HITACHI RAR 1480A, JYM505 Diagram

SERVICE MANUAL

*** CONTENTS ***

1.Safety Instructions

2. General Alignment

3. IC BLOCK DIAGRAM

4. TROUBLE SHOOTING

5. BLOCK DIAGRAM

6. CIRCUIT DIAGRAM

* * * WARNING * * *

In order to prevent electric shock, do not remove cover.

No user-serviceable parts inside, Refer servicing to qualified service personal.

1. SAFETY INSTRUCTIONS

PRECAUTIONS DURING SERVICING

1. In addition to safety, other parts and assemblies are specified for conformance with such

regulations as those applying to spurious radiation. These must also be replaced only with

specified replacements.

Examples : RF converters, tuner units, antenna selection switches, RF cables, noise-blocking

capacitors, noise-blocking filters, etc.

2. Use specified internal Wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leags

3. Use specified insulating materials for hazardous live parts. Note especially:

1) Insulation Tape

2) PVC tubing

3) Spacers (Insulation barriers)

4) Insulation sheets for transistors

5) Plastic screws for fixing micro switches

4. When replacing AC primary side components (transformers, power cords, noise blocking

capacitors etc), wrap ends of wires securely about the terminals before soldering.

5. Make sure that wires do not contact heat-generating parts (heat sinks, oxide metal film resistors,

fusible resistors, etc.)

6. Check if replaced wires do not contact sharply edged or poi nt ed parts.

7. Make sure that foreign objects (screws, solder droplets, etc.) do not remain inside the set.

MAKE YOUR CONTRIBUTION T O PROTECT THE ENVIR ONMENT

Used batteries with the ISO symbol for recycling as well as small accumulators (rechargeable

batteries), mini-batteries (cells) and starter batteries should not be thrown into garbage can. Please

leave them at an appropriate depot.

WARNING

Before servicing this TV receiver, read the X-RAY RADIATION PRECAUTION, SAFETY

INSTRUTION and PRODUCT SAFETY NOTICE.

X-RAY RADIATION PRECAUTION

1. Excessively high voltage can produce potentially hazardous X-RAY RADIATION. To avoid

such hazards, the high voltage must not exceed the specified limit. The normal value of the high

voltage of this TV receiver is 24 kV at zero beam current (minimum brightness).

The high voltage must not exceed 27.5 kV under an circumstances : Each time when a receiver

require servicing, the high voltage should be checked. The reading of the high voltage is

recommended to be recorded as a part of the service record. It is important to use an accurate

and reliable high voltage meter.

2. The only source of X-RAY RADIATION in this TV receiver is the picture tube. For continued

X-RAY RADIATION protection, the replacement tube must be exactly the same type as

specified in the parts list.

3. Some parts in this TV receiver have special safety related characteristics for X-RAY

RADIATION protection. For continued safety, the parts replacement should be under taken only

after referring the PRODUCUT SAFETY NOTICE.

SAFETY INSTRUCTIONS

The service should not be attempted by anyone unfamiliar with the necessary instructions on this

TV receiver. The following are the necessary instructions to be observed before servicing.

1. An isolation transformer should be connected in the power line between the receiver and the AC

line when a service is performed on the primary of the converter tran sformer of the set.

2. Comply with all caution and safety related provided on the back of the cabinet, inside the

cabinet, on the chassis or picture tube.

3. To avoid a shock hazard, always discharge the picture tube’s anode to the chassis ground before

removing the anode cap.

4. Completely discharge the high potential voltage of the picture tube before handling. The picture

tube is a vacuum and if broken, the glass will explode.

5. When replacing a MAIN PCB in the cabinet, always be certain that all protective are installed

properly such as control knobs, adjustment covers or shields, barriers isolation resistor networks

etc.

6. When servicing is required, observe the original lead dressing. Extra precau tion should be giv en

to assure correct lead dressing in the high voltage area.

7. Keep wires away from high voltage or high temperature components.

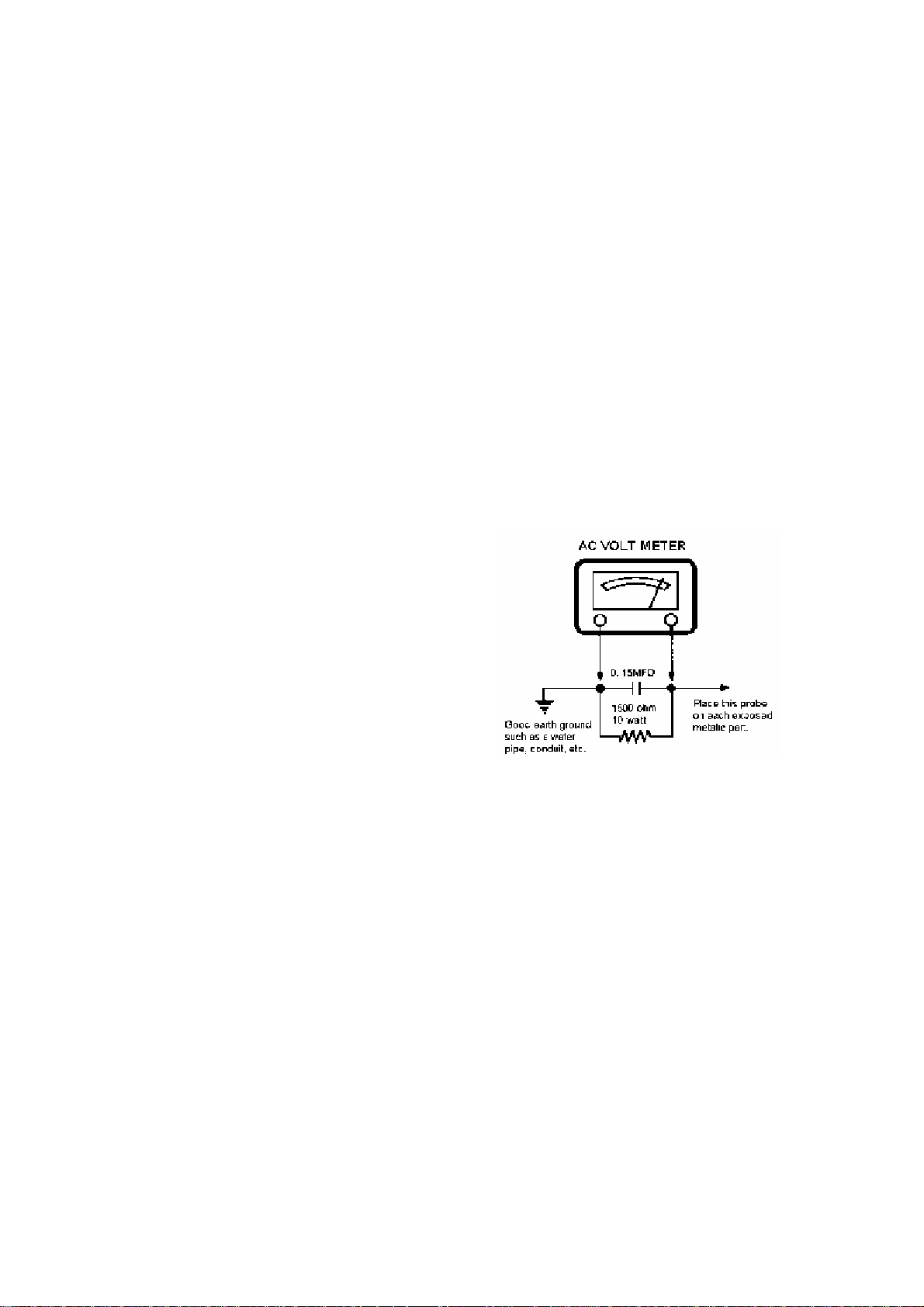

8. Before returning the set to the customer, always perform an AC leakage current check on the

exposed metallic parts of the cabinet, such as antennas, terminals, screw heads, metal overlays,

control shafts etc., to be sure the set is safe to operate without danger of electrical shock. Plug

the AC line cord directly to the AC outlet (do not use a line isolation transformer during this

check). Use an AC voltmeter having 5k ohms per volt sensitivity or more in the following

manner. Connect a 1.5k ohm 10 watt resistor paralleled by a 0.15uF AC type capacitor, between

a good earth ground (water pipe, conductor etc.) and the exposed metallic parts, one at a time.

Measure the AC voltage across the combination of 1.5k ohms resistor and 0.15uF capacitor.

Reverse the AC plug at the AC outlet and repeat AC voltage measurements for each exposed

metallic part. The measured Voltage must not exceed 0.3V RMS. This corresponds to 0.5mA AC.

Any value exceeding this limit constitutes a potential shock hazard and must be corrected

immediately .

The resistance measurement should be done

between accessible exposed metal parts and

power cord plug prongs with the power

switch “ON”. The resistance should be more

than 6M ohms.

PROODUCT SAFETY NOTICE

Many electrical and mechanical parts in this TV receiver have special safety-related

characteristics. These characteristics are often passed unnoticed by a visual insp ection and the

protection afforded by them cannot necessarily be obtained by using replacement components

rated for higher voltage, wattage, etc. Replacement part which have these special safety

characteristics are identified in this manual and its.

Supplements : Electrical components having such features are identified by shading on the

schematic diagram and the part list. Before replacing any of these components, read the parts

list in this manual carefully. The use of substitute replacement parts which do not have same

safety characteristics as specified in the parts list may create shock, fire or other hazards.

2. GENERAL ALIGNMENT

CPT MAGNET ADJUSTMENT

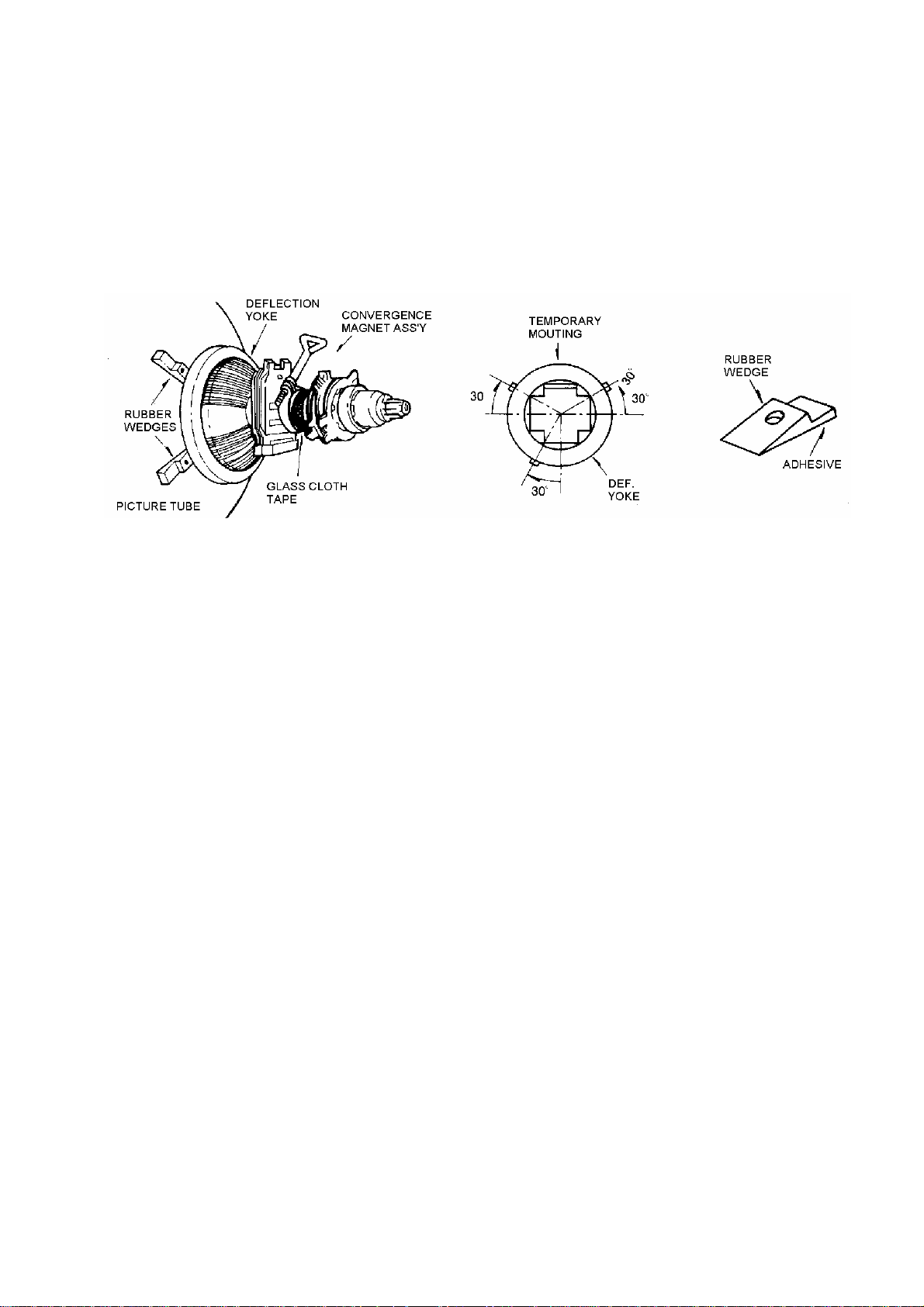

CONVERGENCE MAGNET ASSEMBLY POSITIONING

Convergence magnet assembly and rubber wedges need mechani cal pos it i oni n g follo wi n g fig ure 1.

FIG 1 Rubber Wedges Location

COLOR-PURITY-ADJUSTMENT

NOTE : Before attempting any purity adjustments, the receiver should be operated for at least 15

minutes.

1. Demagnetize the picture tube and cabinet using a degaussing coil.

2. Turn the CONTRAST and BRIGHTNESS controls to maximum.

3. Adjust RED and BLUE Bias controls to provide only a green rather.

4. Loosen the clamp screw holding the yoke, and slide the yoke backward to provide vertical green

belt(zone) in the picture screen.

5. Remote the Rubber Wedges.

6. Rotate and spread the tabs of the purity magnet(See figure 2) around the neck of the picture tube

until the green belt is in the center of the screen. At the same time, center the raster vertically.

7. Move, the yoke slowly forward until a uniform green screen is obtained. Tighten the clamp screw

of the yoke temporarily.

8. Check the purity of the red and blue raster by adjusting the BIAS controls.

9. Obtain a white raster, referring to "CTR GRAY SCAL ADJUSTMENT".

10. Proceed with convergence adjustment

FIG 2

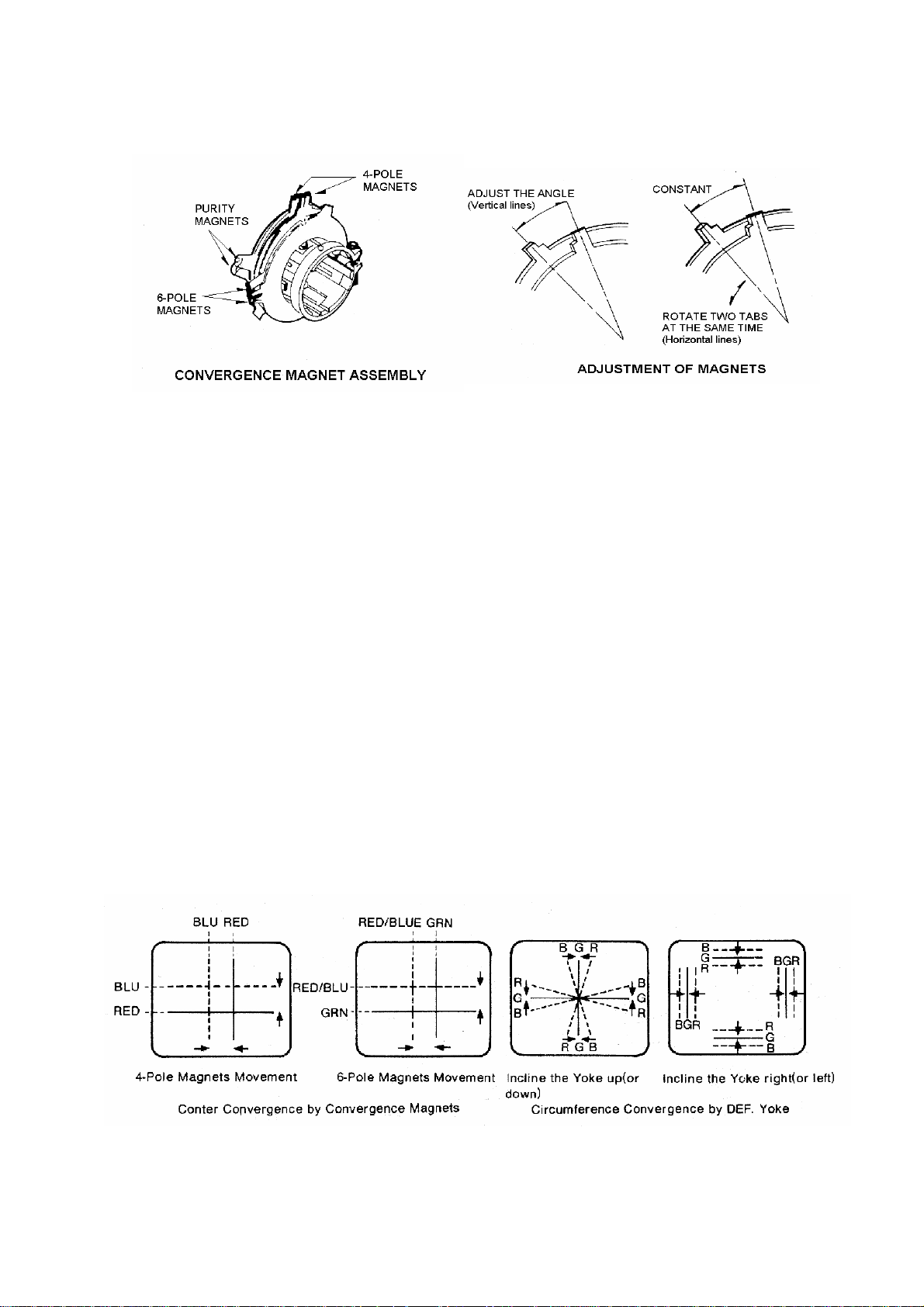

CONVERGENCE ADJUSTMENTS

NOTE : Before attempting any convergence adjustments, the receiver should be operate for at least

15 minutes.

CENTER CONVERGENCE ADJUSTMENT

1. Receiver crosshatch pattern with a color bar signal generator.

2. Adjust the BRIGHTNESS and CONTRAST Controls for well defined pattern.

3. Adjust two tabs of the 4-Pole Magnets to change the angle between them (See figure 3) and

superimpose red and blue vertical lines in the center area of the picture screen.

4. Turn both tabs at the same time keep in their angles constant to superimpose red and blue

horizontal lines at the center of the screen. (See figure 4.)

5. Adjust two tabs of 6-Pole Magnets to superimpose red/blue line with green one. Adjusting the

angle affects the vertical lines and rotating both magnets affects the horizontal lines

6. Repeat adjustment 3, 4, 5 Keeping in mind red, green and blue moment, because 4-Pole Magnets

and 6-Pole Magnets interact and make dot movement complex.

FIG 3 FIG 4

CIRCUMFERENCE CONVERGENCE ADJUSTMENT

NOTE : This adjustment requires Rubber Wedge Kit.

1. Loosen the clamping screw of deflection yoke to allow the yoke to tilt.

2. Place a wedge as shown in figure (1) temporarily.

(Do not remove cover paper on adhesive part of the wedge.)

3. Tilt front of th e deflection yoke up or down to obtain better convergence in circumference.(See

figure 4) Push the mounted wedge into the space between picture tube and the yoke to hold the

yoke temporarily.

4. Place other wedge into bottom space and remove the cover paper to stick.

5. Tilt front of the yoke right or left to obtain better convergence in circumference.(See figure 4).

6. Hold the yoke position and put another wedge in either upper space. Remove cover paper and

stick the wedges, recheck overall convergence.

7. Detach the temporarily mounted wedge and put it in another upper space. Stick it on picture tube

to fix the yoke.

8. After placing three wedges, recheck overall convergence. Tighten the screw firmly to hold the

yoke tightly in place.

9. Stick 3 adhesive tapes on wedges as shown in figure 1.

CHASSIS ADJUSTMENT MANUAL

How to enter the service the service mode using the user remote control

Push buttons of remote control in sequences as follows

‘DISPLAY’-‘MUTE’-‘SLEEP’-‘FUSSY’

1.HEAT RUN(AUTO POWER ON MODE) : F4

- It need in assembly line during heat run that protect to auto power off after no

signal 15 minutes and

auto power on for input power of sets on/off by line condition which

sometimes line power connection of palette with main power line would be

badly contacted by shaking during the sets through on assembly lines.

- Heat run function is operated by pressing the F4 key.

- To cancel this function press the F4 key one more or power on/off.

- It must be canceled before final output.

Loading...

Loading...