Page 1

YK

S

TAN

D

B

Y

/O

N

IN

P

UT

K

EY

S

T

O

N

E

R

ES

ET

LANP

TENP

POWER

No.0534E

(C3SM4)

(C3XM4)

SERVICE MANUAL

Warning

CP-S318

CP-X328

The technical information and parts shown in this

manual are not to be used for: the development,

design, production, storage or use of nuclear, chemical,

biological or missile weapons or other weapons of

mass destruction; or military purposes; or purposes that

endanger global safety and peace. Moreover, do not

sell, give, or export these items, or grant permission for

use to parties with such objectives. Forward all inquiries

to Hitachi Ltd.

Caution

Be sure to read this manual before servicing. To assure safety from fi re, electric shock, injury, harmful radi-

ation and materials, various measures are provided in this Hitachi Multimedia LCD Projector. Be sure to

read cautionary items described in the manual to maintain safety before servicing.

Service Warning

1. When replace the lamp, to avoid burns to your fi ngers. The lamp becomes too hot.

2. Never touch the lamp bulb with a fi nger or anything else. Never drop it or give it a shock. They may

cause bursting of the bulb.

3. This projector is provided with a high voltage circuit for the lamp. Do not touch the electric parts of

power unit (main), when turn on the projector.

4. Do not touch the exhaust fan, during operation.

5. The LCD module assembly is likely to be damaged. If replacing to the LCD LENS/PRISM assembly, do

not hold the FPC of the LCD module assembly.

6. Use the cables which are included with the projector or specifi ed.

Contents

1. Features --------------------------------------------------- 2

2. Specifi cations---------------------------------------------2

3. Names of each part ------------------------------------- 3

4. Adjustment ------------------------------------------------ 5

5. Troubleshooting---------------------------------------- 12

6. Service points ------------------------------------------ 17

7. Wiring diagram ----------------------------------------- 30

8. Disassembly diagram--------------------------------- 36

9. Replacement parts list-------------------------------- 38

10.RS-232C communication ---------------------------- 39

11.Block diagram------------------------------------------- 45

12.Connector connection diagram -------------------- 46

13.Basic circuit diagram---------------------------------- 47

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT.

Multimedia LCD Projector

July 2003 Digital Media Division

Page 2

CP-S318(C3SM4) / CP-X328(C3XM4)

1. Features

High brightness high resolution

Full connectivity

Easy and flexible keystone adjustment

My screen

Wide angle lens

Low noise

2. Specifications

Liquid crystal

panel

Lamp

Video input

Drive system

Panel size

Number of pixels

System

Level

CP-S318 CP-X328

TFT active matrix

0.7 inches

800 (H) × 600 (V) 1024 (H) × 768 (V)

150W UHB

NTSC, PAL(BGDHI), SECAM, PAL-M, PAL-N, NTSC4.43, PAL60

Composite

S-video

Component

1.0 0.1Vp-p (75 termination)

Y : 1.0 0.1Vp-p (75 termination)

C : 0.286 0.1Vp-p (NTSC burst signal, 75 termination)

0.3 0.1Vp-p (

Y : 1.0 0.1Vp-p (75 termination)

B/CR

: 0.7 0.1Vp-p (75 termination)

C

P

B/PR

: 0.7 0.1Vp-p (75 termination)

PAL/SECAM burst signal, 75 termination

)

RGB input /

output

Audio

Speaker output

Power supply

Power consumption

Dimensions

Weight

Temperature range

Accessories

Analog RGB

Sync.

Iuput

Output

0.7Vp-p (75 termination)

200mVrms, output impedance 1k

AC100~120V/2.7A, AC220~240V/1.3A

295 (W) × 87.5 (H) × 231 (D) mm

2.74kg (6.04lbs)

Operation : 0~35°C

Storage : -20~60°C

Remote control transmitter × 1

RGB cable × 1

Video/Audio cable × 1

USB cable × 1

TTL level

200mVrms, 47k

1.0W (mono)

240W

POWER cord × 3

Battery × 2

Carrying bag × 1

User's manual

(with Safety Instructions)

× 1

2

Page 3

CP-S318(C3SM4) / CP-X328(C3XM4)

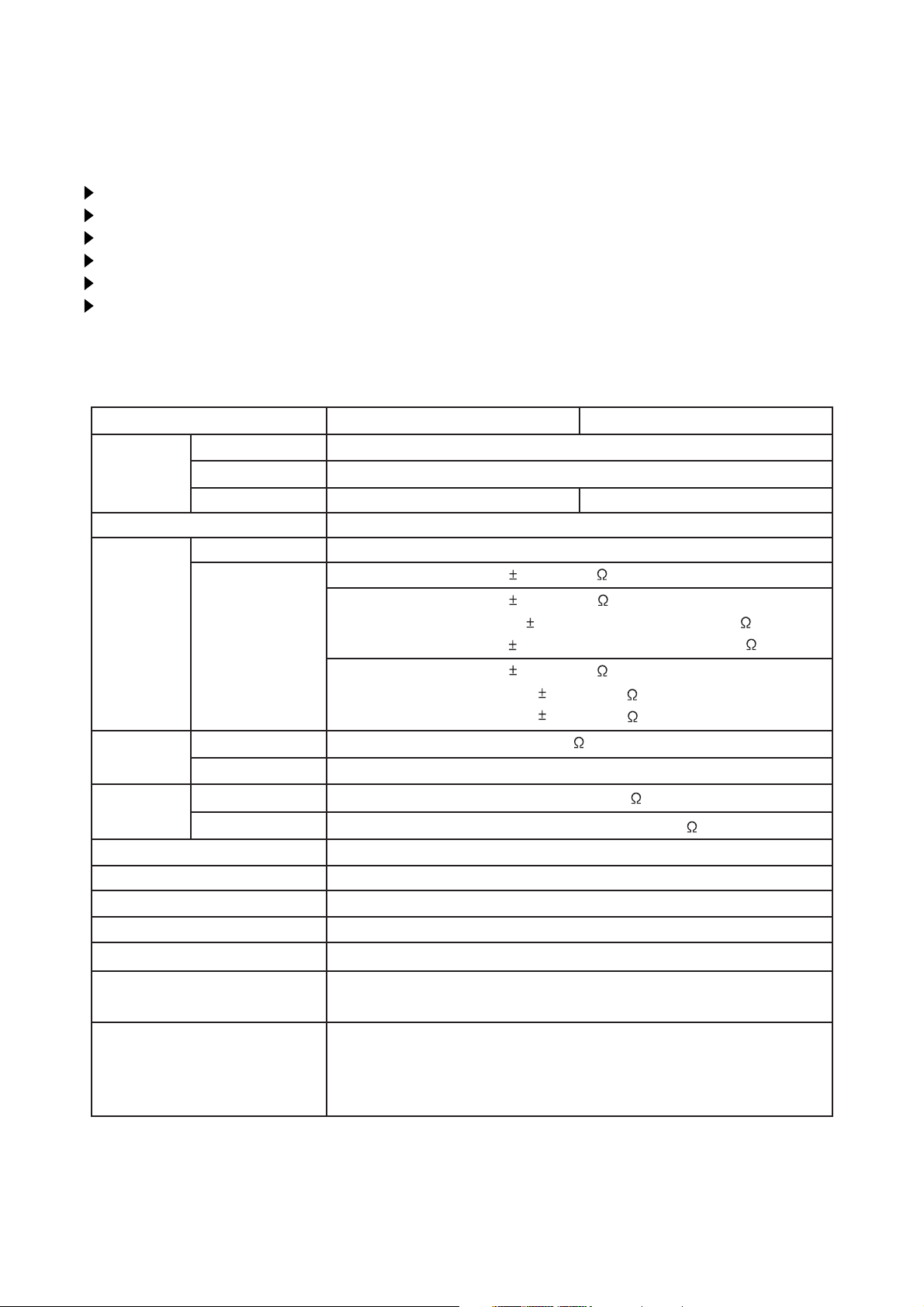

Zoom ring

Focus ring

Air filter

Elevator button

Elevator button

KEYSTONE button

STANDBY/ON button

INPUT button

RESET button

MENU button

LAMP LED

TEMP LED

POWER LED

Remote sensor

AC power inlet

S-VIDEO IN port

RGB IN 1 and 2 ports

AUDIO IN R and L ports

VIDEO IN port

CONTROL port

RGB OUT port

USB port

COMPONENT VIDEO port

Power switch

3. Names of each part

Parts names

STA

N

D

T

SE

ER

POW

TENP

P

LAN

B

Y

/O

N

IN

P

U

T

K

E

YS

TO

N

E

LANP

TENP

PO

W

ER

R

E

S

ET

E

R

E

N

TO

S

EY

K

T

PU

IN

N

Y/O

B

D

AN

T

S

3

Page 4

CP-S318(C3SM4) / CP-X328(C3XM4)

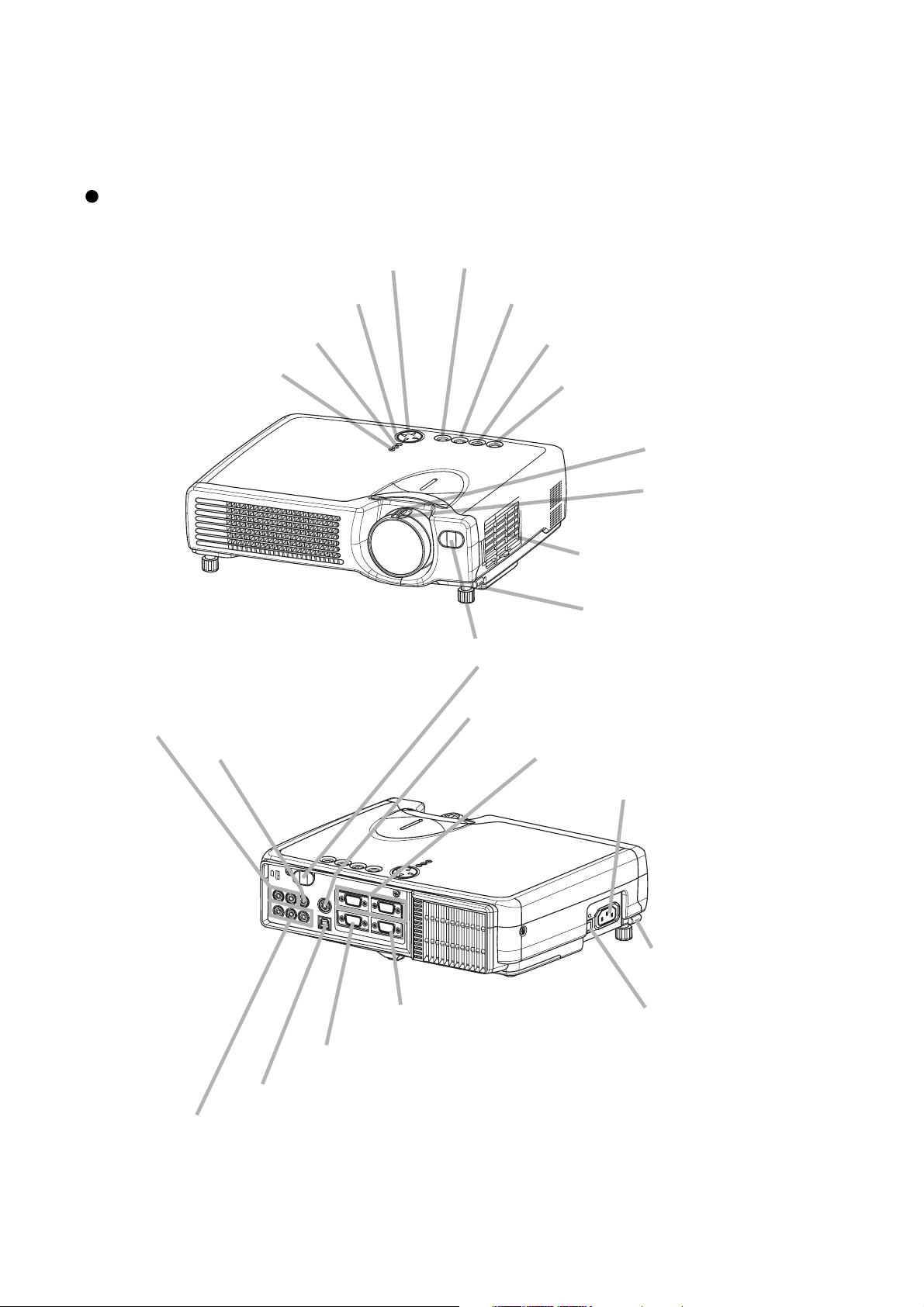

STANDBY/ON button

VIDEO button

MENU button

RGB button

BLANK button

SEARCH button

VOLUME button

MUTE button

KEYSTONE button

ASPECT button

AUTO button

MAGNIFY button

KEYBOARD buttons

FREEZE button

POSITION button

ESC button

,,,

Cursor buttons

RESET button

ENTER button

VIDEO

RGB SEARCH

ASPECT

HOME

MAGNIFY

ON

END

OFF

ENTER

ESC RESET

STANDBY/ON

AUTO BLANK

PAGE UP VOLUME

PAGE DOWN

MUTE

KEYSTONEFREEZE

MENUPOSITION

Remote control transmitter

4

Page 5

CP-S318(C3SM4) / CP-X328(C3XM4)

4. Adjustment

4-1 Before adjusting

4-1-1 Selection of adjustment

When any parts in the table 4-1 are changed, choose

the proper adjusting items with the chart.

4-1-2 Setting of condition before adjustment

1. Before starting adjustment, warm up the projector

for about 10 minutes.(Blank white)

2. Set Zoom Wide to Max. And project an image

with more than 40 inches in diagonal size.

3. Normalizing the video adjustment.

(Press the [MENU] button of the Remote control

transmitter to display the MAIN menu, and then

press the [RESET] button. And select the

[DEFAULT]. Next, open MAIN menu and press the [

] key to display the PICTURE1 menu, then press

the [RESET] key to set to [DEFAULT].)

*note :The MAIN and PICTURE1 menu is not

reset with no signal.

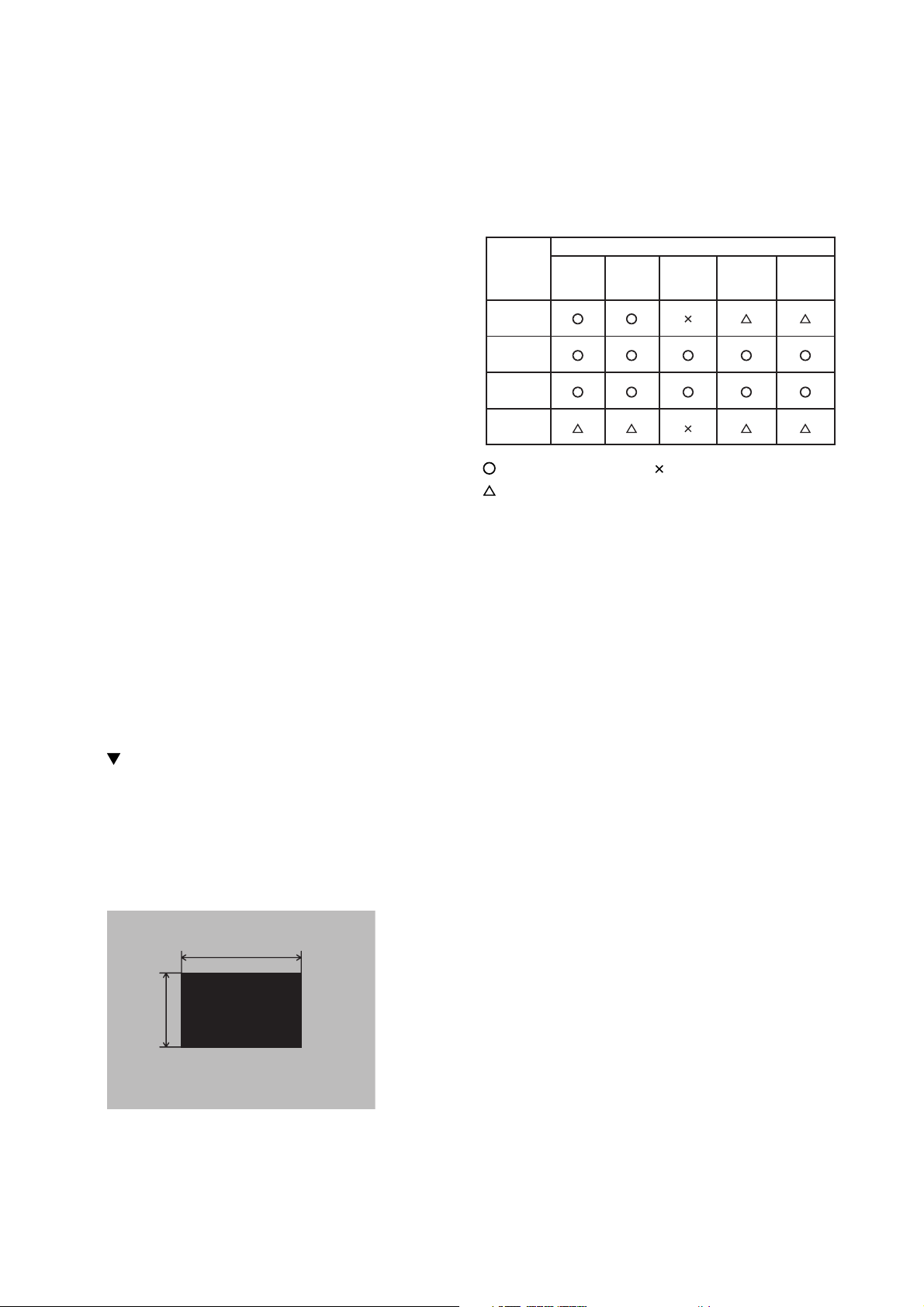

Table 4-1: Relation between the replaced part and adjustment

Adjustment

Replaced

part

Dichroic

optics unit

LCD/LENS

prism

assembly

PWB

assembly

drive

Lamp

unit

assembly

Ghost

(Chap.4-2)

Flicker

(Chap.4-3)

PSIG/NRSH

(Chap.4-4)

(Chap.4-5)

White

balance

Color

uniformity

(Chap.4-6)

: means need for adjustment. : means not need for adjustment.

: means recommended.

4. Set the normal at OPT-WHISPER in the menu.

5. Reset KEYSTONE correction.

6. Perform all adjustments from the Adjustment

menu.

Perform the following operations to display the

Adjustment menu.

a. Press the [MENU] button of the Remote

control transmitter (the MAIN menu will

appear).

b. Next, press the [RESET] button one time. And

press the [RESET] button again for 5 seconds

or more (the Adjustment menu will appear).

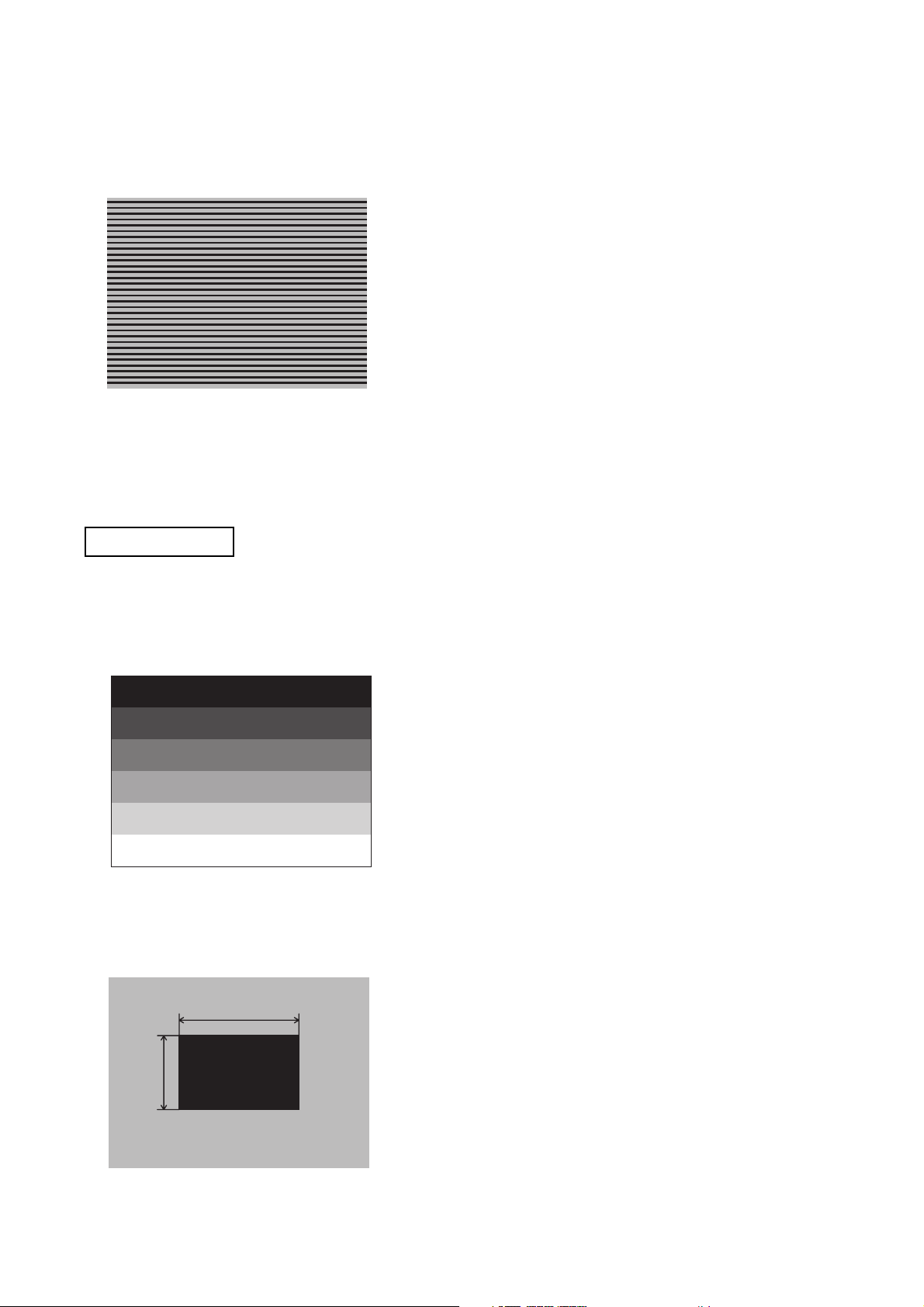

4-2 Ghost adjustment

Signals for internal adjustment

30%

30%

0/255

112/255

Adjustment procedure

1. Use DAC-P - GHOST - R: in the Adjustment

menu to adjust so that R color ghost is at a

minimum.

(Set the adjustment value to default, and then raise

the value. When a ghost appears to the left of a

vertical line, reduce the value by 2 steps.)

2. In the same way, use DAC-P - GHOST-G: in the

Adjustment menu to adjust so that G color ghost

is at a minimum.

3. In the same way, use DAC-P - GHOST-B: in the

Adjustment menu to adjust so that B color ghost

is at a minimum.

5

Page 6

CP-S318(C3SM4) / CP-X328(C3XM4)

4-3 Flicker adjustment

Signals for internal adjustment

(V.COM adjustment)

CP-S318 ONLY

4-4 PSIG adjustment

4-4-1 PSIG-G adjustment

Adjustment procedure

1. Make this adjustment after completing the

adjustment in 4-2 Ghost adjustment.

2. Use DAC-P - V.COM - R: in the Adjustment menu

to adjust so that the flicker at the center of the

screen is less than the flicker at the periphery.

(When the flicker is about the same across the

whole screen, adjust so that the flicker at the

center of the screen is somewhat less than

elsewhere.)

3. In the same way, use DAC-P - V.COM-G: in the

Adjustment menu to adjust the G color flicker.

4. In the same way, use DAC-P - V.COM-B: in the

Adjustment menu to adjust the B color flicker.

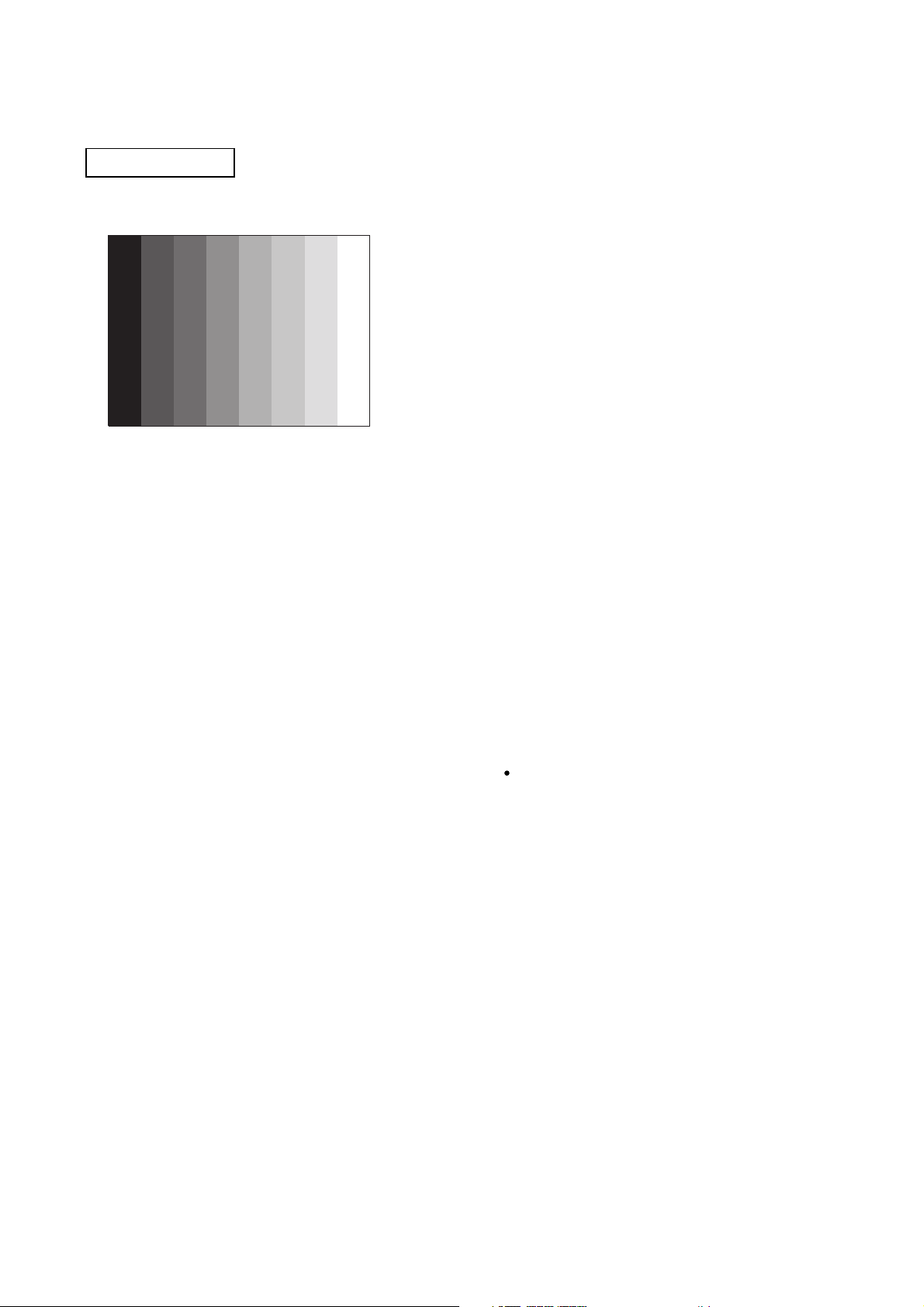

Signals for internal adjustment

(vertical stripe adjustment)

192/255

160/255

128/255

96/255

64/255

32/255

4-4-2 PSIG-B adjustment

(vertical streaks adjustment)

Signals for internal adjustment

30%

30%

0/255

112/255

Adjustment procedure

1. Make this adjustment after completing the

adjustment in 4-3 Flicker adjustment.

2. Use DAC-P - PSIG - G: in the Adjustment menu

to adjust so that the vertical lines spaced every 6

or 12 dots are as inconspicuous as possible.

Adjustment procedure

1. Make this adjustment after completing the

adjustment in 4-3 Flicker adjustment.

2. Use DAC-P - PSIG - B: in the Adjustment menu

to adjust so that the vertical streaks on the upper

of window pattern.

6

Page 7

CP-X328 ONLY

4-4

NRSH adjustment

Signals for internal adjustment

72

48

24

/255

/255

/255

(vertical stripe adjustment)

144

120

96

/255

/255

/255

CP-S318(C3SM4) / CP-X328(C3XM4)

Adjustment procedure

1. Make this adjustment after completing the

adjustment in 4-3 Flicker adjustment.

2. Use DAC-P - NRSH - R: in the Adjustment menu

168

/255

192

/255

to adjust so that the vertical lines spaced every 6

dots are as inconspicuous as possible.

(Reduce the adjustment value when black stripes

appear in the 2nd or 3rd tone from the black side.

Note that when the adjustment value is lowered,

white stripes may appear in the 2nd or 3rd tone

from the bright side. Should this happen, adjust so

that the stripes are as inconspicuous as possible.)

3. In the same way, use DAC-P - NRSH - G: in the

Adjustment menu to adjust vertical stripes of G

color.

4. In the same way, use DAC-P - NRSH - B: in the

Adjustment menu to adjust vertical stripes of B

color.

4-5

White balance adjustment (visual inspection)

Preparations

1. Perform these adjustments after the PSIG or

NRSH adjustment described in Section 4-4.

Adjustment procedure

1. First, adjust the G color.

2. Select GAMMA, SUB-CONTRAST, and G: in the

Adjust menu. If the background is white solid,

press the [ENTER] key on the Remote control

transmitter to change to [G] monochrome in the

28-tone grayscale.

3. Adjust GAMMA, SUB-CONTRAST, and G: in the

Adjust menu so that brightness of 28 steps is

best.

4. Don’t adjust GAMMA, SUB-BRIGHT, and G: in

the Adjust menu. Because we want to keep the

best contrast ratio.

5. Then adjust colors R and B.

2. Reset gamma correction before adjustment.

Place the cursor on [GAMMA] in the Adjustment

menu, press the [RESET] key and select

[DEFAULT].

6. Select GAMMA, SUB-CONTRAST, and G: in the

Adjust menu. If the background is white solid,

press the [ENTER] key on the Remote control

trasmitter to change to [W] monochrome in the

28-tone grayscale.

7. Adjust GAMMA, SUB-BRIGHT, R: and B: in the

Adjust menu so that low-brigtness white balance

is best.

8. Adjust GAMMA, SUB-CONTRAST, R: and B: in

the Adjust menu so that middle-brightness white

balance is best.

9. Repeat steps 7 to 8 above, and adjust so that

brightness white balance of 28 steps is best.

7

Page 8

CP-S318(C3SM4) / CP-X328(C3XM4)

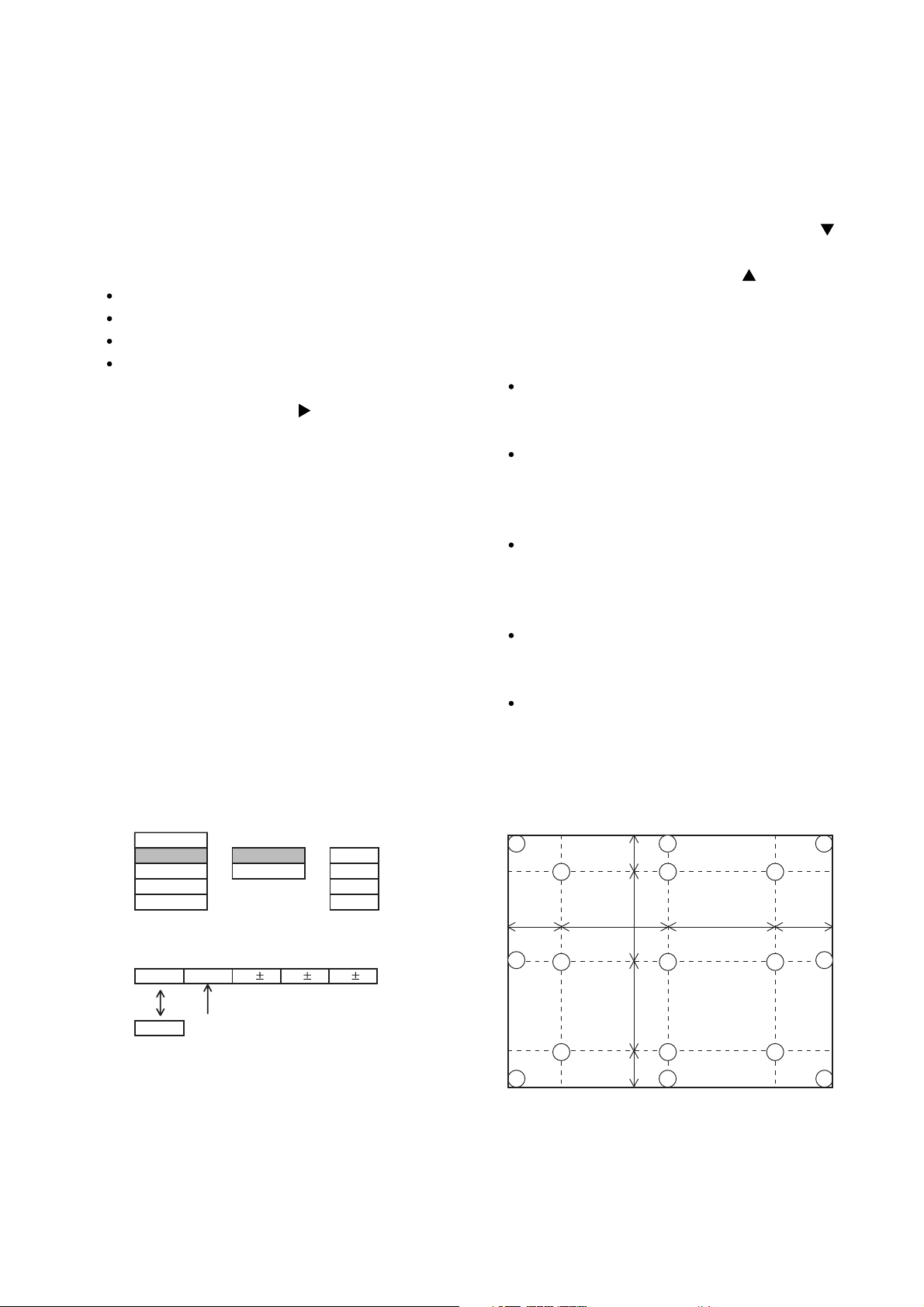

4-6 Color uniformity adjustment

Preparations

1. Perform these adjustments after the white

balance adjustment described in Section 4-5.

2. Make a color uniformity adjustment for the

following four tones.

MIN tone (approx. 4% input signal)

MID-L tone (approx. 14% input signal)

MID-H tone (approx. 25% input signal)

MAX tone (approx. 57% input signal)

3. Place the cursor on the tone to be adjusted in the

Adjust menu and press the [ ] key. This displays

the Adjust Tone menu at the bottom of the screen.

Select the major adjustment lattice point No. and

color, and then adjust them.

4. The major adjustment lattice point numbers (a

total of 17 points) corresponds to the major

adjustment lattice point positions in the diagram

on the right. The color uniformity of the entire

screen can be adjusted by adjusting the white

balance for each of the points starting in order

from the low numbers.

5. Adjustment point No.1 should not be adjusted,

because it controls the brightness of the entire

screen.

6. To temporarily turn correction off, place the cursor

on “ON” in the Adjust Tone menu and press the [

key. To turn it on again, place the cursor on OFF in

the Adjust Tone menu and press the [ ] key.

7. Although this adjustment can also be made using

internal signals, we will here use the [ENTER] key

on the Remote control transmitter to select the

following two signals.

Solid monochrome adjustment color (use G

color adjustment when a color differential meter

is used).

Solid white (use for adjustment other than

above).

8. Reset color-shading correction before

adjustment.

When 4 tones and all colors are to be reset,

place the cursor on [C.UNIF.] in the Adjustment

menu, press the [RESET] key and select

[DEFAULT].

When only 1 tone is to be reset, place the

cursor on the tone to be reset, press the

[RESET] key and select [DEFAULT].

Single tone and monochrome resets cannot be

performed.

]

Adjust menu

VID-AD

C. UNIF.

DAC-P

GAMMA

Adjust Tone menu

No. 1 R 0

ON

Major adjustment lattice point No.

OFF

LEVEL

BLACK

MIN

MID-L

MID-H

MAXSTRIPE

G 0 B 0

Major adjustment lattice point position

14 12

6 4 8

H/6 H/3 H/3 H/6

10 11

15 17

2 1 3

7 5 9

V/6

V/3

V/3

V/6

13

8

16

Page 9

CP-S318(C3SM4) / CP-X328(C3XM4)

Adjustment procedure 1

(when a color differential meter is used)

1. First adjust [MID-L] tone [G:].

2. Select adjustment point [No.2][G:].

When the background is not [G] monochrome,

press the [ENTER] key on the Remote control

transmitter to change to solid [G] monochrome.

3. Measure the illumination at adjustment points No.

2, No.3, No.10 and No.11.

The values should be:

No.2 = Y2 [lx] No.10 = Y10 [lx]

No.3 = Y3 [lx] No.11 = Y11 [lx]

4. No.2 and No.3 adjustment point have the average

of Y2 and Y3.

Y2 = ( Y2 + Y3 ) / 2 ± 2 [%]

Y3 = ( Y2 + Y3 ) / 2 ± 2 [%]

5. No.10 and No.11 adjustment point have the

average of Y10 and Y11.

Y10 = ( Y10 + Y11 ) / 2 ± 2 [%]

Y11 = ( Y10 + Y11 ) / 2 ± 2 [%]

6. Then adjust [MID-L] tone [R] and [B].

When the background is [G] monochrome, press

the [ENTER] key on the Remote control

transmitter to change to solid white.

7. Measure the color coordinates of adjustment

point [No.1] and make a note of them.

Assume that they are x = x1, y = y1.

Note: When the CL-100 color and color

difference meter is used, the [

mode is convenient. When adjustment

point [No.1] color coordinate has been

selected, set the slide switch on the side to

[

](delta) while holding down the [F] button

on the front panel. The measurement

shown after this displays the deviation from

measurement point 1.

8. Measure the color coordinates of measurement

point [No.2] and adjust [No.2][R:] and [B:] so that

the coordinates are as follows.

x = x1 ± 0.005 , y = y1 ± 0.010

](delta)

9. Similarly, measure adjustment points [No.3] to

[No.17] and adjust their color coordinates starting

in order from the small number points.

This completes adjustments required for [MIN].

Note: Since excessive correction may lead to a

correction data overview during internal

calculations, use the following values for

reference.

[No.2] to [No.5] ± 40 or less

[No.6] to [No.9] ± 50 or less

[No.10] to [No.13] ± 70 or less

[No.14] to [No.17] ± 120 or less

10. Then adjust [MIN] tone [G] so that the adjustment

data set two times as much as [MID-L] tone [G].

This completes [G] color adjustments.

11. Then adjust [MIN] tone [R] and [B].

Select [No.2] [B:] and press the [ENTER] key on

the Remote control transmitter to change to solid

white.

12. Measure the color coordinates of adjustment

point [No.1] and make a note of them.

Assume that they are x = x1, y = y1.

13. Now measure the color coordinates of

measurement point [No.2] and adjust [No.2][R:]

and [B:] so that the coordinates are as follows.

x = x1 ± 0.005 , y = y1 ± 0.010 (Target)

x = x1 ± 0.020 , y = y1 ± 0.040

14. Similarly, measure adjustment points [No.3] to

[No.17] and adjust their color coordinates starting

in order from the small number points.

This completes [MIN] tone adjustments.

15. Now make similar adjustments for [MID-H] tone.

(Adjust [MID-H] tone [G] so that the adjustment

data set half as many as [MID-L] tone [G].)

16. Now make similar adjustments for [MAX] tone.

(Adjust [MAX] tone [G] so that the adjustment

data set half as many as [MID-L] tone [G].)

9

Page 10

CP-S318(C3SM4) / CP-X328(C3XM4)

Adjustment procedure 2

(visual inspection)

1. First adjust [MIN] tone [G:].

2. Select [No.2] [G:].

If the background is [G] monochrome, press the

[ENTER] key on the Remote control transmitter to

change to solid white.

3. View measurement point [No.2] and [No.3].

Lower the [G] color intensity only of the color

point whose [G] color is more intense than

measurement point [No.1].

4. View measurement point [No.10] and [No.11].

Lower the [G] color intensity only of the color

point whose [G] color is more intense than

measurement point [No.1], and raise the intensity

of the point whose color intensity is lower than

measurement point [No.1].

5. Now adjust the [MIN] tone for colors [R] and [B].

6. View measurement points [No.2], [No.3], [No.10]

and [No.11]. Adjust the [R] and [B] of each

measurement point so that they have the same

color as measurement point [No.1].

Adjustment technique:

First, adjust [B:] of the point whose color is to be

adjusted so that it approximates that of [No.1]. If

[R:] is low at this time, the image will have cyan

cast, in which case [R:] is increased. On the other

hand, if [R:] is excessive, the image will have a

magenta cast, in which case [R:] is decreased.

Overall, a cyan cast makes it easy to see color

shading.

7. Next, view measurement points [No.4], [No.5],

[No.12], [No.13] and make similar adjustments.

8.

Then adjust measurement points [No.6], [No.7], [No.8],

[No.9], [No.14], [No.15], [No.16] and [No.17].

This completes the [MIN] tone adjustments.

9. Make similar another three tones as described in

steps 1 to 8 above.

10

Page 11

CP-S318(C3SM4) / CP-X328(C3XM4)

No. 2 deviation range No. 10 deviation range No. 3 deviation range No. 11 deviation range

14

10

15 13

No. 4 deviation range No. 12 deviation range No. 5 deviation range No. 13 deviation range

15 13

No. 6 deviation range No. 7 deviation range No. 8 deviation range No. 9 deviation range

12

6

4

2

1

5

7

5

7

16

8

3

11

9

17

1614 12

86 4 84

9

17

1614 12

86 4 84

14 12

6

10

2

7

15 13

6

10 1

2

7

15 13

6

16

8

4

3

1

5

5

11

9

17

1614 12

3

11

9

17

1614 12

14

10

15

14

10 1

15

14

12

6

4

2

1

5

7

13

12

6

4

5

7

13

12

6

4

16

8

3

11

9

17

16

8

3 112

9

17

16

8

14 12

6

10

2

7

15 13

14 12

6

10

2

7

15 13

14 12

16

4

8

1

3

11

5

9

17

16

4

8

1

3

113 11210 1

9

5

17

16

46

8

3

3 11210 1

9

5

7

15 13

No. 14 deviation range No. 15 deviation range No. 16 deviation range No. 17 deviation range

6

10

5

7

15 13

17

1614 12

84 84

3 112 1

9

17

10 12

10 12

15

5

7

1315

6

5

7

13

11

9

17

1614 12

3

11

9

17

10

7

15

14

6

10

7

15

13

12

4

13

3 112

1

9

5

17

16

8

32

1

5

11

9

17

10

2

7

15

14 12

2

10

7

15

13

1 3 11

95

5

1713

16

46

8

1 3511

9

5

17

11

Page 12

CP-S318(C3SM4) / CP-X328(C3XM4)

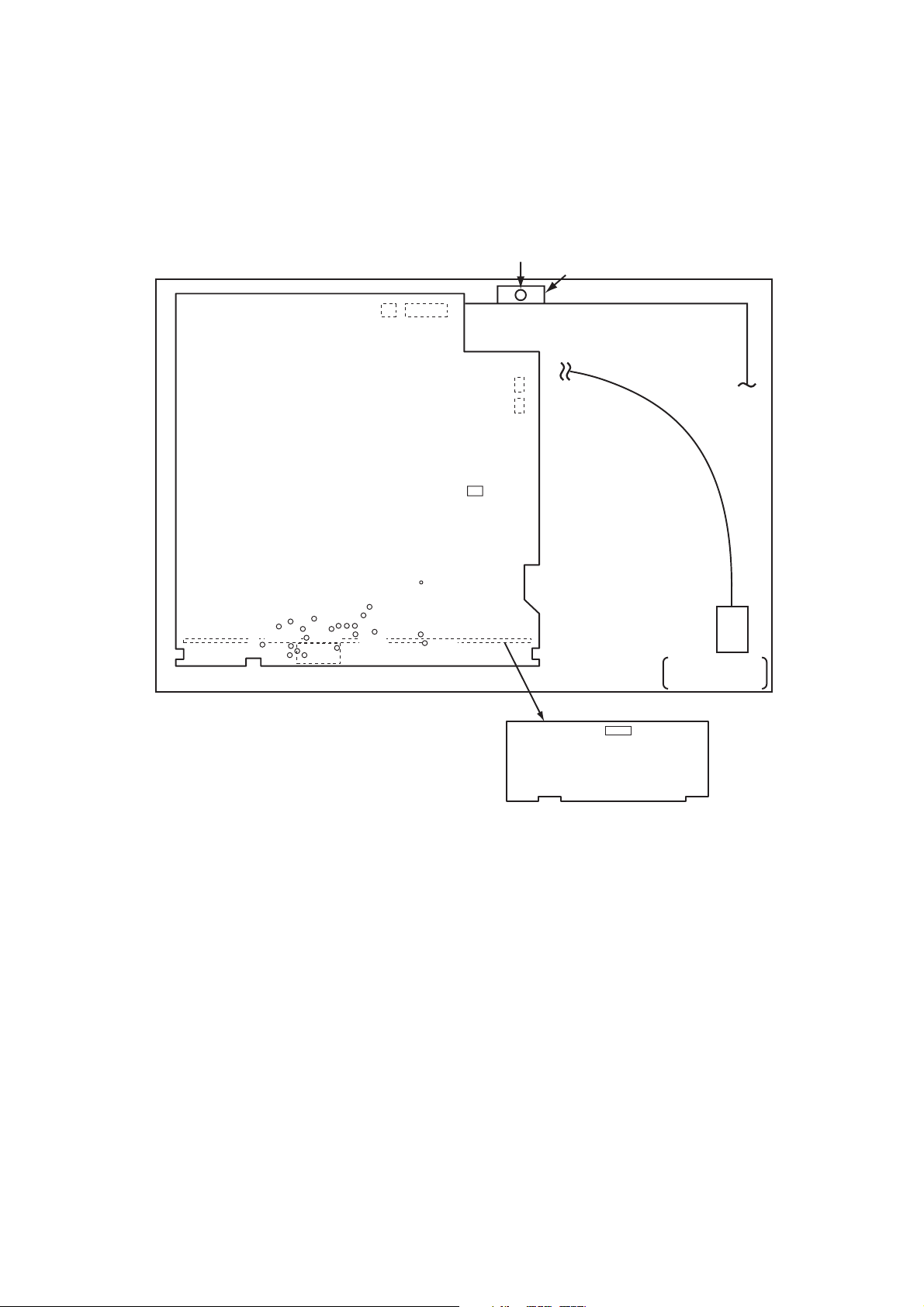

5. Troubleshooting

Check points at trouble shooting

12141

E302 E800

E805

E807

TH950

PWB assembly SENSOR

1

4

1

2

PWB assembly Drive

TP04

TP03

TP05

TP06

TP110

TP105

35

TP101

TP116

TP114

36

TP115

E101

TP01

TP02

1

TP104

70

TP1H

TP108

TP109

TP103

TP118

TP106

CHJ17

TP117

TP102

1

I256

1120

10

TSW

TEMPERATURE

SENSOR

IS01

PWB assembly Signal

12

Page 13

CP-S318(C3SM4) / CP-X328(C3XM4)

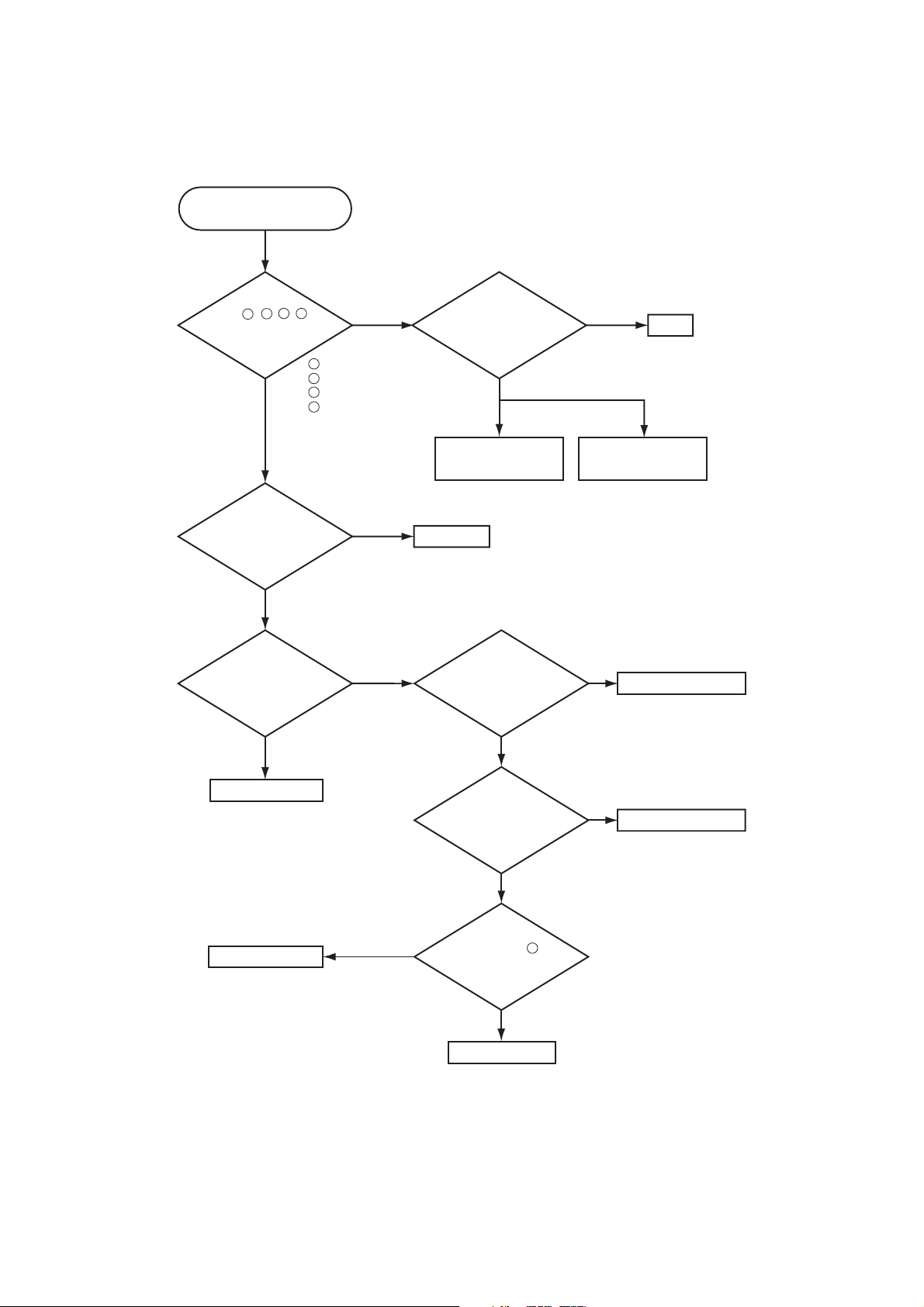

Power can not be turned on

Are

voltage input

at pins , , , of

E800 on the PWB assembly

Drive at standby

3

2

mode?

4 5

YES

: +14V

2

: +17V

3

: +6V

4

: +4.3V

5

NO

Disconnect

TSW form Power unit

(circuit). And check

TSW short or

open?

Short

Open

TSW

What is the state of

TEMP indicator?

Not light

What is the state of

LAMP indicator?

Not light

PWB assembly Drive

Blinks

Blinks

Power unit (circuit)

DC Fan

Is the LAMP COVER

set?

OK

Is the LAMP

connection?

OK

Fuse

on Power unit (circuit)

NG

Set the LAMP COVER

NG

Set the LAMP again

PWB assembly Drive

H (More than 6V)

Measure

voltage at the of

2

E807 on the PWB

assembly drive.

L (OV)

PWB assembly SW

13

Page 14

CP-S318(C3SM4) / CP-X328(C3XM4)

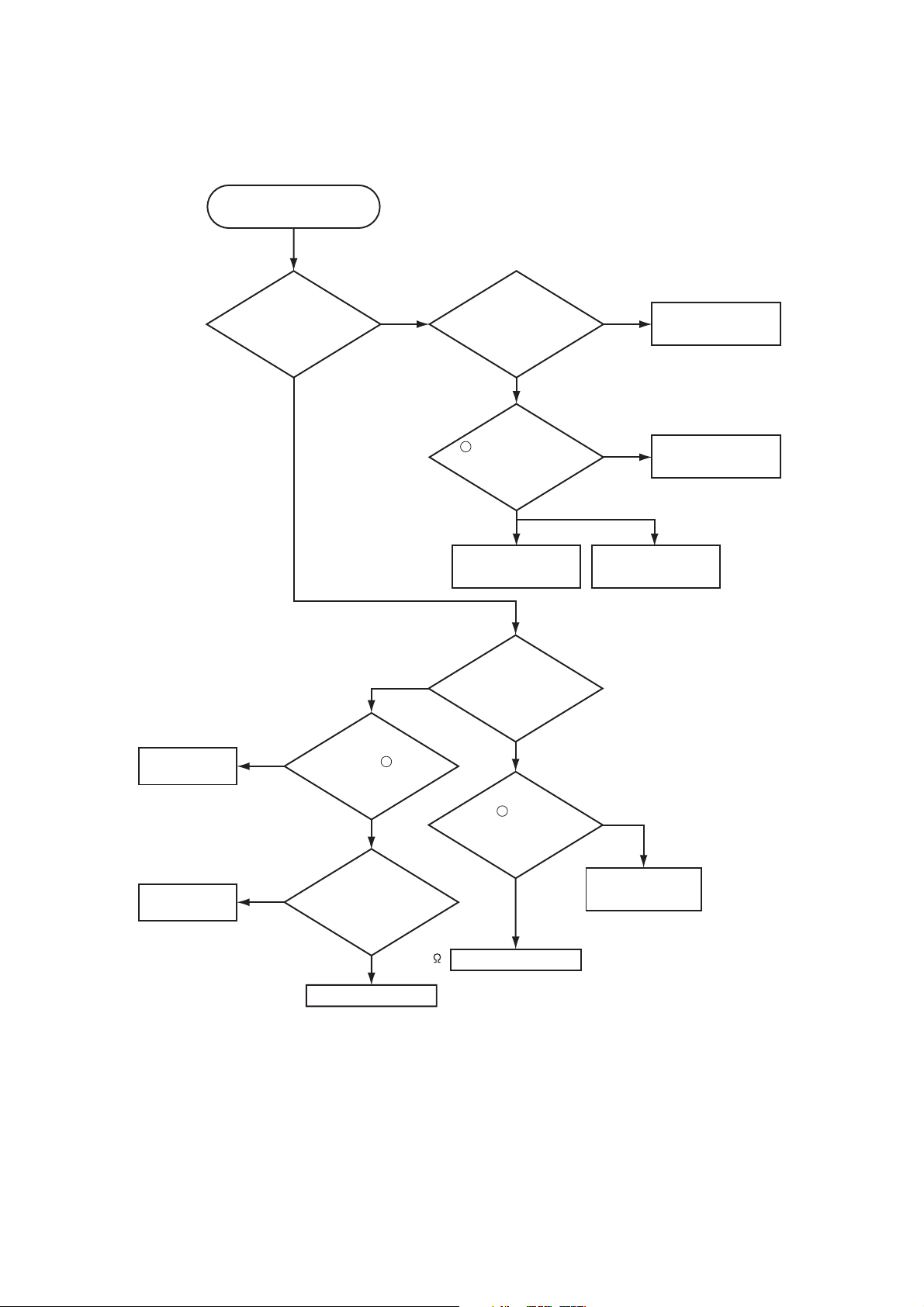

Lamp does not light

DC FAN

(INTAKE A/B)

PWB assembly

SENSOR

What is the state of

LAMP indicator

during operation?

Not light

H (3.3V)

Infinity

Measure sure

voltage at the of I256

on the PWB assembly

the resisitance of

TH950 on the PWB

assembly SENSOR at

disconnecting

Light

2

Drive.

L (OV)

Measure

E302.

about 10k

Blinks

Change the lamp.

Does lamp light?

Not light

Is the

voltage at the

1

of E805 on the PWB

assembly Drive fixed to "L"

during warming-up?

"L" = 0V

NO

Power unit (ballast)

What is the state of

TEMP indicator?

Not light

Is the voltage

3

at the of E805 on

the PWB assembly Drive

set to "L" during

warming-up?

YES

Power unit (ballast)

Light

YES

Power unit (circuit)

"L" = 0V

PWB assembly Drive

PWB assembly Drive

NO

Lamp

PWB assembly Drive

14

Page 15

CP-S318(C3SM4) / CP-X328(C3XM4)

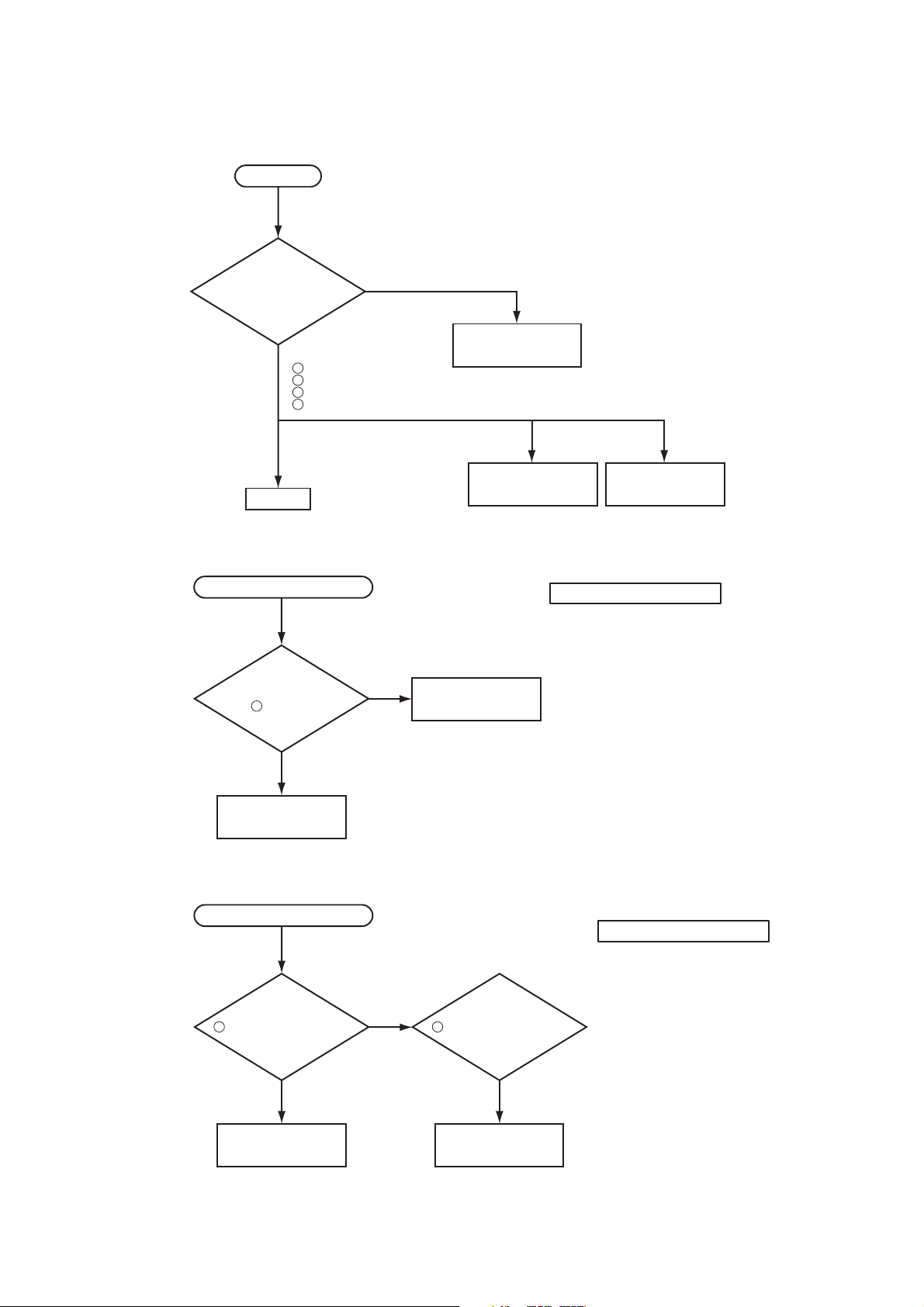

Picture is not displayed only

when the RGB signal is input

Check at operating mode

Are

signal input

at each pin of E101 on

the PWB assembly

Drive?

(TP06) , : R signal

YES

(TP02) , : G signal

(TP04) , : B signal

(TP106) , : H sync

Are

voltage input

at pins , , , of

2 3 4 5

E800 on the PWB

assembly

Drive?

(CHJ17) , : V sync

2

YES

3

4

5

: +14V

: +17V

:+6V

:+4.3V

NO

5 66

3 68

1 70

8

7 64

NO

Change the IS01 on the

PWB assembly Signal

PWB assembly Signal.

It is repaired ?

YES

IC (IS01)

63

EL4332CS

Power unit

(circuit)

PWB assembly Drive

Picture is not displayed only when the

VIDEO, S-VIDEO, Component Signal is input

LCD panel

Check at operating mode

Are

voltage input at

2 3 4

pins , , , of

5

E800 on the PWB

assembly

Drive?

YES

Are signal

input at these

pins of E101 on the

PWB assembly

Drive?

YES

22 49

, VIDEO (Composit) (TP112)

26 45

, S-VIDEO (Y) (TP110)

24

47

, S-VIDEO (C) (TP111)

35

36

, Component (Y) (TP01)

33

38

, Component (Cb) (TP03)

31

40

, Component (Cr) (TP05)

2

: +14V

3

: +17V

4

: +6V

5

: +4.3V

NO

Power unit (circuit)

NO

PWB assembly Signal

PWB assembly Drive

LCD module assembly

15

Page 16

CP-S318(C3SM4) / CP-X328(C3XM4)

No sound

Check at operating mode

Are the

signals input

at each pin of E101

on the PWB assembly

Drive?

NO

YES

56

(TP117) : MUTE (0V)

17

(TP104) : CLK-VOLUME Control

54

(TP115) : DATA-VOLUME Control

57

(TP118) : POWER-AUDIO (+3.3V)

Speaker

Can not operate to Mouse

At the time

of remote control

operation. Are the signals puls

13

of E101 (RMT) on

at pins

the PWB assembly

Drive ?

YES

NO

PWB assembly Drive

PWB assembly Signal

PWB assembly Drive

Power unit (circuit)

The check after PWB change

1. PC power supply OFF

2. Connection of cable

3. Projector starting

4. PC starting

*When not operating :

PC set up change of cable.

PWB assembly Input

Can not control to RS-232C

Are the

signals data at pins

52

of E101 (TP114:RD) on

the PWB assembly

Drive ?

NO NO

PWB assembly Input

YES

Are the

signals data at pins

19

of E101 (TP105:TD) on

the PWB assembly

Drive ?

PWB assembly Drive

16

The check after PWB change

1. PC power supply OFF

2. Connection of cable

3. Projector starting

4. PC starting

*When not operating :

PC set up change of cable.

Page 17

CP-S318(C3SM4) / CP-X328(C3XM4)

6. Service points

Lead free solder [CAUTION]

This product uses lead free solder (unleaded) to help preserve the environment. Please read these instructions

before attempting any soldering work.

Caution: Always wear safety glasses to prevent fumes or molten solder from getting into the eyes. Lead

free solder can splatter at high temperatures (600˚C).

Lead free solder indicator

Printed circuit boards using lead free solder are engraved with an "F."

Properties of lead free solder

The melting point of lead free solder is 40-50˚C higher than leaded solder.

Servicing solder

Solder with an alloy composition of Sn-3.0Ag-0.5Cu or Sn-0.7Cu is recommended.

Although servicing with leaded solder is possible, there are a few precautions that have to be taken. (Not taking

these precautions may cause the solder to not harden properly, and lead to consequent malfunctions.)

Precautions when using leaded solder

Remove all lead free solder from soldered joints when replacing components.

If leaded solder should be added to existing lead free joints, mix in the leaded solder thoroughly after the lead

free solder has been completely melted (do not apply the soldering iron without solder).

Servicing soldering iron

A soldering iron with a temperature setting capability (temperature control function) is recommended.

The melting point of lead free solder is higher than leaded solder. Use a soldering iron that maintains a high

stable temperature (large heat capacity), and that allows temperature adjustment according to the part being

serviced, to avoid poor servicing performance.

Recommended soldering iron:

Soldering iron with temperature control function (temperature range: 320-450˚C)

Recommended temperature range per part:

Part Soldering iron temperature

Mounting (chips) on mounted PCB 320˚C±30˚C

Mounting (chips) on empty PCB 380˚C±30˚C

Chassis, metallic shield, etc. 420˚C±30˚C

The PWB assembly which has used lead free solder

PWB assembly DRIVE

PWB assembly INPUT

PWB assembly SENSOR

PWB assembly SWITCH

PWB assembly REMOTE

17

Page 18

CP-S318(C3SM4) / CP-X328(C3XM4)

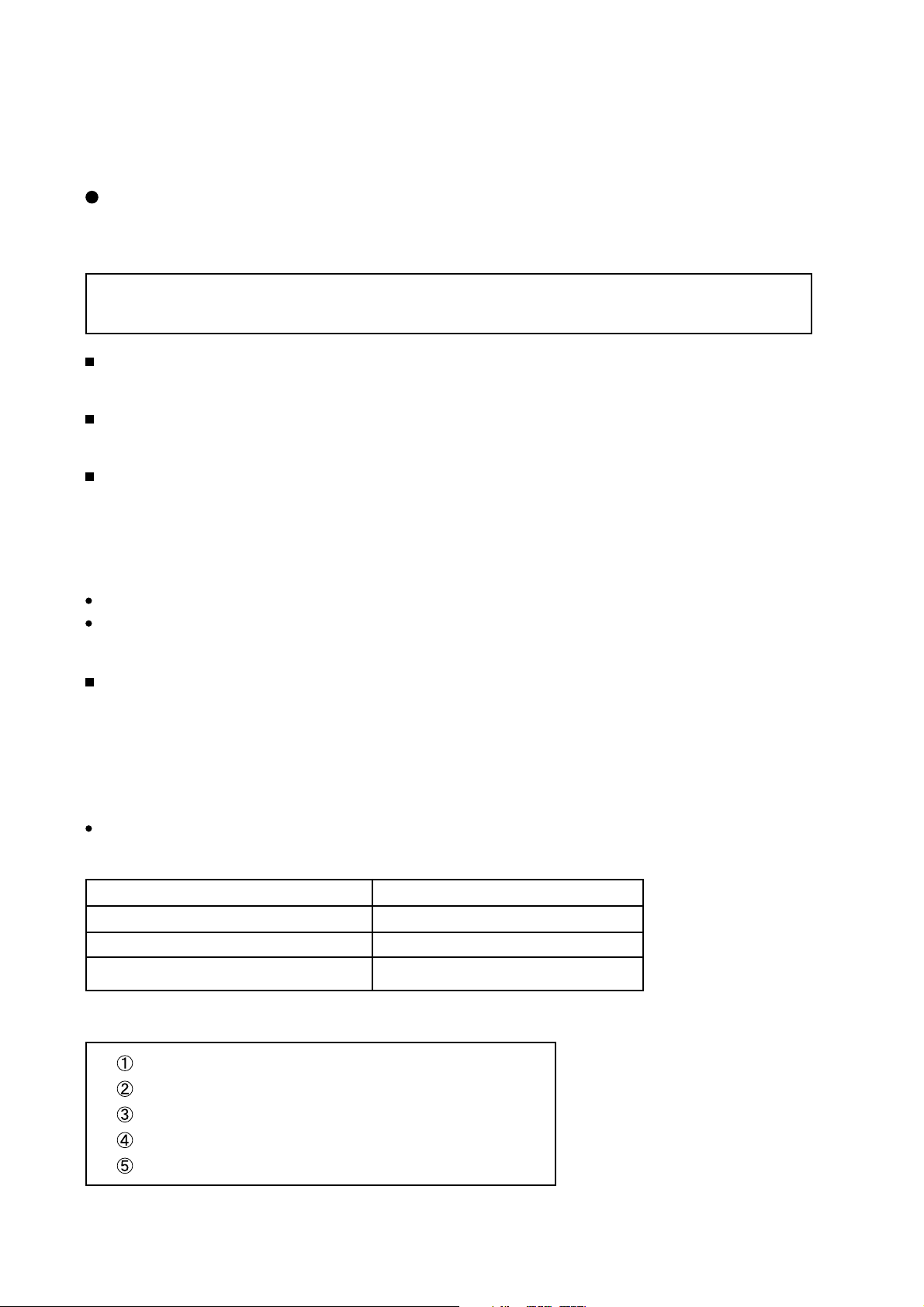

Cautions when removing the PWB assembly Drive

When removing the PWB assembly Drive, there is danger of damaging the connector connecting cables and the

PWB assembly Signal.

1) Disconnect 7 cables and remove 3 screws.

PWB assembly Drive

Disconnect 7 cables

Remove 3 screws

2) Lift up the rearward of the PWB assembly Drive to the front.

FRONT

PWB assembly Drive

REAR

3) Disconnect 5 cables lifting the PWB assembly Drive.

Disconnect 5 cables

Lift up

Disconnect the board-to-board connector.

Cautions when removing the POWER UNIT (BALLAST)

When removing the cable (CNBAR) connected to POWER UNIT (BALLAST) there is danger of damaging the

small PWB connecting cables.

219'470+6$#..#56

J1

Disconnect the CNBAR from connector J2,

CNBAR

while pressing the sub-board (to prevent the

J2

stress on the sub-board).

18

Page 19

CP-S318(C3SM4) / CP-X328(C3XM4)

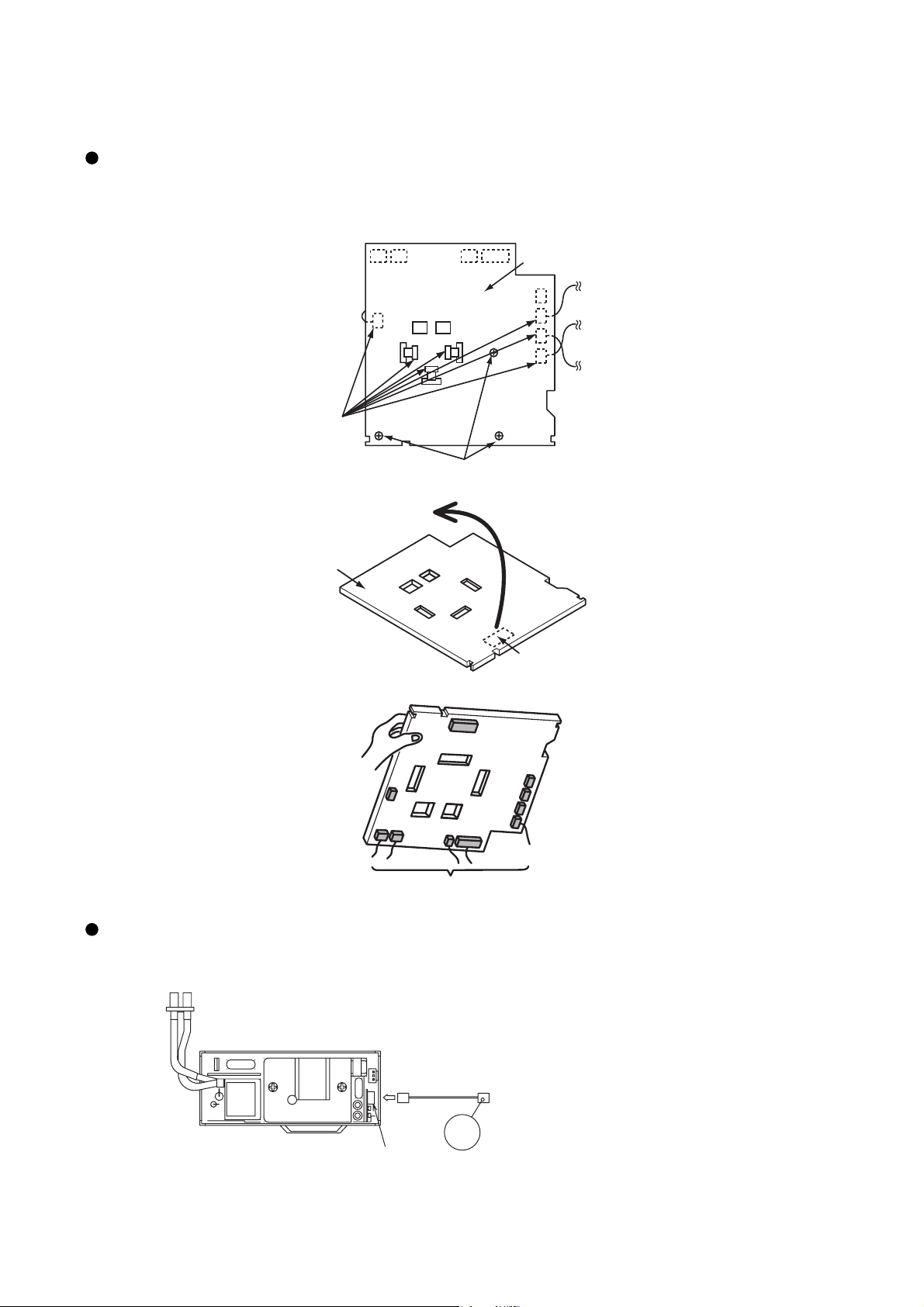

1

Remove the battery

cover

Slide back and remove

the battery cover in the

direction of the arrow.

Insert the batteries

Align and insert the two AA

batteries (that came with the

projector) according to their plus

and minus terminals (as indicated

in the remote control).

Close the battery

cover

Replace the battery cover

in the direction of the arrow

and snap it back into place.

2 3

CAUTION

Precautions to observe in regards to the batteries

Always handle the batteries with care and use them only as directed. Improper use may result in

battery cracking or leakage, which could result in fire, injury and/or pollution of the surrounding environment.

• Keep the battery away from children and pets.

•

Be sure to use only the batteries specified for use with the remote control. Do not mix new batteries with used ones.

•

When inserting batteries, verify that the plus and minus terminals are aligned correctly (as indicated in the remote control).

• When you dispose the battery, you should obey the law in the relative area or country.

Before Replacing the LCD / Lens Prism

You should not replace separately the parts of the liquid crystal LCD / Lens Prism because it works properly only

when used together. Therefore, regarding these parts, you can either replace part , LCD / Lens Prism assembly,

or send the whole unit LCD / Lens Prism assembly back to Hitachi, where we will replace the malfunctioning

part, recondition the device and send it back to you.

G Panel

DISTRIBUTOR HITACHI

Do not disassemble the unit

because replacement of separate

parts is not possible.

Replacement of G Panel

Return

Reconditioning

Using the Rremote control

19

Page 20

CP-S318(C3SM4) / CP-X328(C3XM4)

HIGH VOLTAGE

HIGH TEMPERATURE

HIGH PRESSURE

WARNING

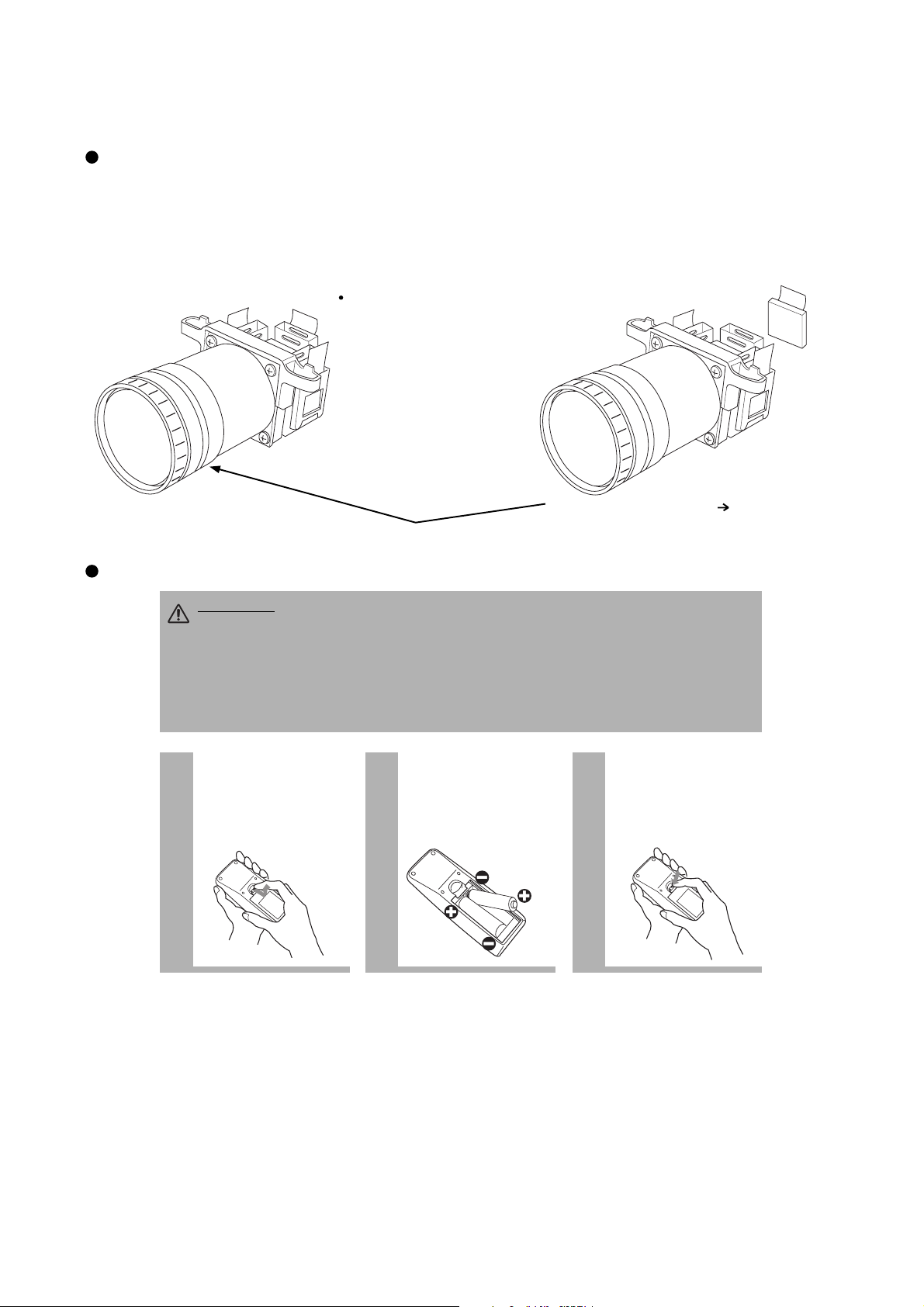

Caring for the air filter

The air filter should be cleaned about every 100 hours. If the LAMP indicator and

TEMP indicator blink red simultaneously, or a message prompts you to clean the air

filter when you turn on the unit, the filter needs to be cleaned. (See "Related

Messages" and "Regarding the Indicator Lamps" for details.)

Turn off the projector, and unplug the power cord

1

Apply a vacuum cleaner to

2

the top of the air filter cover

to clean the air filter

Air Filter Cover

Turn on the projector, and use the menu to reset the filter

3

timer

• To reset the air filter timer, from the OPTION menu, select FILTER TIME.

(Depress the RESET button for at least 3 seconds while filter time is being displayed.

The reset menu then appear. Select RESET on the menu with the button.)

Lamp (

Option Lamp: DT00511)

HIGH VOLTAGE

HIGH TEMPERATURE

HIGH PRESSURE

Before replacing the lamp, check the serial number of the replacement lamp bulb (sold separately:

DT00511), then contact your local dealer. Before replacing the lamp, turn off the power, and

unplug the power cord, then wait at least 45 minutes, in order to ensure that the lamp is

is properly cooled. Removing the lamp bulb while it is still hot could cause burns, or cause the

lamp bulb to burst.

WARNING

bang, or burn out, if jolted or scratched, or through wear over time. Each lamp has a

different lifetime, and some may burst or burn out soon after you start using them. In

addition, when the bulb bursts, it is possible for shards of glass to fly into the lamp housing,

and for gas containing mercury to escape from the projector's vent holes.

.

Handle with care: jolting or scratching could cause the lamp bulb to burst during use.

.

If the replace lamp indicator (see "Related Messages" and "Regarding the

indicator Lamps") comes on, replace the lamp as soon as possible. Using the

lamp for long periods of time, or past the replacement date, could cause it to burst. Do

not use old (used) lamps; this is a cause of breakage.

.

If the lamp breaks soon after the first time it is used, it is possible that there are electrical problems

elsewhere besides the lamp. If this happens, contact your local dealer.

.

If the lamp should break (it will make a loud bang when it does), ventilate the room well, and make

sure not to breathe the gas that comes out of the projector vents, or get it in your eyes or mouth.

.

If the lamp should break (it will make a loud bang when it does), unplug the power cord from

the outlet, and make sure to request a replacement lamp from your local dealer. Note that

shards of glass could damage the projector's internals, or cause injury during handling, so

please do not try to clean the projector or replace the lamp yourself.

.

Obey local ordinances when disposing of used lamps. In most cases, it is possible to dispose of used

bulbs in the same manner as used glass bottles, but in some cases, bulbs are sorted separately.

.

Do not use the projector with the lamp cover removed.

The LCD projector uses a glass lamp bulb. It is a mercury lamp with high

internal pressure. High-pressure mercury lamps can break with a loud

20

Page 21

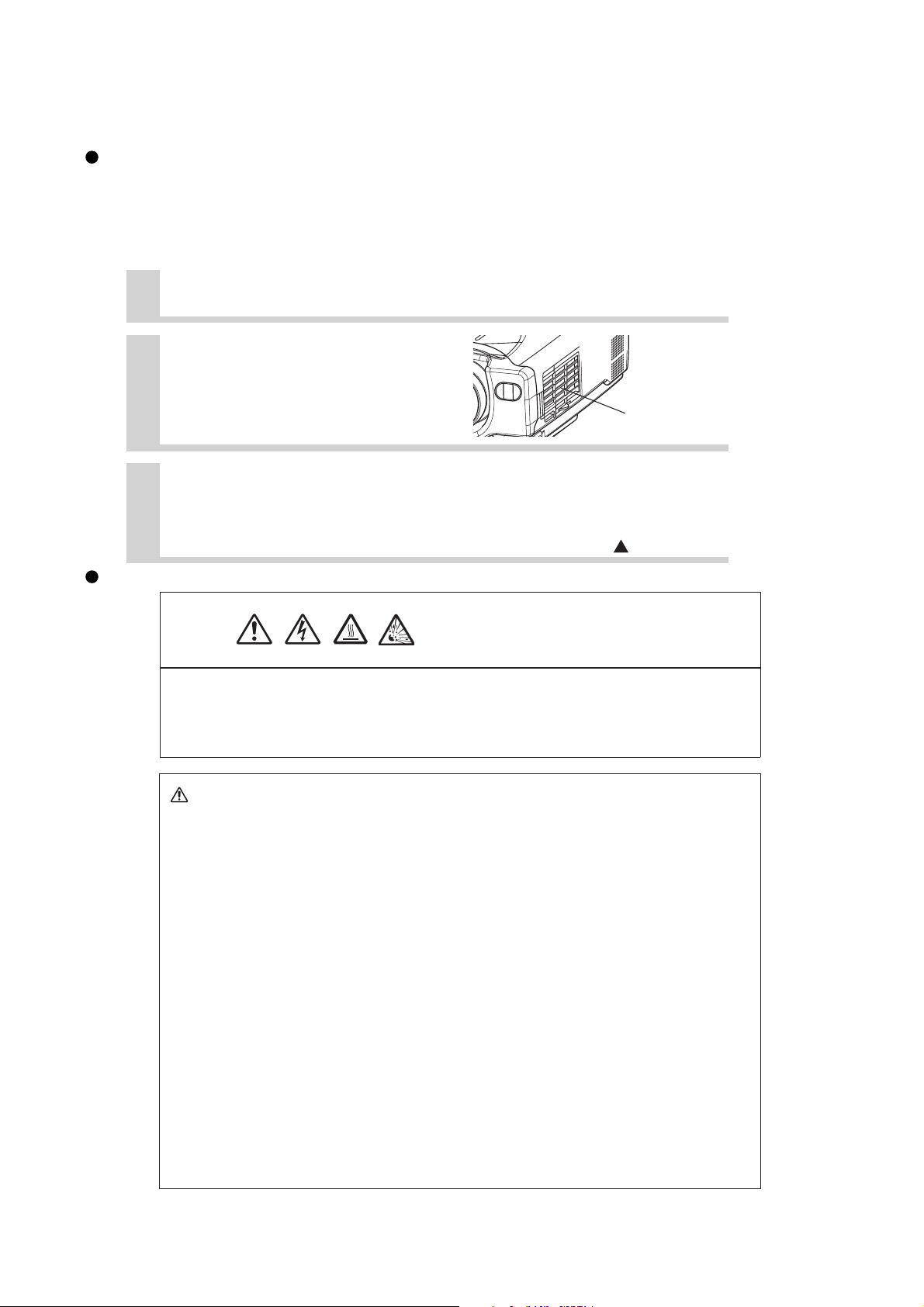

Replacing the Lamp

NOTE

ATTENTION

All projector lamps will wear out eventually. If used for long periods of time, the image could become

darkened, and the color contrast could be impacted as well. We recommend that you replace your lamps

early. If the LAMP indicator turns red, or a message prompts you to replace the lamp when you power up

the projector, the lamp needs to be replaced. (See "Related Messages" and "Regarding the

Indicator Lamps" for details.)

CP-S318(C3SM4) / CP-X328(C3XM4)

Turn off the projector, and unplug the

1

power cord. Allow the lamp bulb to cool

for at least 45 minutes, and prepare a

new lamp (sold separately: DT00511)

After making sure that the projector has

2

cooled adequately, slowly flip over the

projector, so that the bottom is facing up

Unscrew the 2

3

screws, and

remove the

lamp cover

Unscrew the 1 screw, and slowly pull

4

out the lamp by the handle

•

Be careful not to touch the inside of the lamp case.

Insert the new lamp, and tighten the 1

5

screw firmly to lock it in place

•

Also steadily push the opposite side of the

screwed side of the

Replace the lamp cover, and tighten

6

the 2 screws firmly to lock it in

place

Slowly turn the projector so that

7

the top is facing up

Turn on the projector power, and using

8

the menu, reset the lamp timer

•

To reset the lamp timer, from the OPTION

menu, select LAMP TIME.

lamp into the unit.

ATTENTION

• Do not use with lamp cover removed.

•

Do not reset the lamp timer without replacing the lamp. Reset the lamp timer always when replacing

the lamp. The message functions will not operate properly if the lamp timer is not reset correctly.

• When the lamp has been replaced after the message of "CHANGE THE LAMP ...THE POWER

WILL TURN OFF AFTER 0 hr." is displayed, or the LAMP indicator is red, complete the following

operation within 10 minutes of switching power ON.

NOTE

Before replacing the lamp, switch power OFF, wait approximately 20 minutes, and switch power

ON again. If the LAMP indicator is still red, replace the lamp.

•

Make sure that the screws are screwed in firmly. Loose screws could result in damage or injury.

• The LAMP indicator is also red when the lamp unit reaches high temperature.

21

Page 22

CP-S318(C3SM4) / CP-X328(C3XM4)

Resetting the Lamp Timer

Reset the lamp timer after replacing the lamp. When the lamp has been replaced after the LAMP indicator is red,

or the CHANGE THE LAMP message is displayed, complete the following operation within ten minutes of

switching power ON. The power will be turned off automatically in over 10 minutes.

1. Switch power ON, and select the LAMP TIME on the OPTION menu.

2. Depress the RESET button for at least 3 seconds while lamp time is being displayed.

The reset menu will then appear.

3. Select RESET on the menu with the

button, and wait until the timer display is cleared.

NOTE:

Do not reset the lamp timer without replacing the lamp. Reset the lamp timer always when replacing the lamp.

The message functions will not operate properly if the lamp timer is not reset correctly.

STANDBY/ON

RGB SEARCH

VIDEO

ASPECT

AUTO BLANK

HOME

MAGNIFY

STANDBY/ON

INPUT

2

1, 3

KEYSTONE

L

A

N

P

T

E

N

P

P

O

W

E

R

RESET

3

ESC RESET

PAGE UP VOLUME

ON

END

PAGE DOWN

ENTER

MUTE

KEYSTONEFREEZE

MENUPOSITION

1

OFF

2

1

22

Page 23

CP-S318(C3SM4) / CP-X328(C3XM4)

Notice of AUTO adjustment

Use of AUTO adjustment with the image through RGB input optimizes VPOSI, HPOSI, HSIZE and HPHASE

automatically.

In case that projected image has dark tone around its peripheral, AUTO operation sometimes makes artifacts in

the image, shifts capture area and so on. Those failures are caused by period of image data is not exactly

distinguished to period of blanking on signal processing.

To avoid such phenomena, AUTO function should be used with the full size picture that has bright tone on its

peripheral.

Image when AUTO operates correctly

Note

1) The phenomenon at the failure of AUTO adjustment depends on resolution of input source, scene of picture

etc.

2) There is no failure above in AUTO with video source through VIDEO, S-VIDEO or COMPONENT input. The

reason is why recognition of input signal’s standard does not need to search the capture range from input signal

itself.

Image when AUTO fails.

Noting image of top or bottom lines.

Shift of the image to East or West.

Artifacts on image. Etc.

23

Page 24

CP-S318(C3SM4) / CP-X328(C3XM4)

PIN LOCK System

If the following PIN BOX menu appears after power on the projector, the PIN LOCK system has been activated.

Under such a condition, key operations and signal displaying are inhibited. To open the PIN LOCK system, we

need to input the correct 4 digits PIN CODE. If correct PIN CODE is not input in 5 min., the lamp will be

automatically turned off.

PIN BOX

Returning repaired unit

Use the Master PIN code. See the paragraph of Releasing the PIN LOCK system inactivation.

Swap unit/Returned unit

Inactivate the PIN LOCK system. See the paragraph of the PIN LOCK system inactivation.

Releasing the PIN LOCK System

When the PIN BOX menu is displayed, sequentially enter the codes with remote controller as follows. In

accordance with remote controller button entry, “

Master PIN codes

1st entry code: Press the “MENU” button.

2nd entry code: Press the “

3rd entry code: Press the “KEYSTONE ” button.

4th entry code: Press the “

Note: The Master PIN codes can be used up to 30 times. The codes cannot be used thereafter. If the Master

PIN codes cannot be used, see the paragraph of the PIN LOCK system inactivation.

” button.

” button.

” mark appears in the PIN BOX menu.

The PIN LOCK System inactivation

1. When the PIN BOX menu is displayed, press “RESET ” for 3 seconds or more in order to get the ID Inquiring

Code.

Inquiring Code

PIN BOX (ID Inquiring Code)

2. Send HITACHI sales company the Inquiring code (10 digits) to inquire the correct PIN code.

3. With the PIN BOX menu displayed, input the correct PIN code. Enter the correct PIN CODE that HITACHI

sales company informed.

4. Open menu and select “TURN OFF” from the PIN LOCK items in the OPTION menu. Then the PIN BOX menu

appears.

5. Input the correct PIN code in the PIN BOX menu.

6. And then, the OPTION menu appears.

After the PIN LOCK system is inactivated, the PIN BOX is no longer displayed in the OPTION menu.

If the PIN LOCK items are kept displaying, the PIN LOCK system is not inactivated yet. Input the correct PIN

CODE again.

24

Page 25

CP-S318(C3SM4) / CP-X328(C3XM4)

Set operating time display method (accumulated lamp time display method)

1. Select [Option] from the [Menu] display, then select [Lamp Time].

2. Press the [Reset] button once, then press [Keystone] for 3 seconds or more to display the screen shown

below. (The menu will close after 10 seconds if there are no further operations.)

3. Use “

” or “ ” to select the usage status number. (The usage status is as shown below.)

Usage status number (see below)

LAMP TIME

Usage status number

0 ..... Total usage status

1 ..... Current usage status

2 ..... Usage status before first reset

3 ..... Usage status before second reset

8 ..... Usage status before seventh reset

0

ON

Off

||

Time

Number of times on

Number of times off

25

Page 26

CP-S318(C3SM4) / CP-X328(C3XM4)

When the unit's power is ON, messages such as those shown below may be displayed. When

any such message is displayed on the screen, please respond as described below.

Note 1: Although this message will be automatically disappeared after around 3 minutes, it will be

reappeared every time the power is turned ON.

Note 2: Lamps have a finite product life. Lamps are characterized by the fact that, after long hours of

usage, a lamp will no longer light up, or the lamp will break or burst, etc. This unit is equipped

with an automatic shut-down function, such that the power will automatically be turned OFF

when lamp usage time has reached 2,000 hours. Please be aware, however, that among lamp

types, there are major differences in product lifetimes; a lamp may thus fail to light even prior

to the functioning of the automatic shut-down function of this unit.

NOTES

Message Description

CHANGE THE LAMP

AFTER REPLACING LAMP,

RESET THE LAMP TIMER.

(Note 1)

Lamp usage time is approaching 2,000 hours. (Note 2)

Preparation of a new lamp, and an early lamp change, is

recommended. After you have changed the lamp, please be

sure to reset the lamp timer.

CHANGE THE LAMP

AFTER REPLACING LAMP,

RESET THE LAMP TIMER.

THE POWER WILL TURN OFF

AFTER

hr.

(Note 1)

Lamp usage time is approaching 2,000 hours. A lamp change

within

hours is recommended. (Note 2)

When lamp usage reaches 2,000 hours, the power will

automatically be turned OFF. Please change the lamp by

referring to “THE LAMP” in Vol.1 (Basic). After you have

changed the lamp, please be sure to reset the lamp

timer.

CHANGE THE LAMP

AFTER REPLACING LAMP,

RESET THE LAMP TIMER.

THE POWER WILL TURN OFF

AFTER 0 hr.

As lamp use has reached 2,000 hours, the power will soon be

automatically turned OFF. (Note 2)

Please immediately turn the power OFF, and follow the

instructions in the “THE LAMP” section of the separate booklet,

Vol.1 (Basic).

After you have changed the lamp, please be sure to reset the

lamp timer.

CLEAN THE AIR FILTER

AFTER CLEANING AIR FILTER,

RESET THE FILTER TIMER.

A note of precaution when cleaning the air filter.

After cleaning the filter, operate FILTER TIME of the OPTION

Menu, and perform reset of the filter timer.

NO INPUT IS DETECTED

ON

There is no input signal.

Please confirm the signal input connection, and the status of the

signal source.

SYNC IS OUT OF RANGE

ON

kHz Hz

The horizontal or vertical wavelength of the inputted signal is

outside of the response parameters of this unit. Please confirm

the specs for this unit or the signal source specs.

CHECK THE AIR FLOW

The internal portion temperature is rising. Please turn the power

OFF, and allow the unit to cool down for approximately 20

minutes. After having confirmed the following items, then please

resent the power to ON.

•

Is there blockage of the air passage aperture?

•

Is the air filter dirty?

•

Does the peripheral temperature exceed 35°C?

fH fV

Related Messages

26

Page 27

CP-S318(C3SM4) / CP-X328(C3XM4)

Lighting and flashing of the POWER indicator, the LAMP indicator, and the

TEMP indicator have the meanings as described in the Table below.

Please respond in accordance with the instructions within the Table.

POWER

indicator

LAMP

indicator

TEMP

indicator

Description

The orange

lamp is lighted

Turned OFF

(Not lighted)

Turned OFF

(Not lighted)

The STANDBY mode is set

Flashing of the green lamp

Turned OFF Turned OFF

The unit is warming up. Please wait.

The green lamp is lighted

Turned OFF Turned OFF

The unit is in an ON state. Ordinary operations may be performed.

Flashing of the orange lamp

Turned OFF Turned OFF

The unit is cooling down. Please wait.

Blink of the red

lamp

- -

The unit is cooling down. Please wait.

A certain error has been detected. Wait until the POWER indicator lamp has finished

flashing, and then perform the proper response measure using the item descriptions

below as reference.

The red lamp

is lighted, or

blink

The red lamp

is lighted

Turned

OFF

The lamp does not light.

There is a possibility that the interior portion has become heated. Turn the power OFF and wait

approximately 20 minutes. After the main unit has cooled down, please confirm whether or not

there is blockage of the air passage aperture, whether or not the filter is dirty, and/or whether or

not the peripheral temperature exceeds 35°C, etc. After performing any needed maintenance,

turn the power ON again; if the same display is displayed, then please change the lamp.

The red lamp

is lighted, or

blink

Blink of the red

lamp

Turned

OFF

Either there is no lamp and/or lamp cover, or either of these has not been properly fixed

(attached). Turn the power OFF and wait approximately 45 minutes. After the main unit has

sufficiently cooled down, please make confirmation of the attachment state of the lamp and

lamp cover. After performing any needed maintenance, turn the power ON again

.

The red lamp

is lighted, or

blink

Turned

OFF

The cooling fan is not operating. Turn the power OFF and wait approximately 20 minutes. After the

main unit has cooled down, please make confirmation that no foreign matter has become caught in

the fan, etc. After performing any needed maintenance, turn the power ON again

.

The red lamp is

lighted, or blink

Turned

OFF

The red lamp is

lighted

There is a possibility that the interior portion has become heated. Turn the power OFF and wait

approximately 20 minutes. After the main unit has cooled down, please confirm whether or not

there is blockage of the air passage aperture, whether or not the filter is dirty, and/or whether or

not the peripheral temperature exceeds 35°C, etc. After performing any needed maintenance,

turn the power ON again

.

The green lamp

is lighted

Alternative blink with

the red lamp

There is a possibility that the interior portion has become overcooled. Please use the unit within

the usage temperature parameters (0°C to 35°C).

turn the power ON again

.

The green

lamp is lighted

Simultaneous blink

with the red lamp

This is a notification that it is time to clean the filter.

After cleaning the filter, operate the FILTER TIME portion of the OPTION Menu, and perform

reset of the FILTER TIME.

When the interior portion has become overheated, for safety purposes, the power source is automatically turned OFF,

and the indicator lamps may also be turned OFF. Press the “

” (power OFF) side of the main power switch, and wait

for approximately 20 minutes. Please then use the unit only after having first confirmed that the unit has sufficiently

cooled down.

NOTE

Regarding the Indicator Lamps

Blink of the red

lamp

After performing any needed maintenance,

Check the connector CNTH connecting.

27

Page 28

CP-S318(C3SM4) / CP-X328(C3XM4)

SERVICE MENU

To display the OSD for “SERVICE MENU” set up.

SERVICE

FANSPEED

B-SPEED

DURABLE MODE

VIDEO NR

LENS

MUTE COLOR

FILTER TIME

yellow(selected item)

input picture

or

start_up screen

By the control panel By the remote control transmitter

1. Display the menu by the

“MENU” button.

2. Select the “OPT.” on the menu.

3. Continue press the button “

fi rst, then press the button “ ”

1. Display the menu by the

“MENU” button.

2. Select the “OPT.” on the menu.

”

3. Continue pressing the button

“MAGNIFY OFF” for 3 seconds.

together with “RESET”, and

hold for 3 seconds.

Setup of a Cooling Fan Speed

When using this projector in the place where altitude is high, we recommend you to set a cooling fan’s speed as

“HIGH”. It is because the cooling effi ciency of a projector falls and the temperature inside a projector rises easily

in such a place, since the density of air becomes low.

Setting Method of Cooling Fan Speed

1. Select the “FAN SPEED” on the OSD using button “ ” by the SERVICE MENU.

same as the menu color

white(not selected item)

FANSPEED

HIGHNORMAL

yellow(selected item)

2. Select the “HIGH” on the OSD using the button “ ”. To reset this setup, select the “NORMAL” using the

button “ ”.

3. The OSD will be ended by no operation for 10 seconds or change of input signal. To end immediately, use one

of buttons except buttons “ ”, “ ”, “ ”, “ ”.

NOTE:

The “HIGH” mode makes the fan noisy than “NORMAL” mode.

The recall of factory setting sets the fan speed to “NORMAL” mode. You must set the fan speed after recall of

factory setting if you need “HIGH” mode.

28

Page 29

CP-S318(C3SM4) / CP-X328(C3XM4)

Setup of Filter time (“ON” or “OFF”)

1. Select the “FILTER TIME” on the OSD using button “ ” by the SERVICE MENU.

SERVICE

FANSPEED

B-SPEED

DURABLE MODE

VIDEO NR

LENS

MUTE COLOR

FILTER TIME

yellow(selected item)

input picture

or

start_up screen

same as the menu color

white(not selected item)

FILTER TIME

ONOFF

2. ON : Select the “ON” on the OSD using button “ ”.

OFF : Select the “OFF” on the OSD using button “

”.

3. The OSD will be ended by no operation for 10 seconds or change of input signal. To end immediately, use one

of buttons except buttons “ ”, “ ”, “ ”, “ ”.

29

Page 30

7. Wiring diagram

CP-S318(C3SM4) / CP-X328(C3XM4)

CNBAR

CNPWR

FEB2

Cut off the sheet by bending it back

and forth 2 or 3 times.

Connect the FEB2 (ferrite core) to the

CNPWR then move the CNPWR to

the connector as illustrated below:

Connect the CNPWR to connector

J1 then make sure that the CNPWR

Wiring for Ballast Power Supply Board

(1) Keep a record of the ballast power supply lot number in the 100% inspection record.

(2) Cut off the PVC sheet.

(3) Connect the CNPWR.

(4) Install the FEB2.

(5) Connect the CNBAR.

(6) Install the ballast shield (in accordance with the general assembly drawing).

TSW

J1

J2

is completely locked.

2-8pin

1pin

Connect the CNBAR to connector J2,

while holding down the small board mounted

with the J2 (to prevent stress on the small board).

CNPOW

Connect the FEB3 (ferrite core)

to pins 2-8 of the CNPOW.

9-14pin

Igniter transformer

Perforation

Cut off the PVC sheet by bending it back and forth 2 or 3 times with

your hand, while holding down the double-coated adhesive tape affixed

to the igniter transformer so the tape cannot come off.

C3SM4 / C3XM4 Chassis Wiring diagram 1

FEB3

Pass the leads through the

board holder notch.

CN102

Make sure that the CN102 and the CN104 have been securely

CN104

CN101

Sensor board

Wiring for Circuit Power Supply Board

(1) Keep a record of the circuit power supply lot number in the 100% inspection record.

(2) Connect the TSW.

(3) Install the FEB3.

(4) Connect the CNPOW.

(5) Connect the CNTH.

Wiring for Circuit Power Supply and Ballast Power Supply Boards

(6) Apply the TAP3.

connected (since they cannot be checked in subsequent processes).

Install the sensor board after completing the following steps:

30

TAP 3

Make sure that connector E950 has

been securely connected then apply

the TAP3 (to prevent detachment).

Sensor board

Connect the CNTH to connector

E950 on the sensor board.

E950

CNTH

Page 31

Lamp

lead

CP-S318(C3SM4) / CP-X328(C3XM4)

CNBAR

CNTH

Radiating

CN101

plate

CNTH

Pass the CNTH lead through the hook

on the ballast cover then apply the TAP10

to fix the lead as illustrated below:

TAP10

Hook

TAP6

Apply the TAP6 to the specified position

on the lamp leads shown in the illustration.

50 5

Push the CNPWR cable into the

clearance between the power

supply board holder and the

power supply board heat radiating

plate (do not lay the cable over

the radiating plate).

CNPWR

J2

Radiating

CN101

Connect the CNPWR to connector CN101 then

make sure that it is completely locked.

plate

C3SM4 / C3XM4 Chassis Wiring diagram 2

J1

During power supply assembling

(1) Wire and connect the CNPWR.

(2) Lay the lamp leads.

(3) Apply the TAP6.

(4) Hook the CNTH lead and apply the TAP10.

Wiring for Power Supply (for Board Sub-assembling)

31

Lamp

lead

Lay the lamp leads on the left sidewall

in the manner as illustrated.

Page 32

CNBAR

CP-S318(C3SM4) / CP-X328(C3XM4)

Lamp

lead

TSW

CNPOW

CNTH

Before installing the optical unit, put all of leads away from where the

optical unit is installed as illustrated below so no lead can become entangled.

Fix the CNSP with the TAP4.

A83

For details, see the assembly drawing.

Input board assembly

C3SM4 / C3XM4 Chassis Wiring diagram 3

TAP4

During bottom case assembling

(1) Connect the CNSP to the A83.

(2) Take care not to entangle any

Wiring for Bottom Case Assembling

lead when installing the optical unit.

32

CNSP

Pass the CNSP lead behind the SP

fixing rib so the lead cannot be caught

between the rib and the input board.

A83

When connecting and detaching the connector,

hold the connector housing with your hand and

take care not to stress where the A83 is

soldered and the CNSP lead.

Input board

CNSP

SP fixing rib

Page 33

CP-S318(C3SM4) / CP-X328(C3XM4)

Tape

TSW

Lay the lamp leads so the lamp house

notch catches the tape applied to the

lamp leads.

Lamp

lead

Lamp

house

Arrange the lamp lead on the set's rear

side so as it comes outside as illustrated.

This arrangement prevents the lamp lead

from being caught when installing the

upper case.

Laying the lax lamp lead inside prevents

it from protruding towards the outside.

CNBAR

Fan for panel B

#6222

CNPOW

CNTH

Boss

Lens barrel

Pass the CNRM through the specified

position as illustrated and avoid passing

it between the boss and the lens barrel

(to prevent the lens from contacting the

cable).

CNRM

CNLC

E941

SW board

Connect the CNLC to

the SW board before

installing the SW board.

CNLC

C3SM4 / C3XM4 Chassis Wiring diagram 4

Exhaust fan

#3020

RC board

During optical unit installation

(1) Connect the CNRM.

(2) Apply the TAP1.

(3) Connect the CNLC.

(4) Connect the lamp leads.

(5) Lay the SP lead (A83-CNSP).

Wiring for Optical Unit Installation

E901

#6220

Fan for panel R

#6221

Fan for panel G

33

TAP1

Tense the CNRM lead then

fix it by applying the TAP1.

CNRM

INP. RC. board assembly

Put the connected A83 (SP) and CNSP

and their leads into the clearance between

the optical unit and the input board to

prevent those parts from being caught

when installing the upper case.

Take care not to stress where the SP is

soldered.

Page 34

CP-S318(C3SM4) / CP-X328(C3XM4)

Apply the TAP7 to fix the cable guide.

TAP7

Do not loosen the TSW cable (to keep the cable

from coming near the power supply primary side).

Fix the TSW cable and the #3020 lead with the

cable guide on the ballast cover.

CNBAR

CNPOW

CNTH

Make a loop when passing the TSW lead through

TSW

Solder spot

(holding the

wires together)

Hold the lamp leads and the TSW,

however, take care not to hold

the solder spot on the TSW

lead.

the guide hole on the ballast cover.

Lamp

lead

Solder spot

TSW

Check the model code.

Bend the ends of the lamp leads in the arrowed

direction (to prevent the leads from being caught

when installing the upper case).

(holding the

wires together)

Side stamped

with the model

code

Model: 120AR1U1N

Install the TSW with the

model code facing

downwards (so the

model code cannot be

seen after installation).

TSW

Pass the #3020 lead through

the guide hole on the ballast cover.

Fan for panel B

#6222

Before drive board installation

(1) Wire the CNBAR.

(2) Wire and install the TSW.

(3) Lay and fix the lamp leads.

(4) Lay the #3020 lead.

(5) Wire the TSW.

(6) Apply the TAP7.

RC board

Wiring before Drive Board Installation

#6220

#6221

Fan for panel G

Fan for panel R

34

CNLC

C3SM4 / C3XM4 Chassis Wiring diagram 5

Exhaust fan

#3020

INP. RC. board assembly

CNRM

Page 35

CP-S318(C3SM4) / CP-X328(C3XM4)

TAP2

CNLC

CNLC lead laying range

E302

21

8

9

E800

14

CNBAR

Fan for panel B

#6222

CNTH

Pass the #6222 lead over the ballast cover

(if the lead is passed from the side of the

ballast power supply, it will contact the power

CNPOW

Entwine the CNBAR lead with the CNTH lead

(to prevent them from contacting the primary

side of the power supply).

supply primary side).

CNBAR

CNLC

E302

TAP2

Lay the CNLC lead so it can be on the

ballast cover and cannot be nearer to

the input board than the SW board

setscrew then tape the lead.

E801

E805

E807

E804

CNPOW

E800

P701

CNTH

P501

#3020

P601

Exhaust fan

Install the upper case with care

so the lamp leads cannot be

caught on the case

(pay attention to the rib on the

upper case).

SW board setscrew

During drive board installation

(1) Connect the CNTH, the CNPOW, the #6220 and the #6221.

(2) Wire and connect the CNBAR and the #6222.

(3) Connect the CNRM, the CNLC and the #3020.

(4) Apply the TAP2.

(5) Connect the flexible cable for the liquid crystal panel.

Procedure

(1) Before installing the drive board, connect the CNBAR and the #6222 while

holding the drive board with your hand.

(2) Put the drive board in the position where you install it then connect the CNTH,

the CNPOW, the #6220 and the #6221 while lifting the rear of the board.

Wiring for Drive Board Installation

(3) Connect the CNRM, the CNLC, the #3020 and the panel flexible cable.

(6) Take care not to entangle the lamp leads when installing the upper case.

#6220

Fan for panel R

#6221

Fan for panel G

35

E802

E803

E806

CNRM

(1) Securely insert the flexible

cable into the connector base

(note that the connector is a

bottom contact type so make

sure that the direction in which

you insert it is appropriate).

Flexible

Put the connector CNRM lead into the clearance

between the optical unit and the bottom case

(to prevent the lead from being caught when

installing the upper case).

For details on flexible cable installation, see the

1

2

following drawing:

C3SM4 / C3XM4 Chassis Wiring diagram 6

Drive board assembly

(2) Move the lock hinge in the

arrowed direction until it is

securely locked.

cable

Connector

base

Page 36

CP-S318(C3SM4) / CP-X328(C3XM4)

8. Disassembly diagram

M : Meter screw

T : Tapping screw

M3X8

M3X10

18

M3X10

25

T3X12

T3X12

11

A

28

24

M3X8 DT

M3X8 DT

10

6

9

26

8

13

12

36

Page 37

CP-S318(C3SM4) / CP-X328(C3XM4)

M : Meter screw

T : Tapping screw

M3X10

A

22

17

5

M3X10

M3X8

M3X10

M3X8

21

16

27

T3X12

M3X8

T3X12

7

M3X10

15

3

T3X12

2

T3X12

23

19

20

1

4

T2X5

M3X8

M3X8 DT

M3X8

29

M3X8 DT

14

14

37

Page 38

CP-S318(C3SM4) / CP-X328(C3XM4)

9. Replacement Parts list

PRODUCT SAFETY NOTE : Components marked with a have special characteristics important to safety. Before replacing any of there

components, read carefully, the PRODUCT SAFETY NOTICE of this Service Manual. Don't degrade the safety of the receiver through

improper servicing.

CP-S318

SYMBOL PARTS SYMBOL PARTS

NO. NO. DESCRIPTION NO. NO. DESCRIPTION

1 JP06012 PWB ASS'Y INPUT 22 HA01101 POWER UNIT (BALLAST)

2 JP06013 PWB ASS'Y REMOTE CONTROL 23 HA00911 POWER UNIT (CIRCUIT)

3 JP06014 PWB ASS'Y LIMIT SWITCH 24 GK00562 SPEAKER

4 JP06015 PWB ASS'Y SENSOR 25 FH00209 TEMPERATURE SENSOR

5 JP07021 PWB ASS'Y DRIVE 26 QD34891 LENS CAP

6 MU01691 AIR FILTER 27 EA01031R CPC30 LOW CONNECTOR

7 PC04817 CONTROL BUTTON ASS'Y 28 DT00511 LAMP UNIT ASS'Y

8 PE00112 RUBBER FOOT 29 CK31602R EL4332CS

9 QD36616 FRONT BEZEL ASS'Y

10 QD35241 BOTTOM CASE ASS'Y SH

11 QD36596 UPPER CASE ASS'Y EV01682 POWER SUPPLY CORD(UK TYPE) W/CORE

12 QD34861 LAMP DOOR ASS'Y EV01662 POWER SUPPLY CORD(US TYPE) W/CORE

13 QD34851 FILTER COVER EV01672 POWER SUPPLY CORD(EUROPE TYPE) W/CORE

14 QJ01111 ADJUST FOOT EW06661 RGB-D CABLE(15PIN MALE TO 15PIN MALE)

15 UE21012 DICHROIC OPTICS UNIT EW05941 USB CABLE

16 UX09282 LCD/LENS PRISM ASS'Y EW06031 3 CONDUCTOR VIDEO/AUDIO CABLE

17 2722447 FUSE 5A HL01891 REMOTE CONTROL UNIT

18 GS00641 DC FAN (EXHAUST) NX05741 CLEANING TOOL FOR DUST

19 GS00881 DC FAN (INTAKE R) NX05742 COTTON STICK L70

20 GS00882 DC FAN (INTAKE G) QR57441 INSTRUCTION MANUAL

21 GS00883 DC FAN (INTAKE B)

CP-X328

SYMBOL PARTS SYMBOL PARTS

NO. NO. DESCRIPTION NO. NO. DESCRIPTION

1 JP06018 PWB ASS'Y INPUT 22 HA01101 POWER UNIT (BALLAST)

2 JP06013 PWB ASS'Y REMOTE CONTROL 23 HA00911 POWER UNIT (CIRCUIT)

3 JP06014 PWB ASS'Y LIMIT SWITCH 24 GK00562 SPEAKER

4 JP06015 PWB ASS'Y SENSOR 25 FH00209 TEMPERATURE SENSOR SWITCH

5 JP07011 PWB ASS'Y DRIVE 26 QD34891 LENS CAP

6 MU01691 AIR FILTER 27 EA01031R CPC30 LOW CONNECTOR

7 PC04817 CONTROL BUTTON ASS'Y 28 DT00511 LAMP UNIT ASS'Y

8 PE00112 RUBBER FOOT 29 CK31602R EL4332CS

9 QD36615 FRONT BEZEL ASS'Y

10 QD35241 BOTTOM CASE ASS'Y SH

11 QD36595 UPPER CASE ASS'Y EV01682 POWER SUPPLY CORD(UK TYPE) W/CORE

12 QD34861 LAMP DOOR ASS'Y EV01662 POWER SUPPLY CORD(US TYPE) W/CORE

13 QD34851 FILTER COVER EV01672 POWER SUPPLY CORD(EUROPE TYPE) W/CORE

14 QJ01111 ADJUST FOOT EW06661 RGB-D CABLE(15PIN MALE TO 15PIN MALE)

15 UE21016 DICHROIC OPTICS UNIT EW05941 USB(A-B) CABLE W/CORE

16 UX09286 LCD/LENS PRISM ASS'Y EW06031 3 CONDUCTOR VIDEO/AUDIO CABLE

17 2722447 FUSE 5A HL01891 REMOTE CONTROL UNIT

18 GS00641 DC FAN (EXHAUST) NX05741 CLEANING TOOL FOR DUST

19 GS00881 DC FAN (INTAKE R) NX05742 COTTON STICK L70

20 GS00882 DC FAN (INTAKE G) QR57441 INSTRUCTION MANUAL S-ASS'Y

21 GS00883 DC FAN (INTAKE B)

38

Page 39

CP-S318(C3SM4) / CP-X328(C3XM4)

(1)

Turn off the projector and computer power supplies and connect with the RS-232C cable.

(2) Turn on the computer power supply and after the computer has started up, turn on the

projector power supply.

Control jack

D-sub 15-pin shrink jack

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

RD

TD

GND

SELO

RTS

1

2

3

4

5

6

7

8

9

CD

RD

TD

DTR

GND

DSR

RTS

DTS

RI

1

2345

67

8

9

RS-232C jack

D-sub 9-pin

Projector Computer

Communications setting

19200bps, 8N1

1 Protocol

Consist of header (7 bytes) + command data (6 bytes).

2 Header

BE + EF + 03 + 06 + 00 + CRC_low + CRC_high

CRC_low : Lower byte of CRC flag for command data.

CRC_high : Upper byte of CRC flag for command data.

3 Command data

byte_0 byte_1 byte_2 byte_3 byte_4 byte_5

Action Type Setting code

low high low high low high

Command data chart

Action (byte_0 - 1)

Action Classification Content

1 SET Change setting to desired value.

2 GET Read projector internal setup value.

4 INCREMENT Increment setup value by 1.

5 DECREMENT Decrement setup value by 1.

6 EXECUTE Run a command.

10. RS-232C communication

39

Page 40

CP-S318(C3SM4) / CP-X328(C3XM4)

r.

'

Requesting projector status (Get command)

(1) Send the request code Header + Command data (‘02H’+‘00H’+ type (2 bytes)

+‘00H’+‘00H’) from the computer to the projector.

(2) The projector returns the response code ‘1DH’+ data (2 bytes) to the computer.

Changing the projector settings (Set command)

(1) Send the setting code Header + Command data (‘01H’+‘00H’+ type (2 bytes) +

setting code (2 bytes)) from the computer to the projector.

(2) The projector changes the setting based on the above setting code.

(3) The projector returns the response code ‘06H’ to the computer.

Using the projector default settings (Reset Command)

(1) The computer sends the default setting code Header + Command data (‘06H’+‘00H’+

type (2 bytes) +‘00H’+‘00H’) to the projector.

(2) The projector changes the specified setting to the default value.

(3) The projector returns the response code ‘06H’ to the computer.

Increasing the projector setting value (Increment command)

(1) The computer sends the increment code Header + Command data (‘04H’+‘00H’+

type (2 bytes) +‘00H’+‘00H’) to the projector.

(2) The projector in creases the setting value on the above setting code.

(3) The projector returns the response code ‘06H’ to the computer.

Decreasing the projector setting value (Decrement command)

(1) The computer sends the decrement code Header + Command data (‘05H’+‘00H’+

type (2 bytes) +‘00H’ + ‘00H’) to the projector.

(2) The projector decreases the setting value on the above setting code.

(3) The projector returns the response code ‘06H’ to the computer.

When the projector cannot understand the received command

When the projector cannot understand the received command, the error code '15H' is sent

back to the computer.Sometimes the projector cannot properly receive the command. In such

a case, the command is not executed and the error code e15H f is sent back to the compute

If this error code is returned, send the same command again.

When the projector cannot execute the received command

When the projector cannot execute the received command, the error code '1cH' + 'xxxxH

is sent back to the computer.

When the data length is greater than indicated by the data length code, the projector will

ignore the excess data code.

Conversely, when the data length is shorter than indicated by the data length code,

an error code will be returned to the computer.

NOTE

undefined command or data.

Provide an interval of at least 40ms between the response code and any other code.

•

• The projector outputs test data when the power supply is switched ON, and when the

lamp is lit. Ignore this data.

• Commands are not accepted during warm-up.

• Operation cannot be guaranteed when the projector receives an

40

Page 41

CP-S318(C3SM4) / CP-X328(C3XM4)

Command data chart

Names Operation type Header

CRC Action Type Setting code

Command data

Blue BE EF 03 06 00 CB D3 01 00 00 30 03 00

White BE EF 03 06 00 6B D0 01 00 00 30 05 00

Blank Color

Set

Black BE EF 03 06 00 9B D0 01 00 00 30 06 00

MyScreen BE EF 03 06 00 FB CA 01 00 00 30 20 00

ORIGINAL BE EF 03 06 00 FB E2 01 00 00 30 40 00

Get BE EF 03 06 00 08 D3 02 00 00 30 00 00

Normal BE EF 03 06 00 C7 D2 01 00 01 30 00 00

H Inverse BE EF 03 06 00 57 D3 01 00 01 30 01 00

Mirror

Set

V lnverse BE EF 03 06 00 A7 D3 01 00 01 30 02 00

H&V Inverse BE EF 03 06 00 37 D2 01 00 01 30 03 00

Get BE EF 03 06 00 F4 D2 02 00 01 30 00 00

Normal BE EF 03 06 00 83 D2 01 00 02 30 00 00

Freeze BE EF 03 06 00 13 D3 01 00 02 30 01 00

Freeze

Set

Get BE EF 03 06 00 B0 D2 02 00 02 30 00 00

ORIGINAL BE EF 03 06 00 0B D2 01 00 04 30 00 00

Startup

Set

OFF BE EF 03 06 00 9B D3 01 00 04 30 01 00

MyScreen BE EF 03 06 00 CB CB 01 00 04 30 20 00

Get BE EF 03 06 00 38 D2 02 00 04 30 00 00

English BE EF 03 06 00 F7 D3 01 00 05 30 00 00

Français BE EF 03 06 00 67 D2 01 00 05 30 01 00

Deutsch BE EF 03 06 00 97 D2 01 00 05 30 02 00

Español BE EF 03 06 00 07 D3 01 00 05 30 03 00