Hitachi P50H401, P50T501, P50H4011 Schematic

PA No. 0224

Important Note: Panel as well as all panel PWB's; SDRs, Y SUS, X SUS, Logic, and ABUS PWB's are

NOT interchangeable between the "A" and the non- "A" models. See Service

Bulletin 09-01SB.pdf for details.

P50H401 / DW3-U

P50T501 / DW3-U

SERVICE MANUAL

P50H4011 / DW3-U

R/C: CLU-4371UG2 p/n HL02075 P50H401

R/C: CLU-4372UG2 p/n HL02076 P50H4011

R/C: CLU-4371A p/n HL02401 P50T551

SERVICE MANUAL REVISION HISTORY INFORMATION

DATE REVISION # REASON

Feb, 23, 2007 SM00001 FIRST ISSUE OF MANUAL

Apr, 27, 2007 CH1 Digital Main PWB reference (Page 110)

Oct, 29, 2007 CH2 Updated Troubleshooting Flowchart (Page 55)

Oct, 29, 2007 CH2 Updated LED Diagnostics (Page 58)

Oct, 31, 2007 CH3 Added Remote Control Info. How to enter Service Menu (Page 114)

Nov, 06, 2007 CH4 Added In-Depth Video Troubleshooting Flowchart (Page 115)

Nov, 06, 2007 CH4 Added In-Depth Audio Troubleshooting Flowchart (Page 120)

Nov, 12, 2007 CH5 Added In-Depth 50AE1 Panel Troubleshooting Flowchart (Page 122)

Nov, 26, 2007 CH6 Added additional adjustment details about power supply (Page 45)

Jan, 19, 2007 CH8 Corrected Front Bezel (F Cosmetics) Part Numbers (Page 75)

Feb, 09, 2008 CH9 Added Digital Module (Digi-Main) Block Diagram (Page 61-A)

SPECIFICA TIONS AND P ARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

Version 1022-09

Updated 10/

22/2009

PLASMA DISPLAY PANEL

FEBRUARY 2007 HHEA-MANUFACTURING DIVISION

PA No. 0224

Important Note: Panel as well as all panel PWB's; SDRs, Y SUS, X SUS, Logic, and ABUS PWB's are

NOT interchangeable between the "A" and the non- "A" models. See Service

Bulletin 09-01SB.pdf for details.

P50H401 / DW3-U

P50H4011 / DW3-U

SERVICE MANUAL

TO GO TO A CHAPTER, CLICK ON ITS HEADING BELOW

IMPORTANT SAFETY PRECAUTIONS ................................................................... 2

PRODUCT SAFETY NOTICE .................................................................................. 3

SERVICING PRECAUTIONS ................................................................................... 4

AGENCY REGULATORY INFORMATION .............................................................. 9

ACKNOWLEDGMENTS AND TRADEMARKS ........................................................ 10

INTRODUCTION ...................................................................................................... 11

SPECIFICATIONS .................................................................................................... 12

BASIC SETUP & OPERATION ................................................................................ 24

ADJUSTMENTS ....................................................................................................... 42

TROUBLESHOOTING FLOWCHARTS .................................................................. 55

BLOCK DIAGRAMS ................................................................................................. 60

CONNECTOR DIAGRAMS ...................................................................................... 62

FINAL WIRING DIAGRAM ....................................................................................... 63

QUICK DISASSEMBLY GUIDE ............................................................................... 64

FINAL ASSEMBLY GUIDE ....................................................................................... 75

WAVEFORMS .......................................................................................................... 84

DC VOLTAGES ........................................................................................................ 85

CIRCUIT SCHEMATIC DIAGRAMS ......................................................................... 86

PRINTED CIRCUIT BOARDS .................................................................................. 96

PARTS LIST ............................................................................................................. 105

QUICK REFERENCE PARTS LIST ......................................................................... 112

REMOTE CONTROLS used in the DW-1, DW-2, DW-3 Entering Service Menu ..... 114

IN-DEPTH VIDEO / AUDIO TROUBLESHOOTING FLOWCHARTS ....................... 115 / 120

IN-DEPTH PANEL 50AE1 TROUBLESHOOTING FLOWCHARTS ......................... 122 ~ 135

P50T551 / DW3-U

R/C: CLU-4371UG2 p/n HL02075 P50H401

R/C: CLU-4372UG2 p/n HL02076 P50H4011

R/C: CLU-4371A p/n HL02401 P50T551

CONTENTS

(Pg 45 Updated 10/07)

(Updated 09/07 / 09/07)

(Added Pg 61-A 02/08)

(Updated 01/08)

(Updated 04/07)

(Added 10/07)

(Added 11/07)

(Added 11/07)

CAUTION:

Components having special safety characteristics are identified by a ! on the schematics and on the parts list in this

Service Data and its supplements and bulletins. Before servicing the chassis, it is important that the service technician

Read and follow the “Important Safety Instructions” in this Service Manual.

These servicing instructions are for use by qualified service personnel only. To reduce the risk of

Electric shock do not perform any servicing other than that contained in the operating instructions

Unless you are qualified to do so. Before servicing this chassis, it is important that the service

Technician read the “IMPORTANT SAFETY INSTRUCTIONS” in this service manual.

SAFETY NOTICE

USE ISOLATION TRANSFORMER WHEN SERVICING

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

Version 1024-09

Updated 10/22

FEBRUARY 2007 HHEA-MANUFACTURING DIVISION

/2009

PLASMA DISPLAY PANEL

SAFETY PRECAUTIONS

NOTICE: Comply with all cautions and safety-related notes

located on or inside the cover case and on the chassis or plasma

module.

WARNING: Since the chassis of this receiver is connected to

one side of the AC power supply during operation, whenever the

receiver is plugged in service should not be attempted by any-

one unfamiliar with the precautions necessary when working on

this type of receiver.

1. When service is required, an isolation transformer should be

inserted between power line and the receiver before any

service is performed on a “HOT” chassis receiver.

When replacing a chassis in the receiver, all the protective

2.

devices must be put back in place, such as barriers, nonmetallic knobs, insulating cover-shields, and isolation

resistors, capacitors, etc.

DW3U

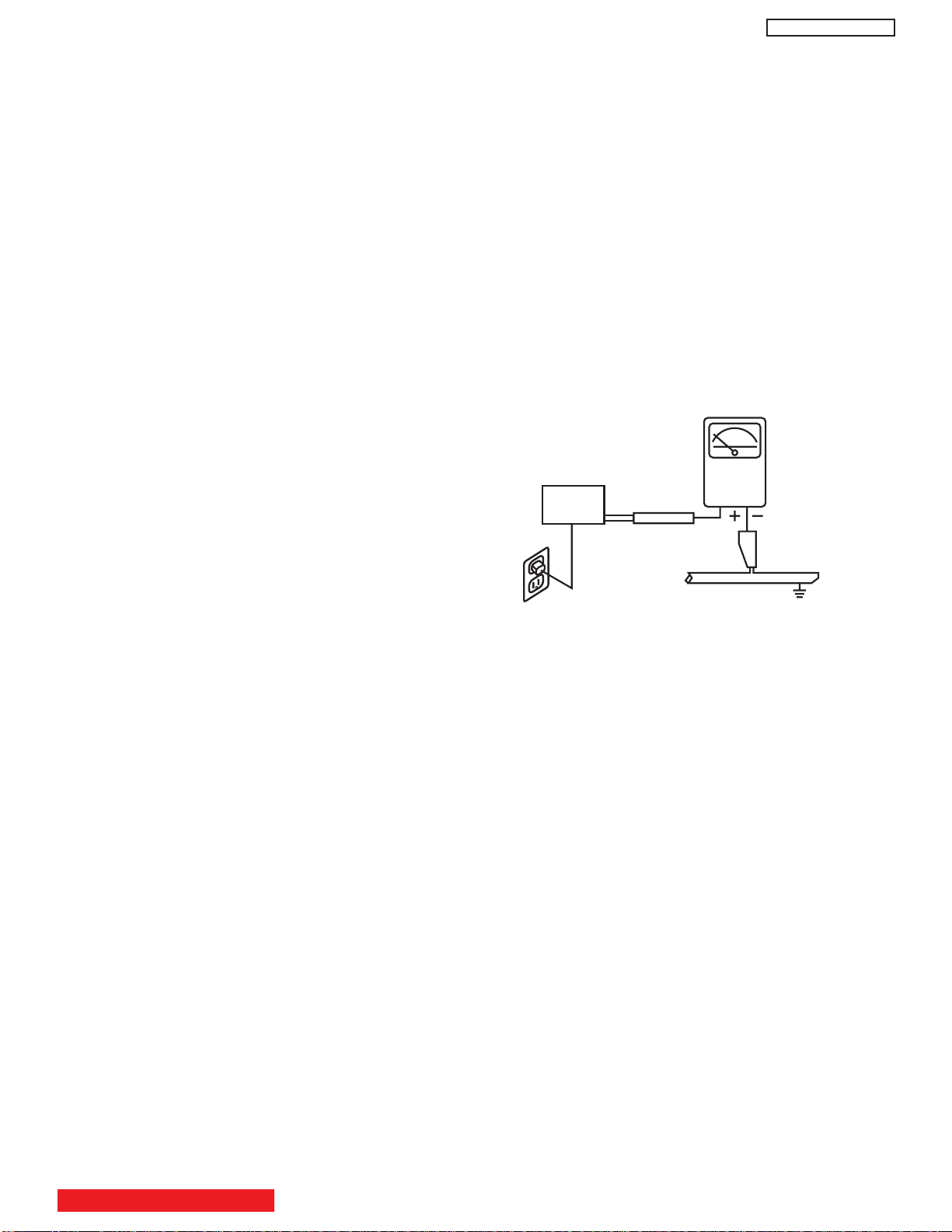

Leakage Current Hot Check

Plug the AC line cord directly into a 120V AC outlet. (Do not use an

isolation transformer during this test.) Use a leakage current

tester or a metering system that complies with the American

National Standards Institute (ANSI) C101.0 Leakage Current

for Appliances. In the case of the PDP monitor set the AC

switch first in the ON position and then in the OFF position,

measure from across Line 1 and Line 2 of the three plug

prongs, do not connect with the third prong, which is physical

ground, to all exposed metal parts of the instrument

(antennas, handle bracket, metal cabinet, screw heads,

metallic overlays, control shafts, etc.), especially any exposed

metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5 MIU. Reverse the

instrument power cord plug in the outlet and repeat test.

3. When service is required, observe the original lead dress.

4. Always use manufacturer’s replacement components. Critical

components as indicated on the circuit diagram should not be

replaced by another manufacturer’s. Furthermore, where a

short circuit has occurred, replace those components that

indicate evidence of over heating.

5. Before returning a serviced receiver to the customer, the

service technician must thoroughly test the unit to be certain

that it is completely safe to operate without danger of electrical

shock, and be sure that no protective device built into the

receiver by the manufacturer has become defective, or

inadvertently defeated during servicing.

Therefore, the following checks should be performed for the

continued protection of the customer and service technician.

Leakage Current Cold Check

With the AC plug removed from the 120V AC 60Hz source,

place a jumper across Line 1 and Line 2 of the three plug

prongs, do not connect with the third prong, which is physical

ground.

Using an insulation tester (DC500V), connect one of its leads

to the AC plug jumper and touch with the other lead each

exposed metal part (antennas, screwheads, metal overlays,

control shafts, etc.), particularly any exposed metal part

having a return path to the chassis should have a resistor

reading over 4MΩ. Any resistance value below this range

indicates an abnormality which requires corrective action. An

exposed metal part not having a return path to the chassis will

indicate an open circuit.

AC LEAKAGE TEST

(READING

SHOULD NOT

BE ABOVE 0.5MIU)

EARTH

GROUND

DEVICE

UNDER

TEST

TEST ALL

EXPOSED

METAL SURFACES

3-WIRE CORD

ALSO TEST WITH PLUG

REVERSED

(USING AC ADAPTER

PLUS AS REQUIRED)

LEAKAGE

CURRENT

TESTER

ANY MEASUREMENTS NOT WITHIN THE LIMITS OUTLINED

ABOVE ARE INDICATIVE OF A POTENTIAL SHOCK HAZARD

AND MUST BE CORRECTED BEFORE RETURNING THE

RECEIVER TO THE CUSTOMER.

TABLE OF CONTENTS

2

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in HITACHI television

receivers have special safety-related characteristics. These are

often not evident from visual inspection nor can the protection

afforded by them necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement

parts which have these special safety characteristics are

identified in this Service Manual.

Electrical components having such features are identified with a

mark in the schematics and parts list in this Service Manual.

!

The use of a substitute replacement component which does not

have the same safety characteristics as the HITACHIrecommended replacement component, shown in the parts list in

this Service Manual, may create shock, fire, X-radiation, or other

hazards.

Product safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current HITACHI Service Manual. A subscription to,

or additional copies of HITACHI Service Manuals may be

obtained at a nominal charge from HITACHI Sales Corporation.

DW3U

PDP Module Handling

When there is need to replace a broken PDP module which is the

displaying device from the Plasma monitor unit, consider the

following:

1. When carrying the PDP module, two persons should stand at

both shorter-edge sides of the glass-panel and transport it with

their palms. Avoid touching the Flexible Printed Circuits or the

chip tube on the corner of the glass-panel. Handle only by the

surface of the glass panel. In case of some PDP modules,

electrode repair is done by connecting between regular

terminal with Cu tape and Cu wire. Please do not hook and/or

damage this repair line. If it is damaged, the module will not

function unless the glass-panel is exchanged with a new

glass-panel.

2. When carrying PDP module, watch surrounding objects, such

as tables, and also do not carry it alone since it may be

dangerous and it will be damaged due to excessive stress to

the module (glass-panel).

3. Please do not stand the module with the edge of the glasspanel on the table since this might result in damage to the

glass-panel and/or flexible printed circuits due to excessive

stress to the module (glass-panel).

1. Follow the general caution recommendations from “Safety

precautions” section.

P50H401/P50T501/P50H4011 - Plasma Monitor Unit

1. Follow the general caution recommendations from “Safety

precautions” section.

2. Since the Panel module and front filter are made of glass,

sufficient care shall be taken when handling the broken

module and filter in order to avoid injury.

3. If necessary to replace Panel module, this work must be

started after the panel module and the AC/DC Power supply

becomes sufficiently cool.

4. Special care must be taken with the display area to avoid

damaging its surface.

5. The Panel Module shall not be touched with bare hands to

protect its surface from stains.

6. It is recommended to use clean soft gloves during the

replacing work of the Panel module in order to protect, not

only the display area of the panel module but also the

serviceman.

7. The Chip Tube of the panel module (located upper left of the

back of the panel module) and flexible cables connecting

Panel glasses to the drive circuitry Printed Wiring Boards

(P.W.B.) are very weak, so sufficient care must be taken to

prevent breaking or cutting any of these. If the Chip Tube

breaks the panel module will never work, replacement for a

new plasma panel module will be needed.

8. AV Digital Block, power supply and PDP driving circuit

P.W.B.’s are assembled on the rear side of the PDP module,

take special care with this fragile circuitry; particularly, Flexible

Printed Circuits bonded to surrounding edges of the glass

panel. They are not strong enough to withstand harsh outer

mechanical forces. Avoid touching the flexible printed circuits

by not only your hands, but also tools, chassis, or any other

object. Extreme bending of the connectors must be avoided

too. In case the flexible printed circuits are damaged, the

corresponding addressed portions of the screen will not be lit

and exchange of a glass panel will be required.

WARNING

Lead in solder used in this product is listed by the California

Health and Welfare agency as a known reproductive toxicant

which may cause birth defects or other reproductive harm

(California Health and Safety Code, Section 25249.5).

When servicing or handling circuit boards and other components

which contain lead in solder, avoid unprotected skin contact with

solder. Also, when soldering make sure you are in a well

ventilated area in order to avoid inhalation of any smoke or

fumes released.

SAFETY NOTICE

USE ISOLATION TRANSFORMER

WHEN SERVICING

POWER SOURCE

This plasma television is designed to operate on 120 Volts

60Hz, AC house current. Insert the power cord into a 120 Volts

60Hz outlet.

NEVER CONNECT THE PLASMA TELEVISION TO OTHER

THAN THE SPECIFIED VOLTAGE OR TO DIRECT CURRENT

AND TO 50HZ. TO PREVENT ELECTRIC SHOCK, DO NOT

USE THE PLASMA TELEVISION’S (POLARIZED) PLUG WITH

AN EXTENSION CORD, RECEPTACLE, OR THE OUTLETS

UNLESS THE BLADES AND GROUND TERMINAL CAN BE

FULLY UNSERTED TO PREVENT BLADE EXPOSURE.

TABLE OF CONTENTS

3

SERVICING PRECAUTIONS

CAUTION: Before servicing instruments covered by this

service data and its supplements and addenda, read and

follow the “Important Safety Instructions” on page 3 of this

publication.

NOTE: If unforeseen circumstances create conflict between

the following servicing precautions and any of the safety

precautions on page 3 of this publication, always follow the

safety precautions. Remember: Safety First.

DW3U

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some fieldeffect transistors and semiconductor “chip” components. The

following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

General Servicing Guidelines

1. Always unplug the instrument AC power cord from the AC

power source before:

a. Removing or reinstalling any component, circuit

board, module, or any other instrument assembly.

b. Disconnecting or reconnecting any instrument

electrical plug or other electrical connection.

c. Connecting a test substitute in parallel with an

electrolytic capacitor in the instrument.

CAUTION: A wrong part substitution or incorrect

polarity installation of electrolytic

capacitors may result in an explosion

hazard.

2. Do not spray chemicals on or near this instrument or any

of its assemblies.

3. Unless specified otherwise in these service data, clean

electrical contacts by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or

comparable nonabrasive applicator: 10% (by volume)

Acetone and 90% (by volume) isopropyl alcohol (90%99% strength).

CAUTION: This is a flammable mixture. Unless

specified otherwise in these service data,

lubrication of contacts is not required.

4. Do not defeat any plug/socket of voltage interlocks with

which instruments covered by this service data might be

equipped.

5. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heatsinks are correctly installed.

6. Always connect the test instrument ground lead to the

appropriate instrument chassis ground before connecting

the test instrument positive lead. Always remove the test

instrument ground lead last.

7. Use with this instrument only the test fixtures specified in

this service data.

CAUTION: Do not connect the test fixture ground strap

to any heatsink in this instrument.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a

known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device,

which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge

buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or

desolder ES devices.

4. Use only an anti-static type solder removal device. Some

solder removal devices not classified as “anti-static” can

generate electrical charges sufficient to damage ES

device.

5. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its

protective package until immediately before you are

ready to install it. (Most replacement ES devices are

packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive

material.)

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly into

which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or

circuit, and observe all other safety

precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the

lifting of your foot from a carpeted floor can generate

static electricity sufficient to damage an ES device.)

TABLE OF CONTENTS

4

DW3U

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintain tip

temperature within the range 500°F to 600°F.

2. Use an appropriate lead free solder (see page 8). Lead

solder can be used, but there is a possibility of failure due

to insufficient strength of the solder.

3. Keep the soldering iron tip clean and well-tinned.

4. Thoroughly clean the surfaces to be soldered. Use a

small wire-bristle (0.5 inch or 1.25 cm) brush with a metal

handle. Do not use freon-propelled spray-on cleaners.

5. Use the following desoldering technique.

a. Allow the soldering iron tip to reach normal

temperature (500°F to 600°F).

b. Heat the component lead until the solder melts.

Quickly draw away the melted solder with an antistatic, suction-type solder removal device or with

solder braid.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach normal

temperature (500°F to 600°F).

b. First, hold the soldering iron tip and solder strand

against the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of

the component lead and the printed circuit foil, and

hold it there only until the solder flows onto and

around both the component lead and the foil.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil or components.

Removal

1. Desolder and straighten each IC lead in one operation by

gently prying up on the lead with the soldering iron tip as

the solder melts.

2. Draw away the melted solder with an anti-static suctiontype solder removal device (or with solder braid) before

removing the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad

and solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to areas.)

“Small-signal” Discrete Transistor Removal/Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a “U” shape the end of each of the three leads

remaining on the circuit board.

3. Bend into a “U” shape the replacement transistor leads.

4. Connect the replacement transistor leads to the

corresponding leads extending from the circuit board and

crimp the “U” with long nose pliers to insure metal to

metal contact, then solder each connection.

Power Output Transistor Devices Removal/Replacements

1. Heat and remove all solder from around the transistor

leads.

2. Remove the heatsink mounting screw (if so equipped).

3. Carefully remove the transistor from the circuit board.

d. Closely inspect the solder area and remove any

excess or splashed solder with a small wire-bristle

brush.

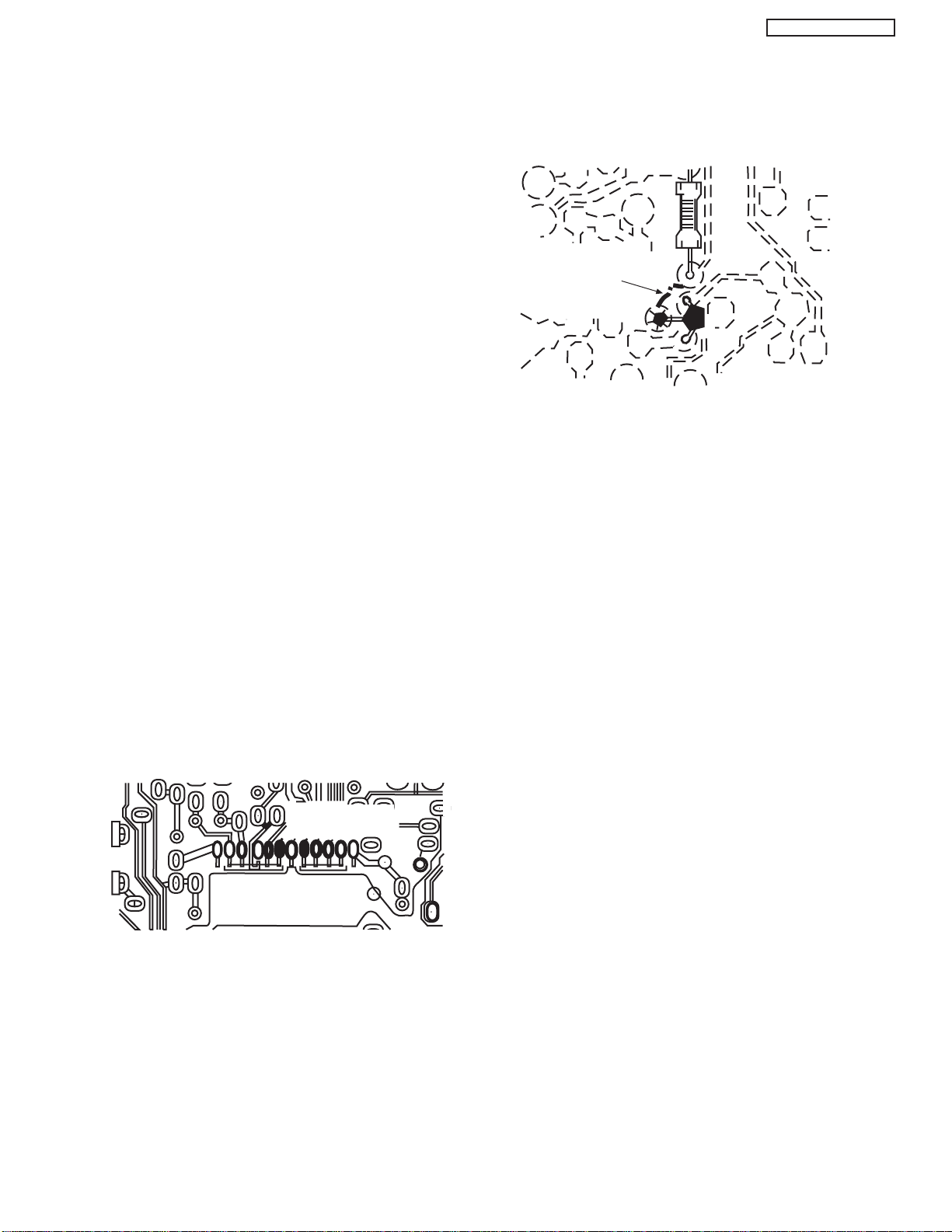

Use Soldering Iron to Pry Leads

IC Removal/Replacement

Some Hitachi unitized chassis circuit boards have slotted

holes (oblong) through which the IC leads are inserted and

then bent flat against the circuit foil. When holes are the

slotted type, the following technique should be used to

remove and replace the IC. When working with boards using

the familiar round hole, use the standard technique as

outlined in paragraphs 5 and 6 above.

4. Insert new transistor in circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heatsink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicularly to the

circuit board.

3. Observing diode polarity, wrap each lead of the new

diode around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints

of the two “original leads”. If they are not shiny, reheat

them and, if necessary, apply additional solder.

5

DW3U

Fuses and Conventional Resistor Removal/Replacement

1. Clip each fuse or resistor lead at top of circuit board

hollow stake.

2. Securely crimp leads of replacement component around

stake 1/8 inch from top.

3. Solder the connections.

CAUTION: Maintain original spacing between the

replaced component and adjacent

components and the circuit board, to

prevent excessive component

temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed

circuit board will weaken the adhesive that bonds the foil to

the circuit board, causing the foil to separate from, or “liftoff,” the board. The following guidelines and procedures

should be followed whenever this condition is encountered.

In Critical Copper Pattern Areas

High component/copper pattern density and/or special

voltage/current characteristics make the spacing and

integrity of copper pattern in some circuit board areas more

critical than in others. The circuit foil in these areas is

designated as Critical Copper Pattern. Because Critical

Copper Pattern requires special soldering techniques to

ensure the maintenance of reliability and safety standards,

contact your Hitachi personnel.

At Other Connections

Use the following technique to repair defective copper

pattern at connections other than IC Pins. This technique

involves the installation of a jumper wire on the component

side of the circuit board.

DEFECTIVE

COPPER

REMOVED

Insulated Jumper Wire

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both wire sides of

the pattern break and locate the nearest component

directly connected to the affected copper pattern.

At IC Connections

To repair defective copper pattern at IC connections, use the

following procedure to install a jumper wire on the copper

pattern side of the circuit board. (Use this technique only on

IC connections.)

1. Carefully remove the damaged copper pattern with a

sharp knife. (Remove only as much copper as absolutely

necessary.)

2. Carefully scratch away the solder resist and acrylic

coating (if used) from the end of the remaining copper

pattern.

BARE JUMPER

WIRE

CRIMP AND

SOLDER

Install Jumper Wire and Solder

3. Bend a small “U” in one end of a small-gauge jumper wire

and carefully crimp it around the IC pin. Solder the IC

connection.

3. Connect insulated 20-gauge jumper wire from the

nearest component on one side of the pattern break to

the lead of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is

dressed so that it does not touch

components or sharp edges.

4. Route the jumper wire along the path of the cut-away

copper pattern and let it overlap the previously scraped

end of the good copper pattern. Solder the overlapped

area, and clip off any excess jumper wire.

6

DW3U

NOTE: These components are affixed with glue. Be careful not to break or damage any foil under the

component or at the pins of the ICs when removing. Usually applying heat to the component for a short

time while twisting with tweezers will break the component loose.

Leadless Chip Components

(surface mount)

Chip components must be replaced with identical

chips due to critical foil track spacing. There are no

holes in the board to mount standard transistors or

diodes. Some chip capacitor or resistor board solder

pads may have holes through the board, however the

hole diameter limits standard resistor replacement to

1/8 watt. Standard capacitors may also be limited for

the same reason. It is recommended that identical

chip components be used. .

Chip resistors have a three digit numerical resistance

code -1st and 2nd significant digits and a multiplier.

Example: 162 = 1600 or 1.6KΩ resistor, 0 = 0Ω

(jumper).

Chip capacitors generally do not have the value

indicated on the capacitor. The color of the component

indicates the general range of the capacitance.

Chip transistors are identified by a two letter code. The

first letter indicates the type and the second letter, the

grade of transistor.

Chip diodes have a two letter identification code as

per the code chart and are a dual diode pack with

either

common anode or common cathode. Check the parts

list for correct diode number.

Component Removal

1. Use solder wick to remove solder from component

end caps or terminals.

2. Without pulling up, carefully twist the component

with tweezers to break the adhesive.

3. Do not reuse removed leadless or chip

components since they are subject to stress

fracture during removal .

Chip Component Installation

1. Put a small amount of solder on the board

soldering pads.

2. Hold the chip component against the soldering

pads with tweezers or with a miniature alligator

clip and apply heat to the pad area with a 30 watt

iron until solder flows. Do not apply heat for more

than 3 seconds

TYPE

Chip Components

C

GRADE

SOLDER

CAPS

How to Replace Flat-lC

—Required Tools—

• Soldering iron • iron wire or small awl

• De-solder braids • Magnifier

1. Remove the solder from all of the pins of a Flat-lC

by using a de-solder braid.

De-Solder

Braid

Soldering

Iron

2. Put the iron wire under the pins of the Flat-lC and

pull it in the direction indicated while heating the

pins using a soldering iron. A small awl can be

used instead of the iron wire.

Pull

Soldering

Iron

3. Remove the solder from all of the pads of the

Fiat-lC by using

a de-solder braid.

4. Position the new Flat-lC in place (apply the pins of

the Flat-lC to the soldering pads where the pins

need to be soldered). Properly

determine the positions of the

soldering pads and pins by

correctly aligning the polarity

symbol.

5. Solder all pins to the soldering pads using a fine

tipped soldering iron.

Iron

Wire

Awl

Soldering

Iron

Soldering

Iron

De-Solder

Braid

Flat-IC

Polarity Symbol

B

ANODES

E

COMMON CATHODE

MH DIODE

TRANSISTOR

SOLDER CAPS

1ST DIGIT

RESISTOR

CAPACITOR

2ND DIGIT

MULTIPLIER

= 1600 = 1.6K

Solder

Soldering

Iron

6. Check with a magnifier for solder bridge between

the pins or for dry joint between pins and soldering

pads. To remove a solder bridge, use a de-solder

braid as shown in the figure below.

De-Solder

Braid

Bridge

Solder

7

Soldering

Iron

Information for service about lead-free solder introduction

Hitachi introduced lead-free solder to conserve the "Earth Environment".

Please refer to the following before servicing.

(1) Characteristic of lead-free solder

Melting point of lead free solder is 40-50

(2) Solder for service

Following composition is recommended.

" Sn - 3.0Ag - 0.5Cu " , or " Sn - 0.7 Cu "

Lead solder can be used, but there is a possibility of failure due to insufficient strength of the solder.

Caution when using solder containing lead.

Please remove previous solder as much as possible from the soldering point.

When soldering, please perfectly melt the lead-free solder to mix well with the previous solder.

(3) Soldering iron for lead-free solder.

Melting point of lead-free solder is higher than solder containing lead.

Use of a soldering tool "with temperature control" and "with much thermal capacitance" is recommended.

(Recommended temperature control : 320

o

C higher than solder containing lead.

o

C - 450oC)

DW3U

Recommended temperature

PWB with chip parts

PWB without chip parts

Chassis, metal, shield etc.

320oC +/- 30oC

380oC +/- 30oC

420oC +/- 30oC

(4) Identification of lead-free PWB

2004 models >> lead-free solder is introduced

2007 models >> lead-free solder apply

On lead-free PWB, "F" is added at the beginning of stamp on PWB. (e.g. DW2-POD F)

8

AGENCY REGULATORY

INFORMATION

Federal Communications Commission Notice

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates, uses and can radiate radio frequency energy and if not

installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/television technician for help.

FCC Information

This device complies with part15 of the FCC Rules.Operation is subject to the following two conditions :

(1) This decide may not cause harmful interference and (2) This decide must accept any interference

received, including interference that may cause undesired operation.

DW3U

Modifications

The FCC requires the user to be notified that any changes or modifications made to this device that are not

expressly approved by Hitachi America ,Ltd. Home Electronics Division may void the user’s authority to

operate the equipment.

Cables

Connections to this device must be made with shielded cables with metallic RFI/EMI connector hoods to

maintain compliance with FCC Rules and Regulations.

Any cables that are supplied with the system must be replaced with identical cables in order to assure

compliance with FCC rules. Order Hitachi spares as replacement cables.

Note

This Plasma Television receiver will display television closed captioning, ( or ), in accordance with

paragraph 15.119 and 15.122 of the FCC rules.

INDUSTRY CANADA AGENCY REGULATORY INFORMATION

Cable Compatible Television Apparatus- Tèlèvision câblocompatible, Canada.

TABLE OF CONTENTS

9

ACKNOWLEDGMENTS

AND TRADEMARKS

This Plasma Television complies with VESA DDC2B specifications, Plug & Play

is a system with computer, peripherals (including monitors) and operating

system. It works when the monitor is connected to a DDC ready computer that

is running an operating system software that is capable for the plug & play.

When a Plug and Play PC is powered on, it sends a command to the Monitor

requesting identification. The Monitor sends back a string of data including its

characteristics.

TRADEMARK ACKNOWLEDGMENT

TM

DDC is a trademark of Video Electronics Standard Association.

IBM PC/AT and VGA are registered trademarkds of International Business Machines Corporation of the U.S.A.

Apple and Macintosh are registered trademarks of Apple Computer, Inc.

VESA is a trademark of a nonprofit organization, Video Electronics Standard Association.

DW3U

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Cable Compatible Television Apparatus- Tèlèvision câblocompatible, Canada.

Notes on Closed Caption:

This Plasma Television receiver will display television closed captioning, ( or ), in accordance with

paragraph 15.119 of the FCC rules.

*Manufactured under license from Dolby Laboratories. “Dolby” and the double-D symbol are

trademarks of Dolby Laboratories.

TABLE OF CONTENTS

10

DW3U

INTRODUCTION

The Digital AV Block is inside of the Panel assembly controls most of the user functions of the complete TV set and conditions the signal

to the plasma panel.

The 50” monitor contains the displaying device, which is the plasma display panel module, and the driving circuitry, which

receives the signal from the Digital AV Block and after processing, delivers the image to the display module.

This HITACHI Service Manual is intended for the qualified service personnel and it contains the necessary information for

troubleshooting the Plasma television set in case of malfunction.

DIMENSIONS:

POWER RATINGS:

No.

1 P50H401/T501 460W 3.9A 282W 0.6W ------- DW3A

Model Name

P50H4011

P50H401/P50T501/P50H4011

Indicated Value

Max Rating

(W) (A)

Average

Rating (W)

P

Without POD.

less than 1W

ST(W)

With POD.

less than 14W

Chassis

CIRCUIT PROTECTION

CAUTION: Below is an EXAMPLE only. See Replacement Parts List for details. The following symbol near the fuse

Example:

indicates fast operation fuse (to be replaced). Fuse ratings appear within the symbol.

F

10 A 125V

“RISK OF FIRE - REPLACE FUSE AS MARKED”

TABLE OF CONTENTS

The rating of fuse F9A1 is 10 A- 125V.

Replace with the same type fuse for continued protection

against fire.

11

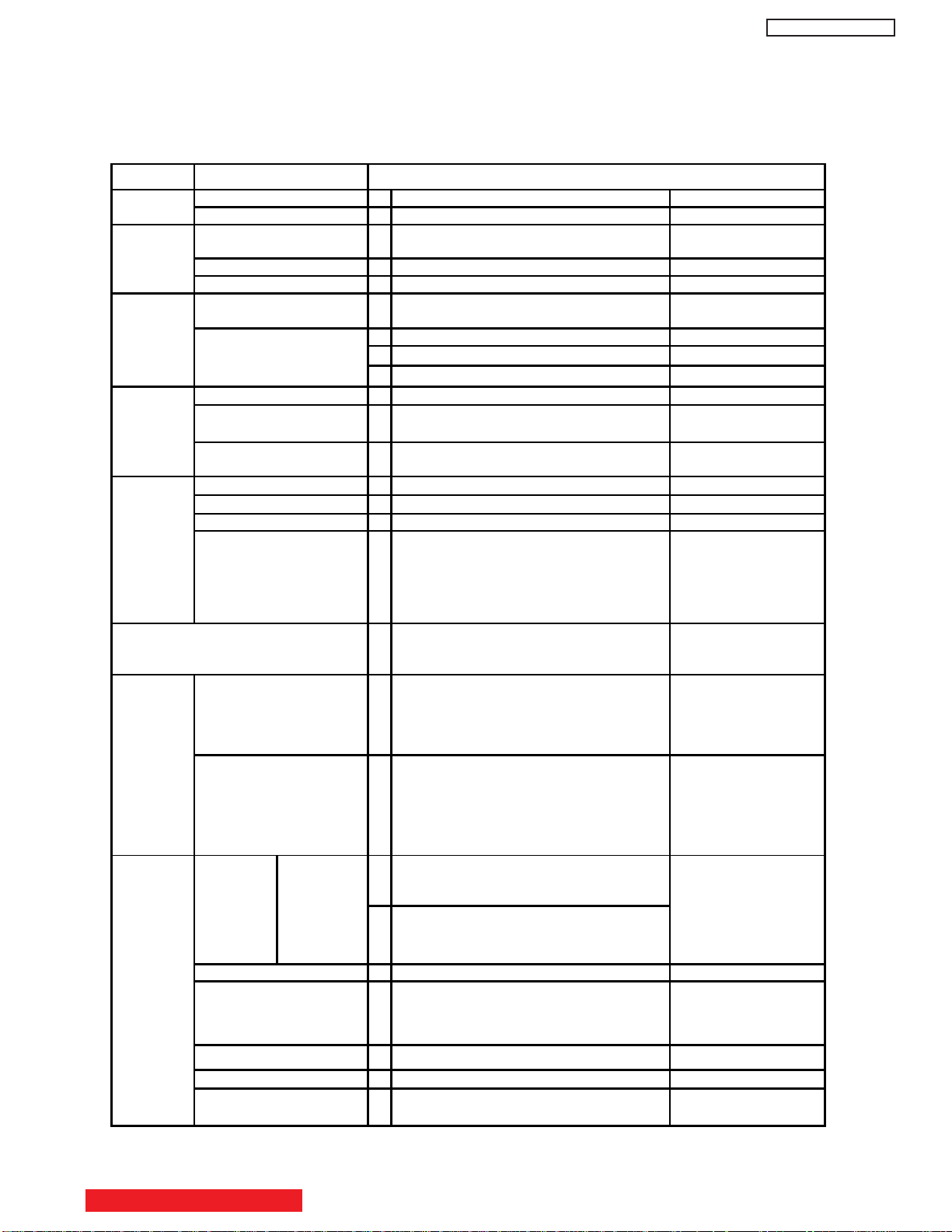

SPECIFICATIONS

FEATURES

2007 50" Plasma models

Model

Dimension Size

Weight 2 53 Kg

A/C Input

Voltage

Front End

Input Signal

Input AC Voltage

Input AC Frequency

Power Consumption

Front End(NTSC & ATSC)

Available Channel

Video Signal

Component Signal

1

3

4

5

6

7

8 14 ~ 69

9

10

11480i, 480p, 720p,1080i

P50H401/P50T501/P50H4011

1240mm x 880.85mm x 422mm

AC108V~132V (with 3 Plug AC Power Cord inlet

type ,1.8m length)

60Hz

460W, SBY less than 1W

ENGD6305

NTSC/ATSC(8VSB),64QAM,256QAM)

2~13

A-5~A-1,A~W,W+1~W+94

NTSC

DW3U

VHP

UHF

CATV

HDMI Signal

Picture

Sound Enhancement

Adjustment

General

Function

Y/C Separation

Line Correction

I-P Conversion

Picture Mode

Settings for Video Signal

Settings for Sound

PinP Split

Mode

12

480i, 480p, 720p, 1080i, 1080p (EIA -861B) *1)

13

3D Y/C (ON fix)

14 No

15

Motion Adaptive & Multi Angle Interpolation

16

Day(Dynamic), Day(Normal),Night

17

BassBoost (On,Off) & Surround (Normal, Wide, Off)

18

Picture Mode, Contrast, Brightness, Color, Tint, Sharpness

Color Temperature, Black Enhancement, Contrast Mode,

Noise Reduction, MPEG-NR, Auto Movie Mode, Aspect,

Black Side Panel.

19

Volume, Balance, Bass, Treble, Audio Source, Internal

Speakers, Auto Noise Cancel, Perfect Volume, Mute,

Soft Mute, Loudness, DRC.

With(ANT/CABLE DIGITAL CHANNEL & Video 480i ,720p,

20

1080i)

Only P50T501 model

Wide Mode

Aspect Video Selection

Film Theater

Color Temperature

Input Signal Selection

TABLE OF CONTENTS

21

Freeze

*1) When HDMI input a 1080p signal, the length of the cable should be less than 5 meters.

With(3Pix:only ANT/CABLE DIGITAL CHANNEL,

Video, 480i).

22

7 Mode

23

4:3 Standard/16:9 Standard1 /16:9 Standard 2

4:3 Expanded/Zoom1/Zoom 2/16:9 Zoom

24

With(Auto Movie Mode:On/Off)

25

3 Mode (High/Medium/Standard)

26

Input1/2/3/Front, Cable/ Air,HDMI1/2/Front,Photo

Input

Photo Input only P50T501

12

SPECIFICATIONS

FEATURES (continued)

DW3U

Model

General Gamma Correction

Function Picture Enhancer

Input Signal Identification

Audio Special Mode

Power Save Mode

Burning Protection

OSD Language (VIDEO)

Swivel

R/C Handset

In/Out

Terminal

Composite Video Input

(Input 1~3, Front )

S-ln(S2 Terminal) (Video/S are

common selector, priority is S-ln) .

Component Signal Input

(Input 2, Input 3)

Digital Input(HDM I-HDCP)

Audio In (L/R) (Lch:mono)

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

P50H401/P50T501/P50H4011

Only for Service Menu

yes

No

With (On/Off) (Video In) LED Normal: Blue

Power Save: Orange

Standby:Red

With (Raster Shift:3 option.AII White Pattern)

ENGLISH, FRANCAIS, ESPAÑOL

H401: Fix, T501 : Manual Swivel

CLU-4371UG2 (P50H401)/CLU-4372UG2 HOSHIDEN/PANASONIC

(P50H4011)/CLU-4371A (P50T501)

4 Input: RCA pin* 5(1 Input Front Panel)

1 Input: Mini Din-4P x 2

3 lnput:RCA pin x 9(Y of input 1/2/5 is common

input for Composit e-In)

3 lnput:HDMI(19P)X3

4 lnput:RCApinx8

Auto Link

Video Control Terminal (BS)

U/V Ant Input

BS-I/F Input

Video Monitor Out Terminal

Audio Output Terminal

Audio Monitor Out Terminal

RS-232C Terminal 49

Photo Input

Audio Optical Output

Front Main Power Switch

Key

Option

Power On/off Switch

IR Receiving Unit

Power Indicator LED

Menu Control Key

POP TV Stand

Wall Mount Unit

42

1 Input (Input 3 LINK)

43

No

44

CABLE / AIR

45

No

46

1 Output: RCA pin x 1

47

1 Output L/R:RCA pinx 2

48

1 Output L/R:RCA pinx 2 (common input for No.60)

1 (Female type)

50

1 (On Front panel)

51

1 (Square type)

52

Yes , below panel

53

Yes, on Front panel

Yes, on Front panel

54

55

Yes, on Front panel

56

Yes, on Front panel (Channel U/D, Vol U/D, A/V

Input Select , Menu Select)

57

With

58

With

Auto Link Function

P50T501 model only

13

DW3U

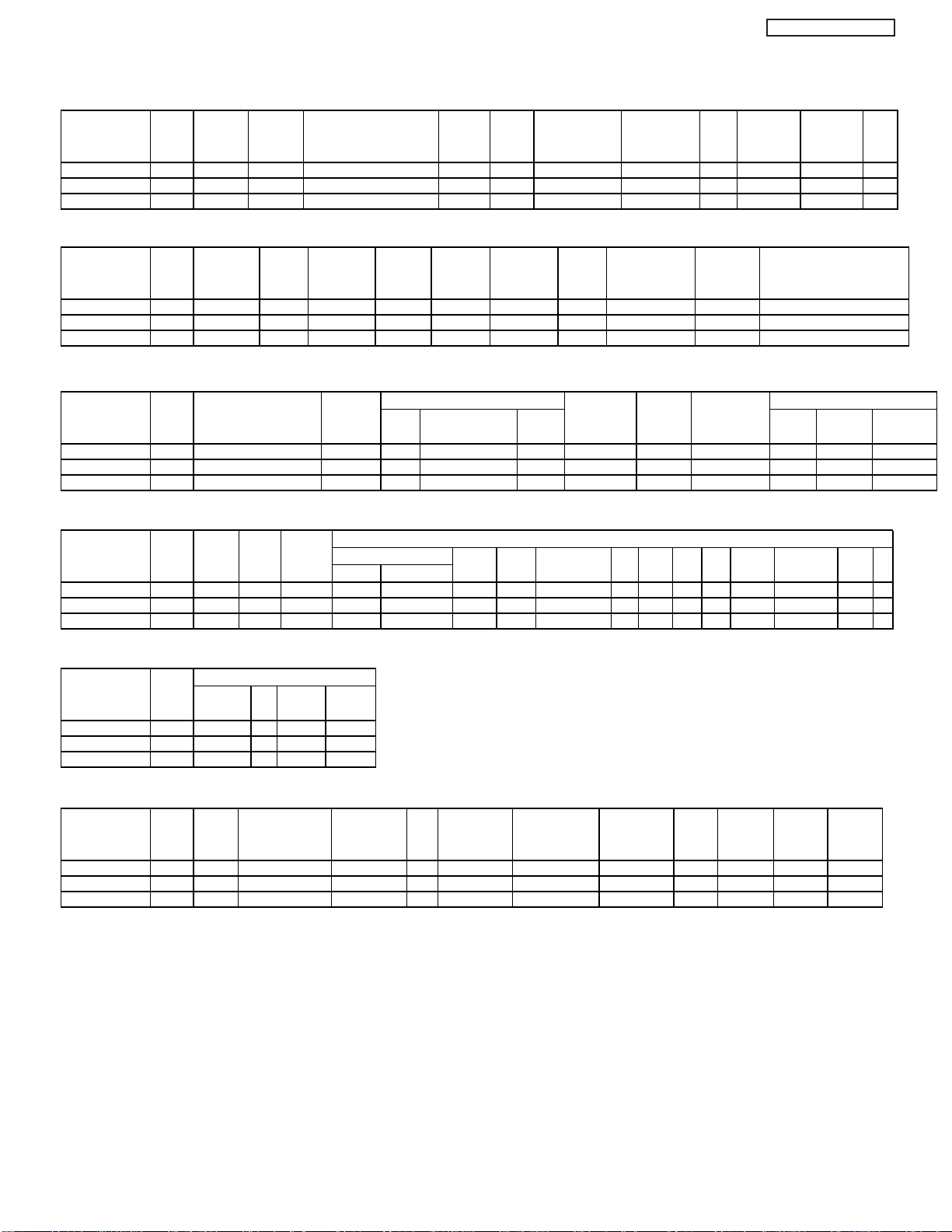

FEATURES & DIFFERENCES BETWEEN 50" MODELS

QAM Basic

Model Name Class Chassis Series Cabinet Aspect ATSC ATSC/NTSC Digital POD MPEG EPG M/C

Name Design 1Tuner Cable Decoder Gemstar

P50H401

P50T501

P50H4011

H

T501

H4011

Model Name Class

P50H401

P50T501

P50H4011

H401

T501

H4011

Model Name Class

P50H401

P50T501

P50H4011

H401

T501

H4011

401

DW3A

DW3A

DW3A

UltraVision Bottom Speaker Silver 16x9 X X X - X - SD

Cineform WW Bottom Speaker Black/Silver 16x9 X X X - X - SD

UltraVision Slim Spkr Black/Metallic Black Bezel 16x9 X X X - X - SD

DTV Memory

NTSC Seine 3/2 Fill by Shield Comb Resolution OSD Color Temp

FORMAT Pulldown Mode inputs Filter

1080i Seine2 Auto/off 7modes

X 36% mesh 3DYC 1280x1080 07 OSD B 3Mode(High, Med,Std)

1080i Seine2 Auto/off 7modes X 31% mesh 3DYC 1280x1080 07 OSD C 3Mode(High, Med,Std)

1080i Seine2 Auto/off 7modes X 36% mesh 3DYC 1280x1080 07 OSD B 3Mode(High, Med,Std)

Remote Sound function

PIP AV NET Type Source Simple IR Discrete Dolby Perfect Surround BassBoost

Color UEI Pass Thru Code Volume

Digital Tuner/Ext SPLIT

---- - TVU Hoshiden/Silver - - X AC3 Downmix × × ×

----

- TVU PANA/Black - - X AC3 Downmix × × ×

- TVU Hoshiden/Black - - X AC3 Downmix × × ×

Model Name Class

P50H401

P50T501

P50H4011

H401

T501

H4011

Model Name Class

P50H401 H401

P50T501 T501

P50H4011 H4011

Model Name Class

P50H401 H401

P50T501 T501

P50H4011 H4011

Rear Jacks

TV Output Speaker RS232C IR-Out YPbPr S IN AV IN S V AUDIO Y As 6CH RF

Center Watt

L/mono 20 2FR L/mono 20 2FR - 2 1- 2(1H,2H,2.14H) 1 3 1 1 1 X OPT 1

L/mono 20 2FR - 2 1-2(1H,2H,2.14H) 1 3 1 1 1 X OPT 1

Front Jacks

Composite L/R Y,Pb,Pr

HDMI

Digital I/F

IEEE1394 HDMI OUT OUT OUT Composite OUT

2 1- 2(1H,2H,2.14H) 1 3 1 1 1 X OPT 1

111 111 111 -

Downloadable Option Swivel Table Top Hotel Adjust Color Contrast

Power V Chip Energy Star PLC Wall mount

Stand Mode Color Manage Mode

LED Decoder

Blue X X X X Fixed × BLK(9000) × - - X

Blue X X X X Manual × SIL(9000) × - - X

Blue X X X X Fixed × BLK(9000) × - - X

14

General Specifications

A

(

)

e

)

)

g

yp)

h

(

757m)

DW3U

Model Specifications

Model NameItem

Destination U.S.A. / CANAD

Exterior

Cabinet Dimensions

(Main Body) (Speaker &

stand inclusive)

Frame Color Screen

Stand

Weight (Main Body)

(Speaker & stand

inclusive)

Main Body: Packed

Screen Siz

Display Panel

Resolution

Dot Pitch (H

Dot Pitch (V

Front Filter Surface Finishin

Brightness

Peak Brightness (1%

window)

P50H401/P50T501/P50H4011

1240mm x 880.85mm x 422mm

Metallic Black (T501/H4011)

Brightness Silver (H401)

Inclusive

46.8 kg (53 kg)

60 kg typ.64.0 kg

921x523.8mm

1280x1080 pixels

0.864mm

0.580mm

0.4ohm Mesh

326 (280) cd/m2 or more

(When VIDEO, Day Dynamic mode,

Color temperature 'HIGH',Input Signal

Amplitude 100 % is set)

Environment Specifications

NO

1

2

3

4

5

6

7

8

9

Item Specification

Operating Temp.

Stock Temp.

Operating Humidity

Stock Humidity

Operating Atmosphere

Pressure

Stock Atmosphere Pressure

Warranty Gravity Vertical

Warranty Drop High

Tilt Angle 12° Over

+5°C~+35°C

-15°C

~+60°C

20%~80%RH

20%~90%RH

700~1114hPa

(1888m~-757m)

300~1114h P a

4727m~-

0.85 G

30cm

All White Pattern

56 (48) cd/m

Contrast Contrast ratio 800 : 1 (t

Audio Output Audio Output

Panel Operation

Main Power Switc

Power Switch

10W+10W(5ohm>,10%Distortion)

PUSH (LOCK) 1 switch

PUSH (NON-LOCK) 1 switch

Input Terminal Video/Audio Input RCA, HDMI, S

Output Terminal

Audio Line Output

RCA

Connector 3 Polarity ReceptaclePower Supply

Source

Input Voltage

Single Phase AC108-132V, 60 Hz

2

or more

15

DW3U

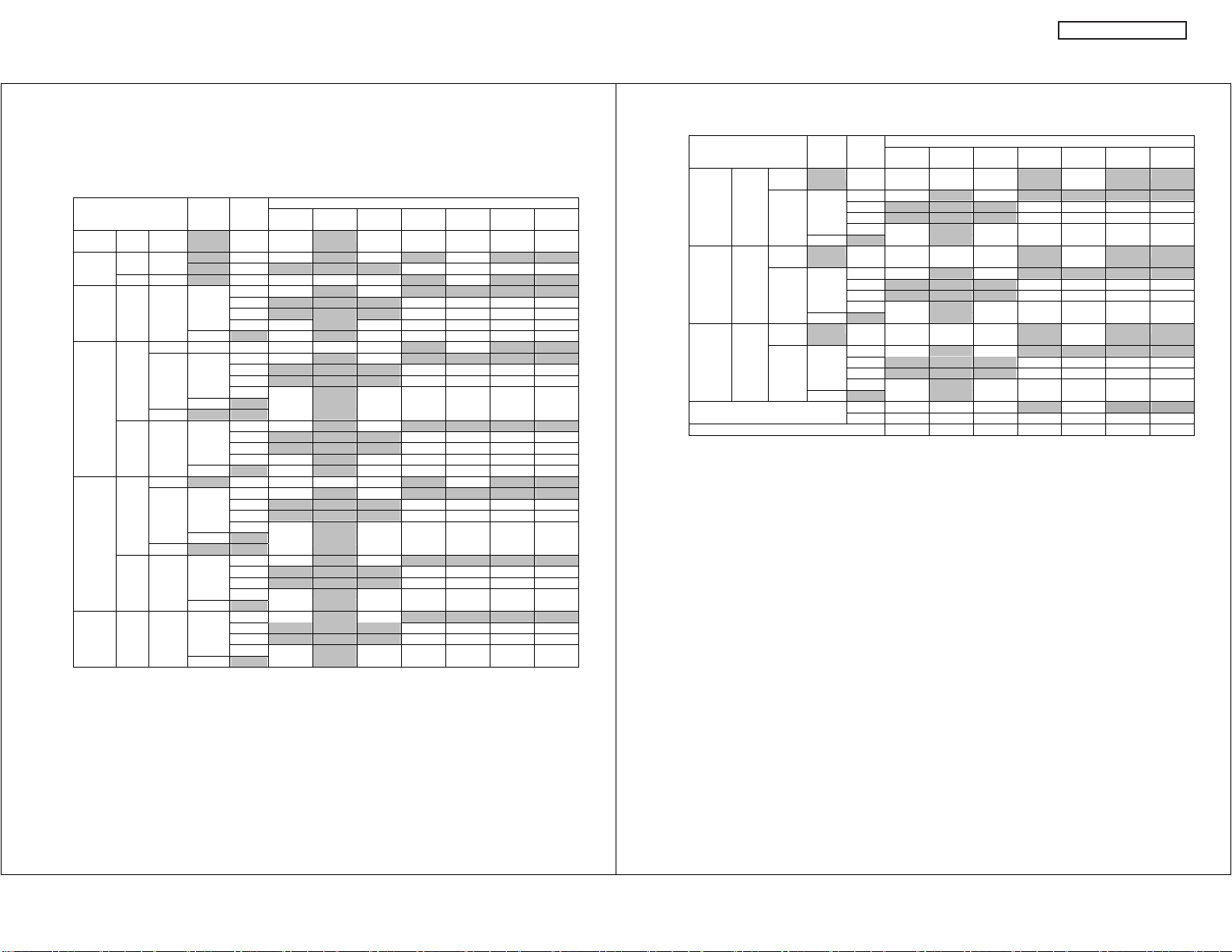

9. Display Specification

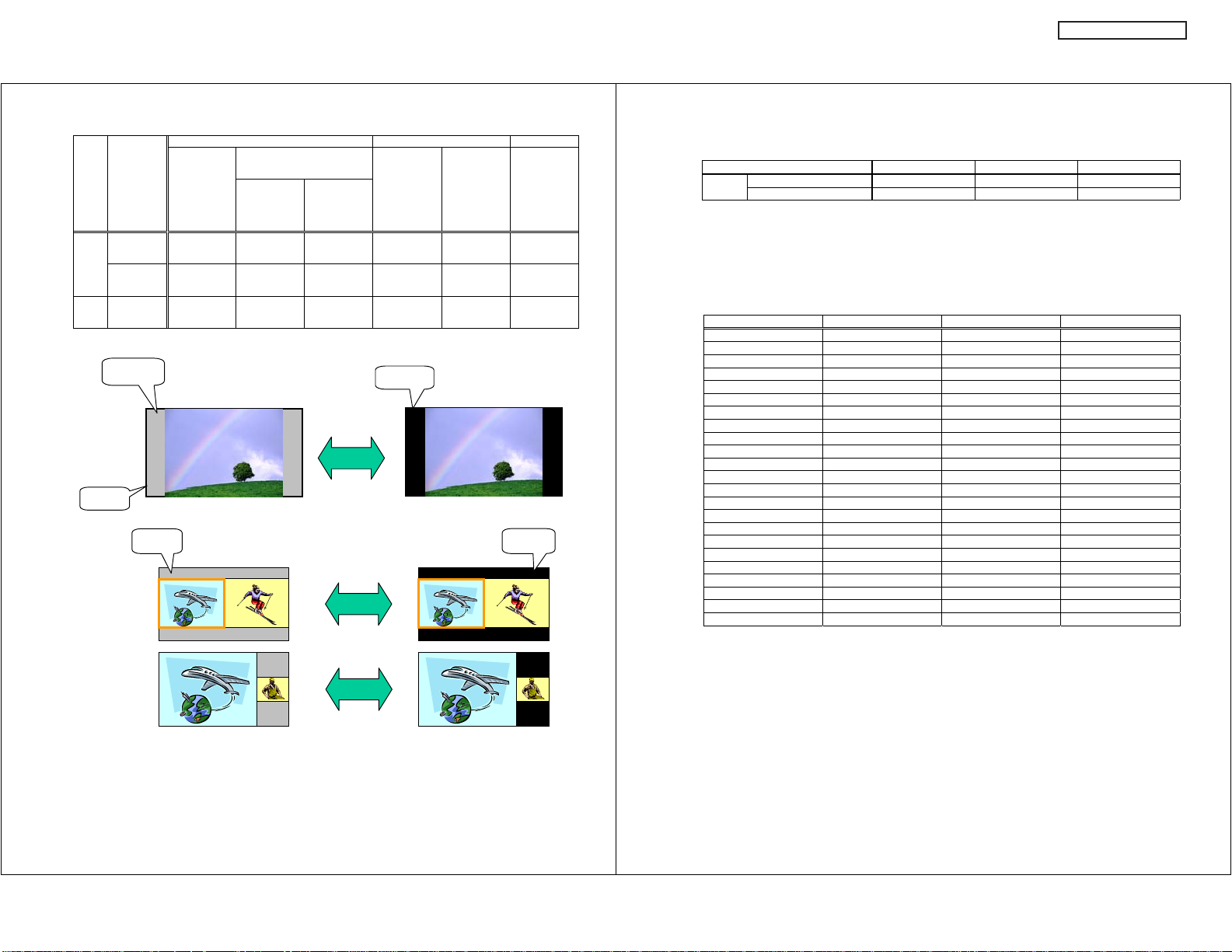

9.1 Picture Format for Each Input Source

Aspect, Vertical Position, Black Side Panel, PIP Mode

9.1.1 Aspect

Input Auto Aspect Aspect

Signal Aspect Video ID 16:9

ANT

Video NTSC

Analog

ANT YCBCR 480p - 16x9 Yes - Yes - Yes - -

Digital 480i

YPBPR 1080i/720p - 16x9 Yes Yes Yes - Yes - -

Input 1 Video NTSC Auto ON 16 x9 Yes Initial - Yes - - - -

S-Video Letter

4x3 - - - Yes Yes Initial Yes Yes

No ID Yes - Yes Yes Yes Yes Yes

Auto OFF

Input 2 YPBPR 1080i/720p - 16x9 Yes Yes Yes - Yes - -

480p Auto ON 16x9 Yes Initial - Yes - - - -

480i Letter - - - Yes Yes Yes Initial Yes

4x3 - - - Yes Yes Initial Yes Yes

No ID Yes

Auto OFF -

No Signal - -

Video NTSC Auto ON 16x9 Yes Initial

Letter - - - Yes Yes Yes Initial Yes

4x3 - - - Yes Yes Initial Yes Yes

No ID Yes

Auto OFF - Yes - Yes Yes Yes Yes Yes

Input 3 YPBPR 1080i/720p - 16x9 Yes Yes Yes - Yes - -

480p Auto ON 16x9 Yes Initial - Yes - - - -

480i Letter - - - Yes Yes Yes Initial Yes

4x3

No ID Yes - Yes Yes Yes Yes Yes

Auto OFF -

No Signal

Video NTSC Auto ON 16x9 Yes Initial - Yes - - - -

Letter - - - Yes Yes Yes Initial Yes

4x3

No ID Yes - Yes Yes Yes Yes Yes

Auto OFF

Input Video NTSC Auto ON 16x9 Yes I nitial - Yes - - - -

Front Letter - - - Yes Yes Yes Initial Yes

4x3

No ID Yes - Yes Yes Yes Yes Yes

Auto OFF -

-

-

-

Standard 1

4x3 Yes

-

4x3

-

-

-

-

Yes

-

-

-

Yes : Selectable - : Un-selectable

16:9

16:9

4:3

Standard 2

-

-

-

-

-

-

-

-

-

-

Zoom

Standard

Yes Yes Yes Yes Yes

-

-

Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes

Yes

Yes Yes Yes Yes Yes

-

-

-

4:3

Expanded

Yes Yes Yes Yes

Yes Yes Yes Initial Yes

-

-

Yes Yes Initial Yes Yes

Yes Yes Initial Yes Yes

Yes Yes Initial Yes Yes

4:3

Zoom 1

-

4:3

Zoom 2

-

(

Continuation)

Input Auto Aspect Aspect

Signal Aspect Video ID 16:9

HDMI1 HDMI

(Input1 4 80p Auto O N 16x9 Yes Initial - Yes - - - -

-DVI) 480i Letter

4x3 - - - Yes Yes Initial Yes Yes

No Info Yes - Yes Yes Yes Yes Yes

Auto OFF

HDMI2 HDMI

(Input2 4 80p Auto O N 16x9 Yes Initial - Yes - - - -

-DVI) 480i Letter

4x3 - - - Yes Yes Initial Yes Yes

No Info Yes

Auto OFF -

HDMI

Front

(InputFront 480p Auto ON 16x9 Yes Initial

-DVI) 480i Letter - - - Yes Yes Yes Initial Yes

4x3 - - - Yes Yes Initial Yes Yes

No Info Yes

Auto OFF -

Horizontal Expansion 16x9 105% 100% 133%

4x3 105% 100% 133% 75% 100% 100% 133%

Vertical Expansion 105% 100% 133% 110% 110% 133% 176%

(DVI)

(DVI)

HDMI

(DVI)

1080p/

1080i/720p

1080p/

1080i/720p

1080p/

1080i/720p

-

- 16x9 Yes Yes Yes - Ye s - -

- 16x9 Yes Yes Yes - Ye s - -

Standard 1

16x9 Yes Yes Yes

-

16:9

16:9

4:3

4:3

4:3

Standard 2

-

-

Zoom

Standard

Expanded

-

Yes

-

-

-

-

-

-

Yes Yes Yes Initial Yes

-

Yes Yes Yes Initial Yes

Yes Yes Yes Yes Yes

-

Yes

Yes Yes Yes Yes Yes

-

-

133%

Zoom 1

4:3

Zoom 2

-

-

-

-

-

-

16

DW3U

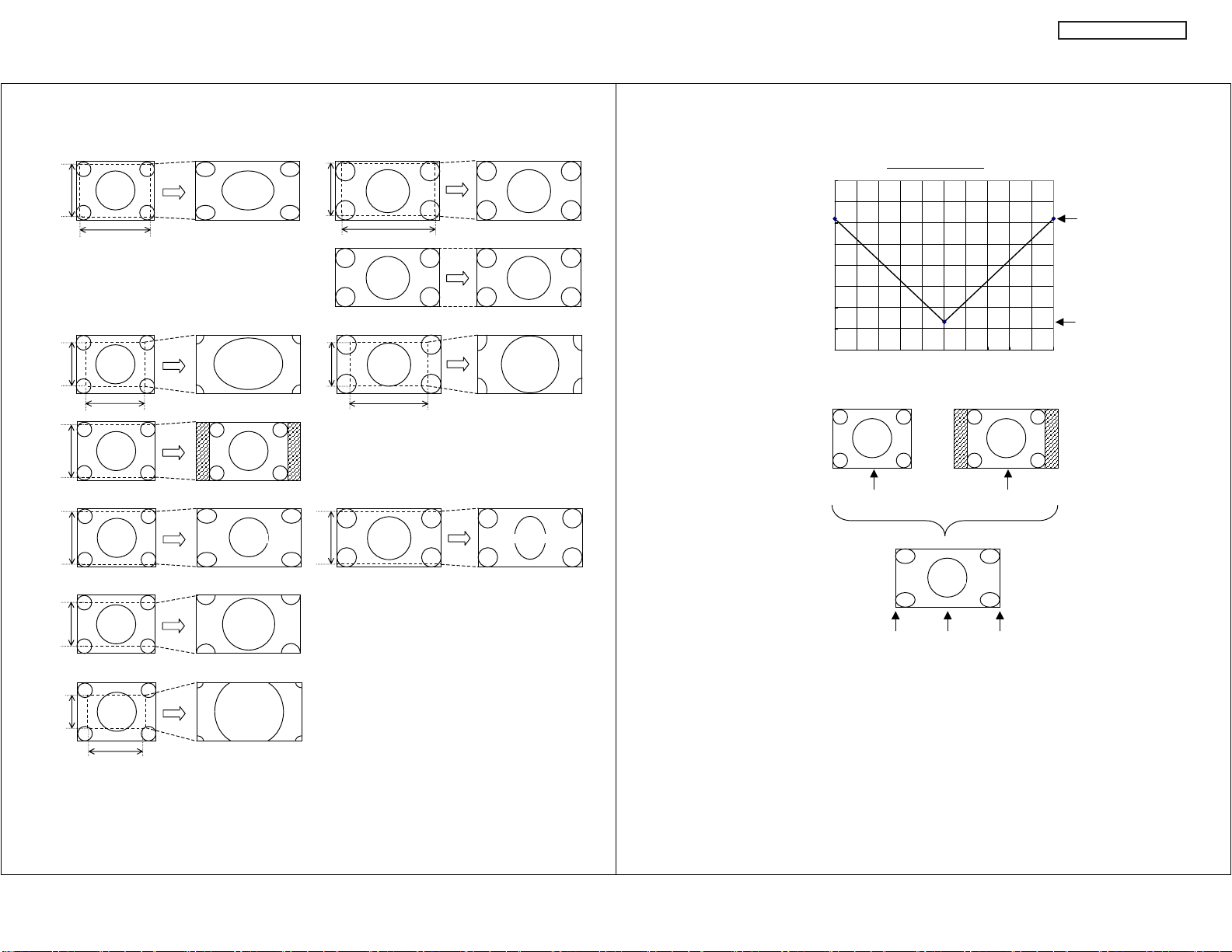

[Expansion]

90%

75%

90%

90%

75%

56%

4x3

90%

4x3

75%

4x3

4x3

4x3

4x3

75%

<4x3 Format> <16x9 Format>

16:9

Standard1

16:9

Zoom

4:3

Standard

4:3

Expanded

4:3

Zoom1

4:3

Zoom2

90%

75%

90%

16x9

90%

16x9

16x9

75%

16x9

16:9

Standard1

16:9

Standard2

16:9

Zoom

4:3

Expanded

Horizontal

Expansion

Ratio

(%)

180

170

160

150

140

130

120

110

100

0 102030405060708090100

4:3 Expanded Mode

Horizontal Position

4x3

Format

100%

162%

4:3

Expanded

113%

16x9

Format

100%

162%

162%

113%

17

DW3U

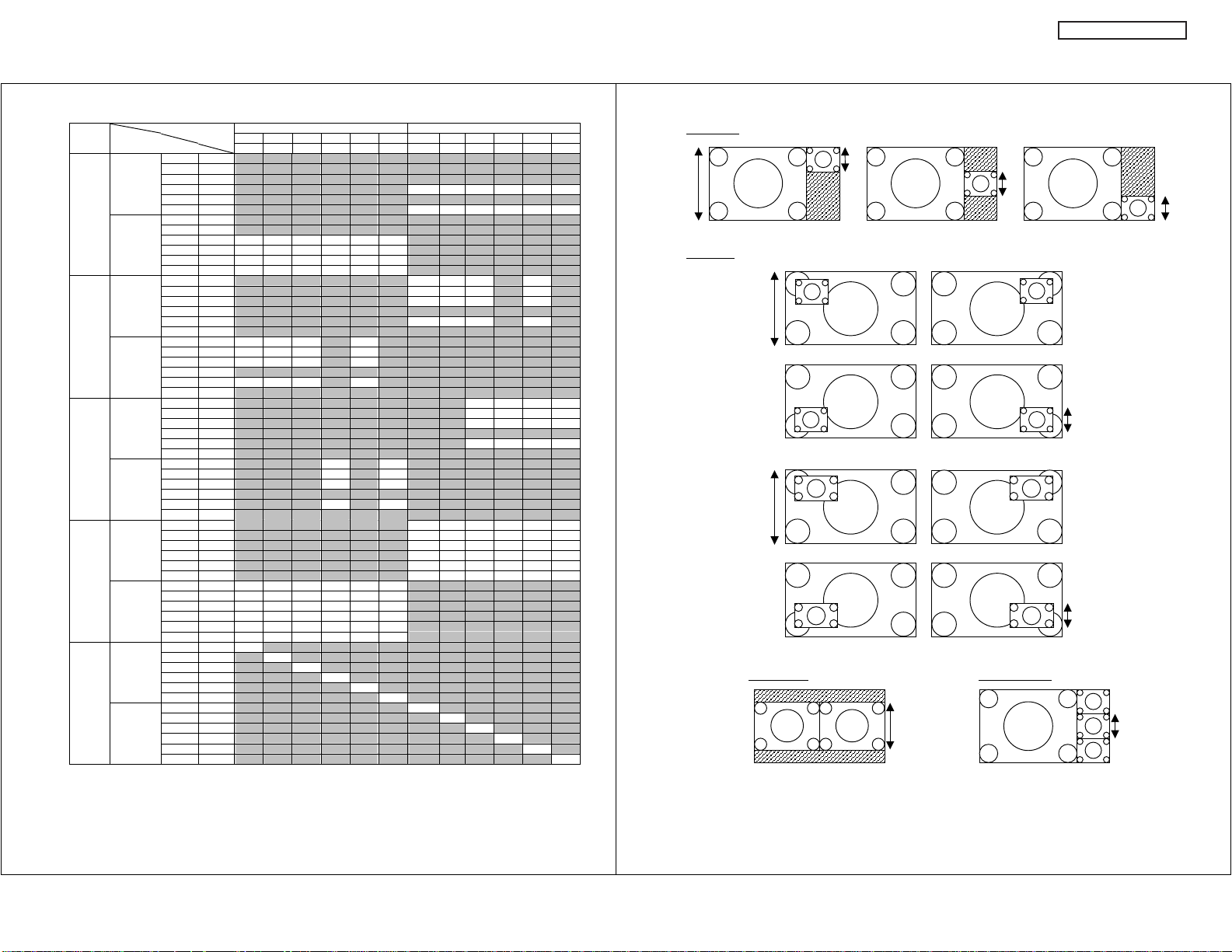

9.1.2 Aspect Key Operation

(1) ANT Analog Channel

(2) ANT Digital Channel

16:9

Standard1

Aspect

Key

4:3

Zoom2

(a) Aspect: 16x9

(b) Aspect: 4x3

Aspect

16:9

Standard1

Aspect

4:3

Expanded

4:3

Standard

Aspect

4:3

Zoom2

Key

Aspect

Key

Key

Key

Aspect

Key

Aspect

Key

Aspect

Key

Aspect

Key

16:9

Zoom

4:3

Zoom1

(3) HDMI/YPBPR: 1080p/1080i/720p

Aspect

Standard2

Aspect

Key

Expanded

16:9

16:9

Zoom

4:3

4:3

Zoom1

Key

Aspect

Key

Aspect

Key

(This mode is for

1080p/1080i/720p only.)

Standard

Aspect

Key

Expanded

4:3

4:3

(4) HDMI/YPBPR: 480p/480i, Video/S-Video

(4-1) Auto Aspect OFF

Standard1

(4-2) Auto Aspect ON

(a) Video ID/HDMI Info: 16x9

Video ID: 16x9

Power ON Initial

16:9

4:3

Zoom2

Aspect

Key

16:9

Standard1

Aspect

Key

4:3

Expanded

Aspect

Key

Aspect

Key

16:9

Standard1

Aspect

Key

Aspect

Key

16:9

Zoom

4:3

Zoom1

Aspect

Aspect

Key

Key

Standard2

Aspect

Key

16:9

16:9

Zoom

Aspect

Key

Aspect

Key

16:9

Zoom

Aspect

Key

4:3

Standard

4:3

Expanded

18

DW3U

(b) Video ID/HDMI Info: Letter

(c) Video ID/HDMI Info: 4x3

(d) No Video ID, No HDMI Info

16:9

Standard

Aspect

4:3

Zoom2

Key

4:3

Standard

Aspect

4:3

Zoom2

4:3

Standard

4:3

Zoom2

Aspect

Key

Aspect

Key

Aspect

Key

Key

Aspect

Key

Aspect

Key

Aspect

Key

Aspect

Key

16:9

Zoom

4:3

Zoom1

9.1.3 Vertical Position Operation

4:3

Expanded

Aspect

Key

4:3

Zoom1

4:3

Expanded

Aspect

Key

4:3

Zoom1

Aspect

Key

Aspect

Key

Video ID: Letter

Power ON Initial

Video ID: 4x3

Power ON Initial

4:3

Standard

Aspect

Key

4:3

Expanded

Input Vertical Position

16:9

ANT

Analog

ANT

Digital

4 80p 4x3

4 80i 16x9 ±0 step

4x3 - - ±0 step

Input 1 Video

Input 2 - 3 YPBPR 1080i

4 80p

Video NTSC - ±0 step

Input

Front

HDMI1 HDMI 1080p

4 80p

HDMI2 HDMI 1080p

4 80p

HDMI

Front

4 80p

PIP Mode SPLIT/POP/

Video NTSC 4 x3 ±0 step

YPBPR 1080i

S-Video

Video NTSC

HDMI 1080p

PIP/STROBE

720p

NTSC - ±0 step

720p

480i

1080i

720p

480i

1080i

720p

480i

1080i

720p

480i

±0 step

Standard1/2

Gray out

16x9 ±0 step

Gray out

-

Gray out

Gray out

16x9 ±0 step

Gray out

16x9

±

4x3

Gray out

Gray out

- ±

Gray out

16x9 ±0 step

Gray out

16x9

±0 step

4x3

Gray out

16x9 ±0 step

Gray out

16x9

±0 step

4x3

Gray out

16x9 ±0 step

Gray out

16x9

±0 step

4x3

Gray out

Gray out

16:9

Zoom

±

(±30 lines)

±10 step

(±30 lines)

-

±10 step

(±30 lines)

±10 step

(±30 lines)

±10 step

(±30 lines)

0 step

±

(±30 lines)

±10 step

(±30 lines)

0 step

±

(±30 lines)

±10 step

(±30 lines)

±10 step

(±30 lines)

±10 step

(±30 lines)

±10 step

(±30 lines)

±

(±30 lines)

±10 step

(±30 lines)

10 step

10 step

10 step

10 step

4:3

Standard

±

Gray out

- ±10 step

±

Gray out

- ±10 step

Gray out

±0 step

Gray out

- ±10 step

±

Gray out

±0 step

Gray out

±

Gray out

- ±10 step

±0 step

Gray out

- ±10 step

±0 step

Gray out

-

±0 step

Gray out

0 step

0 step

0 step

0 step

4:3

Expanded

10 step

±

(±10 lines)

(±10 lines)

10 step

±

(±10 lines)

(±10 lines)

±10 step

(±10 lines)

±10 step

(±10 lines)

(±10 lines)

10 step

±

(±10 lines)

±10 step

(±10 lines)

10 step

±

(±10 lines)

(±10 lines)

±10 step

(±10 lines)

(±10 lines)

±10 step

(±10 lines)

10 step

±

(±10 lines)

±10 step

(±10 lines)

4:3

Zoom 1

±

(±30 lines)

- -

±

(±30 lines)

- -

±10 step

(±30 lines)

±10 step

(±30 lines)

- -

±

(±30 lines)

±10 step

(±30 lines)

±

(±30 lines)

- -

±10 step

(±30 lines)

- -

±10 step

(±30 lines)

-

±10 step

(±30 lines)

10 step

10 step

10 step

10 step

4:3

Zoom 2

10 step

±

(±50 lines)

10 step

±

(±50 lines)

±10 step

(±50 lines)

±10 step

(±50 lines)

10 step

±

(±50 lines)

±10 step

(±50 lines)

10 step

±

(±50 lines)

±10 step

(±50 lines)

±10 step

(±50 lines)

-

±10 step

(±50 lines)

19

DW3U

9.1.4 Black Side Panel Operation

Model Input Aspect POP/SPLIT/ FREEZE PIP/STOROBE

16:9 Standard1

16:9 Zoom

ALL 480p

1080i/720p

ANT_Analog

S-Video/Video

480i

Default

4:3

Standard

Gray

SPLIT

POP

16:9 Standard2

16:9 Standard

4:3 Expanded

4:3 Zoom1

4:3 Zoom2

Full

Gray

4:3 Standard

Normal

Real

Black Side Panel

“Off”

- Gray Black Gray Black Gray

- Gray Black Gray Black Gray

Black Panel

OFF

Black Side Panel

Black Side Panel

“On”

“Off”

Black

Black Side Panel

“On”

Black Panel

ON

-

Black

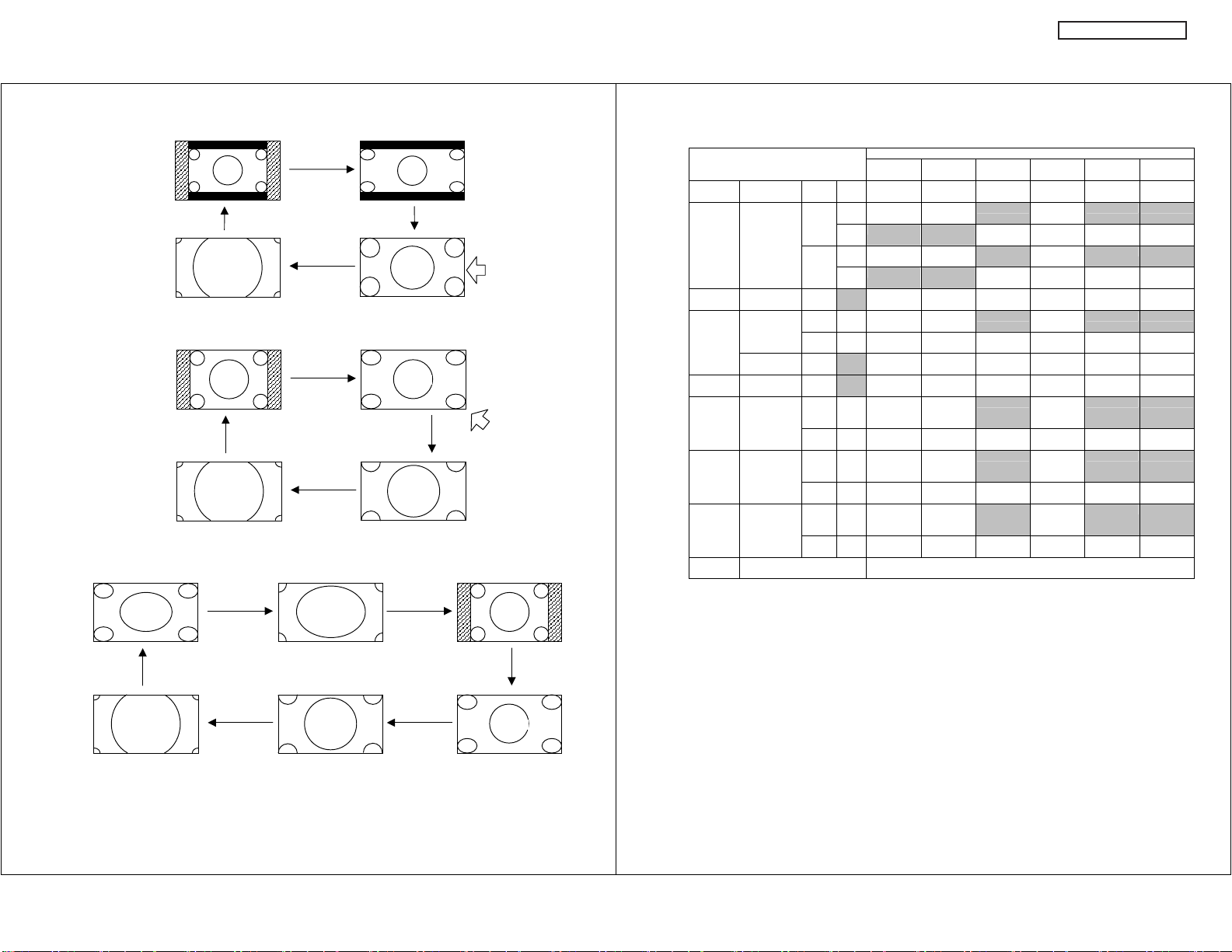

9.1.5 PIP Mode

<Available Function on Each Model>

Model PIP/POP SPLIT Freeze

T Series - X X

PDP

H Series - - -

X: Available, -: Not available

<The Restricti

on of Main/Sub Source>

Main Sub Available or Not

Digital (Air) Digital (Air) -

Digital (Cable) Digital (Cable) -

Analog (Air) Analog (Air) -

Analog (Cable) Analog (Cable) -

Digital (Air) Analog (Cable) -

Digital (Cable) Analog (Cable) -

Digital (Air) Analog (Air) -

Digital (Cable) Analog (Air) -

Analog (Air) Analog (Cable) -

Analog (Cable) Analog (Air) -

Analog (Air) Digital (Air) -

Analog (Cable) Digital (Cable) -

Analog (Air) Digital (Cable) -

Analog (Cable) Digital (Air) -

Input or HDMI Input or HDMI -

Input or HDMI Digital (Air) X

Input or HDMI Digital (Cable) X

Input or HDMI Analog (Air) -

Input or HDMI Analog (Cable) -

Digital (Air) Input or HDMI X

Digital (Cable) Input or HDMI X

Analog (Air) Input or HDMI -

Analog (Cable) Input or HDMI -

X: Available, -: Not available

20

DW3U

PIP Sub Digital Component/Composite/S-IN/HDMI

Mode 1080i 720p 480p 480p 480i 480i 1080i/p 7 20p 480p 480p 480i 480i

Main 16x9 16x9 16x9 4x3 16x9 4x3 16x9 16x9 1 6x9 4x3 16x9 4x3

Digital

POP

(Air or

Cable)

Component

Composite

S-IN

HDMI

Digital

PIP

(Air or

16x9

Cable)

Component

Composite

S-IN

HDMI

Digital

PIP

(Air or

4x3

Cable)

Component

Composite

S-IN

HDMI

Digital

SPLIT

(Air or

Cable)

Component

Composite

S-IN

HDMI

Digital

STROBE

(Air or

(4pix)

Cable)

Component

Composite

S-IN

HDMI

Yes*1: Auto Aspect OFF

Yes*2: Auto Aspect ON

1080i 16x9 - - - - - - - - - - - -

720p 16x9 - - - - - - - - - - - -

480p 16x9 - - - - - - - - - - - -

480p 4x3 - - - - - - Yes Yes Yes Yes Yes Yes

480i 16x9 - - - - - - - - - - - -

480i 4x3

1080i/p 16x9 - - - - - - - - - - - -

720p 16x9 - - - - - - - - - - - -

480p 16x9 Yes*1 Yes*1 Yes*1 Yes*1 Yes*1 Yes*1 - - - - - -

480p 4x3 Yes Yes Yes Yes Yes Yes - - - - - -

480i 16x9 Yes*1 Yes*1 Yes*1 Yes*1 Yes*1 Yes*1 - - - - - -

480i 4x3 Yes Yes Yes Yes Yes Yes

1080i 16x9

720p 16x9

480p 16x9

480p 4x3

480i 16x9 - - - - - - Yes Yes Yes*2 - Yes*2 -

480i 4x3

1080i/p 16x9 Yes Yes Yes - Yes - - - - - - -

720p 16x9 Yes Yes Yes - Yes - - - - - - -

480p 16x9 Yes*2 Yes*2 Yes*2 - Yes*2 - - - - - - -

480p 4x3 - - - - - - - - - - - -

480i 16x9 Yes*2 Yes*2 Yes*2 - Yes*2 - - - - - - -

480i 4x3

1080i 16x9 - - - - - - - - Ye s*1 Yes Yes*1 Yes

720p 16x9 - - - - - - - - Yes*1 Yes Yes*1 Yes

480p 16x9 - - - - - - - - Yes*1 Yes Yes*1 Yes

480p 4x3 - - - - - - - - - - - -

480i 16x9

480i 4x3

1080i/p 16x9

720p 16x9

480p 16x9

480p 4x3 - - - - - - - - - - - -

480i 16x9 - - - Yes*2 - Yes *2 - - - - - -

480i 4x3

1080i 16x9 - - - - - - Yes Yes Yes Yes Yes Yes

720p 16x9 - - - - - - Yes Yes Yes Yes Yes Yes

480p 16x9 - - - - - - Yes Yes Yes Yes Yes Yes

480p 4x3 - - - - - - Yes Yes Yes Yes Yes Yes

480i 16x9 - - - - - - Yes Yes Yes Yes Yes Yes

480i 4x3

1080i/p 16x9 Yes Yes Yes Yes Yes Ye s - - - - - -

720p 16x9 Yes Yes Yes Yes Yes Yes - - - - - -

480p 16x9 Yes Yes Yes Yes Yes Yes

480p 4x3 Yes Yes Yes Yes Yes Yes

480i 16x9 Yes Yes Yes Yes Yes Yes

480i 4x3 Yes Yes Yes Yes Yes Yes

1080i 16x9 Yes

720p 16x9

480p 16x9 - - Yes - - - - - - - - -

480p 4x3 - - - Yes - - - - - - - -

480i 16x9 - - - - Yes - - - - - - -

480i 4x3

1080i/p 16x9 - - - - - - Yes - - - - -

720p 16x9 - - - - - - - Yes - - - -

480p 16x9 - - - - - - - - Yes - - -

480p 4x3 - - - - - - - - - Yes - -

480i 16x9 - - - - - - - - - - Yes -

480i 4x3

- - - - - - Yes Yes Yes Yes Yes Yes

- - - - - -

Yes Yes Yes*2

- - - - - -

- - - - - -

- - - - - -

- - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - - - -

- - - - - - - - - - - -

- - -

- - -

- - -

- - - - - - - - - - - -

- - - - - - Yes Yes Yes Yes Yes Yes

- - - - - - - - - - -

Yes

-

- - - - - Yes - - - - - -

- - - - - - - - - - - Yes

Yes

Yes

Yes*2

- - - - - - - - - -

Yes Yes Yes*2

Yes Yes Yes*2

Yes*1 Yes Yes*1 Yes

Yes

-

-

-

- - - - - -

Yes

- - - - - -

Yes*2

- - - - - -

- - - - - -

- - - - - -

- - - - - -

- - - - - -

Yes*2

-

Yes*2

-

Yes*2

-

POP Mode

1024/768 Lines

PIP Mode

-

-

-

:

4x3

:

1024/768 Lines

SPLIT Mode

4x3

4x3

4x3

4x3

341/256 Lines

16x9

16x9

16x9

16x9

16x9

16x9

: STROBE Mode:

4x3

768/576 Lines (93%)

1024/768 Lines

4x3

4x3

16x9

16x9

16x9

16x9

4x3

341/256 Lines

4x3

4x3

341/256 Lines

4x3

341/256 Lines

16x9

16x9

341/256 Lines

4x3

4x3

4x3

4x3

341/256 Lines

21

g

ABA

A

A A

ABA

DW3U

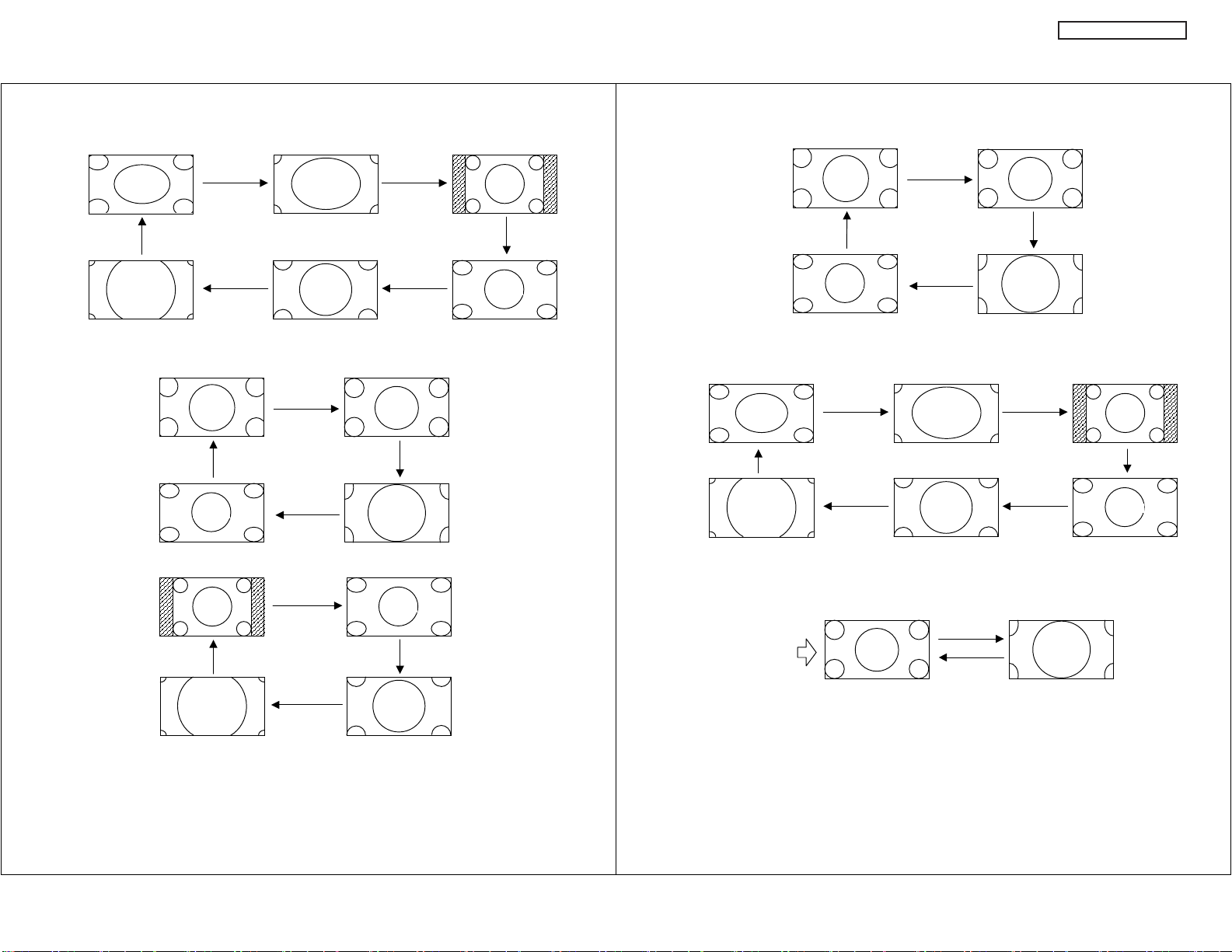

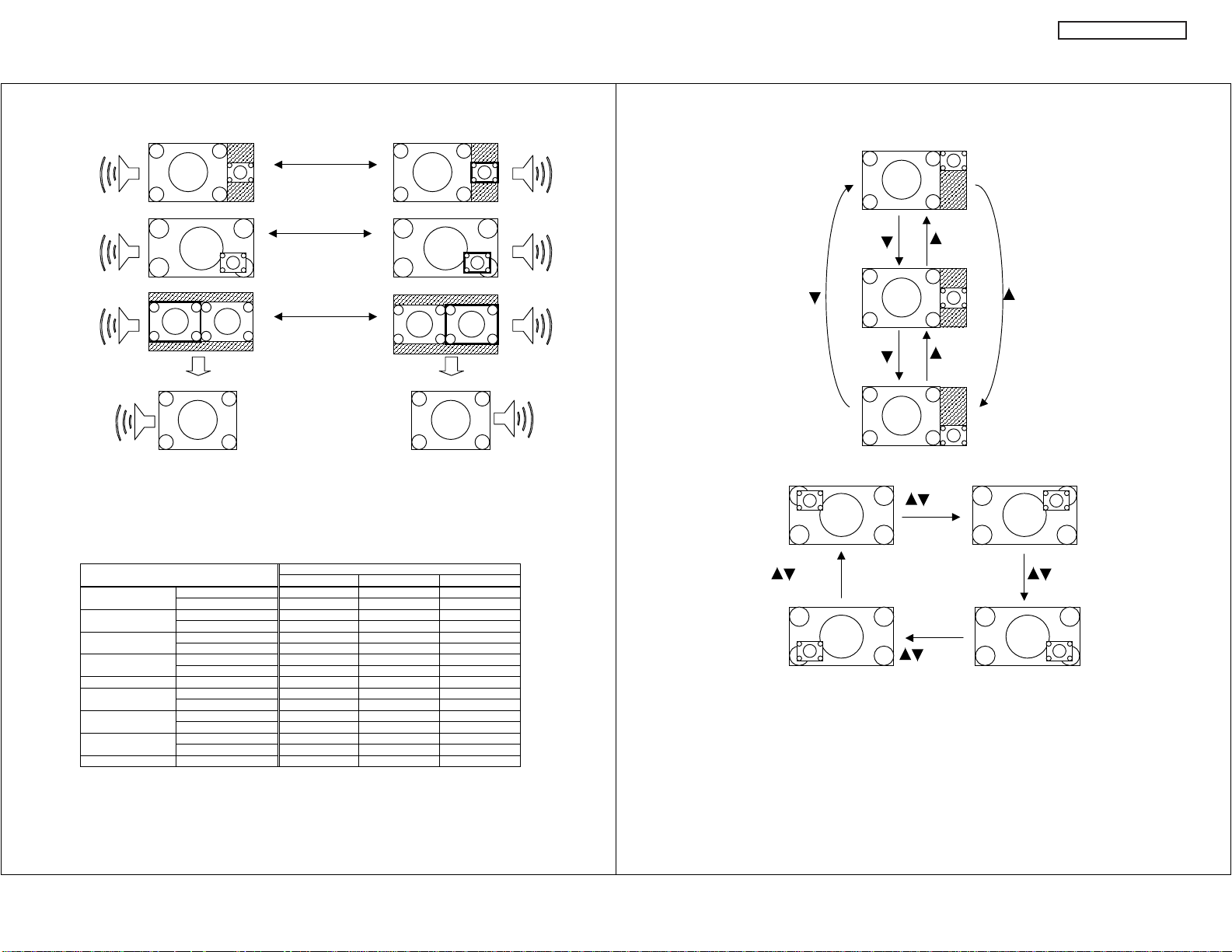

(1) PIP Key Operation

(Note)

If PIP Key is pushed from a Normal screen, PIP of Last Mode will be displayed.

A shipment setup of PIP Mode is SPLIT Mode.

POP/PIP Mode cannot display 720p/480p signals. Therefore, it displays by SPLIT Mode.

・When Last mode is POP/PIP Mode and a Main signal is 1080i, PIP Mode is set to PIP.

・When Last mode is POP/PIP Mode and a Main signal is 480i/NTSC, PIP Mode is set to PIP.

・SURF Mode is not displayed at a V-Chip setup. SPLIT Mode is displayed at this time.

When EXIT Key is pushed, PIP turns off.

When PIP is turns off, PIP Mode of a display turns into Last Mode.

SPLIT

Normal Viewing

PIP

Key

PIP

Key

Exit

Key

POP

PIP

4x3

PIP

16x9

PIP

Key

(2) Freeze Operation

(3) SWAP Operation

Main

Audio

Main

Audio

Main

Audio

(Note)

When right and left Key are pushed, the sound of Main and Sub interchanges.

A Channel/Input change can do the screen out of which the sound has come.

When PIP OFF [EXIT Key], the screen where sound is sounding turns into a normal screen.

Freeze

Key

B

B

PIP OFF

Freeze

Key

Main

Movin

Freeze

Key

STROBE

Main

Frozen

Sub

Frozen

△

△

△

▽

Key

▽

▽

Freeze

Key

Key

Key

Exit

Key

B

B

PIP OFF

B

Sub

Audio

Sub

Audio

Sub

Audio

22

A

A

A

AB A

A

A

DW3U

(4) Monitor Out

Main

Audio

Main

Audio

Main

Audio

(Note)

When right and left Key are pushed, the sound of Main and Sub interchanges.

The picture and sound of the selected picture are outputted from Monitor out.

When the selected picture is Component or HDMI signal and audio out is monitor,

monitor out is no picture and no audio.

When the selected picture is Component or HDMI signal and audio out is HiFi out,

monitor out is no picture but audio is output.

When the selected picture is Composite Video signal, S-Video of monitor out is no picture.

When Macrovision signal is included in the ANT Digital channel, monitor out is no picture and no audio.

(AIR or CABLE) Analog Channel - YES YES

Photo Input - - -

B

B

Main

Audio

Input Mode Monitor Out

S-Video Video L/R

ANT Digital Channel YES YES YES

Input 1 S-Video_1 YES YES YES

Video_1 - YES YES

Input 2 YPBPR_2 - - -

Video_2 - YES YES

Input 3 YPBPR_3 - - -

Video_3 - YES YES

Input-Front Video_Front - YES YES

HDMI 1 HDMI_1 - - -

DVI_1 - - -

HDMI 2 HDMI_2 - - -

DVI_2 - - -

HDMI-Front HDMI_Front - - -

DVI_Front - - -

Monitor Out

Key

△

▽

B

Key

△

▽

B

Key

△

▽

B

Monitor Out

B

Sub

Audio

Sub

Audio

Sub

Audio

Sub

Audio

(4) PIP Position Operation

(Note)

The Sub screen position of POP Mode moves up and down by the upper and lower sides Key.

A Sub screen position of PIP Mode moves clockwise by the upper and lower sides Key.

Key

Key Key

Key

Key

Key

Key

Key

Key

Key

23

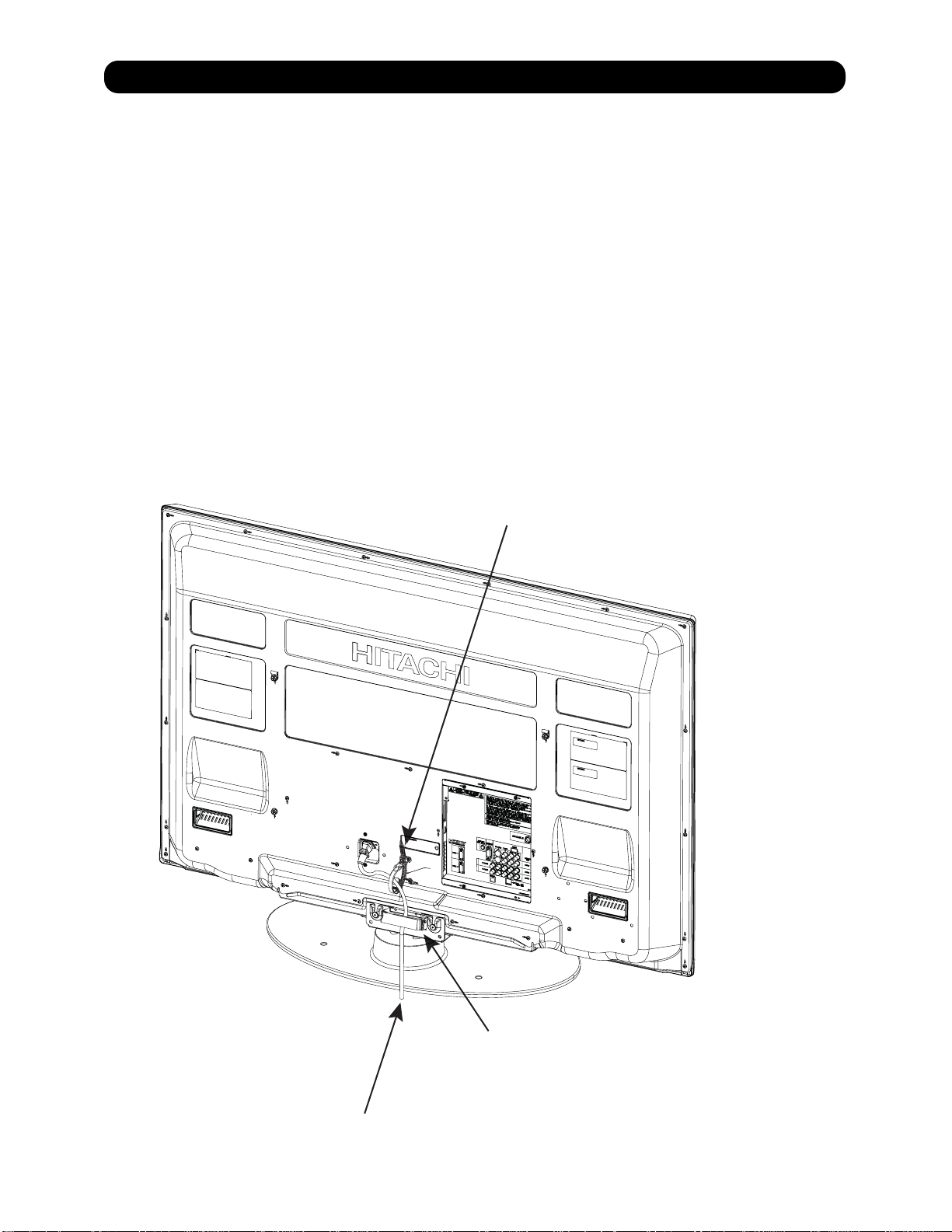

How to set up your new HITACHI Plasma Television

To take measures to prevent the Plasma Television from tipping over and prevent possible injury

it is important to mount the unit in a stable and flat surface.

Securing to a table-top

1. Using wood screws (two) fasten the set to the

clamping screw holes on the rear of the Plasma

TV stand as shown below.

2. Using commercially available wood screws, secure

the set firmly in position.

Wire

Wood screw

two places

Securing to a Wall

1. Keep the Plasma television 4 inches away from the

wall except when mounted using the wall mount

bracket.

2. Secure the television to the wall as shown.

A

A

4 in.

50"

10 cm

* Please adjust the wire length to avoid

touching the wall when turning the TV.

ANTENNA

Unless your Plasma Television is connected to a cable

TV system or to a centralized antenna system, a good

outdoor color TV antenna is recommended for best

performance. However, if you are located in an

exceptionally good signal area that is free from

interference and multiple image ghosts, an indoor

antenna may be sufficient.

LOCATION

Select an area where sunlight or bright indoor

illumination will not fall directly on the picture screen.

Also, be sure that the location selected allows a free

flow of air to and from the perforated back cover of the

set. In order to prevent an internal temperature

increase, maintain a space of 10 cm (4 inches) from the

sides/back of the Television, and 30 cm (12 inches)

from the top of the television to the wall. To avoid

cabinet warping, cabinet color changes, and increased

chance of set failure, do not place the TV where

temperatures can become excessively hot, for

example, in direct sunlight or near a heating appliance,

etc.

30 cm (12 inches)

10 cm (4 inches)

10 cm (4 inches)

NOTES: 1. Do not block the ventilation holes of the

Plasma Television. Blocking the ventilation

holes might cause fire or defect.

2. In case of an abnormal symptom, unplug

the AC cord.

3. If you purchased the wall mount bracket

option, please ask for professional installer.

Do not install

by yourself.

4. Install the unit at a proper area where it does

not expose anyone to any danger of hitting

themselves (for example their hands, head

or face, etc.) against the edge of the unit and

cause personal injury.

Caution when moving the main unit

As this product is heavy, whenever it is moved, two

people arerequired to transport it safely. Whenever the

unit is moved it should be lifted forward using the top

and base on both sides of the Television for stability.

When moving the Television, lift the handles , then

support the top frame as shown below.

TURNING RADIUS

The maximum turning radius is 30˚ (left and right). Do

not place any objects on the path of the monitor when

using the swivel feature.

C

CD

15 in. 16.85 in.

50"

D

38.1 cm 42.8 cm

TABLE OF CONTENTS

50”

24

How to set up your new HITACHI Plasma Television

AC CORD INSTALLATION INSTRUCTION

The AC cord provided with your new Plasma Television needs to be installed correctly

to avoid the AC cord from disconnecting when rotating the TV on its Table top stand.

Located on the back of the TV are 2 plastic clamps to hold the AC cord. Please follow the

instructions below.

쐃

Pass the AC cord through Clamp #1 and connect

AC cord to the TV.

쐇

The AC cord and the signal cables can all be

held together with Clamp #2.

쐋

Depend on the model size 42", 50" or 55", the

clamp may be different shapes. Only for 50" models

the clamp #2 will be included on the accessories

bag.

Clamp #1 : Pass the AC cord through this clamp ;

쐃

then pull the clamp to tighten the AC

cord to the TV.

AC CORD

Clamp #2: Use this clamp to hold the AC cord and

쐇

the signal cables. For 50 " model please

assemble this Clamp on the middle hole

of the base metal.

25

How to set up your new HITACHI Plasma Television

VIEWING

The best picture is seen by sitting directly in front of

the TV and about 10 to 18 feet from the screen.

During daylight hours, reflections from outside light

may appear on the screen. If so, drapes or screens

can be used to reduce the reflection or the TV can

be located in a different section of the room.

If the TV’s audio output will be connected to a Hi-Fi

system’s external speakers, the best audio

performance will be obtained by placing the

speakers equidistant from each side of the receiver

cabinet and as close as possible to the height of

the picture screen center. For best stereo

separation, place the external speakers at least

four feet from the side of the TV, place the surround

speakers to the side or behind the viewing area.

Differences in room sizes and acoustical

environments will require some experimentation

with speaker placement for best performance.

ANTENNA CONNECTIONS TO REAR JACK

PANEL

R

4" Minimum

4" Minimum

L

S

80

BEST

HORIZONTAL

5'

10'

VIEWING ANGLE

80

15' 20'

S

VHF (75-Ohm) antenna/CATV (Cable TV)

When using a 75-Ohm coaxial cable system, connect CATV coaxial cable to the AIR/CABLE (75-Ohm) terminal.

Or if you have an antenna, connect the coaxial cable to the same AIR/CABLE terminal.

AIR / CABLE

To CATV cable

VHF (300-Ohm) antenna/UHF antenna

When using a 300-Ohm twin lead from an outdoor

antenna, connect the VHF or UHF antenna leads to

screws of the VHF or UHF adapter. Plug the adapter

To outdoor antenna

or

into the antenna terminal on the TV.

AIR / CABLE

When both VHF and UHF antennas are

connected

Attach an optional antenna cable mixer to the TV

antenna terminal, and connect the cables to the

antenna mixer. Consult your dealer or service store for

the antenna mixer.

To UHF

antenna

AIR / CABLE

Antenna Mixer

To outdoor VHF

or UHF antenna

To outdoor antenna

or CATV system

NOTE: Connecting a 300-Ohm twin lead connector may cause interference. Using a 75-Ohm coaxial

cable is recommended.

26

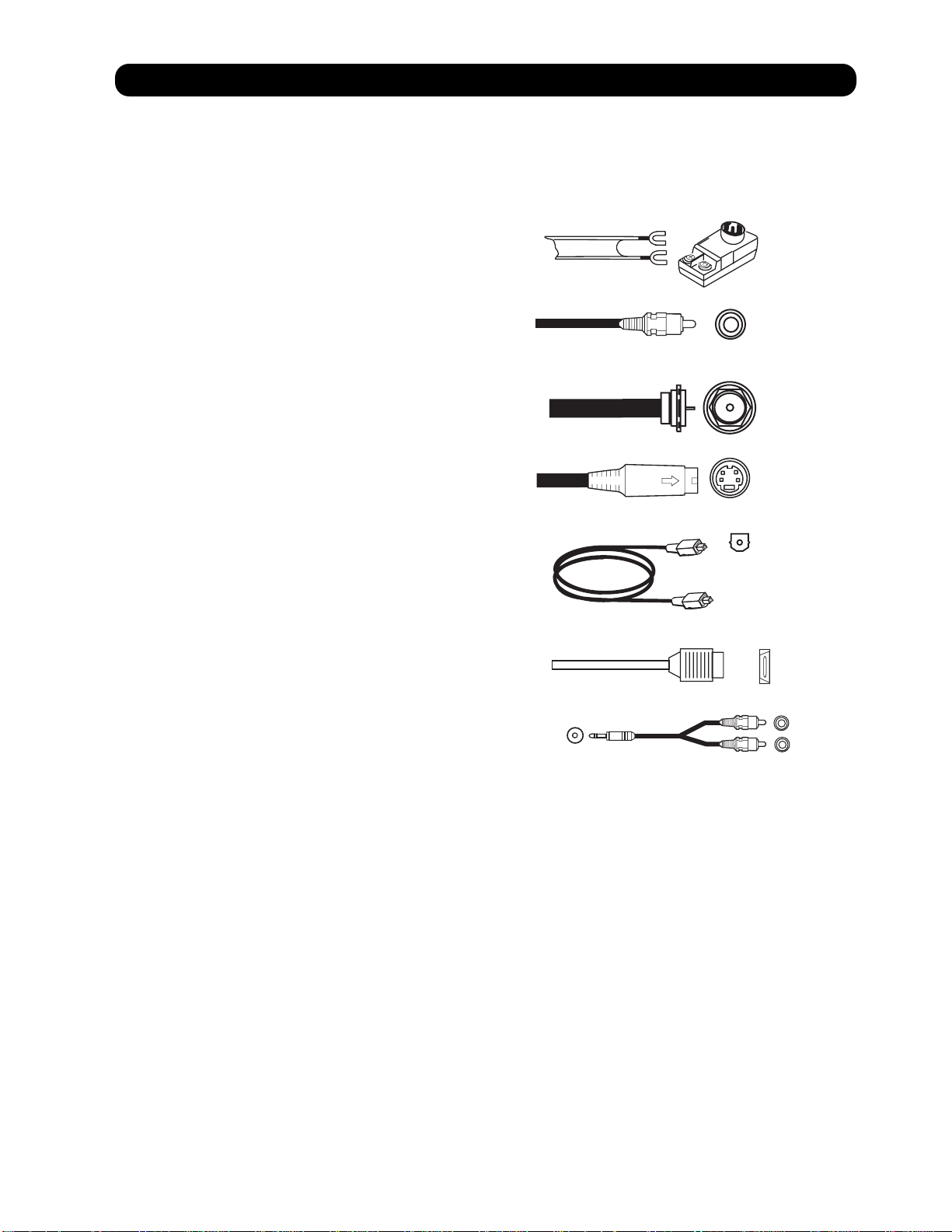

Hook-up Cables and Connectors

Most video/audio connections between components can be made with shielded video and audio cables that have

phono connectors. For best performance, video cables should use 75-Ohm coaxial shielded wire. Cables can be

purchased from most stores that sell audio/video products. Below are illustrations and names of common

connectors. Before purchasing any cables, be sure of the output and input connector types required by the

various components and the length of each cable.

300-Ohm Twin Lead

Cable

This outdoor antenna cable must be connected to an

antenna adapter (300-Ohm to 75-Ohm).

Phono

Cable

Used on all standard video and audio cables which

connect to inputs and outputs located on the

television’s rear jack panel and front control panel.

“F” Type 75-Ohm Coaxial Antenna

For connecting RF signals (antenna or cable TV) to the

antenna jack on the television.

S-Video (Super Video)

Cable

This connector is used on camcorders, VCRs and laserdisc players with an S-Video feature in place of the

standard video cable to produce a high quality picture.

Optical Cable

This cable is used to connect to an audio amplifier with