Page 1

TECHNICAL DATA

AND

SERVICE MANUAL

JIG SAW

CJ 65S3

CJ 65V3

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

LIST Nos. CJ 65S3: E510

CJ 65V3: E509

Nov. 2005

C

MODELS

CJ 65S3

CJ 65V3

Hitachi

Power Tools

Page 2

REMARK:

Throughout this TECHNICAL DATA AND SERVICE MANUAL, a symbol(s)

is(are) used in the place of company name(s) and model name(s) of our

competitor(s). The symbol(s) utilized here is(are) as follows:

Symbol Utilized

Competitor

Company Name

Model Name

C-1

BOSCH

PST650

Page 3

Page

CONTENTS

1. PRODUCT NAME ........................................................................................................................... 1

2. MARKETING OBJECTIVE ............................................................................................................. 1

3. APPLICATIONS ..............................................................................................................................1

4. SELLING POINTS ..........................................................................................................................1

4-1. Selling Point Descriptions .............................................................................................................. 2

5. SPECIFICATIONS ..........................................................................................................................4

6. COMPARISONS WITH SIMILAR PRODUCTS .............................................................................. 5

6-1. Specification Comparisons ............................................................................................................ 5

6-2. Comparison of Cutting Speeds ...................................................................................................... 5

7. PRECAUTIONS IN SALES PROMOTION .....................................................................................6

7-1. Handling Instructions ..................................................................................................................... 6

7-2. Cautions on the Name Plate .......................................................................................................... 6

7-3. Overload Durability Characteristics ............................................................................................... 6

7-4. Use of Guide Roller ....................................................................................................................... 6

8. BLADES ......................................................................................................................................... 7

8-1. Applicable Blade ............................................................................................................................ 7

9. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY ............................................................8

9-1. Disassembly .................................................................................................................................. 8

9-2. Reassembly ................................................................................................................................. 10

9-3. Lubrication .................................................................................................................................... 11

9-4. Tightening Torques ....................................................................................................................... 11

9-5. Wiring Diagram ............................................................................................................................ 12

9-6. Connection to the Switch ............................................................................................................. 13

9-7. Insulation Tests ............................................................................................................................ 14

9-8. No-Load Current Values .............................................................................................................. 14

10. STANDARD REPAIR TIME (UNIT) SCHEDULES ..................................................................... 15

Assembly Diagram for CJ 65S3

Assembly Diagram for CJ 65V3

Page 4

--- 1 ---

1. PRODUCT NAME

Hitachi Electric Jig Saw, 65 mm Models CJ 65S3 and CJ 65V3

2. MARKETING OBJECTIVE

There is an increasing demand for a low-price jig saw from the sales engineers. To correspond to this demand,

the new Models CJ 65S3 and CJ 65V3 are developed. These models are of the new design and connectable to

the Hitachi Koki's dust collector. The key features of the Models CJ 65S3 and CJ 65V3 are as follows:

Higher cutting capacity 65 mm

Low price

Easy-to-operate large trigger switch

Comfortable soft grip

Connectable to Hitachi Koki's dust collector through the connection nozzle without use of any optional

accessory

Guard bar for safety

Higher-power blower

3. APPLICATIONS

Cutting various lumber and pocket cutting

Cutting mild steel plate, aluminum plate and copper plate

Cutting synthetic resins, such as phenol resin and vinyl chloride

Cutting thin and soft construction materials

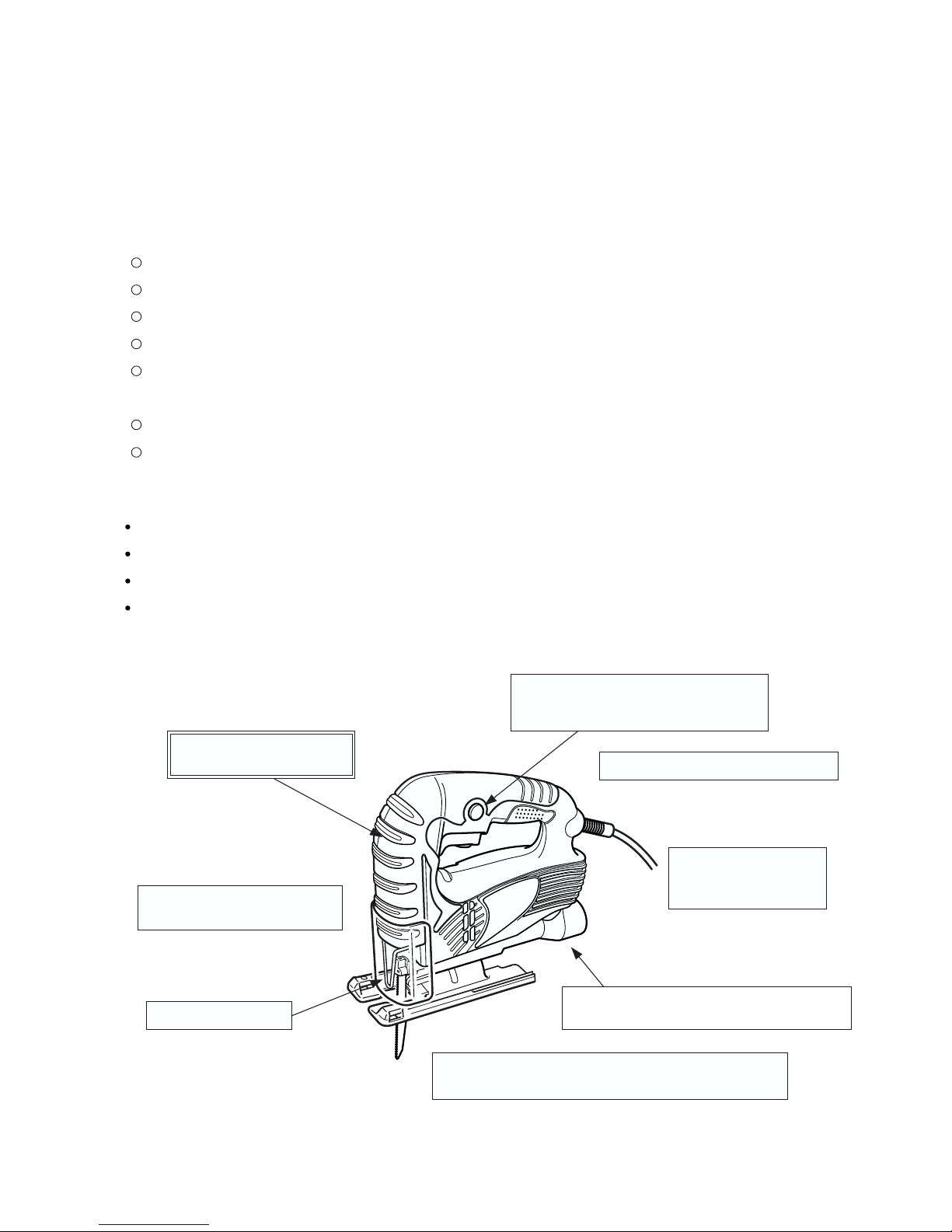

4. SELLING POINTS

Connectable to Hitachi Koki's dust collector

without use of any optional accessory

Lightweight and compact (1.5 kg)

Nonskid large soft grip

for comfortable operation

Max. cutting capacity

Wood: 65 mm

Mild steel: 6 mm

Powerful dust blowing allows

a clear view of the ink line.

Two-ball-bearing armature design for longer service

life and high efficiency motor power transmission

Easy-to-operate large trigger switch

The Model CJ 65V3 is equipped with

the speed control dial.

Guard bar for safety

Page 5

--- 2 ---

4-1. Selling Point Descriptions

(1) Higher cutting capacity

The Models CJ 65S3 and CJ 65V3 can cut wood workpieces up to 65 mm in thickness in the same manner as

7-inch circular saws. They are convenient because each model can be widely used for home-use applications

that do not require a circular saw level cutting speed, such as curved cutting (used as a jig saw) and cutting of

thick workpieces.

(2) Nonskid large soft grip

Most of the conventional soft grips cover only the handle. The Models CJ 65S3/CJ 65V3 are equipped with

the nonskid grip that largely covers both the handle and the housing (front side) to prevent slipping even if the

operator holds the Models CJ 65S3/CJ 65V3 in various ways.

(3) Large-trigger switch for more convenient operation

Adoption of a large trigger switch (room enough for two fingers) ensures easier triggering for improved control

and operation.

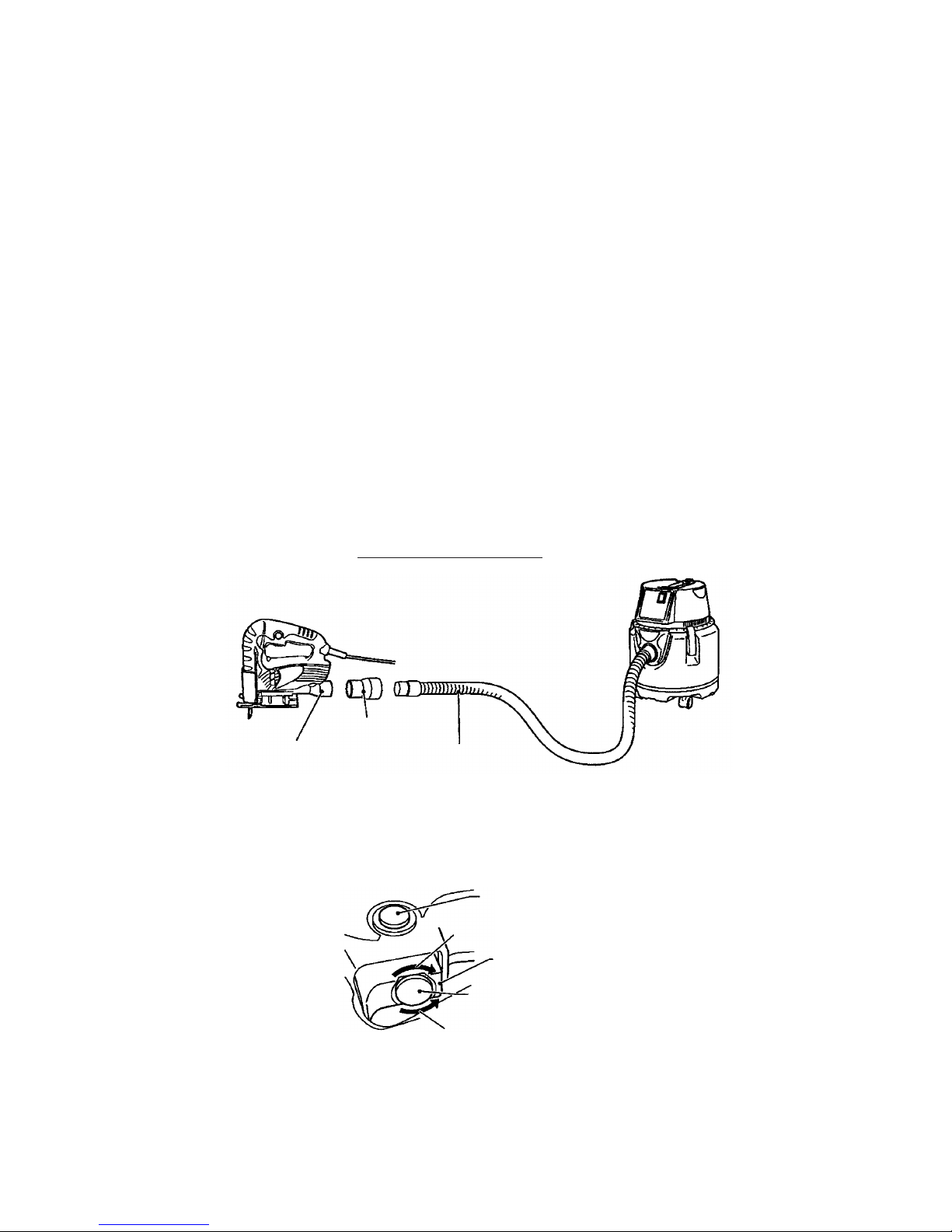

(4) Nozzle for connection with dust collector (standard accessory)

The Models CJ 65S3 and CJ 65V3 are connectable to the Hitachi Koki's dust collector through the standard

connection nozzle without use of any optional accessory for cutting operation in a clean environment.

Stopper

Adapter

Connection to dust collector

Dust collector

High speed

Adapting mouth

for dust collector

Hose

(5) Trigger switch with speed control dial (Model CJ 65V3 only)

The Model CJ 65V3 has the trigger switch with speed control dial. The triggering amount can be adjusted to

keep at a speed suitable for each job.

Low speed

Speed control dial

Switch

(6) Guard bar for safety

The guard bar prevents contact of the operator's fingers with the blade.

Page 6

--- 3 ---

214 (8-1/2")

199 (7-7/8")

67.5 (2-5/8")

1.7 (3.8 lbs.)

Maker

Length (mm)

Model

(7) Splinter guard protects easily splintered materials

Use of the splinter guard can significantly reduce cut-surface roughness of wood materials.

(8) Two-ball-bearing armature design for longer service life and high efficiency motor power transmission

The ball bearings are employed on both sides of the armature to improve durability and reliability.

(9) Lightweight and compact

Height (mm)

Weight (kg)

Width (mm)

Bearings

Dimensions

CJ 65S3/CJ 65V3

197 (7-3/4")

195 (7-3/4")

67 (2-5/8")

1.5 (3.3 lbs.)

FCJ 55/FCJ 55VA

185 (7-1/4")

186 (7-3/8")

67 (2-5/8")

1.4 (3.1 lbs.)

HITACHI

C-1

Page 7

--- 4 ---

Jig saw blade No. 31

••••••••••••••••••••••••••••••••••••••••••••••••••• •••••••••••••

1 pc.

Chip cover

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• •••••••••••••••••••

1 pc.

Splinter guard

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• ••••••••••••••

1 pc.

Hex. bar wrench

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• •••••••••

1 pc.

879330

879331

879332

879333

879334

879335

879356

879357

879391

230

1.8

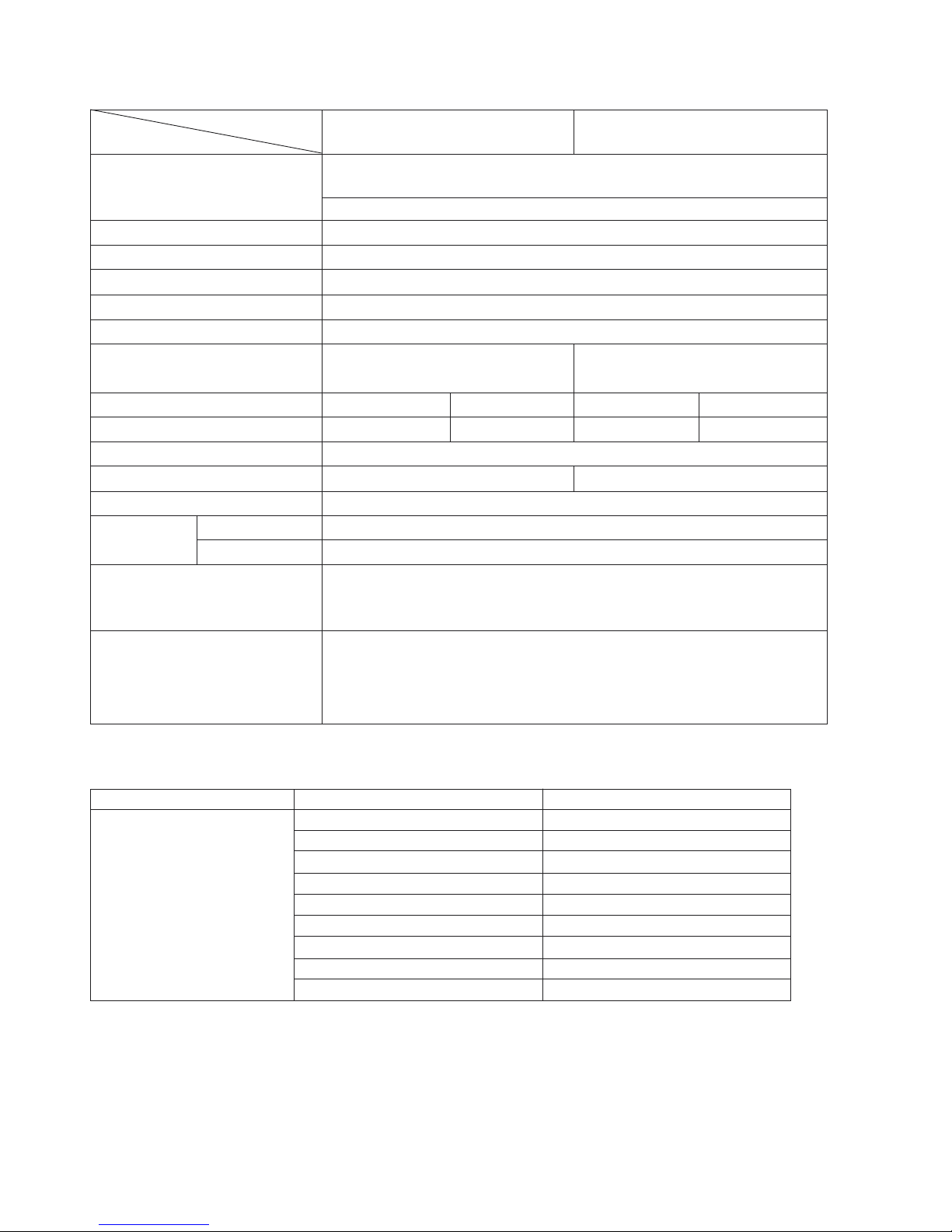

5. SPECIFICATIONS

Full-load output (A)

Number of stroke

Cord

Standard accessories

CJ 65S3

3,000/min

Performance Max. cutting thickness Wood 65 mm (2-5/8")

Mild steel plate 6 mm (1/4")

Min. cutting radius Without guide 25 mm (1")*

Trigger switch w/stopper

Type of switch

Power consumption 400 (W)

Length of stroke

18 mm (45/64")

Tilting angle of base

Right/left: 0 to 45û

Power source AC single phase 50/60 Hz

1.5 kg (3.3 lbs.) (Exclud. cord)

1.9 kg (4.2 lbs.)

Product

* Based on plate thickness of 18 mm (45/64") or less, and use of saw blade Nos. 2 and 3.

Model

Item

CJ 65V3

Type of motor Single phase AC commutator motor

Glassfiber reinforced polycarbonate resin + elastomer

Outer frame

Double insulation

Insulation

Trigger switch w/stopper

(Variable speed type w/adjust knob)

Voltage (V)

110

3.8

220

1.9

240

1.8

0 to 3,000/min

Weight

Packed

2-cord cabtire cord

Nominal sectional area: 0.75 mm2 (1.2 x 10-3 inch2)

Length: 2.5 m (8.2 ft.)

Optional accessories

Blade (No. 1) (5 pcs.)

Blade (No. 2) (5 pcs.)

Blade (No. 3) (5 pcs.)

Blade (No. 4) (5 pcs.)

Blade (No. 5) (5 pcs.)

Blade (No. 6) (5 pcs.)

Blade (No. 31) (5 pcs.)

Blade (No. 41) (5 pcs.)

Guide

Item

Code No.

Page 8

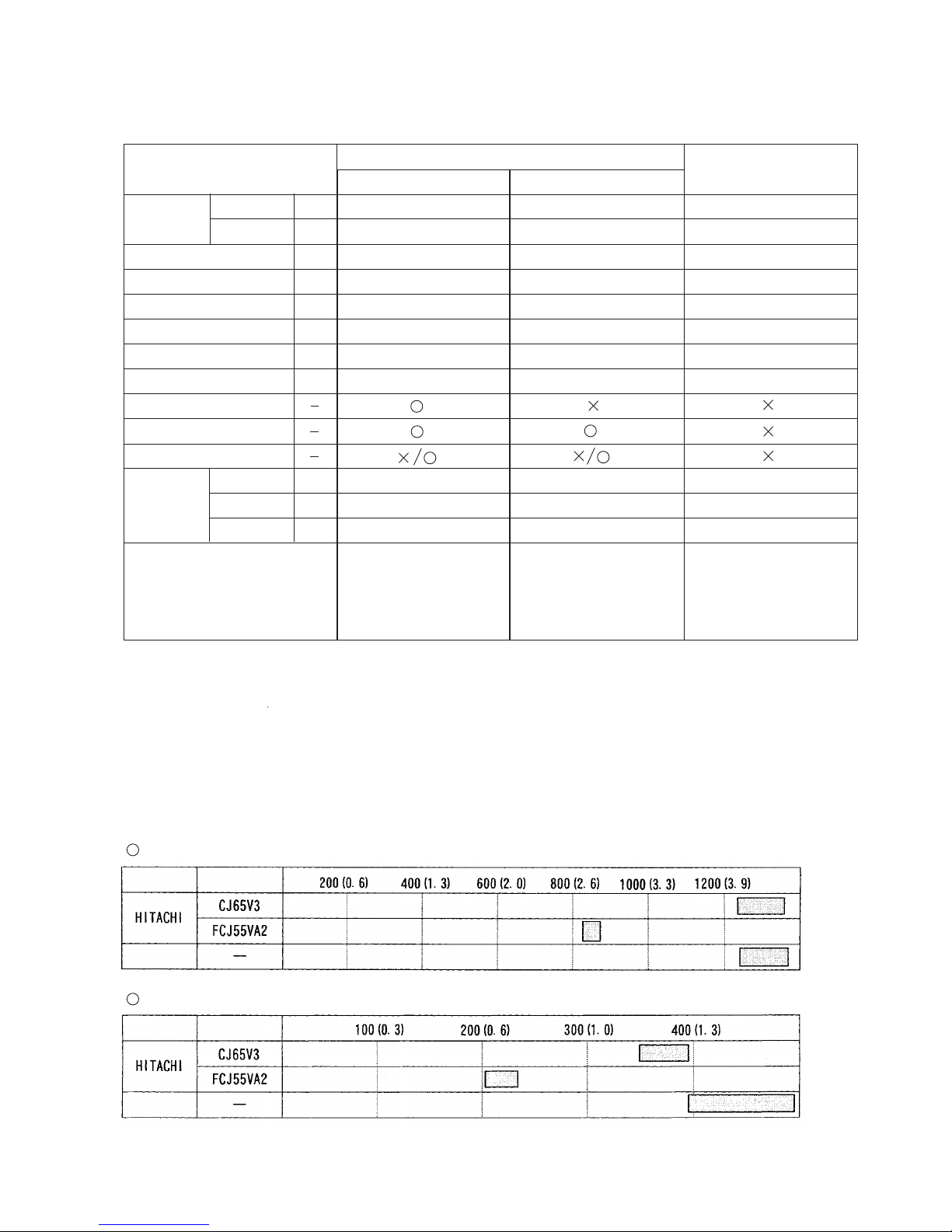

--- 5 ---

Cutting of wood, 18 mm (45/64") thick Cutting speed [mm (ft)/min]

Capacity

Power input

Number of stroke

Base tilting angle

Length of stroke

Weight

Actual weight

Soft grip

Dimensions

Standard accessories

Wood

Mild steel

mm

W

1/min

mm

mm

deg

kg

mm

mm

mm

Length

Height

Width

6. COMPARISONS WITH SIMILAR PRODUCTS

6-1. Specification Comparisons

HITACHI

CJ 65S3/CJ 65V3

65 (2-5/8")

67 (2-5/8")

195 (7-3/4")

197 (7-3/4")

1.5 (3.3 lbs.)

L/R 45û

1.5 (3.3 lbs.)

3000/0 to 3000

400

18 (3/4")

6 (1/4")

Jig saw blade No. 31 ... 1 pc.

Chip cover ............... 1 pc.

Splinter .................... 1 pc.

Hex. bar wrench ...... 1 pc.

* Subject to change by area.

C-1

kg

Splinter guard

Speed control dial

FCJ 55/FCJ 55VA

55 (2-5/32")

67 (2-5/8")

186 (7-3/8")

185 (7-1/4")

1.4 (3.1 lbs.)

L/R 45û

1.4 (3.1 lbs.)

3000/0 to 3000

400

18 (3/4")

3 (1/8")

Jig saw blade No. 31 ... 1 pc.

Chip cover ............... 1 pc.

Splinter .................... 1 pc.

Hex. bar wrench ...... 1 pc.

65 (2-5/8")

67.5 (2-5/8")

199 (7-7/8")

214 (8-1/2")

1.7 (3.8 lbs.)

L/R 45û

1.7 (3.8 lbs.)

3100

450

22 (7/8")

6 (1/4")

Jig saw blade ........ 1 pc.

Chip cover ............. 1 pc.

6-2. Comparison of Cutting Speeds

Cutting speeds fluctuate widely depending on cutting conditions. The data in the tables below were obtained

while minimizing fluctuations as much as possible. Also, all plunger speeds were set to full (maximum speed),

and blades recommended by each manufacturer for the materials cut were used. Thrust (pressing force) was

limited to 2 kg, within the range of normal cutting thrust.

Cutting of soft steel plate, 2 mm (5/64") thick Cutting speed [mm (ft)/min]

Maker

Model

C-1

Maker

Model

C-1

Page 9

--- 6 ---

7. PRECAUTIONS IN SALES PROMOTION

In the interest of promoting the safest and most efficient use of the Models CJ 65S3 and CJ 65V3 Jig Saws by all

of our customers, it is very important that at the time of sale the salesperson carefully ensures that the buyer

seriously recognizes the importance of the contents of the Handling Instructions, and fully understands the

meaning of the precautions listed on the Caution Plate attached to each tool.

7-1. Handling Instructions

Although every effort is made in each step of design, manufacture, and inspection to provide protection against

safety hazards, the dangers inherent in the use of any electric tool cannot be completely eliminated. Accordingly,

general precautions and suggestions for the use of electric power tools, and specific precautions and

suggestions for the use of the electric jig saw are listed in the Handling Instructions to enhance the safe, efficient

use of the tool by the customer. Salespersons must be thoroughly familiar with the contents of the Handling

Instructions to be able to offer appropriate guidance to the customer during sales promotion.

7-2. Cautions on the Name Plate

Each tool is provided with a Name Plate which lists the following basic safety precautions in the use of the tool.

7-3. Overload Durability Characteristics

The Models CJ 65S3 and CJ 65V3 have been designed specifically for home use, and their ability to withstand

overload is inferior to jig saws for professional use. Because oleo metal and polycarbonate resin are used for the

bearings and external components respectively, heat generation is high and heat radiation is inferior. Customers

should be cautioned that use of these models for professional level work could result in melting of the oleo metal

components and possible serious damage to other sections.

7-4. Use of Guide Roller

The new models are equipped with a guide roller which supports the load applied on the blade and bearing during

cutting operation, and helps prevent breakage of the blade and early wear of the bearing. When using the guide

roller, users should be instructed to pay particular attention to the following items described in the Instruction

Manual.

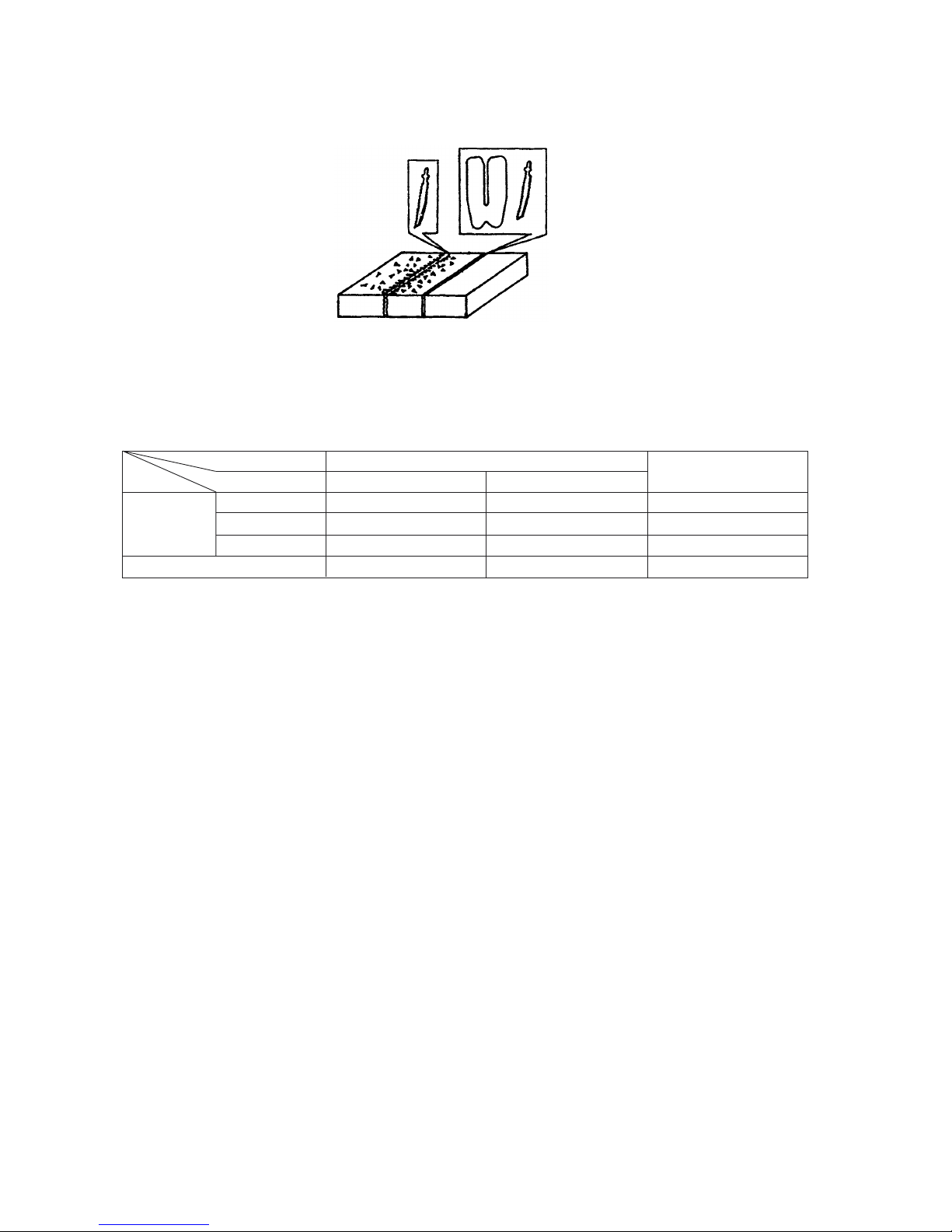

(1) Use a blade having a straight back portion (the back of the blade that contacts the guide roller) which is 50 mm

(2") or more in length (see Fig. a.). If a blade with an inclined back portion (see Fig. b.) is used, it will cause

excessive force on the plunger assembly, resulting in early malfunction of the bearing and the guide roller.

(2) The guide roller should be mounted so that its roller gently contacts the back of the blade. If the roller is

pressed too strongly against the blade during use, it will cause early malfunction of the bearing and other

parts, as described in paragraph (1) above.

Page 10

--- 7 ---

(3) When cutting thick plate materials which apply a particularly heavy load on the blade, be sure to mount the

guide roller before the cutting operation. As failure to mount the guide roller before cutting such materials will

result in early malfunction of the bearing portion, particular precaution is necessary.

Use a blade with a straight back

portion 50 mm (2") or more in length.

Do not use a blade with an inclined back.

Fig. a

Fig. b

8. BLADES

8-1. Applicable Blade

NOTE: As illustrated on the right, the guide roller can become jammed in the recessed portion

of the jig saw blade, causing damage to the blade and/or guide roller. Accordingly, it is

necessary to withdraw the guide roller so that it will not contact the blade. In addition,

the thickness of the jig saw blade must be 1.3 mm (3/64") or less.

Maker

Blade shape and dimensions

Installation

HITACHI

C-1

8 mm

(5/16")

6.2

(15/64")

7

(9/32")

6.2

8

Page 11

--- 8 ---

9. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

The [Bold] numbers in the descriptions below correspond to the part numbers in the Model CJ 65V3 Parts List.

The disassembly and reassembly procedures are the same for the Model CJ 65S3, with the exception of the

switch and the wiring diagrams. Where the part numbers are different, those in parentheses are for the Model

CJ 65S3.

9-1. Disassembly

9-1-1. Removal of the Chip Cover [1]

In the same manner as it is slid up and down for positioning, slide the Chip

Cover [1] upward to remove it from the main body.

9-1-2. Removal of the Guard Bar [2]

Stretch both ends of the Guard Bar [2] and remove it from the main body.

9-1-5. Disassembly of the plunger

Loosen the Seal Lock Hex. Socket Hd. Bolt M3 x 8 [25] and remove the Blade Holder [22], Plunger Holder [21]

and Felt [24].

9-1-6. Disassembly of the armature and the stator

(1) From housing (A) of Housing (A).(B) Set [4], remove the Brush Holders [15], and take out the Carbon

Brushes [14] (two pieces).

(2) From housing (A) of Housing (A).(B) Set [4], remove the Holder [29], Stator Ass'y [33] and Armature [31] in

a single body. Then separate the individual parts.

9-1-3. Disassembly of Housing (B)

(1) Remove the Hex. Socket Hd. Bolt M4 x 16 [19] with the Hex. Bar Wrench 3 mm [501] (standard accessory),

and remove the Base [11] and the Roller Holder [17].

(2) Remove the seven Tapping Screws (W/Flange) D4 x 20 (Black) [7], and take off housing (B) of Housing (A).(B)

Set [4].

9-1-4. Disassembly of the gear

(1) From housing (A) of Housing (A).(B) Set [4], take out the Plunger [23] and the Plunger Holder [21] (two

pieces).

(2) Lift the Gear [27] upward and remove it from the Holder [29]. Washer (C) [28] can be removed at the same

time.

How to remove the chip cover

Holder [29]

Gear removal procedure

Lift upward.

Gear [27]

Housing (A)

Page 12

--- 9 ---

9-1-7. Removal of the Switch (1P Pillar Type) [5]

Loosen the cord mounting screws of the Switch (1P Pillar Type) [5] and pull out the cord.

Cord mounting screws

Cord

To remove the internal wires of the Stator Ass'y [33] and the Noise Suppressor [6], insert the small-diameter

screwdriver or a pin into the concave next to each terminal and pull the internal wire lightly.

Concave

Concave

Page 13

--- 10 ---

9-2. Reassembly

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special attention

should be given to the following items.

9-2-1. Wiring Connection

Referring to the wiring diagrams and leadwire arrangements in item 9-5.

9-2-2. Reassembly of the armature and the stator

(1) Press-fit the Ball Bearing 608VVC2PS2L [30] and the Ball Bearing 626VVC2PS2L [32] onto the Armature [31].

Stop press-fitting when the Ball Bearing 608VVC2PS2L [30] comes in contact with the fan. With vernier

calipers or a similar tool, check that the press-fit dimension is 119.9 . As excessive press-fitting can cause

deformation or other damage to the fan, particular attention is required. Also, if press-fitting is insufficient, it

will cause loss of thrust of the Armature [31], resulting heat generation. Accordingly, press-fit the Ball Bearing

626VVC2PS2L [32] until it butts against the stepped portion of the shaft.

(2) Insert the Armature [31] into the Holder [29] and put the assembly into the Stator Ass'y [33].

Armature, stator and holder assembly sequence

Fan

Holder [29]

Armature [31]

Stator Ass'y [33]

Ball Bearing

608VVC2PS2L

[30]

Difference of shaft

Ball Bearing 626VVC2PS2L [32]

9-2-3. Others

(1) When re-mounting housing (A) of Housing (A).(B) Set [4], be very careful to ensure that the leadwires are not

excessively slack, and that they are not pinched between components during reassembly.

(2) When reassembling the Chip Cover [1] onto the main body, be sure it is mounted in the correct direction.

- 0.3

0

Chip Cover [1]

The antislip grooved portion is at the top.

119.9

- 0.3

0

Page 14

--- 11 ---

9-4. Tightening Torques

Tapping Screw (W/Flange) D4 x 20

Tapping Screw (W/Flange) D4 x 16

Hex. Socket Hd. Bolt M3 x 8

Hex. Socket Hd. Bolt M4 x 8

Hex. Socket Hd. Bolt M4 x 16

2.0 0.5 N•m (20 5 kgf•cm)

2.0 0.5 N•m (20 5 kgf•cm)

1.5 0.5 N•m (15 5 kgf•cm)

2.0 0.5 N•m (20 5 kgf•cm)

2.0 0.5 N•m (20 5 kgf•cm)

9-3. Lubrication

Housing (A) and housing (B): 13 g each

Tooth section of the Gear [27]

Pinion section of the Armature 220V --- 230V [31]

Contact section of the Plunger [23] and the Plunger Holder [21]

Pin of the Holder [29]

Washer (C) [28]

Inside diameter of the Gear [27] and the sliding surfaces of the

Connecting Piece [26] and Washer (C) [28]

Inside and outside diameters of the Connecting Piece [26]

Hitachi Motor Grease No. 29

ATTOLUB MS No. 2

Page 15

--- 12 ---

9-5. Wiring Diagram

(1) Model CJ 65S3

(a) Products with noise suppressor

(b) Products without noise suppressor

Page 16

--- 13 ---

(2) Model CJ 65V3

(a) Products with noise suppressor

(b) Products without noise suppressor

9-6. Connection to the Switch

Solder the tips of the internal wires of the Stator Ass'y [33] and the Noise Suppressor [6]. Then insert them into

the terminals of the Switch (1P Pillar Type) [5].

Internal wire

Solder

7

Page 17

--- 14 ---

9-7. Insulation Tests

On completion of disassembly and repair, measure the insulation resistance and conduct dielectric strength test.

9-8. No-Load Current Values

After 30 minutes of no-load operation, current values should be as follows:

110 V

115 V

120 V

127 V

Less than 1.8 A

220 V

.........

Less than 1.0 A

230 V

.........

Less than 0.9 A

240 V

.........

Less than 0.9 A

Page 18

--- 15 ---

10. STANDARD REPAIR TIME (UNIT) SCHEDULES

MODEL 10 20 30 40

Fixed

Variable

CJ 65V3

Work Flow

Housing

(A).(B) Set

Plunger Holder

Plunger

Connecting

Piece

Gear

Holder

Felt

Blade Holder

Chip Cover

Guard Cover

60 min.

50

General Assembly

Base

Roller Holder

Stator Ass'y

Armature

Ball Bearing

(608VV)

Ball Bearing

(626VV)

Switch

Cord Armor

Cord Armor

Carbon Brush

x 2

CJ 65S3

Page 19

ELECTRIC TOOL PARTS LIST

LIST NO. E510

JIG SAW

Model CJ 65S3

2005 • 10 •12

(E1)

Hitachi Power Tools

1

2

4

5

6

7

8

9

10

12

11

3

14

15

16

17

18

20

21

23

26

27

28

29

30

31

32

33

34

501

19

502

503

12

22

21

24

25

13

Page 20

*

ALTERNATIVE PARTS--- 2 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

10 -- 05

CJ 65S3

1 325-163 CHIP COVER 1

2 325-164 GUARD BAR 1

3 HITACHI LABEL 1

4 325-167 HOUSING (A).(B) SET 1

5 323-575 SWITCH (1P PILLAR TYPE) 1

6 930-039 NOISE SUPPRESSOR 1

7 301-653

TAPPING SCREW (W/FLANGE) D4X20 (BLACK) 7

8 NAME PLATE 1

9 960-266 CORD CLIP 1

10 984-750 TAPPING SCREW (W/FLANGE) D4X16 2

11 325-161 BASE 1

12 949-811 HEX. SOCKET HD. BOLT M4X8 (10 PCS.) 2

13 962-991 PLATE NUT 1

14 999-041 CARBON BRUSH (1 PAIR) 2

15 930-483 BRUSH HOLDER 2

16 930-487 CORD ARMOR D8.2 1

17 325-162 ROLLER HOLDER 1

18 323-210 BOLT WASHER M4 (BLACK) 1

19 949-754 HEX. SOCKET HD. BOLT M4X16 (10 PCS.) 1

20 500-409Z CORD 1 (CORD ARMOR D8.2)

21 325-159 PLUNGER HOLDER 2

22 325-247 BLADE HOLDER 1

23 325-246 PLUNGER 1

24 325-248 FELT 1

25 325-241

SEAL LOCK HEX. SOCKET HD. BOLT M3X8

2

26 325-158 CONNECTING PIECE 1

27 325-157 GEAR 1

28 991-733 WASHER (C) 1

29 325-155 HOLDER 1

30 608-VVM BALL BEARING 608VVC2PS2L 1

31 360-724E ARMATURE 220V-230V 1

32 626-VVM BALL BEARING 626VVC2PS2L 1

33 340-631E STATOR ASS’Y 220V-230V 1 INCLUD. 34

34 960-356 TERMINAL (A) M3.5 (10 PCS.) 2

Page 21

*

ALTERNATIVE PARTS --- 3 ---10 -- 05

STANDARD ACCESSORIES

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

CJ 65S3

501 943-277 HEX. BAR WRENCH 3MM 1

502 305-810 TABLE INSERT 1

503 879-356 JIG SAW BLADES NO. 31 (5 PCS.) 1

601 879-330 JIG SAW BLADES NO. 1 (5 PCS.) 1

602 879-331 JIG SAW BLADES NO. 2 (5 PCS.) 1

603 879-332 JIG SAW BLADES NO. 3 (5 PCS.) 1

604 879-333 JIG SAW BLADES NO. 4 (5 PCS.) 1

605 879-334 JIG SAW BLADES NO. 5 (5 PCS.) 1

606 879-335 JIG SAW BLADES NO. 6 (5 PCS.) 1

607 879-357 JIG SAW BLADE NO. 41 (5 PCS.) 1

608 879-391 GUIDE FOR JIG SAW 1

Page 22

--- 4 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

10 -- 05

CJ 65S3

Printed in Japan

(051012N)

Page 23

ELECTRIC TOOL PARTS LIST

LIST NO. E509

JIG SAW

Model CJ 65V3

2005 • 10 •12

(E1)

Hitachi Power Tools

1

2

4

5

6

7

8

9

10

12

13

11

3

14

15

16

17

18

20

21

23

26

27

28

29

30

31

32

33

34

501

19

502

503

12

22

21

24

25

Page 24

*

ALTERNATIVE PARTS--- 2 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

PARTS

10 -- 05

CJ 65V3

1 325-163 CHIP COVER 1

2 325-164 GUARD BAR 1

3 HITACHI LABEL 1

4 325-167 HOUSING (A).(B) SET 1

5 323-086 SWITCH (1P PILLAR TYPE) 1

6 930-039 NOISE SUPPRESSOR 1

7 301-653

TAPPING SCREW (W/FLANGE) D4X20 (BLACK) 7

8 NAME PLATE 1

9 960-266 CORD CLIP 1

10 984-750 TAPPING SCREW (W/FLANGE) D4X16 2

11 325-161 BASE 1

12 949-811 HEX. SOCKET HD. BOLT M4X8 (10 PCS.) 2

13 962-991 PLATE NUT 1

14 999-041 CARBON BRUSH (1 PAIR) 2

15 930-483 BRUSH HOLDER 2

16 930-487 CORD ARMOR D8.2 1

17 325-162 ROLLER HOLDER 1

18 323-210 BOLT WASHER M4 (BLACK) 1

19 949-754 HEX. SOCKET HD. BOLT M4X16 (10 PCS.) 1

20 500-409Z CORD 1

21 325-159 PLUNGER HOLDER 2

22 325-247 BLADE HOLDER 1

23 325-246 PLUNGER 1

24 325-248 FELT 1

25 325-241

SEAL LOCK HEX. SOCKET HD. BOLT M3X8

2

26 325-158 CONNECTING PIECE 1

27 325-157 GEAR 1

28 991-733 WASHER (C) 1

29 325-155 HOLDER 1

30 608-VVM BALL BEARING 608VVC2PS2L 1

31 360-724E ARMATURE 220V-230V 1

32 626-VVM BALL BEARING 626VVC2PS2L 1

33 340-631E STATOR ASS’Y 220V-230V 1 INCLUD. 34

34 960-356 TERMINAL (A) M3.5 (10 PCS.) 2

Page 25

*

ALTERNATIVE PARTS --- 3 ---10 -- 05

STANDARD ACCESSORIES

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

CJ 65V3

501 943-277 HEX. BAR WRENCH 3MM 1

502 305-810 TABLE INSERT 1

503 879-356 JIG SAW BLADES NO. 31 (5 PCS.) 1

601 879-330 JIG SAW BLADES NO. 1 (5 PCS.) 1

602 879-331 JIG SAW BLADES NO. 2 (5 PCS.) 1

603 879-332 JIG SAW BLADES NO. 3 (5 PCS.) 1

604 879-333 JIG SAW BLADES NO. 4 (5 PCS.) 1

605 879-334 JIG SAW BLADES NO. 5 (5 PCS.) 1

606 879-335 JIG SAW BLADES NO. 6 (5 PCS.) 1

607 879-357 JIG SAW BLADE NO. 41 (5 PCS.) 1

608 879-391 GUIDE FOR JIG SAW 1

Page 26

--- 4 ---

ITEM

NO.

CODE NO.

DESCRIPTION REMARKS

NO.

USED

10 -- 05

CJ 65V3

Printed in Japan

(051012N)

Page 27

Loading...

Loading...