Hitachi C21-TF641S, C21-TF641SN, C21-TF641ST, C21-TF641SNT, C21-TF651S Service Manual

...

…

…

…

…

…

…

HITACHI

HITACHI

HCPT

C21-TF641S/SN/ST/SNT

C21-TF651S/SN/ST/SNT

T1-001

SERVICE MANUAL

C21-TF751S/SN/ST/SNT

C21-TF571S/SN/ST/SNT

T1 Chassis

CAUTION :

CONTENTS

SAFETY PRECAUTIONS ...………………...…………….……………………………………………

PRODUCT SAFETY NOTICE …………...…………….………...……………...…………….………

REMOTE CONTROL UNIT ……………..………...…………….……………………………………

Before servicing this chassis, it is important that the service techician reads the " Safety Precaution "

and " Product Safety Notices " in this Service Manual.

2

2

3

GENERAL OPERATIONS GUIDE .………………...…………….……………………………………

CIRCUIT DESCRIPTION …………...…………….……………………………………………………

ADJUSTMENT INSTRUCTIONS ……………………...…………….…………………………………

REPLACEMENT PARTS LIST …………………...…………….………………………………………

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT.

COLOR TELEVISION

4

5

6

12

MARCH 2005 Hitachi Consumer Products ( THAILAND ) , Ltd.

SAFTY PRECAUTIONS

WARNING: The following precautions should be

opserved.

1. Do not install , remove, or handle the picture tube in could produce X-radiation moderately in excess of de any manner unless shatter proof goggles are worn. sign levels. The high voltage must not, under any cir People not so equipped should be kept away while cumstances, exceed 32kV on the chassis.

picture tubes are handled. Keep picture tube away

from the body while handing.

2. When service is required, an isolation transformer receiver is the picture tube. The tube utilized for the

should be inserted between power line and the above mentioned function in this chassis is specially

receiver before any service is performed on the constructed to limit X - radiatuion.

chassis. For continued X-radiation protection, replace tube with

3. When replacing the chassis in the cabinet,ensure

all the protective devices are put back in place,such

as barriers, non - metallic knobs, adjustment or

compartment covers or shields, isolation resistors/ Many electrical and mechanical parts in HITACHI

capacitors, etc. television receiver have special safety related

4. When service is required, observe the original lead evident from visual inspection, nor can be protection

dressing. Extra precaution should be taken to afforded by them necessarily be obtained by using

assure correct lead dressing in the high voltage

circuitry area. Particularly note the R. G. B. lead wattage, etc. Replacement parts which have these

dressing. Ensure they are dressed well away from special safety characteristics are identified by marking

the horizontal scan and F.B.T. circuitry. with a on the schematics and replacement

5. Always use the manufacturer ' s replacement

component. Always replace original spacers and safety characteristics as the HITACHI recommended

maintain lead lengths. Especially critical components replacement one, shown in the parts list in this Service

are indicated thus on the parts list and Manual, may create electrical shock, fire, X - radiation,

should not be replaced by other makes.

Furthermore, where a short circuit has occurred,

replace those components that indicate evidence of Product Safety is continuously under review and new

overheating. instructions are issued from time to time. For the latest

6. Before returning a serviced receiver to the customer, Manual. A subscription to ,or additional copies of

the service technician must thoroughly test the unit HITACHI Service Manuals may be obtained at a nominal

to be certain that it is completely safe to operate charge from your HITACHI sales offices.

without danger of electrical shock, and be sure that

no protective device built into the instrucment by the

manufacturer has became defective, or inadvertenly The line output stage can develop voltages in excess

damaged during servicing. Therefore, the following of 25 kV; if the E.H.T cap is required to be removed,

checks are recommended for the continued discharge the anode cap to chassis via a high value

protection of the customers and service techninians. resistor, prior to its removal from the tube.

HIGH VOLTAGE

High voltage should always be kept at the rated value

of the chassis and no higher. Operating at higher

voltages may cause a failure of the picture tube or high

voltage supply, and also, under certain circumstances

X-RADIATION

TUBES : The primary source of X - radiation in this

the same type as the original, HITACHI approved type.

PRODUCT SAFETY NOTICE

characteristics. These characteristics are often not

replacement components rated for higher voltage,

parts list in this Service Manual.The use of a substitute

replacement component which does not have the same

or other hazards.

information,always consult the current HITACHI Service

TUBE DISCHARGE

INSULATION

Insulation resistantce should not be less than 4.5 Mohm

at 500 VDC between the mains poles and any accessible

metal parts. Also, no flashover or breakdown should

occur during the dielectric strength test, applying 3.2kV

AC for two seconds between the main poles and

accessible metal parts.

- 2 -

R

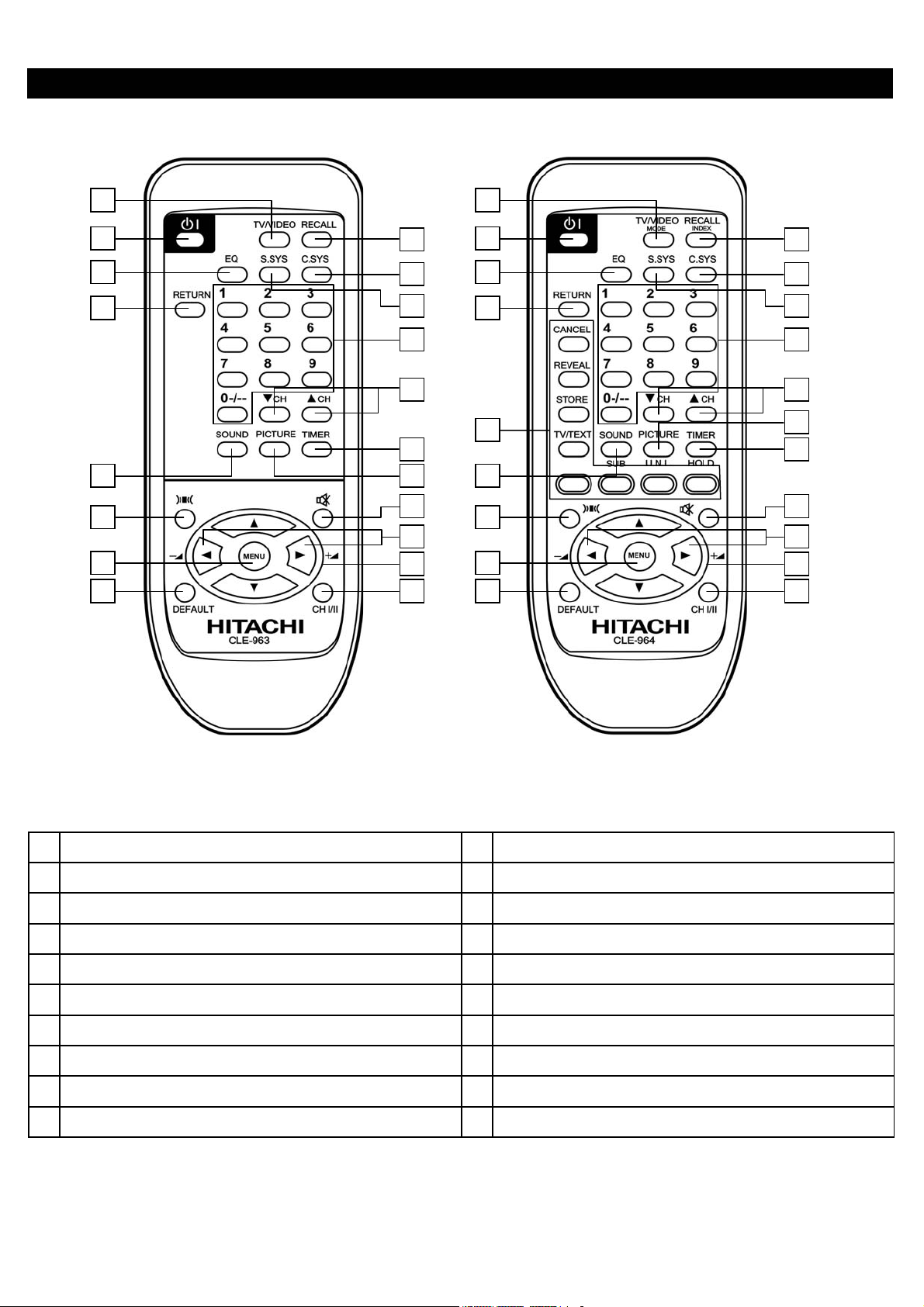

REMOTE CONTROL UNIT

19

16

10

11

2

1

6

7

5

17

18

14

4

8

9

12

3

15

13

19

16

20

10

11

2

1

6

7

5

17

18

14

4

9

8

12

3

15

13

Models without Teletext Models with Teletext

1. 11.

POWER ON/OFF SWITCH DEFAULT

2. 12.

INPUT SELECTOR MUTE

3. 13.

VOLUME UP/DOWN CHI/II (FOR NICAM/A2 MODELS)

4. 14.

PROGRAMME UP/DOWN PROGRAMME SELECTOR (DIRECT KEY)

5. 15.

RECALL CURSO

6. 16.

SURROUND SOUND RETURN

7. 17.

MENU COLOR SYSTEM

8. 18.

TIMER SOUND SYSTEM

9. 19.

PICTURE EQUALIZER

10. 20

SOUND T/TEXT FUNCTION KEY (T/TEXT MODELS ONLY)

- 3 -

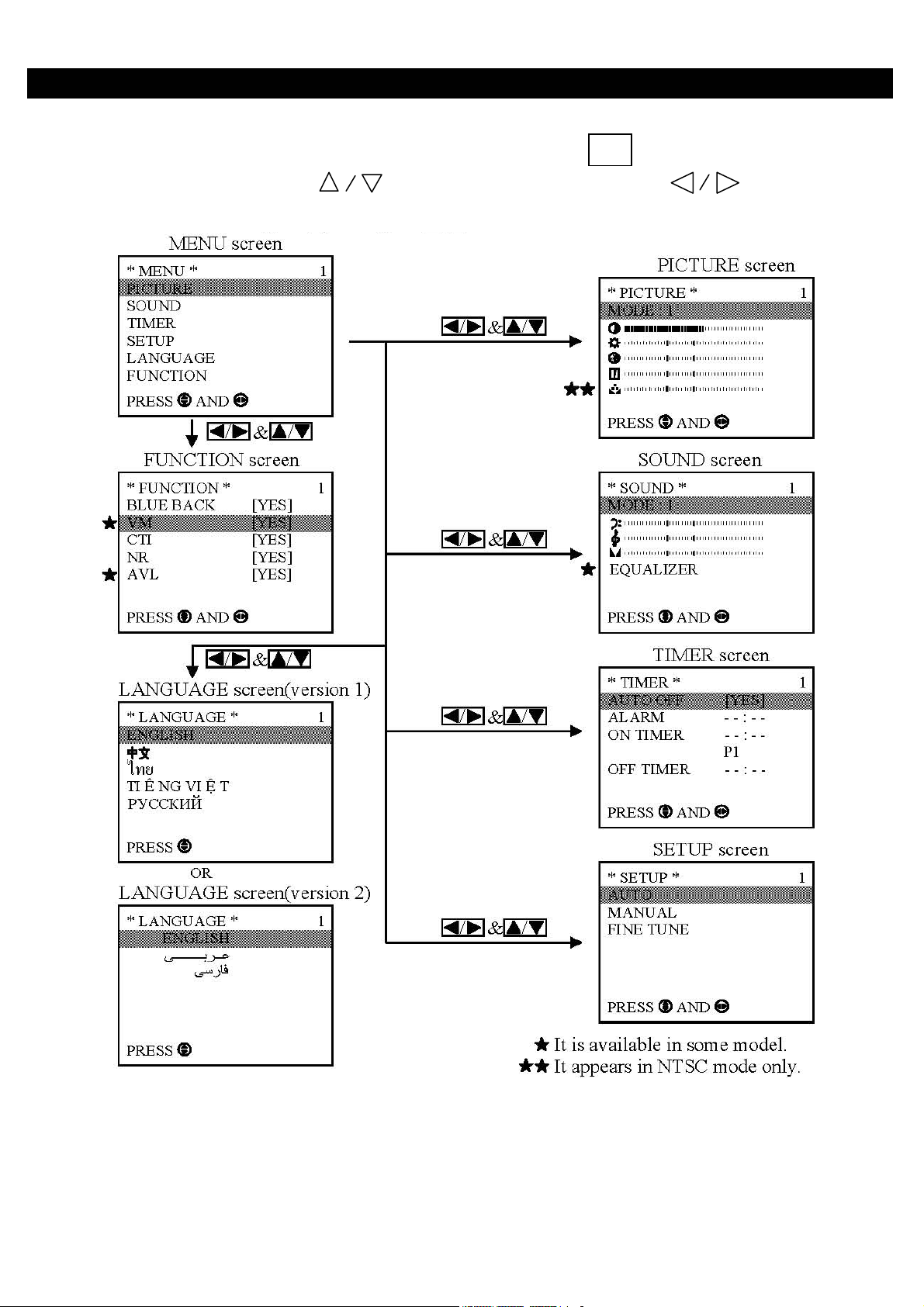

GENERAL OPERATIONS GUIDE

With this set, all adjustments/settings are performed by selecting from menu screens. Different menu screens and details

of adjustments/settings are shown below. To access the menu screen, press the button, then select the item by

pressing the up/down cursor buttons and adjust by the left/right cursor buttons .

MENU

- 4 -

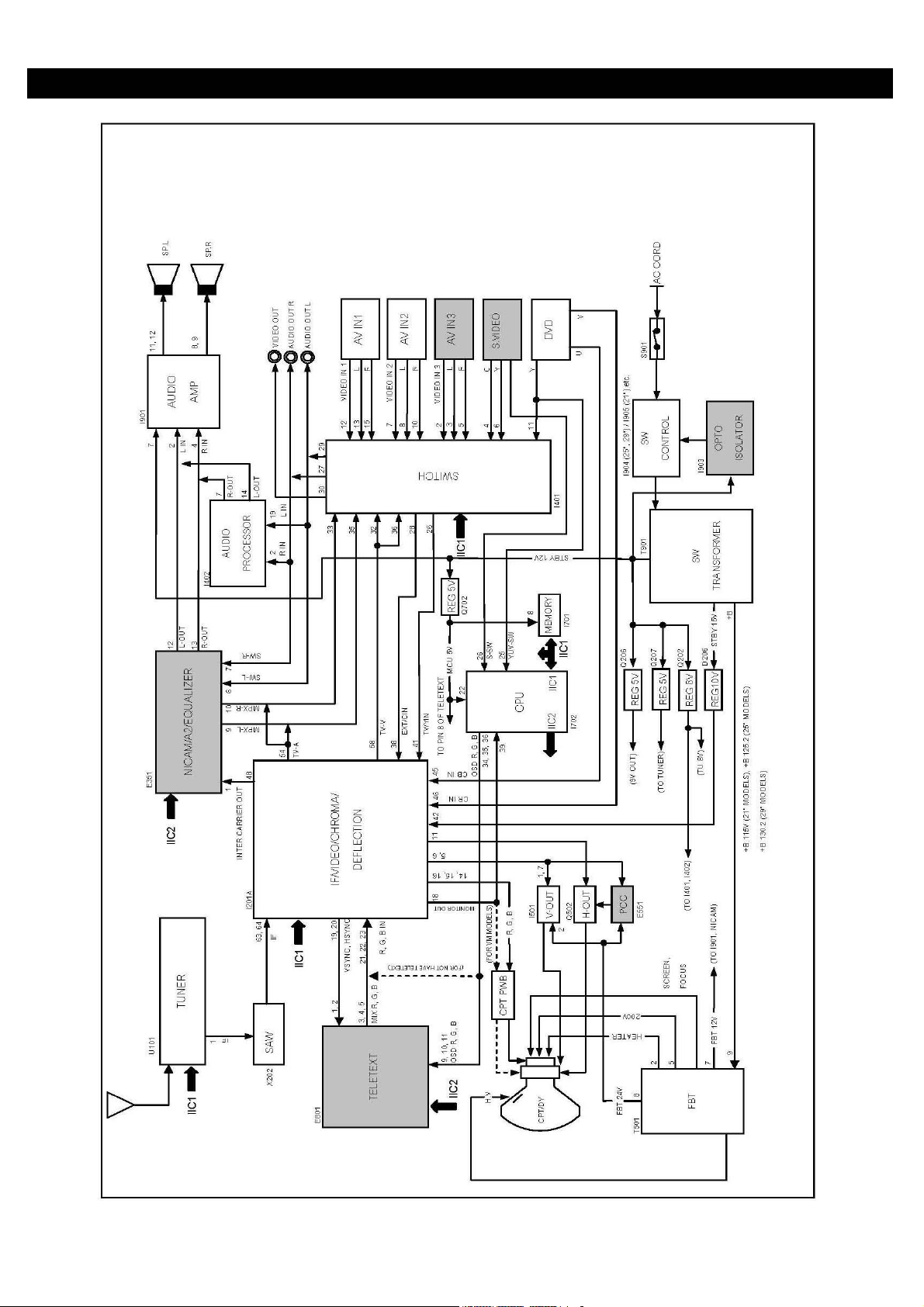

BLOCK DIAGRAM

- 5 -

A

A

DJUSTMENT INSTRUCTIONS

HOW TO GO TO SERVICE MODE

1. How to go to adjustment mode no 001 ~ 022

Procedure

(1) Turn TV off by power switch on the TV set.

(2) Press " FUNCTION " button on the TV set and kept depress the button.

(3) Turn TV on by power switch on the TV set.

2. How to go to adjustment mode no 101 ~ 328

Procedure

(1) Set volume to be “0”.

(2) Press button on remote control to go to standby mode.

(3) Press “TV/VIDEO” button on the TV set, and kept depress the button.

(4) Press button on remote control to go to operation mode.

(5) TV will show service table,then please cancel to keep depress the "TV/VIDEO" button.

Note : 1. Press the UP/DOWN cursor buttons

2. Adjust data by the left/right cursor buttons .

3. Press "RECALL" buttons to restore the data.

+B ADJUSTMENT

PREPARATION PROCEDURES

1

AC input voltage 230 +

2 Turns on the set and set the brightness and contrast +B voltage : TP902

to Max.(Signal : Philips Pattern) GND : TP901

3 After 30 sec heat-run, check & adjust the +B voltage

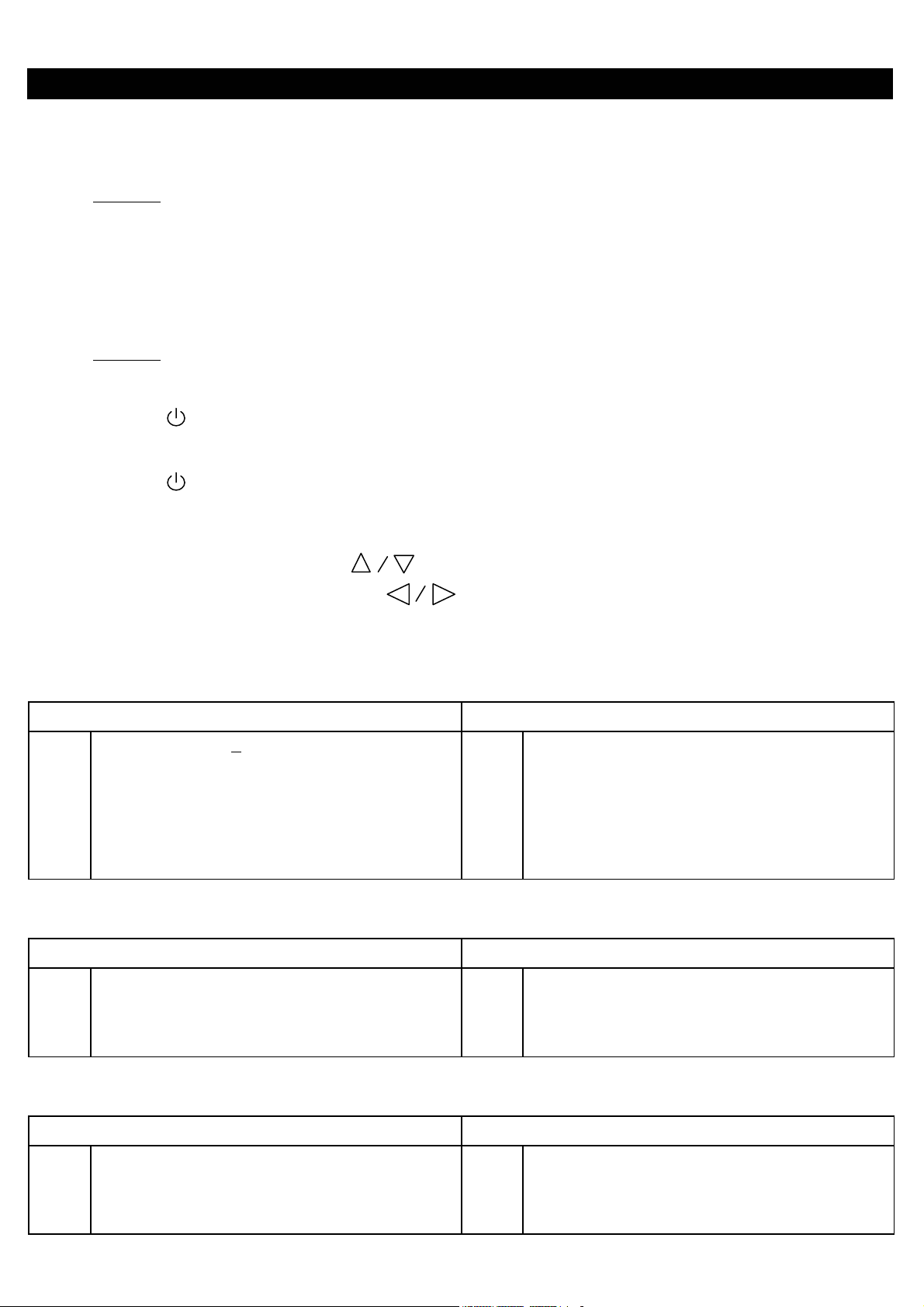

FREE RUN FREQUENCY ADJUSTMENT

Receive a PAL-I monoscope signal on TV mode.

1

5V(50Hz)

PREPARATION PROCEDURES

to select adjustment mode no.

1

1

djust R954 to obtain +B voltage as below

Select adjustment mode no. 1 and press "MENU" button

one time.

VIF-VCO FREE RUN FREQUENCY ADJUSTMENT

PREPARATION PROCEDURES

Receive a PAL-I monoscope signal on TV mode.

1

Select adjustment mode no. 2 and press "MENU" button

1

one time.

- 6 -

SOUND TRAP FREQUENCY ADJUSTMENT

A

PREPARATION PROCEDURES

Receive a PAL-I monoscope signal on TV mode.

1

Select adjustment mode no. 3 and press "MENU" button

1

one time.

SECAM R-Y OFFSET ADJUSTMENT

PREPARATION PROCEDURES

1 Receive a secam color bar signal on Video 2. 1 Select adjustment mode no. 4.

2 Connect oscilloscope probe to pin 5 of E701. 2 Adjust output level at pin 5 of E701 as indicated below

using service mode no. 4.

0 +

0.1 V

SECAM B-Y OFFSET ADJUSTMENT

PREPARATION

1 Receive a secam color bar signal on Video 2. 1

2 Connect oscilloscope probe to pin 5 of E701. 2

Select adjustment mode no. 5.

djust output level at pin 5 of E701 as indicated below

PROCEDURES

using service mode no. 5.

0.1 V

0 +

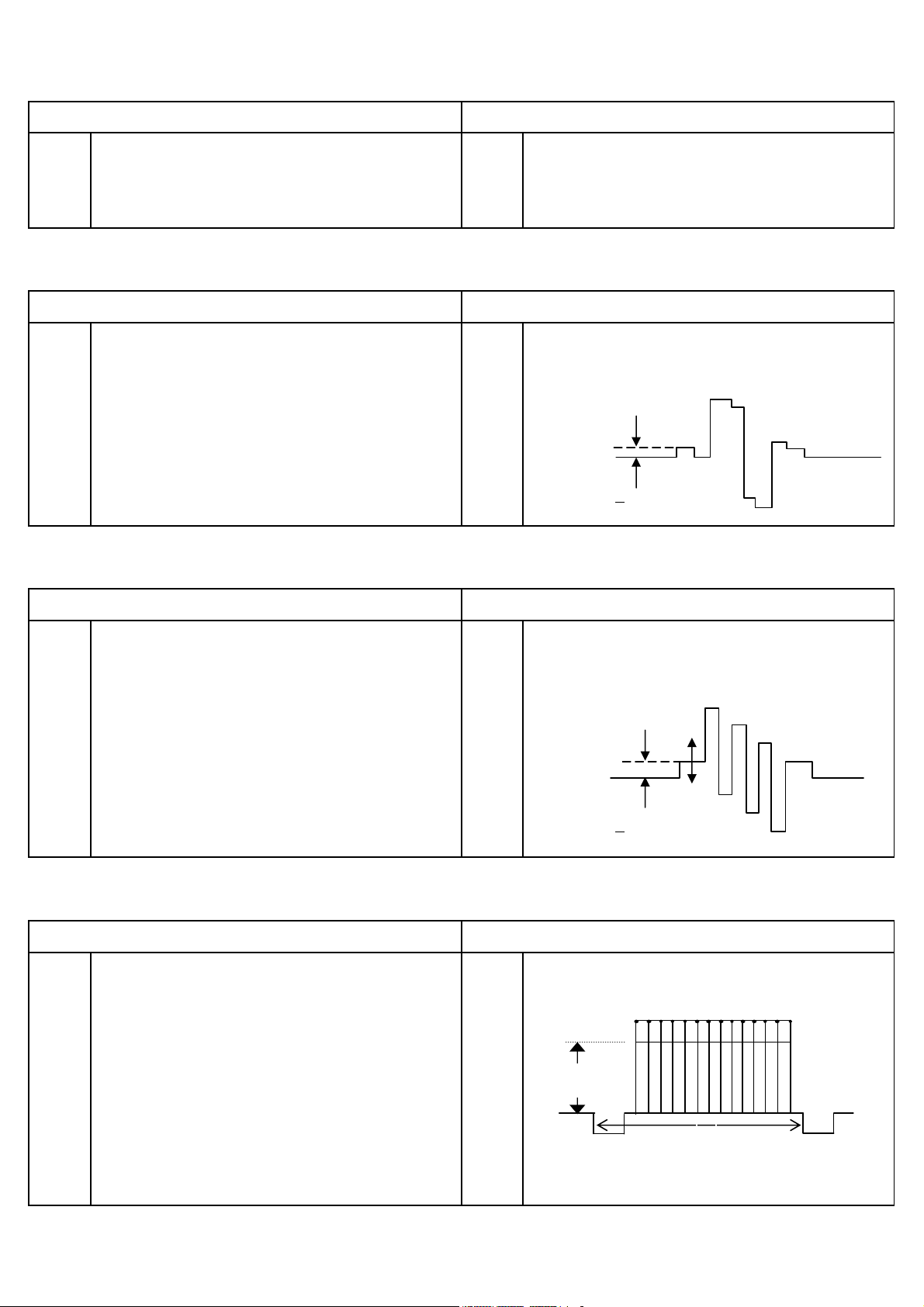

WHITE PEAK LEVEL ADJUSTMENT

PREPARATION PROCEDURES

1 Connect oscilloscope probe to pin 3 of E202 on CPT 1 Adjust output level at pin 3 of E202 as indicated below

P.W.B with respect to ground. using service mode no. 15.

2 Input PAL cross hatch signal to Video 2 terminal.

Cross hatch signal input level : 1 Vpp + 10%(with load

A

75 ohm) or 2 Vpp + 10%(no load).

3 Set CONTRAST to MAX.

1H

4 Set data in adjustment mode no.15 to 90. A = 2.8 + 0.1Vpp

- 7 -

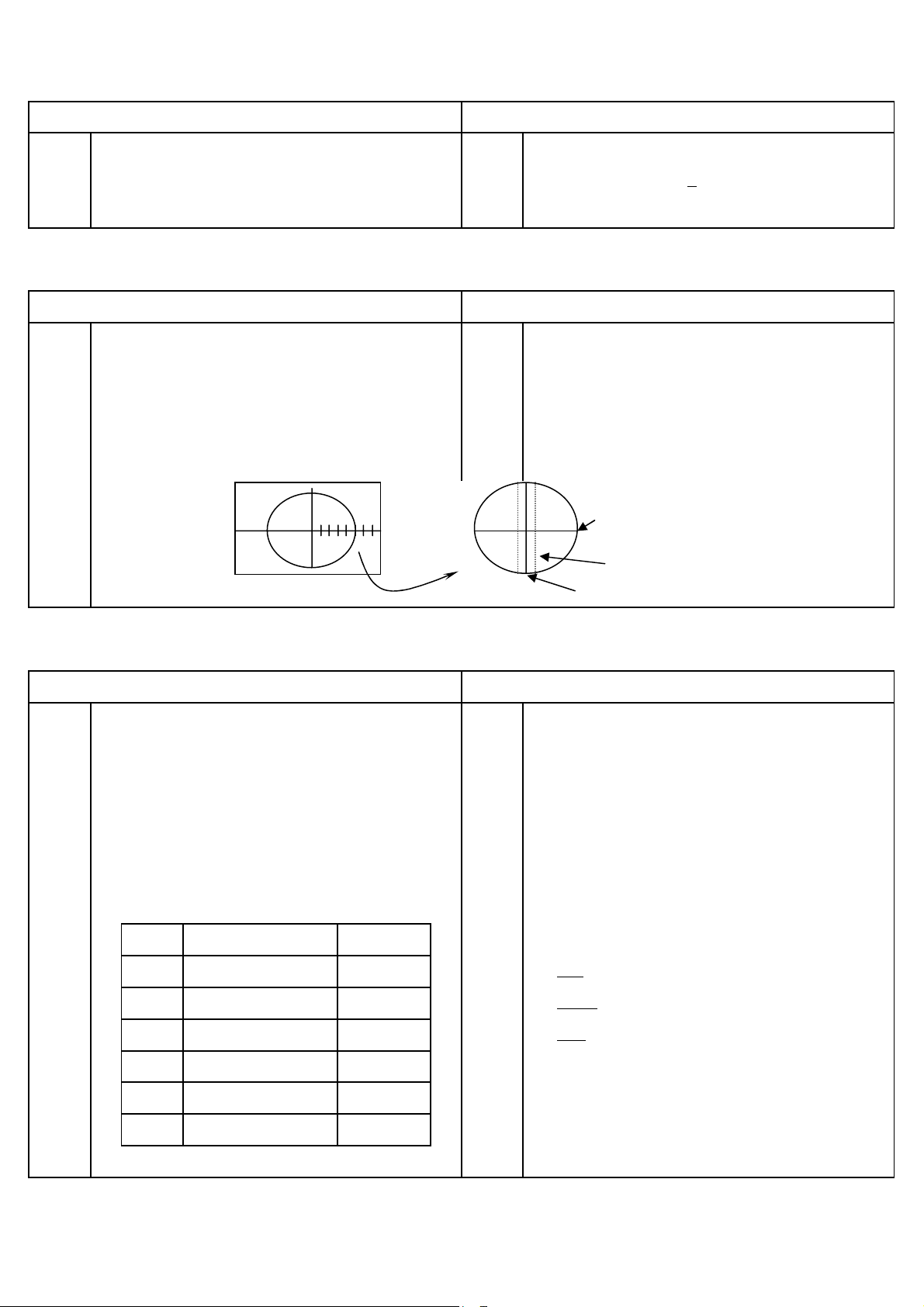

VERTICAL SHIFT ADJUSTMENT

PREPARATION PROCEDURES

1 Preheat more than 5 minutes of power supply. 1 Select the IIC control address No. 11.

2 Receive PAL Philips pattern signal. 2 Set the horizontal center line to vertical center maker

of CRT by adjustment of IIC.

Vertical center marker of CRT

VERTICAL SIZE ADJUSTMENT

PREPARATION PROCEDURES

1 Preheat more than 5 minutes of power supply. 1 Select the IIC control address No. 12.

2 Receive Philips pattern signal. 2 Adjust IIC data to obtain the following conditions.

PAL

Check vertical amplitude as below by

3

NTSC circle pattern.

NTSC

4 If picture isn't center, go back to IIC control No. 11 and

adjust IIC data to obtain the following conditions.

- 8 -

HORIZONTAL CENTER ADJUSTMENT

s

PREPARATION PROCEDURES

1 Side pin adjustment should be already completed. 1 Adjust adjustment mode no. 13 so that the average

2 Receive circle pattern signal. reading of R and L is 2.0 +

0.5 at circle pattern signal.

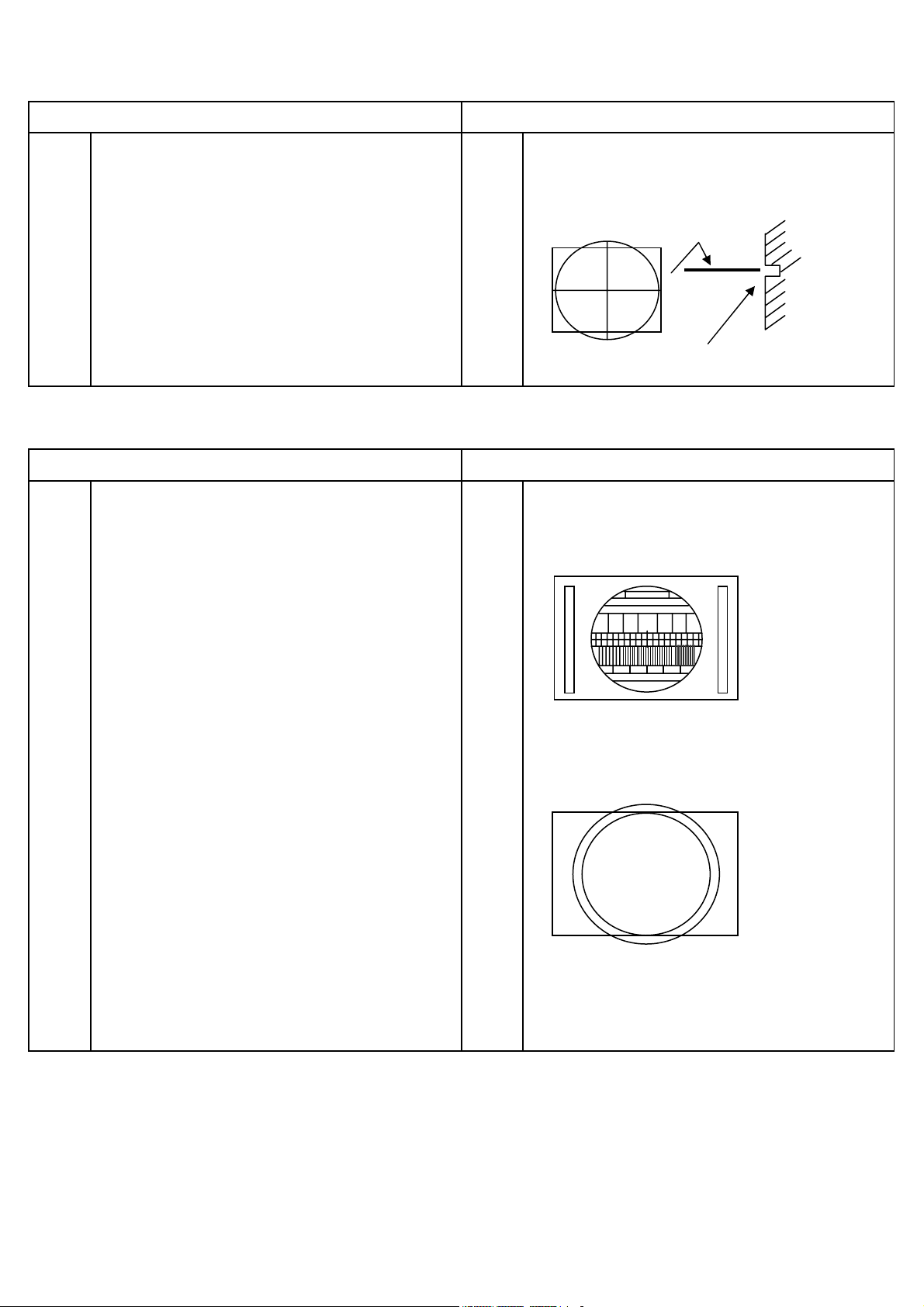

FOCUS ADJUSTMENT

PREPARATION PROCEDURES

1 Receive Philips pattern signal. 1 Set picture to mode 1

2 Vertical amplitude adjustment should be already 2 Turn the focus VR gradually clockwise from the full

completed. counterclockwise and adjust so that the halo of vertical

3 Adjust the cut-off after pre-adjust focus VR. center line does not appear, and horizontal line is

4 Check the cut-off in case focus is re-adjusted MIN. width.

HORIZONTAL

1 2 3 4 5 6 7

NO.5

ZOOM

HALO

VERTICAL

WHITE BALANCE ADJUSTMENT

PREPARATION PROCEDURES

1 Adjust the W/B after the Power is turned ON for 20 minute

1 Turn the screen adjusting VR clockwise and set it to the

2 Purity adjustment should be completed. position where the bright line starts appearing on CPT

3 Set the vertical incident illumination on the CPT surface screen.

to 20 lux or less. 2 Take the first appeared color as the reference. Adjust the

4 Receive white raster signal. other colors by remote until both appear to be the same

5 Set adjustment mode data as table on the next page level as the reference. (A white horizontal line is seen at

to default.

Disp No ITEM Default

R-CUTOFF

016

G-CUTOFF

017

B-CUTOFF

018

R-DRIVE

019

B-DRIVE

020

127

127

127

63

63

the CPT center.)

Low brightness adjustment data

Red

Green

Blue

………. ”1” key for up, “4” key for down.

………. ”2” key for up, “5” key for down.

………. ”3” key for up, “6” key for down

Don’t change the data of the reference color

3 Exit the lateral line mode. (Press “MUTE” by remote).

021

SUB-BRIGHT

127

4 Set white balance meter at the center of the screen.

- 9 -

WHITE BALANCE ADJUSTMENT(Continued)

A

PREPARATION PROCEDURES

6 Turn the screen adjustment VR fully counterclockwise. 5

7 Set to lateral line mode by Press “MUTE” button on

djust brightness control so that the indication of the

brightness meter is a prescribed value of brightness

remote control . adjustment. Adjust white balance with the white balance

control data (Red/Blue).

High brightness adjustment data

Red

Blue

………. ”7” key for up, “0” key for down.

………. ”8” key for up, “9” key for down.

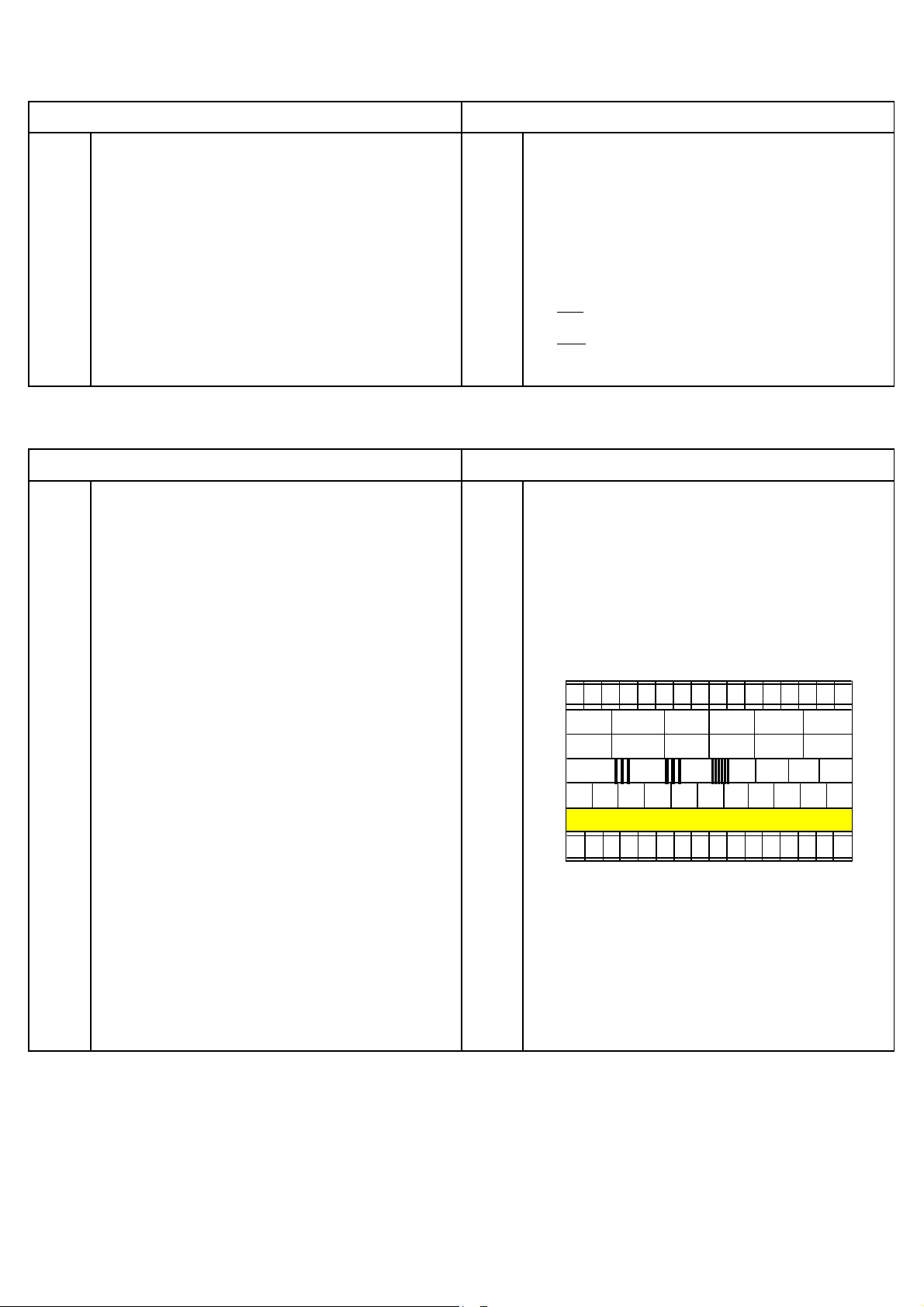

SUB-BRIGHTNESS ADJUSTMENT

PREPARATION PROCEDURES

1 Turn the TV set on and heat run for 20 minutes or more. 1 Press "PICTURE" key until go to picture mode 2.

2 Horizontal size adjustment and side pin adjustment 2 The sub-brightness should be adjusted (Adjustment

should be completed. mode no. 21) using11 steps gray scale (A1-A1) of color

3 Receive Philips pattern signal. bar pattern

Set picture mode 2 as shown below. 3 Adjust until A10 is complete black and A9 is lightly black.

4 Go out from service mode.

CONTRAST : 0

COLOR : 0

BRIGHTNESS : 50

A

11

A10A

A8A7A6A5A4A3A2A

9

1

5 Adjust picture mode 2 as below.

CONTRAST : 100

COLOR : 60

BRIGHTNESS : 50

6 Press "PICTURE" key until go to picture mode 1.

- 10 -

Loading...

Loading...