Page 1

MODEL VH 650

1. ASSEMBLY/DISASSEMBLY GUIDE:

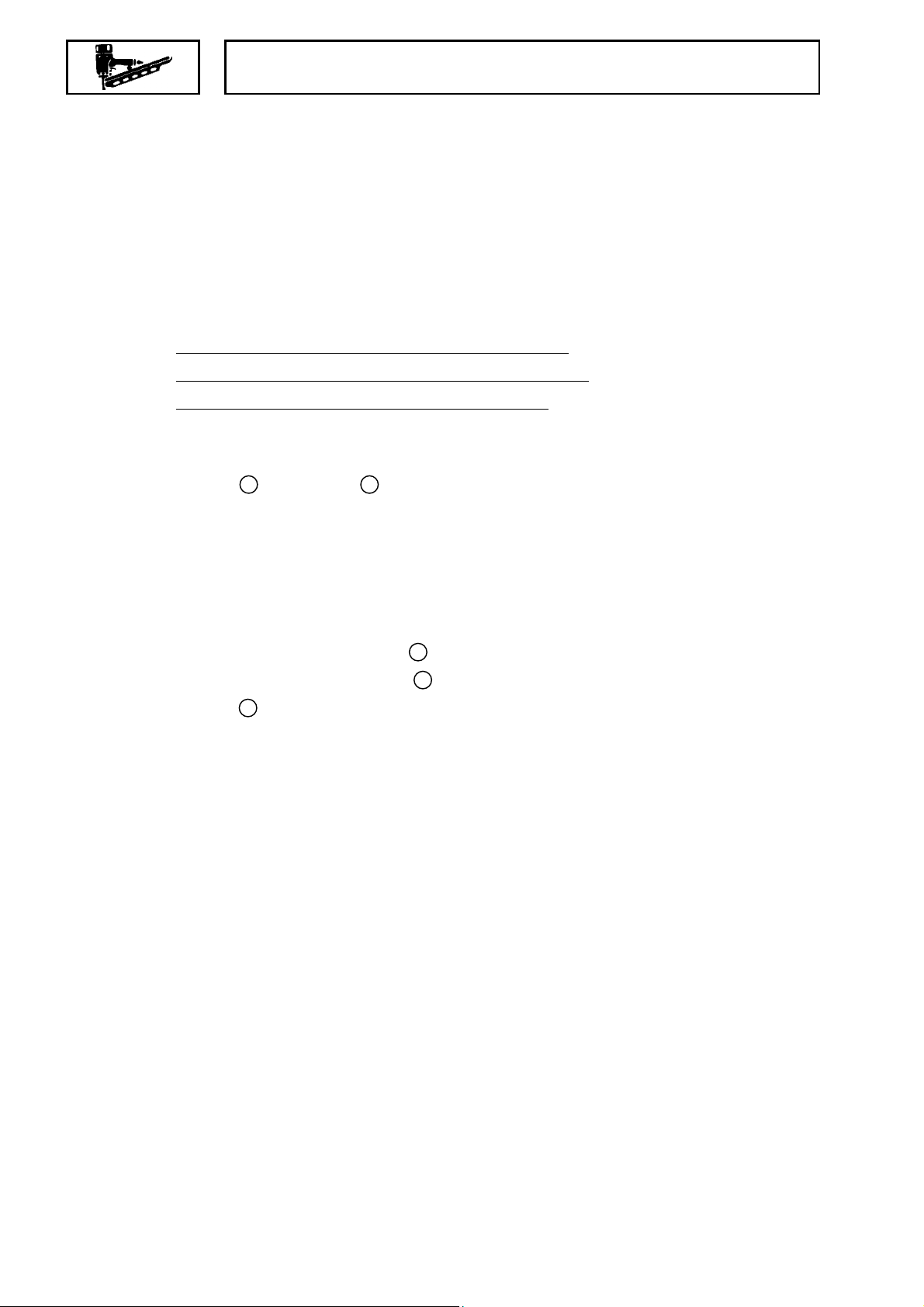

As mentioned above, the Type VH-650 can be said to consist of four

major sections : the Output Section, the Valve Section, the Nail

Feeder Section, and the Magazine Section. The descriptions below

explain important points in the disassembly and assembly of these

sections. The circled numbers in the descriptions correspond to

the part numbers in the Parts Price List.

CAUTION: Assembly/disassembly should be performed only after

the hose is removed from the nailer and any compressed

air remaining in the nailer is completely discharged.

1-1. Output Section:

A. Piston Damper

27

, Packing (A) 29, etc.

Tools Required:

φ

z#

3 Roll Pin Remover

z#

5 mm Hexagonal Bar Spanner (for M6 bolt)

z#

4 mm Hexagonal Bar Spanner (for M5 bolt)

(1) Disassembly:

z#

By removing the φ 3 x 30 Roll Pin 25, taking out the

M5 x 30 Hexagon Socket Hd. Bolt

Magazine

81

, the four M6 x 20 Hexagon Socket Hd.

65

retaining the

−

−

1

Page 2

Bolts 73, retaining the Tail Cover 36, the Piston

Damper

and Packing (A)

27

, Damper Ring 28, Cylinder Damper 26,

29

, can be removed. (see Fig. 9)

(Please note that the M6 x 20 Hexagon Socket Hd. Bolts

can be easily removed if the Nail Guide

23

Body

26

Cylinder Damper

27

Piston Damper

28

Damper Ring

29

Packing (A)

36

Tail Cover

13

92

is left open.)

43

Safety Plunger (B)

25

Roll Pin

Piston

55

Safety Lever

65

M5 x 30 Hex. Socket Bolt

83

81

Magazine

Cover

56

M5 Nut

2

Washer (2 pcs.)

73

M6 x 20

Hex. Socket Bolt

(4 pcs.)

57

58

Safety Guard

59

M5 x 10 Hex. Socket Bolt

Fig. 9 Piston damper, Packing (A)-di sassembl y/reassembly

(2) Assembly:

Assembly can be accomplished by following the disassembly

procedures in reverse. However, special attention should

be given to the following items:

Ensure that the Piston Ass’y 13 is positioned so its

z#

semicircular groove faces toward the Magazine

81

(see Fig. 10 below).

As Safety Plunger (B) 43, may drop out during dis-

z#

assembly, ensure it is properly assembled.

92

Nail Guide

M5 x 12 Hex. Socket Bolt (2 pcs.)

Ensure that the air vent on Packing (A) 21 is properly

z#

aligned with the air vent on the Tail Cover

Assembly can be more easily accomplished if the two

z#

M5 x 12 Hexagon Socket Hd. Bolts

36

.

57

which connect

− 2 −

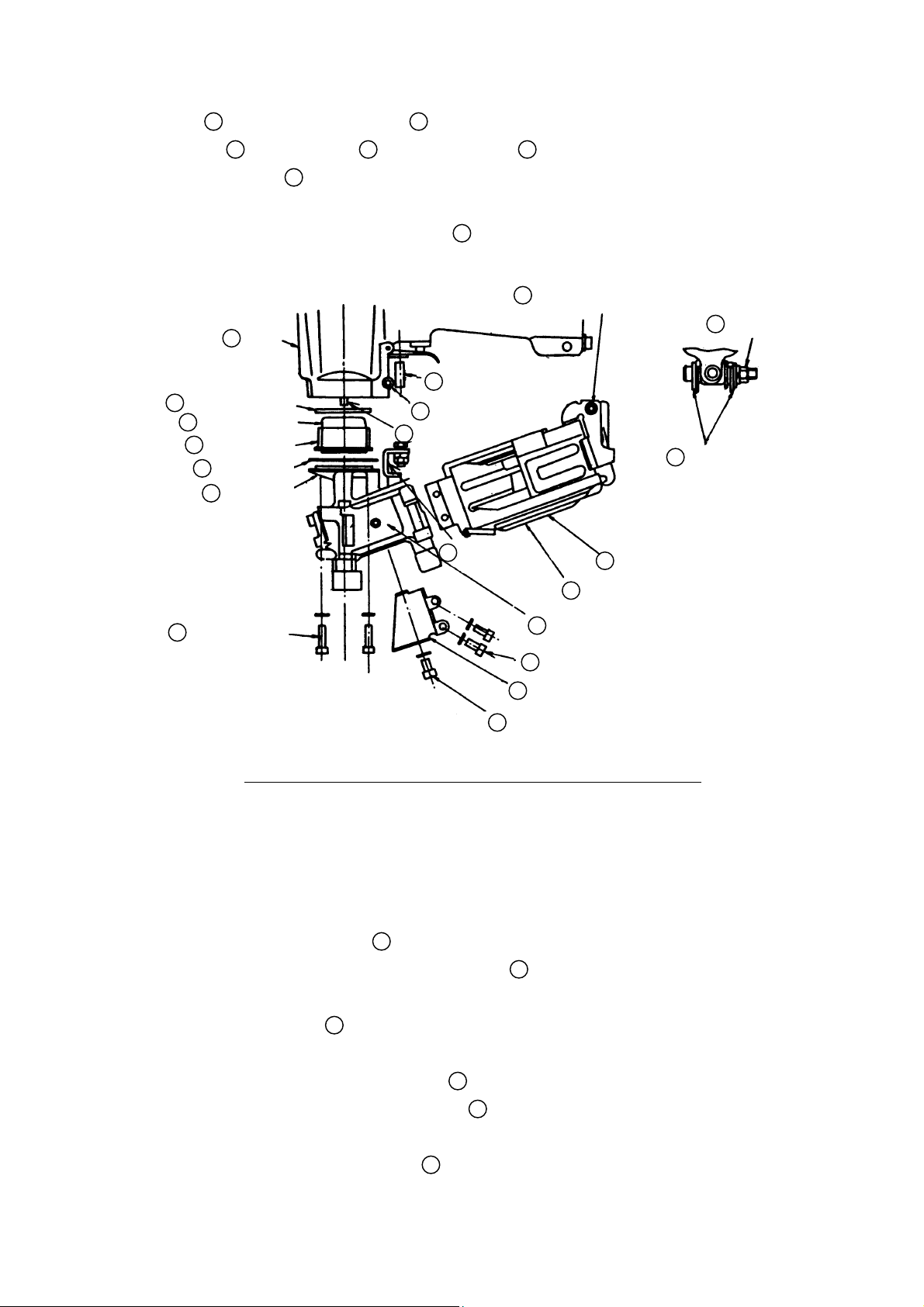

Page 3

the Tail Cover 36 and Magazine 81 are loosened.

Assemble the Body 23, Tail Cover 36, and

z#

81

Magazine

in the following sequence:

(a) Loosely assemble the Body

23

and Tail Cover

with the four M6 x 20 Hexagon Socket Hd. Bolts 73.

(b) After assembling the Safety Lever Ass’y

loosely assemble the Magazine

Cover

Hd. Bolts

36

with the two M5 x 12 Hexagon Socket

57

.

(c) Finally, assemble the Magazine

81

81

55

,

to the Tail

to the Body

with the M5 x 30 Hexagon Socket Hd. Bolt 65,

tightening it to rated torque.

(d) In the sequence of (b) (a) (c), ensure that all bolts

are securely tightened to rated torque.

Drive Bit

Piston

Piston Ass’y

Fig. 10 Semi-circle groove of piston ass’y

36

23

Semicircular Groove

B. Cylinder 18, Piston Ass’y 13, etc.:

Tools Required:

5 mm Hexagon Bar

z#

Spanner (for M6 bolt)

(1) Disassembly:

By removing the

z#

four M6 x 25

Hexagon Socket

Hd. Bolts

4

and taking off the

Exhaust Cover

Ass’y

Cylinder Plate

Packing (B)

the Cylinder

6

and

7

18

16

,

,

,

and the Piston

Ass’y

13

can be

removed. (see

7

Packing (B)

6

Exhaust Cover

4

M6 x 25

Hex. Socket

Bolt

13

Piston

18

Cylinder

16

Cylinder Plate

Fig. 11 Disassembly of Upper

Part of main body

Fig. 11)

− 3 −

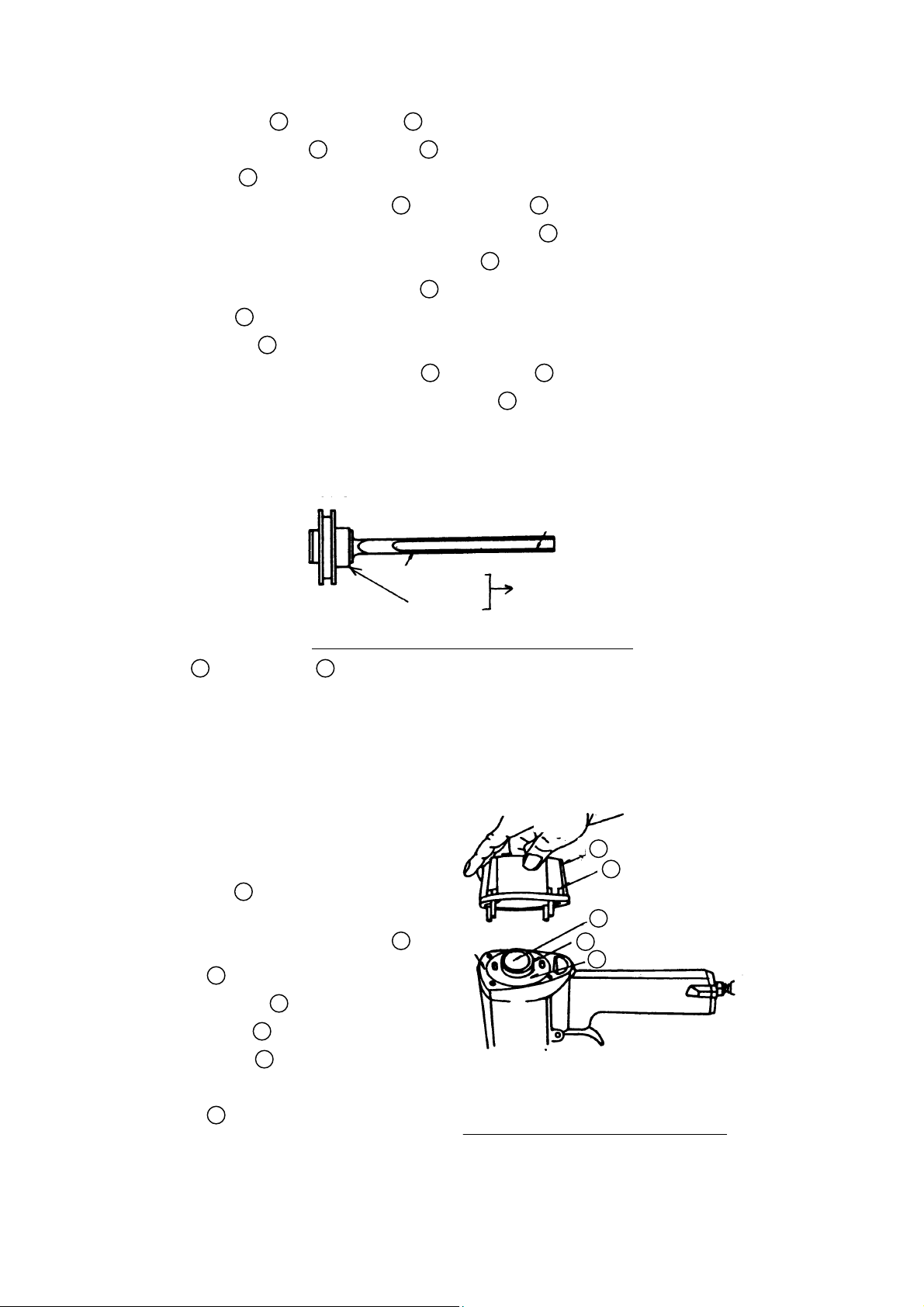

Page 4

If it is difficult to

z#

remove the Cylinder

Plate

16

, insert

two of the M6 x 25

Hexagon Socket Hd.

Bolts 4 part way

into the matching M6

holes on the Cylinder

Plate, and pull upwards while turning.

(see Fig. 12)

The Cylinder Spring

20

and other components which

constitute the Output

Section (see Fig. 13)

can then be removed.

Should it be difficult

z#

to remove the Cylinder

18

, first remove the

36

Tail Cover

, and

push the Cylinder

upwards and out from

below.

(2) Assembly:

Assembly can be accomplished by following the

disassembly procedures

in reverse. During

assembly, ensure that

the semicircular groove

on the Piston Ass’y

faces toward the Magazine

81

(as described above),

and that the air vent on

7

Packing (B)

is properly aligned with the air

vent on the Body

23

13

.

Fig. 12 Removal of

Cylinder plate

Cylinder

Cylinder spring

Cylinder guide

Body

23

4

M6 x 25

Cylinder plate

16

18

20

21

Hex. Socket Bolt

16

M6 threaded hole

16

Cylinder Plate

C. Head Cap Ass’y

Valve Rubber Ass’y

11

and

10

:

Tools Required:

4 mm Hexagon Bar Spanner (for M5 bolt)

z#

(1) Disassembly:

Remove the Exhaust Cover Ass’y (as described above).

z#

Fig. 13 Main body output

disassembly

− 4 −

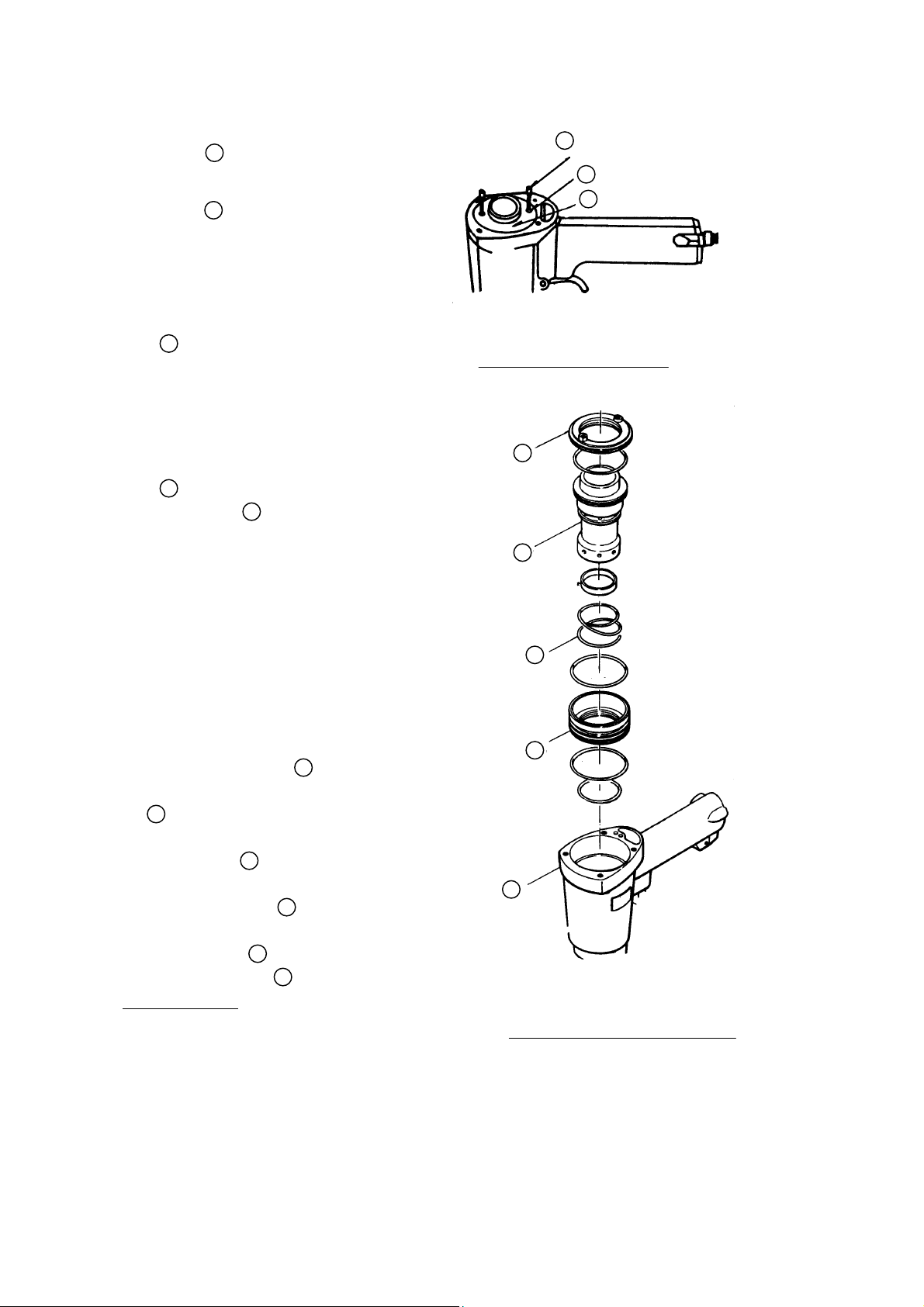

Page 5

Take out the two M5 x 35

z#

Hexagon Socket Hd.

Bolts

1

and remove the

Head Cap Ass’y

Valve Rubber Ass’y

and Packing (C)

(see Fig. 14)

(2) Assembly:

Assembly can be accom-

z#

plished by following the

11

8

M5 x 35

Hexagon Socket

1

,

10

,

Bolt

Top Cover

3

.

Exhaust

Cover

6

disassembly procedures

in reverse. During

assembly, be very careful

not to damage the O-Rings.

1-2. Valve Section:

A. Trigger Valve Bushing and

Safety Valve Bushing:

Tools Required:

φ

3 Roll Pin Remover

z#

Minus-Hd. Screwdriver

z#

(1) Disassembly:

Remove the Magazine

z#

section and Tail Cover

section as described in

section 1-1 above.

Take out the two φ 3 x 30

z#

Roll Pins

Remove the Trigger 42,

z#

25

Trigger Plunger

Safety Plunger (B)

(see Fig. 15)

Insert the minus-hd.

z#

screwdriver into the

groove of the Trigger Valve Bushing

Packing (C)

Valve rubber

Ass’y

Head cap

Ass’y

8

10

11

Fig. 14 Disassembly of main

body, upper parts

32

81

Plunger Spring

36

25

φ 3 x 30

Roll pin

39

.

49

, and

43

.

Safety plunger (A)

40

Safety valve bushing

47

Valve plate

48

Trigger Valve

bushing

49

Trigger

plunger

42

Trigger

25

φ 3 x 30

Roll pin

43

Safety

plunger (B)

Fig. 15 Disassembly of Valve

48

, and loosen it

by turning it counterclockwise, being careful not to

damage the groove. (see Fig. 15)

After the Trigger Valve Bushing 48 has been loosened,

z#

the Safety Valve Bushing

40

and Trigger Valve Bushing

− 5 −

48

Page 6

can be removed by pulling the Safety Valve Bushing 40.

(see Fig. 15)

(2) Assembly:

Assembly can be

z#

accomplished

by following

the disassembly

procedures in

reverse. During

assembly, be

vary careful not

to twist the

Plunger Spring

37

or damaged the

external O-Rings.

B. Adjustment of the Safety

Assembly

55

(see Fig. 16)

39

Safety

Plunger (A)

43

Safety

Plunger (B)

54

Safety Bolt

,

56

M5 Nut

55

36

Tail Cover

)

″

Safety Ass’y

(1) The Safety Ass’y

can be adjusted by

loosening the M5 Nut

56

and turning the

Safety Bolt

54

(2) Perform adjustment

to a point where the

pressure of Safety

Plunger (B)

43

pushing up Safety

Plunger (A)

39

be felt when the Safety Ass’y

the lower end of the Tail Cover

from the lower end of the Safety Ass’y

(0.118″ ± 0.020″).

1-3. Nail Feeder Section:

92

A. Nail Guide

(see Fig. 17):

Tools Required:

φ

3 Roll Pin Puller

z#

M3 Spanner

z#

(1) Disasembly:

Remove the φ 2 x 15 Split Cotter Pin 86 from the Tail

z#

.

can

55

Fig. 16 Safety assembly

55

is raised. At this point,

36

should be separated

55

by 3 mm ± 0.5 mm

± 0.020

″

3 ± 0.5mm

(0.118

adjustment

− 6 −

Page 7

Cover 36, take out the Nail Guide 85, and

remove the Nail Guide Ass’y

Loosen the M3 Nylon Nut 93, and remove the Stopper

z#

Bolt

Take out the φ 3 x 30 Roll Pin 25, and remove the Main

z#

Nail Stopper

Spring

To disassemble the Guide Lock 79, pull out the

z#

φ

3 x 10 Roll Pin

and the Spring 80.

Tail Cover

Nail Guide Shaft

92

.

90

and the two Thrust Washers 91.

74

, Sub Nail Stopper 75, Main Stopper

76

, and Sub Stopper Spring 77.

31

, and remove the Guide Lock

74

Main Nail Stopper

36

75

Sub-Nail Stopper

76

85

86

φ 2 Split

Cotter Pin

Thrust Washer

77

Sub-Stopper

Spring

25

φ 3 x 30 Roll Pin

Stopper Bolt

79

Main Stopper Spring

90

92

Nail Guide

91

93

78

M3 Nylon Nut

Lock Shaft

79

Guide Lock

80

Spring

31

φ 3 x 10 Roll Pin

Fig. 17 Disassembly and Reassembly of Nail Guide

(2) Assembly:

Assembly can be accomplished by following the disassembly

procedures in reverse. However, special attention should

be given to the following items:

Carefully clean any plastic particles or dust from the

z#

groove on the Nail Guide

When re-inserting the φ 3 x 30 Roll Pin 25, first tempo-

z#

rarily tighten the Stopper Bolt

Spring

76

and Sub Stopper Spring 77 in position. This

92

prior to assembly.

90

to hold the Main Stopper

will facilitate assembly.

− 7 −

Page 8

With the Thrust Washers 91, perform adjustment so

z#

that the protrusion of the Sub Nail Stopper

75

is within

2.3 mm ± 0.5 mm (0.09″ ± 0.020″), as illustrated in

Fig. 18.

91

90

Stopper bolt

Thrust Washer

Fig. 18 Assembly of Sub-nail stopper section

B. Safety Ass’y

55

By removing the φ 3 x 30 Roll Pin 25 as described in section

1-2, and then removing the Safety Guard

Ass’y

55

and the Safety Spring 53 can be removed.

58

, the Safety

)

″

± 0.020

″

2.3 ± 0.5mm

(0.09

70

C. Feed Pist on

, Main Feeder 34, and Sub Feeder 35:

Tools Required:

φ

2.5 and φ 3 Roll Pin Removers

z#

4 mm Hexagon Bar Spanner (for M5 bolt)

z#

(1) Disassembly:

Disassemble the Tail Cover 36 from the Body 23 as

z#

described in section 1-1, and remove the Magazine

and the Safety Ass’y 48. (see Fig. 19)

81

Magazine Ass’y

55

Safety Ass’y

53

Safety Spring

25

φ 3 x 30 Roll Pin

59

M5 x 10 Hex. Socket

Bolt (1 pc.)

58

Safety Guard

57

M5 x 12

Hex. Socket

Bolt (2 pcs.)

83

23

Body Ass’y

36

Tail Cover

73

M5 x 20 Hex. Socket Bolt (4 pcs.)

Fig. 19 Tail Cover Disassembly

− 8 −

Page 9

Take out the φ 2.5 x 10 Roll Pin from the Feed Piston 70,

z#

loosen the two M5 x 12 Hexagon Socket Hd. Bolts

67

and remove the Feed Piston Cover

68

. (see Fig. 20)

Pressing the Feed Piston 70 with a finger (as indicated

z#

by arrow mark

1

in Fig. 20), turn the Feeder

and Packing (E)

35

1/4 turn (arrow mark 2), and pull out the Feeder Shaft

33

(arrow mark 3). The Feed Piston 70, Feed

Spring

and Sub Feeder

72

, Main Feeder 34, Main Feeder Spring 30,

34

Main Feeder

30

Main Feeder Spring

35

can then be removed. (see Fig. 20)

(φ 2.5 Roll Pin Hole)

70

Feed Piston (72 Feed Spring)

68

33

Feeder Shaft

1

57

,

Packing (E)

67

Feed Piston Cover

35

Sub Feeder

71

φ 2.5 x 10 Roll Pin

Fig. 20 Feed Piston Disassembly

Take out the φ 3 x 10 Roll Pin 31 from the Feeder

z#

Shaft

Sub Feeder

33

, and disassemble the Feeder Shaft 33,

35

, and Sub Feeder Spring 32. (see

Fig. 21)

30

Main Feeder Spring

33

Feeder Shaft

57

M5 x 12 Hex. Socket Bolt (2 pcs.)

69

34

Main Feeder

72

Feed Spring

70

Feed Piston

O-Ring (P16)

31

φ 3 x 10 Roll Pin

32

Sub Feeder Spring

Fig 21 Feed Piston, Main Feeder, and

35

Sub-Feeder

Sub-Feeder Disassembly

− 9 −

Page 10

(2) Assembly:

Assembly can be accomplished by following the disassembly

procedures in reverse. However, special attention should

be given to the following items:

Ensure that the Sub

z#

Feeder 35 and the

Feeder Shaft

are assembled so

33

33

Feeder Shaft

that the groove on

the shaft is on the

right-hand side as

illustrated in

Fig. 22.

In assembling the

z#

31

φ 3 x 10 Roll Pin

Fig. 22 Sub-feeder

Feed Piston section,

first put the Feed

Spring 72 onto the

Feed Piston 70,

ensuring that the

O-Ring (R16)

69

is properly fitted to

the O-Ring groove

on the Piston. Next,

while pressing the

Feed Piston 70 in

with a finger as

illustrated Fig. 23,

insert the Main

Feeder 34 from

Fig. 23 Feed piston assembly

below, and set the

Main Feeder Spring 30.

Then, insert the

Feeder Shaft

33

through the holes of

the Main Feeder

Spring 30, Main

Feeder 34, and the

Feed Piston 70.

Main Feeder

Foot

Finally, align the

φ

2.5 groove on the

Fig. 24 Installing Main

Feeder Shaft 33 with

the φ 2.5 hole in the

Feed Piston 70, and insert the φ 2.5 x 10 Roll Pin 71.

At this time, ensure that the Main Feeder Spring

30

spring hook section securely catches on the foot of the

Main Feeder 34, as illustrated in Fig. 24.

For assembly of the Body 23 and Magazine 81, please

z#

refer to section 1-1.

φ 2.5 Groove

32

Sub Feeder Spring

35

Sub Feeder

assembly

34

Main Feeder

Feeder Piston is

pushed up

33

Feeder Shaft

Main Feeder

Spring Hook

feeder spring

70

Feeder Piston

− 10 −

Page 11

1-4. Magazine Section:

Tools Required:

5 mm Hexagon Bar Spanner

z#

(1) Disassembly:

As described in section 1-1, remove the M5 x 30 Hexagon

z#

Socket Hd. Bolt

Bolts

57

, and the M5 x 10 Hexagon Socket Hd. Bolts 59,

and take off the Magazine Ass’y

Open the cover, remove the M5 Hexagon Socket Round Hd.

z#

Screw

83

Remove the M5 x 25 Hexagon Socket Hd. Bolt 66, push

z#

84

, and disassemble the Washer 64, Nail Holder

, and Holder Spring 82.

out the Magazine Stopper

the Magazine Stopper

the Collar

65

, the two M5 x 12 Hexagon Socket Hd.

62

. (see Fig. 25)

81

.

61

from below, and disassemble

61

, Magazine Lock Spring 60, and

(2) Assembly:

Assembly can be accomplished by following the disassembly

procedures in reverse.

CAUTION: The Magazine Lock Spring

into the Magazine Stopper

60

must be inserted

61

from above.

81

Magazine Ass’y

82

Holder Spring

66

M5 x 25

Hex. Socket Bolt

84

64

Washer

83

Nail Holder

M5 Hex. Socket Screw

Fig. 25 Magazine ass’y disassembly

60

Magazine Lock Spring

61

Magazine Stopper

62

Collar

56

M5 Nut

− 11 −

Page 12

1-5. Assembly Precauti ons:

The O-Rings and their associated parts should be carefully

z#

lubricated. Hitachi Electric Tool Grease or Hitachi Motor

Grease is recommended. When fitting the O-Rings, particular

attention should be exercised to avoid damaging the O-Rings

and allowing drift and dust from entering the assembly.

Damaged, worn, or deformed packings should be replaced, and

z#

the assembly should be checked for air leaks.

Ensure that no foreign matter is allowed to enter the Valve

z#

Section.

The sliding portions of the Nail Feeder should be lubricated

z#

with grease or accessory oil.

The table below lists the appropriate tightening torque for

z#

various bolts, nuts and screws.

Table 8

Type of Screw Tightening Torque

M6 Hex. Socket Bolt

M5 Hex. Socket Bolt

M5 Hex. Socket Screw

M5 Nut

M3 Nylon Nut

100 ± 8 kg-cm (7.2 ± 0.6 ft. lb)

65 ± 5 kg-cm (4.7 ± 0.4 ft. lb)

43 ± 3 kg-cm (3.1 ± 0.2 ft. lb)

35 ± 3 kg-cm (2.5 ± 0.2 ft. lb)

9 ± 0.7 kg-cm (0.7 ± 0.05 ft. lb)

1-6. Checks After Assembl y:

Manually check the Main Feeder, Sub Feeder, Main Nail Stopper,

z#

and Sub Nail Stopper to ensure they are properly assembled and

function correctly.

Check each component for air leaks.

z#

Check for reliable performance of the Feed Piston under pneumatic

z#

pressure of 3 kg/cm

2

(43 psi). (Perform this check with the Nail

Guide open and with idling operation.)

Nailing operation at 4 kg/cm2 (60 psi) should not result in idling

z#

operation or bending of the nails.

Check the tightening torque of all nuts, bolts and screws.

z#

− 12 −

Loading...

Loading...