Hitachi RAS-4-12HRNM2E, RAS-4-10HRNS2E, RAS-2-3HVRNS2, RAS-4-6HVRNS2E, RAS-2HVRN2 Service Manual

...

Service Manual

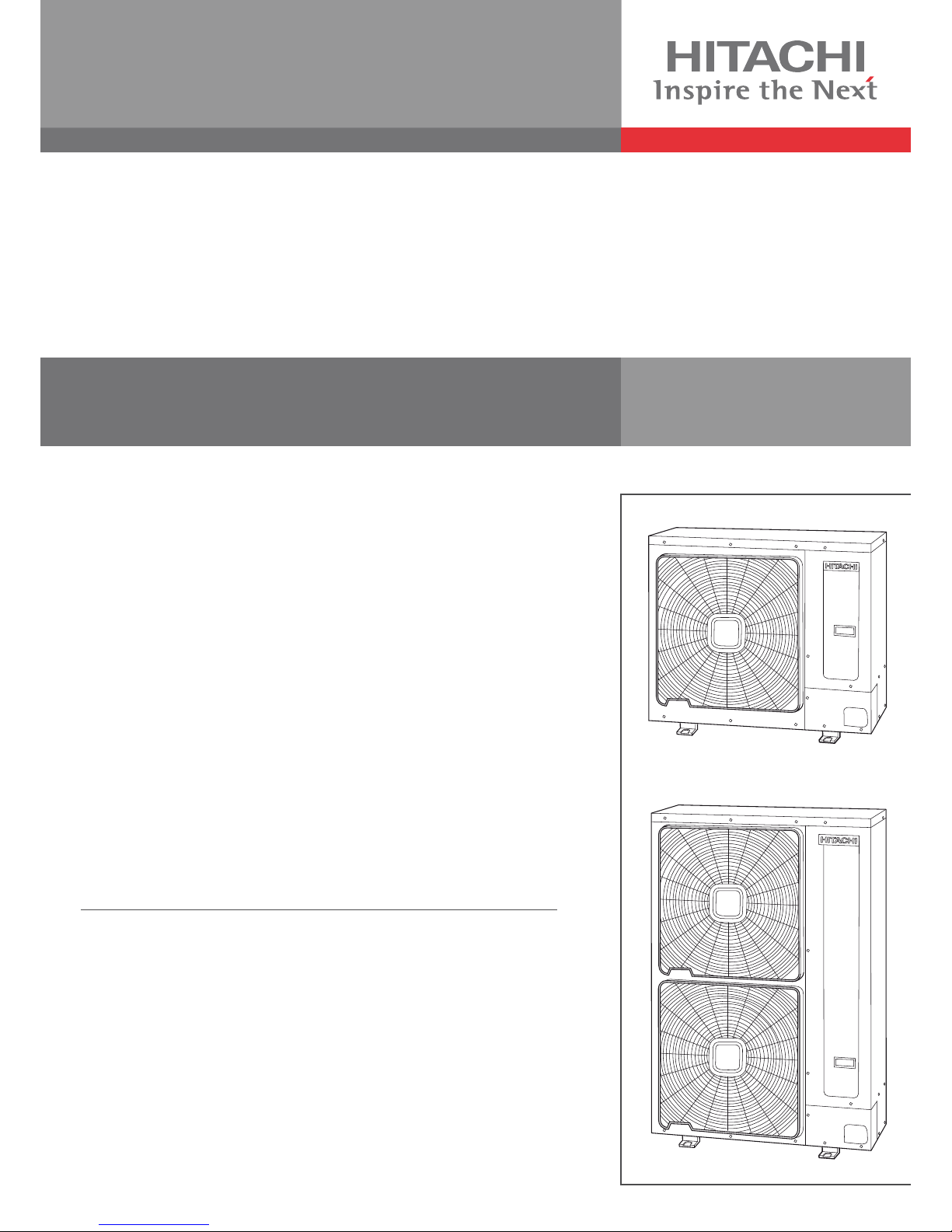

UTOPIA DC-INVERTER IVX/(2/2.5)HP/ES SERIES

H(V)RN(S)(2)(E)

H(V)RNM(2)(E)

RAS-(3-6)HVRNM2E

RAS-(4-12)HRNM(2)(E)

RAS-(2-3)HVRN(S)(2)

RAS-(4-6)HVRNS2E

RAS-(4-10)HRNS(2)E

III

SMGB0064 rev.0 - 08/2011

Index

1

2

3

4

5

6

7

8

9

10

11

12

I n d e x

General information

Unit Installation

Piping work and refrigerant charge

Electrical Wiring

Control System

Optional functions

Test Run

Troubleshooting

Spare Parts

Servicing

Electrical checks of main parts

Maintenace notes

IV

SMGB0064 rev.0 - 08/2011

Index

v

Contens

SMGB0064 rev.0 - 08/2011

1. General information .......................................................................................................1

1.1 General information .................................................................................................................................... 2

1.1.1 General note .................................................................................................................................................... 2

1.1.2 Introduction ...................................................................................................................................................... 2

1.1.3 Environment-friendly units ............................................................................................................................... 2

1.2 Applied symbols ..........................................................................................................................................3

1.3 Product guide .............................................................................................................................................4

1.3.1 Classication of IVX series outdoor unit models ............................................................................................. 4

1.3.2 Classication of ES series outdoor unit models .............................................................................................. 4

1.3.3 Product guide: Outdoor units ........................................................................................................................... 5

1.3.4 Accessory code list .......................................................................................................................................... 6

2. Unit Installation ............................................................................................................... 7

2.1 Safety summary .......................................................................................................................................... 8

2.2 Transportation of outdoor unit ..................................................................................................................... 9

2.3 Center of gravity .......................................................................................................................................10

2.4 Factory-supplied accessories for RAS-(8-12)HRNM ................................................................................ 11

2.5 Installation space (Initial ckeck) ................................................................................................................12

2.5.1 RAS-3HVRNM2E / RAS-(2-3)HVRN(S)2 / RAS-(4-10)H(V)RNS2E ............................................................. 12

2.5.2 RAS-(4-6)H(V)RNM2E / RAS-(8/10)HRNSE ................................................................................................. 16

2.5.3 RAS-(8-12)HRNM ......................................................................................................................................... 20

2.6 Place provision .........................................................................................................................................22

2.6.1 Place provision for RAS-(3-12)H(V)RNM(2)(E) and RAS-(4-10)H(V)RNS(2)E ............................................. 22

2.6.2 Place provision only for RAS-(2-3)HVRN(S)2 ............................................................................................... 25

2.7 Optional parts and installation ..................................................................................................................28

2.7.1 Optional parts and installation for RAS-(2-3)HVRN(S)2 ................................................................................ 28

2.7.2 Optional parts and installation RAS-3HVRNM2E / RAS-(4-6)H(V)RNS2E ................................................... 33

2.7.3 Optional parts and installation RAS-(4-6)H(V)RNM2E / RAS-(8/10)HRNSE ............................................... 37

2.7.4 Optional parts and installation RAS-(8-12)HRNM ......................................................................................... 42

3. Piping work and refrigerant charge ............................................................................ 49

3.1 General notes ........................................................................................................................................... 50

3.2 Piping work connection considerations.....................................................................................................52

Contents

vi

Contens

SMGB0064 rev.0 - 08/2011

3.2.1 Piping Materials ............................................................................................................................................. 52

3.2.2 Three principles on refrigerant piping work ................................................................................................... 54

3.2.3 Suspension of refrigerant piping .................................................................................................................... 54

3.2.4 Brazing work .................................................................................................................................................. 55

3.2.5 Refrigerant charge ......................................................................................................................................... 56

3.2.6 Caution of the pressure by check joint .......................................................................................................... 56

3.2.7 Refrigerant charge quantity ........................................................................................................................... 57

3.2.8 Pump down refrigerant .................................................................................................................................. 59

3.3 Outdoor Units IVX Series..........................................................................................................................60

3.3.1 Piping connection .......................................................................................................................................... 60

3.3.2 Refrigerant piping length ............................................................................................................................... 65

3.3.3 Refrigerant piping selection ........................................................................................................................... 66

3.3.4 Twin and triple system installation ................................................................................................................. 67

3.3.5 Drain discharging boss .................................................................................................................................. 68

3.4 Outdoor Units ES Series...........................................................................................................................70

3.4.1 Piping connection .......................................................................................................................................... 70

3.4.2 Refrigerant piping length ............................................................................................................................... 75

3.4.3 Refrigerant piping selection ........................................................................................................................... 77

3.4.4 Twin and triple system installation ................................................................................................................. 78

3.4.5 Connecting are adapter (only for RAS-(2/2.5)HVRN2) ................................................................................ 79

3.4.6 Drain discharging boss .................................................................................................................................. 80

4. Electrical Wiring ...........................................................................................................81

4.1 General check...........................................................................................................................................82

4.2 Electrical wiring for the outdoor unit IVX Series........................................................................................83

4.2.1 Electrical wiring connection for the outdoor unit ............................................................................................ 83

4.2.2 Setting the DIP switches for the outdoor unit ................................................................................................ 84

4.3 Electrical wiring for the outdoor unit ES Series.........................................................................................88

4.3.1 Electrical wiring connection for the outdoor unit ............................................................................................ 88

4.3.2 Setting the DIP switches for the outdoor unit ................................................................................................ 89

4.4 Electrical wiring between indoor unit and outdoor unit .............................................................................93

4.5 Wire sizes ................................................................................................................................................. 95

4.5.1 Wire sizes for IVX Series ............................................................................................................................... 95

4.5.2 Wire sizes for ES Series ................................................................................................................................ 97

4.5.3 H-LINK II System ........................................................................................................................................... 99

4.6 Electrical wiring diagrams .......................................................................................................................108

4.6.1 Electrical wiring diagrams for IVX Series .................................................................................................... 108

4.6.2 Electrical wiring diagrams for ES Series ......................................................................................................112

vii

Contens

SMGB0064 rev.0 - 08/2011

5. Control System ........................................................................................................... 117

5.1 Device control system.............................................................................................................................118

5.1.1 Device control system for IVX Series ...........................................................................................................118

5.1.2 Device control system for ES Series ........................................................................................................... 120

5.2 Outdoor units PCB .................................................................................................................................. 122

5.2.1 Outdoor units PCB for IVX Series ............................................................................................................... 122

5.2.2 Outdoor units PCB for ES Series ................................................................................................................ 123

5.3 Protection and safety control .................................................................................................................. 126

5.3.1 Protection and safety control for IVX Series ................................................................................................ 126

5.3.2 Protection and safety control for ES Series ................................................................................................. 127

5.4 Standard operation sequence.................................................................................................................128

5.4.1 Standard operation sequence for IVX Series .............................................................................................. 128

5.4.2 Standard operation sequence for ES Series ............................................................................................... 135

5.5 Standard control functions ......................................................................................................................142

5.5.1 Standard control functions for IVX Series ................................................................................................... 142

5.5.2 Standard control functions for ES Series .................................................................................................... 151

6. Optional functions ...................................................................................................... 161

6.1 Outdoor units IVX and ES series ............................................................................................................162

6.1.1 Available ports ............................................................................................................................................. 162

6.1.2 Conguration ............................................................................................................................................... 164

6.1.3 Description of optional input signals ............................................................................................................ 165

6.1.4 Description of optional output signals .......................................................................................................... 166

6.1.5 Optional functions ........................................................................................................................................ 167

7. Test Run ......................................................................................................................173

7.1 Checking procedure before the test run .................................................................................................174

7.2 Test run procedure using the remote control switch ...............................................................................176

7.3 Test run procedure using the wireless remote control switch .................................................................178

7.4 Test run procedure from the outdoor unit side ........................................................................................ 180

7.5 Check list ................................................................................................................................................ 181

7.5.1 Check list for IVX Series .............................................................................................................................. 181

7.5.2 Check list for ES Series ............................................................................................................................... 189

8. Troubleshooting .........................................................................................................195

8.1 Initial troubleshooting for IVX an ES Series ............................................................................................ 196

8.1.1 Checking by means of the 7-segment display ............................................................................................. 196

8.1.2 Failure of the power supply to the indoor unit and the remote control switch ............................................. 197

viii

Contens

SMGB0064 rev.0 - 08/2011

8.1.3 Abnormal transmission between the remote control switch and the indoor unit .......................................... 198

8.1.4 Abnormal operation of the devices .............................................................................................................. 198

8.2 Troubleshooting procedure for IVX an ES Series ...................................................................................204

8.2.1 Alarm code ................................................................................................................................................. 204

8.2.2 Troubleshooting in check mode ................................................................................................................... 283

8.2.3 Troubleshooting by means of the 7-segment display .................................................................................. 290

8.2.4 Troubleshooting by means of the ashing alarm LEDs for RPK-FSN2M .................................................... 294

8.2.5 Cause of inverter stoppage ......................................................................................................................... 295

8.3 Procedure for checking each main part .................................................................................................299

8.3.1 Self-checking procedure of PCB by means of the Remote Control Switch ................................................. 299

8.3.2 Self-checking of the remote control switch .................................................................................................. 301

8.3.3 Self-Checking procedure of the Indoor Unit PCB (only for RPK) ................................................................ 303

9. Spare Parts.................................................................................................................. 325

9.1 Spare parts for IVX Series ......................................................................................................................326

9.2 Spare parts for ES Series .......................................................................................................................341

10. Servicing ...................................................................................................................359

10.1 Introduction ...........................................................................................................................................360

10.2 Servicing for IVX series ........................................................................................................................361

10.2.1 Outdoor unit RAS-3HVRNM2E ................................................................................................................. 361

10.2.2 Outdoor units RAS-(4-6)H(V)RNM2E ........................................................................................................ 372

10.2.3 Oudoor units RAS-(8-12)HRNM ................................................................................................................ 385

10.3 Servicing for ES Series ......................................................................................................................... 401

10.3.1 Outdoor Units RAS-(2/2.5)HVRN2 and RAS-3HVRNS2 ........................................................................... 401

10.3.2 Outdoor Units RAS-(4-6)H(V)RNS2E ........................................................................................................ 408

10.3.3 Outdoor Units RAS-(8/10)HRNSE ............................................................................................................. 420

11. Electrical checks of main parts ............................................................................... 439

11.1 Inverter ..................................................................................................................................................440

11.1.1 Inverter for IVX Series ............................................................................................................................... 440

11.1.2 Inverter for ES Series ................................................................................................................................ 445

11.2 Thermistor .............................................................................................................................................451

11.3 Electronic expansion valve ...................................................................................................................453

11.4 High pressure protection device ...........................................................................................................454

11.5 Noise lter (NF) .....................................................................................................................................455

11.5.1 Noise lter for 3N~ ..................................................................................................................................... 455

11.5.2 Noise lter for 1~ ....................................................................................................................................... 456

ix

Contens

SMGB0064 rev.0 - 08/2011

11.6 Capacitor (CB1 CB2) ............................................................................................................................457

11.7 Reactor (DCL) .......................................................................................................................................458

11.7.1 Reactor (DCL) for 3N~ .............................................................................................................................. 458

11.7.2 Reactor (DCL) for 1~ ................................................................................................................................ 458

11.8 Scroll compressor .................................................................................................................................459

11.8.1 Reliable mechanism for low vibrating and low sound ................................................................................ 459

11.8.2 Principle of compression ........................................................................................................................... 459

12. Maintenace notes .....................................................................................................461

12.1 Checking the power source and the wiring connection ........................................................................462

12.2 Burnt-out compressor due to an insufcient refrigerant charge ............................................................ 463

12.3 Insufcient cooling performance when a long piping is applied ............................................................ 464

12.4 Abnormally high operation sound (in the ceiling type indoor unit). .......................................................465

12.5 Alarm code “31” ....................................................................................................................................466

12.6 Not cooling well due to insufcient installation space for the outdoor unit ............................................ 467

12.7 Caution with the refrigerant leakage .....................................................................................................468

12.7.1 Maximum permissible concentration of the HCFC gas ............................................................................. 468

12.7.2 Calculation of the refrigerant concentration ............................................................................................... 468

12.7.3 Countermeasure for the refrigerant leakage according to the KHK standard ........................................... 468

12.8 Maintenance work.................................................................................................................................469

12.9 Service and maintenance record ..........................................................................................................470

12.10 Service and maintenance record using the 7-segment display .......................................................... 472

12.11 Service and maintenance record by remote control switch ................................................................474

12.12 Pump-down method for replacing the compressor .............................................................................476

x

Contens

SMGB0064 rev.0 - 08/2011

1 General information

1

SMGB0064 rev.0 - 08/2011

1

Index

1.1. General information .................................................................................................................................2

1.1.1. General note ................................................................................................................................................ 2

1.1.2. Introduction .................................................................................................................................................. 2

1.1.3. Environment-friendly units ........................................................................................................................... 2

1.2. Applied symbols ......................................................................................................................................3

1.3. Product guide .........................................................................................................................................4

1.3.1. Classication of IVX series outdoor unit models ......................................................................................... 4

1.3.2. Classication of ES series outdoor unit models .......................................................................................... 4

1.3.3. Product guide: Outdoor units ....................................................................................................................... 5

1.3.4. Accessory code list ...................................................................................................................................... 6

G e n e r a l i n f o r m a t i o n

1.

1 General information

2

SMGB0064 rev.0 - 08/2011

1.1 General information

1.1.1 General note

No part of this publication may be reproduced, copied, led or transmitted in any shape or form without the permission of

HITACHI Air Conditioning Products Europe, S.A.

Within the policy of continuous improvement of its products, HITACHI Air Conditioning Products Europe, S.A. reserves the

right to make changes at any time without prior notication and without being compelled to introducing them into products

subsequently sold. This document may therefore have been subject to amendments during the life of the product.

HITACHI makes every effort to offer correct, up-to-date documentation. Despite this, printing errors cannot be controlled by

HITACHI and are not its responsibility.

As a result, some of the images or data used to illustrate this document may not refer to specic models. No claims will be

accepted based on the data, illustrations and descriptions included in this manual.

No type of modication must be made to the equipment without prior, written authorisation from the manufacturer.

1.1.2 Introduction

Hitachi UTOPIA series is an outdoor unit series designed with the goal to cover the requirements of the split and multisplit

systems, for installations where from one indoor unit (single system) to up to four indoor units (quad system) are connected

to the same outdoor unit.

UTOPIA series consists in three different outdoor unit series: IVX, (2/2.5)HP and ES. All of them incorporate the

Hitachiinverter technology, which makes possible to adapt automatically and without the user operation the capacity of the

unit, so the power input, to the real demand of the installation, increasing the system efciency to unattainable levels with

other technologies. All UTOPIA units are equipped with a heat pump, resulting in an air conditioning system valid for the

whole year, in which the installation of additional and specic systems a not necessary.

2/2.5HP

Series composed by the smallest capacity units, specially designed for installation where a single combination is the most

suitable solution.

IVX

With nominal capacities from 7.1 kW to 30.0 kW (cooling mode), IVX series is the series with the highest efciency inside

UTOPIA range, allowing the installation with up to four different indoor units (quad system). In addition, to reduce as much

as possible the energy consumption and improve the energy efciency, IVX outdoor units include the “individual operation”

mode, performing an individual control over the connected indoor units to create a zone-based control.

ES

ES(Eco&Small) series stands out because of its efciency with outdoor units of small dimensions. The series is composed

by units with nominal capacities from 7.1 kW to 25.0 kW (cooling mode), allowing also the installation of up to four different

indoor units.

IU

One of the main merits of Hitachi units range is the combinability and exibility of its indoor units SYSTEM FREE. This

outstanding technology makes possible to use the same indoor units with both UTOPIA and SET FREE outdoor units,

making easier the design, installation and control of the air conditioning installations.

1.1.3 Environment-friendly units

This range of HITACHI outdoor units uses environmentally-friendly

R410A gas refrigerant, and the RoHS and Green Dot regulations

are applied throughout the manufacturing and installation process

to reect HITACHI’s awareness of environmental respect and

commitment.

R410A is totally environmentally-friendly since it does not contain

any substances that damage the ozone layer:

ODP (ozone depleting product) =0.

HITACHI’s UTOPIA series are very efcient and allow signicant

energy savings compared with conventional systems.

This energy efciency means less production of CO2, which causes the greenhouse effect.

1 General information

3

SMGB0064 rev.0 - 08/2011

1

1.2 Applied symbols

During normal air conditioning system design work or unit installation, greater attention must be paid in certain situations

requiring particular care in order to avoid damage to the unit, the installation or the building or property.

Situations that jeopardise the safety of those in the surrounding area or that put the unit itself at risk will be clearly indicated

in this manual.

To indicate these situations, a series of special symbols will be used to clearly identify these situations.

Pay close attention to these symbols and to the messages following them, as your safety and that of others depends on it.

D A NG E R

• The text following this symbol contains information and instructions relating directly to your safety and physical wellbeing.

• Not taking these instructions into account could lead to serious, very serious or even fatal injuries to you and

others in the proximities of the unit.

In the texts following the danger symbol you can also nd information on safe procedures during unit installation.

C A UT I O N

• The text following this symbol contains information and instructions relating directly to your safety and physical wellbeing.

• Not taking these instructions into account could lead to minor injuries to you and others in the proximities of

the unit.

• Not taking these instructions into account could lead to unit damage.

In the texts following the caution symbol you can also nd information on safe procedures during unit installation.

N O TE

• The text following this symbol contains information or instructions that may be of use or that require a more

thorough explanation.

• Instructions regarding inspections to be made on unit parts or systems may also be included.

1 General information

4

SMGB0064 rev.0 - 08/2011

1.3 Product guide

1.3.1 Classication of IVX series outdoor unit models

Unit type (Outdoor unit): RAS

Position-separating hyphen (xed)

Capacity (HP): 3, 4, 5, 6, 8, 10, 12

H = Heat Pump

V = Single phase unit (1~ 230V 50Hz)

- = Three phase unit (3N~ 400V 50Hz)

R= Inverter system

N=R410A refrigerant

M=IVX

Series

E = Made in Europe

– = Made in Japan

RAS – XX H (V) R N M (2) (X)

1.3.2 Classication of ES series outdoor unit models

Unit type (outdoor unit): RAS

Position-separating hyphen (xed)

Capacity (HP): 2, 2.5, 3, 4, 5, 6, 8, 10

H = Heat Pump

V = Single phase unit (1~ 230V 50Hz)

- = Three phase unit (3N~ 400V 50Hz)

R= Inverter system

N=R410A refrigerant

S= ES

Series

E = Made in Europe

– = Made in Japan

RAS – XX H (V) R N (S) (2) (X)

1 General information

5

SMGB0064 rev.0 - 08/2011

1

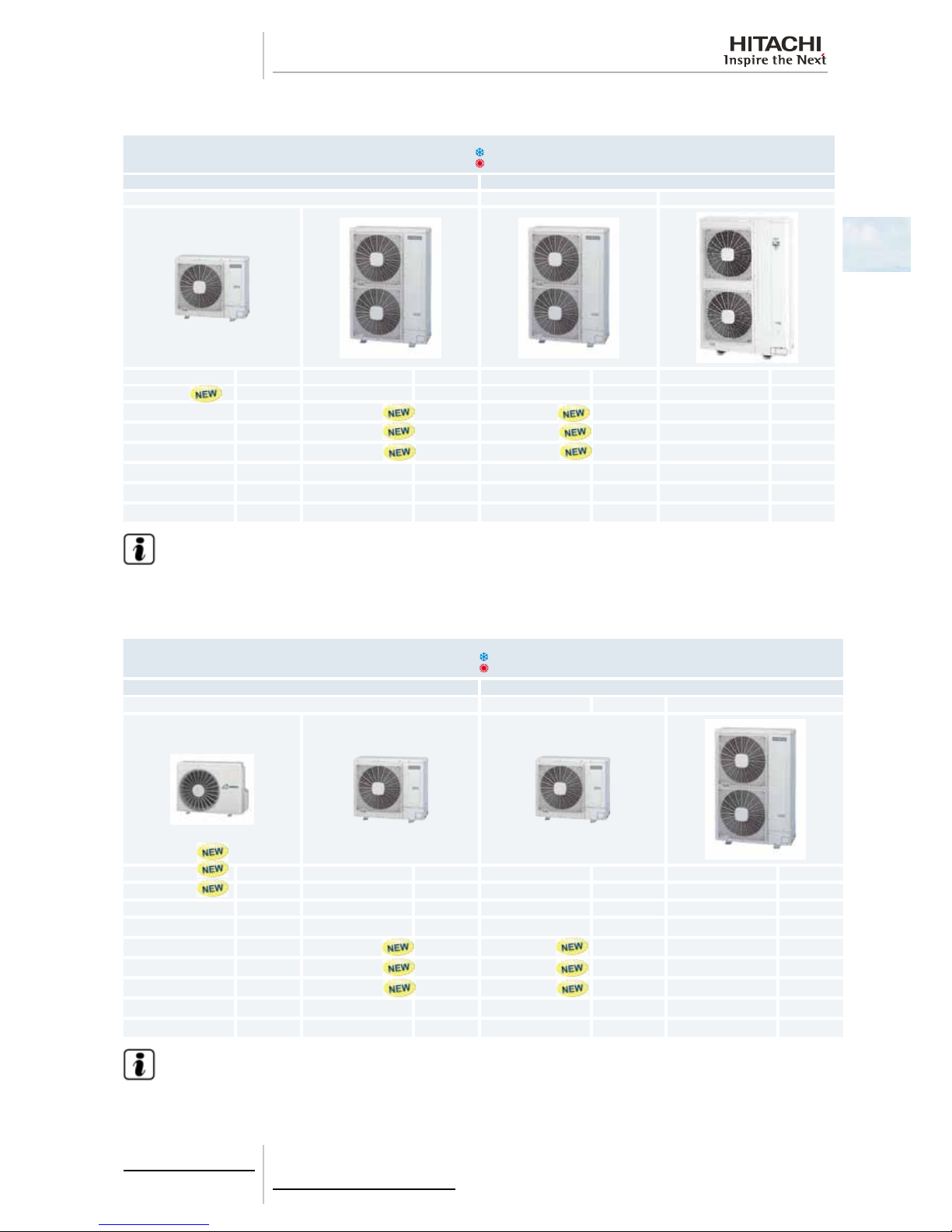

1.3.3 Product guide: Outdoor units

IVX series

Outdoor Units IVX

Single phase (1~) Three phase (3~)

HVRNM2E HRNM1E HRNM

Unit Code Unit Code Unit Code Unit Code

RAS-3HVRNM2E 7E305018

RAS-4HVRNM2E 7E305020 RAS-4HRNM2E 7E305120

RAS-5HVRNM2E 7E305021 RAS-5HRNM2E 7E305121

RAS-6HVRNM2E 7E305022 RAS-6HRNM2E 7E305122

RAS-8HRNM 60278972

RAS-10HRNM 60278973

RAS-12HRNM 60278974

N O TE

• Check the exact classication for each unit (model, type, power and series) in Classication of IVX series out-

door unit models, see on page 4.

ES series

Outdoor Units ES

Single phase (1~) Three phase (3~)

HVRN(2)(E) HRNSE

Unit Code Unit Code Unit Unit Code

RAS-2HVRN2 60288390 7E306107

RAS-2.5HVRN2 60288391 7E306108

RAS-3HVRNS2 60288392 7E306109

RAS-4HVRNS2E 7E306020 RAS-4HRNS2E

RAS-5HVRNS2E 7E306021 RAS-5HRNS2E

RAS-6HVRNS2E 7E306022 RAS-6HRNS2E

RAS-8HRNSE 7E314110

RAS-10HRNSE 7E314111

N O TE

• Check the exact classication for each unit (model, type, power and series) in Classication of ES series out-

door unit models, see on page 4 .

1 General information

6

SMGB0064 rev.0 - 08/2011

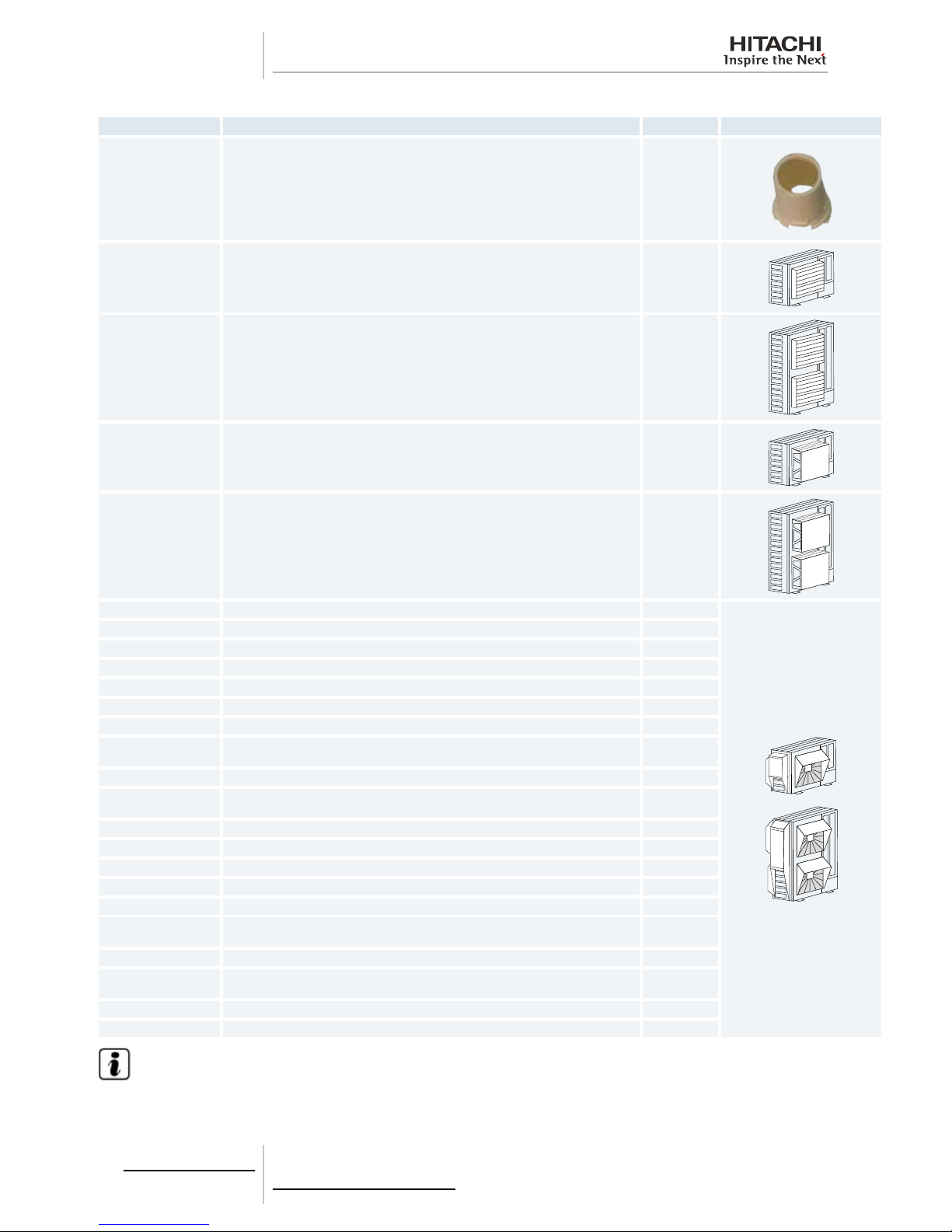

1.3.4 Accessory code list

Name Description Code Figure

DBS-26 Drain discharge connection 60299192

AG-264 Air ow guide (For 2/2.5HP and 3HP ES) -

AG-335A Air ow guide (For 3-12HP IVX and 4-10HP ES) 60291431

WSP-264 Wind guard (For 2/2.5HP and 3HP ES) 60291728

WSP-335A Wind guard (For 3-12HP IVX and 4-10HP ES) 60291432

ASG-NP80F Snow protection hood; air outlet (Zinc plate) (For 2/2.5HP and 3HP ES) -

ASG-NP80FS2 Snow protection hood; air outlet (Stainless plate) (For 2/2.5HP and 3HP ES) -

ASG-NP335F Snow protection hood; air outlet (Zinc plate) (For 3-12HP IVX and 4-10HP ES) 60291433

ASG-NP335FS2 Snow protection hood; air outlet (Stainless plate) (For 3-12HP IVX and 4-10HP ES) -

ASG-NP56B Snow protection hood; air inlet of rear side (Zinc plate) (For 2/2.5HP and 3HP ES) -

ASG-NP63BS2 Snow protection hood; air inlet of rear side (Stainless plate) (For 2/2.5HP and 3HP ES) -

ASG-NP80B Snow protection hood; air inlet of rear side (Zinc plate) (For 3HP IVX and 4-6HP ES) -

ASG-NP160BS2

Snow protection hood; air inlet of rear side (Stainless plate) (For 3HP IVX and 4-6HP

ES)

-

ASG-NP280B Snow protection hood; air inlet of rear side (Zinc plate) (For 4-6HP IVX and 8/10HP ES) -

ASG-NP280BS2

Snow protection hood; air inlet of rear side (Stainless plate) (For 4-6HP IVX and

8/10HP ES)

-

ASG-NP335B Snow protection hood; air inlet of rear side (Zinc plate) (For 8-12HP IVX ) 60291434

ASG-NP335BS2 Snow protection hood; air inlet of rear side (Stainless plate) (For 8-12HP IVX ) -

ASG-NP56L Snow protection hood; air inlet of left side (Zinc plate) (For 2/2.5HP and 3HP ES) -

ASG-NP63LS2 Snow protection hood; air inlet of left side (Stainless plate) (For 2/2.5HP and 3HP ES) -

ASG-NP80L Snow protection hood; air inlet of left side (Zinc plate) (For 3HP IVX and 4-6HP ES) -

ASG-NP160LS2

Snow protection hood; air inlet of left side (Stainless plate) (For 3HP IVX and 4-6HP

ES)

-

ASG-NP280L Snow protection hood; air inlet of left side (Zinc plate) (For 4-6HP IVX and 8/10HP ES) -

ASG-NP280LS2

Snow protection hood; air inlet of left side (Stainless plate) (For 4-6HP IVX and 8/10HP

ES)

-

ASG-NP335L Snow protection hood; air inlet of left side (Zinc plate) (For 8-12HP IVX ) 60291435

ASG-NP335LS2 Snow protection hood; air inlet of left side (Stainless plate) (For 8-12HP IVX ) -

N O TE

HITACHI has a range of accessories and remote control systems that can be used with the UTOPIA outdoor units. Please,

refer to the Controls Technical Catalogue.+

2 Unit Installation

7

SMGB0064 rev.0 - 08/2011

2

U n i t I n s t a l l a t i o n

2.

Index

2.1. Safety summary ......................................................................................................................................8

2.2. Transportation of outdoor unit .................................................................................................................9

2.3. Center of gravity .................................................................................................................................... 10

2.4. Factory-supplied accessories for RAS-(8-12)HRNM............................................................................. 11

2.5. Installation space (Initial ckeck).............................................................................................................12

2.5.1. RAS-3HVRNM2E / RAS-(2-3)HVRN(S)2 / RAS-(4-10)H(V)RNS2E .......................................................... 12

2.5.2. RAS-(4-6)H(V)RNM2E / RAS-(8/10)HRNSE ............................................................................................. 16

2.5.3. RAS-(8-12)HRNM ...................................................................................................................................... 20

2.6. Place provision ...................................................................................................................................... 22

2.6.1. Place provision for RAS-(3-12)H(V)RNM(2)(E) and RAS-(4-10)H(V)RNS(2)E ......................................... 22

2.6.2. Place provision only for RAS-(2-3)HVRN(S)2 ........................................................................................... 25

2.7. Optional parts and installation ............................................................................................................... 28

2.7.1. Optional parts and installation for RAS-(2-3)HVRN(S)2 ............................................................................ 28

2.7.2. Optional parts and installation RAS-3HVRNM2E / RAS-(4-6)H(V)RNS2E ............................................... 33

2.7.3. Optional parts and installation RAS-(4-6)H(V)RNM2E / RAS-(8/10)HRNSE ........................................... 37

2.7.4. Optional parts and installation RAS-(8-12)HRNM ..................................................................................... 42

2 Unit Installation

8

SMGB0064 rev.0 - 08/2011

2.1 Safety summary

D A NG E R

• Install the outdoor unit with sufcient clearance around it for operation and maintenance as shown in the next

pages.

• Install the outdoor unit where good ventilation is available.

• Do not install the outdoor unit where exists a high level of oil mist salty air or sulphurous atmosphere.

• Install the outdoor unit as far as practical (being at least 3 meters) from electromagnetic wave radiator such

as medical equipment.

• Keep clearance between units of more than 50 mm and avoid obstacles that could hamper air intake when

installing more than one unit together.

• Install the outdoor unit in the shade or not exposed to direct sunshine or direct radiation from high temperature heat source.

• Do not install the outdoor unit in a place where a seasonal wind directly blows into the outdoor fan.

• For cleaning use non-inammable and nontoxic cleaning liquid. Use of inammable agent may cause explo-

sion or re.

• Work with sufcient ventilation for working in an enclosed space could cause oxygen deciency. Toxic gas

may be produced when cleaning agent is heated to high temperature by e.g. being exposed to re.

• Cleaning liquid shall be collected after cleaning.

• Pay attention not to clamp cables when attaching the service cover to avoid electric shock or re.

C A UT I O N

• Check the foundation to be at leveled and strongly enough.

• Install the unit in a restricted area not accessible by the general public.

• Aluminium ns have very sharp edges. Pay attention to the ns in order to avoid injury.

• Do not install the indoor units in a ammable environment to avoid a re or an explosion.

• Check to ensure that the ceiling slab is strong enough. If not strong enough the indoor unit may fall down on

you.

• Do not install the indoor units outdoor unit remote control switch and cable within approximately 3 meters

from strong electromagnetic wave radiators such as medical equipment.

• Do not install the indoor units in a machinery shop or kitchen where vapour from oil or mist ows to the indoor units. The oil will deposit on the heat exchanger thereby reducing the indoor unit performance and may

deform. In the worst case the oil damages the plastic parts of the indoor unit.

• To avoid any corrosive action to the heat exchangers do not install the indoor units in an acid or alkaline environment.

• When lifting or moving the indoor unit use appropriate slings to avoid damage and be careful not to damage

the insulation material on units surface.

• This appliance must be used only by adult and capable people having received the technical information or

instructions to handle properly and safely this appliance.

• Turn OFF all power switches before maintenance is performed.

• Do not start the cleaning procedures before 5 minutes of the stop of the unit.

D A NG E R

• Avoid obstacles which may hamper the air intake or the air discharge ow.

• Children must be supervised to ensure that they do not play with the electrical appliances.

• Before obtaining access to terminals all supply circuits bust be disconnected.

2 Unit Installation

9

SMGB0064 rev.0 - 08/2011

2

2.2 Transportation of outdoor unit

D A NG E R

Do not put any foreign material into the outdoor unit and check to ensure that none exists in the outdoor unit

before the installation and test run. Otherwise a re or failure will occur.

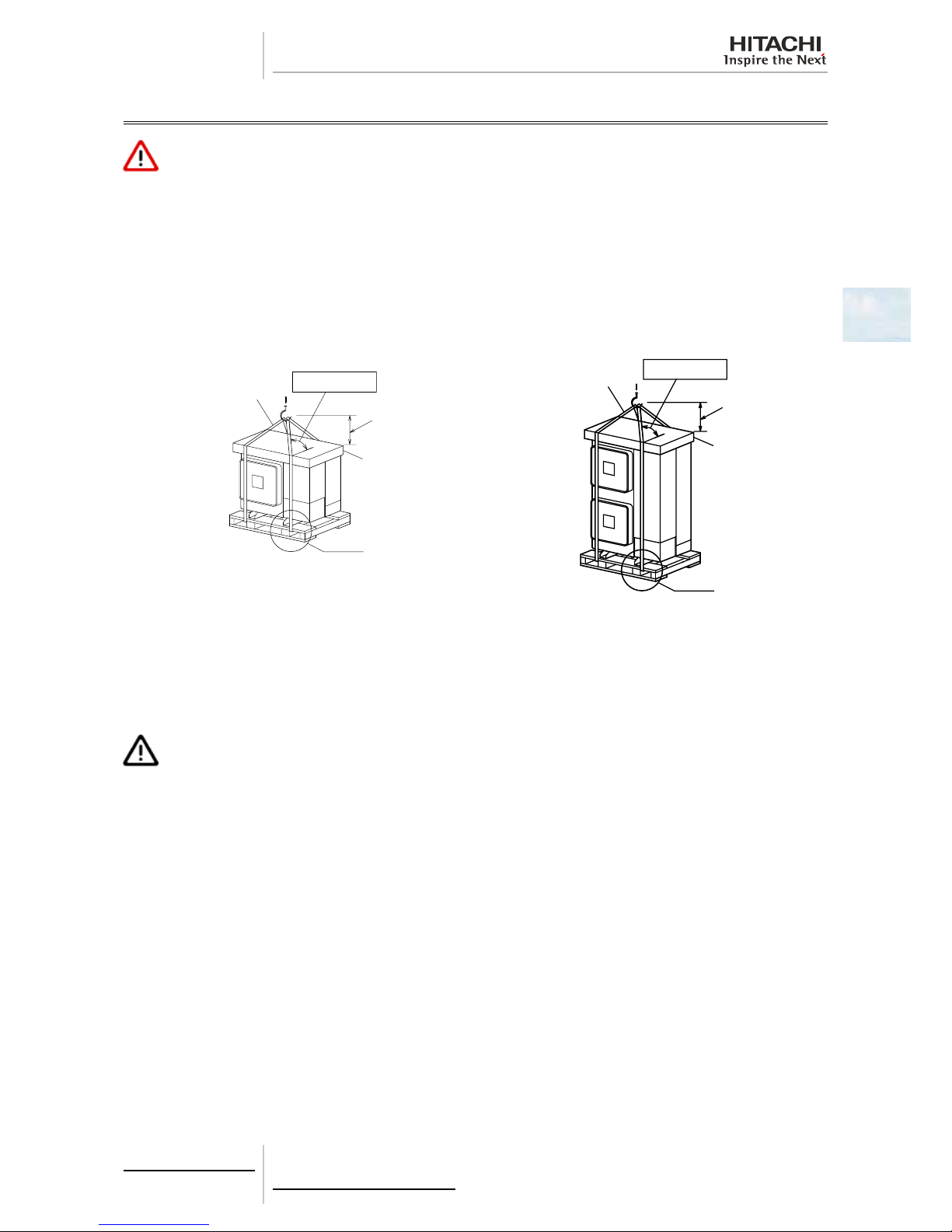

Hanging Method

When hanging the unit ensure the balance of the unit check safety and lift it up smoothly. Do not remove any packing materials and hang the unit under packing condition with two ropes as shown below.

RAS-3HVRNM2E RAS-(4-6)H(V)RNM2E

RAS-(2-3)HVRN(S)2 RAS-(8-12)HRNM

RAS-(4-6)H(V)RNS2E RAS-(8/10)HRNSE

1

A

B

C

D

1

A

B

C

D

1. Wire rope.

A. Over 60º.

B. 0.7 to 1.0 m.

C. Do not remove the plastic band or the corrugate paper frame.

D. Pass the wire ropes through each lifting hole in the wooden base as shown.

C A UT I O N

• Lift the outdoor unit in its factory packaging with 2 wire ropes.

• For safety reasons ensure that the outdoor unit is lifted smoothly and does not lean.

• Do not attach lifting equipment to the plastic band or the corrugated paper frame because of the ropes will slip

or break the materials.

• Ensure that the exterior of the unit is adequately protected with cloth or paper.

2 Unit Installation

10

SMGB0064 rev.0 - 08/2011

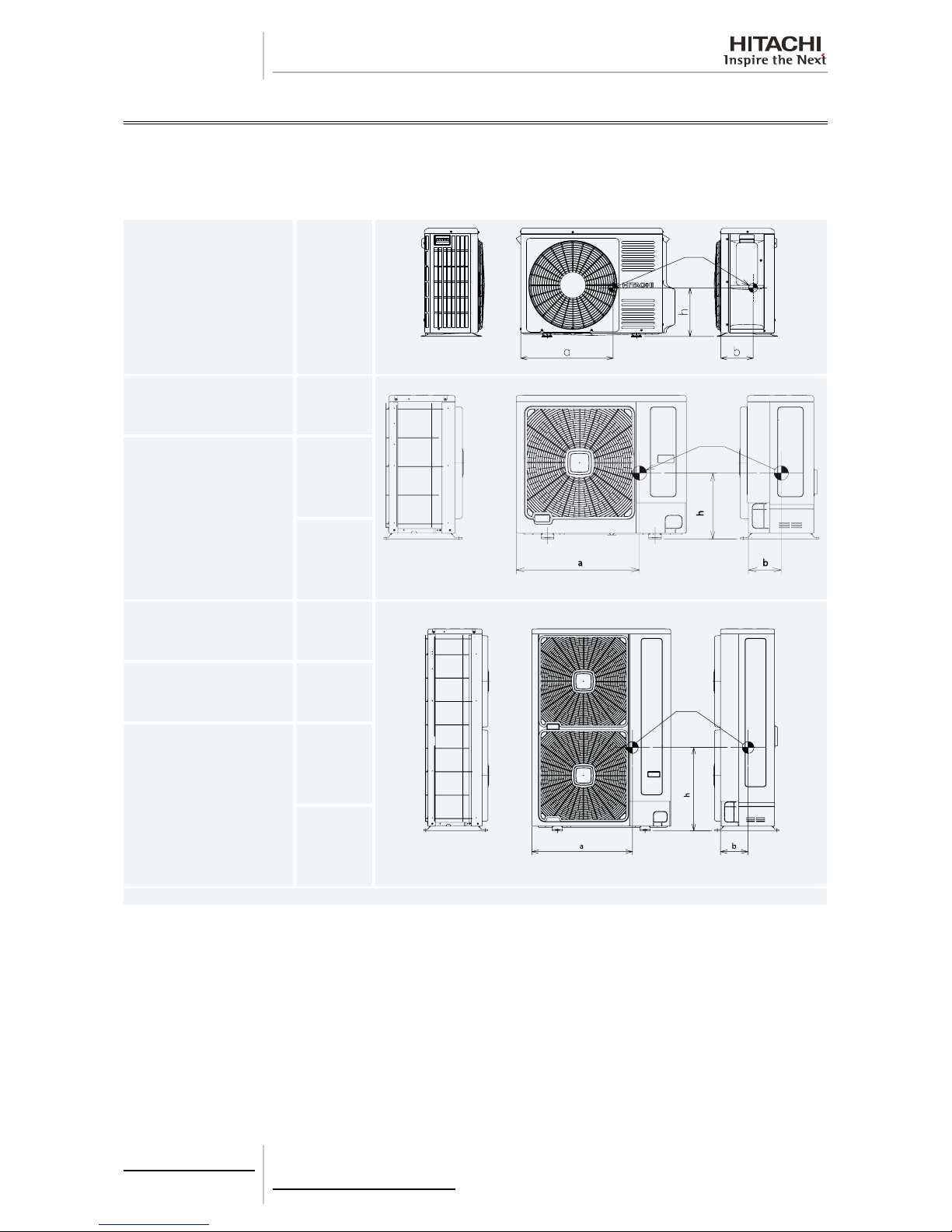

2.3 Center of gravity

Hanging Method

When hanging the unit ensure the balance of the unit check safety and lift it up smoothly. Do not remove any packing

materials and hang the unit under packing condition with two ropes as shown below. At leat two persons are needed to

move the unit.

RAS-(2-3)HVRN(S)2

a. 515 mm

b. 180 mm

h. 275 mm

1

RAS-3HVRNM2E

a. 590 mm

b. 185 mm

h. 370 mm

1

RAS-(4-6)H(V)RNS2E

For 4 HP:

a. 635 mm

b. 180 mm

h. 335 mm

For 5-6 HP:

a. 630 mm

b. 190 mm

h. 360 mm

RAS-(4-6)H(V)RNM2E

a. 615 mm

b. 190 mm

h. 570 mm

1

RAS-(8-12)HRNM

a. 615 mm

b. 190 mm

h. 570 mm

RAS-(8/10)HRNSE

For 8 HP:

a. 325 mm

b. 206 mm

h. 565 mm

For 10HP:

a. 325 mm

b. 213 mm

h. 585 mm

1 Center of gravity

2 Unit Installation

11

SMGB0064 rev.0 - 08/2011

2

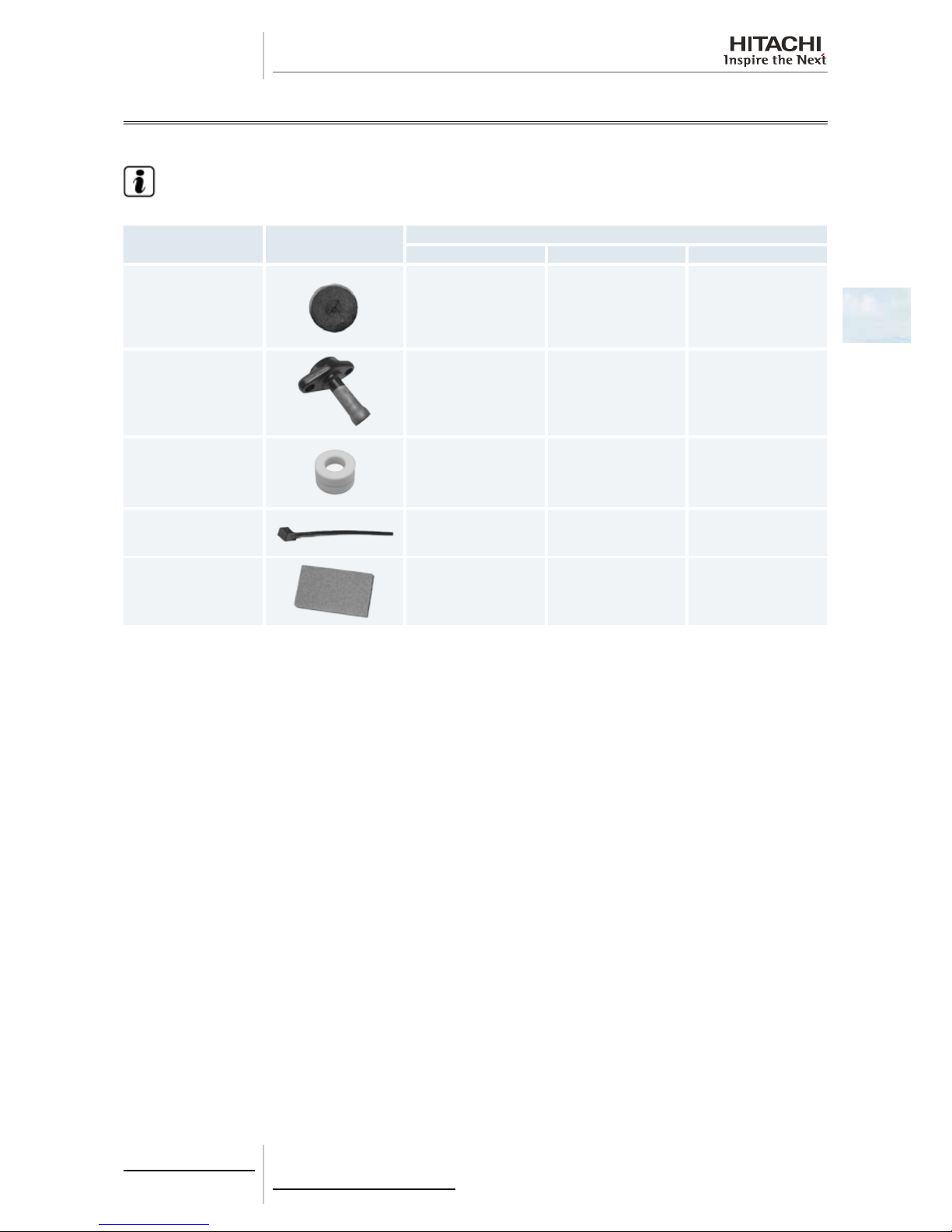

2.4 Factory-supplied accessories for RAS-(8-12)HRNM

Make sure that the following accessories are packed with the unit.

N O TE

• If any of these accessories are not packed with the unit please contact your dealer.

Accessory Appearance

Quantity

RAS-8HRNM RAS-10HRNM RAS-12HRNM

Gasket

1 1 1

Pipe ange for refrigerant

gas piping

1 1 1

Ring core

1 1 1

Cable tie 1 1 1

Compressed sheet

1 1 1

2 Unit Installation

12

SMGB0064 rev.0 - 08/2011

2.5 Installation space (Initial ckeck)

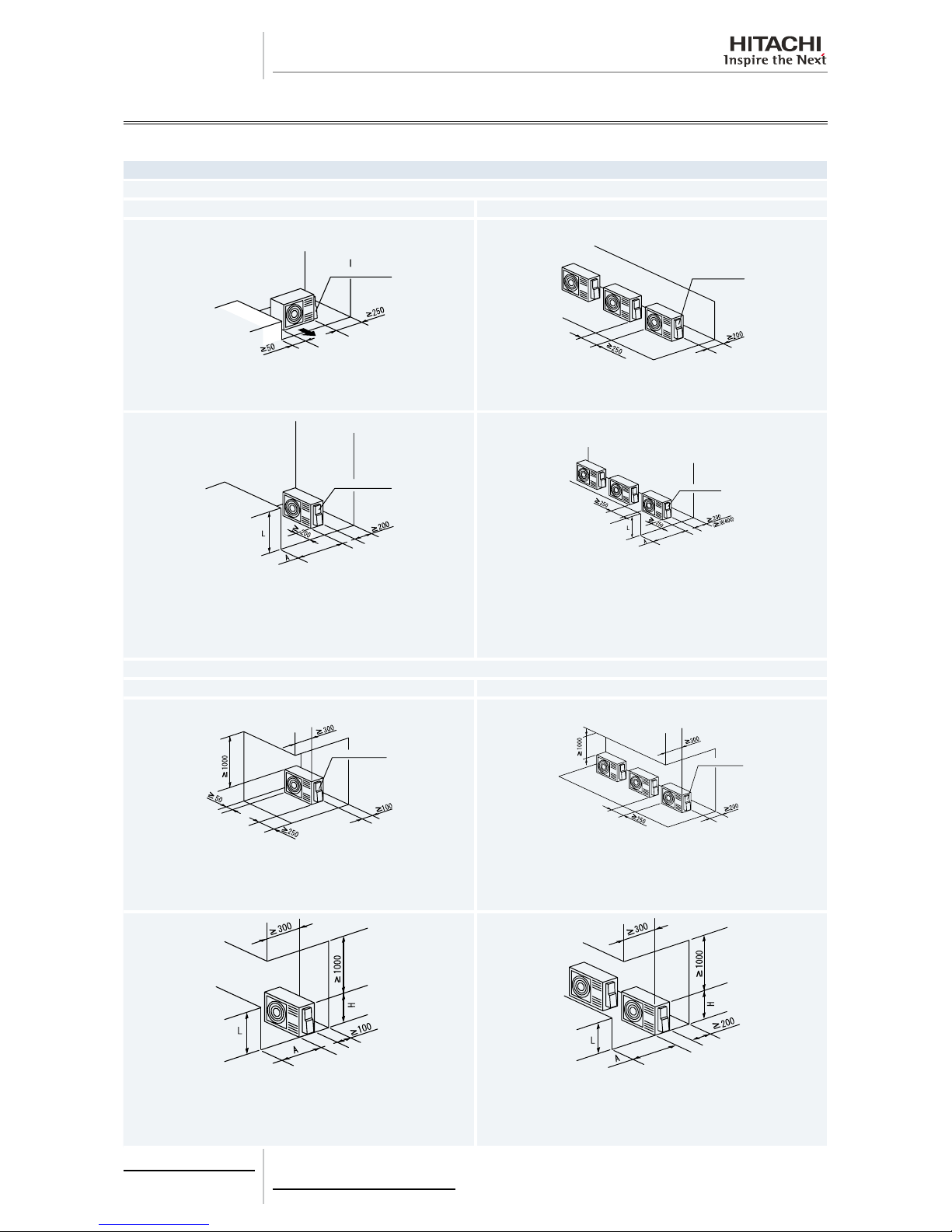

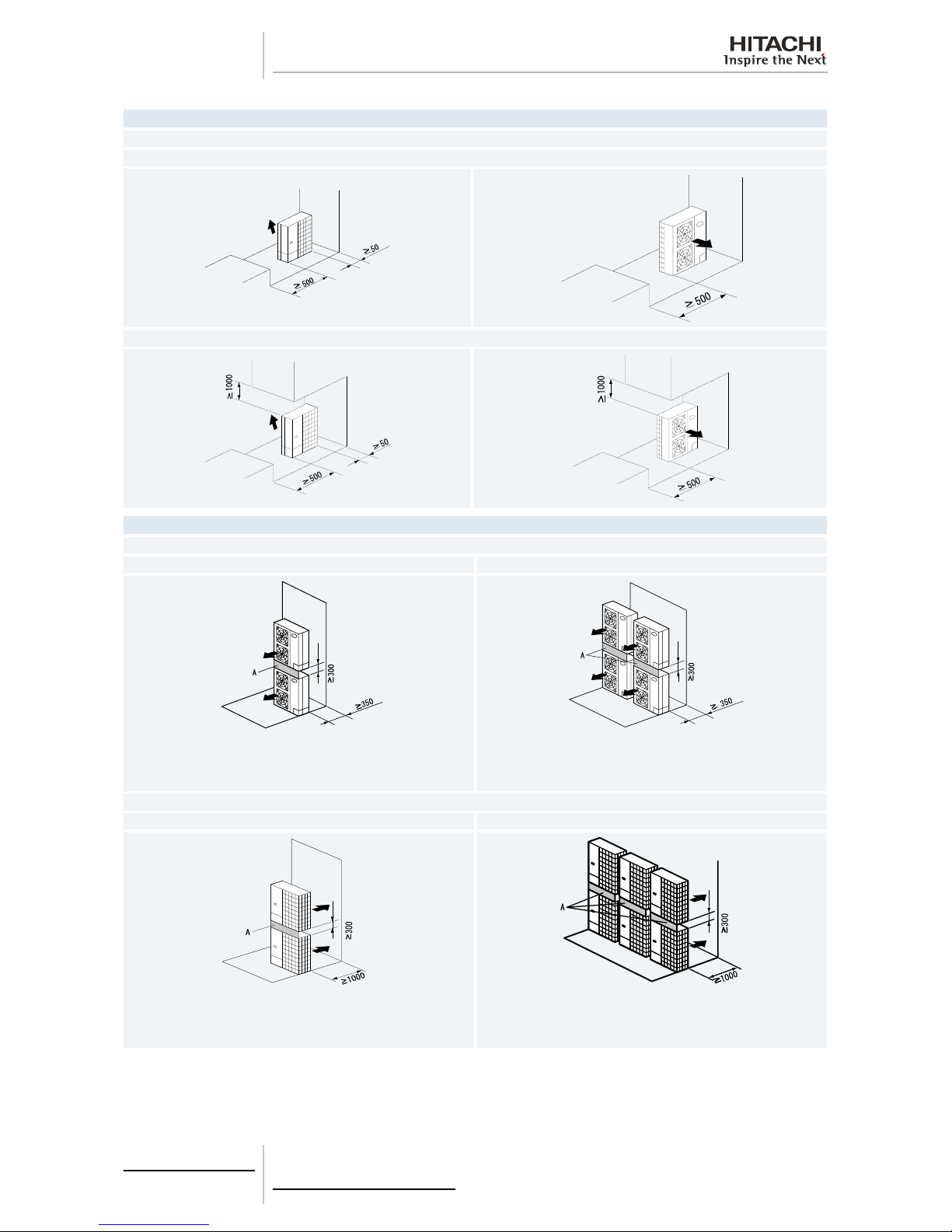

2.5.1 RAS-3HVRNM2E / RAS-(2-3)HVRN(S)2 / RAS-(4-10)H(V)RNS2E

Blocked in Inlet Side

Upper Side Open

Single Installation Multiple Installation (Two units or more)

Pipe Cover

Pipe Cover

Ensure 250 mm or more of the side space on the pipe cover side.

Allow 250 mm of space between units. Leave open both right and left

sides.

Pipe Cover

Pipe Cover

Be sure to use the fan direction guide. Leave open both right and left sides.

Ensure 250 mm or more of the side space on the pipe cover side.

Be sure to use the fan direction guide.

Allow 250 mm of service space between units. Leave open both right

and left sides. When subject to direct sunlight on the back wall ensure

the length marked with . be 400 or greater.

Ensure 250 mm or more of the side space on the pipe cover side.

Upper Side Blocked

Single Installation Multiple Installation (Two units or more)

Pipe Cover

Pipe Cover

Fifteen mm of space is acceptable for one of the lateral sides.

Ensure 250 mm or more of the side space on the pipe cover side.

Allow 250 mm of service space between units. Leave open both right

and left sides.

Ensure 250 mm or more of the side space on the pipe cover side.

Be sure to use the fan direction guide. Leave open both right and left sides.

Ensure 250 mm or more of the side space on the pipe cover side.

Be sure to use the fan direction guide.

Allow 250 mm of service space between units. Leave open both right

and left sides. Serial installation allowed up to two units.

Ensure 250 mm or more of the side space on the pipe cover side.

2 Unit Installation

13

SMGB0064 rev.0 - 08/2011

2

Blocked in Inlet Side

The length A is as show in the following table:

L A

0<L=1/2H 500 or greater

1/2H<L≤H 1000 or greater

When L > H use a base for outdoor unit to make L ≤ H.

Close the base not to allow the outlet air bypassed.

Outlet Side Blocked

Upper Side Open

Single Installation Multiple Installation (Two units or more)

Pipe Cover

Pipe Cover

Ensure 250 mm or more of the side space on the pipe cover side.

Allow 250 mm of service space between units. Both right and left sides

shall be open.

Pipe Cover

Pipe Cover

Be sure to use the fan direction guide. Leave open both right and left

sides.

Be sure to use the fan direction guide. Allow 250 mm of service space

between units. Serial installation allowed up to two units.

Leave open both right and left sides.

The length A is as show in the following table:

L A

0<L=1/2H 100 or greater

1/2H<L≤H 200 or greater

When L > H use a base for outdoor unit to make L ≤ H.

Close the base not to allow the outlet air bypassed.

The length A is as show in the following table:

L A

0<L=1/2H 150 or greater

1/2H<L≤H 250 or greater

When L > H use a base for outdoor unit to make L ≤ H.

Close the base not to allow the outlet air bypassed.

2 Unit Installation

14

SMGB0064 rev.0 - 08/2011

Lateral Side Blocked

Upper Side Open

Single Installation

Pipe Cover

Pipe Cover

Ensure 250 mm or more of the side space on the pipe cover side. Ensure 250 mm or more of the side space on the pipe cover side.

Upper Side Blocked

Pipe Cover

Pipe Cover

Ensure 250 mm or more of the side space on the pipe cover side. Ensure 250 mm or more of the side space on the pipe cover side.

2 Unit Installation

15

SMGB0064 rev.0 - 08/2011

2

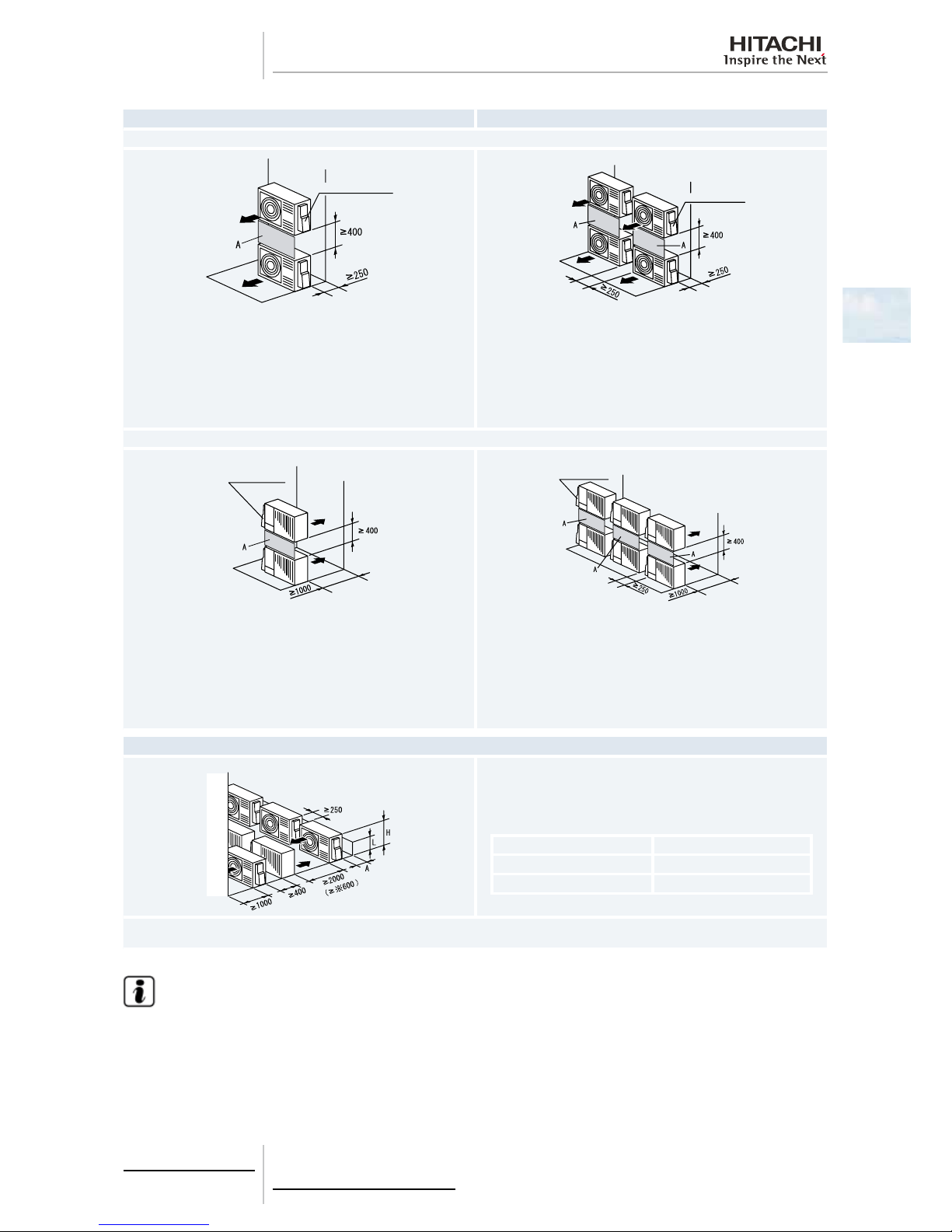

Single Installation Multiple Installation

Blocked in Inlet Side

Pipe Cover

Pipe Cover

Close the part A not to allow the outlet air bypassed. Install to avoid the

drain water from upper unit falling on the lower unit.

Ensure 250 mm or more of the side space on the pipe cover side.

Allow 400 mm of service space above the top board.

Allow 250 mm of service space between units. Serial sideways installation allowed up to two units.

Leave open both right and left sides. Close the part A not to allow the

outlet air bypassed. Install to avoid the drain water from upper unit falling

on the lower unit.

Ensure 250 mm or more of the side space on the pipe cover side.

Allow 400 mm of service space above the top board.

Outlet Side Blocked

Pipe Cover

Pipe Cover

Be sure to use the fan direction guide. Close the part A not to allow the

outlet air bypassed. Install to avoid the drain water from upper unit falling

on the lower unit.

Ensure 250 mm or more of the side space on the pipe cover side.

Allow 400 mm of service space above the top board.

Be sure to use the fan direction guide. Allow 250 mm of service space

between units. Serial side way installation allowed but leave open both

right and left sides. Close the part A not to allow the outlet air bypassed.

Install to avoid the drain water from upper unit falling on the lower unit.

Ensure 250 mm or more of the side space on the pipe cover side.

Allow 400 mm of service space above the top board.

Multiple Installation in Multiple Rows

Ensure 250 mm or more of the side space on the pipe cover side. Allow

400 mm of service space above the top board.

The length A is as show in the following table:

L A

0<L=1/2H 150 or greater

1/2H<L≤H 250 or greater

When L > H use a base for outdoor unit to make L ≤ H. Close the base not to allow the outlet air bypassed. Be sure to use the fan direction guide in

order to ensure the length marked with ..

N O TE

• All units are in (mm).

• Do not stack more than two units in height.

• Close gap (*) to avoid recirculating discharge air ow.

2 Unit Installation

16

SMGB0064 rev.0 - 08/2011

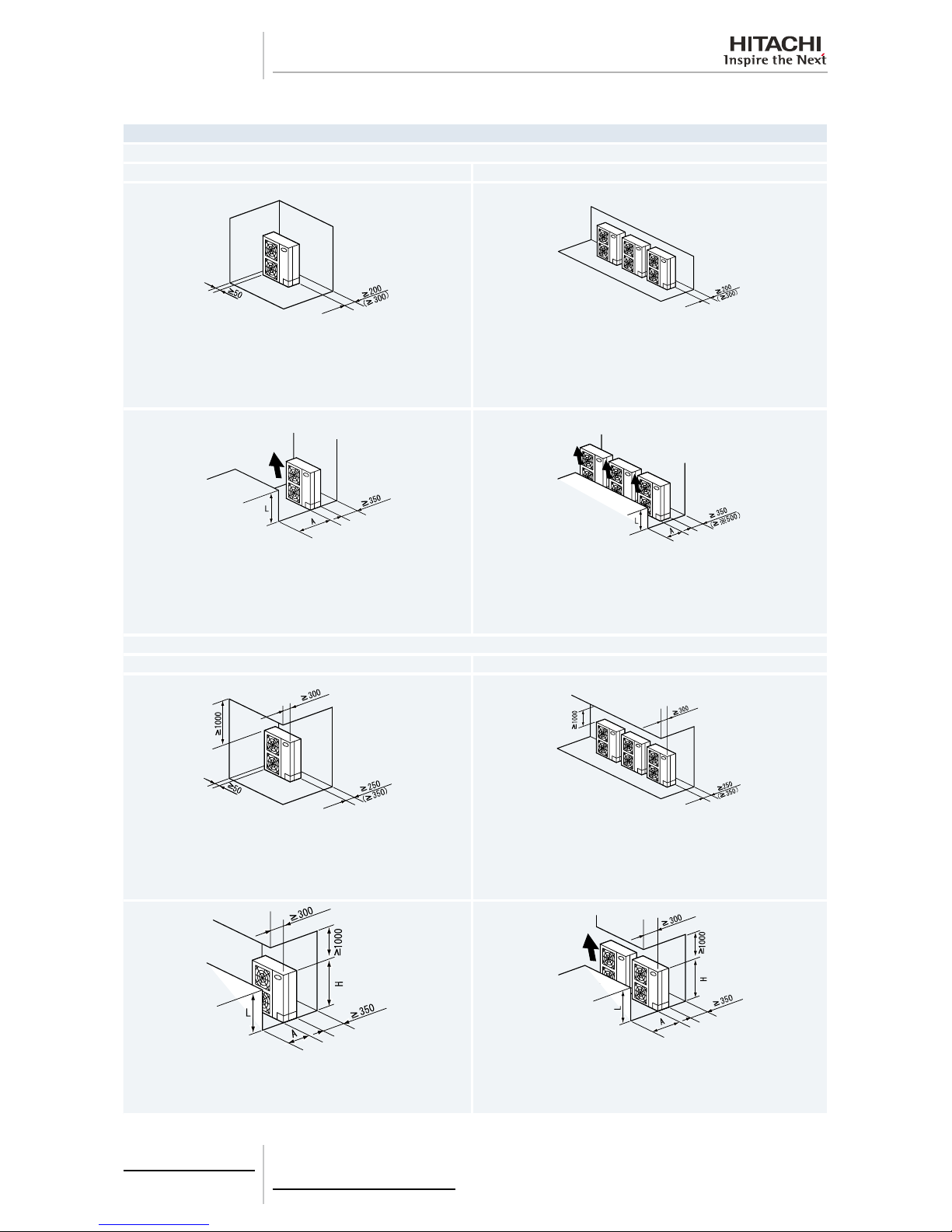

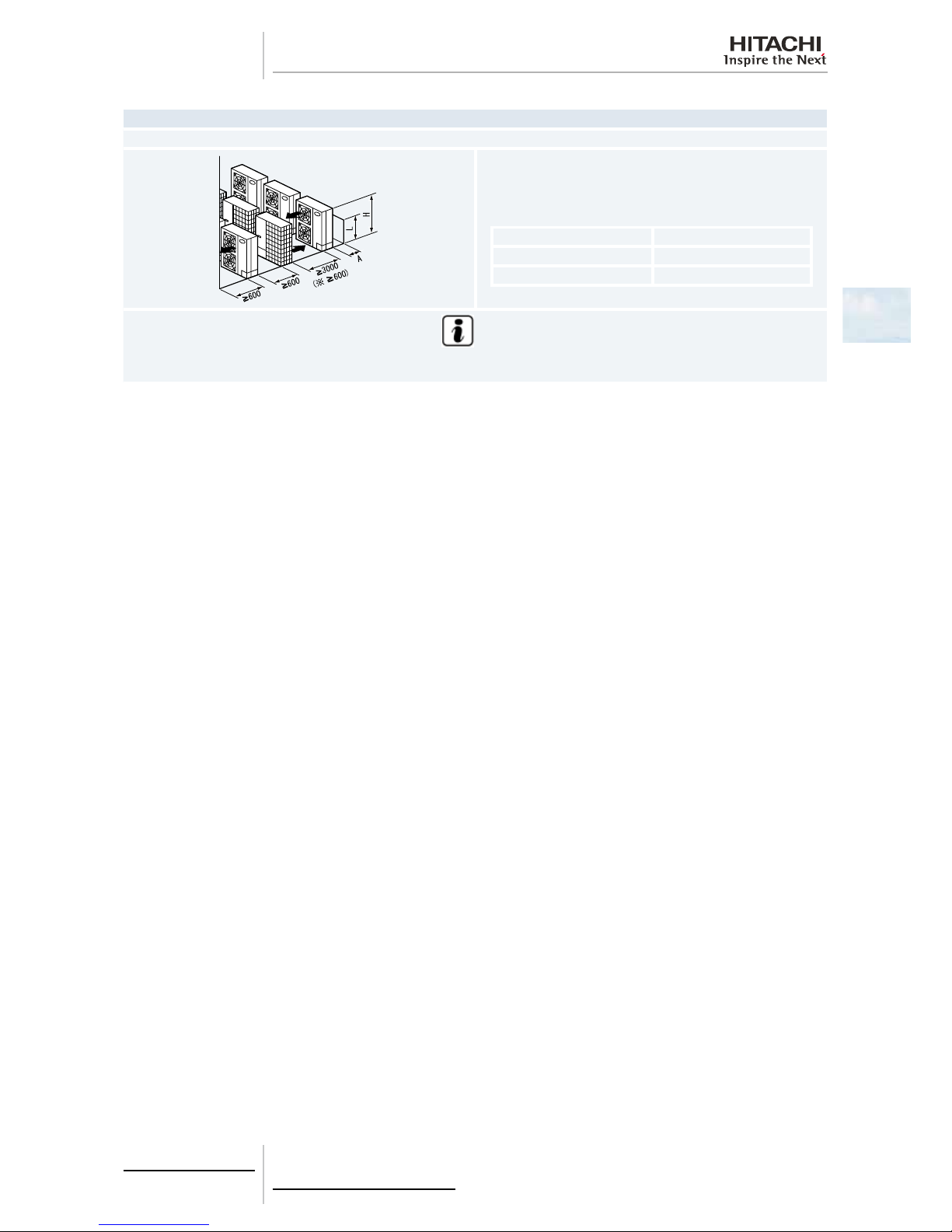

2.5.2 RAS-(4-6)H(V)RNM2E / RAS-(8/10)HRNSE

Blocked in Inlet Side

Upper Side Open

Single Installation Multiple Installation (Two units or more)

100 mm or more of the side space is acceptable on the service cover

side. Dimensions in ( ) shows numbers especially for IVX 4-10 HP and

ES 8/10 HP. 150 or more (200 or more) of the back space is acceptable

when the right and left sides are open.

Allow 100 mm of space between units. Leave open both right and left

sides.

Dimensions in ( ) shows numbers especially for IVX 4-10 HP and ES

8/10 HP.

Be sure to use the fan direction guide. Leave open both right and left

sides.

Be sure to use the fan direction guide. Allow 100 mm of space between

units. Leave open both right and left sides.

When subject to direct sunlight on the back wall ensure the length marked

with . be 500 or greater.

Upper Side Blocked

Single Installation Multiple Installation (Two units or more)

100 mm or more of the side space is acceptable on the service cover

side.

Dimensions in ( ) shows numbers especially for IVX 4-10 HP and ES

8/10 HP.

Allow 100 mm of space between units. Leave open both right and left

sides.

Dimensions in ( ) shows numbers especially for IVX 4-10 HP and ES

8/10 HP.

Be sure to use the fan direction guide.

Leave open both right and left sides.

Be sure to use the fan direction guide. Allow 100 mm of space between

units. Leave open both right and left sides.

Serial installation allowed up to two units.

2 Unit Installation

17

SMGB0064 rev.0 - 08/2011

2

Blocked in Inlet Side

The length A is as shown in the following table:

L A

0 < L ≤ 1/2H 600 or greater

1/2H < L≤ H 1200 or greater

Be sure to use the fan direction guide. Allow 100 mm of space between units. Leave open both right and left sides. Serial installation allowed up to

two units.

Outlet Side Blocked

Upper Side Open

Single Installation Multiple Installation (Two units or more)

Allow 100 mm of space between units. Both right and left sides shall be

open.

Be sure to use the fan direction guide. Leave open both right and left

sides.

Be sure to use the fan direction guide. Allow 100 mm of space between

units. Serial installation allowed up to two units. Leave open both right

and left sides.

The length A is as shown in the following table:

L A

0 < L ≤ 1/2H ≤ 200

1/2H < L≤ H ≤ 300

When L > H use a base for outdoor unit to make L ≤ H.

Close the base not to allow the outlet air bypassed.

The length A is as shown in the following table:

L A

0 < L ≤ 1/2H ≤ 250

1/2H < L≤ H ≤ 350

When L > H use a base for outdoor unit to make L ≤ H.

Close the base not to allow the outlet air bypassed.

2 Unit Installation

18

SMGB0064 rev.0 - 08/2011

Lateral Side Blocked

Upper Side Open

Single Installation

Upper Side Blocked

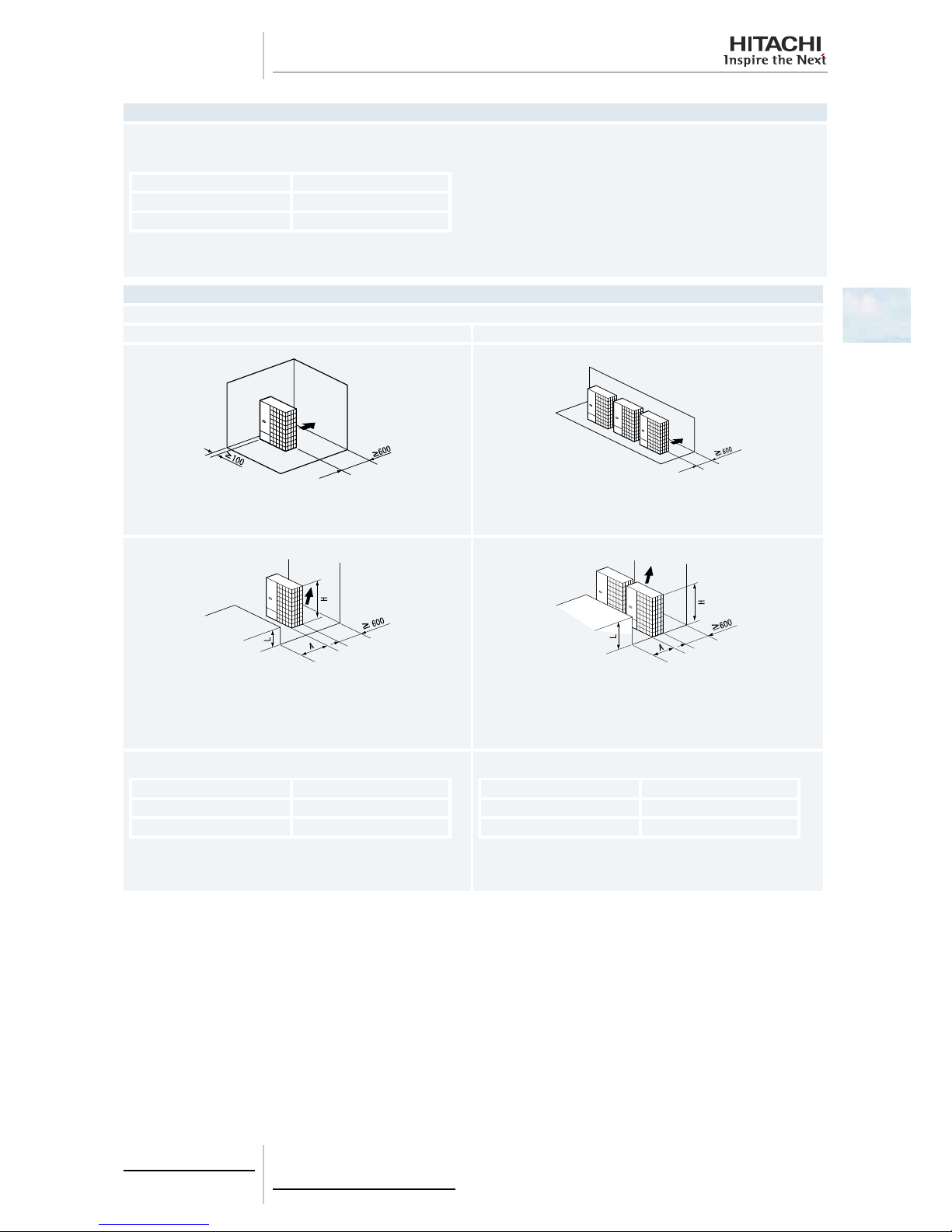

Stack installation (allowed up to 2 Units)

Upper Side Open

Single Installation Multiple Installation

Close the part A not to allow the outlet air bypassed. Install to avoid the

drain water from upper unit falling on the lower unit.

Allow 100 mm of space between units. Serial sideways installation

allowed up to two units. Leave open both right and left sides. Close the

part A not to allow the outlet air bypassed. Install to avoid the drain water

from upper unit falling on the lower unit.

Upper Side Blocked

Single Installation Multiple Installation

Be sure to use the fan direction guide. Close the part A not to allow the

outlet air bypassed. Install to avoid the drain water from upper unit falling

on the lower unit.

Be sure to use the fan direction guide. Allow 100 mm of space between

units. Serial side way installation allowed. but leave open both right and

left sides. Close the part A not to allow the outlet air bypassed. Install to

avoid the drain water from upper unit falling on the lower unit.

2 Unit Installation

19

SMGB0064 rev.0 - 08/2011

2

Multiple Installation in Multiple Rows

Serial Installation in Multiple Rows (E.g. Rooftop)

Allow approx. 100 mm of space from the side unit. Leave open both right

and left sides.

The length A is as shown in the following table:

L A

0 < L ≤ 1/2H ≤ 200

1/2H < L≤ H ≤ 300

N O T E

When L > H use a base for outdoor unit to make L = H. Close the base not to allow the outlet air bypassed. Be sure to use the fan direction

guide in order to ensure the length marked with ..

2 Unit Installation

20

SMGB0064 rev.0 - 08/2011

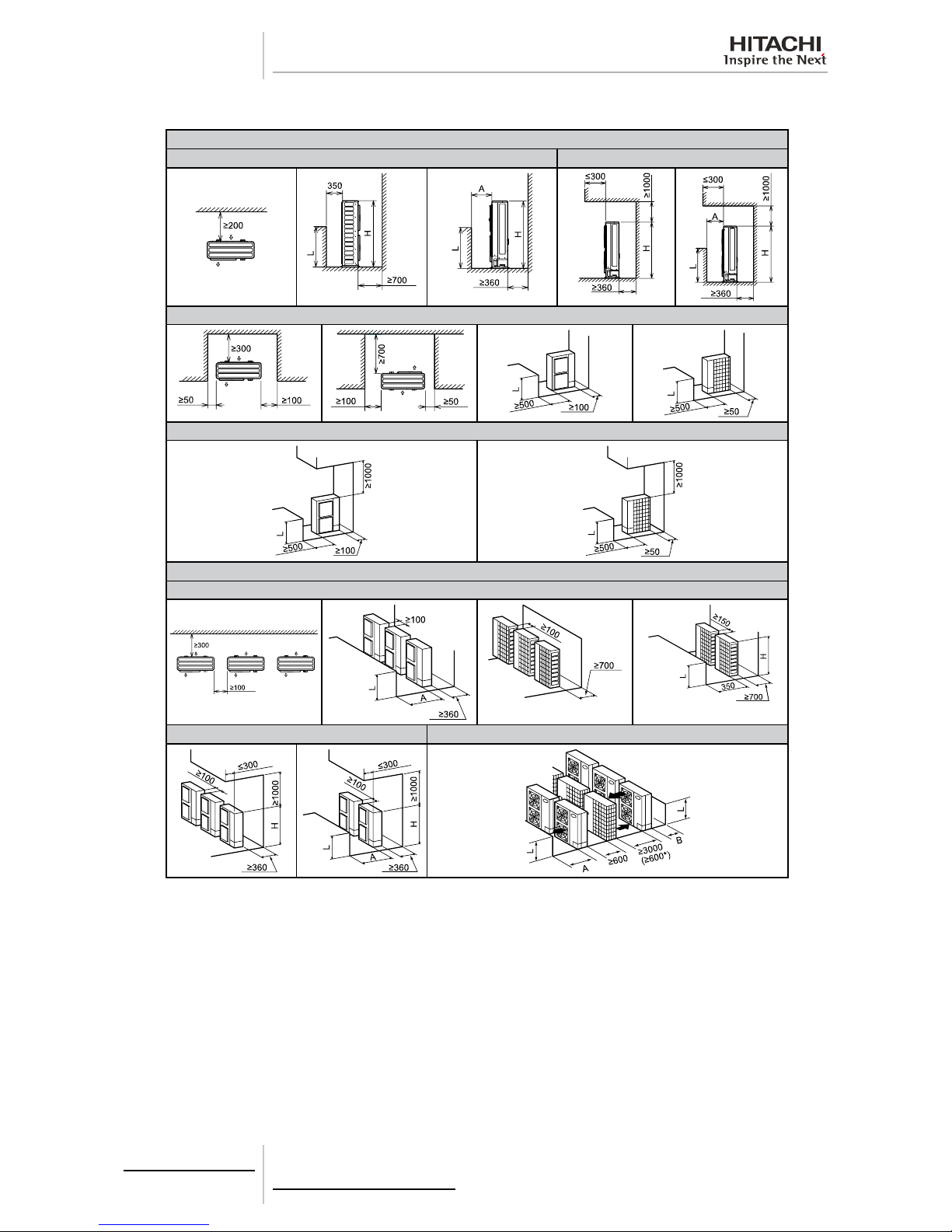

2.5.3 RAS-(8-12)HRNM

Single installation

Around sides are open Around sides are open with obstacles above

Around sides are closed

Around sides are open with obstacles above

Multiple installation

Around sides are open

Around sides are open with obstacles above

Multi-Row

Loading...

Loading...