Hitachi RAS-3HVRNS3, RAS-3HVNC1, RAS-2.5HVNP1, RAS-2HVNP1 Installation And Operation Manual

Page 1

UTOPIA IVX PREMIUM / IVX STANDARD SERIES

RAS-(2/2.5)HVNP1 / RAS-3HVNC1

UTOPIA ES SERIES

RAS-3HVRNS3

INSTALLATION AND OPERATION MANUAL

Page 2

Page 3

English

Specications in this manual are subject to change without notice in order that HITACHI may bring the latest innovations to

their customers. Whilst every effort is made to ensure that all specications are correct, printing errors are beyond Hitachi’s

control; HITACHI cannot be held responsible for these errors.

Page 4

CAUTION

This product shall not be mixed with general house waste at the end of its life and it shall be retired according to the

appropriated local or national regulations in a environmentally correct way.

Due to the refrigerant, oil and other components contained in Air Conditioner, its dismantling must be done by a professional installer according to the applicable regulations.

Contact to the corresponding authorities for more information.

Page 5

English

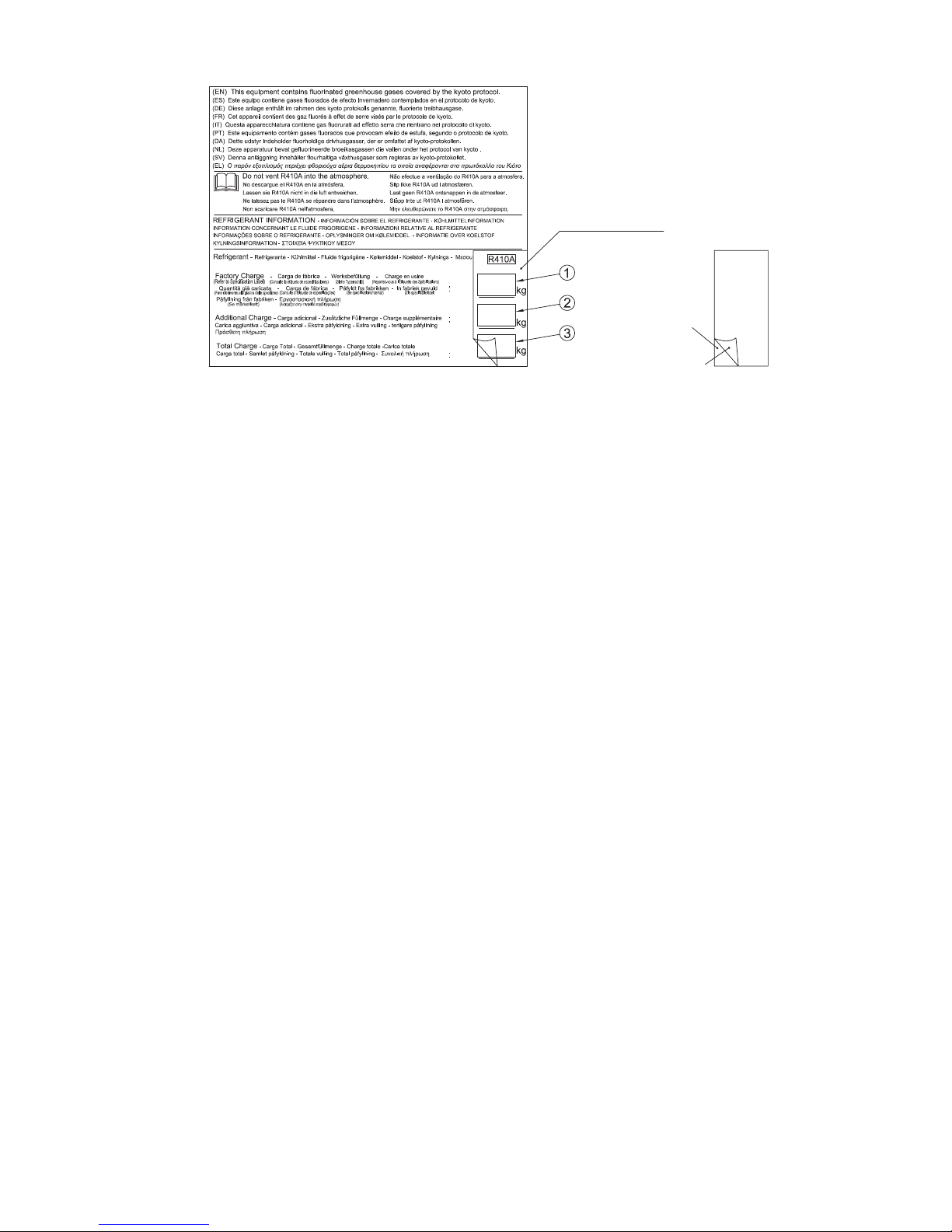

From 4th July 2007 and following Regulation EC Nº 842/2006 on Certain Fluorinated Greenhouse gases, it is mandatory to ll in the label attached to the unit

with the total amount of refrigerant charged on the installation.

Do not vent R410A/R407C into the atmosphere: R410A & R407C are uorinated greenhouse gases covered by the Kyoto protocol global warming potential

(GWP) R410A/R407C: = 1975/1652.5.

Page 6

English

Instructions to ll in the "F-Gas Label":

1.- Fill in the Label with indelible ink the refrigerant amounts:

- Factory Charge, - Additional Charge & - Total Charge.

2.- Stick the Protection Plastic Film on the F-Gas Label (delivered in a plastic bag with the Manual). To see Figure nº 2.

Figure 1. F-Gas Label with Protection Plastic Film Figure 2. Protection Plastic Film

Protection Plastic Film

Adhesive Surface

Peel-off Paper

Page 7

MODELS CODIFICATION

Important note: Please, check, according to the model name, which is your air conditioner type,

how it is abbreviated and referred to in this instruction manual. This Installation and Operation Manual is only related to Indoor Units FSN(H)(2/3/4)(M/E)(i)(k) combined with Outdoor Units

HVN(P/C)1 & RAS-3HVRNS3.

Page 8

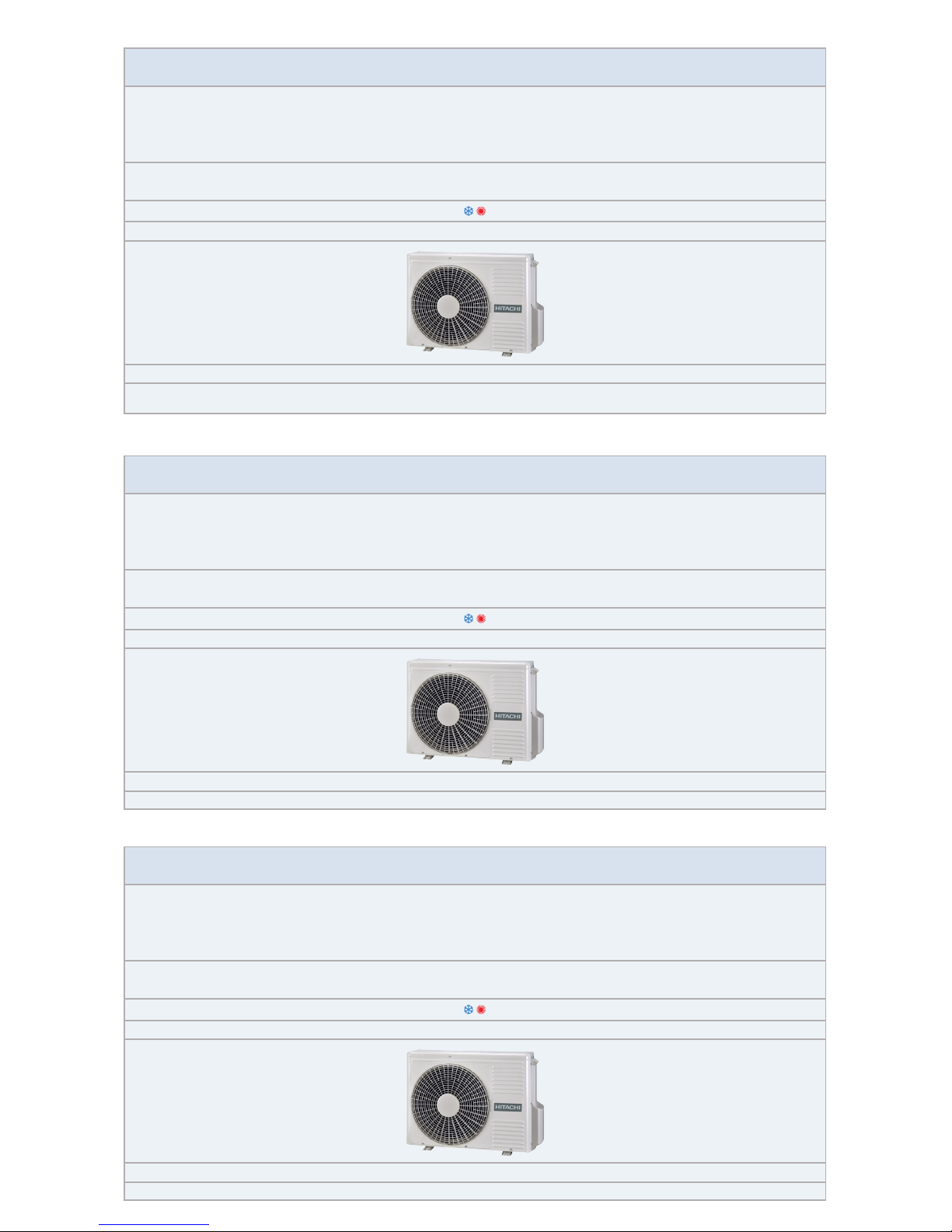

IVX Premium series

OUTDOOR UNIT · UNIDAD EXTERIOR · AUßENEINHEIT · UNITÉ EXTÉRIEURE · UNITÀ ESTERNA ·

UNIDADE EXTERIOR · UDENDRS AGGREGAT · BUITENTOESTEL · UTOMHUSENHET · ΕΞΩΤΕΡΙΚΗ ΜΟΝΑΔΑ

HEAT PUMP MODELS - MODELOS CON BOMBA DE CALOR

WÄRMEPUMPENMODELLE - MODÈLES POMPE À CHALEUR

MODELLI POMPA DI CALORE - MODELOS BOMBA DE CALOR

VARMEPUMPEMODELLER - MODELLEN MET WARMTEPOMP

MODELLER ENDAST FÖR KYLNINGSFUNKTION - ΜΟΝΤΕΛΑ ΜΕ ΑΝΤΛΙΑ ΘΕΡΜΟΤΗΤΑΣ

Single Phase - Monofásico - Einphasig - Monophasé - Monofase

Monofásico - Enfaset - Eenfasig - En fas - Μονοφασικά

1~ 230V 50Hz

Unit

RAS-2HVNP1

RAS-2.5HVNP1

IVX Standard series

OUTDOOR UNIT · UNIDAD EXTERIOR · AUßENEINHEIT · UNITÉ EXTÉRIEURE · UNITÀ ESTERNA ·

UNIDADE EXTERIOR · UDENDRS AGGREGAT · BUITENTOESTEL · UTOMHUSENHET · ΕΞΩΤΕΡΙΚΗ ΜΟΝΑΔΑ

HEAT PUMP MODELS - MODELOS CON BOMBA DE CALOR

WÄRMEPUMPENMODELLE - MODÈLES POMPE À CHALEUR

MODELLI POMPA DI CALORE - MODELOS BOMBA DE CALOR

VARMEPUMPEMODELLER - MODELLEN MET WARMTEPOMP

MODELLER ENDAST FÖR KYLNINGSFUNKTION - ΜΟΝΤΕΛΑ ΜΕ ΑΝΤΛΙΑ ΘΕΡΜΟΤΗΤΑΣ

Single Phase - Monofásico - Einphasig - Monophasé - Monofase

Monofásico - Enfaset - Eenfasig - En fas - Μονοφασικά

1~ 230V 50Hz

Unit

RAS-3HVNC1

ES series

OUTDOOR UNIT · UNIDAD EXTERIOR · AUßENEINHEIT · UNITÉ EXTÉRIEURE · UNITÀ ESTERNA ·

UNIDADE EXTERIOR · UDENDRS AGGREGAT · BUITENTOESTEL · UTOMHUSENHET · ΕΞΩΤΕΡΙΚΗ ΜΟΝΑΔΑ

HEAT PUMP MODELS - MODELOS CON BOMBA DE CALOR

WÄRMEPUMPENMODELLE - MODÈLES POMPE À CHALEUR

MODELLI POMPA DI CALORE - MODELOS BOMBA DE CALOR

VARMEPUMPEMODELLER - MODELLEN MET WARMTEPOMP

MODELLER ENDAST FÖR KYLNINGSFUNKTION - ΜΟΝΤΕΛΑ ΜΕ ΑΝΤΛΙΑ ΘΕΡΜΟΤΗΤΑΣ

Single Phase - Monofásico - Einphasig - Monophasé - Monofase

Monofásico - Enfaset - Eenfasig - En fas - Μονοφασικά

1~ 230V 50Hz

Unit

RAS-3HVRNS3

Page 9

INDEX ÍNDICE

PART I OPERATION

1. GENERAL INFORMATION

2. SAFETY

3. PRODUCT GUIDE

4. IMPORTANT NOTICE

5. SYSTEM DESCRIPTION

6. TRANSPORTATION AND HANDLING

7. BEFORE OPERATION

8. REMOTE CONTROLLER OPERATION

9. AUTOMATIC CONTROLS

10. BASIC TROUBLESHOOTING

PART II INSTALLATION

11. NAME OF PARTS

12. REFRIGERANT CYCLE

13. UNITS INSTALLATION

14. REFRIGERANT PIPING & REFRIGERANT CHARGE

15. DRAIN PIPING

16. ELECTRIC WIRING

17. INSTALLATION OF REMOTE CONTROLLER

18. TEST RUNNING

19. SAFETY SUMMARY & CONTROL DEVICE SETTING

20. TROUBLESHOOTING

1ª PARTE: FUNCIONAMIENTO

1. INFORMACIÓN GENERAL

2. SEGURIDAD

3. GUÍA DE PRODUCTO

4. AVISO IMPORTANTE

5. DESCRIPCIÓN DEL SISTEMA

6. TRANSPORTE Y MANIPULACIÓN

7. ANTES DEL FUNCIONAMIENTO

8. FUNCIONAMIENTO DEL CONTROL REMOTO

9. CONTROLES AUTOMÁTICOS

10. RESOLUCIÓN DE PROBLEMAS BÁSICOS

2ª PARTE: INSTALACIÓN

11. NOMBRE DE LAS PIEZAS

12. CICLO DE REFRIGERANTE

13. INSTALACIÓN DE LAS UNIDADES

14. TUBERÍA Y CARGA DE REFRIGERANTE

15. TUBERÍA DE DESAGÜE

16. CABLEADO ELÉCTRICO

17. INSTALACIÓN DEL CONTROL REMOTO

18. PRUEBA DE FUNCIONAMIENTO

19. RESUMEN DE SEGURIDAD Y AJUSTE DE LOS

DISPOSITIVOS DE CONTROL

20. RESOLUCIÓN DE PROBLEMAS

INHALTSVERZEICHNIS INDEX

TEIL I – BETRIEB

1. ALLGEMEINE INFORMATIONEN

2. SICHERHEIT

3. PRODUKTÜBERSICHT

4. WICHTIGER HINWEIS

5. SYSTEMBESCHREIBUNG

6. TRANSPORT UND BEDIENUNG

7. VOR DER INBETRIEBNAHME

8. BETRIEB MIT FERNBEDIENUNG

9. AUTOMATISCHE STEUERUNG

10. GRUNDLEGENDE FEHLERBESEITIGUNG

TEIL II – INSTALLATION

11. TEILEBEZEICHNUNG

12. KÜHLKREISLAUF

13. GERÄTEINSTALLATION

14. KÄLTEMITTELROHRE UND KÄLTEMITTELMENGE

15. ZUSÄTZLICHE KÜHLMITTELMENGE

16. VERKABELUNG

17. INSTALLATION EINER FERNBEDIENUNG

18. TESTLAUF

19. SICHERHEITSÜBERSICHT UND EINSTELLUNG DER

STEUERGERÄTE

20. FEHLERBEHEBUNG

PARTIE I – FONCTIONNEMENT

1. INFORMATIONS GÉNÉRALES

2. SÉCURITÉ

3. GUIDE DU PRODUIT

4. REMARQUES IMPORTANTES

5. DESCRIPTION DU SYSTÈME

6. TRANSPORT ET MANIPULATION

7. AVANT L’UTILISATION

8. FONCTIONNEMENT DE LA TÉLÉCOMMANDE

9. CONTRÔLES AUTOMATIQUES

10. DÉPANNAGE DE BASE

PARTIE II – INSTALLATION

11. NOMENCLATURE DES PIÈCES

12. CYCLE DU FLUIDE FRIGORIGÈNE

13. INSTALLATION DES UNITÉS

14. TUYAUTERIE DU FLUIDE FRIGORIGÈNE ET

CHARGE DU FLUIDE FRIGORIGÈNE

15. TUYAUTERIE D’ÉVACUATION DES CONDENSATS

16. CÂBLAGE ÉLECTRIQUE

17. INSTALLATION DE LA TÉLÉCOMMANDE

18. TEST DE FONCTIONNEMENT

19. SOMMAIRE DES DISPOSITIFS DE SÉCURITÉ &

RÉGLAGE DES ORGANES DE CONTRÔLE

20. DEPANNAGE

INDICE ÍNDICE

PARTE I FUNZIONAMENTO

1. INFORMAZIONI GENERALI

2. SICUREZZA

3. GUIDA DEL PRODOTTO

4. NOTA IMPORTANTE

5. DESCRIZIONE DEL SISTEMA

6. TRASPORTO E MOVIMENTAZIONE

7. PROCEDURA PRELIMINARE

8. FUNZIONAMENTO DEL COMANDO REMOTO

9. CONTROLLI AUTOMATICI

10. RISOLUZIONE DEI PROBLEMI MINORI

PART II INSTALLAZIONE

11. NOMENCLATURA DEI COMPONENTI

12. CICLO REFRIGERANTE

13. INSTALLAZIONE DELLE UNITÀ

14. LINEA DEL REFRIGERANTE E CARICA DI

REFRIGERANTE

15. LINEA DI DRENAGGIO

16. COLLEGAMENTI ELETTRICI

17. INSTALLAZIONE DEL COMANDO REMOTO

18. PROVA DI FUNZIONAMENTO

19. PRECAUZIONI PER LA SICUREZZA E IMPOSTAZIONI

DEI DISPOSITIVI DI CONTROLLO

20. ELIMINAZIONE DEI GUASTI

PARTE I FUNCIONAMENTO

1. INFORMAÇÃO GERAL

2. SEGURANÇA

3. GUIA DO PRODUTO

4. NOTA IMPORTANTE

5. DESCRIÇÃO DO SISTEMA

6. TRANSPORTE E MANUSEAMENTO

7. ANTES DE ARRANCAR A UNIDADE

8. FUNCIONAMENTO DO CONTROLO REMOTO

9. CONTROLOS AUTOMÁTICOS

10. RESOLUÇÃO DE PROBLEMAS BÁSICOS

PARTE II INSTALAÇÃO

11. NOME DAS PEÇAS

12. CICLO DE REFRIGERAÇÃO

13. INSTALAÇÃO DAS UNIDADES

14. TUBAGEM DE REFRIGERANTE E CARGA DE

REFRIGERANTE

15. TUBAGEM DE ESGOTO

16. LIGAÇÕES ELÉCTRICAS

17. INSTALAÇÃO DO CONTROLO REMOTO

18. PROVA DE FUNCIONAMENTO

19. SUMÁRIO DE SEGURANÇA E AJUSTE DE

DISPOSITIVO DE CONTROLO

20. RESOLUÇÃO DE PROBLEMAS

Page 10

INDHOLDSFORTEGNELSE INHOUDSOPGAVE

DEL I - BETJENING

1. GENEREL INFORMATION

2. SIKKERHED

3. PRODUKTVEJLEDNING

4. VIGTIG MEDDELELSE

5. SYSTEMBESKRISELVE

6. TRANSPORT OG HÅNDTERING

7. FØR OPERATION

8. FJERNBETJENING

9. AUTOMATISK KONTROLLER

10. BASIS FEJLFINDING

DEL II- MONTERING

11. NAVN PÅ DELE

12. KØLEKREDSLØB

13. MONTERING AF ENHEDER

14. KØLERØRSYSTEM OG PÅFYLDNING AF

KØLEMIDDEL

15. AFLØBSRØR

16. ELEKTRISK LEDNINGSFØRING

17. MONTERING AF FJERNBETJENING

18. TESTKØRSEL

19. OVERSIGT OVER INDSTILLINGER FOR

SIKKERHEDS- OG KONTROLENHEDER

20. FEJLFINDING

DEEL I BEDIENING

1. ALGEMENE INFORMATIE

2. VEILIGHEID

3. PRODUCTGIDS

4. BELANGRIJKE MEDEDELING

5. SYSTEEMBESCHRIJVING

6. TRANSPORT EN HANTERING

7. VOORDAT U HET SYSTEEM IN GEBRUIK NEEMT

8. GEBRUIK VAN DE EXTERNE BEDIENING

9. AUTOMATISCHE BESTURING

10. ELEMENTAIRE PROBLEMEN OPLOSSEN

DEEL II INSTALLATIE

11. NAMEN VAN ONDERDELEN

12. KOUDEMIDDELCYCLUS

13. INSTALLATIE VAN DE UNITS

14. KOELMIDDELLEIDINGEN & KOELMIDDEL VULLEN

15. AFVOERLEIDING

16. ELEKTRISCHE BEDRADING

17. INSTALLATIE VAN AFSTANDSBEDIENING

18. PROEFDRAAIEN

19. VEILIGHEIDSSAMENVATTING

& BESTURINGSINRICHTING

20. PROBLEMEN OPLOSSEN

INNEHALLSFÖRTECKNING ΕΥΡΕΤΗΡΙΟ

DEL I ANVÄNDNING

1. ALLMÄN INFORMATION

2. SÄKERHET

3. PRODUKTGUIDE

4. VIKTIG ANMÄRKNING

5. SYSTEMÖVERSKIT

6. TRANSPORT OCH HANTERING

7. FÖRE DRIFT

8. FJÄRRKONTROLL

9. AUTOMATIK KONTROLLANORDNING

10. GRUNDLÄGGANDE FELSÖKNING

DEL II INSTALLATION

11. DELARNAS NAMN

12. KYLMEDIETS CYKEL

13. INSTALLATION AV ENHETER

14. KYLRÖR & PÅFYLLNING AV KYLMEDIUM

15. DRÄNERINGSRÖR

16. ELEKTRISKA KABLAR

17. INSTALLATION AV FJÄRRKONTROLL

18. PROVKÖRNING

19. SÄKERHETSSAMMANFATTNING OCH

SÄKERHETSINSTÄLLNINGAR

20. FELSÖKNING

ΜΕΡΟΣ Ι – ΛΕΙΤΟΥΡΓΙΑ

1. ΓΕΝΙΚΕΣ ΠΛΗΡΟΦΟΡΙΕΣ

2. ΑΣΦΆΛΕΙΑ

3. ΟΔΗΓΟΣ ΠΡΟΪΟΝΤΟΣ

4. ΣΗΜΑΝΤΙΚΗ ΠΑΡΑΤΗΡΗΣΗ

5. ΠΡΙΝ ΤΗ ΛΕΙΤΟΥΡΓΙΑ

6. ΜΕΤΑΦΟΡΆ ΚΑΙ ΧΕΙΡΙΣΜΌΣ

7. ΠΡΙΝ ΤΗ ΛΕΙΤΟΥΡΓΙΑ

8. ΛΕΙΤΟΥΡΓΙΑ ΤΗΛΕΧΕΙΡΙΣΤΗΡΙΟΥ

9. ΑΥΤΟΜΑΤΕΣ ΛΕΙΤΟΥΡΓΙΕΣ

10. ΑΝΤΙΜΕΤΩΠΙΣΗ ΠΡΟΒΛΗΜΑΤΩΝ - ΒΑΣΙΚΑ

ΜΕΡΟΣ ΙΙ – ΕΓΚΑΤΑΣΤΑΣΗ

11. ΟΝΟΜΑΤΑ ΕΞΑΡΤΗΜΑΤΩΝ

12. ΚΥΚΛΟΣ ΨΥΞΗΣ

13. ΕΓΚΑΤΑΣΤΑΣΗ ΕΣΩΤΕΡΙΚΩΝ ΜΟΝΑΔΩΝ

14. ΣΩΛΗΝΩΣΕΙΣ ΨΥΚΤΙΚΟΥ & ΠΛΗΡΩΣΗ ΜΕ

ΨΥΚΤΙΚΟ ΜΕΣΟ

15. ΣΩΛΗΝΩΣΕΙΣ ΑΠΟΧΕΤΕΥΣΗΣ

16. ΗΛΕΚΤΡΙΚΗ ΚΑΛΩΔΙΩΣΗ

17. ΕΓΚΑΤΑΣΤΑΣΗ ΤΟΥ ΧΕΙΡΙΣΤΗΡΙΟΥ

18. ΔΟΚΙΜΑΣΤΙΚΗ ΛΕΙΤΟΥΡΓΙΑ

19. ΣΥΝΟΠΤΙΚΕΣ ΠΡΟΦΥΛΑΞΕΙΣ ΑΣΦΑΛΕΙΑΣ

& ΡΥΘΜΙΣΕΙΣ ΣΥΣΚΕΥΩΝ ΕΛΕΓΧΟΥ

20. ΑΝΤΙΜΕΤΩΠΙΣΗ ΠΡΟΒΛΗΜΑΤΩΝ

EN English Original version

ES Español Versión traducida

DE Deutsch Übersetzte Version

FR Français Version traduite

IT Italiano Versione tradotta

PT Português Versão traduzidal

DA Dansk Oversat version

NL Nederlands Vertaalde versie

SV Svenska Översatt version

EL Ελληνικα Μεταφρασμένη έκδοση

Page 11

General information

1

PMML0318A - P5415337

ENGLISH

PART I- OPERATION

1.2 ENVIRONMENT-FRIENDLY UNITS

1 GENERAL INFORMATION

1.1 GENERAL NOTES

© Copyright 2014 HITACHI Air Conditioning Products Europe,

S.A.U – All rights reserved.

No part of this publication may be reproduced, copied, led or

transmitted in any shape or form without the permission of

HITACHI Air Conditioning Products Europe, S.A.U.

Within the policy of continuous improvement of its products,

HITACHI Air Conditioning Products Europe, S.A.U. reserves the

right to make changes at any time without prior notication and

without being compelled to introducing them into products subse-

quently sold. This document may therefore have been subject to

amendments during the life of the product.

HITACHI makes every effort to offer correct, up-to-date documentation. Despite this, printing errors cannot be controlled by

HITACHI and are not its responsibility.

As a result, some of the images or data used to illustrate this

document may not refer to specic models. No claims will be accepted based on the data, illustrations and descriptions included

in this manual.

This range of HITACHI outdoor units uses environmentally-friendly R410A gas refrigerant, and the RoHS and Green Dot regulations are applied throughout the manufacturing and installation

process to reect HITACHI’s awareness of environmental respect

and commitment.

2 SAFETY

2.1 APPLIED SYMBOLS

During normal air conditioning system design work or unit installation, greater attention must be paid in certain situations requiring particular care in order to avoid injuries an damage to the

unit, the installation or the building or property.

Situations that jeopardise the safety of those in the surrounding

area or that put the unit itself a risk will be clearly indicated in this

manual.

To indicate these situations, a series of special symbols will be

used to clearly identify these situations.

Pay close attention to these symbols and to the messages following them, as your safety and that of others depends on it.

DANGER

• The text following this symbol contains information and

instructions relating directly to your safety and physical

wellbeing.

• Not taking these instructions into account could lead to

serious, very serious or even fatal injuries to you and

others in the proximities of the unit.

In the text following the danger symbol you can also nd information on safe procedures during unit installation.

CAUTION

• The text following this symbol contains information and instructions relating directly to your safety and physical wellbeing.

• Not taking these instructions into account could lead to minor

injuries to you and others in the proximities of the unit.

• Not taking these instructions into account could lead to unit

damage.

In the text following the caution symbol you can also nd information on safe procedures during unit installation.

NOTE

• The text following this symbol contains information or instructions that may be of use or that require a more thorough explanation.

• Instructions regarding inspections to be made on unit parts or

systems may also be included.

1

Page 12

2

PMML0318A - P5415337

Product guide

DANGER

• Do not pour water into the indoor or outdoor unit. These products are equipped with electrical parts. If water

contacts with electrical components then it will cause a

serious electrical shock.

• Do not touch or adjust safety devices inside the indoor or

outdoor units. If these devices are touched or adjusted, it

may cause a serious accident.

• Do not open the service cover or access the indoor or

outdoor units without disconnecting the main power

supply.

• In case of re Turn OFF the main switch, put out the re

at once and contact your service contractor.

CAUTION

• Do not use any sprays such as insecticide, lacquer, hair spray

or other ammable gases within approximately one (1) meter

from the system.

• If circuit breaker or fuse is often activated, stop the system

and contact your service contractor.

• Do not make service or inspections tasks by yourself. This

works must be performed by qualied service person.

• Do not put any strange material (sticks, etc...) into the air inlet

and outlet. These units have high speed rotating fans and it is

dangerous that any object touches them.

• Refrigerant leakage can cause difculty with breathing due to

insufcient air.

• This appliance must be used only by adult and capable

people, having received the technical information or instructions to handle properly and safely this appliance.

• Children should be supervised to ensure that they do not play

with the appliance.

NOTE

It is recommended to ventilate the room every 3 or 4 hours.

2.2 ADDITIONAL INFORMATION ABOUT SAFETY

3 PRODUCT GUIDE

3.1 CLASSIFICATION OF IVX OUTDOOR UNITS MODELS

Unit type (Outdoor unit): RAS

Position-separating hyphen (xed)

Compressor power (HP): 2, 2.5, 3

H = Heat pump

V = Single phase unit (1~ 230V 50Hz)

N = R410A refrigerant

P: Premium series

C: Standard series

Series

RAS – X H V N X 1

3.2 CLASSIFICATION OF ES OUTDOOR UNITS MODELS

Unit type (Outdoor unit): RAS

Position-separating hyphen (xed)

Compressor power (HP): 3

H = Heat pump

V = Single phase unit (1~ 230V 50Hz)

R = Inverter system

N = R410A refrigerant

S: ES series

Series

RAS – X H V R N S 3

3

Page 13

Important notice

3

PMML0318A - P5415337

ENGLISH

4 IMPORTANT NOTICE

• Verify, in accordance with the manuals which appear in the

outdoor and indoor units, that all the information required for

the correct installation of the system is included. If this is not

the case, contact your distributor.

• HITACHI pursues a policy of continuing improvement

in design and performance of products. The right is therefore

reserved to vary specications without notice.

• HITACHI cannot anticipate every possible circumstance that

might involve a potential hazard.

• This air conditioner has been designed for standard air conditioning for human beings. For use in other applications, please contact your HITACHI dealer or service contractor.

• No part of this manual may be reproduced without written permission.

• If you have any questions, contact your service contractor of

HITACHI.

• This manual should be considered as a permanent part of the

air conditioner. This manual gives a common description and

information for this air conditioner which you operate as well

as for other models.

• Check and make sure that the explanations of each part of

this manual correspond to your air conditioner model.

• Refer to the models codication to conrm the main characteristics of your system.

• Signal words (DANGER, WARNING and CAUTION) are used

to identify levels of hazard seriousness. Denitions for identifying hazard levels are provided below with their respective

signal words.

• It is assumed that this unit will be operated and serviced by

English speaking people. If this is not the case, the customer

should add safety, caution and operating signs in the native

language of the personal.

• This air conditioner has been designed for the following temperature. Operate the air conditioner within this range:

Temperature

Maximum Minimum

Cooling mode

Indoor 32°C DB/23°C WB 21°C DB/15°C WB

Outdoor 46°C DB (*) -5°C DB

Heating mode

Indoor 27°C DB 15°C DB

Outdoor 15°C WB -20°C WB

DB: Dry Bulb Temperature

WB: Wet Bulb Temperature (*) 43ºC RAS-3HVRNS3

• These operations modes are controlled by the remote control

switch.

DANGER

Pressure Vessel and Safety Device: This air conditioner is equipped with a high pressure vessel under PED

(Pressure Equipment Directive). The pressure vessel has

been designed and tested before shipment according to

PED. Also, in order to prevent the system from an abnormal pressure, a high pressure switch, which needs no

eld adjustment, is utilized in the refrigeration system.

Therefore, this air conditioner is protected from abnormal

pressures. However, if abnormally high pressure is applied to

the refrigeration cycle including the high pressure vessel(s),

it will result in serious injury or death due to explosion of

the pressure vessel. Do not apply a pressure higher than the

following pressure to the system, by modifying or changing

the high pressure switch.

CAUTION

This unit is designed for commercial and light industrial application. If installed in house hold appliance, it could cause electromagnetic interference.

Start-up and Operation: Check to ensure that all the stop valves

are fully opened and no obstacle exists at the inlet/outlet sides

before start-up and during the operation.

Maintenance: Periodically check the high pressure side pressu-

re. If the pressure is higher than the maximum allowable pressure, stop the system and clean the heat exchanger or remove the

cause.

4

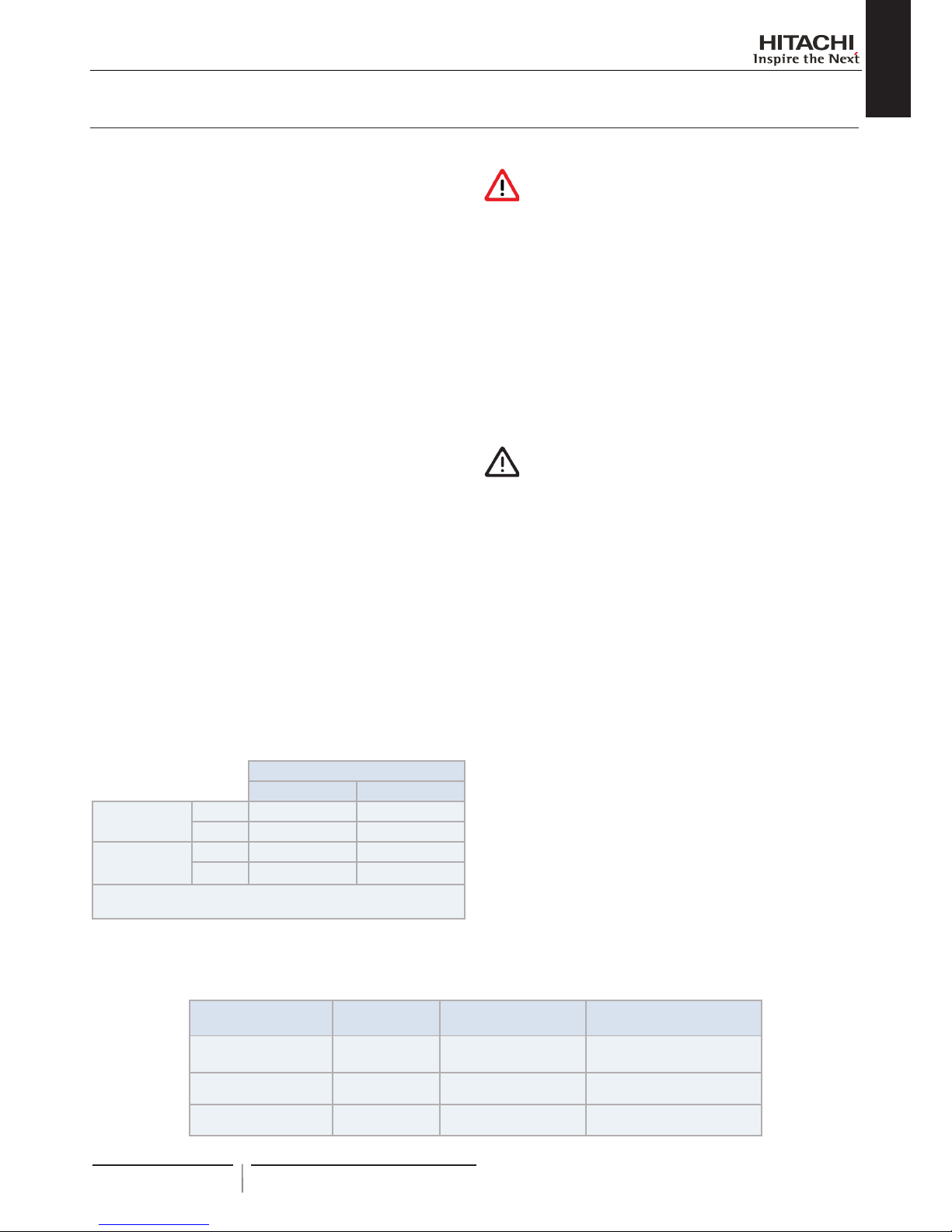

Maximum allowable pressure and high pressure cut-out value:

Outdoor unit model Refrigerant

Maximun allowable

pressure (MPa)

High pressure switch cut-out

value (MPa)

RAS-2HVNP1

RAS-2.5HVNP1

R410A 4.15 4.00 ~ 4.10

RAS-3HVNC1 R410A 4.15 4.00 ~ 4.10

RAS-3HVRNS3 R410A 4.15 4.00 ~ 4.10

Page 14

4

PMML0318A - P5415337

System description5

NOTE

The label for the vessel under PED are attached on the high pressure vessel. The pressure vessel capacity and vessel category

are indicated on the vessel.

Location of High Pressure Switch

Compressor

NOTE

The high pressure switch is indicated on the electrical wiring

diagram in the outdoor unit as PSH connected to printed circuit

board (PCB1) in the outdoor unit.

Structure of High Pressure Switch

Contact point

Pressure detected

Connected to the electrical wire

DANGER

• Do not change the high-pressure switch locally or change the high pressure cut-out set value locally. If changed,

it will cause serious injury or death due to explosion.

• Do not attempt to turn service valve rod beyond its stop.

5 SYSTEM DESCRIPTION

• Long piping for high-rise buildings.

• Various combinations of indoor units type.

• Flexibility of indoor unit control.

• High reliability.

• Space saving.

• Easy installation.

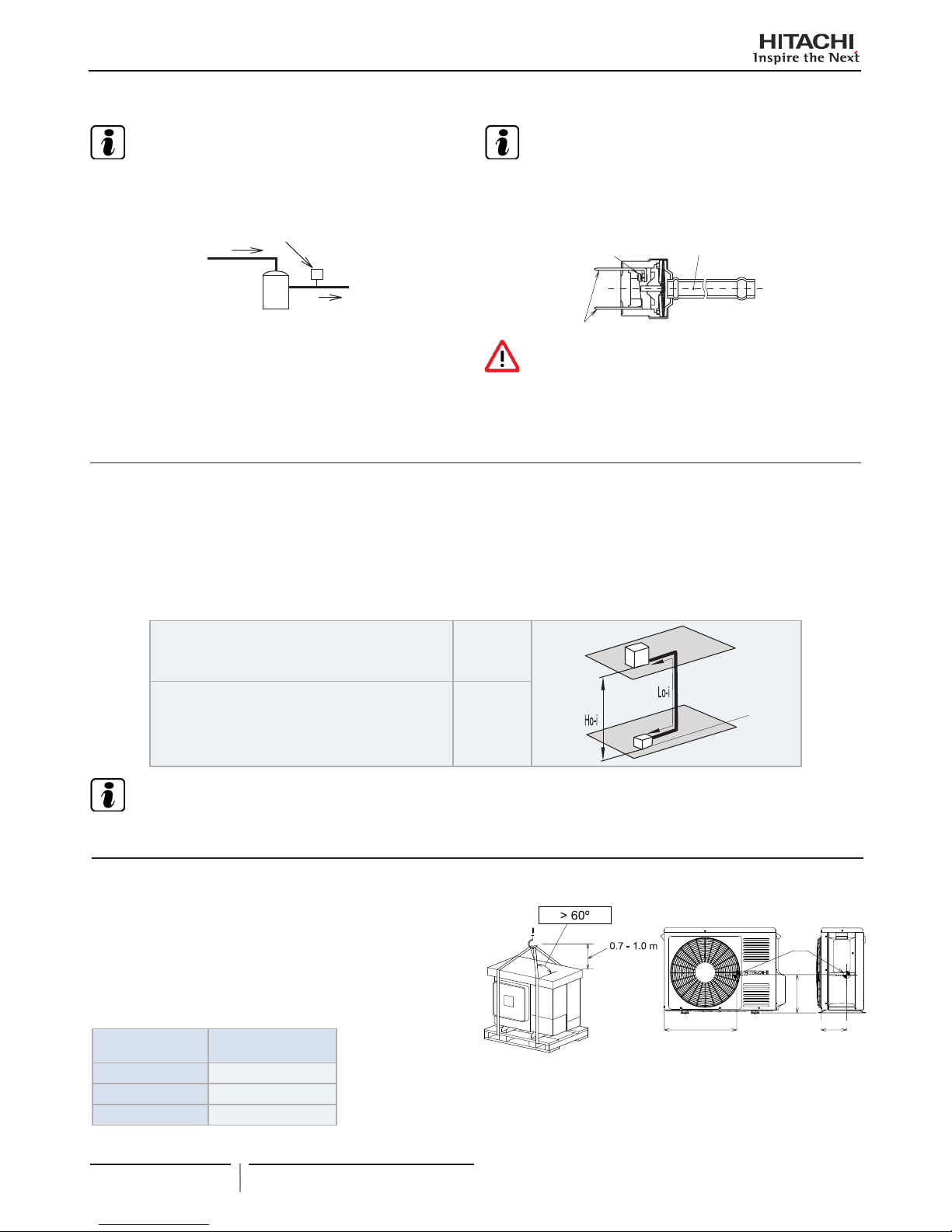

Maximum piping length Lo-i:

- Actual length

- Equivalent length

50

70

Maximum height difference Ho-i:

- Outdoor unit is higher than indoor unit

- Indoor unit is higher than outdoor unit

30

20

NOTE

RCI-FSN3 (High efciency – 4 step fan speed) indoor unit can connect in 1 indoor unit combination only. For use in 2 indoor units

combination, please contact your Hitachi dealer or service contractor.

6 TRANSPORTATION AND HANDLING

When hanging the unit, ensure a balance of the unit, check safety

and lift it up smoothly.

Do not remove any packing materials.

Hang the unit under packing condition with two ropes.

For safety reasons ensure that the outdoor unit is lifted smoothly

and does not lean.

Model

Unit Gross Weight

(kg)

RAS-(2-2.5)HVNP1 48

RAS-3HVNC1 49

RAS-3HVRNS3 49

1

515 mm

180 mm

275 mm

Center of

gravity

Page 15

Before operation

5

PMML0318A - P5415337

ENGLISH

8 REMOTE CONTROLLER OPERATION

It is advisable to use PC-ART or PC-ARF remote controller (both optional). For more information about it installation and operation,

please refer to its corresponding Installation and Operation Manuals.

7

7 BEFORE OPERATION

CAUTION

• Supply electrical power to the system for approximately 12

hours before start-up or a long shutdown. Do not start the

system immediately after power supply, it may cause a compressor failure because the compressor is not heated well.

• When the system is started after a shutdown longer that approximately 3 months, it is recommended to check the system

by your service contractor.

• Turn OFF the main switch when the system is to be stopped

for a long period of time: If the main switch is not turned OFF,

electricity will be used, because the oil heater is always energised during compressor stopping.

• Make sure that the outdoor unit is not covered with snow or

ice. If covered, remove it by using hot water (approximately

50°C). If the water temperature is higher that 50°C, it will cau-

se damage to plastic parts.

9 AUTOMATIC CONTROLS

The system is equipped with the following functions.

Three minute guard

The compressor remains off for at least 3 minutes once it has stopped. If the system is started within approximately 3 minutes after it

has stopped, the RUN indicator is activated. However, the cooling

operation or the heating operation remains off and does not start

until after 3 minutes has elapsed.

Operation may stop for 6 minutes maximum to protect compressor.

Frost prevention during cooling operation

When the system is operated in a low temperature room, the cooling operation may be changed to fan operation for a while to

avoid frost formation on the indoor heat exchanger.

Automatic restart after power failure

If the power supply is interrupted for short periods of time (up to

2 seconds) the Remote Control switch will retain the settings and

the unit will restart when the power is restored.

If Automatic Restart is required after periods of lost power supply

in excess of 2 seconds please contact your distributor (optional

function).

Slow air control during heating operation

When the compressor is stopped while the thermostat is OFF, or

the system is performing the automatic defrosting operation, the

fan speed is set at the slow position.

Automatic defrosting cycle

When the heating operation is stopped by pressing RUN/STOP

switch, frosting on the outdoor unit is checked and the defrosting

operation may be performed for the maximum of 10 minutes.

Prevention of overload operation

When the outdoor temperature is too high during heating operation, heating operation is stopped due to activation of the outdoor

thermistor until the temperature becomes low.

Hot start during heating operation

To prevent cold air discharge, the fan speed is controlled from

the slow position to the set position according to the discharge air

temperature. At this time the lover is xes horizontally.

Page 16

6

PMML0318A - P5415337

Basic troubleshooting

10 BASIC TROUBLESHOOTING

CAUTION

• When water leakage from the indoor unit occurs, stop the

operation and contact your contractor

• When you smell or white smoke occurs from the unit, stop the

system and contact your contractor.

This is not abnormal

• Sound from deforming part

During system starting or stopping, and abrading sound might

be heard. However, this is due to thermal deformation of plastic

parts. It is not abnormal.

• Refrigerant ow sound

While the system is being started or stopping, sound from the

refrigerant ow may be heard.

• Smells from indoor unit

Smell adheres on indoor unit after a long period of time. Clean the

air lter and panels or make a good ventilation.

• Steam from outdoor heat exchanger

During defrosting operation, ice on the outdoor heat exchanger is

melted, resulting in making steam.

• Dew on air panel

When the cooling operation continues for a long period of time

under high humidity conditions (higher than 27°C DB/80% R.H.),

dew can form on the air panel.

• Dew on cabinet

When the cooling operation continues for a long period of timer

(higher than 27°C DB/80% R.H.), dew can form on the cabinet.

• Sound for the indoor unit heat exchanger

During the cooling operation, a sound may be heard from the indoor unit heat exchanger due to water freezing or melting.

No operation

Check whether the SET TEMPERATURE is set at the correct

temperature.

Not cooling well or heating well

- Check for obstruction of air ow of the outside or inside

units.

- Check if too much heat source exists in the room.

- Check if the air lter is clogged with dust.

- Check to see if the doors or windows are opened or not.

- Check if the temperature condition is not within the ope-

rating range.

Abnormal swing louver’s position

Check if the four louver’s position at the air outlet are in same

position.

If trouble still remains...

If the trouble still remains even after checking the above items,

contact your service contractor and inform the following data:

- Unit model name

- Content of trouble

- Alarm code number on liquid crystal display

NOTE

Except for a long period of shutdown, keep the main switch ON,

since the oil heater is energised when the compressor is stopped.

10

Page 17

Name of parts

7

PMML0318A - P5415337

ENGLISH

PART II-INSTALLATION

11 NAME OF PARTS

If do you want more information check the technical catalogue.

RAS-(2/2.5)HVNP1 / RAS-3HVNC1 / RAS-3HVRNS3

579

600

21

26

792

69

37

298

320

340

11

No. Part Name

1 Compressor

2 Accumulator

3 Heat exchanger

4 Fan

5 Fan motor

6 Strainer

7 Distributor

8 Reversing valve

9 Expansion valve

10 Stop valve for gas line

No. Part Name

11 Stop valve for liquid line

12 Check joint for high/low pressure (Cool/Heat)

13 Control box

14 High pressure switch for protection

15 Pressure switch for control

16 Oil heater

17 Vibration isolation rubber

18 Air outlet

19 Air inlet

Page 18

8

PMML0318A - P5415337

Refrigerant cycle

12 REFRIGERANT CYCLE

Refrigerant ow direction

(cooling)

Refrigerant ow direction

(heating)

Field refrigerant piping Flare connection Brazing connection

12

No. Part name

1 Compressor

2 Heat exchanger

3 Accumulator

4 Expansion valve

5 Reversing valve

6 Strainer 1/4

7 Distributor

8 Check joint

No. Part name

9 High pressure switch for protection

10 Pressure switch for control

11 Stop valve for gas line

12 Stop valve for liquid line

13 Discharge thermistor

14 Pipe thermistor

15 Ambient thermistor

Page 19

Units installation

9

PMML0318A - P5415337

ENGLISH

13 UNITS INSTALLATION

13.1 OUTDOOR UNITS INSTALLATION

CAUTION

• Transport the products as close to the installation location as

practical before unpacking.

• Do not put any material on the products.

• Apply four lifting wires on to the outdoor, when lifting it by crane.

CAUTION

• Install the outdoor unit with sufcient clearance around it for

operation and maintenance as shown in the next gures.

Install the outdoor unit where good ventilation is available

• Do not install the outdoor unit where is a high level of oil mist,

salty air or sulphurous atmosphere.

• Install the outdoor unit as far as practical (being at least 3

meters) from electromagnetic wave radiator (such as medical

equipment).

• For cleaning, use noninammable and nontoxic cleaning liquid. Use of inammable agent may cause explosion or re.

• Work with sufcient ventilation, since working in an enclosed

space may cause oxygen deciency. Toxic gas may be pro-

duced when cleaning agent is heated to high temperature by,

e.g., being exposed to re.

• Cleaning liquid shall be collected after cleaning.

• Pay attention not to clamp cables when attaching the service

cover to avoid electric shock or re.

CAUTION

• Keep clearance between the units of more than 50mm, and

avoid obstacles that may hamper air intake, when installing

more than one units together.

• Install the outdoor unit in the shade or not exposed to direct

sunshine or direct radiation from high temperature heat source.

• Do not install the outdoor unit in a space where a seasonal

wind directly blows to the outdoor fan.

• Check to ensure that the foundation is at, level and sufciently strong.

• Install the unit in a restricted area not accessible by the general public

• Aluminum ns have very sharp edges. Pay attention to the

ns to avoid injury.

13

13.2 INSTALLATION SPACE

≥

≥

≥≥

≥≥

Page 20

10

PMML0318A - P5415337

Units installation

a) In case of front side and either of the sides are open (single unit) b) In case that surrounding wall exist (single unit)

100

500

1000

500

50

c) In case that upper side obstacles exist (single unit)

50

100

≤ 300

50

300

100

0 < L ≤ 1/2 H A ≥ 500

1/2 H < L ≤ H A ≥ 1000

d) In case that upper side obstacles exist (serial units) e) In case of front side and either of the sides are open (serial units)

200

300

0 < L ≤ 1/2 H A ≥ 500

1/2 H < L ≤ H A ≥ 1000

≤ 300

f) In case that surrounding wall exist (serial units)

0 < L ≤ 1/2 A ≥ 500

1/2 H < L ≤ H A ≥ 1000

A

L

1000

0 < L ≤ 1/2 H A ≥ 200

1/2 H < L ≤ H A ≥ 350

g) Horizontal (multiple units) h) Vertical (multiple units)

0 < L ≤ 1/2 H A ≥ 100

1/2 H < L ≤ H A ≥ 200

≥ 1000

≥ 400

≥ 2000

≥ 250

400

≥ 250

≥ 250

400

250

≥ 250

Do not stack more than two units in height.

Close gap (*) to avoid recirculating discharge air ow.

13

Page 21

Units installation

11

PMML0318A - P5415337

ENGLISH

Installing location where the unit will be exposed to strong wind.

Follow the instructions below to install on the rooftop or a location without surrounding buildings,

where strong wind is expected against the product.

Choose a location where the outlet or inlet side of

the product will not be exposed to strong wind.

When the outlet is exposed to strong wind:

Direct strong wind may cause lack of air ow and

adversely affect to the operation.

CAUTION

Excessive strong wind against the outdoor unit

outlet may cause inverse rotation and damage

the fan and motor.

In case of blowing strong wind to air outlet the wind

guard (optional) is available to avoid strong wind

Wind guard model

Model Number of set required

WSP-264 1

NOTE

• The wind guard must be set at annual cooling operation (in DSW2 switch 3).

• For ambient temperature ≤ 10ºC, it is recommended to set the wind guard at cooling operation.

Air ow guide wind guard and snow protection hood

Optional parts Model

Air ow guide AG-264

1 Air ow guide

2 Wind Guard

3 Snow protection hood

Wind guard WSP-264

Snow protection

hood

Zinc Plate

Air outlet ASG-NP80F

Air inlet of rear side ASG-NP56B

Air inlet of side face ASG-NP56L

Stainless plate

(NSSC180)

Air outlet ASG-NP80FS2

Air inlet of rear side ASG-NP63B52

Air inlet of side face ASG-NP63LS2

1

1

2

3

11

4

21

5

1

BA C

1. Fixing screw (accessories)

2. Air inlet hood

3. Wire rope (optional for over turning protection)

4. Air discharge hood

5. Outdoor unit

A. Rear side

B. Left side

C Front side

13

Page 22

12

PMML0318A - P5415337

Units installation

13.3 INSTALLATION PLACE PROVISION

13

1 Secure the outdoor unit with the anchor

Max 17mm

Concrete

Filled mortar

Anchor bolts

Special

washer

(M12)

Nut

Base of

outdoor unit

Fix the outdoor unit to the anchor bolts by special washer of factory-supplied accessory.

2 When installing the outdoor unit, x the unit by anchor bolts.

Regarding the location of xing holes.

Front side

Pipe cover

M10 Hole for anchor bolt (Ø 12)

3 Example of xing outdoor unit by anchor bolts.

A

Concrete

Anchor bolt

Cut this portion when

this type of anchor

bolt is used. If not, it

is dicult to remove

the service cover

4 Provide an adequate drainage around the foundation. When

installing the unit on a roof or a veranda, drain water may

turn to ice in a cold morning. Therefore, avoid draining in an

area where people often use because it is slippery. In case of

installing such a place, provide the additional drainage around

the foundation.

(30x80)

(30x80)

76

339

147

(228)

4-R8

58

40

42

Drain hole

Drain hole

Position for drain

boss (optional)

Drain hole

Front side

5 The whole of the base of the outdoor unit should be installed

on a foundation. When using vibration-proof mat, it should

also be positioned the same way. When installing the outdoor

unit on a eld supplied frame, use metal plates to adjust the

frame width for stable installation as shown in gure.

INCORRECT

57mm

Base width of

outdoor unit

Outdoor unit

is unstable

60mm

Frame width

(eld supplied)

Frame

CORRECT

Outdoor unit

is stable

57mm

Base width of

outdoor unit

100mm or more

Metal plate

Metal plate

Frame

Recommended metal plate size (eld-supplied)

- Material: Hot-rolled mild steel plate (SPHC)

- Plate thickness: 4.5T

Page 23

Refrigerant piping & refrigerant charge

13

PMML0318A - P5415337

ENGLISH

14.1.1 Piping materials

1 Prepare locally-supplied copper pipes.

2 Select the piping size with the correct thickness and correct

material which can have sufcient pressure strength.

3 Select clean copper pipes. Make sure there is no dust and

moisture inside. Blow the inside of the pipes with oxygen free

nitrogen to remove any dust and foreign materials before connecting pipes.

4 After connecting the refrigerant piping, seal the open space

between Knockout hole and refrigerant pipes by using insulation material as shown bellow:

Insulation material

Field-supplied

Insulation material

Insulation material

Unit

side

NOTE

• A system with no moisture or oil contamination will give maximum performance and lifecycle compared to that of a poorly

prepared system. Take particular care to ensure all copper

piping is clean and dry internally.

• There is no refrigerant in the cycle of the indoor unit.

CAUTION

• Cap the end of the pipe when pipe is to be inserted through

a hole.

• Do not put pipes on the ground directly without a cap or vinyl

tape at the end of the pipe.

• If piping installation is not completed until next day or over

a longer period of time, braze off the ends of the piping and

charge with oxygen free nitrogen through a Schrader valve

type access tting to prevent moisture and particle contamination.

Insulate pipes

After connecting the refrigerant piping, seal the refrigerant pipes

by using the eld-supplied insulation material. Insulate the unions

and are-nuts at the piping connections completely. Insulate the

liquid piping and gas piping completely to avoid decreasing of

performance and dewing on the surface of the pipe.

CAUTION

• Do not use insulation material that contains NH3 because it

can damage cooper pipe material and can be a source of future leakage.

• Completely insulate both refrigerant gas piping and liquid pi-

ping between the indoor unit(s) and the outdoor unit.

• If not insulated, dew will ocur on the piping surface.

14.1.2 Suspension of refrigerant piping

Suspend the refrigerant piping at certain points and prevent the

refrigerant piping from touching the weak part of the building such

as wall, ceiling, etc…

(If touched, abnormal sound may occur due to the vibration of the

piping. Pay special attention in case of short piping length).

1~15m

Indoor unit

Fire-proof section

treatment

Do not x the refrigerant piping directly with the metal ttings (The

refrigerant piping may expand and contract).

Some examples for suspension method are shown below.

For suspending

heavies

For piping along

the wall

For instant

installation work

14.1.3 Brazing work

CAUTION

• Use nitrogen gas for blowing during pipe brazing. If oxygen,

acetylene or uorocarbon gas is used, it will cause an explosion or poisonous gas.

• A lot of oxidation lm will occur inside of tubes if no nitrogen

gas blowing is performed during brazing work. This lm will

be ecked off after operation and will circulate in the cycle,

resulting in clogged expansion valves, etc. This will cause bad

inuence to the compressor.

• Use a reducer valve when nitrogen gas blowing is performed

during brazing. The gas pressure should be maintained within

0.03 to 0.05Mpa. If a excessively high pressure is applied to a

pipe, it will cause an explosion.

14 REFRIGERANT PIPING & REFRIGERANT CHARGE

14.1 REFRIGERANT PIPING WORK

14

Page 24

14

PMML0318A - P5415337

Refrigerant piping & refrigerant charge

14.2 PIPING CONNECTION FOR OUTDOOR UNIT

1 Take the piping cover away from the unit. Then fetch the pipes

through the rear side and route piping according to the installation place as shown in the gure. Make holes by cutting

along the guideline at the rear of the cover or punching with

a driver. Remove the burr with a cutter, and place a insulation

(eld supplied) to protect cables and pipes.

Pipe cover

Rear side

piping

Stop valve

Direction to remove pipe cover

Connec

-

ting piping

2 Attach the pipe cover in order to prevent rainwater from ente-

ring inside the cabinet.

3 Use a pipe bender for pipe bending work when connecting

pipes.

4 Check to ensure that the stop valves are completely closed

before connecting pipes.

5 Connect the eld supplied refrigerant pipes to the indoor unit

and outdoor unit. Apply the oil thinly at the seat are nut and

pipe before tightening.

The required tightening torque is as follows:

Pipe Size Tightening Torque (Nm)

Ø 6.35 mm (1/4) 14-18

Ø 9.52 mm (3/8) 34-42

Ø 12.70 mm (1/2) 49-61

Ø 15.88 mm (5/8) 68-82

Ø 19.05 mm (3/4) 100-120

Use two spanners

here for pipe con-

nection

Do not work with

two spanners

here.

Refrigerant

leakage shall

occur

6 After connecting the refrigerant piping, seal the open space

between knockout hole and refrigerant pipes by using insulation material.

Unit

Side

Nº Description

Insulation Material

Insulation Material

Field Supplied

Insulation Material

7 Operation of stop valve should be performed according to the

gure below.

8 Close before shipment

14.2.1 Outdoor unit stop valve

Operation of stop valve should be performed according to the

gures and tables below:

Spindle Type

Stop valve (liquid)

Stop valve (gas)

Spindle valve

Flare nut

Cap

Check joint for service port

Outdoor unit

Tightening Torque (Nm)

Gas

valve

Liquid

valve

Gas

valve

Liquid

valve

Gas

valve

Liquid

valve

Gas

valve

Liquid

valve

RAS-(2-2.5)HVNP1 7-9 7-9 34-42 34-42 33-42 33-42 14-18 14-18

RAS-3HVNC1 9-11 7-9 68-82 34-42 33-42 33-42 14-18 14-18

RAS-3HVRNS3 9-11 7-9 68-82 34-42 33-42 33-42 14-18 14-18

Refrigerant

pressure

Closed before shipment

Refrigerant piping

Hexagonal wrench

(eld supplied) (*)

Spindle valve

Tighten the spindle with a torque above:

Counterclockwise…. Open

Clockwise …. Close

Check joint

(Only charging hose can

be connected)

Tighten the cap with 16 N.m torque.

Cap

Tighten the cap with 37 N.m torque

(Attach this after work)

14

Page 25

Refrigerant piping & refrigerant charge

15

PMML0318A - P5415337

ENGLISH

14.3.2 Piping system for header branch

1 indoor unit system

2 indoor units system

(pictures are as example)

Maximum refrigerant piping length

(m)

Outdoor Unit

IVX ES

2HP 2.5HP 3HP 3HP

Maximum piping

length between the

outdoor unit and the

farthest indoor unit

Actual Length (L)

50

Equivalent Length

(EL)

70

Total piping length 2 units (A+B+C)

50 60

Maximum piping line

after rst branch

2 units (B, C)

10

Main piping length A

A > B, C

Maximum height difference

Outdoor / Indoor (H)

(Outdoor Unit is Higher / Lower.)

30 / 20

Maximum height difference Indoor / Indoor

3 3 0.5

Maximum height difference:

branch pipe/Indoor (2 indoor units system)

3 0.5

(B-C)

< 8

NOTE

• The liquid piping and the gas piping must be of the same

piping length and run along the same route.

• Install the branch piping as much as possible near the indoor

units

• Install Multikits at the same horizontal level.

14

Hexagonal wrench size used for spindle valve:

(*) Size

2HP, 2.5HP 3HP

Gas valve 4 mm 5 mm

Liquid valve 4 mm 4 mm

Do not apply two spanners

at this position. If applied,

leakage will occur.

Stop valve

(Spindle type)

Flare nut

CAUTION

• At the test run, fully open the spindle and ball stop valve.

• If not fully opened, the devices will be damaged.

• Do not attempt to turn service valve rod beyond its stop.

• Do not loosen the stop ring. If the stop ring is loosened, it is

dangerous since the spindle will hop out.

• An excess or a shortage of refrigerant is the main cause of

trouble to the units. Charge the correct refrigerant quantity

according to the description of label at the inside of service

cover.

• Check for refrigerant leakage in detail. If a large refrigerant

leakage occurs, it will cause difculty with breathing or harmful gases would occur if a re was being used in the room.

14.3 REFRIGERANT PIPING LENGTH

The refrigerant piping between the indoor unit and the outdoor unit should be designed using the beside chart.

Keep the design point within the dark area of the chart, which is showing the applicable height difference according to piping length.

In case that a piping length is shorter than 5 meters, contact the Hitachi dealer.

14.3.1 Piping Length specication

Page 26

16

PMML0318A - P5415337

Refrigerant piping & refrigerant charge14

14.3.3 Refrigerant piping selection

Select the piping connection sizes according to the following procedures

• Between outdoor unit and branch pipe: Select the same pipe

connection size as the pipe size of the outdoor unit.

• Between branch pipe and indoor unit: Select the same pipe

connection size as the pipe size of the indoor unit.

1 indoor unit system

(mm)

Outdoor Unit HP

Pipe Size (L)

Gas Liquid

2 / 2.5 Ø12.70 Ø6.35

3 Ø15.88 Ø9.52

2 indoor units system

(mm)

Outdoor

Unit HP

Pipe Size (A) Multi-kit

Gas Liquid IVX Series

ES

series

2 / 2.5 Ø12.70 Ø6.35 TE-03N1 -

3 Ø15.88 Ø9.52 TE-03N1

Pipe connection size after branch pipe

(mm)

Indoor Unit capacity

Pipe Size (B, C)

Gas Liquid

≤ 1.5 HP Ø12.70 Ø6.35

1.8 / 2.0 HP Ø15.88 Ø6.35

14.3.4 2 indoor units system installation

Height difference between indoor units and distributor

It is recommended to install all indoor units at the same height.

When the height difference between the indoor units due to building construction is necessary, this should be less than the value

indicated in the table.

ื

10m (IVX-P)

3m

0.5m

(IVX-C)

(ES)

ืืืื

20m

ื

30m

IU1

IU2

OU1

OU1

ื

3m (ES ืP

ื

3m (ES ืP

Installing Distributor

1 Selecting the distributor

Install the distributor supplied by HITACHI on request the T-joint

can not be installed instead of a branch pipe.

2 Installing the distributor

Fix the branch pipe horizontally to the pillar, wall or ceiling. Piping

must not be xed rigidly to the wall as thermal expansion and

contraction can cause pipe fracture.

Horizontal

To indoor

unit

To outdoor unit

Vertical

To indoor unit

Fixing the branch pipe to

the surface of pillar or wall

Horizontal

Horizontal

Fixing the branch pipe to

ceiling or beam

NOTE

Fix the piping from outside of insulation or inserting absorber bet-

ween the pipe and a xing metal.

3 Correct position of twin distributor

• This is the correct position of twin branch pipe:

Greater

than 0.5 m

Main pipe

Refrigerant

direction

Up

Branch pipe

Main pipe

Refrigerant

direction

Down

• This is wrong position:

Main pipe

Refrigerant direction

Branch pipe

Branch pipe

Refrigerant

direction

Main pipe

Branch pipe

14.3.5 Connecting are adapter

Flare nut (accessories)

Pipe (accessories)

Indoor unit

Flare adapter (accessories)

Gas line

Pipe

(eld

supplield)

Liquid line

The piping sizes for indoor unit and outdoor unit are different.

Attach the are adapter (accessories) at the indoor piping union

part.

Use the adequate are adapter as follows:

Indoor unit

Flare adapter

Gas pipe Liquid pipe

2.0 HP

Big size

(∅15.88→∅12.70)

-

2.5 HP

Big size

(∅15.88→∅12.70)

Small size

(∅9.52→∅6.35)

Page 27

Refrigerant piping & refrigerant charge

17

PMML0318A - P5415337

ENGLISH

CAUTION

• Do not charge OXYGEN, ACETYLENE, or other ammable

and poisonous gases into the refrigerant because an explosion can occur. It is recommended that oxygen free nitrogen

be charged for these types of tests cycle when performing

a leakage test or an airtight test. These types of gases are

extremely dangerous,

• Insulate the unions and are-nuts at the piping connection

part completely.

• Insulate the liquid piping completely to avoid a decrease of

performance; if not, it will cause sweating on the surface of

the pipe.

• Charge refrigerant correctly. Overcharging or insufcient char-

ging could cause a compressor failure.

• Check for refrigerant leakage in detail. If a large refrigerant

leakage occurred, it would cause difculty with breathing or

harmful gases would occur if a re were being used in the

room.

• If the are nut mut is tigthened too hard, the are nut may

crack after a long time and cause refrigerant leakage.

Evacuation and refrigerant charge

Evacuation and refrigerant charging procedure should be performed according to the following instructions.

The stop valve has been closed before shipment. However, make

sure that the stop valves are closed completely.

- Connect the indoor unit and the outdoor unit with eldsupplied refrigerant piping.

- Connect the gauge manifold using charging hoses with a

vacuum pump or a nitrogen cylinder to the check joints of

the liquid line and the gas line stop valve.

- Check for any gas leakage at the are nut connection, by

using nitrogen gas to increase the pressure at 4.15MPa

for outdoor units inside of the eld-supplied piping.

- Operate the vacuum pump for 1 to 2 hours until the pressure decreases lower than a pressure of 756 mmHg in

vacuum.

- For charging refrigerant, connect the gauge manifold

using charging hoses with a refrigerant charging cylinder

to the check joint of the liquid line stop valve.

- Charge the proper quantity of refrigerant according to

the piping length (Calculate the quantity of the refrigerant

charge).

- Fully open the gas line stop valve, and slightly open the

liquid line stop valve.

- Charge refrigerant by opening the gauge manifold valve.

- Charge the required refrigerant within the difference range

of ±0.5kg by operating the system in cooling.

- Fully open the liquid line stop valve after completing refrigerant charge.

- Continue cooling operation for more than 10 minutes to

circulate the refrigerant.

- Remove the “close” plate from the stop valve and hook the

attached “Open” plate at the stop valve.

Gas line

Liquid line

Liquid stop valve

Gas stop valve

Nitrogen tank

(For air tight test & nitrogen blow

during brazing)

Vacuum cylinder

Manifold

gauge

Outdoor unit

Example of Evacuation and Refrigerant Charge for HVN(P/C)1

14

14.4 REFRIGERANT CHARGE

When the pressure is measured, use the check joint of gas stop

valve, and use the check joint of liquid piping in the gure below.

At that time, connect the pressure gauge according to the following table because of high pressure side and low pressure side

changes by operation mode.

Cooling

Operation

Heating

Operation

Check Joint for Gas Stop Valve Low Pressure High Pressure

Check Joint for Liquid Stop Valve

Exclussive for Vacuum Pump

and Refrigerant Charge

NOTE

Be careful that refrigerant and oil do not splash to the electrical

parts at removing the charge hoses.

Stop valve (liquid)

Stop valve (gas)

14.5 CAUTION OF THE PRESSURE BY CHECK JOINT

Page 28

18

PMML0318A - P5415337

Refrigerant piping & refrigerant charge14

14.6 REFRIGERANT CHARGING QUANTITY

In case of the actual piping length is more than the specied length, the additional refrigerant quantity should be charged according

to the table below:

Outdoor unit refri-

gerant charge (kg)

Chargeless length (m)

Additional refrigerant charge (P)

(kg/m)

Max additional

charge (kg)

1 IU 2 IU 1 IU 2 IU

RAS-2HVNP1 1.6 30 0 0.03 0.03 1.5

RAS-2.5HVNP1 1.6 30 0 0.03 0.024 1.2

RAS-3HVNC1 1.9 20 20 0.04 0.04 1.2

RAS-3HVRNS3 1.9 20 20 0.04 0.04 1.2

1 Determine an additional refrigerant quantity according to the following procedure, and charge it into the system.

2 Record the additional refrigerant quantity to facilitate service activities thereafter.

CAUTION

• When charging refrigerant accurately measure refrigerant to be charged.

• Overcharging or undercharging of refrigerant can cause compressor trouble.

• In case of actual piping length less than 5 m, consult your distributor.

Additional refrigerant quantity calculation

Calculate piping length L(m)

Outdoor unit

Indoor unit

L: Piping Length

l: Chargeless length

P: Additional refrigerant charge

(a): No additional charge is required: L≤l

(b): Additional charge is required: L≥l

W (additional charge quantity) = (L-l) x P

Example:

L: 50 m

l: 30 m

P: 0.03

L = 50

Outdoor unit

RAS-2HVNP1

Indoor unit

W (additional charge quantity) = (50-30) x 0.03 = 0.6 kg

Setting of Pipe Length DSW.

DSW2 setting will be required only when the refrigerant pipe

length is shorter than 5 m or longer than 30 m. Pipe length setting

shall be performed as shown below.

(The side in the table below shows the DSW location)

DSW2 on Outdoor PCB1

Factory setting Pipe Length ≤ 5m Pipe Length ≥ 30m

Page 29

Drain piping

19

PMML0318A - P5415337

ENGLISH

14.7 REFRIGERANT PUMP DOWN

When the refrigerant should be collected into the outdoor unit due

to indoor/outdoor unit relocation, collect the refrigerant as follows:

1 Attach the manifold gauge to the gas stop valve and the liquid

stop valve

2 Turn ON the power source

3 Set the DSW1-1 pin of the outdoor unit PCB at the “ON” side

for cooling operation. Close the liquid stop valve and collect

the refrigerant.

4 When the pressure at lower pressure side (gas stop valve)

indicates -0.01 MPa (-100 mmHg), perform the following procedures immediately.

- Close the gas stop valve.

- Set the DSW1-1 pin at the “OFF” side (To stop the unit

operation).

5 Turn OFF the power source.

CAUTION

Measure the low pressure by the pressure gauge and keep it not

to decrease than -0.01 MPa. If the pressure is lower than -0.01

MPa, the compressor may be faulty.

15 DRAIN PIPING

15.1 DRAIN DISCHARGING BOSS

15

When the base of the outdoor unit is temporarily utilized as a drain receiver and the drain water in it is discharged, this drain boss

is utilized to connect the drain piping.

Model Applicable Model

DBS-12L

RAS-(2/2.5)HVNP1

RAS-3HVNC1

RAS-3HVRNS3

Connecting procedure

1 Insert the plastic cap into the drain boss up to the extruded

portions.

2 Insert the boss into the unit base up to the extruded portions.

3 Size of the drain boss is 15 mm (O.D.)

4 A drain pipe should be eld-supplied.

NOTE

• Do not use this drain boss set in a cold area, because the

drain water may freeze.

• This drain boss is not sufcient to collect all the drain water. If

collecting drain water is completely required, provide a drainpan that is bigger than the unit base and install it under the

unit with drainage.

Drain pipe

Plastic cap

Plastic cap

Drain hole

100 mm

Plastic cap

Drain hole

Push Push

≥ O.D. ∅ 16 mm

Speciers/installers have responsibility to follow local codes and

regulation which specify safety requirements against refrigerant

leakage.

14.8.1 Maximum permissible concentration of HCFC/

HFC gas

The refrigerant R410A, charged in the system, is an incombustible and non-toxic gas. However, if leakage occurs and gas lls a

room, it may cause suffocation.

The maximum permissible concentration of HCFC/HFC gas,

R410A in air is 0.44 kg/m³, according to EN378-1.

Therefore, some effective measure must be taken to lower the

R410A concentration in air below 0.44 kg/m³, in case of leakage.

14.8.2 Calculation of refrigerant concentration

1 Calculate the total quantity of refrigerant R (kg) charged in

the system connecting all the indoor units of rooms to be airconditioned.

2 Calculate the room Volume V (m³) of each room.

3 Calculate the refrigerant concentration C (kg/m³) of the room

according to the following equation:

R R: Total quantity of charged refrigerant (kg)

≤ C V: Room volume (m³)

V C: Refrigerant concentration 0.44 kg/m³ for R410A

14.8.3 Countermeasure for refrigerant leakage

1 Provide a shutterless opening which allow fresh air to circula-

te into the room.

2 Provide a doorless opening of 0.15% or more size to the oor

area.

3 Pay a special attention to the place, such as a basement, etc.,

where refrigerant can stay, since refrigerant is heavier than

air.

14.8 CAUTION ON REFRIGERANT LEAKAGE

Page 30

20

PMML0318A - P5415337

Electrical wiring

16 ELECTRICAL WIRING

16.1 GENERAL CHECK

1 Ensure that the eld-supplied electrical components (mains

power switches, circuit breakers, wires, connectors and wire

terminals) have been properly selected according to the electrical data indicated. Make sure that they comply with national

and regional electrical codes.

2 Following the Council Directive 2004/108/EC(89/336/EEC),

relating to electromagnetic compatibility, next table indicates:

Maximum permissible system impedance Z

max

at the interface

point of the user’s supply, in accordance with EN61000-3-11

MODEL

Z max

(Ω)

MODEL

Z max

(Ω)

RAS-2HVNP1 - RAS-3HVNC1 -

RAS-2.5HVNP1 - RAS-3HVRNS3 -

3 Harmonics situation of each model regarding IEC 61000-3-2

and IEC 61000-3-12 is as follows:

MODELS SITUATION REGARDING

IEC 61000-3-2 AND IEC 61000-3-12

Ssc “xx”

MODELS

Equipment complying with IEC 61000-3-2

(professional use)

RAS-2HVNP1

RAS-2.5HVNP1

RAS-3HVNC1

RAS-3HVRNS3

4 Check to ensure that the power supply voltage is within +/-

10% of the rated voltage.

5 Check to ensure that power supply has an impedance low

enough to warranty not reduce the starting voltage more than

85% of the rated voltage.

6 Check to ensure that the ground wire is connected.

7 Connect a fuse of specied capacity.

NOTE

Check and test to ensure that if there is more than one source of

power supply, that all are turned OFF.

CAUTION

• Check to ensure that screws for terminal block are tightly

tightened.

• Check to ensure that the indoor fan and the outdoor fan have

stopped before electrical wiring work or periodical check is

performed.

• Protect the wires, drain pipe, electrical parts, from rats or

other small animals. If not protected, rats may damage unpro-

tected parts, and at the worst, a re will occur.

• Wrap the accessory packing around the wires, and plug the

wiring connection hole with the seal material to protect the

product from any condensed water and insects.

• Tightly secure the wires with the cord clamp inside the indoor

unit.

• Lead the wires through the knockout hole in the side cover

when using conduit.

• Secure the cable of the remote control switch with the cord

clamp inside the electrical box.

• Electrical wiring must comply with national and local codes.

Contact your local authority in regards to standards, rules, regulations, etc.

• Check that the ground wire is securely connected.

• Connect a fuse of specied capacity.

DANGER

• Do not connect of adjust any wiring or connections un-

less the main power switch is OFF.

• Check that the earth wire is securely connected, tagged

and locked in accordance with national and local codes.

16

16.2 ELECTRICAL WIRING CONNECTION FOR OUTDOOR UNITS

The electrical wiring connection for the outdoor unit is shown in

gure below:

L1

L2

N

1 2

Power Supply AC 230 V

Control cable (5V)

Instructions for wiring and electrical board:

Power wires

PCB

Earth terminal

Side cover

Transmission

wires

Page 31

Electrical wiring

21

PMML0318A - P5415337

ENGLISH

16.2.1 Setting of DIP switches for outdoor unit

Quantity and Position of DIP Switches

The PCB in the outdoor unit is operating with 7 types of DIP switches, and 4 push switch. The location is as follows:

DSW301: Test run mode

Setting before shipment

1 2 3 4 5 6

ON

Cooling

Heating

Forced stop of compressor

DSW1: No setting is required

When set pin number 1 to ON, the electric

current detection is cancelled. Pin number

1 should be set back to OFF after electrical

work

DSW2: Optional function setting and piping lenght

Factory setting

Piping length ≤ 5m

Piping lenght ≥ 30m

Optional function setting

Optional function setting

1 2 3 4 5 6

ON

External input/output setting mode

DSW3: Capacity Setting (No setting is required)

Model RAS-2HVNP1

Setting position

Model RAS-2.5HVNP1

Setting position

Model

RAS-3HVNC1

RAS-3HVRNS3

Setting position

DSW4 / RSW1: Refrigerant cycle number setting

(Setting is required)

Setting for the ten digit

Setting position.

Set by inserting slotted screwdriver into the

groove (setting for the last digit)

DSW5: End terminal resistance (No setting is required)

Setting before shipment

DSW6: Setting of multiple indoor units simultaneous

operation (setting is required) (IVX series only)

Optional function setting

For individual operation (factory

setting position) for IVX series

For simultaneous operation

Set pin number 1 at OFF for simulta-

neous operation

DSW6: Not available for ES series

Factory setting

Empty

or

16

Page 32

22

PMML0318A - P5415337

Electrical wiring

16.3 COMMON WIRING

16.3.1 Electrical wiring between indoor unit and

outdoor unit

• Connect the electrical wires between the indoor unit and the

outdoor unit, as shown below.

• If the refrigerant piping and the control wiring are connected to

the units in the same refrigerant cycle.

• Use twist pair wire (more than 0.75 mm²) for operation wiring

between outdoor unit and indoor unit, and operation wiring

between indoor unit and indoor unit.

• Use 2-core wire for the operating line (Do not use wire with

more than 3 cores).Use shielded wires for intermediate wiring

to protect the units from noise obstacle at length of less than

300 m and size complied with local code.

• Open a hole near the connection hole of power source wiring

when multiple outdoor units are connected from one power

source line.

• The recommended breaker sizes are detailed in the Wire size

section.

• In the case that a conduit tube for eld-wiring is not used, x

rubber bushes with adhesive on the panel.

• H-LINK twist pair shielded cable must be grounded in the

outdoor unit side.

CAUTION

Pay attention to the connection of the operating line. Incorrect

connection may cause the failure of PCB.

All the eld wiring and electrical components must comply with

local codes.

16

Power source from the outdoor IVX unit to the indoor unit

(example)

Independent power source of outdoor IVX unit and indoor unit

(example)

No. 0 System

Outdoor unit

No. 0 System

Outdoor unit

Operating Line

(Shielded Pair Cable)

DC5V (Non-Pole Transmission,

H-LINK System)

Remote Control Switch

(Twisted Shielded Pair

Cable)

Operating Line

(Twisted Shielded

Pair Cable)

DC5V (Non-Pole

Transmission, H-LINK

System)

Indoor Unit

Indoor Unit

Terminal board

Circuit Breaker

Earthleakage Breaker

Field Wiring

Field supplied

Optional Accessory

Remote Control Switch

(Twisted Shielded Pair

Cable)

Indoor Unit

Indoor Unit

12

ON

DSW6

12

ON

DSW6

12

ON

DSW6

Operating line

Operating line Operating line

Remote control

line

Remote control

line

Remote control

line

Individual control

Running ON/OFF individually

Thermo.ON/OFF individually

Individual control

Running ON/OFF simultaneously

Thermo.ON/OFF individually

Simultaneous control

Running ON/OFF simultaneously

Thermo.ON/OFF simultaneously

(IVX series only)

Page 33

Electrical wiring

23

PMML0318A - P5415337

ENGLISH

16.3.2 Wire size

Connection wiring

Recommended minimum sizes for eld provided wires:

Model Power supply

Power source cable size Transmitting cable size

EN60 335-1 EN60 335-1

All Indoor Units 1~ 230V 50Hz 0.75 mm²

0.75 mm²

RAS-2HVNP1 1~ 230V 50Hz 2.5 mm

2

RAS-2.5HVNP1 1~ 230V 50Hz 4.0 mm

2

RAS-3HVNC1 1~ 230V 50Hz 4.0 mm

2

RAS-3HVRNS3 1~ 230V 50Hz 4.0 mm

2

NOTE

• Follow local codes and regulations when selecting eld wires, Circuit breakers and Earth Leakage breakers

• Use the wires which are not lighter than the ordinary polychloroprene sheathed exible cord (code designation H05RN-F)

Main switch protection

Select the main switches according to the next table:

Model Power supply Max. current (A) CB (A) ELB (no.poles/A/mA)

All Indoor Units 1~ 230V 50Hz 5.0 6 2/40/30

ELB: Earth switch; CB: Circuit braker

IVX Premium and Standard series, and ES series

Outdoor unit Power supply MC (A) CB (A) ELB

RAS-2HVNP1 1~ 230V 50Hz 13.8 16

2/40/30

RAS-2.5HVNP1 1~ 230V 50Hz 15.8 20

RAS-3HVNC1 1~ 230V 50Hz 17.8 20

RAS-3HVRNS3 1~ 230V 50Hz 17.8 20

16

Page 34

24

PMML0318A - P5415337

Electrical wiring

16.3.3 H-LINK system

The H-LINK system can not be applied to the cycle with the old

model unit or the unit with old transmission

1 Application

The new H-LINK wiring system requires only two transmission

wires connecting each indoor unit and outdoor unit for up to 16

refrigerant cycles, and connecting wires for all indoor units and all

outdoor units in series.

2 Features

- The total wiring length is remarkably reduced.

- Only one connection is required for the wiring between the

indoor unit and outdoor unit.

- Easy wiring connection to the central controllers.

3 Specications

- Transmission Wire: 2-Wire

- Polarity of transmission wire: Non-polar wire

- Maximum outdoor units to be connected: 16 units per

H-LINK system.

- Maximum indoor units to be connected: 3 units per cycle

and 48 units per H-LINK system

- Maximum wiring length: Total 1000m (including CSNET

WEB). In case that the total wiring length is longer than

1000m, contact the Hitachi dealer.

- Recommended cable: Twist pair cable with shield, over

0.75mm2 (Equivalent to KPEV-S)

- Voltage: DC5V

4 Example of H-LINK system

Using H-Link system only for air conditioners.

There are two typical cases of using H-LINK system:

a. Using H-LINK system only for air conditioners, without

control device.

Examples:

• Line connection with all units

Do not make

wiring in a

loop

Indoor

units

Outdoor

units

• Line connection for each oor

Indoor

units

Outdoor

units

b. Using H-LINK system for air conditioners with central con-

trol device.

In case that H-LINK is not applied when electrical wiring is performed.

Indoor units

Outdoor

units

NOTE

• Do not make a wiring in a loop.

• In the case that H-LINK is not applied after the when electrical wiring is performed as shown above, H-LINK is applied

after the instrument wiring is completed. Therefore, the dip

switches are required to be set according to setting of Dip

switches on PCB.

5 Dip Switch Setting of Indoor PCB and Outdoor PCB

It is required to set dip switches of every indoor unit and outdoor

unit.

16

Page 35

Electrical wiring

25

PMML0318A - P5415337

ENGLISH

16.3.4 DIP switch setting for multiple H-LINK system

The DIP switches of all the outdoor and indoor units have to be set as follows:

Unit Name of DIP switch Mark

Setting before the

shipment

Function

Outdoor unit

Terminal resistance DSW5

DSW5-1 is “ON” position before shipment.

• It is not necessary to set when H-LINK is connected with

only one outdoor unit.

• When H-LINK is connected with more than one outdoor unit,

set as follows:

- First outdoor unit: Keep DSW5-1 in “ON”.

- Other outdoor units: Set DSW5-1 to “OFF”.

Refrigerant cycle

DSW4

RSW1

For setting the refrigerant cycle address of the outdoor unit. Set

the DSW4 and RSW1 to overlap the setting of other outdoor

units in the same H-LINK system.

Indoor unit

Refrigerant cycle

DSW5

RSW2

DSW5

RSW2

For setting the refrigerant cycle address of the indoor unit. Set

the DSW5 and RSW2 corresponding to the address of outdoor

unit in the same refrigerant cycle.

Address of the

indoor unit

DSW6

RSW1

DSW6

RSW1

Setting indoor unit address. Set the DSW6 and RSW1 not to

overlap the setting of other indoor units in the same refrigerant

cycle. (If no set, the automatic address function is performed.)

16

Example of the setting of the DIP switches.

(00) (01)

(02)

(00) (00) (00) (00) (01) (01)

(02)

(02) (02)

(00) (01) (02) (03) (00) (01)

(00)

(01) (02)

Indoor

units

Outdoor

units

Cycle number 0

Cycle number 1

Cycle number 2

DSW5

Terminal resistance

DSW4

Number of refrigerant cycle.

(setting for tenth digit

)

RSW1

Number of refrigerant cycle

(setting for last digit)

DSW6

Address of the indoor unit

(setting for the tenth digit)

.

DSW5

Number of refrigerant cycle.

(setting for tenth digit)

RSW2

Number of refrigerant cycle

(setting for last digit)

RSW1

Address of the indoor unit

(setting for the last digit)

Page 36

26

PMML0318A - P5415337

Installation of remote controller17

17 INSTALLATION OF REMOTE CONTROLLER

17.1 INSTALLATION OF REMOTE CONTROL SWITCH (PC-ART EXAMPLE)

PC-ART

All data related to Installation about Remote Control Switch are in the specic Installation Manual.

Please refer to Installation Manual PMML0177A for PC-ART and PMML0225A for PC-ARF.

18 TEST RUNNING

When installation is completed, perform test run according to the

following procedure, and hand over the system to the customer.

Perform test run regarding indoor units one by one in order, and

conrm that the electrical wiring and the refrigerant piping are

correctly connected.

Test run should be performed according to the Test run procedure

on next page.

CAUTION

Do not operate the system until all the check points have been

cleared:

• Check to ensure that the electrical resistance is more than

1 MΩ, by measuring the resistance between ground and the

terminal of the electrical parts. If not, do not operate the system until the electrical leakage is found and repaired. Do not

impress the voltage on the terminals for transmission 1 and 2.

• Check to ensure that the stop valves of the outdoor unit are

fully opened, and then start the system.

• Check to ensure that the switch on the main power source has

been ON for more than 12 hours, to warm the compressor oil

by the oil heater.

• Pay attention to the following items while the system is running:

• Do not touch any of the parts by hand at the discharge gas

side, since the compressor chamber and the pipes at the discharge side are heated higher than 90°C.

• DO NOT PUSH THE BUTTON OF THE MAGNETIC

SWITCH(ES), it will cause a serious accident.

• Do not touch any electrical components for more than three

minutes after turning OFF the main switch