Page 1

POWER TOOLS

TECHNICAL DATA

AND

SERVICE MANUAL

CORDLESS STUD CUTTER

CL 10D2

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

LIST No. F842 Jan. 2001

C

MODEL

CL 10D2

Page 2

Notice for use

Specifications and parts are subject to change for improvement.

Refer to Hitachi Power Tool Technical News for further information.

Page 3

Page

CONTENTS

1. PRODUCT NAME .........................................................................................................................1

2. MARKETING OBJECTIVE ...........................................................................................................1

3. APPLICATIONS............................................................................................................................1

4. SELLING POINTS ........................................................................................................................2

4-1. Selling Point Descriptions ............................................................................................................. 2

5. SPECIFICATIONS ........................................................................................................................7

5-1. Specifications................................................................................................................................ 7

5-2. Optional Accessories .................................................................................................................... 8

6. COMPARISONS WITH SIMILAR PRODUCTS ............................................................................9

6-1. Specification Comparisons ........................................................................................................... 9

7. PRECAUTIONS IN SALES PROMOTION .................................................................................10

7-1. Safety Instructions ...................................................................................................................... 10

7-2. Suggestions and Precautions for Efficient Use of Charger ......................................................... 14

8. REPAIR GUIDE ..........................................................................................................................15

8-1. Precautions in Disassembly and Reassembly ............................................................................ 15

8-2. Reassembly ................................................................................................................................ 21

8-3. Precautions in Disassembly and Reassembly of Battery Charger.............................................. 27

9. STANDARD REPAIR TIME (UNIT) SCHEDULES .....................................................................28

Assembly Diagram for CL 10D2

Page 4

--- 1 ---

1. PRODUCT NAME

Hitachi 10 mm Cordless Stud Cutter, Model CL 10D2

2. MARKETING OBJECTIVE

One of the primary uses of studs is for hanging of electric cable racks, air-conditioning ducts, and plumbing pipes

and drains. Studs are usually sold in standard lengths of 1 to 3 meters, and must be cut to desired lengths in

accordance with installation needs. They are currently being cut by cut-off machines, disc grinders, or manual

hack saws, frequently require the use of files and grinders for deburring and finishing before they can be used.

The Model CL 10D2 is the upgraded version of the Model CL 10D and is easier to operate and less expensive

with the same features such as clean cutting without sparks, dust and noise, minimal damage to studs and easy

processing after cutting. Thanks to the weight reduction of the motor, decelerating and cutting mechanisms, the

Model CL 10D2 weighs only 3.2 kg even though it uses the 12 V battery while the Model CL 10D using the 9.6 V

battery weighs 3.4 kg. The Model CL 10D2 becomes low price thanks to renewing the manufacturing processes

and sharing components with other models. In addition, the Model CL 10D2 is capable of cutting up to 550 studs

per single charge (when cutting M10 soft steel studs using the 12 V NiMH battery with nominal capacity 3.0 Ah).

This is about 4 times the capacity of the Model CL 10D. The Model CL 10D2 can correspond to various

applications with the wide selection of cutters (M10, M8, M6 and W3/8) and

can be used anywhere since it is cordless.

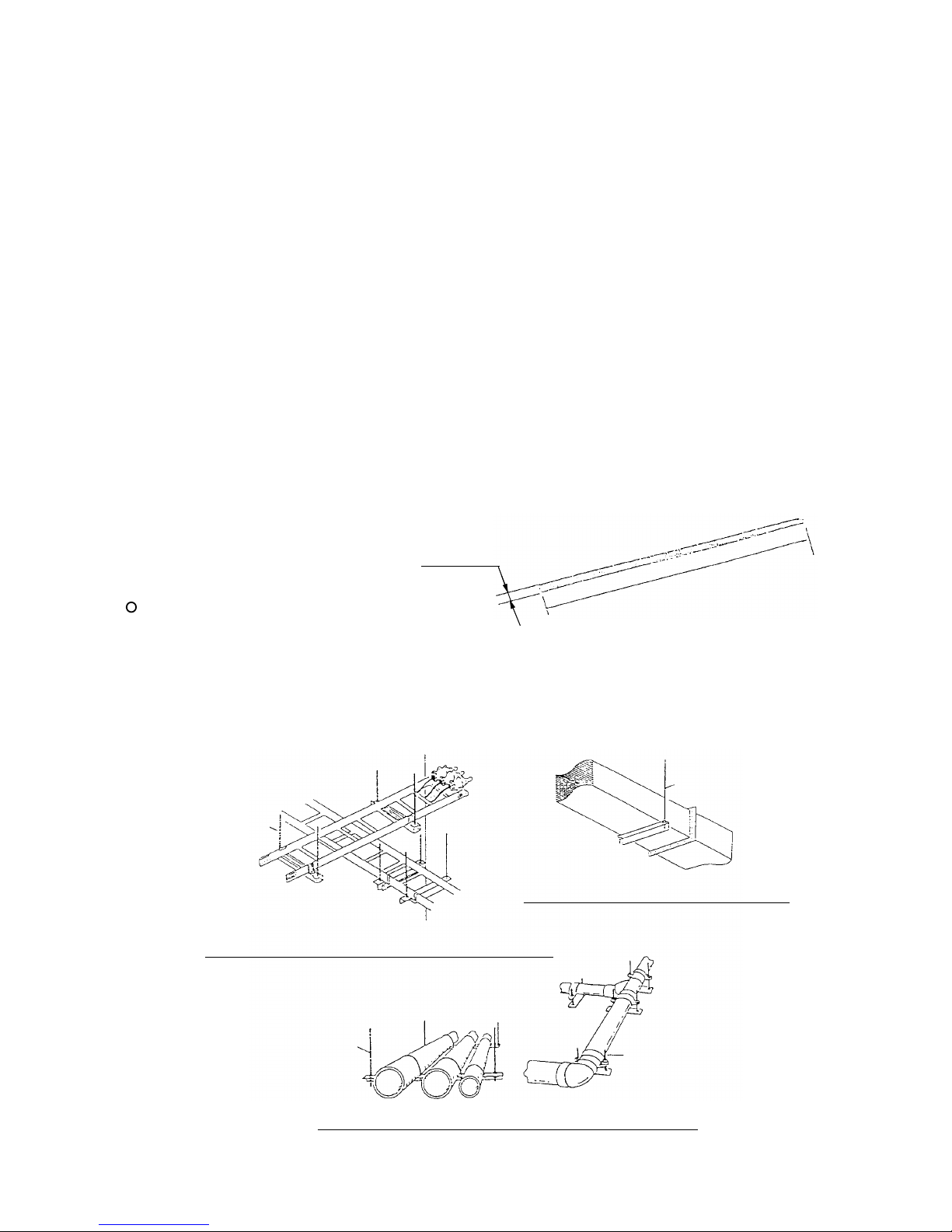

3. APPLICA TIONS

Cutting of mild-steel studs

[Typical threaded stud applications]

Electric installation

•••••••••••••••••••

Suspension of luminaiers, cable racks, conduit pipes, etc.

Air-conditioning

•••••••••••••••••••••••

Suspension of air-conditioning ducts, exhaust ducts, etc.

Plumbing installation

••••••••••••••••

Suspension of feed and drain pipes

Fig. 1

1 to 3 m

M6 to M10

Fig. 2

(2) Suspension of air-conditioning ducts

(3) Suspension of feed and drain pipes in plumbing work

(1) Suspension of cable racks in electrical installation

Stud

Stud

Stud

Stud

Page 5

--- 2 ---

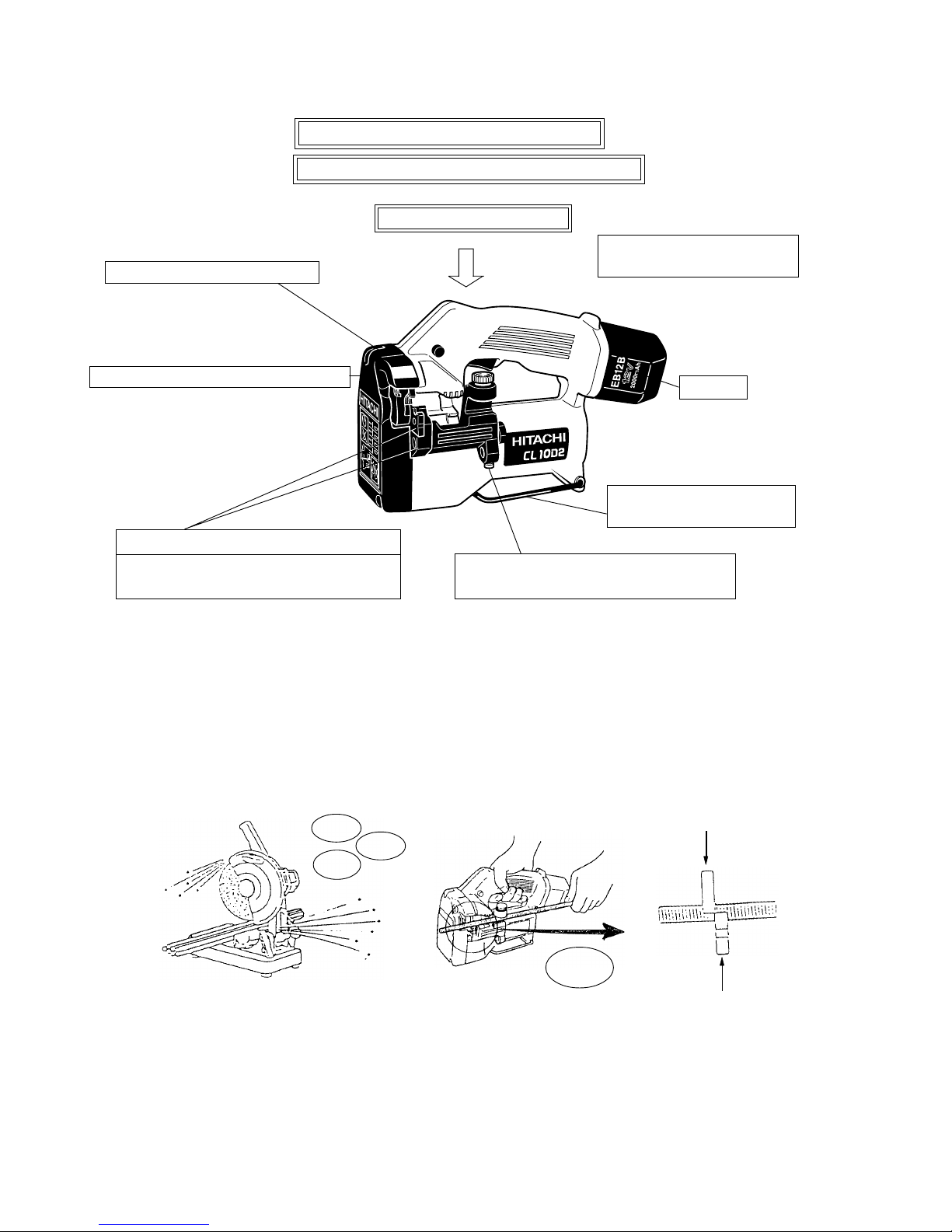

4-1. Selling Point Descriptions

(1) Clean cutting without sparks, chips and noise

A safer and better working environment without fear of fire or scattering of chips and dust is ensured because the

Model CL 10D2 does not produce the chips, dust, and sparks unlike cut-off machines and disc grinders.

4. SELLING POINTS

Fig. 5 Clean shearing with Model CL 10D2

Fig. 3

Fig. 4 Cutting by cut-off machine

Excellent working efficiency

Clean cutting without sparks, chips and noise

24 mm minumum cutting length

Special steel made long service life cutter

Service life of cutters increased through

use of four cutting edges

Convenient stud mounting hole facilitates

cutting studs to specified lengths

Convenient hook facilitates

operation in high places

Cordless

Cam-operated auto-return mechanism

Lightweight 3.2 kg (7.05 lbs.)

(CL 10D: 3.4 kg (7.5 lbs.))

Shearing force: 2500 kg

Clean

cutting

Sparks

Chips

Noise

Minimal damage to studs permits easy processing

Page 6

--- 3 ---

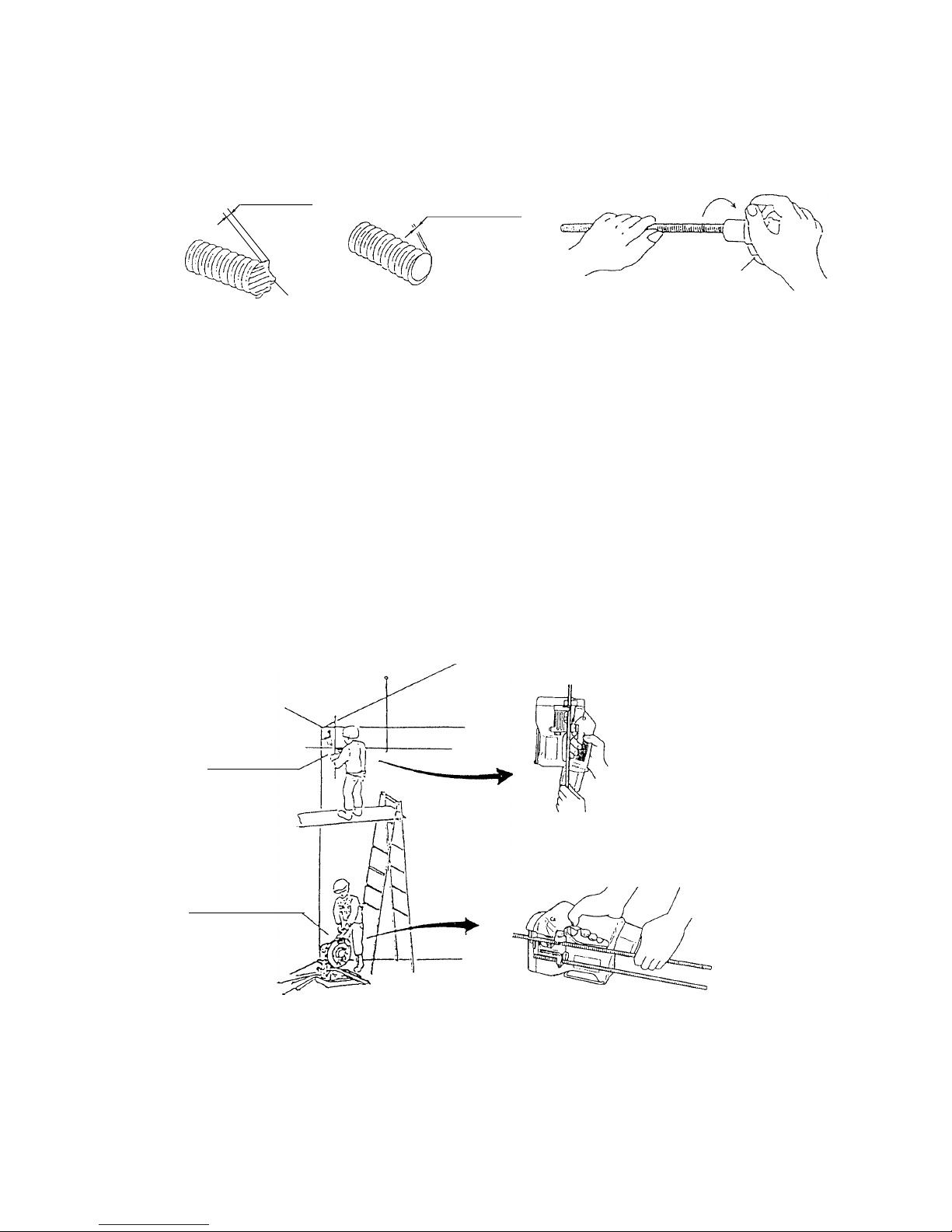

(2) Minimal damage to studs permits easy processing

Because of the special cutters employed, few burrs are caused during cutting, and nuts can be attached to the

studs smoothly and easily. Deburring can be done easily and quickly by means of the provided trimmer.

(3) Cordless

The length of a stud is basically determined by the various needs of the work site. If the ceiling is slanted, for

example, it is hard to determine appropriate lengths. In such a case, it is common to hang studs which are longer

than the required length, and mark and cut them off later. When mounting ducts, up to 20 studs can be cut at a

time at floor level (with a cut-off machine, for example). When mounting luminaiers, however, often only two studs

are cut in one spot. This means that the cut-off machine must be moved from one spot to another over a wide

area.

The Model CL 10D2 is compact, lightweight, and cordless, so it is easily transportable and particularly convenient

for cutting off hanged studs. In addition, it is capable of cutting up to 550 studs per single charge, so it has

sufficient operability to cut many studs at floor level as well.

(1) 20 to 30 % of studs are cut after being hanged.

Fig. 8 Illustration of stud cutting work

Fig. 6 Comparison of stud condition after cutting

Fig. 7 Deburring of stud with trimmer

2 to 3 mm

0.2 to 0.3 mm

Necessary torque: 5 kg-cm or below

Trimmer

Disc grinder

Cut-off machine

(2) 70 to 80 % of studs are cut at floor level.

[Stud cut with cut-off machine]

[Stud cut with Model CL 10D2]

Burr

Page 7

--- 4 ---

Cutter (1)

4th

3rd2nd

1st

(4) Long service life through use of stud cutting edges

Because of the uniquely shaped cutters specially developed by HITACHI, each cutter has four (front, back, upper,

and lower) which can be used in turn for cutting studs. Each cutter is made of high wear-resistant, special steel,

and is capable of cutting up to 500 studs with each of its cutting edges. Accordingly, up to 2,000 studs can be cut

with appropriate use of the four cutting edges.

(5) Excellent working efficiency

In conventional cutting with a cut-off machine or disc grinder, considerable time is required for deburring after the

studs have been cut. In actual tests, the Model CL 10D2 is approximately three times more efficient than cut-off

machines or disc grinders.

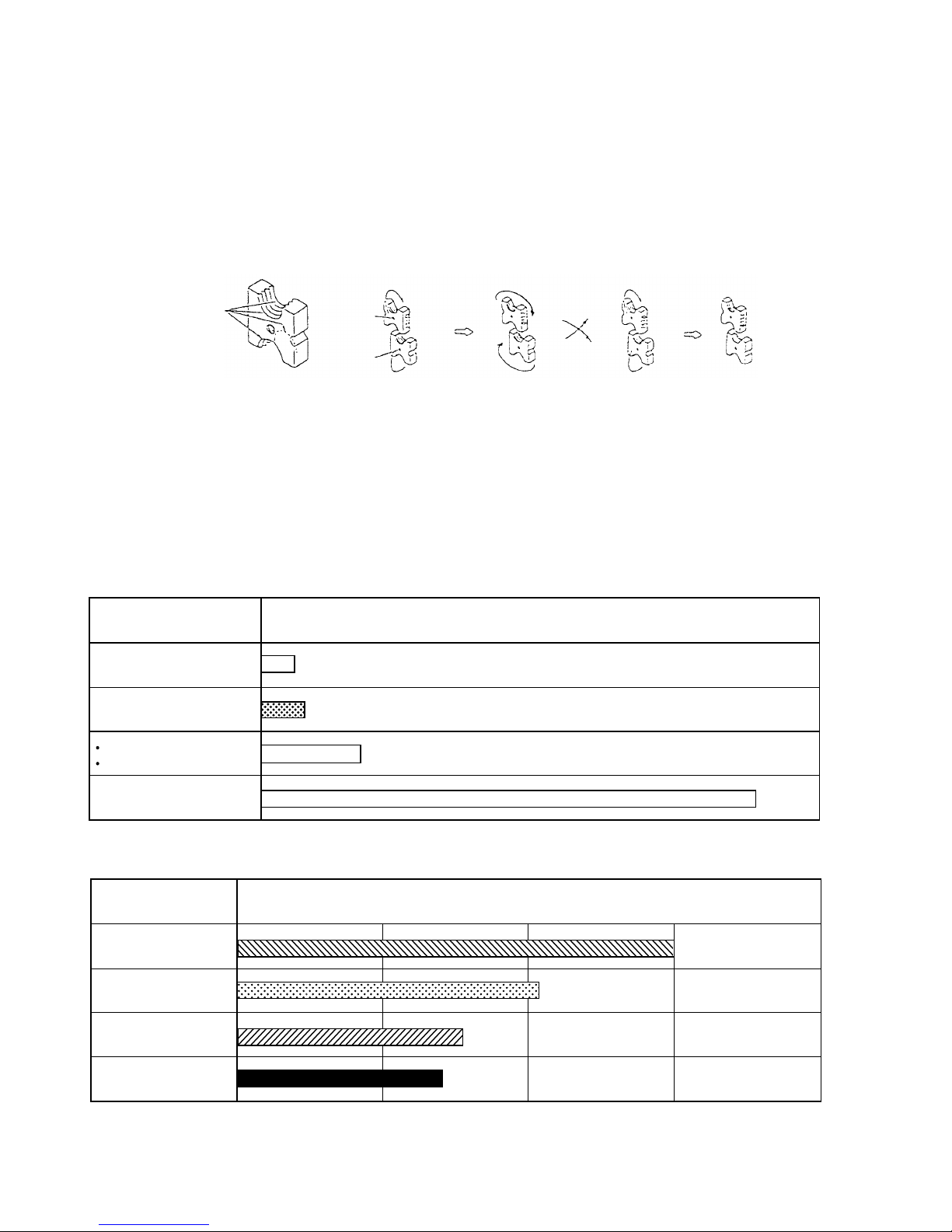

Table 1. Cutting time comparison

Table 2. Number of studs that can be cut per battery charge

Fig. 9

Four cutting edges

Reverse cutters

by turning each,

top to bottom.

Cutter (2)

Reverse cutters

by turning each,

side to side.

Reverse cutter (1)

and cutter (2)

mounting positions.

Reverse cutters

by turning each,

top to bottom.

Type of cutting tool

Cordless stud cutter CL 10D2

Cordless stud cutter CL 10D

High-speed cut-off machine

Grinder

Hand saw

Cutting time

10

(sec.)

2.6 (M10)

2.4 (M10)

30 to 60

8

20

30

Stud size

M6

M8

W 3/8"

M10

Number of cuts per charge

EB 1230H

EB 12B

(Piece)

1270

850

850

570

550

370

620

410

Page 8

--- 5 ---

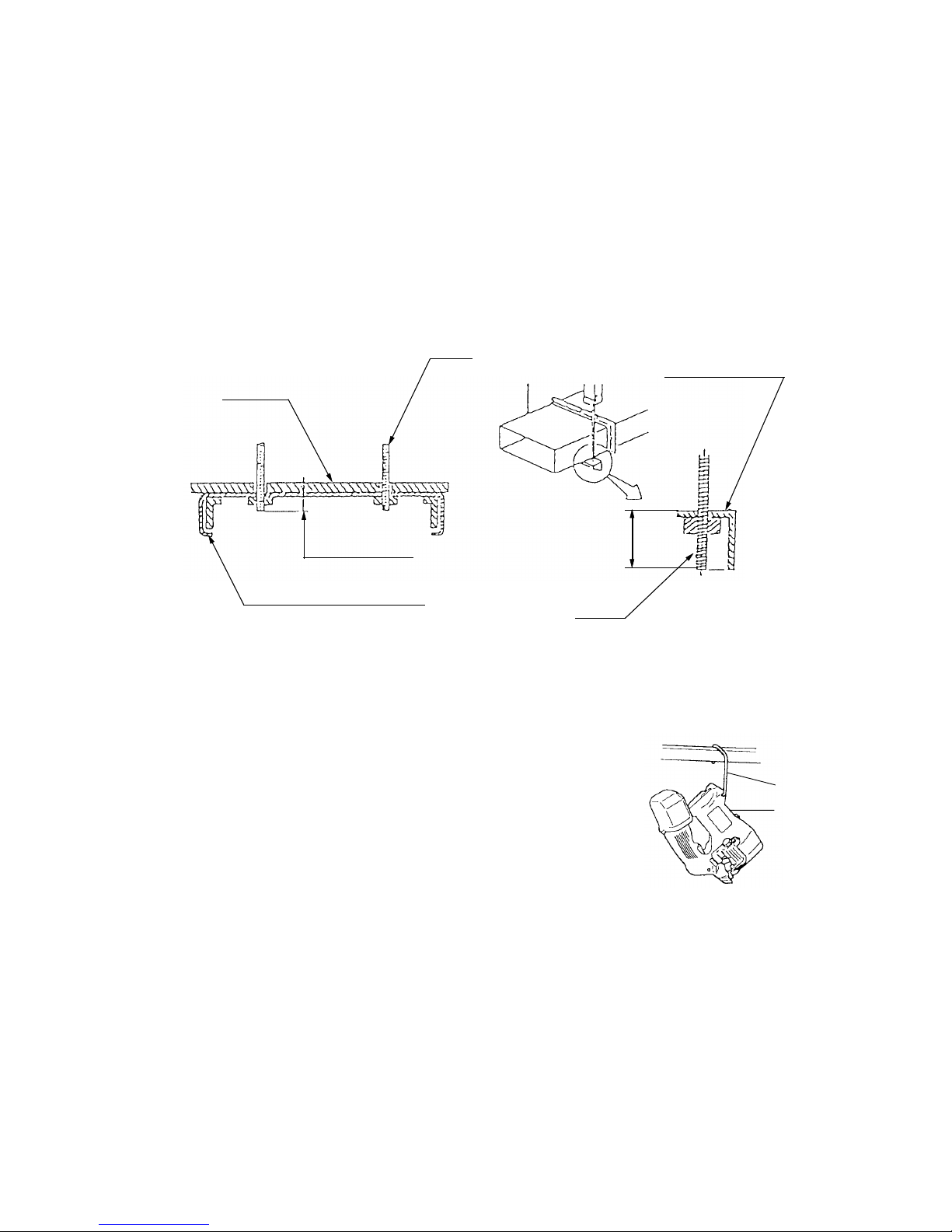

(6) Minimum cutting length

As illustrated in Fig. 10, it is sometimes necessary to cut studs 30 mm or less from the ceiling surface when

installing fluorescent lamps in electrical installation work. The Model CL 10D2 permits cutting protruding studs to

a minimum length of 24 mm from the ceiling surface.

In addition, when installing ducts in air-conditioning equipment installation work, it may be necessary to enclose

the ducts with insulation (lagging) after installation to prevent the formation of dew. In such a case, studs must be

cut as short as possible so that they do not protrude from L-shaped angles, in order to prevent damage of the

lagging. As illustrated, the Model CL 10D2 permits cutting of studs within an L-shaped angle measuring 25 mm x

25 mm x 3 mm (t).

Fig. 10 Minimum cutting length

(7) Convenient hook facilitates operation in high places

When performing equipment installation work in high places, cutting of

hanging studs is often only one of several jobs that must be performed.

Accordingly, it is sometimes necessary to put the stud cutter aside and use

both hands for some other job. In such cases, the hook is very useful for

hanging the stud cutter from a nearby conduit, steel grounding material,

cable rack, or similar support when not in use.

30 mm or less

Fluorescent lamp fixture

L-shaped angle

25

Ceiling

Stud

Stud

Fig. 11 Convenient hook facilitates

operation in high places

Hook

Latch

Page 9

--- 6 ---

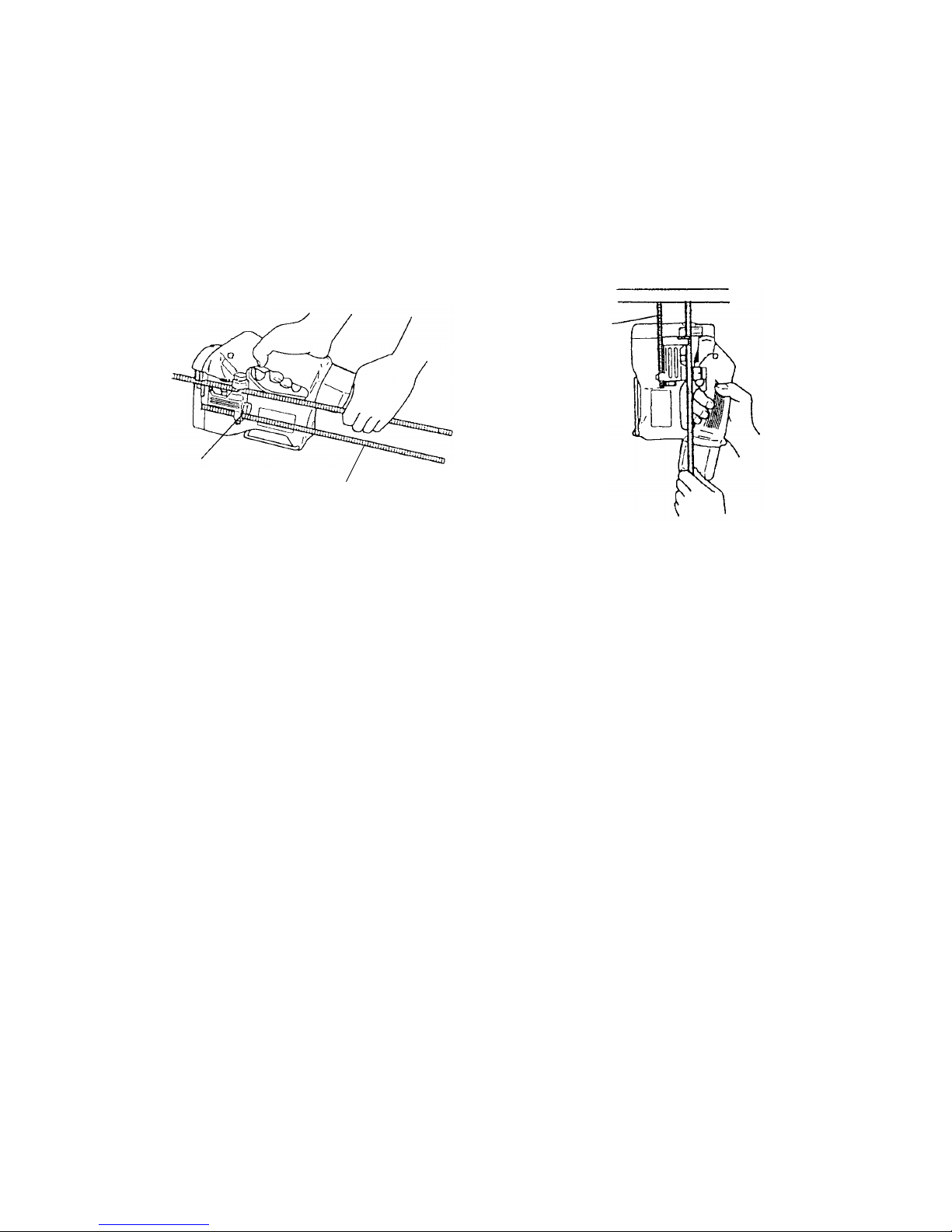

(8) Convenient stud mounting hole facilitates cutting studs to specified lengths

The stud mounting hole is very convenient when cutting many studs to the same length at floor level. The

adjustable stud mounting hole permits mounting of M6 to M10 studs, and can be used as an accurate cutting

length guide for the full range of applicable studs. It can be used not only to align cutting lengths to the rear of the

main body, as shown in Fig. 12-(1), but also to align cutting lengths to the front of the main body, as shown in

Fig. 12-(2). The stud mounting hole is particularly convenient when it is necessary to cut several studs at the

same length from, for example, the surface of a ceiling.

Fig. 12-(1) Length alignment to rear of

main body

Fig. 12-(2) Length alignment to front

of main body

Fig. 12 Stud mounting hole facilitates cutting to specified lengths

(9) Cam-operated auto-return mechanism

After cutting, the cutter is forcibly returned (opened) by means of a plate cam commonly called a "return plate".

This mechanism prevents such malfunctions as the cutter becoming jammed and not returning.

Stud mounting hole

Specified-length guide stud

Specified-length

guide stud

Page 10

--- 7 ---

Battery (Type EB 12B)

Capacity

Number of cuttings per battery charge (M10)

Cutting time

Type of motor

Enclosure

Type of switch

No-load stroke

Main body

Battery

5. SPECIFICATIONS

5-1. Specifications

Mild steel studs: M10, M8, M6 or W3/8"

550 cuts powered by Battery EB 1230H

2.3 (sec.)

DC magnet motor

Main body : Glass fiber reinforced polyamide resin

Battery: ABS resin

Charger: ABS resin

Trigger switch with forward/reverse changeover (with brake)

30/min.

3.2 kg (7.05 lbs.) (includes battery)

EB 1230H: 0.66 kg (14.6 lbs.), EB 12B: 0.67 kg (14.8 lbs.)

Corrugated cardboard box < W/Plastic case: 6.2 kg (13.7 lbs.)>

Standard accessories

W/Charger

Plastic case............................................................................ 1 pc.

Battery (EB 1230H or EB 12B) .............................................. 1 pc.

Charger (UC 14YF2).............................................................. 1 pc.

Hex. bar wrench..................................................................... 1 pc.

M8 cutter ass'y ....................................................................... 1 pc.

M8 trimmer ............................................................................. 1 pc.

Sealed cylindrical nickel-cadmium batteries

Nominal voltage: DC 12V

Nominal life: Charging/discharging approximately 1,000 cycles

(in case of Model UC 14YF2)

Nominal capacity: 2.0 Ah

Sealed cylindrical nickel-metal hydride batteries

Nominal voltage: DC 12V

Nominal life: Charging/discharging approximately 500 cycles

(in case of Model UC 14YF2)

Nominal capacity: 3.0 Ah

Battery (Type EB 1230H)

Sealed power source: Single-phase AC 50/60 Hz

Voltage: Depending on the order specification

Power input: 44 W

Charging system: Constant current charge with full wave phase control

Overcharge protection system: (1) Battery voltage detection (

2

V system)

(2) Battery surface temperature detection

(thermostat or thermistor)

(3) 120-minute timer

Output voltage: 7.2 V --- 14.4 V

Output current: 1.9 A

Charging time: Approx. 60 minutes (for B-type storage battery at 20˚C (68˚F))

Approx. 90 minutes (for H-type storage battery at 20˚C (68˚F))

Product weight: 1.3 kg

Operable ambient temperature range: 0˚C --- 40˚C (32˚F --- 104˚F)

The maximum allowable temperature of the EB 12B type battery is 60˚C

(140˚F) and the EB 1230H type battery is 45˚C (113˚F).

Charger (Type UC 14YF2)

Weight

Packaging and

packaged weight

Page 11

--- 8 ---

Read pilot lamp

remains lit or flashes.

Green pilot lamp is lit.

Prior to charging

During charging

Charging completed

Charging not possible

High battery

temperature

Blinks

Lit

Blinks

Flickers

Lit

0.5 sec ON, 0.5 sec OFF

0.5 sec ON, 0.5 sec OFF

Stays ON constantly

Stays ON constantly

0.1 sec ON, 0.1 sec OFF

Storage battery or

charger is faulty.

Charging not possible

because storage battery

temperature is too high.

Pilot lamp indications (UC 14YF2)

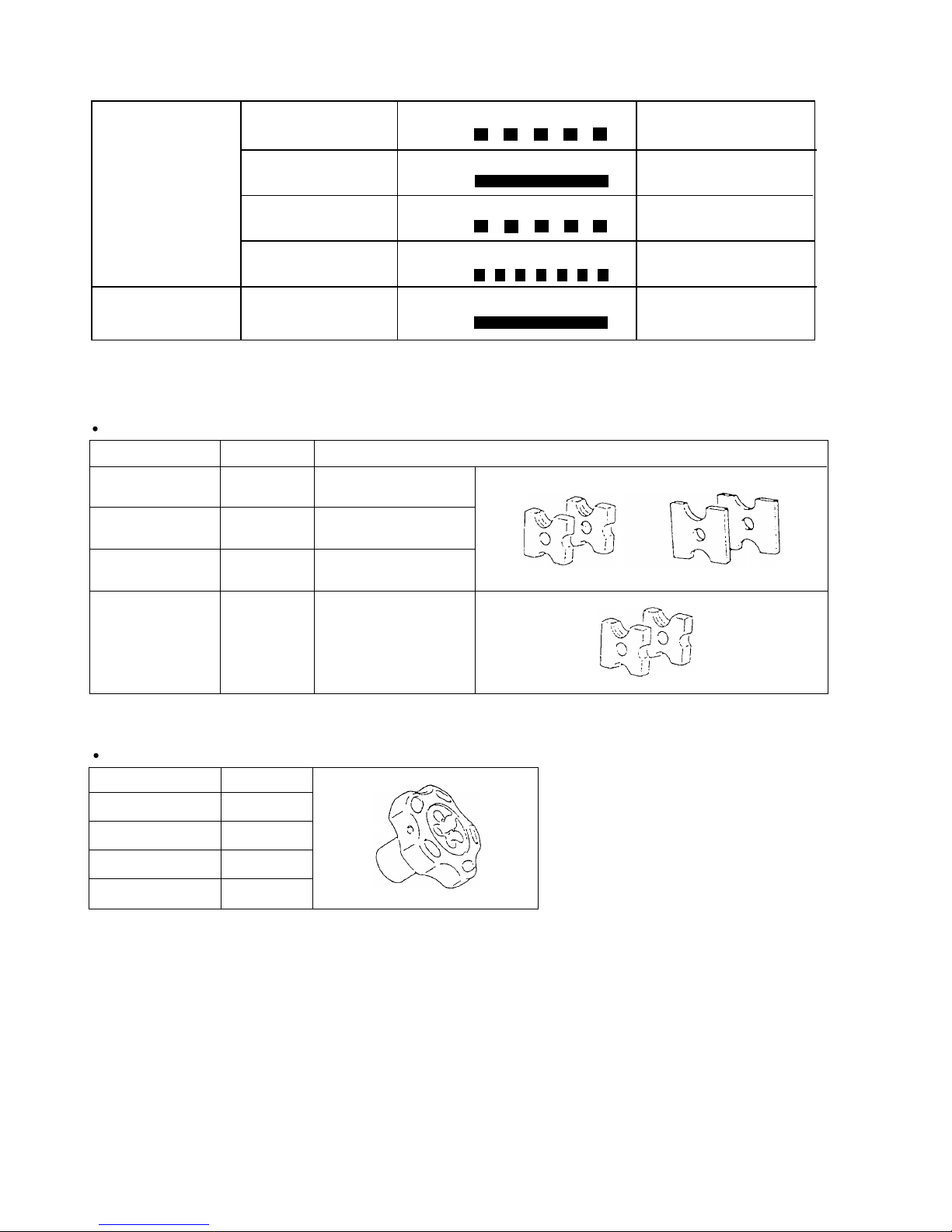

5-2. Optional Accessories

Cutter ass'y

Stud size

Code No.

Combining cutters and spacers

M10 x 1.5

M10 Cutter 2

M10 Spacer 2

308565

*

W3/8" x 1.5875

M6 x 1

M8 x 1.25

308563

308564

M8 Cutter 2

M8 Spacer 2

M6 Cutter 2

M6 Spacer 2

W3/8" Cutter 2

998479

+

Trimmer

Stud size

Code No.

M10 x 1.5

308570

* W3/8" x 1.5875

M6 x 1

M8 x 1.25

308568

308569

308567

* The W3/8" is used without spacers.

Page 12

--- 9 ---

Hitachi

M10 x 1.5

M8 x 1.25

M6 x 1

W3/8" x 1.5875

DC 12

30

61

281 mm (11-1/16")

179 mm (7-3/64")

107 mm (4-7/32")

Voltage

Power input

No-load stroke

No-load sound pressure level

Dimensions

V

W

min

-1

dB (A)

6. COMPARISONS WITH SIMILAR PRODUCTS

6-1. Specification Comparisons

Maker, model

Catalog specifications

CL 10D2

M10 x 1.5

M8 x 1.25

M6 x 1

W3/8" x 1.5875

AC 230 or more

190

0 to 32

73

235 mm (9-1/4")

182 mm (7-11/64")

107 mm (4-7/32")

M10 x 1.5

M8 x 1.25

M6 x 1

W3/8" x 1.5875

DC 9.6

0 to 28

66

258 mm (10-5/32")

179 mm (7-3/64")

107 mm (4-7/32")

Capacity:

Soft steel studs (Size of studs for cutting)

CL 10D

CL 10SA

Length

Height

Width

Weight

3.2 kg (7.05 lbs.)

(including battery)

3.4 kg (7.5 lbs.)

(including battery)

2.7 kg (5.95 lbs.)

(excluding cord)

2.4

550

2.6

140

2.4

NA

Cutting time (M10)

Number of cuttings per battery charge

(M10)

Type of motor

DC magnet

AC single-phase

series commutator

motor

DC magnet

Trigger switch with

forward/reverse

changeover pushing

button with brake

Trigger switch with

forward/reverse

changeover pushing

button with brake and

variable

Trigger switch with

forward/reverse

changeover pushing

button with brake and

variable

Type of switch

Battery Type

Nominal capacity Ah

Nominal voltage V

Charger Model

EB 1230H or EB 12B

EB 1230H: 3.0

EB 12B: 2.0

12

UC 14YF2

Standard accessories

EB 9B

9.6

UC 12Y

Plastic tool case

Charger (UC 14YF2)

Hexagon bar wrench

M8 cutter ass'y

M8 trimmer

Plastic tool case

Charger (UC 12Y)

Hexagon bar wrench

M8 cutter ass'y

M8 trimmer

Hexagon bar wrench

M8 cutter ass'y

M8 trimmer

Item

sec.

2.0

Page 13

--- 10 ---

7. PRECAUTIONS IN SALES PROMOTION

7-1. Safety Instructions

In the interest of promoting the safest and most efficient use of these tools by all of our customers, it is very

important that at the time of sale the salesperson carefully ensures that the buyer seriously recognizes the

importance of the contents of the Handling Instructions, and fully understands the meaning of the precautions

listed on the Caution Plate and Name Plate attached to each tool.

A. Handling Instructions

Salespersons must be thoroughly familiar with the contents of the Handling Instructions in order to give pertinent

advice to the customer. In particular, they must have a thorough understanding of the precautions in the use of

the cordless (battery charger type) electric power tool which are different from those of ordinary electric power

tools.

(1) Before use, ensure that the unit is fully charged.

New units are not fully charged. Even if the units were fully charged at the factory, long periods out of use,

such as during shipping, cause the storage battery to lose its charge. Customers must be instructed to fully

charge the unit prior to use.

(2) When charging storage batteries, use only the exclusive Model UC 14YF2 Charger provided with the tool.

Because of the designed rapid-charging feature (about one hour), use of other battery chargers is hazardous.

(3) Follow prescribed steps in using the Charger.

First connect the EB 1230H or EB 12B Storage Battery to the Model UC 14YF2 Charger, then plug the

Charger into an AC outlet (ensuring that the voltage matches that indicated on the unit). If this order is

reserved, the charger may not function properly.

(4) Ensure the power source voltage is the same as that indicated on the name plate of the Charger. Use of any

other power source (DC outlet, fuel powered generator, etc.) will cause the Charger to overheat and burn out.

(5) Do not use any voltage increasing equipment (transformer, etc.) between the power source and the Charger.

If the Charger is used with voltage over and above that indicated on the unit, it will not function properly.

(6) Conduct battery charging at an ambient temperature range of 0˚C to 40˚C (32˚F to 104˚F).

Special temperature sensitive devices are employed in the Charger to permit rapid charging. Ensure that

customers are instructed to use the Charger at the indicated ambient temperature range. At temperature

under 0˚C (32˚F), the thermostat will not function properly, and the storage battery may be over-charged.

At temperature over 40˚C (104˚F), the storage battery cannot be sufficiently charged.

The optimum temperatures range is 20˚C to 25˚C (68˚F to 77˚F).

(7) The battery charger should not be used continuously.

At high ambient temperatures, if over three storage batteries are charged in succession, the temperature of

the coils on the transformer will rise and there is a chance that the temperature fuse inserted in the interior of

the transformer will inadvertently melt. After charging one battery, please charge the next battery after about a

fifteen-minute interval.

(8) The Charger case is equipped with air vents to protect the internal electronic components from overheating.

Caution the customer not to allow foreign materials, such as metallic or flammable objects, to be dropped or

inserted into the air vents. This could cause electrical shock, fire or other serious hazards.

Page 14

--- 11 ---

(9) Do not attempt to disassemble the storage battery or the charger.

Special devices, such as a thermostat, are built into the storage battery and charger to permit rapid charging.

Incorrect parts replacement and/or wiring will cause malfunctions which could result in fire or other hazards.

Instruct the customer to bring these units to an authorized service center in the event repair or replacement is

necessary.

(10) Disposal of the Model EB 1230H or EB 12B Storage Battery

Ensure that all customers understand that Model EB 1230H or EB 12B Storage Batteries should be turned

into any Hitachi Power Tool sales outlet or authorized service center when they are no longer capable of

being recharged or repaired. If thrown into a fire, the batteries may explode, or, if discarded indiscriminately,

leakage of the cadmium compound contained in the battery may cause environmental pollution.

(11) Perform cutting only after confirming that the threads of the stud cutter properly engage the threads of the

stud. If the threads are not properly engaged, damage to the threads of the stud during cutting may make the

stud unusable, and/or the cutter blade may be damaged.

(12) Ensure that the portion cut off of the stud is at

least 10 mm in length.

As the blade portion of the cutter is very thin,

if only one or two threads of the cutter are

engaged with the threads of the stud, as

illustrated in Fig. 13, the excessive

concentration of load on the blade portion will

cause it to break after only a few cutting

operations. The length of stud cut off should

be at least 10 mm. Instruct customers to

confirm that all of the threads of the cutter

engage the threads of the stud during cutting.

(13) Care should be exercised when performing cutting in narrow places.

For example, in building construction work, studs that are used to hang ducts are often fitted with L-shaped

angles. Instruct the customers to ensure that there is a clearance of at least 8 mm between the stud and the

angle when 25 mm or 30 mm L-shaped angles are used, as illustrated in Fig. 14, before starting the cutting

operation. If the clearance is less than 8 mm, Bracket (A) will come in contact with the side surface of the

angle, preventing proper engagement of the threads of the cutters and the threads of the stud, and causing

damage to the threads of the stud and/or the cutter blade.

Also, since the minimum cutting length of a stud is 14 mm from the surface of the nut, the stud can be cut off

at a point 5 mm within the tip of the angle in the case of a 30 mm L-shaped angle, and approximately even

with the tip of the angle in the case of a 25 mm L-shaped angle, as illustrated in Fig. 14. If cutting is

attempted shorter than indicated, Bracket (A) will come in contact with the nut, causing possible damage to

the cutter. Accordingly, particular caution is necessary.

Fig. 13

Cutter

Cutter

Damaged blade

10 mm or more

Page 15

--- 12 ---

(14) Precautions in cutter replacement

The cutters must be mounted in the proper directions. Instruct the customers to ensure that the notched

grooves on the side surfaces of the cutters are in a "Yes" and "No" relationship when viewed from the front

end of the main body, as illustrated in Fig. 15. In other words, when the notched groove is present (Yes) on

one cutter, it must not be present (No) on the other. If the two cutters are in "Yes" and Yes" alignment, or

"No" and "No" alignment, the pitch of the threads of the stud will not match the pitch of the threads of the

cutters, as illustrated in Fig.16. In such a case, the cutter blade will be damaged and/or the main body of the

stud cutter will become defective after a short period of operation.

(15) Never attempt cutting operation at the position.

If the storage battery charge runs out and motor rotation stops during

cutting, pull the switch (in the position) while pressing the

forward/reverse changeover button from the left, as shown in Fig. 17,

to disengage the cutter from the stud. As the motor is locked

at the position, cutting of a stud cannot be performed, even

if the storage battery is fully charged. In addition, as excessive

pressure or twisting force applied to the main body can seriously

damage the tool, the customers should be instructed never to

attempt to forcibly free the cutters from the stud.

Fig. 17

Fig. 14

Fig. 16

Fig. 15 Cutter replacement method

Notched groove

"Yes"

"Yes"

"No"

"No"

Stud

(30 mm L-shaped angle)

(24 mm L-shaped angle)

L-shaped angle

8 mm or more

Nut

25

14

30

5

0

Page 16

--- 13 ---

(16) The amount of work possible per battery charge varies. The nominal capacity of the storage battery in the

main body is 3.0 or 2.0 Ah. However, the actual capacity varies plus or minus approximately 10% depending

on the ambient temperature during charging/discharging and the number of times the battery has been

recharged. As the amount of work per charge also varies depending on the working conditions (ambient

temperature, sharpness of the cutters, etc.), the data contained herein is intended for reference value only.

(17) The Model CL 10D2 is designed for cutting mild steel studs. If the tool is used for cutting brass or stainless

steel studs, the threads of the studs will be deformed so that nuts cannot be applied. In addition, as use of

the tool to cut hardened bolts, different-sized studs, reinforcing rods, etc. will cause damage to the main

body, the customers should be cautioned never attempt to use the tool for such purposes.

(18) Carefully ensure that replacement cutters are appropriate for the stud sizes. As use of wrong-sized cutters

will cause damage to the studs and/or cutter blades, the customers should be cautioned to ensure that

correct cutters are used.

(19) If the cutters are not mounted in the proper direction, or if the fastening hexagon socket head bolts are not

properly tightened, it will cause damage to the cutters and the main body of the tool. Instruct the customer to

ensure that the cutters are properly mounted.

(20) When operating the tool in high places, the falling cut-off stud portions are extremely dangerous.

The customers should be cautioned to be particularly careful at such times. In addition, the tool should be

stored in a safe, secure place when not in use.

(21) When the tool is being carried, when it is stored away, or when it is temporarily not in use, instruct the

customer to set the forward/reverse changeover button to the position so that the switch cannot be

turned on inadvertently.

(22) When operating the switch, carefully ensure that fingers are kept away from the cutters. To enhance safe

operation, the Model CL 10D2 is provided with a cover for the moving portion of the cutters, a housing

shaped so that fingers are kept away from the cutters, a switch without a stopper, and other safety features.

However, the opening to the cutters must be exposed to permit operation. Should the switch be turned on

inadvertently when the fingers are carelessly near the cutters during replacement or cleaning of the cutters,

while carrying the tool, or at any other time, serious injury could result. The customers should be cautioned

to keep fingers away from the cutters whenever the storage battery is installed in the tool.

B. Caution Plate

(1) The following cautions are listed on the caution plate attached to each Model EB 1230H or EB 12B Storage

Battery.

For Europe

Page 17

--- 14 ---

7-2. Suggestions and Precautions for Efficient Use of Charger

Batteries may not be chargeable immediately after use:

If the type EB 1230H or EB 12B storage batteries are exposed to direct sunshine for an extended period, of if the

temperature of the batteries is 40˚C (104˚F) or higher immediately after they have been used in the tool, the pilot

lamp may not light up when the batteries are connected to the Model UC 14YF2 Charger. This is because the

built-in-thermostat functions to stop the charging when the temperature of the storage batteries reaches 40˚C

(104˚F) or more. In such a case, the customer should be advised to place the batteries in a shaded area with a

good airflow, and allow sufficient cooling before recharging.

This phenomenon is common to all existing batteries which employ temperature sensitive over-charge devices.

The cooling time required before charging can be accomplished varies from a few minutes to about 30 minutes,

depending on the load, duration of use, and ambient temperature.

Page 18

--- 15 ---

Fig. 18

8. REPAIR GUIDE

WARNING: Without fail, remove the storage battery from the main body of the tool before starting repair

or maintenance work. If the battery is left in and the switch is activated inadvertently, the

motor will start rotating unexpectedly, which could cause serious injury.

8-1. Precautions in Disassembly and Reassembly

The [Bold] numbers in the description below correspond to the item numbers in the Parts List and exploded

assembly diagram for the Model CL 10D2.

8-1-1. Preparation to disassembly (Fig. 18)

Before disassembly, set the Pushing Button [3] to the position and depress the trigger switch until Bracket

(A) [42] opens. Then release the trigger switch and remove the storage battery.

Remove the two Special Bolts M5 x 9 [50] from the two Cutter Ass'y M8 [52] with the Hex. Bar Wrench 4 mm [11]

(standard accessory). Insert the storage battery in the main body. Depress the trigger switch keeping the

Pushing Button set to the position until Bracket (A) [42] is positioned to the maximum cutting position. Then

release the trigger switch and remove the storage battery.

Fig. 19

On completion of the above preparation, be sure to

disconnect and remove the battery. Remove the

Bolt W3/8 x 75 [48], loosen the Spring Washer M10

[47], and take off the Stud Guide Ass'y [46]. (Fig. 19)

(a) (b)

Maximum

cutting

position

position

[38]

[37]

[50]

[52]

[42]

[3]

[46]

[47]

[48]

Page 19

--- 16 ---

8-1-2. Disassembly

(1) Bracket ass'y section

(a) Removal of the Cover [38] (Fig. 18)

Remove the two Machine Screws (W/Washers) M4 x 20 (Black) [37] from the Cover [38] and remove the

Cover [38].

(b) Removal of the Return Plate [41] (Fig. 20)

Remove the two Seal Lock Screws (W/SP. Washer) M4 x 12 [40] and remove the Return Plate [41].

(c) Removal of the Gear Cover [19] (Fig. 20)

Remove the four Tapping Screws (W/Flange) D5 x 25 (Black) [17] and the two Tapping Screws D5 x 35 [43].

Hold Bracket (B) [44] and Bracket (A) [42] and remove them being careful not to move Bracket (A) [42].

Then the Second Gear [22] and the Third Pinion [21] can be removed (Fig. 21).

Fig. 20

Fig. 21

Press-fitted

[43]

[17]

[41]

[40]

[44]

[19]

[42]

[21]

[22]

Page 20

--- 17 ---

Fig. 24

Fig. 22 Fig. 23

(d) Removal of the Final Gear [35] (Fig. 22)

Remove the Retaining Ring for D18 Shaft [36] that retains the Final Gear [35] and the Cam Shaft [55] with

the stop ring pliers. Remove the Final Gear [35] and the two Feather Keys 5 x 5 x 10 [56]. Then the Cam

Shaft [55] can be removed.

(e) Removal of the bracket ass'y (Figs. 23 and 24)

Remove the three Hex. Socket Hd. Bolts M5 x 12 [34] from Bracket (B) [44] with the Hex. Bar Wrench 4 mm

[11]. Holding Bracket (A) [42] and Bracket (B) [44], remove the bracket ass'y being careful not to make the

Return Spring [18] jump up.

[34]

[56]

[55]

[36]

[35]

[18]

[42]

[44]

Page 21

--- 18 ---

Fig. 26

(f) Disassembly of the bracket ass'y

(i) Removal of Bolt (A) [39] (Fig. 25)

Bolt (A) [39] that secures Bracket (A) [42] to Bracket (B) [44] is press-fitted into Bracket (B) [44] and

tightened with the Lock Nut M12 [45]. Hold Bracket (B) [44] with a vise and loosen the Lock Nut M12 [45]

with a wrench (loosening torque: about 350 kg•cm). Supporting around the head of Bolt (A) [39] of

Bracket (A) [42], push the screw side of Bolt (A) [39] with a hand press to separate Bracket (A) [42] from

Bracket (B) [44].

(ii) Removal of Roller (A) [53] (Fig. 26)

The Roller Pin [54] that secures Roller (A) [53] is press-fitted into Bracket (A) [42]. Remove the Roller Pin

[54] by pushing in either direction with a hand press. Then Roller (A) [53] can be removed.

Push with a

large hand

press.

Hold at these positions with a vise and

loosen the Lock Nut M12 [45].

Support

here.

Fig. 25

[39]

[42]

[45]

[44]

[44]

[39]

[42]

[42]

[54]

[53]

Page 22

--- 19 ---

(2) Housing ass'y section

(a) Removal of the Hook [6] (Fig. 27)

Remove the Retaining Ring (E-Type) for D4 Shaft [10] that retains the Hook [6] with a small flat-blade

screwdriver. Then the Hook [6] can be removed.

(b) Removal of Housing (B) [2]

Remove the nine Tapping Screws (W/Flange) D4 x 20 (Black) [8] that secure Housing (A) [2] to Housing (B)

[2]. Holding the compartment of the Gear Cover [19] in Housing (A) [2] and Housing (B) [2] or the

compartment of the battery, remove Housing (B) [2] carefully.

Fig. 27

Housing (A) [2]

Housing (B) [2]

[10]

[8]

[6]

Page 23

--- 20 ---

(c) After removal of Housing (B) [2], the internal assemblies and parts can be removed (Fig. 28).

First, remove the Switch Holder [12]. Holding the Pushing Button [3] and the Spring [4], remove the Switch

[13]. Remove the Terminal Support [15]. Remove the Motor [33] and the Second Pinion [28] from Housing

(A) [2].

Fig. 28

[15]

[3]

[4]

[14]

[12]

[13]

[28]

[33]

(3) Power supply unit section

Remove the internal wires coming from the Motor [33] and the Switch Ass'y [14] from the Switch [13] with a

soldering iron.

CAUTION: Do not apply heat to the Switch [13] for a long time with the soldering iron when removing the

internal wires. Otherwise, the electronic circuit in the Switch [13] can be damaged.

Page 24

--- 21 ---

(4) Second pinion section (Fig. 29)

Remove the Ball Bearing 6001VVCMPS2L [32] press-fitted into the Second Pinion [28] with a bearing puller.

Then the Washer [31] can be removed. Remove the Ball Bearing 609VVC2PS2L [24] in the same manner

and remove the Retaining Ring for D15 Shaft [25] with the stop ring pliers. Then the Washer [26] can be

removed. Remove the Needle [30] and the Idle Gear [29].

8-2. Reassembly

Reassembly can be accomplished by following the disassembly procedures in reverse. However, particular

attention should be given to the following items.

(1) Reassembly of the power supply unit section

Be sure to perform wiring connections as indicated in the wiring diagram below (Fig. 30).

Fig. 30

Fig. 31

Red

Blue

Brown

Brown

Blue

Black

Red

Black

[33]

[15]

[13]

[13]

"+" side

"---" side

Red mark

The "+" side is indicated with a red mark on the Motor [33] (Fig. 31).

[24]

[25]

[26]

[28]

[29] [30]

[32]

[31]

Fig. 29

[14]

Page 25

--- 22 ---

(2) Reassembly of the housing section

(a) Second Pinion [28] (Fig. 32)

Before inserting the Needle [30] in the Second Pinion [28], apply grease (Nippeco SEP-3A) to the inner

circumference of the two Idle Gears [29]. Mount the Washer [31] facing its smaller diameter side to the Ball

Bearing 6001VVCMPS2L [32]. Mount the Washer [26] and then the Retaining Ring for D15 Shaft [25] using

the stop ring pliers. Press-fit the Ball Bearing 6001VVCMPS2L [32] and the Ball Bearing 609VVC2PS2L [24].

Check that the Ring Gear [27]

and the Second Pinion [28] are

rattling in a direction at the right

angle to the straight line

connecting the two Needles [30].

(b) Planet gear (Fig. 33)

First, apply grease (Nippeco SEP-3A) to the inner circumference of the Ring Gear [27]. Mount the pinion of

the Motor [33] to the Second Pinion [28] assembled according to the above step (a) and mount the Ring Gear

[27]. Check that the Ring Gear [27] and the Second Pinion [28] are rattling. If there is no rattle (gears are not

engaged properly), the Motor [33] will be locked. Mount this assembly to Housing (A) [2] mating the

protrusion of the Ring Gear [27] to the groove of Housing (A) [2].

Smaller diameter side

Fig. 32

[24]

[31]

[25]

[26] [28]

[29]

[30]

[32]

[12]

[13]

[3]

[4]

Housing (A) [2]

[33]

[7]

[27]

Upper: Blue "---"

Lower: Brown "+"

[27]

[28]

[30]

Fig. 33

Protrusions

(Upper and lower)

Page 26

--- 23 ---

(3) Reassembly of the bracket ass'y section

(a) Lubrication (Fig. 36)

Sufficiently apply grease to Bracket (A) [42], Bracket (B) [44], Roller (A) [53],

Cam Shaft [55], coupling portion and rotating portion of Bolt (A) [39] because high loads are applied to these

parts. Also apply grease to the inner circumferences of the punched holes of the Return Plate [41] and the

sliding portions of the Return Spring [18] and Bracket (A) [42]. Apply TUFREX 251 grease to the shafts, holes

and surfaces indicated with diagonal lines and two-dot chain lines in Fig. 36. Carefully apply grease to the

inner circumference of the hole of Roller (A) [53] until the grooves in the hole are completely greased.

(b) Mounting Roller (A) [53]

Check the position of the smaller diameter end of the Roller Pin [54] and insert the Roller Pin [54] in the hole

of Bracket (A) [42] in the proper direction as shown in Fig. 36. Align Roller (A) [53] with the hole of Bracket (A)

[42] and press-fit the Roller Pin [54] until it becomes flush with the end surface of Bracket (A) [42] (Fig. 36).

(c) Power supply unit (Fig. 33)

Mount the power supply unit assembled according to the above step (1) to Housing (A) [2]. Connect the

internal wires of the Switch Ass'y [14] locating the blue internal wire at the upper position and the brown

internal wire at the lower position. (Housing (A) [2] and Housing (B) [2] are indicated with "+" and "---"

respectively. Be sure to connect the brown internal wire to the "+" side and the blue internal wire to the "---"

side. Otherwise the Switch [13] can be broken.) Then mount the Switch Holder [12] being careful of the

direction.

(d) Mount the Pushing Button [3] mating its groove to the lever of

the Switch [13] (Fig. 34).

(e) Mount the Spring [4] to the Pushing Button [3] (Fig. 33).

(f) Mount the Wrench Holder [7] to Housing (A) [2] (Fig. 33).

(g) Place the internal wires to the proper positions in Housing (A)

[2]. Secure Housing (B) [2] with the nine Tapping Screws (W/

Flange) D4 x 20 (Black) [8] being careful not to catch the

internal wires.

(h) Mount the Hook [6] in the proper direction.

Mount the Retaining Ring (E-type) for D4 Shaft [10] (Fig. 35).

Fig. 35

Fig. 34

Groove

Lever

[13]

[3]

[2] Housing (B)

Housing (A) [2]

[6]

[10]

Fig. 36

[42]

[53]

[41]

[40]

[39]

[44]

[45]

[54]

[55]

Apply grease.

Apply grease.

Apply grease.

Apply grease.

Align the end

surfaces.

Smaller

diameter

end

Page 27

--- 24 ---

(c) Press-fitting Bolt (A) [39]

Put Bolt (A) [39] through the hole of Bracket (A) [42] and

press-fit it in Bracket (B) [44] completely (Fig. 36). At this

time, a clearance is made between Bracket (A) [42] and

Bracket (B) [44] due to the dimensional tolerance.

(d) Observe the specified tightening torque of the Lock Nut

M12 [45] because it is very important for the strength.

(e) Reassembly of the bracket ass'y

(i) Mount the Return Spring [18] to the Gear Cover [19]

(Fig. 37).

(ii) Mount the bracket ass'y assembled in the above steps

(b) and (c) to the Gear Cover [19] hooking the

Return Spring [18] on Bracket (A) [42] (Fig. 37).

(iii) Tighten the three Hex. Socket Hd. Bolts M5 x 12 [34] with

the Hex. Bar Wrench 4 mm [11] at the specified tightening

torque because they are very important for the strength

(Fig. 38).

(iv) Mount the Ball Bearing 629VVC2PS2L [20] to the

Gear Cover [19] (Fig. 38).

(v) Mount the two Feather Keys 5 x 5 x 10 [56] to the Cam

Shaft [55]. Insert the Final Gear [35] in the proper

direction. Mount the Retaining Ring for D18 Shaft [36] to

it using the stop ring pliers (Fig. 39).

Apply grease (Nippeco SEP-3A) to the outer circumference

of the Final Gear [35].

[19]

[42]

[18]

[44]

Fig. 38

Fig. 39

[20]

[19]

[34]

Face the side where the

boss portion is lower than

the end surface of the

gear to the Retaining

Ring for D18 Shaft [36].

[35]

[36]

[35]

[56]

[55]

Fig. 37

Page 28

--- 25 ---

(f) Mounting the assembly to the main body

(i) Insert the Ball Bearing 608VVC2PS2L [23] in the ball bearing chamber of Housing (A) [2] (Fig. 40).

(ii) Press-fit the Third Pinion [21] in the Second Gear [22] and insert it in the Ball Bearing 608VVC2PS2L [23] of

Housing (A) [2] (Fig. 40). At this time, apply grease (Nippeco SEP-3A) to the outer circumference of the

Second Gear [22].

(iii) Mount the Gear Cover [19] to the housing keeping Bracket (A) [42] at the maximum cutting position in the

same manner as the removal procedure (be careful of the spring force) (Fig. 41).

(iv) Tighten the four Tapping Screws (W/Flange) D5 x 25 (Black) [17] and the two Tapping Screws D5 x 35 [43]

(Fig. 41).

CAUTION: Check that there is no scratch, dust or chips on the surfaces of the cam and the roller.

(g) Reassembly of the Return Plate [41]

Align the Return Plate [41] with the Roller Pin [54] and Bolt (A) [39]. Insert the pin of the Cam Shaft [55] in

the hole of the Return Plate [41] and secure them with the two Seal Lock Screws (W/SP. Washer) M4 x 12

[40] (Fig. 41).

Maximum

cutting

position

Fig. 40

Fig. 41

[21]

[22]

[23]

[17]

[41]

[40]

[43]

Page 29

--- 26 ---

(h) Confirmation after reassembly

Before mounting the Cover [38]. Install the battery and check the following operations.

(i) Set the Pushing Button [3] to the position and check that the Cam Shaft [55] rotates clockwise as shown

in Fig. 42.

(ii) Set the Pushing Button [3] to the position and depress the trigger switch. Check that the motor does not

rotate.

(iii) Pressing the Pushing Button [3] to the position, depress the trigger switch. Check that the Cam Shaft

[55] rotates counterclockwise (in the reverse direction of Fig. 42).

(iv) Check that the Pushing Button [3] returns to the position when releasing the Pushing Button [3].

Fig. 42 Rotating direction of the Cam Shaft [55] when the Pushing Button [3] is set to the position

Clockwise

Page 30

--- 27 ---

(g) Mounting the Cover [38] or the Cutter Ass'y M8 [52]

Remove the Battery [16], and fasten the Cover [38] with the two Machine Screws (W/Washers) M4 x 20

(Black) [37].

The Cutter Ass'y M8 [52] must be mounted in the proper directions. As shown in Fig. 43, they must be

mounted so that if the groove in the side of one cutter is present (Yes), the groove in the side of the outer

cutter is not present (No). After mounting direction has been confirmed, fasten the cutters with the two

Special Bolts M5 x 9 [50].

(h) Fasten the Stud Guide Ass'y [46] with the Bolt W3/8 x 75 [48] and Spring Washer M10 [47] as shown in

Fig. 19.

(i) Tightening torques are as follows:

Tapping Screw (W/Flange) D4 x 20 (Black) [8] 1.96 0.49 N•m (20 5 kgf•cm, 17.4 4.3 in-lbs.)

Machine Screw (W/Washers) (Black) M4 x 20 [37] 1.76 0.49 N•m (18 5 kgf•cm, 15.7 4.3 in-lbs.)

Seal Lock Screw (W/SP. Washer) M4 x 12 [40] 1.76 0.49 N•m (18 5 kgf•cm, 15.7 4.3 in-lbs.)

Tapping Screw (W/Flange) D5 x 25 (Black) [17] 3.43 0.49 N•m (35 5 kgf•cm, 30.5 4.3 in-lbs.)

Tapping Screw D5 x 35 [43] 3.43 0.49 N•m (35 5 kgf•cm, 30.5 4.3 in-lbs.)

Hex. Socket Hd. Bolt M5 x 12 [34] 5.88 1.47 N•m (60 15 kgf•cm, 52.2 13 in-lbs.)

Special Bolt M5 x 9 [50] 5.88 1.47 N•m (60 15 kgf•cm, 52.2 13 in-lbs.)

Lock Nut M12 [45] 34.3 7.35 N•m (350 75 kgf•cm, 304.5 65 in-lbs.)

Bolt W3/8 x 75 [48] 15.68 3.92 N•m (160 40 kgf•cm, 139.2 35

in-lbs.)

8-3. Precautions in Disassembly and Reassembly of Battery Charger

Refer to the Technical Data and Service Manual for precautions in disassembly and reassembly of the Model

UC 14YF2 battery charger.

Fig. 43

[51]

[52]

[38]

[50]

Groove is

not present.

[37]

Groove is

present.

Size Attachment

W3/8"

M10

M6

M8

[44]

[52]

[42]

[50]

[51]

[52]

[51]

[50]

[50]

[44][52]

[52]

[42]

[50]

Page 31

--- 28 ---

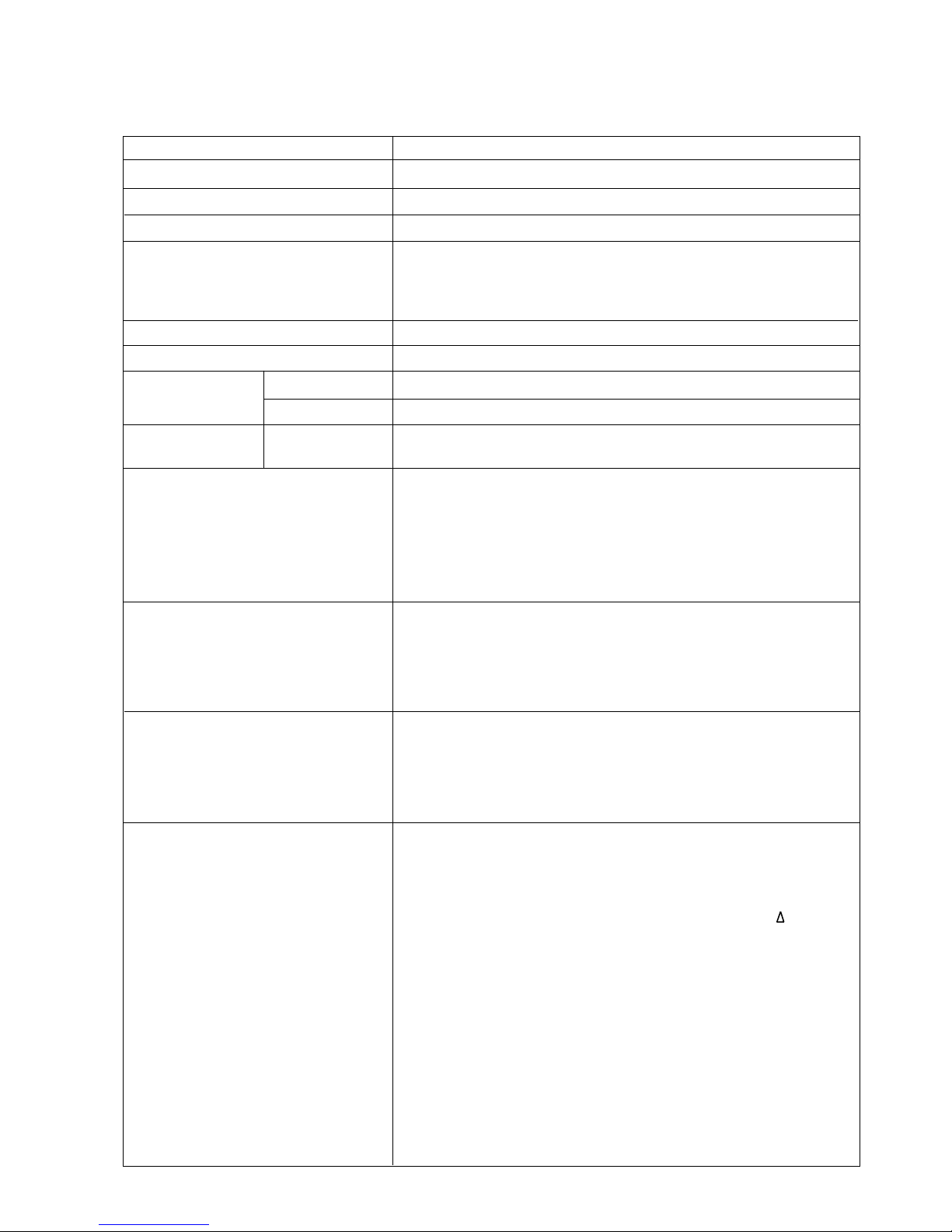

9. STANDARD REPAIR TIME (UNIT) SCHEDULES

MODEL 10 20 30 40

Fixed

Variable

CL 10D2

Work Flow

Final Gear

Feather Key

(5 x 5 x 10) x 2

Retaining Ring

for D18 Shaft

60 min.

50

Second Pinion

Ball Bearing

(6001VV)

Washer x 2

Ball Bearing

(609VV)

Retaining Ring

for D15 Shaft

Ring Gear

Needle x 2

Idle Gear x 2

Bolt (A)

Lock Nut M12

Bracket (B)

Cam Shaft

Stud Guide Ass'y

General Assembly

Pushing Button

Spring

Terminal Support

Switch Ass'y

Housing

(A).(B)

Set

Motor

Hook

Retaining Ring

(E-type) for

D4 Shaft

Cover

Second Gear

Third Pinion

Ball Bearing

(629VV)

Ball Bearing

(608VV)

Gear Cover

Return Spring

Return Plate

Bracket (A)

Roller (A)

Roller Pin

Page 32

ELECTRIC TOOL PARTS LIST

LIST NO.

CORDLESS STUD CUTTER

Model CL 10D2

2001 • 1•25

(E1)

F842

Page 33

*

ALTERNATIVE PARTS

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

CL 10D2

1 -- 01

1 CAUTION PLATE (C) 1

2 319-416 HOUSING (A).(B) SET 1

3 307-604 PUSHING BUTTON 1

4 319-773 SPRING 1

5 HITACHI LABEL 1

6 319-401 HOOK 1

7 307-607 WRENCH HOLDER 1

8 301-653 TAPPING SCREW

(W/FLANGE) D4X20 (BLACK)

9

9 NAME PLATE 1

10 968-643 RETAINING RING (E-TYPE) FOR D4 SHAFT 1

11 944-458 HEX. BAR WRENCH 4MM 1

12 319-839 SWITCH HOLDER 1

13 303-988 SWITCH (IP SOLDER TYPE) W/O LOCK 1

14 319-414 SWITCH ASS’Y 1 INCLUD.13

15 991-666 TERMINAL SUPPORT 1

* 16 318-370 BATTERY EB 1230H (W/ENGLISH N.P.) 1

* 16 310-378 BATTERY EB 12B (W/ENGLISH N.P.) 1

17 305-558 TAPPING SCREW (W/FLANGE) D5X25 (BLACK) 4

18 307-624 RETURN SPRING 1

19 307-622 GEAR COVER 1

20 629-VVM BALL BEARING 629VVC2PS2L 1

21 319-407 THIRD PINION 1

22 319-406 SECOND GEAR 1

23 608-VVM BALL BEARING 608VVC2PS2L 1

24 609-VVM BALL BEARING 609VVC2PS2L 1

25 939-544 RETAINING RING FOR D15 SHAFT (10 PCS.) 1

26 302-714 WASHER 1

27 310-254 RING GEAR 1

28 319-405 SECOND PINION 1

29 319-404 IDLE GEAR 2

30 307-609 NEEDLE 2

31 307-608 WASHER 1

32 600-1VV BALL BEARING 6001VVCMPS2L 1

33 319-413 MOTOR 1

34 998-471 HEX. SOCKET HD. BOLT M5X12 3

35 319-393 FINAL GEAR 1

36 939-546 RETAINING RING FOR D18 SHAFT (10 PCS.) 1

37 307-606 MACHINE SCREW (W/WASHERS) M4X20 (BLACK) 2

38 319-838 COVER 1

39 319-396 BOLT (A) 1

40 987-203 SEAL LOCK SCREW (W/SP. WASHER) M4X12 2

41 319-398 RETURN PLATE 1

42 319-397 BRACKET (A) 1

43 931-875 TAPPING SCREW D5X35 2

44 319-395 BRACKET (B) 1

45 949-574 LOCK NUT M12 (10 PCS.) 1

46 309-180 STUD GUIDE ASS’Y 1 INCLUD.47,48

47 949-458 SPRING WASHER M10 (10 PCS.) 1

48 309-621 BOLT W3/8X75 1

49 CAUTION PLATE (F) 1

50 998-486 SPECIAL BOLT M5X9 2

Page 34

*

ALTERNATIVE PARTS

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

PARTS

CL 10D2

1 -- 01

51 308-779 SPACER M8 (10 PCS.) 2

52 308-564 CUTTER ASS’Y M8 (1 PAIR) 2 INCLUD.51

53 319-399 ROLLER (A) 1

54 319-400 ROLLER PIN 1

55 319-394 CAM SHAFT 1

56 948-015 FEATHER KEY 5X5X10 2

Page 35

*

ALTERNATIVE PARTS

STANDARD ACCESSORIES

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

CL 10D2

Printed in Japan

(010125N)

1 -- 01

501 319-774 CASE 1

502 CHARGER (MODEL UC 14YF2) 1

503 308-569 TRIMMER M8 1

601 308-563 CUTTER ASS’Y M6 (1 PAIR) 2 INCLUD.602

602 309-181 SPACER M6 (10 PCS.) 2

603 308-565 CUTTER ASS’Y M10 (1 PAIR) 2 INCLUD.604

604 308-780 SPACER M10 (10 PCS.) 2

605 998-479 CUTTER W3/8" (1 PAIR) 2

606 308-568 TRIMMER M6 1

607 308-570 TRIMMER M10 1

608 308-567 TRIMMER W3/8" 1

Page 36

Loading...

Loading...