Page 1

Cut-Off Machine

Tronzadora

Cortadora de disco abrasivo

CC 14ST ・ CC 14STD

CC14ST CC14STD

Read through carefully and understand these instructions before use.

Leer cuidadosamente y comprender estas instrucciones antes del uso.

Antes de usar, leia com cuidado para assimilar estas instruções.

Handling instructions

Instrucciones de manejo

Instruções de uso

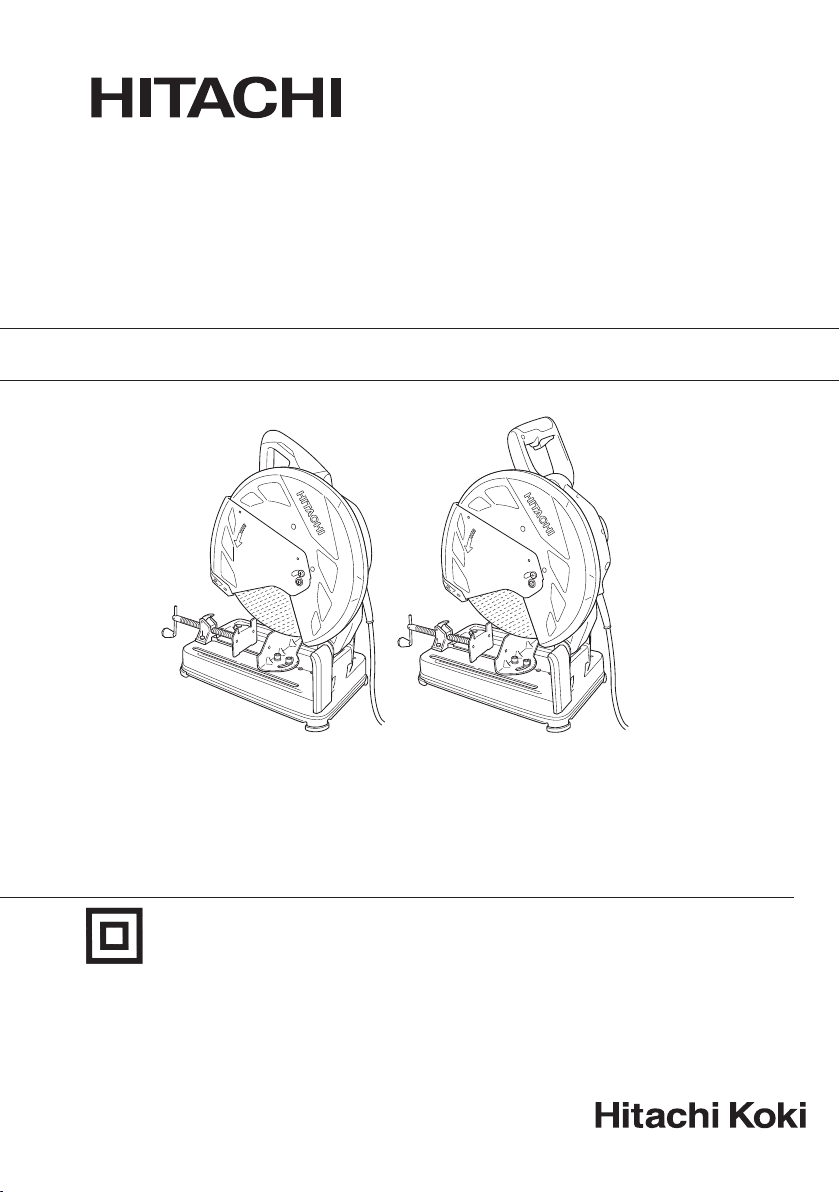

Page 2

12

4

3

9

8

4

5

7

r

h

t

2

e

u

1

6

w

3

8

345

u

e

r

t

7

w

q

@

#

$

%

!

(

7

$

&

#

*

^

!

)

(

#

678

w

e

r

(

w

(

200 mm

165 mm

235 mm

w

q

u

t

e

91011

d

e

o

w

y

i

1

u

i

a

p

s

Page 3

12 13 14

f

6

5

g

h

j

18 mm

k

6 mm

2

Page 4

English Español Português

1

Wheel cover Cubierta del disco Protetor do disco

2

Lower guard (A) Protector inferior (A) Protetor inferior (A)

3

Handle Mango Cabo

4

D-type Handle Mango en "D" Cabo em D

5

Carrying handle Mango de transporte Cabo de transporte

6

Spark chute Parachispas Protetor contra fagulhas

7

Hex. bar wrench Llave de barra hexagonal Chave de barra sextavada

8

Switch Interruptor Gatilho

9

Switch lock Bloqueador de interruptor Trava do gatilho

0

Motor Motor Motor

!

Cut-off wheel Rueda cortadora Disco abrasivo

@

Stopper Retenedor Detentor

#

Wheel washer Arandela del disco Arruela do disco

$

Stopper pin Pasador retenedor Pino de trava

%

Hole of wheel washer Orifi cio de la arandela de la rueda Orifício da arruela do disco

^

Cut-off wheel spindle Eje de la rueda cortadora Eixo do disco abrasivo

&

Sleeve Manguito Eixo

*

O-ring Junta tórica Anel em ‘O’

(

10 mm bolts Pernos de 10 mm Parafusos de 10 mm

)

Washer (A) Arandela (A) Arruela (A)

q

Workpiece material Material de la pieza de trabajo Peça a trabalhar

w

Vise (B) Tornillo de banco (B) Torno (B)

e

Vise (A) Tornillo de banco (A) Torno (A)

r

Clutch Embrague Embreagem

t

Screw handle Empuñadura roscada Alavanca do parafuso

y

Long workpiece material Material de trabajo largo Suporte para peças longas

u

Base Base Base

i

Block Bloque Bloco

o

Dimension of workpiece to be cut

p

Square block Bloque cuadrado Bloco quadrado

a

Dimension of square block Dimensiones del bloque cuadrado Dimensão do bloco quadrado

s

Lock nut Tuerca de seguridad Porca de travamento

d

Stopper bolt Perno retenedor Pino de travamento

f

Screw Tornillo Parafuso

g

Chain hook Gancho para cadena Gancho da corrente

h

Chain Cadena Corrente

j

Carbon brush Escobilla de carbón Escova de carvão

k

Wear limit Límite de desgaste Limite de desgaste

Dimensiones de la pieza de trabajo

por cortar

Dimensão da peça a ser cortada

3

Page 5

English

GENERAL OPERATIONAL PRECAUTIONS

WARNING! When using electric tools, basic safety

precautions should always be followed to reduce the risk

of fi re, electric shock and personal injury, including the

following.

Read all these instructions before operating this product and

save these instructions.

For safe operations:

1. Keep work area clean. Cluttered areas and benches

invite injuries.

2. Consider work area environment. Do not expose power

tools to rain. Do not use power tools in damp or wet

locations. Keep work area well lit.

Do not use power tools where there is risk to cause fi re or

explosion.

3. Guard against electric shock. Avoid body contact with

earthed or grounded surfaces. (e.g. pipes, radiators,

ranges, refrigerators).

4. Keep children away. Do not let visitors touch the tool or

extension cord. All visitors should be kept away from

work area.

5. Store idle tools. When not in use, tools should be stored

in a dry, high or locked up place, out of reach of children.

6. Do not force the tool. It will do the job better and safer at

the rate for which it was intended.

7. Use the right tool. Do not force small tools or attachments

to do the job of a heavy duty tool. Do not use tools for

purposes not intended; for example, do not use circular

saw to cut tree limbs or logs.

8. Dress properly. Do not wear loose clothing or jewellery,

they can be caught in moving parts. Rubber gloves and

non-skid footwear are recommended when working

outdoors. Wear protecting hair covering to contain long

hair.

9. Use eye protection. Also use face or dust mask if the

cutting operation is dusty.

10. Connect dust extraction equipment.

If devices are provided for the connection of dust

extraction and collection facilities ensure these are

connected and properly used.

11. Do not abuse the cord. Never carry the tool by the cord or

yank it to disconnect it from the receptacle. Keep the cord

away from heat, oil and sharp edges.

12. Secure work. Use clamps or a vise to hold the work. It

is safer than using your hand and it frees both hands to

operate tool.

13. Do not overreach. Keep proper footing and balance at all

times.

14. Maintain tools with care. Keep cutting tools sharp

and clean for better and safer performance. Follow

instructions for lubrication and changing accessories.

Inspect tool cords periodically and if damaged, have it

repaired by authorized service center. Inspect extension

cords periodically and replace, if damaged. Keep handles

dry, clean, and free from oil and grease.

15. Disconnect tools. When not in use, before servicing, and

when changing accessories such as blades, bits and

cutters.

16. Remove adjusting keys and wrenches. Form the habit

of checking to see that keys and adjusting wrenches are

removed from the tool before turning it on.

17. Avoid unintentional starting. Do not carry a plugged-in

tool with a fi nger on the switch. Ensure switch is off when

plugging in.

18. Use outdoor extension leads. When tool is used

outdoors, use only extension cords intended for outdoor

use.

19. Stay alert. Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

20. Check damaged parts. Before further use of the tool, a

guard or other part that is damaged should be carefully

checked to determine that it will operate properly and

perform its intended function. Check for alignment of

moving parts, free running of moving parts, breakage

of parts, mounting and any other conditions that may

aff ect its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized

service center unless otherwise indicated in this handling

instructions. Have defective switches replaced by an

authorized service center. Do not use the tool if the

switch does not turn it on and off .

21. Warning

The use of any accessory or attachment, other than those

recommended in this handling instructions, may present

a risk of personal injury.

22. Have your tool repaired by a qualifi ed person.

This electric tool is in accordance with the relevant safety

requirements. Repairs should only be carried out by

qualifi ed persons using original spare parts. Otherwise

this may result in considerable danger to the user.

PRECAUTIONS ON USING CUT-OFF MACHINE

1. Inspect the cutting wheel before use, do not use chipped

or otherwise defect cutting wheels. Always make a trial

run before use to confi rm that the Cut-off Machine does

not involve abnormalities.

2. Use the normal cut-off wheel on its normal working

surface.

3. Guard against cut-off sparks.

4. Properly replace the cut-off wheel.

5. Always pay attention that the cut-off wheel clamping parts

are never impaired. Defective parts will cause damage to

the cut-off wheel.

6. Ensure that the workpiece is free of foreign matter such

as nails.

7. Use only cutting wheels recommended by the

manufacturer which have a marked speed equal to or

greater than the speed marked on the nameplate of the

machine.

8. Abrasive wheels shall be stored and handled with care in

accordance with manufacturer’s instructions.

9. Ensure that mounted wheel are fi tted in accordance with

the manufacture’s instructions.

10. Do never use the machine without the guard in place.

11. Do not saw blade.

12. Do not use the machine in explosive atmospheres and

environments where sparks could fi re, explosion etc.

13. This product is not a toy. Do not allow children to play

with it.

4

Page 6

English

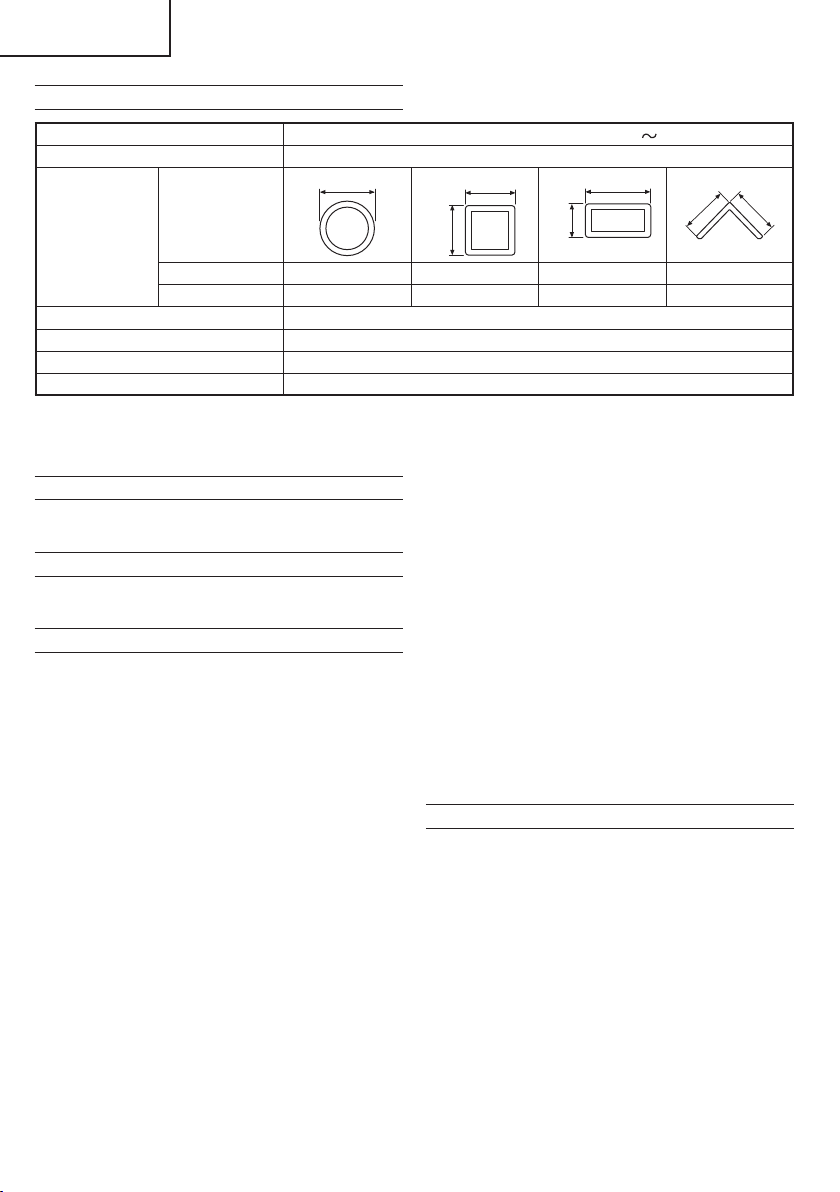

SPECIFICATIONS

Voltage (by areas)*

Power Input*

Max. cutting

dimensions*

Height × width

Cut-off wheel ø355 × ø25.4 × 4 mm (Reinforced resinoid cut-off wheel)

No-load speed 3800 / min

Max. working peripheral speed 4800 m / min

Weight (Only main body) 17.0 kg

*1 Be sure to check the nameplate on product as it is subject to change by areas.

*2 The maximum cutting dimensions are the permissible cutting dimensions when the cut-off wheel is not remarkably worn by

cutting material.

1

1

Shape of material

to be cut

2

A

(120 V, 127 V, 220 V, 230 V, 240 V)

2000 W (127 V), 2200 W

A

A

B

A

A × B

Cutting angle 0° 130 mm 120 mm 95 mm × 200 mm 137 mm

Cutting angle 45° 115 mm 104 mm 115 mm × 104 mm 100 mm

A

A

STANDARD ACCESSORIES

(1) Cut-off wheel ................................................................1

(2) Hex. bar wrench ...........................................................1

APPLICATION

Cutting of various metallic materials such as pipes, round

bars and shaped steel.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specifi ed on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position. If the

plug is connected to a receptacle while the power switch

is in the ON position, the power tool will start operating

immediately, which could cause a serious accident.

3. Extension cord

When the work area is removed from the power source,

use an extension cord of suffi cient thickness and rated

capacity. The extension cord should be kept as short as

practicable.

4. Install the machine on a level fl at place, and keep it in

a stable condition. Prior to shipping, the equipment is

subjected to a rigid factory inspection to prevent electric

shocks during operation.

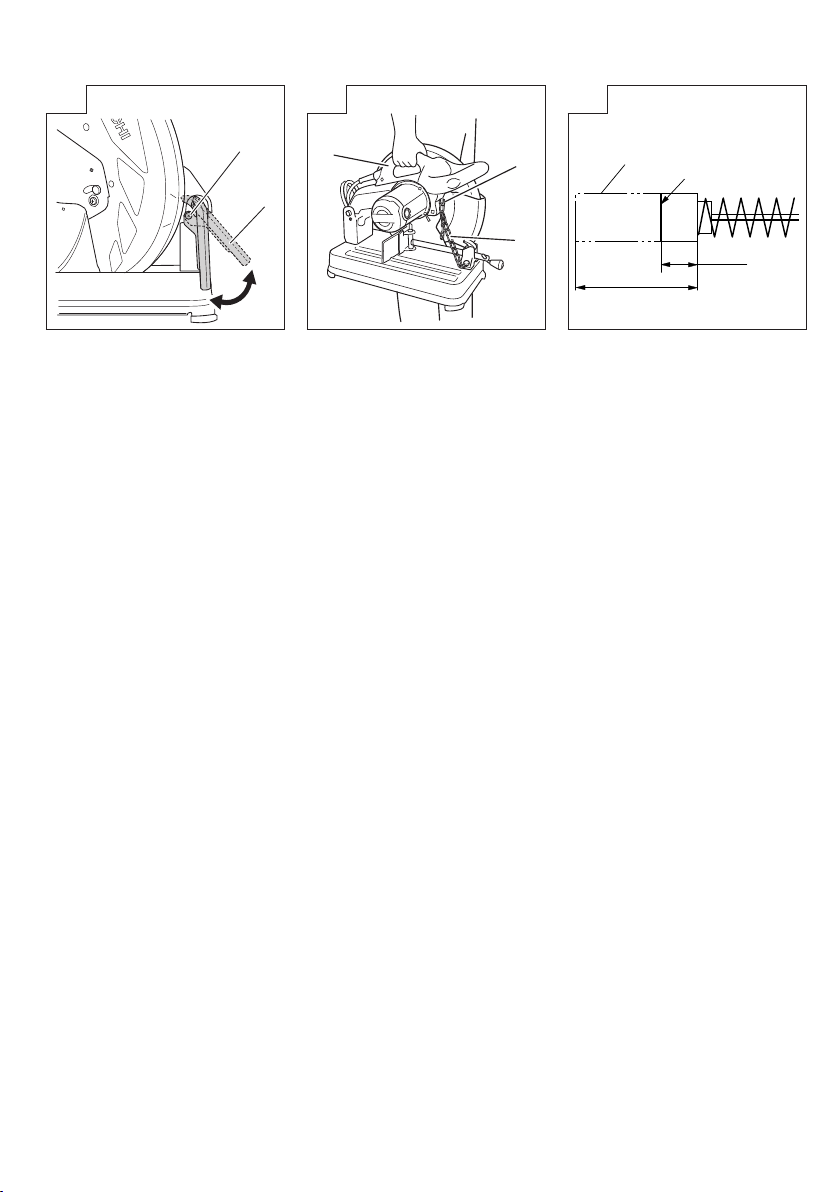

5. Since movable portions are secured by tension of a chain

while in transit, remove the chain from the chain hook by

slightly depressing the switch handle.

6. Ascertain that all cut-off wheels are in perfect condition,

and do not display scars and cracks.

7. Although they have been fully clamped at the factory

prior to delivery, reclamp the clamping nuts securely for

safety.

8. Possible accidents such as a cracked cut-off wheel

is prevented by this protective cover (wheel cover).

Although it has been fully clamped at the factory prior

to delivery, securely reclamp the mounting screws for

safety.

9. When replacing the cut-off wheel, ensure that the

replacement cutting wheel has a designed circumferential

speed in excess of 4800 m/min.

10. Ensure that the bar spanner used for tightening or

removing the cut-off wheel is not attached to the machine.

11. Check that the work piece is properly supported. Ensure

that the material is securely fastened with the vise. If it is

not, a serious accident could be caused if the material

comes loose or the cut-off wheel breaks during operation.

12. Ensure that the abrasive wheel is correctly fi tted and

tightened before use and run the machine at no-load for

30 second in safe position, stop immediately if there is

a considerable vibration or if other defects are detected.

If this condition occurs, check the machine to determine

the cause.

13. Rotate the cut-off wheel to inspect any facial defl ection.

A heavy defl ection will cause the cut-off wheel to shift.

14. Ensure that ventilation openings are kept clear when

working in dusty conditions. If it should become

necessary to clear dust, fi rst disconnect the machine

from the mains supply.

CUTTING PROCEDURES

CAUTION

It is dangerous to remove or install the workpiece while

the cut-off wheel turning.

1. Operating the switch

Switch operations diff er in accordance with the region.

Power will be turned on when the switch is pulled, and

turned off when released. (Fig.2)

<Lock-on Switch Operations>

For models equipped with a switch lock, press the switch

lock when the switch is being pulled to enable operations

to be continued ever after the switch is released. (Fig.2)

2. Cutting

(1) Rotate the cut-off wheel, gently press down the handle,

and bring the cut-off wheel close to the cutting material.

(2) When the cut-off wheel contacts the cutting material,

gently press down the handle further and start cutting.

(3) When cutting (or designated slotting) is completed, raise

the handle and restore it to its original position.

5

Page 7

English

(4) At the termination of each cutting process, turn OFF the

switch to stop rotation and proceed with the subsequent

cutting job.

CAUTION

It does not necessarily cut rapidly when putting more

force on the handle.

Too much force on the handle will put excessive pressure

on the motor and reduce its capacity.

Do not fail to switch OFF the switch after operation is

completed and pull the plug out.

MOUNTING AND DISMOUNTING THE CUT-OFF

WHEEL

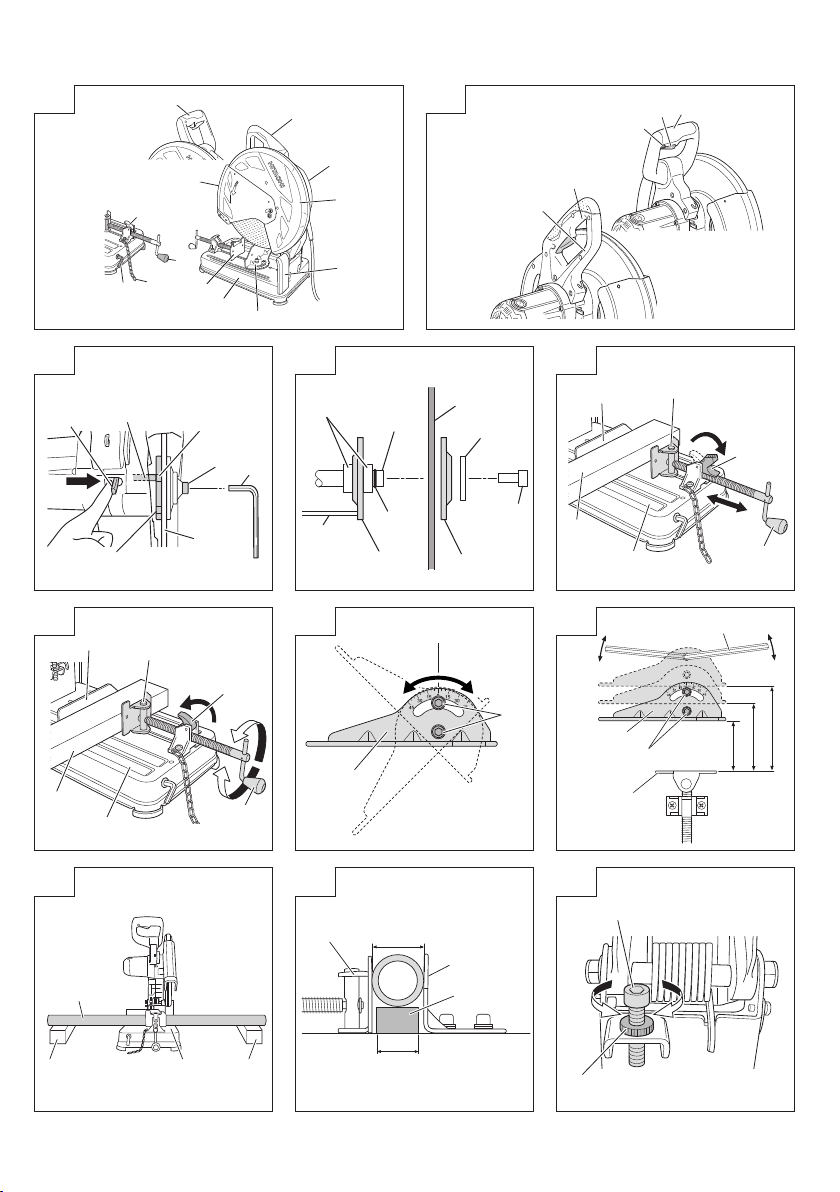

1. Dismounting the cut-off wheel (Fig. 3 and 4)

(1) Raise lower gurd (A) .

Press down on the stopper pin to bring it into contact with

the wheel washer.

Rotate the cut-off wheel, pass the stopper pin through the

hole on the wheel washer, and then remove the M10 bolt

with the hexagonal bar wrench supplied.

(2) Remove the bolt, washer (A), and the wheel washer and

detach the cut-off wheel. (Fig. 4)

CAUTION

Do not remove the O-ring or sleeve from the cut-off wheel

spindle.

2. Mounting the cut-off wheel

Throughly remove dust from the wheel washers and

bolt then mount the wheel by following the dismounting

procedures in reverse order. Return lower gurd (A) to its

original position.

CAUTION

Confi rm that the stopper which was used for installation

and removal of the cut-off wheel has returned to the

retract position.

HOW TO OPERATE

1. Procedure for fi xing the cutting material (Fig. 5

and 6)

Place the workpiece material between vise (A) and vise

(B), raise the clutch and push the screw handle to bring

vise (A) lightly into contact with the workpiece material,

as shown in Fig. 5.

Then, turn the clutch down, and securely fi x the

workpiece material in position by turning the screw

handle. When the cutting job is completed, turn the

screw handle 2 or 3 times to loosen the vise (A),

and remove the workpiece material, as shown in

Fig. 6.

CAUTION

Never remove or install a workpiece material while the

cut-off wheel is rotating, to avoid personal injury.

2. Cutting at angles (Fig. 7)

(1) The machine permits cutting at angles of 0° – 45°.

(2) Loosen the two M10 hexagon socket head bolts on the

vice (B), then set the working surface on the vice-jaw at

any angles of 0°, 30°, or 45° . Upon completion of setting,

securely tighten the two 10 mm bolts.

3. Moving the stationary vise-jaw (Fig. 8)

The vise opening is set at the maximum of

165 mm when shipped from the factory. In case an

opening of more than 165 mm is required, move the vise

to the position shown by the chain line after unscrewing

the two bolts. The maximum opening can be set in two

steps 200 mm and 235 mm. When the cutting material

is excessively wide, the vise can be eff ectively used by

repositioning the stationary side of the vise-jaws.

4. Cutting Long Workpiece Materials (Fig.9)

Make sure you place both ends of long workpiece

materials on blocks that are the same height as the base

to stabilize it prior to beginning work.

5. How to use square block (Fig. 10)

When the cut-off wheel has a reduced outer diameter,

insert between the vise (A) and (B) a square block slightly

smaller than the dimension of workpiece being cut to use

the cut-off wheel economically.

6. Adjusting the Cutting Depth (Fig. 11)

When the cut-off wheel has a reduced outer diameter,

change the height of the stopper bolt to adjust the cutting

depth. Adjustments are made by loosening the lock nut

and rotating the stopper bolt. When fi nished, retighten

the lock nut to fi x the stopper bolt in place.

It is possible to eradicate splinters depending on the

material.

CAUTION

○ Make sure the height of the stopper bolt is readjusted

when the cut-off wheel is replaced.

○ If the stopper bolt is too low, there is a chance that the

cut-off wheel will cut into the base.

7. Adjusting the Spark Sheet (Fig.12)

Loosen the screw holding the spark sheet in place with a

Phillips screwdriver to adjust the angle.

Change the angle in accordance with the prevalent

environment and the work required to adjust the direction

in which the sparks fl y.

8. Transporting the Unit (Fig.13)

When moving the unit, attach the chain hook onto the

chain and grip the carrying handle to carry it.

MAINTENANCE AND INSPECTION

CAUTION

Be sure to switch off and pull off the plug from the power

outlet before inspection and maintenance.

1. Replacing a cut-off wheel

When the cut-off wheel has already become dull while

continually using, the unnecessary load is got from the

motor. Consequently, redress or replace a dull cut-off

wheel to ensure grinding effi ciency.

2. Inspecting the carbon brushes (Fig. 14)

The Motor employs carbon brushes which are

consumable parts. When they become worn to or near

the “wear limit”, it could result in motor trouble. When an

auto-stop carbon brush is equipped, the motor will stop

automatically. At that time, replace both carbon brushes

with new ones shown in the fi gure. In addition, always

keep carbon brushes clean and ensure that they slide

freely within the brush holders.

3. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws be

loose, retighten them immediately. Failure to do so could

result in serious hazard.

4. Replacing supply cord

If the replacement of the supply cord is necessary, this

has to be done by Hitachi Authorized Service Center in

order to avoid a safety hazard.

5. Lubrication

Supply oil in the following oil supply points once a month

so as to keep the machine workable for a long time.

Oil supply points

○ Rotary part of shaft

○ Rotary part of vise

○ Slide way of vise (A)

6

Page 8

English

6. Cleaning

Wipe off chip and waste adhered to the machine with a

cloth or the like time to time. Be careful not to make the

motor portion wet with oil or water.

7. Service parts list

CAUTION

Repair, modifi cation and inspection of Hitachi Power

Tools must be carried out by a Hitachi Authorized Service

Center.

This Parts List will be helpful if presented with the tool to

the Hitachi Authorized Service Center when requesting

repair or other maintenance.

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

MODIFICATIONS

Hitachi Power Tools are constantly being improved

and modifi ed to incorporate the latest technological

advancements.

Accordingly, some parts may be changed without prior

notice.

NOTE:

Due to HITACHI’s continuing program of research and

development, the specifi cations herein are subject to change

without prior notice.

7

Page 9

Español

PRECAUCIONES GENERALES PARA LA

OPERACIÓN

¡ADVERTENCIA! Cuando utilice herramientas eléctricas,

tome las medidas de seguridad básicas para reducir el riesgo

de incendios, descargas eléctricas, y lesiones, incluyendo

lo siguiente. Lea todas estas instrucciones antes de utilizar

este producto y guárdelas.

Para realizar operaciones seguras:

1. Mantener el área de trabajo limpia, áreas y bancos de

trabajo desordenados son causa de daños personales.

2. Considerar el medio ambiente del área de trabajo. No

exponer las herramientas eléctricas a la lluvia. No usar

herramientas eléctricas en lugares moja dos o húmedos.

Mantener el área de trabajo bien iluminada.

No utilice herramientas eléctricas cuando exista el riesgo

de incendios o de explosión.

3. Protegerse contra descargas eléctricas. Evitar el

contacto del cuerpo con las superfi cies puestas a

tierra. (p. ej., tubos, radiadores, hornos de microondas,

o refrigeradores.)

4. Mantener a los niños alejados. No dejar que los visitantes

toquen las herramientas ni los cables de extensión.

Todos los visitantes deberán mantenerse alejados del

área de trabajo.

5. Guardar las herramientas que no se usen y ponerlos en

lugares secos, altos o cerrados, fuera del alcance de los

niños.

6. No forzar las herramientas, éstas trabajarán más

y con mayor seguridad cuando cumplan con las

especifi caciones para las cuales fueron diseñadas.

7. Usar las herramientas apropiadas. No forzar pequeñas

herramientas o accesorios a realizar el trabajo de

herramientas de mayor potencia. No utilizar herramientas

para otros propósitos para los cuales no fueron

diseñadas, por ejemplo, no utilizar sierras circulares para

cortar ramas de árboles o troncos.

8. Vestir apropiadamente. No ponerse ropas que queden

fl ojas ni tampoco joyas. Estas podrian quedar atrapadas

en las partes móviles de las herramientas. Cuando se

trabaje en exteriores, se recomienda el uso de guantes

de goma y calzado que no resbale.

9. Utilice protección para los ojos. También utilice una

máscara facial o contra el polvo si la operación de corte

es polvorienta.

10. Conecte un equipo colector de polvo.

Si existen dispositivos para la conexión de equipos de

extracción y recolección de polvo, cerciórese de que

éstos estén conectados adecuadamente, y de utilizarlos

en la forma correcta.

11. Cuidar del cable. Nunca lleve las herramientas colgando

del cable, tampoco tire del cable para efectuar la

desconexión de las herramientas. Mantener el cable

alejado del calor, aceite y bordes agudos.

12. Asegurar la pieza de trabajo usando para ello

abrazaderas o un tornillo. Esto es más seguro que usar

las manos, además, ambas manos quedan libres para

operar la herramienta.

13. No extenderse excesivamente para efectuar un trabajo.

Mantener en todo momento un buen balance y base de

apoyo.

14. Mantener cuidadosamente las herramientas. Tenerlas

siempre limpias y afi ladas para obtener un mejor

rendimiento y un funcionamiento más seguro. Seguir

siempre las instrucciones para la lubricación y el cambio

de accesorios. Inspeccionar periódicamente los cables

de las herramientas y si estuviesen danãdos, hacer

que los reparen técnicos o expertos. Inspeccionar

periódicamente los cables de extensión y cambiarlos

si estuviesen dañados. Mantener los mangos secos,

limpios, y libres de aceite y grasa.

15. Desconectar las herramientas cuando no se usen, antes

de repararlas, y cuando se cambien accesorios como

por ejemplo, cuchillas, brocas, cortadores, etc.

16. Quitar las cuñas y las llaves de tuercas. Acostumbrarse

a comprobar si se han quitado las cuñas y las llaves

de tuercas antes de poner las herramientas en

funcionamiento.

17. Evitar puestas en funcionamiento sin fi n alguno. No

llevar las herramientas con los dedos en los inerruptores

mientras que éstas están conectadas. Cuando se

conecten las herramientas, cerciorarse de que los

interruptores estén en la posición de desconectados.

18. Para usos en exteriores usar cables de extensión. Cuando

las herramientas vayan a ser usadas en exteriores,

usar solamente cables de extensión diseñados para tal

propósito.

19. Estar siempre alerta y poner atención a lo que se está

haciendo, usar el sentido común y no operar con la

herramienta cuando se esté cansado.

20. Comprobar las piezas dañadas. Antes de seguir con

el funcionamiento de las herramientas, las piezas que

estén dañadas deberán comprobarse cuidadosamente

para determinar si pueden funcionar apropiadamente y

cumplir con la función para las que fueron diseñadas.

Comprobar el alineamiento y agarrotamiento de piezas

móviles, rotura de piezas, montura, y cualquier otra

anomalía que pudiese afectar al rendimiento de la

herramienta. Cualquier pieza que estuviese dañada

deberá repararse apropiadamente o cambiarse en un

centro de reparaciones autorizado, al menos que se

indique, lo contrario en este manual de instrucciones.

Procurar que los interruptores defectuosos los cambie

un centro de reparaciones autorizado.

No usar las herramientas si sus interruptores no

funcionasen apropiadamente.

21. Advertencia

La utilización de cualquier accesorio o aditivo no

recomendado en este manual de instrucciones puede

conducir al riesgo de lesiones.

22. En caso de avería, haga que su herramienta sea reparada

por un técnico cualifi cado.

Esta herramienta eléctrica está de acuerdo con los

requisitos de seguridad pertinentes. Las reparaciones

solamente deberán realizarlas técnicos cualifi cados

utilizando piezas de repuesto originales. De lo contrario,

el usuario podría lesionarse.

PRECAUCIONES SOBRE EL USO DE LA

TRONZADORA

1. Inspeccionar la rueda cortadora antes del uso. No utilizar

ruedas cortadoras rajadas o defectuosas. Antes de

usarla, efectúe una prueba para asegurarse de que la

máquina cortadora no tenga problemas.

2. Utilizar la rueda cortadora normal con su superfi cie de

trabajo normal.

3. Portegerse de las chispas.

4. Reemplazar la rueda cortadora cuando sea necesario.

5. Tener especial cuidado de que las piezas de sujeción

de la rueda cortadora no estén dañadas. Las piezas

defectuosas pueden danãr la rueda cortadora.

6. Asegurarse de que la pieza de trabajo esté libre de

cuerpos extraños tales como clavos.

7. Utilizar únicamente las ruedas cortadoras recomendadas

por el fabricante que lleven una marca de velocidad igual

o mayor que la indicada en la placa de identifi cación de

la máquina.

8

Page 10

Español

8. Las ruedas abrasivas se deben guardar y manejar con

cuidado de acuerdo con las instrucciones del fabricante.

9. Asegurarse de que la rueda se encuentre instalada de

conformidad con las instrucciones del fabricante.

10. Nunca utilizar la máquina sin el protector en su lugar.

11. No utilizar la hoja de sierra.

12. No utilizar la máquina en atmósferas ni entornos

explosivos o sea, en lugares donde las chispas puedan

causar incendio, explosión, etc.

13. Este producto no es un juguete, no deje que niños

jueguen con él.

ESPECIFICACIONES

Voltaje (por áreas)*

Acometida*

Dimensiones

máx. de corte*

Altura × Anchura

Rueda cortadora ø355 × ø25,4 × 4 mm (Rueda cortadora de resinoide reforzado)

Velocidad sin carga 3 800 / min

Velocidad periférica de trabajo máxima

Peso (Cuerpo principal solamente) 17,0 kg

*1

Verifi car indefectiblemente los datos de la placa de características de la máquina, pues varían de acuerdo al país de destino.

*2 Las dimensiones máximas de corte son las dimensiones de corte permitidas mientras la rueda cortadora no esté notablemente

gastada por el material de corte.

ACCESORIOS ESTÁNDAR

(1) Rueda cortadora .......................................................... 1

(2) Llave de barra hexagonal ............................................. 1

APLICACIÓN

Corte de diversos materiales metálicos, como tubos, barras,

acero perfi lado.

ANTES DE LA PUESTA EN MARCHA

1. Alimentación

Asegurarse de que la alimentación de red que ha de

ser utilizada responda a las exigencias de corriente

especifi cadas en la placa de características del

producto.

2. Conmutador de alimentación

Asegurarse de que el conmutador de alimentación esté

en la posición OFF (desconectado). Si la clavija está

conectada en la caja del enchufe mientras el conmutador

de alimentación esté en posición ON (conectado)

las herramientas eléctricas empezarán a trabajar

inmediatamente, provocando un serio accidente.

3. Cable de prolongación

Cuando está alejada el área de trabajo de la red de

alimentación, usar un cable de prolongación de un grosor

y potencia nominal sufi ciente. El cable de prolongación

debe ser mantenido lo más corto posible.

4. Instale la máquina sobre una superfi cie plana y nivelada,

y manténgala en condiciones de estabilidad. Antes

del envío, la máquina ha sido sometida a una rigurosa

inspección en fábrica para evitar descargas eléctricas

durante la operación.

5. Como las partes móviles están aseguradas por la tensión

de una cadena durante el transporte, extraiga dicha

cadena de su gancho empujando ligeramente el asa.

9

1

1

Forma del material

por cortar

2

A

(120 V, 127 V, 220 V, 230 V, 240 V)

2 000 W (127 V), 2 200 W

A

A

B

A

A × B

Ángulo de corte 0° 130 mm 120 mm 95 mm × 200 mm 137 mm

Ángulo de corte 45° 115 mm 104 mm 115 mm × 104 mm 100 mm

4 800 m / min

6. Asegúrese de que todas las ruedas cortadoras estén en

perfectas condiciones y que no tengan rebabas y rajas.

7. Aunque las tuercas de fi jación se han apretado

completamente en fábrica antes del envío, vuelva a

apretarlas para mayor seguridad.

8. La cubierta de esta máquina (cubierta de la rueda

cortadora) evita posibles accidentes debido a la rotura de

la rueda cortadora, etc. Aunque los tornillos de montaje

se han apretado completamente en fábrica antes del

envío, vuelva a apretarlos para mayor seguridad.

9. Cuando reemplace la rueda cortadora, asegúrese de

utilizar otra que haya sido diseñada para una velocidad

circunferencial superior a 4 800 m/min.

10. Asegúrese de que la llave de barra utilizada para apretar

o extraer la rueda cortadora no quede colocada en la

máquina.

11. Verifi que que la pieza de trabajo se encuentre

correctamente soportada. Asegúrese de que el material

esté fi rmemente apretado con el tornillo de banco. Si

no, se podrían producir serios accidentes al afl ojarse el

material, o la rueda cortadora podría romperse durante la

operación.

12. Antes del uso, asegúrese de que la rueda abrasiva se

encuentre correctamente instalada y apretada, y haga

funcionar la máquina sin carga durante 30 segundos en

condiciones de seguridad. Deténgala inmediatamente si

hay vibraciones considerables u otros defectos. En tal

caso, inspeccione la máquina para localizar la causa.

13. Gire la rueda cortadora para inspeccionar cualquier

defl exión facial. Una defl exión pronunciada causará el

desplazamiento de la rueda cortadora.

14. Cuando trabaje en condiciones polvorientas, asegúrese

de que no se obstruyan las rejillas de ventilación. En

caso de que sea necesario eliminar el polvo, primero

desconecte la máquina de la fuente de alimentación de

la red.

A

A

Page 11

Español

PROCEDIMIENTOS DE CORTE

PRECAUCIÓN

Es muy peligroso extraer o instalar la pieza de trabajo

con la máquina cortadora en funcionamiento.

1. Accionamiento del interruptor

Los usos del interruptor varían de acuerdo a la región.

La herramienta se encenderá cuando se accione el

interruptor y se apagará cuando se lo libere. (Fig. 2)

<Usos del interruptor de encendido/bloqueo>

En modelos equipados con un bloqueador de interruptor,

pulse el bloqueador de interruptor cuando el interruptor

se accione para permitir que las operaciones continúen

después de soltar el interruptor. (Fig. 2)

2. Corte

(1) Gire la rueda cortadora presionando ligeramente el asa,

y acérquela al material que desee cortar.

(2) Cuando la rueda cortadora entre en contacto con el

material, presione ligeramente hacia abajo el asa para

iniciar el corte.

(3) Cuando fi nalice el corte (o el ranurado diseñado), levante

el asa y devuélvala a la posición original.

(4) Al terminar cada proceso de corte, ponga el interruptor

en OFF a fi n de parar la rotación y efectúe el trabajo de

corte siguiente.

PRECAUCIÓN

La aplicación de más fuerza al asa no signifi ca

necesariamente un corte más rápido. Si aplica demasiada

fuerza sobre el asa el motor recibirá demasiada presión

y se reducirá su capacidad. No se olvide de poner

el interruptor en OFF, ni de desconectar el cable de

alimentación, después de haber fi nalizado la operación

de corte.

MONTAJE Y DESMONTAJE DE LA RUEDA

CORTADORA

1. Desmontaje de la rueda cortadora (Figs. 3 y 4)

(1) Levantar el protector inferior (A).

Presione el perno retenedor para que entre en contacto

con la arandela de la rueda.

Gire la rueda cortadora, pase el perno retenedor por

el orifi cio de la arandela de la rueda y, a continuación,

quite el perno M10 con la llave de barra hexagonal

suministrada.

(2) Extraiga el perno, la arandela (A), y la arandela de la

rueda cortadora, y desmonte ésta. (Fig. 4)

PRECAUCIÓN

No quite la junta tórica ni el manguito del eje de la rueda

cortadora.

2. Montaje de la rueda cortadora

Limpie cuidadosamente el polvo de las arandelas y el

perno de la rueda cortadora, y monte ésta siguiendo los

procedimientos anteriores en orden inverso. Vuelva a

colocar el protector inferior (A) en su posición original.

PRECAUCIÓN

Confi rme que el retenedor utilizado para el montaje y

desmontaje de la rueda cortadora esté replegado.

UTILIZACIÓN

1. Procedimiento de fi jación del material de corte

(Figs. 5 y 6)

Coloque el material de la pieza de trabajo entre el

tornillo de banco (A) y el tornillo de banco (B), levante el

embrague y empuje la empuñadura roscada hasta que

el tornillo de banco (A) haga un contacto ligero con el

material de la pieza de trabajo, tal como se observa en la

Fig. 5.

Luego, gire el embrague hacia abajo y fi je fi rmemente

el material de la pieza de trabajo en su lugar girando

la empuñadura roscada. Al terminar de cortar, gire la

empuñadura roscada 2 ó 3 veces para afl ojar el tornillo

de banco (A), y retire el material de la pieza de trabajo, tal

como se muestra en la Fig. 6.

PRECAUCIÓN

Para evitar lesiones personales, no retire ni instale el

material de la pieza de trabajo mientras está girando la

rueda de corte.

2. Corte en ángulo (Fig. 7)

(1) La máquina permite cortar en ángulos de 0° – 45°.

(2) Afl oje los dos pernos de cabeza hueca hexagonales M10

en el tornillo de banco (B) y, a continuación, coloque la

superfi cie de trabajo en la mordaza del tornillo de banco,

en cualquier ángulo de 0°, 30° o 45°. Después del ajuste,

apriete fi rmemente los dos pernos de 10 mm.

3. Movimiento de la mordaza estacionaria del tornillo

de banco (Fig. 8)

La abertura de las mordazas se ha ajustado en fábrica

a un máximo de 165 mm. En caso de requerirse una

abertura de más de 165 mm, mueva el tornillo de

banco hasta la posición mostrada mediante la línea de

la cadena después de desatornillar los dos pernos de

cabeza hexagonal. La abertura máxima podrá ajustarse

en dos pasos a 200 mm y 235 mm. Cuando el material

que desee cortar sea demasiado ancho, el tornillo de

banco podrá utilizarse efectivamente cambiando la

posición del lado estacionario de las mordazas del

tornillo.

4. Corte de materiales de trabajo largos (Fig. 9)

Asegúrese de colocar ambos extremos de los materiales

de trabajo largos sobre bloques de la misma altura,

utilizados como base para estabilizar la pieza de trabajo

antes de comenzar a trabajar.

5. Cómo utilizar un bloque cuadrado (Fig. 10)

Cuando el disco de corte tiene un diámetro exterior

reducido, coloque entre los tornillos de banco (A) y (B)

un bloque cuadrado apenas más pequeño que la pieza

de trabajo que se cortará, a fi n de utilizar el disco de corte

de forma económica.

6. Ajustar la profundidad de corte (Fig. 11)

Cuando el disco de corte tiene un diámetro exterior

reducido, cambie la altura del perno retenedor para

regular la profundidad del corte. Los ajustes se realizan

afl ojando la tuerca de seguridad y girando el perno

retenedor. Cuando termine, vuelva a ajustar la tuerca de

seguridad para colocar el perno retenedor en su lugar.

Es posible erradicar las astillas dependiendo del

material.

PRECAUCIÓN

○ Corrobore que se reajuste la altura del perno retenedor

cuando se cambie la rueda cortadora.

○ Si el perno retenedor está muy bajo, existe la posibilidad

de que la rueda cortadora corte hacia la base.

7. Ajuste de la hoja parachispas (Fig.12)

Afl oje el tornillo, sujetando la hoja parachispas en su

lugar, con un destornillador Phillips para regular el

ángulo.

Cambie el ángulo de acuerdo con el ambiente prevalente

y el trabajo requerido para ajustar la dirección en que

salen despedidas las chispas.

8. Transporte de la unidad (Fig.13)

Al mover la unidad, fi je el gancho para cadena en

la cadena y sujete el mango de transporte para

transportarla.

10

Page 12

Español

MANTENIMIENTO E INSPECCION

PRECAUCIÓN

Antes de inspeccionar la máquina cortadora y efectuar

su mantenimiento, asegúrese de poner el interruptor en

OFF y desconectar el enchufe del cable de alimentación

de la toma de la red.

1. Reemplazo de la rueda cortadora

Cuando se utilice continuamente una rueda cortadora

sin fi lo, el motor recibirá una carga innecesaria.

Consecuentemente, rectifi que o reemplace dicha rueda

para asegurar la máxima efi cacia de corte.

2. Inspeccionar los carbones de contacto (Fig. 14)

El motor emplea escobillas de carbón que son partes

consumibles. Cuando se gastan o están cerca del “limite

de desgaste” pueden causar problemas al motor.

Al equiparse la escobilla de carbón de parada automática,

el motor se detendrá automáticamente en ese momento

hay que proceder a cambiar ambas escobillas de

carbón por la nuevas, que tienen los mismos números

de escobillas de carbón como se muestra en la fi gura.

Además siempre hay que mantener las escobillas

de carbón limpias y asegurarse de que se muevan

libremente en sus porta-escobillas.

3. Inspeccionar los tornillos de montaje

Regularmente inspeccionar todos los tornillos de montaje

y asegurarse de que estén apretados fi rmemente. Si

cualquier tornillo estuviera suelto, volver a apretarlo

inmediatamente. El no hacer esto provocaría un riesgo

serio.

4. Sustitución del cable de alimentación

La sustitución del cable de alimentación deberá ser

realizada por un Centro de servicio autorizado de Hitachi

para evitar riesgos de seguridad.

5. Lubricación

Aplique aceite a los puntos de engrase una vez al mes

a fi n de mantener la máquina en buenas condiciones

durante mucho tiempo.

Puntos de engrase

○ Parte giratoria del eje

○ Parte giratoria del tornillo de banco

○ Parte deslizante del tornillo de banco (A)

6. Limpieza

Limpie de vez en cuando las virutas y el polvo de la

máquina utilizando un paño o algo por el estilo. Tenga

cuidado para que el motor no se moje con aceite o

agua.

7. Lista de repuestos

PRECAUCIÓN

La reparación, modifi cación e inspección de las

herramientas eléctricas Hitachi deben ser realizadas por

un Centro de Servicio Autorizado de Hitachi.

Esta lista de repuestos será de utilidad si es presentada

junto con la herramienta al Centro de Servicio Autorizado

de Hitachi, para solicitar la reparación o cualquier otro

tipo de mantenimiento.

En el manejo y el mantenimiento de las herramientas

eléctricas, se deberán observar las normas y reglamentos

vigentes en cada país.

MODIFICACIONES

Hitachi Power Tools introduce constantemente mejoras

y modifi caciones para incorporar los últimos avances

tecnológicos.

Por consiguiente, algunas partes pueden ser modifi cadas

sin previo aviso.

NOTA

Debido al programa continuo de investigación y desarrollo

de HITACHI estas especifi caciones están sujetas a cambio

sin previo aviso.

11

Page 13

Português

PRECAUÇÕES GERAIS QUANTO À OPERAÇÃO

PRECAUÇÃO! Ao usar ferramentas elétricas, observe as

precauções básicas de segurança para evitar o risco de

incêndio, choques elétricos e acidentes pessoais, inclusive

o seguinte.

Leia todas estas instruções antes de usar este equipamento,

e guarde-as em um lugar seguro.

Para operações seguras:

1. Mantenha o local de trabalho arrumado. A desordem no

local de trabalho pode ser motivo de acidentes.

2. Leve em consideração o ambiente que o rodeia. Não

exponha as ferramentas elétricas à chuva. Não use

ferramentas elétricas em locais úmidos ou molhados.

Trabalhe em um local bem iluminado.

Não use ferramentas elétricas em locais onde haja risco

de incêndios ou explosões.

3. Evite choques elétricos. Evite o contato com superfícies

conectadas à terra. (p. ex. tubos, radiadores, fogões,

refrigeradores).

4. Mantenha as crianças afastadas. Não deixe que terceiros

toquem na ferramenta ou no cabo elétrico. Não permita

que crianças permaneçam no local de trabalho.

5. Guarde as ferramentas que não estão sendo usadas.

As ferramentas que não estão sendo usadas devem ser

guardadas em um local seco, alto ou fechado, fora do

alcance de crianças.

6. Não sobrecarregue a ferramenta. O trabalho será melhor

e mais seguro se forem observados os limites indicados

para cada ferramenta.

7. Use ferramentas apropriadas. Não use ferramentas ou

acessórios pequenos para executar o trabalho de uma

ferramenta de serviço pesado. Não use ferramentas para

fi nalidades para as quais tais ferramentas não sejam

destinadas; não use, por exemplo, uma serra circular

manual para cortar galhos ou troncos de árvores.

8. Escolha o vestuário apropriado para o trabalho.

Não use roupas largas ou jóias, pois podem prender-

se em alguma peça móvel. Nos trabalhos externos,

aconselha-se o uso de luvas de borracha e sapatos que

não escorreguem. Se tiver cabelo comprido, prenda-os

com algo apropriado.

9. Use equipamentos de proteção para os olhos e mascara

facial ou de proteção contra poeira se usar este

equipamento em locais empoeirados.

10. Conecte equipamento de remoção de poeira. Se forem

fornecidos dispositivos para a conexão de equipamentos

de remoção de poeira e aspirador de pó, certifi que-se de

que sejam conectados e usados de maneira apropriada.

11. Não force o cabo elétrico. Nunca transporte a ferramenta

pelo cabo e não o puxe para desconectar o plugue da

tomada. Proteja o cabo contra o calor e evite o seu

contato com óleo e objetos cortantes.

12. Mantenha fi xa a peça a trabalhar. Use dispositivos de

fi xação ou uma morsa para prender a peça a trabalhar. É

mais seguro do que a fi xação manual e permite manejar

a ferramenta com ambas as mãos.

13. Controle sua posição. Escolha uma posição segura e

mantenha sempre o equilíbrio.

14. Realize uma manutenção cuidadosa das ferramentas.

Tenha as ferramentas sempre afi adas e limpas para que

possa trabalhar bem e em segurança. Siga as instruções

para lubrifi cação e troca de acessórios. Inspecione

periodicamente os cabos elétricos da ferramenta e,

se estiverem danifi cados, mande-os para conserto

nas ofi cinas autorizadas. Mantenha as empunhaduras

secas, limpas e livres de óleo e graxa.

15. Não mantenha a ferramenta conectada à rede elétrica.

Quando não estiver em uso ou ao trocar de acessório

como, por exemplo, cortadores, brocas e lâminas,

mantenha a máquina desconectada da rede elétrica.

16. Retire as chaves de ajuste. Habitue-se a verifi car se as

chaves de ajuste foram retiradas da ferramenta antes de

ligá-la.

17. Evite ligações involuntárias. Não transporte ferramentas

conectadas à rede elétrica com o dedo colocado no

interruptor de comando. Antes de conectar a ferramenta

à rede elétrica, certifi que-se de que o interruptor de

comando esteja desligado.

18. Use cabos de extensão para uso externo.

Ao ar livre, use apenas um cabo de extensão adequado

para este fi m.

19. Mantenha-se sempre alerta. Ao sentir-se cansado, não

use a ferramenta.

20. Verifi que se as peças apresentam danos. Antes de

continuar a usar a ferramenta, verifi que cuidadosamente

se os dispositivos de proteção e peças que apresentam

pequenos danos estão operacionais. Verifi que se as

peças móveis estão alinhadas, movimentando-se

com fl uência, se existem peças danifi cadas, se estão

perfeitamente montadas ou se existem quaisquer outros

problemas que possam afetar sua operação. Todas

as peças e dispositivos de proteção que não estejam

funcionando perfeitamente devem ser consertados ou

substituídos numa ofi cina autorizada, a menos que haja

indicações contrárias nestas instruções de uso. Não use

a ferramenta se o interruptor não ligar nem desligar.

21. Advertência

O uso de quaisquer acessórios ou aparelhos adicionais

que não se encontrem nestas instruções de uso podem

apresentar riscos de acidentes pessoais.

22. Use os serviços de pessoas qualifi cadas. Esta ferramenta

elétrica está de acordo com os requisitos de segurança

relevantes. Os consertos devem ser realizados apenas

por pessoal qualifi cado, usando peças sobressalentes

originais. Caso contrário, o usuário pode correr um risco

considerável.

PRECAUÇÕES AO USAR A CORTADORA DE

DISCO ABRASIVO

1. Inspecione o esmeril antes de usar, não utilize esmeris

lascados ou com outros tipos de defeitos. Sempre faça

um teste de funcionamento antes de usar para verifi car

se a cortadora de disco abrasivo não possui nenhuma

anormalidade.

2. Use o disco abrasivo normal em sua superfície de

trabalho normal.

3. Proteja-se contra as faíscas provocadas pela operação.

4. Substitua corretamente o disco abrasivo.

5. Esteja sempre atento para que as peças de retenção

do disco abrasivo não fi quem nunca defeituosas. Peças

com defeito causam danos ao disco abrasivo.

6. Certifi que-se de que a peça a trabalhar esteja livre de

corpos estranhos como pregos.

7. Use apenas esmeris recomentados pelo fabricante que

possuam uma velocidade marcada igual ou maior que a

velocidade marcada na placa de identifi cação da máquina.

8. Discos abrasivos devem ser armazenados e manuseados

com cuidado, de acordo com as instruções do fabricante.

9. Certifi que-se de que o disco montado foi ajustado

conforme as instruções do fabricante.

10. Não utilize nunca a máquina sem a proteção no lugar.

11. Não utilize a lâmina de serra.

12. Não utilize a máquina em atmosferas e ambientes

infl amáveis onde faíscas podem provocar incêndios,

explosões, etc.

13. Este produto não é um brinquedo, não deixe que

crianças brinquem com ele.

12

Page 14

Português

ESPECIFICAÇÕES

Voltagem (por áreas)*

Potência de entrada*

Dimensões

máximas de

2

corte*

Altura × Largura

Disco abrasivo ø355 × ø25,4 × 4 mm (Esmeris resinóides reforçados)

Rotação sem carga 3 800 / min

Velocidade máxima periférica de

trabalho

Peso (Somente do corpo principal) 17,0 kg

*1 Certifi que-se de verifi car a voltagem na placa de identifi cação no produto, pois ela está sujeita a alterações conforme a área.

*2 As dimensões de corte máximas são possíveis apenas se o disco abrasivo não estiver muito desgastado pelo uso.

1

1

Formato do material

a ser cortado

A

(120 V, 127 V, 220 V, 230 V, 240 V)

2 000 W (127 V), 2 200 W

A

A

B

A

A

A × B

Ângulo de corte 0° 130 mm 120 mm 95 mm × 200 mm 137 mm

Ângulo de corte 45° 115 mm 104 mm 115 mm × 104 mm 100 mm

4 800 m / min

A

ACESSÓRIOS PADRÕES

(1) Disco abrasivo .............................................................1

(2) Chave de barra sextavada ........................................... 1

APLICAÇÕES

Corte de vários materiais metálicos como tubos, barras

redondas e aço perfi lado.

ANTES DA OPERAÇÃO

1. Fonte de energia

Certifi que-se de que a fonte de energia que será usada

satisfaça as exigências especifi cadas na placa de

identifi cação do produto.

2. Interruptor de alimentação

Certifi que-se de que o interruptor de alimentação

esteja na posição de desligado (OFF). Se o plugue for

conectado a uma tomada elétrica com o interruptor na

posição de ligado (ON), a ferramenta elétrica começará

a funcionar imediatamente, podendo provocar um grave

acidente.

3. Cabo de extensão

Quando o local de trabalho não possuir uma fonte de

energia, use um cabo de extensão de espessura e de

potência nominal sufi cientes. A extensão deve ser

mantida o mais curta possível.

4. Instale a máquina num local nivelado e mantenha-a

em condições estáveis. Antes de sair da fábrica, o

equipamento é sujeito a uma inspeção rígida para evitar

choques elétricos durante a operação.

5. Como as peças móveis são presas pela tensão de

uma corrente durante o transporte, retire a corrente do

gancho apertando levemente o cabo do interruptor.

6. Certifi que-se de que os discos abrasivos estejam em

perfeitas condições e sem marcas e rachaduras.

7. Embora as porcas de retenção tenham sido totalmente

apertadas na fábrica antes da entrega, por medida

de segurança, reaperte-as bem antes de usar o

equipamento.

8. Possíveis acidentes como um disco abrasivo rachado

são evitados pela tampa protetora (protetor do disco).

Embora ela tenha sido totalmente presa na fábrica antes

da entrega, por medida de segurança, reaperte bem os

parafusos de fi xação.

9. Ao substituir o disco abrasivo, certifi que-se de que o

disco de corte substituto tenha uma velocidade periférica

designada acima de 4 800 m/min.

10. Certifi que-se de que a chave de barra usada para apertar

ou retirar o disco abrasivo não esteja presa na máquina.

11. Verifi que se o local do trabalho está apoiado de maneira

correta. Certifi que-se de que o material está bem preso

com o torno. Se não estiver, um acidente grave pode

acontecer caso o material se solte ou o disco abrasivo se

quebre durante a operação.

12. Antes de colocar a máquina sem carga para trinta em

funcionamento, certifi que-se de que o esmeril está

ajustado e apertado corretamente em posição segura;

se houver vibração considerável ou se outros defeitos

forem detectados pare imediatamente o funcionamento.

Caso isto ocorra, proceda a uma verifi cação na máquina

para descobrir a causa do defeito.

13. Gire o disco abrasivo para inspecionar quaisquer desvios

da face. Um grande desvio provoca deslocamento do

disco abrasivo.

14. Certifi que-se de que os orifícios de ventilação estão

desobstruídos em ambientes empoeirados. Se for

necessário limpar a poeira, desconecte primeiramente a

máquina da fonte de alimentação.

PROCEDIMENTOS DE CORTE

PRECAUÇÃO

É perigoso retirar ou instalar a peça a trabalhar enquanto

o disco abrasivo estiver girando.

1. Operação do interruptor

O uso do gatilho desligar varia de acordo com a região.

A ferramenta é acionada quando o gatilho é puxado e

desligada quando ele é solto (Fig. 2).

<Lock-on Switch Operations>

Em modelos com trava, pressione a trava com o gatilho

puxado para a ferramenta continuar funcionando depois

que o gatilho for solto. (Fig.2)

13

Page 15

Português

2. Corte

(1) Gire o disco abrasivo, pressione gentilmente o cabo

e leve o disco abrasivo para perto do material a ser

cortado.

(2) Quando o disco abrasivo entrar em contato com o

material a ser cortado, pressione ligeiramente um pouco

mais o cabo e comece a cortar.

(3) Quando o corte (ou o entalhamento designado) tiver sido

completado, levante o cabo e coloque-o na sua posição

original.

(4) Ao fi nal de cada processo de corte, desligue o interruptor

para parar a rotação e prossiga com o trabalho seguinte

de corte.

PRECAUÇÃO

Exercer mais força no cabo não corta mais rápido

necessariamente.

Força demasiada no cabo coloca uma pressão excessiva

no motor e reduz sua capacidade.

Ao terminar uma operação, certifi que-se de desligar

o interruptor e de desconectar o plugue da tomada

elétrica.

MONTAGEM E DESMONTAGEM DO DISCO

ABRASIVO

1. Desmontagem do disco abrasivo (Fig. 3 e 4)

(1) Levante o protetor inferior (A).

Pressione o pino de trava para baixo para colocá-lo em

contato com a arruela do disco.

Gire o disco abrasivo, introduza o pino de trava pelo

orifício na arruela do disco e retire o parafuso M10

usando a chave de barra hexagonal fornecida com o

equipamento.

(2) Retire o parafuso, arruela (A) e a arruela do disco e, em

seguida, desprenda o disco abrasivo. (Fig. 4)

PRECAUÇÃO

Nunca retire o anel em ‘O’ ou a manga do eixo do disco

abrasivo.

2. Montagem do disco abrasivo

Retire minuciosamente a poeira das arruelas do disco

e do parafuso e, em seguida, monte o disco seguindo

os procedimentos de desmontagem na ordem inversa.

Coloque o protetor inferior (A) de volta na posição inicial.

PRECAUÇÃO

Confi ra se o detentor usado para a instalação e remoção

do disco abrasivo voltou à sua posição retraída.

MODO DE OPERAÇÃO

1. Procedimento para prender o material de corte

(Fig. 5 e 6)

Coloque a peça a trabalhar entre o torno (A) e o torno (B),

levante a embreagem e empurre a alavanca do parafuso

para colocar o torno (A) levemente em contato com a

peça a trabalhar, como mostrado na Fig. 5.

Depois, vire a embreagem para baixo e prenda bem

a peça a trabalhar em posição, girando a alavanca do

parafuso. Quando o trabalho de corte tiver terminado,

gire a alavanca do parafuso duas ou três vezes para

desapertar o torno (A) e retire a peça, como mostrado na

Fig. 6.

PRECAUÇÃO

Para evitar ferimentos pessoais, nunca retire nem instale

a peça a trabalhar enquanto o disco abrasivo estiver

girando.

2. Corte em ângulos (Fig. 7)

(1) A máquina permite cortar em ângulos de 0° – 45°.

(2) Solte os dois parafusos hexagonais M10 no torno (B) e

posicione a superfície a ser trabalhada no torno em um

ângulo de 0°, 30° ou 45°. Depois de completar o ajuste,

aperte bem os dois parafusos de 10 mm.

3. Movimento do mordente do torno estacionário

(Fig. 8)

A abertura do torno é ajustada para o máximo de 165

mm ao sair da fábrica. No caso de se necessitar de

uma abertura de mais de 165 mm, mova o torno para

a posição mostrada pela linha da corrente depois de

desapertar os dois parafusos. A abertura máxima pode

ser ajustada em dois passos de 200 mm e 235 mm.

Ao cortar um material excessivamente largo, o torno

pode ser usado efi cazmente reposicionando-se o lado

estacionário dos mordentes do torno.

4. Corte de peças longas (Fig.9)

Antes de começar a trabalhar com peças longas,

coloque as duas extremidades da peça em blocos da

mesma altura que a base para estabilizá-la.

5. Como usar blocos quadrados (Fig. 10)

Se o disco abrasivo tiver diâmetro externo reduzido,

coloque um bloco quadrado ligeiramente menor que a

peça a ser cortada entre as mandíbulas (A) e (B) do torno

para usar o disco abrasivo de forma mais econômica.

6. Ajuste da profundidade do corte (Fig. 11)

Se o disco de corte tiver diâmetro externo reduzido,

ajuste a altura do pino de travamento para modifi car

a profundidade do corte. Para ajustar, solte a porca

de travamento, gire o pino de travamento e, quando

terminar, aperte novamente a porca para fi xar a posição

do pino.

Dependendo do material, é possível eliminar a produção

de lascas.

PRECAUÇÃO

○ Ajuste a altura do pino de travamento quando trocar o

disco abrasivo.

○ Se o pino de travamento estiver em posição baixa

demais, o disco abrasivo pode cortar a base.

7. Ajuste do protetor contra fagulhas (Fig.12)

Solte o parafuso fi xador do protetor com uma chave de

fenda para ajustar o ângulo.

Mude o ângulo de acordo com ambiente de uso e o

trabalho a ser realizado para modifi car a direção em que

as fagulhas voam.

8. Transporte da ferramenta (Fig.13)

Ao transportar a ferramenta, coloque o gancho da

corrente na corrente e segure a ferramenta pelo cabo.

MANUTENÇÃO E INSPEÇÃO

PRECAUÇÃO

Certifi que-se de desligar o interruptor de alimentação e

de desconectar o plugue da tomada elétrica antes de

realizar a inspeção e manutenção.

1. Substituição do disco abrasivo

Depois que o disco abrasivo fi car desafi ado durante o

uso continuado, há uma carga desnecessária ao motor.

Em conseqüência, retifi que ou substitua o disco abrasivo

desafi ado para assegurar a efi cácia do esmerilhamento.

2. Inspeção das escovas de carvão (Fig. 14)

O motor emprega escovas de carvão que são peças

de consumo. Quando elas estiverem gastas ou quase

chegando ao “limite de uso”, podem causar problemas

no motor. Quando o motor estiver equipado com uma

escova de carvão de parada automática, ele pára

automaticamente. Nesse momento, troque ambas as

escovas de carvão por novas que possuam o mesmo

número mostrado na ilustração. Além disso, mantenha

sempre limpas as escovas de carvão e certifi que-se de

que elas deslizem livremente nos suportes de escova.

14

Page 16

Português

3. Inspeção dos parafusos de montagem

Inspecione regularmente todos os parafusos de

montagem e certifi que-se de que estejam apertados

corretamente. Se algum deles estiver frouxo, reaperte-o

imediatamente. Deixar de fazer isso pode resultar em

graves perigos.

4. Substituir o cabo de alimentação

Se for necessária a substituição do cabo de alimentação,

esta tem de ser efectuada por um centro de assistência

autorizado da Hitachi de modo a evitar um perigo de

segurança.

5. Lubrifi cação

Coloque óleo uma vez por mês nos seguintes pontos

de suprimento para manter a máquina trabalhando por

muito tempo.

Pontos de suprimento de óleo

○ Parte giratória do eixo

○ Parte giratória do torno

○ Guia corrediça do torno (A)

6. Limpeza

Limpe de vez em quando os fragmentos e detritos que

aderiram à máquina com um pano ou algo similar. Tome

cuidado para não molhar com óleo ou com água a parte

do motor.

7. Lista de peças para conserto

PRECAUÇÃO

Os consertos, modifi cações e inspeções das

Ferramentas Elétricas da Hitachi devem ser realizados

por uma Ofi cina Autorizada da Hitachi.

Esta lista de peças pode ser útil se for apresentada com

a ferramenta na Ofi cina Autorizada da Hitachi ao solicitar

conserto ou manutenção.

Na operação e na manutenção das ferramentas

elétricas, devem-se observar as normas de segurança e

os padrões estabelecidos por cada país.

MODIFICAÇÕES

As Ferramentas Elétricas da Hitachi estão sempre sendo

aperfeiçoadas e modifi cadas para incorporar os mais

recentes avanços tecnológicos.

Dessa forma, algumas peças (isto é, números de código

e/ ou design) podem sofrer modifi cações sem aviso

prévio.

NOTA:

Devido ao contínuo programa de pesquisa e desenvolvimento

da HITACHI, as especifi cações aqui contidas estão sujeitas

a modifi cações sem aviso prévio.

15

Page 17

16

Page 18

CC14ST

1

8

7

13

16

15

14

33

32

31

61

35

A

2

4

3

11

10

9

12

18

17

34

37

36

62

39

38

64

63

5

5

6

20

22

5

19

18

16

30

29

43

42

41

40

60

77

78

80

81

65

66

67

68

69

70

71

72

73

74

75

76

79

82

83

21

25

24

23

46

45

47

49

56

57

58

59

84

85

65

88

89

28

27

26

49

50

48

49

51

53

54

55

86

87

74

73

30

A

90

17

Page 19

CC14ST

Item

No.

1 LOWER GUARD SET 1

2 LOWER GUARD SET 1

3 LOWER GUARD PAD 1

4 LOWER GUARD 1

5 RUBBER PAD 4

6 M5 NUT 1

7 M5X10 FLANGE SCREW 1

8 SUB COVER 1

9 RUBBER PAD 1

10 M6X15 FLANGE SCREW 1

11 PLATE WASHER 1

12 M5X10 FLANGE SCREW 1

13 WHEEL 1

14 M10 HEX. SOKET BOLT 1

15 FLANGE WASHER 1

16 WHEEL WASHER 2

17 O-RING 1

18 SHAFT SLEEVE 2

19 M5X25 SCREW 4

20 WHEEL COVER 1

21 GEAR SET 1

22 BALL BEARING 1

23 BEARING HOLDER 1

24 O-RING 1

25 GEAR 1

26 SPINDLE 1

27 KEY 1

28 BALL BEARING 1

29 M5 NUT 1

30 M6 NUT 2

31 SPRING 1

32 PIN SLEEVE 1

33 STOPPER PIN 1

34 ARMATURE SET 1

35 BALL BEARING 1

36 RUBBER PIN 1

37 ARMATURE 1

38 BALL BEARING 1

39 FAN GUIDE 1

40 STATOR 1

41 RUBBER SLEEVE 1

42 HOUSING 1

43 M5X55 SCREW 4

45 SWITCH 1

46 D4X10 TAPPING SCREW 1

47 HOOK 1

48 NEEDLE ROLLER 1

49 D4X16 TAPPING SCREW 10

50 M5X45 SCREW 3

51 CORD CLIP 1

53 CORD ARMOR 1

54 CORD 1

55 HANDLE SET 1

56 TAIL COVER 1

57 BRUSH HOLDER 2

58 CARBON BRUSH 2

Part Name Q’TY

Item

No.

59 BRUSH CAP 2

60 M5X8 HEX. SOKET SCREW 2

61 GEAR CASE 1

62 HINGE SHAFT 1

63 TORSION SPRING 1

64 D5X80 TAPPING SCREW 2

65 D8 RETAINER RING 2

66 VISE HANDLE 1

67 VISE SCREW 1

68 SCREW HOLDER 1

69 HEX. BAR WRENCH 1

70 WRENCH HOLDER 1

71 BASE 1

72 BASE RUBBER 4

73 D10 WASHER 2

74 M10 NUT 2

75 M6X12 SCREW 1

76 SPARK SHOOT 1

77 VISE SET 1

78 M8X30 HEX. SOKET BOLT 2

79 CHAIN 1

80 VISE NUT 1

81 ROLL PIN 1

82 D16 RETAINER RING 1

83 MOVING VISE 1

84 VISE SHAFT 1

85 D8 WASHER 1

86 M10X20 HEX. SOKET BOLT 2

87 FIXED VISE 1

88 M10X45 HEX. SOKET BOLT 1

89 M10 STOP Nut 1

90 M6X12 HEX. SOKET BOLT 1

Part Name Q’TY

18

Page 20

CC14STD

19

Page 21

Item

No.

1 Lower Guard Set 1

2 Lower Guard Pad 1

3 Lower Guard 1

4 Rubber Pad 4

5 M5×10 Flange Screw 1

6 M6×15 Flange Screw 1

7 Plate Washer 1

8 Wheel 1

9 M10×20 Hex. Soket Bolt 1

10 Flange Washer 1

11 Wheel Clamp Washer 2

12 O-ring 1

13 Shaft Sleeve 2

14 M5×25 Screw 4

15 Wheel Guard 1

16 Gear-Spindle Set 1

17 Ball Bearing 6203Z MX 1

18 Bearing Holder 1

19 O-ring 1

20 Gear 1

21 Spindle 1

22 Key 1

23 Ball Bearing 6000Z MX 1

24 M5 Nut 1

25 M6 Nut 2

26 Switch with lock 1

27 D4×10 Tapping Screw 1

28 D4×14 Tapping Screw 8

29 H Handle Set light green 1

30 Carry Handle Set 1

31 D6 Tapping Screw 2

32 Locking Spring 1

33 Pin Sleeve 1

34 Locking Pin 1

35 Armature Set 1

36 Ball Bearing 1

37 Rubber Pin 1

38 Armature 1

39 Ball Bearing 629RZ C&U 1

40 Fan Guide 1

41 Stator 1

42 Handle frame 1

43 Rubber Sleeve 1

44 Housing lignt green 1

45 M5×55 Screw 4

46 Hook 1

47 Pin 1

48 M5×45 Screw 3

49 D4×16 Tapping Screw 4

50 Cord Clip 1

51 Cord Armor 1

52 Cord 1

53 Tail Cover 1

54 Brush Holder 2

55 Carbon Brush 2

56 Brush Cap 2

57 M5×8 Hex. Soket Screw 2

Part Name Q'TY

CC14STD

Item

No.

58 Gear Case 1

59 Hinge Shaft 1

60 Torsion Spring 1

61 D5×80 Tapping Screw 2

62 D8 Retainer Ring 2

63 Vise Handle 1

64 Vise Screw Bar 1

65 Screw Bar Seat 1

66 Hex. Bar Wrench 1

67 Wrench Holder 1

68 Base 1

69 Base Rubber Foot 4

70 D10 Washer 2

71 M10 Nut 2

72 M6×12 Screw 1

73 Spark Guard 1

74 Vise Set 1

75 M8×30 Hex. Soket Bolt 2

76 Chain 1

77 Vise Nut 1

78 Roll Pin 1

79 D16 Retainer Ring 1

80 Moving Vise 1

81 Vise Shaft 1

82 D8 Washer 1

83 M10×20 Hex. Soket Bolt 2

84 Miter Fence 1

85 M10×45 Hex. Soket Bolt 1

86 M10 Stop Nut 1

87 M6×12 Hex. Soket Bolt 1

Part Name Q'TY

20

Page 22

21

Page 23

22

Page 24

Issued by

Shinagawa Intercity Tower A, 15-1, Konan 2-chome,

Minato-ku, Tokyo 108-6020, Japan

Distributed by

Avenida Isaac Newton No.286, Piso 2, Colonia Polanco Sección V,

Delegación Miguel Hidalgo, C. P. 11560

México, D. F.

Code No. C99208844 A

Printed in China

501

Loading...

Loading...