Page 1

SEIKI - SEICOS

å10L/å16T/å18T/å21L

INSTRUCTION MANUAL

PROGRAMMING

42 Edition 1.01 NO-0000-1-0211-E-1-01

Hitachi Seiki Deutschland

Werkzeugmaschinen GmbH

Page 2

2

Page 3

INTRODUCTION

This manual explains about the programming system of SEICOS-Σ10L, Σ16T,Σ18T and Σ21L.

The manual contains explanation on all functions, however, there are certain functions that are not

applicable depending on the type of the machine used. On this matter, please refer to the

instruction manual of each machine model when you utilize these functions.

Items requiring attention when reading this manual.

(1) In this manual, those functions not specifically remarked “able” should be understood as

“unable”.

(2) The contents of this manual may be changed without notice to meet a future machine

improvement.

(3) In this manual, all the descriptions take G18 (Z-X) plane as the subject plane, unless otherwise

specifically mentioned. For cutting processes made on a plane other than G18, refer to “7.8

Lathe turning on other than the G18 plane”.

ΣΣ

Σ10L,

ΣΣ

The processing programs of Σ10L, Σ16T, Σ18T and Σ21L are nearly 100% compatible.

As exceptions, Σ21L does not have the following functions.

ΣΣ

Σ16T,

ΣΣ

[1] 2.4 Helical interpolation

[2] 2.5 Virtual axis interpolation

[3] 4.6 Automatic corner override

[4] 5.2 Inside arc cutting speed change

[5] 6.5 Floating reference point return

ΣΣ

Σ18T and

ΣΣ

ΣΣ

Σ21L

ΣΣ

Page 4

Page 5

CONTENTS

1. G CODE................................................................................................ 1 - 1

1.1 G Code System............................................................................................................. 1 - 1

1.2 List of G Code Groups................................................................................................... 1 - 3

1.3 List of G Codes .............................................................................................................1 - 4

2. INTERPOLATION FUNCTION............................................................. 2 - 1

2.1 Positioning (G00)........................................................................................................... 2 - 1

2.2 Linear Interpolation ........................................................................................................2 - 3

2.3 Circular Interpolation (G02, G03) ...................................................................................2 - 5

2.4 Helical Interpolation (G02, G03) .....................................................................................2 - 9

2.5 Virtual Axis Interpolation (G07)..................................................................................... 2 - 1 1

2.6 Cylindrical Interpolation (G271).................................................................................... 2 - 12

2.7 Polar Coordinate Interpolation (G120, G121)............................................................... 2 - 17

2.8 Angle Designated Linear Interpolation .........................................................................2 - 25

2.9 Skip Function (G31).....................................................................................................2 - 27

3. THREAD CUTTING .............................................................................. 3 - 1

3.1 Thread Cutting (G32).....................................................................................................3 - 1

3.2 Continuous Thread Cutting (G32) ................................................................................. 3 - 3

3.3 Multi-thread Cutting........................................................................................................3 - 4

3.4 Variable Lead Thread Cutting (G34) ..............................................................................3 - 5

4. FEED FUNCTION ................................................................................ 4 - 1

4.1 Feed Per Minute (G98) .................................................................................................. 4 - 1

4.2 Feed Per Revolution (G99)............................................................................................4 - 2

4.3 Dwell (G04) ...................................................................................................................4 - 3

4.4 Exact Stop (G09)...........................................................................................................4 - 4

4.5 Exact Stop Mode (G61) .................................................................................................4 - 5

4.6 Automatic Corner Override Mode (062).........................................................................4 - 6

4.7 T apping Mode (G63) ......................................................................................................4 - 8

4.8 Cutting Mode (G64) .......................................................................................................4 - 9

4.9 Multibuffer (G251) ........................................................................................................4 - 10

4.10 Acceleration/Deceleration Control ............................................................................... 4 - 11

5. SPEED CONTROL .............................................................................. 5 - 1

5.1 Feed Speed Command (F Data)................................................................................... 5 - 1

5.3 Scroll Cutting Speed Control (G128) ............................................................................. 5 - 4

5.4 Speed Control of Independent Axis ..............................................................................5 - 10

i

Page 6

6. REFERENCE POINT ........................................................................... 6 - 1

6.1 Automatic Reference Point Return (G28)......................................................................6 - 1

6.2 Reference Point Return Check (G27) ...........................................................................6 - 2

6.3 Return from Reference Point (G29) ..............................................................................6 - 3

6.4 2nd-4th Reference Point Return (G30)..........................................................................6 - 4

6.5 Floating Reference Point Return (G301) .......................................................................6 - 5

7. COORDINATE SYSTEM ..................................................................... 7 - 1

7.1 Tool Nose Coordinate System....................................................................................... 7 - 1

7.2 Plane Designation (G17, G18, G19) ..............................................................................7 - 4

7.3 Work Coordinate System Change (G50) ......................................................................7 - 6

7.4 Work Length Modification (G54/G55).............................................................................7 - 7

7.5 Machine Coordinate System Selection (G53) ............................................................... 7 - 8

7.6 Setting the Local Coordinate System (G59) ..................................................................7 - 9

7.7 Work Coordinate System Preset (G921) ....................................................................7 - 10

7.8 Lathe Turning Other than the G18 Plane (Z-X) ............................................................ 7 - 11

8. COORDINATE...................................................................................... 8 - 1

8.1 Diameter Designation and Radius Designation.............................................................8 - 1

8.2 Absolute/Incremental Programming (G90, G91) ...........................................................8 - 2

8.3 Inch/mm Input (G20, G21) .............................................................................................8 - 3

9. SPINDLE FUNCTIONS........................................................................ 9 - 1

9.1 Spindle Functions (Function S) ..................................................................................... 9 - 1

9.2 Constant Surface Speed Control (G96, G97)................................................................ 9 - 2

9.3 Maximum Spindle Speed Setting (G50) .........................................................................9 - 3

9.4 Spindle Speed V ariation Detection (G25/G26) ...............................................................9 - 4

10. TOOL FUNCTION............................................................................ 10 - 1

10.1 Tool Function (T Function)........................................................................................... 10 - 1

10.2 ATC Canned Cycle...................................................................................................... 10 - 5

10.3 Rotary Tool Offset Auto Conversion (G159) .............................................................. 10 - 11

10.4 ATC Type-E Offset Automatic Change........................................................................10 - 16

11. MISCELLANEOUS FUNCTION....................................................... 11 - 1

11.1 Miscellaneous Function (M Function) .......................................................................... 1 1 - 1

11.2 2nd Miscellaneous Function ........................................................................................ 1 1 - 3

12. COMPENSATION FUNCTION ........................................................ 12 - 1

12.1 Automatic Tool Nose Radius Compensation and Cutter Compensation.....................12 - 1

12.2 Automatic Tool Nose Radius Compensation...............................................................12 - 2

12.3 Groove Width Compensation (G150, G151, G152)...................................................12 - 15

ii

Page 7

12.4 Multiple Offsets.......................................................................................................... 12 - 18

12.5 Cutter Compensation (G38-G42) .............................................................................. 12 - 22

12.6 Detailed Description of Cutter Compensation ........................................................... 12 - 28

13. CONVERTING FUNCTION.............................................................. 13 - 1

13.1 Programmable Mirror Image (G501, G511) .................................................................13 - 1

13.2 Setting Mirror Image ....................................................................................................13 - 3

13.3 Chamfering, Corner R .................................................................................................13 - 5

13.4 Optional Angle Chamfering/Corner R (, C, R) ............................................................. 13 - 7

13.5 Three Dimensional Coordinate Conversion (G268, G269)........................................13 - 10

14. SINGLE TYPE FIXED CYCLE........................................................ 14 - 1

14.1 O.D./I.D. Cutting Cycle (G90) ......................................................................................14 - 1

14.2 Canned Cycle for Thread Cutting (G92)......................................................................14 - 2

14.3 End/side Cutting Cycle (G94)......................................................................................14 - 5

14.4 Cautions Concerning Single Type Fixed Cycle............................................................14 - 6

15. MULTIPLE REPETITIVE CYCLE................................................... 15 - 1

15.1 Rough Planing of Inside & Outside Diameter (G71)....................................................15 - 2

15.2 Rough Planing Cycle of End Side (G72) .....................................................................15 - 9

15.3 Planing Cycle of Close Loop (G73) ...........................................................................15 - 12

15.4 Finish Cycle (G70).....................................................................................................15 - 14

15.5 Edge Cutting Cycle (G74) ......................................................................................... 15 - 15

15.6 Outside Diameter Edge Cutting Cycle (G75) ............................................................15 - 17

15.7 Combined Type Thread Cutting Cycle (G76) ............................................................ 15 - 19

15.8 Cautions Relating to Combined Type Fixed Cycle .................................................... 15 - 24

15.9 Alarms Relevant to Combined T ype Fixes Cycle ...................................................... 15 - 27

16. CANNED CYCLE FOR DRILLING .................................................. 16 - 1

16.1 Canned Cycle for Drilling (G80-G89, G831, G841, G861) ........................................... 16 - 1

16.2 Direct Tapping Cycle (G842, G843)........................................................................... 16 - 16

17. DATA SETTING............................................................................... 17 - 1

17.1 Programmable Data Input (G10) ................................................................................. 17 - 1

17.2 Programmable Parameter Input ..................................................................................17 - 5

18. STROKE LIMIT ................................................................................ 18 - 1

18.1 Stored Stroke Limit 1 ...................................................................................................18 - 1

18.2 Stroke Limit 2 to 4 (G22, G23) .....................................................................................18 - 3

18.3 Stroke Limit Check before Move.................................................................................. 18 - 6

iii

Page 8

19. PROCESSING.................................................................................. 19 - 1

19.1 Rear Processing .........................................................................................................19 - 1

19.2 Polygon Turning (Polygon Turning Between S pindles) .............................................. 19 - 12

20. OPERATION ..................................................................................... 20 - 1

20.1 Program Resumption ..................................................................................................20 - 1

20.2 Return to Machining Interruption Point.........................................................................20 - 5

20.3 Sequence Number Comparison and Stop................................................................... 20 - 7

20.4 Manual Absolute ON/OFF............................................................................................20 - 8

20.5 Reset (Reset Associated with Automatic Operation) ................................................ 20 - 11

21. CUSTOM MACROS ........................................................................ 21 - 1

21.1 Program Call .............................................................................................................. 21 - 1

21.2 Multi-Call......................................................................................................................21 - 7

21.3 Argument Designation...............................................................................................21 - 12

21.4 Variables....................................................................................................................21 - 17

21.5 System V ariable ........................................................................................................21 - 20

21.6 Expression and Computation .................................................................................... 21 - 33

21.7 Control Command.....................................................................................................21 - 38

21.8 External Output Command........................................................................................21 - 41

22. COMPATIBILITY WITH SEICOS-LII/LIII......................................... 22 - 1

22.1 Drilling Fixes Cycle (G80-G89)....................................................................................22 - 2

23. MISCELLANEOUS .......................................................................... 23 - 1

23.1 Preread Stop Command .............................................................................................23 - 1

iv

Page 9

1.1 G Code System

Three kinds of G code systems including A, B, and C are available for selection. Any G code

systems are almost the same in their functions and programming methods except only part

of the G codes are different.

When S pecifying the position of each axis, however, there is a difference in the absolute and

incremental programming methods between the A system and non-A systems.

1.1.1 A system

Absolute programming and incremental programming use an axial address to specify an

axial position. When X, Y, Z, B, or C is used for the axial address, they assume absolute

programming, and when U, V, W, D, or H is used, they assume incremental programming.

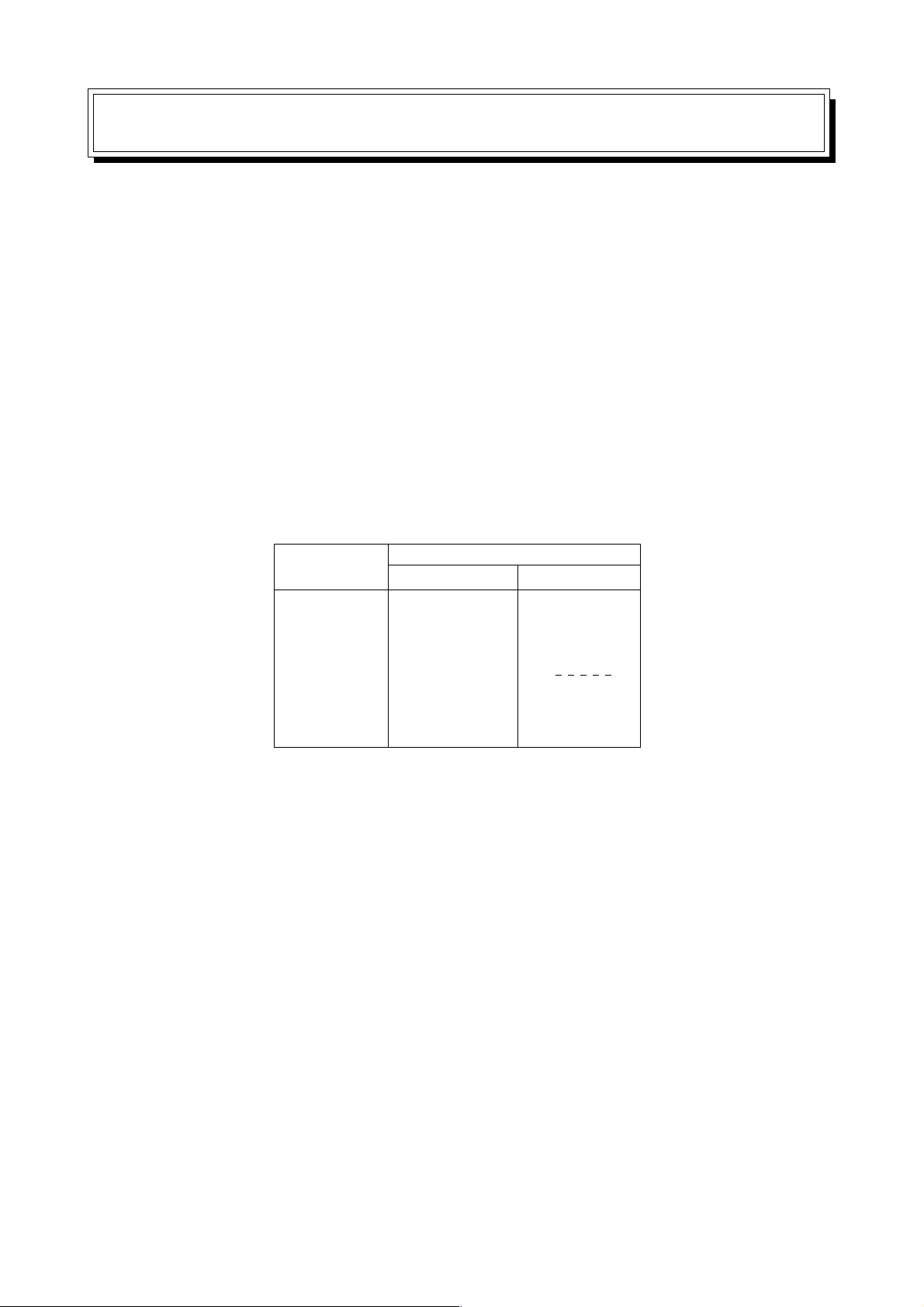

The following table shows the relations between axial names and axial addresses.

1. G CODE

Axial Name

Absolute Incremental

X axis X U

Y axis Y V

Z axis Z W

A axis A

B axis B D

C axis C H

Axis A does not have the address of the incremental command. It is always specified by

absolute. However , only for commands G28, G30 and G301, absolute commands and

incremental commands of axis A can be switched over as follows.

(1) When address Q is present on the same block

• Q=0 → Absolute command

• Q≠0 → Incremental command

(2) When address Q is not present on the same block

• Parameter AINC=0 → Absolute command

• Parameter AINC=1 → Incremental command

(AINC means 3 bits of parameter number 3404.)

Axial Address

1 - 1

Page 10

1.1.2 B and C Systems

The following G codes are used to specify either absolute programming or incremental

programming.

G90 : Absolute programming

G91 : Incremental programming

These G codes are modal ones of Group 03.

(Note 1) The G code system A, B, and C are selected by the parameters GSB and GSC

(parameter No.3400.)

(Note 2) This command manual is described with the G codes of the A system unless

otherwise specified.

1 - 2

Page 11

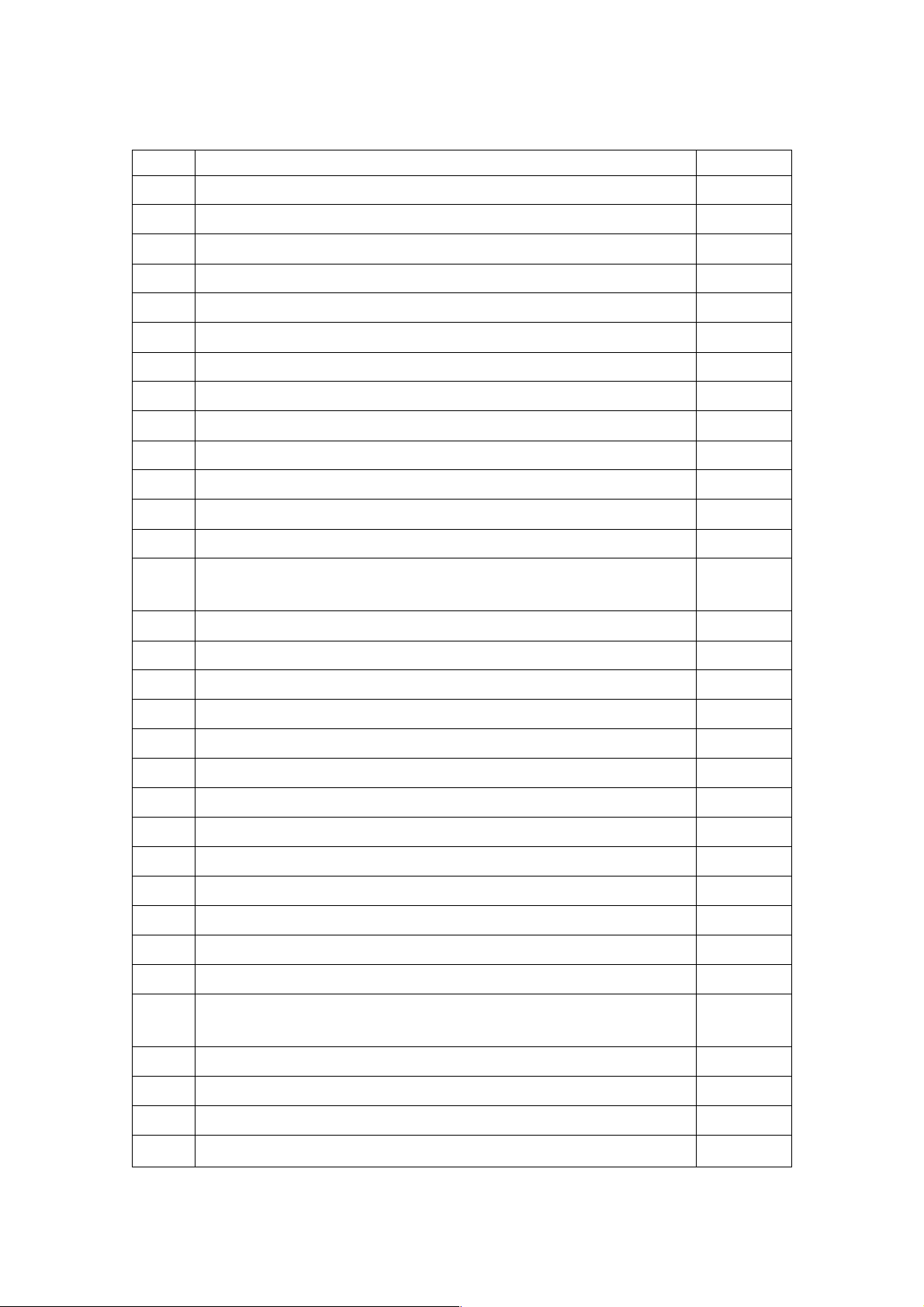

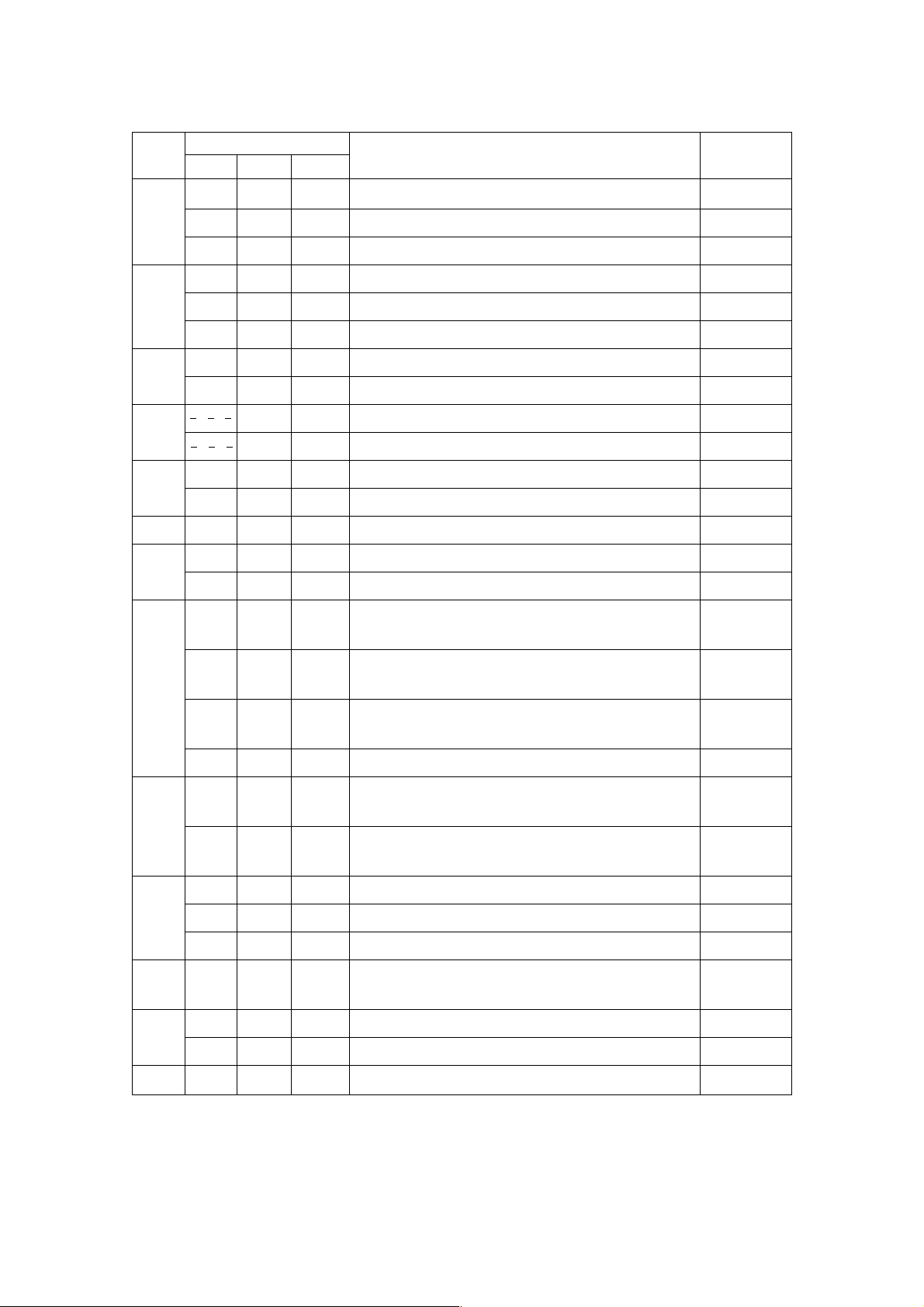

1.2 List of G Code Groups

Group Function Remarks

00 Non-modal

01 Positioning/linear interpolation/circular interpolation

02 Plane designation

03 (Absolute programming/incremental programming)

04 Stored stroke check

05 Feed per minute/feed per revolution

06 Inch/metric conversion

07 Cutter compensation

08 *2

09 Canned cycle for drilling

10 Initial point return/R-point return

11 *2

12 Work length modification

13 Cutting mode/exact stop mode/automatic corner override

mode

14 Macro modal call

15 Programmable mirror image

16 Groove width compensation

17 Constant surface speed control

18 Tool life management

19 *2

20 *2

21 *2

22 Polar coordinate interpolation

23 Spindle speed fluctuation detection

24 *2

25 Mirror image for double turrets *

26 *2

27 Automatic tool nose radius compensation/cutter

compensation enable/disable

28 *2

29 *2

30 *2

31 *2

(Notes) *2 Spare G code group for improvement of the functions.

1 - 3

Page 12

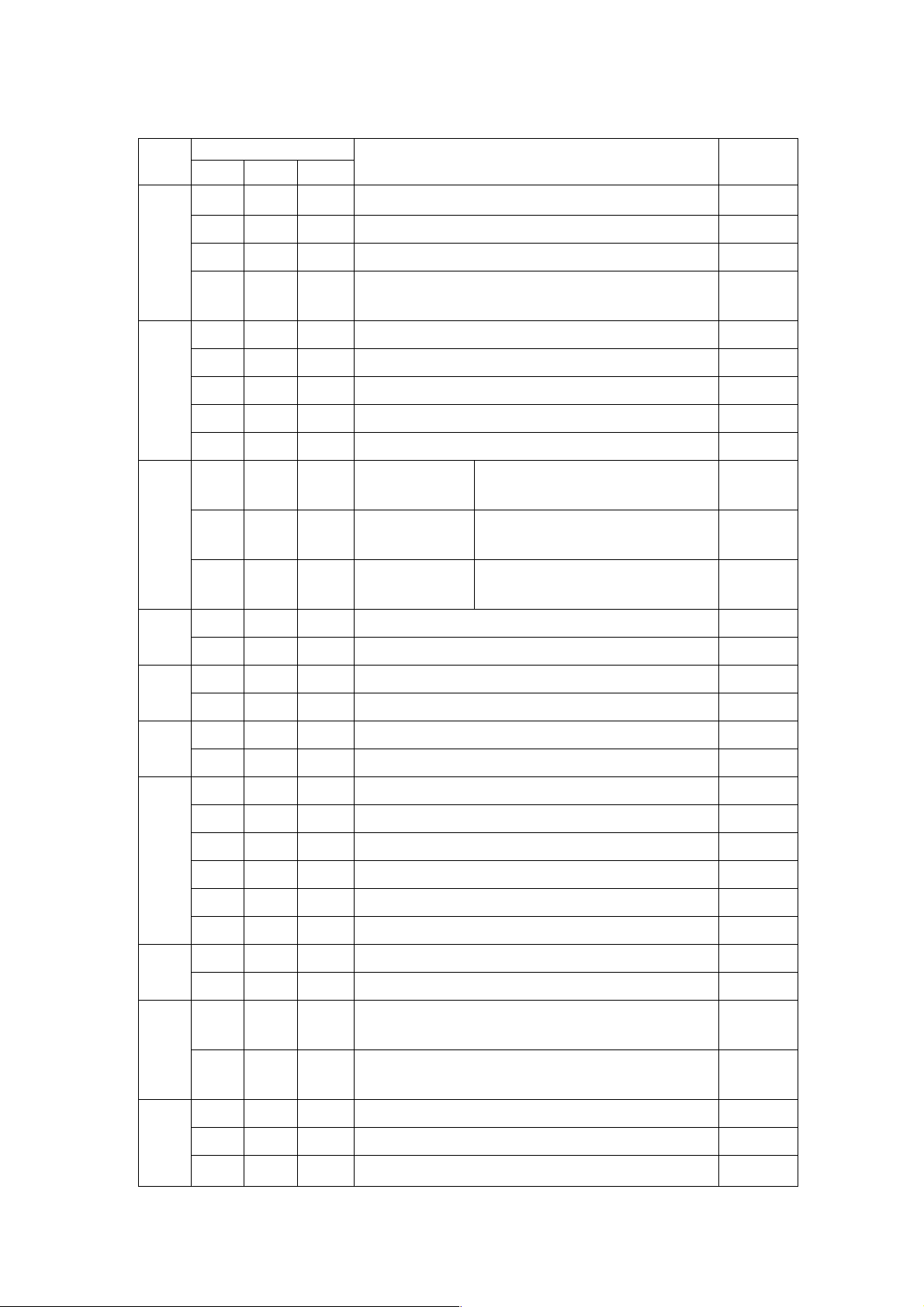

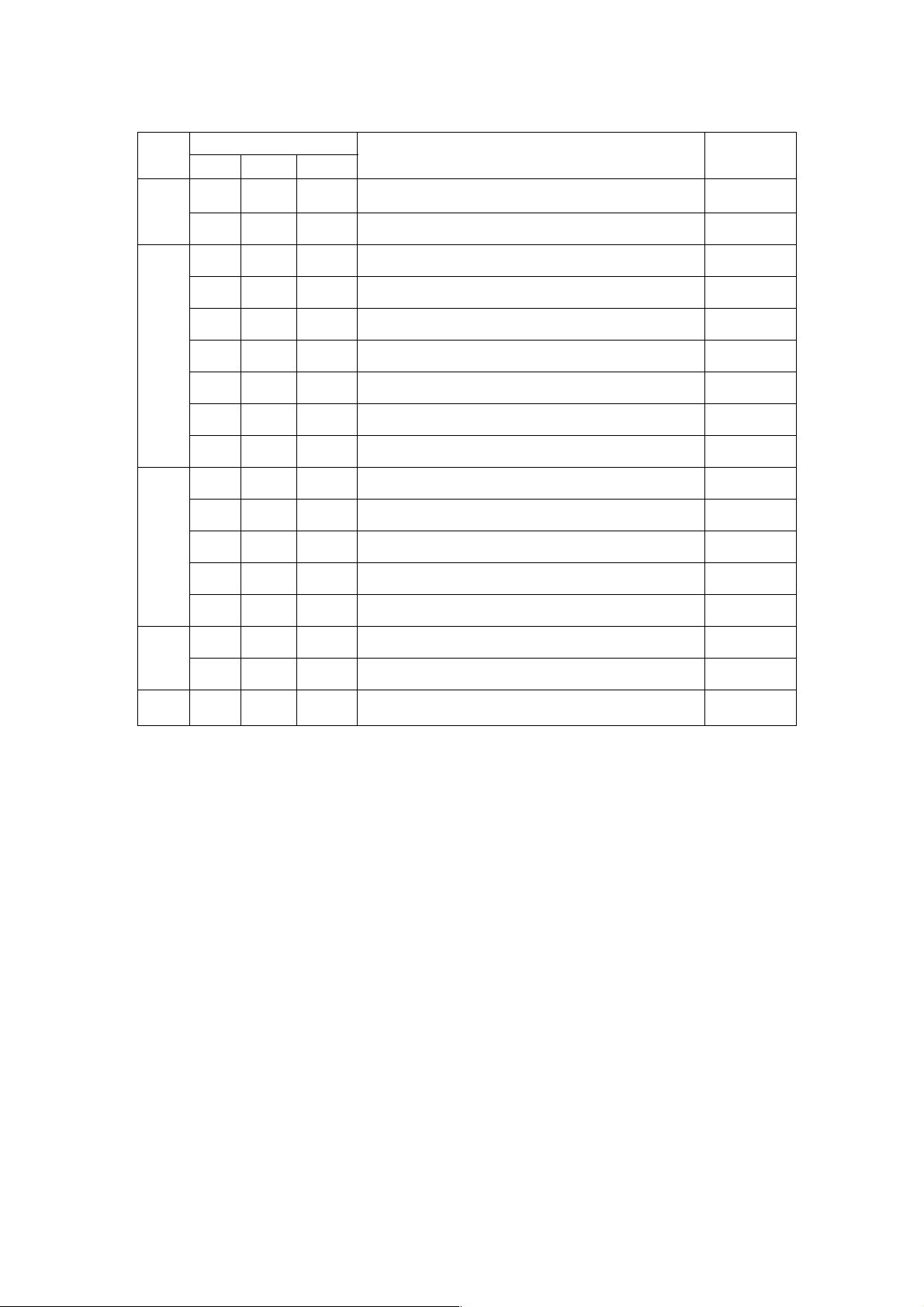

1.3 List of G Codes

Group

01 G00 G00 G00 Positioning

00 G04 G04 G04 Dwell

02 G17 G17 G17 Xp-Yp plane Xp: X axis or its

G code system

ABC

G01 G01 G01 Linear interpolation

G02 G02 G02 Circular interpolation/helical interpolation CW

G03 G03 G03 Circular interpolation/helical interpolation

CCW

G07 G07 G07 Virtual axis interpolation

G09 G09 G09 Exact stop

G10 G10 G10 Data setting

G11 G11 G11 Data setting mode cancel

designation parallel axis

G18 G18 G18 Zp-Xp plane Yp: Y axis or its

designation parallel axis

G19 G19 G19 Yp-Zp plane Zp: Z axis or its

designation parallel axis

Function Remarks

06 G20 G20 G70 Inch input

G21 G21 G71 Metric input

04 G22 G22 G22 Stored stroke check ON

G23 G23 G23 Stored stroke check OFF

23 G25 G25 G2 5 Spindle speed fluctuation detection OFF

G26 G26 G26 Spindle speed fluctuation detection ON

00 G27 G27 G27 Reference point return check

G28 G28 G2 8 Reference point return

G29 G29 G29 Return from reference point

G30 G30 G30 2nd, 3rd, 4th reference point return

G301 G301 G301 Floating reference point return

G31 G31 G31 Skip function

01 G32 G32 G3 2 Thread cutting

G34 G34 G34 Variable lead thread cutting

00 G38 G38 G38 Tool nose radius compensation/cutter

compensation vector hold

G39 G39 G39 Tool nose radius compensation/cutter

compensation corner arc

07 G40 G40 G40 Cutter compensation cancel

G41 041 G41 Cutter compensation to the left

G42 G42 G42 Cutter compensation to the right

1 - 4

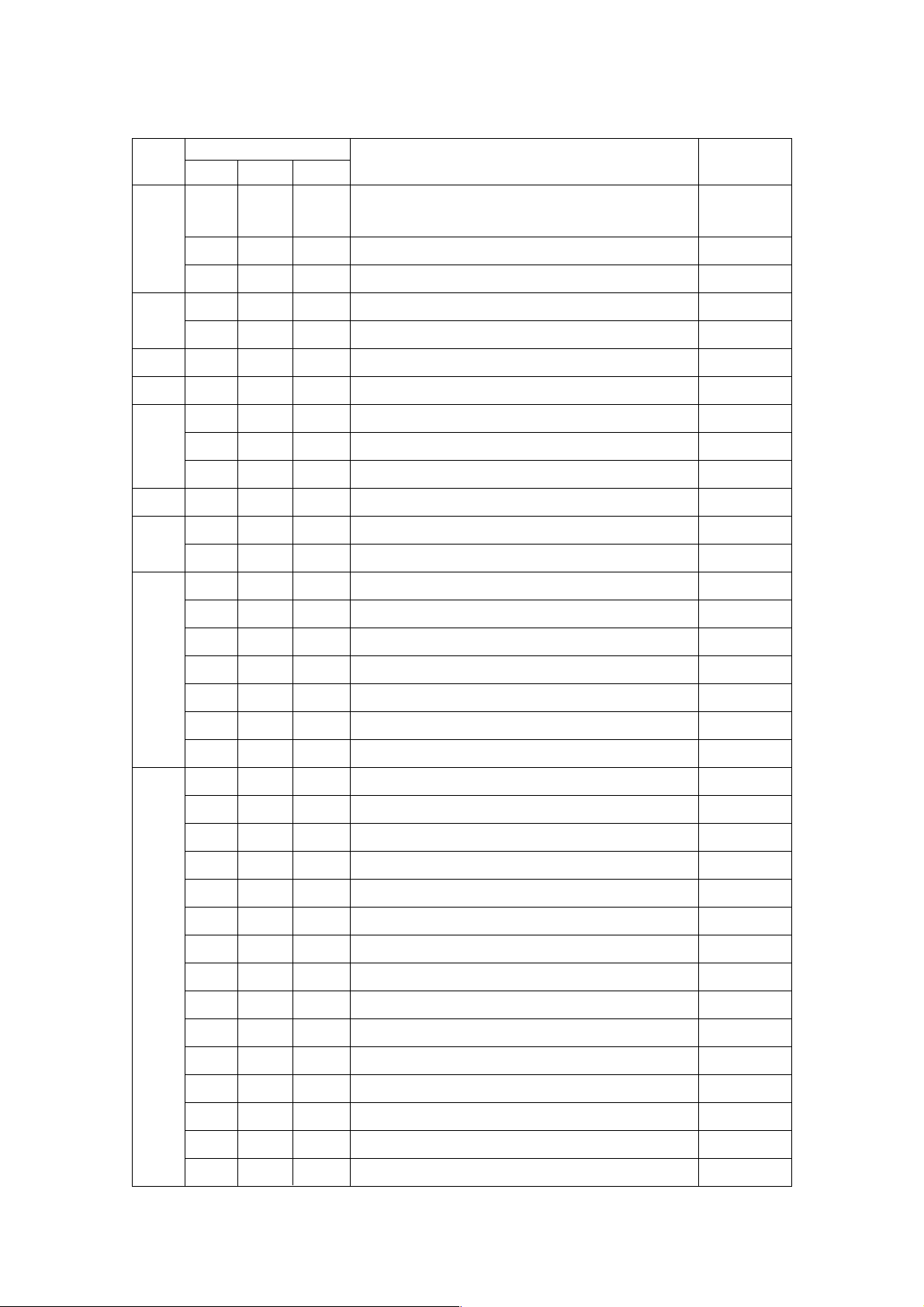

Page 13

Group

01 G50 G92 G92 Coordinate system setting/spindle

12 G54 G54 G54 Work length modification 1

00 G59 G59 G59 Local coordinate system setting

13 G61 G61 G61 Exact stop mode

00 G65 G65 G65 Macro calling

14 G66 G66 G66 Macro modal call

00 G70 G70 G72 Finishing cycle

G code system

ABC

maximum speed setting

G52 G52 G52 Back face machining mode Back

G53 G53 G53 Machine coordinate system selection

G55 G55 G55 Work length modification 2 *1

G62 G62 G62 Automatic corner override mode

G63 G63 G63 Tapping mode

G64 G64 G64 Cutting mode

G67 G67 G67 Macro modal call cancel

Function Remarks

G71 G71 G73 O.D./I.D. roughing cycle

G72 G72 G74 End face roughing cycle

G73 G73 G75 Closed loop turning cycle

G74 G74 G76 End face cutting-off cycle

G75 G75 G77 O.D./I.D. cutting-off cycle

G76 G76 G78 Compound type thread cutting cycle

09 G80 G80 G80 Drilling cycle cancel

G81 G81 G81 Drilling cycle, spot drilling cycle

G82 G82 G82 Drilling cycle, counter boring cycle

G83 G83 G83 Peck drilling cycle

G831 G831 G831 Peck drilling cycle

G84 G84 G84 Tapping cycle

G841 G841 G841 Counter tapping cycle

G842 G842 G842 Direct tapping cycle *1

G843 G843 G843 Counter direct tapping cycle *1

G85 G85 G85 Boring cycle

G86 G86 G86 Boring cycle

G861 G861 G861 Fine boring cycle

G87 G87 G87 Back boring cycle

G88 G88 G88 73. Boring cycle

G89 G89 G89 74. Boring cycle

1 - 5

Page 14

Group

01 G9 0 G77 G20 O.D./I.D. turning cycle

17 G96 G96 G96 Constant surface speed control

05 G98 G94 G94 Feed per minute

03 G90 G90 Absolute programming

22 G120 G120 G120 Polar coordinate interpolation mode cancel

00 G128 G128 G128 Scroll cutting speed control

18 G130 G130 G130 Tool life management OFF

G code system

ABC

G92 G78 G21 Single type thread cutting cycle

G94 G79 G24 End face turning cycle

G196 G196 G196 Constant surface speed control (Back) Back

G97 G97 G97 Constant surface speed control cancel

G99 G95 G95 Feed per rotation

G91 G91 Incremental programming

G121 G121 G121 Polar coordinate interpolation mode

G131 G131 G131 Tool life management ON

Function Remarks

27 G140 G140 G140 Automatic tool nose compensation/cutter

compensation cancel mode

G143 G143 G143 Automatic tool nose compensation enable

mode

G144 G144 G144 Automatic tool nose radius compensation

enable mode (G144 = G143)

G145 G145 G145 Cutter compensation enable mode

00 G141 G141 G141 Automatic tool nose radius compensation

to the left

G142 G142 G142 Automatic tool nose radius compensation

to the right

16 G150 G150 G150 Groove width compensation cancel

G151 G151 G151 Groove width compensation for end face

G152 G152 G152 Groove width compensation for O.D./I.D.

00 G159 G159 G159 Automatic Conversion of Rotation A TC-C

Tool Offset

25 G170 G170 G170 Face machining mode Back

G171 G171 G171 Back face machining mode Back

00 G194 G194 G194 External measurement compensation

1 - 6

Page 15

Group

10 G198 G198 G198 Canned cycle for drilling initial point return

01 G212 G212 G212 Circular thread cutting CW *1

00 G251 G251 G251 Multibuffer

G code system

ABC

G199 G199 G199 Canned cycle for drilling R-point return

G213 G213 G213 Circular thread cutting CCW *1

G216 G216 G216 S pline interpolation *1

G222 G222 G222 Involute interpolation CW *1

G223 G223 G223 Involute interpolation CCW *1

G232 G232 G232 Exponential function interpolation CW *1

G233 G233 G233 Exponential function interpolation CCW *1

G261 G261 G261 S-designation for the spindle

G262 G262 G262 S-designation for the rotary tool

G263 G263 G263 S-designation for the subspindle Back

Function Remarks

G271 G271 G271 Cylindrical interpolation

15 G501 G501 G501 Resetting programmable mirror image

G511 G511 G511 Setting programmable mirror image

00 G921 G921 G921 Work coordinate system preset

(Note 1) *1 Reserve G code and not available for the moment.

(Note 2) The G code systems, A,B, are selected by the parameters GSB and GSC

(parameter No. 3400).

(Note 3) “Back” in the Remarks column indicates availability for the back machining

system.

1 - 7

Page 16

1 - 8

Page 17

2. INTERPOLA TION FUNCTION

2.1 Positioning (G00)

Each axis moves to a program-specified position at an independent rapid traverse rate to

perform positioning.

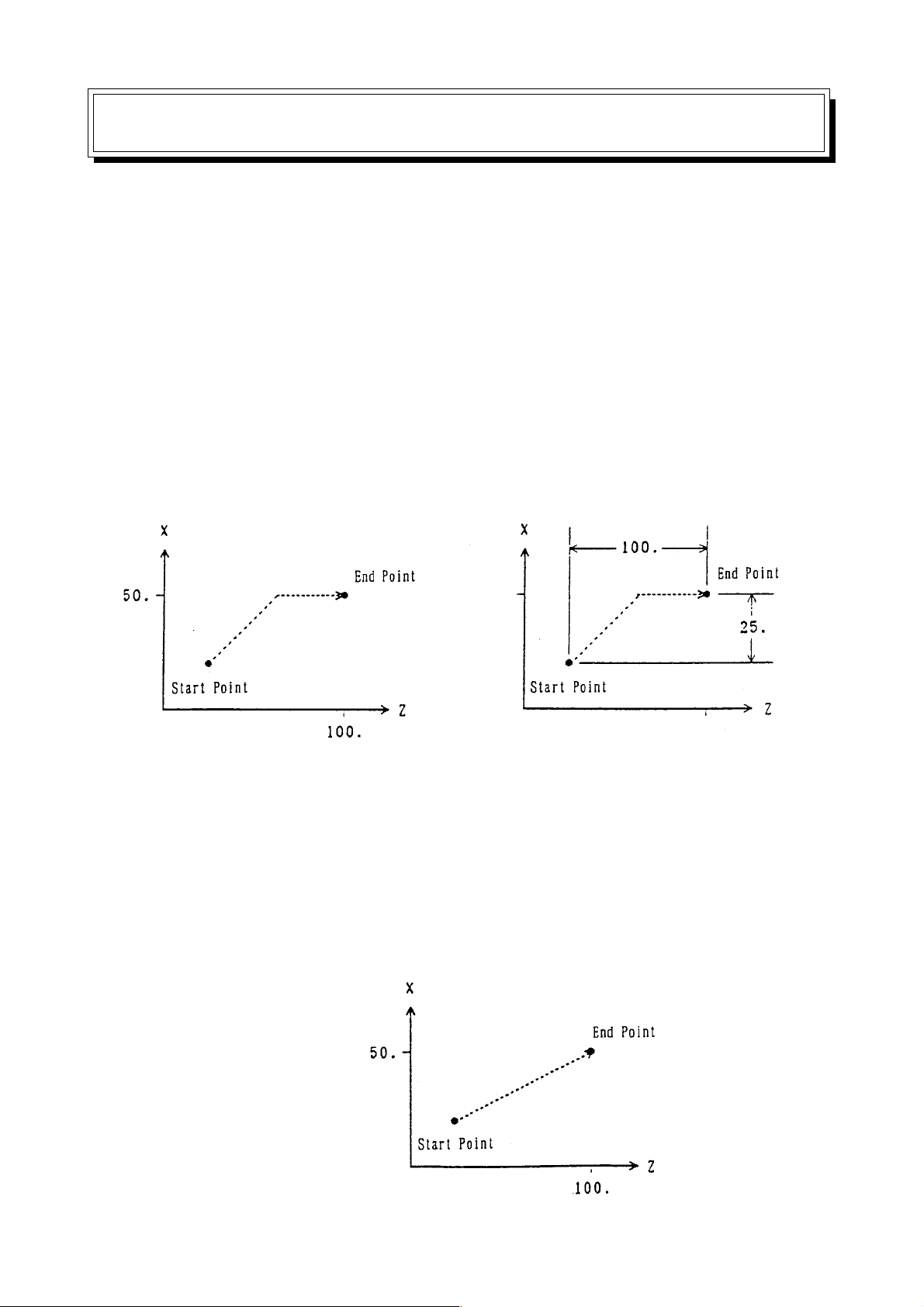

2.1.1 Command Format

G01 X___ Y___ Z___ ...... F___ ;

2.1.2 Sample Program

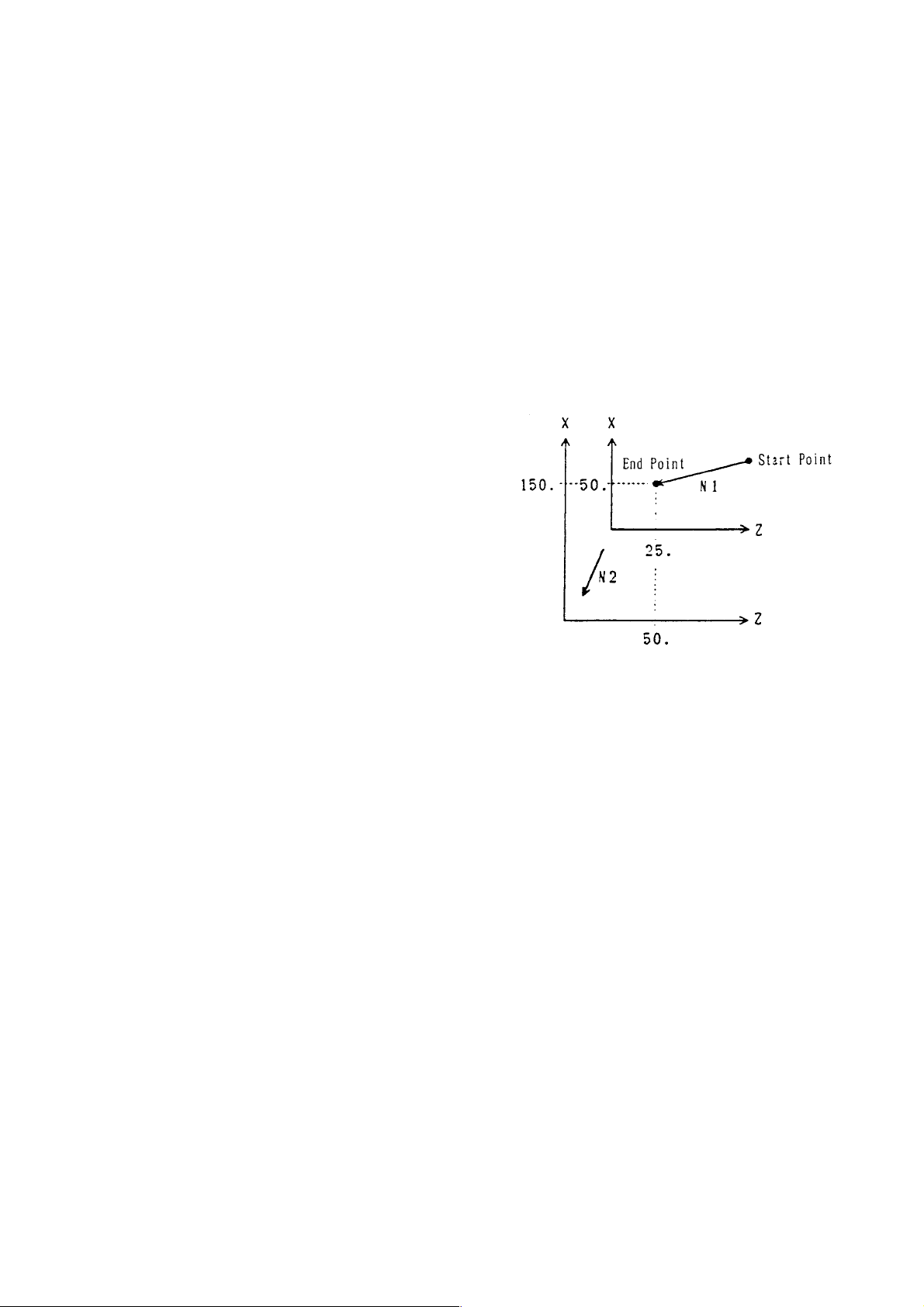

(1) Absolute programming (2) Incremental programming

G00 X50, Z100, ; G00 X50, Z100, ;

2.1.3 Cautions

(1) The rapid traverse rate has been set independently for each axis.

(2) The tool path is non-linear . See to it that the tool does not interfere with the workpiece.

(3) Linear acceleration/deceleration is applied. Confirm imposition (an accumulated

amount due to servo delay is within tolerance) at the end of the block, and then,

proceed to the next block.

(4) The tool path can be made linear by altering the parameter.

G00 X50, Z100, ;

2 - 1

Page 18

When linear interpolation positioning has been selected, shifting takes place in the

speed which assures the shortest positioning time within the scope not exceeding

rapid traverse rate for each axis.

(5) You can set with the parameter whether the reset state is to be the G00 or G01 mode.

2.1.4 Associated Parameters

No.1401, #1= 0 Positioning system is non-linear type.

= 1 linear type (linear interpolation).

No.1401, #6= 0 Dry run disabled for rapid traverse command.

Dry run enabled for rapid traverse command.

No.3402, #0 = 0 Reset state is G00 mode.

= 1 Reset state is G01 mode.

No.1420 Rapid traverse rate for each axis.

No.1620 Time constant of rapid traverse linear acceleration/deceleration for each axis.

2 - 2

Page 19

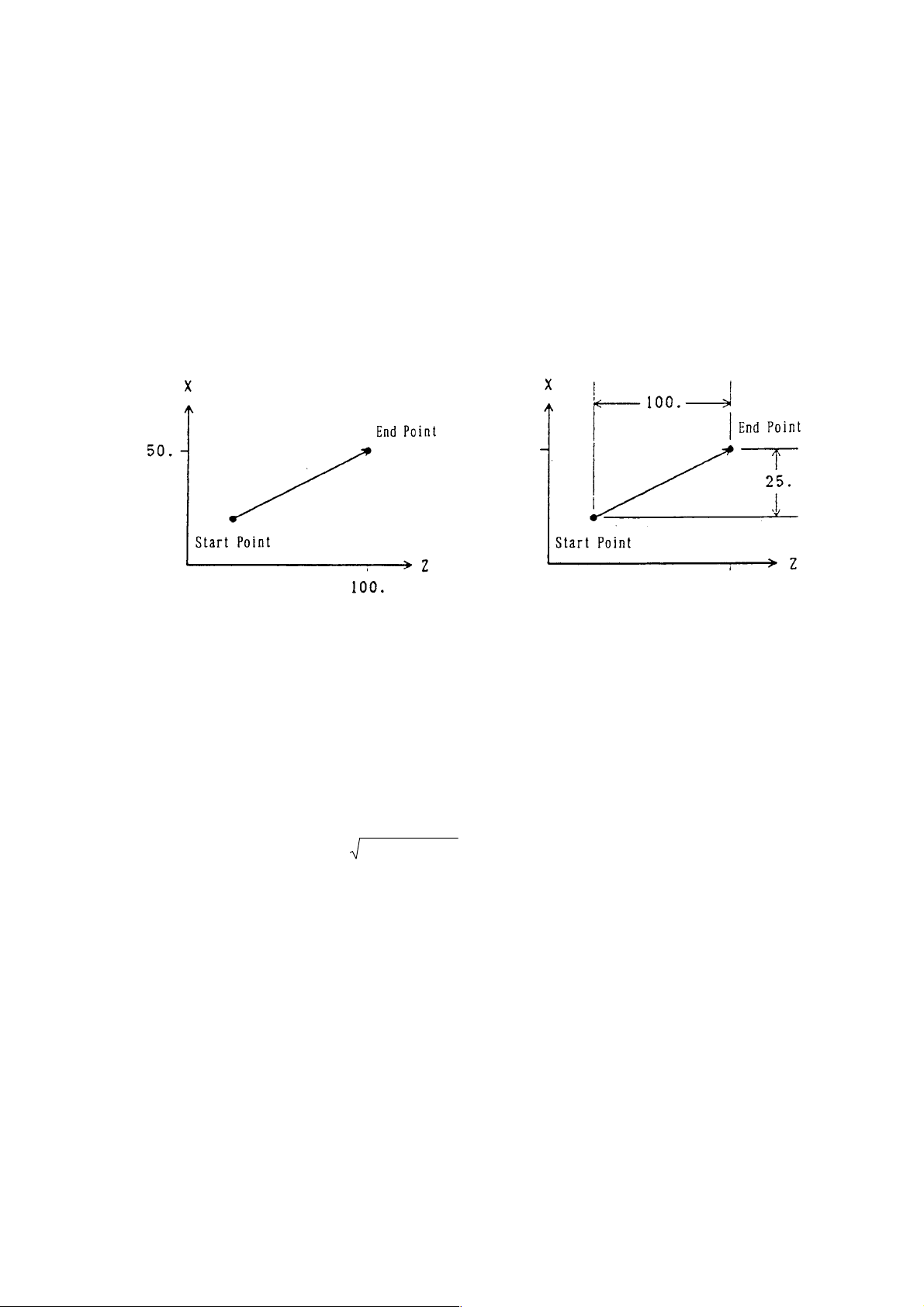

2.2 Linear Interpolation

The toolmvoes linearly to a program-specified position at the cutting feed rate specified with

an F code.

2.2.1 Command Format

2.2.2 Sample Program

(1) Absolute programming (2) Incremental programming

G01 X50. Z100. F200 ; G01 X50. W100. F200 ;

2.2.3 Cutting Feed Rate

The cutting feed rate specified with an F code is the speed at which the toolmoves linearly.

In this case, the cutting feed rate is a composite speed of all the specified axes; the cutting

feed rate of each axis is as follows.

G01 Ua Vb Wc Ff ;

X-axis cutting feed rate Fx = af/2L

Y-axis cutting feed rate Fy = bf/L

Z-axis cutting feed rate Fz = cf/L

where; L = (a/2)

(Note) When the rotary axis is specified in the identical block, linear interpolation is

performed taking it as a linear axis in the units of degree.

2+b2+c2

2 - 3

Page 20

2.2.4 Cautions

(1) An alarm results when no F code has been specified in the G01 block or before.

(2) Exponential type acceleration/deceleration is applied.

(3) Set with the parameter whether the reset state is to be the G00 or G01 mode.

2.2.5 Associated Parameters

No.3402, #0 = 0 The reset state is the G00 mode

= 1 The reset state is the G01 mode

No.1422 Maximum cutting feed speed (common to all axes)

No.1622 Time constant of cutting feed exponential type acceleration/deceleration

No.1623 FL speed of cutting feed exponential type acceleration/deceleration

2.2.6 Associated Alarms

No.102 F has not been specified in cutting feed. Or, F0 has been specified.

2 - 4

Page 21

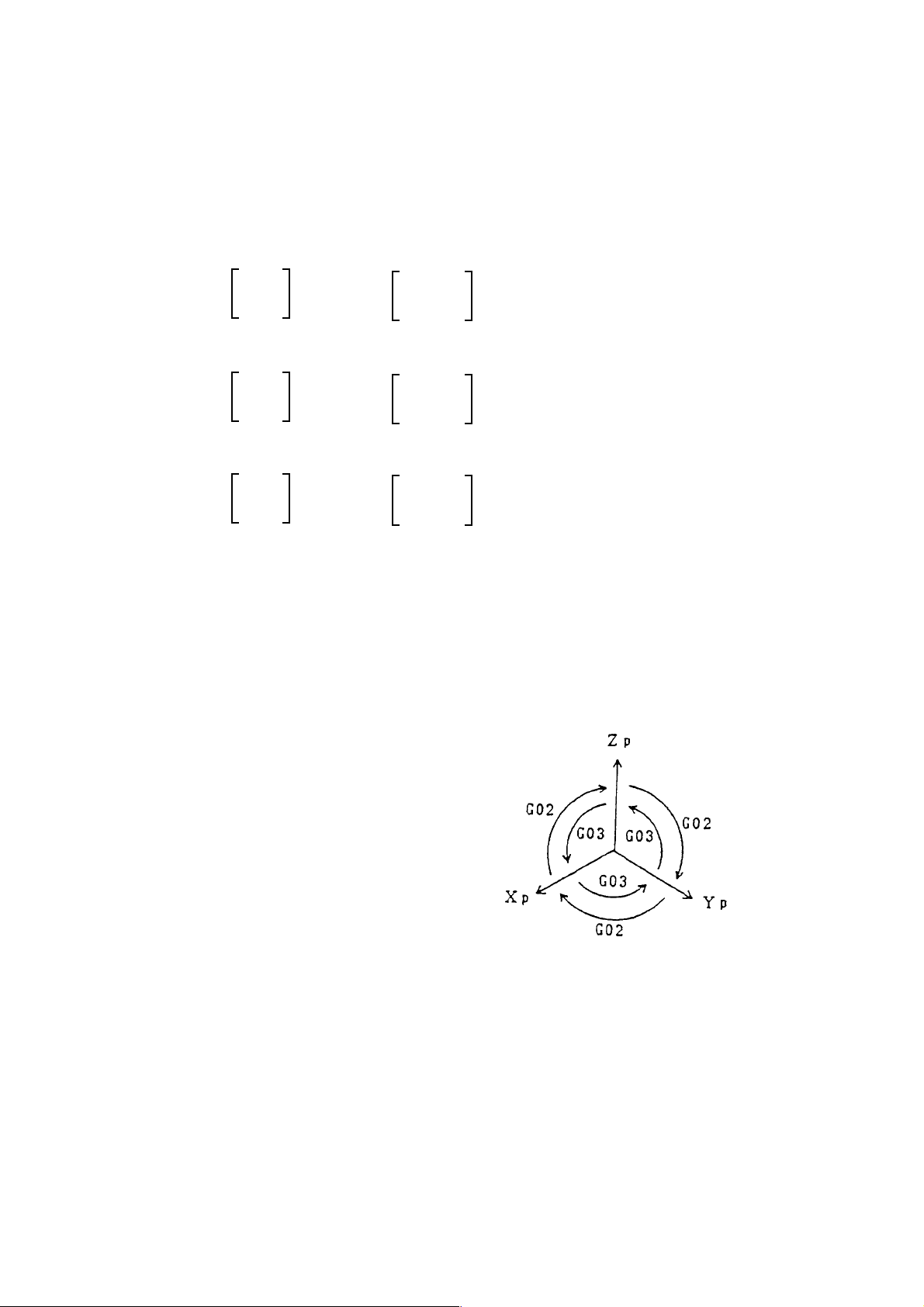

2.3 Circular Interpolation (G02, G03)

The tool moves to a program-specified position along an arc within the plane selected with a

plane selection G code(G17, G18,G19) at the cutting feed rate specified with an F code.

2.3.1 Command Format

(1) Xp-Yp plane

G17

(2) Zp-Xp plane

G18

(3) Yp-Zp plane

G19

G02

G03 R_

G02

G03 R_

G02

G03 R_

Xp_ Yp_

Zp_ Xp_

Yp_ Zp_

I_ J_

K_ I_

J_ K_

F_ ;

F_ ;

F_ ;

where, Xp : X axis or its parallel axis

Yp : Y axis or its parallel axis

Zp : Z axis or its parallel axis

2.3.2 Arc Rotating Direction

G02 : Clockwise (CW)

G03 : Counterclockwise (CCW)

2 - 5

Page 22

2.3.3 Arc Plane

The arc plane is specified with G17, G18, or G19.

G17 : Xp-Y p plane

G18 : Zp-Xp plane

G19 : Y p-Zp plane

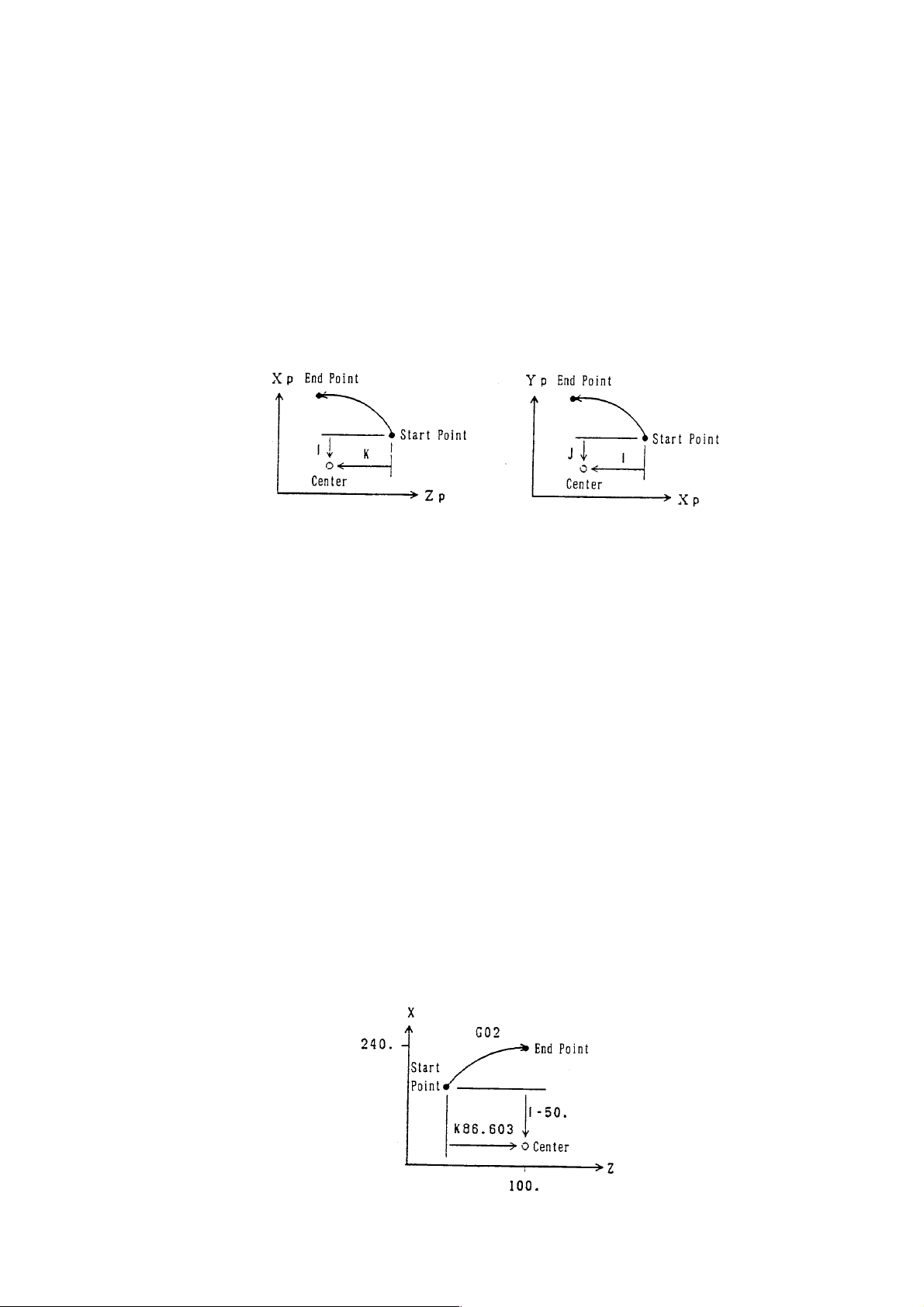

2.3.4 Arc Center

The arc center is specified with I, J, or K corresponding to Xp, Yp, and Zp, respectively. In

this case, I, j, and K are the vector components when viewing the arc center from its start

point.

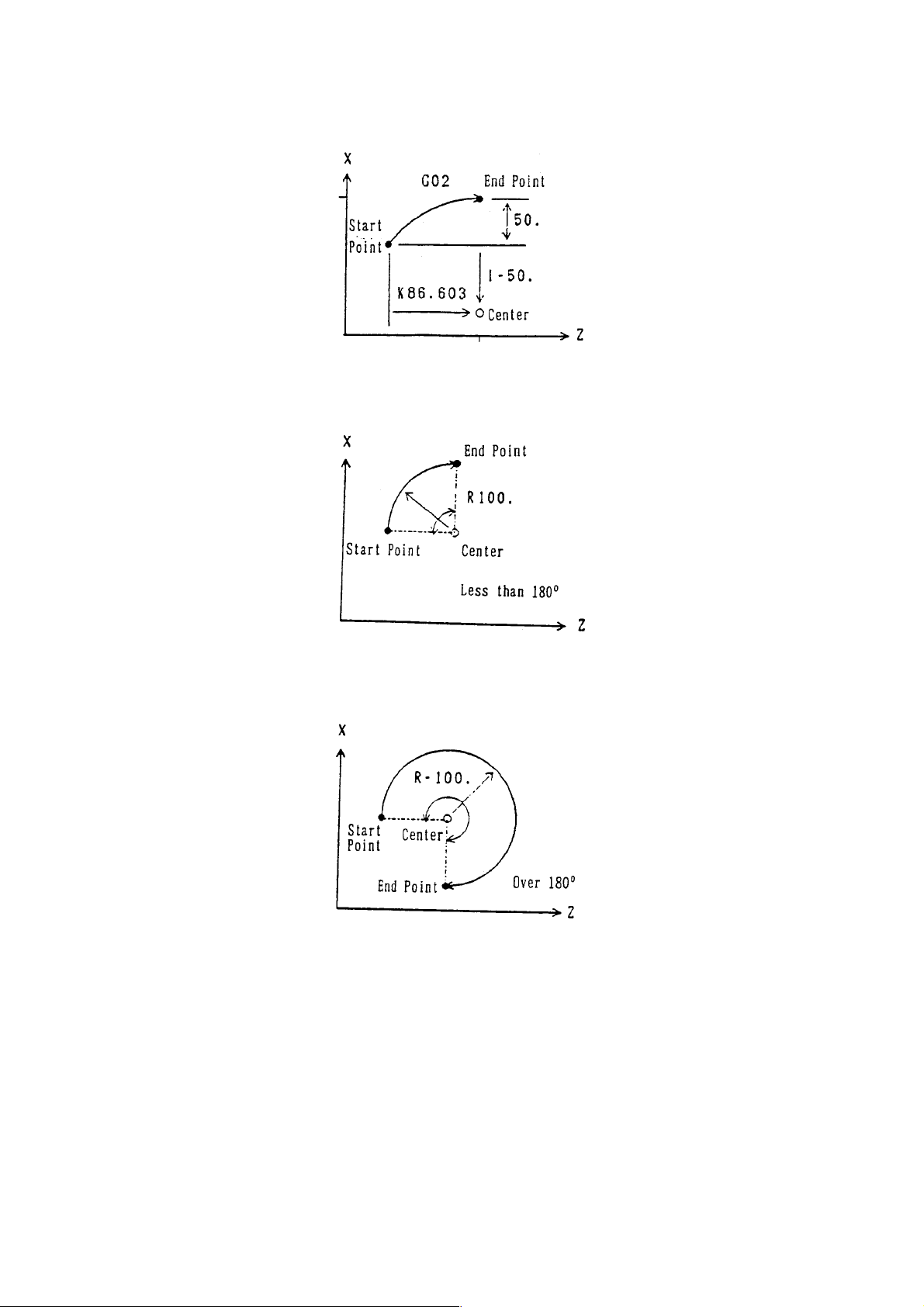

(Note 1) Instead of using I, J, and K, you can use R to assign an arc radius.

(R assignment of arc radius) When applying R assignment to an arc of 180°

and above, specify an R in minus.

(Note 2) A full circle (360°) is not applicable in R assignment. Use I, J, and K for a full

circle.

When an arc close to 180° or to 360° is specified in R assignment, calculation

error may be produced, resulting in center deviation.

In this case, assign the center by using I, J, and K.

2.3.5 Cutting Feed Rate

The cutting feed rate specified with an F code is the speed at which the tool moves on the

arc.

2.3.6 Program Example

(1) Absolute Command Using I, J, and K:

G18 G00 X140. Z13.397 ;

G02 X240. Z100. I-50. K86.603 F200 ;

2 - 6

Page 23

(2) Incremental Command Using I, J, and K:

G18 G02 U100. W86.603 I-50. K86.603 F200 ;

(3) An Arc of 180° or Less Using Radius R Assignment:

G18 G02 U200. W100. R100. ;

(4) An Arc of 180° or more Using Radius R Assignment:

G18 G02 U200. W100. R100. ;

2.3.7 Cautions

(1) An alarm results when no F code has been specified in the G02/G03 block or before.

(2) Exponential type acceleration/deceleration is applied.

(3) An alarm results if an arc radius = 0 is specified.

(4) I0, J0, and K0 are omissible.

2 - 7

Page 24

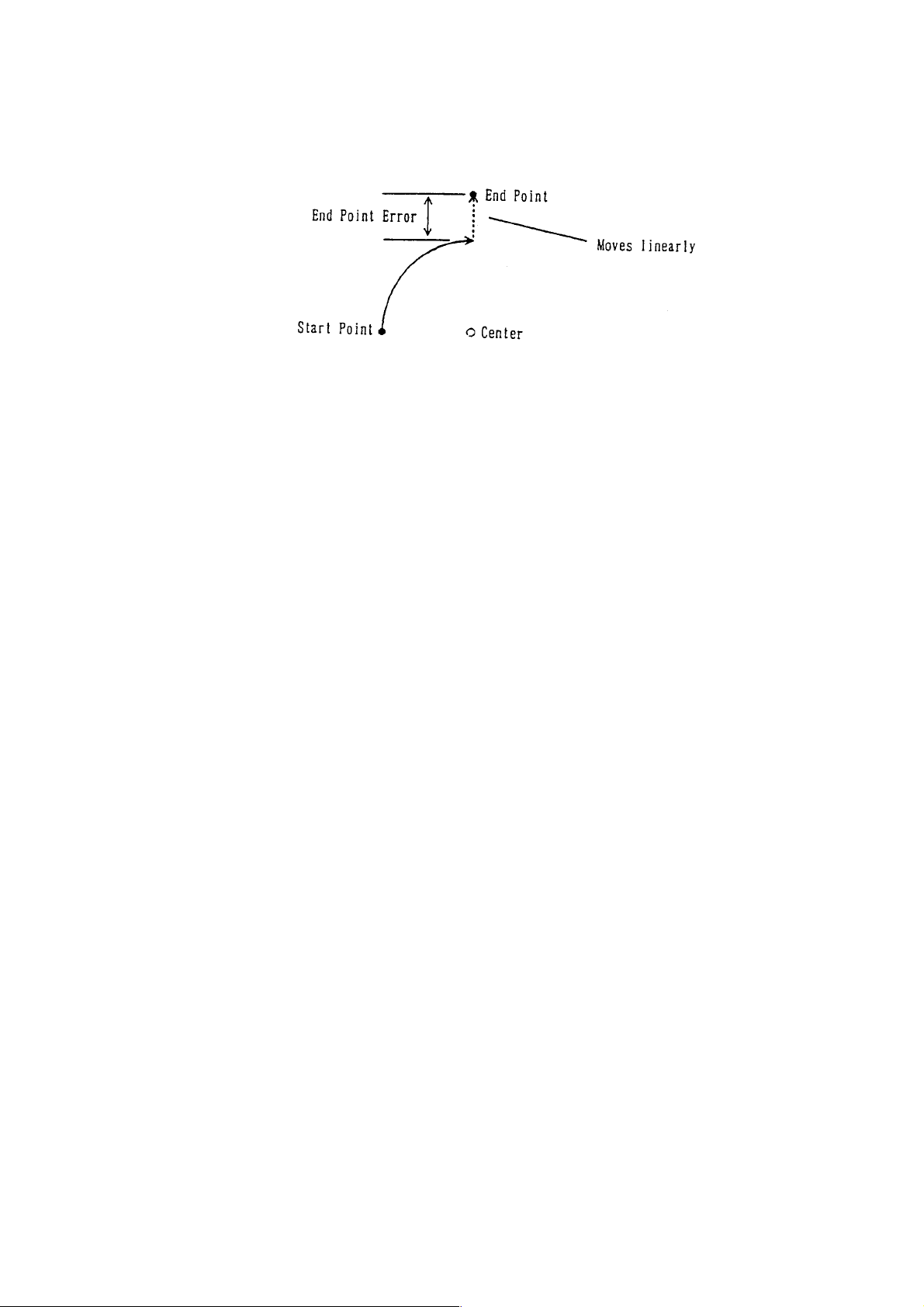

(5) When there is no end point on the arc, the tool moves linearly the rest after moving

along an arc if the end point error of circular interpolation is within the parameter set

value. Also, an alarm results if it is other than the p arameter set value.

(6) An alarm results if the axis not for the arc plane is specified.

(7) When R is specified in the same block as I, J, and K, R is given priority.

(8) When the canter of a circular arc is not calculated, alarm takes place.

2.3.8 Associated Parameters

No.1422 Maximum cutting feed speed (common to all axes)

No.1622 Time constant of cutting feed exponential type acceleration/deceleration

No.1623 FL speed of cutting feed exponential type acceleration/deceleration

No.3459 Arc radius error limit value

2.3.9 Associated Alarms

No.102 No F has been commanded in cutting feed. Or, F0 has been commanded.

No.131 The R value in arc radius R assignment is erroneous.

No.132 An arc for which difference in radius values between the start point and the

end point is larger than the parameter set value has been commanded.

(#001) No center command (I, J, K)

(#002) Center command (I, J, K) is 0.

(#003) Arc end point allowable error is too large.

(Note) When an option for helical interpolation is not added, specifying the axis for other

than the arc plane results in the alarm #191 (OPTION COMMAND).

2 - 8

Page 25

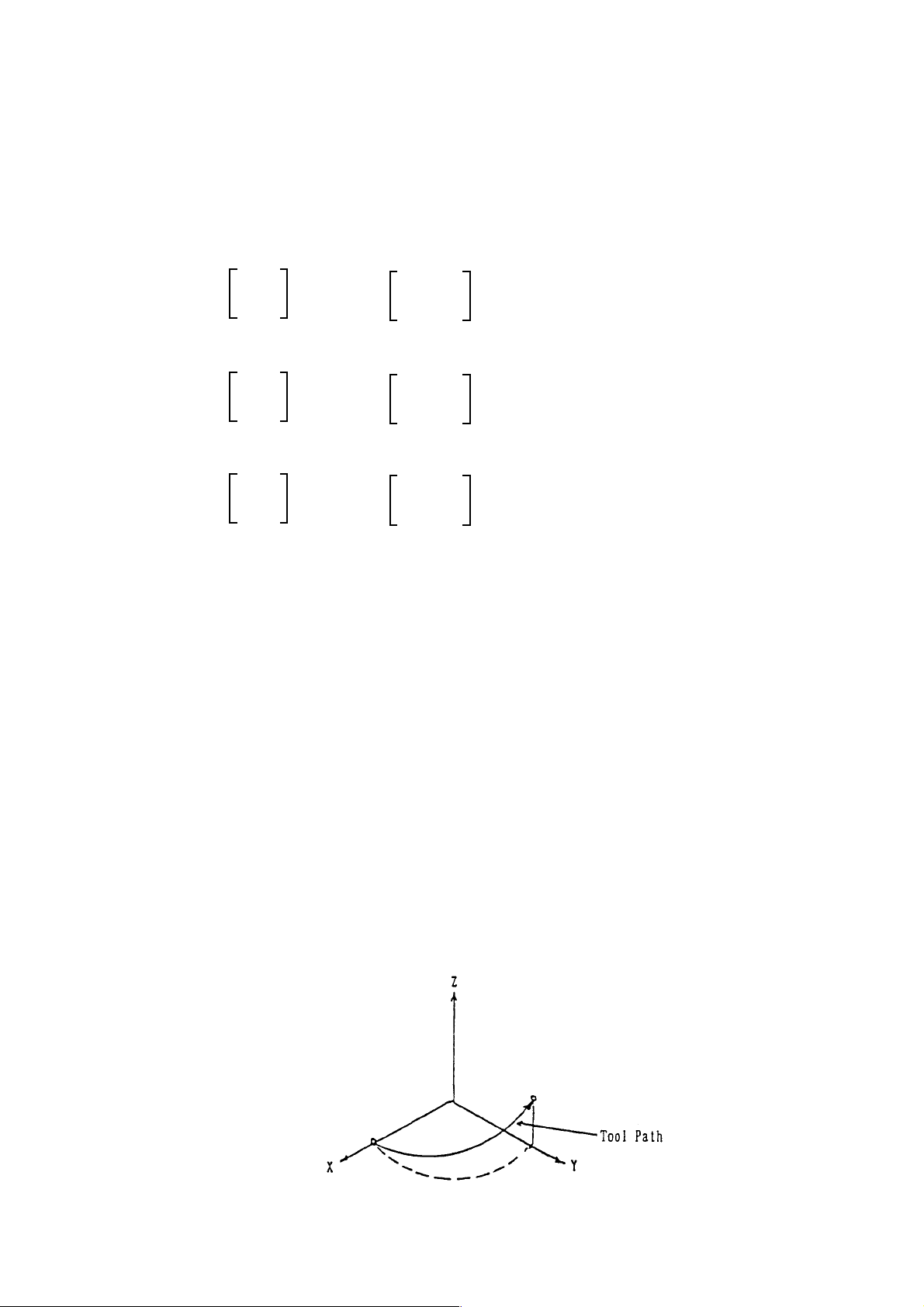

2.4 Helical Interpolation (G02, G03)

If an arc command and any one axis for other than arc are specified, helical interpolation is

enabled by control which performs linear interpolation synchronously with arc movement.

2.4.1 Command Format

(1) Xp-Yp plane

G17

(2) Zp-Xp plane

G18

(3) Yp-Zp plane

G19

G02

G03 R_

G02

G03 R_

G02

G03 R_

Xp_ Yp_

Zp_ Xp_

Yp_ Zp_

I_ J_

K_ I_

J_ K_

.... Not available with

a_ F_ ;

a_ F_ ;

a_ F_ ;

ΣΣ

Σ21L.

ΣΣ

where; Xp : X axis or its parallel axis

Yp : Y axis or its parallel axis

Zp : Z axis or its parallel axis

α : Any optional linear axis for other than circular interpolation (up to 2 axes)

F : Arc speed

2.4.2 Feed Speed

Feed speed command F in helical interpolation is equal to the speed in which a tool moves

on an arc.

Speed of the straight line axis = F × (length of the straight line axis/the arc length)

2.4.3 Sample Program

G17 G03 U-200. V100. R100. W50. F200 ;

2 - 9

Page 26

2.4.4 Cautions

(1) See to it that the linear axis speed does not exceed the maximum value.

(2) Cutter compensation is applied to circular interpolation.

(3) The axes for other than circular interpolation can be specified up to 2 axes.

Specifying 3 axes or more results in an alarm.

(4) The tool speed can be the composite speed of arc and linear speeds by parameter

setting.

2.4.5 Associated Parameters

2.4.6 Associated Alarms

No.149 In helical cutting, 3 or more linear axes have been commanded.

2 - 10

Page 27

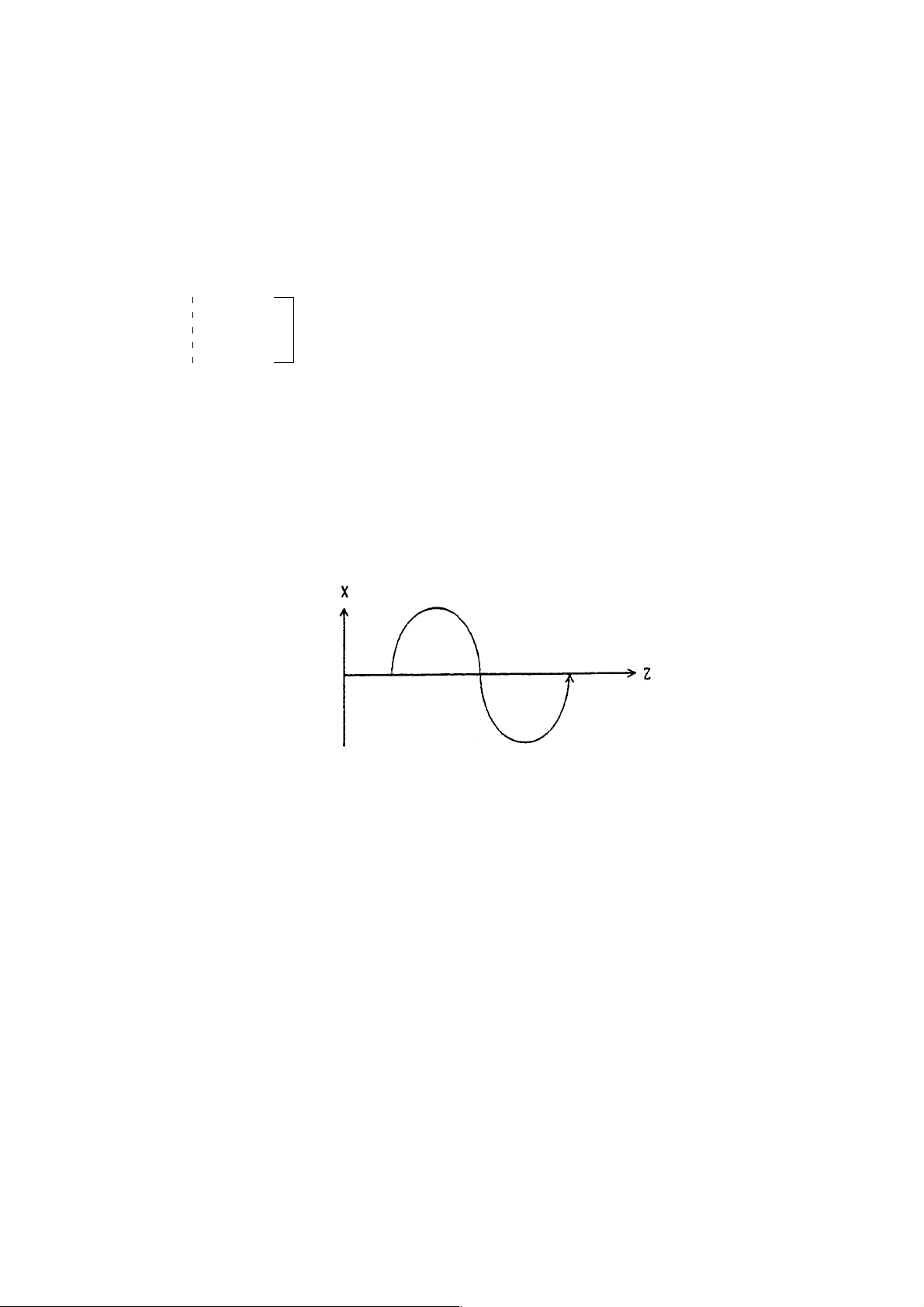

2.5 Virtual Axis Interpolation (G07)

When a virtual axis is assigned, axis shift does not take place.

In helical interpolation, by making one of circular command axes as a virtual axis, you can

perform SIN interpolation.

2.5.1 Command Format

G07 α 0 ; Sets the α axis as the virtual axis

The α axis is the virtual axis in this section

G07 α 1 ; Cancels the α axis as the virtual axis

where ; α : Any one axis

2.5.2 Sample Program

G07 Y0 ;

G17 G03 U0 V0 I-50. Z100. F200 ;

.... Not available with

ΣΣ

Σ21L.

ΣΣ

2.5.3 Cautions

(1) Virtual axis assignment is applicable only to 1 axis. If 2 or more axes should be

assigned, alarm takes place.

(2) When axial shift has been commanded for the axis assigned as a virtual axis, dwell

state equal to the shift time is produced.

(3) Command the virtual axis in incremental.

2.5.4 Associated Alarms

No.139 Two or more virtual axes are specified.

2 - 11

Page 28

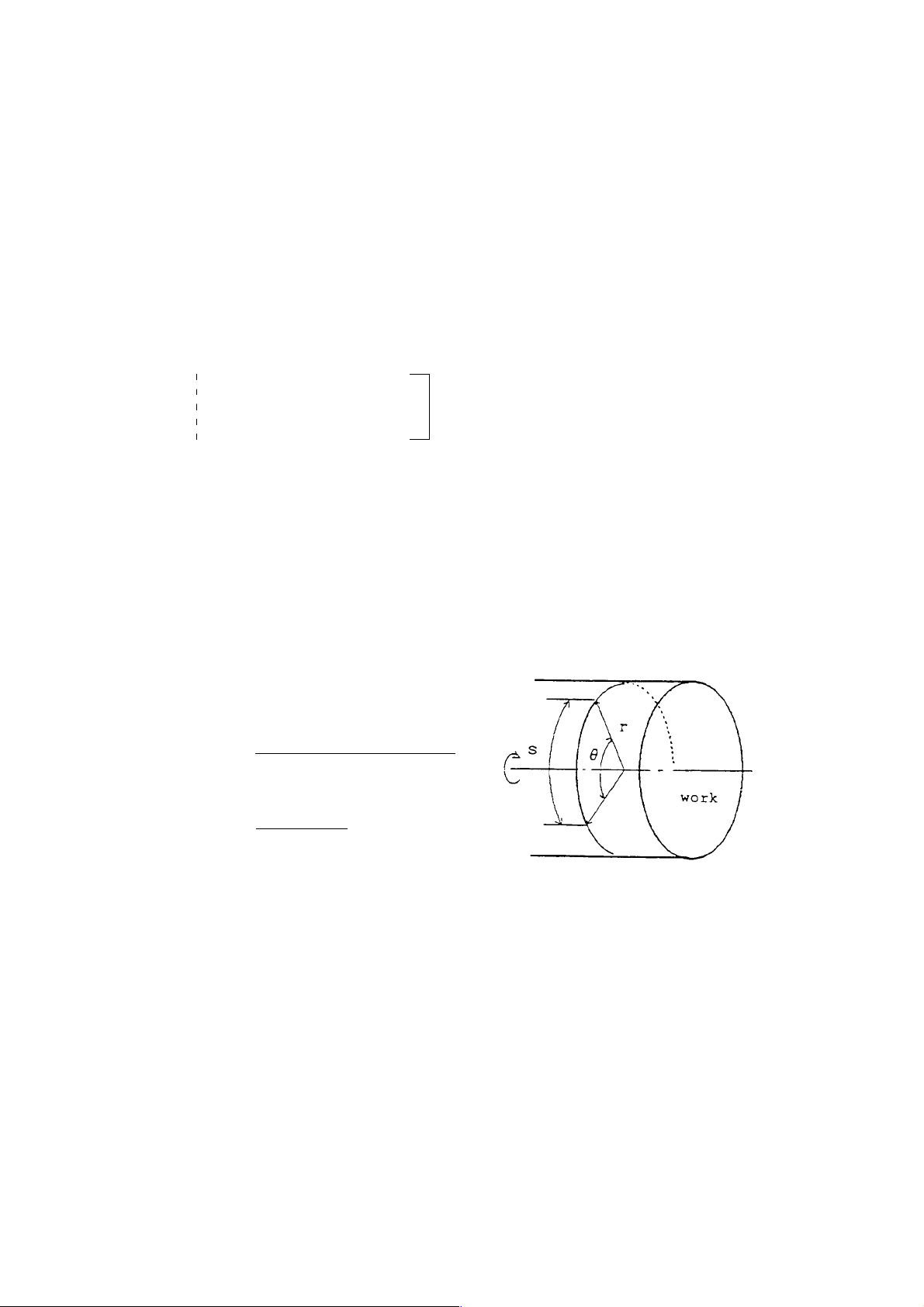

2.6 Cylindrical Interpolation (G271)

The stroke of the rotary axis internally specified in terms of angle is converted into the

circumferential distance by specifying the stroke of the linear axis and the angle of the rotary

axis with a program command. Since the circumferential distance can be regarded as the

stroke of the linear axis on the circumference, linear interpolation and circular interpolation

can be performed with other linear axes. Af ter interpolation, it is reconverted into the angle of

the rotary axis.

2.6.1 Command Format

G271 C Cylinder radius ; Cylindrical interpolation ON

Cylindrical interpolation mode

G271 C0 ; Cylindrical interpolation cancel

C denotes the rotary axis.

The move angle of the rotary axis is calculated back from the circumferential stroke.

For example, when you want to move 100.0 on the circumference of a cylinder whose

radixis is 50.0, the move angle of the rotary axis is obtained from the following expression.

r : Cylinder radius

θ : Move angle

s : Circumferential stroke

Move angle=

(Circumferenttial stroke)

(Cylinder radius)

360×100.0 =

=

2×

π×50.0

114.591

2 - 12

Page 29

2.6.2 Feed Rate

Feed rate command F in the cylindrical interpolation mode is the speed at which the tool

moves around the perimeter of a cylinder .

2.6.3 Circular Interpolation Axis

A linear as well as a rotating axis for which circular interpolation is performed are set in

parameters beforehand (S traight line axis: No.3426, Rot ary axis: No.3427).

The set range for both parameters, however, should be within 1~ no. of control axes and

the parameters should not be the same for both axis.

2.6.4 Circular Interpolation Plane

During the circular interpolation mode, a plane for which the rotating axis is set to 1st plane

axis and the straight line axis to 2nd plane axis is automatically selected.

2 - 13

Page 30

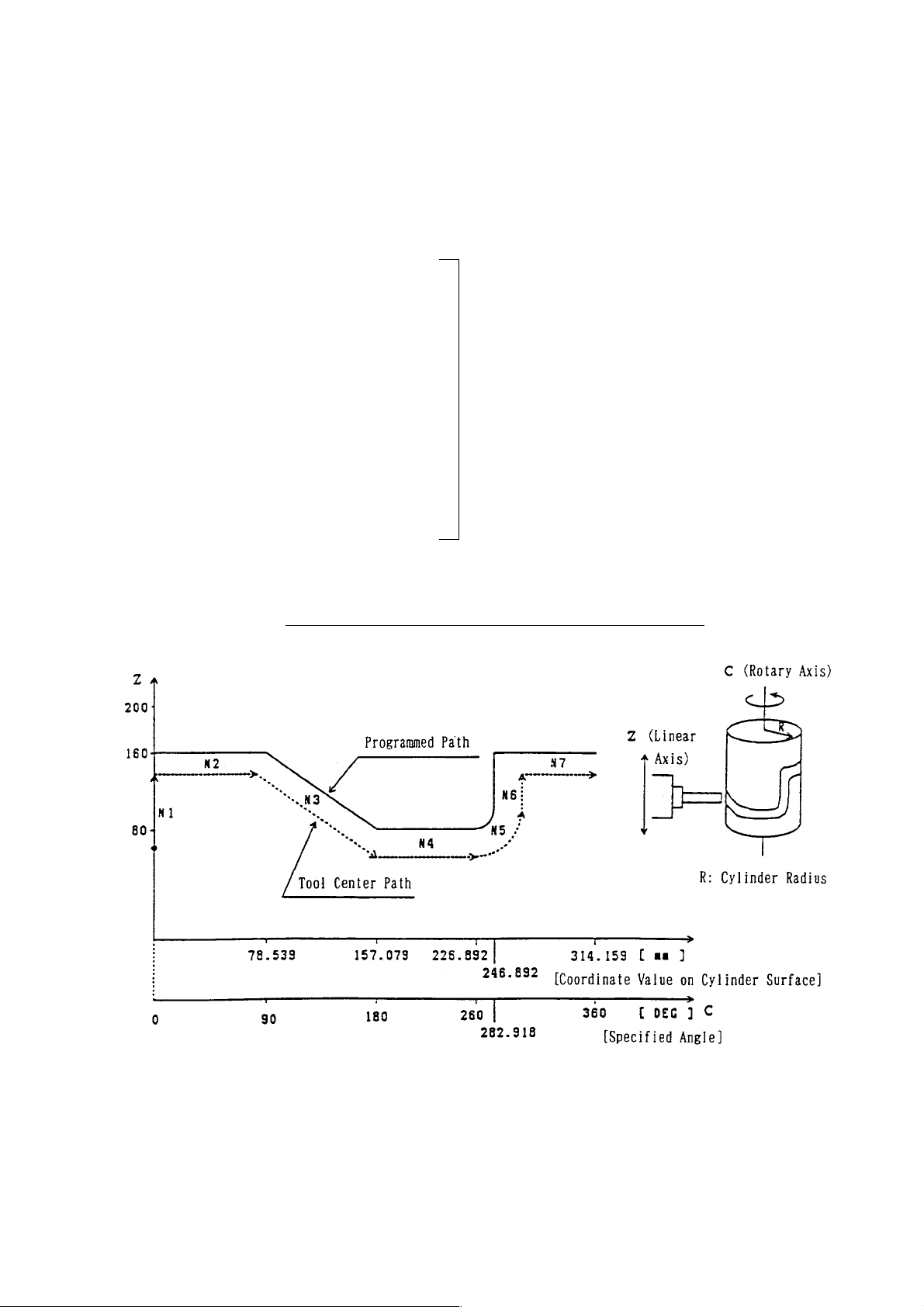

2.6.5 Sample Program (X Axis is Diameter Specification)

(C-Z plane selected with Parameter No. 3426/3427.)

T0100 ;

G98 G145 G40 G80 ;

G00 X120.0 Z-120.0 C0 ;

G145 ;

G271 C50.0 ; Cylindrical interpolation mode ON

N1 G42 G01 Z-40.0 F500 ; (Cylinder radius = 50.0)

G01 X100.0 F100 ;

N2 C90.0 F500 ;

N3 Z-100.0 C180.0 ;

N4 C260.0 ; In the cylindrical

N5 G03 Z-80.0 C282.918 R20.0 ; interpolation mode

N6 G01 Z-60.0 ;

N7 G02 W20.0 H22.918 R20.0 ;

N8 G01 C360.0 ;

N9 G40 G01 Z-120.0 ;

G271 C0 ; Cylindrical interpolation mode OFF

G00 Z50.0 C0 ;

Developed View of Cylinder Surface with Radius of 50.0

2 - 14

Page 31

2.6.6 Cautions

(1) Arc radius programming with I, J, or K is not allowed during the cylindrical interpolation

mode. Use radius designation on arc and specify it with the coordinate value on the

cylinder surface.

(2) During cylinder interpolation mode, the plane (plane selected by G17 - G19) before

entering the cylinder interpolation node will be canceled once, and then restored after

completion of the cylinder interpolation mode.

(3) The circular arc radius specification method (which of the addresses I, J, K to use)

when performing circular arc interpolation during the cylinder interpolation mode, will

be decided depending on which axis of the basic coordinate system the second axis

(straight line axis) of the cylinder interpolation plane corresponds to, as shown below.

• When the straight line axis is the X axis or parallel to it, Zp-Xp plane will be taken,

specified by K, I.

• When the straight line axis is the Y axis or parallel to it, Xp-Yp plane will be taken,

specified by I, J.

• When the straight line axis is the Z axis or parallel to it, Yp-Zp plane will be taken,

specified by J, K.

Also, the circular arc radius can be specified by the R command.

(4) (G271 Cxx)

(5) An alarm results if 2 or more rotary axes are specified with the G271 command.

(6) Cylindrical interpolation is not available for the following functions:

• Machining break point return

• Manual intervention by manual absolute ON

(7) An alarm results if the following commands are given during the cylindrical

interpolation mode.

G28, G30, G53 Machine coordinate system

Thhttxx; (T command), G54, G50 Work coordinate system

G70-G76, G81-G89, G831-G861, G861

G90-94 Various canned cycles

G31, G121, G232 Others

(8) In the cylindrical interpolation mode, the angle of the rotary axis is converted into the

distance on the circumference, and after interpolation, it is converted the other way

around. When this is done, a slight conversion error occurs.

(9) Due to the above conversion error, a circular interpolation alarm may occur if circular

interpolation with a small circular arc radius is performed during the cylindrical

interpolation mode. When using, care should be taken. Also, a cutter compensation

alarm may occur at the time of cutter compensation due to the above reason.

(10) An alarm results if G271 Cxx; (C ≠ 0) (cylindrical interpolation mode ON) is specified

during the cylindrical interpolation mode.

(1 1) The remaining stroke indicates the value at the time of moving on the perimeter of the

cylinder.

2 - 15

Page 32

2.6.7 Related Parameters

No.3426 Axis number (1 - No of control axes) of the straight line axis for performing

circular interpolation

No.3427 Axis number (1 - No of control axes) of the rotating axis for performing circular

interpolation

2.6.8 Related Alarm

No.126 An error exists in cylindrical interpolation command.

(#001) No rotary axis command exists.

(#002) No independent command exists.

(#003) Modal G code is not in correct state.

No.127 An erroneous command has been give while in cylindrical interpolation mode.

(#001) An erroneous G code has been commanded.

(#003) Rotary axis shifting command has been given in G00 mode.

(#004) Cylindrical interpolation has been commanded again while in cylindrical

interpolation mode.

No.189 (G271) Parameter setting is erroneous.

• Parameters No. 3426/No.3427 do not fall within 1 ~ no. of control axes. Or,

No.3426 and No.3427 are equal.

• The straight line axis set in Parameter No.3427 does not correspond to or

parallel to any of the basic three axes (X, Y, Z).

2 - 16

Page 33

2.7 Polar Coordinate Interpolation (G120, G121)

Polar coordinate interpolation is a function to provide contour control by converting the

command programmed in the orthogonal coordinate system into the movement of the linear

axis (tool movement) and that of the rotary axis (workpiece rotation).

<Orthogonal Coordinate System> <Polar Coordinate System>

The relationship between (X1, C1) and (X1’, C1’) is as follows.

2

X1’ = X

1

+ C

2

1

C1’ = tan-1 (C1/X1)

2.7.1 G Codes

G121 : Polar coordinate interpolation mode

G120 : Polar coordinate interpolation mode cancel

2.7.2 Command Format

G121 ; Turns polar coordinate interpolation mode ON

Performs polar coordinate interpolation.

G120 ; Cancels polar coordinate interpolation mode.

2.7.3 Polar Coordinate Interpolation Axes

A straight line axis as well as a rotating axis for the polar coordinate interpolation are set in

the parameters beforehand (S traight line axis: No.3418, Rot ating axis: No.3419).

The set range for both parameters should be within 1 ~ no. of control axes and the

parameters should not be the same for both axis.

2.7.4 Polar Coordinate Interpolation Plane

When G121 is specified, the polar coordinate interpolation mode is put in effect, and the

plane (polar coordinate interpolation plane) is selected, which assumes the origin of the

work coordinate system as that of the coordinate system, the linear axis as the first

plane axis, and virtual axis (rotary axis) orthogonal to the linear axis as the second plane

2 - 17

Page 34

axis. Polar coordinate interpolation is performed on this plane. For the position specified

by G121, the angle will be taken as 0 and polar coordinate interpolation started, regardless

of the actual position. Therefore, create the program by taking the work coordinate value

of the rotating axis as 0 when G121 has been specified.

2.7.5 Program Command

(1) The program command in the polar coordinate interpolation mode is given in terms of

the orthogonal coordinate value of the polar coordinate interpolation plane.

The rotary axis address is used for the command address of the 2nd plane axis.

However, the programmable unit is not degrees; the same unit as that for the 1st

plane axis, linear axis (mm or inch). The 2nd plane axis assumes the same

designation as the rotary axis; it is neither diameter designation nor radius designation.

(2) During the polar coordinate interpolation mode, linear interpolation (G01) and circular

interpolation (G02, G03) can be specified. Both absolute programming and

incremental programming are allowed.

(3) When performing circular interpolation on the polar coordinate interpolation plane, the

circular arc specifying-method (which one of I, J, and K is to be used as the address)

is determined as follows depending on to which axis of the basic coordinate system

the 1st plane axis (linear axis) corresponds (parameter setting: No.1011).

• When the linear axis is either X axis or its parallel axis, the Xp-Yp plane is

assumed, and I/J is used to specify the circular arc radius.

• When the linear axis is either Y axis or its p arallel axis, the Yp-Zp plane is assumed,

and J/K is used to specify the circular arc radius.

• When the linear axis is either Z axis or its parallel axis, the Zp-Xp plane is assumed,

and K/I is used to specify the circular arc radius.

It is also possible to specify the circular arc radius with an R command.

(4) Cutter compensation can be applied to the program command. Polar coordinate

interpolation is performed for the profile after cutter compensation.

However, specify G121 and G120 in the cutter compensation cancel mode (G40).

(5) For feed rate, specify the shift speed of the tool in the polar coordinate interpolation

plane (orthogonal coordinate system) by F.

Since this is normally specified by feed per minute (G98), the units of F will be mm/

min, inch/min.

2 - 18

Page 35

2.7.6 Sample Program (X Axis [Diameter Assigned]: Linear Axis/C Axis[Radius

Assigned]: Rotary Axis)

G00 X130.0 C0 ; Positioning to start position

G145 ; Tool Diameter Compensation Effective mode

G121 ; Polar coordinate interpolation started.

N1 G42 G01 X80.0 F100 ;

N2 C40.0 ;

N3 G03 X60.0 C50.0 R10.0 ;

N4 G01 X-60.0 ; Profile program,

N5 C-15.0 ; Program with orthogonal coordinate

N6 G03 X-50.0 C-20.0 I5.0 J0 ; values on the X-C’ plane

N7 G01 X80.0 ;

N8 C0 ;

N9 G40 X130.0 ;

G120 Polar coordinate interpolation cancelled.

2 - 19

Page 36

2.7.7 Speed Clamping of the Rotating Axis

The maximum cutting feed speed for the polar coordinate interpolation can be set in the

parameter . (Parameter No.3464)

When any speed above this level is specified while in polar coordinate interpolation, it is

clamped to this speed. With the set value being 0, clamping is performed to the ordinary

maximum cutting feed speed (Parameter 1422) even while in polar coordinate

interpolation.

Further, in polar coordinate interpolation, as a shape having been programmed in the

orthogonal coordinate system are converted into movement of the straight line and the

rotating axes, rotating axis speed is increased in movement around the work center (origin

of the coordinate system), even exceeding the limit speed of Machine.

In the above case, the allowable speed of the rotating axis can be set in the parameter as

follows:

Allowable speed of rotating axis = Max. cutting feed speed (Parameter No. 3404) x

Allowable ratio (Parameter No.3420)

When the speed component of the rotating axis exceeds the allowable speed while in

polar coordinate interpolation, override shown below is automatically applied (Automatic

override):

Allowable speed of rotating axis

Override =

Speed component

× 100(%)

When the speed component of the rotating axis still exceeds the allowable speed even

with override being applied, feed speed is clamped so that the speed component of the

rotating axis does not exceed the maximum cutting feed speed. (Automatic speed clamp)

2.7.8 Rapid Traverse (G00) Operation

You can issue the G00 command during the polar coordinate interpolation mode.

However, only the start point and the end point will be converted to the positions of the

polar coordinate system for the G00 block.

There will be no conversion during the path from the start point to the end point.

Example: In the G121 mode, if the following command is issued:

G00 X100. C50.0 ;

The path will be the same as specified in the following command in the G120 mode:

G01 X141. 421 C45.0 ;

In the shift of the rotating axis by G00, close rotation (shift within +/-180 degrees) will be

performed and the processing time will be reduced.

2 - 20

Page 37

2.7.9 Special Specification A for Polar Coordinate Interpolation (Optional)

Through parameter setting, machining by a program of the X-Y coordinate system is made

available in the same manner with the machining center.

In G121 mode, the following conversion processes will be performed immediately after the

program is read in.

• X axis commands are processed as radius commands.

(X axis command is doubled)

• Y axis commands are converted to C axis commands. (Y → C, V → H)

(Note 1) Since the above conversion processes are performed on the basis of axis

name, the parameters must be set with the straight line axis as the X axis and

the rotating axis C axis that are subject to the polar coordinate interpolation.

(Note 2) Although X axis commands are possible with radius values, the coordinate

indication will follow the convention of the mechanical specification. (usually

diameter values)

(Note 3) Evan if the special specification A for polar coordinate interpolation is employed,

either the standard of special specification can be selected with the parameters.

2 - 21

Page 38

2.7.10 Cautions

(1) G120 and G120 should be specified in an independent block.

(2) Before specifying G121, the work coordinate system where the center of the rotary

axis serves as the origin of the coordinate system must be set. During the G121

mode, the coordinate system must not be altered.

(3) The plane(selected by G17, G18, or G19) prior to G121 is cancelled once by G121 and

restored by G120.

(4) The following G codes can be specified in the G121 mode:

G00, G01, G02, G03, G04, G09, G40, G41, G42, G65, G66, G67, G98, G99, G140,

G143, G144, G145

(5) For the axis move command outside the plane of the G121 mode, the axis moves

regardless of polar coordinate interpolation.

(6) The display of the “remaining stroke” in the G121 mode represents that in the polar

coordinate plane (orthogonal coordinates).

For G00 block, however, the unit for the ordinary case is applied.

(7) The following functions are not available for the blocks which are in the G121 mode:

Program restart, Machining break point return, Manual intervention by manual absolute

ON

(8) On completion of polar coordinate interpolation (G120), the work coordinate of the

rotating axis can be rounded at 360° through parameter setting. (0° coordinate

value < 360°)

(9) When the work coordinate value of straight line axis during G121 command is

negative for the first shift block, only the end point will be converted to the polar

coordinate system position. There will be no conversion during the shift. (Same as

the straight line type G00 in the G121 mode.)

From the next shift block, polar coordinate conversion will be performed for the shift

path. For the first, shift block, only G00 and G01 can be specified; G02 and G03

cannot be specified.

(10) Through parameter setting, you can specify G codes (G120/G121) for polar coordinate

interpolation by using G126/G127.

In specification with G126/G127, they are converted into standard G codes (G120/

G121) when an NC program is read into the buffer .

Therefore, command values and alarms are displayed in the standard G codes.

<

=

2 - 22

Page 39

2.7.1 1 Associated Parameters

No.3404, #4= 0 Work coordinates of rotating axis is not rounded on completion of

polar coordinate interpolation.

= 1 Work coordinates of rotating axis is rounded at 360° completion of

polar coordinate interpolation.

No.3404, #6= 0 Y-axis command in the polar coordinate interpolation is moved as Y-

axis command.

= 1 Y-axis command in the is moved by being replaced by C-axis

command.

No.3404, #7= 0 X-axis command in polar coordinate interpolation mode follows

machine specifications.

= 1 X-axis command in polar is taken as radius assignment.

No.3409, #0= 0 G codes for polar coordinate interpolation are G120/G121 (standard)

= 1 G126/G127

No.3410, #1= 0 Neither automatic override nor automatic speed clamp is performed

while in polar coordinate interpolation mode.

= 1 Automatic override and automatic speed clamp are performed while in

polar coordinate interpolation mode.

No.3418 Axis number of the linear axis for which polar coordinate interpolation is

performed

No.3419 Axis number of the rotary axis for which polar coordinate interpolation is

performed

No.3420 Axis number of the linear axis for which polar coordinate interpolation is

performed.

No.3464 Maximum cutting feed speed while in polar coordinate interpolation.

2 - 23

Page 40

2.7.12 Associated Alarms

No.1 13 An error exists in the polar coordinate interpolation command.

(#001) G120/G121 commands is not independent type.

(#002) When G120/G121 is specified, cutter compensation has not been cancelled.

(#003) When the work coordinate value of the linear axis is in minus on specification

of G121, a command other than G00/G01 has been specified in the first shift

block.

No.1 14 An erroneous command has been specified while in the polar coordinate

interpolation mode.

(#001) A G code not useable has been specified.

(#002) A T code has been specified.

No.189 (G121) An error exist s in parameter setting.

• Parameters No.3418/No.3419 are not within 1 ~ no. of control axes, or

No.3418 is equal to No.3419.

• The linear axis set in Parameter No.3418 is none of the basic three axes

(X/Y/Z), or not parallel to any of them.

2 - 24

Page 41

2.8 Angle Designated Linear Interpolation

By commanding an angle (A) formed between X or Z axis shifted and +Z axis, you can

perform angle designated linear interpolation.

2.8.1 Command Format

G01 X___ A___ ;

G01 Z___ A___ ;

2.8.2 Angle A

(1) Scope of angle A

<

-360.000 A 360.000 (deg)

(2) Angle A code

Plus ..........Counterclockwise angle from +Z axis

Minus ........Clockwise angle from +Z axis

<

=

=

2.8.3 Program Example

G18 G01 U20. A60. ;

W20. ;

W10. A-30. ;

30°

2 - 25

Page 42

2.8.4 Cautions

(1) When A is used as an axis name, this function is made invalid.

Address A indicates A axis, not an angle.

(2) Angle designated linear interpolation on other planes (G17/G19) is available.

As this angle A, an angle formed by the horizontal axis of the coordinate system in

plus direction (G17:+X, G19:+Y) is commanded.

(3) When the shift direction of the commanded axis and the shift direction after calculation

are opposite, alarm takes place.

G01 W100. A100. ;

<<Available A Range for Commanding in +Z Direction Command>>

2.8.5 Associated Parameters

2.8.6 Associated Alarms

No.177 An error exists in the command of angle designate linear interpolation.

(#001) Angle A value is out of the range.

(#002) An angle in opposite shift direction has been commanded.

2 - 26

Page 43

2.9 Skip Function (G31)

Linear interpolation is performed by a G31 command. If an external skip signal is input

during linear interpolation, the program proceeds to the next block, stopping the axes and

discarding the remaining stroke.

2.9.1 Command Format

G31 X___ Y___ Z___ ....... F___ ;

2.9.2 Sample Program

N1 G98 G31 W50. F100 ;

N2 G01 U50. W25. ;

2.9.3 Cautions

(1) G31 cannot be specified while in the corner R compensation/tool system

compensation mode.

(2) When the block next to the G31 command has been given by incremental

programming, the next block functions in the incremental manner from the

positioninterrupted by the skip signal.

(3) The G31 command is effective only in the block where it is specified.

(4) Position where skip has been input (work coordinates) can be read by the macro

system variable.

2.9.4 Associated Parameters

No.6200, #7= 0 Automatic acceleration/deceleration is made invalid to G31 skip

command.

= 1 Automatic acceleration/deceleration is made valid to G31 skip

command.

2.9.5 Associated Alarms

2 - 27

Page 44

2 - 28

Page 45

3. THREAD CUTTING

3.1 Thread Cutting (G32)

With a G32 command, straight threads and tapered threads can be cut ata equal leads

synchronously with the pulses from the spindle encoder.

3.1.1 Command Format

(1) Straight thread cutting at equal leads

G32 α___ F___ (E___) ;

where; α : Any one axis

F (E) : Thread lead

(2) Tapered thread cutting at equal leads

G32 α___ β___ F___ (E___) ;

where; α, β : Any one axis

F (E) : Thread lead

(3) Thread cutting at equal leads by specifying the number of threads per inch

G32 α___ β___ E___ ;

where; α, β : Any one axis

E : No. of threads per inch

(Note) Use a parameter to set whether to specify the thread lead with an E code or the

number of threads per inch.

3.1.2 Sample Program

(1) Straight thread cutting at equal leads

G32 W-10. F2.0 ;

(2) Tapered thread cutting at equal leads

G32 U-10. W-20. F2.0 ;

(3) Straight thread cutting at equal leads by specifying the number of threads per inch

G32 W-50. E5.0 ;

(5 threads per inch; Thread lead = 5.08 mm)

3 - 1

Page 46

3.1.3 The Range of Thread Lead will be as Follows

(a) Metric programming

F35 : 0.00001 ~ 999.99999 (mm/rev)

F26 : 0.000001 ~ 99.999999(mm/rev)

(b) Inch programming

F26 : 0.000001 ~ 99.999999 (inch/rev)

F17 : 0.0000001 ~ 9.9999999 (inch/rev)

(Note) The number of significant digits for F and E is the same.

3.1.4 Cautions

(a) The feed hold function is disabled during thread cutting. If the FEED HOLD button is

pressed during thread cutting, the program stops at the end point of the block next to

the non-thread cutting block.

(b) Cutting feed override and spindle override is disabled and fixed at 100 % during thread

cutting.

(c) An alarm results if 3 axes or more are specified in the same block.

(d) Give the thread lead (F or E) in the first G32 mode.

(e) If E is given during the G32 mode, it remains effective until F is given. Also, if F and E

are given in the same block, F is given priority.

3.1.5 Associated Parameters

No.1401, #5= 0 Dry run disabled during thread cutting and tapping.

= 1 Dry run enabled during thread cutting and tapping.

No.3401, #4= 0 F/E code for thread cutting in inch input is F26.

= 1 F/E code for thread cutting in inch input is F17.

No.3401, #5= 0 F/E code for thread cutting in mm input is F35.

= 1 F/E code for thread cutting in mm input is F26.

No.3403, #7= 0 E code for thread cutting is equal to the number of threads per inch of

the thread lead.

3 - 2

Page 47

3.1.6 Associated Alarms

No.103 An error exists in the thread cutting command.

(#001) Commands have been given for 3 or more axes.

3.2 Continuous Thread Cutting (G32)

Continuous thread cutting is enabled by continuously specifying the thread cutting command

blocks.

3.2.1 Sample Program

N1 G32 U-10.0 W-20.0 F3.0 ;

N2 W-10.0 ;

N3 U10.0 W20.0 ;

3.2.2 Cautions

(a) Stop at single block is not possible during thread cutting.

3 - 3

Page 48

3.3 Multi-thread Cutting

If you specify Q together with the thread cutting command (G32, G34, G76, G92), you can

shift the thread cutting start angle by the specified shift Q.

If you execute thread cutting of the same shape after changing the Q value, you can execute

multi-thread cutting.

3.3.1 Command Format

G32 α___ β___ Q___ F___ ;

Where, alpha, beta: Any one axis

: Thread lead in the direction of the longitudinal axis

F

Q : Thread cutting start shift angle (0 to 360 degrees)

Other thread cutting commands are similar to the one described above.

3.3.2 Example of Program

G32 W-30.0 F2.0 Q180 ;

Shift by 180 degrees with respect to the reference point.

3.3.3 Precautions

(1) Either 1 degree or 0.001 can be selected as the unit for shift angle Q, by parameter

setting.

(2) If you have selected 1 degree as the unit for Q, specify Q without the decimal point.

• Q1 → Indicates 1 degree

• Q1.0 → Indicates 1000 degrees

(3) If you have selected 0.001 as the unit for Q, specify Q with the decimal point.

• Q1 → Indicates 0.001 degrees

• Q1.0 → Indicates 1.0 degree

(4) When you use a macro variable in Q, select 0.001 degree as the unit for Q. Example:

Q#510

(5) Even if you select 0.001 in the unit for Q, since the feedback pulse from the spindle

encoder is normally 4096 pulse / rev . , the actual resolution will become 360 degrees/

4096 = 0.088 degree.

(6) The Q specification for continuous thread cutting will be effective only in the thread

cutting start block.

(7) If the Q specification exceeds the 0 to 360 degree range, alarm will occur .

3.3.4 Related Parameters

No.3404, #2= 0 Unit for the shift angle Q is 1 degree.

= 1 Unit for the shift angle Q is 0.001 degree.

3.3.5 Related Alarm

No.103 An error exists in the thread cutting command.

(#001) Commands have been given for 3 or more axes.

(#002) Q command value has exceeded the set range.

3 - 4

Page 49

3.4 Variable Lead Thread Cutting (G34)

Variable lead threads can be cut by specifying an incremental or decremental amount per

revolution of thread in the G34 command block.

3.4.1 Command Format

G34 α___ β___ F___ K___ ;

where; α, β : Any one axis

F : Thread lead in the longitudinal direction at thread cutting start time

K : Incremental amount (decremental amount for a nagative value) per

revolution

The programmable range of K is as follows.

Metric system : ±0.001 to ±99999.999 (mm/rev)

Inch system : ±0.0001 to ±9999.9999 (inch/rev)

3.4.2 Sample Program

Straight thread cutting at variable leads

(Thread lead at start time: 2.0 mm, Incremental amount per rev. : 0.5mm)

G34 W-10.0 F2.0 K0.5 ;

In variable lead thread cutting, feed speed is changed constantly as above so that lead is

changed for every rotation.

The lead for 1st rotation in thread cutting becomes “F± (K/2)” and the lead for 2nd rotation

on is increased/decreased by K for every rotation.

3.4.3 Cautions

(1) A G34 command with K omitted results in thread cutting at equal leads (G32

command).

3 - 5

Page 50

3 - 6

Page 51

4. FEED FUNCTION

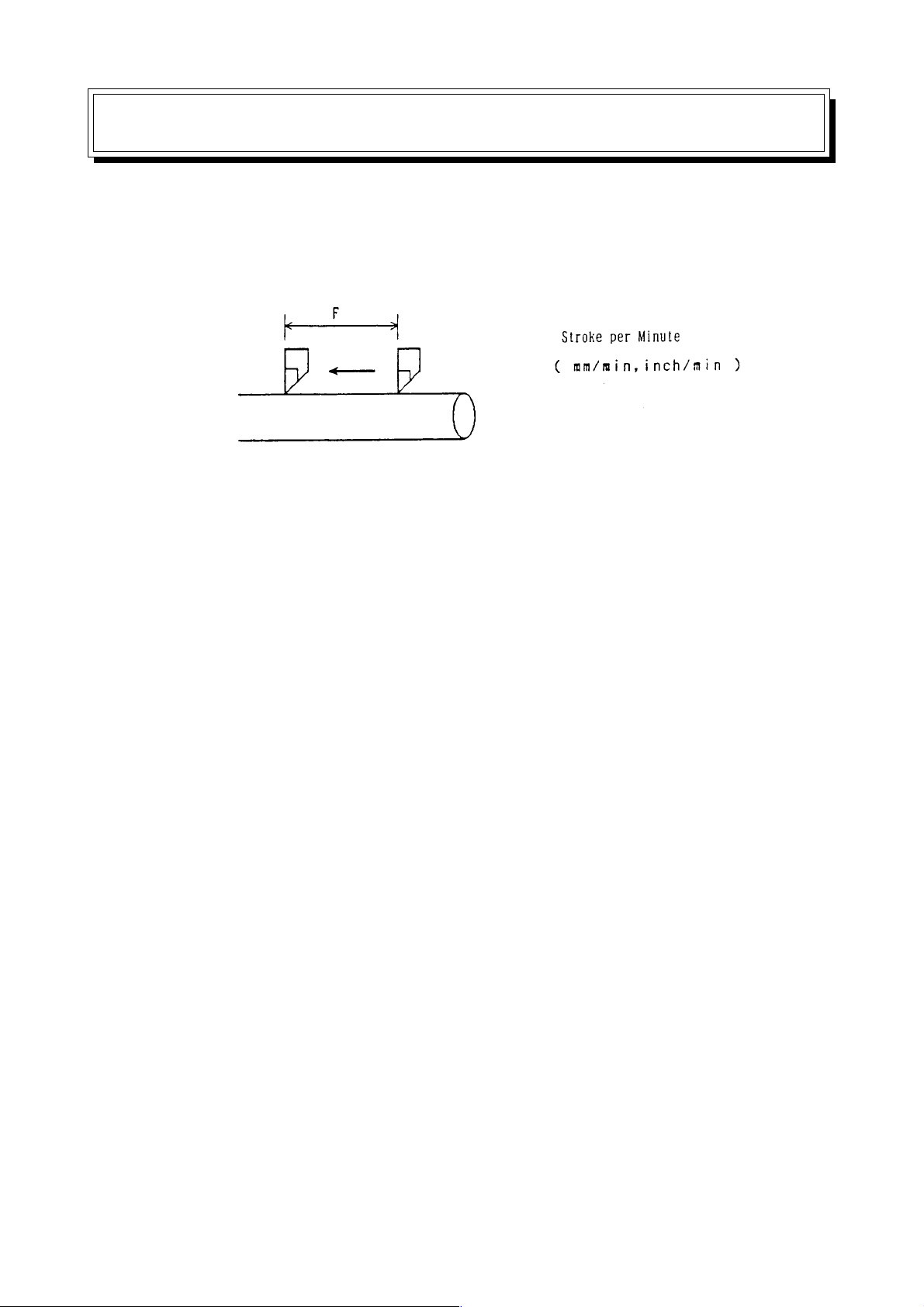

4.1 Feed Per Minute (G98)

Until G99 is specified after G98, specify the stroke per minute (mm/min., inch/min.) with a

numerical value following F as to the cutting feed rate.

4.1.1 Command Format

G98 ;

4.1.2 Sample Program

G98 F100 ; The cutting feed rate is 100 mm per minute.

4.1.3 The F Code Programmable Range is as Follows

(1) Metric system

F60 : 1~ 999999 (mm/min)

F61 : 0.1~ 999999.9 (mm/min)

(2) Inch system

F51 : 0.1~ 99999.9 (inch/min)

F52 : 0.01~ 99999.99 (inch/min)

4.1.4 Cautions

(1) One of F60, F61, F51, and F52 is selected by. parameter setting.

(2) When F61 is specified without a decimal point in the metric system, the least input

increment of 1 mm/min. or 0.1 mm/min. can be selected by parameter setting.

(3) In case of thread cutting (G33), feed per revolution is assumed temporarily even

during the G98 mode.

4.1.5 Associated Parameters

No.3400, #1= 0 The unit without a decimal point for metric input F61 is 1mm/min.

= 1 The unit without a decimal point for metric input F61 is 0.1mm/min.

No.3401, #2= 0 Feed per minute for inch input is F51.

= 1 Feed per minute for inch input is F52.

No.3401, #3= 0 Feed per minute for metric input is F60.

= 1 Feed per minute for metric input is F61.

4.1.6 Associated Alarms

No.102 F has not been specified in cutting feed. Or, F0 has been specified.

4 - 1

Page 52

4.2 Feed Per Revolution (G99)

Until G98 is specified after G99, specify the stroke per minute (mm/rev., inch/rev.) with a

numerical value following F as to the cutting feed rate.

4.2.1 Command Format

G99 ;

4.2.2 Sample Program

G99 F12 ; The cutting feed rate is 1.2 mm per revolution.

4.2.3 The F Code Programmable Range is as Follows

(1) Metric system

F32 : 0.01 ~ 999.99 (mm/rev)

F33 : 0.001 ~ 999.999 (mm/rev)

(2) Inch system

F23 : 0.001 ~ 99.999 (inch/rev)

F24 : 0.0001 ~ 99.9999 (inch/rev)

4.2.4 Cautions

(1) One of F32, F33, F23, and F24 is selected by parameter setting.

4.2.5 Associated Parameters

No.3401, #0 = 0 Feed per rotation for inch input is F23.

= 1 Feed per rotation for inch input is F24.

No.3401, #1= 0 Feed per rotation for metric input is F32.

= 1 Feed per rotation for metric input is F33.

4.2.6 Associated Alarms

No.102 F has not been specified in cutting feed. Or, F0 has been specified.

4 - 2

Page 53

4.3 Dwell (G04)

A G04 command can delay migration of operation to the next block.

When specifying by time: The command causes the machine to wait for the

When specifying by revolutions: The command causes the machine to wait while the

4.3.1 Command Format

(1) When specifying by time

G98 G04 P___ ;

P: Dwell time (0.001 to 99999.999 sec.)

(2) When specifying by revolutions

G99 G04 P___ ;

P: Dwell revolutions (0.001 to 99999.999 rev .)

(Note) X or U can be used instead of P.

4.3.2 Sample Program

specified time.

spindle rotates the number of revolutions specified.

G98 G04 P2000 ; Dwell time 2 seconds

G04 X2.0 ; Dwell time 2 seconds

4.3.3 Cautions

(1) It is normally set to dwell specified by time (per-minute dwell).

Through parameter setting, however , dwell specified by rot ation (per-rot ation dwell)

can be set in the per-rotation feed mode.

4.3.4 Associated Parameters

No.3400, #5= 0 G04 always specfies by time

1 G04 follows G94 or G95

4 - 3

Page 54

4.4 Exact Stop (G09)

If a G09 command is specified in the same block as a move block, it decelerates and stops

the machine upon completion of one block, and after confirming that the machine position is

within the range in which a command position was specified, executes the next block.

4.4.1 Command Format

G09 .......... ;

4.4.2 Sample Program

N1 G09 G01 W50.0 F2.0 ;

N2 G01 U-50.0 ;

4.4.3 Associated Parameters

No.1801, #4= 0 Imposition width for cutting feed is Parameter No.1826 (Common to

rapid traverse)

= 1 Imposition width for cutting feed is Parameter No.1827 (Common to

rapid traverse)

No.1826 Imposition width of each axis

No.1827 Imposition width of each axis for cutting feed

4 - 4

Page 55

4.5 Exact Stop Mode (G61)

Until G62, G63, or G64 is specified after G61 was specified, this function decelerates and

stops the machine, confirms that the machine position is within the specified range, and

then, proceeds to the next block.

4.5.1 Command Format

G61 ;

4.5.2 Sample Program

N1 G61 G01 W-100. F1.0 ;

N2 U50. ;

N3 W-100. ;

The corner has an edge when the G61 mode is

effective.

The corner is rounded when the G61 is ineffective.

4.5.3 Switching Into M Code

Through setting a parameter, you can specify Exact Stop mode by using M21 command

instead of using G61 command.

M21, as it is replaced by G61 inside NC for execution, is not output in Machine side. Also,

with M21 command, G62 to G64 modes are cancelled.

4.5.4 Associated Parameters

No.1801, #4 = 0 Imposition width for cutting feed is Parameter No.1826 (Common to

rapid traverse)

= 1 Imposition width for cutting feed is Parameter No.1827 (Common to

rapid traverse)

No.3409, #1 ON/OFF command system for Exact Stop mode is:

= 0 G61 (ON) / G64 (OFF)

= 1 G61 or M21 (ON) / G64 or M22 (OFF)

No.1826 Imposition width of each axis

No.1827 Imposition width of each axis for cutting feed

4 - 5

Page 56

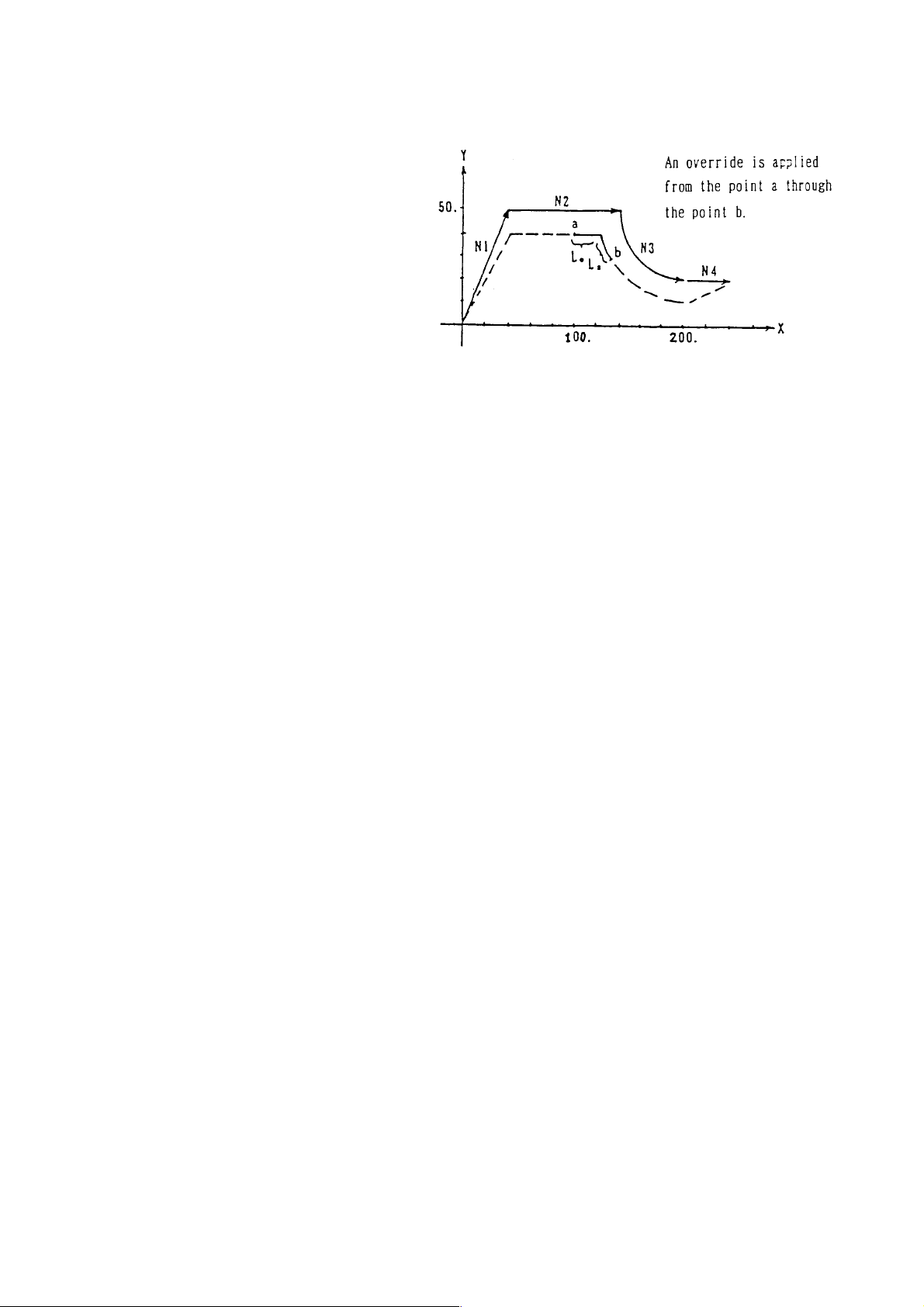

4.6 Automatic Corner Override Mode (062)

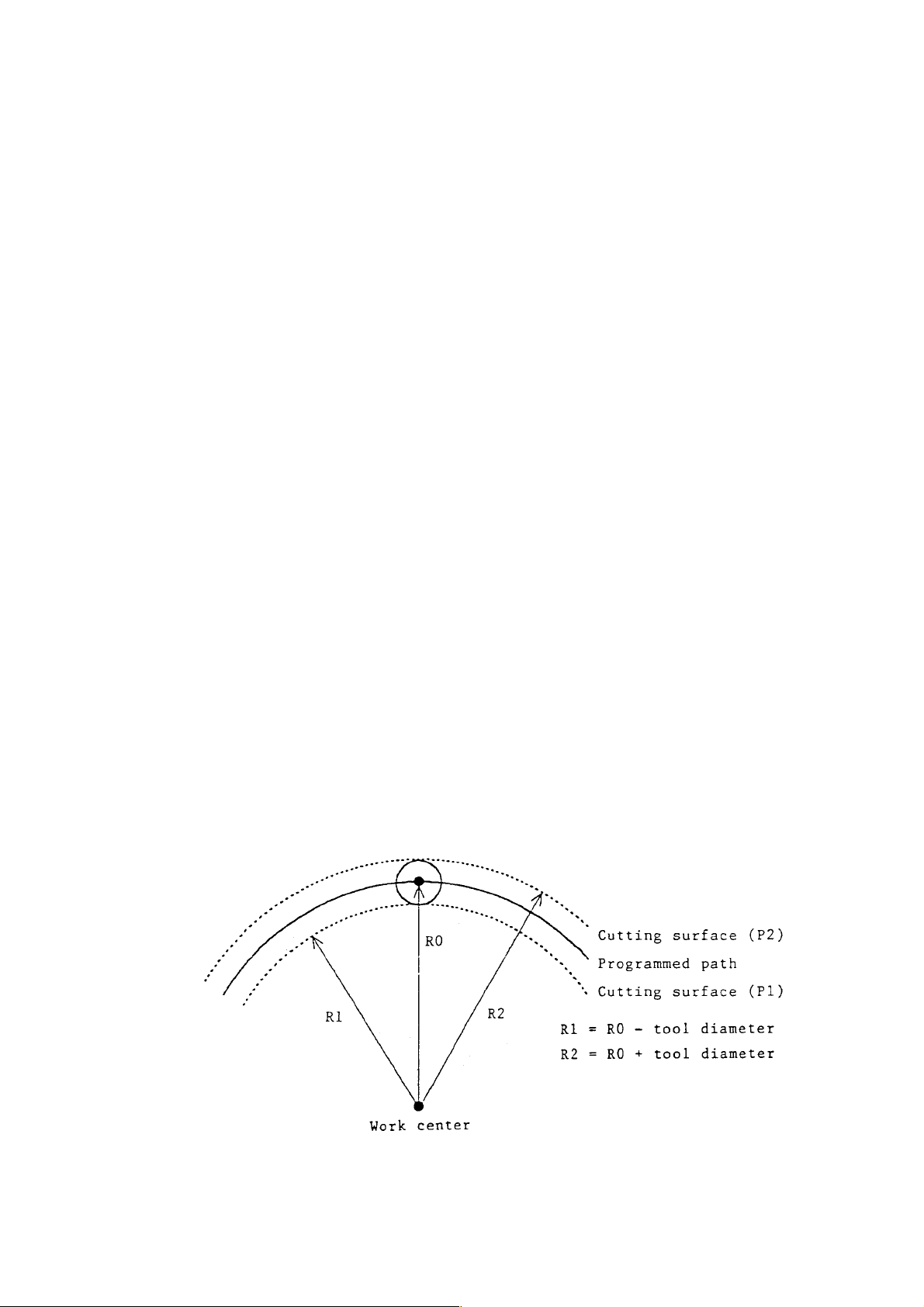

When cutter compensation is applied, since the tool center path is located inside the

program-specified path in the inner corner and inner arc area and a cutting load increases,

an override is applied automatically to the cutting feed ate to reduce the cutting load.

Once G62 is specified, it remains effective until G61, G63, or G64 is specified.

4.6.1 Command Format

G62 ;

4.6.2 Override Conditions

When the following conditions are met with respect to the blocks which are located before

and after the corner in the cutter compensation mode, an override is applied to cutting feed

automatically.

(a ) When the G code of Group 01 is G1, G02, or G03.

(b ) When an offset amount is not 0 in the cutter compensation offset mode.

(c ) When an offset is inside at the corner

(d ) When there is an axis in the offset plane.

(e ) When the G41 or G42 is not contained.

( f ) When an inner corner angle is smaller than a parameter set value. (θ)

(g ) When a corner start distance and a corner end distance are other than 0 and internal.

(Le, Ls)

.... Not available with

ΣΣ

Σ21L

ΣΣ

4.6.3 Override Amount

<

1 Automatic corner override 100 (%)

=

An actual cutting feed rate is as follows.

F × Automatic corner override × Cutting feed rate override

where; θ : Inner criterion angle

Le : Start distance

Ls : End distance

An override is applied to cutting feed

from the point a through the point b.

<

=

4 - 6

Page 57

4.6.4 Sample Program

N1 G62 G42 G00 U40. V50. ;

N2 G01 U100. F200 ;

N3 G03 U60. V-30. R30. ;

N4 G64 G40 G00 U40. ;

4.6.5 Cautions

(1) When a block not shifting has been specified between two blocks subject to automatic

corner override, tool diameter compensation is supplied while automatic corner

override is not.

4.6.6 Associated Parameters

No.1711 Inner criterion angle of automatic corner override (θ : deg.)

No.1712 Override of automatic corner override (%)

No.1713 Start distance (Le) of automatic corner override

No.1714 End distance (Ls) of automatic corner override

4 - 7

Page 58

4.7 Tapping Mode (G63)

The control state of the NC unit is as follows until G61, G62, or G64 is specified after G63 is

specified.

(1) Cutting feed rate override fixed at 100 %

(2) Spindle override fixed at 100 %

(3) Single block disabled

(4) Dry run disabled

(5) Feed hold disabled

(6) Decelerated stop disabled at the joint of the blocks (imposition check disabled)

(7) Tapping mode signal output

The G63 mode is effective until G61, G62, or G64 is specified.

4.7.1 Command Format

G63 ;

4.7.2 Sample Program

N1 G63 G01 X10. F200 ;

N2 Z0 ;

N3 X20. ;

N4 Z-5. ; Tapping mode effective blocks.

N5 X30. ;

N6 Z-10. ;

N7 G64 X40. ;

4.7.3 Cautions

(1) By parameter setting, you can invalidate dry run disabled.

4.7.4 Associated Parameters

No.1401, #5= 0 Enables dry run during thread cutting and tapping.

= 1 Disables dry run during thread cutting and tapping.

4 - 8

Page 59

4.8 Cutting Mode (G64)

Until G61, G62, or G63 is specified after G64 was specified, the next block is executed

continuously without decelerating to a stop between the blocks.

The G64 mode is effective until G61, G62, or G63 is specified.

When cutting is performed in the G64 mode, the corner may be rounded at the time of

cutting feed.

4.8.1 Command Format

4.8.2 Sample Program

N1 G64 G01 X10. F200 ;

N2 Z0 ;

N3 X20. ;

N4 Z-5. ; Cutting mode effective blocks

N5 X30. ;

N6 Z-10. ;

N7 G61 X40. ;

4.8.3 Switching Into M Code

Through setting a parameter , you can specify Cutting mode by using M22 command

instead of using G64 command.

M22, as it is replaced by G64 inside NC for execution, is not output in Machine side. Also,

with M22 command, G61 to G63 modes are cancelled.

4.8.4 Associated Parameters

No.3409, #1 ON/OFF command system for Exact Stop mode is:

= 0 G61 (ON) / G64 (OFF)

= 1 G61 or M21 (ON) / G64 or M22 (OFF)

4.8.5 Cautions

(1) G64 is set in the reset state.

(2) A G00 command decelerates the machine to a stop regardless of the G64 mode.

4 - 9

Page 60

4.9 Multibuffer (G251)

During automatic operation, the number of blocks to be preread is as follows.

(1) During the automatic tool nose radius compensation enable mode (G143) → 4 blocks

(2) During cutter compensation (G41/G42 in the G145 mode) → Max. 4 blocks

(3) Others → 1 block

A multibuffer command prereads up to 12 blocks.

This function makes it possible to reduce a stop time between the blocks when executing

the program having very small continuous blocks.

4.9.1 Command Format

G251 P0 ; or G251 ; Multibuffer mode ON

G251 P1 ; Multibuffer mode ON

4.9.2 Sample Program

G251 ; Multibuffer mode ON

Prereads up to 12 blocks in this portion.

G251 P1 ; Multibuffer mode OFF

4.9.3 Cautions

(1) The macro statement is not included in the number of preread blocks.

(2) Specify the G251 command in an independent block.

(3) When the very small blocks are executed continuously, there will be no preread

blocks, making an execution time shorter than the processing time of one block.

(4) The blocks may not be preread even in the multibuffer mode ON state, depending on

the commands.

(Example) G10, G20, G21, G22, G23

G28, G30, G31, G53

M00, M01, M02, M30

Coordinate system setting by a T command

(5) The reset state can be turned to the multibuffer mode ON state by parameter setting.

4.9.4 Associated Parameters

No.3402, #6= 0 Multibuffer mode OFF at reset time

= 1 Multibuffer mode ON at reset time

4.9.5 Associated Alarms

No.130 There is an erroneous command in the block.

(#001) G251 is not an independent command.

4 - 10

Page 61

4.10 Acceleration/Deceleration Control

4.10.1 Automatic Acceleration/Deceleration

Acceleration/deceleration are automatically applied at the start and the end of shifting so

that the machine system is protected from shock.

Acceleration/deceleration include the following types:

[Linear type [Exponential type

acceleration/deceleration] acceleration/deceleration]

[Bell type