Hitachi L700 SERIES Quick Reference

HITACHI INVERTER

L700 SERIES

Quick Reference Guide

Read through this Instruction Manual, and keep it handy for future reference.

NT2211X

Introduction

Thank you for purchasing the Hitachi L700 Series Inverter.

This Quick Reference guide describes how to handle and maintain the Hitachi L700 Series Inverter.

Read this Instruction Manual carefully before using the inverter, and then keep it handy for those who

operate, maintain, and inspect the inverter.

Before and during the installation, operation and inspection of the inverter, always refer to this Instruction

Manual to obtain the necessary related knowledge, and ensure you understand and follow all safety

information, precautions, and operating and handling instructions for the correct use of the inverter.

Always use the inverter strictly within the range of the specifications described in this Quick Reference

guide and correctly implement maintenance and inspections to prevent faults occurring.

When using the inverter together with optional products, also read the manuals for those products.

In the manual that relates to this inverter, there are another of this Quick Reference guide and "L700

series Instruction Manual".

Please read when you want to hear of a more detailed content about this inverter. It is not described in

Quick Reference guide, and a detailed content can be confirmed.

Note that this Quick Reference guide and the manual for each optional product to be used should be

delivered to the end user of the inverter.

Handling of this Instruction Manual

- The contents of this Instruction Manual are subject to change without prior notice.

- Even if you lose this Instruction Manual, it will not be resupplied, so please keep it carefully.

- No part of this Instruction Manual may be reproduced in any form without the publisher’s permission.

- If you find any incorrect description, missing description or have a question concerning the contents of

this Instruction Manual, please contact the publisher.

Revision History

No. Revision content Date of issue Manual code

1 First edition July,2010 NT2211X

- The current edition of this Instruction Manual also includes some corrections of simple misprints,

missing letters, misdescriptions and certain added explanations other than those listed in the above

Revision History table.

Safety Instructions

M

Safety Instructions

Be sure to read this Instruction Manual and appended documents thoroughly before installing, operating, maintaining,

or inspecting the inverter.

In this Instruction Manual, safety instructions are classified into two levels, namely WARNING and CAUTION.

! WARNING

! CAUTION

Note that even a level situation may lead to a serious consequence according to circumstances.

Be sure to follow every safety instruction, which contains important safety information. Also focus on and observe the

items and instructions described under "Notes" in the text.

any of the drawings in this Instruction Manual show the inverter with covers and/or parts blocking your view being

removed.

Do not operate the inverter in the status shown in those drawings. If you have removed the covers and/or parts, be

sure to reinstall them in their original positions before starting operation, and follow all instructions in this Instruction

Manual when operating the inverter.

1. Installation

- Install the inverter on a non-flammable surface, e.g., metal. Otherwise, you run the risk of fire.

- Do not place flammable materials near the installed inverter. Otherwise, you run the risk of fire.

- When carrying the inverter, do not hold its top cover. Otherwise, you run the risk of injury by dropping the inverter.

- Prevent foreign matter (e.g., cut pieces of wire, sputtering welding materials, iron chips, wire, and dust) from

entering the inverter. Otherwise, you run the risk of fire.

- Install the inverter on a structure able to bear the weight specified in this Instruction Manual. Otherwise, you run

the risk of injury due to the inverter falling.

- Install the inverter on a vertical wall that is free of vibrations. Otherwise, you run the risk of injury due to the

inverter falling.

- Do not install and operate the inverter if it is damaged or its parts are missing. Otherwise, you run the risk of injury.

- Install the inverter in a well-ventilated indoor site not exposed to direct sunlight. Avoid places where the inverter is

exposed to high temperature, high humidity, condensation, dust, explosive gases, corrosive gases, flammable

gases, grinding fluid mist, or salt water. Otherwise, you run the risk of fire.

- The inverter is precision equipment. Do not allow it to fall or be subject to high impacts, step on it, or place a

heavy load on it. Doing so may cause the inverter to fail.

2. Wiring

: Indicates that incorrect handling may cause hazardous situations, which may result in serious

personal injury or death.

: Indicates that incorrect handling may cause hazardous situations, which may result in moderate

or slight personal injury or physical damage alone.

! CAUTION

CAUTION

!

CAUTION

!

!

WARNING

- Be sure to ground the inverter. Otherwise, you run the risk of electric shock or fire.

- Commit wiring work to a qualified electrician. Otherwise, you run the risk of electric shock or fire.

- Before wiring, make sure that the power supply is off. Otherwise, you run the risk of electric shock or fire.

- Perform wiring only after installing the inverter. Otherwise, you run the risk of electric shock or injury.

- Do not remove rubber bushings from the wiring section. Otherwise, the edges of the wiring cover may damage

the wire, resulting in a short circuit or ground fault.

CAUTION

!

- Make sure that the voltage of AC power supply matches the rated voltage of your inverter. Otherwise, you run the

risk of injury or fire.

- Do not input single-phase power into the inverter. Otherwise, you run the risk of fire.

- Do not connect AC power supply to any of the output terminals (U, V, and W). Otherwise, you run the risk of injury

or fire.

- Do not connect a resistor directly to any of the DC terminals (PD, P, and N). Otherwise, you run the risk of fire.

- Connect an earth-leakage breaker to the power input circuit. Otherwise, you run the risk of fire.

- Use only the power cables, earth-leakage breaker, and magnetic contactors that have the specified capacity

(ratings). Otherwise, you run the risk of fire.

- Do not use the magnetic contactor installed on the primary and secondary sides of the inverter to stop its

operation.

- Tighten each screw to the specified torque. No screws must be left loose. Otherwise, you run the risk of fire.

- Before operating, slide switch SW1 in the inverter, be sure to turn off the power supply. Otherwise, you run the risk

of electric shock and injury.

- Since the inverter supports two modes of cooling-fan operation, the inverter power is not always off, even when

the cooling fan is stopped. Therefore, be sure to confirm that the power supply is off before wiring. Otherwise, you

run the risk of electric shock and injury.

i

Safety Instructions

3. Operation

WARNING

- While power is supplied to the inverter, do not touch any terminal or internal part of the inverter, check signals, or

connect or disconnect any wire or connector. Otherwise, you run the risk of electric shock or fire.

- Be sure to close the terminal block cover before turning on the inverter power. Do not open the terminal block

cover while power is being supplied to the inverter or voltage remains inside. Otherwise, you run the risk of

electric shock.

- Do not operate switches with wet hands. Otherwise, you run the risk of electric shock.

- While power is supplied to the inverter, do not touch the terminal of the inverter, even if it has stopped. Otherwise,

you run the risk of injury or fire.

- If the retry mode has been selected, the inverter will restart suddenly after a break in the tripping status. Stay

away from the machine controlled by the inverter when the inverter is under such circumstances. (Design the

machine so that human safety can be ensured, even when the inverter restarts suddenly.) Otherwise, you run the

risk of injury.

- Do not select the retry mode for controlling an elevating or traveling device because output free-running status

occurs in retry mode. Otherwise, you run the risk of injury or damage to the machine controlled by the inverter.

- If an operation command has been input to the inverter before a short-term power failure, the inverter may restart

operation after the power recovery. If such a restart may put persons in danger, design a control circuit that

disables the inverter from restarting after power recovery. Otherwise, you run the risk of injury.

- The [STOP] key is effective only when its function is enabled by setting. Prepare an emergency stop switch

separately. Otherwise, you run the risk of injury.

- If an operation command has been input to the inverter before the inverter enters alarm status, the inverter will

restart suddenly when the alarm status is reset. Before resetting the alarm status, make sure that no operation

command has been input.

- While power is supplied to the inverter, do not touch any internal part of the inverter or insert a bar in it. Otherwise,

you run the risk of electric shock or fire.

CAUTION

!

- Do not touch the heat sink, which heats up during the inverter operation. Otherwise, you run the risk of burn injury.

- The inverter allows you to easily control the speed of motor or machine operations. Before operating the inverter,

confirm the capacity and ratings of the motor or machine controlled by the inverter. Otherwise, you run the risk of

injury.

- Install an external brake system if needed. Otherwise, you run the risk of injury.

- When using the inverter to operate a standard motor at a frequency of over 60 Hz, check the allowable motor

speeds with the manufacturers of the motor and the machine to be driven and obtain their consent before starting

inverter operation. Otherwise, you run the risk of damage to the motor and machine.

- During inverter operation, check the motor for the direction of rotation, abnormal sound, and vibrations.

Otherwise, you run the risk of damage to the machine driven by the motor.

4. Maintenance, inspection, and parts replacement

!

WARNING

- Before inspecting the inverter, be sure to turn off the power supply and wait for 10 minutes or more. Otherwise,

you run the risk of electric shock.

(Before inspection, confirm that the Charge lamp on the inverter is off and the DC voltage between terminals P

and N is 45 V or less.)

- Commit only a designated person to maintenance, inspection, and the replacement of parts.

(Be sure to remove wristwatches and metal accessories, e.g., bracelets, before maintenance and inspection work

and to use insulated tools for the work.)

Otherwise, you run the risk of electric shock and injury.

5. Others

!

WARNING

- Never modify the inverter. Otherwise, you run the risk of electric shock and injury.

!

CAUTION

- Do not discard the inverter with household waste. Contact an industrial waste management company in your area

who can treat industrial waste without polluting the environment.

ii

Safety Instructions

Precautions Concerning Electromagnetic Compatibility (EMC)

The L700 series inverter conforms to the requirements of Electromagnetic Compatibility (EMC) Directive

(2004/108/EC). However, when using the inverter in Europe, you must comply with the following

specifications and requirements to meet the EMC Directive and other standards in Europe:

!

WARNING: This equipment must be installed, adjusted, and maintained by qualified engineers who

have expert knowledge of electric work, inverter operation, and the hazardous circumstances that can

occur. Otherwise, personal injury may result.

1. Power supply requirements

a. Voltage fluctuation must be -15% to +10% or less.

b. Voltage imbalance must be ±3% or less.

c. Frequency variation must be ±4% or less.

d. Total harmonic distortion (THD) of voltage must be ±10% or less.

2. Installation requirement

a. A special filter intended for the L700 series inverter must be installed.

3. Wiring requirements

a. A shielded wire (screened cable) must be used for motor wiring, and the length of the cable must be

according to the following table (Table 1).

b. The carrier frequency must be set according to the following table to meet an EMC requirement

(Table 1).

c. The main circuit wiring must be separated from the control circuit wiring.

4. Environmental requirements (to be met when a filter is used)

a. Ambient temperature must be within the range -10°C to +40°C.

b. Relative humidity must be within the range 20% to 90% (non-condensing).

c. Vibrations must be 5.9 m/s

2.94 m/s

d. The inverter must be installed indoors (not exposed to corrosive gases and dust) at an altitude of

1,000 m or less.

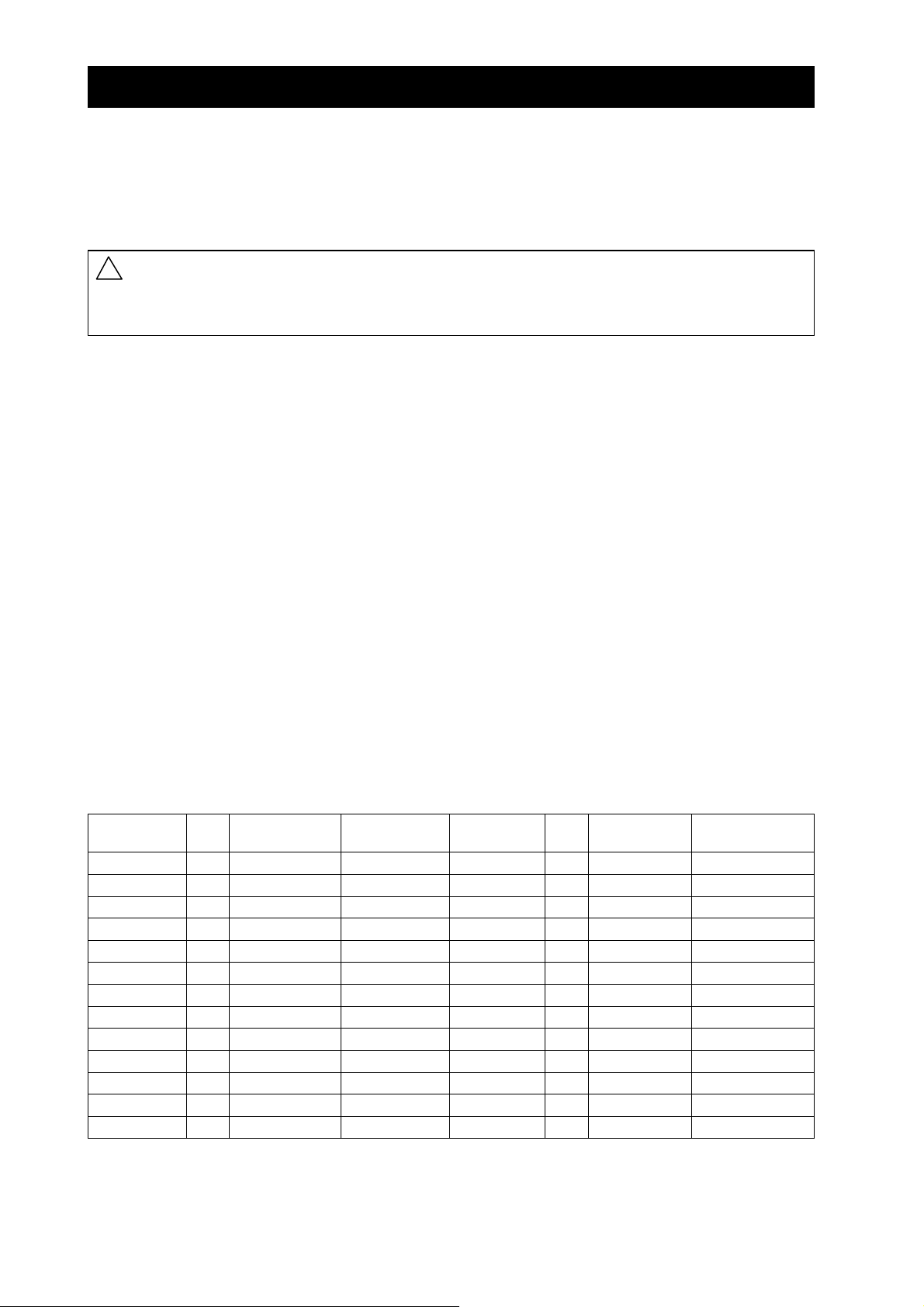

model cat. cable length(m)

L700-110L C3 1 1 L700-110H C3 1 2.5

L700-150L C3 1 1 L700-150H C3 1 2.5

L700-185L C3 1 1 L700-185H C3 1 2.5

L700-220L C3 1 1 L700-220H C3 1 2.5

L700-300L C3 5 2.5 L700-300H C3 1 2.5

L700-370L C3 5 2.5 L700-370H C3 1 2.5

L700-450L C3 5 2.5 L700-450H C3 1 2.5

L700-550L C3 20 3 L700-550H C3 5 2.5

L700-750L C3 20 3 L700-750H C3 5 2.5

L700-900H C3 10 2.5

L700-110H C3 10 2.5

L700-1320H C3 10 2.5

L700-1600H C3 10 2.5

2

(0.6 G) (10 to 55 Hz) or less. (11 to 30kW)

2

(0.3 G) (10 to 55Hz) or less. (37 to 160kW)

carrier

frequency(kHz)

model cat. cable length(m)

Table 1

carrier

frequency(kHz)

iii

Safety Instructions

Precautions Concerning Compliance with UL and cUL Standards

(Standards to be met: UL508C and CSA C22.2 No. 14-05)

These devices are open typeand/or Enclosed Type 1 (when employing accessory Type 1 Chassis Kit) AC

Inverters with three phase input and three phase output. They are intended to be used in an enclosure.

They are used to provide both an adjustable voltage and adjustable frequency to the ac motor. The inverter

automatically maintains the required volts-Hz ration allowing the capability through the motor speed range.

1. “Use 60/75 C CU wire only” or equivalent. For models L700 series except for L700-110H and

L700-150H.

2. “Use 75C CU wire only” or equivalent. For models L700-110H and L700-150H.

3. “Suitable for use on a circuit capable of delivering not more than 100 k rms symmetrical amperes,

240 V maximum”. For models with suffix L.

4. “Suitable for use on a circuit capable of delivering not more than 100 k rms symmetrical amperes,

480 V maximum”. For models with suffix H.

5. “Install device in pollution degree 2 environment”.

6. “Maximum Surrounding Air Temperature 45 or 50°C”.

7. “CAUTION- Risk of Electric Shock- Capacitor discharge time is at least 10 min.”

8. “Integral solid state short circuit protection does not provide branch circuit protection. Branch circuit

protection must be provided in accordance with the NEC and any additional local codes.”

9. “Solid state motor overload protection is provided in each model”

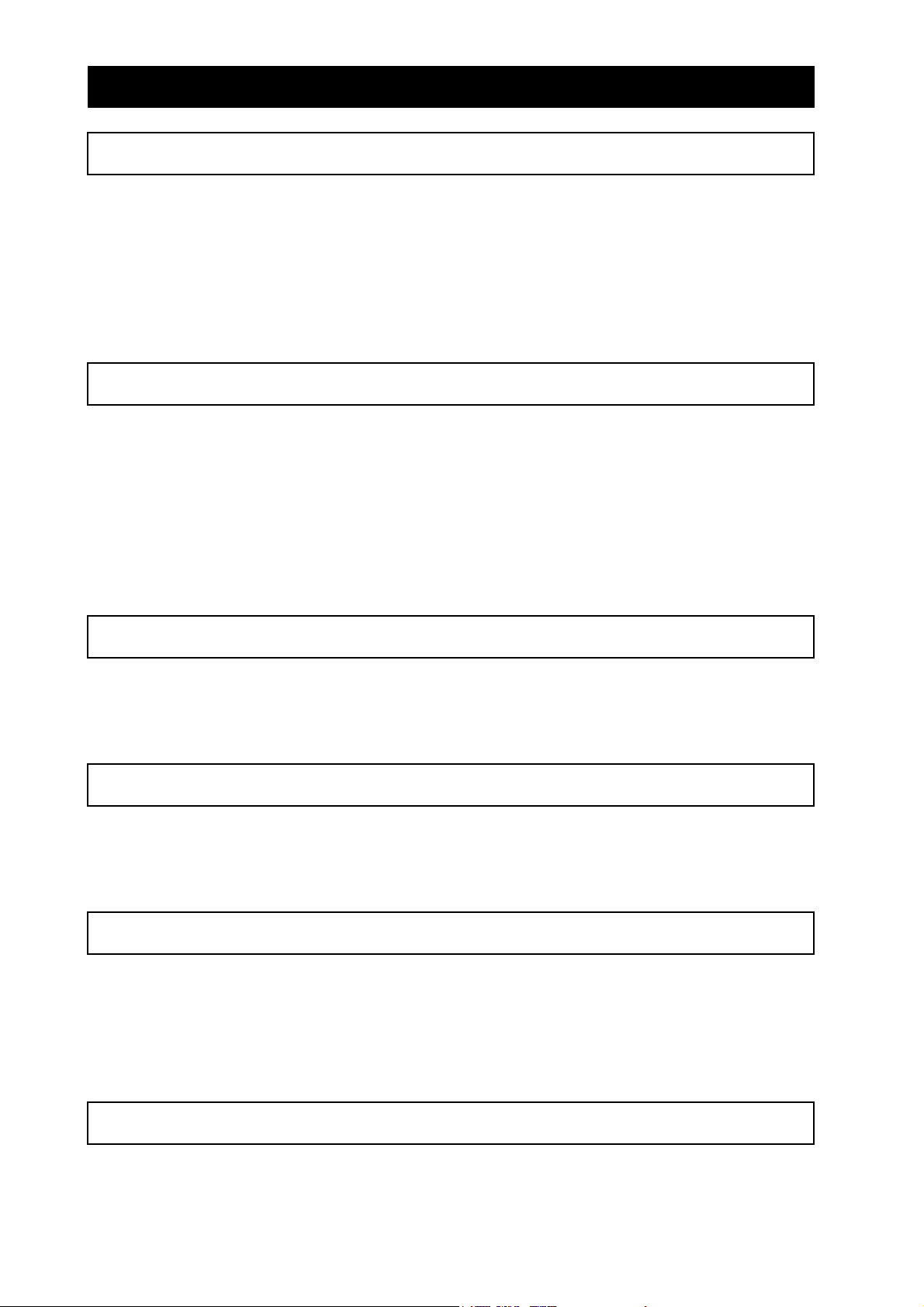

10. Tightening torque and wire range for field wiring terminals are in the table below:

Model No. Required torque (N-m) Wire range (AWG)

L700-110L 4.0 6

L700-150L 4.0 6-4

L700-185L 4.9 2

L700-220L 4.9 1

L700-300L 8.8 1 or 1/0

L700-370L 8.8 2/0 or Parallel of 1/0

L700-450L 20.0 4/0 (Prepared wire only) or Parallel of 1/0

L700-550L 20.0 4/0 (Prepared wire only) or Parallel of 1/0

L700-750L 19.6 350 kcmil

(Prepared wire only) or Parallel of 2/0 (Prepared wire only)

Model No.

L700-110H 4.0 10

L700-150H 4.0 8

L700-185H 4.9 6

L700-220H 4.9 6

L700-300H 4.9 6 or 4

L700-370H 4.9 3

L700-450H 20.0 1

L700-550H 20.0 1

L700-750H 20.0 2/0

L700-900H 20.0 Parallel of 1/0

L700-1100H 20.0 Parallel of 1/0

L700-1320H 35.0 Parallel of 3/0

L700-1600H 35.0 Parallel of 3/0

Required Torque (N.m) Wire Range (AWG)

iv

Safety Instructions

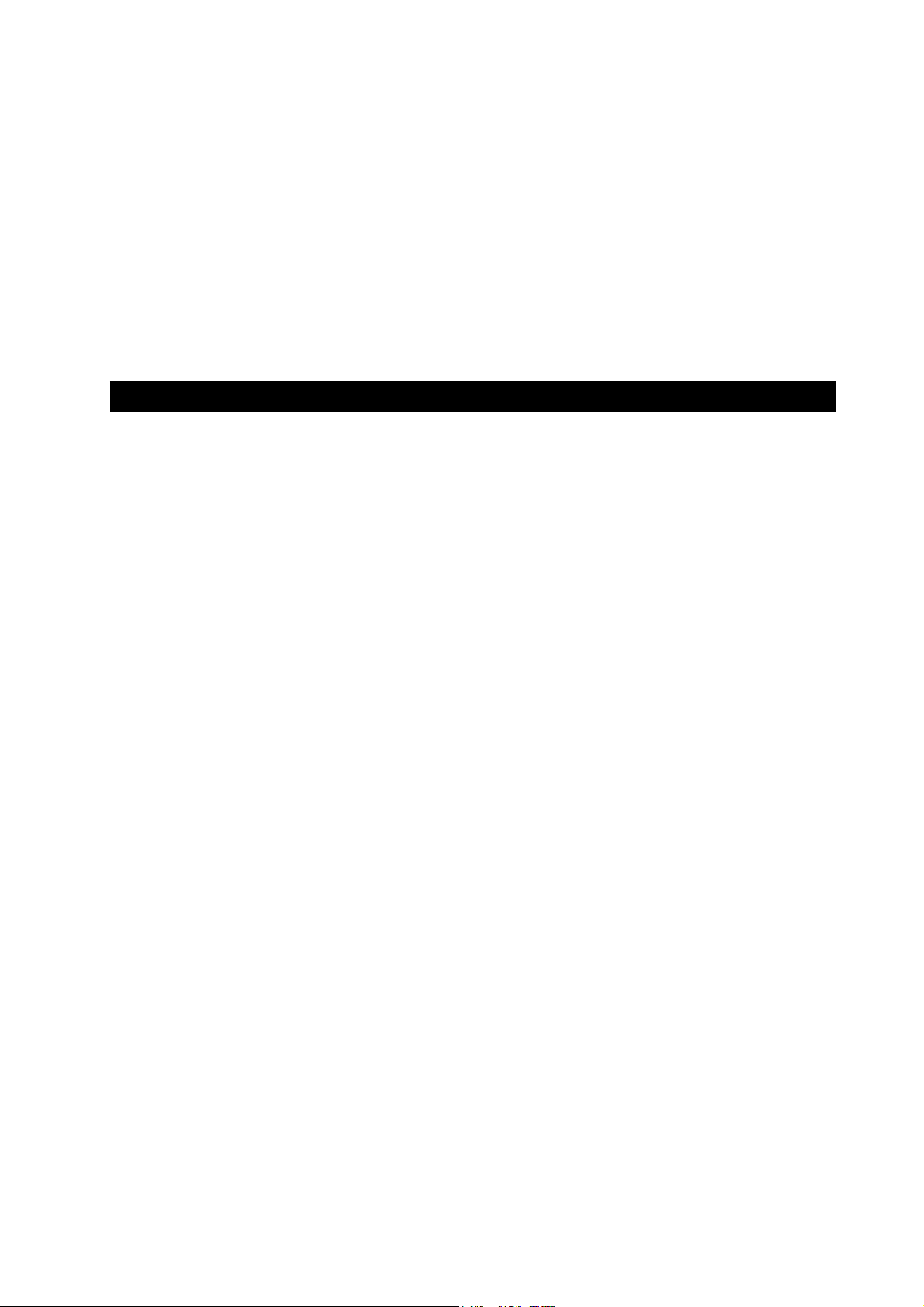

11. Distribution fuse / circuit breaker size marking is included in the manual to indicate that the unit shall be

connected with a Listed inverse time circuit breaker, rated 600 V with the current ratings as shown in

the table below:

Model No. Fuse Size (Maximum A) Circuit Breaker (Maximum A)

Type Rating Type Rating

L700-110L J 60 A Inverse time 60 A

L700-150L J 100 A Inverse time 100 A

L700-185L J 100 A Inverse time 100 A

L700-220L J 100 A Inverse time 100 A

L700-300L J 125 A Inverse time 125 A

L700-370L J 175 A Inverse time 175 A

L700-450L J 225 A Inverse time 225 A

L700-550L J 250 A Inverse time 250 A

L700-750L J 300 A Inverse time 300 A

L700-110H J 30 A Inverse time 30 A

L700-150H J 40 A Inverse time 40 A

L700-185H J 50 A Inverse time 50 A

L700-220H J 50 A Inverse time 50 A

L700-300H J 75 A Inverse time 75 A

L700-370H J 80 A Inverse time 80 A

L700-450H J 100 A Inverse time 100 A

L700-550H J 125 A Inverse time 125 A

L700-750H J 150 A Inverse time 150 A

L700-900H J 225 A Inverse time 225 A

L700-1100H J 225 A Inverse time 225 A

L700-1320H J 300 A Inverse time 300 A

L700-1600H J 350 A Inverse time 350 A

12. “Field wiring connection must be made by a UL Listed and CSA Certified ring lug terminal connector

sized for the wire gauge being used. The connector must be fixed using the crimping tool specified by

the connector manufacturer.”

v

Contents

Chapter 1 Overview

1.1 Inspection of the Purchased Product ························································································ 1 - 2

1.1.1 Inspecting the product ································································································ 1 - 2

1.1.2 Instruction manual (this manual) ················································································ 1 - 2

1.2 Method of Inquiry and Product Warranty ·················································································· 1 - 3

1.2.1 Method of inquiry········································································································ 1 - 3

1.2.2 Product warranty ········································································································ 1 - 3

1.2.3 Warranty Terms ·········································································································· 1 - 3

1.3 Exterior Views and Names of Parts ·························································································· 1 - 4

Chapter 2 Installation and Wiring

2.1 Installation ································································································································· 2 - 2

2.1.1 Precautions for installation ························································································· 2 - 3

2.1.2 Backing plate ·············································································································· 2 - 5

2.2 Wiring ········································································································································ 2 - 6

2.2.1 Terminal connection diagram and explanation of terminals and switch settings ······· 2 - 7

2.2.2 Wiring of the main circuit ···························································································· 2 - 11

2.2.3 Wiring of the control circuit ························································································· 2 - 18

2.2.4 Wiring of the digital operator ······················································································ 2 - 19

2.2.5 Selection and wiring of regenerative braking resistor (on 11 kW to 30 kW models) · 2 - 20

Chapter 3 Operation

3.1 Operating Methods ··················································································································· 3 - 2

3.2 How To Operate the Digital Operator ························································································ 3 - 4

3.2.1 Names and functions of components ········································································· 3 - 4

3.2.2 Code display system and key operations ·································································· 3 - 5

Chapter 4 List of Data Settings

4.1 Precautions for Data Setting ····································································································· 4 - 2

4.2 Monitoring Mode ······················································································································· 4 - 2

4.3 Function Mode ·························································································································· 4 - 3

4.4 Extended Function Mode ·········································································································· 4 - 4

Chapter 5 Error Codes

5.1 Error Codes and Troubleshooting ····························································································· 5 - 2

5.1.1 ·································································································································· Error

codes ··························································································································· 5 - 2

5.1.2 ·································································································································· Trip

conditions monitoring ··································································································· 5 - 4

5.2 Warning Codes ························································································································· 5 - 5

Chapter 6 Specifications

6.1 Specifications ···························································································································· 6 - 2

6.2 External dimensions ·················································································································· 6 - 5

vi

Chapter 1 Overview

This chapter describes the inspection of the purchased product, the product

warranty, and the names of parts.

1.1 Inspection of the Purchased Product ··············· 1 - 2

1.2 Method of Inquiry and Product Warranty ········· 1 - 3

1.3 Exterior Views and Names of Parts ················· 1 - 4

Chapter 1 Overview

1.1 Inspection of the Purchased Product

1.1.1 Inspecting the product

After unpacking, inspect the product as described below.

If you find the product to be abnormal or defective, contact your supplier or local Hitachi Distributor.

(1) Check the product for damage (including falling of parts and dents in the inverter body) caused during

transportation.

(2) Check that the product package contains an inverter set and this Instruction Manual.

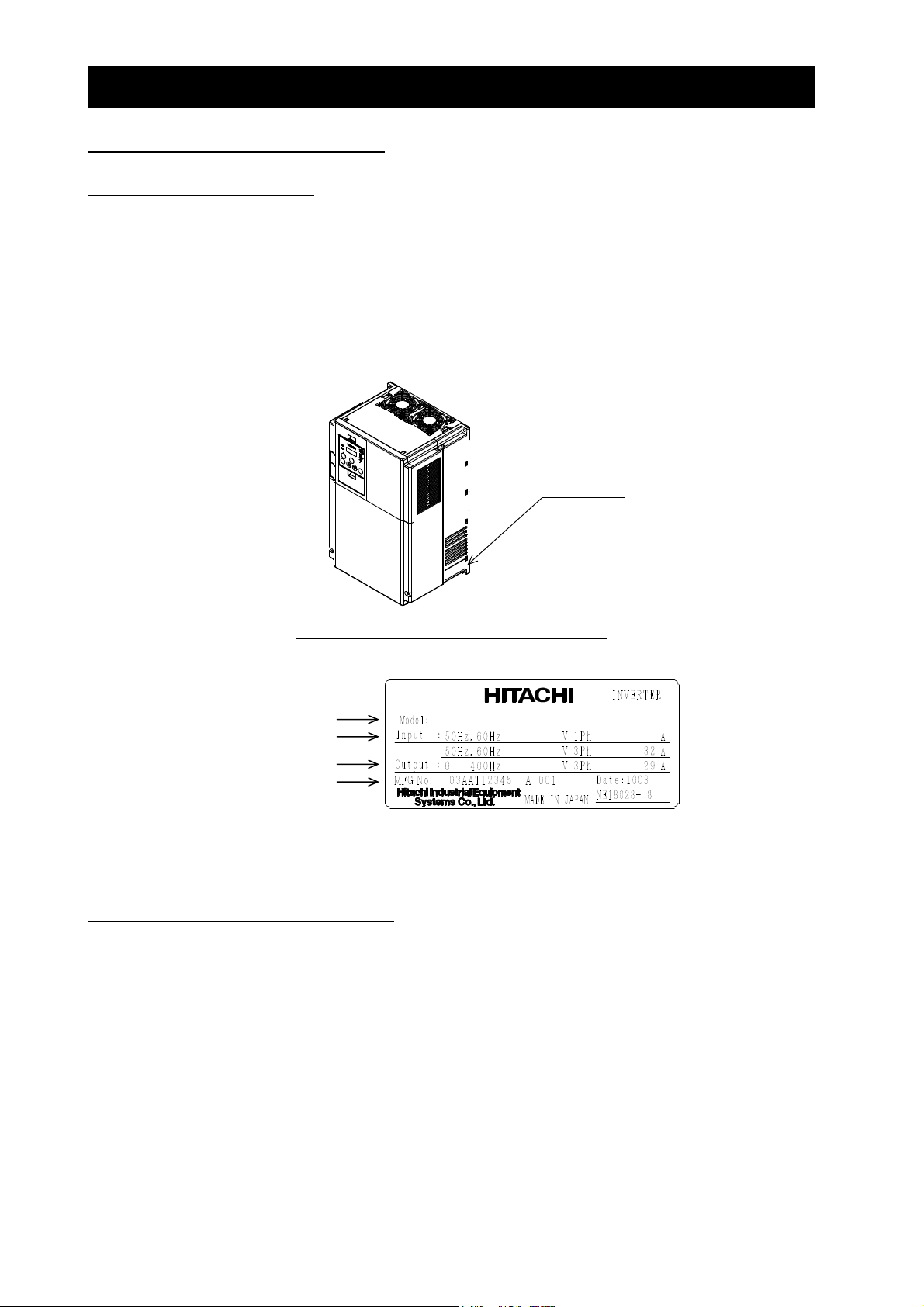

(3) Check the specification label to confirm that the product is the one you ordered.

Specification

label

Figure 1-1 Location of the specifications label

Inverter model

Input ratings

Output ratings

Serial number

L700-150HFF

380 - 480

380 - 480

Figure 1-2 Contents of the specifications label

1.1.2 Instruction manual (this manual)

This Instruction Manual (Quick Reference Guide) describes how to operate the Hitachi L700 Series

Inverter.

Read this Instruction Manual thoroughly before using the inverter, and then keep it handy for future

reference.

When using the inverter, together with optional products for the inverter, also refer to the manuals supplied

with the optional products.

Note that this Instruction Manual and the manual for each optional product to be used should be delivered

to the end user of the inverter.

1 - 2

Chapter 1 Overview

1.2 Method of Inquiry and Product Warranty

1.2.1 Method of inquiry

For an inquiry about product damage or faults or a question about the product, notify your supplier of the

following information:

(1) Model of your inverter

(2) Serial number (MFG No.)

(3) Date of purchase

(4) Content of inquiry

- Location and condition of damage

- Content of your question

1.2.2 Product warranty

The product will be warranted for one year after the date of purchase.

Even within the warranty period, repair of a product fault will not be covered by the warranty (but the repair

will be at your own cost) if:

(1) the fault has resulted from incorrect usage not conforming to the instructions given in this Instruction

Manual or the repair or modification of the product carried out by an unqualified person,

(2) the fault has resulted from a cause not attributable to the delivered product,

(3) the fault has resulted from use beyond the limits of the product specifications, or

(4) the fault has resulted from disaster or other unavoidable events.

The warranty will only apply to the delivered inverter and excludes all damage to other equipment and

facilities induced by any fault of the inverter.

The warranty is effective only in Japan.

Repair at the user's charge

Following the one-year warranty period, any examination and repair of the product will be accepted at your

charge. Even during the warranty period, examination and repairs of faults, subject to the above scope of

the warranty disclaimer, will be available at charge.

To request a repair at your charge, contact your supplier or local Hitachi Distributor.

The Hitachi Distributors are listed on the back cover of this Instruction Manual.

1.2.3 Warranty Terms

The warranty period under normal installation and handling conditions shall be two (2) years from the date

of manufacture (“DATE” on product nameplate), or one (1) year from the date of installation, whichever

occurs first. The warranty shall cover the repair or replacement, at Hitachi’s sole discretion, of ONLY the

inverter that was installed.

(1) Service in the following cases, even within the warranty period, shall be charged to the purchaser:

a. Malfunction or damage caused by mis-operation or modification or improper repair

b. Malfunction or damage caused by a drop after purchase and transportation

c. Malfunction or damage caused by fire, earthquake, flood, lightening, abnormal input voltage,

contamination, or other natural disasters

(2) When service is required for the product at your work site, all expenses associated with field repair

shall be charged to the purchaser.

(3) Always keep this manual handy; please do not loose it. Please contact your Hitachi distributor to

purchase replacement or additional manuals.

1-3

Chapter 1 Overview

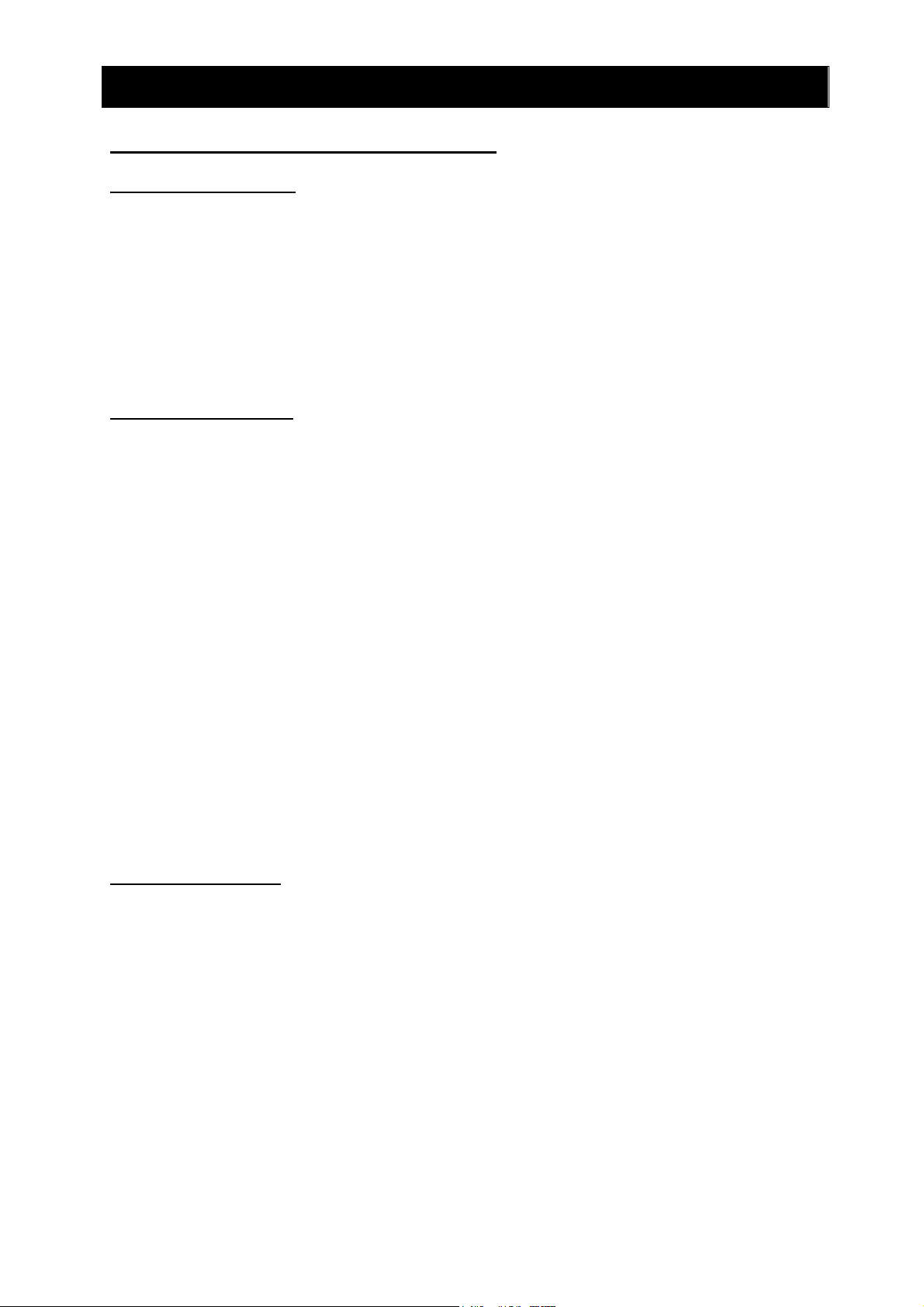

1.3 Exterior Views and Names of Parts

The figure below shows an exterior view of the inverter (model L700-185LFF/HFF to L700-300LFF/HFF).

Terminal block cover

For the wiring of the main circuit and control circuit terminals, open the terminal block cover.

For mounting optional circuit boards, open the front cover.

Position to mount optional board 1

Position to mount optional board 2

Control circuit terminals

Front cover

POWER lamp

ALARM lamp

Digital operator

Spacer cover

Specification label

Exterior view of shipped inverter

Main circuit terminals

Backing plate

Exterior view of inverter with front and terminal block covers removed

1 - 4

Chapter 2 Installation and Wiring

This chapter describes how to install the inverter and the wiring of main circuit

and control signal terminals with typical examples of wiring.

2.1 Installation ························································ 2 - 2

2.2 Wiring ······························································· 2 - 6

Chapter 2 Installation and Wiring

2.1 Installation

CAUTION

!

- Install the inverter on a non-flammable surface, e.g., metal. Otherwise, you run the risk of fire.

- Do not place flammable materials near the installed inverter. Otherwise, you run the risk of fire.

- When carrying the inverter, do not hold its top cover. Otherwise, you run the risk of injury by dropping

the inverter.

- Prevent foreign matter (e.g., cut pieces of wire, sputtering welding materials, iron chips, wire, and

dust) from entering the inverter. Otherwise, you run the risk of fire.

- Install the inverter on a structure able to bear the weight specified in this Instruction Manual.

Otherwise, you run the risk of injury due to the inverter falling.

- Install the inverter on a vertical wall that is free of vibrations. Otherwise, you run the risk of injury due

to the inverter falling.

- Do not install and operate the inverter if it is damaged or its parts are missing. Otherwise, you run the

risk of injury.

- Install the inverter in a well-ventilated indoor site not exposed to direct sunlight. Avoid places where

the inverter is exposed to high temperature, high humidity, condensation, dust, explosive gases,

corrosive gases, flammable gases, grinding fluid mist, or salt water. Otherwise, you run the risk of fire.

- The inverter is precision equipment. Do not allow it to fall or be subject to high impacts, step on it, or

place a heavy load on it. Doing so may cause the inverter to fail.

2 - 2

Chapter 2 Installation and Wiring

A

2.1.1 Precautions for installation

(1) Transportation

The inverter uses plastic parts. When carrying the inverter, handle it carefully to prevent damage to the

parts.

Do not carry the inverter by holding the front or terminal block cover. Doing so may cause the inverter

to fall. Do not install and operate the inverter if it is damaged or its parts are missing.

(2) Surface on which to install the inverter

The inverter will reach a high temperature (up to about 150°C) during operation. Install the inverter on

a vertical wall surface made of nonflammable material (e.g., metal) to avoid the risk of fire.

Leave sufficient space around the inverter. In particular, keep sufficient distance between the inverter

and other heat sources (e.g., braking resistors and reactors) if they are installed in the vicinity.

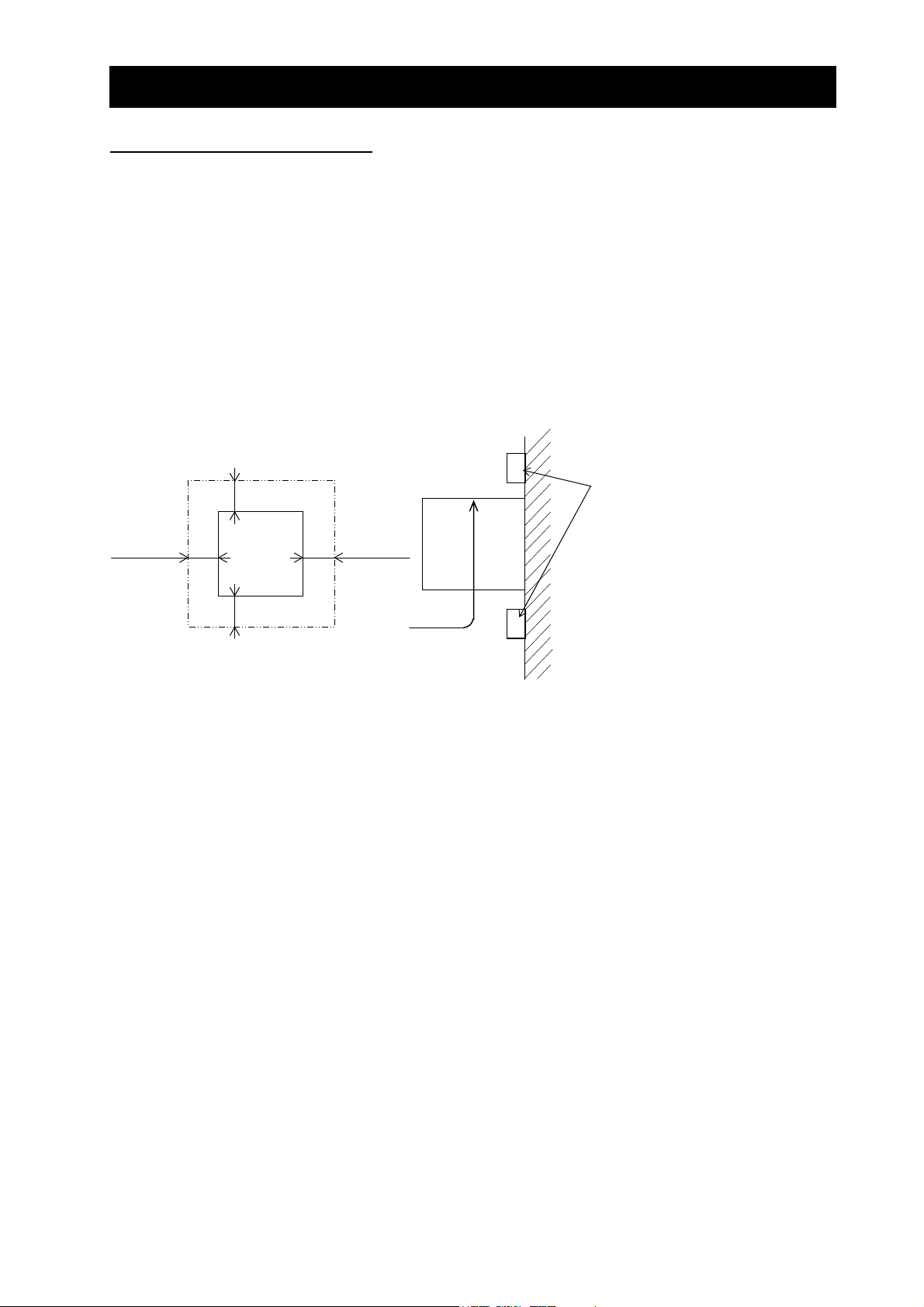

(*1)

ir flow

Inverter

Inverter

5 cm or more 5 cm or more

(*2)

(3) Ambient temperature

Avoid installing the inverter in a place where the ambient temperature goes above or below the

allowable range (-10°C to +40°C), as defined by the standard inverter specification.

Measure the temperature in a position about 5 cm distant from the bottom-center point of the inverter,

and check that the measured temperature is within the allowable range.

Operating the inverter at a temperature outside this range will shorten the inverter life (especially the

capacitor life).

(4) Humidity

Avoid installing the inverter in a place where the relative humidity goes above or below the allowable

range (20% to 90% RH), as defined by the standard inverter specification.

Avoid a place where the inverter is subject to condensation.

Condensation inside the inverter will result in short circuits and malfunctioning of electronic parts. Also

avoid places where the inverter is exposed to direct sunlight.

(5) Ambient air

Avoid installing the inverter in a place where the inverter is subject to dust, corrosive gases,

combustible gases, flammable gases, grinding fluid mist, or salt water.

Foreign particles or dust entering the inverter will cause it to fail. If you use the inverter in a

considerably dusty environment, install the inverter inside a totally enclosed panel.

Keep enough clearance between the inverter

and the wiring ducts located above and

below the inverter to prevent the latter from

obstructing the ventilation of the inverter.

*1 10 cm or more for 11 to 75kW

30cm or more for 90 to 160kW

*2 10 cm or more for 11 to 75kW

30cm or more for 90 to 160kW

But for exchanging the DC bus capacitor,

take a distance.

22cm or more for 18.5 to 75kW

Wall

30cm or more for 90 to 160kW

2 - 3

Chapter 2 Installation and Wiring

(6) Installation method and position

Install the inverter vertically and securely with screws or bolts on a surface that is free from vibrations

and that can bear the inverter weight.

If the inverter is not installed vertically, its cooling performance may be degraded and tripping or

inverter damage may result.

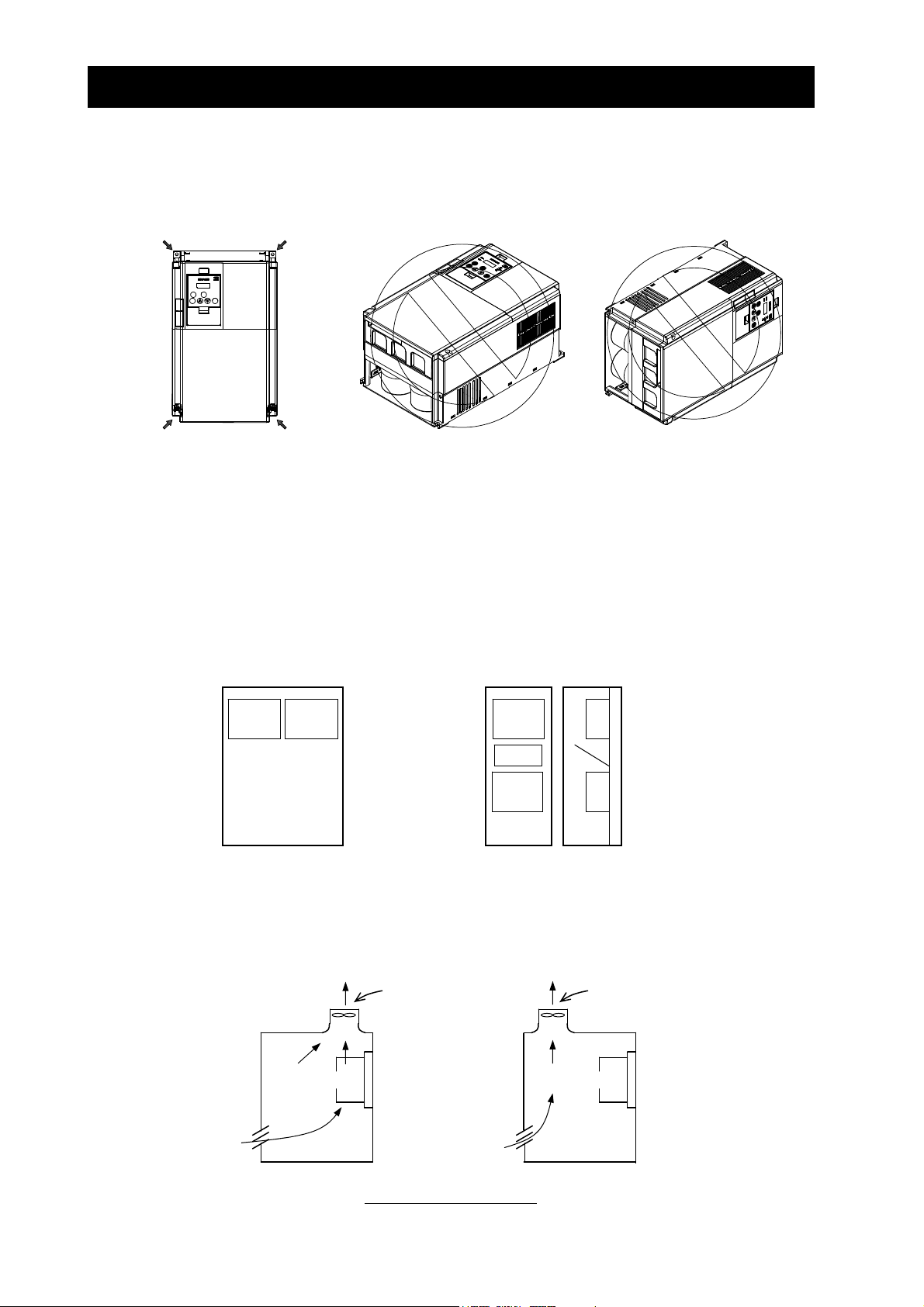

(7) Mounting in an enclosure

Heat in the inverter rises from the under to the upper part of the inverter up with the fan built into the

inverter, and make it to the one without the obstacle even if the influence of heat is received, please

when you arrange apparatus up.

Moreover, please usually arrange it sideways like the left side of the figure below when you store two or

more inverters in the same enclosure.

The temperature in an upper inverter rises because of the heat of a lower inverter when it places one

behind another unavoidably to reduce the space of the enclosure, it causes the inverter breakdown,

and set it up, please so that the heat of a lower inverter should not influence an upper inverter.

Please note it enough as ventilation, ventilation, and the size of the board are enlarged so that the

ambient temperature of the inverter should not exceed the permissible value when two or more

inverters are stored on the enclosure.

(8) When mounting multiple inverters in an enclosure with a ventilation fan, carefully design the layout of

the ventilation fan, air intake port, and inverters.

An inappropriate layout will reduce the inverter-cooling effect and raise the ambient temperature. Plan

the layout so that the inverter ambient temperature will remain within the allowable range.

Inverter Inverter

Enclosure

Sideways

Inverter

(Acceptable)

Inverter

Guide

Plate

Inverter

Enclosure

Behind another

Ventilation fan

Position of ventilation fan

2 - 4

Ventilation fan

Inverter

(Unacceptable)

Chapter 2 Installation and Wiring

(9) Reduction of enclosure size

If you mount the inverter inside an enclosure such that the heat sink of the inverter is positioned

outside the enclosure, the amount of heat produced inside the enclosure can be reduced and likewise

the size of the enclosure.

Mounting the inverter in an enclosure with the heat sink positioned outside requires an optional

dedicated special metal fitting.

To mount the inverter in an enclosure with the heat sink positioned outside, cut out the enclosure panel

according to the specified cutting dimensions.

The cooling section (including the heat sink) positioned outside the enclosure has a cooling fan.

Therefore, do not place the enclosure in any environment where it is exposed to waterdrops, oil mist,

or dust.

(10) Approximate loss by inverter capacity

Inverter capacity (kW) 11 15 18.5 22 30 37 45 55 75 90 110 132 160

Loss with 70% load (W) 435 575 698 820 1100 1345 1625 1975 2675 3375 3900 4670 5660

Loss with 100% load (W) 600 800 975 1150 1550 1900 2300 2800 3800 4800 5550 6650 8060

Efficiency at rated output (%) 94.8 94.9 95.0 95.0 95.0 95.1 95.1 95.1 95.2 95.2 95.2 95.2 95.2

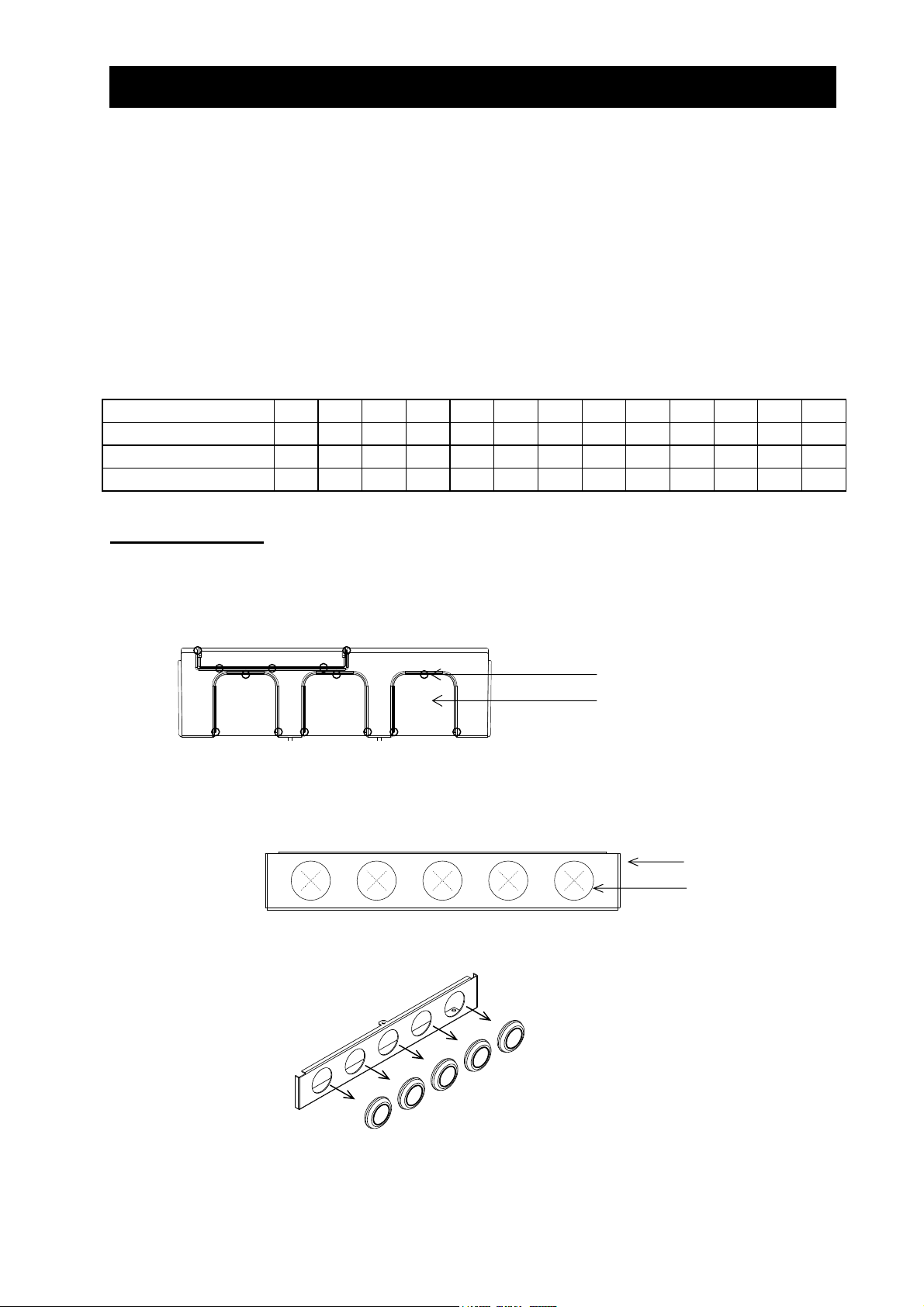

2.1.2 Backing plate

(1) For models with 30 kW or less capacity

On the backing plate, cut the joints around each section to be cut off with cutting pliers or a cutter,

remove them, and then perform the wiring.

Joint

Section to be cut off

(2) For the models with 37 kW to 75kW

1) For wiring without using conduits

Cut an X in each rubber bushing of the backing plate with cutting pliers or a cutter, and then perform

the wiring.

Backing plate

Rubber bushing

2) For wiring using conduits

Remove the rubber bushings from the holes to be used for wiring with conduits, and then fit conduits

into the holes.

Note: Do not remove the rubber bushing from holes that are not used for wiring with a conduit.

If a cable is connected through the plate hole without a rubber bushing and conduit, the cable

insulation may be damaged by the edge of the hole, resulting in a short circuit or ground fault.

2 - 5

Chapter 2 Installation and Wiring

2.2 Wiring

WARNING

!

- Be sure to ground the inverter. Otherwise, you run the risk of electric shock or fire.

- Commit wiring work to a qualified electrician. Otherwise, you run the risk of electric shock or fire.

- Before wiring, make sure that the power supply is off. Otherwise, you run the risk of electric shock or

fire.

- Perform wiring only after installing the inverter. Otherwise, you run the risk of electric shock or injury.

- Do not remove rubber bushings from the wiring section. Otherwise, the edges of the wiring cover may

damage the wire, resulting in a short circuit or ground fault.

CAUTION

!

- Make sure that the voltage of AC power supply matches the rated voltage of your inverter. Otherwise,

you run the risk of injury or fire.

- Do not input single-phase power into the inverter. Otherwise, you run the risk of fire.

- Do not connect AC power supply to any of the output terminals (U, V, and W). Otherwise, you run the

risk of injury or fire.

- Do not connect a resistor directly to any of the DC terminals (PD, P, and N). Otherwise, you run the

risk of fire.

- Connect an earth-leakage breaker to the power input circuit. Otherwise, you run the risk of fire.

- Use only the power cables, earth-leakage breaker, and magnetic contactors that have the specified

capacity (ratings). Otherwise, you run the risk of fire.

- Do not use the magnetic contactor installed on the primary and secondary sides of the inverter to stop

its operation.

- Tighten each screw to the specified torque. No screws must be left loose. Otherwise, you run the risk

of fire.

- Before operating, slide switch SW1 in the inverter, be sure to turn off the power supply. Otherwise, you

run the risk of electric shock and injury.

- Since the inverter supports two modes of cooling-fan operation, the inverter power is not always off,

even when the cooling fan is stopped. Therefore, be sure to confirm that the power supply is off before

wiring. Otherwise, you run the risk of electric shock and injury.

2 - 6

Chapter 2 Installation and Wiring

RSTR0T0UVWPPDRBNFW7618FM

O

LAM

SN

2

ALARM

VA

運転

停止/

リセット

11

RTTH

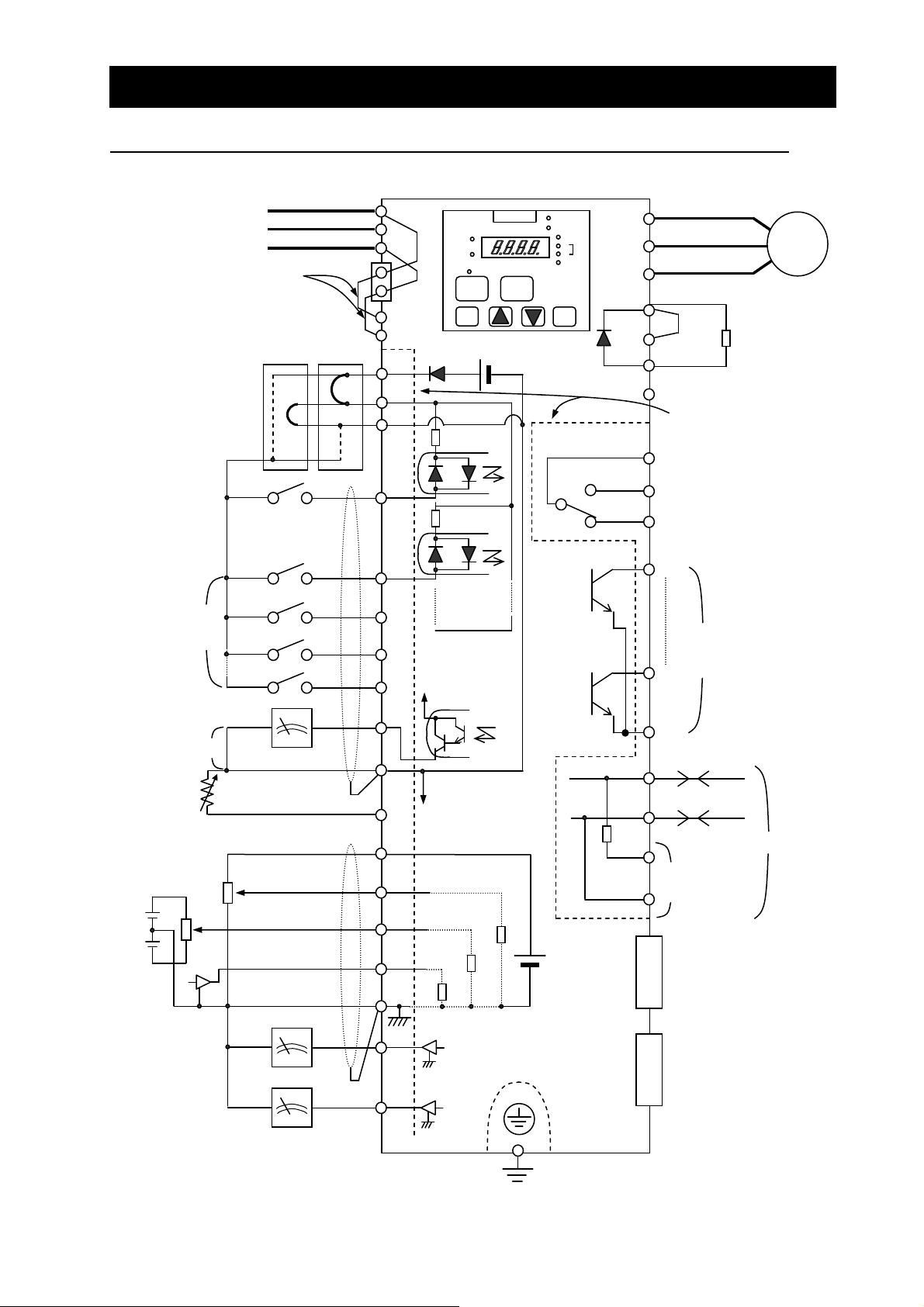

2.2.1 Terminal connection diagram and explanation of terminals and switch settings

3-phase power supply

200 V class: 200 to 240 V +10%, -15%

(50/60 Hz ±5%)

400 V class: 380 to 480 V +10%, -15%

(50/60 Hz ±5%)

When connecting separate

power supplies to main and

control circuits, remove J51

connector cables beforehand.

(See page 2-17)

Default jumper position

(sinking type inputs)

Forward rotation

command

Intelligent input

(8 contacts)

Jumper

Power supply for

control circuit

J51

P24

PLC

CM1

RUN

PRG

機能

FUNC

RUN

HITACHI

1

DC24V

STOP/RESET

POWER

記憶

STR

Hz

kW

%

Jumper

bar

The dotted line indicates the

detachable control terminal

AL0

board.

AL1

Intelligent relay output contact

(default: alarm output)

IM

Motor

Braking resistor

(optional)

(Models with 30kW

or less capacity

have a built-in BRD

circuit.)

AL2

15

Intelligent output

(5 terminals)

Digital monitor output

(PWM output)

Frequency

setting circuit

500 to 2,000Ω

Analog monitor

output (voltage

output)

Analog monitor

output (current

output)

Thermistor

0 to 10 VDC (12 bits)

-10 to +10 VDC (12 bits)

4 to 20 mA (12 bits)

0 to 10 V (10 bits)

4 to 20 mA (10 bits)

CM1

H

O2

OI

AMI

100Ω

10kΩ

CM2

SP

RP

For terminating

resistor

SN

10kΩ

DC10V

Option 1

Option 2

Type-D grounding (for 200 V class model)

Type-C grounding (for 400 V class model)

(See page 2-12.)

RS485

2 - 7

Chapter 2 Installation and Wiring

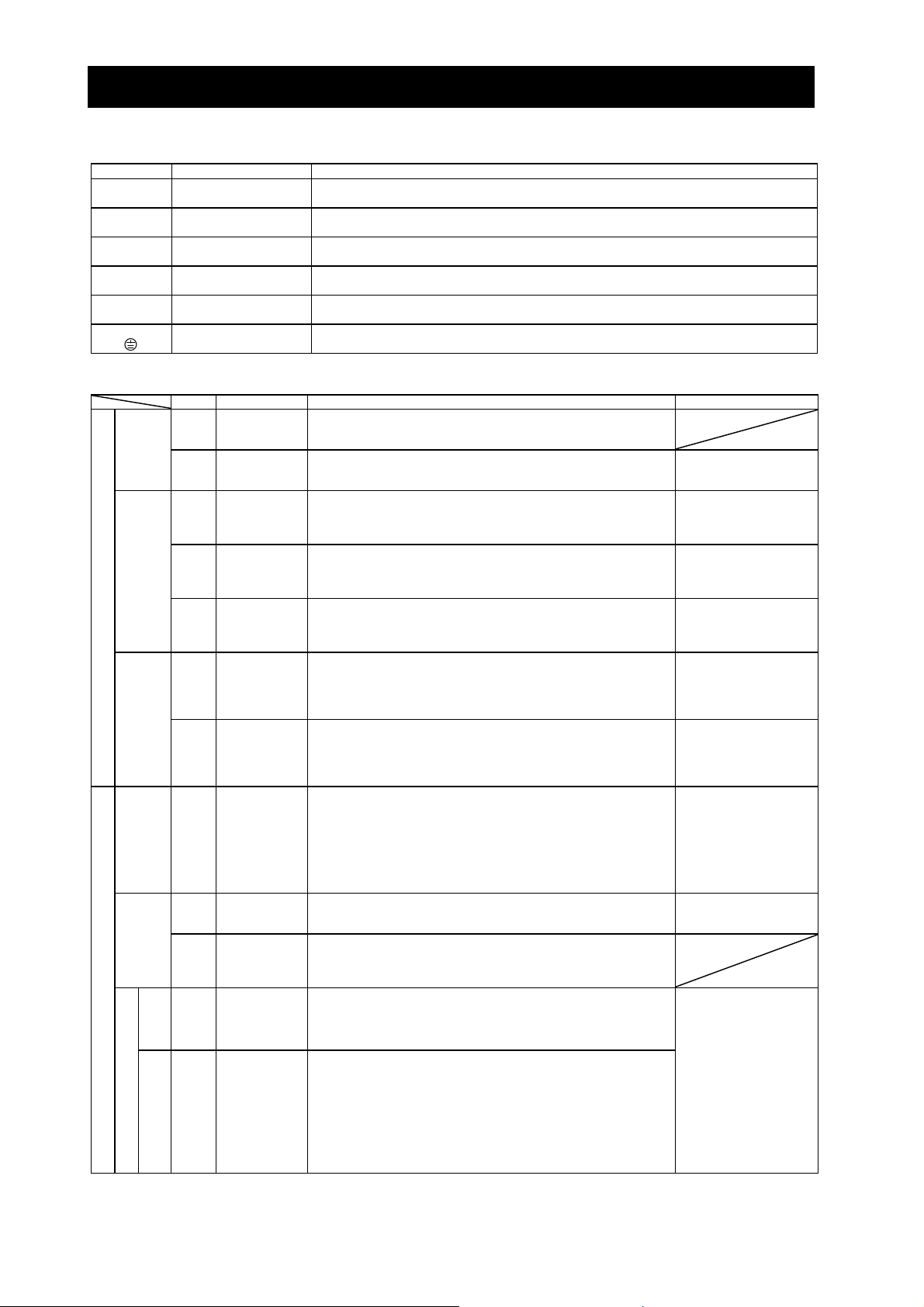

(1) Explanation of main circuit terminals

Symbol Terminal name Description

R, S, T

(L1, L2, L3)

U, V, W

(T1, T2, T3)

PD, P

(+1, +)

P, R B

(+, RB)

P, N

(+, -)

G

Main power input

Inverter output Connect a 3-phase motor.

DC reactor connection

External braking

resistor connection

Regenerative braking

unit connection

Inverter ground

(2) Explanation of control circuit terminals

Symbol Terminal name Description Electric property

Power

supply

Analog

Frequency setting input

Monitor output

AMI

Monitor output

P24

CM1

Power supply

Digital (contact)

Operation

command

Contact input

switching

Function selection and logic

L

H

O

O2

OI

AM

FM

FW

1

2

3

4

5

6

7

8

Analog power

supply

(common)

Frequency

setting power

supply

Frequency

command

(voltage)

Auxiliary

frequency

command

(voltage)

Frequency

command

(current)

Analog monitor

(voltage)

Analog monitor

(current)

Digital monitor

(voltage)

Interface power

supply

Interface power

supply

(common)

Forward rotation

command

Intelligent input

Connect to the AC power supply.

Leave these terminals unconnected when using a regenerative converter (HS900 series).

Remove the jumper from terminals PD and P, and connect the optional power factor reactor

(DCL).

Connect the optional external braking resistor.

(The RB terminal is provided on models with 30 kW or less capacity.)

Connect the optional regenerative braking unit (BRD).

Connect to ground for grounding the inverter chassis by type-D grounding (for 200 V class

models) or type-C grounding (for 400 V class models).

This common terminal supplies power to frequency command terminals (O,

O2, and OI) and analog output terminals (AM and AMI). Do not ground this

terminal.

This terminal supplies 10 VDC power to the O, O2, OI terminals.

Input a voltage (0 to 10 VDC) as a frequency command. 10 V specifies the

maximum frequency.

To specify the maximum frequency with a voltage of 10 V or less, set the

voltage using function "A014".

Input a voltage (0 to ±10 VDC) as a signal to be added to the frequency

command input from the O or OI terminal. You can input an independent

frequency command from this terminal (O2 terminal) alone by changing the

setting.

Input a current (4 to 20 mA DC) as a frequency command. 20 mA specifies

the maximum frequency.

The OI signal is valid only when the AT signal is on. Assign the AT function

to an intelligent input terminal.

This terminal outputs one of the selected "0 to 10 VDC voltage output"

monitoring items. The monitoring items available for selection include

output frequency, output current, output torque (signed or unsigned),

output voltage, input power, electronic thermal overload, LAD frequency,

motor temperature, heat sink temperature, and general output.

This terminal outputs one of the selected "4 to 20 mA DC current output"

monitoring items. The monitoring items available for selection include

output frequency, output current, output torque (unsigned), output voltage,

input power, electronic thermal overload, LAD frequency, motor

temperature, heat sink temperature, and general output.

This terminal outputs one of the selected "0 to 10 VDC voltage output

(PWM output mode)" monitoring items. The monitoring items available for

selection include output frequency, output current, output torque

(unsigned), output voltage, input power, electronic thermal overload, LAD

frequency, motor temperature, heat sink temperature, general output,

digital output frequency, and digital current monitor.

For the items "digital output frequency" and "digital current monitor," this

terminal outputs a digital pulse signal at 0/10 VDC with a duty ratio of 50%.

This terminal supplies 24 VDC power for contact input signals.

If the source logic is selected, this terminal is used as a common contact

input terminal.

This common terminal supplies power to the interface power supply (P24),

thermistor input (TH), and digital monitor (FM) terminals. If the sink logic is

selected, this terminal is used as a common contact input terminal. Do not

ground this terminal.

Turn on this FW signal to start the forward rotation of the motor; turn it off to

stop forward rotation after deceleration.

Select eight of a total 60 functions, and assign these eight functions to

terminals 1 to 8.

Note:

If the emergency stop function is used, terminals 1 and 3 are used

exclusively for the function. For details, see Item (3), "Emergency stop

function" (on page 2-8).

Allowable load current:

20 mA or less

Input impedance: 10kΩ

Allowable input voltages:

-0.3 to +12 VDC

Input impedance: 10kΩ

Allowable input voltages:

0 to ±12 VDC

Input impedance: 10kΩ

Maximum allowable

current: 24 mA

Maximum allowable

current: 2 mA

Allowable load impedance:

250Ω or less

Maximum allowable

current: 1.2 mA

Maximum frequency:

3.6 kHz

Maximum allowable output

current: 100 mA

[Conditions for turning

contact input on]

Voltage across input and

PLC: 18 VDC or more

Input impedance between

input and PLC: 4.7kΩ

Maximum allowable voltage

across input and PLC:

27 VDC

Load current with 27 VDC

power: about 5.6 mA

2 - 8

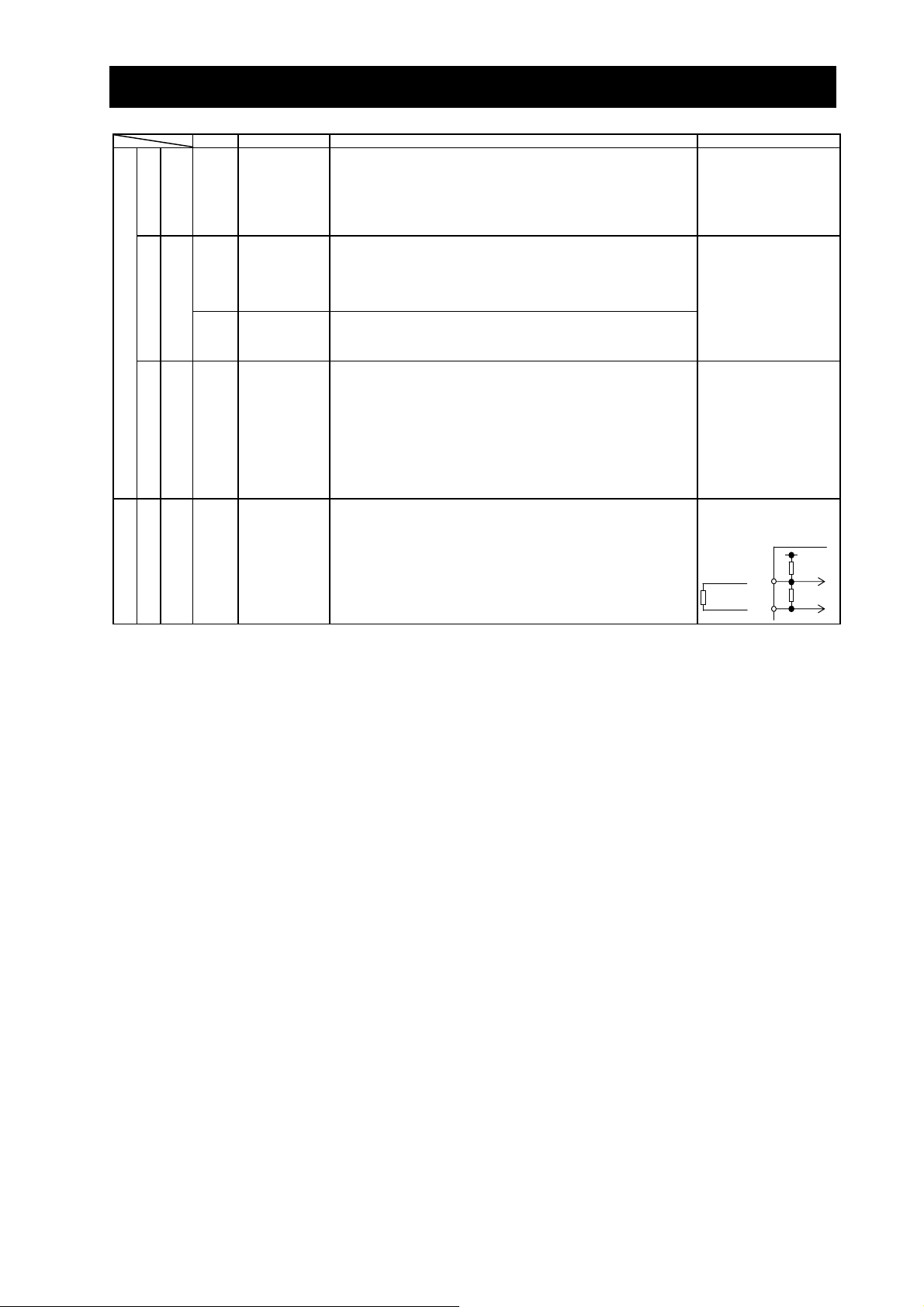

Chapter 2 Installation and Wiring

Symbol Terminal name Description Electric property

Intelligent input

PLC

Contact input

Function selection

and logic switching

11

12

13

14

15

Status and factor

Open collector output

Digital (contact)

Relay contact output

Analog

Analog input

CM2

AL0

AL1

AL2

Status and alarm

TH

Sensor

(common)

Intelligent output

Intelligent output

(common)

Intelligent relay

output

External

thermistor input

To switch the control logic between sink logic and source logic, change the

jumper connection of this (PLC) terminal to another terminal on the control

circuit terminal block.

Jumper terminals P24 and PLC for the sink logic; jumper terminals CM1

and PLC for the sink logic.

To use an external power supply to drive the contact inputs, remove the

jumper, and connect the PLC terminal to the external interface circuit.

Select five of a total 51 functions, and assign these five functions to

terminals 11 to 15.

If you have selected an alarm code using the function "C062", terminals 11

to 13 or 11 to 14 are used exclusively for the output of cause code for alarm

(e.g., inverter trip). The control logic between each of these terminals and

the CM2 terminal always follows the sink or source logic.

This terminal serves as the common terminal for intelligent output terminals

[11] to [15].

Select functions from the 43 available, and assign the selected functions to

these terminals, which serve as C contact output terminals.

In the initial setting, these terminals output an alarm indicating that the

inverter protection function has operated to stop inverter output.

Connect to an external thermistor to make the inverter trip if an abnormal

temperature is detected.

The CM1 terminal serves as the common terminal for this terminal.

[Recommended thermistor properties]

Allowable rated power: 100 mW or more

Impedance at temperature error: 3kΩ

The impedance to detect temperature errors can be adjusted within the

range 0Ω to 9,999Ω.

Voltage drop between each

terminal and CM2 when

output signal is on: 4 V or

less

Maximum allowable

voltage: 27 VDC

Maximum allowable

current: 50 mA

(Maximum contact

capacity)

AL1-AL0: 250 VAC, 2 A

(resistance) or 0.2 A

(inductive load)

AL2-AL0: 250 VAC, 1 A

(resistance) or 0.2 A

(inductive load)

(Minimum contact capacity)

100 VAC, 10 mA

5 VDC, 100 mA

Allowable range of input

voltages

0 to 8 VDC

[Input circuit]

TH

Thermistor

CM1

DC8V

10kΩ

1kΩ

2 - 9

Chapter 2 Installation and Wiring

ON

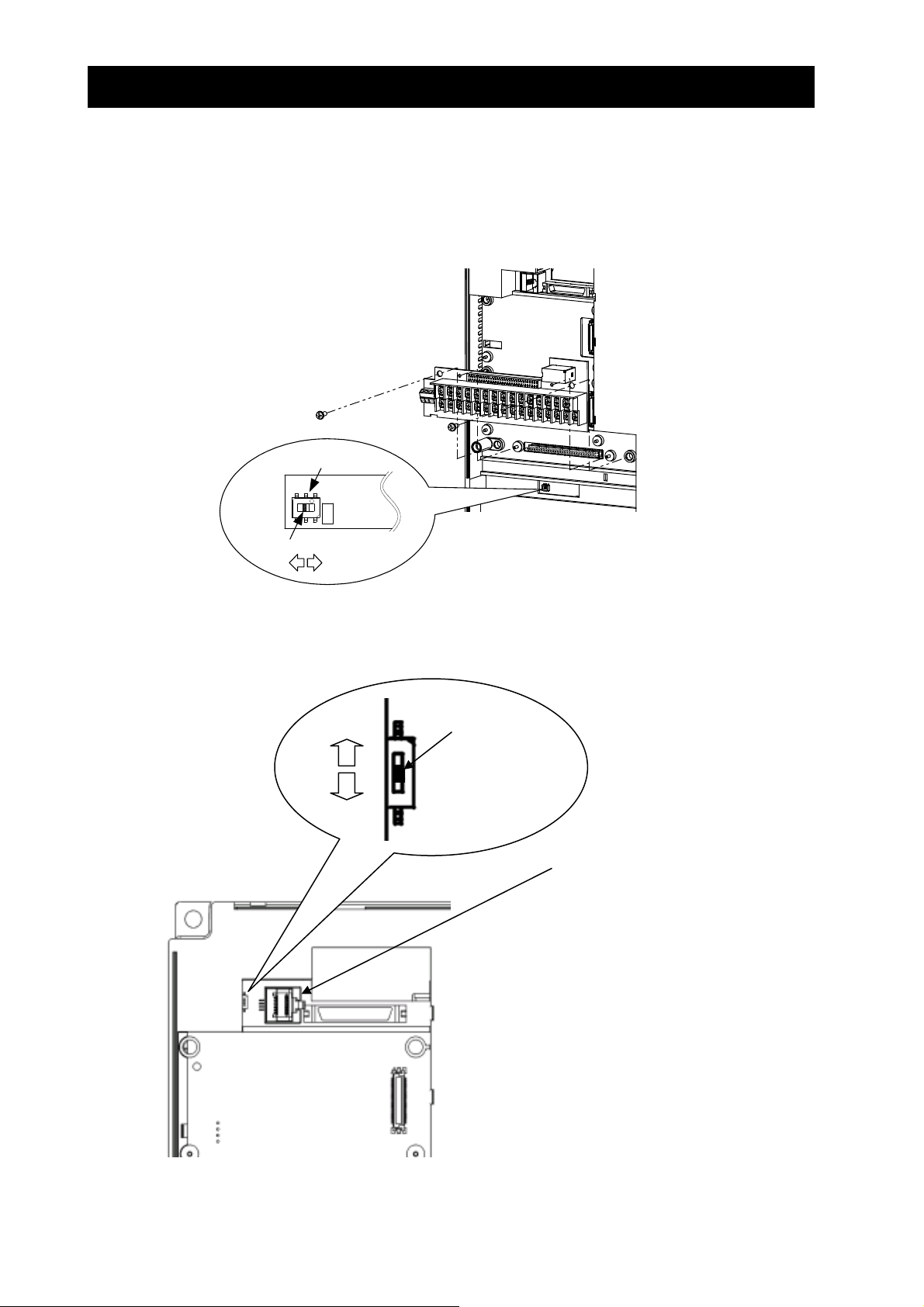

(3) Explanation of switch

SW1: It is a switch that switches effective and the invalidity of the urgent disconnect function (The

state of the factory shipment: this function invalidity).

Please use the urgent invalidity function after perusing "4.4 urgent disconnect function".

Note: Slide Switch 12

Some models have slide switch in the position as shown below. Default setting of this switch is at "ON" position.

Please don't change the setting. If it is changed, inverter may trip and disabled to run.

Slide switch SW1

ON

Slide lever (factory setting: OFF)

OFF

OFF

ON

ON

Slide switch SW12

Slide lever

(factory setting: ON)

Logic board

2 - 10

Loading...

Loading...