Page 1

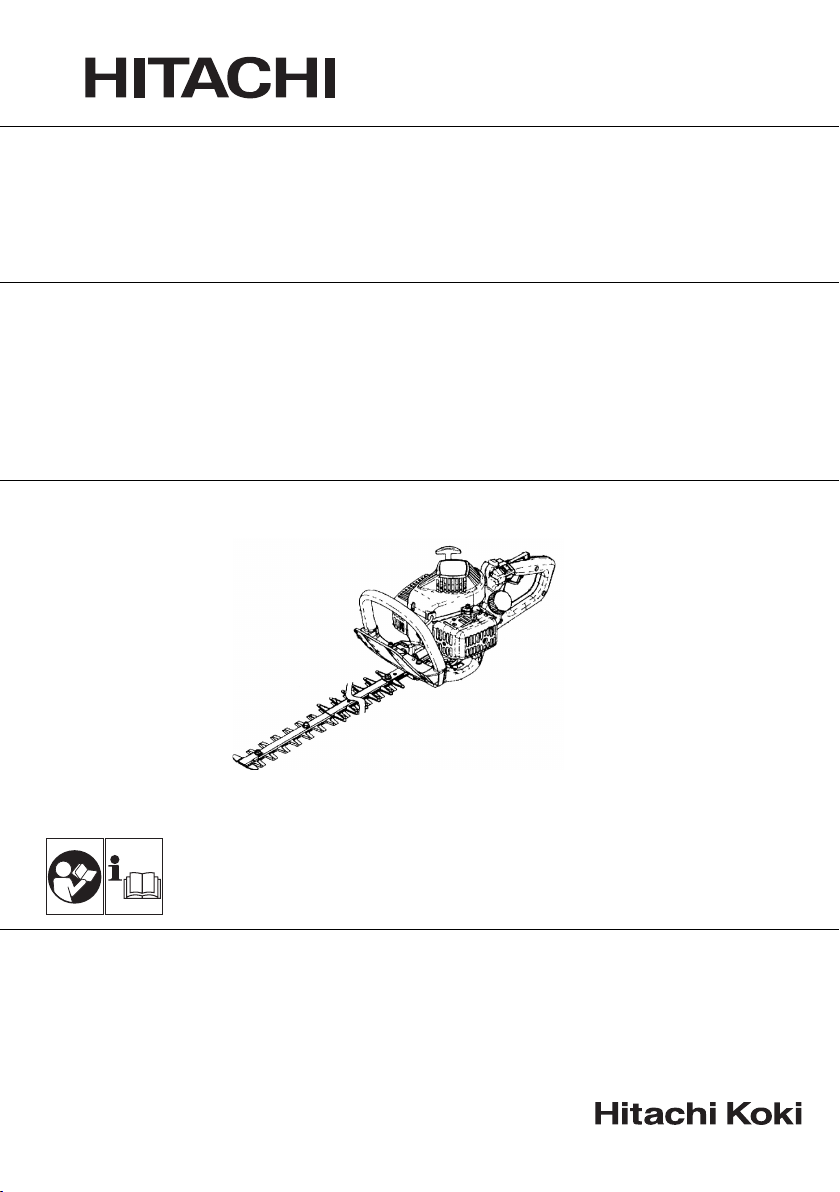

Hedge Trimmer

Cortasetos

Corta-sebes

CH 50EA (ST)/CH 50EB/CH 55EB (ST)

CH 62EA (ST)/CH 66EB (ST)/CH 66ED (TP)

CH 78EB (C)/CH 78EC (ST)/CH 78ED (TP)

CH 78EC (C)/CH 78EC (SC)/CH 78ED (CP)

CH 105EC (C)

CH66EB (ST)

Read through carefully and understand these instructions before use.

Leer cuidadosamente y comprender estas instrucciones antes del uso.

Antes de usar, leia com cuidado para assimilar estas instruções.

Handling instructions

Instrucciones de manejo

Instruções de uso

970-83243-200 2009.06

Page 2

123

3

4

1, 2

5

6

456

7

8

A

7

8

A

9

10

789

B

C

11

10 11 12

45゚

14

15

2

90゚

12

13

F

Page 3

13

F

14 15

T

15

16 17 18

F

0.6 mm

19 20

3

Page 4

21

22

16

16

4

Page 5

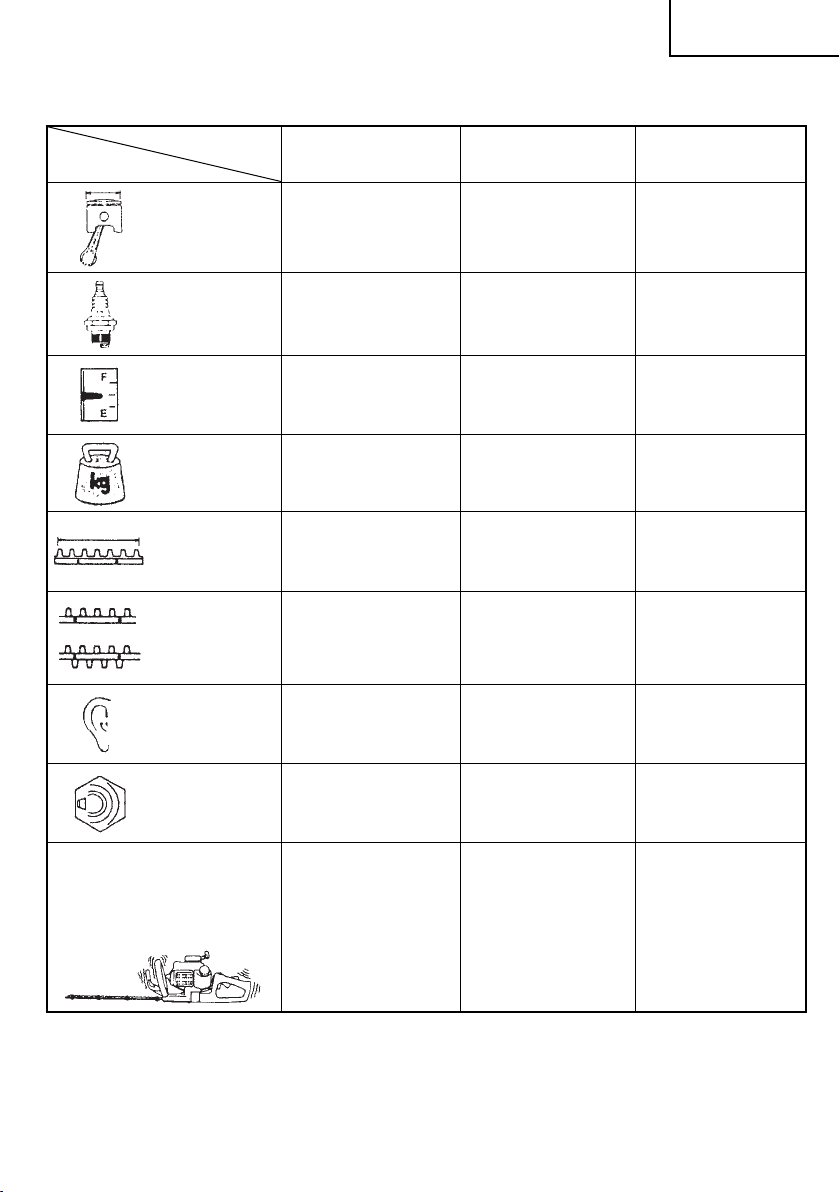

MEANINGS OF SYMBOLS

NOTE: Some units do not carry them.

Symbols

WARNING

The following show symbols used for the machine. Be sure that you understand their meaning before use.

It is important that you read, fully understand and observe the following safety precautions and warnings.

Careless or improper use of the unit may cause serious or fatal injury.

Read, understand and follow all warnings and instructions in this manual and on the unit.

Always wear eye, head and ear protectors when using this unit.

English

Before using your machine

• Read the manual carefully.

• Check that the cutting equipment is correctly assembled and adjusted.

• Start the unit and check the carburetor adjustment. See “MAINTENANCE”.

Contents

WHAT IS WHAT? ...............................................................................6

WARNINGS AND SAFETY INSTRUCTIONS ...................................7

SPECIFICATIONS .............................................................................8

ASSEMBLY

OPERATING PROCEDURES ..........................................................10

MAINTENANCE ...............................................................................10

PROCEDURES ............................................................ 10

5

Page 6

English

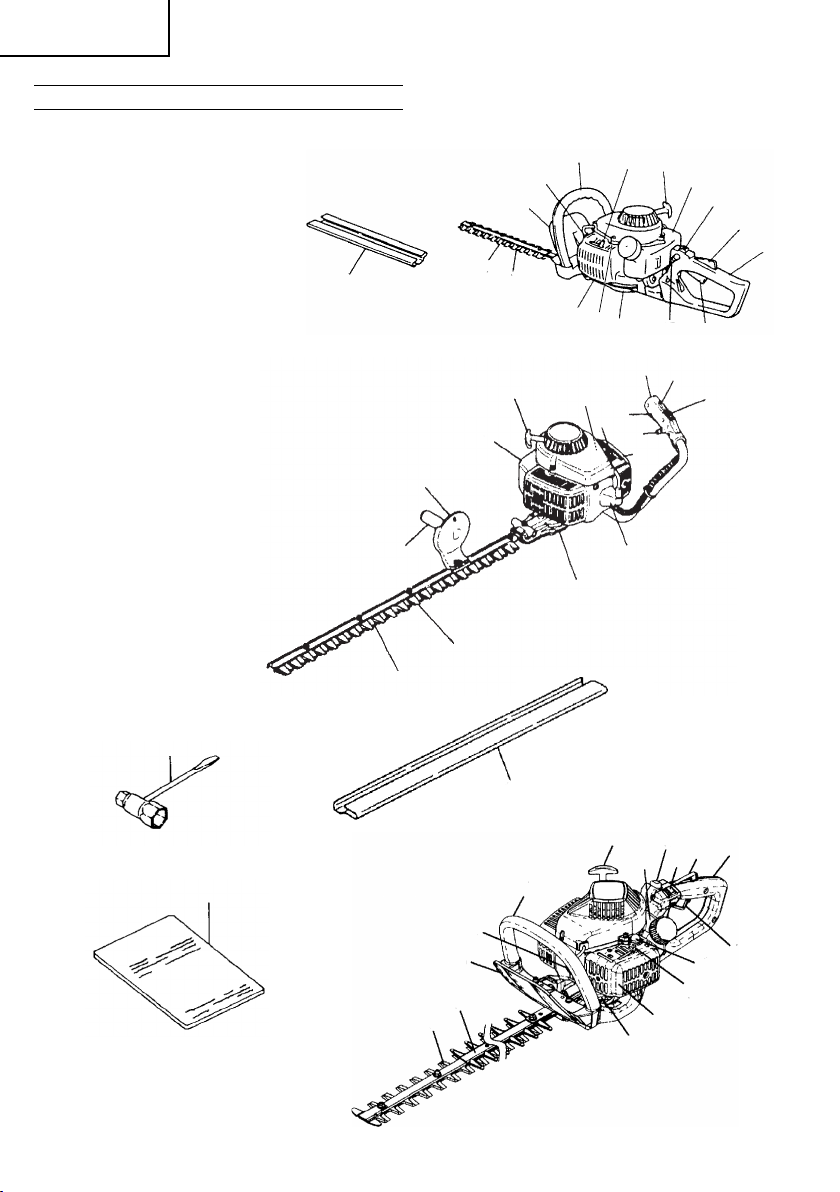

WHAT IS WHAT?

Since this manual covers several models, there may be some

diff erence between these illustrations and your unit. Use the

instructions that apply to your unit.

1. Recoil starter

2. Fuel tank

3. Throttle trigger lookout

4. Throttle trigger

5. Front handle

6. Rear handle

7. Spark plug

guard

8. Hand

9. Cutting blade

10. Air cleaner

11. Ignition switc h

12. Blunt guard

13. Gear case

14. Choke lever

15. Loc k button (opt iona l)

16. Blade cover

17. Lock button

18. Priming pump

19. Combi box spanner

20. Handling instructions

16

5

14

7

8

12

9

10

18

1

2

8

18

14

1

2

11

3

6

13

15

4

CH50EB

6

3

4

15

10

11

5

CH78EB (C), CH78EC (SC)

12

9

19

20

7

8

12

9

CH78EC (C), CH105EC (C)

CH78ED (CP)

16

5

CH66EB (ST)

CH55EB (ST), CH50EA (S T), CH62EA (ST)

CH78EC (ST)

CH66ED (TP), CH78ED (TP)

7

13

1

17

3

11

2

10

13

6

4

18

14

6

Page 7

English

WARNINGS AND SAFETY INSTRUCTIONS

Operator safety

○ Always wear a safety face shield or goggles.

○ Always wear heavy, long pants, boots and gloves. Do not wear

loose clothing, jewelry, short pants, sandals or go barefoot.

Secure hair so it is above shoulder length.

○ Do not operate this tool when you are tired, ill or

infl uence of alcohol, drugs or medication.

○ Never let a child or inexperienced person operate the machine.

○ Wear hearing protection.

○ Never start or run the engine inside a closed room or building.

Breathing exhaust fumes can kill.

○ Keep handles free of oil and fuel.

○ Keep hands

○ Do not grab or hold the unit by the cutting equipment.

○ When the unit is turned off , make sure the cutting attachment

has stopped before the unit is set down.

○ When operation is prolonged, take a break from time to time

so that yo u

(HAVS) which is caused by vibration.

WARNING

○ Antivibration systems do not guarantee that you will not sustain

Hand-Arm Vibration Syndrome or carpal tunnel syndrome.

Therefore, continual and regular users should monitor closely

the condition of their hands and fi ngers. If any sym ptoms of the

above appear, seek medical advice immediately.

○ If you are using any

as a pacemaker, consult your physician as well as the device

manufacturer prior to operating any power equipment.

Unit/machine safety

○ Inspect the entire unit/machine before each use. Replace

damaged part s. Check for fuel leaks and make sure all

fasteners are in place and securely tightened.

Replace parts that are cracked, chipped or damaged in any way

○

before using the unit/machine.

○ Make sure the safety guard is properly attached.

○ Keep others away when making carburetor adjustments.

○ Use only accessories as recommended for this unit/machine by

the manufacturer.

WARNING

Never modify the unit/machine in any way. Do not use your unit/

machine for any job except that for which it is intended.

Fuel safety

○ Mix and pour fuel outdoors and where there are no sparks or

fl ames.

○ Use a container approved for fuel.

○ Do not smoke or

while using the unit/machine.

○ Wipe up all fuel spills before starting engine.

○ Move at least 3 m away from fueling site before starting engine.

○ Stop engine before removing fuel cap.

○ Empty the fuel tank before storing the unit /machine. It is

recommended

left in the tank, store so fuel will not leak.

○ Store unit/machine and fuel in area where fuel vapors cannot

reach sparks or open fl ames from water heaters, electric motors

or switches, furnaces, etc.

WARNING

Fuel is easy to ignite or get explosion or inhale fumes, so that

pay special attention when handling or fi lling fuel.

Cutting safety

○ Do not cut any material other than plant hedge.

○ Inspect the area to be cut before each use. Remove objects

which can be thrown or become

○ For respiratory protection, wear an ae rosol protection mask

when cutting the grass after insecticide is scattered.

○ Keep others including children, animals, bys tanders and

helpers outside the 15 m hazard zo ne. Stop the engine

immediately if you are approached.

away from cutting equipment.

may avoid possible Hand-Arm Vibration Syndrome

medical electric/electronic devices such

allow smoking near fuel or the unit/machine or

that the fuel be emptied after each use. If fuel is

entangled.

under the

○ Hold the unit/machine fi rmly with both hands.

○ Keep fi rm

○ Keep all parts of your body away from the muffl er and cutting

○ Keep cutting tool below shoulder level. NEVER operate unit

○ When relocating to

○ Never place the machine on the ground when running.

○ Always carr y a fi rst-aid kit when operating any power

○ Never start or run the engine inside a closed room

Maintenance safety

○ Maintain the unit/machine according to recommended

○ Disconnect the spark plug before per forming maintenance

○ Keep others away when making carburetor adjustments.

○ Use only genuine Hitachi replacement parts as re commended

Tra ns po rt and storage

○ Carry the unit /machine by hand with the engine stopped and

○ Allow the engine to cool, empt y the fuel tank, and secure the

○ Empty the fuel tank before storing the

○ Store unit/machine out of the reach of children.

○ Clean and maintenance the unit carefully and store it in a dry

○ Make sure engine

○ When transporting in a vehicle or storage, cover blade with

If situations occur which are not covered in this manual, take care

and use common sense. Contact your Hitachi dealer if you need

assistance. Pay special attention to statements preceded by

following words:

WARNING

Indicates a strong possibility of severe personal injury or loss of

CAUTION

Indicates a possibility of personal injur y or equipment damage,

NOTE

Helpful information for correct function and use.

CAUTION

Do not disassemble the recoil starter. You may get a

footing and balance. Do not over-reach.

attachment when the engine is running.

from a ladder, while in a tree or from any unstable support.

machine and ensure that all cutting attachments are stopped.

equipment.

and/or near the infl ammable liquid. Breathing exhaust fumes

can kill.

procedures.

except for carburetor adjustments.

the manufacturer.

by

the muffl er away from your body.

unit/machine before storing or transporting in a vehicle.

recommended that the fuel be emptied after each use. If fuel is

left in the tank, store so fuel will not leak.

place.

blade cover.

life, if instructions are not followed.

if instructions are not followed.

of personal injury with recoil spring.

a new work area, be sure to shut off the

or building

unit/machine. It is

switch is off when transporting or storing.

the

possibility

7

Page 8

English

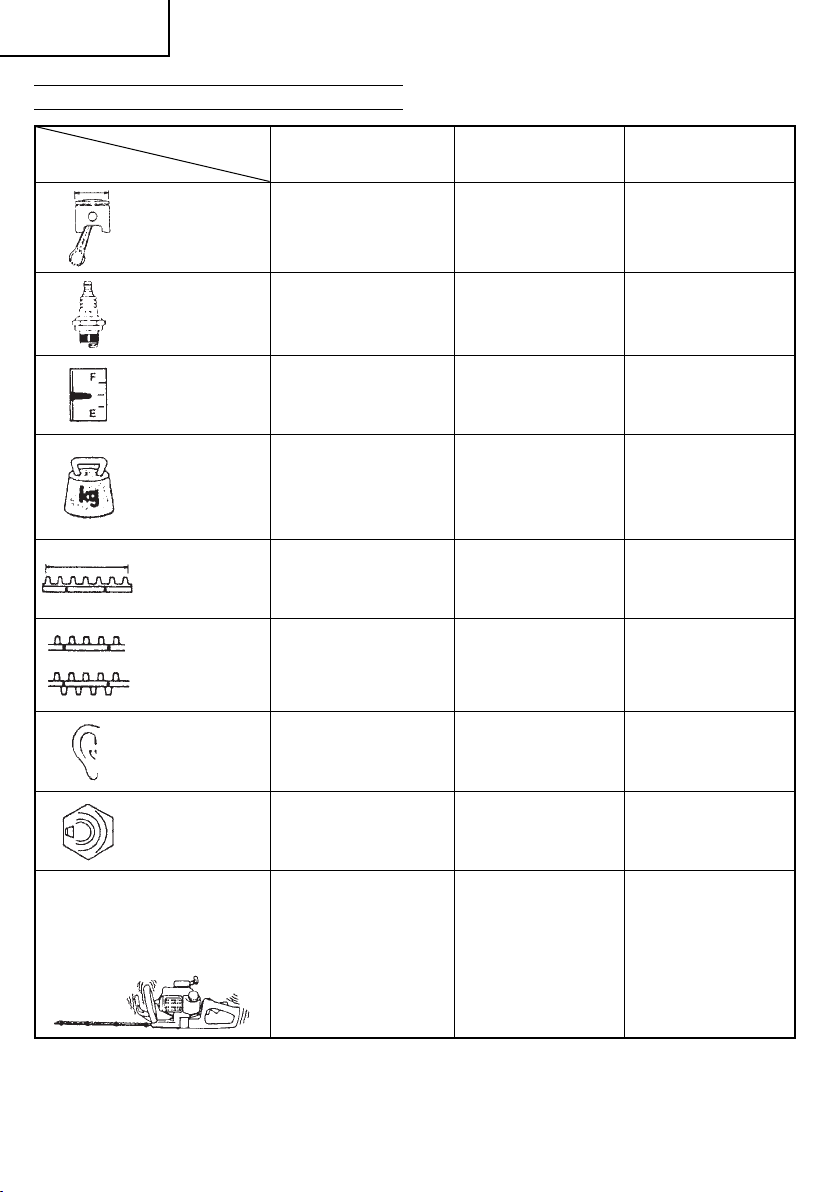

SPECIFICATIONS

Engine Size (ml) 22 24 22

CH50EB/CH66EB (ST)

MODEL

CH55EB (ST)/CH50EA (ST)

CH62EA (ST)

CH78EC (ST) CH78EB (C)

Spark Plug

Fuel Ta nk Capac ity (l) 0.35 0.35 0.35

Dry Weight (kg)

Overall cutter length

(mm)

:○

Blade type

△

:

Sound pressure level

LpA (dB(A))

(EN 27917)

Sound power level

LwA (dB( A))

(2000/14/EC)

Vibration level (m/s

Front handle

Rear handle

2

) (ISO 7916)

NGK BPM-6A or BPMR-6A

Champion CJ-8Y or RCJ-8Y

CH50EB .......................... 4.1

CH55EB (ST) .................. 4.5

CH66EB (ST) .................. 5.0

CH50EA (ST) .................. 4.3

CH62EA (ST) .................. 4.6

CH50EA (ST)/CH50EB

CH66EB (ST) .................. 650

CH55EB (ST) .................. 550

CH62EA (ST) .................. 620

...... 500

△△

CH50EB ....................... 100.0

CH66EB (ST) .................. 9 2.1

CH55EB (ST) .................. 9 3.6

CH50EA (ST) /CH62EA (ST)

CH66EB (ST) ..................

CH50EB ..........................

CH55EB (ST) ..................

CH50EA (ST) /CH62EA (ST)

CH66EB (ST) ..................

CH50EB ..........................

CH55EB (ST) ..................

CH50EA (ST) /CH62EA (ST)

..... 97.0

104 104 104

4.5

5.3

4.2

.......

5.1/6.5

5.2

11. 5

12.3

.......

11. 3/ 9 . 2

NGK BPM-6A or BPMR-6A

Champion CJ-8Y or RCJ-8Y

5.3 5.2

770 770

91.1 91.4

7.6

6.2

NGK BPM-6A or BPMR-6A

Champion CJ-8Y or RCJ-8Y

○

3.5

5.3

NOTE

Equivalent noise level/vibration level are calculated as the time-weighted energy total fo r noise/vibration levels under var ious working

conditions with the following time distribution : 1/2 idle, 1/2 racing.

* All data is subject to change without notice.

8

Page 9

English

MODEL

Engine Size (ml) 24 24 24

Spark Plug

Fuel Ta nk Capac ity (l)

Dry Weight (kg)

Overall cutter length

(mm)

:○

Blade type

△

:

Sound pressure level

LpA (dB(A))

(EN 27917)

CH78EC (SC)

CH78EC (C)

CH105EC (C)

NGK BPM-6A or BPMR-6A

Champion CJ-8Y or RCJ-8Y

0.35

CH78EC (SC) ........ 5.2

CH78EC (C) ..........5. 2

CH105EC (C) ........5.6

CH78EC (SC) ........ 770

CH78EC (C) ..........770

CH105EC (C) ........1000

○

CH78EC (SC) ........ 93.9

CH78EC (C)

CH105EC (C) ........96.7/96 .7

CH66ED (TP)

CH78ED (TP)

NGK BPM-6A or BPMR-6A

Champion CJ-8Y or RCJ-8Y

0.33 0.33

CH66ED (TP) ...........5.3

CH78ED (TP) ...........5.6

CH66ED (TP) .......... 650

CH78ED (TP) .......... 770

△

98.3 98.3

CH78ED (CP)

NGK BPM-6A or BPMR-6A

Champion CJ-8Y or RCJ-8Y

5.6

770

○

Sound power level

LwA (dB( A))

(2000/14/EC)

2

Front handle

Rear handle

) (ISO 7916)

CH78EC (SC) ........ 4.7

CH78EC (C)

CH105EC (C) ........6.8

CH78EC (SC) ........ 6.4

CH78EC (C)

CH105EC (C) ........5.6

Vibration level (m/s

NOTE

Equivalent noise level/vibration level are calculated as the time-weighted energy total fo r noise/vibration levels under various working

conditions with the following time distribution : 1/2 idle,

* All data is subject to change without notice.

104 104 104

1/2 racing.

CH66ED (TP) ...........8.9

CH78ED (TP) ...........7.8

CH66ED (TP) ...........6.3

CH78ED (TP) ...........5.3

6.1

11.1

9

Page 10

English

ASSEMBLY PROCEDURES

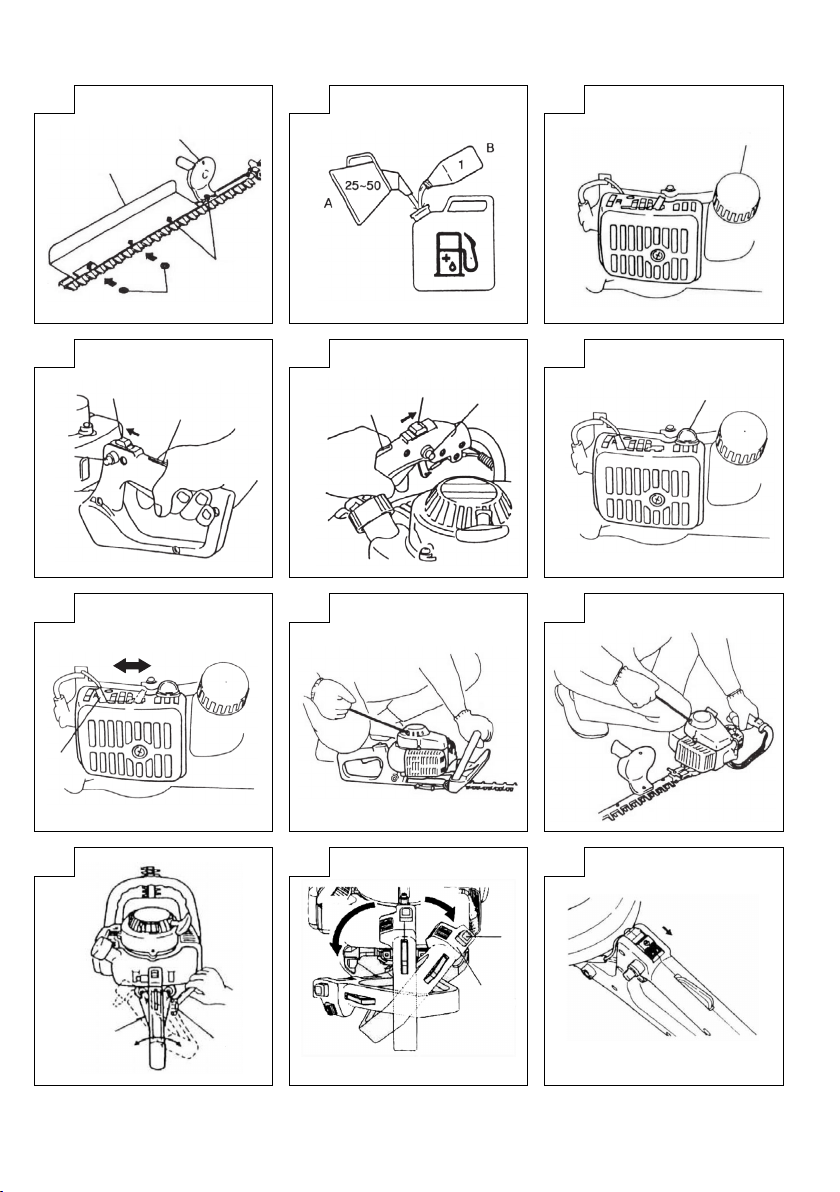

Handle B (3) and Gathering plate (4) (Fig. 1)

1. Remove the four washers and nuts (1) from cutting blade end.

NOTE

In case of Handle B installation only, remove only the nut on the

longest bolt.

2. Set the gathering plate on the cutter guide, then fi nger tighten

the three washers

* Use one each (5) of the two washers, which have been

provided, under the gathering plate or on the two blade-fi xing

bolts from the cutting-blade end to install the gathering plate

on CH105EC (C). (If so equipped)

3. Set the handle B on the longest bolt and

washer and nut.

4. Before securing the fi nger-tightened nuts, screw the blade fi xing

bolts (2) to be seated, then loosen the bolts approx. 1/2 turn.

5. With the bolts set at that position tighten the blade fi xing nuts.

and nuts.

fi nger tighten with the

OPERATING PROCEDURES

Fuel (Fig. 2)

WARNING

The hedge trimmer is equipped with a two- stroke engine.

Always run the engine on fuel, mixed with oil.

Provide good ventilation, when fueling or handling fuel.

Fuel

○ Always use branded 89 octane unleaded gasoline.

○ Use genuine two-cycle oil or use a mix between 25:1 to 50:1,

please consult

○ If genuine oil is not avail able, use an anti-oxidant added quality

oil expressl y labeled for air-cooled 2-cycle engine use (JASO

FC GRADE OIL or ISO EG C GRADE). Do not use BIA or TCW

(2-str oke water-cooling type) mixed oil.

○ Never use

○ Always mix fuel and oil in a separate clean container.

Always start by fi lling half the amount of fuel, which is to be used.

Then add the whole amount of oil. Mix (sh ake) the fuel mixture. Add

the remaining amount of fuel.

Mix (shak e) the

Fuelin g

WARNING (Fig. 3)

○ Always shut off the engine before refueling.

○ Slowly open the fuel tank (6), when fi lling up with fuel, so that

possible over-pressure disappears.

○ Tighten the fuel cap carefully, after fueling.

○ Always move the unit at least 3 m from the fueling area before

starting.

fueling, clean the tank cap area carefully, to ensure that

Before

no dir t falls into the tank. Make sure that the fuel is well mixed by

shaking the container, before fueling.

Starting

CAUTION

Before starting, make sure the cutting attachment does not

touch anything.

1. Set ignition switch (7) to ON position (A).

* Push priming bulb (10) several times so that fuel fl ows through

the bulb or return pipe. (If so equipped) (Fig. 6)

2. With the safety lever (8) pressed, pull throt tle trigger and push

lock button (9) (If so equipped), then slowly release thrott le the

trigger fi

starting position. (Fig. 4, 5)

3. Set choke lever (11) to CLOSED position (B). (Fig. 7)

the oil bottle for the ratio or Hitachi dealer.

multi-grade oil (10W/3 0) or waste oil.

fuel-mix thoroughly before fi lling the fuel tank.

(Fig. 4, 5)

rst, then the safety lever. This will lock the throttle in

4. Pull recoil st arter briskly, taking care to keep the handle in your

grasp and not allowing it to snap back. (Fig. 8, 9)

5. When you hear the engine at tempts to start, return choke lever

to RUN position (o pen) (C). Then pull recoil starter briskly

again.

NOTE

If engine does

6. After starting engine, allow the engine about 2-3 minutes to

warm up before subjecting it to any load.

Cutting

When cutting, operate engine at full throttle as this maintains proper

cutter speed. When trimming top of hedge, hold trimmer so blades

are between

swing trimmer in an arc toward edge of hedge to sweep cuttings off .

When trimming sides of hedge, hold blade vertic ally and swing unit

in an arc.

NOTE

○ Multi-position twist handle (Fig. 10)

In case your trimmer is

the cutting angle can be adjusted by loosening handle locking

nut (13) . After adjustment has been made, be sure to retighten

the nut.

○ Five positioning twist handle (Fig. 11)

The rear handle can be set in fi ve diff erent positions by pushing

the lock button (14) and turning the rear handle (15).

It is extremely important that the handle is locked in the selected

position.

The lock button will not work while the throttle trigger is being

pulled.

○ The throttle trigger will not work if the rear handle is unlocked.

Stopping (Fig.

Decrease engine speed, and push ignition switch to stop position

(F).

not start, repeat procedures from 2 to 4.

15 and 30 degrees from a horizontal position and

twist handle type (12), please note that

12, 13 )

MAINTENANCE

MAINTENANCE, REPLACEMENT OR REPAIR OF THE EMISSION

CONTROL DE VICES AND SYSTEM MAY BE PERFORM ED

BY ANY NONROAD ENGINE REPAIR ESTABLISHMENT OR

INDIVIDUAL.

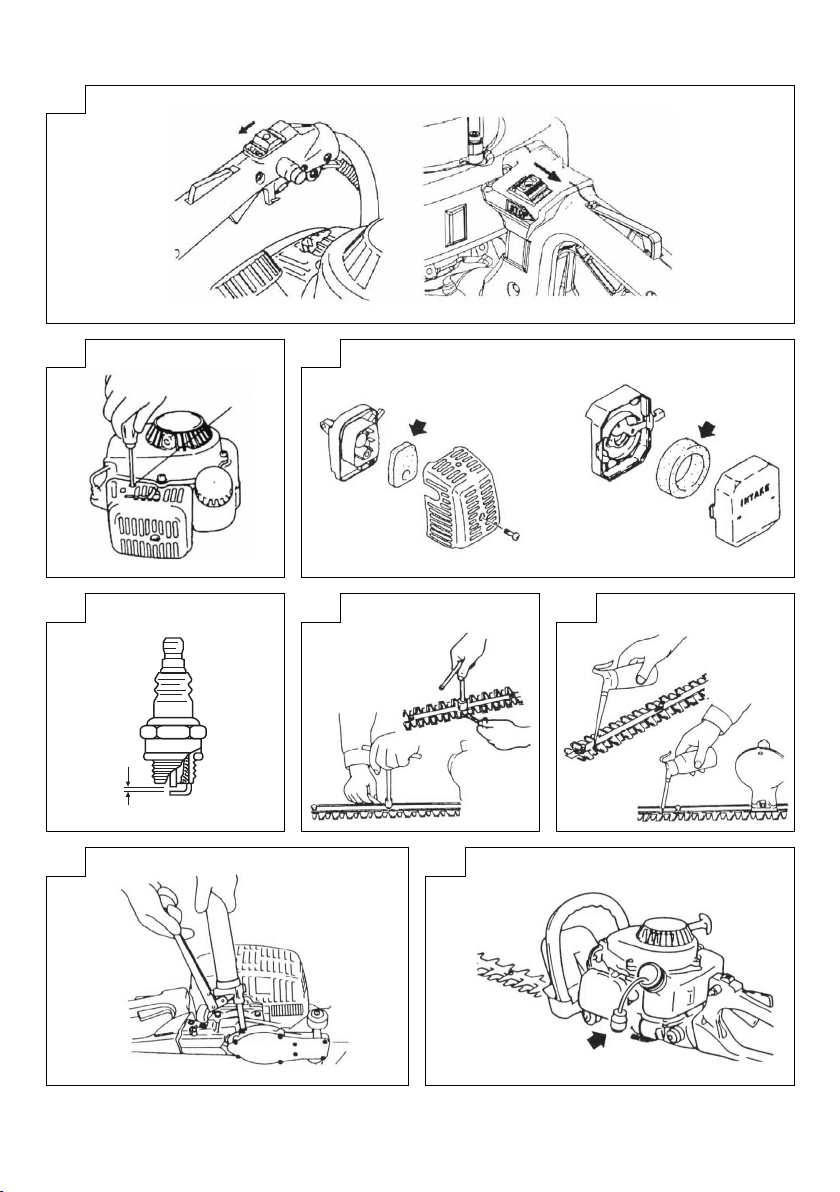

Carburetor adjustment (Fig. 14)

WARNING

○ The cutting attac hment may be spinning during carburetor

adjustments.

○ Never star t the engine without the complete clutch cover.

Otherwise the clutch can come loose and cause personal

injuries.

In the carburetor, fuel is mixed with air. When the engine is test run

at the fac tory, the carburetor is adjusted.

be required, according to climate and altitude. The carburetor has

one adjustment possibility:

T = Idle speed adjustment screw.

Idle speed adjustment (T)

Check that the air fi lter is clean. When the idle speed is correct, the

cutting attachment will not rotate. If adjustment is required, close

(clo ckwi se) the T-screw, with the engine running, until the cut ting

attachment starts to rotate. Open (co unte r-clo ckwi se) the screw

until the cutting attachment stops. You have reached the correct idle

speed when the engine runs smoothly in all positions well below the

rpm when the cutting attachment starts to rotate.

cutting at tachment still rotates after idle speed adjustment,

If the

contact Hitachi dealer.

A further adjustment may

10

Page 11

English

Air fi lter (Fig. 15)

The air fi lter must be cleaned from dust and dirt in order to avoid:

○ Carburetor malfunctions.

○ Starting problems.

○ Engine power reduction.

○ Unnecessary wear on the engine parts.

○ Abnormal fuel consumption.

Clean the air fi lter daily or more often if working in exceptiona lly

dusty areas.

the air fi lter

Cleaning

Remove the air fi lter cover and the fi lter. Rinse it in warm soap suds.

Check that the fi lter is dr y before reassembly. An air fi lter that has

been used for some time cannot be cleaned completely. Therefore,

it must regularly be replaced by a new one. A

always be replaced.

NOTE

Saturate the element in 2-cycle oil or the equivalent. Squeeze

the element to distribute the oil completely and to remove any

excess oil.

Spark plug (Fig. 16)

The spark plug condition is infl uenced by:

○ An incorrect carburetor setting.

○ Wrong fuel mixture (too much

○ A dirty air fi lter.

○ Hard running conditions (such as cold weather).

These factors cause deposits on the spark plug electrodes, which

may result in malfunction and starting di ffi culties. If the engine

is low on power, diffi cult to start or runs poorly at idling

always check the spark plug fi rst. If the spark plug is dirty, clean it

and check the electrode gap. Readjust if necessary. The correct

gap is 0.6 mm. The spark plug should be replaced after about 100

operation hours or earlier if the electrodes are badly eroded.

NOTE

In some

Cutter blade (Fig. 17, 18)

The blades are installed to the cut ter guide with the four or fi ve

bolts.

can move smoothly.

When clearance is too small

The cutters do not move properly and the sliding surfaces may

seize.

When clearance is too large

The cutters are poor in sharpness.

To adjust the cutter clearance

1. Loosen the cutter fi xing nuts.

2. Fully tighten the cutter fi xing bolts and then loosen them approx.

3. With the bolts set at that position, tighten the cutter fi xing nuts.

Be sure to replace cutter guide fi xing bolts when they are loosened,

worn or damaged. Also be sure to replace damaged cutter blade.

NOTE

Properly

Gear case (Fig. 19)

Apply a good quality lithium based grease through the grease fi tting

until a small amount comes out bet ween the cutter blades and the

gear case.

NOTE

Lubrication should be applied at 50 hour intervals and more

areas, local law requires using a resistor spark plug

to suppress ignition signals. If this machine was originally

equipped with resistor spark plug, use the same type of spark

plug for replacement.

Those bolts are tightened with a clearance so that the cut ters

1/2 turn.

lubricate the cutter sliding surfaces with machine oil.

frequently with heavy

oil in the gasoline).

use.

damaged fi lter must

speed,

Fuel fi lter (Fig. 20)

Remove the fuel fi lter from the fuel tank and thoroughly wash it in

solvent. After that, push the fi lter into the tank completely.

NOTE

If the fi lter is hard due to dust and dirt, replace it.

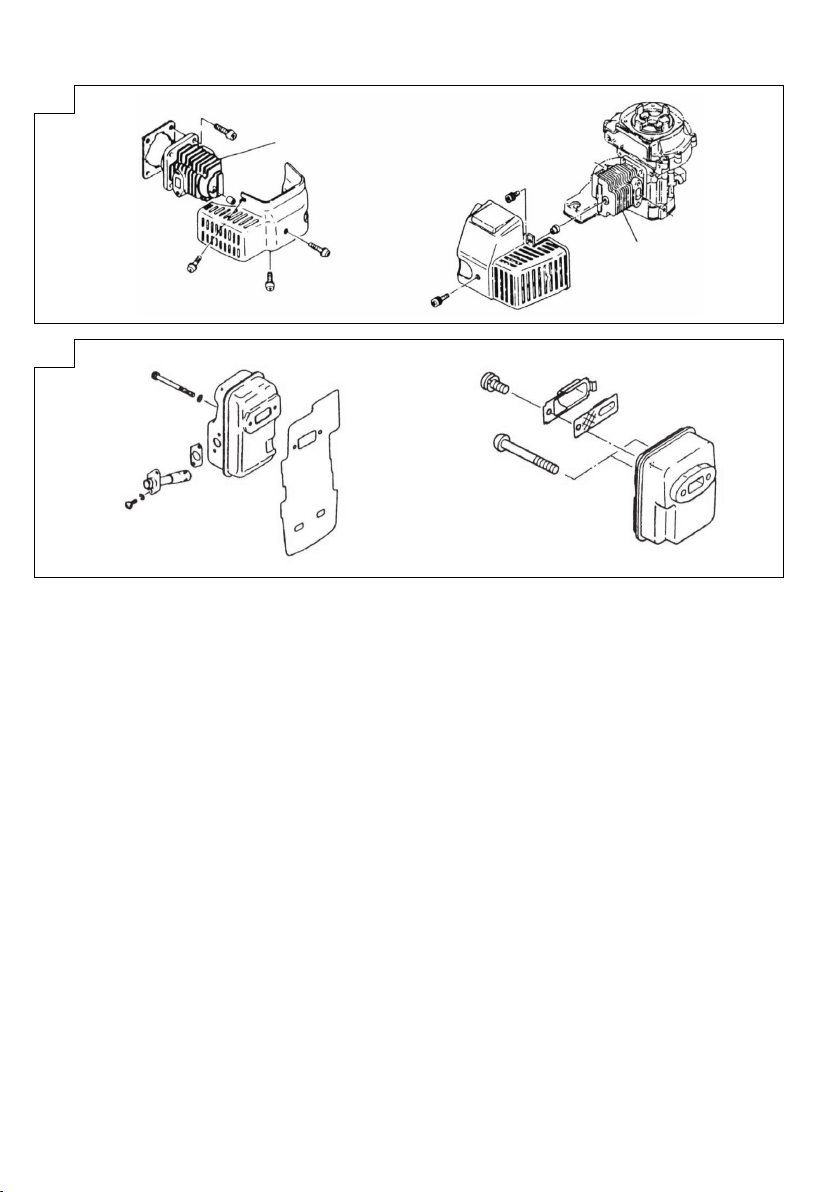

Cleaning the cylinder fi ns (Fig. 21)

When leaves get caught

may overheat , resulting in lower output. To avo id this, always keep

cylinder fi ns and fan case clean.

Every 10 0 operating hours, or once a yea r (more often if conditions

require), clean fi ns and ex ternal surfaces of engine of dust, dirt and

oil deposits which can

Cleaning the muffl er (Fig. 22)

Remove the muffl er and spark arrestor (if so equipped), and clean

out any excess carbon from the exhaust port or muffl er inlet every

100 hours of operation.

For long-term storage

Drain all fuel from the fuel tank. Start

Repair any damage which has resulted from use. Clean the unit with

a clean rag, or high pressure air hose. Put a few drops of two-cycle

engine oil into the cylinder through the spark plug hole, and spin the

engine over several times

it in a dry area.

Maintenance schedule

Below you will fi nd some general maintenance instructions. For

further information please contact your Hitachi dealer.

Daily maintenance

○ Clean the exterior of the hedge trimmer.

○ Check the blade guard for damage or cracks. Change the guard

in case of impacts or cracks.

○ Check that the blade is sharp, and without cracks.

○ Check that the blade nut is suffi ciently tightened.

○ Make sure that the blade transport guard is undamaged and

that it can be securely fi tted.

○ Check that nuts and screws are suffi ciently

Weekl y maintenance

○ Check the starter, especially cord and return spring.

○ Clean the exterior of the spark plug.

○ Remove it and check the electrode gap. Adjus t it to 0.6 mm, or

change the spark plug.

○ Clean the cooling fi ns on the cylinder and check that the air

○ Check gear case is fi lled with grease.

○ Clean the air fi lter.

Monthly maintenance

○ Rinse the fuel tank with gasoline.

○ Clean the exterior of the carburetor and the space around it.

○ Clean the fan and the space around it.

the starter is not clogged.

intake at

between cylinder fi ns (16), the engine

contribute to improper cooling.

and let engine run until it stops.

to distribute oil. Cover the unit and store

tightened.

11

Page 12

Español

LOS SIGNIFICADOS DE LOS SÍMBOLOS

NOTA: Algunos aparatos no están provistos de ellos.

Símbolos

ATENCIÓN

A continuación se muestran los símbolos usados para la máquina. Asegúrese de comprender su signifi cado

antes del uso.

Es importante que usted lea, entienda totalmente y observe las siguientes precauciones y advertencias de

seguridad. El uso descuidado o incorrecto de la unidad podrá causarle lesiones serias o fatales.

Lea, comprenda y siga todas las advertencias y demás instrucciones de este manual y las que hay en la

máquina.

Utilice siempre las protecciones para los ojos, cabeza y oídos cuando trabaje con la máquina.

Antes de usar la unidad

• Leer cuidadosamente el manual del operador.

• Veri fi car que el equipo de corte esté correctamente montado y ajustado.

• Arrancar la unidad y comprobar el ajuste del carburador. Ver la sección

Contenido

¿QU É ES QUÉ? ...............................................................................13

ADVERTENCIAS E INSTRUCCIONES DE SEGURIDAD ..............14

ESPECIFICACIONES ......................................................................16

PROCEDIMIENTO DE MONTAJE...................................................18

MODO DE USO ...............................................................................18

MANTENIMIENTO ...........................................................................18

de “Mantenimiento”.

12

Page 13

¿QU É ES QUÉ?

Ya que este manual es aplicable a va rios modelos, es posible

que haya diferencias entre las imagenes y su aparato. Utilice las

instruciones que sean relevantes para su unidad.

1. Arrancador retráctil

2. Ta nq ue de combustible

3. Palanca de tope del acelerador

4. Acelerador

5. Manija frontal

Mango posterior

6.

7. Bujía de encendido

8. Protector de mano

9. Cuchilla de corte

10. Filtro de aire

11. Llave de ignición

12. Protec ción redondeada

13. Caj a de engranajes

14. Mando del estrangulador

15. Botón de bloqueo (opc iona l)

16. Cubier ta de la cuchilla

17. Botón de bloqueo

18. Bomba

19. Llave combinada de cubo

20. Instrucciones de manejo

de cebado

16

Español

5

14

7

8

12

9

10

18

1

2

8

18

14

1

2

11

3

6

13

15

4

CH50EB

6

3

4

15

10

11

5

CH78EB (C), CH78EC (SC)

12

9

19

20

7

8

12

9

CH78EC (C), CH105EC (C)

CH78ED (CP)

16

5

CH66EB (ST)

CH55EB (ST), CH50EA (S T), CH62EA (ST)

CH78EC (ST)

CH66ED (TP), CH78ED (TP)

7

13

1

17

3

11

2

10

13

6

4

18

14

13

Page 14

Español

ADVERTENCIAS E INSTRUCCIONES DE

SEGURIDAD

Seguridad del usuario

○ Lleve siempre las protecciones tales como la pantalla o gafas

de seguridad.

○ Use siempre pantalones largos gruesos, botas y guantes. No

utilice prendas sueltas, adorno s, pantalón cor to, sandalias ni

ande descalzo. Sujete el cabello para que quede por encima

de los hombros.

○ No opere esta máquina

la infl uencia del alcohol, drogas o medicamentos.

○ No deje que los niños o personas inexpertas operen esta

máquina.

○ Lleve las protecciones de oídos.

○ Nunca ponga en marcha esta máquina dentro de un local

cerrado o edifi cio. La respiración de los gases

puede causar la muerte.

○ Mantenga la manilla limpia de aceite y combustible.

○ Mantenga las manos alejadas de la cuchilla de corte.

○ No agarre esta unidad por el equipo de corte.

○ Cuando pare la unidad, asegúsere de que el aditamento de

corte se haya detenido antes de apoyarla

○ Durante una operación prolongada, se recomienda interrumpir

de vez en cuando el trabajo para evitar una excesiva exposición

a las vibraciones que podría ocasionar los llamados “dedos

blancos”.

ATE NCI ÓN

○ Los sistemas antivibratorios no garantizan que no sufra el

síndrome de dedos blancos o síndrome de túnel carpiano.

Por lo tanto, los usuarios continuos o regulares deberán

controlar frecuentemente el estado de sus manos y dedos. Si

aparece alguno de los síntomas citados, deberá solicitarse

inmediatamente asistencia médica.

Si usa algún dispositivo médico eléctrico o electrónico tales

○

como marcapasos, consulte a su médico así como al fabricante

del dispositivo antes de operar cualquier equipo de potencia.

Seguridad de la unidad de máquina

○ Inspeccione siempre la unidad de máquina antes de usarla.

Sustituya las piezas dañadas. Compruebe que no haya

de combustible y asegúrese de que todas las piezas estén bien

apretadas en su sitio.

○ Sustituya las piezas agr ietadas, rotas o deterioradas antes de

poner en marcha la unidad de máquina.

○ Asegúrese de que el protector de seguridad esté perfectamente

colocado.

○ Al ajustar el carburador, no permita que

personas.

○ Utilice únicamente los accesorios para esta máquina que hayan

sido recomendados por el fabricante.

ATE NCI ÓN

No deberá modifi carse de ninguna manera la maquina. No usar

su máquina de corte para otra tarea más que para la cual se ha

destinado.

Seguridad sobre el combustible

○ Mezcle y cargue el combustible al aire libre, en lugares donde

no se produzcan chispas ni fuegos.

○ Utilice para

○ No fume ni deje fumar a otras personas en las cercanías del

combustible o de la maquina mientras esta está en marcha.

○ Limpie los residuos de combustible antes de poner en marcha

el motor.

○ Antes de poner en marcha el motor, apártese como mínimo

metros del lugar en el que se ha repostado.

○ Pare el motor antes de quitar el tapón del depósito de

combustible.

○ Antes de guardar la máquina, vacíe el depósito de combustible.

Es conveniente vaciar el depósito cada vez que se ha usado la

máquina. Si se deja combustible

que no puedan producirse fugas.

el combustible un recipiente adecuado.

cuando esté cansado, enfermo o bajo

de escape

sobre el suelo.

fugas

se acerquen otras

en el depósito, asegúrese de

○ Guarde la máquina y el combustible en un lugar donde los

vapores del combustible no puedan entrar en contacto con

chispas o llamas de calentadores de agua, motores eléctricos,

interruptores, hornos, etc.

ATE NCI ÓN

El combustible puede encenderse o explotar fácilmente o ser

inhalados los humos, por lo tanto preste especial atención

cuando maneje o cargue combustible.

Seguridad en el corte

○ No cortar ningún otro material más que plantas.

○ Inspeccione siempre el área que hay que cortar antes de iniciar

el trabajo. Quite

enredarse en el cabezal de corte.

○ Para proteger las vías respiratorias durante el corte de plantas

que hayan sido fumigadas, deberá usarse la máscara de

protección contra aerosoles.

○ Mantenga a otras personas, niños, animales, ayudantes

y personas de alrededor fuera de la

metros. Pare el motor inmediatamente si se acerca alguien.

○ Sujete fi rmemente la máquina con ambas manos.

○ Mantenga estable el cuerpo, con los pies bien apoyados sobre

el suelo. No estire demasiado el cuerpo.

○ Manténga su cuerpo apar tado del silenciador de escape y el

aditamento

○ Mantenga la herramienta de cor te por debajo del hombro.

Nunca trabaje con la unidad desde una escalera, subido a un

árbol o subido a cualquier soporte inestable.

○ Cuando se reubique en una nueva área de trabajo, asegúrese

de parar la máquina y

corte se hayan detenido.

○ Jamás coloque la máquina sobre el suelo cuando esté en

marcha.

○ Lleve siempre un botiquín de primeros auxilios consigo cuando

opere cualquier equipo de potencia.

○ Jamás arranque o haga funcionar el motor dentro de un recinto

o edifìcio cerrado

de los humos de escape puede ser letal.

Seguridad en el mantenimiento

○ Mantenga la unidad de máquina según las recomendaciones.

○ Antes de iniciar el mantenimiento desconecte la bujía, excepto

si hay que ajustar el carburador.

○ No permita que se acerquen otras

ajustando el carburador.

○ Utilice únicamente repuestos y accesorios originales de Hitachi

recomendados por el fabricante.

Tra ns po rt e y almacenamiento

○ Tra ns p or te la unidad de máquina con el motor y el silenciador

apartados del cuerpo.

○ Antes de almacenar o transportar la unidad de máquina en

un vehículo, espere a

depósito de combustible y asegúrela bien.

○ Vací e el depósito antes de guardar la unidad de la máquina. Es

recomendable vaci ar el depósito cada vez que se ha usado la

máquina. Si deja combustible en el depósito, asegúrese de que

no puedan producirse

○ Almacene la unidad de máquina fuera del alcance de los niños.

○ Limpie y mantenga la unidad en perfecto estado, y guárdela en

un lugar seco.

○ Asegúrese de que está desconectado el conmutador del motor

al transportarlo o al almacenarlo.

○ Si se transporta en un vehículo o se almacena,

con una cubierta de cuchilla.

3

Si ocurren situaciones que no se han previsto en este manual,

utilice el sentido común. Contacte con su distribuidor Hitachi

si necesita ayuda. Dedique especial atención a los apartados

precedidos por las palabras siguientes:

ATE NCI ÓN

Indica gran peligro de daños per sonales graves e incluso la

muerte, si no se siguen las instrucciones.

los objetos que puedan salir despedidos o

zona de peligro de 15

de corte mientras está en marcha el motor.

asegure que todos los accesorios de

y/o cerca del líquido infl amable. La inhalación

personas mientras está

que se haya enfriado el motor, vacíe el

fugas.

cubra la cuchilla

14

Page 15

IMPORTANTE

Indica posibilidad de daños personales o materiales, si no se

siguen las instrucciones.

NOTA

Indica información útil para un correcto uso y funcionamiento

de la máquina.

IMPORTANTE

No se desmonte el dispositivo de arranque de retroceso sobre

el aparato. Uno podría herirse a causa del resorte de retroceso.

Español

15

Page 16

Español

ESPECIFICACIONES

MODELO

Tam añ o del motor

(ml)

Bujía

Capacidad

del tanque de

combustible (l)

Peso en vacío (kg)

Largo total de la

cortadora (mm)

:○

Tipo de hoja

:△

CH50EB/CH66EB (ST)

CH55EB (ST)/CH50EA (ST)

CH62EA (ST)

22 24 22

NGK BPM-6A o BPMR-6A

Champion CJ-8Y o RCJ-8Y

0,35 0,35 0, 35

CH50EB .......................... 4,1

CH55EB (ST) .................. 4,5

CH66EB (ST) .................. 5,0

CH50EA (ST) .................. 4,3

CH62EA (ST) .................. 4,6

CH50EA (ST)/CH50EB

CH66EB (ST) .................. 650

CH55EB (ST) .................. 550

CH62EA (ST) .................. 620

...... 500

△△

CH78EC (ST) CH78EB (C)

NGK BPM-6A o BPMR-6A

Champion CJ-8Y o RCJ-8Y

5,3 5,2

770 770

NGK BPM-6A o BPMR-6A

Champion CJ-8Y o RCJ-8Y

○

Nivel de presión de

sonido

LpA (dB(A))

(EN 27917)

Nivel de potencia de

sonido

LwA (dB( A))

(2000/14/EC)

2

Nivel de vibración (m/s

Manija frontal

Manija posterior

NOTA

Los niveles de ruido/vibración equivalentes se calculan como la energía ponderada en tiempo en varia s condiciones de trabajo con la

distribución de tiempo siguiente: 1/2 de ralentí, 1/2 de veloc idad de aceleración al máximo.

* Tod os los datos están sujetos a cambio sin previo aviso.

) (ISO 7916)

CH50EB ....................... 100,0

CH66EB (ST) .................. 9 2,1

CH55EB (ST) .................. 9 3,6

CH50EA (ST) /CH62EA (ST)

CH66EB (ST) ..................

CH50EB ..........................

CH55EB (ST) ..................

CH50EA (ST) /CH62EA (ST)

CH66EB (ST) ..................

CH50EB ..........................

CH55EB (ST) ..................

CH50EA (ST) /CH62EA (ST)

..... 97,0

104 104 104

4,5

5,3

4,2

.......

5,1/6,5

5,2

11, 5

12,3

.......

11, 3/ 9 , 2

91,1 91,4

7,6

6,2

3,5

5,3

16

Page 17

Español

MODELO

Tam añ o del motor

(ml)

Bujía

Capacidad

del tanque de

combustible (l)

Peso en vacío (kg)

Largo total de la

cortadora (mm)

:○

Tipo de hoja

:△

Nivel de presión de

sonido

LpA (dB(A))

(EN 27917)

CH78EC (SC)

CH78EC (C)

CH105EC (C)

24 24 24

NGK BPM-6A o BPMR-6A

Champion CJ-8Y o RCJ-8Y

0,35

CH78EC (SC) ........ 5,2

CH78EC (C) ..........5, 2

CH105EC (C) ........5,6

CH78EC (SC) ........ 770

CH78EC (C) ..........770

CH105EC (C) ........1000

○

CH78EC (SC) ........ 93,9

CH78EC (C)

CH105EC (C) ........96,7/96 ,7

CH66ED (TP)

CH78ED (TP)

NGK BPM-6A o BPMR-6A

Champion CJ-8Y o RCJ-8Y

0,33 0,33

CH66ED (TP) ...........5,3

CH78ED (TP) ...........5,6

CH66ED (TP) .......... 650

CH78ED (TP) .......... 770

△

98,3 98,3

CH78ED (CP)

NGK BPM-6A o BPMR-6A

Champion CJ-8Y o RCJ-8Y

5,6

770

○

Nivel de potencia de

sonido

LwA (dB( A))

(2000/14/EC)

2

Nivel de vibración (m/s

Manija frontal

Manija posterior

NOTA

Los niveles de ruido/vibración equivalentes se calculan como la energía ponderada en tiempo en varia s condiciones de trabajo con la

distribución de tiempo siguiente: 1/2 de

* Tod os los datos están sujetos a cambio sin previo aviso.

) (ISO 7916)

CH78EC (SC) ........ 4,7

CH78EC (C)

CH105EC (C) ........6,8

CH78EC (SC) ........ 6,4

CH78EC (C)

CH105EC (C) ........5,6

ralentí, 1/2 de velocidad de aceleración al máximo.

104 104 104

CH66ED (TP) ...........8,9

CH78ED (TP) ...........7,8

CH66ED (TP) ...........6,3

CH78ED (TP) ...........5,3

6,1

11,1

17

Page 18

Español

PROCEDIMIENTO DE MONTAJE

Manija B (3) y placa de recogida (4) (Fig. 1)

1. Desmontar las cuatro arandelas y tuercas (1) del extr emo de la

cuchilla de corte.

NOTA

En el caso de la instalación de la manija B solamente,

desmontar sólo la tuerca del tornillo más largo.

2. Instalar la placa de recogida sobre

apretar con los dedos las tres arandelas y tuercas.

* Se necesitan dos arandelas especiales (5) de cada una

por debajo de la placa de recogida o sobre los dos tornillos

fi jadores para instalar la placa de recogida sobre el CH105EC

tiene equipado)

(C). (Si lo

3. Colocar la manija B en el tornillo más largo y ajustar con los

dedos la arandela y la tuerca.

4. Antes de apretar las tuercas ajustadas con los dedos, enroscar

los tornillos de fi jación (2) de la cuchilla para que queden bien

sujetos, luego afl ojar aprox, 1/2 vuelta

5. Con los tornillos colocados en esa posición, ajustar las tuercas

de fi jación de la cuchilla.

la bar ra de guía luego

los tornillos.

MODO DE USO

Combustible (Fig. 2)

ATE NCI ÓN

El motor es de dos tiempos y ha de funcionar siempre con una

mezcla de gasolina y aceite.

Asegurarse siempre de que hay buena ve ntilación en los

lugares donde se maneja el combustible.

Gasolina

○ Utilice siempre gasolina sin plomo de marca de 89 de octanos.

○ Use ac eite de dos

a 50:1, sírvase ver la relación en la botella o consulte con un

distribuidor Hitachi.

○ Si no dispone de aceite original, use un aceite con antioxidante

de calidad que esté etiquetad o expr esamente para motores de

dos tiempos enfriados por aire (JASO FC

EGC GRADE). No utilice aceite mezclado BIA o TCW (t ipo de 2

tiempos refrigerado por agua).

○ No utilice nunca aceites multigrado (10W/30 ) ni residuales.

○ Mezcle siempre la gasolina y el aceite en un recipiente especial

para ello que esté limpio.

Empiece llenando el rec ipiente hasta la

añada luego todo el aceite. Sacuda la mezcla y añada el resto de

la gasolina.

Antes de llenar el depósito agite la mezcla cuidadosamente.

Repostar

ATE NCI ÓN (Fig. 3)

○ Parar siempre el motor antes de repostar.

○ Para llenar el combustible del tanque, deberá abrirse

lentamente la tapa del tanque de combustible (6) para que

escape la sobrepresión que pueda contener.

○ Después de haber repostado, apretar bien la tapa.

○ Antes de arrancar la unidad,

del área de carga de combustible.

Antes de repostar, limpiar cuidadosamente el área del tapón del

tanque, para garantizar que no entra suciedad en el depósito.

Asegurarse de que el combustible está bien mezclado agitando

bien el recipiente antes de verter su contenido en

Arranque

IMPORTANTE

Antes del arranque, asegúrense de que el aditamento de cor te

no esté rozado con nada.

18

tiempos original o use una mezcla de 25:1

GRADE OIL o ISO

mitad con gasolina y

deberá alejarse por lo menos 3 m

el depósito.

1. Coloque el interruptor de encendido (7) en la posición ON

(con ecta do) (A). (Fig. 4, 5)

* Presione va rias veces el cebador (10) , de manera que el

combustible fl uya a través del cebador o de la tubería de

retorno (Si lo tiene equipado). (Fig. 6)

2. Con la palanca

palanquita del acelerador y empujar el botón de bloqueo (9) (Si

lo tiene equipado), soltar después lentamente el acelerador. Se

cerrará así la mariposa en la posición de arranque. (Fig. 4, 5)

3. Coloque la palanca del estár ter (11) en la posición CLOSED

(cer rado) (B). (Fig. 7)

4. Tirar enérgicamente del arrancador de retroceso y teniendo

cuidado de no soltar el mango. (Fig. 8, 9)

5. Cuando escuche que el motor intenta arrancar, vuelva la

palanca del estárter a la posición RUN (abi erto) (C). Entones

tire de nuevo el arrancador de retroceso

NOTA

Si el motor no se pone en marcha, repita los puntos 2 al 4.

6. Después de arrancar el motor, pemita que el motor se caliente

unos 2-3 minutos antes de someter a cualquier carga.

Corte

Al efectuar el corte, operar el motor con el acelerador a fondo para

la velocidad apropiada de corte.

mantener

Cuando se recor te la parte superior de un seto, mantener la

recortadora de manera que las cuchillas for men un ángulo de 15

y 30 grados con la horizontal y oscilar la recortadora en forma de

arco contra el borde del seto para eliminar los recortes.

se recorten los costados de un seto, mantener

Cuando

vertica lmente la cuchilla y mover la unidad en forma de arco.

NOTA

○ Empuñadura con eje de torsión multi-posición (Fig. 10)

En caso de que su desbrozadora sea de tipo empuñadura

con eje de torsión (12), el ángulo de cortado puede ajustarse

afl ojando la tuerca de bloqueo de la empuñadura (13) . Una vez

realizado el ajuste, asegúrese de volver a apretar la tuerca.

○ Empuñadura con eje de torsión de cinco posiciones (Fig.

11)

La empuñadura trasera puede ajustarse en cinco posiciones

diferentes presionando el botón de bloqueo (14) y girando la

empuñadura trasera (15).

Es muy importante bloquear la empuñadura en la posición

seleccionada.

El botón de bloqueo no funcionará cuando se tire de la

esbrozadora reguladora.

○ La esbrozadora reguladora no funcionará si se desbloquea la

empuñadura posterior.

Parada (Fig. 12, 13 )

Reduzca la velocida d del motor y empuje el interruptor

encendido a la posición de stop (F).

de seguridad (8) presionada, tirar de la

com fuerza.

de

MANTENIMIENTO

EL MANTENIMIENTO, REEM PLAZO O REPARACIÓN DE LO S

DISPOSITIVOS Y SISTEMAS DE CONTROL DE GAS PUEDEN

HACERSE EN CUALQUIER TALLER DE REPARACIÓN DE MOTOR

NO PARA CARRERAS O PERSONALMENTE.

Ajuste del carburador (Fig. 14)

ATE NCI ÓN

○ Es posible que el accesorio de corte dé vueltas durante los

ajustes del carburador.

○ Jamás deberá arrancarse el motor sin la cubierta completa

del embrague, ya que podría afl ojarse el embrague y causar

lesiones personales.

En el carburador se mezcla el combustible con el aire. Durante

prueba del motor en la fábrica , el carburador está ajustado.

la

Sin embargo, puede ser necesario reajustarlo según el clima y la

altitud. El carburador tiene una posibilidad de ajuste:

T = Tornillo para el ajuste de las revoluciones de ralentí.

Page 19

Español

Ajuste de precisión de ralentí (T)

Comprueben que el fi ltro de aire esté limpio. Cuando la velocidad

de ralentí es correcta, el aditamento de corte no ha de girar. Si

necesita ajustarlo, cierre (hacia la derecha) el tornillo T con el motor

en marcha hasta que el aditamento de corte empiece

(hacia la izquierda) el tornillo T hasta que la cuchilla se detenga. Se

habrá alcanzado el ralentí correcto cuando el motor funcione con

regularidad en cualquier posición por debajo de las revoluciones

por minuto en las que empieza a girar el aditamento de corte.

Si la cuchilla

ralentí, comuníquese con un distribuidor Hitachi.

Filtro de aire (Fig. 15)

Este fi ltro debe limpiarse con regularidad quitando polvo y suciedad

a fi n de evitar:

○ Perturb aciones en el funcionamiento del carburador.

○ Problemas de arranque.

○ Pérdidas de potencia.

○ Desgaste innecesario de

○ Consumo de combustible excesivo.

Limpie el fi ltro de aire diariamente; si las condiciones de trabajo son

desfavorables.

Limpieza del fi ltro de aire

Desmontar la cubier ta del fi ltro y sacarlo. Limpiar el fi ltro con agua

jabonosa caliente. Antes de volver a montarlo, comprobar que

está seco. Un fi ltro

podrá quedar completamente limpio, por lo que los fi ltros deberán

sustituirse por otros nuevos a intervalos regulares. Cambie siempre

los fi ltros que estén dañados.

NOTA

Bañe el elemento en aceite de 2 ciclos o equivalente.

Bujía (Fig. 16)

El estado de la bujía depende de lo siguiente:

○ Carburador mal ajustado.

○ Mezcla incorrecta de combustible y aceite (exceso de aceite).

○ Filtro de aire sucio.

○ Condiciones de funcionamiento difíciles (co mo clima frío).

Tod os estos factores dan lugar a la

electrodos pudiendo causar per turbaciones en el funcionamiento

y difi cultades de arranque. Si en la cortadora se nota falta de

potencia, si los arranques son difíciles y si el ralentí es inestable,

controlar siempre primero la bujía antes de adoptar otras medidas.

Si la bujía está

electrodos, que ha de ser de 0,6 mm. La bujía debe cambiarse

después de unas 10 0 horas de funcionamiento o antes si los

electrodos están muy gastados.

NOTA

En algunas áreas, los reglamentos locales requieren el uso de

Hoja de la cortadora (Fig. 17, 18)

Las cuchillas van instaladas en la guía de la

o cinco tornillos apretados con una holgura que permite el libre

movimiento de las mismas.

Cuando la holgura es muy pequeña

Las cuchillas no pueden moverse correctamente, y podrían

agarrotarse las superfi cies deslizantes.

Cuando la holgura es excesiva

Las cuchillas no cortan efi cazmente.

todavía gira después del ajuste de la velocidad al

las piezas del motor.

de aire que ha prestado largo servicio nunca

Comprima el elemento para distribuir el aceite completamente

y para retirar cualquier exceso de aceite.

formación de sedimentos en los

muy sucia, limpiarla y controlar la separación entre

una bujía de encendido de

de ignición. En el caso de que esta máquina esté equipada

originalmente de la bujía de encendido de resistencia, debe

usar algún tipo de bujía de encendido de resistencia como

repuesto.

resistencia para eliminar señales

a girar. Abra

barra mediante cuatro

Para ajustar la holgura de

1. Afl oje las tuercas que las sujetan a la guía.

2. Apriete por completo los tornillos de sujeción de las cuchillas, y

luego afl ójelos aproximadamente 1/2 vuelta.

3. Con los tornillos en esta posición, apriete las tuercas de

sujeción de las cuchillas.

Asegúrese de cambiar los tornillos de

cortasetos cuando compruebe que están fl ojos, gastados o

dañados. Tam bi é n asegúrese de cambiar la cuchilla del cortasetos

dañada.

NOTA

Lubrique correctamente las superfi cies deslizantes del

cortasetos con aceite.

Caja de engranajes (Fig. 19)

Aplíquese grasa a base de litio de buena calidad a través de

grasera hasta que una cantidad pequeña aparezca entre las hojas

cortantes y la caja de engranajes.

NOTA

Hay que efectuar la lubricación a intervalos de 50 horas o con

más frecuencia en caso de trabajo intenso.

Filtro de combustible (Fig. 20)

Quitar el fi ltro de combustible del tanque de combustible y

totalmente con disolvente. Posteriormente, vuelva a insertar

totalmente el fi ltro en el tanque.

NOTA

Si el fi ltro estuviera obstr uido debido al polvo y la suciedad,

deberá reemplazarse.

Limpieza de las aletas del cilindro (Fig. 21)

El aprisionamiento de las hojas entre las aletas de cilindro

(16) puede ocasionar el sobrecalentamiento

consiguiente pérdida de potencia. Par a evitar esto, mantenga

siempre separadas las aletas y el ventilad or.

Cada 10 0 horas de operación, o una vez al año (o con más

frecuencia cuando sea necesario), limpiar las aletas y la superfi cie

exterio r del motor, para eliminar los sedimentos de

y aceite que causen el enfriamiento inadecuado.

Limpieza del silenciador (Fig. 22)

Desmontar el silenciador y parachispas (si lo tiene equipado), y

limpiar cualquier exceso de carbón de la boca de escape o entrada

del silenciador cada 100 horas de operación.

Para el almacenamiento durante largos periodos

Drenar totalmente el

el motor y dejarlo en funcionamiento hasta que se pare. Reparar

cualquier daño que haya sufrido por el uso. Limpiar la unidad con

trapo limpio o soplar con la manguera de aire de alta presión.

Aplicar algunas gotas de aceite de motor para motocicletas dentro

del cilindro a través del orifi cio de la bujía de encendido y girar el

motor varias veces para que se distribuya el aceite. Cubrir la unidad

y almacenar en un lugar seco.

Esquema de mantenimiento

A continuación se muestran algunas instrucciones generales de

mantenimiento. Para obtener información adicional, contacte con

su distribuidor Hitachi.

Cuidados diarios

○ Limpie la máquina por fuera.

○ Compruebe la protección de la hoja que no esté deteriorada ni

tenga grietas.

○ Cambie la protección si ha estado expue sta a golpes o tiene

grietas. Compruebe que la hoja esté afi lada y no tenga grietas.

○ Compruebe que esté

○ Compruebe que esté entera la protección de transpor te de la

hoja y que pueda sujetarse bien.

○ Compruebe que las tuercas y tornillos estén apretados.

las cuchillas

sujeción de la guía del

del motor, con la

polvo, suciedad

contenido del tanque de combustible. Arrancar

bien apretada la tuerca de la hoja.

la

lavar

19

Page 20

Español

Cuidados semanales

○ Compruebe el aparato de arranque, la cuerda y el muelle de

recuperación.

○ Limpie la bujía por fuera.

○ Desmóntela y compruebe que la distancia entre los electrodos

sea de 0,6 mm, o cambie la bujía.

○ Limpie las aletas de refrigeración del cilindro y controle que no

ha obstruido la admisión de aire.

se

○ Compruebe que la caja de cambios esté bien engrasada.

○ Limpie el fi ltro de aire.

Cuidados mensuales

○ Limpie el depósito de combustible con gasolina.

○ Limpie el carburador por fuera y los alrededores del mismo.

○ Limpie el ventilador y sus alrededores.

20

Page 21

SIGNIFICADO DOS SÍMBOLOS

NOTA: Os símbolos referidos não se encontram em todos os

modelos.

Símbolos

ADVERTÊNCIA

A seguir aparecem os símbolos utilizados pela máquina. Assimile bem seus signifi cados antes do uso.

É importante que você leia, compreenda integralmente e observe as seguintes precauções e advertências

de segurança. O uso descuidado ou incorreto do aparelho pode causar lesões graves ou até fatais.

Leia, compreenda e siga todas as advertências e instruções contidas neste manual e no aparelho.

Sempre use protetores para os olhos, cabeça e ouvidos durante o uso deste aparelho.

Português

Antes de usar a ferramenta

• Leia o manual atentamente.

• Veri fi que se o equipamento de corte está montado e ajustado corretamente.

• Ligue a ferramenta e veri fi que o ajuste do carburador. Consulte “MANUTENÇÃO”.

Sumário

DESCRIÇÃO DE CADA

ADVERTÊNCIAS E INSTRUÇÕES DE SEGURANÇA ...................23

ESPECIFICAÇÕES ..........................................................................24

PROCEDIMENTOS DE MONTAGEM .............................................2 6

PROCEDIMENTOS DE OPER AÇÃO ..............................................2 6

MANUTENÇÃO ...............................................................................26

COMPONENTE ........................................2 2

21

Page 22

Português

DESCRIÇÃO DE CADA COMPONENTE

Como este manual cobre vários modelos, podem exi stir algumas

diferenças entre as ilustrações e a sua fer ramenta. Use as

instruções que se aplicam à sua ferrame nta.

1. Acionador de arranque de recuo

2. Ta nq ue de combustível

3. Visor do gatilho do acelerador

4. Gatilho do acelerador

5. Cabo frontal

traseiro

6. Cabo

7. Vela de ignição

8. Protetor da mão

9. Lâmina de corte

10. Filtro de ar

11. Interr uptor de ignição

12. Pe nte de proteção

13. Cai xa de engrenagens

14. Alavanca do afogador

15. Botão de bloqueio (opc iona l)

16. Cober tura protetora da lâmina

17. Botão de bloqueio

18. Bomba de escorva

19. Chave combinada

20. Instruções

de manipulação

16

5

14

7

8

12

9

10

18

1

2

8

18

14

1

2

11

3

6

13

15

4

CH50EB

6

3

4

15

10

11

5

CH78EB (C), CH78EC (SC)

12

9

19

20

7

8

12

9

CH78EC (C), CH105EC (C)

CH78ED (CP)

16

5

CH66EB (ST)

CH55EB (ST), CH50EA (S T), CH62EA (ST)

CH78EC (ST)

CH66ED (TP), CH78ED (TP)

7

13

1

17

3

11

2

10

13

6

4

18

14

22

Page 23

Português

ADVERTÊNCIAS E INSTRUÇÕES DE

SEGURANÇA

Segurança do operador

○ Sempre use uma máscara ou óculos de proteção.

○ Sempre use calças pesadas e compridas, botas e luvas. Não

use roupas folgad as, jóias e bijuteria, calções, sandálias e

nunca trabalhe descalço. Prenda o cabelo para que ele não

caia por cima dos ombros.

○ Não use esta fer ramenta

sob efeitos de álcool, drogas ou medicamentos.

○ Nunca deixe uma criança ou uma pessoa inexperiente operar

esta ferramenta.

○ Use uma proteção para os ouvidos.

○ Nunca arranque nem deixe o motor funcionando no interior de

um quarto ou prédio. A inalação dos gases de escape

provocar a morte.

○ Mantenha os cabos livres de óleo e gasolina.

○ Mantenha as mãos afastadas do mecanismo de corte.

○ Não agarre nem segure a ferramenta pelo mecanismo de corte.

○ Depois de desligar a ferramenta , certifi que-se de que o

mecanismo de corte tenha parado antes de deixá-la em

lugar.

○ Durante trabalhos prolongados, faça pausas de vez em quando

para prevenir a síndrome de vibração das mãos e braços

(HAVS) causada pela vibração.

ADVERTÊNCIA

○ Sistemas anti-vibratórios não garantem que o operador não

sofra da síndrome de vibração das mãos e braços ou da

síndrome do túnel carpal. Portan to, os usuários freqüentes

e contínuos devem estar sempre atentos ao estado das suas

mãos e dedos. Se você perceber qualquer um dos sintomas

mencionados acima,

○ Se você estiver usando um dispositivo médico elétrico/

eletrônico como, por exemplo, um marcapasso, consulte o

seu médico e o fabricante do aparelho antes de trabalhar com

equipamentos motorizados.

Segurança da ferramenta

○ Inspecione toda a ferramen ta antes de cada uso. Substitua

as peças danifi cadas. Ver ifi

combustível e certifi que-se de que todos os parafusos e porcas

estejam instalados e apertados corretamente.

○ Substitua todas as peças que estiverem rachadas, lascadas ou

danifi cadas antes de usar esta ferrament a.

○ Certifi que-se de que o protetor de segurança esteja instalado

corretamente.

○ Mantenha

carburador.

○ Use somente os acessóri os rec omendados pelo fabric ante

para esta ferramenta.

ADVERTÊNCIA

Nunca modifi que a ferra menta de qualquer maneira. Não use a

ferramenta para qualquer outra fi nalidade que não tenha sido

concebida para a mesma.

Segurança do combustível

○ Misture e abasteça o combustível ao ar livre e num local onde

não haja faíscas ou chamas.

○ Use um recipiente aprovado para

○ Não fume e proíba o fumo nas proximidades do combustível

ou da fer ramenta e, acima de tudo, durante o trabalho com a

ferramenta .

○ Limpe qualquer combustível derramado antes de arrancar o

motor.

○ Afaste-se pelo menos 3 m do local de abastecimento antes de

arrancar o motor.

○ Apague

combustível.

○ Esvazie o tanque de combustível antes de guardar a

ferramenta . É recomendável esvaziar o tanque de combustível

após cada uso. Se tiver que deixar o combustível no tanque,

guarde a ferram enta de forma que não haja vaz amento de

combustível.

○

Guarde a ferramenta num local onde os vapores do combustível

não possam entrar em contato com faíscas ou chamas aber tas

de aquecedores de água, motores ou interruptores elétricos,

fornos, etc.

outras pessoas afastada s ao fazer ajustes no

o motor antes de retirar a tampa do tanque de

quando estiver cansado, doente ou

pode

algum

consulte um médico imediatamente.

que se ex istem vazame ntos de

combustível.

ADVERTÊNCIA

O combustível é facilmente infl amável e altamente explosivo,

bem como pode provocar a inalação de fumos e, portanto,

tome muito cuidado ao manipular ou abastecer o combustível.

Segurança durante o corte

○ Não corte nenhum material que não seja sebe viva.

○ Inspecione a área a ser cortada antes de

coisas que possam ser lançadas ou fi car emaranhadas.

○ Para a proteção das vias respiratórias após uma aplicação de

inseticidas, use uma máscara de proteção contra aerossóis.

○ Mantenha outras pessoas, incluindo crianças, animais,

curiosos ou ajudantes fora da zona de perigo de 15 metros.

Apague o motor

○ Segure fi rmemente a ferramenta com ambas as mãos.

○ Mantenha o equilíbrio e olhe onde anda. Não exceda o seu raio

de alcance.

○ Quando o motor estiver em funcionamento, mantenha todas as

partes do corpo afastadas do silenciador e do mecanismo de

corte.

○ Mantenha o

NUNCA opere a ferramenta enquanto estiver em uma escada,

em uma árvore ou em qualquer apoio instável.

○ Quando se deslocar para outra área de trabalho, apague o

motor e certifi que- se de que o mecanismo de corte esteja

parado.

○ Nunca coloque

○ Sempre tenha um estojo de primeiros socorros per to quando

trabalhar com equipamentos motorizados.

○ Nunca arranque nem deixe o motor funcionando em locais

fechados e/ou nas proximidades de líquidos infl amáveis. A

inalação dos gases de escape pode provocar a morte.

Segurança durante a manutenção

○

Faça a manutenção da ferrament a de acordo com os

procedimentos recomendados.

○ Desconecte a vela de ignição antes de iniciar a manutenção,

exceto se tiver que fazer ajustes no carburador.

○ Mantenha outras pessoas afastadas ao fazer ajustes no

carburador.

○ Use somente peças sobressalentes genuínas da Hitachi, tal

como recomendado pelo

Tra ns po rt e e armazenamento

○ Tra ns p or te a ferramenta com as mãos, com o motor parado e

com o silenciador afastado do corpo.

○ Deixe o motor se esfriar, esvazie o tanque de combustível,

e segure a fer ramenta fi rmemente antes de guardá-la ou

transportá-la num veículo.

○ Esvazie o tanque de combustível antes

ferramenta . É recomendável esvaziar o tanque de combustível

após cada uso. Se tiver que deixar o combustível no tanque,

guarde a ferram enta de forma que não haja vaz amento de

combustível.

○ Guarde a ferramenta fora do alcance das crianças.

○ Limpe a ferramenta e realize a sua manutenção

cuidadosamente

○ Certifi que-se de que o interruptor de ignição esteja desligado

quando transportar ou guardar a ferramenta.

○ Para transportar ou guardar a ferramenta num veículo, cubra a

lâmina com a sua cobertura protetora.

Se ocorrer algo que não estiver coberto neste manual, seja

cauteloso e

Hitachi quando precisar de assistência técnica. Preste especial

atenção aos textos precedidos pelos seguintes termos:

ADVERTÊNCIA

Indica uma forte possibilidade de sofrer ferimentos pessoais ou

de perder a vida, se as instruções não forem observadas.

PRECAUÇÃO

Indica uma possibilidade de ferim entos pessoais ou danos

materiais, se as instruções não forem observadas.

NOTA

Informações úteis sobre o funcionamento e uso correto.

PRECAUÇÃO

Não desmonte o acionador de arranque

sofrer ferimentos pessoais com a mola de recuo.

imediatamente se alguém se aproximar.

mecanismo de corte abaixo do nível da cintura.

a ferramenta em funcionamento no solo.

fabricante.

antes de guardá-la num local seco.

atue com o senso comum. Contate o seu revendedor

cada uso. Retire

de guardar a

de recuo. Você pode

23

Page 24

Português

ESPECIFICAÇÕES

MODELO

Cilindrada (ml) 22 24 22

Vela de ignição

Capacidade

do tanque de

combustível (l)

Peso a seco (kg)

Comprimento total do

cortador (mm)

:○

Tipo de lâmina

△

:

CH50EB/CH66EB (ST)

CH55EB (ST) CH50EA (ST)

CH62EA (ST)

NGK BPM-6A ou BPMR-6A

Champion CJ-8Y ou RCJ-8Y

0,35 0,35 0, 35

CH50EB .......................... 4,1

CH55EB (ST) .................. 4,5

CH66EB (ST) .................. 5,0

CH50EA (ST) .................. 4,3

CH62EA (ST) .................. 4,6

CH50EA (ST)/CH50EB

CH66EB (ST) .................. 650

CH55EB (ST) .................. 550

CH62EA (ST) .................. 620

...... 500

△△

CH78EC (ST) CH78EB (C)

NGK BPM-6A ou BPMR-6A

Champion CJ-8Y ou RCJ-8Y

5,3 5,2

770 770

NGK BPM-6A ou BPMR-6A

Champion CJ-8Y ou RCJ-8Y

○

Nível de pressão

sonora

LpA (dB (A))

(EN 27917)

Nível de potência

sonora

LwA (dB (A))

(2000/14/EC)

2

Nível de vibração (m/s

NOTA

Os níveis de ruído/vibrações equivalentes foram calculados como a energia total do tempo ponderado para os níveis de ruído/vibração

em diferentes condições de trabalho, com a seguinte distribuição do tempo: 1/2 ao ralenti, 1/2 em aceleração.

* Tod os os dados estão sujeitos a modifi cações sem aviso prévio.

Cabo frontal

Cabo traseiro

) (ISO 7916)

CH50EB ....................... 100,0

CH66EB (ST) .................. 9 2,1

CH55EB (ST) .................. 9 3,6

CH50EA (ST) /CH62EA (ST)

CH66EB (ST) ..................

CH50EB ..........................

CH55EB (ST) ..................

CH50EA (ST) /CH62EA (ST)

CH66EB (ST) ..................

CH50EB ..........................

CH55EB (ST) ..................

CH50EA (ST) /CH62EA (ST)

..... 97,0

104 104 104

4,5

5,3

4,2

.......

5,1/6,5

5,2

11, 5

12,3

.......

11, 3/ 9 , 2

91,1 91,4

7,6

6,2

3,5

5,3

24

Page 25

Português

MODELO

Cilindrada (ml) 24 24 24

Vela de ignição

Capacidade

do tanque de

combustível (l)

Peso a seco (kg)

Comprimento total do

cortador (mm)

:○

Tipo de lâmina

△

:

Nível de pressão

sonora

LpA (dB (A))

(EN 27917)

CH78EC (SC)

CH78EC (C)

CH105EC (C)

NGK BPM-6A ou BPMR-6A

Champion CJ-8Y ou RCJ-8Y

0,35

CH78EC (SC) ........ 5,2

CH78EC (C) ..........5, 2

CH105EC (C) ........5,6

CH78EC (SC) ........ 770

CH78EC (C) ..........770

CH105EC (C) ........1000

○

CH78EC (SC) ........ 93,9

CH78EC (C)

CH105EC (C) ........96,7/96 ,7

CH66ED (TP)

CH78ED (TP)

NGK BPM-6A ou BPMR-6A

Champion CJ-8Y ou RCJ-8Y

0,33 0,33

CH66ED (TP) ...........5,3

CH78ED (TP) ...........5,6

CH66ED (TP) .......... 650

CH78ED (TP) .......... 770

△

98,3 98,3

CH78ED (CP)

NGK BPM-6A ou BPMR-6A

Champion CJ-8Y ou RCJ-8Y

5,6

770

○

Nível de potência

sonora

LwA (dB (A))

(2000/14/EC)

2

Nível de vibração (m/s

NOTA

Os níveis de ruído/vibrações equivalentes foram calculados como a energia total do tempo ponderado para os níveis de ruído/vibração

em diferentes condições de trabalho, com a

* Tod os os dados estão sujeitos a modifi cações sem aviso prévio.

Cabo frontal

Cabo traseiro

) (ISO 7916)

CH78EC (SC) ........ 4,7

CH78EC (C)

CH105EC (C) ........6,8

CH78EC (SC) ........ 6,4

CH78EC (C)

CH105EC (C) ........5,6

104 104 104

CH66ED (TP) ...........8,9

CH78ED (TP) ...........7,8

CH66ED (TP) ...........6,3

CH78ED (TP) ...........5,3

seguinte distribuição do tempo: 1/2 ao ralenti, 1/2 em aceleração.

6,1

11,1

25

Page 26

Português

PROCEDIMENTOS DE MONTAGEM

Cabo B (3) e chapa coletora (4) (Fig. 1)

1. Retire as quatro arruelas e porcas (1) da extremid ade da lâmina

de corte.

NOTA

No caso de instalação somente do cabo B, retire somente a

porca no parafuso mais longo.

2. Coloque a chapa coletora na guia do cortador e, em seguida,

aperte as três arruelas e porcas com a mão.

* Use uma (5) das duas arruelas, que foram fornecidas, sob a

chapa coletora ou nos dois parafusos de fi xação da lâmina

desde a extremi dade da lâmina de corte para instalar a chapa

coletora no modelo CH105EC (C). (Se houver)

3. Coloque

4. Antes de fi xar as porcas apertadas com a mão, aparafuse os

5. Com os parafusos colocados na posição

o cabo B no parafuso mais longo e aperte- o com a

arruela e porca com a mão.

parafusos de fi xação da lâmina (2) e, em seguida, afrouxe os

parafusos aproximadamente 1/2 volta.

porcas de fi xação da lâmina.

adequada, aperte as

PROCEDIMENTOS DE OPERAÇÃO

Combustível (Fig. 2)

ADVERTÊNCIA

O aparador de sebe viva está equipado com um motor de dois

tempos. Sempre opere o motor com combustível, misturado

com óleo.

Providencie uma boa venti lação quando manipular ou

abastecer o combustível.

Combustível

○ Sempre use gasolina sem chumbo de 89 octanas como o

combustível.

○ Use óleo genuíno para motores

de 25:1 a 50:1. Consulte as instruções do óleo ou o revendedor

Hitachi para saber a relação de mistura exata.

○ Se não conseguir encontrar óleo genuíno, use um óleo

de qualidade com aditivos antioxidantes, que indique

expressa mente a sua compatibilidade com motores a

tempos refrig erados por ar (JA SO FC GRADE OIL ou ISO

EGC GR ADE). Não use óleo misturado BIA ou TCW (tipo

refrigeração por água a 2 tempos).

○ Nunca use óleo multi-grau (10W/3 0) ou óleo usado.

○ Sempre misture o combustível e o óleo num rec ipiente limpo

separado.

Sempre comece enchendo a

combustível. Logo, adicione a quantidade inteira de óleo. Misture

(agi te) a mistura de combustível. Finalmente, adicione a quantidade

restante de combustível.

Misture (ag ite) bem a mistura de combustível antes de abastecê-la

no tanque de combustível da ferramenta .

Abastecimento de combustível

ADVERTÊNCIA (Fig. 3)

○ Sempre apague o motor antes de abastecer o combustível.

○ Quando abastecer o combustível, abra lentamente a tampa do

tanque de combustível (6) para aliviar qualquer sobrepressão

existente.

○ Após o abastecimento, aperte a tampa do tanque de

combustível cuidadosamente.

○ Afaste a ferr amenta pelo menos 3 m

antes de arrancar o motor.

Antes de abastecer o combustível, limpe a área da tampa do tanque

com cuidado, para evitar que nenhuma sujeira entre no tanque.

Certifi que-se de que o combustível esteja bem misturado antes de

abastecer, agitando o recipiente para isso.

26

a 2 tempos ou use uma mistura

2

metade da quantidade necessária de

da área de abastecimento

Arranque

PRECAUÇÃO

Antes de arrancar, certifi que-se de que o mecanismo de corte

não esteja em contato com nada.

1. Coloque o interruptor de ignição (7) na posição ON (A). ( Fig. 4,

5)

* Pressione o bulbo de escorva (10) várias vezes, de forma que

o combustível fl ua pelo bulbo ou

houver) (Fig. 6)

2. Com a alavanca de sequrança (8) pressionada, puxe o gatilho

do acelerador e pressione o botão de bloqueio (9) (se houver);

logo, solte lentamente o gatilho do acelerador e, depois,

a alavanca de segurança. Isso bloqueará o acelerador na

posição de

3. Coloque a alavanca do afogador (11) na posição CLOSED (B).

(Fig. 7)

4. Puxe o cabo de arranque com força, tomando cuidado para

manter o cabo fi rmemente na mão, não deixando que o cabo

salte para trás. (Fig. 8, 9)

5. Quando ouvir a

alavanca do afogador para a posição RUN (aber ta) (C). Logo,

puxe novamente o cabo de arranque com força.

NOTA

Se o motor não arrancar, repita os passos de 2 a 4.

6. Após o arranque do motor, deixe-o aquecer durante 2 a 3

minutos

esforço.

Corte

Quando cortar, opere o motor na aceleração máxima, pois isso

mantém a velocidade apropriada do cortador. Ao aparar a parte

superior de uma sebe viva, segure o aparador de fo rma que as

lâminas fi quem entre 15 e 30 graus desde a posição

mova o aparador em um arco na direção da borda da sebe viva para

realizar cortes de varri do. Ao aparar os lados da sebe viva, segure

a lâmina vertical mente e mova a ferramenta em um arco.

NOTA

○ Cabo giratório multiposições (Fig. 10)

Caso o aparador seja do tipo

o ângulo de corte pode ser ajustado afrouxando-se a porca de

bloqueio do cabo (13). Após o ajuste, certifi que- se de reapertar

a porca.

○ Cabo giratório de cinco posições (Fig. 11)

O cabo traseiro pode ser colocado em cinco posições

diferentes, pressionando-se o

o cabo traseiro (15).

É extremamente importante que o cabo seja bloqueado na

posição selecionada.

O botão de bloqueio não funcionará enquanto o gatilho do

acelerador estiver sendo puxado.

○ O gatilho do acelerador não funcionará se o cabo traseiro

estiver desbloqueado.

Parada (Fig. 12,

Reduza a velocidade do motor e, em seguida, coloque o interruptor

de ignição na posição de parada (F).

arranque. (Fig. 4, 5)

ten tativa de arranque do motor, retorn e a

mais ou menos, antes de submetê-lo a qualquer

13)

pelo tubo de retorno. (Se

horizontal e

de cabo giratório (12), repare que

botão de bloqueio (14) e girando

MANUTENÇÃO

A MANUTENÇÃO, SUBSTITUIÇÃO OU REPARO DO SISTEMA E

DOS DISPOSITIVOS DE CONTROLE DE EMISSÕES DEVEM SER

REALIZADOS POR UMA OFICINA OU TÉCNICO DE SERVIÇO DE

MOTORES NÃO RODOVIÁRIOS.

Ajuste do carburador (Fig. 14)

ADVERTÊNCIA

○ O mecanismo de corte pode girar durante os ajustes do

carburador.

○ Nunca arranque o motor sem a tampa completa da

embraiagem. Caso contrário, a embraiagem pode soltar-se e

causar ferimentos.

Page 27

Português

No carburador, o combustível é misturado com ar. O carburador

é regulado na fábrica durante o te ste de funcionamento do motor.

Mais ajustes podem ser necessários de acordo com o clima e a

altitude. O carburador oferece uma possibilidade de ajuste:

T = Parafuso de ajuste da velocidade de ralenti.

velocidade de ralenti (T)

Ajuste da

Veri fi que se o fi ltro de ar está limpo. Se a velocidade de ralenti

estiver correta, o mecanismo de corte não girará. Se for preciso

ajustar, feche o parafuso T (sen tido horário), com o motor em

funcionamento, até que o mecanismo de corte comece a girar.

Abra o parafuso (sent ido anti-horário) até que o mecanismo de

corte pare. A velocidade de ralenti estará correta quando o motor

funcionar suavemente em todas as posições bem abaixo das

revoluções quando o mecanismo de corte começar a girar.