Hitachi HTC426030G7CE00, HTC426020G7CE00, HTC426060G9AT00, HTC426040G9AT00, HTC426030G7AT00 Quick Installation Guide

...

Quick installation guide

Hitachi Travelstar C4K60

Models:

Handling precautions

y Set the drive down gently to prevent damage from impact or vibration.

y Handle the drive carefully by the edges. Do not touch the exposed printed circuit board or any electronic components.

y Do not press on the top or bottom of the drive.

y Before handling the drive, discharge any static electricity from yourself and your clothing. With one hand touch an

unpainted metal surface, then touch the ESD bag with the other hand. Remain in contact with the chassis and the bag for a

minimum of two seconds.

HTC426030G7CE00

HTC426020G7CE00

HTC426060G9AT00

HTC426040G9AT00

HTC426030G7AT00

HTC426020G7AT00

y Vibration, shock and static electricity to the drive will damage the precision parts. In particular, prevent vibration or shock

generated by dropping, knocking over or hitting the drive. Also, avoid touching the electrical components directly, which

can discharge electrostatic energy and damage the drive.

Page 1 version 1.0

Hitachi Global Storage Technologies

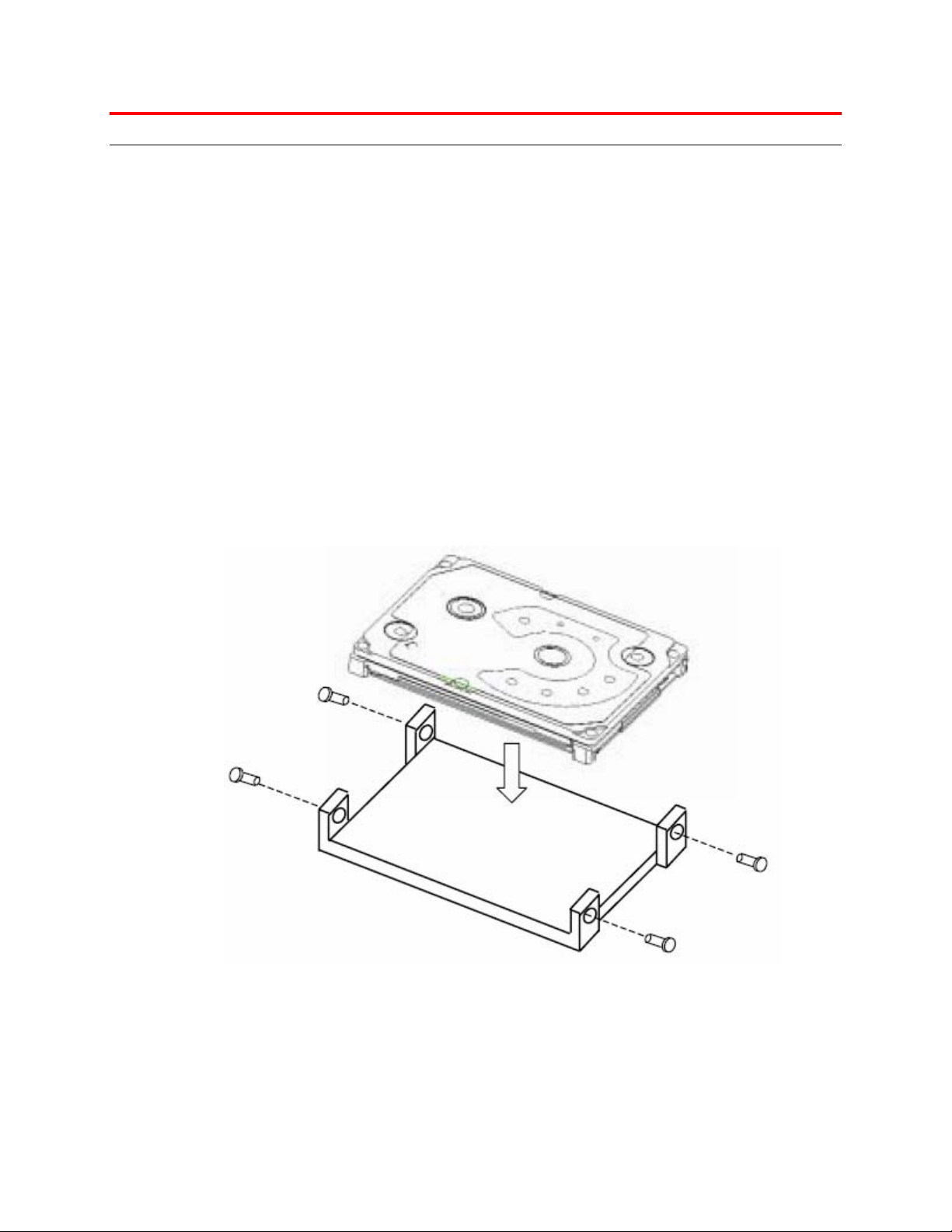

Mounting Instructions

Caution: Mount the hard drive according to the following instructions to ensure optimal performance.

• Mount the hard drive with M2.0 screws (screw engagement of 2.3mm max). Be careful not to add any

distorting force to the hard drive when mounting.

• Use either the bottom or side screw holes to secure drive. Do not attempt to use both bottom and side

screw holes simultanesly.

• The torque for fixing the screws is 2.5±05kgcm(2.2±0.4 lb. inch).

• The temperature of the center of the hard drive cover should remain less than 65°C at all times.

• The inertia of the chassis around the Z-axis of the gravity center of the device must be more than 3 x

• In case of general Sub-notebook PC weight (1.7kg), the inertia of the chassis around the Z-axis of the

• If installing the C4K60 next to a steel plate, the cover of the C4K60 and the steel plate must have at

• The PCBA side of the drive should be covered with insulation if it is in contact with any metal part of

-4

kg m2.

10

gravity center of the device is greater than 100 x 10-4 kg m2. Therefore, the required inertia level does

not conflict with the general electronic equipment.

least 2mm of space between them. This is necessary for air flow and cooling requirements.

the host system. Contact between the PCBA and metal may result in drive failure.

Page 2 version 1.0

Loading...

Loading...