Page 1

SERVICE MANUAL

MANUEL D'ENTRETIEN

WARTUNGSHANDBUCH

CAUTION:

Before servicing this chassis, it is important that the service technician read the “Safety

Precautions” and “Product Safety Notices” in this service manual.

No. 0421

«MODEL NAMES»

CML156XW

CML158XW

Data contained within this Service

manual is subject to alteration for

improvement.

ATTENTION:

Avant d’effectuer l’entretien du châassis, le technicien doit lire les «Précautions de sécurité»

et les «Notices de sécurité du produit» présentés dans le présent manuel.

VORSICHT:

Vor Öffnen des Gehäuses hat der Service-Ingenieur die „Sicherheitshinweise“ und „Hinweise

zur Produktsicherheit“ in diesem Wartungshandbuch zu lesen.

Les données fournies dans le présent

manuel d’entretien peuvent faire l’objet

de modifications en vue de perfectionner

le produit.

Die in diesem Wartungshandbuch

enthaltenen Spezifikationen können sich

zwecks Verbesserungen ändern.

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

LCD Colour Monitor

November 2003

Page 2

SAFETY PRECAUTIONS

WARNING: The following precautions must be observed.

ALL PRODUCTS

Before any service is performed on the chassis an

isolation transformer should be inserted between the

power line and the product.

1. When replacing the chassis in the cabinet, ensure

all the protective devices are put back in place.

2. When service is required, observe the original

lead dressing. Extra precaution should be taken to

ensure correct lead dressing in any high voltage

circuitry area.

3. Many electrical and mechanical parts in

HITACHI products have special safety related

characteristics. These characteristics are often not

evident from visual inspection, nor can the

protection afforded by them necessarily be

obtained by using replacement components rated

for higher voltage, wattage, etc. Replacement

parts which have these special safety

characteristics are identified by marking with a

! on the schematics and the replacement parts

list.

The use of a substitute replacement component

that does not have the same safety characteristics

as the HITACHI recommended replacement one,

shown in the parts list, may create electrical

shock, fire, X-radiation, or other hazards.

4. Always replace original spacers and maintain lead

lengths. Furthermore, where a short circuit has

occurred, replace those components that indicate

evidence of overheating.

5. Insulation resistance should not be less than 2M

ohms at 500V DC between the main poles and

any accessible metal parts.

6. No flashover or breakdown should occur during

the dielectric strength test, applying 3kV AC or

4.25kV DC for two seconds between the main

poles and accessible metal parts.

7. Before returning a serviced product to the

customer, the service technician must thoroughly

test the unit to be certain that it is completely safe

to operate without danger of electrical shock. The

service technician must make sure that no

protective device built into the instrument by the

manufacturer has become defective, or

inadvertently damaged during servicing.

CE MARK

1. HITACHI products may contain the CE mark on

the rating plate indicating that the product

contains parts that have been specifically

approved to provide electromagnetic

compatibility to designated levels.

2. When replacing any part in this product, please

use only the correct part itemised in the parts list

to ensure this standard is maintained, and take

care to replace lead dressing to its original state,

as this can have a bearing on the electromagnetic

radiation/immunity.

PICTURE TUBE

1. The line output stage can develop voltages in

excess of 25kV; if the E.H.T. cap is required to be

removed, discharge the anode to chassis via a

high value resistor, prior to its removal from the

picture tube.

2. High voltage should always be kept at the rated

value of the chassis and no higher. Operating at

higher voltages may cause a failure of the picture

tube or high voltage supply, and also, under

certain circumstances could produce X-radiation

levels moderately in excess of design levels. The

high voltage must not, under any circumstances,

exceed 29kV on the chassis (except for projection

Televisions).

3. The primary source of X-radiation in the product

is the picture tube. The picture tube utilised for

the above mentioned function in this chassis is

specially constructed to limit X-radiation. For

continued X-radiation protection, replace tube

with the same type as the original HITACHI

approved type

4. Keep the picture tube away from the body while

handling. Do not install, remove, or handle the

picture tube in any manner unless shatterproof

goggles are worn. People not so equipped should

be kept away while picture tubes are handled

LASERS

If the product contains a laser avoid direct exposure to

the beam when the cover is open or when interlocks are

defeated or have failed.

Page 3

1. ELECTRICAL REQUIREMENTS

1.1 LCD Panel Specification ...................................................................................................................... 2

1.2 Input Signals ........................................................................................................................................ 7

1.3 Supported Timing ................................................................................................................................ 8

1.4 Power Management............................................................................................................................. 9

1.5 Plug & Play .......................................................................................................................................... 9

1.6 External Connection ............................................................................................................................ 9

2. ADJUSTMENT OF POWER SUPPLY

3. VL-563 DISPLAY CONTROL BOARD

3.1 Description......................................................................................................................................... 11

3.2 Features............................................................................................................................................. 11

3.3 BLOCK DIAGRAM............................................................................................................................. 12

3.4 Connector Locations.......................................................................................................................... 12

3.5 Connector Type ................................................................................................................................. 13

3.6 Connector pin assignment ................................................................................................................. 13

4. VK-580 CONTROL PANEL AND AUDIO BOARD

(CML158XW)

4.1 Description......................................................................................................................................... 16

4.2 Electrical characteristics (Tamb=25°)................................................................................................ 16

4.3 Connector type .................................................................................................................................. 16

4.4 Connector pin Assignment ................................................................................................................ 17

4.5 Switch definition................................................................................................................................. 18

4.6 LED definition .................................................................................................................................... 18

4.7 Variable resistor................................................................................................................................. 18

5. VK-570 CONTROL PANEL (CML156XW)

5.1 Description......................................................................................................................................... 19

5.2 Connector pin Assignment ................................................................................................................ 19

5.3 Switch definition................................................................................................................................. 19

5.4 LED definition .................................................................................................................................... 19

6. VP-570 POWER BOARD

6.1 Description......................................................................................................................................... 20

6.2 Features............................................................................................................................................. 20

6.3 Interface Signals ................................................................................................................................ 20

6.4 Electrical Specification:...................................................................................................................... 21

6.5 Isolation Check .................................................................................................................................. 23

6.6 Environmental.................................................................................................................................... 24

7. INTRODUCTION

7.1 Front Panel Control and Led.............................................................................................................. 25

7.2 Rear Panel connector Input Signals .................................................................................................. 27

8. TROUBLESHOOTING

8.1 Main Procedure ................................................................................................................................. 28

APPENDIX A: DISPLAY UNIT ASSEMBLY......................................................................33

1

Page 4

1. ELECTRICAL REQUIREMENTS

1.1 LCD Panel Specification

1.1.1 LCD Panel Model (HSD150SX84-C)

• Display Type Active matrix colour TFT LCD

• Resolution 1024 x 768 pixels

• Display Dot 1024 x (RGB) x 768

• Display Area 304.1mm (H) x 228.1mm (V)

• Pixel Pitch 0.297mm (H) x 0.297mm (V)

• Display Colour 262,144

(Monitor display colour 16.7M

with FRC or dithering)

• Maximum Brightness 250 cd/m

(6mA for each lamp after 30 min.)

• Contrast Ratio 400:1 typ.

• Response Time (Tr+Tf) 35ms typ

• Lamp Voltage 660Vrms typ.

• Lamp Current 3~7mA rms. typ. x 2 (Lamp)

• View Angle (Hor./Ver.) 65°(L), 65°(R) / 45°(H), 55°(L). typ.

• Uniformity =(Bmin/Bmax)x100% 70% min.

Bmax: Maximum Brightness

Bmin: Minimum Brightness

• Weight 950g. typ.

2

typ.

(Contrast Ratio ≥ 10)

2

Page 5

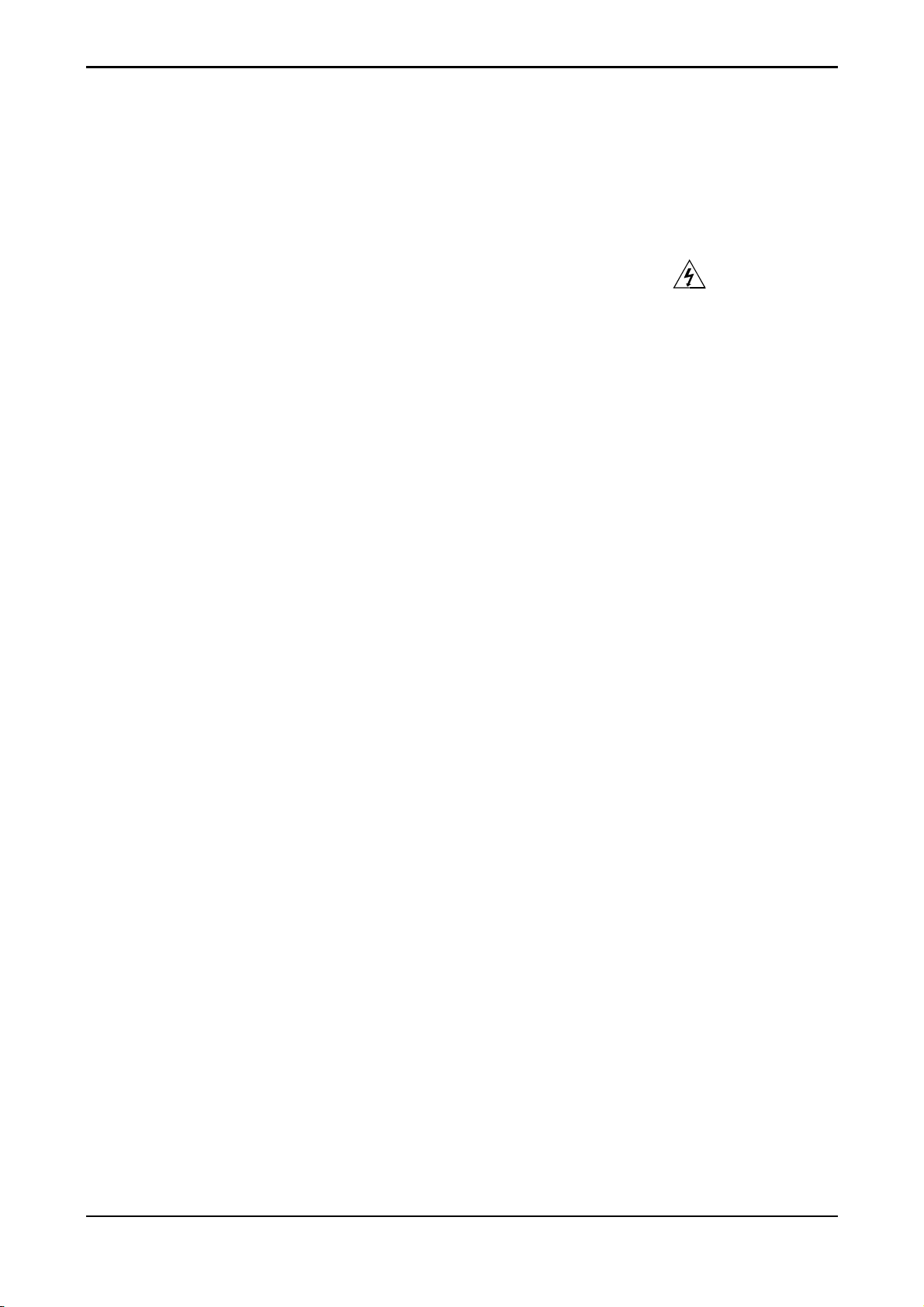

1.1.2 Optical Characteristics

Measuring Condition

■ Measuring surroundings : dark room

■ Lamp current I

■ V

■ Surrounding temperature : 25 ±2°C

■ 30min. Warm-up time.

=3.3V, fv =60Hz, f

DD1

Measuring Equipment

■ LCD-7000 (Otsuka Electric Corp.) utilises MCPD-7000 for Chromaticity and BM-5A for

other optical characteristics.

■ Measuring spot size : 10~12mm

Optical Specification

: (6.0) ±0.1mA, Lamp freq. FL =50KHz

BL

=32.5MHz

DCLK

3

JS555-E26

Page 6

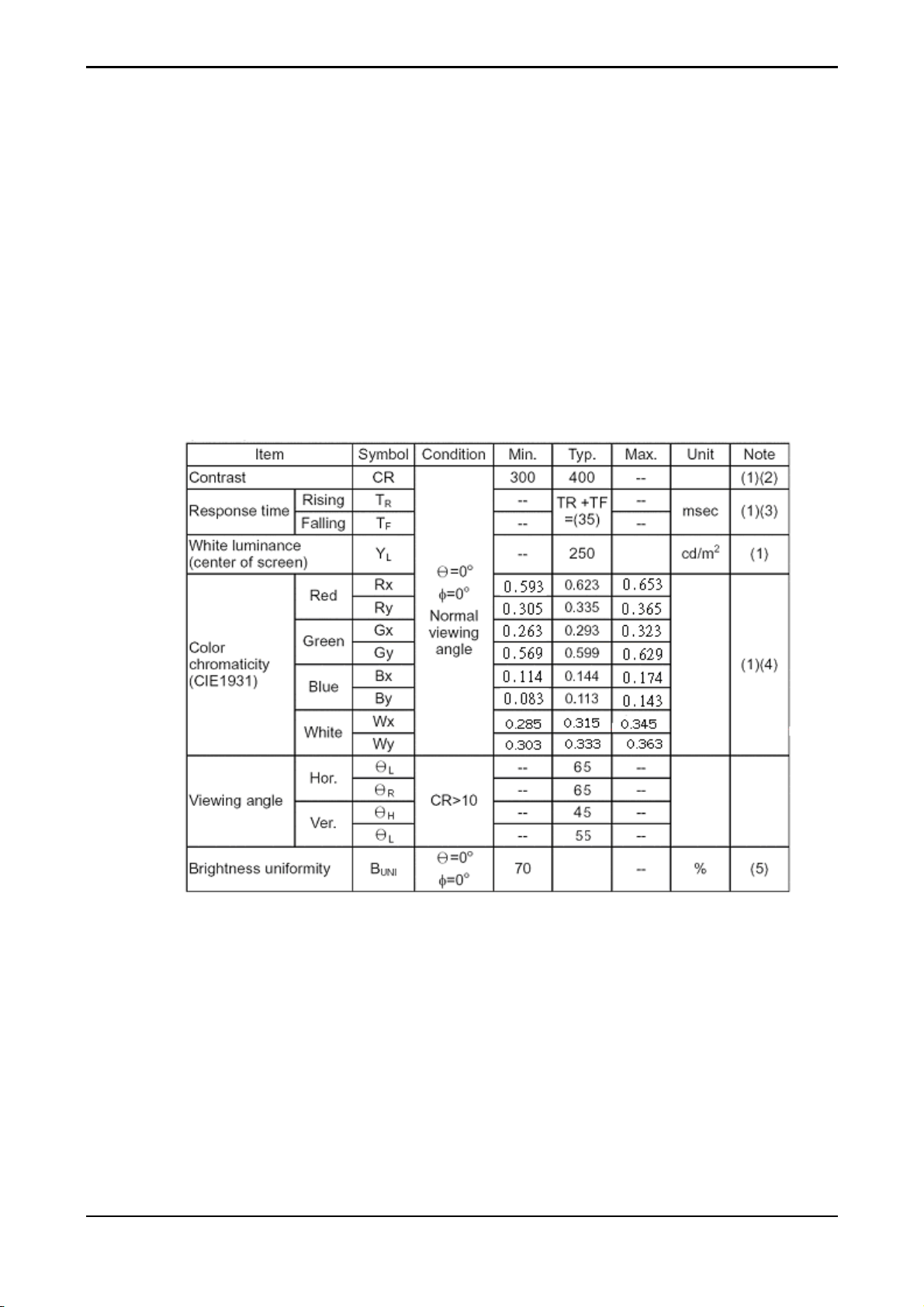

Note (1) Definition of Viewing Angle:

Note (2) Definition of Contrast Ratio (CR):

Measured at the centre point of panel

Luminance with all pixels white (L63)

CR = ———————————————

Luminance with all pixels white (L0)

4

Page 7

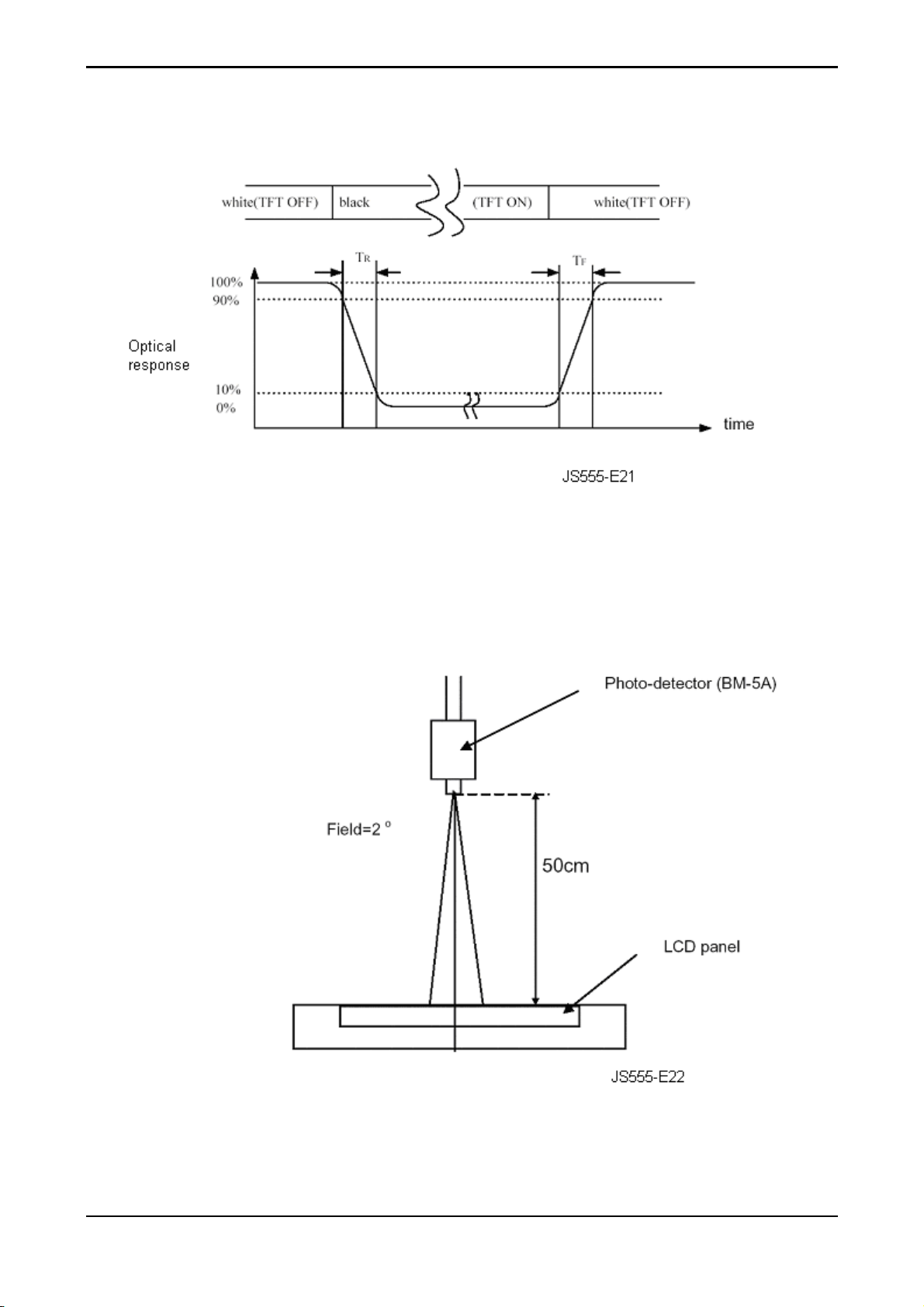

Note (3) Definition of Response Time: Sum of TR and TF

Note (4) Optical Characteristic Measurement Setup

5

Page 8

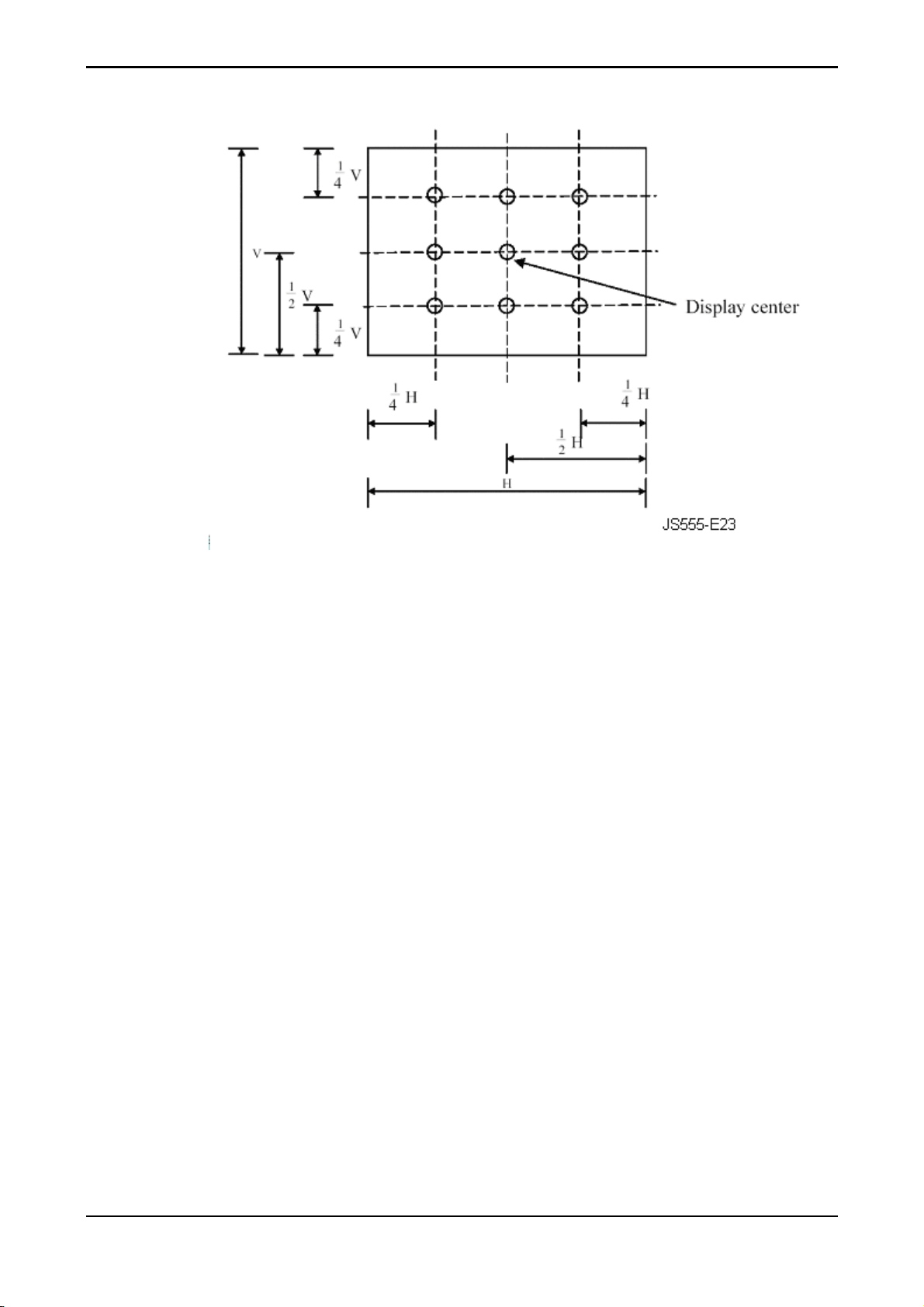

Note (5) Definition of Brightness Uniformity

6

Page 9

1.2 Input Signals

1.2.1 Video Input

• Type Analog RGB.

• Input Impedance 75 ohm ± 2%

• Polarity Positive

• Amplitude 0 - 0.7 ± 0.05 Vp-p

• Display Colour same as LCD panel

1.2.2 Sync Input

• Signal separate horizontal and vertical sync.

• Polarity positive and negative.

1.2.3 Interface Frequency

which are TTL compatible, composite sync(H+V)

The following frequency range is generalised by supported timing. If the entered

mode does not match the supported timing the display optimisation will not be

assured.

• Horizontal Frequency 24KHz ---61KHz

• Vertical Frequency 49Hz -------75Hz

7

Page 10

1.3 Supported Timing

TIMING FH(KHZ)

FV(HZ)

31.469 + 800 640 96 16 48 25.175 640x350

VGA-350

NEC PC9801

VGA-GRAPH

NEC PC9821

VGA-480

VESA-480-72Hz

VESA-480-75Hz

VGA-400-TEXT

SVGA

VESA-600-60Hz

VESA-600-72Hz

VESA-600-75Hz

XGA

COMPAQ-XGA

VESA-768-70Hz

VESA-768-75Hz

APPLE MAC-800

VESA-PAL

70.087 − 449 350 2 37 60

24.83 − 848 640 64 64 80 21.05 640x400

56.42 − 440 400 8 7 25

31.469 − 800 640 96 16 48 25.175 640x400

70.087 + 449 400 2 12 35

31.5 − 800 640 64 16 80 25.197 640x400

70.15 − 449 400 2 13 34

31.469 − 800 640 96 16 48 25.175 640x480

59.94 − 525 480 2 10 33

37.861 − 832 640 40 24 128 31.5 640x480

72.809 − 520 480 3 9 28

37.5 − 840 640 64 16 120 31.5 640x480

75 − 500 480 3 1 16

31.469 − 900 720 108 18 54 28.322 720x400

70.087 + 449 400 2 12 35

35.156 + 1024 800 72 24 128 36 800x600

56.25 + 625 600 2 1 22

37.879 + 1056 800 128 40 88 40 800x600

60.317 + 628 600 4 1 23

48.077 + 1040 800 120 56 64 50 800x600

72.188 + 666 600 6 37 23

46.875 + 1056 800 80 16 160 49.5 800x600

75 + 625 600 3 1 21

48.363 − 1344 1024 136 24 160 65 1024x768

60.004 − 806 768 6 3 29

53.964 + 1328 1024 176 16 112 71.664 1024x768

66.132 + 816 768 4 8 36

56.476 − 1328 1024 136 24 144 75 1024x768

70.069 − 806 768 6 3 29

60.023 + 1312 1024 96 16 176 78.75 1024x768

75.029 + 800 768 3 1 28

49.725 - 1152 832 64 32 224 57.2832 832x624

74.55 - 667 624 3 1 39

31.469 - 800 640 96 16 48 25.175 640X480

50.030 - 629 480 2 62 85

SYNC

POLARITY

TOTAL

(DOT/LINE)

ACTIVE

(DOT/LINE)

SYNC

WIDTH

(DOT/LINE)

FRONT

PORCH

(DOT/LINE)

BACK

PORCH

(DOT/LINE)

PIXEL

FREQUENCY

(MHZ)

Note1: Mode 640x350, 640x400 and 720x400 cannot be expanded to full screen in vertical direction.

Note 2: Below 800x600 (i.e. 640x??? and 720x???), modes do not support NTAA (No Touch Auto-Adjustment)

8

Page 11

1.4 Power Management

1. Meets VESA DPMS Proposal

2. Power Consumption

Meets VESA DPMS Proposal

On mode 30 Wmax Green

Stand-by 3 Wmax Amber

Suspend 3 Wmax Amber

Off mode 3 Wmax Amber

DC power off 3 Wmax Dark

disconnection 3 Wmax

Measured from AC input end of AC power and do not include audio at power-saving state

The stand-by, suspend and off mode recover to on-mode in about 3 seconds.

1.5 Plug & Play

(supports VESA DDC1 and DDC2B functions)

1. Amber (stand-by; suspend; off-mode)

2. Dark (DC power off)

1.6 External Connection

1.6.1 AC Inlet (Rich-Bay R-30190)

1.6.2 Signal Connector (13 pin D-sub connector)

Pin assignment:

Pin NO. Signal

1 Vertical Sync

2 Horizontal Sync

3 Blue Video Ground

4 Blue Video

5 Green Video Ground

6 Green Video

7 Red Video Ground

8 Red Video

9 Shield Ground

10 DDC-SCL

11 DDC-SDA

12 PC-DETECT

13 PC-5V

1.6.3 Video Cable

(1.5M, with 15 pin D-sub VGA connector)

9

Page 12

2. ADJUSTMENT of Power Supply

Input voltage AC 100 ~ 240Vac

Rated input voltage AC 90 ~ 264Vac

Frequency 50 / 60 Hz

Rated frequency 47 ~ 63 Hz

DC output

Out voltage +12V +5V

Maximum output current +1.5A +1.5A

Minimum output current 0A +0.1A

Range of voltage Regulation

+25%~-5% +5%~-3%

10

Page 13

3. VL-563 DISPLAY CONTROL BOARD

3.1 Description

The VL-563 display control board is designed to directly convert the analog RGB signals from

standard VGA display card to optimum LCD timing signals so as to construct a high display

quality LCD monitor.

3.2 Features

•

Support for image expansion and reduction.

• Fast and automatic optimisation of phase, H size, Vert & Horz Position.

• On board micro-processor to detect display timings and control user functions.

• Uses MRT design to generate optimum LCD timings.

• Uses EEPROM to memorise every adjusted parameter.

• Supports up to 16 display modes from VGA to XGA.

• Offers full screen expansion function on non-XGA mode (automatic).

• Flexible colour temperature selection function including 9300, 6500 and user mode.

• Supports OSD functions.

• Supports VESA DPMS function.

• Supports DDC1/2B functions.

• Supports 8 languages for OSD description.

• The longest time for mode change is 3 seconds.

11

Page 14

3.3 BLOCK DIAGRAM

3.3.1 System Block Diagram

3.4 Connector Locations

12

Page 15

3.5 Connector Type

Location Number of pins

CN6 6

CN4,CN5 40

CN2 8

CN9 10

CN1 13

CN8 2

CN7 3

3.6 Connector Pin Assignment

3.6.1 CN1

Pin NO. Signal Comment

1 VS Vertical Sync Input.

2 HS Horizontal Sync Input.

3 Ground Ground.

4 B-Video Blue Video Input.

5 Ground Ground.

6 G-Video Green Video Input.

7 Ground Ground

8 R-Video Red Video Input.

9 Ground Ground.

10 SCL DDC 2B

11 SDA DDC 1/2B

12 PCDETECT PCDETECT Input.

13 5VCC DDC Power Input.

13

Page 16

3.6.2 CN4/CN5

I/O CONNECTION PIN ASSIGNMENT - Interface FPC Connector (40-pins x 2)

(JAE:FH1B040H52)

I/F FRC Connector (J1) CN4 I/F FRC Connector (J2) CN5

Pin Symbol Description Pin. Symbol Description

1 NC No Connecting 1 VDD Digital Power Input (DC+3.3V)

2 NC No Connecting 2 VDD Digital Power Input (DC+3.3V)

3 GND Ground 3 GND Ground

4 GND Ground 4 GND Ground

5 EB5 Even-dot Blue Data bit 5 (MSB) 5 OB5 Odd-dot Blue Data bit 5 (MSB)

6 EB4 Even-dot Blue Data bit 4 6 OB4 Odd-dot Blue Data bit 4

7 EB3 Even-dot Blue Data bit 3 7 OB3 Odd-dot Blue Data bit 3

8 EB2 Even-dot Blue Data bit 2 8 OB2 Odd-dot Blue Data bit 2

9 EB1 Even-dot Blue Data bit 1 9 OB1 Odd-dot Blue Data bit 1

10 EB0 Even-dot Blue Data bit 0 (LSB) 10 OB0 Odd-dot Blue Data bit 0 (LSB)

11 GND Ground 11 GND Ground

12 EG5 Even-dot Green Data bit 5 (MSB) 12 OG5 Odd-dot Green Data bit 5 (MSB)

13 EG4 Even-dot Green Data bit 4 13 OG4 Odd-dot Green Data bit 4

14 EG3 Even-dot Green Data bit 3 14 OG3 Odd-dot Green Data bit 3

15 EG2 Even-dot Green Data bit 2 15 OG2 Odd-dot Green Data bit 2

16 EG1 Even-dot Green Data bit 1 16 OG1 Odd-dot Green Data bit 1

17 EG0 Even-dot Green Data bit 0 (LSB) 17 OG0 Odd-dot Green Data bit 0 (LSB)

18 GND Ground 18 GND Ground

19 ER5 Even-dot Red Data bit 5 (MSB) 19 OR5 Odd-dot Red Data bit 5 (MSB)

20 ER4 Even-dot Red Data bit 4 20 OR4 Odd-dot Red Data bit 4

21 ER3 Even-dot Red Data bit 3 21 OR3 Odd-dot Red Data bit 3

22 ER2 Even-dot Red Data bit 2 22 OR2 Odd-dot Red Data bit 2

23 ER1 Even-dot Red Data bit 1 23 OR1 Odd-dot Red Data bit 1

24 ER0 Even-dot Red Data bit 0 (LSB) 24 OR0 Odd-dot Red Data bit 0 (LSB)

25 GND Ground 25 GND Ground

26 CPH1 Pixel Clock Input 26 CPH2 Pixel Clock Input

27 GND Ground 27 GND Ground

28 GND Ground 28 GND Ground

29 STH Horizontal Start Pulse 29 NC No Connecting

30 LOAD Source Driver Latch Pulse 30 NC No Connecting

31 POL Source Driver Output Polarity control 31 NC No Connecting

32 REV Data Reverse Control Signal 32 NC No Connecting

33 GND Ground 33 NC No Connecting

34 GND Ground 34 NC No Connecting

35 STV1 Vertical Start Pulse1 35 NC No Connecting

36 STV2 Vertical Start Pulse2 36 NC No Connecting

37 CPV Vertical Clock Input 37 NC No Connecting

38 OE Gate Driver Output Enable Signal 38 NC No Connecting

39 GND Ground 39 GND Ground

40 GND Ground 40 GND Ground

14

Page 17

3.6.3 CN6

Pin No. Signal Comment

1 VCC(5V) Power Input

2 VCC(5V) Power Input

3 GND GND

4 GND GND

5 BLON Bright Light ON/OFF

6 BRIGHTNESS Brightness Adjustment

3.6.4 CN2

Pin NO. Signal Comment

1 KEY-R Function select clockwise key

2 LED-OR Power saving mode

3 LED-GRN Monitor is ON

4 GND GND

7 POWER Power ON/OFF key

8 KEY-L Function select anti-clockwise key

6 KEY-UP Adjust up key

5 KEY-DOWN Adjust down key

15

Page 18

4. VK-580 Control Panel and Audio Board (CML158XW)

4.1 Description

The VK-580 is designed to offer an user interfaced control panel which passes and receives

signals to and from VL-563 display control board. Also there is a stereo audio amplifier to drive

a pair of speakers. When in power saving mode the audio circuit can be turned off by the

control signal from VL-563 board.

4.2 Electrical Characteristics (Tamb=25 °°°°)

Audio amplifier (Use Panasonic VP-7723A Audio Analyzor).

Item Audio Input Freq. Spec. Comment

Min. Typ. Max.

Frequency

Response

Distortion 500mVrms 1KHz 2%

Output Watt. 500mVrms 1KHz 0.5W

Volume Control Analog

500mVrms 100Hz~20KHz -3dB +3dB

Volume Max., load 4Ω

Volume Max., load 4Ω

Volume Max., load 4 Ω

4.3 Connector Type

Location Number of pins

J1 10

J2 7

J3 2

J4 2

J5 8

Connector and Switch

Locations

16

Page 19

4.4 Connector Pin Assignment

4.4.1 J1

Pin NO. Comment

1 Audio out L+

2 Audio out L-

3 Audio out R-

4 Audio out R+

5 Audio volume adjust

6 VDD for audio volume adjust

7 GND

8 EAR phone out L

9 EAR phone out R

10 EAR phone Detector

4.4.2 J5

Pin NO. Signal Comment

1 KEY-R Function select clockwise key

2 LED-OR Power saving mode

3 LED-GRN Monitor is ON

4 GND GND

5 POWER Power ON/OFF key

6 KEY-L Function select anti-clockwise key

7 KEY-UP Adjust up key

8 KEY-DOWN Adjust down key

4.4.3 J3 and J4

Pin NO. Signal Comment

1 GND GND

2 OUTL (OUTR) Speaker out

17

Page 20

4.5 Switch Definition

Location Definition

S5 Power ON/OFF

S1 Function select by clockwise direction

S4 Function select by anti-clockwise direction

S3 Adjust up

S2 Adjust down

4.6 LED Definition

Location Definition

D1 Green for ON mode; Amber for power saving.

4.7 Variable Resistor

VR1: Volume control: clockwise for increasing, anti-clockwise for decreasing

18

Page 21

5. VK-570 Control Panel (CML156XW)

5.1 Description

The VK-570 is designed to offer an user interfaced control panel which passes and receives

signals to and from VL-563 display control board. When in power saving mode the audio

circuit can be turned off by the control signal from VL-563 board.

5.2 Connector Pin Assignment

5.2.1 J5

Pin NO. Signal Comment

3 KEY-R Function select clockwise key

4 LED-OR Power saving mode

3 LED-GRN Monitor is ON

4 GND GND

5 POWER Power ON/OFF key

6 KEY-L Function select anti-clockwise key

7 KEY-UP Adjust up key

8 KEY-DOWN Adjust down key

5.3 Switch Definition

Location Definition

S5 Power ON/OFF

S1 Function select by clockwise direction

S4 Function select by anti-clockwise direction

S3 Adjust up

S2 Adjust down

5.4 LED Definition

Location Definition

D1 Green for ON mode; Amber for power saving.

19

Page 22

6. VP-570 POWER Board

6.1 Description

This specification defines the performance and characteristic for the VP-570 power board. It

supplies the following items :

1) A constant 5V output source for logic board.

2) A constant 5V output source for audio power source.

2) A constant 12V output source for inverter power source.

6.2 Features

Wide input range : AC input 90 ~ 264Vrms

High efficiency : η>75%

Inverter brightness adjustment by continual mode

Protection function : DC output is design by auto-recovery.

It includes OPP, SCP.

6.3 Interface Signals

6.3.1 Input

1. AC Inlet: RICHBAY R-301-90

2. J701 :SCJ-0345-I-X-S SC 3Pin

6.3.2 Output

J801: The wire set of Pin2.0 /7Pin to Pin1.25/7 Pin , 110mm length

PIN NO. Function Function

1 +5V +5V supply for logic board

2 +5V +5V supply for logic board

3 GND Ground

4 GND Ground

5 VEN Enable signal for inverter (Low active , <1V)

6 VBRI Brightness signal for inverter (0V to 3.3V)

7 --

8 +5V +5V supply for audio’s power

9 GND Audio ground

J901 & J902: Inverter High Voltage Output

PIN NO. Function Comment

1 LV Low voltage (common)

2 HV High voltage for lamp

20

Page 23

t

6.4 Electrical Specification:

6.4.1 AC-DC Electrical Specification

6.4.1 Input Specification

No Item Condition Min. Typ. Max. Unit

1 Input Voltage

2 Input Frequency ----- 47 --- 63 Hz

3 Input Current 100Vac @ Type load 1.5A --- --- 1.0 Arms

Cold Start @ Vin=100Vrms --- 30 A

4 Inrush Current

Cold Start @ Vin=220Vrms

5 Hold Up Time

6 Turn on time Vin =110Vac --- 1.0 --- S

7 Efficiency +12V/1.5A ,+5Vcc/1.5A 70 --- --- %

8

Input Power

Consumption

@ full load & 100Vac input and Type

-----

load

Vin=220Vac --- --- 1.2 W

100 --- 240 Vac

---

--- 50 A

10 --- --- ms

0-P

0-P

*Cold start-up of Inrush Current : Power board off (keep over 1 hour) and Tamb=25degree C

6.4.1 AC-DC Output Specification

• Output

Tolerance Output Current

Output Voltage - MIN MAX

Voltage Tolerance

+5Vdc +5 /-3 % 0.05A 1.5A 4.85~5.25V dc

+12Vdc +25/-5 % 0A 1.5A 11.4~15Vdc

Ripple

Noise

Dynamic Load

Regulation

Over / Under

Shoo

1. Measured at DC output

terminals which are

paralleled with a 10uF

E-Cap & 0.1uF Ceramic

Cap.

2.Band width is limited

50~100% or 100~50%

load change of any DC

output @50% duty of

1MHz (min.)

@ Power line on/off ---

--- 1%

--- 3%

---

±5%

±5%

+5Vdc:50mVp-p

+12Vdc:120mVp-p

+5Vdc:150mVp-p

+12Vdc:360mVp-p

---

*+5Vcc load regulation test: +12V loading at 1.0A

*+12Vcc load regulation test: +5V loading at 1.0A

Protection Function: Auto-recovery design is acceptable but input power must

be less than 5W

21

Page 24

(

)

)

1)SCP: Short circuit protection must act on both outputs

2)OPP: Should be protected when output power consumption is within 40W ~ 70W

3)OCP:

Min. Max. Test condition

+5Vdc(for logic) 2A 6A +12V @1.5A

+12Vdc 1.8A

4.5 +5V(for logic) @1.5A

6.4.2

Inverter Electrical Specification:

For Hannstar HSD150SX84-B

Input Voltage --- --- 12 --- V

Condition

Min. Typ. Max. Unit

Input Current

Backlight ON/OFF Control

Brightness Adjust

Lamp Current Control

Output Voltage Vin=12V, Iout=6.5mA --- 750 --- Vrms

Brightness

Output Current(Each

connector

Frequency

Open Lamp Voltage --- 1350 --- --- Vrms

Striking Time --- --- 1.0 --- S

Lamp Current Balance --- --- ±0.3 --- mA

Efficiency Vin=12V --- 80 --- %

Min. Luminance / Max.

Luminance

--- --- 1.0 --- A

ON --- 0 --- V

OFF

HSD150SX84-B 200 250 ---

HSD150SX84-D 175 200 ---

Vbri=0V~3.3V 3 6.5 7 mA

--- 40 50 70 KHz

--- 3.0 --- V

--- 55% --- ---

Cd/m²

Operating Life Time --- 30000 --- --- Hr

*The open lamp voltage is tested at output connector terminal

*

Life time (Hr) can be defined as the time in which it continues to operate under the condition:

Ta=25±3°C, I

1. When the brightness becomes 50%

2. When the startup voltage (Vs) at 0°C becomes higher than the maximal value of Vs

=6.0Ma (ms) and fL=30 KHz until one of the following event occurs:

L

specified above

22

Page 25

6.4.3

Connector & Pin Assignment:

Output Connector:

J801 (for main board ) :

Pin No.

Symbol Description

1,2

3,4 GND Common Ground

5 Ven

6 Vbri

7 ---

8

9 GND

Vcc +5Vdc for main board

Backlight ON/OFF control, low active

Brightness adjustable range 0~3.3V

-----

Vaudio

+5Vdc for audio power

Audio ground

J901 & J902

Pin No.

Symbol Description

1

2 LV Low Voltage Output For Low Side CCFL

HV High Voltage Output For High Side CCFL

6.5 Isolation Check

6.5.1 Leakage Current: 0.25mA @ 100VAC

6.5.1 Insulation Resistance: more than 3M ohms while withstanding a voltage of 500VAC

6.5.1 Hi-Pot: 3KVAC using 3mA cut-off current

23

Page 26

6.6 Environmental

The PS shall be capable of withstanding the following

6.6.1 Temperature Range

Operating 0 to +40 degC

Storage -20 to +85 degC

6.6.2 Humidity

Operating 10 to 95% RH

Storage 10 to 95% RH

6.6.3 Altitude

Operating 0 to 10,000 feet

Non-Operating 0 to 25,000 feet

6.6.4 Vibration

Operating 1.0mm, 10-25Hz

15mm per cycle of each axis (XYZ)

Non-Operating: The power supply shall be designed to withstand normal transportation

vibration per MIL-STD-810D, method 514, procedure X.

24

Page 27

7. INTRODUCTION

7.1 Front Panel Control and LED

CML158XW (With Audio)

Front Panel Controls

Item Control Function

Figure 2-1

1

Stereo Speakers

Speaker Volume

2

Control

3

DC Power Switch

4

DC Power-On Indicator

Function Select

5

Buttons

Adjustment Control

6

Buttons

External Headphone

7

Jack

PC Audio Stereo output.

Increase Volume - Turn knob clockwise.

Decrease Volume - Turn knob anti-clockwise

Press the power switch to switch the monitor

ON/OFF.

LED lights Green color --- Power is ON.

LED lights Yellow --- Monitor is in "Power Saving

Mode".

LED is off --- Power is OFF.

Press either left or right control button for OSD (On

Screen Display) menu selection.

Press the left button to decrease the OSD setting

and press the right button to increase the OSD

setting.

The monitor speakers will be disabled when using

an external headphone or external speakers.

25

Page 28

CML156XW (Without Audio)

Front Panel Controls

Item Control Function

1 DC Power Switch

2 DC Power-On Indicator

3 Function Select Buttons

Adjustment Control

4

Buttons

Press the power switch to switch the monitor

ON/OFF.

LED lights Green color --- Power is ON.

LED lights Yellow --- Monitor is in "Power

Saving Mode".

LED is off --- Power is OFF.

Press either left or right control button for OSD

(On Screen Display) menu selection.

Press the left button to decrease the OSD setting

and press the right button to increase the OSD

setting.

26

Page 29

7.2 Rear Panel Connector Input Signals

Rear Panel Cable and Connector

Item Cable / Connector Function

1 Signal Cable Connect the video port

2 AC IN Power Connect Connect the AC power cord

Audio connector

3

(CML158XW

Only)

Connect the audio port

27

Page 30

8. TROUBLESHOOTING

8.1 Main Procedure

28

Page 31

8.1.1 Power Circuit Troubleshooting

29

Page 32

8.1.2 Backlights Troubleshooting

30

Page 33

8.1.3 Performance Troubleshooting

31

Page 34

8.1.4 Function Troubleshooting

32

Page 35

APPENDIX A

DISPLAY UNIT ASSEMBLY DIAGRAMS

CML158XW

CML156XW

33

Page 36

CML158XW

Display Unit Assembly

Page 37

CML156XW

Display Unit Assembly

Page 38

THE UPDATED PARTS LIST

FOR THIS MODEL IS

AVAILABLE ON ESTA

Page 39

Hitachi, Ltd. Tokyo, Japan

International Sales Division

THE HITACHI ATAGO BUILDING,

No. 15 –12 Nishi Shinbashi, 2 – Chome,

Minato – Ku, Tokyo 105-8430, Japan.

Tel: 03 35022111

HITACHI EUROPE LTD,

Whitebrook Park

Lower Cookham Road

Maidenhead

Berkshire

SL6 8YA

UNITED KINGDOM

Tel: 01628 643000

Fax: 01628 643400

Email: consumer-service@hitachi-eu.com

HITACHI EUROPE GmbH

Munich Office

Dornacher Strasse 3

D-85622 Feldkirchen bei München

GERMANY

Tel: +49-89-991 80-0

Fax: +49-89-991 80-224

Hotline: +49-180-551 25 51 (12ct/min)

Email: HSE-DUS.service@hitachi-eu.com

HITACHI EUROPE srl

Via Tommaso Gulli N.39, 20147

Milano, Italia

ITALY

Tel: +39 02 487861

Tel: +39 02 38073415 Servizio Clienti

Fax: +39 02 48786381/2

Email: customerservice.italy@hitachi-eu.com

HITACHI EUROPE S.A.S

Lyon Office

B.P. 45, 69671 BRON CEDEX

FRANCE

Tel: 04 72 14 29 70

Fax: 04 72 14 29 99

Email: france.consommateur@hitachi-eu.com

HITACH EUROPE AB

Egebækgård

Egebækvej 98

DK-2850 Nærum

DENMARK

Tel: +45 43 43 6050

Fax: +45 43 60 51

Email: csgnor@hitachi-eu.com

Hitachi Europe Ltd

Bergensesteenweg 421

1600 Sint-Pieters-Leeuw

BELGIUM

Tel: +32 2 363 99 01

Fax: +32 2 363 99 00

Email: sofie.van.bom@hitachi-eu.com

www.hitachidigitalmedia.com

HITACHI EUROPE S.A.

364 Kifissias Ave. & 1, Delfon Str.

152 33 Chalandri

Athens

GREECE

Tel: 1-6837200

Fax: 1-6835964

Email: service.hellas@hitachi-eu.com

HITACHI EUROPE S.A.

Gran Via Carlos III, 101-1

08028 Barcelona

SPAIN

Tel: 93 409 2550

Fax: 93 491 3513

Email: atencion.cliente@hitachi-eu.com

HITACHI HOME ELECTRONICS (NORDIC) AB

Box 77 S-164 94 Kista

SWEDEN

Tel: +46 (0) 8 562 711 00

Fax: +46 (0) 8 562 711 13

Email: csgswe@hitachi-eu.com

HITACHI EUROPE LTD (Norway) AB

STRANDVEIEN 18

1366 Lysaker

NORWAY

Tel: 67 5190 30

Fax: 67 5190 32

Email: csgnor@hitachi-eu.com

HITACHI EUROPE AB

Neopoli / Niemenkatu 73

FIN-15140 Lahti

FINLAND

Tel : +358 3 8858 271

Fax: +358 3 8858 272

Email: csgnor@hitachi-eu.com

HITACHI EUROPE LTD

Na Sychrove 975/8

101 27 Pr aha 10 – Bohdalec

CZECH REPUBLIC

Tel: +420 267 212 383

Fax: +420 267 212 385

Email: csgnor@hitachi-eu.com

Loading...

Loading...