Hitachi CH 22ECP2 62ST, CH 22EA2 50ST, CH 22EC2 62ST, CH 22ECP2 78ST, CH 22EC2 78ST Handling Instructions Manual

...Page 1

Hedge Trimmer

Heckenschere

Taille-Haies

Tosasiepi

Motor heggenschaar

Cortasetos

Read the manual carefully before operating this machine.

Lesen Sie vor der Verwendung diese Anleitung sorgfältig durch.

Lire attentivement le manuel avant d’utiliser la machine.

Leggere attentamente il manuale prima di mettere in funzione questa apparecchiatura.

Lees de handleiding zorgvuldig door voordat u de machine bedient.

Antes de utilizar esta máquina, lea cuidadosamente el manual.

Leia o manual atentamente antes de operar esta máquina.

Läs noga igenom bruksanvisningen innan maskinen tas i bruk.

Læs denne brugsvejledning omhyggeligt, inden maskinen tages i brug.

Bruksanvisningen må leses nøye før bruk av maskinen.

Lue ohjekirja huolellisesti ennen koneen käyttämistä.

Handling instructions

Bedienungsanleitung

Mode d’emploi

Istruzioni per l’uso

Gebruiksaanwijzing

Instrucciones de manejo

Instruções de uso

Bruksanvisning

Brugsanvisning

Bruksanvisning

Käyttöohjeet

Corta-sebes

Häcksax

Hækkeklipper

Hekksaks

Pensasleikkuri

CH 22EAP2 (50ST)/CH 22EA2 (50ST)/CH 22EBP2 (62ST)

CH 22EB2 (62ST)/CH 22ECP2 (62ST)/CH 22EC2 (62ST)

CH 22ECP2 (78ST)/CH 22EC2 (78ST)

CH22ECP2 (62ST)

Page 2

2

0.6 mm

1 2 3

4 5 6

7 8

9 10 11

5

4

1

2

3

D

E

6

2

T

C

B

F

A

Page 3

3

12 13 14

15 16

7

Page 4

4

English

(Original instructions)

MEANINGS OF SYMBOLS

NOTE: Some units do not carry them.

Symb ols

WARNIN G

The foll owing show symbols used for the machin e. Be sure that you understa nd their meaning before us e.

It is important that you read, fully understand and

obser ve the followi ng safety precautions and

warnings. Careless or improper use of the unit may

cause serious or fatal injury.

O /Stop

Read, understand and follow all warnings and

instructions in this manual and on the unit.

Emergency stop

Always wear eye, hea d and e ar protectors when using

this uni t.

Fuel and o il mixture

Choke - Run position (Open) Hot sur face

Choke - Choked position (Closed)

Befo re using your ma chine

• Read the manual carefully.

• Check that the cut ting equipme nt is correctly

assembled and adjusted.

• Star t the unit and check the carburetor adjustment.

See “MA INTENANCE”.

On/St art

Conten ts

WHAT IS WHAT? ..............................................................................5

WARNINGS AND SAFETY INSTRUCTIONS ..................................6

SPECIFICATIONS ............................................................................ 7

OPERATING PROCEDURES ........................................................... 7

MAINTENANCE ................................................................................8

TROUBLESHOOTING ...................................................................... 9

Page 5

5

English

5

8

12

9

1

2

15

4

6

3

11

16

14

10

7

13

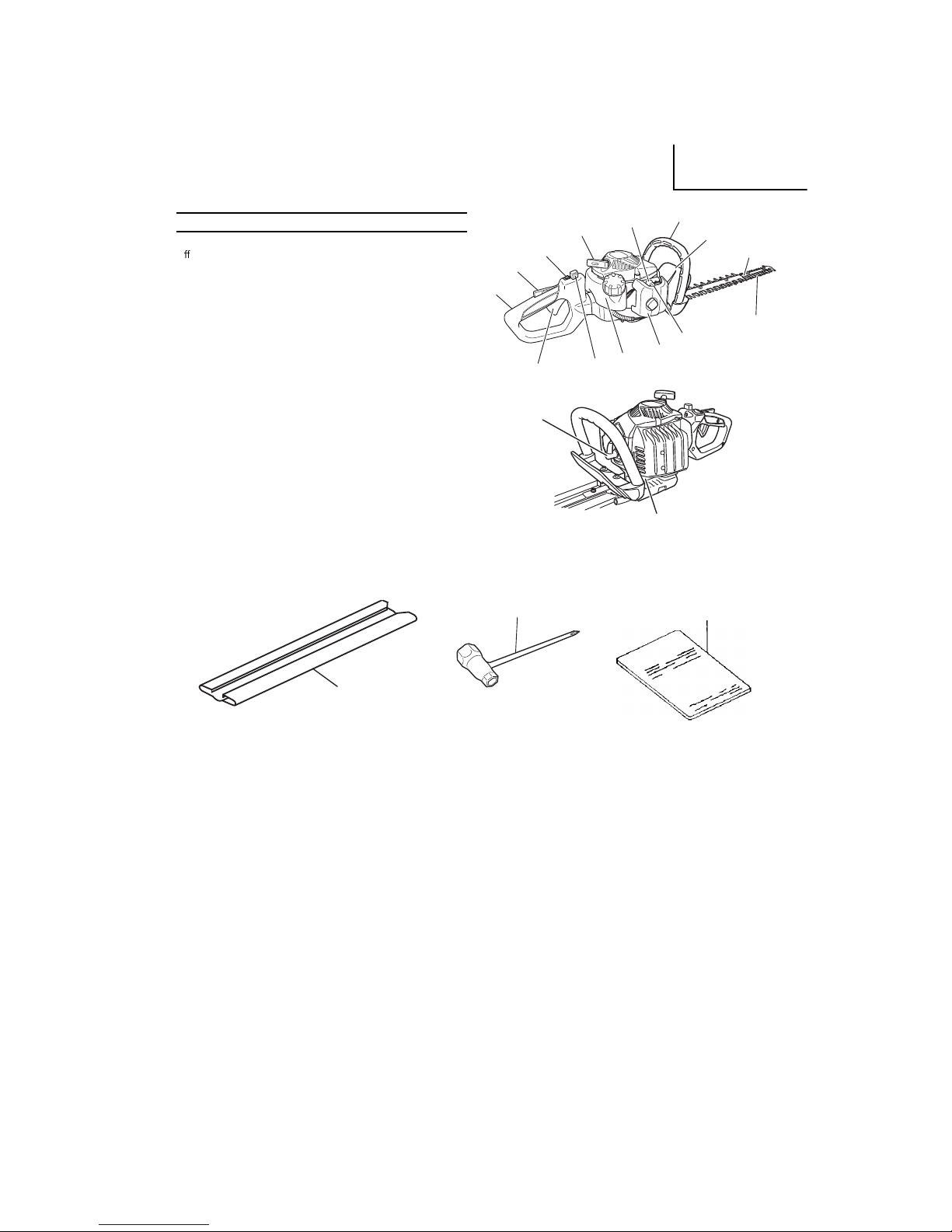

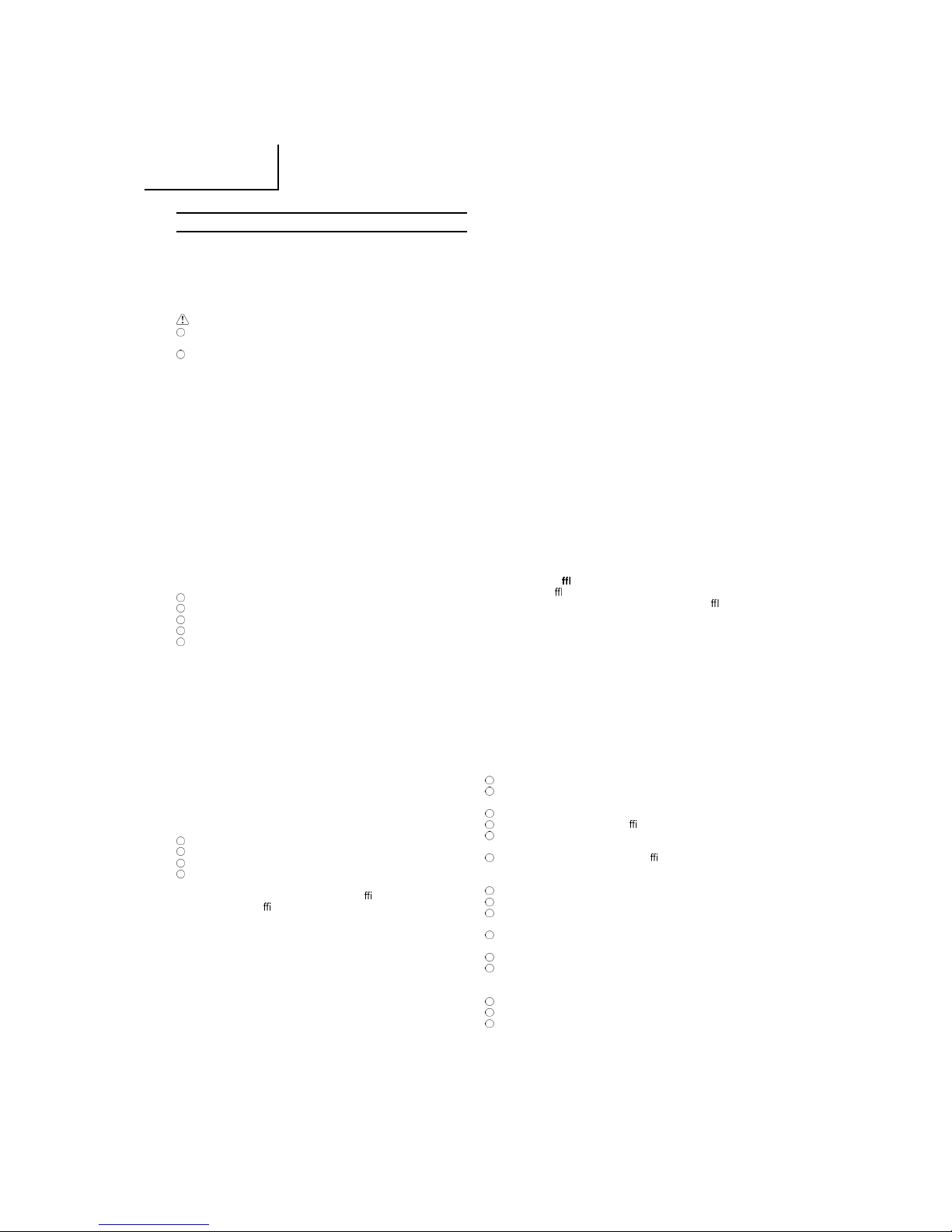

WHAT IS WHAT?

Since thi s manual covers several m odels, there may be some

di eren ce between these illustrations and your unit. Use the

instructions that apply to your unit.

1. Re coil starter

2. Fuel tank

3. Th rottle lever lockout

4. Th rottle lever

5. Front handle

6. Rea r handle

7. Spark plug

8. Hand guard

9. Cu tting blade

10. Air cleaner

11. Stop switch

12. Blade guide

13. Gear case

14. Choke lever

15. Lock lever

16. Primi ng pump

17. Blade case

18. Combi box spanner

19. Handling instr uctions

17

18

19

CH 22EAP2 (50ST), CH 22EA2 (50ST )

CH 22EBP2 (62ST), CH 22EB2 (62ST)

CH 22ECP2 (62ST), CH 22EC2 (6 2ST)

CH 22ECP2 (78ST), CH 22EC2 (78ST)

Page 6

6

English

WARNINGS AND SAFETY INSTRUCTIONS

Keep fo r future refe rence.

THIS HEDGE TRIMMER CAN CAUSE SERIOUS INJURIES. Rea d

the instructions carefully for the correct ha ndling, preparation,

maintenance, starting and stopping of the hedge tr immer. Become

familiar with all controls and the proper use of the hedge tri mmer.

Oper ator safe ty

Always wear a safety face shield or goggles.

Always wea r heavy, long pants, boots and gloves. Do not wear

loose clothi ng, jewelry, short pants, sanda ls or go barefo ot.

Secure hair so it is above shoul der length.

Do not operate this tool when you are tired, ill or under the

infl uence of alcohol, dru gs or medicati on.

Never let a child or inexperienced person operate the machine.

Beware of overh ead power lines.

Wea r hearing protection.

Never start or run the en gine inside a closed room or building.

Breath ing exhaust fumes can kill.

Keep handles free of oil and fuel.

Keep hands away from cutting equipment.

Do not grab or hold the unit by the cutting equipment.

When the unit is turned o , make sure the cutting attachment

has stopped befor e the unit is set down.

When operation is prolon ged, take a break from time to time

so that yo u may avoid possible Hand-Arm Vibration Syndrome

(HAVS) which is caused by vibration.

If the cutting mechanis m strikes any foreign object or the

hedge trimmer starts making any unusual noise or vibration,

shut o the power source and allow the hedg e trimmer to stop.

Disconnect th e spark pl ug wire from the spark plu g and take the

followi ng steps:

Inspect for damage;

Check for, and tighten, any loose parts;

Have any damaged parts replaced or repaired with parts

having equivalen t specifi cations.

WARNING

Antivibration systems do not guar antee that you will not sustain

Hand-Arm Vibration S yndrome or c arpal tunnel syndr ome.

Therefore, continual and regular users should monitor closely

the condition of their hands and fi nger s. If any sy mptoms of th e

above appear, seek medical advice immediately.

If you are using any medica l electri c/electroni c devices such

as a pacemaker, consult your physician as well a s the device

manufacturer pr ior to operating any power equipment.

When a fore ign obje ct is caught in the bla de, turn o the

engine, and remove the foreign obje ct carefully using a plier

etc., af ter the hedge trimmer has been cooled down. Be careful

when removin g the foreign object, since the blade may move

because of the back lash.

Unit /machine safety

Inspect the entire un it/machine before e ach u se. Re place

damaged parts. Check for fuel le aks and make sure all

fasten ers are in place and securely tightened.

Rep lace parts that are cracked, chippe d or damaged in any way

before using the uni t/machine .

Keep others away when making carburetor adjustments.

Use only accessorie s as rec ommended for this unit /machine by

the manu facturer.

WARNING

Never modify the unit /machine in an y way. Do not u se your unit/

machine for any job except that for which it is intended.

Fuel sa fety

Mix and pour fuel outdoors and where there are no sparks or

fl ames.

Use a contain er approved for fuel.

Never remove the fuel cap or add fuel with the power source

runni ng. Allow engine and exhaust compone nts to cool down

before refuellin g.

Do not smoke or allow smokin g near fuel or the unit/m achine or

while using the unit/mach ine.

Never refuel in doors.

Wipe up all fuel spills before starting engine.

Move at least 3 m away from fueling site befo re starting engine.

Stop engine before removing fuel cap.

Empty the fuel tank before storing the unit/machi ne. It i s

recommended that the fuel be emptied af ter each use. If fuel is

left in the tank, store so fuel will not leak.

Store unit/mach ine and f uel in ar ea where fuel vapors cannot

reach sparks or open fl ames from water heaters, electric motors

or switches, furnaces, etc.

WARNING

Fuel is easy to ignite or get explosion or inhale fumes, so tha t

pay special atten tion when handling or fi lling fuel.

Cutti ng safet y

Do not cut any material other than plant hedge.

Inspect the area to be cut before each use. Remove objects

which can be thrown or become entangled.

For respiratory protec tion, wear an aerosol protection mask

when cutting the grass after insecticide is scattered.

Keep others including ch ildren, ani mals, bystanders and

helper s o utside the 15 m hazard zone. Stop t he engine

immedi ately if you are approached.

Hold the unit /machine fi rmly with both hands.

Keep fi rm footing and balance. Do not over-reach.

Keep all parts of your body away from the mu er and cutting

attachment when the engin e is running.

Keep cuttin g tool below shoulder level. NEVER operate uni t

from a ladder, while in a tree or from an y unstab le support.

When relocating to a new work area, be sure to shut o the

machine and ensure that all cutting attachme nts are stopped.

Never place the machine on the groun d when ru nning.

Always carry a fi rst-aid kit when operating any power

equipment.

Never st art or run the engine inside a closed room or buil ding

and/or near the infl ammable liquid. Breathi ng exhaust fumes

can kill.

Mainte nance sa fety

Maintain the unit/mach ine accordi ng to r ecommended

procedures.

Di sconnect t he spa rk plu g before performing mainten ance

except for carburetor adjustments.

Keep others away when making carburetor adjustments.

Use only genuine Hitachi replacement pa rts as reco mmended

by the man ufacturer.

When the h edge trimmer is stopped for servicing, inspection or

storage, shut o the power source, disconn ect the spark pl ug

wire from t he spark plug and make sure all moving parts have

come to a stop.

Allow the hedge trimmer to cool before maki ng any inspecti on,

adjustments, etc .

Transpor t and stora ge

Car ry the unit/mac hine by ha nd wi th th e eng ine stopped and

the mu er away from your body.

Allow the engine to c ool, empty the fuel tank, and secure the

unit /machin e before storin g or transporti ng in a vehicle.

Empty the fuel tank before storing the unit/machi ne. It i s

recommended that the fuel be emptied af ter each use. If fuel is

left in the tank, store so fuel will not leak.

Store unit /machin e out of the reach of children.

Cl ean and maintenance the unit carefully an d store it in a dry

place.

Make sure engine switch is o when transporting or storing.

When trans porting in a vehic le or storage, co ver blade with

blade cover.

If situations occur which are not covered in this manual, take care

and use common sense. Contact your Hitachi deale r if you need

assistance. Pay special attention to stateme nts preceded by the

followi ng words:

WARNING

Indicates a strong possibilit y of severe personal injur y or loss of

life, if in structions are not followed.

CAUTIO N

Indicates a possibility of per sonal inju ry or equ ipment damage,

if instruction s are not followed.

Page 7

7

English

NOTE

Helpful information for correct function and use.

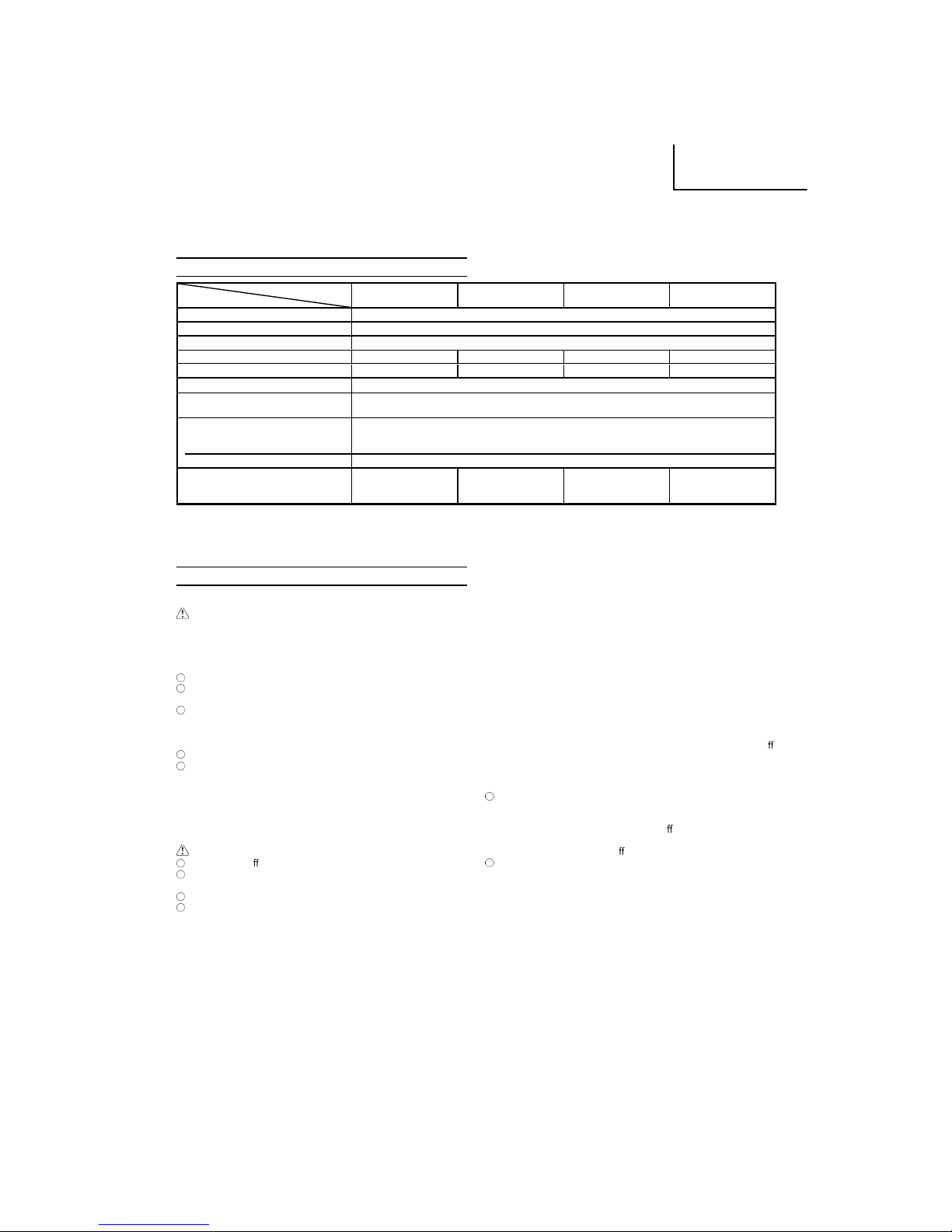

SPECIFICATIONS

MODEL

CH22EAP2 (50ST)

CH22EA2 (50ST)

CH22EBP2 (62ST)

CH22EB2 (62ST)

CH22ECP2 (62ST)

CH22EC2 (62ST)

CH22ECP2 (78ST)

CH22EC2 (78ST)

Engine Size (ml) 21.1

Spark Pl ug NGK BMR 7A (Europ e and Australia) or Champion CJ 6 (other regions)

Fuel Tank Capac ity (l) 0.30

Dry Weight (kg) 4.3 4.7 5.0 5.2

Overall blade length (mm) 500 620 620 780

Blade t ype

Double-sided

Sound pressure level

LpA (dB(A)) (ISO 10517) 97

Sound power level

Lw measured (dB (A))

(2000/14/EC, ISO 10517)

102

LwA (dB (A)) 104

Vibration level (m/s2) (ISO 10517)

Front handle

Rear han dle

7.0

7.5

9.1

9.1

2.8

3.4

2.8

2.8

NOTE

Equi valent noise level/vibration level are calculated as the time-we ighted energy total for noi se/vibration levels under var ious working

condit ions with the fo llowing time distribution : ISO 10517.....1/5 idle, 4/5 rac ing. 2000/14/EC.....only racing .

* All data subjec t to change with out notice.

OPERATING PROCEDURES

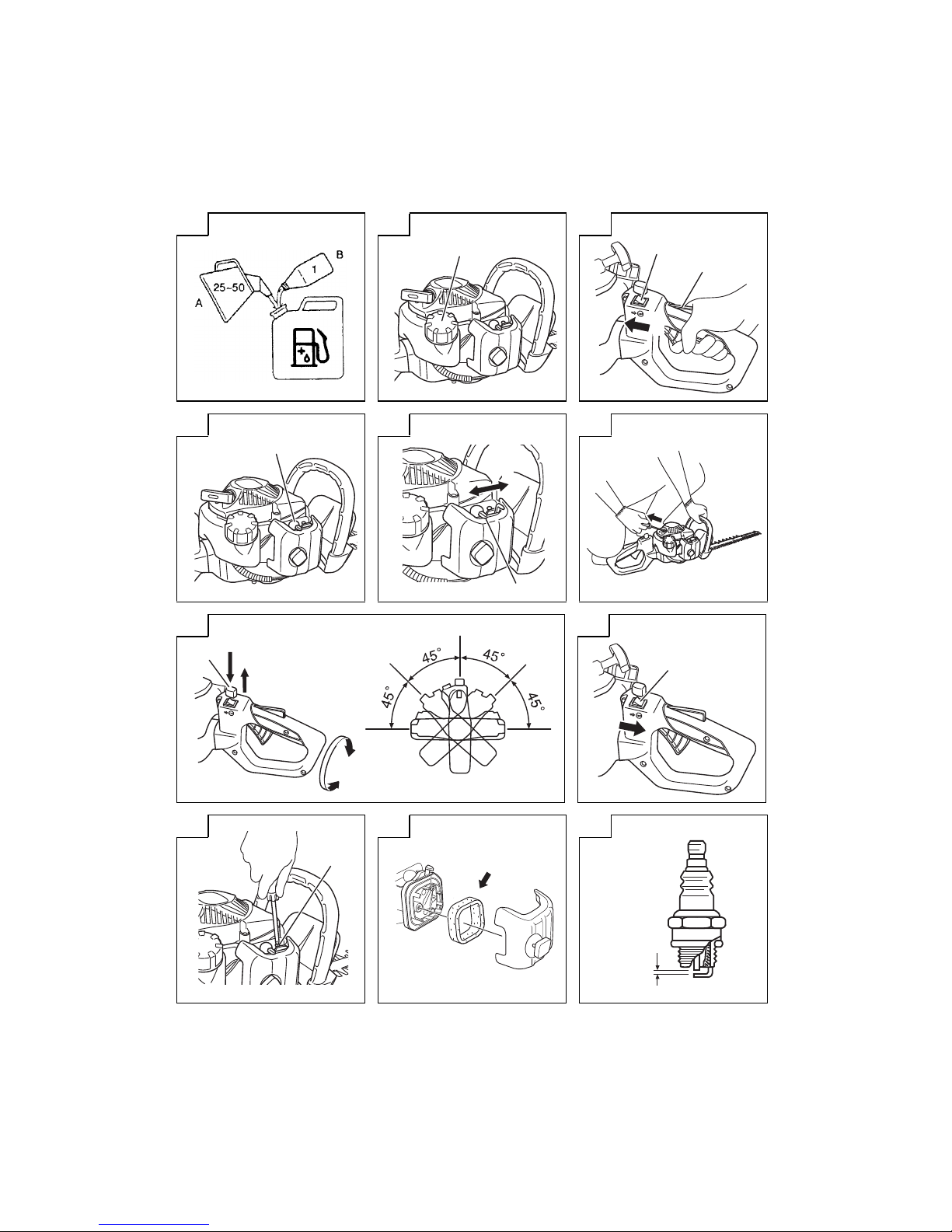

Fuel (Fig . 1)

WARNIN G

The hedge tri mmer is equipped wi th a two- stroke engine.

Always run the engin e on fuel, mixed with oil.

Provide good ventilation, when fueling or handling fuel.

Fuel

Always use branded 89 octane unleaded gasoline.

Use genuine two-cycle oil or use a mix be tween 25:1 to 50:1,

please consult the oil bot tle for the ratio or Hitachi dealer.

If genuine oil is not available, use an anti -oxidant added qua lity

oil expressly labeled for air-cooled 2-cycle engine use (JASO

FC GR ADE OIL or ISO EGC GRADE ). Do not use BIA or TCW

(2-stroke water-cooling type) mixed oil.

Never use mult i-grade oil (10W/30) or waste oil.

Always mix fuel and oil in a se parate cl ean containe r.

Always start by fi lling half the amount of fuel, which is to be used.

Then add the whole amount of oil. Mix (shake) the fuel mixture. Add

the rema ining amount of fuel.

Mix (shake) the fuel-mix thoroughly before fi l ling the fuel ta nk.

Fueling

WARNIN G (Fig. 2)

Always shut o the engine before refue ling.

Slowly open the fuel ta nk (1), wh en fi lling up with fuel, so that

possi ble over-pressure disappears.

Ti ghten the fuel ca p carefully, after fueling .

Always move the unit at lea st 3 m from the fueling area before

starting.

Before fu eling, clean t he tank cap area ca refully, to ensur e that

no dirt falls into the tank. Make sure th at the fuel is wel l mixed by

shaking the cont ainer, before fueling.

Star ting

CAUTIO N

Before starting, make sure the cutting attachment does not

touch anything.

1. Set stop sw itch (2) to ON position (A). (Fig. 3)

* Push priming pump (4) severa l times so that fuel fl ows through

the pump or return pipe. (Fig. 4)

CAUTIO N

Do not dis assemble the recoil starter. you may get a possibili ty

of personal injury with recoil spring.

2. Set choke l ever (5) to CLOSED position (B). (Fig. 5)

3. Pull recoil s tarter briskly, taking ca re to keep the handle in your

grasp and not allowing it to snap back. (Fig. 6)

4. When you hear the e ngine attempts to start, ret urn choke lever

to RUN position (open) (C). Then pull re coil starter briskly

again.

NOTE

If engine does not start, repeat pro cedures from 2 to 4.

5. After st arting engine, allow the engine about 2-3 minute s to

warm up before subjecting it to any load.

Cutti ng

When cutting, operate engine at full throttle as this maintains proper

blade speed. When trimming top of hedge, hold trimmer so blades

are between 15 an d 30 degrees fr om a horizont al position and

swing t rimmer in an arc toward edge of hedge to sweep cut tings o .

When trimming sides of hedge, hold blade vertically and swing unit

in an arc.

NOTE

Multi-position twist handle (Fig. 7)

The rear control handle turns 90 degre es to provide

comfortable use while accommodating a variety of cutting

angles. The handle allows for fi ve di er ent locking positions.

Before attempti ng to adjust rear handle, make sure the machine

is at idle or engine is shut o .

Th e throttle lever cannot be engaged i f t he handle i s n ot

secured (the lock lever is pressed).

To rotate the handle; push the lock lever (6) allowing the handl e

to turn. Rotate the handle to the desired 0°, 4 5° or 90° locking

posit ion and release the lock lever (6) to lock the handle in

place.

D: LOCK

E: UNLOCK

Stopp ing (Fig. 8)

Decrea se engine speed, and push stop switch to stop position (F).

NOTE

If the engi ne does not stop, it can be forced to stop by r otating

the choke lever to the choked position.

Before restar ting the engine, ask Hitachi Au thorized Service

Centers for repairs.

Page 8

8

English

Lubri cating th e blade (Fig.12)

During trimming, sap adhering to the blade edge will increase load.

Use machine o il (or bicycl e oil or the like) to lubricate the blade and

wipe the blade with a cloth. To prevent the blade from rusting, be

sure to lubricate the blade after use and when it will not be used for

an exten ded period of time before placing it in the blade case.

Gear c ase (Fig. 13)

Apply a good quality lithium base d greas e throu gh the grease fi t ting

until a small amount co mes out between the cutting blades and the

gear case. Lubricate the grease from th e grease nipple (indicated

by an arrow) next to the gear case using a commercia lly available

cartridge grease gun.

NOTE

Lubricatio n should be applied 3g at 20 hour interval s and more

freque ntly with heav y use.

Fuel fi lter (Fig. 14)

Remove the fuel fi lter from the fu el tank and thoroughly wash it i n

solvent. After that, push the fi l ter into th e tank co mpletely.

NOTE

If the fi lter is hard due to dust and dirt, repl ace it.

Clea ning the cyli nder fi n s (Fig. 15)

When leaves get ca ught bet ween cylinder fi ns (7), the engine may

overhea t, resulting in lower output. To avoid th is, always keep

cylinder fi ns and cylinder cover clean.

Every 100 operating hours, or once a year (more often if conditions

require), clean fi ns an d external surfaces of eng ine of dust, dirt and

oil depo sits which ca n contribute to improper cooling.

Clea ning the mu er (Fig. 16)

Remove the mu er and spark arrestor (if so equipped), and clean

out any excess ca rbon from the exhaust port or mu er inlet every

100 hours of operati on.

For lon g-term s torage

Drain all fuel from the fuel tank . Start and let engine run until it stops.

Repair any damage which has resulted from use. Clean the unit with

a clea n rag, or high pressure air hose. Put a few drops of two-cycle

engine oil into the cylinder through the spark plug h ole, and spin t he

engine over several times to distribute oil. Cover the unit and store

it in a dry area.

Mainte nance sch edule

Below you will fi nd some general maintenance instructions. For

further inform ation please contact yo ur Hitachi dealer.

Daily maintenanc e

Cl ean the exterior of the hedge trimmer.

Ch eck the blade guide for damage or cr acks. Change the guard

in case of impacts or cracks.

Ch eck that the blade is sharp, and without cracks.

Ch eck that the blade nut is su ciently tightened.

Make sure that the blade blu nt guard is undamaged and that it

can be securely fi tted.

Ch eck that nuts and screws are su ciently tightened.

Weekl y maintena nce

Ch eck the starter, especia lly cord and retu rn spring.

Cl ean the exterior of the spar k plug.

Rem ove it and check the electrode gap. Adjust it to 0.6 mm, or

change the spark plug.

Cl ean t he cooling fi ns on the cylinder and check that the air

intake at the starter is not clo gged.

Ch eck gear case is fi lled with gre ase.

Cl ean the air fi lter.

Mont hly mainte nance

Rinse the fuel tank with gasoline.

Cl ean the exterior of the car buretor and the space around it.

Cl ean the fan and the space arou nd it.

MAINTENANCE

MAINTENANCE, REPLACEMENT OR REPAIR OF THE EMISSION

CONTROL DEV ICES AND SYSTEM MAY BE PERFORMED

BY ANY NONROAD ENGINE REPAIR ESTABLISHMENT OR

INDIVIDUAL.

Carbu retor adjus tment (Fig . 9)

WARNING

Th e cutting attachment may be spinning during car buretor

adjustments.

Never start the eng ine without the complete cleaner cover.

Other wise t he clutch can come loose and cause personal

injuries.

In the carburetor, fu el is mixed with air. When the engine is tes t run

at the factory, th e carburetor is adjusted. A further adjustment may

be required, according to climate and altitude. The ca rburetor has

one adjustment possibility:

T = Idle s peed adjus tment scr ew.

Idle s peed adjus tment (T)

Check that the air fi lter is clean. Wh en the idle speed is corr ect, the

cutting attachment will not r otate. If adjustment is required, close

(clock wise) the T-screw, with the engine running, until the cutting

attachment starts to rotate. Open (cou nter-clock wise) the screw

until th e cutting attachment stops. You have reached the co rrect idle

speed when the engine run s smoothly in all positions well below the

rpm when the cutting attachment starts to rotate.

If the cutting attachment still rotates after idle speed adjustme nt,

contac t Hitachi dealer.

Air fi lter (Fig . 10)

The air fi lter must be cleaned from dust and dir t in order to avoid:

Car buretor malfunction s.

Starting problems.

En gine power reduction.

Unn ecessary wear on the engine par ts.

Abnormal fuel consu mption.

Clean the air fi lter daily or more often if working in exceptionally

dusty areas.

Clea ning the air fi lt er

Remove th e cleaner cover and the fi lter. Rinse it in warm soa p suds.

Check that the fi lter is dry before reassembly. An air fi lter that has

been used for some time cannot be cleaned completely. Therefore,

it must regularly be rep laced by a new one. A damaged fi lter must

always be replaced.

NOTE

Saturate the ele ment in 2-cycle oil or the e quivalent. Squeeze

the element to distribute the oil completely and to remove any

excess oil.

Spar k plug (Fig. 11)

The spark plug con dition is infl uenced by:

An incorrec t carburetor s etting.

Wrong fuel mix ture (too much oil in the gasoline).

A dirty air fi lter.

Ha rd running conditions (such as cold weather).

These factors cause deposits on the spark plug electrodes, which

may result in mal function and star ting di culties. If t he engine

is low on power, di cult to start or runs poorly at idling speed,

always check the spark plug fi r st. If the spark pl ug is dirty, clean it

and check the electrode gap. Readju st i f nece ssary. The correct

gap is 0.6 mm. Th e spark plug should be replaced after about 100

operation hours or earlie r i f the electrodes are badly erode d.

NOTE

In some areas, local law requires using a resistor spark plug

to suppress ignition sign als. If this machine was originally

equipped with resistor spark plug, use the same type of spar k

plug for replacem ent.

Page 9

9

English

TROUBLESHOOTING

Use the inspe ctions in the table below if the tool does not operate n ormally. If this does not remedy the problem, c onsult your dealer or th e

Hitachi Authorized Service Center.

Symptom Possible cause Remedy

Tool Does not operate. Foreign matter is lodged in th e blade. When there is foreign matter in the blade, use a

pair of tongs or similar tool to remove it.

Take great care since the tool may start

operating when the foreign matter has been

removed.

Sap or rust may also prevent the blade from

operating. Use a wi re brus h or similar tool to

remove sap or rust.

The tool does not tri m well. The blade stopped because it was used to cut

a branch whose width exceede d the blade’s

cutting capaci ty.

NOTE

Work that will repeatedly cause the bla de to

stop wil l e ve ntually damag e the tool.

Some garden trees have wood tha t is very

hard and may be beyond the capaci ty of the

tool even if it is of a width that is within normal

capacity. Use a pair of pruning shear to remo ve

thick branches before starting work.

An oblique cut may also exceed the capacit y of

the tool since the le ngth of the cut increases.

Be sure to trim thick branche s at right angles.

Page 10

CH22EA2 (50ST)

74

Page 11

CH22EA2 (50ST)

Item

No.

Part Name Q’TY

1 COVER FIXING BOLT COMP. 1

2 CLEANER C OVER 1

3 CLEANER SPONGE 1

4 CHOKE VALVE 1

5

MACHINE SCREW

(W/WASHERS) M5×60

2

6 CLEANER BO DY 1

7 CHOKE HANDL E 1

8

TAPPING SCREW (W/FL ANGE)

D4×12

1

9

THROTTLE ADJUST SCREW

(TAS)

1

10 SE T SCREW (B) 3

11 SE T SCREW (D) 4

12 SYR INGE 1

13 PRI MER BASE 1

14 PUMP G ASKET 1

15 PUMP DIAPHRAGM 1

16 ST RAINER 1

17 GUI DE PIN ROLLER 1

18 SYR INGE RETAINER 1

19 SE T SCREW (E) 1

20 BALL PLUG RETAINER 1

21

ADJUSTING SC REW

(MAIN MIXTUR E)

1

22 METERING L EVER SPRING 1

23 PIN 1

24 METERING DIAPHRAGM 1

25 METERING COVER 1

26 SET SCREW (C) 3

27 POST 1

28 ROTOR COVER 1

29

RETAINING RING (E-TYPE) FOR

D2.5 SHAFT

1

30 O-RING 1

31 INLET NEEDLE VALVE 1

32 SET SCREW (A) 1

33 METERING L EVER 1

34 METERING GA SKET 1

35

CARBURETOR ASS 'Y

(INCLUD.9-3 4)

1

36 LOCK NUT M6 1

37 CARBURETOR INSU LATOR 1

38 INTAKE PACKING 1

39 GLASS WASHER 4

40 CARBURETOR PACKING 1

41

SEAL LOCK HEX . SOCKET

BOLT (W/WASHERS)M5×25

2

42

HEX. SOCKET HD. BOLT

(W/WASHERS) M4×18

2

43 CORD 1

44

SEAL LOCK HEX . SOCKET HD.

BOLT M4×12

1

45 CYLINDER COVER 1

46 METAL OF PLUG CAP (60) (B) 1

47 PLUG CAP 1

48 CORD INSUL ATION TUBE 1

49 IGNITION COIL 1

50 SPARK PLUG 1

51 CYLI NDER 1

52 COVER PACKING 2

53 INTAKE COVER (A) 1

54 SEAL LOCK SCRE W M 4×10 4

55 HEAT PROTECTION PANEL 1

56 MUFFLER 1

57 BOLT WASHER M6 2

58 HEX. SOCKET HD. BOLT M6×55 2

Item

No.

Part Name Q’TY

59 INTAKE COVER (B) 1

60 PISTON PIN 1

61 PISTON 1

62

HEX. SOCKET HD. BOLT

(W/SP.WAS HER) M5×18

8

63 CYLINDER PACKING 1

64 PISTON RING 1

65 CIR CLIP 2

66 FLYWHEEL NUT M7 1

67 BOLT WASHER D7 1

68 STARTER PAWL 2

69 STARTER PAWL SPRING 2

70 MAGNETO ROTOR 1

71 RETAINING RING D4 2

72

CRANK CASE (B) ASS'Y

(INCLUD.73,74)

1

73 OIL SEAL TB 12227 2

74 BALL BE ARING 6001C3 2

75 SHIM T0.2 1

76 SHIM T0.3 1

77 CRANK SHAF T 1

78

CRANK CASE (A) ASS'Y

(INCLUD.73,74,80)

1

79 CRANK CASE PACKING 1

80 KNOCK PIN 4×12 2

81 CLUTCH ASS'Y (B) 1

82 CLUTCH DRUM 1

83 BALL BEARIN G 6002ZC3 2

84

RETAINING RING FOR D15

SHAFT

1

85 GREASE NIPPLE COMP. 1

86

TAPPING SCREW (W/FL ANGE)

D5X20

1

87 MUFFLER PROTECTOR 1

88

MACHINE SCREW

(W/SP.WAS HERS) M5×16

1

89 HEX. HOLE B OLT 6×18/S 4

90

HEX. SOCKET HD. BOLT

(W/BUTTON) M5×20

2

91 FIXATION PLATE (A) 1

92 FIXATION PLATE (B) 1

93 TAIL PIPE (A) 1

94 EXHAUST COVER 1

95 HITACHI LABEL 1

96 TAPPING SCREW D4.5×16 1

97 PLATE 1

98 STARTER KNOB 1

99 STARTER ROPE 1

100

HEX. SOCKET HD. BOLT

(W/BUTTON) M5×20

3

101 RECOIL SPRING 1

102 STARTER ROPE REEL 1

103 DAMPER SPRING 1

104 CAM PLATE 1

105 SET SCREW 1

106

RECOIL STARTER ASS'Y

(INCLUD.97-99,101-10 5)

1

107 AIR DEFLECTOR 1

108

FUEL TANK CAP ASS'Y

(INCLUD.109)

1

109 TANK CAP CHAIN 1

110 F UEL GROMMET 1

111 FUEL PIPE 1

112 F UEL PIPE (PINK) 1

113 R ETURN GROMMET 1

114 C LIP 1

115 P UMP FILTER 1

Item

No.

Part Name Q’TY

116 C USHION RUBBER 4

117 TANK 1

141 NAME PLATE 1

142 HANDLE 1

143

SEAL LOCK HEX . SOCKET HD.

BOLT M5×40

2

144 SPRING WASHER M5 2

145 BRAKE AXI S WASH ER 2

146 HANDLE A 1

147 CAUTION LABEL 1

148 SPRING (A) 1

149 LOCK LEVER 1

150 THROTTLE LEV ER 1

151 TRIGGER LOCKOUT 1

152 THROTTLE LEV ER SPRING 1

153 STOP SWITCH 1

154 HANDLE B 1

155

TAPPING SCREW (W/FL ANGE)

D4×16

4

156 THROTTLE WIRE 1

157 PROTECTION TUBE 1

158 STOP SWITCH CORD 1

159 STOP SWITCH CORD (B) 1

160 FIXATION PLATE (B) 1

161 NYLON NUT M5 2

162 SMALL WASHER 5 2

163 SPACER 1

164

HEX. SOCKET HD. BOLT

(W/BUTTON) M5×25

2

165 U-NUT M5 5

166 WASHER (B) 5

167 WASHER M7 5

168

SHOULDER BUTTON BOLT

M5×25

5

169 BLADE ASS'Y (INCLUD.164-16 8) 1

170 BLADE CASE (A) 1

171 HANDLE BRACKET 1

172 CLIP 1

173 BOLT WASHER D5 3

174

SEAL LOCK HEX . SOCKET

BOLT (W/WASHERS) M5×16

3

175

GEAR CASE (A) ASS'Y

(INCLUD.176)

1

176 GUIDE PLATE (C) 1

177 GEAR 2 1

178 GUIDE PLATE (A) 1

179 FELT PA CKING (A) 1

180 GEAR CASE PACKING 1

181 GEAR CASE COVER 1

182

HEX. SOCKET HD. BOLT

(W/SP.WAS HER) M5×12

6

501 BOX WRENCH 10/19MM 1

75

Page 12

CH22EBP2 (62ST)

76

Page 13

Item

No.

Part Name Q’TY

1 COVER FIXING BOLT COMP. 1

2 CLEANER C OVER 1

3 CLEANER SPONGE 1

4 CHOKE VALVE 1

5

MACHINE SCREW

(W/WASHERS) M5×60

2

6 CLEANER BO DY 1

7 CHOKE HANDL E 1

8

TAPPING SCREW (W/FL ANGE)

D4×12

1

9

THROTTLE ADJUST SCREW

(TAS)

1

10 SE T SCREW (B) 3

11 SE T SCREW (D) 4

12 SYR INGE 1

13 PRI MER BASE 1

14 PUMP G ASKET 1

15 PUMP DIAPHRAGM 1

16 ST RAINER 1

17 GUI DE PIN ROLLER 1

18 SYR INGE RETAINER 1

19 SE T SCREW (E) 1

20 BALL PLUG RETAINER 1

21

ADJUSTING SC REW

(MAIN MIXTUR E)

1

22 METERING L EVER SPRING 1

23 PIN 1

24 METERING DIAPHRAGM 1

25 METERING COVER 1

26 SET SCREW (C) 3

27 POST 1

28 ROTOR COVER 1

29

RETAINING RING (E-TYPE) FOR

D2.5 SHAFT

1

30 O-RING 1

31 INLET NEEDLE VALVE 1

32 SET SCREW (A) 1

33 METERING L EVER 1

34 METERING GA SKET 1

35

CARBURETOR ASS 'Y

(INCLUD.9-3 4)

1

36 LOCK NUT M6 1

37 CARBURETOR INSU LATOR 1

38 INTAKE PACKING 1

39 GLASS WASHER 4

40 CARBURETOR PACKING 1

41

SEAL LOCK HEX . SOCKET

BOLT (W/WASHERS)M5×25

2

42

HEX. SOCKET HD. BOLT

(W/WASHERS) M4×18

2

43 CORD 1

44

SEAL LOCK HEX . SOCKET HD.

BOLT M4×12

1

45 CYLINDER COVER 1

46 METAL OF PLUG CAP (60) (B) 1

47 PLUG CAP 1

48 CORD INSUL ATION TUBE 1

49 IGNITION COIL 1

50 SPARK PLUG 1

51 CYLI NDER 1

52 COVER PACKING 2

53 INTAKE COVER (A) 1

54 SEAL LOCK SCRE W M 4×10 4

55 HEAT PROTECTION PANEL 1

56 MUFFLER 1

57 BOLT WASHER M6 2

58 HEX. SOCKET HD. BOLT M6×55 2

59 INTAKE COVER (B) 1

Item

No.

Part Name Q’TY

60 PISTON PIN 1

61 PISTON 1

62

HEX. SOCKET HD. BOLT

(W/SP.WAS HER) M5×18

8

63 CYLINDER PACKING 1

64 PISTON RING 1

65 CIR CLIP 2

66 FLYWHEEL NUT M7 1

67 BOLT WASHER D7 1

68 STARTER PAWL 2

69 STARTER PAWL SPRING 2

70 MAGNETO ROTOR 1

71 RETAINING RING D4 2

72

CRANK CASE (B) ASS'Y

(INCLUD.73,74)

1

73 OIL SEAL TB 12227 2

74 BALL BE ARING 6001C3 2

75 SHIM T0.2 1

76 SHIM T0.3 1

77 CRANK SHAF T 1

78

CRANK CASE (A) ASS'Y

(INCLUD.73,74,80)

1

79 CRANK CASE PACKING 1

80 KNOCK PIN 4×12 2

81 CLUTCH ASS'Y (B) 1

82 CLUTCH DRUM 1

83 BALL BEARIN G 6002ZC3 2

84

RETAINING RING FOR D15

SHAFT

1

85 GREASE NIPPLE COMP. 1

86

TAPPING SCREW (W/FL ANGE)

D5×20

1

87 MUFFLER PROTECTOR 1

88

MACHINE SCREW

(W/SP.WAS HERS) M5×16

1

89 HEX. HOLE B OLT 6×18/S 4

90

HEX. SOCKET HD. BOLT

(W/BUTTON) M5×20

2

91 FIXATION PLATE (A) 1

92 FIXATION PLATE (B) 1

93 TAIL PIPE (A) 1

94 EXHAUST COVER 1

95 HITACHI LABEL 1

96 TAPPING SCREW D4.5×16 1

97 PLATE 1

98 STARTER KNOB 1

99 STARTER ROPE 1

100

HEX. SOCKET HD. BOLT

(W/BUTTON) M5×20

3

101 RECOIL SPRING 1

102 STARTER ROPE REEL 1

103 DAMPER SPRING 1

104 CAM PLATE 1

105 SET SCREW 1

106

RECOIL STARTER ASS'Y

(INCLUD.97-99,101-10 5)

1

107 AIR DEFLECTOR 1

108

FUEL TANK CAP ASS'Y

(INCLUD.109)

1

109 TANK CAP CHAIN 1

110 F UEL GROMMET 1

111 FUEL PIPE 1

112 F UEL PIPE (PINK) 1

113 R ETURN GROMMET 1

114 C LIP 1

115 P UMP FILTER 1

116 C USHION RUBBER 4

117 TANK 1

Item

No.

Part Name Q’TY

118 CAUTION LABEL 1

141 NAME PLATE 1

142 HANDLE 1

143

SEAL LOCK HEX . SOCKET HD.

BOLT M5×40

2

144 SPRING WASHER M5 2

145 BRAKE AXI S WASH ER 2

146 HANDLE A 1

147 CAUTION LABEL 1

148 SPRING (A) 1

149 LOCK LEVER 1

150 THROTTLE LEV ER 1

151 TRIGGER LOCKOUT 1

152 THROTTLE LEV ER SPRING 1

153 STOP SWITCH 1

154 HANDLE B 1

155

TAPPING SCREW (W/FL ANGE)

D4×16

4

156 THROTTLE WIRE 1

157 PROTECTION TUBE 1

158 STOP SWITCH CORD 1

159 STOP SWITCH CORD (B) 1

160 FIXATION PLATE (B) 1

161 NYLON NUT M6 2

162 BOLT WASHER 6 2

163 U-NUT M5 5

164 WASHER (A) 2

165 RUBBER WASHER 2

166 COLLER 1

167 SUPPORT PLATE 1

168 BOLT WASHER D6 2

169

BLADE ASS' Y

(INCLUD.163,172-173)

1

170

HEX. SOCKET HD. BOLT

(W/FLANGE) M5×8

1

171 GUARD PLATE 1

172

HEX. SOCKET HD. BOLT

(W/BUTTON) M6×25

1

173 WASHER (A) 5

174 WASH ER M7 5

175

SHOULDER BUTTON BOLT

M5×25

4

176

SHOULDER BUTTON BOLT

M5×31

1

177 BLADE CASE 1

178 HANDLE BRACKE T 1

179 CLIP 1

180 BOLT WASHER D5 3

181

SEAL LOCK HEX . SOCKET

BOLT (W/WASHERS) M5×16

3

182

GEAR CASE (A) ASS'Y

(INCLUD.183)

1

183 BALL BEARING 608ZZC3 2

184

HEX. SOCKET HD. BOLT

(W/BUTTON) M6×25

1

185 GUIDE PLATE (B) 2

186 CAM ROD 2

187 GEAR 2 1

188 FELT PACKING (B) 2

189 FELT PACKING (C) 1

190 GEAR CASE PACKING 1

191

GEAR CASE (B) ASS'Y

(INCLUD.183)

1

192

HEX. SOCKET HD. BOLT

(W/SP.WAS HER) M5×14

6

501 BOX WRENCH 10/19MM 1

CH22EBP2 (62ST)

77

Page 14

CH22EB2 (62ST)

78

Page 15

CH22EB2 (62ST)

Item

No.

Part Name Q’TY

1 COVER FIXING BOLT COMP. 1

2 CLEANER C OVER 1

3 CLEANER SPONGE 1

4 CHOKE VALVE 1

5

MACHINE SCREW

(W/WASHERS) M5×60

2

6 CLEANER BO DY 1

7 CHOKE HANDL E 1

8

TAPPING SCREW (W/FL ANGE)

D4×12

1

9

THROTTLE ADJUST SCREW

(TAS)

1

10 SE T SCREW (B) 3

11 SE T SCREW (D) 4

12 SYR INGE 1

13 PRI MER BASE 1

14 PUMP G ASKET 1

15 PUMP DIAPHRAGM 1

16 ST RAINER 1

17 GUI DE PIN ROLLER 1

18 SYR INGE RETAINER 1

19 SE T SCREW (E) 1

20 BALL PLUG RETAINER 1

21

ADJUSTING SC REW

(MAIN MIXTUR E)

1

22 METERING L EVER SPRING 1

23 PIN 1

24 METERING DIAPHRAGM 1

25 METERING COVER 1

26 SET SCREW (C) 3

27 POST 1

28 ROTOR COVER 1

29

RETAINING RING (E-TYPE) FOR

D2.5 SHAFT

1

30 O-RING 1

31 INLET NEEDLE VALVE 1

32 SET SCREW (A) 1

33 METERING L EVER 1

34 METERING GA SKET 1

35

CARBURETOR ASS 'Y

(INCLUD.9-3 4)

1

36 LOCK NUT M6 1

37 CARBURETOR INSU LATOR 1

38 INTAKE PACKING 1

39 GLASS WASHER 4

40 CARBURETOR PACKING 1

41

SEAL LOCK HEX . SOCKET

BOLT (W/WASHERS)M5×25

2

42

HEX. SOCKET HD. BOLT

(W/WASHERS) M4×18

2

43 CORD 1

44

SEAL LOCK HEX . SOCKET HD.

BOLT M4×12

1

45 CYLINDER COVER 1

46 METAL OF PLUG CAP (60) (B) 1

47 PLUG CAP 1

48 CORD INSUL ATION TUBE 1

49 IGNITION COIL 1

50 SPARK PLUG 1

51 CYLI NDER 1

52 COVER PACKING 2

53 INTAKE COVER (A) 1

54 SEAL LOCK SCRE W M 4×10 4

55 HEAT PROTECTION PANEL 1

56 MUFFLER 1

57 BOLT WASHER M6 2

58 HEX. SOCKET HD. BOLT M6×55 2

59 INTAKE COVER (B) 1

Item

No.

Part Name Q’TY

60 PISTON PIN 1

61 PISTON 1

62

HEX. SOCKET HD. BOLT

(W/SP.WAS HER) M5×18

8

63 CYLINDER PACKING 1

64 PISTON RING 1

65 CIR CLIP 2

66 FLYWHEEL NUT M7 1

67 BOLT WASHER D7 1

68 STARTER PAWL 2

69 STARTER PAWL SPRING 2

70 MAGNETO ROTOR 1

71 RETAINING RING D4 2

72

CRANK CASE (B) ASS'Y

(INCLUD.73,74)

1

73 OIL SEAL TB 12227 2

74 BALL BE ARING 6001C3 2

75 SHIM T0.2 1

76 SHIM T0.3 1

77 CRANK SHAF T 1

78

CRANK CASE (A) ASS'Y

(INCLUD.73,74,80)

1

79 CRANK CASE PACKING 1

80 KNOCK PIN 4×12 2

81 CLUTCH ASS'Y (B) 1

82 CLUTCH DRUM 1

83 BALL BEARIN G 6002ZC3 2

84

RETAINING RING FOR D15

SHAFT

1

85 GREASE NIPPLE COMP. 1

86

TAPPING SCREW (W/FL ANGE)

D5×20

1

87 MUFFLER PROTECTOR 1

88

MACHINE SCREW

(W/SP.WAS HERS) M5×16

1

89 HEX. HOLE B OLT 6×18/S 4

90

HEX. SOCKET HD. BOLT

(W/BUTTON) M5×20

2

91 FIXATION PLATE (A) 1

92 FIXATION PLATE (B) 1

93 TAIL PIPE (A) 1

94 EXHAUST COVER 1

95 HITACHI LABEL 1

96 TAPPING SCREW D4.5×16 1

97 PLATE 1

98 STARTER KNOB 1

99 STARTER ROPE 1

100

HEX. SOCKET HD. BOLT (W/

BUTTON) M5×20

3

101 RECOIL SPRING 1

102 STARTER ROPE REEL 1

103 DAMPER SPRING 1

104 CAM PLATE 1

105 SET SCREW 1

106

RECOIL STARTER ASS'Y

(INCLUD.97-99,101-10 5)

1

107 AIR DEFLECTOR 1

108

FUEL TANK CAP ASS'Y

(INCLUD.109)

1

109 TANK CAP CHAIN 1

110 F UEL GROMMET 1

111 FUEL PIPE 1

112 F UEL PIPE (PINK) 1

113 R ETURN GROMMET 1

114 C LIP 1

115 P UMP FILTER 1

116 C USHION RUBBER 4

117 TANK 1

Item

No.

Part Name Q’TY

141 NAME PLATE 1

142 HANDLE 1

143

SEAL LOCK HEX . SOCKET HD.

BOLT M5×40

2

144 SPRING WASHER M5 2

145 BRAKE AXI S WASH ER 2

146 HANDLE A 1

147 CAUTION LABEL 1

148 SPRING (A) 1

149 LOCK LEVER 1

150 THROTTLE LEV ER 1

151 TRIGGER LOCKOUT 1

152 THROTTLE LEV ER SPRING 1

153 STOP SWITCH 1

154 HANDLE B 1

155

TAPPING SCREW (W/FL ANGE)

D4×16

4

156 THROTTLE WIRE 1

157 PROTECTION TUBE 1

158 STOP SWITCH CORD 1

159 STOP SWITCH CORD (B) 1

160 FIXATION PLATE (B) 1

161 NYLON NUT M6 2

162 BOLT WASHER 6 2

163 U-NUT M5 5

164 WASHER (A) 2

165 RUBBER WASHER 2

166 COLLER 1

167 SUPPORT PLATE 1

168 BOLT WASHER D6 2

169

BLADE ASS' Y

(INCLUD.163,172-173)

1

170

HEX. SOCKET HD. BOLT

(W/FLANGE) M5×8

1

171 GUARD PLATE 1

172

HEX. SOCKET HD. BOLT

(W/BUTTON) M6×25

1

173 WASHER (A) 5

174 WASH ER M7 5

175

SHOULDER BUTTON BOLT

M5×25

4

176

SHOULDER BUTTON BOLT

M5×31

1

177 BLADE CASE 1

178 HANDLE BRACKE T 1

179 CLIP 1

180 BOLT WASHER D5 3

181

SEAL LOCK HEX . SOCKET

BOLT (W/WASHERS) M5×16

3

182

GEAR CASE (A) ASS'Y

(INCLUD.183)

1

183 BALL BEARING 608ZZC3 2

184

HEX. SOCKET HD. BOLT

(W/BUTTON) M6×25

1

185 GUIDE PLATE (B) 2

186 CAM ROD 2

187 GEAR 2 1

188 FELT PACKING (B) 2

189 FELT PACKING (C) 1

190 GEAR CASE PACKING 1

191

GEAR CASE (B) ASS'Y

(INCLUD.183)

1

192

HEX. SOCKET HD. BOLT

(W/SP.WAS HER) M5×14

6

501 BOX WRENCH 10/19MM 1

79

Page 16

CH22ECP2 (62ST) / CH22ECP2 (78ST)

80

Page 17

CH22ECP2 (62ST) / CH22ECP2 (78ST)

Item

No.

Part Name Q’TY

1 COVER FIXING BOLT COMP. 1

2 CLEANER C OVER 1

3 CLEANER SPONGE 1

4 CHOKE VALVE 1

5

MACHINE SCREW

(W/WASHERS) M5×60

2

6 CLEANER BO DY 1

7 CHOKE HANDL E 1

8

TAPPING SCREW (W/FL ANGE)

D4×12

1

9

THROTTLE ADJUST SCREW

(TAS)

1

10 SE T SCREW (B) 3

11 SE T SCREW (D) 4

12 SYR INGE 1

13 PRI MER BASE 1

14 PUMP G ASKET 1

15 PUMP DIAPHRAGM 1

16 ST RAINER 1

17 GUI DE PIN ROLLER 1

18 SYR INGE RETAINER 1

19 SE T SCREW (E) 1

20 BALL PLUG RETAINER 1

21

ADJUSTING SC REW

(MAIN MIXTUR E)

1

22 METERING L EVER SPRING 1

23 PIN 1

24 METERING DIAPHRAGM 1

25 METERING COVER 1

26 SET SCREW (C) 3

27 POST 1

28 ROTOR COVER 1

29

RETAINING RING (E-TYPE)

FOR D2.5 SHAF T

1

30 O-RING 1

31 INLET NEEDLE VALVE 1

32 SET SCREW (A) 1

33 METERING L EVER 1

34 METERING GA SKET 1

35

CARBURETOR ASS 'Y

(INCLUD.9-3 4)

1

36 LOCK NUT M6 1

37 CARBURETOR INSU LATOR 1

38 INTAKE PACKING 1

39 GLASS WASHER 4

40 CARBURETOR PACKING 1

41

SEAL LOCK HEX . SOCKET

BOLT (W/WASHERS)M5×25

2

42

HEX. SOCKET HD. BOLT

(W/WASHERS) M4×18

2

43 CORD 1

44

SEAL LOCK HEX . SOCKET HD.

BOLT M4×12

1

45 CYLINDER COVER 1

46 METAL OF PLUG CAP (60) (B) 1

47 PLUG CAP 1

48 CORD INSUL ATION TUBE 1

49 IGNITION COIL 1

50 SPARK PLUG 1

51 CYLI NDER 1

52 COVER PACKING 2

53 INTAKE COVER (A) 1

54 SEAL LOCK SCRE W M 4×10 4

55 HEAT PROTECTION PANEL 1

56 MUFFLER 1

57 BOLT WASHER M6 2

58

HEX. SOCKET HD. BOLT

M6×55

2

Item

No.

Part Name Q’TY

59 INTAKE COVER (B) 1

60 PISTON PIN 1

61 PISTON 1

62

HEX. SOCKET HD. BOLT

(W/SP.WAS HER) M5×18

8

63 CYLINDER PACKING 1

64 PISTON RING 1

65 CIR CLIP 2

66 FLYWHEEL NUT M7 1

67 BOLT WASHER D7 1

68 STARTER PAWL 2

69 STARTER PAWL SPRING 2

70 MAGNETO ROTOR 1

71 RETAINING RING D4 2

72

CRANK CASE (B) ASS'Y

(INCLUD.73,74)

1

73 OIL SEAL TB 12227 2

74 BALL BE ARING 6001C3 2

75 SHIM T0.2 1

76 SHIM T0.3 1

77 CRANK SHAF T 1

78

CRANK CASE (A) ASS'Y

(INCLUD.73,74,80)

1

79 CRANK CASE PACKING 1

80 KNOCK PIN 4X12 2

81 CLUTCH ASS'Y (B) 1

82 CLUTCH DRUM 1

83 BALL BEARIN G 6002ZC3 2

84

RETAINING RING FOR D15

SHAFT

1

85 GREASE NIPPLE COMP. 1

86

TAPPING SCREW (W/FL ANGE)

D5×20

1

87 MUFFLER PROTECTOR 1

88

MACHINE SCREW

(W/SP.WAS HERS) M5×16

1

89 TAIL PIPE 1

90 FIXATION PLATE (A) 1

91

MACHINE SCREW

(W/WASHERS) M4×10

1

92 FIXATION PLATE (B) 1

93 HEX. HOLE BOLT 6×18/S 4

94 HITACHI LABEL 1

95 TAPPING SCREW D4.5×16 1

96 PLATE 1

97 STARTER KNOB 1

98 STARTER ROPE 1

99

HEX. SOCKET HD. BOLT

(W/BUTTON) M5×20

3

100 RECOIL SPRING 1

101 STARTER ROPE REEL 1

102 DAMPER SPRING 1

103 CAM PLATE 1

104 SET SCREW 1

105

RECOIL STARTER ASS'Y

(INCLUD.97-99,101-10 5)

1

106 AIR DEFLECTOR 1

107

FUEL TANK CAP ASS'Y

(INCLUD.109)

1

108 TANK CAP CHAIN 1

109 FUEL GROMMET 1

110 F UEL PIPE 1

111 FUEL PIPE (PINK) 1

112 R ETURN GROMMET 1

113 C LIP 1

114 P UMP FILTER 1

115 C USHION RUBBER 4

116 TANK 1

Item

No.

Part Name Q’TY

117 CAUTION LABEL 1

141

HEX. SOCKET HD. BOLT

(W/FLANGE) M6×32

4

142 FRONT HANDLE 1

143 CAUTION LABEL 1

144 FRAME 1

145 NAME PLATE 1

146 DAMPER 1

147 HANDLE A 1

148 FLEXIBLE GRO MMET 1

149 SPRING (A) 1

150 LOCK LEVER 1

151 THROTTLE LEVE R 1

152 TRIGGER LOCKOUT 1

153 THROTTLE LEV ER SPRING 1

154 STOP SWITCH 1

155 HANDLE B 1

156

TAPPING SCREW (W/FL ANGE)

D4×16 (BLACK)

4

157 THROTTLE WIRE 1

158 PROTECTION TUBE 1

159 STOP SWITCH CORD 1

160 STOP SWITCH CORD (B) 1

161

HEX. SOCKET HD. BOLT

(W/FLANGE) M6×22

4

162 CLIP 1

163 NYLON NUT M6 2

164 BOLT WASHER 6 2

165 U-NUT M5 5

166 WASHER (A) (FOR 620MM) 2

167

RUBBER WASHER

(FOR 620MM)

2

168 COLLAR (FOR 620 MM) 1

169 SUPPORT PLATE 1

171 SPRING HOLDER 4

172

HEX. SOCKET HD. BOLT

(W/FLANGE) M5×10

4

173 ANTIVIBR ATION SPR ING 4

174

BLADE ASS' Y

(INCLUD.165,177-181)

1

175

HEX. SOCKET HD. BOLT

(W/FLANGE) M5×8

1

176 GUARD PLATE 1

177

HEX. SOCKET HD. BOLT

(W/BUTTON) M6×25

1

178 WASHER (A) 5

179 WASHER M7 5

180

SHOULDER BUTTON BOLT

M5×25

4

181

SHOULDER BUTTON BOLT

M5×31

1

182 BLADE CASE 1

183

GEAR CASE (A) ASS'Y

(INCLUD.184)

1

184 BALL BEARIN G 608ZZC3 2

185

HEX. SOCKET HD. BOLT

(W/BUTTON) M6×25

1

186 GUIDE PLATE (B) 2

187 CAM ROD 2

188 GEAR 2 1

189 FELT PACKING (B) 2

190 FELT PACKING (C) 1

191 GEAR CASE PACKING 1

192

GEAR CASE (B) ASS'Y

(INCLUD.184)

1

193

HEX. SOCKET HD. BOLT

(W/SP.WAS HER) M5×14

6

501 BOX WRENCH 10/19MM 1

81

Page 18

CH22EC2 (62ST) / CH22EC2 (78ST)

82

Page 19

CH22EC2 (62ST) / CH22EC2 (78ST)

Item

No.

Part Name Q’TY

1 COVER FIXING BOLT COMP. 1

2 CLEANER C OVER 1

3 CLEANER SPONGE 1

4 CHOKE VALVE 1

5

MACHINE SCREW

(W/WASHERS) M5×60

2

6 CLEANER BO DY 1

7 CHOKE HANDL E 1

8

TAPPING SCREW (W/FL ANGE)

D4X12

1

9

THROTTLE ADJUST SCREW

(TAS)

1

10 SE T SCREW (B) 3

11 SE T SCREW (D) 4

12 SYR INGE 1

13 PRI MER BASE 1

14 PUMP G ASKET 1

15 PUMP DIAPHRAGM 1

16 ST RAINER 1

17 GUI DE PIN ROLLER 1

18 SYR INGE RETAINER 1

19 SE T SCREW (E) 1

20 BALL PLUG RETAINER 1

21

ADJUSTING SC REW

(MAIN MIXTUR E)

1

22 METERING L EVER SPRING 1

23 PIN 1

24 METERING DIAPHRAGM 1

25 METERING COVER 1

26 SET SCREW (C) 3

27 POST 1

28 ROTOR COVER 1

29

RETAINING RING (E-TYPE) FOR

D2.5 SHAFT

1

30 O-RING 1

31 INLET NEEDLE VALVE 1

32 SET SCREW (A) 1

33 METERING L EVER 1

34 METERING GA SKET 1

35

CARBURETOR ASS 'Y

(INCLUD.9-3 4)

1

36 LOCK NUT M6 1

37 CARBURETOR INSU LATOR 1

38 INTAKE PACKING 1

39 GLASS WASHER 4

40 CARBURETOR PACKING 1

41

SEAL LOCK HEX . SOCKET

BOLT (W/WASHERS)M5×25

2

42

HEX. SOCKET HD. BOLT

(W/WASHERS) M4×18

2

43 CORD 1

44

SEAL LOCK HEX . SOCKET HD.

BOLT M4×12

1

45 CYLINDER COVER 1

46 METAL OF PLUG CAP (60) (B) 1

47 PLUG CAP 1

48 CORD INSUL ATION TUBE 1

49 IGNITION COIL 1

50 SPARK PLUG 1

51 CYLI NDER 1

52 COVER PACKING 2

53 INTAKE COVER (A) 1

54 SEAL LOCK SCRE W M 4×10 4

55 HEAT PROTECTION PANEL 1

56 MUFFLER 1

57 BOLT WASHER M6 2

58 HEX. SOCKET HD. BOLT M6×55 2

59 INTAKE COVER (B) 1

Item

No.

Part Name Q’TY

60 PISTON PIN 1

61 PISTON 1

62

HEX. SOCKET HD. BOLT

(W/SP.WAS HER) M5×18

8

63 CYLINDER PACKING 1

64 PISTON RING 1

65 CIR CLIP 2

66 FLYWHEEL NUT M7 1

67 BOLT WASHER D7 1

68 STARTER PAWL 2

69 STARTER PAWL SPRING 2

70 MAGNETO ROTOR 1

71 RETAINING RING D4 2

72

CRANK CASE (B) ASS'Y

(INCLUD.73,74)

1

73 OIL SEAL TB 12227 2

74 BALL BE ARING 6001C3 2

75 SHIM T0.2 1

76 SHIM T0.3 1

77 CRANK SHAF T 1

78

CRANK CASE (A) ASS'Y

(INCLUD.73,74,80)

1

79 CRANK CASE PACKING 1

80 KNOCK PIN 4×12 2

81 CLUTCH ASS'Y (B) 1

82 CLUTCH DRUM 1

83 BALL BEARIN G 6002ZC3 2

84

RETAINING RING FOR D15

SHAFT

1

85 GREASE NIPPLE COMP. 1

86

TAPPING SCREW (W/FL ANGE)

D5X20

1

87 MUFFLER PROTECTOR 1

88

MACHINE SCREW

(W/SP.WAS HERS) M5×16

1

89 TAIL PIPE 1

90 FIXATION PLATE (A) 1

91

MACHINE SCREW

(W/WASHERS) M4×10

1

92 FIXATION PLATE (B) 2

93 HEX. HOLE BOLT 6×18/S 4

94 HITACHI LABEL 1

95 TAPPING SCREW D4.5×16 1

96 PLATE 1

97 STARTER KNOB 1

98 STARTER ROPE 1

99

HEX. SOCKET HD. BOLT

(W/BUTTON) M5×20

3

100 RECOIL SPRING 1

101 STARTER ROPE REEL 1

102 DAMPER SPRING 1

103 CAM PLATE 1

104 SET SCREW 1

105

RECOIL STARTER ASS'Y

(INCLUD.97-99,101-10 5)

1

106 AIR DEFLECTOR 1

107

FUEL TANK CAP ASS'Y

(INCLUD.109)

1

108 TANK CAP CHAIN 1

109 FUEL GROMMET 1

110 F UEL PIPE 1

111 FUEL PIPE (PINK) 1

112 R ETURN GROMMET 1

113 C LIP 1

114 P UMP FILTER 1

115 C USHION RUBBER 4

116 TANK 1

Item

No.

Part Name Q’TY

141

HEX. SOCKET HD. BOLT

(W/FLANGE) M6×32

4

142 FRONT HANDLE 1

143 CAUTION LABEL 1

144 FRAME 1

145 NAME PLATE 1

146 DAMPER 1

147 HANDLE A 1

148 FLEXIBLE GRO MMET 1

149 SPRING (A) 1

150 LOCK LEVER 1

151 THROTTLE LEVE R 1

152 TRIGGER LOCKOUT 1

153 THROTTLE LEV ER SPRING 1

154 STOP SWITCH 1

155 HANDLE B 1

156

TAPPING SCREW (W/FL ANGE)

D4×16 (BLACK)

4

157 THROTTLE WIRE 1

158 PROTECTION TUBE 1

159 STOP SWITCH CORD 1

160 STOP SWITCH CORD (B) 1

161

HEX. SOCKET HD. BOLT

(W/FLANGE) M6×22

4

162 CLIP 1

163 NYLON NUT M6 2

164 BOLT WASHER 6 2

165 U-NUT M5 5

166 WASHER (A) (FOR 620MM) 2

167

RUBBER WASHER

(FOR 620MM)

2

168 COLLAR (FOR 620 MM) 1

169 SUPPORT PLATE 1

171 SPRING HOLDER 4

172

HEX. SOCKET HD. BOLT

(W/FLANGE) M5×10

4

173 ANTIVIBR ATION SPR ING 4

174

BLADE ASS' Y

(INCLUD.165,177-181)

1

175

HEX. SOCKET HD. BOLT

(W/FLANGE) M5×8

1

176 GUARD PLATE 1

177

HEX. SOCKET HD. BOLT

(W/BUTTON) M6×25

1

178 WASHER (A) 5

179 WASHER M7 5

180

SHOULDER BUTTON BOLT

M5×25

4

181

SHOULDER BUTTON BOLT

M5×31

1

182 BLADE CASE 1

183

GEAR CASE (A) ASS'Y

(INCLUD.184)

1

184 BALL BEARIN G 608ZZC3 2

185

HEX. SOCKET HD. BOLT

(W/BUTTON) M6×25

1

186 GUIDE PLATE (B) 2

187 CAM ROD 2

188 GEAR 2 1

189 FELT PACKING (B) 2

190 FELT PACKING (C) 1

191 GEAR CASE PACKING 1

192

GEAR CASE (B) ASS'Y

(INCLUD.184)

1

193

HEX. SOCKET HD. BOLT

(W/SP.WAS HER) M5×14

6

501 BOX WRENCH 10/19MM 1A

83

Page 20

84

Page 21

85

Page 22

86

Page 23

Englis h Nederlands

Object of declaration: Hitachi Hedge Trimmer CH22EAP2, CH22EBP2, CH22ECP2

EC DECLARATION OF CONFORMITY

(Applies to Europe only)

We declare under our sole responsibility that this product is in conformity with Directive

2006/42 /EC, 2004/108/EC and 2000/14/EC. The following standards have been taken

into consideration.

ISO 10517, EN55012

Annex V (2000/14/EC):

Measured sound power level: 102 dB

Guaranteed sound power level: 104 dB

The European Standards Manager at Hitachi Koki Europe Ltd. i s authorized to compil e

the technical fi le.

This declaration is applicable to the product a xed CE marking.

Onderwerp van verklaring: Hitachi Motor heggenschaar CH22EAP2, CH22EBP2, C H22ECP2

EC VERKLARING VAN CONFORMITEIT

(Geldt alleen voor Euro pa)

Wij verklaren onder ei gen verantwoordelijkheid dat dit product voldoet aan de richtlijn

2006/42 /EC, 2004/108/EC en 2000/14/EC. De volgende standaards zijn toegepast .

ISO 10517, EN55012

Aanvulling V (2000/14/EC):

Gemeten geluidsdruk: 102 dB

Gegarandeerde geluidsdruk: 104 dB

De manager voor Europese normen van Hitachi Koki Europe Ltd. heeft de bevoegdheid

tot het samenstellen van het technische bestand.

Deze verklaring is van toepassing op produkten voorzien van de CE-markeringen.

Deuts ch Españo l

Gegenstand der Erklärung: Hitachi Heckenschere CH22EAP2, CH22EBP2, CH22ECP2

EG-KONFORMITÄTSERKLÄRUNG

(Gilt nur für Europa)

Wir erklären eigenverantwortlich, dass dieses Produkt den Bestimmungen der Ri chtlinien

2006/42 /EG, 2004/108/EG und 2000/14/EG des Europäischen Rates entspricht. Die

nachfol genden Standards wurden in Betracht gezogen.

ISO 10517, EN55012

Anhang V (2000/14/EG):

Gemessener Schallleistungspegel: 102 dB

Garantierter Schallleistungspegel: 104 dB

Der Manager für europäische Standard s be i der Hitachi Koki Europe Ltd. ist zum Verfassen

der technischen Datei befugt.

Diese Erklärung gilt für Produkte, die die CE-Markierung tragen.

Objeto de declaración: Hitachi Cortasetos CH22EAP2, CH22EBP2, CH22ECP2

DECLARACIÓN DE CONFORMIDAD DE LA CE

(De aplicación sólo en Eu ropa)

Declaramos bajo nuestra exclusiva responsabilidad que este producto es conforme con

las Direct ivas 2006/42/CE, 2004/108/CE y 2000/14/CE. Se han teni do en consideración

las siguientes normas.

ISO 10517, EN55012

Anexo V (2000/14/CE):

Nivel de potencia acústica medida: 102 dB

Nivel de potencia acústica garantizada: 104 dB

El Jefe de Normas Europeas de Hitachi Koki Europe Ltd. está autorizado para recopilar

archivos técnicos.

Esta declaración se aplica a los productos con marcas de la CE.

França is

Português

Objet de la déclaration: Hitachi Taille-Haies CH22EAP2, CH22EBP2, CH22ECP2

DECLARATION DE CONFORMITE CE

(Concerne l’Euro pe uniquement)

Nous déclarons sur la foi de notre seule responsabilité que ce produit est conforme aux

dispositions des Directives du Conseil de l'Union européenne 2006/42/EC, 2004/108/EC

et 2000/14/EC. Les nonnes suivantes ont été prises en considération.

ISO 10517, EN55012

Annexe V (2000/14/EC):

Niveau de puissance sonore mesuré: 102 dB

Niveau de puissance sonore garanti: 104 dB

Le responsable des normes européennes d’Hitac hi Koki Europe Ltd. est au torisé à compi ler

les données techniques.

Cette déclaration s’applique aux produits désignés CE.

Objeto de declaração: Hi tachi Corta-sebes CH22EAP2, CH22EBP2, CH22ECP2

DECLARAÇÃO DE CONFORMIDADE CE

(Aplica-se apena s à Europa)

Declaramos para os devidos efeitos que este produto cumpre os requisitos das directivas

comunitárias 2006/42/CE, 2004/108/CE e 2000/14/CE. As seguintes normas harmonizadas

foram aplicadas.

ISO 10517, EN55012

Anexo V (2000/14/CE):

Nível medido de potência de som: 102 dB

Nível garantido de potência de som: 104 dB

O Gestor de Normas Europeias da Hitachi Koki Europe Ltd. está autorizado a compilar

o fi cheiro técnico.

Esta declaração se aplica aos produtos designados CE.

Italia no

Oggetto della dichiarazione: Hitachi Tosasiepi CH22EAP2, CH22EBP2, CH22ECP2

DICHIARAZIONE DI CONFORMITÀ CE

(Si applica solo all ’Europa)

Dichiariamo sotto la nostra esclusiva responsabilit à che questo prodotto è conforme

alle Direttive del Consiglio 2006/42 /CE, 2004/108/CE e 2000/14/CE. Sono stati presi in

considerazione i seguenti standard.

ISO 10517, EN55012

Allegato V (2000/14/CE):

Livello di potenza sonora misurato: 102 dB

Livello di potenza sonora garantito: 104 dB

Il Responsabil e dell e Norme Europee di Hitachi Koki Ltd. è autorizzato a compilare la

scheda tecnica.

Questa dichiarazione è applicabile ai prodotti cui sono applicati i marchi CE.

Hitachi Koki Europe Ltd.

Clonshaugh Business & Technology Park, Dublin 17, lreland

Representative o ce in Europe

Hitachi Power Tools Europe GmbH

Siemensring 34, 47877 Willich 1, F. R. Germany

Head o ce in Japan

Hitachi Koki Co., Ltd.

Shinagawa Intercity Tower A, 15-1, Konan 2-chome,

Minato-ku, Tokyo, Japan

28. 4. 2013

Mr. John de Loughry

European Standards and

Compliance Manager

28. 4. 2013

F. Tashimo

Vice-President & Director

Page 24

304

Code No. E99252872 NA

Printed in China

Svenska Norsk

Objekt för deklaration: Hitachi Häcksax CH22EAP2, CH22EBP2, CH22ECP2

EF-DEKLARATION BETRÄFFANDE LIKFORMIGHET

(Gäller endast Europa)

Vi int ygar under ensamt ansvar, att denna produkt motsvarar bestämmelserna i direktiven

2006/42 /EF, 2004/108/EF och 2000/14/EF.

Vi har tagit hänsyn till följande standards.

ISO 10517, EN55012

Bilaga V (2000/14/EF):

Uppmätt ljudstyrkenivå: 102 dB

Garanterad ljudstyrkenivå: 104 dB

Den europeiska standardan svarige på Hi tachi Koki Europe Ltd. är a uktoriserad att utarbeta

den tekniska fi len.

Denna deklaration gäller för CE-märkningen pà produkten.

Erklæringens objekt: Hitachi Hekksaks CH22EAP2, CH22EBP2, CH22ECP2

EF’S ERKLÆRING OM OVERENSSTEMMELSE

(Gjelder bare for Europa)

Vi erklærer med vårt eneansvar at dette produktet er i overensstemmelse med EU direktiv

2006/42 /EF, 2004/108/EF og 2000/14/EF.

Det er tatt hensyn ti l følgende standarder.

ISO 10517, EN55012

Anneks V (2000/14/EF):

Målt lyde ektnivå: 102 dB

Garantert lyde ektnivå: 104 dB

Lederen for europeiske standarder ved Hitachi Koki Europe Ltd. har fullmakt til å utarbeide

det tekniske dokumentet.

Denne erklæringen gjelder produktets påklistrede CE-merking.

Dansk Suomi

Genstand for erklæring: Hitachi Hækkeklipper CH22EAP2, CH22EBP2, CH22ECP2

EF-OVERENSS TEMMELSESERKLÆRING

(Gælder kun for Europa)

Vi erklærer som eneansvarlige, at dette produkt er i overensstemmelse med Rådsdirektiv

2006/42 /EF, 2004/108/EF og 2000/14/EF.

De følgende standarder har været iagttaget.

ISO 10517, EN55012

Appendiks V (2000/14/EF):

Målt lydstyrkeniveau: 102 dB

Garanteret lydstyrkeniveau: 104 dB

Chefen for e uropæiske sta ndarder hos Hitachi Koki Europe Ltd. er autoriseret til at kompilere

den tekniske fi l.

Denne erklæring qælder produkter, der er mærket med CE.

Ilmoituksen kohde: Hitachi Pensasl eikkuri CH22EAP2, CH22EBP2, CH22ECP2

EY-ILMOITUS YHDENMUKAISUUDESTA

(Koskee vain Eurooppaa)

Ilmoitamme yksinomaisella vastuullamme, että tämä tuote on direktiivien 2006/42/EY,

2004/108/EY ja 2000/14/EY vaatimusten mukainen.

Seuraavat standardit on huomioitu.

ISO 10517, EN55012

Liite V (2000/14/EY):

Mitattu äänenpainetaso: 102 dB

Taat tu äämempanetaso: 104 dB

Hitachi Koki Europe Ltd.:n eurooppalaisten standardien johtaja on valtuutettu laatimaan

tekniset asiakirjat.

Tämä ilmoitus sovelletaan tuotekohtaiseen CE-merkintään.

Hitachi Koki Europe Ltd.

Clonshaugh Business & Technology Park, Dublin 17, lreland

Representative o ce in Europe

Hitachi Power Tools Europe GmbH

Siemensring 34, 47877 Willich 1, F. R. Germany

Head o ce in Japan

Hitachi Koki Co., Ltd.

Shinagawa Intercity Tower A, 15-1, Konan 2-chome,

Minato-ku, Tokyo, Japan

28. 4. 2013

Mr. John de Loughry

European Standards and

Compliance Manager

28. 4. 2013

F. Tashimo

Vice-President & Director

Loading...

Loading...