MODEL DH 24PE

1. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

[Bold]

The

assembly diagram.

1-1. Disassembly

(1) Disassembly of the Striking Mechanism Section

numbers in the descriptions below correspond to the item numbers in the Parts List and exploded

With a drill bit or screwdriver bit, push in the Second Hammer

*

O-Ring RPM810

Set the Change Lever

*

[7]

, insert a small slotted-head screwdriver into the concave position located on the rear end of the Change

Lever

*

*

*

[13]

, and pull it off. (It is very important to ensure that the Change Lever

between the "Drill"and "Hammer"marks when it is disassembled or assembled.)

Loosen the four Tapping Screws D5 x 35

the Housing

[47]

to be pulled out at the same time, c aus ing dam age to the Carbon Brushes

Remove Spring (B)

Piston

[40]

mounted on it can be removed from the Inner Cover

With a bearing puller (the Special Repair Tool J-30 Bearing Puller Ass'y, Code No. 970804, is

recommended), remove the First Gear

Bearing

the 9 mm diameter end of the Second Shaft

[30]

can then be disconnected fr om the Piston Pin

[40]

[27]

.

[13]

to a position halfway between the "Drill" and"Hammer"marks on the Gear Cover

[8]

, and remove the Gear Cover

[54]

are loosely fitted together. Attempting to pull them out first could cause the Arm ature Ass ' y

[34]

from the end of the Second Shaft

moves to its max imum upper pos ition (inner c over side) . The arm of the Rec iprocating Bearing

[31]

, and t he Second Shaft

[33]

as a unit.

[41]

from the Second Shaft

. At this time, carefully note that the First Gear

[35]

.

[25]

to release the Striker

[13]

is positioned halfway

[7]

. The Inner Cover

[64]

.

[35]

, and turn the Second Shaft

[35]

and the components

[35]

. Then take off the Reciprocating

[41]

must be aligned with and pre ss-fitted onto

[28]

[35]

so that the

from the

[33]

and

Move the Clutch

*

The Clutch Spring

(2) Disassembly of the Chuck Section

As shown in Fig. 10, slide the Grip

indicated by the arrow mark, and rem ove the Front Cap

The Grip

Spring

removed from the Cylinder

[2]

[4]

, Washer (B)

[38]

to the pinion side of the Second Shaft

[37]

and Washer (B)

, Ball Holder

[5]

[36]

[2]

[3]

inside the Grip

and S teel B all

[20]

.

can then be removed from the Second Shaft

in the direction

[18]

can then be

[2]

, Holder

[1]

[35]

, and pull off the O-Ring S-8

.

Fig. 10

[39]

[35]

.

Front Cap

Grip

.

[1]

[2]

−1−

(3) Disassembly of the Cy linder , Second Gear (Slip Mechanis m S ec tion) and related parts

φ

Take the Inner Cover

*

Retaining Ring for D20 Shaft

Snap Ring Pliers [Code No. 970976] is recom m ended.) Then, turn the Gear Cover

press to extrac t the Cylinder

Cylinder

Remove the Retaining Ring for D30 Shaft

[21]

O-Ring

Cylinder

970977] onto the outer circumfer ence of the O-Ring

employed to prevent idle striking, please advise customers to replace it with a new one whenever it is

disassembled.

Extract the Retaining Ring for D37 Hole

a hand press to extract the Ball Bearing

the hand press to extract the Oil Seal

with a new one whenever it is disas s em bled.

[20]

. At this time, be very careful not to los e the three Steel Balls

, Spring (A)

[27]

from the inner part of the Cylinder

[20]

. (For easy extraction of this O-Ring

[33]

off from the Gear Cover

[22]

, and Washer (A)

[6]

. (For easy removal of this retaining ring, use of Special Repair Tool J-200

[20]

from the Gear Cover

[24]

[23]

can then be removed from the Cylinder

[17]

, turn the Gear Cover

[16]

from the Gear Cover

[14]

from the Gear Cover

[7]

, and remove the entire chuck section. Extract the

[7]

upright and use a hand

[7]

. The Sleeve

from the upper part of the Cylinder

[20]

, and the Sec ond Ham mer

[27]

, fit a S pecial Repair Tool J-201 Spring Hook [Code No.

[27]

, and pull it out. see Fig. 13) As the O-Ring

[7]

[7]

[15]

can then be extracted from the

[19]

.

[20]

. The Second Gear

[20]

. Then, extract the

[25]

can be extracted from the

so that its tip portion is upward, and use

[7]

. Next, turn the Gear Cover

. Ensure that t he Oil Seal

[14]

[27]

[7]

and use

is replaced

is

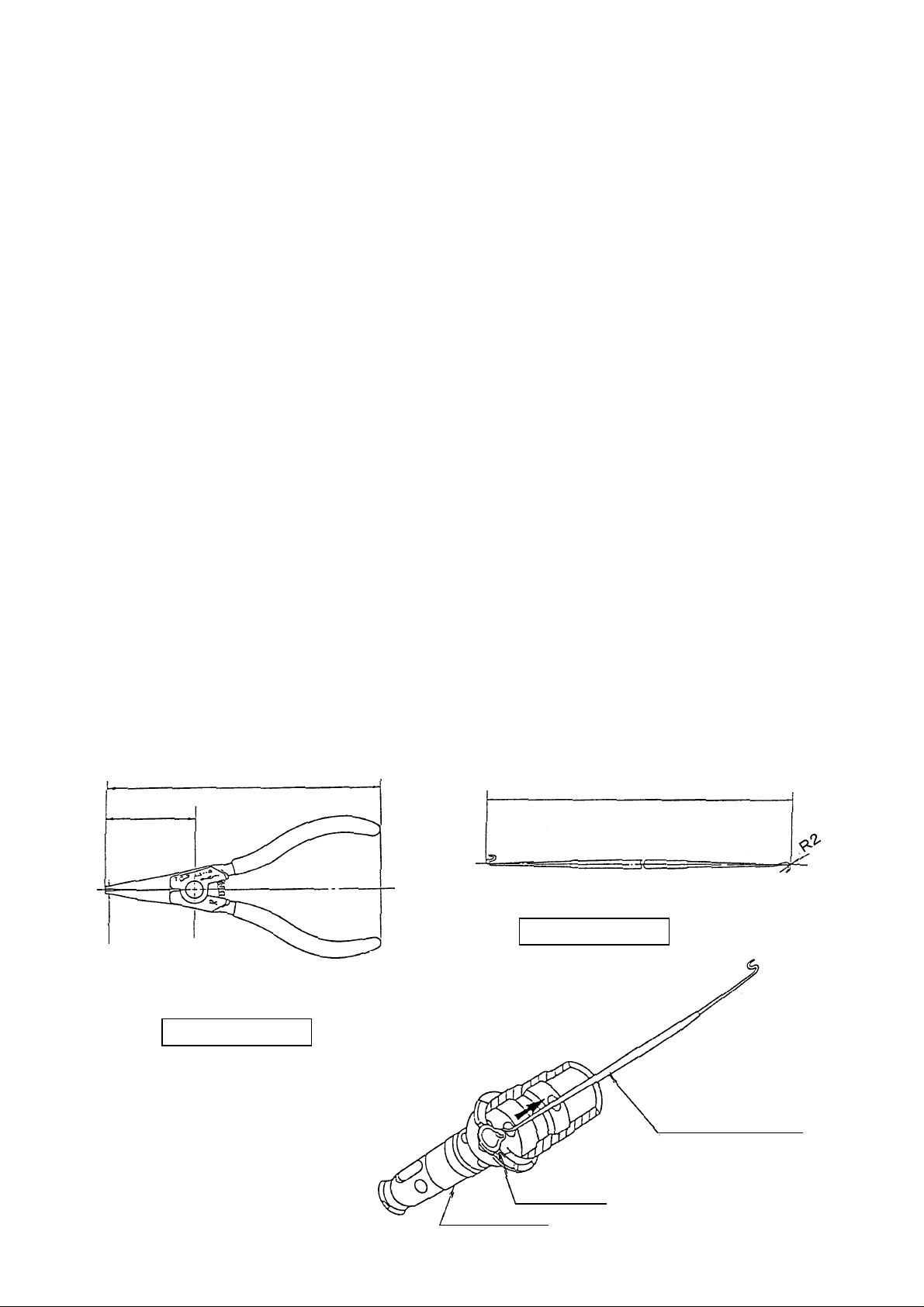

* Use of Special Repair Tools

* Snap Ring Pliers [J - 200]: (See Fig. 11)

Used to remove the Retaining Ring for D20 Shaft

[7]

Cover

* Spring Hook [J-201]: (See Fig. 12)

Used to extract the O-Ring

grip the Striker

[27]

1.2

.

[27]

inserted at the inner part of the Cylinder

[28]

to prevent idle striking. As shown in Fig. 13, fit the Spring Hook [J-201] onto the O-Ring

from its outer circ um fer enc e, and pull it out.

140

45

(1) Snap Ring Pliers (J-200)

[6]

which fixes the Cylinder

217

(2) Spring Hook

Code No. 970977

[20]

at the tip end of the Gear

[20]

which is designed to catch and

Fig. 12

Code No. 970976

Fig. 11

J-201 Spring Hook

O-Ring

Cylinder

−2−

[20]

[27]

Fig. 13

1-2. Reassembly

Perform reassembly in the rever se order of disass embly while observing the given precautions and taking care

of the following points.

(1) To make reassembly eas ier, coat grease on the Steel Balls

[10]

[14]

[13]

and Steel Ball

[11]

[13],

and then forcefully pus h the Change Lever

(2) Reassembly of the Change Lever

With a slotted-head screwdriver or s imilar tool, m ove the Clutch

that the claw (protruding portion) of the Reciprocating Bearing

[38]

Clutch

After inserting the S pring ( H)

grease to the pin portion of the Change Lever

Gear Cover

that should the mounting position of the change lever be incorrect, it will deform the claws of the c hange

lever.

(3) Reassembly of the Oil Seal

Prior to reassembly, apply grease to the inner circumference of the Oil Seal

grease to its outer circumference. Also, when press-fitting the Oil Seal

are in contact.

[7]

so that it is positioned midway between the "Hammer" mark and the " Drill" mark. Be careful

[11], [18], [19]

[38]

[40]

into the recessed portion of the Gear Cover

.

and the Recipr ocating Bearing

and the claw (protruding por tion) of the

[13]

[14]

. Howev er, do not apply

[14]

, ensure it is s traight and level.

[7]

1-3. Lubrication

Apply special grease (N.P.C. FG-6A, Code No. 980927, is recommended) to the inner and outer

[40]

so

, apply

into the

circumferences of the Piston Pin

[26]

(B)

[40]

[20]

without fail, insert 70 g (0.15 lbs.) of spec ial gr eas e ins ide the Gear Cov er

mounted on the Second Hammer

mounting portion of the Se cond Shaft

, the inner circumference of t he metal inside th e Inner Cover

[31]

and Piston

[30]

, O-Ring (A)

[25]

, the Reciproc ating Bearing

[35]

, the O-Ring

[27]

and the clutch- claw portions of the Cylinder

1-4. Tightening Torque

M4 Tapping Screws

M5 Tapping Screws

[58], [68]

[8]

............

.......................2.9 0.5 Nm (30 5 kgfcm, 26.0 4.3 in-lbs)

2.0 0.5 Nm (20 5 kgfcm, 17.4 4.3 in-lbs)

[29]

mounted on the Striker

[40]

, the Reciproc ating Bearing

[33]

and grooves of the Clutch

[7]

.

[28]

[38]

, O-Ring

. Also,

−3−

1-5. Wiring Diagram

Cord

Speed control switch

M1

1

2

C1

C2

M2

Gray White

Red Black

Stator

Stator

Fig. 14

1-6. Internal Wire Arrangement and Wiring Work

A. Internal Wire Arrangement

Reversing switch

2

1

4

3

Blue

Armature

Brown

Armature

Put the Lead wires from the stator under the Brush Holder

Push button

Brush Holder

[65]

Black (from the Stator

Brown (from the Carbon Brush

White (from the Stator

Blue (from the Carbon Brus h

Speed control switch and

reversing switch

Gray (from the Stator

Red (from the Stator

[71]

Cord

[65]

[50]

.

)

[64]

)

[50]

)

[64]

)

[50]

)

[50]

)

Fig. 15 Schematic diagra m

−4−

B. Additional Wiring Work

General inter nal wiring can be accomplished by

referring to paragraphs 9- 5 and 9- 6. The following ar e

special instructions for switc h connection.

(1) Wiring of reversing switch

Insert the lead wire (blac k ) coming from the stator

into the terminal (1) of the reversing switch, and the

lead wire (white) into the ter minal ( 2) as s hown in

Fig. 16. Insert the lead wire (brown) coming from

the carbon brush into the terminal (3) and the lead

wire (blue) into the terminal (4). A fter the insertion,

pull each lead wire slightly to check the lead wires

do not come off. To disconnect the lead wires,

insert a small slotted-head scre wdriver into the

windows near the terminals and pull out the lead

wires.

(Stator)

Black

Blue

(Carbon brush)

Fig. 16

(Carbon brush)

Brown

White

(Stator)

(Stator)

(2) Wiring of speed control switch

Insert each cord into the ter minal 1 and term inal

2 of the speed control s witc h as s hown in Fig.17

and tighten the screw (tightening torque: 0.6 0.2

Nm (6 2 kgfcm, 5.2 1.7 in-lbs)). Insert the

lead wire (gray) coming from the stator into the

terminal M1 and the lead wire (red) into the terminal

M2. After the insertion, pull eac h lead wire slightly

to check the lead wires do not come off. To

disconnect the lead wires, insert a small

slotted-head screwdriver into the windows near the

lead wires and pull out the lead wires.

1-7. Insulation Tests

On completion of reas sembly after repair, measure the insulation r esis tance and c onduct the dielectric s trength

test.

Insulation resistance : 7 MΩ or more with DC 500 V Megohm Tester

Fig. 17

Black or Br own

(Cord)

Red

White or Blue

(Cord)

(Stator)

Gray

Dielectric strength :AC 2,500 V/1 minute, with no abnormalities 110 V - 115 V

1-8. No-load Current Values

After no-load operation for 30 minutes, the no-load current values should be as follows .

Voltage (V) 110 115

Current (A) max. 3.0 3.0

−5−

2. STANDARD REPAIR TIME (UNIT) SCHEDULES

MODEL

DH24PE

Variable

Fixed

General Assembly

Fixed Cost

Switch 0 min.

Cord 10 min.

Other 20 min.

10 20

Work Flow

Speed Control

Switch

Cord

Change Lever

Armature

A'ssy

Inner Cover

O-Ring(P-22)

Ball Bearing

(608DDM)

Washer(A) x 2

Ball Bearing

(608VVM)

Front Cap

Grip

Oil Seal

Steel Ball

30

Housing

Stator

Cylinder

Steel Ball x 3

Second Gear

Spring(A)

Washer(A)

Second

Hammer

O-Ring(B)

O-Ring(FPM)

Retaining Ring

for D20

Retaining Ring

for D30

40 50

Gear Cover

Ball Bearing

(6904CM)

Retaining Ring

for D37

60 min.

Striker

O-Ring(A)

Piston

Piston Pin

Washer(C)

Spring(B)

Second Shaft

Washer(B)

Clutch Spring

Clutch

O-Ring(S8)

Reciprocating

Bearing

First Gear

Spacer

Ball Bearing

(626VVMC)

−6−

Loading...

Loading...