Page 1

Rotary Hammer

Model DH 28PC

Handling instructions

Note:

Before using this Electric Power Tool, carefully read through these

HANDLING INSTRUCTIONS to ensure efficient, safe operation. It is

recommended that these INSTRUCTIONS be kept readily available

as an important reference when using this power tool.

Page 2

English

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result

in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust.

Power tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away while

operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools.

Unmodified plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric shock if

your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions.

Water entering a power tool will increase the

risk of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk

of electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication.

A moment of inattention while operating power

tools may result in serious personal injury.

b) Use personal protective equipment. Always wear

eye protection.

Protective equipment such as dust mask, nonskid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce

personal injuries.

2

c) Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source and/or battery pack, picking up or

carrying the tool.

Carrying power tools with your finger on the

switch or energising power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left attached to a rotating part

of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

Loose clothes, jewellery or long hair can be

caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of dust collection can reduce dust related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better and

safer at the rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off.

Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools.

Such preventive safety measures reduce the risk

of starting the power tool accidentally.

d) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tools operation.

If damaged, have the power tool repaired before

use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions, taking

into account the working conditions and the

work to be performed.

Use of the power tool for operations different from

those intended could result in a hazardous situation.

Page 3

English

5) Service

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool

is maintained.

PRECAUTION

Keep children and infirm persons away.

When not in use, tools should be stored out of reach of

children and infirm persons.

PRECAUTIONS ON USING ROTARY HAMMER

1. Wear ear protectors.

Exposure to noise can cause hearing loss.

2. Use auxiliary handle(s), if supplied with the tool.

Loss of control can cause personal injury.

3. Hold power tool by insulated gripping surfaces,

when performing an operation where the cutting

accessory may contact hidden wiring or its own

cord. Cutting accessory contacting a "live" wire

may make exposed metal parts of the power tool

"live" and could give the operator an electric shock.

4. Do not touch the bit during or immediately after

operation. The bit becomes very hot during

operation and could cause serious burns.

5. Before starting to break, chip or drill into a wall,

floor or ceiling, thoroughly confirm that such items

as electric cables or conduits are not buried inside.

6. Always hold the body handle and side handle of

the power tool firmly. Otherwise the counterforce

produced may result in inaccurate and even

dangerous operation.

7. Wear a dust mask

Do not inhale the harmful dusts generated in

drilling or chiseling operation. The dust can

endanger the health of yourself and bystanders.

SPECIFICATIONS

Voltage (by areas)* (110 V, 115 V, 120 V, 127 V, 220 V, 230 V, 240 V)

Power input 720 W*

No-load speed 0 – 1050 min

Full-load impact rate 0 – 4000 min

Capacity: concrete 4 – 28 mm

Weight (without cord and side handle) 3.5 kg

*Be sure to check the nameplate on product as it is subject to change by areas.

steel 13 mm

wood 32 mm

-1

-1

STANDARD ACCESSORIES

(1) Plastic case ................................................................. 1

(2) Side handle ................................................................ 1

(3) Stopper ........................................................................ 1

Standard accessories are subject to change without

notice.

3

Page 4

English

OPTIONAL ACCESSORIES (sold separately)

Tool Adapters

䢇

Drilling holes in concrete or tile

Use on jobs facing upwards

Drill bit

䢇 Drilling anchor holes

Drill bit (Taper shank)

䢇 Large hole boring

Rotation + Hammering

Guide plate Center pin Core bit

䢇Anchor setting

Anchor setting adapter

䢇 Bolt placing operation with

Chemical Anchor

Hexagon socket

䢇 Demolishing operation

Bull point

(Square type)

Bull point*

(Round type)

䢇 Groove digging and edging

Hammering only

Cold chisel Cutter

䢇 Grooving

Dust cup

Dust collector (B)

+

Taper shank

adapter

Core bit shank

Chemical anchor adapter

Cotter

䢇 Driving screws

, Driver bit - Driver bit

䢇 Drilling in steel or wood

Drill bit for steel Drill bit for

Rotation only

4

Grooving chisel

wood

+ +

Special

screw

Drill chuck

(13 VLRB-D)

Chuck

adapter

Page 5

English

䢇 Drilling holes in concrete or tile

SDS-plus Drill bit

Outer dia. Overall length Effective length

4.0 mm 110 mm 50 mm

5.0 mm

5.5 mm 110 mm 50 mm

6.5 mm 160 mm 100 mm

7.0 mm 160 mm 100 mm

8.0 mm 160 mm 100 mm

8.5 mm 160 mm 100 mm

9.0 mm 160 mm 100 mm

12.0 mm

12.7 mm 166 mm 100 mm

14.0 mm 166 mm 100 mm

15.0 mm 166 mm 100 mm

16.0 mm

17.0 mm 166 mm 100 mm

19.0 mm 260 mm 200 mm

20.0 mm 250 mm 200 mm

22.0 mm 250 mm 200 mm

25.0 mm 450 mm 400 mm

䢇 Drilling anchor holes

110 mm 50 mm

160 mm 100 mm

166 mm 100 mm

260 mm 200 mm

166 mm 100 mm

260 mm 200 mm

Taper shank adapter

Taper mode

Morse taper No.1

Morse taper No.2

A-Taper

B-taper

䢇 Large hole boring

Core bit

Outer dia. Overall length

25 mm*

29 mm*

32 mm

35 mm (A)

38 mm

45 mm

50 mm

65 mm

80 mm

* Without guide plate

䢇 Anchor setting

Center pin

Not applicable

(B) 300 mm

Anchor setting adapter

Anchor size

W 1/4”

W 5/16”

W 3/8”

W 1/2”

W 5/8”

Core bit shank

105 mm

300 mm

Optional accessories are subject to change without notice.

5

Page 6

English

APPLICATIONS

Rotation and hammering function

䡬 Drilling anchor holes

䡬 Drilling holes in concrete

䡬 Drilling holes in tile

Rotation only function

䡬 Drilling in steel or wood

(with optional accessories)

䡬 Tightening machine screws, wood screws

(with optional accessories)

Hammering only function

䡬 Light-duty chiselling of concrete, groove digging

and edging.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, which could cause

a serious accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

4. Mounting the drill bit (Fig. 1)

CAUTION

To prevent accidents, make sure to turn the switch

off and disconnect the plug from the receptacle.

NOTE

When using tools such as bull points, drill bits, etc.,

make sure to use the genuine parts designated by

our company.

(1) Clean the shank portion of the drill bit.

(2) Insert the drill bit in a twisting manner into the tool

holder until it latches itself (Fig. 1).

Part of

SDS-plus shank

Front cap

Grip

Grip

Fig. 2

5. Installation of dust cup or dust collector (B)

(Optional accessories) (Fig. 3, Fig. 4)

When using a rotary hammer for upward drilling

operations attach a dust cup or dust collector (B)

to collect dust or particles for easy operation.

䡬 Installing the dust cup

Use the dust cup by attaching to the drill bit as

shown in Fig. 3.

When using a bit which has big diameter, enlarge

the center hole of the dust cup with this rotary

hammer.

Dust cup

Fig. 3

䡬 Installing dust collector (B)

When using dust collector (B), insert dust collector

(B) from the tip of the bit by aligning it to the

groove on the grip (Fig. 4).

Dust collector (B)

Drill bit

Fig. 1

(3) Check the latching by pulling on the drill bit.

(4) To remove the drill bit, fully pull the grip in the

direction of the arrow and pull out the drill bit (Fig.

2).

6

Fig. 4

CAUTION

䡬 The dust cup and dust collector (B) are for exclusive

use of concrete drilling work. Do not use them for

wood or metal drilling work.

䡬 Insert dust collector (B) completely into the chuck

part of the main unit.

Page 7

English

䡬 When turning the rotary hammer on while dust

collector (B) is detached from a concrete surface,

dust collector (B) will rotate together with the drill

bit. Make sure to turn on the switch after pressing

the dust cup on the concrete surface. (When using

dust collector (B) attached to a drill bit that has

more than 190 mm of overall length, dust collector

(B) cannot touch the concrete surface and will rotate.

Therefore please use dust collector (B) by attaching

to drill bits which have 166 mm, 160 mm, and 110

mm overall length.)

䡬 Dump particles after every two or three holes when

drilling.

䡬 Please replace the drill bit after removing dust

collector (B).

6. Selecting the driver bit

Screw heads or bits will be damaged unless a bit

appropriate for the screw diameter is employed to

drive in the screws.

7. Confirm the direction of bit rotation (Fig. 5)

The bit rotates clockwise (viewed from the rear

side) by pushing the R-side of the push button.

The L-side of the push button is pushed to turn the

bit counterclockwise.

Push button

HOW TO USE

CAUTION:

To prevent accidents, make sure to turn the switch off

and disconnect the plug from the receptacle when the

drill bits and other various parts are installed or removed.

The power switch should also be turned off during a

work break and after work.

NOTE:

Ensure that the wing bolt in the side handle is

properly tightened before using the tool.

1. Switch operation

The rotation speed of the drill bit can be controlled

steplessly by varying the amount that the trigger

switch is pulled. Speed is low when the trigger

switch is pulled slightly and increases as the switch

is pulled more.

However, the switch trigger can only be pulled in

halfway during reverse and rotates at half the speed

of forward operation.

2. Rotation + hammering

This rotary hammer can be set to rotation and

hammering mode by pressing the push button and

turning the change lever to the

Turn the grip slightly and confirm that the clutch

has been engaged with a click.

mark (Fig. 6).

Push button

Fig. 5

8. Selecting the function mode

You can switch functions to the 3 modes of

“hammering only, “rotation + hammering”, and

“rotation only” by turning the change lever while

pressing the push button. Set the ▲ mark position

of the change lever to that of the mode to be used.

CAUTION:

䡬 Before operating the change lever, check and make

sure that the motor has stopped.

A failure can occur if it is operated while the motor

is running.

䡬 To operate the change lever, press the push button,

and release the lock of the change lever. Also, check

and make sure after operation that the push button

has returned and that the change lever has been

locked.

䡬 Switch the change lever without mistake. If it is

used at a position halfway, there is a fear that the

service life of the switching mechanism may be

shortened.

9. RCD

The use of a residual current device with a rated

residual Current of 30mA or less at all times is

recommended.

Change lever

Fig. 6

(1) Mount the drill bit.

(2) Pull the trigger switch after applying the drill bit

tip to the drilling position. (Fig. 7)

Fig. 7

(3) Pushing the rotary hammer forcibly is not necessary

at all. Pushing slightly so that drill dust comes out

gradually is sufficient.

CAUTION:

When the drill bit touches construction iron bar, the

bit will stop immediately and the rotary hammer

will react to revolve. Therefore grip the side handle

and handle tightly as shown in Fig. 7.

7

Page 8

English

3. Rotation only

This rotary hammer can be set to rotation only

mode by pussing the push button and turning the

change lever to the

Push button

Change lever

Turn the grip slightly and confirm that the clutch

has been engaged with a click.

To drill wood or metal material using the drill chuck

and chuck adapter (optional accessories), proceed

as follows.

Installing drill chuck and chuck adapter: (Fig. 9)

Chuck adapter

Drill chuck

(1) Attach the drill chuck to the chuck adapter.

(2) The part of the SDS-plus shank is the same as the

drill bit. Therefore, refer to the item of “Mounting

the drill bit” for attaching it.

CAUTIONS:

䡬 Application of force more than necessary will not

only expedite the work, but will deteriorate the tip

edge of the drill bit and reduce the service life of

the rotary hammer in addition.

䡬 Drill bits may snap off while withdrawing the rotary

hammer from the drilled hole. For withdrawing, it

is important to use a pushing motion.

䡬 Do not attempt to drill anchor holes or holes in

concrete with the machine set in the rotation only

function.

䡬 Do not attempt to use the rotary hammer in the

rotation and hammering function with the drill chuck

and chuck adapter attached. This would seriously

shorten the service life of every component of the

machine.

4. When driving machine screws (Fig. 10)

First, insert the bit into the socket in the end of

chuck adapter (D).

Next, mount chuck adapter (D) on the main unit

using procedures described in 4 (1), (2), (3), put the

tip of the bit in the slots in the head of the screw,

grasp the main unit and tighten the screw.

mark. (Fig. 8)

Fig. 8

Front cap

Part of

SDS-plus shank

Grip

Fig. 9

Bit

Socket

Chuck adapter (D)

Fig. 10

CAUTIONS:

䡬 Exercise care not to excessively prolong driving

time, otherwise, the screws may be damaged by

excessive force.

䡬 Apply the rotary hammer perpendicularly to the

screw head when driving the screw; otherwise, the

screw head or bit will be damaged, or driving force

will not be fully transferred to the screw.

䡬 Do not attempt to use the rotary hammer in the

rotation and hammering function with the chuck

adapter and bit attached.

5. When driving wood screws (Fig. 10)

(1) Selecting a suitable driver bit

Employ cross-recessed screws, if possible, since the

driver bit easily slips off the heads of slotted-head

screws.

(2) Driving in wood screws

䡬 Prior to driving in wood screws, make pilot holes

suitable for them in the wooden board. Apply the

bit to the screw head grooves and gently drive the

screws into the holes.

䡬 After rotating the rotary hammer at low speed for

a while until the wood screw is partly driven into

the wood, squeeze the trigger more strongly to

obtain the optimum driving force.

CAUTION:

Exercise care in preparing a pilot hole suitable for

the wood screw taking the hardness of the wood

into consideration. Should the hole be excessively

small or shallow, requiring much power to drive

the screw into it, the thread of the wood screw may

sometimes be damaged.

6. Hammering only

This rotary hammer can be set to hammering only

mode by pressing the push button and turning the

change lever to the

mark (Fig. 11).

Front cap

Grip

Push button

Change lever

Fig. 11

8

Page 9

English

(1) Mount the bull point or cold chisel.

(2) Press the push button and set the change lever to

mark. (Fig. 12)

Push button

Change lever

Fig. 12

The rotation is released, turn the tool and adjust

the tool to desired position. (Fig. 13)

Fig. 13

(3) Turn the change lever to

Then bull point or cold chisel is locked.

7. Using the stopper (Fig. 14)

(1) Loosen the wing bolt, and insert the stopper into

the mounting hole on the side handle.

(2) Adjust the stopper position according to the depth

of the hole and tighten the wing bolt securely.

Stopper

Fig. 14

8. How to use the drill bit (taper shank) and the taper

shank adapter

(1) Mount the taper shank adapter to the rotary hammer.

(Fig. 15)

(2) Mount the drill bit (taper shank) to the taper shank

adapter. (Fig. 15)

mark. (Fig. 11)

Mounting hole

Wing bolt

Side handle

Drill bit

Tape shank adapter

(3) Turn the switch ON, and drill a hole in prescribed

depth.

(4) To remove the drill bit (taper shank), insert the

cotter into the slot of the taper shank adapter and

strike the head of the cotter with a manual hammer

supporting on a rests. (Fig. 16)

Cotter

9. Using the side handle

When you wish to change a position of the side

handle, turn grip of the side handle counterclockwise

to loosen it, and then fasten it firmly.

CAUTION:

When boring a hole, there can be a case where the

machine attempts to rotate by the reaction at the

time of penetrating a concrete wall and/or when a

tip of the blade comes in contact with the rebar.

Firmly fasten the side handle and hold the machine

with both of your hands. Unless you hold it securely,

an accident can occur.

Front cap

Fig. 15

Tape shank adapter

Fig. 16

Grip

Rests

HOW TO USE THE CORE BIT

(FOR LIGHT LOAD)

When boring penerating large holes use the core bit (for

light loads). At that time use with the center pin and the

core bit shank provided as optional accessories.

1. Mounting

CAUTION

Be sure to turn power OFF and disconnect the plug

from the receptacle.

(1) Mount the core bit to the core bit shank. (Fig. 17).

Lubricate the thread of the core bit shank to facilitate

disassembly.

9

Page 10

English

Core bit

Thread

Core bit shank

Fig. 17

(2) Mount the core bit to the rotary hammer (Fig. 18).

Fig. 18

(3) Insert the center pin into the guide plate until it

stops.

(4) Engage the guide plate with the core bit, and turn

the guide plate to the left or the right so that it

does not fall even if it faced downward. (Fig. 19).

CAUTION

When removing the center pin and the guide plate,

turn OFF the switch and disconnect the plug from

the receptacle.

Fig. 20

3. Dismounting (Fig. 21)

Remove the core bit shank from the rotary hammer

and strike the head of the core bit shank strongly

two or three times with a manual hammer holding

the core bit, then the thread becomes loose and

the core bit can be removed.

Core bit shank

Guide plate

Center pin

Core bit tip

Core bit

Fig. 19

2. How to bore (Fig. 20)

(1) Connect the plug to the power source.

(2) A spring is installed in the center pin.

Push it lightly to the wall or the floor straight.

Connect the core bit tip flush to the surface and

start operating.

(3) When boring about 5 mm in depth the position of

the hole will be established. Bore after that removing

the center pin and the guide plate from core bit.

(4) Application of excessive force will not only expedite

the work, but will deteriorate the tip edge of the

drill bit, resulting in reduced service life of the

rotary hammer.

10

Fig. 21

GREASE REPLACEMENT

This machine is full air-tight construction to protect

against dust incursion and to prevent lubricant leakage.

This machine can be used without grease replenishment

for an extended period of time. However, perform the

grease replacement to extend the service life. Replace

the grease as described below.

1. Grease Replacement Period

You should look at the grease when you change

the carbon brush. (See item 4 in the section

MAINTENANCE AND INSPECTION.)

Ask for grease replacement at the nearest authorized

Hitachi Service Center.

In the case that you are forced to change the grease

by yourself, please follow the following points.

2. How to replace grease

CAUTION:

Before replacing the grease, turn the power off and

pull out the plug from the receptacle.

(1) Disassemble the crank cover and thoroughly wipe

off the old grease inside. (Fig. 22)

Page 11

English

Crank cover

Fig. 22

(2) Supply 25g of Hitachi Electric Hammer Grease A

(standard accessory, contained in tube) in the crank

case.

(3) After replacing the grease, reassemble the crank

cover securely. At this time, do not damage or lose

the oil seal.

NOTE:

The Hitachi Electric Hammer Grease A is of the low

viscosity type. When the grease is consumed,

purchase from the authorized Hitachi Service

Center.

MAINTENANCE AND INSPECTION

1. Inspecting the drill bits

Since use of a dull tool will cause motor

malfunctioning and degraded efficiency, replace the

drill bit with new ones or resharpen them without

delay when abrasion is noted.

2. Inspecting the mounting screws:

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

4. Inspecting the carbon brushes

For your continued safety and electrical shock

protection, carbon brush inspection and replacement

on this tool should ONLY be performed by a HITACHI

AUTHORIZED SERVICE CENTER.

5. Replacing supply cord

If the supply cord of Tool is damaged, the Tool

must be returned to Hitachi Authorized Service

Center for the cord to be replaced.

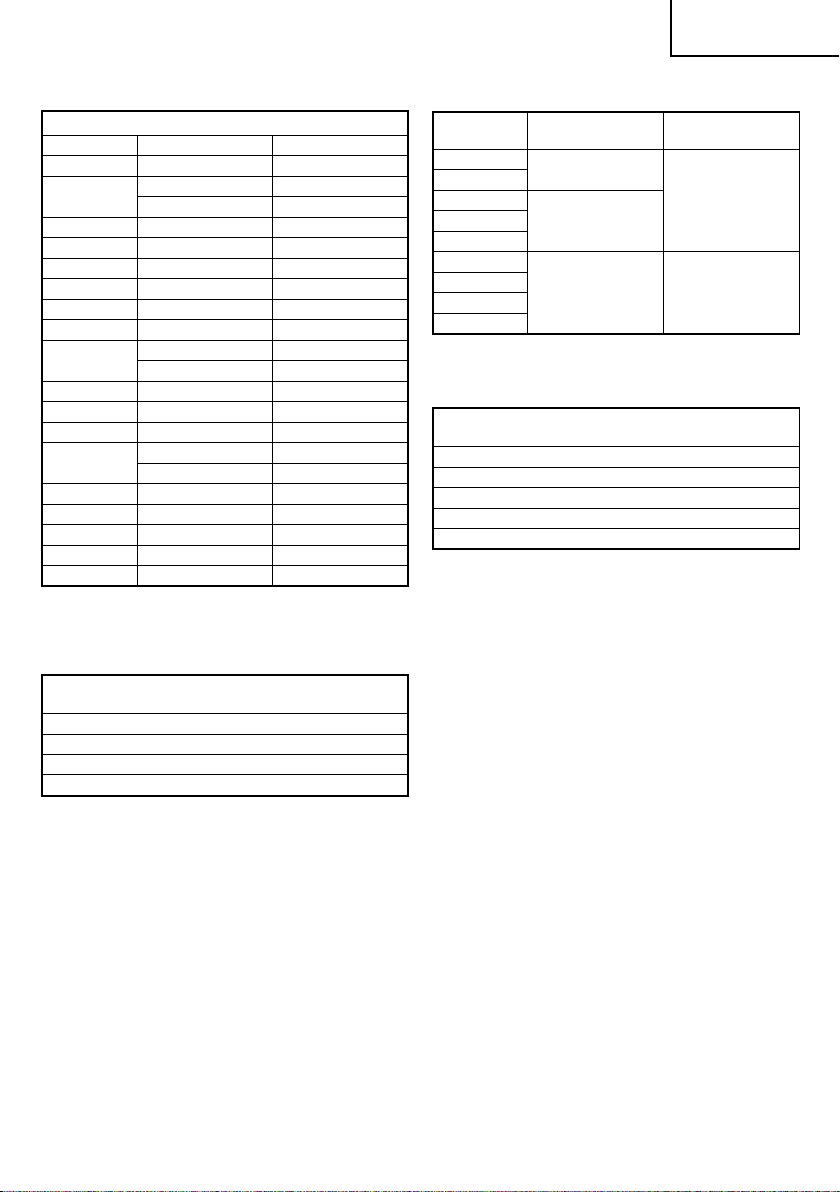

6. Service parts list

A: Item No.

B: Code No.

C: No. Used

D: Remarks

CAUTION

Repair, modification and inspection of Hitachi Power

Tools must be carried out by an Hitachi Authorized

Service Center.

This Parts List will be helpful if presented with the

tool to the Hitachi Authorized Service Center when

requesting repair or other maintenance.

In the operation and maintenance of power tools,

the safety regulations and standards prescribed in

each country must be observed.

MODIFICATIONS

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts (i.e. code numbers and/or

design) may be changed without prior notice.

NOTE:

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

11

Page 12

1

2

501

502

3

4

5

6

10

11

12

13

14

15

7

8

9

504

16

20

21

22

23

30

31

17

18

19

58

24

25

26

27

28

29

57

56

64

32

33

34

31

35

36

37

66

67

68

38

40

39

69

70

42

41

43

39

44

45

47

46

49

48

75

71

72

73

74

77

76

78

52

51

50

53

54

55

79

80

112

85

83

81

82

503

98

99

505

506

507

508

509

510

100

101

102

103

98

62

61

60

59

63

65

83

84

104

105

85

86

87

88

89

90

89

91

92

89

93

94

106

107

84

108

109

110

111

96

95

96

97

87 96

12

Page 13

ABC D

1 306345 1

2 306340 1

3 324527 1

4 330192 1

5 324526 1

6 330191 1

7 992803 4 M6×20

8 330174 1

9 990067 1

10 328867 1

11 330175 1

12 330184 1

13 304020 1

14 6905DD 1 6905DDCMPS2L

15 330176 1

16 330177 1

17 330178 1

18 330179 1

19 330187 1

20 959156 1 D7.0

21 330180 1

22 323058 1

23 330181 1

24 330182 1

25 330183 1

26 331672 1

27 330186 1

28 331673 1

29 323062 1

30 330185 1

31 319577 2 I.D. 19.2

32 330188 1

33 330189 1

34 330190 1

35 330173 1

36 330172 1

37 319585 1

————

38

39 886342 2

40 330256 1

41 331677 1

42 322853 1

43 316228 4 M4×10

44 307028 3 D4×25

45-1 330254 1

45-2 330217 1 “GBR(110V)”

46-1 330255 1

46-2 330218 1 “GBR(110V)”

47 984750 2 D4×16

48 960266 1

49 953327 1 D8.8

50 317492 1

51 325566 1

52 330215 1

53 330216 1 L270

54 959140 1

————

55

56 321867 1

57 983162 1 M4×12

58 321309 1

59 330207 1

60 322064 1

61 330206 1

62 330205 1

63 321312 1 D2×10

64 321310 1

65 321311 1

1

1

ABC D

66 6001DD 1 60 01DDCMPS2L

67 971736 1

68-1 360857C 1 110V

68-2 360857U 1 120V “66, 67, 70, 71”

68-3 360857E 1 230V

68-4 360857F 1 240V

69 330202 1

70 982631 1

71 608VVM 1

72 980864 2 D5×40

73-1 340739C 1 110V

73-2 340739G 1 120V

73-3 340739E 1 230V

73-4 340739H 1 230V “SIN”

73-5 340-739J 1 240V

74 330201 1 “77, 79”

75 935829 2

76 999004 2

77 957051 2

78 302089 2 D5×20

79 938477 2 M5×8

80 310111 1

81 330203 1

82 307811 2 D4×16

83 330196 1

84 981851 2

85 330197 1

86 330194 1

87 6001DD 1 60 01DDCMPS2L

88 909542 1

89 992503 3

90 330198 1

91 959155 8 D3.97

92 992916 1

93 992926 2

94 980877 2

95 330199 1

96 608VVM 2

97 330200 1

98 994192 6 M5×16

99 330204 1

100 324544 1

101 331 674 1

102 3 31675 1

103 324060 4 M5×40

104 3301 69 1

105 3 316 76 1

106 3 301 70 1

107 9 44109 1 3×3×8

1086002DD 1 6002DDCMPS2L

109 972767 1 S-32

110 9 48 0 0 1 1

111 3 3 0 1 7 1 1

11 2330195 1 “83, 85, 87-96”

501 330220 1

502 982671 1

503 330208 1 “504-510”

504 330209 1

505 307947 1 M6×12

506 330210 1

507 949556 1 M6

508 330212 1

509 330211 1

510 330213 1 M8×45

13

Page 14

14

Page 15

15

Page 16

Shinagawa Intercity Tower A, 15-1, Konan 2-chome,

Hitachi Koki Co., Ltd.

Minato-ku, Tokyo, Japan

Code No. C99174812 F

107

Printed in China

Loading...

Loading...