Page 1

|

Modo, CS33ET c,.i°s..

ModUle Tron£onneuse

Modelo CS33EA Motosierrar

I

CS33ET

(

SAFETY iNSTRUCTiONS AND iNSTRUCTiON MANUAL

;_\ WA,, RNING

iMPROPER OR UNSAFE use of this power tool can result in death or serious bodily

injury!

This manual contains important information about product safety. Please read and

understand this manual BEFORE operating the power tool. Please keep this manual

available for other users and owners before they use the power tool. This manual should

be stored in safe place.

NSTRUCTIONS DE SECURITE ET MODE D'EMPLOI

_!\ AVERTISSEMENT

Une utilJsation INCORRECTE OU DANGEREUSE de cet outil motorise peut entrainer la

mort ou de serieuses blessures corporelles!

Ce mode d'emploi contient d'importantes informations & propos de la securit6 de ce

produit. Priere de life et de comprendre ce mode d'emploi AVANT d'utiliser I'outil

motorise. Garder ce mode d'emploi & la disponibilite des autres utilisateurs et proprietaires

avant qu'ils utilisent I'outil motorise. Ce mode d'emploi dolt 6tre conserve dans un

endroit sQr.

INSTRUCCl0NESDESEGURIDADYMANUALDEINSTRUCCl0NES

:!: ADVERTENClA

iLa utilizaci6n INAPROPIADA O PEUGROSA de esta herramienta electrica puede

resultar en lesiones de gravedad o la muerte!

Este manual contiene informaci6n importante sobre la seguridad del producto. Lea y

comprenda este manual ANTES de utilizar la herramienta electrica. Guarde este manual

para que puedan leerlo otras personas antes de utilizar la herramienta electrica. Este

manual debe ser guardado en un lugar seguro.

Hitachi Koki

970-82950-200 2010.2

Page 2

English j

Meanings of symbols

NOTE! Some units do not carry them.

symboms

_WARNmNG

The following show symbols used for the machine. Be sure

4\\

\

It is important that you read, fully understand and observe the following safety precautions and

warnings. Careless or improper use of the unit may cause serious or fatal injury.

Read, understand and follow all warnings and instructions in this manual and on the unit.

that you understand their meaning before use.

@

Always wear eye, head and ear protectors when using this unit.

Warning, kickback danger. Be careful sudden and accidental upward and/or backward mo-tion

of the guide bar.

One-handed usage not permitted. While cutting, hold saw firmly with both hands with thumb

firmly locked around front handle.

Before using your machine

• Read the manual carefully.

,, Check that the cutting equipment is correctly assembled and adjusted.

,, Start the unit and check the carburetor adjustment. See "Maintenance".

Contents

What is what? ............................................................... 2

Warnings and safety instructions .................................. 3

Specifications ................................................................ 5

Assembly procedures .................................................... 6

Operating procedures ................................................... 7

Maintenance .................................................................. 11

Parts breakdown ........................................................... 45

Page 3

English

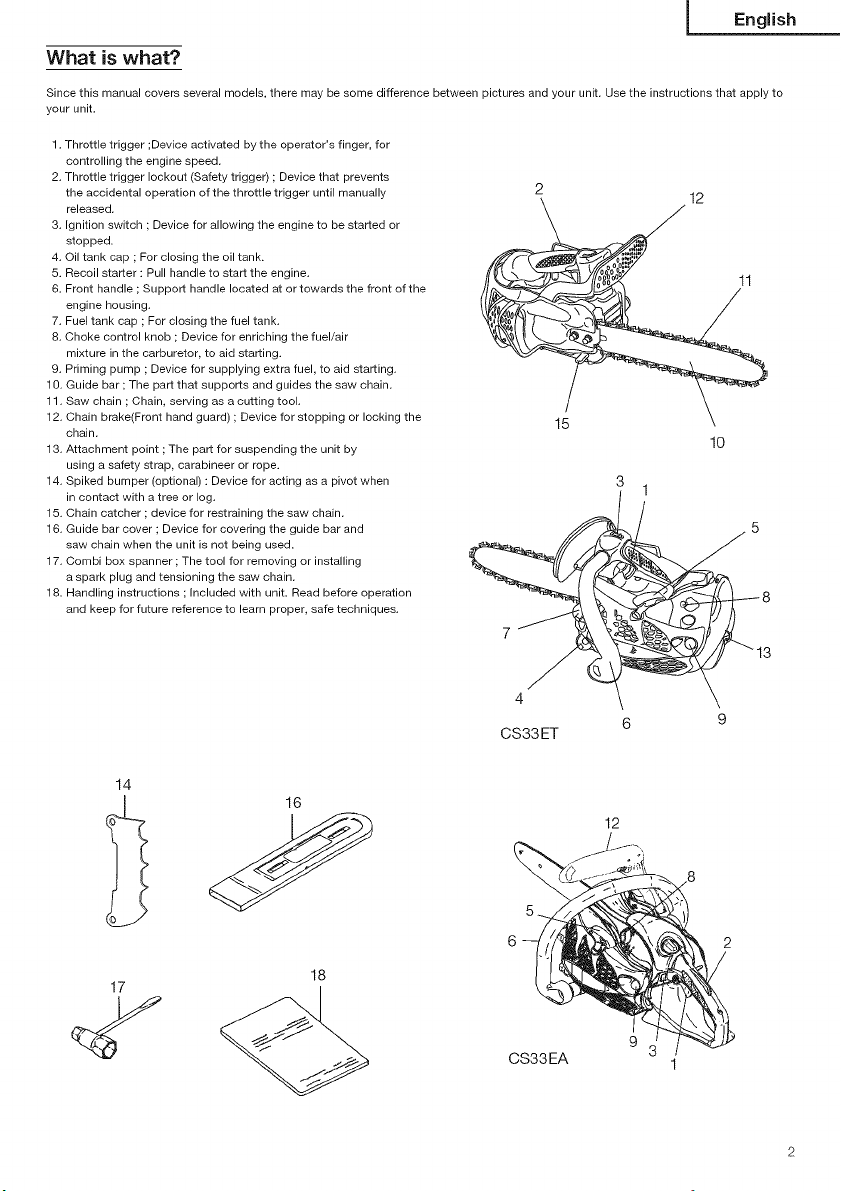

What is what?

Since this manual covers several models, there may be some difference between pictures and your unit. Use the instructions that apply to

your unit.

1. Throttle trigger ;Device activated by the operator's finger, for

controlling the engine speed.

2. Throttle trigger lockout (Safety trigger) ; Device that prevents

the accidental operation of the throttle trigger until manually

released.

3. Ignition switch ; Device for allowing the engine to be started or

stopped.

4. Oil tank cap ; For closing the oil tank.

5. Recoil starter : Pull handle to start the engine.

6. Front handle ; Support handle located at or towards the front of the

engine housing.

7. Fuel tank cap ; For closing the fuel tank.

8. Choke control knob ; Device for enriching the fuel/air

mixture in the carburetor, to aid starting.

9. Priming pump ; Device for supplying extra fuel, to aid starting.

10. Guide bar ;The part that supports and guides the saw chain.

11. Saw chain ; Chain, serving as a cutting tool.

12. Chain brake(Front hand guard) ; Device for stopping or locking the

chain.

13. Attachment point ; The part for suspending the unit by

using a safety strap, carabineer or rope.

14. Spiked bumper (optional) : Device for acting as a pivot when

in contact with a tree or log.

15. Chain catcher ; device for restraining the saw chain.

16. Guide bar cover ; Device for covering the guide bar and

saw chain when the unit is not being used.

17. Combi box spanner ; The tool for removing or installing

a spark plug and tensioning the saw chain.

18. Handling instructions ; Included with unit. Read before operation

and keep for future reference to learn proper, safe techniques.

2

12

J 11

15

10

3

1

(/ 8

7

3

4

CS33ET

6 9

14

12

17

18

9

CS33EA

Page 4

English I

Warnings and safety instructions

Operator safety

/_ WARNING!

This chain saw (CS33ET) is designed especially for tree care

and surgery. Only persons trained in tree care and surgery

may use this saw. Observe all literature, procedures and

recommendations from the relevant professional organization.

Failure to do so constitutes a high accident risk. We

recommend always using a rising platform for sawing in trees.

Rappelling techniques are extremely dangerous and require

special training. The operator must be trained in and familiar

with the use of safety equipment and working and climbing

techniques. Always use the restraining equipment for both the

operator and the saw.

Always wear a safety face shield or goggles.

Always use the gloves to reduce the effects of vibration.

Gloves should be used when sharpening chain.

Always wear safety protective equipment such as jacket,

trousers, gloves, helmet, boots with steel toe-caps and non-slip

soles whenever you use a chain saw. For working in trees the

safety boots must be suitable for climbing techniques. Do not

wear loose clothing, jewelry, short pants, sandals or go barefoot.

Secure hair so it is above shoulder length.

Do not operate this tool when you are tired, ill or under the

influence of alcohol, drugs or medication.

Never let a child or inexperienced person operate the machine.

Wear hearing protection. Pay attention to your surroundings.

Be aware of any bystanders who may be signaling a problem.

Remove safety equipment immediately upon shutting off engine.

Wear head protection.

Never start or run the engine inside a closed room or building.

Breathing exhaust fumes can kill.

For respiratory protection, wear a protection mask while emitting

the chain oil mist and dust from sawdust.

Keep handles free ofoil and fuel.

Keep hands away from cutting equipment.

Do not grab or hold the unit by the cutting equipment.

When the unit is turned off, make sure the cutting attachment has

stopped before the unit is set down.

When operation is prolonged, take a break from time to time so

that you may avoid possible whitefinger disease which is caused

by vibration.

The operator must obey the local regulations of cutting area.

_ WARNING!

Antivibration systems do not guarantee that you will not

sustain whitefinger disease or carpal tunnel syndrome.

Therefore, continual and regular users should monitor closely

the condition of their hands and fingers, if any of the above

symptoms appear, seek medical advice immediately.

/!_ WARNING!

Long or continuous exposure to high noise levels may cause

permanent hearing impairment. Always wear approved hearing

protection when operating a unit/machine.

/_ WARNING !

if you are using any medical electric/electronic devices such

as a pacemaker, consult your physician as well as the device

manufacturer prior to operating any power equipment.

Unit / machine safety

Inspect the entire unit/machine before each use. Replace

damaged parts. Check for fuel leaks and make sure all fasteners

are in place and securely tightened.

Replace parts that are cracked, chipped or damaged in any way

before using the unit/machine.

Make sure the side case is properly attached.

Keep others away when making carburetor adjustments.

Use only accessories as recommended for this unit/machine by

the manufacturer.

Never let the chain strike any obstacle. Ifthe chain makes

contact, the machine should be stopped and checked carefully.

Make sure the automatic oiler is working.Keep the oil tank filled

with clean oil. Never let chain run dry on the bar.

All chainsaw service, other than the items listed in the operator's/

owner's manual, should be performed by competent chain-saw

service personnel. (For example, if improper tools are used to

remove the flywheel or if an improper tool is used to hold the

flywheel in order to remove the clutch, structural damage to the

flywheel could occur and could subsequently cause the flywheel

to burst.)

_\ WARNING!

Never modify the unit/machine in any way. Do not use your

unit/machine for any job except that for which it is intended.

_ WARNING!

Never use chain saw without any safety equipment or that

has faulty safety equipment, it could result in serious personal

injury.

WARNING!

Using guide bar/chain other than recommended by the

manufacturer which are not approved, could result in a high

risk of personal accidents or injury.

Fuel safety

Mix and pour fuel outdoors and where there are no sparks or

flames.

Use a container approved for fuel.

Do not smoke or allow smoking near fuel or the unit/machine or

while using the unit/machine.

Wipe up all fuel spills before starting engine.

Move at least 10ft (3m) away from fueling site before starting

engine.

Stop engine before removing fuel cap.

Empty the fuel tank before storing the unit/machine. It is

recommended that the fuel be emptied after each use. If fuel is

left in the tank, store so fuel will not leak.

Store unit/machine and fuel in area where fuel vapors cannot

reach sparks or open flames from water heaters, electric motors

or switches, furnaces, etc.

_\ WARNING ]

Fuel is easy to ignite or get explosion or inhale fumes, so that

pay special attention when handling or filling fuel

Page 5

Cuttingsafety

Donotcutanymaterialotherthanwoodorwoodenobjects.

Forrespiratoryprotection,wearanaerosolprotectionmaskwhen

cuttingthewoodafterinsecticidehasbeenapplied.

Keepothersincludingchildren,animals,bystandersandhelpers

outsidethehazardzone,Stoptheengineimmediatelyifyouare

approached.

Holdtheunit/machinefirmlywiththerighthandontherear

handleandthelefthandonthefronthandle.

Keepfirmfootingandbalance.Donotover-reach.

Keepallpartsofyourbodyawayfromthemufflerandcutting

attachmentwhentheengineisrunning.

KeepBar/Chainbelowwaistlevel.

Beforefellingatree,theoperatormustbeaccustomedtothe

sawingtechniquesofthechainsaw.

Besuretopre-planasafeexitfromafailingtree.

Whilecutting,holdsawfirmlywithbothhandswiththumbfirmly

lockedaroundfronthandle,andstandwithfeetwellbalanced

andyourbodybalanced.

Standtothesideofthesawwhencuttingneverdirectlybehindit.

Alwayskeepthespikedbumperfacetoatree,becausethechain

maysuddenlybedrawnintoatree.

Whencompletingacut,bereadytoholduptheunitsasitbreaks

intoclear,soitwillnotfollowthroughandcutyourlegs,feetor

body,orcontactanobstruction.

Bealertagainstkickback(whensawkicksupandbackat

operator).Nevercutwiththenoseofthebar.

Whenrelocatingtoanewworkarea,besuretoshutoffthe

machineandensurethatallcuttingattachmentsarestopped.

Neverplacethemachineonthegroundwhenrunning.

Alwaysensurethattheengineisshutoffandanycutting

attachmentshavecompletelystoppedbeforeclearingdebrisor

removinggrassfromthecuttingattachment.

Alwayscarryafirst-aidkitwhenoperatinganypowerequipment.

Neverstartorruntheengineinsideaclosedroomorbuilding

and/orneartheinflammableliquid.Breathingexhaustfumescan

kill.

I English

Transport and storage

* Carry the uniVmachine by hand with the engine stepped and the

muffler away from your body.

Allow the engine to cool, empty the fuel tank, and secure the unit/

machine before storing or transporting in avehicle.

Empty the fuel tank before storing the unit/machine, it is

recommended that the fuel be emptied after each use. If fuel is

left in the tank, store so fuel will not leak.

Store unit/machine out of the reach of children.

Clean and maintenance the unit carefully and store it in a dry

place.

Make sure engine switch is off when transporting or storing.

When transporting in a vehicle or storage, cover chain with chain

cover.

if situations occur which are not covered in this manual, take care

and use common sense. Contact HiTACHi dealer if you need

assistance. Pay special attention to statements preceded by the

following words:

/1\ WARNING!

indicates a strong possibility of severe personal injury or loss

of life, if instructions are not followed,

CAUTION!

Indicates a possibility of personal injury or equipment damage, if

instructions are not followed.

NOTE!

Helpful information for correct function and use.

Maintenance safety

Maintain the unit/machine according to recommended

procedures.

Disconnect the spark plug before performing maintenance except

for carburetor adjustments.

Keep others away when making carburetor adjustments.

Use only genuine HITACHI replacement parts as recommended

by the manufacturer.

CAUTION!

Do not disassemble the recoil starter on. You may get a possibility

of personal injury with recoil spring.

WARNING!

improper maintenance could result in serious engine damage

or in serious personal injury,

Page 6

English j

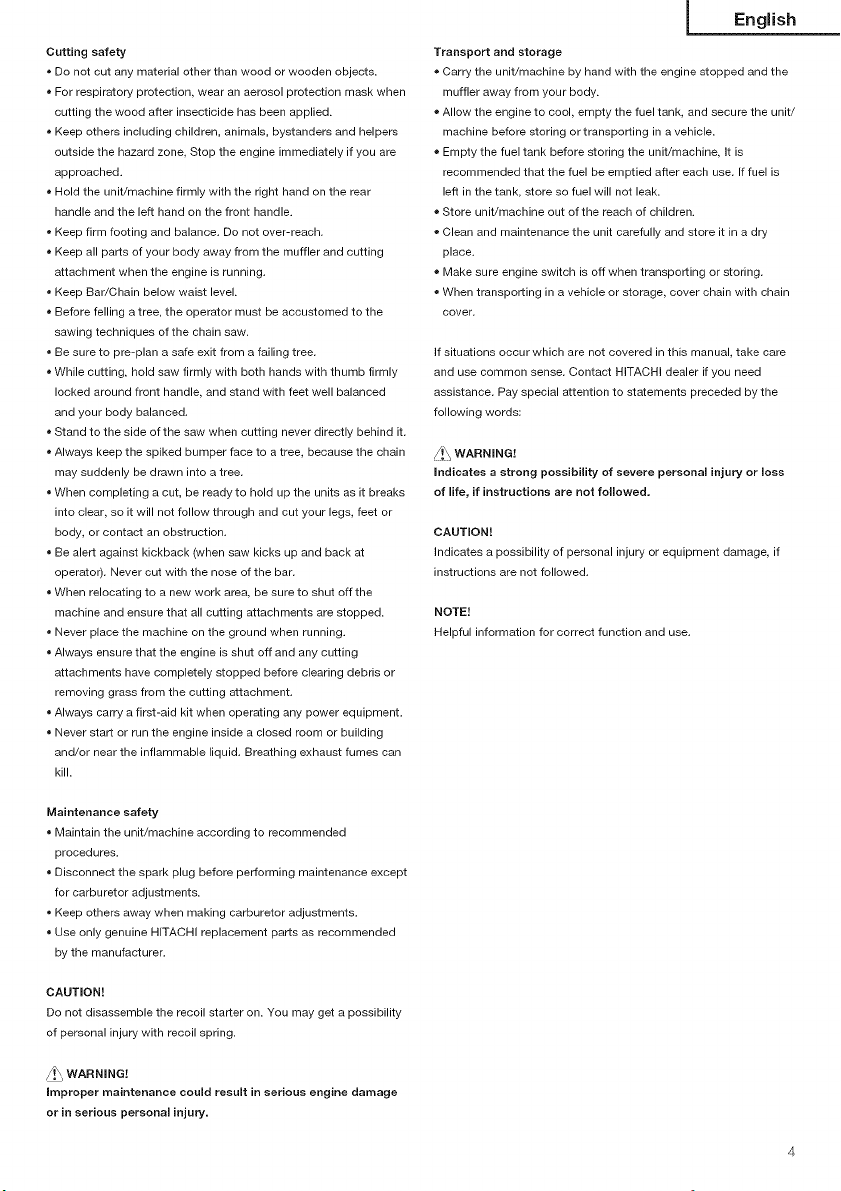

Specifications

...........................

"i_jpe of equipment Chain saw, portable

MODEL CS33ET CS33EA

Engine Size (cu. in) 1.96 (32.2mQ)

Spark Plug NGK BPM-6A or equivalent

FuelTank Capacity (pt) (300m_)

oo_o Chain Oil Tank Capacity (pt) 0.40 (190mQ)

Dry Weight (Ibs) 9.0 9.2

(Without guide bar and chain)

_ Guide bar length (in) 12 (30Omm) _ 14 (350mm)

Chain pitch (in) 3/8 (9.52mm)

Chain gauge (in) 0.05 (1.27mm)

Sound pressure level

LpA (dB(A)) 97.7 98.1

by ISO22868

Sound power level

Lw measured (dB(A))

by ISO22868

@

Sound power level LwA (dB(A))

by 2000/14/EC

Vibration level (m/s 2)

by ISO22867

Front handle

Rear handle

Max. engine power

by ISO 7293(kW)

e_ Max. engine speed (min _) 12000

rpr_AX

e_ Idle engine speed (min _) 3000

rpr_lN

Specific fuel consumption (g/kWh) 575

@:o

Type of guide bar O

(4.1 kg) (4.2kg)

111 109

4.0 3.6

6.0 4.4

0.64

112

1.2/8500

Type of chain (Oregon)

_ Max. chain speed (m/sec)

(_ Sprocket (number of teeth)

NOTE : Equivalent noise level/vibration levels are calculated as the time-weighted energy total for noise/vibration levels under various

working conditions with the following time distribution: 1/3 idle, 1/3 full, 1/3 racing speed.

* All data subject to change without notice.

5

91 VG

22.9

6

Page 7

Assembly procedures

/i\ WARNING!

Never try to start engine without side case securely fastened.

1. Remove chain bar clamp nuts (1).

2. Remove the side case (2) as pinching the rear part of the side

case (2) ,(Fig. 1)

00

D

English

5. Guide the chain drive links into the bar groove all around the bar.

6. Install the side case (2) onto the guide bar clamp bolts on the

engine case.

Then fix the clamp nuts temporarily. (Fig. 1)

7. Raise the bar end, and tighten the chain (10) by turning the

tension adjustment bolt (11) clockwise. To check proper tension,

lightly lift up the center of chain and there should be about

O.O2~O.O4in (O.5.-1.Omm) clearance between bar and edge of

drive link (12). (Fig. 5, 6)

Fig. 1

* In case of installing the spiked bumper (3), remove the guide

plate A (4) first and install the spiked bumper (3) (if so equipped)

to the unit with two screws, and then install the guide plate A (4)

in place. (Fig.2)

Fig. 2

3. install, the chain bar (5) onto the bolts (6), then push it toward

the sprocket (7) as far as it will go. Make sure that the boss of

chain tension adjust bolt (8) fits into the hole of the bar (9). (Fig. 3)

NOTE!

Slightly move the bar back and forth and make sure the chain

tension boss (8) fits into the hole (9) in the bar properly. (Fig. 3)

4. Confirm the direction of saw chain (10) is correct as in the figure,

and align the chain on the sprocket. (Fig. 4)

7 5

9 6

Fig. 3

11 10

ram)

Fig. 5

Fig. 6

CAUTION!

PROPERTENSION IS EXTREMELY IMPORTANT!

8. Raise the bar end and securely tighten the chain bar clamp nuts

with the combi box spanner. (Fig. g)

9. A new chain will stretch so adjust the chain after a few cuts and

watch chain tension carefully for the first half hour of cutting.

NOTE!

Check the chain tension frequently for optimum performance and

durability.

CAUTION!

When the chain is excessively tightened, the bar and chain will

be damaged rapidly. Conversely, when the chain is excessively

loosened, it may get out of the groove inthe bar.

Always wear gloves when touching the chain.

Fig. 4

/_ WARNING!

During operation, hold chain saw firmly with both hands, A

single hand operation may cause serious injury.

Page 8

English j

Operating procedures

Fuel (Fig. 7)

A_B

Fig. 7

/_\ WARNING!

= The chain saw is equipped with a two-stroke engine. Always

run the engine on fuel, which is mixed with oil. Provide good

ventilation, when fueling or handling fuel

* Fuel contains highly flammable and it is possible to get the

serious personal injury when inhaling or spilling on your body.

Always pay attention when handling fuel. Always have good

ventilation when handling fuel inside building.

Fuel

* Always use branded 89 octane unleaded gasoline.

* Use genuine two-cycle oil or use a mix between 25:1 to 50:1,

please consult the oil bottle for the ratio or HITACHI dealer.

Only for the state of California at 50:1.

If genuine oil is not available, use an anti-oxidant added quality

oil expressly labeled for air-cooled 2-cycle engine use(JASO FC

GRADE OiL or ISO EGC GRADE). Do not use BIA orTCW (2-stroke

water-cooling type) mixed oil.

Never use multi-grade oil (10 W/30) or waste oil.

Always mix fuel and oil in a separate clean container.

Always start by filling half the amount of fuel, which is to be used.

Then add the whole amount of oil. Mix (shake) the fuel mixture. Add

the remaining amount of fuel.

Mix (shake) the fuel-mix thoroughly before filling the fuel tank.

Fueling

J!\_WARNING! (Fig. 8)

= Always shut off the engine before refueling.

* Slowly open the fuel tank (13), when filling up with fuel, so

that possible overpressure disappears.

* Tighten the fuel cap carefully, after fueling.

* Always move the unit at least 10ft (3m) from the fueling area

before starting.

* Always Wash any spilled fuel from clothing immediately with

soap.

= Be sure to check any fuel leaking after refueling.

13 1478_-_

NOTE!

When pouring fuel (13) or chain oil (14) into the tank, place the unit

with cap side up. (Fig. 8)

ADJUSTMENT OF CHAIN OIL SUPPLY

The chain oil quantity discharged through the lubrication system is

factory adjusted to the maximum. Adjust the quantity in accordance

with the operating condition.

Turn the adjusting screw (15) counter-clockwise to increase the

quantity and turn it clockwise to decrease the quantity. (Fig. 9)

(standard setting turns counter-clockwise 1-1 1/2 from slightly

seated)

15

®

Fig. 9

Starting (Fig. 10, 11)

/_._WARNING]

When the engine starts with the throttle lock engaged, the

engine speed is high enough to make the chain rotate.

CAUTION!

Before starting, make sure the chain brake is engaged (if so

equipped) and that the bar/chain does not touch anything.

1. Set ignition switch (16) to ON position.

*Push priming bulb (18) several times so that fuel flows through

bulb into carburetor. (If so equipped) (Fig. 10)

ON 17

_- _18

Fig. 10

2. Push the choke lever (17) down to choked position. This will

automatically lock the throttle in starting position. (Fig. 10)

3. Pull recoil starter briskly, taking care to keep the handle in your

grasp and not allowing it to snap back. (Fig. 10)

4. When you hear the engine want to start, with the safety trigger (19)

pressed pull throttle trigger (20). This will release the throttle from

starting position to ran position and will automatically return the

choke lever to run position. (Fig.10, 11)

Fig. 8

Before fueling, clean the tank cap area carefully, to ensure that

no dirt falls into the tank. Make sure that the fuel is well mixed by

shaking the container, before fueling.

Chain oil (Fig. 8)

Fill up with chain oil (14). Always use good quality chain oil. When

the engine is running, the chain oil is automatically discharged.

20 1_

Fig. 11

Page 9

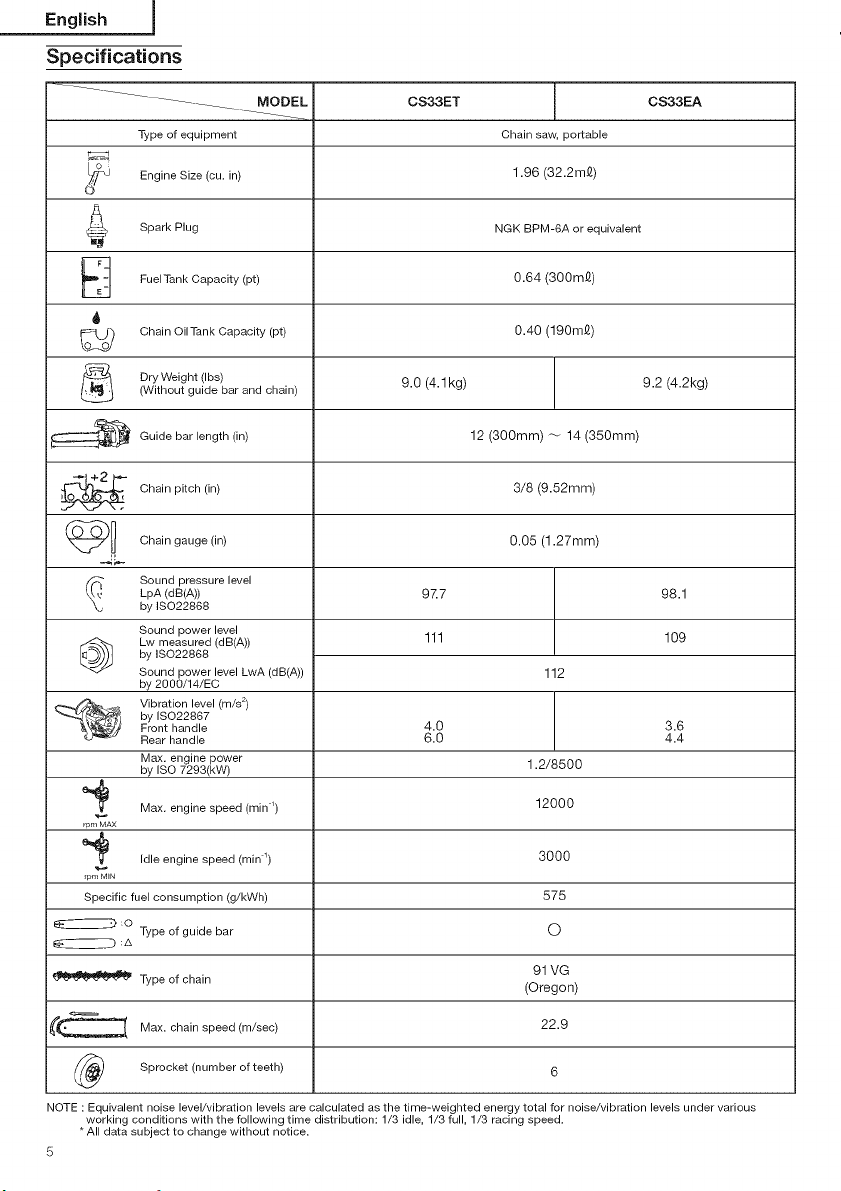

5.Pullrecoilstarterbrisklyagainintheaforementionedmanner.

(Fig.12)

Afterenginestarts,makesurethechainbrakeisdisengaged.

English

Stopping (Fig. 14)

Decrease engine speed, and push ignition switch to stop position.

STO_)_

Fig.12

NOTE!

ifenginedoesnotstart,repeatproceduresfrom2to5.

6.Afterstartingengine,pullthrottletriggertoreleasethrottlelock.

Thenallowtheengineabout2-3minutestowarmupbefore

subjectingittoanyload.

Chain brake operation (Fig, 13)

Chain brake (21) (If so equipped) is designed to activate in an

emergency such as kickback action. Please check to verify that it

works properly before use.

Application of brake is made by moving the front guard towards the

bar. During the chain brake operation, even if the throttle lever is

pulled, the engine speed does not increase

and the chain does not turn. To release the brake, pull up the chain

brake lever.

Re\e_,_

Fig. 13

How to confirm:

1)Turn off the engine.

2) Holding the chain saw horizontally, release your hand from the

front handle, hit the tip of the guide bar to a stump or a piece of

wood, and confirm brake operation. Operating level varies by

bar size.

in case the brake is not effective, ask our dealer for inspection and

repairs, if the engine keeps rotating at high speed with the brake

engaged, the clutch will overheat causing trouble.

When the brake engages during operation, immediately release the

throttle lever to stop the engine.

_.\ WARNING!

Do not carry the machine with the engine running,

O_q

CS33ET

7,

CS33EA

Fig. 14

_ WARNING!

KICKBACK DANGER (Fig, 15)

Fig. 15

One of the most severe dangers when working with a chain saw

is the possibility of kickback. Kickback may occur when the upper

tip of the guide bar touches an object, or when the wood closes

in and pinches the saw chain in the cut.Tip contact in some cases

may cause a lightning fast reverse reaction, kicking the guide bar

up and back toward you. Pinching the saw chain along the top of

the guide bar may also push the guide bar rapidly back towards

you. Either of these reactions may cause you to lose control of the

saw which could result in serious personal injury. Even though your

saw has safety built into its design, you should not rely on these

safety features exclusively. Know where your bar tip is at all times.

Kickback does occur if you allow the kickback zone (22) of the bar

totouch an object. Do not use that area. Kickback from pinching is

caused by a cut closing and pinching the upper side of the guide

bar. Study your cut and make sure it will open as you cut through.

Maintain control when the engine is running by always keeping a

firm grip on the saw with your right hand on the rear handle, your

left hand on the front handle and your thumbs and fingers encircling

the handles. Always hold the saw with both hands during operation

and cut at high engine speed.

/t\ WARNING!

Do not overreach or cut above shoulder height,

/!_ WARNING!

Use extra caution when felling, and do not use the saw in a

nose-high position or above shoulder height,

Page 10

English j

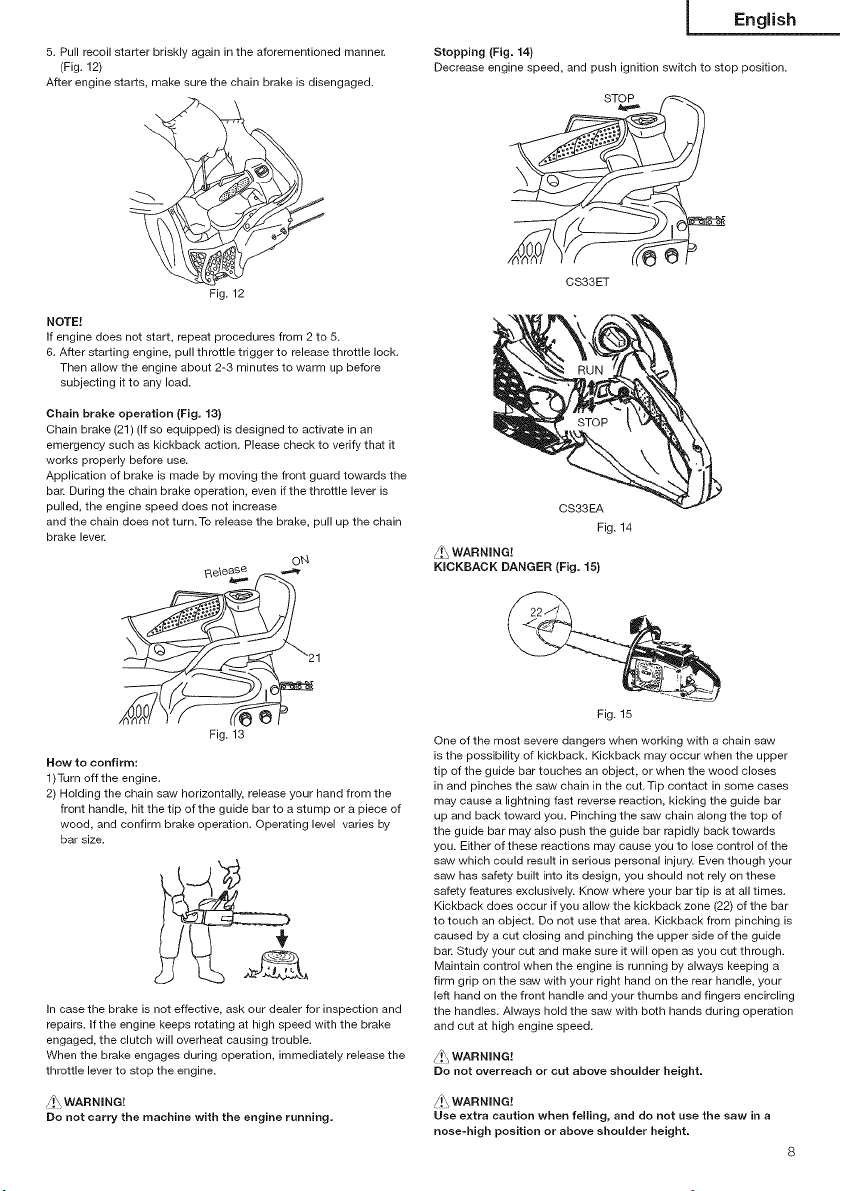

CHAIN CATCHER

The chain catcher is located on the power head just below the

chain to further prevent the possibility of a broken chain striking the

chainsaw user.

/._, WARNING!

Do not stand in-line with chain when cutting.

BASICTECHNIQUES FOR MAKING FELLING, MMBING AND

BUCKING CUTS

The intention of the following information is to provide you with the

general introduction to wood cutting techniques.

/_\ WARNING!

This information does not cover all specific situations, which

may depend on differences in terrain, vegetation, kind of wood,

form and size of trees, etc. Consult your servicing dealer,

forestry agent or local forestry schools for advice on

specific woodeutting problems in your area,This will make your

work more efficient and safer.

/I._ WARNING!

Avoid cutting Jn adverse weather conditions, such as dense

fog, heavy rain, bitter cold, high winds, etc.

Adverse weather is often tiring to work Jn and creates

potentially dangerous conditions such as slippery ground.

High winds may force the tree to fall in an unexpected direction

causing property damage or personal injury.

CAUTION!

Never use a chainsaw to pry or for any purpose for which it is not

intended.

/g._WARNING!

Avoid stumbling on obstacles such as stumps, roots, rocks,

branches and fallen trees. Watch out for holes and ditches. Be

extremely cautious when working on slopes or uneven ground.

Shut off the saw when moving from one work place to another.

Always cut at wide open throttle. A slow moving chain can

easily catch and force the saw to jerk.

Never use the saw with only one hand.

You cannot control the saw properly and you may lose control

and injure yourself severely.

Keep the saw body close to your body to improve control and

reduce strain.

When cutting with the bottom part of the chain the reactive

force will pull the saw away from you towards the wood you

are cutting.

The saw will control the feeding speed and sawdust will be

directed towards you. (Fig. 16)

When cutting with the upper part of the chain the reactive force

will push the saw towards you and away from the wood you are

cutting. (Fig. 17)

Fig. 17

/t\ WARNING!

There is a risk of kickback if the saw is pushed far enough so

that you begin to cut with the nose of the bar.

The safest cutting method is to cut with the bottom part of the

chain. Sawing with the upper part makes it much more difficult

to control the saw and increases the risk of kickback.

NOTE!

Always keep the spiked bumper face to a tree, because the chain

may suddenly be drawn into a tree.

FELLING

Felling is more than cutting down atree.You must also bring it

down as near to an intended place as possible without damaging

the tree or anything else.

Before felling a tree, carefully consider all conditions which may

effect the intended direction, such as:

Angle of the tree. Shape of the crown. Snow load on the crown.

Wind conditions. Obstacles within tree range (e.g., other trees,

power lines, roads, buildings, etc.).

/!\WARNING!

Always observe the general conditions of the tree. Look for

decay and rot in the trunk which will make it more likely to snap

and start to fall before you expect it.

Look for dry branches, which may break and hit you when you

are working,

Always keep animals and people at least twice the tree length

away while felEng, Clear away shrubs and branches from

around the tree.

Prepare a path of retreat away from the felling direction.

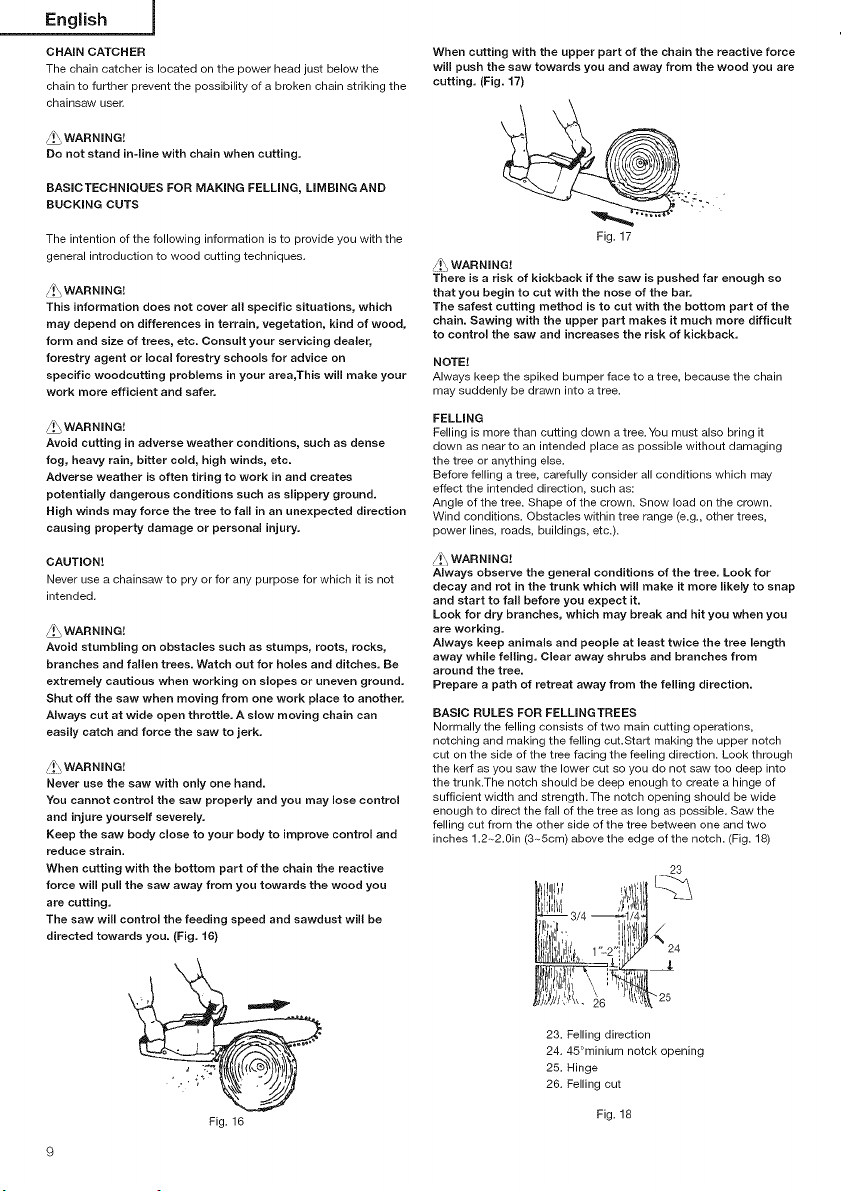

BASIC RULES FOR FELMNGTREES

Normally the felling consists of two main cutting operations,

notching and making the felling cut.Start making the upper notch

cut on the side of the tree facing the feeling direction. Look through

the kerf as you saw the lower cut so you do not saw too deep into

the trunk.The notch should be deep enough to create a hinge of

sufficient width and strength. The notch opening should be wide

enough to direct the fall of the tree as long as possible. Saw the

felling cut from the other side of the tree between one and two

inches 1.2~2.0in (3._5cm) above the edge of the notch. (Fig. 18)

23

Fig. 16

23. Felling direction

24.45°minium notck opening

25. Hinge

26. Felling cut

Fig. 18

Page 11

Neversawcompletelythroughthetrunk.Alwaysleaveahinge.

Thehingeguidesthetree.ifthetrunkiscompletelycutthrough,

youlosecontroloverthefellingdirection.

insertawedgeorafellingleverinthecutwellbeforethetree

becomesunstableandstartstomove.Thiswillpreventtheguide

barfrombindinginthefellingcutifyouhavemisjudgedthefalling

direction.Makesurenopeoplehavecomeintotherangeofthe

fallingtreebeforeyoupushitover.

FELLING CUT, TRUNK DIAMETER MORE THAN TWICE GUIDE

BAR LENGTH

Cut a large, wide notch.Then cut a recess into the center of the

notch. Always leave a hinge on both sides of the center cut.

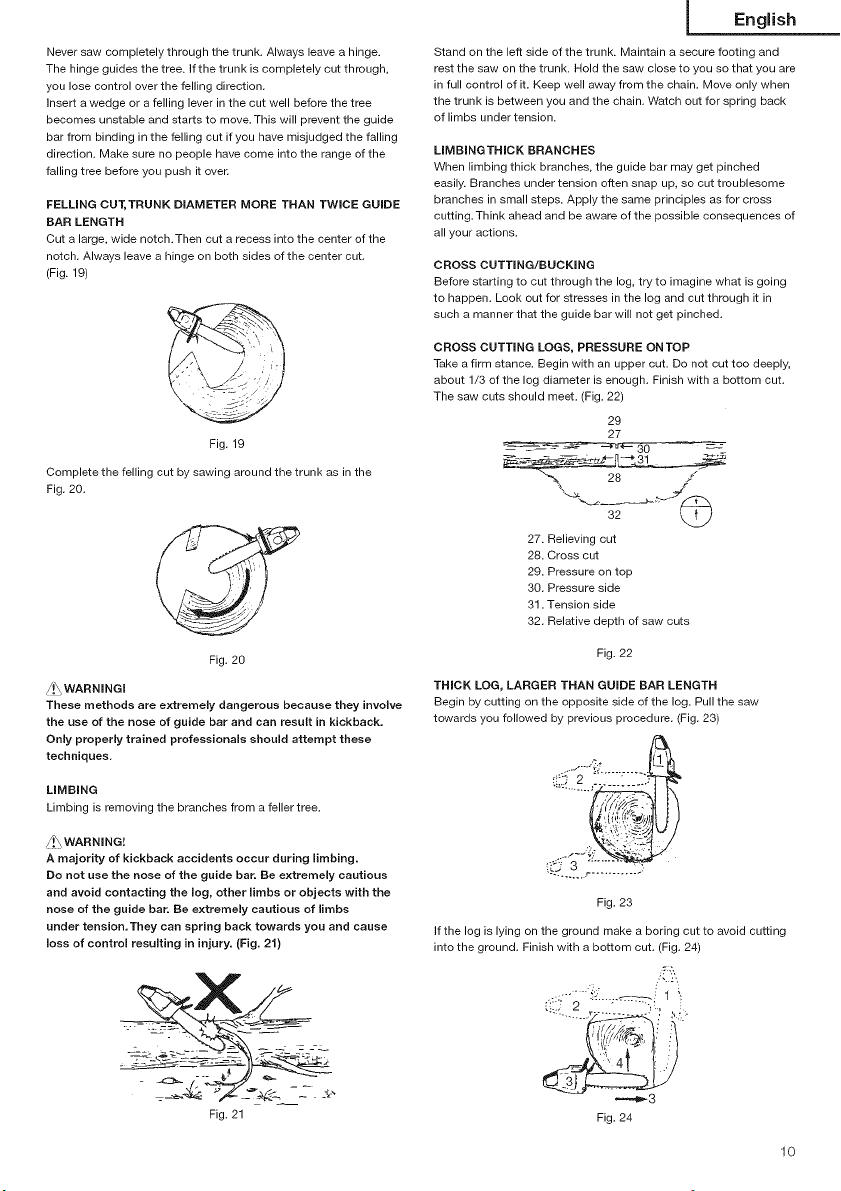

(Fig. 19)

Fig. 19

Complete the felling cut by sawing around the trunk as in the

Fig. 20.

Fig. 20

/!\ WARNINGI

These methods are extremely dangerous because they involve

the use of the nose of guide bar and can result in kickback.

Only properly trained professionals should attempt these

techniques.

LIMBING

Limbing is removing the branches from a feller tree.

A\WARNING!

A majority of kickback accidents occur during iimbing.

Do not use the nose of the guide bar. Be extremely cautious

and avoid contacting the log, other limbs or objects with the

nose of the guide bar. Be extremely cautious of limbs

under tension,They can spring back towards you and cause

loss of control resulting in injury. (Fig. 21)

English

Stand on the left side of the trunk. Maintain a secure footing and

rest the saw on the trunk. Hold the saw close to you so that you are

in full control of it. Keep well away from the chain. Move only when

the trunk is between you and the chain. Watch out for spring back

of limbs under tension.

LIMBINGTHICK BRANCHES

When limbing thick branches, the guide bar may get pinched

easily. Branches under tension often snap up, so cut troublesome

branches in small steps. Apply the same principles as for cross

cutting.Think ahead and be aware of the possible consequences of

all your actions.

CROSS CUTTING/BUCKING

Before starting to cut through the log, try to imagine what is going

to happen. Look out for stresses in the log and cut through it in

such a manner that the guide bar will not get pinched.

CROSS CUTTING LOGS, PRESSURE ONTOP

Take a firm stance. Begin with an upper cut. Do not cut too deeply,

about 1/3 of the log diameter is enough. Finish with a bottom cut.

The saw cuts should meet. (Fig. 22)

29

27

32 LLJ

27. Relieving cut

28. Cross cut

29. Pressure on top

30. Pressure side

31. Tension side

32. Relative depth of saw cuts

Fig. 22

THICK LOG, LARGER THAN GUIDE BAR LENGTH

Begin by cutting on the opposite side of the log. Pull the saw

towards you followed by previous procedure. (Fig. 23)

Fig. 23

if the log is lying on the ground make a boring cut to avoid cutting

into the ground. Finish with a bottom cut. (Fig. 24)

/:-,,

:,. :,.

(:i:.:/-2 :_":'_J 1 _

Fig. 21

=='=_3

Fig. 24

1o

Page 12

English j

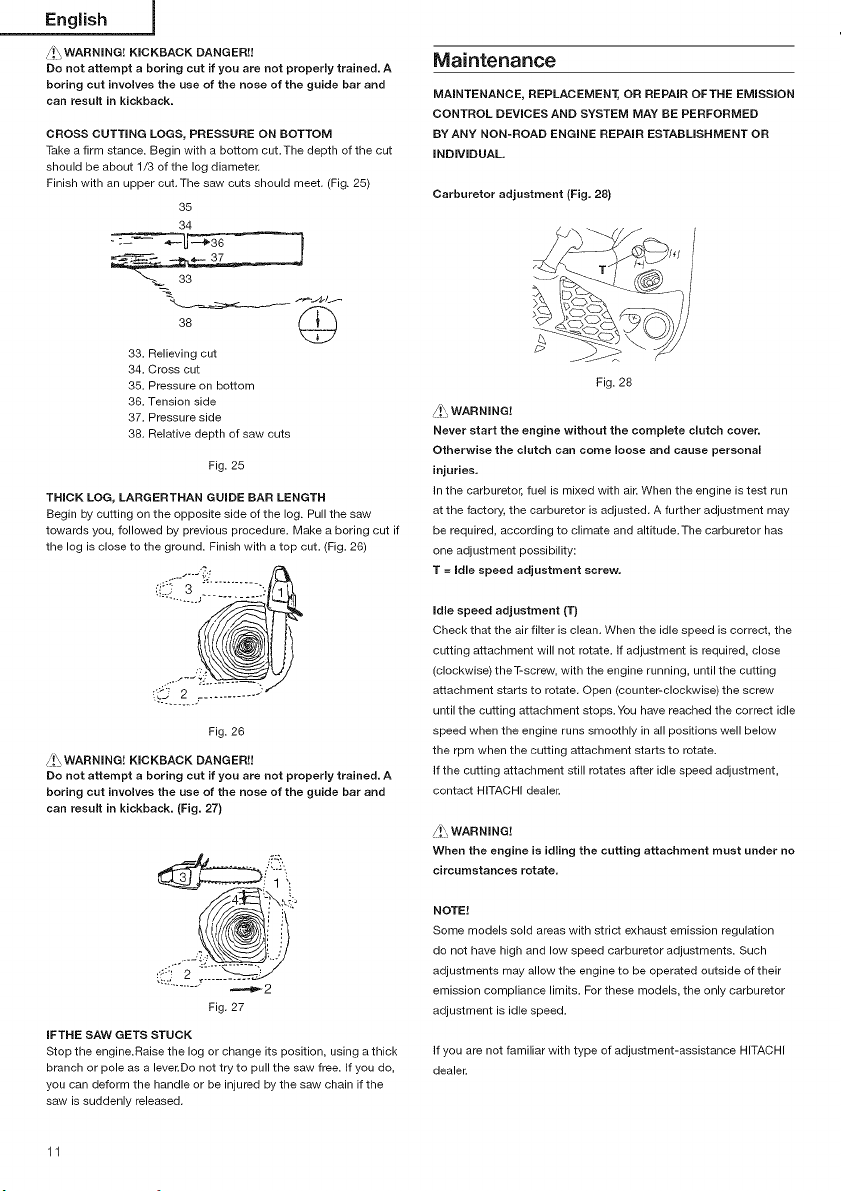

/!\WARNING! KICKBACK DANGER!!

Do not attempt a boring cut ifyou are not properly trained. A

boring cut involves the use of the nose of the guide bar and

can result in kickback.

CROSS CUTTING LOGS, PRESSURE ON BOTTOM

Take a firm stance. Begin with a bottom cut.The depth of the cut

should be about 1/3 of the log diameter.

Finish with an upper cut. The saw cuts should meet. (Fig. 25)

35

34

"_._ 33

33. Relieving cut

34. Cross cut

35. Pressure on bottom

36. Tension side

37. Pressure side

38. Relative depth of saw outs

Fig. 25

THICK LOG, LARGERTHAN GUIDE BAR LENGTH

Begin by cutting on the opposite side of the log. Pull the saw

towards you, followed by previous procedure. Make a boring cut if

the log is close to the ground. Finish with a top cut. (Fig. 26)

Maintenance

MAINTENANCE, REPLACEMENT, OR REPAIR OFTHE EMISSION

CONTROL DEVmCESAND SYSTEM MAY BE PERFORMED

BY ANY NON-ROAD ENGINE REPAIR ESTABLISHMENT OR

iNDiViDUAL.

Carburetor adjustment (Fig. 28)

Fig. 28

/!\_ WARNING!

Never start the engine without the complete clutch cover.

Otherwise the clutch can come loose and cause personal

injuries.

in the carburetor, fuel is mixed with air. When the engine is test run

at the factory, the carburetor is adjusted. A further adjustment may

be required, according to climate and altitude.The carburetor has

one adjustment possibility:

T = Idle speed adjustment screw.

Fig. 26

/_!_WARNING! KICKBACK DANGER!!

Do not attempt a boring cut if you are not properly trained. A

boring cut involves the use of the nose of the guide bar and

can result in kickback. (Fig. 27)

Fig. 27

IFTHE SAW GETS STUCK

Stop the engine.Raise the log or change its position, using a thick

branch or pole as a lever.Do not try to pull the saw free. If you do,

you can deform the handle or be injured by the saw chain if the

saw is suddenly released.

11

Idle speed adjustment (T)

Check that the air filter is clean. When the idle speed is correct, the

cutting attachment will not rotate, if adjustment is required, close

(clockwise) theT-screw, with the engine running, until the cutting

attachment starts to rotate. Open (counter-clockwise) the screw

until the cutting attachment stops. You have reached the correct idle

speed when the engine runs smoothly in all positions well below

the rpm when the cutting attachment starts to rotate.

if the cutting attachment still rotates after idle speed adjustment,

contact HiTACHi dealer.

/!\_ WARNING!

When the engine is idling the cutting attachment must under no

circumstances rotate.

NOTE!

Some models sold areas with strict exhaust emission regulation

do not have high and low speed carburetor adjustments. Such

adjustments may allow the engine to be operated outside of their

emission compliance limits. For these models, the only carburetor

adjustment is idle speed.

if you are not familiar with type of adjustment-assistance HITACHI

dealer.

Page 13

Air filter (Fig, 29)

The air filter (40), (43) and cleaner sponge (41), (42) must be cleaned

from dust and dirt in order to avoid:

Carburetor malfunctions.

Starting problems.

Engine power reduction.

Unnecessary wear on the engine parts.

Abnormal fuel consumption.

Clean the air filter daily or more often if working in exceptionally

dusty areas.

(For CS33ET)

Remove the air filter cover (39), air filter (40) and the cleaner sponge

(41), (42).

NOTE!

When removing the air filter (40) from the unit, turn the air filter

1/8th counter-clockwise (CS33ET)

(For CS33EA)

Remove the air filter cover (39) and pull the tab (46) on the air filter

(43).

NOTE!

When installing the air filter (43) on the unit, please take the

following steps:

1.Set the hole (45) on the air filter to the boss (46) first.

2. Fit the installing hole (47) on the air filter on the part (48) on the

rear handle. Push the air filter down till you hear the click.

Cleaning the air filter

Remove the air filter cover (39) and the filter (40), (43).

I

English

Spark plug (Fig. 30)

The spark plug condition is influenced by:

An incorrect carburetor setting.

Wrong fuel mixture (too much oil in the gasoline)

A dirty air filter.

Hard running conditions (such as cold weather).

These factors cause deposits on the spark

plug electrodes, which may result in malfunction and starting

difficulties. If the engine is low on power, difficult to start or runs

poorly at idling speed, always check the spark plug first. If the

spark plug is dirty, clean it and check the electrode gap. Readjust

if necessary. The correct gap is 0.024" (0.6 mm).The spark plug

should be replaced after about 100 operation hours or earlier if the

electrodes are badly eroded.

Fig. 30

NOTE!

In some areas, local law requires using a resistor spark plug to

suppress ignition signals. If this machine was originally equipped

with resistor spark plug, use same type of spark plug for

replacement.

Oiler port (Fig, 31)

Clean the chain oiler port (49) whenever possible.

O 41 39

CS33EA

NOTE!

When removing the filter from the unit, turn the filter 1/8 turn to

counter-clockwise.

Rinse them in warm soap suds. Check that the filter is dry before

reassembly, An air filter that has been used for some time cannot

be cleaned completely,Therefore, it must regularly be replaced with

a new one. A damaged filter must always be replaced.

48

Fig. 29

49

/

Fig. 31

Guide bar (Fig. 32)

Before using the machine, clean the groove and oiler port (50) in

the bar with the special gauge offered as an optional accessory.

5O

Fig. 32

12

Page 14

English j

Side case {Fig. 33)

Always keep the side case and drive area clean of saw dust and

debris.Periodically apply oil or grease to this area to protect from

corrosion as some trees contain high levels of acid.

CHAIN SHARPEMNG Parts of a cutter. (Fig. 36, 37)

/_._WARNING!

Gloves should be used when sharpening chain.

/!\ WARNING!

Be sure to round off the front edge to reduce the chance of

kickback or tie-strap breakage.

52 51

54

Fig. 33

Fuel filter (Fig. 34)

Remove the fuel filter from the fuel tank and thoroughly wash it in

solvent. After that, push the filter into the tank completely.

Fig. 34

NOTE!

If the filter is hard due to dust and dirt, replace it.

Chain oil filter (Fig. 35)

Remove the oil filter and thoroughly wash it in solvent.

I

Fig. 35

For long-term storage

Drain all fuel from the fuel tank. Start and let engine run until it

stops. Repair any damage which has resulted from use. Clean the

unit with a clean rag, orthe use of high pressure air hose. Put a few

drops of two-cycle engine oil into the cylinder through the spark

plug hole, and spin the engine over several times to distribute oil.

Cover the unit and store it in a dry area.

59

51. Top plate

52. Working corner

53. Side plate

54. Gullet

55. Heel

56. Chassis

57_ Rivet hole

58. Toe

59. Depth gauge

Fig. 36

60 61

63

60. Correct angle on top plate (degree of angle depends on chain type)

61. Slightly protruding "hook" or point (curve on non-chisel chain)

62. Top of depth gauge at correct height below top plate

63. Front of depth gauge rounded off

Fig. 37

LOWERING DEPTH GAUGES WiTH A FILE

1) If you sharpen your cutters with a file holder, check and lower the

depth.

2) Check depth gauges every third sharpening.

3) Place depth gauge tool on cutter. If depth gauge projects, file it

level with the top of the tool. Always file from the inside of the

chain toward an outside cutter. (Fig. 38)

Fig. 38

13

Page 15

4) Round off front corner to maintain original shape of depth gauge

after using depth gauge tool. Always follow the recommended

depth gauge setting found in the maintenance or operator

manual for your saw. (Fig. 39)

Fig. 39

GENERAL INSTRUCTIONS FOR FILING CUTTERS

File (64) cutter on one side of the chain from the inside out.

File on forward stroke only. (Fig. 40)

Fig. 40

5) Keep all cutters the same length. (Fig. 41)

I _ I__ I

Fig. 41

6) File enough to remove any damage to cutting edges (side plate

(65) and top plate (66)) of cutter. (Fig. 42)

English

Daily maintenance

* Clean the exterior of the unit.

Clean the chain oil filter port.

Clean the groove and oil filter port in the guide bar.

Clean the side case of saw dust.

Check that the saw chain is sharp.

Check that the bar nuts are sufficiently tightened.

Make sure that the chain transport guard is undamaged and that

it can be securely fitted.

Check that nuts and screws are sufficiently tightened.

Weekly maintenance

Check the starter, especially cord.

Clean the exterior of the spark plug.

Remove the spark plug and check the electrode gap. Adjust it

to 0.024" (0.6mm) or change the spark plug.

Check that the air intake at the starter is not clogged.

Clean the air filter.

Monthly maintenance

Rinse the fuel tank with gasoline, and clean fuel filter.

Clean chain oil filter.

Clean the exterior of the carburetor and the space around it.

Quarterly maintenance

Clean the cooling fins on the cylinder.

Clean the fan and the space around it.

Clean the muffler of carbon,

CAUTION

Cleaning of cylinder fins, fan and muffler shall be done by a

HITACHI Authorized Service Center.

MODEL NO. BAR NO. LENGTH- CHAIN NO.

OREGON TYPE

CS33ET/ 120SDEA041 12"-DG 91VG-045X

CS33EA 140SDEA041 14"-DG g1VG-052X

DG-DOUBLE GUARD TM (is registered trademark of BLOUNT

International) ... Reversible reduced kickback-bar.

65 66

Fig. 42

SHARPENING ANGLES FOR SHARPENING SAW CHAIN

1. Part Number 91VG

2. Pitch 3/8"

3. Deth Gauge Settig 0.025"

4. Side Plate Filing Angle 80 °

5. Top Plate Angle 30 °

_ 6. File Guide Angle 90 °

Maintenance schedule

Below you will find some general maintenance instructions. For

further information please contact HITACHI dealer.

14

Page 16

Francois 1

Signification des symboles

REMARQUE " Certains appareils n'en sont pas pourvus.

Symboles

ATTENTION

Les symboles suivants sont utilis&s pour I'outil. Bien se familiariser

avec leur signifi cation avant d'utiliser I'outil.

II est essentiel que vous lisiez et compreniez parfaitement les consignes de s&curit6 et autres

avertissements suivants et que vous les observiez strictement. I_utilisation inattentive ou

inad6quate de cette machine risque de provoquer des blessures graves ou fatales.

Lisez, comprenez et suivez toutes les instructions et tous les avertissements donn6s dans ce

manuel et sur le produit.

Utilisez toujours des lunettes de protection ainsi qu'une protection pour la t6te et les oreilles

Iorsque vous utilisez ce produit.

Portez une attention particuli_re aux ph6nom_nes de rebond. Prenez garde aux mouvements

possibles soudains et accidentels du guide-cha_ne de votre trongonneuse.

@

4\\

\

@C)

15

I_utilisation d'une trongonneuse avec une seule main n'est pas autoris&e. Lorsque vous

coupez avec votre machine, tenir celle-ci fermement avec les deux mains, le pouce enserrant

la poign6e avant.

Avant I'utilisation de votre nouvelle machine

• Lisez attentivement le manuel d'utilisation.

• V6rifi ez que I'equipement de coupe est mont6 et r6g16correotement.

• Demarrez la machine et v6rifiez le reglage du carburateur.Voir la section "ENTRETIEN".

Sornmaire

Description .................................................................... 16

Pr6cautions et consignes de s6curit6 ........................... 17

Caract6ristiques ............................................................ 19

Montage ....................................................................... 20

Utilisation ....................................................................... 21

Entretien ........................................................................ 26

Liste des pi_ces d6tach6es ........................................... 45

Page 17

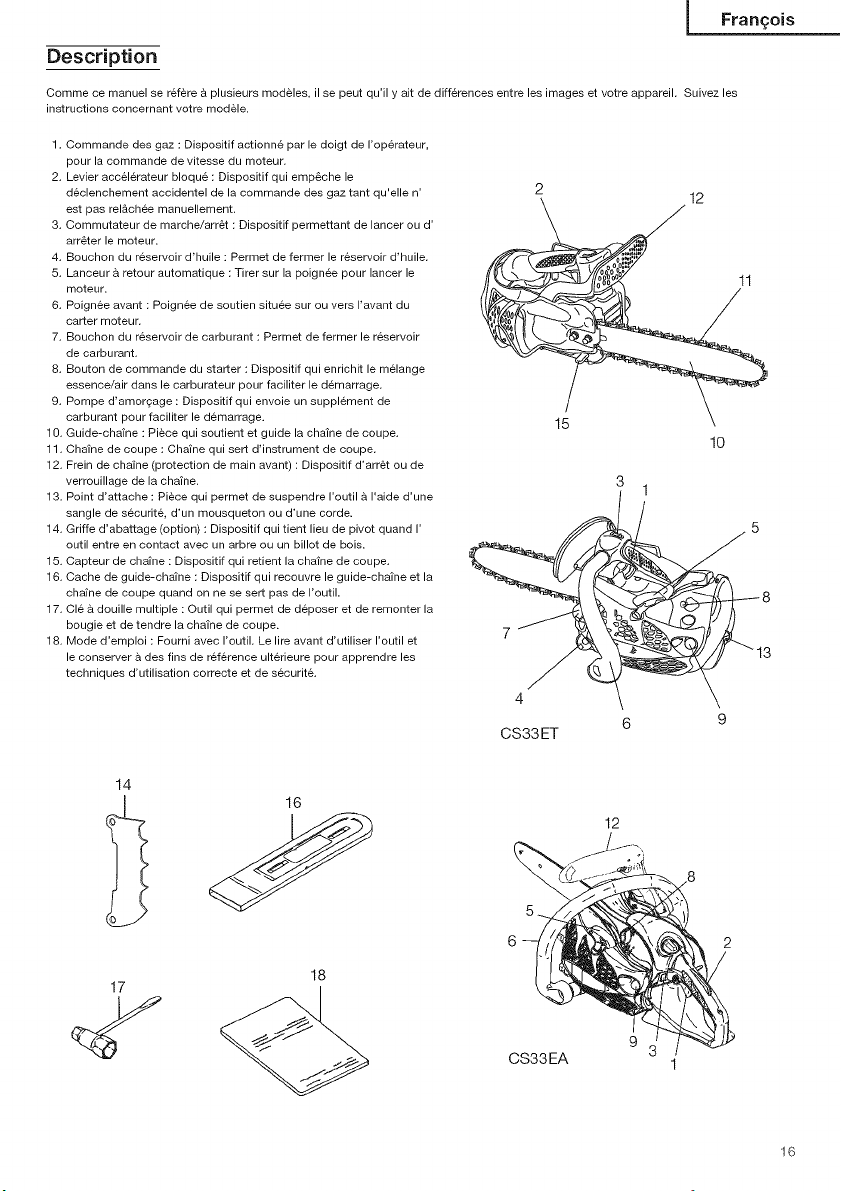

Description

Comme ce manuel se refere & plusieurs modeles, il se peut qu'il y ait de differences entre les images et votre appareil. Suivez les

instructions concernant votre modele.

1. Commande des gaz : Dispositif actionn_ par le doigt de I'op@ateur,

pour la commande de vitesse du moteur.

2. Levier accelerateur bloqu6 : Dispositif qui empeche le

declenchement accidentel de la commande des gaz tant qu'elle n'

est pas rel&chee manuellement.

3. Commutateur de marche/arret : Dispositif permettant de lancer ou d'

arr_ter le moteur.

4. Bouchon du reservoir d'huile : Permet de fermer le reservoir d'huile.

5. Lanceur a retour automatique : Tirer sur la poignee pour lancer le

moteur.

6. Poignee avant : Poignee de soutien situee sur ou vers I'avant du

carter moteur.

7. Bouchon du reservoir de carburant : Permet de fermer le reservoir

de carburant.

8. Bouton de commande du starter : Dispositif qui enrichit le melange

essence/air dans le carburateur pour faciliter le demarrage.

9. Pompe d'amorgage : Dispositif qui envoie un supplement de

carburant pour faciliter le demarrage.

10. Guide-chaine : Piece qui soutient et guide la chaine de coupe.

11. Chaine de coupe : Chafne qui sert d'instrument de coupe.

12. Frein de chaine (protection de main avant) : Dispositif d'arret ou de

verrouillage de la chafne.

13. Point d'attache : Piece qui permet de suspendre I'outil & I'aide d'une

sangle de securite, d'un mousqueton ou d'une corde.

14. Griffe d'abattage (option) : Dispositif qui tient lieu de pivot quand I'

outil entre en contact avec un arbre ou un billet de bois.

15. Capteur de chafne : Dispositif qui retient la chaine de coupe.

16. Cache de guide-chatne : Dispositif qui recouvre le guide-chatne et la

chatne de coupe quand on ne se sert pas de I'outil.

17. Cle a douille multiple : Outil qui permet de deposer et de remonter la

bougie et de tendre la chaine de coupe.

18. Mode d'emploi : Fourni avec I'outil. Le lire avant d'utiliser I'outil et

le conserver a des fins de reference ult@ieure pour apprendre les

techniques d'utilisation correcte et de securit&

2

7

4

CS33ET

15

3

(/ 8

6 9

12

10

1

Fran£ois

3

14

12

17

18

9

CS33EA

16

Page 18

Fran£ois I

Pr6cautions et consignes de s_curJt6

S_curite de I'utilisateur

ATTENTION!

Cette tron_onneuse (CS33ET) est speciaiement destinee

I'entretien et a la chirurgie des arbres. Tous les travaux

effectues avec cette tron_onneuse ne peuvent _tre

effectues que par un personnel _lagueur. Consultez la

documentation et les informations correspondantes des

instances professionnelles. La non-observation peut entra_ner

d'importants risqaee d'accidente. Si vous travaillez avec la

tron_onneuse dane ies arbres, nous vous recommandons de

toujours utiliser une plate-forme de travail montante. Le travail

avec la technique de descente en rappel est extr&mement

dangereux et ne peut 6tre effectue qu'& I'issue d'une

formation speciale. L'utilisateur dolt &tre initie a I'atilisation

des 6quipements de securit_ et des techniques de travail et

d'escalade. Si des travaux sent effectues dans lee arbres,

I'usage de sangles, de cordes et de mousquetons est imperatif.

Utiliser des systemes de retenue pour la tron{;onneuse et pour

I'utilisateur.

Portez toujours une visiere et des lunettes de protection.

Portez toujours des gants pour reduire les effets des vibrations.

Vous devez toujours porter des gants de protection Iorsque vous

affOter la chafne.

Toujours la s0rete d'usure equipement protectif tel que veston,

le pantalon, les gants, le casque, les bottes avec les orteil-

casquettes d'acier et les semelles non-erreur quand vous utilisez

une cha;ne a vu. Pour travailler dans les arbres les bottes de

sorer6 doivent 6tre convenables pour la monteeles techniques

de ing. Evitez les v_tements amples, les shorts, les sandales et

les pieds nus. Veillez A attacher vos cheveux s'ils sont longs.

N'utilisez cette machine que si vous 6tes en pleine possession

de vos moyens physiques. Evitez strictement la consommation

d'alcool, de drogue ou de medicaments.

Ne jamais laisser un enfant ou une personne inexp6rimentee se

servir de ces machines,

Portez un dispositif de proteclion contre le bruit pour vos oreilles.

Ne mettez jamais le moteur en marche dans un local clos, les

gaz d'echappement etant toxiques. Restez vigilant & tout ce qui

vous entoure. Soyez attentif dans I'eventualit6 oQ une personne

situ6e & proximit6 vous signalerait un probleme. Retirez les

equipements de s6curite immediatement apres avoir coup6 le

moteur de I'appareil.

Protegez-vous la t6te.

Pour la protection respiratoire, porter un masque quand le

brouillard d'huile de cha;ne et la poussiere forment de la sciure.

Nettoyez les poignees de toute trace d'huile ou de carburant.

N'approchez jamais les mains du guide-chafne et de la chafne,

Ne jamais attraper, ni tenir la machine par I'extremite du guide-

chaine.

Apres I'arr6t de la tronconneuse, attendez I'arr6t complet de la

cha;ne de coupe avant de poser la machine.

Lors d'une utilisation prolongee, veillez A faire une pause

p6riodiquement, afin d'eviter des troubles eventuels provoques

par les vibrations.

L'utilisateur de la machine doit se conformer aux reglementations

locales de la region dans laquelle il effectue la coupe.

ATTENTION !

Lee syst_mes anti-vibrations, aussi ben soient-ils, ne

garantissent pas que vous ne puissiez pas souffrir de la

maladie des doigts blancs, ni du syndrome da canal carpien.

Par consequent, si vous vous servez de fa£on reguii_re et

continue de vetre tron£onneuse, surveiHez soigneusement

I'_tat de ves mains et de vos deigts. Si I'un des sympt6mes ci-

dessus venait a appara_tre, il serait indispensable de vous faire

examiner immediatement par votre m6decin.

_\ ATTENTION !

Si vous 6tee 6quip6 d'un appareiHage m_dical _iectrique/

61ectronique (par ex. un pacemaker), censultez votre m6decin

et le fabricant de cet appareiHage avant d'utiliser tout appareil

61ectrique/thermique.

_/!_ ATTENTION!

Exposition Iongue ou continue aux hauts bruits peut causer les

troubles d'audience permanents. Toujours I'usure a approuve

entendant la protection en fonctionnant une unit,/machine.

R_gles de securit6 concernant I'utilisation de la machine.

* Contr61ez entierement votre machine avant chaque utilisation.

Remplacez les pieces endommagees. Verifiea I'absence de fuites

de carburant et assurez-vous que tous les dispositifs de fixation

sont en place et solidement fixes.

* Remplacez les elements Tanaka de la machine qui presentent des

fissures, des ebrechures ou route autre avarie.

* Assurez-vous que le capot lateral est correctement install&

* Ne laissez personne s'approcher Iorsque vous reglez le

carburateur.

*Utilisez uniquement les accessoires recommand6s par le

constructeur pour cette machine.

* Ne jamais laisser la cha;ne frapper contre un obstacle

quelconque. Si la cha;ne rencontre un obstacle, il est necessaire

d'arr6ter le fonctionnement de la machine et de I'inspecter

soigneusement pour voir si elle n'est pas endommagee.

Assurez-vous que le syst_me de graissage automatique

fonctionne normalement. Le reservoir d'huile devra toujours 6tre

suffisamment rempli d'huile propre. Ne jamais laisser la chafne

tourner a sec sur le guide-cha;ne.

Tous les travaux employant latronconneuse, outre que les

rubriques indiqu6es dans le manuel d'entretien de I'utilisateur,

doivent _tre effectues par un personnel apte au service apres-

vente des tronconneuses. (Par exemple, si on emploie des outils

incorrects pour extraire le volant, ou si on utilise un outil incorrect

pour maintenir le volant avant de retirer I'embrayage, il se peut

que cette procedure entra;ne I'avarie structurale du volant et

provoque ensuite I'eclatement de celui-ci.)

/'!_ ATTENTION!

Ne modifiez en aucun cas ia machine. N'utilisez jamais ia

tron£onneuse pour tout autre t_che que celles auxqueHes elle

est destinee.

ATTENTION!

Ne jamais utiliser une tron£onneuse sans aucun 6quipement de

securit6 ou ceHe dont Pequipement de securite est inadapt& II

pourrait aboutir a des blessures graves.

//._\_,ATTENTION!

Si on emploie un guide ou une cha_ne diff_rente de celle qai a

6t6 recommandee par le fabricant et qui n'est pas homologu6e,

il pourrait s'ensuivre an risque probable.

d'accidents ou de blessures.

17

Page 19

S_curite au rliveau du carburarlt

Faites le melange et le plein & I'air libre, & distance de toute

etincelle ou flamme

Utilisez pour I'essenoe un recipient agree.

Ne fumez pas et ne laissez personne fumer & proximit6 du

carburant ou de la machine, ni Iorsque vous utilisez la machine.

Essuyez soigneusement routes les traces de carburant avant de

mettre le moteur en marohe.

= Pour demarrer la tronconneuse, ecartez vous d'au moins 10ft (3m)

de I'endroit oQ vous avez fait le plein.

Arr6tez le moteur avant de d6visser les bouchons des reservoirs

de carburant ou d'huile.

Vidangez le reservoir de carburant avant de remiser la machine

II est en fait recommande de le faire apres chaque utilisation.

Si le r6servoir West pas vide, rangez alors la machine dans une

position telle que le oarburant ne risque pas de couler.

Rangez la machine et le carburant dans un endroit oQ les vapeurs

d'essence ne risquent pas d'entrer en contact avec des etincelles

ou une flamme en provenance d'un chauffe-eau, d'un moteur

electrique, d'un commutateur, d'une chaudiere, etc.

ATTENTION !

Le carburant peut s'erlflammer facilemerlt ou expioser

et I'irlhalatiorl de ses vapeurs est darlgereuse. Faites

partioulieremerlt atterltiorl Iorsque vous marlipulez le carburarlt

ou faites I'appoint du r_servoir.

S6curite au rliveau de la coupe

*N'essayez pas de couper des mat6riaux autres que du bois ou

des objets en bois avec ces tronconneuses.

Pour assurer la protection de vos voies respiratoires, porter un

masque de protection contre les aerosols Iorsque vous coupez

du bois qui a et6 traite avec des insecticides.

Eloignez toutes les personnes (enfants, passants, aides, etc..) et

tous les animaux se trouvant dans la zone dangereuse. Arr6tez

immediatement le moteur si quelqu'un s'approche de vous.

Tenir I'unite/machine fermement avec la main droite sur la

poignee posterieure et le gauche sur la poignee de devant.

*Tenez vous bien en equilibre sur vos deux jambes. Ne travaillez

jamais en porte-A-faux.

Demeurez toujours eloign6 du silencieux d'echappement et de

I'ensemble de coupe Iorsque le moteur est en fonctionnement.

Maintenir le guide-chafne en-dessous de la taille.

Avant d'abattre un arbre, I'utilisateur devra se familiariser avec les

techniques de coupe et d'abattage A I'aide d'une tronconneuse.

Avant d'abattre un arbre, s'assurer de I'existence d'un abri A

proximit&

Au cours d'une op6ration de tronconnage maintenir la machine

fermement des deux mains avec le pouce bien bloque autour de

la poignee avant et les pieds bien stables au sol.

Se tenir legerement sur le c6te de la trongonneuse Iorsqu'on

effectue une coupe et non pas dans I'axe derriere la machine.

*Toujours maintenir la griffe d'abattage & la surface de I'arbre,

parce que la chafne peut 6tre entra;n6e soudainement vers

I'interieur de I'arbre.

Lorsque la coupe est terminee, se tenir pr6t & tenir fermement

I'outil car il se lib_re brusquement, pour ne pas en perdre le

contr61e et risquer de se couper les jambes, les pieds ou le corps,

ni de le toucher.

Faire attention A tout retour en arriere (Iorsque la scie a cha;ne

portative avance et recule par rapport a I'operateur), et ne couper

lamais avec I'extremite du guide-chafne.

Quand vous deplacez I'appareil d'un lieu a un autre, verifiez que

I'appareil est completement arr6te et que tous les accessoires de

coupe sont & I'arr_t.

Ne placez jamais I'appareil sur le sol en cours de fonctionnement.

I Fran£ois

Assurez-vous toujours que le moteur est arr_t_ et que tous les

accessoires de coupe sont completement & I'arr_t avant de

nettoyer I'accessoire principal de coupe de tout d6bris ou amas

d'herbe.

Lors de I'utilisation de tout appareil electrique/thermique,

emportez toujours avec vous une trousse de premiers soins.

Ne demarrez jamais le moteur de I'appareil/N'utilisez jamais

I'appareil dans un local clos ou A I'int6rieur d'un b_timent et/ou

proximite d'un produit inflammable. L'inhalation des fumees

d'echappement peut _tre mortelle.

S6curite au rliveau de I'erltretierl

*Entretenez votre machine selon les recommandations du

constructeur,

D6branchez la bougie avant route intervention intervention

d'entretien, & I'exception des op6rations de reglages du

carburateur.

Ne laissez personne s'approcher de la machine Iorsque vous

proc6dez au reglage du carburateur.

Utilisez uniquement des pieces de rechange d'origine HITACHI.

IMPORTANT!

Ne pas demonter le demarreur de recul sur I'appareil. On pourrait

se blesser a cause du ressort de recul.

/._\ ATTENTTON !

Url entretierl irlcorrect pourrait aboutir & des avaries

importarltes du moteur ou a des blessures graves.

Trarlsport et rarlgemerlt

*Portez la machine avec moteur arr6t6 et silencieux oriente vers

I'exterieur.

Laissez le moteur refroidir, videz le r6servoir de carburant et

veillez a ce que la machine ne risque pas de tomber Iorsque vous

la rangez ou la chargez & bord d'un vehicule.

Vidangez le reservoir de carburant avant de remiser la machine,

II est en fait recommande de le faire apres chaque utilisation. Si

le reservoir n'est pas vide, rangez alors votre tronconneuse dans

une position telle que le carburant ne risque pas de couler.

Remisez la machine hors de portee des enfants.

Nettoyer et entretenir I'outil soigneusement et le remiser dans un

endroit sec.

Assurez vous que le commutateur d'arr6t du moteur est bien sur

la position "stop" Iors du transport ou du remisage de la machine.

Lors des transports en vehicule ou des remisages, recouvrez la

cha;ne de son fourreau de protection.

Dans I'eventualit6 de situations qui ne seraient pas prises en

compte par le present manuel, redoublez d'attention et usez de

Don sens.

Communiquez avec un concessionnaire HITACHI pour toute

assistance.

Faites particulierement attention aux stipulations introduites par les

mots ci-dessous.

/'!\ ATTENTION!

Irlformatiorl de premiere importance pour _viter des dommages

corporels graves ou morteis.

iMPORTANT!

Information importante afin d'eviter les dommages corporels ou

materiels.

REMARQUE!

Information importante pour la comprehension d'une intervention,

evitant ainsi des erreurs.

18

Page 20

Fran£ois j

Caract6ristiques

i ...................................................... __MODELL CS33ET CS33EA

]_ype d'equipement Trongonneuse portative

_ Taille du moteur (cu. in) 1.96 (32.2mQ)

Bougie d'allumage NGK BPM-6A ou equivalent

0.84

Contenance du reservoir de

carburant (pt)

8 Contenance du reservoir d'huile

_O de chaine 0.40 (190mQ)

(pt)

(300mQ)

Poids a sec (Ibs) (4.1 kg) (4.2kg)

de

_ Longueur 12 (30Omm) _ 14 (350mm)

Pas de chaine (in) 3/8 (9.52mm)

Calibre de chatne (in) 0.05 (1.27mm)

guide-chaine (in)

9.0 9.2

_j.;_

Niveau de pression sonore

LpA (dB(A)) 97.7 98.1

selon ISO22868

Niveau de puissance sonore Lw

mesure (dB(A)) nach ISO22868

@

Niveau de puissance sonore

LwA (dB(A)) mesure 2000/14/E0

Niveau de vibrations (m/s 2)

nach ISO22867

Poignee avant 4.0 3.6

Poignee arriere 6.0 4.4

Puissance max. du moteur

selon ISO 7293(kW)

Regime max. du moteur (min _)

rpmMAX

Regime de ralenti (min _) 3000

rpm MIN

Consommation specifique en carburant (g/kWh) 575

_:::::Z:_ :o O

:A ]_jpe de guide-chatne

]_jpe de chaine (Oregon)

111 109

112

1.2/8500

12000

91 VG

[_ Vitesse max. de chaine

(_ Pignon (nombre de dents) 6

REMARQUE : Les niveaux de bruiVvibrations equivalents sont calcules comme total d'energie pond@ee en fonction du temps pour les

19

(m/sec) 22.9

niveaux de bruit/vibrations dans diverses conditions de travail avec la repartition temporelle suivante : 1/3 ralenti, 1/3 plein

regime, 1/3 vitesse de course.

*Toutes les donnees sont sujettes a modifier sans preavis.

Page 21

Montage

/J\ ATTENTmON!

Ne jamais essayer de mettre le moteur en marche sans le

carter lateral solidement fi×e.

1. Retirer I'ecrou de bloeage (1) du guide- cha_ne.

2. Retirer le carter lateral (2) en maintenant la _artie arriere du

carter lat@al (2). (Fig. 1)

OoO

Fig. 1

*Si vous devez monter la griffe (3) : demontez d'abord la plaque

de guidage A (4). Puis montez la griffe (3) (le cas echeant) sur I'

appareil & I'aide des deux vis. Ensuite, remontez la plaque de

guidage A (4). (Fig. 2)

Fran£ois

5.

Placez les maillons d'entrainement de la cha_ne dans la rainure

tout autour du guide- cha_ne.

6.

Embottez le capet lateral (2) sur les vis de serrage de la barre de

guidage situees sur le carter de I'appareil.

Puis fixer provisoirement les ecrous de serrage. (Fig. 1)

Soulever I'extremite du guide-chaine et regler la tension de la

chatne (10) en tournant la vis de reglage de tension (11) dans le

sens des aiguilles d'une montre. Pour verifier que la tension de la

chatne est adequate, soulever leg@ement le centre de la chatne.

II faut qu'il y ait alors un jeu de 0.02~0.04in (0.5~1.0mm) entre le

guide-cha;ne et le bord des maillons d'entratnement de la chatne

(12). (Fig. 5, 6)

11 10

){@)4Jt_

ram)

Fig. 5

Fig. 2

3. installer le guide de cha;ne (5) sur les boulons (6), puis le

pousser au maximum vers le pibnon (7). S'assurer que le

moyeu duboulon de reglage de tension de cha;ne (8) s'adapte

correetement dans le trou dans le trou du guide de cha;ne (9).

(Fig. 3)

REMAROUE !

Deplacez leg@ement le guide-chaine vers I'avant et vers I'arri@e

jusqu'& ce que I'ergot (8) penetre correctement dans le trou du

guide-cha;ne (9). (Fig. 3)

4. V@ifiez si la direction de la cha;ne est correete comme indique

sur la figure et alignez la cha;ne sur le pignon (Fig. 4).

7 5

9 6

Fig. 3

Fig. 4

_ tt- f

Fig. 6

IMPORTANT !

UNETENSiON CORRECTE DE LA CHAINE EST EXTREMEMENT

IMPORTANTE !

8. Seulevez I'extremit6 du guide-cha;ne et, avec la cle universelle

speciale, resserrez fermement les ecrous de la bride du guide-

chaTne. (Fig. 6)

9. Une chaTne neuve peut s'allonger. Pour cette raison, il convient

d'ajuster la tension apres quelques coupes et d'observer

attentivement et regulierement satension durant la premiere

demi-heure d'utilisation.

REMARQUE !

V@ifiez reguli@ement la tension de la chafne afin de conserver A

la trongonneuse des performances optimales et durables.

IMPORTANT !

Lorsque la chaine est trop tendue, le guide- cha;ne ainsi que la

chafne risquent d'6tre endommages rapidement, inversement,

Iorsque la chalne est trop detendue, elle risque de sortir de la

rainure du guide- chafne.

Toujours mettre des gants Iorsque vous manipulez la chafne.

/_\ ATTENTION!

Durant I'atilisation de la tron_onnease, tenir celle-ci fermement

I'aide des deax mains. L'utilisation de la machine avec une

seale main peut entrainer des blessures graves,

2O

Page 22

Fran£ois j

Utilisation

Carburant (Fig. 7)

Fig. 7

/_\ATTENTION!

La tronQonneuse est 6quipee d'un moteur a deux temps qui

doit imperativement &tre alimente avec un melange essence/

huile. Veillez a une bonne aeration pendant I'operation de

rempiissage du reservoir.

= Le carburant centient des substances hautement

inflammables. Vous risquez des blessures sev6res en cas

d'inhalation de vapeurs ou de renversement accidentel du

produit sur votre corps. Usez toujours de precaution Iorsque

vous manipulez le carburant. Si vous prevoyez de manipuler

le carburant en int6rieur, faites-le dans un local bien ventile.

Essence

Toujours utiliser de I'essence sans plomb aveo un taux d'octane

de 89.

Utilisez une huile pour moteur & deux temps ou un melange

variant de 25:1 a 50:1 ; veuillez consulter le contenant d'huile

pour la proportion du melange ou communiquez avec un

concessionnaire HITACHI.

Et une proportion 50:1 pour I'Etat de la Californie uniquement.

Si vous n'utilisez pas une huile d'origine, utilisez une huile

de qualite contenant un antioxydant recommandee pour 6tre

utilisee avec un moteur & deux temps refroidi & I'air (HUILE JASO

QUAUTE FC OU ISO QUALITE EGC). Ne jamais utiliser des huiles

melangees BIA ouTCW (pour les moteurs & essence 2 temps &

refroidissement par eau).

Ne jamais utiliser d'huile Multigrade (lOW/30), ni d'huile usagee.

Effectuez toujours le melange dans un recipient propre.

Toujours commencer par verser la moiti6 de I'essence & melange[

Verser ensuite la totalite de I'huile. Melanger en agitant le recipient.

Enfin, verser le reste de I'essence, puis agiter le recipient afin de

melanger soigneusement le carburant avant de faire le plein.

Faire le plein

/_\ ATTENTION! (Fig. 8)

* Ne jamais faire ie piein iorsque le moteur est en

fonctionnement.

i Desserrer lentement le bouchon du reservoir de carburant (13)

pour effectuer le remplissage afin de laisser echapper une

surpression eventuelle.

* Serrer le beuchon soigneusement apr_s avoir rempli le

reservoir de carburant.

* Avant de redemarrer le meteur, teujours s'eloigner d'au moins

10ft (3m) de I'endreit eu veus avez fait ie plein de carburant.

ER cas de renversement accidentel de carburant sur vos

vetements, lavez-ies imm_diatement avec du saven.

*Apr_s chaque appoint de carburant, verifiez teujours I'absence

de fuite.

Pendant le remplissage respectez les regles de propret&

Essuyez autour du bouchon du reservoir afin d'eviter que des

corps etrangers ne penetrent dans le reservoir Les saletes qui se

trouveraient dans le reservoir risquant d'occasionner des troubles

de fonctionnement.

Veillez a ce que le melange soit bien homog_ne en agitant &

intervalle regulier le recipient avant et pendant le remplissage.

Huile de chaine (Fig. 8)

Remplir le reservoir (14) avec de I'huile pour chaine. Utilisez toujours

de I'huile de cha;ne de bonne qualit& Lorsque le moteur est en

fonctionnement I'huile de cha;ne est distribuee automatiquement.

REMARQUE !

Lorsqu'on remplit les resemoirs soit avec du carburant (13), soit.

avec de I'huile de chaine (14), placer la machine sur le c6te avec les

bouchons orientes vers le haut (Fig. 8).

REGLAGE DE L'ALIMENTATION EN HUILE DE CHAINE

La quantite d'huile de cha;ne distribuee par le syst_me de

lubrification est reglee d'origine par I'usine au debit maximum.

Ajuster la quantite d'huile en conformite avec les conditions locales

d'utilisation.

Tourner la vis ajustant (15) counterclockwise pour augmenter

la quantite et le toume dans le sens des aiguilles d'une montre

diminuer la quantit& (Fig. 9)

(le cadre de norme toume counterclockwise 1-1 1/2 de leg_rement

assis)

15

®

Fig. 9

Oemarrage (Fig. 10, 11)

!i\ ATTENTION!

Lorsque le moteur demarre avec le dispo- sitif de verrouiHage

de la commande des gaz engage le regime du moteur est

suffisant pour entrafner la chaine.

IMPORTANT !

Avant de commencer, assurez-vous que le frein de chaine est

enclenche (le cas echeant) et que la barre/cha?ne ne touche rien.

1. Placez le cemmutateur "marche=arr_t" (1G)en position marche" (ON).

*Presser la poire de la pompe d'amorcage (18) (si la machine en

est munie) a plusieurs reprises pour que le carburant puisse

s'ecouler vers le carburateur (Fig. 10).

ON 17

13 14/__'_

Fig. 8

Fig. 10

21

Page 23

2. Poussez le levier d'etranglement (17) & fond vers le bas. Cette

operation permettra de verrouiller automatiquement le papillon

du carrburateur dans la position de d6marrage. (Fig. 10)

3. Tirer vivement sur la poignee du lanceur & retour automatique (6),

ne pas rel&cher la poignee brusquement mais d'accompagner

son retour (Fig. 10).

4. Lorsque vous entendez que le moteur va demarrer, tirer la

gachette d'accel6rateur (20) avec la gachette de s6curite pressee

(19). Le papillon des gaz passe ainsi de la position de demarrage

la position de fonctionnement et ramene automatiquement le

levier d'etranglement en position de fonctionnement. (Fig.10, 11)

[ Fran£ois

Methode de verification:

1) Arr_ter le moteu_

2) En maintenant la tronconneuse horizontalement avec les deux

mains, enlever la main de la manette avant et appli-quer

I'extr6mite de la barre de guidage a une souche pour v6rifier

le bon fonctionnement du frein. La hauteur d'opera-tion sera

differente selon la taille du guide de chaine.

20 1_

Fig. 11

5. Tirer de nouveau vivement sur le starter a recul de la maniere

indiqu6e prec6demment. (Fig. 12)

Apres que le moteur a d6marre, assurez-vous que le frein de chafne

se desenclenche.

Fig. 12

REMARQUE !

Si le moteur ne demarre pas, repeter la procedure d6crite entre les

points 2 et 5.

6. Apres avoir demarr6 le moteur, presser la commande des gaz

pour liberer le dispositif de blocage de celle-ci. Laissez ensuite

le moteur chauffer pendant 2 & 3 minutes avant de commencer &

utiliser la tronconneuse.

Fonctionnement du frein de chaine (Fig. 13)

Le frein de chafne (21) (si la machine en est manie) a et6 concu

pour entrer en action en cas d'urgence tel qu'un mouvement de

rebond. V6rifier s'il fonctionne correctement avant d'utiliser la

tronconneuse.

Le frein est actionne en deplacant la protection de la poignee avant

vers le guide-chaine. Durant le fonctionnement du frein de chaine,

m6me si la commande des gaz est press6e, le regime du moteur

n'augmente pas et la chatne ne tourne pas. Pour d6gager le frein

de chaine, tirer d'un coup sec la protection de la poignee avant

vers I'arriere.

Re\e_

ON

Lorsque le frein fonctionne mal, adressez-vous & votre conces-

sionnaire pour le faire reparer.

Si I'on laisse tourner le moteur & grande vitesse en appliquant le

frein, I'embrayage sera chauffe et cela entrafne des causes de

pannes.

Lorsque le frein s'applique accidentellement pendant le

fonctionnement, degager le doigt du papillon imm6diatement pour

arr6ter le moteur.

/!\ATTENTION!

Ne pas transporter la machine avec le moteur en

fonctionnement.

Arr6t de la trongonneuse (Fig. 14)

Reduire la vitesse et placer le commutateur d'arr_t sur la position

"Stop"

STOP

\

CS33ET

7,

Fig. 13

CS33EA

Fig. 14

22

Page 24

Fran£ois j

/!\_ATTENTIONt

DANGER DE REBOND (Fig. 15)

Fig. 15

L'un des plus grands dangers qui guette I'utilisateur d'une

trongonneuse est le risque d'un rebond ou d'un brusque

mouvement de la machine vers I'arriere. Les rebonds peuvent

survenir Iorsque I'extr6mite sup@ieure du nez du guide-cha;ne

entre en contact avec un objet ou Iorsque le bois coince la cha;ne

durant la coupe.

Les contacts avec le nez du guide-cha;ne peuvent provoquer dans

certains cas une rapide reaction inverse, poussant le guide-chafne

du haut en bas vers vous. Bloquer la chafne de la trongonneuse

du c6te sup@ieur du guide-chaine risque egalement de pousser

soudainement le guide-chaine vers vous. Chacune de ces r6actions

soudaines peuvent provoquer la perte de contr61e de la machine

par I'utilisateur et provoquer de graves blessures.

Bien que votre tronconneuse ait et6 mise au point en tenant

compte de la securit6 de I'utilisateur vous ne pouvez compter

uniquement sur ces dispositifs de s6curite pour assurer une

utilisation parfaitement sore. Contr61ez &tout moment la position

du nez du guide-chafne. Le rebond se produira si vous laissez la

zone de rebond (22) du guide-chafne entrer en contact avec un

objet. En consequence prenez garde de ne pas utiliser cette zone.

Le rebond provoque par un pincement ou un blocage est caus6 par

une coupe se refermant et coincant la partie sup@ieure du guide-

chalne. Etudiez soigneusement votre coupe et assurez vous que la

fente de coupe s'ouvrira au fur et a mesure de I'avancement de la

coupe. Conserver le contr61e de la machine Iorsque le moteur est

en fonctionnement en la maintenant toujours fermement avec votre

main droite tenant la poignee arri@e, votre main gauche placee

sur la poignee avant vos pouces et vos doigts pass6s autour des

poignees.Tenez toujours la trongonneuse des deux mains durant

les op@ations de coupe a haut regime du moteur.

/_\ ATTENTION!