Page 1

Handling instructions

H ng d n s d ng

Petunjuk pemakaian

en

zh

ko

vi

th

ar

id

DH 45ME DH 45MEY

en

zh

ko

vi

th

ar

id

Page 2

2

English

Carrying power tools with your fi nger on the switch

or energising power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left attached to a rotating part of

the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

Loose clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of dust collection can reduce dust-related

hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better and safer

at the rate for which it was designed.

b) Do not use the power tool if the switch does not

turn it on and o .

Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/

or the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may a ect the

power tool s operation.

If damaged, have the power tool repaired before

use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed.

Use of the power tool for operations di erent from

those intended could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts.

This will ensure that the safety of the power tool is

maintained.

PRECAUTION

Keep children and infi rm persons away.

When not in use, tools should be stored out of reach of

children and infi rm persons.

GENERAL POWER TOOL SAFETY

WARNINGS

WARNING

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in

electric shock, fi re and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless)

power tool.

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

fl ammable liquids, gases or dust.

Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools.

Unmodifi ed plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the

risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired

or under the infl uence of drugs, alcohol or

medication.

A moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always

wear eye protection.

Protective equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the o position before connecting to

power source and/or battery pack, picking up or

carrying the tool.

Page 3

3

English

ROTARY HAMMER SAFETY

WARNINGS

1. Wear ear protectors

Exposure to noise can cause hearing loss.

2. Use auxiliary handle(s), if supplied with the tool.

Loss of control can cause personal injury.

3. Hold power tool by insulated gripping surfaces,

when performing an operation where the cutting

accessory may contact hidden wiring or its own

cord.

Cutting accessory contacting a “live” wire may make

exposed metal parts of the power tool “live” and could

give the operator an electric shock.

ADDITIONAL SAFETY WARNINGS

1. Ensure that the power source to be utilized conforms

to the power requirements specifi ed on the product

nameplate.

2. Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the power

switch is in the ON position, the power tool will start

operating immediately, which could cause a serious

accident.

3. When the work area is removed from the power source,

use an extension cord of su cient thickness and rated

capacity. The extension cord should be kept as short as

practicable.

4. Do not touch the bit during or immediately after

operation. The bit becomes very hot during operation

and could cause serious burns.

5. Before starting to break, chip or drill into a wall, fl oor or

ceiling, thoroughly confi rm that such items as electric

cables or conduits are not buried inside.

6. Always hold the body handle and side handle of the

power tool fi rmly. Otherwise the counterforce produced

may result in inaccurate and even dangerous operation.

7. Wear a dust mask.

Do not inhale the harmful dusts generated in drilling or

chiseling operation. The dust can endanger the health of

yourself and bystanders.

8. Mounting the tool

To prevent accidents, make sure to turn the switch o

and disconnect the plug from the receptacle.

When using tools such as bull points, drill bits, etc.,

make sure to use the genuine parts designated by our

company.

Clean the shank portion of the drill bit. Then smear the

shank portion with the grease or machine oil.

9. The rotation speed cannot be changed by pressing the

rotation speed selector switch while the motor is rotating.

To change speeds, switch o the tool fi rst.

10. RCD

The use of a residual current device with a rated residual

current of 30mA or less at all times is recommended.

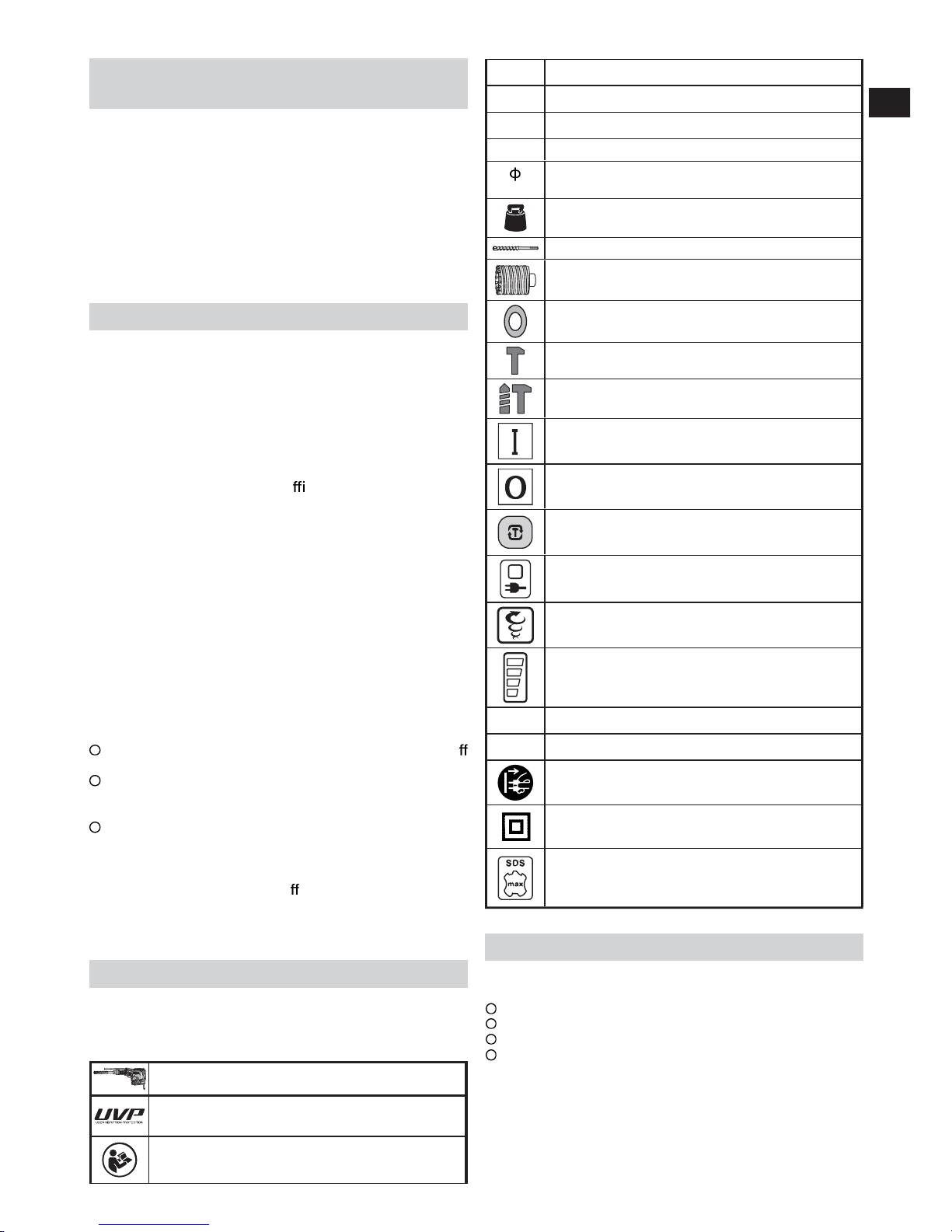

SYMBOLS

WARNING

The following show symbols used for the machine.

Be sure that you understand their meaning before

use.

DH45ME / DH45MEY: Rotary Hammer

User Vibration Protection

Read all safety warnings and all instructions.

V

Rated voltage

P

Power Input

n

0

No-load speed

Bpm Full-load impact rate

max

Drilling diameter, max.

kg

Weight

Drill bit

Core bit

Adjustment of the tool position function

Hammering only function

Rotation and hammering function

Switching ON

Switching OFF

Continuous operation button

Power lamp

Rotation speed selector switch

Display lamp

Ls

Low speed / impact rate

Hs

High speed / impact rate

Disconnect mains plug from electrical outlet

Class II tool

SDS max shank

STANDARD ACCESSORIES

In addition to the main unit (1 unit), the package

contains the accessories listed in the below.

Plastic case ................................................................ 1

Side handle ................................................................. 1

Stopper ...................................................................... 1

Hammer Grease A ..................................................... 1

Standard accessories are subject to change without notice.

Page 4

4

English

APPLICATIONS

Rotation and hammering function

Drilling anchor holes

Drilling holes in concrete

Hammering only function

Crushing concrete, chipping, digging, and squaring

(by applying optional accessories)

SPECIFICATIONS

The specifi cations of this machine are listed in the Table on

page 30.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifi cations herein are subject to

change without prior notice.

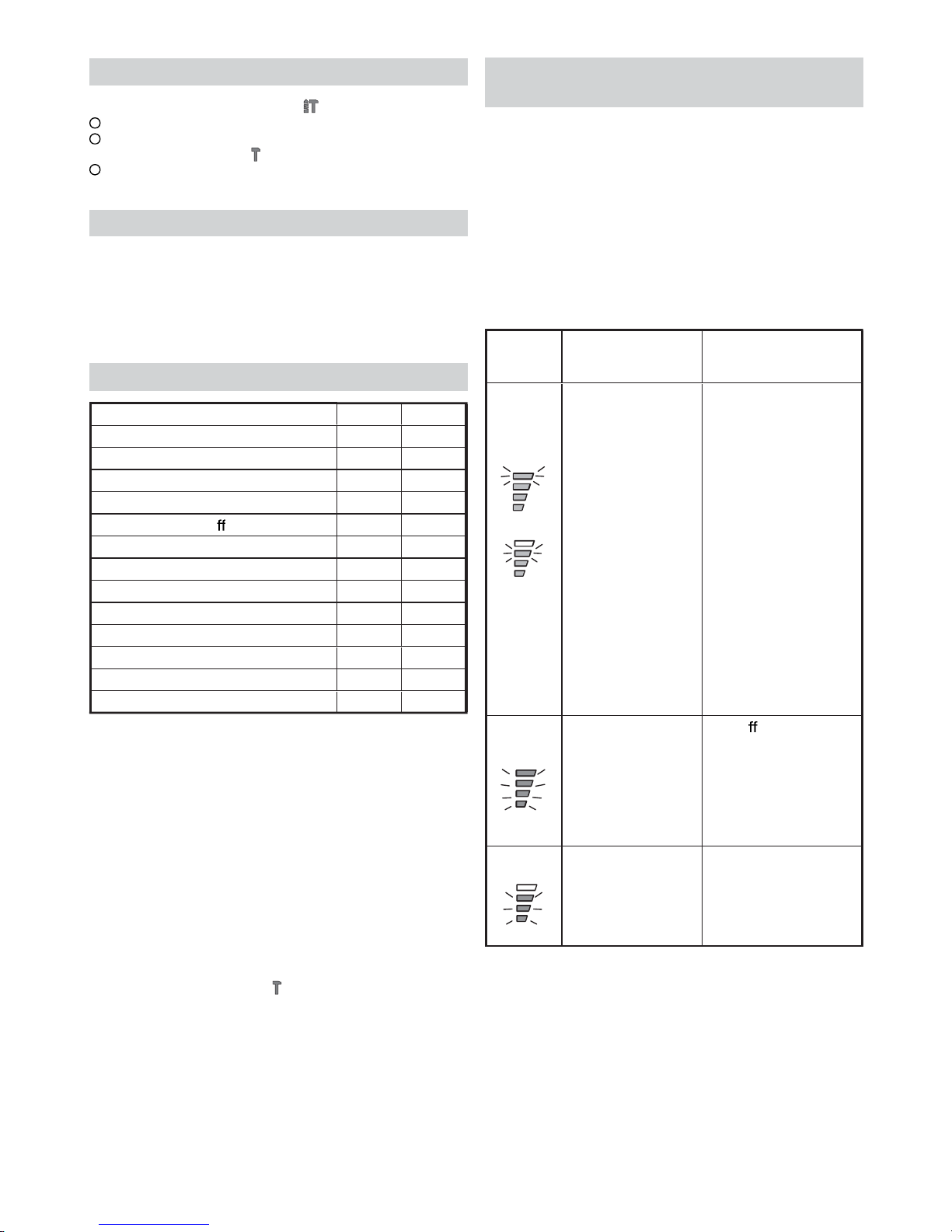

MOUNTING AND OPERATION

Action Figure Page

Inserting SDS-max tools 1 31

Removing SDS-max tools 2 31

Changing tool direction 3 31

Selecting the operating mode 4 31

Switching on and o 5 31

About the power lamp 6 32

Speed change 7 32

Install the stopper 8 32

Using tapershank adapter 9 33

Removing tapershank adapter 10 33

Mounting core bit 11 33

Mounting guide plate and center pin 12 33

Selecting accessories* –

34, 35

* For detailed information regarding each tool, contact a

Hitachi authorized service center.

Warming up (Fig. 13)

The grease lubrication system in this unit may require

warming up in cold regions.

Position the end of the bit so makes contact with the

concrete, turn on the switch and perform the warming

up operation. Make sure that a hitting sound is produced

and then use the unit.

CAUTION

When the warming up operation is performed, hold the

side handle and the main body securely with both hands

to maintain a secure grip and be careful not to twist your

body by the jammed drill bit.

Using Continuous operation button

The Continuous operation button feature is only available

for “Hammering Mode ”. Pressing the Continuous

operation button will switch on a blue LED that indicates

the activation of the Continuous operation function which

will keep the tool running even after the trigger switch is

released. To cancel the function, press the Continuous

operation button again or push the trigger switch to the

ON position. (Fig. 14)

NOTE

Continuous operation will be deactivated when the switch

is pressed. During continuous operation, keep your hand

away from the switch and grip the lower part of the handle

to avoid any unintentional contact with the switch. (

Fig.15

)

ABOUT THE PROTECTION

FUNCTION

This tool has a built-in protection circuit for preventing

damage to the unit in the event of an abnormality. Depending

on the nature of the abnormality, the display lamp will fl ash

as shown in Table 1 and the unit will cease to operate. In

such cases, verify the problem indicated by the fl ashing and

take whatever steps are necessary to correct the problem.

NOTE

Repair may be required if the display lamp continues

to fl ash after taking all necessary steps to correct the

problem. If the problem persists, please arrange for

repairs.

Table 1

Display

lamp

fl ashing

Cause Solution

Flash

or

(110 V,

120 V,

127 V

ONLY)

The tool’s

temperature

increase protection

function gradually

reduced the

rotation speed

as the internal

temperature of the

tool approached

the specifi ed

temperature range

for automatic

shutdown.

(Power regulation

function)

* The power

regulation function

will not activate if

only one or two of

the display lamp

bars are lighting.

The tool will return to

normal power once the

temperature is lowered

by reducing its load.

Continued operation

may result in automatic

shutdown by the tool’s

temperature increase

protection function.

(See row below)

Flash

Internal temperature

has risen beyond

the unit’s specifi ed

temperature.

(Temperature

increase protection

function)

Turn o the unit

and allow it to cool

down for about 15 to

30 minutes.

When the temperature

goes down, press the

rotation speed selector

switch to recover.

Flash

Excessive pressure

applied to the tool

has resulted in an

overload.

(Overload

protection function)

Press the rotation

speed selector switch

to recover. Try to avoid

tasks that will apply

excess pressure to

the unit.

Page 5

5

English

Flash

ï Tool fails to

startup or has

shut down due

to the unit being

connected to a

power source

whose voltage is

either too high or

too low.

î Tool has shut

down due to a

voltage signal

read error that

occurred from

the unit’s power

cord being

plugged in and

out at short

intervals.

(Circuit protection

function)

ï Connect the unit

to a power supply

matching the input

voltage specifi ed

on the nameplate.

Press the rotation

speed selector

switch to recover.

î Allow for an interval

of 3 seconds or

more when plugging

the power cord

in and out. Press

the rotation speed

selector switch to

recover.

Flash

Sensor signal read

error.

(Control monitoring

function)

Press the rotation

speed selector switch

to recover. Repair may

be required if this error

continuously occurs.

GREASE REPLACEMENT

This Rotary Hammer is of full air-tight construction to protect

against dust and to prevent lubricant leakage.

Therefore, this Rotary Hammer can be used without

lubrication for long periods. Replace the grease as described

below.

Grease Replacement Period

After purchase, replace grease after every 6 months of

usage. Ask for grease replacement at the nearest authorized

Service Center.

MAINTENANCE AND INSPECTION

1. Inspecting the drill bits

Since use of a dull tool will cause motor malfunctioning

and degraded e ciency, replace the drill bit with new

ones or resharpen them without delay when abrasion is

noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws be

loose, retighten them immediately. Failure to do so could

result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the power

tool.

Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

4. Replacing supply cord

If the replacement of the supply cord is necessary, this

has to be done by the manufacturer of this agent in order

to avoid a safety hazard.

CAUTION

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifi cations herein are subject to

change without prior notice.

Page 6

30

DH45ME DH45MEY

V

(110 V, 120 V, 127 V, 220 V, 230 V, 240 V)

P

1500 W

n

0

110 V, 120 V, 127 V : 120 – 270 /min

220 V, 230 V, 240 V : 120 – 310 /min

Bpm

110 V, 120 V, 127 V : 1200 – 2500 /min

220 V, 230 V, 240 V : 1200 – 2950 /min

max

45 mm

max

125 mm

kg

9.0 kg 9.5 kg

Page 7

31

1

3

1

5

2

4

2 3

1

2

4 5

Page 8

32

6

7

8

1

2

Ls

Hs

110 V

120 V

127 V

n

0

120 170 220 270

Bpm 1200 1600 2100 2500

220 V

230 V

240 V

n

0

120 180 240 310

Bpm 1200 1700 2300 2950

Page 9

33

9

10 11

12 13

Page 10

34

14 15

300 mm : 313466 (D < 35)

313467 (D > 38)

313464

944477

313465

930515

321813 313468

12,7 mm : 313469

19,0 mm : 313470

D

956009 (D < 35)

955165 (D > 38)

Page 11

35

30 g : 981840

971786

313477

313479

W50 × 400 mm : 313475

400 mm : 313476

313478

313479

320859

318085

150 mm

280 mm : 313471

400 mm : 313472

280 mm : 313473

400 mm : 313474

949859

333227

338165

949556

337577

330209

338166

339060

Page 12

412

Code No. C99713532 M

Printed in Malaysia

Loading...

Loading...