HITACHI WH 12DH, WR 12DH REPAIR GUIDE

MODEL WH 12DH, WR 12DH

1. REPAIR GUIDE

WARNING: Without fail, remove the Model EB 12B or EB 12H Battery from the main body before starting

repair or maintenance work. Because the tool is cordless, if the battery is left in and the

switch is activated inadvertently, the motor will start rotating unexpectedly, which could

cause serious injury.

1-1. Precautions in Disassembly and Reassembly

The [bold] and <bold> numbers correspond to the item numbers in the Parts List and the exploded assembly

diagram. ( [ ]: WH 12DH, < >: WR 12DH )

1-1-1. Disassembly

(1) Removal of the Hammer Case [6] <2> and the Inner Cover [21] <19>

Remove the four Tapping Screws D4 x 30 [5] <1> that connect the Hammer Case [6] <2> with the Housing

(A).(B) Set [28] <26>. Remove the Hammer Case [6] <2>, the Inner Cover [21] <19> and the Damper [22]

<20> together from the Housing (A).(B) Set [28] <26>.

(2) Removal of Housing (B)

Remove the seven Tapping Screws D4 x 20 [26] <24> from the main body to remove Housing (B).

(3) Remove the DC-Speed Control Switch [30] <28>, the Fin Ass'y [32] <30>, the Motor [23] [21], Grip (F) [33]

[31] and Grip (R) [37] <35> together. Remove the Pushing Button [31] <29> and the Strap [35] <33>.

(4) Disassembly of the switch ass'y

Remove the two Machine Screws M3 x 5 [29] <27> that secure the flag terminal and then disconnect the

internal wires (purple and black) of the Motor [23] <21> from the DC-Speed Control Switch [30] <28>.

Remove the S-Tight Screw D3.5 x 6 [36] <34> to remove the Fin Ass'y [32] <30> from the FET of the DCSpeed Control Switch .

(Note) Do not disconnect the three FET internal wires soldered to the DC-Speed Control Switch.

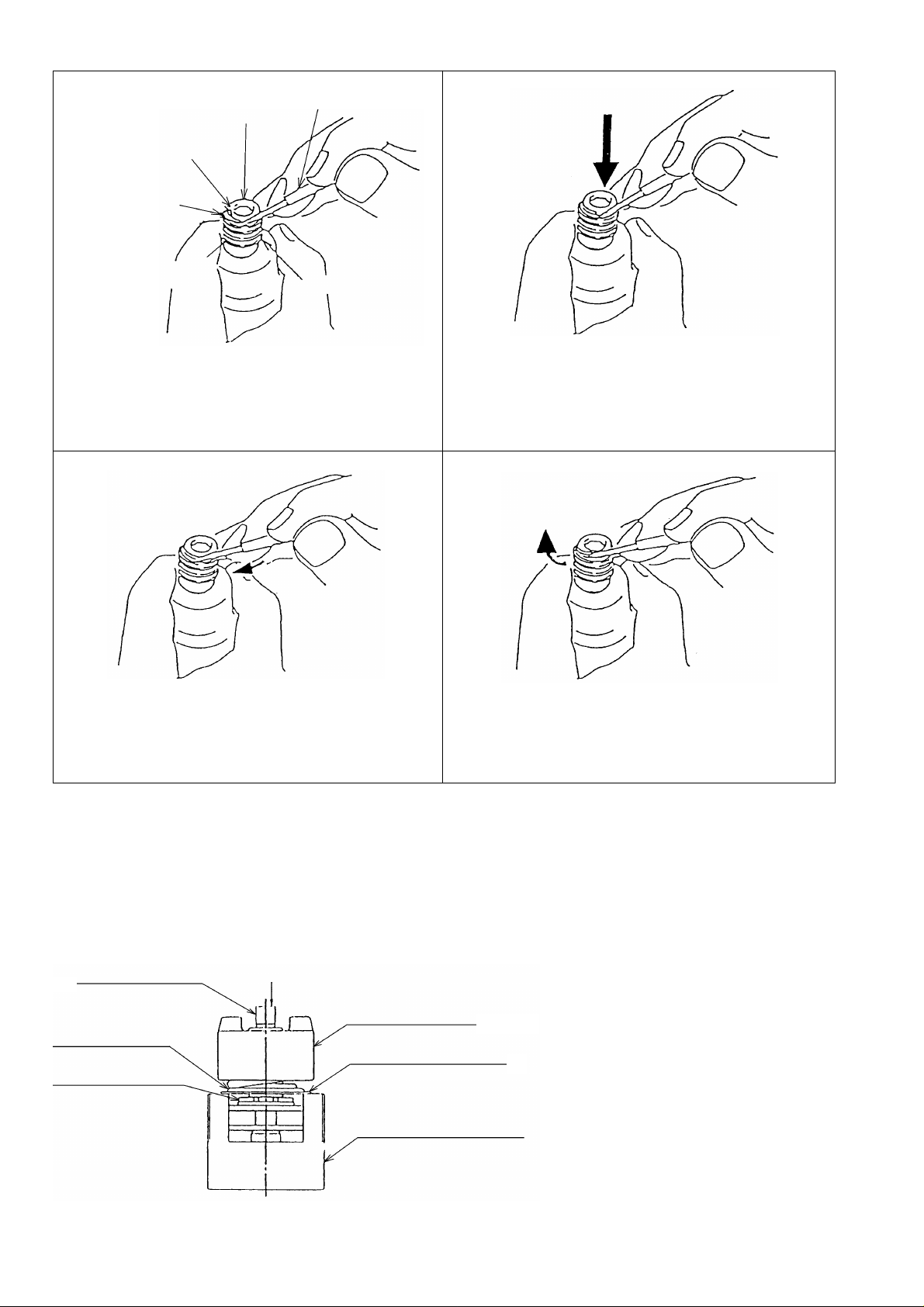

(5) Removal of the Guide Sleeve [4] (for WH 12DH only)

By following the procedure shown in Figs. 1-1 to 1-4, you can remove the Retaining Ring [1], Washer (D) [2],

the Guide Spring [3] and the Guide Sleeve [4] in this order. Be sure not to lose the Steel Ball D3.5 [7] in Anvil

(B) [8].

--- 1 ---

1

Retaining

Ring [1]

Washer (D) [2]

Gap of retaining ring

Anvil (B) [8]

Small flat-blade

screwdriver

Guide Sleeve [4]

2

Fig. 1-1

Hold the body and adjust gap of the retaining ring to

groove of the anvil (B), then insert a small flat-blade

screwdriver into the groove at an angle.

3

Fig. 1-3

Slide the screwdriver under one side of the gap of

the retaining ring.

Fig. 1-2

Press down the washer (D) with the screwdriver.

4

Fig. 1-4

Slowly raise the retaining ring using the end face of

the guide sleeve as a fulcrum.

Then slowly raise the other side of the retaining ring with the screwdriver until it is free. The Guide Sleeve [4] can

now be removed. Avoid quickly raising the retaining ring or it may fly out forcefully.

The retaining ring can also be easily removed by widening the gap of the retaining ring with the jig for retaining

ring and slowly raising the retaining ring with a small flat-blade screwdriver.

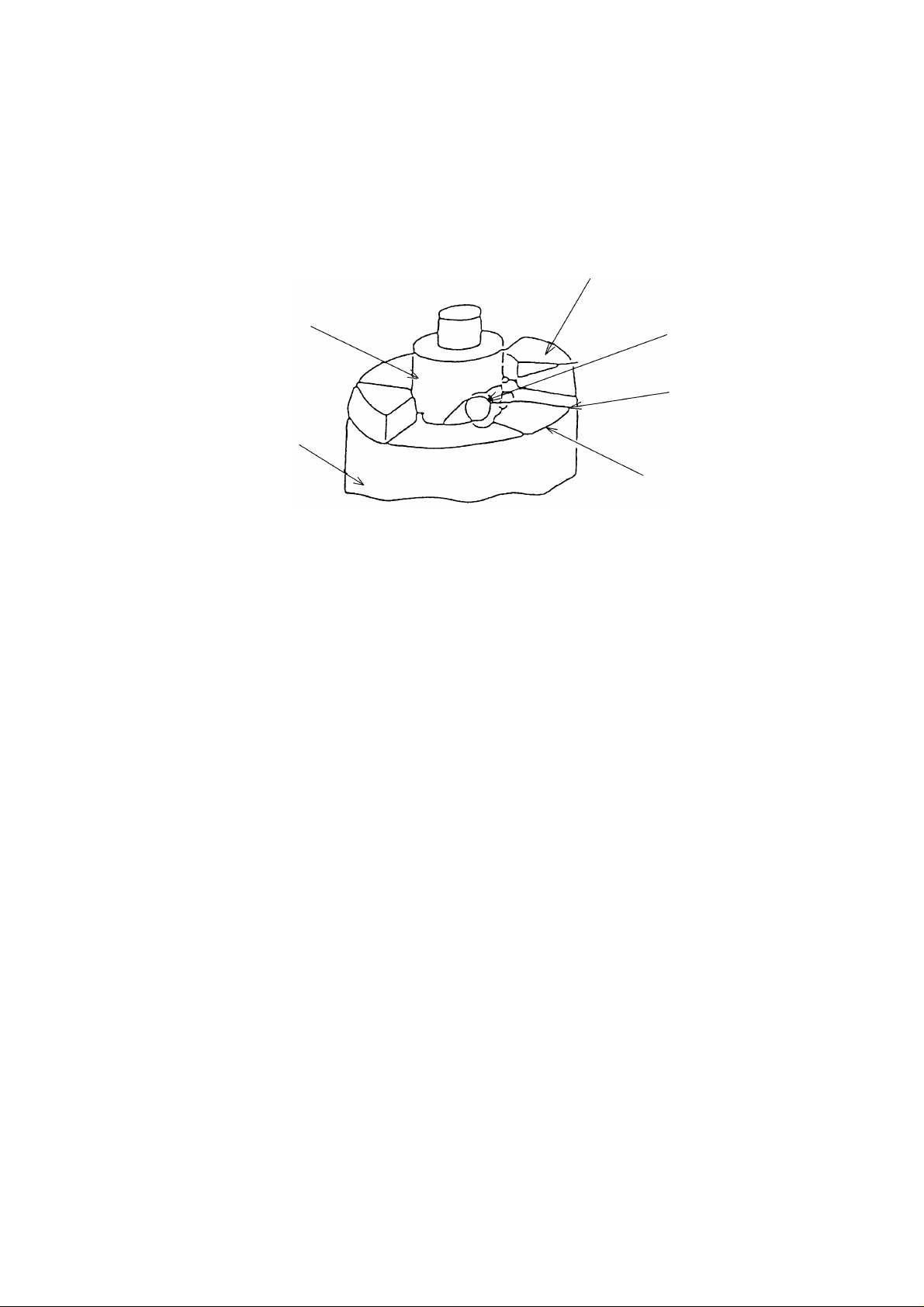

(6)

Spindle [15] <13>

Spring [12] <10>

Stopper [14] <12>

Push down.

Hammer [10] <7>

Washer (S) [13] <11>

J-297 Base for washer (S)

Fig. 2

Mount the hammer assembly onto the

J-297 base for washer (S). With a

hand press, push down the top of the

Spindle [15] <13> to compress the

Spring [12] <10>. In this position,

remove the Stopper [14] <12> with a

flat-blade screwdriver, then release

the hand press. (See Fig. 2.)

--- 2 ---

Remove the hammer assembly from the J-297 base for washer (S) and support the end surface of the Spindle

[15] <13>. With a hand press, push down either of the raised faces of the Hammer [10] <7> to compress the

Spring [12] <10>. In this position, extract the two Steel Balls D5.556 [9] <6> from the cam grooves of the

Spindle [15] <13> and the Hammer [10] <7> with a small flat-blade screwdriver or a similar tool. Then, slowly

release the hand press and lift the Hammer [10] <7> and Washer (S) [13] <11> together to extract them from

the Spindle [15] <13>. The Spring [12] <10> can then be removed.

Raised faces

of hammer

Spindle [15] <13>

Top of spindle cam

Steel Ball [9] <6>

Hammer [10] <7>

Steel ball

guide groove

Fig. 3

1-1-2. Reassembly

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special

attention should be given to the following items.

(1) Reassembly of Housing (A) assembly

(a) Be sure to follow the wiring diagram (Fig. 4-1) for proper wiring.

(b) When connecting the internal wires of the Motor [23] <21> to the DC-Speed Control Switch [30] <28>,

tightly fasten them with the Machine Screw M3 x 5 [29] <27> paying close attention to the direction of the

flag terminal (Fig. 4-2).

(c) Mount the Motor [23] <21> into Housing (A) so that the CB cap of the Motor [23] <21> and the rib for

preventing motor body from rotating fit in Housing (A).

(Note) Make sure that the internal wire (purple) is passed under the Motor so that it is not caught between

the Motor and Housing (A).

(d) Mount the DC-Speed Control Switch [30] <28> to Housing (A) so that the projection of the forwarding/

reversing lever at the top of the Switch is inserted into the U-shaped groove of the Pushing Button [31]

<29>. Secure the Fin Ass'y [32] <30> to the FET of the DC-Speed Control Switch [30] <28> with the S-

Tight Screw D3.5 x 6 [36] <34>.

(Note) Make sure that the three internal wires from the FET are passed above the DC-Speed Control

Switch [30] <28>.

(2) Reassembly of the Housing (A).(B) Set [28] <26>

Mount the Strap [35] <33>, Grip (F) [33] <31>, Grip (R) [37] <35> and Housing (B) to Housing (A), and secure

them with the seven Tapping Screws D4 x 20 [26] <24>.

--- 3 ---

Loading...

Loading...