YUTAKI S80 SERIES

DHWS(200/260)S-2.7H2E

INSTRUCTION MANUAL

MANUAL DE INSTRUCCIONES

BEDIENUNGSANLEITUNG

MANUEL D’UTILISATION

MANUALE DI ISTRUZIONI

MANUAL DE INSTRUÇÕES

BRUGSANVISNING

INSTALLATIEHANDLEIDING

INSTALLATIONSHANDBOK

ΕΓΧΕΙΡΊΔΙΟ ΟΔΗΓΙΏΝ

Domestic hot water tank

English

Specications in this manual are subject to change without notice in order that HITACHI may bring the latest innovations

to their customers.

Whilst every effort is made to ensure that all specications are correct, printing errors are beyond Hitachi’s control;

HITACHI cannot be held responsible for these errors.

Español

Las especicaciones de este manual están sujetas a cambios sin previo aviso a n de que HITACHI pueda ofrecer las

últimas innovaciones a sus clientes.

A pesar de que se hacen todos los esfuerzos posibles para asegurarse de que las especicaciones sean correctas, los

errores de impresión están fuera del control de HITACHI, a quien no se hará responsable de ellos.

Deutsch

Bei den technischen Angaben in diesem Handbuch sind Änderungen vorbehalten, damit HITACHI seinen Kunden die

jeweils neuesten Innovationen präsentieren kann.

Sämtliche Anstrengungen wurden unternommen, um sicherzustellen, dass alle technischen Informationen ohne Fehler

veröffentlicht worden sind. Für Druckfehler kann HITACHI jedoch keine Verantwortung übernehmen, da sie außerhalb

ihrer Kontrolle liegen.

Français

Les caractéristiques publiées dans ce manuel peuvent être modiées sans préavis, HITACHI souhaitant pouvoir toujours

offrir à ses clients les dernières innovations.

Bien que tous les efforts sont faits pour assurer l’exactitude des caractéristiques, les erreurs d’impression sont hors du

contrôle de HITACHI qui ne pourrait en être tenu responsable.

Italiano

Le speciche di questo manuale sono soggette a modica senza preavviso afnché HITACHI possa offrire ai propri

clienti le ultime novità.

Sebbene sia stata posta la massima cura nel garantire la correttezza dei dati, HITACHI non è responsabile per eventuali

errori di stampa che esulano dal proprio controllo.

Português

As especicações apresentadas neste manual estão sujeitas a alterações sem aviso prévio, de modo a que a HITACHI

possa oferecer aos seus clientes, da forma mais expedita possível, as inovações mais recentes.

Apesar de serem feitos todos os esforços para assegurar que todas as especicações apresentadas são correctas,

quaisquer erros de impressão estão fora do controlo da HITACHI, que não pode ser responsabilizada por estes erros

eventuais.

Dansk

Specikationerne i denne vejledning kan ændres uden varsel, for at HITACHI kan bringe de nyeste innovationer ud til

kunderne.

På trods af alle anstrengelser for at sikre at alle specikationerne er korrekte, har Hitachi ikke kontrol over trykfejl, og

Hitachi kan ikke holdes ansvarlig herfor.

Nederlands

De specicaties in deze handleiding kunnen worden gewijzigd zonder verdere kennisgeving zodat HITACHI zijn klanten

kan voorzien van de nieuwste innovaties.

Iedere poging wordt ondernomen om te zorgen dat alle specicaties juist zijn. Voorkomende drukfouten kunnen echter

niet door Hitachi worden gecontroleerd, waardoor Hitachi niet aansprakelijk kan worden gesteld voor deze fouten.

Svenska

Specikationerna i den här handboken kan ändras utan föregående meddelande för att HITACHI ska kunna leverera de

senaste innovationerna till kunderna.

Vi på Hitachi gör allt vi kan för att se till att alla specikationer stämmer, men vi har ingen kontroll över tryckfel och kan

därför inte hållas ansvariga för den typen av fel.

Eλλhnika

Οι προδιαγραφές του εγχειριδίου μπορούν να αλλάξουν χωρίς προειδοποίηση, προκειμένου η HITACHI να παρέχει τις

τελευταίες καινοτομίες στους πελάτες της.

Αν και έχει γίνει κάθε προσπάθεια προκειμένου να εξασφαλιστεί ότι οι προδιαγραφές είναι σωστές, η Hitachi δεν μπορεί

να ελέγξει τα τυπογραφικά λάθη και, ως εκ τούτου, δεν φέρει καμία ευθύνη για αυτά τα λάθη.

! CAUTION

This product shall not be mixed with general house waste at the end of its life and it shall be retired according to the

appropriated local or national regulations in a environmentally correct way.

Contact to the corresponding authorities for more information.

! PRECAUCIÓN

Éste producto no se debe eliminar con la basura doméstica al nal de su vida útil y se debe desechar de manera respetuosa con el

medio ambiente de acuerdo con los reglamentos locales o nacionales aplicables.

Para obtener más información, póngase en contacto con las autoridades competentes.

! VORSICHT

Dass Ihr Produkt am Ende seiner Betriebsdauer nicht in den allgemeinen Hausmüll geworfen werden darf, sondern entsprechend den

geltenden örtlichen und nationalen Bestimmungen auf umweltfreundliche Weise entsorgt werden muss.

Für weitere Informationen setzen Sie sich bitte mit den entsprechenden Behörden in Verbindung.

! ATTENTION

Ne doit pas être mélangé aux ordures ménagères ordinaires à la n de sa vie utile et qu’il doit être éliminé conformément à la

réglementation locale ou nationale, dans le plus strict respect de l’environnement.

En raison du frigorigène, de l’huile et des autres composants que le climatiseur contient, son démontage doit être réalisé par un

installateur professionnel conformément aux réglementations en vigueur.

Pour plus d’informations, contacter les autorités compétentes.

! AVVERTENZA

Indicazioni per il corretto smaltimento del prodotto ai sensi della Direttiva Europea 2002/96/EC e Dlgs 25 luglio 2005 n.151

Il simbolo del cassonetto barrato riportato sull’ apparecchiatura indica che il prodotto alla ne della propria vita utile deve essere raccolto

separatamente dagli altri riuti.

L’utente dovrà, pertanto, conferire l’apparecchiatura giunta a ne vita agli idonei centri di raccolta differenziata dei riuti elettronici ed

elettrotecnici, oppure riconsegnarla al rivenditore al momento dell’ acquisto di una nuova apparecchiatura di tipo equivalente.

L’adeguata raccolta differenziata delle apparecchiature dismesse, per il loro avvio al riciclaggio, al trattamento ed allo smaltimento

ambientalmente compatibile, contribuisce ad evitare possibili effetti negativi sull’ ambiente e sulla salute e favorisce il riciclo dei materiali

di cui è composta l’ apparecchiatura.

Non tentate di smontare il sistema o l’unità da soli poichè ciò potrebbe causare effetti dannosi sulla vostra salute o sull’ ambiente.

Vogliate contattare l’ installatore, il rivenditore, o le autorità locali per ulteriori informazioni.

Lo smaltimento abusivo del prodotto da parte dell’utente può comportare l’applicazione delle sanzioni amministrative di cui all’articolo 50

e seguenti del D.Lgs. n. 22/1997.

! CUIDADO

O seu produto não deve ser misturado com os desperdícios domésticos de carácter geral no nal da sua duração e que deve ser

eliminado de acordo com os regulamentos locais ou nacionais adequados de uma forma correcta para o meio ambiente.

Contacte as autoridades correspondentes para obter mais informações.

! FORSIGTIG

At produktet ikke må smides ud sammen med almindeligt husholdningsaffald, men skal bortskaffes i overensstemmelse med de

gældende lokale eller nationale regler på en miljømæssig korrekt måde.

Kontakt de pågældende myndigheder for at få yderligere oplysninger.

! LET OP

Dit houdt in dat uw product niet wordt gemengd met gewoon huisvuil wanneer u het weg doet en dat het wordt gescheiden op een

milieuvriendelijke manier volgens de geldige plaatselijke en landelijke reguleringen.

Neem contact op met de betreffende overheidsdienst voor meer informatie.

! VARNING

Det innebär att produkten inte ska slängas tillsammans med vanligt hushållsavfall utan kasseras på ett miljövänligt sätt i enlighet med

gällande lokal eller nationell lagstiftning.

Ta kontakt med ansvarig myndighet om du vill ha mer information.

! ΠΡΟΣΟΧΗ

Σημαίνει ότι το προϊόν δεν θα πρέπει να αναμιχθεί με τα διάφορα οικιακά απορρίμματα στο τέλος του κύκλου ζωής του και θα πρέπει να

αποσυρθεί σύμφωνα με τους κατάλληλους τοπικούς ή εθνικούς κανονισμούς και με τρόπο φιλικό προς το περιβάλλον.

Για περισσότερες λεπτομέρειες, επικοινωνήστε με τις αντίστοιχες αρχές.

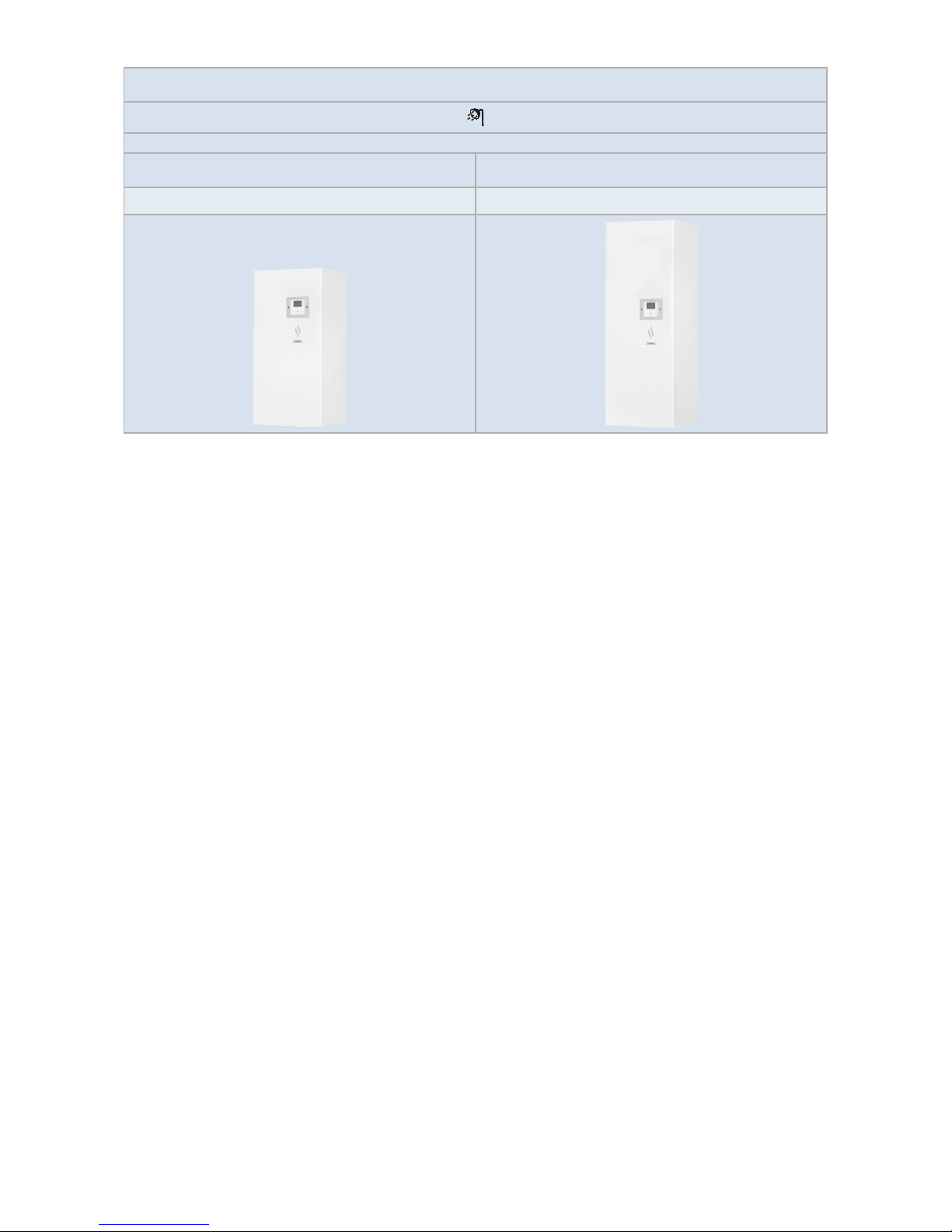

MODELS CODIFICATION

Important note: Please, check, according to the model name, which is your heat

pump system, how it is abbreviated and referred to in this Instruction Manual. This

Instruction Manual is only related to Domestic hot water tank (DHWS(200/260)

S-2.7H2E) combined with YUTAKI S80 indoor units TYPE 2 (RWH-(V)NFWE).

CODIFICACIÓN DE MODELOS

Nota importante: Compruebe, de acuerdo con el nombre del modelo, el tipo de

tipo de bomba de calor del que dispone, su abreviatura y su referencia en este

Manual de Instrucciones. Este manual de instrucciones hace referencia solo al

depósito de agua caliente sanitaria (DHWS(200/260)S-2.7H2E) combinado con la

unidad interior YUTAKI S80 TIPO 2 (RWH-(V)NFWE).

MODELLCODES

Wichtiger Hinweis: Bitte stellen Sie anhand der Modellbezeichnung den Typ

der Wärmepumpe und das entsprechende, in diesem Technischen Handbuch

verwendete Kürzel fest. Dieses Betriebshandbuch bezieht sich nur auf den

Warmwasserspeicher (DHWS(200/260)S-2.7H2E) in Kombination mit den

Innengeräten YUTAKI S80 TYP 2 (RWH-(V)NFWE).

CODIFICATION DES MODÈLES

Remarque importante : Veuillez déterminer, d’après le nom du modèle, quel est

votre type de pompe à chaleur et quelle est son abréviation et référence dans

ce manuel d’instruction. Le présent manuel d’instructions ne concerne que les

ballons d’ECS (DHWS(200/260)S-2.7H2E) combinés à des unités intérieures

YUTAKI S80 TYPE 2 (RWH-(V)NFWE).

CODIFICAZIONE DEI MODELLI

Nota importante: in base al nome del modello, vericare il tipo di pompa di

calore in possesso nonché il tipo di abbreviazione e di riferimento utilizzati in

questo manuale di istruzioni. Questo manuale di istruzioni si riferisce solo al

serbatoio di acqua calda domestica (DHWS(200/260)S-2.7H2E) in combinazione

con le unità interne YUTAKI S80 di tipo 2 (RWH-(V)NFWE).

CODIFICAÇÃO DE MODELOS

Nota importante: Comprove, de acordo com o nome do modelo, qual é o tipo

da sua bomba de calor e a respetiva abreviatura e menção neste manual de

instruções. Este manual refere-se exclusivamente ao depósito de água quente

sanitária (DHWS(200/260)S-2.7H2E) em combinação com as unidades interiores

YUTAKI S80 do TIPO 2 (RWH-(V)NFWE).

MODELKODIFICERING

Vigtig information: Check venligst dit varmepumpetype i henhold til modelnavnet, hvordan det er forkortet, og hvilken reference det har i denne vejledning.

Denne vejledning omfatter udelukkende varmtvandsbeholderen (DHWS(200/260)

S-2.7H2E) YUTAKI S80 indendørs enheder TYPE 2 (RWH-(V)NFWE).

CODERING VAN DE MODELLEN

Belangrijke opmerking: Controleer aan de hand van de modelnaam welk type

warmtepomp u heeft, hoe de naam wordt afgekort en hoe ernaar wordt verwezen

in deze installatiehandleiding. Deze installatiehandleiding geldt uitsluitend voor

de warmwaterketel (DHWS(200/260)S-2.7H2E) in combinatie met YUTAKI S80binnenunits TYPE 2 (RWH-(V)NFWE).

MODELLER

Viktigt!: Kontrollera med modellnamnet vilken typ av värmepump du har, hur

den förkortas och hur den anges i den här handboken. Denna handbok gäller

endast för DHW-tank (DHWS(200/260)S-2.7H2E) i kombination med YUTAKI S80

inomhusenhet TYPE 2 (RHW-(V)NFWE).

ΚΩΔΙΚΟΠΟΙΗΣΗ ΜΟΝΤΕΛΩΝ

Σημαντική σημείωση: Ελέγξτε, σύμφωνα με το όνομα μοντέλου, τον τύπο του

δικού σας αντλίας θέρμανσης και με ποια σύντμηση δηλώνεται και αναφέρεται

σε αυτό το εγχειρίδιο οδηγιών. Αυτό το εγχειρίδιο οδηγιών αναφέρεται μόνο

στην δεξαμενή ζεστού νερού οικιακής χρήσης (DHWS(200/260)S-2.7H2E) σε

συνδυασμό με τις εσωτερικές μονάδες τύπου 2 YUTAKI S80 (RWH-(V)NFWE).

YUTAKI S80 DHW Tank - Depósito de ACS - Warmwasserspeicher - Ballon d’ECS - Serbatoio di ACD - Depósito de DHW -

Varmtvandsbeholder - Warmwaterketel - Tappvarmvattentank - Δεξαμενή DHW

1~ 230V 50Hz

Unit - Unidad - Gerät - Unité - Unità

- Unidade - Enhed - Unit - Enhet - Μονάδα

Unit - Uniidad - Gerät - Unité - Unità

- Unidade - Enhed - Unit - Enhet - Μονάδα

DHWS200S-2.7H2E DHWS260S-2.7H2E

? NOTE

• The tank can be installed integrated above the indoor unit or

beside the indoor unit. In this case, the dedicated accessory kit

for installation with tank beside the indoor unit (ATW-FWP-02)

is required.

• Icons between brackets mean possible extra operations to the

factory-supplied operations.

? NOTA

• El depósito se puede instalar encima o al lado de la unidad

interior. En este último caso es necesario el kit accesorio

(ATW-FWP-02).

• Los iconos que se muestran entre paréntesis son posibles

funciones extra que se pueden añadir a las funciones de las

que la unidad dispone de fábrica.

? HINWEIS

• Der Speicher kann über dem Innengerät oder neben

dem Innengerät installiert werden. In diesem Fall ist das

vorgesehene Zubehör-Set (ATW-FWP-02) zur Installation des

Speichers neben dem Innengerät erforderlich.

• Die in Klammern stehenden Symbole bedeuten, dass

zusätzliche Betriebsfunktionen neben den werksseitig

bereitgestellten Betriebsfunktionen möglich sind.

? REMARQUE

• Le ballon peut être intégré au-dessus ou à côté de l’unité

intérieure. Dans ce cas, le kit dédié d’installation avec le ballon

à côté de l’unité intérieure (ATW-FWP-02) est nécessaire.

• Les icônes entre parenthèses indiquent d’éventuelles fonctions

additionnelles à celles fournies.

? NOTA

• Il serbatoio può essere installato integrato sopra l’unità interna

o accanto ad essa. In questo caso, è richiesto l’apposito kit

accessorio per l’installazione con il serbatoio accanto all’unità

interna (ATW-FWP-02).

• Le icone tra parentesi indicano possibili operazioni aggiuntive

oltre a quelle in dotazione.

? NOTA

• O depósito pode ser instalado sobre ou ao lado da unidade

interior. Neste caso, é necessário o acessório especíco

(ATW-FWP-02) para a instalação do depósito ao lado da

unidade interior.

• Os ícones entre parêntesis representam possíveis funções

suplementares relativamente às funções disponibilizadas de

fábrica.

? BEMÆRK

• Beholderen kan monteres oven på indendørsenheden eller ved

siden af indendørsenheden. I så fald skal man anvende det til

formålet beregnede tilbehørssæt til montering af beholder ved

siden af indendørsenheden (ATW-FWP-02).

• Symbolerne i parentes betyder mulige ekstra funktioner

foruden de fra fabrikken leverede funktioner.

? OPMERKING

• De warmwaterketel kan hetzij boven hetzij naast de binnenunit

worden gemonteerd. In dat laatste geval is een speciale

kit (ATW-FWP-02) nodig om de warmwaterketel naast de

binnenunit te installeren.

• De icoontjes tussen haken verwijzen naar extra functies naast

de standaardfuncties.

? OBS!

• Tanken kan byggas in ovanför eller bredvid inomhusenheten. I

detta fall så krävs den speciella tillbehörssatsen för installation

av tanken bredvid inomhusenheten (ATW-FWP-02).

• Ikoner inom parentes betyder att det nns möjliga

extrafunktioner för de medföljande funktionerna.

? ΣΗΜΕΙΩΣΗ

• Η δεξαμενή αυτή μπορεί να εγκατασταθεί πάνω ή δίπλα στην

εσωτερική μονάδα. Σ’ αυτή την περίπτωση, είναι αναγκαίο το

ειδικό κιτ εξάρτημα για εγκατάσταση με δεξαμενή δίπλα στην

εσωτερική μονάδα (ATW-FWP-02).

• Τα εικονίδια σε παρένθεση υποδηλώνουν πιθανές επιπλέον

λειτουργίες εκτός από αυτές που παρέχονται από το εργοστάσιο.

INDEX

1 GENERAL INFORMATION

2 SAFETY

3 GENERAL DIMENSIONS

4 REFRIGERANT AND WATER PIPING

5 ELECTRICAL AND CONTROL SETTINGS

6 INSTALLATION

7 DHW TANK OPERATION

8 CONTROL DEVICE SETTING

9 COMMISSIONING

10 MAINTENANCE

ÍNDICE

1 INFORMACIÓN GENERAL

2 SEGURIDAD

3 DIMENSIONES GENERALES

4 TUBERÍAS DE AGUA Y DE REFRIGERANTE

5 AJUSTES ELÉCTRICOS Y DE CONTROL

6 INSTALACIÓN

7 FUNCIONAMIENTO DEL DEPÓSITO DE AGUA CALIENTE

SANITARIA

8 AJUSTE DEL DISPOSITIVO DE CONTROL

9 PUESTA EN MARCHA

10 MANTENIMIENTO

INHALTSVERZEICHNIS

1 ALLGEMEINE INFORMATIONEN

2 SICHERHEIT

3 ALLGEMEINE ABMESSUNGEN

4 KÄLTEMITTEL- UND WASSERLEITUNGEN

5 ELEKTRISCHE UND STEUERUNGS-EINSTELLUNGEN

6 INSTALLATION

7 WARMWASSERSPEICHERBETRIEB

8 STEUERUNGS-EINSTELLUNG

9 INBETRIEBNAHME

10 WARTUNG

INDEX

1 INFORMATIONS GÉNÉRALES

2 SÉCURITÉ

3 DIMENSIONS GÉNÉRALES

4 TUYAUTERIE FRIGORIFIQUE ET D'EAU

5 RÉGLAGES DE COMMANDE ET ÉLECTRIQUES

6 INSTALLATION

7 FONCTIONNEMENT DU BALLON D'EAU CHAUDE

SANITAIRE

8 RÉGLAGE DES DISPOSITIFS DE CONTRÔLE

9 MISE EN SERVICE

10 MAINTENANCE

INDICE

1 INFORMAZIONI GENERALI

2 SICUREZZA

3 DIMENSIONI GENERALI

4 LINEE DELL'ACQUA E DEL REFRIGERANTE

5 IMPOSTAZIONI ELETTRICHE E DI CONTROLLO

6 INSTALLAZIONE

7 FUNZIONAMENTO DEL SERBATOIO DELL'ACQUA CALDA

DOMESTICA

8 IMPOSTAZIONI DEL DISPOSITIVO DI CONTROLLO

9 MESSA IN ESERCIZIO

10 MANUTENZIONE

ÍNDICE

1 INFORMAÇÃO GERAL

2 SEGURANÇA

3 DIMENSÕES GERAIS

4 TUBAGEM DE REFRIGERANTE E DE ÁGUA

5 AJUSTES DE CONTROLO E ELÉTRICOS

6 INSTALAÇÃO

7 FUNCIONAMENTO DO DEPÓSITO DE ÁGUA QUENTE

SANITÁRIA

8 AJUSTE DO CONTROLO DO DISPOSITIVO

9 COLOCAÇÃO EM FUNCIONAMENTO

10 MANUTENÇÃO

INDHOLDSFORTEGNELSE

1 GENEREL INFORMATION

2 SIKKERHED

3 GENERELLE MÅL

4 KØLEMIDDEL- OG VANDRØR

5 ELEKTRISKE INDSTILLINGER OG

KONTROLINDSTILLINGER

6 MONTERING

7 BETJENING AF DHW BEHOLDER

8 INDSTILLING AF STYREENHED

9 IDRIFTSÆTTELSE

10 VEDLIGEHOLDELSE

INHOUDSOPGAVE

1 ALGEMENE INFORMATIE

2 VEILIGHEID

3 ALGEMENE AFMETINGEN

4 KOUDEMIDDEL- EN WATERLEIDINGEN

5 ELEKTRISCHE EN BESTURINGSINSTELLINGEN

6 INSTALLATIE

7 DE WARMWATERKETEL BEDIENEN

8 INSTELLINGEN VAN BESTURING

9 IMBEDRIJFSSTELLING

10 ONDERHOUD

INNEHÅLLSFÖRTECKNING

1 ALLMÄN INFORMATION

2 SÄKERHET

3 ALLMÄNA MÅTT

4 KYL- OCH VATTENRÖR

5 EL- OCH STYRINSTÄLLNINGAR

6 INSTALLATION

7 DRIFT AV VARMVATTENTANK

8 INSTÄLLNING AV STYRENHET

9 DRIFTSÄTTNING

10 UNDERHÅLL

ΕΥΡΕΤΗΡΙΟ

1 ΓΕΝΙΚΕΣ ΠΛΗΡΟΦΟΡΙΕΣ

2 ΑΣΦΑΛΕΙΑ

3 ΓΕΝΙΚΕΣ ΔΙΑΣΤΑΣΕΙΣ

4 ΨΥΚΤΙΚΟ ΚΑΙ ΣΩΛΗΝΩΣΕΙΣ ΝΕΡΟΥ

5 ΡΥΘΜΙΣΕΙΣ ΗΛΕΚΤΡΙΚΩΝ ΣΤΟΙΧΕΙΩΝ ΚΑΙ ΕΛΕΓΧΟΥ

6 ΕΓΚΑΤΑΣΤΑΣΗ

7 ΛΕΙΤΟΥΡΓΙΑ ΔΕΞΑΜΕΝΗΣ DHW

8 ΡΥΘΜΙΣΗ ΣΥΣΚΕΥΗΣ ΕΛΕΓΧΟΥ

9 ΕΝΑΡΞΗ ΛΕΙΤΟΥΡΓΙΑΣ

10 ΣΥΝΤΗΡΗΣΗ

EN English Original version

ES Español Versión traducida

DE Deutsch Übersetzte Version

FR Français Version traduite

IT Italiano Versione tradotta

PT Português Versão traduzidal

DA Dansk Oversat version

NL Nederlands Vertaalde versie

SV Svenska Översatt version

EL Ελληνικα Μεταφρασμένη έκδοση

ENGLISH

1 GENERAL INFORMATION

No part of this publication may be reproduced, copied, led

or transmitted in any shape or form without the permission of

HITACHI Air Conditioning Products Europe, S.A.U.

Within the policy of continuous improvement of its products,

HITACHI Air Conditioning Products Europe, S.A.U. reserves

the right to make changes at any time without prior notication

and without being compelled to introducing them into products

subsequently sold. This document may therefore have been

subject to amendments during the life of the product.

HITACHI makes every effort to offer correct, up-to-date

documentation. Despite this, printing errors cannot be controlled

by HITACHI and are not its responsibility.

As a result, some of the images or data used to illustrate this

document may not refer to specic models. No claims will be

accepted based on the data, illustrations and descriptions

included in this manual.

2 SAFETY

2.1 APPLIED SYMBOLS

During normal heat pump system design work or unit

installation, greater attention must be paid in certain situations

requiring particular care in order to avoid injuries an damage to

the unit, the installation or the building or property.

Situations that jeopardise the safety of those in the surrounding

area or that put the unit itself a risk will be clearly indicated in

this manual.

To indicate these situations, a series of special symbols will be

used to clearly identify these situations.

Pay close attention to these symbols and to the messages

following them, as your safety and that of others depends on it.

! DANGER

• The text following this symbol contains information and

instructions relating directly to your safety and physical

wellbeing.

• Not taking these instructions into account could lead to serious,

very serious or even fatal injuries to you and others in the

proximities of the unit.

In the text following the danger symbol you can also nd

information on safe procedures during unit installation.

! CAUTION

• The text following this symbol contains information and instructions

relating directly to your safety and physical wellbeing.

• Not taking these instructions into account could lead to minor injuries

to you and others in the proximities of the unit.

• Not taking these instructions into account could lead to unit damage.

In the text following the caution symbol you can also nd

information on safe procedures during unit installation.

? NOTE

• The text following this symbol contains information or instructions that

may be of use or that require a more thorough explanation.

• Instructions regarding inspections to be made on unit parts or systems

may also be included.

2.2 ADDITIONAL INFORMATION ABOUT SAFETY

! DANGER

• DO NOT CONNECT THE POWER SUPPLY TO THE INDOOR UNIT

AND DHW TANK PRIOR TO FILLING BOTH CIRCUITS WITH

WATER AND CHECKING WATER PRESSURE AND THE TOTAL

ABSENCE OF ANY WATER LEAKAGE.

• Do not pour water over the electrical parts. If the electrical

components are in contact with water a seri ous electrical shock

will take place.

• Do not touch or adjust the safety devices inside the air to water

heat pump. If these devices are touched or adjusted, a serious

accident can take place.

• In case of re Turn OFF the main switch, put out the re at once

and contact your service contractor.

• It must ensure that the DHW tank cannot op erate accidentally

without water neither with air inside hydraulic system.

! CAUTION

• Do not use any sprays such as insecticide, lacquer, hair spray or other

ammable gases within approximately one meter from the system.

• If installation circuit breaker or the unit fuse is often activated, stop the

system and contact your service contractor.

• Do not make service or inspections tasks by yourself. This work must

be performed by a qualied service person.

• This appliance must be used only by adult and capable people,

having received the technical information or instructions to handle

this appliance properly and safely.

• Children should be supervised to ensure that they do not play with

the appliance.

• Do not let any foreign body into the water inlet and outlet piping of

the DHW tank.

GENERAL INFORMATION

PMML0344B rev.0 - 04/2016

1

2.3 IMPORTANT NOTICE

• The supplementary information about the purchased

products is supplied in a CD-ROM, which can be found

bundled with the indoor unit. In case that the CD-ROM is

missing or it is not readable, please contact your HITACHI

dealer or distributor.

• PLEASE READ THE MANUAL AND THE FILES ON THE

CD-ROM CAREFULLY BEFORE STARTING TO WORK ON

THE INSTALLATION OF THE AIR TO WATER HEAT PUMP

SYSTEM. Failure to observe the instructions for installation,

use and operation described in this documentation may

result in operating failure including potentially serious faults,

or even the destruction of the air to water heat pump system.

• This document contains the information referred to the

HITACHI DHW tank. The HITACHI DHW tank must be

connected with the YUTAKI S80 indoor unit TYPE 2 only.

Please, refer to the YUTAKI S80 Indoor unit Instruction

manual “PMML0340B” (space heating information) or

to the CD‑ROM bundled with the unit for the complete

information of the system.

• Verify, in accordance with the manuals which appear in the

outdoor, indoor unit and DHW tank, that all the information

required for the correct installation of the system is included.

If this is not the case, contact your distributor.

• HITACHI pursues a policy of continuous improvement in

product design and performance. The right is therefore

reserved to vary specications without notice.

• HITACHI cannot anticipate every possible circumstance that

might involve a potential hazard.

• This air to water heat pump has been designed for standard

water heating for human beings only. Do not use this for

other purposes such as for drying clothes, heating foods or

for any other heating process (except swimming pool).

• No part of this manual may be reproduced without written

permission.

• If you have any questions, contact your service contractor of

HITACHI.

• Check and make sure that the explanations of each part

of this manual correspond to your air to water heat pump

model.

• Refer to the models codication to conrm the main

characteristics of your system.

• Signal words (NOTE, DANGER and CAUTION) are used

to identify levels of hazard seriousness. Denitions for

identifying hazard levels are provided in initial pages of this

document.

• The operation modes of these units are controlled by the unit

controller.

• This manual should be considered as a permanent part of

the system. It gives a common description and information

for this system which you operate as well as for other

models.

• Keep the water temperature of the system above the

freezing temperature.

SAFETY

PMML0344B rev.0 - 04/2016

2

ENGLISH

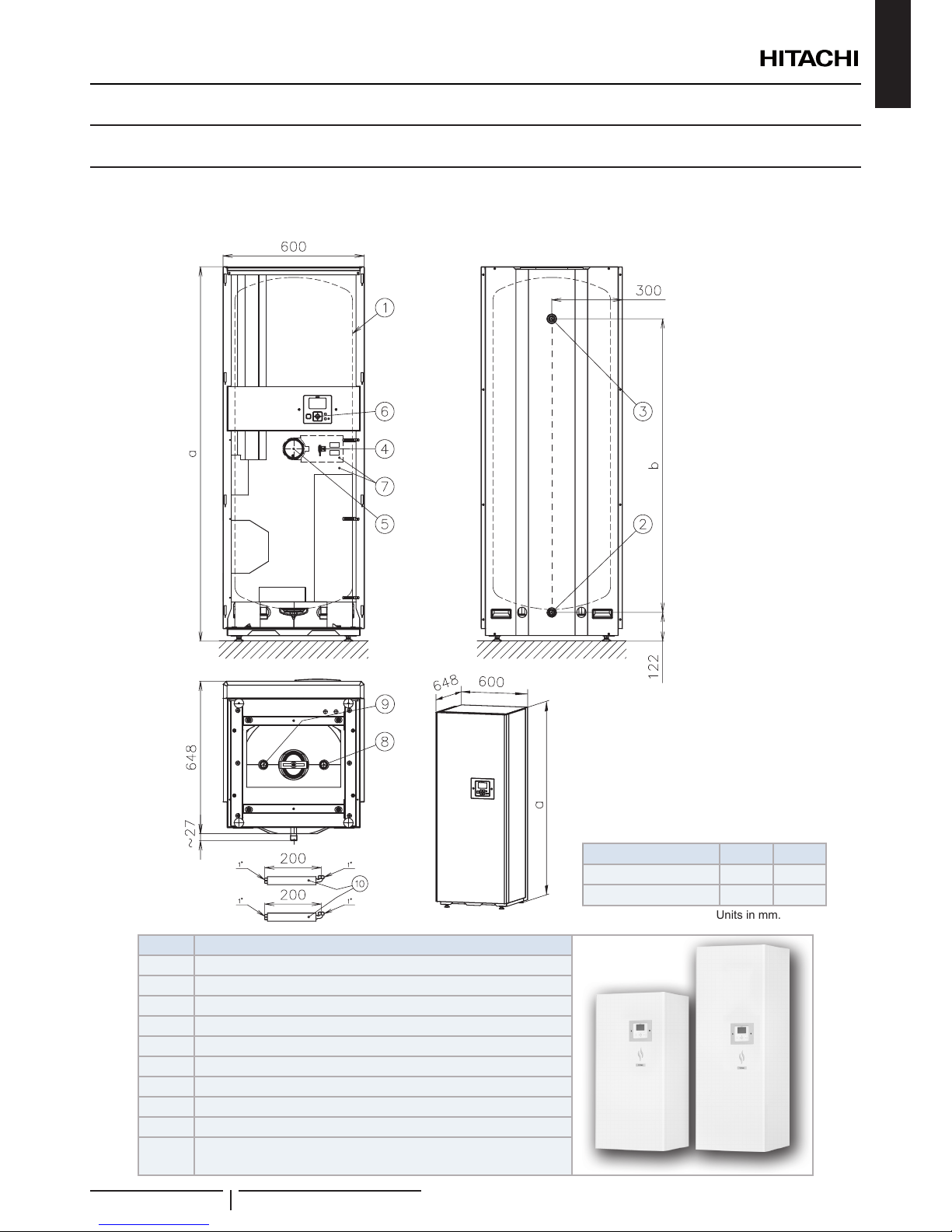

3 GENERAL DIMENSIONS

3.1 NAME OF PARTS AND DIMENSIONAL DATA

DHWS(200/260)S-2.7H2E

Front view Rear view

Top view

Unit/Dimension a b

DHWS200S-2.7H2E 1282 938.5

DHWS260S-2.7H2E 1591 1247.5

Dimensions according the unit

Units in mm.

XEKS 1719

Number Part name

1 Domestic hot water tank

2 DHW inlet G 3/4” male

3 DHW outlet G 3/4” male

4 DHW tank thermistor

5 Heater+ thermostat

6 Unit Controller

7 Tank insulation

8 Heating coil inlet connection G 1” male

9 Heating coil outlet connection G 1” male

10 Flexible pipe (x2)

GENERAL DIMENSIONS

PMML0344B rev.0 - 04/2016

3

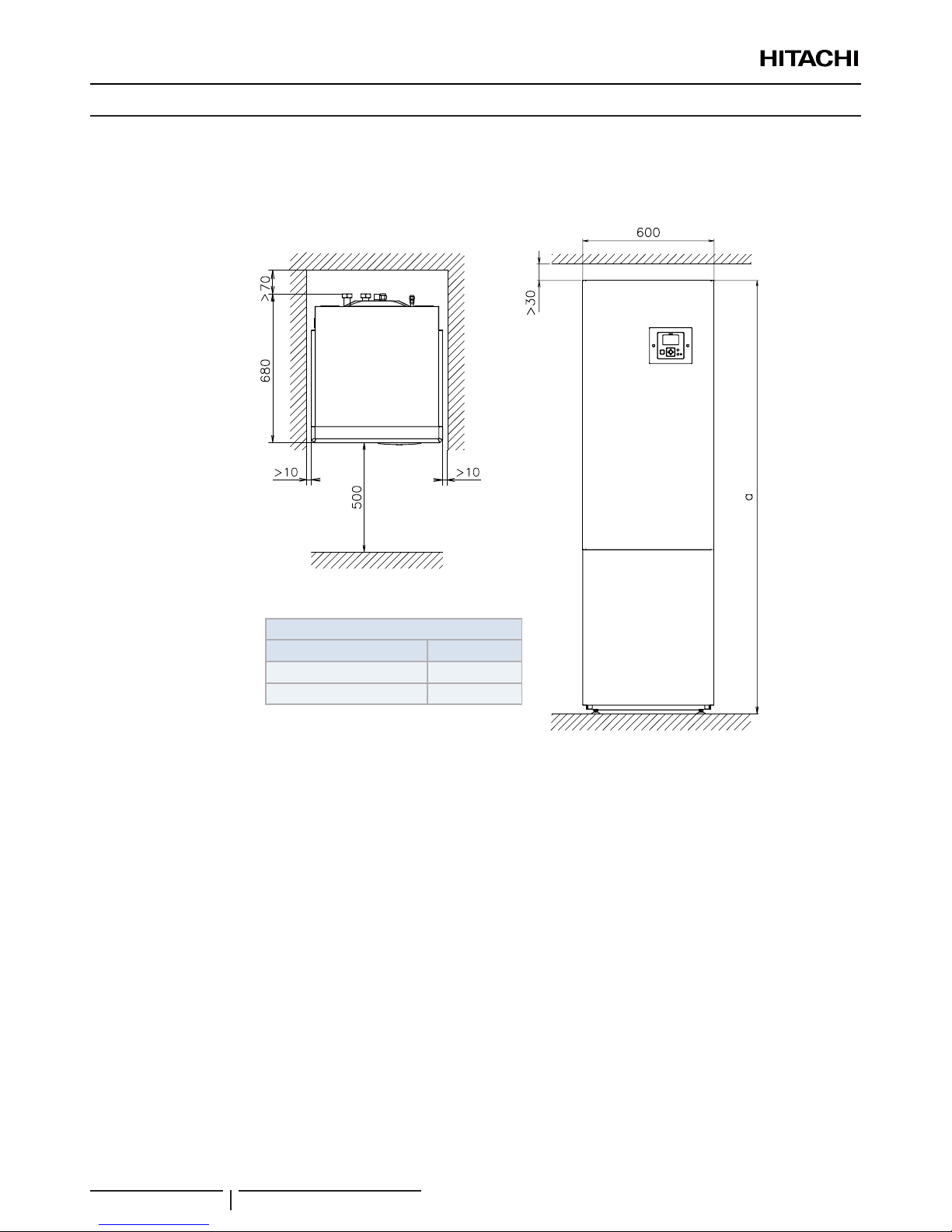

3.2 SERVICE SPACE

3.2.1 Indoor unit TYPE 2 + Domestic hot water tank above the indoor unit

RWH-(4.0-6.0)(V)NFWE + DHWS(200/260)S-2.7H2E

Service with this space is possible

but, for an easier servicing of some

components it is recommended to

let a space >500mm

Units in mm.

Top view

Left side

Front view

Right side

>500mm

(Min. distance for

E-box removal)

(*) Minimum

distance for piping

connection back

outlet

Dimensions according to the unit (mm)

Unit Dimension "a"

RWH + DHWS200S-2.7H2E 1980

RWH + DHWS260S-2.7H2E 2289

GENERAL DIMENSIONS

PMML0344B rev.0 - 04/2016

4

ENGLISH

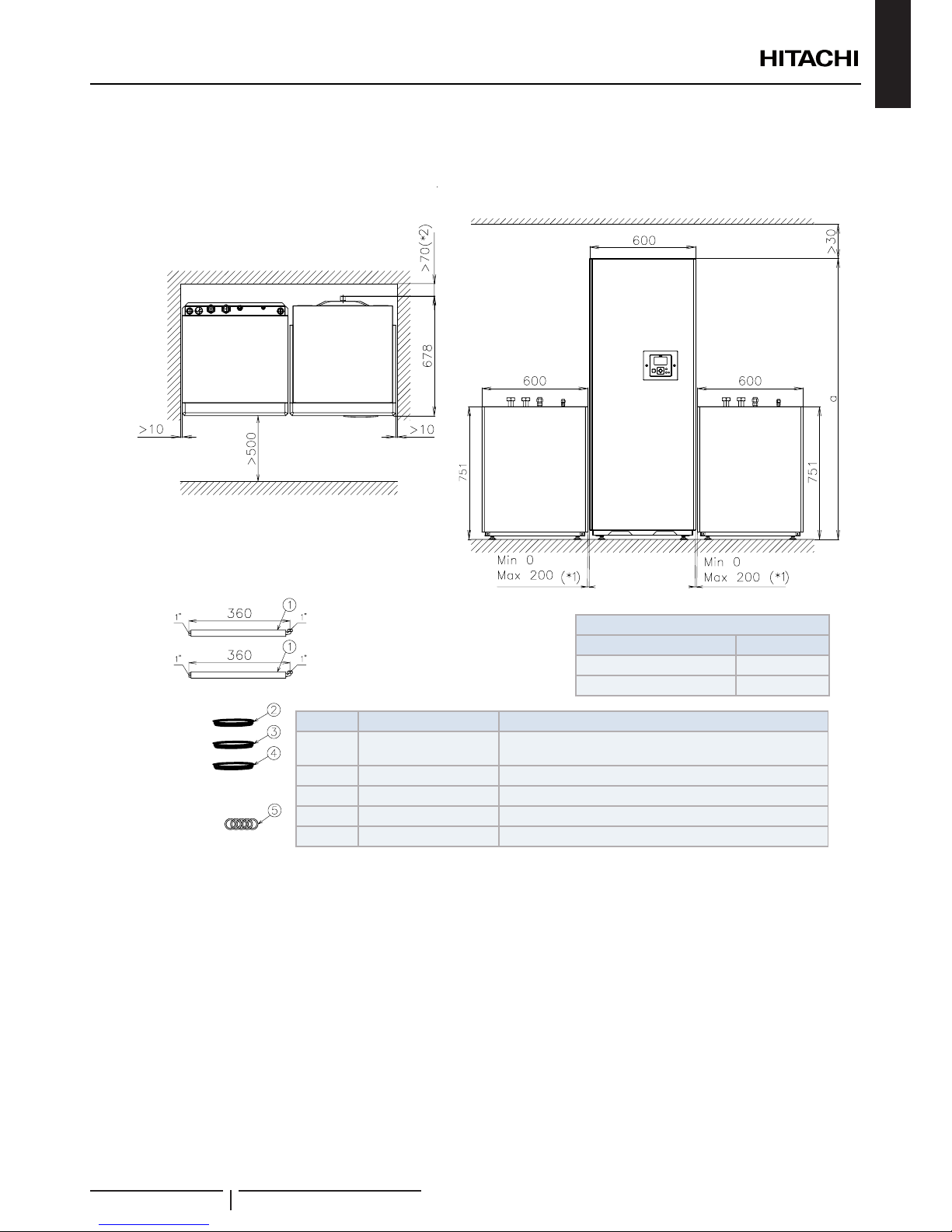

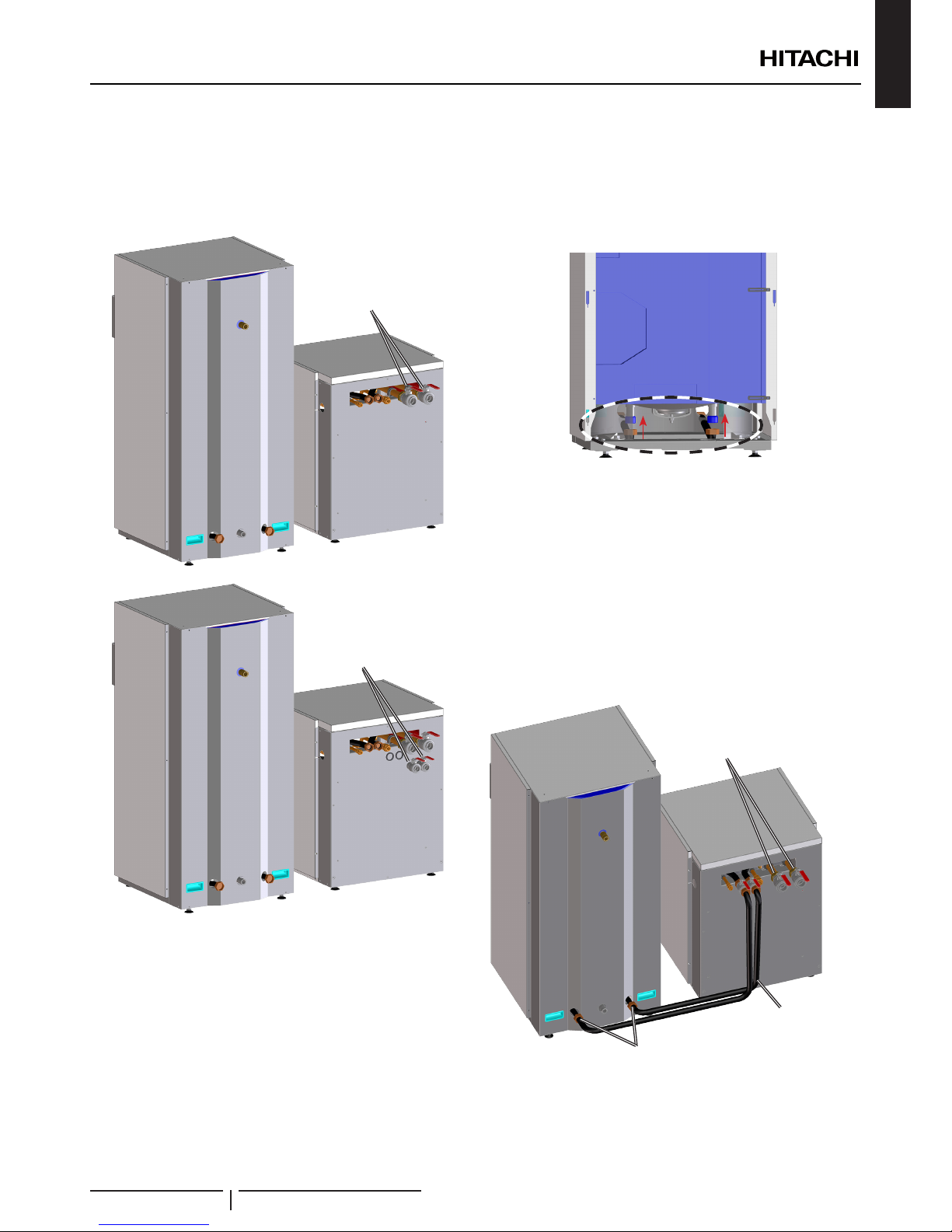

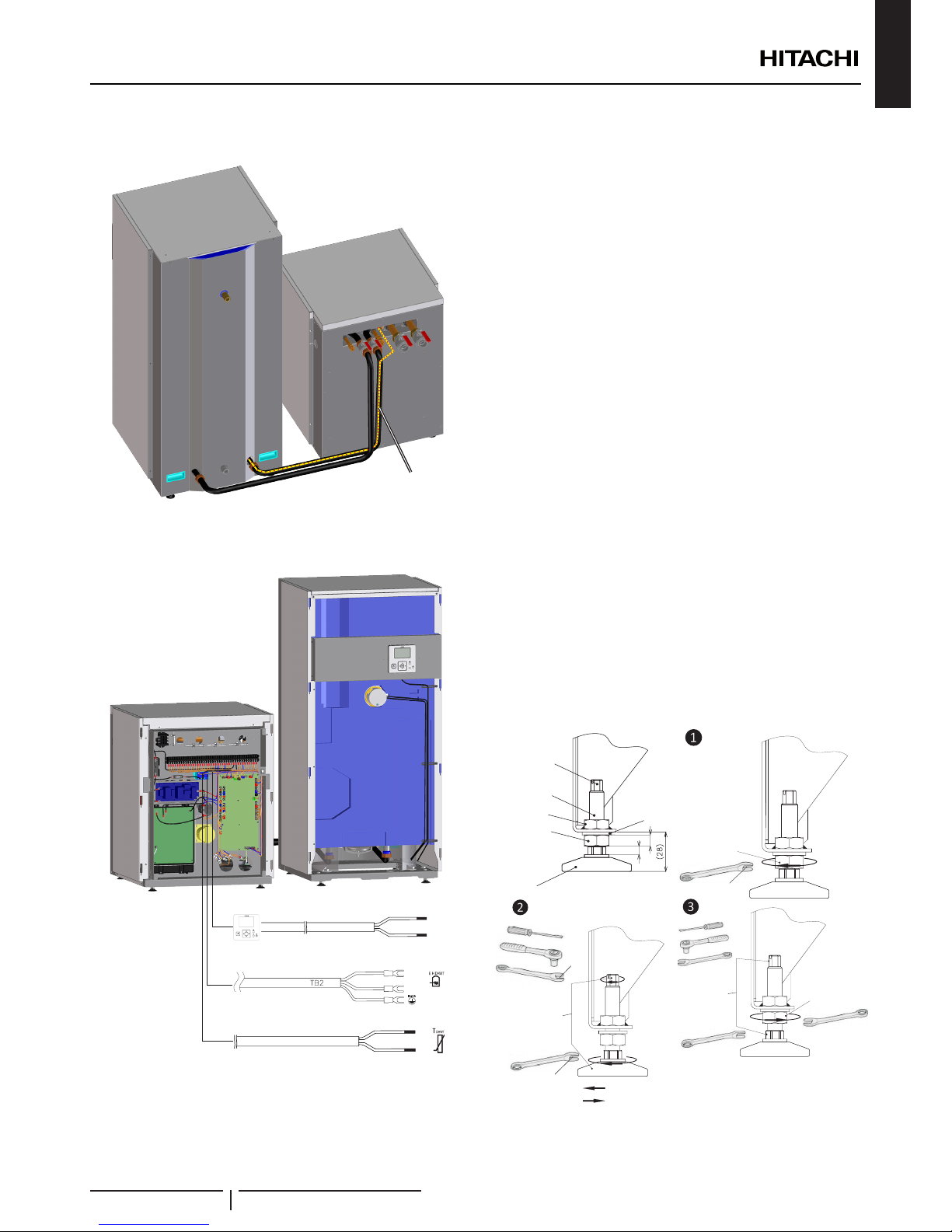

3.2.2 Indoor unit TYPE 2 + Domestic Hot water tank beside the indoor unit

RWH-(4.0-6.0)(V)NFWE + DHWS(200/260)S-2.7H2E

Units in mm.

Mark Part name Remarks

1 Flexible water pipe (x4)

For heating coil inlet and outlet connections of indoor unit

and DHW tank

2 Extension cables For tank electric heater

3 Extension cables For tank thermistor

4 Extension cables For unit controller

5 Gasket (x5) Gaskets (x5) for each exible water pipe end (+1 for spare)

Top view

Left side

Front view

Right side

>500mm (Min. distance

for E-box removal)

(*2) Minimum distance for

piping connection back

outlet

Dimensions according to the unit (mm)

Unit Dimension "a"

RWH + DHWS200S-2.7H2E 1980

RWH + DHWS260S-2.7H2E 2289

(*1) Recommended distance

between indoor unit and tank

may vary from 0 to 200 mm

Option 1

Option 2

Indoor unit at the

left side of tank

Indoor unit at the

right side of tank

Indoor unit

Tank

Service with this

space is possible

but, for an easier

servicing of some

components it is

recommended

to let a space

>500mm

GENERAL DIMENSIONS

PMML0344B rev.0 - 04/2016

5

4 REFRIGERANT AND WATER PIPING

4.1 SPACE HEATING AND DHW

! DANGER

Do not connect the power supply to the indoor unit prior to lling the space heating and DHW circuit with water and checking water pressure

and the total absence of any water leakage.

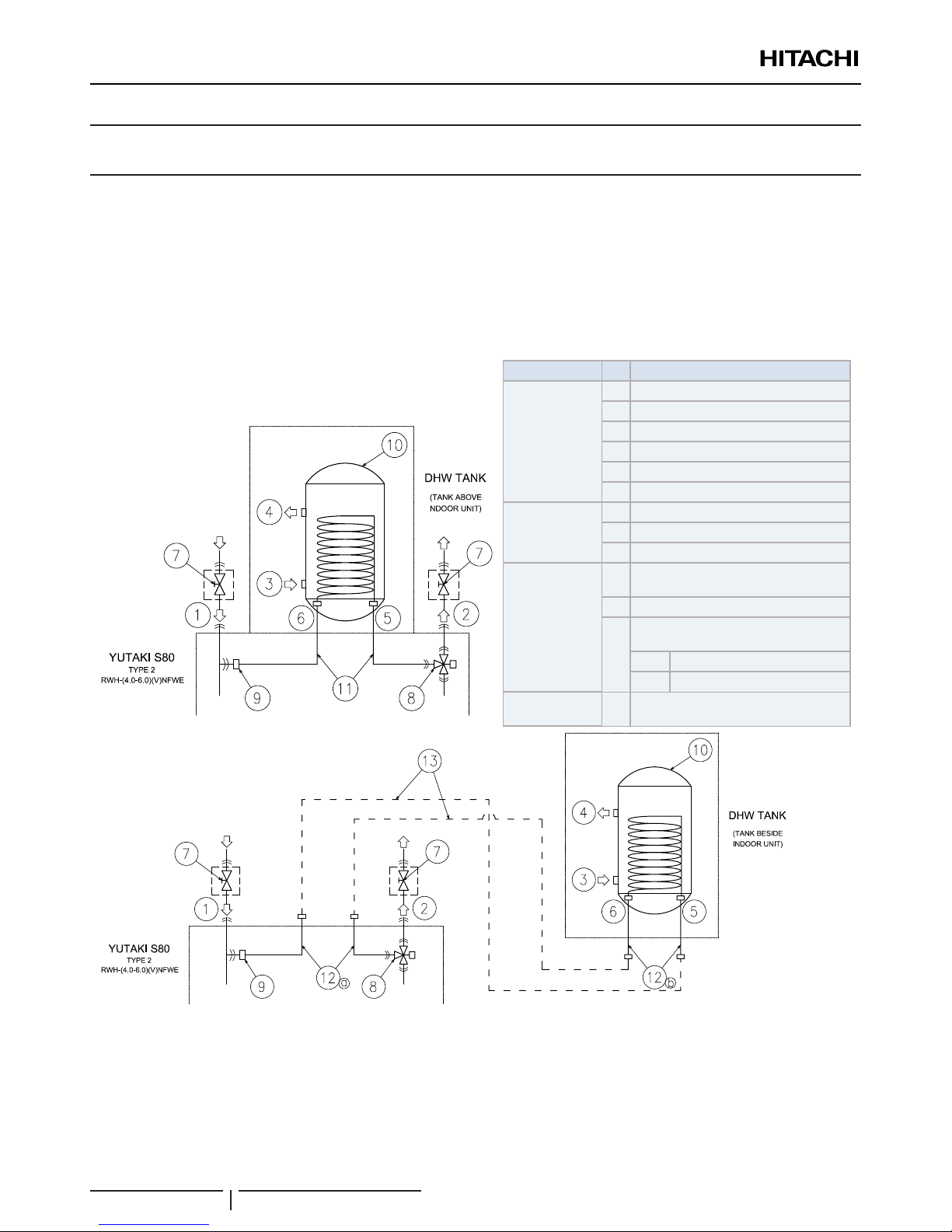

4.1.1 Additional hydraulic necessary elements for DHW

TYPE 2: Version for operation with Hitachi DHW tank

Type Nº Part name

Piping

connections

1 Water inlet (Space heating)

2 Water outlet (Space heating)

3 Heating coil inlet

4 Heating coil outlet

5 Water inlet (DHW)

6 Water outlet (DHW)

Factory supplied

7 Shut-off valve (factory-supplied)

8 3-way valve

9 T-branch

Accessories

10

Domestic hot water tank

(DHWS(200/260)S-2.7H2E accessory)

11 Heating coil pipes

12

Flexible water pipe kit

(ATW-FWP-02 accessory)

12a Indoor unit pipes

12b DHW tank pipes

Field supplied 13

Water pipes between indoor unit and

DHW tank

DHW tank integrated

above the indoor unit

DHW tank beside the

indoor unit

When installing the YUTAKI S80 indoor unit TYPE 2 (RWH-(4.0-6.0)(V)NFWE) in combination with the HITACHI DHW tank

(DHWS(200/260)S-2.7H2E) the following elements to provide DHW operation are needed:

• The YUTAKI S80 domestic hot water tank (DHWS(200/260)S‑2.7H2E accessory) (10) is required in combination with YUTAKI

S80 indoor unit. This tank accessory is factory-supplied with two exible water pipes (11). Respect the following instructions

depending on the DHW tank location (integrated above the indoor unit or beside it).

- For DHW tank integrated above the indoor unit, use one of the factory-supplied pipes (11) for the connection between 3-way

valve and the heating coil inlet coil of the DHW tank, and the other one for the connection between the T-branch and the

heating coil outlet coil of the DHW tank accessory.

REFRIGERANT AND WATER PIPING

PMML0344B rev.0 - 04/2016

6

ENGLISH

- For DHW tank beside the indoor unit (both right or left side), the pipes factory-supplied with the DHW tank accessory (11) are

not required. In this case, the dedicated HITACHI exible water pipe kit (ATW-FWP-02 accessory) (12) is needed. This kit is

provided with the following items:

4 exible water pipes (Two pipes (12a) to connect to the indoor unit (3-way (8) valve and T-branch (9)) and other two

pipes (12b) to connect to the heating coil inlet/outlet connections of the DHW tank (5-6). To connect the indoor unit with

the DHW tank, two additional eld-supplied pipes are required (13).

9 gaskets (2 gaskets for each exible water pipe end and 1 spare gasket).

3 extension cables (1 for the tank’s electric heater, 1 for the tank’s thermistor and 1 for the unit controller).

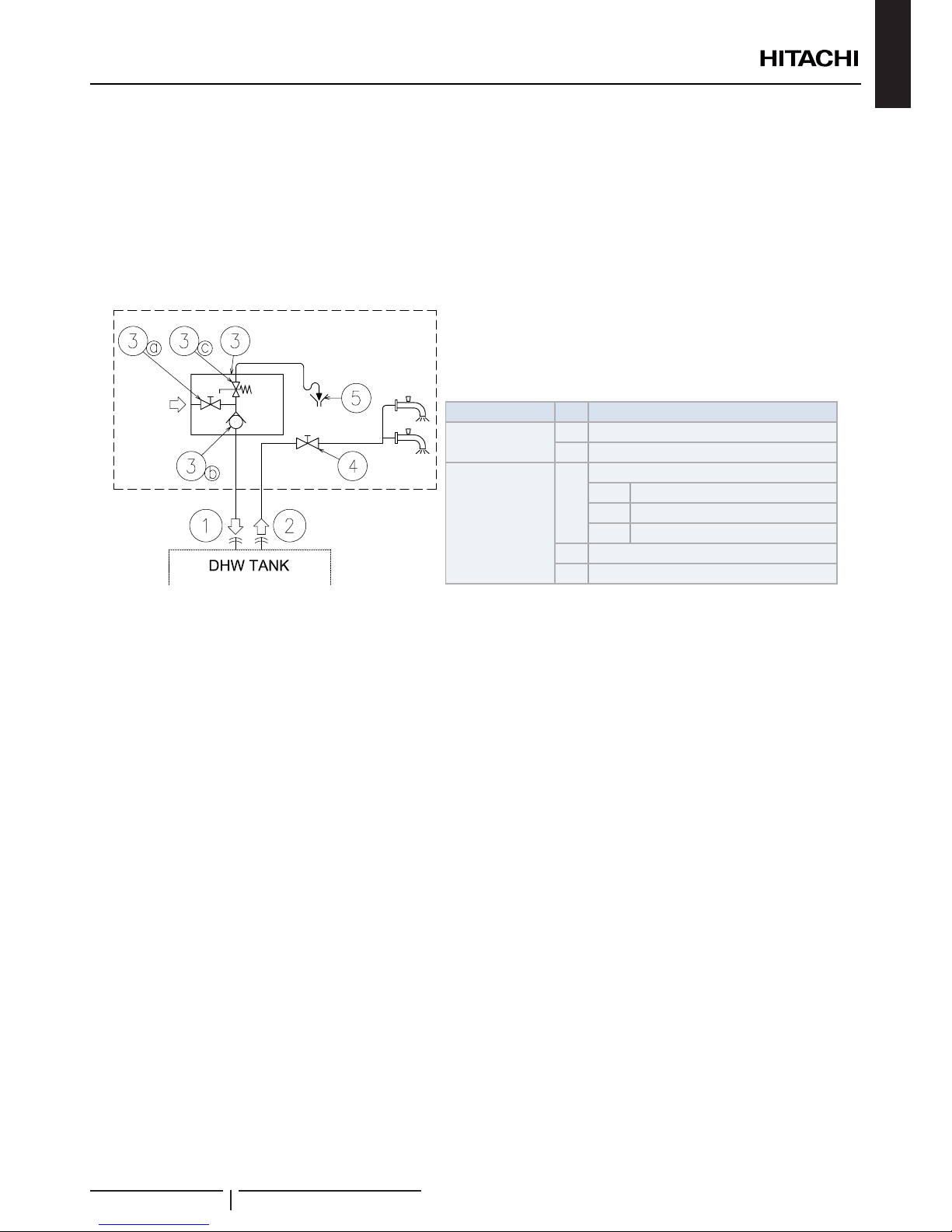

Additionally, the following elements are required for the DHW circuit:

Type Nº Part name

Piping connections

1 Water inlet (DHW)

2 Water outlet (DHW)

Field supplied

3

Pressure and temperature relief valve

3a Shut-off valve

3b Water check valve

3c Pressure relief valve

4 Shut-off valve

5 Draining

• 1 Shut-down valve (eld supplied): one shut-down valve (4) must be connected after the DHW outlet connection of the DHW

tank (2) in order to make easier any maintenance work.

• A Security water valve (Field‑supplied): this accessory (3) is a pressure and temperature relief valve that must be installed as

near as possible to the DHW inlet connection of the DHW tank (1). It should ensure a correct draining (5) for the discharge valve

of this valve. This security water valve should provide the following:

- Pressure protection

- Non-return function

- Shut-down valve

- Filling

- Draining

? NOTE

The discharge pipe should always be open to the atmosphere, free of frost and in continuous slope to the down side in case that water leakage exists.

REFRIGERANT AND WATER PIPING

PMML0344B rev.0 - 04/2016

7

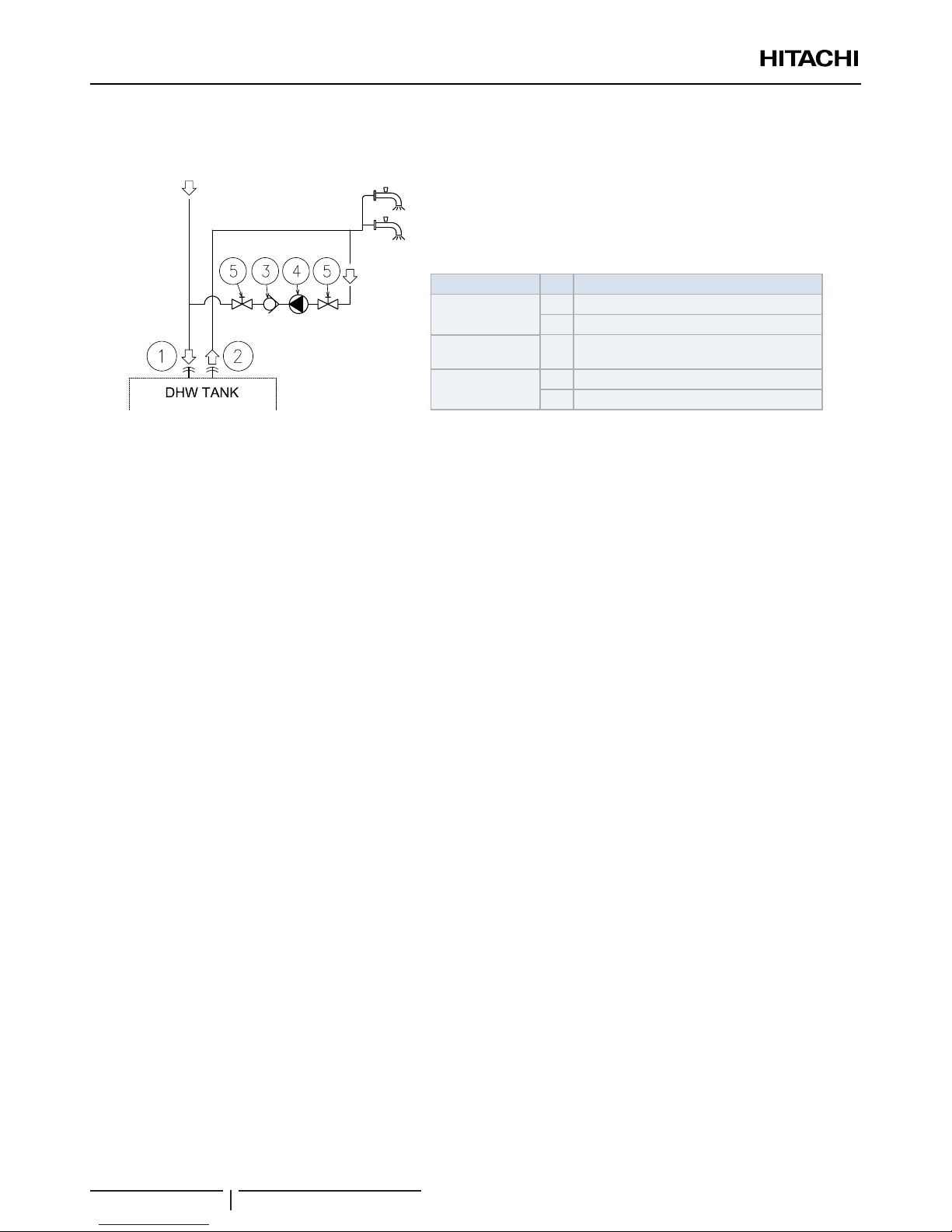

4.1.2 Additional hydraulic optional elements (For DHW)

In case of a recirculation circuit for the DHW circuit:

Type Nº Part name

Piping connections

1 Water inlet (DHW)

2 Water outlet (DHW)

Accessories 3

Water check valve

(ATW-WCV-01 accessory)

Field supplied

4 Water pump

5 Shut-off valve

• 1 Recirculation water pump (eld supplied): this water pump (3) will help to correctly recirculate the hot water to the DHW

inlet.

• 1 Water check valve (ATW-WCV-01 accessory): this Hitachi accessory (4) is connected after the recirculation water pump (31)

in order to ensure the non-return of water.

• 2 Shut-down valves (eld supplied) (5): one before the recirculation water pump (3) and other after the water check valve

accessory (4).

4.1.3 Requirements and recommendations for

the hydraulic circuit

• The storage capacity of the tank has to meet with the daily

consumption in order to avoid stagnation of water.

• Fresh water must circulate inside the DHW tank water

circuit at least one time per day during the rst days after

the installation has been performed. Additionally, ush the

system with fresh water when there is no consumption of

DHW during long periods of time.

• Try to avoid long runs of water piping between the tank

and the DHW installation in order to decrease possible

temperature losses.

• When using the indoor unit in combination with the YUTAKI

S80 DHW tank, the heating coil of the tank is placed in a

higher position than the indoor unit air purger. Then, to totally

purge the space heating circuit, it is very important that the

heating coil of the tank is fully air purged.

• lf the domestic cold water entry pressure is higher than the

equipment’s design pressure (6 bar), a pressure reducer

must be tted with a nominal value of 7 bar.

• Ensure that the installation complies with applicable

legislation in terms of piping connection and materials,

hygienic measures, testing and the possible required use of

some specic components like thermostatic mixing valves,

Differential pressure overow valve, etc.

• Make sure that all eld supplied components installed in the

piping circuit can withstand the water pressure and the water

temperature range in which the unit can operate.

• Do not add any type of glycol to the water circuit.

4.1.4 Water lling

Heating coil circuit

Fill the DHW tank heating coil from the space heating circuit

lling in point. Follow the instructions explained in the “4.1

Space heating and DHW” chapter to correctly perform the

operation.

! CAUTION

• Check that the heating coil pipes are correctly connected between

indoor unit and tank before lling the tank’s heating coil.

• Ensure the correct water quality of the indoor unit water circuit.

Domestic hot water tank and DHW circuit

1 Open the outlet water taps of the DHW installation one after

each other, to expel all the air from inside the water circuit.

2 Open the main DHW inlet valve in order to ll the tank. If

there is a shut-off valve installed in the DHW outlet, open it

to allow circulation through the DHW installation.

3 When water begins to ow from the outlet water taps of the

DHW installation, close all these taps.

4 Finally, close the main DHW inlet valve when the pressure

reaches approximately 6 bars.

! CAUTION

• Check carefully for leaks in the water circuit, connections and circuit

elements.

• Check that the water pressure in the circuit is lower than 7 bars.

• A pressure and temperature relief valve should be installed at the

DHW inlet connection of the tank. If it is the case, manually operate its

relief valve to ensure that the water ows free through the discharge

pipe.

• Fill in the circuit with tap water. The water in the heating installation

must comply with EN directive 98/83 EC. Non-sanitary controlled

water is not recommended (for example, water from wells, rivers,

lakes, etc.).

REFRIGERANT AND WATER PIPING

PMML0344B rev.0 - 04/2016

8

ENGLISH

5 ELECTRICAL AND CONTROL SETTINGS

5.1 GENERAL CHECK

• Make sure that the following conditions related to power supply installation are satised:

- The power capacity of the electrical installation is large enough to support the power demand of the YUTAKI system (outdoor

unit + indoor unit + DHW tank).

- The power supply voltage is within ±10% of the rated voltage.

- The impedance of the power supply line is low enough to avoid any voltage drop of more than 15% of the rated voltage.

• Check to ensure that existing installation (mains power switches, circuit breakers, wires, connectors and wire terminals) already

complies with the national and local regulations.

• The use of the DHW tank heater is disabled as factory setting. If it is desired to enable the DHW tank heater operation during

normal indoor unit operation, adjust the DSW4 pin 3 of the PCB1 to the ON position and use the adequate protections.

• Check to ensure that the eld supplied electrical components (mains power switches, circuit breakers, wires, connectors and

wire terminals) have been properly selected according to the electrical data indicated on this chapter and they comply with

national and local codes. If it is necessary, contact with your local authority in regards to standards, rules, regulations, etc.

• Ensure specically that there is an Earth Leakage Breaker (ELB) installed for the units (indoor, outdoor and the optional DHW

tank).

• If the installation is already equipped with an Earth Leakage Breaker (ELB), ensure that its rated current is large enough to hold

the current of the units (indoor, outdoor and the optional DHW tank).

! DANGER

• Do not connect the power supply to the indoor unit and DHW tank prior lling of water both circuits and checking water pressure and

the total absence of any water leak.

• Never connect the DHW tank to the main power supply. Always connect it to the YUTAKI S80 indoor unit as explained in the

“6 INSTALLATION” chapter.

• Do not connect or adjust any wiring or connections unless the main power switch is OFF.

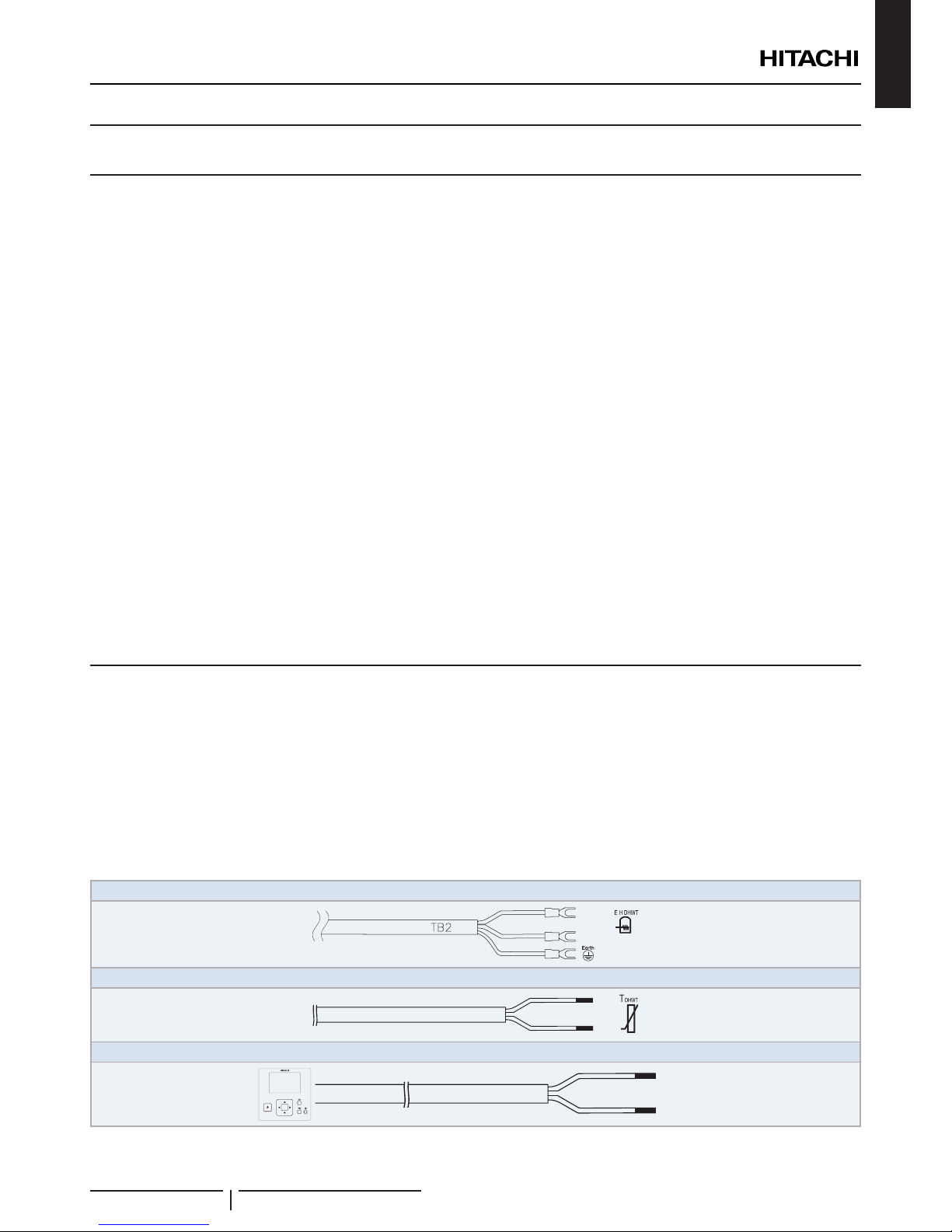

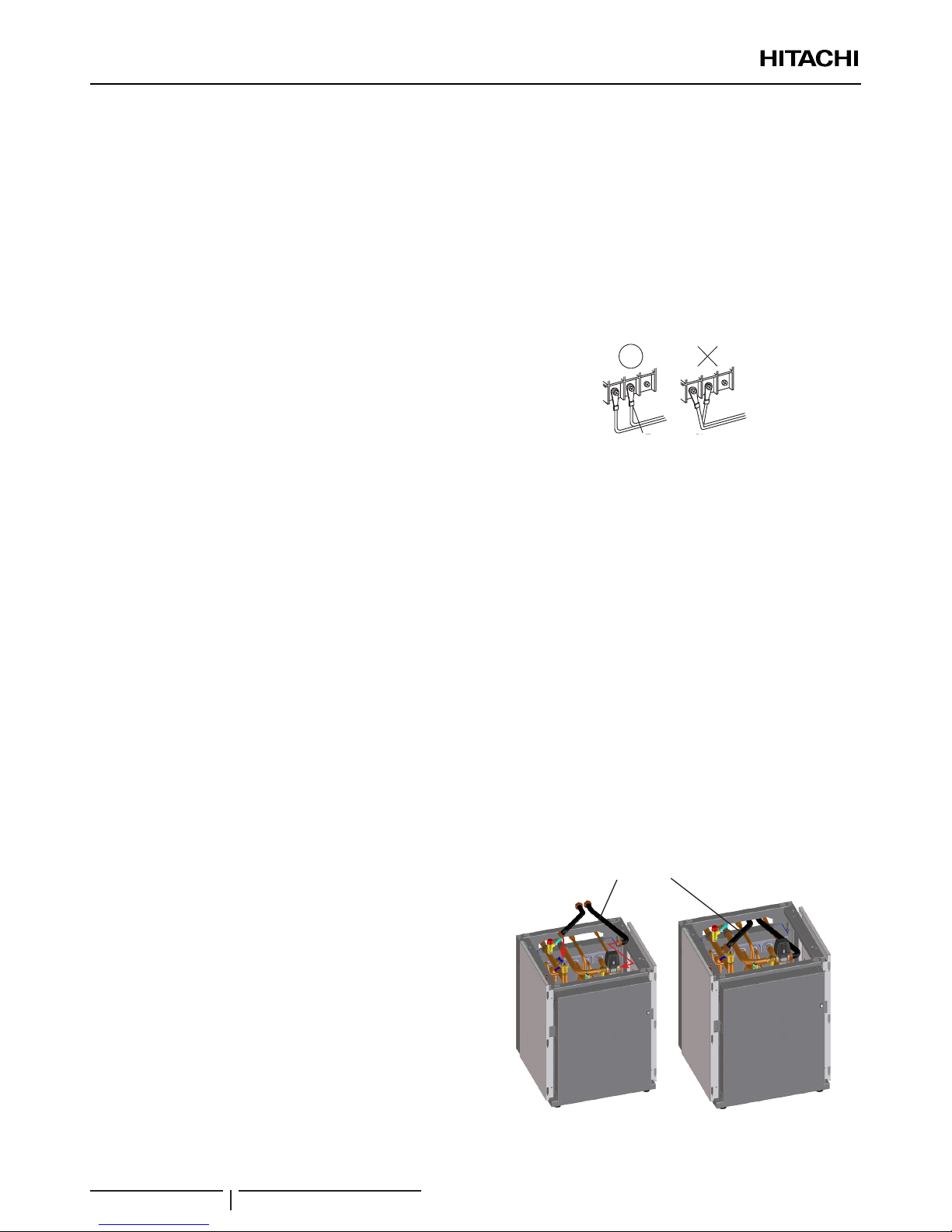

5.2 ELECTRICAL WIRING BETWEEN INDOOR UNIT AND DHW TANK

? NOTE

Please, refer to the YUTAKI S80 indoor unit Installation and operation manual, to know the specic protection for the combination of indoor unit and

DHW tank.

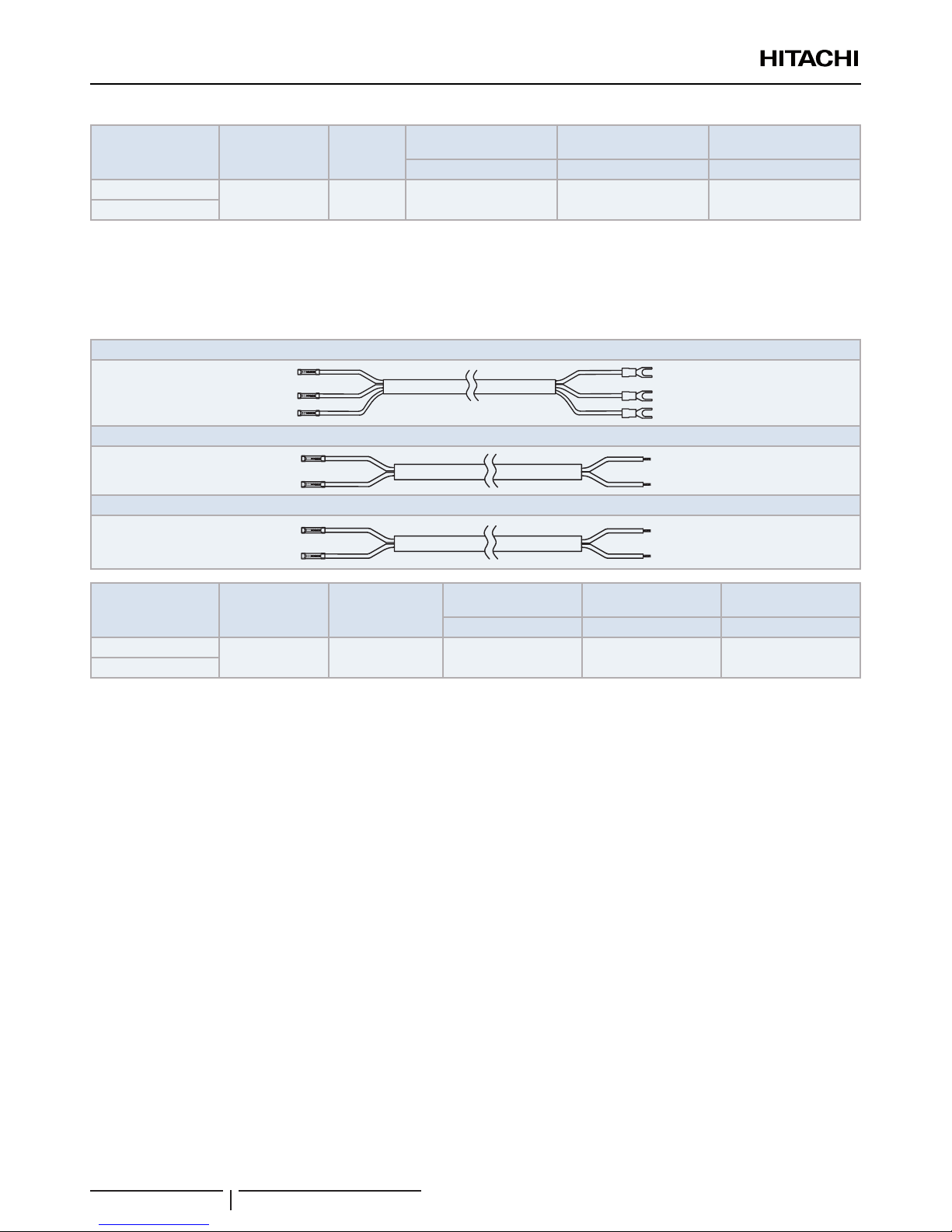

Factory supplied wire sizes

The supplied wires for the connection between the DHW tank and the indoor unit are already connected to the DHW tank. They

are located at the bottom front side of the tank fastened with clamps. The Unit controller electrical cable at the right and the electric

heater and thermistor cables at left.

Electric heater connection cable

30(N)

31(L)

}

Thermistor connection cable

5

6

Unit controller connection cable

3(A)

4(B)

OK

ELECTRICAL AND CONTROL SETTINGS

PMML0344B rev.0 - 04/2016

9

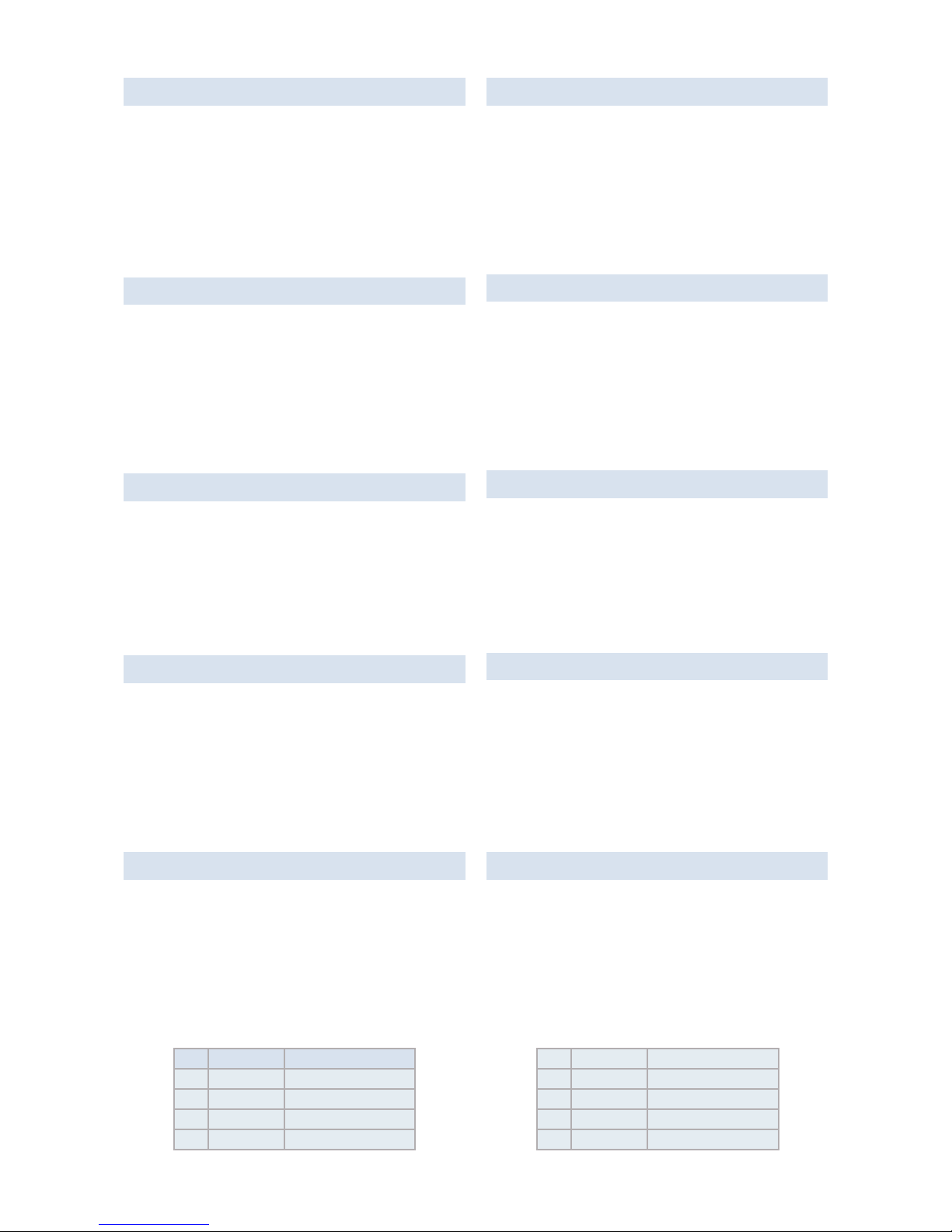

Model Power supply

Maximum

current

(A)

Unit controller

connection cable size

Electric heater

connection cable size

Thermistor connection

cable size

EN60335-1 EN60335-1 EN60335-1

DHWS200S-2.7H2E

1~ 230V 50Hz 8.7 6 x 0.5 mm2 x 1.8m 3 x 2.5 mm2 x 1.8m 2 x 0.3 mm2 x 2.0m

DHWS260S-2.7H2E

Extension cables (supplied with the ATW-FWP-02 accessory. Only for installation of the DHW tank

beside the indoor unit)

When the domestic hot water tank is installed beside the indoor unit, it is needed to extend the cables up to the terminal board 2

(TB2) of the indoor unit, which is placed at certain distance from the tank. These cables are the following:

Extension cable for the electric heater

Extension cable for the thermistor

Extension cable for the LCD controller

Model Power supply

Maximum current

(A)

Unit controller

extension cable size

Electric heater

extension cable size

Thermistor extension

cable size

EN60335-1 EN60335-1 EN60335-1

DHWS200S-2.7H2E

1~ 230V 50Hz 8.7 6 x 0.5 mm2 x 3.5m 3 x 2.5 mm2 x 3.5m 2 x 0.3 mm2 x 3.5m

DHWS260S-2.7H2E

ELECTRICAL AND CONTROL SETTINGS

PMML0344B rev.0 - 04/2016

10

ENGLISH

6 INSTALLATION

6.1 GENERAL NOTES

6.1.1 Components at receipt

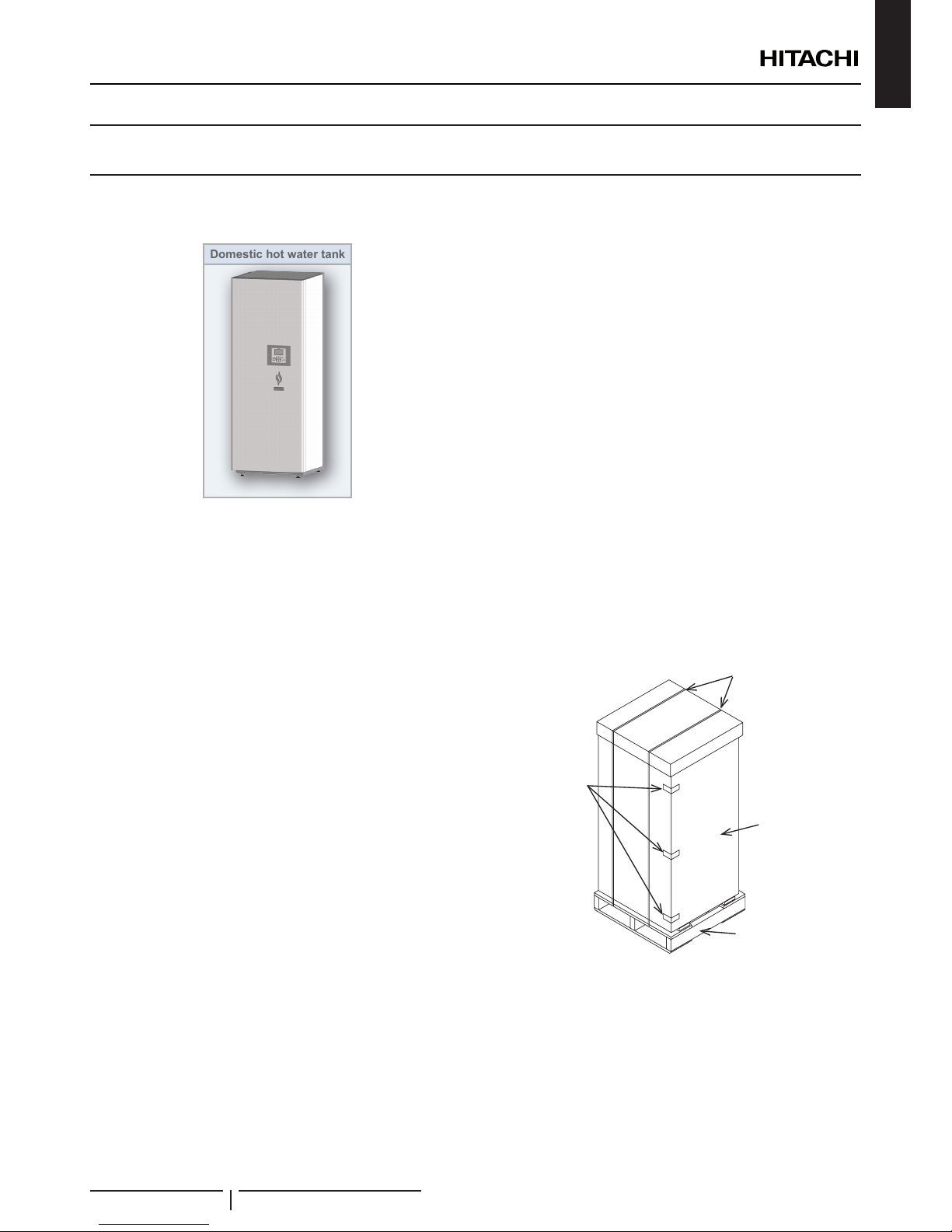

Domestic hot water tank

? NOTE

The unit controller (PC-ARFHE) is integrated in the DHW tank.

6.1.2 Selection of the installation location

The domestic hot water tank must be installed following these

basic requirements:

• The tank is intended to be installed in an indoor place.

• The tank is prepared to be integrated over the YUTAKI

S80 indoor unit, so make sure that selected oor is at

and is made of a non-combustible surface, strong enough

for supporting the indoor weight and also the DHW tank’s

weight completely water lled.

• The tank can be also oor mounted (Tank beside the indoor

unit both left or right sides). In this case, try to keep an

access point for the connection of the dedicated Flexible

Water Pipes Kit (ATW-FWP-02).

• Be sure to maintain the recommended servicing space for

future unit servicing (See “3.2 Service space” section).

• It is necessary to plan a xing point between the wall and the

DHW tank.

• Take into account the space needed to install a necessary

pressure and temperature relief valve, which must be

installed at the DHW inlet connection of the tank (as close as

possible to the tank). 1 shut-off valve (eld supplied) must be

also installed at the DHW outlet connection.

• Keep water draining provisions. The safety valve and the air

purge are provided with a drain pipe which are located at the

bottom side of the indoor unit.

• Protect the DHW tank unit against the entry of small animals

(like rats) which could making contact with the wires, the

drain pipe, electrical parts and may damage unprotected

parts, and at the worst, a re will occur.

• Install it in a no-frost environment.

• Install the DHW tank as far as possible from all sources of

electromagnetic wave radiation.

• Install the unit in a place where in case of water leakage,

any damage to the installation space cannot be produced.

• To avoid re or explosion, do not install the set in a

ammable environment.

• The tank must be installed by a service technician.

The installation must comply with local and European

regulations.

6.1.3 Unpacking

All units are supplied with a wooden base, packed by a

cardboard box and plastic bag.

Firstly to unpack it, place the unit on the assembly area as close

as possible to its nal installation location, to avoid damages in

transport. Two persons are required.

1 Cut the strapping bands and remove the adhesive tapes.

2 Remove the carton assembly and then the plastic bag

around the unit.

3 Unscrew the 4 screws which x the unit to the wooden base.

4 Remove the indoor unit from the wooden base and place it

carefully on the oor, as near as possible to its nal location.

Wooden

base

Carton

assembly

Strapping

bands

Adhesive

tapes

! CAUTION

• There are four adjustable mounting foot at the bottom of the unit.

Each one can be adjusted up to 30 mm, but keep the mounting foot

in the factory supplied position until the unit has been installed in its

nal position.

• Be careful with the Installation and Operation manual and with the

accessories factory-supplied with the unit.

• Two people are required when lifting because of the weight of the

unit.

INSTALLATION

PMML0344B rev.0 - 04/2016

11

6.1.4 Factory-supplied indoor unit components

Accessory Image Qty. Purpose

Flexible water

pipe (1”)

2

Heating coil pipes (for

connection between indoor

unit and DHWT)

M10 bolts 4

To x the tank to the indoor

unit

Gaskets 4+2

4 x1”for the heating coil pipes

2 x3/4” for the DHW

connection

CD-ROM 1

With the detailed Installation

and operation manual

Instruction

manual

1

Basic instructions for the

installation of the device.

Declaration of

conformity

- 1 -

? NOTE

• The previous accessories are supplied inside the packing assembly

(in the accessory box).

• Additional refrigerant piping (eld supplied) for connections to indoor

unit needs to be available.

• If some of these accessories are not packed with the unit or any

damage to the unit is detected, please contact your dealer.

6.1.5 DHWT main parts (Descriptions)

Nº Part Nº Part

1 Front cover 7 Handles

2 Left cover 8 Heating coil inlet (G1” male)

3 Right cover 9 Heating coil outlet (G1” male)

4 DHW outlet (G3/4” male) 10 “Inspection” hatch

5 Unit controller 11 DHWT electric heater

6 DHW inlet (G 3/4” male) 12 LCD support

1

2

7

3

5

4

6

7

12

9

8

10

11

6.1.6 Flexible water coil pipes considerations

Process for coil pipes connection (to avoid leakage).

1 Put a gasket inside the nut.

a)

b)

c)

Gasket

Nut

2 Check that the nut turns free.

3 Be sure that the tube is aligned with the connection.

4 IMPORTANT! Ensure that the gasket is in contact and it is

seating uniformly with the connection.

5 By hand, rotate smoothly the nut and screw it into the

connection. The screwing may be easy and it should not

offer too much resistance, so if that happens, loosen the nut

and check that the pipe and the gasket position are correct

and proceed again with point 3 and 4.

6 With a spanner, nish the screwing process of the nut until

rm but without damaging the gasket.

? CAUTION

• Always bend the water tubes with a radius > 90 mm.

R>90mm

• The tube will not spring back.

• Don’t install the stainless steel tube in a twisted position.

• Don’t bend these stainless steel tube more often than

required to avoid breaking it.

INSTALLATION

PMML0344B rev.0 - 04/2016

12

ENGLISH

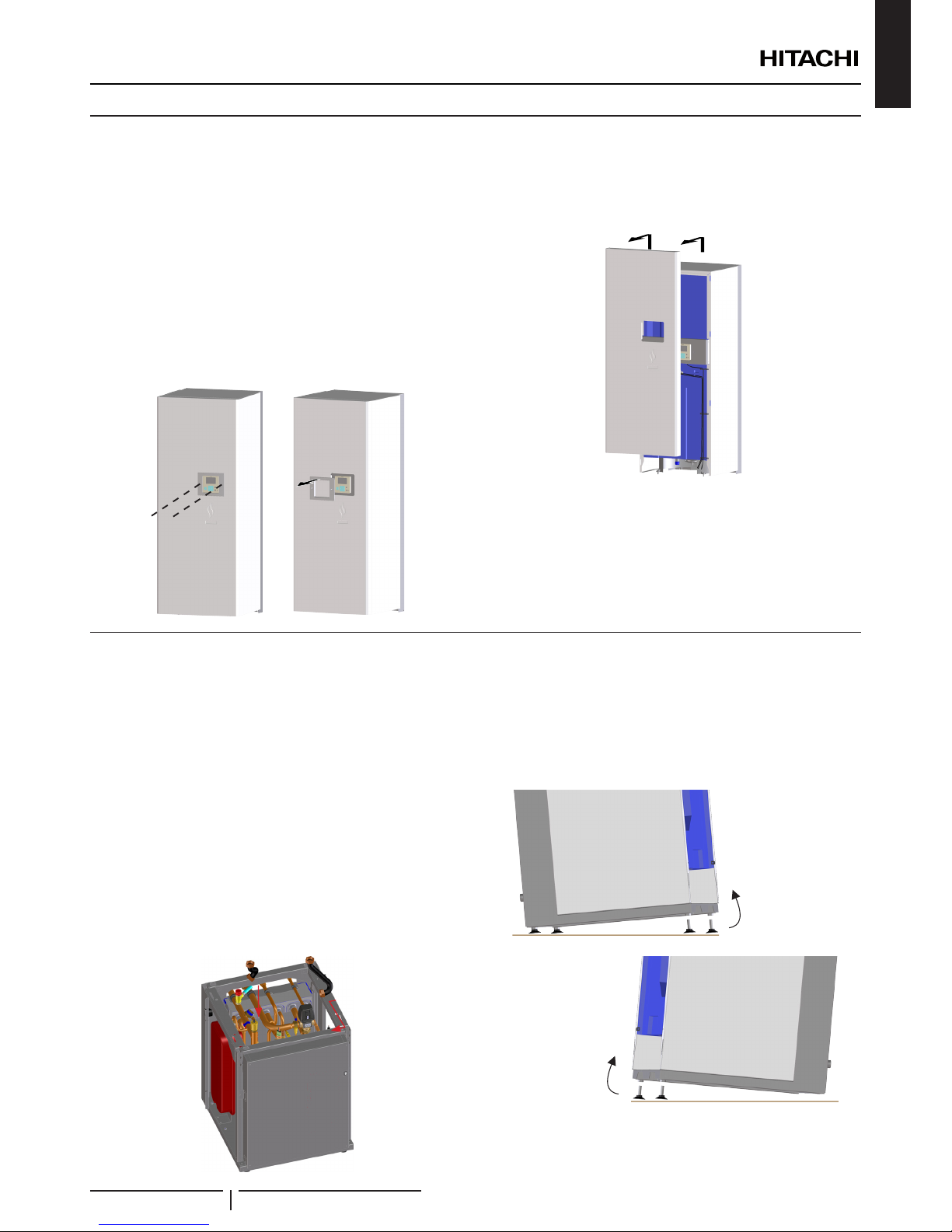

6.2 REMOVING THE FRONT COVER

For the installation of the tank it is necessary to remove the front

cover of the DHWT to get access to the inner parts.

? NOTE

• The pictures shown correspond to DHWS260S-2.7H2E, but

the procedure for removing covers is exactly the same for the

DHWS200S-2.7H2E.

• Front cover needs to be removed for any task inside the unit.

Removing the front cover

1 Unscrew the 2 xing screws of the Unit controller frame.

Gently pull the unit controller frame backwards.

! CAUTION

Take care wit the LCD display when removing the unit controller frame.

2 Pull the front cover upwards and the backward to remove it.

! CAUTION

• Pay attention of no falling off the front cover.

• Be careful not to damage the LCD display and/or the unit controller

itself when removing the front cover.

6.3 INSTALLATION OF DHW TANK WITH YUTAKI S80 INDOOR UNIT

6.3.1 Version with tank on top of the indoor

unit

? NOTE

Please, try to perform all this procedure following all the steps in the exact

order in which they are presented below.

Installation procedure

1 Water pipes connection to the indoor unit (space heating

pipes).

? NOTE

• Pipes are already preformed from factory. This pre-bend side

should be connected to the S80 indoor unit.

• When connected to the S80 indoor unit, pre-form the pipes in

order to let the non connected end pointing to the top.

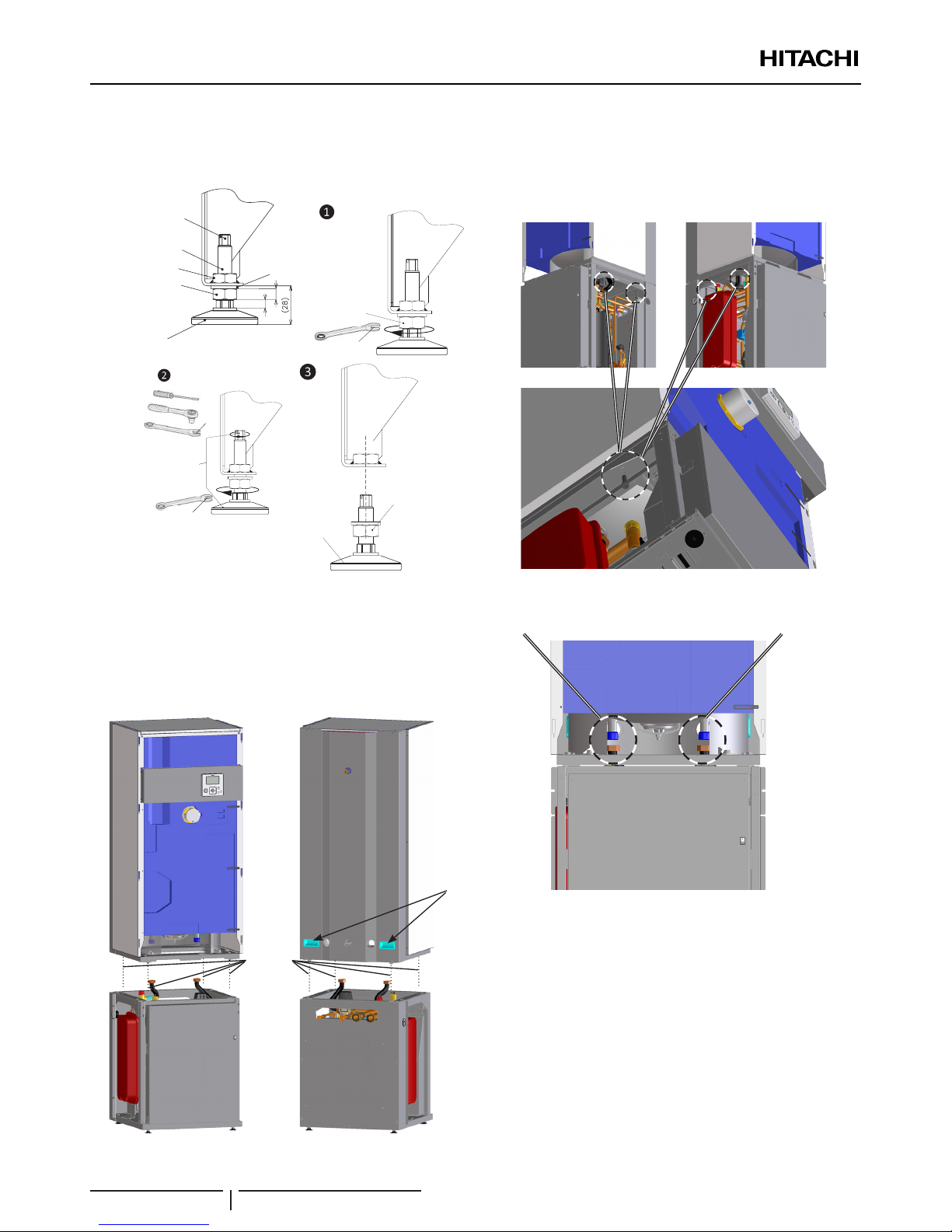

2 Remove the mounting foot from the tank (mounting foot

are assembled from factory and should be removed when

installing the tank on the top of the YUTAKI S80 indoor unit).

• Tilt the tank to one side so that the mounting feet are free to

be unscrewed. When screwed, repeat the same operation to

the other side to remove the remaining feet.

INSTALLATION

PMML0344B rev.0 - 04/2016

13

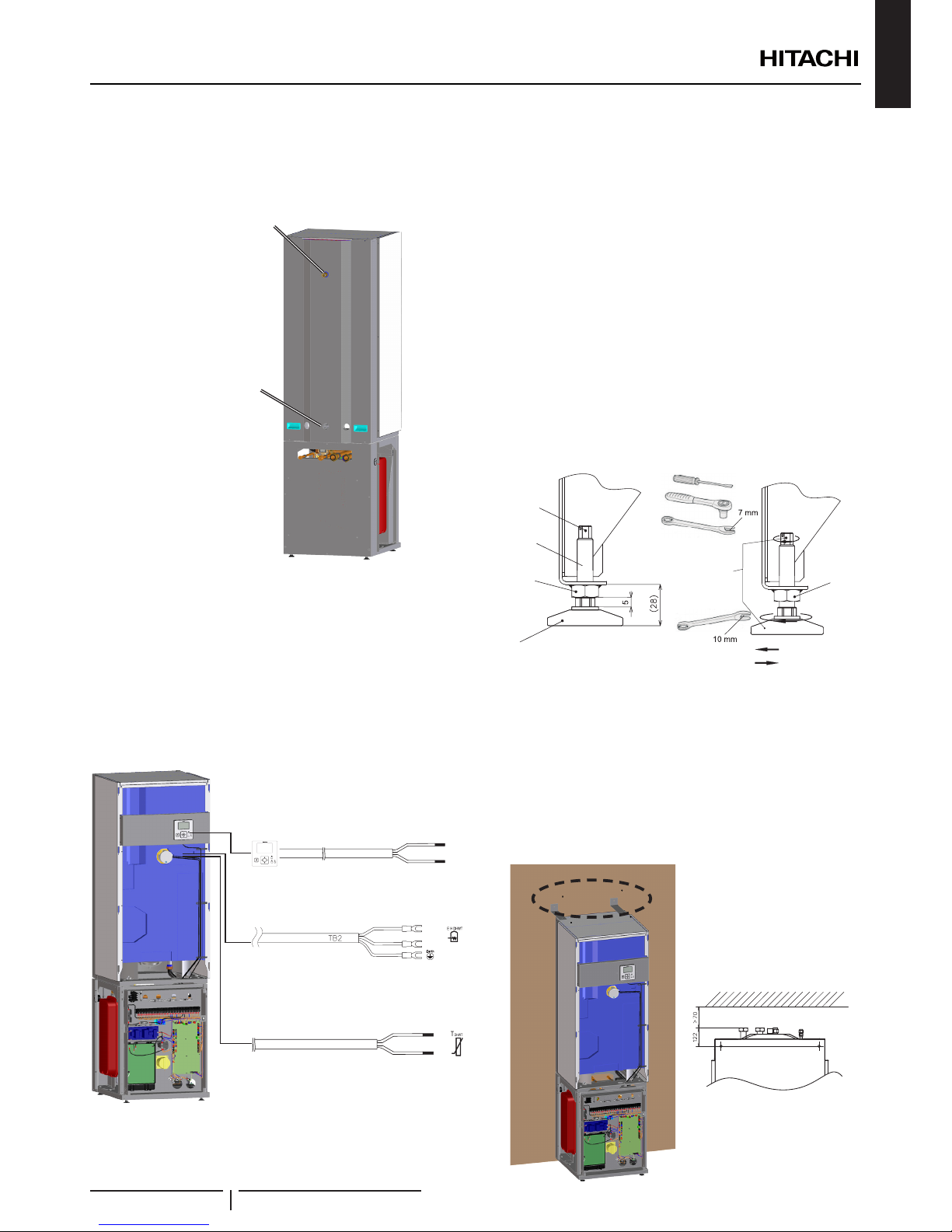

• Loosen the locknut of the mounting foot using a wrench.

• Turn the mounting foot anticlockwise to remove it (Use the

hexagon or slot designed for this purpose in the shaft end)

5

8

Hexagon and slot

for help in the foot

removal procedure

Threaded shaft

Welded nut

Locknut

Mounting

foot base

17 mm

Loosen locknut

7 mm

10 mm

Remove the

mounting foot

Locknut

Mounting

foot base

3 Assemble the tank on the S80 indoor unit

• Lift the tank using the handles placed at the rear of the

indoor unit

! CAUTION

The tank is too heavy. This procedure must be done with two persons

or serious lesions may occur.

Handles

Alignment

of bolts

4 Place the tank on the top of the indoor unit aligning the

welded nuts of the tank unit with the screw holes of the

YUTAKI S80 indoor unit.

5 Screw the M10 bolts (factory supplied) to join the indoor unit

with the tank.

6 Connect the pre-bend pipes to the coil of the tank unit.

Front

view

Heating coil inlet

connection (G 1” male)

Heating coil outlet

connection (G 1” male)

DHW tank

YUTAKI S80

Indoor unit

• The pipe connected to the 3-way valve must be connected

to the heating coil inlet connection of the tank.

• The pipe connected to the T-branch must be connected to

the heating coil ouconnection of the tank.

INSTALLATION

PMML0344B rev.0 - 04/2016

14

ENGLISH

7 Connection of the water pipes to the DHW installation.

• Connect the pipes of the DHW installation to the inlet and

outlet connections of the DHW tank.

DHW outlet connection

(G 3/4” male)

Rear view

DHW outlet connection

(G 3/4” male)

8 Connetion of the tank wiring to the indoor unit.

• The three electrical wires are already connected to the DHW

tank. They are located at the front side of the DHW tank

fastened with clamps.

• Take the three cables and drive them through the rubber

grommets in the partition plate at the bottom of the tank unit

and again through the rubber grommets at the rear side of

the Ebox.

• Connect each cable in the correct place according to the

wiring diagram. (See next picture)

30(N)

31(L)

}

5

6

3(A)

4(B)

OK

Electric heater connection cable

Thermistor connection cable

Unit controller connection cable

9 Levelling procedure

Once the connections of the tank have nished, it is

necessary to levelling the unit.

? NOTE

• Adjust only the necessary mounting foot of the unit.

• Start with all four feet screwed in as far as possible (factory

supplied position).

• Two people are necessary for the levelling procedure.

Follow the process:

Turn the mounting foot to extend the height (use the

hexagon or slot designed for this purpose in the shaft end).

! CAUTION

• Take care do not turn the weld nut when turning the mounting foot.

Use an slot with a height prole lower than 5 mm.

• Never work on more than one foot at the same time. When

nishing, all 4 lock-nuts must be tightened rmly.

Foot

Weld nut

Threaded

shaft

Hexagon and

slot for help

in the foot

adjustment

process

Adjust the

foot’s height as

needed

(2 options)

Extend

Take in

!

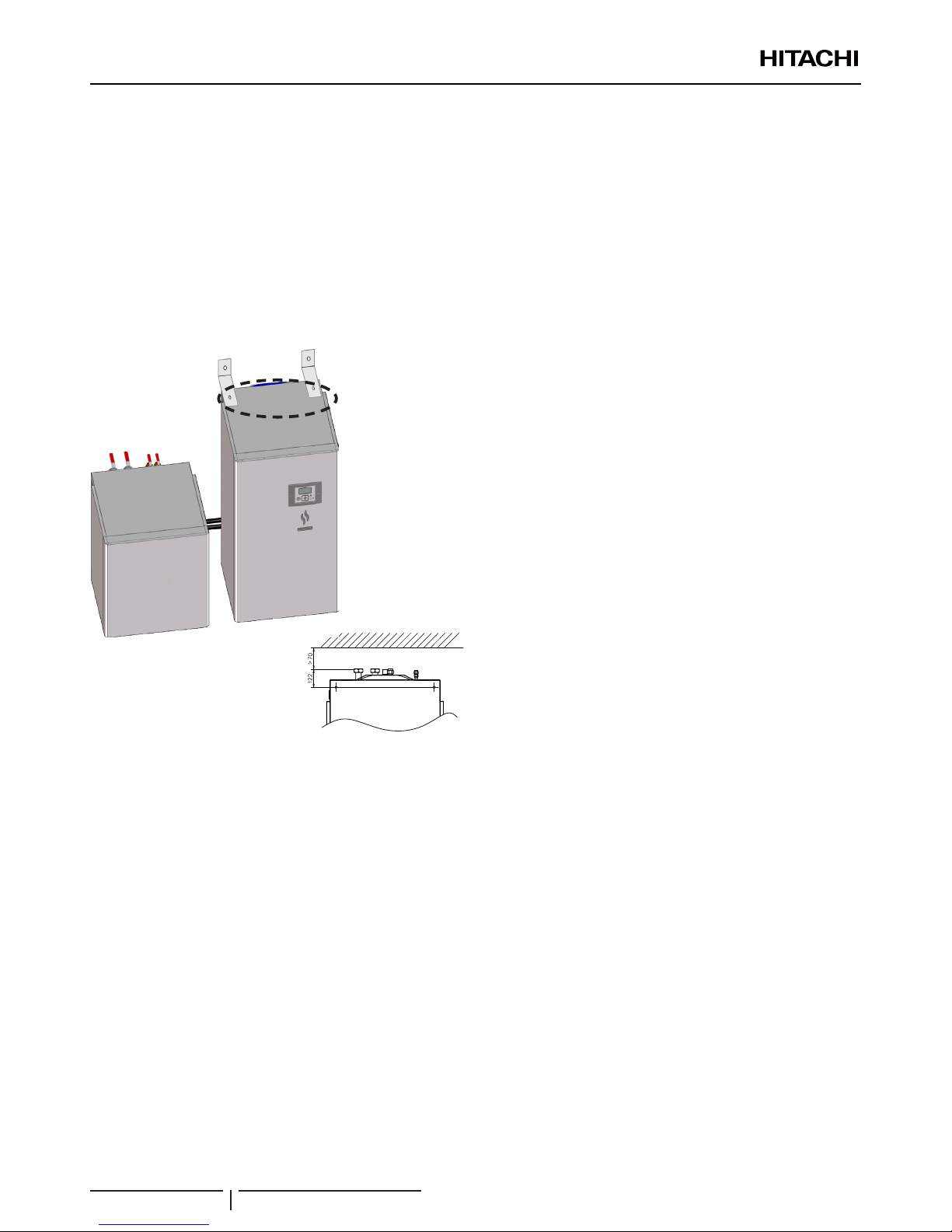

10 Tank xation to the wall

In case of indoor unit with integrated tank it is mandatory,

when there is not upper restriction, to x the domestic hot

water tank to the wall in order to provide a higher stability.

The accessory and screws for that purpose are eld

supplied.

The distance and measure are shown in the next picture.

• Fix the accessory to the DHW tank on the upper cover

through the holes.

122 mm: minimum distance

between the end of the male

tting and the wall xing hole

INSTALLATION

PMML0344B rev.0 - 04/2016

15

? NOTE

Use the accessory slotted hole to x the DHW tank to the wall at the

desired distance.

• Fix the accessory to the wall with eld supplied screws.

? NOTE

Check that the set (indoor unit with integrated tank) is installed totally

vertical.

11 Test and check.

Before assembling the covers, test and check the following

items:

• Water leakage

• Refrigerant leakage

• Electrical connection

• ...

? NOTE

The following documents must be referred:

• Refer to the chapters “4.1.4 Water lling” and “9 COMMISSIONING”

in this document (Tank)

• Refer to the YUTAKI S80 indoor unit Installation and operation

manual, for the information about the refrigerant charge, water

lling and Commissioning of the indoor unit.

• For the specic details about refrigerant charge tasks refer the

Outdoor unit Installation and Operation manual.

! DANGER

DO NOT CONNECT THE POWER SUPPLY TO THE INDOOR UNIT

AND DHW TANK PRIOR TO FILLING BOTH CIRCUITS WITH

WATER AND CHECKING WATER PRESSURE AND THE TOTAL

ABSENCE OF ANY WATER LEAKAGE.

12 Cover’s assembly

Finally, reassembly all the cover’s removed.

Safety instructions

? NOTE

Check the requirements and recommendations in the chapter “5 Electrical

and control settings”

! DANGER

• Do not connect the power supply to the DHW tank prior to

lling the space heating circuit and DHW circuit with water and

checking water pressure and the total absence of any water

leakage.

• Do not connect or adjust any wiring or connections unless the

main power switch is OFF.

• When using more than one power source, check and ensure that

all of them are turned OFF before operating the unit.

• Wait for 3 minutes after switching off the power of the unit before

any electrical work. This is necessary to ensure the discharge of

internal capacitors in order to avoid electrical shock.

• Check to ensure that the indoor fan (inverter box) and the

outdoor fan have stopped before electrical wiring work or

periodical check is performed.

• Avoid wiring installation in contact with the refrigerant pipes,

water pipes, edges of plates and electrical components inside

the unit to prevent damage, which may cause electric shock or

short circuit.

! CAUTION

• Use a dedicated power circuit for the DHW tank. Do not use a power

circuit shared with the outdoor unit or any other appliance.

• Make sure that all wiring and protection devices are properly selected,

connected, identied and xed to the correspond ing terminals of

the unit, specially the protection (earth) and power wiring, taking

into account the applicable national and local regulations. Establish

proper earthing; Incomplete earthing may cause electrical shock.

• Protect the unit against the entry of small animals (like rodents)

which could damage the drain pipe and any internal wire or any other

electrical part, leading to electric shock or short-circuit.

• Keep a distance between each wiring terminal and attach insulation

tape or sleeve as shown in the gure.

Tape or sleeve

6.3.2 Version with tank next to the indoor unit

? NOTE

Please, try to perform all this procedure following all the steps in the exact

order in which they are presented below.

Installation procedure

1 Water pipes connection to the indoor unit (space heating

pipes).

When installing the tank next to the YUTAKI S80 indoor unit,

the ATW-FWP-02 accessory is required. This accessory is

composed with 3 extension cables for the wiring supplement

and 4 exible pipes for the connection between the indoor

unit and the DHW tank.

? NOTE

• Pipes are preformed from factory. This pre-bend side should be

connected to the S80 indoor unit.

• When connected to the S80 indoor unit, pre-form the pipes in

order to let the non connected end pointing to the top.

Flexible pipes.

Factory supplied with the

YUTAKI S80 indoor unit

INSTALLATION

PMML0344B rev.0 - 04/2016

16

ENGLISH

2 The YUTAKI S80 comes with 2 shut-off valves factory

supplied to be connected to the water inlet and outlet of

the unit. It is recommended to connect 2 additional shut-off

valves (eld supplied) to the inlet and outlet pipes for space

heating- That will ease the maintenance operation of the

indoor unit.

Shut-off valves

factory supplied

Shut-off valves

eld supplied

3 Water pipes connection to the inlet and outlet of the tank.

For this operation it is necessary to use 2 of the 4 pipes

supplied with the ATW-FWP-02 accessory

• Run the 2 pipes through the rear holes of the DHW tank.

• Attach and screw the are nuts to the inlet and outlet pipes

of the DHW tank.

4 Place the tank next to the indoor unit

• Place the tank next to the YUTAKI S80 indoor unit according

to the designed layout.

! CAUTION

The tank is too heavy. This procedure must be done with two persons

or serious lesions may occur

5 Connect the 2 long pipes of the ATW-FWP-02 accessory

between the exible pipes already connected to the space

heating of the S80 unit and the exible pipes connected to

the inlet and outlet of the coil of the tank.

S80 space heating

connections

DHWT space heating

connections

Long exible pipes from

ATW-FWP-02 accessory

INSTALLATION

PMML0344B rev.0 - 04/2016

17

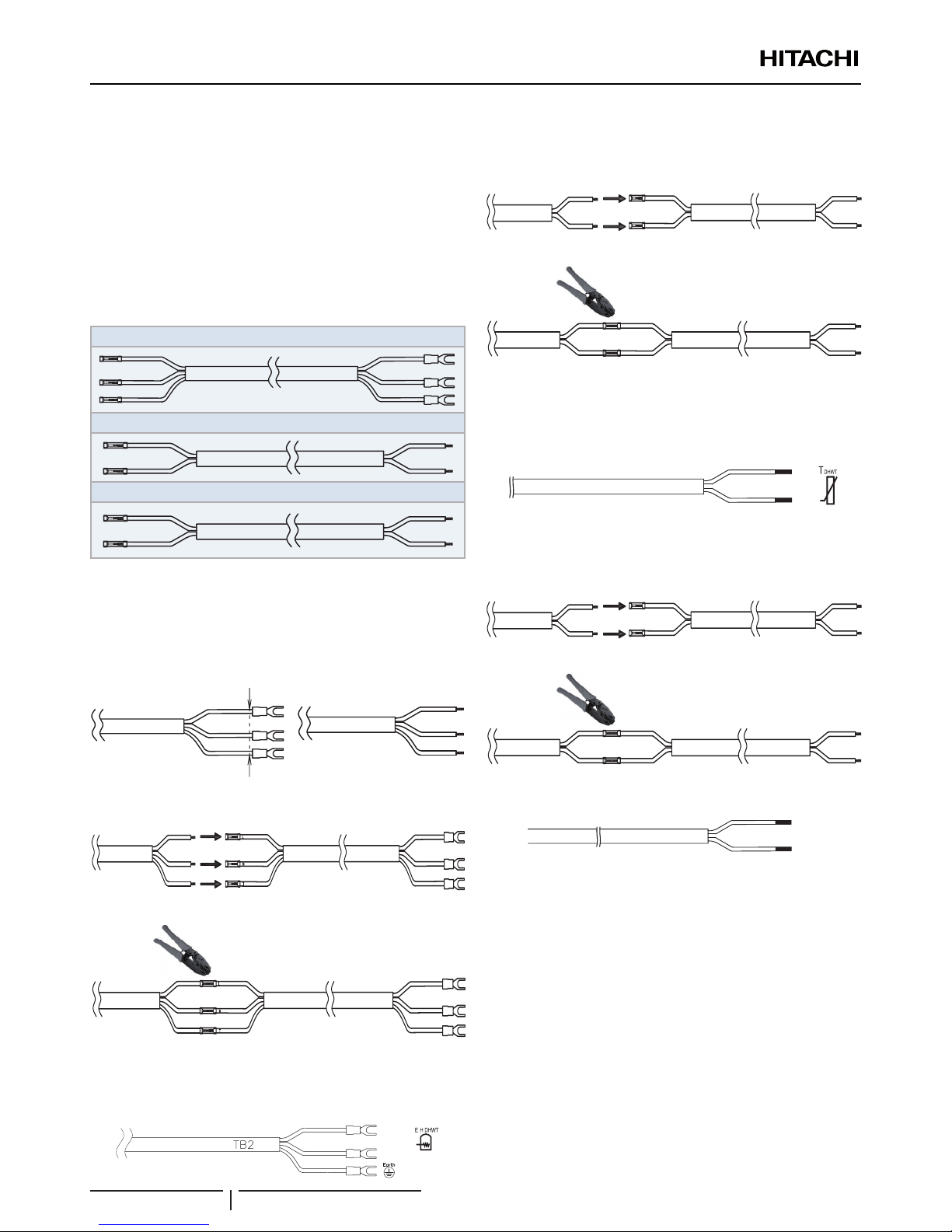

6 Connect the tank wiring to the indoor unit.

• The three electrical wires are already connected to the DHW

tank. They are located at the front side of the DHW tank

fastened with clamps.

• When the domestic hot water tank is installed beside the

indoor unit, it is needed to extend the cables up to the

terminal board 2 (TB2) of the indoor unit, which is placed

at certain distance from the tank. These cables are the

following:

Extension cables (supplied with the ATW-FWP-02 accessory)

Extension cable for the electric heater

Extension cable for the thermistor

Extension cable for the unit controller

Cables connection

Electric heater of the tank

• Cut and strip the free end of the 3 wires of the factory

supplied electric heater cable.

1.1)

1.2)

Connect the extension cable to the factory supplied cable.

(Factory supplied cable)

2.1)

(Extension cable)

(Factory supplied cable)

(Extension cable)

2.2)

(*)

(*): Use a crimping tool to crimp the cables.

• Connect the earth wire to the correct terminal, as shown in

the picture For more information refer to the wiring diagram.

30(N)

31(L)

}

Tank thermistor

• Connect the extension cable to the factory supplied cable.

(Factory supplied cable)

(Extension cable)

1.1)

(Factory supplied cable)

(Extension cable)

1.2)

(*)

(*): Use a crimping tool to crimp the cables.

• Connect the extension cables to the correct terminal, as

shown in the picture. For more information refer to wiring

diagram.

5

6

LCD controller

• Connect the extension cable to the factory supplied cable.

(Factory supplied cable)

(Extension cable)

1.1)

(Factory supplied cable)

(Extension cable)

1.2)

(*)

(*): Use a crimping tool to crimp the cables.

3(A)

4(B)

• Take the three cables and drive them through the rear cover

of the tank unit.

INSTALLATION

PMML0344B rev.0 - 04/2016

18

ENGLISH

7 Run the cables together with the exible pipes. Fix them with

plastic bands.

Extension wires

• Connect the extension cables to the correct terminal, as

shown in the picture. For more information refer to wiring

diagram.

30(N)

31(L)

}

Electric heater connection cable

5

6

Thermistor connection cable

3(A)

4(B)

OK

Unit controller connection cable

8 Levelling procedure

Indoor unit

Follow the same procedure explained in Installation of indoor

unit alone (Without tank) on the YUTAKI S80 indoor unit

Installation and operation manual.

Domestic hot water tank

If it is necessary, adjust the height of the mounting foot as

follows:

? NOTE

• All the procedure must be done before lling the water tank.

• Adjust only the necessary mounting foot of the DHW tank with the

foot locknuts and when the tank is in the nal position (moving the

DHWT after levelling can make it uneven again).

• Start with all four feet screwed in as far as possible (factory supplied

position).

• Use two or more people for levelling procedure.

Follow the process:

1 Loosen the locknut of the mounting feet which needs to be

extended (using a wrench).

2 Turn the mounting foot to extend the height (use the

hexagon or slot designed for this purpose in the shaft end).

3 When the mounting foot is in his end position, lock the

locknut. It may be necessary holding the foot to keep it from

turning while tightening the locknut. Use for this purpose the

hexagon or slot in the shaft end.

If it is needed to proceed with the levelling procedure with

a second foot (process 1 to 3), never work over one foot

at same time. When nish, all 4 locknut must be tightened

rmly.

5

8

Foot

Locknut

Weld nut

Washer

Threaded shaft

Hexagon and slot

for help in the

foot adjustment

process

17 mm

Loosen locknut

7mm

10 mm

Adjust the

foot’s height

as needed

(2 options)

Extend

Take in

Hold the foot

shaft to keep

it from turning

(2 options)

Lock the foot

turning the

locknut

INSTALLATION

PMML0344B rev.0 - 04/2016

19

6.3.3 DHW tank xation to the wall

Fix the domestic hot water tank to the wall in order to provide a

higher stability (use the factory supplied accessory intended for

this purpose).

1 Fix the accessory to the DHW tank on the upper cover

through the holes with the bundled factory supplied screws.

? NOTE

Use the accessory slotted hole to x the DHW tank to the wall at the

desired distance.

2 Fix the accessory to the wall with eld supplied screws.

122 mm: minimum distance between

the end of the male tting and the

wall xing hole.

? NOTE

Check that the tank is installed totally vertical.

6.3.4 Test and check

Before assembling the covers, test and check the following

items:

• Water leakage

• Refrigerant leakage

• Electrical connection

• ...

? NOTE

The following documents must be referred:

• Refer to the chapters “4.1.4 Water lling” and “9 COMMISSIONING”

in this document (Tank)

• Refer to the YUTAKI S80 indoor unit Installation and operation

manual, for the information about the refrigerant charge, water lling

and Commissioning of the indoor unit.

• For the specic details about refrigerant charge tasks refer the

Outdoor unit Installation and Operation manual.

! DANGER

DO NOT CONNECT THE POWER SUPPLY TO THE INDOOR UNIT

AND DHW TANK PRIOR TO FILLING BOTH CIRCUITS WITH WATER

AND CHECKING WATER PRESSURE AND THE TOTAL ABSENCE OF

ANY WATER LEAKAGE.

6.3.5 Cover’s assembly

Finally, reassembly all the cover’s removed.

INSTALLATION

PMML0344B rev.0 - 04/2016

20

ENGLISH

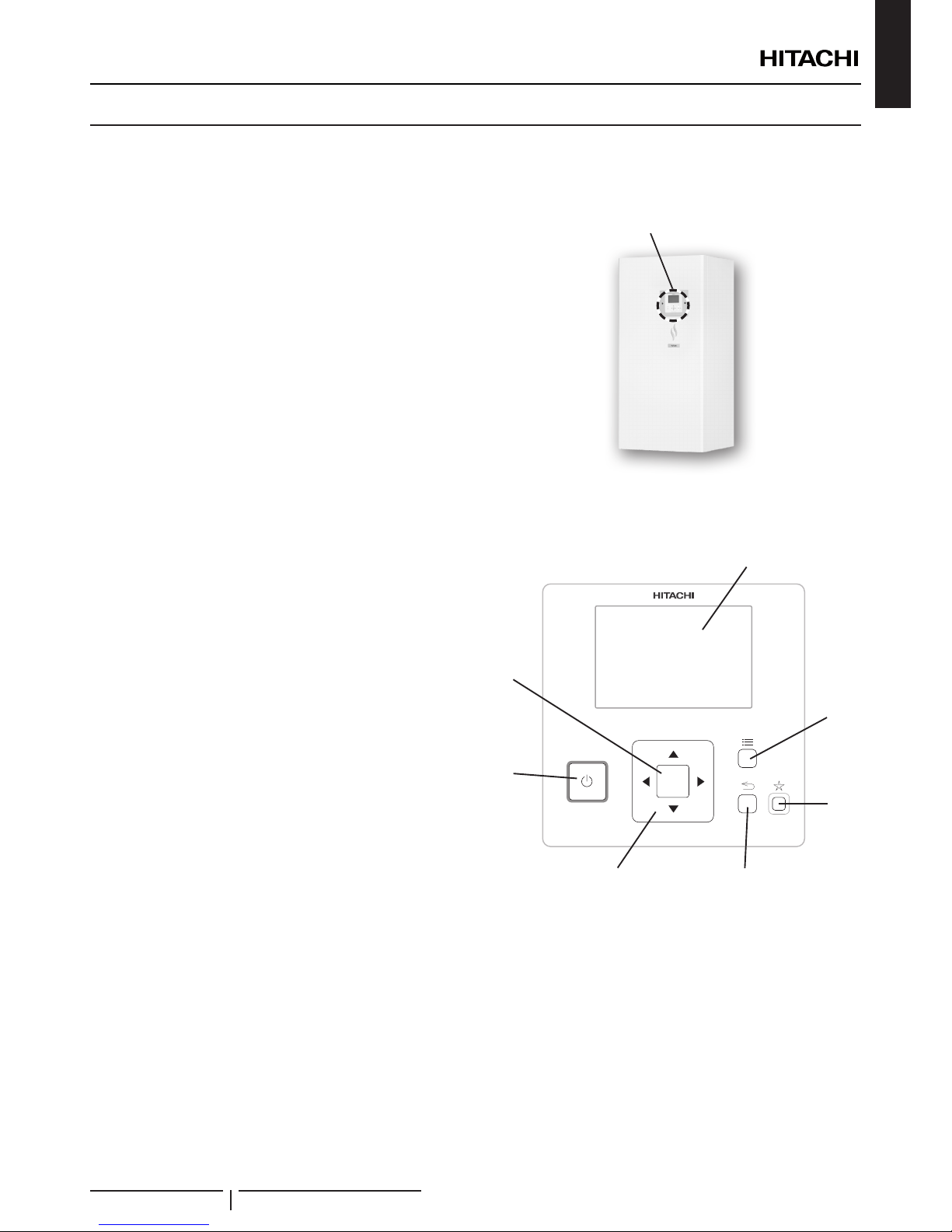

7 DHW TANK OPERATION

Operation switches location

The Unit controller (PC-ARFHE) is integrated into the DHW tank.

Unit controller

PC-ARFHE

The LCD controller working mode is very simple, with 7 buttons that make possible the access to all the display menus, which can

be shown by the LCD liquid crystal display.

Liquid Cristal display

Screen where controller software is displayed.

OK button

To select the variables to be edited and to conrm the selected

values

Arrows key

It helps the user to move through the menus and views

Run/Stop

It works for all zones if none of the zones is selected or only for

one zone when selected.

Menu button

It shows the different conguration options of the user controller.

Return button

To return to the previous screen.

Favourite button

When this button is pressed, the selected favourite action (ECO,

Holidays, simple timer or DHW boost) is directly executed.

OK

DHW TANK OPERATION

PMML0344B rev.0 - 04/2016

21

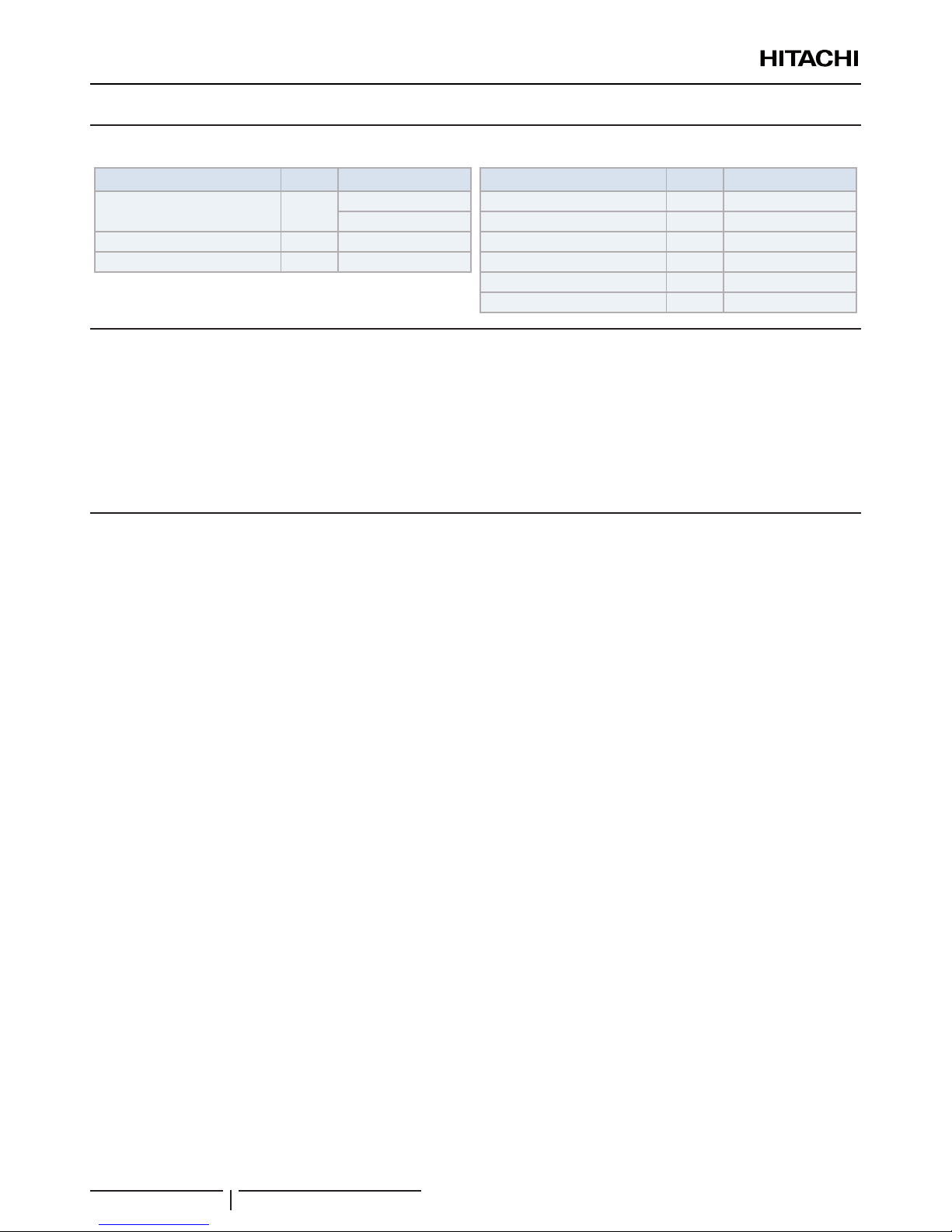

8 CONTROL DEVICE SETTING

Thermostat (manual reset) Units DHW tank

Cut-Out contactors ºC

28~80 ±5ºC

Safety: 90 ±7ºC

Current A 16 (AC1)

Voltage V 250V

Heating resistances Units DHW tank

Power input kW 2.7

Voltage V 230V

Diameter mm 8

Resistances whole xing are nut “G 1 3/4 (brass)

Material - Incoloy 800

Sensor - NTC 20k at 25ºC

9 COMMISSIONING

When installation is complete, perform commissioning according to the following procedure and hand over the system to the

customer. Perform the commissioning of the units methodically, and check that the electrical wiring and the piping are correctly

connected.

? NOTE

Please, refer to YUTAKI S80 Indoor unit Installation and operation manual for the complete information of the commissioning.

9.1 PRELIMINARY CHECK

9.1.1 Checking the unit

• Check external appearance of the unit to look for any

damage due to transportation or installation.

• Check that all the covers are totally closed.

• Check that there is respected the service space

recommended (see “3.2 Service space” in this document

for the tank and the Outdoor and indoor unit Installation and

operation manuals).

• Check that the unit has been correctly installed and that the

mounting foot are correctly adjusted.

9.1.2 Electrical checking

! CAUTION

Do not operate the system until all the check points have been cleared:

• DO NOT CONNECT THE POWER SUPPLY TO THE INDOOR UNIT

AND DHW TANK PRIOR TO FILLING BOTH CIRCUITS WITH

WATER AND CHECKING WATER PRESSURE AND THE TOTAL

ABSENCE OF ANY WATER LEAKAGE.

• Do not touch any electrical components before than three minutes

after turning OFF the main switch

• Check to ensure the electrical wiring of the DHW tank and the indoor

unit are connected as shown in the corresponding chapter.

• Check to ensure the external wiring is correctly xed to avoid problems

with vibrations, noises and cut out wires with the plates.

9.1.3 Hydraulic circuit checking

• Check that the circuit and the tank have been properly

ushed and lled with water and that the installation has

been drained: the pressure of the heating coil circuit must be

1.8 bar (at least 1.5 bar).

• The pressure of the DHW circuit in the tank has to be lower

than 7 bars.

• Check that the water tank heating coil is completely lled.

• Check for any leakage in water cycle. Pay special attention

to the water piping connections.

• Make sure the system’s internal water volume is correct.

• Make sure the DHW tank internal water volume is correct.

• Check that the hydraulic circuit’s valves are fully open.

! CAUTION

• Operating the system with closed valves will damage the unit.

• Check to see that air purge valve is open and that the heating coil

hydraulic circuit is air purged. The installer is responsible of completely

air purging the installation.

• Check that the water pump of the space heating and heating coil

circuits work within the pump operating range and that the water ow

is over the pump’s minimum. If the water ow is under 12 liters/minute

(with ow switch tolerance), alarm will be displayed on the unit.

• Remember that water connection must be accordance with local

regulations.

• Water quality must comply with EU directive 98/83 EC.

CONTROL DEVICE SETTING

PMML0344B rev.0 - 04/2016

22

Loading...

Loading...