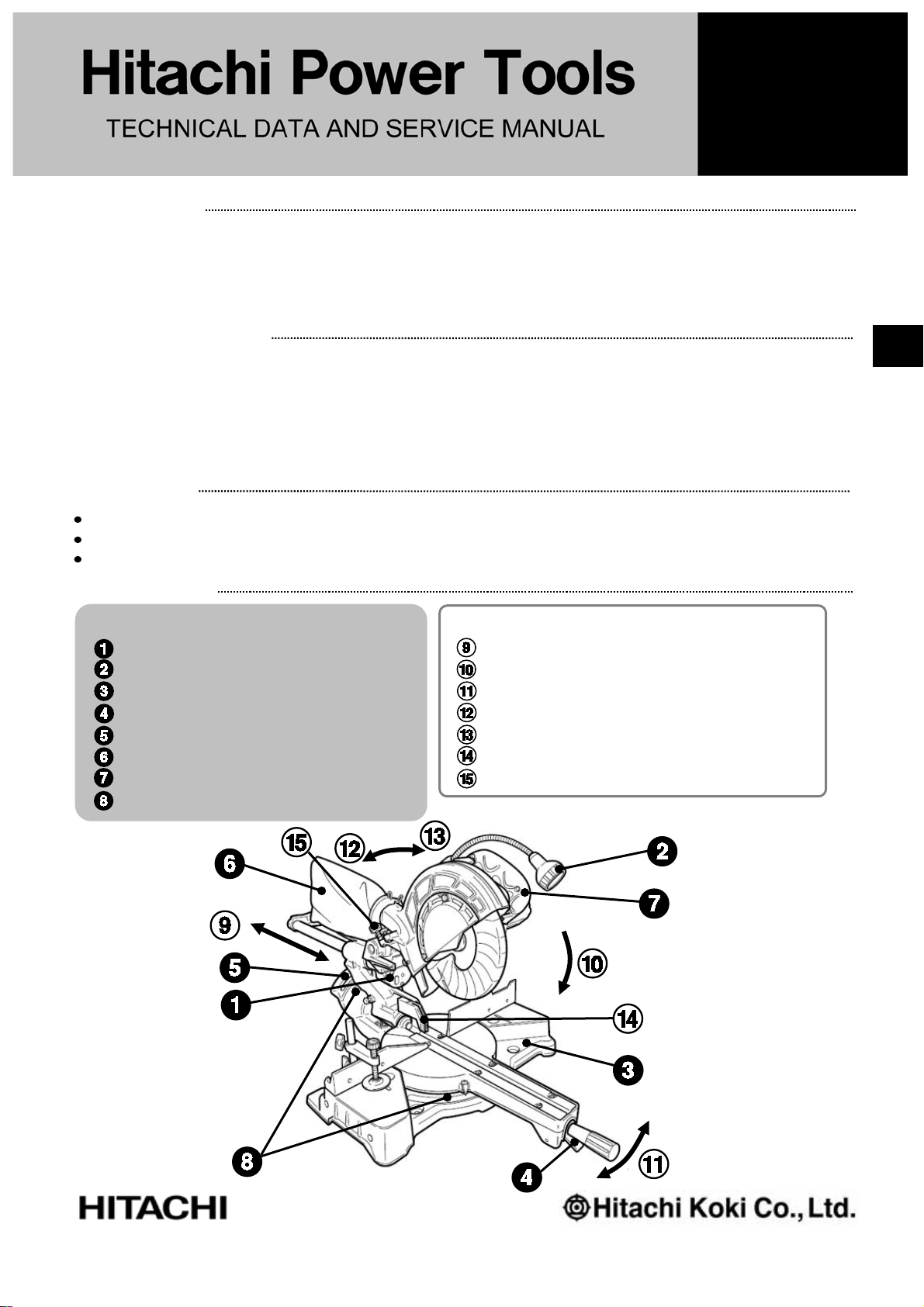

Page 1

PRODUCT NAME

Hitachi Slide Compound Miter Saw

Models C 8FSE, C 8FSHE

LIST Nos.

C 8FSE: E948

C 8FSHE: E949

Feb. 2008

MARKETING OBJECTIVE

The new slide compound miter saws Models C 8FSE and C 8FSHE are developed to bring to the European

market at the prices as low as the competitors’ products. The Model C 8FSHE is equipped with a laser marker

for easier alignment with the ink line and an LED light to illuminate the working surface brightly. In addition, the

Model C 8FSE that is mostly the same as the Model C 8FSHE except that it is not equipped with the laser

marker and the LED light is introduced in tandem with the Model C 8FSHE. With the new Models C 8FSE and

APPLICA TIONS

Cutting various types of wood workpieces

Cutting workpieces of plywood, decoration panels, soft fiberboards and hard boards

Cutting aluminum sashes

SELLING POINTS

[ NEW FEATURES ]

Laser marker (Only the Model C 8FSHE)

LED light (Only the Model C 8FSHE)

Lightweight

Positive angle stoppers

Bevel cutting range: Left 48° to right 5°

High dust collecting performance

Soft grip handle

Legible scale

<Same features as the conventional models>

Slide cutting

Press cutting

Miter cutting

Right and left bevel cutting

Compound miter and left bevel cutting

Splinter guard, also serving for cut alignment

Groove cutting

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT.

C

C 8FSHE

International Sales Division

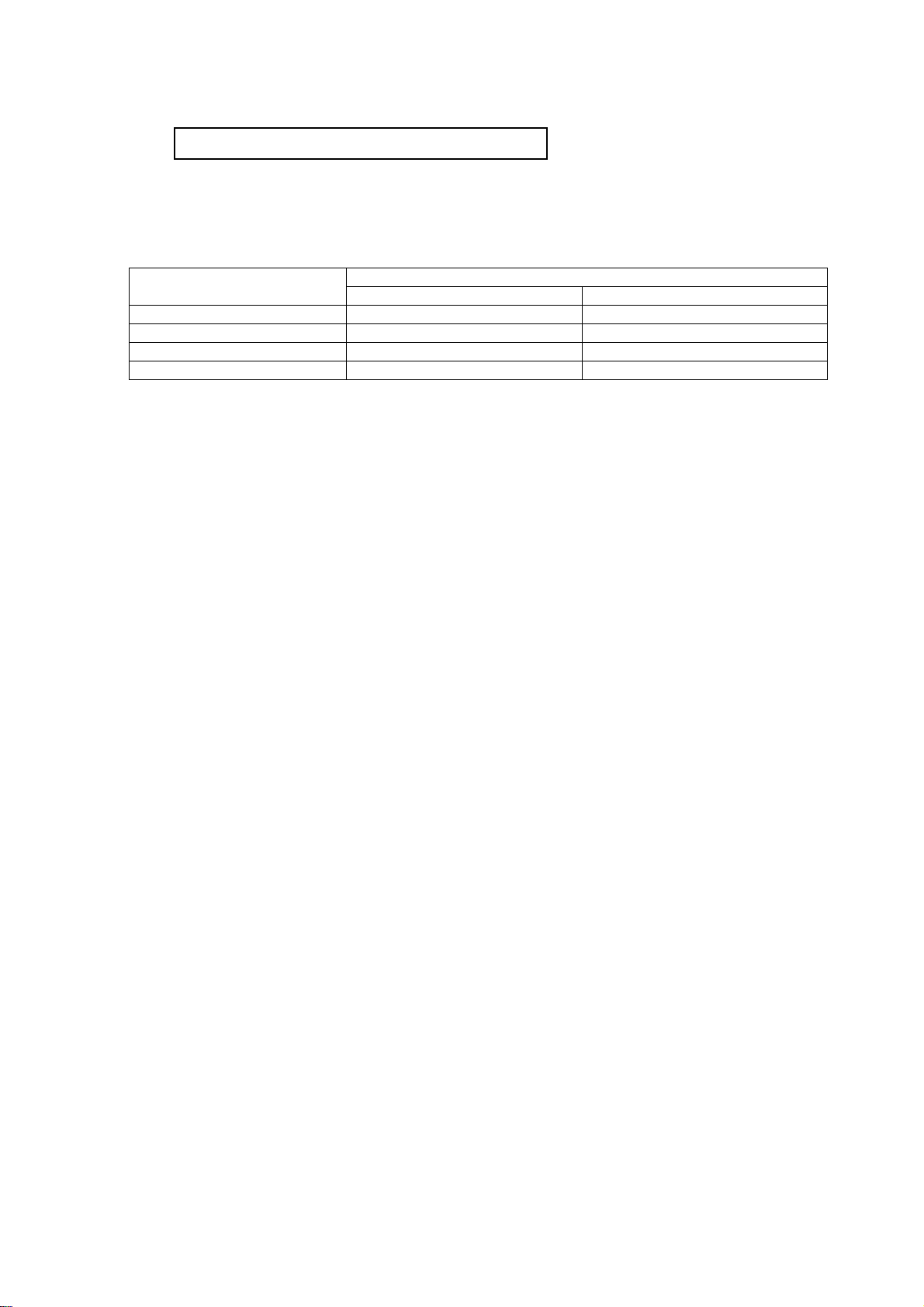

Page 2

REMARK:

For more information about HANDLING INSTRUCTIONS, visit our website at:

http://www.hitachi-koki.com/manual_view_export/

Throughout this TECHNICAL DATA AND SERVICE MANUAL, a symbol(s) is(are) used in the place of

company name(s) and model name(s) of our competitor(s). The symbol(s) utilized here is(are) as follows:

Symbols Utilized

P1 DEWALT DW707

P2 DEWALT DW777

P3 DEWALT DW712

B BOSCH GCM8S

Competitors

Company Name Model Name

Page 3

CONTENTS

Page

SELLING POINT DESCRIPTIONS-----------------------------------------------------------------------------------------1

SPECIFICATIONS --------------------------------------------------------------------------------------------------------------6

1. Specifications

COMPARISONS WITH SIMILAR PRODUCTS--------------------------------------------------------------------------8

1. Specification comparisons

PRECAUTIONS IN SALES PROMOTION------------------------------------------------------------------------------ 12

1. Safety instructions

2. Precautions requiring particular attention during sales promotion

ADJUSTMENT AND OPERATIONAL PRECAUTIONS------------------------------------------------------------- 16

1. Confirmation of saw blade lower limit position

2. Confirmation for use of sub fence (Optional accessory)

3. Position adjustment of laser line (Only the Model the C 8FSHE)

4. How to use the vise assembly

5. Adjustment of table insert position

6. Cutting operation

ADJUSTMENT OF COMPONENTS ------------------------------------------------------------------------------------- 24

1. Bevel angle adjustment

2. Ball bushing (Linear bearing)

-------------------------------------------------------------------------------------------------------------------------------- 6

------------------------------------------------------------------------------------------------------------- 8

----------------------------------------------------------------------------------------------------------------------- 12

------------------------------------------ 15

-------------------------------------------------------------------------- 16

---------------------------------------------------------- 16

-------------------------------------------- 17

--------------------------------------------------------------------------------------------------- 18

--------------------------------------------------------------------------------------------- 18

------------------------------------------------------------------------------------------------------------------------- 19

-------------------------------------------------------------------------------------------------------------- 24

----------------------------------------------------------------------------------------------------- 24

PACKING ----------------------------------------------------------------------------------------------------------------------- 25

REPAIR GUIDE---------------------------------------------------------------------------------------------------------------- 26

1. Precautions in disassembly and reassembly

2. Troubleshooting guide

----------------------------------------------------------------------------------------------------------------- 43

---------------------------------------------------------------------------- 26

STANDARD REPAIR TIME (UNIT) SCHEDULES-------------------------------------------------------------------- 48

Assembly diagram for C 8FSHE

Assembly diagram for C 8FSE

Page 4

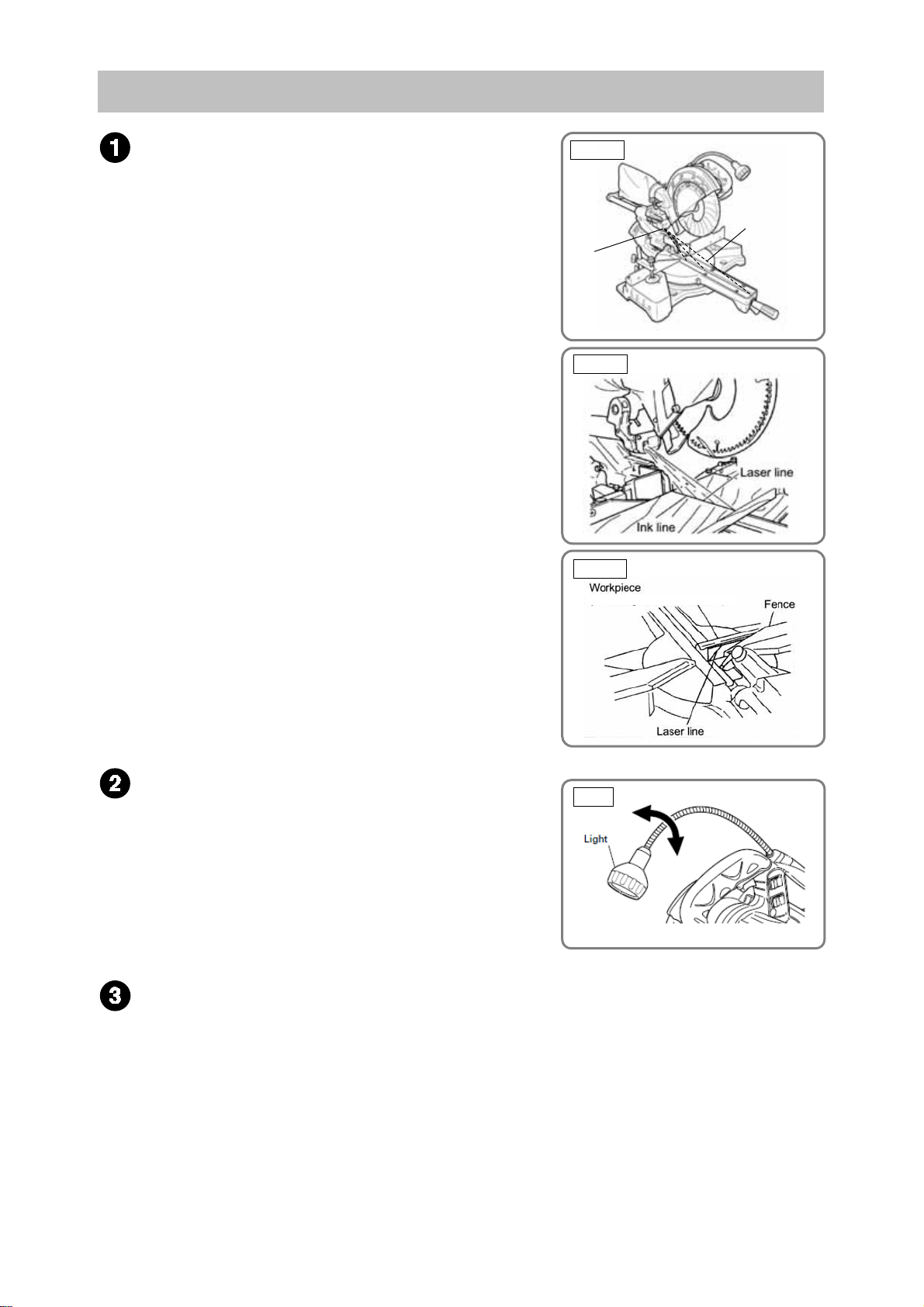

SELLING POINT DESCRIPTIONS

r

r

Laser marker (Only the Model C 8FSHE)

Use the laser marker for aligning with the ink line on the

workpiece.

(1) Cutting position can be properly adjusted by aligning the

positioning ink line with the laser line. There is no need to

make a long ink line on the workpiece.

(2) There is no need to lower the motor head to align with the

ink line because the laser marker makes a laser line on the

workpiece. In addition, cutting position can be easily

adjusted because the operator can hold the workpiece with

both hands to move.

(3) Cutting position can be easily adjusted because the laser

line can be aligned with an optionally angled ink line.

(4) Even the workpieces such as crown moldings and base

boards that have decorative surfaces and are difficult to be

made an ink line can be cut just by aligning the laser line

with the ink line on the fence side. The laser line is

adjusted to the width of the saw blade at the time of factory

shipment. Depending upon the user's cutting choice, the

laser line can be aligned with the left side of the cutting

width (saw blade) or the ink line on the right side. Adjust

the position of the laser line according to "Position

adjustment of laser line" on page 17.

Fig. 1-a

Lase

marke

Fig. 1-b

Fig. 1-c

(molding, base board, etc.)

Laser beam

LED light (Only the Model C 8FSHE)

The Model C 8FSHE is equipped with an LED light to light up

over a table brightly. The two LEDs incorporated in it light up the

materials and the point of the saw blade brightly. The LED light

can freely move at the time of right and left bevel cutting

because the support is flexible. Therefore, it lights up the

materials and the point of the saw blade brightly at any time.

Fig. 2

Lightweight

The Model C 8FSE is most lightweight (14 kg) in the class of 8” (216 mm) slide compound miter saws

because the reinforcement rib of the table is placed in the most suitable position.

-1-

Page 5

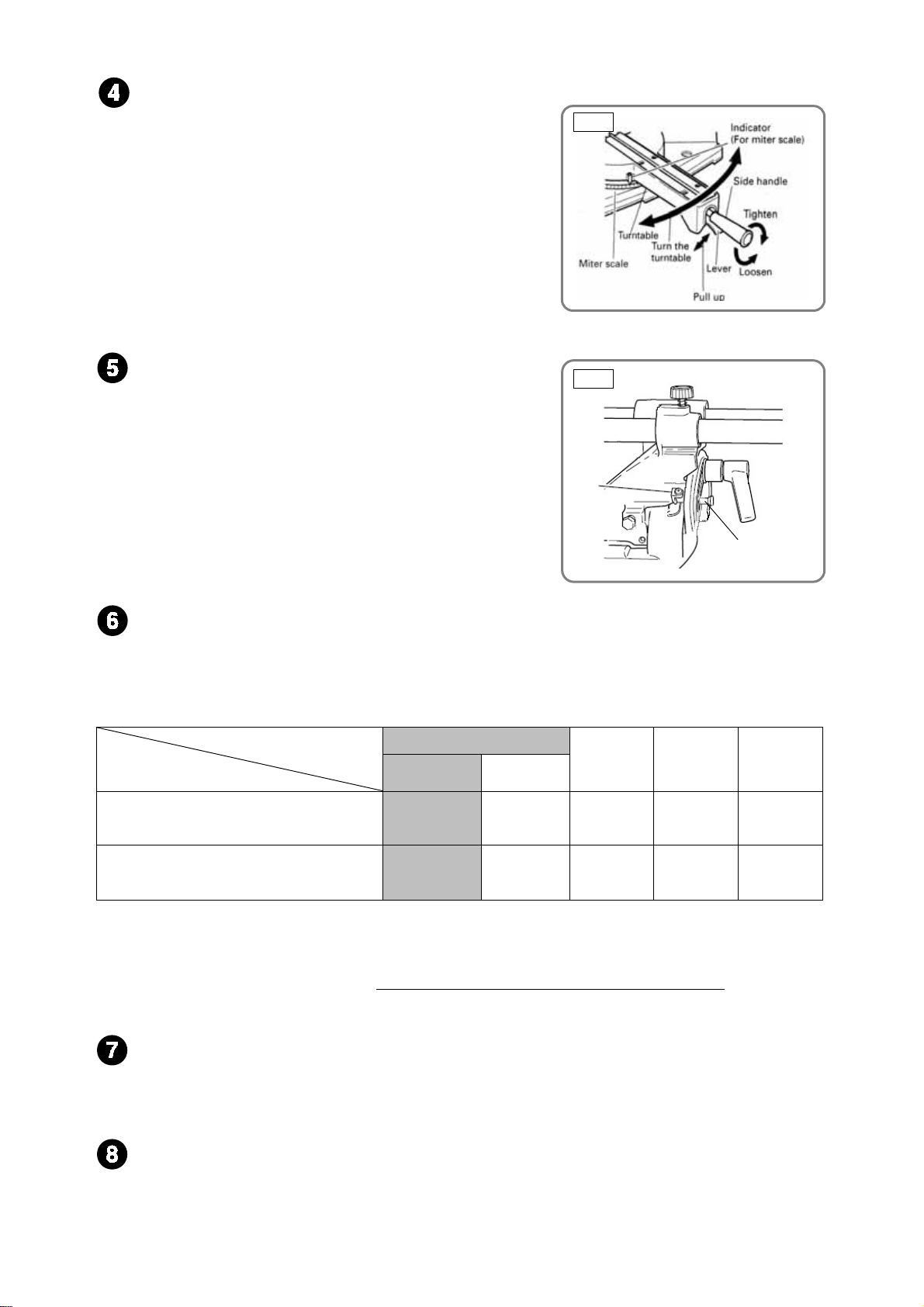

Positive angle stoppers

The Models C 8FSE and C 8FSHE have positive angle

stoppers in the turn table at the right and the left of the 0°

center setting, at 15°, 22.5°, 31.6° and 45° settings.

Thanks to the positive angle stoppers, positioning can be

done more securely than the ball index method utilized in

the current Model C 8FB2. In addition, a lever is provided

at the lower tip of the turn table to secure or release the

positive angle stoppers.

Adjustment of the turn table and positioning can be easily

done while holding the side handle.

Bevel cutting range: Left 48° to right 5°

Possible range of bevel cutting is from left 48 degrees to right 5

degrees. By the simple operation of the set pin, you can set the

position of the right angle and left 45 degrees.

In addition, setting to approximately 30 degrees and 33.9

degrees for crown molding cutting can be done by this set pin.

Fig. 3

Fig. 4

Set pin

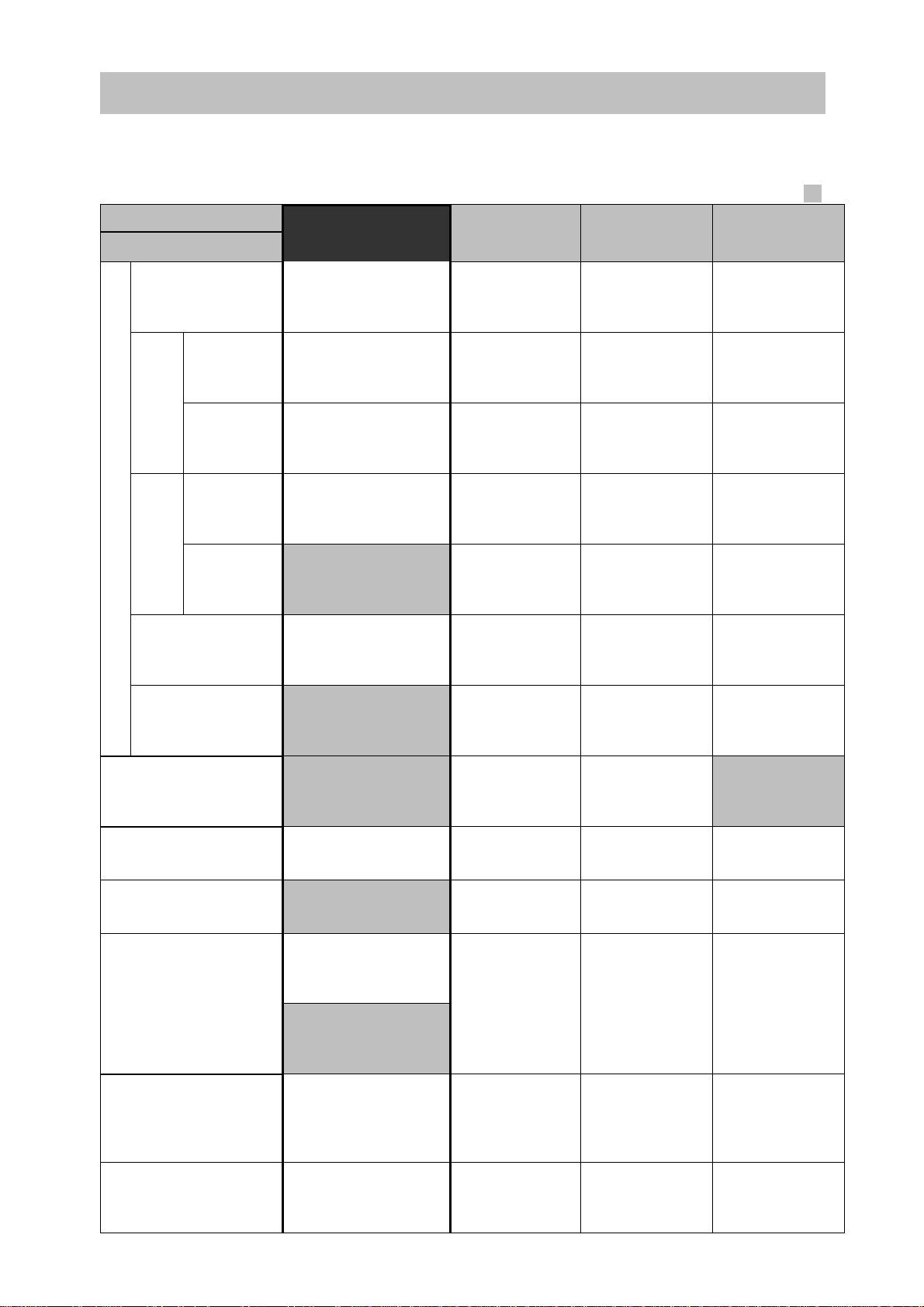

High dust collecting performance

The dust collecting performance of the Models C 8FSE and C 8FSHE are remarkably higher than the other

models thanks to the adoption of new dust guide and gear case.

Table 1

Cutting

method

Press cutting *

(Size of the workpiece:

60 mm x 60 mm (2-3/8” x 2-3/8”))

Slide cutting *

(Size of the workpiece:

30 mm x 150 mm (1-3/16” x 5-29/32”))

*1: This is a method to cut a workpiece by shaking the motor head.

*2: This is a method to cut a workpiece by sliding the motor head from the front.

The dust collecting performance is obtained from the following formula:

Dust collecting performance (%) = x 100

1

2

Maker

Model

C 8FSHE

Weight of sawdust accumulated in the dust bag (g)

HITACHI

C 8FSE

75.0 25.0 5.9 31.3 62.2

80.0 45.0 11.0 72.3 74.5

Weight of all sawdust during cutting (g)

C 8FB2

P1 and P2 P3 B

(%)

Soft grip handle

The handles are widely covered with soft-touch elastomer (rubber-like soft resin).

It is slip-resistant and securely fits in the palm of a hand even if the gripping hand sweats.

Legible scale

The Models C 8FSE and C 8FSHE have legibly labeled angle scale and bevel scale while the current

Model C 8FB2 has the scale printed on the die casting.

-2-

Page 6

Slide cutting

dimensio

dimensio

Table 2

Maker

Max.

Model

cutting

n

Height x Width

(H x W)

C 8FSE

C 8FSHE

65 x 312

(2-9/16” x 12-1/4”)

75 x 262

(2-15/16” x 10-5/6”)

with aux. board

width 30 (1-3/16”)

HITACHI

C 8FB2

65 x 305

(2-9/16” x 12”)

75 x 265

(2-15/16” x 10-7/16”)

P1 and P2 P3 B

60 x 270

(2-3/8” x 10-3/8”)

Workpieces as wide as shown in Table 2 can be cut with the motor

70 x 300

(2-3/4” x 11-13/16”)

Fig. 5

Unit: mm (inch)

60 x 270

(2-3/8” x 10-3/8”)

head sliding. The lower limit position of the saw blade is factoryadjusted so that workpieces up to 65 mm (2-9/16") high and 312 mm

(12-1/4") wide can be cut as shown in Fig. 6-a. When cutting a

workpiece of 75 mm (2-15/16") in height as indicated in [ ] in Table 2,

adjust the saw so that there is a clearance of 2 to 3 mm (3/32" to 1/8")

between the bottom surface of the head and the top surface of the

workpiece at the lower limit position of the saw blade as shown in Fig. 6-b. (See the Instruction Manual

"Lower limit position of saw blade when cutting a large workpiece.")

Please note that, when cutting in this position, it is necessary to use an auxiliary board of 30 mm (1-3/16")

wide so that the workpiece on the fence side can be cut fully in width.

Fig. 6-bFig. 6-a

Press cutting

Table 3

Maker

Max.

cutting

Height x Width

Model

n

(H x W)

C 8FSE

C 8FSHE

65 x 65

(2-9/16” x 2-9/16”)

Press cutting with the head swiveling enables cutting square

workpieces as large as shown in Table 3 in a single sawing

operation. It is convenient for cutting narrow workpieces (Fig. 7).

HITACHI

65 x 65

(2-9/16” x 2-9/16”)

C 8FB2

60 x 60

(2-3/8” x 2-3/8”)

Unit: mm (inch)

P1 and P2 P3 B

70 x 40

(2-3/4” x 1-9/16”)

Fig. 7

60 x 68

(2-3/8” x 2-11/16”)

-3-

Page 7

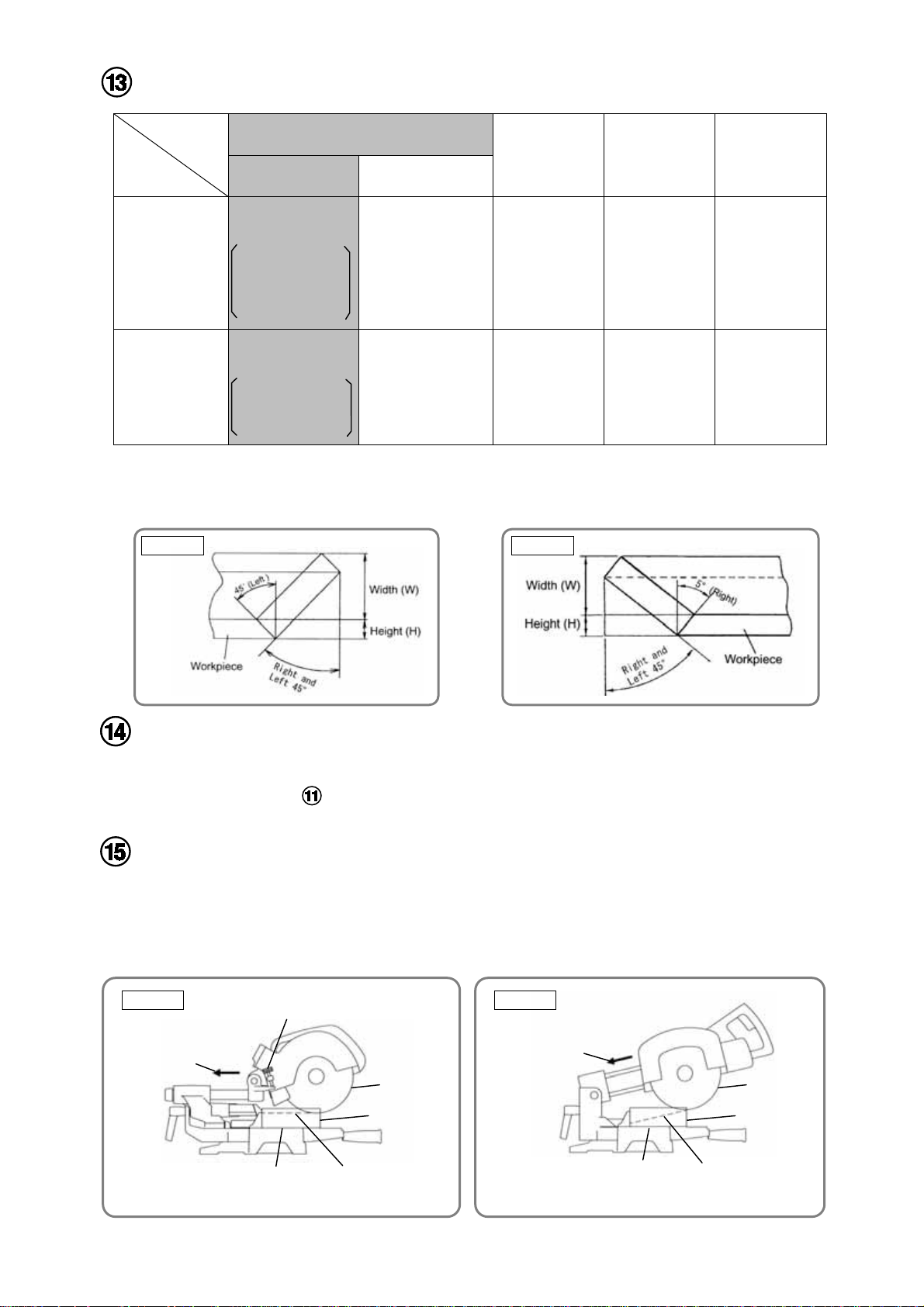

Miter cutting

dimensio

dimensio

Table 4

Unit: mm (inch)

Maker

Max.

Model

cutting

n

Right and

left 45°

Height x Width

(H x W)

Right 57°

Height x Width

(H x W)

C 8FSE

C 8FSHE

65 x 220

(2-9/16” x 8-21/32”)

75 x 185

(2-15/16” x 7-1/4”)

with aux. board

width 20 (13/16”)

65 x 170

(2-9/16” x 6-11/16”)

75 x 140

(2-15/16” x 5-1/2”)

with aux. board

width 20 (13/16”)

HITACHI

C 8FB2

65 x 220

(2-9/16” x 8-21/32”)

65 x 175

(2-9/16” x 6-7/8”)

Wide workpieces as wide as shown in Table 4 can be cut

by swiveling the turn table (right and left).

The maximum cutting dimensions in [ ] in Table 4 are those

obtained by adjusting the lower limit position of the saw

blade indicated in Fig. 6-b, also with an auxiliary board.

P1 and P2 P3 B

60 x 190

(2-3/8” x 7-15/32”)

-

70 x 212

(2-3/4” x 6-11/32”)

70 x 160

(2-3/4” x 6-5/16”)

60 x 190

(2-3/8” x 7-15/32”)

60 x 155

(2-3/8” x 6-3/32”)

Fig. 8

Right and left bevel cutting

Maker

Max.

Model

cutting

n

Left 45°

Height x Width

(H x W)

Right 5°

Height x Width

(H x W)

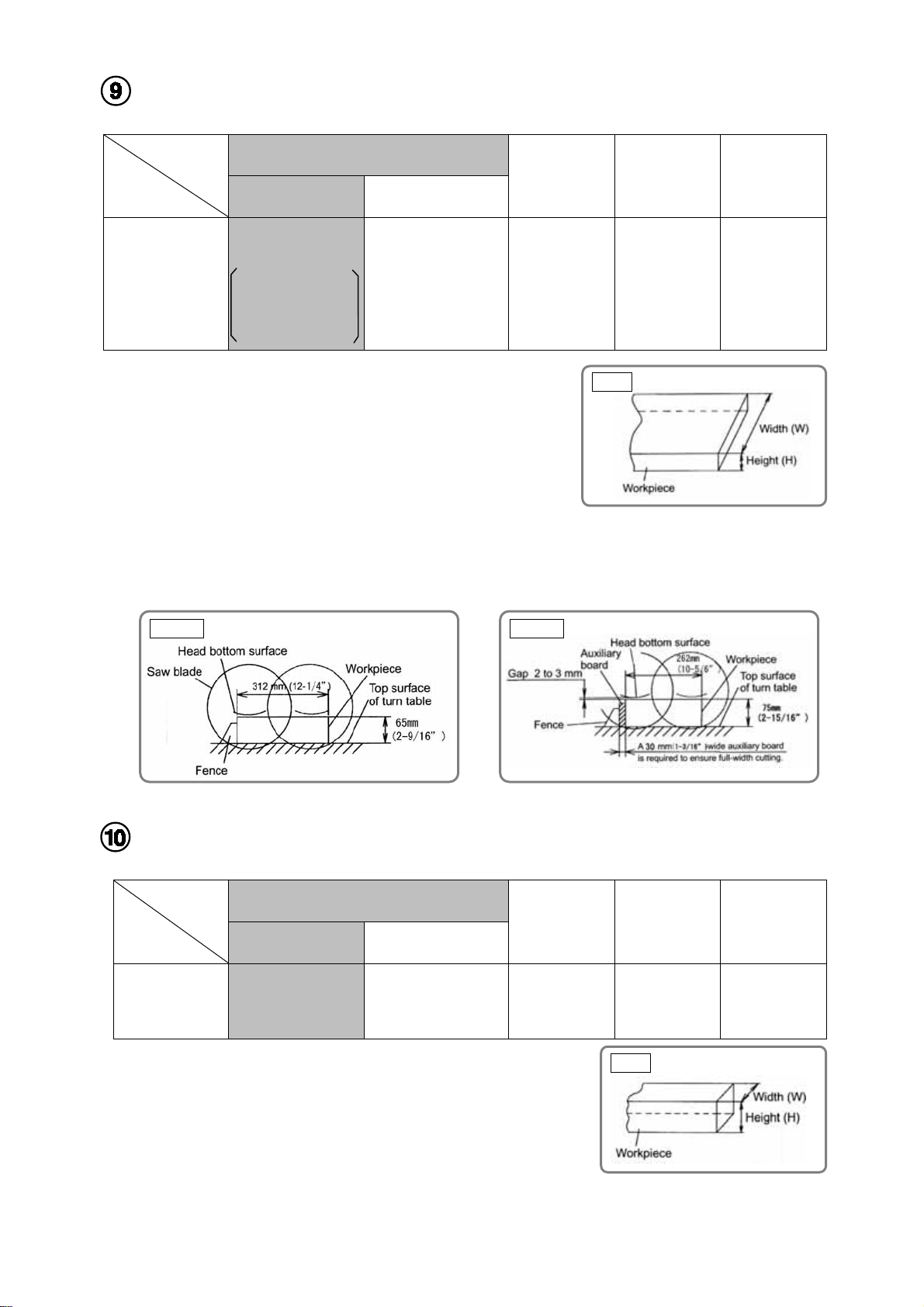

Fig. 9

C 8FSE

C 8FSHE

45 x 312

(1-25/32” x 12-1/4”)

50 x 252

(1-15/16” x 9-15/16”)

with aux. board

width 30 (1-3/16”)

60 x 312

(2-9/16” x 12-1/4”)

70 x 252

(2-3/4” x 9-15/16”)

with aux. board

width 30 (1-3/16”)

HITACHI

C 8FB2

45 x 305

(1-25/32” x 12”)

Table 5

P1 and P2 P3 B

48 x 270

(1-7/8” x 10-3/8”)

--

50 x 300

(1-15/16” x 11-13/16”)

-

Unit: mm (inch)

42 x 270

(1-21/32” x 10-3/8”)

-

-4-

Page 8

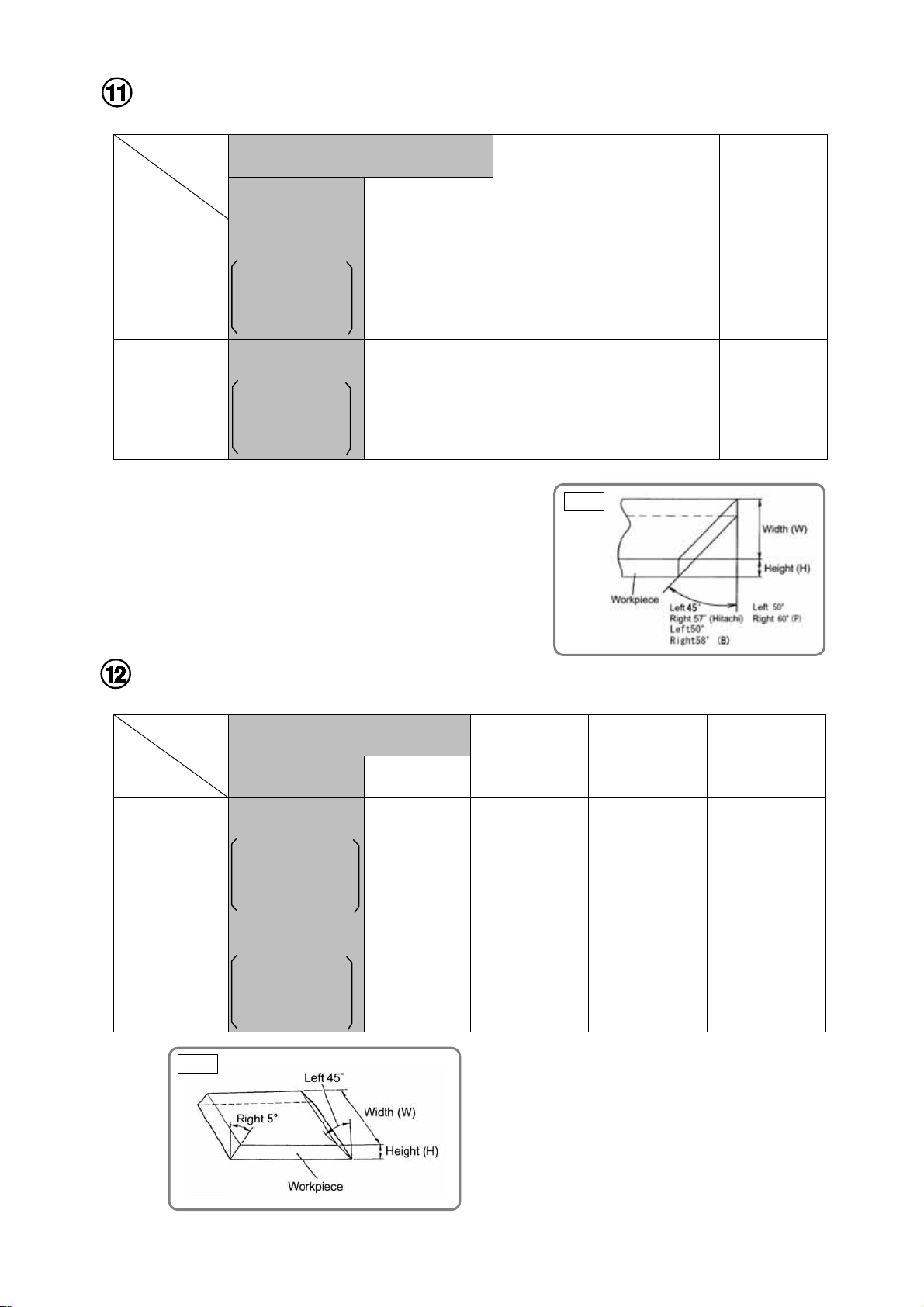

Compound miter and bevel cutting

dimensio

Table 6

Max.

cutting

Maker

Model

n

C 8FSE

C 8FSHE

HITACHI

C 8FB2

Unit: mm (inch)

P1 and P2 P3 B

Miter left/right

45°

Bevel left 45°

Height x Width

(H x W)

Miter left/right

45°

Bevel right

45°

Height x Width

(H x W)

45 x 220

(1-25/32” x 8-21/32”)

50 x 170

(1-15/16” x 6-11/16”)

with aux. board

width 30(1-3/16”)

60 x 220

(2-9/16” x 8-21/32”)

70 x 170

(2-3/4” x 6-11/16”)

with aux. board

width 30(1-3/16”)

45 x 220

(1-25/32” x 8-21/32”)

----

48 x 190

(1-7/8” x 7-15/32”)

50 x 212

(1-15/16” x 6-11/32”)

42 x 190

(1-21/32” x 7-15/32”)

By turning the turn table to the left or right and inclining the saw blade section (head) to the left or right, the

Models C 8FSE and C 8FSHE are capable of compound cutting (bevel and miter, see Figs. 10-a and 10-b)

of workpieces with the maximum dimensions shown in Table 6.

Fig. 10-bFig. 10-a

Splinter guard, also serving for cut alignment

When cutting the ends of a workpiece, splinters may drop on the saw blade and be cut into pieces. The

Models C 8FSE and C 8FSHE are equipped with a splinter guard to prevent such splinter cutting.

(Refer to "SELLING POINTS .") Safe cutting is also ensured in bevel cutting because the splinter guard

is tilted with the saw blade.

Groove cutting

The Models C 8FSE and C 8FSHE can cut grooves at desired depth by adjusting the 6-mm depth adjustment bolt

manually. (Refer to "Groove cutting procedures" described in the Instruction Manual for details.)

NOTE: The Models C 8FSE and C 8FSHE cannot cut grooves at const ant depth unless the sa w blade

slides in parallel with the base surface.

Fig. 11-a

Slide direction

6 mm depth adjustment bolt

Base surface

[Model C 8FSE/C 8FSHE]

Saw blade

Workpiece

Groove

Fig. 11-b

Slide direction

Base surface

[Model P1 and P2]

Saw blade

Workpiece

Groove

-5-

Page 9

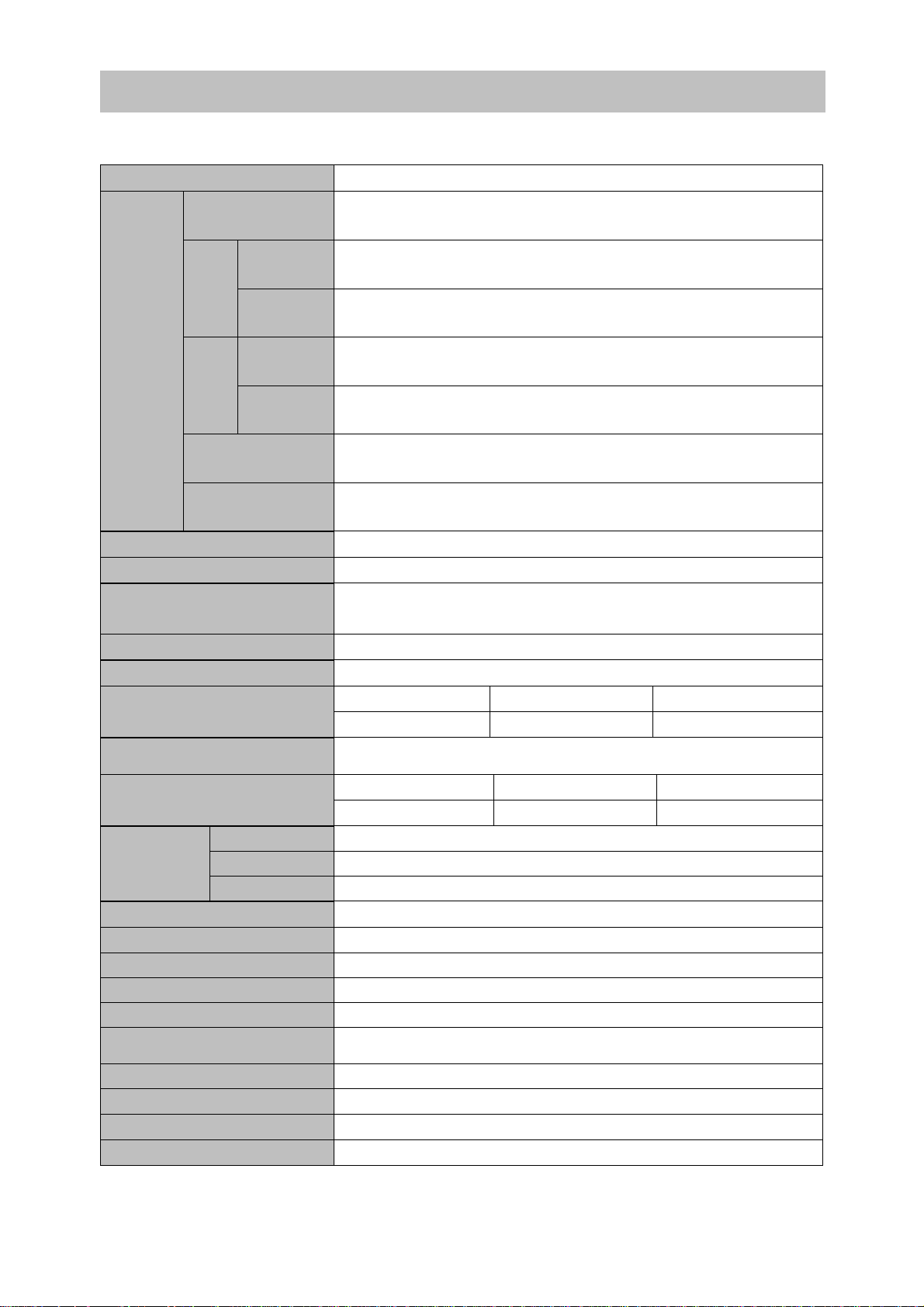

1. Specifications

SPECIFICATIONS

Model

0°(Right angle)

Left/right 45°

Miter

Maximum

Right 57°

cutting

dimensions

Height x

Width

mm (inch)

Bevel

Left 45°

Right 5°

Miter left/right 45°+

bevel left 45°

Miter left/right 45°+

bevel right 5°

Miter cutting ranges

Bevel cutting ranges

Compound (miter + bevel)

cutting ranges

Angle stopper positions

Applicable saw blade

Saw blade bore

External diameter of applicable

saw blades

Lower guard lock

Laser marker

(Only the

Model

C 8FSHE)

Maximum output < 1 mW (CLASS II)

Wave length 400 nm to 700 nm

Laser medium Laser diode

Power source type and voltage

Type of motor

Full-load current

No-load rotation speed

Max. output

Main unit dimensions

(Width x depth x height)

Weight

Coating

Packaging

Cord

C 8FSE/C 8FSHE

65 mm x 312 mm (2-9/16” x 12-1/4”),

75 mm x 262 mm (2-15/16” x 10-5/6”) (with aux. board 30 mm (1-3/16”))

65 mm x 220 mm (2-9/16” x 8-21/32”),

75 mm x 185 mm (2-15/16” x 7-1/4”) (with aux. board 20 mm (13/16”))

65 mm x 170 mm (2-9/16” x 6-11/16”),

75 mm x 140 mm (2-15/16” x 5-1/2”) (with aux. board 20 mm (13/16”))

45 mm x 312 mm (1-25/32” x 12-1/4”),

50 mm x 252 mm (1-15/16” x 9-15/16”) (with aux. board 30 mm (1-3/16”))

60 mm x 312 mm (2-3/8” x 12-1/4”),

70 mm x 252 mm (2-3/4” x 9-15/16”) (with aux. board 30 mm (1-3/16”))

45 mm x 220 mm (1-25/32” x 8-21/32”),

50 mm x 170 mm (1-15/16” x 6-11/16”) (with aux. board 30 mm (1-3/16”))

60 mm x 220 mm (2-3/8” x 8-21/32”),

70 mm x 170 mm (2-3/4” x 6-11/16”) (with aux. board 30 mm (1-3/16”))

Left 0° - 45°, Right 0° - 57°

Left 0° - 48°, Right 0° - 5°

Miter left 45° to right 45° + left bevel 0° to 45°

Miter left 45° to right 45° + right bevel 0° to 5°

0°, Right/left 15°, 22.5°, 31.6° and 45°

216 mm (8-1/2") external dia.

U.S.A./Canada Europe/Australia Others

15.9 mm (5/8”) 30 mm (1-11/64”) 25.4 mm (1”)

200 mm to 220 mm (7-7/8" to 8-21/32")

U.S.A./Canada Europe/Australia Others

Not provided Provided Not provided

AC single phase 50/60 Hz, 110 V, 120 V, 220 V to 240 V

AC single phase commutator series motor

110 V: 10 A, 120 V: 9.2 A, 220 V: 5 A, 230 V: 4.8 A, 240 V: 4.6 A

5,500 min

Approx. 2,100 W

555 mm x 790 mm x 485 mm (21-27/32" x 31-3/32" x 19-3/32")

C 8FSE 14 kg (31 lbs.) C 8FSHE 14.5 kg (32 lbs.)

-1

Gunmetallic silver

Corrugated cardboard box

Type: 2-conductor cabtire cable Length: 1.8 m (6 ft)

-6-

Page 10

Standard accessories

Optional accessories

·

216 mm (8-1/2") TCT saw blade (15.9 mm (5/8”) bore, NT24,

Code No. 998840 for USA/CAN) --------------------- for wood cutting

·

216 mm (8-1/2") TCT saw blade (30 mm (1-11/64”) bore, NT24,

Code No. 998859 for Europe/AUS) ----------------- for wood cutting

·

216 mm (8-1/2") TCT saw blade (25.4 mm (1”) bore, NT24,

Code No. 998858 for others) ------------------------- for wood cutting

·

Dust bag

·

Vise ass’y

·

10 mm box wrench

·

Holder

·

Side handle

·

Sub fence (for USA/CAN)

·

216 mm (8-1/2") TCT saw blade (15.9 mm (5/8”) bore, NT36,

Code No. 998860 for USA/CAN) ------------------- for wood cutting

·

216 mm (8-1/2") TCT saw blade (30 mm (1-11/64”) bore, NT36,

Code No. 998861 for Europe/AUS) --------------- for wood cutting

·

216 mm (8-1/2") TCT saw blade (25.4 mm (1”) bore, NT36,

Code No. 996210 for others) ----------------------- for wood cutting

·

216 mm (8-1/2") TCT saw blade (15.9 mm (5/8”) bore, NT60,

Code No. 998862 for USA/CAN) ---------- for aluminum sash cutting

·

216 mm (8-1/2") TCT saw blade (30 mm (1-11/64”) bore, NT60,

Code No. 998863 for Europe/AUS) ------ for aluminum sash cutting

·

216 mm (8-1/2") TCT saw blade (25.4 mm (1”) bore, NT60,

Code No. 996288 for other) ---------------- for aluminum sash cutting

·

Extension holder and stopper (Code No. 321553)

·

Crown molding vise ass’y (Code No. 329782)

(Including crown molding stopper (L))

·

Crown molding stopper (L) (Code No. 321374)

·

Crown molding stopper (R) (Code No. 321373)

·

Sub fence ass’y (Code No. 329464)

-7-

Page 11

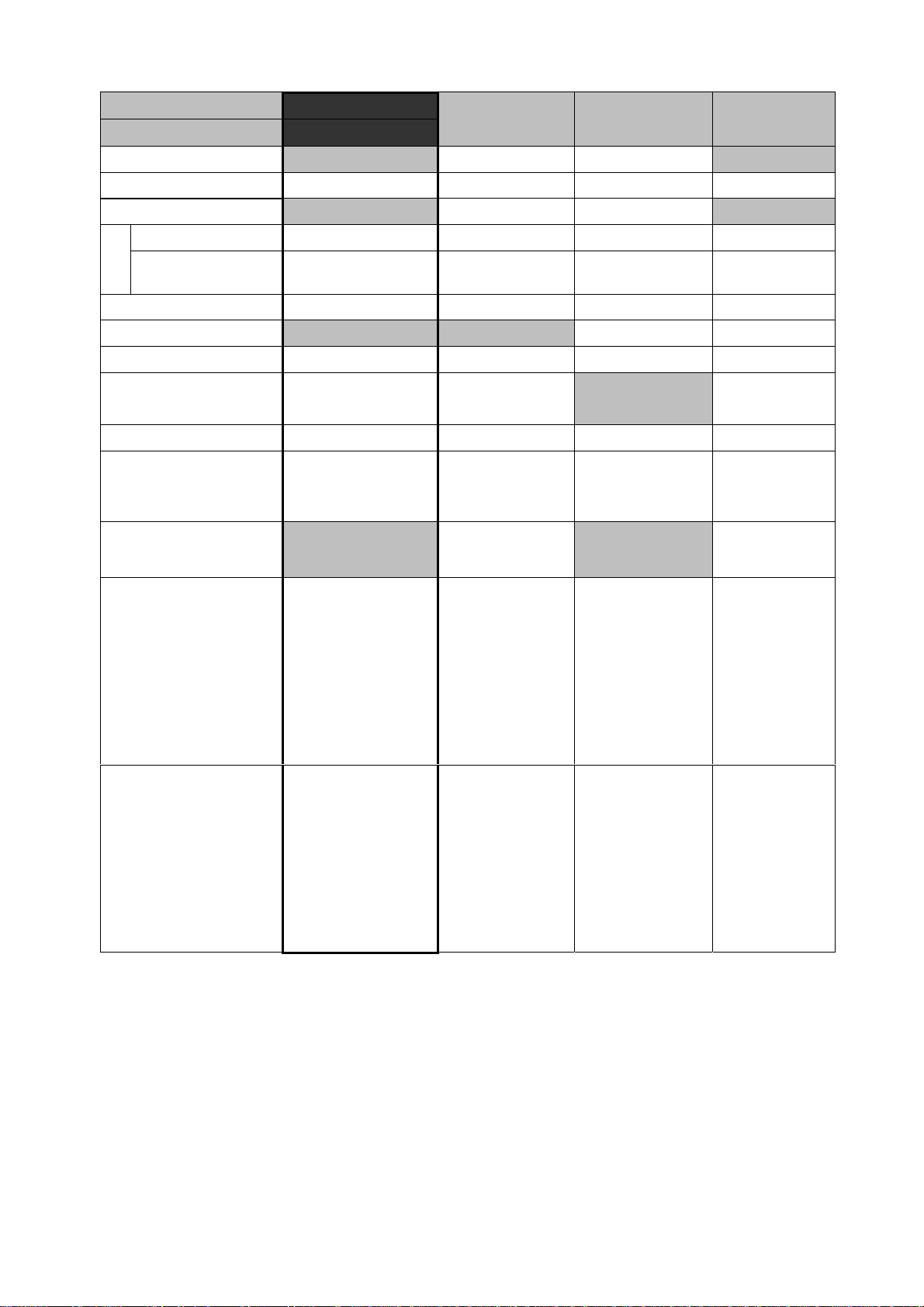

COMPARISONS WITH SIMILAR PRODUCTS

1. Specification comparisons

[For Europe and others (Except for the U.S.A and Canada)]

Maker

Model name

0゚(Right angle)

Miter

Bevel

Left/right 45°

Right 57°

Left 45°

Right 5°

65 x 312 (2-9/16” x 12-1/4”)

75 x 262 (2-15/16” x 10-5/6”)

(with aux. board 30 (1-3/16”))

65 x 220 (2-9/16” x 8-21/32”)

75 x 185 (2-15/16” x 7-1/4”)

(with aux. board 20 (13/16”))

65 x 170 (2-9/16” x 6-11/16”)

75 x 140 (2-15/16” x 5-1/2”)

(with aux. board 20 (13/16”))

45 x 312 (1-25/32” x 12-1/4”)

50 x 252 (1-15/16” x 9-15/16”)

(with aux. board 30 (1-3/16”))

60 x 312 (2-3/8” x 12-1/4”)

70 x 252 (2-3/4” x 9-15/16”)

(with aux. board 30 (1-3/16”))

HITACHI

C 8FSE/C 8FSHE

P1 P2 B

60 x 270

(2-3/8” x 10-3/8”)

60 x 190

(2-3/8” x 7-15/32”)

--

48 x 270

(1-7/8” x 10-3/8”)

---

60 x 270

(2-3/8” x 10-3/8”)

60 x 190

(2-3/8” x 7-15/32”)

48 x 270

(1-7/8” x 10-3/8”)

(Superior specifications:

60 x 270

(2-3/8” x 10-3/8”)

60 x 190

(2-3/8” x 7-15/32”)

60 x 155

(2-3/8” x 6-3/32”)

42 x 270

(1-21/32” x 10-3/8”)

)

Miter left/right 45°+

bevel left 45°

Maximum cutting dimensions: Height x Width mm (inch)

Miter left/right 45°+

bevel right 5°

Groove cutting width

Miter cutting ranges

Bevel cutting ranges

Compound

(miter + bevel)

cutting ranges

45 x 220 (1-25/32” x 8-21/32”)

50 x 170 (1-15/16” x 6-11/16”)

(with aux. board 30 (1-3/16”))

60 x 220 (2-3/8” x 8-21/32”)

70 x 170 (2-3/4” x 6-11/16”)

(with aux. board 30 (1-3/16”))

Possible

(with bolt height

adjustment)

Left 0° - 45°

Right 0°

Left 0° - 48°

Right 0° - 5°

Miter left and right

0°

Bevel left 0°

Miter left and right

0° - 45°

Bevel right 0° - 5°

-

45°

-

57°

-

45°

48 x 190

(1-7/8” x 7-15/32”)

--

Impossible Impossible

-

-

45°

50°

-

50°

-

Left 0°

Right 0°

Left 0° - 48° Left 0° - 48° Left 0° - 45°

Miter left and right

0°

Bevel left 0°

48 x 190

(1-7/8” x 7-15/32”)

Left 0°

Right 0°

Miter left and right

0°

Bevel left 0°

45°

-

45°

-

50°

-

50°

-

42 x 190

(1-21/32” x 7-15/32”)

-

Possible

(with screw height

adjustment)

Left 0°

Right 0°

Miter left and right

0°

-

45°

Bevel left 0°

45°

-

50°

-

58°

-

45°

Angle stopper positions

Saw blade external

diameter mm (inch)

(No. of teeth)

0°, Right/left 15°, 22.5°,

31.6° , 45°

216 (8-1/2") (24P) 216 (8-1/2") (24P) 216 (8-1/2") 216 (8-1/2") (24P)

0°, Right/left 15°,

22.5°, 30°, 45°, 50°

0°, Right/left 15°,

22.5°, 30°, 45°, 50°

0°, Right/left 15°,

22.5°, 30°, 45°

-8-

Page 12

Maker

Model name

Laser marker

Laser output

Light

Full-load current (A)

No-load revolution

Motor

-1

(min

)

Insulation structure

Splinter guard

Type of angle stopper

HITACHI

P1 P2 B

C8FSE/C8FSHE

Provided Not provided Not provided Provided

< 1 mW

--

< 1 mW

Provided (2 LEDs) Not provided Not provided Provided

230 V - 4.8 A 230 V - 5.6 A 230 V 230 V - 6.1 A

5,500 6,700 6,300 5,000

Double insulation Double insulation Double insulation Double insulation

Provided Provided Not provided Not provided

Positive stopper Positive stopper Positive stopper Positive stopper

Sub fence

Capacity of dust bag (l)

Main unit dimensions

[Width x Depth x Height]

mm (inch)

Product weight kg (lbs.)

Standard accessories

Optional accessories

Not provided (Option) Not provided

2

555 x 790 x 485

(21-27/32" x 31-3/32"

x 19-3/32")

C 8FSE: 14 (31)

C 8FSHE: 14.5 (32)

·

216 mm (8-1/2") TCT

saw blade (NT24)

for wood cutting

·

Dust bag --------------1

·

Vise ass’y ------------ 1

·

10 mm box wrench ---1

·

Holder ---------------- 1

·

Sub fence------------- 1

(for USA/CAN)

· Extension holder and

stopper

·

Crown molding vise

ass’y (Including crown

molding stopper (L))

·

Crown molding

stopper (L)

·

Crown molding

stopper (R)

-------1

460 x 560 x 590

(18-1/8” x 22-1/16”

x 23-7/32”)

·

216 mm (8-1/2") TCT

saw blade (NT24)

for wood cutting

·

Hex. bar wrench -- 2

·

Fence insert------- 1

·

Legstand

·

Vise ass’y

· Roller table

Length stop for short

·

workpieces

-

14.5 (32) 14 (31) 15 (33.1)

460 x 560 x 590

(18-1/8” x 22-1/16”

x 23-7/32”)

·

216 mm (8-1/2") TCT

saw blade

--- 1

for wood cutting

·

Hex. bar wrench -- 2

·

Dust bag ----------1

·

Dust extraction

nozzles

·

Legstand

·

Vise ass’y

· Roller table

Length stop for short

·

workpieces

·

Dust extraction tubes

·

Three-way connector

Provided Not provided

2

450 x 610 x 510

(17-23/32” x 24”

x 20-3/32”)

·

216 mm (8-1/2")

TCT saw blade

--- 1

(NT24)

·

·

Vise ass’y ------1

Hex. bar wrench

---------1

-----------------1

----------- 2

·

Extension bars

·

216 mm (8-1/2")

TCT saw blade

(NT48)

-9-

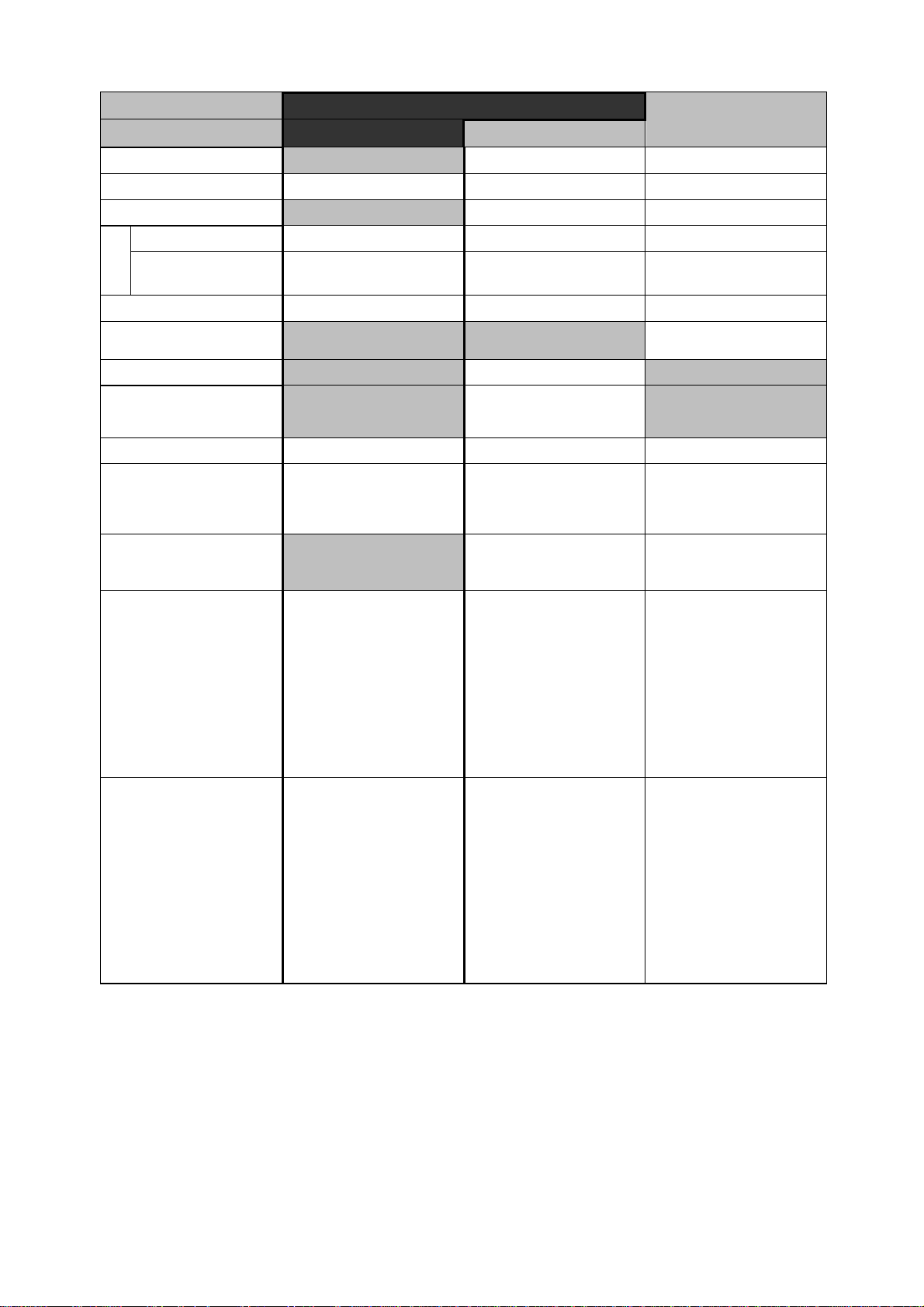

Page 13

[For the U.S.A and Canada]

Maker

Model name

C 8FSE/C 8FSHE C 8FB2

HITACHI

(Superior specifications:

P3

)

0° (Right angle)

Left/right 45°

Miter

Right 57°

Left 45°

Bevel

Right 5°

Miter left/right 45°+

bevel left 45°

Maximum cutting dimensions: Height x Width mm (inch)

Miter left/right 45°+

bevel right 5°

65 x 312 (2-9/16” x 12-1/4”)

75 x 262 (2-15/16” x 10-5/6”)

(with aux. board 30 (1-3/16”))

65 x 220 (2-9/16” x 8-21/32”)

75 x 185 (2-15/16” x 7-1/4”)

(with aux. board 20 (13/16”))

65 x 170 (2-9/16” x 6-11/16”)

75 x 140 (2-15/16” x 5-1/2”)

(with aux. board 20 (13/16”))

45 x 312 (1-25/32” x 12-1/4”)

50 x 252 (1-15/16” x 9-15/16”)

(with aux. board 30 (1-3/16”))

60 x 312 (2-3/8” x 12-1/4”)

70 x 252 (2-3/4” x 9-15/16”)

(with aux. board 30 (1-3/16”))

45 x 220 (1-25/32” x 8-21/32”)

50 x 170 (1-15/16” x 6-11/16”)

(with aux. board 30 (1-3/16”))

60 x 220 (2-3/8” x 8-21/32”)

70 x 170 (2-3/4” x 6-11/16”)

(with aux. board 30 (1-3/16”))

65 x 305 (2-9/16” x 12”)

75 x 265 (2-15/16” x 10-7/16”)

65 x 220

(2-9/16” x 8-21/32”)

65 x 175

(2-9/16” x 6-7/8”)

45 x 305

(1-25/32” x 12”)

--

45 x 220

(1-25/32” x 8-21/32”)

--

70 x 300

(2-3/4” x 11-13/16”)

70 x 212

(2-3/4” x 6-11/32”)

70 x 160

(2-3/4” x 6-5/16”)

50 x 300

(1-15/16” x 11-13/16”)

50 x 212

(1-15/16” x 6-11/32”)

Groove cutting width

Miter cutting ranges

Bevel cutting ranges

Compound

(miter + bevel)

cutting ranges

Angle stopper positions

Saw blade external

diameter mm (inch)

(No. of teeth)

Possible

(with bolt height adjustment)

Left 0° - 45°

Right 0° - 57°

Left 0° - 48°

Right 0° - 5°

Miter left and right

0° - 45°

Bevel left 0° - 45°

Miter left and right

0° - 45°

Bevel right 0° - 5°

0°, Right/left 15°, 22.5°,

31.6° , 45°

216 (8-1/2") (24P) 216 (8-1/2") (24P) 216 (8-1/2") (30P)

Possible

(with screw height

adjustment)

Left 0° - 45°

Right 0° - 57°

Left 0° - 45°

Miter left and right

0° - 45°

Bevel left 0° - 45°

0°, Right/left 15°, 22.5°,

31.6°, 35.3°, 45°

Possible

(with screw height

adjustment)

Left 0° - 50°

Right 0° - 60°

Left 0° - 48°

Right 0° - 2°

Miter left and right

0° - 45°

Bevel left 0° - 45°

0°, Right/left 10°,15°, 22.5°,

31.6°, 45°,

Left 50°, Right 60°

-10-

Page 14

Maker

Model name

Laser marker

Laser output

Light

Full-load current (A)

No-load revolution

Motor

-1

(min

)

Insulation structure

Splinter guard

Type of angle stopper

HITACHI

P3

C 8FSE/C 8FSHE C 8FB2

Provided Not provided Not provided

< 1 mW

--

Provided (2 LEDs) Not provided Not provided

120 V – 9.2 A 115 V – 9.5 A 120 V - 15 A

5,500 4,900 5,400

Double insulation Double insulation Double insulation

Provided Provided

Not provided

(Option)

Positive stopper Ball index Positive stopper

Sub fence

Provided Not provided Provided

Capacity of dust bag (l) 2 2

Main unit dimensions

[Width x Depth x Height]

mm (inch)

Product weight kg (lbs.)

Standard accessories

Optional accessories

555 x 790 x 485

(21-27/32" x 31-3/32"

x 19-3/32")

C 8FSE: 14 (31)

C 8FSHE: 14.5 (32)

·

216 mm (8-1/2") TCT

saw blade (NT24)

for wood cutting

·

Dust bag ------------------ 1

·

Vise ass’y ---------------- 1

·

10 mm box wrench ------- 1

·

Holder -------------------- 1

·

Sub fence----------------- 1

(for USA/CAN)

· Extension holder and

stopper

·

Crown molding vise

ass’y (Including crown

molding stopper (L))

·

Crown molding

stopper (L)

·

Crown molding

stopper (R)

----------- 1

520 x 755 x 500

(20-15/32” x 29-23/32”

x 19-11/16”)

17.5 (38.6) 19.5 (43)

·

216 mm (8-1/2") TCT

saw blade (NT24)

for wood cutting

·

Dust bag ----------------- 1

·

10 mm box wrench. ----- 1

·

Vise ass’y ---------------- 1

·

Slide fence ass’y --------- 1

·

Stopper

·

216 mm (8-1/2") TCT

saw blade (NT36)

for wood cutting

·

216 mm (8-1/2") TCT

saw blade (NT60)

for wood cutting

·

216 mm (8-1/2") TCT

saw blade (NT60)

for aluminum cutting

---------- 1

-

580 x 720 x 555

(22-27/32” x 28-11/32”

x 21-27/32”)

·

216 mm (8-1/2")

TCT saw blade

(NT30)

·

·

·

·

·

------------------- 1

Blade spanner------------ 1

Legstand

Fence insert

Dust extraction kit

Carrying strap

-11-

Page 15

PRECAUTIONS IN SALES PROMOTION

1. Safety instructions

In the interest of promoting the safest and most efficient use of the Models C 8FSE and C 8FSHE Slide

Compound Miter Saws by all of our customers, it is very important that at the time of sale the salesperson

carefully ensures that the buyer seriously recognizes the importance of the contents of the Instruction

Manual, and fully understands the meaning of the precautions listed on the Warning Labels, Warning Signs

and Caution Labels attached to each machine.

A. Instruction manual

Although every effort is made in each step of design, manufacture and inspection to provide protection

against safety hazards, the dangers inherent in the use of any slide compound miter saw cannot be

completely eliminated. Accordingly, general precautions and suggestions for the use of electric power tools,

and specific precautions and suggestions for the use of the slide compound miter saw are listed in the

Instruction Manual to enhance the safe, efficient use of the tool by the customer. Salespersons must be

thoroughly familiar with the contents of the Instruction Manual to be able to offer appropriate guidance to

the customer during sales promotion.

B. Warning labels and caution labels

(1) Precautions on the name plate

Each of the Models C 8FSE and C 8FSHE is furnished with a Name Plate that lists the following precautions.

For the U.S.A. and Canada

Fig. 12-a

For Europe

Fig. 12-b

For Australia and Asia

Fig. 12-c

For China

Fig. 12-d

-12-

Page 16

For Taiwan

Fig. 12-e

(2) Warning label (A) (for the U.S.A. and Canada)

Fig. 13

Warning label (A) specified by the UL is affixed on the left side of the gear case.

Please instruct users to strictly observe the 11 items of precautions in warning label (A) shown above.

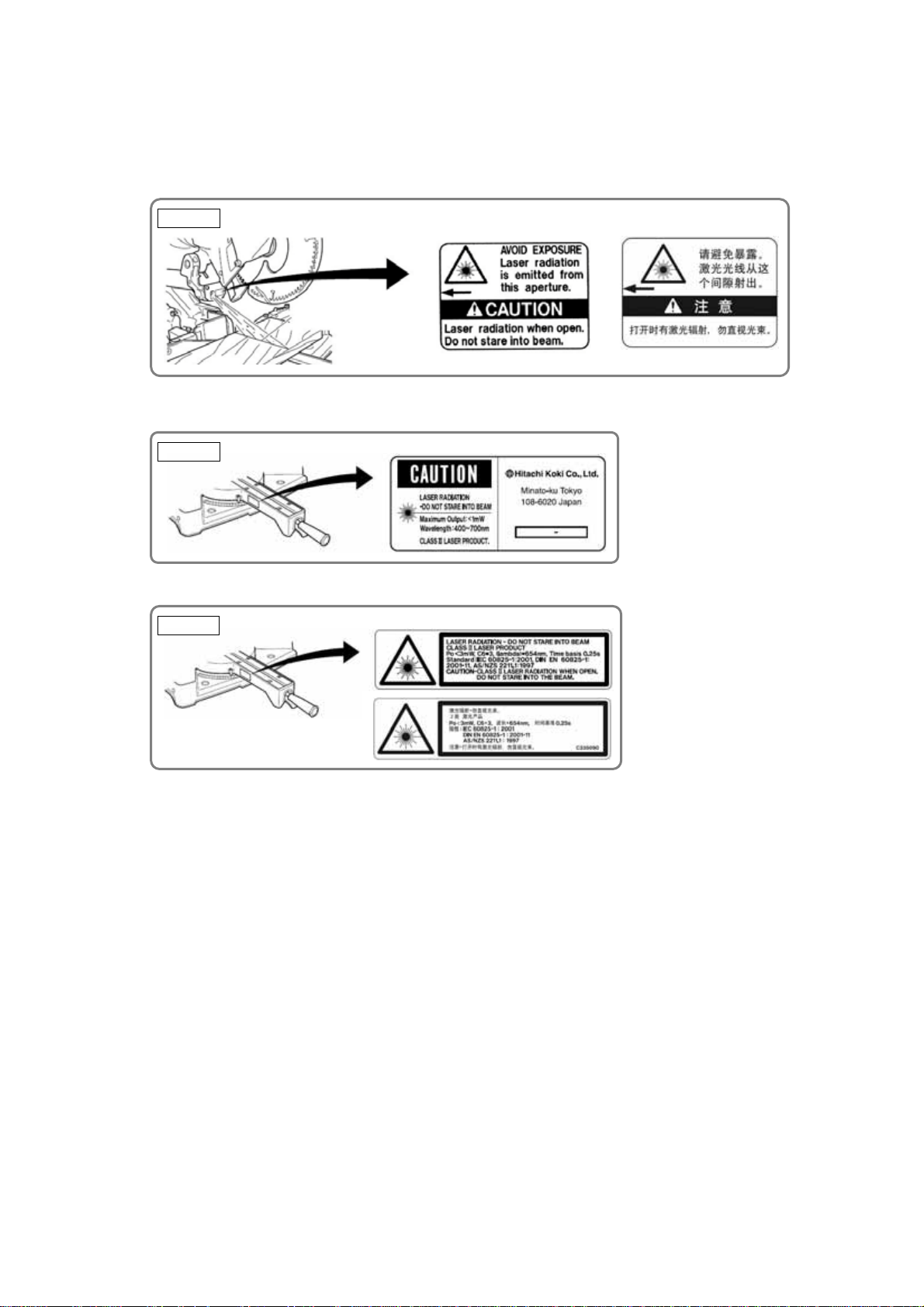

(3) Caution labels (A) and (B) (at the front of the base)

·

Caution label (A) (at the front of the base)

For the U.S.A., Canada, Europe, Australia and Asia

Fig. 14-a

·

Caution label (B) (at the front of the base)

For China

Fig. 14-b

-13-

Page 17

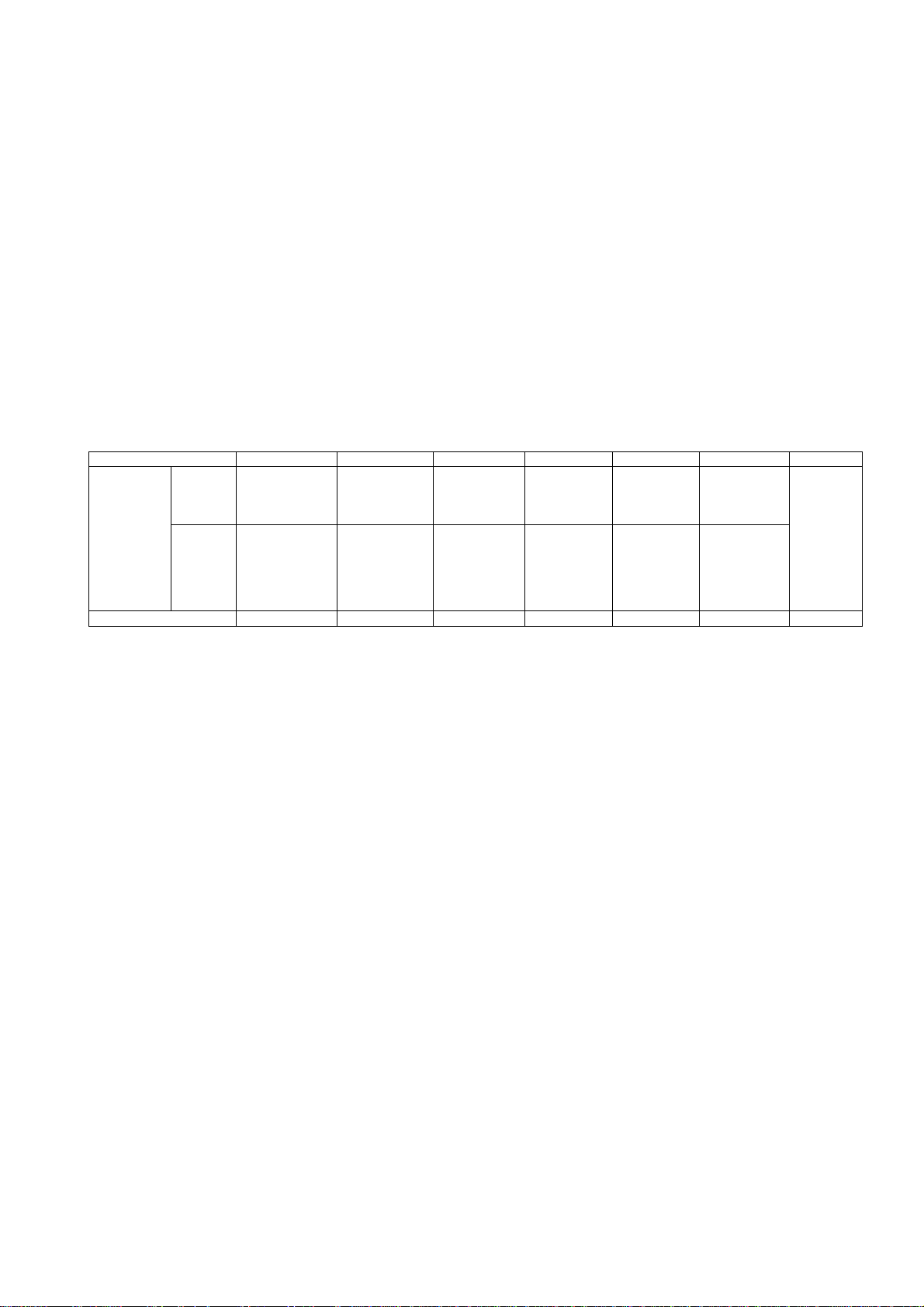

(4) Caution label (J) (at the front of the hinge) and caution labels (C) and (E) (at the front left of the turn

table) (only the Model C 8FSHE)

Do not stare into laser beam. If your eye is exposed directly to the laser beam, it can be hurt. Caution

label (J) and caution labels (C) and (E) are adhered to each machine to comply with the

standards for the safe use of laser equipment.

·

Caution label (J) (at the front of the hinge) (only the Model C 8FSHE)

Fig. 15-a

·

Caution labels (C) and (E) (at the front left of the turn table) (only the Model C 8FSHE)

For the U.S.A. and Canada

Fig. 15-b

For Europe, Australia, China and Asia

Fig. 15-c

C. Relative standards

Standards, regulations and guidelines for the safe use of laser equipment

[The U.S.A.] FDA CDRH 21 CFR

[AUS/NZL] AS/NZS 2211.1: 2001

[Europe] EN 60825-1: 2001-11

D. Laser marker (only the Model C 8FSHE)

The Model C 8FSHE is equipped with the laser marker that complies with the Class II requirements of the

standard specified in "Relative standards." The Class II laser is defined as follows:

·

The laser power is low and it is safe by the protective measures such as blinking.

However, it is dangerous if the operator’s eyes are exposed directly to the laser for a protracted period.

·

The operator can use the laser equipment without particular training and instruction.

·

The amount of light exposure (output) is 1 mW or less at the position where the operator can be exposed

to the laser radiation during operation. (This is in the case of the U.S.A. The measuring methods and the

output values are different depending on the standards.)

The saw blade unit prevents access of the operator’s eye to the laser-emitting aperture less than 65 mm.

In addition, the amount of light exposure (output) is 1 mW or less (about 0.4 mW) at this position. Thus

the Model C 8FSHE satisfies the Class II requirements adequately. There is no ill effect on the operator’s

body if looking at the laser line on the workpiece during operation.

-14-

Page 18

CAUTION: (1) Be sure to disconnect the power cord plug from the receptacle before removing the

laser marker for repair. If it is unavoidable to check the operation of the removed

laser marker with the power turned on, face the laser emitting aperture to the ground

to show the laser line on the ground.

(2) Laser radiation when open. DO NOT STARE INTO BEAM OR VIEW DIRECTL Y WITH

OPTICAL INSTRUMENTS.

The life span of the laser marker in the Model C 8FSHE is about 3,600 hours. (About 3 years: 5 hours of

use/day x 240 days/year)

2. Precautions requiring particular attention during sales promotion

A. Ambient illuminance and visibility of laser line (only the Model C 8FSHE)

The visibility of the laser line on the workpiece changes depending on the brightness of the working

environment. Instruct the customer to consider the brightness of the working environment when using the

laser marker referring to the following table.

Table 7 Ambient illuminance and visibility of laser line

Illuminance (lux) 3000 or more 3000 or more 3000 - 2500 800 - 600 300 - 200 150 - 80 30 or less

Outdoor

Ambient

conditions

(reference)

Indoor

Laser line Invisible Visible Visible Visible Visible Glaring Glaring

Under direct

sunlight of fine

weather

-

Shaded area

in fine weather

Near the

window under

fine weather

Cloudy

weather

Indoor under

fine weather

Shaded area

in cloudy

weather

Near the

window

under

cloudy

weather

Just before

the sunset in

cloudy

weather

Indoor under

cloudy

weather

-

Near the

window

under cloudy

weather, just

before the

sunset

Ink line is

invisible.

(The working environment where the illuminance is 200 luxes or less is dark and difficult to operate the

Model C 8FSHE.)

The laser line is invisible under direct sunlight of fine weather. Prepare a shaded area or relocate to a

shaded area to operate the Model C 8FSHE.

When a laser line is dazzling, please light up the laser line with a LED light. You can watch a laser line if you

do so.

B. Precautions concerning brake

The Models C 8FSE and C 8FSHE are equipped with a "brake" that stops running when the switch is

turned off. Normally the operation is stopped in 5 - 6 seconds when the switch is turned off. If it takes 10

seconds or more to stop, absolutely avoid further use of this machine. In this event, ensure that your

customers bring this machine in their local Hitachi power tools dealer or Hitachi power tools center for

servicing.

(1) Be sure to use the carbon brushes dedicated to the Models C 8FSE and C 8FSHE (110 V to 120 V:

Code No. 999021, 220 V to 240 V: Code No. 999001). Use of other carbon brushes will adversely affect

the brake performance.

(2) If the brake should fail to work, check the carbon brushes. Replace the carbon brushes with new ones if

their length is shorter than 6 mm. If the brake still does not work, replace the armature ass’y.

-15-

Page 19

ADJUSTMENT AND OPERATIONAL PRECAUTIONS

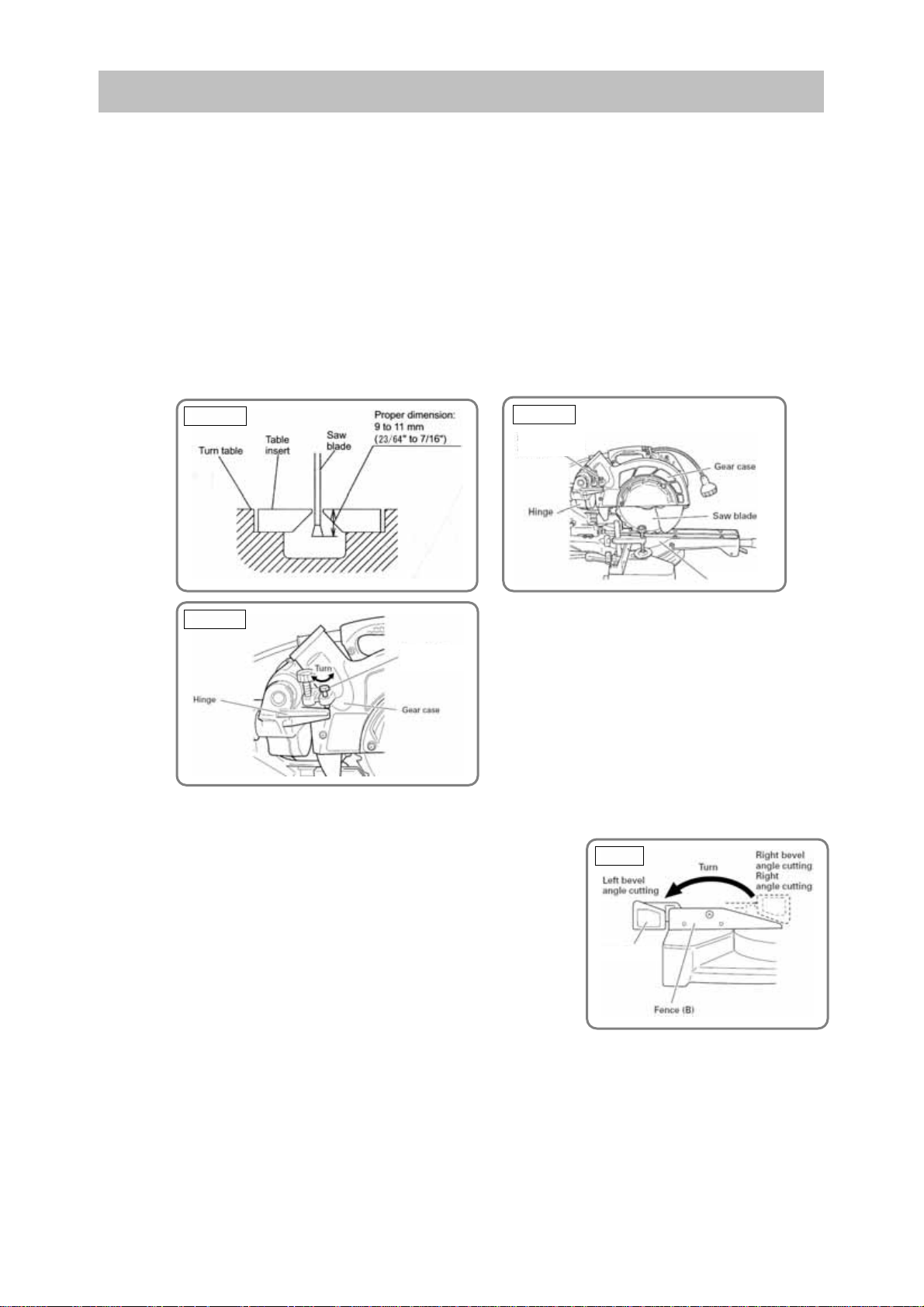

1. Confirmation of saw blade lower limit position

The lower limit of the saw blade cutting depth is factory-adjusted so that when the saw blade is fully

lowered, its cutting edge is 10 to 11 mm (13/32" to 7/16") below the upper surface of the turn table in order

to cut workpieces completely without cutting the bottom of the turn table groove. Lower the saw blade and

check that it stops at the correct position (Fig. 16-a).

When changing the position of the 8 mm depth adjustment bolt that serves as the lower limit position

stopper of the saw blade, perform the following steps.

(1) Make the tip of the 8 mm depth adjustment bolt contact with the hinge.

(2) Turn the 8 mm depth adjustment bolt with a 13-mm wrench to adjust the lower limit position of the saw

blade (Fig. 16-c).

CAUTION: Perform the adjustment carefully to ensure that the saw blade does not cut into the turn

table.

Fig. 16-a

Fig. 16-b

8 mm depth

adjustment bolt

Turn table

Fig. 16-c

8 mm depth

adjustment bolt

2. Confirmation for use of sub fence (Optional accessory)

The sub fence is optionally available (located at the front right of the

base). Use the sub fence for miter cutting and right bevel cutting. The

sub fence supports the workpiece widely for stable cutting. In the

case of left bevel cutting, raise the sub fence as illustrated in Fig. 17

and turn it counterclockwise.

*For the U.S.A. and Canada, the Models C 8FSHE and C8FSE are

equipped with the sub fence as a standard accessory.

Fig. 17

Sub fence

NOTE: Mount the sub fence as follows.

Insert the flat-head sc re w M6 into f ence (B) and mo unt t he sub fe nce a nd the plate. Then t ig hten

the nylon nut M6 with the attach ed 10-mm box wrench so th at the sub fence c an turn smoothly.

WARNING: In the case of left bevel cutting, turn the sub fence counterclockwise. Otherwise the

main body or the saw blade may contact the sub fence resulting in an injury. Be sure to

instruct the customers to tu rn the s ub fence c ountercl ock wise in the case of l ef t bev el

cutting.

-16-

Page 20

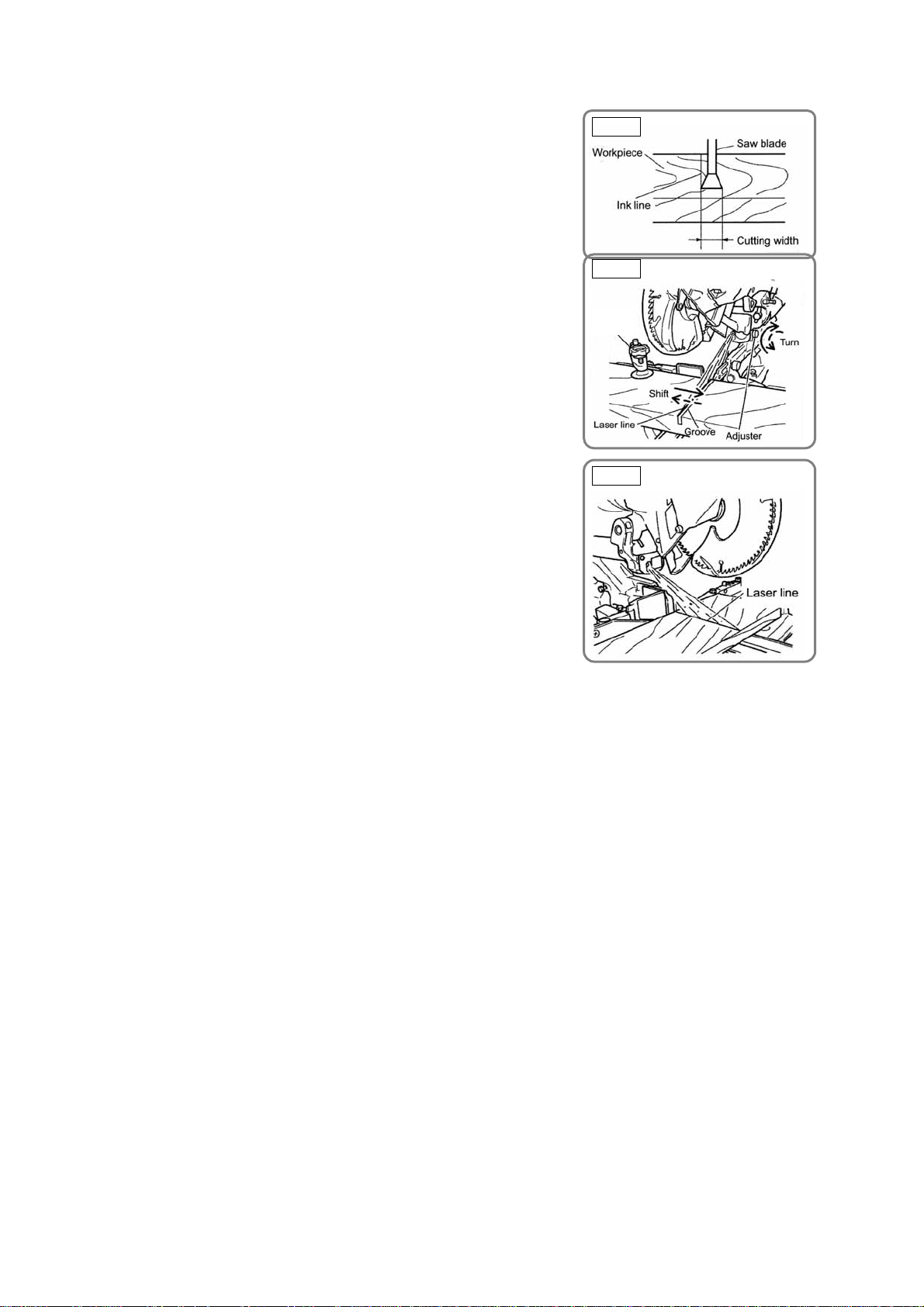

3. Position adjustment of laser line (Only the Model C 8FSHE)

The laser line is adjusted to the width of the saw blade at the

time of factory shipment. Depending upon the cutting choice,

align the laser line with the left side of the cutting width (saw

blade) or the right side according to the following procedure.

First, make a right-angle ink line on the workpiece that is about

20 mm (25/32") in height and 150 mm (5-29/32") in width.

To cut the right side of the ink line with the saw blade as shown

in Fig. 18, align the left side of the saw blade with the ink line

on the workpiece and make a groove of about 5 mm deep on

the workpiece to the middle. Hold the grooved workpiece by

the vise as it is and do not move it. (For grooving work, refer to

the Instruction Manual "Groove cutting procedures.")

Light up the laser marker. Turn the adjuster to align the laser

line with the ink line. (Turning the adjuster clockwise will shift

the laser line position to the right and turning counterclockwise

will shift to the left.) (Fig. 19)

Thus the cutting position matches the laser line position. Align

the ink line on the workpiece with the laser line. When aligning

the ink line, slide the workpiece little by little and secure it by

vise at a position where the laser line overlaps with the ink line

(Fig. 20). Work on the grooving again and check the position

of the laser line. When the ink line and the laser line are

overlapped, the strength and weakness of light will change,

resulting in a stable cutting operation because you can easily

discern the conformity of lines. This ensures the minimum

cutting errors.

Fig. 18

Fig. 19

Vise

assembly

Fig. 20

WARNING:

• Make sure before plugging the power plug into the receptacle tha t the main body and the laser

marker are turned off.

• Exercise utmost caution in handling a switch trigger for the position adjustment of the laser line,

as the power plug is plugged into the receptacle during operation. If the switch trigger is pulled

inadvertently, the saw blade can rotate and result in unexpected accidents.

• Do not remove the laser marker to be used for other purposes.

CAUTION:

• Laser radiation - Do not stare into beam.

• Laser radiation on work table - Do not stare into beam.

If your eye is exposed directly to the laser beam, it can be hurt.

• Do not dismantle it.

• Do not give strong impact to the laser marker (main body of tool); otherwise, the position of a

laser line c a n go out of o r d e r, res u l t i n g i n t h e d a m a g e o f t h e l a s e r m a r k e r a s we l l as a short e n e d

service life.

• Keep the laser marker lit only during a cutting operation. Prolonged lighting of the laser marker

can result in a shortened service life.

NOTE:

• Perform cutting by overlapping the ink line with the laser line. When the ink line and the laser line

are overlapped, the strength and weakness of light will change, resulting in a stable cutting operati on

because you can easily discern the conformity of lines. This ensures the minimum cutting errors.

• In outdoor or near-the-window operations, it may become difficult to obs erve the laser line due to

the sunlight. Under such circumstances, move to a place that is not directly under the sunlight

and engage in the operation.

• Do not tug on the cord behind the motor head or hook your finger, wood and the like around it;

otherwise, the cord may come off and the laser marker may not be lit up.

Instruct the above precautions on the laser marker to the customers.

-17-

Page 21

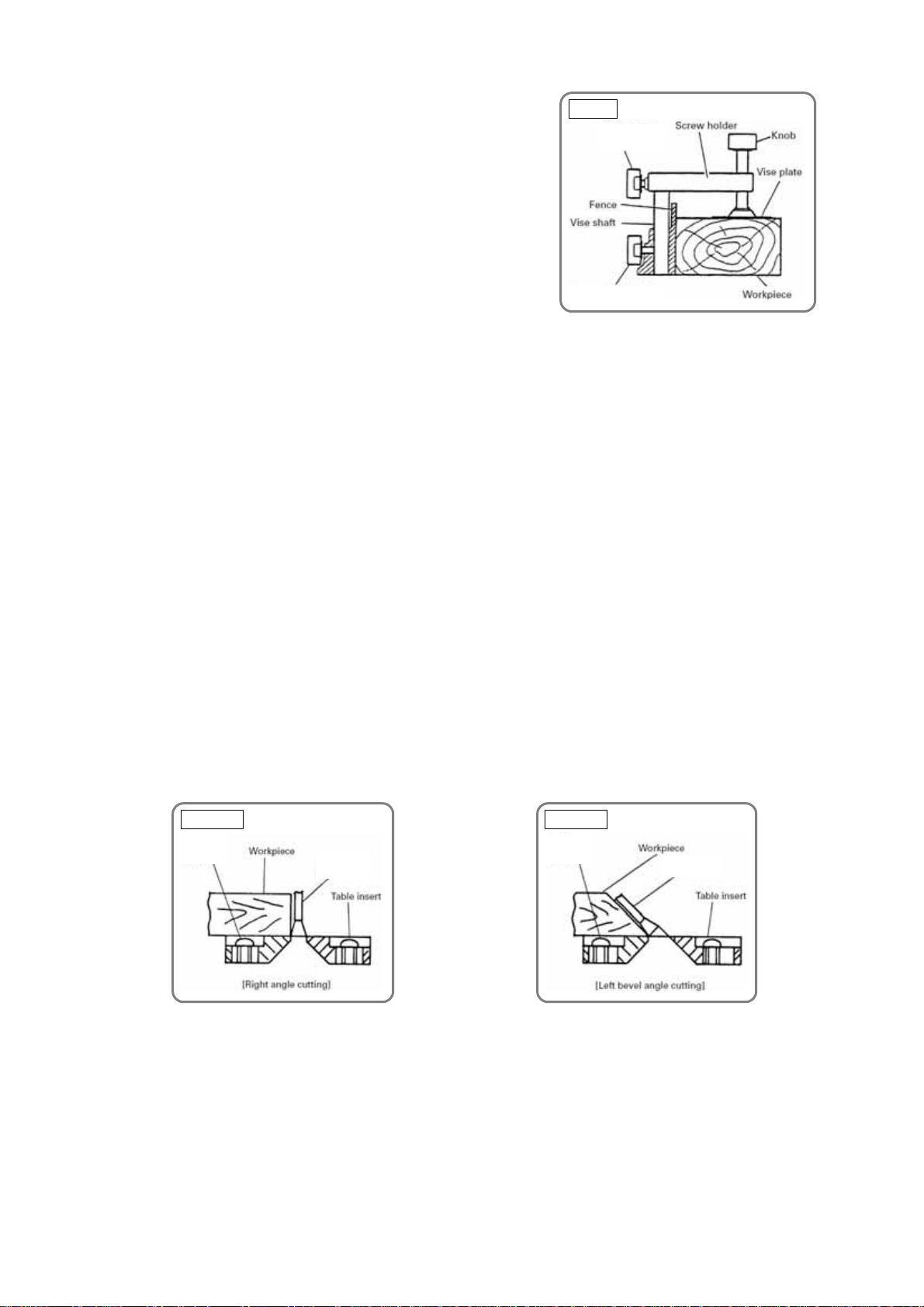

4. How to use the vise assembly

(1) The vise assembly can be mounted on either the left fence

(fence (B)) or the right fence (fence (A)) by loosening 6 mm

wing bolt (A).

(2) The screw holder can be raised or lowered according to the

height of the workpiece by loosening 6 mm wing bolt (B).

After the adjustment, firmly tighten 6 mm wing bolt (B) and fix

the screw holder.

(3) Turn the upper knob and securely fix the workpiece in position

(Fig. 21).

WARNING: Always firmly clamp or vise to secure the workpiece to the fence; otherwise the

workpiece might be thrust from the table and cause bodily harm.

CAUTION: Always confirm that the motor head does no t contact the vise assembly when it is

lowered for cutting. If there is any danger that it may do so, loosen 6 mm wing bolt (B)

and move the vise assembly to a position where it will not contact the saw blade.

Fig. 21

6 mm wing

bolt (B)

6 mm wing bolt (A)

5. Adjustment of table insert position

The table inserts are installed on the turn table. When the machine is shipped from the factory, the table

inserts are positioned so that there is no chance that the saw blade will come in contact with either side of

the saw blade slot even if the machine is used for 45° bevel cutting. Before operating the machine, adjust

the position of the table inserts so that the sides of the saw blade align with the edges of the table inserts

according to the following procedure.

First, loosen the three 6-mm machine screws that fasten the table inserts, and temporarily tighten the two

outside screws (front and back). Next, clamp a workpiece (about 200 mm (7-7/8") wide) with the vise

assembly and cut the workpiece. Align the cutting surfaces with the table inserts as shown in Figs. 22-a and

b, and securely tighten the front and back 6-mm machine screws. Finally, remove the workpiece and

securely tighten the middle 6-mm machine screw.

If adjustment is done as described, workpieces can be cut precisely by aligning the appropriate side edge

of the table inserts with the ink line on the workpiece. Adjust the table inserts as necessary for the type of

cutting desired (right-angle or left bevel cutting).

6 mm

machine

screw

Saw blade

-18-

Fig. 22-bFig. 22-a

6 mm

machine

screw

Saw blade

Page 22

6. Cutting operation

(1) Cutting efficiency will be reduced if a dull saw blade is used,

if an excessively long extension cord is used, or if the wire

gauge of the extension cord is too small. (For details, refer

to the Instruction Manual "USE PROPER EXTENSION

CORD.") This is particularly important when cutting materials

with dimensions which are at or near the maximum capacity

for the machine.

(2) The customer should be advised to thoroughly inspect the

workpiece to ensure that there are no metallic objects (nails

in particular), sand, or other foreign matter in or on the

workpiece. Contacting such foreign matter will not only

shorten the service life of the saw blade, but could cause

serious accident. Should the saw blade tips be broken off,

the tips may fly toward the operator.

Fig. 23

(3) Press cutting ( 3

in Fig. 23)

The Models C 8FSE/C 8FSHE can be used for press

cutting of workpieces up to 65 mm square in a single

operation by simply pushing the saw blade section

3

downward in the same manner as the Model C 8FB2.

Slide the hinge to the end of holder (A) and tighten the slide

securing knob securely.

CAUTION: (For Europe and Australia)

This slide compound miter saw is equipped with a saw head lock as a safety device.

T o lo wer the saw head to cut, the lock must be released by pressing the lock lever with your thumb.

(4) Slide cutting ( 1

to 5 in Fig. 23)

Slide cutting procedures and precautions are described below.

1 Loosen the slide securing knob.

2 Grip the handle and pull the saw blade section in the arrow direction (toward the operator).

3 Push the handle downward and cut the workpiece (press cutting).

(For Europe and Australia)

Push the handle downward while holding down the lock lever with your thumb and cut the workpiece.

CAUTION: If the handle is pushed down forcibly and excessively fast, it could cause the saw blade

vibration and partial sliding which would leave unwanted cutting marks on the

workpiece. Instruct the customer to slowly and carefully press down the handle.

4 While pressing down on the handle, slide the saw blade section in the arrow direction and cut the

workpiece.

CAUTION: Interrupting the cutting operation partway through the material or sliding the saw blade

section in a jerky manner will produce unwanted cutting marks similar to those

described in

3 above. As a guide, instruct the customer to cut a workpiece of 30 mm

(1-3/16") high and 300 mm (11-7/8") wide in 10 to 15 seconds.

Carefully instruct the customer never, ever to perform slide cutting in the direction toward the operator

(reverse direction of the above). Such operation is extremely hazardous, as the saw blade could ride up

over the workpiece and cause the saw blade section to kick upward unexpectedly, causing possible serious

injury. Instruct the customer to always slide the saw blade section toward the fence while cutting, as shown

by the arrow 4 in Fig. 23.

5 On completion of the cutting operation, turn the switch off and wait for the saw blade to come to a

complete stop before raising the handle to its original position. Raising the handle while the saw blade

is still rotating may cause unwanted cutting marks on the workpiece.

-19-

Page 23

NOTE:

Techniques to avoid unwanted cutting marks

Uneven and unwanted cutting marks can be avoided by shifting from 3 press cutting to 4 slide

cutting in a single, uninterrupted motion.

Techniques to avoid burnt marks

Burnt marks can be avoided by shifting from 3 press cutting to 4 slide cutting in a single,

uninterrupted motion in the same manner as the above, applying a slight lateral force toward the

cut-off side. Advise the customer that he or she will quickly develop a "feel" and skill for smooth

cutting after performing two or three practice cutting operations.

(5) Miter cutting

Miter cutting is accomplished by turning the turn table. (For details, please refer to the Instruction

Manual "Miter cutting procedures.")

(6) Bevel cutting

Bevel cutting of 0 - 45° to the left or 0 - 5° to the right is accomplished by inclining the motor head

section. (For details, refer to the Instruction Manual "Bevel cutting procedures.")

WARNING: When the workpiece is secured on the left or right side of the blade, the short cut-off

portion will come to rest on the right or left side of the saw blade. Always turn the power

off and let the saw blade stop completely before raising the handle from the workpiece.

If the handle is raised while the saw blade is still rotating, the cut-off piece may become

jammed against the saw blade causing fragments to scatter a bout dangerously. When

stopping the bevel cutting operation halfway, start cutting after pulling back the motor

head to the initial position. Starting from half way, without pulling back, causes the

safety cover to be caught in the cutting groove of the workpiece and to contact the saw

blade.

CAUTION: When cutting a workpiece of 50 mm (1-15/16”) height in the le f t 45° bev el cutting position

or a workpiece of 70 mm (2-3/4”) height in the right 5° bevel cutting position, adjust the

lower limit position of the motor head so that the gap between the lower edge of the

motor head and the workpiece will be 2 to 3 mm (5/64" to 1/8") at the lower limit position

(refer to the Instruction Manual "Checking the saw blade lower limit position").

(7) Compound (miter + bevel) cutting

Compound (miter + bevel) cutting can be accomplished by combining the miter cutting and bevel cutting

operations described in paragraphs (5) and (6) above. (For details, refer to the Instruction Manual

"Compound cutting procedures.") When the saw blade is inclined 45° to the left, the turn table can be

turned up to 45° to the left and right.

(8) Cut surface quality during miter/bevel cutting

The quality of the cut surface depends on the type

Fig. 24

of cutting operation (miter or bevel), the type and

sharpness of the saw blade, whether the workpiece

is cut to the left or right, and various other factors.

In miter and bevel cutting in particular, cutting is

performed across the wood grain, so the condition

of the cut surface depends on whether the wood is

cut with or against the grain. This is the same as

when using electric portable planers. Customers

should be advised of these phenomena so that they

understand that in cases when the cut surface may

not be as smooth as expected or hoped for, it is not

caused by the performance of the saw blade or the

Models C 8FSE/C 8FSHE.

In the cutting examples illustrated in Fig. 24, the cut surfaces on the sides marked ( A ) (cut with the

-20-

Page 24

grain) are better than those on the sides marked ( B ).

(9) Crown molding cutting

This machine can cut two types of crown molding workpieces by combining the miter and bevel cutting

operations. Figure 25 shows two common crown molding types having angles of (θ) 38° and 45°. For

the typical crown molding fittings, see Fig. 26.

Fig. 26Fig. 25

The table below shows the miter angle and the bevel angle settings that are ideal for the two crown molding

types.

NOTE : For convenience, positive stops are provided for the miter setting (left and right 31.6°)

positions.

For miter cut setting

If the turn table has been set to either of the angles described, move the turn table adjusting side handle

a little to the right and left to stabilize the position and to properly align the miter scale and the tip of the

indicator before the operation starts.

For bevel cut setting

Move handle on miter section to the right and left and check that the position is stable and the angle

scale and the tip of the indicator are properly aligned. Then tighten the clamp lever.

Table 8

Type of

crown

molding

45° type Right 35.3°

38° type Right 31.6°

To process crown molding at positions

1 and 4 in Fig. 26.

Miter angle

setting

Bevel angle

setting

Left 30°

( mark)

( mark)

Left 33.9°

( mark)

( mark)

30° and 33.9° left slant setting method

1 Loosen the clamp lever and slant to the left a little at a time

while pushing the set pin into the main unit. At this time, the

set pin will enter one step and fit into the 30° left slant and

33.9° left slant setting slots.

2 With the set pin in the slot as described above, setting to the

30° left slant position is possible by pushing to the right side.

3 Also, with the set pin in the slot as described above, setting

to the 33.9° left slant position is possible by pushing to the

left side.

4 Look at the bevel scale and indicator to recheck whether or

not the settings match and then tighten the clamp lever.

To process crown molding at positions

2 and 3 in Fig. 26.

Miter angle

setting

Left 35.3°

( mark)

Left 31.6°

( mark)

Bevel angle

setting

Left 30°

( mark)

Left 33.9°

( mark)

Fig. 27

Clamp

lever

Tight en

Bevel scale

(1) Setting to cut crown moldings at positions

1 and 4 in Fig. 26 (see Fig. 28; tilt the head to the left):

1 Turn the turn table to the right and set the miter angle as follows:

* For 45° type crown moldings: 35.3° ( mark)

* For 38° type crown moldings: 31.6° ( mark)

-21-

Page 25

2 Tilt the motor head to the left and set the bevel angle as follows:

* For 45° type crown moldings: 30° ( mark)

* For 38° type crown moldings: 33.9° ( mark)

3 Position the crown molding so that the upper surface (

in Fig. 25) contacts the fence as indicated in

Fig. 30.

(2) Setting to cut crown moldings at positions

2 and 3 in Fig. 26 (see Fig. 29; tilt the head to the left):

1 Turn the turn table to the left and set the miter angle as follows:

* For 45° type crown moldings: 35.3° ( mark)

* For 38° type crown moldings: 31.6° ( mark)

2 Tilt the head to the left and set the bevel angle as follows:

* For 45° type crown moldings: 30° ( mark)

* For 38° type crown moldings: 33.9° ( mark)

3 Position the crown molding so that the lower surface (

in Fig. 25) contacts the fence as shown in Fig. 31.

Fig. 29Fig. 28

Turn table

Fig. 31Fig. 30

Turn table

Cutting method of crown molding without tilting the saw blade

(1) Crown molding stoppers (L) and (R) (optional accessories)

allow easier cuts of crown molding without tilting the saw

blade. Mount them to both sides the base as shown

in Fig. 32-a. After mounting, tighten the 6 mm knob bolts to

secure the crown molding stoppers.

[Optional accessories used]

• Crown molding vise ass’y (including crown molding stopper (L))

• Crown molding stopper (L)

• Crown molding stopper (R)

(2) The crown molding vise (B) (optional accessory) can be

mounted on either the left fence (fence (B)) or the right

fence (fence (A)). It can unite with the slope of the crown

molding and the vice can be pressed down.

Then turn the upper knob, as necessary, to securely attach

the crown molding in position. To raise or lower the vise

assembly, first loosen the 6 mm knob bolt.

After adjusting the height, firmly tighten the 6 mm wing bolt;

then turn the upper knob, as necessary, to securely attach

the crown molding in position. (see Fig. 32-b)

Fig. 32-a

Crown molding vise ass’y

(optional accessory)

6 mm knob bolt

6 mm wing bolt

Fig. 32-b

Crown molding vise ass’y

(optional accessory)

6 mm knob bolt

6 mm wing bolt

Crown molding stopper (R)

(optional accessory)

6 mm knob

bolt

Crown molding stopper (L)

(optional accessory)

-22-

Page 26

WARNING: Always firmly clamp or vise to secure the crown molding to the fence; otherwise the

crown molding might be thrust from the table and cause bodily harm.

Do not perform bevel cutting. The main body or the saw blade may contact the sub

fence, resulting in an injury.

CAUTION: Always confirm that the motor head does not cont act the cro wn molding vise ass’y when

it is lowered for cutting. If there is any danger that it may do so, loosen the 6 mm knob

bolt and move the crown molding vise ass’y to a position where it will not contact the

saw blade.

Position crown molding with its WALL CONTACT EDGE against the guide fence and its CEILING

CONTACT EDGE against the crown molding stoppers as shown in Fig. 32-b. Adjust the crown molding

stoppers according to the size of the crown molding. Tighten the 6 mm wing bolt to secure the crown

molding stoppers. Refer to the following table for the miter angle.

Table 9

For inside corner

For outside corner

Position in Fig. 26

1

2

3

4

Miter angle Finished piece

Right 45° Save the right side of blade

Left 45°

Save the left side of blade

Save the right side of blade

Right 45° Save the left side of blade

-23-

Page 27

ADJUSTMENT OF COMPONENTS

1. Bevel angle adjustment

Before shipping from the factory, the height of 8-mm bolts (A) and (B) is adjusted so that the saw blade

section (head) will stop at 0° (right angle), and 45° to the left. To change the head stop positions, instruct

the customer to adjust the height of 8-mm bolts (A) and (B) by turning them.

CAUTION:

If there is any clearance between the tip of 8-mm bolt (A) (stopper for 0°) and the fixing pin, the

angle of the saw blade relative to the upper surface of the turn table may not be an exact right angle.

(8-mm bolts (A) and (B) are located at the holder (A).) Press do wn on holder (A) and lock it in

position with the clamp lever so that there is no clearance between the fixing pin and 8-mm bolt (A).

Fig. 33-bFig. 33-a

8 mm bolt (A)

(Stopper for 0°)

8 mm bolt (B)

(Stopper for left 45° bevel angle)

2. Ball bushing (Linear bearing)

(1) Structure of the ball bushing

The ball bushing is commonly called a linear

ball bearing. Inside the bearing is elongated

guide grooves in which steel balls circulate

and roll when a load is applied. (as indicated

by the arrow marks in Fig. 34). This type of

device is widely used in automated machine

tools. The advantage of the ball bushing is

that its friction coefficient remains largely

unchanged even when the load is increased,

ensuring smooth sliding movement.

In addition, slide pipe (B), made of bearing steel and heat treated to a high degree of hardness (HRC 62

to 65), is highly resistant to wear.

Sales persons should have a good understanding of the structure and rugged characteristics of this

exceptional mechanism to enhance sales promotion.

(2) Lubrication

If it is necessary to replace the ball bushing, apply approximately 2 grams (0.1 oz) of grease (Nippeco

SEP 3A) on the steel balls and within the guide grooves of the new ball bushing. If grease is not applied,

it will shorten the service life of the ball bushing, and subsequent abrasive contact between the steel

balls and slide pipe (B) will cause abnormal noise during slide cutting operations. Customers should be

instructed to thoroughly remove sawdust and other foreign matter from slide pipe (A) and slide pipe (B)

and liberally coat them with machine oil at least once a month.

Fig. 34

-24-

Page 28

PACKING

(1) How to install packings (A) and (B)

Remove the dust bag from the main body. Slide

the head section toward the operator and insert

packing (A) between the slide pipe, hinge and

holder (A). Push the head back and secure the

slide in position with packing (A) inserted by

means of the slide securing knob.

Turn the turn table to the right 57° and remove

the side handle. Place packing (B) under the

head and push the head down. Insert the locking

pin while pressing packing (B) to secure the

head section in position (Fig. 35).

Fig. 35

Turn table

Packing (A)

Packing (B)

Slide securing knob

(2) How to install packings (C) and (D)

Put the main body mounted with packings (A)

and (B) in the carton box aligning with the base

packing and the inner frame (Fig. 36).

Put packing (C) in the left side of the carton box

on the top of holder (A).

Put packing (D) in the right side of the carton box

on the top of the switch handle.

Place the accessories in the space at the rear

of the base (Fig. 37).

(3) How to install top packing (E)

Insert packing (E) in packings (C) and (D).

Close the lids of the carton box and bind them

together (Fig. 38).

Fig. 36

Inner frame

Fig. 37

Packing (C) Packing (D)

Fig. 38

Lid

Base packing

Packing (E)

-25-

Packing (C)

Packing (D)

Page 29

REPAIR GUIDE

y

Before attempting disassembly or reassembly, ensure without fail that the switch is turned off and the plug

is disconnected from the power source outlet.

1. Precautions in disassembly and reassembly

Special attention in disassembly should be given to the following items. The circled numbers in the figures

and the [Bold] numbers in the descriptions below correspond to the item numbers in the parts list and

exploded assembly diagram of the Model C 8FSHE. For the Model C 8FSE, refer to the parts list

separately.

* Be sure to first disconnect the power plug when performing disassembly or replacement of the saw blade.

[Only the Model C 8FSHE]

Do not stare into the laser emitting aperture during disassembly and reassembly of the laser marker. Do not

observe beam directly with an optical instrument. Use of controls or adjustments or performance of

procedures other than those specified in this TECHNICAL DATA AND SERVICE MANUAL and the

Instruction Manual may result in hazardous radiation exposure.

Disassembl

1. Turn table and base ass'y

(1) Remove the Tapping Screw (W/Flange) D5 x 25 (Black) [122] and then remove the Guard Ass’y [125].

(2) Hold the Nylon Nut M6 [48] with a 10-mm wrench and remove the Flat Hd. Screw M6 x 25 [51] then

remove the Sub Fence [50] and the Plate [49].

(3) Remove the four Bolts M8 x 35 [43], Spring Washer M8 [44] and Bolt Washer M8 [45]. And then

remove Fence (A) [55] and Fence (B) [47].

(4) Loosen the Clamp Lever [2] and remove the Machine Screw (W/Washers) M4 x 12 (Black) [1]. Turn the

Bolt (Left Hand) D10 [3] to remove from Holder (A) [124].

(5) Remove the Hex. Socket Set Screw M6 x 8 [121] and tap the end of Hinge Shaft (A) [9] with a flat-blade

screwdriver and a hammer to remove it from the Turn Table [13]. This enables to remove the head and

the slide mounted on Holder (A) [124] together from the Turn Table [13].

(6) Remove Shaft (B) [14] and remove the Turn Table [13] from the Base Ass'y [56].

(7) Remove the Side Handle [23] and Retaining Ring (E-Type) for D5 Shaft [22]. Then pull out Shaft (A)

[21].

(8) Remove the Machine Screw M4 x 8 [7]. Then Spring (E) [30], Stopper (A) [31] and Pin Cover [34] can

be removed from the Turn Table [13].

(9) Remove the Seal Lock Hex. Socket Set Screw M6 x 6 [29] and pull out the Lever Shaft [24]. Then the

Lever [25] and Spring (D) [26] can be removed. Shaft (C) [28], Cover (B) [32] and Thrust Washer [33]

can be removed from the Turn Table [13] by removing the Machine Screw M4 x 8 [7].

(10) Remove each mounting screw of Spacer (A) [20] and the Table Insert [19] to remove Spacer (A)

and the Table Insert [19] from the Turn Table [13].

(11) Pull out four Base Rubbers [57] from the Base Ass'y [56].

[20]

-26-

Page 30

Fig. 39-a

Fig. 39-b

-27-

Page 31

2. Lower guard, link, spindle ass'y and dust guide

(1) Remove the Bolt (W/Washers) M6 x 16 (Black) [207] and the Machine Screws (W/Washers) M5 x 8

[191] with the Box Wrench 10 mm [501]. Remove the Spindle Cover [192] from the Gear Case [198].

(2) Remove the Bolt (Left Hand) W/Washer M7 x 17.5 [210] with the Box Wrench 10 mm [501]. Remove

Washer (D) [221], TCT Saw Blade [211] and Washer (D) [221] in this order from the Spindle Ass’y

[217].

(3) Remove the two Flat Hd. Screws M4 x 10 [213]. Remove the Cover [214] and the Lower Guard [215]

from the Bearing Holder [219].

NOTE: Be sure to release the hook of the Return Spring [216] from the groov e of the Lower Guard

[215] then remove the Lower Guard [215] from the Bearing Holder [219].

(4) Remove the Machine Screw M5 x 12 [89] then remove the Spacer [90] and the Link [91] from Hinge (A)

Ass’y [87].

(5) Remove the two Machine Screws M5 x 20 [222] and then remove the Spindle Ass'y [217] by gently

hammering the Gear Case [198] with a plastic hammer.

(6) Remove the Machine Screws (W/Washers) M4 x 12 (Black) [194] and then remove the Dust Guide

[208] and the Guide Holder [209].

Fig. 40

3. Spring, support, hinge ass'y, ball bushing, bushing, holder (A) and gear case

(1) Remove the Machine Screw (W/Washers) M4 x 12 (Black) [111] to remove the Nylon Clip [112].

Remove the Machine Screw (W/Washers) M4 x 12 (Black) [195] and remove the Nylon Clip [196] from

the Gear Case [198] (head).

(2) Push out the Cord Bush [154] from the inside of the Housing Ass’y [155]. Disconnect the connector of

the Switching Power Supply Ass’y [165] and the Laser Marker [107]. Open the Cord Bush [154] to

remove it from the cord of the Laser Marker [107].

(3) Remove the Seal Lock Hex. Socket Hd. Bolt M5 x 10 [197].

NOTE: The Seal Lock Hex. Socket Hd. Bolt M5 x 10 [197] acts as the up per limit stopper of the Gear

Case [198] (head). Be careful that the Gear Case [198] (he ad) is raised by the force of the

Spring [85] when the Seal Lock Hex. Socket Hd. Bolt M5 x 10 [197] is removed.

(4) Remove the Hex. Socket Set Screw M6 x 8 [121]. Make a flat-blade screwdriver contact with the end

surface of Hinge Shaft (A) [92] and lightly tap the screwdriver with a plastic hammer to remove Hinge

Shaft (A) [92].

NOTE: Be sure to hold the Gear Case [198] (head) with hand during disassembly to prevent the

Gear Case [198] (head) from being dropped when removing Hinge Shaft (A) [92] from the

hole of the Gear Case [198] (head). Then the Spring [85] and the Sleev e [84] can be remov ed

from the Gear Case [198] (head).

(5) Remove the two Hex. Socket Set Screws M8 x 10 [86]. Then gently hammer the Support [113] outward

and remove it from slide pipes (A) and (B).

-28-

Page 32

(6) Remove the Knob Bolt M6 x 25 [116] and the Lock Spring [117]. Remove Hinge (A) Ass'y [87] from

Holder (A) [124] by sliding Hinge (A) Ass'y [87].

(7) Remove the Machine Screw M4 x 8 [81]. Lightly tap the end surface of Holder (A) [124] with a plastic

hammer to remove the Ball Bushing [114].

(8) Remove the Seal Lock Hex. Socket Set Screw M6 x 10 [118] from Holder (A) [124]. Remove the

Bushing [115] from Holder (A) [124].

NOTE: Prepare a shaft of 25 mm in diameter and 50 mm in length. Make the shaft contact with the

end surface of the Bushing [115] and lightly tap the shaft with a plastic hammer to remove

the Bushing [115] from Holder (A) [124].

Fig. 41

-29-

Page 33

4. Armature ass'y and lock lever

(1) Remove the Brush Cap [161] and the Carbon Brush [160].

(2) Removing the three Machine Screws (W/Washers) M5 x 40 (Black) [157] allows you to remove the

Housing Ass’y [155] together with the Handle Cover [164] from the Gear Case [198].

(3) Remove the Lock Lever [177] and the Spring [176].

(4) Remove the two Special Screws M6 [205] and remove the Lock Lever [204] and the Lock Lever Spring

[203].

(5) Disassembly of the Armature Ass'y [187]

(a) Remove the Housing Ass'y [155] from the Gear Case [198] according to the above step 4-(1)(2). If

the Rubber Bushing [186] stays in the Housing Ass’y [155], remove it with long nose pliers.

(b) Remove the Armature Ass'y [187] by gently hammering the Gear Case [198] with a plastic hammer.

Fig. 42

-30-

Page 34

5. Handle cover, switch, light, cord, stator ass'y and housing ass'y

(1) Remove the motor section according to the above step 4-(1)(2).

(2) Remove the seven Tapping Screws (W/Flange) D4 x 20 (Black) [163] and remove the Handle Cover

[164].

(3) Disconnect the connectors of the Switching Power Supply Ass’y [165] and Light (H) Ass’y [175] and

remove Light (H) Ass’y [175].

(4) Turn Cap (A) [174] and remove it, then you can remove the Clear Cover [173].

(5) (For the U.S.A. and Canada)

Cut off the two Connectors [168] that are crimped onto the internal wires coming from the Stator Ass'y

[181] and the Switch (3P Faston Type) W/O Lock [170].

(Except for the U.S.A. and Canada)

Loosen the screw of Pillar Terminal(A) [171] with a flatblade screwdriver and disconnect the internal

wires.

(6) Removal of the Switch (3P Faston Type) W/O Lock [170]:

(a) Remove the Handle Cover [164] from the Housing Ass'y [155] according to the above step 5-(1)(2).

Then the Switch (3P Faston Type) W/O Lock [170] can be removed.

(b) The Stator Ass’y [181] and Internal Wire (G) [169] are provided with a claw to prevent coming off of

the connector. When removing the Stator Ass’y [181] and Internal Wire (G) [169] from the Switch

(3P Faston Type) W/O Lock [170], pull out the Stator Ass’y [181] and Internal Wire (G) [169] while

pressing the claw.

(7) Disconnect the faston of the Switching Power Supply Ass’y [165] from the two Switches (W/Cover)

[167] for the Laser Marker [107] and Light (H) Ass’y [175]. Push the Switch (W/Cover) [167] from the

inside of the Housing Ass’y [155] and remove the Switch (W/Cover) [167].

(8) Remove the Tapping Screw (W/Flange) D4 x 16 [151] and remove the Switching Power Supply Ass’y

[165] from the Housing Ass’y [155].

(9) Removal of the Stator Ass’y [181]:

(a) Remove the Fan Guide [178] from the Housing Ass’y [155].

(b) Remove the two Hex. Hd. Tapping Screws D4 x 60 [179] that secure the Stator Ass’y [181] to the

Housing Ass’y

(c) Pull out the Stator Ass’y [181] by lightly tapping the Housing Ass’y [155] at the surface where the

Gear Case [198] is mounted with a plastic hammer.

(10) Remove the two Tapping Screw (W/Flange) D4 x 16 [151] and remove the Cord [110] and the Cord

Armor D10.1 [152].

[155]. Remove the two Brush Terminals [180] from the Brush Holder [159].

Fig. 43

-31-

Page 35

6. Laser marker

(1) Remove the Machine Screw M4 x 8 [81] and

remove the Cover [83] from the rear of Hinge (A)

Ass’y [87].

(2) Remove the three Machine Screws M4 x 8 [108]

and remove Plate (A) [105] and Cover (A) [104]

from Hinge (A) Ass’y [87].

(3) Remove the Adjuster [88] and push the Clutch

Screw [96] from behind Hinge (A) Ass’y [87].

Then Holder (B) [106] can be removed together

with the Laser Marker [107].

NOTE: At this time, the Spring [100] and the

Clutch Spring [101] pop out. Be careful

not to lose them.

(4) Remove the Clutch Screw [96]. Then the Laser

Marker [107] can be removed from Holder (B)

[106].

NOTE: At this time, the two Springs [102] pop out.

Be careful not to lose them.

Fig. 44

7. Vise ass’y

(1) Remove the Wing Bolt M6 x 15 [36] to remove the

Vise Shaft [39].

(2) Remove the Machine Screw M4 x 10 [41] to

remove the Vise Plate [40].

(3) Remove the Knob Bolt M10 x 66 [35] from the

Screw Holder [37].

Fig. 45

-32-

Page 36

Reassembl

y

1. Special attention

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special

attention should be given to the following items.

(1) Prior to reassembly, measure the insulation

resistance of the armature, stator, switch and

other electrical components and confirm that

the insulation resistance of each part is more

than 5 MΩ.

(2) When replacing the Spring [85], apply 3 grams