TK No. 8104E

VK-S274/S274E

SERVICE MANUAL

VK-K274/K274E

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

COLOR & B/W VIDEO CAMERA

2001September

Digital Media Products Division,Tokai

Cautions

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts have special safety-related characteristics. These are often not evident from visual

inspection nor can the protection afforded by them necessarily be obtained by using replacement components rated for a

higher voltage, wattage, etc. Replacement parts which have these special safety characteristics are identified in this

Service Manual. Electrical components having such features are identified by marking with a on the schematics and

the parts list in this Service Manual. The use of a substitute replacement component which does not have the same safety

characteristics as the HITACHI recommended replacement one, shown in the parts list in this Service Manual, may create

shock, fire, or other hazards. Product safety is continuously under review and new instructions are issued from time to time.

For the latest information, always consult the current HITACHI Service Manual. A subscription to, or additional copies for,

HITACHI Service Manual may be obtained at a nominal charge from HITACHI SALES CORPORATION.

!

How to discriminate the "TYPE" identifications in the manual

The parts and circuits are identified by "TYPE" in this manual to discriminate the differences between models. The

TYPE numbers are the same as the model numbers. The table below shows how to read the type identifications.

TYPE identification Model name

TYPE S VK-S274

TYPE SE VK-S274E

TYPE K VK-K274

TYPE KE VK-K274E

Microsoft, MS, MS-DOS, Windows and Windows NT are registered trademarks of Microsoft Corporation.

Pentium and Celeron are registered trademarks of Intel Corporation.

Manufactured under license from Dolby Laboratories.

"Dolby" and double-D symbol are trademarks of Dolby Laboratories.

Confidential unpublished works. (C) 1992-1997 Dolby Laboratories Inc. All rights reserved.

IBM is registered trademarks of International Business Machines Corporations.

Other company names and product names listed are trademarks or brand names belonging to each company.

CAUTION- 1

Notes When Using Service Manual

The following shows the contents to be noted when using service manual:

1. Value units used in parts list

Certain symbols are indicated below for value units of

resistors, capacitors and coils in parts list. When you read

them note the following regular indications:

Parts

Resistor

Capacitor

Coil

Indication in list Regular indication

...........................................

KOHM

................................................

UF

................................................

PF

................................................

UH

...............................................

MH

2. Values in schematic diagrams

The values, dielectric strength (power capacitance) and

tolerances of the resistors (excluding variable resistors)

and capacitors are indicated in the schematic diagrams

using abbreviations.

[Resistors]

Item

Value

Tolerance

Power

capacitance

Indication

No indication

...................................................

K

..................................................

M

No indication

(All tolerances other than ±5% are

indicated in schematic diagrams)

No indication

(1/16W for leadless resistors without

indication)

All capacitances other than the above

are indicated in schematic diagrams.

...................................

.............................

............................

±5%

1/8W

k

M

k

µF

pF

µH

mH

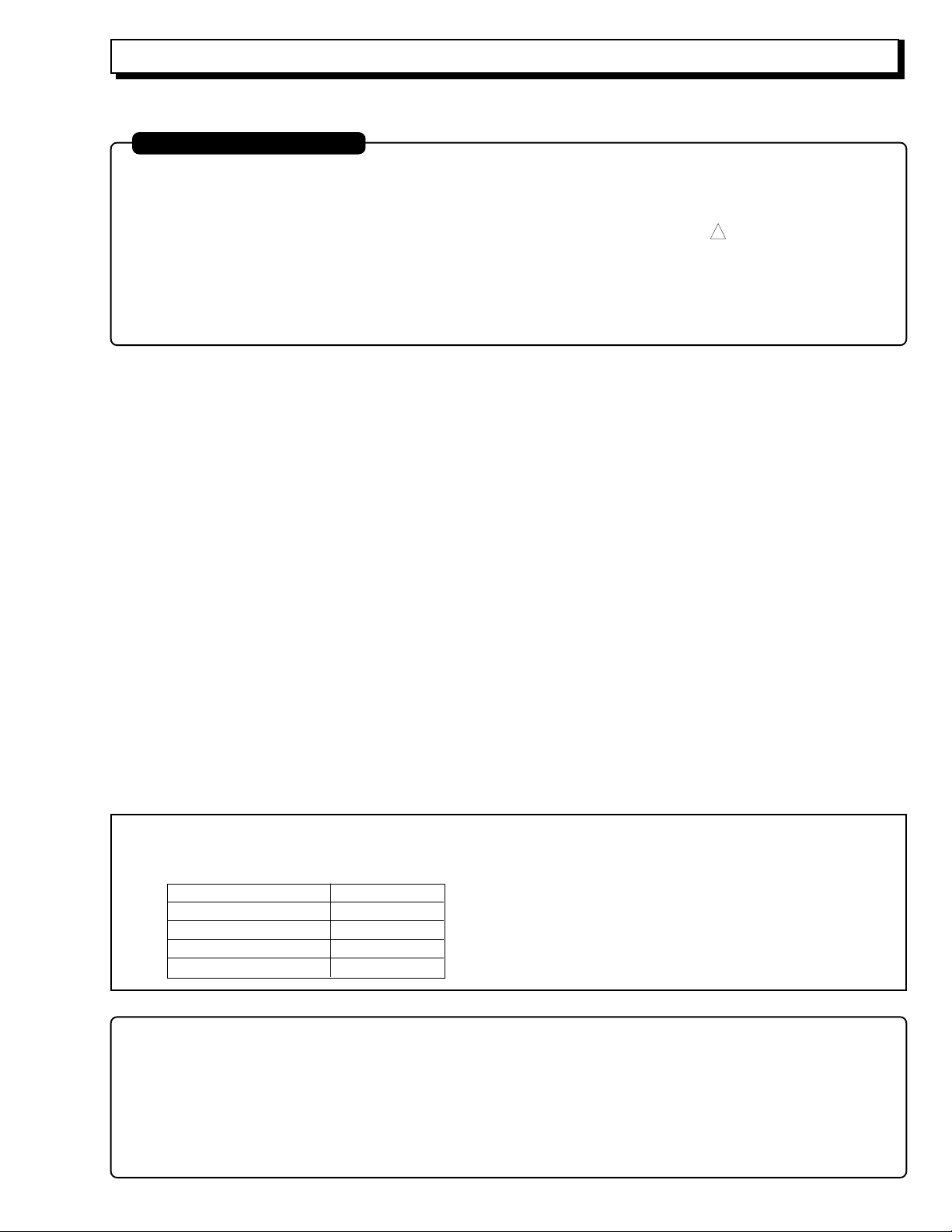

3. Identifications of sides A/B in

circuit board diagrams

1) Board having a pattern on one side and parts on both

sides.

Side A: Shows discrete parts, viewed from the pattern

side.

Side B: Shows leadless parts, viewed from the

pattern side.

2) Board having patterns on both sides and parts on

both sides.

Side A: Shows parts and patterns which can be seen

when the case is opened.

Side B: Shows parts and the pattern on the back of

side A.

4. Table for indexing locations of parts

This table shows locations of each part on circuit board

diagrams. The locations are indicated using the guide

scales on the external lines of diagrams.

1) One diagram indicated for each board

Symbol

No.

IC

IC1201

Circuit No.

2) Two diagrams indicated for each board

Parts

Location

Type of part

2 A

Zone "A" on board diagram

Zone "2" on board diagram

[Capacitors]

Item

Value

Dielectric

strength

[Coils]

Item

Value

CAUTION- 2

Indication

No indication

...................................................

P

No indication

(All dielectric strengths other than 50V

are indicated in schematic diagrams)

Indication

....................................................

µ

..................................................

m

.................................

..............................

µF

pF

50V

µH

mH

Symbol

No.

IC

IC1201

Circuit No.

Parts

Location

A - 2 A

A: Shows side A

B: Shows side B

Type of

part

Zone "A" on board

diagram

Zone "2" on board

diagram

Contents

CHAPTER 1 GENERAL INFORMATION

1. Specifications

2. Comparison with Previous Model

2.1 Comparison of Specifications

2.2 Comparison of ICs

.........................................................

..........................

.........................

..........................................

1-1

1-2

1-2

1-2

CHAPTER 2 DISASSEMBLY

1. Procedure

..............................................................

2-1

CHAPTER 3 ELECTRIC CIRCUIT

ADJUSTMENT

1. Test Equipment/Jigs Necessary for Adjustment

1.1 List of Equipment and Jigs

1.2 List of Charts for Adjustment

1.3 Test Equipment, etc.

2. Before Stating Adjustment

2.1 Connections for Adjustment

2.2 Notes

2.3 Setting Test Equipment

3. List of Adjustment Items

4. Starting Adjustment Program (SMAP)

5. Data Initilize Procedure

5.1 Data Initilize

6. Electronic Volume Adjustment Procedure

6.1 CDS Sampling Pulse Adjustment

7. Camera Adjustment (Adjustment) Procedure

7.1 Auto Iris Control Adjustment

7.2 Matrix Adjustment [For TYPE S/SE]

7.3 White Balance Adjustment [For TYPE S/SE]..3-9

7.4 Chroma Gain Adjustment [For TYPE S/SE]

8. Autofocus Adjustment Procedure

8.1 Zoom/Focus Tracking Adjustment

8.2 AF Noise Level Adjustment

8.3 Check of Zoom Trace

9. Spot Noise Adjustment Procedure

9.1 Spot noise Adjustment

10. Error Messages

10.1 Error massage of Electronic Volume and

10.2 Error massage of Autofocus Adjustment

10.3 Error massage of Spot Noise Adjustment

10.4 Troubleshooting of Autofocus

(1) No zoom and focus operation

(2) No focus lens operation

(3) No zoom operation

(4) No autofocus operation

(5) Subject is greatly out-of-focus

...............................................................

..........................................

.....................................................

......................................................

Camera Adjustment

when zoomed

................................................

..............................

...........................

.......................................

.....................................

............................

...................................

.........................................

...................

...................

...........................

..........................

..................

.............................

......................................

.........................

....................................

........................................

.........................

.......................

................................

.......................................

.................................

....

.............

........

...............

....

.......

......

3-1

3-1

3-1

3-1

3-2

3-2

3-2

3-3

3-4

3-5

3-6

3-6

3-7

3-7

3-8

3-8

3-8

3-10

3-11

3-11

3-12

3-12

3-13

3-13

3-14

3-14

3-15

3-15

3-16

3-16

3-18

3-19

3-20

3-21

CHAPTER 4 EXPLODED VIEW

1. Exploded View

.......................................................

CHAPTER 5 REPLACEMENT

PARTS LIST

1. Mechanical Parts List

2. Electrical Parts List

.............................................

................................................

CHAPTER 6 SCHEMATIC, CIRCUIT

BOARD AND BLOCK

DIAGRAMS/MICROPRO

CESSOR PIN FUNCTION

TABLES

Schematic Diagrams

Connection Diagram

Waveforms

Sensor [SP]

Process [PC] (For Display)

Process [PC] (For Printing) <A-a>

Process [PC] (For Printing) <A-b>

Switching Regulator [CSR]

...................................................................

..................................................................

Circuit Board Diagrams

PC -Side A/B-

Identification of Parts Location

SP -Side A/B-

Identification of Parts Location

CSR -Side A/B-

Identification of Parts Location

Block Diagrams

Overall

.........................................................................

Microprocessor Pin Function Tables

Digital Microprocessor (IC1201: D-µP)

....................................................

..........................................

...............................

...............................

..........................................

..............................................................

...............................

...............................................................

...............................

............................................................

...............................

........................

4-1

5-1

5-2

6-1

6-1

6-2

6-3

6-4

6-5

6-6

6-9

6-7

6-10

6-7

6-10

6-8

6-11

6-12

CONTENTS-1

CHAPTER 1 GENERAL INFORMATION

1. Specifications

Note: The specifications are subject to change for improvement without notice.

Signal VK-S274: NTSC Format

VK-S274E: PAL Format

VK-K274: EIA Format

VK-K274E: CCIR Format

Scanning System 2:1 Interlaced

Image Sensor 4.5 mm Dia. (1/4-inch) CCD Image Sensor

Number of Effective Pixels VK-S274/K274: 380 k [786 (H) × 494 (V)]

VK-S274E/K274E: 440 k [752 (H) × 582 (V)]

Total Number of Pixels VK-S274/K274: 410 k [811 (H) × 508 (V)]

VK-S274E/K274E: 470 k [795 (H) × 596 (V)]

Scanning Frequency VK-S274/K274: Horizontal 15.734 kHz

Vertical 59.94 Hz

VK-S274E/K274E: Horizontal 15.625 kHz

Vertical 50 Hz

Lens F1.6 to 3.8 (4 to 88 mm) 22 : 1 power zoom lens with autofocus

Video Signal Output VK-S274/S274E: Composite Signal 1.0 Vp-p

VK-K274/K274E: Y (Luminance) Signal 1.0 Vp-p

Minimum Required Illumination VK-S274/S274E: Standard 1.0 lx

DS shutter 0.1 lx

VK-K274/K274E: Standard 0.1 lx

DS shutter 0.01 lx

S/N Ratio 50 dB or more

Horizontal Resolution 470 TV Line or more

Operating Temperature 0 to 60 °C

Operating Humidity 10 to 90 %

Power Input DC 9 V ± 0.5 V

Power Consumption 3.3 W or less

Dimensions 50 (W) × 60 (H) × 89.5 (D) mm

Weight Approx. 225 g

1 - 1

2. Comparison with Previous Model

2.1 Comparison of Specifications

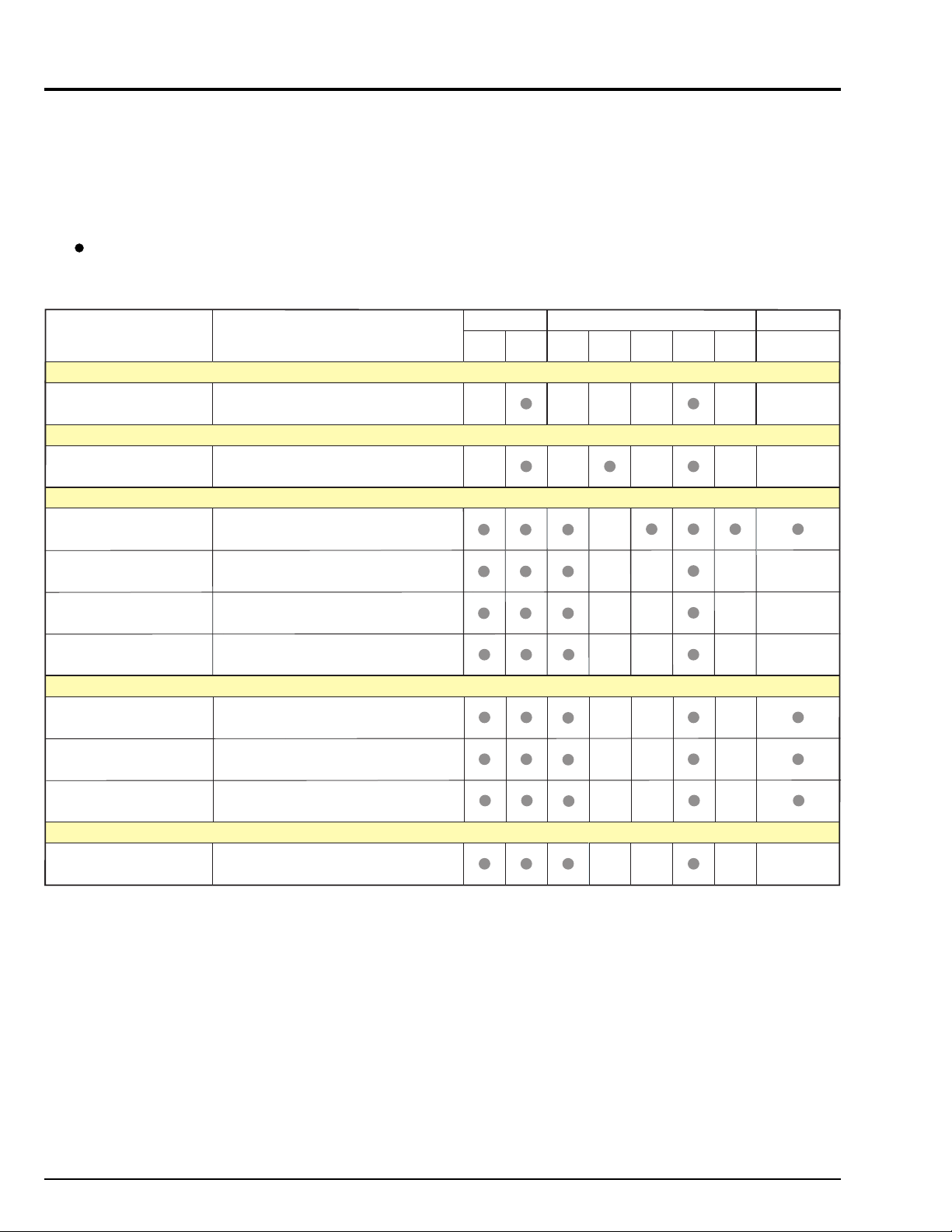

ITEM

Signal Format

Power Requirements

Power Consumption

Dimensions (W × H × D mm)

Weight

Lens

Operating Temperature/Humidity

Image Sensor

Number of Effective Pixels

Total Number of Pixels

Scanning System

Horizontal Scanning Frequency

Vertical Scanning Frequency

Sync Format

Video Signal Output

S/N Ratio

Horizontal Resolution

Minimum Required Illumination

(Standard)

IR cf Mode

VK-S274/VK-S274E

VK-K274/VK-K274E

VK-S274: NTSC

VK-S274E: PAL

VK-K274: EIA

VK-K274E: CCIR

DC 9 V

3.3 W (MAX)

50 × 60 × 89.5

Approx. 225 g

Power zoom × 22 (4.0 - 88.0 mm)

F 1.6

0 °C to 60 °C (Recommendation: 0 °C to 40 °C)

10 % to 90 %

4.5mm Dia. (1/4 inch) CCD

VK-S274/K274: 786 (H) × 494 (V)

VK-S274E/K274E: 752 (H) × 582 (V)

VK-S274/K274: 811 (H) × 508 (V)

VK-S274E/K274E: 795 (H) × 596 (V)

2 : 1 Interlaced

VK-S274/K274: 15.734 kHz

VK-S274E/K274E: 15.625 kHz

VK-S274/K274: 59.94 Hz

VK-S274E/K274E: 50 Hz

Internal/External

VK-S274/S274E:

Composite Signal 1.0 Vp-p

VK-K274/K274E:

Y (Luminance) Signal 1.0Vp-p

50 dB or more

470 TV Line or more

VK-S274/S274E: 1.0 lx

VK-K274/K274E: 0.1 lx

Not Provided

VK-S234/VK-S234E

VK-K234/VK-K234E

VK-S234: NTSC

VK-S234E: PAL

VK-K234: EIA

VK-K234E: CCIR

VK-S234/K234: 768 (H) × 494 (V)

VK-S234E/K274E: 752 (H) × 582 (V)

VK-S234/K234: 811 (H) × 508 (V)

VK-S234E/K234E: 795 (H) × 596 (V)

VK-S234/K234: 15.734 kHz

VK-S234E/K234E: 15.625 kHz

VK-S234/K234: 59.94 Hz

VK-S234E/K324E: 50 Hz

VK-S234/S234E:

Composite Signal 1.0 Vp-p

VK-K234/K234E:

Y (Luminance) Signal 1.0Vp-p

46 dB or more

VK-S234: 470 TV Line or more

VK-S234E: 460 TV Line or more

VK-K234/K234E: 500 TV Line or more

VK-S234/S234E: 3.0 lx

VK-K234/K234E: 0.1 lx

2.2 Comparison of ICs

ITEM

CCD Sensor

Sensor Drive (or Drive Pulse Gen.)

CDS AGC & A/D CONV.

Camera Digital Signal Processor (DSP)

DRAM

Inv.

Clock Generator (or Inv.)

Camera (or Digital) µP

EEPROM

Reset Pulse Gen.

Zoom Motor Drive

Focus Motor Drive

F.Det./Iris Drive

PWM

Y/C Mix. & Video Amp

Level Shift

VCO/Phase Compa.

FV Pulse Gen.

1 - 2

VK-S274/VK-S274E

VK-K274/VK-K274E

VK-S274: ICX278AK-L (IC1001)

VK-S274E: ICX279AK-L (IC1001)

VK-K274: ICX278AL-7 (IC1001)

VK-K274E: ICX279AL-7 (IC1001)

µPD16510GR (IC1002)

HD49323AF (IC1101)

HG73C053FE (IC1121)

MSM51V18165F (IC1122)

TC7SU04FU (IC1173)

TC7SHU04FUL (IC1174)

HD64F2238AFA13-S274 (IC1201)

X25097V1-2.7 (IC1202)

RN5VD27AA (IC1203)

TC7SH14FU (IC1204/IC1205)

TC7S08FU (IC1206)

MPC17AT85VM (IC1301)

MPC17AT85VM (IC1302)

µPD5023GS-147-GJG (IC1351)

TL1464IPT (IC1501)

BA7664FV (IC1601)

HD74HCT125T (IC1602)

74VHC4046MTCX (IC1603)

IDC-7S08 (IC1604)

VK-S234/VK-S234E

VK-K234/VK-K234E

VK-S234: ICX208AK-6 (IC1001)

VK-S234E: ICX209AK-6 (IC1001)

VK-K234: ICX208AL-6 (IC1001)

VK-K234E: ICX209AL-6 (IC1001)

TC7SHU04F (IC1173)

TC7SU04F (IC1174)

HD6432237M (IC1201)

RN5VT28AA (IC1203)

TC7SH14FU (IC1204/IC1205)

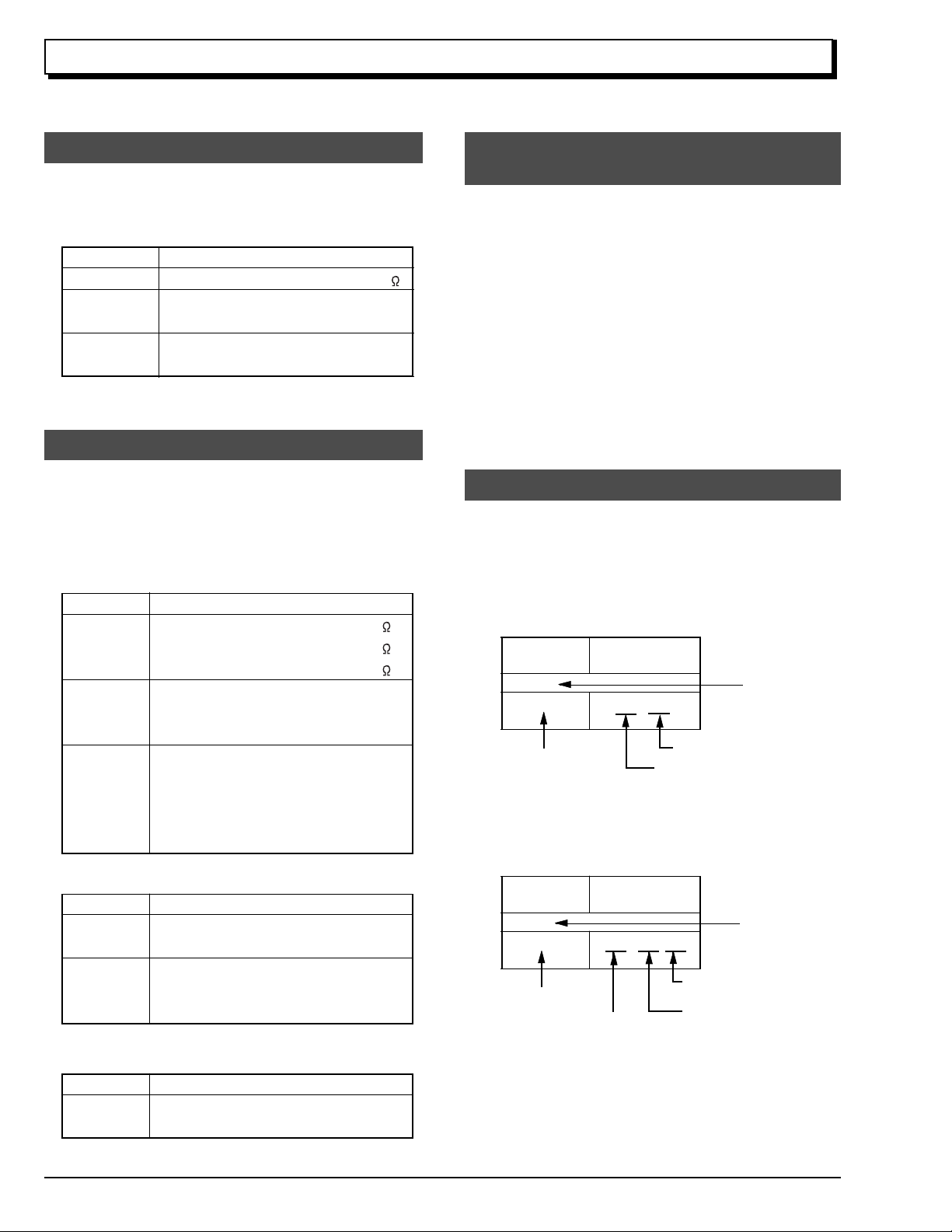

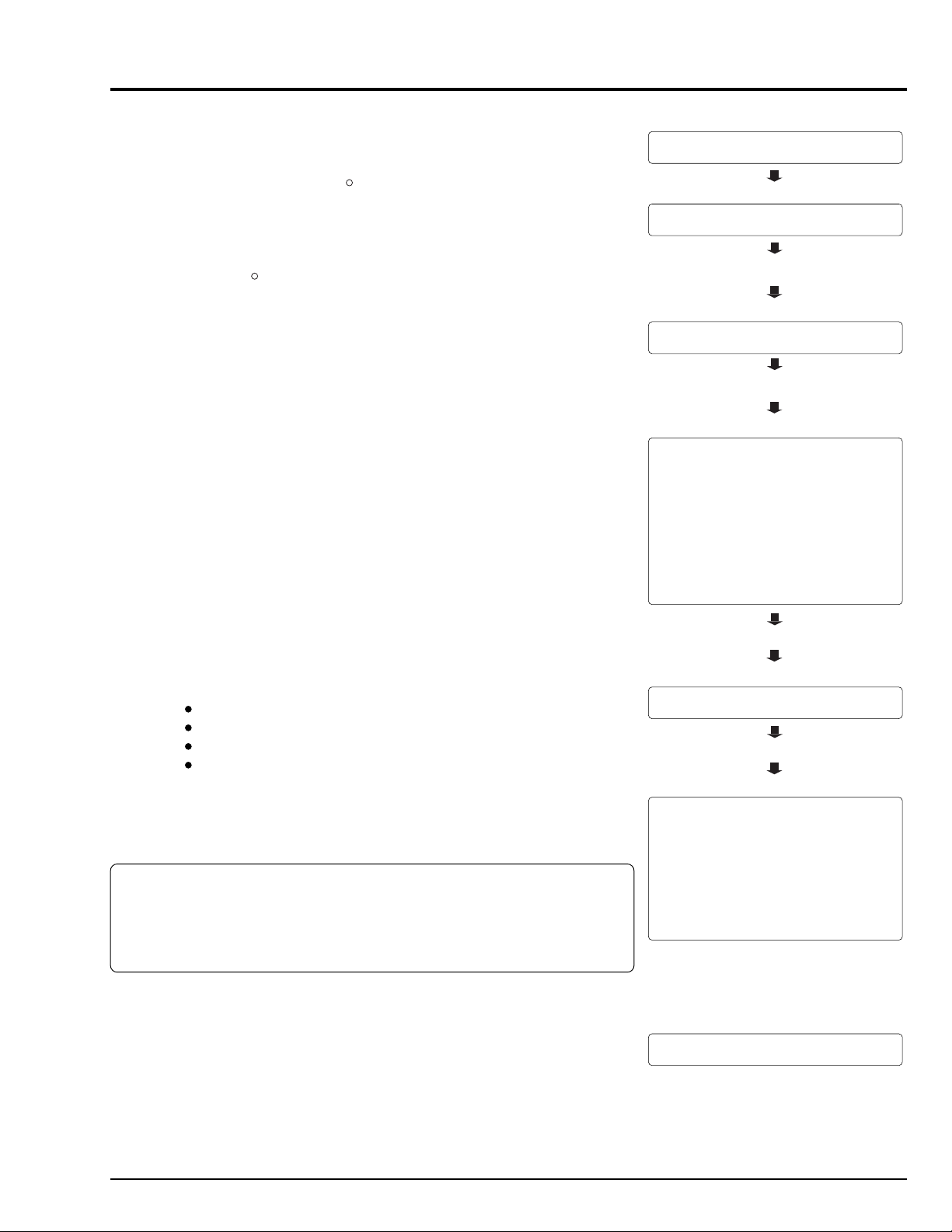

CHAPTER 2 DISASSEMBLY

1. Procedure

CHASSIS (R)

D

(5) REMOVE ONE SCREW

(4) DISCONNECT

FLAT CABLE

(*1)

(6) REMOVE THE

PC CIRCUIT

BOARD

(10) REMOVE

PC CIRCUIT

C

CRYSTAL

FILTER

LENS

BLOCK

BOARD

RUBBER

A

CCD

SENSOR

B

TWO

SCREWS

SP

CIRCUIT

BOARD

(9) REMOVE TWO

SCREWS

(*2)

CSR

CIRCUIT

BOARD

(11) REMOVE

A

TWO

SCREWS

(7) REMOVE

ONE

(8) REMOVE

THE CSR

CIRCUIT

BOARD

SCREW

CAMERA

CHASSIS

(12) REMOVE

(1)

(1)

(2)

(1) Release the lock of the connector

on the left and right.

(2) Pull out the flat cable

Fig. 2-1-2

ONE

SCREW

CHASSIS (L)

(1) REMOVE

TWO

SCREWS

Fig. 2-1-1

(2) REMOVE

TWO

SCREWS

B

D

C

(3) REMOVE

TWO

SCREWS

*1

: Do not the pull out the flat cable or touch the exposed

terminal at the connecting position with your bare

hands as it could cause a defective (1) and (2) shown

in Fig. 2-1-2.

*2

: When the SP circuit board is removed, the crystal filter

and rubber are also removed.

Be careful not to damege and lose them.

2 - 1

CHAPTER 3 ELECTRIC CIRCUIT ADJUSTMENT

1. Test Equipment/Jigs Necessary for Adjustment

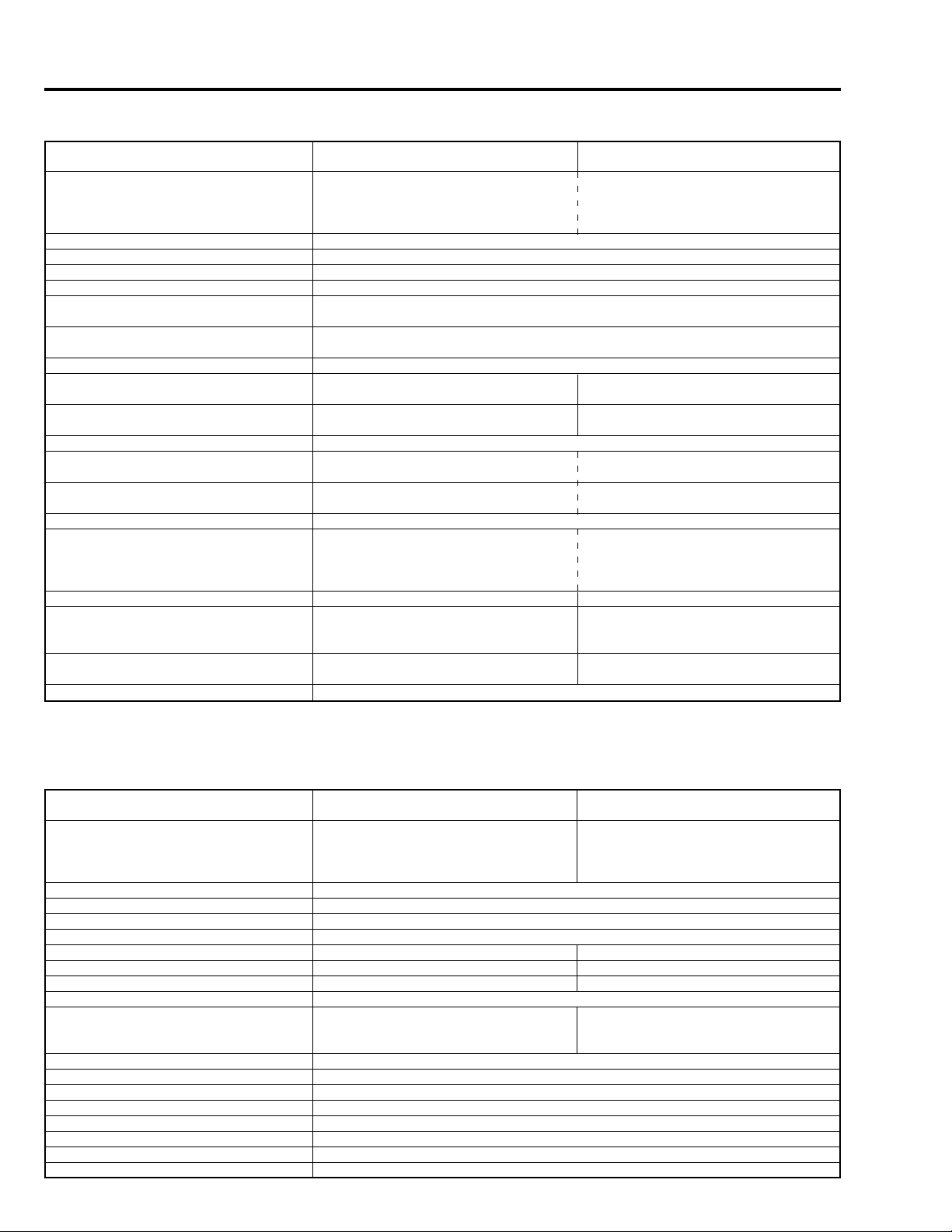

1.1 List of Equipment and Jigs

New

Adjutsment Floppy

Disk (

*1

)

Personal Computer (PC)

[Goods on the Market]

DSP Interface Connect Jig

No. 7069179

Personal Computer Cable

RS-232C (9 or 25 pins)

Straight Type

[Goods on the Market]

1.2 List of Charts for Adjustment

DSP-R Jig

No.7099448

*1

: The adjustment floppy disk is not for sale: It will be

supplied only when service maintenance contract

is concluded.

C12 Light Balancing Filter

No.7099369

Color Bar Chart Gray Scale Chart Backfocus Chart

1.3 Test Equipment, etc.

Color video monitor (color TV for monitoring)

Oscilloscope

Vectorscope [If not available, adjustment is still possible, but easier if this is used]

Digital voltmeter (DVM)

3100 K light box

DC power supply (9 V/3 A) [To power of video camera]

DC power supply (5 V/1 A) [To power of DSP-R jig]

3 - 1

2. Before Starting Adjustment

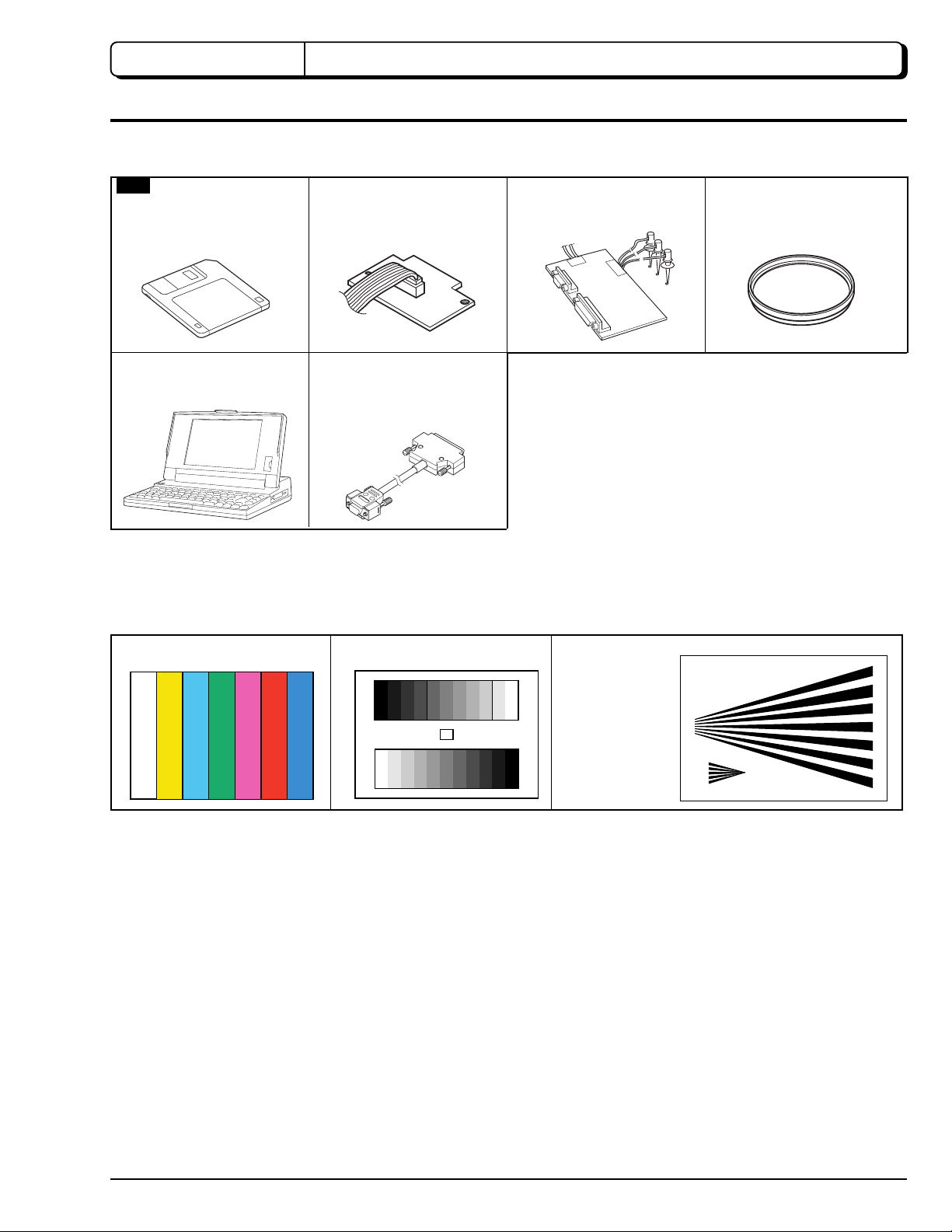

2.1 Connections for Adjustment

Connect the video camera to the test equipment and jigs as shown in Fig. 2-1.

LIGHT

BOX

DC POWER

SUPPLY

(9V/3A)

+

GND

DC POWER

SUPPLY

(5V/1A)

VIDEO CAMERA

PG1601

DSP INTERFACE CONNECT JIG

1

RD WHT

2

SD BRW

3

GND BRW

4

+B BRW

5

GND BRW

6

VIDEO BRW

7

GND(VIDEO) BRW

8

EX. FV BRW

9

GND BRW

YEL

RED

9PIN FLAT CABLE

(ACCESSORY)

9

1

2345

1

6

78

WHT

BLK

COLOR VIDEO

MONITOR

9

VIDEO IN

PERSONAL

COMPUTER

+

GND

BLK

DSP-R JIG

PERSONAL

COMPUTER

CABLE (RS-232C)

Fig. 2-1

2.2 Notes

1) All adjustments are performed using the adjustment program and personal computer (PC). The adjustment program is

subject to change without notice for improvements in functions and operability, and the actual instructions on PC screen

may be different from those in this manual: If so, follow the instructions on PC screen to proceed with adjustment.

2) Since this chapter uses the device with the highest performance among the models listed to explain adjustment, the actual

instructions on PC screen may be different from those in this manual, depending on whether some functions are provided

or not: If so, follow the instructions on PC screen to proceed with adjustment.

3) The adjustment program will not operate normally unless the video camera, PC and test equipment/jigs are all turned on.

3 - 2

4) Be sure to connect the video output of video camera to a color video monitor (terminate the video output with 75 ohm:

If the video output is not connected to the monitor (and if it is not terminated with 75 ohm), the output video signal level

cannot be measured correctly.

5) Use light box that does not flicker and whose color temperature is controlled, for adjustment. If an inappropriate light box is

used, precise adjustment will not be possible, and the adjustment program will not operate normally.

6) Take care with the following when pointing the video camera at a chart (light box):

Focus the chart correctly.

Set the chart (light box) 30-50 cm away from the lens surface, and avoid any effects from surrounding light (except for

a case where some designation is given).

Aim at the chart and let chart fill the screen (video period). (Except for a case where some designation is given.)

2.3 Setting Test Equipment

1) Set the switches, knobs and each mode of oscilloscope as follows for adjustment:

Probe: 10:1

TIME/DIV: 10 or 20 µs (except for a case where some designation is given)

VOLTS/DIV: Will vary depending on the measurement object (except for a case where some designation is

given)

Synchronization: Internal sync (except for a case where some designation is given)

AC/DC/GND: AC (except for a case where some designation is given)

Note: The names of switches, knobs, modes, etc. of oscilloscope may vary slightly depending on the manufacturer or

model. Since some oscilloscopes may have switches, etc. other than the above that must be set, see the instruction

manual of the particular oscilloscope for details.

3 - 3

3. List of Adjustment Items

The following table shows the adjustment items, their purposes, and whether or not check is required after replacing major

components.

The components shown in the table below are the minimum to be checked after replacing major components: If several

components have been replaced - or depending on the cause of a defect - more components may need to be checked.

: CHECK

Items Purpose Adjustment

Data Initialize

Data Initilize (*2)

Initilizing EEPROM.

Electric Volume

To suppress noise in the CCD sensor

CDS Sampling Pulse

output signal and maximize the signal

level.

Camera Adjustment (Adjustment)

Auto Iris

Matrix (*3)

White Balance (*3)

Chroma Gain (*3)

To set the iris control data.

To compensate for uneveness in the

chroma signal

To input the automatic white balance

control data.

To set the color satuation under the

reference color temperrature.

Auto Focus

Zoom/Focus Tracking

AF Noise Level

To set the out-of -focus correction level

during zooming.

To set the noise level in the autofocus

circuit.

Circuit Boards

PC

SP

(*1)

Electrical Parts

IC1001 IC1101 IC1201

IC1250

(*1)

IC1351

Other

Lens Block

Check of Zoom Trace

To check the autofocus adjustment.

Spot Noise

Spot Noise

*1: When replacing the PC circuit board (containing EEPROM) or EEPROM, be sure to perform all adjustments

only after "Data Initialize".

*2: Since all adjustments must be performed any time "Data Initialize" is done, do not perform it indiscriminately.

*3: For the color video camera (TYPE S/SE).

To correct spot noise.

3 - 4

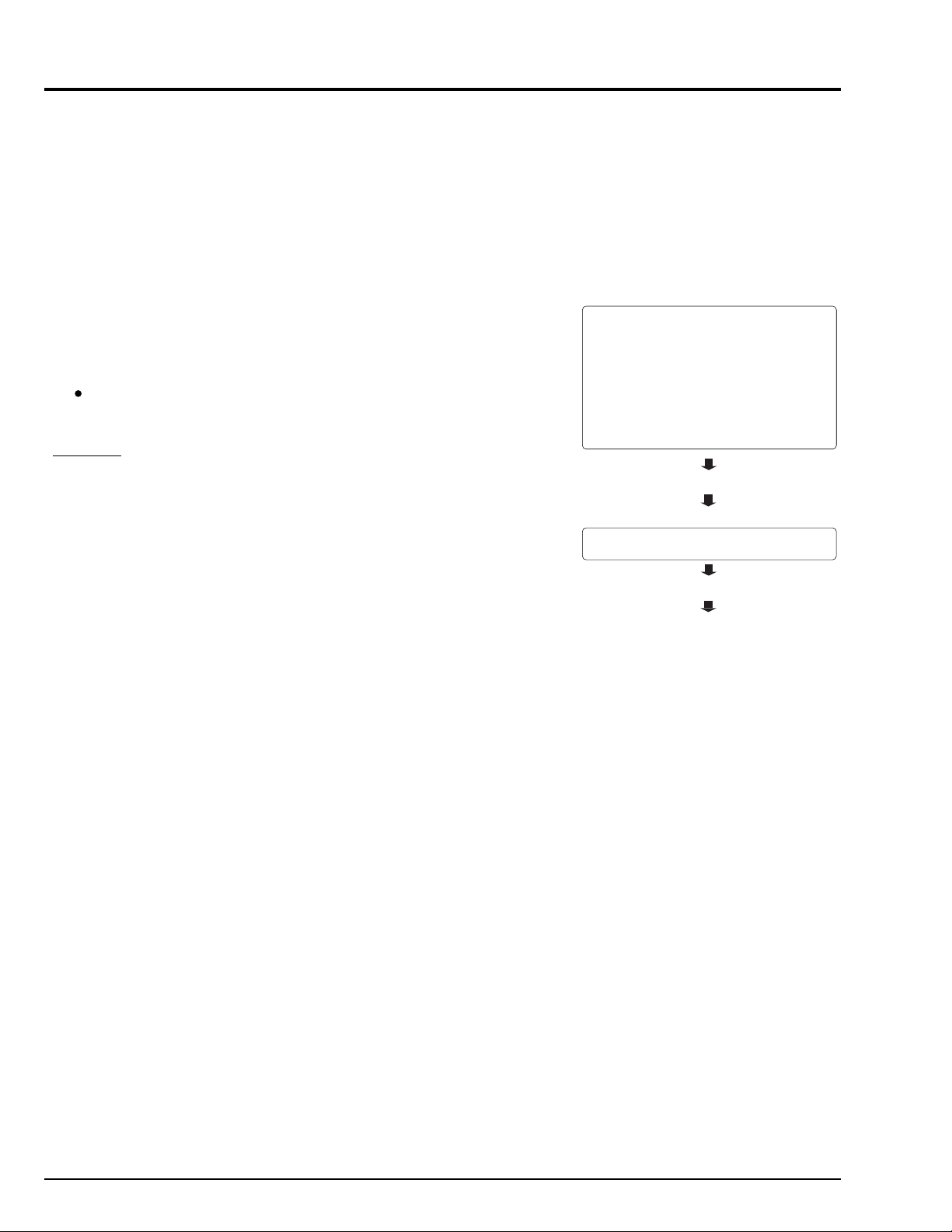

4. Starting Adjustment Program (SMAP)

C>A:

A>

C>A:

A>SMAP_IBM 1

***********************************************************

MODEL SELECT

***********************************************************

[1] ЧЧЧЧЧЧЧЧ

[2] ЧЧЧЧЧЧЧЧ

[3] ЧЧЧЧЧЧЧЧ

[4] ЧЧЧЧЧЧЧЧ

[5] ЧЧЧЧЧЧЧЧ

[P] NEXT SELECTION

[ESC] END

Please select the type of the set

Press [1] - [5] or [P] or [ESC]

Selected model is ЧЧЧЧЧЧЧЧ

Are you sure ? (Y/N)

CAN NOT FIND THE DATA FILE

**** PRESS ANY KEY ****

***********************************************************

MANUAL ADJUSTMENT PROGRAM

***********************************************************

[A] DATA INITIALIZE

[B] ELECTRIC VOLUME

[C] ADJUSTMENT

[D] AUTO FOCUS

[E] SPOT NOISE

[ESC] END

Please select [A] - [F] or [ESC]

C>

Note: If error message appears during adjustment, refer to "10. Error Messages".

1) Connect the video camera, DSP-R jig and PC as shown in Fig. 2-1, and supply

power to them. (*1)

2) Operate the PC to start MS-DOS . (*2)

R

3) Make sure that the adjustment floppy disk is write-protected.

4) Insert the adjustment floppy disk into the floppy disk drive of PC.

5) Use the PC keyboard to type A: and press Enter key. (*3) (See the MS-DOS

screen-1 and 2)

6) Type SMAP_IBM (space) 1 and press Enter key. (*4) (See the SMAP input

R

screen)

7) The SMAP will start: Make sure that the model select screen appears on the

PC display. (*5) (See the model select screen)

8) If the appropriate model is displayed on the model select screen, input the

number to PC. If the appropriate model name is not shown on the model select

screen, input P to PC until the model name appears. (*6)

9) The screen for verifying the model name will appear on PC display: If it is

correct, input Y to PC. If it is incorrect, input N and start over (from step 8).

10)Make sure that the main menu appears on PC display: If it does not appear,

check whether model selection (in step 8) is correct.

*1: If the connection of jig, etc. is inappropriate or power is not supplied, the

adjustment program will not start normally.

*2: For details on how to start MS-DOS, refer to the instruction manual of PC,

since this varies for each PC.

*3: The letter to be input is to designate the drive into which the adjustment

floppy disk has been inserted. If using a drive other than A, designate the

drive.

*4: The number to be input after a space is to designate the serial port no. of

PC. If the PC has two or more serial ports, and the DSP-R jig is connected

to a port other than serial port 1, input the serial port number.

*5: If the model select screen does not appear, make sure of the following:

Power is supplied to the video camera and DSP-R jig.

The designation of drive (in step 5) is correct.

The designation of serial port is correct.

The correct adjustment floppy disk has been correctly inserted.

*6: If an erroneous model name or number is selected, misoperation message

will appear on PC display: Press any key to restore the model select

screen.

MS-DOS screen-1

MS-DOS screen-2

Type SMAP_IBM 1.

SMAP input screen

Press Enter key.

Model select screen

Model select (Input the number).

Screen for verifying model name

Input Y.

Main menu

To terminate the adjustment program (SMAP):

Press the Esc key once to three times until the PC display returns from

each menu screen to the MS-DOS screen.

When the MS-DOS screen appears on PC display, turn off the video camera

and jig.

Referrence

Misoperation message

3 - 5

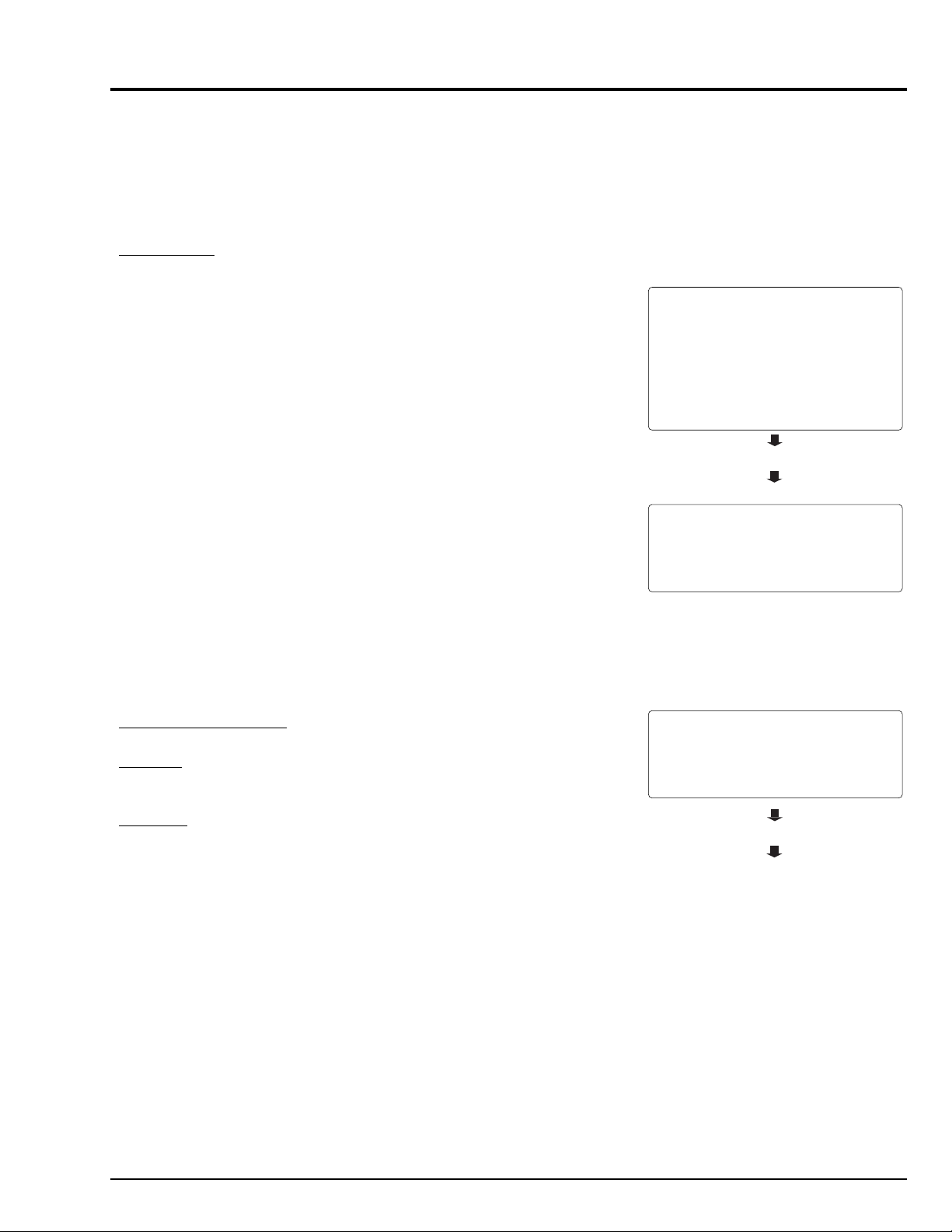

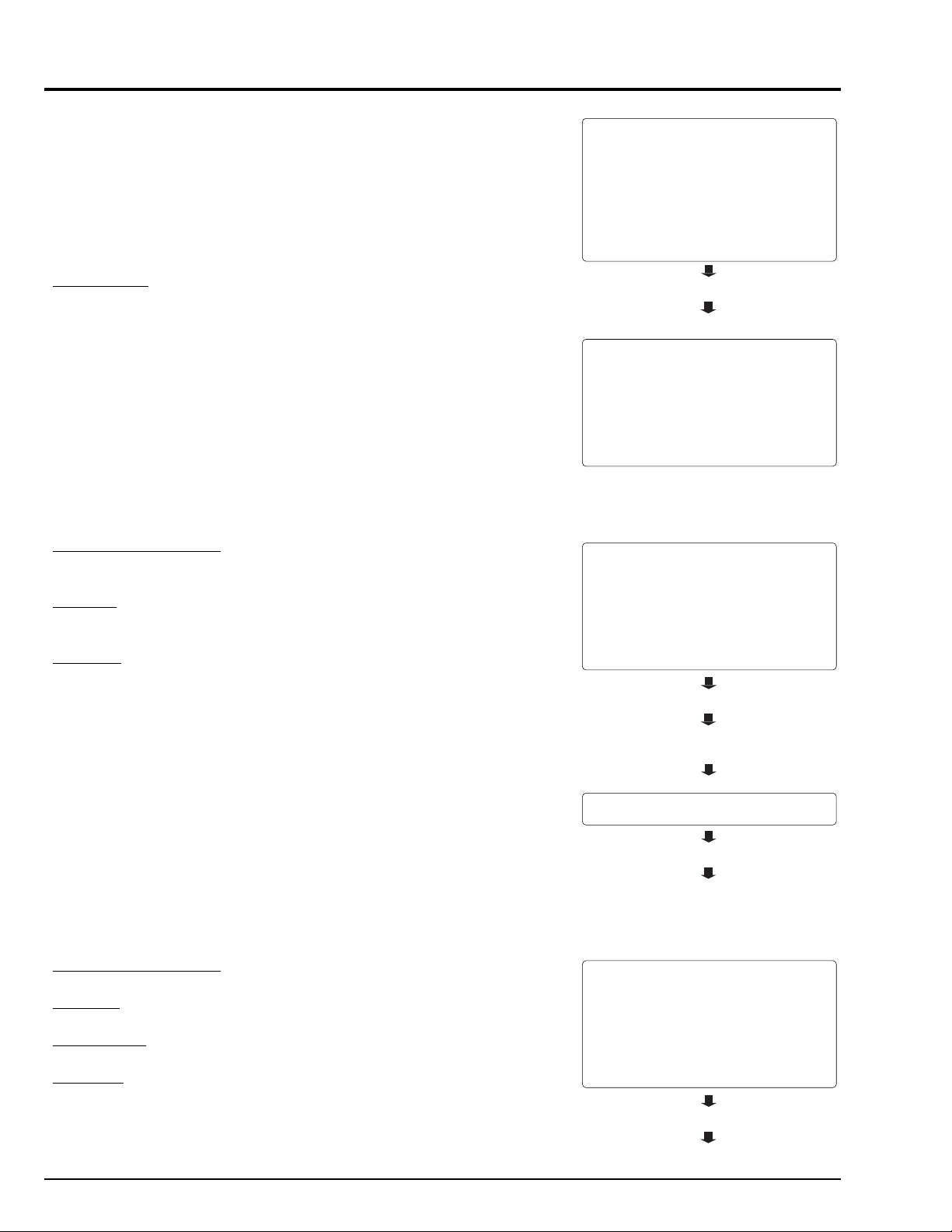

5. Data Initialize Procedure

The following explains the adjustment procedure using the adjustment program (SMAP), following the order of items on PC

display.

Refer to "4. Starting Adjustment Program (SMAP)" in advance, start SMAP and display the main menu on PC display.

In actual work, it is possible to adjust one item independently.

Note: If error message appears on PC display during adjustment, perform troubleshooting, referring to "10. Error Messages".

5.1 Data Initialize

This procedure initializes the data in EEPROM (including the adjustment data).

Any time you replace the PC circuit board (containing EEPROM) or EEPROM, be

sure to perform this procedure. [Generally, this procedure is not necessary after

replacing other circuit board (components).]

Important:

After completing this adjustment, be sure to perform all adjustment items as

follows.

Procedure:

1) Input A to PC on the main menu screen.

2) The screen for verifying the initialization will appear: Input Y to PC. (*1)

3) Follow the instructions on PC display thereafter.

*1: Entering N on the screen for verifying initialization will restore the

data main menu screen.

Main menu

***********************************************************

MANUAL ADJUSTMENT PROGRAM

***********************************************************

Screen for verifying initialization

[A] DATA INITIALIZE

[B] ELECTRIC VOLUME

[C] ADJUSTMENT

[D] AUTO FOCUS

[E] SPOT NOISE

[ESC] END

Please select [A] - [F] or [ESC]

Input A.

<< DATA WRITING >>

START TO SEND DATA. (Y/N)

Input Y.

Follow the instructions on PC display

thereafter.

3 - 6

***********************************************************

ELECTRIC VOLUME

***********************************************************

[1] CDS SAMPLING PULSE

[ESC] RETURN TO MAIN MENU

Please select [1] or [ESC]

***********************************************************

MANUAL ADJUSTMENT PROGRAM

***********************************************************

[A] DATA INITIALIZE

[B] ELECTRIC VOLUME

[C] ADJUSTMENT

[D] AUTO FOCUS

[E] SPOT NOISE

[ESC] END

Please select [A] - [F] or [ESC]

6. Electronic Volume Adjustment Procedure

***********************************************************

ELECTRIC VOLUME

***********************************************************

[1] CDS SAMPLING PULSE

[ESC] RETURN TO MAIN MENU

Please select [1] or [ESC]

The following explains the adjustment procedure using the adjustment program (SMAP), following the order of items on PC

display.

Refer to "4. Starting Adjustment Program (SMAP)" in advance, start SMAP and display the main menu on PC display.

In actual work, it is possible to adjust one item independently.

Note: If error message appears on PC display during adjustment, perform troubleshooting, referring to "10. Error Messages".

Before starting:

1) Input B to PC on the main menu screen to display the electronic volume

menu screen. (*1)

*1: Pressing the Esc key on the adjustment menu screen will restore the

main menu screen.

Main menu

Input B.

Electronic volume menu

6.1 CDS Sampling Pulse Adjustment

Incompleted Phenomenon:

Diagonal beats and horizontal noise occur.

Condition:

Leave the video camera for more than 2 minutes until the circuits are

stabilized after turing it on, then start adjustment.

Procedure:

1) Input 1 to PC on the adjustment menu screen.

2) Follow the instruction on PC display thereafter.

Electronic volume menu

Input 1.

Follow the instructions on PC display

thereafter.

3 - 7

7. Camera Adjustment (Adjustment) Procedure

The following explains the adjustment procedure using the adjustment program

(SMAP), following the order of items on PC display.

Refer to "4. Starting Adjustment Program (SMAP)" in advance, start SMAP and

display the main menu on PC display.

In actual work, it is possible to adjust one item independently.

Note: If error message appears on PC display during adjustment, perform

troubleshooting, referring to "10. Error Messages".

Before starting:

1) Input C to PC on the main menu screen to display the adjustment menu

screen.

2) Input to PC the appropriate adjustment number. (*1)

*1: Pressing the Esc key on the adjustment menu screen will restore

the main menu screen.

7.1 Auto Iris Control Adjustment

Incompleted Phenomenon:

The picture becomes too bright.

The picture becomes too dark.

Condition:

Set the zoom to wide end and point at the light box, without chart inserted, to

fill the screen.

Procedure:

1) Input 1 to PC on the adjustment menu screen.

2) Follow the instruction on PC display thereafter.

3) After the AIC (auto iris control) adjustment complete screen appears,

press any key to restore the adjustment menu screen.

4) Turn the video camera off, leave as is for at least 5 seconds, and then

turn it on again. (*1)

*1: When the video camera is turned on again, the SMAP may not

operate normally, and the following adjustments may not be possible.

If this happens, press the Esc key to restore the MS-DOS screen,

and then restart the SMAP.

Main menu

***********************************************************

MANUAL ADJUSTMENT PROGRAM

***********************************************************

Adjustment menu

***********************************************************

***********************************************************

Adjustment menu

***********************************************************

***********************************************************

Follow the instructions on PC display

thereafter.

AIC adjustment complete

[A] DATA INITIALIZE

[B] ELECTRIC VOLUME

[C] ADJUSTMENT

[D] AUTO FOCUS

[E] SPOT NOISE

[ESC] END

Please select [A] - [F] or [ESC]

Input C.

ADJUSTMENT

[1] AUTO IRIS CONTROL

[2] MATRIX

[3] WHITE BALANCE

[4] CHROMA GAIN

[ESC] RETURN TO MAIN MENU

Please select [1] - [3] or [ESC]

ADJUSTMENT

[1] AUTO IRIS CONTROL

[2] MATRIX

[3] WHITE BALANCE

[4] CHROMA GAIN

[ESC] RETURN TO MAIN MENU

Please select [1] - [3] or [ESC]

Input 1.

ADJUSTMENT FINISHED

PRESS ANY KEY

Press any key.

7.2 Matrix Adjustment [For TYPE S/SE] (Fig. 7-1)

Incompleted Phenomenon:

Color reproduction becomes defective.

Test Point:

Video Out (PG1601-6)

Equipment/Jig:

Oscilloscope

Conditions:

Point at a color bar chart.

3 - 8

Turn the video camera off.

Adjustment menu

***********************************************************

***********************************************************

ADJUSTMENT

[1] AUTO IRIS CONTROL

[2] MATRIX

[3] WHITE BALANCE

[4] CHROMA GAIN

[ESC] RETURN TO MAIN MENU

Please select [1] - [3] or [ESC]

Input 2.

Procedure:

<< ADJUSTMENT OF BLUE MATRIX >>

ROUGH ADJUSTMENT

FINE ADJUSTMENT

[Crt] + [U] UP

[Crt] + [D] DOWN

[ENTER] SAVE & RETURN TO MENU

[ESC] QUIT

[U] UP

[D] DOWN

<< ADJUSTMENT OF BLUE MATRIX >>

DATA WRITING INTO EEPROM

<< ADJUSTMENT OF BLUE MATRIX >>

ADJUSTMENT FINISHED

PRESS ANY KEY

***********************************************************

ADJUSTMENT

***********************************************************

[1] AUTO IRIS CONTROL

[2] MATRIX

[3] WHITE BALANCE

[4] CHROMA GAIN

[ESC] RETURN TO MAIN MENU

Please select [1] - [3] or [ESC]

<< ADJUSTMENT OF WHITE BALANCE >>

ADJUSTMENT FINISHED

PRESS ANY KEY

1) Input 2 to PC on the adjustment menu screen.

2) The matrix adjustment screen will appear.

3) Press the D key to minimize the yellow (YEL) level.

Press the U key so the ratio between yellow (YEL) and blue (BLU) levels

is 1:4.

Press the Ctrl key and hold it down, then press the U and D keys so the

ratio between yellow (YEL) and blue (BLU) levels is 1:4.

4) Press the Enter key: The PC display will switch from the matrix data write

screen to matrix adjustment complete screen.

5) Press any key to restore the adjustment menu screen.

Matrix adjustment

Set the ratio between yellow (YEL) and blue

(BLU) levels is 1:4.

YELLOW (YEL)

BLU : YEL

BLUE (BLU)

1 : 4

Fig. 7-1

7.3 White Balance Adjustment [For TYPE S/SE]

Incompleted Phenomenon:

Color of the subject is different from that of the picture.

A white subject is not seen as white.

Equipment/Jig:

C12 light balance filter

Conditions:

Attach a C12 light balance filter to lens.

Set the zoom to wide end, and point at a gray scale chart.

Procedure:

1) Input 3 to PC on the adjustment menu screen.

2) Follow the instructions on PC display thereafter.

3) After the white balance adjustment complete screen appears, press any

key to restore the adjustment menu screen.

Press Enter key.

Matrix data write

Matrix adjustment complete

Press any key.

Adjustment menu

Input 3.

Follow the instructions on PC display

thereafter.

White balance adjustment complete

Press any key.

3 - 9

7.4 Chroma Gain Adjustment [For TYPE S/SE] (Figs. 7-2, 7-3, 7-4)

Incompleted Phenomenon:

Color of the picture is denser than that of the subject.

Color of the picture is lighter than that of the subject.

Test Point:

Video Out (PG1601-6)

Equipment/Jig:

Oscilloscope or Vectorscope

C12 light balance filter

Condition:

Attach a C12 light balance filter to lens

Point the at a color bar chart.

Procedure:

1) Input 4 to PC on the adjustment menu screen.

2) The chroma gain adjustment screen will appear.

3)

When using an oscilloscope (Fig. 7-2):

Press the D or U key to set the red level on waveform to approx. 620

mVp-p.

Then, while holding down the Ctrl key, press the D or U key to set the

red level on waveform to approx. 620 mV ± 20 mVp-p.

When using a vectorscope (Figs. 7-3, 7-4):

Press the D or U key to set the red vector to approx. 220% of burst

vector.

Then, while holding down the Ctrl key, press the D or U key to set the

red vector to approx. 220% ± 5% of burst vector.

4) Press the Enter key: The PC display will switch from the chroma gain data

write screen to chroma gain adjustment complete screen.

5) Press any key to restore the adjustment menu screen.

Adjustment menu

***********************************************************

***********************************************************

Chroma gain adjustment

<< ADJUSTMENT OF CHROMA GAIN >>

[U] CHROMA GAIN UP

[D] CHROMA GAIN DOWN

[Crt] + [U] CHROMA GAIN UP

[Crt] + [D] CHROMA GAIN DOWN

[ENTER] SAVE & RETURN TO MENU

[ESC] QUIT

ADJUSTMENT

[1] AUTO IRIS CONTROL

[2] MATRIX

[3] WHITE BALANCE

[4] CHROMA GAIN

[ESC] RETURN TO MAIN MENU

Please select [1] - [3] or [ESC]

Input 4.

ROUGH ADJUSTMENT

FINE ADJUSTMENT

When using an oscilloscope

Set the red level on waveform to 620 mV

± 20 mVp-p.

When using a vectorscope

Set the red vector to 220 % ± 5 % of

burst vector.

Press Enter key.

RED

620 mV

± 20 mV

Fig. 7-2

RED

BURST

BURST

220 %

± 5 %

100 %

100 %

RED

Fig. 7-3 [For TYPE S] Fig. 7-4 [For TYPE SE]

220 %

± 5 %

Chroma gain data write

<< ADJUSTMENT OF CHROMA GAIN >>

DATA WRITING INTO EEPROM

Chroma gain adjustment complete

<< ADJUSTMENT OF CHROMA GAIN >>

ADJUSTMENT FINISHED

PRESS ANY KEY

Press any key.

3 - 10

***********************************************************

MANUAL ADJUSTMENT PROGRAM

***********************************************************

[A] DATA INITIALIZE

[B] ELECTRIC VOLUME

[C] ADJUSTMENT

[D] AUTO FOCUS

[E] SPOT NOISE

[ESC] END

Please select [A] - [F] or [ESC]

***********************************************************

AUTO FOCUS ADJUSTMENT

***********************************************************

[1] ADJUSTMENT OF ZOOM/FOCUS TRACKING

[2] ADJUSTMENT OF AF NOISE LEVEL

[3] CHECK OF ZOOM TRACE

[ESC] RETURN TO MENU

Please select [1] - [3] or [ESC]

***********************************************************

AUTO FOCUS ADJUSTMENT

***********************************************************

[1] ADJUSTMENT OF ZOOM/FOCUS TRACKING

[2] ADJUSTMENT OF AF NOISE LEVEL

[3] CHECK OF ZOOM TRACE

[ESC] RETURN TO MENU

Please select [1] - [3] or [ESC]

8. Autofocus Adjustment Procedure

The following explains the adjustment procedure using the adjustment program (SMAP), following the order of items on PC

display.

Refer to "4. Starting Adjustment Program (SMAP)" in advance, start SMAP and display the main menu on PC display.

In actual work, it is possible to adjust one item independently.

Note: If error message appears on PC display during adjustment, perform troubleshooting, referring to "10. Error Messages".

Before starting adjustment:

1) Input D to PC on the main menu screen to display the AF menu screen.

2) Input the appropriate adjustment number to PC. (*1)

*1: Pressing the Esc key on the AF menu screen will restore the main

menu screen.

8.1 Zoom/Focus Tracking Adjustment

Incompleted Phenomenon:

Focus is lost during zooming.

Condition:

Point at the backfocus chart, 1500 ± 5mm away from the lens surface.

Light the backfocus chart with 200 - 400 lx.

Caution when Adjustment:

1) Measure the distance between the chart and lens surface precisely.

2) Place the chart as parallel as possible to the lens surface.

3) The backfocus chart should always be at the center of the monitor screen

when the zoom is set to the wide-angle and telephoto ends.

4) The zoom trace adjustment procedure is completed within 2 minutes after

it is selected.

5) Do not place any obstruction between the lens and chart during

adjustment.

Procedure:

1) Input 1 to PC on the AF menu screen.

2) Follow the instructions on PC display thereafter.

Main menu

Input D.

AF menu

AF menu

Input 1.

Follow the instructions on PC display

thereafter.

3 - 11

8.2 AF Noise Level Adjustment

Incompleted Phenomenon:

It takes time until a subject is brought into focus.

Correct focus is not obtained.

Condition:

Point at a light box without a chart inserted at a distance of up to 10cm.

Caution when Adjustment:

1) Place the light box as parallel as possible to the lens surface.

2) The AF noise level adjustment procedure will be completed within thirty

seconds after it is selected.

Procedure:

1) Input 2 to PC on the AF menu screen.

2) Follow the instructions on PC display thereafter.

AF menu

***********************************************************

***********************************************************

[1] ADJUSTMENT OF ZOOM/FOCUS TRACKING

[2] ADJUSTMENT OF AF NOISE LEVEL

[3] CHECK OF ZOOM TRACE

[ESC] RETURN TO MENU

Follow the instructions on PC display

thereafter.

AUTO FOCUS ADJUSTMENT

Please select [1] - [3] or [ESC]

Input 2.

8.3 Check of Zoom Trace

Incompleted Phenomenon:

Focus is lost during zooming.

Condition:

Point at the backfocus chart, 1500 ± 5mm away from the lens surface.

Light the backfocus chart with 200 - 400 lx.

Caution when Adjustment:

1) Measure the distance between the chart and lens surface precisely.

2) Place the chart as parallel as possible to the lens surface.

3) The backfocus chart should always be at the center of the monitor screen

when the zoom is set to the wide-angle and telephoto ends.

4) Do not place any obstruction between the lens and chart during

adjustment.

Procedure:

1) Input 3 to PC on the AF menu screen.

2) Follow the instructions on PC display thereafter.

If error message appears, readjust the following items:

8.1 Zoom/Focus Tracking Adjustment

8.2 AF Noise Level Adjustment

AF menu

***********************************************************

***********************************************************

[1] ADJUSTMENT OF ZOOM/FOCUS TRACKING

[2] ADJUSTMENT OF AF NOISE LEVEL

[3] CHECK OF ZOOM TRACE

[ESC] RETURN TO MENU

Follow the instructions on PC display

thereafter.

AUTO FOCUS ADJUSTMENT

Please select [1] - [3] or [ESC]

Input 3.

3 - 12

<< DATA WRITING >>

START TO SEND DATA. (Y/N)

FINISHED WRITING DATA

PRESS ANY KEY

9. Spot Noise Adjustment Procedure

***********************************************************

MANUAL ADJUSTMENT PROGRAM

***********************************************************

[A] DATA INITIALIZE

[B] ELECTRIC VOLUME

[C] ADJUSTMENT

[D] AUTO FOCUS

[E] SPOT NOISE

[ESC] END

Please select [A] - [F] or [ESC]

The following explains the adjustment procedure using the adjustment program (SMAP), following the order of items on PC

display.

Refer to "4. Starting Adjustment Program (SMAP)" in advance, start SMAP and display the main menu on PC display.

In actual work, it is possible to adjust one item independently.

Note: If error message appears on PC display during adjustment, perform troubleshooting, referring to "10. Error Messages".

Important:

Spot noise refers to bright points that appear on the screen, which are caused by a defect in pixel of CCD image sensor.

Perform this adjustment after specified components have been replaced (see "List of Adjustment Items").

Perform this adjustment if spot noise occurs under abnormal usage conditions or after long-term use.

If spot noise still occurs after this adjustment is complete, the CCD image sensor may be defective.

Perform this adjustment after completing all other adjustments. (Perform this adjustment in normal video status.)

9.1 Spot Noise Adjustment

Incompleted Phenomenon:

Spot noise occurs under abnormal usage conditions or after long-term use.

Equipment:

Color video monitor (CRT type is desirable)

Condition:

Cap the lens (so that no light enters).

Procedure:

1) Input E to PC on the main menu screen.

2) Follow the instructions on PC display thereafter.

3) The screen for verifying writing of spot noise data will appear: Input Y. (*1)

4) When writing data is complete, the spot noise data write complete screen

will appear: Press any key to restore the main menu screen.

*1: Entering N on the screen for verifying writing of spot noise data will

restore the main menu screen.

Main menu

Input E.

Follow the instructions on PC display

thereafter.

Screen for verifying writing of spot noise data

Input Y.

Spot noise data write complete

3 - 13

10. Error Messages

A message may appear while you are adjusting the video camera. If a message appears, refer to the following table and take

appropriate corrective action.

10.1 Error Message of Electric Volume and Camera Adjustment

ERROR MESSAGE COUNTERMEASURE

ERROR OCCURRED. IRIS TROUBLE

PRESS ANY KEY

ERROR OCCURRED ON da× ADJUSTMENT

PRESS ANY KEY Defective soldering, damage to pattern, etc. in the above circuit.

D RANGE OVER. ERROR ON da× ADJUSTMENT

PRESS ANY KEY. Defective soldering, damage to pattern, etc. in theabove circuit.

ERROR OCCURRED ON da0 and

da1 ADJUSTMENT circuits.

PRESS ANY KEY Defective soldering, damage to pattern, etc. in the above circuits.

FILE NOT FOUND !!!!

PRESS ANY KEY Check the adjustment floppy disk and replace it if necessary.

FILE OPEN ERROR !!!!

PRESS ANY KEY Check the adjustment floppy disk and replace it if necessary.

ERROR OCCURRED ON C DUTY ADJUSTMENT

PRESS ANY KEY Defective soldering, damage to pattern, etc. in the above circuit.

ERROR OCCURRED ON FDET ADJUSTMENT

PRESS ANY KEY

ERROR OCCURRED. ZOOM DOES NOT WORK

PRESS ANY KEY

TOO BRIGHT

PRESS ANY KEY Move the camera further away from the light box.

TOO DARK

PRESS ANY KEY

D RANGE OVER ERROR ON HALL AMP

IRIS CANNOT OPEN ANY MORE

PRESS ANY KEY

STAURATION ERROR. TOO BRIGHT

PRESS ANY KEY Move the camera further away from the light box.

CAN'T ADJUST WHITE BALANCE

PLEASE RETRY

PRESS ANY KEY

Check whether or not power is supplied.

Check the values of the iris drive circuit.

Defective soldering, damage to pattern, etc. in the above circuit.

Check the iris block and replace it if necessary.

Check the values in the hall amp circuit.

Check the values in the hall amp circuit.

Check the values in the hall amp circuit and its peripheral

The adjustment program (file) cannot be found.

The adjustment program (file) does not start.

Check the values of the iris drive circuit.

Supply power again and re-adjust.

Check the values in the hall amp circuit.

Defective soldering, damage to pattern, etc. in the above circuit.

Supply power again and re-adjust.

The subject is too bright.

The subject is too dark.

Check the light box.

Move the camera closer to the light box.

Supply power again and re-adjust.

The subject is too dark.

Check the light box.

Move the camera closer to the light box.

Check the values in the hall amp circuit.

Defective soldering, damage to pattern, etc. in the above circuit.

The subject is too bright.

The subject is too bright or too dark.

Check the light box.

Move the camera closer to or away from the light box.

Supply power again and re-adjust.

3 - 14

10.2 Error Message of Autofocus Adjustment

ERROR MESSAGE COUNTERMEASURE

ERROR OCCURRED. ZOOM DOES NOT WORK

PRESS ANY KEY

TIME OUT ERROR ON FOCUS

TIME OUT ERROR ON ZOOM

TIME OUT ERROR ON AF STEP

AF LIMIT OVER

AF ERROR

TOO DARK

Supply power again and re-adjust.

Check the conditions of subject.

If this error message appears even when the adjustment is

performed 2 or 3 times, the autofocus circuit system is defective.

Refer to (1) of TROUBLESHOOTING OF AUTOFOCUS.

If this error message appears even when the adjustment is

performed 2 or 3 times, the autofocus circuit system is defective.

Refer to (2) of TROUBLESHOOTING OF AUTOFOCUS.

Check the conditions of subject.

If this error message appears even when the adjustment is

performed 2 or 3 times, the autofocus circuit system is defective.

Refer to (1) of TROUBLESHOOTING OF AUTOFOCUS.

Check the conditions of subject.

If this error message appears even when the adjustment is

performed 2 or 3 times, the autofocus circuit system is defective.

Refer to (2) of TROUBLESHOOTING OF AUTOFOCUS.

If this error message appears even when the adjustment is

performed 2 or 3 times, the autofocus circuit system is defective.

Refer to (1) of TROUBLESHOOTING OF AUTOFOCUS.

Insufficient lighting. Check the subject.

10.3 Error Message of Spot Noise Adjustment

ERROR MESSAGE COUNTERMEASURE

ERROR!!

SPOT NOISE COMPENSATION IS EEPROM.

STOPPED BY INITIAL DATA.

PLEASE CHECK THE EEPROM.

PRESS ANY KEY. Check the EEPROM, and if necessary, replace it.

ERROR!!

THRESHOLD DATA ERROR.

PLEASE CHECK THE EEPROM.

PRESS ANY KEY.

ERROR!!

THE SPOT NOISE IS TOO MANY. limit.

CAN'T COMPENSATE ANY MORE.

PRESS ANY KEY.

Spot noise compensation is inhibited by the data in the

Turn the power on again.

Data in the EEPROM is defective. (Initialize it.)

Turn the power on again.

Data in the EEPROM is defective. (Initialize it.)

Check the EEPROM, and if necessary, replace it.

The amount of spot noise that can be compensated reaches the

Turn the power on again.

Check the CCD image sensor, and if necessary, replace it.

3 - 15

3 - 16

1

Check the connections

of the lens flat cable.

TL1346:3V

TL1335:PULSE

Lens block faulty

IC1201 faulty.

R1215 faulty.

Q1201 faulty.

Check the 3V line

Correct the connections

of the cable.

NG

OK

OK

OK

OK

OK

NG

NG

NG

NG

2

IC1301-3:PULSE

IC1301-4:PULSE

Check IC1301

3

IC1201 faulty.

IC1201 faulty.

OK

NG

IC1301-30:PULSE

IC1201 faulty.

(1) NO ZOOM AND FOCUS OPERATION

10.4 Troubleshooting of Autofocus

This troubleshooting corresponds to "10.2 Error Messages of Autofocus Adjustment". If an error message appears during

autofocus adjustment, use this troubleshooting after referring to "10.2 Error Messages of Autofocus Adjustment".

TL1301:9V

Check IC1201 and

EEPROM

When power turned on:

TL1336:PULSE

TL1331-TL1334:PULSES

IC1301-2,10,29:5V

IC1301-12,20:9V

IC1301-28 (TL1311):

OK

OK

NG

OK

OK

PULSE

OK

2

NG

NG

OK

NG

NG

NG

L1301 faulty

1

Lens block faulty.

Check the 5V line

Check the +B line

IC1201 faulty

3

4

Check the connections

of the lens flat cable.

TL1346:3V

TL1344:PULSE

Lens block faulty.

IC1201 faulty.

R1214 faulty.

Q1201 faulty.

Check the 3V line

Correct the connections

of the flat cable.

NG

NG

NG

OK

OK

OK

When power turned on:

TL1345:PULSE

OK

TL1347-TL1350:PULSES

NG

IC1302-2,10,29:5V

OK

IC1302-12,20:9V

OK

IC1302-28 (TL1312):

PULSE

OK

IC1302-3:PULSE

OK

IC1302-30:PULSE

NG

OK

NG

NG

NG

NG

NG

4

Lens block faulty.

Check the 5V line

Check the +B line.

IC1201 faulty.

IC1201 faulty.

IC1201 faulty.

IC1302 faulty.

3 - 17

OK

3 - 18

1

OK

OK

OK

NG

NG

NG

Check the connections

of the lens flat cable

TL1346:3V

TL1344:PULSE

Lens block faulty.

IC1201 faulty.

R1214 faulty.

Q1201 faulty.

Check the 3V line

Correct the connections

of the flat cable.

(2) NO FOCUS LENS OPERATION

Does zoom operate

normally?

YES

When power turned on:

TL1336:PULSE

OK

TL1347-TL1350:PULSES

NG

IC1302-2,10,29:5V

OK

IC1302-12,20:9V

OK

IC1302-28 (TL1312):

PULSE

OK

IC1302-3:PULSE

NO

NG

OK

NG

NG

NG

NG

See "(1)No zoom and

focus operation."

1

Lens block faulty.

Check the 5V line

Check the +B line

IC1201 faulty.

IC1201 faulty.

IC1302-30:PULSE

IC1302 faulty.

OK

OK

OK

NG

IC1201 faulty.

(3)NO ZOOM OPERATION

1

Check the connections

of the lens flat cable.

TL1346:3V

TL1335:PULSE

Lens block faulty.

2

IC1301-3:PULSE

IC1301-4:PULSE

IC1301 faulty

Correct the connections

of the flat cable.

Check the 3V line

IC1201 faulty.

R1215 faulty.

Q1201 faulty.

IC1201 faulty.

IC1201 faulty.

NG

NG

NG

NG

NG

OK

OK

OK

OK

OK

IC1301-30:PULSE

IC1201 faulty.

NG

OK

Does focus operate

normally?

zoom switch unit.

Check IC1201 and

EEPROM

When power turned on:

TL1336:PULSE

TL1331-TL1334:PULSES

IC1301-2,10,29:5V

IC1301-12,20:9V

YES

OK

OK

NG

OK

NO

NGCheck the

NG

OK

NG

NG

See "(1) No zoom and

focus operation."

Zoom switch faulty.

1

Lens block faulty.

Check the 5V line

Check the +B line

IC1301-28:PULSE

3 - 19

2

OK

OK

NG

IC1201 faulty.

3 - 20

3

TL1346:3V

TL1344:PULSE

Lens block faulty.

IC1201 faulty.

R1214 faulty.

Q1201 faulty.

Check the 3V line

Correct the connections

of the flat cable.

NG

OK

NG

OK

NG

OK

Check the connections

of the lens flat cable.

1

Set the zoom to the

wide-angle end.

Point at the objects

from the infinity to

close-up ends.

Is there a point at

which focus is obtained

between the infinity

and close-up ends?

Check IC1201 and

EEPROM

NO

OK

NG

YES

TL1345:PULSE

2

3

Initialize the unit

and adjust autofocuss.

Does autofocus

operate normally?

IC1201 faulty.

END

NO

YES

Note: For the item marked , perform all

the adjustments required when the

unit is initialized, before

adjusting autofocus.

(4) NO AUTOFOCUS OPRATION

Does zoom operate

normally?

Connect an oscilloscope

to video output

YES

NO

See "(1) No zoom and

focus operation."

VIDEO SIGNAL:

360mVp-p or more

YES

1

NO

Increase the illumination

of the subject.

Does the video

level increase?

YES

NO

Camera circuit faulty.

2

(5) SUBJECT IS GREATLY OUT-OF-FOCUS WHEN ZOOMED.

NG

NO

NO

OK

Check the Zoom switch

unit.

IC1201-49:1.2-1.6V

Initialize the unit and

adjust autofocus

Does autofocus

operate normally?

END

IC1201 faulty.

D1201,C1207,R1205

faulty.

Zoom switch faulty.

Note: For the item marked , perform all

the adjustments required when the

unit is initialized, before

adjusting autofocus.

YES

YES

TL1347-TL1350:PULSES

NG

IC1302-2,10,29:5V

OK

IC1302-12,20:9V

OK

IC1302-28 (TL1312):

PULSE

OK

IC1302-3:PULSE

OK

IC1302-30:PULSE

OK

IC1302 faulty.

OK

NG

NG

NG

NG

NG

Lens block faulty.

Check the 5V line

Check the +B line

IC1201 faulty.

IC1201 faulty.

IC1201 faulty.

3 - 21

1 234

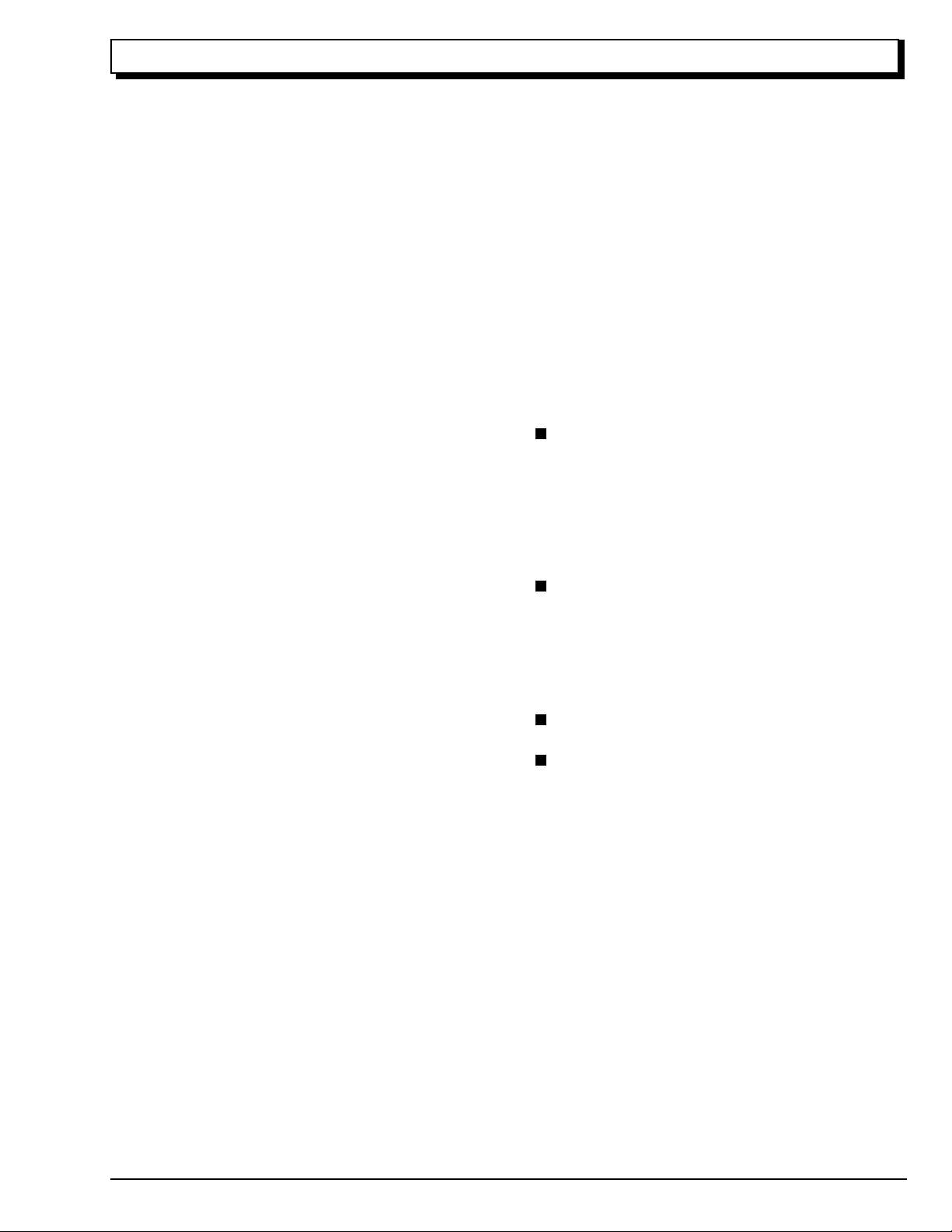

CHAPTER 4 EXPLODED VIEW

1. Exploded View

138

D

908

PC

CIRCUIT

BOARD

E

SP

C

A

603

CIRCUIT

BOARD

907

906

CSR

CIRCUIT

D

BOARD

102

104

B

601

136

906

A

906

908

C

913

D

C

B

906

B

137

913

A

909

1 234

4 - 1

CHAPTER 5 REPLACEMENT PARTS LIST

1. MECHANICAL PARTS LIST

SYMBOL

NO

102 NX11252 RUBBER

104 DT10251 CRYSTAL FILTER [TYPE S/SE]

104 DT10361 GLASS [TYPE K/KE]

136 NA19642 CHASSIS,CAMERA

137 NA31541 CHASSIS(L)

138 NA31551 CHASSIS(R)

601 KQ10752 LENS ASSY

603 UE15521 CCD IMAGE SENSOR [TYPE S]

603 UE15522 CCD IMAGE SENSOR [TYPE SE]

603 UE15523 CCD IMAGE SENSOR [TYPE K]

603 UE15524 CCD IMAGE SENSOR [TYPE KE]

906 7775945 SCREW(2X5)

907 8650103 SCREW(2X3)

908 8650105 SCREW (2X5)

909 8749103 2X3 BIND SCREW

913 7775963 SCREW(2X3)

P-NO DESCRIPTION

MECHANISM SECTION

2. ELECTRICAL PARTS LIST

SYMBOL

NO

C1001 0893107 CERAMIC CHIP 5PF+-0.25% 50V

C1003 0893044 CERAMIC CHIP 0.01UF+-10% 50V

C1004 0893211 CERAMIC CHIP 1500PF+-10% 50V

C1005 AA00422R CERAMIC CHIP 10UF 16V

C1006 0893222 CERAMIC CHIP 0.01UF+-10% 50V

C1007 AA00393R CHIP CERAMIC 1.0UF+80-20% 50V

C1008 AA00393R CHIP CERAMIC 1.0UF+80-20% 50V

C1009 0893222 CERAMIC CHIP 0.01UF+-10% 50V

C1010 AA00393R CHIP CERAMIC 1.0UF+80-20% 50V

C1011 0893062 CERAMIC CHIP 1UF+80-20% 16V

C1012 0893062 CERAMIC CHIP 1UF+80-20% 16V

C1018 0893062 CERAMIC CHIP 1UF+80-20% 16V

C1101 0893062 CERAMIC CHIP 1UF+80-20% 16V

C1102 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1103 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1104 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1105 0893008 CERAMIC CHIP 0.1UF +-10% 16V

C1106 AA00441R CHIP CAPACITOR 22UF+-20% 6.3V

C1107 0893062 CERAMIC CHIP 1UF+80-20% 16V

C1108 0893062 CERAMIC CHIP 1UF+80-20% 16V

C1109 0893179 CERAMIC CHIP 0.1UF+-10% 16V

C1110 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1111 AA00951R CERAMIC CAPACITOR 1.0UF+-10% 16V

C1112 AA00951R CERAMIC CAPACITOR 1.0UF+-10% 16V

C1113 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1114 0893179 CERAMIC CHIP 0.1UF+-10% 16V

C1115 AA00442R CERAMIC CAPACITOR 10UF 6.3V

C1116 AA00441R CHIP CAPACITOR 22UF+-20% 6.3V

C1121 AA00441R CHIP CAPACITOR 22UF+-20% 6.3V

C1122 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1123 AA01111R CERAMIC CHIP 1UF 6.3V

C1124 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1125 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1127 0893086 CERAMIC CHIP 0.1UF+80-20% 50V

C1128 0893107 CERAMIC CHIP 5PF+-5% 50V

C1129 0893107 CERAMIC CHIP 5PF+-5% 50V

C1130 0893014 CERAMIC CHIP 0.01UF+-10% 25V

C1131 AA00951R CERAMIC CAPACITOR 1.0UF+-10% 16V

C1132 0893119 CERAMIC CHIP 33PF+-5% 50V

C1133 AA00412R CERAMIC CHIP 10UF+-80-20% 16V

C1134 AA00412R CERAMIC CHIP 10UF+-80-20% 16V

C1135 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1136 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1137 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1138 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1139 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1140 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1141 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1142 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1143 AA00442R CERAMIC CAPACITOR 10UF 6.3V

C1144 AA00441R CERAMIC CAPACITOR 22UF 6.3V

C1145 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1160 0893062 CERAMIC CHIP 1UF+80-20% 16V

C1162 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1176 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1177 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1178 0893123 CERAMIC CHIP 56PF+-5% 50V

C1180 0893123 CERAMIC CHIP 56PF+-5% 50V

C1182 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1183 0202322 CHIP CERAMIC 33PF+-2% 50V

C1184 0893125 CERAMIC CHIP 82PF+-5% 50V

C1185 0893104 CERAMIC CHIP 2.0PF 50V

P-NO DESCRIPTION

CAPACITORS

5 - 1

SYMBOL

NO

C1186 0202321 CHIP CERAMIC 27PF+-2% 50V

C1187 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1191 0893175 CERAMIC CHIP 1000PF+-5% 50V

C1192 0893175 CERAMIC CHIP 1000PF+-5% 50V

C1201 AA00442R CERAMIC CAPACITOR 10UF 6.3V

C1202 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1203 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1204 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1205 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1206 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1207 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1208 AA00442R CERAMIC CAPACITOR 10UF 6.3V

C1212 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1215 0893177 CAPACITOR 0.068UF+-10% 16V

C1216 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1217 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1218 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1250 0893239 CERAMIC CHIP 0.01UF+80-20% 50V

C1251 AA01111R CERAMIC CHIP 1UF+-10% 6.3V

C1252 0893239 CERAMIC CHIP 0.01UF+80-20% 50V

C1300 AA00422R CERAMIC CHIP 10UF 16V

C1301 0893222 CERAMIC CHIP 0.01UF+-10% 50V

C1302 0893215 CERAMIC CHIP 3300PF+-10% 50V

C1303 0893217 CERAMIC CHIP 4700PF+-10% 50V

C1304 0893217 CERAMIC CHIP 4700PF+-10% 50V

C1305 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1306 0893222 CERAMIC CHIP 0.01UF+-10% 50V

C1307 0893215 CERAMIC CHIP 3300PF+-10% 50V

C1308 0893217 CERAMIC CHIP 4700PF+-10% 50V

C1309 0893217 CERAMIC CHIP 4700PF+-10% 50V

C1310 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1311 AA00422R CERAMIC CHIP 10UF 16V

C1312 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1313 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1317 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1318 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1319 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1320 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1351 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1352 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1353 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1354 0893132 CERAMIC CHIP 270PF+-5% 50V

C1355 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1356 0893007 CERAMIC CHIP 0.082UF+-10% 16V

C1357 0893013 CERAMIC CHIP 0.22UF+-10% 16V

C1358 0893113 CERAMIC CHIP 10PF+-0.5% 50V

C1359 0893133 CERAMIC CHIP 330PF+-5% 50V

C1360 0893133 CERAMIC CHIP 330PF+-5% 50V

C1361 0893133 CERAMIC CHIP 330PF+-5% 50V

C1362 0893008 CERAMIC CHIP 0.1UF +-10% 16V

C1501 0206672 CHIP CAPACITOR 10UF+-20% 16V

C1502 0893165 CERAMIC CHIP 180PF+-5% 50V

C1503 0893202 CERAMIC CHIP 330PF+-10% 50V

C1504 0893008 CERAMIC CHIP 0.1UF +-10% 16V

C1505 0893008 CERAMIC CHIP 0.1UF +-10% 16V

C1506 AA00422R CERAMIC CHIP 10UF 16V

C1507 0209942 CERAMIC CHIP 100PF+-5% 50V

C1508 0893013 CERAMIC CHIP 0.22UF+-10% 16V

C1510 0893008 CERAMIC CHIP 0.1UF +-10% 16V

C1512 0893008 CERAMIC CHIP 0.1UF +-10% 16V

C1513 0893165 CERAMIC CHIP 180PF+-5% 50V

C1514 0893202 CERAMIC CHIP 330PF+-10% 50V

C1515 0893158 CERAMIC CHIP 56PF+-5% 50V

C1516 0893203 CERAMIC CHIP 390PF+-10% 50V

C1517 0893165 CERAMIC CHIP 180PF+-5% 50V

P-NO DESCRIPTION

SYMBOL

NO

C1518 0893202 CERAMIC CHIP 330PF+-10% 50V

C1519 0893062 CERAMIC CHIP 1UF+80-20% 16V

C1520 0206671 ELECTROLYTIC 10UF 10V

C1521 AA00381R CERAMIC CHIP 10UF +-10% 6.3V

C1522 0893062 CERAMIC CHIP 1UF+80-20% 16V

C1523 0206671 ELECTROLYTIC 10UF 10V

C1524 AA00441R CHIP CAPACITOR 22UF+-20% 6.3V

C1525 0893062 CERAMIC CHIP 1UF+80-20% 16V

C1526 0206671 ELECTROLYTIC 10UF 10V

C1527 0893062 CERAMIC CHIP 1UF+80-20% 16V

C1528 0893062 CERAMIC CHIP 1UF+80-20% 16V

C1529 0893062 CERAMIC CHIP 1UF+80-20% 16V

C1530 AA00393R CHIP CERAMIC 1.0UF+80-20% 50V

C1531 0893062 CERAMIC CHIP 1UF+80-20% 16V

C1532 AA00393R CHIP CERAMIC 1.0UF+80-20% 50V

C1601 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1602 0206671 ELECTROLYTIC 10UF 10V

C1603 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1604 0806129 ELECTROLYTIC 22UF 10V

C1605 AD10273R CHIP RESISTOR 100UF+-20% 6.3V

C1606 AD10252R ELECTROLYTIC 1.0UF 20V

C1608 0893225 CERAMIC CHIP 0.1UF+80-20% 16V[TYPE K/KE]

C1610 0893179 CERAMIC CHIP 0.1UF+-10% 16V[TYPE S/SE]

C1611 0893193 CERAMIC CHIP 0.01UF+-10% 25V

C1612 0893179 CERAMIC CHIP 0.1UF+-10% 16V

C1613 0893011 CERAMIC CHIP 0.15UF+-10% 16V

C1614 AA00951R CERAMIC CAPACITOR 1.0UF+-10% 16V

C1615 0893008 CERAMIC CHIP 0.1UF +-10% 16V

C1616 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

C1617 0893114 CERAMIC CHIP 12PF+-5% 50V[TYPE SE]

C1617 0893117 CERAMIC CHIP 22PF+-5% 50V[TYPE S]

C1626 AA00381R CERAMIC CHIP 10UF+-10% 6.3V

C1650 0893206 CERAMIC CHIP 680PF+-10% 50V

C1651 0893225 CERAMIC CHIP 0.1UF+80-20% 16V

CP1151 5172801 FILTER,LOW PASS

CP1171 BE10501R FILTER

CP1601 BV10211R FILTER

R1001 0103853 CHIP RESISTOR 6.8KOHM+-5% 0.1W

R1002 0790024 CHIP RESISTOR 100 OHM+-5% 1/16W

R1004 0790077 CHIP RESISTOR 1MOHM+-5% 1/16W

R1007 0103867 CHIP RESISTOR 100KOHM+-5% 0.1W

R1101 AQ00231R CHIP RESISTOR 24KOHM+-1% 1/16W

R1121 0790028 CHIP RESISTOR 220 OHM+-5% 1/16W

R1122 BM00132R BLM11P600SPT

R1123 0790025 CHIP RESISTOR 120 OHM+-5% 1/16W

R1124 0790025 CHIP RESISTOR 120 OHM+-5% 1/16W

R1125 0790028 CHIP RESISTOR 220 OHM+-5% 1/16W

R1126 AQ00215R CHIP RESISTOR 6.2KOHM+-1% 1/10W

R1128 0790061 CHIP RESISTOR 56KOHM+-5% 1/16W

R1155 AQ00198R CHIP RESISTOR 1.5KOHM+-1% 1/16W

R1156 AQ00212R CHIP RESISTOR 4.7KOHM+-1% 1/16W

R1157 0790037 CHIP RESISTOR 1KOHM+-5% 1/16W

R1158 AQ00194R CHIP RESISTOR 1.0KOHM+-1% 1/16W

R1159 0104545 CHIP RESISTOR 1.24KOHM+-1% 1/16W

R1162 0790037 CHIP RESISTOR 1KOHM+-5% 1/16W[TYPE S/SE]

R1164 AQ00205R CHIP RESISTOR 2.7KOHM+-1% 1/16W[TYPE S/SE]

R1165 AQ00194R CHIP RESISTOR 1.0KOHM+-1% 1/16W[TYPE S/SE]

R1173 0790051 CHIP RESISTOR 10KOHM+-5% 1/16W

R1174 0790059 CHIP RESISTOR 47KOHM+-5% 1/16W

R1175 0790059 CHIP RESISTOR 47KOHM+-5% 1/16W

R1176 0790059 CHIP RESISTOR 47KOHM+-5% 1/16W

R1177 0790077 CHIP RESISTOR 1MOHM+-5% 1/16W

P-NO DESCRIPTION

RESISTORS

5 - 2

SYMBOL

NO

R1178 AQ00192R CHIP RESISTOR 820 OHM+-1% 1/16W

R1179 0790077 CHIP RESISTOR 1MOHM+-5% 1/16W

R1201 0790059 CHIP RESISTOR 47KOHM+-5% 1/16W

R1202 0790037 CHIP RESISTOR 1KOHM+-5% 1/16W

R1203 0790064 CHIP RESISTOR 100KOHM+-5% 1/16W

R1204 0790031 CHIP RESISTOR 330 OHM+-5% 1/16W

R1205 AQ00223R CHIP RESISTOR 12KOHM+-1% 1/16W

R1206 0790051 CHIP RESISTOR 10KOHM+-5% 1/16W

R1207 0790031 CHIP RESISTOR 330 OHM+-5% 1/16W

R1208 0790068 CHIP RESISTOR 220KOHM+-5% 1/16W

R1209 0790037 CHIP RESISTOR 1KOHM+-5% 1/16W

R1210 0790064 CHIP RESISTOR 100KOHM+-5% 1/16W

R1211 0790072 CHIP RESISTOR 390KOHM+-5% 1/16W

R1214 0790027 CHIP RESISTOR 180OHM+-5% 1/16W

R1215 0790027 CHIP RESISTOR 180OHM+-5% 1/16W

R1216 0790061 CHIP RESISTOR 56KOHM+-5% 1/16W

R1217 0790061 CHIP RESISTOR 56KOHM+-5% 1/16W

R1220 0790059 CHIP RESISTOR 47KOHM+-5% 1/16W

R1221 0790055 CHIP RESISTOR 22KOHM+-5% 1/16W

R1222 0790046 CHIP RESISTOR 4.7KOHM+-5% 1/16W

R1229 0790037 CHIP RESISTOR 1KOHM+-5% 1/16W

R1230 0790051 CHIP RESISTOR 10KOHM+-5% 1/16W

R1231 0790051 CHIP RESISTOR 10KOHM+-5% 1/16W

R1250 0790031 CHIP RESISTOR 330 OHM+-5% 1/16W

R1251 0790031 CHIP RESISTOR 330 OHM+-5% 1/16W

R1252 0790031 CHIP RESISTOR 330 OHM+-5% 1/16W

R1253 0790031 CHIP RESISTOR 330 OHM+-5% 1/16W

R1254 0790031 CHIP RESISTOR 330 OHM+-5% 1/16W

R1255 0790051 CHIP RESISTOR 10KOHM+-5% 1/16W

R1256 0790051 CHIP RESISTOR 10KOHM+-5% 1/16W

R1257 0790051 CHIP RESISTOR 10KOHM+-5% 1/16W

R1306 0103818 CHIP RESISTOR 8.2OHM+-10% 0.1W

R1307 0103813 CHIP RESISTOR 3.3 OHM+-10% 0.1W

R1308 0790051 CHIP RESISTOR 10KOHM+-5% 1/16W

R1309 0790051 CHIP RESISTOR 10KOHM+-5% 1/16W

R1310 0103818 CHIP RESISTOR 8.2OHM+-10% 0.1W

R1311 0103813 CHIP RESISTOR 3.3 OHM+-10% 0.1W

R1313 0103813 CHIP RESISTOR 3.3 OHM+-10% 0.1W

R1314 0103818 CHIP RESISTOR 8.2OHM+-10% 0.1W

R1315 0790051 CHIP RESISTOR 10KOHM+-5% 1/16W

R1316 0790051 CHIP RESISTOR 10KOHM+-5% 1/16W

R1317 0103813 CHIP RESISTOR 3.3 OHM+-10% 0.1W

R1318 0103818 CHIP RESISTOR 8.2OHM+-10% 0.1W

R1351 0790039 CHIP RESISTOR 1.5KOHM+-5% 1/16W

R1352 0790069 CHIP RESISTOR 0.27MOHM+-5% 1/16W

R1353 0790053 CHIP RESISTOR 15KOHM+-5% 1/16W

R1354 0790064 CHIP RESISTOR 100KOHM+-5% 1/16W

R1355 0790064 CHIP RESISTOR 100KOHM+-5% 1/16W

R1356 0790077 CHIP RESISTOR 1MOHM+-5% 1/16W

R1357 0790051 CHIP RESISTOR 10KOHM+-5% 1/16W

R1358 0790054 CHIP RESISTOR 18KOHM+-5% 1/16W

R1359 0790067 CHIP RESISTOR 180KOHM+-5% 1/16W

R1360 0790053 CHIP RESISTOR 15KOHM+-5% 1/16W

R1361 0790054 CHIP RESISTOR 18KOHM+-5% 1/16W

R1362 0790067 CHIP RESISTOR 180KOHM+-5% 1/16W

R1363 0790053 CHIP RESISTOR 15KOHM+-5% 1/16W

R1364 0790052 CHIP RESISTOR 12KOHM+-5% 1/16W

R1365 0790052 CHIP RESISTOR 12KOHM+-5% 1/16W

R1366 0790054 CHIP RESISTOR 18KOHM+-5% 1/16W

R1367 0790052 CHIP RESISTOR 12KOHM+-5% 1/16W

R1368 0790064 CHIP RESISTOR 100KOHM+-5% 1/16W

R1370 0790044 CHIP RESISTOR 3.3KOHM+-5% 1/16W

R1371 0790029 CHIP RESISTOR 270 OHM+-5% 1/16W

R1372 0790046 CHIP RESISTOR 4.7KOHM+-5% 1/16W

R1374 0790049 CHIP RESISTOR 8.2KOHM+-5% 1/16W

P-NO DESCRIPTION

SYMBOL

NO

R1375 0790036 CHIP RESISTOR 820 OHM+-5% 1/16W

R1376 0790047 CHIP RESISTOR 5.6KOHM+-5% 1/16W

R1378 0790047 CHIP RESISTOR 5.6KOHM+-5% 1/16W

R1501 0790052 CHIP RESISTOR 12KOHM+-5% 1/16W

R1505 0790048 CHIP RESISTOR 6.8KOHM+-5% 1/16W

R1509 0790048 CHIP RESISTOR 6.8KOHM+-5% 1/16W

R1510 AQ00231R CHIP RESISTOR 24KOHM+-1% 1/16W

R1512 0790049 CHIP RESISTOR 8.2KOHM+-5% 1/16W

R1515 0790041 CHIP RESISTOR 1.8KOHM+-5% 1/16W

R1516 0790051 CHIP RESISTOR 10KOHM+-5% 1/16W

R1517 0790048 CHIP RESISTOR 6.8KOHM+-5% 1/16W

R1519 0790051 CHIP RESISTOR 10KOHM+-5% 1/16W

R1520 0790052 CHIP RESISTOR 12KOHM+-5% 1/16W

R1521 0790049 CHIP RESISTOR 8.2KOHM+-5% 1/16W

R1522 0790052 CHIP RESISTOR 12KOHM+-5% 1/16W

R1524 AQ01021R CHIP RESISTOR 10KOHM+-0.5% 1/16W

R1525 AQ01007R CHIP RESISTOR 1KOHM+-0.5% 1/16W

R1526 AQ01016R CHIP RESISTOR 4.7KOHM+-0.5% 1/16W

R1527 AQ01027R RESISTOR 33KOHM +-0.5% 1/16W

R1528 AQ01024R RESISTOR 18KOHM +-0.5% 1/16W

R1529 AQ01021R CHIP RESISTOR 10KOHM+-0.5% 1/16W

R1531 AQ01014R CHIP RESISTOR 3.3KOHM +-0.5% 1/16W

R1532 AQ01021R CHIP RESISTOR 10KOHM+-0.5% 1/16W

R1533 AQ01028R CHIP RESISTOR 39KOHM +-0.5% 1/16W

R1534 AQ01029R CHIP RESISTOR 47KOHM +-0.5% 1/16W

R1535 0105205 CHIP RESISTOR 510 OHM+-0.5% 1/16W

R1536 0105194 CHIP RESISTOR 2400OHM+-0.5% 1/16W

R1601 0103829 CHIP RESISTOR 68OHM+-5% 0.1W

R1605 0790033 CHIP RESISTOR 470 OHM+-5% 1/16W

R1606 0104153 CHIP RESISTOR 470 OHM+-10% 0.125W

R1607 0790064 CHIP RESISTOR 100KOHM+-5% 1/16W

R1608 0790064 CHIP RESISTOR 100KOHM+-5% 1/16W

R1610 0790034 CHIP RESISTOR 560 OHM+-5% 1/16W

R1611 0790046 CHIP RESISTOR 4.7KOHM+-5% 1/16W

R1612 0790055 CHIP RESISTOR 22KOHM+-5% 1/16W

R1613 0790057 CHIP RESISTOR 33KOHM+-5% 1/16W

R1614 0790042 CHIP RESISTOR 2.2KOHM+-5% 1/16W

R1616 0790051 CHIP RESISTOR 10KOHM+-5% 1/16W

R1617 0790063 CHIP RESISTOR 82KOHM+-5% 1/16W

R1618 0790073 CHIP RESISTOR 470KOHM+-5% 1/16W

R1620 0790073 CHIP RESISTOR 470KOHM+-5% 1/16W

R1621 0790046 CHIP RESISTOR 4.7KOHM+-5% 1/16W

R1625 0790037 CHIP RESISTOR 1KOHM+-5% 1/16W

R1626 AQ00205R CHIP RESISTOR 2.7KOHM+-1% 1/16W

R1627 AQ00203R CHIP RESISTOR 2.2KOHM+-1% 1/16W

R1628 0103851 CHIP RESISTOR 4.7KOHM+-5% 0.1W

R1629 0790044 CHIP RESISTOR 3.3KOHM+-5% 1/16W

R1630 0790032 CHIP RESISTOR 390 OHM+-5% 1/16W

R1639 0790037 CHIP RESISTOR 1KOHM+-5% 1/16W

R1640 0790037 CHIP RESISTOR 1KOHM+-5% 1/16W

RM1121 AQ00064R CHIP RESISTOR 100KOHM+-5% 1/16W

RM1122 AQ00064R CHIP RESISTOR 100KOHM+-5% 1/16W

RM1123 AQ00064R CHIP RESISTOR 100KOHM+-5% 1/16W

RM1124 AQ00064R CHIP RESISTOR 100KOHM+-5% 1/16W

D1002 CC10291R DIODE 1SS353

D1151 5337352 DIODE MA132WA

D1171 5337471 DIODE KV1470

D1201 5337422 DIODE DA221

D1202 5337352 DIODE MA132WA

D1351 5337422 DIODE DA221

D1501 CC10291R DIODE 1SS353

D1502 5337352 DIODE MA132WA

P-NO DESCRIPTION

SEMI-CONDUCTORS

5 - 3

SYMBOL

NO

D1503 CC10291R DIODE 1SS353

D1601 5337391 DIODE D1FS4

D1602 CC10463R DIODE MA3100L

IC1002 CK12061R IC UPD16510GR

IC1101 CK21332U IC HD49323AF

IC1121 CK22461U IC HG73C053FE

IC1122 CK23712U IC MSM51V18165F-60TS

IC1173 CK15051R IC TC7SU04FU

IC1174 CK18421R IC TC7SHU04FUL

IC1202 CK21351R IC X25097V1-2.7

IC1204 CK20501R IC TC7SH14FU

IC1205 CK20501R IC TC7SH14FU

IC1206 CK16201R IC TC7S08FU

IC1251 CK20403R IC RN5VD27AA

IC1301 1366804 IC MPC17AT85VM

IC1302 1366804 IC MPC17AT85VM

IC1351 CK20621R IC UPD5023GS-147-GJG

IC1501 1366251 IC TL1464IPT

IC1601 CK23321R IC BA7664FV

IC1602 1366081 IC HD74HCT125T