Page 1

Dec 2004

(ver g)

Training Materials Prepared by: ALVIE RODGERS C.E.T.

MODEL RELEASE

HD READY PTV

Chassis Model # Aspect

DP-27 51SWX20B 16X9

57SWX20B

65SWX20B

DP-27D 57TWX20B 16X9

65TWX20B

DP-26 65XWX20B 16X9

57XWX20B

51XWX20B

DP-24 43FWX20B 16X9

DP-23G 57GWX20B 16X9

51GWX20B

DP-23K 46F500 16X9

DP-23 57UWX20B 16X9

57F500

57G500

51UWX20B

51F500

51G500

2002 and 2003

DIGITAL

CONTENTS... 2002 DP-2X Chassis Projection Television Information

INSTRUCTOR… Alvie Rodgers C.E.T. (Chamblee, GA.)

Page 2

THIS PAGE LEFT BLANK

Page 3

Dec 2004

(ver f)

TOPICS PAGE

SECTION (1) POWER SUPPLY DIAGRAMS:

•

+6V Lo Voltage Regulation

•

+6V Lo Voltage Regulation

•

+6V Lo Voltage Regulation

•

Power On Relay Controls

•

Power On Relay Controls

•

Power On Relay Controls

•

Power On Relay Controls

•

Low Voltage Shut Down

•

Low Voltage Shut Down

•

SW +115V Hi Voltage Regulation

•

SW +115V Hi Voltage Regulation

•

Additional

•

Additional

•

Protect (Deflection) Hi Volt Shut Down

•

Protect (Deflection) Hi Volt Shut Down

•

LEDs

•

LEDs

•

LEDs

•

LEDs

SECTION (2) MICROPROCESSOR INFORMATION:

•

Microprocessor

•

Microprocessor

•

Microprocessor

•

Microprocessor

•

Microprocessor

•

Microprocessor

•

Microprocessor

SECTION (3) VIDEO CIRCUIT INFORMATION:

•

Video NTSC

•

Video NTSC

•

Video NTSC

•

Video NTSC

•

Video Component, OSD & NTSC

•

Video Component, OSD & NTSC

•

Video Component, OSD & NTSC

•

Video Component, OSD & NTSC

•

ATSC (Digital Tuner)

Hi Voltage Shut Down

Hi Voltage Shut Down

(Visual Trouble Shooting) Lo Voltage Power Supply Circuit Diagram Explained ----

(Visual Trouble Shooting)

(Visual Trouble Shooting)

(Visual Trouble Shooting)

DP-2X TABLE OF CONTENTS

Circuit Diagram Explained ------------------------------------------

Circuit Diagram

Circuit Diagram

Circuit Diagram Explained ---------------------------------------------

Circuit Diagram

Circuit Diagram

Circuit Diagram

Circuit Diagram Explained ---------------------------------------------

Circuit Diagram -----------------------------------------------------------

Circuit Diagram Explained ----------------------------------

Circuit Diagram -----------------------------------------------

Circuit Diagram Explained -----------------------------------

Circuit Diagram ------------------------------------------------

Circuit Diagram DP-23, 23G and DP-24

Circuit Diagram DP-26

Circuit Diagram DP-27 and DP-27D

DATA COMMUNICATION

DATA COMMUNICATION

DATA COMMUNICATION

Sync Input

Sync Input

Sync Input

Sync Input

Circuit Diagram Explained

Circuit Diagram

Circuit Diagram

Circuit Diagram

Circuit Diagram Explained

Circuit Diagram

Circuit Diagram

Circuit Diagram

----------------------------------------------------------- 03-01

Circuit Diagram DP-23, 23G, 27 & 27D

Circuit Diagram DP-24

Circuit Diagram DP-26

Circuit Diagram Explanation --------------------------------

Circuit Diagram

Circuit Diagram

Circuit Diagram

Block Diagram

DP-26 Only

Materials prepared by

Alvie Rodgers C.E.T.

DP-26 and DP-27

DP-23, DP-23G and DP-24

DP-23, DP-23G and DP-24

DP-26

---------------------------------------------------

DP-27 and DP-27D

Circuit Diagram Explained ---------------------------

Circuit Diagram ----------------------------------------

------------------------------------------------

Explanation

Circuit Diagram DP-23, 23G, 24, 27 & 27D

Circuit Diagram DP-26

Circuit Diagram DP-23, 23G, 27 & 27D

Circuit Diagram DP-24

Circuit Diagram DP-26

------------------------------------------------ 03-04

------------------------------------------------ 03-05

DP-23, 23G, 27 & 27D

DP-24

DP-26

------------------------------------------------- 03-11

-------------------------------------

----------------------------

-------------------------------

-------------------------------------

-------------------------------

-----------------------------------

------------------------------------- 02-01

---------- 02-04

------------------------------ 02-05

----------------------------------------- 02-06

---------------- 02-07

-------------------------------- 02-08

-------------------------------- 02-09

-------------------------------- 03-03

------------------------

----------------------------------------

----------------------------------------

Continued on Next Page

01-01

01-02

01-03

01-04

01-06

01-07

01-08

01-09

01-13

01-14

01-15

01-16

01-17

01-18

01-19

01-20

01-21

01-22

01-23

03-06

03-08

03-09

03-10

Table of Contents Page 1 of 4

Page 4

Dec 2003 (ver g)

SECTION (3) VIDEO CIRCUIT INFORMATION: (Continued)

•

•

•

•

•

•

•

•

•

SECTION (4) AUDIO CIRCUIT INFORMATION:

•

•

SECTION (5) DEFLECTION CIRCUIT:

•

•

•

•

•

•

•

•

•

SECTION (6) DIGITAL CONVERGENCE CIRCUIT INFORMATION:

•

•

•

•

•

•

•

•

•

•

•

SECTION (7) ADJUSTMENT INFORMATION:

•

•

•

•

TOPICS PAGE

Rainforest IC Pulse

Circuit Diagram Explanation

ABL

Circuit Diagram

ABL

ABL Switch

Audio Video Mute

Audio Video Mute

Input Circuit Diagram

DVI

Component Sync

Component Sync

Main Terminal Circuit Diagram Explanation

Audio

Main Terminal Circuit Diagram

Audio

Horizontal Drive

Horizontal Drive

IH01 Horizontal Drive IC

Sweep Loss

Sweep Loss

Vertical Output

Vertical Output

Pincushion Circuit

Pincushion Circuit

Digital Convergence Interconnect

Digital Convergence Interconnect

Digital Convergence Interconnect

Remote CLU4321UG

Remote CLU5721TSI

Remote CLU5722TSI

43" Overlay

46" Overlay

51" Overlay

57" Overlay

65" Overlay

Adjustment Order ------------------------------------------------------------------------------------ 07-01

Pre Heat Run ------------------------------------------------------------------------------------------ 07-02

Cut Off

Pre-Focus

Adjustment

DP-2X TABLE OF CONTENTS

Explanation Explained

------------------------------------------------------------------- 03-13

---------------------------------------------------------------------------------- 03-14

(Black Side Bars) Circuit Diagram and Explanation

Circuit Diagram Explanation

Circuit Diagram

---------------------------------------------------------------------------- 03-19

Circuit Diagram Explanation ----------------------------------------------------Circuit Diagram ---------------------------------------------------------------------

Circuit Diagram Explanation

Circuit Diagram

Voltages and Waveforms (Also, Not Running Info.)

Detection Circuit Diagram Explanation

Detection Circuit Diagram

Circuit Diagram Explanation

Circuit Diagram

Diagram

Diagram

(Digital Convergence Mode Functions)

(Digital Convergence Mode Functions)

(Digital Convergence Mode Functions)

Dimensions

Dimensions

Dimensions

Dimensions

Dimensions

Adjustment

----------------------------------------------------------------------------- 06-10

----------------------------------------------------------------------------- 06-11

----------------------------------------------------------------------------- 06-12

----------------------------------------------------------------------------- 06-13

----------------------------------------------------------------------------- 06-14

----------------------------------------------------------------------------------- 07-03

-------------------------------------------------------------------------------- 07-04

----------------------------------------------------------------- 03-18

------------------------------------------------------------------ 05-03

-------------------------------------------------------------------- 05-08

-------------------------------------------------------------------------- 05-09

-------------------------------------------------------------------------- 05-10

Circuit Diagram Explanation

Circuit Diagram DP-23, 23G, 26, 27 & 27D

Circuit Diagram DP-24

-------------------------------------------------------- 03-12

------------------------------------------------- 03-16

---------------------------------------------- 04-01

------------------------------------------------------------- 04-02

--------------------------------------------------- 05-01

---------------------------------------------- 05-05

------------------------------------------------------------- 05-06

---------------------------------------------------- 05-07

------------------------------------------ 06-06

Materials prepared by

Alvie Rodgers C.E.T.

------------------------------ 03-15

------------ 05-04

------------------------------ 06-01

----------------------- 06-05

DP-23, DP-23G & DP-24

DP-26

-------------------------- 06-08

DP-27

-------------------------- 06-09

-------- 06-07

03-20

03-21

Continued on Next Page

Table of Contents Page 2 of 4

Page 5

Dec 2003 (ver f)

TOPICS PAGE

DP-2X TABLE OF CONTENTS

Materials prepared by

Alvie Rodgers C.E.T.

SECTION (7) ADJUSTMENT INFORMATION (Continued):

•

DCU Crosshatch Phase Settings ------------------------------------------------------------------- 07-05

•

Horizontal Position (Coarse)

•

Raster Tilt

•

Beam Alignment

•

Off-Set for Red and Blue Raster Position

•

Vertical Size

•

Horizontal Size

•

Beam Form

•

Lens Focus

•

Static Focus

•

DCU Character Set-Up

•

DCU Pattern (Sensor Position) Set-Up

•

43" Overlay

•

51" Overlay

•

57" Overlay

•

65" Overlay

•

Remote CLU5721TSI

•

Remote CLU5722TSI

•

Remote CLU4321UG

•

Read from ROM Notes ------------------------------------------------------------------------------ 07-24

◊

DIGITAL CONVERGENCE ALIGNMENT PROCEDURE

◊

(Clearing RAM)

◊

Centering Magnet

◊

Static Centering

◊

Green

◊

Red and Blue

◊

Green

◊

Red and Blue

◊

Green

◊

Red and Blue

◊

Storing

◊

Initializing Magic Focus Sensors ------------------------------------------------------------------- 07-34

◊

Convergence Touch Up

◊

ERROR CODES for DCU HD FOCUS Description -------------------------------------------- 07-36

•

Blue De-Focus

•

White Balance and Sub Brightness

•

White Balance

•

Sub Picture (PIP) Amplitude

•

Horizontal Position (Fine)

•

Magnet Locations ------------------------------------------------------------------------------------- 07-42

Adjustment

Adjustment

Adjustment

Adjustment

Adjustment

Adjustment

Adjustment

Dimensions

Dimensions

Dimensions

Dimensions

(Digital Convergence Mode Functions)

Clearing Digital Convergence Data

Adjustment

Adjustment (Freeze Button)

Mode Adjustment

3X3

Mode Adjustment

3X3

Mode Adjustment

7X5

Mode Adjustment

7X5

Mode Adjustment

9X13

Mode Adjustment

9X13

Digital Convergence Data (

Adjustment

Adjustment Flow Chart

Adjustment

------------------------------------------------------------------------------- 07-07

------------------------------------------------------------------------ 07-08

----------------------------------------------------------------------------- 07-10

-------------------------------------------------------------------------- 07-11

------------------------------------------------------------------------------ 07-12

------------------------------------------------------------------------------- 07-13

------------------------------------------------------------------------------ 07-14

and

DCU Data Confirmation

----------------------------------------------------------------------------- 07-17

----------------------------------------------------------------------------- 07-18

----------------------------------------------------------------------------- 07-19

----------------------------------------------------------------------------- 07-20

(Digital Convergence Mode Functions)

(Digital Convergence Mode Functions)

---------------------------------------------------------------------- 07-25

------------------------------------------------------------------------ 07-27

------------------------------------------------------------------------ 07-29

----------------------------------------------------------------------- 07-31

Minor Adjustments

--------------------------------------------------------------------------- 07-37

Adjustment

Adjustment

--------------------------------------------------------- 07-06

Adjustment

Adjustment

------------------------------------------------------ 07-26

--------------------------------------------------------------- 07-28

--------------------------------------------------------------- 07-30

-------------------------------------------------------------- 07-32

Write to ROM) ---------------------------------------------- 07-33

------------------------------------------------------ 07-35

Adjustment

------------------------------------------------------------ 07-39

--------------------------------------------------------- 07-40

------------------------------------------------------------- 07-41

----------------------------------------- 07-09

Adjustment

--------------------------------------------- 07-16

--------------------------------- 07-21

--------------------------------- 07-22

---------------------------------- 07-23

-------------------------------------------- 07-25

------------------------------------------------- 07-38

-------------------------- 07-15

------------------------------ 07-25

Continued on Next Page

Table of Contents Page 3 of 4

Page 6

Dec 2003

SECTION (8) MISCELLANEOUS IN FOR MATI O N:

•

•

•

•

•

•

•

•

•

•

SECTION (9) THINGS YOU SH OULD KNOW / SERVICE BULLETINS / ETC ….:

•

•

(ver f)

TOPICS PAGE

Rear Panel

Rear Panel

Rear Panel

Rear Panel

Signal PWB

Deflection PWB

Power Supply PWB

CRT PWBs

All but DP-24

DP-24

Front Control PWBs

This section changes often, the index for this section is shown on the

Things You Should Know section divider.

Please go to Section 9 section divider cover page for details -------------------------------------

Download this Section Separately.

DP-2X TABLE OF CONTENTS

DP-27 and DP-27D (Terminal Input) Drawing

DP-23 and DP-23G (Terminal Input) Drawing

DP-26 (Terminal Input) Drawing

DP-24 (43FWX20B Only Terminal Input) Drawing

Drawing

Drawing

Front Control PWBs

--------------------------------------------------------------------------------- 08-05

Drawing

---------------------------------------------------------------------------- 08-06

Drawing

---------------------------------------------------------------------------------- 08-08

----------------------------------------------------------------------- 08-07

Drawing

Drawing

----------------------------------------------------- 08-03

---------------------------------------------------- 08-09

-------------------------------------------------------------- 08-10

-------------------------------------- 08-01

-------------------------------------- 08-02

------------------------------- 08-04

Materials prepared by

Alvie Rodgers C.E.T.

09-00

Table of Contents Page 4 of 4

Page 7

POWER SUPPLY

INFORMATION

DP-2X

CHASSIS DIAGRAMS

SECTION 1

Page 8

THIS PAGE LEFT BLANK

Page 9

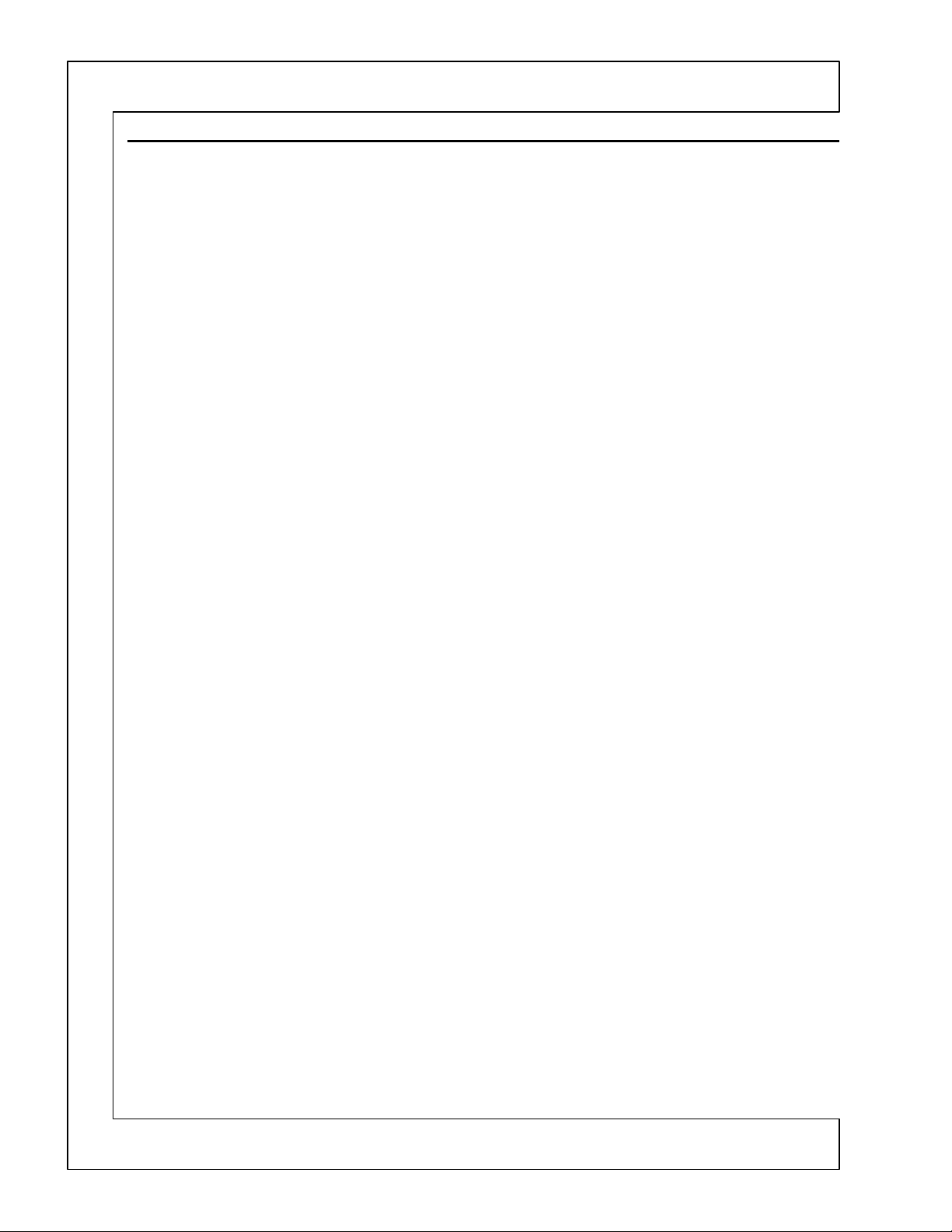

DP-2X +6V POWER SUPPLY REGULATION EXPLANATION

+6V Power Supply Circuit Diagram explanation:

(See DP-26, DP-27 and DP-27D +6V Regulation Circuit Diagram for details).

(Also, see DP-23, DP-23G and DP-24 +6V Regulation Circuit Diagram for details).

Note: Items described below for the DP-23, 23G and DP-24 are shown in brackets [ ].

THIS POWER SUPPLY RUNS ALL THE TIME:

When a Projection set is plugged into an AC outlet, it must produce a power supply to energize certain circuits.

These circuits are responsible for monitoring the Infrared input or Front control Keys as well as the Auxiliary

inputs if the Auto Link feature is active.

These power supplies are generally labeled as Always power supplies or Standby power supplies. As an example

would indicate a +6V power supply that’s always present. If the power supply has an Sby prefix, (example

A+6V

Sby +6V) this too is always present if the set is plugged into the AC outlet.

The DP-2X power supply Standby voltages are regulated by monitoring the

Sby +5V

The

by

REGULATION:

The primary route for the

However, the regulation route is to pin 1 of

the

pin 4 to pin 3 ground. This action causes pin 6 of

turn causes the frequency of the drive pulse delivered to the Gate of the internal SMOSFET (Switch Metal Oxide

Semiconductor Field Effect Transistor) to manipulate the frequency of the pulse generated on the primary of

T901

internally to pin 2 and then to floating ground pin

low ohm resistors,

SMOSFET is monitored. If this current exceeds a specific value, the voltage developed by these low ohm resistors is routed back into pin 5 which is the Over Current Protection circuit. This pin will inhibit the drive signal to

the gate of the SMOSFET. As soon as the excessive current situation is eliminated, the IC will recover and continue functioning.

B+ GENERATION FOR THE LOW VOLTAGE POWER SUPPLY DRIVER IC:

Vcc for the Driver IC is first generated by the AC input. This voltage is called Start Up Voltage.

16V

When AC is applied, AC is routed through the main fuse

to prevent any internal high frequency radiation for radiating back into the AC power line. After passing the filters it arrives at the main full wave bridge rectifier

supplied to the power supply switching transformer

However, one leg of the AC is routed to a half wave rectifier

R907

of

begins the operation of

When the power supply begins to operate by turning on and off the internal Switch MOS FET, the Raw 150V DC

routed through

Switch MOS FET is routed out of pin 2 through three low ohm resistors to hot ground. When the internal Switch

MOS FET turns on, it causes the transformer to saturate building up the magnet field. When the internal Switch

MOS FET turns off, the magnet field collapses and the EMF is coupled over to the secondary windings, as well

as the drive windings. The drive windings at pin

D905

Note too that Hot Ground is the Negative Leg of the bridge rectifier

T901.

after it is regulated by

Control +6V

and becomes a

C954

Control +6V

. Pin

DC to operate normal. However, it will begin operation at

(both a 68K ohm resistor), filtered by

as start up voltage. When this voltage reaches 6.8Vdc, the internal Regulator of

I901

, filtered by

is generated on the Secondary of

Power Supply.

+6V

Note: Items for the DP-23, 23G and DP-24 are shown in brackets [ ].

Control +6V

voltage fluctuations. The internal receiver receives this light and acts as a variable resistor from

6 [3]

of

T901

is routed to pin 1 of

T901

R908, R909

.

I901

, to

C911

in on pin 1 (Drain) and out on pin 2 which is the Source. The Source of the internal

I901

then routed clamped by

.

I909

is to pin 3 of

and

R910 [R908, R909

I904

I901

C911

The Primary Chassis Discussed is the DP-27 and DP-27D.

Control +6V

pin

T901

and output as

I909

. Internally, the LED is illuminated by degrees dependant upon

to manipulate the internal oscillator within

I901

which is the Drain of the SMOSFET. The source is connected

of

9 [6]

, clamped by a 30V Zener

8 [5]

D907

T901

] to hot ground. Here, the current drain of the internal

F901

where it is converted to Raw 150V DC voltage to be

D901

pin 2 [1].

T901

of

T901

and now becomes run voltage (

. The pulse is rectified by

10 [7]

Sby. +5V

. The floating ground is monitored by three [two]

6.8V DC

(a 6 Amp fuse), then through the Line filter

D904

produce a run voltage pulse which is rectified by

on pin 3 of

where it is rectified, routed through

and made available to pin (3)

D907

and the Floating Ground is pin

D901

which becomes the

from pin 2.

.

I901

is turned On and

I901

) for

16V

D941

I901

I901

I901

and filtered

. This in

requires

L901

R906

pin 3.

9 [6]

and

of

PAGE 01-01

Page 10

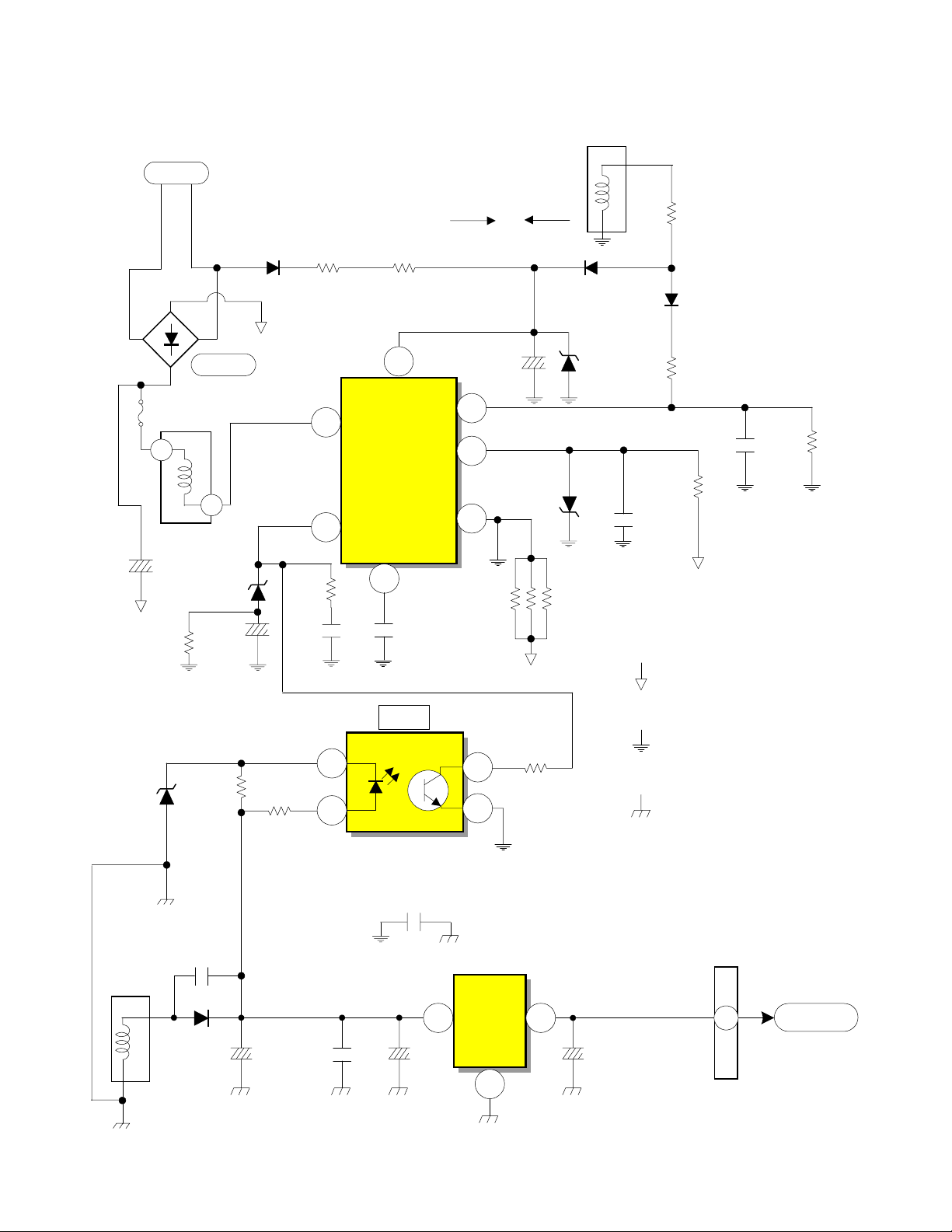

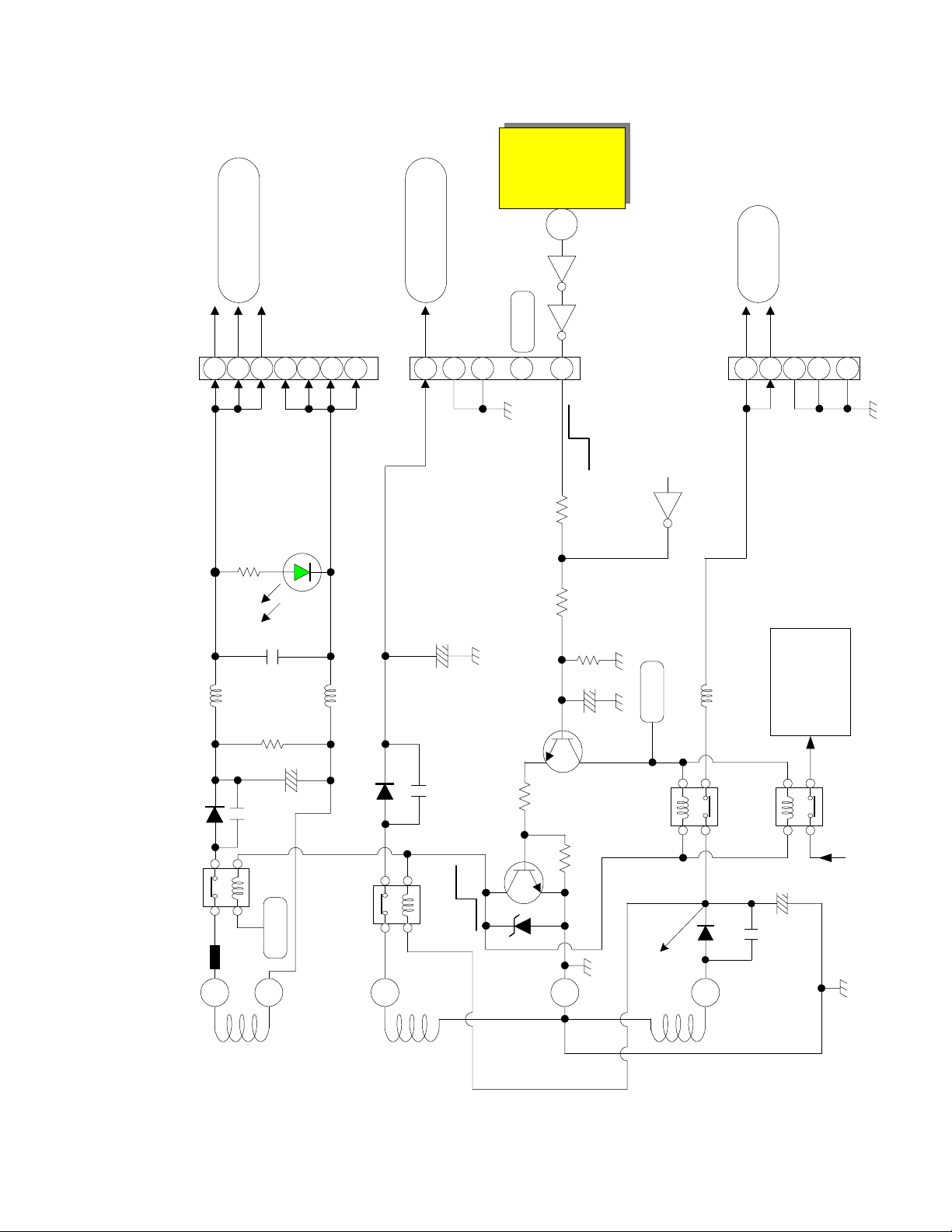

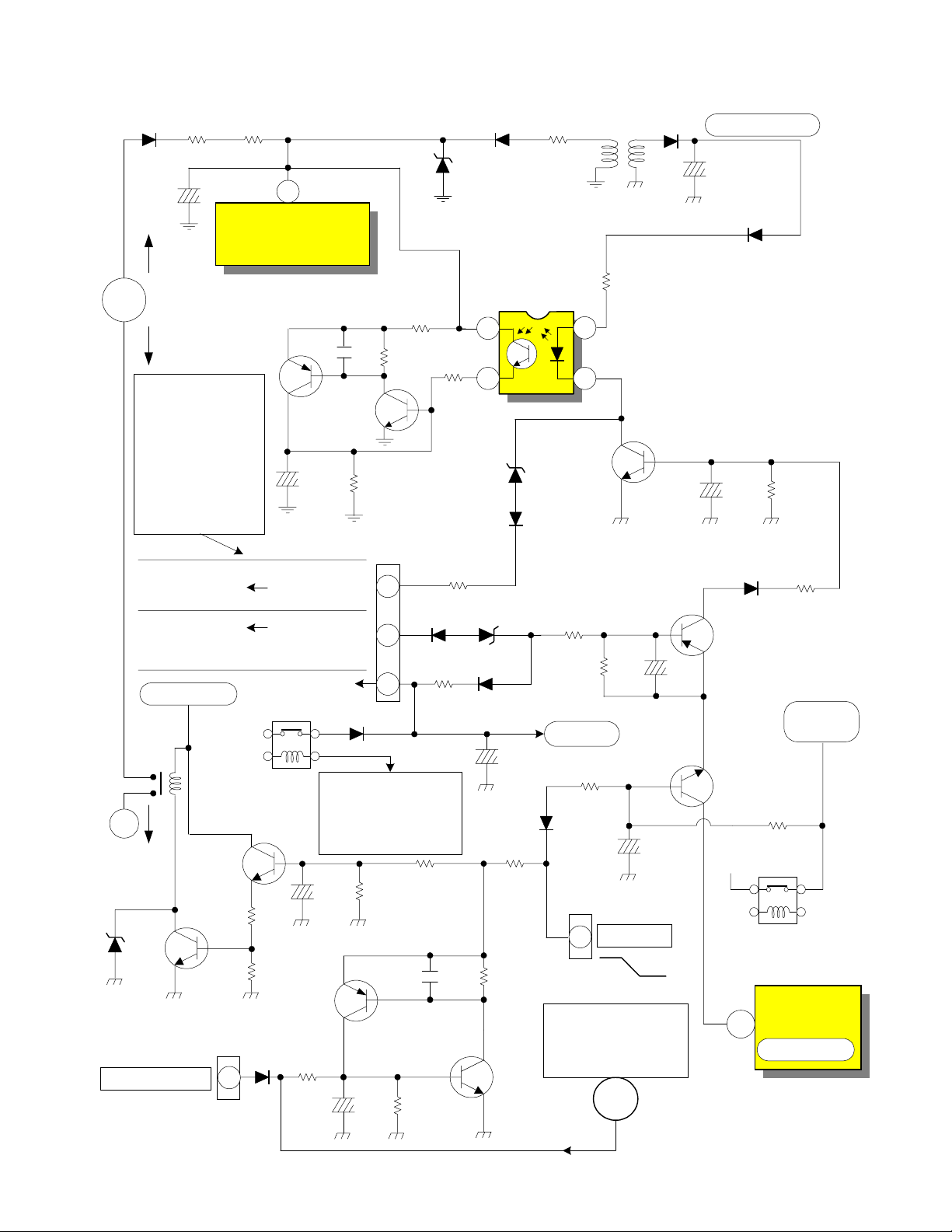

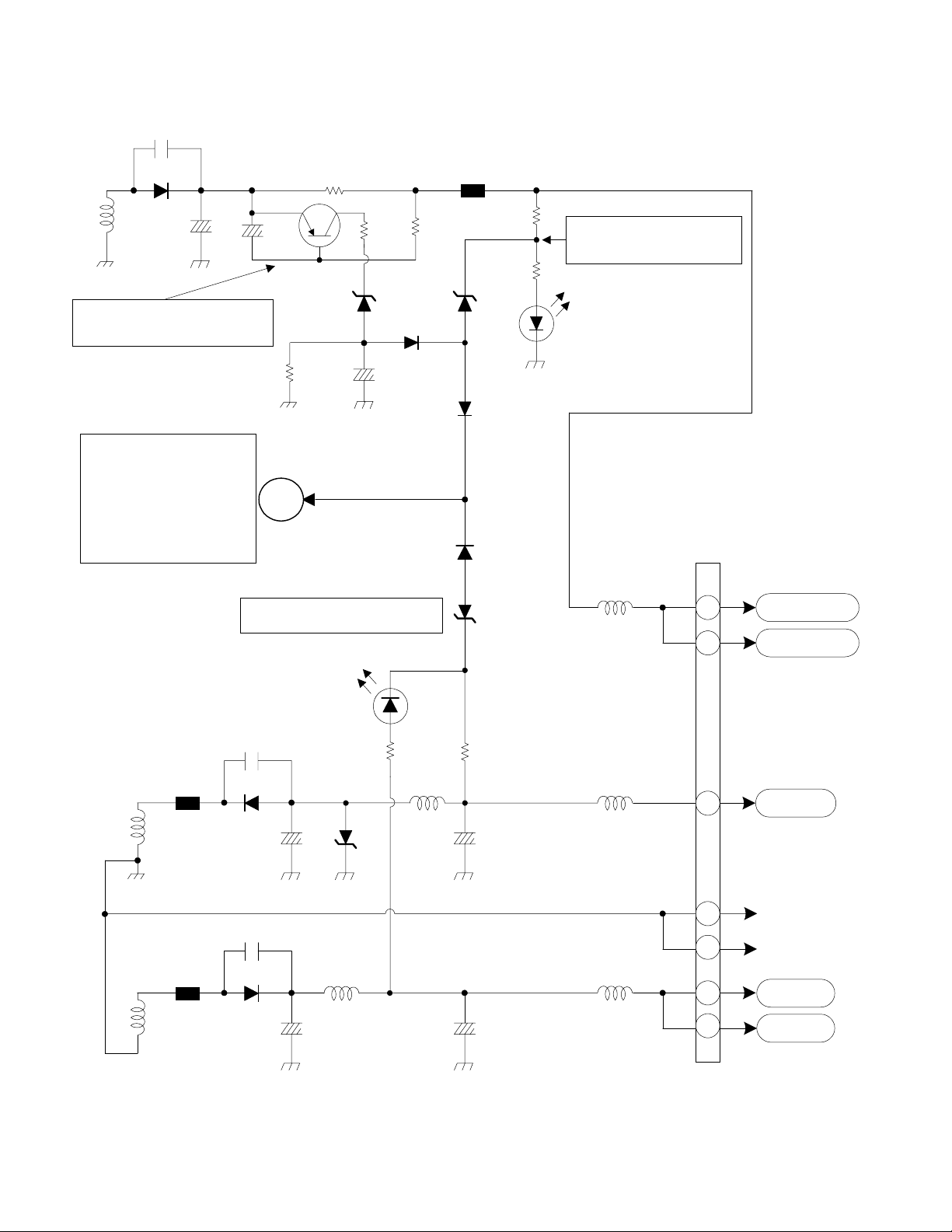

DP-26, DP-27 and DP-27D CHASSIS POWER SUPPLY Sby +6V REGULATION

Lo Voltage Power Supply

T902

AC

8

C910A

R917

D953

D901

F902

2

T901

150V

6

D908

C918

R958

D904

R957

R906

16.3V

1

D

I901

Driver/

Output IC

6

FB/OLP

ABS

R916

C917

2

1

Regulator Photocoupler

4

R907

3

C915

FB

I904

Osc B+

BD

OCP

S

Start Up

7

5

2

4

3

C911

D906

R915

Run

D905

D907

R908

R909

R910

9

0.47

Ohm

R913

D910

R911

R912

C914

Hot Ground from

negative leg of

Bridge D901

Floating Ground

from pin 9 of T901

Cold Ground Pin 11

Secondary of

T901

C916

R914

Control

T901

10

11

+6V

C969

D941

C954

1.79A

C904

I909

3 2

+5V

Reg

C985C972 C973

1

0.0685A

PPS3

2

Sby +5V

PAGE 01-02

Page 11

AC

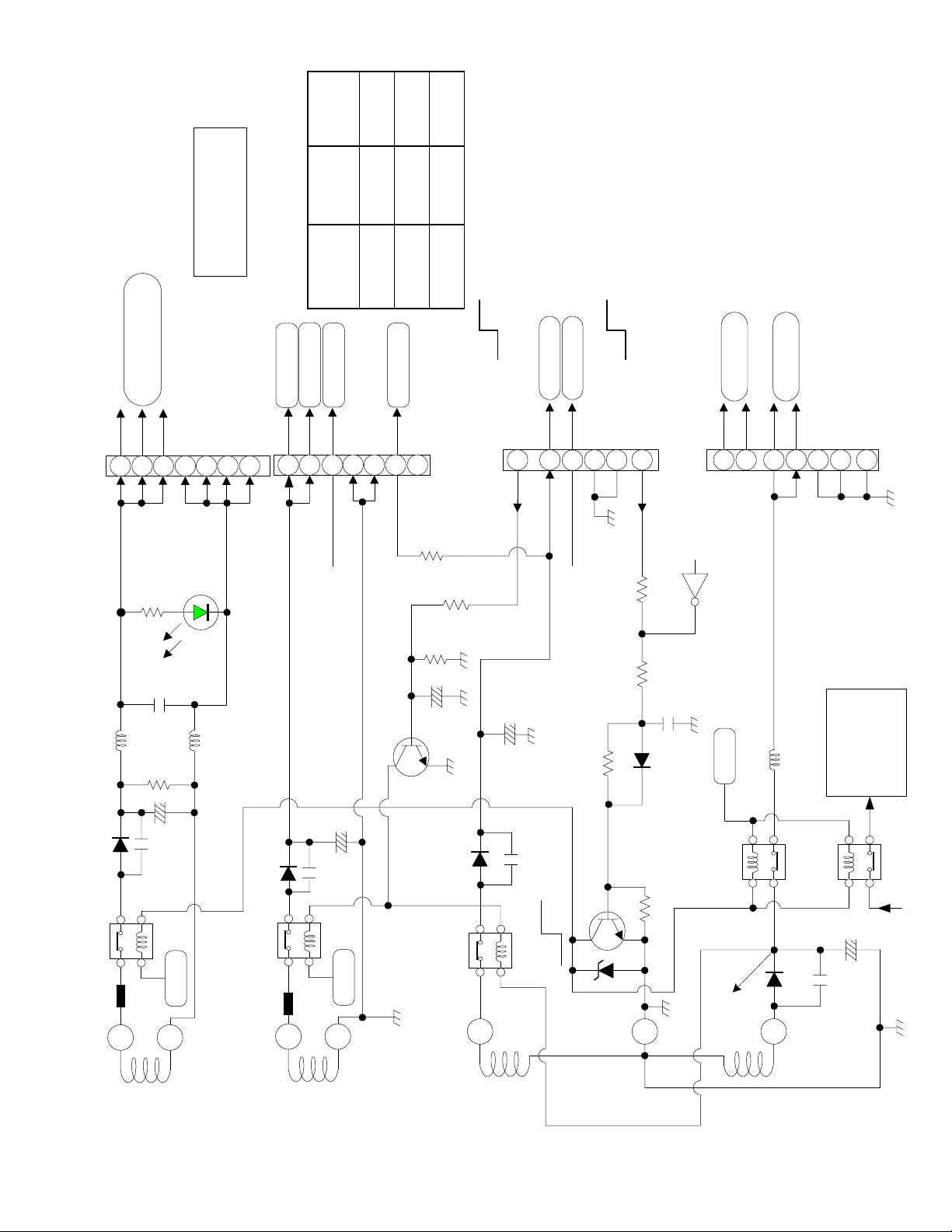

DP-23, DP- 23G and DP-24 Chassis

+6.0 V Low Voltage Regulation

T901

5

C910A

R917

D901

F902

1

T901

150V

3

D908

C918

D904

C913

R916

C917

R906

1

6

R907

16.3V

3

Osc B+

D

I901

Driver/

Output IC

FB/OLP

ABS

4

BD

OCP

C915

Start Up

7

5

2

S

R908

R909

0.47

Ohm

FB

C911

D906

D905

D907

6

Run

R912

C914

Hot Ground from

R913

D910

R911

negative leg of

Bridge D901

C916

R914

D953

Control

T901

+6V

7

8

R958

C969

D941

C954

2

I904

1

R957

Regulator Photocoupler

C904

1.79A

3 2

R915

4

3

Cold Ground from

pin 8 of T901

I909

+5V

Reg

C972 C973

C985

1

Floating Ground

from pin 6 of T901

PPS3

0.0685A

2

Sby +5V

PAGE 01-03

Page 12

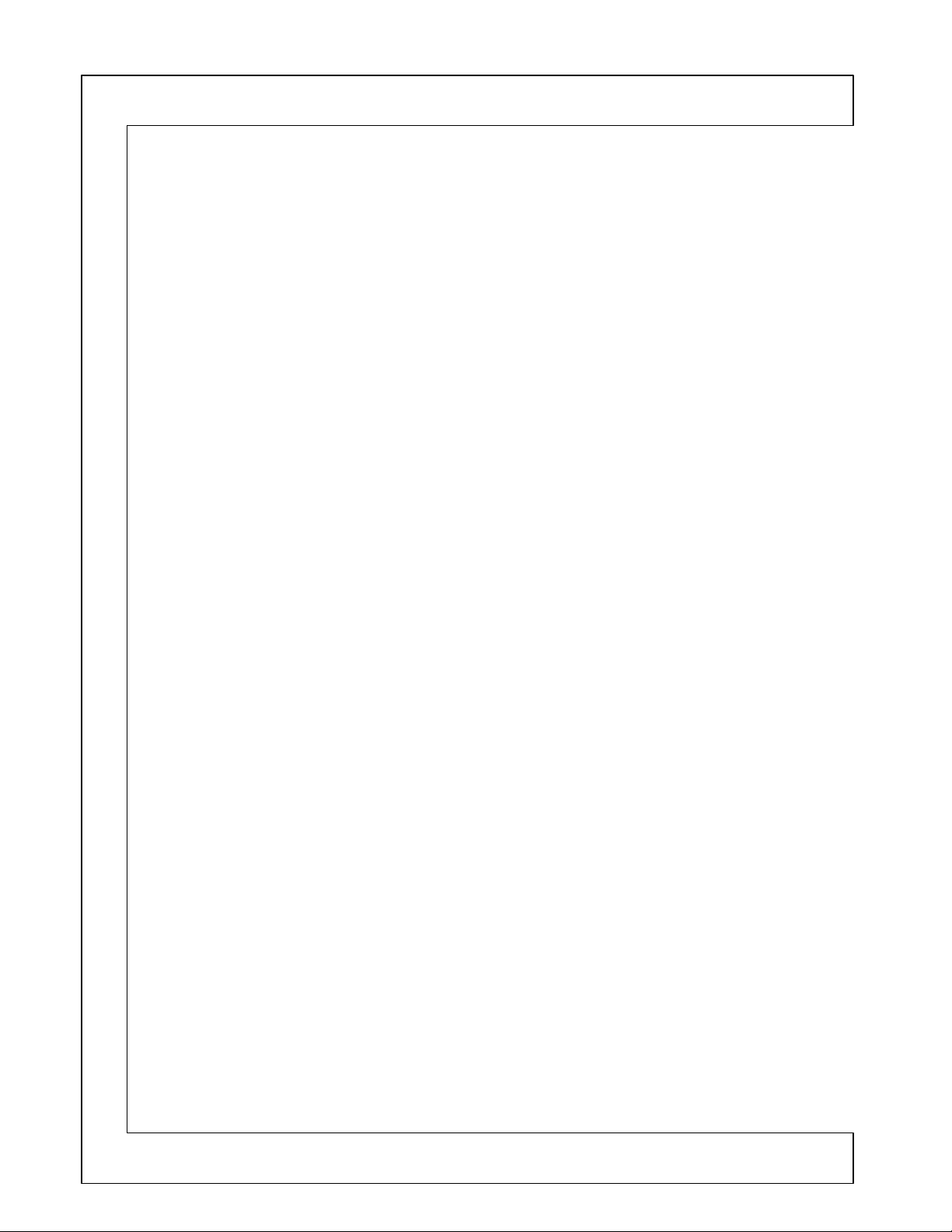

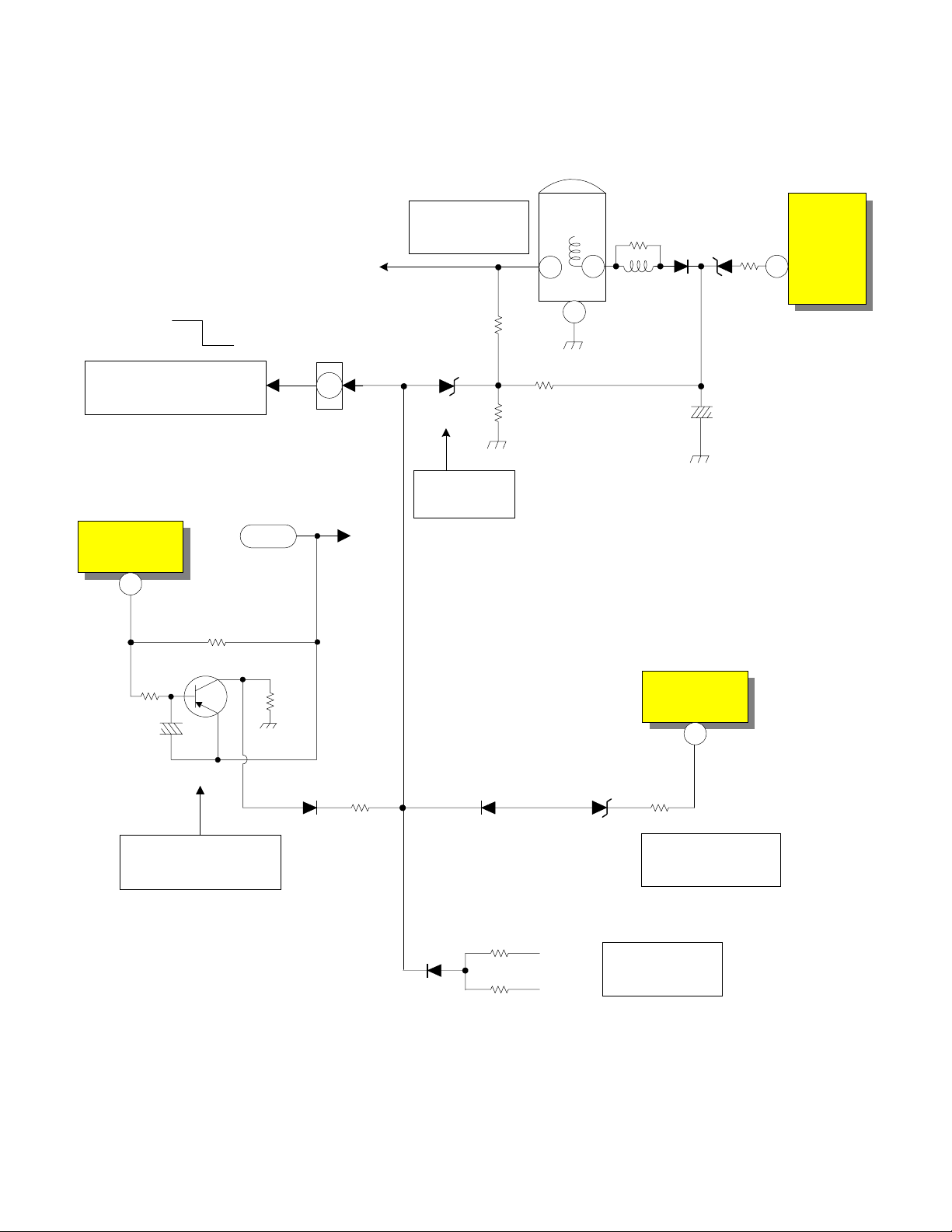

DP-2X POWER ON RELAY CONTROLS EXPLANATION

Relay Controls Circuit Diagram explanation:

(See DP-23, DP-23G, DP-24 and DP-27, DP-27D Relay Controls Circuit Diagram for details)

POWER ON:

When the Customer presses the Power On button on the Front control panel or the Remote control, the Microprocessor

and it’s collector connected to the Sty +5V line goes low. This action in turn causes the base of

and turns

5V.

This high is routed to the

(See the Lo Voltage Power Supply Shut Down Circuit for details), then the High from pin 4 is routed to the base

of

Q908

When

Q908

the base of

RELAYS ENERGIZED BY Q907 (DP-23, DP-23G, DP-24, DP-27 and DP-27D:

Note: This description refers specifically to the DP-27 and DP-27D chassis. Components identified inside brackets [ ] are for the DP-23, 23G and DP-24 chassis.

S901

This completes the path for AC to reach the High Voltage power supply bridge diode

age Regulation Circuit for details). This action starts the High Voltage power supply

circuit.

S902

This completes the path for the pulse generated from pin

and [+29V for DP-23, DP-23G and DP-24] to reach the Audio B+ rectifier diode

is generated and output from the

[+29V]

S903

This completes the path for the pulse generated from pin

which produces

and

IP53

S905

This completes the path for the pulse generated from pin

rectifier diode

Tuners pin 9.

DP-26 ONLY: RELAYS ENERGIZED BY POWER _1 and POWER _2:

(See DP-26 Relay Controls Circuit Diagram for details)

Power _1: (High when the Set is turned On.)

• When the Customer presses the Power On button on the Front control panel or the Remote control, the

• This high is routed to the

• When

output a High from pin 59. This high is routed to the base of

I001

to turn Off.

Q025

PPS3

turning it On.

turns on, it’s collector is connected to the

turning it On. When

Q907

SW+6V

(Switched +5V regulator) on the Signal PWB.

D943

Microprocessor

transistor On and it’s collector connected to the Sty +5V line goes low. This action in turn causes the

base of

line and it’s collector pulls up to 5V.

tivated, (See the Lo Voltage Power Supply Shut Down Circuit for details), then the High from pin 4 is

routed to the base of

Q025

Q907

to reach the

. Here the

I001

to go low and turns

turns on, it causes the following relays to energize.

collector is also connected to the

Q025

connector pin 4. Provided the

Q907

PPS5

PPS4

SW+35V

output a High from pin 59. This high is routed to the base of

Q907

is generated and output from the

connector pin 4. Provided the

PPS3

turning it On.

which turns this transistor On

Q026

Q025

Sby +5V

Short Detection

Sby +5V

turns on, it causes the following relays to energize.

connector pins 1, 2 and 3 and on to the Audio output circuit.

connector pins 7 and 6 and on to

to turn Off.

Q025

line. It’s emitter pulls up and supplies a high to

of

14 [11]

10 [7]

13 [10]

T901

of

T901

of

T901

collector is also connected to the

Q025

line and it’s collector pulls up to

transistor

D902

SW+115V

, (+38V for DP-26, DP-27 and DP-27D)

. Here the

D944

(Control +6V), rectified by diode

(Switched +3.3V regulator)

IP52

(+35V) to reach the Tuning Voltage B+

connector pin 8 and on to the

PPS3

Short Detection

isn’t activated,

Q903

. (See the High Volt-

for the deflection

Audio +38V

which turns this

Q026

transistor

to go low

Sby +5V

isn’t ac-

Q904

D941

(Continued on page 5)

PAGE 01-04

Page 13

DP-2X POWER ON RELAY CONTROLS EXPLANATION

RELAYS ENERGIZED BY Q907: Activated by Power _1

•

•

•

Power _2: (High when the set is turned On and/or when the Timer is On).

RELAYS ENERGIZED BY Q909

•

•

TIMER (Unattended Recording) OPERATION:

NOTE: Power _2

Tuners, Selector IC and Monitor output become active. During this time,

This way, the Selector IC, Tuners, Audio Circuit and Monitor outputs remain active.

The Table below shows the logic state of Power _1 and Power _2.

S901

This completes the path for AC to reach the High Voltage power supply bridge diode

High Voltage Regulation Circuit for details). This action start the High Voltage power supply

SW+115V

S902

This completes the path for the pulse generated from pin 14 of

tifier diode

and on to the Audio output circuit.

3

S903

This completes the path for the pulse generated from pin 10 of

D941

+3.3V regulator) and

• When the Customer presses the Power On button on the Front control panel or the Remote control, the

Microprocessor

• DM +9V REGULATOR:

• When Power _2 goes high, it's routed to pin 2 of

tor and it turns on. Input to pin 5 is the

to the Digital Module (ATSC Tuner) pin 12 PMS1.

3

• The DM +9V is also routed to the Terminal PWB pin 21of the

tor IC

• Power _2 is also routed to the

to the base of

• When

S905

This completes the path for the pulse generated from pin 13 of

age B+ rectifier diode

and on to the Tuners pin 9. This voltage is also routed out the PPS7 connector pin 6

come tuning voltage for the Digital Tuner (ATSC) via pin 1 of the

S906

This completes the path for the pulse generated from pin

rectifier diode

and on to the DM +9V regulator

from pin 3 to the Digital Module (ATSC Tuner) pin

for the deflection circuit.

, (+38V) to reach the Audio B+ rec-

T901

. Here the

D944

which produces

I001

and the Monitor Out Circuit.

IX01

Q909

turns on, it causes the following relays to energize.

Q909

D945

is also high when the Timer is set for unattended recordings. When the Timer is activated, the

Audio +38V

SW+6V

IP53

output a High from pin 58. This high is routed to two different circuits.

turning it On.

D943

. Here the

to reach the

(Switched +5V regulator) on the Signal PWB.

PPS3

: Activated by Power _2

. Here the

DM +10V

is generated and output from the

(Control +6V), rectified by diode

T901

connector pins 7 and 6 and on to

PPS4

on the Signal PWB. This is the

IP01

DM +10V, IP01

connector pin 4 and then to the Power Supply. This high is routed

SW+35V

. Input to pin 5,

IP01

is generated and output from the

is generated and output from the

regulates this down to 9V and output it from pin

connector. This turns on the Selec-

PST2

(+35V) to reach the Tuning Volt-

T901

PMS2

Digital Module +10V) of

17 (

regulates this down to

IP01

12

of the

PMS1

connector.

Power_1

connector pins 1, 2 and

PPS5

IP52

PPS3

connector.

connector pin 2 and 3

PPS7

+9V

remains Low.

. (See the

D902

(Switched

DM +9V

connector pin 8

DM +28V

T901

and outputs it

regula-

, to be-

to reach the

MODE POWER _1 POWER _2

Stand By L L

Timer L H

Power ON H H

PAGE 01-05

Page 14

I001

59

Micro

Audio + 29V

Audio Gnd

Audio Gnd

Audio Gnd

Audio Gnd

1

2

3

4

5

6

7

PPS5

1.30A

D965

R985

GREEN L.E.D.

C978

L922

L921

R992

Sby 5V comes from I909 pin 2

SW + 35V

8

PPS3

0.0165A

Gnd

3

C956

Gnd

7

Sby +5V

4

2

POWER _1

R962 R963

Q908

Q025 Q026

On

R961

C957

Off

SW + 6V

Gnd

Gnd

6

7

5

Gnd

4

3

PPS4

Short Det.

See Power Supply Shut Down Circuit

1.33A

Q903

Sby +5V

L923

AC to D902

High Voltage

Power Supply

D943

C962

D944

C957

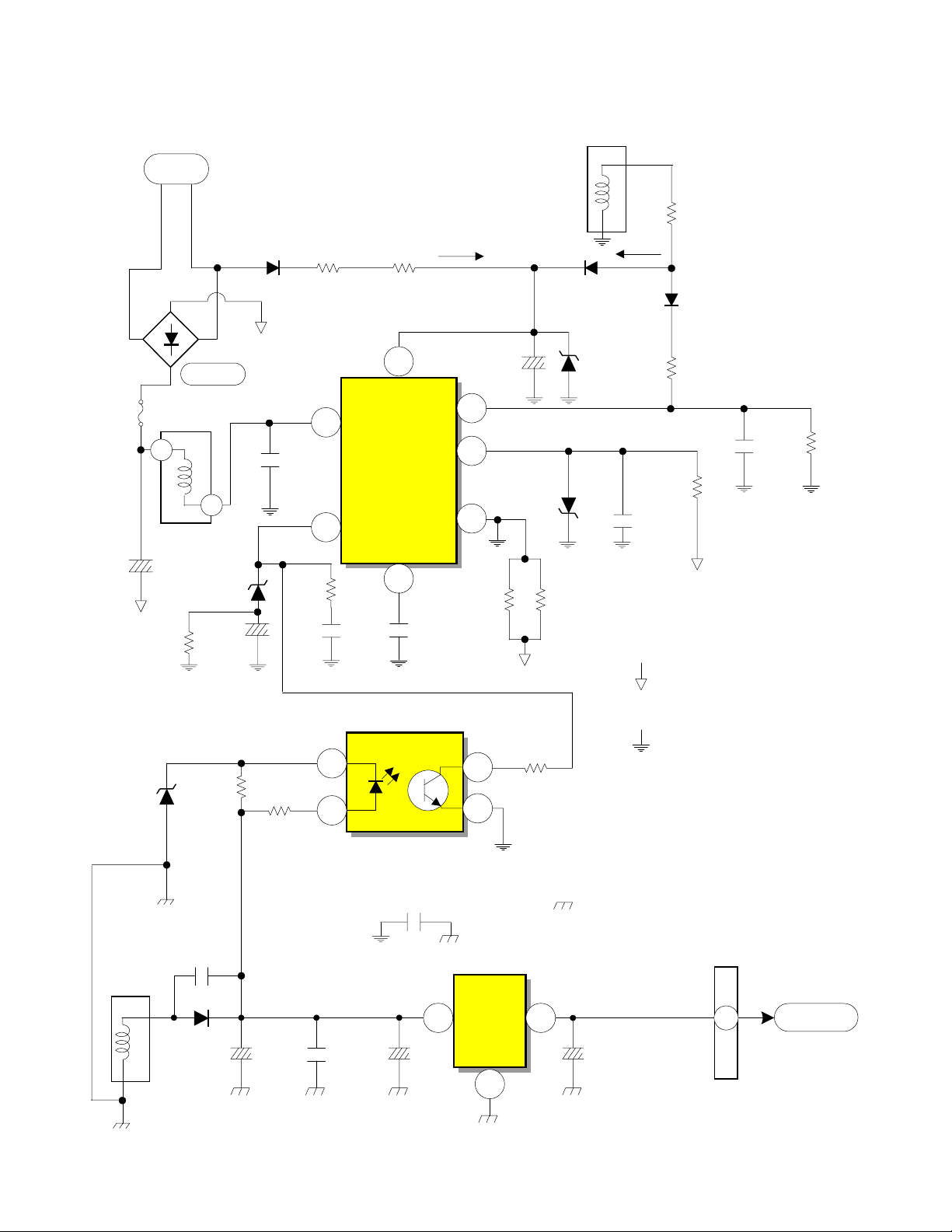

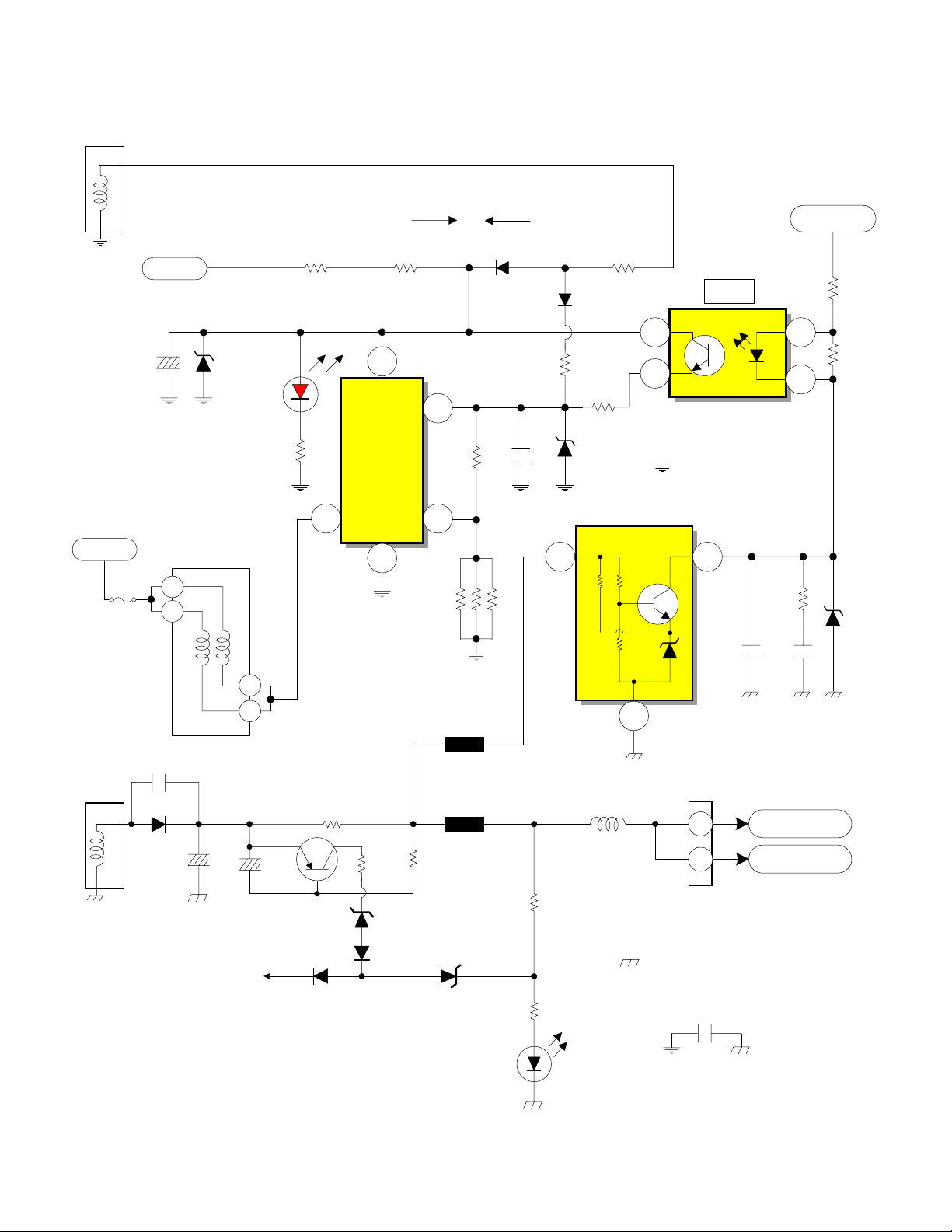

DP-23, DP-23G and DP-24 Chassis Power On Relay Controls

C961

R960

R959

Q907

Off

Supply Relay

S-902 Audio Power

E911

11

+29V

T901

Sby +5V

12

Supply Relay

S-905 SW +35V

10

+35V

On

D954

8

T901

Supply Relay

S-903 SW +6V

Control +6V

S-901 Main

Power Relay

AC

D941

C959

C954

7

PAGE 01-06

Page 15

Sby 5V comes

from I909 pin 3

_2

POWER

_1

POWER

MODE

L

H

L

L

Timer

Stand By

H

H

TV On

From Micro Pin 58

From I909

On

From Micro Pin 59

From I911

On

Audio + 38V

Audio Gnd

Audio Gnd

Audio Gnd

Audio Gnd

1

2

3

4

5

6

7

PPS5

1.55A

R985

D965

GREEN L.E.D.

DP-26 RELAY CONTROLS

L922

C978

L921

R992

DM +10V

2

1.55 A

DM +10V

Sby +10V

1

3

0.36 A

From D942

DM +28V

Audio Gnd

Audio Gnd

4

5

6

0.006 A

Q909

N/C

7

PPS7

R973

R963

C968

R984

Off

POWER _2

5

PPS3

C956

SW + 35V

1

1.30A

0.25 A

SBY + 5V

Gnd

3

2

R960

POWER _1

Gnd

7

4

R962 R963

Off

PPS4

Q904

C957

D972

SW + 9V

1

SW + 6V

6

7

2

1.06A

1.54A

Short Det.

Shut Down Circuit

See Power Supply

Sby +5V

L923

Gnd

5

Gnd

Gnd

4

3

AC to D902

High Voltage

Power Supply

D944

S-902

SW +35V Relay

E911

14

+38V

Audio

C952

T901

C957

Sby +5V

15

D945

S-906 Digital

Module 10 V Relay

E912

17

C963

16

T901

C958

Sby +5V

D943

Supply Relay

S-905 SW +35V

13

+35V

C961

Off

On

Q907

D954

T901

R959

11

Supply Relay

S-903 SW +6V

Control +6V

10

S-901 Main

Power Relay

D941

C954

C959

PAGE 01-07

AC

Page 16

I001

59

Micro

Audio + 38V

Audio Gnd

Audio Gnd

Audio Gnd

Audio Gnd

1

2

3

4

5

6

7

PPS5

1.95A

D965

R985

GREEN L.E.D.

C978

L922

L921

R992

Sby 5V comes from I909 pin 3

SW + 35V

8

PPS3

0.0165A

Gnd

3

C956

Gnd

7

Sby +5V

4

2

POWER _1

R962 R963

Q908

Q025 Q026

On

R961

C957

Off

SW + 6V

Gnd

Gnd

6

7

5

Gnd

4

3

PPS4

Short Det.

See Power Supply Shut Down Circuit

1.33A

Q903

Sby +5V

L923

AC to D902

High Voltage

Power Supply

C961

R960

R959

Supply Relay

S-903 SW +6V

D944

C962

C957

D943

Q907

Off

DP-27 and DP-27D CHASSIS RELAY CONTROLS on the POWER SUPPLY

Supply Relay

S-902 Audio Power

E911

14

+38V

T901

Sby +5V

15

Supply Relay

S-905 SW +35V

13

+35V

On

D954

11

Control +6V

10

D941

S-901 Main

Power Relay

C959

AC

C954

PAGE 01-08

Page 17

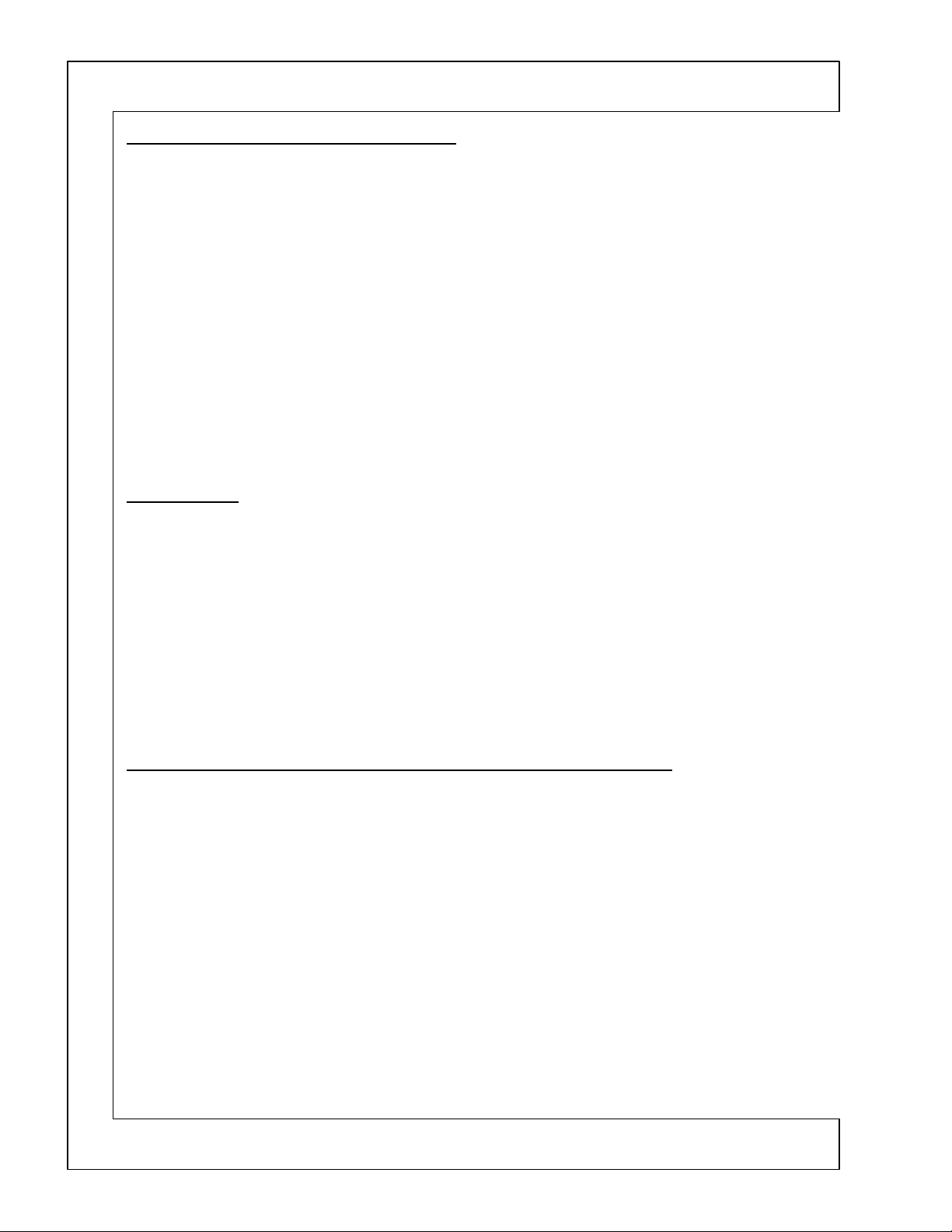

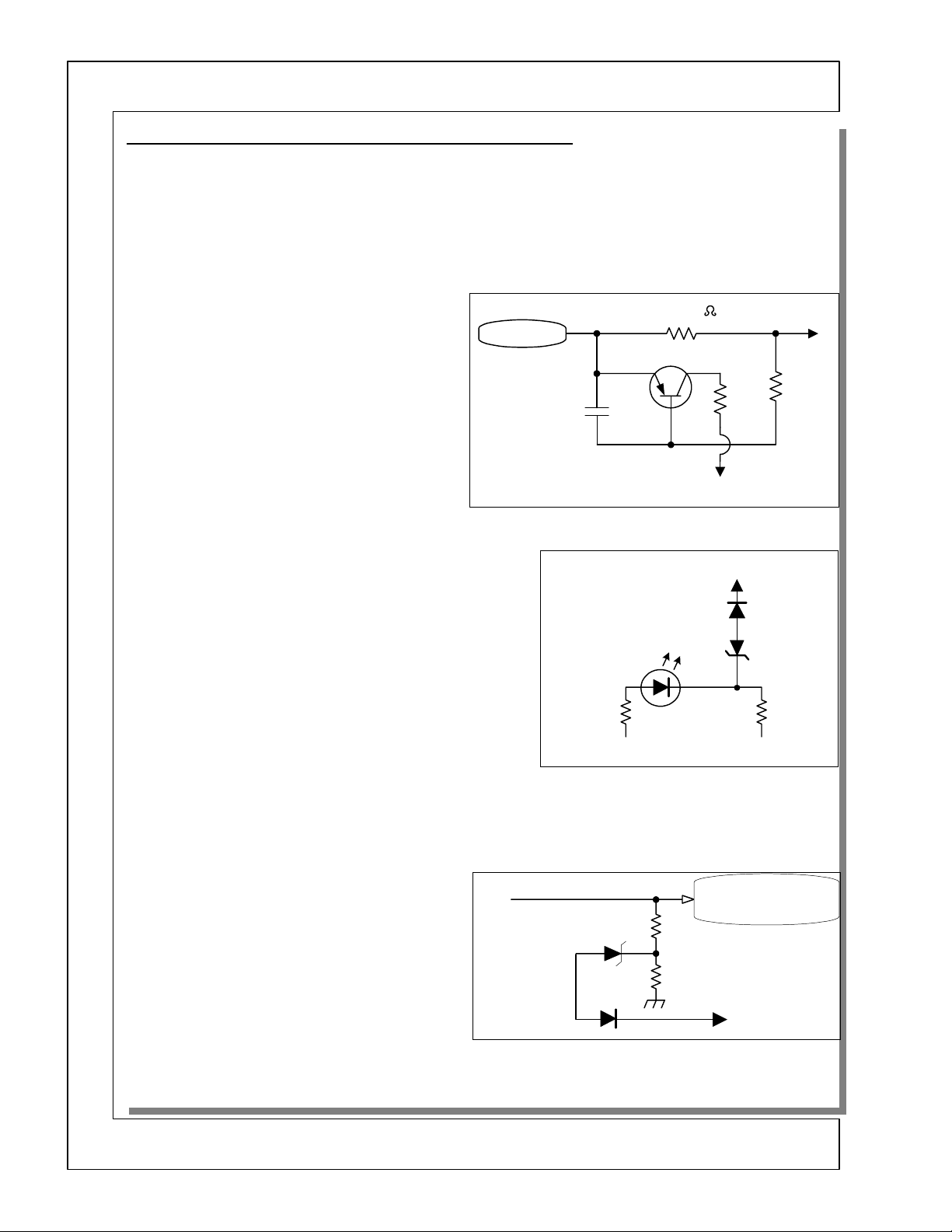

DP-2X LOW VOLTAGE POWER SHUT DOWN EXPLANATION

Low Voltage Power Supply Shut Down Circuit Diagram explanation:

(See DP-27 Signal Power Supply (Low Voltage) Shut-Down Circuit Diagram for details)

The Low Voltage power supply is centered around the Switching Transformer

This power supply creates the Standby voltages

let. It also creates other voltages that are Switched on when the Set is turned on.

Audio +38V

SW +35V

SW +9V

SW +HVcc

The following explanation will describe the Low Voltage Power Supply Shut Down Circuit.

POWER SUPPLY SHUTDOWN PHOTO COUPLER I905 EXPLANATION

This chassis utilizes I901 as the Osc.\Driver \Switch for the Low Voltage power supply, just as the previous chassis have done. The Shutdown circuit, (cold ground side detection), removes

circuit,

signal to the Hot Ground side,

it removes B+ from pin (3) of

The Power Supply utilizes a Shutdown circuit that can trigger

tection circuits are not operational in Stand By mode).

forward biases the internal LED. The light from this internal LED is then coupled to the receiver transistor. The

receiver transistor turns On and output a High from pin 3. This high is routed to the base of

which grounds out the Vin at pin (3) of

Q902

The individual Shut Down circuits will be discussed later.

GENERAL INFORMATION:

All of the Power Supply Shutdown circuitry can be broken down into the following category;

•

•

•

•

The following will explain all of these commonly used circuits. The Service Technician should become familiar

with the appearance of these circuit and their function.

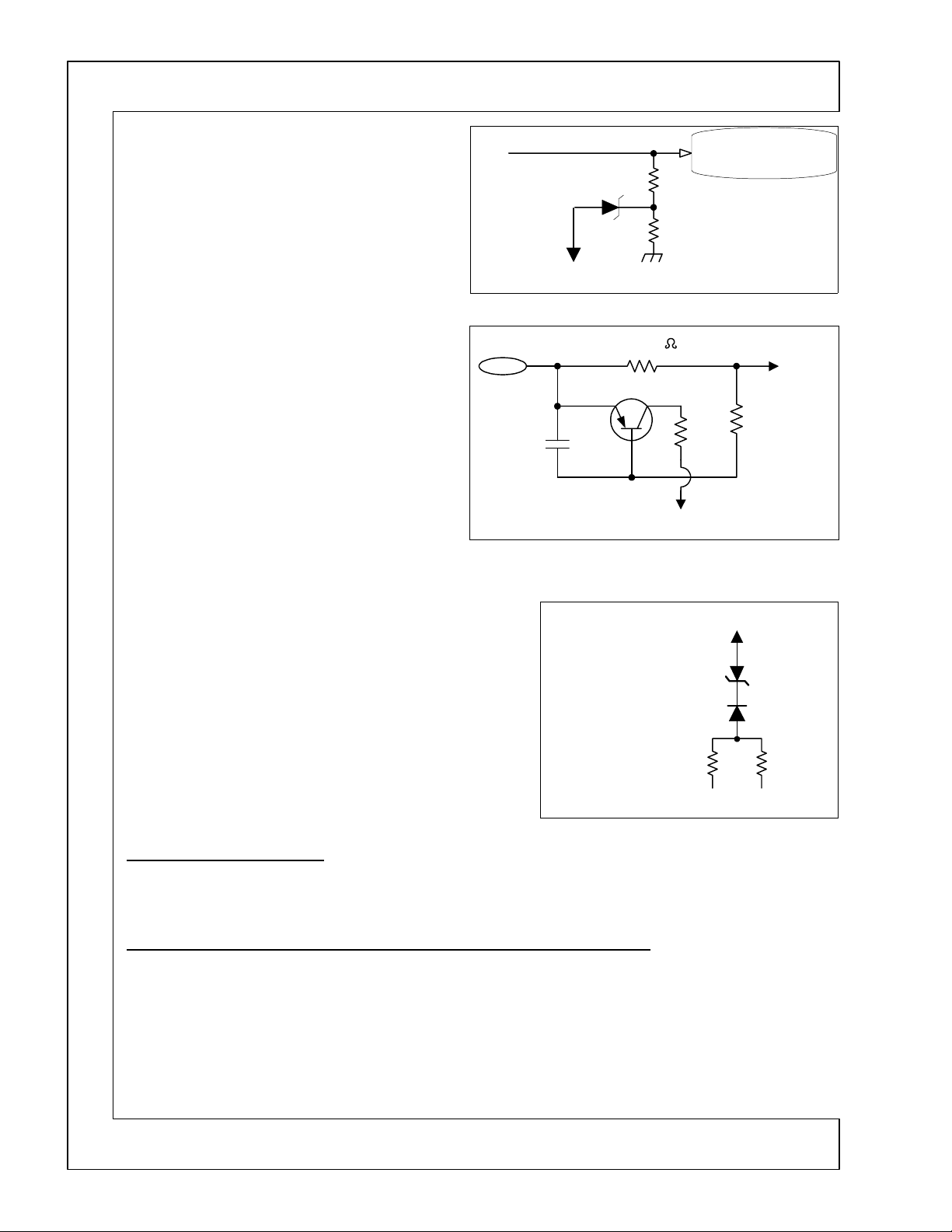

VOLTAGE LOSS or SHORT DETECTION

(See Figure 1)

One circuit used is the

cuit. This is a very simple circuit that detects a loss of

a particular power supply and supplies a Pull-Down

path for the base of a PNP transistor.

This circuit consist of a diode connected by its cathode to a positive B+ power supply. Under normal

conditions, the diode is reversed biases, which keeps

the base of Q1 pulled up, forcing it OFF. However, if

there is a short or excessive load on the B+ line that’s

being monitored, the diode in effect will have a LOW

on its cathode, turning it ON. This will allow a current path for the base bias of Q1, which will turn it

ON and generates a Shutdown Signal.

(the Photo Coupler), which isolates the Hot ground from the Cold ground and couples the Shutdown

I905

on the hot ground side and

Q902

(the Vin pin).

I901

I901

as long as there is any voltage available at its Emitter.

Voltage Missing Detection or Short Detection

Voltage Too High Detection

Excessive Current Detection

Negative Voltage Loss Detection

Voltage Loss Detection

SBY +5V

, disabling the power supply.

cir-

which runs anytime the set is plugged into an AC out-

Q901

Q902

is activated by a Low being applied to pin 2, which

I905

Voltage

Loss

Detector

Figure 1

and

T901

B+ at pin 3 via the following

I901

which latches

from 2 input sources. (1 of these Short De-

Q901

Q902

will keep a high on the base of

I901.

on. When

turning it On,

Q902

Any Positive

B+ Supply

Q902

B+

is on,

Q1

Shut-Down Signal

(Continued on page 10)

PAGE 01-09

Page 18

DP-2X LOW VOLTAGE POWER SHUT DOWN EXPLANATION

VOLTAGE TOO HIGH DETECTION

(See Figure 2)

Another circuit used is the

circuit. In the example shown in Figure 2, the

tion

zener diode

the voltage source rises too high, the voltage at the

divider center point will rise as well and trigger or fire

the zener diode which produces a Shutdown signal.

EXCESSIVE CURRENT DETECTION

(See Figure 3)

One very common circuit used in many Hitachi television products is the B+

circuit. In this circuit is a low ohm resistor in series

with the particular power supply, (labeled B+ in the

drawing). The value of this resistor is determined by

the maximum current allowable within a particular

power supply. In the case of Figure 1, the value is

shown as a

ohm value. When the current demand increases, the

voltage drop across the resistor increases. If the voltage drop is sufficient to reduce the voltage on the base

of the transistor, the transistor will conduct, producing

a Shutdown signal that is directed to the appropriate

circuit.

NEGATIVE VOLTAGE LOSS DETECTION

(See Figure 4)

The purpose of the Negative Voltage Loss detection circuit is to

compare the negative voltage with its’ counter part positive voltage. If at any time, the negative voltage drops or disappears, the

circuit will produce a Shutdown signal.

In Figure 5, there are two resistors of equal value. One to the

positive voltage, (shown here as +12V) and one to the negative

voltage, (shown here as -12V). At their tie point, (neutral point),

the voltage is effectually zero (0) volts. If however, the negative

voltage is lost due to an excessive load or defective negative

voltage regulator, the neutral point will go positive. This in turn

will cause the zener diode to fire, creating a Shutdown Signal.

SPECIFIC INFORMATION:

In addition, there are 7 Hot Ground side Shutdown inputs that are specifically detected by the main power driver

IC

HOT GROUND SIDE SHUT DOWN SENSING CIRCUITS. (Specific to I901).

LATCHED SHUT DOWN MONITORS:

1. (OVP)

2. (TSD)

3. (OLP) Over Load Protection monitors the difference between the Hot Ground and Floating Ground.

RECOVERING SHUT DOWN INPUT:

4. (OCP)

. These sensors circuits protect

I901

is connected to a voltage divider. If

D1

0.47 ohm

is monitored for Over Voltage Protection at pin 3 of

Pin 3

itself is monitored for Excessive Heat. This block is labeled TSD. (Thermal Sensing Device).

I901

monitors the low ohm resistors,

Pin 5

Voltage Too High Detec-

Excessive Current Sensing

, however it could be any low

Voltage Too High

Detector

Shut-Down Signal

B+

Current Sensor

Figure 3

R1

0.47

Shut-Down Signal

Shut-Down Signal

Any Positive

Voltage

Loss

Detector

from excessive current, temperature or over voltage.

I901

(AC must be removed to recover).

(Driver IC will recover on it’s own when trouble is removed.)

R908, R909,

and

Figure 4

.

I901

. If these resistors have an excessive

R910

+12V -12V

(Continued on page 11)

B+ Supply

Figure 2

Base

Bias

PAGE 01-10

Page 19

DP-2X LOW VOLTAGE POWER SHUT DOWN EXPLANATION

current condition caused by monitoring the current through the internal Switch MOS FET, the voltage will

rise and pin 5 has an internal Over Voltage detection op-amp. If this voltage rises enough to trigger this opamp, the IC will stop producing a drive signal.

5. (ABS)

of High Voltage.

6. (BD)

COLD GROUND SIDE SHUT DOWN SENSING CIRCUITS.

(See DP-27 Signal Power Supply (Low Voltage) Shut-Down Circuit Diagram for details)

Looking at Pin 2 of

D963, D962:

The cathode of

connected directly to the

this line down,

a Shut Down event. See Power Supply Shutdown Photo Coupler I905 Explanation on the previous page.

Q910:

This transistor’s base is connected to

the Shut down enable circuit.

DP-27 SHUT DOWN CIRCUIT:

There are a total of 3 individual Shutdown inputs to the photo coupler

There are a total of 3 individual Shutdown inputs to the Relay Inhibit transistor

There are a total of 4 individual Shutdown inputs to the Relay Inhibit transistor

cuit. For a total of 10 individual Shutdown inputs that will kill the Lo Voltage Power Supply. (Note: The Hi Volt-

age Power Supply Shutdown will be discussed later.)

All of the Cold Ground side Shutdown detection circuits can be categorized by the two previously described circuits

In the following explanation, the Shutdown circuits will be grouped. This will assist the Service Technician with

trouble shooting the Chassis, by understanding these circuits and having the associated circuit routs, the technician can then “Divide and Conquer”.

Voltage Loss Detection through I905 Photo coupler

• Shorted STBY +3.3V generated by

to (

• Shorted SW+2.2V (

on Low Voltage Power Supply PWB. Labeled

• Shorted SW+3.3V (

(

• Shorted SW+5V (

(

Q903 Relay Inhibit Activation.

From the Power Supply.

SW +115V Voltage Too High Detection

• Monitored by (

SW +115V Excessive Current Detection

• Monitored by (

also has

Pin 4

Monitors the Run Voltage generated by pin 18 of

Pin 7

I905

is connected through

D963

would forward bias and supply a current path for pin 2 of

D963

) on Low Voltage Power Supply PWB. Labeled

D963

) on Low Voltage Power Supply PWB. Labeled

D961

) on Low Voltage Power Supply PWB. Labeled

D961

D927

Q905

monitoring spike current in case the CRTs “Snap” indicating a quick discharge

C915

the shut down events are triggered by two routes.

to pin 10 of

R982

power supply produced by

3.3V

through

Q911

pin 5) on Signal PWB monitored by

IP52

pin 2) on Signal PWB monitored by

IP52

pin 2) on Signal PWB monitored by

IP53

) See additional Shut Down Circuit Diagram for details.

) See additional Shut Down Circuit Diagram for details

D955. Q911

and monitored by (

IP81

IP81

PROT-SW

for excessive voltage.

T901

(AC must be removed to recover).

. This in turn is connected to

PPS3

on the Signal PWB. If something were to load

This in turn would produce

I905.

emitter is connected to

.

I905

Q903

Q903

) on Signal PWB through

R298

PROT-SBY

RP53

on the Schematic.

DP53, RP53

PROT-SW

DP54, RP53

PROT-SW

on the Schematic.

through

on the Schematic.

on the Schematic.

Q912

from the power supply.

from the Deflection Cir-

pin 11 to to (

PPS3

through

through

PPS3

PPS3

which is

R298

. This transistor is

pin 10

PPS3

D961

pin 11 to to

pin 11 to to

(Continued on page 12)

)

PAGE 01-11

Page 20

DP-2X LOW VOLTAGE POWER SHUT DOWN EXPLANATION

SW –28V Loss Detection

• Monitored by (

From the Deflection Circuit PPD3 connector pin 6.

Vertical B+ 28V Voltage Excessive Current Detection

• Monitored by (

Excessive High Voltage Detection

• Monitored by (

-5V Loss Detection

• Monitored by (

Side Pincushion Failure Detection

• Monitored by (

If any one of these circuits activate the base of

connector pin 4 and the power supply will STOP.

SOME SHUTDOWN CIRCUITS ARE DEFEATED IN STANDBY MODE. (Set Off).

As indicated in the Power Supply (Lo Voltage) Shutdown circuit diagram, 3 of the shut down inputs are not active when the set is in standby.

• Shorted SW+2.2V (

on Low Voltage Power Supply PWB. Labeled

• Shorted SW+3.3V (

(

) on Low Voltage Power Supply PWB. Labeled

D961

• Shorted SW+5V (

(

) on Low Voltage Power Supply PWB. Labeled

D961

These voltage loss sensing circuits are defeated because the SW (Switched) power supplies are turned off in

standby. So to prevent faults triggering of the shutdown circuit, the sensing circuits are turned off also..

supplies the high for shutdown if any of the voltage loss circuits become activated.

Q911

voltage to operated. Emitter voltage is supplied from the emitter of

on/off line. When the set is not on or turned off, the power on/off line goes Low. This Low pulls the cathode of

low, removing the base voltage of

D956

this circuit can not function. The base of

for this circuit to function.

B+ GENERATION FOR THE LOW VOLTAGE POWER SUPPLY DRIVER IC:

Vcc for the Driver IC is first generated by the AC input. This voltage is called Start Up Voltage.

DC to operate normal. However, it will begin operation at

16V

When AC is applied, AC is routed through the main fuse

to prevent any internal high frequency radiation for radiating back into the AC power line. After passing the filters it arrives at the main full wave bridge rectifier

supplied to the power supply switching transformer

However, one leg of the AC is routed to a half wave rectifier

(both a 68K ohm resistor), filtered by

R907

of

as start up voltage. When this voltage reaches 6.8Vdc, the internal Regulator of

I901

begins the operation of

When the power supply begins to operate by turning on and off the internal Switch MOS FET, the Raw 150V DC

routed through

MOS FET is routed out of pin (2) through three low ohm resistors to hot ground. When the internal Switch MOS

FET turns on, it causes the transformer to saturate building up the magnet field. When the internal Switch MOS

FET turns off, the magnet field collapses and the EMF is coupled over to the secondary windings, as well as the

drive windings. The drive windings at pin (8) produce a run voltage pulse which is rectified by

then routed clamped by

C911

T901

) See additional Shut Down Circuit Diagram for details

D937

) See Deflection Protect Power Supply Shutdown Diagram for details.

Q604

) See Deflection Protect Power Supply Shutdown Diagram for details.

DH15

) See Deflection Protect Power Supply Shutdown Diagram for details.

DK90

D702, D703

IP53

.

I901

, in on pin 1 (Drain) and out on pin 2 which is the Source. The Source of the internal Switch

) See Deflection Protect Power Supply Shutdown Diagram for details

will go High and remove the Power On High from

Q903

pin 5) on Signal PWB monitored by

IP52

PROT-SW

pin 2) on Signal PWB monitored by

IP52

pin 2) on Signal PWB monitored by

turning it OFF. This removes the emitter voltage from

Q912

is also connected to the

Q912

F901

where it is converted to Raw 150V DC voltage to be

D901

pin (2).

T901

D904

, clamped by a 30V Zener

C911

and now becomes run voltage (

D907

on the Schematic.

PROT-SW

DP54, RP53

PROT-SW

Q912. Q912s

6.8V DC

(a 6 Amp fuse), then through the Line filter

where it is rectified, routed through

16V

through

RP53

DP53, RP53

on the Schematic.

on the Schematic.

SW +6V

on pin (3) of

D907

) for

through

through

base is connected to the power

line. This voltage must be active

and made available to pin (3)

pin 3.

I901

PPS3

Q911

I901

I901

PPS3

pin 11 to to (

PPS3

pin 11 to to

PPS3

requires emitter

I901

.

is turned On and

D905

D961

pin 11 to to

Q911

requires

R906

, filtered by

)

and

L901

and

PAGE 01-12

Page 21

DP-2X SIGNAL POWER SUPPLY (Low Voltage) SHUT-DOWN CIRCUIT

D904

R906

R907

16.97V

T901

D905

D941

8

10

Control +6V

C911

AC

Monitors

SW +5V

SW +3.3V

SW +2.5V

and

Stby +3.3V

for Short

To R298

Monitors IP81

To RP53

Monitors IP52

and IP53

Sby +5V

S901

Relay

AC

To Hi Volt

Power

Supply

D954

HZS11B1

Protect _Def

4 from Deflection

See Deflection Shut

Down Circuits

Q907

16.3V

Q901

S-905

SW +35V

Supply

Relay

R960

R959

6

PPD3

Vin

3

I901

Power IC

Q902

C920

R921

Protect _Sby

3.3V Reg

Protect _Sw

+5V Reg

SW +35V

Q908

C957

Q904

D933

R940

C944

R919

C919

47 Ohm

R920

PPS3

10

11

R980

8

D946

See Relay Control

Diagram for all

Relay Controls

R962

R962

1K

C987

Q903

R938

D907

R922

D962

HZS3C1

D963

R982

D960D961

D957

4

R963

220

R939

10K

R913

I905

HZS4A1

C956

9

11

R956

1

23

Q910

C969

Q911

R967

R966

C970

SW +35V

R969

D956

C971

PPS3

Power _1

4

Off

On

See additional

Power Supply Shut

Down Circuits

A

C955

D952

D955

Q912

+6V

S-903 SW +6V

Supply Relay

2

R964

R965

SW +6V

R968

I909

Sby +5V

PAGE 01-13

Page 22

DP-2X SW +115V POWER SUPPLY REGULATION EXPLANATION

Hi-Voltage Power Supply Circuit Diagram explanation:

(See DP-27 Chassis Power Supply SW+115V Regulation Circuit Diagram for details)

THIS POWER SUPPLY RUNS ONLY WHEN THE SET IS TURNED ON:

TURNING ON THE SW +115V POWER SUPPLY:

When the Set is turned on, the Microprocessor

command is routed through

provided the Short Detection Shut Down sensor

Q908

it’s emitter will go high and drive the base of

power on Relay

See Relay Controls on the Power Supply for details.

This rectifier develops raw 150V which is routed through

through the primary coil inside

Switch MOS FET. The Ground return path for the primary voltage is out pin 2 of

internal Switch MOS FET and then through three low ohm resistors

Regulation Circuit Diagram for details.

SW +115 REGULATION

SW +115V pulse is generated from pin 11 of

routed through the Excessive Current sensing circuit

The primary route for the

to the Deflection Circuit.

However, the regulation route is through

variable resistor whose resistance is dependant upon the

resistor manipulates the current flow from pin 2 to pin 3 ground. This will cause the voltage at pin 2 of

manipulated. Internally, the LED is illuminated by degrees dependant upon the

The internal receiver receives this light and acts as a variable resistor from pin 4 to pin 3 which is the regulation

control signal.

This action causes pin 1 of

quency of the drive pulse delivered to the Gate of the internal SMOSFET (Switch Metal Oxide Semiconductor

Field Effect Transistor) to manipulate the frequency of the pulse generated on the primary of

drain of the internal SMOSFET is monitored by the three low ohm resistors mentioned above. If this current exceeds a specific value, the voltage developed by these low ohm resistors is routed back into pin 1 which is the

Over Current Protection circuit as well as the Regulation Control pin. This pin will inhibit the drive signal to the

gate of the SMOSFET. As soon as the excessive current situation is eliminated, the IC will recover and continue

functioning.

B+ GENERATION FOR THE HIGH VOLTAGE POWER SUPPLY DRIVER IC:

Vcc for the Driver IC is first generated by the AC input. This voltage is called Start Up Voltage.

DC to operate normal. However, it will begin operation at

16V

When AC is applied to the main full wave bridge rectifier

to be supplied to the power supply switching transformer

However, one leg of the AC is routed to a half wave rectifier consisting of

sistor), filtered by

When this voltage reaches 6.8Vdc, the internal Regulator of

When the power supply begins to operate by turning on and off the internal Switch MOS FET, the Raw 150V DC

routed through

MOS FET is routed out of pin (2) through three low ohm resistors to hot ground. When the internal Switch MOS

FET turns on, it causes the transformer to saturate building up the magnet field. When the internal Switch MOS

FET turns off, the magnet field collapses and the EMF is coupled over to the secondary windings, as well as the

drive windings. The drive windings at pin (8) produce a run voltage pulse which is rectified by

then routed clamped by

C923

The RED LED

turning it on. When the relay is energized, AC is supplied to the Bridge rectifier

S901

SW +115V

, clamped by a 36V Zener

C923

, in on pin 1 (Drain) and out on pin 2 which is the Source. The Source of the internal Switch

T902

can be used to determine if the B+ to I902 is present or not.

D915

and

Q025

and out pins 5 and 6 to pin 3 of

T902

to manipulate the internal oscillator within

I902

and now becomes run voltage (

D912

to the

Q026

is through

E906

Outputs a Power On command via pin 59. This Power On

I001

PPS3

high turning it on. This will supply a ground path for the

Q907

. This pulse is rectified by

T902

E907, L914

to pin 1 of

D912

connector pin 4. This High will be passed to the base of

isn’t activated. When the base of

Q903

to Pins 1 and 2 of

F903

which is the Drain of the internal

I902

R926, R927

D915

and

R941

to pin 9 and 10 of

I907

SW +115V

D902

T902

and made available to pin 4 of

I902

.

Q905

. Internally, the regulator transistor works as a

voltage fluctuations. The internal variable

I902

6.8V DC

where it is converted to Raw 150V DC voltage

pin 1 and 2.

on pin 4 of

R924

is turned On and begins the operation of

) for

16V

I902

. This voltage is routed

T902

which is the Source of the

I902

and

, filtered by

PPD6

SW +115V

. This in turn causes the fre-

and

pin 4.

. See SW+115V

R928

and output as

voltage fluctuations.

.

I902

(both a 3.9K ohm re-

R925

as start up voltage.

I902

Q908

C927

. The current

T902

I902

D911

goes high,

D902

and then

SW +115V

I906

requires

, filtered by

.

to be

I902

.

PAGE 01-14

Page 23

T902

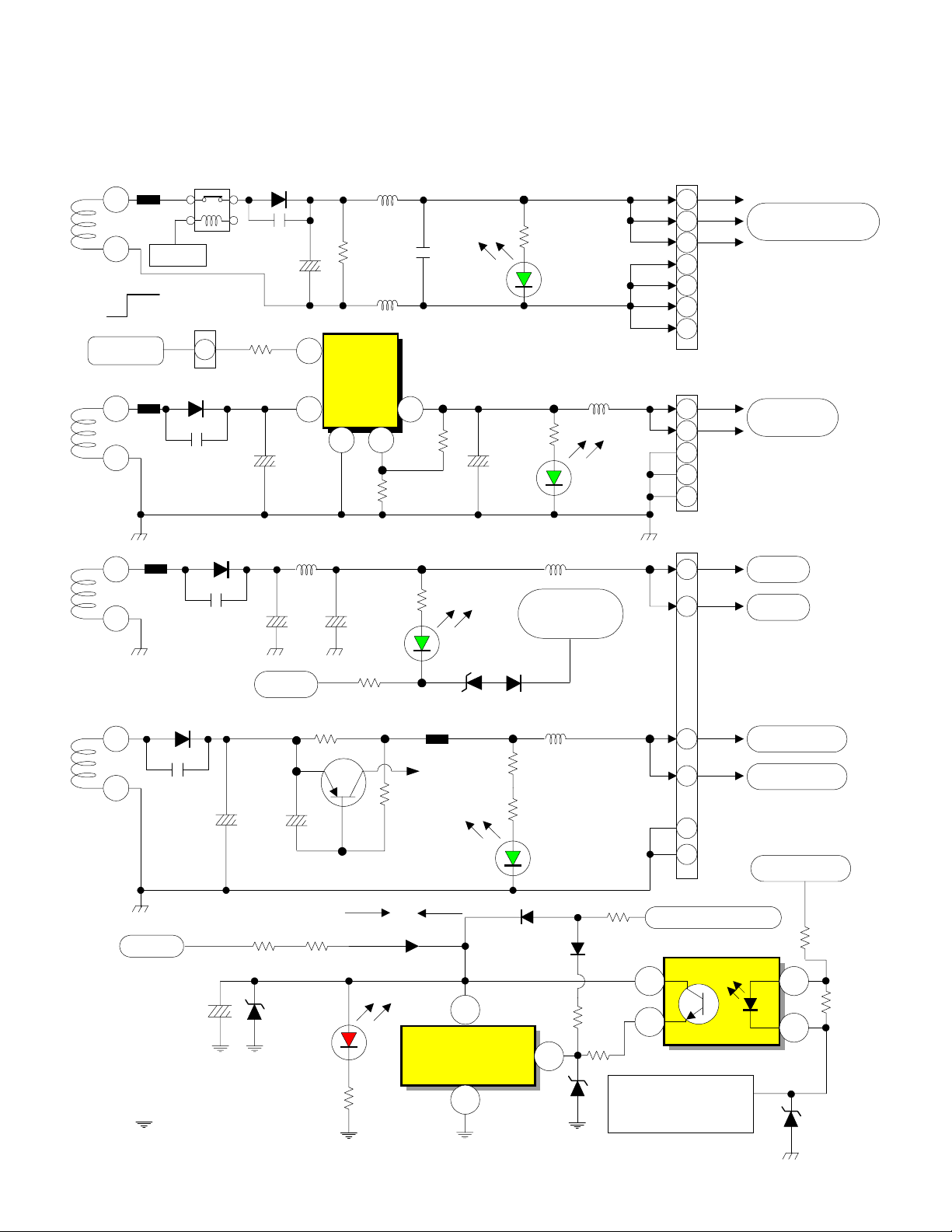

DP-2X CHASSIS POWER SUPPLY SW +115V REGULATION

High Voltage Power Supply

8

7.5P/P

9

AC

From Relay S901

C923

AC for D902

Supplied from

Relay S901

From Bridge D902

150V

1

F903

2

D912

T902

D915

RED L.E.D.

R934

R924

16.3V

4

I902

Driver/

Output IC

3 2

DS

6

R925

OCP

Start Up

Osc B+

1

R929

R926

R927

R928

0.22

Ohm

Run

D911

R930

D914

R931

R932

C926

D913

I907

1 2

4

3

Regulator Photocoupler

I906

Hot Ground from

pin 9 of T902

R936

SW + 115V

R937FB

1

R935

2

D922

T902

11

12

C933

D915

C927

C945

X-Ray

Protect

5

6

Q905

R941

0.47 Ohm

D924

D925

D926

R943

R942

D927

E906

0.5K

3K

E907

R945

R946

L914

Deflection

B+ 115V

D928

C942

3

PPD6

0.69A

9

10

Cold Ground from

pin 12 of T902

C905

C941

SW +115V

SW +115V

PAGE 01-15

Page 24

DP-2X ADDITIONAL SHUTDOWN CIRCUITS EXPLANATION

Additional Power Supply Shut Down Circuit Diagram explanation:

(See DP-27 Additional Power Supply Shut Down Diagram for details)

Use this explanation and Diagram in conjunction with the following diagrams.

DP-2X Signal Power Supply (Low Voltage) Shut Down Circuit (Continuation A)

The following circuits are routed to the Lo Voltage Shut Down Circuit through connection point (A) depicted on the Circuit drawing:

SW +115V EXCESSIVE CURRENT DETECTION

(See Figure 1)

One very common circuit used in many Hitachi television products is the B+

circuit. In this circuit is a low ohm resistor in series

with the SW +115V. The value of this resistor

. When the current demand increases, the voltage

ohm

drop across the resistor increases. If the voltage drop

is sufficient to reduce the voltage on the base of

, the transistor will conduct, producing a Shut-

Q905

down signal that is directed to the appropriate circuit

indicated on the drawing as point

NEGATIVE VOLTAGE LOSS DETECTION

(See Figure 2)

The purpose of the Negative Voltage Loss detection circuit is to

compare the negative voltage with its’ counter part positive voltage. If at any time, the negative voltage drops or disappears, the

circuit will produce a Shutdown signal.

In Figure 2, there are two resistors of equal value, (15K). One to

the positive voltage SW +28V and one to the negative voltage

SW –28V. At their tie point, (neutral point), the voltage is effec-

tually zero (0) volts. If however, the negative voltage is lost, the

neutral point will go positive. This in turn will cause the zener

diode D937 to fire, creating a Shutdown Signal through

and on to the appropriate circuit indicated on the drawing as

point

Note: The LED

supply.

VOLTAGE TOO HIGH DETECTION

(See Figure 3)

Another circuit used is the

tion

zener diode

the voltage source rises too high, the voltage at the

divider center point will rise as well and trigger or fire

the zener diode which produces a Shutdown signal

through

cated on the drawing as point

.

(A)

D940

circuit. In the example shown in Figure 3, the

D927

and on to the appropriate circuit indi-

D926

Excessive Current Sensing

0.47

.

(A)

used for visual trouble shooting is illuminated by the current draw from +28V to the –28V

Voltage Too High Detec-

is connected to a voltage divider. If

.

(A)

SW +115V

D936

Figure 3

Figure 1

Figure 2

SW +28V

D927

D926

0.47

R941

Current Sensor

Q905

Shut-Down Signal

Shut-Down Signal

Voltage

Loss

Detector

D940

Voltage Too

High Detector

Base

Bias

D936

D937

SW -28V

SW +115V

Shut-Down

Signal

PAGE 01-16

Page 25

T902

DP-2X ADDITIONAL POWER SUPPLY SHUT DOWN DIAGRAM

C933

3K

E907

Deflection B+ 115V

D915

Q905

R941

0.47 Ohm

11

C927

12

Deflection B+ (115V)

Excessive Current Det.

See Signal Power Supply

(Lo Voltage)

Shut Down Circuit

Diagram

for continuation.

C945

R943

D924

R944

C946

D925

A

SW-28V Short or Loss Det.

R942

D927

D926

R945

R946

D936

D937

Deflection B+ (115V)

Excessive Voltage Det.

D928

Deflection B+ 115V

PPD6

L914

0.69A

9

10

SW +115V

SW +115V

T902

T902

15

13

14

10K

E901

10K

E902

C934

D917

C928

C935

D918

C929

-

+

+

-

D940

R952

D971

L913

L912

C950

C949

R951

-

+

+

-

L915

L916

0.575A

1.09A

5

3

4

1

2

SW -28V

Gnd

Gnd

SW +28V

SW +28V

PAGE 01-17

Page 26

DP-2X PROTECT SHUTDOWN CIRCUIT EXPLANATION

0.68

DK90

.

SW +28V

Figure 1

through

.

D703

PPD3

and

DH15

R629

Current Sensor

Q604

through

pin 6.

DH13

.

DH14

to stop producing the Hi

IH01

0.68

Shut-Down Signal

pin 6. This signal is

PPD3

Shut-Down Signal

DK90

+5V -5V

and

Base

Bias

Voltage

Loss

Detector

Protect Shut Down Circuit Diagram explanation:

(See DP-27 Protect Shut Down Diagram for details)

Use this explanation and Diagram in conjunction with the following diagram,

DP-2X Signal Power Supply (Low Voltage) Shut Down Circuit (PROTECT _DEF)

The following circuits are routed to the Lo Voltage Shut Down Circuit through connection point

(PROTECT _DEF) depicted on the Circuit drawing:

EXCESSIVE HIGH VOLTAGE DETECTION

Whenever the High Voltage fluctuates, every other pin off the flyback will fluctuate as well. In this case, a lower

voltage source can be used to determine the status of the High Voltage.

Pin 5 (50P) is used to monitor for excessive High Voltage. The pulse off the flyback is rectified by

filtered by

is a HZ22V zener. If the voltage at the cathode rises too high, the zener will fire and send a Shut Down

DH15

signal through

The Shut Down signal is depicted as

is a HZ36V zener. If the voltage at the cathode rises too high, the zener will fire and send a Shut Down

DH14

signal through to pin 7 of

Voltage Drive signal from pin 1.

EXCESSIVE CURRENT TO THE VERTICAL OUTPUT IC DETECTION

(See Figure 1)

This circuit uses a low ohm resistor

with the SW +28V. The value of this resistor

. When the current demand increases, the volt-

ohm

age drop across the resistor increases. If the voltage

drop is sufficient to reduce the voltage on the base of

, the transistor will conduct, producing a Shut-

Q604

down signal through

signal is routed to the appropriate circuit on the Lo

Voltage Shut Down Circuit. The Shut Down signal

is depicted as

SIDE PINCUSHION FAILURE DETECTION

If the side pincushion circuit fails in such a way as to produce an excessive high on the cathode of D702 (a

HZS7C3) the zener will fire producing a Shutdown signal through

routed to the appropriate circuit on the Lo Voltage Shut Down Circuit. The Shut Down signal is depicted as

PROTECT _DEF

-5V LOSS DETECTION

The purpose of the Negative Voltage Loss detection circuit is to compare the

negative voltage with its’ counter part positive voltage. If at any time, the negative voltage drops or disappears, the circuit will produce a Shutdown signal.

In Figure 2, there are two resistors of equal value. One to the positive voltage

+5V and one to the negative voltage -5V). At their tie point, (neutral point), the

voltage is effectually zero (0) volts. If the negative voltage is lost, the neutral

point will go positive. This high is routed through

This signal is routed to the appropriate circuit on the Lo Voltage Shut Down Circuit. The Shut Down signal is depicted as

. This voltage sets on the cathode of two zener diodes

CH17

pin 6. This signal is routed to the appropriate circuit on the Lo Voltage Shut Down Circuit.

PPD3

PROTECT _DEF

which is the OVP input pin. This high will cause

IH01

in series

R629

through

D608

PROTECT _DEF

.

.

pin 6. This

PPD3

PROTECT _DEF

Figure 2

PAGE 01-18

Page 27

DP-2X DEFLECTION PROTECT POWER SUPPLY SHUTDOWN DIAGRAM

RH32 allows ABL fluctuations to

manipulate the Trigger Point of Shut

Down as screen brightness varies. ABL

is inverse proportionate to brightness.

This prevents false triggering.

Active

Normal

PPD3

PROTECT _DEF

See Power Supply Shut Down

Circuit Diagram for continuation.

Vertical Output Circuit

I601

10

28V

75

Hi Volt

H. Drive

IH01

OVP

Flyback

High Voltage

ABL Voltage

Too High Det.

ABL

RH32

TH01

3

5OP

4

6

DH15

Excessive Hi

Voltage Det.

RH24

Any fluctuations in High Voltage will

also be reflected by the 50P output P/P.

By monitoring the 50P (50 Pulse) rises

in High Voltage will be sensed. If High

Voltage climbs too high, DH15 will fire

and trigger a shut down event.

Sensing Circuit

RH23

LH06

29.01V

CH17

DH13

RH26

DH14

Stops H. Drive

R629 0.68 Ohm

Q604

R630

C610

Excessive Vertical

Current Det.

If the Vertical Output IC has a problem,

R629 will sense the current rise. The

voltage drop will be reflected at the base

of Q604 turning it on and producing a

Shut Down high.

R631

D608

R632

D702 monitors the Side Pin

Drive IC. If the voltage at

pin 7 rises too high, D702

will fire generating a Shut

Down high.

D703

Convergence Out Circuit

RK97

-5V

RK98

DK90

A loss of the Negative 5V will cause the

positive 5V to be felt on the anode of

DK90 which forward biases the diode

and delivers a Shut Down high.

+5V

Side Pincushion Circuit

R717

D702

HZS7C3

Side Pin Failure

-5V Loss

Detection

I701

7

High Det.

PAGE 01-19

Page 28

DP-2X LED (Visual Trouble Detection) CIRCUIT EXPLANATION

LED Used for Visual Trouble Shooting Circuit Diagram explanation:

(See DP-2X LED (Visual Trouble Detection) Diodes Signal Power Supply Diagram for details)

5 LEDS, 4 GREEN AND 1 RED

In the DP-2X chassis, there are 5 total LEDs that can be used for Visual Trouble shooting. 4 Green and 1 Red.

Use these LEDs to determine if the set is experiencing a problem.

The LEDs can be used in the following ways.

OFF:

• If the LED is off, then the power supply that is being monitored is unavailable. (Excluding the possibility

that the LED itself is malfunctioning). NOTE: If

tion because of it’s current flow explained below.

• If the LED turns on but then quickly goes off before the others, then the power supply that is being moni-

tored can be suspected.

RED LED D915

is used to monitor the Start Up and Run voltage for the Driver IC

D915

lowing voltages.

SW +115V

220V

HEATER

SW+7V

SW-7V

SW +28V

SW -28V

This LED is attached to pin 4 of

GREEN LEDs D965, D954, D940 and D928.

D965 (Audio +38V)

• Monitors the

D954 (SW +9V)

• Monitors the

pin 1 and 2.

D940 (SW +28V)

• Monitors the SW +28V output from the

• Note: This LED requires the SW –28V power supply to be functioning to operated. If the LED opens, or

the negative SW –28V is shorted, this LED will not illuminate and the set will shut down.

D928 (SW +115V)

• Monitors the

Audio +38V

SW +9V

SW +115V

. If the voltage is missing, the LED will not light.

I902

output from the

generated by the SW +9V regulator

PPD6

output from the

PPD6

LED opens, then the set will be in shut down condi-

D940

connector pin 1, 2 and 3.

PPS5

connector pin 1 and 2.

connector pin 9 and 10.

. This IC is used to generate the fol-

I902

pin 3 output from the

I911

PPS4

connector

PAGE 01-20

Page 29

DP-23, DP-23G and DP-24 CHASSIS

L.E.D. (Visual Troubleshooting) Low Voltage Power Supply

(5 Total L.E.D. for visual trouble sensing , 4 Green and 1 Red)

T901

T901

T902

E911

11

12

Off

Power _1

E909

9

8

14

E902

+28V

13

S-902 Audio Power

Supply Relay

Sty +5V

On

PPS3

4

D942

C960

D918

C935

R990

1.92A

1.13A

C929

D944

C962

C957

- 28V

C955

L913

C950

1.55A

2

5

L922

R992

L921

I911

SW+9V

Reg

1

D940

R951

4

R952

3

R977

R976

GREEN L.E.D.

C978

GREEN L.E.D.

C977

GREEN L.E.D.

D937 D936

R979

L916

See Shut

Down Circuit

R985

D965

1.30A

L924

D954

0.57A

1.09A

PPS5

1

2

3

4

5

6

7

PPS4

1

2

3

4

5

PPD6

1

2

Audio + 29V

Audio Gnd

Audio Gnd

Audio Gnd

Audio Gnd

SW + 9V

Gnd

Gnd

Gnd

+ 28V

+ 28V

+115V D915

T902

11

12

C933

C927

Osc B+

AC

From

Relay

S901

C923

Hot Ground from

pin 9 of T902

Q905

C945

RED L.E.D.

R941 0.47 Ohm

R925R924

D912

D915

R934

Start Up

E907

+115V

Over

Current

D928

Run

D911

16.3V

4

I902

Driver/Output IC

6

L914

R945

R946

GREEN L.E.D.

R931

1

D913

0.69A

R930

7.5P/P

D914

4

3

R932

Regulator Photocoupler

From I907 pin 2 of

Regulator IC

9

10

6

Gnd

7