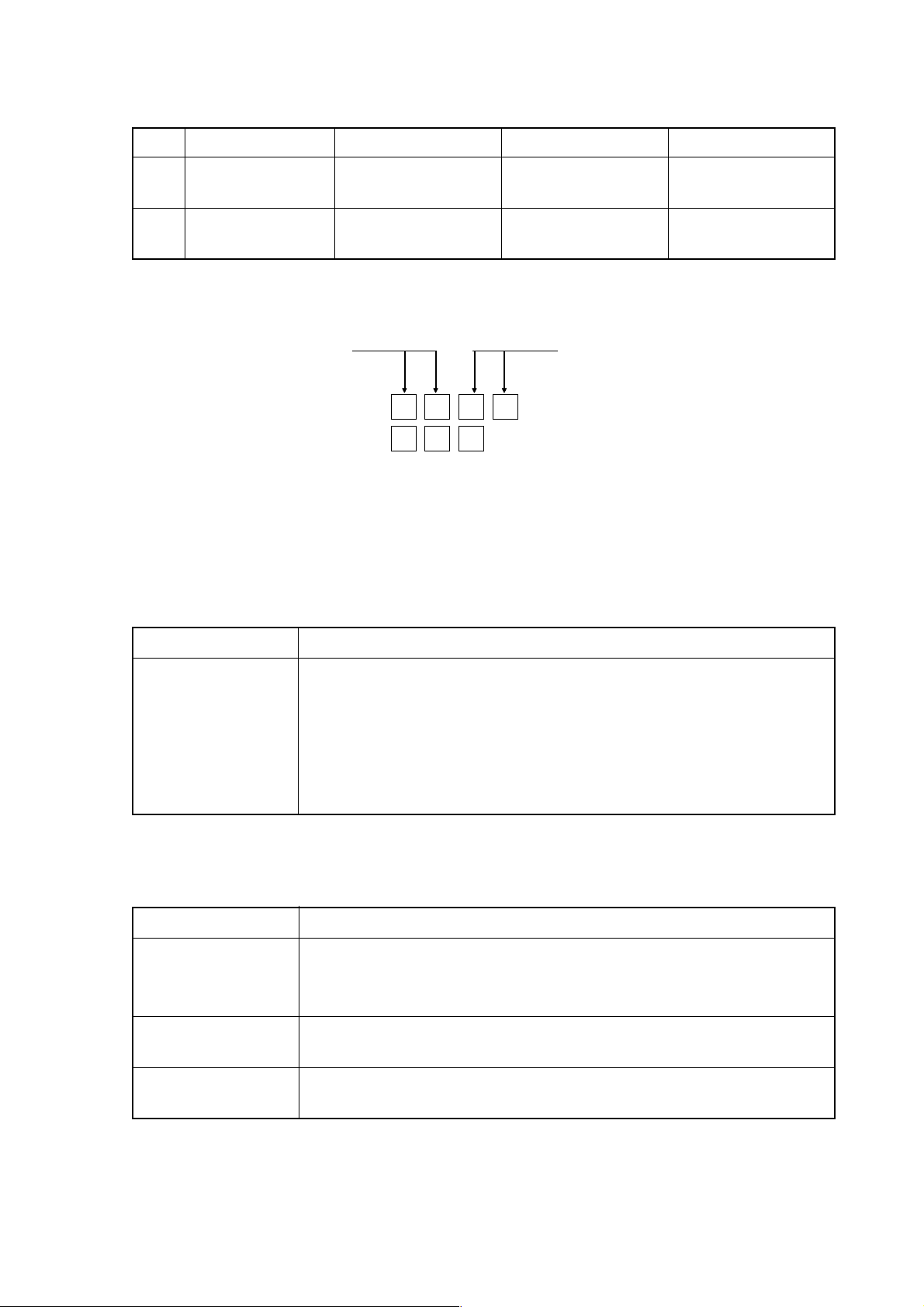

2.1.4 Card Mounting Positions

①Axis

Control Card

No Name Specification Function Remark

① A17B-3300-0100

Axis control

card

② Display

Contorol Card

Axis control

③

CPU Card

Mother Board

8 axes (Allowed only for

Σ 16)

A17B-3300-0101

A20B-3300-0030

A20B-3300-0031

② A20B-3300-0020

Display control

card

③ A20B-3300-0050

CPU card

A20B-3300-0023

A20B-3300-0070

Text display/

graphic display

CNC control

6 axes (Allowed only for

Σ 16/18)

4 axes

2 axes

10.4-inch color

9.5-inch monochrome

Pentium (Σ 16/18)

486DX2 (Σ 21)

1 - 39

Page 44

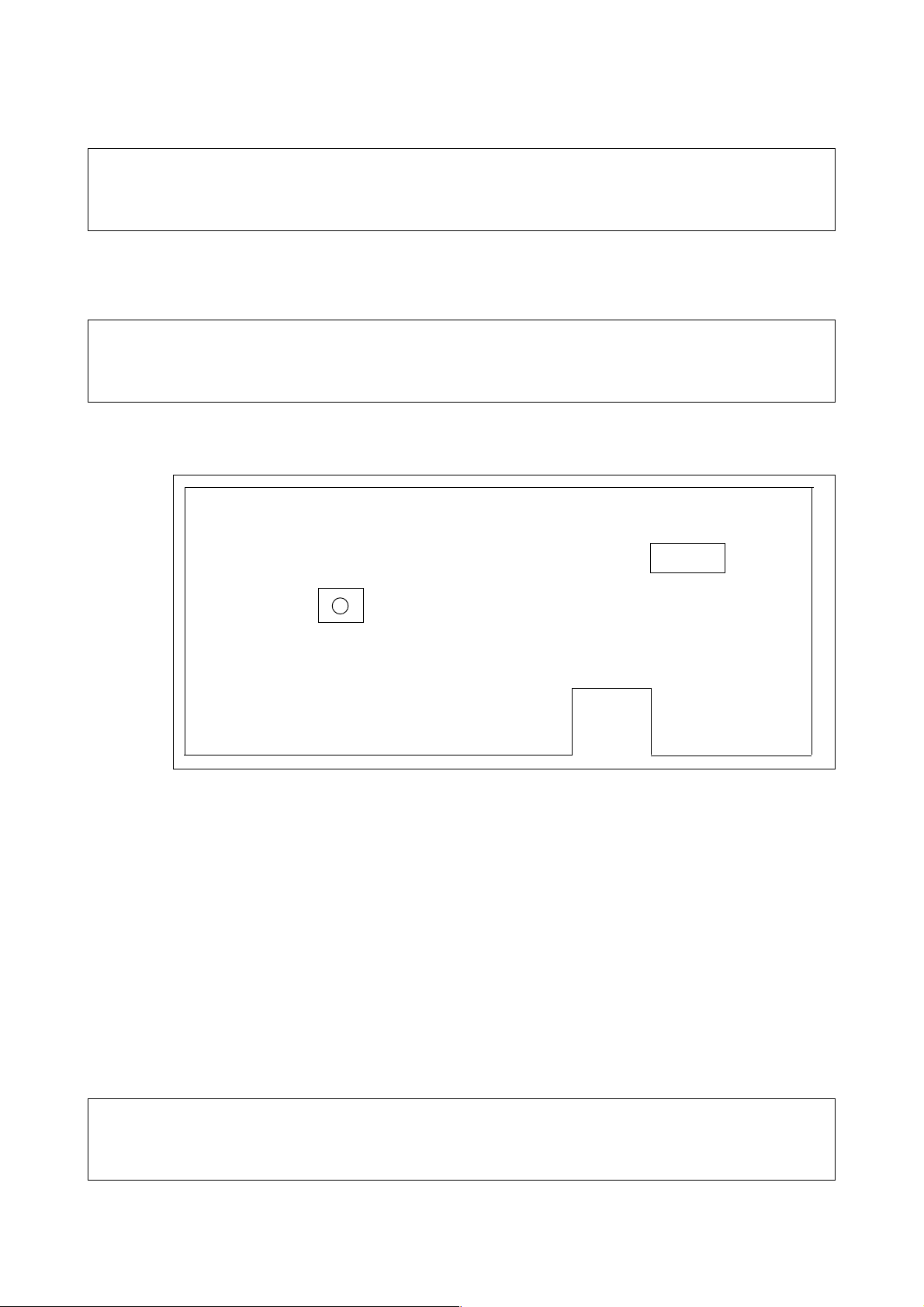

2.1.5 DIMM Module Mounting Positions

(1) FROM/SRAM module

② SRAM Module①From Module

DIMM Module Socket

Mother Board

No Name Specification Function Remark

① A20B-3900-0010

FROM module

A20B-3900-0011

A20B-3900-0012

② A20B-3900-0020

SRAM module

A20B-3900-0060

A20B-3900-0061

A20B-3900-0052

CNC system,

Servo system,

PMC ladder

System SRAM

graphic display

16 M (Allowed only for Σ

16/18)

12 M (Allowed only for Σ

16/18)

8 M

3 M

(Allowed only

2 M

for Σ 16/18)

1 M

512 K

1 - 40

Page 45

(2) DRAM module

③ DRAM Module

Connector

CPU Card

Side B

No Name Specification Function Remark

① A20B-3900-0040

DRAM module CNC System RAM 12 M (Allowed only for Σ

A20B-3900-0041

DIMM Module Socket

16/18)

8 M

1 - 41

Page 46

2.2 Inverter PCBs

2.2.1 Specifications

Inverters 10.4" color (For 0 or 2 slots) A20B-2002-0500

10.4" color (For 4 slots) A20B-8100-0200

9.5" monochrome (For 0 or 2 slots) A20B-2002-0480

9.5" monochrome (For 4 slots) A20B-2002-0550

2.2.2 Connector Mounting Positions

(1) Overall

Name Specification

Battery

Rear of Unit

CP8

CN39A CN39B

Inverter PCB

1 - 42

Mother Board

Page 47

(2) PCB alone

① With no slots or 2 slots

CN39A CN39B

CP1

CN3

② With 4 slots

CN39BCN39A

CP1

Connector No. Application

CN39A Fan power

CN39C CN39D

CN3

CP8

CP8

CN39B

CN39C

CN39D

CP8 Battery

CP1 LCD backlight power

CN3 Inverter PCB power

1 - 43

Page 48

2.3 Serial Communication Board (Remote Buffer)/C Language Board

2.3.1 Specifications

Name Specification Remark

Serial communication board

A (Remote buffer)

C language board

2.3.2 Connector Mounting Positions

(1) Serial communication board A (Remote buffer)

JNA

F-BUS Back Plane Connector

A20B-8100-0152

A20B-8100-0151 Allowed only for Σ 16/18

JD28A

JD6A

Connector No. Application

JD28A RS-232C serial port

JD6A RS-422 serial port

(2) C language board

JNA

F-BUS Back Plane Connector

(Note) The C language board has no connectors to link to the outside.

1 - 44

Page 49

2.3.3 Card Mounting Position

5

5

5

5

5

5

5

5

5

5

5

5

5

5

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

Connector

DIMM Module Socket

(Mounted onto the CPU Card)

JD28A

JD6A

CPU Card

Name Specification Function Remark

CPU Card A20B-3300-0070 486DX2

Serial communication function, PMC

C language function

1 - 45

Page 50

2.4 RISC Board

2.4.1 Specifications

Name Specification Remark

RISC board A20B-8100-0170 Allowed only for Σ 16M allowed

2.4.2 Connector Mounting Positions

JNA

F-BUS Back Plane Connector

(Note) The RISC board has no connectors to link to the outside.

2.4.3 Card Mounting Position

(Note) No cards are mounted onto the RISC board.

1 - 46

Page 51

2.5 Data Server Board

12345678901234

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

12345678901234

2.5.1 Specifications

Name Specification Remark

Data server board

2.5.2 Connector Mounting Positions

JNA

F-BUSQ Back Plane Connector

CNH1

* CD27 is mounted above the ADD-ON board.

A20B-8100-0160 Allowed only for Σ 16/18

ADD-ON Board

234567890123

234567890123

234567890123

234567890123

234567890123

234567890123

234567890123

234567890123

234567890123

234567890123

234567890123

234567890123

234567890123

234567890123

234567890123

234567890123

234567890123

234567890123

CD27

Connector No. Application

CNH1 IDE hard disk interface

CD27 AUI interface

2.5.3 Card Mounting Position

(Note) No cards are mounted onto the data server board.

1 - 47

Page 52

2.6 List of Units and PCBs

2.6.1 Basic Units

Model Unit Name Drawing No. Remark

Σ16 No slots A02B-0236-C511 Soft keys (10 + 2)

Basic unit A4, 10.4" color

Basic unit A5, 10.4" color

Basic unit A6, 10.4" color

Basic unit A32, 10.4"

color

Basic unit A13, 9.5"

monochrome

Basic unit A14, 9.5"

monochrome

Basic unit A15, 9.5"

monochrome

Basic unit A35, 9.5"

monochrome

Σ18 No slots A02B-0238-C511 Soft keys (10 + 2)

Σ21 No slots A02B-0247-C515 Soft keys (10 + 2) RA5

Basic unit A4, 10.4" color

Basic unit A5, 10.4" color

Basic unit A6, 10.4" color

Basic unit A32, 10.4"

color

Basic unit A13, 9.5"

monochrome

Basic unit A14, 9.5"

monochrome

Basic unit A15, 9.5"

monochrome

Basic unit A35, 9.5"

monochrome

Basic unit A13, 10.4"

color

Basic unit A14, 10.4"

color

Basic unit A17, 9.5"

monochrome

Basic unit A18, 9.5"

monochrome

2 slots A02B-0236-C512 Soft keys (10 + 2)

4 slots A02B-0236-C513 Soft keys (10 + 2)

3 slots A02B-0236-C518 Soft keys (10 + 2)

No slots A02B-0236-C541 Soft keys (10 + 2)

2 slots A02B-0236-C542 Soft keys (10 + 2)

4 slots A02B-0236-C543 Soft keys (10 + 2)

3 slots A02B-0236-C548 Soft keys (10 + 2)

2 slots A02B-0238-C512 Soft keys (10 + 2)

4 slots A02B-0238-C513 Soft keys (10 + 2)

3 slots A02B-0238-C518 Soft keys (10 + 2)

No slots A02B-0238-C541 Soft keys (10 + 2)

2 slots A02B-0238-C542 Soft keys (10 + 2)

4 slots A02B-0238-C543 Soft keys (10 + 2)

3 slots A02B-0238-C548 Soft keys (10 + 2)

2 slots A02B-0247-C516 Soft keys (10 + 2) RA5

No slots A02B-0247-C545 Soft keys (10 + 2) RA5

2 slots A02B-0247-C546 Soft keys (10 + 2) RA5

1 - 48

Page 53

2.6.2 Controller PCBs

Type Name Drawing No. ID Remark

Master PCB Σ 16

Card PCBs Σ 16/18

DIMM module Σ 16/18

Option PCBs Σ 16/18

Back Panel

Others For no or

Mother board

Σ 18

Σ 21

CPU card (For

mother board)

CPU card (For communication/C

language board)

Display control card

Axis control card

DRAM module

SRAM module

FROM module

C language board

Serial communication board A

RISC board

Data server board

Back panel

Inverters

Σ 21

A

C

Σ 16

Σ 18

Σ

Σ 21

Σ 16/18

Σ 21

16/18

Σ

Σ 21

Σ 16M

Σ 16/18

16/18

Σ

Σ 21

2 slots

For 4 slots

21

A20B-8100-0130

A20B-8100-0135

A20B-8100-0136

A20B-3300-0050

A20B-3300-0070

A20B-3300-0070

A20B-3300-0020

A20B-3300-0023

A17B-3300-0100

A17B-3300-0101

A20B-3300-0030

A20B-3300-0031

A20B-3900-0040

A20B-3900-0041

A20B-3900-0020

A20B-3900-0060

A20B-3900-0061

A20B-3900-0052

A20B-3900-0010

A20B-3900-001 1

A20B-3900-0012

A20B-8100-0151

A20B-8100-0152

A20B-8100-0170

A20B-8100-0160

A20B-2100-0230

A20B-2100-0000

A20B-2100-0220

A20B-2002-0500

A20B-2002-0480

A20B-8100-0200

A20B-2002-0550

(Note) x: PCB version number

1xD5

1xC5

1xD7 PMC-RA5

01 Pentium

09 486DX2

09 486DX2

0E 10.4" color

06 9.5" monochrome

x3 8 axes

x2 6 axes

x1 4 axes

x0 2 axes

87 12 M

86 8 M

05 3 m

04 2 M

03 1 M

02 512 K

47 16 M

45 12 M

43 8 M

OxCD

2xCD Remote buffer

0xCF

1xA3

- 4 slots

- 3 slots

- 2 slots

- 10.4" color

- 9.5" monochrome

- 10.4" color

- 9.5" monochrome

1 - 49

Page 54

3. TROUBLESHOOTING

When a trouble occurred, check “what you were operating when it occurred,” “what it is like,”

and “how often it happens.”

3.1 T racking through the ALARM Screen

When an alarm occurs during operation, an alarm message is displayed at the top of the

screen. Depending on the alarm, its details are displayed in the Diagnosis screen. If this

is the case, operate as follows to confirm what is displayed in the Diagnosis screen.

[Diagnosis Screen Display Operation]

With the NC Overall screen displayed, operate as follows to display the Diagnosis

screen.

(OPER./MAINTE) → F4/SYSTEM → 3 0 (F MENU) INPUT →

△

2 (F_SYSTEM) INPUT → F7 DGNOS

Enter the diagnosis number you want to refer to and press

F6/NO. SRH . The data for that diagnosis number is displayed.

(It is also possible to change with the page key.)

(Note 1) When [F SYSTEM] is selected in the above-mentioned operation

sequence, but [DIAGNOSE] is not displayed at F7, press (RETURN)

several times.

(Note 2) To return from the Diagnosis screen, press ALTER , not (RETURN).

△

△

1 - 50

Page 55

4. POWER-ON ADJUSTMENT

4.1 Power-on Procedure

① Enter (set) the PMC ladder and others.

② Enter (set) the CNC parameters.

③ Turn off the power and turn it on again.

(Note) When system software has not been entered into the CNC internal memory,

transfer it into the CNC internal memory according to the instructions in

[APPENDIX] BOOT SYSTEM, and then, go through the above-mentioned steps.

4.2 System Table

This CNC unit sets allocations of the data areas such as machining programs, tool offset

amounts, and so on through the “system table.”

To display the System Table screen, operate in the following order in the Overall screen.

(OPER./MEINTE) → F4/SYSTEM → 2 5 (SYSTEM TABLE) → INPUT

△

SYSTEM T ABLE

BASIC RAM SIZE 38E40 EXT. RAM SIZE 0

No. TABLE SIZE OFFSET No. TABLE SIZE OFFSET

01 SYSTEM 10000 0 11 0 0

02 TOOL 5000 0 12 0 0

03 SPARE 3900 0 13 0 0

04 MONI 6F00 0 14 0 0

05 PRGRM 13000 0 15 DUMMY 6600 32800

06 0 0 16 0 0

07 0 0 17 0 0

08 0 0 18 0 0

09 0 0 19 0 0

10 0 0 20 0 0

When initially starting up the system, press F5/SYSTEM CLR to initialize the system.

When this is done, the basic RAM capacity and extended RAM capacity are automatically

set.

Pressing F3/TABLE brings the cursor into the table. According to Table Names versus

Capacities provided on the next page, set the table names and capacities, using the

cursor and alphanumerals plus the INPUT key.

1 - 51

Page 56

(Note 1) The numbers 01 through 15 are the tables for the basic RAM, 16 through 20 are

those for the extended RAM. When the extended RAM capacity is 0 (zero), do

not set to the numbers 16 through 20.

(Note 2) Set the capacity in an increment of 100, suffixing a number with “H” (indicates

hexadecimal).

(Note 3) If the capacity is entered, the offset for the next table will be automatically set.

Unlike the S-III, the last table capacity is not adjusted. Set a dummy table

before the last table capacity so that it will be the prescribed capacity.

(Note 4) The table number has a fixed table name of “SYSTEM” and capacity of

“10000H.” For the other tables, you can set any table names in any places.

(Note 5) A standard set value varies from one model to anther. When actually setting it,

follow the materials for each model.

(Note 6) When the system table is changed, be sure to turn off and on the power to

make sure that “790 System Table Error” does not occur, and then, operate the

system.

1 - 52

Page 57

<<Table Names versus Capacities>>

Function Table Spec.

System

Data

Tool offset

Tool life

management

Cutting

monitoring

Machining

program

Highprecision

contour

control

SYSTEM 10000H

TOOL 32 pairs 600H C00H

1,000 pairs BC00H

SPARE 32 pairs B00H

1,000 pairs

MONI 32 pairs 2800H

1,000 pairs

PRGRM 80 m A000H

HPCC 10000H

Capacities

Σ 16/18M Σ 18L Σ 21L

64 pairs C00H 1400H

100 pairs 1400H 2800H

200 pairs 2800H 5000H

400 pairs 5000H

500 pairs 5E00H

64 pairs F00H 400H

100 pairs 1300H

200 pairs 2000H

400 pairs 3900H

500 pairs

64 pairs 2E00H 2000H

100 pairs 3500H

200 pairs 4800H

400 pairs 6F00H

500 pairs

160 m 13000H

320 m 24000H

500 m 37000H

640 m 4A000H

1,000 m 6F000H

1,280 m 8B000H

2,000 m D5000H

2,560 m 10E000H

4,000 m 1A1000H

5,120 m 200000H

Remark

Table number fixed at

01

The 100 pairs in the

Spec. column

represents;

M-system: 100 pairs,

L-system: 99 pairs

The Spec. column

represents the

number of tool offset

pairs.

The Spec. column

represents the

number of tool offset

pairs. (Not allowed

for the Σ 21L)

The maximum

number of

registerable

programs is

irrelevant.

Allowed only for the

Σ 16M

1 - 53

Page 58

4.3 SLBUS Table

In order to allocate the addresses for the input signals (X contact) and output signal (Y

contact) on the part of the machine, itis necessary to set ths SLBUS table.

To display the SLBUS TABLE screen, operate as follows in the OVERALL screen.

[ ] (OPRE/MAINTE) → [F4/SYSTEM] → [2][4](SLBUS) → [INPUT]

SLBUS TABLE

△

Lead Ch. Chanels Bytes Address

No. Loc# Type Slave Division

Buffer Size IN OUT IN OUT IN OUT

01 00 0 00 00 00 00 00 00 F0 F0

02 00 0 01 01 02 00 00 10 00 00

03 00 0 00 00 00 00 00 00 00 00

04 00 0 00 00 00 00 00 00 00 00

05 00 0 00 00 00 00 00 00 00 00

06 00 0 00 00 00 00 00 00 00 00

07 00 0 00 00 00 00 00 00 00 00

08 00 0 00 00 00 00 00 00 00 00

09 00 0 00 00 00 00 00 00 00 00

10 00 0 00 00 00 00 00 00 00 00

11 00 0 00 00 0000 0000 0000

12 00 0 00 00 00 00 00 00 00 00

13 00 0 00 00 00 00 00 00 00 00

14 00 0 00 00 00 00 00 00 00 00

15 00 0 00 00 00 00 00 00 00 00

16 00 0 00 00 00 00 00 00 00 00

High

Speed

To alter the set value, press [F9/ALTER]. The message, “DO YOU WANT TO ALTER

? (Y/N),” is messaged. Press [Y]. Aframe cursor appears in the table, allowing you to

alter the set value. Make setting according to the machine specifications.

When you start up the system for the first time, press [F8/CLEAR ALL] to initialize the

data, and then, set each item.

After alteration is completed, press [F9/REFER] to end the setting mode.

1 - 54

Page 59

5. DAILY MAINTENANCE AND INSPECTION

The S-Σ 16/18/21 has the CNC unit on the back of the CNC display. (Display integrated

CNC unit)

5.1 Replacing the Batteries

5.1.1 CNC Memory Backup Batteries

The CNC unit has batteries to hold the memory where the programs, offset amounts,

parameters, and so on are stored. If a battery voltage drops, a warning, “794

BATTERY ALARM,” is displayed on the screen. If this is displayed, replace the

batteries as soon as possible.

until the battery is replaced.

(1) CNC memory backup battery replacement procedure

Prepare lithium batteries (A02B-0200-K102) in advance.

[WARNING]

Unless the batteries are correctly replaced, there may be an explosion. Use only

the specified batteries (A02B-0200-K102).

Try not to turn off the CNC unit as much as possible

① Turn on the power for the machine (CNC) for about 30 seconds, and then, turn

it off.

② Remove the batteries from the upper section of the CNC unit. Disconnect a

connector and remove the batteries from a battery case.

③ Replace the batteries and reconnect the connector.

(Note) The battery case is located;

• At the upper middle of the unit as shown in the figure below, if the option

slots are provided.

• At the upper right end of the unit, if the option slots are not provided.

Battery Case

Connector

Lithium Batteries

A02B-0200-K102

1 - 55

Page 60

[CAUTION]

The above-mentioned steps ① through ③ should be carried out within 30

minutes. Note that if the unit is left without the batteries for a long time, the

memory contents will be lost.

If the batteries may not be replaced within 30 minutes, save the contents of the

SRAM memory collectively in the memory card. This way, the memory contents

can be easily recovered, if they are lost by any chance.

For an operating method, see “APPENDIX: BOOT SYSTEM.”

5.1.2 Replacing the Absolute Encoder Batteries

[WARNING]

Turn on the power for the machine (CNC), press the EMERGENCY STOP

button, and replace the batteries. As this work is carried out with the power

turned on and the cabinet opened, only the qualified personnel trained for

maintenance and safety is allowed for this work. When opening the cabinet to

replace the batteries, do not touch a high-voltage circuit. If the cover is not in

place and you touch inside, you will get an electric shock.

When the machine is provided with an absolute encoder such as an absolute pulse

coder or absolute linear scale, absolute encoder batteries have been also installed in

addition to the memory backup batteries.

When an APC alarm F307 or F308 occurs, replace the battery as soon as possible.

Unless it is replaced, an absolute position will be lost and you will have to manually

perform reference point return again.

(1) Absolute encoder battery replacement procedure (α series servo amplifier

module)

① Turn on the power for the machine (CNC).

② Detach the front battery case of the CCC series servo amplifier module (SVM).

Hold the top and bottom of the case and pull it to this side.

③ Detach a connector from the batteries.

④ Replace the batteries and reconnect the connector.

⑤ Reattach the battery case.

⑥ Turn off the power for the machine (CNC).

1 - 56

Page 61

Battery Case

αSeries

SVM

(2) Absolute encoder battery replacement procedure (Standalone pulse coder)

① Turn on the power for the machine (CNC).

② Loosen the screws of the battery case and detach the cover.

③ Replace the batteries in the case. Put two each of them in the reverse

direction.

Connector CX5X

Connector

Batteries

A06B-6073-K001

④ After replacement is completed, put back the cover.

⑤ Turn off the power for the machine (CNC).

[CAUTION]

Screws

Cover

Replace the batteries with the CNC power turned on. Note that if they are

replaced with the power turned off, an absolute position in the memory will be

lost.

1 - 57

Page 62

5.2 Replacing the Fuse for the Control Unit

[WARNING]

Prior to replacing the fuse, eliminate a cause for its blowing. Therefore, only the

qualified personnel fully trained for maintenance and safety is allowed for this work.

When you open the cabinet to replace the fuse, be careful not to touch a highvoltage circuit. If the cover is not in place and you touch inside, you will get an

electric shock.

5.2.1 Fuse Mounting Position

Back of Unit

Mother Board

5.2.2 Arrangement Specifications of Fuse

Basic Unit Arrangement Spec. Rating Individual Spec.

Σ 16/18/21 A02B-0236-K100 5A A60L-0001-0290#LM50

Fuse

1 - 58

Page 63

5.3 Replacing the Fan Motor

[WARNING]

When you open the cabinet to replace the fuse, be careful not to touch a high-

voltage circuit. If the cover is not in place and you touch inside, you will get an

electric shock.

5.3.1 Arrangement Specifications of Fan

For the unit with no option slots A90L-0001-0441 2 pieces

For the unit with 2 option slots A90L-0001-0423#105 2 pieces

For the unit with 4 option slots A90L-0001-0423#105 4 pieces

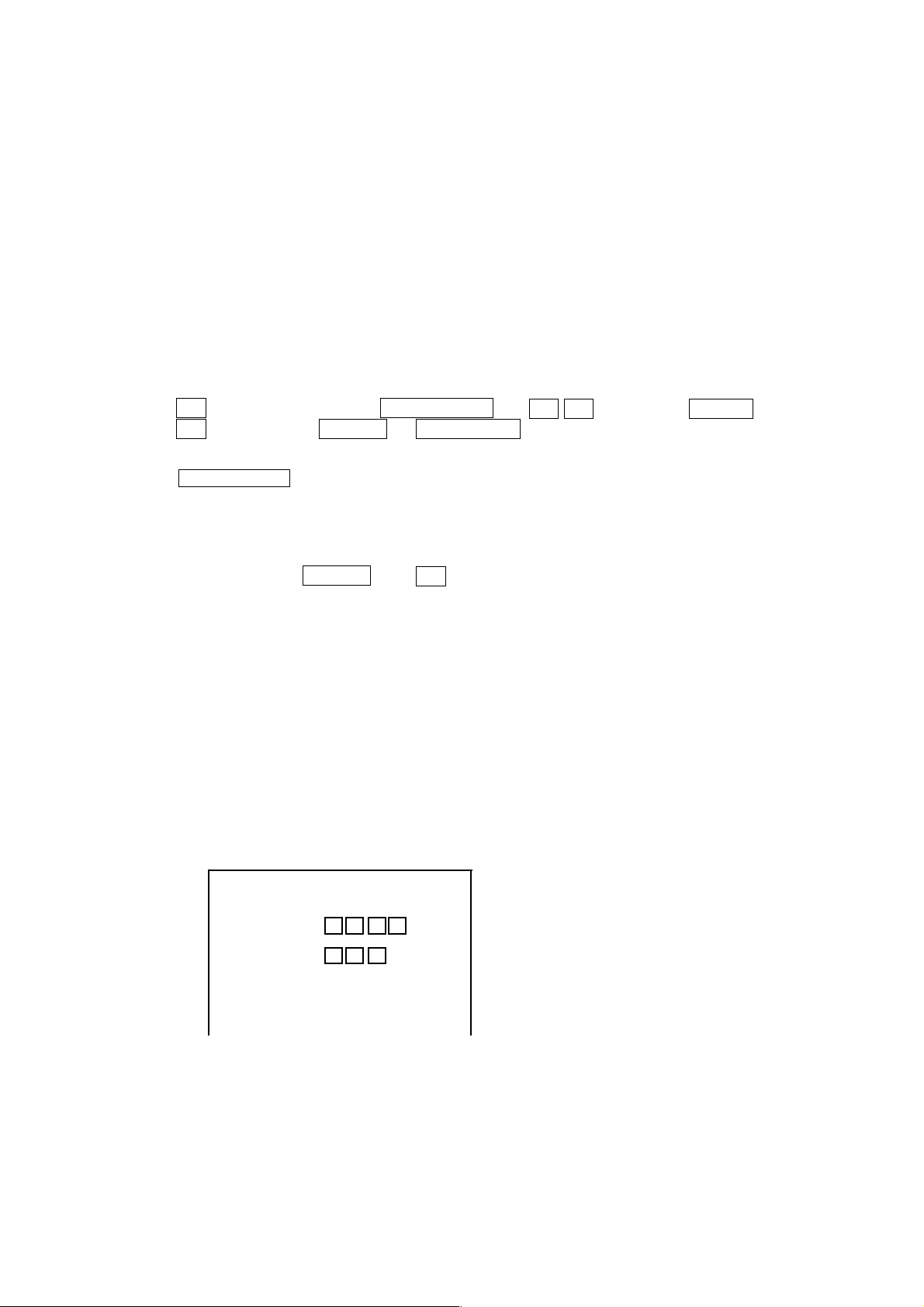

5.3.2 Replacing the Fan Motor

(1) When the unit is provided with no or two option slots

① When replacing the fan motor, be sure to turn off the power for the machine

(CNC).

Arrangement Spec. Required Q’ty

② Disconnect a connector from the fan motor you want to replace. The connector

is latched. Holding down the latch at the lower part of the connector with a

regular screwdriver, etc., pull it out.

③ Unlatch the fan motor and take it out.

④ Insert a new fan motor into a fan case and reconnect the connefctor.

Connector

Fan Motor

Fan Case

(Note) Pay attention to the fan motor’s direction so that the air flows from the bottom

to the top. (A label should face upward)

1 - 59

Page 64

(2) When the unit is provided with four option slots

① When replacing the fan motor, be sure to turn off the power for the machine

(CNC).

② Disconnect a connector from the fan motor you want to replace. The connector

is latched. Holding down the latch at the lower part of the connector with a

regular screwdriver, etc., pull it out.

③ Unlatch the fan cover and take it out.

④ The fan motor is fixed to the fan cover. Unlatch and take out the fan motor.

⑤ Attach a new fan motor to the fan cover. Then, reattach the fan cover to the

unit and reconnect the connector.

Fan Cover

Connector

(Note) Pay attention to the fan motor’s direction so

that the air flows from the bottom to the top.

(A label should face upward)

Fan Motor

1 - 60

Page 65

5.4 Adjusting the Contrast of the Monochrome Display

When using the monochrome display, its contrast can be adjusted in the following manneIn