Hitachi HDS721680PLAT80, Deskstar 7K160, HDS721616PLA380, HDS721616PLA320, HDS721680PLA380 Specifications

...Page 1

Hard Disk Drive Specification

Deskstar 7K160

3.5 inch hard disk drive

Models:

HDS721616PLAT80

HDS721612PLAT80

HDS721680PLAT80

HDS721616PLA380

HDS721616PLA320

HDS721680PLA380

HDS721680PLA320

HDS721612PLA380

Version 2.0 6 July 2009

Page 2

Page 3

Hard Disk Drive Specification

Deskstar 7K160

3.5 inch hard disk drive

Models:

HDS721616PLAT80

HDS721612PLAT80

HDS721680PLAT80

HDS721616PLA380

HDS721616PLA320

HDS721612PLA380

HDS721680PLA380

HDS721680PLA320

Version 2.0 6 July 2009

Page 4

1st Edition (Revision 0.1) (14 June 2006) Revised

2nd Edition (Revision 1.0)(14 July 2006) Revised

3rd Edition (Revision 1.5)(10 January 2007) Revised

4th Edition (Revision 1.6)(19 January 2007) Revised

5th Edition (Revision 1.7)(28 January 2007) Revised

6th Edition (Revision 1.8)(09 March 2007) Final

7th Edition (Revision 1.9)(26 September 2008) Revised

8th Edition (Revision 2.0)(6 July 2009) Revised

The following paragraph does not apply to the United Kingdom or any country where such provisions are

inconsistent with local law: HITACHI GLOBAL STORAGE TECHNOLOGIES PROVIDES THIS PUBLICATION "AS IS" WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer or express or implied warranties in

certain transactions, therefore, this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are periodically made to the

information herein; these changes will be incorporated in new editions of the publication. Hitachi may make

improvements or changes in any products or programs described in this publication at any time.

It is possible that this publication may contain reference to, or information about, Hitachi products (machines and

programs), programming, or services that are not announced in your country. Such references or information must not

be construed to mean that Hitachi intends to announce such Hitachi products, programming, or services in your country.

Technical information about this product is available by contacting your local Hitachi Global Storage Technologies

representative or on the Internet at

http://www.hitachigst.com

Hitachi Global Storage Technologies may have patents or pending patent applications covering subject matter in this

document. The furnishing of this document does not give you any license to these patents. ©Copyright Hitachi Global Storage Technologies

Note to U.S. Government Users - Documentation related subject to restricted rights - Use, duplication or disclosure is

subject to restrictions set forth in GSA ADP Schedule Contract with Hitachi Global Storage Technologies Inc.

Page 5

Table of Contents

1.0. General.........................................................................................................................1

1.1. Introduction........................................................................................................... 1

1.2. References............................................................................................................. 1

1.3. Abbreviations........................................................................................................ 1

1.4. Caution.................................................................................................................. 3

2.0. General features of the drive .....................................................................................5

3.0. Fixed-disk subsystem description..............................................................................9

3.1. Control electronics................................................................................................ 9

3.2. Head disk assembly ............................................................................................. 9

3.3. Actuator ................................................................................................................ 9

4.0. Drive characteristics.................................................................................................11

4.1. Default logical drive parameters......................................................................... 11

4.2. Data sheet............................................................................................................ 12

4.3. World Wide Name Assignment.......................................................................... 12

4.4. Drive organization.............................................................................................. 12

4.4.1 Drive format ..............................................................................................12

4.4.2 Cylinder allocation ....................................................................................13

4.5. Performance characteristics................................................................................ 15

4.5.1 Command overhead ...................................................................................15

4.5.2 Mechanical positioning .............................................................................15

4.5.3 Drive ready time ........................................................................................17

4.5.4 Operating modes ........................................................................................17

5.0. Defect flagging strategy............................................................................................19

6.0. Electrical interface specification..............................................................................21

6.1. Connector location .............................................................................................. 21

6.1.1 4 pin DC power connector .........................................................................22

6.1.2 AT signal connector ..................................................................................22

6.2. Signal definitions (PATA model)....................................................................... 23

6.3. Signal descriptions.............................................................................................. 24

6.4. Interface logic signal levels (pata model)........................................................... 27

6.5. Signal definition (SATA model) ........................................................................ 27

6.5.1 TX+ / TX- ..................................................................................................27

6.5.2 RX+ / RX- .................................................................................................28

6.5.3 Out of band signaling (SATA model) .......................................................28

6.6. Reset timings ...................................................................................................... 29

6.7. PIO timings......................................................................................................... 30

6.7.1 Write DRQ interval time ...........................................................................30

6.7.2 Read DRQ interval time ............................................................................30

6.8. Multi-word DMA timings................................................................................... 31

6.9. Ultra DMA timings............................................................................................. 32

6.9.1 Initiating Read DMA .................................................................................32

6.9.2 Host Pausing Read DMA ..........................................................................33

Page 6

6.9.3 Host Terminating Read DMA ...................................................................34

6.9.4 Device Terminating Read DMA ...............................................................35

6.9.5 Initiating Write DMA ................................................................................36

6.9.6 Device Pausing Write DMA ......................................................................37

6.9.7 Device Terminating Write DMA ...............................................................38

6.9.8 Host Terminating Write DMA ..................................................................39

6.10. Addressing of registers..................................................................................... 40

6.10.1 Cabling ....................................................................................................40

7.0. Specification ..............................................................................................................43

7.1. Jumper settings ................................................................................................... 43

7.1.1 Jumper pin location ...................................................................................43

7.1.2 Jumper pin identification ...........................................................................43

7.1.3 Jumper pin assignment ..............................................................................44

7.1.4 Jumper positions ........................................................................................45

7.2. Environment ....................................................................................................... 49

7.2.1 Temperature and humidity ........................................................................49

7.2.2 Corrosion test .............................................................................................50

7.3. DC power requirements...................................................................................... 50

7.3.1 Input voltage ..............................................................................................51

7.3.2 Power supply current (typical) ..................................................................52

7.3.3 Power supply generated ripple at drive power connector .........................53

7.4. Reliability ........................................................................................................... 54

7.4.1 Data integrity .............................................................................................54

7.4.2 Cable noise interference ............................................................................54

7.4.3 Start/stop cycles .........................................................................................54

7.4.4 Preventive maintenance .............................................................................54

7.4.5 Data reliability ...........................................................................................54

7.4.6 Required power-off sequence ....................................................................54

7.5. Mechanical specifications................................................................................... 55

7.5.1 Physical dimensions and weight ................................................................55

7.5.2 Mounting hole locations ............................................................................56

7.5.3 Connector locations ...................................................................................57

7.5.4 Drive mounting ..........................................................................................58

7.5.5 Heads unload and actuator lock .................................................................58

7.6. Vibration and shock............................................................................................ 59

7.6.1 Operating vibration ....................................................................................59

7.6.2 Nonoperating vibration ..............................................................................59

7.6.3 Operating shock .........................................................................................60

7.6.4 Nonoperating shock ...................................................................................60

7.6.5 Nonoperating rotational shock ..................................................................60

7.7. Acoustics............................................................................................................. 61

7.8. Identification labels ............................................................................................ 61

7.9. Safety.................................................................................................................. 62

7.9.1 UL and CSA approval ...............................................................................62

7.9.2 German safety mark ..................................................................................62

7.9.3 Flammability ..............................................................................................62

Page 7

7.9.4 Safe handling .............................................................................................62

7.9.5 Environment ..............................................................................................62

7.9.6 Secondary circuit protection ......................................................................62

7.10. Electromagnetic compatibility.......................................................................... 63

7.10.1 CE Mark ..................................................................................................63

7.10.2 C-TICK mark ...........................................................................................63

7.10.3 BSMI mark ..............................................................................................63

7.10.4 MIC Mark ................................................................................................63

7.11. Packaging.......................................................................................................... 63

7.11.1 Substance restriction requirements ..........................................................63

8.0. General.......................................................................................................................65

8.1. Introduction......................................................................................................... 65

8.2. Terminology ....................................................................................................... 65

8.3. Deviations from standard.................................................................................... 65

9.0. Registers.....................................................................................................................67

9.1. Register set.......................................................................................................... 67

9.2. Alternate Status Register .................................................................................... 68

9.3. Command Register ............................................................................................. 68

9.4. Cylinder High Register....................................................................................... 68

9.5. Cylinder Low Register........................................................................................ 68

9.6. Data Register ...................................................................................................... 69

9.7. Device Control Register .................................................................................... 69

9.8. Drive Address Register....................................................................................... 70

9.9. Device/Head Register......................................................................................... 70

9.10. Error Register.................................................................................................... 71

9.11. Features Register .............................................................................................. 71

9.12. Sector Count Register....................................................................................... 71

9.13. Sector Number Register.................................................................................... 72

9.14. Status Register.................................................................................................. 72

10.0. General operation...................................................................................................75

10.1. Reset response .................................................................................................. 75

10.2. Register initialization ........................................................................................ 76

10.3. Diagnostic and Reset considerations................................................................ 77

10.4. Sector Addressing Mode................................................................................... 78

10.4.1 Logical CHS addressing mode ................................................................78

10.4.2 LBA addressing mode .............................................................................78

10.5. Power management features............................................................................. 79

10.5.1 Power mode .............................................................................................79

10.5.2 Power management commands ...............................................................79

10.5.3 Standby timer ...........................................................................................79

10.5.4 Interface capability for power modes ......................................................80

10.6. S.M.A.R.T. Function ........................................................................................ 81

10.6.1 Attributes .................................................................................................81

10.6.2 Attribute values .......................................................................................81

10.6.3 Attribute thresholds .................................................................................81

10.6.4 Threshold exceeded condition .................................................................81

Page 8

10.6.5 S.M.A.R.T. commands ............................................................................81

10.6.6 Off-line read scanning .............................................................................81

10.6.7 Error log ...................................................................................................82

10.6.8 Self-test ....................................................................................................82

10.7. Security Mode Feature Set................................................................................ 83

10.7.1 Security mode ..........................................................................................83

10.7.2 Security level ...........................................................................................83

10.7.3 Passwords ................................................................................................84

10.7.4 Operation example ...................................................................................84

10.7.5 Command table ........................................................................................88

10.8. Host Protected Area Feature............................................................................. 90

10.8.1 Example for operation (In LBA Mode) ...................................................90

10.8.2 Security extensions ..................................................................................91

10.9. Seek overlap...................................................................................................... 92

10.10. Write cache function....................................................................................... 93

10.11. Reassign function............................................................................................ 94

10.11.1 Auto Reassign function .........................................................................94

10.12. Power-Up in Standby feature set.................................................................... 95

10.13. Advanced Power Management feature set (APM)......................................... 96

10.14. Automatic Acoustic Management feature set (AAM).................................... 97

10.15. Address Offset Feature................................................................................... 98

10.15.1 Enable/Disable Address Offset Mode ...................................................98

10.15.2 Identify Device Data ..............................................................................99

10.15.3 Exceptions in Address Offset Mode .....................................................99

10.16. 48-bit Address Feature Set............................................................................ 100

10.17. Streaming feature Set.................................................................................... 100

10.17.1 Streaming commands ..........................................................................101

10.17.2 Urgent bit .............................................................................................101

10.17.3 Flush to Disk bit ..................................................................................101

10.17.4 Not Sequential bit ................................................................................101

10.17.5 Read Continuous bit ............................................................................102

10.17.6 Write Continuous bit ...........................................................................102

10.17.7 Handle Streaming Error bit .................................................................102

10.17.8 Streaming Logs ....................................................................................102

10.18. SATA BIST (Built-in Self Test)................................................................... 102

10.19. SATA Interface Power Management............................................................ 102

10.20. Software Setting Preservation....................................................................... 102

10.20.1 COMRESET Preservation Requirements ............................................103

10.21. SATA II Optional Features........................................................................... 104

10.21.1 Asynchronous Signal Recovery ..........................................................104

10.21.2 Device Power Connector Pin 11 Definition ........................................104

10.21.3 Phy Event Counters .............................................................................104

10.21.4 READ LOG EXT Log Page 11h .........................................................106

10.22. SCT Command Transport Feature Set.......................................................... 107

10.22.1 SCT Command Protocol ......................................................................108

10.22.2 SCT Command Set ..............................................................................116

Page 9

11.0. Command protocol ...............................................................................................127

11.1. PIO Data In commands................................................................................... 127

11.2. PIO Data Out Commands............................................................................... 128

11.3. Non-data commands...................................................................................... 130

11.4. DMA commands............................................................................................. 131

12.0. Command descriptions.........................................................................................133

12.1. Check Power Mode (E5h/98h) ....................................................................... 138

12.2. Configure Stream (51h).................................................................................. 139

12.3. Device Configuration Overlay (B1h) ............................................................. 141

12.3.1 DEVICE CONFIGURATION RESTORE (Subcommand C0h) .........141

12.3.2 DEVICE CONFIGURATION FREEZE LOCK (subcommand C1h) ..141

12.3.3 DEVICE CONFIGURATION IDENTIFY (subcommand C2h) .........142

12.3.4 DEVICE CONFIGURATION SET (subcommand C3h) ......................142

12.4. Download Microcode (92h)............................................................................ 145

12.5. Execute Device Diagnostic (90h)................................................................... 147

12.6. Flush Cache (E7h) .......................................................................................... 148

12.7. Flush Cache Ext (EAh)................................................................................... 149

12.8. Format Track (50h)......................................................................................... 150

12.9. Format Unit (F7h)........................................................................................... 152

12.10. Identify Device (ECh)................................................................................... 153

12.11. Idle (E3h/97h).............................................................................................. 164

12.12. Idle Immediate (E1h/95h)............................................................................. 165

12.13. Initialize Device Parameters (91h) ............................................................... 166

12.14. Read Buffer (E4h)......................................................................................... 167

12.15. Read DMA (C8h/C9h).................................................................................. 168

12.16. Read DMA Ext (25h).................................................................................... 170

12.17. Read Log Ext (2Fh)...................................................................................... 172

12.17.1 General Purpose Log Directory ...........................................................174

12.17.2 Extended Comprehensive SMART Error Log ....................................175

12.17.3 Extended Self-test log sector ...............................................................177

12.17.4 Read Stream Error Log ........................................................................178

12.17.5 Write Stream Error Log .......................................................................180

12.17.6 Streaming Performance Log ................................................................181

12.18. Read Long (22h/23h).................................................................................... 183

12.19. Read Multiple (C4h)..................................................................................... 185

12.20. Read Multiple Ext (29h)............................................................................... 186

12.21. Read Native Max ADDRESS (F8h)............................................................. 188

12.22. Read Native Max Address Ext (27h)............................................................ 189

12.23. Read Sectors (20h/21h)................................................................................. 190

12.24. Read Sector(s) Ext (24h) .............................................................................. 192

12.25. Read Stream DMA (2Ah)............................................................................. 194

12.26. Read Stream PIO (2Bh)................................................................................ 198

12.27. Read Verify Sectors (40h/41h)..................................................................... 201

12.28. Read Verify Sectors Ext (42h)...................................................................... 203

12.29. Recalibrate (1xh) .......................................................................................... 205

12.30. Security Disable Password (F6h).................................................................. 206

Page 10

12.31. Security Erase Prepare.................................................................................. 207

12.32. Security Erase Unit (F4h)............................................................................. 208

12.33. Security Freeze Lock (F5h).......................................................................... 210

12.34. Security Set Password (F1h)......................................................................... 211

12.35. Security Unlock (F2h) .................................................................................. 213

12.36. Seek (7xh).................................................................................................... 215

12.37. Set Features (EFh) ........................................................................................ 216

12.37.1 Set Transfer mode ................................................................................217

12.37.2 Write Cache .........................................................................................217

12.37.3 Advanced Power Management ............................................................217

12.37.4 Automatic Acoustic Management .......................................................219

12.38. Set Max ADDRESS (F9h)............................................................................ 220

12.38.1 Set Max Set Password (Feature=01h) .................................................222

12.38.2 Set Max Lock (Feature=02h) ..............................................................223

12.38.3 Set Max Unlock (Feature = 03h) .........................................................224

12.38.4 Set Max Freeze Lock (Feature = 04h) .................................................225

12.39. Set Max Address Ext (37h)........................................................................... 226

12.40. Set Multiple (C6h)........................................................................................ 228

12.41. Sleep (E6h/99h)............................................................................................ 229

12.42. S.M.A.R.T. Function Set (B0h).................................................................... 230

12.42.1 S.M.A.R.T. Function Subcommands ..................................................231

12.42.2 Device Attribute Data Structure ..........................................................235

12.42.3 Device Attribute Thresholds data structure .........................................238

12.42.4 S.M.A.R.T. Log Directory ...................................................................240

12.42.5 S.M.A.R.T. summary error log sector .................................................240

12.42.6 Self-test log data structure ..................................................................242

12.42.7 Selective self-test log data structure ....................................................243

12.42.8 Error reporting .....................................................................................244

12.43. Standby (E2h/96h)........................................................................................ 246

12.44. Standby Immediate (E0h/94h)...................................................................... 248

12.45. Write Buffer (E8h)........................................................................................ 249

12.46. Write DMA (CAh/CBh)............................................................................... 250

12.47. Write DMA Ext (35h)................................................................................... 252

12.48. Write DMA FUA Ext (3Dh)......................................................................... 254

12.49. Write Log Ext (3Fh) ..................................................................................... 256

12.50. Write Long (32h/33h)................................................................................... 257

12.51. Write Multiple (C5h).................................................................................... 259

12.52. Write Multiple Ext (39h).............................................................................. 261

12.53. Writer Multiple FUA Ext (CEh)................................................................... 263

12.54. Write Sectors (30h/31h)................................................................................ 265

12.55. Write Sector(s) Ext (34h).............................................................................. 267

12.56. Write Stream DMA (3Ah)............................................................................ 269

12.57. Write Stream PIO (3Bh)............................................................................... 271

13.0. Timings ..................................................................................................................275

Page 11

List of Tables

Table 1: Formatted capacities.....................................................................................11

Table 2: Mechanical positioning performance ...........................................................12

Table 3: Word Wide Name Assignment.....................................................................12

Table 4: Command overhead......................................................................................15

Table 5: Mechanical positioning performance ...........................................................15

Table 6: Full stroke seek time.....................................................................................16

Table 7: Single track seek time...................................................................................16

Table 8: Latency Time................................................................................................17

Table 9: Drive ready time...........................................................................................17

Table 10: Description of operating modes..................................................................17

Table 11: Mode transition times.................................................................................18

Table 12: PATA Plist physical format........................................................................19

Table 13: Signal definitions........................................................................................23

Table 14: Special signal definitions for Ultra DMA ..................................................24

Table 15: System reset timing chart ...........................................................................29

Table 16: System reset timing ....................................................................................29

Table 17: PIO cycle timings chart ..............................................................................30

Table 18: Multiword DMA cycle timing chart...........................................................31

Table 19: Multiword DMA cycle timings ..................................................................31

Table 20: Ultra DMA cycle timings (Initiating Read)................................................32

Table 21: Ultra DMA cycle timing chart (Host pausing Read)..................................33

Table 22: Ultra DMA cycle timings (Host pausing Read) .........................................33

Table 23: Ultra DMA cycle timing chart (Host pausing Read)..................................34

Table 24: Ultra DMA cycle timings (Host pausing Read) .........................................34

Table 25: Ultra DMA cycle timing chart (Host pausing Read)..................................35

Table 26: Ultra DMA cycle timings (Device Terminating Read)..............................35

Table 27: Ultra DMA cycle timing chart (Initiating Write) .......................................36

Table 28: Ultra DMA cycle timing chart (Device Pausing Write).............................37

Table 29: Ultra DMA cycle timings (Device Pausing Write) ....................................37

Table 30: Ultra DMA cycle timing chart (Device Terminating Write)......................38

Table 31: Ultra DMA cycle timings (Device TerminatingWrite) ..............................38

Table 32: Ultra DMA cycle timing chart (Host Terminating Write)..........................39

Table 33: Ultra DMA cycle timings (Host Terminating Write).................................39

Table 34: I/O address map..........................................................................................40

Table 35: Jumper positions for capacity clip to 32GB ...............................................47

Table 36: Jumper settings for Disabling Auto Spin....................................................47

Table 37: Temperature and humidity .........................................................................49

Table 38: Limits of temperature and humidity...........................................................50

Table 39: Input voltage...............................................................................................51

Table 40: Power supply current of 80GB and 160GB models...................................52

Table 41: Power supply generated ripple at drive power connector ..........................53

Table 42: Random vibration PSD...............................................................................59

Table 43: Random vibration PSD profile break points (operating) ............................59

Page 12

Table 44: Random Vibration PSD profile breakpoints (nonoperating)......................59

Table 45: Sinusoidal shock wave ...............................................................................60

Table 46: Rotational shock .......................................................................................60

Table 47: Sound power levels.....................................................................................61

Table 48: Register Set .................................................................................................67

Table 49: Alternate Status Register............................................................................68

Table 50: Device Control Register .............................................................................69

Table 51: Drive Address Register...............................................................................70

Table 52: Device Head/Register.................................................................................70

Table 53: Error Register .............................................................................................71

Table 54: Status Register............................................................................................72

Table 55: Reset response table ...................................................................................75

Table 56: Default Register Values..............................................................................76

Table 57: Diagnostic codes.........................................................................................76

Table 58: Reset error register values ..........................................................................77

Table 59: Power conditions ........................................................................................80

Table 60: Initial setting...............................................................................................85

Table 61: Usual operation for POR ............................................................................86

Table 62: Password lost..............................................................................................87

Table 63: Seek overlap ...............................................................................................92

Table 64: Device address map before and after Set Feature ......................................98

Table 65: Phy Event Counter Identifiers ..................................................................105

Table 66: Read Long EXT Log Page 11h data structure definition .........................106

Table 67: Feature Code List .....................................................................................121

Table 68: Command Set ...........................................................................................133

Table 69: Command Set (subcommand) ..................................................................136

Table 70: Check Power Mode command (E5h/98h) ................................................138

Table 71: Configure Stream (51h)............................................................................139

Table 72: Check Power Mode Command (E5h/98h) ...............................................141

Table 73: Device Configuration Overlay Features register values...........................141

Table 74: Device Configuration Overlay Data structure..........................................143

Table 75: DCO error information definition ............................................................144

Table 76: Downlad Microcode Command (92h)......................................................145

Table 77: Execute Device Diagnostic command (90h)............................................147

Table 78: Flush Cache command (E7h) ...................................................................148

Table 79: Flush Cache Ext Command (EAh)...........................................................149

Table 80: Format Track command (50h)..................................................................150

Table 81: Format Unit command (F7h)....................................................................152

Table 82: Identify Device command (ECh)..............................................................153

Table 83: Identify device information .....................................................................154

Table 84: Identify device information......................................................................156

Table 85: Identify device information .....................................................................158

Table 86: Identify device information......................................................................159

Table 87: Identify device information......................................................................160

Table 88: Identify device information......................................................................161

Table 89: Idle command (E3h/97h)..........................................................................164

Page 13

Table 90: Idle Immediate command (E1h/95h)........................................................165

Table 91: Initialize Device Parameters command (91h) ..........................................166

Table 92: Read Buffer (E4h) ....................................................................................167

Table 93: Read DMA command (C8h/C9h).............................................................168

Table 94: Read DMA Ext Command (25h)..............................................................170

Table 95: Read Log Ext Command (2Fh) ................................................................172

Table 96: Log Address Definition............................................................................173

Table 97: General Purpose Log Directory................................................................174

Table 98: Extended Comprehensive SMART Error Log .........................................175

Table 99: Extended Error log data structure.............................................................175

Table 100: Command data structure.........................................................................176

Table 101: Error data structure.................................................................................176

Table 102: Read Stream Error Log...........................................................................178

Table 103: Stream Error Log entry...........................................................................180

Table 104: Write Stream Error Log..........................................................................181

Table 105: Streaming Performance Parameters log .................................................182

Table 106: Sector Time Array Entry (Linearly Interpolated)...................................182

Table 107: Access Time Array Entry (Linearly Interpolated)..................................182

Table 108: Read Long (22h/23h)..............................................................................183

Table 109: Read Multiple (C4h)...............................................................................185

Table 110: Read DMA Ext Command (25h)............................................................186

Table 111: Read Native Max ADDRESS (F8h).......................................................188

Table 112: Read Native Max Address Ext command (27h).....................................189

Table 113: Read Sectors Command (20h/21h).........................................................190

Table 114: Read Sector(s) Ext command (24h) ......................................................192

Table 115: Read Stream DMA Command (2Ah).....................................................194

Table 116: Read Stream PIO (2Bh)..........................................................................198

Table 117: Read Verify Sectors (40h/41h)...............................................................201

Table 118: Read Verify Sectors Ext command (42h)...............................................203

Table 119: Recalibrate (1xh) ....................................................................................205

Table 120: Security Disable Password (F6h) ...........................................................206

Table 121: Password Information for Security Disable Password command ..........206

Table 122: Security Disable Password (F3h) ...........................................................207

Table 123: Security Erase Unit (F4h).......................................................................208

Table 124: Erase Unit information ...........................................................................208

Table 125: Security Freeze Lock command (F5h) ...................................................210

Table 126: Security Set Password command (F1h)..................................................211

Table 127: Security Set Password Information ........................................................211

Table 128: Security Unlock command (F2h) ...........................................................213

Table 129: Seek command (7xh)..............................................................................215

Table 130: Set Features command (EFh) .................................................................216

Table 131: Set Max ADDRESS command (F9h).....................................................220

Table 132: Set Max Set Password command ...........................................................222

Table 133: Set Max Set Password data contents ......................................................222

Table 134: Set Max Lock command.........................................................................223

Table 135: Set Max Unlock command (F9h) ...........................................................224

Page 14

Table 136: Set Max Freeze Lock (F9h)....................................................................225

Table 137: Set Max Address Ext command (37h)....................................................226

Table 138: Set Multiple command (C6h).................................................................228

Table 139: Sleep command (E6h/99h) .....................................................................229

Table 140: S.M.A.R.T. Function Set command (B0h).............................................230

Table 141: Device Attribute Data Structure.............................................................235

Table 142: Individual Attribute Data Structure........................................................235

Table 143: Device Attribute Thresholds Data Structure ..........................................239

Table 144: Individual Threshold Data Structure ......................................................239

Table 145: S.M.A.R.T. Log Directory......................................................................240

Table 146: S.M.A.R.T. summary error log sector ..................................................240

Table 147: Error log data structure..........................................................................241

Table 148: Command data structure.........................................................................241

Table 149: Error data structure.................................................................................241

Table 150: Self-test log data structure......................................................................242

Table 151: Selective self-test log data structure.......................................................244

Table 152: S.M.A.R.T. Error Codes.........................................................................244

Table 153: Standby (E2h/96h)..................................................................................246

Table 154: Standby Immediate (E0h/94h)................................................................248

Table 155: Write Buffer (E8h) .................................................................................249

Table 156: Write DMA (CAh/CBh).........................................................................250

Table 157: Write DMA Ext Command (35h)..........................................................252

Table 158: Write Log Ext Command (3Fh) ............................................................256

Table 159: Write Long (32h/33h).............................................................................257

Table 160: Write Multiple (C5h)..............................................................................259

Table 161: WriteMultiple Ext Command (39h) .......................................................261

Table 162: Write Sectors command (30h/31h).........................................................265

Table 163: Write Sectors Ext....................................................................................267

Table 164: Write Stream DMA Command (3Ah)....................................................269

Table 165: Write Stream PIO Command (3Bh) .......................................................271

Page 15

1.0 General

1.1 Introduction

This document describes the specifications of the Deskstar 7K160, a 3.5-inch hard disk drive with ATA interface

and a rotational speed of 7200 RPM.

HDS721616PLAT80

HDS721612PLAT80

HDS721680PLAT80

HDS721616PLA380

HDS721612PLA380

HDS721680PLA380

These specifications are subject to change without notice.

, HDS721616PLA320 160 GB

, HDS721680PLA320 80 GB

160 GB

120 GB

80 GB

120 GB

1.2 References

• Information Technology - AT Attachment with Packet Interface-7.

1.3 Abbreviations

Abbreviation Meaning

AAmpere

AC alternating current

AT Advanced Technology

ATA Advanced Technology Attachment

BIOS Basic Input/Output System

C Celsius

CSA Canadian Standards Association

C-UL Canadian-Underwriters Laborato ry

Cyl cylinder

DC Direct Current

DFT Drive Fitness Test

DMA Direct Memory Access

ECC error correction code

EEC European Economic Community

EMC electromagnetic compatibility

ERP Error Recovery Procedure

ESD E lectrostatic Discharge

FCC Federal Com munications Commission

Deskstar 7K160 Hard Disk Drive Specification

1

Page 16

FRU field replacement unit

G gravity (a uni t of force)

2

G

/Hz (32 ft/sec)2 per Hertz

Gb 1,000,000,000 bits

GB 1,000,000,000 bytes

GND ground

h hexadecimal

HDD hard disk drive

Hz Hertz

I Input

ILS integrated lead suspension

I/O Input/Output

ISO International Standards Organization

KB 1,000 bytes

Kbpi 1000 bits per inch

kgf-cm kilogram (force)-centimeter

KHz kilohertz

LBA logical block addressing

Lw unit of A-weighted sound power

mmeter

max maximum

MB 1,000,000 bytes

Mbps 1,000,000 bits per second

MHz megahertz

MLC Machine Level Control

mm millimeter

ms millisecond

us, ms microsecond

OOutput

OD Open Drain Programmed Input/Output

POH power on hours

Pop population

P/N p art number

p-p peak-to-peak

PSD power spectral density

RES radiated electromagnetic susceptibility

RFI radio frequency interference

RH relative humidity

RMS root mea n square

RPM revolu t ions per minute

RST reset

R/W read/write

sec second

Deskstar 7K160 Hard Disk Drive Specification

2

Page 17

SELV secondary low voltage

S.M.A.R.TSelf-Monitoring, Analysis, and Reporting Technology

TPI tracks per inch

Trk track

TTL transistor-transistor logic

UL Underwriters Laboratory

Vvolt

VDE Verband Deutscher Electrotechniker

Wwatt

3-state transistor-transistor tristate logic

1.4 Caution

• Do not apply force to the top cover.

• Do not cover the breathing hole on the top cover.

• Do not touch the interface connector pins or the surface of the printed circuit board

• This drive can be damaged by electrostatic discharge (ESD). Any damages incurred to the drive after its

removal from the shipping package and the ESD protective bag are the responsibility of the user.

Deskstar 7K160 Hard Disk Drive Specification

3

Page 18

Deskstar 7K160 Hard Disk Drive Specification

4

Page 19

2.0 General features of the drive

• Formatted capacities of 160 GB, 120 GB and 80 GB

• Spindle speeds of 7200 RPM

• Fluid Dynamic Bearing motor

• Enhanced IDE interface

• Sector format of 512 bytes/sector

• Closed-loop actuator servo

• Load/Unload mechanism, non head disk contact start/stop

• Automatic Actuator lock

• Interleave factor 1:1

• Seek time of 8.8 ms in Read Operation. 8.5 ms typical without Command Overhead

• Sector Buffer size of

• Ring buffer implementation

• Write Cache

• Native command queuing support (SATA model)

• Advanced ECC On The Fly (EOF)

• Automatic Error Recovery procedures for read and write commands

• Self Diagnostics on Power on and resident diagnostics

• PIO Data Transfer Mode 4 (16.6 MB/s)

• DMA Data Transfer

• Multiword mode Mode 2 (16.6 MB/s)

• Ultra DMA Mode 6 (133 MB/s)

• Serial ATA Data Transfer 3Gbps / 1.5Gbps

• CHS and LBA mode

• Power saving modes/Low RPM idle mode (APM)

• S.M.A.R.T. (Self Monitoring and Analysis Reporting Technology)

• Support security feature

• Quiet Seek mode (AAM)

2048K and 8192 K (Upper 292 KB is used for firmware)

• 48-bit addressing feature

• Adaptive BPI

• ATA-7 compliant

• UDMA 133 support

• Streaming feature set support

• World Wide Name

Deskstar 7K160 Hard Disk Drive specification

5

Page 20

Deskstar 7K160 Hard Disk Drive Specification

6

Page 21

Part 1. Functional specification

Deskstar 7K160 Hard Disk Drive specification

7

Page 22

Deskstar 7K160 Hard Disk Drive Specification

8

Page 23

3.0 Fixed-disk subsystem description

3.1 Control electronics

The drive is electronically controlled by a microprocessor, several logic modules, digital/analog modules, and various drivers and receivers. The control electronics performs the following major functions:

• Controls and interprets all interface signals between the host controller and the drive.

• Controls read write accessing of the disk media, including defect management and error

recovery.

• Controls starting, stopping, and monitoring of the spindle.

• Conducts a power-up sequence and calibrates the servo.

• Analyzes servo signals to provide closed loop control. These include position error signal and

estimated velocity.

• Monitors the actuator position and determines the target track for a seek operation.

• Controls the voice coil motor driver to align the actuator in a desired position.

• Constantly monitors error conditions of the servo and takes corresponding action if an error

occurs.

• Monitors various timers such as head settle and servo failure.

• Performs self-checkout (diagnostics).

3.2 Head disk assembly

The head disk assembly (HDA) is assembled in a clean room environment and contains the disks and actuator

assembly. Air is constantly circulated and filtered when the drive is operational. Venting of the HDA is accomplished via a breather filter.

The spindle is driven directly by an in-hub, brushless, sensorless DC drive motor. Dynamic braking is used to

quickly stop the spindle.

3.3 Actuator

The read/write heads are mounted in the actuator. The actuator is a swing-arm assembly driven by a voice coil

motor . A closed-loop position ing servo controls the movement of the actuator. An embedded servo pattern supplies

feedback to the positioning servo to keep the read/write heads centered over the desired track.

The actuator assembly is balanced to allow vertical or horizontal mounting without adjustment.

When the drive is powered off, the actuator automatically moves the head to the actuator ramp outside of the disk

where it parks.

Deskstar 7K160 Hard Disk Drive Specification

9

Page 24

Deskstar 7K160 Hard Disk Drive Specification

10

Page 25

4.0 Drive characteristics

4.1 Default logical drive parameters

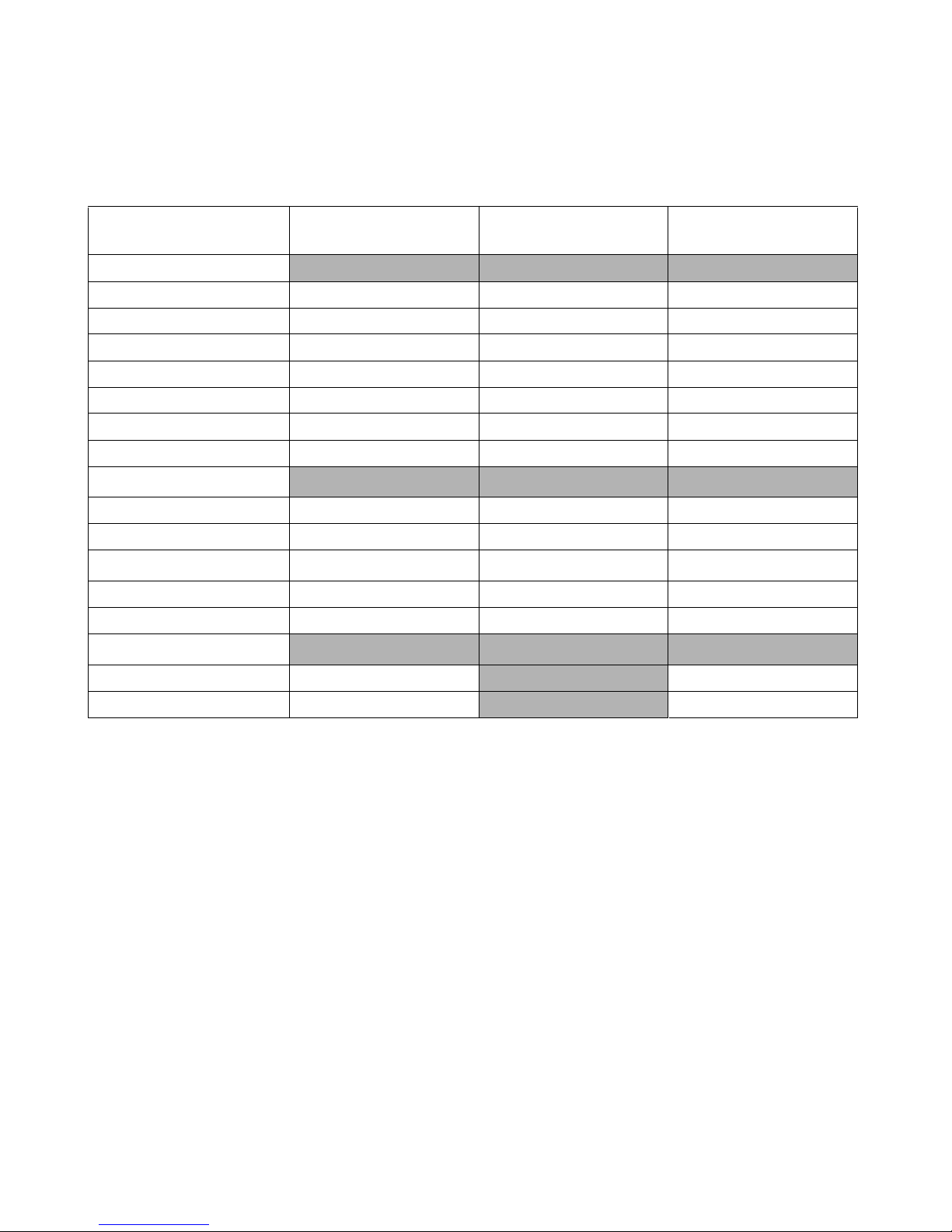

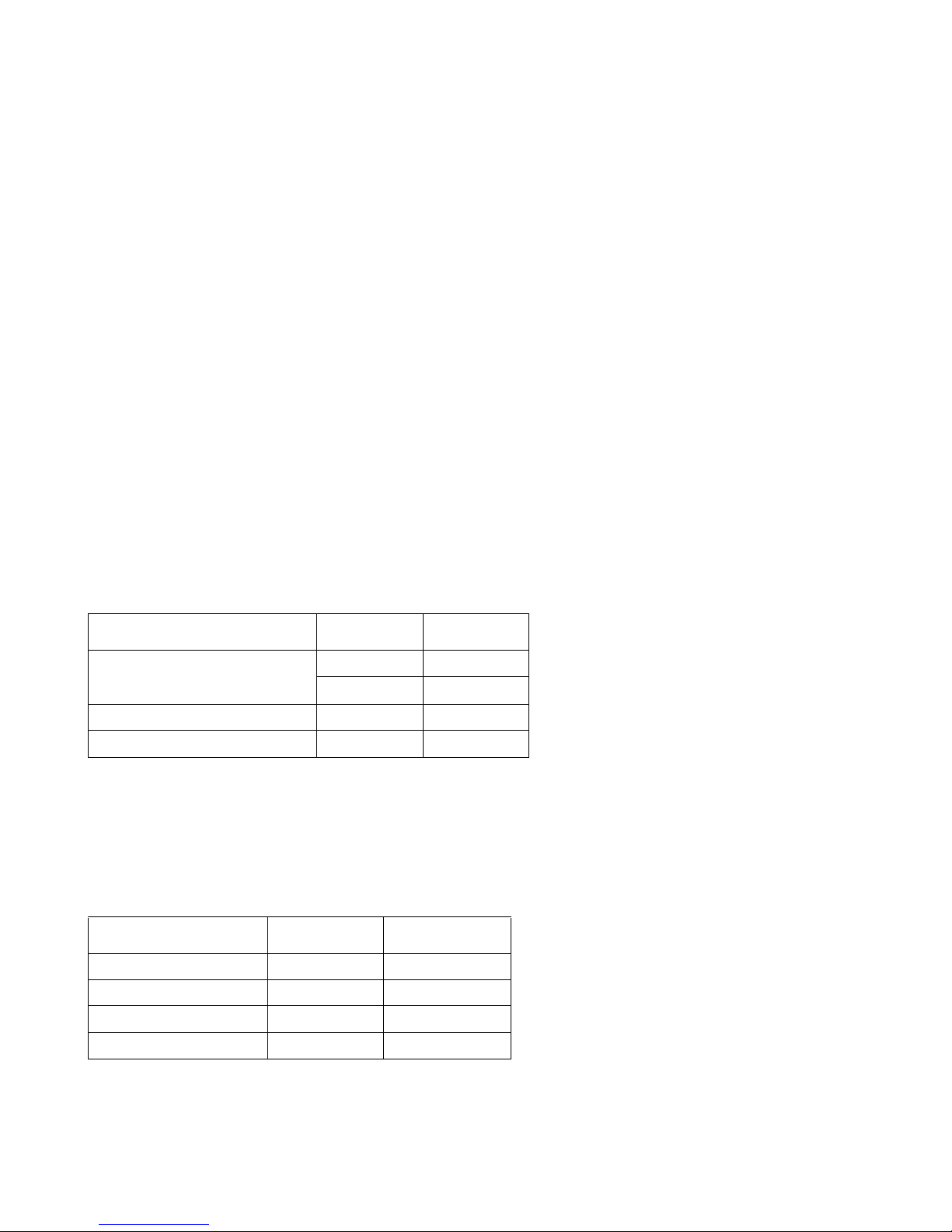

Table 1: Formatted capacities

PATA

SATA

HDS721680PLAT80

HDS721680PLA3

x0

HDS721612PLAT80

HDS721612PLA380

HDS721616PLAT80

HDS721616PLA3

Physical Layout

Label capacity (GB) 80 120 160

Bytes per sector 512 512 512

Sectors per track 720-1500 672-1280 720-1500

Number of heads 1 2 2

Number of disks 1 1 1

Data sectors per cylinder 567-1170 1134-2340 1440-3000

Data cylinders per zone 256-9088 1152-6656 256-9088

Logical layout

1

Number of heads 16 16 16

Number of Sectors per track 63 63 63

Number of Cylinders

2

16,383 16,383 16383

Number of sectors 160,836,480 241,256,720 321,672,960

Total logical data bytes 82,348,277,760 123,522,416,640 164,696,555,520

IDEMA Std. Capacity

3

Number of Sectors 156,301,488 312,581,808

x0

Total Logical Data Bytes 80,026,361,856

160,041,885,696

Notes:

1.

Number of cylinders: For drives with capacities greater than 8.45 GB the Identify Device information word 01

limits the number of cylinders to 16, 383 per the ATA specification.

2.

Logical layout: Logical layout is an imaginary drive parameter (that is, the number of heads) which is used to

access the drive from the system interface. The logical layout to Physical layout (that is, the actual Head and Sectors ) translation is done automatically in the drive. The default setting can be obtained by issuing an IDENTIFY

DEVICE command.

3.

Applies to part numbers beginning with 0Y3.

Deskstar 7K160 Hard Disk Drive Specification

11

Page 26

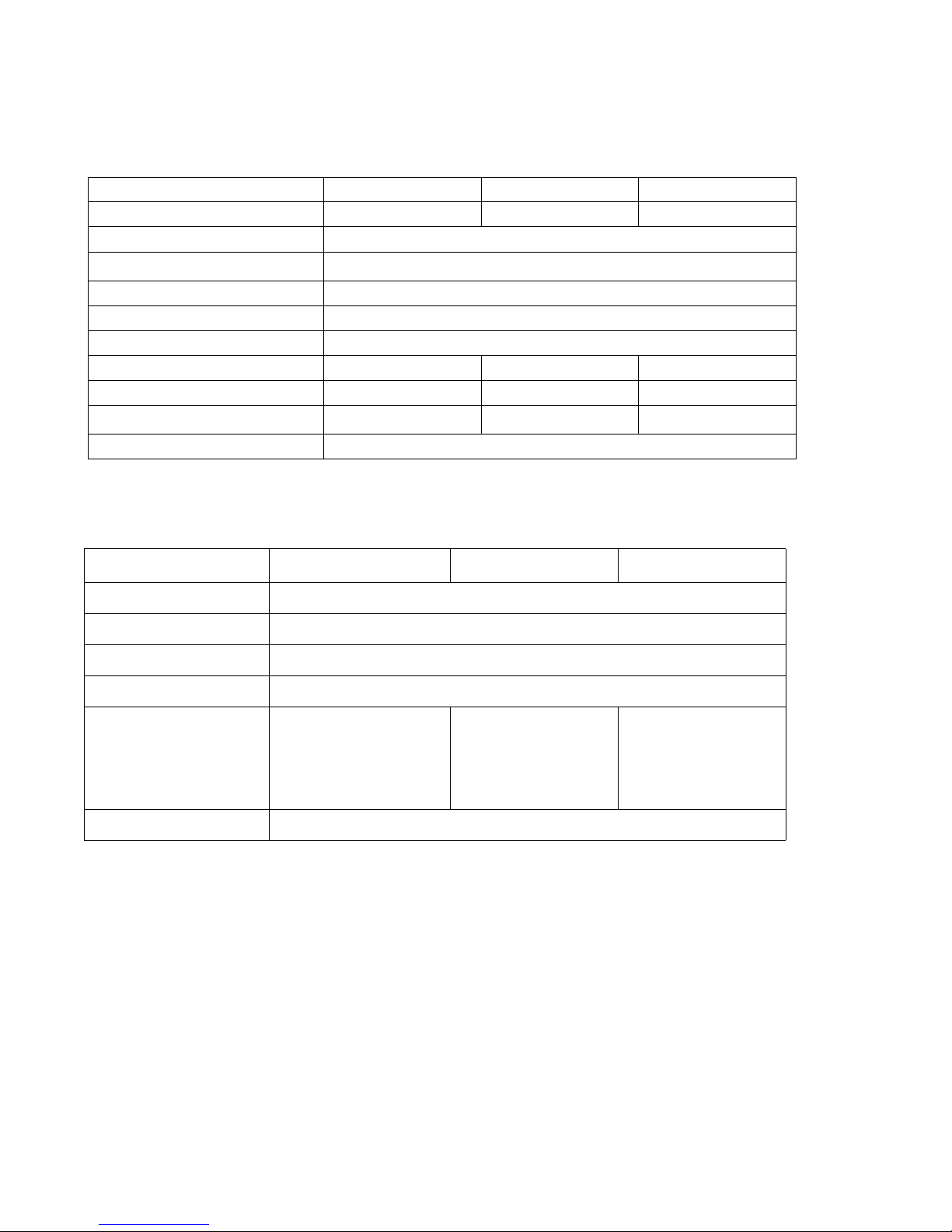

4.2 Data sheet

Table 2: Mechanical positioning performance

Description 80GB Model 1 20GB Model 160GB Model

Data transfer rates (Mbps) 966 824 966

Interface transfer rates (Mb/s) 133 (PATA) / 300 (SATA)

Data buffer size

Rotational speed (RPM) 7200

Number of buffer segments (read) up to 128

Number of buffer segments (write) up to 63

Recording density - max (Kbpi) 900 733 900

Track density [TPI] 135 125 135

Areal density - max (Gbits/in

Number of data bands 30

1

(KB)

2

)

120 92 120

2048 (80GB & 160GB), 8192

4.3 World Wide Name Assignment

Table 3: Word Wide Name Assignment

Description

Organization Hitachi GST

Manufacturing Site Excelstor Plant China / Hitachi GST China Plant (GSP)

Product Deskstar 7K160

OUI 000CCAh

SHBU Block Assignment 320h for ExcelStor,China

Port/Node ID 11b

80 GB model 120 GB model 160 GB model

324h for Hitachi

GST China Plant

326h for ExcelStor,China

328h for Hitachi

321h for ExcelStor,China

325h for Hitachi

GST China Plant

4.4 Drive organization

4.4.1 Drive format

Upon shipment from manufacturing the drive satisfies the sector continuity in the physical format by means of the

defect flagging strategy described in Section 5.0, “Defect flagging strate gy” on page 21 in order to provide the

maximum performance to users.

Deskstar 7K160 Hard Disk Drive Specification

12

Page 27

4.4.2 Cylinder allocation

Physical cylinder is calculated from the starting data track of 0. It is not relevant to logical CHS. Depending on the

capacity some of the inner zone cylinders are not allocated.

Zone Start Logical cyl. Stop Logical cyl. #cyl

0 0 4607 4608

1 4608 13695 9088

2 13696 21375 7680

3 21376 29055 7680

4 29056 35071 6016

5 35072 41855 6784

6 41856 45823 3968

7 45824 48895 3072

8 48896 56191 7296

9 56192 63231 7040

10 63232 67967 4736

11 67968 74111 6144

12 74112 80383 6272

13 80384 85247 4864

14 85248 88447 3200

15 88448 94207 5760

16 94208 99711 5504

17 99712 104063 4352

18 104064 108415 4352

19 108416 113151 4736

20 113152 117759 4608

21 117760 118783 1024

22 118784 121599 2816

23 121600 124031 2432

24 124032 126335 2304

25 126336 129023 2688

26 129024 131711 2688

27 131712 131967 256

28 131968 133119 1152

29 133120 134271 1152

Data cylinder

This cylinder contains the user data which can be sent and retrieved via read/write commands and a spare area for

reassigned data.

Spare cylinder

Deskstar 7K160 Hard Disk Drive Specification

13

Page 28

The spare cylinder is used by Hitachi Global Storage Technologies manufacturing and includes data sent from a

defect location.

Deskstar 7K160 Hard Disk Drive Specification

14

Page 29

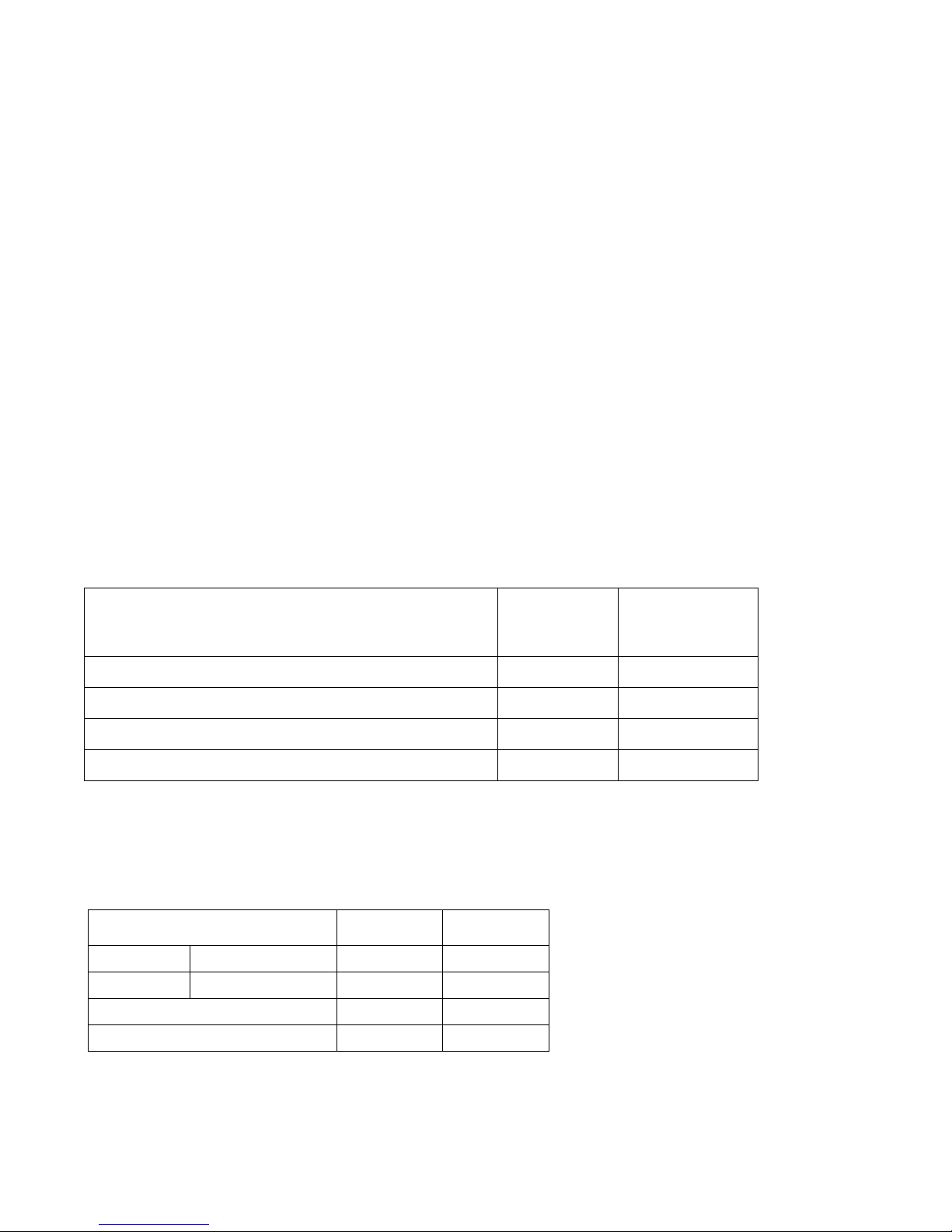

4.5 Performance characteristics

Drive performance is characterized by the following parameters:

• Command overhead

• Mechanical head positioning

- Seek time

- Latency

• Data transfer speed

• Buffering operation (Look ahead/Write cache)

All the above parameters contribute to drive performance. There are other parameters that contribute to the performance of the actual system. This specification tries to define the bare drive characteristics, not system throughput,

which depends on the system and the application.

4.5.1 Command overhead

Command overhead is defined as the time required from the time the command is written into the command register by a host to the assertion of DRQ for the first data byte of a READ command when the requested data is not in

the buffer excluding Physical seek time and Latency.

The table below gives average command overhead.

Table 4: Command overhead

Command type (Drive is in quiescent state) Time (typical)

(ms)

Read (cache not hit) (from Command Write to Seek Start)

Read (cache hit) (from Command Write to DRQ)

Write (from Command Write to DRQ)

Seek (from Command Write to Seek Start)

0.5 0.5

0.1 0.2

0.015 0.2

0.5 not applicable

Time (typical) for

queued command

(ms)

4.5.2 Mechanical positioning

4.5.2.1 Average seek time (without command overhead, including settling)

Table 5: Mechanical positioning performance

Command type Typical (ms) Max (ms)

Read 40-80GB 8.5 9.5

Write 40-80GB 9.5 10.5

Read (Quiet Seek mode) 14.0 14.7

Write (Quiet Seek mode) 15.0 15.7

Deskstar 7K160 Hard Disk Drive Specification

15

Page 30

The terms “Typical” and “Max” are used throughout this document and are defined as follows:

Typical The average of the drive population tested at nominal environmental and voltage conditions.

Max Maximum value measured on any one drive over the full range of the environmental and voltage

conditions. The seek time is measured from the start of the actuator’s motion to the start of a reliable read or write operation. A reliable read or write implies that error correction or recovery is not

used to correct arrival problems. The average seek time is measured as the weighted average of all

possible seek combinations.

max

Σ (m10 n)(Tnin + Tnout)

n=1

Weighted Average = ––––––––––––––––––––––––––––

(max + 1)(max)

where

max = Maximum seek length

n= Seek length (1 to max)

Tnin = Inward measured seek time for an n track seek

Tnout = Outward measured seek time for an n track seek

4.5.2.2 Full stroke seek time (without command overhead, including settling)

Table 6: Full stroke seek time

Function Typical (ms) Max (ms)

Read

Write

15.1 18.1

16.1 19.1

Read (Quiet Seek mode) 32.5 35.5

Write (Quiet Seek mode) 33.5 36.5

Full stroke seek is measured as the average of 1,000 full stroke seeks with a random head switch from both directions (inward and outward).

4.5.2.3 Single track seek time (without command overhead, including settling)

Table 7: Single track seek time

Function Typical (ms) Max (ms)

Read 0.8 1.5

Write 1.3 2.0

Read (Quiet Seek mode) 0.8 1.5

Write (Quiet Seek mode) 1.3 2.0

Single track seek is measured as the average of one (1) single track seek from every track in both directions

(inward and outward).

Deskstar 7K160 Hard Disk Drive Specification

16

Page 31

4.5.2.4 Average latency

Table 8: Latency Time

Rotational speed

(RPM)

Time for one

revolution (ms)

Average latency

(ms)

7200 RPM 8.3 4.17

4.5.3 Drive ready time

Table 9: Drive ready time

Power on to ready Typical (sec) Maximum (sec)

820

Ready The condition in which the drive is able to perform a media access command (for exam-

ple- read, write) immediately.

Power on This includes the time required for the internal self diagnostics.

Note: Max Power On to ready time is the maximum time period that Device 0 waits for Device 1 to assert PDIAG.

4.5.4 Operating modes

4.5.4.1 Description of operating modes

Table 10: Description of operating modes

Operating mode Description

Spin-up

Seek

Write

Read

Unload Idle

Idle

Standby

Sleep

Start up time period from spindle stop or power down.

Seek operation mode

Write operation mode

Read operation mode

Spindle rotation at 7200 RPM with heads unloaded.

Spindle motor and servo system are working normally. Commands can be received and processed immediately.

Actuator is unloaded and spindle motor is stopped. Commands can be received immediately.

TActuator is unloaded and spindle motor is stopped. Only soft reset or hard reset can change

the mode to standby.

Note: Upon power down or spindle stop a head locking mechanism will secure the heads in the OD parking position.

Deskstar 7K160 Hard Disk Drive Specification

17

Page 32

4.5.4.2 Mode transition time

Table 11: Mode transition times

From To RPM

Standby Idle 0 ---> 7200 6 20

Idle Standby 7200 ---> 0 Immediately Immediately

Standby Sleep 0 Immediately Immediately

Sleep Standby 0 Immediately Immediately

Unload idle Idle 7200 0.7 20

Idle Unload idle 7200 0.7 20

Low RPM Idle Idle 4500 ---> 7200 3 20

Transition time (sec)

Typical Maximum

Note: The command is processed immediately (within 1ms) but there will be an actual spin down time reflecting

the seconds passed until the spindle motor stops.

Deskstar 7K160 Hard Disk Drive Specification

18

Page 33

5.0 Defect flagging strategy

Media defects are remapped to the next available sector during the Format Process in manufacturing. The

mapping from LBA to the physical locations is calculated by an internally maintained table.

Shipped format

• Data areas are optimally used.

• No extra sector is wasted as a spare throughout user data areas.

• All pushes generated by defects are absorbed by the spare tracks of the inner zone.

Table 12: PATA Plist physical format

NN+1 N+2 N+3

Defects are skipped without any constraint, such as track or cylinder boundary.

defe ct defect

skip

skip

Deskstar 7K160 Hard Disk Drive Specification

19

Page 34

Deskstar 7K160 Hard Disk Drive Specification

20

Page 35

6.0 Electrical interface specification

6.1 Connector location

Refer to the following illustration to see the location of the connectors

PATA

SATA

Deskstar 7K160 Hard Disk Drive Specification

21

Page 36

6.1.1 4 pin DC power connector

The DC power connector is designed to mate with AMP part number 1-480424-0 using AMP pins part number

350078-4 (strip), part number 61173-4 (loose piece), or their equivalents. Pin assignments are shown in the figure

below.

Pin Voltage

4 3 2 1

1+12 V

2GND

3GND

4+5V

6.1.2 AT signal connector

The AT signal connector is a 40-pin connector.

Deskstar 7K160 Hard Disk Drive Specification

22

Page 37

6.2 Signal definitions (PATA model)

The pin assignments of interface signals are listed as follows:

Table 13: Signal definitions

PIN SIGNAL I/O Type PIN SIGNAL I/O Type

01 RESET- I TTL

03 DD7 I/O 3–state

05 DD6 I/O 3–state

07 DD5 I/O 3–state

09 DD4 I/O 3–state

11 DD3 I/O 3–state

13 DD2 I/O 3–state

15 DD1 I/O 3–state

17 DD0 I/O 3–state

19 GND

21 DMARQ O 3–state

23 DIOW-(*) I TTL

25 DIOR-(*) I TTL

27 IORDY-(*) O 3–state

29 DMACK- I TTL

31 INTRQ O 3–state

33 DA1 I TTL

35 DA0 I TTL

37 CS0- I TTL

02 GND

04 DD08 I/O 3–state

06 DD09 I/O 3–state

08 DD10 I/O 3–state

10 DD11 I/O 3–state

12 DD12 I/O 3–state

14 DD13 I/O 3–state

16 DD14 I/O 3–state

18 DD15 I/O 3–state

(20) Key

22 GND

24 GND

26 GND

28 CSEL I TTL

30 GND

32

34 PDIAG- I/O OD

36 DA02 I TTL

38 CS1- I TTL

39 DASP- I/O OD

40 GND

Notes:

O designates an output from the drive

I desi gnates an input to the drive

I/O designates an input/outp ut common

OD designates an Open-Drain output

The signal lines marked with (*) are redefined during the Ultra DMA protocol to provide special functions. These

lines change from the conventional to special definitions at the moment the host decides to allow a DMA burst, if

the Ultra DMA transfer mode was previously ch os e n vi a Set Features. The drive becomes aware of this change

upon assertion of the DMACK- line. These lines revert back to their original definitions upon the deassertion of

DMACK- at the termination of the DMA burst.

Deskstar 7K160 Hard Disk Drive Specification

23

Page 38

6.3 Signal descriptions

Table 14: Special signal definitions for Ultra DMA

Special Definition

(for Ultra DMA)

Conventional

Definition

DDMARDY- IORDY

Write Operation

HSTROBE DIORSTOP DIOWHDMARDY- DIOR-

Read Operation

DSTROBE IORDY

STOP DIOW-

DD00–DD15

A 16-bit bi-directional data bus between the host and the drive. The lower 8 lines, DD00-07, are used for Register and ECC access. All 16 lines, DD00–15, are used for data transfer. These are 3-state lines with 24 mA current sink capability.

DA00–DA02

These are addresses used to select the individual register in the drive.

CS0-

The chip select signal generated from the Host address bus. When active, one of the Command Block Registers

[Data, Error (Features when written), Sector Count, Sector Number, Cylinder Low , Cylinder High, Drive/Head

and Status (Command when written) register] can be selected. (See Table 34: “I/O address map” on page 40.)

CS1-

The chip select signal generated from the Host address bus. When active, one of the Control Block Registers

[Alternate Status (Device Control when written) and Drive Address register] can be selected. (See Table 34:

“I/O address map” on page 40.)

RESET-

This line is used to reset the drive. It shall be kept at a Low logic state during power up and kept High thereafter.

DIOW-

The rising edge of this signal holds data from the data bus to a register or data register of the drive.

DIOR-

When this signal is low , it enables data from a register or data register of the drive onto the data bus. The data on

the bus shall be latched on the rising edge of DIOR-

INTRQ

The interrupt is enabled only when the drive is selected and the host activates the IEN- bit in the Device Control

Register. Otherwise, this signal is in high impedance state regardless of the state of the IRQ bit. The interrupt is

set when the IRQ bit is set by the drive CPU. The IRQ is reset to zero by a host read of the status register or a

write to the Command Register. This signal is a 3-state line with 24mA of sink capability.

Deskstar 7K160 Hard Disk Drive Specification

24

Page 39

DASP-

This is a time-multiplexed signal which indicates that a drive is active or that device 1 is present. This signal is

driven by an Open-Drain driver and internally pulled up to 5 volts through a 10 kW resistor. During a Power-On

initialization or after RESET- is negated, DASP- shall be asserted by Device 1 within 400 ms to indicate that

device 1 is present. Device 0 shall allow up to 450 ms for device 1 to assert DASP-. If device 1 is not present,

device 0 may assert DASP- to drive an LED indicator. The DASP- signal shall be negated following acceptance

of the first valid command by device 1. Anytime after negation of DASP-, either drive may assert DASP- to

indicate that a drive is active.

During Power-On initialization or after RESET- is negated, DASP- shall be asserted by Device 1 within 400 ms

to indicate that device 1 is present. Device 0 shall allow up to 450ms for device 1 to assert DASP-. If device 1 is

not present, device 0 may assert DASP- to drive a LED indicator.

DASP- shall be negated following acceptance of the first valid command by device 1. At anytime after negation of DASP-, either drive may assert DASP- to indicate that a drive is active.

PDIAG-

This signal shall be asserted by device 1 to indicate to device 0 that it has completed the diagnostics. This line is

pulled up to 5 volts in the drive through a 10 kΩ resistor.

Following a Power On Reset, software reset, or RESET-, drive 1 shall negate PDIAG- within 1 ms (to indicate

to device 0 that it is busy). Drive 1 shall then assert PDIAG- within 30 seconds to indicate that it is no longer

busy and is able to provide status.

Following the receipt of a valid Execute Drive Diagnostics command, device 1 shall negate PDIAG- within 1