Page 1

NOVEMBER, 1999 Prepared by: ALVIE RODGERS C.E.T.

This training package is geared specifically to the 61HDX98B HDTV. However, most of

the material will cross over to the 60SDX88B progressive scan HDTV capable set. The

necessary understanding that the 60SDX88B requires a Set-Top-Box to receive SDTV and

HDTV signals is important. The 60SDX88B does NOT have a DM-1 module. This module

is built into the 61HDX98B which allows this set to receive all ATSC formats as well as

Direct TV, NTSC, SDTV or HDTV. It does not have Component Inputs.

The 60SDX88B has a built in FLEX converter that translates any input into either 480P for

NTSC or SDTV and/or 1080I for HDTV. It does have Component Inputs.

The Power Supplies are the same for either set.

The Deflection circuit is very similar between the two sets.

The Signal PWB is very similar between the two sets, minus the differences mentioned

above.

Digital Convergence is the same between the two sets.

61HDX98B is a DP-85 chassis with a 16X9 aspect screen.

60SDX88B is a DP-86 chassis with a 3X4 aspect screen.

SEE DP-86 TRAINING SECTION IN THE BACK OF THE PACKAGE.

CONTENTS... 1999 DP-85 HDTV Projection Television Information

Page 2

DP-85 CHASSIS TRAINING and INFORMATION” HDTV

CONTENTS

”SECTION” “PAGE”

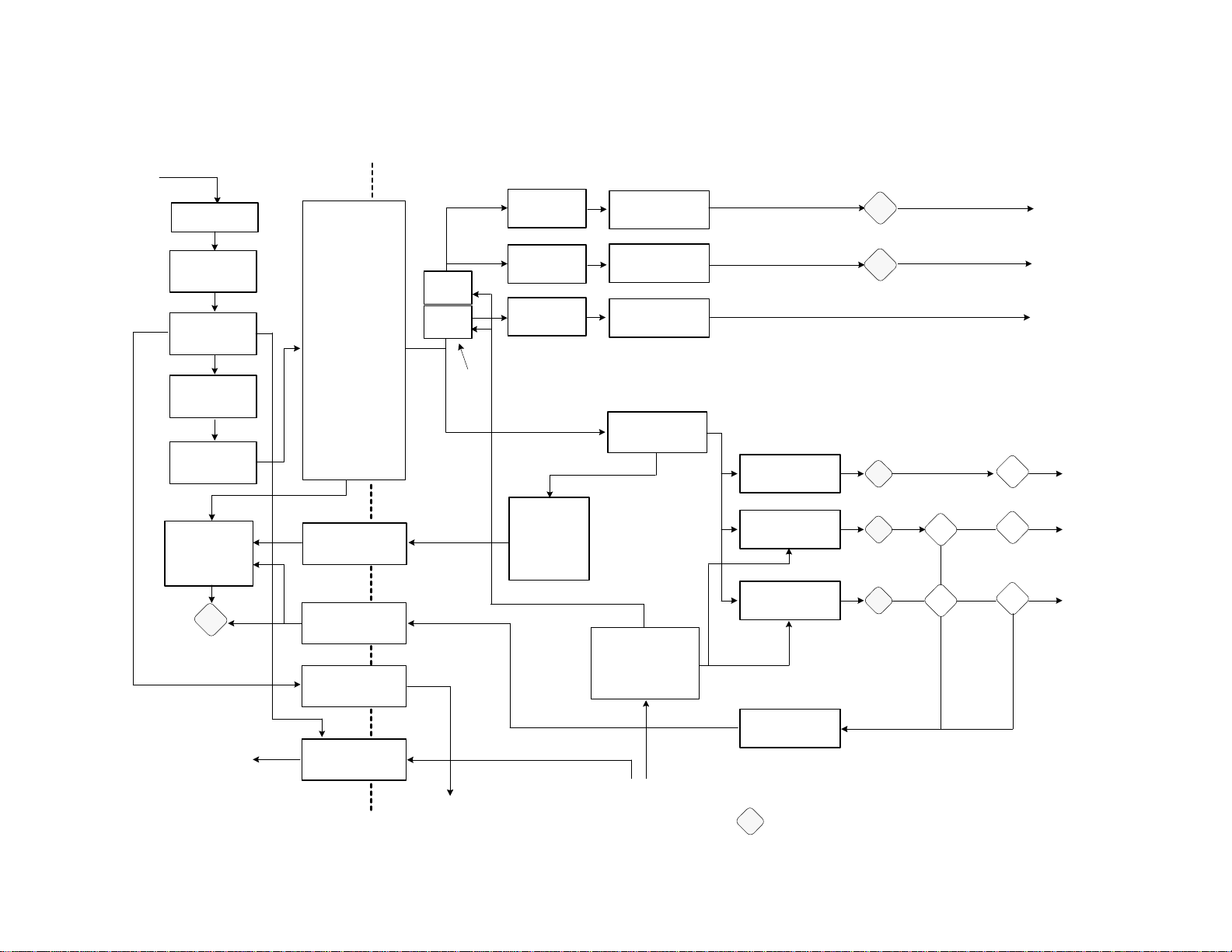

1): GENERAL BLOCK DIAGRAMS, SECTION:

• Power Supply Block Explanation --------------------------------------------------------- 01-01

• Power Supply Block Diagram ------------------------------------------------------------- 01-02

• DM-1 Module Front End Block Explanation -------------------------------------------- 01-03

• DM-1 Module Front End Block Diagram ------------------------------------------------ 01-05

• AV Selector Block Explanation ------------------------------------------------------------ 01-06

• AV Selector Block Diagram ---------------------------------------------------------------- 01-07

• System Control Block Explanation ------------------------------------------------------- 01-08

• System Control Block Diagram ----------------------------------------------------------- 01-10

• 2H Video Block Explanation --------------------------------------------------------------- 01-11

• 2H Video Block Diagram ------------------------------------------------------------------- 01-12

• Deflection Circuit Block Explanation ---------------------------------------------------- 01-13

• Deflection Circuit Block Diagram -------------------------------------------------------- 01-16

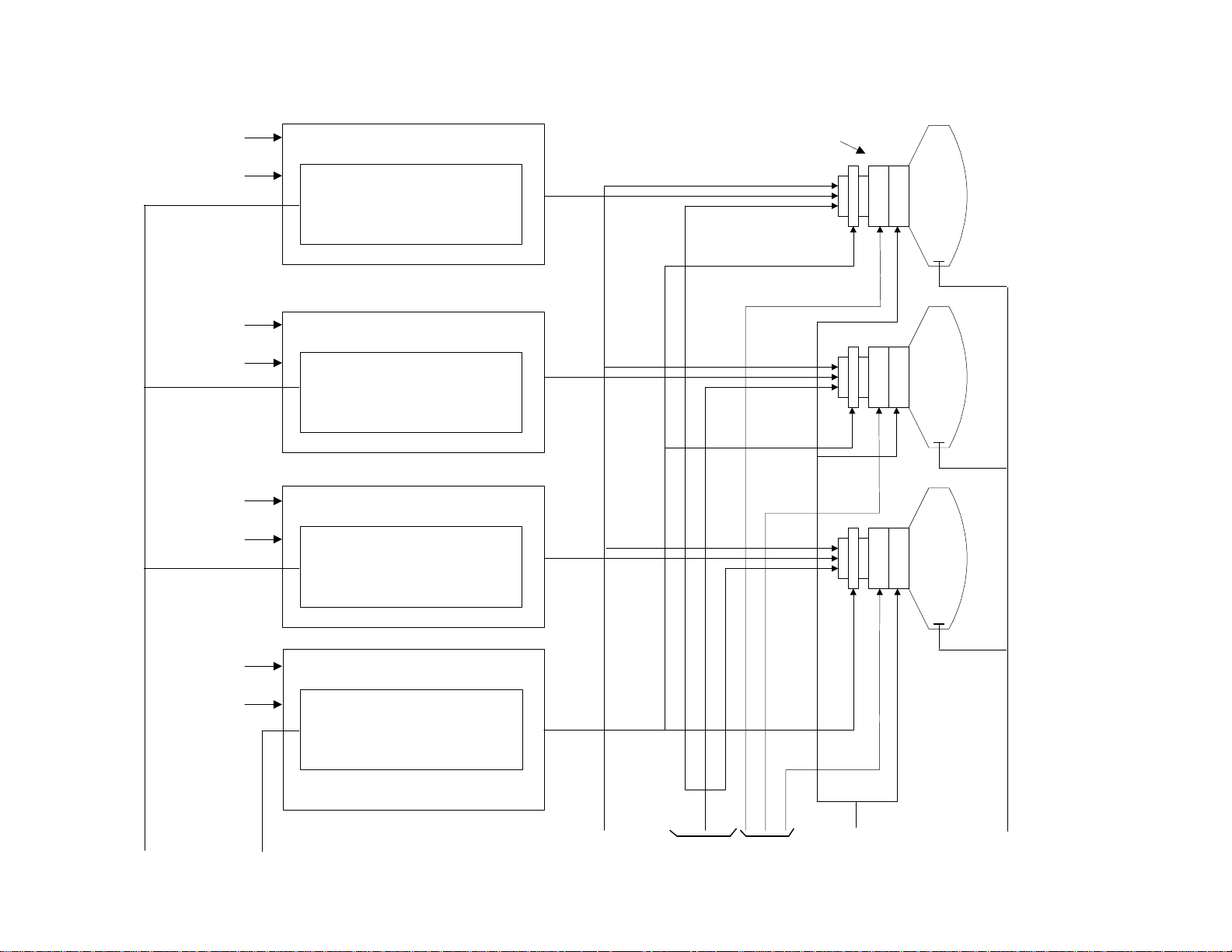

• CRT Block Diagram ------------------------------------------------------------------------- 01-17

• Audio Output Block Diagram ------------------------------------------------------------- 01-18

• Rear Panel Diagram ------------------------------------------------------------------------- 01-19

• 4X3 Displayed on 16X9 Four Possible Modes ------------------------------------------- 01-20

2): POWER SUPPLY INFORMATION, SECTION:

• Digital Circuit Power Supply SHUT DOWN Block Diagram -------------------------- 02-01

• Digital Circuit Power Supply SHUT DOWN Circuit Diagram ------------------------- 02-02

• Digital Circuit Power Supply Visual Trouble Shooting LED's Diagram ------------- 02-03

• Digital Circuit Power Supply Distribution Diagram -------------------------------------- 02-04

• Deflection and High Voltage Power Supply SHUT DOWN Block Diagram --------- 02-05

• Deflection and High Voltage Power Supply SHUT DOWN Circuit Diagram -------- 02-06

• Deflection Power Supply Visual Trouble Shooting LED's Diagram ------------------ 02-07

• Deflection Power Supply Distribution Diagram ------------------------------------------ 02-08

3): HORIZONTAL DRIVE, SECTION:

• Horizontal Drive Circuit Diagram --------------------------------------------------------- 03-01

4): VIDEO SIGNAL INFORMATION:

• Video Signal Main and Terminal Circuit Diagram -------------------------------------- 04-01

• ABL Circuit Diagram ------------------------------------------------------------------------- 04-02

• Horizontal and Vertical SWEEP LOSS DETECTION Circuit ------------------------ 04-03

5): AUDIO CIRCUIT INFORMATION:

• Audio Signal Main and Terminal Board Circuit Diagram ----------------------------- 05-01

• Audio SURROUND Board Circuit Diagram ---------------------------------------------- 05-02

• Audio and Video MUTE Circuit Diagram ------------------------------------------------ 05-03

• Audio MUTE Surround Board Circuit Diagram ----------------------------------------- 05-04

• Audio MUTE Audio Output Board Circuit Diagram ------------------------------------ 05-05

6): DIGITAL CONVERGENCE CIRCUIT INFORMATION:

• Digital Convergence INTER-CONNECTION Diagram -------------------------------- 06-01

CONTENTS PAGE (A-1)

Page 3

DP-85 CHASSIS TRAINING and INFORMATION” HDTV

CONTENTS

”SECTION” “PAGE”

• Digital Convergence OVERLAY Information -------------------------------------------- 06-02

• Digital Convergence OVERLAY DIMENSIONS --------------------------------------- 06-03

• Digital Convergence REMOTE CONTROL Button Identification ------------------- 06-04

7): MICROPROCESSOR

• Microprocessor Port Definitions ......................................................................................07-01

• Microprocessor Data Port Block Diagram .......................................................................07-03

• Microprocessor Data Communications Block Diagram ...................................................07-04

8): ADJUSTMENTS

• Adjustment Order ...............................................................................................................08-01

2

• I

C Bus Alignments in the Field ...........................................................................................08-02

• Centering Magnets Location ...............................................................................................08-06

• Pre Heat Run Condition .......................................................................................................08-07

• Cut Off and Focus Adjustment ............................................................................................08-08

• Digital Convergence Unit Crosshatch Phase ......................................................................08-09

• Horizontal Position “Coarse” Adjustment ..........................................................................08-10

• Raster Tilt (Deflection Yoke) Adjustment ..........................................................................08-11

• Beam Alignment Adjustment ..............................................................................................08-12

• Centering Magnet and Beam Shape Magnet Identifications ............................................08-13

• Static Centering and Center Adjustment ........................................................................08-14

• Horizontal Blanking Phase Adjustment ..............................................................................08-15

• Horizontal & Vertical Size Adjustment ................................................................................08-16

• Trapezoid Distortion Adjustment .......................................................................................08-17

• Side Pincushion Distortion Adjustment ..............................................................................08-18

• Beam Form Adjustment ......................................................................................................08-19

• Optical System Alignment (Lens) ........................................................................................08-20

• Blue Defocus Adjustment ....................................................................................................08-21

• Red, Green and Blue White Balance Tracking .....................................................................08-22

• Sub Brightness Adjustment Alternate Method .....................................................................08-23

• Horizontal Position “Fine” Adjustment ...............................................................................08-24

DIGITAL CONVERGENCE ALIGNMENT PROCEDURE

• Digital Convergence Overlay Smooth and Full .................................................................08-25

• (3X3) and (7X5) Stopping positions .....................................................................................08-26

• (13X9) Stopping positions ....................................................................................................08-27

• Digital Convergence Remote Control .................................................................................08-28

• Clearing RAM Data . ............................................................................................................08-29

• Raster Centering .................................................................................................................08-30

FULL MODE

• Green 3X3 Adjustment ......................................................................................................................08-31

• Red and Blue 3X3 Adjustment ..........................................................................................................08-32

• Green 7X5 Adjustment ......................................................................................................................08-33

CONTENTS PAGE (A-2)

Page 4

DP-85 CHASSIS TRAINING and INFORMATION” HDTV

ADJUSTMENTS CONTINUED

”SECTION” “PAGE”

• Red and Blue 7X5 Adjustment ..........................................................................................................08-34

• Green 13X9 Adjustment ....................................................................................................................08-35

• Red and Blue 13X9 Adjustment ........................................................................................................08-36

• Storing New Dig. Conv. Data ...........................................................................................................08-37

• Magic Focus Initialization ................................................................................................................08-38

SMOOTH MODE

Change Screen Format to SMOOTH Mode and repeat steps below.

• Green 7X5 Adjustment (If necessary) ...............................................................................................08-33

• Red and Blue 7X5 Adjustment (If necessary) ...................................................................................08-34

• Green 13X9 Adjustment ....................................................................................................................08-35

• Red and Blue 13X9 Adjustment ........................................................................................................08-36

• Storing New Dig. Conv. Data ...........................................................................................................08-37

• Magic Focus Initialization ................................................................................................................08-38

• Static Centering Adjustment .......................................................................................................... 08-39

Minor Digital Convergence Adjustment

• Minor Adjustments Needed ............................................................................................................08-40

• Accessing Digital Convergence Error Codes ..................................................................................08-41

Adjustments Continued

• Memory Initialization Procedure .......................................................................................................08-42

9): TROUBLE SHOOTING

• No Raster No Power ..........................................................................................................................09-01

• A and B: No Relay Click, Def. Red LED Blinking ...................................................................09-02

• C and R: No Red LED B+ .........................................................................................................09-03

• D, E and F: All LED’s going off at the same time Def. and Power PWB ................................09-04

• G One LED going off a little before the others Dig. and Sig. Power PWB ..............................09-05

• DM-1 Trouble Shooting Figure .......................................................................................................09-06

• DM-1 Troubleshooting Checks ........................................................................................................09-07

• DM-1 Waveforms used for Troubleshooting ..................................................................................09-08

• DM-1 Video Waveforms Troubleshooting Checks ........................................................................09-08

• Deflection Waveforms Troubleshooting Checks ............................................................................09-10

• Other Key Waveforms Troubleshooting Checks ............................................................................09-13

• Smart Card Troubleshooting Checks .............................................................................................09-18

10): COMPONENT IDENTIFICATION AND PARTS INFORMATION

• Component and Parts Identification ...............................................................................................10-01

CONTENTS

CONTENTS PAGE (A-3)

Page 5

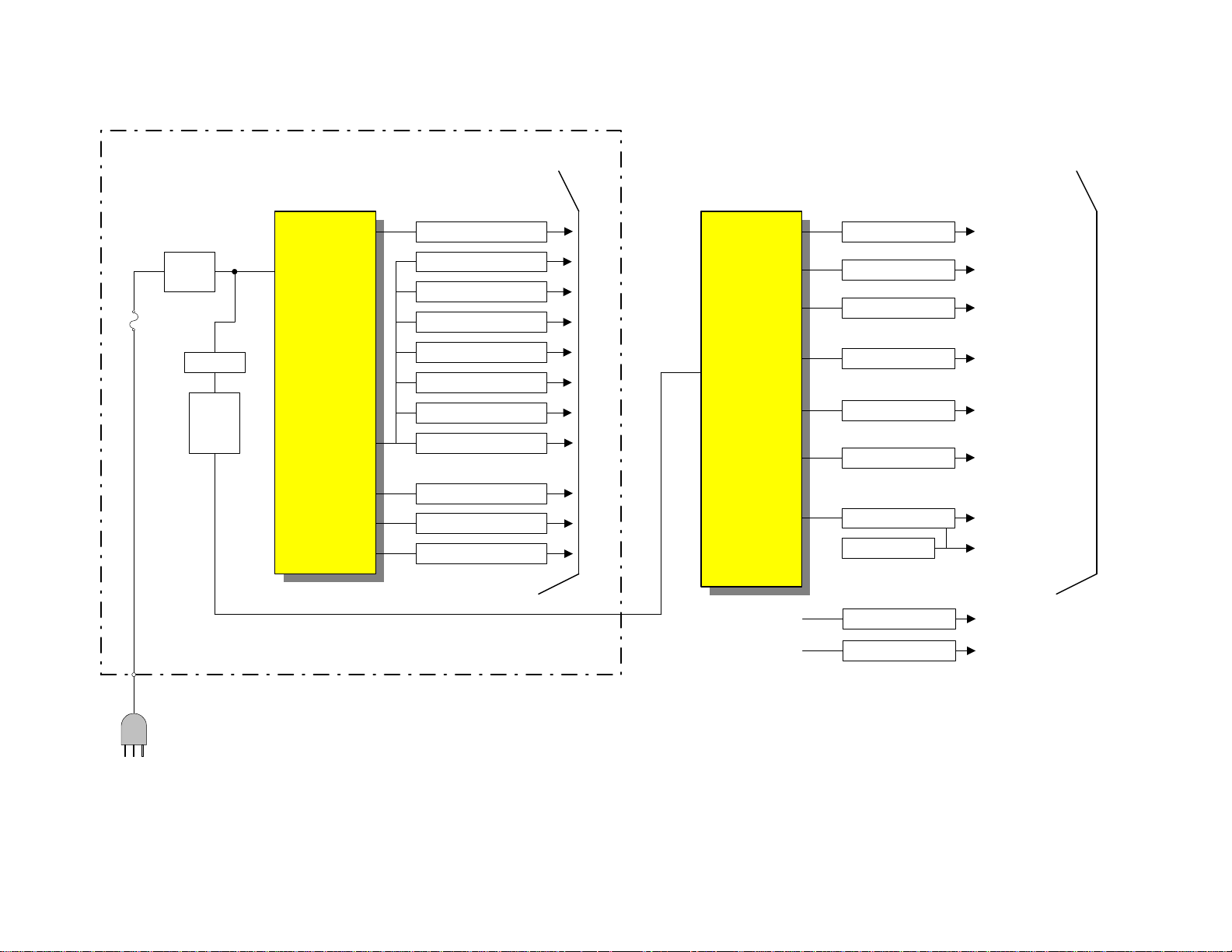

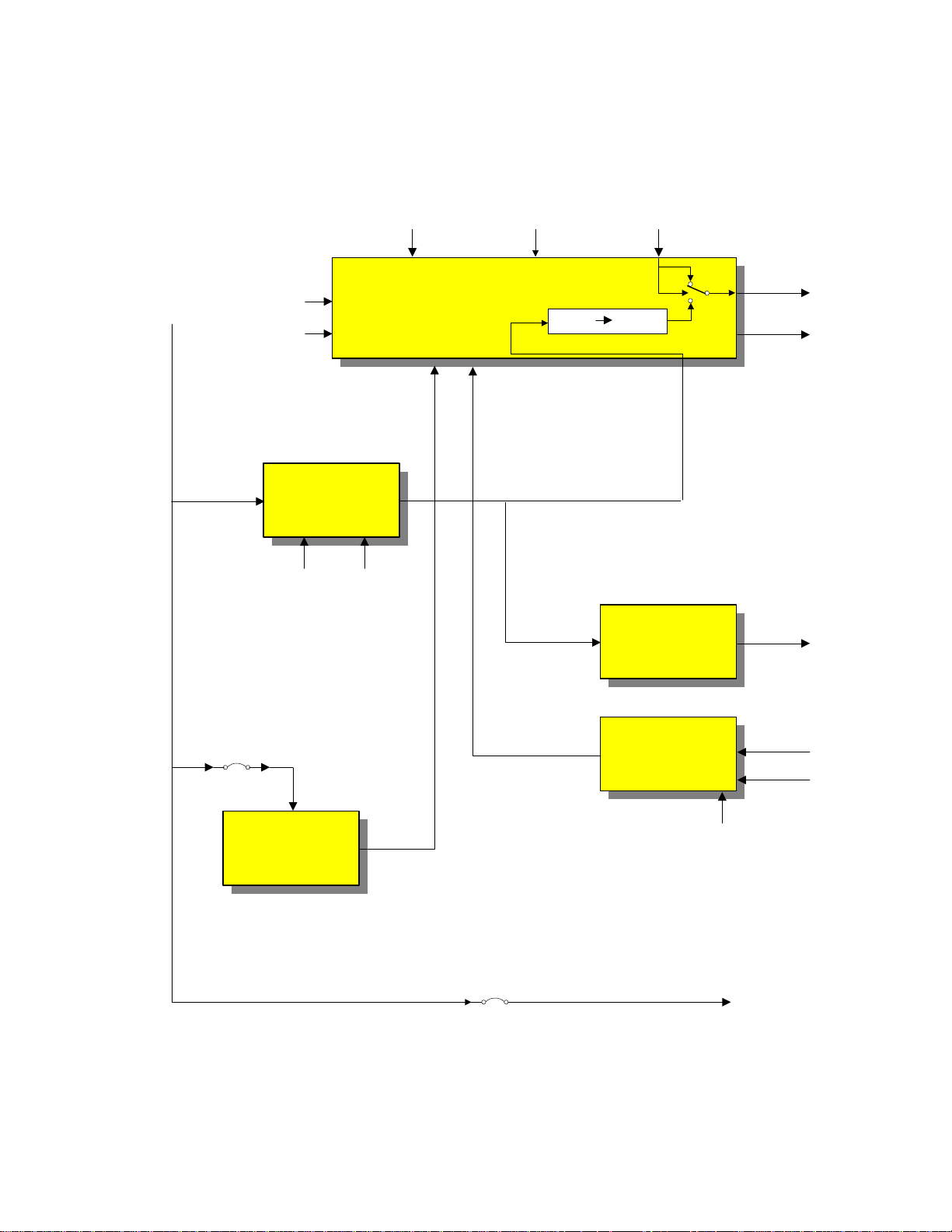

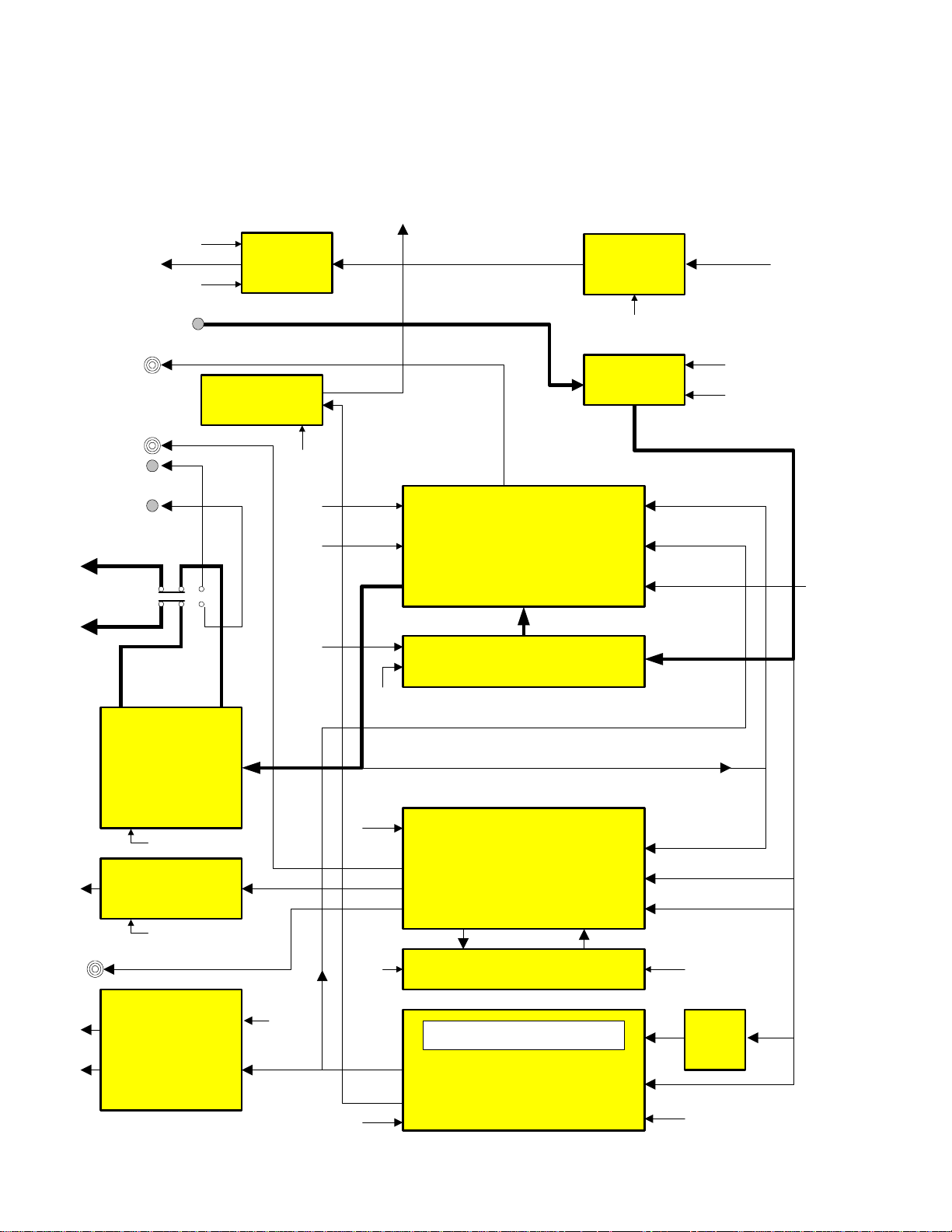

BLOCK DIAGRAM EXPLANATION POWER SUPPLY BLOCK

The 61HDX98B utilizes two switching power supplies.

DP-85's stand by switching mode operation is different

from AP-7X and 8X chassis's. Switching frequency of

AP-7X and 8X chassis is dropped to 20kHz during

stand by mode. But the DP-85's power supply is not

dropped during stand by mode. DP-85's is operated

about 100kHz.

Normally Power Supply switching is operated as following.

T901: 25- 56 kHz (Normal)

100-200 kHz (Stand by)

TP91 30- 53 kHz (normal)

POWER SUPPLY UTILIZED FOR THE DIGITAL AND SIGNAL CIRCUITS:

(Sub Power Supply PWB)

This supplies power primarily to the Digital circuits, i.

e. DM-1 module. This supply runs anytime the set is

plugged into an AC outlet.

The voltages produced are;

• +33V,

• Power for the Satellite dish which is switched be-

tween 13V and 19V dependant upon the channel

being received.

• Stand By 12V also called A12V

• TV9V

• TV5V

• 3.3V

• -5V

POWER SUPPLY UTILIZED FOR THE DEFLECTION, AUDIO and DIGITAL CONVERGENCE CIRCUITS: (Deflection PWB)

This supply only operates when the set is turned ON.

When the ON command is received from the DM-1

module, relay S-901 energizes and delivers AC to the

main bridge rectifier D903 located on the Sub Power

Supply PWB.

This supplies power primarily to the Deflection circuit

for the collector of the High Voltage generation circuit

and the collector of the Deflection Output transistor.

Also, the Convergence output amps and the Audio

output amps derive their voltages from here as well.

The voltages produced are;

• +130V used for Deflection and High Voltage cir-

cuits.

• 220V used for the collectors of the R, G, B drivers

on the CRT PWB and the Velocity Modulation

circuits.

• 6.3V to drive the CRT Heaters.

• +28V for the Convergence, Velocity modulation

and Audio Out circuit.

• +13V for Vertical.

• -13V for Vertical and also converted down to

the –5V for the Digital Convergence Unit.

The TV9V supply generated from the Power Supply

for Digital listed above, is regulated down to +5V for

the Digital Convergence Unit and the A12V for the

Power Supply for Digital is used as a switched On/Off

for the Deflection Vcc by the Rainforest IC.

Page 01-01

Page 6

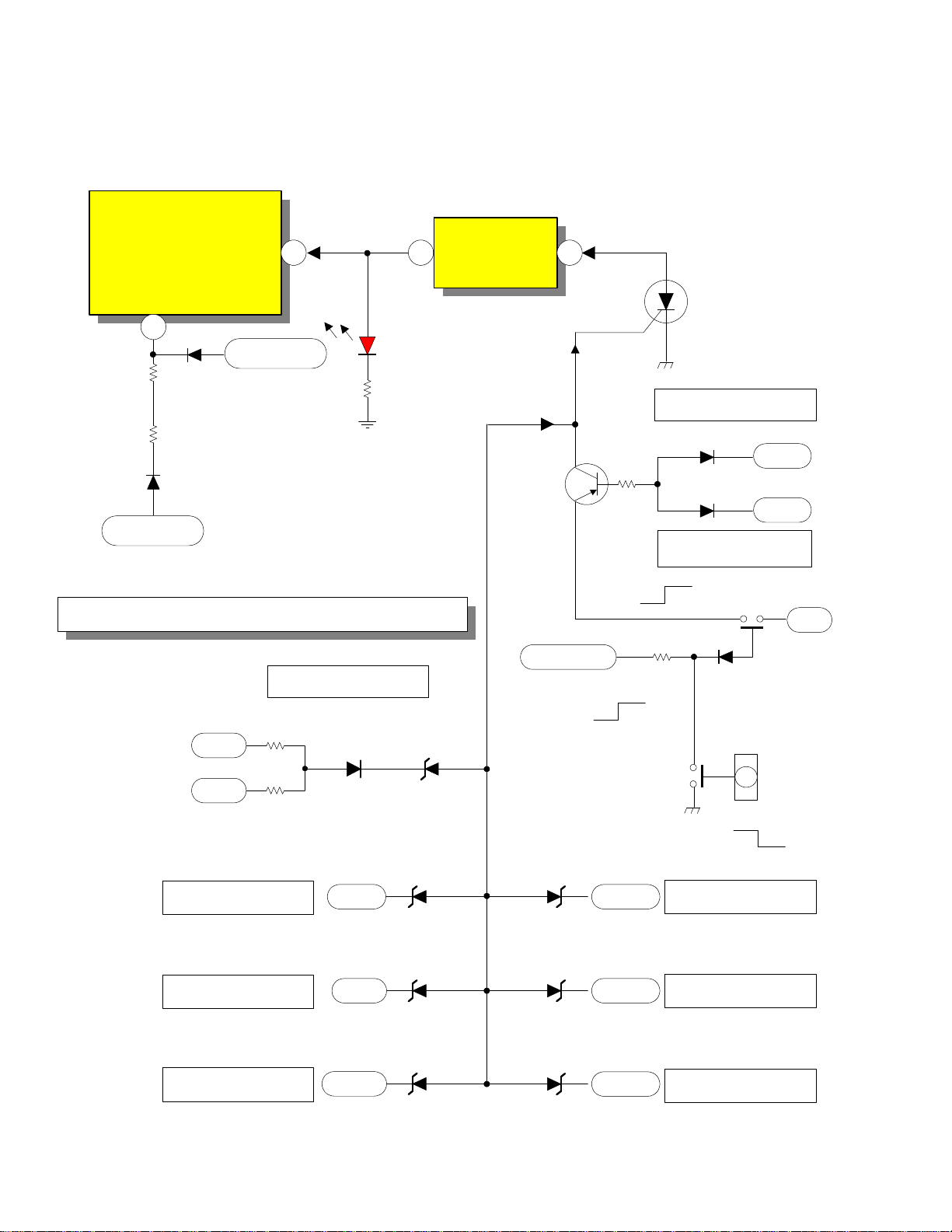

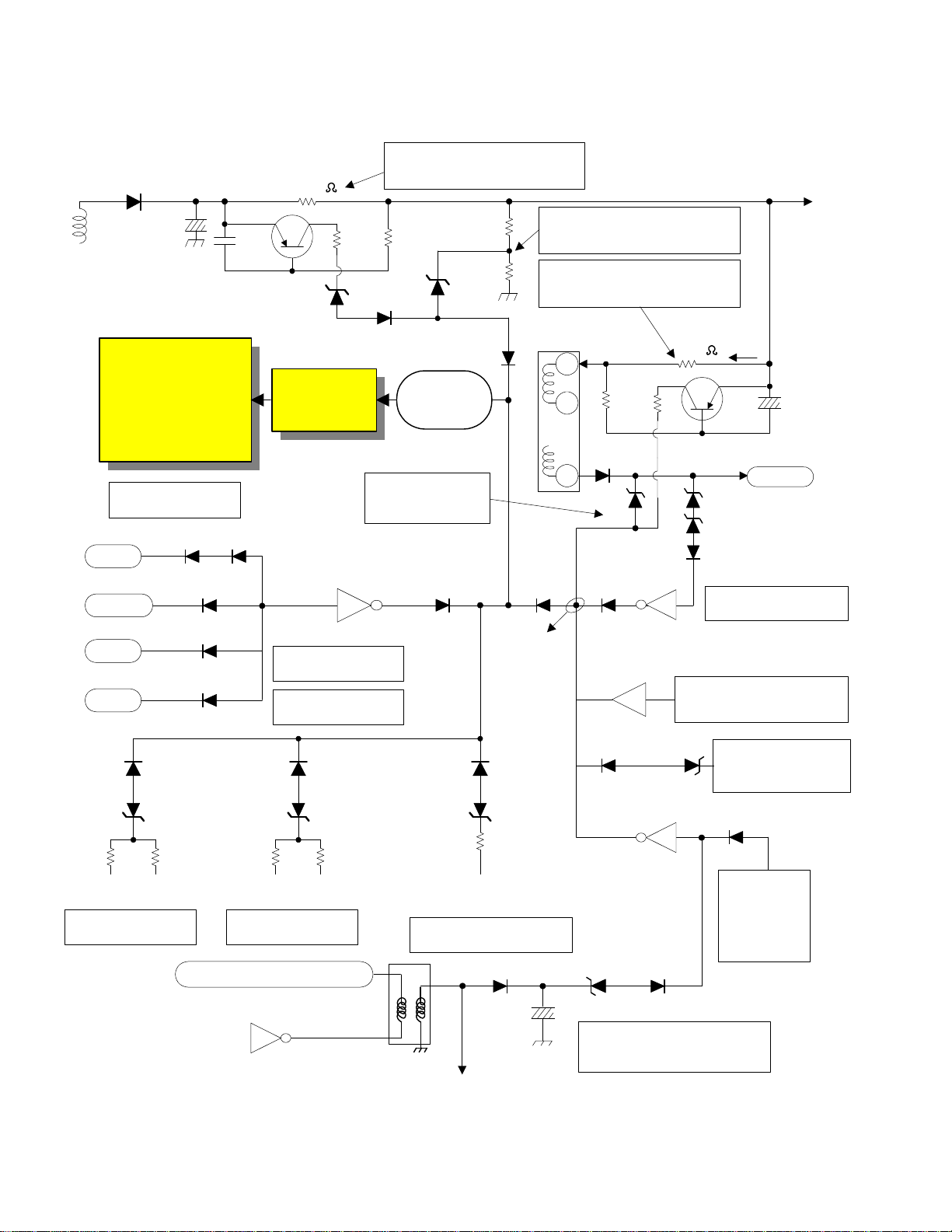

DP85 POWER SUPPLY BLOCK

DIAGRAM

Fuse

Line

Filter

Relay

Line

Filter

R

POWER SUB P.W.B.

STAND BY

35V

L. NB Sw. Reg.

A12V Sw. Reg.

I901

Sub

Switching

Regulator

EE42

24.5V

-7V

R/F 28V

C21V

9V Sw. Reg. TV9V

5V Sw. Reg. TV5V

3.3V Sw. Reg.

3.3V Sw. Reg.

+33VS Reg

Power Fail

-5V Sw. Reg.

28V

21V

SWITCHED

Switching

Regulator

To Signal Block

POWER DEFLECTION P.W.B.

(130V) Reg

220V

6.3V

IP01

Main

EE49

+28V

-28V

+13V Reg.

-13V Sw. Reg.

-5V Reg.

Def. +B V1&V2

CRT &

Vm Out

Heater

Convergence

Velocity Mod.

Audio Out

Convergence

Vertical

To Deflection Block

Vertical (M13)

DCU

AC108-

132V/

Page 01-02

60Hz.

AC Inlet Type

+5V Reg.TV9V

DCU

HVcc12VA12V

Page 7

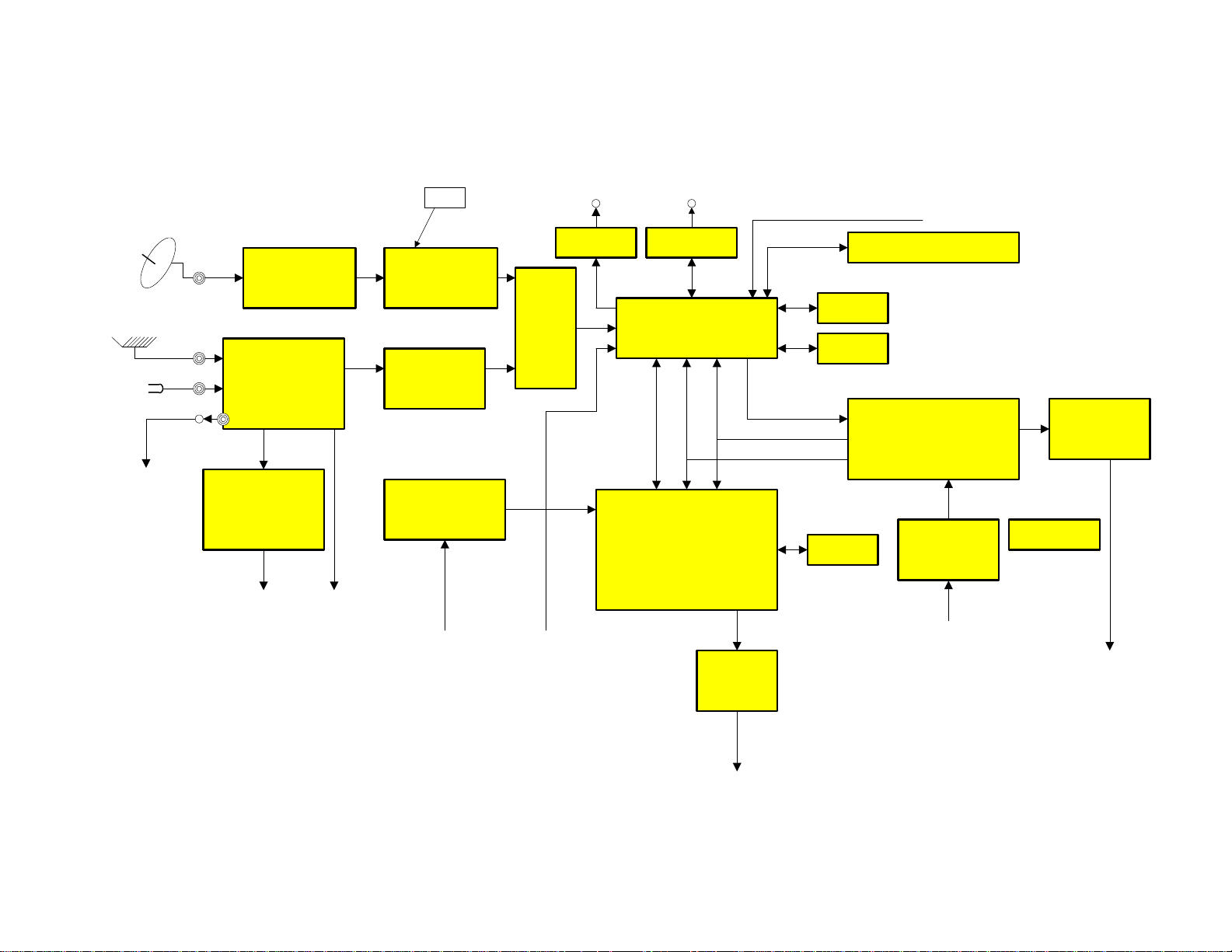

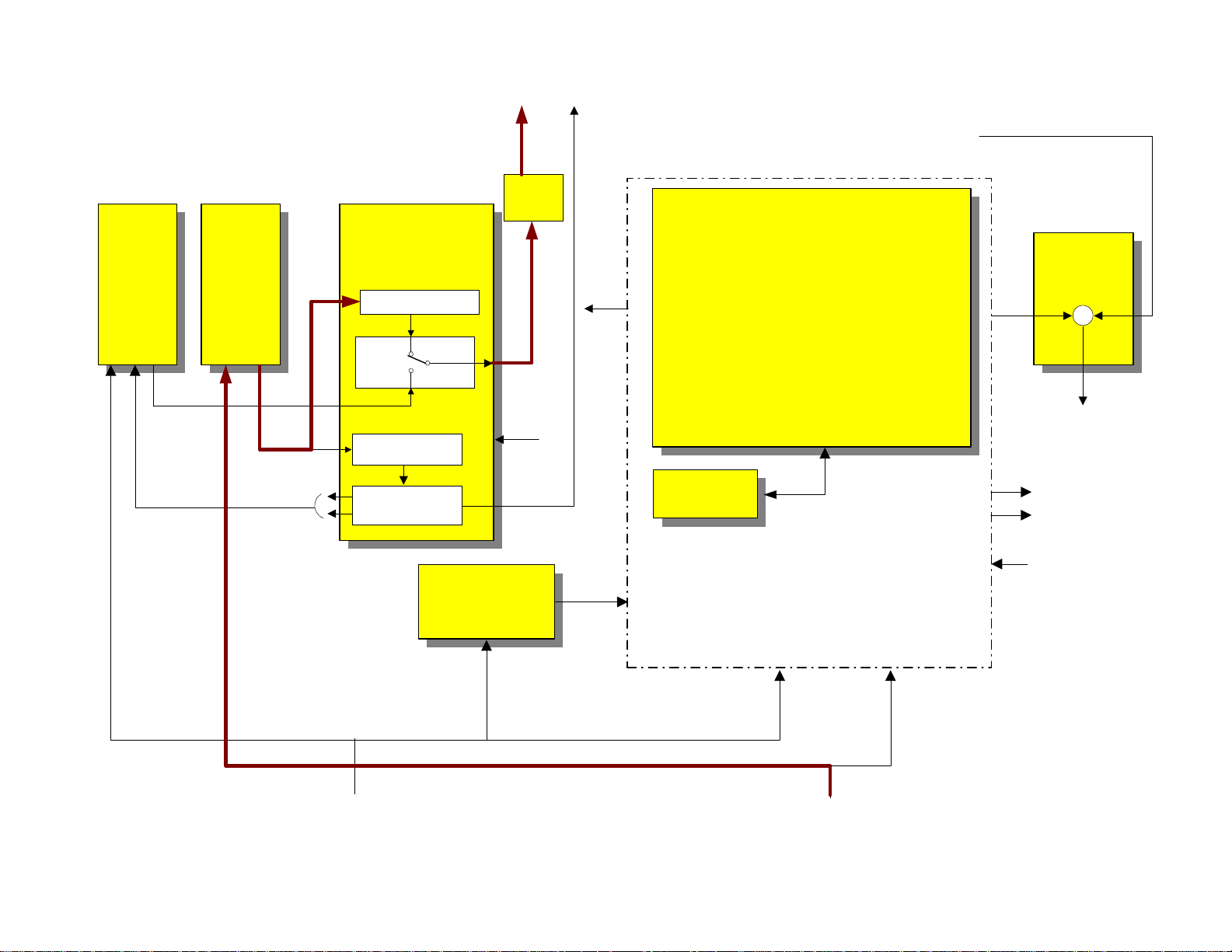

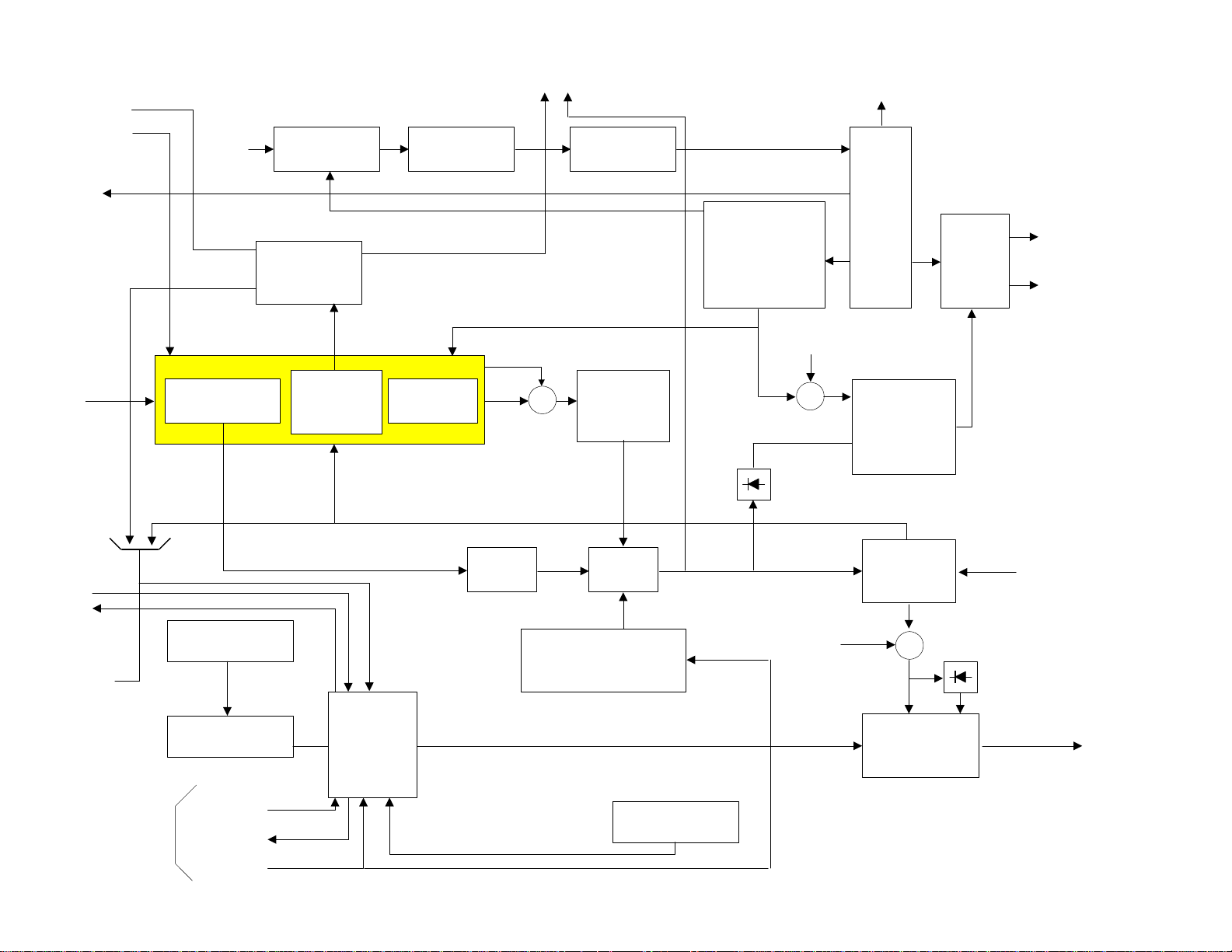

BLOCK DIAGRAM EXPLANATION FRONT END

The 61HDX98B utilizes a non-repairable Front End

Assembly called the DM-1 Module. This module contains the main System control center, NTSC Front

End, Direct TV Receiver and ATSC Tuner. The block

diagram indicates the internal blocks contained within

the Front End Assembly, hear after called the DM-1.

Starting counterclockwise from the upper left.

SATELLITE:

This represents the Direct TV satellite dish connection

to the back of the set.

SATELLITE TUNER/IF:

This is the internal IRD, (Integrated Receiver and Decoder). This receives the satellite signal from the LNB

(Low Noise Block) located on the Dish. This block

converts the signal to a usable signal for decoding.

SATELLITE CARD and SATELLITE LINK

BLOCK:

To receive Direct TV signals, the customer is required

to insert an active Security Card into the back of the

set. This care contains a programmable chip that contains the consumer’s information and the channels that

the consumer is allowed to receive. Also, this card is

used when billing information is retrieved by Direct

TV.

LINK/MIX:

This block passes the particular signal that the customer has decided to view on screen. Either the Direct

TV signal or the ATSC tuner.

TERRESTRIAL:

This indicates the outside antenna the consumer has

erected to receive NTSC signals as well as ATSC signals.

CABLE:

This is the input from the consumer’s cable signal.

HD/NTSC TUNER/IF SPLITTER:

This block receives the Terrestrial signal and dependant upon which source the consumer has decided to

view, processes the signal through the appropriate

tuner.

• HD: Receives the Terrestrial Signal and routes it

to the ATSC tuner. This tuner is capable of receiving all 18 ATSC formats.

• NTSC: Receives the Terrestrial Signal and route

it to the NTSC Tuner.

• The NTSC signal is routed out of this block on the

line labeled Composite Video to the Signal Selector IC which selects the appropriate signal according to the consumer’s choice. Either Tuner,

AVX1, 2 or 3 and/or S-In 1,2 or 3.

• The NTSC audio IF signal is routed to the MTS

STEREO DECODER.

• SPLITTER:

• The splitter routes the NTSC signal out to the RF

Out PinP Tuner path to the PinP Tuner.

MTS STEREO DECODER:

Decodes the NTSC Audio IF signal an decodes it into

Left Total and Right Total. This signal is routed to the

Dolby® Pro-Logic decoder.

HDTV LINK:

This block routs the ATSC signal received by the

ATSC tuner to the Link Mix.

NTSC YUV A/D:

This block receives the NTSC luminance and chroma

signals and converters them to a digital signal to be

utilized by the MPEG VIDEO decoder.

FROM MAIN MICRO:

This is communication in and out for the SubMicroprocessor. Information such as the Selector IC

selection, power on/off commands, etc.., are routed

from the ARM/Transport or Main Microprocessor section.

SD-A/V:

This is the output of the AC-3 digital audio to be used

by an off board AC-3 decoder.

MODEM:

Direct TV polls the Direct TV receiver section through

the customer’s phone lines and determines such things

as Pay for View authorization, customer’s information, Card authorization and billing information.

ARM/TRANSPORT:

The Arm/Transport block receives all signals from Direct TV, ATSC. It also receives the Infrared remote control signals, Front panel Key data, and Slave Microprocessor information. This is the Main Microprocessor section of the DM-1 module. Dynamic RAM and ROM information is processed from Soft ward load into ROM

and determines the state of the Television. Information

from ATSC and/or Direct TV is routed to the MPEG

VIDEO DECODER.

Page 01-03

Page 8

BLOCK DIAGRAM EXPLANATION FRONT END

MPEG VIDEO DECODER, NTSC UPCONVERSION, OSD:

What ever signal is requested by the consumer as the

source for viewing is processed through this block and is

output to the YUV D/As.

YUV/DAs:

This block takes the digital signals provided to it and

converts them to an analog signal which is usable by the

signal processing circuits.

All signals are routed out through the line labeled 2.14

YUV/YIQ, (NTSC Signal up converted to 480P or 2.14

HYPBPR which is the HDTV output as 1080I.

MPEG/AC-3 AUDIO DECODER:

This block processes the audio component from the

ARM/TRANSPORT or the block A/Ds AUDIO, which

is the NTSC audio processed by the Pro Logic decoding

circuit, labeled as 5.1, (Front Left, Front Right, Center,

Rear Left and Rear Right + Sub Woofer audio also called

LFE. Then this block processes the signal and outputs all

audio to the Audio D/As.

AUDIO D/As:

This block is the Digital to Analog converter which converts the digital audio signal sent to it by the ARM/

TRANSPORT block and converts it to a usable analog

signal to be processed by the audio output section.

The audio labeling is comprised of the following:

L/R = Audio Front Left and Right

LS/RS = Rear or Surround audio Left and Right

C/LFE = C for Center and LFE for Sub Woofer, also

called Low Frequency Effects.

Page 01-04

Page 9

DP85 FRONT END

BLOCK

Satellite

Terrestrial

Cable

RF Out

PinP

Tuner

DM-1 Module

SATELLITE

TUNER/IF

HD/NTSC

TUNER/IF

SPLITTER

MTS

STEREO

DECODER

L/R

Composite

Video

SATELLITE

VSB

Satellite

Card

LINK

HDTV

LINK

NTSC YUV

A/D

1HYIQ

SD-A/V MODEM

LINK

MIX

MPEG VIDEO

UPCONVERSION

From

Main

Micro

PhoneSD-

ARM/

TRANSPORT

DECODER

NTSC

OSD

YUV

D/As

IR from Ft. Panel

Dimmer, AD, Key In

DRAM

ROM

Data

Address

Handshake

SRAM

From Main Micro

NRSS/ISO7815

MPEG/AC-3

AUDIO

DECODER

5.1 Audio

Digital

A/D's

AUDIO

L/R

AUDIO

D/A's

EEROM

L/R

LS/RS

C/LFE

Page 01-05

2.14YUV/YIQ

2.14 HYPBPR

To 2H Video Circuit

Page 10

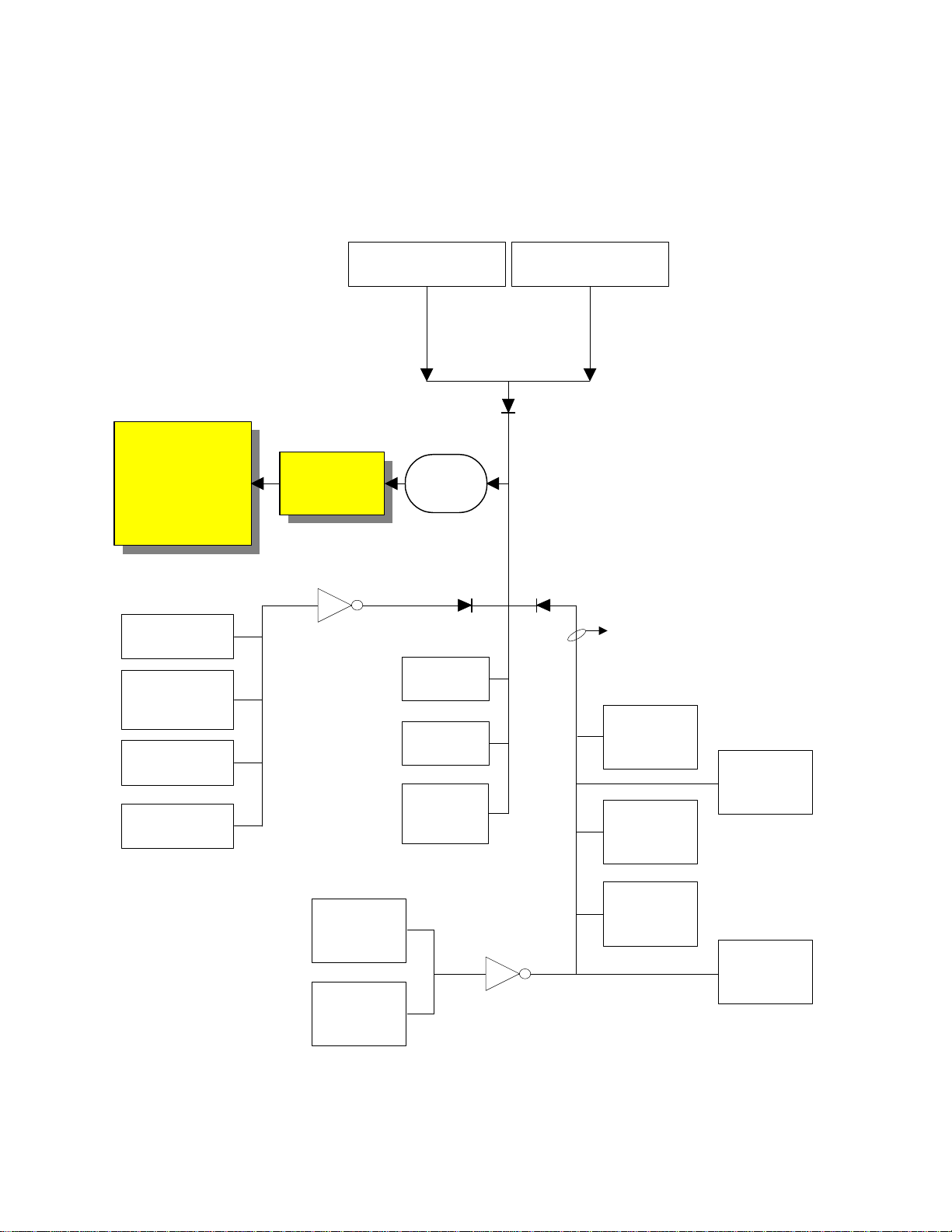

BLOCK DIAGRAM EXPLANATION A/V SELECTOR

C. VIDEO (MAIN) and R/L (AUDIO MAIN):

NTSC Video and NTSC Audio is routed from the

DM-1 Block diagram. They are shown in the Block

Diagram as one line, but they are separate signals.

Anytime a signal is routed from the DM-1 or going to

the DM-1 module, they must be sent through a DM-1

I/F block. This block reduces the noise by a noise cancellation process. This process uses the output of a

comparator and routes the output back to the negative

input to subtract the noise. It also level shifts the signal

to make it useable by the circuit to which it is routed.

DM-1 I/F BA4558:

This is the noise cancellation and level shift block.

AUDIO/VIDEO SELECTOR TA8851BN:

This is the selector IC. Dependant upon the customer’s

viewing preference, the DM-1 will communicate via

I2C bus communications and select the NTSC signal

which is sent to the demodulator. The demodulator

prepares the NTSC signal for the DM-1 module.

This IC selects the following inputs;

Main tuner

Video One, Two or Three

S-In One, Two or Three

PinP Video and Audio outputs. This can be any of the

input provided above except the PinP has it’s own

tuner.

Note: PinP isn’t available when the customer has selected Direct TV or ATSC as it’s source. This is because, as will be shown later, the PinP Video is super

exposed upon the NTSC video only.

Any video source selected for the Main picture will be

routed to the 3D Y/C module.

Note: There are NO Component inputs on this set.

Page 01-06

Page 11

C. Video (Main)

R/L (Audio Main)

A/V SELECTOR BLOCK DP85

CHASSIS

TERMINAL P.W.B.

DM-1

I/F

B4558

Comp. Video (Main) R/L (Main)

RF from DM-1

Tuner U001

VT+33V

Video 4 V4, S4, L/R4

PinP Video and

Selected L/R

(NTSC Main Audio)

+5V +9V

PinP

Lock

Clock

Data

Enable

MonoAudio

PinP

Video

Mono

AUDIO/VIDEO

SELECTOR

TA8851BN

PinP Video

to PinP Unit

Video D YC

To 3DYC

9V

I2C

PinP L/R Out

To Audio Out PWB

Video One In

Video Two In

V1 S1 L/R1

V2 S2 L/R2

V3 S3 L/R3

Video Three In

Page 01-07

Page 12

BLOCK DIAGRAM EXPLANATION

SYSTEM CONTROL AND SIGNAL PROCESSING

MAIN VIDEO FROM SELECTOR IC:

At the bottom left hand side is shown the Main Video

from Selector label. This is the NTSC video from the

selector IC. This is routed to two blocks.

3D Y/C:

The 3D Y/C separates luminance from the chroma. It

also add the 3D effect, (if the 3D Y/C is turned on

within the menu). Noise is canceled and the two separate components are output to the Video/Chroma Demodulator.

VIDEO/CHROMA DEMODULATOR:

This IC decodes the signal down to it’s Luminance and

Chroma. components and outputs it as 1HYIQ.

DM-1 I/F:

Noise cancellation and level shifting preparing the signal for the DM-1 module.

1HYIQ:

1HY = Standard NTSC format luminance. (Also

known as 480I).

I and Q = Standard NTSC format, demodulated

chroma components.

SYNC DET.:

Separates the Sync signal from the composite video signal.

SYNC DET.:

This block outputs composite sync to the PinP unit which

is used for timing for display. This is specifically related

to the Demodulator, D/As and Read/Write clock. The

Read/Write clock also is controlled by the frequency of

the Subcarrier also called fsc.

The Composite sync is also sent to the DM-1 on the line

labeled as 1H Composite Sync. The DM-1 uses this signal for OSD positioning, auto channel detection and AFC

loop activation.

TV uCOM MICROPROCESSOR:

This is the slave Microprocessor or Sub-Microprocessor.

This IC is in constant communications with the DM-1

module. The slave uP. Receives or outputs the following

signals;

HBLK: = Input; this is the Horizontal Blanking signal.

Used for Service OSD signal creation timing.

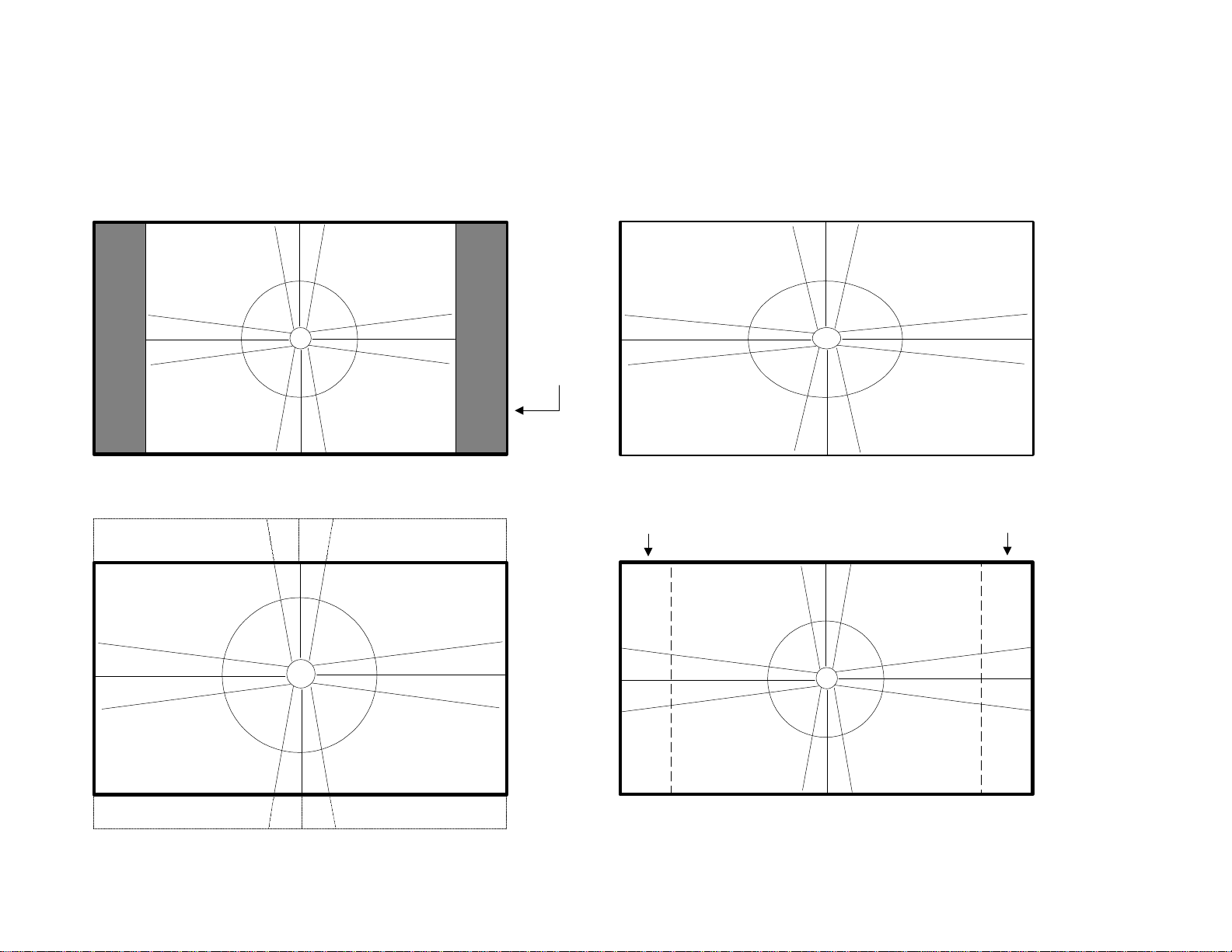

S.WIDE: = Output; when the customer watches regular

NTSC 4X3 aspect source, they have a choice of viewing

the signal in one of 4 ways.

Normal: This will display a standard 4X3 picture

with black panels on each side of the picture.

Fill: This will expand the picture to fill the screen.

The top and bottom will be cropped.

Full: This will expand the picture side ways and fill

the screen. However the picture will be non-linear.

Smooth Wide: This will keep the center of the picture linear and stretch the outside edges to fill the

screen.

With the four choices above, the DM-1 module controls

the signal for 3 of them; Normal, Fill and Full. However,

during Smooth Wide, the deflection circuit is switched to

perform the stretching of the sides. The slave Microprocessor outputs S.Wide during this time.

CUT OFF: = Output; labeled as V. Stop, during the Ser-

vice adjustments for Cut Off, (Screen Background controls), the vertical must be collapsed. This output causes

the B+ to the vertical output IC front end to be grounded

and grounds the vertical trigger pulse called V. Saw.

D. SIZE: = Output; labeled as Digicon Size, during

Smooth Wide mode, the Digital Convergence Unit, hear

after called DCU, must know that the set is in the distorted deflection mode. This signal tells the DCU just

that.

MAGIC SW: = Input; when the customer presses the

Magic Focus button on the control panel, the DCU notifies the slave micro. That it is busy performing Magic

Focus. The slave micro. Notifies the DM-1 module and

the DM-1 module ignores infrared pulses from the remote control.

CLOSED CAP. DATA: = Input; This input receives the

composite sync signal and decodes the Closed Caption

Data. (Data Slice line 21) and the communicates with the

DM-1 Module. The DM-1 Module actually introduces

the Closed Caption Characters into the Video stream.

F. PANEL: = Output, Dependant upon the customer’s

menu selection, will determine the IRE level of the side

panels when 4X3 Normal mode is used. By raising the

side panel IRE levels, the 4X3 picture won’t burn in the

CRT’s.

MAIN SYNC DET: = Input; this is used for detecting the

Closed Caption Data. This information is routed to the

DM-1 module for OSD generation. NOTE: the submicro. Doesn’t produce OSD characters for Closed Caption.

PinP SYNC DET: = Input; PinP tuner sync is routed to

the sub-micro. And is used during PinP tuner channel

Page 01-08

Page 13

BLOCK DIAGRAM EXPLANATION

SYSTEM CONTROL AND SIGNAL PROCESSING

selection to activate AFC.

MAIN SYNC DET. = Input; This input is used for Service OSD positioning and Auto Programming channel

detection.

PinP SYNC DET. = Input; This input is used for judgement of the Slave Microprocessor to determine the AFC

Loop activity of the PinP Tuner.

MUTE (Audio): = Output; during channel change, external video selection with no input, power up or power

off, and loss of Vertical Blanking, the audio and video

are muted.

V.MUTE (Video): = Output; during child lock, channel

change, or power on/off, the video is muted.

POWER: = Output; when the front power button or the

remote power button is pressed, the DM-1 module notifies the sub-micro. And the sub-micro. Outputs a power

on/off command to the relay driver Q-007. Outputs high

for ON and low for OFF.

OSD & OSD BLK: = Output, this is the on screen characters for the Service Menu only. OSD Blk is OSD

blanking. This cleans us the video where the OSD is to

be inserted.

HV BLK: = Input; this inputs are utilized by the Microprocessor for Service OSD positioning.

HV BLK PH: = Output; during Service Adjustment and

in the NTSC normal mode. This picture doesn’t fill the

screen. The areas on the side of the picture are called

Side Panels. This can be adjusted. The HV BLK PH,

controls the timing of the side panel OSD outputs.

SIDE PANEL APL FROM 2H VIDEO PWB: = Input;

the Microprocessor receives a pulse created within the

2H video PWB. This pulse represents the timing pulse

for the Side Panel OSD production.

Blocks continued;

OSD MIX: Only the Service menu OSD is output from

the Slave Microprocessor. The Digital convergence unit

puts out OSD characters as well. This characters product

the Service Grid and other text during Digital Convergence adjustments and/or Magic Focus. The two OSD

sources are received by the OSD Mix. This is comprised

of a quad Or Gate and outputs the signal to be superimposed upon the video signal path from the DM-1 Module.

PinP VIDEO FROM SELECTOR IC: The video from

the PinP tuner is routed to the PinP unit and the Sub Microprocessor for Closed Caption decoding.

Page 01-09

Page 14

DP-85 CHASSIS SYSTEM CONTROL & SIGNAL PROCESSING

BLOCK

PinP

Unit

PinP

Video

3D

Y/C

Unit

Y/C

Y/C

H Sync

V Sync

1 H Composite

Sync

I2C

Closed Cap. Data

Digital OSD / Busy

TV uCOM

Microprocessor

HBlk

S. Wide

Cut. Off

D. Size

Magic Sw.

F Panel

Main Sync Det

PinP Sync Det

Mute (Audio)

V.Mute (Video)

Power

OSD & OSD Blk

for Service Menu

OSD RGB Ys

OSD

MIX

+

RGB Ys

OSD

AD8056

VIDEO/

CHROMA

DEMOD

YIQ

Mix

YIQ

1HYIQ

DM-1

I/F

Clamp

I2C

Sync Det.

Y

MEMORY

Sync Det.

PinP

Sync Det.

I2C

HV BLK

H BLK PH

Side Panel

APL

from 2H

Video PWB

Page 01-10

PinP Video from Selector

IC

PinP V

SIGNAL P.W.B.

CCD Video

CCD Video

PinP

Main Video from Selector IC

Main

Page 15

BLOCK DIAGRAM EXPLANATION 2H VIDEO

The 2H Video PWB is similar to the Rainforest circuits used in the past. The YUV/YIQ

(480P) and/or the Y-PR/PB (1080I) is routed

through another DM-1 Interface IC for noise

cancellation and level shifting and into the

Rainforest chip, IX01. Here the signal is prepared for the CRT’s. Pedestal level detection,

Chroma preparation, OSD RGB from either

the DCU or the Slave Microprocessor is input

here.

Remember that the OSD for Customer usage

such as the Channel numbers, clock, Main

Menu, etc.. is generated by the DM-1 Module.

Also, ABL controls the brightness and

Contrast; as well as the color level at this

chip.

The Velocity modulation control signal is

produced from the Rainforest IC. This signal

is a representative of the Peak White components of luminance and drives the Velocity

Modulation coils on each CRT.

Page 01-11

Page 16

2 H VIDEO BLOCK DP-85

CHASSIS

2H VIDEO P.W.B.

OSD RGBABLI2C

YUV/YIQ/

Y PB PR

2.14 HV SYNC

YUV/YIQ/

Y PB PR

2.14 HV SYNC

+9V

+5V

DM-1

I/F

+5V -5V

RGB PROCESSOR

TA1276AN

Clamp H/V Blk.

YUV RGB

Y

YUV

YIQ

YPBPR

APL

DETECT

RGB

VM

SPANEL

Side Panel

APL

2.14 HV SYNC

CLAMP

GEN.

Clamp

HV. Blk.

Gen.

HBLK PH

HV Blk

+9V

2.14 SYNC

Page 01-12

Page 17

BLOCK DIAGRAM EXPLANATION DEFLECTION BLOCK

The 61HDX98B deflection circuit differs from conventional Hitachi product. It utilizes in a sense, two

horizontal output circuits. One for Deflection and on

for High Voltage. The notations around the Block diagram will be described in a counter clock wise fashion

as best a possible.

CUT OFF:

Cut of collapses the Vertical circuit during I2C Bus

alignments, during CRT Set Up.

I2C:

Communication from the Sub Microprocessor I001

during sweep variations due to Standard/NTSC 480P

mode and 1080I High Definition mode.

ABL:

ABL voltage is generated by monitoring the current

through the flyback transformer. This voltage will

fluctuate down when the scene is bright and up when

the scene is dark. The ABL voltage will manipulate

the screen brightness and contrast to prevent blooming

under these conditions.

HV SYNC:

The composite sync is routed into the Sync processor

which determines the sweep condition for the signal

being provided.

H and V BLK:

Horizontal and Vertical Blanking is developed within

the Deflection circuit. The Horizontal Blanking pulse

operates around 13V P/P and is produced by taking a

sample pulse from the Deflection transformer T752.

The Vertical Blanking pulse is generated from the

Vertical output IC, I601 pin 7. This pulse normally

operates at 23V P/P.

IR:

The Infrared Pulses coming from the remote control

are routed through the Deflection PWB to the Digital

Convergence Unit. During DCAM (Digital Convergence Adjustment Mode), the Remote Control provides manipulation pulses for the DCU.

DIG RGB BUSY:

This indicates Digital RGB and BUSY.

Digital RGB represents the on screen characters produced by the DCU for generating the Digital Convergence adjustment grid and text produced during certain conditions such as Magic Focus, Sensor Initialization, Data Storage, etc…

Busy notifies the sub Microprocessor I901 which in

turn notifies the DM-1 module that the DCU has entered the DCAM. During this time, the DM-1 module

ignores the remote control commands.

MAGIC SW:

When the customer presses the Magic Focus button on

the front of the set, it produces a command for the

DCU to begin the Magic Focus process.

D SIZE:

Digital Size is a control signal for raster enlargement

when MAGIC FOCUS is operated. Raster enlargement is required for the MAGIC FOCUS PATTERN

to hit the photo sensors.

This signal is output from DCU and input to the Sub

Microprocessor I901. The Sub Microprocessor controls the I702 on the DEF.SUB PWB) for enlarging

raster size.

In case of AP-85, this control signal is called "A.

SIZE". It's the same function between DIG.SIZE and

A.SIZE.

S WIDE:

Smooth Wide is a condition entered through the Menu

by the customer while watching an NTSC 4X3 aspect

video source and the customer wants to fill the screen.

TO CONVERGENCE YOKES:

The DCU provides compensation signal for deflection

abnormalities to the convergence output IC. The Convergence output IC in turn, amplify the signals and

rout them to the convergence yokes.

+26V, 26VP and RETRACE PULSE:

The positive 26V and the negative 26V is routed to the

Deflection transformer I752. They enter the transformer as a pure DC voltage. A 15V P/P horizontal

pulse is added to the DC voltage and leaves as +26VP

and –26VP. From here these voltages are routed to the

Convergence output section and they are rectified.

They become +33V and -33V respectively. This process prevents the need for another power supply.

+B 130V:

The Deflection transformer receives the 130V V1 DC

source.

DF OUT:

Generated from the I702 on the Sub Deflection PWB

and the Horizontal Blanking pulses, a Dynamic Focus

waveform is created. This is a parabolic waveform that

Page 01-13

Page 18

BLOCK DIAGRAM EXPLANATION DEFLECTION BLOCK

is superimposed upon the static focus voltage to compensate for beam shape abnormalities which occur on

the outside edges of the screen because the beam has

to travel further to those locations.

HV PARABOLA:

Described above.

SCREEN 700V: 700V Supplied to the screen grids on

the CRT’s.

FOCUS 9KV:

Focus voltage supplied to the CRT’s.

32Kv HV:

32,000 volts DC supplied to the CRT’s anodes.

TO DEFLECTION YOKES:

Horizontal and Vertical deflection wave forms driving

the deflection yokes.

INTERNAL BLOCKS DESCRIPTION

HV CONTROL:

The uPc1344C IC generates the horizontal drive signal

utilized by the High Voltage circuit. The HV control

IC receives it’s locking pulse from the Deflection circuit. A feed back voltage is sampled from the High

Voltage Regulation Detector circuit and compared

with a reference voltage to maintain an accurate 32KV

on the CRT’s.

VERTICAL OUTPUT:

The vertical output utilized in the 61HDX98B operates

differently from previous chassis. This circuit utilizes

a +13V and a –13V to generate the waveform to drive

the vertical deflection yokes. A pump up circuit is utilized to product the retrace pulse for the vertical deflection yoke. It’s at this time when a higher pulse is

needed because the beam has to travel from the bottom

of the screen to the top very rapidly. The vertical output IC receives it’s trigger pulse from the ramp generator.

SYNC PROCESSOR:

The Sync Processor located in I702 on the Sub Deflection PWB, detects the horizontal sync rate for the displayed signal, either 480P or 1080I.

VERTICAL RAMP GENERATOR:

I702 on the Sub Deflection PWB generates the Vertical Saw signal. This signal is controlled by several

factors. The Sync Processor detection and I2C data

communication.

DIST CONTROL:

Distortion control is another signal produce by I702

and sent to the Side Pin cushion circuit. These compensation parabolic wave forms are combined with the

horizontal circuit to compensate for Side pincushion

errors.

H-SIZE SIDE-PIN CONTROL:

This circuit generates the Side Pincushion Distortion

compensation pulse which is impressed onto a coil

located in the output side of the Deflection Output section and compensates for Pin Cushion distortion.

HORZ. DRIVE and HORZ. OUT:

This circuit comprises the Drive and Output for the

Deflection output circuit.

S-CORRECT (SMOOTH MODE):

During Smooth mode, the deflection circuit is manipulated so that the outside 1/3 of the picture is stretched

to fill the screen. The center 2/3 of the picture is left

undistorted. When an S Wide signal is received, a capacitor is switched off on the output side of the Deflection output circuit.

PHOTO SENSOR:

There are 8 sensors located on the internal outside

edges of the cabinet. These Photo Cells receive the

light patterns being generated during MAGIC FOCUS

or SENSOR INITIALIZATION and deliver this voltage to the Sensor Distribution circuit.

SENSOR DISTRIBUTION:

This represents the amplifiers that receive the Photo

receivers (Photo Cells) inputs during Magic Focus operation.

DIGITAL CONV. UNIT:

This is the Digital Convergence Unit. This is a nonrepairable unit. It contains the distortion compensation

wave form generation circuits, RAM, ROM and D/A’s

for the convergence circuit.

SERVICE SWITCH:

When the set needs a convergence alignment, the Ser-

Page 01-14

Page 19

BLOCK DIAGRAM EXPLANATION DEFLECTION BLOCK

vice Switch is pressed. This switch is located on the

deflection PWB. By removing the front speaker grill,

the Service Technician has access to this switch.

CONV. OUT:

The Convergence output block represents the two (2)

Convergence output IC’s. These two IC’s contain the

amplifiers for the Red, Green and Blue convergence

outputs.

HDT T752:

Represents the Deflection output transformer. By

separating the Deflection circuit from the High Voltage, any distortions that would be generated by fluctuations within the High Voltage won’t be visible

within deflection.

DYNAMIC FOCUS OUT:

This circuit amplifies the parabolic signals provided

by the Deflection circuit and I702 on the Sub Deflection PWB and impresses these wave forms onto the

static DC voltage use for focus. This keeps the beam

as sharp or focused as possible in the corners of the

screen.

HIGH VOLTAGE REGULATION DETECTOR:

This circuit monitors a feed back voltage produced

from the High Voltage Flyback transformer and routes

an output signal to two circuits.

1.) A sample voltage is sent to the Horizontal Driver

IC for regulation of the High Voltage and;

2.) If the High Voltage climbs too high, a shut down

signal is produced to shut down the power supply until

a repair can be made.

FOCUS PACK:

The focus pack receives the Focus voltage and the

High Voltage and distributes them to the CRT’s.

FBT TH01:

Is the main Flyback Transformer producing High

Voltage.

Page 01-15

Page 20

Cut Off

I2C

HV Control

(uPC1344C)

DP-85 DEFLECTION BLOCK

HV DRIVE

(MC3415IP)

DIAGRAM

To Deflection YokesTo Deflection Yokes

HV OUT

(IMB12-140)

ABL

32Kv

HV

High Voltage

Transformer

HV Sync

V Blk

IR

Dig RGB

Busy

HV Blk

Page 01-16

ABL

H Blk

From uP

C

2

I

SYNC.

PROCESSOR

H Drive

PHOTO

SENSOR

/ 8

SENSOR

DISTRIBUTION

Magic SW

D Size

VERTICAL

OUT

LA7648

VERTICAL

RAMP

GEN.

Busy

Dig RGB

8

/

DC couple

/

S Corrected

V-SAW

H Blk

IR

DIGITAL

CONV.

UNIT

3

DIST.

CONTROL

HV Blk

6

/

V Parabola

Saw

Modulator

HORZ.

DRIVE

Size Regulation

Control

H-SIZE

+

Diode

(SMOOTH MODE)

SIDE-PIN

CONTROL

HORZ.

OUT

S-CORRECT

SERVICE

SWITCH

REGULATION

Vcp

S Wide

VOLTAGE

DETECTOR

Parabola

1100V

+26V,

HV

+

26V

FBT

THO1HIGH

FOCUS

PACK

Focus

12Kv

DYNAMIC

FOCUS OUT

2SC4686X3

Deflection Transformer

HDT

T752

+

CONV.

OUT

DF

Out

Retrace Pulse

34v, -34v

6

/

To Convergence

3

Focus

/

(9KV)

Screen

/

(700V)

3

+B (130V)

Yokes

S Wide

Page 21

220V

12V

CPT P.W.B. (R)

VIDEO OUTPUT

AMP

DP-85 CRT PWB BLOCK DIAGRAM

Beam Shape, Beam Alignment,

Focus, VM Coil,

Deflection and Convergence Yokes

R

220V

12V

220V

12V

220V

26V

CPT P.W.B. (G)

VIDEO OUTPUT

AMP

CPT P.W.B. (B)

VIDEO OUTPUT

AMP

VM OUT P.W.B.

VM OUT

G

B

Page 01-17

RGB

VM

SCREEN

FOCUS CONV.

Def.

Yokes

30KV

HV

Page 22

AUDIO OUTPUT SECTION DP-85

CHASSIS

To

Headphone

Jack

L/R

From DM-1

TL/TR

Fixed Vari

Out L/R

FR Ext

Out

FL Ext

Out

FR

to Spk

FL

+9V

-9V

DM-1

I/F

Headphone

Amp

+9V

+9V

Clock

Data

I2C

HL/R

HL/R

L/R LS/RS/C/LFE

TL/TR

CONTROL

Graphic Equalizer

Perfect

Volume

+9V

DM-1

I/F

L/R

RL/RR

PinP L/R

L/R

From

Audio/Video

Selector IC

+9V

9V

PinP L/R

From

Selector IC

L R

Front

Audio

Amp

26V

Center

Audio Amp

21V

Sub Woofer

Rear

R

Audio

L

Amp

FL/R

28V

Clock

Data

RL/RR

HP L/R

I2C

+9V

I2C

L/R

C

LFE

CONTROL

Graphic Equalizer

Headphone L/R

CONTROL

FL/FR

L/R

C/LFE

+9V

L+C

R+C

+9V

L/R

C

LS/RS

Page 01-18

Page 23

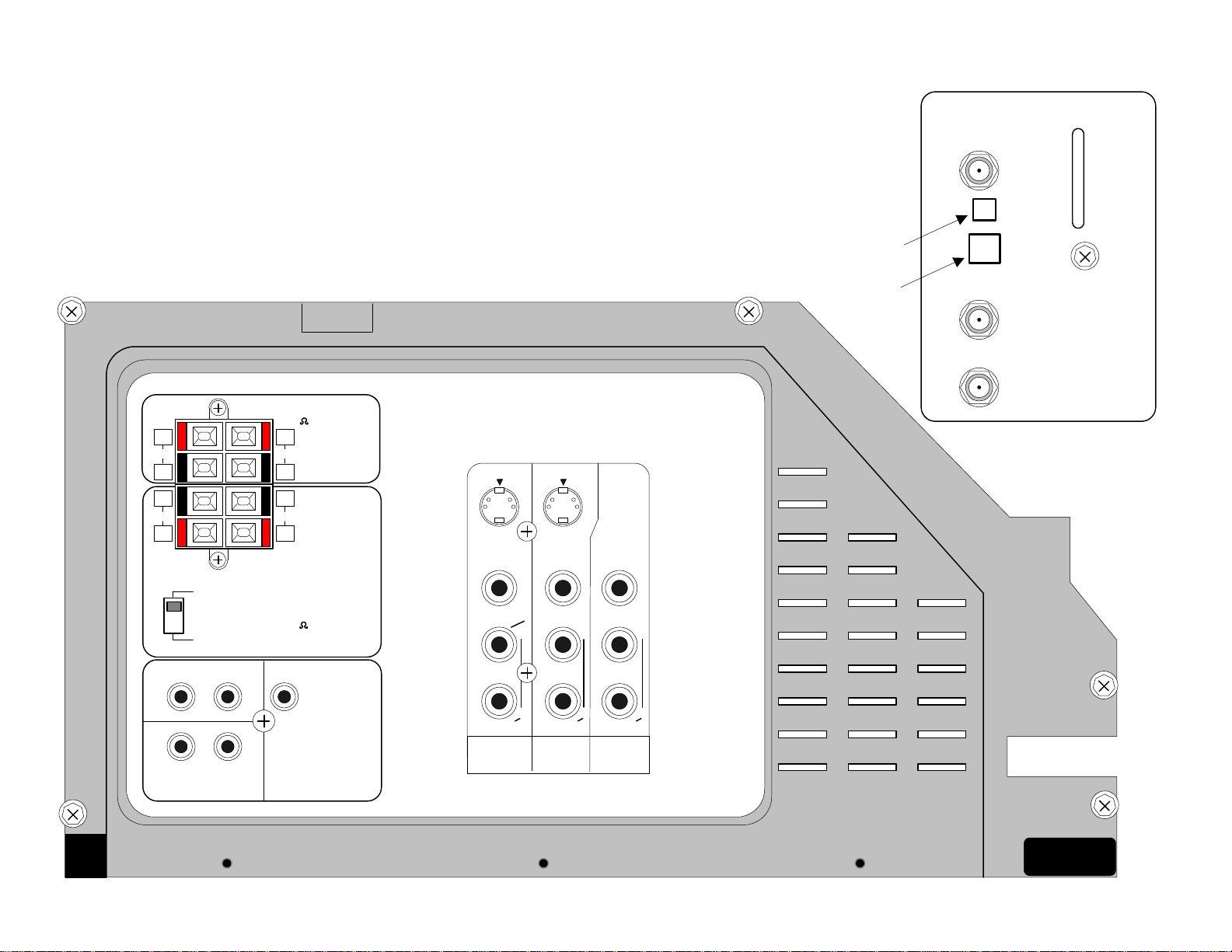

DP-85 REAR PANEL (61HDX98B)

DSS IN

DM-1 MODULE

Rear Panel 1

SMART

CARD

SLOT

AC-3 Jack

Telephone

Interface

ANT B

ANT A

REAR SPEAKER

8 ONLY

+

R

-

-

R

+

INT.

EXT.

+

L

-

-

L

+

FRONT SPEAKER

8 ONLY

S-VIDEO S-VIDEO

VIDEO

(MONO)

VIDEO VIDEO

(MONO)

L

(MONO)

L

L

Page 01-19

TRANSMITTER

OUT

R L

R L

FIX/VARIABLE

OUT

LFE/SUB

WOOFER OUT

R

AUDIO AUDIO AUDIO

INPUT 1 INPUT 2

R

INPUT 3

R

Page 24

DP-85 CHASSIS 4 MODES TO DISPLAY A (4x3) IMAGE ON (16X9) DISPLAY

DM-1 Module controls the video content for Normal, Full and Fill modes,

while the deflection circuit is manipulated for the Smooth Wide mode.

NORMAL MODE (4x3) FULL MODE (4x3)

Side PanelSide Panel

Normal Mode 4X3 with Black Mask (Linear)

FILL MODE (4x3)

Cropped

Slightly

above

black

to avoid

4X3

burning

an image

Full Mode 4X3 Stretched to fit (Non-Linear)

Stretched Stretched

SMOOTH WIDE MODE (4x3)

Linear

Linear

Page 01-20

Cropped

Fill Mode 4X3 Cropped (Linear)

Deflection Circuit remains at 33.75KHz for all modes, (NTSC & SDTV = 540P, HDTV = 1080I. (Labeled in schematic as 2.14H)

Smooth Wide Mode 4X3 Center (Linear)

Outside edges Stretched to fit (Non-Linear)

Page 25

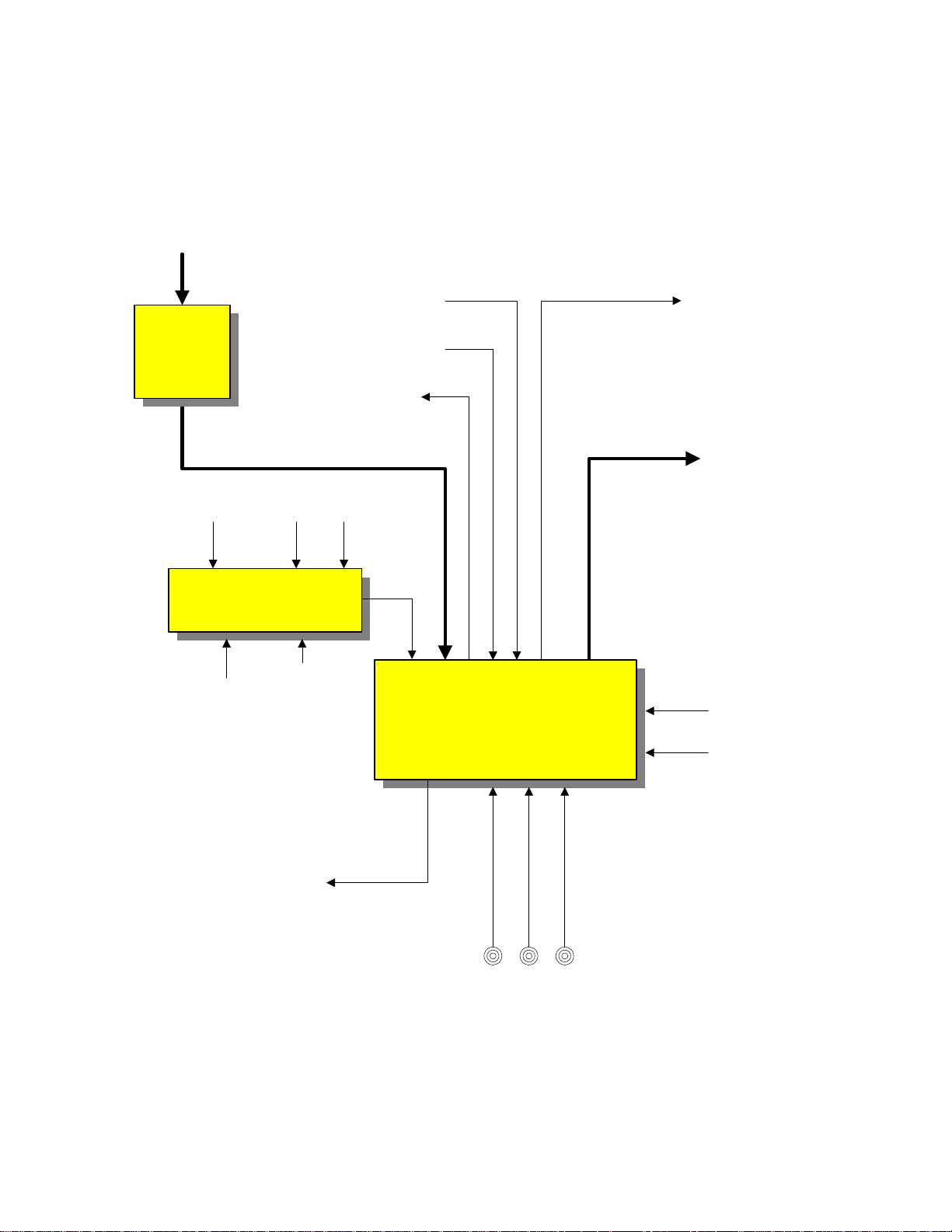

DP-85 DIGITAL CIRCUIT POWER SUPPLY SHUTDOWN BLOCK

I901

ShutDown Pin (7)

I905

on Power Supply

7 3 2

Photocoupler

Driver &

Output IC

Shut Down SCR

+5V Short Det.+3.3V Short Det.

+9V Short Det.-5V Loss Det.

+3.3Vs Too Hi Det.+5V Too Hi Det.

+5Vs Too Hi Det.+9V Too Hi Det.

+12VS Too Hi Det.D3.3V Too Hi Det.

Page 02-01

Page 26

DP-85 DIGITAL CIRCUIT POWER SUPPLY SHUTDOWN DIAGRAM

DIGITAL & SIGNAL

I901

ShutDown Pin (7)

on Power Supply

Driver &

Output IC

5

R907

D905

POWER SUPPLY SHUT-DOWN

Active High

7 3 2

I905

Photocoupler

D908

Run B+

R919

Red LED

Shut Down

Identification

DIGITAL & SIGNAL

POWER SUPPLY SHUT-DOWN

Active Low

Q913

ShutDown

S.C.R.

TV 5V Short Det.

R908

D964

1/2 AC In

Start Up B+

NOTE: +12VS is the same as A12V and STBY12V

No Start Up B+ = Off

Normal = Glowing

Blinks during Shutdown because

of the internal current draw.

15.1V ~ 22.5V pin 5 I901

-5V Loss Det.

R975

-5VS

R976

+5VS

D974

TV 5V Too Hi Det.

+5V +3.3Vs

Q917

D972

+5V

D925

+9V

TV 9V Short Det.

On

STBY +12V

Off

R9A

0

E C

B

Vcc

Q916

D958

On

D953D952

Off

Q914

B

Off

PQS1

Power5

On

C

E

D934

+3.3V Too Hi Det.

TV 9V Too Hi Det.

D3.3V Too Hi Det.

+9V

D3.3V

D975

D938

D933

D936

+5Vs

+12VS

+5V Too Hi Det.

+12VS Too Hi Det.

Page 02-02

Page 27

Audio

F/R 28V

R927

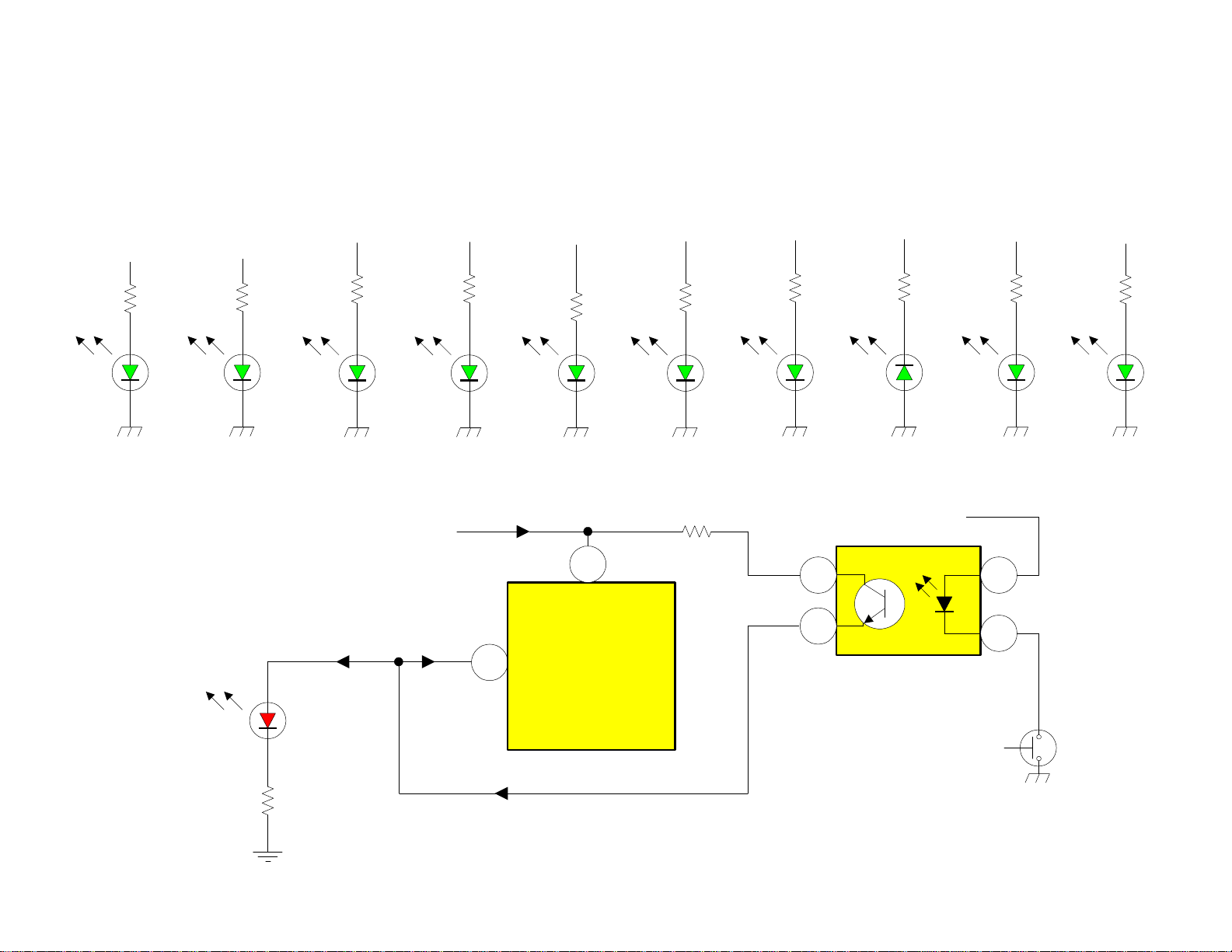

DP-85 CHASSIS L.E.D. (VISUAL TROUBLE DETECTION) DIODES

(SUB POWER PWB) DIGITAL POWER SUPPLY 10 GREEN L.E.D.s and 1 RED L.E.D.

(11 Total L.E.Ds. for visual trouble sensing observation)

LNB Power

Audio

Center 21V

R928

TV 9V

R945

TV 5V

R9E3

+12VS

R956

13V/19V

R939

+5VS

R965

-5VS

+3.3VS

R966

D3.3V

R972

R969

D919

D908 is a RED L.E.D.

Off = No I901 B+

On (Mid) = I901 B+

On (Bright) = Shutdown

Page 02-03

D920

D908

R919

D930

Osc B+

1.9V

D971

ALL GREEN L.E.D.s

D928 D924

Start Up or Run

24.2V

5

I901

Driver/Output IC

100% Dead Time &

7

IC B+ Detection

R916

D943

24.2V

1.9V

D962 D945

D947

Vcc

I905

4

3

I905 Shutdown

Photocoupler

12 Shut Down

Inputs

1

2

Q913

Shutdown

SCR

Page 28

DP-85 DIGITAL CIRCUIT POWER SUPPLY DISTRIBUTION DIAGRAM

Page 02-04

AC Plug

AC Input

FUSE

F901

Noise Filter

L901, 2, 3

Rectifier

D901

Protector

E992: 7K

Switching

Control

I901

D908:

Protect Red LED

To

Deflection

Power Supply

Protection

Block

Live Cold

Switching

Transformer

T901

Feedback

I904

Protect

I905

AC Clock

I906

RELAY

S901

Relay

S902

Relay

S903

DP86

Only

AC Clock

60Hz

Protector

E994 : 7K

Protector

E995 : 7K

Protector

E996 : 5K

Voltage

Control

24, 5V

Q915

Rectifier

+28V : D911

Rectifier

+21V : D912

Rectifier

+35V : D918

Rectifier

+24V, 5:D914

TV ON/OFF

Switch

Q914, Q918

TV Main ON/OFF

ON = LO

OFF = Hi

D919 : F28

D920 : C21

A12V

Regulator

+12 : I907

Regulator

TV9V : I908

Regulator

TV5V : I914

Protector

SCR: Q913

= RED OR GREEN L.E.D.

STAND BY +12V

D928 : +12V

D930 : TV9V

D971 : TV5V

Short Circuit

Detector

REAR +28V

CENTER +21V

D

D

"D"

D925:

<4V

D925:

<4V

Audio

+28V

Audio

+21V

33VS :

D936 : >14.7V

ZD

D975 : >10.8V

ZD

D933 : >6.7V

ZD

Over

Voltage

Detector

+33V

+12VS

+9V

+5V

Page 29

DP-85 DEFLECTION POWER SUPPLY SHUTDOWN

BLOCK DIAGRAM

IP01

ShutDown Pin (7)

on Power Supply

Driver &

Output IC

220V Short Det.

Heater

Short Det.

13V

Short Det.

28V Short Det.

Deflection B+ (130V)

Excessive Current Det.

IP06

Photocoupler

QP06

QP05

ShutDown

S.C.R.

DP25

Heater Too

High Det.

-M13V

Loss Det.

-M28V

Loss Det

Deflection B+ (130V)

Excessive Voltage Det.

DP23

DP34

X-RAY

PROTECT

Flyback

Excessive

Current Det.

Heater Loss

Det.

Excessive

High Voltage

Det.

Deflection

Transformer

Failure Det.

Side Pin

Failure Low

Det.

Q754

Side Pin

Failure High

Det.

High Voltage

Stability Too

High Det.

Page 02-05

Page 30

DP-85 DEFLECTION POWER SUPPLY SHUTDOWN DIAGRAM

TP91

DP11

13

CP16

IP01

ShutDown Pin (7)

on Power Supply

Driver &

Output IC

200V Short Det.

DP37

220V

Heater

DP36

DP35 ?

QP04

RP31

0.47

DP17

DP19

IP06

Photocoupler

Excessive High

Voltage Det.

DP35 May Not Be in Set.

Deflection B+ (130V)

Excessive Current Det.

DP18

DP23

QP05

ShutDown

S.C.R.

DP25

DP34

Deflection B+ 130V

Deflection B+ (130V)

Excessive Voltage Det.

Deflection Flyback

Excessive Current Det.

Flyback

TH01

9

QH03

10

DH24

5

DH31

QH07

DH30

RH23

1.2

Heater

DH25

DH26

DH27

Heater Loss Det.

Doesn't

go to

CRT's

DP30

13V

DP31

28V

DP27

DP26

RP45 RP44

-M28V

-28V Loss Det. -13V Loss Det.

+28V

Deflection B+ 130V V1

DP29

DP28

RP41 RP40

-M13V

Q777

QP06

13V Short Det.

28V Short Det.

+13V

6

1

DP33

DP32

Heater from Def. Power Supply. Goes

to CRT's

Heater To High Det.

7

8

T752

H.Blk

X-RAY

PROTECT

RP42

D759

C769

QH06

High Voltage Stability Too

D753

D757

Deflection Transformer

D754

Q754

D756

Inoperative Det.

High Det.

Side Pin Failure High

Det.

D760

Side Pin

Failure

Low Det.

Page 02-06

Page 31

13V

DP-85 CHASSIS L.E.D. (VISUAL TROUBLE DETECTION) DIODES

DEFLECTION PWB 5 GREEN L.E.D.s and 1 RED L.E.D.

(6 Total L.E.Ds. for visual trouble sensing observation)

130V

+28V

Deflection B+

RP39

-M28V-M13V

DP06 is a RED L.E.D.

Off = No IP01 B+

On (Mid) = IP01 B+

On (Bright) = Shutdown

Page 02-07

RP23

DP15

RP17

DP06

Osc B+

1.9V

RP37

ALL GREEN L.E.D.s

Start Up or Run

24.2V

5

IP01

Driver/Output IC

100% Dead Time &

7

IC B+ Detection

RP38

RP60

24.2V

1.9V

RP26

DP16DP22DP20

4

3

Vcc

IP06

IP06 Shutdown

Photocoupler

16 Shut Down

Inputs

RP46

DP21

1

2

QP05

Shutdown

SCR

Page 32

DP-85 DEFLECTION POWER SUPPLY DISTRIBUTION DIAGRAM

Page 02-08

Power Supply

Block

Protector

EP91: 4K

Switching

Control

IP01

DP06:

Protect

Red LED

Live Cold

Switching

Transformer

TP91

Feedback

IP05

Protect

IP06

Protector

EP92: 4K

Protector

EP93: 5K

Protector

EP94: 7K

Protector

EP95: 7K

Protector

EP96: 7K

Protector

EP97: 7K

Voltage Control

+130V: IP04

Rectifier

+220V:DP07

Rectifier

+7V:DP08

Rectifier

+15V:DP09

Rectifier

+15V:DP10

Rectifier

+28V:DP12

Rectifier

-28V:DP13

Rectifier

+130V:DP11

Regulator

+6.3V: IP02

Regulator

+13V: IP03

Regulator

-13V: QP01

Protector

EP96: 7K

Protector

SCR: QP05

DP36,

DP37:<4V

D

DP35: <4V DP32: >7.4V

D

DP15: +13V DP30: <5V

D

DP16: M-13V DP28: > -13V

D

DP20: +28V DP31: <5V

D

DP21: -28V

DP22: +130V QP04: >1.4V

Protect In

DP25: >-24V

D

D

Short

Circuit

Detector

On/Off

Over

Voltage

Detector

Power

ZD

DP28: >20V

ZD

DP26:

>32V

ZD

DP18:

>166

V

ZD

HVcc

Switch

QP08

Video

+220V

Heater

+6.3V

Vert/HVcc:

+13V

Vert:

-13V

Conver:

+28V

Conver:

-28V

Deflection

+130V

HVcc

+12V

DP-85 Deflection

Circuit Protection

Page 33

DM-1

Module

Power On/Off

by Remote or

Front Pannel

DP-85 DEFLECTION Vcc PRODUCTION CIRCUIT

PQD2

From I907 A12V Reg.

5

5

I001

Slave Micro

Power On/Off

Q007

53

Power ON

Driver

(Relay Driver)

A12V

PQS1

Other Power

On/Off Circuits

3

DEFLECTION PWBSUB POWER PWBSIGNAL PWB

A12V or STBY +12V

Start Up Power

QP08

23

3

I702

DVccVRef-In

I701

5V Reg.

I703

Comp.

1

1

2

DP41

1

PDD1

8

SUB DEFLECTION PWB

Run Power

RP66

13V

From IP03

13V Reg.

Page 02-09

Page 34

DP-85 SERIES CHASSIS HORIZONTAL DRIVE

CIRCUIT

Q701

PDD1

7

9

To I001 OSD

Position

To PinP

Unit

I702

H Out

18 16

29

FBP In

17

26

PSD2

6

H.Blk.

AVCC

Switched AVCC

Osc.

H. Sync In

Q751

Q755

To Convergence Circuit

To Sweep Loss Det. Circuit

C770

C771

IH01

Q1

A1

1

28V

12

T751

3

1

10

6

4

Osc

Q777

130V V1

IH02

Drive

H. Def. Yoke R

H. Def. Yoke G

H. Def. Yoke B

T752

1

6

QH08 QH01

7

8

H Pulse

11

12

9

10

QH09

Def.

+28V

+28P

M28V

M28P

7

To Side Pin Circuit

To Dynamic Focus

To Deflection Loss

To X-Ray Protect

130V V2

TH01

9

High

Voltage

10

Page 03-01

12

13

Clamp

E

QH10

14

1

Ref. V.

FBP In

QH05

QH04

HV Sample

12

QH06

HV Sample too High

X-Ray Protect

r

r

o

r

Page 35

DP-85 SERIES CHASSIS VIDEO SIGNAL PATH (Main & Terminal)

V1

Aux Inputs

V2

V3

4V

Avx 4 In

S-4 In

PinP TUNER (Mono)

S-1 In

S-2 In

Front Control PWB

DM-1

Digital Control Center

U001

Always PinP

S Det.

Aux Input 4

PMT1

Signal PWB

20

S Det.

S Det.

Terminal PWB

2

S-Y4

S-C4

Q202

PST1

3

S-Y1

S-C1

S-Y2

S-C2

PFV

8

5

3

I201

3

+

-

2

PinP Video

Terminal

PWB

1

20

21

23

5

3

7

9

11

13

15

17

50

Main Video

NTSC

I301

Yout1

Cout1

Lum/Audio

Selector IC

PinP V Out

36

44

42

Q035

Q301

3DY

Q302

3DC

Q039

PST1

11

13

Q034

6

C In

40

Y In

20

3

2

PMZ

I008

Y Out

I009

+

-

PCX

11

13

9

7

B-Y

Out

R-Y

Out

PST2

Comp/S-Y

S-C

3DY

3DC

Y1 In

29

B-Y1 In

30

R-Y1 In

31

21

22

1

PMS2

1

Q041

Q040

3DYC

Comb

Filter

I011

3

+

-

2

I010

3

+

-

2

U002

11

5

6

7

1

1

PinP V

Y

I

Q

PinP

Unit

Page 04-01

PZC

B

1

To CRT PWB

G

3

R

5

Signal Sub PWB

QX23

QX28

QX33

41

42

43

IX01

Rainforest

IC

53

51

52

Y

V/PR

U/PB

QX07

QX08

QX09

V/PR

U/PB

IX02

Y

1

QX01

3

+

-

2

Y

1

14

Y

DM1

IX03

1

1

QX03

3

+

-

2

QX05

3

+

-

2

V/PR

U/PB

3

5

PWB

ATSC/

NTSC

12

10

V (Cr)

U (Cb)

Page 36

DP-85 CHASSIS A.B.L. CIRCUIT DIAGRAM

See uP

Data

Signal

Path

PSZ2

RX78

RX79

QX14

RX80

9V

DX02

RX82

ABL

9

DX01

CX21

CX20

RX81

CX24

CX39

PSZ1

SDA2

16

SCL2

17 28

RH22

High Voltage B+

130V V2

QH03

See XRay Protect

RH23

CH18

Collector of Horz.

Output Transistor

Rainforest

45

27

SDA2

SCL2

To QH01

IX01

IC

B+

C

TH01

Signal Sub

PWB

To Anodes

To

Focus

ABL

3

Page 04-02

Signal

PWB

PSD2

1

ABL Pull-Up Resistors

Deflection PWB

Deflection B+ 130V

V1

[ Current Path ]

13V

RH59RH58

Clamp

As Brightness goes Up, ABL Voltage goes Down. (Inverse Proportional)

CH25

RH56

DH33

Page 37

DP-85 SWEEP & AC LOSS DETECTION CIRCUIT

12V

Vertical

Blanking

From

Pin 9 I601

V. Blk.

24V P/P

Horizontal

Blanking

From

Q755 Emitter

CN04

H. Blk.

11.6V P/P

SPOT

From Pin 9

of Micro I001

Cut Off

Vertical

Output IC

I601

Invert Input

Non Invert

Input

5V

CN01

R604

R605

QN01

RN01

RN02

CN03

QN05

RN11

RN12

PSD

2

2

3

Vert SAW

R602

5

4

Q601

Q602

Stops Vertical Drive

during Cut Off

adjustment, I2C

RN03

12V

RN10

RN09

DN04

DN05

Prevents CRT Burn

Q610

RN04

DN01

CN02

QN03

DN06

RN13

Spot Inhibit

QN07

RN06

8.57V

DN02

DN03

RN07

0V

RN08

DN11

RN16

RN15

CN05

DN07

9.72V

RN17

QN02

12V

8.57V

CN06

RN05

QN04

DN16

DN14

DN09

DN10

QN06

Horz. 13V Loss/

Start Up Spot Killer

QH02

14

1

13 Error Out

12

7

Stops High Voltage

Drive Signals From

being produced

during 13V start up

RN14

DN08

RN17

RH40

High Voltage

Driver IC

IH02

Reference

Feed Back

Error In

Drive

From I906 Pin 3

AC Photo Coupler

10V P/

P

ACK 5V

RN18

Page 04-03

Page 38

DP-85 SERIES CHASSIS AUDIO SIGNAL PATH

(Main, Terminal & Audio Output)

Page 05-01

4L

Avx 4 In

4R

NOTE: The J31101 Lum type connector Pins are

Aux Input 4

opposite of PMT1. They are correct here.

Front Control PWB

DM-1

Digital Control Center

I001

Microprocessor

Signal PWB 1 of 2

Surround PWB 2 of 2

Left Rear Spk Jack

Right Rear Spk Jack

External Right Spk Jack

External Left Spk Jack

Front Left Spk

Front Right Spk

PL

2

PR

2

Int.

Spk.

SS01

Center Spk

J31101

SCL1

47

SDA1

43

Ext.

Spk.

2

5

PMT1

7

4

PST3

5

4

PSP1

5

7

1

3

PCL

2

PFV

8

7

L-Audio (NTSC)

R-Audio (NTSC)

Terminal PWB

Rear Left

Rear Right

12

I401

FT/

Audio

Output

7

IC

Center

Terminal PWB

I202

3

+

-

2

5

+

-

6

2

4

11

12

1

7

SCL1

SDA1

Front Left

Front Right

I402

Center Audio

Output IC

20

22

Lum/Audio

Selector IC

6

Main Audio

4

27

26

Rear Output IC

12

I403

7

Q403

2

11

I301

Main Audio

PinP

Audio

Out

PinP

Audio

In

2

4

11

D414

D415

Q407

8

AVX 1

10

14

AVX 2

16

51

AVX 3

49

PST1

45

43

L

35

R

33

1

3

Audio Output PWB

D420

D421

Mute (PAS1 Pin 5)

D426

D427

Center Speaker Off

(PAS1 Pin 2)

Q411

Front Speaker Off (PAS1 Pin 1)

Mute (PAS1 Pin 5)

Left Total

10

Right Total

11

PinP Left

13

PinP Right

14

1

Mono PinP

Rear Speaker Off (PAS1 Pin 3)

Mute (PAS1 Pin 5)

Main Audio

Signal PWB

Left Select

Right Select

Signal PWB

2 of 2

20

PinP Tuner

Rear Left

Rear Right

F L Out

F R Out

LFE/SW

Sub Woofer

Center

1L

1R

2L

2R

3L

3R

PSU1

1

2

9

10

PAS2

8

9

1

2

4

6

Aux Inputs

(See Surround Audio Signal Path)

(See Surround Audio Signal Path)

Page 39

Right

Front

Left

Front

PAS2

2

1

DP85 SURROUND AUDIO SIGNAL

PATH

ISO1

Ft\

30

28

PinP Audio

PSU1

10

9

R

L

See Main Audio

Selector/Signal

PWB

Trans-

mitter

Audio

Cont

Rt

2

Selected Audio

Lt

1

Selected Audio

10

1

ISO8

Perfect

Volume

8

3

QS03 QS04

13

20

QS01 QS12

Transmitter

Out Jacks

FL/FR/RL/RR/PinP L/R

IG01

R

L

15

18

23

10

1

7

3

+

L Ft

-

2

R Ft

5

+

-

6

MAIN AUDIO

NOTE:

The connector Pins on

the DM-1 are backwards

compared to PMS1.

PMS1

R

1

1

3

L

1

3

2

3

2

IS10

+

-

IS09

+

-

Right

Total

In

Left

Total

In

MODULE

DM-1

To Audio Output PWB

Fixed/Vari

Audio Out L

Fixed/Vari

Audio Out R

Sub Woofer

LFE/

6

Sw

Center

4

To Audio Output PWB

R Ft + Center

L Ft + Center

Rear Right

Rear Left

QS13

LFE/Sw

IS12

1

7

Center

32

1

QS07QS08

QS09QS10

+

-

+

-

Center

3

2

5

6

13

CENT/LFE

20

15

18

Graphic EQ

ISO2

Mix/Vari

Audio

Cont.

R Ft

L Ft

R Ft

L Ft

5

3

1

32

1

IG15

Graphic EQ

LFE

(Sub Woofer)

Center

R Ft

L Ft

3

+

-

2

1

7

7

1

Center

IS07

IS05

LFE

(Sub

5

3

+

-

2

5

+

-

6

5

+

-

6

3

+

-

2

7

15

13

Woofer)

Center

R Ft

(Right

Front)

L Ft

(Left

Front)

MODULE

DM-1

9

10

Rear Right

Rear Left

5

6

3

2

IS04

+

-

+

-

7

1

2

3

6

5

IS06

IS11

+

-

+

-

Right

5

+

-

6

3

+

-

2

11

9

Rear

Left

Rear

PHP

1

7

1

3

To

Head

Phone

Jacks

R Ft +

7

1

Center

L Ft +

Center

Rear Right

Rear Left

32

1

15

18

ISO3

Rear/

Head-

Phone

Audio

Cont.

5

3

20

R R

L R

HPL

HPR

13

Page 05-02

Page 40

DP-85 Series Chassis AUDIO and VIDEO MUTE Circuit

Also see Mute Circuit Diagram (Surround and Audio Output PWB)

I001

V MUTE

Micro

Processor

MUTE

56

10

A5V

RO10

RO52

RO51

R145

D009

9V

A12V

RO93

Q022

RO92

D008

Mute 2

D010

R095

RO70

R094

Q008

PSD2

6

R096

R097

D011

C012

R098

V. Mute

"SPOT"

Horizontal & Vertical

Sweep Loss Det.

AC Loss Det.

(From Deflection PWB)

Q009

R099

Q010

V Mute 2

V Mute

Mute

2H Video PWB

From QZ13 and IZ07

HVBlk

PSZ2

Spot

14

DX05

PZC

7

PZC

7

Spot

Grounds Bias to Q8A3,

PSU1

16

V Mute 2

15

Mute 2

Rainforest

IX01

RY04

CRT PWBs

Q853 & Q803

Surround PWB

25

FBP

In

Page 05-03

Signal PWB

Page 41

DP-85 MUTE CIRCUIT DIAGRAM (SURROUND PWB)

Also see Audio and Video Mute Circuit Diagram

Also see Mute Circuit Diagram (Audio Output PWB)

VMUTE2

MUTE2

PSU1

16

15

Transmiter Right

DS20 DS21

Transmiter Left

DS22 DS23

Fixed/Variable Right

DS24 DS25

VMUTE2

Fixed/Variable

DS26 DS27

Left

QS05

RSC6

QS06

RSC7

QS11

RSF4

QS12

RSC4

RSC5

RSF2

RSF3

CS86RSH3CS73

CS87RSH4CS74

CS84RSH1CS77

CS85RSH2CS78

Transmiter Right

Out

Transmiter Left

Out

Fixed/Variable

Right Out

Fixed/Variable

Left Out

MUTE2

DS28

DS29

PSA1

VMUTE2

MUTE2 MUTE

4

5

VMUTE

LFE/Sub

Woofer

DS30

RSF5

QS14

RSF9

See Audio

Output Mute

Circuit

Diagram

RSF8

CS83CS82

LFE/Sub

Woofer Out

Page 05-04

Page 42

DP-85 MUTE CIRCUIT DIAGRAM (AUDIO OUTPUT PWB)

Also see Audio and Video Mute Circuit Diagram

Also see Mute Circuit Diagram (Surround PWB)

MUTE

Ft Spk Off

VMUTE 4

PAS1

5

1

D412

D413

D414

D415

D424

Front Right

Front Left

R418

C409

Rear Right

R415

Q401

R416

Q402

R417

Q403

Q409

R448

R412C401

R413C402

R444C440

R420

C403

R414

C404

R415

C442

R446

4

2

11

C409

4

Front

Right

Front Audio

Output IC

Front

Left

Mute

Rear

Right

Rear Audio

Output IC

I401

I403

Rear Spk

Off

Center

Spk Off

R413C402

Rear Left

C404

Rear

2

Left

Q410

3

D425

D426

D427

D418

R450

C447

Rear Left

R451

R449

Q411

R452

R431C423

Q406

2

D419

D420

D421

R436

C429

R437

R449

Q407

R438

R447

C425

R433

11

C448

2

11

C430

Mute

Center Audio Output IC

I402

Center

Center Audio

Output IC

Mute

Page 05-05

Page 43

DP-85 CHASSIS "DIGITAL CONVERGENCE" INTERCONNECTION CIRCUIT DIAGRAM

DM-1

2 4

9

5V

2

HMO1

IR Receiver

3

Ft. Control

Sensor

8 Total

Page 06-01

Sensors

PMF

1

QM05

PWB

PWB

LED

S0-S7

12

11

10

9

3

4

5

6

IR In

7

Out

QM01

I002

PMS2

IR

PFS

2

Memory

IP

IR

Out

I001

Main Up