--- 1 ---

1. REPAIR GUIDE

Without fail, remove the EB 24B battery from the main body before starting maintenance work. Because the

tool is cordless, if the battery is left in and the switch is activated inadvertently, the motor will start rotation

unexpectedly, resulting in serious hazard.

1-1. Precautions and Suggestions for Disassembly and Reassembly of the Main Body

The [Bold] numbers in the descriptions below correspond to the item numbers in the Parts List and

exploded assembly diagrams.

1-1-1. Disassembly

(1) Disassembly of the chuck section

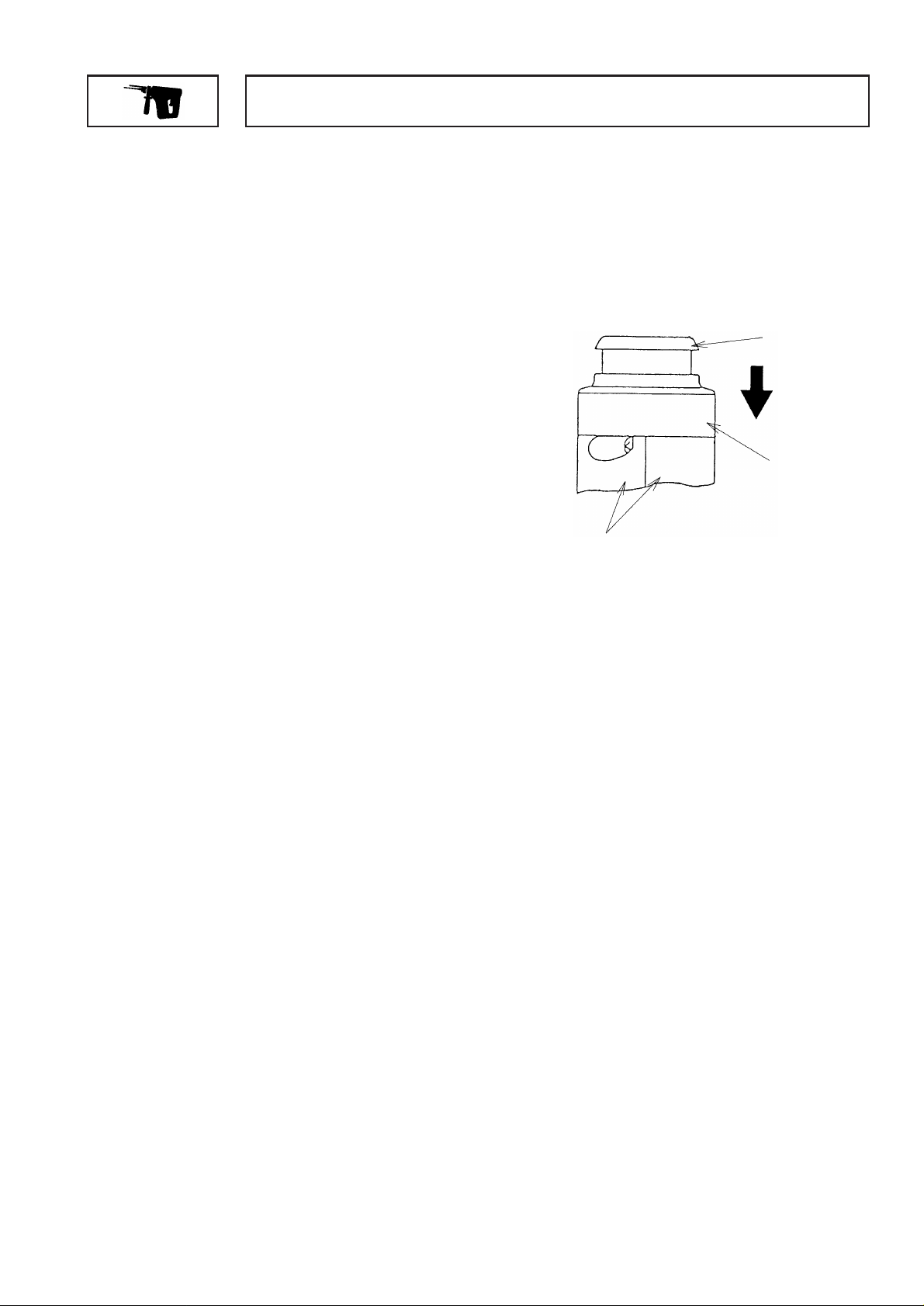

As shown in Fig. 1, slide the Grip [2] in the direction

indicated by the arrow mark, and remove the Front Cap

[1]. The Grip [2], the Ball Holder [3] inside the Grip,

Holder Spring [4] and two Steel Balls [9] can then be

removed from the Cylinder [11].

(2) Disassembly of the housing

After removing the chuck section, loosen and remove the nine D4 x20 Tapping Screws (Black) [33] and

the two D4 x14 Tapping Screws [32] which fix the main body. Then, separate the Housing (A)(B) Set

[31] by removing Housing (B) from Housing (A).

(3) Disassembly of the hammering mechanism section

When the Cylinder [11] and the Piston [21] are removed from Housing (A) in a single body, the arm of

the Reciprocating Bearing [40] will be extracted from the Piston [21]. Then extract the Piston [21] from

the Cylinder [11], and with a screwdriver or slender rod push the Second Hammer [16] out through the

hole in the tip end of the Cylinder [11] to disconnect the Striker [19] retained by O-Ring (D) [18].

Pull out the First Gear [44] without the bearing from the Second Pinion [36]. Then remove the Collar

[41] and the Reciprocating Bearing [40]. Next, move the Clutch [38] toward the pinion side at the top of

the Second Pinion [36], and remove the O-Ring [39]. The Clutch [38] and the Clutch Spring [37] can

then be removed from the Second Pinion [36]. Remove the Retaining Ring for D14 Shaft [50] which

fixes the Change Lever [46] on the inner side of Housing (A), and extract the Change Lever [46] from

Housing (A). Be very careful not to lose the D3.97 Steel Ball [48].

(4) Disassembly of the cylinder and the second gear (slip mechanism section)

Extract the Retaining Ring [5] from the Cylinder [11]. Pull the Oil Seal [6] off of the Cylinder [11].

Extract the Retaining Ring for D20 Shaft [7], and remove the 6904CM Ball Bearing [8] from the Cylinder

[11] with a bearing puller. Be very careful not to lose the four D5.556 Steel Balls [10]. The Second

Gear [12], Spring (A) [13] and Washer (A) [14] can then be removed from the Cylinder [11]. Extract O-

Ring (D) [18] from deep within the Cylinder [11], and remove the Second Hammer [16] from the Cylinder

[11]. [O-Ring (D) can be easily removed by using the J-201 spring hook (Code No. 970977 is

recommended) to pull it out from the outside.] To prevent idle hammering, be sure to replace O-Ring

(D) [18] whenever the unit is disassembled.

Fig. 1

Front Cap [1]

Grip [2]

Housing (A),(B) Set [31]

MODEL DH 20DV

--- 2 ---

(5) Disassembly of the switch and the terminal

Remove Housing (B) and pull out the Internal Wires [54] [55] from Brush Holder (L) [59] and (R) [60].

Then the Terminals [66] [68], the Switch [53] and the Internal Wires [54] [55] can be removed together.

Perform the following procedure for disassembly of the Terminals [66] [68], the Switch [53] and the

Internal Wires [54] [55].

Disconnect the Internal Wires [54] (red) and [55] (black), and the Terminals [66] (brown) and [68] (blue)

from the Switch [53] by melting their soldered connections with a soldering iron (350 ˚C, within 5

seconds). Take care not to apply too much heat because it can damage the variable-speed function of

the switch. Remove the two D4 Tapping Screws [65] from the Terminals [66] [68].

(6) Removal of the rubber seal

Pull out Rubber Seal (A) [63] gently from the Oil Seal [6] on the housing ass'y. Pull out Rubber Seal (B)

[64] by sliding with your fingers. Take care not to scratch the rubber seals to prevent grease leakage.

(7) Removal of the armature and the magnet

Hook the spring of Brush Holder (L) [59] and Brush Holder (R) [60] on the edge of each Brush Holder.

Then remove the Armature [28] and the Magnet [29] together.

(8) Removal of the brash holders

Remove the two D3 Tapping Screws [58] from both sides of Brush Holder (L) [59] and also Brush Holder

(R) [60] (four in total). Then Brush Holders can be removed.

(9) Replacement of the carbon brushes

Remove the Armature [28] and the Magnet [29] together according to the step (7). Pull out each

terminal of the Carbon Brushes [57] from the brush holder terminal with a small flat-blade screwdriver,

and then remove the Carbon Brushes by pulling them inward. Push each terminal of the new Carbon

Brushes in the Brush Holder as far as it will go. Be careful not to contact the spring of the Brush Holder

with the wire of the Carbon Brush (pay attention to inserting orientation of the Carbon Brush) or not to

hook the spring on the edge of the Brush Holder. Thus, the two Carbon Brushes can be replaced.

1-1-2. Reassembly

Reassembly can be generally be carried out as the reverse of the disassembly procedures, with some items

to be noted as follows:

(1) Be sure to perform wiring connection as indicated in Fig. 2.

(2) Pay attention to the polarity of the Terminal Piece [67], and the Internal Wires [54] and [55] when

mounting them to Housing (A). Be careful that the blue and brown Internal Wires cross at the midpoint.

(3) Insert the Armature [28] into the Magnet [29] facing its no-notch side inward. Be careful not to scratch

the Armature [28] because the magnet attracts the Armature [28].

(4) Position the Washer [43] between the wall of Housing (A) and the V-ring [42] when mounting the

Second Pinion [36] to the main body. Be careful not to position the Washer [43] between the wall of

Housing (A) and the First Gear [44].

--- 3 ---

Red

Upper side black

Lower side red

Upper side blue

Lower side brown

Upper side brown

Lower side blue

D4x14 Tapping Screw [32]

(2 pcs.)

Washer [43]

Detail drawing

V-ring [42]

Washer [43]

First Gear [44]

Wall of housing (A)

Switch [53]

Application silicon rubber (Three Bond 1211) ( Code No. 306927)

Fig. 2 Wiring arrangement and port locations

Fig. 3 Installation direction of various parts

First Gear [44]

Collar [41]

Press fit the First Gear [44]

so that their surfaces are

evenly aligned

The closed side of

Washer (C) [23] must

face forward

Forward

The shorter dimension L side

of the Second Hammer [16]

must face forward.

L

--- 4 ---

(5) When installing Washer (C) [23] and the Second Hammer [16], be very careful to ensure they are

installed in the proper direction. (See Fig. 3)

(6) When pressure fitting the First Gear [44], ensure that its surface is flush with the surface of the Second

Pinion [36]. At this time, also check to ensure that there is a slight clearance between the Collar [41]

and the First Gear [44] to allow the Collar to rotate. (See Fig. 3)

(7) During reassembly, coat JF-375 grease on the following places. Also insert 50 g of JF-375 (Code No.

930037) grease around the Reciprocating Bearing [40].

The gear teeth of the pinion on the motor, the gear teeth of the First Gear [44], the teen of the Second

Pinion [36], the sliding portions of the Clutch [38] and the Reciprocating Bearing [40], the outer

circumference of the Second Hammer [16], O-Ring (B) [17] mounted on the Second Hammer [16], the

outer circumference of the Piston [21], the outer circumference of the Striker [19], O-Ring (A) [20]

mounted on the Striker [19], the gear teeth and claw portions of the Second Gear [12], the inner

surface of the Metal [24], the lip portion of the Oil Seal [6], the outer circumference and hole portion of

the Piston Pin [22], the pin portion, thin portion and O-ring portion of the Change Lever [46], the outer

circumference of the groove on the Clutch [38], the inner surface of the Cylinder [11], and the O-Ring

[49]. Also, coat NPC SEP-3A when reassembling the Steel Balls [9], [10] and [48].

(8) When installing the two D4 x14 Tapping Screws [32], be very careful not to install the D4 x20 Tapping

Screws (W/Flange) [33] (black color) by mistake. Their positions are clearly designated in

Fig. 2.

(9) Tightening Torque

Tighten screws to the designated torque.

D3 x10 Tapping Screws [58]

••••••••••••••••••••••••••••

10.5 ---- 13.5 kgf•cm (1.03 ---- 1.32 N•m, 9 ---- 12 in•lbs)

D4 x10 Tapping Screws [65]

••••••••••••••••••••••••••••

15 ---- 25 kgf•cm (1.47 ---- 2.45 N•m, 13 ---- 22 in•lbs)

D4 x14 Tapping Screws [32]

••••••••••••••••••••••••••••

17 ---- 27 kgf•cm (1.67 ---- 2.65 N•m, 15 ---- 23 in•lbs)

D4 x20 Tapping Screws [33]

••••••••••••••••••••••••••••

20 ---- 30 kgf•cm (1.96 ---- 2.94 N•m, 17 ---- 26 in•lbs)

(10) On completion of reassembly, confirm without fail that the rotation direction conforms to the push-

button setting indications. When the push-button is set to the (R) side, the rotation direction must be

clockwise when viewed from the rear (handle) end of the tool.

1-2. Precautions on Disassembly and Reassembly of the Charger

Please refer to Technical Data and Service Manual for Model UC 24YF for precautions on disassembly and

reassembly.

--- 5 ---

2. STANDARD REPAIR TIME (UNIT) SCHEDULES

MODEL

Fixed

10 20 30 40 50 60 min.

Variable

DH 20DV

Oil Seal

Ball Bearing

(6904CM)

Steel Ball x4

Second Gear

Spring (A)

Washer (A)

O-ring (D)

Second Hammer

Cylinder

Piston

Striker

Piston Pin

Washer (C)

Metal

Ball Bearing

(626VV) x2

Second Pinion

Clutch Spring

Clutch

O-ring

Reciprocating

Bearing

Collar

First Gear

Washer (B)

x

2

Housing

(A) (B) Set

Armature DC

Magnet

Switch

Rubber Seal (A)

Rubber Seal (B)

Change Lever

Spring (H)

Steel Ball

O-Ring

Carbon Brush

x

2

Brush Holder

x

2

Slide Lever

Spring

Plate

Front Cap

Grip

Retaining Ring

Work Flow

General Assembly

Loading...

Loading...