Hitachi RAS-3HVRNME-AF, RAS-5HVRNME-AF, RAS-4HVRNME-AF, RAS-6HVRNME-AF, RAS-5HRNME-AF Installation And Operation Manual

...Page 1

INSTALLATION AND OPERATION MANUAL

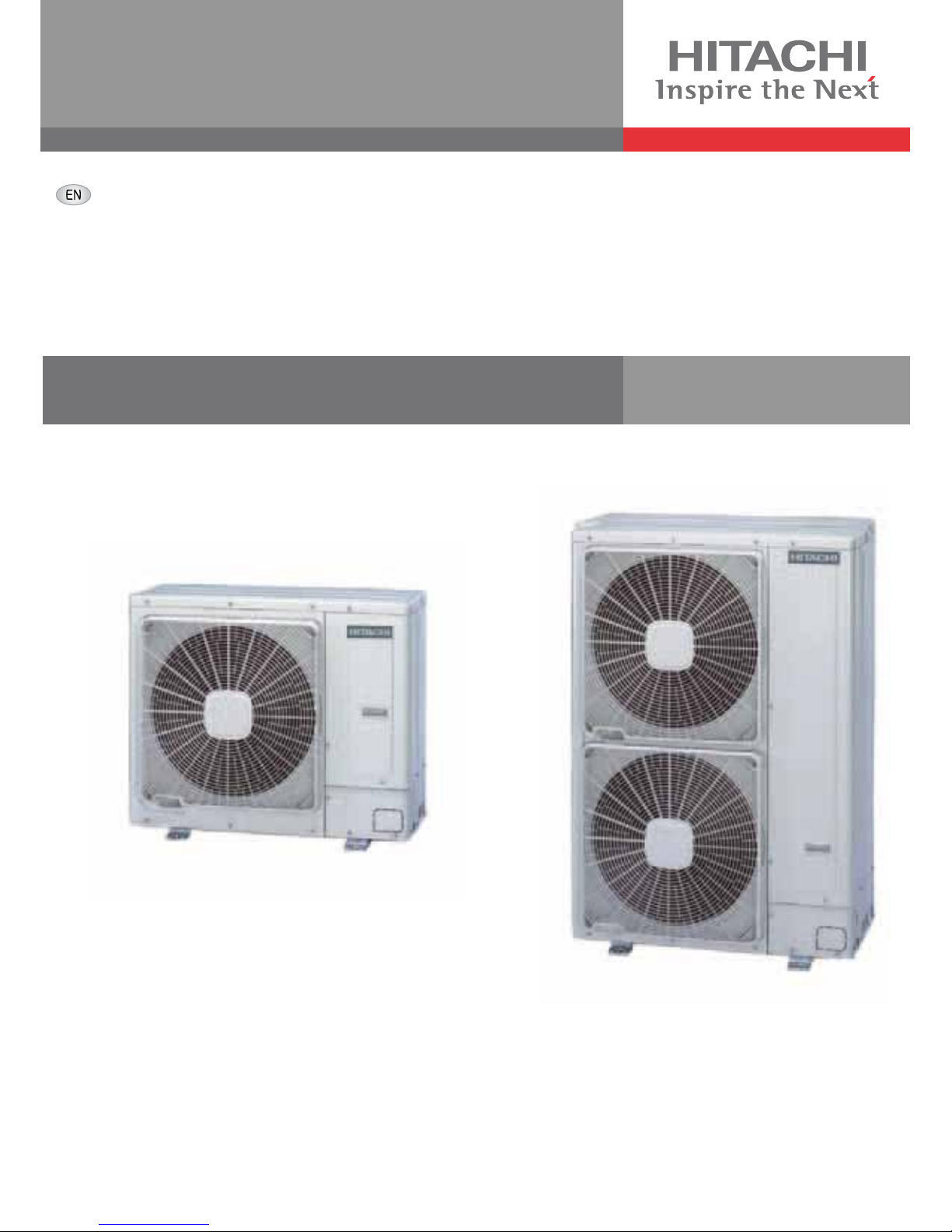

YUTAKI S/S80 Series

RAS-(3-6)H(V)RNME-AF

Outdoor Unit

Page 2

Page 3

Specications in this manual are subject to change without notice in order that HITACHI

may bring the latest innovations to their customers.

Whilst every effort is made to ensure that all specications are correct, printing errors are

beyond Hitachi’s control; Hitachi cannot be held responsible for these errors.

Page 4

ATTENTION:

This product shall not be mixed with general house waste at the end of its life and it shall be retired according to the

appropriated local or national regulations in a environmentally correct way.

Due to the refrigerant, oil and other components contained in Air Conditioner, its dismantling must be done by a

professional installer according to the applicable regulations.

Contact to the corresponding authorities for more information.

Page 5

DANGER – Immediate hazard which WILL result in severe injury or death.

WARNING – Hazards or unsafe practices which COULD result in severe personal injuries or death.

CAUTION – Hazards or unsafe practices which COULD result in minor personal injury or product or property

damage.

Page 6

Page 7

English

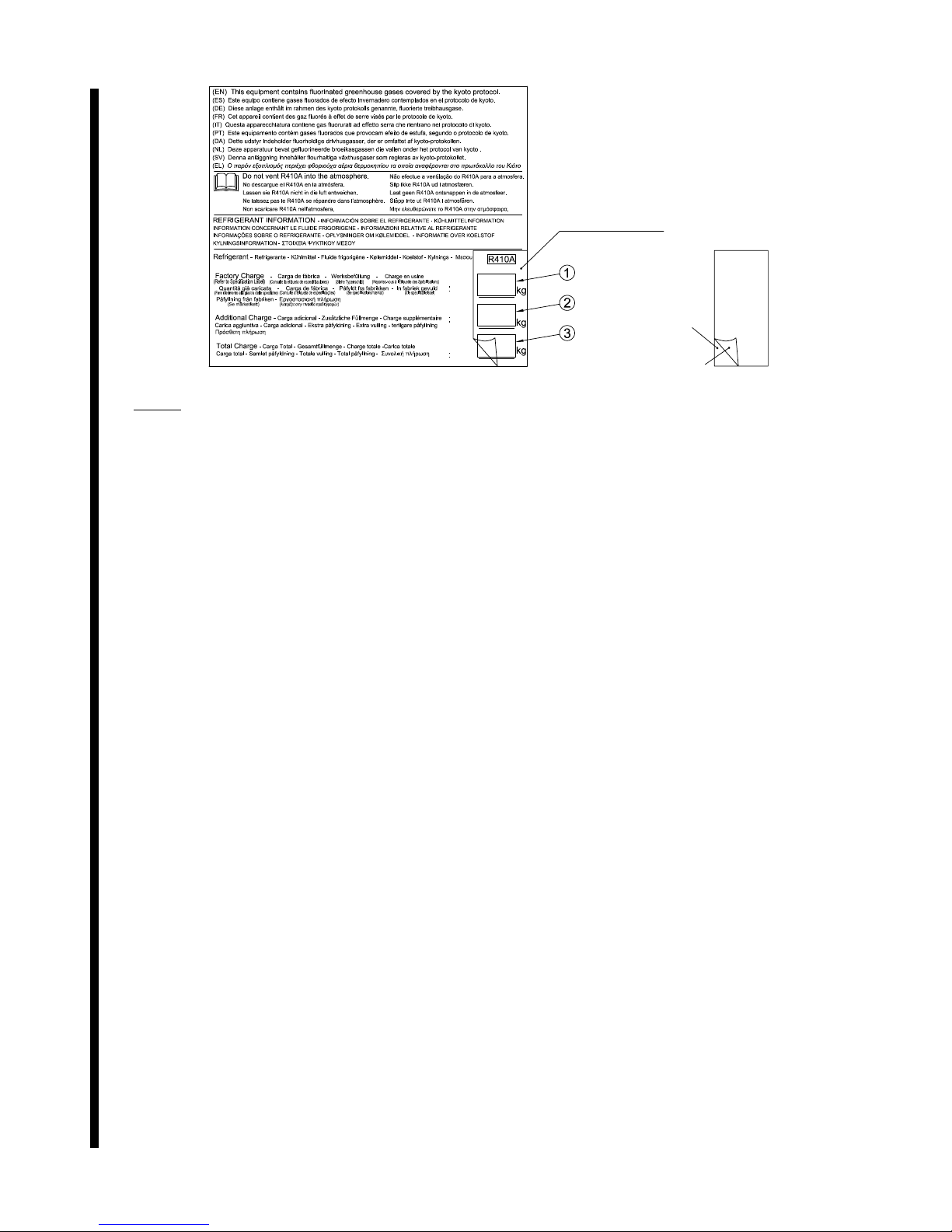

From 4th July 2007 and following Regulation EC Nº 842/2006 on Certain Fluorinated Greenhouse gases, it is mandatory to ll in the

label attached to the unit with the total amount of refrigerant charged on the installation.

Do not vent R410A/R407C into the atmosphere: R410A & R407C are uorinated greenhouse gases covered by the Kyoto protocol

global warming potential (GWP) R410A/R407C: = 1975/1652.5.

Page 8

English

Instructions to ll in the "F-Gas Label":

1.- Fill in the Label with indelible ink the refrigerant amounts:

- Factory Charge, - Additional Charge & - Total Charge.

2.- Stick the Protection Plastic Film on the F-Gas Label (delivered in a plastic bag with the Manual). To see Figure nº 2.

Figure 1. F-Gas Label with Protection Plastic Film Figure 2. Protection Plastic Film

Protection Plastic Film

Adhesive Surface

Peel-off Paper

Page 9

MODELS CODIFICATION

Important note: Please, check, according to the model name, which is your air conditioner type,

how it is abbreviated and referred to in this instruction manual. This Installation and Operation

Manual is only related to RWM-(H)FSN3E/RWH-FS(V)NFE combined with Outdoor Units H(V)

RNME-AF.

Page 10

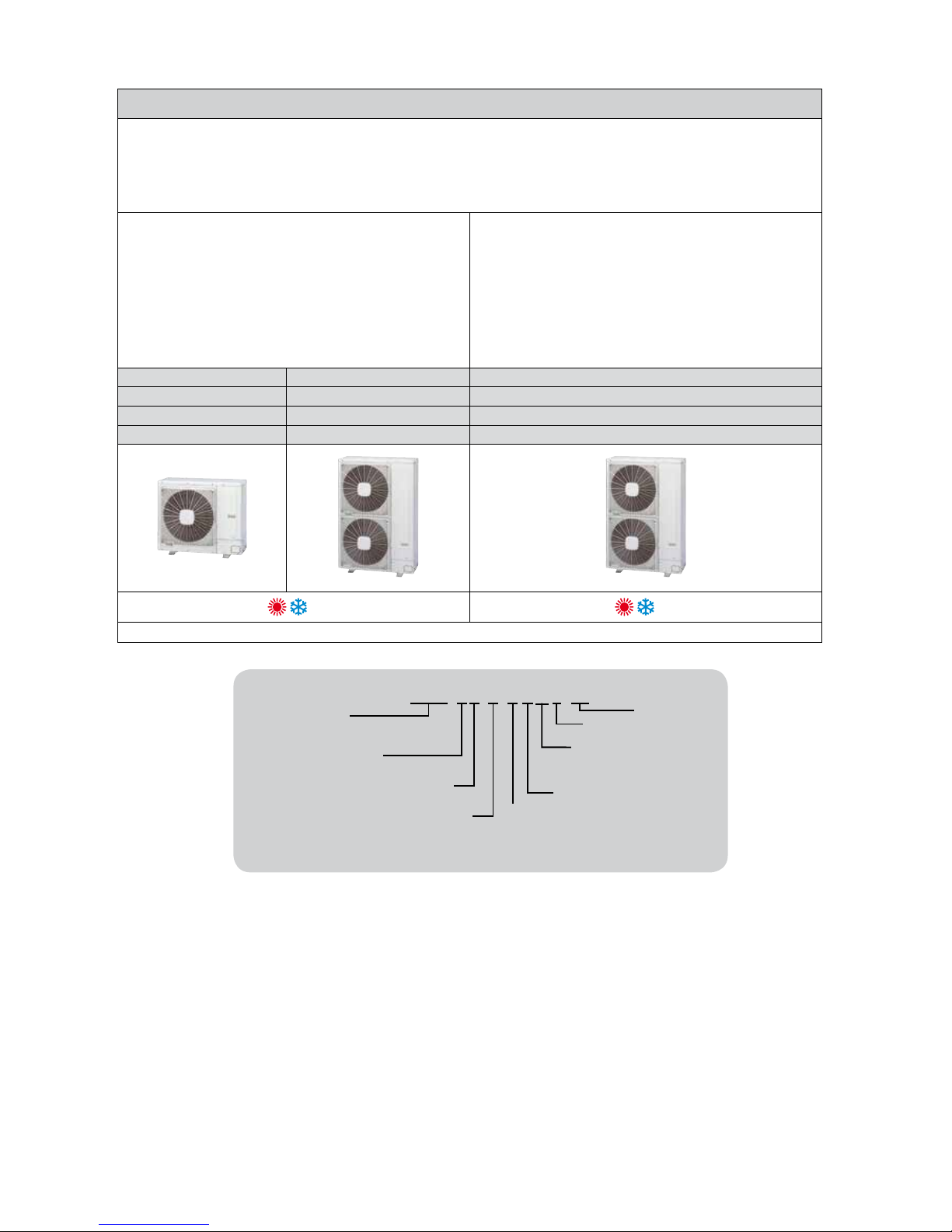

OUTDOOR UNIT · UNIDAD EXTERIOR · AUßENEINHEIT · UNITÉ EXTÉRIEURE · UNITÀ ESTERNA ·

UNIDADE EXTERIOR · UDENDRS AGGREGAT · BUITENTOESTEL · UTOMHUSENHET · ΕΞΩΤΕΡΙΚΗ ΜΟΝΑΔΑ

HEAT PUMP MODELS - MODELOS CON BOMBA DE CALOR

WÄRMEPUMPENMODELLE - MODÈLES POMPE À CHALEUR

MODELLI POMPA DI CALORE - MODELOS BOMBA DE CALOR

VARMEPUMPEMODELLER - MODELLEN MET WARMTEPOMP

MODELLER ENDAST FÖR KYLNINGSFUNKTION - ΜΟΝΤΕΛΑ ΜΕ ΑΝΤΛΙΑ ΘΕΡΜΟΤΗΤΑΣ

Single Phase

Monofásico

Einphasig

Monophasé

Monofase

Monofásico

Enfaset

Eenfasig

En fas

Μονοφασικά

Three Phase

Trifásico

Dreiphasig

Triphasé

Trifase

Trifásico

Trefaset

Driefasig

Trefasig

Tριφασικά

RAS-3HVRNME-AF

RAS-4HVRNME-AF RAS-4HRNME-AF

RAS-5HVRNME-AF RAS-5HRNME-AF

RAS-6HVRNME-AF RAS-6HRNME-AF

1~ 3N~

RAS

RAS-6H(V)RNME-AF

Unit type

(outdoor unit)

RAS

Compressor

Power (HP)

(3~6)

Heat Pump

Compressor type:

DC-Inverter

IVX Series

V: Single phase unit

(1~ 230V 50Hz)

-: Three phase unit

(3N~ 400V 50Hz)

R410A Refrigerant

E: Made in Europe

YUTAKI (S/S80)

Page 11

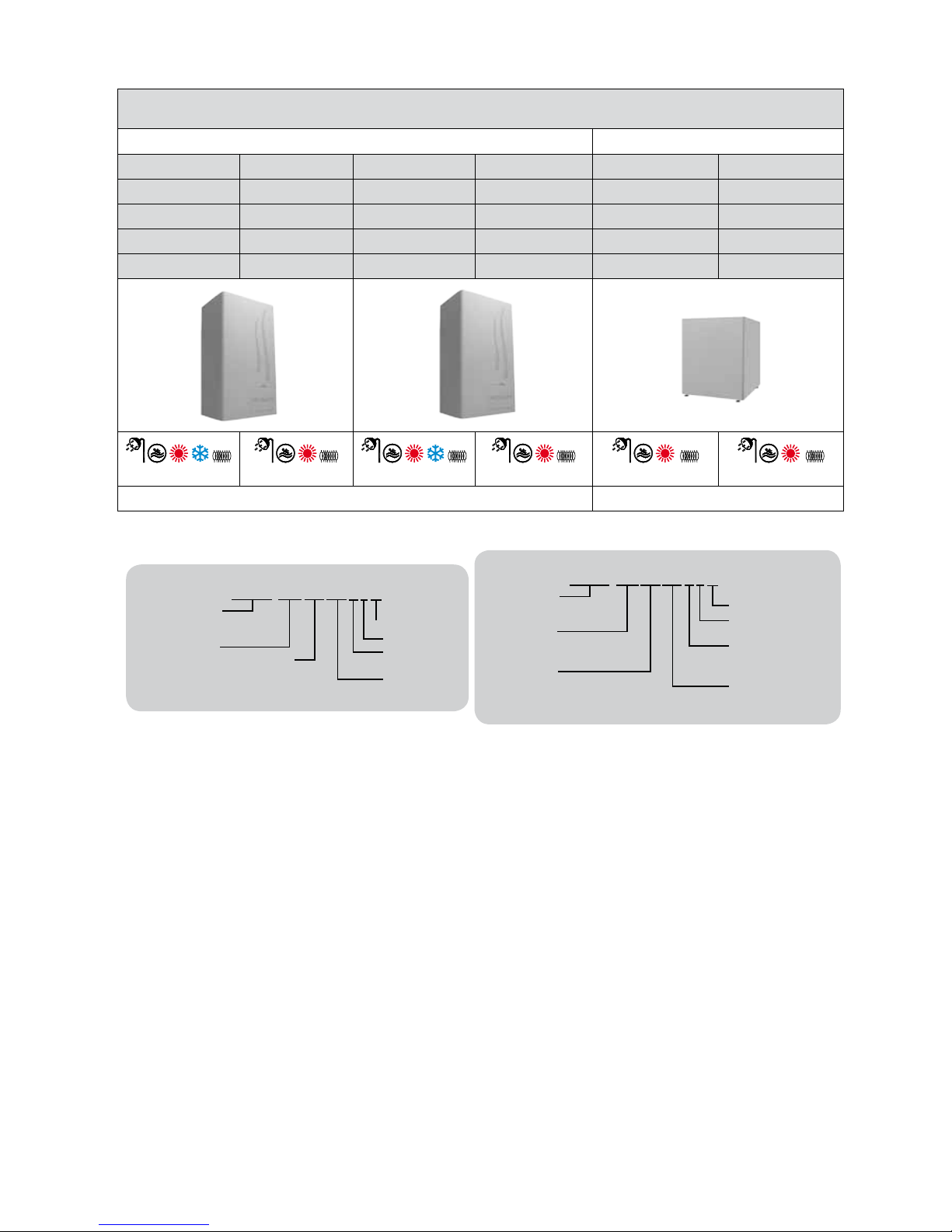

INDOOR UNIT - UNIDAD INTERIOR - INNENGERÄT - UNITÉ INTÉRIEURE - UNITÀ INTERNA -

UNIDADE INTERIOR - INDENDØRSENHED - BINNENUNIT - INOMHUSENHET - ΕΣΩΤΕΡΙΚΗ ΜΟΝΑ∆Α

YUTAKI S YUTAKI S80

Unit Unit Unit Unit Unit Unit

RWM-3.0FSN3E RWM-3.0HFSN3E

RWM-4.0FSN3E RWM-4.0HFSN3E RWH-4.0FSVNFE RWH-4.0FSNFE

RWM-5.0FSN3E RWM-5.0HFSN3E RWH-5.0FSVNFE RWH-5.0FSNFE

RWM-6.0FSN3E RWM-6.0HFSN3E RWH-6.0FSVNFE RWH-6.0FSNFE

1~

1~

1~/3N~

1~/3N~

1~

3N~

RWM RWH

RWM-5.0(H)FSN3E

Unit type:

indoor unit water

module - medium

temperature

Compressor

power (HP):

3.0, 4.0, 5.0, 6.0.

Made in Europe

Series

Refrigerant:

R410A

Only

heating

unit

System Free

RWH-5.0FS(V)NFE

Unit type:

indoor unit water

module - high

temperature

Compressor

power (HP):

4.0, 5.0, 6.0.

Made in Europe

Refrigerant:

R134a

Refrigerant:

R410A

V: Single phase unit

(1~ 230V 50Hz)

-: Three phase unit

(3N~ 400V 50Hz)

System Free

Page 12

INDEX ÍNDICE

PART I OPERATION

1. SAFETY SUMMARY

2. IMPORTANT NOTICE

3. SYSTEM DESCRIPTION

4. BEFORE OPERATION

5. AUTOMATIC CONTROLS

6. BASIC TROUBLESHOOTING

PART II INSTALLATION

7. NAME OF PARTS

8. REFRIGERANT CYCLE

9. UNITS INSTALLATION

10. REFRIGERANT PIPING & REFRIGERANT CHARGE

11. DRAIN PIPING

12. ELECTRIC WIRING

13. TEST RUN

14. SAFETY SUMMARY & CONTROL DEVICE SETTING

15. TROUBLESHOOTING

1ª PARTE FUNCIONAMIENTO

1. RESUMEN DE SEGURIDAD

2. AVISO IMPORTANTE

3. DESCRIPCIÓN DEL SISTEMA

4. ANTES DEL FUNCIONAMIENTO

5. CONTROLES AUTOMÁTICOS

6. RESOLUCIÓN DE PROBLEMAS BÁSICOS

2ª PARTE INSTALACIÓN

7. NOMBRE DE LAS PIEZAS

8. CICLO DE REFRIGERANTE

9. INSTALACIÓN DE LAS UNIDADES

10. TUBERÍA Y CARGA DE REFRIGERANTE

11. TUBERÍA DE DESAGÜE

12. CABLEADO ELÉCTRICO

13. PRUEBA DE FUNCIONAMIENTO

14. RESUMEN DE SEGURIDAD Y AJUSTE DE LOS

DISPOSITIVOS DE CONTROL

15. RESOLUCIÓN DE PROBLEMAS

INHALT INDEX

TEIL I – BETRIEB

1. SICHERHEITSÜBERSICHT

2. WICHTIGER HINWEIS

3. SYSTEMBESCHREIBUNG

4. VOR DEM BETRIEB

5. AUTOMATISCHE STEUERUNGEN

6. GRUNDLEGENDE FEHLERBEHEBUNG

TEIL II – INSTALLATION

7. TEILEBEZEICHNUNG

8. KÜHLKREISLAUF

9. GERÄTEINSTALLATION

10. KÄLTEMITTELROHRE UND KÄLTEMITTELMENGE

11. ABFLUSSLEITUNGEN

12. VERKABELUNG

13. TESTLAUF

14. SICHERHEITSÜBERSICHT UND EINSTELLUNG

DER STEUERGERÄTE

15. FEHLERBEHEBUNG

PARTIE I FONCTIONNEMENT

1. CONSIGNES DE SÉCURITÉ

2. REMARQUES IMPORTANTES

3. DESCRIPTION DU SYSTÈME

4. AVANT L’UTILISATION

5. CONTRÔLES AUTOMATIQUES

6. DÉPANNAGE DE BASE

PARTIE II INSTALLATION

7. NOMENCLATURE DES PIÈCES

8. CYCLE FRIGORIFIQUE

9. INSTALLATION DES UNITÉS

10. TUYAUTERIE FRIGORIFIQUE ET CHARGE DU

FLUIDE FRIGORIGÈNE

11. TUYAU D’ÉVACUATION

12. CÂBLAGE ÉLECTRIQUE

13. TEST DE FONCTIONNEMENT

14.

SOMMAIRE DES DISPOSITIFS DE SÉCURITÉ ET

RÉGLAGE DES DISPOSITIFS DE CONTRÔLE

15. DÉPANNAGE

INDICE ÍNDICE

PARTE I FUNZIONAMENTO

1. PRECAUZIONI PER LA SICUREZZA

2. NOTA IMPORTANTE

3. DESCRIZIONE DEL SISTEMA

4. PROCEDURA PRELIMINARE

5. CONTROLLI AUTOMATICI

6. RISOLUZIONE DEI PROBLEMI

PARTE II INSTALLAZIONE

7. NOMENCLATURA DEI COMPONENTI

8. CICLO REFRIGERANTE

9. INSTALLAZIONE DELLE UNITÀ

10.

LINEA DEL REFRIGERANTE E CARICA DI REFRIGERANTE

11. LINEA DI DRENAGGIO

12. COLLEGAMENTO DELLO SCHEMA ELETTRICO

13. PROVA DI FUNZIONAMENTO

14. RIEPILOGO DELLE IMPOSTAZIONI DEI DISPOSITIVI

DI CONTROLLO E SICUREZZA

15. RISOLUZIONE DEI PROBLEMI

PARTE I FUNCIONAMENTO

1. RESUMO DA SEGURANÇA

2. NOTA IMPORTANTE

3. DESCRIÇÃO DO SISTEMA

4. ANTES DE ARRANCAR A UNIDADE

5. CONTROLOS AUTOMÁTICOS

6. RESOLUÇÃO DE PROBLEMAS BÁSICOS

PARTE II INSTALAÇÃO

7. NOME DAS PEÇAS

8. CICLO DE REFRIGERAÇÃO

9. INSTALAÇÃO DAS UNIDADES

10. TUBAGEM E CARGA DE REFRIGERANTE

11. TUBAGEM DE ESGOTO

12. LIGAÇÕES ELÉCTRICAS

13. FUNCIONAMENTO DE TESTE

14. RESUMO DA SEGURANÇA E AJUSTE DE

DISPOSITIVO DE CONTROLO

15. RESOLUÇÃO DE PROBLEMAS

Page 13

INDEKS INHOUDSOPGAVE

DEL I – BETJENING

1. OVERSIGT OVER SIKKERHED

2. VIGTIG MEDDELELSE

3. SYSTEM BESKRIVELSE

4. FØR DRIFT

5. AUTOMATISKE KONTROLLER

6. BASIS FEJLFINDING

DEL II – MONTERING

7. NAVN PÅ DELE

8. KØLEMIDDELCYKLUS

9. INSTALLATION AF ENHEDER

10. KØLERØRSSYSTEM OG PÅFYLDNING AF

KØLEMIDDEL

11. AFLØBSRØR

12. ELEKTRISK LEDNINGSFØRING

13. TESTKØRSEL

14.

OVERSIGT OVER INDSTILLINGER FOR

SIKKERHEDS- OG KONTROLENHEDER

15. FEJLFINDING

DEEL I - BEDIENING

1. OVERZICHT VEILIGHEID

2. BELANGRIJKE MEDEDELING

3. BESCHRIJVING VAN HET SYSTEEM

4. VOORDAT U HET SYSTEEM IN GEBRUIK NEEMT

5. AUTOMATISCHE BESTURING

6. ELEMENTAIRE PROBLEMEN OPLOSSEN

DEEL II INSTALLATIE

7. NAMEN VAN ONDERDELEN

8. KOELMIDDELCYCLUS

9. INSTALLATIE VAN DE UNITS

10. KOELMIDDELLEIDINGEN & KOELMIDDEL VULLEN

11. AFVOERLEIDING

12. ELEKTRISCHE BEDRADING

13. PROEFDRAAIEN

14. OVERZICHT VEILIGHEID &

BESTURINGSINRICHTING

15. PROBLEMEN OPLOSSEN

INNEHÅLLSFÖRTECKNING ΕΥΡΕΤΗΡΙΟ

DEL I – DRIFT

1. SÄKERHETSSAMMANFATTNING

2. VIKTIG ANMÄRKNING

3. SYSTEMÖVERSIKT

4. FÖRE DRIFT

5. AUTOMATIK KONTROLLANORDNING

6. FELSÖKNING

DEL II - INSTALLATION

7. DELAR

8. KYLMEDIETS CYKEL

9. INSTALLATION AV ENHETER

10. KYLRÖR OCH PÅFYLLNING AV KYLMEDIUM

11. DRÄNERINGSRÖR

12. KABELANSLUTNINGAR

13. PROVKÖRNING

14. SÄKERHETSSAMMANFATTNING OCH

SÄKERHETSINSTÄLLNINGAR

15. FELSÖKNING

ΜΕΡΟΣ Ι ΛΕΙΤΟΥΡΓΙΑ

1. ΣΥΝΟΠΤΙΚΕΣ ΠΡΟΦΥΛΑΞΕΙΣ ΑΣΦΑΛΕΙΑΣ

2. ΣΗΜΑΝΤΙΚΗ ΠΑΡΑΤΗΡΗΣΗ

3. ΠΕΡΙΓΡΑΦΗ ΤΟΥ ΣΥΣΤΗΜΑΤΟΣ

4. ΠΡΙΝ ΤΗ ΛΕΙΤΟΥΡΓΙΑ

5. ΑΥΤΟΜΑΤΕΣ ΛΕΙΤΟΥΡΓΙΕΣ

6. ΑΝΤΙΜΕΤΩΠΙΣΗ ΒΑΣΙΚΩΝ ΠΡΟΒΛΗΜΑΤΩΝ

ΜΕΡΟΣ II ΕΓΚΑΤΑΣΤΑΣΗ

7. ΟΝΟΜΑΤΑ ΕΞΑΡΤΗΜΑΤΩΝ

8. ΚΥΚΛΟΣ ΨΥΞΗΣ

9. ΕΓΚΑΤΑΣΤΑΣΗ ΜΟΝΑΔΩΝ

10. ΣΩΛΗΝΩΣΕΙΣ ΨΥΚΤΙΚΟΥ & ΠΛΗΡΩΣΗ ΜΕ

ΨΥΚΤΙΚΟ ΜΕΣΟ

11. ΣΩΛΗΝΩΣΕΙΣ ΑΠΟΧΕΤΕΥΣΗΣ

12. ΗΛΕΚΤΡΙΚΗ ΚΑΛΩΔΙΩΣΗ

13. ΕΛΕΓΧΟΣ ΛΕΙΤΟΥΡΓΙΑΣ

14.

ΣΥΝΟΠΤΙΚΕΣ ΠΡΟΦΥΛΑΞΕΙΣ ΑΣΦΑΛΕΙΑΣ &

ΡΥΘΜΙΣΕΙΣ ΣΥΣΚΕΥΩΝ ΕΛΕΓΧΟΥ

15. ΑΝΤΙΜΕΤΩΠΙΣΗ ΠΡΟΒΛΗΜΑΤΩΝ

EN English Original version

ES Español Versión traducida

DE Deutsch Übersetzte Version

FR Français Version traduite

IT Italiano Versione tradotta

PT Português Versão traduzidal

DA Dansk Oversat version

NL Nederlands Vertaalde versie

SV Svenska Översatt version

EL ΕΛΛΗΝΙΚΑ Μεταφρασμένη έκδοση

Page 14

Page 15

15

PMML0205A rev.4 - 11/2012

ENGLISH

PART I- OPERATION

1 SAFETY SUMMARY

Identify the compatibility of the outdoor unit with YUTAKI S

and YUTAKI S80 indoor units by checking the black circle

into the indication poster.

YUTAKI S/S80

compatible

Verify, in accordance with the manuals which appear in the

outdoor units, that all the information required for the correct

installation of the system is included. If this is not the case,

contact your distributor.

HITACHI pursues a policy of continuing improvement in

design and performance of products. The right is therefore

reserved to vary specications without notice.

HITACHI cannot anticipate every possible circumstance that

might involve a potential hazard.

No part of this manual may be reproduced without written

permission.

If you have any questions, contact your service contractor of

HITACHI.

This manual gives a common description and information

for this heat pump which you operate as well as for other

models.

Check and make sure that the explanations of each part of

this manual correspond to your air conditioner model.

Refer to the models codication to conrm the main

characteristics of your system.

Signal words (DANGER, WARNING and CAUTION) are

used to identify levels of hazard seriousness. Denitions

for identifying hazard levels are provided below with their

respective signal words.

It is assumed that this unit will be operated and serviced by

English speaking people. If this is not the case, the customer

should add safety, caution and operating signs in the native

language of the personal.

This outdoor unit is exclusively to use for air to water

systems. It can not be used with indoor units in air to air

systems.

This heat pump has been designed for the following

temperature. Operate the air conditioner within this range:

Temperature

Maximum Minimum

Cooling Mode Outdoor 46 °C DB 10 °C DB

Heating Mode Outdoor 46 °C WB -20 °C WB

DB: Dry Bulb Temperature WB: Wet Bulb Temperature

These operations modes are controlled by the remote control

switch.

This manual should be considered as a permanent part of

the heat pump. This manual gives a common description and

information for this heat pump which you operate as well as

for other models.

DANGER:

Pressure Vessel and Safety Device: This heat pump is equipped

with a high pressure vessel under PED (Pressure Equipment

Directive). The pressure vessel has been designed and tested

before shipment according to PED. Also, in order to prevent the

system from an abnormal pressure, a high pressure switch, which

needs no eld adjustment, is utilized in the refrigeration system.

Therefore, this heat pump is protected from abnormal pressures.

However, if abnormally high pressure is applied to the refrigeration

cycle including the high pressure vessel(s), it will result in serious

injury or death due to explosion of the pressure vessel. Do not

apply a pressure higher than the following pressure to the system,

by modifying or changing the high pressure switch.

DANGER:

Do not pour water into the outdoor unit. These products are

equipped with electrical parts. If water contacts with electrical

components then it will cause a serious electrical shock.

Do not touch or adjust safety devices inside the indoor or

outdoor units. If these devices are touched or adjusted, it may

cause a serious accident.

Do not open the service cover or access the indoor or outdoor

units without disconnecting the main power supply.

In case of re Turn OFF the main switch, put out the re at once

and contact your service contractor.

CAUTION:

Refrigerant leakage can cause difculty with breathing due to

insufcient air.

WARNING:

Do not use any sprays such as insecticide, lacquer, hair spray or

other ammable gases within approximately one (1) meter from

the system.

If circuit breaker or fuse is often activated, stop the system and

contact your service contractor.

Do not make service or inspections tasks by yourself. This works

must be performed by qualied service person.

Do not put any strange material (sticks, etc...) into the air inlet

and outlet. These units have high speed rotating fans and it is

dangerous that any object touches them.

NOTE:

It is recommended to ventilate the room every 3 or 4 hours.

Yutaki S indoor unit has two different ranges:

- Heating and cooling version (RWM-(2.0-10.0)FSN3E).

- Heating only version (RWM-(2.0-10.0)HFSN3E).

All the information in this manual related to cooling operation, only

applies to heating and cooling version (RWM-(2.0-10.0)FSN3E).

Yutaki S80:

- Heating only version: RWH-(4.0-6.0)FS(V)NFE

2 IMPORTANT NOTICE

SAFETY SUMMARY

Page 16

PMML0205A rev.4 - 11/2012

16

3 SYSTEM DESCRIPTION

Maximum Allowable Pressure and High Pressure Cut-out Value:

Product Series Outdoor Unit Model Refrigerant

Maximun Allowable

Pressure (MPa)

High Pressure Switch

Cut-out Value (MPa)

H(V)RNME-AF Series RAS-3~6H(V)RNME-AF R410A 4.15 4.00 ~ 4.10

Supply electrical power to the system for approximately

12 hours before start-up or a long shutdown. Do not start

the system immediately after power supply, it may cause a

compressor failure because the compressor is not heated well.

When the system is started after a shutdown longer that

approximately 3 months, it is recommended to check the

system by your service contractor.

Turn OFF the main switch when the system is to be stopped

for a long period of time: If the main switch is not turned

OFF, electricity will be used, because the oil heater is always

energised during compressor stopping.

Make sure that the outdoor unit is not covered with snow or ice.

If covered, remove it by using hot water (approximately 50°C). If

the water temperature is higher that 50°C, it will cause damage

to plastic parts.

Start-up and Operation: Check to ensure that all the stop

valves are fully opened and no obstacle exists at the inlet/outlet

sides before start-up and during the operation.

Maintenance: Periodically check the high pressure side. If the

pressure is higher than the maximum allowable pressure, stop

the system and clean the heat exchanger or remove the cause.

NOTE:

The label for the vessel under PED are attached on the high

pressure vessel. The pressure vessel capacity and vessel

category are indicated on the vessel.

Location of High Pressure Switch

Compressor

NOTE:

The high pressure switch is indicated on the electrical wiring

diagram in the outdoor unit as PSH connected to printed circuit

board (PCB1) in the outdoor unit

Structure of High Pressure Switch

Contact Point Pressure Detected

Connected to the electrical wire

DANGER:

Do not change the high-pressure switch locally or change the

high pressure cut-out set value locally. If changed, it will cause

serious injury or death due to explosion.

Do not attempt to turn service valve rod beyond its stop

HITACHI’s YUTAKI S/S80 heat pumps produce sanitary hot water and heating like any oil or gas boiler but transforms renewable energy from the air outside into heat. Every 1kW of electricity used to power the heat pump can provide up to 4kW of energy for heating;

this can reduce heating bills by up to 60% and cut CO2 emissions by 50% compared to traditional boiler-led systems.

Furthermore, the YUTAKI S/S80 system allows a high exibility of indoor unit control thanks to its wireless remote controller (PCS80TE) which includes a helpful LCD graphic display, one-touch holiday button, weekly timer and frost protection, a high reliability,

space saving and easy installation.

NOTE:

For more information refer to indoor unit installation and operation manual PMML0228A(RWM-(2.0-6.0)FSN3E) or

PMML0258A(RWM-(2.0-6.0)HFSN3E) (YUTAKI S), PMML0224A(RWH-(4.0-6.0)FS(V)NFE) (YUTAKI S80).

4 BEFORE OPERATION

SYSTEM DESCRIPTION

CAUTION:

Page 17

17

PMML0205A rev.4 - 11/2012

ENGLISH

5 AUTOMATIC CONTROLS

The system is equipped with the following functions.

¡ THREE MINUTE GUARD

The compressor remains off for at least 3 minutes once it

has stopped. If the system is started within approximately 3

minutes after it has stopped, the RUN indicator is activated.

However, the cooling operation or the heating operation

remains off and does not start until after 3 minutes has

elapsed.

Operation may stop for 6 minutes maximum to protect

compressor.

¡ FROST PREVENTION DURING COOLING OPERATION

When the system is operated in a low temperature room,

the cooling operation may be changed to fan operation for a

while to avoid frost formation on the indoor heat exchanger.

¡ AUTOMATIC RESTART AFTER POWER FAILURE

If the power supply is interrupted for short periods of time

(up to 2 seconds) the Remote Control switch will retain the

settings and the unit will restart when the power is restored

(optional function).

If Automatic Restart is required after periods of lost power

supply in excess of 2 seconds please contact your distributor.

¡ SLOW AIR CONTROL DURING HEATING OPERATION

When the compressor is stopped while the thermostat is

OFF, or the system is performing the automatic defrosting

operation, the fan speed is set at the slow position.

¡ AUTOMATIC DEFROSTING CYCLE

When the heating operation is stopped by pressing RUN/

STOP switch, frosting on the outdoor unit is checked and the

defrosting operation may be performed for the maximum of

10 minutes.

¡ PREVENTION OF OVERLOAD OPERATION

When the outdoor temperature is too high during heating

operation, heating operation is stopped due to activation of

the outdoor thermistor until the temperature becomes low.

¡ HOT START DURING HEATING OPERATION

To prevent cold air discharge, the fan speed is controlled

from the slow position to the set position according to the

discharge air temperature. At this time the lover is xes

horizontally.

6 BASIC TROUBLESHOOTING

CAUTION:

When you smell or white smoke occurs from the unit, stop the

system and contact your contractor.

¡ THIS IS NOT ABNORMAL

− Sound from deforming Part

During system starting or stopping, and abrading

sound might be heard. However, this is due to thermal

deformation of plastic parts. It is not abnormal.

− Refrigerant Flow Sound

While the system is being started or stopping, sound from

the refrigerant ow may be heard.

− Steam from Outdoor Heat Exchanger

During defrosting operation, ice on the outdoor heat

exchanger is melted, resulting in making steam.

− Dew on Cabinet

When the cooling operation continues for a long period of

timer (higher than 27°C DB/80% R.H.), dew can form on

the cabinet.

¡ NO OPERATION

Check whether the SET TEMPERATURE is set at the correct

temperature.

¡ NOT COOLING WELL OR HEATING WELL

− Check the units to make sure that there are no outside air

ow obstructions or water ow obstructions inside.

− Check the level of the room’s heat load from other sources.

− Check if the water lter is clogged with dust.

− Check if the doors and windows are opened or closed.

− Check if the temperature condition is within the operating

range.

¡ IF TROUBLE STILL REMAINS...

If the trouble still remains even after checking the above

items, contact your service contractor and inform the

following data:

− Unit Model Name

− Content of Trouble

− Alarm Code nº. on LCD Controller

NOTE:

Except for a long period of shutdown, keep the main switch ON,

since the oil heater is energised when the compressor is stopped.

AUTOMATIC CONTROLS

Page 18

PMML0205A rev.4 - 11/2012

18

PART II-INSTALLATION

7 NAME OF PARTS

Name of parts. If do you want more information check the technical catalogue.

7.1. OUTDOOR UNIT (Example of RAS-5H(V)RNME-AF)

Nº. Part Name

1 Compressor

2 Heat Exchanger

3 Fan

4 Fan Motor

5 Strainer

6 Distributor

7 Reversing Valve

8 Expansion Valve

9 Solenoid Valve

10 Stop Valve for Gas Line

11 Stop Valve for Liquid Line

12 Receiver

13 Check Joint

14 Electrical Control Box

15 High-Pressure Switch

16 Pressure Switch

17 Crankcase Heater (for Compressor)

18 Vibration Isolation Rubber

19 Air Outlet

20 Air Inlet

NAME OF PARTS

Page 19

19

PMML0205A rev.4 - 11/2012

ENGLISH

8 REFRIGERANT CYCLE

EXAMPLE:

R410A 4.15 MPa

Refrigerant Flow

for Cooling

Refrigerant Flow

for Heating

Refrigerant Piping

in the installation

Connection With

Flare Nut

Flange Connection Brazing Connection Refrigerant

Airtight Test

Pressure

Nº. Name of Item Nº. Name of Item

1 Compressor 9 High Pressure Switch (Protection)

2 Heat Exchanger 10 Stop Valve for Gas Line

3 Filter 11 Stop Valve for Liquid Line

4 Expansion valve 12 Pressure Switch Control

5 Reverse Valve 13 Solenoid Valve

6 Filter (1/2) 14 Ambient Thermistor

7 Distributor 15 Evaporating Pipe Thermistor

8 Check Joint 16 Discharge Gas Thermistor

REFRIGERANT CYCLE

Page 20

PMML0205A rev.4 - 11/2012

20

9.1. OUTDOOR UNITS INSTALLATION

CAUTION:

Transport the products as close to the installation location as

practical before unpacking.

Do not put any material on the products.

Apply four lifting wires on to the outdoor, when lifting it by crane

WARNING:

- Install the outdoor unit with sufcient clearance around it for

operation and maintenance as shown in the next gures.

Install the outdoor unit where good ventilation is available

- Do not install the outdoor unit where is a high level of oil mist,

salty air or sulphurous atmosphere.

- Install the outdoor unit as far as practical (being at least 3

meters) from electromagnetic wave radiator (such as medical

equipment).

- For cleaning, use noninammable and nontoxic cleaning liquid.

Use of inammable agent may cause explosion or re.

- Work with sufcient ventilation, for working in an enclosed space

may cause oxygen deciency. Toxic gas may be produced when

cleaning agent is heated to high temperature by, e.g., being

exposed to re.

- Cleaning liquid shall be collected after cleaning.

- Pay attention not to clamp cables when attaching the service

cover to avoid electric shock or re.

CAUTION:

Keep clearance between the units of more than 50mm, and

avoid obstacles that may hamper air intake, when installing more

than one units together.

Install the outdoor unit in the shade or not exposed to direct

sunshine or direct radiation from high temperature heat source.

Do not install the Outdoor Unit in a space where a seasonal wind

directly blows to the Outdoor fan.

Check to ensure that the foundation is at, level and sufciently

strong.

Install the unit in a restricted area not accessible by the general

public

Aluminum ns have very sharp edges. Pay attention to the ns to

avoid injury.

9. UNITS INSTALLATION

UNITS INSTALLATION

Page 21

21

PMML0205A rev.4 - 11/2012

ENGLISH

9.1.1. INSTALLATION SPACE

− RAS-(3~6)H(V)RNME-AF

Blocked in Inlet Side

Upper Side Open

Single Installation Multiple Installation (Two units or more)

100 mm or more of the side space is acceptable on the service cover side.

Dimensions in ( ) shows numbers especially for 4 – 6 HP. 150 or more (200 or

more) of the back space is acceptable when the right and left sides are open.

Allow 100mm of space between units. Leave open both right and left sides.

Dimensions in ( ) shows numbers especially for 4 – 6 HP.

Be sure to use the fan direction guide. Leave open both right

and left sides.

Be sure to use the fan direction guide. Allow 100 mm of

space between units. Leave open both right and left sides.

When subject to direct sunlight on the back wall, ensure the

length marked with

be 500 or greater.

Upper Side Blocked

100 mm or more of the side space is acceptable on the service cover side.

Dimensions in ( ) shows numbers especially for 4 – 6 HP.

Allow 100 mm of space between units. Leave open both right and left sides.

Dimensions in ( ) shows numbers especially for 4 – 6 HP.

Be sure to use the fan direction guide.

Leave open both right and left sides.

H

Be sure to use the fan direction guide. Allow 100 mm of

space between units. Leave open both right and left sides.

Serial installation allowed up to two units.

L

H

Be sure to use the fan direction guide. Allow 100 mm of space between units.

Leave open both right and left sides. Serial installation allowed up to two units.

The length A is as shown

in the following table:

L A

0 <L≦

1/2H

600 or greater

1/2H

<L≦

H

1200 or greater

UNITS INSTALLATION

Page 22

PMML0205A rev.4 - 11/2012

22

Outlet Side Blocked

Upper Side Open

Single Installation Multiple Installation (Two units or more)

Allow 100mm of space between units. Both right and left

sides shall be open.

Be sure to use the fan direction guide. Leave open

both right and left sides.

H

L

Be sure to use the fan direction guide. Allow 100 mm of space

between units. Serial installation allowed up to two units. Leave

open both right and left sides.

H

l

The length A is as shown

in the following table:

When L > H, use a base for outdoor unit to make L ≤ H.

Close the base not to allow the outlet air bypassed.

L A

0<L≤1/2H ≤200

1/2H<L≤H ≤300

The length A is as shown

in the following table:

When L > H, use a base for outdoor unit to make L ≤ H.

Close the base not to allow the outlet air bypassed.

L A

0<L≤1/2H ≤250

1/2H<L≤H ≤350

Lateral Side Blocked

Upper Side Open

Single Installation

Upper Side Blocked

UNITS INSTALLATION

Page 23

23

PMML0205A rev.4 - 11/2012

ENGLISH

Stack installation (allowed up to 2 Units)

Blocked in Inlet Side

Single Installation Multiple Installation

Close the part A not to allow the outlet air bypassed. Install to avoid

the drain water from upper unit falling on the lower unit.

Allow 100 mm of space between units. Serial sideways installation

allowed up to two units. Leave open both right and left sides. Close the

part A not to allow the outlet air bypassed. Install to avoid the drain water

from upper unit falling on the lower unit

Outlet Side Blocked

Be sure to use the fan direction guide. Close the part A not to allow

the outlet air bypassed. Install to avoid the drain water from upper

unit falling on the lower unit.

Be sure to use the fan direction guide. Allow 100mm of space between

units. Serial sideway installation allowed. but leave open both right and

left sides. Close the part A not to allow the outlet air bypassed. Install to

avoid the drain water from upper unit falling on the lower unit.

Multiple Installation in Multiple Rows

Serial Installation in Multiple Rows (E.g. Rooftop)

Allow approx. 100 mm of space from the side unit.

Leave open both right and left sides.

The length A is as shown in the following table:

L A

0<L≤1/2H

≤

200

1/2H<L≤H

≤

300

L

H

Note: When L > H, use a base for outdoor unit to make L ≤ H. Close the base not to allow the outlet air bypassed. Be sure to

use the fan direction guide in order to ensure the length marked with .

- Do not stack more than two units in height.

UNITS INSTALLATION

Page 24

PMML0205A rev.4 - 11/2012

24

9.1.2. INSTALLATION PLACE PROVISION

¡

Concrete Foundation

1. Foundation could be on at and is recommended be 100-300

mm higher than ground level.

2. Install a drainage around foundation for smooth drain.

3. When installing the outdoor unit x the unit by anchor bolts of

M10.

4. When installing the unit on a roof or a veranda, drain water

sometimes turns to ice on a cold morning. Therefore, avoid

draining in an area that people often use because it is

slippery.

* Space for downward piping space

Nº Description

Outdoor Unit

Cut this portion of bolt If not, it’s difcult to remove Service Cover

Mortar Hole (Ø100xDepth 150)

Anchor Bolt M10 (Ø12.5 Hole)

Drainage (Wide 100xDepth 150)

Drainage

Vibration-proof rubber

5. The whole of the base of the outdoor unit should be installed

on a foundation. When using vibration-proof mat, it should

also be positioned the same way. When installing the outdoor

unit on a eld supplied frame, use metal plates to adjust the

frame width for stable installation as shown in below gure.

INCORRECT

CORRECT

Outdoor unit is

stable

57 mm

Outdoor unit base width

Frame

Metal plate

100 mm or more

Metal plate

Recommended Metal Plate Size

- (Field-Supplied) Material: Hot-Rolled Mild Steel

- Plate (SPHC) Plate Thickness: 4.5 T

Outdoor unit is

unstable

Frame

60mm

Frame width

(Field supplied)

Base width of outdoor unit

57 mm

UNITS INSTALLATION

Page 25

25

PMML0205A rev.4 - 11/2012

ENGLISH

10.1. PIPING MATERIALS

1. Prepare locally-supplied copper pipes.

2. Select the piping size with the correct thickness and

correct material which can have sufcient pressure

strength.

3. Select clean copper pipes. Make sure there is no dust and

moisture inside. Blow the inside of the pipes with oxygen

free nitrogen to remove any dust and foreign materials

before connecting pipes.

NOTE:

A system with no moisture or oil contamination will give maximum

performance and lifecycle compared to that of a poorly prepared

system. Take particular care to ensure all copper piping is clean

and dry internally.

There is no refrigerant in the cycle of the indoor unit.

CAUTION:

Cap the end of the pipe when pipe is to be inserted through a

hole.

Do not put pipes on the ground directly without a cap or vinyl tape

at the end of the pipe

If piping installation is not completed until next day or over a

longer period of time, braze off the ends of the piping and charge

with oxygen free nitrogen through a Schrader valve type access

tting to prevent moisture and particle contamination.

Do not use insulation material that contains NH3 because it can

damage cooper pipe material and can be a source of future

leakage.

Insulate the unions and are-nuts at the piping connection part

completely.

Completely insulate both refrigerant gas and liquid piping between

the indoor unit and the outdoor unit to avoid a decrease of

performance; if not, dew will occur on the piping surface.

¡ Fix Unit to the wall

1. Fix the Unit onto the wall as the gure

indicates. (eld supplied stay)

2. Ensure the foundation so that avoid the

deforming and noise.

3. In case of prevention from vibration

transfer to the building, use rubber Mat.

¡ Suspended unit

1. Suspend the unit as the drawing

indicates.

2. Ensure that wall can resist the Outdoor

unit weight indicated in specication

label plate.

3. It is recommended to select each foot

support to bear the full weight of the

unit (in order to consider stress fatigue

applied when unit is working too).

CAUTION:

Pay attention to the following for

installation:

1. Installation shall ensure that outdoor

unit will not incline, vibrate, make

noise or fall down by a blast of

wind or in an earthquake. Calculate

quake-resistance strength to

ensure that installation is strong

enough against falling. Fix the unit

with wires (eld supplied) when

installing in a location without walls

or windbreak and likely exposed to

a blast of wind.

2. To use a vibration-proof mat, x four

places to the front and back.

¡ Installing location where the unit will be exposed to strong wind.

Follow the instructions below to install

on the rooftop or a location without

surrounding buildings, where strong

wind is expected against the product.

1. Choose a location where the outlet

or inlet side of the product will not be

exposed to strong wind.

2. When the outlet is exposed to strong

wind:

Direct strong wind may cause lack

of air ow and adversely affect to the

operation.

CAUTION:

Excessive strong wind against the

outdoor unit outlet may cause inverse

rotation and damage the fan and

motor.

10. REFRIGERANT PIPING & REFRIGERANT CHARGE

Mark Dimension

Model 3HVRNME-AF

4~6H(V)RNME-AF

A (mm) 529 796

Wall bracket (*)

Anchor Bolts (*)

(*) Field supplied

Rubber Material

(Field Supplied)

REFRIGERANT PIPING &

REFRIGERANT CHARGE

Page 26

PMML0205A rev.4 - 11/2012

26

10.2. SUSPENSION OF REFRIGERANT PIPING

Suspend the refrigerant piping at certain points and prevent the

refrigerant piping from touching the weak part of the building

such as wall, ceiling, etc…

(If touched, abnormal sound may occur due to the vibration of

the piping. Pay special attention in case of short piping length).

Do not x the refrigerant piping directly with the metal ttings

(The refrigerant piping may expand and contract).

Some examples for suspension method are shown below.

10.3. PIPING CONNECTION FOR OUTDOOR UNIT

1. The pipes can be connected from 4 directions. Make holes

in the piping cover or cabinet for taking out pipes. Take the

piping cover away from the unit, and make holes by cutting

along the guideline at the rear of the cover or punching with

a driver. Remove the burr with a cutter, and place a insulation

(eld supplied) to protect cables and pipes.

Nº Description

Rear side piping work

Pipe Cover

Right side piping work

Bottom side piping work (Knock out hole)

Front side piping work

Piping work

Stop Valve

Removing Direction for Service Cover

CAUTION:

Notes to open/close the service cover:

Remove the screws following the instructions to the above gure.

Slowly press down the cover

NOTE:

Hold the cover with a hand to remove screws as the cover may fall

down.

¡ For the front and side piping

To use racking or conduit tubes, check the size and remove

part following the slit.

NOTE:

Place insulation (eld supplied) to protect cables and pipes from

being damaged by plate edges.

¡ For the downward piping

NOTE:

Cables shall not contact directly to the pipes.

¡ For the rear side piping

NOTE:

Remove the rear pipe cover under the rear cover and remove

part following the slit.

For Suspending

Heavies

For piping along

the wall

For instant

installation work

1~15m

Indor unit

Fire-Proof

Section

Treatment

Front piping hole

Side piping hole

Gas piping

Knock-out hole

Bottom base

Cables

Liquid piping

Service cover

Hook (three places): two fans

Hook (two places): one fan

Rear Cover

REFRIGERANT PIPING &

REFRIGERANT CHARGE

Page 27

27

PMML0205A rev.4 - 11/2012

ENGLISH

2. Mount the piping cover in order to avoid water entering into

the unit. Seal the holes where pipes and wires are inserted,

by using a insulation (eld-supplied).

3. If the eld-supplied piping is connected with stop valves

directly, it is recommended use a tube bender.

4. Check to ensure that the stop valves are closed completely

before connecting pipes.

5. Connect the eld supplied refrigerant pipes to the indoor unit

and outdoor unit. Apply the oil thinly at the seat are nut and

pipe before tightening.

The required tightening torque is as follows:

Pipe Size Tightening Torque (Nm)

Ø 6.35 mm 20

Ø 9.53 mm 40

Ø 12.70 mm 60

Ø 15.88 mm 80

6. After connecting the refrigerant piping, seal the open space

between knockout hole and refrigerant pipes by using

insulation material.

Unit

Side

Nº Description

Insulation Material

Insulation Material

Field Supplied

Insulation Material

7. Operation of stop valve should be performed according to the

gure below.

Close before shipment

Nº Description Remaks

Cap

Allen wrench Hex 4 mm

Refrigerant Piping Field Supplied

Cap

Refrigerant Pressure To Outdoor Unit

Seat Surface Fully closed position

Check Joint Only the charging those can be connected

Cap

O-Ring Rubber

Spindle valve

Open – Counterclockwise

Close – Clockwise

Tighten torque (N.m)

Valve type / Model A B C D

Liquid Valve: 3~6HP 7~9 34~42 34~42 14~18

Gas Valve: 3~6HP 9~11 34~42 68~82 14~18

¡ Outdoor unit stop valve

Do not apply two

spanners at this

position. If applied,

leakage will occur.

Stop valve

Flare nut

CAUTION:

At the test run, fully open the spindle.

If not fully opened, the devices will be damaged.

Do not attempt to turn service valve rod beyond its stop.

Do not loosen the stop ring. If the stop ring is loosened, it is

dangerous since the spindle will hop out.

10.4. REFRIGERANT PIPING

The refrigerant piping between the indoor unit and the outdoor

unit should be designed using the following chart.

Keep the design point within the dark area of the chart, which

is showing the applicable height difference according to piping

length.

10.4.1. REFRIGERANT PIPING LENGHT

When outdoor

unit is installed

higher than

indoor unit

When outdoor

unit is installed

lower than indoor unit

Height difference

(m)

Total length between outdoor unit

and indoor unit.

40

Setting of Pipe Length DSW.

DSW2 setting will be required only when the refrigerant

pipe length is shorter than 5 m. Pipe length setting shall be

performed as shown below.

(The side in the table below shows the DSW location)

DSW2 on Outdoor PCB1

Factory setting Installer setting

Pipe length between 5 m and 30 m Pipe Length 5 m or shorter

REFRIGERANT PIPING &

REFRIGERANT CHARGE

Page 28

PMML0205A rev.4 - 11/2012

28

Example of YUTAKI S80

refrigerant piping length

Maximum piping length between

outdoor unit and indoor unit (Lmax)

Actual piping length 30 m

Equivalent piping length 40 m

Minimum piping length between

outdoor unit and indoor unit (Lmin)

Actual piping length 3 m

Maximum height difference bet-

ween indoor and outdoor unit (H)

Outdoor unit higher

than indoor unit

30 m

Indoor unit higher than

outdoor unit

20 m

10.4.2. REFRIGERANT PIPING SIZE

Piping connection size of Outdoor Unit & Indoor Unit

Outdoor Unit

Pipe Size

Gas Pipe Liquid Pipe

(3 ~ 6) HP Ø 15.88 (5/8”) Ø 9.53 (3/8”)

Indoor Unit

Pipe Size

Gas Pipe Liquid Pipe

(3 ~ 6) HP Ø 15.88 (5/8”) Ø 9.53 (3/8”)

10.4.3. BRAZING WORK

ATTENTION:

Use nitrogen gas for blowing during pipe brazing. If oxygen,

acetylene or uorocarbon gas is used, it will cause an explosion

or poisonous gas.

A lot of oxidation lm will occur inside of tubes if no nitrogen

gas blowing is performed during brazing work. This lm will be

ecked off after operation and will circulate in the cycle, resulting

in clogged expansion valves, etc. This will cause bad inuence to

the compressor.

Use a reducer valve when nitrogen gas blowing is performed

during brazing. The gas pressure should be maintained within

0.03 to 0.05 MPa. If a excessively high pressure is applied to a

pipe, it will cause an explosion.

10.5. CAUTION OF THE PRESSURE BY CHECK JOINT

When the pressure is measured, use the check joint of gas stop

valve (A) and use the check joint of liquid stop valve (C) in the

gure below.

At that time, connect the pressure gauge according to the

following table because high pressure side and low pressure

side changes by operation mode.

Cooling

Operation (*)

Heating

Operation

Check Joint for Gas Stop Valve “A” Low Pressure High Pressure

Check Joint for Piping “B”

Exclusive for Vacuum

and Refrigerant Charge

Check Joint for Liquid Stop Valve “C” High Pressure Low Pressure

3HVRNME-AF

(4-6)H(V)RNME-AF

NOTE:

Be careful that refrigerant and oil do not splash to the electrical

parts at removing the charge hoses.

(*) YUTAKI S: cooling operation only applies some models.

YUTAKI S80: cooling operation is only used as pump down

operation.

REFRIGERANT PIPING &

REFRIGERANT CHARGE

Page 29

29

PMML0205A rev.4 - 11/2012

ENGLISH

10.6. REFRIGERANT CHARGE AND VACUUM

PROCEDURE

CAUTION:

Do not charge OXYGEN, ACETYLENE, or other ammable

and poisonous gases into the refrigerant cycle when performing

a leakage test or an airtight test. These types of gases

are extremely dangerous and an explosion can occur. It is

recommended that oxygen free nitrogen be charged for these

types of tests cycle.

Charge refrigerant correctly. Overcharging or insufcient charging

could cause a compressor failure.

Check for refrigerant leakage in detail. If a large refrigerant

leakage occurred, it would cause difculty with breathing or

harmful gases would occur if a re were being used in the room.

If the are nut is tigthened too hard, the are nut may crack after a

long time and cause refrigerant leakage.

1 Connect the gauge manifold using charging hoses with a ni-

trogen cylinder to the check joints of the liquid line and the gas

line stop valves.

IMPORTANT NOTE:

For YUTAKI S80, supply power to the indoor unit and switch

the DSW1-2 ON of its PCB1. Thereby, solenoid valves SV1

and SV2 of the indoor unit will open to allow the operation

of vacuum and refrigerant charge inside the indoor unit. It

is very important to remind to switch the DSW1-2 OFF when

nishing the whole procedure.

2 Check for any gas leakage at the are nut connection by using

nitrogen gas inside of the eld-supplied piping to increase the

pressure at 4.15 MPa.

3 Connect the vacuum pump to the gauge manifold and opera-

te it for 1 to 2 hours until the pressure decreases lower than a

pressure of 756 mmHg in vacuum.

4 Fully open the gas and liquid stop valves.

5 Operate the outdoor unit in cooling operation for more than 10

minutes to circulate the refrigerant through the whole circuit.

Thermal insulation

Gas line

Cover the are

nut and union

of the piping

connection with

thermal insulation

Liquid line

Liquid stop valve

Gas stop valve

Nitrogen tank

(For air Tight test & Nitrogen

blow during brazing)

Vacuum cylinder

Manifold

gauge

Outdoor unit

Example of Refrigerant Charge.

10.6.1. REFRIGERANT CHARGING QUANTITY

Outdoor unit is factory charged with a refrigerant charge amount

for 30m of piping length. The maximum refrigerant piping length

is 30m so it is not required an additional refrigerant charge.

Outdoor unit Factory Refrigerant charge (Wo Kg) is as follows:

O/U MODEL Wo (Kg)

Chargeless

Length ℓ (m)

RAS-3HVRNME-AF 2.4 30

RAS-4H(V)RNME-AF 3.9 30

RAS-5H(V)RNME-AF 4.0 30

RAS-6H(V)RNME-AF 4.0 30

10.7. PUMP DOWN REFRIGERANT

When the refrigerant should be collected into the outdoor unit

due to indoor/outdoor unit relocation, collect the refrigerant as

follows:

1. Attach the manifold gauge to the gas and the liquid stop

valves.

2. Turn ON the outdoor unit power source.

IMPORTANT NOTE:

For YUTAKI S80 turn ON the indoor unit power source.

3. Set the DSW1-1 pin of the outdoor unit PCB at the “ON” side

for pump down operation (test run cooling). Close the liquid

stop valve to retain all the refrigerant inside the outdoor unit.

4. When the pressure at lower pressure side (gas stop valve)

indicates -0.01 MPa (-100 mmHg), perform the following

procedures immediately.

− Close the gas stop valve.

− Set the DSW1-1 pin at the “OFF” side (To stop the unit

operation).

5. Turn OFF the outdoor unit power source.

CAUTION:

Measure the low pressure by the pressure gauge and keep it not

to decrease than -0.01 MPa. If the pressure is lower than -0.01

MPa, the compressor may be faulty.

IMPORTANT NOTE:

For YUTAKI S80, supply power to the indoor unit and switch

the DSW1-2 ON of its PCB1. Thereby, solenoid valves SV1

and SV2 of the indoor unit will open to allow the operation

of vacuum and refrigerant charge inside the indoor unit. It

is very important to remind to switch the DSW1-2 OFF when

nishing the whole procedure.

REFRIGERANT PIPING &

REFRIGERANT CHARGE

Page 30

PMML0205A rev.4 - 11/2012

30

11.1. DRAIN DISCHARGING BOSS

When the base of the outdoor unit is temporarily utilized as a

drain receiver and the drain water in it is discharged, this drain

boss is utilized to connect the drain piping.

Model Applicable Model

DBS-26 H(V)RNME-AF

Connecting procedure

1. Insert the rubber cap into the drain boss up to the extruded

portions

2. Insert the boss into the unit base and turn approximately

40 degree counterclockwise.

3. Size of the drain boss is 32 mm (O.D.)

4. A drain pipe should be eld-supplied

NOTE:

Do not use this drain boss set in a cold area, because the drain

water may freeze.This drain boss is not sufcient to collect all the

drain water. If collecting drain water is completely required, provide

a drain-pan that is bigger than the unit base and install it under the

unit with drainage.

Rubber cap

Drain Boss

Extruded portion

Drain pipe

Drain pipe

Drain hole of Base

12.1. GENERAL CHECK

1 Ensure that the eld-supplied electrical components (mains

power switches, circuit breakers, wires, connectors and wire

terminals) have been properly selected according to the electrical data indicated. Make sure that they comply with national

and regional electrical codes.

2 Following the Council Directive 2004/108/EC(89/336/EEC),

relating to electromagnetic compatibility, next table indicates:

Maximum permissible system impedance Z

max

at the interface

point of the user’s supply, in accordance with EN61000-3-11

MODEL

Zmax (Ω)

YUTAKI S YUTAKI S80

RAS-3HVRNME-AF - RAS-4HVRNME-AF 0.41 0.41

RAS-5HVRNME-AF 0.29 0.32

RAS-6HVRNME-AF 0.29 0.32

3 Harmonics situation of each model regarding IEC 61000-3-2

and IEC 61000-3-12 is as follows:

MODELS SITUATION REGARDING IEC

61000-3-2 AND IEC 61000-3-12 Ssc “xx”

MODELS

Ssc

“xx”

(KVA)

Equipment complying with IEC 61000-3-2

(professional use)

RAS-3HVRNME-AF

RAS-4HRNME-AF

RAS-5HRNME-AF

RAS-6HRNME-AF

-

Equipment complying with IEC 61000-3-12

RAS-4HVRNME-AF

RAS-5HVRNME-AF

RAS-6HVRNME-AF

-

4 Check to ensure that the power supply voltage is within +/-

10% of the rated voltage.

5 Check to ensure that power supply has an impedance low

enough to warranty not reduce the starting voltage more than

85% of the rated voltage.

6 Check to ensure that the capacity of power supply is enough.

If not, the compressor will be not able to operate because of

abnormal voltage drop at starting.

7 Check to ensure that the ground wire is connected.

8 Connect a fuse of specied capacity.

CAUTION:

Check to ensure that screws for terminal block are tightly tightened.

Check to ensure that the indoor water pump and the outdoor fan have

stopped before electrical wiring work or periodical check is performed.

Protect the wires, drain pipe, electrical parts, from rats or other

small animals. If not protected, rats may damage unprotected

parts, and at the worst, a re will occur.

Avoid the wiring from touching the refrigerant pipes, water pipes,

plate edges and electrical parts inside the unit. If not do, the wires

will be damaged and at worst, a re will occur.

Tightly secure the wires with the cord clamp inside the indoor unit.

Lead the wires through the knockout hole in the side cover when

using conduit.

Secure the cable of the remote control switch with the cord clamp

inside the electrical box.

Electrical wiring must comply with national and local codes.

Contact your local authority in regards to standards, rules,

regulations, etc.

DANGER:

Do not connect of adjust any wiring or connections unless the

main power switch is OFF.

Check that the earth wire is securely connected, tagged and

locked in accordance with national and local codes.

NOTE:

Check and test to ensure that if there is more than one source of

power supply, that all are turned OFF.

12. ELECTRICAL WIRING

11. DRAIN PIPING

DRAIN PIPING

Page 31

31

PMML0205A rev.4 - 11/2012

ENGLISH

12.2. ELECTRICAL WIRING CONNECTION FOR

OUTDOOR UNITS

The electrical wiring connection for the outdoor unit is shown

in gure below:

Power supply AC 230 V

Control cable (5 V)

Control cable (5 V)

Power supply AC 400 V

Table for Terminal Connection

Wiring [Connection (Connection of Terminals)]

Power Supply

[O.U.-O.U.(L1-L1, L2-L2, L3-L3, N-N)]

[I.U.-I.U.(L1-L1, N-N)]

Control [O.U.-I.U., I.U.-I.U.(1-1, 2-2)]

O.U.: Outdoor Unit; I.U.: Indoor unit

Instructions for wiring and electrical Board

12.2.1. SETTING OF DIP SWITCHES FOR OUTDOOR UNIT

¡ Quantity and Position of DIP Switches

The PCB in the Outdoor Unit is operating with 5 types of DIP

Switches, 1 Slide Switch and 3 Push Switch. The location is

as follows:

¡ DSW1: For Test Run

Setting before shipment

¡ DSW2: Optional Function Setting

Setting before shipment

¡ DSW3: Capacity

3HVRNME-AF 4HVRNME-AF

Setting position

5HVRNME-AF 6HVRNME-AF

4HRNME-AF 5HRNME-AF

6HRNME-AF

¡ Refrigerant Cycle No. Setting

DSW4

Setting position

(Setting for the ten digit).

RSW1

Setting position.

(Setting for the last digit).

¡ DSW5: Transmission Setting of End Terminal Resistance

Setting before shipment

¡ DSW6: Function setting (No setting is required)

Power source setting

400 V 230 V

ELECTRICAL WIRING

3~6HVRNME-AF

4~6HRNME-AF

Page 32

PMML0205A rev.4 - 11/2012

32

12.3. COMMON WIRING

CAUTION:

All the eld wiring and electrical components must comply with

local codes.

12.3.1. ELECTRICAL WIRING BETWEEN INDOOR UNIT

AND OUTDOOR UNIT

− Connect the electrical wires between the indoor unit and the

outdoor unit, as shown below.

− Follow local codes and regulations when performing electrical

wiring.

− Use twist pair wire (more than 0.75 mm²) for operation wiring

between outdoor unit and indoor unit, and operation wiring

between indoor unit and indoor unit.

− Use 2-core wire for the operating line (Do not use wire with

more than 3 cores).

− Use shielded wires for intermediate wiring to protect the units

from noise obstacle at length of less than 300 m and size

complied with local code.

− Open a hole near the connection hole of power source wiring

when multiple outdoor units are connected from one power

source line.

− The recommended breaker sizes are shown in Table of

electrical data and recommended Wiring, Breaker Size/1 O.U.

− In the case that a conduit tube for eld-wiring is not used, x

rubber bushes with adhesive on the panel.

− All the eld wiring and equipment must comply with local and

international codes.

ATTENTION:

Pay attention to the connection of the operating line. Incorrect

connection may cause the failure of PCB.

Operating Line

(Twisted shielded pair cable or

shielded pair cable)

DC5V (Non-Pole Transmission,

H-LINK system)

Operating Line

(Twisted shielded pair cable or shielded pair cable)

DC5V (Non-Pole Transmission, H-LINK system)

TB:Terminal Board

CB

:

Circuit Breaker

ELB

:

Earthleakage Breaker

:

Internal Wiring

:

Field Wiring

:

Field-Supplied

1,2

:

Outdoor-Indoor connection

ATTENTION:

The power supply must be connected to the outdoor unit and

indoor unit separately.

ELECTRICAL WIRING

Page 33

33

PMML0205A rev.4 - 11/2012

ENGLISH

12.3.2. WIRE SIZE

Recomended minimum sizes for eld provided wires:

Model Combination Power Source

Max. Current

(A)

Power Source Cable

Size

Transmitting

Cable Size

Actuator Cable

Size

EN60 335-1 EN60 335-1 EN60 335-1

RAS-3HVRNME-AF

YUTAKI S

1~ 230V 50Hz

14.0 2 x 4.0 mm² + GND

2 x 0.75 mm

2

(*Shielded cable)

2 x 0.75 mm

2

RAS-4HVRNME-AF 18.0 2 x 4.0 mm² + GND

RAS-5HVRNME-AF 26.0 2 x 6.0 mm² + GND

RAS-6HVRNME-AF 26.0 2 x 6.0 mm² + GND

RAS-4HRNME-AF

3N~ 400V 50Hz

7.0 4 x 2.5 mm² + GND

RAS-5HRNME-AF 11.0 4 x 4.0 mm² + GND

RAS-6HRNME-AF 13.0 4 x 4.0 mm² + GND

RAS-4HVRNME-AF

YUTAKI S80

1~ 230V 50Hz

18.0 2 x 4.0 mm² + GND

2 x 0.75 mm

2

(*Shielded cable)

2 x 0.75 mm

2

RAS-5HVRNME-AF 23.0 2 x 6.0 mm² + GND

RAS-6HVRNME-AF 23.0 2 x 6.0 mm² + GND

RAS-4HRNME-AF

3N~ 400V 50Hz

7.0 4 x 2.5 mm² + GND

RAS-5HRNME-AF 11.0 4 x 4.0 mm² + GND

RAS-6HRNME-AF 13.0 4 x 4.0 mm² + GND

NOTE:

- Follow local codes and regulations when selecting eld wires, Circuit breakers and Earth Leakage breakers

- Use the wires which are not lighter than the ordinary polychloroprene sheathed exible cord (code designation H05RN-F)

Select the main switches in according to the next table:

Model Combination Power Source

Applicable voltage

Max. Current

(A)

CB (A)

ELB

(no. poles/A/Ma)

U max. (V) U min. (V)

RAS-3HVRNME-AF

YUTAKI S

1~ 230V 50Hz 253 207

14.0 20

2/40/30

RAS-4HVRNME-AF 18.0 20

RAS-5HVRNME-AF 26.0 32

RAS-6HVRNME-AF 26.0 32

RAS-4HRNME-AF

3N~ 400V 50Hz 440 360

7.0 15

4/40/30RAS-5HRNME-AF 11.0 20

RAS-6HRNME-AF 13.0 20

RAS-4HVRNME-AF

YUTAKI S80

1~ 230V 50Hz 253 207

18.0 20

2/40/30RAS-5HVRNME-AF 23.0 25

RAS-6HVRNME-AF 23.0 25

RAS-4HRNME-AF

3N~ 400V 50Hz 440 360

7.0 15

4/40/30RAS-5HRNME-AF 11.0 20

RAS-6HRNME-AF 13.0 20

ELB: Earth leakage breaker; CB: Circuit breaker

ELECTRICAL WIRING

Page 34

PMML0205A rev.4 - 11/2012

34

13. TEST RUN

When installation is complete, perform commissioning according to the following procedure and hand over the system to the

customer. Perform the commissioning of the units methodically, and check that the electrical wiring and the piping are correctly

connected.

Indoor and outdoor unit must be congured by the installer to get the prefect setting and the unit working.

Test run should be performed according to the “Test Run Procedure” on next page.

13.1.1. CHECKING THE UNIT

− Check external appearance of the unit to look for any damage due to

transportation or installation.

− Does installation space carry out Hitachi installations (see Service

space).

− Check that the unit has been correctly installed.

13.1.2. ELECTRICAL CHECKING

CAUTION:

Do not operate the system until all the check points have been

cleared:

− Check to ensure that the electrical resistance is more than

1MΩ, by measuring the resistance between ground and

electrical parts terminal. If not, do not operate the system

until the electrical leakage is found and repaired. Do not

impress the voltage on the terminals for transmission (1 and

2, 3 and 4 and sensors).

− Check to ensure that the switch on the main power source

has been ON for more than 12 hours, in order to give the oil

heater time to warm the compressor.

− In three-phase unit check phase sequence connection on

terminal board.

− Check the power supply voltage (±10% of the rated voltage).

− Check that eld-supplied electrical components (main

switches, breakers, wires, conduit connectors and wire

terminals) have been properly selected according to

the electrical specications given in the unit’s Technical

Catalogue, and check that the components comply with

national and local standards.

− Do not touch any electrical components for more than three

minutes after turning OFF the main switch

− Check the dip switch settings are connected as shown in the

corresponding chapter.

− Check to ensure the electrical wiring of the indoor unit

and the outdoor unit are connected as shown in the

corresponding chapter.

− Check to ensure the external wiring is correctly xed to avoid

problems with vibrations, noises and cut out wires with the

plates.

13.1.3. CHECKING THE REFRIGERANT CIRCUIT

− Check to ensure that the stop valves on the outdoor unit gas and

liquid lines are fully open.

− Check that the size of the piping and the refrigerant charge comply

with the applicable recommendations.

− Check the inside of the unit for refrigerant leakage. If there is a

refrigerant leak, call your dealer.

NOTE:

− For more reference check Troubleshooting chapter on Operation

Part.

TEST RUN

13.1. PRELIMINARY CHECK

Page 35

35

PMML0205A rev.4 - 11/2012

ENGLISH

13.2. TEST RUN PROCEDURE FROM INDOOR UNIT SIDE

User could execute the test run function pressing the “OK” and down “ ” arrow button during 3 seconds.

After that combination, the remote control will ask about the duration of this test.

TEST RUN OUTDOOR UNIT

Conguration for outdoor unit test run

Duration:

CANCEL START

INSTALLER MODE

The duration will be between 00:30 and 12:00 hours.

After press start, Outdoor unit will begin with the test run.

During the execution of this test, it will be showed the following screen.

HITACHI

AM

PM

!

TEST RUN OUTDOOR UNIT

44h 20m 19s

Pending time:

CANCEL

Operation display parameters

System Operation

Unit Status

Actual temperatures

Set-point

€

I II

RUN

T.

III

OFF

SUM

TEST RUN OUTDOOR UNIT

Pending time: 44h 20m 19s

Operation display parameters

System Operation

Unit Status

Actual temperatures

Set-point

On that screen it could be cancelled the test. User could move on same screen through the “Operation display parameters” menu.

Note that when test start it will be exit from the installer mode.

When test run will be set on the outdoor unit, it will appear the test run icon on the notications row.

When test run will nished it will show the following screen.

HITACHI

AM

PM

!

TEST RUN OUTDOOR UNIT

Test Run Completed

EXIT

Operation display parameters

System Operation

Unit Status

Actual temperatures

Set-point

€

I II

RUN

T.

III

OFF

SUM

TEST RUN OUTDOOR UNIT

Test Run Completed

Operation display parameters

System Operation

Unit Status

Actual temperatures

Set-point

Pressing Accept user will go to the global view.

TEST RUN

Page 36

PMML0205A rev.4 - 11/2012

36

TEST RUN

13.3. TEST RUN FROM OUTDOOR UNIT SIDE

The procedure of test run from outdoor unit side is indicated below.

Setting of this DIP switch is available with the power source ON.

WARNING:

− Do not touch any other electrical parts when operating

switches on the PCB.

− Do not attach or detach service cover when the power

source for the outdoor unit is ON and the outdoor unit

is operated.

− Turn all DIP switches of DSW1 OFF when the test run

operation is completed.

Setting of Dip Switch (Before Shipment)

DSW1

Switch for setting of Service Operation and Function

1. Test Run

2. COOL/HEAT

Setting (ON: Heat Operation)

3. OFF (Fixed)

4. Manual Compressor OFF

Operation Dip Switch Setting Operation Remarks

Test Run

Setting of Operation Mode:

Cooling: Set DSW1-4 OFF.

Heating: Set DSW1-2 ON.

Starting Test Run:

In cooling operation set DSW1-1

ON and the operation is started

after a few ~20 seconds.

When heating operation, leave

DSW1-2 at ON

↓

Test Run Heating:

The indoor unit automatically start

to operate when the test run of the

outdoor unit is set.

The ON/OFF operation can be

performed from the remote control

switch or DSW1-1 of the outdoor

unit.

Continuous operation during 2

hours is performed without ThermoOFF.

NOTE:

TEST RUN operation time can

be increased depressing the time

switch in the Remote Control.

Take care that the indoor units start

operation in accord with the test run

operation of the outdoor unit.

The test run is started from the outdoor unit

and stopped from the remote control switch,

the test run function of the remote control

switch is cancelled. However, the test run

function of the outdoor unit is not cancelled

In case that the plural indoor units are

connected with one remote control switch,

all the units start test run operation at the

same time, therefore, turn the power source

OFF for the indoor units not to operate test

run. In this case, the “TEST RUN” indication

of the remote control switch may icker, and

this is not abnormal.

The setting of DSW1 is not required for the

test run from the remote control switch.

Manual

OFF of

Compressor

Setting:

Compressor Manual OFF:

Set DSW1-4 ON.

Compressor ON:

Set DSW1-4 OFF.

When DSW1-4 is ON during

compressor operation, the

compressor stops to operate

immediately and the indoor unit is

under the condition of Thermo-OFF.

When DSW1-4 is OFF, the

compressor starts to operate after

the cancellation of 3-minutes guard.

Do not repeat compressor ON/OFF

frequently.

Manual

Defrost

Manual Defrost Operation Starts

Press PSW1 for more than 3

seconds during heating operation,

the defrost operation is started

after 2 minutes.This function is not

available within 5 minutes after

starting heating operation

Manual Defrost Operation Finishes

Defrost operation is automatically

ended and the heating operation is

started.

Defrost operation is available

regardless of frosting condition and

total time of heating operation.

Defrost operation in not performed

when the temperature of outdoor

heat exchanger is higher than

10°C, high pressure is higher than

3.3 MPa (33kgf/cm

2

G) or Thermo-

OFF.

Do not repeat defrost operation frequently.

Page 37

37

PMML0205A rev.4 - 11/2012

ENGLISH

SAFETY SUMMARY

& CONTROL DEVICE

SETTING

14. SAFETY SUMMARY & CONTROL DEVICE SETTING

Compressor Protection

High Pressure Switch:

This switch cuts out the operation of the compressor when

the discharge pressure exceeds the setting.

Fan Motor Protection

When the thermistor temperature is reached to the setting,

motor output is decreased.

The other way, when the temperature becomes lower,

limitation is cancelled.

Model RAS-3H(V)RNME-AF RAS-4H(V)RNME-AF RAS-5H(V)RNME-AF RAS-6H(V)RNME-AF

For Compressor

Automatic Reset, Non-Adjustable (each one for each compressor)

Pressure Switches

-0.05 -0.05 -0.05 -0.05

High Cut-Out MPa 4.15 4.15 4.15 4.15

-0.15 -0.15 -0.15 -0.15

Cut-In MPa 3.20±0.15 3.20±0.15 3.20±0.15 3.20±0.15

For Control

A

A

40

-

40

2X20

50

2X20

50

2X20

Fuse

1φ, 230V, 50Hz

3φ, 400V, 50Hz

CCP Timer

min.

Non-Adjustable

Setting Time 3 3 3 3

For Condenser Fan Motor

Automatic Reset, Non-Adjustable (each one for each motor)

Internal Thermostat

Cut-Out

o

C - - - -

For Control Circuit

A 5 5 5 5

Fuse Capacity on PCB

15. TROUBLESHOOTING

Alarm Code Indication of Remote Control Switch:

Alarm indication

Alarm code

NOTE:

− For information about troubleshooting by 7-segment, please refer

to the Service Manual.

Alarm

Code

Retry Stop

Code

Origin Detail of Abnormality Main Factors

02 - Outdoor

Activation of Outdoor Unit Protection Device

(Except for Alarm Code 41, 42)

High pressure interrupting device activated

03 - Outdoor Transmission Error

Outdoor fuse meltdown, Indoor/outdoor connection wiring

(breaking, wiring error, etc.)

04 - Outdoor Inverter Transmission Abnormality

Control PCB – Inverter PCB connection wiring (breaking,

wiring error, etc.)

05 - Outdoor Power Phase Detection Abnormality Power source wiring open phase in Indoor Units

06 P8 Outdoor Undervoltage, Overvoltage

Outdoor PCB abnormality, inverter PCB abnormality, DM,

CB abnormality

07 16 Outdoor

Abnormal decrease of discharge gas superheat

degree

Excessive refrigerant, expansion valve open-locked, Fan

motor locked

08 P5 Outdoor Compressor-Top Temp Over-increase

Shortage or leakage of refrigerant, piping clogging, Fan

motor lock

Page 38

PMML0205A rev.4 - 11/2012

38

Alarm

Code

Retry Stop

Code

Origin Detail of Abnormality Main Factors

11 - Indoor Water inlet thermistor abnormally (THM

WI

) Loose, disconnected, broken or short-circuited connector

12 - Indoor

Water outlet thermistor abnormally (THMWO)

Loose, disconnected, broken or short-circuited connector

13 - Indoor

Indoor Liquid Pipe Temp Thermistor Abnormality (THML)

Loose, disconnected, broken or short-circuited connector

14 - Indoor

Indoor Gas Pipe Temp. Thermistor Abnormality (THMG)

Loose, disconnected, broken or short-circuited connector

15 - Indoor

Water outlet C2 thermistor abnormally (THM

WO2

)

Loose, disconnected, broken or short-circuited connector

16 - Indoor

Water DHWT thermistor abnormally (THM

DHWT

)

Loose, disconnected, broken or short-circuited connector

17 - Indoor Swimming pool thermistor abnormally (THM

SWP

) Loose, disconnected, broken or short-circuited connector

18 - Indoor

Water outlet boiler thermistor abnormally (THM

WO3

)

Loose, disconnected, broken or short-circuited connector

20 - Outdoor

Compressor-Top Temp Thermistor Abnormality

Loose, disconnected, broken or short-circuited connector

21 - Indoor

2nd ambient thermistor abnormally (THM

AMB2

)

Loose, disconnected, broken or short-circuited connector

22 - Outdoor Outdoor Temp Thermistor Abnormality Loose, disconnected, broken or short-circuited connector

24 - Outdoor

Outdoor Heat Exchanger Liquid Pipe Thermistor

Abnormality

Loose, disconnected, broken or short-circuited connector

31 - Outdoor Indoor/Outdoor Combination Setting Error

Outdoor/Indoor Unit capacity setting error, Indoor total

capacity excessively large/small

35 - Outdoor Indoor Unit Number Setting Error

Indoor units with the same number exist in a refrigerant

piping system

38 - Outdoor Outdoor Protection Detection Circuit Abnormality Outdoor PCB abnormality, Error in wiring to outdoor PCB

41 - Outdoor Cooling Overload

Outdoor heat exchanger clogging/short circuit, Broken

outdoor fan motor

42 - Outdoor Heating Overload

Outdoor heat exchanger clogging/short circuit, Expansion

valve close-locked

47 15 Outdoor Suction Pressure Decrease Prevention Activated

Shortage or leakage of refrigerant, piping clogging,

Expansion valve close-locked, Fan motor locked

48 17 Outdoor Overload Operation Protection Activation

Cycle abnormality, Inverter PCB abnormality, DM

abnormality, Heat exchanger clogging, etc.

51 17 Outdoor Inverter Current Sensor Abnormality

Error in CT wiring, Outdoor PCB abnormality, Inverter

PCB abnormality

53 17 Outdoor Inverter Module Error

Compressor, ISPM abnormality, Heat exchanger clogging,

etc.

54 P7 Outdoor Inverter Fin Temp. Abnormality

Fin thermistor abnormality, Heat exchanger clogging, Fan

motor abnormality

55 18 Outdoor Inverter Non-Operation Inverter not operating or broken

57

Outdoor Abnormality of fan motor protection (DC fan motor)

59 - Outdoor Inverter Fin Temp Thermistor Abnormality Loose, disconnected, broken or short-circuited connector

b1 - Outdoor Error in Address/Refrigerant System Setting Address/refrigerant system setting over 64

EE - Outdoor Compressor Factor Alarm

Alarm to notify damage to compressor occurs 3 times

within 6 hours

70 P-70 Indoor Hydraulic alarm

Water pressure or water ow is not detected in the

hydraulic cycle

71 - Indoor Water Pump Feedback

72 - Indoor Thermostat Heater Alarm High temperature is detected in Electric Heater T>75ºC

73 - Indoor

Mixing over-temperature limit protection for Mixed

circuit.

Circuit 2 supply temperature > Target temperature +

offset

74 P-74 Indoor

Unit over-temperature limit protection

75 - Indoor

Freeze Protection by Cold water inlet, outlet

temperature detection

76 - Indoor

Freeze Protection Stop by indoor liquid temperature

thermistor

77 - Indoor Opentherm Communication failure

No Opentherm communication for a continuous period of 1

minute.

78 - Indoor RF Communication failure

There is no communication for 1 hour with one or two RF

receivers which are bound to the RF-Bridge.

79 -

Indoor

-outdoor

Unit Capacity setting Error

There is no concordance between indoor outdoor unit

capacity

80 -

Indoor-

LCD

LCD H-link transmission error

No H-link communication for a continuous period of

1 minute between Indoor and LCD User control by

connection wiring (breaking, wiring error, etc.)

81 - Indoor Incorrect PCB operation

TROUBLESHOOTING

Page 39

39

PMML0205A rev.4 - 11/2012

ENGLISH

Alarm

Code

Retry Stop

Code

Origin Detail of Abnormality Main Factors

101

-

2nd

cycle

Activation of high pressure switch The high pressure (Pd) is higher than 3 MPa.

102 P-12

2nd

cycle

Activation of protection control for excessively high

pressure

The high pressure (Pd) is higher than 2.78 MPa during

10 seconds.

103

-

2nd

cycle