Page 1

Slide Compound Miter Saw

Model C 8FSC

Handling instructions

NOTE:

Before using this Power Tool, carefully read through these

HANDLING INSTRUCTIONS to ensure efficient, safe operation. It is

recommended that these INSTRUCTIONS be kept readily available

as an important reference when using this power tool.

Page 2

CONTENTS

PAGE

IMPORTANT SAFETY

INFORMATION .............................................. 2

MEANINGS OF SIGNAL WORDS ................... 2

SAFETY ............................................................... 3

IMPORTANT SAFETY INSTRUCTIONS FOR

USING ALL POWER TOOLS ......................... 3

REPLACEMENT PARTS .................................... 6

DOUBLE INSULATION FOR SAFER

OPERATION ................................................... 7

OPERATION AND MAINTENANCE ................ 8

NAME OF PARTS .............................................. 8

SPECIFICATIONS .............................................. 9

ACCESSORIES ................................................. 10

APPLICATIONS ............................................... 10

PREPARATION BEFORE OPERATION .......... 11

BEFORE USING ................................................ 13

BEFORE CUTTING ........................................... 14

PRACTICAL APPLICATIONS ......................... 17

SAW BLADE MOUNTING AND

DISMOUNTING ........................................... 23

MAINTENANCE AND INSPECTION ............. 25

SERVICE AND REPAIRS ................................. 27

PARTS LIST ...................................................... 28

PAGE

IMPORTANT SAFETY INFORMATION

Read and understand all of the safety precautions, warnings and operating instructions in

the Instruction Manual before operating or maintaining this power tool.

Most accidents that result from power tool operation and maintenance are caused by the

failure to observe basic safety rules or precautions. An accident can often be avoided by

recognizing a potentially hazardous situation before it occurs, and by observing appropriate

safety procedures.

Basic safety precautions are outlined in the “SAFETY” section of this Instruction Manual

and in the sections which contain the operation and maintenance instructions.

Hazards that must be avoided to prevent bodily injury or machine damage are identified by

WARNINGS on the power tool and in this Instruction Manual.

NEVER use this power tool in a manner that has not been specifically recommended by

HITACHI.

MEANINGS OF SIGNAL WORDS

WARNING indicates a potentially hazardous situations which, if ignored, could result in

death or serious injury.

CAUTION indicates a potentially hazardous situations which, if not avoided, may result in

minor or moderate injury, or may cause machine damage.

NOTE emphasizes essential information.

2

Page 3

SAFETY

IMPORTANT SAFETY INSTRUCTIONS FOR USING ALL POWER TOOLS

READ ALL OF THE WARNINGS AND OPERATING INSTRUCTIONS IN

THIS MANUAL BEFORE OPERATING OR MAINTAINING THIS TOOL:

WARNING: When using this electric tool, take all necessary precautions to minimize

the risk of electric shock or other personal injury.

In particular, always comply with the following safety rules:

1. ALWAYS KEEP GUARDS IN PLACE and in working order.

2. ALWAYS REMOVE ADJUSTING KEYS AND WRENCHES BEFORE STARTING TOOL.

Always confirm that all keys and adjusting wrenches have been removed from the tool

before it is turned on.

3. ALWAYS KEEP WORK AREA CLEAN. Avoid injuries by not cluttering the work areas

and work benches.

4. NEVER USE TOOL IN HAZARDOUS ENVIRONMENTS. Never use the power tool in

damp or wet places and never expose it to rain. Always keep the work area well lighted.

5. NEVER PERMIT CHILDREN OR OTHERS TO LOITER NEAR THE WORK AREA. Keep all

people (especially children) away from the work area. Always unplug unattended tools

and keep the work place tamper-proof by installing locks on the doors and on the master

switches. Always remove the lock-off button from the tool and store it in a secure

place, when the tool is not in use.

6. NEVER FORCE THE TOOL. It will do the job better and more safely if it is operated at the

rate for which it was designed.

7. ALWAYS USE THE RIGHT TOOLS. Never force a tool or an attachment to do a job for

which it was not designed.

8. ALWAYS WEAR PROPER APPAREL WHEN WORKING WITH THE TOOL. Never wear

loose clothing, gloves, neckties, rings, bracelets or other jewelry which may get caught

in the moving parts. Always wear non-slip footwear, preferably with steel toes. Wear

protective hair covering to contain long hair.

9. ALWAYS USE EYE PROTECTION WHEN WORKING WITH THE TOOL TO PREVENT EYE

INJURY. Ordinary eyeglasses do not provide adequate protection because the lenses

are not made of safety glass. Also, use a face mask for additional safety and wear a

dust mask if the cutting operation produces dust.

10. ALWAYS SECURE THE WORKPIECE TO THE FENCE OR THE TABLE. Use clamps or a

vise to hold the workpiece in place. It is safer than using your hand and it frees both

hands to operate the tool.

11. NEVER OVERREACH. Always keep proper footing and balance when working with the

tool.

12. ALWAYS MAINTAIN TOOLS WITH CARE. Always keep tools sharp and clean for the

best and safest performance. Always follow instructions for lubricating the tool and for

changing accessories.

3

Page 4

13. ALWAYS DISCONNECT THE TOOL before servicing and before changing blades or

other accessories.

14. NEVER RISK UNINTENTIONAL STARTING WHEN PLUGGING IN THE TOOL. Always

confirm that the switch is in the OFF position before inserting the power plug into the

receptacle.

15. ALWAYS USE RECOMMENDED ACCESSORIES ONLY WHEN OPERATING THIS TOOL.

Consult this instruction manual for descriptions of recommended accessories. To avoid

personal injuries, use only recommended accessories in conjunction with this tool.

16. NEVER STAND ON THE TOOL. Prevent serious injury by not tipping the tool and by not

risking unintentional contact with the saw blade.

17. ALWAYS CHECK FOR DAMAGED PARTS BEFORE USING THE TOOL. Always check the

guard and all other components for damage before using the tool to assure that they

will function properly. Check all moving parts for proper alignment, freedom from

binding and other conditions that might affect proper operation. Always repair or replace

any damaged guards or other damaged components before using the tool.

18. ALWAYS CONFIRM THE ROTATION DIRECTION OF THE BLADE BEFORE USING THE

TOOL. Always feed work into the tool against the rotation direction of the blade in

order to prevent possible injury.

19. NEVER LEAVE THE TOOL RUNNING WHILE UNATTENDED. TURN POWER OFF. Do

not leave tool until it comes to a complete stop. Always turn the power off when the

tool is not in use. Always unplug the power cord when the tool is not in use.

20. This tool was not designed to be used for mass-production applications and should not

be used in mass-production environments.

21. When servicing this tool, use only authorized replacement parts.

22. Apply 240 volts AC only to this tool. Applying the wrong voltage or applying DC power

can cause the POWER TOOL to operate improperly and cause serious personal injury

or damage to the tool.

23. Never raise the saw blade from the workpiece until it has first come to a complete stop.

24. Always use outboard stands to provide support for long workpieces that overhang the

table of the slide compound miter saw.

25. Always return the carriage to the full rear position after each crosscut operation in

order to reduce the risk of injury.

Specific Safety Rules for Use of this Power Tool

WARNING: The following specific operating instructions must be observed when

using this POWER TOOL in order to avoid injury:

DO’s

ALWAYS OBSERVE THE FOLLOWING RULES TO ASSURE SAFE USE

OF THIS TOOL:

1. Review this Handling instruction and familiarize yourself with the safety rules and

operating instructions for this POWER TOOL before attempting to use it.

2. Always confirm that the POWER TOOL is clean before using it.

3. Always wear snug-fitting clothing, non-skid footwear (preferably with steel toes) and

eye protection when operating the POWER TOOL.

4

Page 5

4. Always handle the POWER TOOL carefully. If the POWER TOOL falls or strikes against

a hard object, it might become deformed or cracked or sustain other damage.

5. Always cease operating the saw at once, if you notice any abnormality whatsoever.

6. Always confirm that all components are mounted properly and securely before using

the tool.

7. When replacing the saw blade, always confirm that the rpm rating of the new blade is

correct for use on this tool.

8. Always shut off the power and wait for the saw blade to completely stop rotating before

doing any maintenance or adjustments.

9. During slide cutting, always push the saw blade away from the operator.

10. Always clamp or otherwise secure the workpiece to the fence; otherwise the workpiece

might be thrust form the table and cause bodily harm.

11. During miter or bevel cutting, always wait for the rotation of the blade to stop completely

before lifting the saw blade.

12. Always make a trial run first before attempting any new use of the saw.

13. Always handle the saw blade with care when dismounting and mounting it.

14. Always confirm that the workpiece is free of nails or other foreign objects before

beginning a cut.

15. Always keep your hands out of the path of the saw blade.

16. Always confirm that the safety cover is in the proper place before using the saw.

17. Always confirm that the safety cover does not obstruct the sliding motion of the saw

before attempting slide cutting.

18. Inspect the tool power cords periodically.

19. Always confirm that the proper lengths and types of extension cords are being utilized,

if necessary, before starting the tool.

20. Always confirm that the motor air vents are fully open before using the tool.

21. Always wait until the motor has reached full speed before starting a cut.

22. Always keep the handles dry, clean and free of oil and grease. Hold the tool firmly

when in use.

23. Always use outboard stands to provide support for long workpieces that overhang the

table of the slide compound miter saw.

24. Always operate the tool after ensuring the workpiece is fixed properly with a vise

assembly.

DON’Ts

NEVER VIOLATE THE FOLLOWING RULES TO ASSURE SAFE USE

OF THIS TOOL:

1. Never operate the POWER TOOL unless you fully understand the operating instructions

contained in this Handling instruction.

2. Never leave the POWER TOOL unattended without first unplugging the power cord.

3. Never operate the POWER TOOL when you are tired, after you have taken any

medications, or have consumed any alcoholic beverages.

4. Never use the POWER TOOL for applications not specified in the Handling instruction.

5. Never operate the tool while wearing loose clothing, a necktie or jewelry, or while your

hair is uncovered, to protect against getting caught in the moving machinery.

6. Never reach around the saw blade.

5

Page 6

7. Never touch any moving parts, including the blade, while the saw is in use.

8. Never remove any safety devices or blade guards; use of the tool without them would

be hazardous.

9. Never lock the safety cover; always confirm that it slides smoothly before using the

tool.

10. Never damage the power cord of the tool.

11. Never attempt to move a plugged-in POWER TOOL while your finger is on the starting

switch.

12. Never use the POWER TOOL if the starting switch does not turn on and off properly.

13. Never use the POWER TOOL if the plastic housing or the handle is cracked or deformed.

14. Never use the POWER TOOL near flammable liquids or gases because sparking can

cause an explosion.

15. Never clean plastic components with solvents because the plastic may dissolve.

16. Never operate the saw unless all the blade guards are in place.

17. Never raise the saw blade from the workpiece until it has first come to a complete stop.

18. When slide cutting, never pull the handle toward the operator, since this could cause

the saw blade to kick up from the workpiece. Always push the handle away from the

operator in a single, smooth motion.

19. Never place your limbs inside of the line while the tool is being operated. This may

cause hazardous conditions.

20. Never use abrasive type blades on this saw.

21. Never expose to rain or use in damp locations.

WARNING

FOR YOUR OWN SAFETY READ THIS HANDLING INSTRUCTIONS

BEFORE OPERATING THE SLIDE COMPOUND MITER SAW

1. Always wear eye protection when using the slide compound miter saw.

2. Always keep hands out of the path of the saw blade.

3. Never operate the saw without the guards in place.

4. Never perform any freehand operation with the slide compound miter saw.

5. Never reach around the saw blade.

6. Always turn off tool and wait for saw blade to stop before moving workpiece or changing

settings.

7. Always disconnect power before changing blade or servicing.

8. Saw blade diameter is 216mm (8-1/2").

9. No load speed is 4900/min.

REPLACEMENT PARTS

When servicing use only identical replacement parts.

Repairs should be conducted only by a Hitachi authorized service center.

6

Page 7

DOUBLE INSULATION FOR SAFER OPERATION

To ensure safer operation of this power tool, HITACHI has adopted a double insulation

design. “Double insulation” means that two physically separated insulation systems have

been used to insulate the electrically conductive materials connected to the power supply

from the outer frame handled by the operator. Therefore, either the symbol “

words and “Double insulation” appear on the power tool or on the nameplate.

Although this system has no external grounding, you must still follow the normal electrical

safety precautions given in this Instruction Manual, including not using the power tool in

wet environments.

To keep the double insulation system effective, follow these precautions:

* Only HITACHI AUTHORIZED SERVICE CENTER should disassemble or assemble this

power tool, and only genuine HITACHI replacement parts should be installed.

* Clean the exterior of the power tool only with a soft cloth moistened with soapy water

and dry thoroughly.

* Never use solvents, gasoline or thinners on plastic components; otherwise the plastic

may dissolve.

” or the

SAVE THESE INSTRUCTIONS

AND

MAKE THEM AVAILABLE TO

OTHER USERS

AND

OWNERS OF THIS TOOL!

7

Page 8

OPERATION AND MAINTENANCE

NOTE: The information contained in this Handling instructions is designed to assist you

in the safe operation and maintenance of the power tool. Some illustrations in

this Handling instructions may show details or attachments that differ from those

on your own power tool.

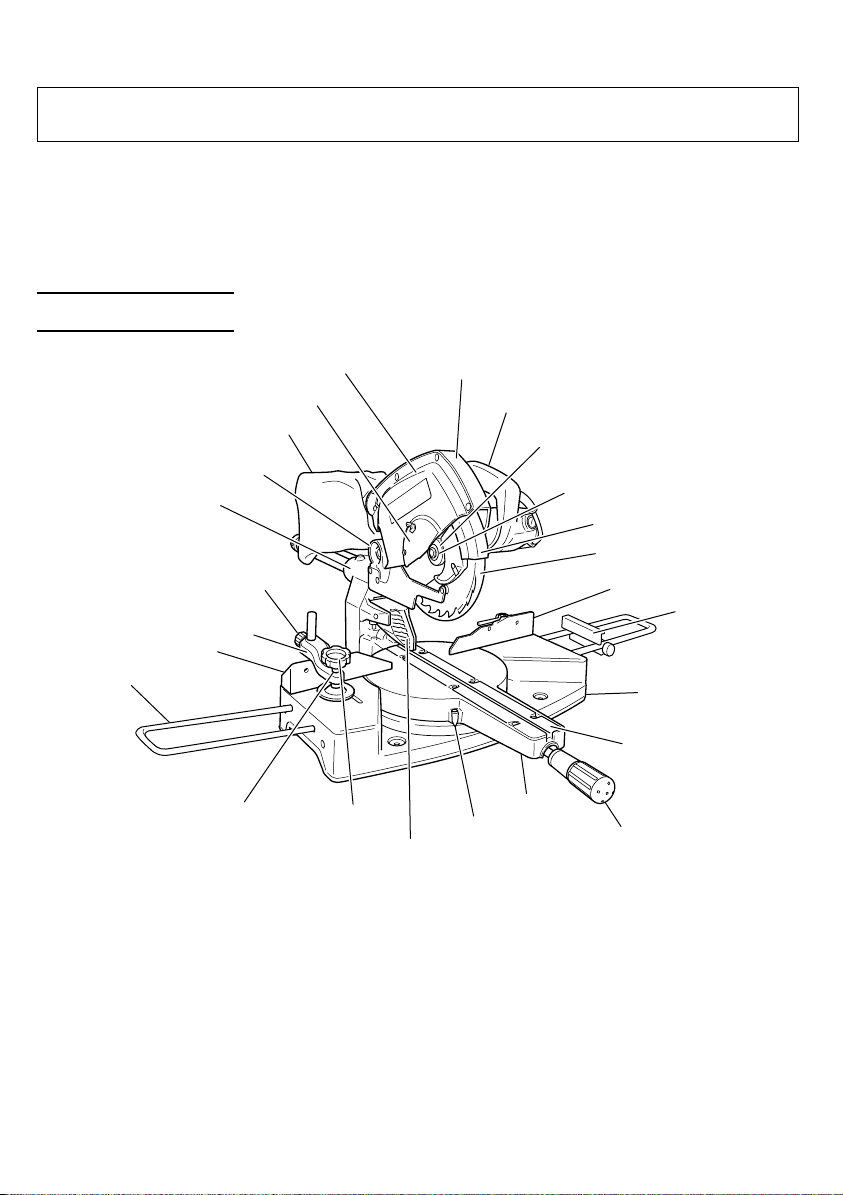

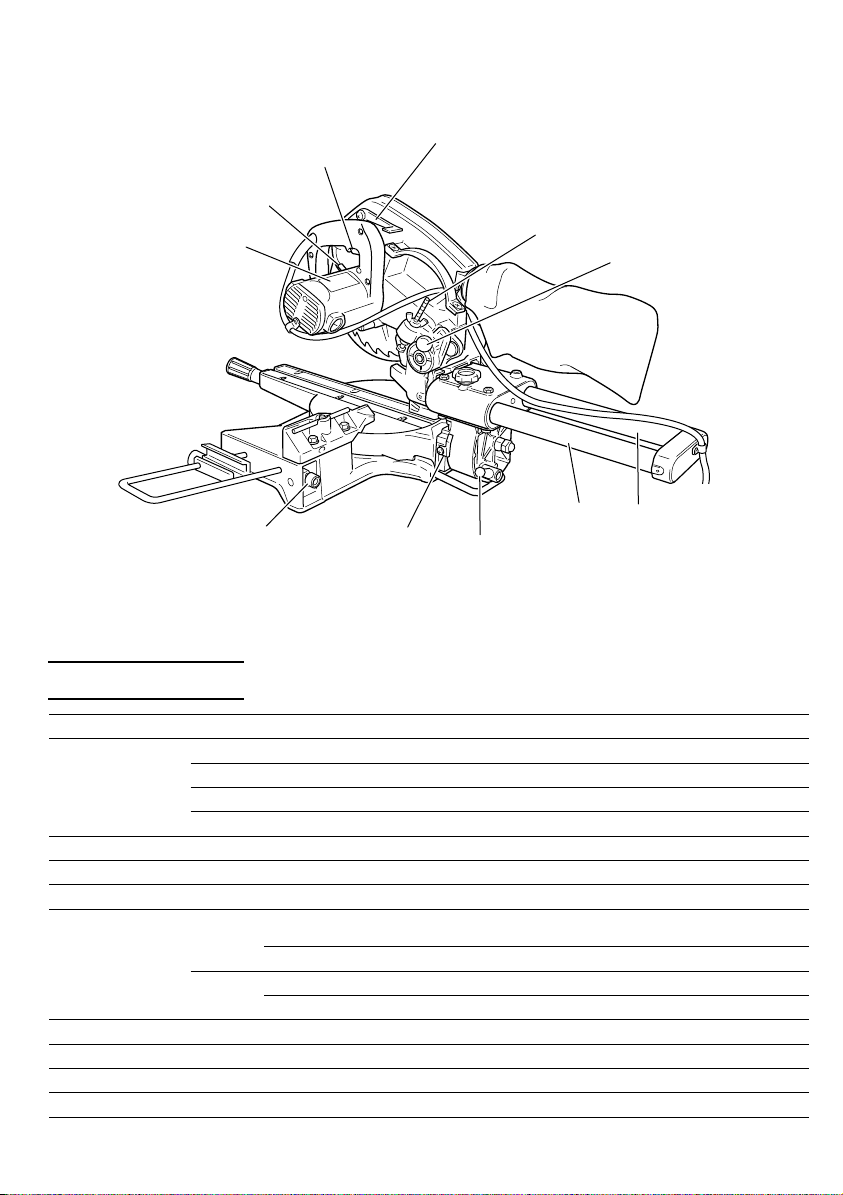

NAME OF PARTS

Holder

Holder (A)

6mm knob bolt

Screw holder

Fence (B)

Vise assembly

Saw cover

Spindle cover

Dust bag

Hinge

Knob

Guard

Fig. 1

Gear case

Indicator

Handle

Washer (C)

Bolt

Sub cover

Safety cover

Fence (A)

Stopper

Base

Table insert

Turntable

Side handle

8

Page 9

Spindle lock

Nameplate

Lock lever

Trigger switch

8mm depth adjustment bolt

Locking pin

Slide pipe (B)

6mm knob bolt

Indicator

Slide pipe (A)

Clamp lever

Fig. 2

SPECIFICATIONS

Item Model C8FSC

Motor Type Series commutator motor

Power source Single-phase AC 50Hz

Voltage (Volts) 240

Full-load current (Amp) 4.6

Applicable Outside Dia. 216mm (8-1/2")

saw blade Hole Dia. 30mm (1-3/16)

No load speed 4900/min

Bevel 0°

Max. sawing Miter 45° Max. Height 65mm (2-9/16") Width 220mm (8-21/32")

dimension

Miter sawing range Left 0° – 45° Right 0° – 57° (Bevel 45°, Left and Right 0° – 45° )

Bevel sawing range Left 0° – 45°

Net weight 17.5 kg (38.6 lbs)

Cord 2 Conductor type cable 2.5m (8ft.)

Bevel 45°

Miter 0°

Miter 0° Max. Height 39mm (1-9/16") Width 305mm (12")

Miter 45° Max. Height 39mm (1-9/16") Width 220mm (8-21/32")

Max. Height 65mm (2-9/16") Max. Height 75mm (2-15/16")

Max. Width 305mm (12") Max. Width 280mm (11")

()

9

Page 10

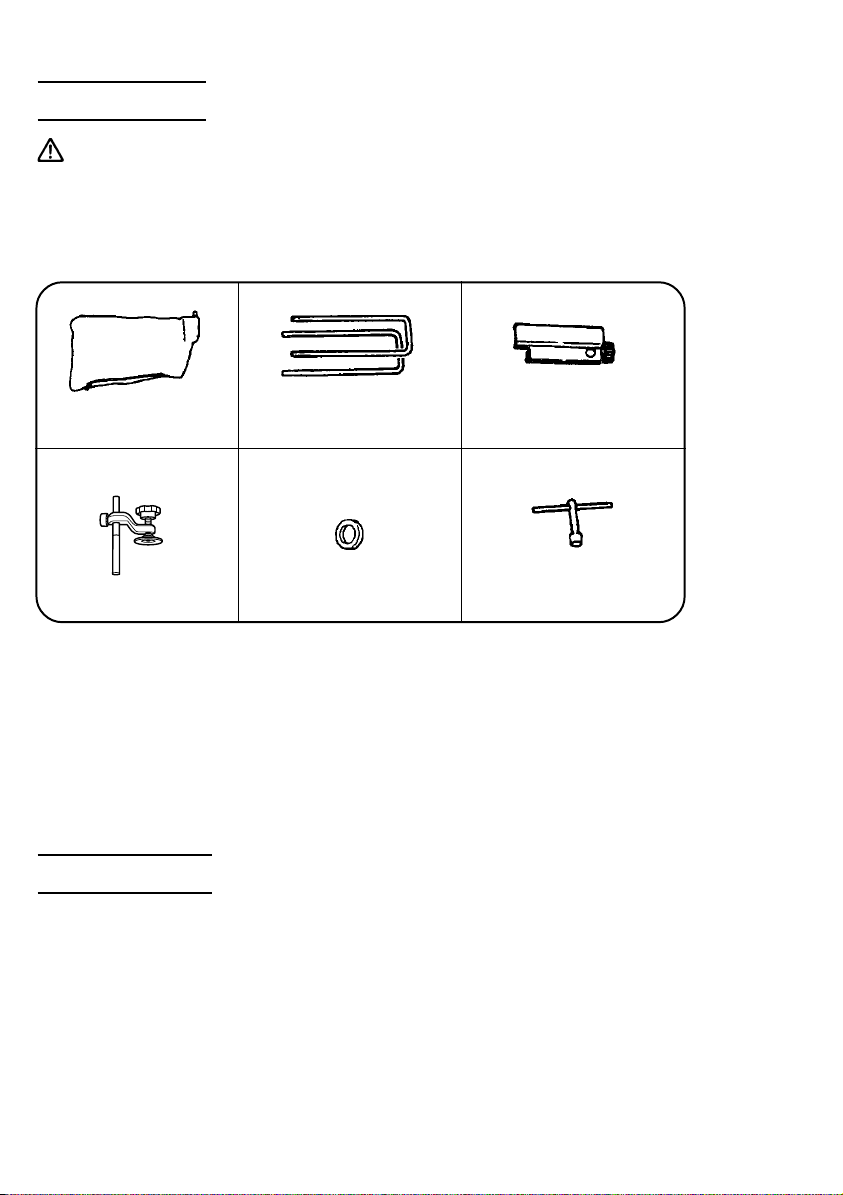

ACCESSORIES

WARNING: Accessories for this power tool are mentioned in this Handling

instructions.

The use of any other attachment or accessory can be dangerous and

could cause injury or mechanical damage.

STANDARD ACCESSORIES

1 Dust bag (1 piece)

2 Holder (2 pieces)

3 Stopper (1 piece)

For how to use, refer to

page 23.

4 Vise assembly w/knob

bolt (1 piece)

For how to use, refer to

page 18.

For how to use, refer to

page 16.

5 Collar (1 piece)

Outside dia. 30mm (1 -3/16")

For how to use, refer to

page 24.

For how to use, refer to

page 16.

6 10mm box wrench (1 piece)

Fig. 3

OPTIONAL ACCESSORIES...sold separately

1 Extension Holder and Stopper (Fig. 1) (Code No. 998866)

2 Saw blade 216mm (8-1/2") TCT Saw blade (Total teeth: 24) (Code No. 998859)

NOTE: Accessories are subject to change without any obligation on the part of the

HITACHI.

APPLICATIONS

Wood and aluminum sash.

10

Page 11

PREPARATION BEFORE OPERATION

Make the following preparations before operating the power tool:

1. Installation

8mm (5/16") boltBase

150mm (5-29/32")

9mm (11/32")

3 Holes

264mm (10-13/32")

300mm (11-13/16")

Work bench 8mm (5/16") nut

Fig. 4

Attach the power tool to a level, horizontal work bench in accordance with Fig. 4.

Select 8mm (5/16") diameter bolts suitable in length for the thickness of the work bench.

Bolt length should be at least 25mm (1") plus the thickness of the work bench.

For example, use 50mm (2") or larger bolts for a 25mm (1") thick work bench.

The holder attached to the rear of the base helps stabilize the power tool.

Base holder adjustment:

Loosen the 6mm bolt with the supplied 10mm

box wrench.

Adjust the base holder until its bottom surface

contacts the work bench surface.

Holder

After adjustment, firmly tighten the 6mm bolt.

25mm (1") thick bench

Adjust the base

holder until its

bottom surface

contacts the work

bench surface.

6mm bolt

Move

Fig. 5

11

Page 12

2. Extension Cord

Ampere rating

(on nameplate) 6 Amp

Ext. cord length

7.5m 1.0mm

Wire gauge size

2

mm

(A.W.G )

2

(25ft.) (18 A.W.G)

15m 1.5mm

2

(50ft.) (16 A.W.G)

22.5m 2.0mm

2

(75ft.) (14 A.W.G)

30m 3.5mm

2

(100ft.) (12 A.W.G)

45m 3.5mm

2

(150ft.) (12 A.W.G)

60mm 5.5mm

2

(200ft.) (10 A.W.G)

To use the power tool when no suitable power

source is nearby, use an extension cord of

suitable size to ensure safety and to prevent

power loss and overheating.

Determine from the accompanying table the

required extension cord wire size.

Check power cords and extension cords for

loose or exposed wires and damaged

insulation before using.

Repair or replace as needed before using the

power tool.

NOTE: The lower the wire size number

means the heavier the wire and the

further it will carry current without

a voltage drop.

WARNING: Never connect this unit to an electrical power source until all

operating instructions have been read and understood.

3. Releasing the locking pin

When the power tool is prepared for shipping, its main parts are secured by a locking

pin. Move the handle slightly so that the locking pin can be disengaged and adjusted as

indicated in Fig. 7.

NOTE: Lowering the handle slightly will enable you to disengage the locking pin more

easily and safely.

During transport, fit the pin into the

deep slot.

Locking pin

Clockwise

During operation fit

Locking pin

Fig. 6

the pin stoppers into

the shallow slot.

Fig. 7

4. Installing the dust bag, holder, stopper and vises assembly.

Attach the dust bag, holder, stopper and vise assembly as indicated in Fig. 1.

12

Pull out to disengage.

Rotate the knob 1/4 turn

and fit the pin stoppers

into the shallow slot.

Page 13

BEFORE USING

1. Make sure the power source is appropriate for the tool.

WARNING: Never connect the power tool unless the available AC power source

is of the same voltage as that specified on the nameplate of the

tool.

Never connect this power tool to a DC power source.

2. Make sure the trigger switch is turned OFF.

WARNING: If the power cord is connected to the power source with the trigger

switch turned ON the power tool will start suddenly and can cause

a serious accident.

3. Check the saw blade for visible defects.

Confirm that the saw blade is free of cracks or other visible damage.

4. Confirm that the saw blade is attached securely to the power tool.

Using the supplied 10mm box wrench, tighten the bolt on the saw blade spindle to

secure the saw blade.

For details, see Fig. 30-a and Fig. 30-b in the section on “SAW BLADE MOUNTING AND

DISMOUNTING”.

5. Check the safety cover for proper operation.

This slide compound miter saw is equipped

with a saw head lock as safety device. To lower

Sub cover

Safety cover

Fig. 8

the saw head to cut, the lock must be released

by pressing the lock lever with your thumb.

When you push down the handle while

pushing the lock lever, check that the safety

cover and sub cover revolves smoothly.

Next, check that the safety cover and the sub

cover returns to the original position when the

handle is raised.

WARNING: NEVER OPERATE THE POWER TOOL if the safety cover does not

function smoothly.

6. Confirm the position of the spindle lock before using the tool.

After installing the saw blade, confirm that the spindle lock has been returned to the

retract position before using the power tool (see Fig. 2).

7. Check the lower limit position of the Saw Blade.

Although it was adjusted before shipment, carefully check the height of the saw blade.

Confirm that the saw blade can be lowered 12mm to 13mm (15/32" to 1/2") below the

table insert. For details, see the section on “Checking the saw blade lower limit position”.

8. Check the Power Receptacle.

To prevent overheating, accidental stopping or intermittent operation, confirm that the

power cord plug fits properly in the electrical receptacle and does not fall out after it is

inserted. Repair or replace the receptacle if it is faulty.

13

Page 14

9. Confirm the tool’s power cord is not damaged.

Repair or replace the power cord if an inspection indicates that it is damaged

AFTER CONNECTING THE POWER PLUG TO AN APPROPRIATE AC POWER SOURCE, CHECK

THE OPERATION OF THE TOOL AS FOLLOWS:

10. Trial Run

After confirming that no one is standing behind, the power tool start and confirm that

no operating abnormalities exist before attempting a cutting operation.

11. Inspect the rotating stability of the saw blade.

For precise cutting, rotate the saw blade and check for deflection to confirm that the

blade is not noticeably unstable; otherwise vibrations might occur and cause an accident.

12. Confirm the correct blade type.

Hitachi miter saws are primarily designed to cut timber.

However, by using the **correct blade type, other materials such as aluminium, other

non-ferrous metals and plastics, can be cut successfully.

** Please consult a saw blade specialist for the correct blade type.

BEFORE CUTTING

1. Cutting a groove on the guard

Vise

assembly

Fence (B)

Guard

Fence (A)

Workpiece

Fig. 9

2. Positioning the table insert

Holder (A) has a guard (see Fig. 9) into

which a groove must be cut.

After placing a suitable wooden piece to

sit on the fence and the table surfaces,

fix it with the vise assembly.

After the switch has been turned on and

the saw blade has reached maximum

speed, slowly lower the handle to cut a

groove on the guard.

CAUTION: Do not cut the groove

too quickly; otherwise

the guard might

become damaged.

6mm

machine

screw

14

Workpiece

(Left)

[Straight cutting]

Saw blade

Table insert

(Right)

Workpiece

(Left)

Saw blade

Table insert

[Bevel cutting]

Fig. 10-a Fig. 10-b

6mm

machine

screw

(Right)

Page 15

Adjust the table insert on the turntable until it is correctly aligned to the saw blade, as

indicated below.

Table insert adjustment:

(1) Loosen the 6mm machine screws securing the right side table insert.

(2) Check that the tabIe insert is positioned fully to the right, and temporarily tighten the

back and front 6mm machine screws.

(3) Secure a piece of wood (about 200mm (7-7/8") wide) to the turntable with the vise

assembly.

(4) Cut the piece of wood at the desired angle.

(5) Align the right side table insert with the cutting line as indicated in Figs. 10-a and 10-b.

(6) Securely tighten the back and front 6mm machine screws.

(7) Remove the workpiece, and securely tighten the center 6mm machine screws.

If the power tool is properly adjusted, cutting can be made accurate by aligning a

premarked ink line with the table insert.

When the power tool is shipped from the factory, the right side table insert is put in a

position where it will not contact the saw blade at a full 45° bevel cut.

Therefore, before operation, adjust the right side table insert to the desired cutting

angle.

3. Checking the saw blade lower limit position

8mm depth adjustment bolt

Table

insert

Turntable

Fig. 11

8mm wing nut

8mm nut

(2 pieces)

Check that the saw can be lowered 12mm to

13mm (15/32" to 1/2") below the table insert.

If necessary, adjust as follows:

(1) Loosen the 8mm wing nut and the two

8mm nuts on the 8mm depth adjustment

bolt.

(2) Turn the 8mm depth adjustment bolt as

necessary to set the lower limit position.

(3) Once the adjustment is complete, fully

tighten the two 8mm nuts and the 8mm

wing nut.

NOTE: Before tightening the two 8mm

nuts and the 8mm wing nut,

confirm that the saw blade is

adjusted so that it will not cut into

the turntable.

15

Page 16

4. Oblique angle

Before the power tool is shipped from the

factory, it is adjusted for 0°, right angle, Ieft

45° bevel cutting angle with the 8mm nylock

bolts.

The positioning and bevel cutting angle can

8mm nylock

bolt

be adjusted by loosening the 8mm nylock bolt

and by changing the height of the 8mm nylock

bolt.

(Maximum bevel cutting angle is 45°)

Fig. 12

5. Securing the workpiece

WARNING: Always clamp or vise to secure the workpiece to the fence;

otherwise the workpiece might be thrust from the table and cause

bodily harm.

6. Installing the holders (Standard Equipment)

The holders help keep longer workpieces

stable and in place during the cutting

6mm knob

bolt

Holder

operation.

(1) As indicated in Fig. 13, use a steel square

for aligning the upper edge of the holders

with the base surface.

(2) After aligning, secure the holders with the

6mm knob bolts.

Steel square Base surface

Fig. 13

7. Stopper for precision cutting (Standard Equipment)

The stopper facilitates continuous precision

cutting in lengths of 265mm to 430mm (10-7/

16" to 16-15/16").

To install the stopper, attach it to the holder

with the 6mm knob bolt as shown in Fig. 14.

16

Workpiece

Stopper

Move

6mm knob bolt

Fig. 14

Holder

Page 17

8. Using an ink line

Handle

Safety cover

Press down the handle to lift the safety

cover as shown in Fig. 15, and align the

premarked ink line with the saw blade.

Fence (B)

Marking

(pre-marked)

Fig. 15

CAUTION: Never lift the safety cover while the saw blade is rotating.

PRACTICAL APPLICATIONS

WARNING:* To avoid personal injury, never remove or place a workpiece on

the table while the tool is being operated.

* Never place your limbs inside of the line while the tool is being

operated. This may cause hazardous conditions (see Fig. 16).

Line

Fig. 16

Line

17

Page 18

1. Switch operation

The tool is turned on when the switch trigger

Trigger switch

is pulled and off when the trigger switch is

released (Fig. 17).

Fig. 17

2. Using the Vise Assembly (Standard accessory)

6mm

knob bolt

Screw holder

Knob

(1) The vise assembly can be mounted

on either the left fence {Fence (B)} or

the right fence {Fence (A)} by

loosening the 10mm knob bolt.

Vise shaft

Vise plate

(2) The screw holder can be raised or

lowered according to the height of the

Fence

workpiece by loosening the 6mm

knob bolt. After the adjustment, firmly

tighten the 6mm knob bolt and fix the

Workpiece

screw holder.

(3) Turn the upper knob and securely fix

10mm knob bolt

Fig. 18

the workpiece in position (Fig. 18).

18

CAUTION: Always confirm that the motor head (see Fig. 1) does not contact

the vise assembly when it is lowered for cutting. If there is any danger

that it may do so, loosen the 10mm knob bolt slightly and move the

vise to a position where it will not contact the saw blade.

Also, always confirm that the vise assembly is mounted on the right

side {Fence (A)} before using the saw for compound cutting

operations (miter + bevel cutting).

Page 19

3. Cutting Operation

Adjusting lineab

(1) As shown in Fig. 19 the width of the saw

blade is the width of the cut. Therefore,

slide the workpiece to the right (viewed

from the operator’s position) when length

b is desired, or to the left when length a

is desired.

(2) After turning on the switch and checking

that the saw blade is rotating at maximum

speed, slowly push down the handle while

holding down the lock lever and bring the

Marking

(pre-marked)

a

(Front View)

a

b

Marking

b

(pre-marked)

saw blade in the vicinity of the material to

Fig. 19

be cut.

(3) Once the saw blade contacts the

workpiece, push the handle down

gradually to cut into the workpiece.

(4) After cutting the workpiece to the desired

depth, turn the power tool OFF and let the

saw blade stop completely before raising

the handle from the workpiece to return it

to the full retract position.

CAUTION: *Increased pressure on the handle will not increase the cutting speed.

On the contrary, too much pressure may result in overload of the

motor and/or decreased cutting efficiency.

WARNING: * Confirm that the trigger switch is turned OFF and the power plug

has been removed from the receptacle whenever the tool is not in

use.

4. Cutting narrow workpieces (Press cutting)

Slide the hinge down to holder (A), then

Slide securing knob

Hinge

Handle

Press

down

tighten the slide securing knob as indicated

in Fig. 20.

Lower the handle to cut the workpiece.

Using the power tool this way will permit

cutting of workpieces of up to 65mm (2-9/16")

square.

Holder (A)

Workpiece

Fig. 20

19

Page 20

5. Cutting wide workpieces (Slide cutting)

1 Pull forward

3 Push rearward to cut

Fig. 21

Handle

2 Press

down

Workpiece

(1) Workpieces up to 65mm (2-9/16") high

(2) Workpieces up to 75mm (2-15/16") high

CAUTION: *If the handle is pressed down with excessive or lateral force, the

saw blade may vibrate during the cutting operation and cause

unwanted cutting marks on the workpiece, thus reducing the

quality of the cut.

Accordingly, press the handle down gently and carefully.

*In slide cutting, gently push the handle back (rearwards) in a single,

smooth operation.

Stopping the handle movement during the cut will cause unwanted

cutting marks on the workpiece.

WARNING: * For slide cutting, follow the procedures indicated above in Fig. 21.

Forward slide cutting (toward the operator) is very dangerous

because the saw blade could kick upward from the workpiece.

Therefore, always slide the handle away from the operator.

*Always return the carriage to the full rear position after each

crosscut operation in order to reduce the risk of injury.

*Never put your hand on the side handle during the cutting operation

because the saw blade comes close to the side handle when the

motor head is lowered.

and 305mm (12") wide:

Loosen the slide securing knob, grip the

handle and slide the saw blade forward.

Then press down on the handle and slide

the saw blade back to cut the workpiece

as indicated in Fig. 21. This facilitates

cutting of workpieces of up to 65mm (2-9/

16") in height and 305mm (12") in width.

and 280mm (11") wide:

Workpieces of up to 75mm (2-15/16") in

height and up to 280mm (11") in width can

be cut in the same manner as described

in paragraph 5-(1) above.

20

Page 21

6. Bevel cutting procedures

Loosen

Indicator

Tighten

Fig. 22

WARNING: When the workpiece is secured on the left or right side of the blade,

the short cut-off portion will come to rest on the right side of the

saw blade. Always turn the power off and let the saw blade stop

completely before raising the handle from the workpiece.

If the handle is raised while the saw blade is still rotating, the cut-off

piece may become jammed against the saw blade causing fragments

to scatter about dangerously.

When stopping the bevel cutting operation halfway, start cutting

after pulling back the motor head to the initial position.

Starting from halfway, without pulling back, causes the safety cover

to be caught in the cutting groove of the workpiece and to contact

the saw blade.

Scale

Clamp lever

(1) Loosen the clamp lever and bevel the saw

blade to the left.

(2) Adjust the bevel angle to the desired

setting while watching the scale and

indicator, then secure the clamp lever.

(3) Follow the procedures indicated in

paragraphs 4 and 5 above. For maximum

dimensions for bevel cutting of up to

39mm (1-9/16") in height and 305mm (12")

width.

7. Miter cutting procedures

Angle scale

Grade scale

Miter scale

Fig. 23

Fig. 24

(1) Loosen the side handle and adjust the

turntable until the indicator aligns with

desired setting on the miter scale (Fig. 25).

a

(2) Re-tighten the side handle to secure the

turntable in the desired position.

(3) The miter scale (Fig. 23) indicates both the

cutting angle on the angle scale and the

gradient on the grade scale.

(4) The gradient, which is the ratio of the

height to the base of the triangular section

to be removed, may be used for setting

the miter scale instead of the cutting

angle, if desired (see Fig. 24).

(5) Therefore, to cut a workpiece at a grade

of 2/10, set the indicator to position a as

indicated in Fig. 23.

21

Page 22

NOTE:* Positive stops are provided at the right

and left of the 0° center setting, at 15°,

22.5°, 30° and 45° settings.

Indicator

Turn the

turntable

Check that the miter scale and the tip

of the indicator are properly aligned.

* Operation of the saw with the miter

Miter

scale

Loosen

Side handle

Tighten

scale and indicator out of alignment,

or with the side handle not properly

tightened, will result in poor cutting

precision.

Fig. 25

8. Compound cutting

Compound cutting can be performed by following the instructions in 6 and 7 above.

At a bevel angle of 45° and a miter angle of 45°, a workpiece of 39mm (1-9/16") in height

and up to 220mm (8-21/32") in width can be cut.

CAUTION: Always secure the workpiece with the right hand side for compound

cutting. Never rotate the turntable to the right for compound cutting,

because the saw blade might then contact the clamp or vise that

secures the workpiece, and cause personal injury or damage.

9. Groove cutting procedures

Cut grooves with saw blade

8mm depth adjustment bolt

Turntable

Fig. 27

Fig. 26

8mm wing nut

Bottom line of

the groove

Grooves in the workpiece can be cut as indicated in Fig. 46 by adjusting the 8mm depth

adjustment bolt.

Cutting depth adjustment procedure:

(1) Loosen the 8mm wing nut and turn the 8mm depth adjustment bolt by hand.

(2) Adjust to the desired cutting depth by setting the distance between the saw blade

and the surface of the base (see b in Fig. 26).

(3) The 8mm wing nut must be properly tightened after the adjustment has been

completed.

22

Page 23

NOTE: When cutting a single groove at either end of the workpiece, remove the

unneeded portion with a chisel.

10. Cutting easily-deformed materials, such as aluminum sash

Materials such as aluminum sash can easily deform when tightened too much in a vise

assembly. This will cause inefficient cutting and possible overload of the motor.

When cutting such materials, use a wood plate to protect the workpiece as shown in

Fig. 28.

When cutting aluminum materials, coat the saw blade with cutting oil (non-combustible)

to achieve smooth cutting and a fine finish.

Vise assembly

Fence

10mm knob bolt

Wood plate

Aluminum

sash

Fig. 28

11. How to use the dust bag (Standard accessory)

Dust bag

Right angle

Duct

Saw cover

Fig. 29

(1) When the dust bag has become full of

sawdust, dust will be blown out of the dust

bag when the saw blade rotates.

Check the dust bag periodically and empty

it before it becomes full.

(2) During bevel and compound cutting,

attach the dust bag at a right angle to the

base plate as shown in Fig. 29.

CAUTION: Empty the dust bag frequently to prevent the duct and the safety

cover from becoming clogged.

Sawdust will accumulate more quickly than normal during bevel

cutting.

Wood plate

SAW BLADE MOUNTING AND DISMOUNTING

WARNING: * To prevent an accident or personal injury, always turn off the trigger

switch and disconnect the power plug from the receptacle before

removing or installing a saw blade.

23

Page 24

1. Mounting the saw blade (Fig. 30-a and Fig. 30-b)

(1) Press in spindle lock and loosen bolt with 10mm box wrench (standard accessory).

Since the bolt is left-hand threaded, loosen by turning it to the right as shown in

Fig. 30-b.

NOTE: If the spindle lock cannot be easily pressed in to lock the spindle, turn the

bolt with 10mm box wrench (standard accessory) while applying pressure

on the spindle lock.

The saw blade spindle is locked when the spindle lock is pressed inward.

Spindle lock

Fig. 30-a

Tighten

Fig. 30-b

Washer (C)

Bolt

Loosen

(2) Remove the bolt, washer (C) and collar.

(3) Before mounting the saw blade, carefully clean and re-install the collar. The collar

has out -side diameters of 30mm (1-3/16") as shown in Fig. 31.

Washer (C)

15.9mm (5/8")

30mm (1-3/16")

Collar

Saw blade

Washer (C)

Bolt 10mm box wrench

Fig. 31

(4) Lift the safety covers (safety covers and sub cover) and mount the saw blade.

WARNING: When mounting the saw blade, confirm that the rotation indicator

mark on the saw blade and the rotation direction of the saw are

properly matched.

(5) Thoroughly clean washer (C) and the bolt, and install them onto the saw blade

spindle.

(6) Press in the spindle lock and tighten the bolt by turning it to the left by 10mm box

wrench as indicated in Fig. 30-b.

24

Page 25

CAUTION: *Confirm that the spindle lock has returned to the retract position

after installing or removing the saw blade.

*Tighten the bolt so it does not come loose during operation.

Confirm the bolt has been properly tightened before the power

tool is started.

2. Dismounting the saw blade

Dismount the saw blade by reversing the mounting procedures described in paragraph

1 above.

The saw blade can easily be removed after lifting the safety cover.

CAUTION: Never attempt to install saw blades larger than 216mm (8-1/2") in

diameter.

Always install saw blades that are 216mm (8-1/2") in diameter or

less.

MAINTENANCE AND INSPECTION

WARNING: To avoid an accident or personal injury, always confirm that the

trigger switch is turned OFF and the power plug has been

disconnected from the receptacle before performing any

maintenance or inspection of this tool.

1. Inspecting the saw blade

Always replace the saw blade immediately upon the first sign of deterioration or damage.

A damaged saw blade can cause personal injury and a worn saw blade can cause

ineffective operation and possible overload to the motor.

CAUTION: Never use a dull saw blade. When a saw blade is dull, its resistance

to the hand pressure applied by the tool handle tends to increase,

making it unsafe to operate the power tool.

2. Adjusting a loose slide pipe

After extended use of the power tool, the slide

8mm hex. socket

set screw

Fig. 32

Bushing

8mm nut

Slide pipe (A)

pipe (A) and the bushing can become loose

due to vibration. Never operate the tool if any

components are loose to avoid personal

injury.

(1) Loosen the 8mm nut and tighten the four

8mm hexagon socket set screws until the

power tool operates smoothly without

looseness. (Fig. 32)

(2) Properly tighten the 8mm nut after

completing these adjustment.

25

Page 26

3. Inspecting the carbon brushes (Fig. 33 and Fig. 34)

The carbon brushes in the motor are expendable parts.

If the carbon brushes become excessively worn, motor trouble might occur.

Therefore, inspect the carbon brushes periodically and replace them when they have

become worn to the wear limit line as shown in Fig. 33.

Also, keep the carbon brushes clean so that they will slide smoothly within the brush

holders.

The carbon brushes can easily be removed after removal of the brush caps (see Fig. 34)

with a slotted (minus) screwdriver.

Wear limit line

43

Brush cap

6mm (1/4")

17mm (11/16")

No. 43 indicates the last

two numbers of carbon

brush Code No.

Groove for driver

Fig. 33

Fig. 34

4. Inspecting the screws

Regularly inspect each component of the power tool for looseness.

Re-tighten screws on any loose part.

WARNING: To prevent personal injury, never operate the power tool if any

components are loose.

5. Inspecting the safety cover for proper operation

Before each use of the tool, test the safety covers (see Fig. 8) to assure that they are in

good condition and that they move smoothly.

Never use the tool unless the safety cover operates properly and unless they are in

good mechanical condition.

6. Storage

After operation of the tool has been completed, check that the following has been

performed:

(1) Trigger switch is in OFF position,

(2) Power plug has been removed from the receptacle an stored in a secure place.

When the tool is not in use, keep it stored in a dry place out of the reach of children.

7. Lubrication

Lubricate the following sliding surfaces once a month to keep the power tool in good

operating condition for a long time (see Fig. 1 and Fig. 2). Use of machine oil is

recommended.

Oil supply points:

*Rotary portion of hinge

*Rotary portion of vise assembly

*Sliding portion of slide pipe (A) and slide pipe (B)

26

Page 27

8. Cleaning

Periodically remove chips, dust and other waste material from the surface of the power

tool with a damp, soapy cloth. To avoid a malfunction of the motor, protect it from

contact with oil or water.

SERVICE AND REPAIRS

All quality power tools will eventually require servicing or replacement of parts because of

wear from normal use. To assure that only authorized replacement parts will be used and

that the double insulation system will be protected, all service (other than routine

maintenance) must be performed by an AUTHORIZED HITACHI POWER TOOL REPAIR

CENTER ONLY.

NOTE: Specifications are subject to change without any obligation on the part of

HITACHI.

27

Page 28

28

Page 29

Item

No.

1 MACHINE SCREW M4×16 1

2 BOLT WASHER M4 1

3 NYLON CLIP 2

4 HINGE ASS'Y (INCLUD.5) 1

5 SUPPORT 1

6 ROLL PIN D6×40 2

7 MACHINE SCREW M5×12 2

8 PACKING COVER 2

9 FELT 4

10 BALL BUSHING 1

11 BUSHING 4

12 HEX. SOCKET SET SCREW M8×81

13 BEARING LOCK 1

14 KNOB BOLT M8×20 1

15 LOCK SPRING 1

16 LOCK NUT M8 4

17 HEX. SOCKET SET SCREW M8×16 4

18 GUARD 1

19 BOLT WASHER M8 1

20 SPRING WASHER M8 1

21 MACHINE SCREW M8×30 1

22 HANDLE 1

23 WING NUT M8 1

24 SEAL LOCK HEX. SOCKET HD. BOLT M5×10 1

25 GEAR CASE (A) 1

26 HEX. SOCKET SET SCREW M6×16 1

27 SLEEVE 1

28 SPRING 1

29 NUT M8 2

30 BOLT M8×100 1

31 STOP SPRING 1

32 SPACER 2

33 WASHER 2

34 SEAL LOCK MACHINE SCREW M5×12 2

35 LOCK LEVER 1

36 STOPPER PIN 1

37 MACHINE SCREW (W/WASHERS) M5×20 1

38 COLLAR (B) 1

39 SPRING 1

40 RETAINING RING (E-TYPE) FOR D7 SHAFT 1

41 SET PIN 1

42 GAUGE SPRING 1

43 ROLL PIN D3×20 1

44 GRIP 1

45 HINGE SHAFT (A) 1

46 MACHINE SCREW (W/WASHERS) M4×12 1

47 CLAMP LEVER 1

48 BOLT (LEFT HAND) M10 1

49 WASHER (I) 1

50 CAP NUT M12 1

51 NUT M12 1

52 BOLT WASHER M12 1

53 HOLDER (A) 1

54 CAUTION LABEL (A) 1

55 TABLE INSERT 2

56 MACHINE SCREW M6×20 6

57 NYLOCK BOLT M8×25 2

58 SLOTTED PIN D8×30 1

59 HOLDER SHAFT 1

60 INDICATOR 1

Part Name Q’TY

Item

No.

61MACHINE SCREW (W/WASHERS) M6×10 1

62 SHAFT 1

63 MACHINE SCREW (W/WASHERS) M4×12 1

64 INDICATOR 1

65 FLAT HD. SCREW M6×16 2

66 HINGE ARM 1

67 TURN TABLE (A) 1

68 SPRING (C) 1

69 STEEL BALL D12.7 1

70 LINER 3

71 BASE ASS'Y (INCLUD.72-77) 1

72 BOLT M6×16 1

73 HOLDER 1

74 KNOB BOLT M6×52 2

75 BASE RUBBER 5

76 BOLT WASHER M5 5

77 MACHINE SCREW M5×20 5

78 VISE ASS'Y (INCLUD.79-85) 1

79 KNOB BOLT M10 1

80 KNOB BOLT M6×11 1

81 WASHER 1

82 VISE PLATE SET 1

83 WASHER 1

84 MACHINE SCREW (W/WASHERS) M5×12 1

85 VISE SHAFT 1

86 KNOB BOLT M10×70 1

87 FENCE (B) 1

88 BOLT (W/WASHERS) M8×35 2

89 SPACER 1

90 MACHINE SCREW M4×10 1

91 SIDE HANDLE 1

92 SHAFT 1

93 RETAINING RING (E-TYPE) FOR D7 SHAFT 1

94 BOLT (W/WASHERS) M8×35 2

95 FENCE (A) 1

96 GUIDE ASS'Y (INCLUD. 74, 97-99) 1

97 STOPPER 1

98 KNOB BOLT M6×11 1

99 HOLDER 1

100 WASHER (T) 1

101 NUT M12 1

102 LOCK NUT M12 1

Part Name Q’TY

29

Page 30

30

Page 31

Item

No.

131 RUBBER RING 1

132 ARMATURE ASS'Y (INCLUDE. 133, 135) 1

133 BALL BEARING 6001VVCMPS2L 1

134 BEARING LOCK 1

135 BALL BEARING 608VVC2PS2L 1

136 FAN GUIDE (B) 1

137 MACHINE SCREW (W/WASHERS) M5×60 2

138 STATOR ASS'Y (INCLUD139) 1

139 BRUSH TERMINAL 2

140 HANDLE COVER 1

141 SWITCH (2P PILLAR TYPE) W/O LOCK 1

142 NAME PLATE 1

143 TAPPING SCREW (W/FLANGE) D4×25 3

144 MACHINE SCREW (W/WASHERS) M5×50 3

145 TAIL COVER 1

146 TAPPING SCREW (W/FLANGE) D4×20 1

147 CORD 1

148 NOISE SUPPRESSOR 1

149 TAPPING SCREW (W/WASHER) D4×16 2

150 CORD CLIP 1

151 TUBE (D) 1

152 CORD ARMOR 1

153 CARBON BRUSH 2

154 BRUSH CAP 2

155 HOUSING ASS'Y (INCLUD.157, 158) 1

156 HEX. SOCKET SET SCREW M5×62

157 BRUSH HOLDER 2

158 WASHER (B) 1

159 TAPPING SCREW (W/FLANGE) D4×25 1

160 MACHINE SCREW (W/WASHERS) M5×81

161 DUCT 1

162 NYLON CLIP D6.3 1

163 MACHINE SCREW (W/WASHERS) M5×16 1

164

FLAT HD.SCREW (W/TOOTHED LOCK WASH)M5×35

165 COVER HOLDER 1

166 SPINDLE ASS'Y (INCLUD.168-170) 1

167 BALL BEARING 6004VVCMPS2L 1

168 BEARING HOLDER 1

169 BALL BEARING 608VVC2PS2L 1

170 PAN HD. SCREW M5×10 4

171 SAW COVER ASS'Y (INCLUD.173-178) 1

172 HITACHI LABEL 1

173 MACHINE SCREW (W/WASHERS) M5×81

174 SPACER 1

175 WING NUT M5 1

176 WASHER M5 1

177 SPINDLE COVER 1

178 BOLT (LEFT HAND) W/WASHER M7×17.5 1

179 WASHER (C) 2

180 COLLAR (A) FOR D30 HOLE 1

181

FLAT HD. SCREW(W/TOOTHED LOCK WASH)M4×12

182 COVER 1

183 SAFETY COVER 1

184 TAPPING SCREW D4×10 1

185 SUB PLATE 1

186 RETURN SPRING 1

188 SUB COVER 1

501 DUST BAG 1

502 BOX WRENCH 10MM 1

601 TCT SAW BLADE 216MM-D30 HOLE-NT24 1

Part Name Q’TY

2

2

31

Page 32

Hitachi Koki Co., Ltd.

706

Code No. C99164611 N

Printed in Japan

Loading...

Loading...