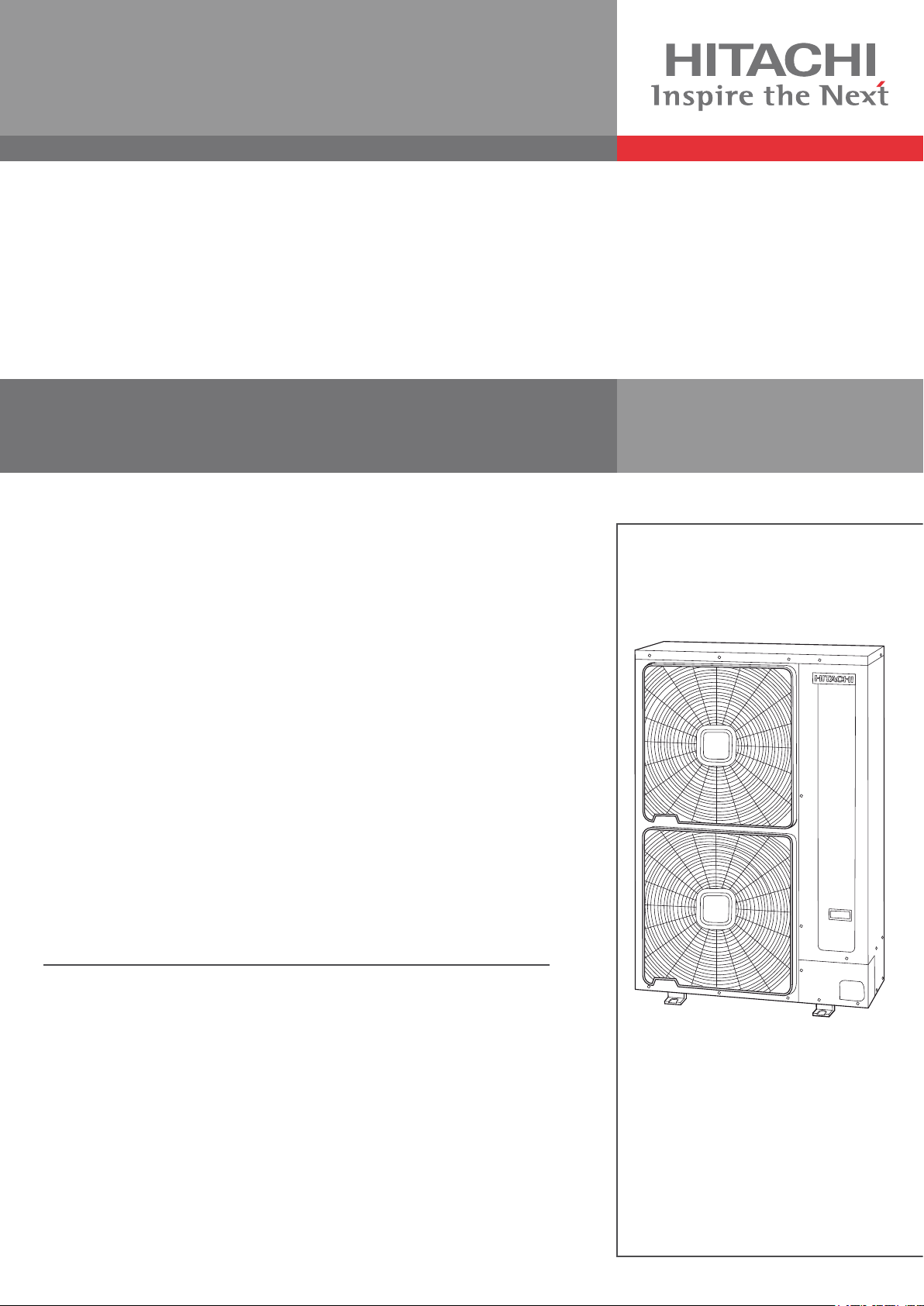

Hitachi RAS-4FSVN2E, RAS-6FSVN2E, RAS-4FSNY2E, RAS-5FSVN2E, RAS-5FSNY2E Technical Catalogue

...

SET-FREE MINI series

Technical Catalogue

RAS-(4-6)FSVN2E

RAS-(4-6)FSNY2E

Index

I n d e x

1

General information

2

Features and benets

3

General data

4

Capacities and selection data

Acoustic characteristic curves

Working range

General dimensions

Refrigerant cycle

Piping work and refrigerant charge

Electrical wiring

Optional functions

5

6

7

8

9

10

11

III

TCGB0068 rev.1 - 08/2012

12

Troubleshooting

Index

IV

TCGB0068 rev.1 - 08/2012

General Index

Index

1. General information ...................................................................................................1

1.1. General information .................................................................................................................................2

1.1.1. General notes .............................................................................................................................................. 2

1.1.2. Introduction .................................................................................................................................................. 2

1.1.3. Environment-friendly units ........................................................................................................................... 2

1.2. Applied symbols ......................................................................................................................................3

1.3. Product guide ..........................................................................................................................................4

1.3.1. Classication of outdoor unit models ........................................................................................................... 4

1.3.2. Classication of indoor unit models ............................................................................................................. 4

1.3.3. Product guide: Outdoor units ....................................................................................................................... 5

1.3.4. Product guide: Indoor units .......................................................................................................................... 6

1.3.5. Accessory code list .................................................................................................................................... 10

2. General data ............................................................................................................. 11

2.1. General data..........................................................................................................................................12

2.1.1. General conditions ..................................................................................................................................... 12

2.1.2. RAS-4FS(V)N(Y)2E ................................................................................................................................... 13

2.1.3. RAS-5FS(V)N(Y)2E ................................................................................................................................... 14

2.1.4. RAS-6FS(V)N(Y)2E ................................................................................................................................... 15

2.2. Component data ....................................................................................................................................16

2.2.1. RAS-(4-6)FSVN2E .................................................................................................................................... 16

2.2.2. RAS-(4-6)FSNY2E .................................................................................................................................... 16

2.2.3. Compressors ............................................................................................................................................. 17

2.3. Electrical data .......................................................................................................................................18

2.3.1. Considerations ........................................................................................................................................... 18

2.3.2. RAS-(4-6)FS(V)N(Y)2E ........................................................................................................................... 18

3. Features and benefits ..............................................................................................19

3.1. Selection benets .................................................................................................................................. 20

3.1.1. Wide range of units, accessories and remote controls .............................................................................. 20

3.1.2. High number of connectable indoor units .................................................................................................. 22

3.1.3. Individual operation ................................................................................................................................... 23

3.1.4. Assisted air conditioning installation design by Hi-Tool kit selection software ........................................... 23

3.2. Installation benets................................................................................................................................24

3.2.1. Easy and exible unit installation ............................................................................................................... 24

3.2.2. Easy and exible electrical installation ...................................................................................................... 24

3.2.3. Easy and exible control connection (Central Station, BMS Interface, CS-NET WEB) ............................. 26

3.3. Start-up benets .................................................................................................................................... 27

3.3.1. Automatic start-up test ............................................................................................................................... 27

3.3.2. Service verication .................................................................................................................................... 28

3.4. Functionality benets.............................................................................................................................29

3.4.1. Expanded temperature range .................................................................................................................... 29

3.4.2. Wide capacity range .................................................................................................................................. 30

3.4.3. Increased maximum piping length ............................................................................................................. 30

V

TCGB0068 rev.1 - 08/2012

General Index

3.4.4. Advanced technology ................................................................................................................................ 31

3.5. Maintenance benets ............................................................................................................................40

3.5.1. Minimum maintenance .............................................................................................................................. 40

3.5.2. Easy accessibility ...................................................................................................................................... 40

3.5.3. Alarm codes ............................................................................................................................................... 40

3.5.4. SMS alarm ................................................................................................................................................. 40

3.5.5. Availability of maintenance tools ............................................................................................................... 40

4. Capacities and selection data ................................................................................. 41

4.1. System selection procedure .................................................................................................................. 42

4.1.1. SET FREE MINI system posibilities .......................................................................................................... 42

4.1.2. Selection parameters ................................................................................................................................. 45

4.1.3. Selection procedure ................................................................................................................................... 45

4.2. Cooling capacity tables .........................................................................................................................51

4.2.1. Cooling capacity curve .............................................................................................................................. 51

4.2.2. Nominal cooling capacity tables ................................................................................................................ 52

4.2.3. Cooling capacity tables according to total power of combined indoor units .............................................. 53

4.3. Heating capacity tables .........................................................................................................................68

4.3.1. Heating capacity curve .............................................................................................................................. 68

4.3.2. Nominal heating capacity tables ................................................................................................................ 69

4.3.3. Heating capacity tables according to total power of combined indoor units .............................................. 70

4.4. Correction factors .................................................................................................................................. 86

4.4.1. Piping length correction factor ................................................................................................................... 86

4.4.2. Defrost correction factor ............................................................................................................................ 89

4.4.3. Correction ratio due to humidity (CR) ........................................................................................................ 89

5. Acoustic characteristic curves ............................................................................... 91

5.1. Overall sound level ................................................................................................................................92

5.2. Sound data ............................................................................................................................................ 93

6. Working range ..........................................................................................................95

6.1. Working range ....................................................................................................................................... 96

6.1.1. Power supply ............................................................................................................................................. 96

6.1.2. Temperature range .................................................................................................................................... 96

7. General dimensions ................................................................................................. 97

7.1. Dimensions............................................................................................................................................98

7.2. Service space ........................................................................................................................................99

8. Refrigerant cycle ....................................................................................................101

8.1. RAS-(4-6)FS(V)N(Y)2E ....................................................................................................................... 102

9. Piping work and refrigerant charge .....................................................................103

9.1. Refrigerant piping selection .................................................................................................................104

9.1.1. Piping size selection ................................................................................................................................ 104

9.1.2. Multi-kit or distributor selection ................................................................................................................ 104

VI

TCGB0068 rev.1 - 08/2012

General Index

9.2. Refrigerant piping range ......................................................................................................................104

9.2.1. Refrigerant piping length ......................................................................................................................... 104

9.2.2. Refrigerant piping size ............................................................................................................................. 107

9.3. Distribution method .............................................................................................................................108

9.3.1. Header branch piping system .................................................................................................................. 108

9.3.2. Line branch piping system ....................................................................................................................... 109

9.3.3. Combination branch piping system ..........................................................................................................111

9.4. Piping materials and connection ......................................................................................................... 112

9.4.1. Copper pipes and sizes ............................................................................................................................112

9.4.2. Pipe connection ........................................................................................................................................113

9.4.3. Insulation ..................................................................................................................................................113

9.5. Refrigerant charge amount.................................................................................................................. 114

9.5.1. Refrigerant charge before shipment (W0 (kg)) ..........................................................................................114

9.5.2. Additional refrigerant charge calculation method .....................................................................................114

9.5.3. Additional refrigerant charge calculation example ...................................................................................115

9.6. Caution in case of refrigerant leakage................................................................................................. 116

9.6.1. Maximum permitted concentration of hydrouorocarbon (HFC) ...............................................................116

9.6.2. Calculation of refrigerant concentration ....................................................................................................116

9.6.3. Countermeasure for refrigerant leakage ...................................................................................................116

10. Electrical wiring ..................................................................................................... 119

10.1. General information ............................................................................................................................. 120

10.1.1. General notes ..........................................................................................................................................120

10.1.2. General verications ................................................................................................................................ 120

10.2. Setting of DIP switches and RSW switches ........................................................................................ 122

10.3. Common wiring ...................................................................................................................................124

10.3.1. Electrical wiring between outdoor and indoor unit ................................................................................... 124

10.3.2. Wiring size ...............................................................................................................................................125

10.4. H-LINK II system .................................................................................................................................126

10.4.1. Application ...............................................................................................................................................126

10.4.2. Features .................................................................................................................................................. 126

10.4.3. Specications .......................................................................................................................................... 126

10.4.4. DIP switch setting for multiple H-LINK system ........................................................................................ 127

10.4.5. Examples of the system of connection between H-LINK and H-LINK II units ......................................... 128

10.4.6. Examples of H-LINK II system ................................................................................................................. 129

11. Optional functions ................................................................................................. 131

11.1. RAS-(4-6)FS(V)N(Y)2E ....................................................................................................................... 132

11.2. For operation with CS-NET WEB ........................................................................................................ 133

12. Troubleshooting ..................................................................................................... 135

12.1. On-screen displays during abnormal operation .................................................................................. 136

12.2. Alarm codes ........................................................................................................................................137

VII

TCGB0068 rev.1 - 08/2012

1 General information

G e n e r a l i n f o r m a t i o n

1.

Index

1.1. General information .................................................................................................................................2

1.1.1. General notes .............................................................................................................................................. 2

1.1.2. Introduction .................................................................................................................................................. 2

1.1.3. Environment-friendly units ........................................................................................................................... 2

1.2. Applied symbols ......................................................................................................................................3

1.3. Product guide ..........................................................................................................................................4

1.3.1. Classication of outdoor unit models ........................................................................................................... 4

1.3.2. Classication of indoor unit models ............................................................................................................. 4

1.3.3. Product guide: Outdoor units ....................................................................................................................... 5

1.3.4. Product guide: Indoor units .......................................................................................................................... 6

1.3.5. Accessory code list ...................................................................................................................................... 9

1

1

TCGB0068 rev.1 - 08/2012

1 General information

1.1 General information

1.1.1 General notes

No part of this publication may be reproduced, copied, led or transmitted in any shape or form without the permission of

HITACHI Air Conditioning Products Europe, S.A.

Within the policy of continuous improvement of its products, HITACHI Air Conditioning Products Europe, S.A. reserves the

right to make changes at any time without prior notication and without being compelled to introducing them into products

subsequently sold. This document may therefore have been subject to amendments during the life of the product.

HITACHI makes every effort to offer correct, up-to-date documentation. Despite this, printing errors cannot be controlled by

HITACHI and are not its responsibility.

As a result, some of the images or data used to illustrate this document may not refer to specic models. No claims will be

accepted based on the data, illustrations and descriptions included in this manual.

No type of modication must be made to the equipment without prior, written authorisation from the manufacturer.

1.1.2 Introduction

Hitachi presents the inverter-driven home central air-conditioning SET FREE mini series product, which is characterized

by energy-saving, high efciency, comfort, environmental protection, stability and reliability. In order to meet the requirement of increasing the control intelligence of equipment and of comfort, the intelligent control, energy-saving operation and

comfortableness are more important. Especially the business building, building ofce, villa, apartment and residential area

etc, need an intelligent and confortable environment through all year. The better air conditioning solution can be provided

for these buildings by inverter- driven and scroll compressor that the structure can been improved.

1.1.3 Environment-friendly units

This range of HITACHI outdoor units uses environmentally-friendly

R410A gas refrigerant, and the RoHS and Green Dot regulations are

applied throughout the manufacturing and installation process to reect

HITACHI’s awareness of environmental respect and commitment.

R410A is totally environmentally-friendly since it does not contain

any substances that damage the ozone layer: ODP (ozone depleting product) =0.

2

TCGB0068 rev.1 - 08/2012

1 General information

1.2 Applied symbols

During normal air conditioning system design work or unit installation, greater attention must be paid in certain situations

requiring particular care in order to avoid damage to the unit, the installation or the building or property.

Situations that jeopardise the safety of those in the surrounding area or that put the unit itself at risk will be clearly indicated

in this manual.

To indicate these situations, a series of special symbols will be used to clearly identify these situations.

Pay close attention to these symbols and to the messages following them, as your safety and that of others depends on it.

D A N G E R

• The text following this symbol contains information and instructions relating directly to your safety and physical wellbeing.

• Not taking these instructions into account could lead to serious, very serious or even fatal injuries to you and

others in the proximities of the unit.

In the texts following the danger symbol you can also nd information on safe procedures during unit installation.

C A U T I O N

• The text following this symbol contains information and instructions relating directly to your safety and physical wellbeing.

• Not taking these instructions into account could lead to minor injuries to you and others in the proximities of

the unit.

• Not taking these instructions into account could lead to unit damage.

In the texts following the caution symbol you can also nd information on safe procedures during unit installation.

N O T E

• The text following this symbol contains information or instructions that may be of use or that require a more

thorough explanation.

• Instructions regarding inspections to be made on unit parts or systems may also be included.

1

3

TCGB0068 rev.1 - 08/2012

1 General information

1.3 Product guide

1.3.1 Classication of outdoor unit models

Unit type (Outdoor unit):

Position-separating hyphen (xed)

Compressor power (HP): 4, 5, 6

FS = SET-FREE system

V = Single phase unit (1~ 230V 50Hz)

N = R410A refrigerant

Y = Three phase unit (3N~ 400V 50Hz)

Series

RAS – X FS (V) N (Y) 2 E

1.3.2 Classication of indoor unit models

E = Made in Europe

Unit type (indoor unit): RCI, RCIM, RCD, RPC, RPI, RPIM, RPK, RPF, RPFI

Position-separating hyphen (xed)

Capacity (HP): 0.8, 1, 1.5, 2, 2.5, 3, 4, 5, 6

FS = SYSTEM FREE

N = R410A refrigerant

H = Hotel (RPK-(1.0/1.5) only)

2/3/4 = series

E = Made in Europe

M = Made in Malaysia

– = Made in Japan

i = Version up (RCI only)

DU = Drain Up (RPIM only)

XXX – X.X FS N (H) X (X) i (-DU)

4

TCGB0068 rev.1 - 08/2012

1 General information

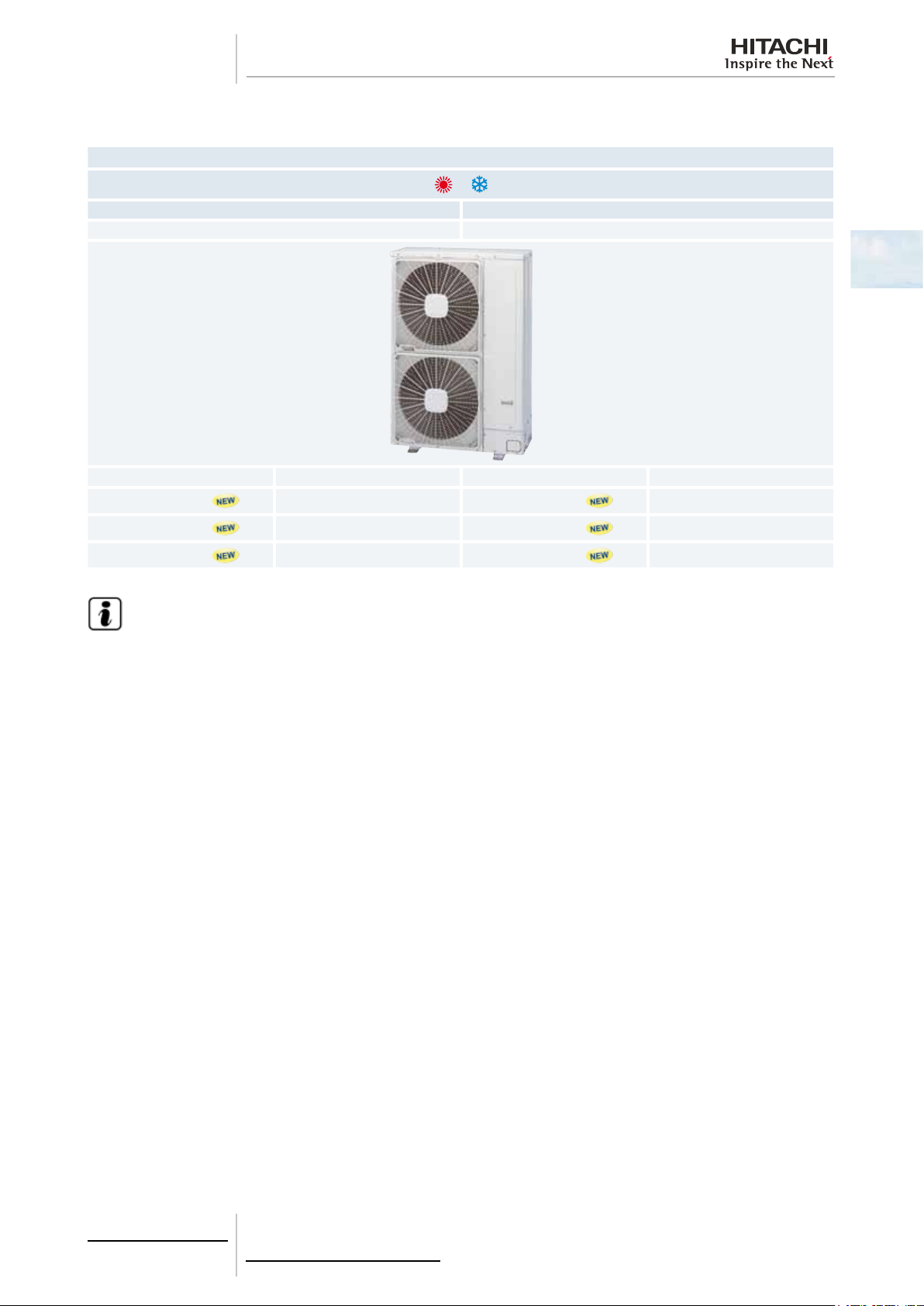

1.3.3 Product guide: Outdoor units

1~ 3N~

FSVN2E FSNY2E

Unit Code Unit Code

RAS-4FSVN2E

RAS-5FSVN2E

RAS-6FSVN2E

7E320007

7E320008

7E320009

Outdoor units

RAS-4FSNY2E

RAS-5FSNY2E

RAS-6FSNY2E

1

7E320107

7E320108

7E320109

N O T E

Check the exact classication for each unit (model, type, power and series) in Classication of outdoor unit mo-

dels.

5

TCGB0068 rev.1 - 08/2012

1 General information

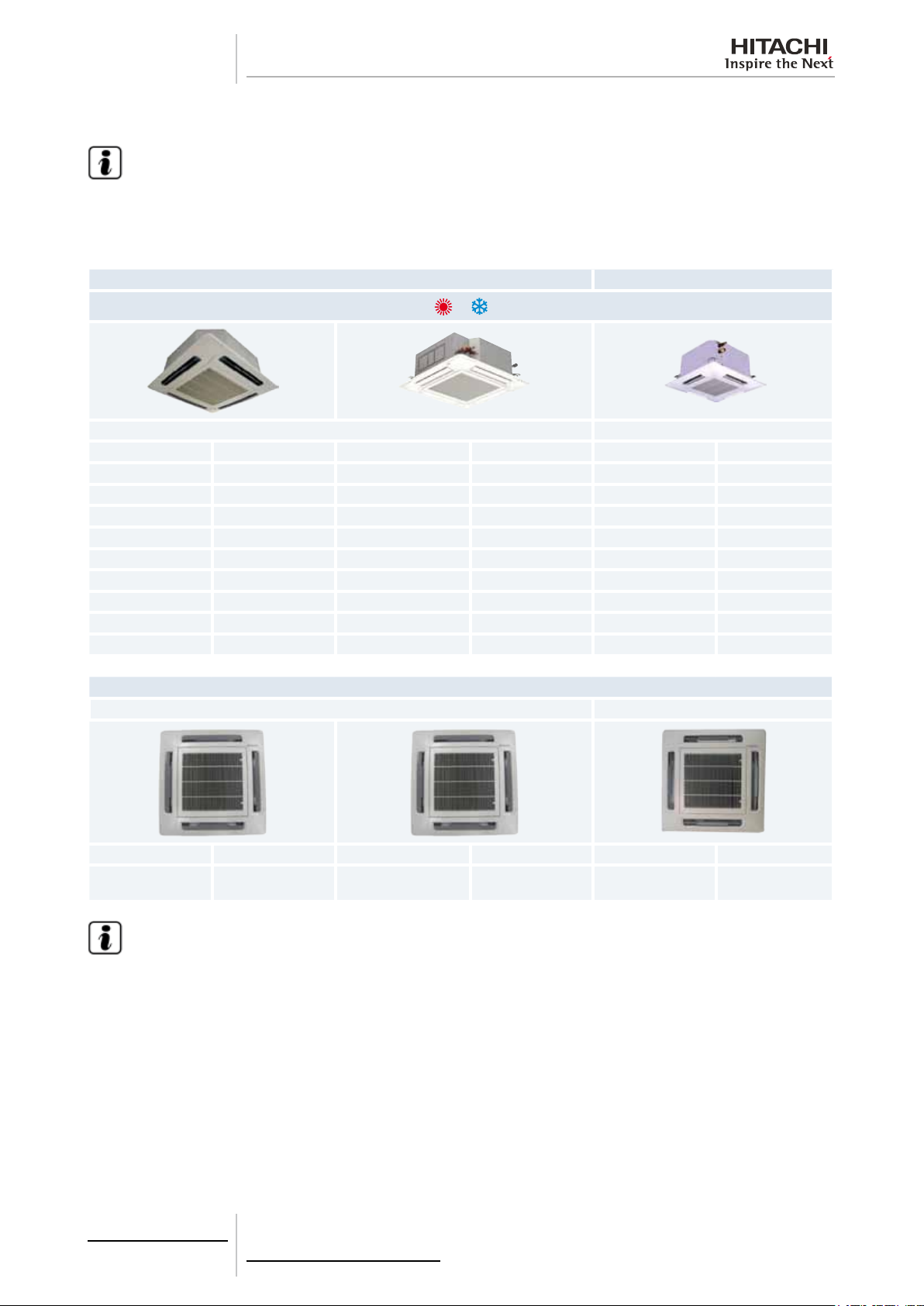

1.3.4 Product guide: Indoor units

N O T E

• The indoor unit models and codes are the last updated at time of publication; other previous models and coming developments could be available for combination with this outdoor unit series.

• Check the exact classication for each unit (model, type, power and series) in Classication of indoor unit

mo dels.

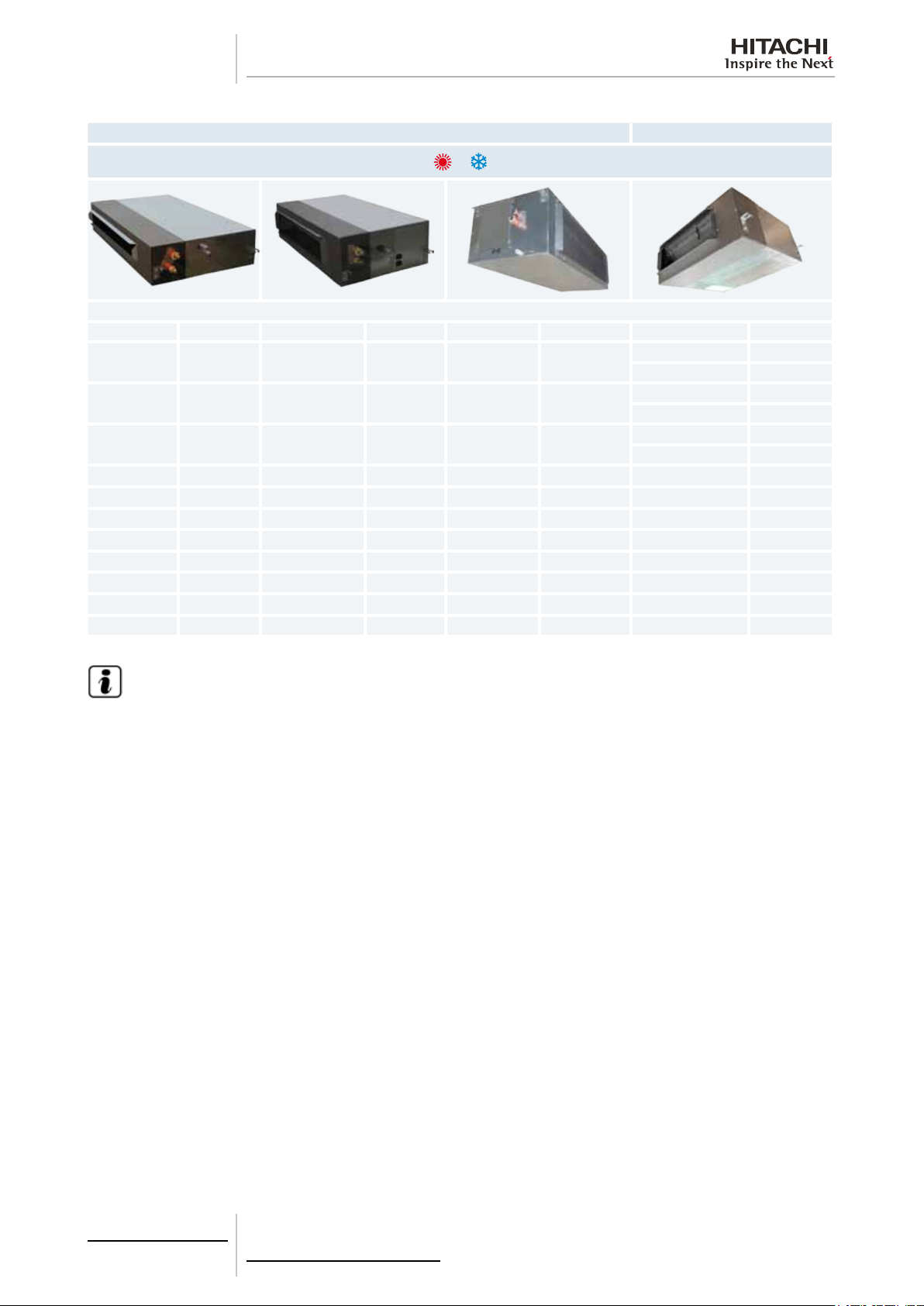

RCI RCIM

4-way cassette 4-way cassette (compact)

Unit Code Unit Code Unit Code

RCIM-0.8FSN2 60278010

RCI-1.0FSN3Ei 7E403014 RCI-1.0FSN3 (*) 60278119 RCIM-1.0FSN2 60278011

RCI-1.5FSN3Ei 7E403015 RCI-1.5FSN3 (*) 60278120 RCIM-1.5FSN2 60278013

RCI-2.0FSN3Ei 7E403016 RCI-2.0FSN3 (*) 60278121 RCIM-2.0FSN2 60278014

RCI-2.5FSN3Ei 7E403017 RCI-2.5FSN3 (*) 60278122

RCI-3.0FSN3Ei 7E403018 RCI-3.0FSN3 (*) 60278123

RCI-4.0FSN3Ei 7E403020 RCI-4.0FSN3 (*) 60278124

RCI-5.0FSN3Ei 7E403021 RCI-5.0FSN3 (*) 60278125

RCI-6.0FSN3Ei 7E403022 RCI-6.0FSN3 (*) 60278126

Panels

RCI RCIM

P-N23NA 70531000 P-AP160NA1 60297215 P-N23WAM 60197160

P-AP160NAE

(With motion sensor)

60297217

N O T E

• The RCI and RCIM models must be used in combination with the panels indicated above.

• (*): Series available from October 2012.

6

TCGB0068 rev.1 - 08/2012

1 General information

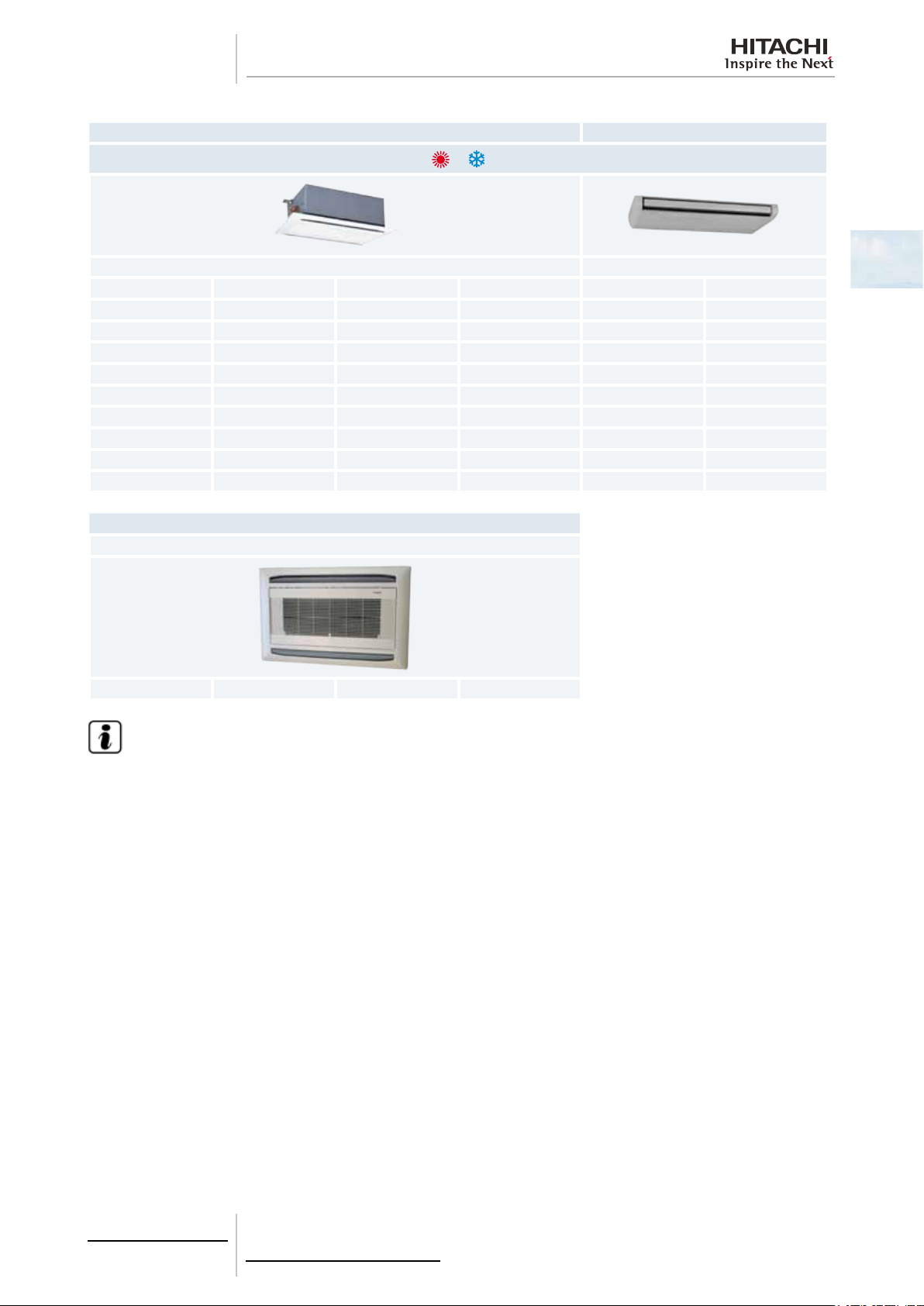

RCD RPC

2-way cassette Ceiling type

Unit Code Unit Code

RCD-1.0FSN2 60278029

RCD-1.5FSN2 60278030

RCD-2.0FSN2 60278031 RPC-2.0FSN2E 7E440003

RCD-2.5FSN2 60278032 RPC-2.5FSN2E 7E440004

RCD-3.0FSN2 60278033 RPC-3.0FSN2E 7E440005

RCD-4.0FSN2 60278034 RPC-4.0FSN2E 7E440007

RCD-5.0FSN2 60278035 RPC-5.0FSN2E 7E440008

RPC-6.0FSN2E 7E440009

1

Panels

RCD

P-N23DNA 60297211 P-N46DNA 60297212

N O T E

RCD models must be used in combination with the panels indicated above.

7

TCGB0068 rev.1 - 08/2012

1 General information

RPI RPIM

Indoor ducted unit

Unit Code Unit Code Unit Code Unit Code

RPI-0.8FSN4E 7E424013

RPI-1.0FSN4E 7E424014

RPI-1.5FSN4E 7E424015

RPI-2.0FSN4E

RPI-2.5FSN4E

RPI-3.0FSN4E

RPI-4.0FSN4E

RPI-5.0FSN4E

RPI-6.0FSN4E

(*)

(*)

(*)

(*)

(*)

(*)

7E424016

7E424017

7E424018

7E424020

7E424021

7E424022

RPI-8.0FSN3E 7E424010

RPI-10.0FSN3E 7E424011

RPIM-0.8FSN4E 7E430013

RPIM-0.8FSN4E-DU 7E431013

RPIM-1.0FSN4E 7E430014

RPIM-1.0FSN4E-DU 7E431014

RPIM-1.5FSN4E 7E430015

RPIM-1.5FSN4E-DU 7E431015

N O T E

(*): Series available from October 2012. Before this date indoor units FSN3E series are available

8

TCGB0068 rev.1 - 08/2012

1 General information

RPK RPF RPFI

Wall type Floor type Floor concealed type

Unit Code Unit Code Unit Code

RPK-0.8FSN3M (*) 60278146

RPK-0.8FSNH3M (*) 60278154

RPK-1.0FSN3M (*) 60278147

RPK-1.0FSNH3M (*) 60278155

RPK-1.5FSN3M (*) 60278148

RPK-1.5FSNH3M (*) 60278156

RPK-2.0FSN3M (*) 60278149 RPF-2.0FSN2E 7E450003 RPFI-2.0FSN2E 7E460003

RPK-2.5FSN3M (*) 60278150 RPF-2.5FSN2E 7E450004 RPFI-2.5FSN2E 7E460004

RPK-3.0FSN3M (*) 60278151

RPK-4.0FSN3M (*) 60278152

EV-1.5N (**) 60291612

RPF-1.0FSN2E 7E450001 RPFI-1.0FSN2E 7E460001

RPF-1.5FSN2E 7E450002 RPFI-1.5FSN2E 7E460002

1

N O T E

• (*): Series available from October 2012. Before this date indoor units FSN(H)2M series are available.

• (**): For RPK-(0.8-1.5)FSNH(2/3)M models only.

9

TCGB0068 rev.1 - 08/2012

1 General information

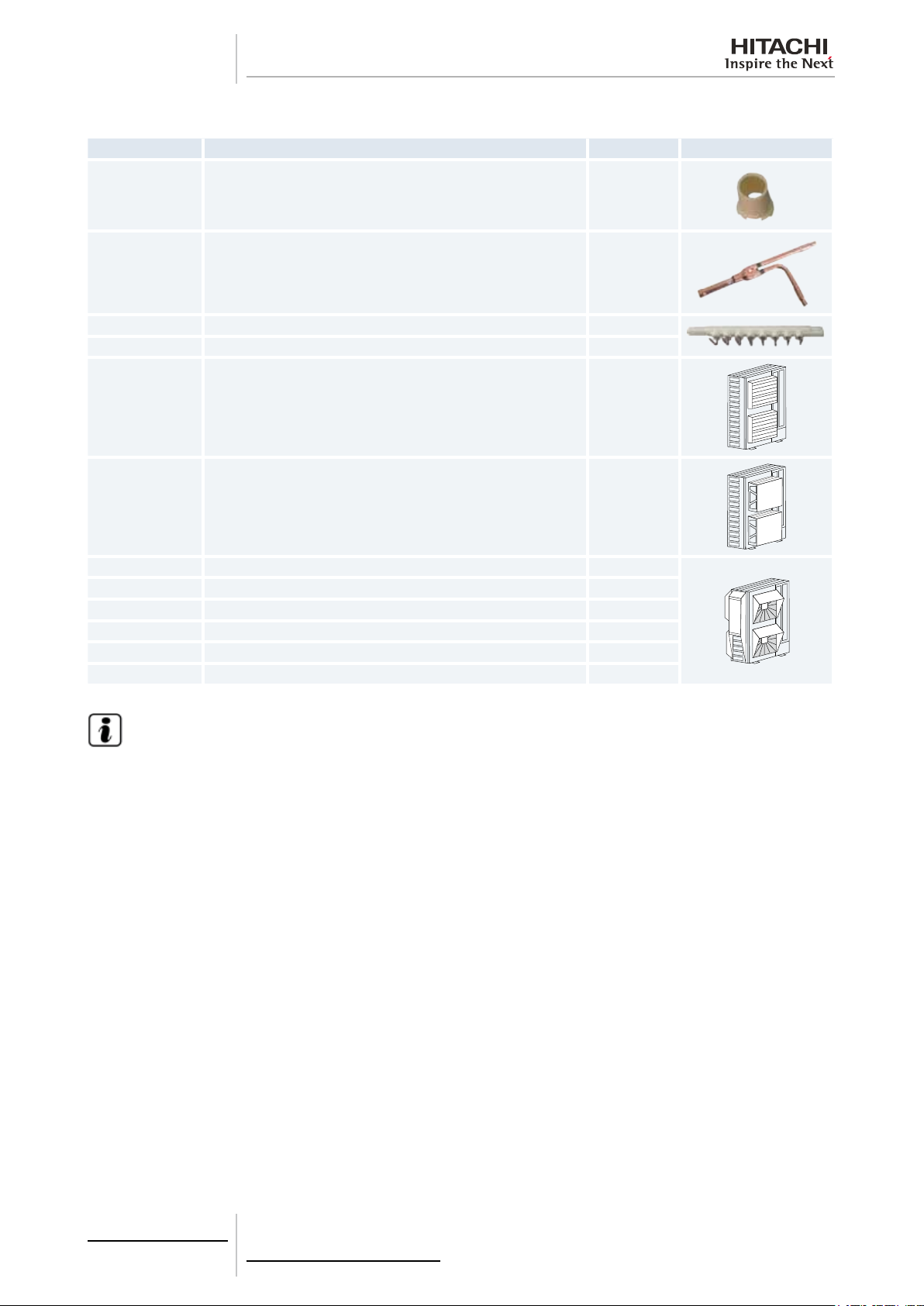

1.3.5 Accessory code list

Name Description Code Figure

DBS-26 Drain discharge connection 60299192

E-102SN2 Branch pipe kit (multikit) 70524001

MH-84AN Header branch (Distributor) 70522007

MH-108AN Header branch (Distributor) 70522008

AG-335A Air ow guide 60291431

WSP-335A Wind guard 60291432

ASG-NP335F Snow protection hood; air outlet (Zinc plate) 60291433

ASG-NP335FS2 Snow protection hood; air outlet (Stainless plate) -

ASG-NP280B Snow protection hood; air inlet of rear side (Zinc plate) -

ASG-NP280BS2 Snow protection hood; air inlet of rear side (Stainless plate) -

ASG-NP280L Snow protection hood; air inlet of left side (Zinc plate) -

ASG-NP280LS2 Snow protection hood; air inlet of left side (Stainless plate) -

N O T E

• HITACHI has a range of accessories and remote control systems that can be used with the SET-FREE mini

outdoor units. Please, refer to the Controls Technical Catalogue.

• HITACHI has also a range of accessories that can be used with the indoor units. Please, refer to the Indoor

Units Technical Catalogue.

10

TCGB0068 rev.1 - 08/2012

2 Features and benets

F e a t u r e s a n d b e n e f i t s

2.

Index

2.1. Selection benets .................................................................................................................................. 12

2.1.1. Wide range of units, accessories and remote controls .............................................................................. 12

2.1.2. High number of connectable indoor units .................................................................................................. 14

2.1.3. Individual operation ................................................................................................................................... 15

2.1.4. Assisted air conditioning installation design by Hi-Tool kit selection software ........................................... 15

2.2. Installation benets................................................................................................................................16

2.2.1. Easy and exible unit installation ............................................................................................................... 16

2.2.2. Easy and exible electrical installation ...................................................................................................... 16

2.2.3. Easy and exible control connection (Central Station, BMS Interface, CS-NET WEB) ............................. 18

2.3. Start-up benets .................................................................................................................................... 19

2.3.1. Automatic start-up test ............................................................................................................................... 19

2.3.2. Service verication .................................................................................................................................... 20

2.4. Functionality benets.............................................................................................................................21

2.4.1. Expanded temperature range .................................................................................................................... 21

2.4.2. Wide capacity range .................................................................................................................................. 22

2.4.3. Increased maximum piping length ............................................................................................................. 22

2.4.4. Advanced technology ................................................................................................................................ 23

2.5. Maintenance benets ............................................................................................................................32

2

2.5.1. Minimum maintenance .............................................................................................................................. 32

2.5.2. Easy accessibility ...................................................................................................................................... 32

2.5.3. Alarm codes ............................................................................................................................................... 32

2.5.4. SMS alarm ................................................................................................................................................. 32

2.5.5. Availability of maintenance tools ............................................................................................................... 32

11

TCGB0068 rev.1 - 08/2012

2 Features and benets

2.1 Selection benets

2.1.1 Wide range of units, accessories and remote controls

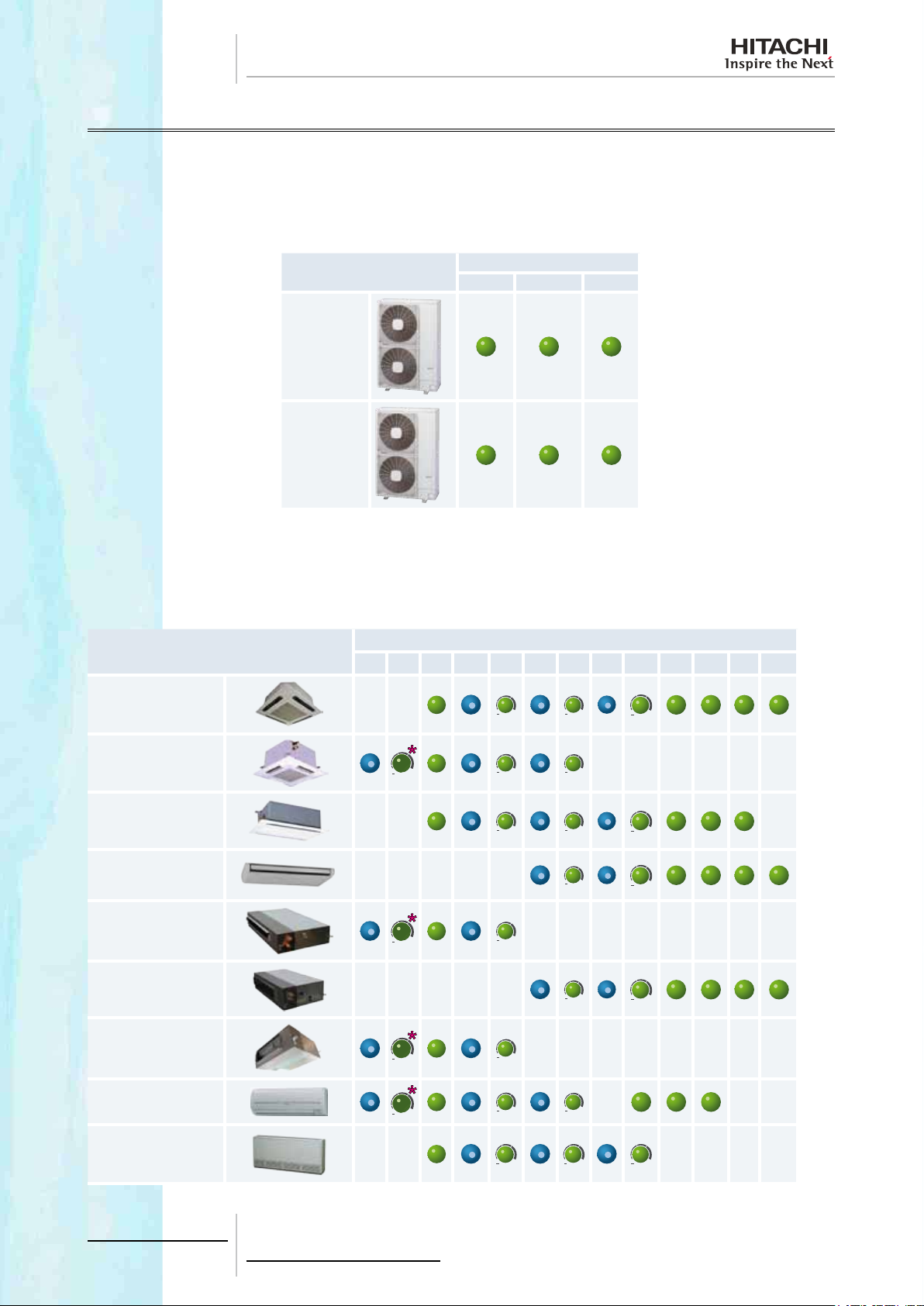

Outdoor unit

The SET-FREE mini series from HITACHI offers (3-6)HP range of outdoor units for being selected in single or three phase

combinations.

Capacity (HP)

4 5 6

Indoor unit

Model

FSVN2E

FSNY2E

The HITACHI indoor units to connect with this SET-FREE mini series have a wide range of capacities: from 0.8 to 6.0 HP.

The capacity of each indoor unit is exible: they are supplied set to the maximum capacity possible and can be easily adjusted to precise lower values in line with installation requirements.

Capacity (HP)

RCI 4-way cassette

Model

0.6 0.8 1.0 1.3 1.5 1.8 2.0 2.3 2.5 3.0 4.0 5.0 6.0

RCIM 4-way cassette

(compact)

RCD 2-way cassette

RPC ceiling type

RPI Indoor ducted unit

(low prole)

RPI Indoor ducted unit

RPIM Indoor ducted

unit

RPK wall type

RPF oor type

12

TCGB0068 rev.1 - 08/2012

2 Features and benets

Model

RPFI oor concealed

type

Constant capacity unit.

Unit with a capacity that can be set to a lower margin using the DIP switch 3 setting for combinations with all

Set Free Series.

Unit of 0.8HP capacity that can be set to 0.6HP using specic DIP switch setting only for combinations with Set

Free Mini Series 2.

Capacity available with the DIP switch conguration.

Accessories

All the outdoor units have a range of accessories that facilitate installation, operation and maintenance.

These accessories are designed to adapt the unit to the type of installation that the air conditioning system requires and

improve its performance, always bearing in mind the quality parameters required.

The range of accessories includes:

• Remote controls, for handling and managing the operation of the installation.

• Multikits and distributors for pipe branches connection of indoor units.

• Drain discharge connection, to collect the draining.

• Air ow guide, wind guard and snow protection hood, to protect the outdoor unit fans and the air inlet/outlet.

0.6 0.8 1.0 1.3 1.5 1.8 2.0 2.3 2.5 3.0 4.0 5.0 6.0

Capacity (HP)

2

Remote controls

HITACHI has a range of remote control systems that are classied according to the type of management and the number

of units they manage:

• Individual remote control systems.

• Centralised remote control systems.

• Building air conditioning systems (CS-NET WEB).

• BMS (Building Management Systems).

Individual remote control systems

The individual remote control systems, whether they are wireless

or connected directly by cable, have a wide range of functions

for easier unit management, the programming of specic settings

or the identication of incidents. Recommended for managing a

small number of units.

Centralised remote control systems

The centralised remote control systems combine the functions of

the remote controls and extend the management and setting possibilities for several air conditioning systems distributed around the

entire oor of a building.

13

TCGB0068 rev.1 - 08/2012

2 Features and benets

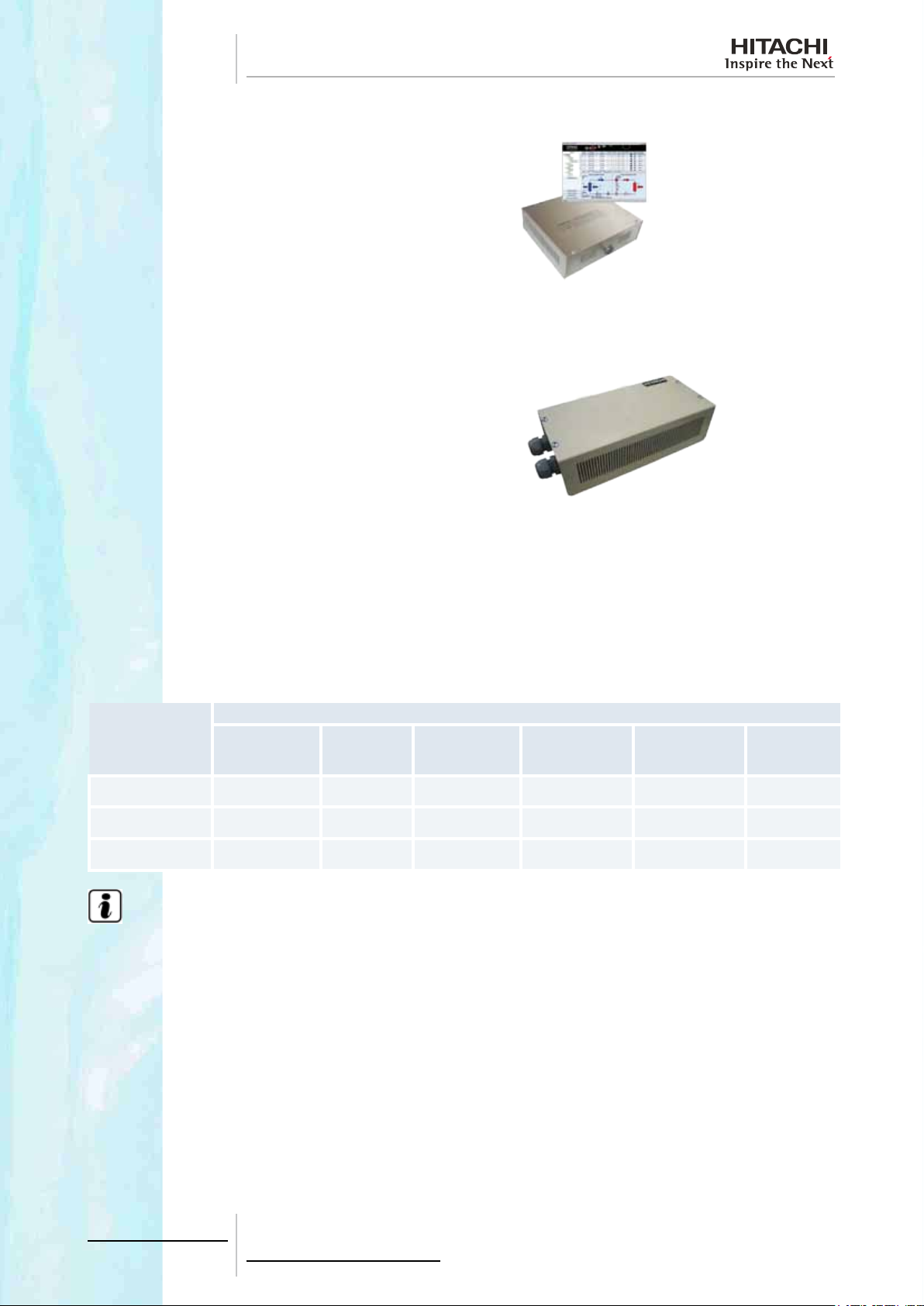

Computerised control systems

Computerised control systems increase management and setting

possibilities and allow this to be carried out from any point of the

local communication network, by means of a two-core non-polarity

cable or even using the Internet.

Recommended when you wish to independently manage more

than two plants in one building.

BMS (Building Management System)

Integration into installations with intelligent management. Gateway

interface with Lonworks, KNX, MODBUS and BACnet BMS systems.

2.1.2 High number of connectable indoor units

With SET-FREE FS(V)N(Y)2E system it is possible to connect one outdoor unit with up to 12 indoor units. Utilizing an

inverter control, a wide range of operation capacity control is also availabale. A maximum total combination horsepower

of 130% and a minimum total combination horsepower of 50% can be chosen by combination of the indoor units when

compared with the nominal outdoor unit capacity. Therefore, the system can meet individual air conditioning requirements

in most ofce buildings.

Indoor unit

Outdoor unit

RAS-4FS(V)N(Y)2E 2.0 4.0 5.2 1 8 0.6 (*)

RAS-5FS(V)N(Y)2E 2.5 5.0 6.5 1 10 0.6 (*)

RAS-6FS(V)N(Y)2E 3.0 6.0 7.8 1 12 0.6 (*)

Minimum nomi-

nal combination

capacity (HP)

Nominal

combination

capacity (HP)

Maximum nominal combination

capacity (HP)

Minimum combi-

nation quantity

of indoor units

Maximum com-

bination quantity

of indoor units

Minimum single operation

capacity (HP)

N O T E

• (*): Indoor unit of 0.8HP set as 0.6HP by specic DSW setting only for combinations with Set Free Mini Series 2.

• Please, refer to the chapter Piping work and refrigerant charge for the specic considerations.

14

TCGB0068 rev.1 - 08/2012

2 Features and benets

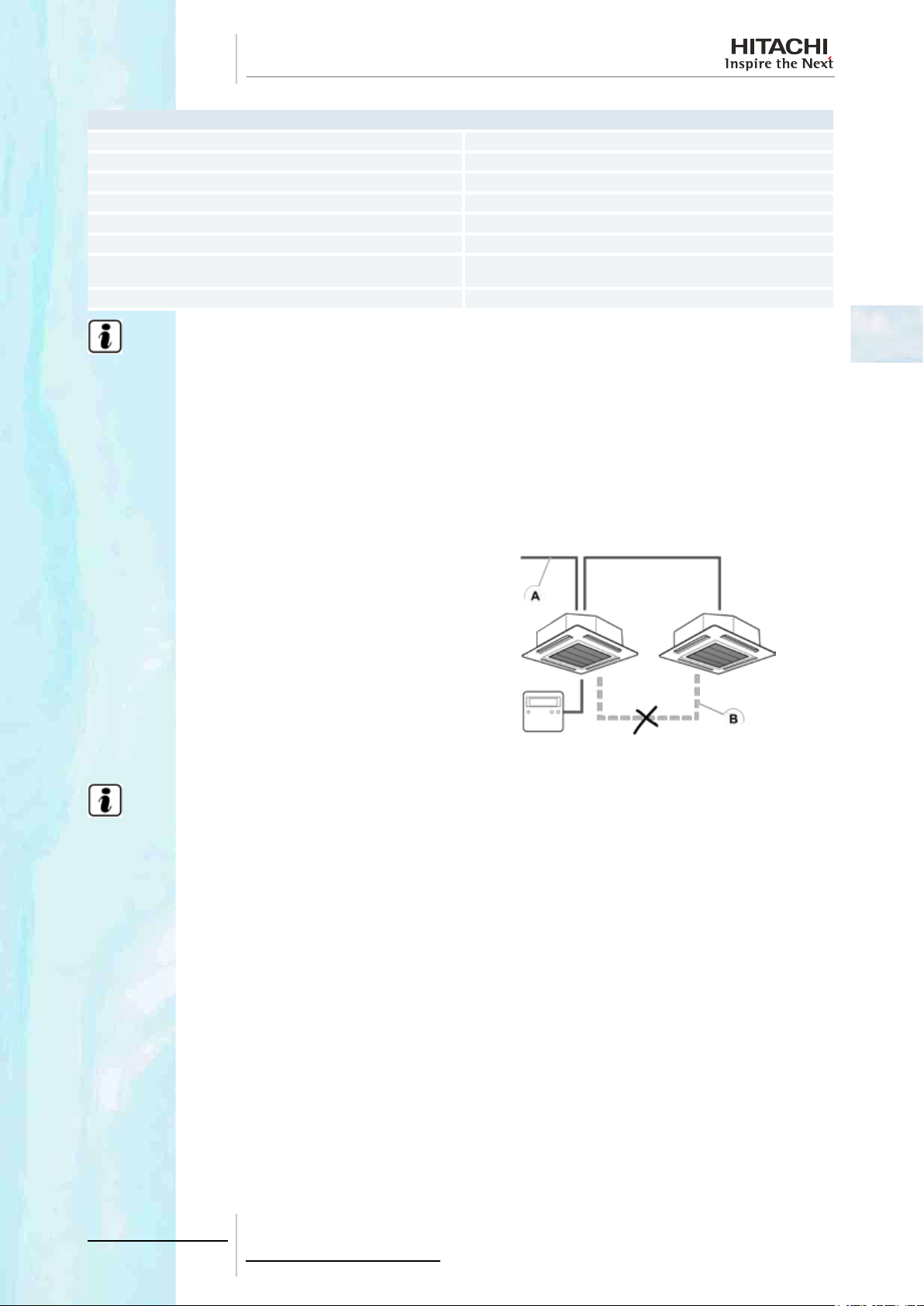

2.1.3 Individual operation

SET-FREE mini series individual operation function allows to control the connected indoor units separately.

• In case of installing the indoors units in the same room, one

unit could continue operating -A- although the other one -Bstops by thermo-off, which means an energy saving and great

comfort.

A

B

2.1.4 Assisted air conditioning installation design by Hi-Tool kit selection software

The Hi-Tool Kit selection software is a tool for designing HVAC

installations and automatically generating all necessary related information to complete the planned installation.

The necessary related information includes:

• Product selection table.

• Cooling and wiring diagram according to the installation design.

• Full list of necessary products to complete the installation.

• Installation start-up management.

2

15

TCGB0068 rev.1 - 08/2012

2 Features and benets

2.2 Installation benets

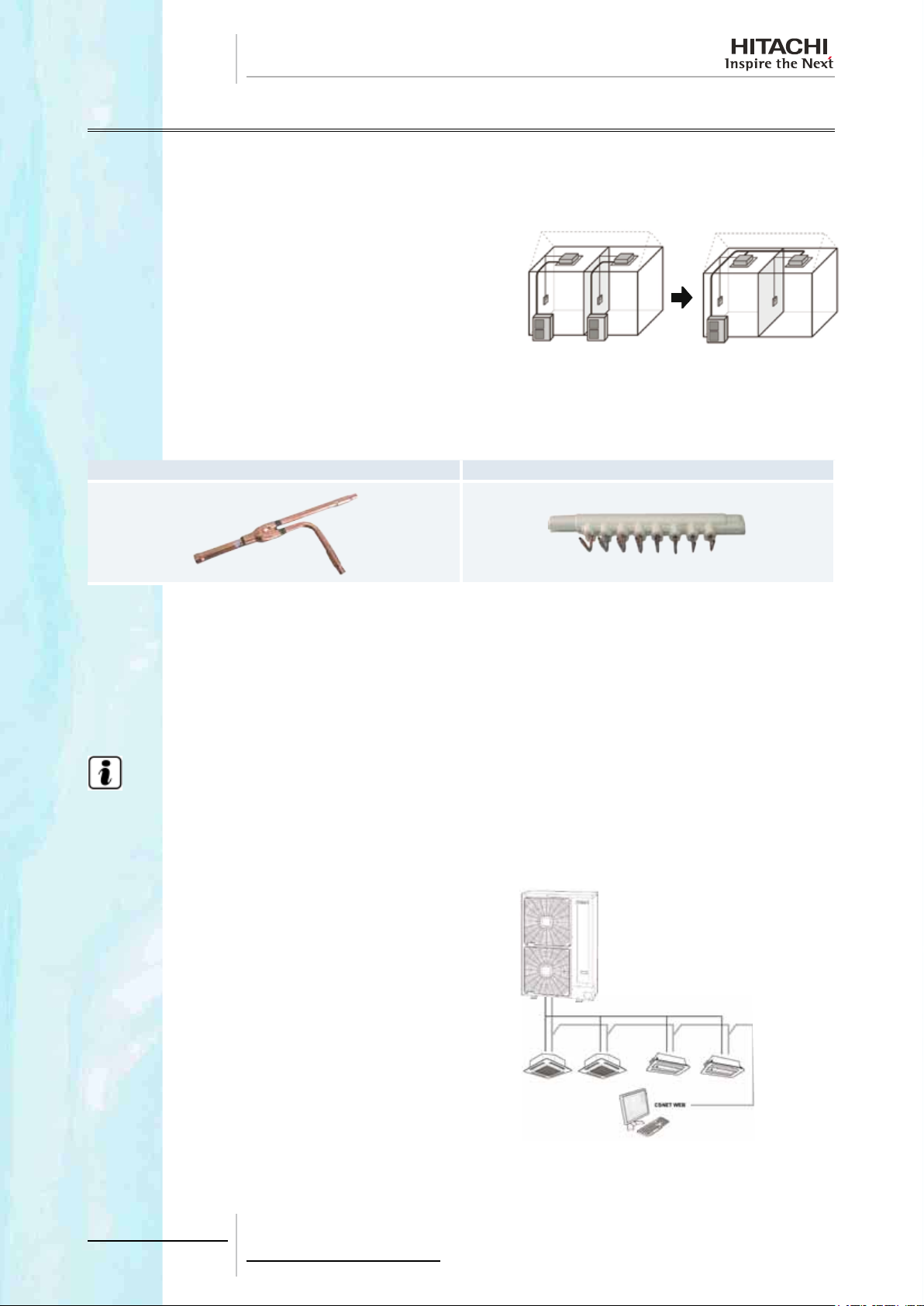

2.2.1 Easy and exible unit installation

Reduced installation space by individual operation

• For Indoor units installed in different rooms, the benets are:

- Outdoor installation space reduced to half.

- Decrease piping installation work and cost.

- Decrease wiring and power equipment.

A. Model without individual operation function.

B. FS(V)N(Y)2E model.

Different mounting accessories available

HITACHI provides all of the accessories required to connect the pipes (distributors and multikits). These accessories make

the installation process more exible and straightforward.

E-SN2 multikit MH-AN distributors

A B

2.2.2 Easy and exible electrical installation

Interconnection of units via H-LINK II

The units interconnect via a bus called H-LINK II, consisting of 2 non-polarity cables wich accept lengths of up to 1,000m.

Accessories are available if required to increase this length up to 5,000m (PSC-5HR).

N O T E

The control system, the indoor units and the remote control must be compatible with the H-LINK II bus.

Up to 160 units connected in a single H-LINK II bus line

It is possible to connect up to 160 indoor units from the SYSTEM

FREE range in a single H-LINK II bus line. To expand the installation or increase the bus lines available, simply add a new line.

All of the units are managed as one through the control systems

installed.

16

TCGB0068 rev.1 - 08/2012

2 Features and benets

Specications

Transmission cable: 2-core

Transmission cable polarity: No polarity

Maximum number of outdoor units connected: 64 units per H-LINK II system

Maximum number of indoor units connected: 160 units per H-LINK II system

Maximum number of units: 200

Maximum wiring length: Total 1,000 m (including CSNET-WEB)

Recommended cable:

Voltage: 5 V DC

Shielded twisted pair cable or shielded pair cable over 0.75 mm

valent to KPEV-S)

2

(equi-

NOTE

• The DIP switches must be adjusted when the H-LINK II bus is used. If they are set incorrectly, a transmission

error may occur.

• The H-Link II system offers a high level of exibility for the design of air conditioning systems, due to its simple installation and the low total cost. Furthermore, centralised management is possible by connecting the

CSNET-WEB control system to the H-LINK II network cables.

• Additionally, using CSNET-WEB, it is possible to manage the installation over the internet.

2

No operating cable for the remote control

In the case of multiple systems the indoor units can be controlled

using a single remote control switch without having to join them

with an operating cable for the remote control.

A. Operation wiring.

B. An operating cable is not required for using the remote control

switch.

N O T E

• When using the H-LINK II system, DIP switches have to be adjusted. If the DIP switches are not set or set incorrectly, an alarm may occur due to transmission failure. Total wiring length for the remote control switch can

be extended to up to 5,000 m. If total wiring length is less than 30 m, it is possible to use the normal wiring (0.3

mm²).

• The H-LINK II system provides maximum exibility for system design; installation is easy, and total costs are

reduced. Furthermore, it can be controlled centrally by connecting CS-NET WEB to H-LINK II wiring.

• You can also control the installation by Internet via CS-NET WEB.

17

TCGB0068 rev.1 - 08/2012

2 Features and benets

2.2.3 Easy and exible control connection (Central Station, BMS Interface, CS-NET WEB)

Fast connection of new units

Extending the air conditioning system is now even easier. To add new units to the communication bus, it is only necessary

to connect the two bus cables to the communication terminals.

The new units that are added to the bus line are recognised by the control system and are congured automatically.

Auto-conguration of system units

The control systems for the air conditioning system are auto-congurable. In other words, they recognise the type of unit

to which they are connected, and the type of indoor unit and its capacity. The installation is started up more quickly and

efciently.

You can also congure all the units manually, so as to adjust the installation following customised parameters.

18

TCGB0068 rev.1 - 08/2012

2 Features and benets

2.3 Start-up benets

2.3.1 Automatic start-up test

The installation is started up automatically, therefore considerably reducing the time required for the process.

There are the following types of start-up:

• Test run and identication of the units forming the system.

• Test run from the remote control.

• Test run from the outdoor unit.

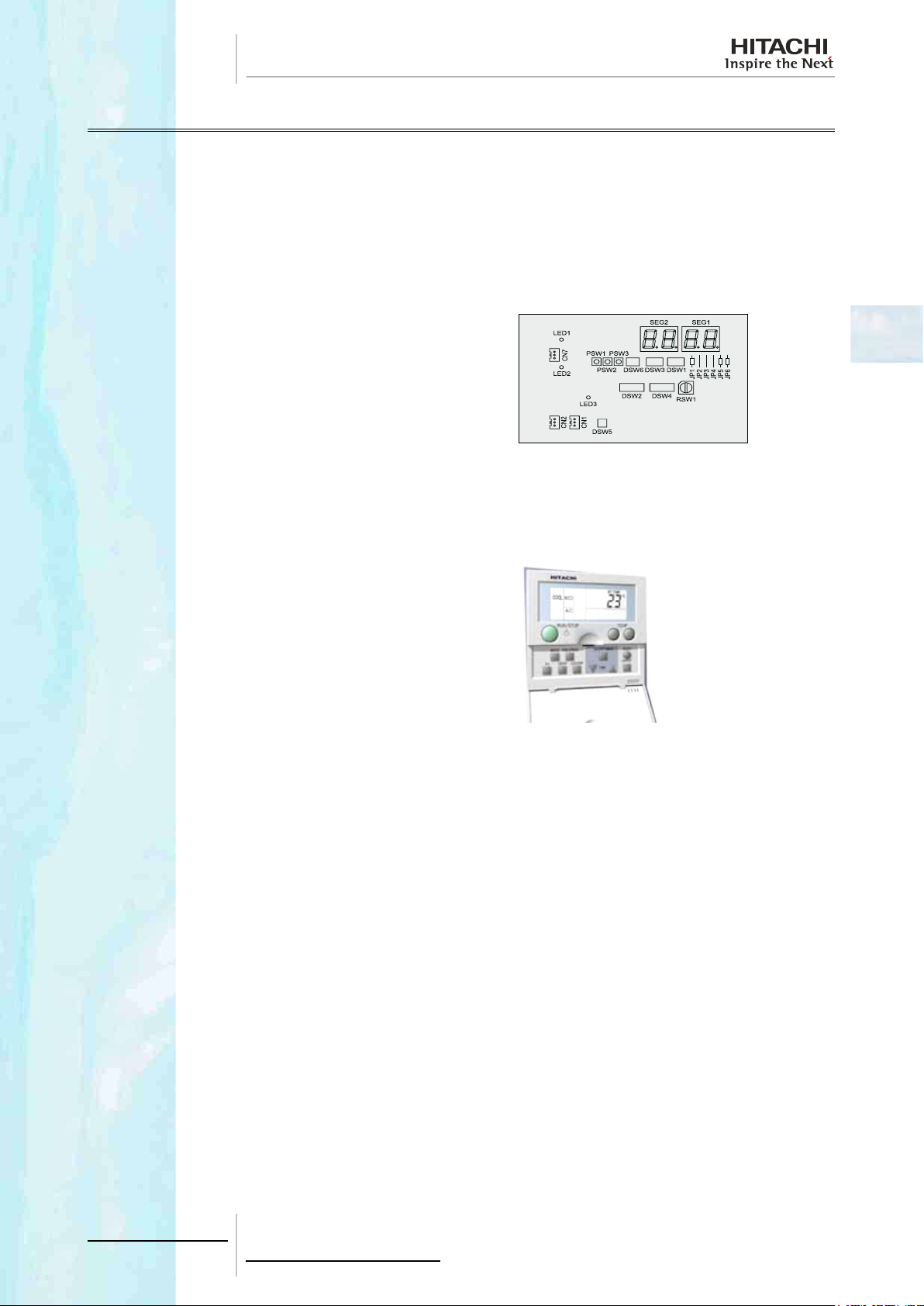

Test run and identication of the system units

The automatic test run can be activated through outdoor unit

DIP switch or indoor unit remote control switch. The outdoor unit

7-segment display gives all the information needed to check the

system is operating correctly.

The units forming part of the system are identied separately for

the outdoor and indoor units:

• Outdoor units: Using the remote control, the series to which

each of the operational outdoor unit belongs (for example, simple or multiple series) can be assigned.

• Indoor units: Using the rotary and DIP switch on each unit.

2

Test run from the remote control

The remote control can run 3 operations.

• Auto-diagnostic: quick check of the operating conditions of the

indoor units and the outdoor unit.

• Data memory query: if an abnormality occurs, the LCD remote

control switch shows an alarm code and saves all the operation settings of the unit at the time the fault occurs, so that a

quick diagnosis can be made of the installation.

• Optional function setting: the remote control switch allows cancellation of the 4-degree offset in the heating mode and an

increase in the fan speed setting, among 29 possible options.

This way, multiple indoor units can be set at the same time. Also, the conguration can easily be changed, even after the

installation has been completed.

Test run from the outdoor unit

The outdoor unit PCB is equipped with a 7-segment display, which depending on the position of the PSWs shows the

following parameters in sequence.

• Outdoor temperature.

• Discharge gas temperature.

• Evaporation temperature in heating mode.

• Condensing temperature.

• Discharge pressure.

• Compressor run time.

This allows quick and accurate diagnosis of the installation during normal operation or test run.

19

TCGB0068 rev.1 - 08/2012

2 Features and benets

2.3.2 Service verication

System operation control

The working order of the system is continuously monitored through the control system. All operating parameters that the

system uses to manage the outdoor and indoor units are continuously supervised.

Assisted-management air conditioning system

The air conditioning system can be managed conveniently using

the assisted management software HITACHI Service Tools.

This software enables, for example, a laptop computer to be connected to the air conditioning system by means of an interface

connected to the H-LINK II bus. Using different menus, the software allows you to manage all the systems connected effectively

and obtain data to optimise system performance.

Compilation of operating data

All the data obtained using HITACHI Service Tools is compiled in different formats and monitored in various ways. The user

of the software can congure the data handling to monitor those parameters that are the most important in each installation.

The data reports allow you to verify the system operation continuously. Any deviation in the stipulated ranges of values are

detected immediately.

20

TCGB0068 rev.1 - 08/2012

2 Features and benets

2.4 Functionality benets

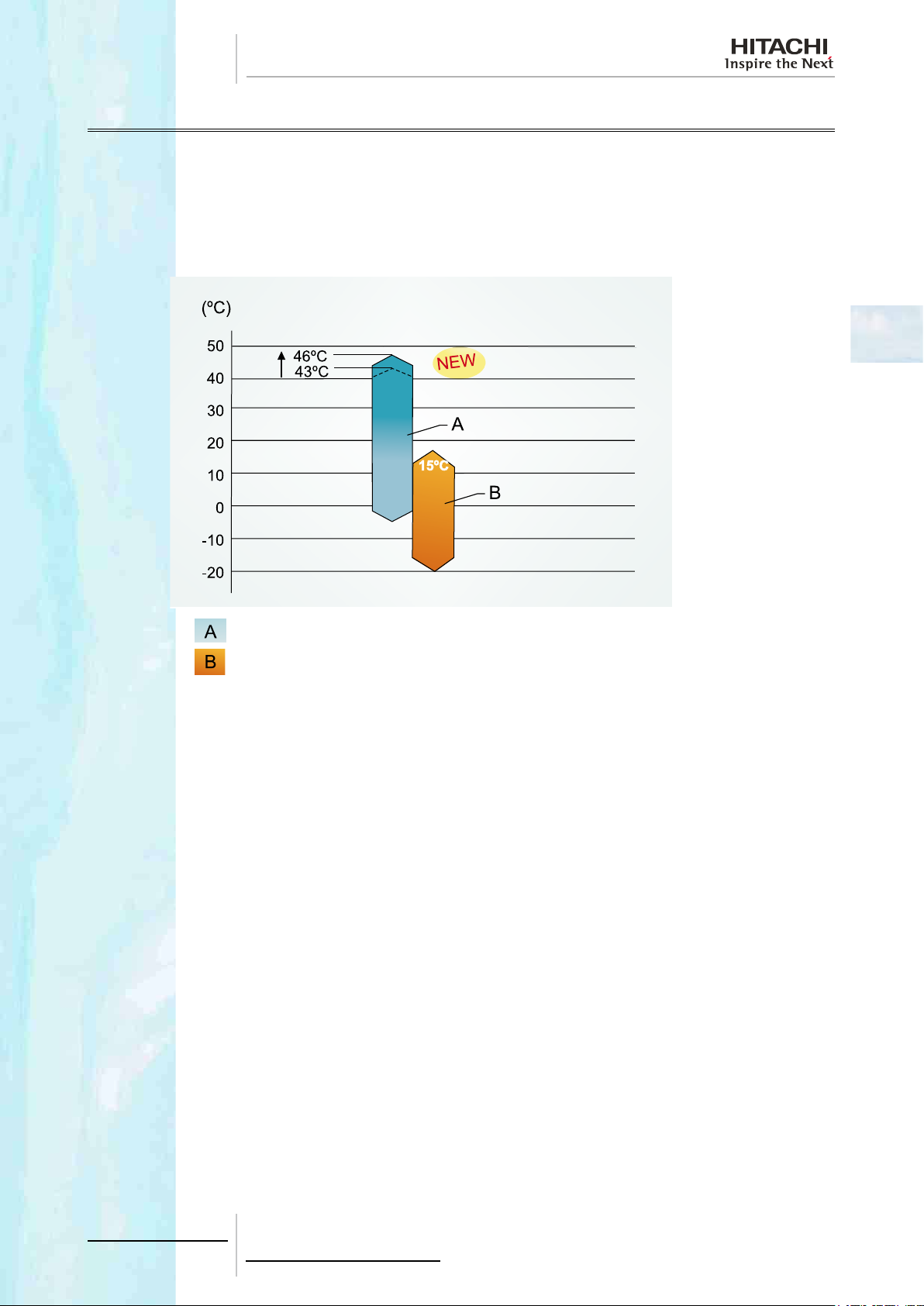

2.4.1 Expanded temperature range

FS(V)N(Y)2E series are able to work in a wide working range (from -5 to 46 ºC (DB) in cooling mode and from -20 to 15ºC

WB in heating mode).

The cooling working range has been increased up to 46ºC in outdoor ambient temperature respect previous model (43ºC).

2

-5ºC

-20ºC

Cooling (DB)

Heating (WB)

Fan regulation at low ambient temperature

• Wide working range thanks to fan control regulation, in cooling mode, for operating at low ambient temperature (down

to -5ºC DB).

• Fan control regulation enables working at low ambient temperature (down to -20ºC WB), in heating mode, reducing

“Defrost operations” or unit “stoppages” compared with conventional units.

21

TCGB0068 rev.1 - 08/2012

2 Features and benets

2.4.2 Wide capacity range

The control frequency system allows a wide capacity application range as shown below:

• Cooling capacity range at conditions: Indoor air inlet: 27/19 ºC (DB/WB); Outdoor air inlet: 35 ºC DB

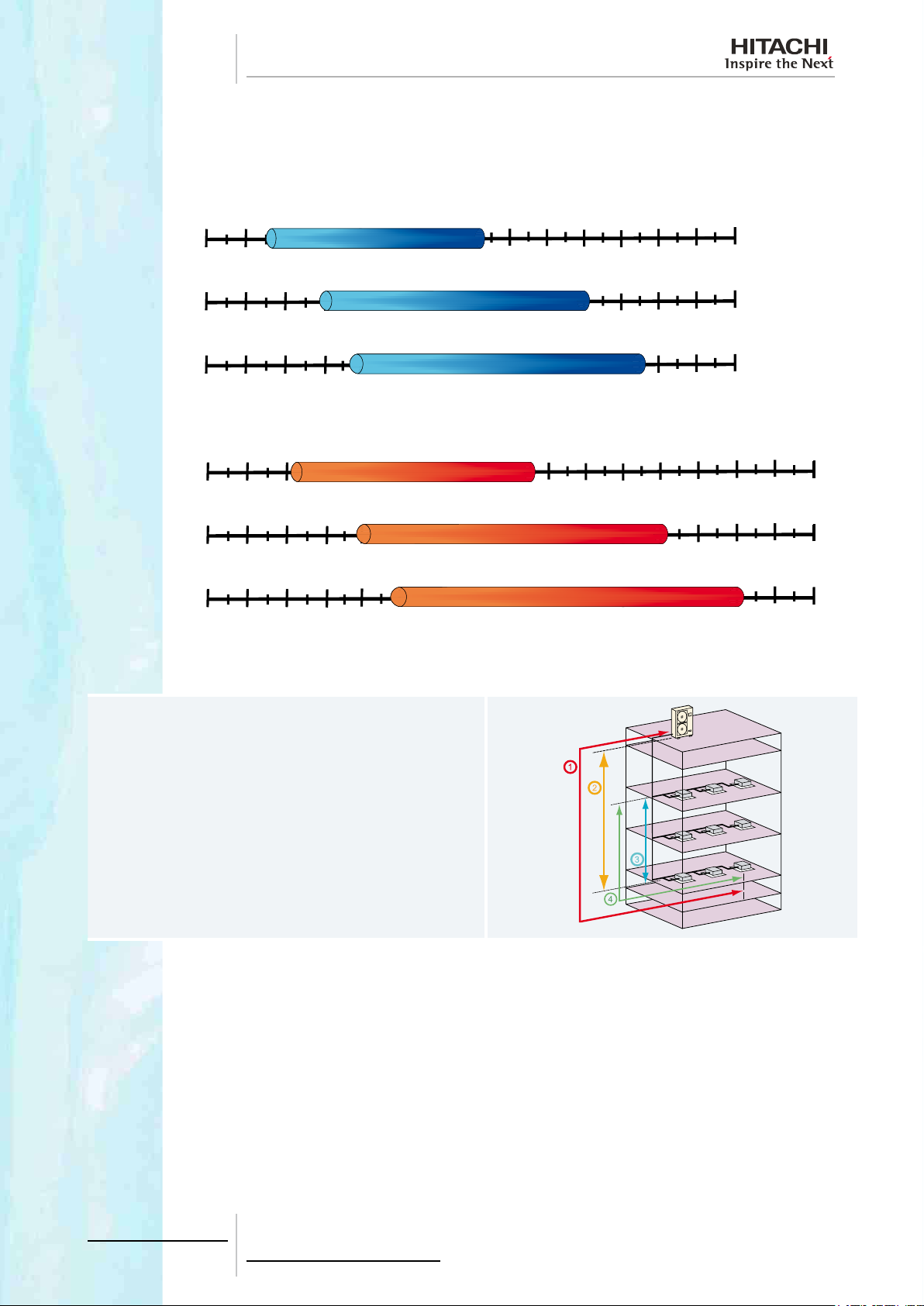

4 kW

RAS-4FS(V)N(Y)2E

6 kW 8 kW 10 kW 12 kW 14 kW 16 kW

18 kW

4 kW

RAS-5FS(V)N(Y)2E

4 kW

RAS-6FS(V)N(Y)2E

6 kW 8 kW 10 kW 12 kW 14 kW 16 kW

6 kW 8 kW 10 kW 12 kW 14 kW 16 kW

• Heating capacity range at conditions: Indoor air inlet: 20 ºC DB; Outdoor air inlet: 7/6 ºC (DB/WB)

4 kW

RAS-4FS(V)N(Y)2E

4 kW

RAS-5FS(V)N(Y)2E

4 kW

RAS-6FS(V)N(Y)2E

6 kW 8 kW 10 kW 12 kW 14 kW 16 kW

6 kW 8 kW 10 kW 12 kW 14 kW 16 kW

6 kW 8 kW 10 kW 12 kW 14 kW 16 kW

2.4.3 Increased maximum piping length

The maximum total piping length is 125m for 4HP and

135m for 5~6HP;

18 kW

18 kW

18 kW

18 kW

18 kW

20 kW

20 kW

20 kW

① Actual Maximum piping length is 75m.

② Height difference between indoor and outdoor units is

30m.

③ Height difference between indoor units is 15m.

④ Piping length from the first multi-kit to the farthest

indoor unit is 40m.

22

TCGB0068 rev.1 - 08/2012

Loading...

Loading...