HITACHI DH 38YE User guide

MODEL DH 38YE

1. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY:

The circled figures in the descriptions below correspond to the item numbers in the Parts List.

1-1. Disassembly:

1-1-1. Piston and Striker O-Rings:

By removing the M6 x 25 Hex Socket Hd. Bolts

Case

Crank Shaft

47

. As the Piston 58 remains in the Crank Case side, removal of the Connecting Rod 60 from the

41

will be sufficient. The Striker 55 can be removed by tapping the Cylinder Case lightly witl

62

, the Cylinder Case 63 may be removed from the Crank

a plastic hammer.

If the Striker cannot be easily removed, reinsert the Piston, together with the Connecting Rod, into the

Cylinder, and pull it out again in a quick motion; the Striker should come out simultaneously.

1-1-2. Disassembly of Cylinder:

Remove the Cylinder Case

63

; and you can then remove the Third Gear 66, Clutch 57, Spring A 18, Cylinder Ring 16, Damper

11

Ring

, Damper 12, and Second Hammer 10.

63

from the Crank Case 47: take the Front Cover 7 off of the Cylinder Case

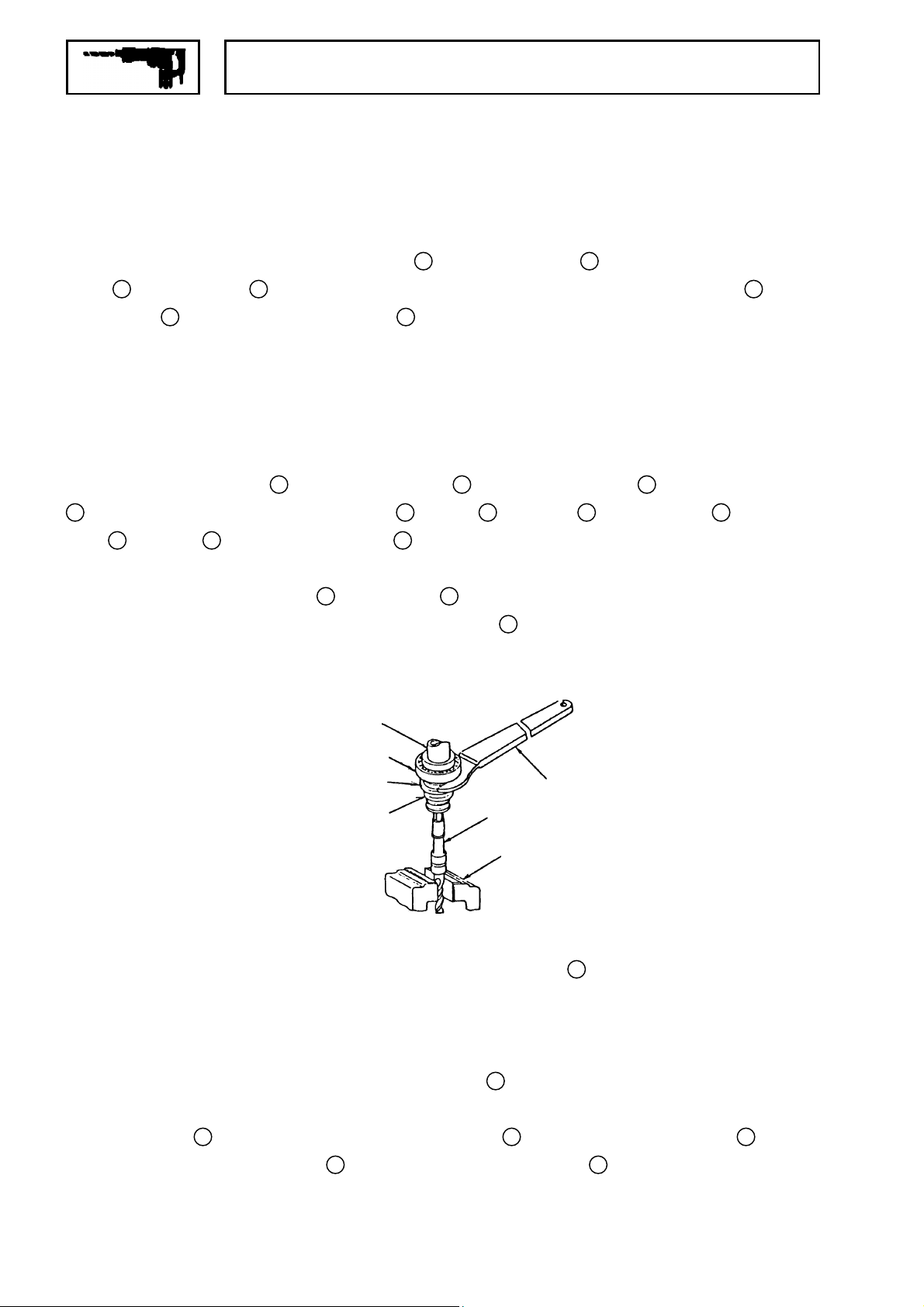

Next, as illustrated below, fit a drill bit into the tool holder, and secure it with a vise.

Then mount the Second Hammer

[Code No. 970885] on the flat surfaces of the Cylinder Cap

10

and Cylinder 54 onto the drill bit. Finally, fit a Wrench (J-123)

13

, and rotate it counterclockwise to loosen

and remove the Cylinder Cap.

Cylinder

Ball Bearing

Cylinder Cap

Second Hammer

Drill Bit

J-123 Wrench

Vise

After the Cylinder Cap has been removed, press off the Ball Bearing 15 with a hand press. The Cylinder

can then be completely removed.

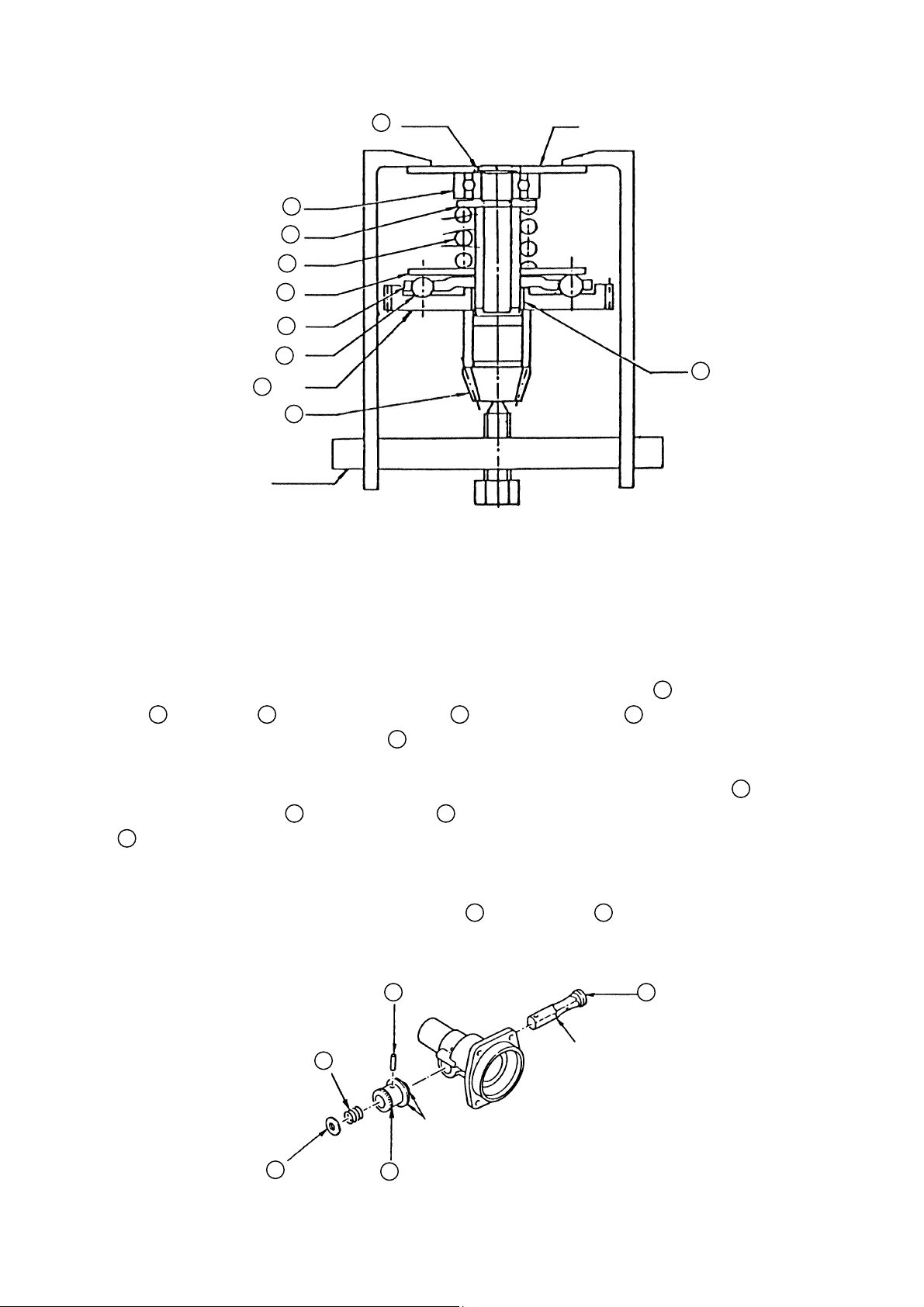

1-1-3. Disassembly of the Slip Clutch Mechanism:

First, place an appropriate steel plate on the Ball Bearing

30

. Then, as illustrated below mount a bearing

puller (special repair tool J-30 Bearing Puller Ass’y [Code No. 970804] recommended) on the steel plate

and Third Pinion

remove the C-Type Retaining Ring

19

, apply pressure from the Second Gear 23 side to compress the Spring 28, and

32

. After removing the Ball Bearing 30, the remaining parts can be

disassembled.

−

−#

1

D9 C-Type Retaining Ring

32

Steel plate

23

29

28

27

26

25

30

19

24

Metal

Ball Bearing

Washer

Spring

Plate

Holder

Steel Balls

Second Gear

Third Pinion

Bearing Puller

1-2. Reassembly:

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special

attention should be given to the following items.

1-2-1. Lubrication:

60

Special Grease must be applied to the Needle Bearing of Connecting Rod Ass’y

55

the Striker

Grease must be inserted in the Crank Case

and Piston 58, the 6007 Ball Bearing 15, and the O-Ring (C) 9. 50g (0.11 Ibs) of Special

47

(Connecting Rod side), and 20g (0.044 Ibs) of Special Grease

the O-Rings attached to

must be inserted in the Cylinder Case.

52

Ensure that Grease (N. P. C. SEP-3A) (Code No. 930035) is applied to the Needle Bearing

82

portion of the Armature Ass’y

53

Cover

.

, and Oil Seal (A) 46. Insert 40g (0.088 Ibs) of Grease into the Gear

, the piston

1-2-2. Reassembly of the Tool Retainer:

5

Ensure that the notched portions (A) of the Stop Lever

and the Knob 3 are properly aligned and assembled, as shown in the illustration. If not corr ectly aligned and assembled, the bull point cannot be properly inserted into the Tool Holder.

4 5

2

Notch

Notch

1

3

−#2 −

Loading...

Loading...