Page 1

SERVICE MANUAL

MANUEL D'ENTRETIEN

WARTUNGSHANDBUCH

CAUTION:

Before servicing this chassis, it is important that the service technician read the “Safety

Precautions” and “Product Safety Notices” in this service manual.

No. 0422

«MODEL NAMES»

CML174SXW2

CML175SXW2

Data contained within this Service

manual is subject to alteration for

improvement.

ATTENTION:

Avant d’effectuer l’entretien du châassis, le technicien doit lire les «Précautions de sécurité»

et les «Notices de sécurité du produit» présentés dans le présent manuel.

VORSICHT:

Vor Öffnen des Gehäuses hat der Service-Ingenieur die „Sicherheitshinweise“ und „Hinweise

zur Produktsicherheit“ in diesem Wartungshandbuch zu lesen.

Les données fournies dans le présent

manuel d’entretien peuvent faire l’objet

de modifications en vue de perfectionner

le produit.

Die in diesem Wartungshandbuch

enthaltenen Spezifikationen können sich

zwecks Verbesserungen ändern.

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

LCD Colour Monitor

November 2003

Page 2

SAFETY PRECAUTIONS

WARNING: The following precautions must be observed.

ALL PRODUCTS

Before any service is performed on the chassis an

isolation transformer should be inserted between the

power line and the product.

1. When replacing the chassis in the cabinet, ensure

all the protective devices are put back in place.

2. When service is required, observe the original

lead dressing. Extra precaution should be taken to

ensure correct lead dressing in any high voltage

circuitry area.

3. Many electrical and mechanical parts in

HITACHI products have special safety related

characteristics. These characteristics are often not

evident from visual inspection, nor can the

protection afforded by them necessarily be

obtained by using replacement components rated

for higher voltage, wattage, etc. Replacement

parts which have these special safety

characteristics are identified by marking with a

! on the schematics and the replacement parts

list.

The use of a substitute replacement component

that does not have the same safety characteristics

as the HITACHI recommended replacement one,

shown in the parts list, may create electrical

shock, fire, X-radiation, or other hazards.

4. Always replace original spacers and maintain lead

lengths. Furthermore, where a short circuit has

occurred, replace those components that indicate

evidence of overheating.

5. Insulation resistance should not be less than 2M

ohms at 500V DC between the main poles and

any accessible metal parts.

6. No flashover or breakdown should occur during

the dielectric strength test, applying 3kV AC or

4.25kV DC for two seconds between the main

poles and accessible metal parts.

7. Before returning a serviced product to the

customer, the service technician must thoroughly

test the unit to be certain that it is completely safe

to operate without danger of electrical shock. The

service technician must make sure that no

protective device built into the instrument by the

manufacturer has become defective, or

inadvertently damaged during servicing.

CE MARK

1. HITACHI products may contain the CE mark on

the rating plate indicating that the product

contains parts that have been specifically

approved to provide electromagnetic

compatibility to designated levels.

2. When replacing any part in this product, please

use only the correct part itemised in the parts list

to ensure this standard is maintained, and take

care to replace lead dressing to its original state,

as this can have a bearing on the electromagnetic

radiation/immunity.

PICTURE TUBE

1. The line output stage can develop voltages in

excess of 25kV; if the E.H.T. cap is required to be

removed, discharge the anode to chassis via a

high value resistor, prior to its removal from the

picture tube.

2. High voltage should always be kept at the rated

value of the chassis and no higher. Operating at

higher voltages may cause a failure of the picture

tube or high voltage supply, and also, under

certain circumstances could produce X-radiation

levels moderately in excess of design levels. The

high voltage must not, under any circumstances,

exceed 29kV on the chassis (except for projection

Televisions).

3. The primary source of X-radiation in the product

is the picture tube. The picture tube utilised for

the above mentioned function in this chassis is

specially constructed to limit X-radiation. For

continued X-radiation protection, replace tube

with the same type as the original HITACHI

approved type

4. Keep the picture tube away from the body while

handling. Do not install, remove, or handle the

picture tube in any manner unless shatterproof

goggles are worn. People not so equipped should

be kept away while picture tubes are handled

LASERS

If the product contains a laser avoid direct exposure to

the beam when the cover is open or when interlocks are

defeated or have failed.

Page 3

CONTENTS

1. INTRODUCTION .......................................................................................................................................... 3

1.1 Scope.....................................................................................................................................................................3

1.2 Description............................................................................................................................................................3

2. ELECTRICAL REQUIREMENTS ................................................................................................................. 4

2.1 Standard Test Conditions......................................................................................................................................4

All tests shall be performed under the following conditions, unless otherwise specified. ..............................................4

2.2 LCD monitor General specification......................................................................................................................5

2.3 LCD Panel Specification.......................................................................................................................................6

2.4 Input Signals .........................................................................................................................................................8

2.5 CONTROLS.........................................................................................................................................................12

2.6 White Color Temperature ...................................................................................................................................14

2.7 POWER SUPPLY................................................................................................................................................15

2.8 Plug & Play(EDID).............................................................................................................................................16

2.9 Audio Technical specification.............................................................................................................................16

3. VL-713 DISPLAY CONTROL BOARD....................................................................................................... 17

3.1 Description..........................................................................................................................................................17

3.2 Features ..............................................................................................................................................................17

3.3 BLOCK DIAGRAM.............................................................................................................................................18

3.4 Connector Locations...........................................................................................................................................18

3.5 Connector Type...................................................................................................................................................19

3.6 Connector pin assignment...................................................................................................................................19

4. VK-713 Control Panel Board .................................................................................................................... 22

4.1 Description..........................................................................................................................................................22

4.2 Connector and Switch Locations ........................................................................................................................22

4.3 Connector type....................................................................................................................................................22

4.4 Connector pin Assignment ..................................................................................................................................22

4.5 Switch definition..................................................................................................................................................23

4.6 LED definition.....................................................................................................................................................23

5. POWER SUPPLY & INVERTER BOARD .................................................................................................. 24

5.1 Description..........................................................................................................................................................24

5.2 Power supply ( AC to DC section)......................................................................................................................24

5.3 Inverter (DC to AC Section)................................................................................................................................25

5.4 Electrical characteristics ....................................................................................................................................25

5.5 Connector locations............................................................................................................................................26

6. TROUBLESHOOTING ............................................................................................................................... 28

6.1 Main Procedure ..................................................................................................................................................28

7. MECHANICAL REQUIREMENTS.............................................................................................................. 32

7.1 Vibration and Shock............................................................................................................................................32

7.2 Package Drop Specification ...............................................................................................................................32

7.3 Dimension Size and Weight.................................................................................................................................33

7.4 Gap Spec.............................................................................................................................................................33

7.5 Tilt Base Rotation ...............................................................................................................................................34

7.6 Swivel Base Rotation...........................................................................................................................................34

7.7 Plastic Material ..................................................................................................................................................34

7.8 GAP Spec. ...........................................................................................................................................................34

Page 4

8. Power Line Transient Test (IEC 61000-4-4 Fast Transients/Burst) ............................................................ 35

8.1 Peak Voltage:......................................................................................................................................................35

8.2 Polarity : + / -..............................................................................................................................................35

8.3 Repetition Frequency of the impulse : 5 KHz. ....................................................................................................35

8.4 Rise-Time : 5ns ± 30%......................................................................................................................................35

8.5 Impulse Duration: 50 nS ± 30% .........................................................................................................................35

8.6 Relation to Power Supply: Asynchronous...........................................................................................................35

8.7 Burst Duration: 15 ms ± 20% .............................................................................................................................35

8.8 Burst Period: 300 ms ± 20%...............................................................................................................................35

8.9 Climatic Conditions:...........................................................................................................................................35

8.10 Test Procedure:...................................................................................................................................................35

9. Power Line Surge Test (IEC 61000-4-5 Surge) ....................................................................................... 37

9.1 Climatic Condition..............................................................................................................................................37

9.2 Test Conditions:..................................................................................................................................................37

9.3 ............................................................................................................................................................................37

9.4 ............................................................................................................................................................................37

9.5 ............................................................................................................................................................................37

9.6 ............................................................................................................................................................................37

9.7 Display set high-resolution mode, AC input use AC 240V. ................................................................................37

10. ENVIROMENT REQUIREMENT ................................................................................................................ 38

10.1 Operating ............................................................................................................................................................38

10.2 Storage or Shipment............................................................................................................................................38

11. REGULATION COMPLIANCE ................................................................................................................... 39

11.1 This product comply to the most current revisions of following regulations:.....................................................39

11.2 Electrostatics Discharge (ESD) ..........................................................................................................................40

12. QUALITY AND RELIABILITY .................................................................................................................... 41

12.1 Quality Assurance ...............................................................................................................................................41

12.2 Reliability............................................................................................................................................................41

APPENDIX A - POWER SUPPLY AND INVERTER BOARD DIAGRAMS............................................... 42

APPENDIX B - MAIN / DISPLAY CONTROL BOARD DIAGRAMS......................................................... 45

2

Page 5

1. INTRODUCTION

1.1 Scope

This specification defines the requirements for the 17” MICRO-PROCESSOR based Multimode supported high resolution colour LCD monitor. This monitor can be directly connected

to general 15 pin D-sub VGA connector and DVI-D digital connector eliminates the

requirement of optional special display card. It also supports VESA DPMS power

management and plug & play function. There is a build-in stereo audio amplifier with

volume control to drive a pair of speakers.

1.2 Description

The LCD monitor is designed with the latest LCD technology to provide a performanceoriented product with no radiation. This will alleviate the growing health concerns. It is also

a space saving design allowing more desktop space and compared to the traditional CRT

monitor, consumes less power and gets less weight in addition MTBF target is 20k hours or

more.

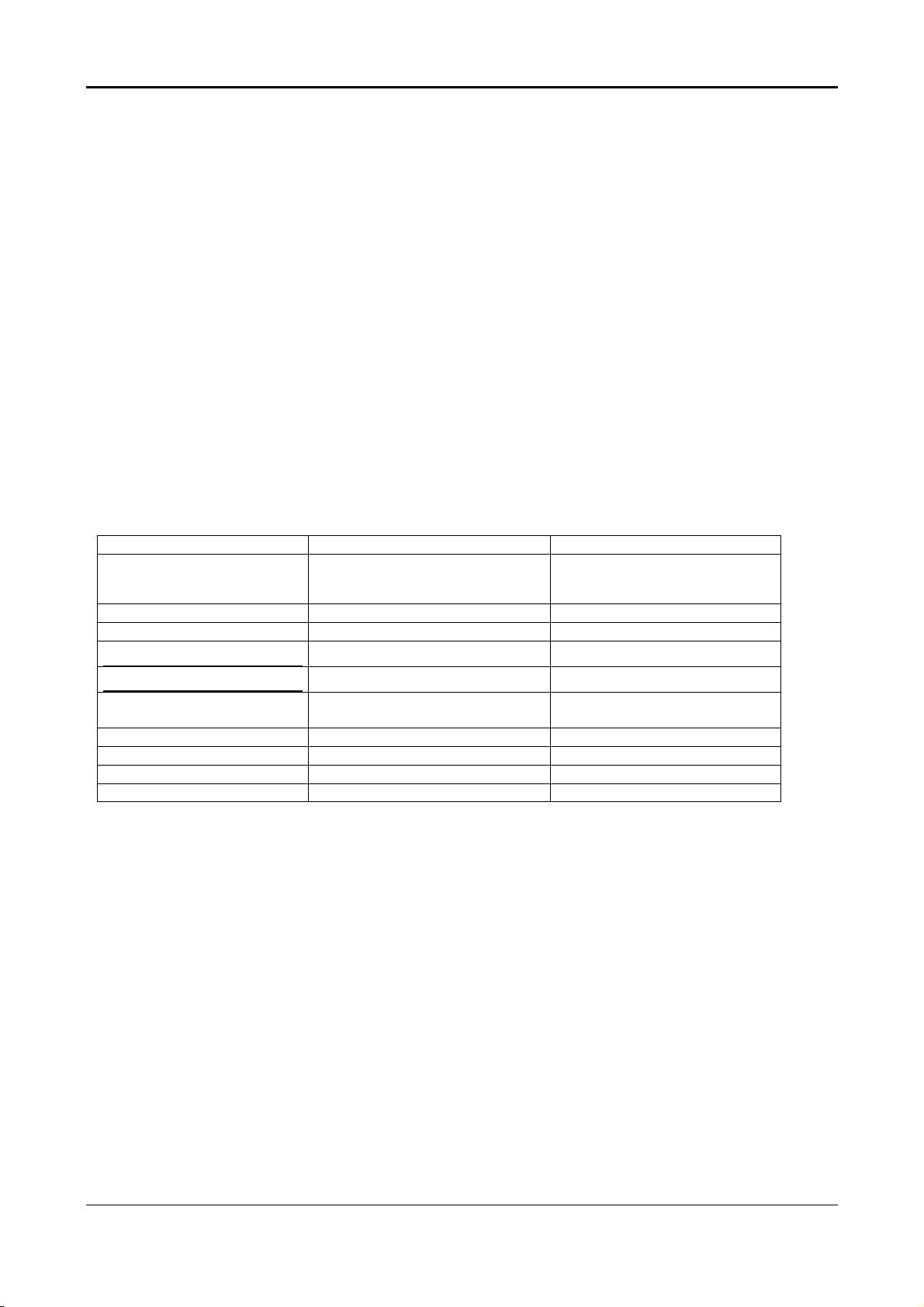

Comparison Chart of CM174SXW2/2B and CML175SXW2/2B

CML174SXW2/2B CML175SXW2/2B

Panel Normal 17” panel

Hydis HT17E12-200

Normal 17” panel

Hydis HT17E12-200

Signal Interface DSUB+DVI-D DSUB+DVI-D

Sync Type for analog input

Colour Temp user adjust

DDC

Speaker No 1W+1W

Headphone Jack No Yes

Microphone Jack No No

USB Hub Not supported Not supported

Tilt / Swivel Yes / No Yes / No

Separate / compatible / Separate / compatible /

Supported

DDC2B DDC2B

Supported

3

Page 6

2. ELECTRICAL REQUIREMENTS

2.1 Standard Test Conditions

All tests shall be performed under the following conditions, unless otherwise specified.

Ambient light

Viewing distance

Warrn up time

: 225 lux

: 50 cm in front of LCD panel

All specifications: 30 minutes

Fully functional: 5 seconds

Measuring Equipment

: Chroma 2250 signal generator or equivalent, directly

Connected to the monitor under test.

Minolta CA100 photometer, or equivalent

Control settings

User brightness control: Maximum (unless otherwise specified )

User contrast control: Typical (unless otherwise specified )

User red/white balance,

Green/white balance and

Blue/white balance control: In the centre (unless otherwise specified )

Power input

Ambient temperature

Analog input mode

: 110Vac or 230Vac

: 20 ± 5˚C (68 ±9˚F)

: 1280 x1024 /60 Hz

2.1.1 MEASUREMENT SYSTEMS

The units of measure stated in this document are listed below:

1 gamma = 1 nano tesla

1 tesla = 10,000 gauss

cm = in x 2.54

lb = kg x 2.2

degrees F = [°C x 1.8] + 32

degrees C = [°F - 32]/1.8

u' = 4x/(-2x + 12y + 3)

v' = 9y/(-2x + 12y + 3)

x = (27u'/4)/[(9u'/2) - 12v' + 9]

y = (3v')/[(9u'/2) - 12v' + 9]

nits = cd/(m2) = Ft-L x 3.426

lux = foot-candle x 10.76

4

Page 7

2.2 LCD Monitor General Specification

Panel Type : 17 '' Active matrix colour TFT LCD

1) Hydis HT17E12-200

Display size : 337.92mm (H) x 270.34mm (V)

Display mode : VGA 720 X 400 (70 Hz)

VGA 640 X 480 (60/66/70/72/75 Hz)

SVGA 800 X 600 (60/70/72/75 Hz)

XGA 1024 X 768 (60/70/75 Hz)

SXGA 1280 X 1024 (60/70/75 Hz) standard resolution

Pixel pitch : 0.088 x 3mm (H) x 0.264mm (V)

Display Dot : 1280 x (RGB) x 1024

Pixel Clock : 25.2 – 135.0MHz

Contrast ratio:

Brightness: 250 cd/m

θ

= 0 ˚ 430:1 (typical)

2

(typical)

Response time (Tr/Tf) : 5 /15 msec

Display colour : 262K (6 bits colour)

Viewing angle: L / R <80 / <80 ( <160 degrees horizontal typical)

≥10) U / D <65 / <65 ( <130 degrees vertical typical)

(CR

Luminance Uniformity : <1.2 % (Lmax/Lmin)

Pc interface: 1) Video : RGB analog 0.7V peak to peak

Sync : TTL positive or negative

2) Digital TMDS

Signal connector : 15 pin Mini D type, (standard VGA video)

DVI-D connector

3.5 mm stereo audio jack (Audio) (CML175SXW2/2B)

3.5 mm miniature stereo Headphone jack (CML175SXW2/2B)

Audio power : 1Wrms+1Wrms ( 300Hz–10KHz (SPL–10 dB)) (CML175)

Front control : power on/off with LED select (up, down) adjustment (+,-)

Interface frequency

Horizontal Frequency 24KHz --80KHz (analog), 31.5– 80KHz (digital)

Vertical Frequency 56Hz ----75Hz

Plug & play : Support VESA DDC2B functions

Power Input voltage : Single phase, 50/60HZ, 100VAC to 240VAC ±10%

Total output power : 48 Watt max.

5

Page 8

2.3 LCD Panel Specification

2.3.1 LCD Panel Model (Hydis HT17E12-200)

• Display Type Active matrix colour TFT LCD

• Resolution 1280 x 1024 pixels

• Display Dot 1280 x (RGB) x 1024

• Display Area 337.92mm(H) x 270.34mm(V)

• Pixel Pitch 0.264mm(H) x 0.264mm(V)

• Display Colour 262K (6 bit colour)

• Lamp Voltage 700 Vrms typ.

• Lamp Current 6.5mA rms.( typ). 4 Lamp

• Weight 1900g .

The test of Optical specifications shall be measured in a dark room (ambient luminance ≤1 lux

and temperature =25 ±2°C) with the equipment of Luminance meter system (Goniometer

system and TOPCON BM-5) and test unit shall be located at an approximate distance 50 cm

from the LCD surface at a viewing angle of θ and φ equal to 0°. We refer to θ

3’oclock direction (the “fight”), θ

(=θ12) as the 12’oclock direction (“bottom”). While

φ=90

scanning θ and/or φ, the center of the measuring spot on the display surface shall stay fixed. The

measurement shall be executed after 30 minutes warm-up period. VDD shall be 5.0V +/-10% at

25°C. Optimum viewing angle direction is 6 o’clock.

(=θ3) as the

φ=0

VDD = 5V , Frame rate= 60Hz, Clock = 54MHz, I

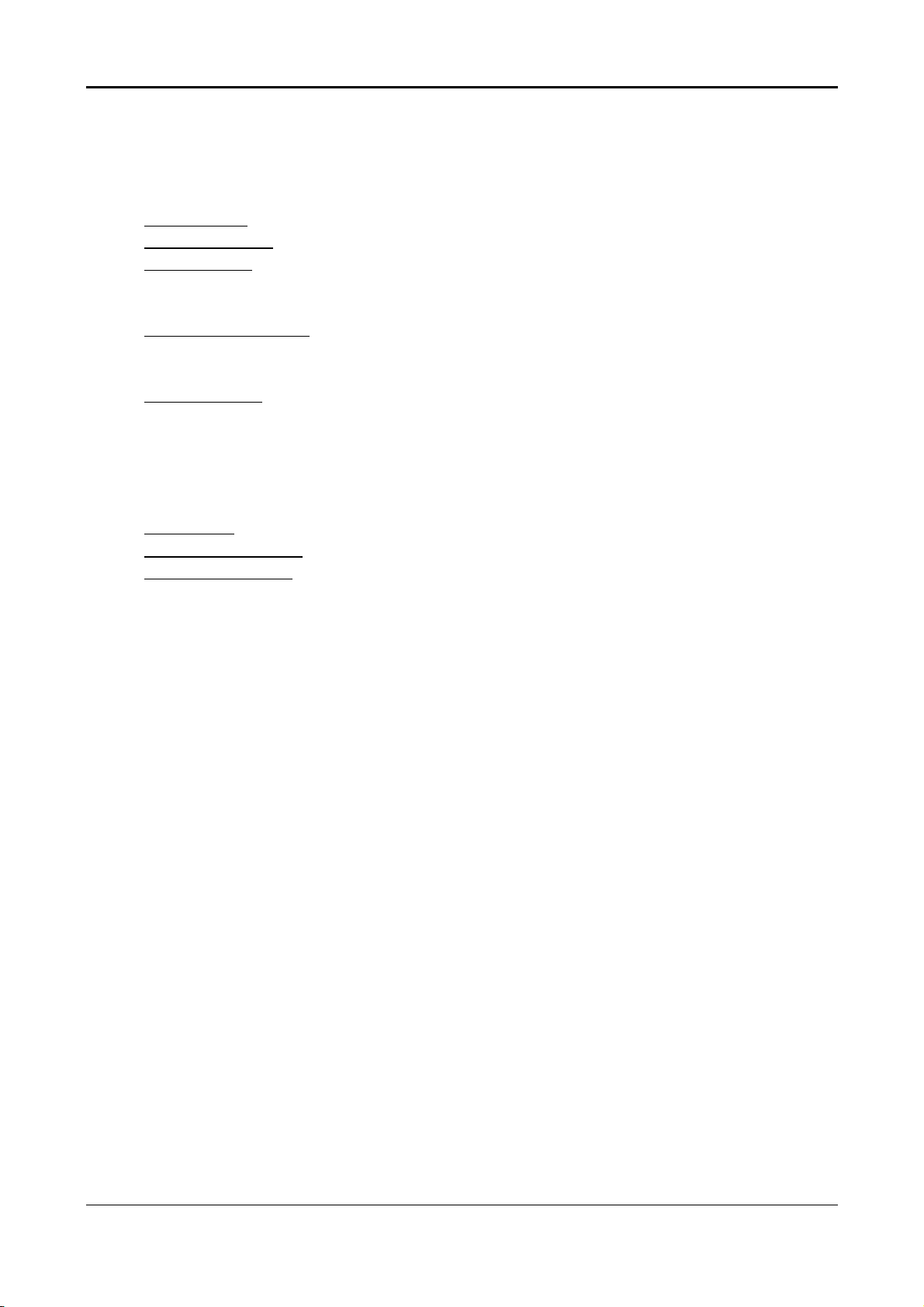

Parameter Symbol Condition MIN. TYP. MAX. UNIT Remark

Hori.

Viewing

Angle

Vert.

Hori.

Vert.

Luminance Contrast

Ratio

Luminance of white Y

White luminance

uniformity

White

Colour

Chromati

Red

city

(CIE)

Green

Blue

Response time

Cross talk CT

θ3

θ

φ

φ

θ3

θ

φ

φ

12

12

9

6

9

6

CR≥10

CR≥5

CR 350 430 - Note 2

w

Y

L

WX 0.270 0.300 0.330

W

0.305 0.335 0.365

Y

R

X

R

Y

G

X

G

0.568 0.598 0.628

Y

θ=0

(Centre)

Normal

Viewing

Angle

BX 0.115 0.145 0.175

B

Y

T

r

T

- 15

d

- 5

- - 2.0 % Note 7

6

= 6.5Ma, Tamb = 25 ± 2°C

BL

75 80 - Deg

75 80 - Deg

60 65 - Deg

60 65 - Deg

80 85 - Deg

Note 1

80 85 - Deg

70 75 - Deg

70 75 - Deg

200 250 - cd/m2 Note 3

- 1.2

Note 4

0.599 0.629 0.659

0.324 0.354 0.384

0.257 0.287 0.317

Note 5

0.073 0.103 0.133

30

msec

Note 6

Page 9

Note 1) Viewing Angle is the angle at which the contrast ratio is greater than 10. Viewing is

determined for the horizontal or 3 & 9 o’clock direction and the vertical or 6 & 12 o’clock

direction with respect to the optical axis which is normal to the LCD surface.

Note 2) Contrast measurements shall be made at viewing angle of θ = 0° and at the centre of the

LCD surface. Luminance shall be measure with all pixels in the view field set first to

white, then to the dark (black) state. Luminance Contrast Ratio (CR) is defined

mathematically.

Luminance when displaying a white raster

CR=

Luminance when displaying a black raster

Note 3) Centre Luminance of white is defined as LCD surface. Luminance shall be measured

with all pixels in the view field set first to white. This measurement shall be taken at the

locations shown in figure 2 for a total of the measurements per display.

Note 4) The White luminance uniformity on LCD surface is then expressed as: Y= maximum

Luminance of five points / Minimum Luminance of five points

Note 5) Colour chromaticity co-ordinate specified shall be calculated from the spectral data

measured with all pixels first in red, green, blue and white. Measurements shall be made

at the centre of the panel.

Note 6) The electro-optical response time measurements shall be made as figure by switching the

“data” input signal ON and OFF. The times needs for the luminance to change from 10%

to 90% is Td, and 90% to 10% is Tr.

Note 7) Cross-Talk of one area of the LCD surface by another shall be measured by comparing

the luminance (Y

the luminance (Y

) of a 25 mm diameter area, with all display pixels set to a grey level to

A

) of that same area when any adjacent is driven dark.

B

7

Page 10

2.4 Input Signals

2.4.1 Video Input

• Type Analog RGB Digital TMDS

• Input Impedance 75 ohm +/- 2%

• Polarity Positive

• Amplitude 0 - 0.7 +/- 0.05 Vp-p

• Display Colour same as LCD panel

2.4.2 Sync Input

• Signal separate horizontal and vertical sync, or composite sync

which are TTL compatible

• Polarity positive and negative.

2.4.3 Interface Frequency

The following frequency range is generalised by supported timing. If the entered

mode does not match the supported timing the display optimisation will not be

assured.

• Horizontal Frequency 24KHz --80KHz (analog), 31.5– 80KHz (digital)

• Vertical Frequency 56Hz ---------75Hz

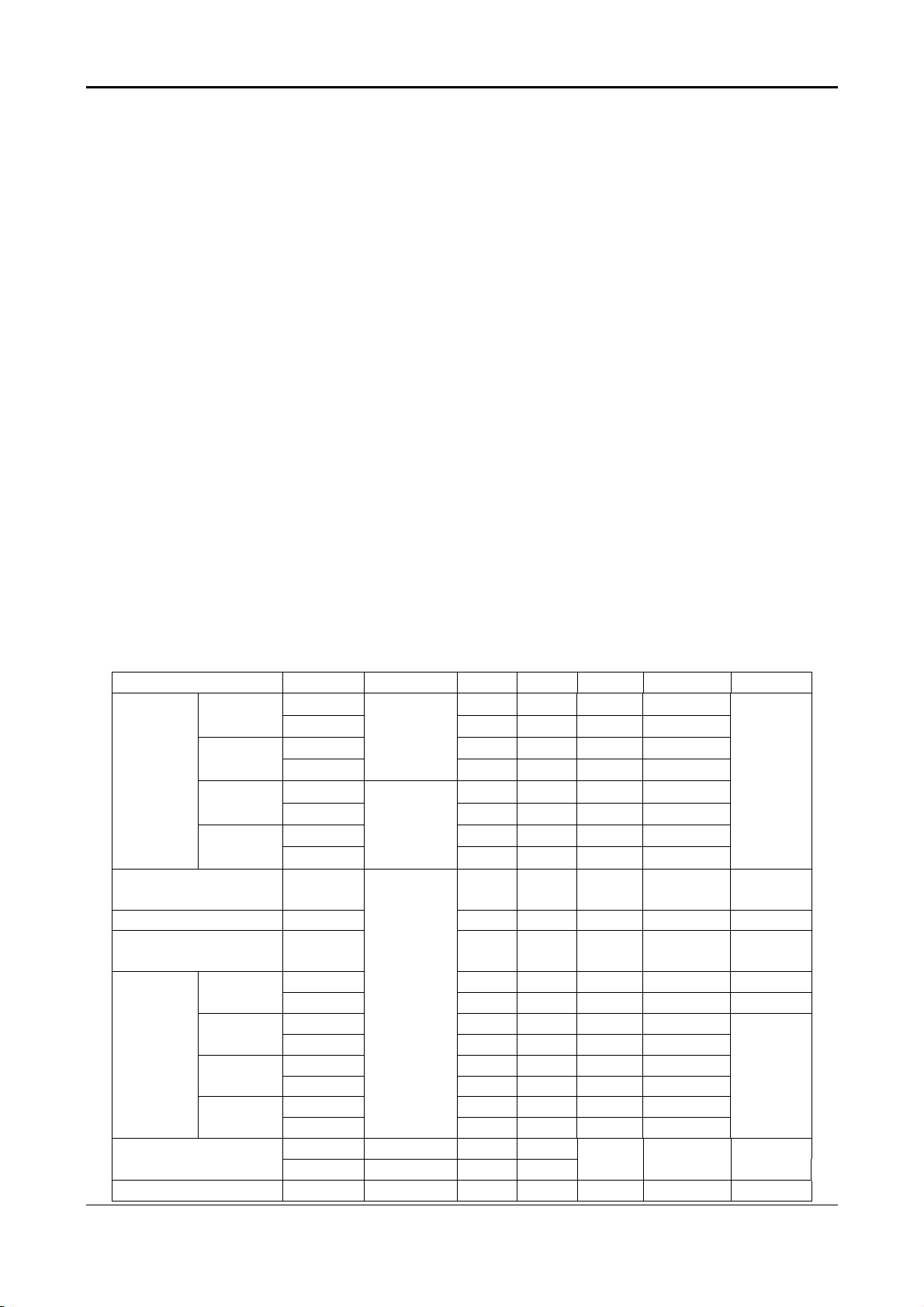

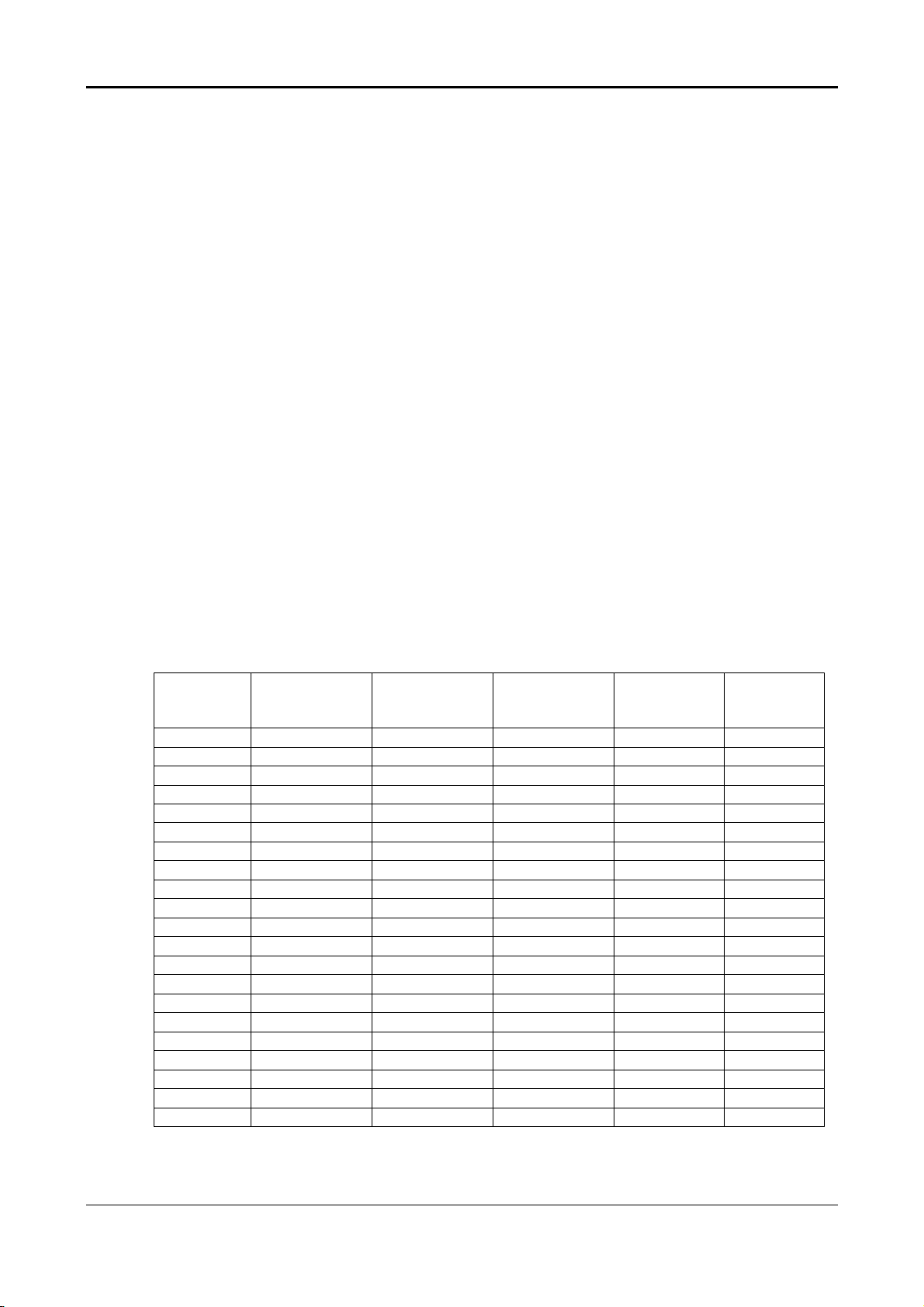

DISPLAY MODES

MONITOR

MODE NO.

1 640x350 31.5 + 70.0 - 25.0 VGA

2 640X400 24.83 - 56.4 - 21.05 NEC

3 640X400 31.5- 70.0+ 25.0 VGA

4 640X400 31.5- 70.1- 25.19 NEC

5 640X480 31.5 - 60.0 - 25.0 Defacto

6 640X480 35.0- 66.67- 30.24 MAC

7 640X480 37.86- 72.80- 31.5 VESA

8 640X480 37.5- 75.0- 31.5 VESA

9 720X400 31.5 - 70.0 + 28.0 Text Defacto

10 832X624 49.72- 74.55 - 57.28 MAC

11 800X600 35.16+ 56.25+ 36.0 SVGA

12 800X600 37.8 + 60.0 + 40.0 VESA

13 800X600 48.07 + 72.18 + 50.0 VESA

14 800X600 46.87+ 75.0+ 49.5 VESA

15 1024X768 48.4 - 60.0 - 65.0 VESA

16 1024X768 53.96 + 66.13 + 71.66 XGA

17 1024X768 56.47 - 70.07 - 75.0 VESA

18 1024X768 60.0 + 75.0 + 78.75 VESA

19 1024x768 60.24- 75.02- 80.0 MAC-768

20 1280X1024 64.0 + 60.0 + 108.5 SXGA

21 1280X1024 80.0 + 75.0 + 135.0 Defacto

SCREEN

RESOLUTION

HORIZONTAL

SYNC RATE

(kHz)

VERTICAL

SYNC RATE

(Hz)

VIDEO CLK

(MHz)

STANDARD

8

Page 11

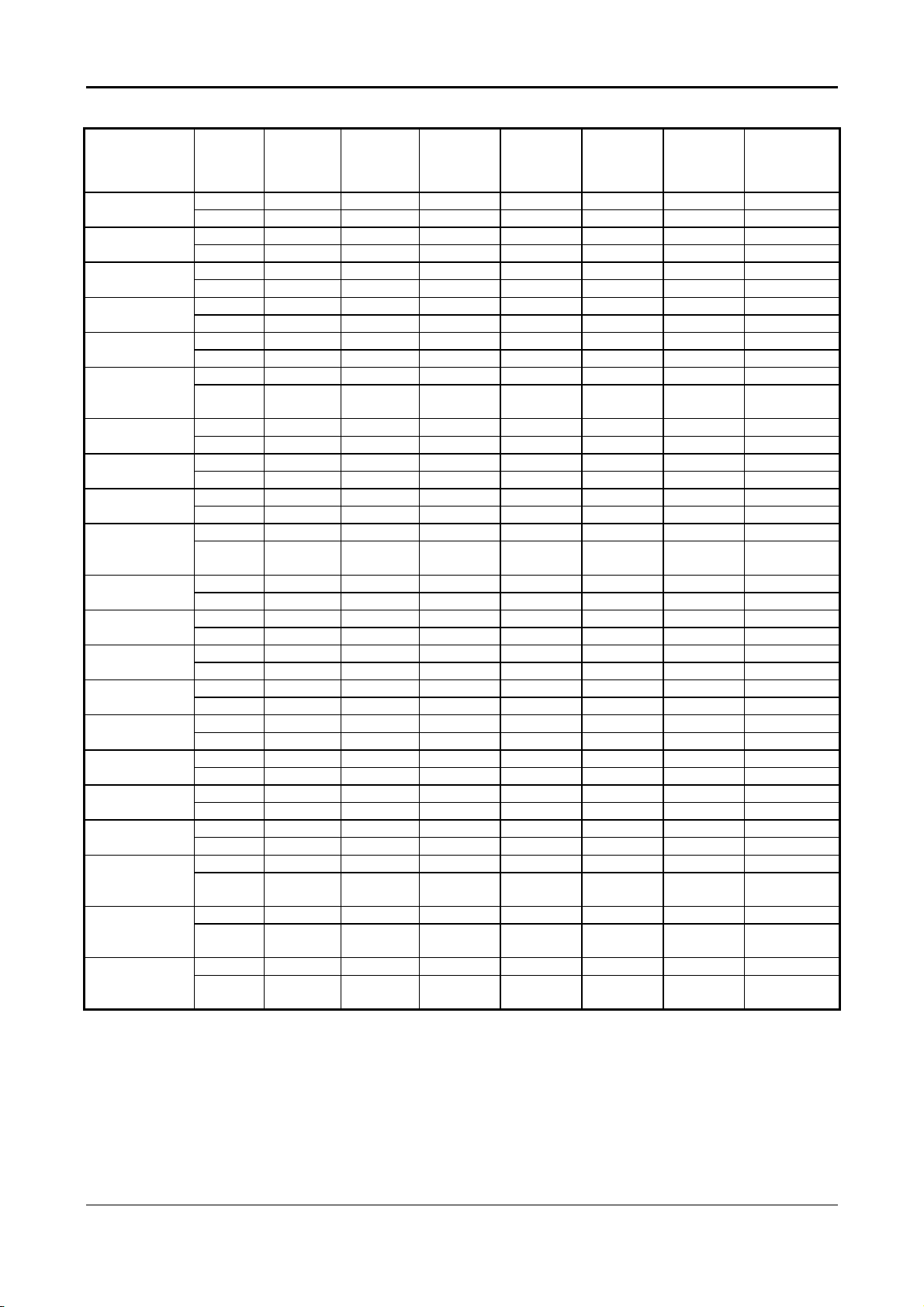

Supported Timing

TIMING

FV (HZ) POLARITY (DOT/LINE) (DOT/LINE) WIDTH PORCH PORCH FREQ.(MHZ)

(DOT/LINE) (DOT/LINE) (DOT/LINE)

640x350 31.469 + 800 640 96 16 48 25.175

VGA-350 70.087 – 449 350 2 37 60

640x400 24.83 – 848 640 64 64 80 21.05

NEC PC9801 56.42 – 440 400 8 7 25

640x400 31.469 – 800 640 96 16 48 25.175

VGA-GRAPH 70.087 + 449 400 2 12 35

640x400 31.5 – 800 640 64 16 80 25.197

NEC PC9821 70.15 – 449 400 2 13 34

640x480 31.469 – 800 640 96 16 48 25.175

VGA-480 59.94 – 525 480 2 10 33

640x480 35.00 – 864 640 64 64 96 30.24

APPLE MAC480

640x480 37.861 – 832 640 40 16 120 31.5

VESA-480-72Hz 72.809 – 520 480 3 1 20

640x480 37.5 – 840 640 64 16 120 31.5

VESA-480-75Hz 75 – 500 480 3 1 16

720x400 31.469 – 900 720 108 18 54 28.322

VGA-400-TEXT 70.087 + 449 400 2 12 35

832x624 49.725 – 1152 832 64 32 224 57.2832

APPLE MAC800

800x600 35.156 + 1024 800 72 24 128 36

SVGA 56.25 + 625 600 2 1 22

800x600 37.879 + 1056 800 128 40 88 40

VESA-600-60Hz 60.317 + 628 600 4 1 23

800x600 48.077 + 1040 800 120 56 64 50

VESA-600-72Hz 72.188 + 666 600 6 37 23

800x600 46.875 + 1056 800 80 16 160 49.5

VESA-600-75Hz 75 + 625 600 3 1 21

1024x768 48.363 – 1344 1024 136 24 160 65

XGA 60.004 – 806 768 6 3 29

1024x768 53.964 + 1328 1024 176 16 112 71.664

COMPAQ-XGA 66.132 + 816 768 4 8 36

1024x768 56.476 – 1328 1024 136 24 144 75

VESA-768-70Hz 70.069 – 806 768 6 3 29

1024x768 60.023 + 1312 1024 96 16 176 78.75

VESA-768-75Hz 75.029 + 800 768 3 1 28

1024x768 60.24 – 1328 1024 96 32 176 80

APPLE MAC768

1280x1024 64 + 1688 1280 112 48 248 108

VESA-102460Hz

1280x1024 80 + 1688 1280 144 16 248 135

VESA-102475Hz

If the input timing is not a timing listed above but within the supported frequency range

(Horizontal: 80KHz,Vertical: 75Hz), this monitor will select a closest mode instead. But the

display quality may not be optimised. If the input timing over the supported frequency range a

message “Input Signal Out of Range” will be shown.

FH (KHZ) SYNC TOTAL ACTIVE SYNC FRONT BACK PIXEL

66.67 – 525 480 3 3 39

74.55 – 667 624 3 1 39

75.02 – 803 768 3 3 29

60 + 1066 1024 3 1 38

75 + 1066 1024 3 1 38

9

Page 12

2.4.4 85Hz Refresh Rate Support

Monitor should display 85Hz refresh rate mode as emergency mode.

Monitor should display “Out of Range” warning menu at this mode.

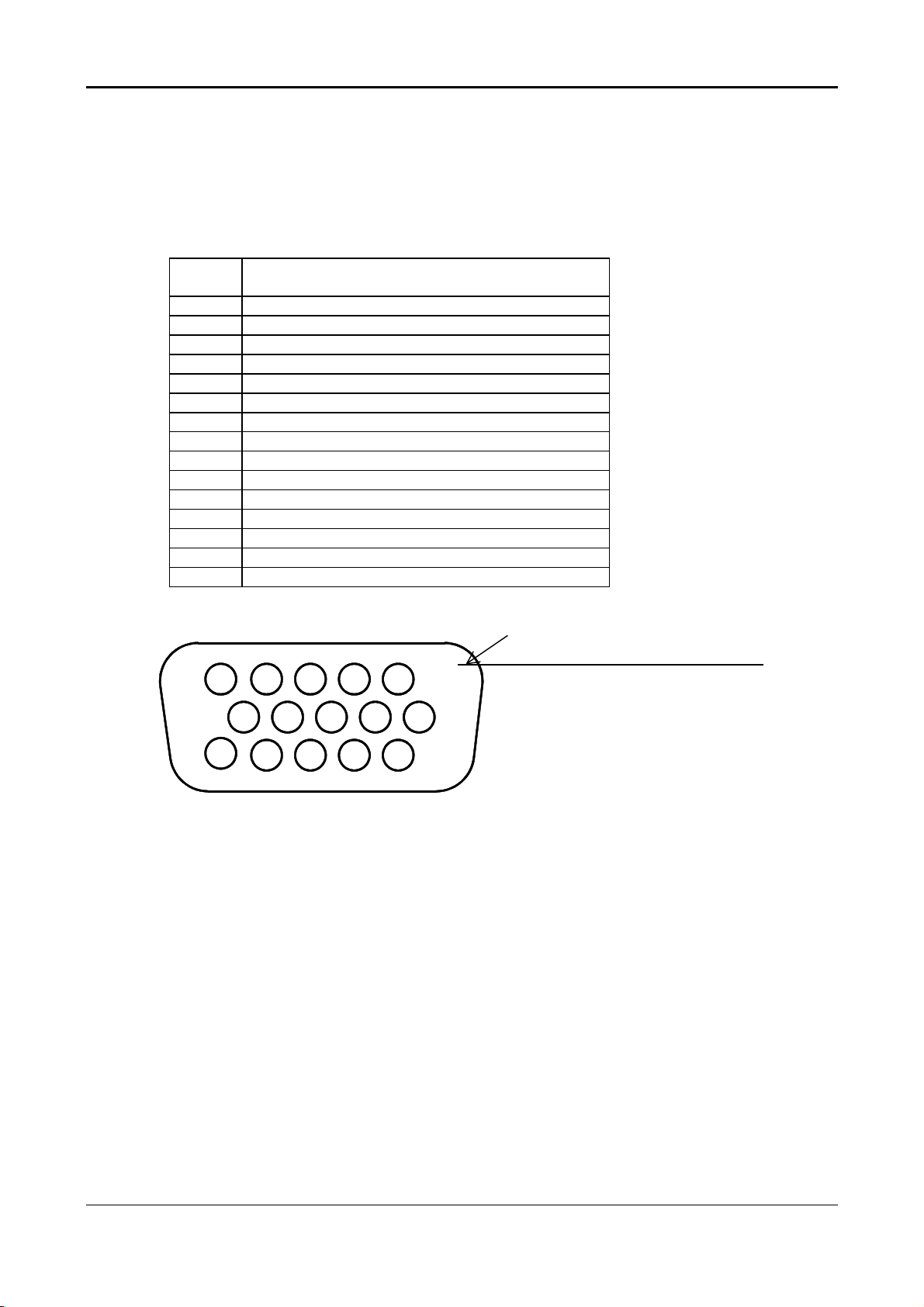

2.4.5 Video Input Connector

Analog Video Input Connector: 15pins mini D-Sub

Table 2.4.5. Pin Assignment for D-sub Connector

PIN

NO.

1 RED VIDEO

2 GREEN VIDEO

3 BLUE VIDEO

4 GROUND

5 GROUND

6 RED GROUND

7 GREEN GROUND

8 BLUE GROUND

9 PC5V (+5V DDC)

10 CABLE DETECTION

11 GROUND

12 SDA

13 H.SYNC

14 V.SYNC

15 SCL

Separate Sync

Colour of Plastic Parts: Blue (PC99)

5 1

10

15

D-sub Connector

6

11

10

Page 13

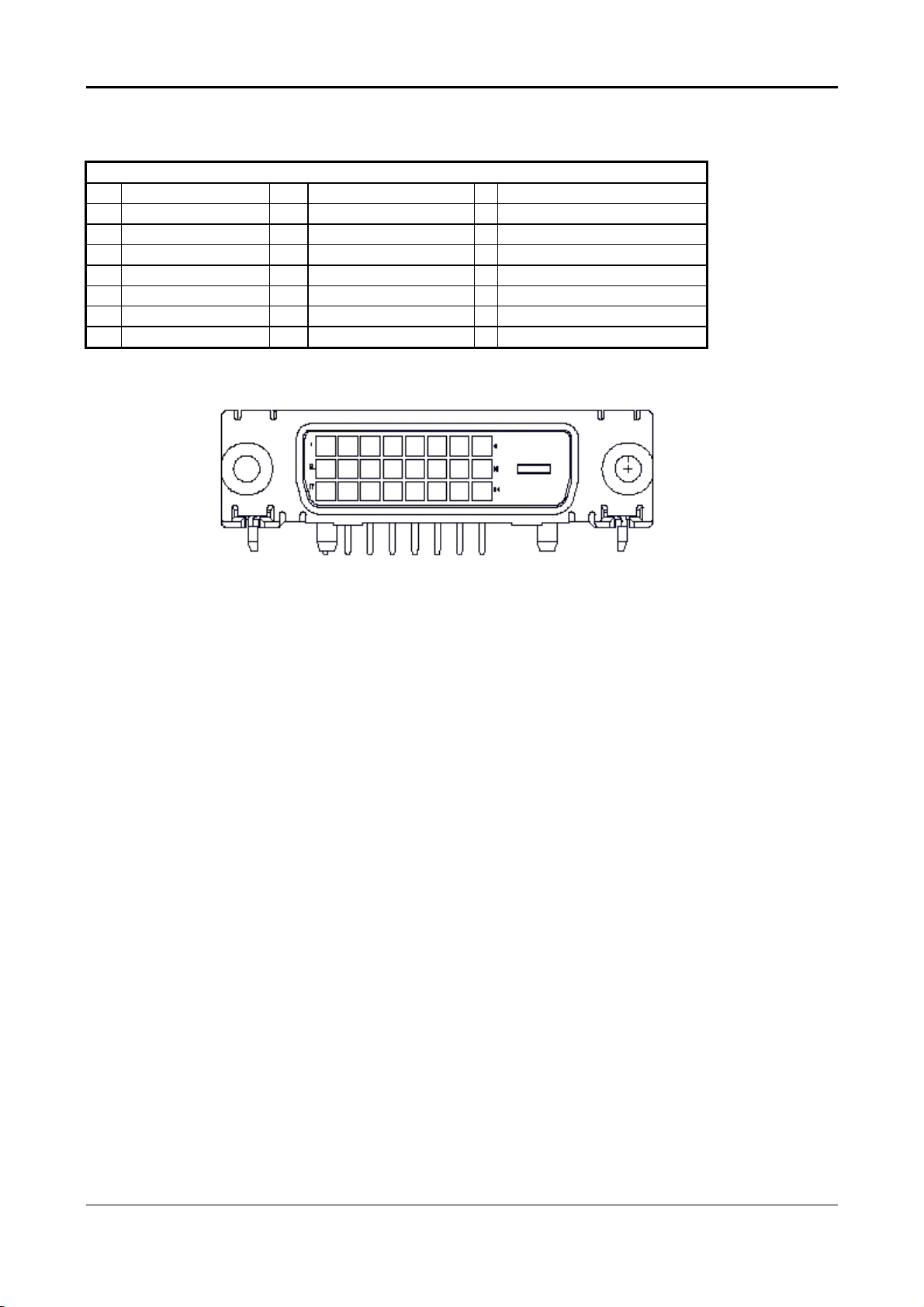

Digital Video Input Connector: DVI-D (T.B.D)

Table 4-3-3. Pin Assignment for DVI-D (24pin) Connector

Pin – Assignment of DVI –D Connector :

1 TX2- 9 TX1- 17 TX0-

2 TX2+ 10 TX1+ 18 TX0+

3 Shield (TX2 / TX4) 11 Shield (TX1 / TX3) 19 Shield (TX0 / TX5)

4 NC 12 NC 20 NC

5 NC 13 NC 21 NC

6 DDC-Serial Clock 14 +5V power *) 22 Shield (TXC)

7 DDC-Serial Data 15 Ground (+5V) 23 TXC+

8 No Connect 16 Hot plug detect 24 TXC-

*) In case, the power of the PC unit is switched off and the power of the monitor is switched on,

no voltage may occur at pin 14.

11

Page 14

2.5 CONTROLS

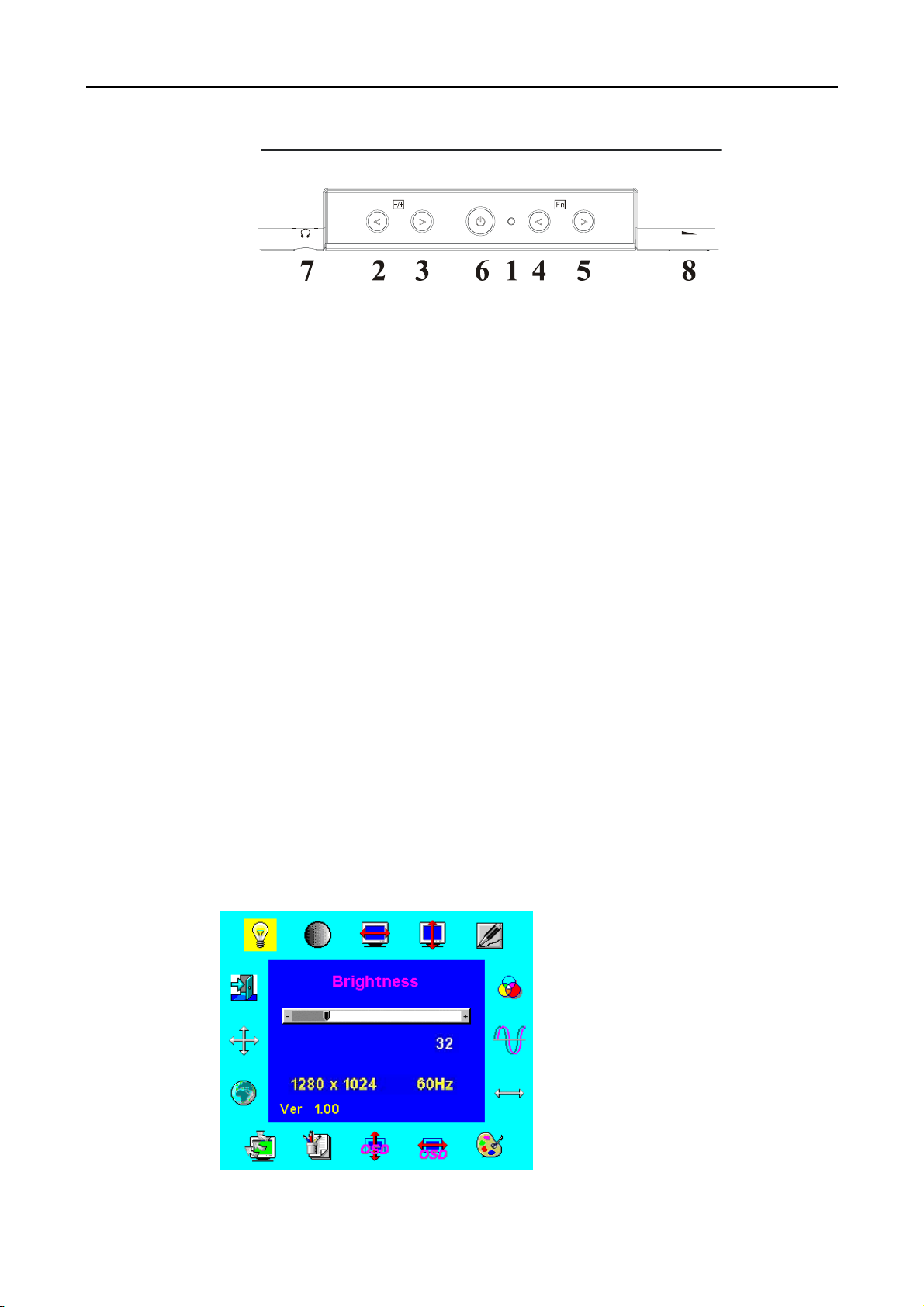

2.5.1 Control Panel (Monitor Front Panel)

1. Power LED, will be green when monitor is on; be amber when in power saving mode.

2. Adjust decrease.

3. Adjust increase.

4. Function select anti-clockwise.

5. Function select clockwise.

6. Power ON/OFF switch, push to ON and push to OFF. (toggle switch)

7. Ear phone jack. (for CML175SXW2/2B only)

8. Volume Control. (for CML175SXW2/2B only)

Note: When OSD Menu is off, press button 2 and 3 at the same time can activate “Auto

Adjustment” immediately.

2.5.2 OSD Functions

• OSD Format: Refer to following figure.

• OSD Border: Cyan colour

• OSD Tunable Item: The 16 icons that around the border.

• Selected Item: Yellow background

• Comment: Magenta foreground, Blue background

page format :

12

Page 15

Description:

• Brightness: Brightness adjustment, the range from 0 to 100. Default = 100

• Contrast: Contrast adjustment, the range from 0 to 100. Default = 50

• H. Position: Horizontal position adjustment.

• V. Position: Vertical position adjustment.

• Phase: Focus adjustment, the range from 0 to 255 steps.

• OSD position: OSD position adjustment.

• Auto Adjustment: This feature will automatically adjust size, position, clock and phase.

It takes 3-5 seconds to finish. When auto start, it shows “Auto

Adjusting….” message.

• Clock: Frequency tracking adjustment. The max range from -50 to +50, but

some modes the range will be limited.

• Graph Text: 640x400 (GRAPH) or 720x400 (TEXT) mode select.

• Language: 5 kinds of language for description, including (English, German,

French, Spanish, Italian)

• Recall: Recall the default value.

• Colour Temp: Colour temperature for standard 9300°, 6500°, 7500° or user defined.

User:

User R: Red signal gain by user defined.

User G: Green signal gain by user defined.

User B: Blue signal gain by user defined.

7500°: Set CIE coordinate at 7500°K colour temperature.

6500°: Set CIE coordinate at 6500°K colour temperature.

9300°: Set CIE coordinate at 9300°K colour temperature.

• Exit: Exit OSD menu function.

Sharpness : Adjust the scale-up effect (smoother or sharper.)

OSD Transparency: Adjust the transparency level of OSD. The range is from 0 to 100 scales.

Comment:

• 1280x1024: Current mode resolution.

• 60 HZ: Current mode vertical frequency ±1Hz.

• VER 1.00: Firmware revision.

13

Page 16

Other Features:

Intellectual-Auto unit can start the Auto-Adjustment automatically when input a new

display mode at first time. After the adjustment, the unit will remember this mode and

switch to optimised condition automatically for this mode whenever encounter this mode

again. Total 27 recent used modes are recorded into the unit.

VESA DPMS Functionality When signaled by the host CPU, the unit shows a black

screen about 3 seconds. If no further signal, then it shows “No Signal” and enter power

saving mode.

2.6 White Colour Temperature

White colour temperature is 4 preset as 9300, 7500, 6500 and User,

Default value of user colour should be user which is maximum setting for panel.

Target of colour setting

Colour

Temp.

9300K 0.281 0.297 +0.03 0.189 0.446 u’v’ < 0.01*

7500K 0.299 0.315 +0.03 0.194 0.459 u’v’ < 0.01*

6500K 0.313 0.329 +0.03 0.198 0.469

User - - - - -

User should follow “Microsoft Windows Colour Quality Specification for Liquid Crystal Display OEMs”.

(http://www.microsoft.com/hwdev/tech/color/ColorTest.asp)

Colour Co-ordinate Tolerance Colour Co-ordinate Tolerance

x y u’ v’

*) TCO’0X A.2.6.1 requirement

u’v’ <

0.01*

14

Page 17

2.7 POWER SUPPLY

2.7.1 Input Voltage Range

The monitor shall operate within specification over the range of 90 to 265VAC power supply.

2.7.2 Input Frequency Range

Input power frequency range shall be from 47.5 to 63Hz over the specified input

voltage range.

2.7.3 Quick Specification Review

• Input Current

1.2A (max) at 90VAC input and full load

0.6A (max) at 264VAC input and full load.

• Inrush Current @ cold start

30A(0-peak) @ 110Vac, 50A (0-peak) @ 220Vac

(measured when switched off for at least 10 mins.)

• Output

Tolerance Output Current

Output Volt - MIN MAX

+5Vdc ±5% 0A 1.0A

+5Vdc ±5% 0A 1.5A 4.8~5.2V dc

+12Vdc +25%/-5% 0A 2.2A 11.4~15Vdc

• Total Output Power: 48 Watt max.

• Withstanding Voltage: 1.5Kvac or 2.2KVdc for 1 minute.

• Leakage Current: < 0.25mA/100Vac, <3.5mA/230Vac

• Efficiency: 70% min. @15V/230VAC, maximum load.

2.7.4 Power Management

2.7.4.1 Meets VESA DPMS Proposal

The monitor must comply with the Microsoft On Now specification, with a minimum of three power

management states, as defined by the VESA DPMS document. The front panel of the monitor must

appropriately display the DPMS state, For example:

Volt Tolerance

4.8~5.2Vdc

(for Audio)

DPMS ON : The power LED is Green

DPMS OFF : The power LED is Amber

2.7.5 Power Consumption

On mode 48 Wmax Green

Off mode 4 Wmax Amber

DC power off 4 Wmax Dark

Power SW off 1 Wmax Dark

Disconnection 4 Wmax

15

Dark (DC power off)

Amber (DC power on)

Page 18

Power saving states are measured with speakers attached but not worked.

The recovery time from stand by /suspend/off mode to on mode is 3 seconds maximun.

2.7.6 Power Connector

All units shall have an IEC/CEE-22 type male power receptacle.

2.8 Plug & Play (EDID)

The monitor will be capable of sending a VESA standardised EDID file through the DDC (pins 12,

15 of the VGA connector).

2.9 Audio Technical Specification (for CML175SXW2/2B only)

2.9.1 General Description:

Output power : 1W + 1W maximum

Total harmonic distortion : Less than 1 % (except speakers distortion)

Input signal sensitivity : 0.5 Vrms for full output

Input impedance : 47 Kohm +/- 5 %

Frequency response range : 100Hz – 20kHz (except speakers response)

Difference of L and R output : Less than 2 dB

°°°°

2.9.2 Electrical Characteristics (Tamb=25

)

Audio Amplifier (USE Panasonic VP-7723A Audio Analyzor)

Item Audio Input Freq.

Spec.

Comment

Min. Typ. Max.

Input Voltage(V) - 5 -

Input Current(m A) - 500 800

Audio Voltage Gain 500m Vrms 1KHz - - 6 d B Volume Max.,load 4 Ω

Frequency Response 500m Vrms 300Hz-20KHz -10dB - +10d B Volume Max.,load 4 Ω

Signal to Noise ratio 500m Vrms 1KHz - - -40dB Volume Max.,load 4 Ω

Total harmonic distortion 500m Vrms 1KHz 1% except speakers distortion

Cross talk 500m Vrms 1KHz - - -30dB Volume Max.,load 4 Ω

Output Watt. 500m Vrms 1KHz - - 1W Volume Max.,load 4 Ω

Volume Control - - - Analog

2.9.3 Speakers

Maximum Power : 1 W per speaker(max)

Impedance : 4 ohm +/- 15 % @ 1KHz 1.0Hz

Frequency response range : 300 Hz – 20 kHz (SPL – 10 dB)

Total harmonic distortion : Less than 5% @ 0.125W 1KHz

2.9.4 Headphone Output

Output Power : 1.6 mW for 32 ohms Headphone

16

Page 19

3. VL-713 DISPLAY CONTROL BOARD

3.1 Description

The VL-713 display control board is designed to directly receive RGB Analog and TMDS

DVI signal to optimum LCD timing signals so as to construct a high display quality LCD

monitor.

3.2 Features

•

Support for image expansion and reduction.

• On board micro-processor to detect display timings and control user functions.

• Uses Genesis design to generate optimum LCD timings.

• Uses EEPROM to memorise every adjusted parameter.

• Supports up to 25 display modes from VGA to SXGA.

• Supports up to 5 display modes from VGA to SXGA by TMDS.

• Offers full screen expansion function on non-XGA mode (automatic).

• Supports OSD functions.

• Supports VESA DPMS function.

• Supports DDC1/2B functions.

• Supports English and Japanese language for OSD description.

• The longest time for mode change is 3 seconds.

17

Page 20

3.3 BLOCK DIAGRAM

System Block Diagram

3.4 Connector Locations

18

Page 21

3.5 Connector Type

Location Type Maker Number of pins

CN1 DVI-D FEMALE 24

CN4 96113-0803 E&T 8

CN6 4501-10 E&T 10

CN5 98210-4011 E&T 40

CN302 98115-0313 E&T 3

CN301 4300-11P E&T 11

CN2 D-SUB E&T 15

3.6 Connector Pin Assignment

3.6.1 CN1

Pin # Signal Name Description Pin # Signal Name Description

1 RX2-

2 RX2+

3 RX2 SHILD

4 NC do not connect 19 RX0

5 NC do not connect 20 NC do not connect

6 DDC/SCL DDC2B clock 21 NC do not connect

7 DDC/SDA DDC2B data 22 RXC SHILD Shield for TMDS clock

8 Analog Vs Analog V-sync 23 RXC-

9 RX1-

10 RX1+

TMDS negative

differential

TMDS positive

differential output,

channel 2

Shield for TMDS

channel 2

TMDS negative

differential output,

channel 1

TMDS positive

differential output,

channel 1

16 HTPLG +5V Supply

17 RXO-

18 RXO+

24 RXC+

TMDS negative

differential output,

channel 0

TMDS positive

differential output,

channel 0

shield for TMDS

channel 0

TMDS negative

differential output,

reference clock

TMDS positive

differential output,

reference clock

11 RX1 SHILD

12 NC do not connect

13 NC do not connect

14 DOC +5VDC DDC2B logic +5V

15 DDC GND DDC2B logic GND

Shield for TMDS

channel 1

19

Page 22

3.6.2 CN5

PIN No. Symbol Function

38 VDD

39 VDD

40 VDD

35 NC No Connection

36 NC No Connection

37 NC No Connection

1,2,3 GND Power Ground

17 RXE3+ Positive Transmission Data of Pixel 3 (EVEN data)

16 RXE3- Negative Transmission Data of Pixel 3 (EVEN data)

14 RXEC+ Positive Sampling Clock (EVEN data)

13 RXEC- Negative Sampling Clock (EVEN data)

11 RXE2+ Positive Transmission Data of Pixel 2 (EVEN data)

10 RXE2- Negative Transmission Data of Pixel 2 (EVEN data)

6,9,12 GND Power Ground

8 RXE1+ Positive Transmission Data of Pixel 1 (EVEN data)

7 RXE1- Negative Transmission Data of Pixel 1 (EVEN data)

15,18,21,24 GND Power Ground

5 RXE0+ Positive Transmission Data of Pixel 0 (EVEN data)

4 RXE0- Negative Transmission Data of Pixel 0 (EVEN data)

32 RXO3+ Positive Transmission Data of Pixel 3 (ODD data)

31 RXO3- Negative Transmission Data of Pixel 3 (ODD data)

29 RXOC+ Positive Sampling Clock (ODD data)

28 RXOC- Negative Sampling Clock (ODD data)

30,33,34,27 GND Power Ground

26 RXO2+ Positive Transmission Data of Pixel 2 (ODD data)

25 RXO2- Negative Transmission Data of Pixel 2 (ODD data)

23 RXO1+ Positive Transmission Data of Pixel 1 (ODD data)

22 RXO1- Negative Transmission Data of Pixel 1 (ODD data)

20 RXO0+ Positive Transmission Data of Pixel 0 (ODD data)

19 RXO0- Negative Transmission Data of Pixel 0 (ODD data)

Power Supply : +5V

3.6.3 CN302

Pin No. Signal Comment

1 Audio-RIN Audio Right Input

2 GND

3 Audio-LIN Audio Left Input

20

Page 23

3.6.4 CN301

Pin No. Signal Comment

1 +5 VDD

2 VR

3 L+

4 L-

5 AGND

6 HP-S

7 HP-L

8 HP-R

9 AGND

10 R+

11 R-

Audio +5V

Audio Volume Control

Audio Left+ Output

Audio Left- Output

Analog GND

HP-Sense

Audio Left Output (Head Phone)

Audio Right Output (Head Phone)

Analog GND

Audio Right+ Output

Audio Right- Output

3.6.5 CN6

Pin NO. Signal Comment

1 +5 V Audio Power

2 GND Audio GND

3 GND GND

4 GND GND

5 BRIGHT Brightness Adjustment

6 PS Power Saving

7 PBIAS Back Light ON/OFF

8 +5VB From USB power

9,10 +5V From main power

3.6.6 CN4

Pin NO. Signal Comment

1 LED-Y Power saving mode

2 LED-G Monitor is ON

3 GND GND

4 KEY-ON/OFF KEY- ON/OFF

5 KEY−UP KEY-Brightness Increase

6 KEY-DOWN KEY-Brightness Decrease

7 KEY-RIGHT KEY-Volume Increase

8 KEY-LEFT KEY-Volume Decrease

21

Page 24

4. VK-713 Control Panel Board

4.1 Description

The VK-713 is designed to offer a user interfaced control panel which passes and receives

signals to and from VK-713 display control board.

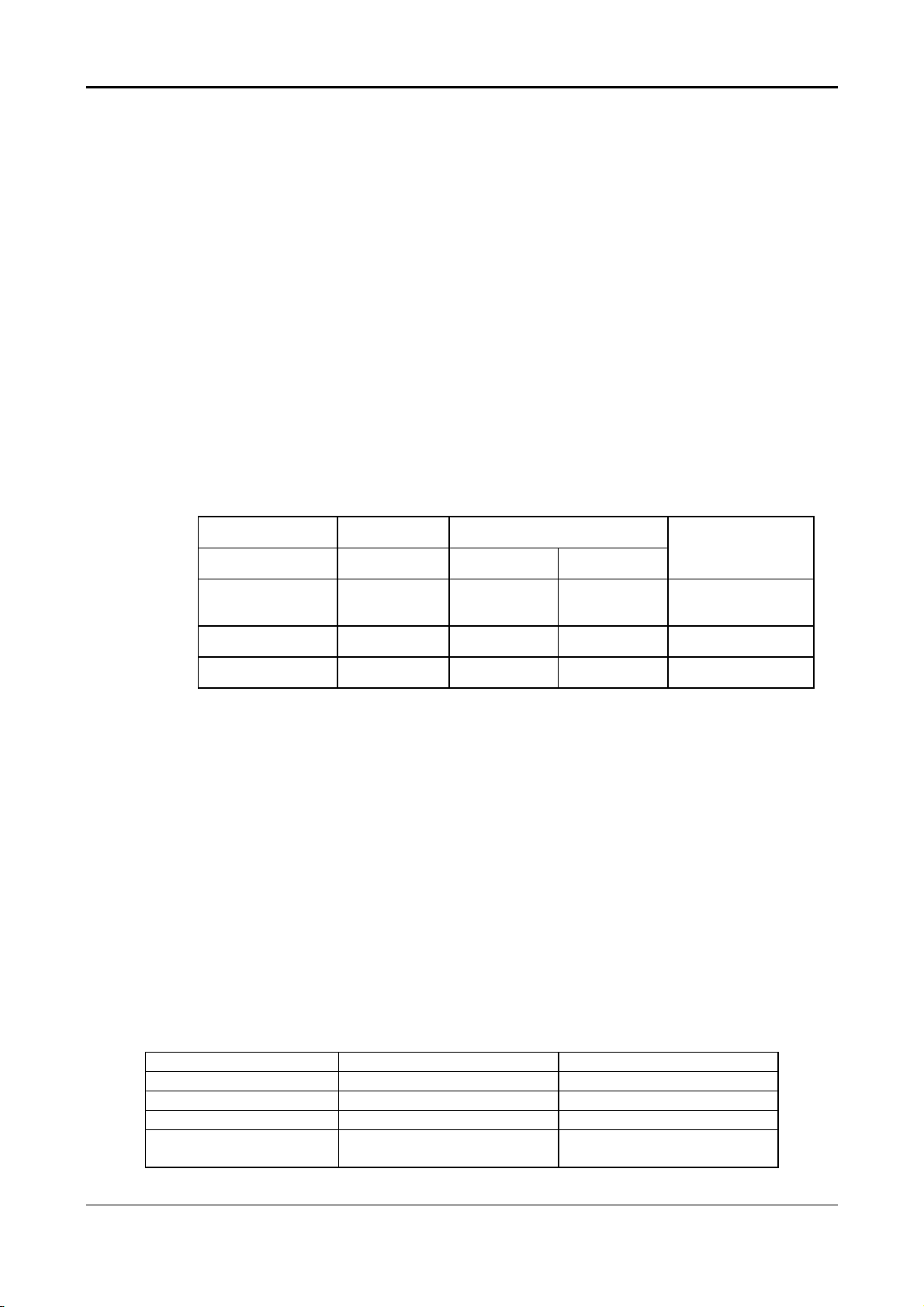

4.2 Connector and Switch Locations

4.3 Connector Type

Location Type Maker Number of Pins

J4 4301-08 E&T 8

J2 4301-11 E&T 11

J1 87502-0200 ACER 2

J3 87502-0200 ACER 2

JP1 SCJ-0348-C SC 9

4.4 Connector Pin Assignment

4.4.1 J4

Pin NO. Signal Comment

1 KEY-LEFT Function select anti-clockwise key

2 KEY-RIGHT Function select anti-clockwise key

3 KEY-DOWN Adjust down key

4 KEY-UP Adjust up key

5 KEY-POWER Power ON/OFF key

6 GND GND

7 LED-G Power is ON

8 LED-Y Power is OFF

4.4.2 J2

Pin NO. Signal Comment

1 +5 VDD Volume Control

2 Volume Volume Control

3 L OUT+ Audio Output L+

4 L OUT- Audio Output L-

5 AGND Audio GND

6 HP-S Audio Earphone sensor

7 HP-L Audio Earphone Output L

8 HP-R Audio Earphone Output R

9 AGND Audio GND

10 R OUT- Audio Output R+

11 R OUT+ Audio Output R-

22

Page 25

4.4.3 J3

Pin NO. Signal Comment

1 L+ OUT Audio Output L+

2 L- OUT Audio Output L-

4.4.4 J1

Pin NO. Signal Comment

1 R+ OUT Audio Output R+

2 R-OUT Audio Output R-

4.5 Switch Definition

Location Definition

S1 Power ON/OFF

S4 Function select in clockwise direction

S5 Function select in anti-clockwise direction

S2 Adjust up

S3 Adjust down

4.6 LED Definition

Location Definition

D1 Green for ON mode; Yellow for OFF mode; yellow for Power Saving mode; Dark for DC

power OFF mode.

23

Page 26

5. POWER SUPPLY & INVERTER BOARD

5.1 Description

The Power supply and Inverter board is designed for the display control board and the

lighting up of the back-lights of LCD module.

5.2 Power Supply ( AC to DC section)

5.2.1 Input Voltage Range

The monitor shall operate within specification over the range of 90 to 265VAC power supply.

5.2.2 Input Frequency Range

Input power frequency range shall be from 47.5 to 63Hz over the specified input

voltage range.

5.2.3 Quick Specification Review

• Input Current

1.2A (max) at 90VAC input and full load

0.6A (max) at 264 VAC input and full load.

• Inrush Current @ cold start

30A (0-peak) @ 110VAC, 50A (0-peak) @ 220VAC

(measured when switched off for at least 10 mins.)

• Output

Tolerance Output Current

Output Volt - MIN MAX

+5Vdc ±5% 0A 1.0A

+5Vdc ±5% 0A 1.5A 4.8~5.2V dc

+12Vdc +25%/-5% 0A 2.2A 11.4~15Vdc

• Total output power: 48Watt max.

• Withstanding voltage: 1.5KVAC or 2.2KVDC for 1 minute.

• Leakage current: < 0.25mA/100VAC, <3.5mA/230VAC

• Efficiency: 70% min. @ 115V/230VAC, maximum load.

Volt Tolerance

4.8~5.2Vdc

(for Audio)

24

Page 27

5.3 Inverter (DC to AC Section)

5.4 Electrical Characteristics

5.4.1 For Hydis PANEL (HT17E12-200)

MIN. TYP. MAX. COMMENT

INPUT VOLTAGE 11.4V 12.0V 15V 12V+25%/-5%

INPUT CURRENT -------- 2A --------

Normal BACKLIGHT

VOLTAGE

LAMP CURRENT

DRIVING

FREQUENCY

EFFICIENCY -------- 75% --------

Vin ON/OFF sequence -------- 0.5S --------

OLP TIME -------- 1S _

BRIGHTNESS

RANGE

Brightness control 0.4V _ 3.3V

Brightness _ 250cd/m

Strike voltage at 0°C 1310 Vrms _ _

-------- 705V rms. --------

3mA rms. 6.5mA rms 7 mA rms

40KHz -------- 60KHz

30% -------- 100%

2

_

Vin=12V,

Vbrite=3.3V

Vin = 12V,max

brightness

Open lamp

protection time

3.3V, brightness

max.

Operating life time 40,000 hrs 50,000 hrs _ (note)

Note:

Life time (hr) can be defined as the time in which it continues to operate under the condition:

Ta=25±2°C, IL =6.5mArms until one of the following event occurs:

1. When the brightness becomes 50%

2. When the startup voltage (Vs) at 0°C becomes higher than the maximal value of Vs specified above.

25

Page 28

5.5 Connector Locations

5.5.1 Connector Type

JM778-

Location Type Maker Number of Pins

J940, J980, SM02 (2.0) B-BHS-1-TB JST 2

J941, J981

P803 96113-1203 E&T 10P

P801 SA-4S-066 Huajie 3

P60 SCJ03451X9 SC 3

P62 98115-0313 E&T 3

5.5.2 Connector Pin Assignment

5.5.2.1 J940, J980, J941, J981

Pin NO. Signal Comment

1 HV High voltage for lamp

2 LV Low voltage for lamp

26

Page 29

5.5.2.2 P803 For Display Control Board (Interface)

Pin NO. Signal Comment

1 +5Vaudio +5Vdc for Audio Circuit

2 GND/Audio Ground for Audio Circuit

3,4 GND Common Ground

5 BRITE Brightness adjustable range:

0.4V<min>~3.3V<max>

6 NC

7 Enable Backlight ON/OFF control (Active High)

ON:1.5~5.5V OFF:-0.3~1.0V.

8,9,10 Vcc +5Vdc supply to Interface BD, always on.

27

Page 30

6. TROUBLESHOOTING

6.1 Main Procedure

28

Page 31

6.1.1 Power Circuit and Backlights Troubleshooting

29

Page 32

6.1.2 Performance Troubleshooting

30

Page 33

6.1.3 Function Troubleshooting

31

Page 34

7. MECHANICAL REQUIREMENTS

7.1 Vibration and Shock

All testing shall be done in each of three mutually perpendicular axes referenced to the

position of the system as it is in front of the user (i.e. front-to back, side-to-side and top-tobottom).

7.1.1 Non-Operating

The unit should suffer minimal visible cosmetic damage or damage that presents a safety

hazard or impairs the setup and operation of the system after testing.

Sinusoidal Vibration: 0.75G zero-to-peak, 10 to 500Hz, 0.5 octave / minute sweep rate.

This requires one sweep, 10 to 500 to 10Hz, along each of the three axes.

Random Vibration: 0.008G

hour for each of the three axes.

Half Sine Wave Shock: 120G peak, half sine pulse, 2ms pulse duration. Testing shall

consist of one shock in each direction in each axis, for a total of 6 shock inputs.

Square Wave Shock: 40G peak acceleration, 160 inches / second velocity change. There

shall be one shock in each direction in each axis, for a total of 6 shock inputs.

2

/Hz, 10 to 500 Hz, nominal 2GRMS. The test shall be for one

7.2 Package Drop Specification

Listed below are standards of drop heights for monitor product

Product Weight Height Specs

<9.1 Kg 0.76 m

9.2~18.2 Kg 0.66 m

18.3~27.2 Kg 0.61 m

27.3~45.4 Kg 0.46 m

7.2.1 Drop Test Sequence

Drop Order Drop Point Drop Times

1 Right Front Bottom Corner 1

2 Right Bottom Edge 1

3 Right Front Edge 1

4 Front Bottom Edge 1

5 Bottom Side 1

6 Top Side 1

7 Front Side 1

8 Back Side 1

9 Left Side 1

10 Right Side 1

32

Page 35

7.3 Dimension Size and Weight

Dimension size 374 (W) x 394.5 (H) x 204 (D)

Net Weight 5Kg

Gross Weight 7Kg

7.4 Gap Spec.

7.4.1 The step between front bezel and back cover shall be within specification.

Top Left and Right

Back cover concavity Back cover concavity

0 mm ≤ X ≤ 0.8 mm 0 mm ≤ X ≤ 0.8 mm

JM777 / JM778 JM777 / JM778

LCD Horizontally

The angle between front bezel and LCD unit in bottom side should not large than 1.0mm.

JM777 JM778

33

Page 36

The angle between from bezel and LCD unit in bottom side should not large than 4.0mm

JM777 JM778

7.5 Tilt Base Rotation

Tilt up 30 ± 1°/ down 5 ±1°

7.6 Swivel Base Rotation

Swivel Right 45 ±1° / Left 45 ±1°

7.7 Plastic Material

Front Bezel ABS 94V-0

Back Cover ABS 94V-0

The Others ABS 94HB

TCO’99 (Optional)

Front Bezel PC + ABS 94 – 5V

BACK COVER PC + ABS 94 – 5V

The others ABS 94 HB

7.8 GAP Spec.

Gap between panel with bezel is 0 mm < gap < 1.5 mm

34

Page 37

8. Power Line Transient Test (IEC 61000-4-4 Fast

Transients/Burst)

TEST CONDITIONS & PROCEDURE: (Follow IEC 61000-4-4)

Test Condition :

The condition is base on operating with 50Ω load.

8.1 Peak Voltage:

2 KV (applies the Level 3 typical Industrial Environment” of IEC 61000-4-4)

8.2 Polarity : + / -

8.3 Repetition Frequency of the impulse: 5 KHz.

±±±±

8.4 Rise-Time: 5ns

8.5 Impulse Duration: 50 nS

8.6 Relation to Power Supply: Asynchronous

30%

±±±±

30%

8.7 Burst Duration: 15 ms

8.8 Burst Period: 300 ms

8.9 Climatic Conditions:

- Ambient Temperature: 15°C to 35°C

- Relative Humidity: 45% to 75%

- Atmospheric Pressure: 86KPa to 106KPa

8.10 Test Procedure:

The monitor Display set high-resolution mode, AC input is AC 240V.

Note :

8.10.1

IEC 61000-4-4 defines that power supply, I/O line and control line all shall perform the

transient test. The I/O line and control line is applied with only half of peak voltage (1

KV).

8.10.2

For the comparison of wave-shape generated by different generator, so the test must uses a

scope with at least 400 MHz bandwidth, and coupled to 50Ω to monitor the rise-time,

impulse, duration and repetition rate of the impulses within one burst.

±±±±

20%

±±±±

20%

35

Page 38

WAVESHAPE

36

Page 39

9. Power Line Surge Test (IEC 61000-4-5 Surge)

9.1 Climatic Condition

The climatic conditions shall be within the following ranges:

9.1.1 Ambient Temperature: 15

9.1.2 Relative Humidity: 10% to 75%

9.1.3 Atmospheric Pressure 86kPa (860 mbar) to 106kPa (1060mbar)

Note: The temperature and relative humidity should be recorded in the test report.

°°°°

C to 35

°°°°

C

9.2 Test Conditions:

9.2.1 Wave-shape of the current surge: (refer to IEC 61000-4-5)

Open circuit voltage: (1.2 / 50 µs)

Short circuit current: (8 / 20 µs)

9.2.2 Polarity: positive / negative

9.2.3 Phase Shifting: in a range between 0º to 270º versus the AC line phase angle

9.2.4 Repetition Rate: at least 1 per minute

9.2.5 Number of Tests: at least 5 positive and 5 negative at the selected points.

9.3

The surge will be applied between lines and between lines and ground.

9.4

If not otherwise specified, the surge to power supply circuits shall be applied synchronised to

the voltage phase at the zero crossing and the peak value of the AC voltage wave. (Positive

and negative)

9.5

The surge voltage for test is from 1KV and increases 1KV for each step.

9.6

The recommended severity levels for the surge voltage test is 2.0KV and without any

degradation or loss of function that is not recoverable due to damage of component or

software allowed.

9.7 Display set high-resolution mode, AC input is AC 240V.

37

Page 40

10. ENVIROMENT REQUIREMENT

10.1 Operating

Temperature 5°C ~ 40°C

Relative Humidity 20% to 80%

Altitude Sea level to 8000ft

10.2 Storage or Shipment

Temperature -20°C ~ +60°C

Relative Humidity 5% to 85%

Altitude Sea level to 40,000ft

10.2.1 TEST PROCEDURE:

• Put in temperature chamber under 60°C Time: 24 hours

• Back to room temperature Time: 4 hours

• Put in temperature chamber under -20°C Time: 24 hours

• Back to room temperature Time: 4 hours

• Repeat the process 2 times.

38

Page 41

11. REGULATION COMPLIANCE

11.1 This product complies with the most current revisions of following

regulations:

UL/CUL

{UL 1950/ CSA C22.2 NO950}

EN 60950/CB Scheme Safety of Information Technology Equipment including Electrical

MPR 1990:8 Test methods for visual display units.

MPR 1990:10 User handbook for evaluation visual display units.

ISO 9241-3: Ergonomic requirements for office work with visual display terminals

ISO 9241-7: Ergonomic requirements for office work with visual display terminals

ISO 9241-8: Ergonomic requirements for office work with visual display terminals

NUTEK/EPA Requirements of power saving according to NUTEK Spec.

TCO 1999 (option) Requirements for Environmental Labeling of Personal Computers.

TUV/GS Safety regulation for displays work places in the office sector.

FCC 47 CFR, Chapter 1,

Subchapter A, Part 15, Subpart B

Standard for Safety of Information Technology Equipment including

Electrical Business Equipment

Business Equipment

(VDTs)-Visual display requirements.

(VDTs)-Requirements for display with reflections.

(VDTs)-Requirements for displayed colours.

803299/94/96, EPA Energy star.

Test methods for Ergonomic, Emission, Energy Efficiency, safety.

A digital device that is marketed for use in a residential environment

not withstanding use in commercial, business and industrial

environments.

CISPR 22 Limits and methods of measurements of radio interference

characteristics of information technology equipment.

CE LVD Directive (73/23/EEC) Safety: EN60950

CE EMC Directive (89/336/EEC)

IEC 61000-4

VCCI (option) Specification for limits and methods of measurement of radio

BSMI (option)

EMI: EN55022 class B

Harmonics: EN61000-3-2

Voltage Fluctuation/Flicker: EN61000-3-3

Immunity: EN55024

IEC 61000-4-2 Electrostatic Discharge

IEC 61000-4-3 Radiated Electromagnetic Field

IEC 61000-4-4 Fast Transients/Burst

IEC 61000-4-5 Surge

IEC 61000-4-6 Conducted Disturbance, Induced by Radio

Frequency Fields

IEC 61000-4-8 Power Frequency Magnetic Field

IEC 61000-4-11 Voltage DIP/Interruption

interference characteristics of information technology equipment.

Class B conformity verification report from the VCCI

CNS 13438, Class B

39

Page 42

11.2 Electrostatics Discharge (ESD)

E.S.D Test

This test follows IEC 61000-4-2

Discharge Voltage Level :

Criteria Contact Discharge (KV) Air Discharge (KV)

Class C ±4 ±4

Class B ±6 ±8

Class A ±8 ±15

Class A : Temporary degradation or loss of function or performance which requires

operator Intervention or system reset.

Class B : Temporary degradation or loss of function or performance which is self-

recoverable

Class C : Normal performance within the specification limits

Discharge times: 20 times for each discharge point, time interval 1 second.

In the case of acceptance tests, the test program and the interpretation of the test results are

subject to agreement between manufacturer and user.

The test documentation shall include the test conditions and the test results.

40

Page 43

Ambient temperature : 15 to 35°C

Relative humidity : 30 to 60%

12. QUALITY AND RELIABILITY

12.1 Quality Assurance

Unless otherwise specified in this specification or the applicable purchase order, the supplier shall

be responsible for maintaining a statistical process program or performing inspections that are

sufficient to assure that the parts supplied meet the requirements specified herein.

12.2 Reliability

The product shall have a designed MTBF of greater than 20,000 hours during its useful life.

41

Page 44

APPENDIX A

POWER SUPPLY AND INVERTER BOARD DIAGRAMS

CML174SXW2

CML175SXW2

42

Page 45

HU AJIE

SA- 4S-066

P801

L

N

FG

1

2

3

F801

T3.15A/250V

C803

102 Y1

C804

102 Y1

L801

CL900007400

3

1

0.33uf X2

4

2

C801

C803A

RT801

SCK085

222 Y1

J801

P802

SW

R801

510K / 1206

R802

510K / 1206

MAIN

POWER

L802

CL900007400

3

1

VA801

ZV07D511

R813

27K/0603

5

RT

2

FB

0.33uf X2

4

2

3

VINGND

U801

SG6841/SOP8

1

C802

EN

5V

3

2

1

R911

100K/0603

P803

10

HEADER 10

R912

100K/0603

2

Q901

2N7002

C930

470uF/25V

ZD922

HZ6.2B

C924

473/0603

ZD962

HZ6.2B

F901

KE40

JP1

3

Q902

2N7002

1

+

C963

473/0603

JP2

R922

10K/0603

R914

47K/ 0603

C902

103/0603

R962

10K/0603

C903

1U/0805

RT

103/X7R/0603

R915

51K/0603

R917

12K/0603

D980

U920

FDS4435

1

S

2

S

3

S

4 5

G D

D981

SB140

1

S

2

S

3

S

4 5

G D

U950

FDS4410

U930

FDS4435

1

S

2

S

3

S

4 5

G D

D983

SB140

1

S

2

S

3

S

4 5

G D

U960

FDS4410

+

C907

D982

SB140

R903

22/ 0603

C904

0.47U/ 0603

+

R913

560K/1%/0603C818

SB140

8

D

7

D

6

D

8

D

7

D

6

D

8

D

7

D

6

D

8

D

7

D

6

D

R901

27K/1%/0603

+

C905

1U/0805

C906

104Z/0603

C908

222/X7R/0603

C922

4.7U/ X7R/1206

C923

4.7U/X7R/1206

U901

OZ960G/SOP20

1

CTIMR

2

OVP

3

ENA

4

SST

5

VDDA

6

GNDA

7

REF

9

FB

10

CMP

6,7

2,3

104/0603

OZ960

47K/1%/0603

R905

T901 EEA-17

37 :2100

R916

1M/0603

C914

T902 EEA-17

6,7

2,3

37 :2100

80.6K/1%/0603

NDRV_B

PDRV_A

CT

RT

PWRGND

LCT

DIM

LPWMRT1

PDRV_C

NDRV_D

1N4148/0603

5

4

8

1

D931

BAV99

2

1

D932

BAV99

2

1

5

4

8

1

D933

BAV99

2

1

D934

BAV99

2

1

R902

20

19

18

17

16

15

14

138

12

11

D906

C980

12p/ 3KV

183/0603

183/0603

3

C981

C981A

183/0603

C983

12p 3KV

3

C984

3

3

INVERTER

C912 220P/ NPO/0805

RT

R906 62K/1%/0603

C911 103/X7R/0603

C910 104/0603

R907 100K/1%/0603

+

C909

4.7U/10v

D941

BAV99

3

3

D942

BAV99

C971

47p/ 3KV

C972

47p/ 3KV

R970

453/1%/0603

C982

222/0603

C980A

12p/ 3KV

C982A

222 /0603

47p/ 3KV

47p/ 3KV

C985

222/0603

R971

453/ 1%/0603

C983A

12p 3KV

C984A

183/0603

R972

5.1K/0603

1

2

1

2

3

C973

BAV99

C974

R945

5.1K/0603

D945

3

BAV99

D946

BAV99

D947

C985A

222 /0603

D943

BAV99

D944

BAV99

R940

5.1K/0603

1

2

D948

BAV99

R946

453 1%/0603

J940

ACES 87210-0236

2

1

2

1

ACES 87210-0236

453/1%/0603

R973

5.1K/0603

1

2

R947

ACES 87210-0236

2

1

2

1

ACES 87210-0236

2

HV

1

LV

3

2

HV

1

LV

3

J980

J941

2

HV

1

LV

3

2

HV

1

LV

3

J981

Q841

BT151

C862

104/0603

+

R954

510/ 1206

ZD952

RLZ5.6

R956

5.1K/ 0603

123456789

GND/Audio

Common Ground

+5 V Audio

D987

NC/0603

1

2

Q950

3

2N3906

Q952

2N3904

3

2

1

ZD901

HZ8.2B

104/0603

BRI. ADJ

R987

NC/ 0603

C952

100 1/2W FUSE

K

A

12

3

2

103 /0603

8

7

R846

150/0603

1

1

U802

KA431Z

C60

R841

R850

47/0603

R

R800

0.2/ 1W FUSE

3

C810

103Z

R820

2/1206

P6KE200A

+

C805

100uf/400V

R807

15/ 1/2W

TVS1

R820A

2/1206

100k/2W

PS1010R

D802

PS104R

Q801

2SK2645

R819A

2/1206

R806

L803

Bead

1

R819

2/1206

2

3

+

-

4

C809

10uf/50v

BD801

2KBP08M

R822

820K/1206

R804

27K/0603

1

+

2

R821

680K/1206

7

VDD

8

GATE

4

RI

SENSE

6

C806

222/1KV

LTV-817M-B

T801

EE-30

5

3

4 9,10,11

6

1,2

C800

222 Y1

103/1KV

U800

4

3 2

102/1KV

D841

ER1002F

D842

SB560

R842

10 1/2W FUSE

C842

103Z

D843

ER302

3.65K/1%/0603

2. 2K/0603

224J MEF

L61

Bead

C841

R848

C850

470uf/25V

C843

470uf/25V

+

12

+

C847

1000uf/10V

470uf/10v

L60

Bead

C846

470uf/25V

+

L842

CHOKE

+

C860

1000uf/10V

C848

R851

2 .4K/0603

VR801

1K

SCJ 03451X9

L62

Bead

470uf/25V

L841

CHOKE

+

+

R843

470 1W

L861

CHOKE

ZD801

+

1N4735

R849

63.4K MF 1%

P60

1

2

3

P62

E&T 98115-0313

ZD841

HZ-6C-2

C950

1U/0805

1

+

5V/1A

R864

4.7K 1/8W

5V/1.5A

R852

100/ 1/2W

R952

33K/ 0603

+

12V/2.2A

C845

470uf/25V

C871

103Z

R863 N.CD801

U803

KIA78R05

1 2

VI VO

4

VDIS

GND

3

33K/ 0603

33K/ 0603

3

2

1

R953

33K/ 0603

C951

104/0603

C861

220uf/10V

R950

R951

Q951

2N3904

R955

3.3K/ 0603R847

R861

1K

C846A

C844

No. 0422

VI-714 POWER+I/B BOARD

Page 46

COMPONENT

(TOP) SIDE

No. 0422

SOLDER

(BOTTOM) SIDE

POWER+INVERTER BOARD

Page 47

APPENDIX B

MAIN / DISPLAY CONTROL BOARD DIAGRAMS

CML174SXW2

CML175SXW2

45

Page 48

DDCA-5V

C1

RED

9

10

11

DDC-SDA

IN-H

IN-V

DDC-SCL

PC-5C

12

13

14

15

15-pin DSUB connector

0.1u

1

3

ZD1

DALC208SC6

CHECK 1117 3904 & RESET IC

CN1

PITCH

2.00mm

1

2

3

4

5

6

7

8

RED

GREEN

BLUE

R-

GRN-

BLU-

6

52

PC-DETECT

4

BLUEGREEN

Video

connector

VCC

VCC

D15

EC10QS04

D1

EC10QS04

PC-DETECT 4

2,4,7

IN-H

IN-V

ZD2

ZD5V6

BLUE

BLU-

GREEN

GRN-

RED

R-

ZD3

C2 0.01u/NC

FB1

0

R1

75 1%#

FB4

0

R2

75 1%#

FB7

0

R3

75 1%#

R7

2.2K

ZD5V6

R17

33

R12

2.2K

C4

75 1%

C7

75 1%

C10

75 1%

R5 33

C12

33P#

33

R10

C14

33P#

FB2

0

FB3

47

FB5

0

FB6

47

FB8

0

FB9

47

U1A

1 2

74LVC14

Optional

U1E

11 10

74LVC14

VCC

R4 0#

R8 0#

U1B

3 4

74LVC14

U1D

9 8

74LVC14

R6 100

R11 100

C3 0.01u

C5 0.01u

C6 0.01u

C8 0.01u

C9 0.01u

C11 0.01u

C13

22P

C15

33P#

U1C

5

SOG 3

BLUE+ 3

12 MILS

BLUE- 3

GREEN+ 3

GREEN- 3

RED+ 3

RED- 3

HSY NC 3

VDD

C17

0.1u

VSYNC 3

6

VDD

2,3,7

DDCA-5V

C16

0.1u

No. 0422

U2

1

NC

2

3

4 5

VCC

NC

VCLK

NC

SCK

VSS SDA

24LC21

NC

R13

R14

8

7

6

4.7K

R15

4.7K

R18 33

R19 33

ZD4

ZD5V6

DDC-SCL

DDC-SDA

ZD5

ZD5V6

R123 4.7K

R55 100#

R56 100#

U12

3

1B

6

2B

8

3B

11

4B

1OE

VCC

7

GND

74CBT3126

R125 0#

2OE

3OE

4OE

14

1A

2A

3A

4A

2

5

9

12

1

4

10

13

DDCA-SCL 4

DDCA-SDA 4

R124

150#

VBLCRL3,4

ISP-EN 4

74LVC14

U1F

13 12

74LVC14

R20 4.7K

R16 4.7K#

BLT_ON 7

VL-720 MAIN / DISPLAY CONTROL BOARD - SHEET 1

Page 49

VCC-DDC

VCC

VC C

1,4,7

DVI -CON

31

SHIELD

32

SHIELD

R27

CN2

TX2-

TX2+

SHIELD1

TX4-

TX4+

DDC CLK

DDC DATA

VSYNC

TX1-

TX1+

SHIELD2

TX3-

TX3+

+5V

GND

HP Detect

TX0-

TX0+

SHIELD3

TX5-

TX5+

TXC SHIELD

TXC+

TXC-

RED

GREEN

BLUE

HSYNC

A-GND

A-GND

CON-DVI

100

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

R25

4.7K

VCC

D4

BAV99

SCL-DDDC

SDA-DDDC

R28

FB10

BLM21P300S

C24

10uF

4.7K

VCC-DDC

C23

0.1u

TX2TX2+

TX1TX1+

TX0TX0+

TXC+

TXC-

R29

2.2K

TX2- 3

TX2+ 3

TX1- 3

TX1+ 3

TX0TX0+

TXC+

TXC-

D14

EC10QS04

C18

D13

EC10QS04

D2

BAV99

0.1u

U3

1

NC

2

NC

3

NC

4 5

VSS SDA

VCC

VCLK

SCK

R21

4.7K

R22

4.7K

8

7

6

R23

4.7K

R24

100

SCL-DDDC

SDA-DDDC

D3

BAV99

R26

24LC21

VDD

100

VDD 1,3,7

D5

BAV99

C19

0.1u#

D6

BAV99

C20

D7

BAV99

0.1u#

D8

BAV99

C21

3

3

3

3

0.1u#

C22

D9

BAV99

D10

BAV99

D11

BAV99

0.1u#

D12

BAV99

No. 0422

VL-720 MAIN / DISPLAY CONTROL BOARD - SHEET 2

Page 50

3.3DIG-ANA

C27

C26

180P

TA

TX2-

TX2+

C28

180P

180 P

VDD

MV PRL

R4 0 0 #

R4 1 0

MV XPR L

VDC2V

MV PRL

R4 2 0 #

MV PRL

R4 3 0 #

VSYNC1

HSYNC1

SOG1

VAA3RGB

BLUE+1

BLUE-1

GREEN+1

GREEN-1

RED+1

RED-1

IN MVXPRL USE R41 DEL R40 R42 R43

IN MVPRL R40 R42 R43 DEL R41

CFG [1:0]

0 0 - >I2C

0 1 - >SPI

- >

1 0

C29

180 P

VDC2V

VDC2V

BL M2 1P300S

FB 14

6-WIRE

3. 3D IG- AN A7

3.3DIG-ANA

3. 3D IG- PLL7

3.3DIG-PLL

C49

100uF/16V

TH IS IS FO R PIN 30

FB 13

BL M2 1P300S

C52

C53

0.1u

1000P

CFG [3:2]

RE SET _M ASC O T4

SCL4

SDA4

IRQ-4

C35

0. 1u

TXC-2

TXC+2

TX0-2

TX0+2

TX1-2

TX1+2

TX2-

TX2-2

TX2+

TX2+2

FB 12

BL M2 1P300S

C54

C55

0.1u

1000P

C58

0.01u

TH IS IN SO LD ER SID E

C59

100uF/16V

T6

C36

330 P

C56

100uF

/16V

R30 10K

VDD

TA

T8T7

VDC2V

T3

0

R4 9

VAA3RGB

R3 5 10K

R3 6 10K

R3 7 100

R3 8 100

R3 9 10K

1

AGNDP

2

AVDDP

3

AVDDC

4

RXCN

5

RXCP

6

AGNDC

7

AVDD0

8

RX0N

9

RX0P

10

AGND0

11

GND0

12

VDD0

13

AVDD1

14

RX1N

15

RX1P

16

AGND1

17

GND1

18

VDD1

19

AVDD2

20

RX2N

21

RX2P

22

AGND2

23

GND2

24

VDD2

25

DGND

26

DGND

27

DVDD

28

DCVDD2V

29

DCVSS

30

VDD3V

31

DGND

32

DTEST

33

VDD2V

34

VGA_VSYNC

35

VGA_HSYNC

36

VAA2A

37

GNDA

38

SOGIN

39

VAA3V

40

AGND

GND-ANA

CP1

150 P

R3 1

10K

CO NFIG 2

CO NFIG 3

160

159

CLK O UT

CONFIG1

T1

T2

158

157

156

155

154

153

152

151

150

149

148

147

146

145

144

143

142

141

140

139

138

SC L

RS T

CPV

SD A

ST V3

IR Q#

D CVSS

DCV DD3 .3 V

ST V1

DC VSS

SC S# / HF S#

OE 3/ <C ON FIG 3>

OE 2/ <C ON FIG 2>

OE 1/ <C ON FIG 1>

PWM0 /<CO NFI G 0>

D OBVSS

LCD_ V BL

LCD_ V EE

LCD_ V DD

DCV DD2 V

DO B VDD3 V

U4

MVXPRL

VR EFCPCZ

VAA3B

BIN +

BIN -

AGN DB

BC LP

VT OP

VBO T

VAA3G

GI N+

GI N-

AGN DG

GCLP

TO UT P

TO UT M

VAA3R

RI N+

RI N-

AGN DR

RCL P

414243444546474849505152535455565758596061626364656667686970717273747576777879

T5

T4

C62

CZ1

0. 015 u

C60

4700 P

C61

0. 01u

0. 01u

C63

4700 P

C64

4700 P

C65

22P

137

RS B R3P

RS B R3N

AD VD D 3V

AD VSS

136

135

134

RS B R2P

RS B R2N

XTAL

XTAL I

R4 8 1M

12 M HZ

CONFIG0

133

RS B R1P

RS B R1N

D CVSS

GPI O 1

Y1

PWM0 7

VDDCT RL 5

R3 2 22

R3 3 22

R3 4 22

VDD

VDC2V

FB 11

C37