Page 1

Backpack Brush Cutter

Desbrozadora de mochila

Roçadora dorsal

CG 40EBF (L)

Read the manual carefully before operating this machine.

Antes de utilizar esta máquina, lea cuidadosamente el manual.

Leia o manual atentamente antes de operar esta máquina.

Handling instructions

Instrucciones de manejo

Instruções de uso

Page 2

123

10

8

1

5

2

6

7

3

4

5

2

9

10

456

16

11

12

14

13

15

78

2

Page 3

910

11 12 13

A

B

17

14 15 16

B

C

A

17 18 19

19

T

A

B

20

18

3

Page 4

20 21 22

23

4

Page 5

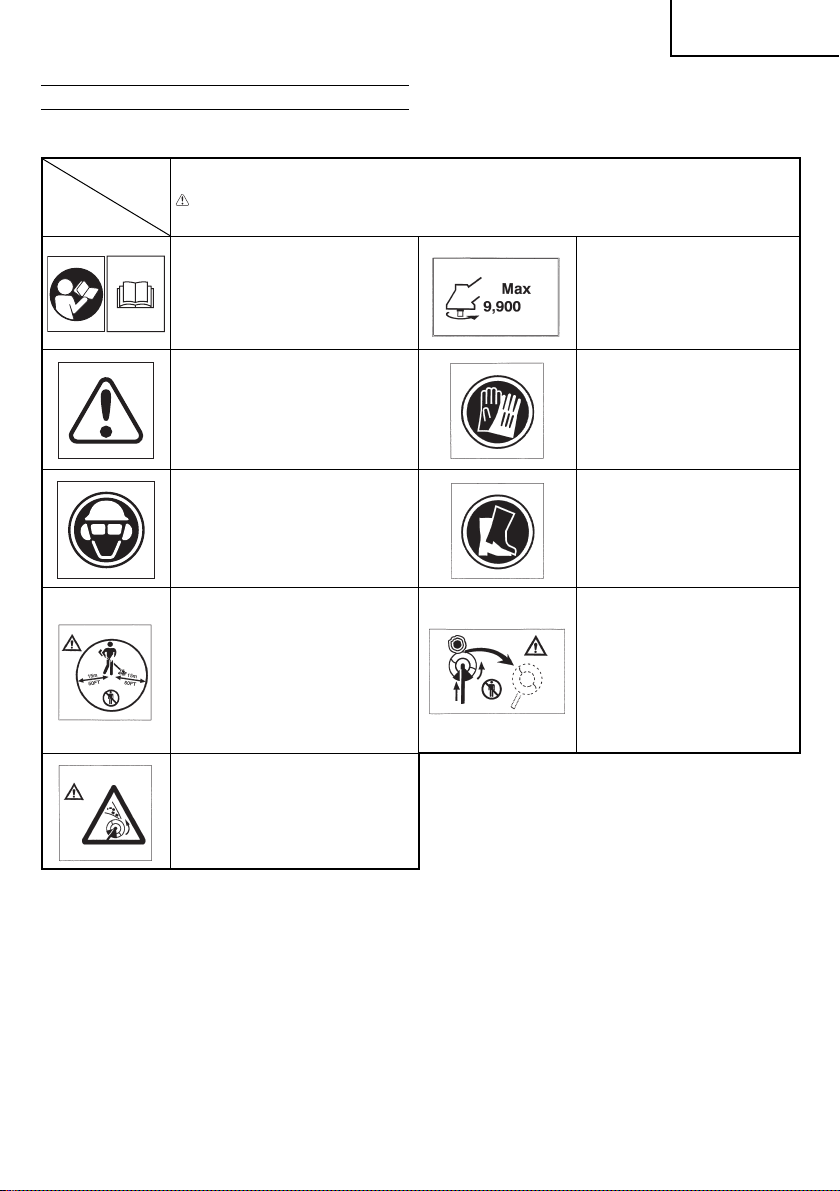

MEANINGS OF SYMBOLS

NOTE: Some units do not c arry them.

Symbols

WARNING

The foll owing show symbols used for the machine. B e sure that you understand their meaning before use.

It is important that you read, fully

understand and observe the following

safety precautions and warnings.

Carele ss or improper use of the unit may

cause serious or fatal injur y.

min

Shows ma ximum shaft s peed. Do not

use the cutting attachment whose max

-1

speed is below th e shaft speed.

English

Read, understand and follow all warnin gs

and instructions in this manual and on

the unit.

Always wear eye, head and ear protectors

when using this unit.

Keep all children, bystanders and helpers

15 m away from the unit. If anyone

approaches you, stop the engine and

cutting attachment immediately.

Be careful of thrown obje cts.

Contents

WHAT IS WHAT .................................................................................6

WARNINGS AND SAFET Y INSTRUCTIONS ...................................7

SPECIFICATIONS .............................................................................8

ASSEMBLY PROCEDURES ..............................................................8

OPERATING PROCEDURES ............................................................8

MAINTEN AN CE .................................................................................9

Gloves should be worn when

necessary, e.g., when assembling

cutting equipment.

Use anti-slip and sturdy foot wear.

Blade thrust may occur when the

spinning blade contacts a solid obje ct

in the critical area. A dangerous

reaction may occur causing the entire

unit and operator to be thrust violently.

This reaction is called blade thrust. As

a result, the operator may lose control

of the unit which may cause serious or

fatal injury. Blade thrust is more likely

to occur in areas where it is diffi cult to

see the material to be cut.

5

Page 6

English

WHAT IS WHAT

Since this manual covers several models, there may be some

diff erence between pictures and your unit. Use the instructions that

apply to your unit.

1. Fuel ca p

2. Throttle lever

3. Ignition switch

4. Blade guard

5. Cutting attachment

6. Dr ive shaft tube

7. H a n d l e

8. Harness

9. Clutch case

10. Starter handle

11. Fuel cock

12. Choke lever

13. Engine

14. Angle transmission

15. Combi b ox spanner

16. Handling instructions

514

7

6

4

2

12

1

13

9

15

3

16

8

11

10

6

Page 7

English

WARNINGS AND SAFETY INSTRUCTIONS

Operator safety

○ Always wear a safet y face shield or goggles.

○ Always wear heavy, long pants, boots and gloves. Do not wear

loose clothing, jewelry, short pants, sandals or go barefoot.

Secure hair so it is above sh oulder length.

○ Do not operate this tool when you are tired, ill or under the

infl uence of alcohol, dr ugs or medication.

○ Never let a c hild or inexperienced person operate the machine.

○ Wear hearing protection. Pay attention to your surroundings.

Be aware of any bystanders who may be signaling a problem.

Remove safety equipment immediately upon shutting off

engine.

○ Wear head protection.

○ Never start or run the engine inside a closed room or building.

Breath ing exhaust fumes can kill.

○ Keep handles free of oil and fuel.

○ Keep hands away from cutting equipment.

○ Do not gra b or hold the unit by the cut ting equipme nt.

○ When the unit is turned off , make sure the cut ting at tachment

has stopped before the unit is set down.

○ When operation is prolonged, take a break from time to time

so that you may avoid possible Hand-Arm Vibration Syndrome

(HAVS) which is c aused by vibrat ion.

WARNING

○ Antivibration systems do not guarantee that you will not sustain

Hand-Arm Vibration Syndrome or carpal tunnel syndrome.

Therefore, continual and regular users should monitor closely

the condition of their hands and fi ngers. If any symptoms of the

above appear, seek medical advic e immediately.

○ If you are using any medical electric/electronic devices such

as a pacemaker, consult your physician as well as the device

manufacturer prior to operat ing any power equipment .

Unit/machine safety

○ Inspect the entire unit/machine before each use. Replace

damaged parts. Check for fuel leaks and make sure all

fasteners are in place and securely tightened.

○ Replace parts that ar e cracked, chipped or damaged in any way

before using the unit/machi ne.

○ Make sure t he safety guard is properly at tached.

○ Keep others away when making carburetor adjustments.

○ Use only accessories as recommended for this unit/machine by

the manufacturer.

WARNING

Never modify the unit /machine in any way. Do not use your unit/

machine for any job except that for which it is intended.

Fuel safety

○ Mix and pour fuel outdoors and where there are no sparks or

fl ames.

○ Use a container approved for fuel.

○ Do not smoke or allow smoking near fuel or the unit/machine or

while using the unit/machine.

○ Wipe up all fuel spills before starting engine.

○ Move at lea st 3 m away from fueling site before starting engine.

○ Stop engine before removing fuel cap.

○ Empty the fuel tank before storing the unit/machine. It is

recommended that the fuel be emptied after each use. If fuel is

left in t he tank, store so fuel will not leak.

○ Store unit/machine and fuel in area where fuel vapors cannot

reach sparks or open fl ames from water heaters, electric motors

or switches, furnaces, etc.

WARNING

Fuel is easy to ignite or get explosion or inhale fumes, so that

pay special attention when handling or fi lling fuel.

Cutting safety

○ Do not cut any material other than grass and brush.

○ Do not perform any operations which may infl uence an

enorm ous shock on the cutting att achment.

Other wise, the fl ex ible shaft may risk to be damage d.

○ Inspect the area to be cut before each use. Remove objects

which can be thrown or become ent angled.

○ For respiratory protection, wear an aerosol protection mask

when cutting the grass after insecticide is scattered.

○ Keep others including children, animals, bystanders and

helpers outside the 15 m hazard zone. Stop the engine

immediately if you are approached.

○ Always keep the driver shaf t tube on the right side of your body.

○ Hold the unit/machine fi rmly with both hands.

○ Keep fi rm footing and balance. Do not over-reach.

○ Keep all parts of your body away from the muffl er and cutting

attac hment when the engine is running.

○ Keep cut ting attachment below waist level.

○ When relocating to a new work area, be sure to shut off the

machine and ensure that all cut ting attach ments are stopped.

○ Never place the machine on the ground when running.

○ Always ensure that the engine is shut off and any cutting

attachments have completely stopped before clearing debris or

removing gras s from the cutting attachment.

○ Always carry a fi rst-aid kit when operating any power

equipment.

○ Never start or run the engine inside a closed room or building

and/or near infl ammable liquids. Breathing exhaust fumes can

kill.

Maintenance safety

○ Maintain the unit/machine according to recommended

procedures.

○ Disconnect the spark plug before performing maintenance

except for carburetor adjustments.

○ Keep others away when making carburetor adjustments.

○ Use only genuine Hitachi replacement par ts as recommended

by the man ufacturer.

Transpor t and storage

○ Carry the unit/machine by hand with the engine stopped and

the muffl er away from your body.

○ Allow the engine to cool, empty the fuel tank, and secure the

unit/machine before storing or transpor ting in a vehicl e.

○ Empty the fuel tank before storing the unit/machine. It is

recommended that the fuel be emptied after each use. If fuel is

left in t he tank, store so fuel will not leak.

○ Store unit/machine out of the reach of children.

○ Clean and maint ain the unit carefully and store it in a dry place.

○ Make sure engine switch is off when transporting or storing.

○ When transporting in a vehic le, cover blade with blade cover.

If situations occur which are not covered in this manual, take care

and use common sense. Contact your Hitachi dealer if you need

assistance. Pay special attention to statements preceded by the

following words:

WARNING

Indicates a strong possibility of severe personal injury or loss of

life, if instructions are not followed.

CAUTION

Indicates a possibility of personal injury or equipment damage,

if instructions are not followed.

NOTE

Helpful information for correct function and use.

CAUTION

Do not disassemble the recoil starter. You may get a possibilit y

of personal injury with recoil spring.

7

Page 8

English

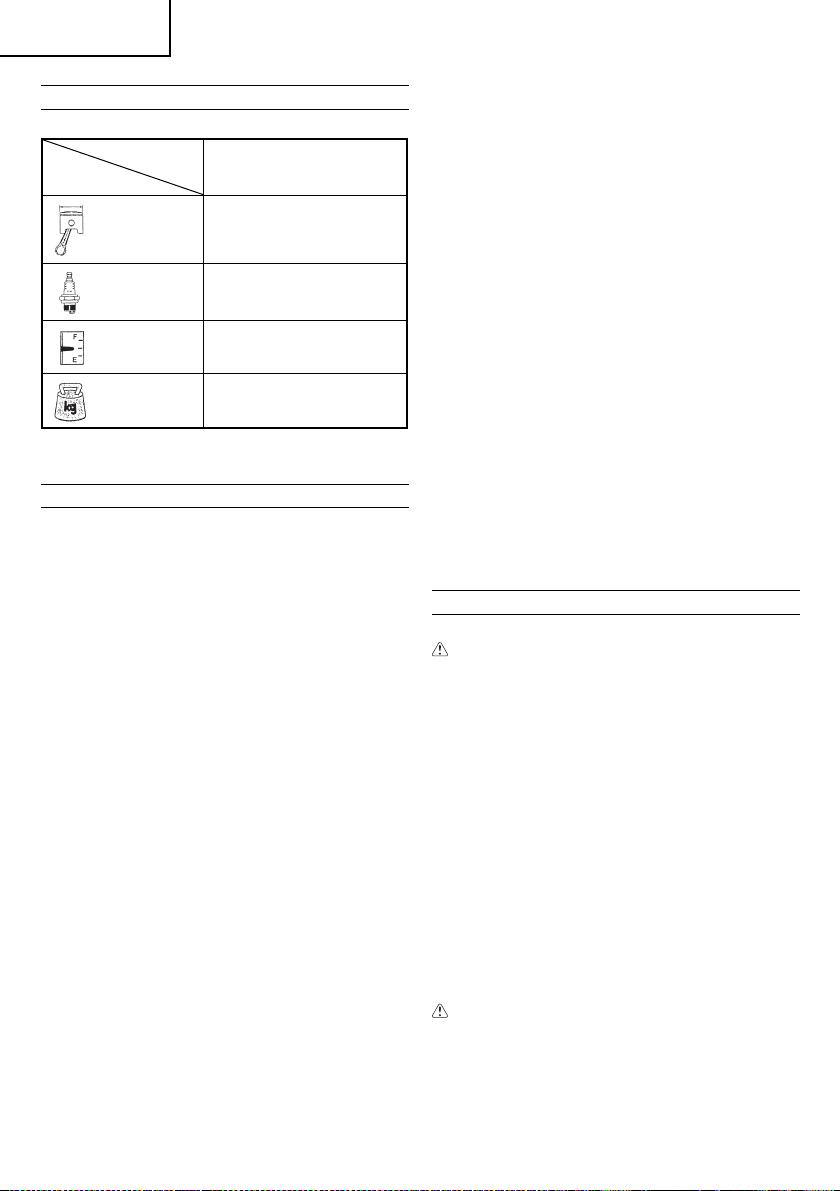

SPECIFICATIONS

Model CG40EBF (L)

Engine Size (ml) 39.8

Spark Plug NGK BPMR6A

Fuel Tank

Capacity (l)

Dry Weight (kg) 9.6

NOTE

* All data is subject to change without notice.

1.2 0

ASSEMBLY PROCEDURES

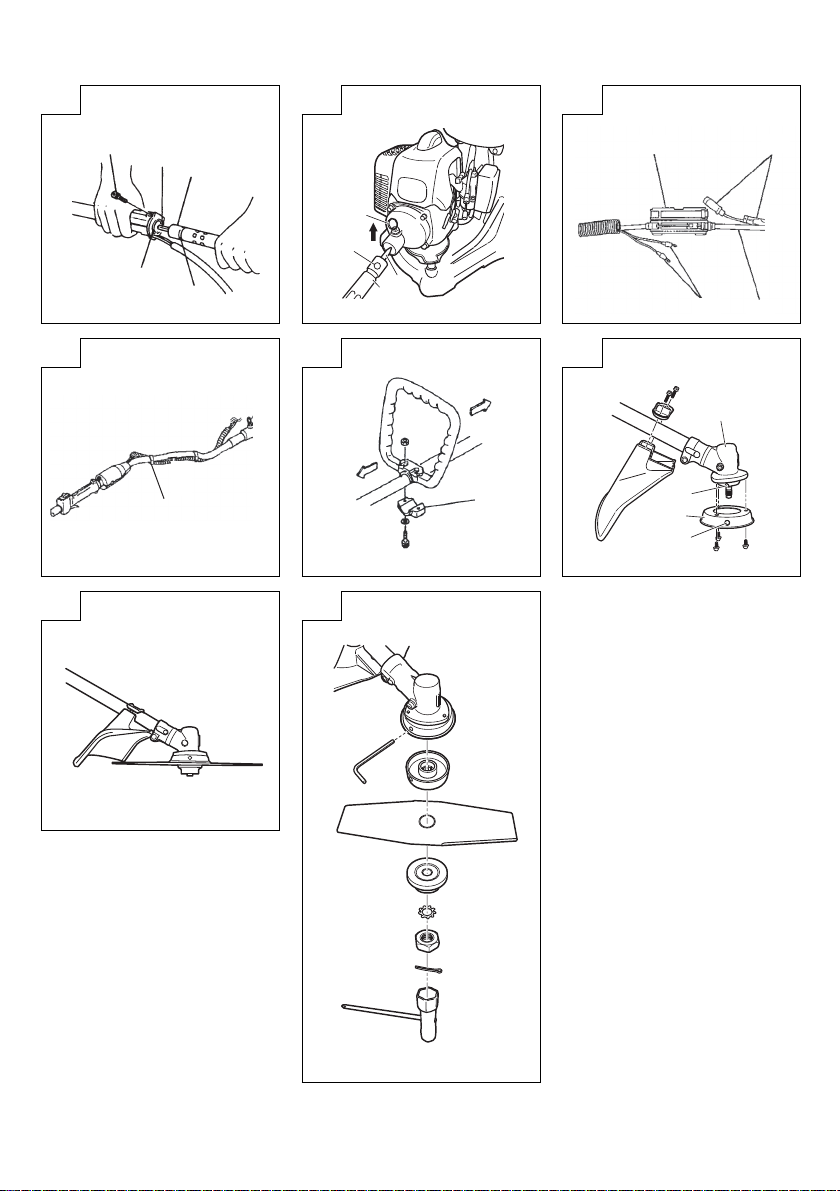

Drive shaft to fl exible shaft (Fig. 1)

Remove joint pipe bolt (1),

Insert the fl exible shaft (2) into the joint pipe (3) of Drive Shaft to the

end and tighten the joint pipe bolt (1) by engaging the bolt to the slot

(4) of fl exible shaft.

NOTE

Make sure to align square end of fl exible inner shaft (5) with

square hole of drive shaft by slightly rotating drive shaft, so that

they are connec ted fi rmly.

Flexible shaf t to engine (Fig. 2)

Lift fl exible-shaft lock pin (6) .

Insert fl exible shaft (2) into clutch case to the end by inserting

square end of fl exible inner shaft (3) into square hole of adaptor in

clutch case.

Release the lock pin to lock the fl exible shaft by lining up the lock

pin and the hole (7) of fl exible shaft.

Throttle cable and stop cord (Fig. 3)

Connect throttle cables (8) by hooking each cut end of the cables

and clamp the jointed part with connector case (9) which locks.

Connect each end of stop c ords (10).

NOTE

○ When removing connector case, insert coin or minus driver in

slot in th e middle and twist it.

○ Fix protection tube on drive shaft or handle using cord clamps

(11). (Fig. 4)

○ Check that the carburetor throttle returns to the idle position

and also that it can be opened wide by operating the throttle

lever.

Installation of handle (Fig. 5)

Remove the handle bracket (12).

Set the handle on, and attach the handle bracket (12) with two

screws slightly. And adjust position of the handle according to your

working style. Then fi x it fi rmly with the screws.

Installation of blade guard (Fig. 6)

Align the notch hole (14) of the gear case with the hole (15) of the

gear case cover (13) to install the gear case cover with 3 screws.

Install the blade guard on drive shaft tube against angle

transmission (16). Tighten the guard bracket fi rmly so that the blade

guard does not swing or move down during operation.

Install the gear case and blade guard so that blade guard contacts

the gear case. (Fig. 7)

8

CAUTION

The blade guard must be in place when operating.

If the blade guard is not in place when operating, you may get

the serious injury.

Installation of cutting blade (Fig. 8)

When installing a cutting blade, make sure that there are no cracks

or any damage in it and that the cutting edges are facing the correct

direction.

Align the notch hole of the cutter holder with the hole on the gear

case cover and insert the Allen wrench to stop turning. Turn the

fi xing nut clockwise and remove the fi xing nut, cutter holder cap,

and toothed lock washers.

The installation of the cutting blade is as follows: insert the Allen

wrench into the notch hole of the cutter holder and the hole on

the gear case. Then, install the cutting blade (check the installing

direction, as referring to Fig. 10), the cutter holder cap and toothed

lock washers onto the cutter holder in this order. Finally, tighten the

fi xing nut securely by turning counterclockwise with the Combi box

spanner. (Fig. 8)

CAUTION

○ When installing the cutting blade, set its center hole to the

convex part of the cutter holder and hold it with the concave

surface of the cutter holder cap. Then, tighten the fi xing nut to

prevent the cutting blade from being eccentric. (Fig. 9)

After installing the cutting blade, be sure to remove the Allen

wrench and Combi box spanner.

○ Before operation, make sure the blade has been properly

installed.

○ Before operation, check the cut ter holder cap under the cutting

blade for wear or cracks. If any damage or wear is found,

replace it, as it is an article of consumption.

NOTE

The blade must be retained with a new cotter pin each time

installed. (Fig. 8)

OPERATING PROCEDURES

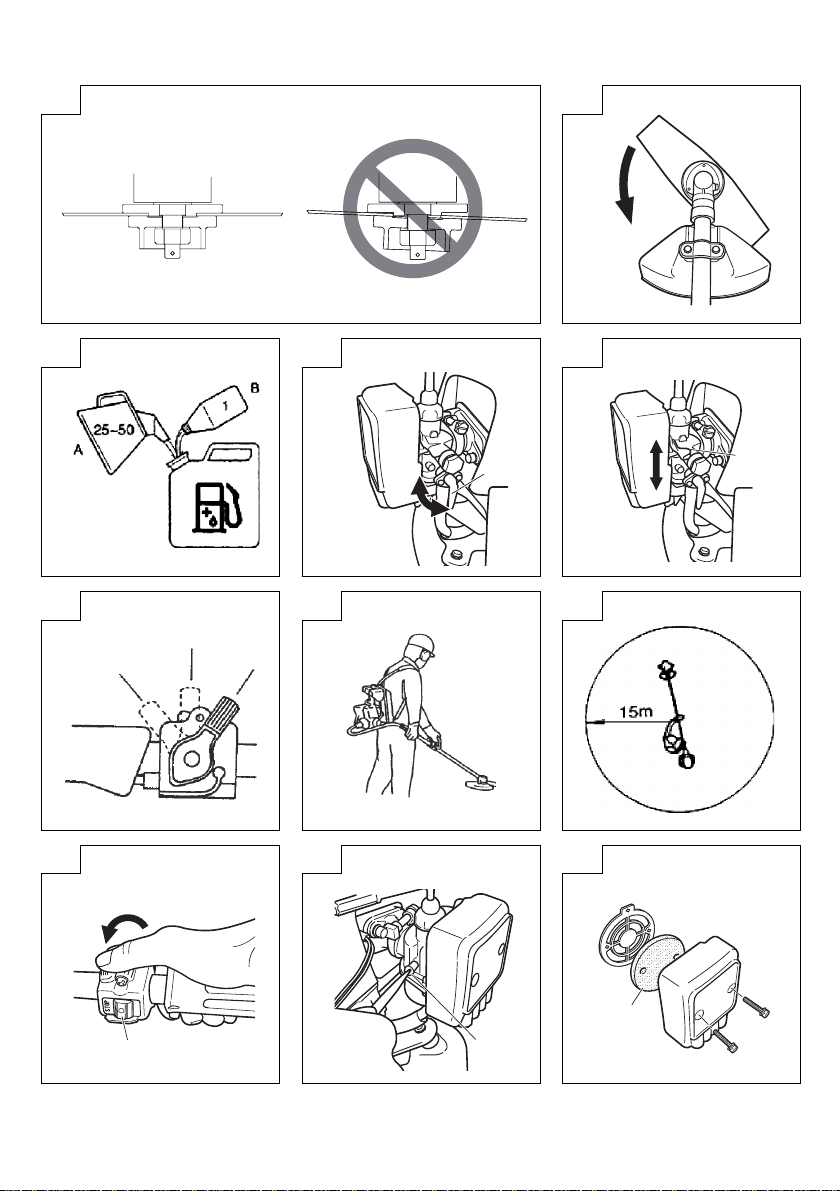

Fuel (Fig. 11)

WARNING

○ The backpack brush cutter is equipped with a two-stroke

engine. Always run the engine on fuel, which is mixed with oi l.

Provide good ventilation, when fueling or handling fuel.

○ Fuel is highly fl ammable and toxic and can result in serious

injur y if it is inhaled or comes into contact with your skin. Always

handle fuel with care. Always have good ventilation when

handling fuel inside building.

Fuel

○ Always use branded 89 oct ane unleaded gasoline.

○ Use genuine two -cycle oil or use a mix between 25:1 to 50:1,

please consult the oil bottle for the ratio or Hi tachi dealer.

○ If genuine oil is not available, use an anti-oxidant added qualit y

oil expressly labeled for air-cooled 2-cycle engine use (JASO

FC GRADE OIL or ISO EGC GRADE). Do not use BIA or TCW

(2-stroke water-cooling type) mixed oil.

○ Never use multi-grad e oil (10 W/30) or wa ste oil.

○ Always mix fuel and oil in a separate clean container.

Always start by fi ling half the amount of fuel, which is to be used.

Then add the whole amount of oil. Mix (shake) the fuel mixture. Add

the remaining amount of fuel.

Mix (shake) the fuel-mix thoroughly before fi lling the fuel tank.

Fueling

WARNING

○ Always shut off the engine before refueling.

○ Slowly open the fuel tank, when fi lling up with fuel, so that

possible over-pressure disappears.

○ Tighte n the fuel cap carefully, after fue ling.

○ Always move the backpack brush cutter at least 3 m from the

fueling area before starting.

○ Always wash any spilled fuel from clothing immediately with

soap.

○ Be sure to check for any fuel leakage after refueling.

Page 9

English

Before fueling, clean the tank cap area carefully, to ensure that

no dirt falls into the tank. Make sure that the fuel is well mixed by

shaking the container, before fueling.

Starting

Open the fuel cock (17). (Fig. 12-B)

Move the throttle lever to start p osition A. (Fig. 14)

NOTE

Starting with full throttle causes sudden high revolution of

Blade, which is dangerous, so please avoid it.

Set the choke lever (18) to CLOSED position. (Fig. 13-A)

Pull the recoil starter briskly, TAKING CARE TO KEEP THE

HANDLE in your grasp, while not allowing it to snap back.

When you hear combustible sounds a couple of times, move the

choke lever to OPEN position. Then pull the recoil starter briskly

again.

After starting the engine, allow it about 2 - 3 minutes to warm up

before subjecting it to any load.

CAUTION

Blade may turn and fl exible shaft may swing as engine starts.

Do not let the blade touch any object when engine starts.

After starting the engine, wear the backpack.

Cutting (Fig. 15, 16)

○ When cutting, operate engine at over 6500 min

time of use at low rpm may wear ou t the clutch prematurely.

○ Cut grass from right to left.

○ When working on a slope, the blade should allow the contour

from top to bottom, with th e operator looking down to the left.

○ Blade thrust may occur when the spinning blade contacts a

solid object in the critical area.

A dangerous reaction may occur causing the entire unit and

operator to be thrust violently. This reaction is called blade

thrust. As a result, the operator may lose control of the unit

which may cause serious or fatal injury. Blade thrust is more

likely to occur in areas where it is diffi cult to see the material to

be cut.

○ The blade turns counter-clockwise, therefore, be advised to

operate the unit from right to lef t for effi cient cutting. Keep

onlookers out of working area at least 15 m.

WARNING

○ If the cut ting attachment should strike stones or other debris,

stop the engine and make sure that the attachment and related

parts are undamaged. When grass or vines wrap around

attac hment, stop engine and attachment and remove them.

Stopping (Fig. 17)

Decrease engine speed and run at an idle for a few minutes, then

turn off ignition switch (19).

After stoppin g the engine, close the fuel cock (17). (Fig. 12-A)

WARNING

A cutting attachment can injure while it continues to spin after

the engine is stopped or power control is released. When the

unit is turned off , make sure the cutting attachment has stopped

before the unit is set down.

-1

. Extended

MAINTENANCE

MAINTENANCE, REPLACEMENT OR REPAIR OF THE EMISSION

CONTROL DEVICES AND SYSTEMS MAY BE PERFORMED

BY ANY NON-ROAD ENGINE REPAIR ESTABLISHMENT OR

INDIVIDUAL.

Carburetor adjustment (Fig. 18)

WARNING

○ The cutting attachment may be spinning during carburetor

adjustments.

○ Never start the engine without the complete clutch cover and

tube assembled! Otherwise the clutch can come loose and

cause personal injuries.

In the carburetor, fuel is mixed with air. When the engine is test

run at the factor y, the carburetor is basically adjusted. A further

adjustment may be required, according to climate and altitude. The

carburetor has one adjustment possibility:

T = Idle speed adjustment screw.

Idle speed adjustment (T)

Check that the air fi lter is clean. When the idle speed is correct, the

cutting attachment will not rotate. If adjustment is required, close

(clockwise) the T-screw, with the engine running, until the cutting

attachment starts to rotate. Open (counter-clockwise) the screw

until the cutting attachment stops. You have reached the correct

idle speed when the engine runs smoothly in all positions well

below th e rpm when the cutting attachment starts to rotate.

If the cutting attachment still rotates after idle speed adjustment,

contact your Hitachi dealer.

NOTE

Standard Idle rpm is 2500– 3000 min

WARNING

When the engine is idling the cutting attachment must under no

circumstances rotate.

Air fi lter (Fig. 19)

The air fi lter must be cleaned from dust and dirt in order to avoid:

○ Carburetor malfunctions

○ Starting problems

○ Engine power reduction

○ Unnecessar y wear on the engine parts

○ Abnormal fuel consumption

Clean the air fi lter daily or more often if working in exceptionally

dusty areas.

Cleaning the air fi lter

Remove the air fi lter cover and the fi lter (20). Rinse it in warm soap

suds. Check that the fi lter is dry before reassembly. An air fi lter

that has been used for some time cannot be cleaned completely.

Therefore, it must regularly be replaced with a new one. A damaged

fi lter must always be repl aced.

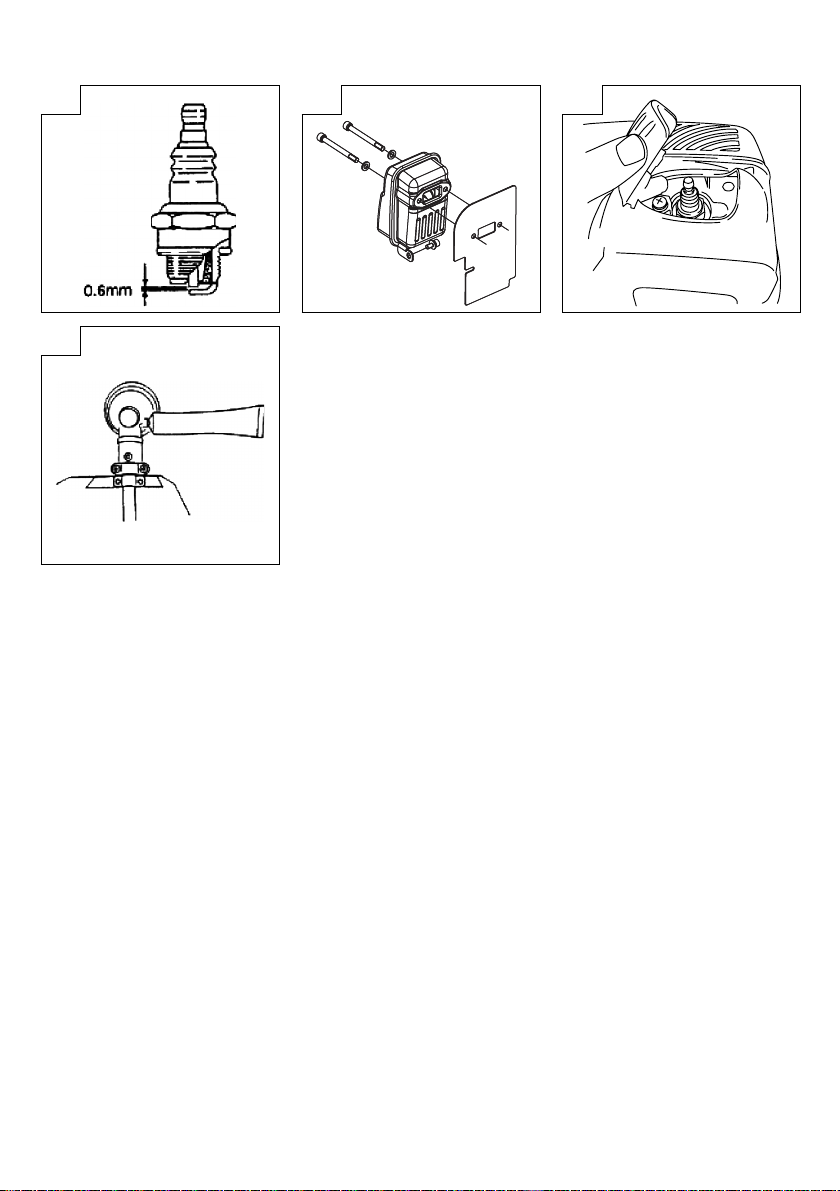

Spark plug (Fig. 20)

The spark plug condition is infl uenced by:

○ An incorrect carburetor setting

○ Wrong fuel mixture (too much oil in the gasoline)

○ A dirt y air fi lter

○ Hard running conditions (such a s cold weather)

These factors cause deposits on the spark plug electrodes, which

may result in malfunction and starting diffi culties. If the engine

is low on power, diffi cult to start or runs poorly at idling speed,

always check the spark plug fi rst. If the spark plug is dirty, clean it

and check the electrode gap. Re-adjust if necessar y. The correct

gap is 0.6 mm. The spark plug should be replaced after about 100

operation hours or earlier if the electrodes are badly eroded.

Muffl er (Fig. 21)

Remove the muffl er and clean out any excess carbon from the

exhaust port or muffl er inlet every 100 hours of operation.

Cylinder (Engine cooling) (Fig. 22)

The engine is air cooled, and air must circulate freely around engine

and over cooling fi ns on cylinder head to prevent overheating.

Every 100 operating hours, or once a year (more often if conditions

require), clean fi ns and external surfaces of engine of dust, dirt and

oil deposits which can contribute to improper cooling.

NOTE

Do not operate engine with engine shroud or muffl er guard

removed as this will cause overheating and engine damage.

Angle transmission (Fig. 23)

Check angle transmission or angle gear for grease level about

every 50 hours of operation by removing the grease fi ller plug on

the side of angle transmission.

If no grease can be seen on the fl anks of the gears, fi ll the

transmission with quality lithium based multipurpose grease up to

3/4. Do not completely fi ll the transmission.

Flexible shaft

When lubricating fl exible shaft, apply grease in the fl exible pipe of

clutch case side. (It is recommended to apply grease after every 1520 hours of use.)

-1

.

9

Page 10

English

Blade

WARNING

○ Use a sharp blade. A dull blade is more likely to snag and

thrust. Replace the fastening nut if it is damaged and hard to

tighten.

○ When replacing blade, purchase one recommended by Hitachi,

with a 25.4 m m (one inch) fi tting hole.

○ When installing a saw blade, always face the stamped side up.

In the case of a 2 tooth blade, it can be used on either side.

○ Use the correct blade for the type of work.

○ When replacin g blades, use appropriate tools.

○ When cutting edges become dull, re-sharpen or fi le as shown

in the illustration. Incorrect sharpening may cause excessive

vibration.

○ Discard blades that are bent, warped, cracked, broken or

damaged in any way.

NOTE

When sharpening blade it is important to maintain an original

shape of radius at the base of the tooth to avoid c racking.

Maintenance schedule

Below you will fi nd some general maintenance instructions. For

further information please contact your Hitachi dealer.

Daily maintenance

○ Clean the exter ior of the unit.

○ Check that the harness is undamaged.

○ Check the blade guard fo r damage or cracks. Change the guard

in case of impacts or cracks.

○ Check that the cut ting attachment is properly centred, sharp,

and without cracks. An off -centre cutting at tachment induces

heavy v ibrations that may damage the unit.

○ Check that the cuttin g attachment nut is suffi ciently tightened.

○ Make sure that the blade transport guard is undamaged and

that it can be securely fi tted.

○ Check that nuts and screws are suffi ciently tightened.

Weekl y maintenance

○ Check the star ter, especially the cord and return spring.

○ Clean the exter ior of the spark plug.

○ Remove it and check the electrode gap. Adjust it to 0.6 mm, or

change the spark plug.

○ Clean the cooling fi ns on the cylinder and check that the air

intake at t he starter is not clogged.

○ Check that the angle gear is fi lled with grease up to 3/4.

○ Clean the air fi lter.

Monthly maintenance

○ Rinse the fuel tank with gasoline.

○ Clean the exter ior of the carburetor and the space around it.

○ Clean the fan and the space around it.

10

Page 11

SIGNIFICADO DE LOS SÍMBOLOS

NOTA: Algunos aparatos no están prov istos de ellos.

Símbolos

ADVERTENCIA

A continuación se muestran lo s símbolos usados para la máquina. Asegúrese de comprender su signifi cado

antes del uso.

Español

Es importante que usted lea, entienda

totalmente y observe las siguientes

precauciones y advertencias de seguridad.

El uso des cuidado o incorrecto del aparato

podrá causarle lesiones serias o fatales.

Lea, comprenda y siga todas las

advertencias y demás instrucciones de

este manual y las q ue se muestran en el

aparato.

Utilice siempre protecciones para los ojos,

la cabeza y los oídos cuando utilice este

aparato.

Haga que los niños, sus ayudantes o

cualquier otr a persona se mantengan a una

distancia de 15 m del aparato. Si alguien

se acerca a usted, detenga el motor y el

mecanismo de corte de inmediato.

min

Muestra la velocidad máxima del eje.

No utilice mecanismos de cor te cuyas

velocidad máximas sean inferiores a

-1

las velo cidad del eje.

Deben utilzarse guantes siempre que

sea necesario, por ejemplo, cuando se

monten equipos de corte.

Utilice calzado antideslizante y

resistente.

Puede producirse una sacudida

de la cuchilla si al encontrarse en

movimiento ésta entra en contacto

con un objeto sólido en la zona crítica.

Puede producirse una reacción

peligrosa que sacuda violentamente el

aparato y al usuario. Esta reacción se

conoce como sacudida de la cuchilla.

Como consecuencia , el usuario

podría perder e l control de la unidad

y ocasionar lesiones graves e incluso

mortales. E xisten más probabilidades

de que se produzcan sacudidas de la

cuchilla en zonas en las que es difícil

ver el material que se está cortando.

Tenga cuidado con los objeto s que puedan

salir despedidos.

Contenido

¿QUÉ ES QUÉ? ...............................................................................12

ADVERTENCIAS E INSTRUCCIONES DE SEGURIDAD ..............13

ESPECIFI CACIONES ...................................................................... 14

PROCEDIMIENTOS DE M ONTAJE ................................................14

PROCEDIMIENTOS DE OPERACIÓN ............................................15

MANTENI MI ENTO ........................................................................... 15

11

Page 12

Español

¿QU É ES QUÉ?

Puesto que este manual cubre varios modelos, puede que existan

diferencias entre los dibujos y su unidad. Utilice las instrucciones

que se refi eran a su unidad.

1. Tapa del depósito de combustible

2. Mango del acelerador

3. Llave de ignición

4. Protector de la cuchilla

5. Mecanismo de cor te

6. Eje de transmisión

7. A s i d e ro

8. Arnés

9. Carcasa del embrague

10. Mango del arrancador

11. Llave de combustible

12. Palanca del estárter

13. Motor

14. Transmisión en ángulo

15. Llave combinada de cubo

16. Instr ucciones de manejo

514

6

4

2

7

12

1

13

9

15

3

16

8

11

10

12

Page 13

Español

ADVERTENCIAS E INSTRUCCIONES DE

SEGURIDAD

Seguridad del usuario

○ Utilice siempre protecciones como caretas o gafas de

seguridad.

○ Utilice siempre pantalones largos, botas y guantes de tejidos

resistentes. No utilice prendas sueltas, joyas, pantalones

cortos o sandalias, y nunca trabaje descalzo. Recójase el pelo

de forma que quede por enc ima del hombro.

○ No opere este aparato si está cansado, enfermo o bajo la

infl uencia del alcohol, drogas o medicamentos.

○ No deje qu e niños o person as inexpertas operen el aparato.

○ Utilice protección para los oídos. Preste atención a su entorno.

Esté atento a personas que pudieran estar avisándole de un

problema. Quítese el equipo de seguridad inmediatamente

después de detener el motor.

○ Utilice casco protector.

○ Nunca encienda el motor o haga funcionar el aparato dentro de

una sala cerrada o un edifi cio. La inhalación de los gases de

escape puede ser mortal.

○ Mantenga los asideros libres de aceite y combustible.

○ Mantenga las manos alejadas del equipo de cor te.

○ No agarre o sostenga el aparato por el equipo de cor te.

○ Cuando el aparato esté apagado, asegúrese de que el

mecanismo de corte se ha detenido antes de apoyarlo sobre el

suelo.

○ Durante periodos de operación prolongados, se recomienda

descansar de vez en cuando para evitar el posible síndrome

de vibración de manos y brazos (HAVS) causado por las

vibraciones.

ADVERTENCIA

○ Los sistemas antivibratorios no garantizan que pudiera verse

afectado por síndrome de vibración de manos y brazos o el

síndrome del túnel carpiano. Por lo tanto, los usuarios que

utilicen el aparato asiduamente o con regularidad deberán

vigilar con atención el estado de sus manos y dedos. Si

aparece cualquiera de los síntomas citados, deberá acudirse a

un médico de inmediato.

○ Si utiliza algún dispositivo médico eléctrico o electrónico,

como por ejemplo un marcapasos, consulte a su médico y al

fabricante del dispositivo antes de operar cualquier equipo

motorizado.

Seguridad del aparato

○ Inspeccione siempre el aparato antes de utilizarlo.

Reemplace las piezas dañadas. Compruebe que no hay

fugas de combustible y asegúrese de que todas las piezas se

encuentran en su sitio y han sido apretadas cor rectamente.

○ Reemplace cualquier pieza agrietada, rota o deteriorada antes

de poner en march a el aparato.

○ Asegúrese de que la protección de seguridad está acoplada

correctamente.

○ No permita que se acerquen personas mientras ajusta el

carburador.

○ Utilice únicamente los accesorios que el fabricante recomiende

para este dispositivo.

ADVERTENCIA

No intente modifi car el aparato en forma alguna. No utilice este

aparato para otras tareas para las que no esté indicado.

Seguridad del combustible

○ Mezcle y llene el combustible al aire libre, en lugares donde no

se produzcan chispas ni llamas.

○ Utilice un recipiente homologado para combustible.

○ No fume ni deje fumar a otras personas en las proximidades

del combustible o del aparato mientras éste se encuentre en

marcha.

○ Limpie los restos de combustible antes de arrancar el m otor.

○ Antes de arrancar el motor, desplácese al menos 3 metros

respecto del lu gar en el que ha llenado el combustible.

○ Detenga el motor antes de quitar la tapa del depósito de

combustible.

○ Vacíe el depósito de combustible antes de guardar el aparato.

Se recomienda vaciar el depósito de combustible cada vez

que termine de utilizar el aparato. Si deja combustible en el

depósito, asegúrese de que no van a producirse escapes.

○ Guarde el aparato y el combustible en un lugar donde los

vapores del combustible no puedan entrar en contacto con

chispas o llamas de calentadores de agua, motores eléctricos,

interruptores, hornos, etc.

ADVERTENCIA

El combustible puede infl amarse, explotar o emitir gases con

facilidad. Por lo tanto, debe prestar especial atención cuando

manipule o recargue el combustible.

Seguridad durante el corte

○ No corte ningún material que no sea hierba o maleza.

○ No realice operaciones que puedan dar lugar a un fuerte

impacto en el accesorio de cor te.

Si no se cumple esta indicació n el eje podría resultar dañado.

○ Inspeccione siempre la zona sobre la que va a cortar antes de

comenzar. Retire cualquier objeto que pueda salir despedido o

enredarse.

○ Para proteger las vías respiratorias, utilice una máscara de

protección contra aerosoles cuando corte hierba tras haber

fumigado con insecticidas.

○ Mantenga a otras personas, niños, animales y ayudantes

a una distancia de 15 m de la zona de riesgo. Detenga

inmediatamente el motor si se le acerca alguna persona.

○ Mantenga el eje de transmisión en el lado derecho respecto de

su cuerpo en todo momento.

○ Sostenga el aparato fi rmemente con ambas manos.

○ Apoye sus pies con fi rmeza y mantenga el equilibrio. No estire

demasiado el cuerpo.

○ Mantenga su cuerpo apar tado del silenciador y del mecanismo

de corte mientras el motor se encuentra en marc ha.

○ Mantenga el mecanismo de corte por debajo del nivel de la

cintura.

○ Cuando cambie de zona de trabajo, asegúrese de detener el

aparato y de que el mecanismo de corte se ha detenido.

○ Nunca deposite el aparato sobre el suelo mientras éste se

encuentra en marcha.

○ Asegúrese siempre de que el motor está apagado y de que

el mecanismo de corte se ha detenido por completo antes de

eliminar resi duos o hierba del mecan ismo de corte.

○ Lleve siempre un botiquín de primeros auxilios consigo cuando

opere cualquier equipo motorizado.

○ Nunca encienda el motor o haga funcionar el aparato dentro de

una sala cerrada o un edifi cio o en las proximidades de líquidos

infl amables. La inhalación de los gases de escape puede ser

mortal.

Seguridad durante el mantenimiento

○ Realice el mantenimiento del aparato siguiendo los

procedimientos recomendados.

○ Antes de realizar el mantenimiento, desconecte la bujía (salvo

si va a ajustar el carburador).

○ No permita que se acerquen personas mientras ajusta el

carburador.

○ Utilice únicamente los repuestos y accesorios originales de

Hitachi recomendados.

Transporte y almacenamiento

○ Transporte el aparato con el motor y el silenciador a una

distancia segura del cuerpo.

○ Antes de almacenar o transportar el aparato en un vehículo,

espere a que se haya enfriado el motor, vacíe el depósito de

combustible y asegúrelo correctamente.

○ Vacíe el depósito de combustible antes de guardar el aparato.

Se recomienda vaciar el depósito de combustible cada vez

que termine de utilizar el aparato. Si deja combustible en el

depósito, asegúrese de que no van a producirse escapes.

○ Guarde el aparato lejos d el alcance de niños.

○ Limpie y lleve a cabo el mantenimiento del aparato con cuidado

y guárdelo en un lugar seco.

○ Asegúrese de que la llave de encendido del motor esté

desconectada cuando transporte o guarde el aparato.

○ Cuando transporte el aparato en un vehículo o lo guarde, cubra

la cuchilla con una cubierta.

13

Page 14

Español

Si se producen situaciones no previstas en este manual, utilice el

sentido común. Póngase en contacto con su distribuidor de Hitachi

si necesita ayuda. Dedique especial atención a los apartados

introducidos por las siguientes palabras:

ADVERTENCIA

Indica un riesgo signifi cativo de que se produzcan daños

personales graves e incluso la muerte si no se siguen las

instrucciones.

PRECAUCIÓN

Indica la posibilidad de que se produzcan daños personales o

materiales si no se siguen las instrucciones.

NOTA

Indica información útil para el uso y correcto funcionamiento

del aparato.

PRECAUCIÓN

No desmonte el arrancador de retroceso. El resorte del

arrancador puede ocasionarle lesiones personales graves.

ESPECIFICACIONES

Modelo CG40EBF (L)

Tamaño del motor

(ml)

Bujía NGK BPMR6A

Capacidad del

depósito de

combustible (l)

Peso en seco (kg) 9,6

NOTA

* Todos los datos están sujeto s a cambios sin previo aviso.

39,8

1,2 0

PROCEDIMIENTOS DE MONTAJE

Eje de distribución a eje fl exible (Fig. 1)

Retire el tornillo del tubo conector (1),

introduzca completamente el eje fl exible (2) en el tubo conector

(3) del eje de distribución y apriete el tornillo del tubo conector (1)

encajando el tornill o en la ranura (4) del eje fl exible.

NOTA

Asegúrese de confrontar el ex tremo cuadrado del eje interior

fl exible (5) con el orifi cio cuadrado del eje de distribución

girando ligeramente el eje de distribución, de modo que

queden fi rmemente conectados.

Eje fl exible a motor (Fig. 2)

Levante el pasador de bloqueo del eje fl exible (6).

Introduzca completamente el eje fl exible (2) en la carcasa del

embrague introduciendo el extremo cuadrado del eje interior

fl exible (3) en el orifi cio cuadrado del adaptador de la carcasa del

embrague.

Libere el pasador de bloqueo para bloquear el eje fl exible haciendo

coincidir el pasador de bloqueo y el orifi cio (7) del eje fl exible.

Cable de aceleración y cordón de parada (Fig. 3)

Conectar los cables de aceleración (8) enganchando todos los

extremos cor tados de los cables y apretar la parte unida con la caja

del conector (9) que se bloquea. Conectar todos los extremos de

los cordones de parada (10).

NOTA

○ Al quitar la caja de conectores, insértese una moneda o un

atomillador con punta derecha en la ranura del medio y hagase

girar.

○ Fijar tubo de proteccion en maneja shaft o handle que utilizan

abraz aderas de cuerda (11). (Fig. 4)

○ Asegúrese de que el acelerador del carburador vuelve a la

posición de ralentí y que se puede abrirse completamente

mediante la palanca del acelerador.

Instalación del asidero (Fig. 5)

Retire la abrazadera del asidero (12).

Coloque el asidero y acople la abrazadera del asidero (12)

ajustándola suavemente con dos tornillos. Ajuste la abrazadera en

la posición adecuada. A continuación apriétela con los tor nillos.

Instalación del protector de la cuchilla (Fig. 6)

Alinee el orifi cio de la entalladura (14) de la cubier ta del engranaje

con el orifi cio (15) de la tapa de la cubierta del engranaje (13) para

instalar la cubierta del engranaje con 3 tornillo s.

Acople l a cubierta del engranaje con los tres tornillos.

Instale el protector de la cuchilla en el tubo del eje de distribución

y contra la transmisión en ángulo (16). Ajuste fi rmemente la

abrazadera del protector de manera que el protector de la

cuchilla no se mueva hacia los lados o hacia abajo durante el

funcionamiento del aparato.

Instale el engranaje y el protector de la cuchilla de modo que el

protector de la cuchilla entre en contacto con el engranaje. (Fig. 7)

PRECAUCIÓN

El protector de la cuchilla debe estar bien instalado durante la

operación.

Si el protector de la cuchilla no estuviera bien instalado durante

la operación, p odría sufrir una lesión grave.

Instalación de la cuchilla cortante (Fig. 8)

Cuando instale una cuchilla, asegúrese de que no presenta

grietas o daños y de que los fi los cor tantes apuntan en la dirección

correcta.

Confronte el agujero de la entalladura del soporte de la cuchilla

con el agujero en la cubierta del engranaje (parte superior del

engranaje) e inserte la llave Allen para evitar que gire. Gire la tuerca

de fi jación hacia la derecha y retire la tuerca de fi jación, la tapa del

sopor te de la cuchill a y los cierres de tuerca dentados.

Instale la cuchilla cortante de la siguiente manera: Inserte la llave

Allen en el agujero de la entalladura del sopor te de la cuchilla y

en el agujero del engranaje. A continuación, instale la cuchilla

cortante (compruebe la dirección de instalación, como se indica en

la Fig. 10), la tapa del soporte de la cuchilla y los cierres de tuerca

dentados en el soporte de la cuchilla en este orden. Por último,

apriete bien la tuerca de fi jación girándola hacia la izquierda con la

llave combinada de cubo. (Fig. 8)

PRECAUCIÓN

○ Cuando instale la cuchilla cortante, coloque el agujero central

en la parte convexa del soporte de la cuchilla y asegúrelo a la

superfi cie cóncava de la tapa del sopor te de la cuchilla. Luego

apriete la tuerca de fi jación para evitar que la cuchilla cortante

se descentre. (Fig. 9)

Tras instalar la cuchilla cortante, asegúrese de retirar la llave

Allen y la llave com binada de cubo.

○ Antes de poner el aparato en funcionamiento, asegúrese de

que la cuchilla se ha instalado correctamente.

○ Antes de poner el aparato en funcionamiento, compruebe

que la tapa del soporte de la cuchilla ubicada bajo la cuchilla

no esté gastada o rota. Si se encuentra algún daño o rotura,

deberá sustituirla, ya que se trata de un artíc ulo consumible.

NOTA

La cuchilla debe sujetarse con un pasador nuevo cada vez que

se instale. (Fig. 8)

14

Page 15

Español

PROCEDIMIENTOS DE OPERACIÓN

Combustible (Fig. 11)

ADVERTENCIA

○ La desbrozadora de mochila está equipada con un motor de

dos tiempos. El motor debe funcionar siempre con combustible

mezclado con aceite.

Asegúrese siempre de que existe una buena ventilación en los

lugares de manipulación o recarga del combustible.

○ El combustible es altamente infl amable y tóxico y puede

ocasionar lesiones graves si se inhala o entra en contacto con

la piel. E xtreme el cuidado cuando maneje el combustible.

Asegure siempre una buena ventilación cuando maneje el

combustible dentro d e un edifi cio.

Combustible

○ Utilice siempre gasolina sin plomo de marca de 89 octanos.

○ Utilice el aceite de dos tiempos del fabricante original o utilice

una mezcla en proporciones de 25:1 a 50:1. Consulte el

recipiente o a un distribuidor Hitachi para obtener la proporción

de aceite correcta.

○ Si no es posible obtener el aceite del fabricante original, utilice

un aceite con antioxidantes de calidad que esté expresamente

indicado para motores de dos tiempos refrigerados por aire

(JASO FC GRADE OIL o ISO EGC GRADE). No utilice aceite

mezclado BIA o TCW (para 2 tiem pos refrigerado por ag ua).

○ No utilice nunca aceites para distintas temperaturas (10 W/30)

ni aceites usados.

○ Mezcle siempre el combustible y el aceite en un recipiente

limpio y destinado a este fi n.

Comience siempre por llenar la mitad del combustible que va

a utilizar. Luego, agregue todo el aceite. Agite la mezcla de

combustible. Añada el resto de la gasolina.

Antes de llenar el depósito de combustible, agi te bien la mezcla .

Recarga de combustible

ADVERTENCIA

○ Apague siempre el motor antes de recargar el combustible.

○ Para llenar el depósito de combustible, abra lentamente la

tapa del depósito para que desaparezca la sobrepresión que

pudiera existir.

○ Después de llenarlo, cierre y apriete bien la tapa.

○ Antes de arrancar la desbrozadora de mochila, deberá alejarse

al menos 3 m del área de recarga de combustible.

○ Lave siempre inmediat amente con jabón cualquier combustible

verti do sobre la ropa.

○ Asegúrese de verifi car si existe alguna fuga de combustible

después del llenado.

Antes de llenar el combustible, limpie cuidadosamente la zona

de la tapa del depósito para garantizar que no entra suciedad en

el depósito. Asegúrese de que el combustible está bien mezclado

agitando el recipiente antes de llenar el depósito.

Arranque

Abra la llave de combustible (17). (Fig. 12-B)

Mueva el mango del acelerador a la posición A de funcionamiento.

(Fig. 14)

NOTA

Si arranca habiendo girado completamente el acelerador, la

cuchilla comenzará a girar a gran velocidad de repente, lo que

resulta peligroso y debe evitarse.

Lleve la palanca del estárter (18) a la posición CLOSED (cerrado).

(Fig. 13-A)

Tire enérgicamente del arrancador de retroceso. TOME LA

PRECAUCIÓN DE MANTENER EL ASIDERO bien sujeto para

evitar que se escape de la mano.

Cuando escuche el amago de arranque del motor, devuelva la

palanca del estárter a la posición OPEN (abier to). A continuación

vuelva a tirar en érgicamente del arrancador de retroceso.

Una vez encendido el motor, deje que se caliente durante 2-3

minuto s antes de someterlo a ninguna presión.

PRECAUCIÓN

La cuchilla puede girar y el eje fl exible puede moverse hacia

los lados cuando arranque el motor. No permita que la cuchilla

toque ningún objeto al ar rancar el motor.

Tras arrancar el motor, colóquese la mochila.

Corte (Fig. 15, 16)

○ Cuando corte, haga funcionar el motor a más de 6500 min

utilización prolongada a pocas rpm podría dañar el embrague

prematuramente.

○ Corte la hierba de derecha a izqu ierda.

○ Si trabaja en pendiente, la cuchilla debe permitir que el

contorno suba y baje, con el usuario mirando hacia abajo y

hacia la izquierda.

○ Puede producirse una sacudida de la cuchilla si al encontrarse

en movimiento ésta entra en contacto con un objeto sólido en la

zona crítica.

Puede producirse una reacción peligrosa que sacuda

violentamente el aparato y al usuario. Esta reacción se conoce

como sacudida de la cuchilla. Como consecuencia, el usuario

podría perder el control de la unidad y provocarse lesiones

graves e incluso mortales. Existen más probabilidades de que

se produzcan sacudidas de la cuchilla en zonas en las que es

difíci l ver el material que se está cort ando.

○ La cuchilla gira en sentido contrario a las agujas del reloj. Por

tanto, para una mayor efi cacia de corte, proceda siempre de

derecha a izquierda. Haga que cualquier persona se sitúe a

una distancia de al menos 15 m.

ADVERTENCIA

○ Si el mecanismo de corte choca contra piedras u otros

obstáculos, detenga el motor y asegúrese de que el

mecanismo de corte y las piezas asociadas se encuentran

en buen estado. Cuando se enreden hierba o ramas en el

mecanismo, detenga el motor y el mecanismo y retírelas antes

de continuar.

Parada (Fig. 17)

Reduzca la velocidad del motor y déjelo permanecer al ralentí

durante unos minutos. A continuación apague la llave de ignición

(19).

Tras detener el motor, cierre la llave de combustible (17). (Fig. 12-

A)

ADVERTENCIA

El mecanismo de corte puede provocar lesiones mientras gira

tras haber detenido el motor o haber apagado el control de la

alimentación. Cuando el aparato esté apagado, asegúrese de

que el mecanismo de corte se ha detenido antes de apoyarlo

sobre el suelo.

-1

. La

MANTENIMIENTO

EL MANTENIMIENTO, SUSTITUCIÓN O REPARACIÓN DE LOS

DISPOSITIVOS Y SISTEMAS DE CONTROL DE EMISIONES

PUEDEN REALIZARSE EN CUALQUIER TALLER O A CARGO DE

CUALQUIER TÉCNICO DE REPARACIONES MECÁNICAS NO

DESTINADAS AL TRANSPORTE .

Ajuste del carburador (Fig. 18)

ADVERTENCIA

○ El mecanismo de cor te podría estar girando mientras ajusta el

carburador.

○ Nunca arranque el motor sin que la cubierta y el tubo del

embrague estén montados. De lo contrario, el embrague podría

soltarse y provocar lesiones personales.

En el carburador, el combustible se mezcla con aire. El carburador

se ajusta durante la prueba del motor en la fábrica. Sin embargo,

puede que sea necesario reajustarlo con arreglo al clima y a la

altitud. El carburador tiene una opción de ajuste:

T = Tornillo de ajuste de la velocidad de ralentí.

15

Page 16

Español

Ajuste de la velocidad de ralentí (T)

Compruebe que el fi ltro de aire está limpio. Cuando la velocidad

de ralentí sea la correcta, el mecanismo de corte no girará. Si es

necesario ajustarlo, cierre el tornillo T (en el sentido de las agujas

del reloj) con el motor en marcha hasta que el mecanismo de

corte empiece a girar. Abra el tornillo T (en el sentido contrario a

las agujas del reloj) hasta que el mecanismo de corte se detenga.

Habrá obtenido la velocidad de ralentí correcta cuando el motor

funcione con suavidad en cualquier posición encontrándose muy

por debajo de las rpm necesarias para que el mecanismo de corte

empiece a girar.

Si el mecanismo de corte sigue girando tras ajustar la velocidad de

ralentí, póngase en contacto con un distribuidor Hitachi.

NOTA

Las rpm normales al ralentí se encuentran entre las 2500–3000

-1

.

min

ADVERTENCIA

Mientras el motor está al ralentí, el mecanismo de corte no

debería girar en ningún caso.

Filtro de aire (Fig. 19)

Limpie el polvo y la suciedad del fi ltro de aire para evitar:

○ Fallos de funcionamie nto del carburador

○ Problemas de arranque

○ Pérdidas de potencia

○ Desgaste inne cesario de las piezas del motor

○ Consumo excesivo de combustible

Limpie el fi ltro de aire diariamente o con mayor frecuencia cuando

trabaje en zonas con gran cantidad de polvo.

Limpieza del fi ltro de aire

Extraiga la cubierta del fi ltro de aire y el fi ltro (20). Lave los

fi ltros con agua caliente y jabón. Antes de volver a montar el

fi ltro, compruebe que éste esté seco. Un fi ltro de aire que ha

sido utilizado durante mucho tiempo, nunca podrá quedar

completamente limpio. Por tanto, los fi ltros deben reemplazarse

por otros nuevos en intervalos regulares. Reemplace los fi ltros que

estén dañados.

Bujía (Fig. 20)

El estado de la bujía se ve afec tado por:

○ Mal ajuste del carburador

○ Mezcla incorrecta de combustible y aceite (exceso de aceite en

la gasolina)

○ Suciedad en el fi ltro de aire

○ Condiciones de funcionamiento extremas (por ejemplo climas

fríos)

Todos estos factores dan lugar a la formación de sedimentos en

los electrodos, los cuales pueden provocar perturbaciones en el

funcionamiento y difi cultades en el arranque. Si el motor tiene poca

potencia, tiene difi cultades para arrancar el aparato o el ralentí se

muestra inestable, verifi que siempre la bujía en primer lugar. Si

la bujía está muy sucia, límpiela y verifi que la distancia entre los

electrodos. Reajústela si es necesario. La distancia correcta es

de 0,6 mm. Se debe reemplazar la bujía tras unas 100 horas de

funcionamiento o antes si los electrodos están muy gastados.

Silenciador (Fig. 21)

Quite el silenciador y limpie cualquier exceso de carbono de la

salida del escape o la entrada del silenciador cada 100 horas de

funcionamiento.

Cilindro (refrigeración del motor) (Fig. 22)

El motor se refrigera por aire. Por tanto, el aire debe circular

libremente en torno al motor y las aletas de refrigeración del

cabezal del cilindro para evitar que se sobrecalienten.

Cada 100 horas de funcionamiento, o una vez al año (o con más

frecuencia cuando sea necesario), limpie las aletas y la superfi cie

exterior del motor, eliminando los sedimentos de polvo, la suciedad

y el aceite que pudieran obstaculizar una refrigeración adecuada .

NOTA

No haga funcionar el motor sin el carenaje o el protector del

silenciador, ya que esto podría causar un sobrecalentamiento y

provocar daños en el motor.

16

Transmisión en ángulo (Fig. 23)

Compruebe el nivel de lubricante de la transmisión o el engranaje

en ángulo cada 50 horas de funcionamiento extrayendo el tapón

del depósito de lubric ante del lateral de la transmisión en ángulo.

Si no se aprecia lubricante en los fl ancos de los engranajes, llene la

transmisión a 3/4 con lubricante universal de litio de buena calidad.

No llene la transmisión por completo.

Eje fl exible

Al lubricar el eje fl exible, aplique lubricante en el tubo fl exible

del lado de la carcasa del embrague. (Se recomienda aplicar

lubricante cada 15-20 horas de uso).

Cuchilla

ADVERTENCIA

○ Utilice una cuchilla afi lada. Una cuchilla roma presenta

más probabilidades de atacarse y dar sacudidas. Sustituya

la tuerca de ajuste si se encuentra dañada o encuentra

difi cultades al apretarla.

○ Cuando sustituya la cuchilla, adquiera una que esté

recomendada por Hitachi y equipada con un orifi cio de 25,4

mm (1 plg).

○ Cuando instale un disco de corte, coloque siempre la parte

impresa hacia arriba. En el caso de las cuchillas de 2 dientes,

pueden colocarse en ambas direcciones.

○ Utilice la cuchilla correcta para cada tipo de trabajo.

○ Cuando sustituya las cuchillas, utilice las herramientas

adecuadas.

○ Cuando los fi los se emboten, afílelos o límelos tal y como se

muestra en la ilustración. Un afi lado incorrecto podría provocar

vibraciones excesivas.

○ Deseche cualquier cuchilla doblada, combada, agrietada, rota

o dañada de cualquier otra forma.

NOTA

Cuando afi le las cuchillas es importante mantener la forma

original del radio en la base de los dientes para evitar

agrietamientos.

Esquema de mantenimiento

A continuación se proporcionan algunas instrucciones generales

de mantenimiento. Para obtener información adicional, póngase en

contacto con un distribuidor de Hitachi.

Mantenimiento diario

○ Limpie el exterior del aparato.

○ Compruebe que el arnés se encuentra en buen estado.

○ Compruebe que no existen daños o grietas en el protector de la

cuchilla. En caso de impactos o grieta s, sustituya el protector.

○ Compruebe que el mecanismo de corte está debidamente

centrado, afi lado y libre de grietas. Si el mecanismo de corte

no está centrado, puede provocar fuertes vibraciones y dañar

el aparato.

○ Compruebe que la tuerca del mecanismo de corte está

sufi cientemente apretada.

○ Aseg úrese de qu e la protec ción para el tra nsporte de la cuchi lla

no está dañada y puede fi jarse con fi rmeza.

○ Comp ruebe que la s tuercas y los t ornillos es tán sufi cientemente

apretados.

Mantenimiento semanal

○ Compruebe el sistema de arranque, en especial la cuerda y el

muelle de retroceso.

○ Limpie el exterior de la bujía.

○ Extraiga la bujía y compruebe la distancia entre los electrodos.

Ajústela hast a 0,6 mm o sustituya la bujía.

○ Limpie las aletas de refrigeración del cilindro y compruebe que

la admisión de aire no se encuentra obstruida.

○ Compruebe que el engranaje en á ngulo está lleno de lubricante

a 3/4 de su capacidad.

○ Limpie el fi ltro de aire.

Mantenimiento mensual

○ Lave el depósito de combustible con gasolina.

○ Limpie el exter ior del carbur ador y los alrededores del mismo.

○ Limpie el ventilador y sus alred edores.

Page 17

SIGNIFICADO DOS SÍMBOLOS

NOTA: Os símbolos referidos não se encontram em todos os

modelos.

Símbolos

ADVERTÊNCIA

A seguir aparec em os símbolos utilizados pela máquina. Assimile bem seus signifi cado s antes do uso.

É impor tante que você leia, compreenda

integralmente e obser ve as seguintes

precauções e advertências de segurança .

O uso descuidado ou incorreto da

ferram enta pode caus ar lesões graves ou

até fatais.

min

Mostra a velocidade má xima do eixo.

Não use um m ecanismo de corte com

-1

velocidade má ximas inferiores às

velocidade do eixo.

Português

Leia, compreenda e siga todas as

advertências e instruçõe s contidas neste

manual e na ferra menta.

Sempre use protetores pa ra os olhos,

cabeça e ouvidos durante o uso desta

ferramenta.

Mantenha todas as crianças, curiosos

e ajudantes a 15 metro s de distância da

ferram enta. Se alguém se aprox imar, pare

imediatamente o motor e o mecani smo

de corte.

Tome cuidado com objetos arremessados.

Sumário

DESCRIÇÃO DE CADA COMPONENTE ........................................18

ADVERTÊNCIAS E INSTRUÇÕES DE SEGURANÇA ...................19

ESPECIFI CAÇÕE S ..........................................................................20

PROCEDIMENTOS DE MONTAGEM .............................................20

PROCEDIMENTOS DE OPERAÇÃO ..............................................20

MANUTENÇÃO ...............................................................................21

Você deve usar luvas quando

necessário, p or exemplo, ao mont ar o

equipamento de corte.

Use calçados robustos e

antiderrapantes.

Pode gerar-se uma força de

compressão na lâmina se a lâmin a

em rotaç ão entrar em contato com um

objeto sólido na área crítica. Isso, por

sua vez, pode provocar uma reação

perigosa na forma de um contra-golpe

violento na ferramenta e no operador.

Esta reação é denominada contragolpe da lâmina. Em conseqüên cia,

o operador pode perder o c ontrole

da ferra menta, o que pode causa r

ferime ntos graves ou fatais. O

contra-golpe da lâmina tem maior

probabilidade de ocorrência onde é

difícil ver o material a ser cortado.

17

Page 18

Português

DESCRIÇÃO DE CADA COMPONENTE

Como este manual cobre vários modelos, podem existir algumas

diferenças entre as ilustrações e a sua ferramenta. Use as

instruções que se aplicam à sua ferramenta.

1. Tampa do tanque de combustível

2. Alavanca do acelerador

3. Interruptor de ignição

4. Protetor da lâmina

5. Mecanismo de cor te

6. Tubo do eixo de transmissão

7. C a b o

8. Alça

9 Caixa da em breagem

10. Cabo de arranque

11. Torneira do combustível

12. Alavanca do afogador

13. Motor

14. Transmissão angular

15. Chave combinada

16. Manual de instruçõe s

514

7

6

4

2

12

1

13

9

15

3

16

8

11

10

18

Page 19

Português

ADVERTÊNCIAS E INSTRUÇÕES DE

SEGURANÇA

Segurança do operador

○ Sempre use uma máscara ou óculos de proteção.

○ Sempre use calças pesadas e compridas, botas e luvas. Não

use roupas folgadas, jóias e bijuteria, calções, sandálias e

nunca trabalhe descalço. Prenda o cabelo para que ele não

caia por cima dos ombros.

○ Não use esta ferramenta quando estiver cansado, doente ou

sob efeitos de álcool, drogas ou m edicamentos.

○ Nunca deixe uma criança ou uma pessoa inexperiente operar

esta ferramenta.

○ Use uma proteção para os ouvidos. Preste atenção ao

arredores. Fique atento a quaisquer observadores que

possam apresentar algum problema. Retire o equipamento de

segurança imediatamente depois de apagar o motor.

○ Use um capacete.

○ Nunca arranque nem deixe o motor funcionando no interior de

um quarto ou prédio. A inalação dos gases de escape pode

provocar a morte.

○ Mantenha os cabos livres de óleo e gasolina.

○ Mantenha as mãos afastadas do mecanismo de corte.

○ Não agar re nem segure a ferramenta pelo mecanismo de corte.

○ Depois de desligar a ferramenta, certifi que-se de que o

mecanismo de corte tenha parado antes de deixá-la em algum

lugar.

○ Durante trabalhos prolongados, faça pausas de vez em quando

para prevenir a síndrome de vibração das mãos e braços

(HAVS) causada pela vibração.

ADVERTÊNCIA

○ Sistemas anti-vibratórios não garantem que o operador não

sofra da síndrome de vibração das mãos e braços ou da

síndrome do túnel cardal. Portanto, os usuários freqüentes

e contínuos devem estar sempre atentos ao estado das suas

mãos e dedos. Se você perceber qualquer um dos sintomas

mencionados acima, consulte um médico imediatamente.

○ Se você estiver usando um dispositivo médico elétrico/

eletrônico como, por exemplo, um marcapasso, consulte o

seu médico e o fabricante do aparelho antes de trabalhar com

equipamentos motorizados.

Segurança da ferramenta

○ Inspecione toda a ferramenta antes de cada uso. Substitua

as peças danifi cadas. Verifi que se existem vazamentos de

combustível e certifi que -se de que todos os parafusos e porcas

estejam instalados e apertados corretamente.

○ Substitua todas as peças que estiverem rachadas, lascadas ou

danifi cadas antes de usar a ferramenta.

○ Certifi que-se de que o protetor de segurança esteja instalado

corretamente.

○ Mantenha outras pessoas afastadas ao fazer ajustes no

carburador.

○ Use somente os acessórios recomendados pelo fabricante

para esta ferramenta.

ADVERTÊNCIA

Nunca modifi que a ferramenta de qualquer maneira. Não use a

ferramenta para qualquer outra fi nalidade que não tenha sido

concebida para a mesma.

Segurança do combustível

○ Misture e abasteça o combustível ao ar livre e num local onde

não haja faíscas ou chamas.

○ Use um rec ipiente aprovado para combustível.

○ Não fume e proíba o fumo nas proximidades do combustível

ou da ferramenta e, acima de tudo, durante o trabalho com a

ferramenta.

○ Limpe qualquer combustível derramado antes de arrancar o

motor.

○ Afaste-se pelo menos 3 m do local de abastecimento antes de

arrancar o motor.

○ Apague o motor antes de retirar a tampa do tanque de

combustível.

○ Esvazie o tanque de combustível antes de guardar a

ferramenta. É recomendável esvaziar o tanque de combustível

após cada uso. Se tiver que deixar o combustível no tanque,

guarde a ferramenta de forma que não haja vazamento de

combustível.

○ Guar de a ferrament a num local on de os vapores do c ombustível

não possam entrar em contato com faíscas ou chamas abertas

de aquecedores de água, motores ou interruptores elétricos,

fornos, etc.

ADVERTÊNCIA

O combustível é facilmente infl amável e altamente explosivo,

bem como pode provocar a inalação de fumos e, portanto,

tome mui to cuidado ao manipular ou abastecer o combustível.

Segurança durante o corte

○ Não cor te nenhum mater ial que não seja relva e mato.

○ Não execute nenhuma operação que possa causar um choque

enorme no anexo de c orte.

Do contrário, o eixo fl exível corre o risco de ser danifi cado.

○ Inspecione a área a ser cortada antes de cada uso. Retire

coisas que possam ser lançadas ou fi car emaranhadas.

○ Para a proteção das vias respiratórias após uma aplicação de

inseticidas, use uma m áscara de proteção contra aerossóis.

○ Mantenha outras pessoas, incluindo crianças, animais,

curiosos ou ajudantes fora da zona de perigo de 15 metros.

Apague o motor imediata mente se alguém se aproximar.

○ Mantenha sempre o tubo do eixo de transmissão lado direito do

corpo.

○ Segure a ferramenta fi rmemente com ambas as mãos.

○ Mantenha o equilíbrio e olhe onde anda. Não exceda o seu raio

de alcance.

○ Quando o motor estiver em funcionamento, mantenha todas as

partes do corpo afastadas do silenciador e do mecanismo de

corte.

○ Mantenha o mecanismo de corte abaixo do nível da cintura.

○ Quando se deslocar para outra área de trabalho, apague o

motor e certifi que-se de que o mecanismo de corte esteja

parado.

○ Nunca coloque a ferramenta em funcionamento no solo.

○ Antes de remover resíduos ou relva do mecanismo de corte,

certifi que-se de que o motor esteja apagado e de que o

mecanismo de corte esteja completamente parado.

○ Sempre tenha um estojo de primeiros socorros por perto

quando trabalhar com e quipamentos m otorizados.

○ Nunca arranque nem deixe o motor funcionando em locais

fechados e/ou nas proximidades de líquidos infl amáveis. A

inalação dos gases de escape pode provo car a morte.

Segurança durante a manutenção

○ Faça a manutenção da ferramenta de acordo com os

procedimentos recomendados.

○ Desconecte a vela de ignição antes de iniciar a manutenção,

exceto se tiver que fazer ajustes no c arburador.

○ Mantenha outras pessoas afastadas ao fazer ajustes no

carburador.

○ Use somente peças sobressalentes genuínas da Hitachi, tal

como recomendado pelo fabri cante.

Transporte e armazenamento

○ Transpor te a ferramenta com as mãos, com o motor parado e

com o silenciador afastado do corpo.

○ Deixe o motor esfriar, esvazie o tanque de combustível,

e sujeite a ferramenta fi rmemente antes de guardá-la ou

transportá-la num veículo.

○ Esvazie o tanque de combustível antes de guardar a

ferramenta. É recomendável esvaziar o tanque de combustível

após cada uso. Se tiver que deixar o combustível no tanque,

guarde a ferramenta de forma que não haja vazamento de

combustível.

○ Guarde a ferramenta fora do alcance de crianç as.

○ Limpe a ferramenta e realize a sua manutenção

cuidadosamente antes de guardá-la num local seco.

○ Certifi que-se de que o interruptor de ignição esteja desligado

quando transportar ou guardar a ferramenta.

○ Para transportar a ferramenta num veículo, cubra a lâmina com

a respectiva proteção.

19

Page 20

Português

Se ocorrer algo que não estiver coberto neste manual, seja

cauteloso e atue com o senso comum. Contate o seu revendedor

Hitachi quando precisar de assistência técnica. Preste especial

atenção aos textos precedidos pelos seguintes termos:

ADVERTÊNCIA

Indica uma forte possibilidade de sofrer ferimentos pessoais ou

de perder a vida, se as instruções não forem observadas.

PRECAUÇÃO

Indica uma possibilidade de ferimentos pessoais ou danos

materiais, se as instruções não forem obser vadas.

NOTA

Informações úteis sobre o funcionamento e uso correto.

PRECAUÇÃO

Não desmonte o acionador de arranque de recuo. Você pode

sofrer ferimentos pessoais com a mola de recuo.

ESPECIFICAÇÕES

Modelo CG40EBF (L)

Cilindrada (ml) 39,8

Vela de ignição NGK BPMR6A

Capacidade

do tanque de

combustível (l)

Peso a seco (kg) 9,6

NOTA

* Todos os dados estão sujeitos a modifi c a ç õ e s s e m a v i s o

prévio.

1,2 0

PROCEDIMENTOS DE MONTAGEM

Eixo de transmissão para eixo fl exívelo motor (Fig. 1)

Remova o parafuso do tubo de união (1),

Insira completamente o eixo fl exível (2) no tubo de união (3) do

Eixo de Transmissão e aperte o parafuso do tubo de união (1)

introduzindo o parafuso na ranhura (4) do eixo fl exível.

NOTA

Alinhe a extremidade quadrada do eixo interno fl exível (5)

com o orifício quadrado do eixo de transmissão rodando

ligeiramente o eixo de transmissão, para que fi quem

correctamente ligados.

Eixo fl exível para o motor (Fig. 2)

Levante o pino de bloqueio do eixo fl exível (6)

Insira completamente o eixo fl exível (2) na caixa de embraiagem

introduzindo a extremidade quadrada do eixo interno fl exível (3) no

orifício quadrado do adaptador na cai xa de embraiagem.

Liberte o pino de bloqueio para bloquear o eixo fl exível alinhando o

pino de bloqueio com o orifício (7) do eixo fl exível.

Cabo do acelerador e cabo de paragem (Fig. 3)

Ligar os cabos do acelerador (8) curvando cada extremo dos cabos

em forma de gancho e apertando as paries articuladas na caixa de

uniao (9) que os trava.

Ligar as pontas dos cabos de paragem (10).

20

NOTA

○ Para remover a caixa de união, insira uma moeda ou uma

chave de fenda no entalhe do centra e gire-a.

○ Prenda a manga de protecção no eixo de accionamento ou na

pega usando as braçadeiras para fi xar o cabo(11). (Fig. 4)

○ Certifi que-se de que o acelerador do carburador retorne à

posição de ralenti e de que possa ser aberto amplamente ao

operar a alavanca do acelerador.

Instalação do cabo (Fig. 5)

Remova o suporte do cabo (12).

Coloque o cabo e fi xe ligeiramente o suporte (12) com dois

parafusos. Ajuste a posição do cabo para se adequar ao seu estilo

de trabalho. Em seguida fi xe-o fi rmemente com os parafusos.

Instalação do protetor da lâmina (Fig. 6)

Alinhe o orifício do entalhe (14) da caixa de engrenagem com o

orifício (15) da tampa da caixa de engrenagem (13) para apertar a

tampa da caixa de engrenagem co m os 3 parafusos.

Instale o protector da lamina no tudo do eixo de transmissão

contra a transmissão angular (16). Aperte fi rmemente o suporte

do protector para que o protector da lâmina não se desloque para

baixo durante o funcionamento.

Instale a caixa de engrenagem e o protector da lâmina de forma

a que o protector da lâmina esteja em contacto com a caixa de

engrenagem. (Fig.7)

PRECAUÇÃO

O protector da lâmina deve estar colocado durante o

funcionamento.

Se o protector da lâmina não estiver colocado durante o

funcionamento, poderão ocorrer ferimentos graves.

Instalação da lâmina de corte (Fig. 8)

Ao instalar uma lâmina de corte, certifi que-se de que a mesma

não contenha rachaduras ou danos e de que os bordos de corte

estejam virados para a direção correta.

Alinhe o orifício do entalhe do suporte do cor tador com o orifício

na tampa da caixa de engrenagens (parte superior da caixa de

engrenagens) e, em seguida, introduza a chave Allen para deter a

rotação. Gire a porca de fi xação no sentido horário, retire a porca

de fi xação, tampa do suporte do cortador e arruelas de pressão

dentadas.

Instale a lâmina de cor te da seguinte maneira: introduza a chave

Allen no orifício de entalhe do suporte do cor tador e no orifício na

caixa de engrenagens. Logo, instale a lâmina de corte (conferindo

a direção de instalação na Fig. 10), a tampa do suporte do cortador

e arruelas de pressão dentadas no suporte do cortador, nessa

ordem. Finalmente, aperte a porca de fi xação fi rmemente girando-a

no sentido anti-horário com a chave combinada. (Fig. 8)

PRECAUÇÃO

○ Quando instalar a lâmina de corte, coloque o seu orifício

central na parte convexa do suporte do cortador e fi xe-a com

a super fície côncava da tampa do suporte do cortador. Logo,

aperte a porca de fi xação para evitar que a lâmina de corte

fi que excêntrica. (Fig. 9)

Após instalar a lâmina de corte, certifi que-se de retirar a chave

Allen e a chave combinada .

○ Antes de usar a fer ramenta, certifi que-se de que a lâmina tenha

sido instalada corretamente.

○ Antes de operar a ferramenta, verifi que a tampa do suporte

do cortador debaixo da lâmina de corte para ver se não há

desga ste ou fendas. Se h ouver danos ou d esgaste, sub stitua-a,

já que a mesma é uma peça consumível.

NOTA

A lâmina deve ser retida com um contrapino novo sempre que

for inst alada. (Fig. 8)

PROCEDIMENTOS DE OPERAÇÃO

Combustível (Fig. 11)

ADVERTÊNCIA

○ A roçadeira de mochila estáé equipada com um motor de

dois tempos. Sempre opere o motor com combustível, que é

misturado com ó leo.

Providencie uma boa ventilação quando manusear ou

abaste cer o combustível.

Page 21

Português

○ O combustível é altamente infl amável e tóxico e pode provocar

ferimentos graves se for inalado ou se entrar em contacto com

a pele. Sempre manuseie o combustível com cuidado. Sempre

providencie uma boa ventilação quando tiver que manusear o

combustível no interi or de um prédio.

Combustível

○ Sempre use gasolina sem chumbo de 89 octanas como o

combustível.

○ Use óleo genuíno para motores de 2 tempos ou use uma

mistura de 25:1 a 50:1. Consulte as instruções do óleo ou o

revendedor Hit achi para saber a relação de mist ura exata.

○ Se não conseguir encontrar óleo genuíno, use um óleo

de qualidade com aditivos antioxidantes, que indique

expressamente a sua compatibilidade com motores de 2

tempos refrigerados por ar (JASO FC GR ADE OIL ou ISO

EGC GRADE). Não use óleo misturado BIA ou TCW (tipo

refrigeração por água de 2 tempos).

○ Nunca use óleo multi- grau (10 W/30) ou óleo usado.

○ Sempre misture o combustível e o óleo num recipiente limpo

separado.

Comece sempre enchendo a metade da quantidade necessária de

combustível. Logo, adicione a quantidade inteira de óleo. Misture

(agite) a mistura de combustível. Finalmente, adi cione a quantidade

restante de combustível.

Misture (agite) bem a mistura de combustível antes de abastecê-la

no tanque de combustível da ferrament a.

Abastecimento de combustível

ADVERTÊNCIA

○ Sempre apague o motor antes de abastecer o combustível.

○ Quando abastecer o combustível, abra lentamente a tampa

do tanque de combustível para aliviar qualquer sobrepressão

existente.

○ Após o abastecimento, aperte a tampa do tanque de

combustível cuidadosamente.

○ Afaste a roçadeira de mochila pelo menos 3 m da zona de

abastecimento antes de arrancar o motor.

○ Sempre lave qualquer combustível derramado na roupa

imediatamente com água e sabão.

○ Certifi que-se de verifi car se há qualquer fuga de combustível

após o abastecimento.

Antes de a bastecer o com bustível, lim pe a área da tampa d o tanque

com cuidado, para evitar que nenhuma sujeira entre no tanque.

Certifi que-se de que o combustível esteja bem misturado antes de

abaste cer, agitando o recipiente para isso.

Arranque

Abra a tor neira do combu stível (17). (Fig. 12-B)

Coloque a alavanca do acelerador na posição A de arranque. (Fig.

14)

NOTA

O arranque com o acelerador completamente pressionado

causará a súbita rotação elevada da lâmina, o que é perigoso,

por isso deve ser evitado.

Coloque a alavanca do afogador (18) na posição CLOSED

(Fechado). (Fig. 13-A)

Puxe o cabo de arranque com força. SEGURE SEMPRE NA PEGA

DO CABO e não permit a que este salte br uscamente.

Quando ouvir o motor a tentar arrancar, coloque a alavanca do

afogador na posição OPEN (Aberto). Em seguida, puxe novamente

o cabo de arranque com força.

Após o arranque do motor, deixe que este aqueça durante cerca de

2-3 minu tos antes de o sujeitar a qualquer carga.

PRECAUÇÃO

A lâmina poderá rodar e o eixo fl exível poderá balançar quando

o motor arrancar. Não deixe que a lâmina toque em qualquer

objecto quando o motor arrancar.

Depois de arrancar o motor, utilize a mochila.

Corte (Fig. 15, 16)

○ Quando cortar, opere o motor acima de 6500 min

prolongado a baixas rotações pode desgastar a embreagem

prematuramente.

○ Corte a relva da direita para a esquerda.