INSTRUCTION MANUAL

HITACHI Oil-Free Rotary Screw Air Compressor

Air-Cooled

DSP-90A6N DSP-110A6N

DSP-90VA6N DSP-110VA6N

Water-Cooled

DSP-90W6N DSP-110W6N

DSP-90VW6N DSP-110VW6N

Prior to operation of this air compressor,

ensure that all operators read and

understand this INSTRUCTION

MANUAL completely, thereby operating

it safely and properly.

Place the INSTRUCTION MANUAL

near the air compressor to make it

available at any time, and refer to it as

the need arises.

● This INSTRUCTION MANUAL explains in detail

the important items that require attention;

observed as the following:

Always observe Instructions of WARNING,

●

CAUTION

considerable risks to safety.

WARNING

CAUTION

Air-Cooled

Water-Cooled

IMPORTANT

and IMPORTANT, as they indicate

GRAPHIC DESCRIPTIONS:

:Indicates warnings. If handled

improperly, death or severe injury

could result.

:Indicates cautions. If handled

improperly, injury and/or physical

damage could result.

:Indicates air-cooled type.

:Indicates water-cooled type.

:Indicates variable speed type.

:Indicates information that needs

attention, other than WARNING and

CAUTION.

:Indicates a reference page.

How to Use This Instruction Manual

● This Instruction Manual covers the standard models of the Hitachi DSP air compressor.

● This Instruction Manual intended to assist daily operators and maintenance personnel

in the installation, operation, control and service of the air compressor.

● Prior to operation of this air compressor, ensure that all operators read and understand

this INSTRUCTION MANUAL completely, thereby operating it safely and properly.

Place the INSTRUTION MANUAL near the air compressor to make it available at any

time, and refer to it as the need arises.

● If there are any questions or comments, please contact the local Hitachi distributor/

master dealer or representative office.

● Fill your compressor’s model name, Serial Number, etc. in Section 13 of this

Instruction Manual. Such information may be helpful when ordering parts, periodic

maintenance, and overhaul.

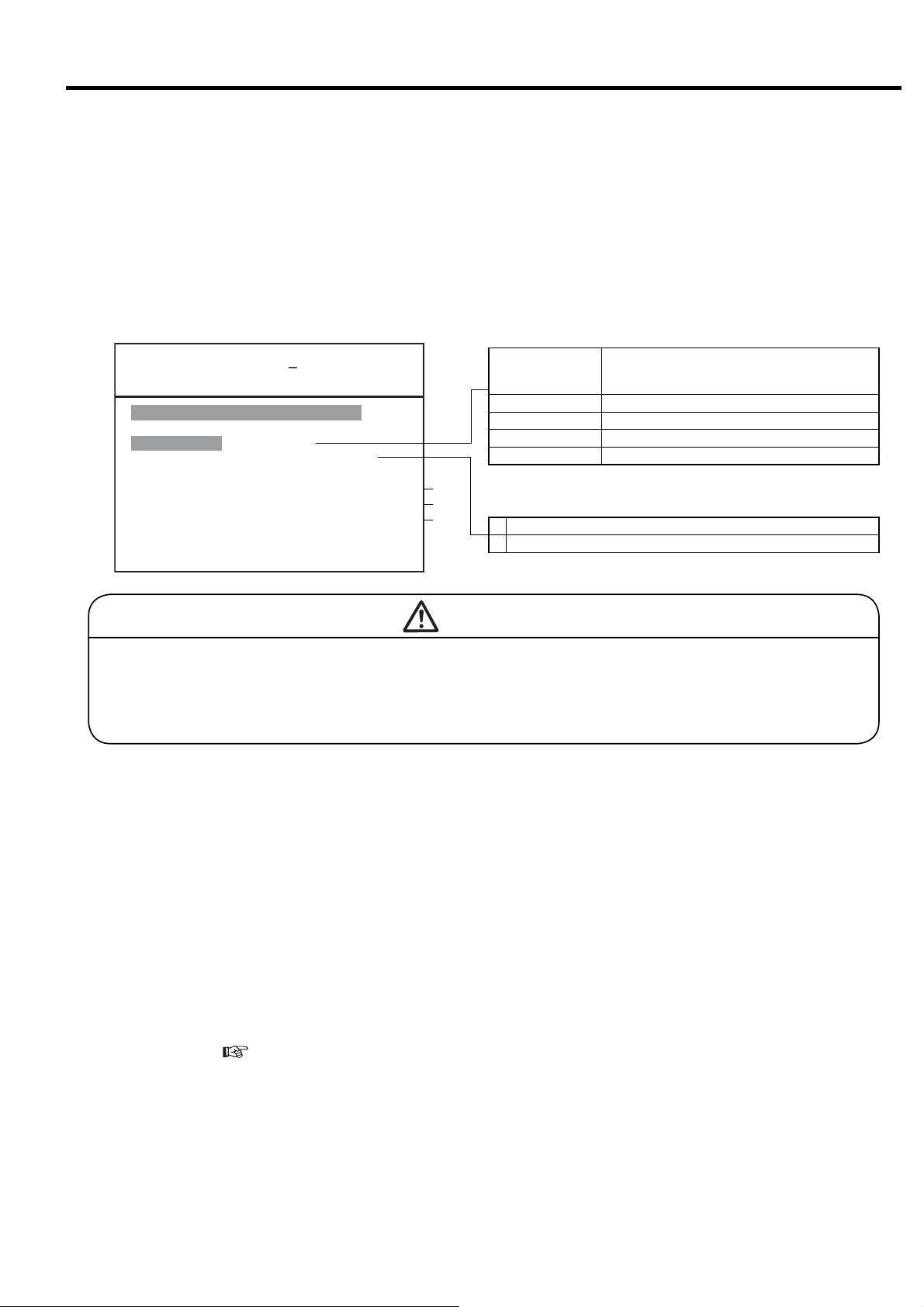

■ Model Code

Dry or Oil-Free Rotary

Screw Air Compressor

WARNING

Never remove a protective device from the air compressor or

modify the air compressor.

It is imperative to install an earth leakage (ground) circuit breaker

on the power cable. This prevents a ground fault accident.

DSP air compressors are not designed, intended or approved for

breathing air applications. Hitachi does not approve specialized

equipment for breathing air applications and assumes no responsibility or liability for compressors used for breathing air services.

DSP-90VA6N

NEXTseries

Frequency (5: 50 Hz, 6: 60 Hz)

Packaged

Cooling Method (A: air-cooled ,

W: water-cooled)

V: V type

without V: fixed-speed type

Nominal Output (kW)

● For improvement of the product, contents in this manual are subject to change without notice. Please be forewarned.

Contents

1. SAFETY PRECAUTIONS ………………………………………………………………………………………… 2

2.1 Appearance

2.

GENERAL DESCRIPTION

2.2 Components …………………………………………………………………… 8

2.3 Daily Operating Components ……………………………………………… 10

3.

OPERATING PROCEDURE

3.2 Start/Stop Operation ………………………………………………………… 14

3.3 How to Use the Liquid Crystal Display (LCD)……………………………… 15

3.4 How to Use the Digital Monitor …………………………………………… 25

3.5 Daily Operation of Air Compressor ………………………………………… 32

3.6 Daily Operation of Oil Mist Remover ……………………………………… 34

3.7 Adjusting Procedure…………………………………………………………… 35

3.1 Instrument Panel ……………………………………………………………… 12

4. TROUBLESHOOTING 4.1 Protective Device……………………………………………………………… 36

4.2 Troubleshooting of Air Compressor………………………………………… 38

4.3 Troubleshooting of Oil Mist Remover……………………………………… 39

5.

INSTALLING AND PIPING

5.1 Unpacking the Air Compressor ……………………………………………… 40

THE DSP 5.2 Conveying the Air Compressor ……………………………………………… 40

5.3 Installing the Air Compressor ……………………………………………… 41

5.4 Piping the Air Compressor …………………………………………………… 42

5.5 Ventilation of Air Compressor Room ……………………………………… 45

……………………………………………………………………… 6

6. STARTUP OPERATION 6.1 Startup Operation of the Air Compressor ………………………………… 47

6.2 Initial Setting of OMR Regulator …………………………………………… 50

7. WIRING 7.1 Power Supply Equipment …………………………………………………… 51

7.2 MIV and WIVM Wiring ………………………………………………………… 51

7.3 Connecting the Power Cable ………………………………………………… 52

7.4 Wiring Diagram………………………………………………………………… 54

7.5 Control Panel /LCD monitor Specifications ……………………………… 54

8.

STANDARD COMPONENTS

AND SUBSYSTEMS

8.3 Cooling Water ………………………………………………………………… 66

8.4 Capacity Control System……………………………………………………… 67

8.5 Oil Mist Remover System …………………………………………………… 73

8.2 Air/Oil/Water Flow……………………………………………………………… 61

8.1 Standard Components………………………………………………………… 60

9. MAINTENANCE 9.1 Periodical maintenance of Air compressor………………………………… 74

9.2 Standard Maintenance Schedule …………………………………………… 75

9.3 Maintenance Schedule for Oil Mist Remover……………………………… 79

9.4 How to Service the Air Compressor………………………………………… 80

10. CAUTIONS FOR A LONG TERM OPERATION SUSPENSION…………………………………………… 94

11. PARTS LIST ………………………………………………………………………………………… 95

12. RELOCATION AND 12.1 Relocation…………………………………………………………………… 119

DISPOSAL 12.2 Disposal……………………………………………………………………… 11 9

13. WARRANTY AND 13.1 Warranty……………………………………………………………………… 120

AFTER-SALES SERVICE

13.2 After-Sales Service ………………………………………………………… 120

14. OPERATION RECORD LOGBOOK…………………………………………………………………………… 121

15. STANDARD SPECIFICATIONS………………………………………………………………………………… 122

1

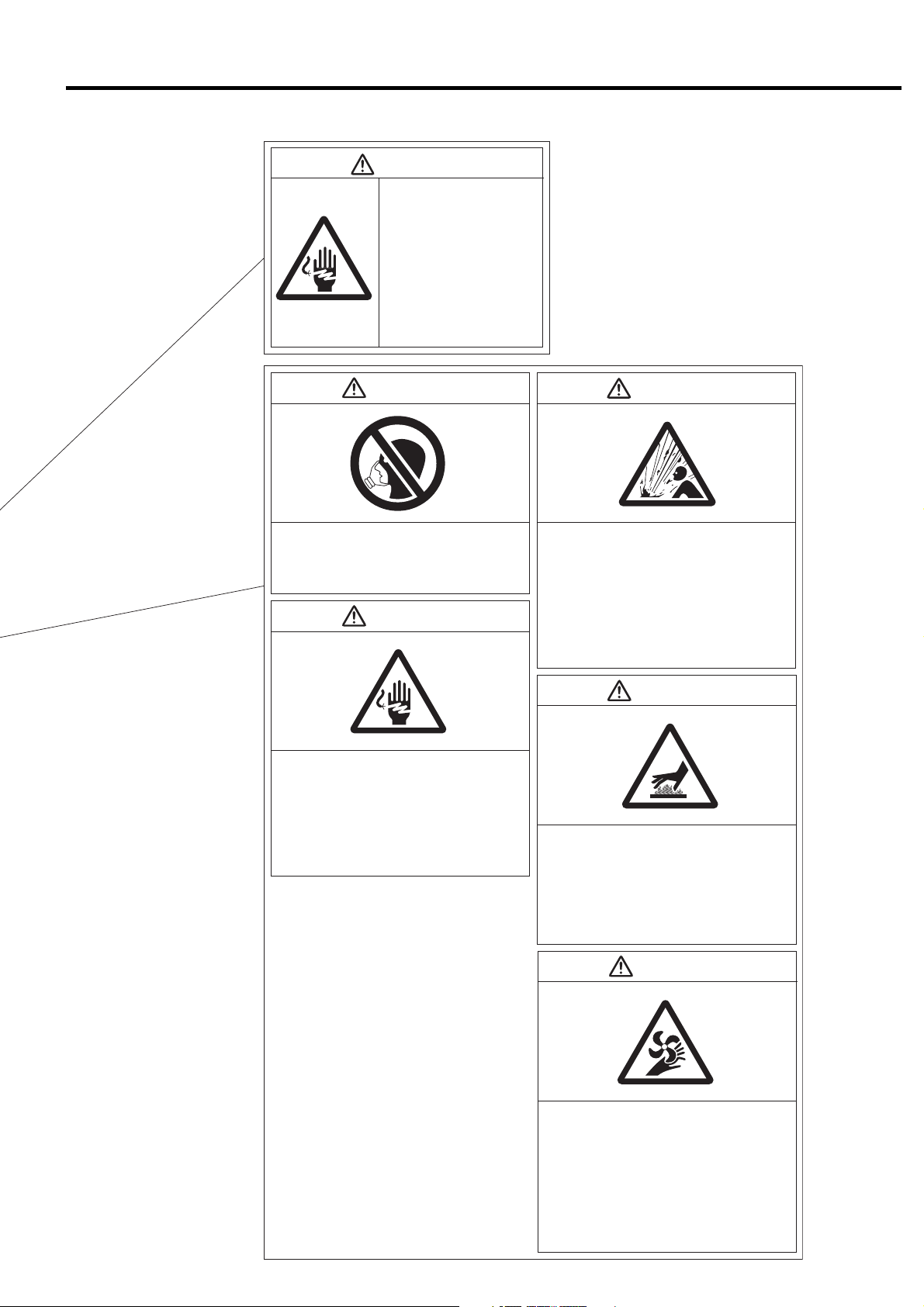

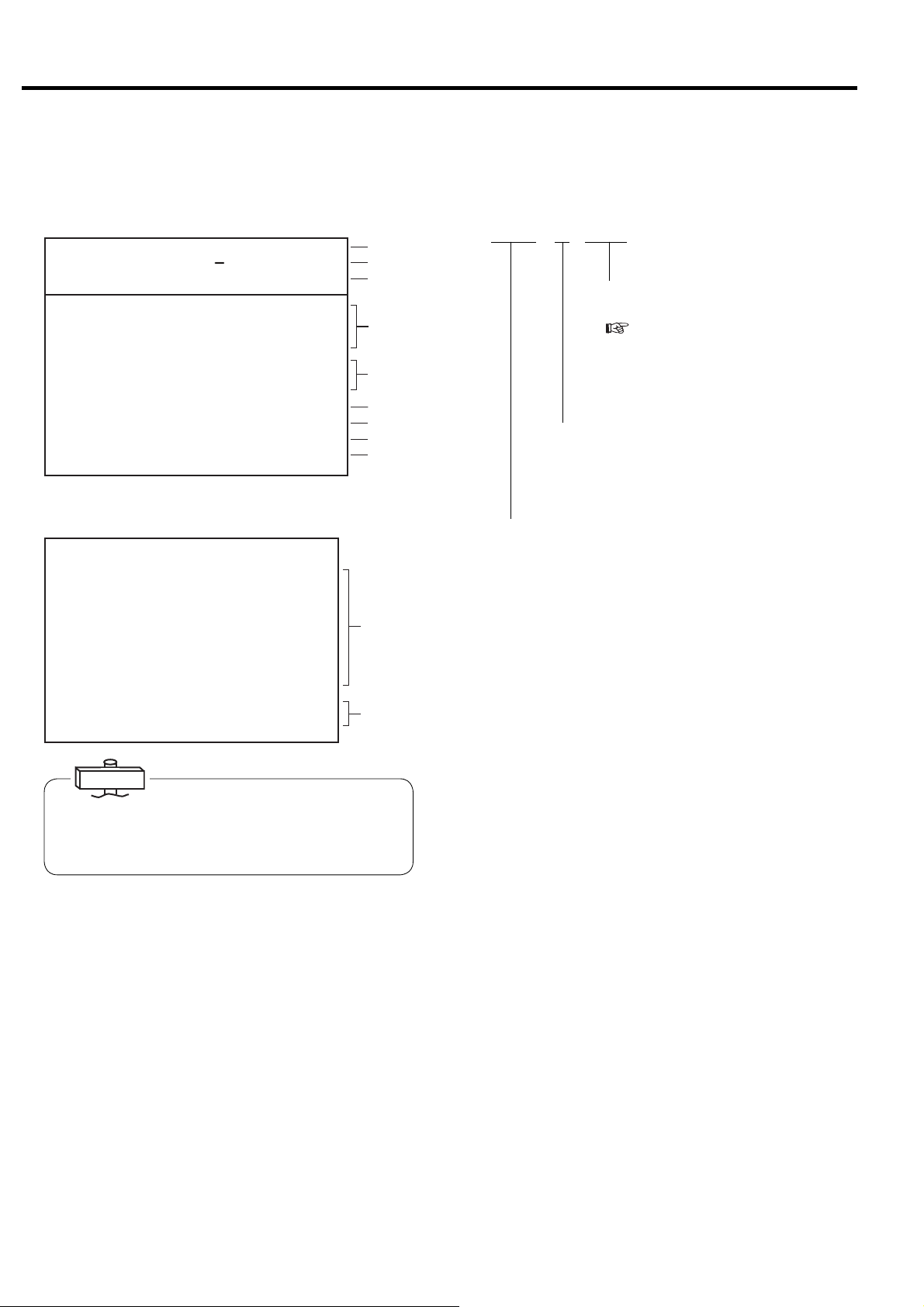

1. SAFETY PRECAUTIONS

013B0816

012B1240012B1240

To ensure safe and proper operation of the air compressor, it is indispensable to carefully

read and understand the following warnings and instructions detailed below. These

warnings and instructions are attached to the air compressor as shown in the figure

below.

Air-Cooled

DSP- 90/110A6N

90/110VA6N

WARNING

Hot Surface!

●Do not directly touch any component

inside the air compressor enclosure

when the air compressor is operating

or immediately after it has stopped,

as the components are extremely hot

and can cause severe injury.

●Before servicing the air compressor,

stop it, disconnect the power, then

wait for the air compressor to cool

down.

Heated!!

WARNING

Rotating Parts!

●Keep hands and rods, etc. away from

the rotating parts (Cooling fans, etc.)

●Use caution at all times, when air com-

pressor is powered. The air compressor may be capable of restarting without hitting the START button.

●When the air compressor is operating,

do not remove or open the enclosure

panels and doors.

●

Before servicing the air compressor,

stop it, disconnect the power, especially when accessing any rotating parts.

Discharge Air pipe

Air End

WARNING

Hot Surface!

●Do not directly touch any component

inside the air compressor enclosure

when the air compressor is operating

or immediately after it has stopped,

as the components are extremely hot

and can cause severe injury.

●Before servicing the air compressor,

stop it, disconnect the power, then

wait for the air compressor to cool

down.

WARNING

Hot Surface!

●Do not directly touch any component

inside the air compressor enclosure

when the air compressor is operating

or immediately after it has stopped,

as the components are extremely hot

and can cause severe injury.

●Before servicing the air compressor,

stop it, disconnect the power, then

wait for the air compressor to cool

down.

Air End

Discharge Air Pipe

Heated!!

2

Aftercooler

Heated!!

Intercooler

1. SAFETY PRECAUTIONS

WARNING

Electric Shock Hazard!

●Before servicing or wiring the

air compressor, disconnect

the power. This will prevent

anyone from turning on the

power and causing an electric shock that could lead to

severe injury or death.

●Do not allow any unlicensed

person to wire the air compressor. Always use a licensed

electrician.

●Ground the air compressor.

WARNING WARNING

Do Not Breathe Air!

Discharge air can contain Carbon Monoxide and

other contaminants. Breathing the air can cause

severe injury or death.

WARNING

Electric Shock Hazard!

●

Before servicing or wiring the air compressor,

disconnect the power. This will prevent anyone

from turning on the power and causing an electric

shock that could lead to severe injury or death.

●

Do not allow any unlicensed person to wire the air

compressor. Always use a licensed electrician.

●Ground the air compressor.

●

High pressure air can cause severe injury or death.

Be careful when air compressor is operating.

Pressurized air can blow out of air relief valves and

etc. at incredibly high velocities.

●When using compressed air to clean equipment,

use extreme caution and/or wear eye protection.

●Before servicing the air compressor, stop it,

disconnect the power, and relieve pressure before

removing filter, plug, fitting or cover.

WARNING

High Pressure Air!

Hot Surface!

●Do not directly touch the air end, discharge air

pipe,and coolers when the air compressor is

operating and immediately after it has stopped,

because these parts are heated then.

Before servicing the air compressor (especially

●

when accessing to the heated parts), stop it, disconnect the power, and wait until it is cooled down.

WARNING

●Keep hands and rods, etc. away from the rotating

Rotating Parts!

parts (Cooling fans, etc.)

●Use caution at all times, when air compressor is

powered. The air compressor may be capable of

restarting without hitting the START button.

●When the air compressor is operating, do not

remove or open the enclosure panels and doors.

●Before servicing the air compressor, stop it, dis-

connect the power, especially when accessing

any rotating parts.

3

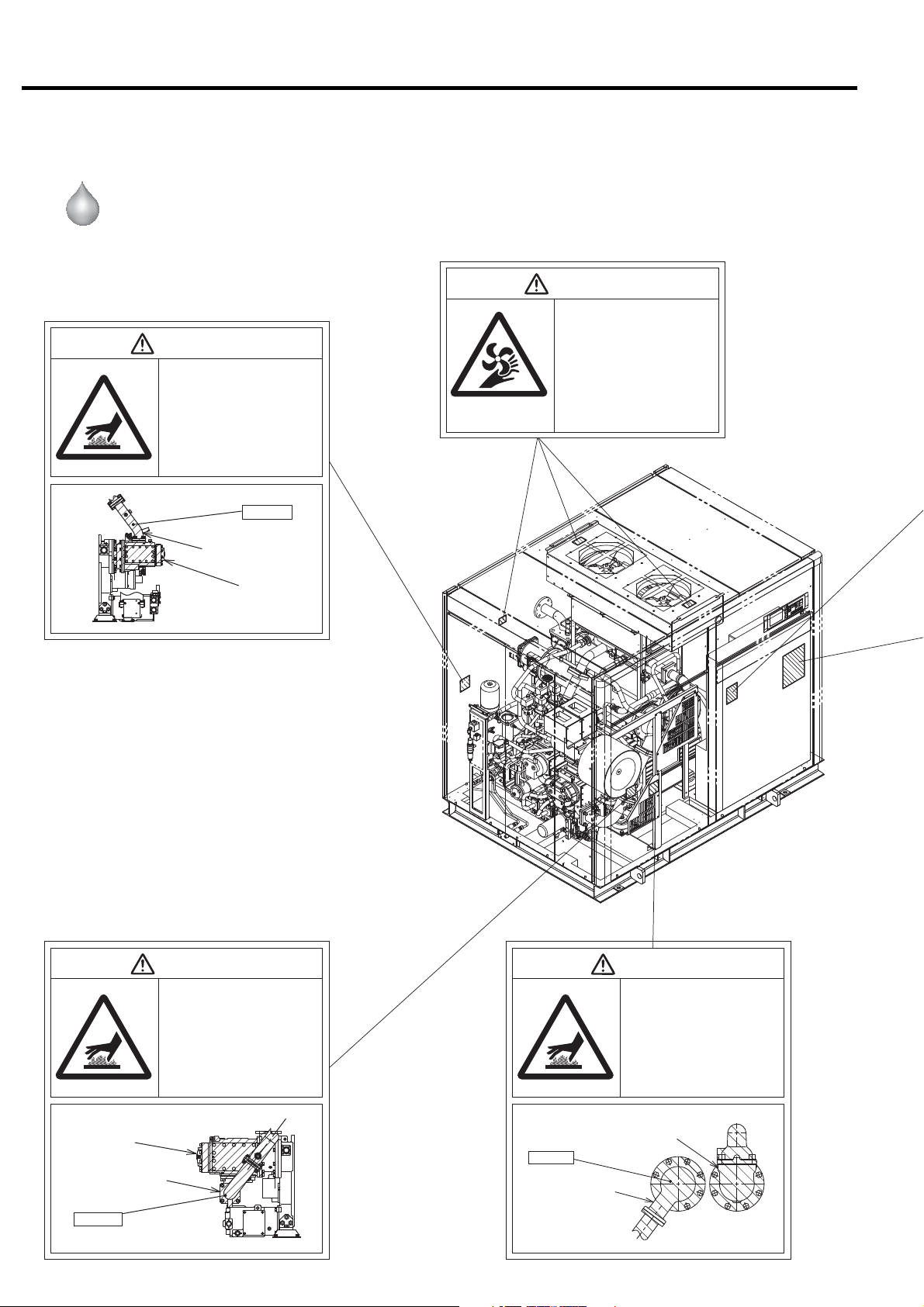

1. SAFETY PRECAUTIONS

013B0816

012B1240012B1240

Water-Cooled

DSP- 90/110W6N

90/110VW6N

WARNING

Hot Surface!

●Do not directly touch any component

inside the air compressor enclosure

when the air compressor is operating

or immediately after it has stopped,

as the components are extremely hot

and can cause severe injury.

●Before servicing the air compressor,

stop it, disconnect the power, then

wait for the air compressor to cool

down.

Heated!!

Discharge Air pipe

Air End

WARNING

Rotating Parts!

●Keep hands and rods, etc. away from

the rotating parts (Cooling fans, etc.)

●Use caution at all times, when air com-

pressor is powered. The air compressor may be capable of restarting without hitting the START button.

●When the air compressor is operating,

do not remove or open the enclosure

panels and doors.

●

Before servicing the air compressor,

stop it, disconnect the power, especially when accessing any rotating parts.

Air End

Discharge Air Pipe

Heated!!

4

WARNING

Hot Surface!

●Do not directly touch any component

inside the air compressor enclosure

when the air compressor is operating

or immediately after it has stopped,

as the components are extremely hot

and can cause severe injury.

●Before servicing the air compressor,

stop it, disconnect the power, then

wait for the air compressor to cool

down.

Heated!!

Intercooler

WARNING

Hot Surface!

●Do not directly touch any component

inside the air compressor enclosure

when the air compressor is operating

or immediately after it has stopped,

as the components are extremely hot

and can cause severe injury.

●Before servicing the air compressor,

stop it, disconnect the power, then

wait for the air compressor to cool

down.

Aftercooler

1. SAFETY PRECAUTIONS

WARNING

Electric Shock Hazard!

●Before servicing or wiring the

air compressor, disconnect

the power. This will prevent

anyone from turning on the

power and causing an electric shock that could lead to

severe injury or death.

●Do not allow any unlicensed

person to wire the air compressor. Always use a licensed

electrician.

●Ground the air compressor.

WARNING WARNING

Do Not Breathe Air!

Discharge air can contain Carbon Monoxide and

other contaminants. Breathing the air can cause

severe injury or death.

WARNING

Electric Shock Hazard!

●

Before servicing or wiring the air compressor,

disconnect the power. This will prevent anyone

from turning on the power and causing an electric

shock that could lead to severe injury or death.

●

Do not allow any unlicensed person to wire the air

compressor. Always use a licensed electrician.

●Ground the air compressor.

●

High pressure air can cause severe injury or death.

Be careful when air compressor is operating.

Pressurized air can blow out of air relief valves and

etc. at incredibly high velocities.

●When using compressed air to clean equipment,

use extreme caution and/or wear eye protection.

●Before servicing the air compressor, stop it,

disconnect the power, and relieve pressure before

removing filter, plug, fitting or cover.

WARNING

High Pressure Air!

Hot Surface!

●Do not directly touch the air end, discharge air

pipe,and coolers when the air compressor is

operating and immediately after it has stopped,

because these parts are heated then.

Before servicing the air compressor (especially

●

when accessing to the heated parts), stop it, disconnect the power, and wait until it is cooled down.

WARNING

●Keep hands and rods, etc. away from the rotating

Rotating Parts!

parts (Cooling fans, etc.)

●Use caution at all times, when air compressor is

powered. The air compressor may be capable of

restarting without hitting the START button.

●When the air compressor is operating, do not

remove or open the enclosure panels and doors.

●Before servicing the air compressor, stop it, dis-

connect the power, especially when accessing

any rotating parts.

5

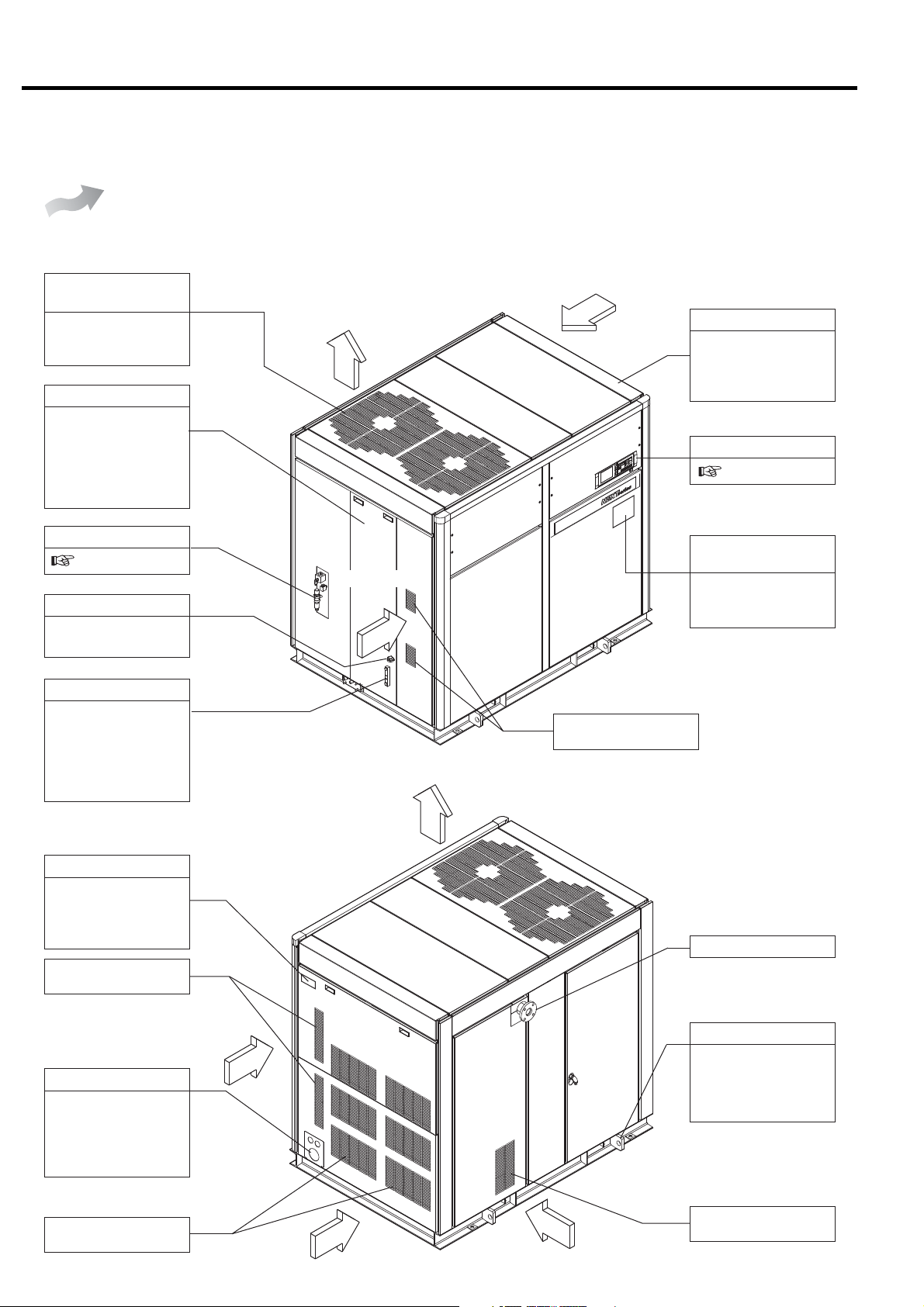

2. GENERAL DESCRIPTION

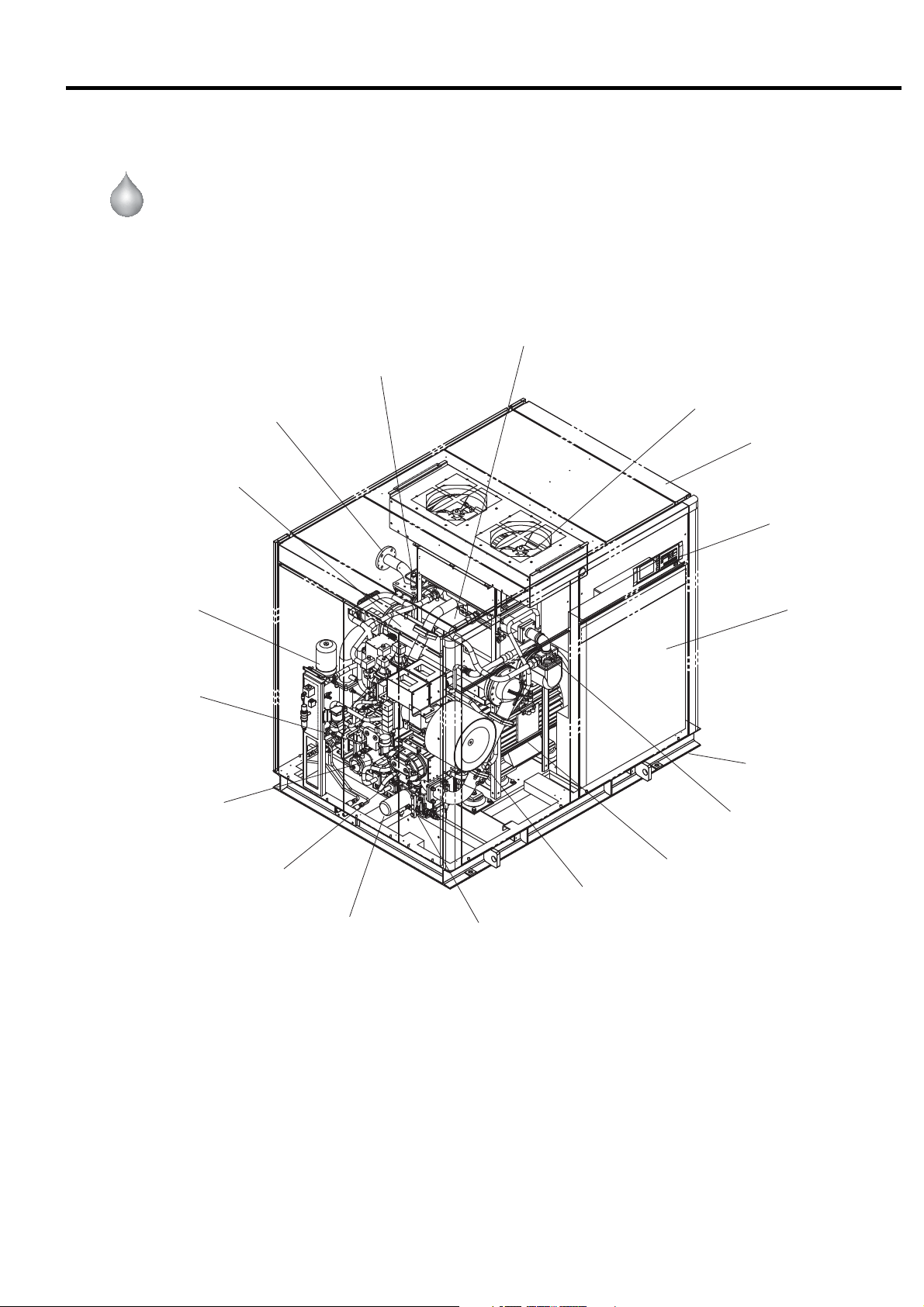

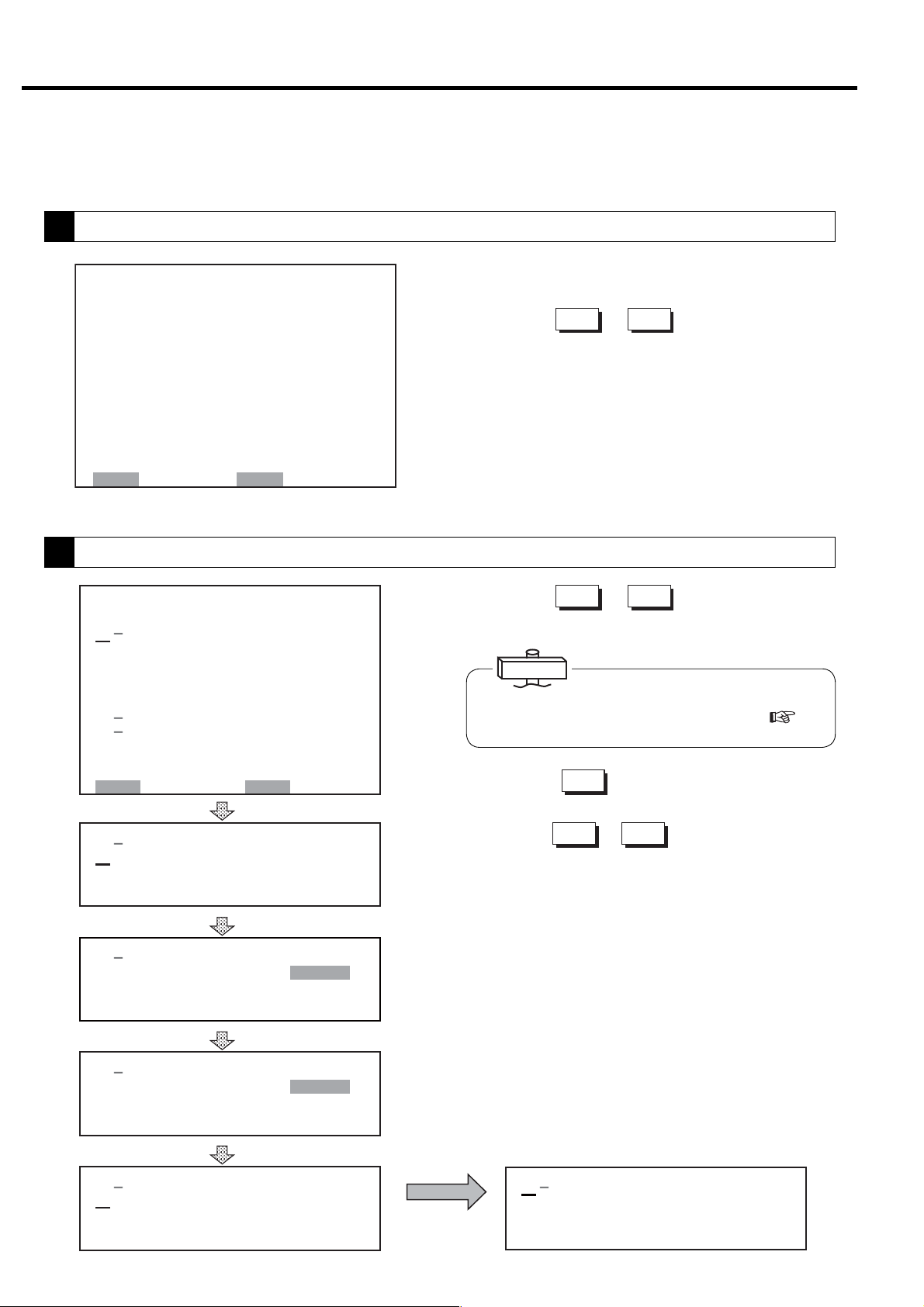

2.1 Appearance

This section illustrates and describes the major components of the DSP air compressor. Be familiar

with the name, location and function of each component before using the DSP air compressor.

Air-Cooled

DSP- 90/110A6N

90/110VA6N

[Front View]

Air Exhaust

(Air Compressor Package)

This panel discharges

the hot air generated

in the air compressor.

Left Door

Open the left door only

when servicing the

DSP air compressor.

Keep it closed when

operating the DSP air

compressor.

OMR

8.5 for the details

Oil Filling Port

Use the port to fill the

gear case with oil.

Air Exhaust

Air Intake

Air Intake

Enclosure

Enclosure panels

lower the sound level

of the air compressor

package.

Instrument Panel

3.1

Plate of Operating /

Servicing Instructions

Read carefully the

plate before operating

and servicing the DSP.

Oil Level Gauge

This indicates the

quantity of the oil in

the gear case. Check

the oil level before

starting the DSP and

when operating it.

[Rear View]

Compressor Name plate

Model designation,

manufacturing number

and specification are

printed.

Air Intake

(Air for inverter)

Air Intake

Power Supply Port

Check the specifications, power supply

and voltage before

connecting the power

supply.

Air Intake

(Inlet to the Air End)

Air Exhaust

Compressed Air Discharge

Sling Fitting

Use the sling fitting

when moving and

installing the DSP air

compressor.

Air Intake

(Air for coolers)

6

Air Intake

Air Intake

Air Intake

(Air Compressor Package)

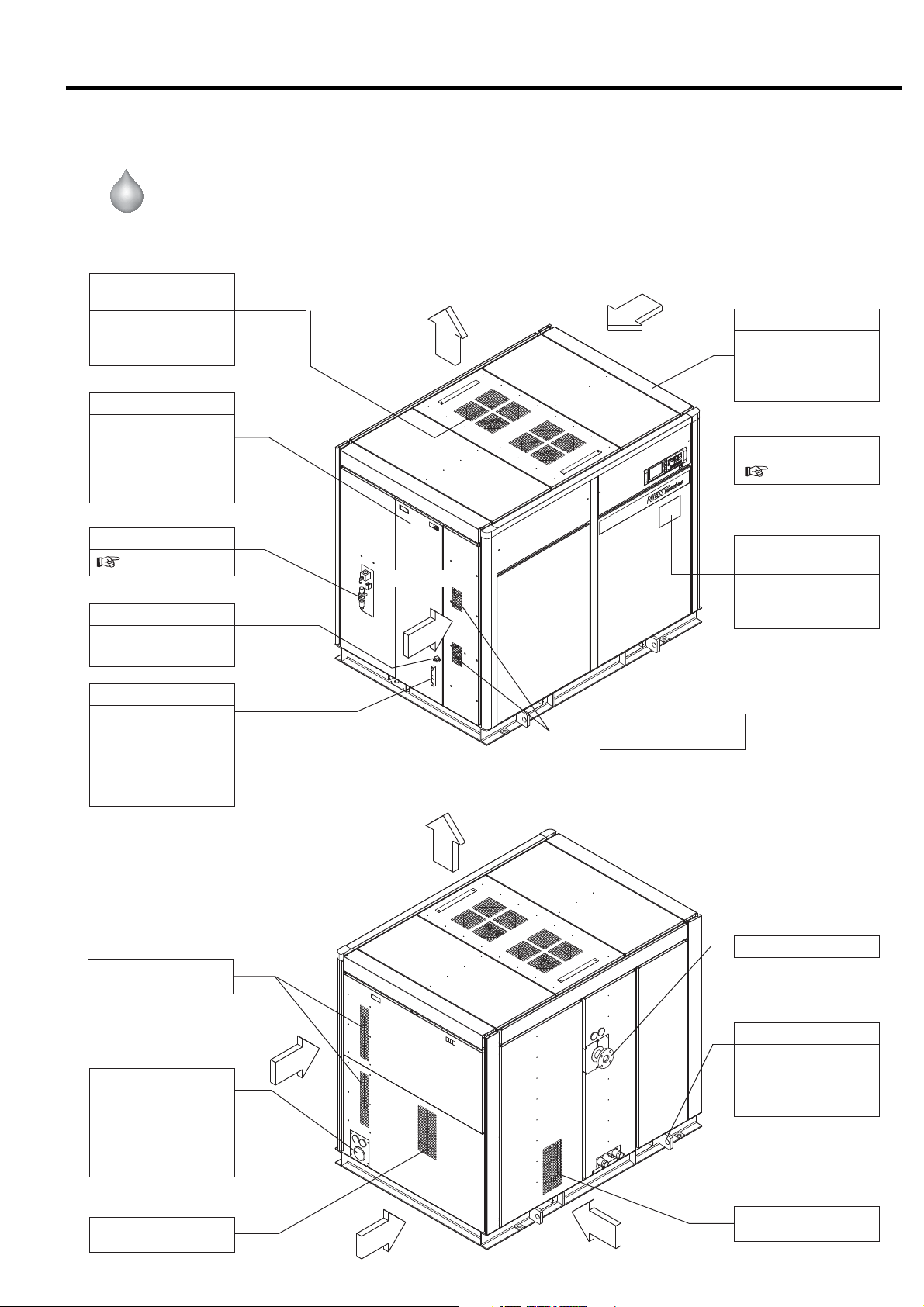

2. GENERAL DESCRIPTION [Appearance]

Water-Cooled

DSP- 90/110W6N

90/110VW6N

[Front View]

Air Exhaust

(Air Compressor Package)

This panel discharges

the hot air generated

in the air compressor.

Left Door

Open the left door

only when servicing

the DSP air compressor. Keep it closed

when operating the

DSP air compressor.

OMR

8.5 for the details

Oil Filling Port

Use the port to fill the

gear case with oil.

Air Exhaust

Air Intake

Air Intake

Enclosure

Enclosure panels

lower the sound level

of the air compressor

package.

Instrument Panel

3.1

Plate of Operating /

Servicing Instructions

Read carefully the

plate before operating

and servicing the DSP.

Oil Level Gauge

This indicates the

quantity of the oil in

the gear case. Check

the oil level before

starting the DSP and

when operating it.

[Rear View]

Air Intake

(Air for inverter)

Air Intake

Power Supply Port

Check the specifications, power supply

and voltage before

connecting the power

supply.

Air Intake

(Inlet to the Air End)

Air Exhaust

Compressed Air Discharge

Sling Fitting

Use the sling fitting

when moving and

installing the DSP air

compressor.

Air Intake

(Air for Package)

Air Intake

Air Intake

Air Intake

(Air Compressor Package)

7

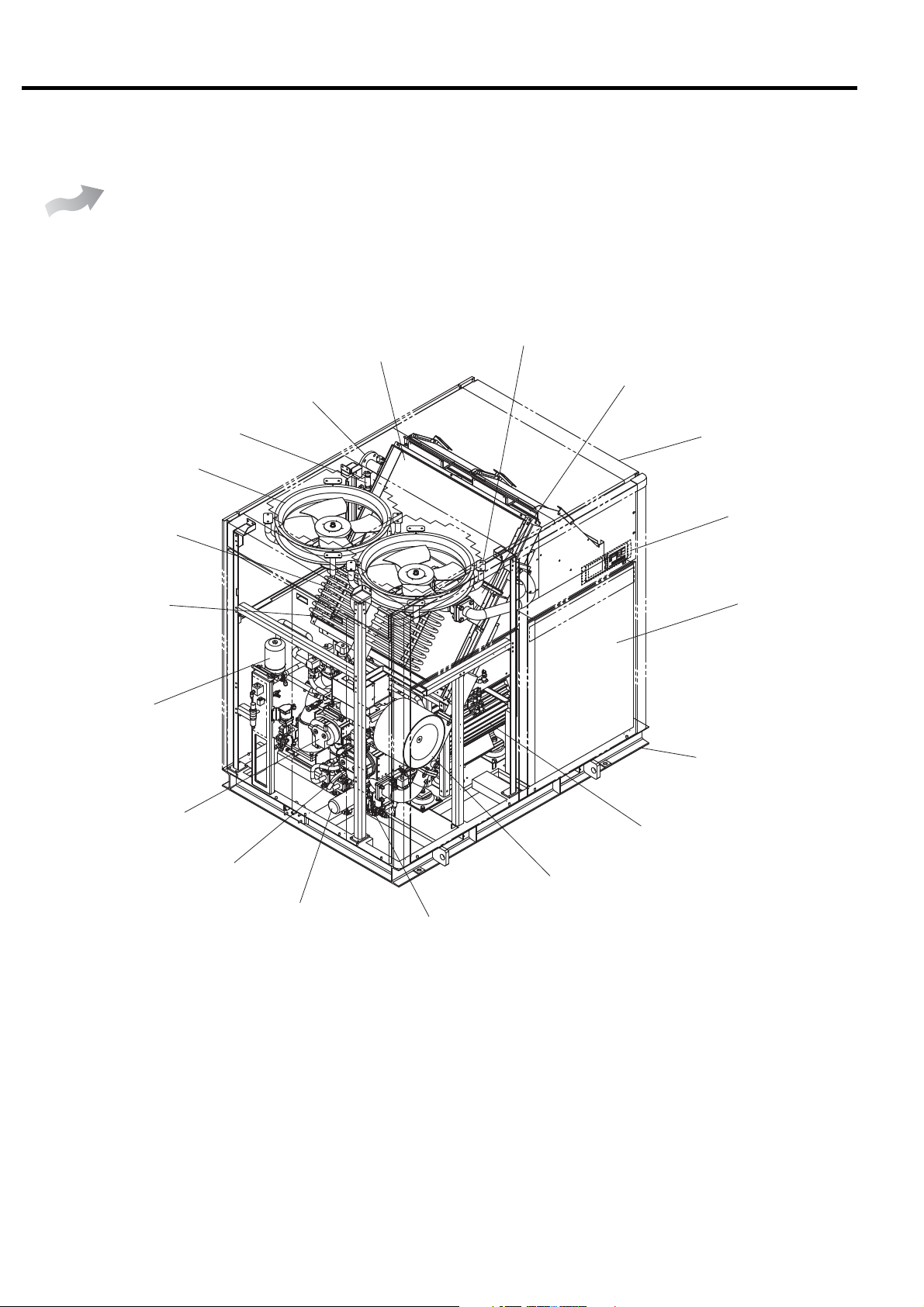

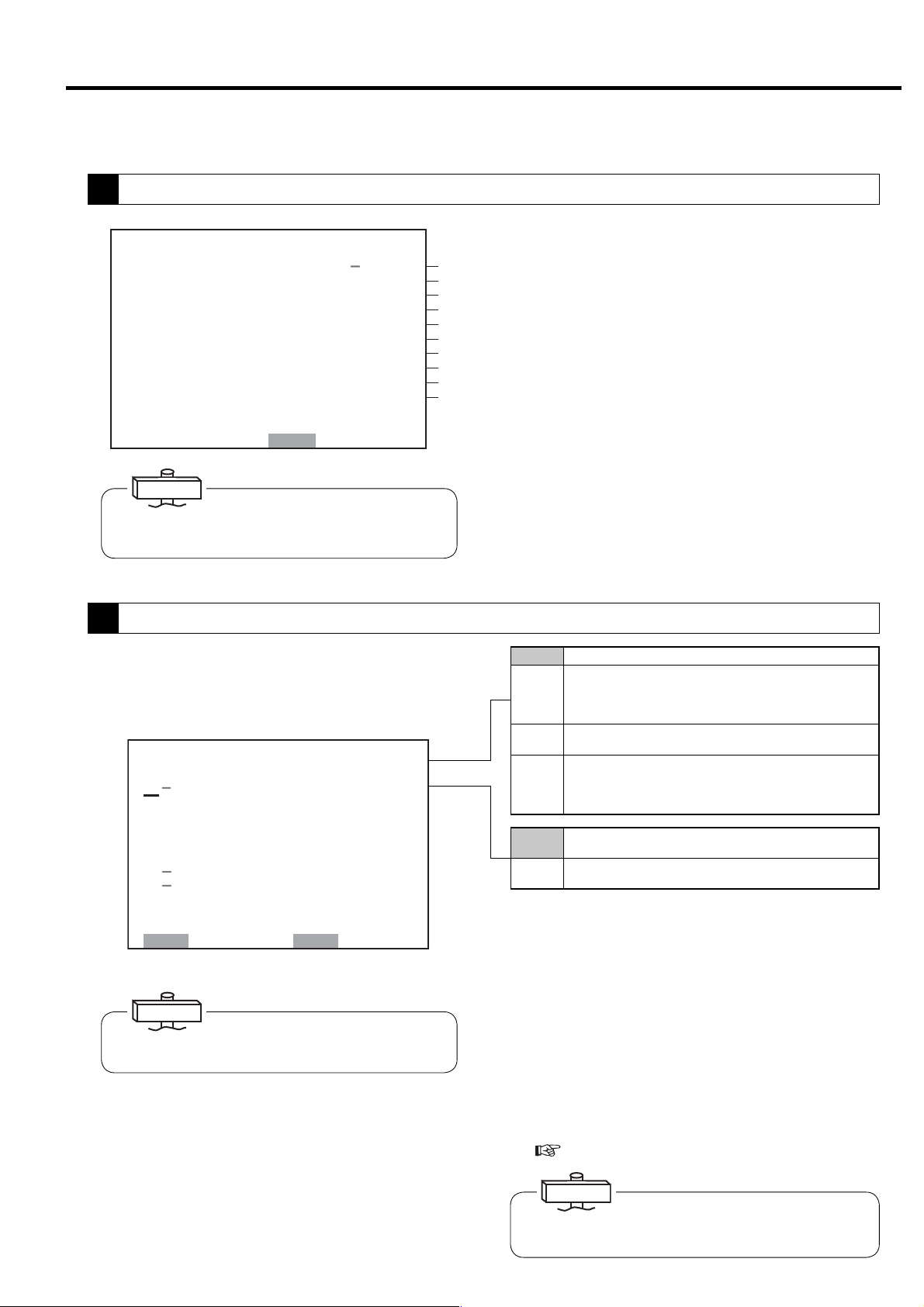

2. GENERAL DESCRIPTION [Components]

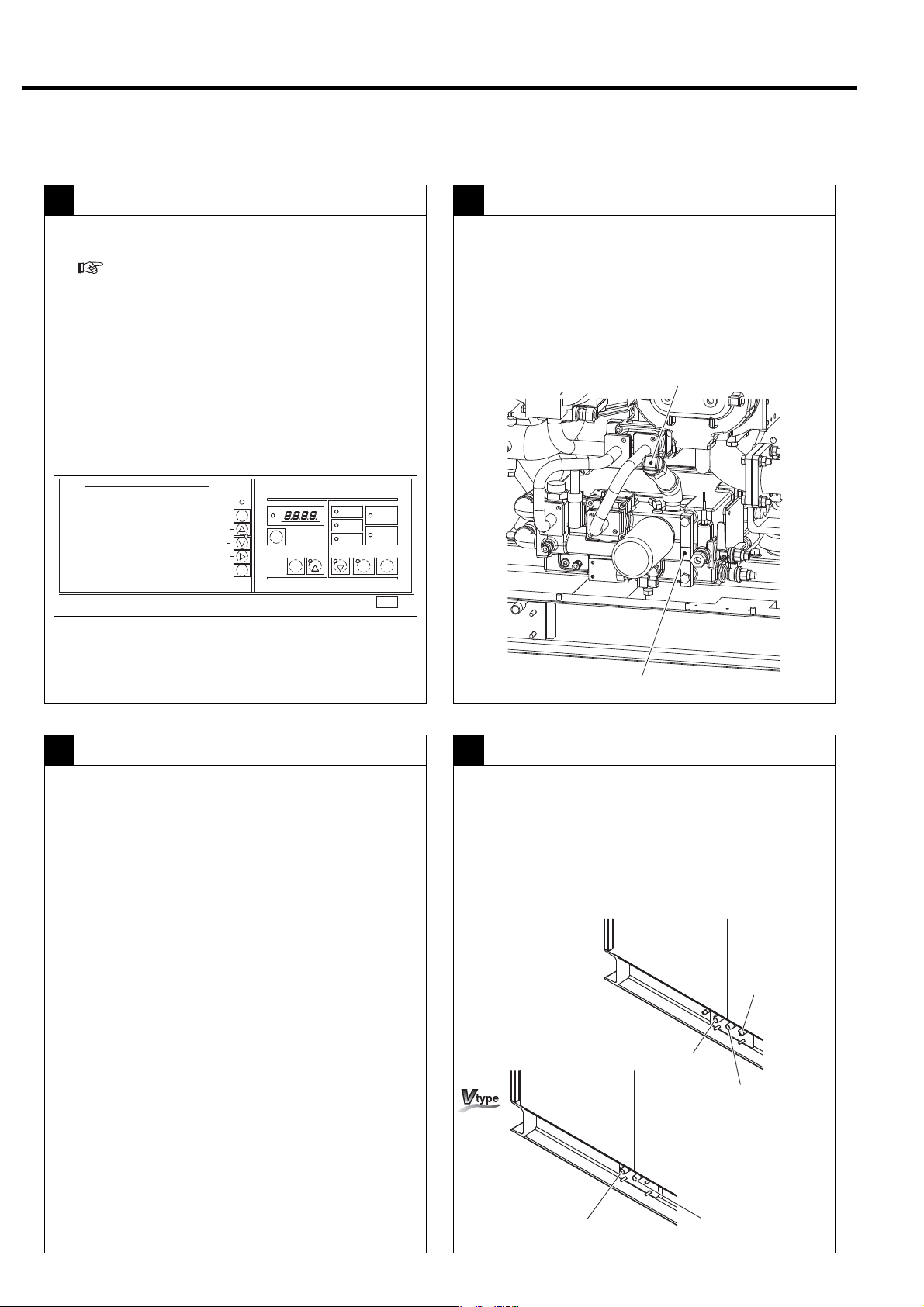

2.2 Components

Air-Cooled

Hi-precooler

DSP- 90/110A6N

90/110VA6N

Discharge pipe (Compressed

Air Discharge)

Air relief valve

Cooling fan

Oil cooler

Check valve

Aftercooler

Intercooler

Enclosure

Instrument panel

Control panel

Oil mist remover

2nd-stage air end

1st-stage air end

Common base

Main motor

Air intake filter

Oil filter

Oil level gauge

8

2. GENERAL DESCRIPTION [Components]

Water-Cooled

Oil mist remover

DSP- 90/110W6N

90/110VW6N

Discharge pipe

(Compressed air discharge)

Intercooler

Aftercooler

Air relief valve

Cooling fan

Enclosure

Instrument panel

Control panel

2nd-stage air end

Oil cooler

1st-stage air end

Oil filter

Common base

Check valve

Main motor

Air intake filter

Oil level gauge

9

2. GENERAL DESCRIPTION [Daily Operating Components]

2.3 Daily Operating Components

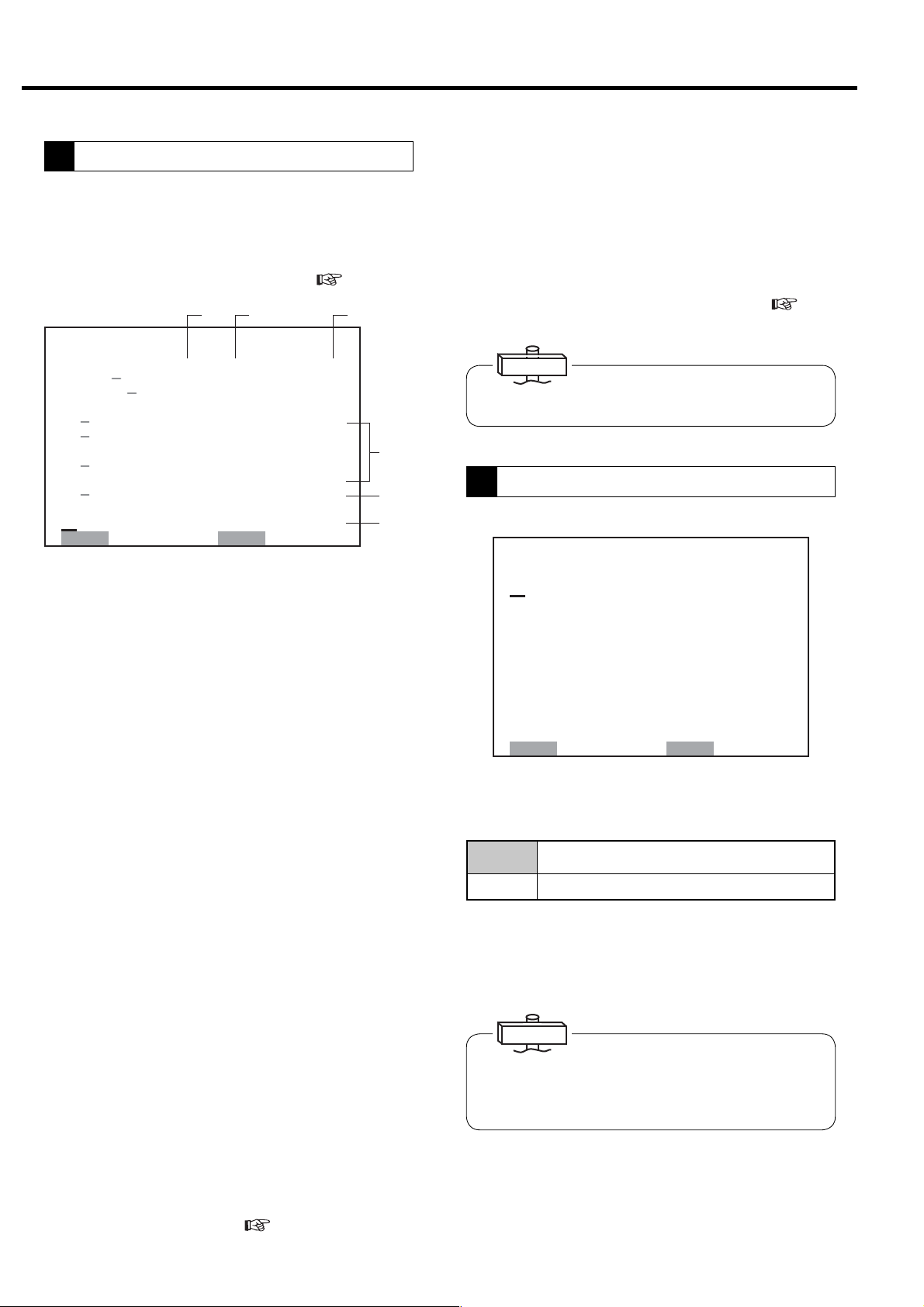

Controls on the Instrument Panel

1 2

● Indicates the operation control section.

(

3.1)

● Power ON → The Power light ON.

● Start: Press the START button. → Start light ON.

● Stop: Press the UNLOAD STOP button. →

The compressor unloads for 5 minutes and then

stops. → Start light OFF.

● Power OFF: → Power light OFF.

MONITOR

AUTO

MONITOR

MENU

+/−

UP/

DOWN

SET

RUNNINGCONTROL

ALARM

FUNC

RESET

REMOTE

STR

[×10h]

SELECT/WIDE

1

RUNNINGMODE

REMOTE

LOAD

SHUTDOWN

2

START

POWER

AUTOSTART

STOP

UNLOAD STOP

Oil Level Gauge

● Verify that the oil stays between the upper and

lower red lines of the oil level gauge during the

operation.

Oil level might be higher than upper line during air

compressor

and pipings.

stopping due to oil returning from the cooler

Oil Filling Port

Lubricating Oil

3 4

Oil: Use genuine Hitachi GL-68 DSP Compressor Oil.

Replace the oil every 8,000h operating hour or every

2-year, whichever comes earlier.

Oil Level Gauge

Aftercooler and Intercooler - Condensate Drain Valve

● Verify that air containing condensate is discharged

intermittently from the intercooler and aftercooler

drain ports.

The higher temperature and humidity, the more condensate

is produced. Condensate may not be produced on the

intercooler side during winter.

[Fixed speed type]

Control pipe filter

drain port

Intercooler

drain port

Aftercooler

drain port

10

Intercooler

drain port

Aftercooler

drain port

Water-Cooled

2. GENERAL DESCRIPTION [Daily Operating Components]

Cooling Water

5

① Stop the cooling water flow when the DSP has

stopped running.

② Open the water drain peacock and the water drain

valve at the water drain port to remove the cooling

water from the system.

③ Take care to completely drain the cooling water

during the winter season to prevent freezing in the

cooling water pipes (

Water drain peacock

8.3)

Control Line Filter

6

[Fixed speed type]

● Check the sight glass on the control line filter to

make sure that the condensate discharged

properly.

Control line filter

Sight Glass

Water drain port

Stopping operation

7

● Normally use the UNLOAD STOP button to stop

the air compressor. The air compressor then

unloads for 5 minutes and stops running.

(In the case of an emergency, press the

EMERGENCY STOP button to stop operation.)

RUNNINGCONTROL

ALARM

FUNC

RESET

REMOTE

STR

MONITOR

AUTO

MONITOR

MENU

+/−

UP/

DOWN

SET

IMPORTANT

Keeping the second-stage air end as dry as possible

is essential for preventing it from rusting due to a long

term operation suspension. When stopping the DSP,

therefore, execute an unloading operation and thereby

remove the moisture from the second-stage air end.

[×10h]

SELECT/WIDE

1

RUNNINGMODE

REMOTE

LOAD

SHUTDOWN

2

START

POWER

AUTOSTART

STOP

UNLOAD STOP

11

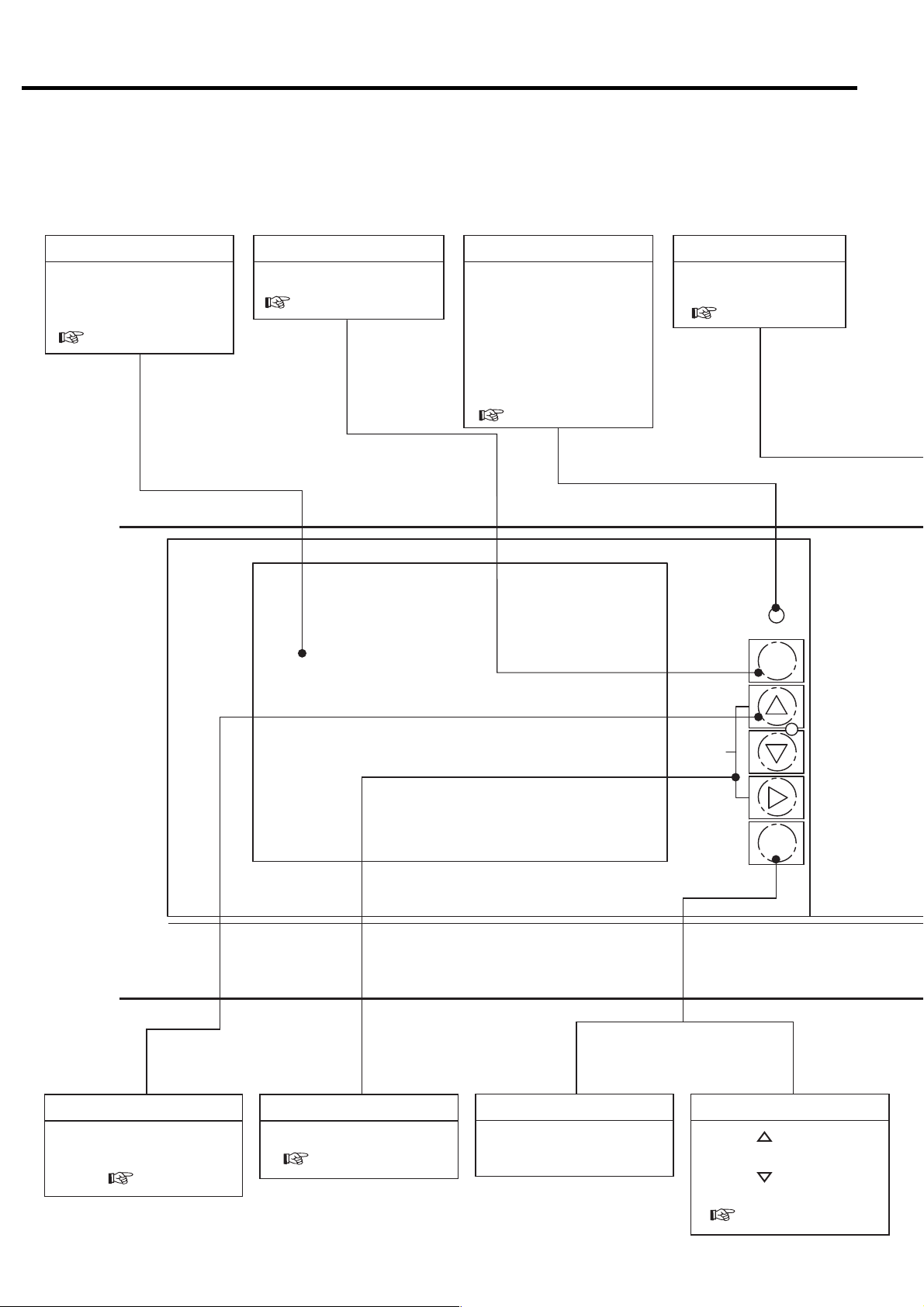

3. OPERATING PROCEDURE

3.1 Instrument Panel

LCD monitor

Displays the operation data,

various settings, shutdown/

alarm information, etc.

( 3.3)

MONITOR Button RESET Button

Switches the monitor display.

( 3.3.1)

AUTO light (yellow)

ON (glowing) when an

automatic operation (an

AUTO operation, a scheduling operation, or lead/lag

operation) is activated.

ON (blinking) when external

calendar or scheduling

operation is abnormal.

( 3.3.3, 3.3.5)

Resets SHUTDOWN

and ALARM screens.

( 3.3.3)

AUTO

MONITOR

MENU Button

Displays the menu screen.

Also used to move the

cursor. ( 3.3.4)

+/- UP DOWN Button

Moves the cursor.

( 3.3.4)

MONITOR

Saves any adjusted set

points.

SET Button

MENU

+/−

UP/

DOWN

SET

Contrast adjustment

SET + [ ] buttons:

Increases brightness.

SET + [] buttons:

Decreases brightness.

( 3.3.6)

12

Digital Monitor

Used for basic settings as well

as other various settings in

combination with the LCD monitor.

( 3.3.6)

● ALARM light (green): Blinks if

an alarm failure occurs.

3. OPERATING PROCEDURE [Instrument Panel]

EMERGENCY STOP button

Stops for emergency.

( 3.2.3)

G

E

R

N

E

M

E

S

C

P

T

O

RUNNING MODE Light

● POWER light (yellow): Lights up when the main power

is turned on.

● REMOTE light (green):

ON (glowing) when the REMOTE button is pressed in

order to activate a remote operation.

ON (blinking) when an external remote-operation-

activation switch has been turned on in order to

activate a remote operation. ( 3.4.6)

● LOAD light (yellow): ON (glowing) when the air

compressor is loading.

● AUTO START light (green):

ON (glowing) while the air compressor is in a stop due

Y

to an AUTO operation,lead/lag operation, or

scheduling operation.

ON (blinking) while the air compressor is in a stop due

to a restartable instantaneous power interruption.

( 3.3.3)

● SHUTDOWN light (red): Blinks if a shutdown failure

occurs. ( 3.3.3)

RUNNINGCONTROL

REMOTE

ALARM

[×10h]

FUNC

Press this button to stop the air compressor.

The air compressor will stop after removing the

condensate from the air end.

※This stop button is effective while a stand alone operation.

RESET

REMOTE

STR

SELECT/WIDE

1

LOAD

SHUTDOWN

2

RUNNINGMODE

POWER

AUTOSTART

START

UNLOAD STOP

STOP Button

Stops the compressor

immediately without unloading.

( 3.2.2)

STOP

UNLOAD STOP Button

Stops the compressor in normal

state.

The compressor stops running

after removing the condensate

from the air end. ( 3.2.2)

REMOTE Button

Activates or deactivates a

remote start/stop operation

locally or on the instrument

panel. ( 3.4.6).

SELECT/WIDE Button/Light (Yellow)

Press to confirm the measurement

values, shutdown history, and

setting status. ( 3.4.1, 3.4.2)

To set the ECOMODE [Energy

saving mode] (Fixed speed type

only), hold down the

SELECT/WIDE

button for at least 7 seconds. The

light blinks and ECOMODE is set.

START Button

Starts the air compressor.

The START light turns ON while

air compressor is running.

13

3. OPERATING PROCEDURE [Start/Stop Operation]

3.2 Start/Stop Operation

3.2.1 Connecting the Power

When the power is connected, the POWER light turns

ON and the following Hitachi logo display appears on

the LCD. After 5 seconds, monitoring display appears;

it shows operation type, discharge air pressure, total

operating hours, etc.

COMPRESSOR MONITOR

CONTROLLER

5 seconds

㻞㻜㻝㻞䠋㻜㻥䠋㻜㻝 㻝㻥䠖㻜㻞

㼀㼅㻼㻱䠖㼂㻿㻰㻭

㻰㻵㻿䠊㻼㻾㻱㻿㻿䠖 㻢㻣㼜㼟㼕

㻾㼁㻺 㻌㻴㻻㼁㻾䠖 㻝 㻞 㻜䡄

㻸㻻㻭㻰㻌 㻴㻻㼁㻾䠖 㻡㻠 䡄

㻸㻻㻭㻰 㼀 㻵 㻹㻱 㻿 䠖 㻝 㻞 㻟

㻸㻻㻭㻰 㻾㻭㼀㻱 䠖 㻝 㻝䠂

㻸㻻㻭㻰 㼀 㻵 㻹㻱 䠖 㻞 㻠 䡏

㼁㻺㻸㻻㻭㻰 㻌 㼀 㻵㻹㻱 䠖 㻝䡏

㻯㼁㻾㻾㻱㻺㼀 䠖 㻡 㻜䠝

㻲㻾㻱㻽㼁㻱㻺㻯㼅䠖 㻞 㻟 㻚 㻤䠤䡖

㻻㼁㼀㻼 㼁㼀 䠖 㻝 㻠 㻚 㻣 㻼

㻌㻌㻌㻌㻖

䠤

3.2.2 Start/Stop

When the START button is pressed, the START light

turns on and the compressor star ts operating.

When the compressor starts running, the asterisk on

the right side of running hours blinks and running time

starts to be counted.

To stop the operation, press the UNLOAD STOP

button. Operation stops after 5-minute drying of air end

and air piping.

To stop the compressor immediately without

unloading, press the STOP button.

Note) If the STOP button is pressed during unloading,

the compressor stops immediately.

IMPORTANT

(1) The air compressor does not start for 10 second after

power on to secure the safety.

For

15 seconds after power-on, the AUTO START light will

blink up to 10 seconds for operation preparation and

then the compressor starts running.

(2) Make sure that the door is closed before starting the

air compressor.

(3) Buttons, such as START/STOP/RESET function shall

be pressed for more than 0.3 seconds.

, if the START button is pressed within 10 to

3.2.3 Emergency Stop

※ The asterisk blinks when the clock and total

running hours are active.

If phase is reversed, “Connection Error: Reverse

Phase” will be displayed on the LCD monitor as a

setting/connection check message. In this case,

exchange 2 out of the 3 main power cables. If the air

compressor has control transformer in the control

panel, Open Phase is indicated as Reverse Phase. So

check the power cable connection of T Phase.

In case of open phase, “Connection Error: Open

Phase” will be displayed on the LCD monitor. In this

case, check the power cables.

Pressing EMERGENCY STOP button, the DSP

compressor immediately stops.

This switch should only be pressed in emergency.

The compressor can not be restarted until the switch is

manually reset.

Turn the switch knob clockwise and press the RESET

button to reset.

14

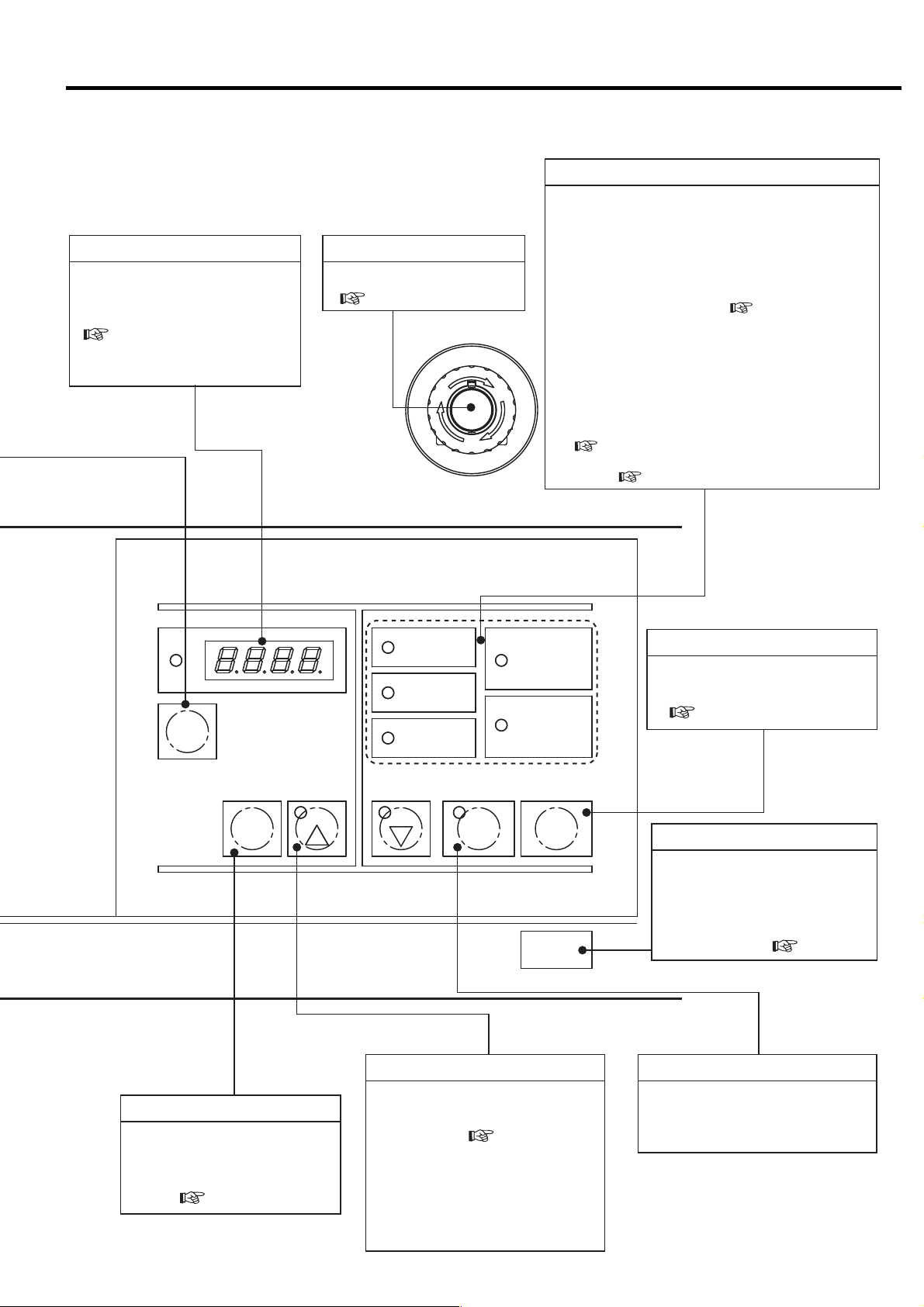

3. OPERATING PROCEDURE [How to Use the Liquid Crystal Display (LCD)]

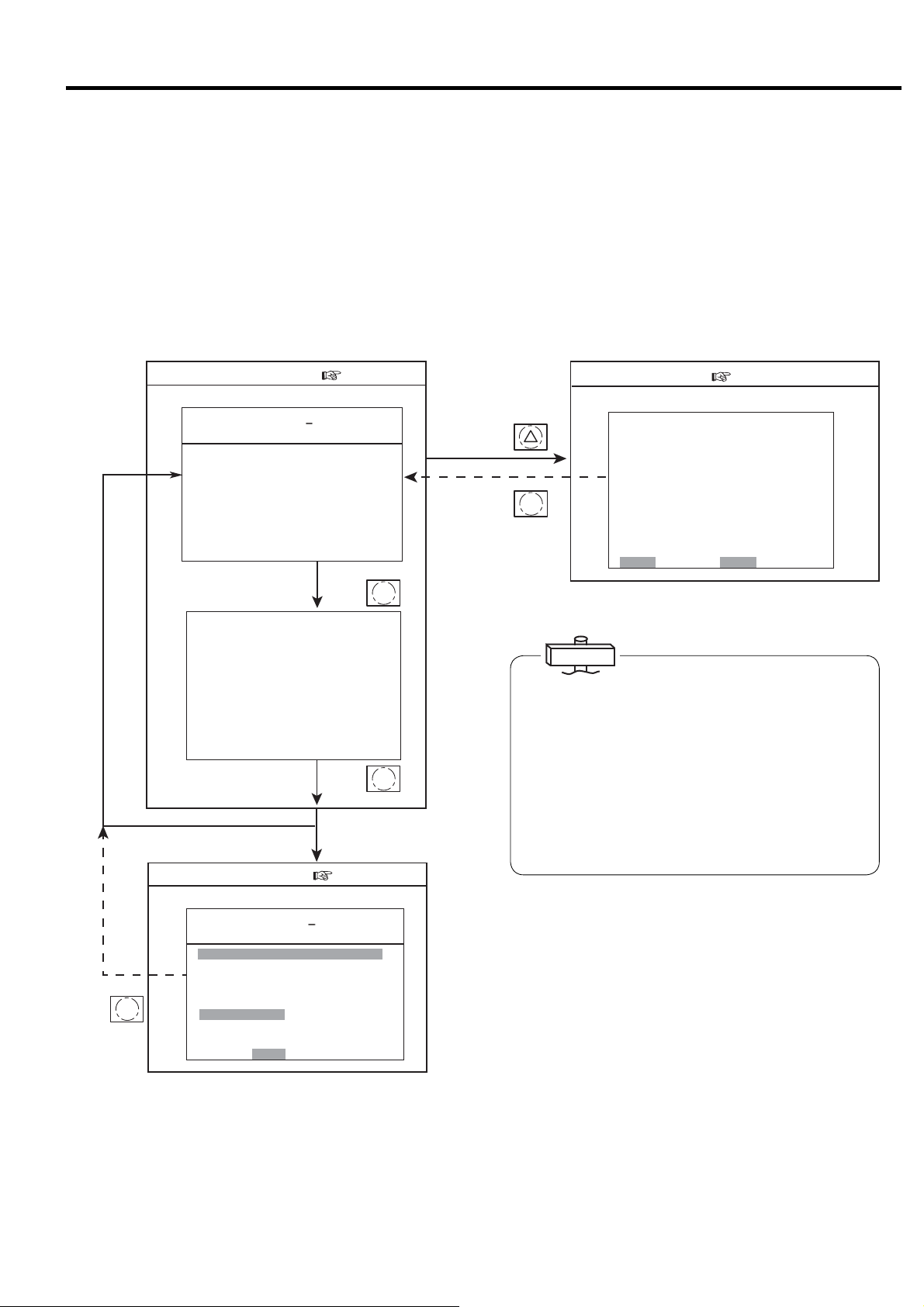

3.3 How to Use the Liquid Crystal Display (LCD)

3.3.1 How to Move between the Various Displays

■Monitoring Displays

There are three monitoring displays as shown

below. This monitoring display is the top screen.

The monitoring display switches every time the

MONITOR button is pressed.

■Monitoring Display ( 3.3.2)

Monitor display 1

㻞㻜㻝㻞䠋㻜㻥䠋㻜㻝 㻝㻥䠖㻜㻞

㼀㼅㻼㻱䠖㼂㻿㻰㻭

㻰㻵㻿䠊㻼㻾㻱㻿㻿䠖 㻢㻣㼜㼟 㼕

㻾㼁㻺 㻌㻴㻻㼁㻾䠖 㻝㻞 㻜 䡄

㻸㻻㻭㻰 㻴㻻㼁㻾䠖 㻡 㻠䡄

㻸㻻㻭㻰 㼀 㻵 㻹㻱 㻿䠖 㻝 㻞 㻟

㻸㻻㻭㻰 㻾㻭㼀㻱 䠖 㻝 㻝䠂

㻸㻻㻭㻰 㼀 㻵 㻹㻱 䠖 㻞 㻠 䡏

㼁㻺㻸㻻㻭㻰 㼀 㻵 㻹㻱 䠖 㻝䡏

㻯㼁㻾㻾㻱㻺㼀 䠖 㻡 㻜䠝

MONITOR

㻲㻾㻱㻽㼁㻱㻺㻯㼅䠖 㻞 㻟 㻚 㻤䠤䡖

㻻㼁㼀㻼 㼁㼀 䠖 㻝 㻠 㻚 㻣

Monitor display 2

㻞㻜㻝㻞䠋㻜㻥䠋㻜㻝 㻝㻥䠖㻜㻞

㻼㻾㻱㻿㻿㼁㻾㻱

㻵㻺㼀㻿㼀㻳䠊㻼䠖 䚷䚷㻞㻥㼜㼟 㼕

㻻㻵㻸㻌㻼㻾㻱㻿䠖 㻌㻌 㻝㻡㼜㼟 㼕

㻯㻸㼀䠊㻼㻾㻱㻿䠖 㻖䠊㻖㻖 㼜 㼟 㼕

㼀㻱㻹㻼㻱㻾㻭㼀㼁㻾㻱

㻰㻵㻿䠊㼀㻱㻹㻼㻝䠖 㻟㻞㻜䉣

㻰㻵㻿䠊㼀㻱㻹㻼㻞䠖 㻟㻝㻟㻤䉣

㻻㻵㻸㻌㼀㻱㻹㻼䠖 㻟㻣䉣

㻯㻸㼀䠊㼀㻱㻹㻼䠖 㻖㻖㻖䉣

㻞㻺㻰 㻌 㻿㼁㻯㼀䠊㼀䠊䠖 㻜㻤 䉣

㻹㻭 㻵 㻺㼀 㻱㻺 㻭㻺㻯㻱

㻴㻾䠊㼀㻻㻌㻹㻭㻵㻺㼀䠖 㻜㻜㻜㻜䡄

㻺㻱㼄㼀㻌 㻹㻭 㻵㻺㼀䠖 㻖㻖㻖㻖

■Message Display ( 3.3.3)

Monitor display 3

㻞㻜㻝㻞䠋㻜㻥䠋㻜㻝 㻝㻥䠖㻜㻞 㻖

㼀㼅㻼㻱䠖㼂㻿㻰㻭

㻰㻵㻿䠊㻼㻾㻱㻿㻿䠖 㻢㻣

䠘㻿 㻴 㼁 㼀 㻰 㻻 㼃 㻺䠚

㻯㻻㻻㻸 㻭㻺㼀 䠖

㻻㻵㻸䠖

㻞䠪㻰㻌 㻿㼁㻯㼀䠊㼀㻱㻹㻼

㻴㻵㻳㻴 㻌㻰㻵㻿䠊㼀㻱㻹㻼䠖

㻯㻻㻺㼀 㻭㻯㼀 㻻㻾 㻌㻱㻾 㻾䠖

㻻㼂㻱㻾 㻸㻻㻭㻰 䠖

㻸㻻㼃㻌㼃䠊 㻵㻺 㼀㻿㼀㻳 㻌 㻼䠊

㻰 㻾 㼅 㻱 㻾 㻌㻌㻌㻌 㼃 䠋 㻻 㻌 㻿 㻱 㻼 䠊

㻱㻸㻱㻹㻱㻺㼀

㻼㼞㼑㼟㼟㻾㻱㻿㻌 㼍㼒 㼠㼑㼞 㻌㻯㻴㻷䠊

㼀㼁

MONITOR

MONITOR

㻌

㻌

䡇䠳

㻝

㼜㼟㼕

■ Menu Displays

Follow the bottom line message on the display.

■ Menu Screen ( 3.3.5)

Function Menu Display

MENU

MONITOR

㼇㻲㼁㻺㻯㼀㻵㻻㻺 㻹㻱㻺㼁㼉

㻝䠊㻮㻭㻿 㻵 㻯 㻿㻱㼀㼁㻼

㻞䠊㻹㼁㻸㼀 㻵 㻙 㼁㻺㻵 㼀

㻟䠊㻯㻭㻼㻭㻯㻵 㼀㼅 㻯㻻㻺㼀㻾㻻㻸

㻠䠊㻿㻯㻴㻱㻰㼁㻸㻱

㻡䠊㻻㻼㻱㻾㻭㼀 㻵㻻㻺 㻰㻭㼀㻭

㻢䠊㻸㻻㻭㻰 㻰㻭㼀㻭

㻣䠊㻭㻸㻭㻾㻹 㻴 㻵 㻿㼀㻻㻾㼅

㻤䠊㻿㻴㼁㼀㻰㻻㼃㻺 㻴 㻵 㻿㼀㻻㻾㼅

㻿㻱㼀䠖㻻㻼㻱㻺 㻹㻻㻺䠖㻮㻭㻯㻷

IMPORTANT

About the LCD Backlight

(1) In the event that no button has been used for 10

minutes, the LCD backlight automatically turns OFF for

protection to the display panel. It comes ON again if

any button is pressed, other than the START and STOP

buttons.

(2) If an event happens while the LCD backlight is off, the

backlight automatically turns ON and stays ON as long

as the event exists. Remote and instant stop mode

can't be set by the LCD monitor. Set after referring to

“3.4 How to Use the Digital Monitor.”

■ Message Display

Automatic restart/stop messages after shutdown or

warning occurrence and inspection/maintenance

messages is preferentially displayed in the Monitor

Display 3.

By pressing the MONITOR button here, the display

can be switched but is back to the Monitor Display 3

after approximately 10 seconds.

15

3. OPERATING PROCEDURE [How to Use the Liquid Crystal Display (LCD)]

3.3.2 Monitoring Displays

■ Monitor Displays during Normal Operation

Monitor Display 1

㻞㻜㻝㻞䠋㻜㻥䠋㻜㻝 㻝㻥䠖㻜㻞

㼀㼅㻼㻱䠖㼂㻿㻰㻭

㻰㻵㻿䠊㻼㻾㻱㻿㻿䠖 㻢㻣㼜㼟㼕

㻾㼁㻺 㻌㻴㻻㼁㻾䠖 㻝㻞㻜䡄

㻸㻻㻭㻰㻌 㻴㻻㼁㻾䠖 㻡 㻠䡄

㻸㻻㻭㻰 㼀㻵㻹㻱㻿䠖 㻝㻞㻟

㻸㻻㻭㻰 㻾㻭㼀㻱 䠖 㻝 㻝䠂

㻸㻻㻭㻰 㼀 㻵 㻹㻱 䠖 㻞 㻠 䡏

㼁㻺㻸㻻㻭㻰 㻌 㼀 㻵 㻹㻱 䠖 㻝䡏

㻯㼁㻾㻾㻱㻺㼀 䠖 㻡 㻜䠝

㻲㻾㻱㻽㼁㻱㻺㻯㼅䠖 㻞 㻟 㻚 㻤䠤䡖

㻻㼁㼀㻼㼁㼀 䠖 㻝 㻠 㻚 㻣䡇

㻹㻭㻿㼀㻱 㻾

Monitor Display 2

㻞㻜㻝㻞䠋㻜㻥䠋㻜㻝 㻝㻥䠖㻜㻞

㻼㻾㻱㻿㻿㼁㻾㻱

㻵㻺㼀㻿㼀㻳䠊㻼䠖 㻌㻌 㻞㻥㼜㼟㼕

㻻㻵㻸㻌㻼㻾㻱㻿䠖 㻌㻌 㻝㻡㼜㼟 㼕

㻯㻸㼀䠊㻼㻾㻱㻿䠖 㻖䠊㻖 㻖㼜 㼟 㼕

㼀㻱㻹㻼㻱㻾㻭㼀㼁㻾㻱

㻰㻵㻿䠊㼀㻱㻹㻼㻝䠖 㻟㻞㻜䉣

㻰㻵㻿䠊㼀㻱㻹㻼㻞䠖 㻟㻝㻟㻤䉣

㻻㻵㻸㻌㼀㻱㻹㻼䠖 㻟㻣䉣

㻯㻸㼀䠊㼀㻱㻹㻼䠖 㻖㻖 㻖䉣

㻞㻺㻰㻌㻿㼁㻯㼀䠊㼀䠊䠖 㻜㻤䉣

㻹㻭 㻵 㻺㼀㻱 㻺㻭 㻺㻯㻱

㻴㻾䠊㼀㻻㻌㻹㻭㻵 㻺㼀䠖 㻜㻜㻜㻜䡄

㻺㻱㼄㼀㻌 㻹㻭 㻵 㻺㼀䠖 㻖 㻖 㻖 㻖

㻝

(1)

㻖

(2)

(3)

VSDA * SAVE

Indicates ECOMODE is activated for

㻖

(4)

(5)

(6)

㼃

(7)

(8)

(9)

Displayed when stop is limited for AUTO

operation (Standard: no symbol)

fixed speed type.

3.4.8)

(

INTE : Indicates fixed speed type used the standard, 2-step

䠆

control system.

AUTO : Indicates fixed speed type used the automatic motor

stop/restart capacity control system.

(10)

VSDB : Indicates Vtype without the AUTO capacity control.

VSDA : Indicates Vtype with the AUTO capacity control

(standard setting for Vtype).

EXIT : Indicated the external capacity control is used.

(11)

MR : Indicates multi unit control system through the

communication is used

IMPORTANT

“CURRENT” reading is an approximate S-phase Amp

reading.

“OUTPUT” reading is an approximate calculated power

reading.

(1) Indicates current time. An asterisk blinks.

(2) Indicates the control state.

(3) Indicates a discharge pressure (DIS.PRESS)

(4) Indicates total running hours (RUN HOUR), total

loaded hours (LOAD HOUR), and total number of

loads (LOAD TIMES).

Blinking asterisk means counting the running

hours.

(5) Indicates a percentage of load to unload of the DSP

air compressor (LOAD RATE).

For Vtype, the rate is calculated based on only

frequency. Indicates “***”, if PQ wide mode is

selected.

(6) Indicates the amperage current of the package

input (CURRENT).

(7) Indicates the operating frequency of the main motor

(FREQUENCY).

(8) Indicates “***” for this air compressor.

(9) Indicates (MASTER), when the air compressor is

master in lead-lag operation.

(10) Indicates each pressure and temperature. “***”

indicates not in use.

(11) Indicates the number of hours until the next

maintenance service (HR. TO MAINT), and the

next maintenance type (NEXT MAINT).

16

3. OPERATING PROCEDURE [How to Use the Liquid Crystal Display (LCD)]

3.3.3 Message Displays

■ Shutdown Messages

① When the shutdown occurs for the compressor, the SHUTDOWN light and shutdown contents on the LCD

monitor (contents are displays on the left side and details are displayed on the right side) blink and the

compressor stops running. There are 2 types of screens for shutdown: SHUTDOWN and FAILURE.

㻞㻜㻝㻞䠋㻜㻥䠋㻜㻝 㻝㻥䠖㻝㻥 㻖

㼀㼅㻼㻱䠖㼂㻿㻰㻭

㻰㻵㻿䠊㻼㻾㻱㻿㻿䠖 㻌㻌 㻢㻣㼜㼟㼕

䠘㻿 㻴 㼁 㼀 㻰 㻻 㼃 㻺䠚

㻯㻻㻻㻸 㻭㻺 㼀 䠖

㻻㻵㻸䠖

㻞䠪㻰 㻌 㻿㼁㻯㼀䠊㼀㻱㻹㻼

㻴㻵㻳㻴 㻌㻰㻵㻿䠊㼀㻱㻹㻼䠖

㻯㻻㻺㼀 㻭㻯 㼀㻻㻾 㻌㻱㻾㻾 䠖

㻻㼂㻱 㻾㻸 㻻㻭㻰 䠖

㻸㻻㼃㻌㼃䠊 㻵 㻺㼀㻿㼀㻳 㻌 㻼䠊

㻰 㻾 㼅 㻱 㻾 㻌㻌㻌㻌 㼃 䠋 㻻 㻌 㻿 㻱 㻼 䠊

㻱㻸㻱㻹㻱㻺㼀

㻼㼞㼑㼟㼟㻾㻱㻿㻌 㼍 㼒 㼠㼑 㼞 㻌㻯㻴㻷䠊

㼀㼁

㻌

(Example)

When the air compressor stops running with blinking

SHUTDOWN and OVERLOAD, it indicates the thermal relay

trip by overload.

2012䠋 01䠋 01 19䠖 19 *

TYPE䠖 VSDA

DIS䠊 PRESS䠖 46ps i

䠘 FA I LURE䠚

SYSTEM ERR䠖

SYSTEM RETRY

PCB ERR䠖

PRESS䠊 SNSR ERR䠖

TEMP䠊 SNSR ERR䠖 1

D 䡅 sconnect power

snd contact

di st r 䡅 but o r

(Example)

When the air compressor stops running with blinking FAILURE

and TEMP.SNSR ERR, the temperature sensor 1 is

disconnected.

② Take the proper corrective action, and press the RESET button.

For further information,

Section 4.

■ Alarm Messages

① When the alarm occurs for the air compressor, the ALARM light and contents / details displayed on alarm screen

on the LCD monitor blink and operation continues. There are 2 types of alarm screens: ALARM and PROBLEM.

㻞㻜㻝㻞䠋㻜㻥䠋㻜㻝 㻝㻥䠖㻝㻥 㻖

㼀㼅㻼㻱䠖

㻰㻵㻿䠊㻼㻾㻱㻿㻿䠖 䚷䚷㻢㻣㼜㼟㼕

䠘㻭 㻸 㻭 㻾 㻹䠚

㻰㻵㻿䠊㼀㻱㻹㻼䠖䠄㻌 㻌 㻌 䠅㻖㻖㻖䉣

㻻㻵㻸㻌㼀㻱㻹㻼䠖 㻖㻖㻖䉣

㻸㻻㼃㻌 㻻䠊㻼䠊䠖 㻖 㻖 㼜 㼟 㼕

㻯㻸㼀䠊㼀㻱㻹㻼䠊䠖 㻖 㻖 㻖䉣

㻸㻻㼃㻌 㻯㻸 㼀䠊㻼䠖 㻖 㻖 㼜 㼟 㼕

㻞䠪㻰㻙㻿䠊㼀㻱㻹㻼 㻌 㻲 㻵 㻺 㻙㼀

㻸㻻㼃㻌㼃䠊 㻸㻻㼃㻌 㻻 㻵 㻸

㻰㻾㼅㻱㻾 㻭㻵 㻾 㻌㻲㻵 㻸㼀㻱㻾

㻸䠊㻯㻻㼁㻺㼀㻌 㻻㼂㻱㻾 㻌㼃䠋㻻㻌 㻿䠊

㻼㼞㼑㼟䡏㻾㻱㻿 㼍㼒 㼠㼑 㼞 㻌㻯㻴㻷䠊

㻿㻰㻭㻌 㻌㻌 㻌㻌㻌

㼂

(Example)

When the ALARM and AIR FILTER blink, it indicates air

intake filter clogs.

㻞㻜㻝㻞䠋㻜㻥䠋㻜㻝 㻝㻥䠖㻝㻥 㻖

㼀㼅㻼㻱䠖 㼂㻿㻰㻭㻌

㻰㻵㻿䠊㻼㻾㻱㻿㻿䠖 䚷䚷㻢㻣㼜㼟 㼕

䠘㻼 㻾 㻻 㻮 㻸 㻱 㻹䠚

㻯㻻㻺㻺 㻱㻯 㼀 㻵 㻻㻺 㻌 㻱 㻾㻾 䠖㻌 㻌 㻌

㻾㼑㼏㼛㼚㼚㼑㼏㼠 㻌 㼜㼛㼣㼑 㼞䠊

㻹㼁㻸 㼀 䠥 㻙 㼁 㻿 㻱 㼀 㻱 㻾㻾

㻿㻯㻴㻱㻰㼁㻸㻱 㻌 㻿㻱㼀 㻌 㻱㻾㻾

㻯㻻㻹䠊㻱㻾㻾㻌㻿㼀㻻㻼䠖㻌㻌㻌㻌㻌

㻯㻻㻹䠊㻱㻾㻾㻌㻭㻸㻹䠖 㻌㻌㻌㻌㻌

㻮㻭㼀㼀 㻱㻾㼅 㻌㻻㼁㼀

㻼㼞㼑㼟㼟㻾㻱㻿 㼍㼒 㼠㼑 㼞 㻯 㻴㻷䠊

㻌㻌 㻌㻌㻌

(Example)

When the PROBLEM and BATTERY OUT blink, it indicates

the battery replacement period.

② Take the proper corrective action, and press the RESET button.

For further information,

Section 4.

NOTE) Malfunction detection of water failure (LOW W) is available for only water cooled single stage compressor.

Malfunction detection of dryer (DRYER) is available for only built-in dr yer models. Malfunction detection of

oil water separator (W/O SEP) is not available.

17

3. OPERATING PROCEDURE [How to Use the Liquid Crystal Display (LCD)]

■ Messages of Automatic Stop Display

When the air compressor stops automatically, the AUTO START light glows or blinks and RESTART display

appears. After the air compressor restarts, monitoring display appears again.

● SCHEDULED STOP: Schedule operation setting

<AUTO light glows>

This indicates that the air compressor has been

㻞㻜㻝㻞䠋㻜㻥䠋㻜㻝 㻝㻥䠖㻜㻞 㻖

㼀㼅㻼㻱䠖 㼂㻿㻰㻭㻌

㻰㻵㻿䠊㻼㻾㻱㻿㻿䠖 䚷䚷㻢㻣㼜㼟㼕

䠘㻾 㻱 㻿 㼀 㻭 㻾 㼀䠚

㻌㻌 㻌㻌㻌

automatically stopped by a pre-set time.

The air compressor starts automatically when the

pre-set restart time comes.

㻾㻱㻿㼀㻭㻾㼀 㻭㼀 䠖 䠆䠆䠖䠆䠆

㻾㻱㻿㼀㻭㻾㼀 㼃㻭 㻵 㼀 䠖 㻌 㻞 㻣䡏

㻺㻻㼃䠈㻿㼀 㻻㻼㻼 㻱 㻰 䠞䠵䠖

㻿㻯㻴㻱㻰㼁㻸㻱 㻿 㼀㻻㻼

㻭㼁㼀㻻㻹㻭㼀 㻵 㻯 㻿 㼀㻻㻼

㻰㻾㼅㻱㻾 㻼㻾 㻱㻿㼀㻭㻾 㼀㻱㻰

㻰㼁㻭㻸䠋㻮㻭㻯㻷㼁㻼

㻵㻼㻵 㻌㻾㻱㻿㼀㻭㻾㼀

㻯㼀㻸㻾䠊㻾㻱㼀㻾㼅

● LEAD/LAG OPERATION STOP (option)

<AUTO light glows>

This indicates that the air compressor is waiting for

starting as a slave unit in a two-unit-alternate

operation or a backup operation.

● DRYER PRESTARTED (Built-in dryer model)

<AUTO light blinks>

This indicates that the dryer has started and air

compressor is waiting for the start. The RESTART

WAIT field shows an expected waiting period until

the air compressor can start in seconds.

● AUTO OPERATION

<AUTO light glows>

This indicates that the air compressor in AUTO

operation has stopped due to the low air demand and

is waiting for restarting when demand is needed.

The RESTART WAIT field shows an expected

waiting period until the air compressor can restart in

seconds.

18

● INSTANT STOP / RETRY (Retry is for only Vtype)

<AUTO light blinks>

For both fixed speed and Vtype, this indicates that

the air compressor has stopped due to an

instantaneous power interruption (IPI). The

RESTART WAIT field shows an expected waiting

period until the air compressor can restart in

seconds.

For Vtype, this indicates that the air compressor has

stopped due to the variable speed drive failure and is

waiting for restart as well. The RESTART WAIT

field shows an expected waiting period until the air

compressor can restart in second.

3. OPERATING PROCEDURE [How to Use the Liquid Crystal Display (LCD)]

■ Maintenance Notice Messages

① Periodical maintenance

A maintenance date is determined by the amount of total operating hours or an elapsed calendar period, whichever

comes first. When the maintenance date or time arrives, the maintenance notice message appears on the display

under the heading of MESSAGE.

This function is only for the notice and is not output externally.

The consumable parts for the suction throttle valve shall be replaced this maintenance notice or L COUNT OVER

appears, whichever comes first.

㻞㻜㻝㻞䠋㻜㻥䠋㻜㻝 㻝㻥䠖㻜㻞 㻖

㼀㼅㻼㻱䠖 㼂㻿㻰㻭㻌

㻰㻵㻿䠊㻼㻾㻱㻿㻿䠖 㻌㻌 㻢㻣㼜㼟 㼕

䠘㻹㻱㻿㻿㻭㻳㻱䠚

㻹㻭 㻵 㻺 㼀䠊 䠖㻝 㼅 㻱 㻭㻾㻌 㻌

㻹㻭 㻵 㻺 㼀䠊䠯䠟䠤䠡䠠䠱㻸䠡 䠖 㻭

㻼㼞㼑㼟㼟㻿㻱㼀㻌㼍 㼒 㼠 㼑㼞 㻌㻯㻴㻷䠊

㻹㻭 㻵 㻺 㼀䠊㻯㻻㻹㻼 㻸 㻱 㼀 㻱㻰

㻿㼃 㻵 㼀㻯㻴㻱 㻰 㻌 㼀㻻 㻌 㻸㻻㻯㻭㻸

㻵㻺㻌㻻㼂㻱㻾䠮㻵㻰㻱 㻹㻻㻰㻱

㻵㻺㻌㼁㻺㻸㻻㻭㻰㻌㻿㼀㻻㻼

㻿㼃 㻵 㼀㻯㻴㻱 㻰 㻌 㼁 㻌 㻹㻻㻰㻱

㻌㻌 㻌㻌㻌

(1)

(2)

(3)

0.5 year, 1.5 years,

2.5 years, 3.5 years,

4.5 years, 5.5 years

1 year, 5 years Yearly + half-yearly

2 years, 4 years 2-yearly + yearly + half-yearly

3 years 3-yearly + yearly + half-yearly

6 years, overhaul 6-yearly + 3-yearly + 2-yearly + yearly + half-yearly

A

Standard Maintenance Schedule (A) (for yearly 8,000-or-less operating hours)

B

Standard Maintenance Schedule (B) (for yearly 4,000-or-less operating hours)

Half-yearly

CAUTION

If a message of maintenance notice is displayed, carefully read it and service the air compressor as

instructed by this manual. After servicing the air compressor, press the SET button and hold it down for

more than seven (7) seconds; the MAINT. COMPLETED message appears. After one (1) minute, the

monitor display appears.

Note:

1. MAINTenance can be reset, if the servicing is done earlier than expected and if the remaining operating time to next maintenance is

less than 2,000h in the case of A, 1,000h in the case of B.

2. On the contrary, if the servicing is done after the maintenance notice has appeared, the remaining operating hours to the next

maintenance has been zero until the maintenance is done. After maintenance and resetting the counter, new counting time starts

just after the maintenance notice message has appeared on the display.

② Other Message Displays

(1) SWITCH TO LOCAL

If set to local by remote operation following

shutdown restoration, the air compressor will

automatically return to local operation in case of

a shutdown, and the message will be displayed

for 1 minute. (

3.4)

(2) IN OVERRIDE MODE.

Indicates that the compressor is in override

mode.

(3) IN UNLOAD STOP

Blinks when the UNLOAD STOP button is used.

The air compressor unloads for 5 minutes and

then stop.

19

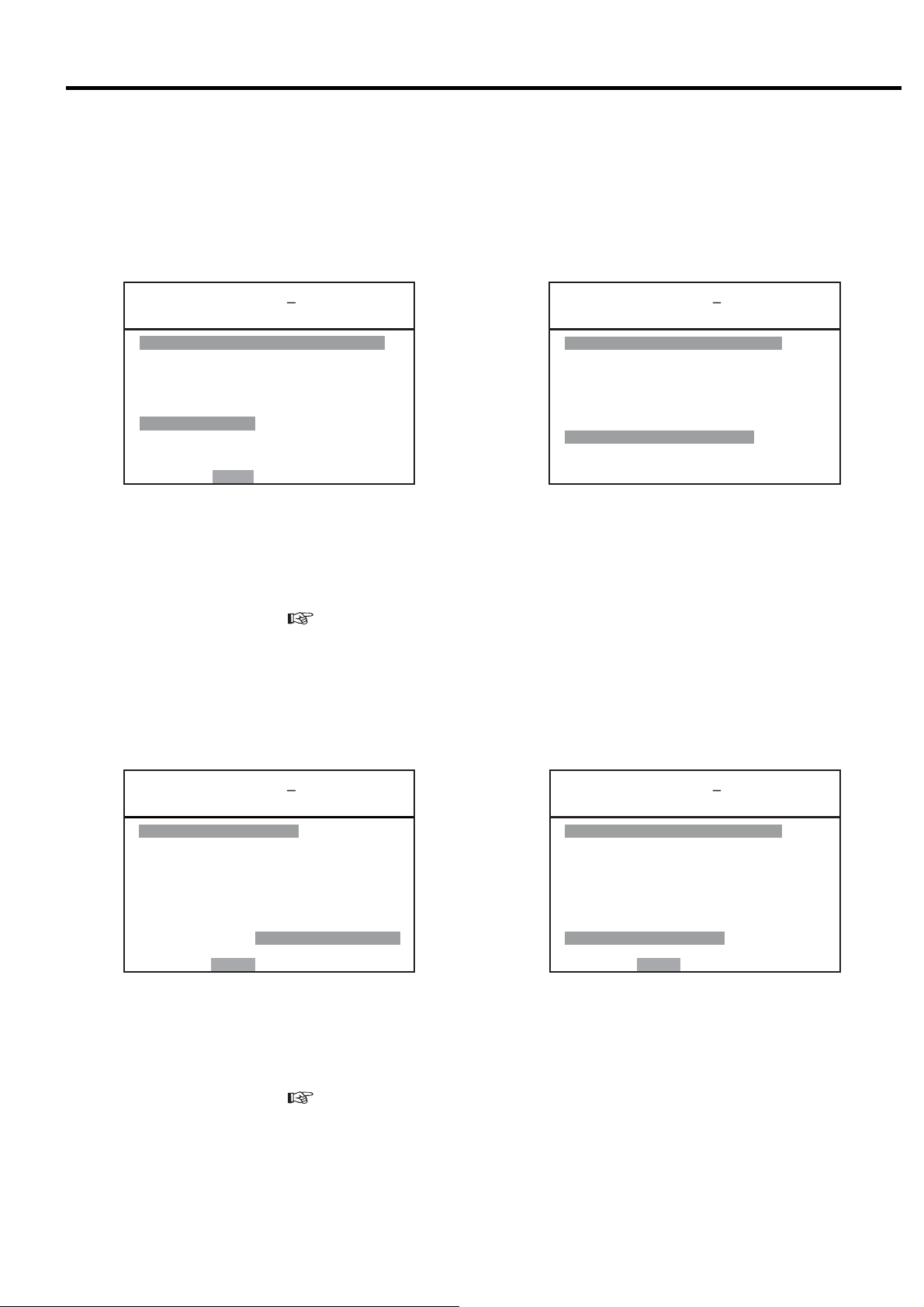

3. OPERATING PROCEDURE [How to Use the Liquid Crystal Display (LCD)]

3.3.4 How to Move within a Menu Display and to Change a Setting

The method and procedure for altering settings is displayed using the following as an example.

How to MOVE within a [FUNCTION MENU] Display

1

[FUNCTION MENU]

1 䠊 BAS I C SE T UP

2 䠊 MUL T I - UN I T

3 䠊 CAPAC I T Y CONTROL

4 䠊 SCHEDULE

5 䠊 OPE RA T I ON DAT A

6 䠊 LOAD DATA

7 䠊 ALARM HI STORY

8 䠊 SHUTDOWN HI STORY

or 2 is appeared

② Press the

desired item number.

③ Press the SET button to open the related setting

display.

The following explanation uses [MULTI-U SETTING

display] as an example.

① Press the MENU button when the monitor display 1

SET䠖 OPE N MON䠖 BACK

How to Select or Change a Setting within a Setting Display

2

㼇㻹㼁㻸㼀㻵㻙㼁㻌㻿㻱㼀㼀㻵㻺㻳㼉

① Press the

desired item number.

㻝

㻹㻻㻰 㻱 䠖 㻳㻸

㻞䠊㻰㼁㻭㻸 㻌 㼀 㻵 㻹㻱䠖 㻌 㻤䠊

㻟䠊㻹㻱㼀㻴㻻㻰䠖 㻭㻼

㻠䠊㻿㼃㻵㼀㻯㻴㻻㼂㻱㻾䠖 㻜㻝㻡 㼟

㻡䠊㻮㻭㻯㻷㼁㻼䠖 㻣㻼

㻢䠊㼁㻺㻸㻻㻭㻰䠖 㻟㻼㻿㼕

㻭㻸㼀䠊㼀 㻵㻹㻱䠖㻌 㻠㻤 㻜㻹 㻵 㻺

㻣

㻯㻻㻺㼀 㻾㻻 㻸 㻹㻻㻰 㻱 䠖 㻮

㻤

㻌㻿㻺

㻻㼂㻾 㻾㻸

㻜㼔

㻿㼕

IMPORTANT

Item number with a dash “-“ cannot be selected on LCD

monitor. It can be selected from digital monitor. (

How to Use the Digital Monitor for the detail.)

△

△

or

or

▽

buttons to move to the

buttons to move to the

▽

3.4

㻿㻱㼀䠖㻿㼀㻻㻾㻱 㻌 㻹㻻㻺䠖㻮㻭㻯㻷

①

㻝 㻹㻻㻰 㻱 䠖

㻞䠊㻰㼁㻭㻸 㻌 㼀 㻵 㻹㻱䠖 㻌 㻤䠊㻜 㼔

㻟䠊㻹㻱㼀㻴㻻㻰䠖

㻠䠊㻿㼃 㻵 㼀㻯㻴㻻㼂㻱㻾䠖 㻜㻝㻡㼟

㻻㼂㻾 㻾㻸

㻳㻸㻿㻺

㻭㻼

②

㻝 㻹㻻㻰 㻱 䠖

㻞䠊㻰㼁㻭㻸 㻌 㼀 㻵 㻹㻱䠖 㻌 㻤䠊㻜 㼔

㻟䠊㻹㻱㼀㻴㻻㻰䠖

㻠䠊㻿㼃 㻵 㼀㻯㻴㻻㼂㻱㻾䠖 㻜㻝㻡㼟

㻻㼂㻾 㻾㻸

㻳㻸㻿㻺

㻭㻼

③

㻝 㻹㻻㻰 㻱 䠖

㻞䠊㻰㼁㻭㻸 㻌 㼀 㻵 㻹㻱䠖 㻌 㻡䠊㻜 㼔

㻟䠊㻹㻱㼀㻴㻻㻰䠖

㻠䠊㻿㼃 㻵 㼀㻯㻴㻻㼂㻱㻾䠖 㻜㻝㻡㼟

㻻㼂㻾 㻾㻸

㻳㻸㻿㻺

㻭㻼

④

㻹㻻㻰 㻱 䠖

㻝

㻞䠊㻰㼁㻭㻸 㻌 㼀 㻵 㻹㻱䠖 㻌 㻡䠊㻜 㼔

㻟䠊㻹㻱㼀㻴㻻㻰䠖

㻠䠊㻿㼃 㻵 㼀㻯㻴㻻㼂㻱㻾䠖 㻜㻝㻡㼟

㻻㼂㻾 㻾㻸

㻳㻸㻿㻺

㻭㻼

② Press the

button to move to the desired

▽

setting field.

③ Press the

△

or

buttons until the desired

▽

setting appears.

④ Press the SET button to return to the item number.

⑤ Press the SET button again to return to the item

number 1. This saves the changed setting.

Press the MONITOR button to return to the

[FUNCTION MENU] display. Press the MONITOR

button again to view the monitoring display.

㻝 㻹㻻㻰 㻱 䠖

⑤

㻞䠊㻰㼁㻭㻸 㻌 㼀 㻵 㻹㻱䠖 㻌 㻡䠊㻜 㼔

㻟䠊㻹㻱㼀㻴㻻㻰䠖

㻠䠊㻿㼃 㻵 㼀㻯㻴㻻㼂㻱㻾䠖 㻜㻝㻡㼟

㻻㼂㻾 㻾㻸

㻳㻸㻿㻺

㻭㻼

20

3. OPERATING PROCEDURE [How to Use the Liquid Crystal Display (LCD)]

3.3.5 [FUNCTION MENU] - Setting Displays

Model Setting Confirmation

1

㼇㻮㻭㻿㻵㻯 㻿㻱㼀㼁㻼㼉

㼂㻱㻾䠊䠖 㻡䠊㻜

㻿㻱㻾 㻵 㻱㻿 㻺㻭㻹㻱䠖 㻰㻿㻼

㻯㻻㻻㻸 㻵 㻺㻳 㻹㻱㼀 㻴㻻㻰 䠖 㼃㼀㻾

㻺㻻䠊㻻㻲 㻿 㼀 㻭㻳 㻱 䠖 㻌 㻞

㻼㻙㻿㻼㻱㻯䠖 䚷㻝 㻜 㻜㼜 㼟 㼕

㻼䠊㻰㻭㼀㻭䠖 䚷䚷 㻢 㻤 㼜 㼟 㼕

䠟䠰 䠖 㻞 㻡 㻜䠝

㻯㻸㼀䠊㻰㻱㻸㻭㼅䠖 㻌 㻡 㼟

㻵㻼㻵䠖 㻵 㻵 㻵

㻭㻰㻾㻱 㻿㻿 㻺㻻䠊䠖 㻌 㻝

㻹㻻㻺 䠖 㻮 㻭㻯㻷

IMPORTANT

When contacting the local Hitachi distributor, inform

this information as a based setting status.

㻡䠊㻜

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

This display contains software version (VER.), air

compressor series (SERIES NAME), cooling method

(COOLING METHOD), number of air compression

stages (NO. OF STAGE), action against instantaneous

power interruption (IPI) and etc. “** ” means the

setting that is not required.

① Indicates board software version.

② Indicates compressor type.

③ Displays cooling type.

④ Displays the number of compressor stages.

⑤ Displays pressure specification.

⑥ Displays interstage pressure.

⑦ Indicates CT setting value.

⑧ Displays water failure detection conditions for water

cooled compressor.

⑨ Displays status of instantaneous power interr uption

(IPI) restart setting.

⑩

Displays compressor number. (Must be distinguished

by number is using communication function.)

Operation Mode Setting

2

Confirm the settings by lead/lag and multi unit

control (option). These options need wiring

modification. Item number with a dash “-“ cannot be

selected on LCD monitor.

㼇㻹㼁㻸㼀㻵㻙㼁㻌㻿㻱㼀㼀㻵㻺㻳㼉

㻝

㻹㻻㻰 㻱 䠖 㻳㻸

㻞䠊㻰㼁㻭㻸 㻌 㼀 㻵 㻹㻱䠖 㻌 㻤䠊

㻟䠊㻹㻱㼀㻴㻻㻰䠖 㻭㻼

㻠䠊㻿㼃㻵㼀㻯㻴㻻㼂㻱㻾䠖 㻜㻝㻡 㼟

㻡䠊㻮㻭㻯㻷㼁㻼䠖 㻌 㻌 㻌 㻣㼜

㻢䠊㼁㻺㻸㻻㻭㻰䠖 㻌 㻌 㻌 㻟㼜 㼟 㼕

㻭㻸㼀䠊㼀 㻵㻹㻱䠖㻌 㻠㻤 㻜㻹 㻵 㻺

㻣

㻯㻻㻺㼀 㻾㻻 㻸 㻹㻻㻰 㻱 䠖 㻮

㻤

㻿㻱㼀䠖㻿㼀㻻㻾㻱 㻌 㻹㻻㻺䠖㻮㻭㻯㻷

1- MODE:

If using the backup function, switch to the digital

monitor for setting.

Operation mode set on the digital monitor.

IMPORTANT

㻌㻿㻺

㻜㼔

㻻㼂㻾 㻾㻸

㼟㼕

2. DUAL TIME: Alternate operation hours of lead/

lag operation.(Setting range : 0.1 to 99.9 hours;

initial value: 8.0)

3. METHOD: Switching method (overlap or interval)

of lead/lag operation.

4. SWITCHOVER: Switching-over or overlapping

period of lead/lag operation. (Setting range : 5 to

300 seconds; initial value: 15)

SNGL Operates an air compressor independently

Operates by multi roller EX of exclusive use for NEXT

series using communication function.

STPR

By this setting RS485 communication port is effective.

The setting of air compressor number is required.

DUAL

BKUP

OVERLAP

INTERVAL

Operates two air compressors alternately according to

a time schedule. The AUTO light comes ON (glowing).

Operates two air compressors according to a preset

back up pressure. Starts the back up slave unit when

the pressure has dropped to the desired preset back up

pressure. The AUTO light comes ON (glowing)

Slave unit starts, master/slave units overlap in operation

for a preset period, and then master unit stops.

Master unit stops, a non-operating interval passes, and

then slave unit starts.

5. BACKUP: Pressure to start a backup unit in a

backup operation (cut-in (load) pressure – α)

6. UNLOAD: Pressure to unload both the units in a

backup operation (cut-out (unload) pressure – α)

7- ALT. TIME: Displays time remaining until switch for

dual / backup operation. Time is not counted down

when operating 2 units for backup operation. When

operation is stopped, remaining time is maintained.

8- CONTROL MODE: Control mode A or B for Vtype

(

3.3.2). “**” is indicated in fixed speed type.

IMPORTANT

The settings can be memorized while the air compressor

is stopped.

21

3. OPERATING PROCEDURE [How to Use the Liquid Crystal Display (LCD)]

Capacity control

3

This function sets the pressures and times for capacity

control. Two dif ferent combinations (P1 and P2) of

pressures can be used. Item number with dot “ . ” can

be select from LCD monitor. Item number with a dash “

- “ can be selected from digital monitor. (

3.4)

①② ③

㼇㻯㻻㻺㼀㻾㻻㻸 㻿㻱㼀㼀 㻵㻺㻳㼉

㻝䠊㼀㼅㻼㻼㻱䠖㼂㻭 㼎㼎㼎 㼏㼏㼏

㻞䠊䠬

㻟䠊䠬 㻵

㻠

㻡

㻢

㻣

㻤䠊㼀 㻵㻹㻱䠖㻝㻤䠖 㻜㻜 㻞㻞䠖 㻜㻜

㻿㻱㼀䠖㻿㼀㻻㻾㻱 㻌 㻹㻻㻺䠖㻮㻭㻯㻷

㻸㻻㻿㻿䠖 㻖㻖 㼜 㼟 㼕

㻯㻭䠖㻖㻖㻖 㻖㻖䠊㻖䡉㻟

䠄㻯㻻㻺㼀㻾㻻㻸䠋㻯㼁㼀㻙 㻵㻺 㻕

㻼㻝䠖 㻌 㻝 㻜㻜䠋㻌 㻌 㻤㻣㼜 㼟 㼕

㻼㻞䠖 㻌 㻝 㻜㻜䠋㻌 㻌 㻤㻣㼜 㼟 㼕

䠄㼀㻭㻾㻳㻱㼀㻌㻼㻝䠋㻼㻞 㻕

㼀㻭㻾㻳㻱㼀䠖

㻌㻌 㻥㻤䠋㻌㻌 㻥㻤㼜㼟 㼕

㼀㻵㻹㻱㻌㻸㻵㻹㻵㼀䠖 㻜㻟㻜㼟

䠄㻼㻞 㻱㻲㻲㻱㻯ࠥ㼀㻵㼂㻱㻕

④

⑤

⑥

1. Type: Indicates the setting data for capacity control

① Type of capacity control (Cannot be changed from

LCD monitor)

Fixed speed type

I: Indicates the standard, 2-step control.

IP: Indicates the motor stop/restart capacity control

to “I”.

Vtype

VA: Indicates motor stop/restart capacity control is

effective.

VB: Indicates motor stop/restart capacity control is

canceled.

② Pressure setting (Cannot be changed from LCD

monitor)

S-1: Indicates pressure setting 1

S-2: Indicates pressure setting 2

EXT: Indicates external pressure setting

S-A : Indicates pressure setting switches by set time

on ⑥.

③ Option condition and setting.

NUL: Indicates no option.

2. - 3. OPTION: Used for options.

4. - 6. Pressure Setting: ④ Indicates cut-in, cut-out

and target pressure setting 1 and 2 can be confirmed.

Target means target pressure for ECOMODE

7. TIME LIMIT (Fixed speed type only)

⑤ Indicates the time limit of load/unload one-cycle

time for ECOMODE. Load/unload one-cycle time

must be 30 seconds or more. (

3.4.8)

8. TIME: ⑥ Can set the time to use pressure setting 2.

When set the value properly, ② is indicated in “ S-A”. If

the start and stop time is set at same value, pressure

setting 2 is not in use and ② is indicated in S-1. And

pressure setting 1 and 2 can be changed by external

switch. Set the F018 on digital monitor “2”. (

3.4.2

and 3.4.7)

IMPORTANT

The settings can be memorized while the air compressor

is stopped.

Scheduled Operation

4

Allows a standard daily scheduling operation.

㼇㻿㻯㻴㻱㻰㼁㻸㻱㻌㻿㻱㼀㼀㻵㻺㻳㼉

㻝䠊㻹㻻㻰㻱 䠖 㻯㻴㻱㻰㼁㻸㻱

㻿㼀㻭㻾㼀 㻿㼀㻿㻻㻼

䠄㻝䠅㻜㻣䠖㻜㻜㻌 㼅 㻞㻜䠖㻜㻜㻌 㼅

䠄㻞䠅㻜㻜䠖㻜㻜㻌 㻺 㻜㻜䠖㻜㻜 㻌 㻺

䠄㻟䠅㻜㻜䠖㻜㻜㻌 㻺 㻜㻜䠖㻜㻜 㻌 㻺

䠄㻠䠅㻜㻜䠖㻜㻜㻌 㻺 㻜㻜䠖㻜㻜 㻌 㻺

䠄㻡䠅㻜㻜䠖㻜㻜㻌 㻺 㻜㻜䠖㻜㻜 㻌 㻺

㻞䠊㻾㻱㻯㻻㻾㻰 㻝䠖 㻝㻜䠖㻜㻜

㻟䠊㻾㻱㻯㻻㻾㻰 㻞䠖 㻝㻥䠖㻜㻜

㻿㻱㼀䠖㻿㼀㻻㻾㻱 㻌 㻹㻻㻺䠖㻮㻭㻯㻷

This illustration indicates a scheduling operation from 7:00 to

20:00. TIME field indicates a current time of 19:07.

㻝㻥䠖㻜㻣

1. MODE:

OFF Operates without a schedule.

Schedule Operates according to a daily 24- hour calendar.

(1) to (5) : Five Start/Stop Time Patterns

・ START : Star ting Time

・ STOP : Stopping Time

・ Y or N : Starts or Stops as scheduled

IMPORTANT

When the schedule is selected, the AUTO light comes ON

(glowing) if the time setting is valid and ON (blinking) if the

time setting is invalid. The settings can be memorized

while the air compressor is stopped.

2.-3. RECORD1, 2 : This function allows for the

capability to record data over a desired time in a day.

To view the recorded data, refer to “5. Operation data

display” on the next page.

22

3. OPERATING PROCEDURE [How to Use the Liquid Crystal Display (LCD)]

Operation Data Display

5

㼇㻻㻼㻱㻾㻭㼀 㻵㻻㻺 㻰㻭㼀㻭㼉

㻝䠊㻜㻤䠋㻜㻝 㻝 㻜 䠖 㻜 㻜

㻼䠖㻜㻠㻢䚸㻜㻝㻥䚸㻜㻝㻢䚸㻖㻖㻖

㻯䠖 㻜

㼀䠖 㻞㻡䚸 㻟㻟䚸㻖㻖䚸㻖㻖䚸㻖㻖

㻸䠖 㻡㻥䚸㻝㻤䠊㻤

㻞䠊㼍 㼍䠋㼎 㼎 㼏 㼏 䠖㼐㼐

㻼䠖㻖㻖㻖䚸㻖㻖㻖䚸㻖㻖㻖䚸㻖㻖㻖

㻯䠖㻖㻖㻖

㼀䠖㻖㻖㻖䚸㻖㻖㻖䚸㻖㻖䚸㻖㻖䚸㻖㻖

㻸䠖㻖㻖㻖䚸㻖㻖㻖㻖㻖

㻹㻻㻺 䠖 㻮 㻭㻯㻷

Data can be recorded for a maximum of twelve (12)

times. The 13th recorded data is automatically deleted

and the 1st recorded data is added. The most recent

data is arranged at the top of the display. If a change to

these settings is desired, the sampled data before the

settings change will be left as is and the new recorded

data will be applied after the change.

Press the

△

or

▽

button to move within the display.

1. and 2. : Indicates the MONTH / DAY HOUR: MINUTE.

P - Represents a pressure (psi) and indicates from left

to right: Discharge air pressure, Interstage

pressure, Oil pressure, ***

C - Represents an amperage current (A)

T - Represents a temperature (°F) and indicates from

left to right: 1st stage discharge air temperature,

2nd stage discharge air temperature, oil

temperature, ***, 2nd stage suction temperature.

L -Represents a load ratio percentage (%)

Unavailable fields are filled with asterisks.

Load Data Display

6

㼇㻸㻻㻭㻰 㻰㻭㼀㻭㼉

㻝䠊㻜㻤䠋㻜㻝

㻭㼂㻳䠊㻼㻾㻱㻿㻿 䠖 㻌 㻌 㻣 㻡 㼜 㼟 㼕

㻭㼂㻳䠊㻯㼁㻾㻾㻱 㻺㼀 䠖 㻜 㻠 㻜䠝

㻭㼂㻳䠊㻸㻻㻭㻰 㻾㻭㼀㻱䠖㻜㻢㻡䠂

㻭㼂㻳䠊㻼䠫䠳䠡䠮䠖 㻌 㻝 㻣 㻚 㻤 㼗㼃

㻞䠊㻜㻝䠋㻜㻝

㻭㼂㻳䠊㻼㻾㻱㻿㻿 䠖 㻌 㻌 㻣 㻡 㼜 㼟 㼕

㻭㼂㻳䠊㻯㼁㻾㻾㻱 㻺㼀 䠖 㻜 㻠 㻜䠝

㻭㼂㻳䠊㻸㻻㻭㻰 㻾㻭㼀㻱䠖㻜㻢㻡䠂

㻭㼂㻳䠊㻼䠫䠳䠡䠮䠖 㻌 㻞 㻟 㻚㻤 㼗㼃

㻹㻻㻺 䠖 㻮 㻭㻯㻷

㻡

This display shows the averaged load data per day. Data

can be recorded for a maximum of 6 days; the 7th day

of averaged load data is automatically deleted and the

1st or most recent averaged data is added. The most

recent data is arranged at the top of the display. Press

the

△

or

▽

button to move within the display.

Data is averaged from start to stop every day. If 24h

operation is done, data is averaged at AM 0:00.

Alarm History

7

㼇㻭㻸㻭㻾㻹 㻴 㻵㻿㼀㻻㻾㼅 㼉

㻝䠊 㼍㼍㼍㼍㼍㼍㼍㼍㼍㼍㼍㼍㼍

㻯㻻㻰㻱䠖㻞㻝㻸 㻺㻻㻿䠊䠖㻌 㻝

㻜㻣䠋㻜㻤䠋㻜㻝 㻝㻥䠖 㻞㻢

㻞䠊 㻖㻖㻖㻖㻖㻖㻖㻖㻖㻖㻖㻖㻖

㻯㻻㻰㻱䠖㻖㻖㻖 㻺㻻㻿䠊䠖㻖㻖

㻖㻖䠋㻖㻖䠋㻖㻖 㻖㻖䠖 㻖㻖

㻟䠊 㻖㻖㻖㻖㻖㻖㻖㻖㻖㻖㻖㻖㻖

㻯㻻㻰㻱䠖㻖㻖㻖 㻺㻻㻿䠊䠖㻖㻖

㻖㻖䠋㻖㻖䠋㻖㻖 㻖㻖䠖 㻖㻖

㻹㻻㻺 䠖 㻮 㻭㻯 㻷

①

This display shows a maximum of 6 alarms and

displays the following information as such: type of

alarm, the number of times, and the date and time. If

the same alarm occurs in a short period of time, the

older data is deleted and the more recent data is stored,

and alarm NOS. is updated. The most recent data is

arranged at the top of the display. Press the

▽

button to move within the display.

△

or

① Indicates operating condition.

L: When loading, U: When unloading,

S: When Stopped

Shutdown History

8

㼇㻲㼁㻺㻯㼀㻵㻻㻺 㻹㻱㻺㼁㼉

㻝䠊㻮㻭㻿㻵 㻯㻌 㻿㻱㼀㼁㻼

㻞䠊㻹㼁㻸㼀 㻵 㻙㼁㻺 㻵 㼀

㻟䠊㻯㻭㻼㻭㻯㻵 㼀㼅 㻯㻻㻺㼀㻾㻻㻸

㻠䠊㻿㻯㻴㻱㻰㼁㻸㻱

㻡䠊㻻㻼㻱㻾㻭㼀 㻵㻻㻺 㻰㻭㼀㻭

㻢䠊㻸㻻㻭㻰 㻰㻭㼀㻭

㻣䠊㻭㻸㻭㻾㻹 㻴㻵 㻿㼀㻻㻾㼅

㻤䠊㻿㻴㼁㼀㻰㻻㼃㻺 㻴㻵 㻿㼀㻻㻾㼅

㻿㻱㼀䠖㻻㻼㻱㻺 㻹㻻㻺䠖㻮㻭㻯㻷

㼇㻰㻱㼀㻭㻵 㻸㻿㼉

㻝䠊 㼍㼍㼍㼍㼍㼍㼍㼍㼍㼍㼍㼍㼍

㻰㻵㻿䠊㻼㻾㻱㻿䠖 㻌㻌 㻠㻤㼜㼟㼕

㻵㻺㼀㻿㼀㻳䠊㻼䠖 㻖㻖㼜㼟㼕

㻻㻵㻸 㻼㻾㻱㻿䠖 㻖㻖㼜㼟㼕

㻯㻸㼀䠊㻼㻾㻱㻿䠖 㻖㻖 㼜 㼟 㼕

㻰㻵㻿䠊㼀㻱㻹㻼䠊㻝䠖 㻝㻤㻜䉣

㻰㻵 㻿䠊㼀㻱㻹㻼䠊㻞䠖 㻝㻤㻜䉣

㻻㻵㻸 㼀㻱㻹㻼䠖 㻖㻖㻖䉣

㻯㻸㼀䠊㼀㻱㻹㻼䠖 㻖㻖㻖䉣

㻞㻺㻰 㻿㼁㻯㼀䠊㼀䠖 㻖㻖 㻖䉣

㻯㼁㻾㻾㻱㻺㼀䠖 㻝㻜㻜㻭

㻹㻻㻺 䠖 㻮 㻭㻯 㻷

This display shows a maximum of 6 shutdowns and

displays the following information as such: type of

shutdown, the number of times the air compressor has

shutdown, and the date and time of the shutdown. The

shutdown history display also shows the operation data

(pressure, temperature, current) sampled at the time of

shutdown.

To view the operation data sampled when the shutdown

occurred; in the shutdown histor y display, move to the

item number of the targeted shutdown to view. Press

the SET button to open the [DETAILS] display.

● How to clear the all alarm and shutdown histories.

Set the F041 on digital monitor “1”. (

3.4.2).

23

3. OPERATING PROCEDURE [How to Use the Liquid Crystal Display (LCD)]

3.3.6. Other Settings

Initial Setting

The calendar and clock are set by Hitachi prior to

delivery. To reset the calendar and clock, contact

the local Hitachi distributor.

Brightness Adjusting

Adjust the LCD brightness as follows:

To brighten:

Hold down the SET button and press the

MONITOR button.

To darken:

Hold down the SET button and press the

FUNCTION button.

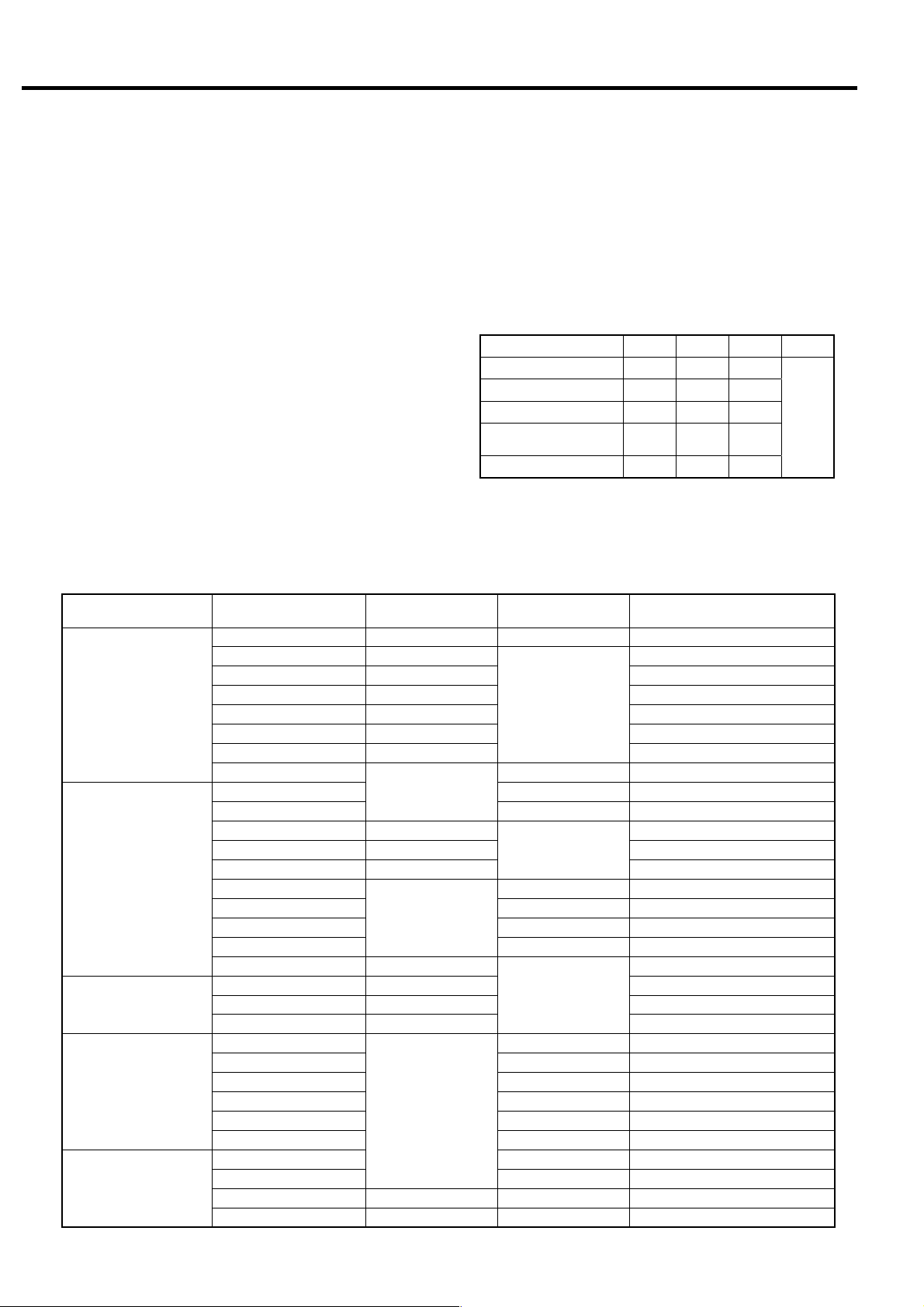

Digital Monitor Operation Classification

The following is a table of contents that can be set by

the LCD monitor and digital monitor (next section).

Function Item

MULTI-U SETTING

display

CONTROL SETTING

display

SCHEDULE SETTING

display

Other settings

Reset

MODE -

DUAL TIME

METHOD

SWITCHOVER

BACKUP

UNLOAD

ALT.TIME

CONTROL MODE

TYPE (left)

TYPE (center)

TYPE (right)

P-LOSS

PI-CA

P1

P2

TARGET - Prohibited to change

TIME LIMIT

TIME

MODE

START/STOP

RECORD 1, 2

Air compressor No.

IPI

Remote operation

Dryer operation

AUTO operation

ECOMODE

Shutdown/Alarm

Load count

Maintenance

Shutdwon/Alarm history

△

3-Language Display Switch

The language of the display can be switched to

Japanese, English or Chinese by the dip switch on

the back of the LCD monitor board. If the language

needs to be changed, consult with the local Hitachi

distributor.

Japanese OFF OFF OFF

English ON OFF OFF

Chinese OFF ON OFF

Setting for United

States

Test mode ON ON OFF

Power must be turned off before setting.

LCD monitor

operation

○

○

○

○

○

(automatic change)

-

○

○

○

-

○

○

○

○

-

○

-

Bit 1 2 3 4 - 8

ON OFF ON

Digital monitor

(F mode)

○ F000

-

○ (Factory set)

○ F019

○ F018

-

○ F022 -

○ F022 -

○ (Factory set)

-

○ F001

○ F002 -

○ F005 -

○ F008 -

○ F011 -

○

○

○

- Set button 7 sec. ON

○ F041

Dual, backup, etc

Differential pressure

Differential pressure

V type only

Example: I type (load/unload type)

Example: Setting 1

Option (not supported)

Option (not supported)

Option (not supported)

Setting 1, Setting 2

Setting 1, Setting 2

Energy saving mode decision time

Function switching

Operation data measurement

Display switch button operation

Reset button operation

Remote + display switch button

Remarks

Not

used

24

3. OPERATING PROCEDURE [How to Use the Digital Monitor]

3.4 How to Use the Digital Monitor

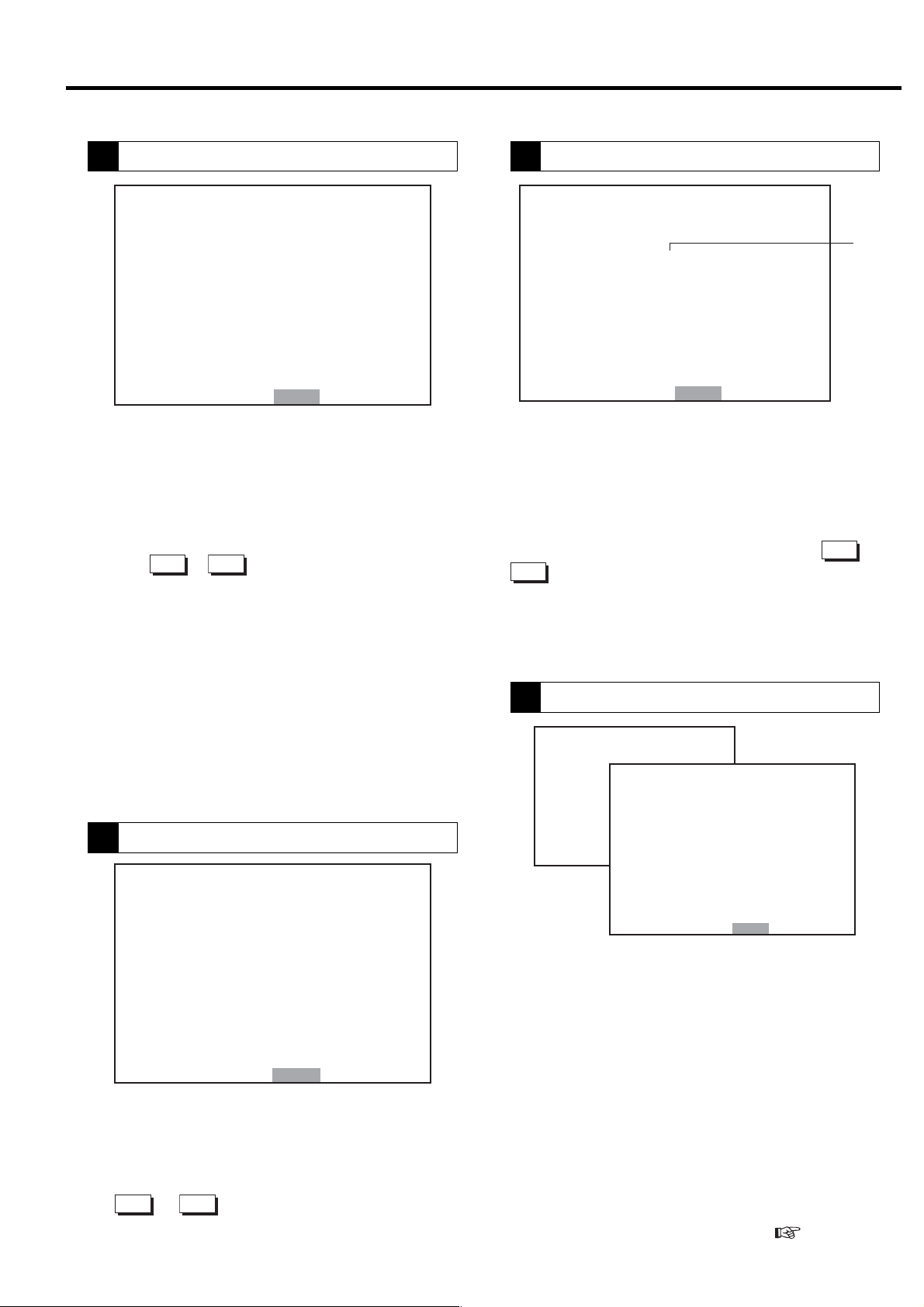

3.4.1 How to Display Operation Status, Shutdown History, and Status of Various Settings

All display contents of the digital monitor are linked with the LCD monitor. All of the following display contents can

be confirmed by the LCD monitor.

Use the following operations to display the contents of other operation/setting status on the LCD monitor and

readily confirm operation status and setting status by the digital monitor.

(1) How to Display the Operation Status

P: Discharge pressure (psi)

SELECT/WIDE

Blinks when operation time is added.

Total running hour (×10)

SEL ECT /WID E

Pres s once to go to

the next item.

Press once to go to

the previous item.

Return to discharge

pressure display

2

RESET

1

To shutdown history display

b: Interstage pressure (psi)

C: 1st-stage air end outlet temp (゜F)

(320゜F)

L: Vtype: Not in use

Fixed speed type: Load ratio (%)

U: Load count (×10,000 times)

H:

Vtype: Main motor operating frequency (Hz)

Fixed speed type: Not in use (display only)

d: Fan motor operating frequency (Hz)

Water-cooled type: Not in use (display only)

IMPORTANT

1. When other than P (Discharge pressure is

displayed), it automatically returns to P in 3 minutes.

2. Load ratio is a reference-calculated value.

1

Press

When the power is turned on, discharge pressure is displayed

on the screen of the digital monitor. Use the following

procedure to switch the digital monitor to other display.

① Press the SELECT/WIDE button. Operation time is

displayed on the screen.

② Press the SELECT/WIDE button. Interstage pressure is

displayed on the screen with “b.”

③ Press the SELECT/WIDE button. 1st-stage air end outlet

temperature is displayed on the screen with “C.”

④

Press the SELECT/WIDE button. Load rate is displayed

on

the screen with “L.”

⑤ Press the SELECT/WIDE button. Load count is displayed

on the screen in units of 10,000 times with “U.”

Air-Cooled

⑥ Press the SELECT/WIDE button. Operation frequency of

the fan motor is displayed on the screen with “d.”

To return to one item at a time, press the

2

button. To

return to discharge pressure, press the RESET button.

● If the alarm or shutdown light is blinking, the shutdown

code is displayed with “E0” (

page 36, 37).

“E0” indicates the contents of the latest shutdown.

● If the alarm or shutdown light is blinking, it indicates that

the alarm or shutdown has not been reset. Check E0.XX

and reset.

25

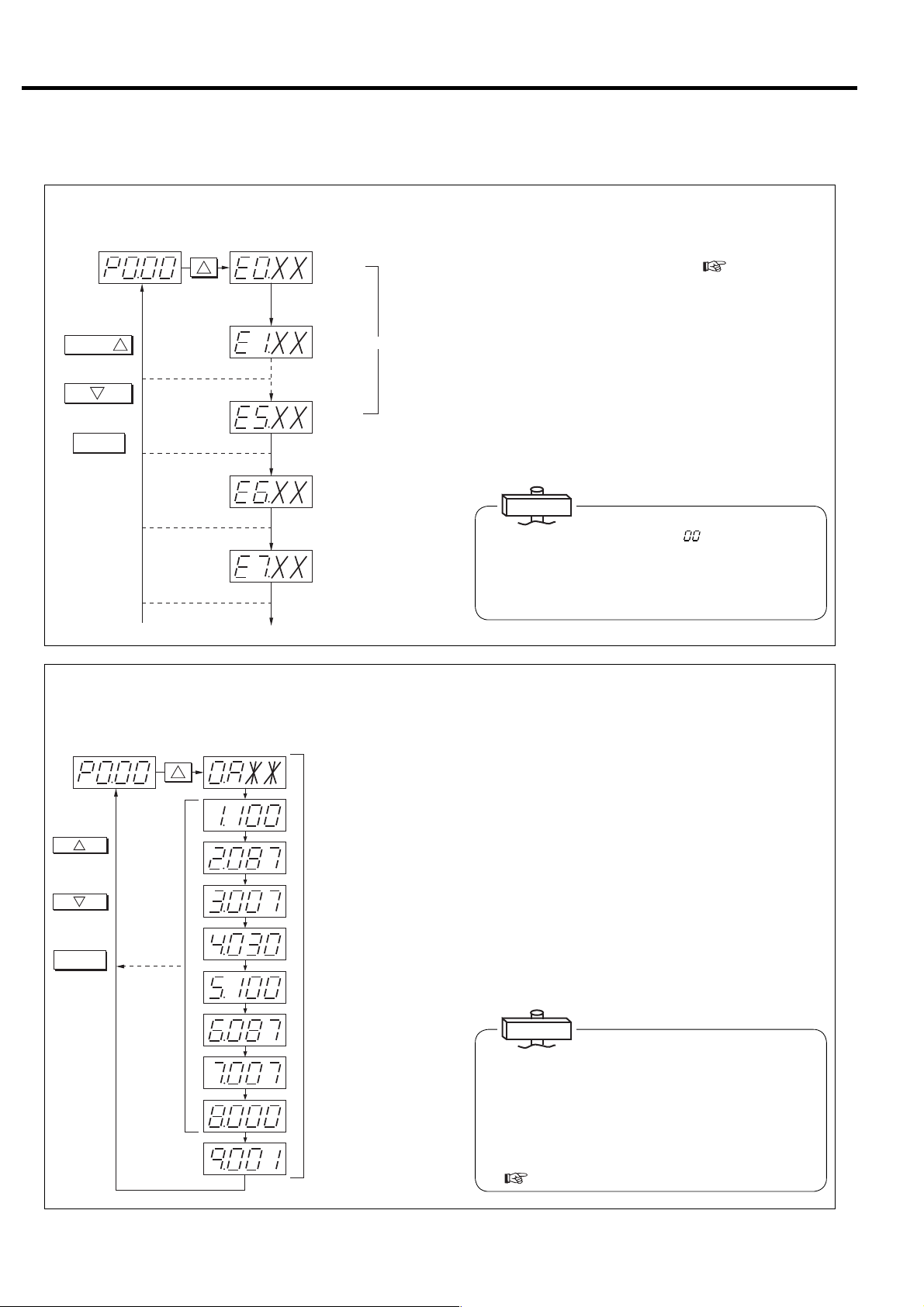

3. OPERATING PROCEDURE [How to Use the Digital Monitor]

(2) How to Display Shutdown History

Discharge pressure display

SELECT/WIDE

Press once to go to

the next item.

Press once to go to

the previous item.

Return to discharge

pressure display.

1

2

RESET

SELECT/WIDE

1

Press 8 times.

[Latest shutdown]

[Previous shutdown]

XX : Shutdown code

[Oldest shutdown]

History consists of 6 date items.

Not used (display only)

Not used (display only)

To display of various settings

Use the following procedure to display shutdown history.

① Press the SELECT/WIDE button 8 times. “E0.” is the

displayed with the shutdown code (

Section 4). “0”

indicates the most recent shutdown. (The display

automatically changed to “E.0” when shutdown or alarm

occurs.)

② Press the SELECT/WIDE button. “E1.” is displayed along

with the shutdown code. “1” indicates shutdown that

occurred previously. Six items of data (0 to 5) are

recorded. “E5” indicates the oldest shutdown.

③ Press the RESET Button. The screen is returns to the

operation status.

IMPORTANT

If the shutdown code “XX ”is “ ”, it Indicates that

there is no shutdown history. Also, when anything

other than shutdown history is displayed without

shutdown resetting, the display is return to the latest

shutdown history in 3 minutes.

(3) How to Display Various Settings (Perform operation only when confirmation is

necessary.)

Dischargepressuredisplay

1

Proceeds by 1

each time pressed.

2

Returns by 1 each

time pressed.

RESET

Returns to

discharge pressure.

SWITCHDISPLAY

1

Press16times.

No.0 : Control status

A : Capacity control type

No.1 : Start pressure 1

100 : 100psi

No.2 : Recover pressure 1

087 : 87psi

No.3 : Pressure differential 1

007 : 7psi

No.4 : ECOMODE

Cycle time

30 second

No.5 : Start pressure 2

100 : 100psi

No.6 : Recover pressure 2

087 : 87psi

No.7 : Pressure differential 2

007 : 7psi

No.8 : Instantaneous power

interruption (IPI) setting

Invalid

:

000

No.9 : Compressor address

001 : No.1

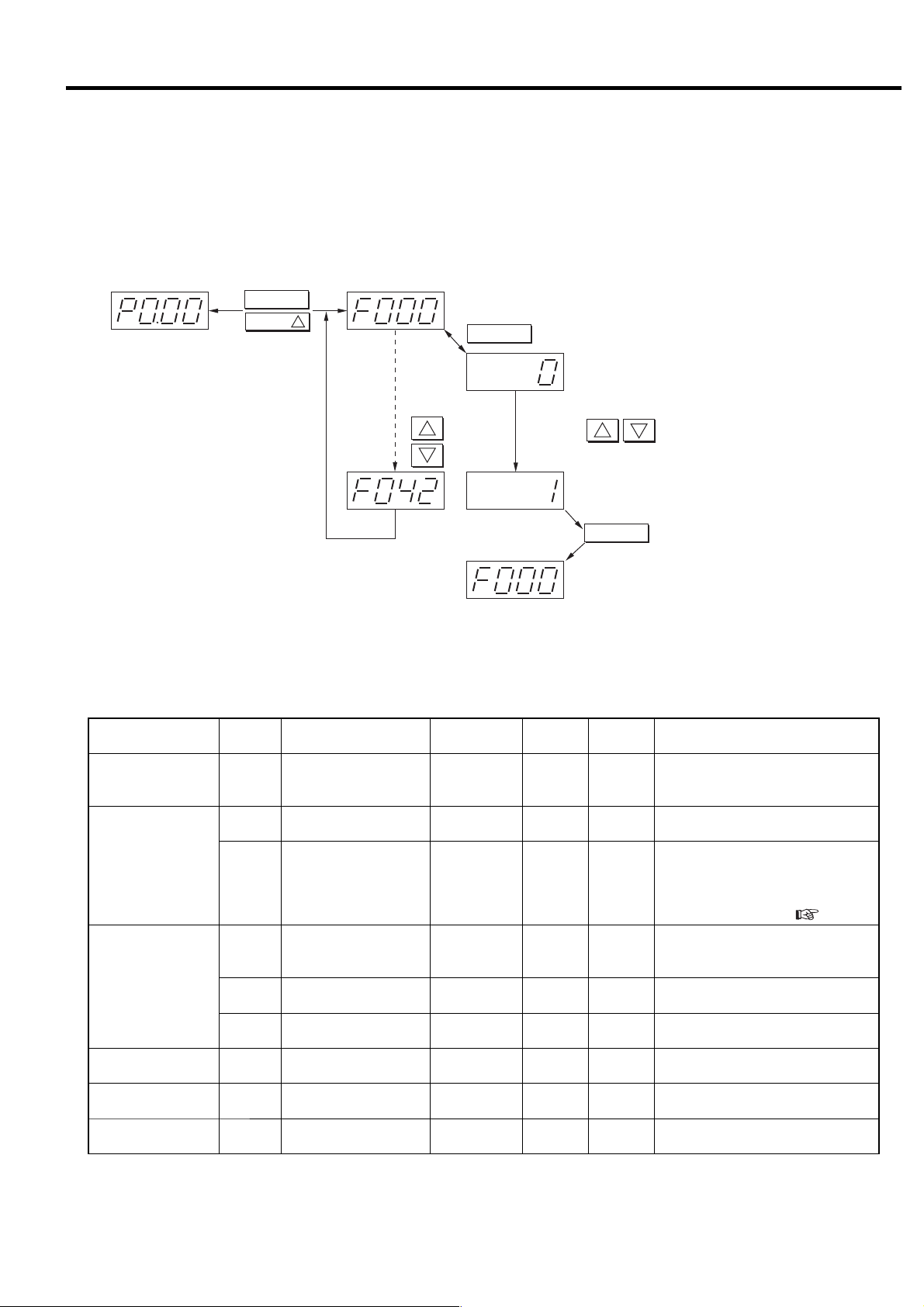

Use the following procedure to display capacity control type

and pressure setting values for confirmation.

① Press the SELECT/WIDE button 16 times. “0.A**” is

then displayed on the screen. The content of “**” varies

depending on specifications. “A” may be “L” or “U”

depending on capacity control specifications.

② Consists of items 0 - 9. Pressure setting status and

optional pressure setting 2 can be confirmed each time

the SELECT/WIDE button is pressed.

③ Press the RESET Button. The screen is returns to the

usual discharge pressure display.

IMPORTANT

Symbol displayed at No. 0 and corresponding capacity

control type

A: AUTO function setting

L: Fixed speed type setting

(INTE …Load/unload operation)

U: Vtype setting (AUTO function canceled)

(

3.3.5 and 8.4)

26

3. OPERATING PROCEDURE [How to Use the Digital Monitor]

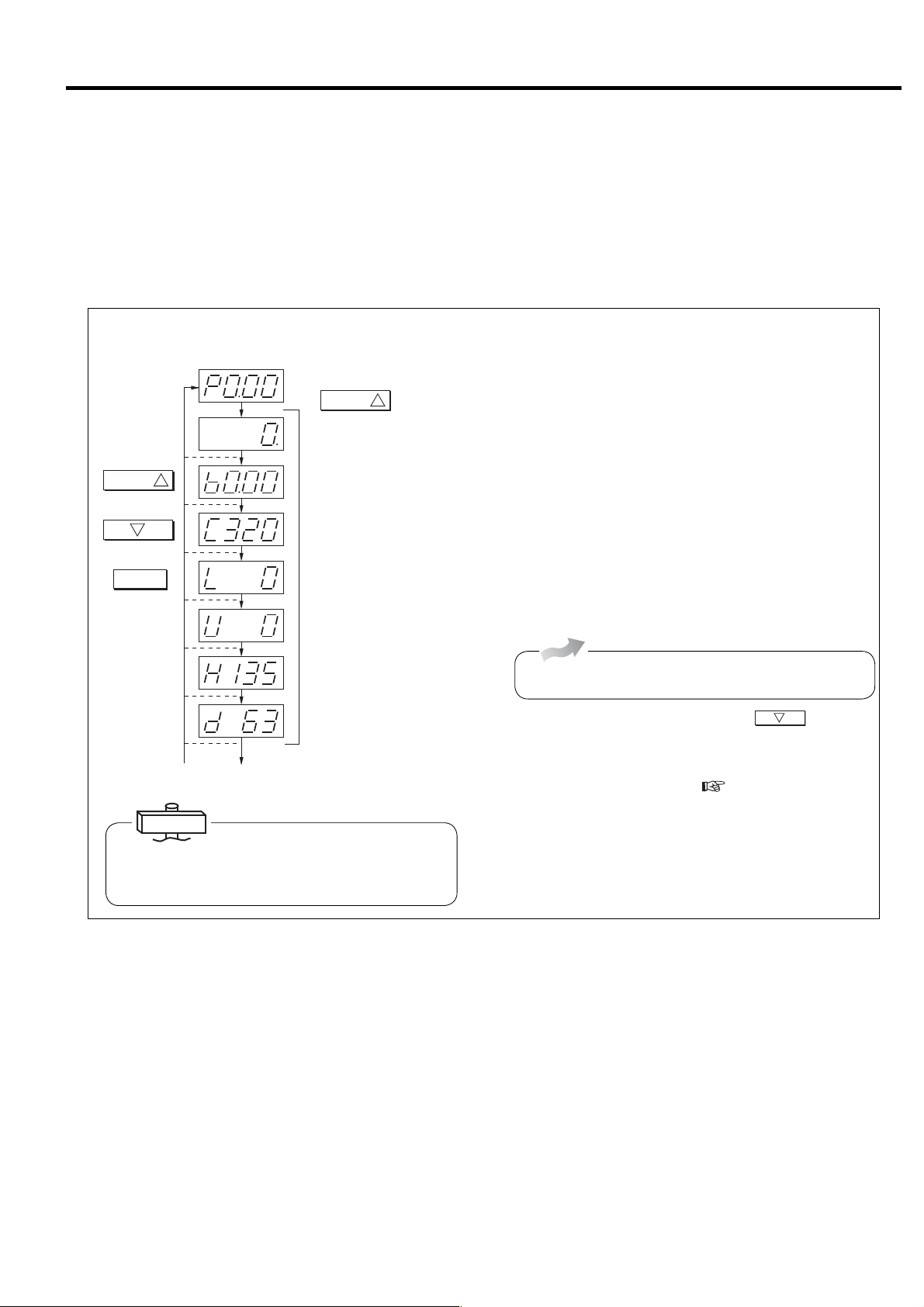

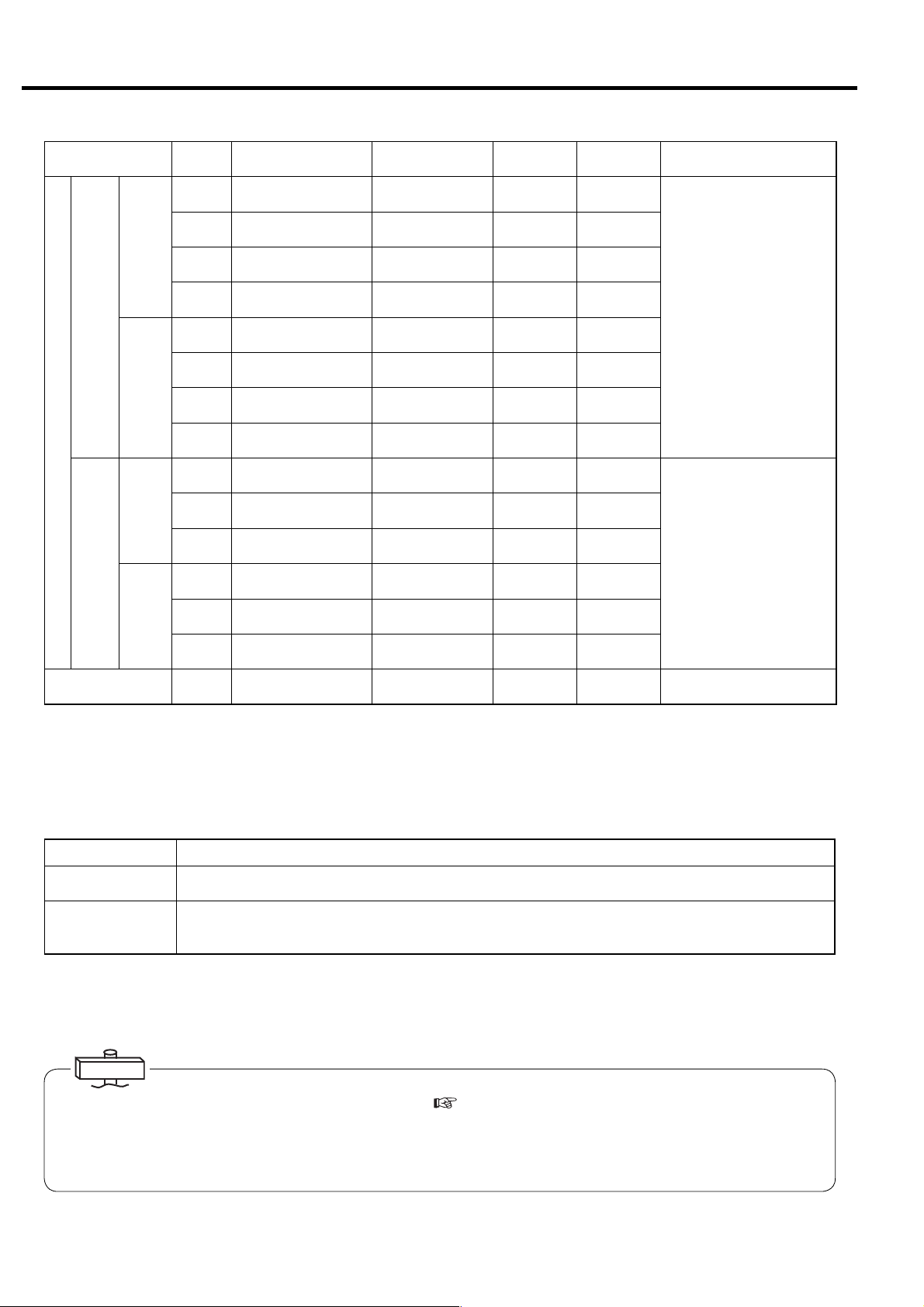

3.4.2 How to Set Control Functions

■ Various settings (instantaneous power interruption (IPI), remote operation, capacity control

setting, pressure setting, etc.)

Switches the display from monitor mode to setting mode (F mode).

RESET

SELECT/WIDE

HolddowntheRESET

buttonandpressthe

SELECT/WIDEbutton

for3secondsor

moretochangeto

theFmode.Perform

sameoperationto

return.

1

Displays000thitemofFmode.

FUNC

SwitcheseachtimeFUNCispressed.

SeetheFmodetableformoredetail.

1

2

Forward

Back

Usebuttonstochangethevalue.

Displayssettingvalue.

F000:(0:SetsStandaloneoperation.)

2

1

F000:(1:Setsmultipleunitcontrol.)

STR

Back

PressSTRtostorethesetting.

Setting can be changed and memorized from the digital monitor without opening the control panel.

■ F Mode table

Function

Multiple unit control

setting

Instantaneous power

interruption (IPI)

restart setting

Remote operation

setting

7 segment

display

Item Range

F000 Control setting 0 - 1 1 0

F002

Instantaneous power

interruption (IPI) setting

0 - 1 1 0 0: Valid, 1: Invalid

Instantaneous power

F003

interruption (IPI)

1 - 5 1 sec 1

detection period setting

F005

F006

F007

Remote control switch

method

Remote operation

method

Remote shutdown

recovery

0 - 3 1 0

0 - 1 1 0 0: Pulse input, 1: Level input

0 - 1 1 0 0: Invalid, 1: Valid

Precision/

unit

Default Remarks

0: Stand alone operation,

1: Multiple unit control

(communication supported)

When the IPI function is available,

instantaneous power interruption is

detected between 20 ms and the

setting detection period set here, and

air compressor restarts. (

0: REMOTE button,

1: Local, 2: Remote,

3: Selectable by external contact

3.4.5).

AUTO setting F011 AUTO operation enabled 0 - 1 1 0 0: Valid, 1: Invalid

Capacity control F018

Function setting

(option)

F021 Pressure control system 0 - 2 1 0

Cut-in/Cut-out pressure

selection

0 - 2 1 0

0: Combination 1, 1: Combination 2,

2: Selectable by external contact

0: Built-in sensor, 1: External contact,

2: Selectable by external contact

27

3. OPERATING PROCEDURE [How to Use the Digital Monitor]

Function

Pressure

setting 1

※2

V type

Pressure

setting 2

※2

Pressure

setting 1

※2

100 / 125 psi (0.69 / 0.86 MPa) specifications

Fixed

speed

type

Pressure

setting 2

※2

7 segment

display

F022

F023

F024

F025

F031

F032

F033

F034

F023

F024

F025

F032

F033

F034

Item Range

Control pressure

setting 1 psi (MPa)

Cut-out pressure 1

psi (MPa)

Cut-in pressure 1

psi (MPa)

Restart pressure 1

psi (MPa)

Control pressure2

psi (MPa)

Cut-out pressure 2

psi (MPa)

Cut-in pressure 2

psi (MPa)

Restart

pressure 2

psi (MPa)

Cut-out pressure 1

psi (MPa)

Cut-in pressure 1

psi (MPa)

Restart pressure 1

psi (MPa)

Cut-out pressure 2

psi (MPa)

Cut-in pressure 2

psi (MPa)

Restart

pressure 2

psi (MPa)

71 〜 125

(0.5 〜 0.86)

71 〜 128

(0.5 〜 0.88)

71 〜 122

(0.5 〜 0.84)

71 〜 122

(0.5 〜 0.84)

71 〜 125

(0.5 〜 0.86)

71 〜 128

(0.5 〜 0.88)

71 〜 122

(0.5 〜 0.84)

71 〜 122

(0.5 〜 0.84)

71 〜 100 [125]

(0.5 〜 0.69 [0.86])

73 〜 86 [110]

(0.5 〜 0.59 [0.76])

73 〜 86 [110]

(0.5 〜 0.59 [0.76])

73 〜 100 [125]

(0.5 〜 0.69 [0.86])

73 〜 86 [110]

(0.5 〜 0.59 [0.76])

73 〜 86 [110]

(0.5 〜 0.59 [0.76])

Precision/

unit

1psi

(0.01MPa)

1psi

(0.01MPa)

1psi

(0.01MPa)

1psi

(0.01MPa)

1psi

(0.01MPa)

1psi

(0.01MPa)

1psi

(0.01MPa)

1psi

(0.01MPa)

1psi

(0.01MPa)

1psi

(0.01MPa)

1psi

(0.01MPa)

1psi

(0.01MPa)

1psi

(0.01MPa)

1psi

(0.01MPa)

Default Remarks

125

(0.86)

128

(0.88)

120

(0.83)

120

(0.83)

125

(0.86)

128

(0.88)

120

(0.83)

120

(0.83)

100 [125]

(0.69 [0.86])

85 [110]

(0.59 [0.76])

85 [110]

(0.59 [0.76])

100 [125]

(0.69 [0.86])

85 [110]

(0.59 [0.76])

85 [110]

(0.59 [0.76])

※Setting can be altered at

any time.

※Setting can be altered at

any time.

Shutdown history clear

F041 (*1)

History clear

0 〜 1

10

0:Enter, 1:History clear

Note:

※ Setting of the items without ※ in remarks can be memorized while the air compressor is stopped.

*1: When set to “1”, history is cleared. After clearing, the value is automatically reset to “0”.

*2: Refer to the below table about the Capacity control pressure setting conditions.

Do not change the setting of F items that are not specified in the table above.

● Capacity control pressure setting conditions

Type Setting conditions (Example of Pressure setting 1)

Fixed-speed

Variable-speed

Note 1: The same setting condition is applied for Pressure Setting 2 (F031 to F034).

IMPORTANT

1. Pressure setting when minimum air receiver tank is installed ( 5.4.4)

Vtype : Pressure differential between cut-out and cut-in shall be 7 psi (0.05 MPa) or more, and pressure differential between

cut-out and target shall be 3 psi (0.02 MPa) or more.

Fixed speed type : Pressure differential between cut-out and cut-in shall be 15 psi (0.1 MPa) or more.

2. External selection of Cut-in/Cut-out pressure combination 1 or 2 is an option. (F018-2)

① F023 shall be set F024 +3 psi (0.02 MPa) or higher, and F025+3 psi (0.02 MPa) or higher.

① F023 shall be set F022+3 psi (0.02 MPa) or higher.

② F024 and F025 shall be set F022 or lower.

28

3. OPERATING PROCEDURE [How to Use the Digital Monitor]

3.4.3 Change of Pressure Setting

Pres.

setting1

FUNC

1

2

Pressthebutton.

Change

values.

Pressthebutton.

STR

3.4.4 Change of Capacity Control Type

AUTOsetting

FUNC

(Initialvalue:0)

1

2

Pressthebutton.

Change

values.

STR

Pressthebutton.

SetAUTOOFF.

Use the following procedure to change the pressure

setting of the capacity control system.

① Switch the display from monitor mode to setting

mode (F mode).

② Set Pressure Setting 1 in F mode.

(

3.4.2)

IMPORTANT

For operation procedure, refer to the various settings.

After entering setting values, be sure to press the

STORE button and return to the monitor mode.

Make sure to press the STORE button to memorize

the setting value.

AUTO (automatic motor stop/restart function) can be

selected properly.

① Switch the display from monitor mode to setting

mode (F mode).

② Set 0 (valid) or 1(invalid) while the air compressor is

stopped.

Capacity control type AUTO ON AUTO OFF

F011 0: Valid 1: Invalid

Digital monitor display 0. AXX0. UXX

After setting change, confirm the capacity control type

by checking the settings on the digital monitor

3.4.1 .

(

(

3.4.7, 3.4.8 and 8.4)

3.4.5 Restart for Instantaneous Power

Interruption

RUNNINGMODE

REMOTE

LOAD

SHUTDOWN

2

IPI is standard function. IPI can be canceled by F002.

refer to the page 27.

START

②③

POWER

AUTOSTART

STOP

UNLOAD STOP

③

In item F018, pressure setting 1 and 2 can be switched.

① This function is available for IPI between 20 ms and

the set value (F003: 1 to 5 sec).

② When IPI occurs , the air compressor stops and the

START light turns of f.

③ After power recovers within F003 set condition, the

AUTO light blinks and the START light turns ON

(glowing) to inform that the air compressor is

waiting for restarting from IPI.

④ The air compressor restarts 15 seconds after power

recovers.

IMPORTANT

(1) IPI means that the power voltage drops to zero (0)

instantaneously.

(2) For the IPI time of less than 20 ms, the air compressor

continues to run.

(3) For the IPI time of more than the setting, the air

compressor judges it as a power failure; the air

compressor stops but does not restart automatically.

Press the START button to restart the air compressor.

29

3. OPERATING PROCEDURE [How to Use the Digital Monitor]

3.4.6 Remote Operation Setting

The REMOTE button on the instrument panel sets

(1) Remote setting by instrument panel

On

(2) Remote setting fixed

REMOTE

IMPORTANT

● When F001 is set to “1:Multi unit control”, remote