Hitachi Vkc317e Service Manual

SERVICE MANUAL

TK No. 8105E

VK-C317E

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

COLOR VIDEO CAMERA

2001September

Digital Media Products Division,Tokai

Contents

CHAPTER 1 GENERAL INFORMATION

1. Specifications

2. Comparison with Previous Model

2.1 Comparison of Specifications

2.2 Comparison of ICs

3. Extrat from the Instruction Manual

Controls and Functions

Connection

.........................................................

..........................

.........................

..........................................

.........................

........................................

...........................................................

1-1

1-2

1-2

1-2

1-3

1-3

1-4

CHAPTER 2 DISASSEMBLY

1. Procedure

..............................................................

2-1

CHAPTER 3 ELECTRIC CIRCUIT

ADJUSTMENT

1. Test Equipment/Jigs Necessary for Adjustment

1.1 List of Equipment and Jigs

1.2 List of Charts for Adjustment

1.3 Test Equipment, etc.

2. Before Stating Adjustment

2.1 Connections for Adjustment

2.2 Notes

2.3 Setting Video Camera

2.4 Setting Test Equipment

3. List of Adjustment Items

4. Starting Adjustment Program (KMAP)

5. Data Initilize Procedure

5.1 Data Initilize

6. Electronic Volume Adjustment Procedure

6.1 CDS Sampling Pulse Adjustment

7. Camera Adjustment (Adjustment) Procedure

7.1 Auto Iris Control Adjustment

7.2 White Balance Adjustment

7.3 Chroma Gain Adjustment

8. Error Messages

...............................................................

..........................................

.....................................................

......................................................

..............................

...........................

.......................................

.....................................

............................

.....................................

...................................

.........................................

...................

...................

...........................

..............................

................................

....

.............

........

3-1

3-1

3-1

3-1

3-2

3-2

3-2

3-3

3-3

3-3

3-4

3-5

3-5

3-5

3-6

3-6

3-6

3-7

3-7

3-8

CHAPTER 4 EXPLODED VIEW

1. Exploded View

.......................................................

4-1

CHAPTER 5 REPLACEMENT

PARTS LIST

1. Mechanical Parts List

2. Electrical Parts List

.............................................

................................................

CHAPTER 6 SCHEMATIC, CIRCUIT

BOARD AND BLOCK DIAGRAMS/

MICROPROCESSOR PIN FUNCTION

TABLES

Schematic Diagrams

Internal Wiring Diagram

Waveforms

Sensor [S]

Process [PC]

Ext, Sync [EXT]

BNC Connector [BNC]

Switch [SW]

Power [PWR]

AC Terminal [AC]

...................................................................

....................................................................

................................................................

............................................................

.................................................................

...............................................................

Circuit Board Diagrams

S -Side A/BPC -Side A/BEXT -Side A/BBNC -Side A/BSW -Side A/BPWR -Side A/B-

...............................................................................

AC

.................................................................

..............................................................

............................................................

............................................................

..............................................................

Identification of Parts Location

...............................................................................

S

...............................................................................

PC

..............................................................................

EXT

...............................................................................

SW

............................................................................

PWR

Block Diagrams

.............................................................................

Main

..............................................................................

Sub

Microprocessor Pin Function Tables

Digital Microprocessor (IC1106: D-µP)

...............................................

.................................................

.........................................................

...........................................................

........................

5-1

5-1

6-1

6-2

6-3

6-6

6-9

6-11

6-12

6-13

6-13

6-15

6-17

6-19

6-20

6-21

6-23

6-24

6-15

6-17

6-19

6-22

6-23

6-25

6-27

6-29

Cautions

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts have special safety-related characteristics. These are often not evident from visual

inspection nor can the protection afforded by them necessarily be obtained by using replacement components rated for a

higher voltage, wattage, etc. Replacement parts which have these special safety characteristics are identified in this

Service Manual. Electrical components having such features are identified by marking with a on the schematics and

the parts list in this Service Manual. The use of a substitute replacement component which does not have the same safety

characteristics as the HITACHI recommended replacement one, shown in the parts list in this Service Manual, may create

shock, fire, or other hazards. Product safety is continuously under review and new instructions are issued from time to time.

For the latest information, always consult the current HITACHI Service Manual. A subscription to, or additional copies for,

HITACHI Service Manual may be obtained at a nominal charge from HITACHI SALES CORPORATION.

Microsoft, MS, MS-DOS, Windows and Windows NT are registered trademarks of Microsoft Corporation.

Pentium and Celeron are registered trademarks of Intel Corporation.

Manufactured under license from Dolby Laboratories.

"Dolby" and double-D symbol are trademarks of Dolby Laboratories.

Confidential unpublished works. (C) 1992-1997 Dolby Laboratories Inc. All rights reserved.

IBM is registered trademarks of International Business Machines Corporations.

Other company names and product names listed are trademarks or brand names belonging to each company.

!

CONTENTS/CAUTION

Notes When Using Service Manual

The following shows the contents to be noted when using service manual:

1. Value units used in parts list

Certain symbols are indicated below for value units of

resistors, capacitors and coils in parts list. When you read

them note the following regular indications:

Parts

Resistor

Capacitor

Coil

Indication in list Regular indication

...........................................

KOHM

................................................

UF

................................................

PF

................................................

UH

...............................................

MH

mH

2. Values in schematic diagrams

The values, dielectric strength (power capacitance) and

tolerances of the resistors (excluding variable resistors)

and capacitors are indicated in the schematic diagrams

using abbreviations.

[Resistors]

Item

Value

Tolerance

Power

capacitance

Indication

No indication

...................................................

K

..................................................

M

No indication

(All tolerances other than ±5% are

indicated in schematic diagrams)

No indication

(1/16W for leadless resistors without

indication)

All capacitances other than the above

are indicated in schematic diagrams.

...................................

.............................

............................

±5%

1/8W

k

M

k

µF

pF

µH

3. Identifications of sides A/B in

circuit board diagrams

1) Board having a pattern on one side and parts on both

sides.

Side A: Shows discrete parts, viewed from the pattern

side.

Side B: Shows leadless parts, viewed from the

pattern side.

2) Board having patterns on both sides and parts on

both sides.

Side A: Shows parts and patterns which can be seen

when the case is opened.

Side B: Shows parts and the pattern on the back of

side A.

4. Table for indexing locations of parts

This table shows locations of each part on circuit board

diagrams. The locations are indicated using the guide

scales on the external lines of diagrams.

1) One diagram indicated for each board

Symbol

No.

IC

IC1201

Circuit No.

2) Two diagrams indicated for each board

Parts

Location

Type of part

2 A

Zone "A" on board diagram

Zone "2" on board diagram

[Capacitors]

Item

Value

Dielectric

strength

[Coils]

Item

Value

CAUTION

Indication

No indication

...................................................

P

No indication

(All dielectric strengths other than 50V

are indicated in schematic diagrams)

Indication

....................................................

µ

..................................................

m

.................................

..............................

µF

pF

50V

µH

mH

Symbol

No.

IC

IC1201

Circuit No.

Parts

Location

A - 2 A

A: Shows side A

B: Shows side B

Type of

part

Zone "A" on board

diagram

Zone "2" on board

diagram

CHAPTER 1

1. Specifications

Signal PAL standard 625 TV Lines, 50 fields

Image sensor 1/4-inch CCD Image sensor

Total number of pixels 795 (H) × 596 (V)

Scanning system 2 : 1 Interlaced

Scanning frequency Horizontal : 15.625 kHz

Sync format Internal/Line Lock

Video signal output VBS : 1.0Vp-p

GENERAL INFORMATION

Number of effective pixels

752 (H) × 582 (V)

Vertical : 50 Hz

Video : approx. 0.7 Vp-p positive

Sync : approx. 0.3 Vp-p negative

Burst : approx. 0.3 Vp-p 8 cycles or more

Impedance : 75 ohm unbalanced

Connector : BNC type

S/N ratio 50 dB or more

Horizontal resolution 450 TV Lines or more

Minimum required illumination 4 lx or less (F 1.2 wide angle AGC mode NORM)

2 lx or less (F 1.2 wide angle AGC mode HIGH)

White balance adjustment Automatic or manual (switchable)

Adjustment range : 2,700 to 8,000 K

Lens F 1.2 Optical zoom × 2.5. f: 2.4 mm to 6.0 mm

Permissible operating Range in which operation is possible:

temperature/humidity -10 to +50 °C / 10 to 85 %

Range in which performance is assured:

+5 to 30 °C / 45 to 75 %

Power input AC 24 V ± 20 % (AC 19.2 V to AC 28.8 V) 50 Hz

DC 12 V (DC 10.8 V to DC 40 V)

Power consumption 3.0 W MAX

Dimensions 64 (W) × 58 (H) × 152 (D) mm (excluding protrusions)

Weight 370 g

1 - 1

2. Comparison with Previous Model

2.1 Comparison of Specifications

ITEM

Signal

Image sensor

Number of effective pixels

Total number of pixels

Scanning system

Scanning frequency

Sync format

Video signal output

VBS

Video

Sync

Burst

Impedance

Connector

S/N ratio

Horizontal resolution

Minimum required illumination

White balance adjustment

Lens

Permissible operation

Power input

Power consumption

Dimensions

Weight

VK-C317E

PAL Standard 625 TV lines, 50 fields

1/4-inch CCD image sensor

752 (H) × 582 (V)

795 (H) × 596 (V)

2 : 1 Interlaced

Horizontal: 15.625 kHz

Vertical: 50 Hz

Internal/Line Lock

1.0 Vp-p

approx. 0.7 Vp-p positive

approx. 0.3 Vp-p negative

approx. 0.3 Vp-p 8 cycles or more

75 ohm unbalanced

BNC type

50 dB or more

450 TV line or more

4 lx or less

(F 1.2 wide angle AGC mode NORM)

2 lx or less

(F 1.2 wide angle AGC mode HIGH)

Automatic or manual (switchable)

Adjustment range : 2,700 to 8,000 K

F 1.2 Optical zoom × 2.5. f: 2.4 mm to 6.0mm

Range in which operation is possible: -10 to +50 °C / 10 to 85 %

Range in which performance is assured: +5 to 30 °C / 45 to 75 %

AC 24 V ± 20% (AC 19.2 V to AC 28.8 V) 50 Hz

DC 12 V (DC 10.8 V to DC 40 V)

3.0 W MAX

64 (W) × 58 (H) × 152 (D) mm (excluding protrusions)

370 g

1/4-inch CCD image sensor

500 (H) × 582 (V)

537 (H) × 597 (V)

330 TV lines or more

2 lx or less

(F 1.2 wide angle AGC mode NORM)

1 lx or less

(F 1.2 wide angle AGC mode HIGH)

VK-C307E

2.2 Comparison of ICs

ITEM

CCD Image Sensor

DrivePulse Gen.

Iris Drive

CDS AGC & A/D Conv.

Digital Process (DSP)

Digital µP

EEPROM

Reset Pulse Gen.

Character Gen.

Inverter (INV)

Pulse Gen.

Phase Det.

Pulse Switch

Inverter (INV)

V.Pulse Shape

PWM

Video Amp

Photo-coupler Switch

1 - 2

VK-C317E

ICX209AK-6 (IC1001)

µPD16510GR (IC1002)

NJM2904 (IC1041)

HD49322BF (IC1102)

HG73C012TE (IC1103)

HD6433042ST50F (IC1106)

S29394AFJA (IC1107)

RN5VT28AA-TL (IC1108)

µPD6466GS (IC1111)

TC7SU04F (IC1112)

TC7SU04F (IC1113)

TC7SU04F (IC1116)

µPD74HC00G (IC1115)

74VHC4046MTCX (IC1202)

µPD4066BG (IC1203)

NJU74HC04M (IC1204)

µPD74HC221AG (IC1207)

TL1464IPT (IC1501)

MM1029AF (IC1601)

HA17431PA (IC3501)

VK-C307E

ICX207AK-6 (IC1001)

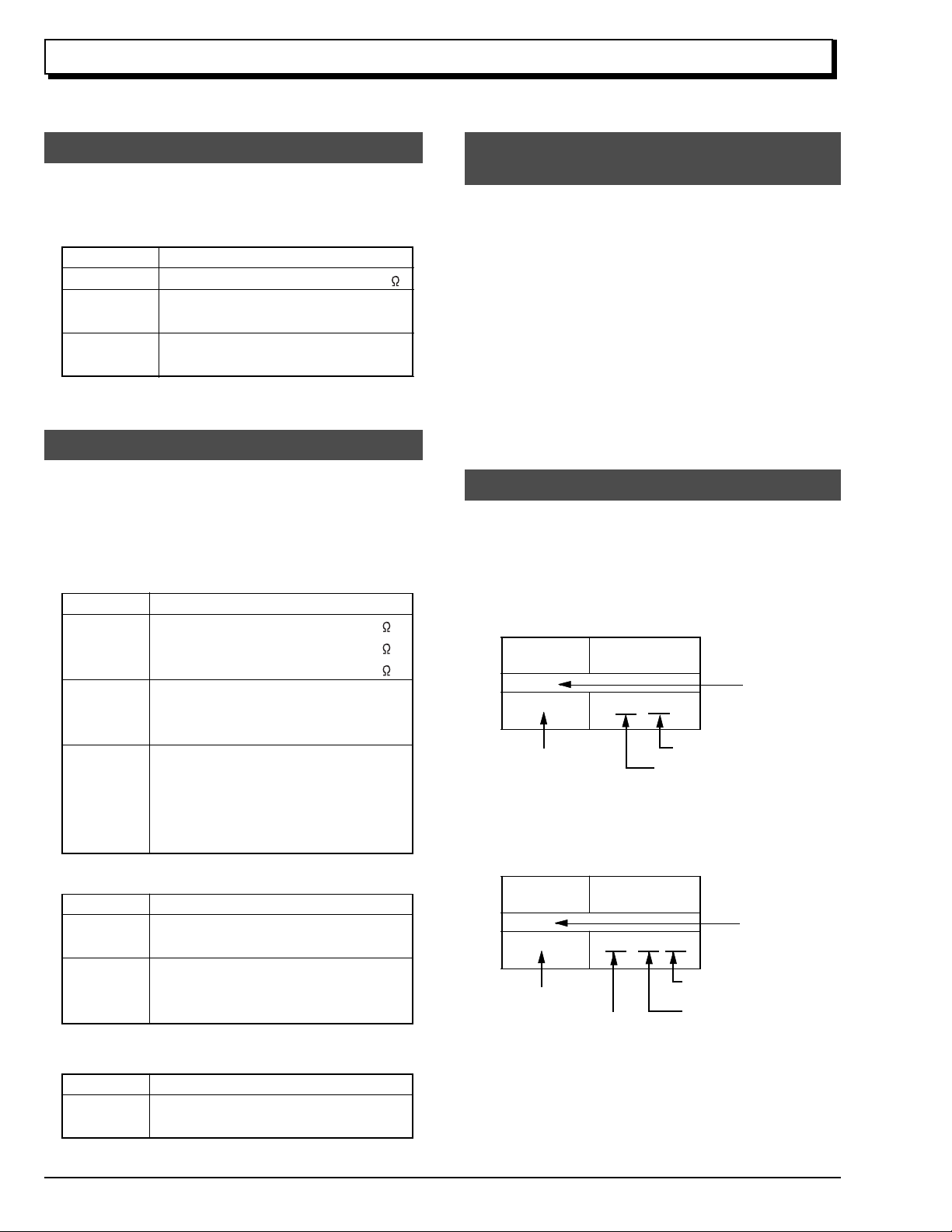

CONTROLS AND FUNCTIONS

1

3. Extrat from the Instruction Manual

CONTROLS AND FUCNTIONS (Cont’d)

5

2

4

VIDEO-OUT

GND

AC24V/DC12V

V

SET

UP

DOWN

AUX

6

7

8

9

3

1. Lens (see pages 9, 10)

2. Screw holes for fixing brackets

Use two holes at the top and bottom to fix the camera to a camera fixing bracket

(optional).

3. Front cover (see page 9)

10

4. VIDEO OUT jack

A composite video signal (VBS) is output from this jack.

(See pages 7, 8)

5. Vø control (see pages 38, 40)

6. SET button (see pages 11~40)

7. UP button (see pages 11~40)

8. DOWN button (see pages 11~40)

9. AUX

Not used.

10. 4-pin terminal (see page 8)

Connect to AC 24V 50Hz or DC 12V power supply.

1 - 3

4

5

1 - 4

8

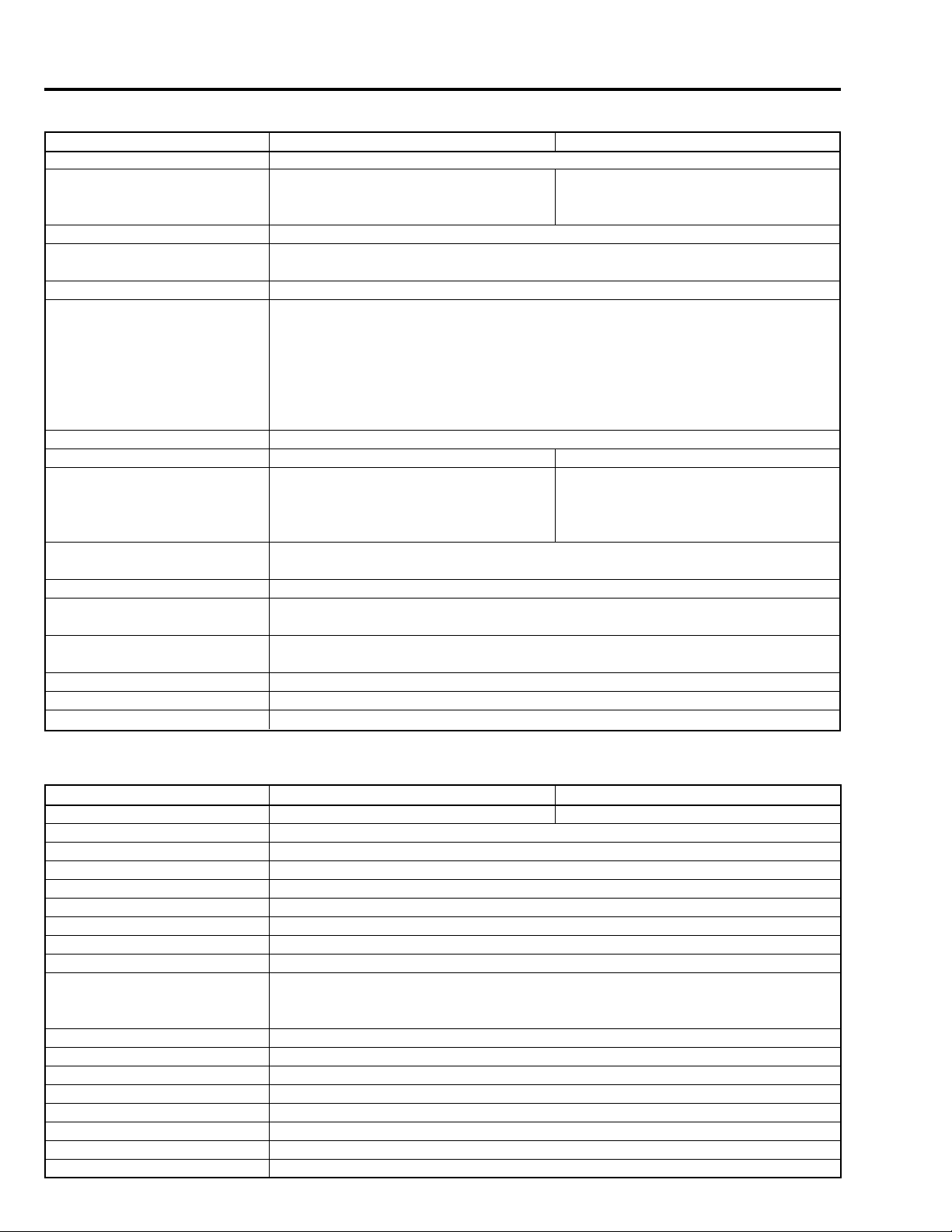

2. Connecting to a VTR

Use a coaxial cable to connect the camera’s VIDEO OUT jack to the VTR’s VIDEO IN

jack.

Since the camera’s internal sync signal is 2:1 interlaced, a good slow-motion picture

or still picture can be played by the VTR.

Also read the VTR’s instruction manual for connecting to a VTR.

SET

V

UP

DOWN

AUX

GND

AC24V/DC12V

VIDEO-OUT

VIDEO OUT

VK-C307E/VK-C317E

OUT

VIDEO

VTR

IN

75 coaxial

cable

75 coaxial cable

OFF

ON

OUT

VIDEO

Colour video monitor

IN

ON

3. Power input

Connect a power supply to the 4-pin terminal on the rear panel.

AC power supply DC power supply

SET

V

UP

DOWN

AUX

GND

AC24V/DC12V

VIDEO-OUT

SET

V

UP

DOWN

AUX

GND

AC24V/DC12V

VIDEO-OUT

AC 24V DC 12V (non-polarity)

4. Connecting to GND

SET

V

UP

DOWN

AUX

GND

AC24V/DC12V

VIDEO-OUT

Ground

CONNECTION

1. Connecting to colour video monitor(s)

If you use one colour video monitor, connect the camera’s VIDEO OUT jack to the

monitor’s VIDEO IN jack using a coaxial cable. Set the 75 ON-OFF switch on the

monitor to ON.

VK-C307E/VK-C317E

VIDEO OUT

If you use two or more colour video monitors, connect the camera’s VIDEO OUT jack

of the first monitor’s VIDEO IN jack using a coaxial cable, connect the first monitor’s

VIDEO OUT jack to the 2nd monitor’s VIDEO IN jack, then connect in this way to the

last monitor. Set the 75 ON-OFF switches on each monitor to OFF apart from the

last monitor which must be set to ON. Use coaxial cables for all connections.

VK-C307E/VK-C317E

VIDEO-OUT

AC24V/DC12V

GND

VIDEO OUT

VIDEO-OUT

V

SET

UP

DOWN

GND

AC24V/DC12V

AUX

75 coaxial cable

Connecting the camera to one monitor

V

75

coaxial

cable

SET

UP

DOWN

AUX

Colour video

monitor 1

VIDEO

IN

Connecting the camera to monitors (two or more)

ON

OUT

OFF

75 coaxial cable

Colour video monitor

Colour video

monitor 2

VIDEO

OFF

IN

OUT

75 coaxial cable

VIDEO

IN

OUT

ON

OFF

ON

OFF

Colour video

VIDEO

OFF

IN

ON

monitor 3

OUT

ON

ON

OFF

7

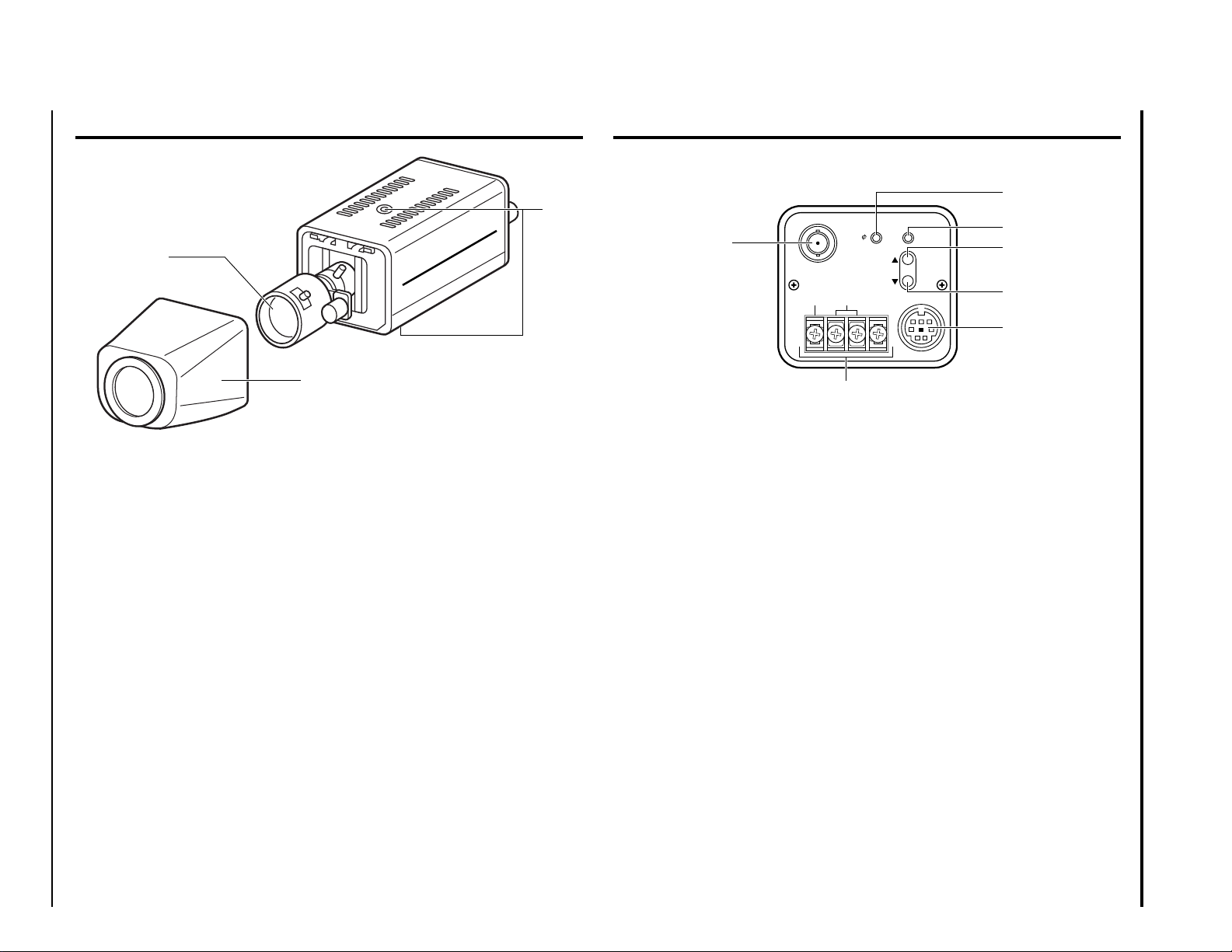

CHAPTER 2 DISASSEMBLY

1. Procedure

The numbers in the followinng tables correspond to those in Fig. 1-1.

Remove each component shown in the following tables according to the order of the numbers.

(1)

(1)

(2)

(3)

(4)

(5)

(6)

Top case

(1)

(2)

CCD

sensor &

S circuit

board

(1)

(2)

(3)

(4)

(5)

(6)

(12)

(13)

(14)

(15)

(16)

(17)

(18)

(19)

(20)

Front

Item

Item

case

Component to be removed

Removal Procedure and Number of

Lens

block

(12)

(13)

(14)

(15)

(16)

(17)

(18)

Component to be removed

Removal Procedure and Number of

Rear

panel

(1)

(2)

(3)

(4)

(5)

AC

circuit

board &

AC

terminal

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(21)

(22)

Rear

frame

a'ssy

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

BNC

circuit

board

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(23)

PWR

circuit

board

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

SW

circuit

board

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(23)

(24)

(25)

EXT &

PC circuit

board

(1)

(2)

(3)

(4)

(5)

(6)

(12)

(13)

(14)

(15)

Bottm

case

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(26)

How to remove

(1) Remove 1 screw holding the front case.

(2) Remove 4 screws holding the top case.

(3) Remove 2 screws holding the rear panel.

(4) Remove 2 screws holding the bottom case.

(5) Release 2 tabs.

(6) Remove 2 screws.

(7) Disconnect 2 connectors on the BNC circuit board.

(8) Disconnect 1 connector on the AC circuit board.

(9) Remove 2 screws holding the PWR frame.

(10) Disconnect 1 connector on the PWR circuit board.

(11) Remove 3 screws holding the PWR circuit board.

(12) Disconnect 3 connectors on the PC circuit board.

(13) Remove 2 screws holding the bottom case.

(14) Remove 1 screw and remove the EXT circuit

board in the direction of the arrow.

(15) Remove the PC circuit board in the direction of

the arrow.

How to remove

(1) Remove 1 screw holding the front case.

(2) Remove 4 screws holding the top case.

(3) Remove 2 screws holding the rear panel.

(4) Remove 2 screws holding the bottom case.

(5) Release 2 tabs.

(6) Remove 2 screws.

(7) Disconnect 2 connectors on the BNC circuit board.

(8) Disconnect 1 connector on the AC circuit board.

Note: Steps (9) to (11) are not necessary.

(12) Disconnect 3 connectors on the PC circuit board.

(13) Remove 2 screws holding the bottom case.

(14) Remove 1 screw and remove the EXT circuit

board in the direction of the arrow.

(15) Remove the PC circuit board in the direction of

the arrow.

(16) Disconnect 1 connector on the S circuit board.

(17) Remove 2 screws holding the lens block. (*1)

(18) Remove 4 screws holding the lens block.

(19) Unsolder 14 points (CCD sensor) on the S circuit

board.

(20) Remove 2 screws holding the S circuit board.

(21) Remove 2 screws holding the AC terminal.

(22) Unsolder 2 points on the AC circuit board.

(23) Unsolder 2 points on the BNC circuit board.

(24) Unsolder 9 points on the SW circuit board.

(25) Remove 1 screw holding the SW circuit board.

(26) Remove 2 screws holding the bottom case.

*1: When the lens block is removed, the crystal filter and rubber are also removed.

Be careful not to damege and lose them.

2 - 1

(13)

FRONT

CASE

CRYSTAL

FILTER

(2)

(1)

RUBBER

(18)

(2)

CCD

SENSOR

TOP CASE

(6)

(17)

S CIRCUIT

BOARD

(16)

(20)

(19)

AUX

CONNECTOR

(14)

(5)

PC

CIRCUIT

BOARD

EXT

CIRCUIT

BOARD

(14)

(3)

(15)

(12)

LENS

BLOCK

PWR

FRAME

(18)

(25)

BNC

CIRCUIT

BOARD

(9)

(23)

(24)

SW CIRCUIT

BOARD

(7)

PWR CIRCUIT

BOARD

(8)

(10)

(22)

(11)

AC

CIRCUIT

BOARD

REAR

PANEL

BNC

CONNECTOR

(21)

AC

TERMINAL

2 - 2

BOTTOM

CASE

(4)

(26)

Fig. 1-1

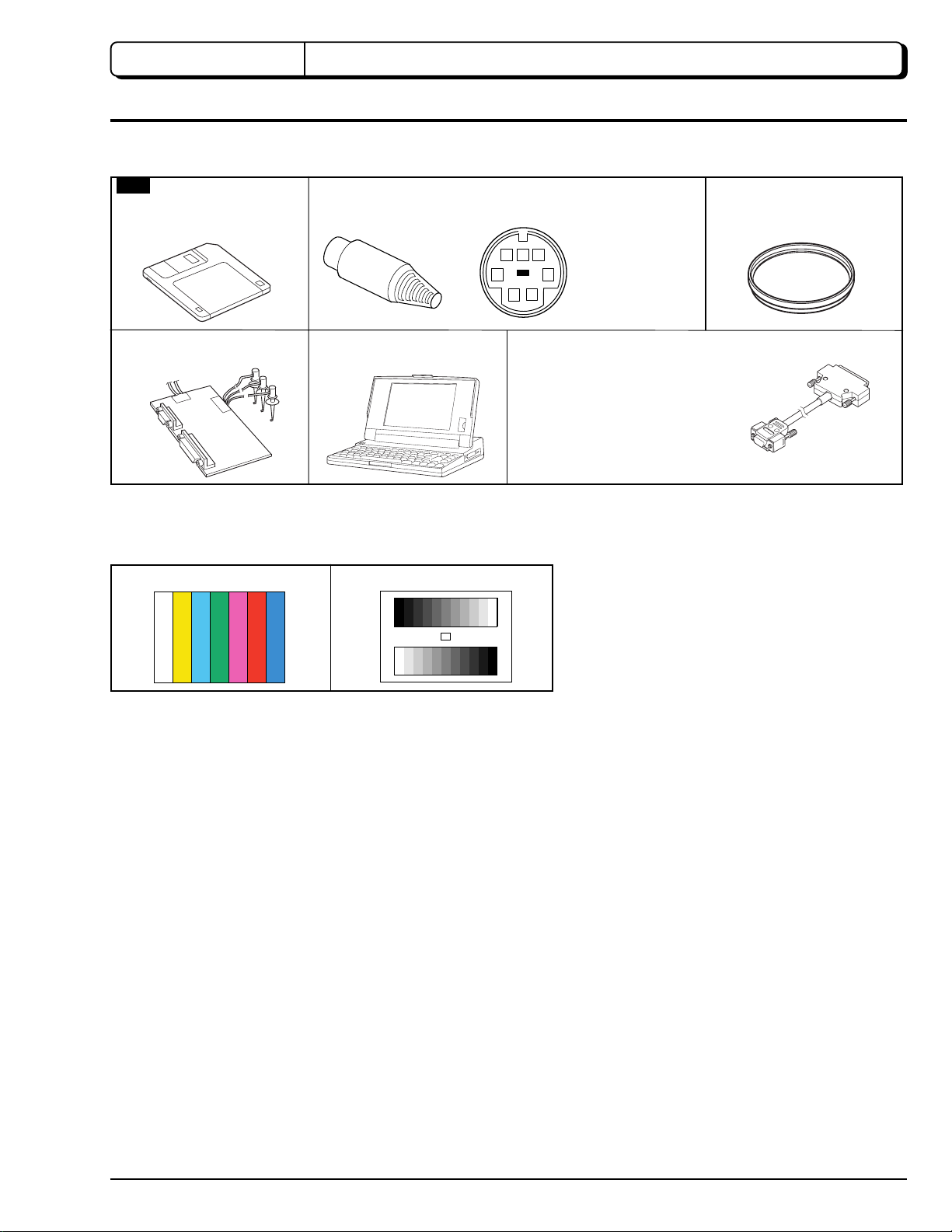

CHAPTER 3 ELECTRIC CIRCUIT ADJUSTMENT

1. Test Equipment/Jigs Necessary for Adjustment

1.1 List of Equipment and Jigs

New

Adjutsment Floppy Disk

(3.5 inch) No. TP11993

DSP-R Jig

No.7099448

Plug

No. 5699073

Personal Computer (PC)

[Goods on the Market]

1.2 List of Charts for Adjustment

Color Bar Chart Gray Scale Chart

AUX

1. -----

2. -----

5

6

7

4

3

21

Personal Computer Cable

RS-232C (9 or 25 pins)

Straight Type

[Goods on the Market]

3. RD

4. -----

5. GND

6. -----

7. SD

C12 Light Balancing Filter

No.7099369

1.3 Test Equipment, etc.

Color video monitor (color TV for monitoring)

Oscilloscope

Vectorscope [If not available, adjustment is still possible, but easier if this is used]

3100 K light box

Power supply (AC24V or DC12V) [To power video camera]

DC power supply (5 V/1 A) [To power DSP-R jig]

3 - 1

2. Before Starting Adjustment

2.1 Connections for Adjustment

Connect the video camera to the test equipment and jigs as shown in Fig. 2-1.

Note: Adjustment can be performed without

removing the top cover.

S CIRCUIT

BOARD

PC CIRCUIT

BOARD

POWER

SUPPLY

AC 24V/50Hz

(DC 12V non-polarity)

BNC CIRCUIT

BOARD

PWR CIRCUIT

BOARD

SW CIRCUIT

BOARD

JAY CIRCUIT

BOARD

BLK

Fig. 2-1 Connections for Adjustment

YEL

WHT

4

DC POWER

SUPPLY

(5V/1A)

RED

DSP-R JIG

AUX

1. -----

3

BLK

RS232-C

CABLE

2. -----

3. RD [YEL]

4. -----

5. GND [BLK]

6. -----

7. SD [WHT]

COLOR

VIDEO

MONITER

PERSONAL

COMPUTER

6

5

7

1

2

2.2 Notes

1) All adjustments are performed using the adjustment program and personal computer (PC). The adjustment program is

subject to change without notice for improvements in functions and operability, and the actual instructions on PC screen

may be different from those in this manual: If so, follow the instructions on PC screen to proceed with adjustment.

2) The adjustment program will not operate normally unless the video camera, PC and test equipment/jigs are all turned on.

3) Be sure to connect the video output of video camera to a color video monitor (terminate the video output with 75 ohm:

If the video output is not connected to the monitor (and if it is not terminated with 75 ohm), the output video signal level

cannot be measured correctly.

4) Use light box that does not flicker and whose color temperature is controlled, for adjustment. If an inappropriate light box is

used, precise adjustment will not be possible, and the adjustment program will not operate normally.

5) Take care with the following when pointing the video camera at a chart (light box):

Focus the chart correctly.

Set the chart (light box) 30 - 50 cm away from the lens surface, and avoid any effects from surrounding light (except for

a case where some designation is given).

Aim at the chart and let chart fill the screen (video period). (Except for a case where some designation is given.)

3 - 2

2.3 Setting Video Camera

Set the switches, knobs and each mode as follows for adjustment:

On the Menu

NEG/POS

WHITE BAL

SHUTTER

ELE-ZOOM

ALC LEVEL

.........................................

......................................

.........................................

.......................................

.......................................

POS

AUTO

1/50

at wide angle

PRESET ON

2.4 Setting Test Equipment

1) Set the switches, knobs and each mode of oscilloscope as follows for adjustment: (except for a case where some

designation is given)

Probe: 10:1

TIME/DIV: 10 or 20 µs

VOLTS/DIV: Will vary depending on the measurement object

Synchronization: Internal sync

AC/DC/GND: AC

Note: The names of switches, knobs, modes, etc. of oscilloscope may vary slightly depending on the manufacturer or

model. Since some oscilloscopes may have switches, etc. other than the above that must be set, see the instruction

manual of the particular oscilloscope for details.

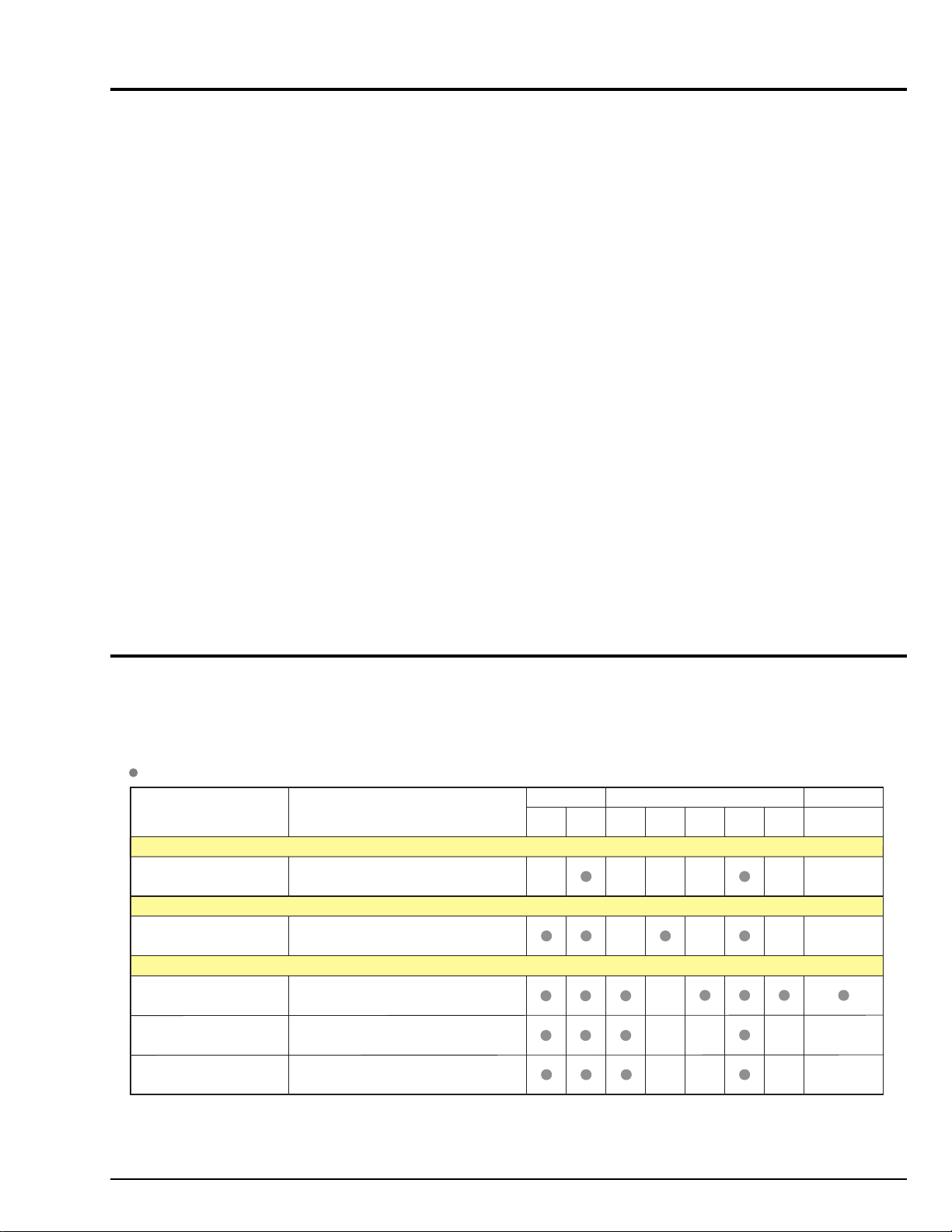

3. List of Adjustment Items

The following table shows the adjustment items, their purposes, and whether or not check is required after replacing major

components.

The components shown in the table below are the minimum to be checked after replacing major components: If several

components have been replaced - or depending on the cause of a defect - more components may need to be checked.

: CHECK or ADJUST

Items Purpose Adjustment

Data Initialize

Data Initilize (*2)

Electric Volume

CDS Sampling Pulse

Camera Adjustment (Adjustment)

Auto Iris

White Balance

Chroma Gain

Initilizing EEPROM.

To suppress noise in the CCD sensor

output signal and maximize the signal

level.

To set the iris control data.

To input the automatic white balance

control data.

To set the color satuation under the

reference color temperrature.

Circuit Boards

PC

S

(*1)

IC1001 IC1103 IC1106

Electrical Parts

IC1107

(*1)

IC1041

Other

Lens Block

*1: When replacing the PC circuit board (containing EEPROM) or EEPROM (IC1107), be sure to perform all adjustments

only after "Data Initialize".

*2: Since all adjustments must be performed any time "Data Initialize" is done, do not perform it indiscriminately.

3 - 3

Loading...

Loading...