Hitachi HTS543212L9SA00, HTS543280L9A300 User Manual

5K320 SATA OEM Specification

Hitachi Global Storage Technologies

Hard Disk Drive Specification

Hitachi Travelstar 5K320

2.5 inch SATA hard disk drive

Models: HTS543232L9A300, HTS543232L9SA00

HTS543225L9A300, HTS543225L9SA00

HTS543216L9A300, HTS543216L9SA00

HTS543212L9A300, HTS543212L9SA00

HTS543280L9A300, HTS543280L9SA00

Revision 1.2 03 April, 2008

1

5K320 SATA OEM Specification

1st Edition (Revision 1.0) (25 Feb 2008)

2nd Edition (Revision 1.1; Correction) (03 Apr 2008)

3rd Edition (Revision 1.2 ; Correction) (03 Apr 2008)

The following paragraph does not apply to the United Kingdom or any country where such

provisions are inconsistent with local law: HITACHI GLOBAL STORAGE TECHNOLOGIES

PROVIDES THIS PUBLICATION "AS IS" WITHOUT WARRANTY OF ANY KIND, EITHER

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow

disclaimer or express or implied warranties in certain transactions, therefore, this statement may

not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are

periodically made to the information herein; these changes will be incorporated in new editions of

the publication. Hitachi may make improvements or changes in any product s or programs described

in this publication at any time.

It is possible that this publication may contain reference to, or information about, Hitachi products

(machines and programs), programming, or services that are not announced in your country. Such

references or information must not be construed to mean that Hitachi intends to announce such

Hitachi products, programming, or services in your country.

Technical information about this product is available by contacting your local Hitachi Global Storage

Technologies representative or on the Internet at http://www.hitachigst.com

Hitachi Global Storage Technologies may have patents or pending patent applications covering

subject matter in this document. The furnishing of this document does not give you any license to

these patents.

©Copyright Hitachi Global Storage Technologies

Note to U.S. Government Users —Documentation related to restricted rights —Use, duplication or

disclosure is subject to restrictions set forth in GSA ADP Schedule Contract with Hitachi Global

Storage Technologies.

2

5K320 SATA OEM Specification

Table of Contents

GENERAL........................................................................................................................................9

1 INTRODUCTION...................................................................................................................................................................... 9

1.1 Abbreviations .........................................................................................................................................................9

1.2 References..............................................................................................................................................................12

1.3 General caution...................................................................................................................................................12

1.4 Drive handling precautions................................ ............................................................................................12

2 OUTLINE OF THE DRIVE.....................................................................................................................................................13

PART 1 FUNCTIONAL SPECIFICATION ......................................................................................14

3 FIXED DISK SUBSYSTEM DESCRIPTION.........................................................................................................................15

3.1 Control Electronics ................................ ............................................................................................................15

3.2 Head disk assembly data ................................................................................................................................ 15

4 FIXED DISK CHARACTERISTICS .......................................................................................................................................16

4.1 Formatted capacity by model number ....................................................................................................... 16

4.2 Data sheet..............................................................................................................................................................17

4.3 Cylinder allocation.............................................................................................................................................17

4.4 Performance characteristics..........................................................................................................................18

5 DATA INTEGRITY..................................................................................................................................................................22

5.1 Data loss on power off ....................................................................................................................................... 22

5.2 Write Cache .......................................................................................................................................................... 22

5.3 Equipment status...............................................................................................................................................22

5.4 WRITE safety.......................................................................................................................................................22

5.5 Data buffer test ...................................................................................................................................................23

5.6 Error recovery................................ ......................................................................................................................23

5.7 Automatic reallocation ..................................................................................................................................... 23

5.8 ECC ..........................................................................................................................................................................24

6 SPECIFICATION....................................................................................................................................................................25

6.1 Environment.........................................................................................................................................................25

6.2 DC power requirements...................................................................................................................................27

6.3 Reliability...............................................................................................................................................................29

6.4 Mechanical specifications................................................................................................................................32

6.5 Vibration and shock...........................................................................................................................................34

6.6 Acoustics................................ .................................................................................................................................36

6.7 Identification labels ...........................................................................................................................................37

6.8 Electromagnetic compatibility................................ ......................................................................................37

6.9 Safety.......................................................................................................................................................................38

6.10 Packaging...............................................................................................................................................................38

6.11 Substance restriction requirements...........................................................................................................38

7 ELECTRICAL INTERFACE SPECIFICATIONS..................................................................................................................39

7.1 Cabling....................................................................................................................................................................39

7.2 Interface connector ................................................................ ............................................................................39

7.3 Signal definitions................................................................................................................................................40

PART 2 INTERFACE SPECIFICATION .........................................................................................44

8 GENERAL................................................................................................................................................................................45

8.1 Introduction .......................................................................................................................................................... 45

8.2 Terminology ..........................................................................................................................................................45

9 DEVIATIONS FROM STANDARD ........................................................................................................................................46

10 PHYSICAL INTERFACE.....................................................................................................................................................46

11 R EGISTERS.......................................................................................................................................................................... 46

11.1 Register naming convention .......................................................................................................................... 47

11.2 Command register .............................................................................................................................................. 47

11.3 Device Control Register ...................................................................................................................................47

11.4 Device Register....................................................................................................................................................48

11.5 Error Register ................................................................ ......................................................................................48

3

5K320 SATA OEM Specification

11.6 Features Register...............................................................................................................................................48

11.7 LBA High Register.............................................................................................................................................49

11.8 LBA Low Register ..............................................................................................................................................49

11.9 LBA Mid Register ............................................................................................................................................... 49

11.10 Sector Count Register ..................................................................................................................................49

11.11 Status Register................................................................................................................................................49

12 GENERAL OPERATION DESCRIPTIONS.......................................................................................................................51

12.1 Reset Response....................................................................................................................................................51

12.2 Diagnostic and Reset considerations .......................................................................................................... 52

12.3 Power-off considerations..................................................................................................................................53

12.4 Sector Addressing Mode ..................................................................................................................................54

12.5 Power Management Feature .........................................................................................................................54

12.6 Advanced Power Management (Adaptive Battery Life Extender 3) Feature...........................56

12.7 Interface Power Management Mode (Slumber and Partial)................................ ............................57

12.8 S.M.A.R.T. Function..........................................................................................................................................57

12.9 Security Mode Feature Set.............................................................................................................................58

12.10 Protected Area Function .............................................................................................................................64

12.11 Seek Overlap....................................................................................................................................................67

12.12 Write Cache Function ..................................................................................................................................67

12.13 Reassign Function.........................................................................................................................................67

12.14 48-bit Address Feature Set ........................................................................................................................68

12.15 Software Setting Preservation Feature Set ........................................................................................69

12.16 Native Command Queuing ......................................................................................................................... 70

12.17 SMART Command Transport (SCT)................................ ......................................................................70

13 C OMMAND PROTOCOL..................................................................................................................................................... 72

13.1 Data In Commands................................ ............................................................................................................72

13.2 Data Out Commands ........................................................................................................................................72

13.3 Non-Data Commands .......................................................................................................................................73

13.4 DMA Data Transfer Commands ..................................................................................................................74

13.5 First-parity DMA Commands .......................................................................................................................74

14 C OMMAND DESCRIPTIONS ............................................................................................................................................. 75

14.1 Check Power Mode (E5h/98h) .......................................................................................................................79

14.2 Device Configuration Overlay (B1h) .......................................................................................................... 80

14.3 Download Microcode (92h) .............................................................................................................................. 84

14.4 Execute Device Diagnostic (90h)..................................................................................................................86

14.5 Flush Cache (E7h) .............................................................................................................................................. 87

14.6 Flush Cache Ext (EAh) ....................................................................................................................................88

14.7 Format Track (50h: Vendor Specific).........................................................................................................89

14.8 Format Unit (F7h: Vendor Specific)...........................................................................................................90

14.9 Identify Device (ECh).......................................................................................................................................91

14.10 Idle (E3h/97h) ................................................................................................................................................103

14.11 Idle Immediate (E1h/95h).........................................................................................................................104

14.12 Initialize Device Parameters (91h) .......................................................................................................105

14.13 Read Buffer (E4h)........................................................................................................................................106

14.14 Read DMA(C8h/C9h)..................................................................................................................................107

14.15 Read DMA Ext (25h) ...................................................................................................................................108

14.16 Read FPDMA Queued (60h)................................ ....................................................................................109

14.17 Read Log Ext(2Fh) .......................................................................................................................................110

14.18 Read Multiple (C4h)................................ ....................................................................................................118

14.19 Read Multiple Ext (29h) ............................................................................................................................119

14.20 Read Native Max Address (F8h)............................................................................................................120

14.21 Read Native Max Address Ext (27h)................................ ....................................................................121

14.22 Read Sector(s) (20h/21h) ...........................................................................................................................122

14.23 Read Sector(s) Ext (24h)............................................................................................................................123

14.24 Read Verify Sector(s) (40h/41h) .............................................................................................................124

14.25 Read Verify Sector(s) Ext (42h)..............................................................................................................125

14.26 Recalibrate (1xh) ................................................................ ..........................................................................126

14.27 Security Disable Password (F6h) ................................................................ ..........................................127

4

5K320 SATA OEM Specification

14.28 Security Erase Prepare (F3h) .................................................................................................................128

14.29 Security Erase Unit (F4h)........................................................................................................................129

14.30 Security Freeze Lock (F5h)......................................................................................................................131

14.31 Security Set Password (F1h)...................................................................................................................132

14.32 Security Unlock (F2h) ................................................................................................................................134

14.33 Seek (7xh)........................................................................................................................................................135

14.34 Sense Condition (F0h : vendor specific)..............................................................................................136

14.35 Set Features (EFh) ......................................................................................................................................137

14.36 Set Max Address (F9h) ..............................................................................................................................139

14.37 Set Max Address Ext (37h) ......................................................................................................................141

14.38 Set Multiple (C6h) .......................................................................................................................................143

14.39 Sleep (E6h/99h).............................................................................................................................................144

14.40 S.M.A.R.T Function Set (B0h) ................................................................................................................145

14.41 Standby (E2h/96h).......................................................................................................................................160

14.42 Standby Immediate (E0h/94h) ................................................................ ...............................................161

14.43 Write Buffer (E8h).......................................................................................................................................162

14.44 Write DMA (CAh/CBh)..............................................................................................................................163

14.45 Write DMA Ext (35h) .................................................................................................................................164

14.46 Write DMA FUA Ext (3Dh).....................................................................................................................165

14.47 Write FPDMA Queued (61h) ...................................................................................................................166

14.48 Write Log Ext (3Fh)................................ ....................................................................................................167

14.49 Write Multiple (C5h)...................................................................................................................................168

14.50 Write Multiple Ext (39h)...........................................................................................................................169

14.51 Write Multiple FUA Ext (CEh)..............................................................................................................170

14.52 Write Sector(s) (30h/31h)................................ ..........................................................................................171

14.53 Write Sector(s) Ext (34h) ................................................................ ..........................................................172

14.54 Write Uncorrectable Ext (45h) ................................................................ ...............................................173

15 TIMINGS.............................................................................................................................................................................175

List of Figures

Figure 1. Limits of temperature and humidity 25

Figure 2. Mounting hole locations 32

Figure 3. Interface connector pin assignments 39

Figure 4. Parameter descriptions 42

Figure 5 Initial Setting 60

Figure 6 Usual Operation 61

Figure 7 Password Lost 62

Figure 8 Set Max security mode transition 66

Figure 9 Seek overlap 67

Figure 10 Selective self -test test span example 147

List of Tables

Table 1. Formatted capacity by model number. 16

Table 2. Data sheet 17

Table 3. Cylinder allocation 17

Table 4. Performance characteristics 18

Table 5. Mechanical positioning performance 19

Table 6. Full stroke seek time 19

Table 7. Single track seek time 19

Table 8. Latency time 19

Table 9. Drive ready time 20

Table 10. Operating mode 21

Table 11. Drive ready time 21

Table 12. Environmental condition 25

Table 13. Magnetic flux density limits 26

Table 14. DC Power requirements 27

5

5K320 SATA OEM Specification

Table 15. Power consumption efficiency 28

Table 16. Physical dimensions and weight 32

Table 17. Random vibration PSD profile breakpoints (operating) 34

Table 18. Swept sine vibration 34

Table 19. Random Vibration PSD Profile Breakpoints (nonoperating) 35

Table 20. Operating shock 35

Table 21. Nonoperating shock 35

Table 22. Weighted sound power 36

Table 23. Interface connector pins and I/O signals 40

Table 24 Register naming convention and correspondence 47

Table 25 Device Control Register 47

Table 26 Device Register 48

Table 27 Error Register 48

Table 28 Status Register 49

Table 29 Reset Response Table 51

Table 30 Default Register Values 52

Table 31 Diagnostic Codes 52

Table 32 Reset error register values 52

Table 33 Device’s behavior by ATA commands 53

Table 34 Power conditions 55

Table 35 Command table for device lock operation 63

Table 36 Command table for device lock operation - continued 64

Table 37 Set Max Set Password data content 66

Table 38 Preserved Software Setting 70

Table 39 SCT Action Code Supported 71

Table 40 Command set 75

Table 41 Command Set - continued 76

Table 42 Command Set (Subcommand) 77

Table 43 Check Power Mode Command (E5h/98h) 79

Table 44 Device Configuration Overlay Command (B1h) 80

Table 45 Device Configuration Overlay Features register values 80

Table 46 Device Configuration Overlay Data structure 82

Table 47 DCO error information definition 83

Table 48 Download Command (92h) 84

Table 49 Execute Device Diagnostic Command (90h) 86

Table 50 Flush Cache Command (E7h) 87

Table 51 Flush Cache EXT Command (EAh) 88

Table 52 Format Track Command (50h) 89

Table 53 Format Unit Command (F7h) 90

Table 54 Identify Device Command (ECh) 91

Table 55 Identify device information 92

Table 56 Identify device information --- Continued --- 93

Table 57 Identify device information --- Continued --- 94

Table 58 Identify device information --- Continued --- 95

Table 59 Identify device information --- Continued --- 96

Table 60 Identify device information --- Continued --- 97

Table 61 Identify device information --- Continued --- 98

Table 62 Identify device information --- Continued --- 99

Table 63 Identify device information --- Continued --- 101

Table 64 Number of cylinders/heads/sectors by models for HTS5432XXL9SA00 / HTS5432XXL9A300 102

Table 65 Idle Command (E3h/97h) 103

Table 66 Idle Immediate Command (E1h/95h) 104

Table 67 Initialize Device Parameters Command (91h) 105

Table 68 Read Buffer Command (E4h) 106

Table 69 Read DMA Command (C8h/C9h) 107

Table 70 Read DMA Ext Command (25h) 108

Table 71 Read FPDMA Queued Command (60h) 109

Table 72 Read Log Ext Command (2Fh) 110

Table 73 Log address definition 110

Table 74 General purpose Log Directory 111

Table 75 Extended comprehensive SMART error Log 112

6

5K320 SATA OEM Specification

Table 76 Extended Error log data structure 112

Table 77 Command data structure 113

Table 78 Error data structure 113

Table 79 Extended Self-test log data structure 114

Table 80 Extended Self-test log descriptor entry 115

Table 81 Command Error information 115

Table 82 Phy Event Counter Identifier 116

Table 83 Phy Event Counter information 117

Table 84 Read Multiple Command (C4h) 118

Table 85 Read Multiple Ext Command (29h) 119

Table 86 Read Native Max Address Command (F8h) 120

Table 87 Read Native Max Address Ext Command (29h) 121

Table 88 Read Sector(s) Command (20h/21h) 122

Table 89 Read Sector(s) Ext Command (24h) 123

Table 90 Read Verify Sector(s) Command (40h/41h) 124

Table 91 Read Verify Sector(s) Ext Command (42h) 125

Table 92 Recalibrate Command (1xh) 126

Table 93 Security Disa ble Password Command (F6h) 127

Table 94 Password Information for Security Disable Password command 127

Table 95 Security Erase Prepare Command (F3h) 128

Table 96 Security Erase Unit Command (F4h) 129

Table 97 Erase Unit Information 129

Table 98 Security Freeze Lock Command (F5h) 131

Table 99 Security Set Password Command (F1h) 132

Table 100 Security Set Password Information 132

Table 101 Security Unlock Command (F2h) 134

Table 102 Security Unlock Information 134

Table 103 Seek Command (7xh) 135

Table 104 Sense Condition Command (F0h) 136

Table 105 Set Features Command (EFh) 137

Table 106 Set Max Address Command (F9h) 139

Table 107 Set Max Address Ext Command (37h) 141

Table 108 Set Multiple Command (C6h) 143

Table 109 Sleep Command (E6h/99h) 144

Table 110 S.M.A.R.T. Function Set Command (B0h) 145

Table 111 Log sector addresses 148

Table 112 Device Attribute Data Structure 150

Table 113 Individual Attribute Data Structure 151

Table 114 Status Flag Definitions 152

Table 115 Device Attribute Thresholds Data Structure 154

Table 116 Individual Threshold Data Structure 155

Table 117 SMART Log Directory 155

Table 118 S.M.A.R.T. error log sector 156

Table 119 Error log data structure 156

Table 120 Command data structure 157

Table 121 Error data structure 157

Table 122 Self-test log data structure 158

Table 123 Selective self-test log data structure 159

Table 124 S.M.A.R.T. Error Codes 159

Table 125 Standby Command (E2h/96h) 160

Table 126 Standby Immediate Command (E0h/94h) 161

Table 127 Write Buffer Command (E8h) 162

Table 128 Write DMA Command (CAh/CBh) 163

Table 129 Write DMA Ext Command (35h) 164

Table 130 Write DMA FUA Ext Command (3Dh) 165

Table 131 Write FPDMA Queued Command (61h) 166

Table 132 Write Log Ext Command 167

Table 133 Write Multiple Command (C5h) 168

Table 134 Write Multiple Ext Command (39h) 169

Table 135 Write Multiple FUA Ext Command (CEh) 170

Table 136 Write Sector(s) Command (30h/31h) 171

7

5K320 SATA OEM Specification

Table 137 Write Sector(s) Ext Command (34h) 172

Table 138 Write Uncorrectable Ext Command (45h) 173

Table 139 Timeout Values 175

8

5K320 SATA OEM Specification

General

1 Introduction

This document describes the specifications of the HITACHI Travelstar 5K320, a 2.5-inch hard disk

drive with Serial ATA interface:

Drive

name

Travelstar

5K320-320

Travelstar

5K320-250

Travelstar

5K320-160

Travelstar

5K320-120

Travelstar

5K320-80

Model Number Max data

transfer rate

(Gbps)

HTS543232L9A300 3.0

HTS543232L9SA00 1.5

HTS543225L9A300 3.0

HTS543225L9SA00 1.5

HTS543216L9A300 3.0

HTS543216L9SA00 1.5

HTS543212L9A300 3.0

HTS543212L9SA00 1.5

HTS543280L9A300 3.0

HTS543280L9SA00 1.5

Capacity

(GB)

320 9.5 5400

250 9.5 5400

160 9.5 5400

120 9.5 5400

80 9.5 5400

Height (mm) Rotation

speed (rpm)

1.1 Abbreviations

Abbreviation Meaning

32 KB 32 x 1024 bytes

64 KB 64 x 1024 bytes

“ inch

A amp

AC alternating current

AT Advanced Technology

ATA Advanced Technology Attachment

Bels unit of sound power

BIOS Basic Input/Output System

°C degrees Celsius

CSA Canadian Standards Association

C -UL Canadian-Underwriters Laboratory

Cyl cylinder

DC direct current

DFT Drive Fitness Test

DMA Direct Memory Access

ECC error correction code

9

5K320 SATA OEM Specification

EEC European Economic Community

EMC electromagnetic compatibility

ERP Error Recovery Procedure

Esd electrostatic discharge

FCC Federal Communications Commission

FRU field replacement unit

G gravity, a unit of force

Gb 1 000 000 000 bits

GB 1 000 000 0 00 bytes

GND ground

h hexadecimal

HDD hard disk drive

Hz hertz

I Input

ILS integrated lead suspension

imped impedance

I/O Input/Output

ISO International Standards Organization

KB 1,000 bytes

Kbit/mm 1,000 bits per mm

Kbit/sq-mm 1000 bits per square mm

KHz kilohertz

LBA logical block addressing

Lw unit of A-weighted sound power

m meter

max. or Max. maximum

MB 1,000,000 bytes

Mbps 1,000,000 Bit per second

Mb/sec 1,000,000 Bit per second

MB/sec 1,000,000 bytes per second

MHz megahertz

MLC Machine Level Control

mm millimeter

ms millisecond

us, ? s microsecond

Nm Newton meter

No. or # number

oct/min oscillations per minute

O Output

10

5K320 SATA OEM Specification

OD Open Drain Programmed Input/Output

PIO Program I/O

POH power on hours

Pop. population

P/N part number

p-p peak-to-peak

PSD power spectral density

RES radiated electromagnetic susceptibility

RFI radio frequency interference

RH relative humidity

% RH per cent relative humidity

RMS root mean square

RPM revolutions per minute

RST reset

R/W read/write

sec second

Sect/Trk sectors per track

SELV secondary low voltage

S.M.A.R.T Self-monitoring, analysis, and reporting technology

Trk. track

TTL transistor-transistor logic

UL Underwriters Laboratory

V volt

VDE Verband Deutscher Electrotechnik er

W watt

3-state transistor-transistor tristate logic

11

5K320 SATA OEM Specification

1.2 References

Serial ATA International Organization : Serial ATA Revision 2.6

1.3 General caution

Do not apply force to the top cover (See figure below).

Do not cover the breathing hole on the top cover (See figure below).

Do not touch the interface connector pins or the surface of the printed circuit board.

The drive can be damaged by shock or ESD (Electric Static Discharge). Any damages incurred to

the drive after removing it from the shipping package and the ESD protective bag are the

responsibility of the user

1.4 Drive handling precautions

Do not press on the drive cover during handling.

12

5K320 SATA OEM Specification

2 Outline of the drive

2.5-inch, 9.5 -mm Height

Perpendicular Recording

Formatted capacities of 320GB, 250GB, 160GB,120GB and 80GB(512 bytes/sector)

SATA Interface conforming to Serial ATA International Organization: Serial ATA Revision

2.6(15-February-2007)

Integrated controller

No-ID recording format

Coding : 100/102 2bit parity (199/200 RC Modulation Encoding)

Multi zone recording

Enhanced ECC

10 bit 40 symbol non Interleaved Read Solomon code

Non interleave On-The –Fly correction

Included 2 symbol system ECC

Segmented Buffer with write cache

8192 KB - Upper 736 KB is used for firmware

Fast data transfer rate

HTS5432xxL9A3xx model : up to 3.0Gbit/s

HTS5432xxL9SAxx model : up to 1.5Gbit/s

Media data transfer rate (max):

775 Mb/s

Average seek time: 12 ms for read

Closed-loop actuator servo (Embedded Sector Servo)

Rotary voice coil motor actuator

Load/Unload mechanism

Mechanical latch

0.55 Watts at idle state

Power on to ready

3.5 sec

Operating shock

3920 m/sec2 ( 400 G)/2ms

1960 m/sec2 (200G)/1ms

Non operating shock

9800 m/sec2 ( 10 00 G)/1ms

Bulk E ncryption optional (HTS5432xxL9SA xx model only)

13

5K320 SATA OEM Specification

Part 1 Functional Specification

14

5K320 SATA OEM Specification

3 Fixed disk subsystem description

3.1 Control Electronics

The control electronics works with the following functions:

Ÿ SATA Interface Protocol

Ÿ Embedded Sector Servo

Ÿ No-ID (TM) formatting

Ÿ Multizone recording

Ÿ Code: 100/102 bit parity (199/200 RC Modulation Encoding)

Ÿ System ECC

Ÿ Enhanced Adaptive Battery Life Extender

3.2 Head disk assembly data

The following techno logies are used in the drive:

Ÿ Femto Slider

Ÿ Perpendicular recording disk and write head

Ÿ TMR head

Ÿ Integrated lead suspension (ILS)

Ÿ Load/unload mechanism

Ÿ Mechanical latch

15

5K320 SATA OEM Specification

4 Fixed disk characteristics

4.1 Formatted capacity by model number

Description

Physical Layout

Bytes per Sector 512 512

Number of Heads 4 3

Number of Disks 2 2

Logical Layout

Number of Heads 16 16

Number of Sectors/

Track

Number of

Cylinders

Number of Sectors 625,142,448 488,397,168

Total Logical Data

Bytes

Description

Physical Layout

Bytes per Sector 512 512 512

Number of Heads 2 2 1

Number of Disks 1 1 1

Logical Layout

Number of Heads 16 16 16

Number of Sectors/

Track

Number of

Cylinders

Number of Sectors 312,581,808 234,441,648 156,301,488

Total Logical Data

Bytes

HTS543232L9A300

HTS543232L9SA00

63 63

16,383 16,383

320,072,933,376 250,059,350,016

HTS543216L9A300

HTS543216L9SA00

63 63 63

16,383 16,383 16,383

160,041,885,696 120,034,123,776 80,026,361,856

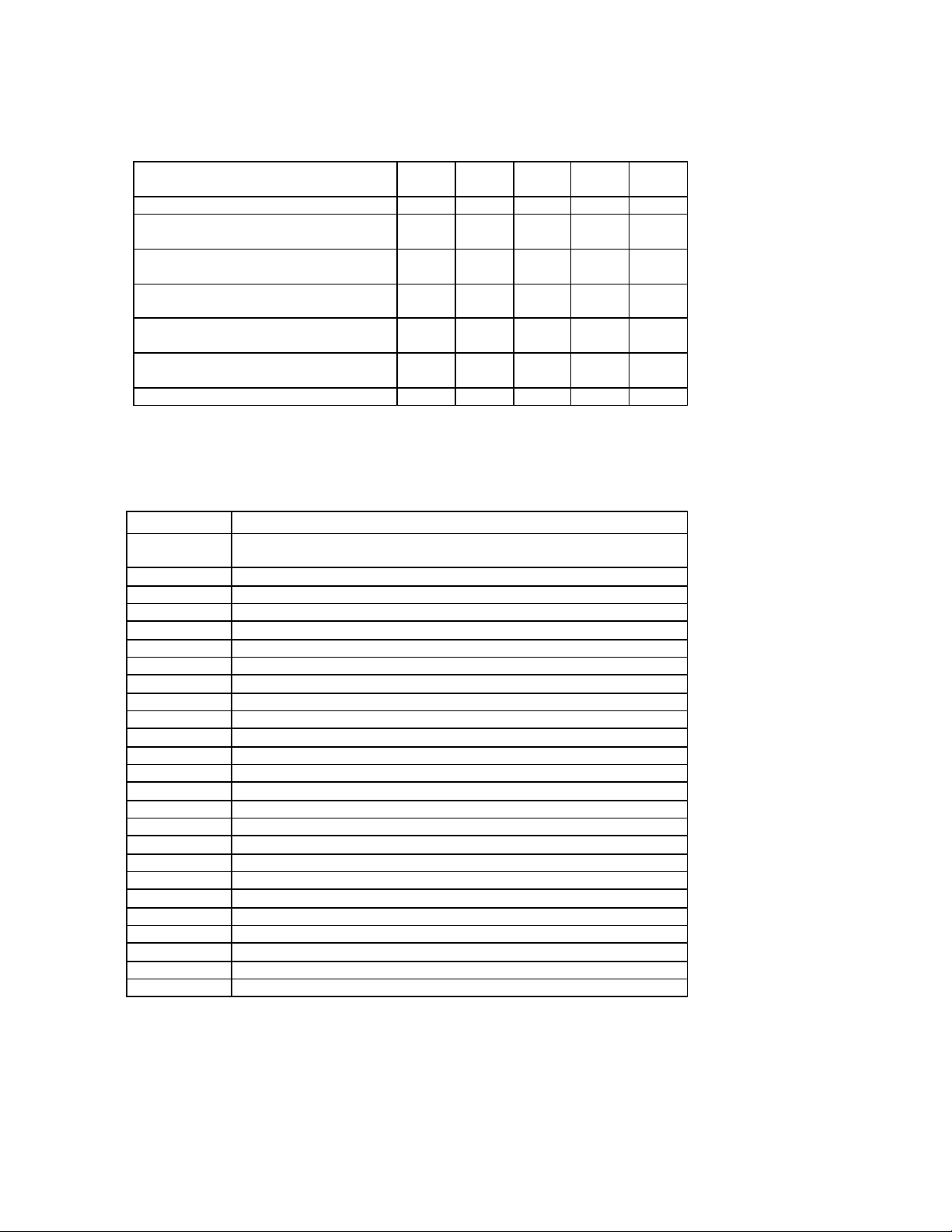

Table 1. Formatted capacity by model number.

HTS543225L9A300

HTS543225L9SA00

HTS543212L9A300

HTS543212L9SA00

HTS543280L9A300

HTS543280L9SA00

16

5K320 SATA OEM Specification

4.2 Data sheet

Rotational Speed (RPM) 5400 5400 5400 5400 5400

Data transfer rates (buffer to/from

media) (Mbps)

Data transfer rates (Gbit/sec) 1.5/

Recording density (Kbit/mm) (Max)

(KBPI) (Max)

Track density ( Ktrack/mm)(Max)

(KTPI) (Ma x)

Areal density (Kbit/sq-mm.- Max)

(Gbit/sq-inch - Max)

Number of zones 24 24 24 24 24

320

GB

729 775 729 674 729

3.0

1154 1207 1154 1066 1154

216

250

250

GB

1.5/

3.0

216

261

160

GB

1.5/

3.0

216

250

120

GB

1.5/

3.0

182

194

80

GB

1.5/

3.0

216

250

Table 2. Data sheet

4.3 Cylinder allocation

Data format is allocated by each head characteristics. Typical format is described below.

Zone Cylinder No. of

0 0 - 8187 1512

1 8188 - 12103 1476

2 12104 - 19045 1440

3 19046 - 26076 1404

4 26077 - 29903 1377

5 29904 - 35866 1350

6 35867 - 40672 1323

7 40673 - 49750 1269

8 49751 - 55624 1242

9 55625 - 59273 1224

10 59274 - 66126 1188

11 66127 - 72979 1134

12 72980 - 76717 1116

13 76718 - 85439 1080

14 85440 - 88910 1044

15 88911 - 92381 1026

16 92382 - 96831 999

17 96832 - 103239 972

18 103240 - 111160 918

19 111161 - 115432 891

20 115433 - 122374 864

21 122375 - 127625 810

22 127626 - 136258 756

23 136259 - 138305 729

Table 3. Cylinder allocation

160GB/p Mid BIP-Mid TPI format

Sectors/Trk

17

5K320 SATA OEM Specification

4.4 Performance characteristics

Drive performance is characterized by the following parameters:

Ÿ Command Overhead

Ÿ Mechanical Positioning

w Seek Time

w Latency

Ÿ Data Transfer Speed

Ÿ Buffering Operation (Look ahead/Write Cache)

Note: All the above parameters contribute to drive performance. There are other parameters which

contribute to the performance of the actual system. This specification defines the essential characteristics

of the drive. This specification does not include the system throughput as this is dependent upon the

system and the application.

The following table gives a typical value for each parameter.

Function

Average Random Seek Time - Read (ms) 12

Average Random Seek Time - Write (ms) 13

Rotational Speed (RPM) 5400

Power-on-to-ready (sec) 3.5

Command overhead (ms) 1.0

Disk-buffer data transfer (Mb/s) (max) 775

Buffer-host data transfer ( Gbit/s) (max) 1.5 / 3.0

Table 4. Performance characteristics

4.4.1 Command overhead

Command overhead time is defined as the interval from the time that a drive receives a command to the

time that the actuator starts its motion.

18

5K320 SATA OEM Specification

4.4.2 Mechanical positioning

4.4.2.1 Average seek time (including settling)

Command Type Typical (ms) Max. (ms)

Read 12 14

Write 13 15

Table 5. Mechanical positioning performance

Typical and Max. are defined throughout the performance specification as follows:

Typical Average of the drive population tested at nominal environmental and voltage conditions.

Max. Maximum value measured on any one drive over the full range of the environmental and

voltage conditions. (See section 6.1, "Environment" and section 6.2, "DC power

requirements" )

The seek time is measured from the start of motion of the actuator to the start of a reliable read or write

operation. A reliable read or write operation implies that error correction/recovery is not employed to

correct arrival problems. The Average Seek Time is measured as the weighted average of all possible

seek combinations.

Σ (max. + 1 – n)(Tnin + Tn

Weighted Average = ––––––––––––––––––––––––––––

(max. + 1)(max)

Where: max. = maximum seek length

n = seek length (1-to-max.)

Tn

Tn

in

out

max.

n=1

= inward measured seek time for an n-track seek

= outward measured seek time for an n-track seek

out

)

4.4.2.2 Full stroke seek

Command Type Typical (ms) Max. (ms)

Read 20.0 25.0

Write 21.0 26.0

Table 6. Full stroke seek time

Full stroke seek time in milliseconds is the average time of 1000 full stroke seeks.

4.4.2.3 Single track seek time (without command overhead, including

settling)

Command Type Typical (ms) Maximum (ms)

Read 1.0 2.0

Write 1.1 2.2

Table 7. Single track seek time

Single track seek is measured as the average of one (1) single track seek from every track in both

directions (inward and outward).

4.4.2.4 Average latency

Rotational Speed

(RPM)

5400 11.1 5.5

Table 8. Latency time

Time for one revolution

(ms)

Average Latency

(ms)

19

5K320 SATA OEM Specification

4.4.2.5 Drive ready time

Condition Typical (sec) Max. (sec)

Power On To Ready 3.5 9.5

Table 9. Drive ready time

Ready The condition in which the drive is able to perform a media access command

(for example —read, write) immediately.

Power On To Ready This includes the time required for the internal self diagnostics.

20

5K320 SATA OEM Specification

4.4.3 Operating modes

Operating mode Description

Spin-Up

Seek

Write

Read

Performance idle

Active idle

Low power idle

Standby

Sleep

Start up time period from spindle stop or power down.

Seek operation mode

Write operation mode

Read operation mode

The device is capable of responding immediately to media access requests. All

electronic components remain powered and the full frequency servo remains

operational.

The device is capable of responding immediately to media access requests. Some

circuitry—including servo system and R/W electronics—is in power saving mode.

The head is parked near the mid-diameter the disk without servoing.

A device in Active idle mode may take longer to complete the execution of a

command because it must activate that circuitry.

The head is unloaded onto the ramp position. The spindle motor is rotating at full

speed.

The device interface is capable of accepting commands. The spindle motor is

stopped. All circuitry but the host interface is in power saving mode.

The execution of commands is delayed until the spindle becomes ready.

The device requires a soft reset or a hard reset to be activated. All electronics,

including spindle motor and host interface, are shut off.

Table 10. Operating mode

4.4.3.1 Mode transition time

From To Transition

Time (typ)

Standby Idle 2.5 9.5

Table 11. Drive ready time

Transition Time

(max.)

4.4.3.2 Operating mode at power on

The device goes into Idle mode after power on or hard reset as an initial state. .

4.4.3.3 Adaptive power save control

The transient timing from Performance Idle mode to Active Idle mode and Active Idle mode to Low Power

Idle mode is controlled adaptively according to the access pattern of the host system. The transient

timing from Low Power Idle mode to Standby mode is also controlled adaptively, if it is allowed by Set

Features Enable Advanced Power Management subcommand.

21

5K320 SATA OEM Specification

5 Data integrity

5.1 Data loss on power off

Ÿ Data loss will not be caused by a power off during any operation except the write operation.

Ÿ A power off during a write operation causes the loss of any received or resident data that has not

been written onto the disk media.

Ÿ A power off during a write operation might make a maximum of one sector of data unreadable. This

state can be recovered by a rewrite operation.

5.2 Write Cache

When the write cache is enabled, the write command may complete before the actual disk write operation

finishes. This means that a power off, even after the write command completion, could cause the loss of

data that the drive has received but not yet written onto the disk.

In order to prevent this data loss, confirm the completion of the actual write operation prior to the power

off by issuing a

Ÿ Soft reset

Ÿ Hard reset

Ÿ Flush Cache command

Ÿ Standby command

Ÿ Standby Immediate command

Ÿ Sleep command

Confirm the command’s completion.

5.3 Equipment status

The equipment status is available to the host system any time the drive is not ready to read, write, or seek.

This status normally exists at the power-on time and will be maintained until the following conditions are

satisfied:

Ÿ The access recalibration/tuning is complete.

Ÿ The spindle speed meets the requirements for reliable operation.

Ÿ The self-check of the drive is complete.

The appropriate error status is made available to the host system if any of the following conditions occur

after the drive has become ready:

Ÿ The spindle speed lies outside the requirements for reliable operation.

Ÿ The occurrence of a Write Fault condition .

5.4 WRITE safety

The drive ensures that the data is written into the disk media properly. The following conditions are

monitored during a write operation. When one of these conditions exceeds the criteria, the write operation

is terminated and the automatic retry sequence is invoked.

Ÿ Head off track

Ÿ External shock

Ÿ Low supply voltage

Ÿ Spindle speed out of tolerance

Ÿ Head open/short

22

5K320 SATA OEM Specification

5.5 Data buffer test

The data buffer is tested at power on reset and when a drive self -test is requested by the host. The test

consists of a write/read '00'x and 'ff'x pattern on all buffers.

5.6 Error recovery

Errors occurring on the drive are handled by the error recovery procedure.

Errors that are uncorrectable after application of the error recovery procedure are reported to the host

system as nonrecoverable errors.

5.7 Automatic reallocation

The sectors that show some errors may be reallocated automatically when specific conditions are met.

The drive does not report any auto reallocation to the host system. The conditions for auto reallocation

are described below.

5.7.1 Nonrecovered write errors

When a write operation cannot be completed after the Error Recovery Procedure (ERP) is fully carried out,

the sectors are reallocated to the spare location. An error is reported to the host system only when the

write cache is disabled and the auto reallocation has failed.

5.7.2 Nonrecoverable read error

When a read operation fails after ERP is fully carried out, a hard error is reported to the host system. This

location is registered internally as a candidate for the reallocation. When a registered location is specified

as a target of a write operation, a sequence of media verification is performed automatically. When the

result of this verification meets the required criteria, this sector is reallocated.

5.7.3 Recovered read errors

When a read operation for a sector fails and is recovered at the specific ERP step, the sector is

reallocated automatically. A media verification sequence may be run prior to the reallocation according to

the predefined conditions.

23

5K320 SATA OEM Specification

5.8 ECC

The 10 bit symbol non interleaved ECC processor provides user data verification and correction

capability. The first 6 symbol of ECC are 4 check symbols for user data and the 2 symbol system ECC.

The other 34 symbols are Read Solomon ECC. Hardware logic corrects up to 16 symbols(20 bytes)

errors on-the-fly.

2 symbol System ECC is generated when HDC receives user data from HOST, and can correct up to 1

symbol(10bit) errors on-the-fly when one transfers to HOST.

24

5K320 SATA OEM Specification

WetBulb 40'C

6 Specification

6.1 Environment

6.1.1 Temperature and humidity

Operating conditions

Temperature

Relative humidity

Maximum wet bulb temperature

Maximum temperature gradient

Altitude

Nonoperating conditions

Temperature

Relative humidity

Maximum wet bulb temperature

Maximum temperature gradient

Altitude

Table 12. Environmental condition

The system is responsible for providing sufficient air movement to maintain surface temperatures below

60°C at the center of top cover and below 63°C at the center of the drive circuit board assembly.

The maximum storage period in the shipping package is one year.

5 to 55°C (See note below)

8 to 90% noncondensing

29.4°C noncondensing

20°C/hour

–300 to 3048 m (10,000 ft)

–40 to 65°C

5 to 95% noncondensing

40°C noncondensing

20°C/hour

–300 to 12,192 m (40,000 ft)

Specification (Environment)

100

90

80

70

60

Non Operating

50

40

Relative Humidity (%)

30

20

10

0

-45 -35 -25 -15 -5 5 15 25 35 45 55 65

Temperature (degC)

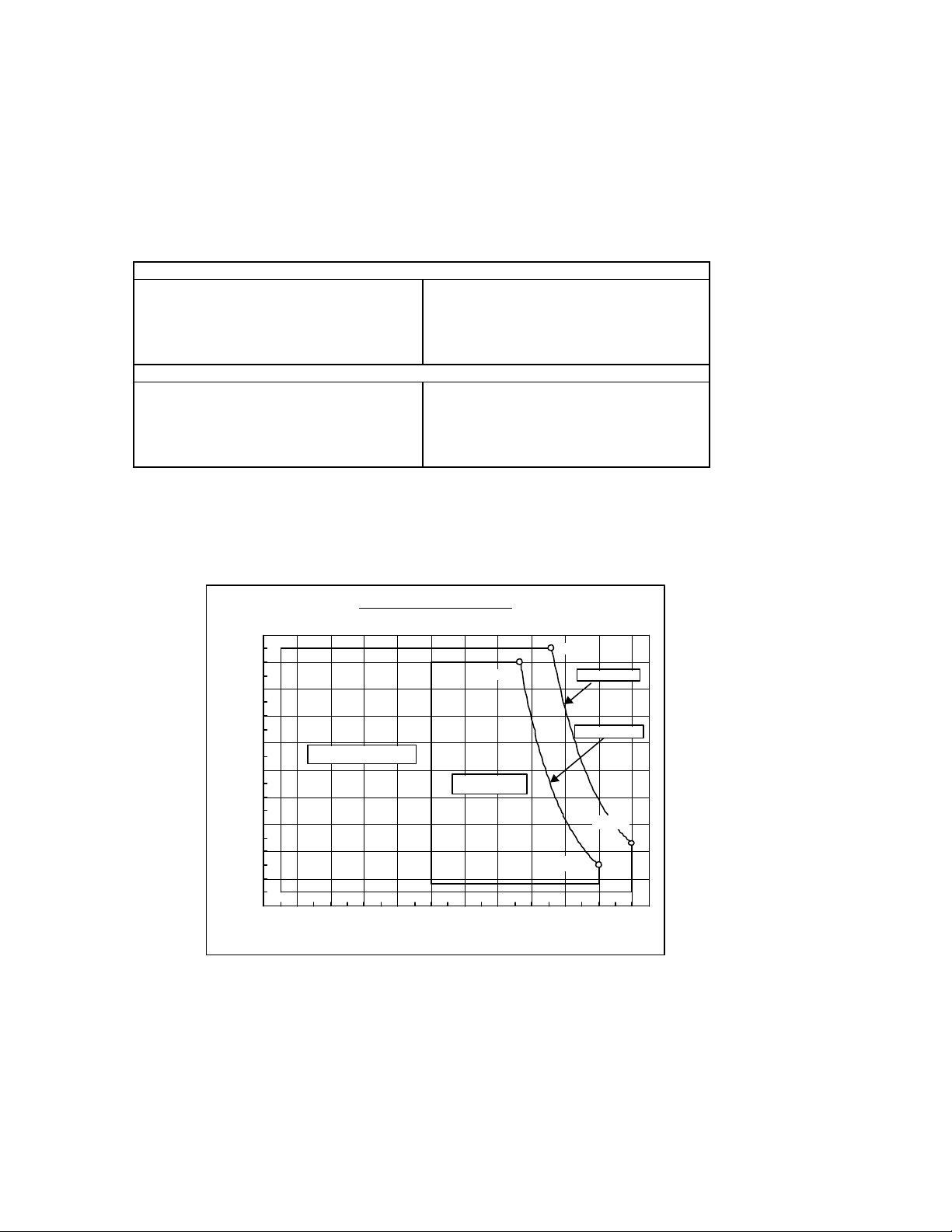

Figure 1 . Limits of temperature and humidity

6.1.2 Corrosion test

41'C/95%

31'C/90%

WetBulb29.4'C

Operating

65'C/23%

55'C/15%

The hard disk drive must be functional and show no signs of corrosion after being exposed to a

temperature humidity stress of 50°C/90%RH (relative humidity) for one week followed by a temperature

and humidity drop to 25'C/40%RH in 2 hours.

25

5K320 SATA OEM Specification

6.1.3 Radiation noise

The disk drive shall work without degradation of the soft error rate under the following magnetic flux

density limits at the enclosure surface.

Frequency (KHz) Limits (uT RMS)

DC 1500 0-p

0 < Frequency =< 60 500 RMS

60 < Frequency =<100 250 RMS

100 < Frequency =< 200 100 RMS

200 < Frequency =< 400 50 RMS

Table 13. Magnetic flux density limits

6.1.4 Conductive noise

The disk drive shall work without soft error degradation in the frequency range from DC to 20 Mhz

injected through any two of the mounting screw holes of the drive when an AC current of up to 45 mA

(p-p) is applied through a 50-ohm resistor connected to any two mounting screw ho les.

26

5K320 SATA OEM Specification

6.2 DC power requirements

Connection to the product should be made in a safety extra low voltage (SELV) circuits. The voltage

specifications are applied at the power connector of the drive.

Item Requirements

Nominal supply +5 Volt dc

Supply voltage –0.3 Volt to 6.0 Volt

Power supply ripple (0–20

MHz)1

Tolerance 2

Supply rise time 1–100 ms

Watts (RMS Typical) 7

Performance Idle average 3

Active Idle average 0.8

Low Power Idle average 0.55

Read average 4

Write average 1.8

Seek average 5

Standby 0.2

Sleep 0.1

Startup (maximum peak) 6

Average from power on to

ready

Table 14. DC Power requirements

100 mV p-p max.

±5%

1.7

1.8

2.2

5.0

3.8

Footnotes:

1. The maximum fixed disk ripple is measured at the 5 volt input of the drive.

2. The disk drive shall not incur damage for an over voltage condition of +25% (maximum

3. The idle current is specified at an inner track.

4. The read/write current is specified based on three operations of 63 sector read/write per

5. The seek average current is specified based on three operations per 100 ms.

6. The worst case operating current includes motor surge.

7. “Typical” mean average of the drive population tested at nominal environmental and

duration of 20 ms) on the 5 volt nominal supply.

100 ms.

voltage conditions.

27

5K320 SATA OEM Specification

6.2.1 Power consumption efficiency

Capacity 320GB 250GB 160GB 120GB 80GB

Power Consumption Efficiency

(Watts/GB)

0.0017 0.0022 0.0034 0.0046 0.0069

Table 15. Power consumption efficiency

Note: Power consumption efficiency is calculated as Power Consumption of Low Power Idle Watt/

Capacity (GB).

28

5K320 SATA OEM Specification

6.3 Reliability

6.3.1 Data reliability

Ÿ Probability of not recovering data is 1 in 10

Ÿ ECC implementation

On-the-fly correction performed as a part of read channel function reco vers up to 16 symbols of error in 1

sector (1 symbol is 10 bits).

14

bits read

6.3.2 Failure prediction (S.M.A.R.T.)

The drive supports Self -monitoring, analysis and reporting technology (S.M.A.R.T.) function. The details

are described in section 11.8, " S.M.A.R.T. Function" and in Section 13.32, "S.M.A.R.T. Function Set

(B0h)"

6.3.3 Cable noise interference

To avoid any degradation of performance throughput or error when the interface cable is routed on top or

comes in contact with the HDA assembly, the drive must be grounded electrically to the system frame by

four screws. The common mode noise or voltage level difference between the system frame and power

cable ground or AT interface cable ground should be in the allowable level specified in the power

requirement section.

6.3.4 Service life and usage condition

The drive is designed to be used under the following conditions:

Ÿ The drive should be operated within specifications of shock, vibration, temperature, humidity, altitude,

and magnetic field.

Ÿ The drive should be protected from ESD.

Ÿ The breathing hole in the top cover of the drive should not be covered.

Ÿ Force should not be applied to the cover of the drive.

Ÿ The specified power requirements of the drive should be satisfied.

Ÿ The drive frame should be grounded electrically to the system through four screws.

Ÿ The drive should be mounted with the recommended screw depth and torque.

Ÿ The interface physical and electrical requirements of the drive should satisfy Serial ATA Revision 2.6.

Ÿ The power-off sequence of the drive should comply with the 6.3 .6.2,"Required power-off

sequence.”

Service life of the drive is approximately 5 years or 20,000 power on hours, whichever comes first, under

the following assumptions:

Ÿ Less than 333 power on hours per month.

Ÿ Seeking/Writing/Reading operation is less than 20% of power on hours.

This does not represent any warranty or warranty period. Applicable warranty and warranty period are

covered by the purchase agreement.

29

5K320 SATA OEM Specification

6.3.5 Preventive maintenance

None.

6.3.6 Load/unload

The product supports a minimum of 600,000 normal load/unloads.

Load/unload is a functional mechanism of the hard disk drive. It is controlled by the drive micro code.

Specifically, unloading of the heads is invoked by the following commands:

Ÿ Standby

Ÿ Standby immediate

Ÿ Sleep

Load/unload is also invoked as one of the idle modes of the drive.

The specified start/stop life of the product assumes that load/unload is operated normally, not in

emergency mode.

6.3.6.1 Emergency unload

When hard disk drive power is interrupted while the heads are still loaded the micro code cannot operate

and the normal 5 -volt power is unavailable to unload the heads. In this case, normal unload is not

possible. The heads are unloaded by routing the back EMF of the spinning motor to the voice coil. The

actuator vel ocity is greater than the normal case and the unload process is inherently less controllable

without a normal seek current profile.

Emergency unload is intended to be invoked in rare situations. Because this operation is inherently

uncontrolled, it is more mechanically stressful than a normal unload.

The drive supports a minimum of 20,000 emergency unloads.

6.3.6.2 Required Power-Off Sequence

The required host system sequence for removing power from the drive is as follows:

Ÿ Step 1: Issue one of the following commands.

Ÿ Standby

Ÿ Standby immediate

Ÿ Sleep

Note: Do not use the Flush Cache command for the power off sequence because this command

does not invoke Unload.

Ÿ Step 2: Wait until the Command Complete status is returned.

In a typical case 500 ms are required for the command to finish completion; however, the host system

time out value needs to be 30 seconds considering error recovery time.

Ÿ Step 3: Terminate power to HDD.

This power-down sequence should be followed for entry into any system power-down state, system

suspend state, or system hibernation state. In a robustly designed system, emergency unload is limited

to rare scenarios, such as battery removal during operation.

6.3.6.3 Power switch design considerations

In systems that use the Travelstar 5K320 consideration should be given to the design of the system

power switch.

Hitachi recommends that the switch operate under control of the host system, as opposed to being

hardwired. The same recommendation is made for cover-close switches. When a hardwired switch is

30

Loading...

Loading...