Page 1

SEIKI - SEICOS

å10M/16M/18M

INSTRUCTION MANUAL

6 PROGRAMMING

Edition 1.01 NP-0000-1-0221-E-1-01

Hitachi Seiki Deutschland

Werkzeugmaschinen GmbH

Page 2

2

Page 3

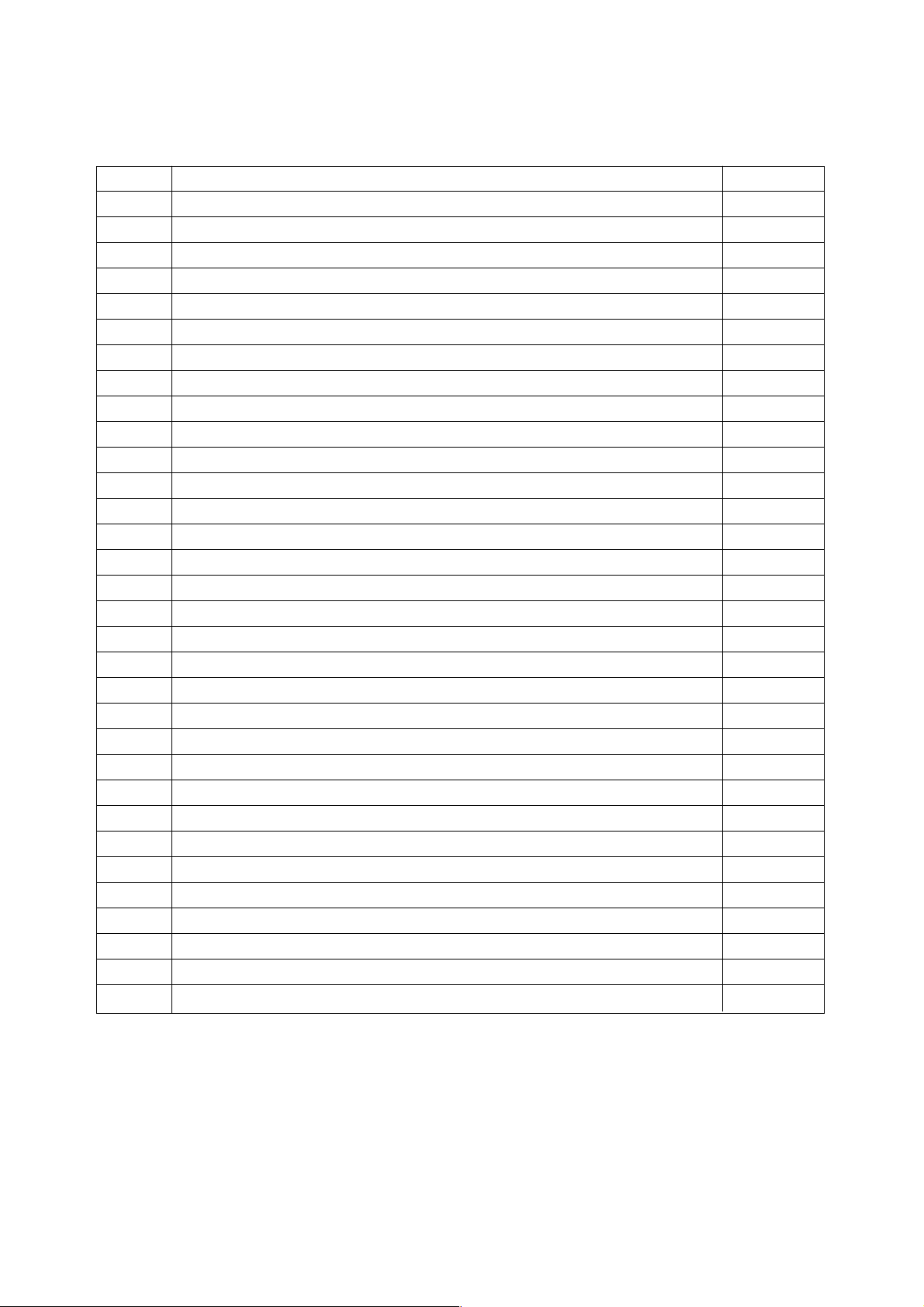

CONTENTS

1. G CODE............................................................................................. 1-1

1-1 List of G Code Group(SEICOSΣ10M/16M/18M) ..........................................................1-1

1-2 List of G Codes (SEICOS Σ10M/16M/18M) ................................................................. 1-2

2. INTERPOLATION FUNCTION........................................................ 2 - 1

2-1 Positioning (G00) ....................................................................................................... 2 - 1

2-2 Linear Interpolation (G01) .......................................................................................... 2 - 2

2-3 Circular Interpolation (G02, G03) ............................................................................... 2 - 3

2-3-1 Radius Designation on Arc.................................................................................. 2 - 5

2-4 Helical Interpolation (G02, G03) ................................................................................. 2 - 7

2-5 Virtual Axis lnterpolation (G07) ................................................................................. 2 - 10

2-5-1 SIN Interpolation (G02, G03, G07) ..................................................................... 2 - 12

2-6 Single Direction positioning (G60) ........................................................................... 2 - 12

2-7 Involute Interpolation (G222, G223).......................................................................... 2 - 15

2-8 Cylindrical Interpolation (G271)................................................................................ 2 - 19

2-8-1 Command Format............................................................................................. 2 - 19

2-8-2 Feed Rate ......................................................................................................... 2 - 19

2-8-3 Cylindrical Interpolation Applied Axes................................................................. 2 - 20

2-8-4 Cylindrical Interpolation Applied Plane ............................................................... 2 - 20

2-8-5 Sample Program.............................................................................................. 2 - 20

2-8-6 Cautions............................................................................................................ 2 - 21

2-8-7 Associated Parameters .................................................................................... 2 - 22

2-8-8 Associated Alarms ............................................................................................ 2 - 22

2-9 Polar Coordinate Interpolation (G120, G121) ........................................................... 2 - 23

2-9-1 G Codes............................................................................................................ 2 - 23

2-9-2 Command Format............................................................................................. 2 - 23

2-9-3 Polar Coordinate Interpolation Axes .................................................................. 2 - 23

2-9-4 Polar Coordinate Interpolation plane.................................................................. 2 - 24

2-9-5 Program Command .......................................................................................... 2 - 24

2-9-6 sample Program (X-axis: Linear Axis, C-axis: Rotary Axis)............................... 2 - 25

2-9-7 Feed Rate Clamp.............................................................................................. 2 - 26

2-9-8 Rapid Traverse(G00) Operation........................................................................ 2 - 26

2-9-9 Precautions....................................................................................................... 2 - 26

2-9-10 Associated parameters ..................................................................................... 2 - 27

2-9-1 1 Associated Alarms ............................................................................................ 2 - 28

3. FEED FUNCTION.............................................................................. 3-1

3-1 Feed per Minute (G94)................................................................................................. 3-1

3-2 Feed per Rotary (G95)................................................................................................. 3-2

3-3 Inverse Time (G93) ...................................................................................................... 3-3

3-4 Exact Stop (G09) ......................................................................................................... 3-4

i

Page 4

3-5 Exact Stop Mode (G61)................................................................................................ 3-4

3-6 Automatic Corner Override (G62)................................................................................ 3-5

3-6-1 Automatic Override in Inner Corner Area............................................................... 3-6

3-6-2 Inner Arc Cutting Speed Change ........................................................................... 3-7

3-7 T apping Mode (G63)..................................................................................................... 3-9

3-8 Cutting Mode (G64).................................................................................................... 3-10

3-9 Automatic Acceleration/Deceleration ......................................................................... 3-1 1

3-10 Dwell (G04)................................................................................................................ 3-11

4. REFERENCE POINT ........................................................................ 4-1

4-1 Automatic Reference Point Return (G28).................................................................... 4-1

4-2 Reference Point Return Check (G27).......................................................................... 4-2

4-3 Return from Reference Point (G29)............................................................................. 4-4

4-4 2nd-4th Reference Point Return (G30)........................................................................ 4-5

4-5 Reset of Floating Reference point (G301) ................................................................... 4-7

5. COORDINATE SYSTEM................................................................... 5-1

5-1 Machine Coordinate System Selection (G53).............................................................. 5-1

5-2 Work Coordinate system selection (G54 - G59).......................................................... 5-2

5-3 Addition of Work Coordinate system Pairs (G540 - G599) .......................................... 5-3

5-4 Local Coordinate System Setting (G52) ...................................................................... 5-5

5-5 Work Coordinate System Change (G92)..................................................................... 5-7

5-6 Work Coordinate System Preset (G921)..................................................................... 5-9

5-7 Work Coordinate System Shift (External Work Zero Point Offset Amount)............... 5-11

5-8 Plane Selection (G17, G18, G19) .............................................................................. 5-12

5-9 Rotary Table Dynamic Fixture Offset......................................................................... 5-14

6. COORDINATE................................................................................... 6-1

6-1 Absolute/Incremental Programming (G90,G91)........................................................... 6-1

6-2 Polar Coordinate Input (G15,G16) ............................................................................... 6-2

6-3 Inch/Metric Input (G20, G21) ........................................................................................ 6-5

7. SPINDLE FUNCTION (S FUNCTION) .............................................. 7-1

8. TOOL FUNCTION (T FUNCTION) .................................................... 8 - 1

9. Miscellaneous Function (M FUNCTION)............................................ 9- 1

9-1 Miscellaneous Function (M Function) .......................................................................... 9-1

9-2 2nd Miscellaneous Function (B Function).................................................................... 9-2

10 . Canned Cycle................................................................................... 10-1

10-1 Canned Cycle (G73, G74, G76, G80 - G89) .............................................................. 10-1

10-2 Direct Tap (G741, G841).......................................................................................... 10-16

10-3 Drilling Pattern Cycle (G70, G71, G72, G77) ........................................................... 10-22

10-4 True Circular Cutting (G302 ~ G305)....................................................................... 10-25

10-5 Square Outside Cutting (G322,323) ........................................................................ 10-34

10-6 Plane Cutting Cycle (G324, G325, G326)................................................................ 10-38

10-7 Poketing (G327 ~ G333) .......................................................................................... 10-50

10-7-1 Circular Poketing (G327)................................................................................... 10-55

ii

Page 5

10-7-2 Square Poketing (G328).................................................................................... 10-59

10-7-3 Track Inside (G329)........................................................................................... 10-64

10-7-4 Circle outside Pocketing (G330) ....................................................................... 10-67

10-7-5 Square Outside Cutting (G331)......................................................................... 10-70

10-7-6 Track Outside (G332)........................................................................................ 10-73

10-7-7 Circle (G333)..................................................................................................... 10-76

10-7-8 Special Fixed Cycles (G322 ~ G333) Type 2 .................................................... 10-78

10-8 A TC Canned Cycle (MO6)....................................................................................... 10-79

10-8-1 A TC Canned Cycle, Type A (VK, VKC, VG, VkII) ................................................ 10-82

10-8-2 A TC CANNED CYCLE TYPE E (VM40III).......................................................... 10-84

10-8-3 A TC CANNED CYCLE TYPE F (HG)................................................................ 10-86

10-8-4 A TC Canned Cycle, Type G (HK)...................................................................... 10-87

10-8-5 A TC Canned Cycle, Type I (Initial HS500) ......................................................... 10-89

10-8-6 A TC Canned Cycle, Type J (VS) ....................................................................... 10-91

10-8-7 A TC Canned Cycle, Type K(HS630) ................................................................. 10-93

10-8-8 A TC Canned Cycle, Type L (New HS500)......................................................... 10-95

10-8-9 A TC Canned Cycle, Type M (VS 16-tool) .......................................................... 10-96

10-8-10 A TC Canned Cycle, Type N (MS400H).............................................................. 10-98

10-9 High-Speed Machining Cycle ................................................................................... 10-99

10-9-1 Trochoid Cycle (G334) ...................................................................................... 10-99

10-9-2 Helical Drilling Cycle (G812, G813) ................................................................. 10-103

10-9-3 High Speed Side Face Cutting Cycle (G335) .................................................. 10-107

10-9-4 Z Feed Fluting Cycle (G336) ............................................................................10-111

10-9-5 Corner Pocket Cycle (G337)........................................................................... 10-113

10-9-6 Square Pocket Cycle (G338) .......................................................................... 10-116

11. COMPENSATION FUNCTION ........................................................ 11-1

11-1 Tool Length Compensation (G43, G44, G49)............................................................. 11-1

11-2 Tool Offset (G45 - G48) ............................................................................................. 11-6

11-3 Tool Diameter Compensation (G38 - G42) ................................................................ 11-9

11-3-1 Detailed Description of Tool Diameter Compensation ...................................... 11-15

11-4 3-D Tool Offset (G40 - G41)..................................................................................... 11-27

11-5 H and D Functions................................................................................................... 11-31

11-6 Tool Offset by Tool Number...................................................................................... 11-33

12. CONVERTING FUNCTION............................................................. 12-1

12-1 Programmable Mirror Image (G501, G51 1) ............................................................... 12-1

12-2 Setting Mirror Image................................................................................................... 12-4

12-3 Scaling (G50, G51) .................................................................................................... 12-7

12-4 Coordinate Ratation (G68, G69) .............................................................................. 12-10

12-5 Optional Angle Chamfering/Corner R (, C, R).......................................................... 12-15

13. MEASURMENT................................................................................ 13-1

13-1 Skip Function (G31)................................................................................................... 13-1

iii

Page 6

13-2 Automatic Measurement of Tool Length (G37)........................................................... 13-3

13-3 Safety Guard (Tool Length) ........................................................................................ 13-5

13-4 Safety Guard (Comparison)....................................................................................... 13-9

14. DATA SETTING............................................................................... 14-1

14-1 Data Setting (G10)..................................................................................................... 14-1

14-1-1 Tool offset amount setting ................................................................................... 14-1

14-1-2 Work coordinate system offset amount setting................................................... 14-1

14-2 Programmable Parameter Input (G10) ...................................................................... 14-3

14-3 Plotting Parameter Setting......................................................................................... 14-5

15. SOFT OT ......................................................................................... 15-1

15-1 Soft OT (Stored Stroke Limit 1).................................................................................. 15-1

15-2 Stored Stroke Limits 2 and 3 (G22 and G23) ............................................................. 15-3

15-3 Soft-OT before Move ................................................................................................. 15-6

16. AXIS CONTROL.............................................................................. 16-1

16-1 Rotary Axis Controlling Function................................................................................ 16-1

16-2 Oscillation Function (G1 13, G114) ............................................................................. 16-4

16-3 Normal Direction Control (G41 1, G421, G401) .......................................................... 16-8

17 . HIGH-SPEED MACHINING............................................................. 17-1

17-1 Multibuffer (G251) ...................................................................................................... 17-1

17-2 Feed Rate Clamp by Circular Arc Radius.................................................................. 17-3

17-3 PRECONTROLLING ................................................................................................. 17-4

17-3-1 PRE-INTERPOLA TION LINEAR ACCELERA TION/DECELERATION ................ 17-5

17-3-2 AUTO CORNER DECELERATION .................................................................... 17-6

17-4 HIGH PRECISION PROFILE CONTROL .................................................................. 17-8

17-5 Smooth Interpolation................................................................................................ 17-10

17-6 NURBS Interpolation................................................................................................ 17-12

17-7 SHG Machining ........................................................................................................ 17-14

18. FIVE-FACE MACHINING ................................................................ 18-1

18-1 Selecting the Machining Plane (G240-G245) ............................................................. 18-1

18-2 Common Work Origin Offset..................................................................................... 18-2

18-3 Axis Changeover........................................................................................................ 18-5

18-3-1 Axis Changeover (T ype A)................................................................................... 18-5

18-3-2 Axis Changeover (T ype B)................................................................................... 18-6

19. AUTOMATIC OPERATION ............................................................. 19-1

19-1 Program Restart........................................................................................................ 19-1

19-2 Block Restart ............................................................................................................. 19-6

19-3 Machining Break Point Return (G206) ..................................................................... 19-11

19-4 Reverse Movement.................................................................................................. 19-14

19-5 Sequence Number Comparison and Stop ............................................................... 19-16

19-6 Reset (Reset Associated with Automatic Operation)............................................... 19-18

19-6-1 Details of Reset (Reset Associated with Automatic Operation) ........................ 19-18

iv

Page 7

20. MANUAL OPERATION .................................................................... 21-1

20-1 Manual Absolute ON/OFF .......................................................................................... 21-1

21 . TEST RUN ....................................................................................... 21-1

21-1 Miscellaneous Function Lock..................................................................................... 21-1

21-2 Miscellaneous Function Finish................................................................................... 21-1

22. CUSTOM MACROS ......................................................................... 22-1

22-1 Outline ....................................................................................................................... 22-1

22-2 Call Commands and Return Command.................................................................... 22-2

22-2-1 Types of Command ............................................................................................. 22-2

22-2-2 Multi-call .............................................................................................................. 22-8

22-2-3 Argument Designation....................................................................................... 22-13

22-3 Variables .................................................................................................................. 22-18

22-4 Representation of Variables..................................................................................... 22-31

22-5 Citation of Variables ................................................................................................. 22-31

22-6 Undefined V ariables ................................................................................................. 22-32

22-7 Expression and Computation .................................................................................. 22-33

22-8 Substitution Command ............................................................................................ 22-36

22-9 Branch Command ................................................................................................... 22-37

22-10Repeat Command ................................................................................................... 22-38

22-11 Naming Command.................................................................................................. 22-39

22-12IF Command............................................................................................................ 22-40

22-13External Output Commands .................................................................................... 22-42

23 . Interrupt Type Custom Macro .......................................................... 23-1

23-1 Custom Macro Interrupt Operation ............................................................................ 23-1

23-2 How to Specify........................................................................................................... 23-2

23-3 Interrupt T ype Custom Macro Proper......................................................................... 23-2

23-4 St atus Trigger Method and Edge T rigger Method (Parameters)................................. 23-2

23-5 Reversion and Modal Information .............................................................................. 23-3

23-6 System Variable in Interrupt Program ........................................................................ 23-3

23-7 Custom Macro Interrupt and Custom Macro Modal Call ............................................ 23-4

23-8 Interrupt Timing and Return Position in Each Mode................................................... 23-4

23-9 Associated Parameters ............................................................................................. 23-7

24. MEMORY OPERATION IN OTHER COMPANIES’ FORMATS ...... 24-1

24-1 Memory Operation in FS15 Format ........................................................................... 24-1

24-2 Memory Operation in i80M Format ............................................................................ 24-2

v

Page 8

vi

Page 9

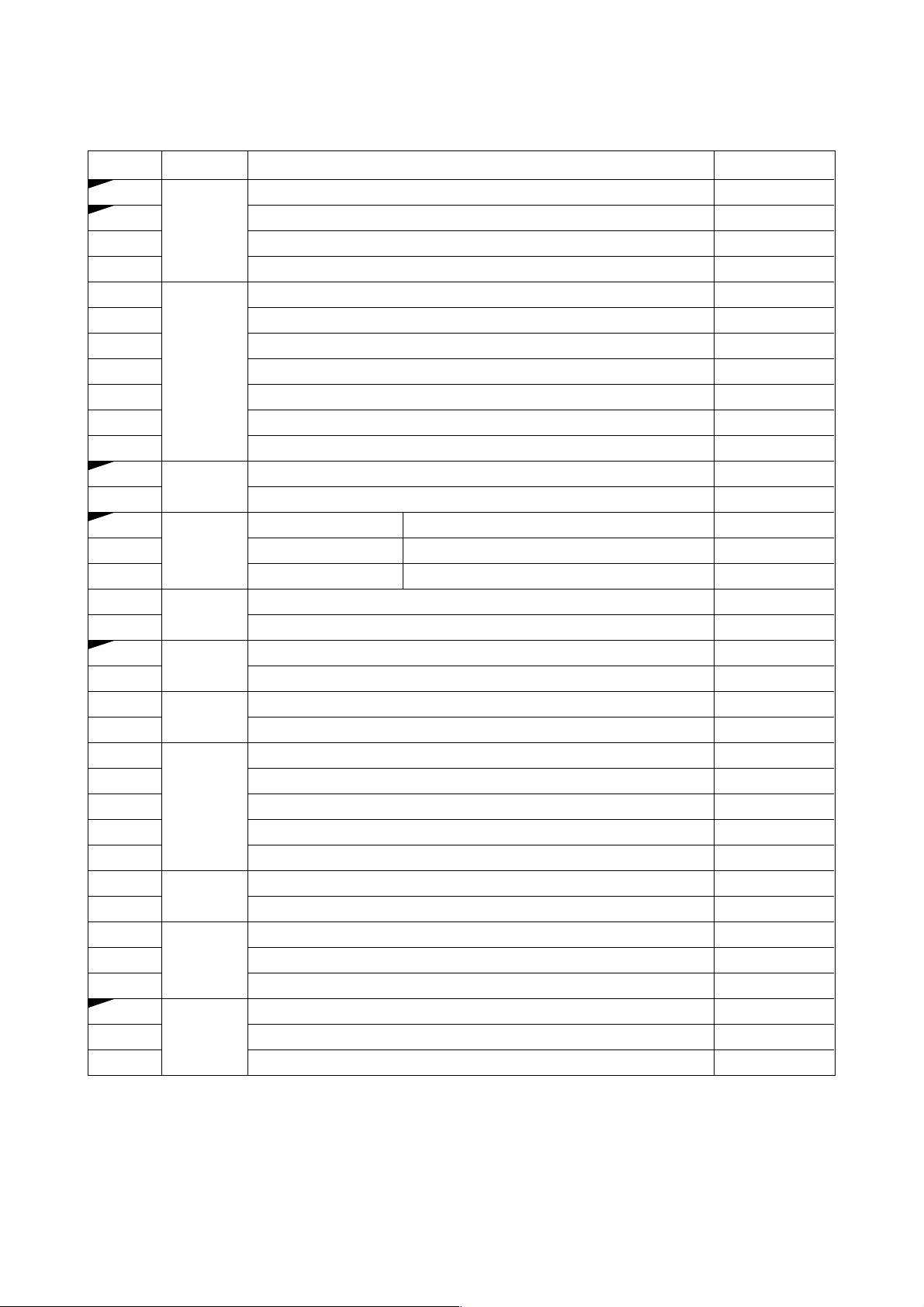

1. G CODE

1-1 List of G Code Group(SEICOS

Group Function Remarks

00 Non-modal

01 Positioning/liner interpolation/circular interpolation

02 Plane designation

03 Absolute programming/incremental programming

04 Stored stroke check

05 Inverse time/feed per minute/feed per revolution

06 Inch/metric conversion

07 Tool diameter compensation

08 Tool length compensation

09 Canned cycle

10 Initial point return/R point return

11 Scaling

12 Work coordinate system Selection

13 Cutting mode/exact stop mode/automatic corner override mode

14 Macro modal call

15 Programming mirror image

16 Coordinator rotation

17 Constant surface speed control *1

18 Tool life management

19 Normal direction control *1

20 Polar coordinate command

21 Oscillation function

22 Polar coordinate interpolation *1

23 Spindle speed fluctuation detection *1

24 Machining plane selection *1

25 Tool nose interference check *1

26 Axis switching/3-D coordinate conversion *1

27 *2

28 *2

29 *2

30 *2

31 *2

ΣΣ

Σ10M/16M/18M)

ΣΣ

(Note) *1 Reserved G code and not available for the moment

*2 Spare G code group for function improvement.

1 - 1

Page 10

1-2 List of G Codes (SEICOS

ΣΣ

Σ10M/16M/18M)

ΣΣ

Code

G00

G01

G02

G03

G04

G05

G07

G08

G09

G10

G1 1

G15

G16

G17

G18

G19

G20

G21

G22

G23

G25

G26

G27

G28

G29

G30

G31

G33

G34

G37

G38

G39

G40

G41

G42

Group

01

00

20

02

06

04

23

00

01

00

07

Function Remarks

Positioning

Linear interpolation

Circular interpolation/helical interpolation CW

Circular interpolation/helical interpolation CCW

Dwell

High-precision profile control

Virtual axis interpolation

Antecedent control

Exact stop

Data setting

Data setting node cancel

Polar coordinate command cancel

Polar coordinate command

XP YP plane where:XP : x axis or its parallel axis

ZP XP plane YP : Y axis or its p arallel axis

YP ZP plane ZP : Z axis or its parallel axis

Inch input

Metric input

Store stroke check ON

Stored stroke check OFF

Spindle speed fluctuation detection OFF *1

Spindle speed fluctuation detection ON *1

Reference point return check

Reference point return

Return from reference point

2nd, 3rd, 4th reference point return

Skip function

Thread cutting *1

Variable lead thread cutting *1

Tool length automatic measurement

Tool diameter compensation vector hold

Tool diameter compensation corner arc

Tool diameter compensation left/3-D tool offset cancel

Tool diameter left/3-D tool offset

Tool diameter compensation right

1 - 2

Page 11

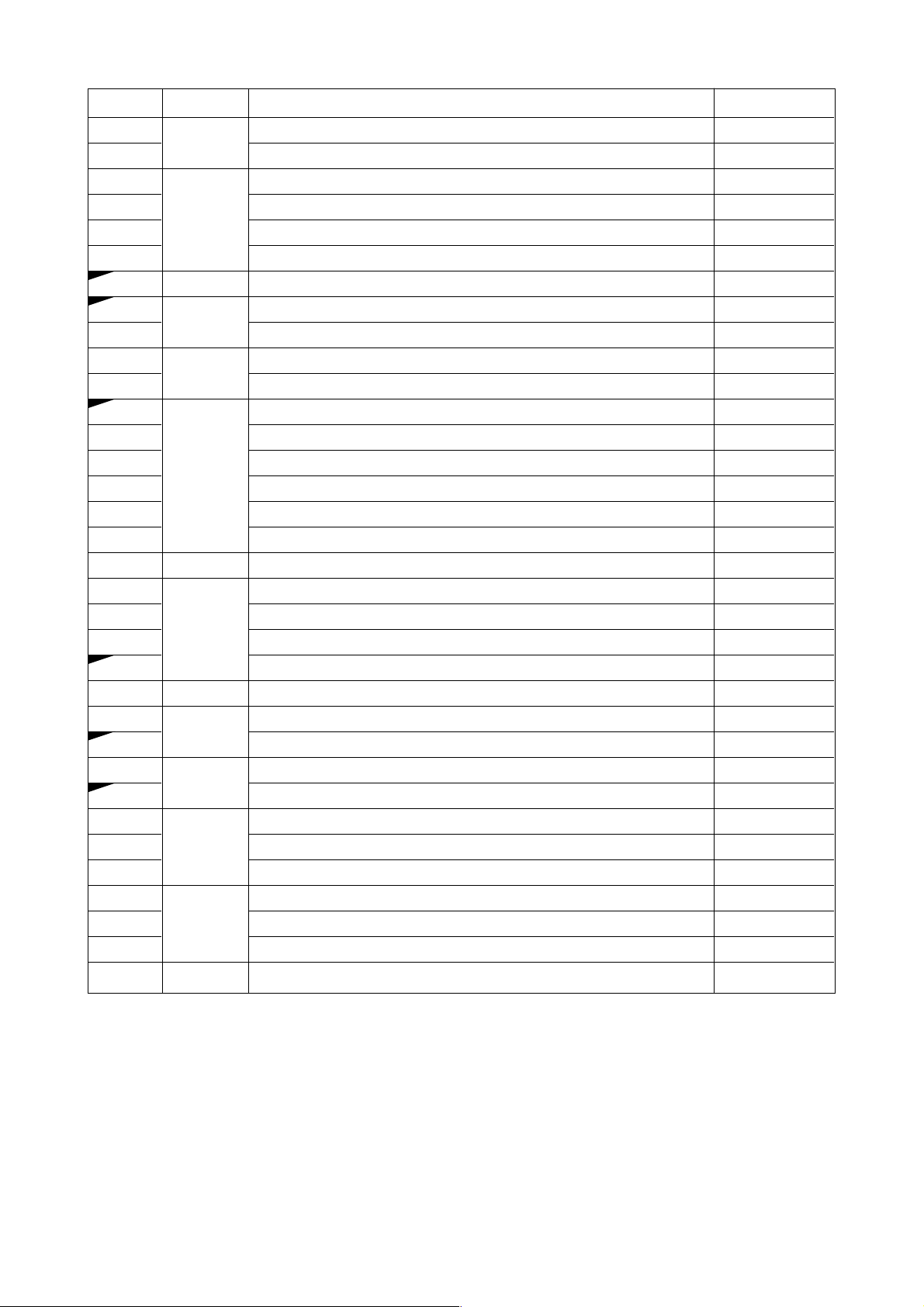

Code

G43

G44

G45

G46

G47

G48

G49

G50

G51

G52

G53

C54

G55

G56

G57

G58

G59

G60

G61

G62

G63

G64

G65

G66

G67

G68

G69

G70

G71

G72

G73

G74

G76

G77

Group

08

00

08

11

00

12

00

13

00

14

16

00

09

00

Function Remarks

Tool length compensation +

Tool length compensation Tool offset extension

Tool offset contraction

Tool offset double extension

Tool offset double contraction

Tool length compensation cancel

Scaling cancel

Scaling

Local coordinate system Setting

Machine coordinate system selection

Work coordinate system 1 selection

Work coordinate system 2 selection

Work coordinate system 3 selection

Work coordinate system 4 selection

Work coordinate system 5 selection

Work coordinate system 6 selection

Single direction positioning

Exact stop mode

Automatic corner override mode

Tapping mode

Cutting mode

Macro call

Macro modal call

Macro modal call cancel

Coordinate rotation

Coordinate rotation cancel

Bolt hole cycle

Arc

Arc

Peck drilling cycle

Counter tapping cycle

Fine boring cycle

Grid cycle

Group 01 by

parameter change

1 - 3

Page 12

Code

G80

G81

G82

G83

G84

C85

G86

G87

G88

G89

G90

G91

G92

G93

G94

G95

G96

G97

G98

G99

G113

G114

G120

G121

G130

G131

G201

G203

G204

G206

G212

G213

G216

Group

09

03

00

05

17

10

21

22

18

00

01

Function Remarks

Canned cycle cancel

Drilling cycle, spot boring

Drilling cycle, counter boring

Peck drilling cycle

Tapping cycle

Boring cycle

Boring cycle

Back boring cycle

Boring cycle

Boring cycle

Absolute programming

Incremental programming

Work coordinate system change/maximun spindle speed setting

Inverse tine feed

Feed per minute

Feed per revolution

Constant surface speed control *1

Constant surface speed control *1

Canned cycle initial level point return

Canned cycle R point level return

Oscillation node ON

Oscillation node OFF

polar coordinate interpolation mode cancel

Polar coordinate interpolation mode

Tool life management OFF

Tool life management ON

PMC data setting *1

High-speed machining program registration start *1

High-speed machining pro-gram registration end *1

Tool retract amount setting

Circular thread cutting CW *1

Circular thread cutting CCW *1

Spline interpolation *1

1 - 4

Page 13

Code

G222

G223

G232

G233

G240

G241

G242

G243

G244

G245

G248

G249

G251

G264

G265

G271

G301

G302

G303

G304

G305

G311

G312

G313

G314

G322

G323

G324

G325

G326

G327

G328

G329

G330

Group

01

24

26

00

25

00

Function Remarks

Involute interpolation CW

Involute interpolation CCW

Exponential function interpolation CW *1

Exponential function interpolation CCW *1

Machining plane 0 selection

(Machining plane

selection cancel)

Machining plane 1 selection

Machining plane 2 selection

Machining plane 3 selection

Machining plane 4 selection

Machining plane 5 selection

(Available for an optional

horizontal/vertical angle)

Axis switching/3-D coordinate conversion ON

Axis switching/3-D coordinate conversion canel

Multi-buffer

Tool nose interference check ON *1

Tool nose interference check OFF *1

Cylindrical interpolation

Floating reference point return

Circular cutting inner diameter CW

Circular cutting inner diameter CCW

Circular cutting outer diameter CW

Circular cutting outer diameter CCW

Multi-step skip function 1 *1

Multi-step skip function 2 *1

Multi-step skip function 3 *1

Multi-step skip function 4 *1

Square outside cutting CW

Square outside cutting CCW

Square plane

Square plane 1-directional

Square plane 2-directional

Circle inside (pocketing)

Square inside (pocketing)

Track inside (pocketing)

circle outside (pocketing)

1 - 5

Page 14

Code

G331

G332

G333

G334

G335

G336

G337

G338

G401

G411

G421

C431

G501

G511

G540~

G599

G611

C653

G661

G721

G722

G741

G841

G812

G813

G921

Group

00

19

08

15

12

00

00

14

00

09

00

Function Remarks

Square outside (pocketing)

Track outside (pocketing)

Circle (pocketing)

Trochoid cycle

High-speed side cutting cycle

Z feed fluting cycle

Corner pocket cycle

Square pocket cycle

Normal direction control cancel node

Normal direction control left side ON

Normal direction control right side ON

Tool axis direction tool length compensation *1

Programmable mirror image Cancel

Programmable mirror image

Additional work coordinate system selection

(60 pairs)

Pre-interpolation acceleration/deceleration *1

Position check (Note) for Maintenance *1

Macro modal call B *1

Rotary copy *1

Parallel copy *1

Counter direct tap cycle

Direct tap cycle

Helical drilling cycle CW

Helical drilling cycle CCW

Work coordinate system preset

(Note 1) *1 Reserved G code and not available for the noment

(Note 2) The G code marked in each group is selected in the reset state.

1 - 6

Page 15

2. INTERPOLATION FUNCTION

2-1 Positioning (G00)

Each axis moves to a Program-specified position at an independent rapid traverse rate to

perform positioning.

(1) command format

G90

G00 X_ Y_ Z_ ;

G91

(2) Sample program

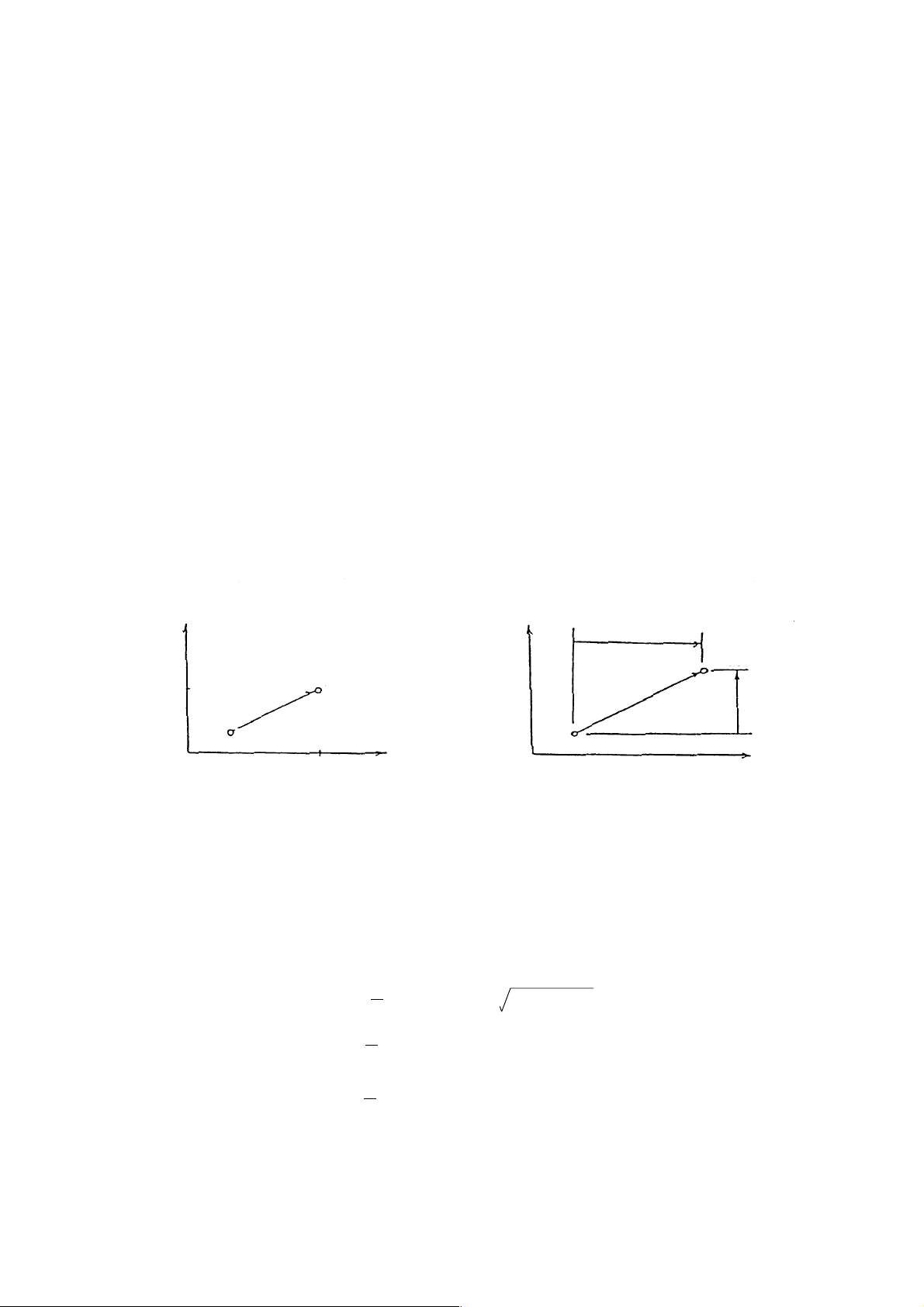

(a) Absolute programming (b) Incremental programming

G90 G00 X100. Y50. : G91 G00 X100. Y50.

50.

Y

End point

Start point

X

100.

Y

Start point

100.

End point

50.

X

(3) Cautions

(a) The rapid traverse rate has been set independently for each axis.

(b) The tool path is non-linear. See to it that the tool does not interfere with the workpiece.

(c) Linear acceleration/deceleration is applied. Confirm imposition (an accumulated

amount due to servo delay is within tolerance) at the end of the block, and then,

proceed to the next block.

(d) G00, G90 are G91 ale modal G codes. Once they are specified, they remain effective

until the next associated G code is specified.

(e) The tool path can be made linear by altering the parameter.

Y

50.

Start point

End point

X

100.

(f) You can set with the parameter whether the reset state is to be the G00 or G01 mode.

2 - 1

Page 16

(4) Associated parameters

No.1401, # 6 = 0 Dry run made invalid for rapid traverse command.

1 Dry run made valid for rapid traverse command.

No.1401, # 1= 0 Non-linear interpolation as positioning interpolation system

1 Linear interpolation as positioning interpolation system

No.3402, # 0= 0 G00 mode in reset state

1 G01 mode in reset state

2-2 Linear Interpolation (G01)

The tool moves linearly to a program-specified position at the cutting feed rate specified with an

F code.

(1) Command format

G90

{ }

G91

G01 X_ Y_ Z_...F_ ;

(2) Sample program

(a) Absolute programming. (b) Incremental programming

G90 G01 X100. Y50. F200; G90 G01 X100. Y50. F200;

Y

100.

End point

50.

Start point

50.

Y

End point

Start point

100.

X

(3) Cutting feed rate

The cutting feed rate specified with an F code is the speed at which the tool moves linearly.

In this case, the cutting feed rate is a composite speed of all the specified axes; the cutting

feed rate of each axis is as follows.

X

G01 G91 Xa Yb Zc Ff:

X-axis cutting feed rate: Fx = , where; L= a

Y-axis cutting feed rate: Fy =

z-axis cutting feed rate, Fz =

af

L

bf

L

cf

L

2

+ b2 + c

2

When the rotary axis is specified in the identical block, linear interpolation is performed

taking it as a linear axis in the units of degree.

2 - 2

Page 17

G01 G91 X100. C90. F200 :

End Point

Cutting feed rate in the rotary axis (C axis) direction:

Start

Point

Fc = (deg/min)

where; L = 100.

90. x 200

L

2

+ 90

2

(mm)

(4) Cautions

(a) An alarm results when no F code has been specified in the G01 block or before.

(b) Exponential type acceleration/deceleration is applied.

(c) Set with the parameter whether the reset state is to be the G00 or G01 mode.

(5) Associated parameters

No.3402, #0 = 0 G00 mode in reset state

1 G01 mode in reset state

(6) Associated alarm

No. 102 F0 was specified in the G01/G02/G03 mode.

2-3 Circular Interpolation (G02, G03)

The tool moves to a program-specified position along an arc within the plane selected with a

plane selection G code (G17, G18, G19) at the cutting feed rate specified with an F code.

(1) Command format

(a) X

plane

P YP

G02

G17 XP- YP- F_ ;

G03

(b) ZP -XP plane

G02

G18 ZP- YP- F_ ;

G03

(c) XP -ZP plane

G02

G19 YP-ZP- F_ ;

G03

Where; XP : X axis or its parallel axis

Y

Z

(Note) To specify with R instead of I, J or K is called radius designation on arc.

R_

I_ J_

R_

K_ I_

R_

J_ K_

: Y axis or its p arallel axis

P

: Z axis or its parallel axis

P

2 - 3

Page 18

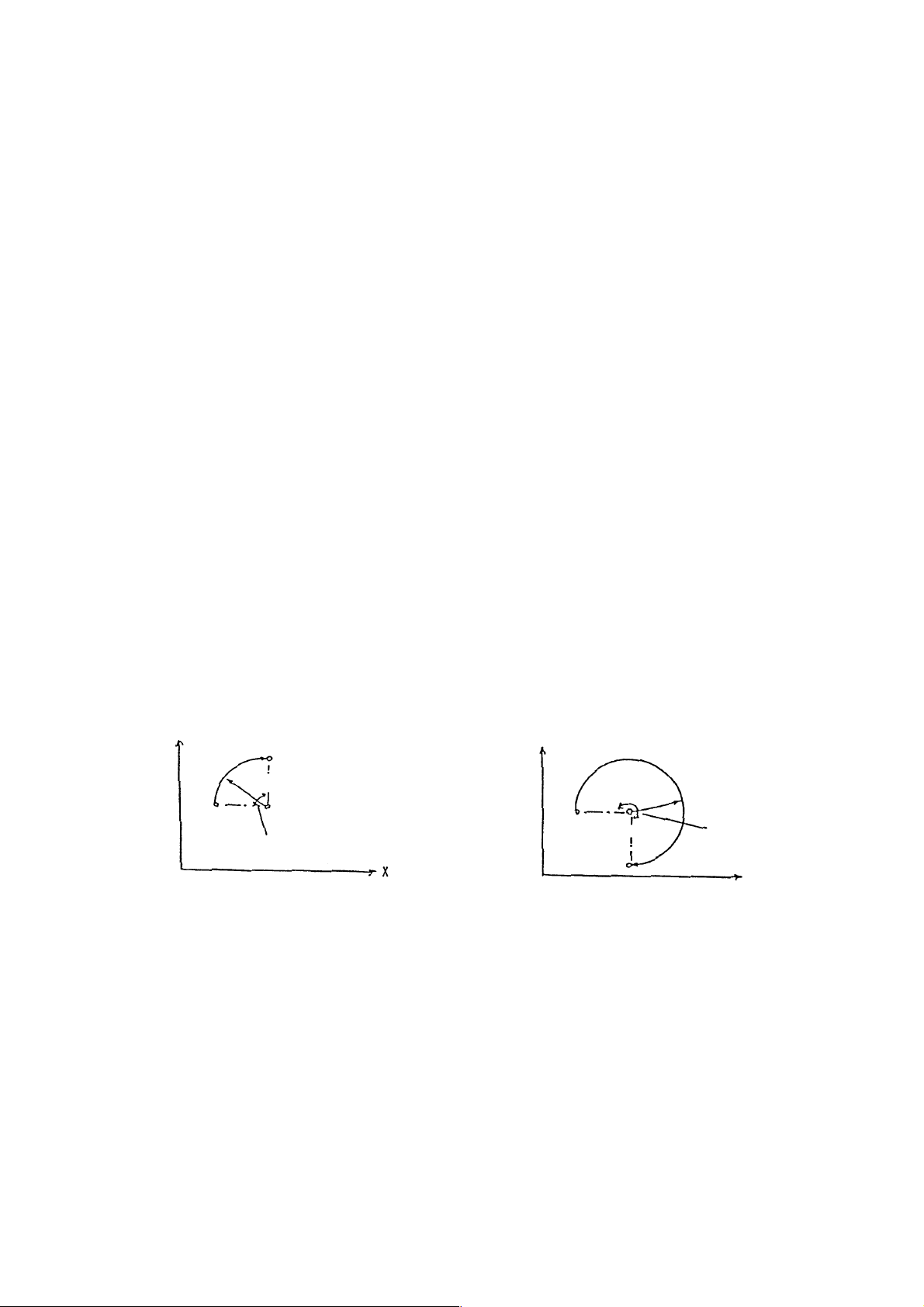

(2) Sample program

(a) Absolute programming (b) Incremental programming

G17 G90 G00 X13.397 Y70. F200: G17 C91 G02 X86.603 Y50

G02 X100. Y120. I86.603 J-50.: I86.603 J-50. F200:

Y

120.

G02

Start point

186.603

End point

J=50

Center

100.

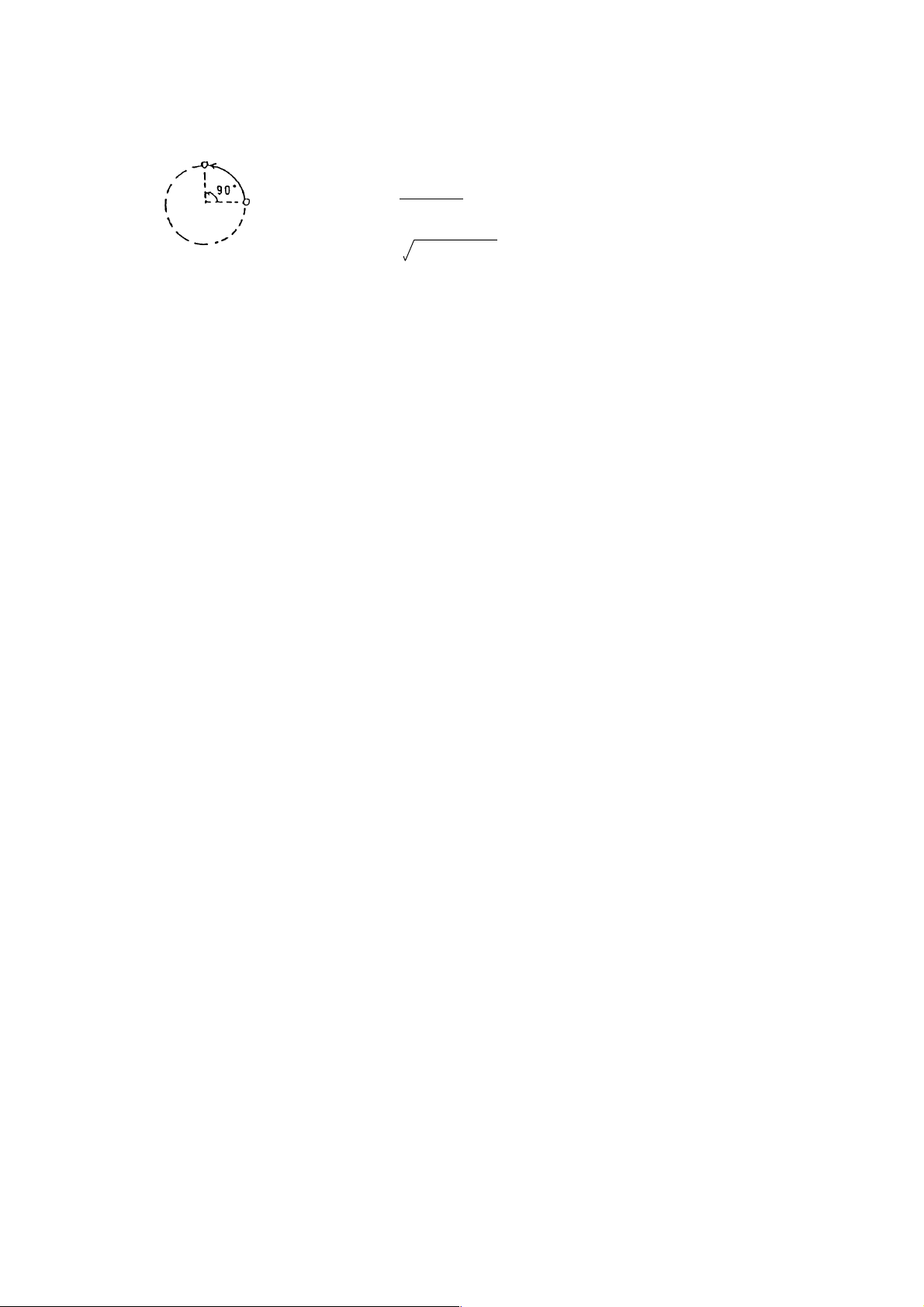

(3) Arc rotating direction

G02 : Clockwise (CW)

G03 : Counterclockwise direction (CCW)

Y

100.

X

G02

X

P

Z

G03

G03

G02

G02

Start point

186.603

P

G03

G02

100.

End point

J=50

Y

P

X

(4) Arc plane

The arc plane is specified with C17, G18 or G19.

G17 : X

G18 : Z

G19 : Y

-YP plane

P

-XP plane

P

-ZP plane

P

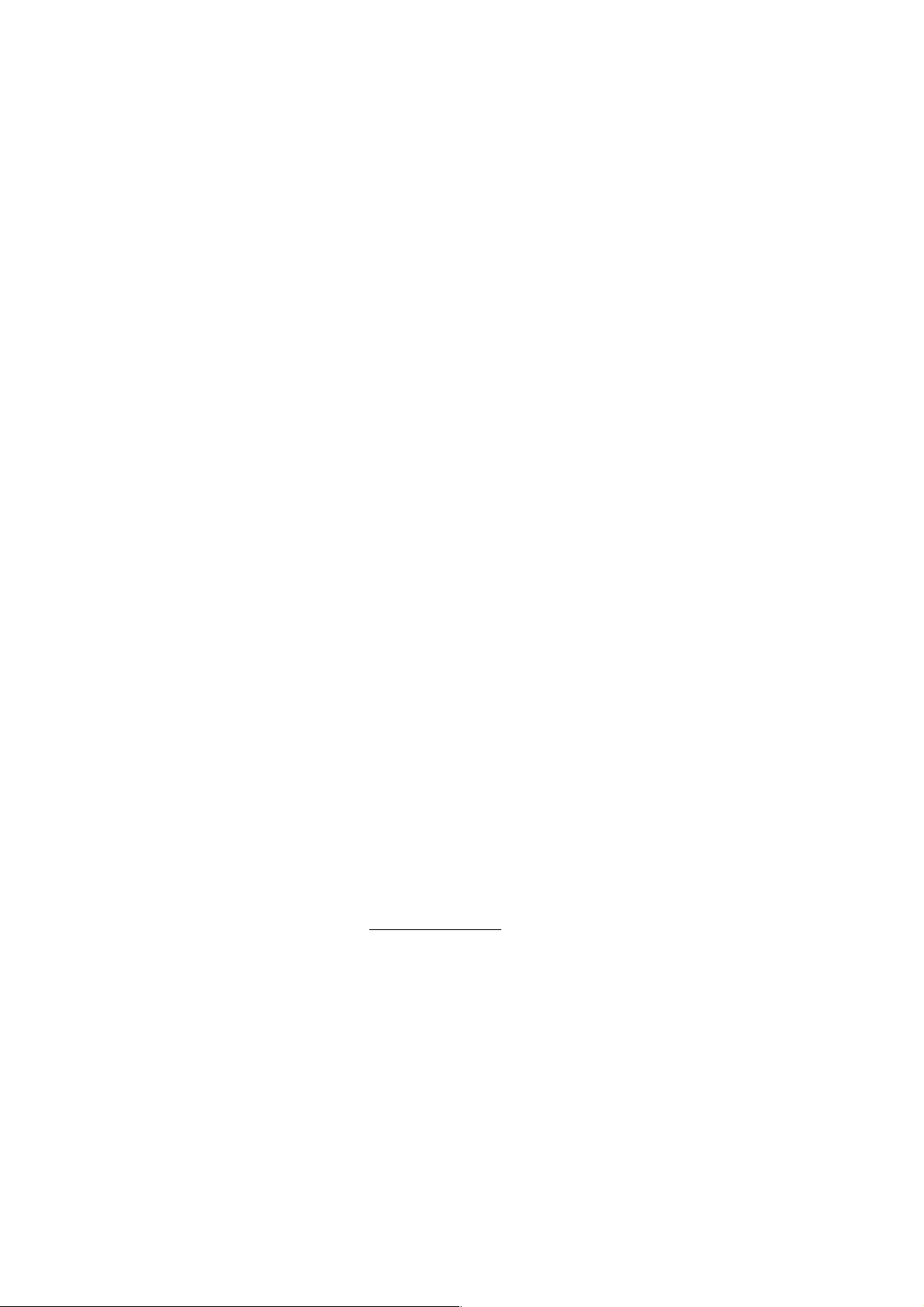

(5) Arc center

The arc center is specified with I, J or K corresponding to X

,YP and ZP respectively. In this

P

case, I, J and K are the vector components when viewing the arc center from its start point.

Y

P

End Point

J I

Center point

Start Point

X

P

X

P

End Point

I K

Center point

Start Point

Z

P

2 - 4

Page 19

(6) Cutting feed rate

The cutting feed rate specified with an F code is the speed at which the tool moves on the

arc.

(7) Cautions

(a) An alarm results when no F code has been specified in the G02/G03 block or before.

(b) An alarm results if an arc radius = 0 is specified.

(c) I0, J0 and K0 are omissible.

(d) When there is no end point on the arc, the tool moves linearly the rest after moving

along an arc if the end point error of circular interpolation is within the parameter set

value. Also, an alarm results if it is other than the parameter set value.

End

Point

error

Start Point

End Point

Moves linearly

Center

(e) An alarm results if the axis not for the arc plane is specified.

(f) When R is specified in the same block as I, J and K, R is given priority.

(g) When the rotary axis is specified in the same block, circular interpolation is performed

taking it as a linear axis in the units of degree.

(h) Exponential type acceleration/deceleration is applied.

(8) Associated parameters

No.3459 Arc end tolerance

(9) Associated alarm

No.102 F0 has been command with G01, G02 and G03.

No.132 Arc interpolation error

(#001) Center command, although available, is 0 in value.

(#002) Difference in radius value between of start and end

(#003) pints has exceeded parameter set value.

2-3-1 Radius Designation on Arc

In case of circular interpolation, an arc radius can be directly specified with R instead of

specifying the arc center with I, J or K.

2 - 5

Page 20

(1) Command format.

(a) X

P-YP

plane

G17 X

(b) Z

P-XP

G02

{ }

G03

plane

_ YP _ R ±_ F_ :

P

G02

G18 Z

(c) Y

P-ZP

{ }

G03

plane

_ YP _ R ±_ F_ :

P

G02

G19 Y

{ }

G03

where; X

P-ZP

: X axis or its parallel axis

P

: Y axis or its p arallel axis

Y

P

Z

: Z axis or its parallel axis

P

R+ : Arc of less than 180

R- : Arc of over 180°

(2) Sample program

(a) For the arc of less than 180°

G17 G91 G02 X100. Y100.

R-100. F200:

_ R ±_ F_ :

°

(b) For the arc of over 180°

G17 G91 G02 X100. Y-100.

R-100. F200 :

Y

End Point

R100.

Start

Point

Center

Less than 180°

X

Y

Start

Point

End Point

R100.

Center

(3) Cautions

(a) When I, J, K and R are specified in the same blocks, R is given priority.

(b) When the arc center is not calculated, an alarm results.

G02

(c) When G91 R_ : is specified, it is taken as a block without axial move.

G03

(4) Associated parameters

More than 180°

X

2 - 6

Page 21

(5) Associated alarms

No. 131 An arc radius R with which arc center position cannot be calculated has

been commanded.

2-4 Helical Interpolation (G02, G03)

If an arc command and any one axis for other than arc are specified, helical interpolation is

enabled by control which performs linear interpolation synchronously with arc movement.

(1) Command format

G02

G17 X

G18 Z

G19 Y

where; X

G03

G02

G03

G02

G03

: X axis or its parallel axis

P

: Y axis or its p arallel axis

Y

P

Z

: Z axis or its parallel axis

P

α : Any optional linear axis for other than circulate interpolation (up to 2 axes)

F : Arc speed

Linear axis speed = F

R _

_ YP _ α_ F_ ;

P

_ YP _ α_ F_ ;

P

_ ZP _ α_ F_ ;

P

I _ J _

R _

I _ J _

R _

I _ J _

Linear arc length

×

Arc length

2 - 7

Page 22

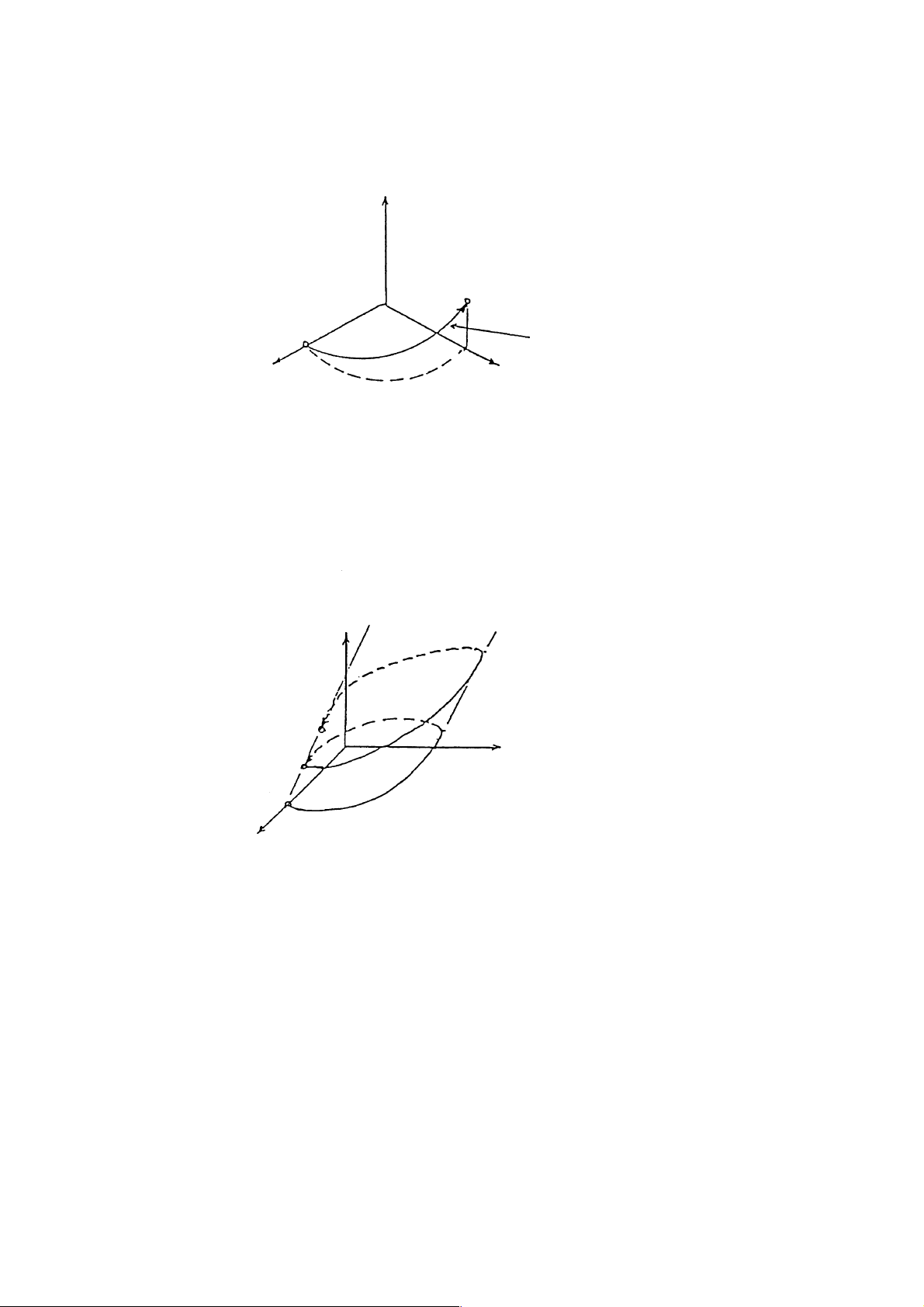

(2) Sample program

G17 G91 G03 X-100. Y-100. R100. Z50. F200 :

Z

End Point

Start Point

X

(3) The axes for other than circular interpolation can be specified up to 2 axes in the same

block.

(Example) G17 G91 G03 I-100. Z100. V50. F200 :

I-100. Z100.V50.;

Z

Tool Path

Y

The V axis must be

parallel with the Y axis.

Y

X

(4) Cautions

(a) See to it that the linear axis speed does not exceed the maximum value.

(b) Tool diameter compensation is applied to circular interpolation.

(c) An alarm results if 3 or more linear axes are specified.

2 - 8

Page 23

(5) Associated parameters

(6) Associated alarms

2 - 9

Page 24

2-5 Virtual Axis lnterpolation (G07)

If the axis is specified as a virtual axis, it does not move.

Interpolation can be perfomed with this axis and other one.

(1) Command format

α 0 ; Sets the α axis as the virtual axis.

G07

: The

: in this section.

G07

α 1 ; Cancels the a axis as the virtual axis.

where ;

(2) Sample program

G07 X0 ; Sets the X axis as the virtual axis.

G17 G91 G02 X0 Y0 I50. Z-1. 0 F200 ; SIN interpolation

G01 X5. F100; Dwell state for the move time of the X axis

G07 X1 ; Cancels the X axis as the virtual aixs.

(3) Cautions

(a) SIN interpolation results if one arc axis for helical interpolation is set as the virtual axis.

(b) The virtual axis is any one axis.

An alarm results if 2 or more axes are set as virtual axes.

(c) If a command is given as to only one axis specified as the virtual axis, the axis move

time valve is placed in the dwell state.

(d) Program virtual axis interpolation in the incremental manner.

Since the virtual axis does not move at any time, it is necessary to be careful when

programming in the absolute manner.

α : Any one axis

α axis is the virtual axis

}

2 - 10

Page 25

(4) Associated parameters

(5) Associated alarms

No.139 Two or more virtual axes have been specified.

2 - 11

Page 26

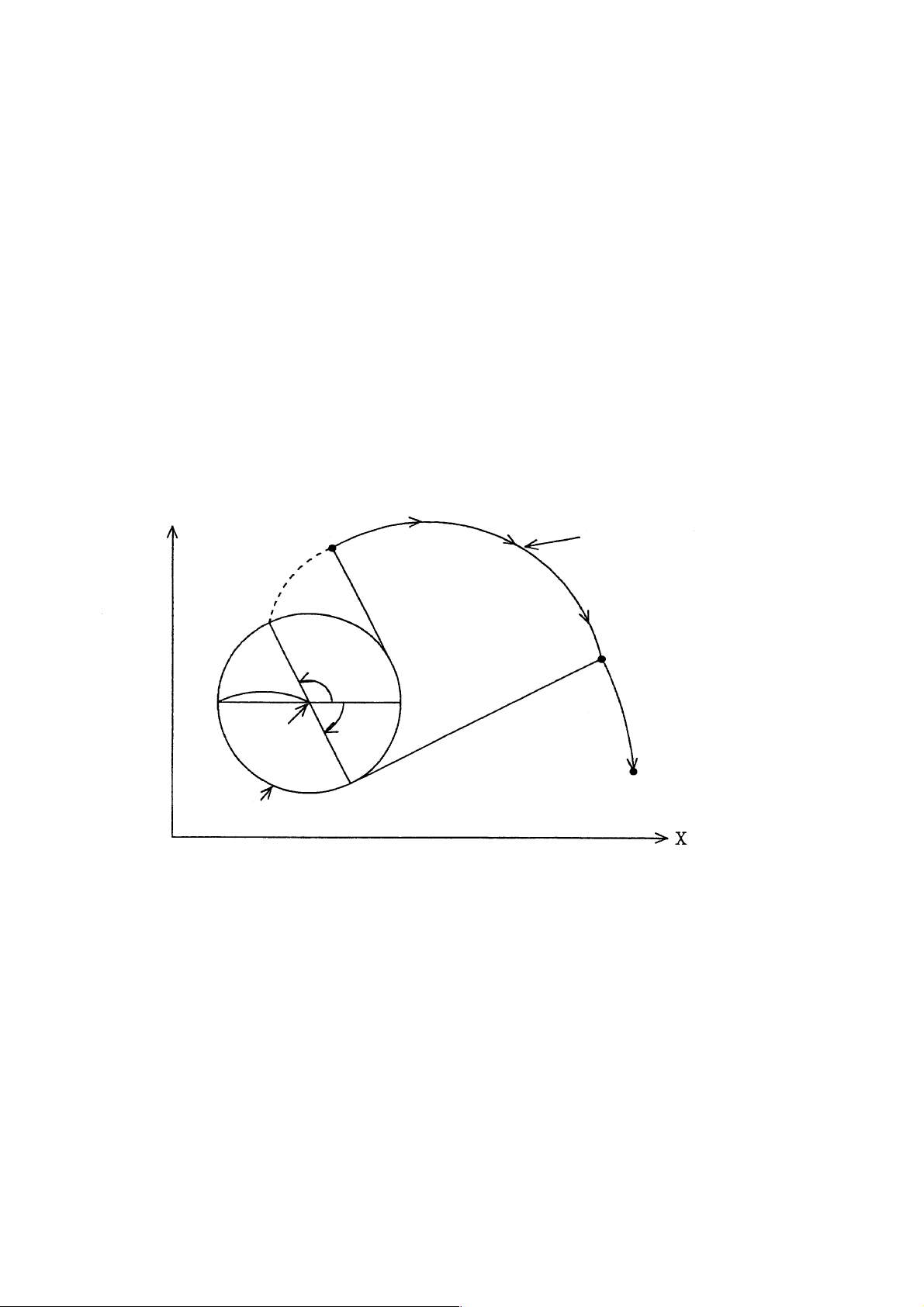

2-5-1 SIN Interpolation (G02, G03, G07)

SIN interpolation can be performed by assuming one of axes for an arc command as a virtual

axis in helical interpolation.

(1) Command format

G87 α0 ; Sets the virtual axis.

specify helical interpolation.

G07

α1 ; Cancels the virtual axis.

α is any one axis for the arc command.

(2) Sample program

G07 X0;

G17 G91 G03 X0 Y0 I-50. Z100. F200 ;

G07 X1;

Y

Z

(3) Cautions

(a) Effective only for automatic operation of the virtual axis.

(b) Program the virtual axis in the incremental manner.

(c) An alarm results if 2 or more virtual axes are specified.

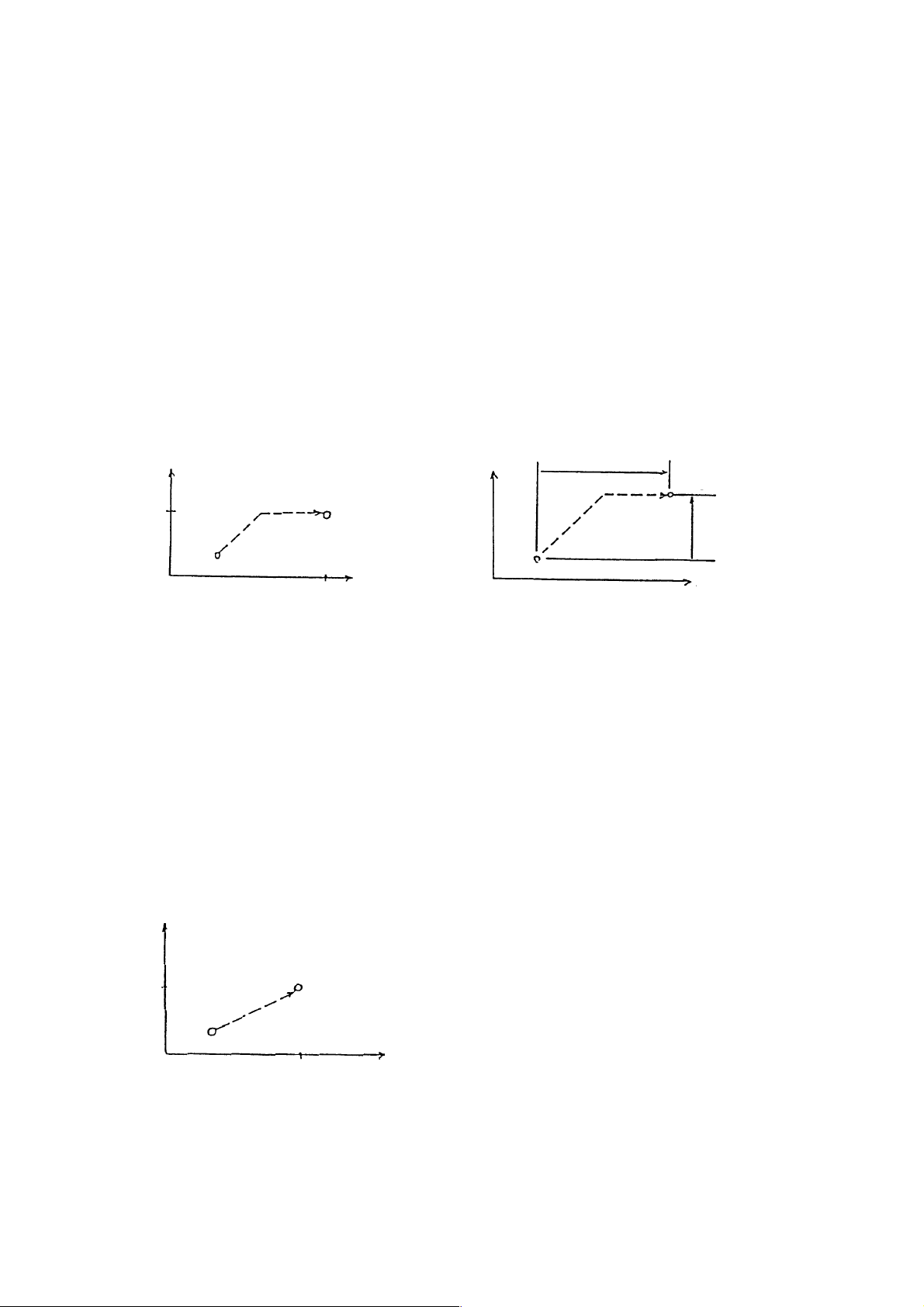

2-6 Single Direction positioning (G60)

Performs final positioning always from a specified single direction.

Using this function allows you to perform high-accuracy positioning.

(1) Command format

(a) For the one-shot G code

G60 X_Y_Z_... ; Effective only in the G60 specified block

2 - 12

Page 27

(b) For the modal G code

G60 X_ Y_ Z_... ;

X_ Y_ Z_...;

:

Single direction

positioning

:

G00 ;

Cancels G60 if any G code in Group 01

other than G60 is given.

(2) Sample program

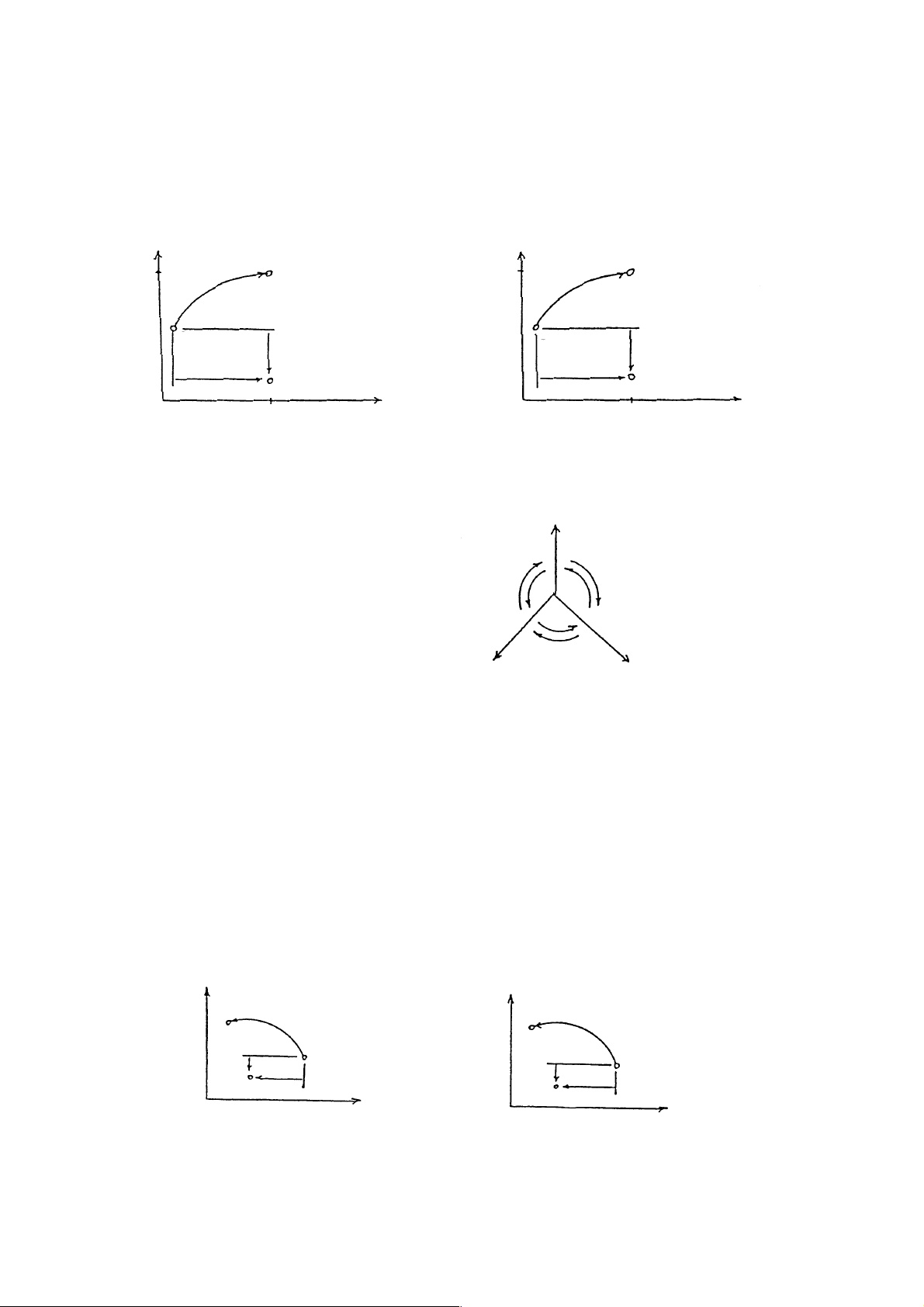

(a) When moving in the (b) When moving in the

+ direction - direction

G60 G91 X100.; G60 G91 X-100.;

Start Point

End

Point

Approach

Amount

End Point

Approach

Amount

Start Point

(3) Final positioning direction

Approach amount > 0 : The positioning direction is the + direction.

Approach amount < 0 : The positioning direction is the - direction.

Approach amount = 0 : Positioning is not performed in the - direction.

(4) Cautions

(a) Whether G610 is to be one-shot or modal is set with the parameter.

(b) In the canned cycle, hole positioning is performed with G60.

However, single positioning is disabled for the shift amount of G76 and G87.

(c) During the mirror image, it is disabled for the approach amount of single direction

positioning.

(5) Associated parameters

2 - 13

Page 28

(5) Associated parameters

No. 3458 Single positioning direction and approach amount of each axis

No. 3400, #2 = 0 G60 is the G code of Group 00 (one-shot).

1 G60 is the G code of Group 01 (modal).

2 - 14

Page 29

2-7 Involute Interpolation (G222, G223)

This function allows machining along an involute curve. It also provides cutter compensation.

(1) Involute curve

The involute curve in the X-Y plane is defined as following.

θ) =R [cosθ + (θ- θ0) sinθ ] +X0

X(

θ) =R [sinθ + (θ- θ0) cosθ ] +Y0

Y(

where;

X0, Y0:Central coordinate of the basic circle

R : Radius of the basic circle

θ 0 : Angle of the point where the involute curve starts

θ : Angle of the contact of the tangent from the current position to the basic circle

θ ), Y(θ ) :Current position of the X-and Y-axis

X(

Y

Start Point

involute Carve

(X, Y)

R

(X0, Y0)

Basic Circle

The involute curves in the Z-X and Y-Z planes are defined in the same manner as that in the XY plane.

θ 0

θ

End Point

2 - 15

Page 30

(2) Command format

(a) X

_ plane

P -YP

G222

G17 XP _YP _ I_ J_ R_ F_ ;

G223

(b) ZP-XP Plane

G222

G18 ZP _ YP_ K_ J_ R_ F_;

G223

(c) YP-ZP plane

G222

G19 YP_ ZP J_ K_ R_ F_ ;

G223

where;

G222 : Clockwise involute interpolation

G223 : Counterclockwise involute interpolation

X

, YP, ZP: Coordinate value of the end point

P

X

P

Y

P

Z

P

: X-axis or its parallel axis

: Y-axis or its parallel axis

: Z-axis or its parallel axis

I, J, K : Central position of the basic circle for the involute curve viewed from the

R : Radius of the basic circle

F : Cutting feed rate

start point

(3) Start point and end point

The end point of the involute curve is specified with the address X, Y, or Z and expressed

with an absolute or incremental value depending on G90 or G91. If the incremental value is

used, specify the coordinate of the end point viewed from the start point of the involute

curve.

When a start or end point command is within the basic circle, an alarm results. The same

results when an offset vector is brought into the basic circle by cutter compensation.

Care should be taken when an offset is applied, in particular, to the inside of the involute

curve.

(4) Basic circle command

The center of the basic circle is specified with I, J, and K, corresponding to X, Y, and Z,

respectively. However, the numerals following I, J, and K are vector components, when the

center of the basic center is viewed from the start point of the involute curve.

They should be always programmed with incremental values, regardless of G90 or G91.

Add a sign to I, J, and K as required.

2 - 16

Page 31

(5) Feed rate

A feed rate for involute interpolation assumes a cutting feed rate specified with an F-code,

and a speed along the involute curve (speed in the tangent direction of the involute curve)

is controlled to be specified feed rate.

(6) Cutter compensation

Cutter compensation can be applied to the involute curve for perform machining. Cutter

compensation is specified with G40, G41, or G42, like straight line or circular arc.

G40 : Cancels cutter compensation

G41 : Offsets to the left of the tool advance direction

G42 : Offsets to the right of the tool advance direction

Cutter compensation for the involute curve is achieved as follows.

First, obtain a circular arc close to the curvature of the involute curve near the start point of

the involute curve. Similarly, obtain the an intersecting point at offset time near the end

point, and assume the involute curve passing those two points to be a tool center path.

You cannot specify cutter compensation start-up or cancel during the involute interpolation

mode.

(7) End point error

When the end point is not located on involute curve passing the start point, the belowmentioned curve is assumed.

An alarm will result if a shift amount between the involute curve passing the start point and

that passing the end point is greater than a value set in a parameter.

When there is an end point error, a feed rate cannot be assured.

End Point

Corrected Path

Start Point

True Involate Curve

2 - 17

Page 32

(8) Modes available for involute interpolation

Involute interpolation is allowed even during the following G-code modes.

G41 : Cutter compensation to the left

G42 : Cutter compensation to the right

G511 : Programmable mirror image

G68 : Coordinate rotation

(9) Limitations

(a) Rpm of the involute curve

Both start point and end point must be within 100 revolutions from an involute curve

start point. The involute curve revolving one or more time can be also specified in one

block.

(b) Unspecifiable function

Optional angle chamfering corner R cannot be specified during the involute

interpolation mode. Helical interpolation and axis scaling are disallowed.

(c) Modes unavailable for involute interpolation

G411: Normal direction control to the left

G412: Normal direction control to the right

G121: Polar coordinate interpolation

G16 : Polar coordinate command

(10) Associated parameters

No. 3465 Initial angle error limit value for involute interpolation

(1 1) Associated alarms

No. F242 A command value has an error.

1 The start or end point has been specified within the basic circle.

2 I, J, K, or R has been specified with 0.

3 The start or end point is beyond 100 revolutions from the involute curve

start point.

No. F243 The end point is not on the involute curve.

2 - 18

Page 33

2-8 Cylindrical Interpolation (G271)

If the move amount of the linear axis and the angle of the rotary axis are given by a program

command, the move amount of the rotary axis given in terms of angle will be internally

converted into a distance on the circumference. Since the distance on the circumference can

be considered the move amount of the linear axis on the circumference, linear or circular

interpolation can be performed with other linear axis. After interpolation, it will be put back into

the angle of the rotary axis again.

2-8-1 Command Format

G271 A Cylinder radius ; Cylindrical interpolation ON

: Cylindrical interpolation mode

G271 A0 ; Cylindrical interpolation cancel

The A-axis is a rotary axis.

The rotating angle of the rotary axis is calculated back from the move amount on the

circumference. For example; when you want to move by 100.0 on the circumference of the

cylinder whose radius is 50.0, obtain the rotating angle of the rotary axis from the following

formula:

r : Cylinder radius

θ : Rotating angle

s: Move amount on the cylinder

circumference

Rotating angle

2-8-2 Feed Rate

During the cylindrical interpolation mode, a feed rate command F is the speed at which the tool

moves on the outer circumference of the cylinder.

θ=

360 x S (Move amount on circumference)

π x r (Cylinder radius)

2

360 x 10.00

= = 114.591

2

π x 50.0

s

r

θ

Work

2 - 19

Page 34

2-8-3 Cylindrical Interpolation Applied Axes

set in the parameters(no. 3426 for the linear axis, and no. 3427 for the rotary axis) the linear

axis and rotary axis to which you want to apply cylindrical interpolation. A setting range for both

parameters is 1 to the number of controlled axes; they must not have the same value.

2-8-4 Cylindrical Interpolation Applied Plane

During the cylindrical interpolation mode, the plane is automatically selected, which assumes

the rotary axis to be the plane first axis, and the linear axis td be the plane second axis.

2-8-5 Sample Program

(Select the A-Y plane with the parameters 3426 and 3427)

G40 G80 ,.

G00 X-1204.0 Y0 A0 ,.

G01 Z100.0 F100

G271 A50.0 ; Cylindrical interpolation mode ON

N1 G42 G01 X-40.0 F500 ; (Cylinder radius = 50.0)

N2 A90.0 F500 ;

N3 X-100.0 A180.0

N4 A260.0 ; In Cylindrical interpolation mode

N5 G03 X-80.0 A282.918 R20.0 ;

N6 G01 X-60.0 ;

N7 G02 X-40.0 A305.836 R20.0 ;

N8 G01 A360.0 ;

N9 G40 G01X-120.0 ;

G271 AO ; Cylindrical interpolation mode OFF

G00 Z120.0 A0 ;

X

Developed View of Cylindrical Surface with Cylinder Radius = 50.0

A C (Rotary Axis)

Programmed Path

X (Linear

Axis)

Tool Center Path

246.892

282.918

Coordinate Value on

Cylinder Surface

Specified Angle

R: (Cylinder Radius)

2 - 20

Page 35

2-8-6 Cautions

(1) When specifying cutter compensation, start up/cancel during the cylindrical interpolation

mode.

(2) The plane (selected by G17 to G19) existing prior to entering the cylindrical interpolation

mode is canceled once during the cylindrical interpolation mode and revived at the end of

the cylindrical interpolation mode.

(3) When performing circular interpolation during the cylindrical interpolation mode, the method

to specify the circular arc radius (which ones of I, J, and K addresses are to be used) is

determined as follows, depending on the axis of the basic coordinate system to which the

2nd axis (linear axis) of the cylindrical interpolation plane corresponds (setting of the

parameter no. 1011).

• When the linear axis is the X-axis or its parallel axis, specify with K and I, considering it

the Z

p-Xp

plane.

• When the linear axis is the Y-axis or its parallel axis, specify with I and J, considering it

the Xp-Yp plme.

• When the linear axis is the Z-axis or its parallel axis, specify with J and K, considering it

the Yp-Zp plane.

It is also possible to specify a circular arc radius with an R-command.

(4) Specify a G271 command (G271 Axx; ) independently in a block.

If there is no axis command (G271;) after the G271 command, an alarm will result.

(5) If the axis not set in the parameter no. 3427 is specified with the G271 command, an alarm

will result.

(6) The follwing functions are not available:

• Return to the machining break point

• Manual intervention by manual absolute ON

(7) If the follwing comands are given during the cylindrical interpolation mode, an alarm will

result:

• G17, G18, G19 ------------------------ Plane designation

• G28, G30, G53 ------------------------ Machine coordinate system

• G54-59, G540-G599, G92, G52 --- Work coordinate system

• G73, G74, G76, G81-G89 ---------- Canned cycle

• G302-G305, G322-G333 ----------- Special canned cycle

• G00 (when including the cylindrical interpolation applied rotary axis)

2 - 21

Page 36

(8) In the cylindrical interpolation mode, the angle of the rotary axis is converted into the

distance on the circumference and converted back into the angle after interpolation. When

this is done, a slight conversion error results.

(9) If circular interpolation with small circular arc radius is executed during the cylindrical

interpolation mode, a circular interpolation alarm may be caused by the above-mentioned

conversion error. Care should be taken when using it. Even at the time of cutter

compensation, a cutter compensation alarm may result due to the above-mentioned

reason.

(10)If cylindrical interpolation mode ON (G271 Axx; (A

≠ 0) ) is specified again during the

cylindrical interpolation mode an alarm will result.

(11) The residual move amount indicates the value when moving on the outer circumference of

the cylinder.

2-8-7 Associated Parameters

No. 3426 Number of the linear axes(1 to number of controlled axes) to which

cylindrical interpolation is to be applied

No. 3427 Number of the linear axes(1 to number of controlled axes) to which

cylindrical interpolation is to be applied

2-8-8 Associated Alarms

No. 126 A cylindrical interpolation command has an error.

(#001) There is no rotary axis command.

(#002) This is not an independent command.

(#003) The modal G-code is not correct.

No. 127 A wrong command was given during the cylindrical interpolation

mode.

(#001) A wrong G-code was given.

(#003) A rotary axis move command was given in the G00 mode.

(#004) Cylindrical interpolation was specified again during the cylindrical

interpolation mode.

No. 189 (G271) The parameter has not been set properly.

• The parameter no. 3426 or no. 3427 is not "1" to the number of controlled

axes, or they have the same value.

• The linear axis set in the parameter no. 3426 is none of the three basic

axes, X, Y, and Z, or not parallelto awy.

2 - 22

Page 37

2-9 Polar Coordinate Interpolation (G120, G121)

polar coordinate interpolation is a function to provide contour control by converting a command

programmed in the orthogonal coordinate system into a linear axis move(tool move) and rotary

axis move(work rotation).

<Orthogonal Coordinate system> <Polar Coordinate System>

C

(X1,C1)

C

1

C

X

X

X

1

The following shows the relations between (X

, C1 ) and. (X1 ' , C1 ' ).

1

C

1

2-9-1 G Codes

G 121 : Polar coordinate interpolation mode

G 120 : Cancel polar coordinate interpolation mode

2-9-2 Command Format

G121 ; Polar coordinate interpolation mode ON

:

: Polar coordinate interpolation mode ON

:

G120 ; Cancels polar coordinate interpolation mode

(X1’,C1’)

X’

C

X

’

1

X’

X’

2-9-3 Polar Coordinate Interpolation Axes

The linear axis and rotary axis to which you want to apply polar coordinate interpolation should

be set in the parameters (no. 3418 for the linear axis and no. 3419 for the rotary axis) in

advance. For both parameters, set within a range of 1 to the number of controlled axes, and

they must not be of identical value.

2 - 23

Page 38

2-9-4 Polar Coordinate Interpolation plane

A G121 command effectuates the polar coordinate interpolation mode, assumes the zero pint of

the work coordinate system to be that of the coordinate system, and selects the plane(polar

coordinate interpolation plane) which assumes the linear axis to the first axis of the plane and a

virtual axis(rotary axis) orthogonal to the linear axis to be the second axis of the plane. Polar

coordinate interpolation is performed on this plane.

Since polar coordinate interpolation is initiated, assuming the G121 specified position's angle to

be zero (0), regardless of an actual position, prepare a program, assuming the work coordinate

value of the rotary axis to be zero (0) when G121 is specified..

2-9-5 Program Command

(1) In the polar coordinate interpolation mode, specify a program command in terms of

orthogonal coordinate value in the polar coordinate interpolation plane. Use the axial

address of the rotary axis as a command address for the second axis of the plane. The unit

for the command is not degrees; specify in the same unit (rpm or in.) as the linear axis, the

first axis of the plane.

(2) The polar coordinate interpolation mode allows you to specify linear interpolation (G01)

and circular interpolation (G02, G03). Both absolute programming and incremental

programming are allowed.

(3) When performing circular interpolation in the polar coordinate interpolation plane, the

circular arc radius specifying method (whether I, J, or K should be used) is determined as

follow, depending on which axis in the basic coordinate system the first axis (linear axis) of

the plane corresponds to(parameter setting: no. 1011).

• When the linear axis is either X-axis or its parallel axis, I and J are used, assuming the X

-YP plane.

• When the linear axis is either Y-axis or its parallel axis, J and K are used, assuming the Y

-ZP plane.

• When the linear axis is either Z-axis or its parallel axis, K and I are used, assuming the Z

-XP plane.

It is also possible to specify the circular arc radius with an R-command.

(4) Cutter compensation can be applied to the program command. Polar coordinate

interpolation is performed on the profile after cutter compensation. However, specify G121

and G120 in the cutter compensation cancellation mode (G40).

P

P

P

2 - 24

Page 39

(5) For an feed rate, use F-code to specify a tool move rate in the polar coordinate

interpolation plane( orthogonal coordinate system ). Normally, it is specified in feed per

minute (G94); the unit for the F-code will be mm/min. or in./min.

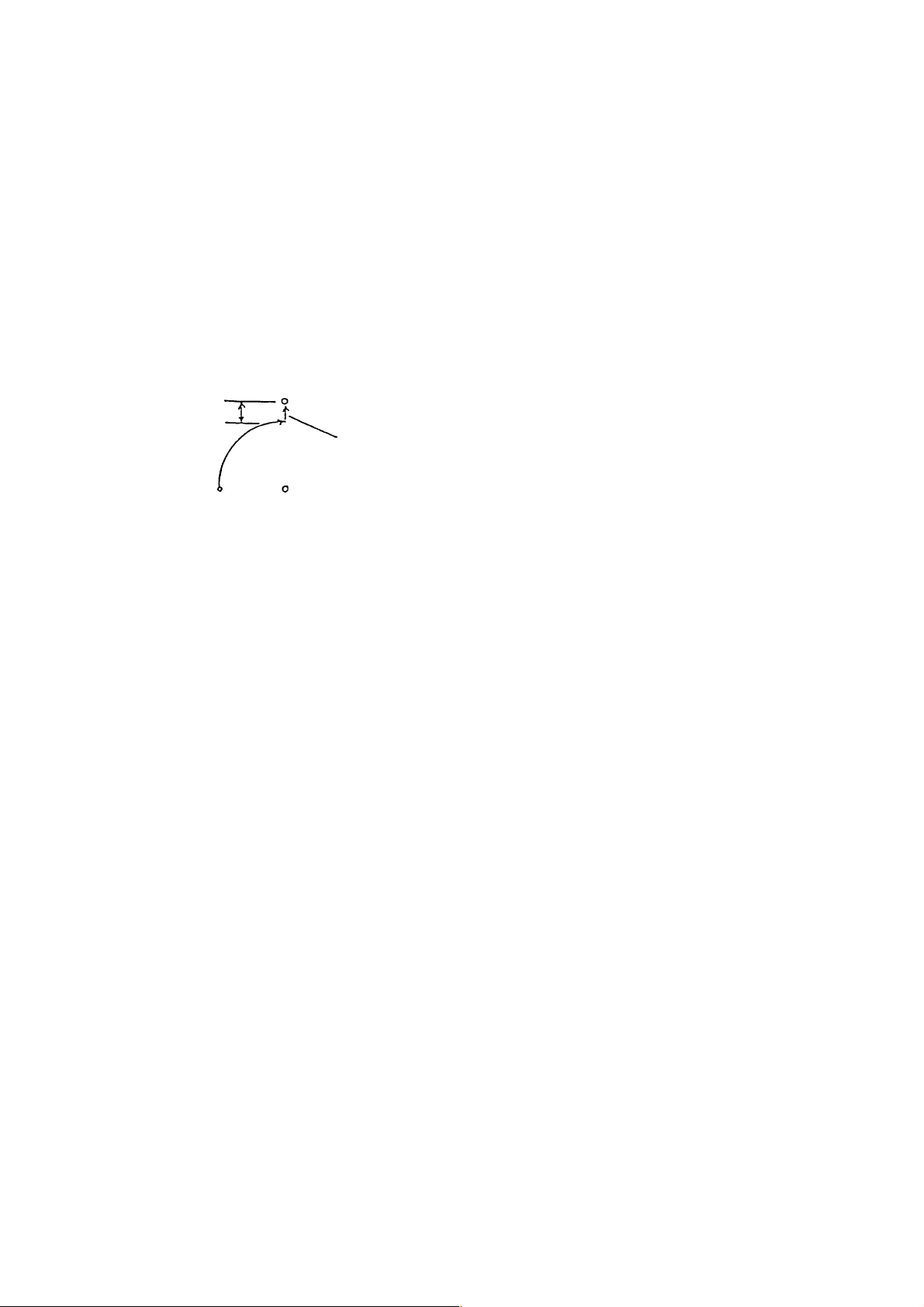

2-9-6 sample Program (X-axis: Linear Axis, C-axis: Rotary Axis)

N1 G00 X50.0 C0 ;

N2 G121 ;

N3 G42 G01 X30.0 F100 ;

N4 C20.0 ;

N5 G03 X20.0 C30.0 R10.0 ;

N6 G01 X-30.0

N7 C-20.0 ;

N8 G03 X-20.0 C-30.0

I0.0 J0;

N9 G01 X30.0;

N10 C0 ;

N11 G40 X50.0 ;

N12 G120 ;

Positions to the start position

Starts polar coordinate interpolation

Profile program(program based on

the orthogonal coordinate value

In the X-C' plane)

Cancels polar coordinate interpolation

Rotaray Axis

Tool

Linear Axis

2 - 25

Page 40

2-9-7 Feed Rate Clamp

The maximum cutting feed rate at polar coordinate interplation can be set in a parameter (no;

3464). If any feed rate higher than this one is specified during polar coordinate interpolation, it

will be clamped to this rate. If a set value is 0, it will be clamped by the normal maximum cutting

feed rate (parameter no. 1422) even during polar coordinate interpolation.

As polar coordinate interpolation converts the profile programmed in the orthogonal coordinate

system into the movements of the linear axis and rotary axis, a move near the work center

(coordinate zero pint) may increase the speed of the rotary axis and exceed the limit speed of

the machine.

If this is the case, the allowable speed of the rotary axis can be set with the parameters as

follows.

Rotary axis allowable speed = Maximum cutting feed rate (parameter no. 3464) x Allowable

ratio(parameter no. 3420)

If the speed component of the rotary axis during polar coordinate interpolation exceeds the

allowable speed, an override calculated by the formula below will be automatically applied.

(Automatic override )

Override = x 100 (%)

If the speed component of the rotary axis stills exceeds the allowable speed even after a

override has been applied, the feed rate will be clamped in such a manner that the speed

component of the rotary axis will not exceed the maximum cutting feed rate. (Automatic speed

clamp)

2-9-8 Rapid Traverse(G00) Operation

A G00 command can be executed during the polar coordinate interpolation mode. to the G00

block, however, only the end point is converted into a position in the polar coordinate system; a

path remains unconverted.

(Example)"AG00 X100.0 C50.0;" in the G121 mode assumes the same path as "G01 X141.421

With G00, the rotary axis takes a short-cut. (move within +/-l80

2-9-9 Precautions

(1) Specify G120 and G121 in an independent block, respectively.

Allowable speed of the rotary axis

Speed component of the rotary axis

C45.0;" in the G120 mode.

° ) to reduce the machining time.

(2) Prior to specifying G121, the work coordinate system must have been set, where the

center of the rotary axis can be the zero point of the coordinate system.

2 - 26

Page 41

(3) The plane prior to G121 (the plane selected with G17, G18,- or- G19) is cancelled once by

specifying G121 and restored by specifying G120.

(4) The following lists the G-codes which cam be specified during the G121 mode.

G00, G01, G02, G03, G04, G09, G40, G41, G42,

G65, G66, G67, G98, G99

(5) Any axis outside the plane in the G121 mode moves independent of polar coordinate

interpolation.

(6) A display of "MOVE AMT." during the G121 mode refers to a remaining move amount in the

polar coordinate plane (orthogonal coordinates). However, the G00 block assumes the

same unit as usual.

(7) The following functions are not available for the block in the G121 mode. Program restart,

Return to machining break point, Manual intervention by manual absolute ON

(8) Upon completion of polar coordinate interpolation (G120) , the work coordinate value of the

rotary axis can be rounded to 360

° through parameter setting. (0° 360°)

<

=

(9) When the work coordinate value of the linear Axis is negative at G121 command. To the

first move block, only the end point is converted into a position in the polar coordinate

system; a path remains unconverted. (Same as linear G00 in the G121 mode)

Starting from the next move block, polar coordinate conversion is applied to the move path.

Only G00 and G01 can be specified in the first move block; G02 and G03 cannot be.

2-9-10 Associated parameters

No. 3410, #1 = 0 Does not Perform automatic override and automatic speed clamp

during the polar coordinate interpolation mode.

= 1 Performs automatic override and automatic speed clamp during the

polar coordinate interpolation mode.

No. 3418 Axis number of the linear axis to which you want to apply polar

coordinate interpolation

No. 3419 Axis number of the rotary axis to which you want to apply polar

coordinate interpolation

No. 3420 Automatic override allowable ratio during the polar coordinate

interpolation mode

No. 3464 Maximum cutting feed rate during the polar coordinate interpolation

mode.

2 - 27

Page 42

2-9-11 Associated Alarms

No. 113 A polar coordinate interpolation command has an error.

(#001) G120 or G121 has not been independently specified.

(#002) When G120 or G121 was specified, cutter compensation had not been

cancelled.

(#003) When the work coordinate value of the linear axis was negative at G121, a

G-code other than G00 and G01 was specified in the first move block.

No. 114 A wrong Command was specified during the polar coordinate interpolation

mode.

(#001) An unavailable G-code was specified.

No. 189 (G121) Parameter Setting is erroneous.

• The setting of the parameters nos. 3418 and 3419 is not within a range of

1 to the number of controlled axes, or the setting of the parameter no.

3418 is equal to that of no. 3419.

• The linear axis set in the parameter no. 3418 is none of the three basic

axes(X, Y, and Z) or not parallel to any of them.

2 - 28

Page 43

3. FEED FUNCTION

3-1 Feed per Minute (G94)

Until G95 is specified after G94 was specified, the stroke per minute (mm/min., inch/min.) is

directly specified with a numerical value following F.

Feed rate F is the stroke per minute

Metric system : mm/min

Inch system : inch/nin.

(1) Command format

G94 ;

(2) Sample program

F100 ; The feed rate is a move of 100 mm per minute.

(3) The F code programmable range is as follows.

(a) Metric system

F60 : 1 ~ 999999 (mm/min.)

F61 : 0.1~999999.9 (mm/min.)

(b) Inch system

F51 : 0.I ~ 99999.9 (inch/min.)

F52 : 0.01 ~ 99999.99(inch/min.)

(5) Cautions

(a) One of F60, F61, F51 and F52 is selected by parameter setting.

(b) then F61 in the metric system is specified without a decimal point, the input

increment of 1 mm/min. or 0.1 m/min. is selected by parameter setting.

(c) In case of thread cutting (G33), feed per revolution is selected, disabling feed per

minute.

(6) Associated parameters

No. 3400, #1= 0 The least input increment for F61 in the metric system without a

decimal point is 1 mm/min.

1 The least input increment for F61 of the metric system without a

decimal point is 0.1 mm/min.

3 - 1

Page 44

No. 3401, #2= 0 F51 for feed per minute in the inch system (inch/min. )

1 F52 for feed per minute in the inch system (inch/min. )

No. 3401, #3= 0 F60 for feed per minute in the metric system (mm/min. )

1 F61 for feed per minute in the metric system (mm/min. )

(7) Associated alarms

3-2 Feed per Rotary (G95)

Until G94 is specified after G95 was specified, the stroke per spindle revolution (mm/rev. inch/

rev.) is directly specified with a numerical value following F.

Feed rate F is the stroke per spindle

revolution

Metric system : mm/rev.

Inch system : inch/rev.

(1) Command format

G95 ;

(2) Sample program

F1, 2 ; The feed rate is 1.2 mm per revolution.

(3) The F code programmable range is as follows.

(a) Metric system

F32 : 0.01 ~999.99 (mm/rev.)

F33 : 0.001 ~ 999.999(mm/rev.)

(b) Inch system

F23 : 0.001 ~ 99.999 (inch/rev.)

F24 : 0.0001 ~ 99.9999 (inch/rev.)

(4) Cautions

(a) One of F32, F33, F23 and F24 is selected by parameter setting.

3 - 2

Page 45

(5) Associated parameters

No. 3401, #0= 0 F23 for feed per revolution in the inch system (inch/rev.)

1 F24 for feed per revolution in the inch system (inch/rev.)

No. 3401, #1= 0 F32 for feed per revolution in the metric system (mm/rev.)

1 F33 for feed per revolution in the metric system (mm/rev.)

3-3 Inverse Time (G93)

when G93 is instructed, the program is put in the INVERSE TIME mode until G94 and G95 are

instructed. Inverse time (FRM) is instructed directly with a value following F.

(1) Command format:

G93 ;

(2) Inverse time (FRN)

(a) For linear interpolation (G01)

FRN = (1/min)

(b) For circular interpolation (G02, G03):

FRN = (1/min)

where; Speed : Metric system (mm/min)

(3) F can be instructed within the following range:

F43 : 0.001 ~ 9999.999

(4) Sample program

G93 ;

G91 G01 X100. F5. ;

Y50. F10.

Speed

Distance

Speed

Distance

Inch system (inch/min)

Distance : Metric system (mm/min)

Inch system (inch)

Spped: 500mm/min

3 - 3

Page 46

(5) Cautions

(a) In G93 mode, F code must be instructed per block.

When F code is omitted, a previously instructed F code becomes valid.

3-4 Exact Stop (G09)

If a G09 command is specified in the same block as a move block, it decelerates and stops the

machine upon completion of one block, and after confirming that the machine position is within

the range in which a command position was specified, proceeds to the next block.

(1) Command format

G09 ------ ;

(2) Sample program

N1 G09 G91 G01 X100. F500 ;

N2 G01 Y-50. ;

The corner has an edge when G09 is specified.

The corner is rounded when G09 is not specified.

(3) Associated parameters

No.1826 Imposition width of each axis

No.1827 Imposition width of each axis on cutting feed

3-5 Exact Stop Mode (G61)

Until G62, G63 or G64 is specified after G61 was specified, this function decelerates and stops

the machine, confirms that the machine position is within the specified range, and then,

proceeds to the next block.

(1) Command format

G61 ;

3 - 4

Page 47

(2) Sample program

N1 G61 G91 G01 X100. F500 ;

N2 Y-50. ;

N3 X - 100. ;

N4 G64;

(3) Cautions

3-6 Automatic Corner Override (G62)

Exact stop effective blocks

The corner has an edge when the G61 mode

is effective.

The corner is rounded when the G61 is

ineffective.

When tool diameter compensation is applied, since the tool center path is located inside the

program-specified path in the inner corner and inner arc area and a cutting load increases, an

override is applied automatically to the cutting feed rate to reduce the cutting load.

Once G62 is specified, it remains effective until G61, G63 or G64 is specified.

(1) Command format

G62 ;

(2) Types of automatic corner override

(a) Automatic override in the

inner corner area.

An overridde is

applied to this part.

Tool Center Path

(b) Inner arc cutting speed change

Programmed Path

Center

Programmed Path

Tool Center Path

3 - 5

Page 48

(3) Cautions

3-6-1 Automatic Override in Inner Corner Area

When the following conditions are met in the corner during the tool diameter condensation

mode, an override is applied to cutting feed automatically.

[ The conditions are as follows for the blocks having the corner between them. ]

(a) When the G code of Group 01 is either G01, G02 or G03.

(b) When an offset amount is other than 0 in the tool diameter offset mode.

(c) When an offset is inside in the corner.

(d) When there is an axis in the offset plane.

(e) When the G41 or G42 is not contained.

(f) When an inner corner angle is smaller than a parameter set value. (

(g) When a corner start distance and a corner end distance are other than 0 and internal.

(Le, Ls)

p

a

b

θ