Page 1

Page 2

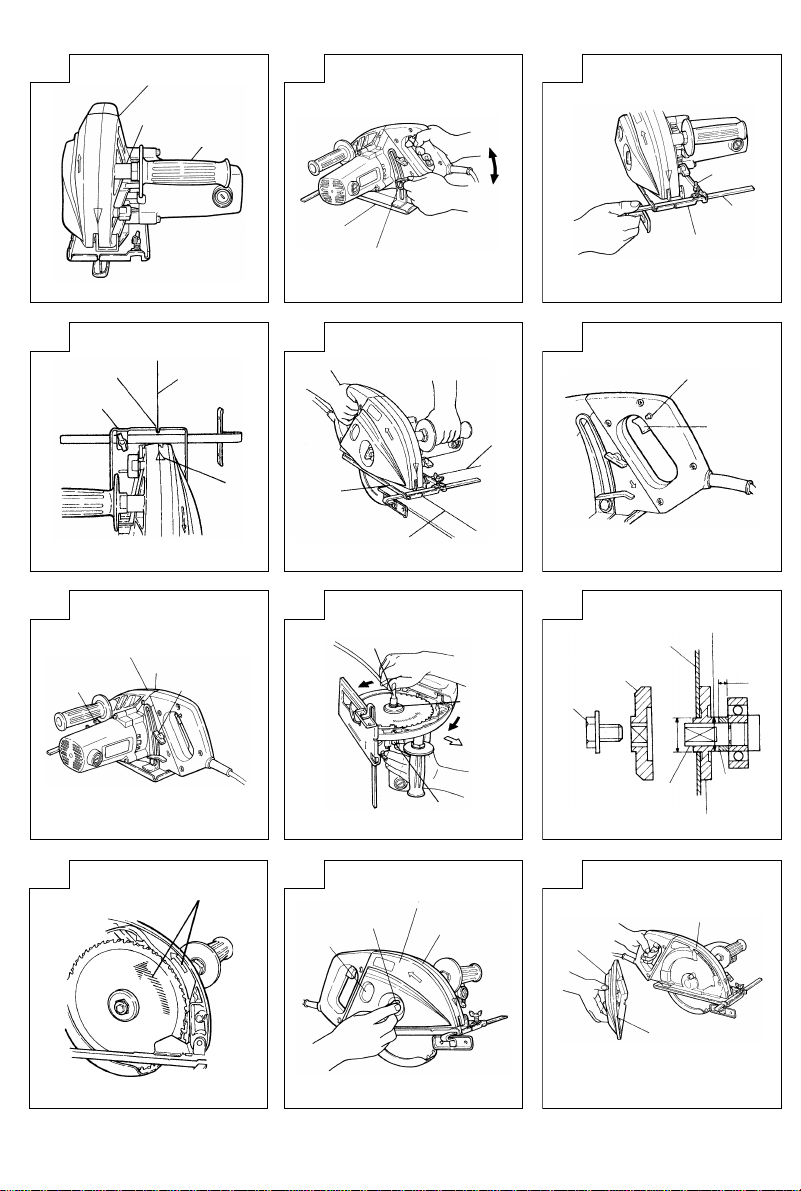

1 2 3

1

2

3

4

5

6

7

4 5 6

=

A

9

D

9

8

6

F

E

7

10

G

H

B

C

A

8 9

J

I9

4

K

M

K

O

φ19

4

5

φ20

N

P

L

B

11 12

H

R

Q

G

G

S

H

1

Page 3

Page 4

GENERAL OPERATIONAL PRECAUTIONS

WARNING! When using electric tools, basic safety

precautions should always be followed to reduce the risk

of fire, electric shock and personal injury, including the

following.

Read all these instructions before operating this product

and save these instructions.

For safe operations:

1. Keep work area clean. Cluttered areas and benches

invite injuries.

2. Consider work area environment. Do not expose

power tools to rain. Do not use power tools in

damp or wet locations. Keep work area well lit.

Do not use power tools where there is risk to

cause fire or explosion.

3. Guard against electric shock. Avoid body contact

with earthed or grounded surfaces. (e.g. pipes,

radiators, ranges, refrigerators).

4. Keep children away. Do not let visitors touch the

tool or extension cord. All visitors should be kept

away from work area.

5. Store idle tools. When not in use, tools should

be stored in a dry, high or locked up place, out

of reach of children.

6. Do not force the tool. It will do the job better and

safer at the rate for which it was intended.

7. Use the right tool. Do not force small tools or

attachments to do the job of a heavy duty tool.

Do not use tools for purposes not intended; for

example, do not use circular saw to cut tree limbs

or logs.

8. Dress properly. Do not wear loose clothing or

jewelry, they can be caught in moving parts.

Rubber gloves and non-skid footwears are

recommended when working outdoors. Wear

protecting hair covering to contain long hair.

9. Use eye protection. Also use face or dust mask

if the cutting operation is dusty.

10. Connect dust extraction equipment.

If devices are provided for the connection of dust

extraction and collection facilities ensure these are

connected and properly used.

11. Do not abuse the cord. Never carry the tool by

the cord or yank it to disconnect it from the

receptacle. Keep the cord away from heat, oil and

sharp edges.

12. Secure work. Use clamps or a vise to hold the

work. It is safer than using your hand and it frees

both hands to operate tool.

13. Do not overreach. Keep proper footing and balance

at all times.

14. Maintain tools with care. Keep cutting tools sharp

and clean for better and safer performance. Follow

instructions for lubrication and changing

accessories. Inspect tool cords periodically and if

damaged, have it repaired by authorized service

center. Inspect extension cords periodically and

replace, if damaged. Keep handles dry, clean, and

free from oil and grease.

15. Disconnect tools. When not in use, before servicing,

and when changing accessories such as blades,

bits and cutters.

16. Remove adjusting keys and wrenches. Form the

habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning

it on.

17. Avoid unintentional starting. Do not carry a

plugged-in tool with a finger on the switch. Ensure

switch is off when plugging in.

18. Use outdoor extension leads. When tool is used

outdoors, use only extension cords intended for

outdoor use.

19. Stay alert. Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

20. Check damaged parts. Before further use of the

tool, a guard or other part that is damaged should

be carefully checked to determine that it will

operate properly and perform its intended function.

Check for alignment of moving parts, free running

of moving parts, breakage of parts, mounting and

any other conditions that may affect its operation.

A guard or other part that is damaged should be

properly repaired or replaced by an authorized

service center unless otherwise indicated in this

handling instructions. Have defective switches

replaced by an authorized service center. Do not

use the tool if the switch does not turn it on and

off.

21. Warning

The use of any accessory or attachment, other

than those recommended in this handling

instructions, may present a risk of personal injury.

22. Have your tool repaired by a qualified person.

This electric tool is in accordance with the relevant

safety requirements. Repairs should only be carried

out by qualified persons using original spare parts.

Otherwise this may result in considerable danger

to the user.

PRECAUTIONS ON USING METAL CUTTER

1. Always use the correct electric power source

voltage which is indicated on the name plate on

the metal cutter.

2. Do not fix the protective cover permanently in

place so that it does not move. Check to see that

it moves smoothly.

3. Use the tipped saw by following the use limitations

indicated on the name plate.

Do not use a tipped saw with bottom blade

diameter of 165 mm or less.

4. Place the materials to be cut on a stable table or

bench.

5. Just before and after the piece has been cut all

the way through, be sure the tipped saw blade

does not get caught between the two pieces

because of the weight of the cut off portion of

the material. Prevent this by supporting the piece

being cut off by placing it on a table or bench.

6. If the piece being cut off is large, support it by

using a stable table or bench. If the cut is to be

made on a work piece lying on a flat surface, keep

the tipped saw blade from touching the surface

below and causing the saw to move by making

sure that the height of the work piece is elevated

above the surface under the work piece at least

three times the distance that tipped saw blade

projects from the saw.

3

Page 5

7. When cutting, hold the body of the metal cutter

firmly.

8. While using the metal cutter, keep the tipped saw

blade, rotating parts and the saw dust exit aperture

away from the hands and face.

9. When making a cut, do not try to pull the metal

cutter out of the cut while it is running. Turn off

the power switch first and wait until the blade

completely stops rotating before taking the metal

cutter out of the cut.

10. If the tipped saw does not seem to operate

normally or makes abnormal sounds, stop using

the tipped saw immediately and contact an

and repair.

11. If the metal cutter is accidentally dropped or

bumped, carefully examine the frame, tipped saw,

etc. to see that there are no cracks, deformation

or any other damage.

12. Make sure that material to be cut is firmly fixed

in place.

13. Keep flaminable and easily damaged objects away

when cutting metal.

14. Do not use the metal cutter to cut hard metal

materials for long continuous periods of time.

15. Do not use cutting oil when cutting materials with

the metal cutter.

Authorized Hitachi Service Center for inspection

SPECIFICATIONS

Voltage 110V

Power input 1140W

No-load speed 4300/min

Max. cutting depth 62.5 mm

Saw blade 185 mm (external dia.) × 1.6 mm (thickness) × 20 mm (hole dia.)

Weight (without cord) 4.4 kg

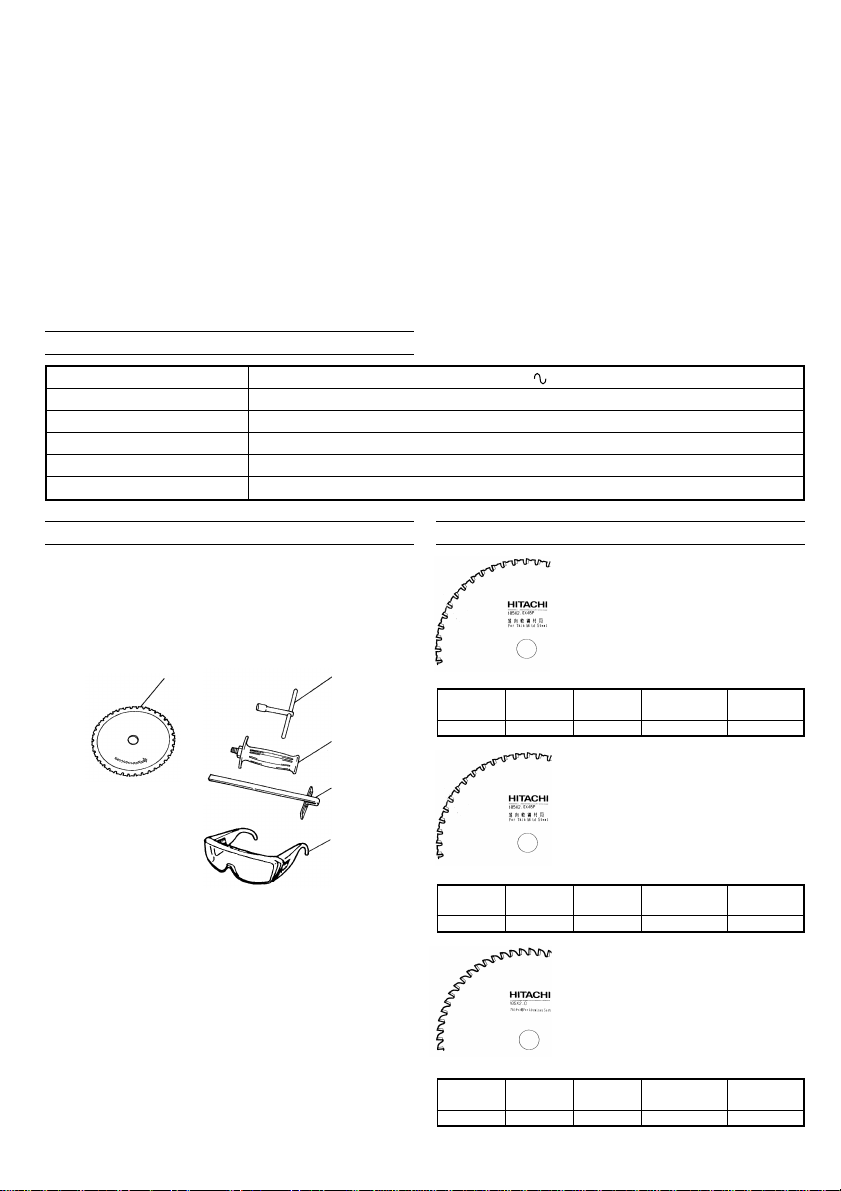

STANDARD ACCESSORIES

1 Carbide Tipped Saw Blade .................................... 1

(Mounted on the unit)

2 Box Wrench .............................................................. 1

3 Side Handle ............................................................... 1

4 Guide .......................................................................... 1

5 Eye Protection ........................................................... 1

1

The 1 tipped saw blade may not be included depending

on the prodact type and must be purchased separately.

Standard accessories are subject to change without notice.

2

3

4

5

OPTIONAL ACCESSORIES (sold separately)

1. Carbide tipped saw blade: Thin,

soft steel material cutting

Use: For cutting soft steel

materials.

Dimensions:

Outer Hole Tip

diameter diameter width

185 mm 20 mm 2 mm 1.6 mm 48 teeth

2. Carbide tipped saw blade: Thin,

soft steel material cutting (Low

noise type)

Use: For cutting soft steel

materials.

Dimensions:

Outer Hole Tip

diameter diameter width

185 mm 20 mm 2 mm 1.6 mm 48 teeth

3. Carbide tipped saw blade:

Aluminum sash material cutting.

Use: For cutting aluminum sash

materials.

Dimensions:

Outer Hole Tip

diameter diameter width

185 mm 20 mm 2 mm 1.5 mm 60 teeth

Thickness of

saw blade

Thickness of

saw blade

Thickness of

saw blade

Number

of teeth

Number

of teeth

Number

of teeth

4

Page 6

4. Carbide tipped saw blade:

Stainless steel, soft steel

material cutting use.

Uses: For cutting stainless steel/

soft steel materials

Dimensions:

Outer Hol e Tip

diameter diameter width

180 mm 20 mm 2 mm 1.6 mm 48 teeth

Thickness of

saw blade

Number

of teeth

Optional accessories are subject to change without

notice.

APPLICATIONS

Blades

Soft steel use blade

Standard

accessories

Tipped saw blades:

Thin, soft steel material

cutting use

Tipped saw blades:

Thin, soft steel material

cutting use (Low noise type)

Tipped saw blades:

Aluminum sash material

cutting use

Tipped saw blades:

Stainless steel/soft steel

materials cutting use.

Optional accessories

嘷

¡

嘷

嘷

¡

嘷

嘷 Refer to Page 6: “Selecting the proper tipped saw

blade for different materials”

Uses

For cutting various types

of soft steel materials

such as flat steel strips,

pipe, steel channels (“C”

channels, “L” angles,

etc.).

Caution: Cannot be used

for cutting tempered

steel materials.

For cutting aluminum

sash materials only.

For cutting various types

of soft steel materials

such as flat steel sheets,

pipe, steel channels, etc.

(“C” channels, “L”

angles, etc.)

Caution: Cannot be used

for cutting tempered

steel materials.

For cutting stainless

steel materials.

PRIOR TO OPERATION

1. This product has double insulation. However, to

avoid electric shocks, be sure to use a power

source that is equipped with a circuit breaker to

cope with power leakage and sudden surges.

2. Power source

Ensure that the power source to be utilized

conforms to the power requirements specified on

the product nameplate.

3. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, inviting serious

accident.

4. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

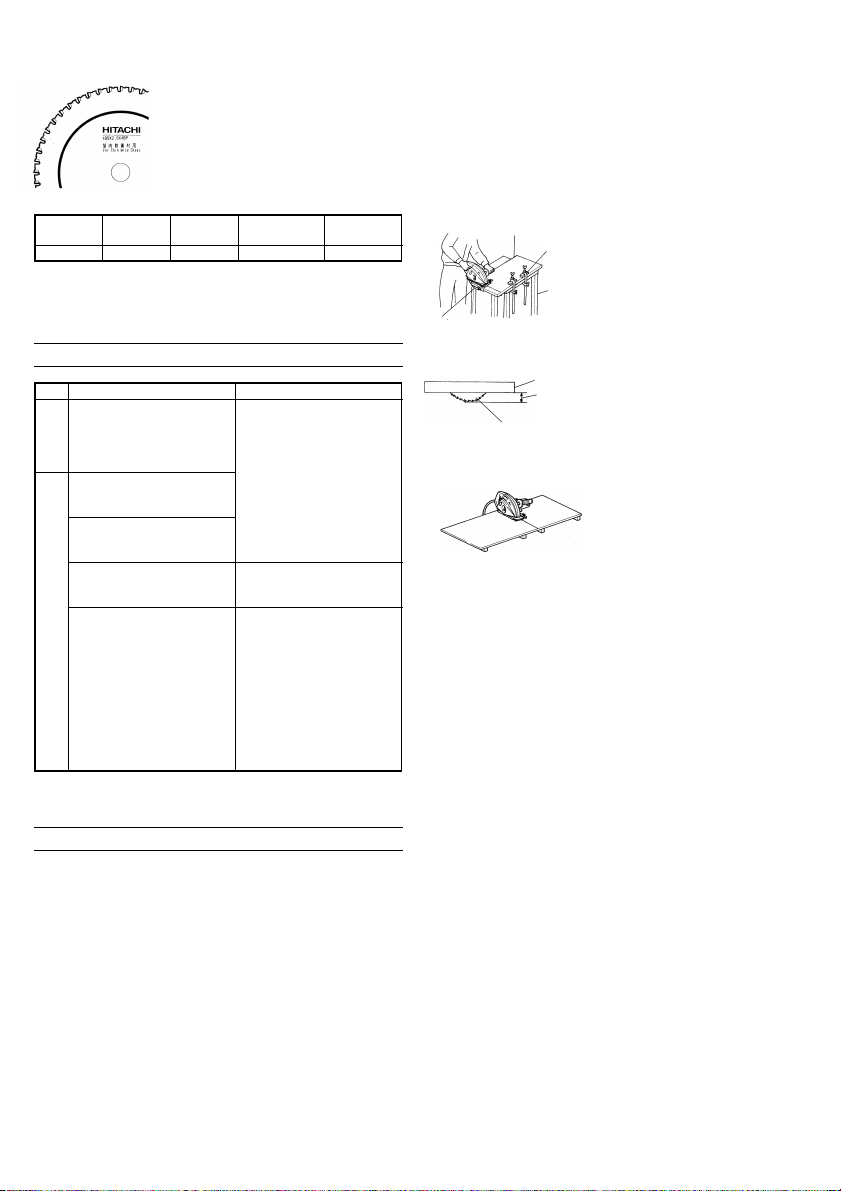

5. Preparing a wooden work bench

The outer edge of the

tipped saw blade projects

Work piece to be cut

Work

bench

Tipped saw blade

from the bottom of the

work piece being cut.

Vise

Therefore, the material

should be placed on a work

bench when cutting.

In addition, care should be

taken to see that the tipped

saw blade and protective

cover do not come into

Work piece

Tipped saw

blade

Projection

distance of

the tipped

saw blade

contact with the surface

below the work piece (e.g.,

the surface of the work

bench or the ground, floor,

etc.). To make sure that this

does not happen, the work

piece (material to be cut)

should be at a height above

the surface below the work

piece that is equal to at

least three times the

distance (width) that the

blade projects below the

bottom of the work piece.

In situations like this, it is safer to make sure that

the material is firmly secured in place using a vise

so that both hands can be used to operate the

metal cutter.

If the piece to be cut off is large in size, care must

be taken to see that the weight of the piece being

cut off does not press on the saw blade. To

prevent the saw blade from being caught between

the two pieces, the piece being cut off should be

supported using a stable bench or braced in place

using wooden supports.

If separate wooden supports are to be used to

support the piece being cut off, when cutting at

a work bench, they should be positioned on a flat

surface and fixed in place. It is dangerous to allow

the work bench to wobble or shift position while

cutting materials with the metal cutter.

6. Checking to see that the tipped saw blade is

attached firmly in position

Always check to see that the tipped saw blade

is attached firmly in position. For details, see Page

7: “Attached and removing the tipped saw blade”.

7. Check the lever to see that is properly tightened.

Insufficient tightening of the cutting adjustment

lever may cause personal injury (See Fig. 2).

Be sure to check that it is firmly tightened.

8. Attaching the side handle

Attach the side handle by screwing it in place in

the socket located on the gear cover. (See

Fig. 1)

5

Page 7

9. Check to see whether the protective cover moves.

CAUTION

Do not fasten the protective cover permanently

in one position. Make sure that it can move

smoothly. Leaving the tipped saw blade

exposed can result in accidents.

The protective cover is used to prevent the body

of the user from coming into contact with tipped

saw blade. Be sure that the protective cover can

be moved into place and is covering the blade.

~~~~~~~~~~~~~~~~~~~~~~~~

If for any reason, the protective cover will not

~~~~~~~~~~~~~~~~~~~~~~~~

move into position to cover the blade, discontinue

~~~~~~~~~~~~~~~~~~~~~~~~

the use of the metal cutter. Please contact an

~~~~~~~~~~~~~~

Authorized Hitachi Service Center for repair.

10. Making adjustments before using the metal cutter

(1) Adjusting the cutting depth (Fig. 2)

~~~~~~~~~~~~~~~~~~

CAUTION

If the cutting depth lever is not firmly tightened,

accidents may result. After adjusting the

cutting depth, make sure to tighten the cutting

depth lever firmly.

Loosen the lever and move the base, then you

(2) Attaching and adjusting the guide (Fig. 3)

Loosen the wing bolt and slide the guide into the

slot at the base. Move the guide left or right to

adjust the location of the cut to be made. After

adjusting the quide, fix it firmly in place by

tightening the wing bolt.

11. Check to see that the brake is functioning properly

This metal cutter is designed so that when the

switch is turned off, the brake automatically

functions. If for any reason the brake fails to

operate, please contact an Authorized Hitachi

Service Center for repair.

CAUTION

The metal cutter will recoil when the brake

operates.

This can cause the operator to drop the metal

cutter, resulting in accidents.

12. Check the power plug

If the power plug is loose or pulls out easily from

the socket, call your local electric repair service

and have the connection repaired.

can adjust the depth of cutting.

SELECTING THE CORRECT TIPPED SAW BLADE FOR DIFFERENT MATERIALS

In order to get the best performance from your metal cutter, it is important to select the correct type

of tipped saw blade for the type of material to cut.

Please use the blades best suited for cutting different thickness of different materials as shown below.

Selecting the best blade by type of material to be cut

Tipped saw

blade type

Blades for cutting

soft steel materials

Blades for cutting

thin, soft steel

materials

Blade for cutting

aluminum sash

materials.

¡• Most suitable

¡‡ Suitable

Blades for cutting

stainless steel/ soft

steel materials

Material T (mm)

Lip channels

T

Light U channels

T

Steel base support

forms

T

Angle forms

T

Steel plate

T

Square pipe

T

Round pipe

Structural use, wiring

()

conduit use, pressure use

T

Aluminum

sashes

Stainless

plate

Stainless

pipe (round)

1.6

1.6 ∼ 2.3 ¡‡ ¡• ¡X ¡•

0.5 ∼ 0.8 ¡• ¡• ¡X ¡•

1.2 ∼ 2.3 ¡• ¡• ¡X ¡•

3.2 ∼ 3.5 ¡‡ ¡‡ ¡X ¡‡

1.2 ∼ 2.8 ¡‡ ¡• ¡X ¡•

3.2 ∼ 3.5 ¡• ¡‡ ¡X ¡‡

T

T

Outer diameter 185mm Outer diameter: 185mm Outer diameter: 185mm Outer diameter: 180mm

Number of teeth: 38 Number of teeth: 48 Number of teeth: 60 Number of teeth: 48

∼ 3.2 ¡‡ ¡• ¡X ¡•

3.2 ¡• ¡• ¡X ¡•

3 ¡‡ ¡• ¡X ¡•

4 ∼ 6 ¡• ¡X ¡X ¡•

4 ∼ 6 ¡‡ ¡X ¡X ¡•

¡X ¡X ¡• ¡X

2 ¡X ¡X ¡X ¡‡

2 ¡X ¡X ¡X ¡‡

6

Page 8

HOW TO USE

CAUTION:

䡬 If the tipped saw blade stops suddenly, makes an

abnormal sound, etc., immediately turn off the

switch.

䡬 Do not use cutting oil on the blade.

Such substances as cutting oil, polishing oils and

waxes can catch fire from sparks when cutting.

䡬 When using the metal cutter, always wear eye

protection.

䡬 Be sure that the materials are secured firmly in

position. If the materials are not properly secured

in position, they may fly about causing damage to

the tipped saw blade.

䡬 When cutting is finished, immediately turn off the

power and unplug the metal cutter.

䡬 Be careful as not to cut the unit cord with the

rotating tipped saw blade.

䡬 Discard cutting dust before the dust cover becomes

completely full.

If the metal cutter is used when the cutting dust

is pressed against the dust cover, the performance

of the dust collector will drop and the temperature

of the dust cover (B) will rise. This may cause dust

cover (C) to warp or melt.

䡬 Wear ear plugs to protect ears from effects of the

sound.

䡬 If the cutting depth adjustment is too shallow, the

cut may tend to open lowering the performance of

the cutting dust collector.

䡬 When cutting the surface of a wall, the rate of

accumulation of cutting dust inside the dust cover

may change and may lower the performance of the

cutting dust collector.

䡬 Use a tipped saw blade that is suitable for the

material being cut.

䡬 When cutting, push the blade straight and forward

without letting the blade curve to the left and right.

䡬 Push the blade forward slowly, especially when

beginning to cut and when coming to the end of

the cut.

䡬 Do not turn on the metal cutter with the blade

pressed against the cutting material. Do not turn

off the metal cutter in the midst of cutting a piece

of material. In a case where it is absolutely necessary

to turn the metal cutter off in the middle of cutting

a work piece, pull the chip saw back with the blade

still turning and after it is no longer in contact with

the work piece material, then turn the power switch

off.

䡬 Do not to try to cut the same work piece two times

in the same location.

1. Place the main body (base) on the surface of the

work piece and align the slit on the forward edge

of the base with the sighting line. The arrow mark

on the gear cover and the slit in the base will be

aligned and can be used for positioning the metal

cutter. (See Fig. 4)

2. Without allowing the blade to touch the material,

~~~~~~~~~~~~~~~~~~~~~~~~~

turn on the power switch. When the blade has

~~~~~~~~~~~~~~

attained its maximum speed, push the metal cutter

slowly forward and maintain the same speed until

the cut is completed.

To keep the cut clean, push the saw forward at the

same speed.

3. The slit in the base indicats the position of the edge

of the blade at further end of the cut. This is useful

when cutting the work piece to a mid-way point.

(See Fig. 5)

4. The power switch is turned on by pulling the trigger.

When the “Stopper” switch is pushed (See Fig. 6),

the saw will remain running even if the finger is

removed from the trigger. This is a convenient

feature when using the saw for continuous work.

When the trigger is pulled a second time, the

“Stopper” switch is turned off and the saw is

stopped.

ATTACHING AND REMOVING BLADES

CAUTION:

䡬 Always turn the power switch off first and remove

the plug from the socket.

䡬 Use the spanner and box wrench that are supplied

with the metal cutter. Do not use other tools as this

may result in over-tightening or in sufficient

tightening of the wing bolt that holds the blade in

place causing accidents.

1. Removing the blade

(1) Loosen the two wing bolts and remove dust covers

(A) and (B). (See Fig. 7).

(2) Adjust the cutting depth of the blade to the minimum

position and place the tipped saw cutter on a flat,

stable surface. (See Fig. 8).

(3) While pushing in the lock lever, slowly unscrew the

bolt using the box wrench provided.

(4) Holding the spindle in position, turn the box wrench

counter-clockwise and remove the bolt and the

washer (B).

(5) Remove the tipped saw blade in direction (A).

2. Attaching the blade

CAUTION:

䡬 After using the tipped saw blade, dust covers (A)

and (B) may become hot. Take caution when

handling.

䡬 Do not forget to use the distance piece.

䡬 Before plugging in the metal cutter, be sure to

check to see whether the lock lever has been returned

to its original position and that the tipped saw blade

can rotate smoothly.

(1) Follow the blade removal routine in reverse.

(2) Remove any cutting dust that may have adhered

to the spindle or the washers.

(3) When a chip saw blade with a 20mm diameter is

to be attached, place washer (A) with the shallow

recessed portion turned toward the blade side.

When the hole diameter is 19mm, place the side

of washer (A) with the more deeply recessed portion

toward the blade.

For both cases, the (B) washer is used with its

recessed portion facing toward the blade. (See

Fig. 9)

(4) Make sure that the arrow mark on the side of the

blade is aiming the direction as the direction of

arrow on the gear cover. (See Fig. 10)

(5) Be sure to tighten the bolt sufficiently.

7

Page 9

THROWING AWAY THE CUTTING DUST

CAUTION:

䡬 To prevent possible accidents, always turn the metal

cutter off and unplug before attempting to empty

out the cutting dust.

䡬 Cutting dust from metal materials may be very hot.

Do not touch the cutting dust or dust covers (A)

or (B) with bare hands.

䡬 Be careful when handling dust covers (A) and (B)

as not to bend them. If they become bent, cutting

dust may spill out.

1. Throwing away the cutting dust

If too much cutting dust accumulates inside dust

covers (A) and (B), the performance of dust collector

may decrease. Be sure to empty out the cutting dust

before the dust receptacle becomes full.

(1) Screw off the dust wing bolts by turning them to

the counterclockwise. (See Fig. 11).

(2) Use the handle to remove dust cover (B) and throw

out the cutting dust (See Fig. 12).

(3) Remove any cutting dust that has adhered to dust

covers (A) and (B) and wipe them with a rag, etc..

Then, replace dust cover (B) and fasten with the

wing bolt.

MAINTENANCE AND INSPECTION

1. Inspecting the carbide tipped saw blade

Since use of a dull saw blade will cause motor

malfunctioning and degraded efficiently, replace with

a new one without delay when abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

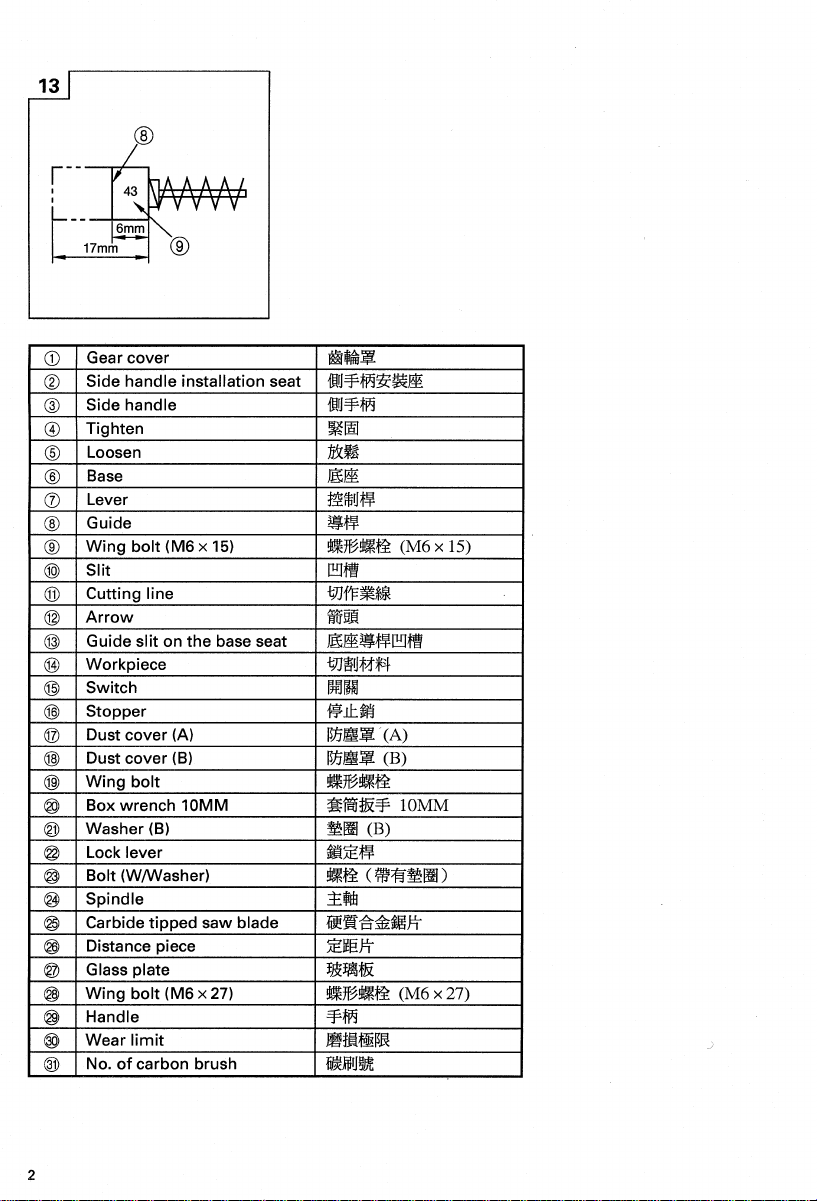

4. Inspecting the carbon brushes (Fig. 13)

The motor employs carbon brushes which are

consumable parts. Since an excessively worn carbon

brush can result in motor trouble, replace the carbon

brushes with new ones having the same carbon

brush No. shown in the figure when they become

worn to or near the “wear limit”. In addition, always

keep carbon brushes clean and ensure that they

slide freely within the brush holders.

5. Replacing carbon brushes

Disassemble the brush caps with a slotted-head

screwdriver. The carbon brushes can then be easily

removed.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

8

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

15

Page 17

005

Code No. C99053131 N

Printed in Japan

Loading...

Loading...