Page 1

SERVICE MANUAL

NN TT SS CC

PA

No. 0193

46F510 DP33KA

46F500A DP33KB

DDPP3333KKAA//BB

R/C: CLU-4328UG

CChhaassssiiss

TO GO TO A CHAPTER, CLICK ON ITS HEADING BELOW

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SERVICING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

TECHNICAL CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CAUTIONS WHEN CONNECTING/DISCONNECTING THE HV CONNECTOR . . . . . .13

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

REMOTE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

CUSTOMIZED PICTURE AND SOUND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . .18

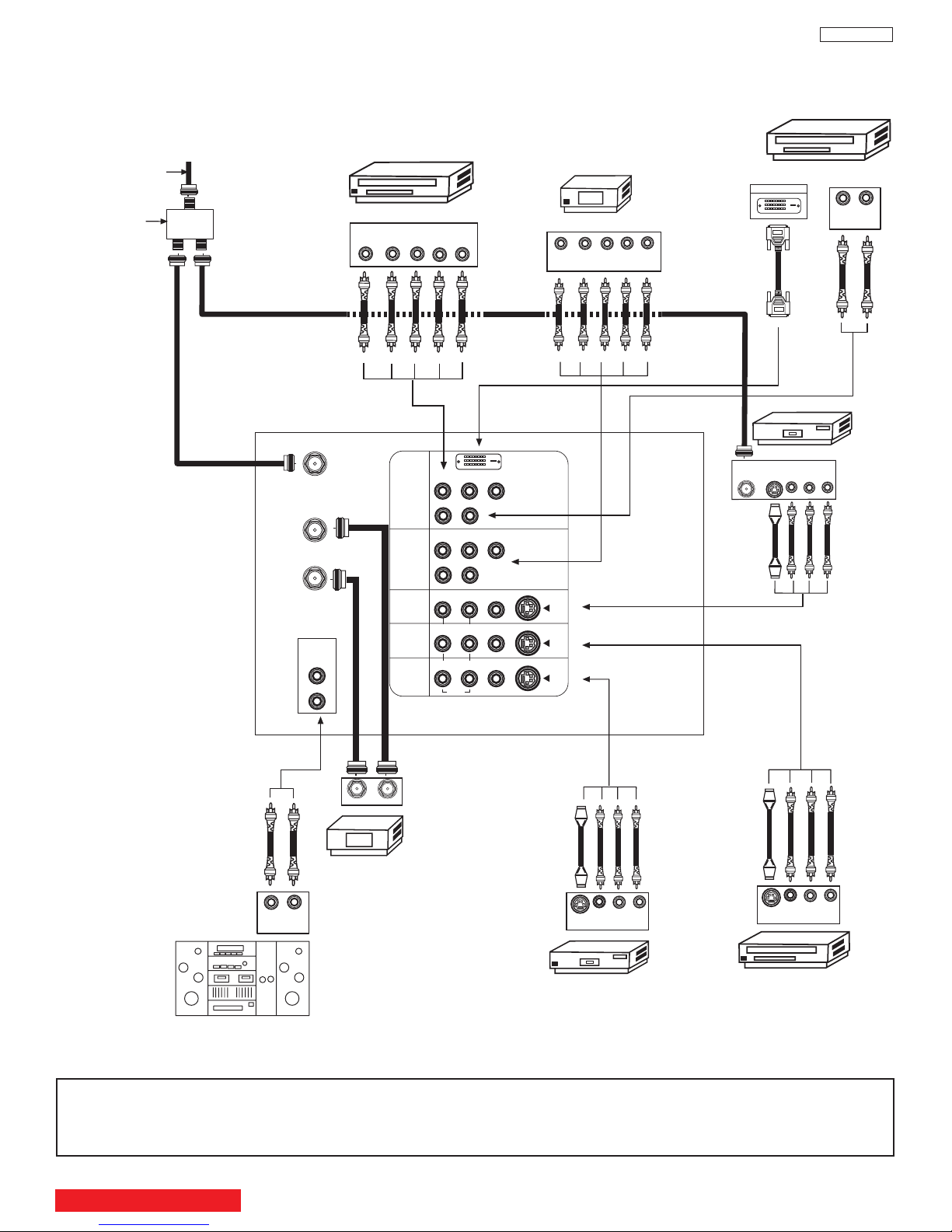

REAR PANEL CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

DISPLAY PICTURE FORMATS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

SERVICE ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

TROUBLESHOOTING FLOW CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

WAVEFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

DC VOLTAGE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

PROTECTION CIRCUIT BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

CIRCUIT SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

PRINTED CIRCUIT BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

FINAL WIRING DRAWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

EXPLODED VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

EXPLODED VIEW PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

DISASSEMBLY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

QUICK REFERENCE PARTS LIST (IC & UNIT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

CAUTION: These servicing instructions are for use by qualified service personnel only. To reduce the risk of

electric shock do not perform any servicing other than that contained in the operating instructions

unless you are qualified to do so. Before servicing this chassis, it is important that the service

technician read the “IMPORTANT SAFETY INSTRUCTIONS” in this service manual.

SAFETY NOTICE

USE ISOLATION TRANSFORMER WHEN SERVICING

Components having special safety characteristics are identified by a on the schematics and on the parts list in this

Service Data and its supplements and bulletins. Before servicing the chassis, it is important that the service technician

read and follow the “Important Safety Instructions” in this Service Manual.

!

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

PROJECTION COLOR TELEVISION

AUGUST 2004 HHEA-MANUFACTURING DIVISION

Page 2

IMPORTANT SAFETY INSTRUCTIONS

USE ISOLATION TRANSFORMER WHEN SERVICING

DP33KA/B

Components having special safety characteristics are identified by a on the schematics and on the parts list in this service

ual and its supplements and bulletins. Before servicing this chassis, it is important that the service technician read and

man

follow the “Important Safety Instructions” in this Service Manual.

For continued X-Radiation protection, replace picture tube with original type or Hitachi approved equivalent type.

This Service Manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer. Qualified

technicians have the necessary test equipment and tools, and have been trained to properly and safely repair complex

products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void warranty. If you

are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so and refer the

repair to a qualified service technician.

!

WARNING

Lead in solder used in this product is listed by the California Health and Welfare agency as a known reproductive toxicant which

may cause birth defects or other reproductive harm (California Health and Safety Code, Section 25249.5).

When servicing or handling circuit boards and other components which contain lead in solder, avoid unprotected skin contact

with solder. Also, when soldering do not inhale any smoke or fumes produced.

This television receiver provides display of television closed captioning in accordance with section 15.119 of the FCC rules.

FEDERAL COMMUNICATIONS COMMISSION NOTICE

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

ient or relocate the receiving antenna.

• Reor

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an e

xperienced radio/television technician for help.

TABLE OF CONTENTS

2

Page 3

IMPORTANT SAFETY INSTRUCTION

Chassis

ground

High Impedance

H.V. meter

Deflection P.W.B.

FBT

(TH01)

High voltage

connector

+

-

LEAKAGE

CURRENT

TESTER

DEVICE

UNDER

TEST

TEST ALL

EXPOSED

METAL

SURFACES

2-WIRE CORD

(READING

SHOULD NOT

BE ABOVE

0.5 mA)

EARTH

GROUND

ALSO TEST WITH

PLUG REVERSED (USING

AC ADAPTER PLUS

AS REQUIRED)

Before returning an instrument to the customer, always

1.

make a safety check of the entire instrument, including

but not limited to the following items.

Be sure that no built-in protective devices are

a.

defective and/or have been deleted during servicing.

(1) Protective shields are provided on this chassis to

protect both the technician and the customer

Correctly replace all missing protective shields,

including any removed for servicing convenience. (2)

When reinstalling the chassis and/or other assemb

in the cabinet, be sure to put back in place all

protective devices, including but not limited to,

nonmetallic control knobs

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks.

this instrument or permit it to be operated without

all protective devices correctly installed and

functioning.

Servicers who defeat safety features

or fail to perform safety checks may be liable for

any resulting damage.

b. Be sure that there are no cabinet openings through

which an adult or child might be able to insert their

fingers and contact a hazardous voltage. Such

openings include, but are not limited to (1) spacing

between the picture tube and cabinet mask, (2)

excessively wide cabinet ventilation slots, and (3) an

improperly fitted and/or incorrectly secured cabinet

back cover.

Antenna Cold Check – With the instrument AC plug

c.

removed from any AC source, connect an electrical

jumper across the two AC plug prongs. Place the

instrument AC switch in the on position. Connect one

lead of an ohmmeter to the AC plug prongs tied

together and touch the other ohmmeter lead in turn to

each tuner antenna input, exposed terminal screw

and, if applicable, to the coaxial connector. If the

measured resistance is less than 1.0 megohms or

greater than 5.2 megohms, an abnormality exists that

must be corrected before the instrument is returned to

Repeat this test with the instr

the customer

witch in the off position.

s

.

, insulating fishpaper,

Do not operate

ument A

DP33KA/B

(READING

SHOULD NOT

BE ABOVE

0.5 MIU)

.

ly

AC Leakage Test

AC LEAKAGE TEST

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE RECEIVER TO THE CUSTOMER.

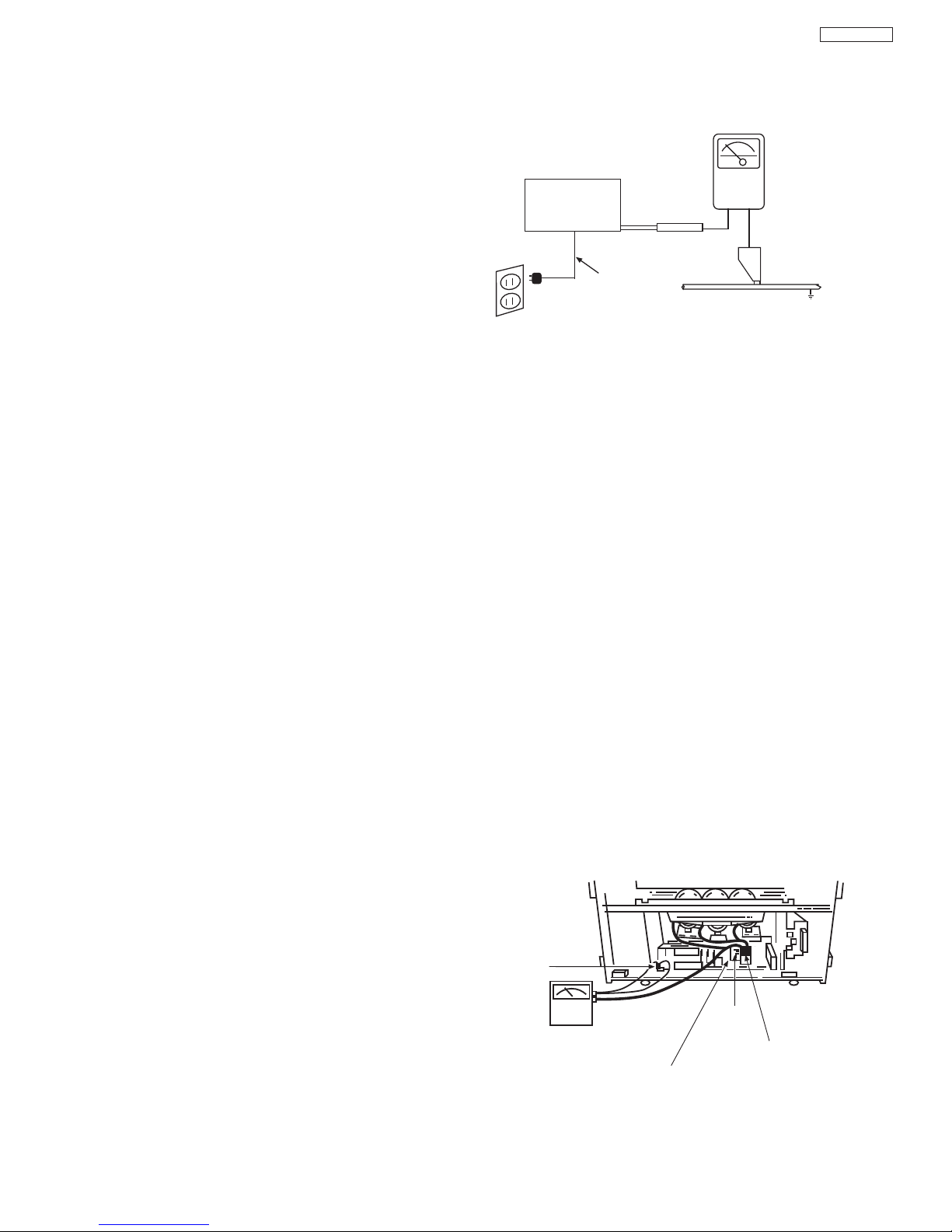

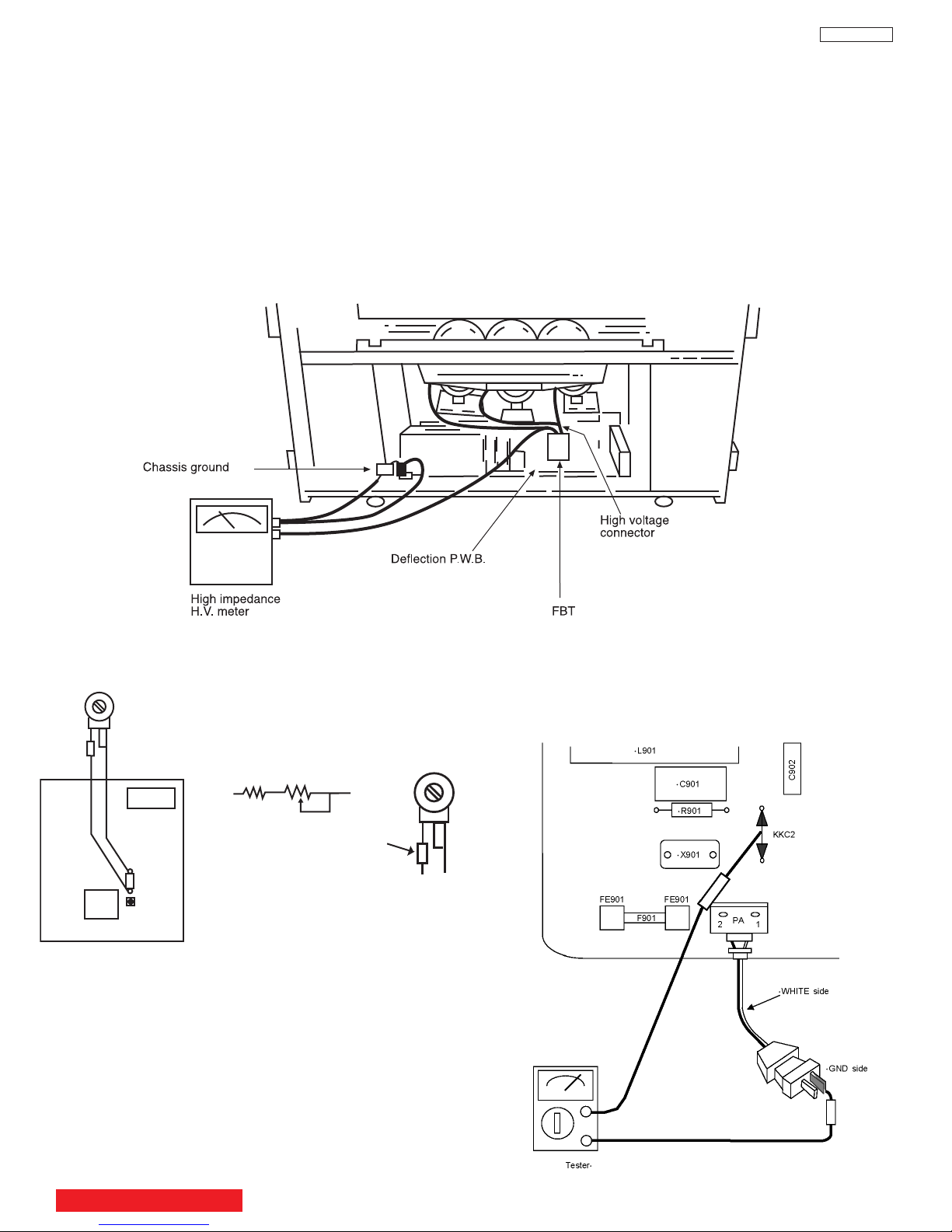

e. High Voltage – This receiver is provided with a

hold down circuit for clearly indicating that voltage has

increased in excess of a predetermined value.

Comply will all notes described in this Service Manual

regarding this hold down circuit when servicing, so

that this hold down circuit may correctly be operated.

Service Warning – With maximum contrast, operating

f.

high voltage in this receiver is lower than

30.5 kV. In

case any component having influence on high voltage

is replaced, confirm that the high voltage with

maximum contrast is lower than

30.5 kV.

To measure H.V. use a high impedance H.V. meter.

Connect (-) to chassis earth and (+) to the CRT anode

utton. (See the following connection diagram.)

b

C

Note: Turn power switch off without fail before the

connection to the anode button is made.

Leakage Current Hot Check -

d.

directly into a 120V

AC 60Hz outlet

isolated transformer for this check). Turn the A C

ON. Using a Leakage Current

power

Model 228 or equivalent), measure for current from all

exposed metal parts of the cabinet (antennas,

screwheads,

overlays, control shafts, etc.)

particularly any exposed

having a return path to the chassis or to a

known earth ground (water pipe, conduit, etc.).

current measured must not exceed 0.5 MIU.

Plug the

(do not use an

ester (Simpson’

T

metal

AC line cord

s

part

Any

3

Page 4

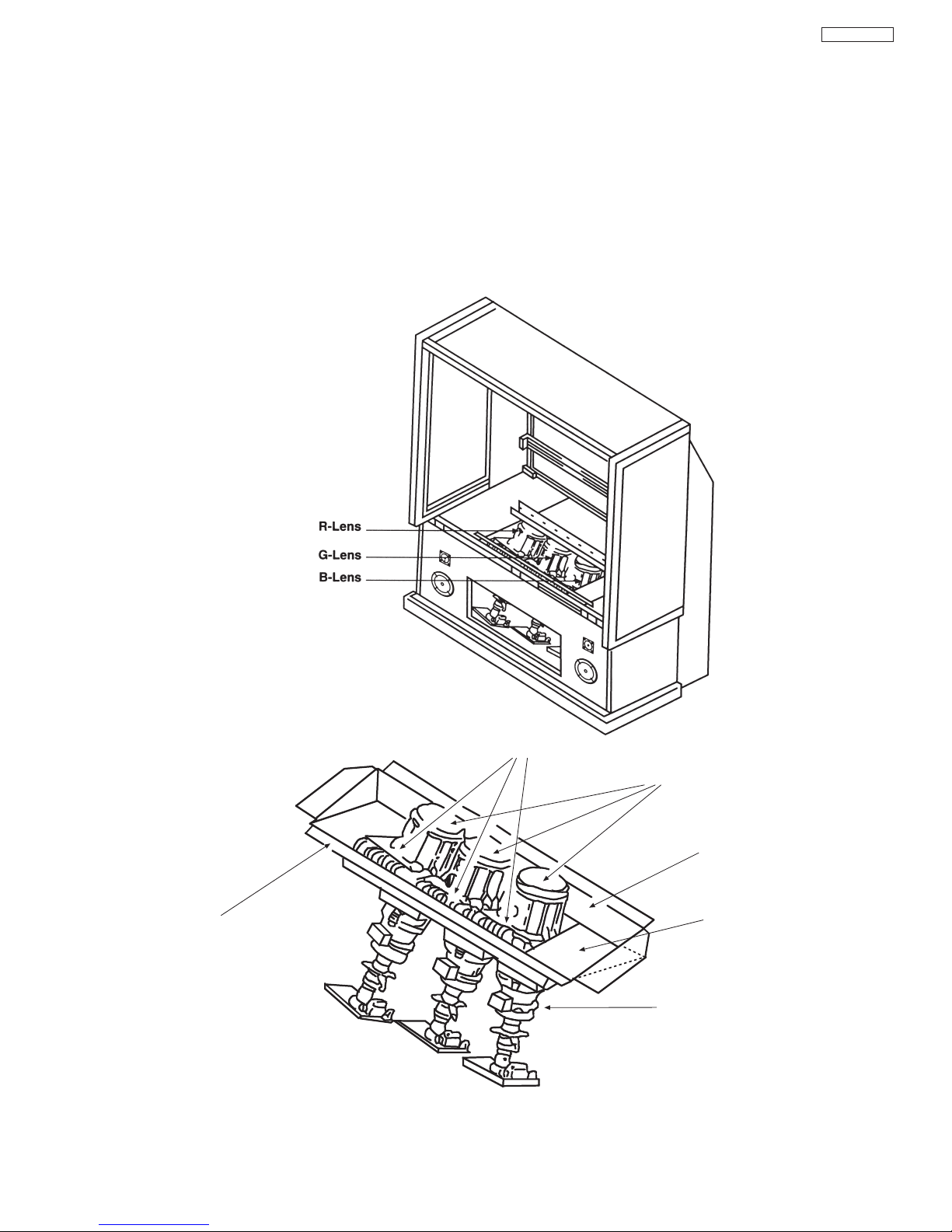

Shield Plate A

Glass Lens for Shielding

Shield Plate B

Shield Plate C

Shield Plate D

Detailing X-radiation shield

Shield Plate C

IMPORTANT SAFETY INSTRUCTIONS

DP33KA/B

g. X-radiation – TUBE: The primary source of X-

radiation in this receiver is the picture tube. The tube

utilized for the above mentioned function in this

chassis is specially constructed to limit X-radiation

emissions.

For continued X-radiation protection, the replacement

tube must be the same type as the original, Hitachi

approved type.

When troubleshooting and making test measurements in a receiver with a problem of excessive high

voltage, avoid being unnecessarily close to the picture

tube and the high voltage component.

Do not operate the chassis longer than is necessary

to locate the cause of excessive voltage.

X-radiation Shield –

h.

1. This receiver is provided with X-ray shield plates

for protection against X-radiation. Do not remove

X-ray shield plates A, B, or C shown in Fig. 1

unnecessarily, when troubleshooting and/or

making test measurements.

2. To prevent X-radiation, after replacement of

picture tube and lens, confirm these components

to be fixed correctly to bracket and cabinet, and

not to be taken off easily.

Installation of shield lens,

1.

Fig.

shield cover and shield plates (oblique view).

4

Page 5

IMPORTANT SAFETY INSTRUCTIONS

DP33KA/B

Read and comply with all caution and safety-related

2.

notes on or inside the receiver cabinet, on the receiver

chassis, or on the picture tube.

3.

Design Alteration Warning – Do not alter or add to

the mechanical or electr

Design alterations and additions including but not

limited to circuit modifications and the addition of

items such as auxiliar

connectors, might alter the safety characteristics of

this receiver and create a hazard to the user. Any

design alter

manufacturer’s warranty and may make you, the

servicer, responsible for personal injury or property

damage resulting therefrom.

Picture Tube Implosion Protection Warning – The

4.

picture tube in this receiver employs integral implosion

protection. For continued implosion protection,

replace the picture tube only with one of the same

type number. Do not remove, install, or otherwise

handle the picture tube in any manner without first

putting on shatterproof goggles equipped with side

shields. People not so equipped must be kept safely

away while picture tubes are handled. Keep the

picture tube away from your body. Do not handle the

picture tube by its neck.

ations or additions may void the

ical design of this TV receiver.

y audio and/or video output

7. Components, parts, and/or wiring that appear to have

verheated or are otherwise damaged should be

o

replaced with components, parts, or wiring that meet

original specifications. Additionally, determine the

cause of o

necessary, take corrective action to remove any

potential safety hazard.

PRODUCT SAFETY NOTICE – Many TV electrical

8.

and mechanical parts have special safety-related

characteristics some of which are often not evident

from visual inspection, nor can the protection the

e necessarily be obtained by replacing them with

giv

components rated for higher voltage, wattage, etc.

Parts that have special safety characteristics are

identified in Hitachi service data by shading on

schematics and by a in the parts list. Use of

substitute replacement that does not have the same

safety characteristics as the recommended replacement part in Hitachi service data parts list might

create shock, fire, and/or other hazards. Product

safety is under review continuously and new

instructions are issued whenever appropriate. For the

latest information, always consult the appropriate

current Hitachi service literature. A subscription to, or

additional copies of service literature may be obtained

at a nominal charge from Hitachi.

verheating and/or damage and, if

!

y

Hot Chassis Warning – a. Some TV receiver chassis

5.

are electrically connected directly to one conductor of

the AC power cord and may be safely serviced without

an isolation transformer only if the AC power plug is

inserted so that the chassis is connected to the

ground side of the AC power source. Confirm that the

AC power plug is inserted correctly with an AC

voltmeter by measuring between the chassis and a

known earth ground. If a voltage reading in excess of

1.0V is obtained, remov

plug in the opposite polarity and again measure the

voltage potential between the chassis and a known

earth ground.

have 85V AC (RMS) between chassis and earth

ground regardless of the AC plug polarity. These

chassis can be safely serviced only with an isolation

transformer inserted in the power line between the

receiver and the AC power source, for both personnel

and test equipment protection.

chassis have a secondary ground system in addition

to the main chassis ground. This secondary ground

system is not isolated from the AC power line.The two

ground systems are electrically separated by

insulating material that must not be defeated or

altered.

6. Observe original lead dress. Take extra care to assure

correct lead dress in the following areas:

edges,

and components do not touch thermally hot parts,

the AC supply, d. high voltage and e. antenna wiring.

Always inspect in all areas for pinched, out-of-plate, or

frayed wiring. Do not change spacing between

components and the printed circuit board. Check AC

power cord for damage.

b. Some TV receiver chassis normally

b. near thermally hot parts – be sure that leads

e and reinsert the AC power

c. Some TV receiver

a. near sharp

c.

5

Page 6

SERVICING PRECAUTIONS

CAUTION: Before servicing instruments covered by this

service data and its supplements and addenda, read and

ollow the “Important Safety Instructions” on page 3 of this

f

publication.

NOTE: If unforeseen circumstances create conflict between

ollowing servicing precautions and any of the safety

the f

precautions on page 3 of this publication, always follow the

safety precautions. Remember: Safety First.

DP33KA/B

7. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heatsinks are correctly installed.

8. Always connect the test instrument ground lead to the

appropr

the test instrument positive lead. Always remove the test

instrument ground lead last.

iate instrument chassis ground before connecting

General Servicing Guidelines

Always unplug the instrument AC power cord from the AC

1.

power source before:

a. Removing or reinstalling any component, circuit

board, module

b. Disconnecting or reconnecting any instrument

electrical plug or other electrical connection.

c. Connecting a test substitute in parallel with an

electrolytic capacitor in the instrument.

UTION:

CA

d. Discharging the picture tube anode.

2. Test high voltage only by measuring it with an appropriate

high voltage meter or other voltage measuring device

(DVM, FETVOM, etc.) equipped with a suitable high

voltage probe. Do not test high voltage by “drawing an

arc.” The H.V. Distribution Box has an internal 400M

resistor (bleeder resistor) connected from the high

voltage to ground. After power is removed from the

instrument the high voltage will discharge through the

high voltage bleeder resistor. If the tubes have high

voltage after power is removed, then the bleeder resistor

is defective or the bleeder ground is disconnected.

, or any other instrument assembly.

A wrong par

polarity installation of electrolytic

capacitors may result in an explosion

hazard.

t substitution or incorrect

9. Use with this instrument only the test fixtures specified in

this service data.

CAUTION: Do not connect the test fixture ground strap

to any heatsink in this instrument.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some fieldeffect transistors and semiconductor “chip” components. The

following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a

known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device,

which should be removed for potential shock reasons

prior to applying power to the unit under test.

Ω

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge

buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or

desolder ES devices.

3. Discharge the picture tube’s anode at any of the R, G, or

B outputs on the H.V. Distribution Box only by (a) first

connecting one end of an insulated clip lead to the

degaussing or kine aquadag g

the point where the picture tube socket ground lead is

connected, and then (b) touch the other end of the

insulated clip lead to the picture tube high voltage

distribution box R, G, or B output, using an insulated

oid personal contact with high voltage.

handle to a

4. Do not spray chemicals on or near this instrument or any

of its assemb

5. Unless specified otherwise in these service data, clean

electr

the contacts with a pipe cleaner, cotton-tipped stick or

comparable nonabrasive applicator: 10% (by volume)

Acetone and 90% (b

99% strength).

CAUTION: This is a flammable mixture. Unless

6. Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service data might be

equipped.

v

.

lies

ical contracts by applying the following mixture to

y volume) isopropyl alcohol (90%-

specified otherwise in these ser

lubrication of contacts is not required.

rounding system shield at

TABLE OF CONTENTS

vice data,

4. Use only can anti-static type solder removal device.Some

solder removal devices not classified as “anti-static” can

generate electrical charges sufficient to damage ES

device.

5. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its

protective package until immediately before you are ready

to install it. (Most replacement ES devices are packaged

with leads electrically shorted together by conductive

foam, aluminum foil or comparable conductive material.)

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly into

which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or

circuit, and observe all other safety

precautions

8. Minimize bodily motions when handling unpackaged

replacement ES de

such as the brushing together of your clothes fabric or the

lifting of your foot from a carpeted floor can generate

6

static electr

icity sufficient to damage an ES device.)

.

. (Otherwise harmless motion

vices

Page 7

Use Solding Iron to Pry Leads

SERVICING PRECAUTIONS

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropr

temperature within the range 500°F to 600°F.

Use an appropriate lead free solder (see page 10). Lead

2.

solder can be used, but there is a possibility of failure due

to insufficient strength of the solder.

iate tip size and shape that will maintain tip

DP33KA/B

Removal

1. Desolder and straighten each IC lead in one operation by

gently prying up on the lead with the soldering iron tip as

the solder melts.

2. Draw away the melted solder with an anti-static suctiontype solder removal device (or with solder braid) before

removing the IC.

3. Keep the soldering iron tip clean and well-tinned.

Thoroughly clean the surfaces to be soldered. Use a

4.

small wire-bristle (0.5 inch or 1.25 cm) brush with a metal

handle. Do not use freon-propelled spray-on cleaners.

5. Use the following desoldering technique.

a. Allow the soldering iron tip to reach normal

temperature (500°F to 600°F).

b. Heat the component lead until the solder melts. Quickly

draw away the melted solder with an anti-static,

suction-type solder removal device or with solder

braid.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach normal

temperature (500°F to 600°F).

b. First, hold the soldering iron tip and solder strand

against the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of

the component lead and the printed circuit foil, and

hold it there only until the solder flows onto and

around both the component lead and the foil.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil or components.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad

and solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to areas.)

“Small-signal” Discrete Transistor Removal/Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a “U” shape the end of each of three leads

remaining on the circuit board.

3. Bend into a “U” shape the replacement transistor leads.

4. Connect to replacement transistor leads to the

corresponding leads extending from the circuit board and

crimp the “U” with long nose pliers to insure metal to

metal contact, then solder each connection.

Power Output Transistor Devices Removal/Replacements

1. Heat and remove all solder from around the transistor

leads.

2. Remove the heatsink mounting screw (if so equipped).

3. Carefully remove the transistor from the circuit board.

d. Closely inspect the solder area and remove any excess

or splashed solder with a small wire-bristle brush.

al/Replacement

IC Remo

Some Hitachi unitized chassis circuit boards have slotted

holes (oblong) through which the IC leads are inserted and

then bent flat against the circuit f

slotted type, the following technique should be used to

remove and replace the IC.When working with boards using

the familiar round hole

outlined in paragraphs 5 and 6 above.

v

When holes are the

oil.

, use the standard technique as

4. Insert new transistor in circuit board.

5. Solder each transistor lead, and clip off excess lead.

Replace heatsink.

6.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicularly to the

circuit board.

3. Observing diode polarity, wrap each lead of the new

diode around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints

of the two “original leads”. If they are not shiny, reheat

them and, if necessary, apply additional solder.

7

Page 8

CRIMP AND

SOLDER

BARE JUMPER

WIRE

Install Jumper Wire and Solder

DEFECTIVE

COPPER

REMOVED

Insulated Jumper Wire

SERVICING PRECAUTIONS

Fuses and Conventional Resistor Removal/Replacement

1. Clip each fuse or resistor lead at top of circuit board

w stake.

hollo

2. Securely crimp leads of replacement component around

e 1/8 inch from top.

stak

3. Solder the connections.

UTION:

CA

Maintain or

replaced component and adjacent

components and the circuit board, to

vent excessive component

pre

temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed

circuit board will w

eaken the adhesive that bonds the foil to

the circuit board, causing the foil to separate from, or “lift-off,”

the board. The following guidelines and procedures should

be followed whenever this condition is encountered.

In Critical Copper Pattern Areas

High component/copper pattern density and/or special

voltage/current characteristics make the spacing and

integrity of copper pattern in some circuit board areas more

critical than in others. The circuit foil in these areas is

designated as Critical Copper Pattern. Because Critical

Copper Pattern requires special soldering techniques to

ensure the maintenance of reliability and safety standards,

contact your Hitachi personnel.

iginal spacing between the

DP33KA/B

At Other Connections

Use the following technique to repair defective copper

pattern at connections other than IC Pins. This technique

involves the installation of a jumper wire on the component

side of the circuit board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both wire sides of the

pattern break and locate the nearest component directly

connected to the affected copper pattern.

At IC Connections

To repair defective copper pattern at IC connections, use the

following procedure to install a jumper wire on the copper

pattern side of the circuit board. (Use this technique only on

IC connections.)

1. Carefully remove the damaged copper pattern with a

sharp knife. (Remove only as much copper as absolutely

necessary.)

2. Carefully scratch away the solder resist and acrylic

coating (if used) from the end of the remaining copper

pattern.

gauge jumper wire

in one end of a small

Bend a small

3.

and carefully cr

connection.

4. Route the jumper wire along the path of the cut-away

copper pattern and let it overlap the previously scraped

end of the good copper patter

area, and clip off any excess jumper wire.

“U”

imp it around the IC pin. Solder the IC

-

Solder the o

n.

v

erlapped

3. Connect insulated 20-gauge jumper wire from the

nearest component on one side of the pattern break to

the lead of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is

dressed so that it does not touch

components or sharp edges.

Frequency Synthesis (FS) Tuning Systems

1. Always unplug the instrument AC power cord before

disconnecting or reconnecting FS tuning system cables

and before removing or inserting FS tuning system

modules

.

2. The FS tuner must never be disconnected from the FS

tuning control module while power is applied to the

instrument.

3. When troubleshooting intermittent problems that might be

caused by defective cable connection(s) to the FS tuning

system, remove the instrument AC power as soon as the

defective connector is found and finish confirming the bad

connection with a continuity test. This procedure will

reduce the probability of electrical overstress of the FS

system semi-conductor components.

8

Page 9

SERVICING PRECAUTIONS

DP33KA/B

NOTE: These components are affixed with glue. Be careful not to break or damage any foil under the

component or at the pins of the ICs when remo

ving. Usually applying heat to the component for a short

time while twisting with tweezers will break the component loose.

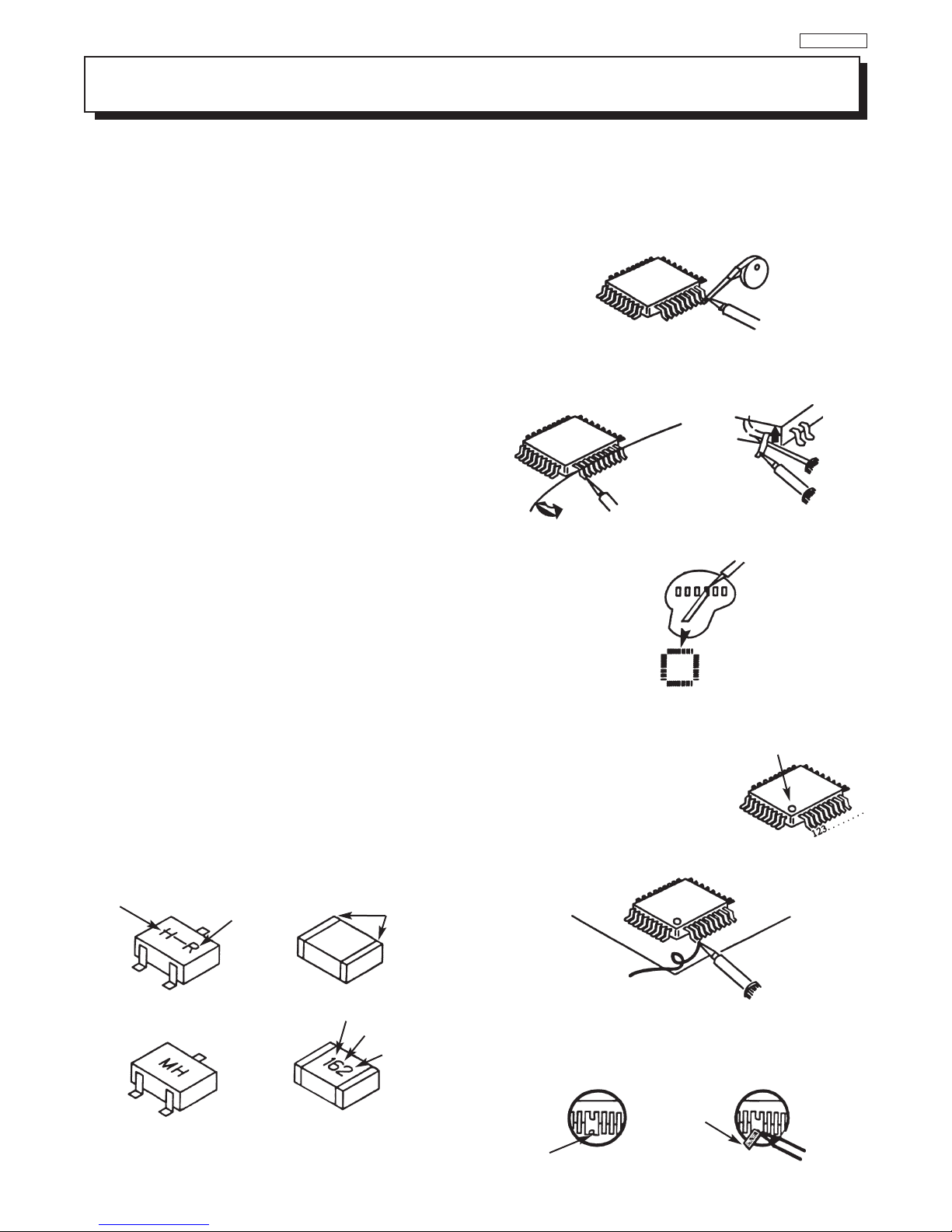

Leadless Chip Components

(surface mount)

Chip components must be replaced with identical

chips due to critical foil track spacing. There are no

holes in the board to mount standard transistors or

diodes. Some chip capacitor or resistor board solder

pads may have holes through the board, however the

hole diameter limits standard resistor replacement to

1/8 watt. Standard capacitors may also be limited for

the same reason. It is recommended that identical

chip components be used. .

Chip resistors have a three digit numerical resistance

code -1st and 2nd significant digits and a multiplier.

Example:

162 = 1600 or 1.6KΩ resistor, 0 = 0Ω

(jumper).

Chip capacitors generally do not have the value

indicated on the capacitor.The color of the component

indicates the general range of the capacitance.

Chip transistors are identified by a two letter code.The

first letter indicates the type and the second letter, the

grade of transistor.

Chip diodes have a two letter identification code as per

the code chart and are a dual diode pack with either

common anode or common cathode. Check the parts

list for correct diode number.

Component Removal

1. Use solder wick to remove solder from component

end caps or terminals.

2. Without pulling up, carefully twist the component

with tweezers to break the adhesive.

3. Do not reuse removed leadless or chip

components since they are subject to stress

fracture during removal .

Chip Component Installation

1. Put a small amount of solder on the board

soldering pads.

2. Hold the chip component against the soldering

pads with tweezers or with a miniature alligator

clip and apply heat to the pad area with a 30 watt

iron until solder flows. Do not apply heat for more

than 3 seconds

TYPE

Chip Components

C

GRADE

SOLDER

CAPS

How to Replace Flat-lC

—Required Tools—

• Soldering iron • iron wire or small awl

De-solder braids • Magnifier

•

1. Remove the solder from all of the pins of a Flat-lC

by using a de-solder braid.

Flat-IC

2. Put the iron wire under the pins of the Flat-lC and

pull it in the direction indicated while heating the

pins using a soldering iron. A small awl can be

used instead of the iron wire.

Iron

Wire

Pull

Soldering

Iron

Soldering

3. Remove the solder from all of the pads of the

Fiat-lC by using

a de-solder braid.

De-Solder

Braid

Flat-IC

4. Position the new Flat-lC in place (apply the pins of

the Flat-lC to the soldering pads where the pins

need to be soldered). Properly

determine the positions of the

ing pads and pins b

solder

y

correctly aligning the polarity

symbol.

5. Solder all pins to the soldering pads using a fine

tipped soldering iron.

Soldering

Iron

Soldering

Iron

Polarity Symbol

De-Solder

Braid

Iron

A

wl

B

E

COMMON CATHODE

ANODES

MH DIODE

TRANSIST

OR

SOLDER CAPS

RESISTOR

CAPACITOR

1ST DIGIT

2ND DIGIT

MUL

= 1600 = 1.6K

TIPLIER

Solder

Soldering

Iron

6. Check with a magnifier for solder bridge between

the pins or for dry joint between pins and soldering

o remove a solder bridge, use a de-solder braid

T

.

pads

wn in the figure below.

as sho

De-Solder

Braid

Bridge

Solder

9

Soldering

Iron

Page 10

Information for service about lead-free solder introduction

Hitachi introduced lead-free solder to conserve the "Earth Environment".

Please refer to the following before servici

ng.

(1) Characteristic of lead-free solder

Melting point of lead free solder is 40-50

o

C higher than solder containing lead.

(2) Solder for service

Following composition is reccomended.

" Sn - 3.0Ag - 0.5Cu " , or " Sn - 0.7 Cu "

Lead solder can be used, but there is a possibility of fai

lure due to insufficient strength of the solder.

Caution when using solder containing lead.

Please remove previous solder as much as possible from the soldering point.

When soldering, please perfectly melt the lead-free solder to mix well with the previous solder.

(3) Soldering iron for lead-free solder.

Melting point of lead-free solder is higher than solder containing lead.

Use of a soldering tool "with temperature control" and "with much thermal capacitance" is reccomended.

(Reccomended temperature control : 320

o

C - 450oC)

Reccomended temperature

PWB with chip parts

320

o

C +/- 30oC

PWB without chip parts

380

o

C +/- 30oC

Chassis, metal, shield etc.

420

o

C +/- 30oC

(4) Identification of lead-free PWB

2003 models >> not applied

2003 models >> mixed

2004 models >> lead-free solder is intoduced

On lead-free PWB, "F" is added at the end of stamp on PWB. (e.g. DP33W

F)

DP33KA/B

10

Page 11

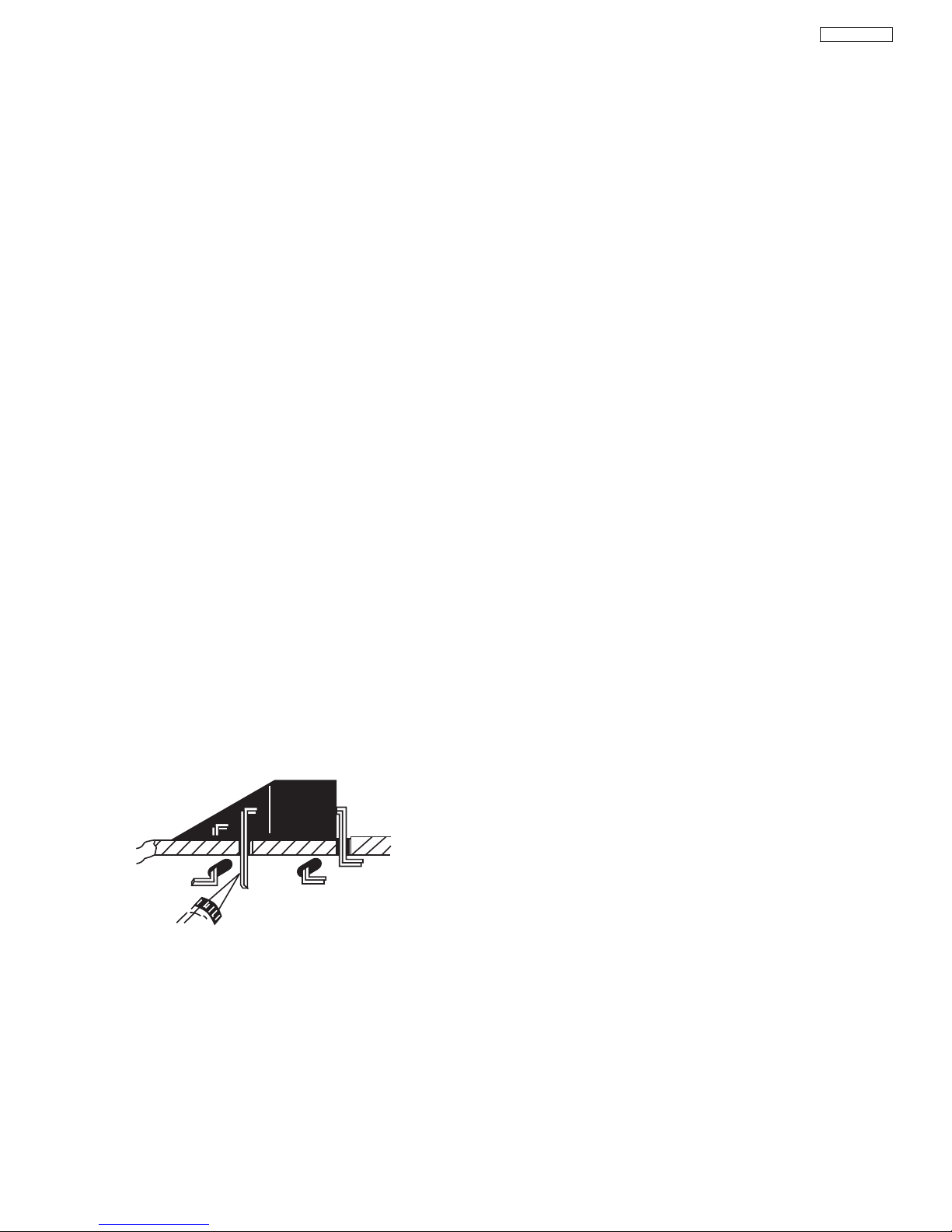

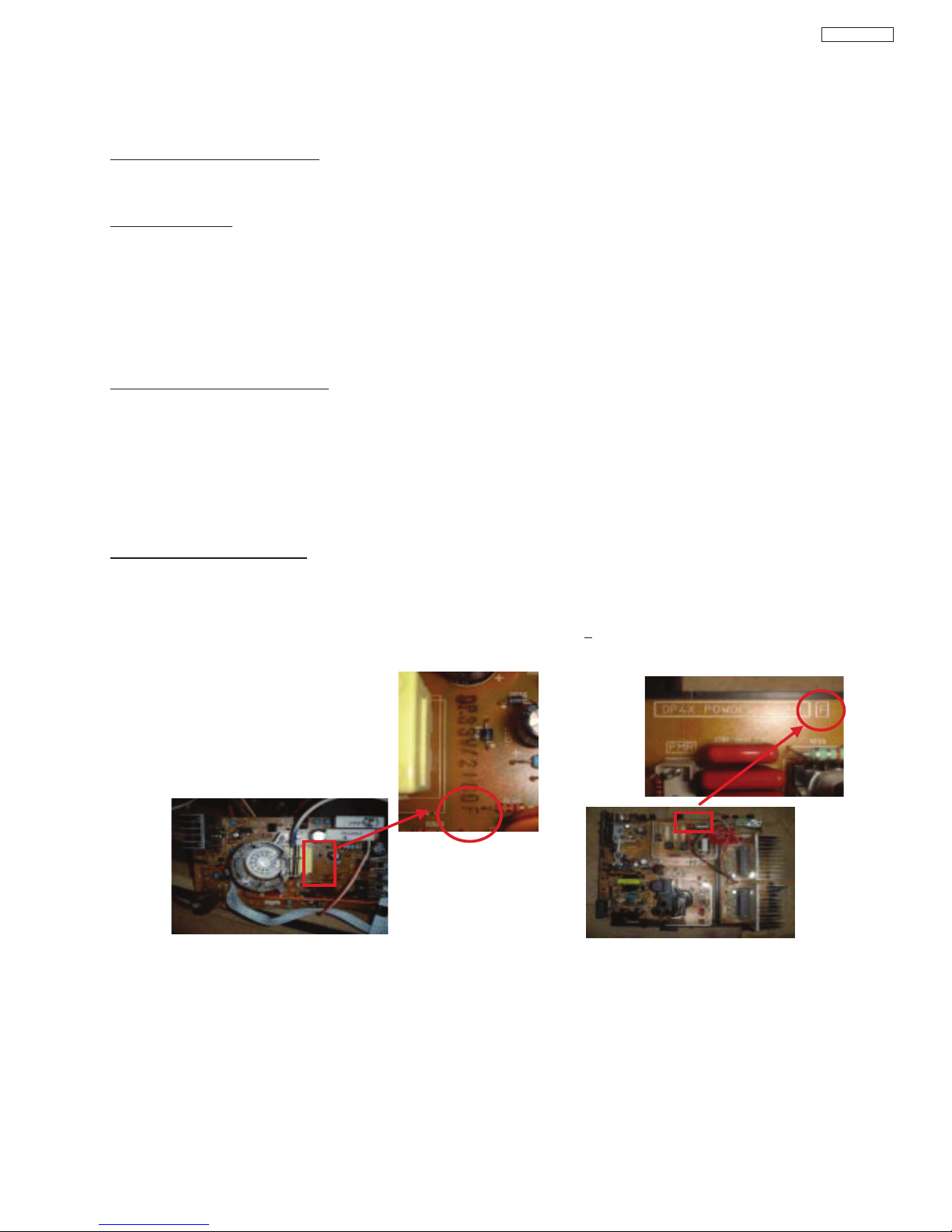

TECHNICAL CAUTIONS

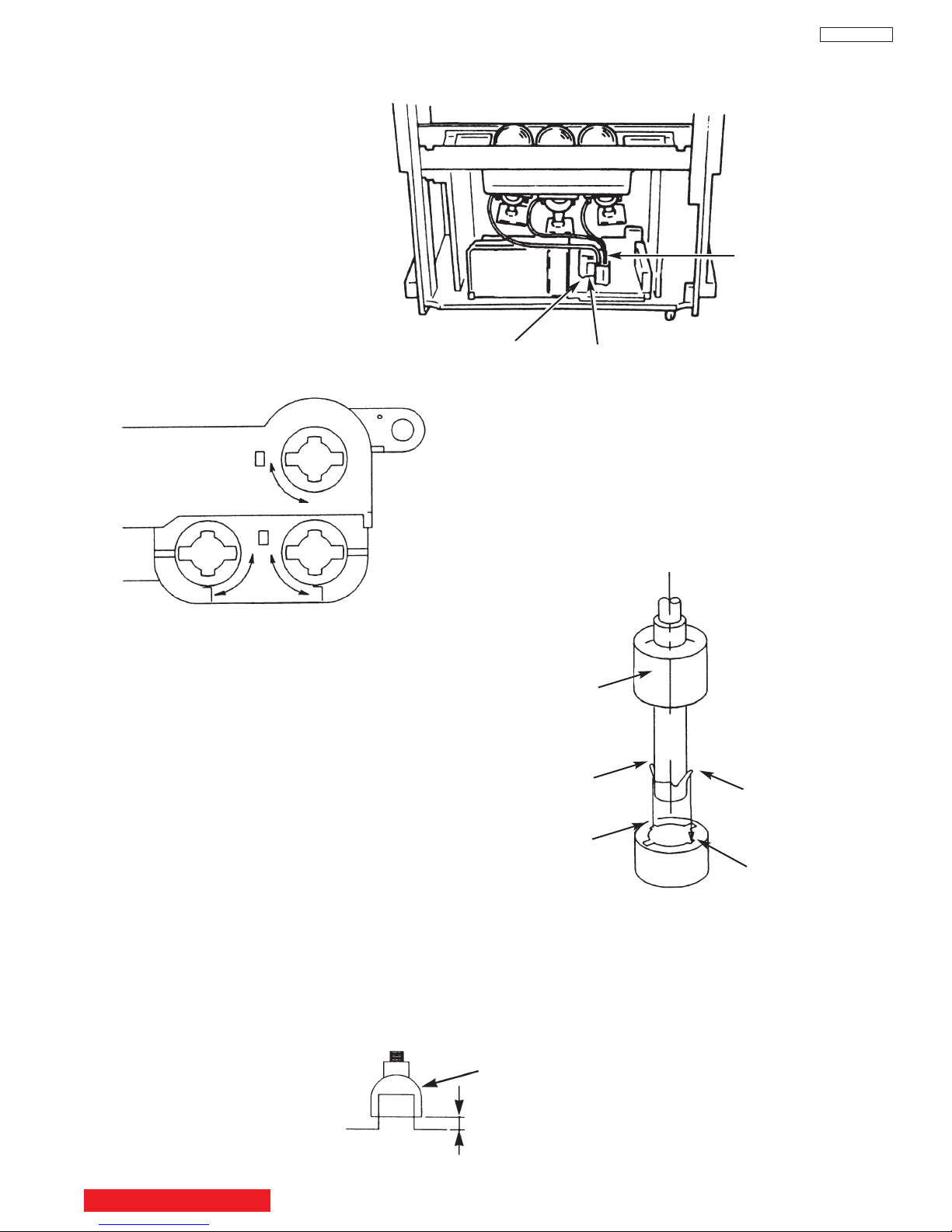

(TH01)

D.C.U

RH19

RH17

Fig. 2. Power/Deflection P.W.B

Remove RH19 and connect 50KΩ VR jig as shown.

TH02

FBT

50KΩ VR

50KΩ VR

33KΩ

Resistor

33KΩ

Voltage limiter circuit operation check.

High

1. Turn off TV and connect jig as shown in Figure 2. Adjust

jig fully counter-clockwise for minimum resistance.

DP33KA/B

4. When the limiter circuit is operating properly, High

Voltage will be less than 31 kV at 1.72mA when TV shuts

wn.

do

2. Set the AC input to 120V AC and turn on TV.

Confirm test pattern on CRT is a usable picture, then

3.

slowly adjust jig until the picture disappears and TV shuts

down.

5. Turn off set immediately after checking circuit operation.

6. Unplug set for one minute to reset shutdown circuit.

Remove jig and voltmeter.

AC CORD POLARITY

This check is based on the UL standard. Use the jigs

specified by the production technology section. The GND

side (wider blade) of the AC power cord should be

connected to K9Y1

TABLE OF CONTENTS

11

Page 12

125V

10A

F

10 A 125V

SPECIFICATIONS

DP33KA/B

Models: 46F510/46F500A

Cathode-Ra

y Tube:

46F510 R=P16LXS00RFA B

46F500A G=P16LXS00HHA B

B=P16LXS00BMB B

Power Input: 120 volts AC, 60 Hz

Power Consumption:

• Stand-By Power

46F510/500A . . . . . . . . . . . . . . . . . . . .0.4W

• Power Consumption (operating)

46F510/500A . . . . . . . . . . . . . . . . . . . .220W

Power Consumption (maximum)

•

46F510/500A . . . . . . . . . . . . . . . . . . . .275W

Antenna Impedance: 75 Ohm Unbalanced

VHF / UHF / CATV

Intermediate Frequency: Picture l-F Carrier 45.75 MHz

Sound l-F Carrier 41.25 MHz

Color Sub Carr

ier 42.17 MHz

Video Input: 1.0 ± 0.2 Volt p-p, 75 Ohm

ermination

T

Video Output: 1.0 ± 0.2 Volt p-p, 75 ohm

Termination

Audio Input: 470 mVrms, 47 k Ohm ±10%

Stereo Audio Output: 470 mVrms, 1 k Ohm ± 10%

Audio Output Power:

Front: 24 watts per channel at 10% distortion,

8 ohm Impedance. Max output 30 watts.

Anode Voltage:

DP33KA/B

30.7±0.2kv (1.52±0.2mA)

Brightness: 46”

(white screen) 290cd/m

2

Receiving Channel: BAND CH

VHF 2~13

UHF 14~69

EXT. Mid (A-5)~(A-1), 4+

CATV Mid. A~I

CATV Super J~W

CATV Hyper (W+1)~(W+28)

CATV Ultra (W+29)~(W+84)

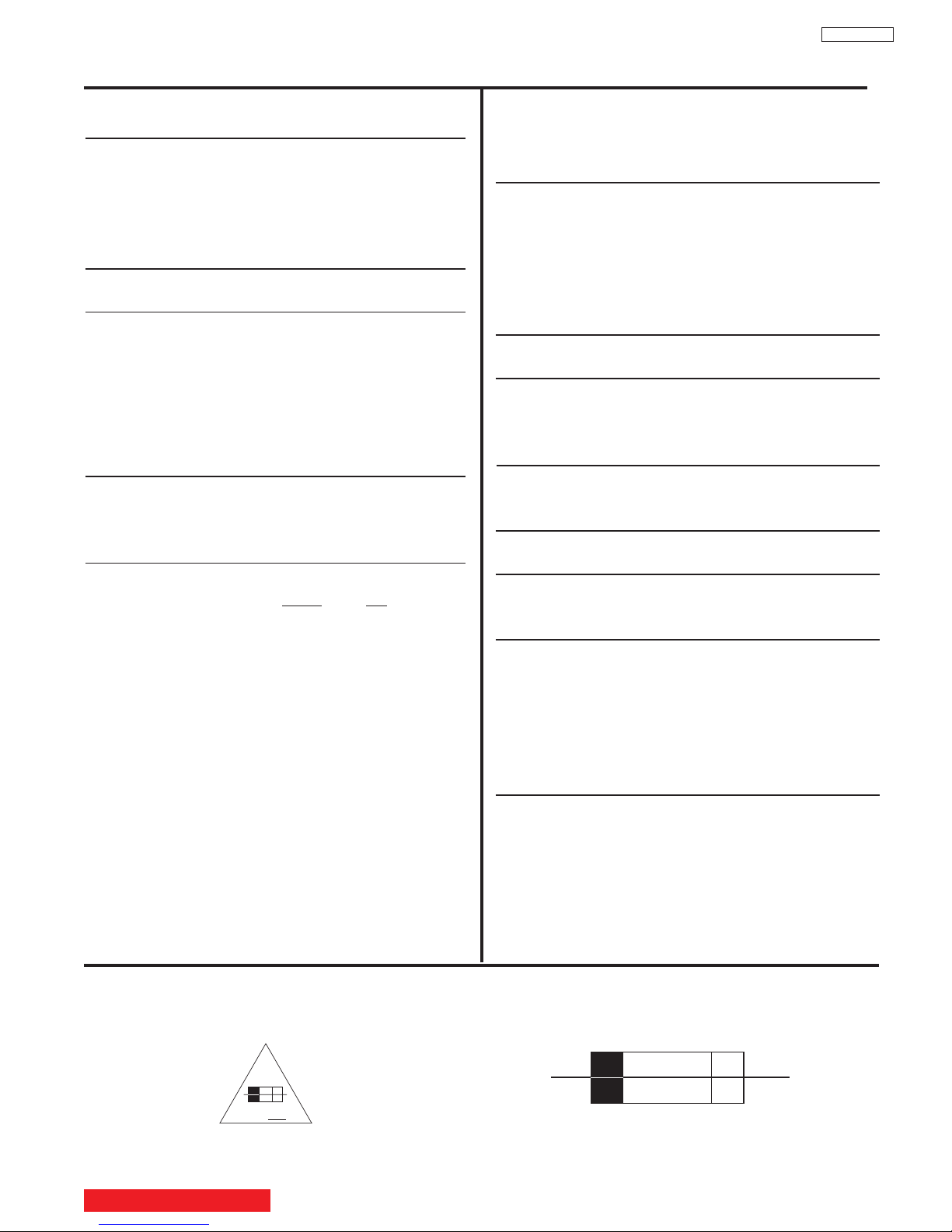

CA

UTION:

w is an EXAMPLE only

Belo

indicates fast operation fuse (to be replaced). Fuse ratings appear within the symbol.

Example:

Speakers: 46” 2 Woofers - 5 inch (12 cm) round

Dimensions:

46F510 46F500A

• Height (in.) 45 9/16 39 13/16

• Width (in.) 44 7/16 44 7/16

• Depth (in.) 26 7/16 24 9/16

• Weight (lbs.) 161 160

(mm) 1,157.0 1,010.5

(mm) 1,128.0

(mm) 671.5 623.5

(kg) 73 72.5

1,128.0

Circuit Board Assemblies:

C.P.T. (B) P.W.B. IR P.W.B.

.

.B

.W

(G) P

.

.T

.P

C

C.P.T. (R) P.W.B. Terminal P.W.B.

Power Supply P.W.B. Signal P.W.B.

.

.B

Control P

Sensor Distribution P.W.B. DVI P.W.B

.W

IR Sub P

Def/Convergence P.W.B.

.W.B.

CIRCUIT PROTECTION

. See Replacement Parts List for details. The following symbol near the fuse

“RISK OF FIRE - REPLACE FUSE AS MARKED”

TABLE OF CONTENTS

The rating of fuse F901 is 10A - 125V.

Replace with the same type fuse for continued protection

against fire.

12

Page 13

CAUTIONS WHEN CONNECTING / DISCONNECTING THE HV CONNECTOR

Perform the following when the

HV connector (anode connector)

is removed or inserted for CPT

replacement, etc.

Anode

connector

DP33KA/B

Deflection P.W.B.

PUSH

PUSH

Fig. A

3. Remove the connector slowly

by pulling it away from the

case.

FBT

During Removal

1. Roll out silicon cover from FBT’s contact area slowly.

2. While turning the connector about 90 degrees

following the arrow (0 position), push the connector

slightly towards the case. (Fig. A)

Silicon cover

Wing

Wing

During Insertion

1. Please refer to direction for insertion as shown in Fig. B (L position). Insert connector until “CLICK” sound is heard.

e sure the connector is pressed r

Mak

2.

3. Confirm the contact by pulling the connector slightly. (Don’t pull hard because it may damage the connector).

4. Cover the high voltage output by carefully pushing silicon cover onto it. (Don’t turn the connector).

(REMARK)

1. Make sure the silicon cover is

covering the high voltage output.

TABLE OF CONTENTS

L Position

Fig. B

ight in, so that it has a good contact with the spr

Silicon Cover

less than 1mm

13

L Position

ing.

Page 14

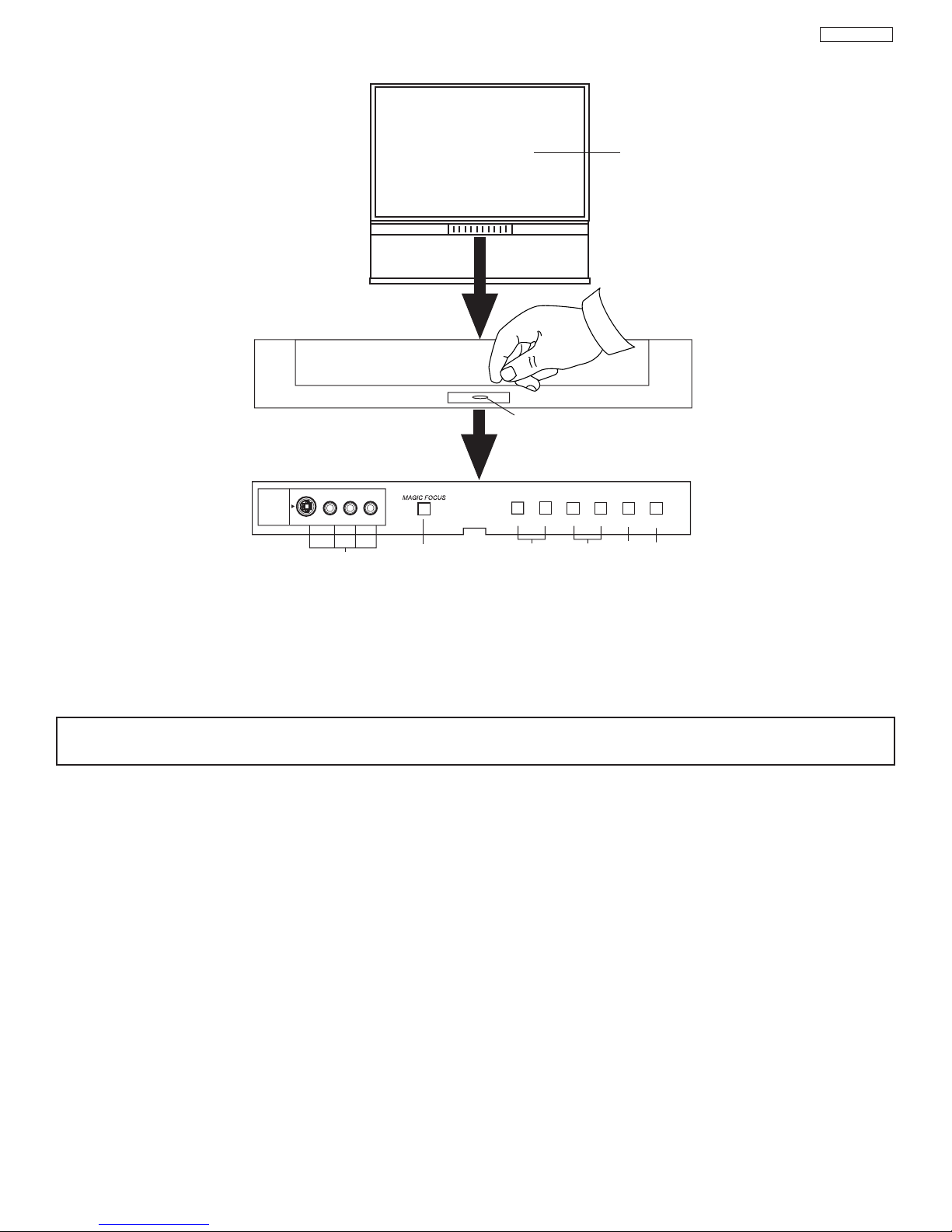

GENERAL INFORMATION

INPUT 5

S-VIDEO

VIDEO

AUDIO

L/MONO

R

EXIT

INPUT

SELECT

MENU

VOL- VOL+ CH- CH+

E

FGH

c

f

a

b

d

g

e

CURSOR

MAGIC

FOCUS

e

h

46F510

DP33KA/B

a MENU/SELECT button

This button allows you to enter the MENU, making it possible to set TV features to your preference without using the remote. This

button also serves as the SELECT button when in MENU mode.

b INPUT/EXIT button

Press this button to select the current antenna source, VIDEO: 1, 2, 3, 4, 5 or alternate antenna source. Your selection is shown in

the top right corner of the screen. This button also serves as the EXIT button when in MENU mode.

NOTES: Your remote control does not have an INPUT button. To change to video inputs, press VID1~VID5 buttons depending

on your choice.

c CHANNEL selector

Press these b

the cursor do

uttons until the desired channel appears in the top r

(

wn

H)

and up

(

uttons when in MENU mode

b

G)

.

ight cor

ner of the

TV screen.

These b

uttons also serve as

d VOLUME level

Press these buttons for your desired sound level. The volume level will be displayed on the TV screen. These buttons also serve

as the cursor left (

F) and right (E) buttons when in MENU mode.

e POWER button/POWER LED

Press this button to turn the TV on or off. This LED light is ON during normal operation.

f MAGIC FOCUS

Use this button to automatically adjust your picture quality to optimum performance. The Magic Focus button will not work when

adjustment mode is set to manual.

CKS (INPUT 5)

g FR

ONT INPUT J

A

Use these audio/video jacks for a quick hook-up from a camcorder or VCR to instantly view your favorite show or new recording.

Press the INPUT button until VIDEO: 5 appears in the top right corner of the TV screen. If you have mono sound, insert the audio

cable into the left audio jac

h IR RECEIVER Sensor

When using the remote control, point it towards the IR receiver for best response.

k.

TABLE OF CONTENTS

14

Page 15

GENERAL INFORMATION

INPUT 5

S-VIDEO

VIDEO

-

AUDIO-

L/MONO

R

EXIT

I

NPUT

SELECT

M

ENU

V

OL- VOL+CH- CH+

EF

G

H

c

f

a

b

d

g

POWER

PULL

e

h

46F500A

DP33KA/B

a MENU/SELECT button

This button allows you to enter the MENU, making it possible to set TV features to your preference without using the remote. This

button also serves as the SELECT button when in MENU mode.

b INPUT/EXIT button

Press this button to select the current antenna source, VIDEO: 1, 2, 3, 4, 5 or alternate antenna source. Your selection is shown in

the top right corner of the screen. This button also serves as the EXIT button when in MENU mode.

NOTES: Your remote control does not have an INPUT button. To change to video inputs, press VID1~VID5 buttons depending

on your choice.

c CHANNEL selector

Press these buttons until the desired channel appears in the top right corner of the TV screen. These buttons also serve as

the cursor down (H) and up (G) buttons when in MENU mode.

OLUME level

d V

olume level will be displayed on the TV screen. These buttons also serve

The v

el.

Press these b

uttons f

as the cursor left (

our desired sound le

or y

F) and r

ight (

uttons when in MENU mode.

E) b

v

e POWER button

Press this button to turn the TV on or off.

f MAGIC FOCUS

Use this button to automatically adjust your picture quality to optimum performance. The Magic Focus button will not work when

adjustment mode is set to man

ual.

g FRONT INPUT JACKS (INPUT 5)

or a quic

Use these audio/video jac

ks f

Press the INPUT button until VIDEO: 5 appears in the top right corner of the TV screen. If you have mono sound, insert the audio

cable into the left audio jack.

k hook-up from a camcorder or

VCR to instantly vie

w y

vorite show or new recording.

a

our f

h IR RECEIVER

The screen area acts as the IR receiver (remote sensor) of the TV. When using the remote control, point it towards the screen for

best response.

15

Page 16

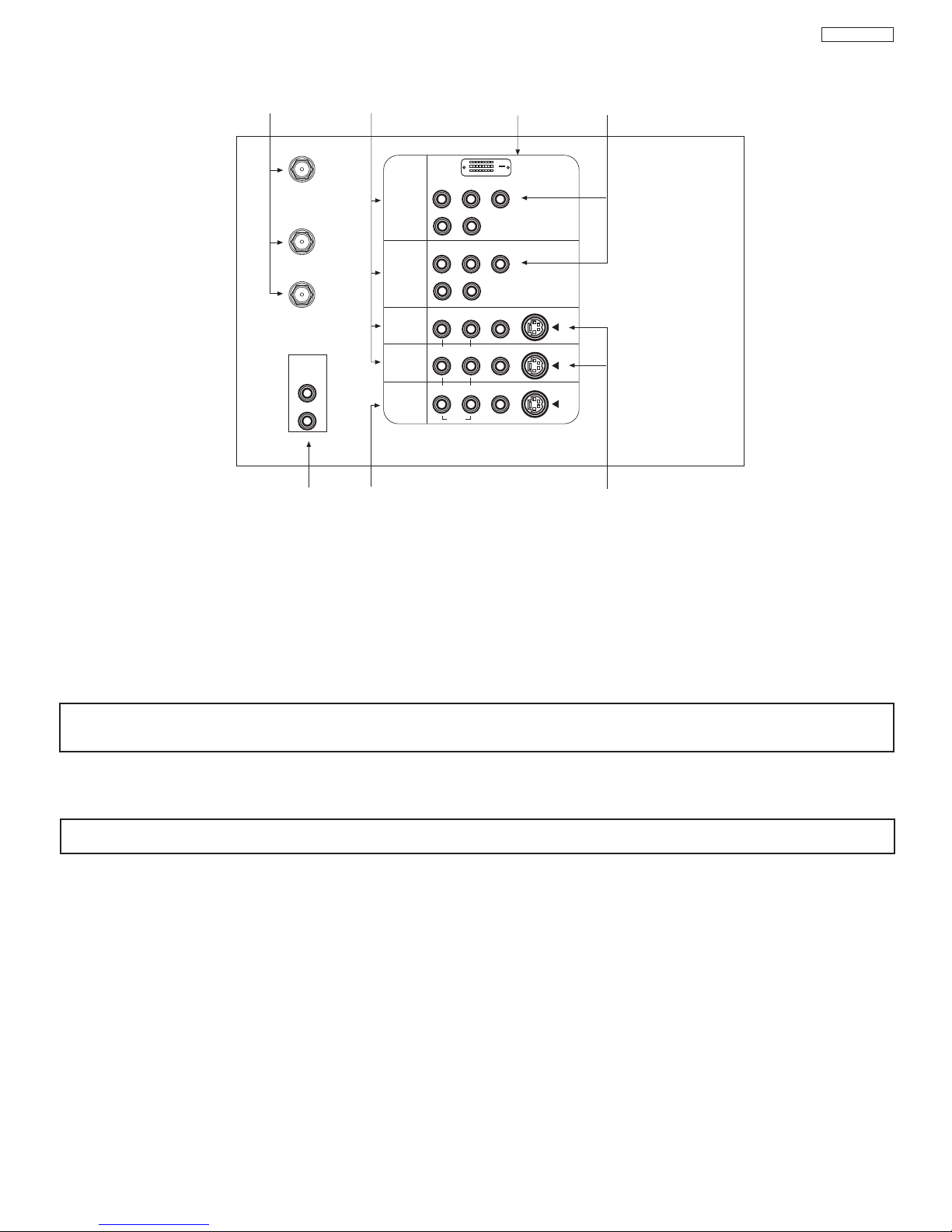

REAR PANEL JACKS

P

B

P

R

P

B

P

R

DVI-HDTV

ANT A

TO

CONVERTER

ANT B

L

AUDIO

TO HI-FI

R

b

a

d

e

f

g

c

Y

R

(MONO)/L

S-VIDEO

S-VIDEO

S-VIDEO

Y/VIDEO

R

(MONO)/L

R

(MONO)/L VIDEO

R

(MONO)/L VIDEO

R

L VIDEO

INPUT 1

INPUT 2

INPUT 3

INPUT 4

MONITOR

OUT

AUDIO

AUDIO

AUDIO

DP33KA/B

a Antenna Input/Output

The remote control allows you to switch between two separate 75-Ohm RF antenna inputs, ANT A and ANT B. ANT A input can

be displayed as a main picture or sub-picture. ANT B can only be displayed as a main picture. (ANT B cannot be displayed as a

sub-picture.) The antenna output labeled “TO CONVERTER” allows the ANT A connection to pass directly to a different source

such as a cable box, only when ANT B is displayed as a main picture.

b Audio/Video Inputs 1, 2, 3 and 4

The VID1~VID4 buttons will select each video source each time they are pressed. Use the audio and video inputs to connect

external devices, such as VCRs, camcorders, laserdisc players, DVD players etc. (If you have mono sound, insert the audio cable

into the left audio jack.)

NOTE: You may use VIDEO or S-VIDEO inputs to connect to INPUT 3 and 4, but only one of these inputs may be used at a

time.

c MONITOR OUT

These jac

output.

NOTE: S-VIDEO Output may be used for recording, only when the input is of S-VIDEO type.

d AUDIO TO HI-FI Output

These jacks provide variable audio output to a separate stereo amplifier. With this connection, the audio to the stereo can be

controlled by the television’s main volume.

e S-VIDEO Inputs 3 and 4

Inputs 3 and 4 provide S-VIDEO (Super Video) jacks for connecting equipment with S-VIDEO output capability.

ks provide fixed audio and video signals which are used for recording. Use the S-VIDEO Output for high quality video

16

Page 17

0

ANT

INFO

VOL CH

POWER

TV

CBL/SAT DVD/VCR

PIP

SWAP PIP MODE

FREEZE

DAY/NIGHT

MENU

MUTE

EXIT

LAST CH

REC

ASPECT

VIRTUAL HD

SELECT

SURF

VID1

VID2

VID3

VID4

VID5

CLU-4324UG: VIDEO

CLU-4328UG: DAY/NIGHT

DP33KA/B

REMOTE CONTROL

TABLE OF CONTENTS

17

Page 18

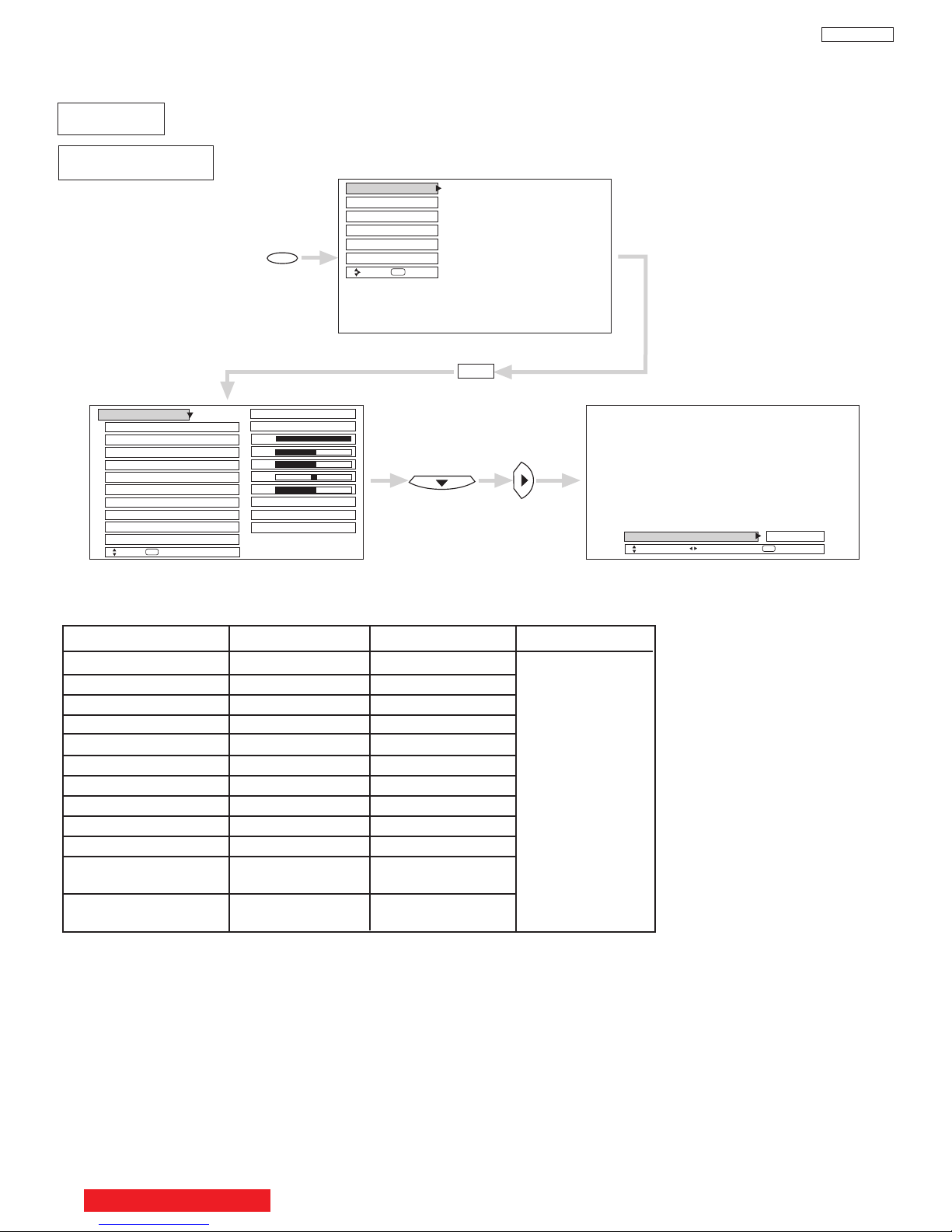

DP33KA/B

Color

Brightness

Contrast

Picture Mode

Video

Move

SEL

Select

Color Temperature

Sharpness

Tint

Reset Video Settings

Edge Enhancement

Setup

Locks

Aspect

Audio

Video

Move

SEL

Sel

Black Enhancement

Chan. Manager

100%

50%

50%

50%

High

ANT A/B

Middle

High

Day

Night

SEL

Select

Picture Mode Day

Night

Return

Next/Prev

MENU

SELECT

Video

Contrast 100% 50%

Brightness 50% 50%

Color 50% 45%

Tint Center Center

Sharpness 50% 50%

Color Temperature High Standard

Black Enhancement Middle Low

Edge Enhancement High Low

Auto Color Off Off

Noise Reduction Off Off

Color Management Off Off

(Set User Colors)

Auto Movie Mode Off Off

(TV/Cinema Detection)

Function Day Night Reset

Reset the video

menu settings on

current input to the

Day or Night

conditions depending

on the selected

VIDEO mode.

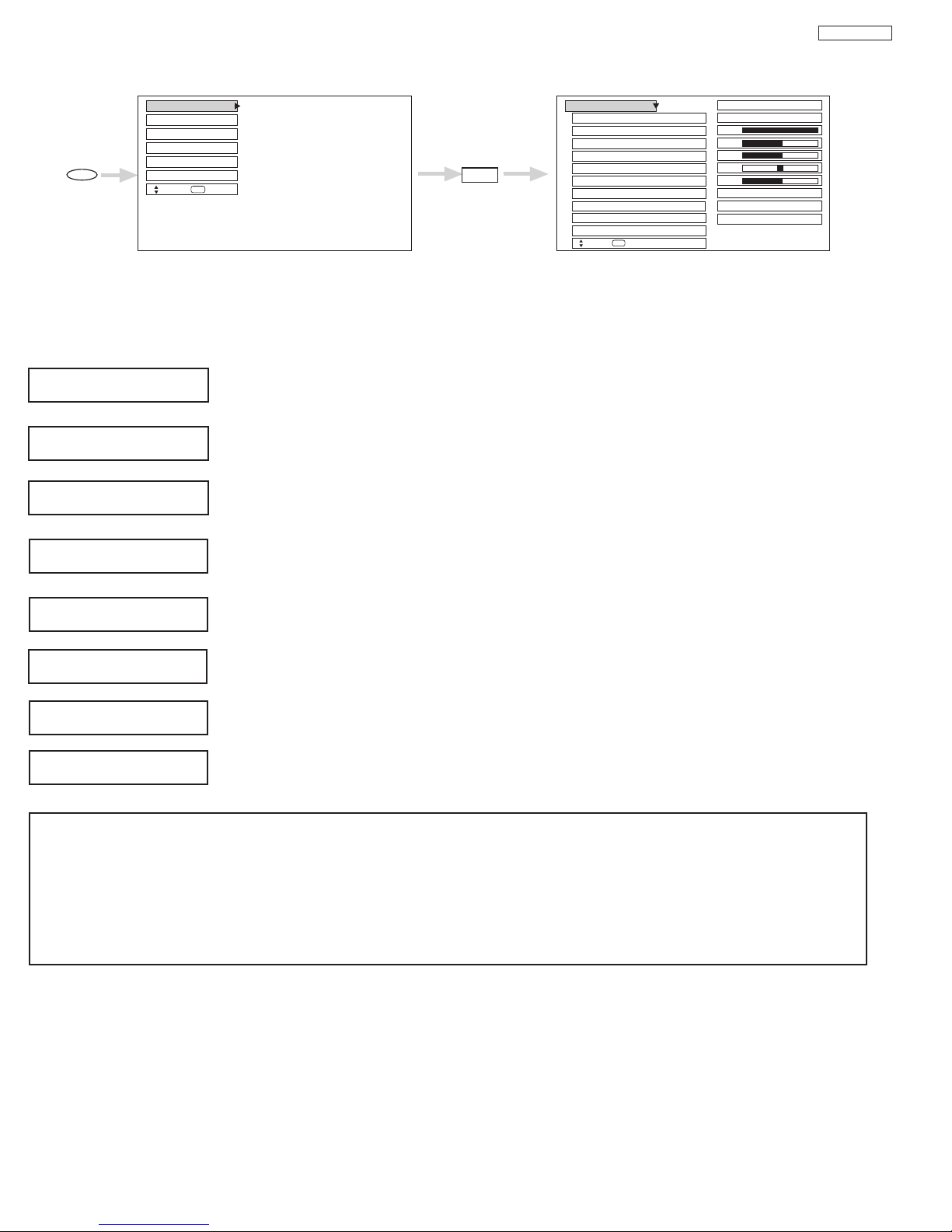

CUSTOMIZED PICTURE AND SOUND ADJUSTMENTS

Select VIDEO to adjust picture settings and improve picture quality. You can independently customize each of the

Video Inputs to your preference to increase viewing performance and pleasure depending upon the video program

being viewed. If RESET is selected, only the selected input will reset to initial conditions.

Picture Mode

Use this function to choose from automatic picture settings to optimize your TV’s performance.

Use CURSOR F or E to highlight and select Picture Mode settings.

PICTURE MODE to return to previous menu.

TABLE OF CONTENTS

18

Press EXIT to quit menu or select

Page 19

CUSTOMIZED PICTURE AND SOUND ADJUSTMENTS

Color

Brightness

Contrast

Picture Mode

Video

Move

SEL

Select

Color Temperature

Sharpness

Tint

Reset Video Settings

Edge Enhancement

Setup

Locks

Aspect

Audio

Video

Move

SEL

Sel

Black Enhancement

Chan. Manager

100%

50%

50%

50%

High

ANT A/B

Middle

High

Day Night

MENU

SELECT

DP33KA/B

Use the CURSOR

G or H to highlight the function to be adjusted.

Press the SELECT button to select the function settings.

Press the CURSOR

F or E to adjust the function.

Press MENU to return to main menu.

Press EXIT to quit menu.

Contrast

Brightness

Color

Tint

Sharpness

Color Temperature

Use this function to change the contrast between black and white levels in the picture.

Use this function to adjust overall picture brightness.

Use this function to adjust the level of color in the picture.

Use this function to adjust flesh tones so they appear natural.

Use this function to adjust the amount of fine detail in the picture. Sharpness function will be disabled

when Noise Reduction is ON.

Set this to High for cooler color with more blue, set to Medium for more natural color, set to Standard for

accurate color or set to Black/White for more reddish color.

Black Enhancement

Use this function to enhance the shadow detail in dark scenes using the settings off, low, middle and high.

Edge Enhancement

Use this function to automatically enhance the edges between light and dark areas using the settings Off,

Low, Middle, and High.

NOTES: 1. If CONTRAST is selected, you are adjusting CONTRAST. The additional menu items BRIGHTNESS, COLOR, TINT,

and SHARPNESS can be selected and adjusted in the same manner.

2. Contrast will decrease automatically if stationary images such as digital still photos are left on the screen for more than

3 minutes.

3. It may be necessary to adjust TINT to obtain optimum picture quality when using the COMPONENT VIDEO Y-PBP

input jacks.

4. Ant A/Ant B have independent Video settings. Also, each of the video inputs have their own independent settings.

19

R

Page 20

CUSTOMIZED PICTURE AND SOUND ADJUSTMENTS

MAGIC

FOCUS

MAGIC FOCUS

Magic Focus Tune Up

Setup

Move

SEL

Return

Aligns the Red, Green, and Blue

colors to correct for Magnetic

Influences.

Auto

Manual

Setup

Locks

Chan. Manager

Aspect

Video

Move

SEL

Sel

Set The Inputs

Set The Clock

Menu Preference

Magic Focus Tune Up

Setup

Move

SEL

Select

Set Black Side Panel

Set Virtual HD

Set The Color System

Adjustment Mode

If you want to adjust now

Start

Audio

About Your TV

Set Closed Caption

Set Event Timer

MAGIC FOCUS

MENU

SELECT

SELECT

SELECT

DP33KA/B

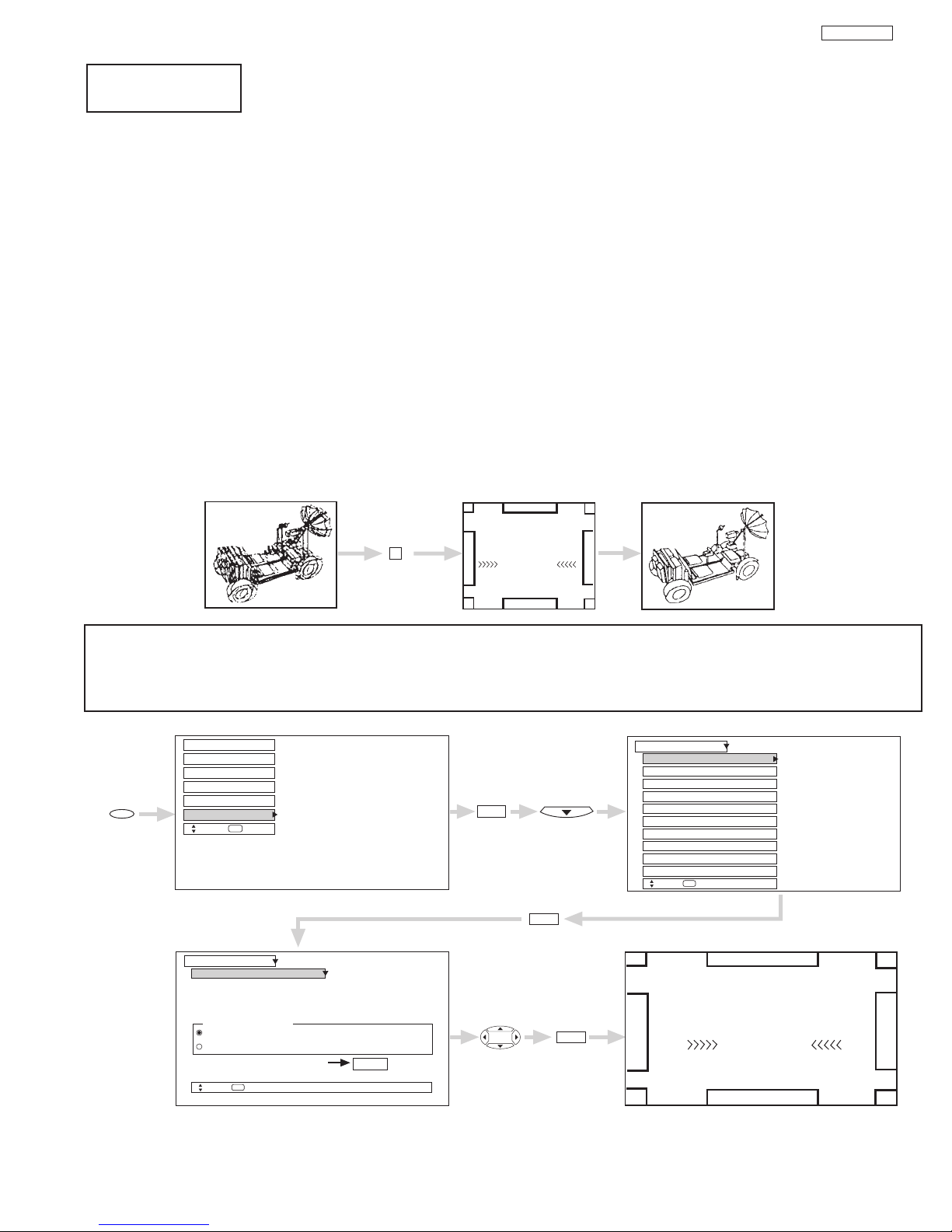

Magic Focus

Tune Up

uto Digital Convergence Adjustment

A

Please turn ON your television for at least 20 minutes before using this feature.

The Magic Focus button on control panel will not work when adjustment mode is set to Manual.

Your HITACHI Projection TV has three color projection tubes: one for red, one for green, one for blue. When mixed together in the proper

proportion, the output of these three color tubes can produce any color. To produce these colors, however, the beams must be precisely

aligned over each other so that the colors can be mixed. The process of aligning these picture beams is called “convergence”.

er a period of time, the picture tubes can drift out of alignment due to normal bumps and vibrations or moving the TV. If you move

Ov

your TV, or if, after a time, you notice color rings or halos around objects in the picture, you may want to converge (align) the colors.

Properly converged, the lines appear white, which is actually a combination of the outputs of the three color tubes. The output of the

green tube is stationary. The outputs of the red and blue tubes can be adjusted. When properly aligned, the outputs of all three tubes

should be directly over each other to produce the white lines.

To simplify convergence, HITACHI incorporates a function called MAGIC FOCUS located on the front control panel, which allows the TV

to self-adjust. Press this MAGIC FOCUS button and the convergence self adjustment will start and this process will take approximately

20 seconds. If this button is pressed during this process, no change in picture quality will occur. After this 20 second self-adjust period,

picture quality will be optimum (do not move the TV during self-adjust).

You may also select MAGIC FOCUS TUNE UP from the Setup Menu.

NOTES: Only a momentary press of the MAGIC FOCUS button is necessary to start AUTO DIGITAL CONVERGENCE. At any

time during this convergence correction process, you may press the MAGIC FOCUS button to exit the MAGIC FOCUS

mode. However, the convergence correction process needs to be completed to SAVE the new corrected convergence

data.

20

Page 21

CUSTOMIZED PICTURE AND SOUND ADJUSTMENTS

Setup

Locks

Chan. Manager

Aspect

Video

Move

SEL

Sel

Audio

Magic Focus Tune Up

Setup

Move

SEL

Return

Aligns the Red, Green, and Blue

colors to correct for Magnetic

Influences.

Auto

Manual

Adjustment Mode

If you want to adjust now

Start

Adjustment Point

Cursor

Set The Inputs

Set The Clock

Menu Preference

Magic Focus Tune Up

Setup

Move

SEL

Select

Set Black Side Panel

Set Virtual HD

Set The Color System

About Your TV

Set Closed Caption

Set Event Timer

MENU

SELECT

SELECT

SELECT

117 Manual Adjust

Please Enter Number.

0.Cancel and go to Normal Mode.

1.Done and go to Normal Mode.

2.Back to Adjust Mode

3.Factory Reset and back to

Adjust Mode.

0-3.Select

EXIT

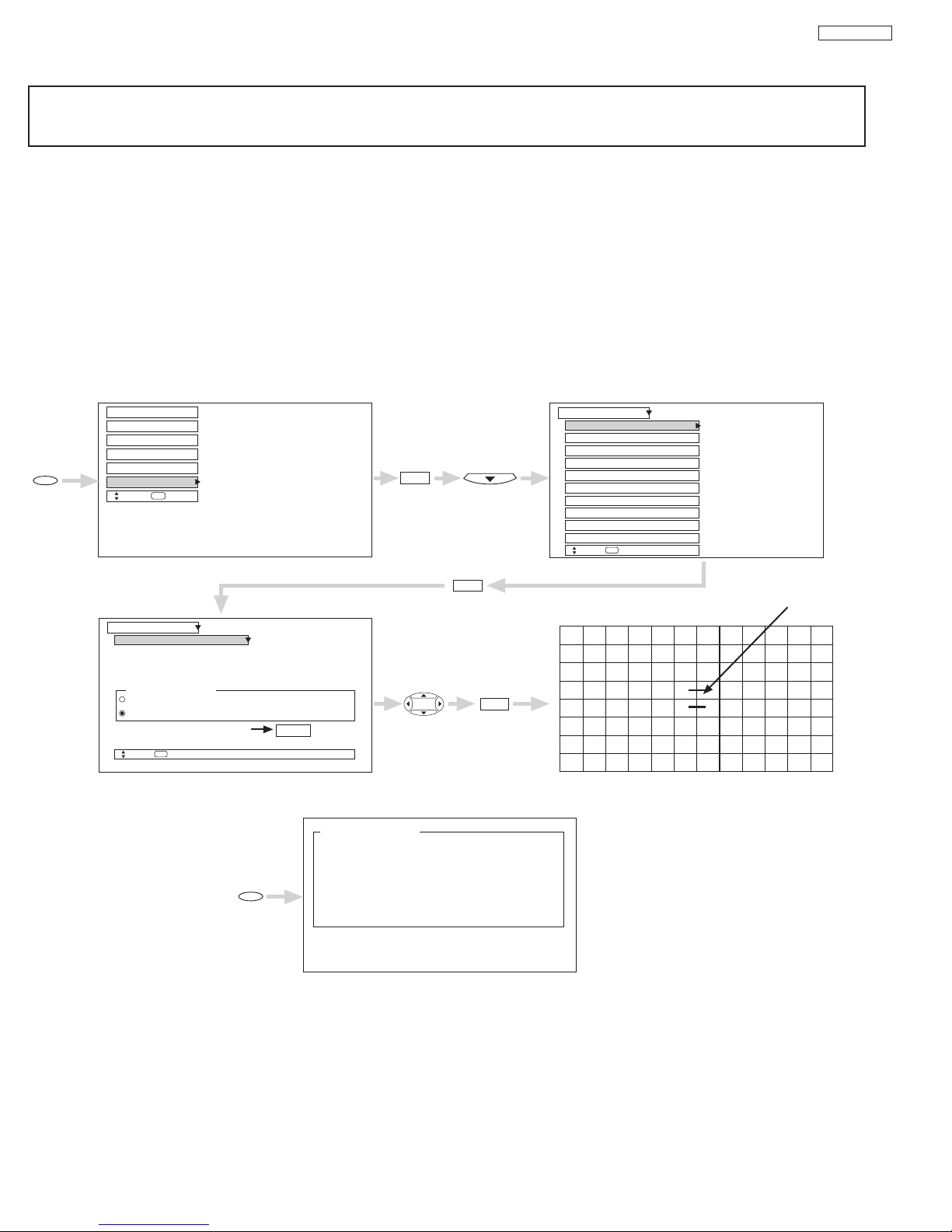

Manual Convergence Adjustment Mode

DP33KA/B

NOTES: 1. Please turn ON your television for at least 20 minutes before using this feature.

2. Auto Adjustment Mode is recommended. If convergence is still not acceptable, use the Manual Adjustment Mode.

3. If Auto Adjust mode is selected or the Magic Focus button is pressed, all manual adjust mode settings will be erased.

Using the Remote Control, select SETUP-MAGIC FOCUS TUNE UP-MANUAL ADJUSTMENT MODE-START to access convergence

crosshatch pattern. The adjustment point is indicated by the Adjustment Point Cursor.

To Move Adjustment Point

To move the adjustment point cursor using the CURSOR buttons, the Adjustment Cursor must be WHITE. Another way to move the

Adjustment Point Cursor is to press the following buttons: [2] up, [4] left, [5] down, [6] right. If you use the number buttons while the

adjustment point is WHITE, it will change to RED.

To Change the Color of Adjustment Point

Press the SELECT button repeatedly (WHITE-RED-BLUE-WHITE...). Green color is fixed and cannot be adjusted.

To Adjust the Convergence

Move the Adjustment Cursor to the point to be adjusted. Use the CURSOR to match the RED and BLUE colors to GREEN (reference

color). Properly aligned, all three colors should appear white.

If convergence is acceptable after Manual Convergence adjustment, press EXIT button to access menu mode.

Press the [0] button on the remote control to CANCEL adjusted data and return to main picture.

Press the [1] button on the remote control to SAVE adjusted data and return to main picture.

Press the [2] b

Press the [3] button on the remote control to recall the factory pre-set convergence data.

utton on the remote control to retur

n to the manual convergence adjustment mode (crosshatch pattern).

21

Page 22

CUSTOMIZED PICTURE AND SOUND ADJUSTMENTS

Audio

Sound Enhancement

Balance

Bass

Treble

Audio

Move

SEL

Return

Internal Speakers

Audio Source

Perfect Volume

Auto Noise Cancel

50%

Off

On

Locks

Chan. Manager

Aspect

Audio

Video

Move

SEL

Sel

Setup

On

On

45%

LR

Stereo

Loudness

On

MENU

SELECT

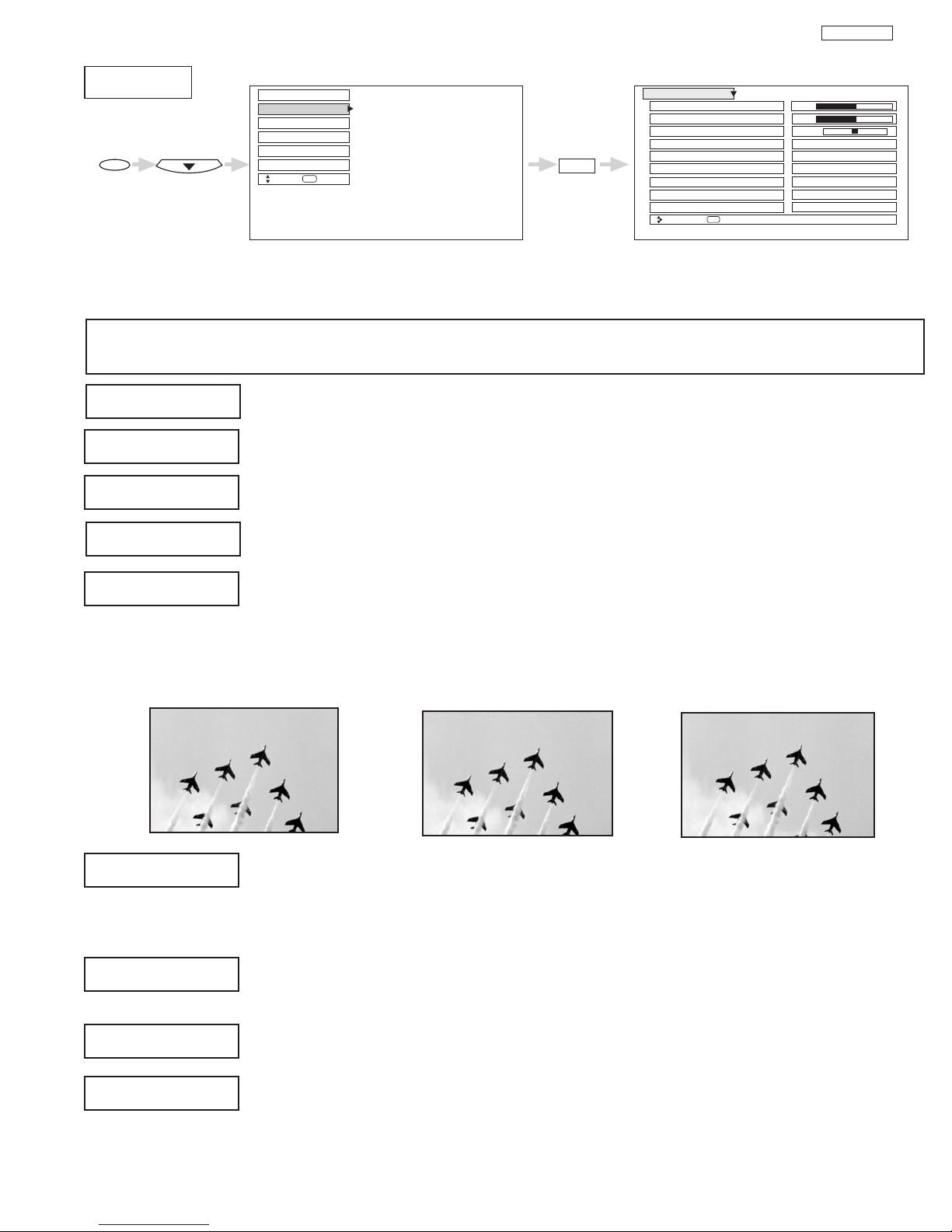

Select AUDIO to adjust the TV to your preference and to improve the sound quality.

DP33KA/B

Press CURSOR

G, H, to select menu item.

Press CURSOR F or E to adjust the function.

Press EXIT to quit the MENU, or select Audio to return to the main menu.

NOTE: If TREBLE is selected you are adjusting treble. The additional menu items Bass and Balance can be selected and

adjusted in the same manner.

Treble

Bass

Sound Enhancement

Balance

Audio Source

This function controls the high frequency audio to all speakers.

This function controls the low frequency audio to all speakers.

This unction will reproduce the “live” sound you would hear in concert halls, sport stadiums, movie theaters,

etc. with only two speakers.

This function will control the left to right balance of the Projection TV internal speakers.

Multi-Channel Television Sound will allow you to select STEREO (a stereo broadcast), MONO (monaural

sound) used when receiving a weak stereo broadcast or 2nd Audio Prog (SAP) which may be a secondary

language, weather report, etc.

The sources received will be displayed at the top right edge of the TV. The source you select will be displayed

above the sources received. See example below for each selection when both stereo and second audio are

received (monaural is always received).

STEREO SELECTED

3:32 PM

Ant A 10

Stereo

R

SAP SELECTED

3:32 PM

Ant A 10

SAP

MONO SELECTED

3:32 PM

Ant A 10

Mono

R

R

Internal Speakers

This function is useful when setting up the external speakers.

ON - Select this f

OFF - Select this feature if you prefer to use only speakers from a separate stereo system.

Auto Noise Cancel

This function eliminates the noise between stations. If a channel is tuned and is noisy, this function will

automatically eliminate the audio f

Perfect Volume

This function will automatically adjust volume so each channel and input has the same average volume

level.

Loudness

This function tur

when listening at low volume levels.

eature if using the internal speakers only.

or that channel.

ns loudness ON or OFF

22

It will impro

.

v

e the quality of both lo

w and high frequency sounds

Page 23

REAR PANEL CONNECTIONS

P

B

P

R

P

B

P

R

Outside antenna or

c

able TV coaxial cable

2-Way signal splitter

Stereo System Amplifier

LR

INPUT

Laserdisc player, VCR,

camcorder, etc.

H

DTV Set-Top Box

DVD Player

Cable TV Box

O

UTPUT

INPUT

VCR #1

ANT

IN

OUTPUT

S-VIDEO

VLR

ANT A

TO

CONVERTER

ANT B

L

Y

R

(MONO)/L

A

UDIO

TO HI-FI

R

S-VIDEO

S-VIDEO

S-VIDEO

Y/VIDEO

R

(

MONO)/L

R

(MONO)/L VIDEO

R

(

MONO)/L VIDEO

R

L VIDEO

INPUT 1

INPUT 2

INPUT 3

INPUT 4

M

ONITOR

OUT

OUTPUT

YP

B/CBPR/CR

L R

VCR #2

V L R

OUTPUT

S-VIDEO

V L R

INPUT

S-VIDEO

OUTPUT

Y P

B

P

R

L R

AUDIO

A

UDIO

AUDIO

DVI-HDTV

D-VHS

DIGITAL OUTPUT

L

R

OUTPUT

TYPICAL FULL-FEATURE SETUP

DP33KA/B

NOTE: 1.

Connect only 1 component to each input jack.

2. Follow connections that pertain to your personal entertainment system.

3. Composite video signal can be input to Input2~Input5.

4. Cables are not included with the purchase of this television.

TABLE OF CONTENTS

23

Page 24

y Picture Formats

4:3

INPUT

4:3 EXPANDED

4:3 ZOOM1

4:3 ZOOM2

16:9 STANDARD

4:3 STANDARD

INPUT

4:3 EXPANDED

4:3 ZOOM1

4:3 ZOOM2

16:9 STANDARD

4:3 STANDARD

INPUT

16:9

16:9 STANDARD 16:9 ZOOM

16:9 ZOOM

16:9 ZOOM

16:9

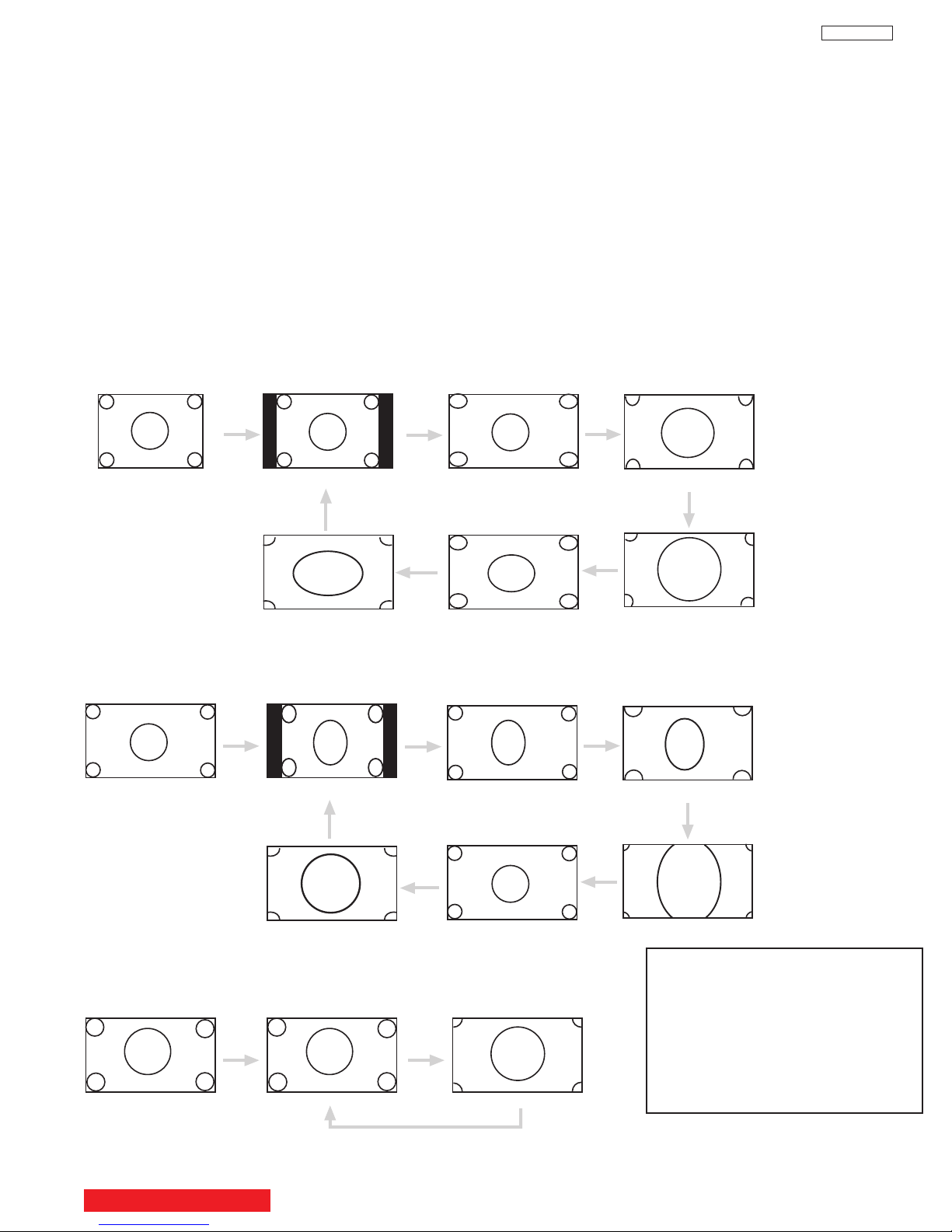

Displa

Press this button to quickly change the picture format ASPECT ratio.

DP33KA/B

Depending on the input signal, the picture f

4:3 Standard

4:3 Expanded use this aspect mode to display conventional (4:3) sources by linearly increasing image expansion from

Zoom1/Zoom2 Use these aspect modes to zoom in on conventional (4:3) sources.

4:3

16:9 Standard Use this aspect mode to display 16:9 sources like HDTV and DVD’s preserving the original 16:9 aspect

16:9 Zoom Use this aspect mode to zoom 16:9 images.

(1) NTSC/480i/480p Input

ormat ratio allows you to adjust the images through the following options.

Use this aspect mode to display conventional (4:3) images. Side panels (gray areas) are placed to the

left and right of the image to preserve the original aspect ratio of the source. Note: Use this mode for

only 15% of your total viewing time to prevent uneven aging of the phosphors. Phosphors in the lighted

area of the picture will age more rapidly than the black areas.

the center towards the edges of the display area in order to fill it.

ratio.

(2) 480i/480p INPUT

(3) 720p/1080i INPUT

NO

TE:

The Aspect Style setting y

ou

select for an ANT input will

automatically be set f

other ANT inputs

or the

ver,

e

w

Ho

.

all five video inputs have

independent Aspect Style

settings

.

TABLE OF CONTENTS

24

Page 25

DP33KA/B

SERVICE ADJUSTMENTS

TO GO TO AN ADJUSTMENT, CLICK ON ITS HEADING BELOW

1. ASSEMBLED P.W.B ADJUSTMENT..................................................................................................................26

1-1. Service Menu Access (NTSC, SDTV and HDTV) ..................................................................................26

1-2. Comb Filter Operation Check ................................................................................................................45

1-3. Video Settings Check..............................................................................................................................45

1-3-1. Color Temperature Check ............................................................................................................45

Black Enhancement......................................................................................................................45

1-3-2.

1-3-3. Edge Enhancement ......................................................................................................................45

1-3-4. Color Management ......................................................................................................................45

1-3-5. Color Coding ................................................................................................................................45

1-3-6. Auto Color ....................................................................................................................................45

1-3-7. Noise Reduction Check ................................................................................................................45

1-3-8. Auto Movie Mode Check ..............................................................................................................45

1-4. High Voltage Adjustment ........................................................................................................................46

2. FINAL ASSEMBLY ADJUSTMENT (Adjustment should be according to below order)..............................46

2-1. Cut Off Adjustment..................................................................................................................................46

2-2. DCU Phase Data Setting ......................................................................................................................46

2-3. Horizontal Position Adjustment (Coarse)................................................................................................47

2-4. Raster Tilt (Deflection Yoke)....................................................................................................................47

2-5. Beam Alignment......................................................................................................................................47

2-6. Raster Position........................................................................................................................................48

2-7. Vertical Size ..........................................................................................................................................48

2-8. Horizontal Size ......................................................................................................................................48

2-9. Beam Form ............................................................................................................................................49

2-10. Lens Focus..............................................................................................................................................49

2-11. Static Focus ............................................................................................................................................51

2-12. Digital Convergence ..............................................................................................................................51

2-12-1. Magic Focus Character Set Up ..................................................................................................52

2-12-2. Magic Focus Pattern Set Up ......................................................................................................53

2-12-3. Convergence Jig Screen Specification ......................................................................................53

2-12-4. Raster Position Adjsutment ........................................................................................................54

2-12-5. Convergence Point Adjustment ..................................................................................................54

2-12-6. Magic Focus Initialize..................................................................................................................55

2-13. Blue Defocus ..........................................................................................................................................59

2-14. White Balance ........................................................................................................................................59

2-15. Sub Brightness........................................................................................................................................60

2-16.

Sub-Picture Signal Amplitude Adjustment

2-17. Horizontal Position ................................................................................................................................62

2-18. Scanning Area Check ............................................................................................................................62

........................................................................................................................

ocus P

k

ack ....................................................................................................................64

2-19.

ADJUSTMENT POINT ........................................................................................................................................64

3.

3-1.

Raster Distor

CPT (R)(G)(B), F

tion Chec

3-2. Signal Block Assembly............................................................................................................................65

..............................................................................................................66

.

.B

3-3.

Main Chassis Deflection P

.W

3-4. Power Supply P.W.B. ..............................................................................................................................74

..............................................................................................61

63

*IMPORTANT

For many of the abo

generator, as well as the usual NTSC (480i) signal generator.

Hitachi recognizes that few companies offer HDTV or SDTV signal generators and that the cost of these generators is

sometimes prohibitive. For this reason, we suggest the use of a set-top-box for HDTV and SDTV adjustments. Usually,

there is a switch on the set-top-box which enables it to output HDTV (1080i or 720P) or SDTV (480P) signals even with

no input. In this case

TABLE OF CONTENTS

ve adjustments,

, the sync is automatically detected by the TV (at the Y-P

it is necessar

ve an HDTV (1080i or 720P) signal generator, SDTV (480P) signal

y to ha

Inputs on the rear panel).

BPR

25

Page 26

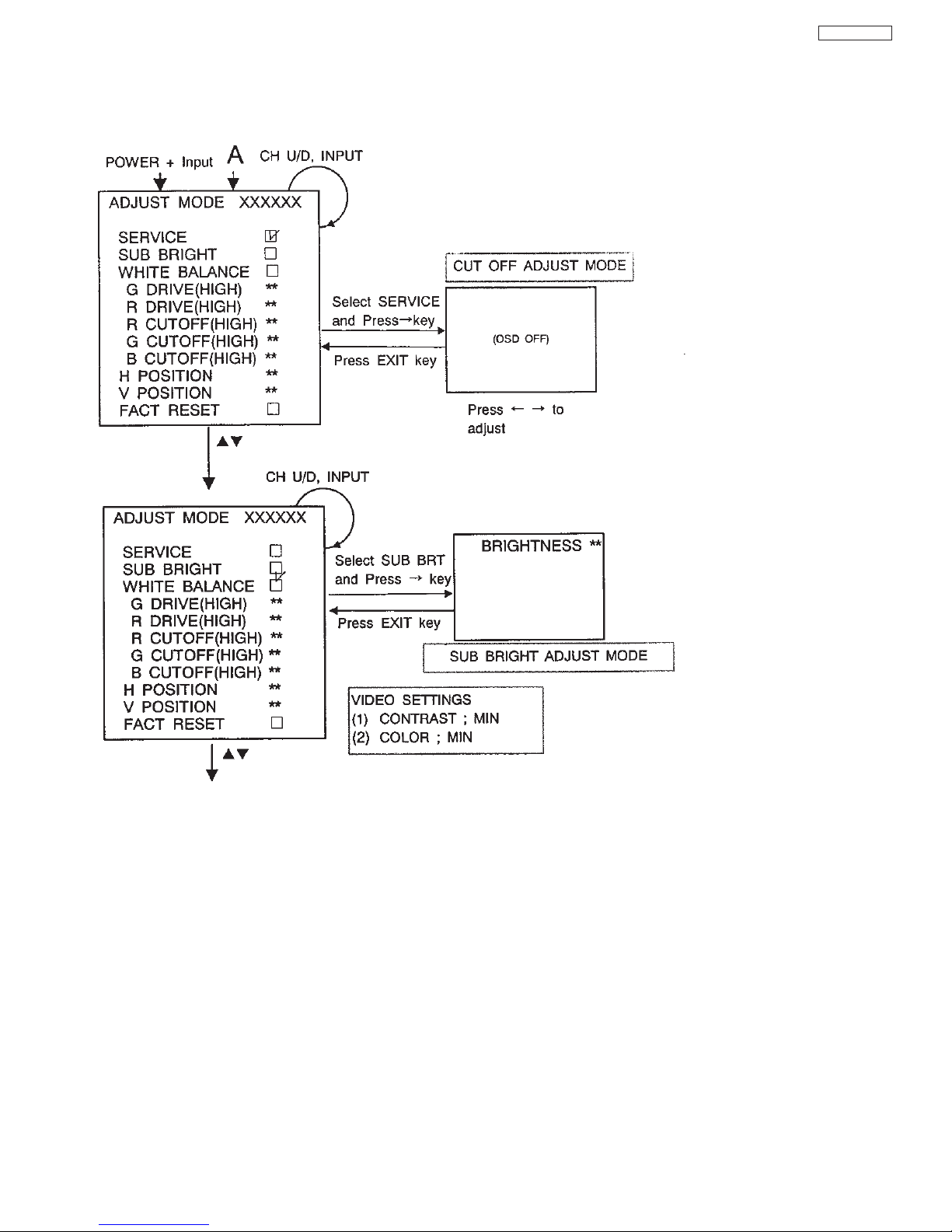

ASSEMBLED P.W.B. ADJUSTMENT

1.

1.1 Ser

vice Menu Access

Adjustment Procedure

(1) Press and hold INPUT key on Control Panel and then press POWER key on control panel to access I2C

adjustment mode.

(2) Receive signal on main picture. (NTSC, SDTV or HDTV).

Some menu pages have I2C adjustments for SDTV and HDTV. The set will automatically allow you to set

these items only when a SDTV or HDTV signal is input to the COMPONENT jacks on the back of the TV. ......

See table below.

(3) Check the OSD according to table on the following pages, using CURSOR G, H on Remote Control.

*: Adjustable Data

Others: Fixed Data (be careful not to change)

(4) Press EXIT key to exit I2C ADJUST mode.

NOTES: (1) If the TV I2C data is different from the I2C Parameter (of the following pages) for fixed data, change

the data.

(2) When exchanging microprocessor or EEPROM and TV is turned on for first time, it requires

2

initialization of Memory Initial of I

C adjustment menu. Press CURSOR E and hold for 3

seconds to initialize memory.

(3) Use FACTORY RESET to set TV to out of factory shipping conditions: Do not use MEMORY

INITIALIZE.

DP33KA/B

IMPORTANT: AFTER PERFORMING A FACTORY RESET OR A MEMORY INITIALIZATION, YOU MUST

UNPLUG THE AC CORD AND THEN PLUG IT BACK IN.

BACK TO ADJUSTMENTS

26

Page 27

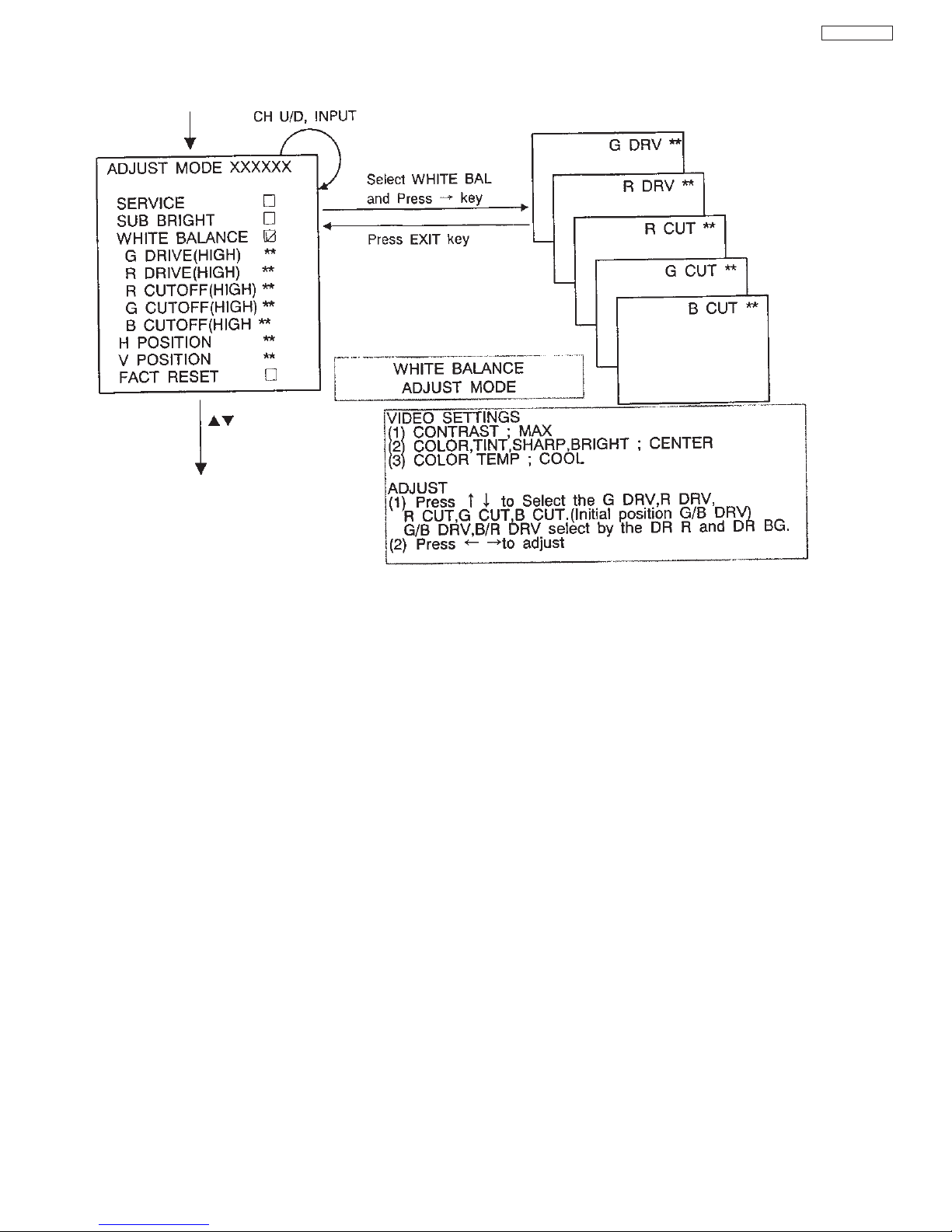

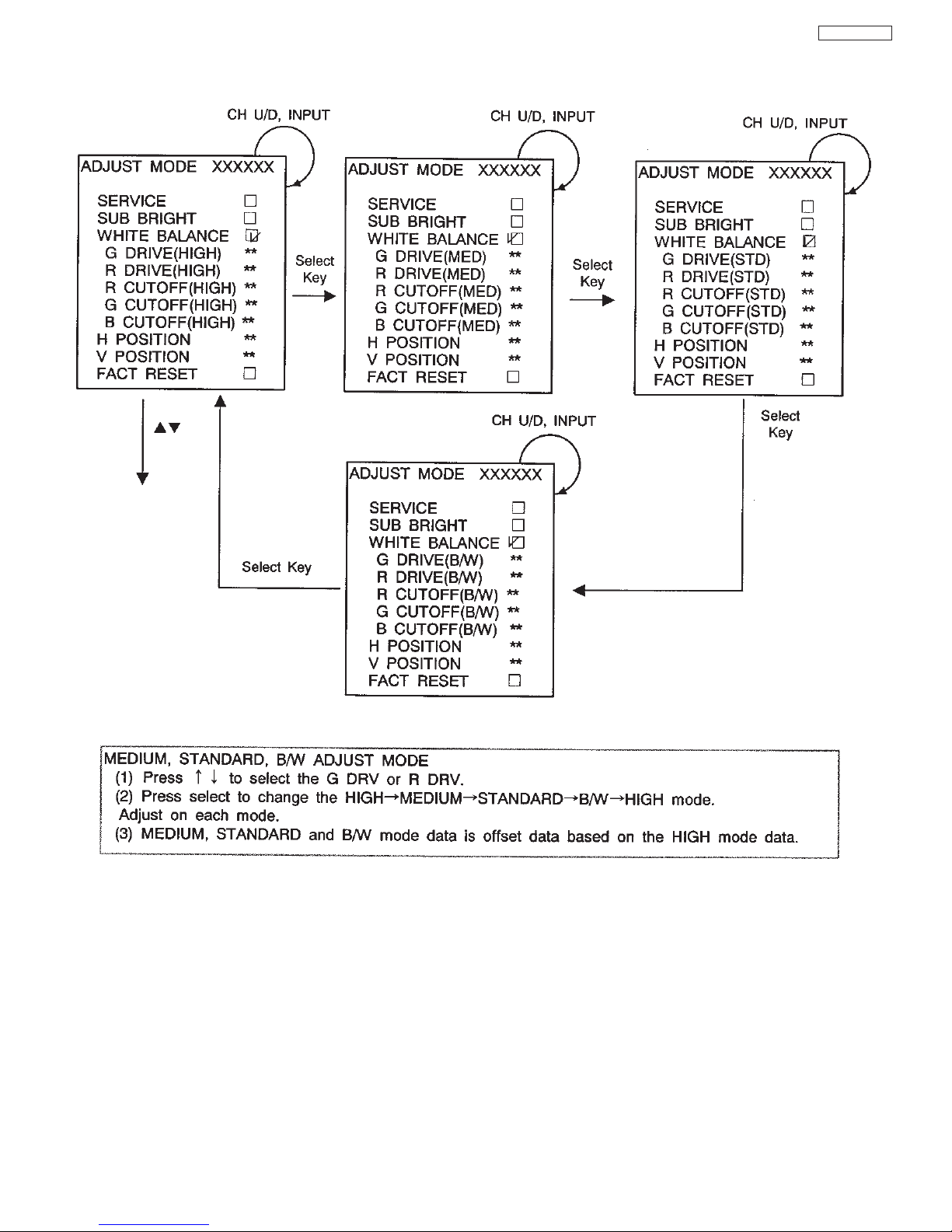

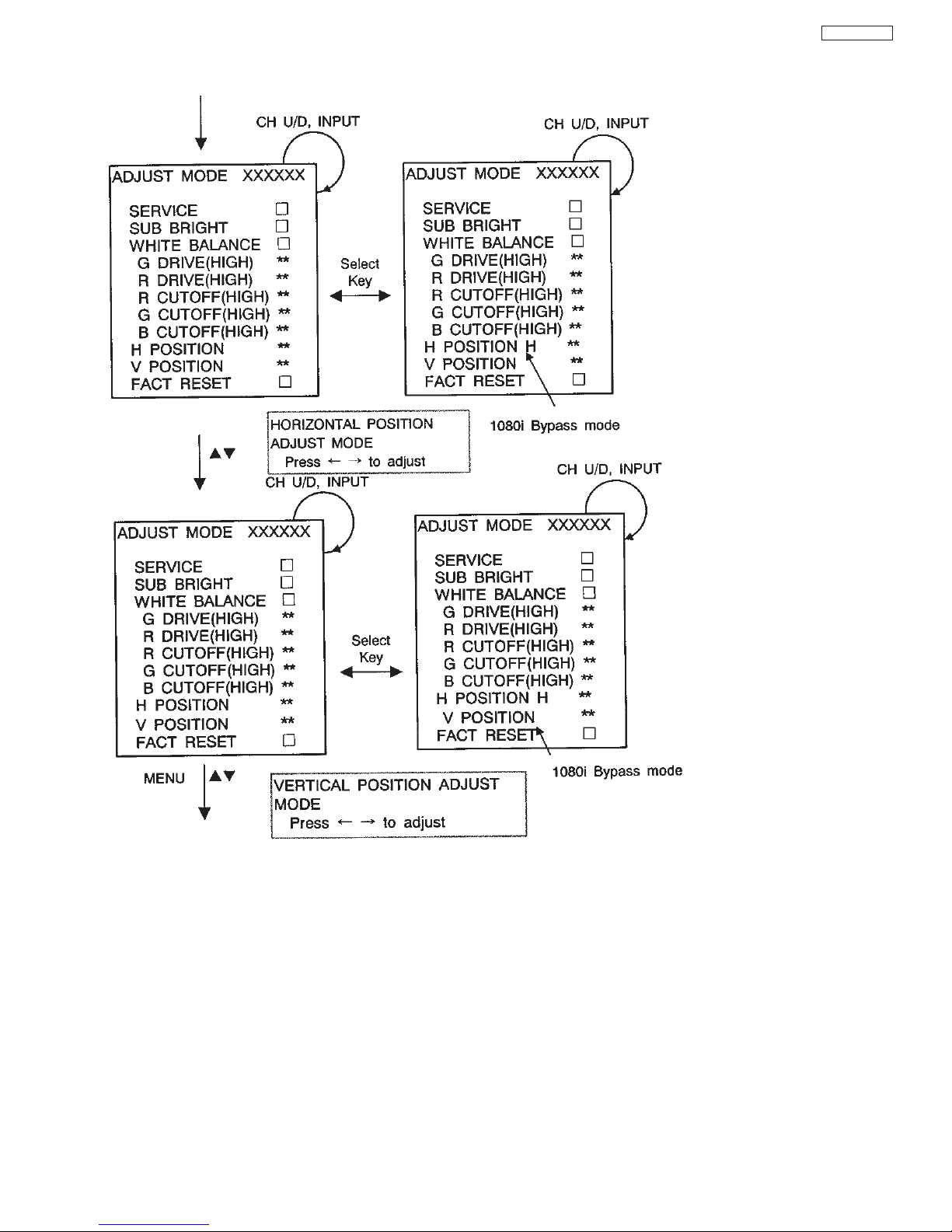

I2C OSD Flowchart

(a) Adjust Mode OSD

Press [POWER] + [INPUT] of Control Panel.

DP33KA/B

*: ADJUSTABLE ITEM

EXIT I2C ADJUST MODE

[EXIT] OR POWER on/off.

27

Page 28

(a) Adjust Mode OSD (continued)

DP33KA/B

28

Page 29

(a) Adjust Mode OSD (continued)

DP33KA/B

29

Page 30

(a) Adjust Mode OSD (continued)

DP33KA/B

30

Page 31

DP33KA/B

(b) I2C Parameter List

Adjustment

Mode

OSD

Adjustment Item Adjustment

Ra

nge(HEX)

Initial

Data(HEX)

Adjustment

Value(HEX)

SERVICE SERVICE OFF

TA1360 (88H)

SUB BRIGHT Sub Brightness 3C~ FF 7F

WHITE BAL White Balance Mode (TA1360 88H)

High 3F

M

edium 49

Standard 4F