Page 1

SERVICE MANUAL

MANUEL D'ENTRETIEN

WARTUNGSHANDBUCH

CAUTION:

Beforeservicing this chassis, itisimportantthat the servicetechnician read the“Safety

Precautions”and“ProductSafetyNotices”inthisservicemanual.

SM0103

HTADD3E

HTADD3EBS

HTADD3W

HTADD3WUN

HTADD3WAU

Data contained within this Service

manual is subject to alteration for

improvement.

ATTENTION:

Avantd’effectuerl’entretienduchâassis,letechniciendoitlireles«Précautionsdesécurité»

etles«Noticesdesécuritéduproduit»présentésdansleprésentmanuel.

VORSICHT:

VorÖffnendesGehäuseshatderService-Ingenieurdie„Sicherheitshinweise“und„Hinweise

zurProduktsicherheit“indiesemWartungshandbuchzulesen.

CONTENTS

SPECIFICATIONS...............................................................................................................................................3

SERVICE POINTS..............................................................................................................................................4

ADJUSTMENT.....................................................................................................................................................8

WIRING DIAGRAM.............................................................................................................................................9

PRINTED WIRING BOARD..............................................................................................................................10

BLOCK DIAGRAM.............................................................................................................................................23

SCHEMATIC DIAGRAM....................................................................................................................................25

EXPLODED VIEW.............................................................................................................................................43

REPLACEMENT PARTS LIST..........................................................................................................................47

Les données fournies dans le présent

manueld’entretienpeuventfairel’objet

demodificationsenvuedeperfectionner

leproduit.

Die in diesem Wartungshandbuch

enthaltenenSpezifikationenkönnensich

zwecksVerbesserungenändern.

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

AV SURROUND SYSTEM

September 2000

Page 2

ENGLISH

SAFETY PRECAUTIONS

WARNING: The following precautions must be observed.

ALL PRODUCTS

Before any service is performed on the chassis an

isolation transformer should be inserted between the

power line and the product.

1. When replacing the chassis in the cabinet, ensure

all the protective devices are put back in place.

2. When service is required, observe the original

lead dressing. Extra precaution should be taken to

ensure correct lead dressing in any high voltage

circuitry area.

3. Many electrical and mechanical parts in

HITACHI products have special safety related

characteristics. These characteristics are often not

evident from visual inspection, nor can the

protection afforded by them necessarily be

obtained by using replacement components rated

for higher voltage, wattage, etc. Replacement

parts which have these special safety

characteristics are identified by marking with a

on the schematics and the replacement parts

list.

The use of a substitute replacement component

that does not have the same safety characteristics

as the HITACHI recommended replacement one,

shown in the parts list, may create electrical

shock, fire, X-radiation, or other hazards.

4. Always replace original spacers and maintain lead

lengths. Furthermore, where a short circuit has

occurred, replace those components that indicate

evidence of overheating.

5. Insulation resistance should not be less than 2M

ohms at 500V DC between the main poles and

any accessible metal parts.

6. No flashover or breakdown should occur during

the dielectric strength test, applying 3kV AC or

4.25kV DC for two seconds between the main

poles and accessible metal parts.

7. Before returning a serviced product to the

customer, the service technician must thoroughly

test the unit to be certain that it is completely safe

to operate without danger of electrical shock. The

service technician must make sure that no

protective device built into the instrument by the

manufacturer has become defective, or

inadvertently damaged during servicing.

CE MARK

1. HITACHI products may contain the CE mark on

the rating plate indicating that the product

contains parts that have been specifically

approved to provide electromagnetic

compatibility to designated levels.

2. When replacing any part in this product, please

use only the correct part itemised in the parts list

to ensure this standard is maintained, and take

care to replace lead dressing to its original state,

as this can have a bearing on the electromagnetic

radiation/immunity.

PICTURE TUBE

1. The line output stage can develop voltages in

excess of 25kV; if the E.H.T. cap is required to be

removed, discharge the anode to chassis via a

high value resistor, prior to its removal from the

picture tube.

2. High voltage should always be kept at the rated

value of the chassis and no higher. Operating at

higher voltages may cause a failure of the picture

tube or high voltage supply, and also, under

certain circumstances could produce X-radiation

levels moderately in excess of design levels. The

high voltage must not, under any circumstances,

exceed 29kV on the chassis (except for projection

Televisions).

3. The primary source of X-radiation in the product

is the picture tube. The picture tube utilised for

the above mentioned function in this chassis is

specially constructed to limit X-radiation. For

continued X-radiation protection, replace tube

with the same type as the original HITACHI

approved type

4. Keep the picture tube away from the body while

handling. Do not install, remove, or handle the

picture tube in any manner unless shatterproof

goggles are worn. People not so equipped should

be kept away while picture tubes are handled

LASERS

If the product contains a laser avoid direct exposure to

the beam when the cover is open or when interlocks are

defeated or have failed.

- 1 -

Page 3

HTA-DD3

Check that exposed parts are acceptably insulated from

the supply circuit before returning the repaired instrument

to the customer.

INSTRUMENT

• Checking method

(Exposed part)

Measure the resistance value between the both poles of

attachment cup (Power supply plug) and the exposed

parts (Parts such as Knob, Cover, etc. where the customer is easy to touch.) and check that the resistance

value is 500 kohms or more.

Insulation tester (DC 500V)

SAFETY PRECAUTIONS

The following precautions should be observed when servicing.

1. Since many parts in the unit have special safety-related characteristics, always use genuine Hitachis replacement parts. Especially critical parts in the power circuit block should not be replaced with other makers. Critical

parts are marked with

2. Before returning a repaired unit to the customer, the service technician must thoroughly test the unit to ascertain

that it is completely safe to operate without danger of electrical shock.

_ in the circuit diagram and printed wiring board.

2

Page 4

HTA-DD3

SPECIFICATIONS

AUDIO SECTION

(Power amplifier) For (E, EBS) For (W, WUN, WAU)

Rated output: Front: 80 W + 80 W (6 Ω/ohms, 20 Hz ~ 20 kHz with 0.1 % T.H.D.) 100 W + 100 W (EIAJ, 6 ohms)

SINUS power: Front: 90 W + 90 W (6 Ω/ohms, 1 kHz, 0.1 %)

Output terminals: Front: A or B 6 to 16 Ω/ohms

(Analog)

LINE input

Input sensitivity / input impedance: 200 mV / 47 kΩ/kohms

Frequency response: 10 Hz ~ 50 kHz: +1, 3 dB

S/N ratio: 93 dB (IHF-A weighted)

Total harmonic distortion: 0.1% (20 Hz ~ 20 kHz)

PHONO input-REC OUT

Input sensitivity / input impedance: 2.5 mV / 47 kΩ/kohms

RIAA deviation: ±1 dB (20 Hz ~ 20 kHz)

S/N ratio: 74 dB (IHF-A weighted, with 5mV input)

Total harmonic distortion: 0.03% (1 kHz, 3V)

Rated output / Maximum output: 150 mV / 7V

Centre: 80 W (6 Ω/ohms, 20 Hz ~ 20 kHz with 0.1 % T.H.D.) 100 W (EIAJ, 6 ohms)

Surround: 80 W + 80 W (6 Ω/ohms, 20 Hz ~ 20 kHz with 0.1 % T.H.D.) 100 W + 100 W (EIAJ, 6 ohms)

Centre: 90 W (6 Ω/ohms, 1 kHz, 0.1 %)

Surround: 90 W + 90 W (6 Ω/ohms, 1 kHz, 0.1 %)

A + B 12 Ω/ohms or more

Center/Surround: 6 to 16 Ω/ohms

•VIDEO SECTION

(Composite)

Input/output level and impedance: 1 Vp-p, 75 Ω/ohms

Frequency response: 5 Hz ~ 10 MHz +1, 3 dB

(S-Video)

Input/output level and impedance: Y=1 Vp-p, C=0.286 Vp-p

Frequency response: 5 Hz ~ 10 MHz +1, 3 dB

(Component)

Input/output level and impedance: Y=1 Vp-p, C

Frequency response: 5 Hz ~ 10 MHz +1, 3 dB

•TUNER SECTION

[FM] (note: µV at 75Ω/ohms, 0 dBF = 1 ∞ 10

Receiving range: 87.50 MHz ~ 108.00 MHz (0.05 MHz step) 522 kHz ~ 1611 kHz (9 kHz step) (E, EBS)

Usable sensitivity: 2.0 µV (17.2 dBf) 600 µV

50 dB quieting sensitivity: STEREO 23µV (38.5 dBf)

S/N ratio: MONO 80 dB (IHF-A weighted)

STEREO 75 dB (IHF-A weighted)

Total harmonic distortion: MONO 0.2% (1kHz)

STEREO 0.4% (1kHz)

=0.7 Vp-p, CR=0.7 Vp-p

B

-15

W) [AM]

522 kHz ~ 1611kHz (9 kHz step),

520 ~ 1710 kHz (10 kHz step) (W, WUN,WAU)

• GENERAL

Power supply: AC 230V, 50 Hz (E,EBS), AC 110 ~ 127V/220 ~ 240V, 50/60 Hz (W, WUN,WAU)

Power consumption: 180 W (Standby mode = 1.5W)

Maximum external dimensions: 434 (W) ∞ 144 (H) ∞ 320 (D) mm

Weight: 8.1 kg

• REMOTE CONTROL UNIT (RB-DD1S)

Batteries: R6P/AA Type (two batteries)

External dimensions: 54 (W) ∞ 172 (H) ∞ 27.2 (D) mm

Weight: 100 g (including batteries)

• Accessory supplied: Operating instructions, Remote control unit (RB-DD1S),

* For purposes of improvement, specifications and design are subject to change without notice.

R6P/AA batteries, AM loop antenna and FM indoor antenna

3

Page 5

HTA-DD3

SERVICE POINTS

1. Removal of Top Cover

(a) Remove 2 screws 1 from each side.

(b) Remove 4 screws 2 from the rear plate.

x 2

1

Top cover

x 2

1

x 4

2

Fig.1

2. Removal of Rear Plate

(a) Remove 28 screws 3 and 1 screw 4 from the rear plate.

(b) Remove 5 screws - from the Bottom Chassis.

Rear Plate

x 28

3

21

x 5

Fig.2

4

x 1

4

Page 6

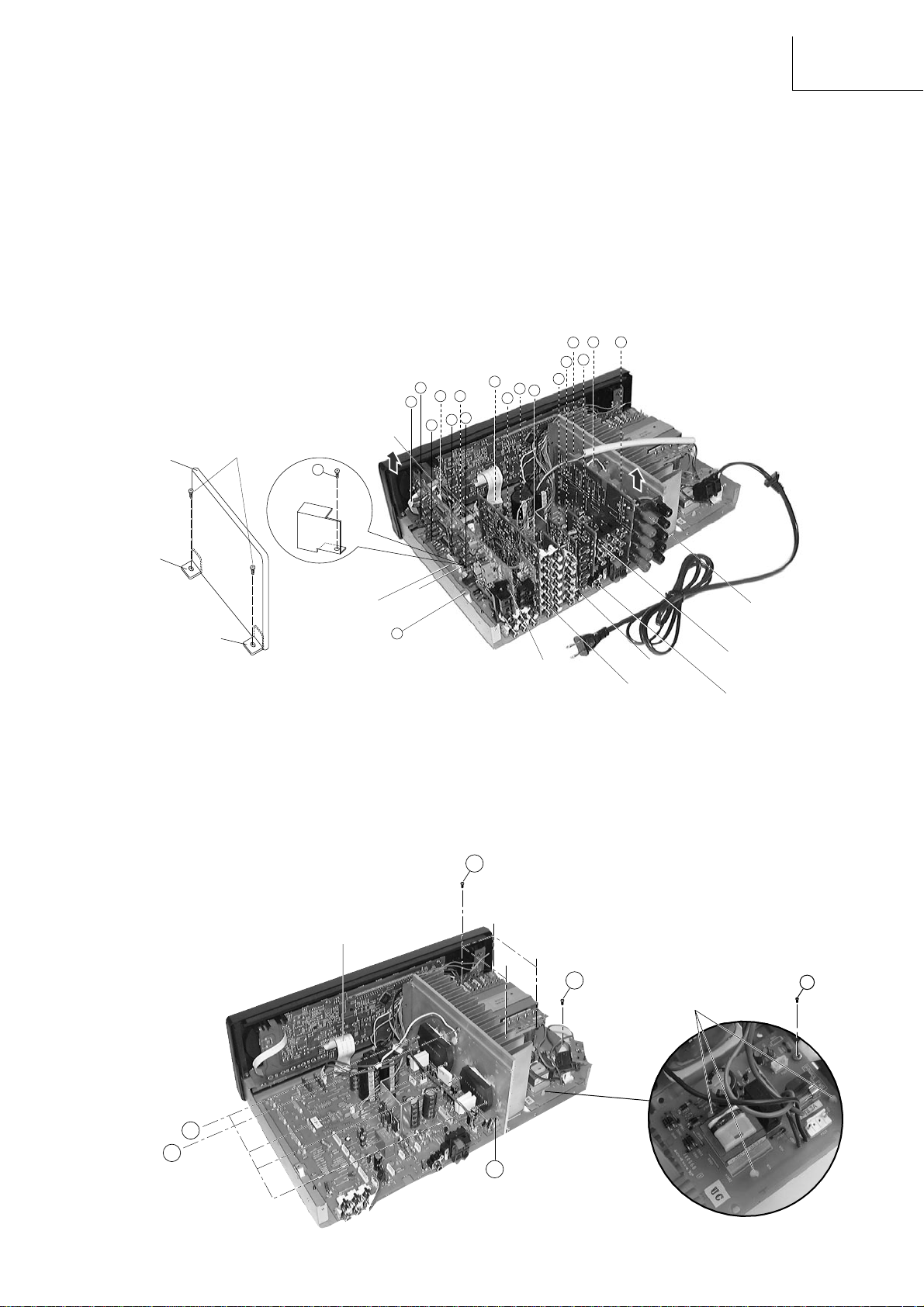

3 . Removal of Tuner & DSP PWB board

(a) Remove the Push Rivet from the Holder (Front) & Holder (Back) then remove the flat cable Z at the Tuner PWB.

(b) Remove 1 screw + to detech the shield plate from the bottom chassis.

(c) Gently pull the Tuner & DSP PWB board upwards to detach its connectors A, B, C, D, E & F from Main

PWB board.

Removal of Audio PWB board

(a) Gently pull the Audio PWB board upwards to detach its 4 connectors H, I, J & K from Main PWB board.

Removal of S Video/Composit PWB board

(a) Gently pull the Composit and S Video PWB board upwards to detach its 2 connectors L & M from Main PWB

board.

Removal of Components PWB board

(a) Gently pull the Components PWB board upwards to detach its connector N from Main PWB board.

P Q

Removal of Relay PWB board

(a) Gently pull the Relay PWB board upwards to

detach its 3 connectors O, P & Q from

Main PWB board.

DSP PWB

Push Rivet

19

for E, E(BS)

A

Z

DSP PWB

H

E

F

D

C

B

J

I

O

N

M

L

K

Fig.3

HTA-DD3

Holder (Front)

SHIELD

Main PWB

Holder (Back)

4. Removal of Transformer

(a) Remove 4 screws 5 from the transformer.

(b) Pull the transformer upward together with the Power PWB section.

PLATE

19

x 1

Tuner

PWB

S Video PWB

Audio PWB

Relay PWB

Component PWB

Composit PWB

Removal of Power PWB board

(a) Remove 1 screw 6 from the Botton chassis at the side.

(b) Release the Power PWB board from its 3 holding claws (PWB support) and gently pull the board free.

Removal of Main PWB board

(a) Detach Flat Cable from FL PWB Board.

(b) Remove 4 screws 7 to release the Power IC from the heat-sink.

(c) Remove 3 screws , to release the bracket from the heat-sink.

(d) Remove 1 screw 8 to release the Component from the heat-sink.

Removal of Heat-Sink

x 4

5

(a) Invert the Botton Chassis, remove 2 screws

9 connect to the heat-sink (Fig 5).

Flat Cable

x 1

6

Claws (PWB Support)

6

7

x 1

8

Fig.4

x 4

5

20

x 3

Page 7

HTA-DD3

5. Removal of Front Panel

(a) Invert the Bottom Chassis and remove 4 screws !.

(b) Remove the Master Vol. & Bass/Treble knob before remove the Front panel.

9

x 2

11

x 1

Bottom Chassis

10

x 4

Front Panel

Bass/Treble Knob

Master V ol.

Fig.5

6. Removal of Inner Panel, Power Switch, Phone Jack & FL board.

(a) Release the inner panel from the bottom chassis by remove 1 screw " (Fig 5) and 2 screws #.

(b) Remove 11 screws $ and 3 nuts to release the FL board.

(c) Remove 2 screws % to release the Power switch.

(d) Remove 2 screws & to release the Phone Jack.

Nut x 2

x 1

12

x 2

14

Inner Panel

x 1

12

Nut x 1

13

Fig.6

6

x 11

x 2

15

Page 8

7. Removal of Foot

(a) Remove 4 screws ( to remove foot.

16

HTA-DD3

x 4

Fig.7

7

Page 9

HTA-DD3

ADJUSTMENTS

1) FM Discriminator

Measuring instrument and condition.

Input terminal Output terminal Measuring instrument Frequency Adjust Reading

FM antenna * R22 DC balance meter 98.1 MHz T4 0±30mV

1kHz, 60dBu,

22.5kHz dev.

* R22

DC balance meter

2) Voltage of covering (Reference)

Band Destination Frequency Specification Note

Limit(V) Average(V)

FM E/EBS 87.50MHz 1.3-3.7 2.4

(50kHz step) 108.00MHz 6.0-9.0 7.5

W/WUN/WAU 87.50MHz 1.3-3.7 2.4

(50kHz step) 108.00MHz 6.0-9.0 7.5

AM E/EBS 522kHz 0.9-1.2 1.1

(9kHz step) 1,611kHz 6.0-9.0 7.5

W/WUN/WAU 522kHz 0.9-1.2 1.1

(9kHz step) 1,611kHz 6.0-9.0 7.5

3) Tuning level (dB) adjusment

Input FM antenna, 1 KHz, 26 dBµV, 75 KHz

Adjust VR1

Limit 26±2dB

(NOTE) Adjust VRI until "Tuned" Indicator light on.

8

Page 10

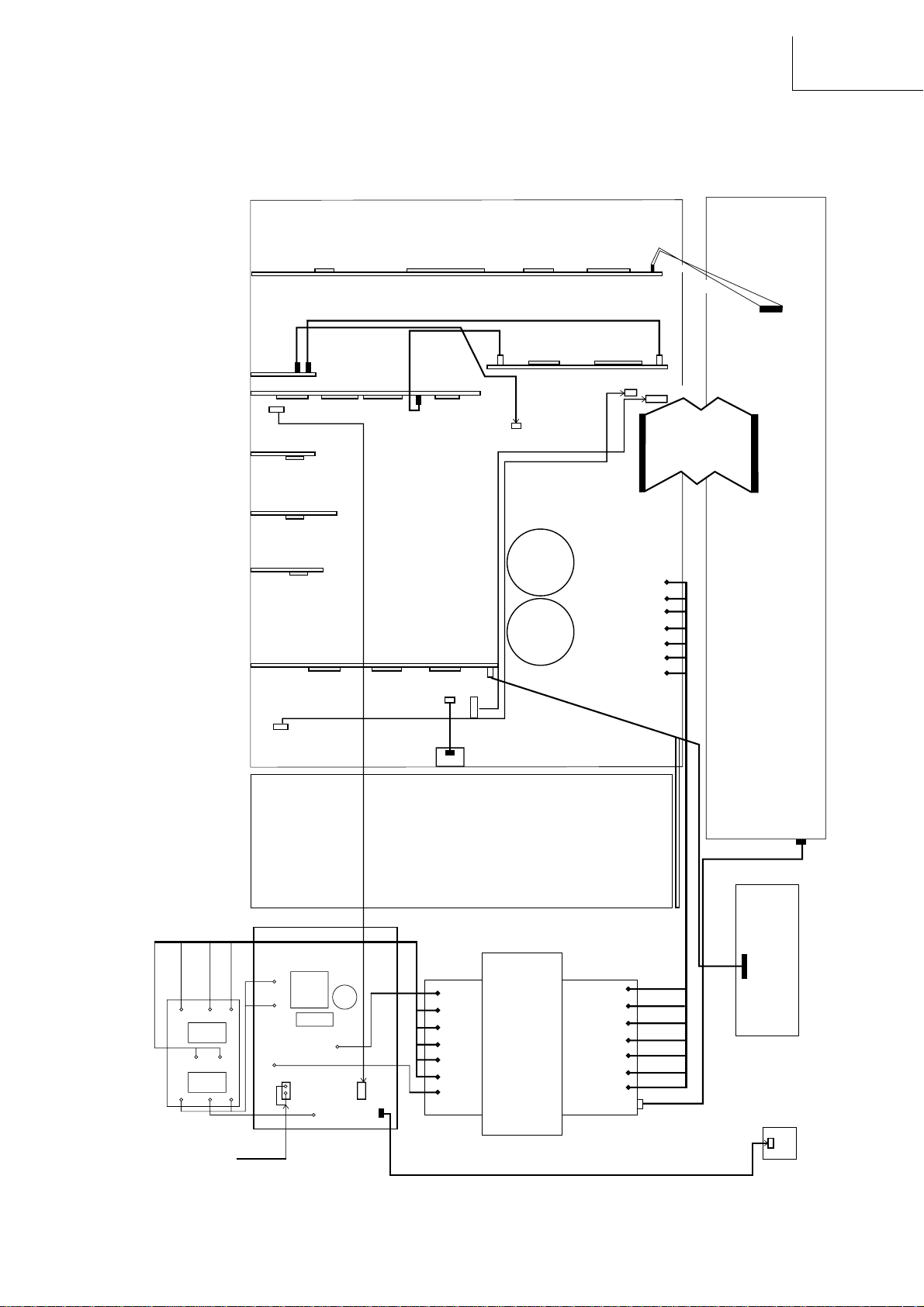

WIRING DIAGRAM

HTA-DD3

CN12

CN14

CN206

CN201A

DIGITAL IN. UNIT

VIDEO(C)IN. UNIT

VIDEO(S)IN. UNIT

PG206

CN1BCN2A

CN1A

DSP UNIT

PG205

W17A

W15A

W16A

W18A

W14A

W19A

W13A

CN1B

CN201

CN2B

FL DISPLAY UNIT

TUNER/VOL UNIT

CN204

AUDIO IN. UNIT

CN204A

PG14

VIDEO(COMP.)IN. UNIT

MAIN UNIT

SPEAKER OUT. UNIT

PG13

PG22

CN205

CN22

THERMAL

UNIT

REMARKS * SHOULD BE FOLLOW PWB ASS'Y.

W1A

W3A

W10A W9A W8A

W6A W7A

W3B

*VOLTAGE SELECTOR

(for W, WUN, W A U)

W1B W2B

PG25

W2A

POWER CORD

POWER CONTROL UNIT

PG12

*CN15

W5B

W7B

W9B

W6B

W8B

W4B

W10B

POWER T .(Pry .) UNIT

POWER T .(2nd) UNIT

W19B

W18B

W17B

W16B

W15B

W14B

W13B

PG3

CN13

*PG15

CN3

PHONES/SPEAKER SW UNIT

POWER SW UNIT

9

Page 11

HTA-DD3

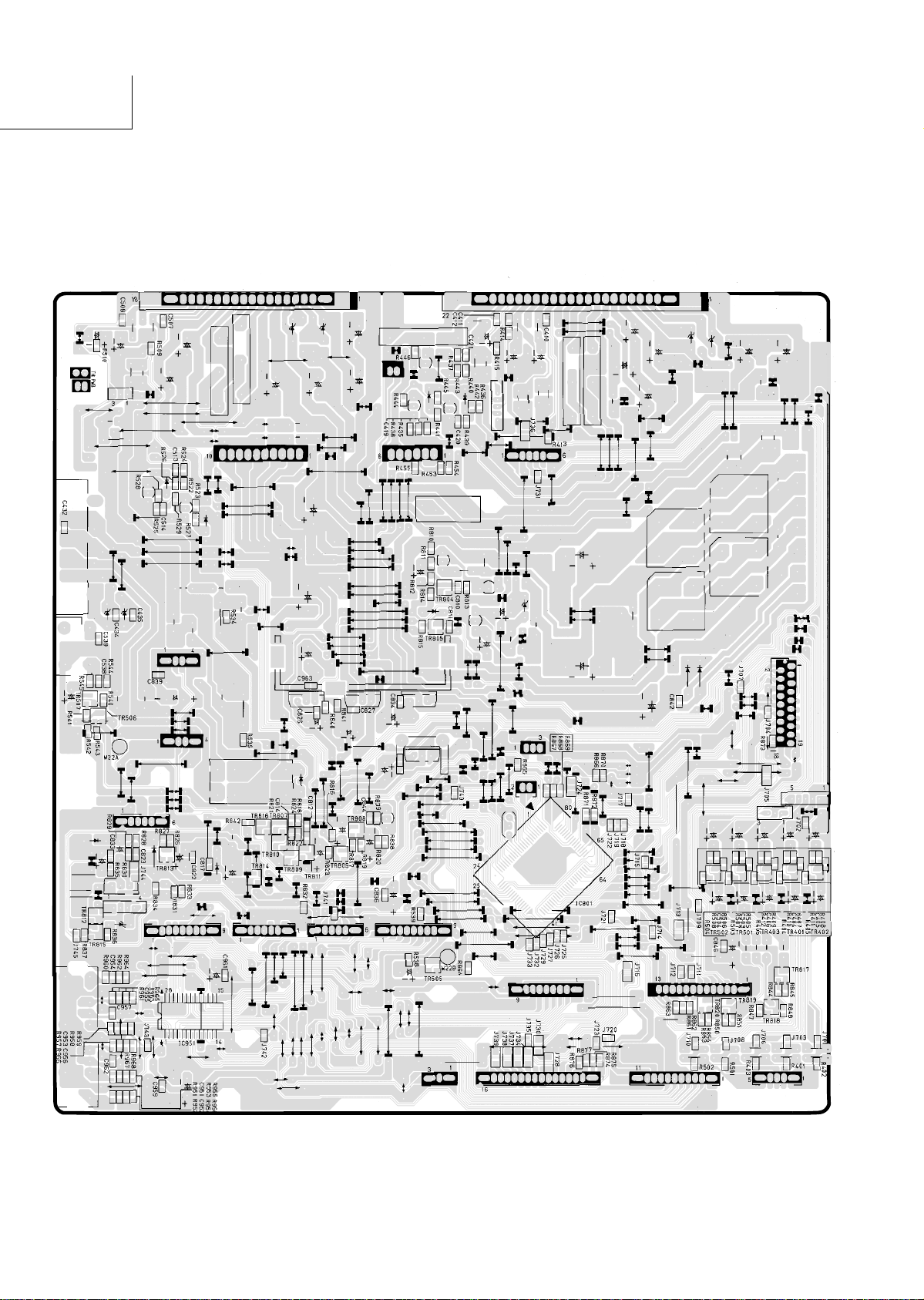

PRINTED WIRING BOARD

Soldering Side

MAIN PWB

- 10 -

Page 12

Component Side

HTA-DD3

MAIN PWB

- 11 -

Page 13

HTA-DD3

Soldering Side

Tuner PWB

- 12 -

Page 14

Component Side

HTA-DD3

Tuner PWB

- 13 -

Page 15

HTA-DD3

Component Side

Soldering Side

Audio PWB

- 14 -

Page 16

Component Side

HTA-DD3

Soldering Side

Relay PWB

- 15 -

Page 17

HTA-DD3

Component Side

Power PWB

Digital PWB

FL PWB

- 16 -

Page 18

Soldering Side

HTA-DD3

Power PWB

Digital PWB

FL PWB

Page 19

HTA-DD3

Soldering Side

Component Side

Component PWB

Page 20

Soldering Side

HTA-DD3

Component Side

DSP PWB

Page 21

HTA-DD3

Soldering Side

S-Video PWB

Composit PWB

PT2 PWB

Page 22

Component Side

HTA-DD3

S-Video PWB

Composit PWB

PT2 PWB

Page 23

HTA-DD3

Soldering Side Component Side

Phone PWB

PT1 PWB

Phone PWB

PT1 PWB

P-SW PWB

P-SW PWB

Page 24

BLOCK DIAGRAM

HTA-DD3

6CH EXT. IN SEL.

6ch EXT. IN

200mV/22k

FRONT Rch

FRONT Lch

STEREO

SURROUND Lch

CENTER

STEREO (WHEN SW)

SURROUND Rch

SUBWOOFER

SR

FRONT Lch-A

24. 5V

28dB

+

MAIN AMP

10dB+10dB

+

TONE CONT.1VTONE CONT.

4dB+4dB

+

PO. AMP

BF LC7536x3

0dB

SL

FRONT Rch-B

CENTER

FRONT Rch-A

FRONT Lch-B

IC50

28dB+28dB+28dB+28dB

+

MAIN AMP

MAIN AMP

BA15218

PO. AMP

PO. AMP

BF

BF

0dB

FR

IC951

CFL

SURROUND Lch

MAIN AMP

14dB+14dB

+

PO.AMP

0dB

0dB

BF

C

FR

0dB

MIX. AMP

BA15218

SURROUND Rch

IC40

MAIN AMP

14dB+21dB

+

PO.AMP

BF

0dB

SL

FL

0dB

MIX. AMP

PRE OUT

SUBWOOFER

SP. RELAY

VOL. MUTE

PO.AMP

BF

SR

F GAIN SW

BA15218

CENTER

SUBWOOFER MUTE

NJM2068x3

0dB

NJM2068x3

SW

4.5dB

+

FRONT Rch

FRONT Lch

HP RELAY

ELE. VOL

SW

PO. AMP

2V

CH. TRIM

HONES Rch

HONES Lch

DVD

MONITOR OUTPUT

TV/DBS

0dB

COMPONENT VIDEO FUNCTION

REMARKS

COMPONENT VIDEO

VCR REC

MONITOR OUTPUT

NJM2267

BU4066BC

IC611

1. THIS DRAWING IS THE HTA-DD3 CIRCUIT BLOCK (LEVEL) DIAGRAM.

3. : u-COM CONTROL SIGNAL

2. : ANALOG SIGNAL, : DIGITAL SIGNAL, : VIDEO SIGNAL

RIAA FUNCTION SW

BA15218 TC9273F-007

BA4558

DSP

BA15218

(ZR38650)

6dB

-

MIX. AMP L. P. F

DIGITAL INPUT SEL.

IC201

BU4066BC

DVD/VDP

S. VIDEO S. VIDEO FUNCTION

NJM2267 ROM

VIDEO FUNCTION

TV/DBS

VCR

10.5dB

+

MIX. AMP

ERR MUTE

6dB

6dB+6dB+6dB+6dB

+

SR BA15218

CODEC AK4527

IC202

0dB

H. P. F

BA4558

BF

0dB

200mV

IC102

+

SL

C BA15218

50mV

ADC -IN

LA1838

FR BA15218

SW

D/A

A/D

IN

+

BF

12dB 0dB

BF

BA15218 BA15218 ADC

FL

LC7272ON

TUNER BLOCK

6dB

+

200mV

SDA SDB-SDD

RDS

IC92

(E, EBS)

96KHz CONT

DTS SEL (CD/DVD)

IC203

SPFRX

TC74HCU04AF TC74HC151F

ANALOG

PHONO

DVD/VDP

CD

TV/DBS

VCR

MD/TAPE

200mV/47k

TAPE RACK

VCR REC

23

DIGITAL INPUT

OPT CD

OPT DVD

OPT TV

VIDEO

DVD/VDP VCR REC

TV/DBS MONITOR OUTPUT

VCR

Page 25

HTA-DD3

24

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

HTA-DD3

EXPLODED VIEW (Cabinet Chassis)

• Nos. are reference Nos. of part list

5

1

32

1

A

31

28

P-SW1 P.W.B.

A

1

14

35

1

13

OUTLET P.W.B.

6

RELAY P.W.B.

MAIN P.W.B.

7

S-VIDEO P.W.B.

COMPOSIT P.W.B.

49

AUDIO P.W.B.

DSP P.W.B.

34

TUNER P.W.B.

COMPONENT P.W.B.

2

50

4

17

(E, EBS)

24

8

25

A

B

33

29

SHIELD PLATE

(E/EBS)

43

43

3

2

51

26

(W/WUN)

A

B

52

38

12

46

42

B

22

37

41

23

15

44

19

B

FL DISP PWB

45

18

9

VOLTAGE SELECTOR

(W/WUN)

48

39

18

30

27

AM LOOP ANTENNA 8T

40

36

Remote Control

47

11

21

36

10

16

27

EDISON PLUG ADAPTER FM ANT

20

43 44

Page 33

THE UPDATED PARTS LIST

FOR THIS MODEL IS

AVAILABLE ON ESTA

Page 34

Hitachi, Ltd. Tokyo, Japan

International Sales Division

THE HITACHI ATAGO BUILDING,

No. 15 –12 Nishi Shinbashi, 2 – Chome,

Minato – Ku, Tokyo 105-8430, Japan.

Tel: 03 35022111

HITACHI EUROPE LTD,

Whitebrook Park

Lower Cookham Road

Maidenhead

Berkshire

SL6 8YA

UNITED KINGDOM

Tel: 01628 643000

Fax: 01628 643400

Email: consumer-service@hitachi-eu.com

HITACHI EUROPE GmbH

Munich Office

Dornacher Strasse 3

D-85622 Feldkirchen bei München

GERMANY

Tel: +49-89-991 80-0

Fax: +49-89-991 80-224

Hotline: +49-180-551 25 51 (12ct/min)

Email: HSE-DUS.service@hitachi-eu.com

HITACHI EUROPE srl

Via Tommaso Gulli N.39, 20147

Milano, Italia

ITALY

Tel: +39 02 487861

Tel: +39 02 38073415 Servizio Clienti

Fax: +39 02 48786381/2

Email: customerservice.italy@hitachi-eu.com

HITACHI EUROPE S.A.S

Lyon Office

B.P. 45, 69671 BRON CEDEX

FRANCE

Tel: 04 72 14 29 70

Fax: 04 72 14 29 99

Email: france.consommateur@hitachi-eu.com

HITACH EUROPE AB

Egebækgård

Egebækvej 98

DK-2850 Nærum

DENMARK

Tel: +45 43 43 6050

Fax: +45 43 60 51

Email: csgnor@hitachi-eu.com

Hitachi Europe Ltd

Bergensesteenweg 421

1600 Sint- Pieters-Leeuw

BELGIUM

Tel: +32 2 363 99 01

Fax: +32 2 363 99 00

Email: sofie.van.bom@hitachi-eu.com

www.hitachidigitalmedia.com

HITACHI EUROPE S.A.

364 Kifissias Ave. & 1, Delfon Str.

152 33 Chalandri

Athens

GREECE

Tel: 1-6837200

Fax: 1-6835964

Email: service.hellas@hitachi-eu.com

HITACHI EUROPE S.A.

Gran Via Carlos III, 101- 1

08028 Barcelona

SPAIN

Tel: 93 409 2550

Fax: 93 491 3513

Email: atencion.cliente@hitachi-eu.com

HITACHI Europe AB

Box 77 S-164 94 Kista

SWEDEN

Tel: +46 (0) 8 562 711 00

Fax: +46 (0) 8 562 711 13

Email: csgswe@hitachi-eu.com

HITACHI EUROPE LTD (Norway) AB

STRANDVEIEN 18

1366 Lysaker

NORWAY

Tel: 67 5190 30

Fax: 67 5190 32

Email: csgnor@hitachi-eu.com

HITACHI EUROPE AB

Neopoli / Niemenkatu 73

FIN-15140 Lahti

FINLAND

Tel : +358 3 8858 271

Fax: +358 3 8858 272

Email: csgnor@hitachi-eu.com

HITACHI EUROPE LTD

Na Sychrove 975/8

101 27 Praha 10 – Bohdalec

CZECH REPUBLIC

Tel: +420 267 212 383

Fax: +420 267 212 385

Email: csgnor@hitachi-eu.com

Loading...

Loading...