Hitachi DSP-160W6N, DSP-200W6N, DSP-240W6N, DSP-160V6WN, DSP-240V6WN Instruction Manual

...

INSTRUCTION MANUAL

HITACHI Oil-Free Rotary Screw Air Compressor

NEXTseries

Water-Cooled

Fixed Speed

DSP-132W6N

DSP-145W6N

DSP-160W6N

DSP-200W6N

DSP-240W6N

Water-Cooled

Variable Speed Drive Control

DSP-160V6WN

DSP-240V6WN

TWO STAGE

●This INSTRUCTION MANUAL explains in detail

the important items that require attention;

observed as the following:

Always observe notations of WARNING, CAUTION

●

and IMPORTANT, as they indicate considerable

risks to safety.

Prior to operation of this air compressor,

ensure that all operators read and

understand this INSTRUCTION MANUAL

completely, thereby operating it safely

and properly.

Place the INSTRUCTION MANUAL near

the air compressor to make it available

at any time, and refer to it as the need

arises.

GRAPHIC DESCRIPTIONS:

WARNING

CAUTION

IMPORTANT

:This is a warning. If handled improp-

erly, death or severe injury could

result.

:This is a caution. If handled improp-

erly, injury and/or physical damage

could result.

:This graphic is Variable Speed-control

Drive (VSD) models.

:This graphic is for items that need

attention, other than WARNING and

CAUTION.

:

This graphic is a page number reference.

How to Use This Instruction Manual

● This Instruction Manual covers the standard models of the Hitachi DSP air compressor.

● This Instruction Manual intended to assist daily operators and maintenance personnel

in the installation, operation, control and service of the Hitachi DSP air compressor.

● Prior to operation of this air compressor, ensure that all operators read and understand

this INSTRUCTION MANUAL completely, thereby operating it safely and properly.

Place the INSTRUTION MANUAL near the air compressor to make it available at any

time, and refer to it as the need arises.

● If there are any questions or comments, please contact the local Hitachi distributor or

the nearest Hitachi office.

Fill your DSP’s model name, Serial Number, etc. into the back cover of this Instruction Manual.

●

Such information may be helpful when ordering parts, periodic maintenance, and overhaul.

WARNING

Never remove a protective device from the air compressor or modify the air compressor.

It is imperative to install an earth leakage (ground) circuit breaker

on the power cable. This prevents a ground fault accident.

DSP air compressors are not designed, intended or approved for

breathing air applications. Hitachi does not approve specialized

equipment for breathing air applications and assumes no responsibility or liability for compressors used for breathing air services.

■ Model Number Nomenclature

DSP-160VW6N

Dry or Oil-Free Rotary

Screw Air Compressor

Packaged

● Hitachi may make improvements and/or changes in the products described in this publication at any time without notice.

N-Type (NEXT Series)

Frequency (6: 60 Hz)

W: Water-Cooled

w/ V: VSD, w/o V: Fixed

Motor Output (kW)

Contents

1. SAFETY ………………………………………………………………………………………… 2

2.

GENERAL DESCRIPTION

2.2 Components …………………………………………………………………… 5

2.3 Daily Operating Components ………………………………………………… 7

2.1 Appearance

………………………………………………………………………

4

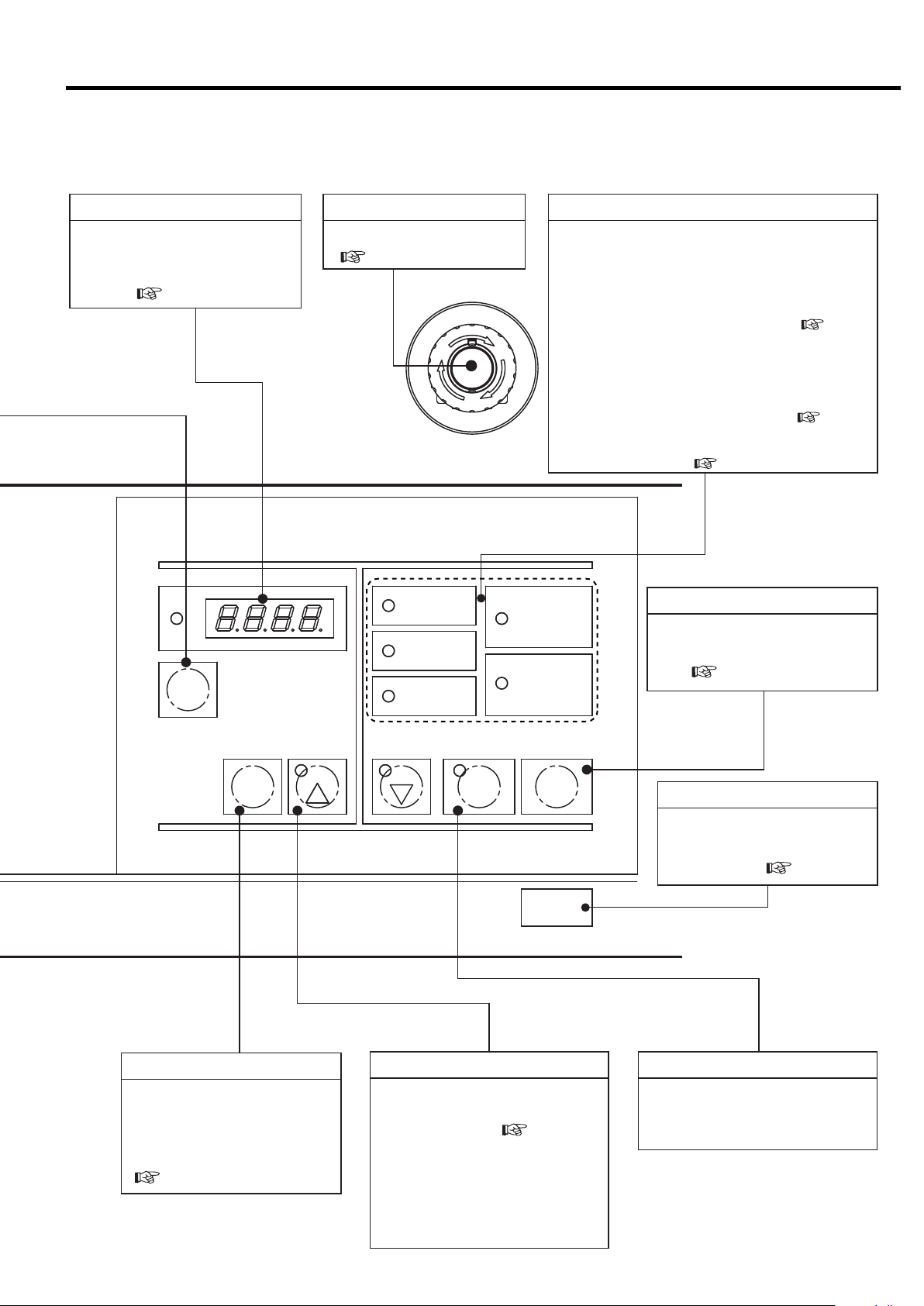

3. OPERATING THE DSP 3.1 Instrument Panel………………………………………………………………… 10

3.2 Start/Stop Operation …………………………………………………………… 12

3.3 How to Use the liquid Crystal Display (LCD)………………………………… 13

3.4 How to Use the Digital Monitor ……………………………………………… 23

3.5 Daily Operation ………………………………………………………………… 30

3.6 Oil Mist Remover Daily Operation…………………………………………… 32

3.7 Adjusting the DSP ……………………………………………………………… 32

4. TROUBLESHOOTING 4.1 Protective Devices ……………………………………………………………… 33

4.2 Troubleshooting the Air Compressor………………………………………… 35

4.3 Troubleshooting the Oil Mist Remover……………………………………… 36

5. INSTALLING 5.1 Unpacking the DSP Air Compressor ………………………………………… 37

AND PIPING THE DSP 5.2 Conveying the DSP Air Compressor ………………………………………… 37

5.3 Installing the DSP Air Compressor ………………………………………… 38

5.4 Piping the DSP Air Compressor ……………………………………………… 39

5.5 Ventilation of Air Compressor Room………………………………………… 43

6. STARTUP OPERATION 6.1 Air Compressor ………………………………………………………………… 44

6.2 Oil Mist Remover ……………………………………………………………… 46

7. WIRING 7.1 Power Supply Transformer and Power Cable ……………………………… 47

7.2 MIV and WIVM wiring ………………………………………………………… 47

7.3 Connecting a Power Cable …………………………………………………… 47

7.4 Wiring Connection Diagram…………………………………………………… 50

7.5 Control Panel /LCD monitor Specifications ………………………………… 50

8.

STANDARD COMPONENTS

AND SUBSYSTEMS

8.3 Cooling Water…………………………………………………………………… 61

8.4 Capacity Control System ……………………………………………………… 62

8.5 Outline of Oil Mist Remover Subsystem …………………………………… 66

9.

MAINTAINING THE DSP

9.2 Standard Maintenance Schedule …………………………………………… 68

9.3 Oil Mist Remover Maintenance ……………………………………………… 72

9.4 How to Service the DSP Air Compressor…………………………………… 73

10.

PRECAUTIONS WHEN THE COMPRESSOR IS TO BE IDLE FOR AN EXTENDED PERIOD OF TIME

8.1 Standard Components ………………………………………………………… 57

8.2 Air/Oil Flow ……………………………………………………………………… 58

9.1 Air Compressor Maintenance………………………………………………… 67

…………… 84

11. PARTS LIST ………………………………………………………………………………………… 85

12. WARRANTY, AFTER-SALES AND SERVICE …………………………………………………………… 103

13. OPERATION RECORD LOGBOOK…………………………………………………………………………… 104

14. STANDARD SPECIFICATIONS ……………………………………………………………………………… 105

1

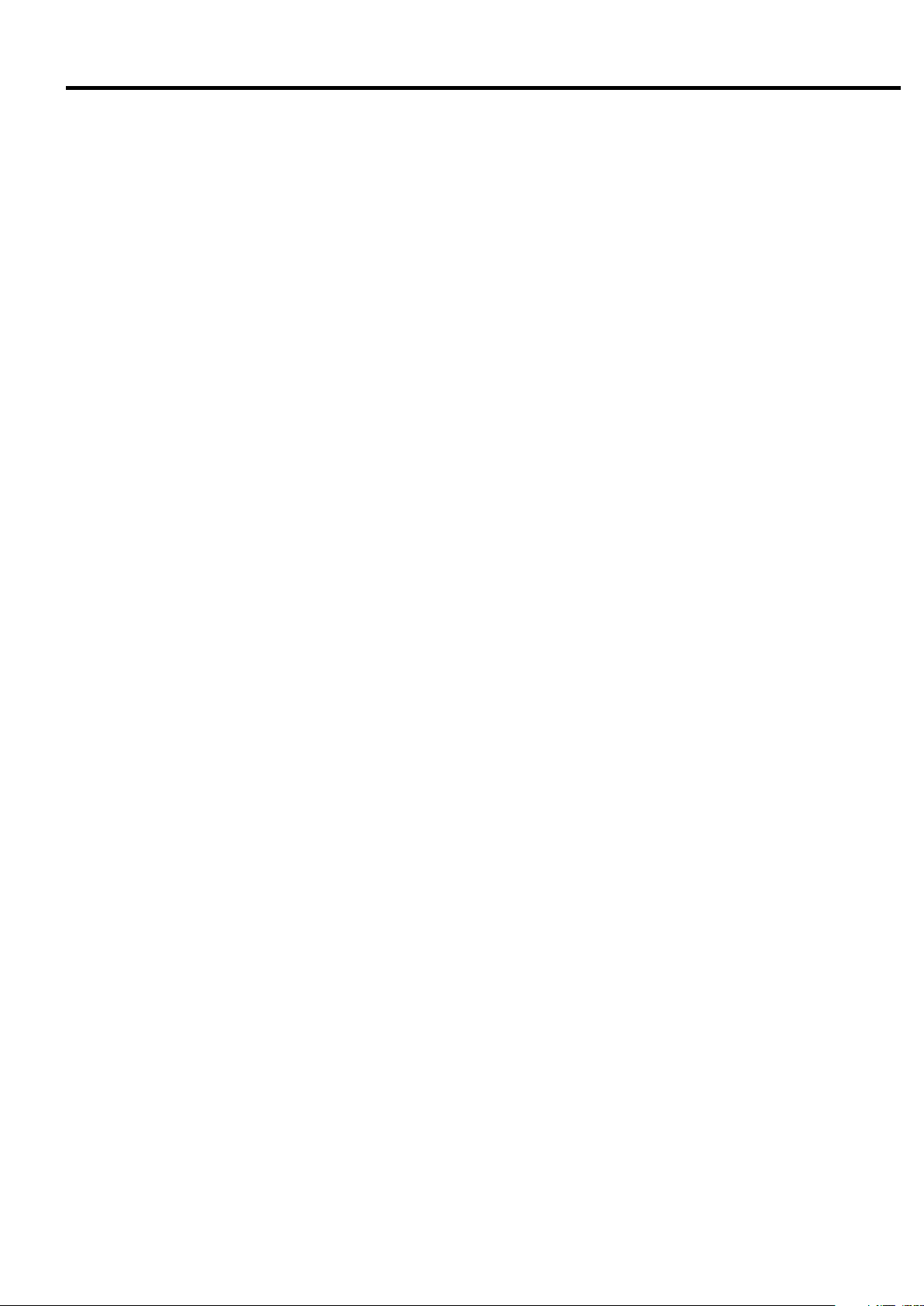

1. SAFETY

To ensure safe and proper operation of the air compressor, it is indispensable to carefully

read and understand the following warnings and instructions detailed below. These warnings and instructions are attached to the air compressor as shown in the figure below.

WARNING

WARNING

Rotating Parts!

●Keep hands and rods, etc. away from

the rotating parts (Cooling fans, etc.)

●Use caution at all times, when air com-

pressor is powered. The air compressor may be capable of restarting without hitting the START button.

●When the air compressor is operating,

do not remove or open the enclosure

panels and doors.

●Before servicing the air compressor,

stop it, disconnect the power, especially

when accessing any rotating parts.

WARNING

Hot Surface!

●Do not directly touch any component

inside the air compressor enclosure

when the air compressor is operating

or immediately after it has stopped,

as the components are extremely hot

and can cause severe injury.

●Before servicing the air compressor,

stop it, disconnect the power, then

wait for the air compressor to cool

down.

Electric Shock Hazard!

●Before servicing or wiring the

air compressor, disconnect

the power. This will prevent

anyone from turning on the

power and causing an electric shock that could lead to

severe injury or death.

●Do not allow any unlicensed

person to wire the air compressor. Always use a licensed

electrician.

●Ground the air compressor.

Intercooler Header

Discharge Air pipe

Discharge Air pipe

Heated!!

Air End

Heated!!

WARNING

Hot Surface!

●Do not directly touch any component

inside the air compressor enclosure

when the air compressor is operating

or immediately after it has stopped,

as the components are extremely hot

and can cause severe injury.

●Before servicing the air compressor,

stop it, disconnect the power, then

wait for the air compressor to cool

down.

Aftercooler Header

Air End

WARNING

Electric Shock Hazard!

●Before servicing or wiring the

air compressor, disconnect

the power. This will prevent

anyone from turning on the

power and causing an electric shock that could lead to

severe injury or death.

●Do not allow any unlicensed

person to wire the air compressor. Always use a licensed

electrician.

●Ground the air compressor.

2

WARNING WARNING

1. SAFETY

Do Not Breathe Air!

Discharge air can contain Carbon Monoxide and

other contaminants. Breathing the air can cause

severe injury or death.

WARNING

Electric Shock Hazard!

●

Before servicing or wiring the air compressor,

disconnect the power. This will prevent anyone

from turning on the power and causing an electric

shock that could lead to severe injury or death.

●

Do not allow any unlicensed person to wire the air

compressor. Always use a licensed electrician.

●Ground the air compressor.

CAUTION

●

High pressure air can cause severe injury or death.

Be careful when air compressor is operating.

Pressurized air can blow out of safety relief valves

and etc. at incredibly high velocities.

●When using compressed air to clean equipment,

use extreme caution and/or wear eye protection.

●Before servicing the air compressor, stop it,

disconnect the power, and relieve pressure before

removing filter, plug, fitting or cover.

WARNING

High Pressure Air!

Hot Surface!

●Do not directly touch the air end, discharge air

pipe,and coolers when the air compressor is

operating and immediately after it has stopped,

because these parts are heated then.

Before servicing the air compressor (especially

●

when accessing to the heated parts), stop it, disconnect the power, and wait until it is cooled down.

WARNING

●

Preoaution against Fire!

Keep any other hazardous materials such as

flammable solvents away from the air compressor.

Also do not use fire nearby it; otherwise a spark

may enter the air compressor and burn it internally.

●Do not remove any protective relayʼ s. Also do

not make a modification of the control circuit that

may result in impairing the protective relayʼ s

function. Remember that the loss of the protective

relayʼ s function may cause serious damage.

●Install an earth leakage circuit breaker between

the air compressor and the power supply. Do not

use a disconnector such as a knife switch

because it cannot protect the air compressor and

may cause burnout of the air end if a ground fault

has occurred.

Rotating Parts!

●Keep hands and rods, etc. away from the rotating

parts (Cooling fans, etc.)

●Use caution at all times, when air compressor is

powered. The air compressor may be capable of

restarting without hitting the START button.

●When the air compressor is operating, do not

remove or open the enclosure panels and doors.

●Before servicing the air compressor, stop it, dis-

connect the power, especially when accessing

any rotating parts.

3

2. GENERAL DESCRIPTION

This section illustrates and describes the major components of the DSP air compressor. Be familiar

with the name, location and function of each component before using the DSP air compressor.

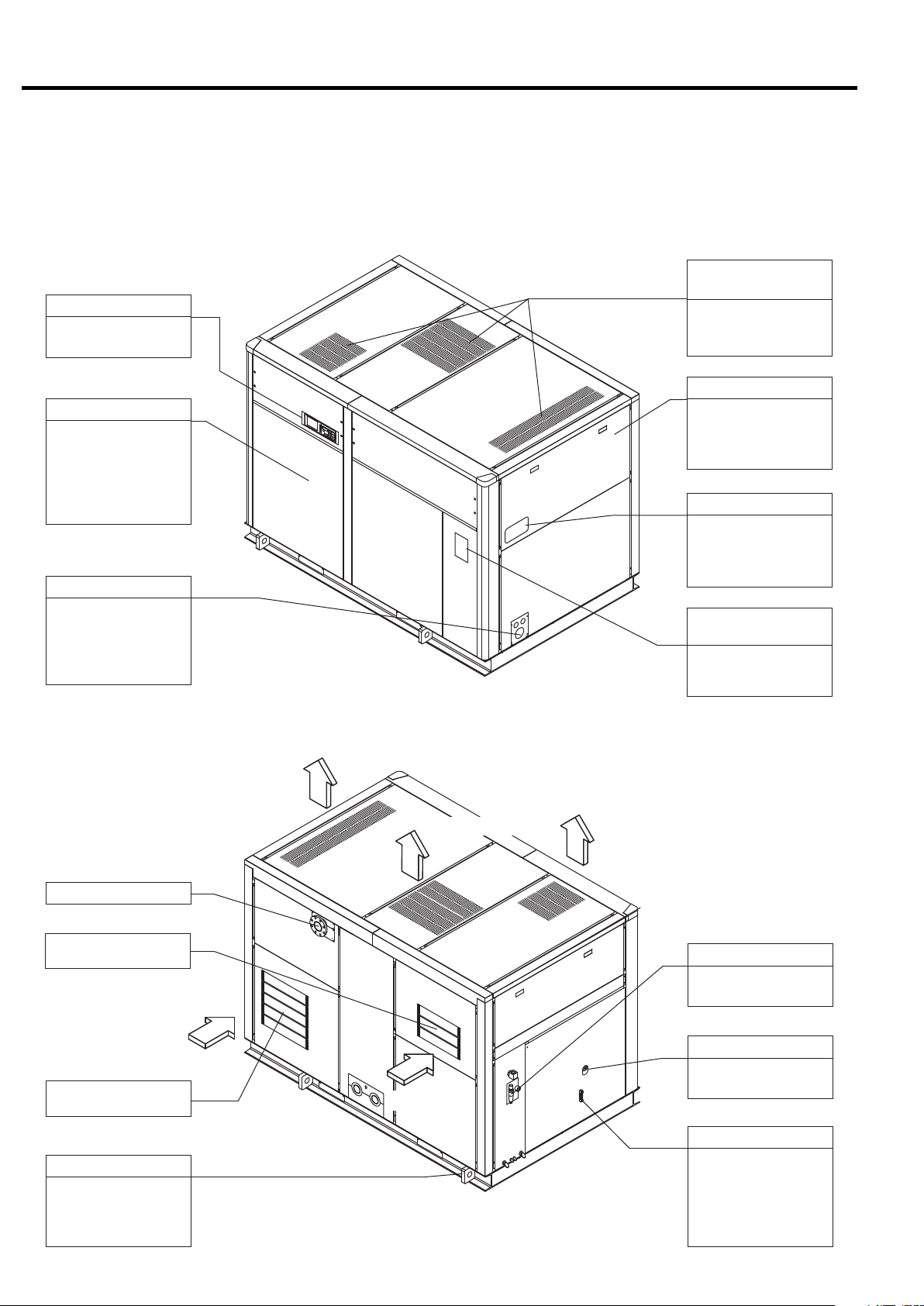

2.1 Appearance

2.1.1 Fixed Speed

[Front View]

Air Exhaust

(Air Compressor Package)

Instrument Panel

See page p. 10, chapter 3, for details.

Front Left Door

Open the front left

door only when servicing the DSP air compressor. Keep it closed

when operating the

DSP air compressor.

Power Supply Port

Check the specifications, power supply

and voltage before

connecting the power

supply.

This panel discharges

the hot air generated

in the air compressor.

Enclosure

Enclosure panels

lower the sound level

of the air compressor

package.

Compressor Name plate

Model designation,

manufacturing number

and specification are

printed.

Plate of Operating /

Servicing Instructions

Read carefully the

plate before operating

and servicing the DSP.

[Rear View]

Compressed Air Discharge

Air Intake

(Inlet to the Air End)

Air Intake

Air Intake

(Air Compressor Package)

Sling Fitting

Use the sling fitting

when moving and

installing the DSP air

compressor.

Air Exhaust

Air Exhaust

Air Exhaust

OMR

See page 55 for the

details

Oil Filling Port

Use the port to fill the

gear case with oil.

Air Intake

Oil Level Gauge

This indicates the

quantity of the oil in

the gear case. Check

the oil level before

starting the DSP and

when operating it.

4

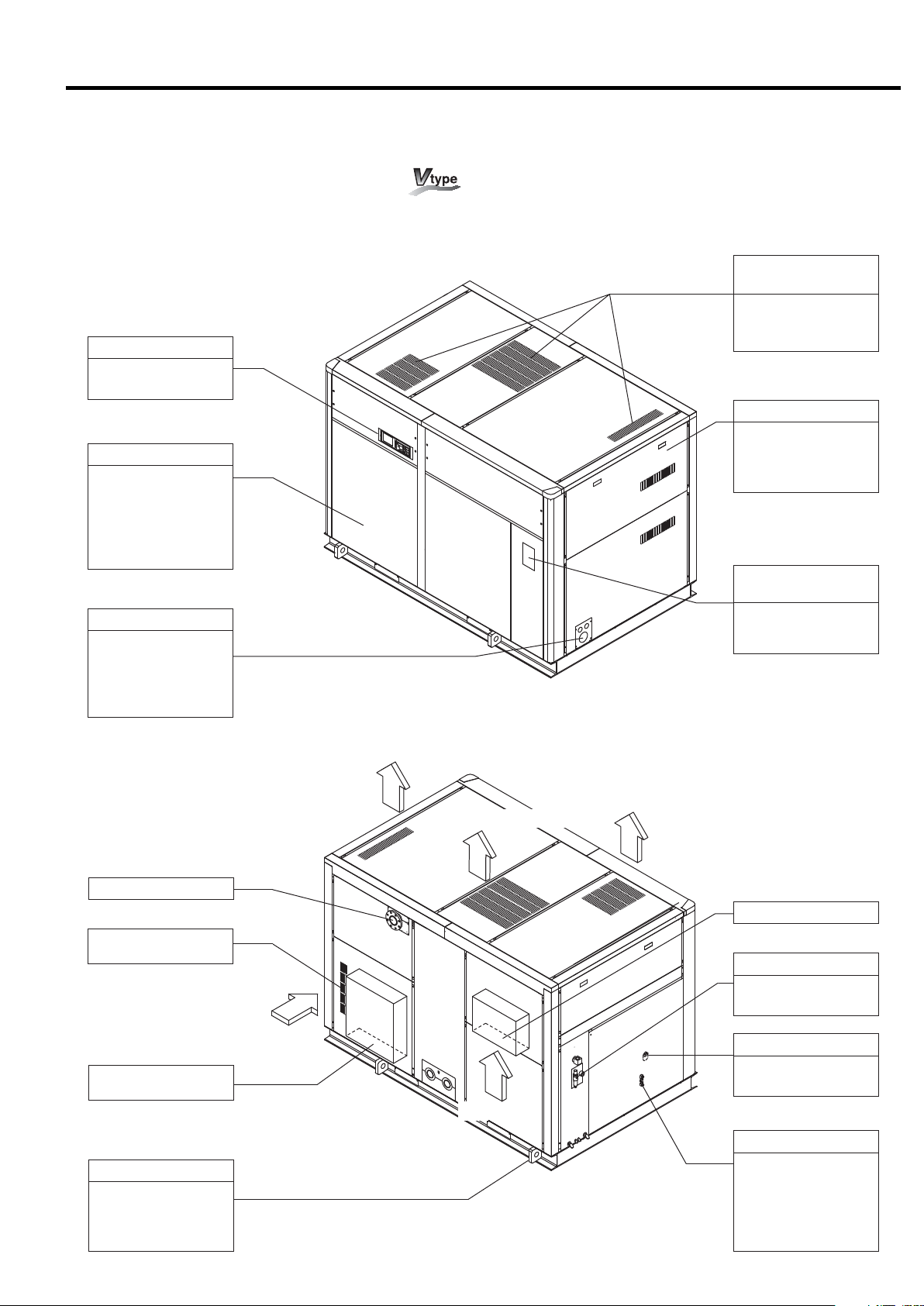

2.1.2 Variable Speed Drive Control

[Front View]

Instrument Panel

See page p. 10, chapter 3, for details.

Front Left Door

Open the front left

door only when servicing the DSP air compressor. Keep it closed

when operating the

DSP air compressor.

Power Supply Port

Check the specifications, power supply

and voltage before

connecting the power

supply.

2. GENERAL DESCRIPTION [Appearance]

Air Exhaust

(Air Compressor Package)

This panel discharges

the hot air generated

in the air compressor.

Enclosure

Enclosure panels

lower the sound level

of the air compressor

package.

Plate of Operating /

Servicing Instructions

Read carefully the

plate before operating

and servicing the DSP.

[Rear View]

Compressed Air Discharge

Air Intake

(Inlet to the Inverter)

Air Intake

Air Intake

(Air Compressor Package)

Sling Fitting

Use the sling fitting

when moving and

installing the DSP air

compressor.

Air Exhaust

Air Exhaust

Air Exhaust

Compressed Air Discharge

OMR

See page 66 for the

details

Oil Filling Port

Use the port to fill the

gear case with oil.

Air Intake

Oil Level Gauge

This indicates the

quantity of the oil in

the gear case. Check

the oil level before

starting the DSP and

when operating it.

5

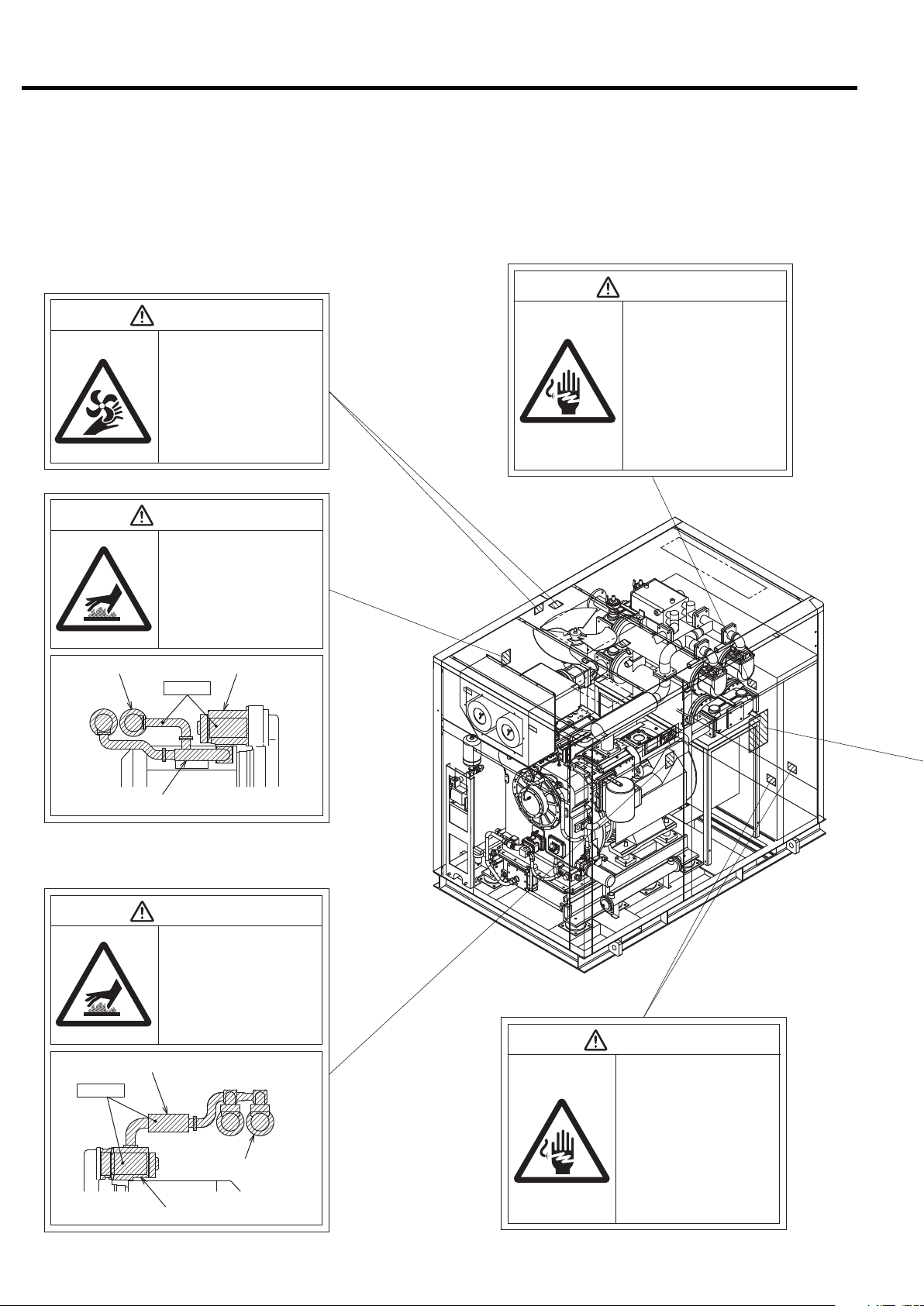

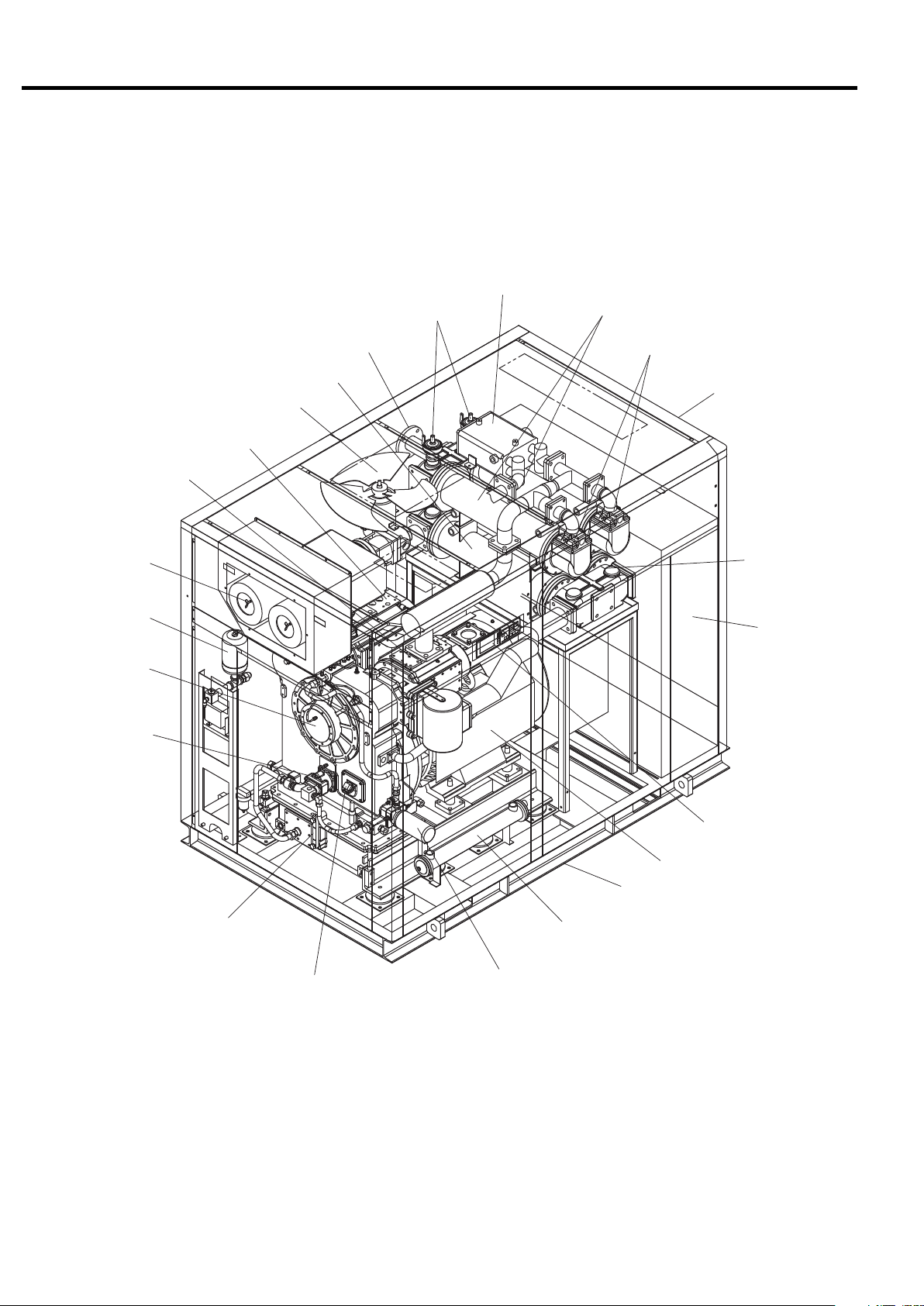

2. GENERAL DESCRIPTION [Components]

2.2 Components

Discharge Pipe

(Compressed Air Discharge)

Blow-off air cooler

Safety Relief Valve

Aftercooler

Check Valve

2nd-Stage Air end

Air Intake Filter

Oil Mist Remover

Gear Case

Oil Pump

Ventilating Fan

1st-Stage Air end

Intercooler

Enclosure

Intercooler

Starter /

Control Box

Instrument Panel

Main Motor

Common Base

Oil Level Gauge

Oil Filling Port

Oil Filter

Oil Cooler

6

2. GENERAL DESCRIPTION [Daily Operating Components]

2.3 Daily Operating Components

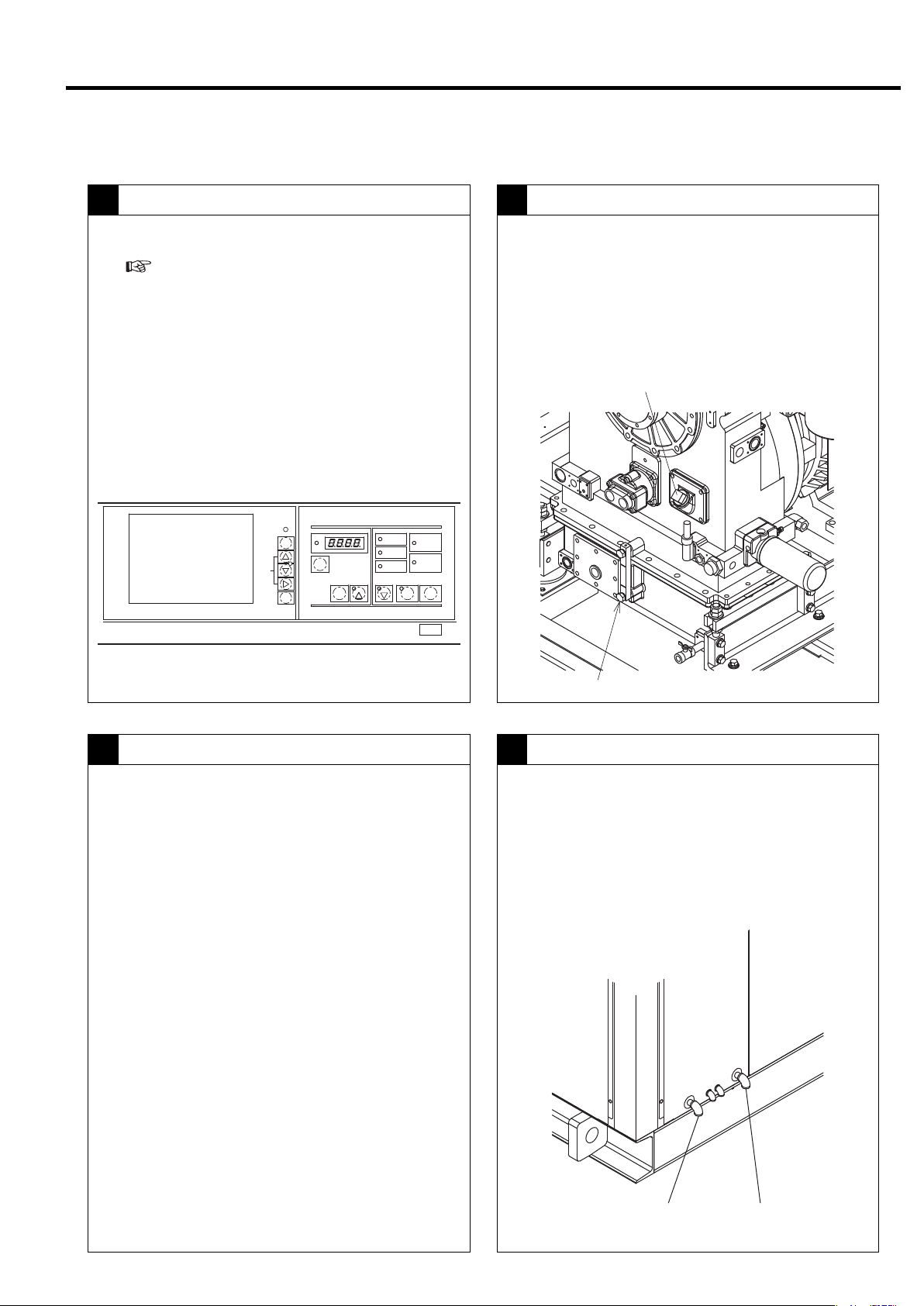

Controls on the Instrument Panel

1 2

● Indicates the operation control section.

(

For more information, see Chapter 3, on

page 10.)

● Operation ON → POWER light on.

● Start: Press START button → Operation Light on

during operation

● Stop: Press UNLOAD STOP button →

unloading

stops for 5 minutes → Operation Light off during

operation

● Power OFF: → POWER light off

MONITOR

自動

AUTO

モニタ

MONITOR

メニュー

MENU

+/−

UP/

DOWN

設定

SET

運転管理

RUNNINGCONTROL

警報

ALARM

機能

FUNC

リセット

RESET

遠方

記憶

STR

[×10h]

表示切替/

ワイド モード

SELECT/WIDE

1

運転状況

RUNNINGMODE

遠方

REMOTE

負荷

LOAD

故障

SHUTDOWN

2

電源

POWER

起動待ち

AUTOSTART

運転 停止

STOP

STARTREMOTE

UNLOAD STOP

Oil Level Gauge

● Verify that the oil level of the lubricating oil is

between the red lines during operation.

Lubricating oil circulates in the cooler and piping during

operation, so the position of the oil level differs when the

compressor is running and when it is off. The level rises

when the compressor stops running.

Oil Filling Port

Lubricating Oil

3 4

Oil: Use genuine Hitachi GL-68 DSP Compressor Oil.

Replace the oil every 8,000h operating hour or

every 2-year, whichever comes earlier.

Oil Level Gauge

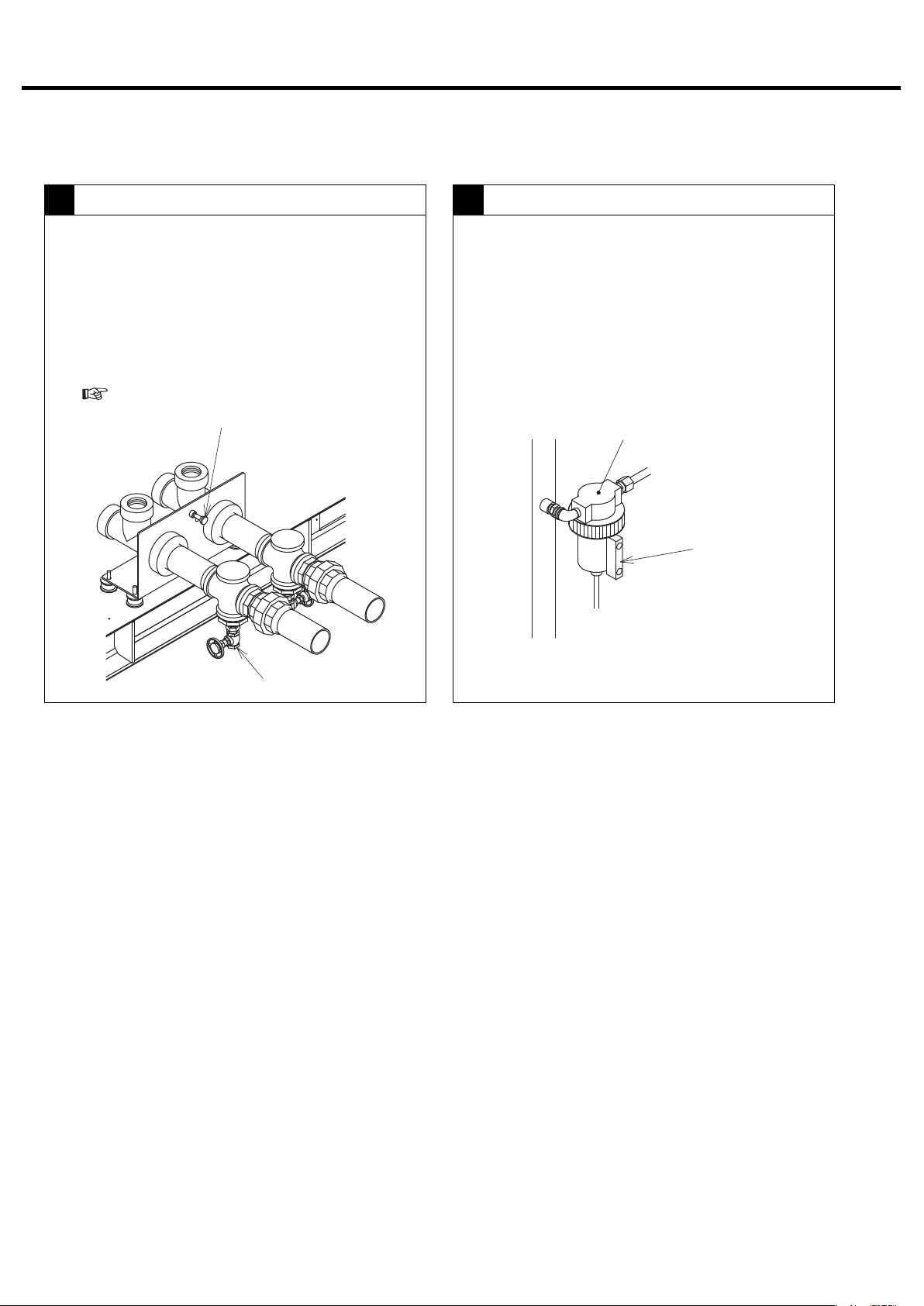

Aftercooler and Intercooler - Condensate Drain Valve

● Verify that air containing drainage is discharged

intermittently from the intercooler and after cooler

drain ports.

The higher the temperature and humidity, the more drainage

is produced. Drainage may not be produced on the intercool-

er side during winter.

After cooler

drain port

Intercooler

drain port

7

2. GENERAL DESCRIPTION [Daily Operating Components]

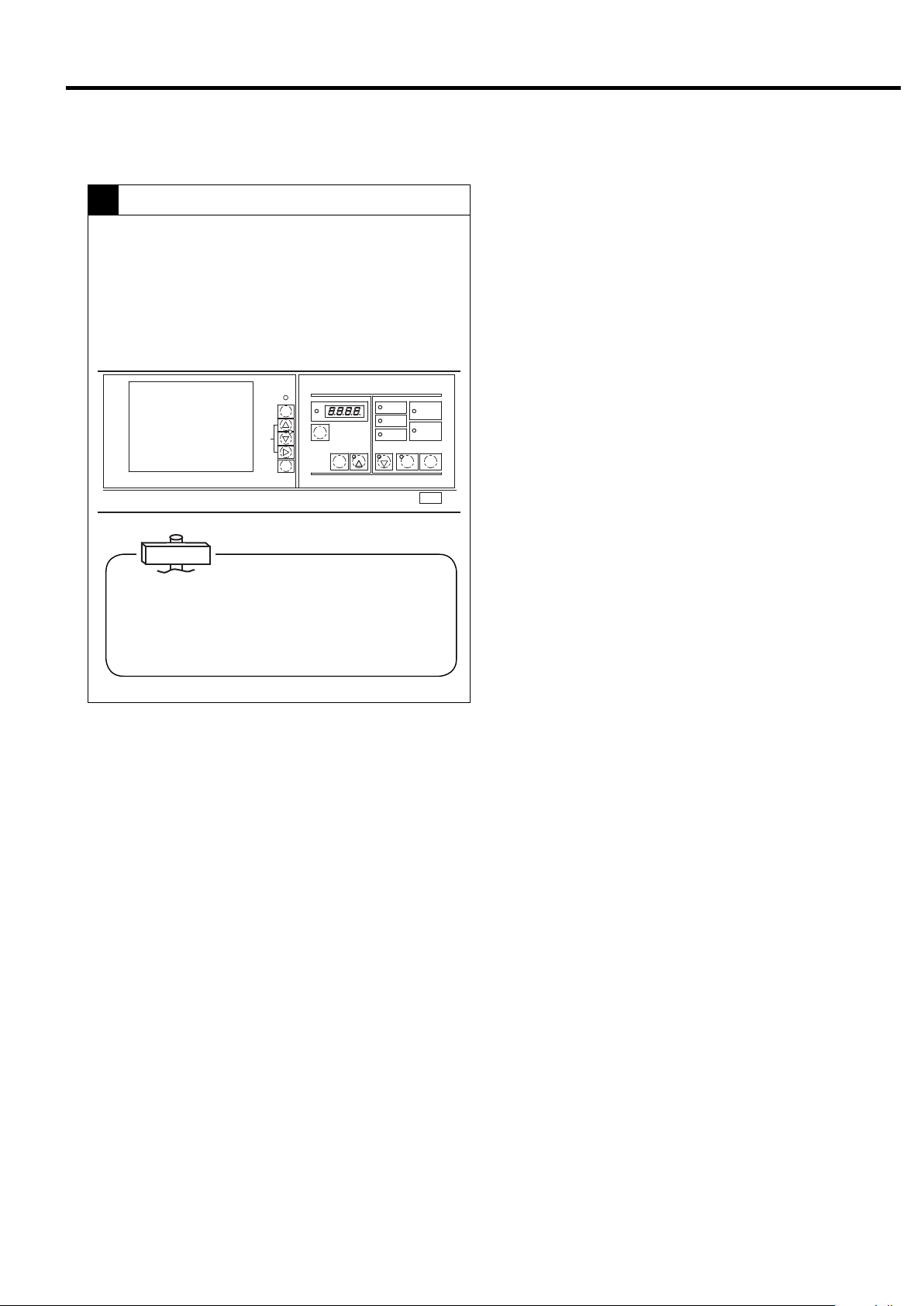

Cooling Water

5

① Shut off the cooling water when the compressor is

off.

② Open the peacock for draining water. Also open

the valve of the water drain port and drain the

cooling water.

③ Be especially careful of freezing during the winter.

(

For details, see page 61.)

Water drain peacock

Control Line Filter (Fixed Speed)

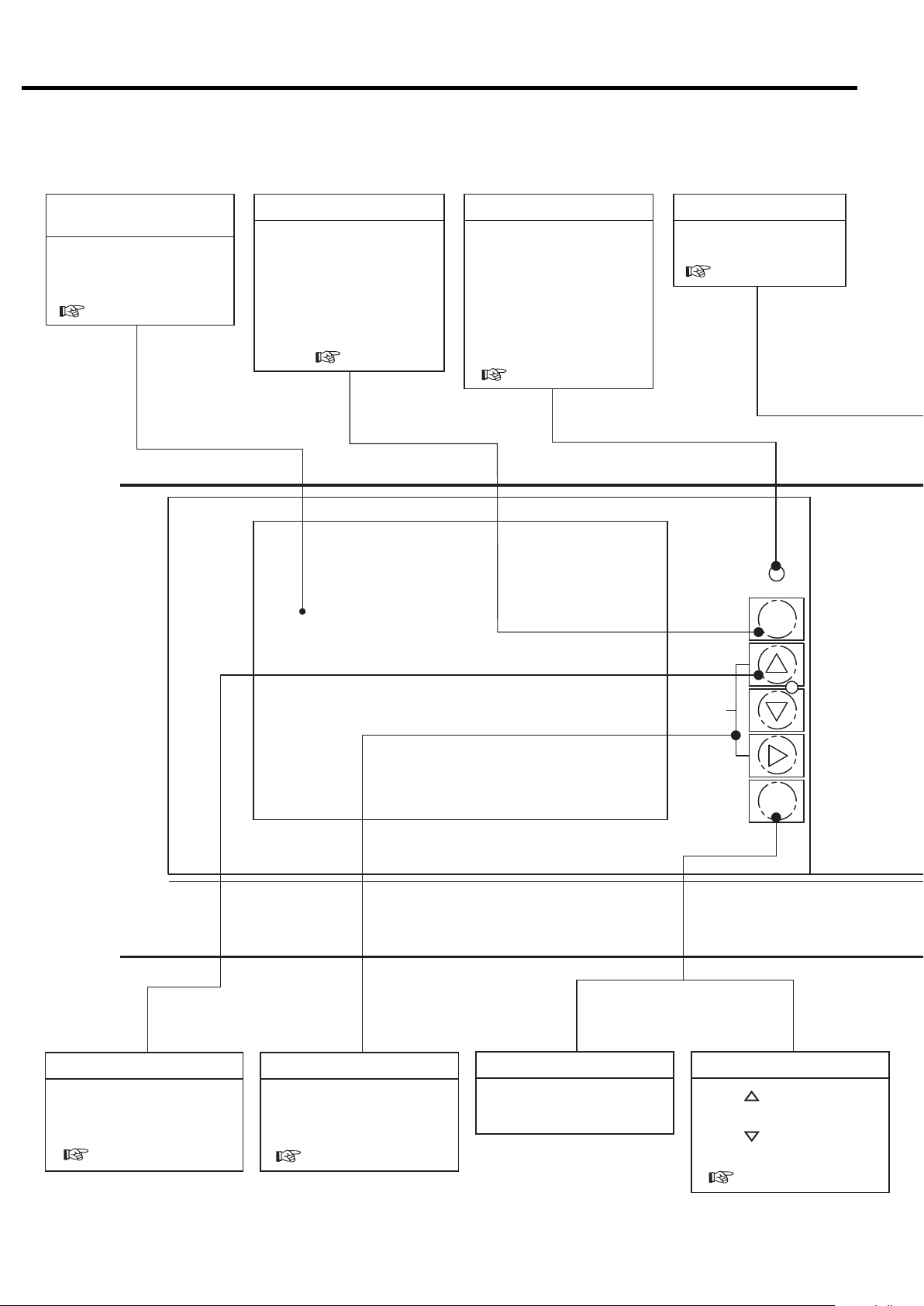

6

● Check the condensate drain discharge from the

control line filter by checking the sight glass on the

control line filter.

Control Line Filter

Sight Glass

Water drain port

8

2. GENERAL DESCRIPTION [Daily Operating Components]

Stopping operation

7

●Normally use UNLOAD STOP button to stop the

compressor. The compressor then unloads for 5

minutes and stops running.

(In the case of an emergency, press the STOP

button to stop operation.)

MONITOR

自動

AUTO

モニタ

MONITOR

メニュー

MENU

+/−

UP/

DOWN

設定

SET

運転管理

RUNNINGCONTROL

警報

ALARM

機能

FUNC

リセット

RESET

遠方

記憶

STR

[×10h]

表示切替/

ワイド モード

SELECT/WIDE

1

運転状況

RUNNINGMODE

遠方

REMOTE

負荷

LOAD

故障

SHUTDOWN

2

電源

POWER

起動待ち

AUTOSTART

運転 停止

STOP

STARTREMOTE

UNLOAD STOP

IMPORTANT

Keeping the second-stage air end as dry as possible is

essential for preventing it from rusting due to a longterm operation suspension. When stopping the DSP,

therefore, execute an unloading operation and thereby

remove the moisture from the second-stage air end.

9

3. OPERATING THE DSP

3.1 Instrument Panel

Liquid Crystal Display

(LCD)

Displays the operation data,

various setting, shutdowns/

alarms information, etc

( page 13)

MONITOR Button

Enables movement within

each of the monitoring

displays (M1, M2) and the

message display (M3). This

button also enables you to

return to the M1 display from

the FUNCTION MENU

display ( page 13).

AUTO light (yellow)

ON (glowing) when an

automatic operation (an

AUTO operation, a scheduling operation, or lead/lag

operation) is activated.

ON (flashing) when external

calendar or scheduling

operation is abnormal.

( page 16, 20)

RESET Button

Reset the system or cancels

the shutdown/alarm circuit

( page 15)

自動

AUTO

モニタ

MONITOR

メニュー

MENU

MENU Button

Functions to display the

menu screen and move the

cursor.

( page 18)

MONITOR

+/- UP DOWN Buttons

Each of these buttons act as

an up-arrow, down-arrow

and right-arrow key.

( page 18)

SET Button

It saves any adjusted set

points.

+/−

UP/

DOWN

設定

SET

Contrast adjustment

SET+[ ] button operation:

Brightens the display.

SET+[ ] button operation:

Darkens the display.

( page 22)

10

3. OPERATING THE DSP [Instrument Panel]

Digital Monitor

In addition to basic settings, used

to set various types of setting

values in combination with the LCD

monitor. ( page 22)

運転管理

RUNNINGCONTROL

警報

ALARM

機能

FUNC

リセット

RESET

遠方

記憶

STR

ワ イド モ ード

EMERGENCY STOP button

Stops for emergency.

( page 12)

遠方

REMOTE

負荷

[× 10h]

LOAD

故障

SHUTDOWN

表示切替/

SELECT/WIDE

1

2

G

E

R

N

E

M

E

S

C

Y

P

T

O

運転状況

RUNNINGMODE

電源

POWER

起動待ち

AUTOSTART

運転 停止

STARTREMOTE

RUNNING MODE Light

POWER light (yellow):

ON (glowing) when the power to the air compressor is turned on.

REMOTE light (green):

ON (glowing) when the REMOTE button is pressed in

order to activate a remote operation.

ON (flashing) when an external remote-operation-activation switch has

been turned on in order to activate a remote operation.

LOAD light (yellow):ON (glowing) when the air compressor is loading.

AUTO START light (green):

ON (glowing) while the air compressor is in a stop due to an

AUTO operation, lead/lag operation, or scheduling operation.

ON (blinking) while the air compressor is in a stop due to a

restartable instantaneous power interruption. ( page 16)

SHUTDOWN light (red):

ON (either glowing or blinking) when a shutdown/alarm

problem has occurred. ( page 15)

( page 28)

STOP Button

Used to stop the compressor

immediately without first unloading. ( page 12)

STOP

UNLOAD STOP Button

Press this button to stop the air compressor.

The air compressor will stop after removing the

condensate from the air end.

※This stop button is effective while a stand alone operation.

REMOTE Button

Activates or deactivates a remote

start/stop operation locally or on

the instrument panel. it also acts

as a right-arrow key stop

( page 28).

UNLOAD STOP

SELECT/WIDE Button/Light (Yellow)

Press to confirm various types of

setting values, shutdown history,

and setting status. (

To set to ECONOMODE (energy

conservation mode) (standard type

only), press and hold the SELECT/

WIDE button for at least 7 seconds.

The light flashes and ECONOMODE

is set.

page 24, 25

)

Used for normal stop. Stops

after the compressor and air

hoses are dry. ( page 12)

START Button

Starts the air compressor.

The OPERATION light (red) turns

on while the compressor is running.

11

3. OPERATING THE DSP [Start/Stop Operation]

3.2 Start/Stop Operation

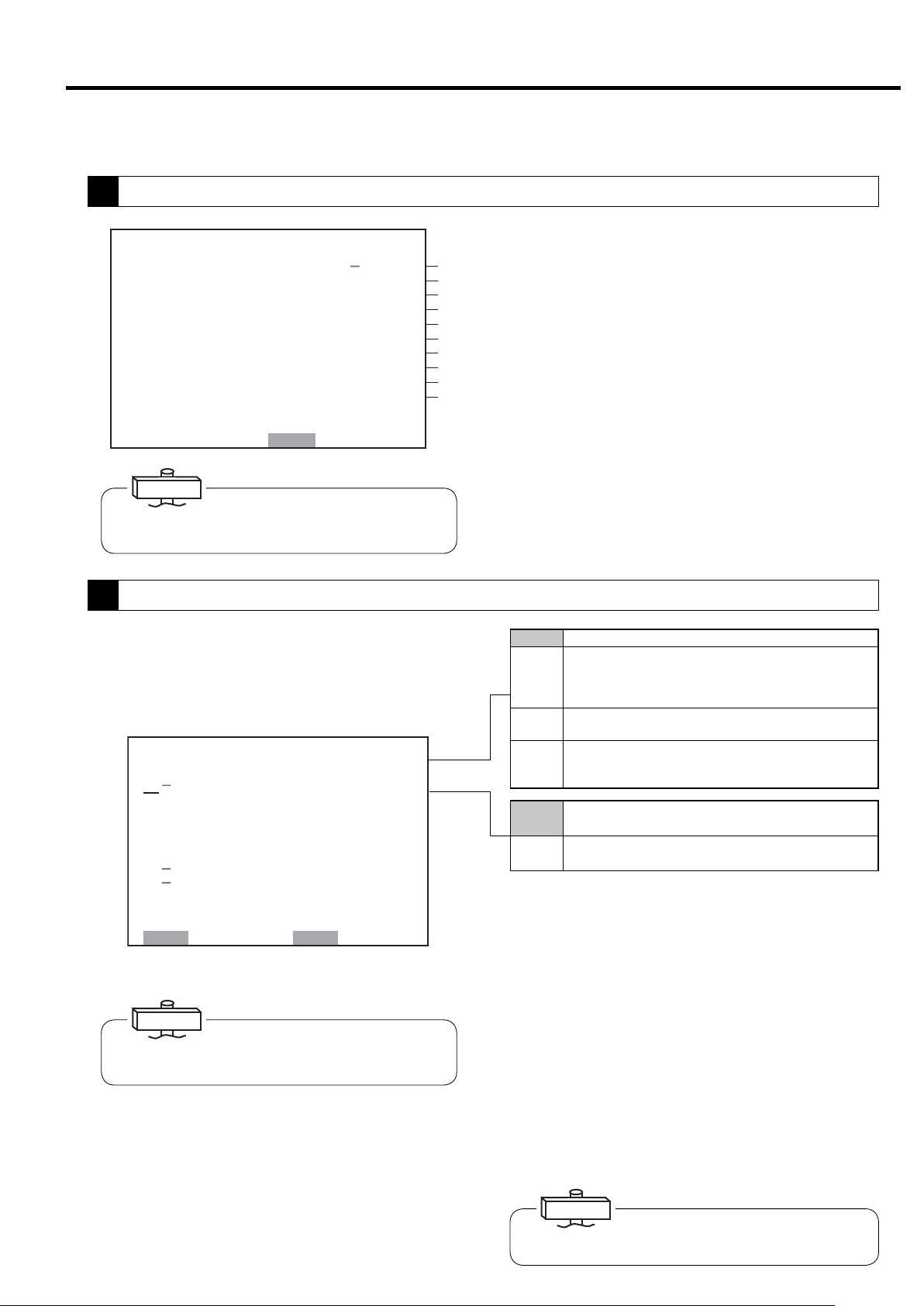

3.2.1 Connecting the Power

When you connect the power, the POWER light turns on

and the LCD monitor displays the following screen for 5

seconds, and then switches to the monitor screen (M1)

that displays control settings, discharge air pressure, and

total operating hours.

COMPRESSOR MONITOR

CONTROLLER

5 sec

㻞㻜㻜㻥䠋㻜㻠䠋㻝㻟 㻝㻥䠖㻜㻞

㼀㼅㻼㻱䠖㼂㻿㻰㻭

㻰 㻵 㻿䠊㻼㻾㻱㻿㻿 䠖 㻜䠊㻜 㻜㼜 㼟 㼕

㻾㼁㻺 㻌㻴㻻㼁㻾 䠖 㻝 㻞 㻜 䡄

㻸㻻㻭㻰 㻌 㻴㻻㼁㻾 䠖 㻡 㻠䡄

㻸㻻㻭㻰 㼀 㻵 㻹㻱㻿 䠖 㻝㻞 㻟

㻸㻻㻭㻰 㻾㻭㼀㻱䠖 㻝 㻝䠂

㻸㻻㻭㻰 㼀 㻵 㻹㻱 䠖 㻞 㻠䡏

㼁㻺㻸㻻㻭㻰 㻌 㼀 㻵㻹㻱 䠖 㻝䡏

㻯㼁㻾㻾㻱㻺㼀 䠖 㻡 㻜䠝

㻲㻾 㻱㻽㼁㻱 㻺㻯㼅䠖 㻞 㻟 㻚 㻤䠤䡖

㻻㼁㼀㻼㼁㼀䠖 㻝 㻜 㻚 㻡䡇䠳

3.2.2 Start/Stop

When the START button is pressed the START light

turns on and the compressor starts operating. When running, the asterisk on the right side of running hours

flashes and running time is counted.

To stop, press the UNLOAD STOP button. Operation

stops when the air end and the air piping have dried for 5

minutes.

To stop the compressor immediately without unloading,

press the STOP button.

Note: If the STOP button is pressed while unloading, the

compressor stops immediately.

3.2.3 Emergency Stop

Pressing EMERGENCY STOP botton, the DSP compressor immediately.

This switch should only be pressed in emergency.

The compressor can not be restarted until the switch is

manually reset. Turn the switch knob clockwise and

press the RESET button to reset.

*The asterisk flashes when the clock and total run-

ning hours are engaged.

If phase is reversed, “Connection Error: Reverse

Phase” is displayed on the LCD monitor for setting and

connection inspection. In this case, switch 2 of the 3

main power cables.

If there is no phase, “Connection Error: No Phase” is

displayed on the LCD monitor. In this case, check the

power cables.

12

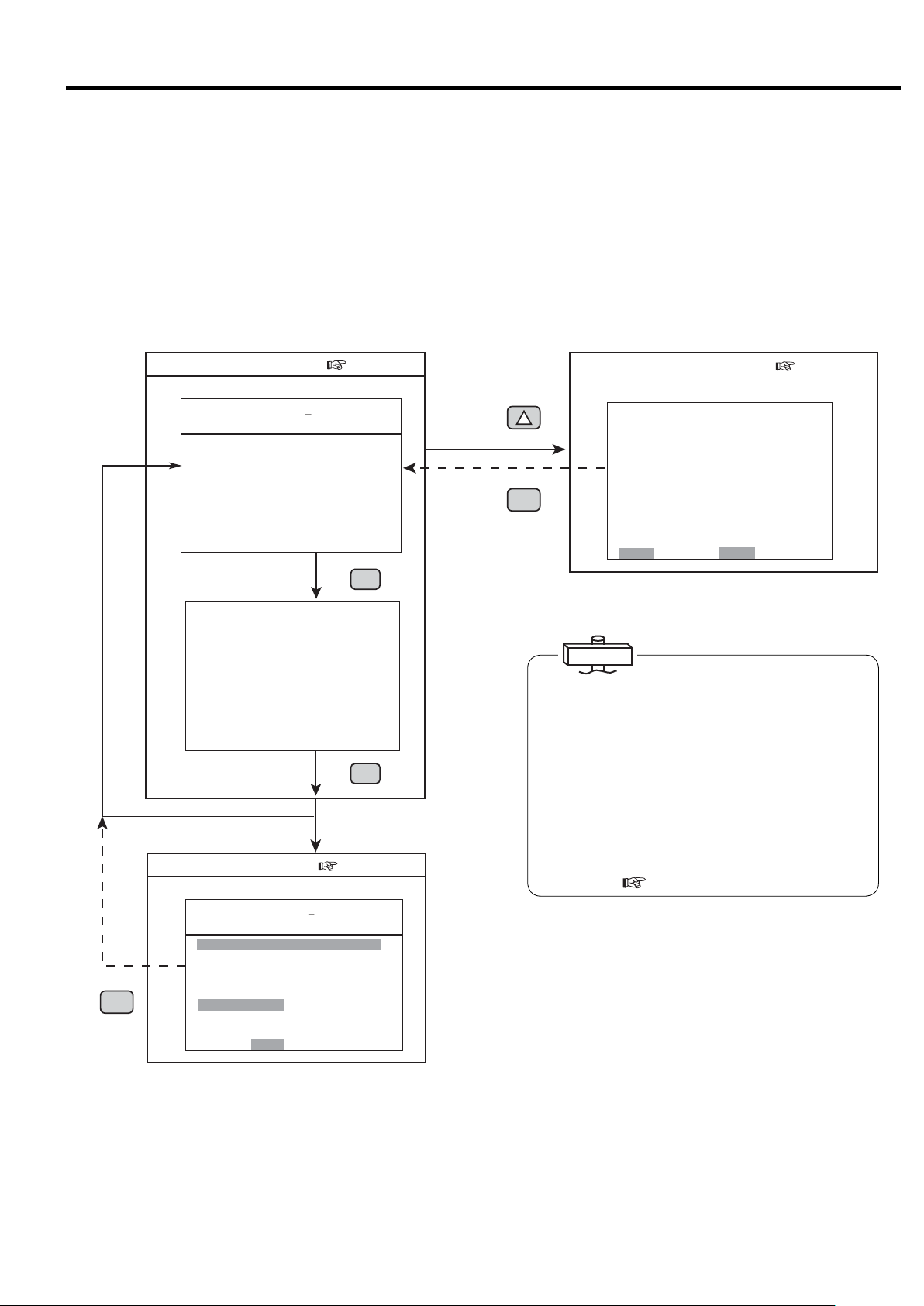

3. OPERATING THE DSP [How to Use the Liquid Crystal Display (LCD)]

3.3 How to Use the liquid Crystal Display (LCD)

3.3.1 How to Move between the Various Displays

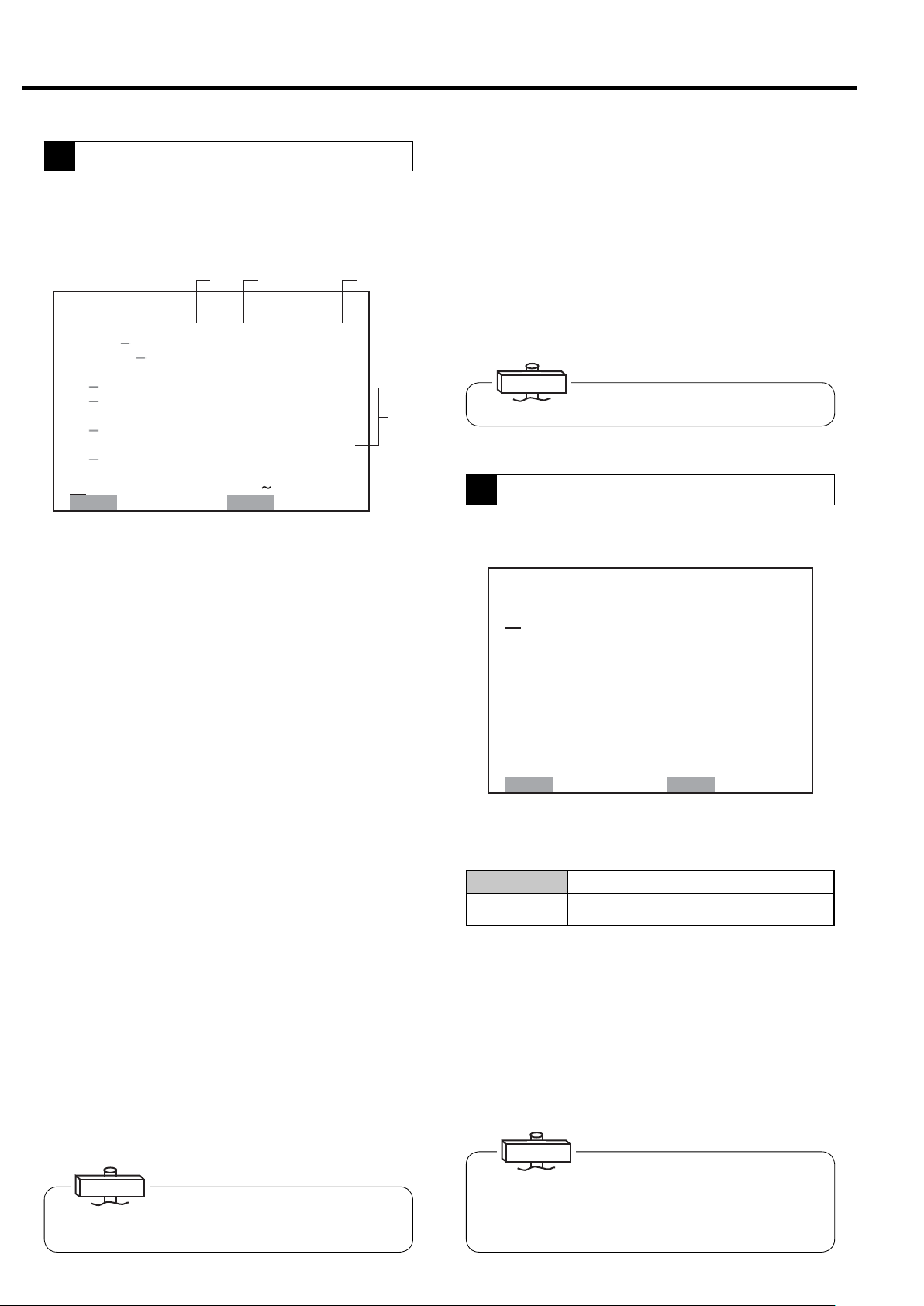

■Monitoring Displays

There are three monitoring displays: M1, M2, and

M3. To move between these displays, press the

MONITOR button.

■Monitoring Display(p.12)

M1 Monitoring Display

㻞㻜㻜㻥䠋㻜㻠䠋㻝㻟 㻝㻥䠖㻜㻞

㼀㼅㻼㻱 䠖㼂㻿㻰㻭

㻰 㻵 㻿䠊㻼㻾 㻱㻿㻿 䠖 㻜䠊 㻜 㻜 㼜 㼟 㼕

㻾㼁㻺 㻌㻴㻻㼁㻾 䠖 㻝 㻞㻜 䡄

㻸㻻㻭㻰 㻌 㻴㻻㼁㻾 䠖 㻡 㻠 䡄

㻸㻻㻭㻰 㼀 㻵 㻹㻱㻿 䠖 㻝 㻞 㻟

㻸㻻㻭㻰 㻾㻭㼀㻱 䠖 㻝㻝䠂

㻸㻻㻭㻰 㼀 㻵 㻹㻱 䠖 㻞㻠 䡏

㼁㻺㻸㻻㻭㻰 㻌 㼀 㻵 㻹㻱䠖 㻝䡏

㻯㼁㻾㻾㻱㻺㼀 䠖 㻡 㻜䠝

㻲㻾㻱 㻽㼁㻱㻺㻯 㼅䠖 㻞 㻟 㻚 㻤䠤䡖

㻻㼁㼀㻼㼁㼀䠖 㻝㻜 㻚 㻡 䡇䠳

モニタ

モニタ

MONITOR

M2 Monitoring Display

㻞㻜㻜㻥䠋㻜㻠䠋㻝㻟 㻝㻥䠖㻜㻞

㻼㻾㻱㻿㻿㼁㻾㻱

㻵 㻺㼀 㻿 㼀㻳 䠊 㻼 䠖 䚷䚷 㻞 㻥 㼜 㼟 㼕

㻻 㻵 㻸 㻌 㻼㻾㻱㻿 䠖 㻌 㻌 㻝㻡 㼜 㼟 㼕

㻯㻸㼀䠊㻼 㻾㻱㻿 䠖 㻖䠊㻖 㻖 㼜 㼟 㼕

㼀㻱㻹㻼㻱㻾㻭㼀㼁㻾㻱

㻰㻵㻿䠊㼀㻱㻹㻼㻝䠖 㻟㻞㻜䉣

㻰 㻵 㻿䠊㼀㻱㻹㻼 㻞 䠖 㻟㻝㻟㻤䉣

㻻 㻵 㻸 㻌 㼀 㻱㻹㻼 䠖 㻟 㻣 䉣

㻯㻸㼀䠊㼀㻱㻹㻼䠖 㻖㻖㻖䉣

㻞㻺㻰 㻌 㻿㼁㻯㼀䠊㼀䠊 䠖 㻜 㻤䉣

㻹㻭 㻵 㻺㼀㻱㻺 㻭㻺㻯㻱

㻴㻾䠊㼀㻻㻌㻹㻭㻵㻺㼀䠖 㻜㻜㻜㻜䡄

㻺㻱㼄㼀㻌㻹㻭 㻵㻺㼀䠖 㻖㻖㻖㻖

■Message Display(p.13)

M3 Monitoring Display

㻞㻜㻜㻣䠋㻜㻤䠋㻜㻝 㻝㻥䠖㻝㻥 㻖

㼀㼅㻼㻱 䠖㼂㻿㻰㻭

㻰 㻵 㻿䠊㻼㻾 㻱㻿㻿 䠖 㻜䠊 㻠 㻢

䠘㻿 㻴 㼁 㼀 㻰 㻻 㼃 㻺䠚

㻯㻻㻻㻸㻭㻺㼀䠖

㻻㻵 㻸䠖

㻞䠪㻰 㻌 㻿 㼁㻯 㼀䠊 㼀 㻱

㻴㻵㻳㻴 㻌㻰㻵㻿䠊㼀㻱㼜㼟㼕

㻯 㻻 㻺 㼀 㻭 㻯 㼀 㻻 㻾 㻌㻱 㻾 㻾 䠖

㻻㼂㻱㻾 㻸㻻㻭㻰 䠖

㻸㻻㼃 㻌㼃 䠊 㻵 㻺 㼀 㻿 㼀㻳 㻌 㻼䠊

㻰 㻾 㼅 㻱 㻾 㻌㻌㻌㻌 㼃 䠋 㻻 㻌 㻿 㻱 㻼 䠊

㻱㻸 㻱㻹㻱㻺 㼀

㻼㼞㼑㼟㼟㻾㻱㻿㻌㼍㼒㼠㼑㼞㻌㻯㻴㻷䠊

㼀㼁

㼜㼟

MONITOR

㻝

モニタ

MONITOR

㼜㼟㼕

㼕

■Menu Displays

Follow the bottom line message on the display.

■Function Menu Display(p.16)

機能

FUNCTION

モニタ

MONITOR

Function Menu Display

㼇 㻲㼁㻺㻯㼀 㻵㻻㻺 㻹㻱 㻺㼁 㼉

㻝䠊㻮㻭㻿 㻵㻯 㻌 㻿 㻱㼀 㼁㻼

㻞䠊㻹 㼁㻸 㼀 㻵 㻙㼁 㻺 㻵 㼀

㻟䠊㻯㻭㻼 㻭㻯 㻵 㼀㼅 㻯㻻㻺㼀㻾㻻㻸

㻠䠊㻿㻯㻴㻱㻰 㼁㻸㻱

㻡䠊㻻㻼㻱㻾㻭㼀㻵 㻻㻺 㻰㻭㼀㻭

㻢䠊 㻸㻻㻭㻰 㻰㻭㼀㻭

㻣䠊㻭㻸㻭㻾㻹 㻴 㻵 㻿㼀㻻㻾㼅

㻤 䠊㻿 㻴㼁 㼀 㻰㻻㼃㻺 㻴 㻵 㻿㼀 㻻㻾 㼅

㻿㻱㼀䠖㻻㻼㻱㻺 㻹㻻㻺䠖㻮㻭㻯㻷

IMPORTANT

About the LCD Backlight

(1) In the event that no button has been used for 10

minutes, the LCD backlight automatically turns OFF

for protection to the display panel. It comes ON

again if any button is pressed, other than the

START and STOP buttons.

(2) If an event happens while the LCD backlight is off,

the backlight automatically turns ON and stays ON

as long as the event exists. Remote and instant

stop mode can't be set by the LCD monitor.

Set after referring to “3.4 How to Use the Digital

Monitor.” (

page 21)

■ Message Display

There is only one message display: M3 (the contents,

however, vary from time to time). It is available only

when some event (air compressor alarm or shutdown,

maintenance notice, etc.) has occurred. Once an event

happens, however, the M3 message display appears

immediately and automatically. From the M3 display,

pressing the MONITOR button will switch the LCD

to the M1 or M2 monitoring displays; but after

approximately ten (10) seconds, the M1 or M2 monitoring displays will revert back to the M3 display.

13

3. OPERATING THE DSP [How to Use the Liquid Crystal Display (LCD)]

3.3.2 Typical Monitoring Displays

When the DSP is operating normally, typical monitoring

displays appear as follows.

M1 Monitoring Display

㻞㻜㻜㻥䠋㻜㻠䠋㻝㻟 㻝㻥䠖㻜㻞

㼀㼅㻼㻱䠖㼂㻿㻰㻭

㻰 㻵 㻿䠊㻼㻾㻱㻿㻿 䠖 㻜 䠊㻜 㻜 㼜 㼟 㼕

㻾㼁㻺 㻌㻴㻻㼁㻾 䠖 㻝 㻞 㻜 䡄

㻸㻻㻭㻰 㻌 㻴㻻㼁㻾 䠖 㻡 㻠 䡄

㻸㻻㻭㻰 㼀 㻵㻹㻱㻿 䠖 㻝 㻞 㻟

㻸㻻㻭㻰 㻾㻭㼀㻱䠖 㻝㻝䠂

㻸㻻㻭㻰 㼀 㻵㻹㻱 䠖 㻞 㻠 䡏

㼁㻺㻸㻻㻭㻰 㻌 㼀 㻵 㻹㻱 䠖 㻝䡏

㻯㼁㻾㻾㻱㻺㼀 䠖 㻡 㻜䠝

㻲㻾 㻱㻽㼁㻱㻺㻯 㼅 䠖 㻞 㻟 㻚 㻤䠤䡖

㻻㼁㼀㻼㼁㼀䠖 㻖 㻖 㻚 㻖 䡇䠳

㻹㻭㻿㼀㻱 㻾

(1)

㻖

(2)

(3)

㻖

(4)

(5)

(6)

(7)

(8)

(9)

VSDA*SAVE

Displayed when stop is limited for AUTO operation (standard: no symbol).

ECOMODE

(Energy Conservation Mode)

“SAVE” is displayed on the monitor

screen.

M2 Monitoring Display

㻞㻜㻜㻥䠋㻜㻠䠋㻝㻟 㻝㻥䠖㻜㻞

㻼㻾㻱㻿㻿㼁㻾㻱

㻵 㻺㼀㻿 㼀㻳䠊㻼 䠖 㻌 㻌 㻞 㻥 㼜 㼟 㼕

㻻 㻵 㻸 㻌 㻼㻾㻱㻿䠖 㻌 㻌 㻝㻡 㼜 㼟 㼕

㻯㻸 㼀䠊㻼㻾㻱 㻿 䠖 㻖䠊 㻖 㻖 㼜 㼟 㼕

㼀㻱㻹㻼㻱㻾㻭㼀㼁㻾㻱

㻰㻵 㻿䠊㼀㻱㻹㻼㻝䠖 㻟㻞㻜䉣

㻰 㻵 㻿 䠊㼀 㻱㻹㻼 㻞 䠖 㻟㻝㻟㻤䉣

㻻 㻵 㻸 㻌 㼀㻱 㻹㻼 䠖 㻟 㻣 䉣

㻯㻸㼀䠊㼀㻱㻹㻼䠖 㻖㻖㻖䉣

㻞㻺㻰 㻌 㻿 㼁㻯㼀䠊㼀䠊 䠖 㻜 㻤 䉣

㻹㻭 㻵 㻺 㼀㻱㻺 㻭㻺㻯 㻱

㻴㻾䠊㼀㻻㻌㻹㻭㻵㻺㼀䠖 㻜㻜㻜㻜䡄

㻺㻱㼄㼀㻌 㻹㻭 㻵㻺㼀䠖 㻖㻖㻖㻖

㻝

IMPORTANT

Current is an approximate S-phase ampere.

Output is reference value of calculated power.

䠆

(10)

(11)

(1) Displays current time. Asterisk flashes.

(2) Indicates a capacity control type.

(3) Displays compressor discharge port pressure.

(4) Indicates total running hours (RUN HOUR), total

loaded hours (LOAD HOUR), and total number of

loads (LOAD TIMES.).

Blink asterisk indicates running time is being mea-

sured.

(5) Indicates a percentage of load to unload of the DSP air

compressor (LOAD RATE), For Vtype, the rate is cal-

culated based on only frequency. Indicates “***”,

if PQ wide mode is selected.

INTE :Fixed speed type control (load/unload operation)

AUTO :Fixed speed type control

(AUTO operation *optional)

VSDB :V type control (AUTO function off)

VSDA : V type control (with AUTO function, V type standard)

EXIT :Setting display when capacity control is executed

externally

MR : Multiple unit control connection by communication

control

(6) Indicates the amperage current of the main motor

(CURRENT).

(7) Displays an operating frequency of main motor.

(V type only. Fixed speed type displays **.*)

(8) Indicates “*** ” for this air compressor.

(9) Displays master or slave control status when in lead/

lag operation mode.

(10) Displays various pressures and temperatures.

(Asterisk indicates not in use.)

(11) Displays time remaining till next inspection as main-

tenance period and next maintenance period.

14

3. OPERATING THE DSP [How to Use the Liquid Crystal Display (LCD)]

3.3.3 Message Displays

■ Shutdown Messages

① When a shutdown occurs for the compressor, the SHUTDOWN light and shutdown contents on the LCD monitor

(contents are displays on the left side and details are displayed on the right side) flash and the compressor stops running. There are 2 types of screens for shutdown: SHUTDOWN and FAILURE.

㻞㻜㻜㻣䠋㻜㻤䠋㻜㻝 㻝㻥䠖㻝㻥 㻖

㼀㼅㻼㻱 䠖 㼂㻿㻰㻭

㻰 㻵 㻿䠊㻼㻾㻱 㻿㻿 䠖 㻌 㻌 㻢 㻣㼜 㼟 㼕

䠘㻿 㻴 㼁 㼀 㻰 㻻 㼃 㻺䠚

㻯㻻㻻㻸㻭㻺 㼀 䠖

㻻㻵 㻸䠖

㻞䠪㻰 㻌 㻿㼁㻯㼀䠊㼀㻱㻹㻼

㻴㻵㻳㻴 㻌㻰㻵㻿䠊㼀㻱㻹㻼䠖

㻯 㻻 㻺 㼀 㻭 㻯 㼀 㻻 㻾 㻌㻱 㻾 㻾 䠖

㻻㼂㻱 㻾㻸 㻻㻭㻰 䠖

㻸㻻㼃 㻌 㼃 䠊 㻵 㻺㼀 㻿 㼀㻳 㻌 㻼䠊

㻰 㻾 㼅 㻱 㻾 㻌㻌㻌㻌 㼃 䠋 㻻 㻌 㻿 㻱 㻼 䠊

㻱㻸㻱㻹㻱 㻺㼀

㻼 㼞 㼑 㼟 㼟 㻾㻱 㻿 㻌 㼍 㼒 㼠 㼑 㼞 㻌 㻯㻴㻷䠊

㼀㼁

㻌

(Example)

In the case the thermal relay trips and the compressor stops

running, SHUTDOWN and OVERLOAD flash and the malfunction part of the main circuit is indicated.

㻞㻜㻜㻥䠋㻜㻤䠋㻜㻝 㻝㻥䠖㻝㻥 㻖

㼀㼅㻼㻱 䠖 㼂㻿㻰㻭㻌

㻰 㻵 㻿 䠊 㻼㻾 㻱 㻿 㻿 䠖 䚷䚷 㻢 㻣 㼜 㼟 㼕

䠘㻲 㻭 㻵 㻸 㼁 㻾 㻱䠚

㻿 㼅 㻿 㼀 㻱 㻹 㻱 㻾㻾 䠖 㼙㼙㼙㼙

㻿㼅㻿㼀㻱㻹 㻌 㻾㻱㼀㻾㼅

㻼㻯㻮㻌㻱㻾㻾䠖 㼚㼚㼚㼚㼚㼚

㻼㻾㻱㻿㻿䠊㻿㻺㻿㻾㻌 㻱㻾㻾䠖 㼛

㼀㻱㻹㻼䠊㻿㻺㻿㻾 㻱㻾㻾䠖 㼜

㻰䡅 㼟㼏㼛㼚㼚㼑㼏㼠 㼜㼛㼣㼑㼞

㼟㼚㼐 㼏㼛㼚㼠 㼍㼏 㼠

㼐 㼕 㼟 㼠 㼞 䡅㼎㼡 㼠㼛 㼞

㻌㻌 㻌㻌㻌

(Example)

Example of temperature sensor malfunction, sensor 1 disconnection FAILURE and TEMPERATURE SENSOR flash and

the location of the abnormality is indicated.

② Take the proper corrective action, and press the RESET button.

③ For further information,

see pages 33, 34.

NOTE) Malfunction detection of water failure is available for only water cooled single stage compressor. Malfunction

detection of dryer is available for only built-in dryer models. Malfunction detection of oil water separator and

element is not available.

■ Alarm Messages

① In the case an alarm occurs for the compressor, the ALARM light and contents / details displayed on alarm screen on

the LCD monitor flash and operation continues. There are 2 types of alarm screens: ALARM andPROBLEM.

㻞㻜㻜㻥䠋㻜㻤䠋㻜㻝 㻝㻥䠖㻝㻥 㻖

㼀㼅㻼㻱 䠖

㻰 㻵 㻿 䠊 㻼㻾 㻱 㻿 㻿 䠖 䚷䚷 㻢 㻣 㼜 㼟 㼕

䠘㻭 㻸 㻭 㻾 㻹䠚

㻰㻵 㻿䠊㼀㻱㻹㻼䠖䠄㻌 㻌 㻌 䠅㻖㻖㻖䉣

㻻㻵 㻸㻌 㼀㻱㻹㻼䠖 㻖㻖㻖䉣

㻸㻻㼃 㻌㻻䠊㻼䠊䠖 㻖䠊㻖 㻖㼜 㼟 㼕

㻯㻸㼀䠊㼀㻱㻹㻼䠊䠖 㻖㻖 㻖䉣

㻸㻻㼃 㻌 㻯㻸 㼀䠊 㻼 䠖 㻖 䠊 㻖 㻖 㼜 㼟 㼕

㻞䠪㻰 㻙 㻿䠊 㼀 㻱㻹㻼 㻌 㻲 㻵 㻺 㻙 㼀

㻸㻻㼃 㻌 㼃 䠊 㻸㻻㼃 㻌 㻻 㻵 㻸

㻰㻾㼅㻱㻾 㻭 㻵㻾 㻌㻲 㻵 㻸㼀㻱㻾

㻸䠊㻯㻻㼁㻺㼀 㻌 㻻㼂㻱 㻾 㻌㼃䠋㻻 㻌 㻿䠊

㻼㼞㼑㼟䡏㻾㻱㻿 㼍㼒㼠㼑㼞㻌㻯㻴㻷䠊

㻿㻰㻭㻌 㻌㻌 㻌㻌㻌

㼂

(Example)

In the case ALARM and AIR FILTER flash while the com-

㻞㻜㻜㻥䠋㻜㻤䠋㻜㻝 㻝㻥䠖㻝㻥 㻖

㼀㼅㻼㻱 䠖 㼂㻿㻰㻭㻌

㻰 㻵 㻿 䠊 㻼㻾 㻱 㻿 㻿 䠖 䚷䚷 㻢 㻣 㼜 㼟 㼕

䠘㻼 㻾 㻻 㻮 㻸 㻱 㻹䠚

㻯㻻㻺㻺㻱㻯 㼀 㻵 㻻㻺 㻌 㻱㻾㻾䠖 㻌 㻌 㻌

㻾㼑㼏㼛㼚㼚㼑㼏㼠 㻌 㼜㼛㼣㼑㼞䠊

㻹㼁㻸㼀䠥 㻙㼁 㻿㻱㼀 㻱㻾㻾

㻿㻯㻴㻱㻰㼁㻸㻱 㻌 㻿㻱 㼀 㻌 㻱㻾㻾

㻯㻻㻹䠊㻱㻾㻾㻌㻿㼀㻻㻼䠖㻌㻌㻌㻌㻌

㻯㻻㻹䠊㻱㻾㻾㻌㻭㻸㻹䠖 㻌㻌㻌㻌㻌

㻮㻭㼀㼀㻱㻾㼅 㻌㻻㼁㼀

㻼 㼞 㼑 㼟 㼟 㻾㻱 㻿 㼍 㼒 㼠 㼑 㼞 㻯 㻴㻷䠊

㻌㻌 㻌㻌㻌

(Example)

Example of battery replacement period.

pressor is running, it indicates the filter is clogged.

② Take the proper corrective action, and press the RESET button.

③ For further information,

see pages 33, 34.

NOTE) Malfunction detection of water failure is available for only water cooled single stage compressor. Malfunction

detection of dryer is available for only built-in dryer models. Malfunction detection of oil water separator and

element is not available.

IMPORTANT

ALARM and PROBLEM messages are treated as alarms, but aside from connection abnormalities that make operation impossible such as reverse phase and no phase when power is turned on, they also may indicate shutdown due to malfunction of the

communication status.

15

3. OPERATING THE DSP [How to Use the Liquid Crystal Display (LCD)]

■ Messages of Automatic Stop Display and Automatic Restart Display

When the DSP air compressor has automatically stopped, the following screen is displayed, the AUTO START light

flashes/lights, and the RESTART message screen and details of contents flash on the LCD monitor.

● SCHEDULED STOP: Schedule operation setting

<AUTO light ON>

When schedule is set on the scheduled operation

㻞㻜㻜㻥䠋㻜㻤䠋㻜㻝 㻝㻥䠖㻜㻞 㻖

㼀㼅㻼㻱 䠖 㼂㻿㻰㻭㻌

㻰 㻵 㻿䠊 㻼㻾 㻱 㻿 㻿 䠖 䚷䚷 㻢 㻣 㼜 㼟 㼕

䠘㻾㻱㻿㼀㻭㻾㼀䠚

㻾 㻱 㻿 㼀 㻭 㻾 㼀 㻭 㼀 䠖 䠆䠆 䠖 䠆䠆

㻾㻱㻿㼀㻭㻾㼀 㼃㻭 㻵 㼀䠖 㻌 㻞㻣䡏

㻺㻻㼃䠈 㻿 㼀 㻻 㻼 㻼 㻱 㻰 䠞䠵 䠖

㻿㻯㻴㻱㻰㼁㻸㻱 㻿㼀㻻㻼

㻭㼁㼀㻻㻹㻭㼀 㻵 㻯 㻿 㼀㻻㻼

㻰㻾㼅㻱㻾 㻼㻾㻱㻿㼀㻭㻾㼀㻱㻰

㻰㼁㻭㻸䠋㻮㻭㻯㻷㼁㻼

㻵 㻼 㻵 㻌 㻾㻱㻿㼀㻭㻾㼀

㻯㼀㻸㻾䠊㻾㻱㼀㻾㼅

㻌㻌 㻌㻌㻌

screen, displays state of operation being stopped by

preset time. Operation starts automatically when the

preset restart time comes.

● LEAD/LAG OPERATION STOP

(Note: applies only to machines equipped with two-

unit alternate operation.)

<AUTO light ON>

When the operation control mode is set to dual or

backup on the operation mode setting screen, standby

status of the slave machine in dual or backup operation

is indicated.

● DRYER PRESTARTED

(Note: Applies only to machines equipped with a

built-in dryer.)

<AUTO START light flashes>

When dryer prestart is set, the dryer starts operating

in advance, and compressor stopped status is indicated.

RESTART WAIT time is counted down.

● AUTO OPERATION

(Note: Applies only to machines equipped with

AUTO function)

<AUTO START light ON>

Indicates status stopped by low load when set to

AUTO operation. AUTO START light flashes during

restart limit while stopped, and RESTART WAIT time

is counted down.

● INSTANT STOP / RETRY

(Note: Retry applies to V type only.)

<AUTO START light flashes>

Displays status of restart for instantaneous power

interruption (IPI) restart and V type retry.

RESTART WAIT time is counted down.

16

3. OPERATING THE DSP [How to Use the Liquid Crystal Display (LCD)]

■ Maintenance Notice Messages

A maintenance date is determined by the amount of total operating hours or an elapsed calendar period, whichever

comes first. When the maintenance date or time arrives, the maintenance notice message appears on the display under

the heading of MAINTenance.

This function is an alarm display only, and does not output alarm externally.

Replace suction throttle valve consumable parts when inspection maintenance is displayed or the 1 million unloader

count alarm is given, whichever comes first.

㻞㻜㻜㻥䠋㻜㻤䠋㻜㻝 㻝㻥䠖㻜㻞 㻖

㼀㼅㻼㻱 䠖 㼂㻿㻰㻭㻌

㻰 㻵 㻿䠊㻼㻾㻱 㻿㻿 䠖 㻌 㻌 㻢 㻣 㼜 㼟 㼕

䠘㻹㻱㻿㻿㻭㻳㻱䠚

㻹㻭 㻵 㻺 㼀䠊 䠖㻝 㼅㻱 㻭 㻾㻌 㻌

㻹㻭 㻵 㻺㼀 䠊䠯䠟䠤䠡䠠䠱 㻸 䠡 䠖 㻭

㻼 㼞 㼑 㼟 㼟㻿㻱 㼀 㻌 㼍 㼒 㼠 㼑 㼞 㻌 㻯㻴㻷䠊

㻹㻭 㻵 㻺 㼀䠊㻯㻻㻹㻼 㻸 㻱 㼀㻱 㻰

㻿㼃 㻵 㼀㻯㻴㻱㻰 㻌 㼀㻻 㻌 㻸㻻㻯㻭㻸

㻵 㻺 㻌 㻻㼂㻱㻾䠮㻵 㻰㻱 㻹㻻㻰㻱

㻵㻺㻌㼁㻺㻸㻻㻭㻰㻌㻿㼀㻻㻼

㻿㼃 㻵 㼀 㻯㻴 㻱 㻰 㻌 㼁 㻌 㻹㻻㻰 㻱

㻌㻌 㻌㻌㻌

(1)

(2)

(3)

Every these calendar periods: Service the DSP according to the schedules:

0.5 years, 1.5 years, 2.5 years

3.5 years, 4.5 years, 5.5 years

1.0 years, 5.0 years Yearly + Half-Yearly

2.0 years, 4.0 years 2-Yearly + Yearly + Half-Yearly

3.0 years 3-Yearly + Yearly + Half-Yearly

6.0 years (for overhauling)

Standard Maintenance Schedule (A) (for yearly 8,000-or-less operating hours)

A

Standard Maintenance Schedule (B) (for yearly 4,000-or-less operating hours)

B

Half-Yearly

6-Yearly + 3-Yearly + 2-Yearly + Yearly + Half-Yearly

CAUTION

If the inspection/maintenance is displayed, check the display contents, refer to maintenance standards

given in the compressor instruction manual and perform inspection/maintenance as soon as possible.

When inspection is complete, press and hold the SET button for at least 7 seconds.

The LCD monitor display contents then move to “Maintenance initial value completed” of the message

screen, and then return to the monitor screen 1 minute later.

NOTES:

1. MAINTenance can be reset, if the servicing is done earlier than expected and if the remaining operating time to next maintenance

is less than 2,000h in the case of A, 1,000h in the case of B.

2. On the contrary, if the servicing is done after the maintenance notice has appeared, the remaining operating hours to the next maintenance has been zero until the maintenance is done. After maintenance and resetting the counter, new counting time starts just

after the maintenance notice message has appeared on the display.

■ Other Messages

(1)SWITCHED TO LOCAL.

If set to local by remote operation following shut-

down restoration, operation automatically returns

to local when shutdown occurs, and the message is

displayed for 1 minute. For setting details, see

“3.4 How to Use the Digital Monitor.”

(

page 25)

(2) IN OVERRIDE MODE.

This message blinks when the DSP is in an over-

ride mode.

(3) UNLOAD STOP

If the UNLOAD STOP button is used, the display

flashes. The compressor unloads for 5 minutes and

then stops.

17

3. OPERATING THE DSP [How to Use the Liquid Crystal Display (LCD)]

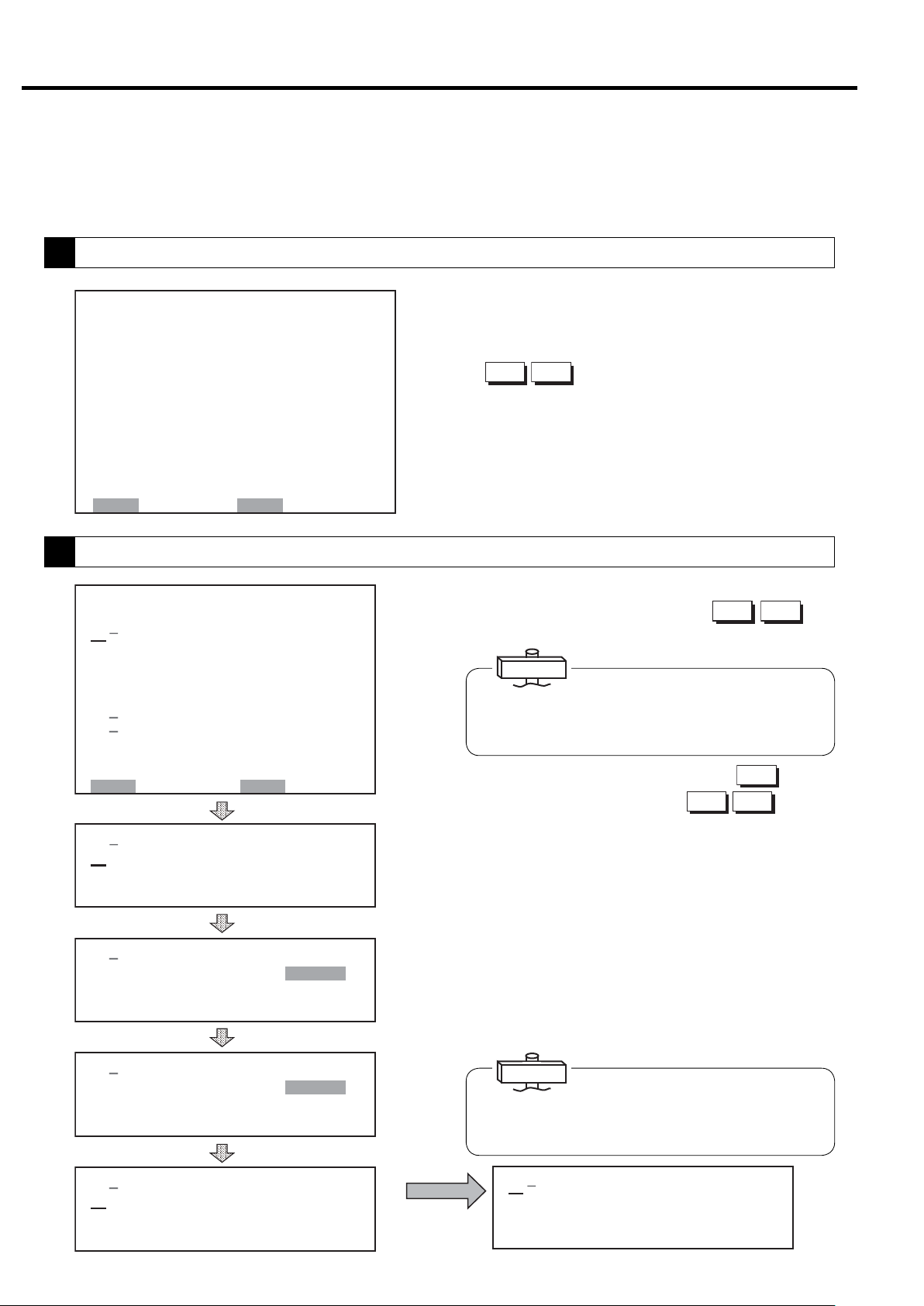

3.3.4 How to Move within a Menu Display and to Change a Setting

ー [FUNCTION MENU] and [MAINTenance DATA MENU] ー

The method and procedure for altering settings is displayed using the following as an example.

How to Move within a [FUNCTION MENU] Display

1

㼇 㻲 㼁㻺㻯㼀 㻵 㻻㻺 㻹㻱㻺㼁 㼉

㻝䠊㻮㻭㻿 㻵 㻯㻌 㻿㻱 㼀㼁㻼

㻞 䠊㻹㼁 㻸 㼀 㻵 㻙 㼁㻺 㻵 㼀

㻟䠊㻯㻭㻼㻭㻯 㻵 㼀㼅 㻯㻻㻺㼀㻾㻻㻸

㻠䠊㻿㻯㻴㻱㻰㼁㻸 㻱

㻡䠊㻻㻼 㻱㻾 㻭㼀 㻵 㻻㻺 㻰 㻭㼀 㻭

㻢䠊㻸㻻㻭㻰 㻰㻭㼀㻭

㻣䠊㻭㻸㻭㻾㻹 㻴 㻵 㻿㼀㻻㻾㼅

㻤 䠊 㻿 㻴㼁㼀㻰㻻㼃㻺 㻴 㻵 㻿㼀 㻻㻾 㼅

1 – 2.

② Select the number of the item to be set with the

▽

△

③ Enter with the SET button. The display then switches

to the detail setting screen for that item.

The following explanation uses [2. Operation Mode

Setting Screen] as an example.

① Press the MENU button displayed on monitor screen

㻿㻱 㼀 䠖 㻻㻼㻱 㻺 㻹㻻㻺䠖 㻮㻭㻯㻷

How to Select or Change a Setting within a Setting Display

2

① When the display switches to the details screen, move

㼇㻹㼁㻸㼀 㻵 㻙㼁 㻌 㻿㻱㼀㼀 㻵 㻺㻳㼉

㻝

㻹㻻㻰 㻱 䠖 㻳㻸

㻞䠊㻰㼁㻭㻸㻌 㼀 㻵 㻹㻱䠖 㻌 㻤䠊

㻟䠊㻹㻱㼀㻴㻻㻰 䠖 㻭㻼

㻠䠊㻿㼃 㻵 㼀㻯㻴㻻㼂㻱㻾䠖 㻜 㻝 㻡 㼟

㻡䠊㻮㻭㻯㻷㼁㻼 䠖 䚷䚷䚷㻣㼜

㻢䠊㼁 㻺㻸㻻㻭㻰䠖 䚷䚷䚷㻟 㼜㼟 㼕

㻭㻸㼀䠊㼀㻵㻹㻱䠖㻌 㻠㻤㻜㻹㻵㻺

㻣

㻯㻻㻺㼀 㻾㻻 㻸 㻹㻻㻰 㻱 䠖 㻮

㻤

㻌 㻿㻺

㻜㼔

㻻㼂㻾 㻾㻸

㼟㼕

to the line to be altered with the

tons.

IMPORTANT

Items with a dash next to their number cannot be altered

on the LCD monitor. In this case, alter from the digital

monitor while referring to the instructions manual for the

compressor.

buttons.

△

▽

but-

㻿㻱㼀䠖㻿㼀㻻㻾㻱 㻌㻹㻻㻺䠖㻮㻭㻯㻷

①

㻝 㻹㻻㻰 㻱 䠖

㻞䠊㻰㼁㻭㻸㻌 㼀 㻵 㻹㻱䠖 㻌 㻤䠊㻜 㼔

㻟䠊㻹㻱㼀㻴㻻㻰 䠖

㻠䠊㻿㼃 㻵 㼀㻯㻴㻻㼂㻱㻾䠖 㻜 㻝 㻡 㼟

㻳㻸㻿㻺

㻭㻼㻻㼂㻾 㻾㻸

②

㻝 㻹㻻㻰 㻱 䠖

㻞䠊㻰㼁㻭㻸㻌 㼀 㻵 㻹㻱䠖 㻌 㻤䠊㻜 㼔

㻟䠊㻹㻱㼀㻴㻻㻰 䠖

㻠䠊㻿㼃 㻵 㼀㻯㻴㻻㼂㻱㻾䠖 㻜 㻝 㻡 㼟

㻳㻸㻿㻺

㻭㻼㻻㼂㻾 㻾㻸

③

㻝 㻹㻻㻰 㻱 䠖

㻞䠊㻰㼁㻭㻸㻌 㼀 㻵 㻹㻱䠖 㻌 㻡䠊㻜 㼔

㻟䠊㻹㻱㼀㻴㻻㻰 䠖

㻠䠊㻿㼃 㻵 㼀㻯㻴㻻㼂㻱㻾䠖 㻜 㻝 㻡 㼟

㻳㻸㻿㻺

㻭㻼㻻㼂㻾 㻾㻸

④

㻹㻻㻰 㻱 䠖

㻝

㻞䠊㻰㼁㻭㻸㻌 㼀 㻵 㻹㻱䠖 㻌 㻡䠊㻜 㼔

㻟䠊㻹㻱㼀㻴㻻㻰 䠖

㻠䠊㻿㼃 㻵 㼀㻯㻴㻻㼂㻱㻾䠖 㻜 㻝 㻡 㼟

㻳㻸㻿㻺

㻭㻼㻻㼂㻾 㻾㻸

Move to the item to be altered with the

②

▽

③

Alter the setting value with the

△

④ After altering the setting value, press the SET button.

The cursor moves to the number.

⑤ Press the SET button again.

The cursor moves to the first number at the top of the

screen and the setting contents are entered.

When setting is complete, pressing the MONITOR button once returns the display to the MENU screen, and

pressing it again returns to MONITOR screen 1.

The same procedure is used to alter settings for other

menus.

IMPORTANT

When altering settings of the LCD screen, number update

by button operation is slow. Press the buttons slowly

when altering settings.

⑤

㻝 㻹㻻㻰 㻱 䠖

㻞䠊㻰㼁㻭㻸㻌 㼀 㻵 㻹㻱䠖 㻌 㻡䠊㻜 㼔

㻟䠊㻹㻱㼀㻴㻻㻰 䠖

㻠䠊㻿㼃 㻵 㼀㻯㻴㻻㼂㻱㻾䠖 㻜 㻝 㻡 㼟

㻳㻸㻿㻺

㻭㻼㻻㼂㻾 㻾㻸

button.

▽

buttons.

18

3. OPERATING THE DSP [How to Use the Liquid Crystal Display (LCD)]

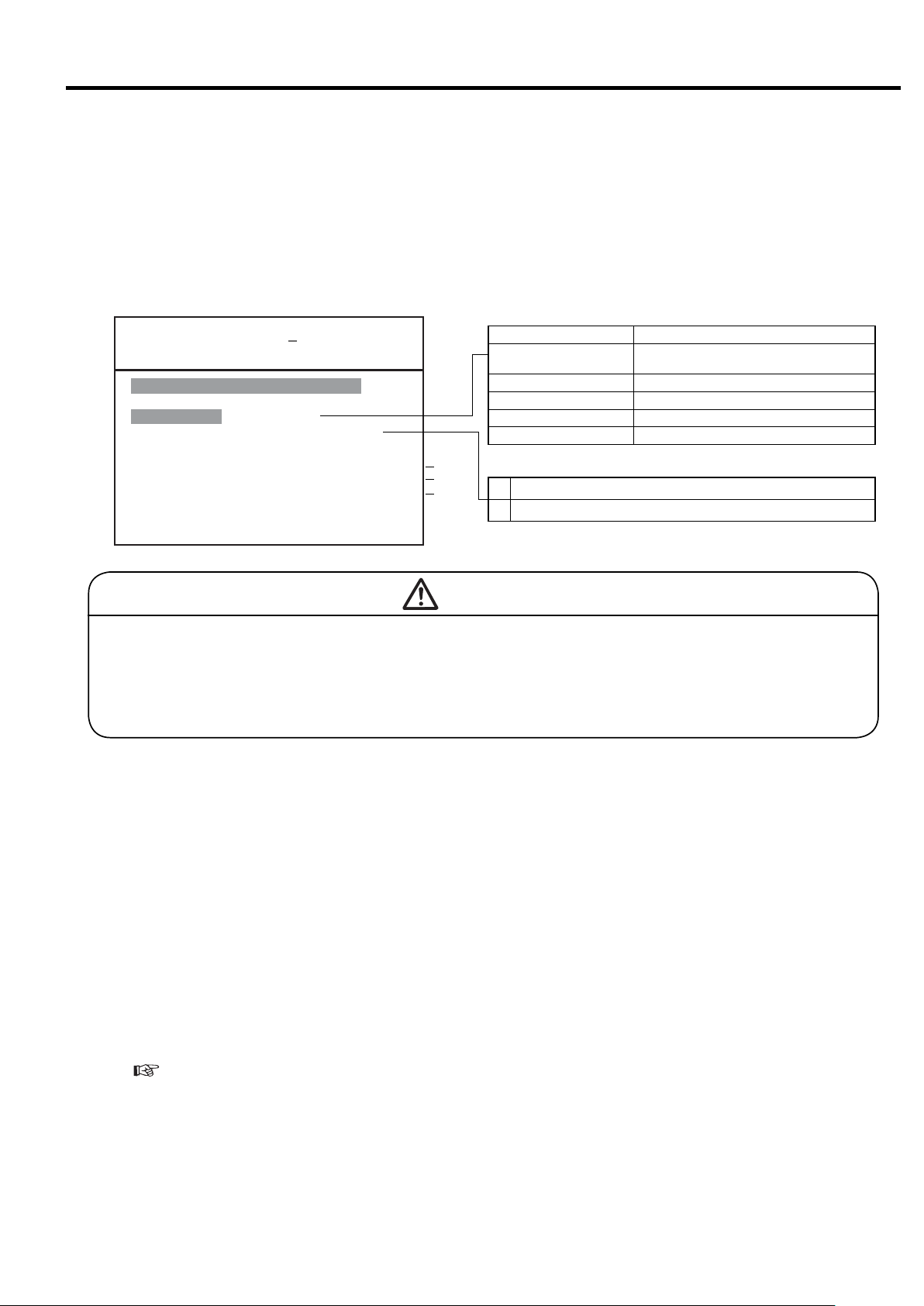

3.3.5 [FUNCTION MENU] −Setting Displays

Model Setting Confirmation

1

㼇㻮㻭㻿㻵㻯 㻿㻱㼀㼁㻼㼉

㼂㻱㻾䠊䠖 㻡䠊㻜

㻿㻱㻾 㻵 㻱㻿 㻺㻭㻹㻱䠖 㻰㻿㻼

㻯㻻㻻㻸 㻵 㻺㻳 㻹㻱 㼀㻴㻻㻰䠖 㼃㼀㻾

㻺㻻䠊㻻㻲 㻿 㼀㻭 㻳㻱 䠖 㻌 㻞

㻼㻙㻿㻼㻱㻯䠖 䚷㻝 㻜㻜㼜㼟㼕

㻼 䠊 㻰 㻭 㼀 㻭 䠖 䚷䚷 㻢 㻤 㼜 㼟 㼕

䠟䠰䠖 㻞㻡㻜䠝

㻯㻸 㼀䠊㻰 㻱 㻸 㻭㼅 䠖 㻌 㻡 㼟

㻵㻼㻵䠖 㻵㻵㻵

㻭㻰㻾 㻱 㻿 㻿 㻺㻻䠊 䠖 㻌 㻝

㻹㻻㻺 䠖 㻮㻭㻯㻷

IMPORTANT

The screen provides the model and serves as a target for

setting status. Check the screen when making an inquiry.

㻡䠊㻜

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

The starter of settings can be confirm the software,

model and setting status of model-specific settings such

as capacity control. (Double asterisks are displayed for

settings that do not require confirmation.)

① Indicates board software version.

② Indicates compressor type.

③ Displays cooling type.

④ Displays the number of compressor stages.

⑤ Displays pressure specification.

⑥ Displays interstage pressure.

⑦ Indicates CT setting value.

⑧ Displays water failure detection conditions for water

cooled compressor.

⑨ Displays status of instantaneous power interruption

(IPI) restart setting.

Displays compressor number. (Must be distinguished by

⑩

number is using communication function.)

Operation Mode Settings

2

Confirm settings by compressor alternate operation

specifications and multiple unit control (communication

support). Wiring must be supplied separately for use.

Items for which a dash is displayed next to their number cannot be set on the LCD monitor.

㼇㻹㼁㻸㼀 㻵 㻙㼁 㻌 㻿㻱㼀㼀 㻵 㻺㻳㼉

㻝

㻹㻻㻰 㻱 䠖 㻳㻸

㻞䠊㻰㼁㻭㻸㻌 㼀 㻵 㻹㻱䠖 㻌 㻤䠊

㻟䠊㻹㻱㼀㻴㻻㻰 䠖 㻭㻼

㻠䠊㻿㼃 㻵 㼀㻯㻴㻻㼂㻱㻾䠖 㻜 㻝 㻡 㼟

㻡䠊㻮㻭㻯㻷㼁㻼 䠖 㻌 㻌 㻌 㻣㼜

㻢䠊㼁 㻺㻸㻻㻭㻰䠖 㻌 㻌 㻌 㻟㼜 㼟 㼕

㻭㻸㼀䠊㼀㻵㻹㻱䠖㻌 㻠㻤㻜㻹㻵㻺

㻣

㻯㻻㻺㼀 㻾㻻 㻸 㻹㻻㻰 㻱 䠖 㻮

㻤

㻿㻱㼀䠖㻿㼀㻻㻾㻱 㻌㻹㻻㻺䠖㻮㻭㻯㻷

㻌 㻿㻺

㻜㼔

㻻㼂㻾 㻾㻸

㼟㼕

1. Operation control: Set operation control is dis-

played on the digital monitor.

IMPORTANT

If using the backup function, switch to the digital monitor and set.

2. LEAD/LAG operation time: Time setting for alter-

nate operation of a pair of compressors (setting

range: 0.1 – 99.9 hours; initial value: 8.0)

3. Switching conditions: Setting of conditions for

switching operation between a pair of compressors

4. Switching time: Switching time setting if switch-

ing conditions are “parallel” or “interval” (setting

range: 5 – 300 seconds, initial value: 15)

Single Operates compressor independently.

Case where multiple unit control is executed by communication

STPR

Multiple

()

Backup

OVER LAP

Interval

function of multi roller EX (dedicated panel of NEXT Series).

Unit control is executed by RS485 communication according to

unit

the settings. Requires separate setting of compressor number.

Operation alternates between a pair of compressors for

Dual

a preset amount of time. AUTO light lights.

Operation mode that adds pressure backup function to

dual operation. When pressure drops, the slave machine

starts. AUTO light lights.

Method whereby first compressor is stopped after switching time for

the other unit in parallel operation when it is time for dual operation.

Method of operating the other compressor after stopping the

first one after switching time when it is time for dual operation.

5. BACKUP: Setting of pressure to start the backup

compressor when set to backup operation (range: 0.00

– 72 psi, initial value: 7, difference from recovery pressure in the minus direction).

6. UNLOAD:

Pressure setting that manually unloads 1 unit

when the preset pressure is reached in backup operation

(range: 0.00 – 72 psi, initial value: 3, difference from control pressure in the minus direction).

7. DUAL TIME:

Displays time remaining until switch for

dual / backup operation. Time is not counted down

when operating 2 units for backup operation. When

operation is stopped, remaining time is maintained.

8.

SPEED CONTROL MODE: Displays control mode of V

type. An asterisk is displayed for the Fixed speed type.

IMPORTANT

Altered setting values can only be entered when the compressor is not running.

19

3. OPERATING THE DSP [How to Use the Liquid Crystal Display (LCD)]

Capacity CONTROL SETTING Display

3

Screen for confirming pressure settings for capacity control. Pressure settings are set from the digital monitor.

Pressure settings consist of setting 1 and setting 2,

which can be used by setting time used.

①② ③

㼇 㻯㻻㻺 㼀㻾㻻㻸 㻿 㻱 㼀 㼀 㻵 㻺㻳 㼉

㻝䠊㼀㼅㻼㻱䠖㼂㻭 㼎㼎㼎 㼏㼏㼏

㻞䠊䠬

㻟䠊䠬 㻵

㻠

㻡

㻢

㻣

㻤䠊㼀 㻵㻹㻱䠖㻝㻤䠖㻜㻜

㻿㻱㼀䠖㻿㼀㻻㻾㻱 㻌㻹㻻㻺䠖㻮㻭㻯㻷

㻸㻻㻿㻿 䠖 㻖 䠊 㻖 㻖 㼜 㼟 㼕

㻯㻭䠖㻖㻖㻖 㻖㻖䠊㻖䡉㻟

䠄㻯㻻㻺㼀㻾㻻㻸䠋㻯㼁㼀㻙 㻵 㻺 㻕

㻼㻝䠖 㻌 㻝 㻜㻜䠋㻌 㻌 㻤㻣㼜㼟 㼕

㻼㻞䠖 㻌 㻝 㻜㻜䠋㻌 㻌 㻤㻣㼜㼟 㼕

䠄㼀㻭㻾㻳㻱㼀㻌 㻼㻝䠋㻼㻞 㻕

㼀㻭㻾㻳㻱 㼀 䠖

㻌㻌 㻥㻤䠋㻌㻌 㻥㻤㼜㼟㼕

㼀㻵㻹㻱㻌㻸 㻵㻹㻵 㼀䠖 㻜㻟㻜㼟

䠄㻼 㻞 㻱 㻲㻲㻱㻯㼀 㻵 㼂㻱 㻕

㻞㻞䠖㻜㻜

④

⑤

⑥

1. TYPE: Displays setting data for capacity control.

① Control settings set by the digital monitor can be con-

firmed.

Fixed speed type: I (load/unload operation) / IP (AUTO

operation specifications * optional)

V type: VB (AUTO function off)/ VA (AUTO operation

specifications)

② Setting type of pressure set by the digital monitor can

be confirmed.

SETTING 1: Standard pressure setting;

SETTING 2: 2nd pressure setting

EXT: External load/unload setting

AUTO: Switches setting 1 and setting 2 by time.

③ Sets optional conditions. With standard specifications,

displays “ordinary” characters.

2 - 3. OPTION: Used for options.

4 - 6. PRESSURE SETTING: Pressure settings set by

the digital monitor, target pressure and time limit can be

confirmed all at once on the LCD monitor. ④

7. TIME LIMIT: (Fixed speed type only)

Preset time limit can be confirmed.

The time limit is effective when ECOMODE (energy

conservation mode) is selected by pressing and holding

the DISPLAY SWITCH button for at least 7 seconds.

The function sets energy conservation mode until control pressure (unload start pressure) drops to the target

value if the load and unload repeat time clears the time

limit. If control pressure and recovery pressure change

time is measured and it exceeds the time limit, control

pressure is lowered so the time limit is no longer

exceeded. ⑤

(Time limit range: 30 - 120 seconds; initial value: 30 seconds)

8. USE TIME: Sets time to use pressure of setting 2. At

that time, it displays automatic at the position of (2) of

the type. When start and stop time become the same

value, the automatic display is returned to setting 1 and

the function is stopped.

IMPORTANT

Settings are selectable when the DSP is in a stop.

Schedule Setting

4

Scheduled operation can be set for 1 day (standard equipment).

㼇 㻿㻯㻴㻱㻰㼁㻸㻱 㻌 㻿 㻱 㼀㼀 㻵 㻺㻳 㼉

㻝䠊㻹㻻㻰㻱 䠖 㻯㻴㻱㻰㼁㻸 㻱

㻿㼀㻭㻾㼀 㻿㼀㻿㻻㻼

䠄㻝䠅㻜㻣䠖㻜㻜㻌 㼅 㻞㻜䠖㻜㻜 㻌 㼅

䠄㻞䠅㻜㻜䠖㻜㻜㻌 㻺 㻜㻜䠖㻜㻜 㻌 㻺

䠄㻟䠅㻜㻜䠖㻜㻜㻌 㻺 㻜㻜䠖㻜㻜 㻌 㻺

䠄㻠䠅㻜㻜䠖㻜㻜㻌 㻺 㻜㻜䠖㻜㻜 㻌 㻺

䠄㻡䠅㻜㻜䠖㻜㻜㻌 㻺 㻜㻜䠖㻜㻜 㻌 㻺

㻞䠊㻾㻱㻯㻻㻾㻰 㻝䠖 㻝㻜䠖㻜㻜

㻟䠊㻾㻱㻯㻻㻾㻰 㻞䠖 㻝㻥䠖㻜㻜

㻿㻱㼀䠖㻿㼀㻻㻾㻱 㻌㻹㻻㻺䠖㻮㻭㻯㻷

The display shows an example setting of scheduled operation from 7:00 to 20:00. “19:07” indicates the current time

㻝㻥䠖㻜㻣

1. MODE: Scheduling Mode

OFF

SCHEDULED

Operates the DSP without a schedule.

Operates the DSP according to a daily 24hour calendar.

1. to 5. : Five Start/Stop Time Patterns

・ START: Starting Time

・ STOP: Stopping Time

・ Y or N :Yes starts or stops as scheduled.

2. DATA MEASUREMENT TIME: Time for recording

operation data twice a day can be set.

Recorded operation data can be confirmed by the “5”

operation data record screen.

IMPORTANT

IMPORTANT

If the time limit is altered, consult with your dealer or the

Hitachi Service Station given on the rear cover.

20

If “SCHEDULE” is set, the AUTO light lights. If there is no

valid setting for time, the AUTO light flashes. Altered setting can only be entered when the compressor is not running.

3. OPERATING THE DSP [How to Use the Liquid Crystal Display (LCD)]

Operation Data Display

5

㼇 㻻㻼㻱 㻾㻭㼀 㻵 㻻㻺 㻰 㻭㼀 㻭 㼉

㻝䠊㻜㻤䠋㻜㻝 㻝㻜䠖㻜㻜

㻼䠖㻌 㻢㻣䚸㻌 㻢㻤䚸㻖㻖㻖䚸㻖㻖㻖

㻯䠖 㻜

㼀䠖 㻣㻣䚸 㻥㻝䚸㻖㻖䚸㻖㻖䚸㻖㻖

㻸䠖 㻡 㻥䚸㻝 㻤䠊㻤

㻞䠊㼍㼍䠋㼎㼎 㼏㼏䠖㼐㼐

㻼䠖㻖㻖㻖䚸㻖㻖㻖䚸㻖㻖㻖䚸㻖㻖㻖

㻯䠖㻖㻖㻖

㼀䠖㻖㻖㻖䚸㻖㻖㻖䚸㻖㻖䚸㻖㻖䚸㻖㻖

㻸䠖㻖㻖㻖䚸㻖㻖㻖㻖㻖

㻹㻻㻺 䠖 㻮㻭 㻯㻷

Records date/time, pressure, current, temperature and

load status at that time as operating state recorded by

data measurement time. Up to 12 times can be recorded,

after which the oldest data is deleted one at a time; the

latest data is displayed for item 1. The screen shows

record for 2 times, and the necessary data can be con-

▽

firmed by

△

button operation. If altered before

time is up, the data prior to change is maintained, and the

time recorded as soon as the data is altered changes.

1. and 2. - :Indicates the MONTH / DAY HOUR: MINUTE.

P - Represents a pressure (psi) and indicates, from left to

right, the: Discharge air pressure, pressure data.

C - Current (A).

T - Represents a temperature (℉)and indicates from

left to right: 1st stage discharge air temperature, 2nd

stage discharge air temperature.

L -

Represents a load ratio percentage (%). and out put (kW).

If there is no data, an asterisk is displayed.

Alarm History

7

If an alarm occurs on the digital monitor, shutdown history is recorded. Up to 6 items of alarm history however

can be recorded aside from shutdown history. Contents

and occurrence state can be confirmed.

㼇 㻭 㻸 㻭 㻾㻹 㻴 㻵 㻿 㼀㻻㻾 㼅 㼉

㻝䠊 㼍㼍㼍㼍㼍㼍㼍㼍㼍㼍㼍㼍㼍

㻯㻻㻰㻱䠖㻞㻝㻸 㻺㻻㻿䠊䠖㻌 㻝

㻜㻣䠋㻜㻤䠋㻜㻝 㻝㻥䠖 㻞㻢

㻞䠊 㻖㻖㻖㻖㻖㻖㻖㻖㻖㻖㻖㻖㻖

㻯㻻㻰㻱䠖㻖㻖㻖 㻺㻻㻿䠊䠖㻖㻖

㻖㻖䠋㻖㻖䠋㻖㻖 㻖㻖䠖 㻖㻖

㻟䠊 㻖㻖㻖㻖㻖㻖㻖㻖㻖㻖㻖㻖㻖

㻯㻻㻰㻱䠖㻖㻖㻖 㻺㻻㻿䠊䠖㻖㻖

㻖㻖䠋㻖㻖䠋㻖㻖 㻖㻖䠖 㻖㻖

㻹㻻㻺 䠖 㻮㻭㻯㻷

①

① Operation state is indicated by a symbol next to the

shutdown code.

L: Load, U: Unload, S: Stop

Displays alarm contents and code, date, time, state and

how many times alarm occurred. If the same alarm continues to occur, it is overwritten as update data, and the

number of times the alarm occurs is updated. The latest

warning is recorded as item 1. If there is no alarm, asterisks are displayed. The screen displays data for 3 types,

▽

and the necessary data can be confirmed by

△

button operation.

Shutdown History Display

8

Load Data Display

6

㼇 㻸㻻㻭㻰 㻰㻭㼀㻭 㼉

㻝䠊㻜㻤䠋㻜㻝

㻭㼂㻳䠊㻼㻾 㻱 㻿㻿 䠖 㻌 㻌 㻣 㻡 㼜 㼟 㼕

㻭㼂㻳䠊㻯㼁㻾㻾㻱㻺㼀䠖 㻜㻠㻜䠝

㻭㼂㻳䠊㻸㻻㻭㻰 㻾㻭㼀㻱䠖㻜㻢㻡䠂

㻭 㼂 㻳 䠊 㻼 䠫䠳 䠡 䠮 䠖 㻌 㻝 㻣 㻚 㻤 㼗 㼃

㻞䠊㻜㻝䠋㻜㻝

㻭㼂㻳䠊㻼㻾 㻱 㻿㻿 䠖 㻌 㻌 㻣 㻡 㼜 㼟 㼕

㻭㼂㻳䠊㻯㼁㻾㻾㻱㻺㼀䠖 㻜㻠㻜䠝

㻭㼂㻳䠊㻸㻻㻭㻰 㻾㻭㼀㻱䠖㻜㻢㻡䠂

㻭 㼂 㻳 䠊 㻼 䠫䠳 䠡 䠮 䠖 㻌 㻝 㻣 㻚 㻤 㼗 㼃

㻹㻻㻺 䠖 㻮㻭㻯㻷

This display shows the averaged load data per day. Data

can be recorded for a maximum of six days; the 7th day of

averaged loaded data is automatically deleted and the 1st

or most recent day of averaged data is added. The most

recent data is arranged at the top of the display.

The screen shows record for 2 times, and the necessary

▽

data can be confirmed by

△

button operation.

Data is averaged from operation start to stop. The average is however fixed at 0.00 minutes in the case of 24

hours operation.

㼇 㻲㼁㻺㻯 㼀 㻵 㻻㻺 㻹㻱 㻺㼁 㼉

㻝䠊㻮㻭㻿 㻵 㻯㻌 㻿㻱 㼀㼁㻼

㻞䠊㻹 㼁㻸 㼀 㻵 㻙 㼁 㻺 㻵 㼀

㻟䠊㻯㻭㻼㻭㻯㻵 㼀㼅 㻯㻻㻺㼀㻾㻻㻸

㻠䠊㻿㻯㻴㻱㻰㼁 㻸㻱

㻡䠊㻻㻼㻱㻾㻭㼀㻵 㻻㻺 㻰㻭㼀㻭

㻢䠊㻸 㻻㻭㻰 㻰㻭㼀 㻭

㻣䠊㻭㻸㻭㻾㻹 㻴 㻵 㻿㼀㻻㻾㼅

㻤䠊 㻿 㻴㼁 㼀㻰 㻻㼃㻺 㻴 㻵 㻿㼀 㻻㻾 㼅

㻿㻱㼀䠖㻻㻼㻱㻺 㻹㻻㻺䠖㻮㻭㻯㻷

㼇㻰㻱 㼀㻭 㻵 㻸㻿 㼉

㻝䠊 㼍㼍㼍㼍㼍㼍㼍㼍㼍㼍㼍㼍㼍

㻰 㻵 㻿䠊㻼㻾㻱㻿 䠖 㻌 㻌 㻠 㻤 㼜㼟 㼕

㻵 㻺 㼀㻿 㼀㻳䠊 㻼 䠖 㻖 䠊 㻖 㻖 㼜 㼟 㼕

㻻 㻵 㻸 㻼㻾㻱㻿 䠖 㻖䠊 㻖 㻖 㼜 㼟 㼕

㻯㻸 㼀䠊㻼㻾㻱㻿 䠖 㻖䠊 㻖 㻖 㼜 㼟 㼕

㻰㻵 㻿䠊㼀㻱㻹㻼䠊㻝䠖 㻝㻤㻜䉣

㻰㻵 㻿䠊㼀㻱㻹㻼䠊㻞䠖 㻝㻤㻜䉣

㻻㻵 㻸 㼀㻱㻹㻼䠖 㻖㻖㻖䉣

㻯㻸 㼀䠊 㼀㻱 㻹㻼䠖 㻖 㻖 㻖 䉣

㻞㻺㻰 㻿 㼁㻯㼀䠊㼀 䠖 㻖㻖 㻖 䉣

㻯㼁㻾㻾㻱㻺㼀䠖 㻝 㻜㻜㻭

㻹㻻㻺 䠖 㻮 㻭㻯 㻷

Up to 6 items of alarm history are recorded aside from

shutdown history. Contents and occurrence state can be

confirmed. Select the number of the shutdown on the

SHUTDOWN HISTORY screen, press the SET button

and the operation state when the shutdown occurred can

furthermore be confirmed on the details screen.

● How to clear shutdown and alarm history.

If you want to clear the entire shutdown history and

alarm history, set F041 from the F mode of the digital

monitor to “1: CLEAR HISTORY” while referring to

the instructions manual of the compressor.

21

3. OPERATING THE DSP [How to Use the Liquid Crystal Display (LCD)]

3.3.6 Other Hardware Setting

Initial Setting

The calendar and clock are set by Hitachi prior to

delivery. To reset the calendar and clock, please contact the local Hitachi distributor.

Brightness Adjusting

Adjust the LCD brightness as follows:

To brighten:

Hold down the SET button and press the

MONITOR button.

To darken:

Hold down the SET button and press the

FUNCTION button.

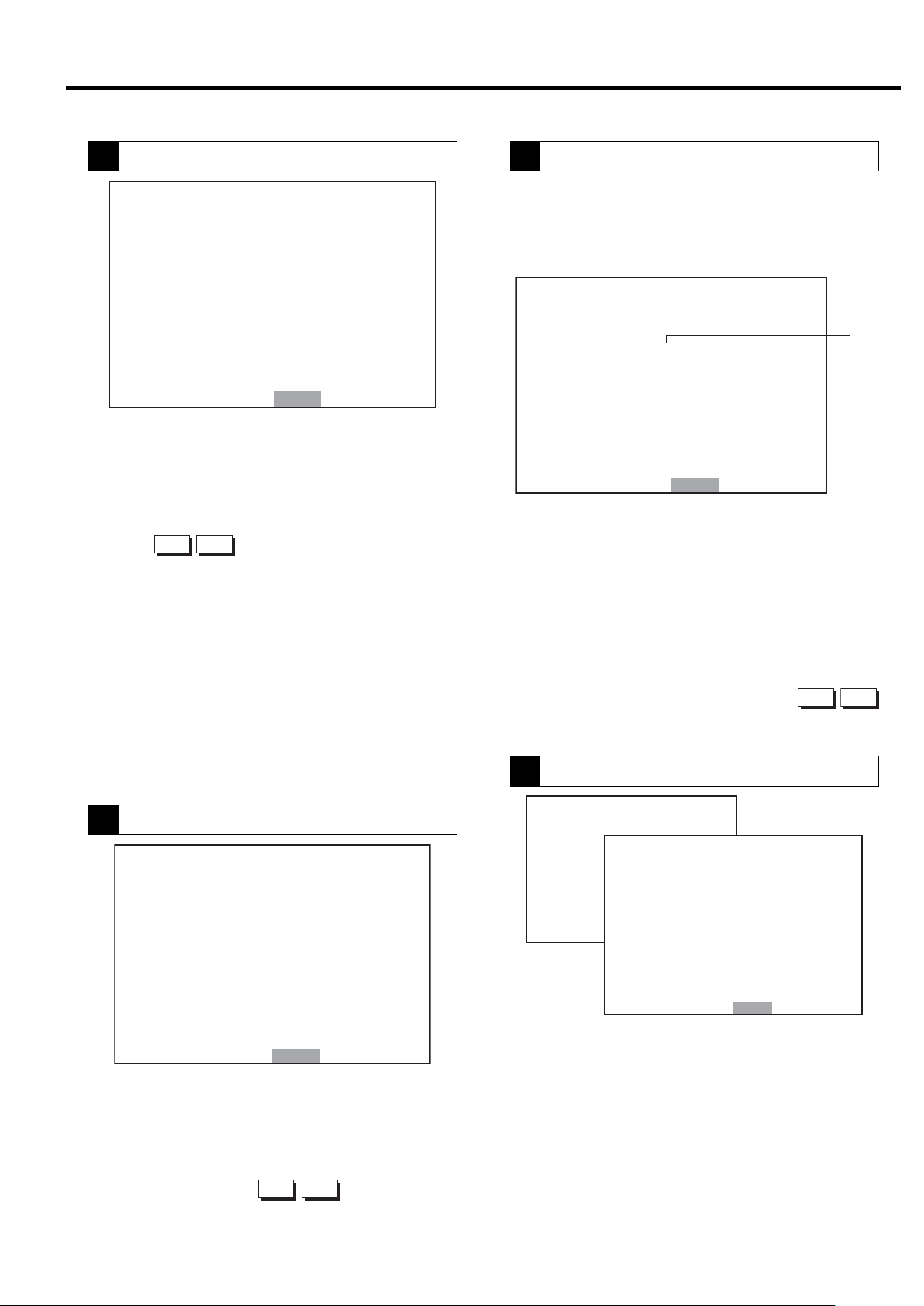

Digital Monitor Operation Classification

The following is a table of contents that can be set by

the LCD monitor and digital monitor (next section).

Function Item

Operation Mode

Screen

Capacity Control

Screen

Scheduled Operation

Screen

Other Settings

Reset

Mode

Dual operation time

Switch conditions

Switch time

Backup pressure

Unload

Dual operation remaining time

Speed control mode

Type (Left: Capacity control)

Type (Center: Setting type)

Type (Right: Function)

Pressure loss

Total piping capacity

Control pressure

Recovery pressure

Target pressure

Time limit

Setting 2: Use time

Contents

Start/stop time

Data measurement time

Compressor No. setting

Instantaneous power interruption (IPI) setting

Remote operation setting

Dryer operation setting

AUTO operation setting

Energy saving mode setting

Shutdown/alarm reset

Load count reset

Maintenance reset

Shutdown/alarm history clear

3-Language Display Switch

The language of the display can be switched to

Japanese, English or Chinese by the dip switch on the

back of the LCD monitor board. If the language needs

to be changed, consult with your dealer or the Hitachi

Service Station given on the rear cover.

Power must be turned off before changing setting.

LCD monitor oper-

ation

− ○ F000

○

○

○

○

○

△(AUTO change)

−

○

○

○

−

○

○

○

○

−

○−

− ○ F041

Bit

Japanese setting

English setting

Chinese setting

Test mode

Digital monitor

(F mode)

−

○(Factory set)

○ F019

○ F018

−

○ F022 〜

○ F022 〜

○ F022 〜

○(Factory set)

−

○ F001

○ F002 〜

○ F005 〜

○ F008 〜

○ F011 〜

○

○

○

1234〜 8

OFF OFF

ON OFF

OFF ON

ON ON

Remarks

Dual, backup, etc.

Differential pressure

Differential pressure

V type only

Example: I type (load/unload type)

Example: Setting 1

Option (not supported)

Option (not supported)

Option (not supported)

Setting 1, Setting 2

Setting 1, Setting 2

Pressure differential

Energy saving mode decision time

Function switch

Operation data measurement

Display switch button operation

Reset button operation

Remote + display switch button

Set button 7 sec. ON

Not used

22

3. OPERATING THE DSP [How to Use the Digital Monitor]

3.4 How to Use the Digital Monitor

3.4.1 How to display operation status, shutdown history, and status of various settings

All display contents of the digital monitor are linked with the LCD monitor. All of the following display contents can be

can be confirmed by the LCD monitor.

Use the following operations to display the contents of other operation/setting status on the LCD monitor and simply

confirm operation status and setting status by the digital monitor.

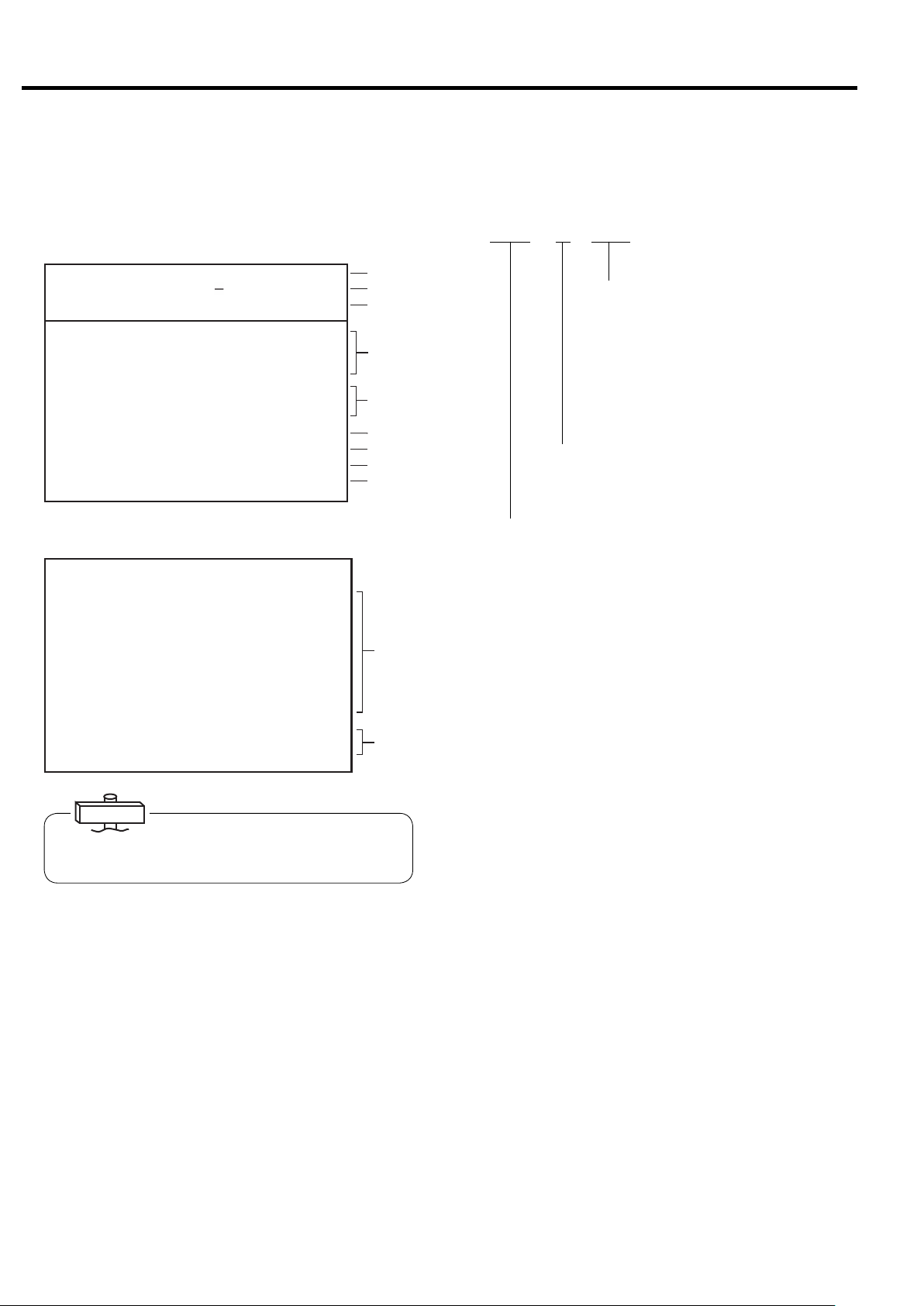

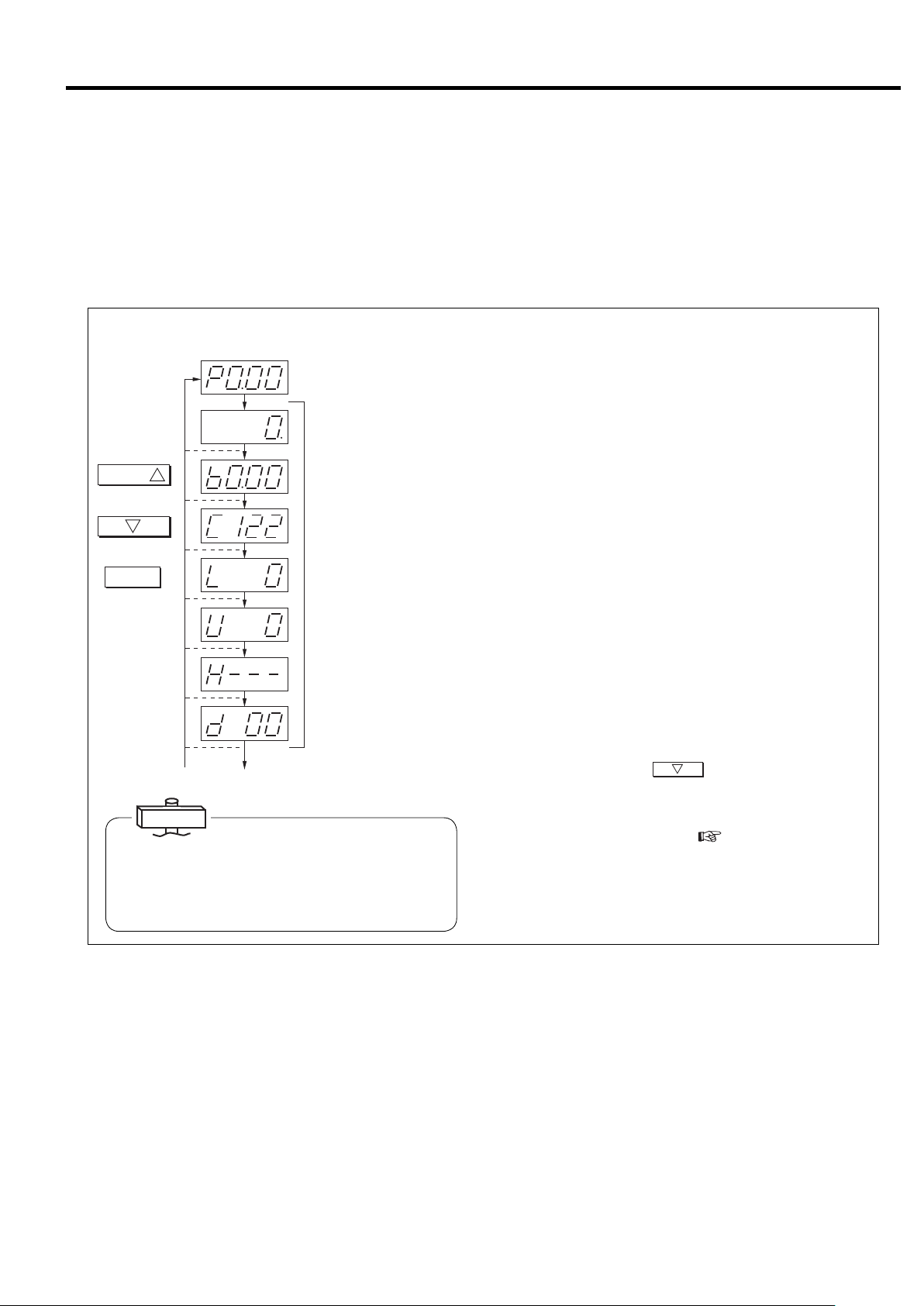

(1) How to Display the Operation Status

P: Dischargepressure(psi)

PressSWITCHDISPLAY.

Flasheswhenoperationtimeisadded.

Operationtime(×10)

表示切替

Proceedsby1each

Returnsby1each

Returnstodischarge

1

timepressed.

2

timepressed.

リセット

pressure.

b: Interstagepressure(psi)

C:Compressordischarge

temperature(℉)

(122℉)

L: Loadrate(%)

U: Loadcount(×10,000times)

H: Notused(displayonly)

d:Notused(displayonly)

Toshutdownhistorydisplay

IMPORTANT

1. When other than P0.00 is displayed, automatically

returns to P0.00 discharge pressure display in 3 minutes.

2. Load rate is a reference value determined by computation.

When the power is turned on, discharge pressure is displayed

on the screen of the digital monitor. Use the following proce-

dure to switch the digital monitor to other display.

Press the

①

SWITCH DISPLAY

button. Operation time is

then displayed on the screen.

Press the

②

SWITCH DISPLAY

button. Interstage pressure

is then displayed on the screen together with “b.”

③ Press the SWITCH DISPLAY button. Compressor discharge

temperature is then displayed on the screen together with

“C.”

Press the

④

SWITCH DISPLAY

button. Load rate is then dis-

played on the screen together with “L.”

Press the

⑤

SWITCH DISPLAY

button. Load count is then

displayed on the screen in units of 10,000 times together

with “U.”

Each time the SWITCH DISPLAY button is subsequently

pressed, it continues on to (2) Display of shutdown history

and (3) Monitor display of various settings. To return one

2

item at a time, press

. To return to discharge pres-

sure, press RESET.

● If the alarm or shutdown light is flashing, the shutdown code

is displayed along with “E0” (

page 33, 34).

“E0” indicates the contents of the latest shutdown.

● If the alarm or shutdown light is flashing, it indicates that

the alarm or shutdown has not been reset. Check E0.XX and

reset.

23

3. OPERATING THE DSP [How to Use the Digital Monitor]

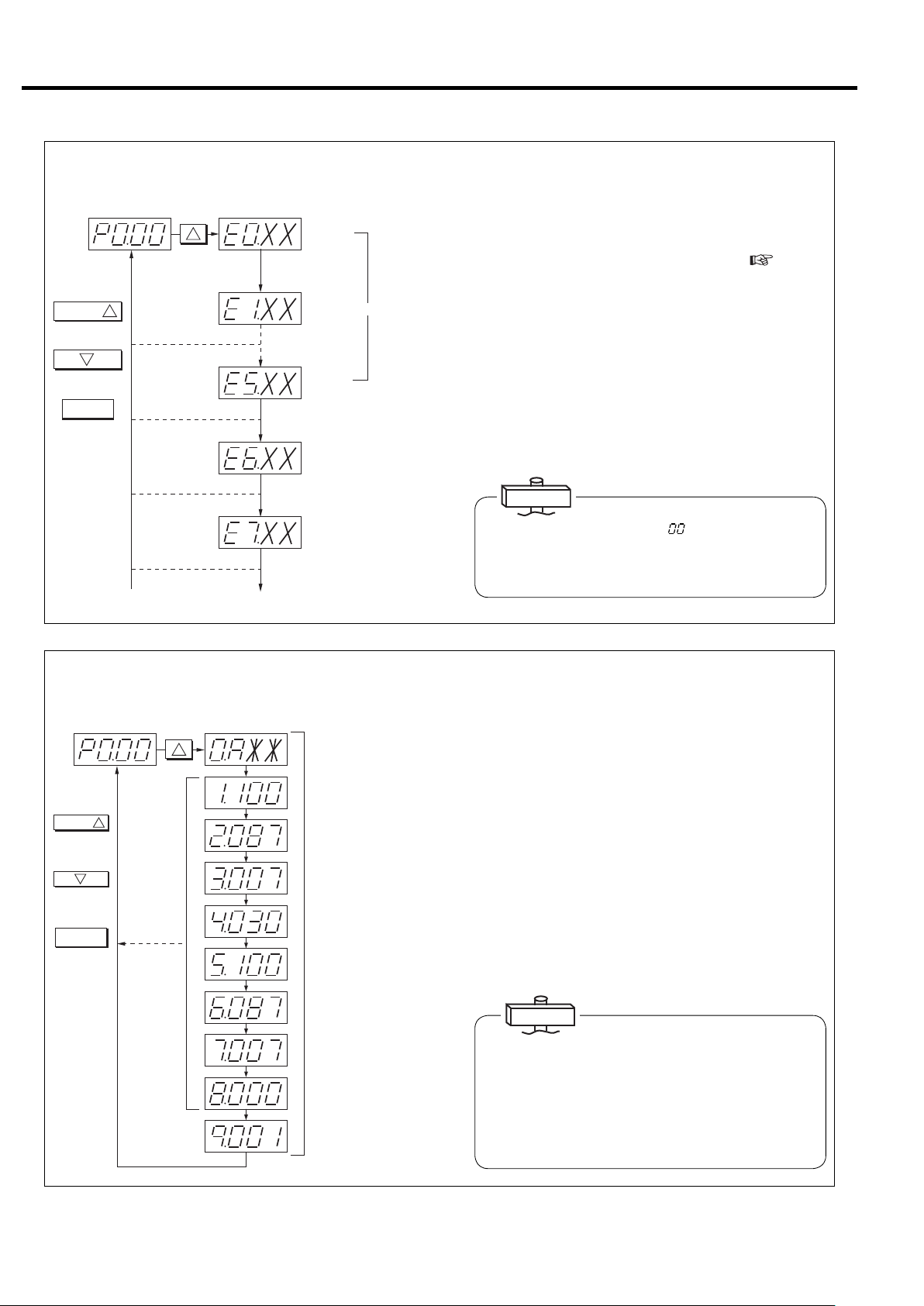

(2) How to Display Shutdown History

Use the following procedure to display shutdown history on the

Dischargepressuredisplay

表示切替

Proceedsby1each

Returnsby1each

Returnstodischarge

1

timepressed.

2

timepressed.

リセット

pressure.

SWITCHDISPLAY

1

Press8times.

[Localshutdown]

[1priorshutdown]

XX : Shutdowncode

[Oldestshutdown]

Historyconsistsof6items.

Notused(displayonly)

screen.

①

② Press the SWITCH DISPLAY button. “E1.” is then dis-

③ Press the RESET Button. The screen then returns to the

Press the

SWITCH DISPLAY

displayed together with the shutdown code (

button 8 times. “E0.” is the

page 33,

34). “0” indicates the latest shutdown. (Automatically chang-

es to “E.0” when shutdown or alarm occurs.)

played along with the shutdown code. “1” indicates shut-

down that occurred previously. Six items of data from 0 – 5

are recorded. “E5” indicates the oldest shutdown.

usual digital monitor display.

IMPORTANT

Notused(displayonly)

If the shutdown code “XX ”is “ ” it means there is no

shutdown history. Also, when anything other than shutdown history is displayed without resetting shutdown,

Todisplayofvarioussettings

it returns to the latest shutdown history in 3 minutes.

(3) How to Display Various Settings (Perform operation only when confirmation is

necessary.)

Dischargepressuredisplay

表示切替

1

Proceedsby1

eachtimepressed.

2

Returnsby1each

timepressed.

リセット

Returnsto

dischargepressure.

SWITCHDISPLAY

1

Press16times.

No.0 : Controlstatus

A : Capacitycontroltype

No.1 : Startpressure1

100 : 100psi

No.2 : Recoverpressure1

087 : 87psi

No.3 : Pressuredifferential1

007 : 7psi

No.4 : ECOMODE

[Energyconservationmode]

Decisiontime

No.5 : Startpressure2

100 : 100psi

Use the following procedure to display capacity control type

and pressure setting values for confirmation.

Press the

①

SWITCH DISPLAY

button 16 times. “0.A**” is

then displayed on the screen. ** changes with specifica-

tions. “A” may be “L” or “U” depending on capacity control

specifications.

② Consists of items 0 - 9. Pressure setting status and optional

pressure setting 2 can be confirmed each time the SWITCH

DISPLAY button is pressed.

③ Press the RESET Button. The screen then returns to the

usual discharge pressure display.

24

No.6 : Recoverpressure2

087 : 87psi

No.7 : Pressuredifferential2

007 : 7psi

No.8 : Instantaneouspower

interruption(IPI)setting

Invalid

000

:

No.9 : Compressoraddress

001 : No.1

IMPORTANT

Symbol displayed at No. 0 and corresponding capacity

control type

A: AUTO function setting

L: Fixed speed type setting

(INTE …Load/unload operation)

U: V type AUTO function off setting

For details on the various types, see pages 20 and 62 - 63.

3. OPERATING THE DSP [How to Use the Digital Monitor]

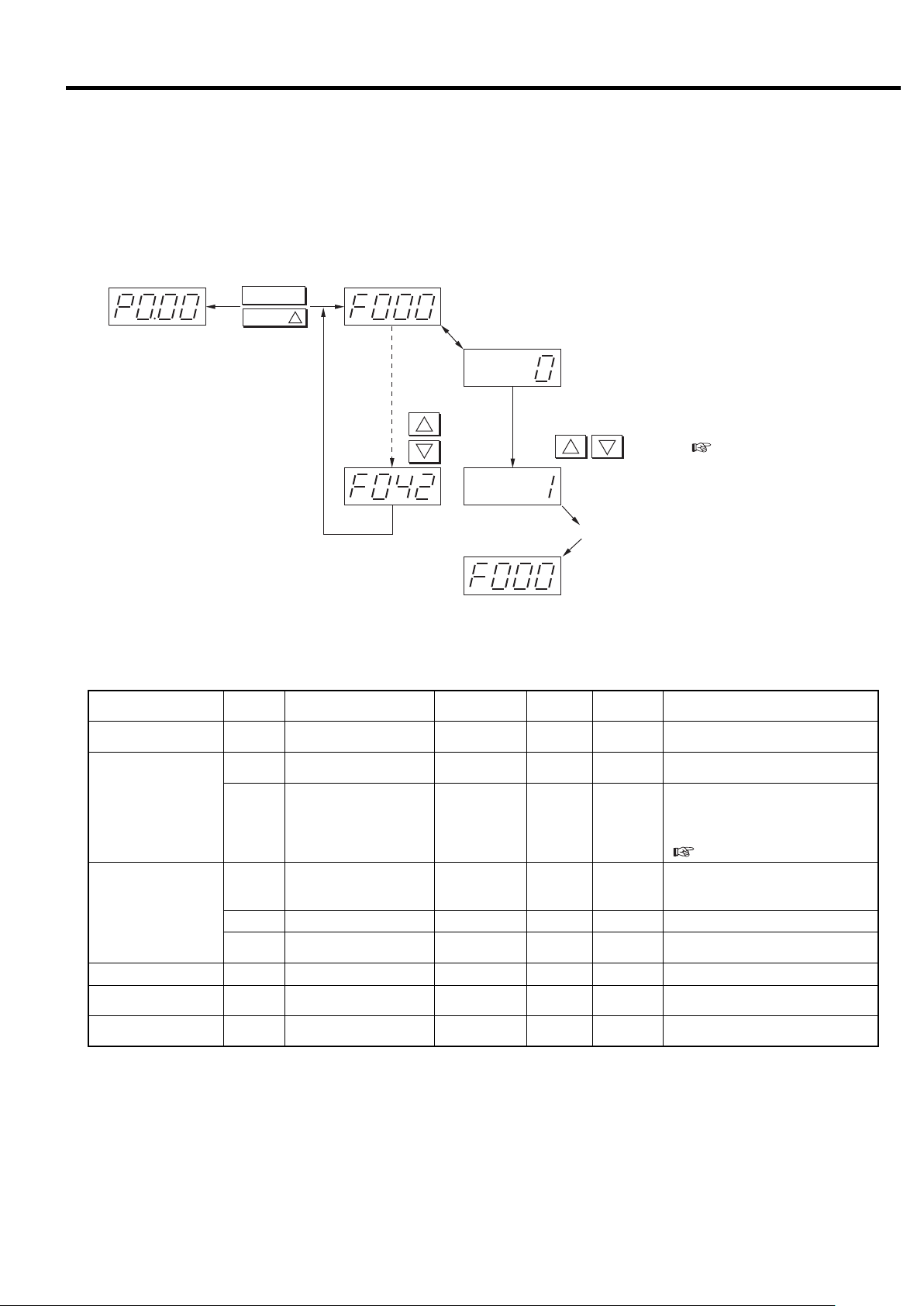

3.4.2 How to Set Control Functions

■ Various settings (instantaneous power interruption (IPI), remote operation, capacity control

setting, pressure setting, etc.)

Switches display from monitor mode to setting mode (F mode).

リセット

表示切替

Pressandhold

simultaneouslyforat

least3seconds.

Performsame

operationtoreturn.

1

Displays000

ChangeseachtimeFUNCTIONispressed.

th

itemofFmode.

Displayssettingcontents.

F000:(0:Setssingleunitoperation.)

Fordetails,seetheFmodetable.

1

2

Forward

Back

Toaltersettings,changethevalueswiththe

2

1

buttons.(page26)

F000:(1:Setsmultipleunitcontrol.)

PressENTERtoenterthesettings.

Back

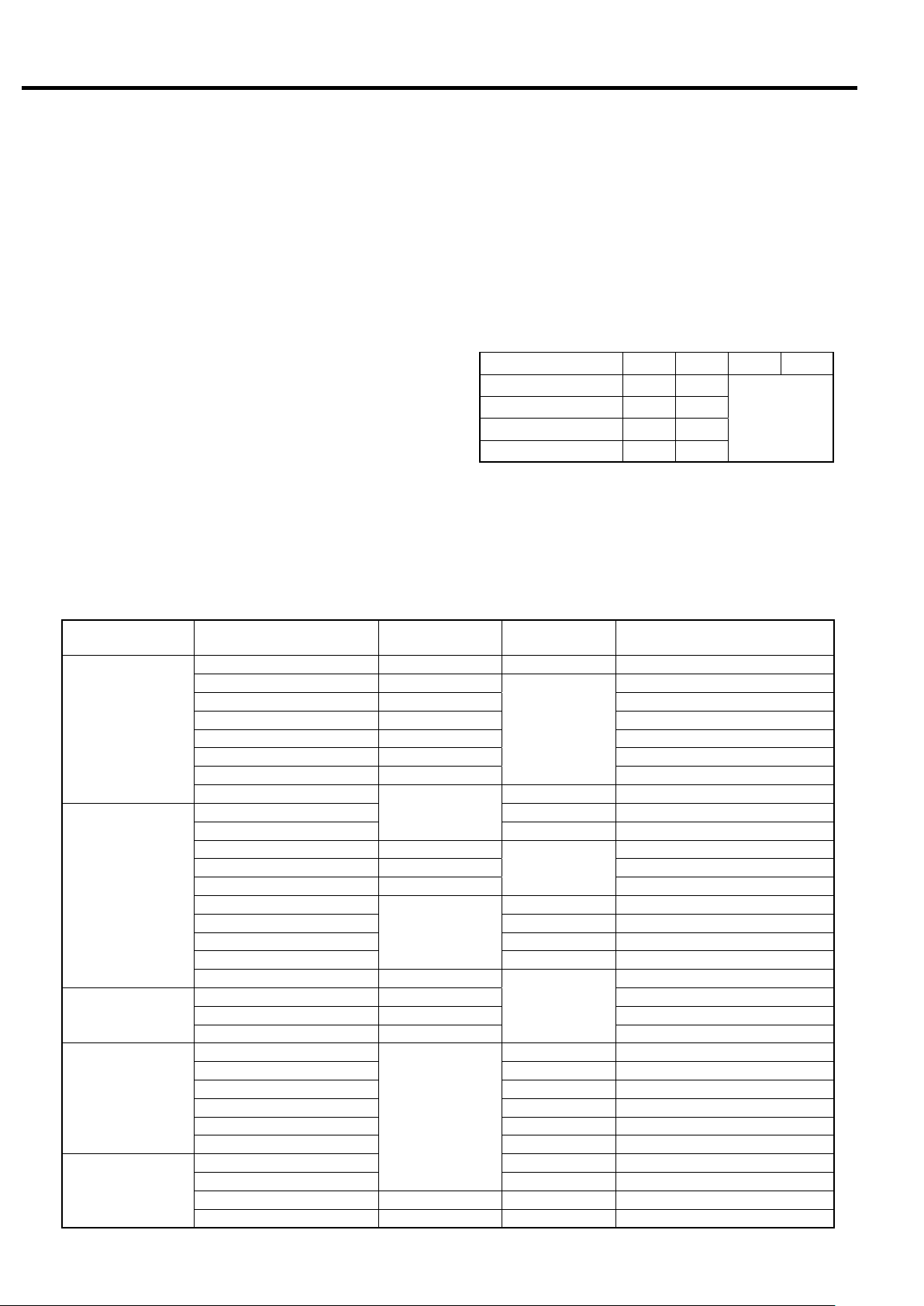

Settings can be altered or entered into the memory from the digital monitor without opening the start panel.

Function

Multiple unit control setting

Instantaneous power interruption (IPI) restart setting

7 segment

display

Item Range

F000 Control setting 0 〜 110

F002

Instantaneous power interruption (IPI) setting

0〜1 1 00:ON、1:OFF

Instantaneous power inter-

F003

ruption (IPI) detection period

1〜511

setting"

Remote control switch

method

Remote operation shutdown recovery

0〜310

0〜1 1 00:Disable, 1:Enable

Remote operation setting

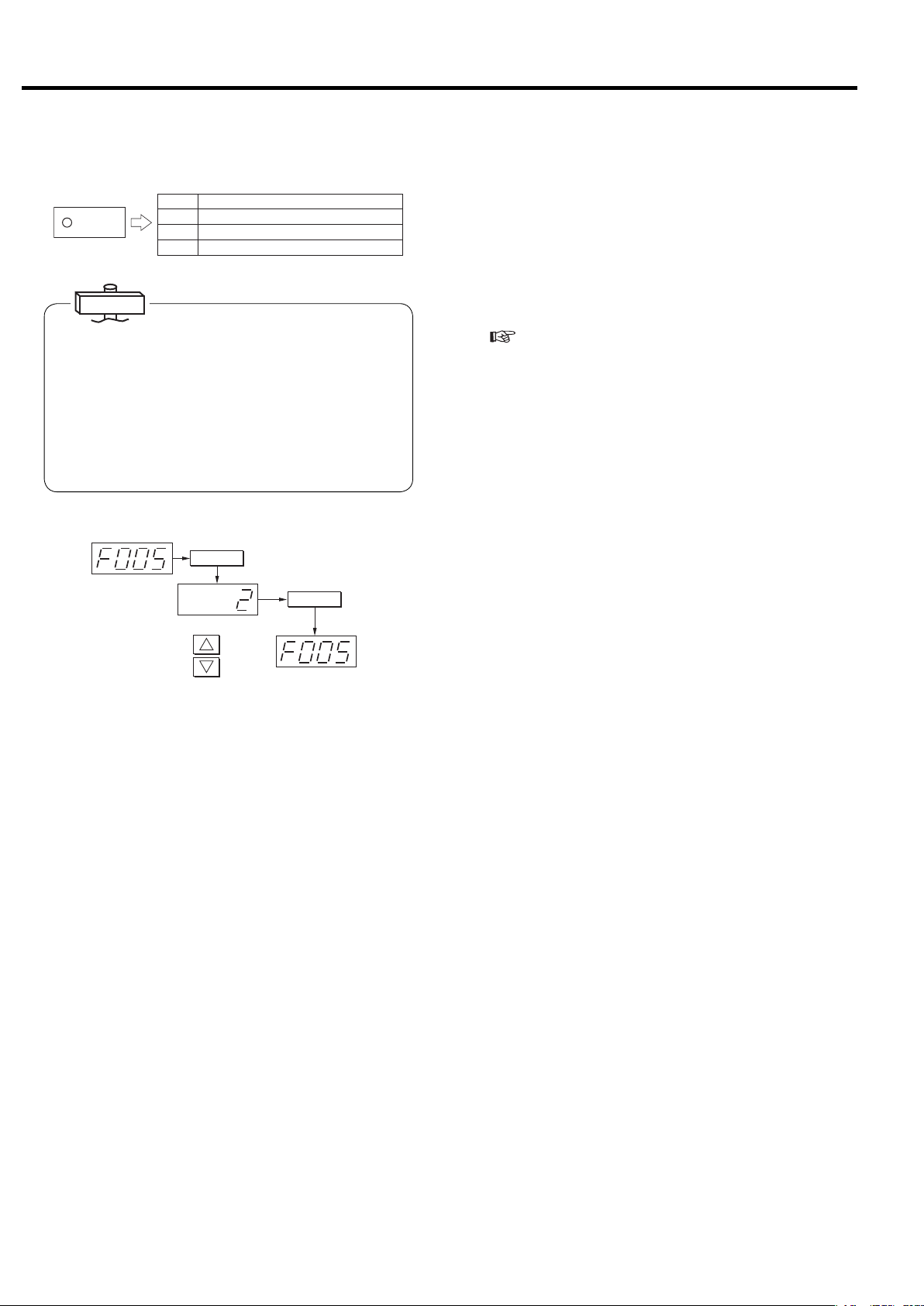

F005

F006 Remote operation method 0〜1 1 00:Pulse input, 1:Level input

F007

AUTO setting (*2) F011 AUTO operation enable 0〜1 1 00:Enable, 1:Disable

Capacity control F018 Control pressure selection 0〜210

Function setting

(optional)

F021 Pressure control mode 0〜210

Note:

※ Setting can be altered at any time other than this.

*1:When set to 1,” history is cleared. After clearing, the value is automatically reset to “0.”

*2:Only the V type is equipped with AUTO function. The AUTO function is available as an option for the Fixed speed type.

*3:Refer to the below chart about the Pressure setting.

Don’t change the setting of digital monitor besides the above parameter F (7 segment display: F

Precision/

unit

Initial value

***).

0: Single operation, 1: Multiple unit

control (communication supported)

When IPI is available, Instantaneous

power interruption is detected between

20ms and the setting detection period,

then the compressor restarts.

(

page 25)

0:Panel setting, 1:Local fi xed,

2:Remote fi xed,

3: Remote switch signal

0:Setting 1, 1:Setting 2,

2:External input

0:Built-in sensor, 1:External contact,

2:External input

25

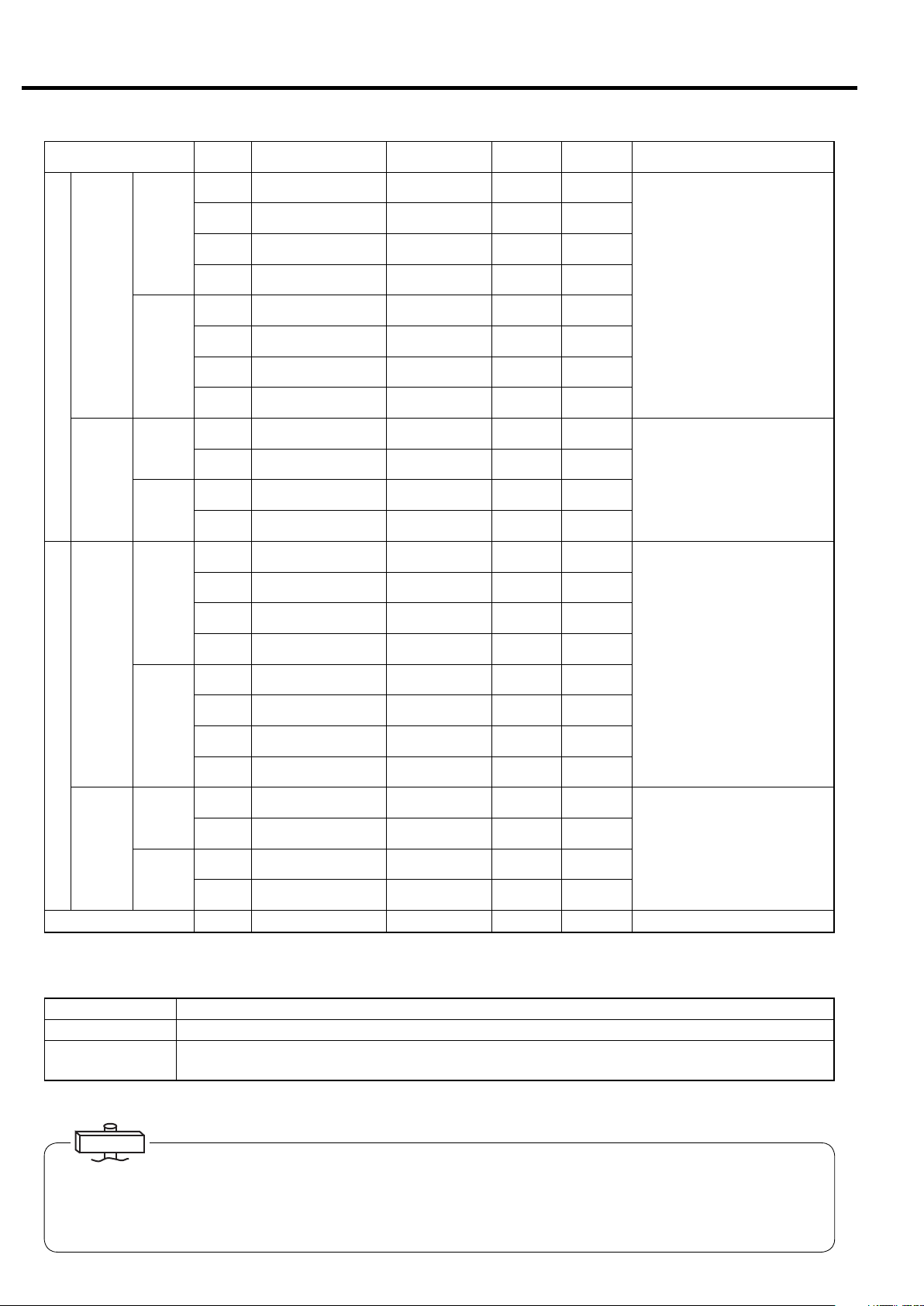

3. OPERATING THE DSP [How to Use the Digital Monitor]

Function

Pressure

setting 1

※

(*3)

psi)

V type

】

125

【

MPa (110

】

0.86

【

0.75

Standard

type

V type

1.0 MPa (145 psi)

Standard

type

Shutdown history clear

Pressure

setting 2

※

(*3)

Pressure

setting 1

※

(*3)

Pressure

setting 2

※

(*3)

Pressure

setting 1

※

(*3)

Pressure

setting 2

※

(*3)

Pressure

setting 1

※

(*3)

Pressure

setting 2

※

(*3)

7 segment

display

F022

F023

F024

F025 (*2)

F031

F032

F033

F034 (*2)

F023

F024

F032

F033

F026

F027

F028

F029

F035

F036

F037

F038

F027

F028

F036

F037

F041 (*1)

Item Range

Control pressure setting 1

(control pressure)

Start pressure 1

(cut out pressure)

Recovery pressure 1

(cut in pressure)

P type recovery pressure 1

(restart pressure)

Control pressure setting 2

(control pressure)

Start pressure 2

(cut out pressure)

Recovery pressure 2

(cut in pressure)

P type recovery pressure 2

(restart pressure)

Start pressure 1

(cut out pressure)

Recovery pressure 1

(cut in pressure)

Start pressure 2

(cut out pressure)

Recovery pressure 2

(cut in pressure)

Control pressure setting 1

(control pressure)

Start pressure 1

(cut out pressure)

Recovery pressure 1

(cut in pressure)

P type recovery pressure 1

(restart pressure)

Control pressure setting 2

(control pressure)

Start pressure 2

(cut out pressure)

Recovery pressure 2

(cut in pressure)

P type recovery pressure 2

(restart pressure)

Start pressure 1

(cut out pressure)

Recovery pressure 1

(cut in pressure)

Start pressure 2

(cut out pressure)

Recovery pressure 2

(cut in pressure)

History Clear 0〜1 1 0 0 : Enter, 1 : History clear

0.5〜0.75 【0.86

(73〜110 【125】)

0.5〜0.77 【0.88

(73〜112 【128】)

0.5〜0.73 【0.84

(73〜106 【122】)

0.5〜0.73 【0.84

(73〜106 【122】)

0.5〜0.75 【0.86

(73〜110 【125】)

0.5〜0.77 【0.88

(73〜112 【128】)

0.5〜0.73 【0.84

(73〜106 【122】)

0.5〜0.73 【0.84

(73〜106 【122】)

0.5〜0.75 【0.86

(73〜110 【125】)

0.5〜0.65 【0.76

(73〜94 【110】)

0.5〜0.75 【0.86

(73〜110 【125】)

0.5〜0.65 【0.76

(73〜94 【110】)

0.5〜1.0

(73〜145)

0.5〜1.02

(73〜148)

0.5〜0.98

(73〜142)

0.5〜0.98

(73〜142)

0.5〜1.0

(73〜145)

0.5〜1.02

(73〜148)

0.5〜0.98

(73〜142)

0.5〜0.98

(73〜142)

0.5〜1.0

(73〜145)

0.5〜0.9

(73〜131)

0.5〜1.0

(73〜145)

0.5〜0.9

(73〜131)

Precision/

】

】

】

】

】

】

】

】

】

】

】

】

unit

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MP

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

0.01MPa

(1.5psi)

Initial value

0.75 【0.86

(110 【125】)

0.77 【0.88

(112 【128】)

0.72 【0.83

(104 【120】)

0.72 【0.83

(104 【120】)

0.75 【0.86

(110 【125】)

0.77 【0.88

(112 【128】)

0.72 【0.83

(104 【120】)

0.72 【0.83

(104 【120】)

0.75 【0.86

(110 【125】)

0.65 【0.76

0.75 【0.86

(110 【125】)

0.65 【0.76

a

(94 【110】)

(94 【110】)

1.0

(145)

1.02

(148)

0.97

(141)

0.97

(141)

1.0

(145)

1.02

(148)

0.97

(141)

0.97

(141)

1.0

(145)

0.9

(131)

1.0

(145)

0.9

(131)

】

】

】

】

Setting can be altered at any time.

※

】

】

】

】

】

】

Setting can be altered at any time.

※

】

】

Setting can be altered at any time.

※

Setting can be altered at any time.

※

●Pressure setting condition

Type Setting condition (Example of Pressure setting 1)

Standard type

V type

①Start pressure (F023) cannot be set below the value of Recovery pressure (F024) (F025) + 3 psi.

① Start pressure (F023) cannot be set below the value of Control pressure (F022) + 3 psi.

② Recovery pressure cannot be set above the value of Control pressure (F022).

Note 1. The higher value, in which value of Recovery pressure (F024) or (F025), becomes the standard type condition ①.

2. The setting condition is same in case of Pressure setting 2 (F031〜F034).

IMPORTANT

1. Pressure setting

V type: Set pressure differential of start pressure and recovery pressure to a minimum of 7 psi when using a standard receiv-

er. Set Pressure differential of start pressure and control pressure to a minimum of 3 psi.

Fixed speed type: Set pressure differential of start pressure and recovery pressure to a minimum of 15 psi.

2. Function for switching to pressure setting 2 by external pressure alteration input is optional.

26

3. OPERATING THE DSP [How to Use the Digital Monitor]

3.4.3 Alteration of Pressure Setting Values

Pressure

setting1

Pressbutton.

機能

Pressbutton.

記憶

1

Alter

values.

2

Use the following procedure to alter the pressure setting

values for the capacity control system.

① Switch from monitor mode to setting mode (F mode).

② Set PRESSURE SETTING 1 of F mode.

(For detailed contents of setting specifications, see

page 26.)

If using pressure setting 2, you must also set pres-

sure setting 2.

For operation method, be sure to refer to the various

settings, and after entering the setting values with the

STORE button, return to the monitor mode.

3.4.4 Capacity Control Mode Setting and

Confirmation

AUTOsetting

機能

Pressbutton.

Pressbutton.

記憶

SettoAUTOOFF.

(Initialvalue0)

1

Alter

values.

2

IMPORTANT

The AUTO function is available for the Fixed speed type

as an option.

3.4.5 Restart for Instantaneous Power

Interruption

運転状況

RUNNINGMODE

遠方

REMOTE

負荷

LOAD

故障

SHUTDOWN

2

電源

POWER

起動待ち

AUTOSTART

運転 停止

START

STOP

UNLOAD STOP

②③

③

You can switch the capacity control mode by the following method according to the application. The V type is a

automatic stop type, but can also be changed to control

mode that does not stop automatically (AUTO OFF).

Capacity control mode setting can be changed by switching the digital monitor from monitor mode to setting

mode (F mode) while the compressor is not running and

setting to “0: Enable” or “1: Disable” by altering the

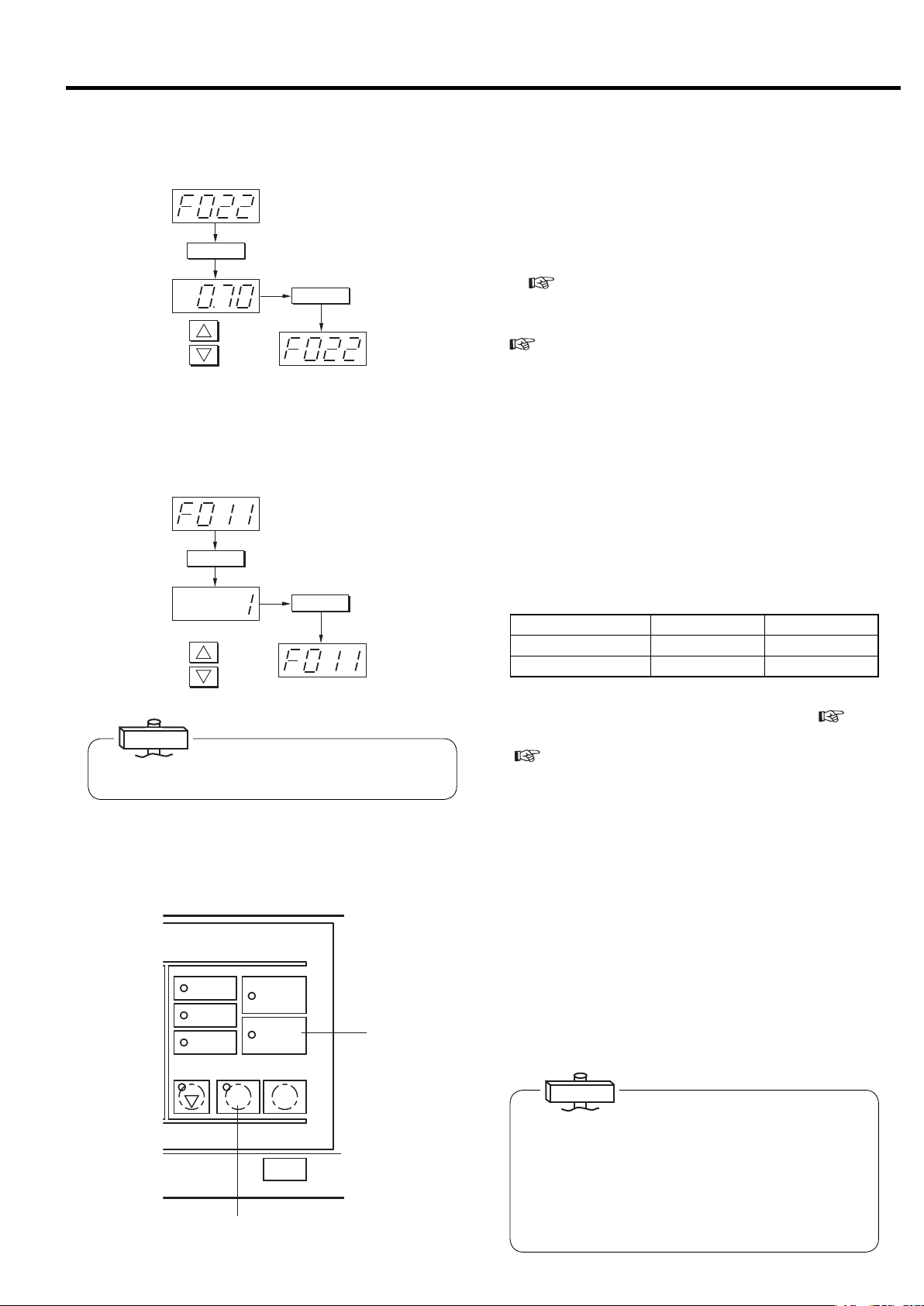

AUTO setting (F011) of F mode.

Capacity control mode AUTO ON AUTO OFF

F011 0 : Enable 1 : Disable

Digital monitor display

0.AXX0.UXX

After altering, confirm the capacity control mode by display of various settings on the digital monitor (

page

23).

For capacity control operation and details, see pages