Page 1

Page 2

1

2

3

2

5

6

1

4

7

9

0

3

4

5

6

9

8

0

9

8

7

0

8

6

10

8

11

A

9

12

C

E

D

B

1

Page 3

13

14

15

16

19

F

G

J

K

C

H

17

20

I

J

M

4

5

6

L

N

18

21

J

K

O

K

J

22

P

73

7 mm

17 mm

2

Q

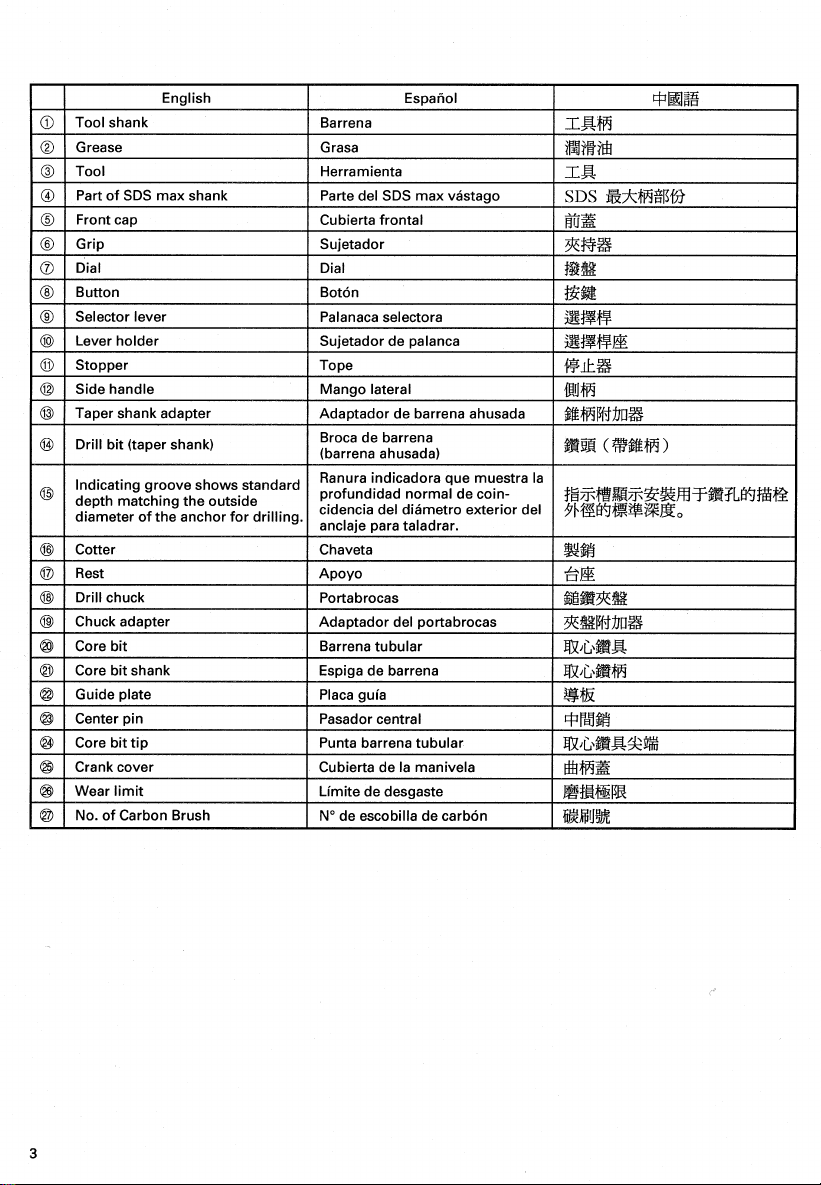

Page 4

Page 5

English

GENERAL OPERATIONAL PRECAUTIONS

WARNING! When using electric tools, basic safety

precautions should always be followed to reduce the risk

of fire, electric shock and personal injury, including the

following.

Read all these instructions before operating this product

and save these instructions.

For safe operations:

1. Keep work area clean. Cluttered areas and benches

invite injuries.

2. Consider work area environment. Do not expose

power tools to rain. Do not use power tools in damp

or wet locations. Keep work area well lit.

Do not use power tools where there is risk to cause

fire or explosion.

3. Guard against electric shock. Avoid body contact

with earthed or grounded surfaces. (e.g. pipes,

radiators, ranges, refrigerators).

4. Keep children away. Do not let visitors touch the

tool or extension cord. All visitors should be kept

away from work area.

5. Store idle tools. When not in use, tools should be

stored in a dry, high or locked up place, out of reach

of children.

6. Do not force the tool. It will do the job better and

safer at the rate for which it was intended.

7. Use the right tool. Do not force small tools or

attachments to do the job of a heavy duty tool. Do

not use tools for purposes not intended; for example,

do not use circular saw to cut tree limbs or logs.

8. Dress properly. Do not wear loose clothing or

jewelry, they can be caught in moving parts. Rubber

gloves and non-skid footwear are recommended

when working outdoors. Wear protecting hair

covering to contain long hair.

9. Use eye protection. Also use face or dust mask if

the cutting operation is dusty.

10. Connect dust extraction equipment.

If devices are provided for the connection of dust

extraction and collection facilities ensure these are

connected and properly used.

11. Do not abuse the cord. Never carry the tool by the

cord or yank it to disconnect it from the receptacle.

Keep the cord away from heat, oil and sharp edges.

12. Secure work. Use clamps or a vise to hold the work.

It is safer than using your hand and it frees both

hands to operate tool.

13. Do not overreach. Keep proper footing and balance

at all times.

14. Maintain tools with care. Keep cutting tools sharp

and clean for better and safer performance. Follow

instructions for lubrication and changing

accessories. Inspect tool cords periodically and if

damaged, have it repaired by authorized service

center. Inspect extension cords periodically and

replace, if damaged. Keep handles dry, clean, and

free from oil and grease.

15. Disconnect tools. When not in use, before servicing,

and when changing accessories such as blades, bits

and cutters.

16. Remove adjusting keys and wrenches. Form the

habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning

it on.

17. Avoid unintentional starting. Do not carry a pluggedin tool with a finger on the switch. Ensure switch is

off when plugging in.

18. Use outdoor extension leads. When tool is used

outdoors, use only extension cords intended for

outdoor use.

19. Stay alert. Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

20. Check damaged parts. Before further use of the tool,

a guard or other part that is damaged should be

carefully checked to determine that it will operate

properly and perform its intended function. Check

for alignment of moving parts, free running of

moving parts, breakage of parts, mounting and any

other conditions that may affect its operation. A

guard or other part that is damaged should be

properly repaired or replaced by an authorized

service center unless otherwise indicated in this

handling instructions. Have defective switches

replaced by an authorized service center. Do not use

the tool if the switch does not turn it on and off.

21. Warning

The use of any accessory or attachment, other than

those recommended in this handling instructions,

may present a risk of personal injury.

22. Have your tool repaired by a qualified person.

This electric tool is in accordance with the relevant

safety requirements. Repairs should only be carried

out by qualified persons using original spare parts.

Otherwise this may result in considerable danger

to the user.

PRECAUTIONS ON USING ROTARY HAMMER

䡬 Wear earplugs to protect your ears during operation.

䡬 Do not touch the bit during or immediately after

operation. The bit becomes very hot during operation

and could cause serious burns.

䡬 Before starting to break, chip or drill into a wall, floor

or ceiling, thoroughly confirm that such items as

electric cables or conduits are not buried inside.

䡬 Always hold the body handle and side handle of the

power tool firmly. Otherwise the counterforce

produced may result in inaccurate and even

dangerous operation.

4

Page 6

English

SPECIFICATIONS

Voltage (by areas)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Power input 950 W*

Capacity Drill bit: 40 mm

No load speed 240 – 480/min

Full-load impact rate 1320 – 2650/min

Weight (without cord, side handle) 6.5 kg

* Be sure to check the nameplate on product as it is subject to change by areas.

Core bit: 105 mm

STANDARD ACCESSORIES

(1) Case (Molded plastic) ................................................. 1

(2) Side Handle ................................................................. 1

(3) Stopper ........................................................................ 1

(4) Hexagon Bar Wrench (for 6 mm screw) ................... 1

(5) Hexagon Bar Wrench (for 5 mm screw) ................... 1

(6) Hexagon Bar Wrench (for 4 mm screw) ................... 1

(7) Hammer Grease A ......................................................1

Standard accessories are subject to change without

notice.

OPTIONAL ACCESSORIES (sold separately)

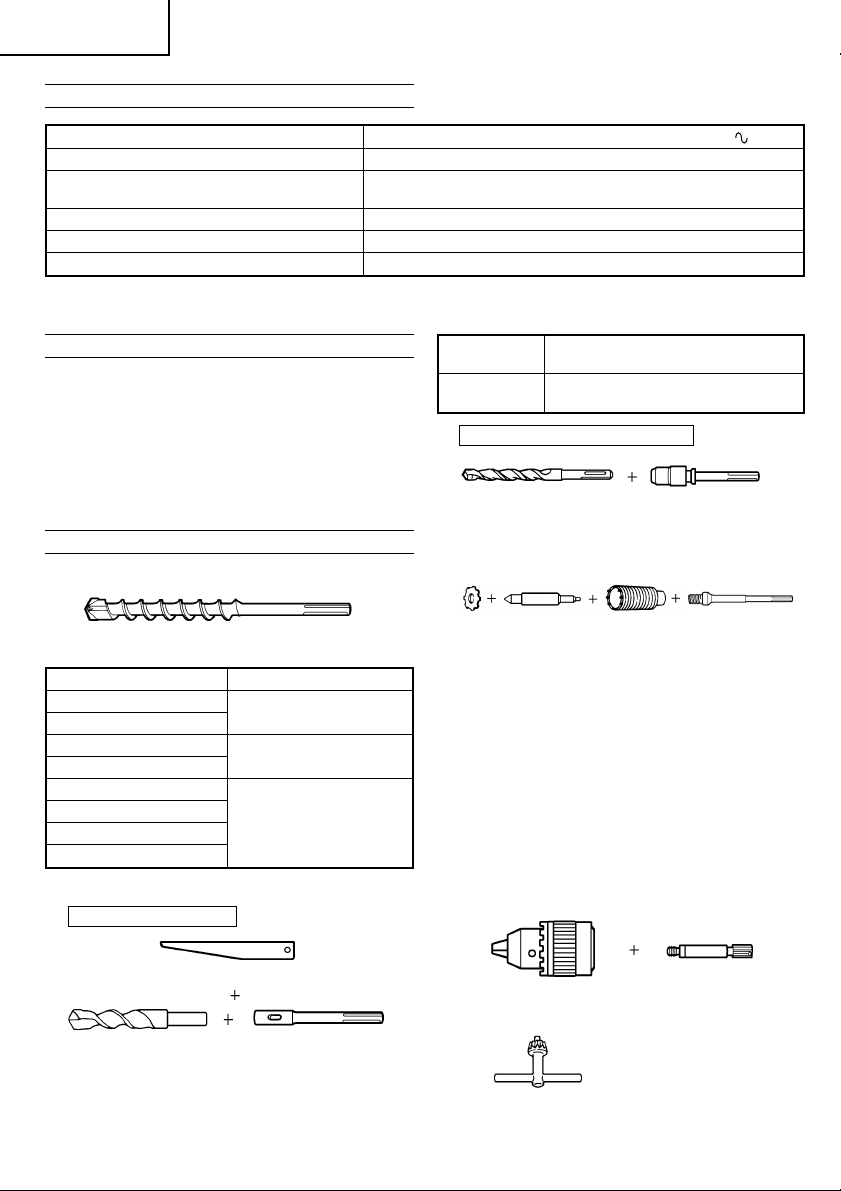

1. Through-hole drilling (Rotation + Hammering)

(1) Drill bit (SDS max shank)

Outer diameter (mm) Overall length (mm)

16

19

22

25

28

32

38

40

2. Anchor hole drilling (Rotation + Hammering)

Drill bit (Taper shank)

340, 540

320, 520

370, 570

Taper shank

adapter

Morse taper Drill bit (taper shank)

(No. 1) 11, 12.3, 12.7, 14.3, 14.5, 17.5 mm

Adapter for SDS-plus shank bit

(1) Drill bit

(SDS-plus shank)

3. Large dia. hole boring (Rotation + Striking)

(Guide

plate)

(1) Center pin

䢇 Applied to core bits from 38 mm to 105 mm

䢇 Applied to core bits 32 mm and 35 mm

NOTE

Do not use core bits 25 mm or 29 mm.

(2) Core bit

䢇 External dia. 25, 29, 32, 35, 38, 45, 54, 64, 79, 94, 105

mm (with guide plate, not applicable to cores 25 mm

or 29 mm)

(3) Core bit shank

䢇 Applied to core bits above 38 mm

䢇 Applied to core bits below 35 mm

4. Drilling holes ...... For drilling metal and wooden

Application drill bit

(1) Center

pin

materials

(2) Adapter for SDS-plus

shank bit

(SDS max shank)

(2) Core

bit

(3) Core bit

shank

(3) Cotter

(1) Drill bit (taper shank)

External dia.: 11, 12.3, 12.7,

5

14.3, 14.5,

17.5 mm

(2) Taper shank

adapter

(SDS max shank)

13 mm drill chuck

(13VLA)

Chuck wrench

Chuck adapter

(SDS max shank)

Page 7

English

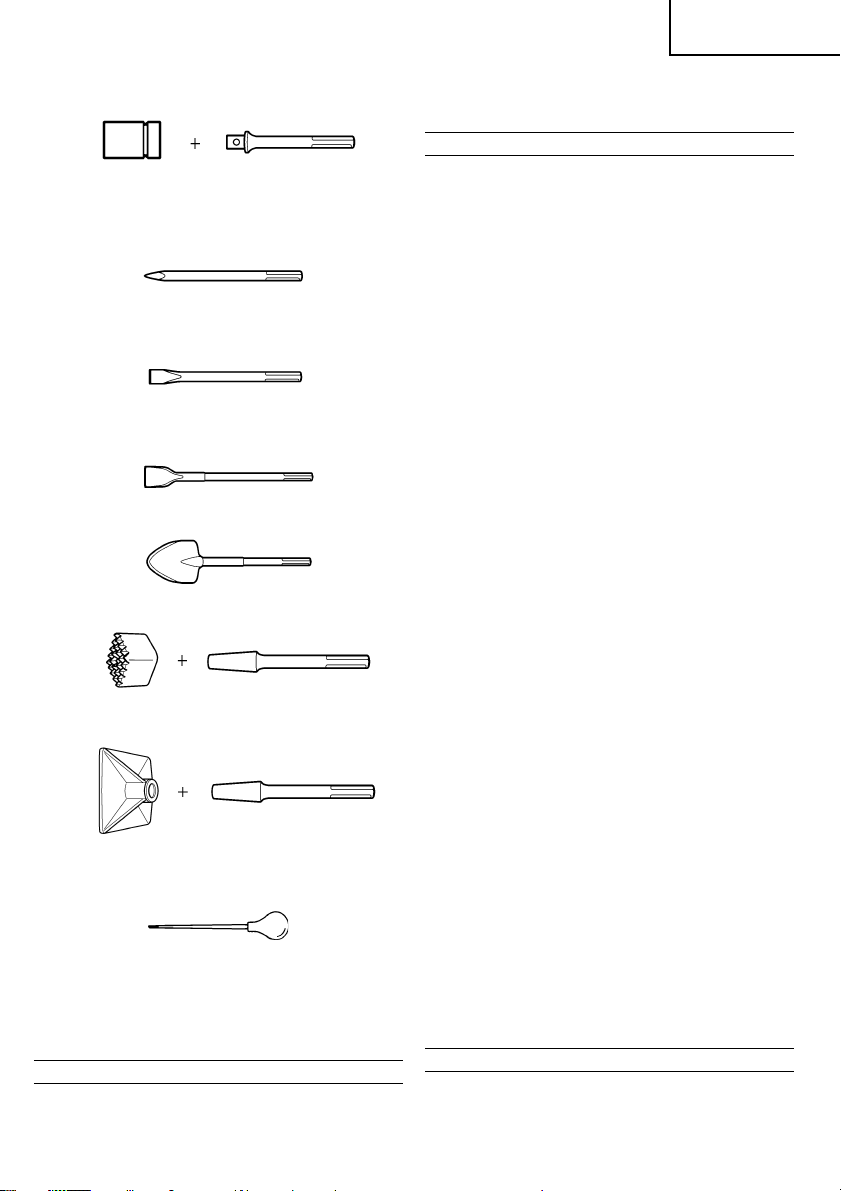

5. Bolt placing operation with Chemical Anchor.

(Rotation + Hammering)

(Standard socket

on the market)

6. Crushing (Hammering)

(1) Bull point

Overall length: 280, 400 mm

7. Groove digging and edging (Hammering)

(1) Cold chisel

8. Asphalt cutting (Hammering)

9. Scooping Work (Hammering)

10. Surface Roughing (Hammering)

(1) Bushing Tool

11. Tamping (Hammering)

(1) Rammer

150 × 150 mm

12. Syringe (for chip removal)

䡬 Hammer grease A

500 g (in a can)

70 g (in a green tube)

30 g (in a green tube)

Optional accessories are subject to change without

notice.

(SDS max shank)

12.7 mm Chemical

Anchor Adaptor

19 mm Chemical

Anchor Adaptor

Overall length: 280, 400 mm

(1) Cutter

(1) Scoop

(2) Shank

(2) Shank

APPLICATIONS

䡬 Drilling holes in concrete

䡬 Drilling anchor holes

䡬 Crushing concrete, chipping, digging, and squaring

(by applying optional accessories)

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a power receptacle while

the power switch is in the ON position, the power

tool will start operating immediately, which could

cause a serious accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be kept

as short as practicable.

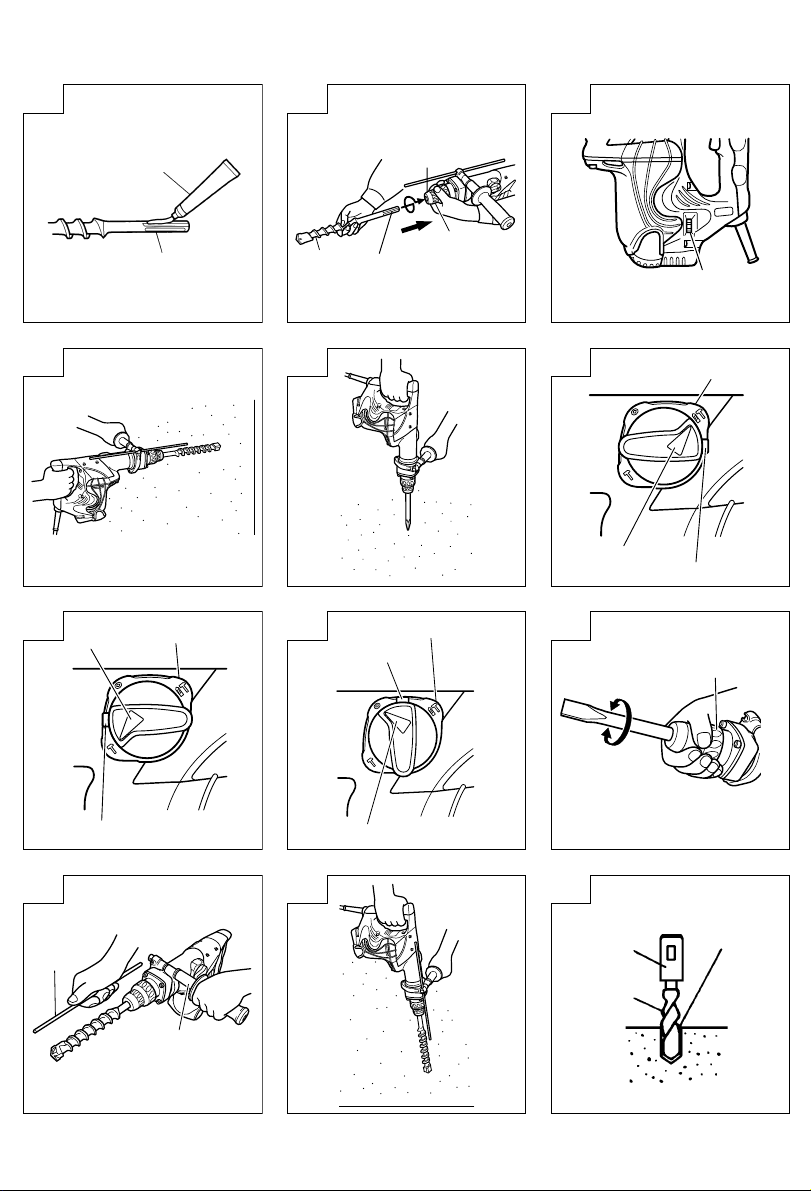

4. How to install tool

NOTE

For tools such as a bull point and a cold chisel, use

only Hitachi genuine parts.

(1) Clean, then smear the tool shank with the grease

provided in the green tube (Fig. 1).

(2) To attach the tool (SDS max shank), insert it into the

hole until it contacts the innermost end of the hole as

illustrated in Fig. 2.

If you continue to turn the tool with slight pressure,

you can feel a spot where there is a hitch. At that

spot, pull the grip to the direction of an arrow mark

and insert the tool all the way until it hits the innermost

end.

Releasing the grip reverts the grip and secures the

tool in place.

(3) Pull the tool to make sure it is locked completely.

(4) To remove the tool, fully pull the grip in the direction

of the arrow and pull out the tool.

5. Regulating the number of rotations and hammering

(Fig. 3)

This Rotary Hammer is equipped with a built-in

electronic control circuit that can adjust and regulate

the number of rotations and times of hammering. This

Rotary Hammer can be used by adjusting the dial,

depending upon the contents of operation, such as

boring holes into fragile materials, chipping,

centering, etc.

The scale ‘1’ of the dial is designed for a minimum

speed with the number of 240 rotations per minute

and 1320 times of blow per minute. The scale ‘6’ is

designed for a maximum speed with the number of

480 rotations per minute and 2650 times of blow per

minute.

CAUTION:

Do not adjust the dial during operation. Doing so can

result in injury because the Rotary Hammer must be

held by only one hand, disabling the steady control

of the Rotary Hammer.

HOW TO USE THE ROTARY HAMMER

1. How to drill holes (Fig. 4)

(1) Pull the switch trigger after applying the drill bit tip to

the drilling position.

6

Page 8

English

(2) It is unnecessary to forcibly press the rotary hammer

main body. It is sufficient to slightly press the rotary

hammer to an extent that shavings are freely

discharged.

CAUTION

Although this machine is equipped with a safety

clutch, if the drill bit becomes bound in concrete or

other material, the resultant stoppage of the drill bit

could cause the machine body to turn in reaction.

Ensure that the main handle and side handle are

gripped firmly during operation.

2. How to chisel or crush (Fig. 5)

By applying the drill bit tip to the chiseling or crushing

position, operate the rotary hammer by utilizing its

empty weight.

Forcible pressing or thrusting is unnecessary.

3. When drilling at “rotation + hammering”:

CAUTION:

If you switch the selector lever during motor rotation,

the tool can start to rotate abruptly, resulting in

unexpected accidents. Be sure to switch the selector

lever when the motor is at a complete stop.

(1) Switching to “rotation + hammering”

(a) Push the button, release lock and turn the selector

lever clockwise.

(b) Align ▲ of the selector lever and

holder as illustrated in Fig. 6.

(c) Release the button to lock the selector lever.

NOTE:

Turn the selector lever (do not push the button) to

check if it is completely locked and make sure that it

does not turn.

4. When chipping and chiseling at “hammering”:

CAUTION:

䡬 If the selector lever is switched during motor rotation,

the tool can start to rotate abruptly, resulting in

unexpected accidents. Make sure to switch the

selector lever when the motor is at a complete stop.

䡬 If the bull point or cold chisel is used at the position

of ”rotation + hammering”, the tool can start to rotate,

resulting in unexpected accidents. Make sure that they

are used at the position of ”hammering”.

(1) Switching to ”hammering”

(a) Push the button, release lock and turn the selector

lever counterclockwise.

(b) Align ▲ of the selector lever and

holder as illustrated in Fig. 7.

(c) Release the button to lock the selector lever.

NOTE:

Turn the selector lever (do not push the button) to

check if it is completely locked and make sure that

it does not turn.

(2) When fixing working positions of tools such as cold

chisel, etc.,

(a) Push the button, release lock and turn the selector

lever.

Align ▲ of the selector lever and

holder as illustrated in Fig. 8.

(b) Release the button to lock the selector lever.

(c) Turn the grip as illustrated in Fig. 9 and fix the

tool to the desired working direction.

(d) Switch the selector lever to “hammering”

according to the procedures mentioned in the

above item (1) and secure the position of the tool.

of the lever

of the lever

of the lever

5. Install the stopper (Fig. 10)

(1) Loosen the side handle and insert the straight portion

of the stopper into the handle bolt hole.

(2) Move the stopper to the specified position and rotate

the grip of the side handle clockwise to fix the stopper.

6. Warming up (Fig. 11)

The grease lubrication system in this unit may require

warming up in cold regions.

Position the end of the bit so makes contact with the

concrete, turn on the switch and perform the warming

up operation. Make sure that a hitting sound is

produced and then use the unit.

CAUTION

When the warming up operation is performed, hold

the side handle and the main body securely with both

hands to maintain a secure grip and be careful not to

twist your body by the jammed drill bit.

DRILLING AND DRIVING-IN OPERATIONS FOR

ANCHORS

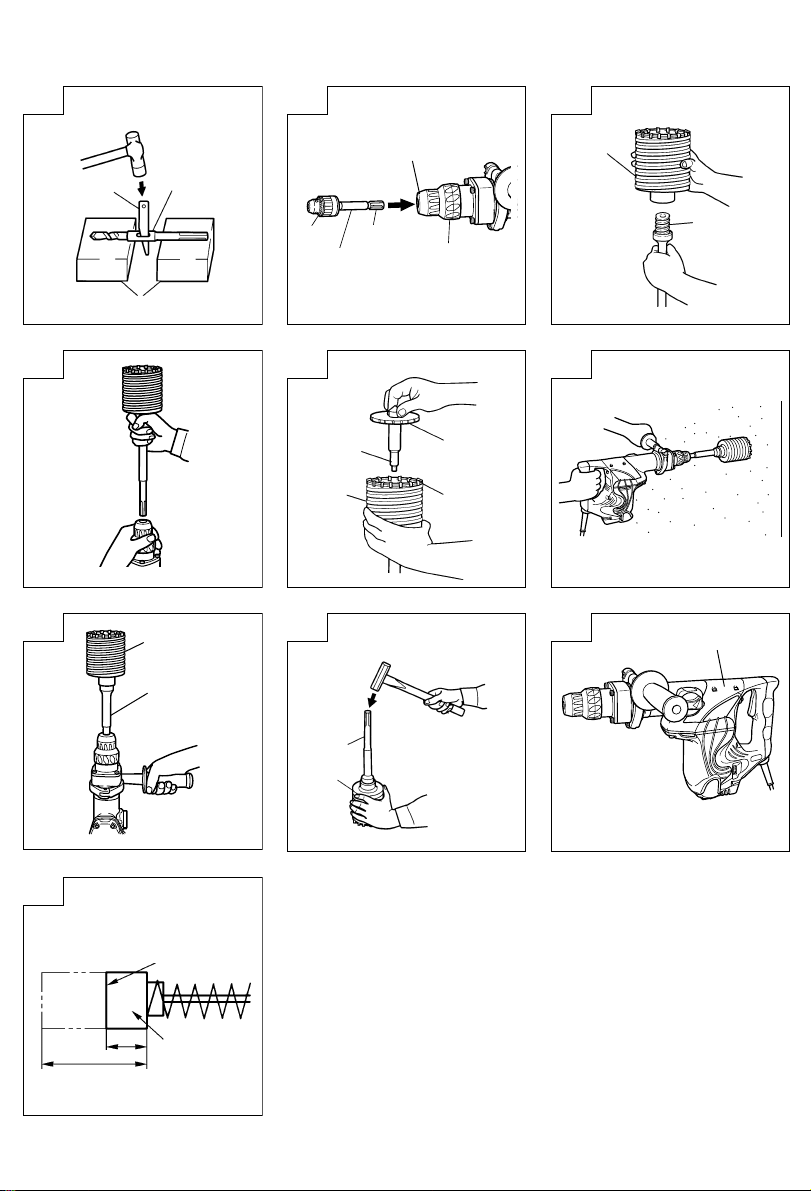

1. When a taper shank adapter is used. (Fig. 12)

(1) Install drill bit with taper shank in the taper shank

adapter.

(2) Turn the power on and drill a base hole to the depth

sounded by indicating groove on the drill bit.

(3) After cleaning out dust with a syringe, attach the plug

to the anchor tip and drive in the anchor with a manual

hammer.

(4) To remove the drill bit (taper shank), insert the cotter

into the slot of the taper shank adapter and strike the

head of the cotter with a manual hammer supporting

on a rest. (Fig. 13)

USING DRILL CHUCK, CHUCK ADAPTER

Note that this machine can be used at “rotation only” if

separately sold parts such as drill chuck and chuck adapter

are attached. Use it with the selector lever positioned at

“rotation + hammering”.

CAUTION:

During operation, be sure to grip the handle and the

side handle firmly to prevent your body from swaying.

(1) Switching to “rotation + hammering”

For switching to “rotation + hammering”, follow the

same procedures mentioned in [3. When drilling at

“rotation + hammering”].

(2) Attaching chuck adapter to drill chuck (Fig. 14)

(a) Attach the chuck adapter to the drill chuck.

(b) The SDS max shank of the chuck adapter is

equivalent to the drill bit. Therefore, follow the

same procedure as [How to install tool] for

attaching and detaching.

(3) Drilling

(a) Even if you apply more-than-required pressure to

the machine body, drilling can never be performed

as quickly as you expect. Applying more force or

pressure to the machine body than what is needed,

on the contrary, damages the drill tip, resulting in

the declined working efficiency and shortened life

of this machine.

(b) A drill can snap sometimes when drilling is almost

finished. It is important to relax your thrusting

pressure when drilling is nearing the end.

7

Page 9

English

HOW TO HANDLE A CORE BIT

When a core bit is used, large diameter holes and blind

holes can be drilled. In this case, use optional accessories

for core bits (such as a center pin and core bit shank) for

more efficient operation.

1. Mounting

CAUTION

Prior to mounting a core bit, always disconnect the

plug from the power supply receptacle.

(1) Mount the core bit on the core bit shank. (Fig. 15)

Before that, feed oil to the screw portion of core bit

shank for easy dismounting.

(2) Mount the core bit shank on the main body in the

same manner as in mounting the drill bit and the bull

point. (Fig. 16)

(3) Insert the center pin into the guide plate until it reaches

the extremity.

(4) Fit in the guide plate by aligning its concaved portion

with the core bit tip. When the position of the concave

is shifted by turning the guide plate right or left, the

guide plate never slips off even when the drill is used

in a downward direction. (Fig. 17)

2. Drilling holes

(1) Insert the plug into a receptacle.

(2) A spring is built in the center pin. By straightly and

gently pressing it to the wall or floor surface, the entire

surface of the core bit tip attains contact to start the

hole drilling job. (Fig. 18)

(3) When the hole depth reaches approximately 5 mm,

the hole position can be determined. Then remove

the center pin and guide plate from the core bit and

continue the hole drilling job.

CAUTION

When removing the center pin and guide plate, always

disconnect the plug from the receptacle.

3. How to dismount the core bit

䡬 By holding the rotary hammer (with the core bit

inserted) in an upward position, drive the rotary

hammer to repeat impact operation two or three

times, whereby the screw is loosened and the rotary

hammer becomes ready for disassembly. (Fig. 19)

䡬 Remove the core bit shank from the rotary hammer,

hold the core bit with one hand, and strongly strike

the head of the SDS max shank portion of the core bit

shank with a manual hammer two or three times,

whereby the round head screw is loosened and the

rotary hammer is ready for disassembly. (Fig. 20)

HOW TO REPLACE GREASE

This machine is of full air-tight construction to protect

against dust and to prevent lubricant leakage. Therefore,

the machine can be used without lubrication for long

periods. Replace the grease as described below.

1. Grease replacement period

After purchase, replace grease after every 6 months

of usage. Ask for grease replacement at the nearest

Hitachi authorized Service center. Proceed for

replacement of grease.

2. Grease replenishment

CAUTION

Before replenishing the grease, turn the power off and

pull out the power plug.

(1) Remove the crank cover and wipe off the grease

inside. (Fig. 21)

(2) Supply 30g of Hitachi Electric Hammer Grease A

(Standard accessory, contained in tube) to the crank

case.

(3) After replenishing the grease, install the crank cover

securely.

NOTE

The Hitachi Electric Hammer Grease A is of the low

viscosity type. If necessary purchase from an Hitachi

authorized Service center.

MAINTENANCE AND INSPECTION

1. Inspecting the tool

Since use of a dull tool will degrade efficiency and

cause possible motor malfunction, sharpen or replace

the tool as soon as abrasion is noted.

2. Inspecting the mounting screws:

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws

be loose, retighten them immediately. Failure to do

so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

4. Inspecting the carbon brushes (Fig. 22)

The Motor employs carbon brushes which are

consumable parts. When they become worn to or near

the “wear limit”, it could result in motor trouble. When

an auto-stop carbon brush is equipped, the motor will

stop automatically. At that time, replace both carbon

brushes with new ones which have the same carbon

brush Numbers shown in the figure. In addition,

always keep carbon brushes clean and ensure that

they slide freely within the brush holders.

5. Replacing carbon brushes

Loosen the two set screws and remove the tail cover.

Remove the brush caps and carbon brushes. After

replacing the carbon brushes, tighten the brush caps

securely and install the tail cover with securely

tightening two set screws.

6. Service parts list

A: Item No.

B: Code No.

C: No. Used

D: Remarks

CAUTION

Repair, modification and inspection of Hitachi Power

Tools must be carried out by an Hitachi Authorized

Service Center.

This Parts List will be helpful if presented with the

tool to the Hitachi Authorized Service Center when

requesting repair or other maintenance.

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

MODIFICATIONS

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts (i.e. code numbers and/or

design) may be changed without prior notice.

8

Page 10

English

NOTE

Due HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

9

Page 11

Español

PRECAUCIONES GENERALES PARA

OPERACIÓN

¡ADVERTENCIA! Cuando utilice herramientas eléctricas,

tome las medidas de seguridad básicas para reducir el

riesgo de incendios, descargas eléctricas, y lesiones,

incluyendo lo siguiente. Lea todas todas estas

instrucciones antes de utilizar este producto y guárdelas.

Para realizar roperaciones seguras:

1. Mantener el área de trabajo limpia, áreas y bancos

de trabajo desordenados son causa de da ños

personales.

2. Considerar el medio ambiente del área de trabajo.

No exponer las herramientas eléctricas a la lluvia.

No usar herramientas eléctricas en lugares mojados

o húmedos. Mantener el área de trabajo bien

iluminada.

No utilice herramientas eléctricas cuando exista el

riesgo de incendios o de explosión.

3. Protegerse contra descargas eléctricas. Evitar el

contacto del cuerpo con las superficies puestas a

tierra. (p. ej., tubos, radiadores, hornos de

microondas, o refrigeradores.)

4. Mantener a los ni ños alejados. No dejar que los

visitantes toquen las herramientas ni los cables de

extensión. Todos los visitantes deberán mantenerse

alejados del área de trabajo.

5. Guardar las herramientas que no se usen y ponerlos

en lugares secos, altos o cerrados, fuera del alcance

de los niños.

6. No forzar las herramientas, éstas trabajarán más y

con mayor seguridad cuando cumplan con las

especificaciones para las cuales fueron diseñadas.

7. Usar las herramientas apropiadas. No forzar

pequeñas herramientas o accesorios a realizar el

trabajo de herramientas de mayor potencia. No

utilizar herramientas para otros propósitos para los

cuales no fueron dise ñadas, por ejemplo, no utilizar

sierras circulares para cortar ramas de árboles o

troncos.

8. Vestir apropiadamente. No ponerse ropas que

queden flojas ni tampoco joyas. Estas podrian

quedar atrapadas en las partes móviles de las

herramientas. Cuando se trabaje en exteriores, se

recomienda el uso de guantes de goma y calzado

que no resbale.

9. Usar gafas de protección. Usar también mascarillas

contra el polvo si las condiciones de corte fuesen

polvorientas.

10. Conecte un equipo colector de polvo.

Si existen dispositivos para la conexión de equipos

de extracción y recolección de polvo, cerciórese de

queéstos estén conectados adecuadamente, y de

utilizarlos en la forma correcta.

11. Cuidar del cable. Nunca lleve las herramientas

colgando del cable, tampoco tire del cable para

efectuar la desconexión de las herramientas.

Mantener el cable alejado del calor, aceite y bordes

agudos.

12. Asegurar la pieza de trabajo usando para ello

abrazaderas o un tornillo. Esto es más seguro que

usar las manos, ademas, ambas manos quedan

libres para operar la herramienta.

13. No extenderse excesivamente para efectuar un

trabajo. Mantener en todo momento un buen

balance y base de apoyo.

14. Mantener cuidadosamente las herramientas.Tener

las siempre limpias y afiladas para obtener un mejor

rendimiento y un funcionamiento más seguro.

Seguir siempre las instrucciones para la lubricación

y el cambio de accesorios. Inspeccionar

periódicamente los cables de las herramientas y si

estuviesen danãdos, hacer que los reparen técnicos

o expertos. Inspeccionar periódicamente los cables

de extensión y cambiarlos si estuviesen da ñados.

Mantener los mangos secos, limpios, y libres de

aceite y grasa.

15. Desconectar las herramientas cuando no se usen,

antes de repararlas, y cuando se cambien accesorios

como por ejemplo, cuchillas, brocas, cortadores, etc.

16. Quitar las cuñas y las llaves de tuercas.

Acostumbrarse a comprobar si se han quitado las

cu ñas y las llaves de tuercas antes de poner las

harramientas en funcionamiento.

17. Evitar puestas en funcionamiento sin fin alguno. No

llevar las herramientas con los dedos en los

inerruptores mientras que éstas cstán conectadas.

Cuando se conecten las herramientas, cerciorarse

de que los interruptores esten en la posición de

desconectados.

18. Para usos en exteriores usar cables de extensión.

Cuando las herramientas vayan a ser usadas en

exteriores, usar solamente cables de extensión

diseñados para tal propósito.

19. Estar siempre alerta y poner atención a lo que se

está haciendo, usar el sentido común y no operar

con la herramienta cuando se esté cansado.

20. Comprobar las piezas dañadas. Antes de seguir con

el funcionamiento de las herramientas, las piezas

que estén dañadas deberán comprobarse

cuidadosamente para determinar si pueden

funcionar apropiadamente y cumplir con la función

para las que fueron dise ñadas. Comprobar el

alineamiento y agarrotamiento de piezas móviles,

rotura de piezas, montura, y cualiquier otra anomalia

que pudiese afectar al rendimiento de la

herramienta. Cualquier pieza que estuviese da ñada

deberá repararse apropiadamente o cambiarse en

un centro de reparaciones autorizado, al menos que

se indique, lo contrario en este manual de

instrucciones. Procurar que los interruptores

defectuosos los cambie un centro de reparaciones

autorizado.

No usar las herramientas si sus interruptores no

funcionasen apropiadamente.

21. Advertencia

La utilización de cualquier accesorio o aditivo no

recomendado en este manual de instrucciones

puede conducir al riesgo de lesiones.

22. En caso de avería, haga que su herramienta sea

reparada por un técnico cualificado.

Esta herramienta eléctrica está de acuerfdo con los

requisitos de seguridad pertinentes. Las

reparaciones solamente deberán realizarlas técnicos

cualificadosutilizando piezas de repuesto originales.

De lo contrario, el usuario podría lesionarse.

10

Page 12

Español

PRECAUCIONES AL USAR EL MARTILLO

PERFORADOR

䡬 Usar protectores de oídos durante el trabajo.

䡬 No tocar la broca durante ni inmdiatamente después

de trabajar, puesto que se pone ardiente y puede

causar quemaduras serias.

䡬 Antes de empezar a romper, picar o perforar en una

pared, suelo o techo, comprobar cuidadosamente que

no hayan objetos empotrados, tales como cables o

conductos eléctricos.

䡬 Sujetar siempre firmemente al asidero del cuerpo y

el asidero lateral de la harrmienta. De lo contrario, la

contrafuerza producida podría causar un

funcionamiento impreciso e incluso peligroso.

ESPECIFICACIONES

Voltaje (por áreas)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Entrada 950 W*

Capacidad Barrena: 40 mm

Velocidad sin carga 240 – 480/min

Impacto a carga plena 1320 – 2650/min

Peso (sin cable ni mango lateral) 6,5 kg

* Verficar indefectiblemente los datos de la placa de características de la máquina, pues varían de acuerdo al país de

destino.

ACCESORIOS ESTANDAR

(1) Caja (Plástica) ............................................................ 1

(2) Mango lateral ............................................................. 1

(3) Tope ............................................................................ 1

(4) Llave de barra hexagonal ......................................... 1

(para tornillos de 6 mm)

(5) Llave de barra hexagonal ......................................... 1

(para tornillos de 5 mm)

(6) Llave de barra hexagonal ......................................... 1

(para tornillos de 4 mm)

(7) Grasa A para martillo ................................................ 1

Los accesorios estándar están sujetos a cambios sin

previo aviso.

ACCESORIOS FACULTATIVOS

(de venta por separado)

1. Perforación por orificio (Rotación + Martilleo)

Barrena tubular: 105 mm

2. Perforación de orificio de anclaje (Rotación + Martilleo)

Barrena (espiga cónica)

(3) Cortadora

(1) Barrena

Diàmetro externo:

11 12,3 12,7 14,3

14,5 17,5 mm

Adaptador de

espiga cónica

Cono Morse Barrena (espiga cónica)

(N°. 1) 11 12,3 12,7 14,3 14,5 17,5 mm

Adaptador para barrena de espiga SDS-plus

Barrena aplicable

(2) Adaptador

de espiga cónica

(Espiga SDS max)

(1) Barrena (Espiga SDS max)

Diámetro externo (mm) Longitud total (mm)

16

19

22

25

28

32

38

40

11

340 540

320 520

370 570

(1) Barrena

(SDS plus vástago)

3. Perforación de orificio de diámetro grande (Rotación

+ Martilleo)

(Placa guía)

(1) Pasador central

䢇 Aplicable a barrenas de 38 mm ~ 105 mm

䢇 Aplicable a barrenas de 32 mm y 35 mm

(1) Pasador

contral

NOTA

No usar barrenas de 25 y 29 mm

(2) Adaptador para

barrena de espiga

SDS-plus

(Espiga SDS max)

(2) Barrena

(3) Espiga de

barrena tubular

Page 13

Español

(2) Barrena

䢇 Diámetro externo

25 29 32 35 38 45 54 64 79 94 105 mm

(Con placa guía no aplicable a barrenas de 25 y 29

mm)

(3) Espiga de barrena tubular

䢇 Aplicable a barrenas de más de 38 mm

䢇 Aplicable a barrenas de menos de 35 mm

4. Perforación ......... Para taladrar materiales de metal y

13 mm portabrocas

(13VLA)

Liave de portabrocas

5. Trabajo de colocación de pernos para anclaje químico

(Rotación + Martilleo)

(Manguito adaptador

a la venta el mercado)

6. Romper (Martilleo)

7. Excavar, ranurado y rebordes (Martilleo)

8. Corte de asfalto (Martilleo)

9. Trabajos con cuchara (Martilleo)

(Para utilizar en lugar de un pico)

10. Desbastadora de superficies (Martilleo)

(1) Desbastadora

madera

Adaptador del

portabrocas

(Espiga SDS max)

(Espiga SDS max)

Adaptador de anclaje

químico de 12,7 mm

Adaptador de anclaje

químico de 19 mm

(1) Puntero

Largo total: 280 400 mm

(1) Cortafrio

Largo total: 280 400 mm

(1) Cortadora

(1) Cuchara

(2) Barrena

11. Apisonamiento (Martilleo)

(1) Pisón

150 × 150 mm

12. Jeringa (extracción de resíduos)

13. Grasa A para martillo

500 g (en una lata)

70 g (en un tubo naranja)

30 g (en un tubo naranja)

Los accesorios facultativos están sujetos a cambios sin

previo aviso.

(2) Barrena

APLICACIONES

䡬 Perforación de orificios en concreto

䡬 Perforación de orificios de anclaje

䡬 Romper hormigón, picar, cavar y cuartear (con

accesorios opcionales).

ANTES DE LA PUESTA EN MARCHA

1. Alimentación

Asegurarse de que la alimentación de red que ha de

ser utilizada responda a las exigencias de corriente

especificadas en la placa de características del

producto.

2. Conmutador de alimentación

Asegurarse de que el conmutador de alimentación

esté en la posición OFF (desconectado). Si la clavija

está conectada en la caja del enchufe mientras el

conmutador de alimentación esté en posición ON

(conectado) las herramientas eléctricas empezarán a

trabajar inmediatamente, provocando un serio

accidente.

3. Cable de prolongación

Cuando está alejada el área de trabajo de la red de

alimentación, usar un cable de prolongación de un

grosor y potencia normal suficiente. El cable de

prolongación debe ser mantenido lo más corto

posible.

4. Montaje de la herramienta

NOTA

Para usar herramientas tales como el puntero y

cortafrío, usar siempre piezas genuinas Hitachi.

(1) Limpiar y engrasar la espiga con la grasa provista

(Fig. 1)

(2) Para fijar la herramienta (espiga SDS max), insértela

en el orificio hasta que entre en contacto con el

extremo interior del mismo, como se muestra en la

Fig. 2. Si continúa girando la herramienta con una

ligera presión, podrá sentir un punto en el que note

un obstáculo. En tal punto, tire del mango lateral en

el sentido de la marca de flecha e inserte la

herramienta completamente hasta que entre en

contacto con el extremo interior.

Al soltar el mango, éste volverá y asegurará la

herramienta en su lugar.

12

Page 14

Español

(3) Tire de la herramienta y compruebe que se encuentre

completamente bloqueada.

(4) Para extraer la herramienta, tire completamente de

la empuñadura en el sentido de la flecha y tire hacia

afuera de la herramienta.

5. Regulación del número de rotaciones y martilleo (Fig.

3)

Este martillo rotativo está provisto de un circuito de

control electrónico que puede ajustar y regular el

número de rotaciones y veces de martilleo.

Este martillo rotativo podrá utilizarse ajustando el dial,

dependiendo del contenido de la operación, como

perforación en materiales frágiles, para cortar con

escoplo, centrar, etc.

La escala ‘1’ del dial corresponde a la velocidad

mínima con un número de 240 rotaciones por minuto

y 1320 veces de martilleo por minuto. La escala ‘6’

corresponde a la velocidad máxima con un número

de 480 rotaciones por minuto y 2650 veces de

martilleo por minuto.

PRECAUCION:

No ajuste el dial durante la operación. Si lo hiciese,

podría dañarse porque tendría que sujetar el martillo

rotativo con una sola mano, y perdería el control

estable del mismo.

MODO DE UTILIZACION

1. Taladrar orificios (Fig. 4)

(1) Oprimir el interruptor de operación luego de apoyar

la punta de la barrena en la posición de taladrar.

(2) No es necesario presionar el cuerpo principal del

martillo perforador. Es suficiente con empujar

ligeramente el martillo de taladrar teniendo en cuenta

que los materiales saltan libremente, al taladrar.

PRECAUCION

Aunque este aparato se equipa con un embrague de

seguridad, si se atasca la barrena de taladrar en el

hormigón u otro material semejante, puede pasar que,

al atascarse la barrena, el cuerpo del martillo gire en

dirección opuesta.

Asegurarse entonces de que el mango principal y el

lateral están bien empuñados durante el uso de esta

herramienta.

2. Forma de picar o romper (Fig. 5)

Aplicando la punta de la barrena en posición de picar

o romper, hacer funcionar el martillo perforador

aplicando su propio peso.

No es necesario presionar o empujar excesivamente.

3. Cuando taladre con “rotación + martilleo”:

PRECAUCION:

Si cambia la palanca selectora mientras el motor esté

girando, la herramienta puede comenzar a girar

bruscamente, lo que puede resultar en accidentes

inesperados. Cerciórese de cambiar la palanca

selectora cuando el motor esté completamente

parado.

(1) Cambio a “rotación + martilleo”

(a) Apriete el botón, desbloquee la palanca selectora

y gírela en el sentido de las agujas del reloj.

(b) Alinee la marca ▲ de la palanca selectora y

del sujetador de palanca, tal como se muestra en

la Fig.6.

(c) Suelte el botón para bloquear la palanca selectora.

NOTA:

Gire la palanca selectora (no apriete el botón) para

comprobar que esté completamente bloqueada y

cerciorarse de que no gire.

4. Para cortar con escoplo y triturar en el modo de

“martilleo”:

PRECAUCION

䡬 Si cambia la palanca selectora mientras el motor esté

girando, la herramienta puede comenzar a girar

bruscamente, lo que puede resultar en accidentes

inesperados. Cerciórese de cambiar la palanca

selectora cuando el motor esté completamente

parado.

䡬 Si utiliza la barreta de punta o el cortafrío en la

posición de “rotación + martilleo”, la herramienta

puede comenzar a girar, lo que puede resultar en

accidentes inesperados. Cerciórese de utilizarlos en

la posición de “martilleo”.

(1) Cambio a “martilleo”

(a) Apriete el botón, desbloquee la palanca selectora

y gírela en el sentido contrario a las agujas del

reloj.

(b) Alinee la marca ▲ de la palanca selectora y

del sujetador de palanca, tal como se muestra en

la Fig.7.

(c) Suelte el botón para bloquear la palanca selectora.

NOTA:

Gire la palanca selectora (no apriete el botón) para

comprobar que esté completamente bloqueada y

cerciorarse de que no gire.

(2) Cuando fije las posiciones de trabajo de herramientas

tales como cortafrío, etc.

(a) Apriete el botón, desbloquee la palanca selectora y

gírela.

(b) Alinee la marca ▲ de la palanca selectora y

sujetador de palanca, tal como se muestra en la Fig.

8.

(c) Gire la palanca selectora como se muestra en la Fig.9

y fije la herramienta en la dirección de travajo deseada.

(d) Cambia la palanca selectora a “martilleo” de acuerdo

con los procedimientos mencionados en el ítem (1)

anterior y asegure la posición de la herramienta.

5. Instalar el tope (Fig. 10)

(1) Alfojar el mango lateral e insertar la parte recta del

tope en el orificio del perno de manija.

(2) Aflojar el mango lateral, y mover el tope a la posición

especificada y rotar la empuñadura del mango lateral

a la derecha para fijar el tope.

6. Calentamiento (Fig. 11)

El sistema de lubricación de esta unidad puede

requerir calentamiento en ciertas regiones.

Coloque el extremo de la broca de forma que entre

en contacto con el hormigón, ponga en ON el

interruptor de alimentación principal de la unidad, y

realice la operación de calentamiento. Cerciórese de

que se produzca un sonido de martilleo, y después

utilice la unidad.

PRECAUCION

Cuando haya realizado la operación de calentamiento,

sujete con seguridad el mango lateral y el cuerpo

principal con ambas manos para asegurar una buena

sujeción y tenga cuidado de no torcer su cuerpo

mediante una broca atascada.

del

13

Page 15

Español

PERFORACION E INCRUSTACION DE

ANCLAJES

1. Cuando se use un adaptador de espiga cónica (Fig.

12)

(1) Instalar la barrena en el adaptador de espiga cónica.

(2) Conectar el aparato y perforar un orificio base a una

profundidad correspondiente a la ranura indicadora

del tope en el orificio del perno de manija por la de la

barrena.

(3) Luego, limpiar el polvo con una jeringa, colocar el

tapón en la punta del anclaje e instertar éste con un

martillo manual.

(4) Para quitar la broca (espiga ahusada), insertar la

chaveta en la ranura del adaptador de la espiga

ahusada y golperar la cabeza de la chaveta con un

martillo. Usar apoyos como se muestra en la Fig. 13.

UTILIZACIÓN DE PORTABARRENAS Y EL

ADAPTADOR PARA PORTABARRENAS

Tenga en cuenta que esta máquina podrá utilizarse en

“rotación solamente” si le instala piezas vendidas aparte,

tales como portabarrenas y adaptador para

portabarrenas. Utilícela con la palanca selectora en la

posición de ”rotación + martilleo”.

PRECAUCION:

Durante la operación, cerció rese de sujetar

firmemente el mango y el mando lateral para evitar

que su cuerpo se balancee.

(1) Cambio a “rotación + martilleo”

Para cambiar a “rotación + martilleo”, realice los

mismos procedimientos que los mencionados en [3.

Cuando taladre con “rotación + martilleo”].

(2) Fijación del adaptador para portabarrenas al

portabarrenas (Fig. 14)

(a) Fije el adaptador para portabarrenas al

portabarrenas.

(b) La espiga SDS max del adaptador para

portabarrenas es equivalente a la barrena. Por lo

tanto, para la instalación y el desmontaje, realice

el mismo procedimiento que el mencionado en

[Fijación de herramientas].

(3) Taladrado

(a) Aunque aplique más de la presión requerida al

cuerpo de la máquina, el taladrado no se realizará

con mayor rapidez de la esperada. Por el contrario,

la aplicación de mayor presión de la necesaria

dañará la punta de la barrena, lo que resultará en

reducción de la eficacia del trabajo y en

acortamiento de la duración útil de esta máquina.

(b) La barrena puede partirse a vece cuando el

taladrado esté a punto de finalizarse. Es muy

importante que usted reduzca la presión cuando

esté a punto de terminar el taladrado.

USO DE BARRENA TUBULAR

Cuando se usa una barrena tubular, pueden perforarse

orificios grandes y orificios ciegos. En este caso, hay que

emplear los accesorios opcionales para barrenas

tubulares (tales como el pasador central y la espiga de

barrena tubular) para trabajar de modo más racional.

1. Montaje

PRECAUCION

Antes de montar una barrena tubular, siempre hay

que desenchufar el aparato del tomacorriente de la

pared.

(1) Colocar la barrena tubular en la espiga

correspondiente (Fig. 15). Antes de ello, agregar aceite

en la parte de rosca de la barrena tubular para facilitar

el desmontaje.

(2) Colocar la barrena tubular en el cuerpo principal del

taladro del mismo modo que se hizo con la barrena y

el puntero (Fig. 16)

(3) Insertar el pasador central en la placa guía gasta que

alcance la extremidad.

(4) Colocar la placa quía alineando su parte cóncava con

la punta de la barrena tubular.

Cuando la posición de la parte cóncava se cambia,

girando la placa guía a derecha o izquierda, ésta nunca

debe salirse, aún cuando el taladro se use en dirección

hacia abajo (Fig. 17).

2. Perforación

(1) Enchufar el aparato en el tomacorriente de pared.

(2) El pasador central tiene un resorte incluido y,

presionándolo levemente y en forma recta, se pone

en contacto toda la superficie de la punta de la barrena

para comenzar a taladrar. (Fig. 18)

(3) Cuando el orificio alcanza una profundidad de 5 mm

la posición del orificio puede determinarse

perfectamente. Luego, quitar el pasador central y la

placa guía de la barrena tubular y continuar

taladrando.

PRECAUCION

Cuando se quita el pasador central y la placa guía,

siempre hay que desenchufar el aparato del

tomacorriente.

3. Desmontaje de la barrena tubular

(1) Sosteniendo el taladro (con la barrena tubular puesta)

en posición invertida, accionar el taladro para que

repita la operación de impacto dos o tres veces con

ello, se afloja el tornillo y el taladro queda listo para

desarmarse. (Fig. 19)

(2) Quitar la espiga de la barrena tubular del taladro,

sosteniendo la barrena tubular con una mano y

golpear con fuerza la cabeza de la parte la espiga SDS

max de la espiga de la barrena tubular, con un martillo

manual dos o tres veces, para aflojar el tornillo de

cabeza redonda, con lo cual, el taladro queda listo

para desarmarse. (Fig. 20)

CAMBIO DE GRASA

Esta máquina es de construcción completamente

cerrada, para evitar que entre polvo y haya fugas de

lubricante. Por ello, la herramienta puede usarse sin

lubricarse por largos periodos.

Cuando so requiere cambiar la grasa, proceder como

sigue:

1. Período de cambio de grasa:

Luego de adquirir la herramienta, cambiarle la grasa

cada 6 meses de uso.

Consultar para ello con el agente de servicio Hitachi

autorizado.

Procedimiento de cambio de grasa.

14

Page 16

Español

2. Rellenado de grasa

PRECAUCION

Antes de rellenar de grasa, desconectar el aparato y

desenchufarlo del tomacorriente.

(1) Quitar la cubierta de la manivela y limpiar la grasa

interna. (Fig. 21)

(2) Aplicar 30g de grasa para martillo eléctrico Hitachi

tipo A (accesorio normales, contenida en tubo) en el

cárter.

(3) Luego de rellenar la grasa, instalar firmemente la

cubierta de la manivela.

NOTA

La grasa A del martillo eléctrico Hitachi es del tipo de

baja densidad. Si es necesario, siempre adquirir la

grasa a un agente de servicio Hitachi autorizado.

MANTENIMIENTO E INSPECCION

1. Inspección de la herramienta

Ya que la utilización de una herramienta de corte

embotada disminuirá la eficiencia de trabajo y podría

causar desperfectos en el motor, afilar o cambiar las

herramientas de corte tan pronto como se note

abrasión en éstas.

2. Inspeccionar los tornillos de montaje:

Regularmente inspeccionar todos los tornillos de

montaje y asegurarse de que estén apretados

firmemente. Si cualquier tornillo estuviera suelto,

volver a apretarlo inmediatamente. El no hacer esto

provocaría un riesgo serio.

3. Mantenimiento de motor:

La unidad de bobinado del motor es el verdadero

“corazón” de las herramientas eléctricas. Prestar el

mayor cuidado y asegurarse de que el bobinado no

se dañe y/o se humedezca con aceite o agua.

4. Inspeccionar los carbones de contacto (Fig. 22)

El motor emplea escobillas de carbón que son partes

consumibles. Cuando se gastan o están cerca del

“limite de desgaste” pueden causar problemas al

motor.

Al equiparse la escobilla de carbón de parada

automática, el motor se detendrá automáticamente

en ese momento hay que proceder a cambiar ambas

escobillas de carbón por la nuevas, que tienen los

mismos números de escobillas de carbón como se

muestra en la figura. Además siempre hay hay que

mantener las escobillas de carbón limpias y

asegurarse de que se muevan libremente en sus

porta-escobillas.

5. Cambio de escobillas de carbón

Quitar la cubierta de cola y luego aflojar el tornillo de

fijación.

Aflojando la tapa de escobilla, pueden quitarse las

escobillas de carbón, al colocar las escobillas, apretar

firmemente la tapa de escobillas y recolocar la

cubierta con dos tornillos.

6. Lista de repuestos

A: N°. ítem

B: N°. código

C: N°. usado

D: Observaciones

PRECAUCIÓN

La reparación, modificación e inspección de las

herramientas eléctricas Hitachi deben ser realizadas

por un Centro de Servicio Autorizado de Hitachi.

Esta lista de repuestos será de utilidad si es presentada

junto con la herramienta al Centro de Servicio

Autorizado de Hitachi, para solicitar la reparación o

cualquier otro tipo de mantenimiento.

En el manejo y el mantenimiento de las herramientas

eléctricas, se deberán observar las normas y

reglamentos vigentes en cada país.

MODIFICACIONES

Hitachi Power Tools introduce constantemente

mejoras y modificaciones para incorporar los últimos

avances tecnológicos.

Por consiguiente, algunas partes (por ejemplo,

nú meros de códigas y/o diseñ o) pueden ser

modificadas sin previo aviso.

OBSERVACION

Debido al programa continuo de investigación y desarollo

de HITACHI estas especificaciones están sujetas a cambio

sin preaviso.

15

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

22

Page 24

23

Page 25

A B C D

1 321-306 1

2 321-305 1

3 318-590 1

4 321-304 1

5 948-131 1

6 600-7DD 1 6007DDUAV2S

7 313-421 2 D8×20

8 321-286 1

9 313-396 1

10 321-287 1

11 321-303 1

12 321-302 1

13 981-942 4 M6×25

14 321-300 1

15 956-996 1 1AS-60

16 321-301 1

17 981-859 1

18 315-868 1

19 321-297 1

20 321-288 1

21 321-289 1

22 321-290 1

23 313-057 4 D6×6

24 321-291 1

25 321-298 1

26 321-299 1

27 321-293 1

28 321-274 1

29 321-292 1

30 310-420 1

31 321-295 1

32 986-104 1

33 321-284 1

34 980-708 1

35 321-285 1

36 321-296 1

38 ———— 1

39 321-315 1

40 ———— 1

41 321-314 1

42 939-540 1

43 321-275 1

44 944-109 1 3×3×8

45 620-3DD 1 6203DDCMPS2L

46 996-363 1 S-40

47 321-274 1

48 321-273 1

49 986-940 4 M6×45

50 944-109 1 3×3×8

51 321-279 1

52 313-050 1

53 600-2DD 1 6002DDCMPS2L

54 313-058 1

55 313-053 1

56 321-281 1

57 321-282 10

58 320-343 10

59 321-280 1

60 321-283 1

61 629-VVM 1 629VVC2PS2L

62 321-2377 1 “11-22”

63 944-525 1

64 313-078 1

A B C D

65 313-080 1

66 971-786 1

67 ———— 1

68 983-162 5 M4×12

69 313-079 1

70 321-309 1

71 311-229 1

72 321-308 1

73 321-307 1

74 873-095 1 P-16

75 321-310 1

76 321-311 1

77 321-312 1 D2×10

78 321-276 1

79 939-299 1 M661

80 321-319 1

81 620-1DD 1 6201DDCMPS2L

82 302-429 1

83 1 360-591U 1 110V-120V “87-90”

83 2 360-591E 1 220V-230V

83 3 360-591F 1 240V

85 953-174 2 D5×55

86 1 340-542C 1 110V “117, 118”

86 2 340-542G 1 120V “117, 118”

86 3 340-542E 1 220V-230V “117, 118”

86 4 340-542F 1 240F

87 982-631 1

88 608-VVM 1 608VVC2PS2L

89 321-320 1

90 930-703 2

92 321-322 1

93 321-318 1 “85, 86”

94 321-313 2 M6×22

95 935-829 2

96 999-073 2

97 971-001 2

98 321-321 1

99 877-839 2 M5×10

100 321-323 1

101 998-485 6 M5×14

102 313-093 1

103 321-324 1

104 301-653 2 D4×20

105 321-317 1

106 1 321-327 1 110V

106 2 321-326 1 120V

106 3 321-328 1 220V-240V

107 980-063 1

108 1 958-049 1 D8.2

108 2 940-778 1 D10.1

109 1 960-266 1

109 2 981-987Z 1 “SUI”

110 984-750 2 D4×16

111 ———— 1

112 959-141 1

113 938-307 1

501 321-325 1

502 981-840 1 30G

503 943-277 1 3MM

504 944-458 1 4MM

505 944-459 1 5MM

24

Page 26

208

Code No. C99118331 N

Printed in Japan

Loading...

Loading...