Page 1

No. 0416

SERVIC E MANUAL

MANUEL D'ENTRETIE N

WARTUNGSHANDBUCH

CAUTION:

Before servicing this chassis, it is important that the service technician read the “Safety

Precautions” and “Product Safety Notices” in this service manual.

ATTENTION:

Avant d’effectuer l’entretien du châassis, le technicien doit lire les «Précautions de sécurité»

et les «Notices de sécurité du produit» présentés dans le présent manuel.

VORSICHT:

Vor Öffnen des Gehäuses hat der Service-Ingenieur die „Sicherheitshinweise“ und „Hinweise

zur Produktsicherheit“ in diesem Wartungshandbuch zu lesen.

CPX1402MS

Data contained within this Service

manual is subject to alteration for

improvement.

Les données fournies dans le présent

manuel d’entretien peuvent faire l’objet

de modifications en vue de perfectionner

le produit.

Die in diesem Wartungshandbuch

enthaltenen Spezifikationen können sich

zwecks Verbesserungen ändern.

NAMES»

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

Monitor

December 1999

Page 2

DESCRIPTION : 14 INCH CCTV WITH 1-CAMERA INPUT

HORIZONTAL RESOLUTION 450 LINES

1) SPECIFICATIONS

COLOR SYSTEM : NTSC 3.58 / PAL-B

POWER INPUT : AC 110-240V (50/60 Hz)

POWER CONSUMPTION : 68W

VIDEO IMPEDANCE : 75 Ohm BNC

SOUND OUTPUT : 1.1 0.2W 8 Ohm

SPEAKER SIZE : 77 mm 40 mm

VIDEO OUTPUT LEVEL : 1.0 ~ 1.2Vp p at 75 Ohm

VIDEO INPUT LEVEL : 1.0 ~ 1.2Vp p at 75 Ohm

AUDIO OUTPUT LEVEL : RCA JACK TYPE

300 50mVrms

AUDIO INPUT LEVEL : RCA JACK TYPE

300 50mVrms

SOUND DISTORTION : Less Than 10%

HUM : Less Than 10mVrms

BUZZ : Less Than 200mVp p

2) FEATURES

RASTER MUTING AT NO SIGNAL

PROTECTION CIRCUIT FOR X-RAY

S-VHS INPUT

VIDEO THROUGH-OUT

3) CONTROLS & SWITCHES

MAIN AC POWER S/W : PUSH LOCK FRONT

PICTURE CONTROL : ROTARY FRONT

(CONTRAST, BRIGHTNESS, TINT, COLOR, SHARPNESS)

VOLUME CONTROL : ROTARY FRONT

S-VHS/CAMERA SELECTION : SLIDE SWITCH BACK

VIDEO IMPEDANCE : SLIDE SWITCH BACK

4) LIGHTINGS

INDICATOR : POWER ON (GREEN)

5) JACK & TERMINALS

2 BNC : VIDEO INPUT/OUTPUT

2 AUDIO RCA : AUDIO INPUT/OUTPUT

S-VHS MINI DIN : S-VHS INPUT

AC INLET : AC INPUT

1

SPECIFICATIONS OF CCTV COLOR MONITOR SET

Page 3

6) ACCESSORIES

WARRANTY CARD

OWNER'S MANUAL

POWER CORD

7) CABINET SIZE

350(W) *332(H) *370(D)

8) PACKING

BOX OUT : 437(W) *427(H) *450(D)

Q

TY SET PER 40 FOOT FCL : 675 SETS

Q

TY SET PER 20 FOOT FCL : 325 SETS

9) REMARKS

WEIGHT : 14 Kg

2

Page 4

Follow these safety, servicing and ESD Precautions to prevent damage and protect against

potential hazards, such as electrical shock and X-rays.

Safety Precautions

1. Be sure that all of the built-in protective devices are replaced.

Restore any missing protective shields.

2. When reinstalling the chassis and its assemblies,

be sure to restore all protective devices, including: nonmetallic control knobs

and compartment covers.

3. Make sure that there are no cabinet openings through which

people-particularly children-might insert fingers and contact dangerous

voltages. Such opening include the spacing between the picture tube and

the cabinet mask, excessively wide cabinet ventilation slots, and improperly

fitted back covers. If the measured resistance is less than 1.0 megohm or

greater than 5.2 megohms, an abnormality exists that must be corrected

before the unit is returned to the customer.

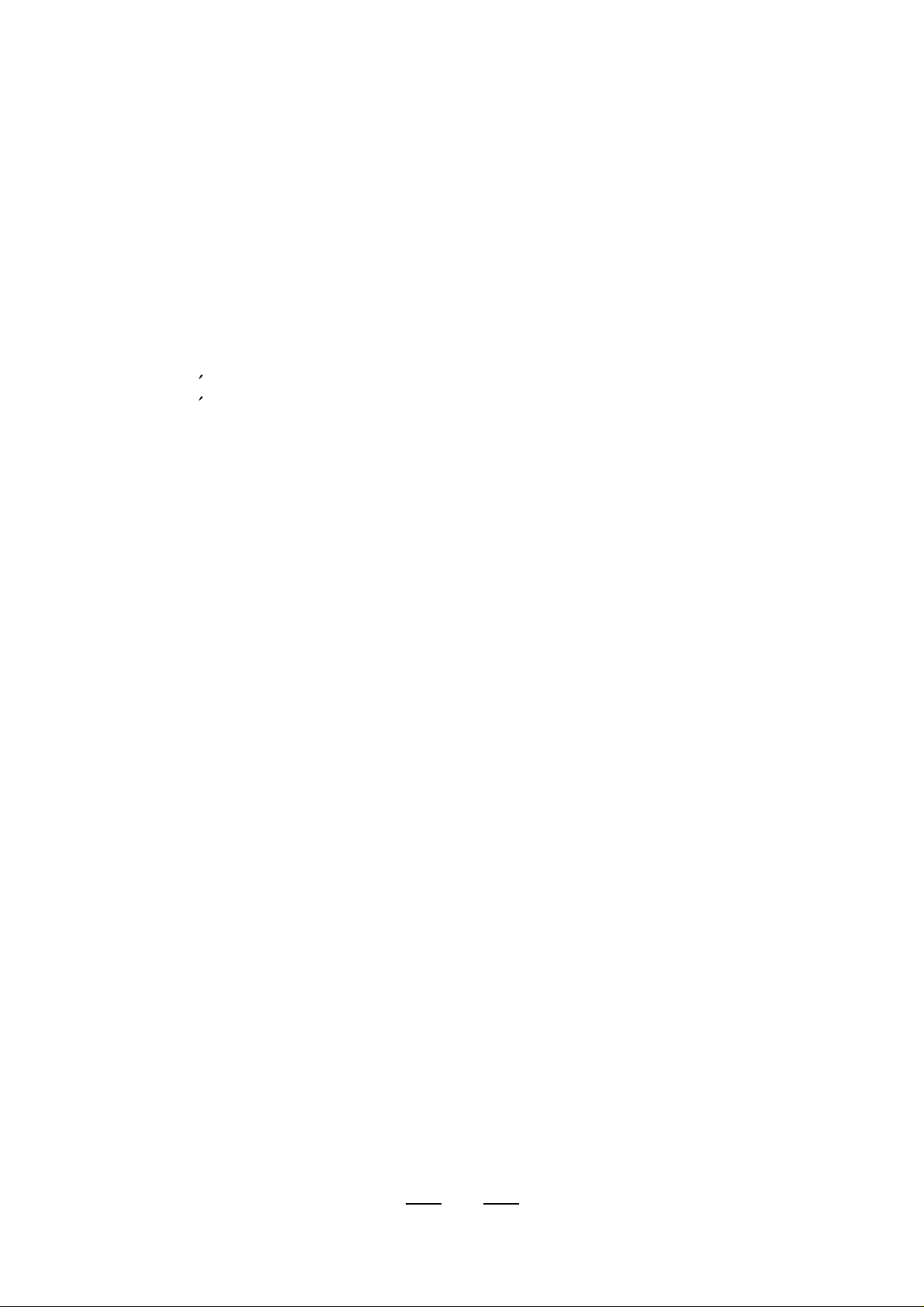

4. Leakage Current Hot Check (Figure 1-1):

Warning:Do not use an isolation transformer during this test.Use a

leakagecurrent tester or a metering system that complies with International

Electrotechnical Commission 65.(IEC 65)

3

FIGURE 1-1 AC LEAKAGE TEST

PRECAUTIONS

Page 5

5. With the unit completely reassembled, plug the AC line cord directly into

the power outlet. @With the unit's AC switch first in the ON position and

then OFF, measure the current between a known earth ground (metal water

pipe,conduit, etc.) and all exposed metal parts, including: handle

brackets, metal cabinets, screwheads and control shafts. The current

measured should not exceed <0.7mA peak AC <2mA DC.

Reverse the power-plug in the AC outlet and repeat the test.

6.X-ray Limits:

The picture tube is especially designed to prohibit X-ray emissions.

To ensure continued X-ray protection, replace the picture tube only with one

that is the same type as the original. Carefully reinstall the picture tube

shields and mounting hardware; these also provide X-ray protection.

7. High Voltage Limits:

High voltage must be measured each time servicing is done on the B+,

horizontal deflection or high voltage circuits.

8. High voltage is maintained within specified limits by close-tolerance,

safety-related components and adjustments. If the high voltage exceeds the

specified limits, check each of the special components.

9. Design Alteration Warning:

Never alter or add to the mechanical or electrical design of this unit.

Example: Do not add auxiliary audio or video connectors. Such alterations

might create a safety hazard. Also, any design changes or additions will

void the manufacturer's warranty.

10. Components, parts and wiring that .appear to have overheated or that are

otherwise damaged should be replaced with parts that meet the original

specifications. Always determine the cause of damage or overheating, and correct any

potential hazards.

11. Observe the original lead dress, especially near the following areas:

Antenna wiring, sharp edges, and especially the AC and high voltage power

supplies. Always inspect for pinched,out-of-place, or frayed wiring.

Do not change the spacing between components and the printed circuit

board. Check the AC power cord for damage. Make sure that leads and

components do not touch thermally hot parts.

12. Picture Tube Implosion Warning:

The picture tube in this receiver employs "integral implosion" protection.

To ensure continued implosion protection, make sure that the replacement

picture tube is the same as the original.

13. Do not remove, install or handle the picture tube without first putting on

shatterproof goggles equipped with side shields.

Never handle the picture tube by its neck. Some "in-line" picture tubes are

equipped with i pernianentlv citticilell deflection yoke; do not try to remove

such "permanently attached" yokes from the picture tube.

4

Page 6

14. Product Safety Notice:

Some electrical and mechanical parts have special safety-related characteristics

which might not be obvious from visual inspection.

These safety features and the protection they give might be lost if the

replacement component differs from the original-even if the replacement is

rated for higher voltage, wattage, etc.

Components that are critical for safety are indicated in the circuit diagram

by shading ( ).

Use replacement components that heave the same ratings, especially for flame

resistance and dielectric strength specifications. A replacement part that

does not have the same safety characteristics as the original might create

shock, fire or other hazards.

Servicing Precautions

Warning 1: First read the "Safety Precaution" section of the manual.

If some unforeseen circumstance creates a conflict between the

servicing and safety precautions,always follow the safety precaution.

Warning 2: An electrolytic capacitor installed with the wrong polarity might

explode

1. Servicing Precautions are printed on the cabinet.Follow them

2. Always unplug the unit's AC power cord from the AC power source before

attempting to: (a) Remove or reinstall any component or assembly,

(b) Disconnect an electrical plug or connector, (c) Connect a test component

in parallel with an electrolytic capacitor.

3. Some components are raised above the printed circuit board for safety.

An insulation tube or tape is sometimes used. The internal wiring is

sometimes clamped to prevent coontact with thermally hot components.

Reinstall all such elements to their original position.

4. After servicing, always check that the screws, components and wiring have

been correctly reinstalled. Make sure that the portion around the serviced

part has not been damaged.

5. Check the insulation between the blades of the AC plug and accessible

conductive parts (examples: metal panels,. input terminals).

6. Insulation Checking Procedure: Disconnect the power cord from the AC

source and turn the power switch ON . Connect an insulation resistance

meter (500V) to the blades of the AC plug.

The insulation resistance between each blade of the AC plug and accessible

conductive parts (see above) should be greater than 1 megohm.

5

Page 7

7. Never defeat any of the B+ voltage interlocks. Do not apply AC power to

the unit (or any of its assemblies) unless all solid-state heat sinks are

correctly installed.

8. Always connect a test instrument's ground lead to the instrument chassis

ground before connecting the positive lead; always remove the instrument's

ground lead list.

Precautions for Electrostatically Sensitive Devices (ESDS)

1. Some semiconductor("solid state")devices are easily damaged by static

electricity.Such components are called Electrostatically Sensitive devices

(ESDs); examples include integrated circuits and some field-effect

transistors.The following techniques will reduce the occurrence of component

damage caused by static electricity.

2. Immediately before handling any semiconductor components or assemblies,

drain the electrostatic charge from your body by, touching a known earth

ground.Alternatively, wear a discharging wrist-strap device. (Be sure to

remove it prior to applying power-this is an electric shock precaution

3. After removing an ESD-equipped assembly,place it on a conductive surface

such as aluminum foil to prevent accumulation of electrostatic charge.

4. Do not use freon-propelled chemicals. These can generate electrical

charges that damage ESDS.

5. Use only a grounded-tip soldering iron when soldering or unsoldering ESDS.

6. Use only an anti-static solder removal device. Many solder removal devices

are not rated as "anti-static"; these can accumulate sufficient electrical

charge to damage ESDS.

7. Do not remove a replacement ESD front its protective package until you are

ready to install it. Most replacement ESDs are packaged with leads that are

electrically shorted together by conductive foam,aluminum foil or other

conductive materials.

8. Immediately before removing the protective material from the leads of a

replacement ESD, touch the protective material to the chassis or circuit

assembly into which the device will be installed.

9. Minimize body motions when unpackaged replacement ESDS. Motion,

such as brushing clothes together, or lifting a foot from a carpeted floor can

generate, enough static electricity to damage an ESD.

6

Page 8

Front View Side View

Rear View

1011 12

13

15

9

14

16

1. POWER BUTTON

2. VOLUME

3. CONTRAST

4. BRIGHT

5. COLOR

6. SHARP

7. TINT

8. POWER LED LAMP

9. POWER INLET

10. IMPEDANCE SWITCH(HIGH/75

)

11. S-VHS/CAMERA SWITCH

12. S-VHS JACK

13. AUDIO IN JACK(RCA)

14. AUDIO OUT JACK(RCA)

15. VIDEO OUT JACK(BNC)

16. CAMERA INPUT JACK(BNC)

WARNING : TO PREVENT FIRE OR SHOCK HAZARD.

DO NOT EXPOSE THIS CCTV TO RAIN OR MOISTURE.

7

LOCATION OF CONTROLS

Page 9

8

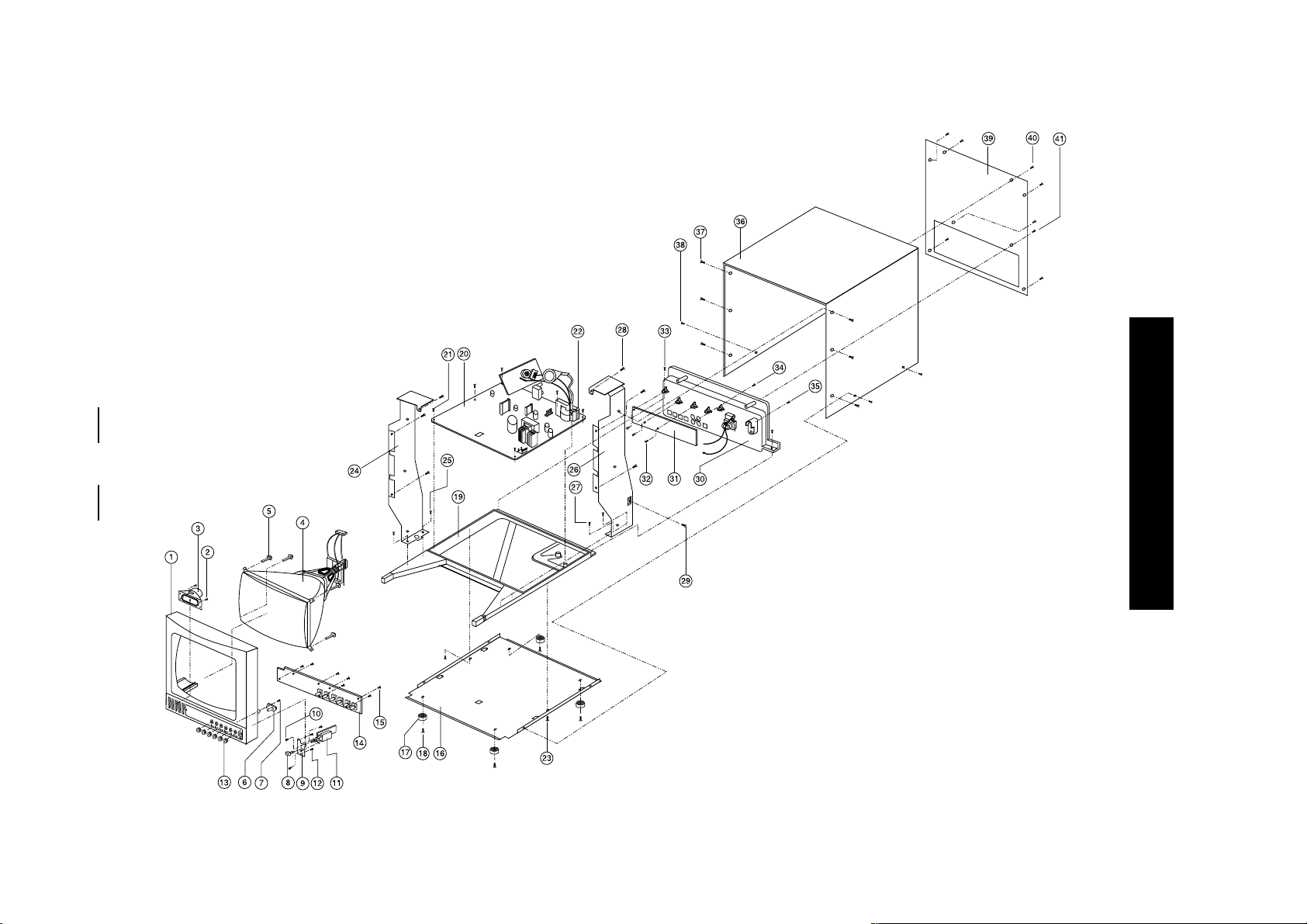

EXPLODED VIEW

Page 10

General Alignment Instructions

1.Usually, a color CCTV needs only slight touch-up adjustment upon

installation. Check the basic characteristics such as height, horizontal and

vertical sync and focus.

2.Observe the picture for good black and white details. There should be no

objectionable color, shading; if color shading is present,demagnetize, perform

purity and convergence adjustments described below.

3.Use the specified test equipment or its equivalent.

4.Correct impedance matching is essential.

5.Avoid overload. Excessive signal from a sweep generator might overload

the front-end of the CCTV SET. When inserting signal markers, do not

allow the marker generator to distort test results.

6.Connect the CCTV SET only to an AC power source with voltage

and frequency as specified on the backcover nameplate.

7.Do not attempt to connect or disconnect any wires while the CCTV SET

is turned on. Make sure that the power cord is disconnected before

replacing any parts.

8.To protect against shock hazard, use an isolation transformer.

Automatic Degaussing

A degaussing coil is mounted around the picture tube, so that external

degaussing after moving the CCTV SET should be unnecessary.

But the receiver must be properly degaussed upon installation.

The degaussing coil operates for about 1 second after the power is switched

ON. If the set is moved or turned in a different direction, the power should

be OFF for at least 10 minutes.

If the chassis or parts of the cabinet become magnetized, poor color purity

will result. If this happens, use an external degaussing coil. Slowly move the

degaussing coil around the faceplate of the picture tube and the sides and

front of the receiver. Slowly withdraw the coil to a distance of about 6 feet

before turning power OFF.

If color shading persists, perform the following Color Purity and Convergence

adjustments.

10

ALIGNMENT AND ADJUSTMENTS

Page 11

High Voltage Check

CAUTION: There is no high voltage adjustment chassis. The B+ power

supply should be 135 volts(see table 5).

(with full color- bar input and normal picture)

1.Connect a digital voltmeter to the second anode of the picture tube.

2.Turn on the SET. Set the Brightness and Contrast controls to minimum

(zero beam current).

3.Adjust the Brightness and contrast controls to both extremes.

Ensure that the high voltage does not exceed Maximum High voltage

(see table 5) under any conditions.

B+(Volts) Maximum High voltage

135 26 KV

Table 5 B+and Maximum High voltage.

FOCUS Adjustment

1.Input a black and white signal.

2.Adjust the tuning control for clearest picture.

3.Adjust the FOCUS control for well defined scanning lines in the center area

of the screen.

Screen Adjustment

1.Connect to the CAMERA signal.

2.Adjust the VR screen for a normal picture is (no blooming or flyback line).

3.Adjust the FOCUS control for well defined scanning lines in the center area

of the screen.

Purity Adjustment

1.Warm up the receiver for at least 20 minutes.

2.Plug in the CRT deflection yoke. Tighten the clamp screw.

3.Plug the convergence yoke into the CRT and set it as shown in Fig. B-1.

4.Input a black and white signal.

5.Fully demagnetize the receiver by using an external degaussing coil.

6.Turn the CONTRAST and BRIGHTNESS controls to maximum.

7.Loosen the clamp screw holding the yoke. Slide the yoke backward

or forward to produce a vertical green belt. (Fig. B-2).

8.Tighten the convergence yoke.

9.Slowly move the deflection yoke forward. Adjust for the best overall green

screen.

10.Temporarily tighten the deflection yoke.

11.Produce blue and red rasters by adjusting the -low-light controls.

Check for good purity in each field.

12.Tighten the deflection yoke.

11

Page 12

12

Center Convergence Adjustment

1.Warm up the receiver for at least 2O minutes.

2.Adjust the two tabs of the 4-pole magnets:Change the angle between them,

and Superimpose the red and blue vertical lines in the center area of the

screen.

3.Adjust the BRIGHTNESS and CONTRAST controls for a well-defined

picture.

4.Adjust the two tabs of the 4-pole magnets;Change the angle between them.

Superimpose the red and the blue vertical lines in- the center area of the

screen.

5.Turn both tabs at the same time, keeping the angle constant: Superimpose

the red and blue horizontal lines in the center of the screen.

6.Adjust two tabs of 6-pole magnets:Superimpose the red and blue lines with

the green. Adjust the angle affects the vertical lines, and rotating both

magnets affects the horizontal lines.

7.Repeat adjustments 2-4 if necessary.

8.Since the 4-pole and 6-pole magnets interact,the dot movement is complex

( FIG. B-3).

FIG. B-1 CONVERGENCE MAGNET ASSEMBLY

Page 13

13

FIG. B-2 CENTER CONVERGENCE ADJUSTMENT

FIG. B-3 CENTER CONVERGENCE ADJUSTMENT

Page 14

DIGITAL VOLTMETER Fluke Model 8060A or equivalent.

OSCILLOSCOPE Kikusui Model cos 2050or equivalent

DIRECT / LOW - CAPACITY PROBE (Accessory of osc)

COLOR - BAR/DOT/CROSSHATCH

GENERATOR Philips Model PM 5518-TXequivalent

SWEEP/MARKER ALIGNMENT

GENERATOR Leader Model 480-080 or equivalent

BIAS SUPPLY Kikusui Model 7314A or equivalent

(Combined in Model 415 generator)

F.S. CIRCUIT CHECK

THE FAIL SAFE (F.S.) CIRCUIT CHECK IS INDISPENSABLE FOR

THE FINAL CHECK WHEN SERVICING.

The checking should be done following the steps below

1. Turn the power switch on and adjust customer controls for normal

operation.

2. Temporarily short Terminal X and Y on the main board with a jumper

wire, and then raster and sound will disappear

3. The receiver must remain in this state even after removing the jumper

wire. this is evidence that the F.S. circuit is functioning properly.

4. To obtain a picture again, temporarily turn the receiver off and allow

the F.S. circuit more than 5 seconds to reset. Then turn the power

switch on to produce a normal picture.

TROUBLESHOOTING GUIDE FOR THE FAIL SAFE CIRCUIT

Check that the set returns to normal operation when Base of Q806

on the main board is grounded with jumper wire.

HORIZONTAL PHASE ADJUSTMENT

If you want to move the center of picture, adjust HORIZONTAL phase

control (R451).

HORIZONTAL size adjustment

1) Input a retma pattern signal.

2) Set contrast and brightness control to max and center each.

3) Adjust R451 for the optimum horizontal size and over scanning.

14

Check if the voltage QF01

“C” is approximately 1.9V

Faulty

Power Circuit

or

Horizontal Circuit

YES

NO

NO

Defective Fail Safe Circuit

YES

TEST EQUIPMENT

Page 15

VRS ADJUSTMENT

1) In put a retma pattern signal.

2) Set Contrast and Brightness Controls to max and center each.

3) Adjust R351 Volume to locate the picture in center vertically.

VERTICAL HEIGHT ADJUSTMENT

The SIZE control R352 on the main board changes the size of the picture,

having an equal effect on the top and the button.

WHITE BALANCE ADJUSTMENT

NOTE : The purpose of this procedure is to optimize the picture tube to obtain

good black and white picture at all brightness levels while at the same time

achieving maximum usable brightness. Normal purity adjustment must be

processed in advance. Press the Service switch to locate service.

1) Tune is a monochrome channel and warm up the set for 15 minutes.

2) Set the R.G.B cut-off controls (R921, R922, R923) clockwise from

the minimum, then set to the Max. 45°position.

3) Set Red and blue driver conrtols (R911, R912) to the middle

position.

4) Rotate the screen control gradually clockwise until the first

horizontal line of a color appears slightly on the screen.

5) Adjust the cut-off controls to obtain the slightly lighted horizontal

lines in the same level of the color (R.G.B). The lines may look like

white if the cut off controls are adjusted properly.

6) Set service switch to locate normal position.

7) Adjust R905, R906 to maintain a good white balance at the Brightness

parts of the screen.

8) Rotate the Brightness and Contrast controls from maximum to

minimum. Observe the screen white balance and if it is not proper in

low and high brightness condition, adjust R.G.B cut-off controls or

R. B drive controls. Respectively in order to maintain a good white

balance under low and high luminance condition.

SUB-BRIGHTNESS ADJUSTMENT

1) Tune in the active station in your area.

2) Set Contrast and Bright Controls to the maximum.

3) Set the color and Tint controls to center.

4) Set the Sub-Bright control R251 to center and leave the receiver for five

minutes in this state.

5) While watching the picture, carefully adjust the Sub-Bright control to

the position where the picture does not show blooming in the high

brightness area and does not appear too dark in the low bright-ness

area.

6) Check for proper picture variation by rotating the Contrast and Bright

control to both extremes.

15

Page 16

16

MAIN SIGNAL PROCESSOR:TDA 8362B

1. FEATURE.

Vision IF amplifier with high sensivity and good differential gain and

phase.

Multistandard FM demodulator(4.5MHz to 6.5MHz)

Integrated chrominance trap and band pass filter

Integrated luminance delay line

PAL/NTSC color decoder with automatically search system.

supply voltage 8V,shrink 52 pin.

2.Pinning and description

audio deemphasis

1

ripple filter

52

tank coil

2

audio mute

51

tank coil

3

audio adjust

50

nc

4

AGC adjust

49

sif in,(volume)

5

IF AGC

48

external aud. in

6

AGC out

47

video det. out

7

IF in

46

ripple filter

8

IF in

45

GND

9

AFT

44

+

8 V

10

VD

43

GND

11

VRAMP

42

decoupling

12

VFB

41

CVBS in

13

phase1 filter

40

ident

14

phase2 filter

39

ext CVBS

15

sandcastle

38

A/V switch

16

H out

37

bright control

17

H osc

36

B - out

18

X 4.43

35

G - out

19

X 3.58

34

R - out

20

H det

33

FB - in

21

x - osc out

32

R - in

22

B - Y out

31

G - in

23

R - Y out

30

B - in

24

R - Y in

29

contrast control

25

B - Y in

28

color control

26

tint control

27

TDA8362B

USING DEVICES AND DESCRIPTION

Page 17

17

3. Block diagram

4. FUNCTIONAL DESCRIPTION

1. Sound circuit

The sound bandfilter and trap filters have to be connected externally.

The filtered intercarrier signal is fed to a limiter circuit and is

demodulated by means of a PLL demodulator.

PLL circuit tunes itself automatically to the incoming

signal,consequently,

no adjustment is required.

2. Synchronization generation circuit.

The sync separator is preceded by a voltage controlled amplifier which

adjusts the sync pulse amplitude to a fixed level.(50%)

3. Integrated video filters

The circuit contains a chrominance BPF and trap circuit.

4. Color decoder

The color decoder in the various ICs contains an alignment-free

crystal oscillator,a color killer circuit and color difference demodulator.

Page 18

5. RGB output circuit

The fast blanking pin has a second detection level at 3.5V

When this level is exceeded the RGB outputs are blanked so that

"on screen display"signals can be applied to the outputs

The output signal has an amplitude of approximately 4V,black to white,

with nominal control setting.

The nominal black level is 1.3V.

BASE BAND DELAYLINE : TDA4665

1.FEATURE

Two combfilters,using the switched-capacitor technique, for one

line delay time(64uS)

Adjust free application

Clamping of AC-coupled input signals.

Output buffer amplifier.

2. Pinning and description

3. BLOCK DIAGRAM

The TDA 4665 is an integrated baseband delay line circuit with one line delay. It is

suitable for decorders with color-difference signal outputs

(R-Y) and (B-Y).

18

digital supply +5V

1

(R-Y) in

16

NC

2

NC

15

digital ground

3

(B-Y) in

14

internal connected

4

NC

13

sandcastle in

5

(B-Y) out

12

NC

6

(R-Y) out

11

internal connected

7

analog ground

10

internal connected

8

analog supply +5V

9

TDA4665

Page 19

VIDEO SWITCH: GL3820

1. FEATURE

2 input 1 output

1 switched video output 2Vpp

crosswalk:50dB

Short circuit protection of inputs and output.

Output buffer amplifier.

2. Pinning and description

External Video will be selected in case that the voltage of the switch

is higher than 7V, and Interner Video seiected in case lower than 7V.

3. BLOCK DIAGRAM

AUDIO OUTPUT :KA2201

1. FEATURE

Wide operating supply voltage : Vcc=3V~14V

Medium output power.

Low quiescent circuit current.

Good ripple rejection.

Minimum number of external parts required.

19

GND

1

8

75

video input

2

7

internal video input

3

6

NC

4

5

GL3820

Page 20

20

2. Pinning and block diagram.

VERTICAL OUTPUT: TDA 3654(TDA 3653)

1. FEATURE

Direct drive to the deflection coil.

Internal blanking guard circuit

Internal voltage stabilizer.

Max output voltage : 60V

Output current : 3Ap-p(TDA3653: 1.5Ap-p)

Pin to pin with TDA3653

2. BLOCK DIAGRAM

POWER CIRCUIT(STR5707)

1. DESCRIPTION

STR-S5707 has a power transistor and hybrid IC(playback converter type,

with internal control circuit for power switching). Its size is small and

standardized due to the reduced parts count and simplified circuit design.

2. Features

COLD SMPS

DIRECT FEED-BACK TYPE

Reduced external parts - Simple power switching design.

pin description

descriptionpin

CB1

NF2

INPUT3

GND4

OUTPUT5

Vcc6

BOOTSTRAP7

RIPPLE8

Page 21

21

3.BLOCK DIAGRAM

4.PIN FUNCTION

5.SPECIAL FUNCTION.

1) OVP function(Overvoltage protection)

The over voltage protection is performed by the pulse by pulse system witch

directly detects the collector voltage of power transistor.

2)Latch circuit

The overvoltage protection circuit OVP or the (overheat protection circuit)

stops the operation of the power circuit by holding the oscillator output low.

The latch circuit current resistor 500uA MAX when the VIN port voltage

registers 5.8V;at this time,if the current through the driving resistor is grater

than 500uA to VIN port then the power circuit remains in stop mode.

3)OHP(OVERHEAT PROTECTION) CIRCUIT

It activates the latch circuit when the HIC frame temperature goes over 150'c(typ);the

actual temperature is detected by the control circuit. But, the

power transistor and the control circuit are prevented from overheating

because they are built in the same frame.

TER-NAME SYMBOL TERMINAL NAME FUNCTION

1 C OCLLECTOR TERMINAL POWER TR COLLECTOR

2 GND GROUND TERMINAL GROUND(POWER TR EMITTER)

3 B BASE TERMINAL POWER TR BASE

4 SINK SINK TERMINAL BASE CURRENT(Is) INPUT

5 OCP OVER CURRENT TERMINAL O/C DETECT SIGNAL INPUT

6 INH INHIBIT TERMINAL STOP OSCILLATION(LATCH)

7 F/B FEED BACK TERMINAL VOLT REG CONTROL INPUT

8 DRIVE DRIVE TERMINAL BASE OPERATING CURRENT

9 VIN POWER IN TERMINAL CONTROL CIRCUIT VCC IN

Page 22

The following chart is for a trouble shooting which will assist you in finding out

a fault and lead you to the correct stage. In order to utilize the chart(fault

tree), first establish the complaint point(for example, No Raster, No Sound).

Locate the position of the complaint point and keep track of the arrow and

progress though the various alternatives until a final block indicates the

defective components or stage.

1. NO POWER ON AND NO RASTER

checked when power sw on.

22

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

TROUBLESHOOTING GUIDE

LED illuminant?

Check C831

normally 13VDC

Check/ replace

D830

Check the

voltage Q801

Check and

replace F801

D801

Check C419

normally 8V

Replace D813,

Q806

Check the

voltage at pin

9 of Q801

normally about

6V DC

F.S. circuit check

Check and

replace

Q802,Q803

D808,D809

D810,D811

Check pin 17

of Q501

normally 3.93V

DC

check and

Replace

Q501

Check the PIN 7

of the Q801

Replace

D807

Check emitter

of Q402

normally 9V DC

check and

Replace

Q402

Replace after check Q801

Check base of

Q404 normally

over 0.6V DC

Replace T401

Replace T461,Q404

Check at C822

normally 135V DC

Page 23

2. NO RASTER (SOUND OK)

3. NO SOUND (PICTURE OK)

Do the volume control in max before check this routine.

23

YES

NO

NO

NO

YES

YES

Check whether the Click sound

occur when touching the pin 3

and 4 of Q601

Check the pin 5 of

Q501 normally 4V DC

Check/Replace C614, R602

R606, R607 Replace above

parts lt’s OK

Check and

Replace Q661

Check/replace

P601, SPEAKER

replace

Q601

Check voltage at

Q601 pin 11

normally 11V DC

Check/replace

R601, L806

D822

YES

NO

NO

NO

NO

YES

Check and Replace Q501

YES

YES

Check C281 normally 170 to 190V DC

Check the Q502, Q901, Q902,

Q903, Q904, Q905, Q906

Check the heater voltage

normally 6.1V AC

Check and Replace CPT

Check/replace D281

Check/replace Q502, Q901,

Q902, Q903, Q904, Q905,

Q906

Check and Replace R999,

D911

Page 24

CHASSIS BLOCK DIAGRAM

No. 0416

CPX1402MS Block Diagram

HITACHI

Page 25

PCB LAYOUTS

Control PCB

25

Page 26

Page 27

P881

S801

CAMERA IN

P101

DC2700K

P151

DC2700K

VIDEO OUT

PMEZ01-2

POWER CORD

AC 90-260V

P802

PMEZ01-3

KSB2178A

L901

M150

2P 2P

P150

CAMERA V-IN

PMEC01

RB26

7.5K

P803

C802

0.47u

AC 275V

P801

9 OHM

S102

KSA-2273S

RV49

82

RB25

7.5K

RB56

510

RB062RB05

R910

C801

0.47u

275Vac

C803-C806 2KV 2200

D801

D3SBA60

2R 22K

L801

DMF-2854

R880

1/2S

4.7M

F801

250V 3.15A

1 2

M503

RB24

36K

3 4

C804

R802

STR-S5707

P503

RB55

9.1K

C806

C805

~~+

C803

TINT

876

8

RB04

12

-

2R 22K

Q801

BRIGHT

COLOR

6 5 4 3 2 1

7

RB34

10K

RB44

3.3K

RB23

15K

RB54

820

RB03

R840

SHARP

CONT8VVOL OUT

5 4 3 2 1

RB33

9.1K

RB

RB32

43

12K

51K

RB51

RB22

10K

11K

RB53

2.7K

RB02

CONTBRICOLORTINT VOLSHARP

RB01 RB02:10K VR12H01C-020FBRB03-RB06:10K VR12H01C-120FB

R801

R811

C807

5W 1

270K

400V

220u

1/2S

R810

100K

C811

16V

220u

9

START

O V P

UP

1

PRE

PEG

2

THERMAL O S C

7

GND

RB01

LATCH PROPORTIONAL

3

CPT BOARD

D901 902 903

1N4148*3

M501

R663

R220 10K

1N4148

220K

R665

18K

R661

12K

8

C209

100u

16V

7

6543

VOLUME CONTROL

C607

C606

10u

4.7u

CF87

3.3u

C201

104M

L502

10u

C203

16V

470u

C230

AX 104

C202

470u

16V

R219

10K

D204

R210

2.2K

R209

3.6K

L009

KRF

9200B

BGR

12

R211

100

R501

100

R502

100

R503

100

R217

82K

R606

20K

C603

332M

C604

10V

1000u

(NON IND)

R215

100K

C212

0.47u

R213 12K

C614

1u

R602

10K

4 3 2 1

KA2201N

C610

R604

10V

1

47u

C605

104M

H

G

C204

224EB

C206

10u

C208

1u

R228

82k

Q601

R607

1K

R605

3.3

1/2R

DF03

1N4148

V

P901

VOLUME

RV10

1K

CF90

3.3u

RF40

100K

QF87

GL3820

1

2

S101

S/VHS SWHS

KSA-2273S

L503

4.7u

C599

104

M

+33V

SHARPNESS

C598

103

M

BW-H

BRIGHT

C250

AX 100

R234

4.7K

R251

50KB FBB

SUB-BRIGHT

CONTRAST

COLOR

TINT

AUDIO OUT

R043

18K

2R

C042

D009

104M

KA33

R231

R232

R233

3.3K*3

C511

C512

C513

220pF*3

P501

W661

SPK1203

8ohm

RF85

10K

RF97

RF96

10K

47K

QF84

KRC111M

QF85

KRC111M

RB21

3.6K

C834

1000u

3

Q806

135V

KLG114E

PMEZ01-4

13V

RS01

QS03

7.5K

KTC3198Y

16V

D116

RS03

200K

RS09

2.2K

CS04

16V

10u

DS01

RS07

9.1B

1K

RS08

DS02

10K

9.1B

R088

470

PV01

P116

M116

A.OUT

RS06 1K

CS01

QS02

10u

C3198Y

16V

RS02

4.7K

CS03

10u

16V

CV02

22u 25V

CV04

1000

LV01

RV09

56u

75

Y IN

C IN

P661

S-VHS IN

M661

PV02

A.IN

KPW-1142

T801

R803

221/2R

Q802

Q803

C3228Y

C815

4.7u

C3228Y

DRIVE

FET

6

D807

1N4937

D808

R804

1N4937

47

R805

C810

10u

10K

D809

MTZ

7.5B

D811

D814

EU1ZV

EU1ZV

R809

1/2R 27R

8

4

C814

R814

16V

1/2

330u

0.33

3

L803

BFS3565

1

D812

EH1ZV1

L804

BFS3565

5

R807

1/2W(PRN)

0.22

R806

C813

102

1K

18

1

17

6

7

D810

EU1Z

8

R808

2.7K

C890

400V

4700

C812

1.6KV

2200

C830

500V

2200

16

15

L823

D830

UF156

BFS

3550

C831

25V

1000u

14

C820

2KV

2200

L821

BFS3565

114

D820

RU3C

C891

400V

4700

C821

200V

100u

Q805

KIA7805P

R823

2R 10

1

L822

KRF

G028

R820

2

C832

390

25V

1000u

KTC3198Y

R821

330

D813

MTZ8.2B

L820

KRF

G028

C822

200V

47u

8V

Q501

TDA8362B

DEEMPHASIS

1

2

IF

DEM

3

IDENT

4

SIF-IN

3.34

VOL-CONT

5

3.93

EXAU-IN

6

V-OUT

7

1.71

DECOUP

8

9

VCC

7.84

(+8V)

10

11

3.59

DECOUP

12

CVBS IN

13

2.94

14

EXT

3.51

CVBS

15

CHROMA

0.33

A/V IN

16

3.93

BRIGHT

17

2.76

B-OUT

18

2.75

G-OUT

19

2.72

R-OUT

20

RGB IN

21

R-IN

22

G-IN

23

B-IN

24

2.52

CONT

25

1.67

COLOR TINT

C213

1u

D202 1N 4148

R601

430

C602

10V

47u

8765

C613

10V

100u

C611

16V

1000u

RF06

47K

QF02

KTC3198Y

RF07

4.7K

VIDEOIDET

DEMODULATOR

LIMITER

SWITCH

VOLUME

COINCIDENCE

DETECTOR

PLL

VIDEO

-AMP

NOISE

DETECTOR

LINE

OSC

TUNING

PHASE1

TRAP

BYPASS

PEAKING

LUMINANCE

SWITCH

CHROM

SWITCH

CHROM

BANDPASS

ACC

AMP

COLOR

OUTPUT

STAGES

LUMINANCE

MATRIX

3

CLAMP

SWITCH

3

PWLY DELAY

MATRIX

THERMAL

PROTECT

DRIVER

IN OUT

C601

2

1 9

103M

2.14 14.8 27.1 5.30 26.8

C301

103M

+135V

RF05

10K

QF01

KTA1266Y

DF02

MTZ

12B

CF01

RF04

104M

10K

**NOTES**

1. The unit of all resistors is the "OHM" unless otherwise listed.

K=1,000 M=1,000,000 1/2S:SOLID 1/2W

1/2R:Metal or Metal Oxide 1/2W 5W:Cement Resistor

KILLER

OUT

STAGE

PROTECT

IN

RF02

1K

AFC

SYSTEM

MANAGER

DEMODU

LATOR

YX

RF01

4.7K

RF03

4.7K

SUPPLY

PREAMP/

MUTE

AGC

H/V

SEPAR

VERT

DRV

TUING

PHASE

DETECTOR

3

CLAMPS

2

TINT

CONTROL

VERTICAL DEFLECTION

Q301

OUT

STAGE

C302

510

1N4148

6.70

52

4.21

51

AU

3.47

OUT

50

49

C106

2.2u

48

AGC

OUT

47

IF-AMP

46

IF

IN

45

AFC

44

3.60

VD

43

2.84

VRAMP

42

OUT

2.43

R419

VFB

41

15K

POWER

RESET

4.0

40

3.60

39

PHASE2

0.47

SND

38

0.35

HD

37

7.31

HOSC

36

X503

4.433619

2.60

4.43

35

XTAL

OSCVERT

SET

3.58

DET

XOUT

B-Y

OUT

R-Y

OUT

R-Y

IN

B-Y

IN

R511 51K

X502

3.579545

34

4.74

33

1.54

32

1.55

31

1.55

30

3.96

29

3.96

28

2.65

2726

TDA3654

FLYBACK

VOLTAGE

GENERATOR

STABILIZER

GUARD

CIRCUIT

8

543

6

7

D302

1N4937

C303

100u

R302

470

1/2S

C304

223M

C483

16V

1000u

R409

100

1/2R

R401

100

DF01

C3228Y

2. All capacitors are the 50V Ceramic ones of which the unit

is " pF" unless otherwise listed.

= PLASTIC CONDENSER

M

C105

2.2u

C402

472M

C401

472M

KIA7808PI

Q401

R301

2.7K

Q482

8V REG

C403

1u

CF19

200

CF18

100

R504

100K

(NON IND)

(NON IND)

C216

4.7u

C305

104M

V-OUT

C473

47u

35V

L481

KRF

9200B

PK : PEAKING COIL

AU OUT

VD

R303

C306

3.3M

104M

33V

C308

472M

R418

3.3

C419

10V

100u

C506

102M

C418

16V

C505

47u

104M

C502

104EB

C501

104EB

R474

100K

H-SIZE

R475

50KB

R473

10K

R476

100

185V VIDEO

+135V

HEATER

26V VER

C413

10u

R406

T401

100

KLN

2019

C412

500V

2200

R

G

D901

B

12

D903

D902

G

R403

820K

R416

4.7K

D505

R505

MTZ

5.1B

47

C414

0.22uF

D403

1N4148

R410

15K

D404

8.2B

C421

223M

R477

1/2R

2.7K

Q412

A1275Y

D472

1N4148

C482

16V

1000u

R411

1

1/2R

R407

27

3. The voltage and waveform is measured between the indicated point

and the chassis ground with the DVM AND THE OSCILOSCOPE.

The input signal is a color bar one with all picture controls at standard.

R478

1/2R

1K

D471

1N4148

KTD2059Y

C050

16v

470u

S201

SERVICE SW

R479

1/2R

330

R472

1/2R

1.2

Q411

C382

35V

1000u

C481

500V

1000

L402

KC5-035

Q404

HOR OUT

KTD2499

R330

C381 500V 1000

C3229

R907

C905

220

102

Q904

C3198Y

R903

2K

R901

6.8K

R902

330

R904

100

Q902

R917

C915

C3229

102

220

Q905

C3198Y

R913

390

R911

6.8K

R912

330

R914

100

C925

Q903

R927

102

C3229

220

Q906

C3198Y

R923

2K

R921

R922

6.8K

330

R924

100

HRS

R451

5KB

C503

102M

1.41

Vi(R-Y)

1.40

C504

102M

2.95

Vi(B-Y)

2.97

C509

R507

16V

10

47uF

C510

103M

D203

1K

R309

1N4148

30K

R310

15K

R352

R312

100

56

V-SIZE

R483

1R 10K

C408

200V

L411

624J

HW-VN

L413

L412

KLN

KLN

3041

3041

C407

C492

200V

50V NP

184J

10u

R281

D281

11/2R

1N4937

C281

250V

33u

D911

1N4937

R381

D381

2F 1

1N4937

R480

D481

2F

1N4937

2.7

D411

C405

RU4DS

752M

1.6KV

C406

630V

D412

104M

RU4DS

Q901

C911

560

C921

560

16

15

14

13

12

11

10

9

C311

0.47u

C901

560

1H DELAY

LINE

Vo(B-Y)

Vo(R-Y)

LINE.LOCKED PLL/

PULSE PROCESSING

R308

6.8K

L902 150u

1/2R 15K

R905

200

1/2R 15K

R916

2.2K

R915

220

1/2R 15K

R926

2.2K

R925

220

Q502

TDA4665

LINE DELAY

+

R307

1/2R

2.2

C409

200V

184J

R481

1/2S

300K

R908

R906

2.2K

L912

150u

R918

L922

150u

R928

LINE DELAY

+

VCO

R306

30K

C312

25V

2200u

1

3

2

9

7

10

7

6

PMEZ01-1

R940

2R 20K

R970

L901

2R 20K

150u

R909

1/2S 1KS

R957

5K

R919

1/2S 1KS

L911

R920

2R 20K

150u

R950

2R 20K

R958

5K

R929

1/2S 1KS

R930

2R 20K

R960

2R 20K

R959

5K

5.2

1

2

3

4

SAND

5

0.47

6

7

8

R305

270

1/2S

VRS

R351

500B

R304

240

1/2R

R311

270

1/2S

L401

KLN2061

R408

1/2R

1K

C410

500V

2200

T461

MCG-14A35

3000

C207

200V

223M

S/S : A34KQV42X01

LG : A34KPU02XX

L921

150u

C307

104M

L491

6800uH

C491

160V

1u

R412

1/2R

560

H

12

F

S

11

8

4

5

R482

1K

1/2R

HG

P401

V901 CPT

C935

222

2KV

R999

1/2R

1.5

23

22

21

20

V

M901

V901L

DSE-1420

OR KYS-60159

OR SHO-M1422

DY C OIL

HV

F

S

No. 0416

CPX1402MS Schematic Diagram

27

HITACHI

Page 28

THE UPDATED PARTS LIST

FOR THIS MODEL IS

AVAILABLE ON ESTA

Page 29

Hitachi, Ltd. Tokyo, Japan

International Sales Division

THE HITACHI ATAGO BUILDING,

No. 15 –12 Nishi Shinbashi, 2 – Chome,

Minato – Ku, Tokyo 105-8430, Japan.

Tel: 03 35022111

HITACHI EUROPE LTD,

Whitebrook Park

Lower Cookham Road

Maidenhead

Berkshire

SL6 8YA

UNITED KINGDOM

Tel: 01628 643000

Fax: 01628 643400

Email: consumer-service@hitachi-eu.com

HITACHI EUROPE GmbH

Munich Office

Dornacher Strasse 3

D-85622 Feldkirchen bei München

GERMANY

Tel: +49-89-991 80-0

Fax: +49- 89-991 80-224

Hotline: +49-180-551 25 51 (12ct/min)

Email: HSE- DUS.service@hitachi-eu.com

HITACHI EUROPE srl

Via Tommaso Gulli N.39, 20147

Milano, Italia

ITALY

Tel: +39 02 487861

Tel: +39 02 38073415 Servizio Clienti

Fax: +39 02 48786381/2

Email: customerservice.italy@hitachi-eu.com

HITACHI EUROPE S.A.S

Lyon Office

B.P. 45, 69671 BRON CEDEX

FRANCE

Tel: 04 72 14 29 70

Fax: 04 72 14 29 99

Email: france.consommateur@hitachi-eu.com

HITACH EUROPE AB

Egebækgård

Egebækvej 98

DK-2850 Nærum

DENMARK

Tel: +45 43 43 6050

Fax: +45 43 60 51

Email: csgnor@hitachi-eu.com

Hitachi Europe Ltd

Bergensesteenweg 421

1600 Sint- Pieters-Leeuw

BELGIUM

Tel: +32 2 363 99 01

Fax: +32 2 363 99 00

Email: sofie.van.bom@hitachi-eu.com

www.hitachidigitalmedia.com

HITACHI EUROPE S.A.

364 Kifissias Ave. & 1, Delfon Str.

152 33 Chalandri

Athens

GREECE

Tel: 1-6837200

Fax: 1-6835964

Email: service.hellas@hitachi-eu.com

HITACHI EUROPE S.A.

Gran Via Carlos III, 101- 1

08028 Barcelona

SPAIN

Tel: 93 409 2550

Fax: 93 491 3513

Email: atencion.cliente@hitachi-eu.com

HITACHI Europe AB

Box 77 S-164 94 Kista

SWEDEN

Tel: +46 (0) 8 562 711 00

Fax: +46 (0) 8 562 711 13

Email: csgswe@hitachi-eu.com

HITACHI EUROPE LTD (Norway) AB

STRANDVEIEN 18

1366 Lysaker

NORWAY

Tel: 67 5190 30

Fax: 67 5190 32

Email: csgnor@hitachi-eu.com

HITACHI EUROPE AB

Neopoli / Niemenkatu 73

FIN-15140 Lahti

FINLAND

Tel : +358 3 8858 271

Fax: +358 3 8858 272

Email: csgnor@hitachi-eu.com

HITACHI EUROPE LTD

Na Sychrove 975/8

101 27 Praha 10 – Bohdalec

CZECH REPUBLIC

Tel: +420 267 212 383

Fax: +420 267 212 385

Email: csgnor@hitachi-eu.com

Loading...

Loading...