Page 1

No. 0102

SERVICE MANUAL

MANUEL D'ENTRETIEN

WARTUNGSHANDBUCH

CAUTION:

Before servicing this chassis, it is important that the service technician read the “Safety

Precautions” and “Product Safety Notices” in this service manual.

ATTENTION:

Avant d’effectuer l’entretien du châassis, le technicien doit lire les «Précautions de sécurité»

et les «Notices de sécurité du produit» présentés dans le présent manuel.

VORSICHT:

Vor Öffnen des Gehäuses hat der Service-Ingenieur die „Sicherheitshinweise“ und „Hinweise

zur Produktsicherheit“ in diesem Wartungshandbuch zu lesen.

Model

C1422R/RS

C1422T/TS

C2122T

CP1422R

CP2122R

CP1422T/TS

CP2022T

CP2122T

CP1422T-481

CP2122T-481

CP1422T-491

CP2022T-491

CP2122T-491

CS1422R

CS2022R

CS2122R

CL1422R/RS

CL2122R

C1432TB/TY

CP1432RB

CP1432RY

Chassis

F1R

F1Y

F4Y

F1GR

F4GR

F1GY

F2GY

F4GY

F1HY

F4HY

F1HY

F2HY

F4HY

F1KR

F2KR

F4KR

F1FR

F4FR

F1R

F1Y

F1Y

TECHNICAL SPECIFICATIONS

SPÉCIFICATIONS TECHNIQUES SPECIFICATIONS TECHNIQUES

TV Standard.......................................625 lines,

STANDARD I (UK)

B/G/H/DK, L/L', (Export)

Channel coverage..............UHF Channels (UK)

UHF/VHF Hyper band (Export)

Aerial input impedance..........................75ohm

Unbalanced

Power Consumption.....................Picture Tube

14” Models < 40W 35.5cm types

20” Models < 48W 48cm types

21” Models < 52W 51cm types

Consumption in standby mode.................<4W

Mains Voltage........................220V/210V, 50Hz

Fuse..........................................2 Amp time-lag

Standard TV.....................................625 lignes,

STANDARD: R-U

B/G/H/DK, L/L': (Export)

Couverture de canaux.........Canaux UHF (R-U)

UHF/VHF Band hyper (Export)

Impédance d'entré e d' ante n n e............75 ohms

Non équilibrée

Consommation électrique.......... Tubes-images

14” Models < 40W 35.5cm types

20” Models < 48W 48cm types

21” Models < 52W 51cm types

Consommation en mode veille.................<4W

Tention secteur......................220V/240V, 50Hz

Fusible......................................2 Amp time-lag

Data contained within this Service

manual is subject to alteration for

improvement.

Les données fournies dans le présent

manuel d’entretien peuvent faire l’objet

de modifications en vue de perfectionner

le produit.

Die in diesem Wartungshandbuch

enthaltenen Spezifikationen können sich

zwecks Verbesserungen ändern.

Fernsehnorm....................................625 Zeilen,

Fernsehnorm I (nur GB)

Fernsehnorm B/G/H/DK, L/L’ (Export)

Kanäle..................................UHF-Bereich (GB)

UHF/VHF/Hyperband Bereich

Antenneneingangsimpedanz..............75 ohms

Unsymmetrisch

Leistungsaufnahme............................Bildröhre

14” Models < 40W 35.5cm types

20” Models < 48W 48cm types

21” Models < 52W 51cm types

Leistungsaufnahme im standby mode......<4W

Netzspannung.........................220/240V, 50Hz

Sicherung..................................2 Amp time-lag

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

Colour Television

December 1998

Page 2

2

Page 3

ENGLISH

SAFETY PRECAUTIONS

WARNING: The following precautions must be observed.

ALL PRODUCTS

Before any service is performed on the chassis an

isolation transformer should be inserted between the

power line and the product.

1. When replacing the chassis in the cabinet, ensure

all the protective devices are put back in place.

2. When service is required, observe the original

lead dressing. Extra precaution should be taken to

ensure correct lead dressing in any high voltage

circuitry area.

3. Many electrical and mechanical parts in

HITACHI products have special safety related

characteristics. These characteristics are often not

evident from visual inspection, nor can the

protection afforded by them necessarily be

obtained by using replacement components rated

for higher voltage, wattage, etc. Replacement

parts which have these special safety

characteristics are identified by marking with a

! on the schematics and the replacement parts

list.

The use of a substitute replacement component

that does not have the same safety characteristics

as the HITACHI recommended replacement one,

shown in the parts list, may create electrical

shock, fire, X-radiation, or other hazards.

4. Always replace original spacers and maintain lead

lengths. Furthermore, where a short circuit has

occurred, replace those components that indicate

evidence of overheating.

5. Insulation resistance should not be less than 2M

ohms at 500V DC between the main poles and

any accessible metal parts.

6. No flashover or breakdown should occur during

the dielectric strength test, applying 3kV AC or

4.25kV DC for two seconds between the main

poles and accessible metal parts.

7. Before returning a serviced product to the

customer, the service technician must thoroughly

test the unit to be certain that it is completely safe

to operate without danger of electrical shock. The

service technician must make sure that no

protective device built into the instrument by the

manufacturer has become defective, or

inadvertently damaged during servicing.

CE MARK

1. HITACHI products may contain the CE mark on

the rating plate indicating that the product

contains parts that have been specifically

approved to provide electromagnetic

compatibility to designated levels.

2. When replacing any part in this product, please

use only the correct part itemised in the parts list

to ensure this standard is maintained, and take

care to replace lead dressing to its original state,

as this can have a bearing on the electromagnetic

radiation/immunity.

PICTURE TUBE

1. The line output stage can develop voltages in

excess of 25kV; if the E.H.T. cap is required to be

removed, discharge the anode to chassis via a

high value resistor, prior to its removal from the

picture tube.

2. High voltage should always be kept at the rated

value of the chassis and no higher. Operating at

higher voltages may cause a failure of the picture

tube or high voltage supply, and also, under

certain circumstances could produce X-radiation

levels moderately in excess of design levels. The

high voltage must not, under any circumstances,

exceed 29kV on the chassis (except for projection

Televisions).

3. The primary source of X-radiation in the product

is the picture tube. The picture tube utilised for

the above mentioned function in this chassis is

specially constructed to limit X-radiation. For

continued X-radiation protection, replace tube

with the same type as the original HITACHI

approved type

4. Keep the picture tube away from the body while

handling. Do not install, remove, or handle the

picture tube in any manner unless shatterproof

goggles are worn. People not so equipped should

be kept away while picture tubes are handled

LASERS

If the product contains a laser avoid direct exposure to

the beam when the cover is open or when interlocks are

defeated or have failed.

3

Page 4

SAFETY AND ISOLATION

1. Under no circumstances should any form of repair or maintenance be attempted by any person other than a

competent technician or engineer. The following precautions should be observed:

2. For purposes of servicing, the chassis should be supplied from an isolation transformer of at least 150W rating.

3. If disturbed, the original lead dressing should be restored. This is particularly important due to the 'hot coil'

nature of the chassis. Lead dressing will also have a bearing on the EMC performance of the chassis.

4. Components marked ! on the circuit diagram are safety approved types and have special safety related

characteristics. Only the manufacturers replacement components should be used. Replacement with alternative

or 'up-rated' parts e.g. higher power resistors definitely does not guarantee the same level of protection and

may create a fire, electric shock or X-radiation hazard.

5. Components not bearing the ! mark should still be replaced with the originally fitted type and should be

mounted in the same way.

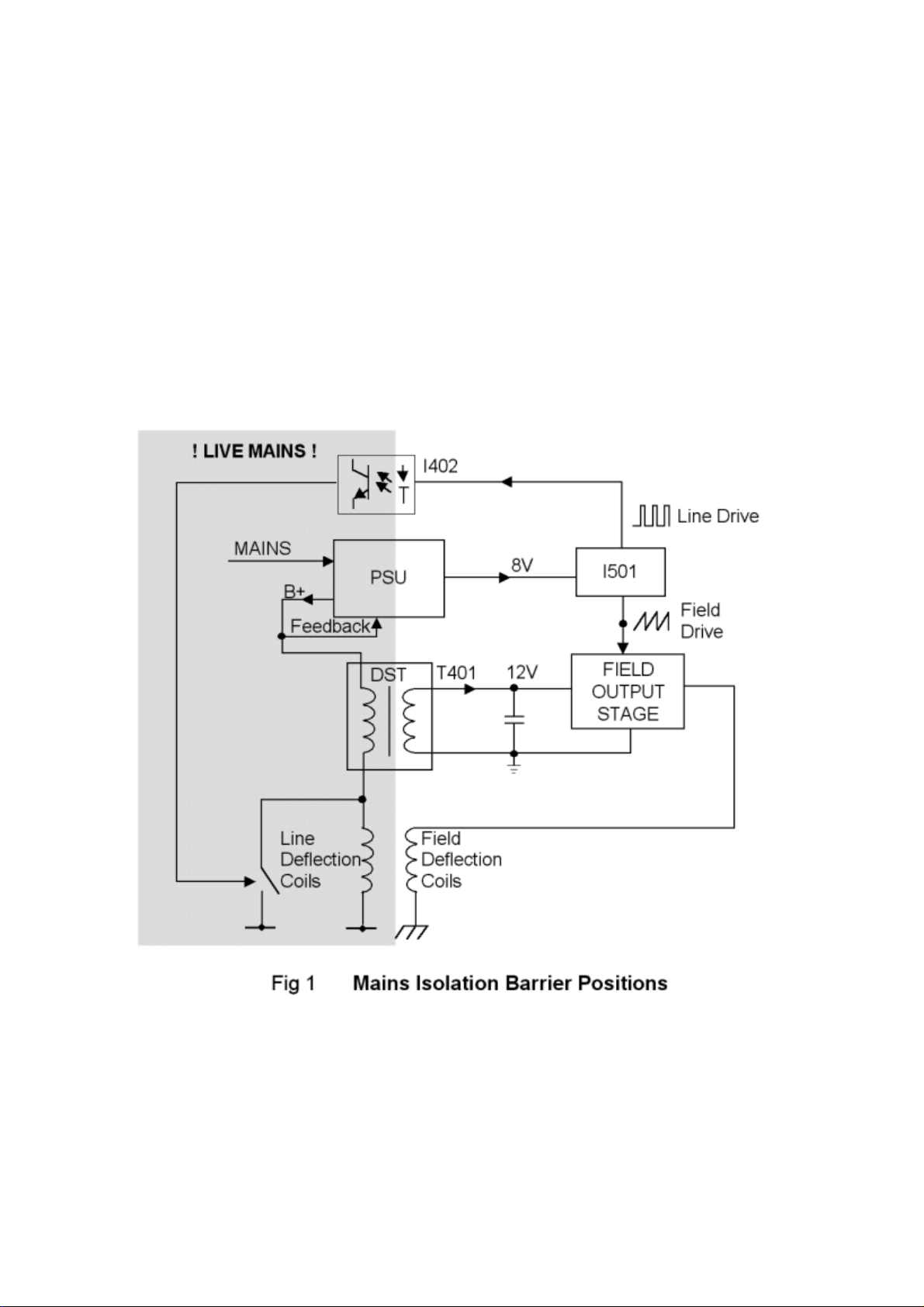

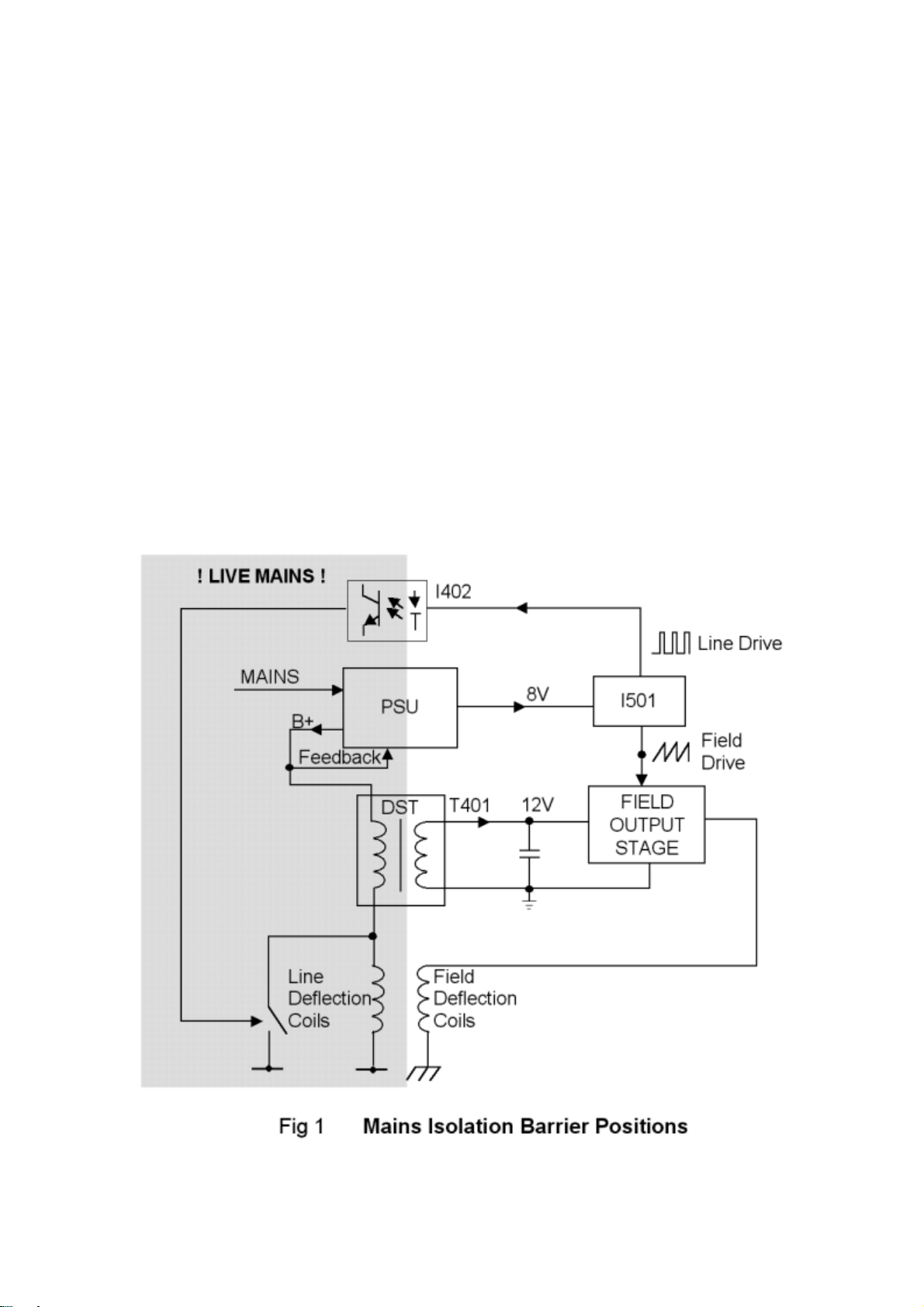

The Isolation Barrier

The chassis is a 'hot-coil' chassis whereby the line deflection coils are NOT isolated from the mains since the PSU does

not provide B+ rail isolation. Consequently, the mains isolation barrier is more convoluted than in a conventional

chassis and a much larger portion of the chassis is non-isolated. Figure 1 shows the isolation barrier position in the

chassis.

It can be seen that both the DST (T401) and the scan coils now straddle the isolation barrier and are, as such, safety

critical components. Also, the opto-coupler (I402) is required to pass line drive from I501 on the 'cold' side to the line

drive stage on the 'hot' side. The isolation barrier therefore consists of T802, T401, I402, C804, R804, R805, the scan

coils and 6mm air gaps. To maintain barrier integrity care should be taken not to reduce any air gaps, e.g. by protruding

wires, following component replacement. Deflection yoke lead dressing is important to maintain double insulation

across the isolation barrier. The position of the deflection lead sleeving is maintained by a tie wrap. Should this be

removed for any reason, the sleeving should be slid towards the deflection yoke and tie wrapped into position.

Semiconductor Device Handling Precautions

The chassis contains devices which may be damaged by static electrical charge during handling, particularly I501, I602,

I701 and Q801. To avoid damage, soldering irons should be earthed and service engineers should ideally wear wrist

straps earthed through a 1M resistor or at least discharge themselves to an earthed point.

4

Page 5

ERVICING

S

Microprocessor Control System

Microcontroller

Micro-controller, I701, is either a SAA5288 (on non-teletext sets) or a SAA5290 (on teletext sets). Both

devices have integrated on-screen display (OSD) generator; the SAA5290 also has an integrated teletext

decoder. The micro-controller has a single 12MHz crystal X701.

The television is controlled by serial (I²C) bus communication, digital switching inputs and outputs, analogueto-digital inputs and pulse-width-modulation (PWM) outputs.

Reset

At power on, C709 is not charged so the voltage on pin 43 of the micro-controller rises with the 5V supply

and resets the micro-controller. An internal resistor to ground at this pin causes C709 to charge up and the

voltage on the reset pin to drop to 0V.

In normal operation, transistor Q702 is switched on and the reset pin is low, but if the 10V supply voltage

drops below about 8V the transistor will switch off and R721 will pull the reset pin high and reset the device.

User Control

User input is via infra-red remote control (Philips' RC5 protocol), internally decoded from the receiver I703,

or from three (non-matrixed) local control keys on active low inputs, I701 pins 18, 19 and 20. The LED

flashes each time a key is detected or remote command received.

Tuning

The tuning control voltage to the tuner is controlled via the PW M at pin 1 of I701 and integrating circuit

around Q001. Minimum voltage is at maximum mark-space ratio (bottom of each band). Band-switching is

controlled by active low outputs on pins 14, 15 and 16 (high, mid, low) and transistors Q002 to Q004. The

controller makes AFC corrections by reading on-tune information from I501 via the I²C bus.

As the tuner is controlled by voltage synthesis, there is no direct correlation between the controller output

and the tuned frequency.

Non-volatile memory

The non-volatile memory, I702, holds configuration information, user settings, parameters as applicable for

I²C controlled ICs and the programme tuning records. It is itself accessed by I²C.

When a new memory IC is fitted, the microcontroller will automatically load default information, which takes a

few seconds during power-up. Regular re-loading of the data, or corruption of settings may indicate I702 is

faulty.

AV switching

Inputs from pins 8 and 16 of SCART 1 are sampled by analogue to digital conversion on pins 9 and 10 of

I701 respectively. The input levels are adjusted such that the controller will automatically switch to AV1

when pin 8 is above 6V and RGB when pin 16 is above 1V. The time constant on pin 16 ensures the

controller will not detect real-time RGB insertion using pin 16.

OSD / Teletext

Line and field timings are obtained from V.sync on pin 37 and H.sync input on pin 36. Teletext (on teletext

sets only) is obtained from the CVBS input on pin 23. The RGB outputs on pins 34, 33 and 32 respectively

are inserted into the TV output when gated by the OSD EN OUT signal on pin 35. OSD / teletext contrast is

controlled by the peak reference level on pin 31, generated from the microcontroller PWM output on pin 2 via

Q305.

Error codes

Under the following fault conditions the television will switch to standby and flash the LED.

5

Page 6

Fault Condition No. of Flashes

Multiple TDA884X I²C errors 1

Over voltage / X-ray protection (OVP) 2

Line start-up sequence failed 3

Black current (BC) loop unstable 4

Vertical scan failure 5

Continuous TDA884X power-on reset 6

Multiple error codes may appear, eg. two quick flashes, pause, four quick flashes etc. for OVP + BC loop

errors.

Adjustments

In order to make service adjustments including setting the height, width, various configuration options, etc.,

the TV should have a suitable signal tuned in; ideally, a geometry test card. A teletext signal is

recommended for setting OSD contrast on a teletext chassis.

To enter service mode, place a shorting link across terminals 2 and 3 of P701.

In service mode, two 2-digit hexadecimal numbers are displayed to the left of the screen; the lefthand one is

the service parameter number, the righthand one is the value for that parameter. Some parameters are

identified by a two-letter code instead of a number, see below.

For example:- 0A 1F shows parameter ten (0A hex) at thirty-one (1F hex).

In this mode of operation some of the remote control keys have different functions;

The up and down and local select keys are used to select a parameter.

The remote and local left and right keys are used to change the value of the current parameter.

The TV button is used to store any changes.

The teletext select and digit '0' keys are used for programme up or down.

The Normalize key selects factory picture settings immediately over-writing user settings.

The digit keys '1', '2',----'8' toggle the state of the individual bits '7', '6',----'0' of the value of the current

parameter, for example, pressing digit key '4' would change value 1F hex to 0F hex.

TO STORE THE CHANGES, PRESS THE TV KEY ON THE HAND UNIT BEFORE REMOVING THE

SERVICE MODE LINK. THE MESSAGE 'STORED' WILL BE DISPLAYED TO CONFIRM THE

OPERATION.

Under certain circumstances, for example abnormal operation due to suspected corruption of the service

parameters, it may be necessary to perform a complete reset of the non-volatile memory (I702). To effect

this, press and hold the X (teletext update) key for about 3 seconds or until the set switches to standby.

Following this it will be necessary to perform a 'set-up' of the television.

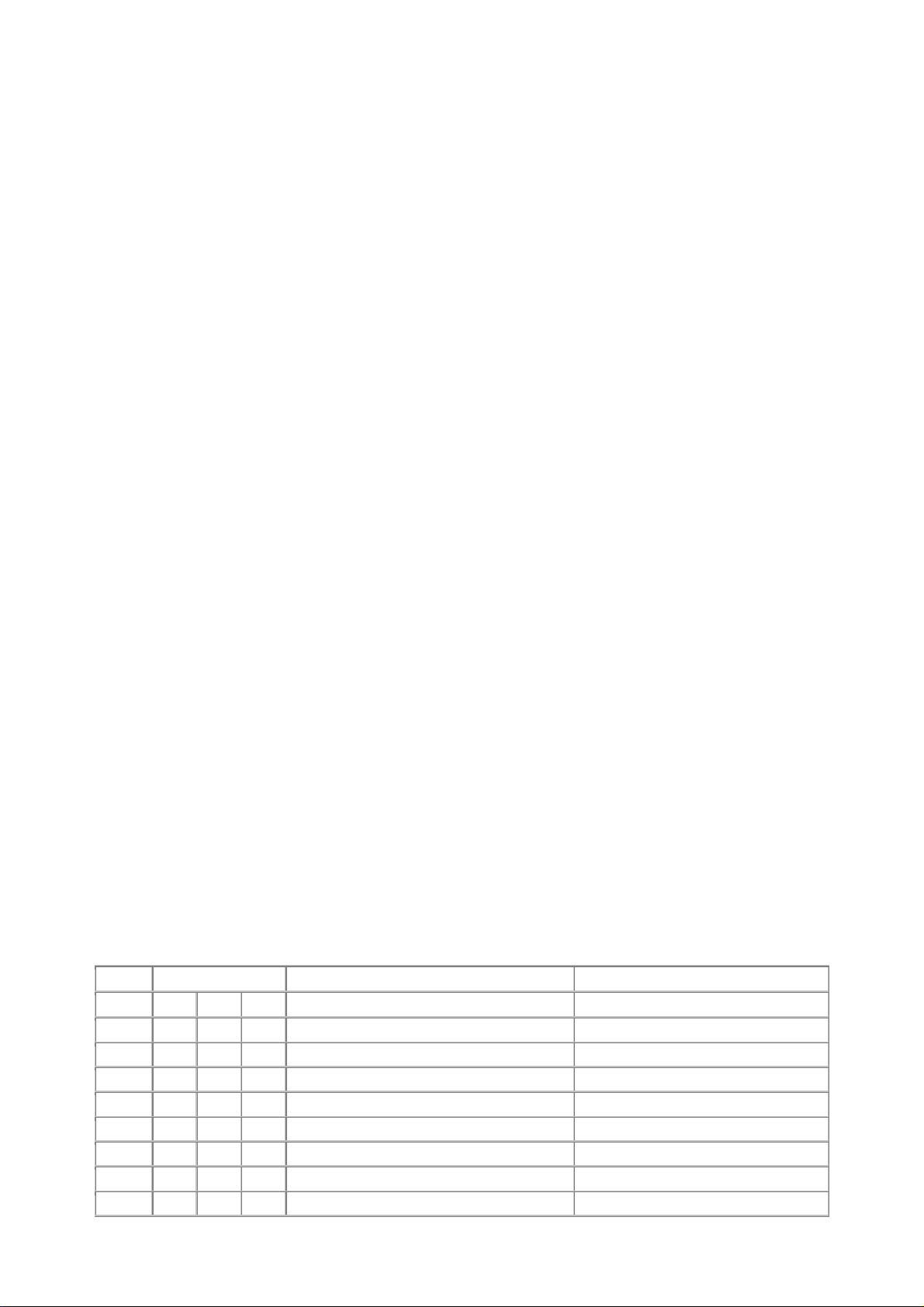

Service Parameters

The following values assume you are watching a tuned in picture, on RF. (On other sources, or with no

signal, some values may differ.)

Service parameters 00 to 1A apply to the control registers of I501 as shown in the following table.

No. Value Function Action

00 02 02 02 System Control Do not adjust

01 D0 D0 D0 System Control Do not adjust

02 1F 1F 1F Hue (SCART NTSC 4.43 playback only) Use picture menu control instead

03 20 1D 27 Horizontal shift Adjust to centre picture horizontally

04-07 00 0 0 00 E-W control Not used on this chassis

08 20 1F 1E Vertical slope (linearity) Adjust for vertical linearity

09 10 0B 1A Height Adjust for correct picture height

0A 44 4A 4A S-correction Adjust for best vertical S-correction

14" 20" 21"

6

Page 7

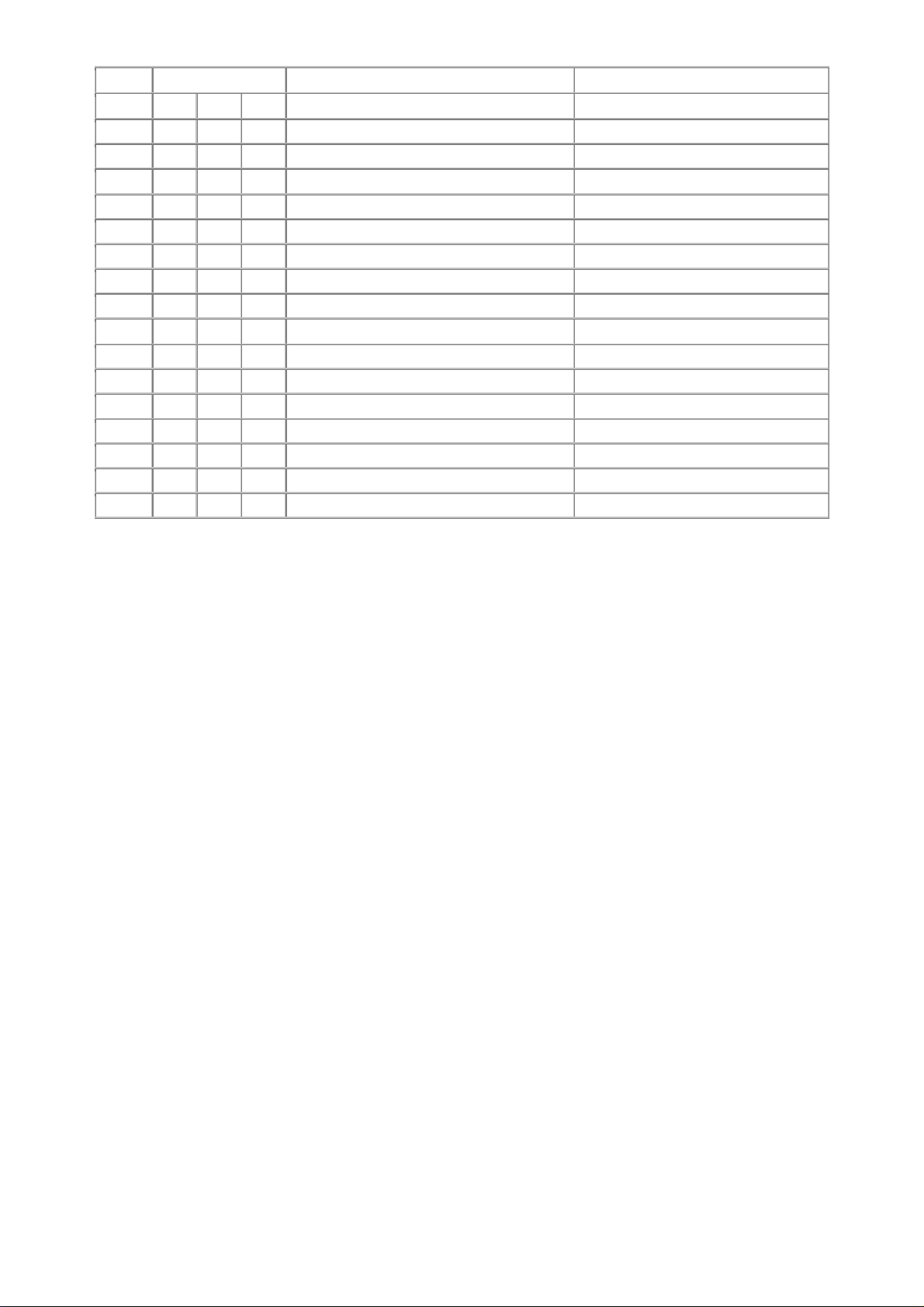

No. Value Function Action

0B 2B 1B 1B Vertical shift Adjust to centre picture vertically

0C 29 38 3D White point - Red

0D 29 38 3D White point - Green

0E 29 38 3D White point - Blue

0F 1C 1C 1C Peaking (sharpness) Use picture menu control instead

10 5C 5C 5C Brightness Use picture menu control instead

11 9C 9C 9C Saturation Use picture menu control instead

12 1C 1C 1C Contrast Use picture menu control instead

13 13 13 13 AGC take-over point

14 0A 0A 0A Volume

15 50 50 50 IF PLL adjustment Set to 50 hex

16 19 19 19 Vertical zoom Not used on this chassis

17 20 20 20 Vertical scroll Not used on this chassis

18 81 81 81 Control 2 Do not adjust

19 08 08 08 Control 3 Do not adjust

1A 00 00 00 Control 4 Do not adjust

14" 20" 21"

See "Adjustments" in Servicing

See "Adjustments" in Servicing

Service Parameter Functions

Parameters above 1A are designated by two-letter codes (except text contrast on a teletext set). These

control configuration.

Text Mode Text (OSD) contrast Set as preferred, see notes below

Ex Export (VHF/UHF) setting 00 for UHF-only, 01 if multi-band tuner

AV AV socket configuration 00 single SCART, 01 single SCART plus phono inputs

It is advisable to make a note of the existing values prior to commencing servicing. (see "Adjustments" in

Servicing)

7

Page 8

Adjustments

H. T. Setting

The HT should be adjusted using R818 to obtain correct width with normal brightness and contrast settings.

A Philips complex test pattern is ideal for the operation.

A1 Control

This should be set using the ‘screen’ control on T401 to achieve 140V black level at the tube base cathodes

with the brightness and contrast settings normalized. In practice the black level of the individual guns will

differ and are set by I501 to achieve equal cut-off points.

White Points

These should be adjusted via service parameters 0C, 0D and CE whilst viewing a picture with little light area

to prevent beam current limiting. The parameters should be adjusted for a black to white swing of 50V ±1V

(14”), 55V ±1V (20”) or 60V ±1V (21”) on each of the three cathodes with the picture normalized.

Text Contrast

White balancing of the red and blue outputs, relative to the green, should be carried out to ensure pure white

text, using RV317 (R) and RV319 (B). As the picture outputs are automatically balanced, text white may be

set using picture white as a reference once the black and white points (See adjustments section) have been

set. The text contrast itself should be adjusted such, that the Text/OSD white parts are approximately 75% of

the intensity of a test pattern peak white area: this corresponds to the 75% grey blocks in part of a ‘Philips

5544’ type test pattern. When the text contrast service parameter is selected the TV switches to teletext mix

mode, page 101. If no text is present P100 will still appear in the top left corner of the screen together with

some text on the bottom row of the display. There is no on-screen parameter: adjust with volume control as

normal and change parameter with programme up/down keys.

AGC

The AGC take-over point should be adjusted via service parameter 13 such, that the tuner output to the

SAW filter is 600mV pk-pk (300mV per side for symmetrical tuner output) using a test pattern with no sound

carrier.

Focus

Adjust the upper control on the rear of the flyback transformer for best focus.

Positioning

Horizontal position should be adjusted via service parameter 03 so as to centre the picture. Vertical position

should be adjusted via service parameter 0B so as to centre the picture. This may be simplified by pressing

‘1’ with service parameter 0B selected to activate service blanking which blanks the lower half of the picture.

The edge of the blanked area may then be aligned with the tube centre marks. Service blanking is disabled

by once again pressing the ‘1’ key.

Linearity

Horizontal linearity is fixed; no adjustment is possible. Vertical linearity is adjusted using service parameters

08 and 0A (linearity and S-correction) whilst displaying a cross hatch pattern. Adjust the linearity for evenly

spaced intervals at the top and bottom of the picture, then adjust the S-correction to achieve equal spacing

accross the whole screen.

Vertical Protection Disable

Vertical protection is used to shut down the chassis in the event of field-scan failure. For diagnostic purposes

this can be disabled by selecting service parameter OA (S-correction) and pressing the number 2 key on the

8

Page 9

hand unit. After repair, vertical protection should always be re-enabled by pressing the number 2 key again

and storing it with the TV key. (The value of parameter OA toggles between two values when the number 2

key is pressed,

the higher

of which indicates that the vertical protection is

enabled

.).

Auto Black Level Disable

I501 independently sets the black level of each CRT gun to equalize the cut-off points and therefore provide

a true black. For diagnostic purposes this control loop may be disabled by selecting service parameter 02

(hue) and pressing the number 2 key on the hand unit. After repair, the auto black level sampling should

always be re-enabled by pressing the number 2 key again and storing it with the TV key. (The value of

parameter 02 toggles between two values when the number 2 key is pressed,

black level sampling is

enabled

).

the lower

of which indicates

Adjustment Locations (Physical)

See adjustment locations PCB

9

Page 10

IRCUIT DESCRIPTION

C

Switched Mode Power Supply

Summary

The power supply is a self-oscillating discontinuous buck converter (step-down chopper) under peak current

control and designed for up to 65W output power at nominally 98V. The main B+ output of this converter

topology is inherently non-isolated and as such, output voltage feedback does not require an opto-coupler.

Some energy is derived in flyback mode via an isolated winding on the buck inductor to provide a low power

10V secondary supply from which are derived switched 8V (video processor) and permanent 5V (µP)

supplies.

In stand-by mode, both the B+ and 10V supplies remain close to their nominal operating levels but with

virtually zero load, the PSU enters a burst-mode whereby typically 180 in 200 cycles are skipped. In this way,

the stand-by power consumption (including degaussing circuit) is less than 4W.

Description of Operation of the Buck Converter

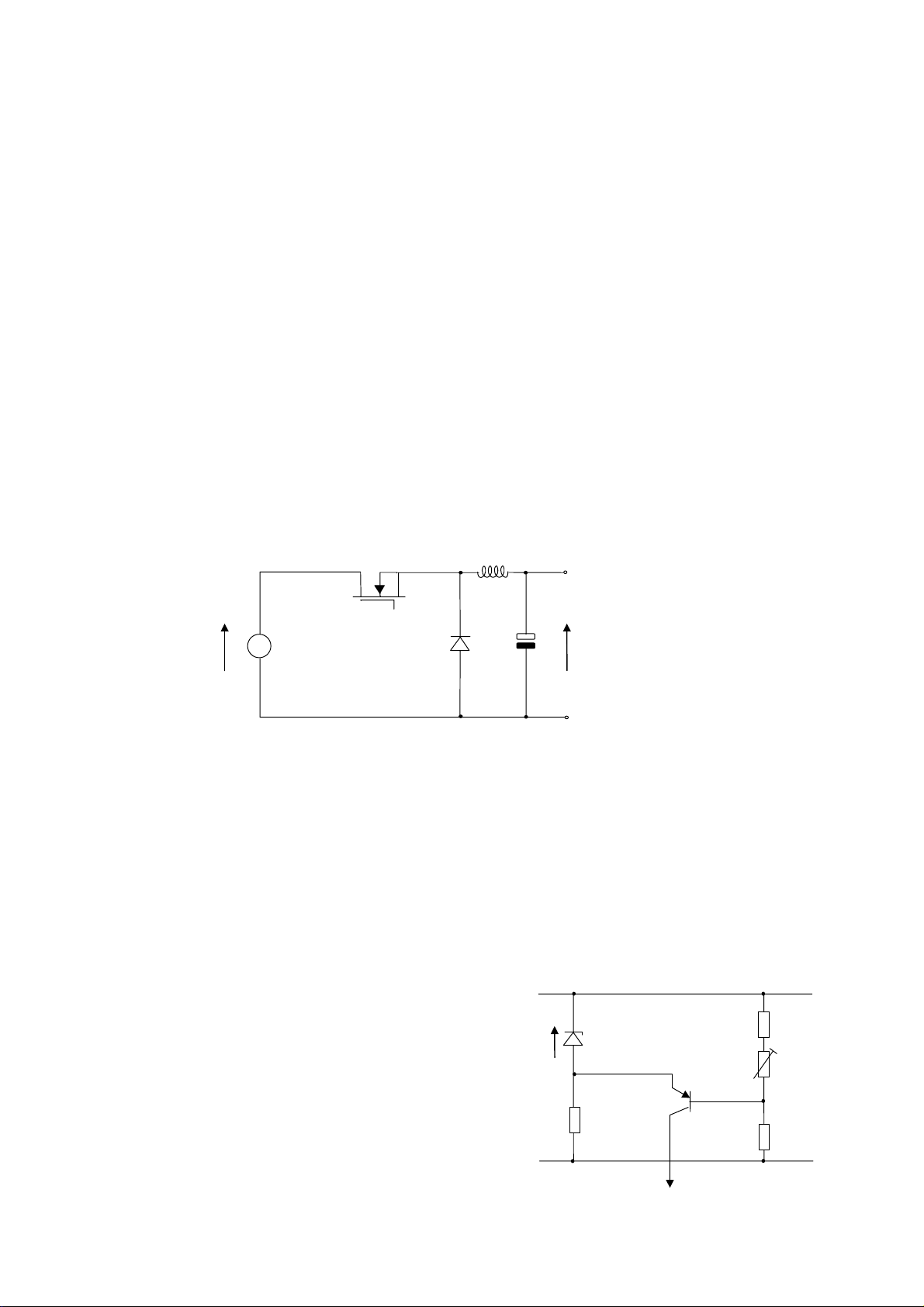

Figure 4 shows the main components of the buck converter. The output voltage may be controlled between

zero and the input voltage by varying the on-time of Q801. During this period, Vin-Vout is applied across the

buck inductor (T802 winding pins 7 & 8) and the current in it ramps up linearly. When Q801 is turned off, Vout is applied across the buck inductor and energy is delivered to the load and C809 combination.

280 - 390

T802 (pins 7 & 8)

Q801

V

IN

Fig 4

The Buck Converter Topology

D804

C809

V

OUT

(100V)

Start-Up

At start-up, the overwind output voltage (T802 winding pins 7 & 8) is not present so a start-up bias circuit is

required. This consists of R806, D802 and R809. Approximately 16V is produced at the junction of R806 and

D802 which is fed via R809 to turn on Q801 for the first time.

Control Method

During the on-time of Q801, the buck inductor voltage flows through the current sense resistor R814 forming

an analogue of the buck inductor current. This is fed to the base of Q802 along with a DC bias current from

the error amplifier (via R813) such that once a certain buck inductor current level is reached, Q802 turns on.

When this happens Q801 is turned off and the inductor current free-wheels through D804. This is peak

current-mode control.

Output Voltage Regulation

The non-isolated B+ rail means that no opto-isolator is

required for direct Vo control. It can be seen from Figure 5 that

Vo minus a small zener voltage drives the emitter of this

transistor (Vo-Vz) whilst a resistive potential divider feeds the

base (kVo, k<1). If, for instance, the output voltage tends to

rise, Ve rises by ∆Vo whereas Vb only rises by ∆kVo. The net

result is an increase in negative bias and an increase in

collector (control) current. R818 in the potential divider

provides an element of control over the B+ voltage.

Vz

R815

D806

Fig 5

Ve

Vb

Control Current

The Error Amplifier

R817

R818

kVo

R820

10

Page 11

Overvoltage Protection

An unfortunate characteristic of the buck converter is that if the power switch Q801 should become shortcircuit, the full rectified mains voltage appears at the output, over stressing components in both the PSU itself

and the load. In order to limit the output voltage rise under these conditions, a 130V 5W zener diode D805 is

fitted across the B+ output. An over-voltage causes conduction of D805, shorting the B+ output and blowing

the fuse F801.

Isolated Supplies

In order to provide low voltage isolated supplies, a secondary winding is included on the buck inductor,

phased such that energy is delivered in flyback mode, that is when Q801 is off. During this interval, the buck

inductor voltage is clamped to the output voltage and the turns ratio is chosen to provide a secondary of 10V

with rectification and smoothing performed by D807 and C812 and overload protection by R821. A

permanent 5V µP supply is derived from this 10V supply by I801 as well as an 8V switched supply under µP

control by Q804, R822, D808 and Q805.

Chassis Start-Up Procedure

The PSU topology used in the chassis has a characteristic which complicates start-up. Until a B+ load is

established (i.e. the line output stage starts), the isolated secondaries are very high impedance - simply

turning on the video processor 8V supply and waiting for line-drive to start-up would fail since the supply

cannot deliver I501's supply current. In order to overcome this problem, a system of 'pseudo line-drive' was

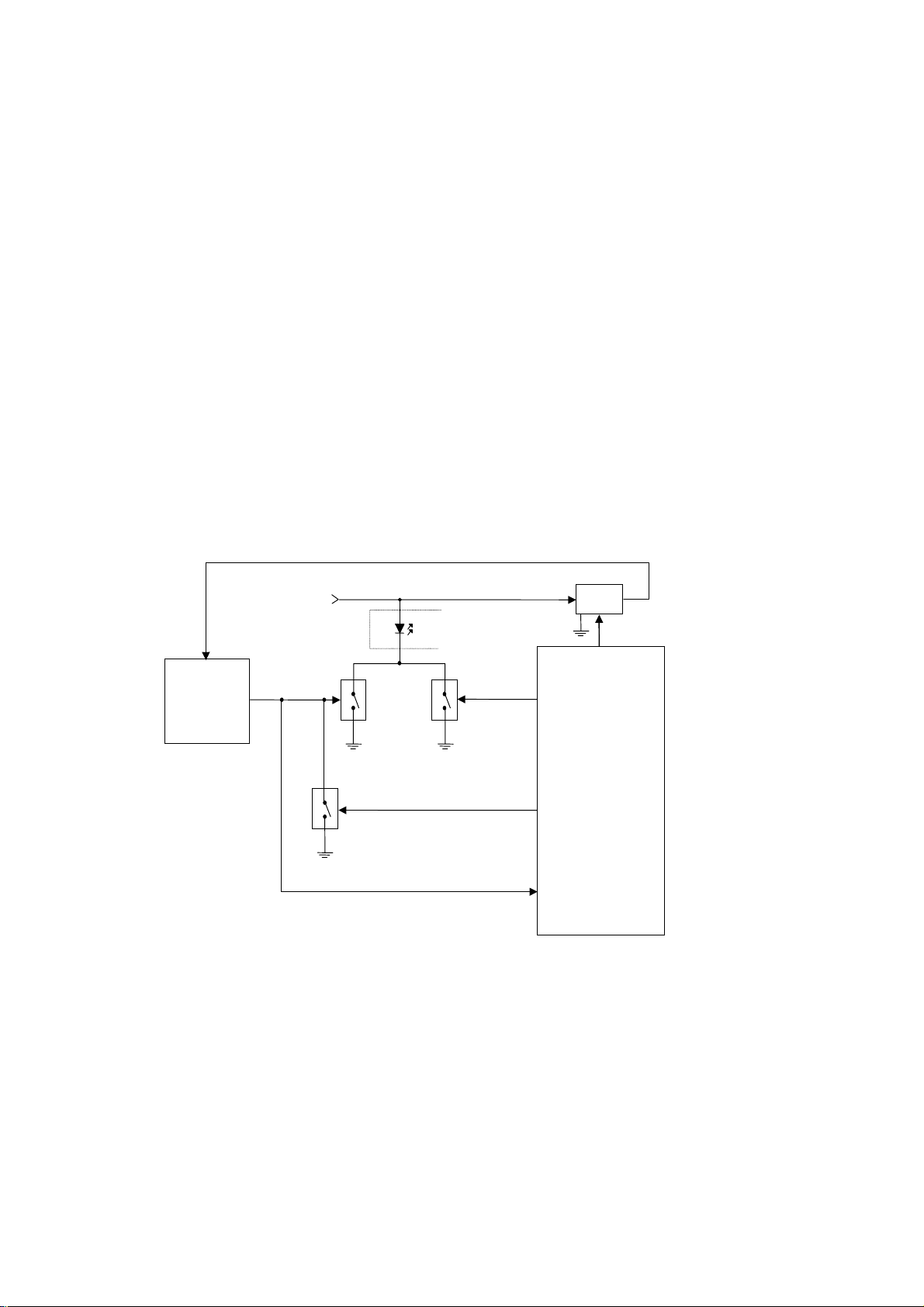

devised which allows the line output stage to be driven by the µP in order to establish a B+ load prior to turnon of the video processor 8V supply. Figure 6 is a block representation of this system.

8V

10V from PSU

I402

12, 37

I501

True Line

H

OUT

40

Fig 6

Start-up Circuit Block Diagram

Q402, R423

Q405, R422

Q406, R427

30

47

7

Pseudo

Line

Drive

True Line

Drive

Gating

True Line

Drive

Detection

8V

48

8V Control

I701

Q804, R822, D808, Q805

The two line drive sources are OR-ed together at the input of I402, the two driver transistors being Q402 and

Q406. The µP is responsible for ensuring that both line drive sources cannot drive the output stage

simultaneously and to achieve this, the true line drive from I501 is monitored (µP pin 47). In this way, the

transition from pseudo to true line-drive is timed to the latter starting up. However, the line-drive stage does

not reliably operate at 31kHz so the soft-start cycle of I501 must be gated out. The µP achieves this by

keeping Q405 on for a fixed time after true line-drive has been detected thus keeping Q402 off. When this

time has elapsed, pseudo line-drive is stopped and Q405 turned off simultaneously, completing the start-up

sequence.

On reverting to stand-by pin 7 reverts to the high state which maintains I402 in conduction via Q406. This

maintains Q403 on and the line output transistor (Q404) off.

11

Page 12

Tuner and IF Stages

Tuner

The main chassis is fitted with a voltage synthesis UHF tuner for system I. Control of the tuned frequency is

achieved by a voltage on pin 2 of the tuner. This voltage is derived from integrating a 33 volt PWM switched

waveform. This PW M waveform is derived from pin 1 of the microcontroller I701.

The AFC is sampled by the microcontroller via the I²C bus from I501 and frequency correction is achieved by

microcontroller adjustment of the duty cycle of the PWM which then modifies the tuner frequency.

AGC Adjustment

For most aerial input signal levels the tuner operates at maximum gain. At high signal levels the gain of the

tuner is reduced by an AGC voltage generated in the IF stage. The AGC output from the IF (pin 54 of I501) is

applied to pin 1 of the tuner (H001).

The AGC maintains a maximum IF voltage of 600mV peak to peak. The voltage level can be adjusted using

the following procedure:

Short circuit pins 2 and 3 of P701 to enter service mode. When in service mode use the programme up and

down keys to select service parameter 13. Using a 40MHz or greater oscilloscope, monitor pin 11 of TU001.

Adjust service parameter 13 using the volume up and down keys for 600mV on pin 11 for a single ended

tuner, and 300mV for a differential output tuner. Press the RV key to store the AGC value.

AFC Adjustment

The AFC voltage is not available at any point on the chassis; it is read by the microcontroller via the I²C bus.

Therefore, one of the following methods can be used to correctly align the AFC.

a) For demodulator tank coil fitted (I501 = TDA884X Mask 1)

Tune a known channel. Using a spectrum analyzer monitor pin 11 of H001. Fine tune the tuner for a

carrier frequency of 38.9MHz. Store the fine tuned frequency (i.e. AFC off). Enter service mode by

applying a short circuit to pins 2 and 3 of P701. When in service mode use the programme up and

down keys to select service parameter 15. Adjust service parameter 15 using the volume up and

down keys until the two bits at the top right of the screen meet the following criteria:

Left hand bit permanently set.

Right hand bit toggles (either 1 to 0 or 0 to 1).

When the AFC value has been set press the TV key to store it.

b) For demodulator tank coil not fitted (I501 = TDA886X Mask 2)

Adjust service parameter 15 using the volume up and down keys until its value is 50.

When the AFC value has been set press the TV key to store it.

Vision Decoding

The majority of the vision and sound, deflection and colour decoding is performed by I501. The IF signal

passes from the tuner through the SAW filter (X001) to filter unwanted frequencies to I501. It is demodulated

internally and the output at pin 6 is buffered by Q501. The sound and vision components are now separated.

Z501 removes the sound from the vision components and Z601/602 filters the FM sound to pin 1 for

demodulation. Video is then fed to the SCART socket output, pin 19 of P501 via Q502.

12

Page 13

Source Selection

Source selection is controlled by the microcontroller via I²C bus commands. The video processor I501 can

select between internal demodulated CVBS video on its pin 13, external CVBS video (AV1) from pin 20 of

P501 on its pin 17 or, if available, from external CVBS video (AV2) from the yellow phono socket of PA501,

which is applied to pin 11. The internally demodulated CVBS video is always available on pin 19 of P501.

External RGB is selected within I501. Fast blanking pulses from pin 16 of P501 are passed via an OR-ing

circuit of Q301-304 and associated components to pin 26 of I501. This pin controls the state of the RGB

outputs to the tube base pins 19, 20 and 21. It has three possible states:

1) Less than 0.4V Internal RGB from colour decoder.

2) Between 0.4V and 4.0V External RGB from pins 7, 11 and 15.

3) Greater than 4V Output blanked for OSD/Text insertion.

When teletext or OSD is displayed, pin 35 of I703 goes from ground to 5.0 Volts. This signal is passed via

Q301 and causes pin 26 of I501 to enter the third state above, independent of the state of the other inputs to

the OR circuit. During mixed TV/Text mode or whilst the OSD is showing on part of the screen this line will

be switching at a high rate. RGB mode can be selected manually by the user and in this case the open-drain

output on pin 8 of the micro-controller will be switched off and will be pulled up to 1.7 volts by R307 and

R306. Q302 then applies a voltage of about 1.0 volts to pin 26 of I501. In the absence of a higher voltage via

Q301 and Q303 from the fast blanking input, pin 16 of P501, this is still sufficient to enter the external RGB

mode.

Audio source switching is controlled via the microprocessor I701. The audio is switched from internal to

external source via I²C in I501. Internal source is fed to I501 at pin 1 and the external source at pin 2. On

models equipped with front AV, the external source is provided either from pins 2 and 6 of P501 or the white

phono socket PA501.The external source selection is controlled by pin 3 of I701 and Q703, then switched by

I602. On models without front AV, I602 is omitted and bypassed via R601. On models equipped with a

headphone socket, the speaker feed from the audio amplifier (I601) is diverted to the headphone when a

headphone jack is plugged into PA601.

13

Page 14

Colour Decoder

The luma signal processing and colour decoding are implemented by I501. The luminance and chrominance

signals are separated internally. A delay line is also incorporated to compensate for the difference between

the luma and chroma processing times. There are no adjustments required on the colour decoder.

On-Screen Display

The micro-controller on-screen display (OSD) supplies blanking and RGB signals for overlaying the

television picture. Pin 35 of I701 provides blanking pulses which are applied to pin 26 of I501 via Q301, to

turn off the decoder RGB output so that the OSD is clearly visible. The RGB signals from pins 34, 33 and 32

of I701 are applied directly to the tube-base via Q306 to Q308 and the text drive colour balance presents

R317 and R319.

14

Page 15

Horizontal and Vertical Deflection

In addition to decoding and switching, I501 provides deflection processing for the horizontal and vertical

time-base circuits. Using video from the IF or external source as appropriate, the timebase circuit of I501

produces horizontal drive pulses at pin 40 to switch horizontal drive transistor Q402, and a differential vertical

ramp at pins 46 and 47 to drive the vertical deflection output amplifier (I401).

All geometry adjustments are performed via the I²C bus with the service parameters (See adjustments

section) with the exceptions of picture width (which is fine tuned by adjusting the B+ voltage by means of

R818) and horizontal linearity (which is fixed by L402.)

Line Circuit

The primary side of the line circuit and the deflection coil are connected to the hot earth. The driver circuit

contains an opto-coupler to create isolation between the low signal parts and the mains. The opto-coupler is

driven by pin 40 of I501 via transistor Q402.

When Q402 is not conducting, the LED of the opto-coupler is also out of conduction, and Q403 is also not

conducting. In this way, Q404 will conduct and the B+ voltage (100V) is placed across winding 2-1 of the line

output transformer (T401). A voltage across winding 2-1 of the line output transformer (T401) will cause a

voltage across the windings 6- 9, 7- 9, 8- 9 and 10- 9. Energy is now transformed from the primary to the

secondary side and charges capacitors C407 (+200V video supply), C408 (+13V field supply) and C409 (13V field supply).

When transistor Q402 conducts, the LED of the opto-coupler is activated. This causes the transistor of the

opto-coupler to conduct, which drives Q403 into conduction. This brings Q404 out of conduction. Due to this

configuration, this circuit is protected against missing line-drive pulses. When a line-drive pulse is missed,

the line output transistor (Q404) stays out of conduction, because the LED of the opto-coupler is forced into

conduction by Q402 and R405 and R406. By this means, damage is avoided when there is no line drive.

The line output transistor Q404 is helped in its switching action by the extra winding 2-3 while C412 helps in

the switching action and prevents Q404 overheating.

C418 prevents Q404 from switching at twice line frequency. Line jitter is reduced by capacitor C417 in the

collector of Q402.

On the secondary side of the line output transformer (T401) there is a blanking circuit which consists of C749

and R734, D501, D502 and D503. As Q404 switches off this circuit sends a pulse to pin 41 of I501 via R532

to blank the picture.

Horizontal Deflection

The voltage across capacitor C809 is the same as the voltage between B+ and the hot earth. (100V) When

Q404 is conducting, this voltage is placed across the horizontal deflection coil via C411 and L402. This

causes a linearly increasing current through this coil, thus creating horizontal deflection. When Q404

switches off, horizontal flyback takes place and then horizontal deflection is repeated and so on. C411 and

L402 are used for linearity correction.

Vertical Deflection

Vertical deflection is based on a balanced input amplifier I401 connected to the +13V supply and -13V

supply. This is driven from pins 46 and 47 of I501 via R407 and R408. A negative going ramp at field rate

from I501 pin 46 is used to control I401. When the ramp is at its highest point, vertical flyback is generated

at I401 output (pin 5) by means of C403 and D411 and a flyback generator internal to I401. After vertical

flyback, the I401 output generates a negative going ramp across the field deflection coil which provides

deflection until the next flyback pulse and so on. R413 is used to damp oscillation of the field deflection coil.

Vertical deflection amplifier stability against self oscillation is maintained by R412, C404 and C402.

15

Page 16

Vertical Protection

When operating normally, the vertical output stage generates a +5.5V pulse during vertical flyback blanking.

This pulse is fed via Q407 to I501 beam current input. Should this pulse fail, the picture tube outputs are

"blanked off" until after about 12 seconds, the micro controller records a failure. For diagnostic purposes,

vertical protection during the 12 second interval may be disabled by pressing the '2' key on the remote

control handunit when in service parameter 'OA'. This should always be re-enabled after repair (See

adjustments section).

16

Page 17

TUBE BASE PANEL

The picture tube amplifiers produce high voltage CRT electrode drives from the low voltage RGB outputs of

the TDA884x (I501). They also produce black current information to maintain the grey-scale characteristics

which is returned to the colour decoder (I501). Also included is circuitry for picture blanking during switch on.

The picture tube aquadag, (P901), is used to provide beam current information for the colour decoder for the

purposes of beam current limiting. The tubebase socket (P902) is fitted with internal spark gaps. D910

provides tube base protection when the spark gaps flash-over.

The panel includes supplies to the tube electrodes and the video amplifiers. Focus and A1 supplies are

connected directly from the flying leads of T401.

Video Drives

All video drive adjustments are done via the I²C bus (See adjustments section) with the exception of the

black level set point (140V) which is set by the A1 control on the line output transformer (T401). An additional

feature for diagnostic purposes is the ability to disable the auto black level circuit by pressing '2' on the

remote control hand set when in service parameter 02 (See adjustments section)

Tubebase Video Amplifier Circuit

Each video amplifier channel includes a bipolar cascode amplifier. A R, G or B signal from the colour

decoder (I501) is fed to each video amplifier input.

The low frequency gain of each video amplifier is approximately 51, this being determined by the ratio of the

feedback resistors to the input resistors. The gain of each video amplifier channel above 2.2 MHz is

increased by including a small capacitor across one of the two input resistors of each channel.

Video Amplifier Switch-On Blanking

The emitters of Q906, Q907 and Q908 are biased from the +200V video HT via R917, R905 and Q910. The

+13V supply to bias the base connections of Q902, Q905 and Q908 is switched on under control from

microcontroller I701 pin 35 (via R435, Q408 and R434 on the main panel) during power up or from standby

after emitter bias of Q906, Q907 and Q908 is established.

Thus picture blanking during power up or from standby is ensured.

Auto Grey Scale

During the field blanking period the colour decoder (I501) measures the total cathode circuit leakage currents

at the video amplifier outputs via Q901, Q902 and Q903: - During field blanking, the colour decoder applies

monitoring pulses to the video amplifier inputs and thence current outputs from Q901, Q902, Q903 are

applied to the colour decoder pin 18 via R904 and R516. (During normal unblanked picture operation, the

colour decoder ignores the information on its pin 18.) . The current outputs from Q901, Q902 and Q903 are

used by I501 to adjust the black current and video gain of each video channel automatically. Thus black level

picture beam current and black to white video drives are maintained. Diodes D903, D905 and D906 prevent

horizontal smearing/ shadowing of the OSD from spreading across the screen.

17

Page 18

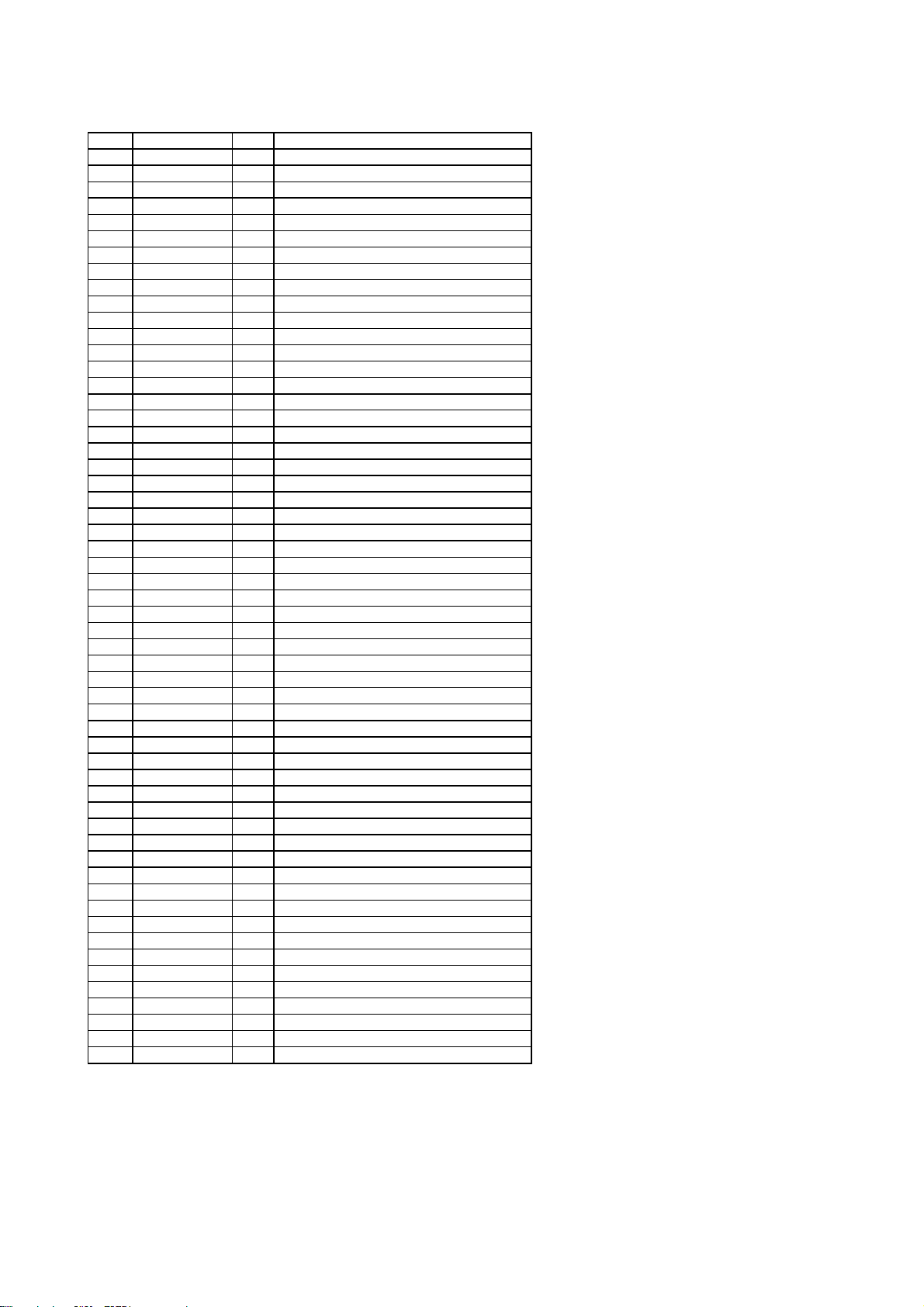

TDA884X Video Processor

Pin Designation I/O Description

1 SNDIF I Sound IF

2 AUDIOEXT I External Audio

3 NC Not Connected

4 NC Not Connected

5 PLLLF IF-PLL loop filter

6 IFVO O IF Video

7 SCL I Serial Clock

8 SDA I/O Serial data

9 DEC

10 CHROMA I Chrominance

11 CVBS/Y I External CVBS/Y

12 VP1 Main supply voltage 1 (+8V)

13 CVBS

14 GND 1 Ground 1

15 AUDIOOUT O Audio

16 SECPLL SECAM PLL de-coupling

17 CVBS

18 BLKIN I Black-current

19 BO O Blue

20 GO O Green

21 RO O Red

22 BCLIN I Beam current limiter input/V-guard input

23 RI I Red input for insertion

24 GI I Green input for insertion

25 BI I Blue input for insertion

27 RGBIN I RGB insertion

27 LUMIN I Luminance

28 LUMOUT O Luminance

29 BYO O (B-Y) signal

30 RYO O (R-Y) signal

31 BYI I (B-Y) signal

32 RYI I (R-Y) signal

33 REFO O Sub-carrier reference

34 XTAL1 3.58MHz crystal connection

35 XTAL2 4.43/3.58MHz crystal connection

36 DET Loop filter phase detector

37 VP2 2nd supply voltage 1 (+8V)

38 CVBS1O O CVBS-1

39 DECDIG De-coupling digital supply

40 HOUT O Horizontal

41 FBISO I/O Flyback input/sandcastle output

42 PH2LF Phase-2 filter

43 PH1LF Phase-1 filter

44 GND2 Ground 2

45 EWD O East-west drive

46 VDRB O Vertical drive B

47 VDRA O Vertical drive A

48 IFIN1 I IF input 1

49I FIN2 I IF input 2

50 EHTO I EHT overvoltage protection

51 VSC Vertical sawtooth capacitor

52 I

53 DEC

54 AGCOUT O Tuner AGC

55 AUDEEM Audio de-emphasis

56 DECSDEM De-coupling sound demodulator

Table 2 – TDA884X

BG

I Internal CVBS

INT

I External CVBS

EXT

I Reference current

REF

AGC de-coupling capacitor

AGC

Pin Designations

Bandgap de-coupling

18

Page 19

RGB 1 INPUT

AA

SW

A

BRI

WHITE P

CONTR

R

R

25 G1

26 BL1

24 G1

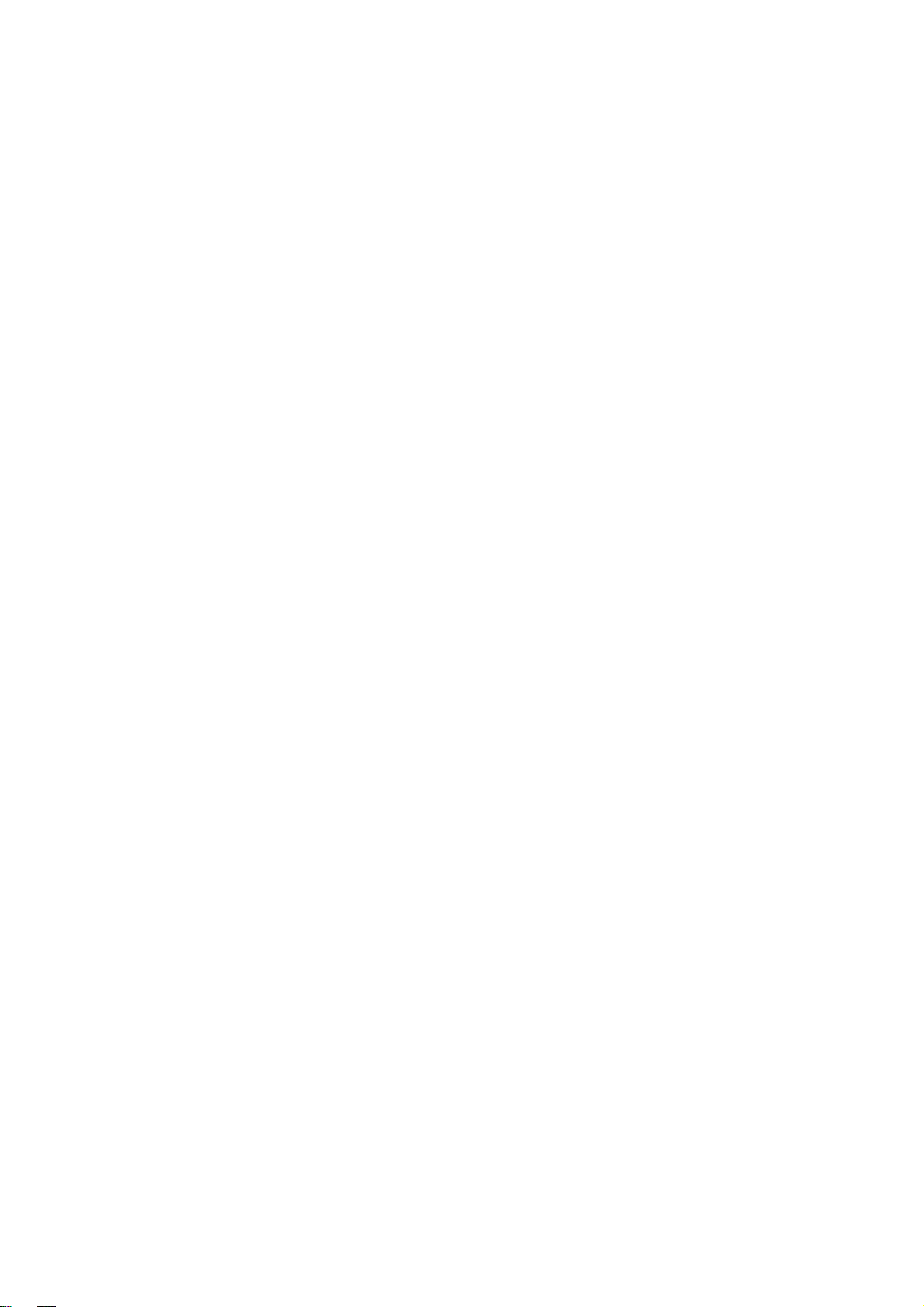

9.2 TDA884X Video Processor

23 R1

22 BEAM CUR

19 B

18 BLACK CUR

21 R

52

47 V. DRIVE

51

46

50 EHT

20 G

VERTICAL

GEOMETRY

H-DRIVE

40

41

2nd LOOP

HOR. OUT

VCO

+ CONTROL

+ 1st LOOP

SYNC SEP.

42

9

37

12

44

14

39

43

H/V DIVIDER

SEPARATOR

VERT. SYNC.

RGB CONTROL

CONTINUOUS

FILTER

BLUE STRETCH

CATHODE

OUTPUT

BLACK

STRETCH

RGB MATRIX

SAT

CALIBRATION

REF

CORING

PEAKING

LUMA DELAY

HUE

REF

TUNING

SW

+ BANDPASS

SD

SCL

TUNER

8

7

53

54

I²C BUS

TOP

AGC FOR IF

R

TRANSCEIVE

+ TUNER

POL

DAC’s

CONTROL

VIDEO

AMPLIFIER

TRAP

CHROMA

MUTE

VIDEO MUTE

SWITCH

CVBS-Y/C

+ MUTE

PRE-AMP.

SKIN TINT

CD MATRIX

SAT. CONTROL

BASE-BAND

DELAY TIME

SC

F

3316343638 113

35

SECAM

PAL/NTSC

DECODER

CVBS/Y

Chr

10 11

CVBS SWITCH

CVBS I

N

PLL DEMOD.

6

TRAP

SOUND

+ PLL DEMOD

VIF AMPLIFIER

48 49

IF-IN

AVL +

SWITCH +

45

VOL SW

VOLUME

56

AFC

IDENT

+ CALIBRATION

5

AFC

VIDEO IDENT

15

55

LIMITER

UDIO OUT

AUDIO IN

Fig 7

Block Diagram

SOUND

BANDPASS

19

Page 20

Remote Control

&

'

(

)

)

*

,

-

/

0

1

The remote control system used is the Philip’s Enhanced RC5 protocol, with sub-address 00000.

Infra-red Transmitter

The hand unit is controlled by IC781, type PCA84C122AT/093, surface mounted on the keypad side of the

PCB. When replacing the part, the /093 is significant as it determines the key codes transmitted. Two AA

type batteries in series provide a 3V power supply.

The IC remains in standby mode (oscillator not running) until a key on the matrix is pressed. The oscillator,

governed by a 4MHz ceramic resonator XL781 is started. The IC decodes the key with suitable debounce

and then transmits the relevant code, repeating as per the RC5 specification until the key is released.

The RC5 pulse train output is modulated within the IC onto a 33.33kHz (f.osc/120) carrier with low (1:3)

hark:space ratio, reducing power consumption and allowing higher LED current. The output on pin 21 of

IC781 drives TR781 which provides high current pulses through infra-red transmitter diode D781. Reservoir

capacitor CE781 reduces momentary battery voltage drop which may otherwise affect the IC.

Infra-red Receiver

The chassis uses an integrated receiver, IC702, which provides a fully demodulated output to the

microcontroller through R703, pulled up by R702.

Keypad N° Symbol Functions Keypad N° Symbol Functions

1

2 1 N° 1 17

! ."

Standby 16

Programme Up

Increase Volume

$"

3 2 N° 2 18

Decrease Volume

%"

4 3 N° 3 19 *Fastext (RED)

5 4 N° 4 20 Menu/*Fastext (GREEN)

6 5 N° 5 21 Menu/*Fastext YELLOW)

7 6 N° 6 22 Menu/*Fastext (CYAN)

8 7 N° 7 23

Normalize/*Hold

"

9 8 N° 8 24

*Expand

"

10 9 N° 9 25

11 0 N° 0 26

*Reveal

"

Status/*Fastext Index

""

12

13

14

."

15

* These functions are only present on chassis fitted with teletext

** These functions are only present on chassis fitted with stereo

Table 3

Keypad Idents and Functions

TV 27

"

*Text/*Mix 28

"

Programme Down 29

Mute 30

+"

"

AV Select

*Time/*Subcode

**Audio Select

"

*Update

"

20

Page 21

Microprocessor Control System

Microcontroller

Micro-controller, I701, is either a SAA5288 (on non-teletext sets) or a SAA5290 (on teletext sets). Both

devices have integrated on-screen display (OSD) generator; the SAA5290 also has an integrated teletext

decoder. The micro-controller has a single 12MHz crystal X701.

The television is controlled by serial (I²C) bus communication, digital switching inputs and outputs, analogueto-digital inputs and pulse-width-modulation (PWM) outputs.

Reset

At power on, C709 is not charged so the voltage on pin 43 of the micro-controller rises with the 5V supply

and resets the micro-controller. An internal resistor to ground at this pin causes C709 to charge up and the

voltage on the reset pin to drop to 0V.

In normal operation, transistor Q702 is switched on and the reset pin is low, but if the 10V supply voltage

drops below about 8V the transistor will switch off and R721 will pull the reset pin high and reset the device.

User Control

User input is via infra-red remote control (Philips' RC5 protocol), internally decoded from the receiver I703, or

from three (non-matrixed) local control keys on active low inputs, I701 pins 18, 19 and 20. The LED flashes

each time a key is detected or remote command received.

Tuning

The tuning control voltage to the tuner is controlled via the PW M at pin 1 of I701 and integrating circuit

around Q001. Minimum voltage is at maximum mark-space ratio (bottom of each band). Band-switching is

controlled by active low outputs on pins 14, 15 and 16 (high, mid, low) and transistors Q002 to Q004. The

controller makes AFC corrections by reading on-tune information from I501 via the I²C bus.

As the tuner is controlled by voltage synthesis, there is no direct correlation between the controller output

and the tuned frequency.

Non-volatile memory

The non-volatile memory, I702, holds configuration information, user settings, parameters as applicable for

I²C controlled ICs and the programme tuning records. It is itself accessed by I²C.

When a new memory IC is fitted, the microcontroller will automatically load default information, which takes a

few seconds during power-up. Regular re-loading of the data, or corruption of settings may indicate I702 is

faulty.

AV switching

Inputs from pins 8 and 16 of SCART 1 are sampled by analogue to digital conversion on pins 9 and 10 of

I701 respectively. The input levels are adjusted such that the controller will automatically switch to AV1 when

pin 8 is above 6V and RGB when pin 16 is above 1V. The time constant on pin 16 ensures the controller will

not detect real-time RGB insertion using pin 16.

21

Page 22

OSD / Teletext

Line and field timings are obtained from V.sync on pin 37 and H.sync input on pin 36. Teletext (on teletext

sets only) is obtained from the CVBS input on pin 23. The RGB outputs on pins 34, 33 and 32 respectively

are inserted into the TV output when gated by the OSD EN OUT signal on pin 35. OSD / teletext contrast is

controlled by the peak reference level on pin 31, generated from the microcontroller PWM output on pin 2 via

Q305.

Error codes

Under the following fault conditions the television will switch to standby and flash the LED.

Fault Condition No. of Flashes

Multiple TDA884X I²C errors 1

Over voltage / X-ray protection (OVP) 2

Line start-up sequence failed 3

Black current (BC) loop unstable 4

Vertical scan failure 5

Continuous TDA884X power-on reset 6

Multiple error codes may appear, eg. two quick flashes, pause, four quick flashes etc. for OVP + BC loop

errors.

Adjustments

In order to make service adjustments including setting the height, width, various configuration options, etc.,

the TV should have a suitable signal tuned in; ideally, a geometry test card. A teletext signal is

recommended for setting OSD contrast on a teletext chassis.

To enter service mode, place a shorting link across terminals 2 and 3 of P701.

In service mode, two 2-digit hexadecimal numbers are displayed to the left of the screen; the lefthand one is

the service parameter number, the righthand one is the value for that parameter. Some parameters are

identified by a two-letter code instead of a number, see below.

For example: - 0A 1F shows parameter ten (0A hex) at thirty-one (1F hex).

In this mode of operation some of the remote control keys have different functions;

The up and down and local select keys are used to select a parameter.

The remote and local left and right keys are used to change the value of the current parameter.

The TV button is used to store any changes.

The teletext select and digit '0' keys are used for programme up or down.

The Normalize key selects factory picture settings immediately over-writing user settings.

The digit keys '1', '2',----'8' toggle the state of the individual bits '7', '6',----'0' of the value of the current

parameter, for example, pressing digit key '4' would change value 1F hex to 0F hex.

TO STORE THE CHANGES, PRESS THE TV KEY ON THE HAND UNIT BEFORE REMOVING THE

SERVICE MODE LINK. THE MESSAGE 'STORED' WILL BE DISPLAYED TO CONFIRM THE

OPERATION.

Under certain circumstances, for example abnormal operation due to suspected corruption of the service

parameters, it may be necessary to perform a complete reset of the non-volatile memory (I702). To effect

this, press and hold the X (teletext update) key for about 3 seconds or until the set switches to standby .

Following this it will be necessary to perform a 'set-up’ of the television.

22

Page 23

Service Parameters

The following values assume you are watching a tuned in picture, on RF. (On other sources, or with no

signal, some values may differ.)

Service parameters 00 to 1A apply to the control registers of I501 as shown in the following table.

No. Value Function Action

00 02 02 02 System control Do not adjust

01 D0 D0 D0 System control Do not adjust

02 1F 1F 1F Hue (SCART NTSC 4.43 Use picture menu control instead

playback only)

03 20 1D 27 Horizontal shift Adjust to centre picture horizontally

04-07 00 00 00 E-W control Not used on this chassis

08 20 1F 1E Vertical slope (linearity) Adjust for vertical linearity

09 10 0B 1A Height Adjust for correct picture height

0A 44 4A 4A S-correction Adjust for best vertical S-correction

0B 2B 1B 1B Vertical shift Adjust to centre picture vertically

0C 29 38 3D White point - Red

0D 29 38 3D White point - Green See adjustments section

0E 29 38 3D White point - Blue

0F 1C 1C 1C Peaking (sharpness) Use picture menu control instead

10 5C 5C 5C Brightness Use picture menu control instead

11 9C 9C 9C Saturation Use picture menu control instead

12 1C 1C 1C Contrast Use picture menu control instead

13 13 13 13 AGC take-over point See adjustments section

14 0A 0A 0A Volume

15 50 50 50 IF PLL adjustment Set to 50 hex.

16 19 19 19 Vertical zoom Not used on this chassis

17 20 20 20 Vertical scroll Not used on this chassis

18 81 81 81 Control 2 Do not adjust

19 08 08 08 Control 3 Do not adjust

1A 00 00 00 Control 4 Do not adjust

Table 4

14" 20" 21"

Service Parameter Functions

Parameters above 1A are designated by two-letter codes (except text contrast on a teletext set). These

control configuration.

Text Mode Text (OSD) contrast Set as preferred, see notes below

Ex Export (VHF/UHF) setting 00 for UHF-only, 01 if multi-band tuner

AV AV socket configuration 00 single SCART, 01 single SCART plus

phono inputs

It is advisable to make a note of the existing values prior to commencing servicing. (See adjustments

section).

23

Page 24

Microprocessor Pin-outs

Pin Designation I/O Purpose

1 P2.0/TPWM O Tuning PWM

2 P2.1/PWM0 O Text contrast PWM

3 P2.2/PWM1 O AV audio control: high = AV2, low = RGB/AV1

4 P2.3/PWM2 O !FM/AM source select (low = AM)

5 P2.4/PWM3 O !SCART/internal sound select (low = internal sound)

6 P2.5/PWM4 O !L’ control select (active high)

7 P2.6/PWM5 O Pseudo line drive

8 P2.7 O Force RGB high = RGB mode

9 P3.0/ADC0 AV1 SCART pin 8 level detection (ADC)

10 P3.1/ADC1 AV1 SCART pin 16 level detection (ADC)

11 P3.2/ADC2 AGC level sampling (ADC)

12 P3.3 –

13 Vssd Digital ground

14 P0.0 I High band tuner select (active low)

15 P0.1 I Mid band tuner select (active low)

16 P0.2 I Low band tuner select (active low)

17 P0.3 O Audio mute control (active low

18 P0.4 I Select key

19 P0.5 I Down key

20 P0.6 I Up key

21 P0.7 –

22 Vssa Analogue ground

23 CVBS0 I Composite video

24 CVBS1 –

25 Black I Video black level storage

26 Iref I Reference current

27 Frame –

28 Test Ground

29 COR –

30 P3.4 TDA884X Line drive gating: high in standby & start-up, low in operation

31 RGBref I RGB reference

32 OSD B O Blue OSD

33 OSD G O Green OSD

34 OSD R O Red OSD

35 OSD EN O OSD enable

36 H sync I Horizontal sync

37 V sync I Vertical sync

38 Vdda +5V display power supply

39 Vddt +5V display power supply

40 Osc gnd Crystal oscillator ground

41 Osc in I 12MHz crystal oscillator

42 Osc out O 12MHz crystal oscillator

43 Reset I Reset (active high)

44 Vddm +5V microcontroller power supply

45 P1.0/Int1 I Remote control

46 P1.1/T0 O Standby/IR LED: low = LED bright, high = LED dim

47 P1.2/Int0 I Line drive from TDA884x

48 P1.3/T1 O Standby control (active low)

49 P1.6/SCL I²C clock

50 P1.7/SDA I²C data

51 P1.4 I Service mode (active low)

52 P1.5 I Halt microcontroller control (active low)

!!!!

NOTE

Table 5

Pin Descriptions

Only used on French chassis

24

Page 25

SAA5290 (Teletext) & SAA5288 (Non-teletext)

Microcontrollers

Note: The SAA5288 microcontroller used on non-teletext models does not perform the functions in the

shaded area.

Black IRef

CVBS0,

CVBS1

Reset

Teletext

Data Slicer

Acquisition

Display

R,G,B,

VDS,

COR

Page

VSync

HSync

Frame

XtalIn

XtalOut

OscGnd

8051

CPU

data

addr

int

Acquisition

Timing

16k x 8

ROM

I²C

Port 1

Timer/

Ctrs

256 x 8

RAM

ADC

Port 0

Text

Interface

Port 3

RAM

PWM

Port 2

Display

Timing

Osc

P1.0 – 1.7 P3.0 – 3.4

P0.0 – 0.7 P2.0 – 2.7

Fig 8

Block Diagram

25

Page 26

SER

U

UIDE

G

Operating Instructions

Using the Menus

Green

Key

Yellow

Key

Blue Key

Red Key

The green, yellow and blue keys select the Menus as listed above. See pages 3 and 4 for full details of their

functions.

In Teletext mode they enable quick access to topical subjects related to the magazine you have selected.

Just press the key with the same colour as the topic at the foot of the page.

Up/Down

Keys

When viewing television these keys will select next/previous TV station.

When using Teletext these keys will select next/previous pages.

Left/Right

Keys

Selects the PICTURE controls menu.

Selects the MANUAL/TUNING menu.

Selects the FEATURES menu.

Used only within the other menus above.

(P+/P-) Move the cursor (coloured bar) when using Menus.

(vol – or

adjustments when using Menus.

!

–) / (vol + or

!

+) Move the cursor (coloured bar), or makes

In TV and Teletext mode they will adjust the volume down and up.

Remote Control Hand Units

FX700 RCHU

FX701 RCHU

26

Page 27

FRANÇAIS

CONSIGNES DE SECURITE

AVERTISSEMENT: vous devez respecter les précautions suivantes

POUR TOUS LES PRODUITS

Avant d’effectuer une intervention d’entretien sur le

châssis, vous devez insérer un transformateur d’isolement

entre la ligne d’alimentation électrique et le produit.

1. Lors de la remontage du châssis dans le coffret,

vérifiez que tous les dispositifs de protection sont

remis en place.

2. Lorsqu’une intervention d’entretien s’avère

nécessaire, respectez l’agencement d’origine des

conducteurs. Vous devez prendre des précautions

supplémentaires pour garantir un agencement correct

des conducteurs dans toutes les zones où des circuits

haute tension sont présents.

3. De nombreux composants électriques et mécaniques

des appareils HITACHI ont des caractéristiques

spéciales de sécurité. Bien souvent, ces

caractéristiques ne sont pas évidentes lors d’un

examen visuel et la protection qu’ils offrent n’est pas

forcément garantie si vous utilisez des composants de

rechange conçus, par exemple, pour une tension plus

élevée, une puissance plus forte. Les pièces de

rechange qui offrent des caractéristiques spéciales de

sécurité sont identifiées par un repérage comportant

le symbole ! sur les schémas et sur la

nomenclature des pièces de rechange.

L’emploi d’un composant de rechange qui ne

respecte pas les mêmes caractéristiques de sécurité

que la pièce de rechange que recommande HITACHI

et qui figure dans la nomenclature risque de

provoquer un choc électrique, un incendie, des rayons

X ou d’autres dangers.

4. Remettez toujours en place les entretoises d’origine

et respectez la longueur des conduites. En outre, à la

suite d’un court-circuit, remplacez les composants

présentant des signes de surchauffe.

5. La résistance d’isolement doit être supérieure ou

égale à 2 méga ohms à 500 V c.c. entre les pôles

principaux et des composants métalliques

accessibles, quels qu’ils soient.

6. Aucun claquage et aucune rupture ne doit se produire

pendant l’essai de résistance diélectrique à la suite de

l’application d’une tension de 3 kV c.a. ou de 4,35

kV c.c. pendant deux secondes entre les pôles

principaux et des composants métalliques

accessibles.

7. Avant de remettre au client un produit qui a fait

l’objet d’un entretien, le technicien qui s’est chargé

de cette intervention doit tester à fond cet ensemble

pour s’assurer qu’il ne présente aucun danger

opérationnel et aucun risque de choc électrique. Ce

technicien doit s’assurer qu’aucun des dispositifs de

protection intégrés à cet instrument par le fabricant

n’est défectueux ou n’a été endommagé de façon

accidentelle lors de l’entretien.

27

LABEL CE

1. Les produits HITACHI peuvent avoir reçu le label

CE qui figure sur la plaque signalétique pour indiquer

que cet ensemble contient des composants qui ont fait

l’objet d’une homologation spécifique de respect des

normes de compatibilité électromagnétique en

fonction de niveaux bien spécifiés.

2. Lors du remplacement d’un des composants de ce

produit, utilisez uniquement le composant correct

identifié dans la nomenclature afin de maintenir le

respect de cette norme ; en outre, vous devez

également ramener l’agencement des conducteurs à

son état d’origine car cela peut avoir une influence au

niveau des rayonnements électromagnétiques et sur la

protection contre ces rayons.

PICTURE TUBE

1. L’étage de sortie des lignes peut développer des

tensions de plus de 25 kV ; s’il faut retirer le chapeau

de protection contre les tensions extrêmement

élevées, il convient de décharger l’anode contre le

châssis par le biais d’une résistance de forte valeur

avant de déposer ce chapeau du tube image.

2. La haute tension doit toujours se maintenir à la valeur

nominale du châssis et ne pas dépasser cette dernière.

Un fonctionnement à des températures élevées peut

provoquer une défaillance du tube image ou l’entrée

d’une tension élevée. Dans certains cas, cela peut

même provoquer des rayons X d’un niveau

légèrement supérieur aux valeurs de calcul. Cette

haute tension ne doit en aucun cas dépasser 29 kV sur

le châssis (à l’exception des téléviseurs de

projection).

3. La principale source de rayons X de cet appareil est

le tube image. Le tube image employé pour assurer la

fonction susmentionnée dans ce châssis est

spécialement construit pour limiter des rayons X.

Pour maintenir cette protection contre les rayons X, il

faut remplacer le tube d’origine d’un type agréé par

HITACHI par un autre tube de même type.

4. Lors des manipulations, ne tenez jamais le tube

image contre le corps. Pendant toutes les opérations

d’installation, de dépose et de manipulation de ce

tube image, quelle que soit la méthode employée,

vous devez toujours porter des lunettes de sécurité

anti-éclatements. Les personnes qui ne portent pas ce

type de lunettes doivent se tenir à l’écart du tube

image lors de la manipulation de ce dernier.

RAYONS LASER

Si ce produit contient un rayon laser, évitez toute

exposition directe à ce faisceau lors de l’ouverture du

couvercle ou lors de l’élimination des verrouillages de

sécurité ou après défaillance de ces verrouillages.

Page 28

SECURITE ET ISOLEMENT

1. Toutes les interventions de réparation ou d’entretien doivent être exclusivement confiées à un technicien

ou ingénieur compétent. Il faut respecter les précautions suivantes : observed:

2. Lors d’un entretien courant, l'appareil doit être alimenté par un transformateur d’isolement offrant une

puissance nominale d’au moins 150 W.

3. Si le revêtement plombé d’origine a bougé, il faut le rétablir. C’est très important car cet appareil est du

type «bobine chaude». Ce revêtement influe également sur les performances de cet appareil en matière

de CEM.

4. Les composants identifiés sur le schéma de circuit sont des ensembles qui ont été agréés sur le plan de

la sécurité et qui offrent des caractéristiques spéciales en ce qui concerne la sécurité. Utilisez

uniquement des composants de rechange fournis par le constructeur. Le remplacement par d’autres

pièces ou des pièces «améliorées», par exemple des résistances plus puissantes, ne garantit en aucun

cas le même niveau de protection et peut même créer un risque d’incendie, de choc électrique ou de

rayons X.

5. Les composants qui ne portent pas ce repère doivent cependant être remplacés par le modèle monté

d’origine et le montage doit se faire de la même façon.

Barrière d’isolement

cet appareil est du type «bobine chaude» c’est-à-dire que les bobines de balayage de ligne NE SONT PAS

isolées du courant secteur étant donné que le groupe d’alimentation électrique ne fournit pas un isolement

sur le rail B+. Par conséquent, la barrière d’isolement secteur présente plus de circonvolutions que celle d’un

appareil traditionnel et une partie nettement plus importante de cet appareil n’est pas isolée. La Figure 1

indique l’emplacement de cette barrière dans l'appareil.

Vous pouvez ainsi voir que le transformateur DST (T401) et les bobines de visionnement sont à cheval sur

la barrière d’isolement et constituent, à ce titre des composants essentiels sur le plan de la sécurité. En

outre, l’opto-coupleur (I402) doit transmettre l’impulsion de ligne de I501, sur le côté «froid», à l’étage

d’impulsion de ligne, sur le côté «chaud». Par conséquent, cette barrière se compose de T802, T401, I402,

C804, R804 et R805, des bobines de visionnement et d’entrefers de 6 mm. Pour maintenir l’intégrité de cette

28

Page 29

barrière, faire très attention de ne pas réduire les entrefers en y laissant pénétrer, par exemple, des fils

faisant saillie, à la suite du remplacement d’un composant. Le revêtement plombé de la tige de déviation

joue un rôle important pour maintenir un double isolement en travers de cette barrière. Un serre-fil maintient

en position le manchon conducteur de balayage. S’il faut retirer ce manchon, quelle qu’en soit la raison, il

convient de le faire glisser vers la tige de déviation et de l’immobiliser en position à l’aide d’un serre-fil.

Précautions pendant la manipulation de semi-conducteurs

Cet appareil contient des dispositifs qui peuvent être endommagés par des charges d’électricité statique lors

des manipulations ; il s’agit en particulier des composants I501, I602, I701 et Q801. Pour éviter ce type de

dégâts, il faut mettre à la masse les fers à souder et il vaudrait mieux que les ingénieurs et techniciens

chargés de l’entretien portent au poignet des bracelets mis à la masse par le biais d’une résistance de 1 M

ou, à tout le moins, se déchargent en un point mis à la terre.

29

Page 30

NTRETIEN COURANT

E

SYSTEME DE COMMANDE A

MICROPROCESSEUR

Microcontrôleur

Le microcontrôleur I701 est un SAA5288 (sur les appareils sans télétexte) ou un SAA5290 (sur les appareils

à télétexte). Ces deux dispositifs ont une génératrice intégrée d’affichage à l’écran (OSD) ; le SAA5290 a

également un décodeur intégré de télétexte. Le microcontrôleur a un seul cristal X701 de 12 MHz.

Ce téléviseur est piloté par des communications sur bus en série (I=B2C), des entrées et sorties de

commutation numérique, des entrées analogiques/numériques et des sorties à modulation de largeur

d’impulsion.

Réinitialisation

Lors de la mise sous tension, C709 n’est pas chargé et, par conséquent, la tension sur la broche 43 du

microcontrôleur s’élève en présence de la tension d’alimentation de 5 V et réinitialise le microcontrôleur. Une

résistance interne mise à la masse au niveau de cette broche provoque la montée en charge de C709 et la

chute de tension sur la broche de réinitialisation (cette tension tombe à 0 V).

Dans le cadre d’un fonctionnement normal, le transistor Q702 est mis sous tension et la broche de

réinitialisation est basse ; cependant, si la tension d’alimentation de 10 V tombe à moins de 8 V environ, ce

transistor se met hors tension et R721 force la broche de réinitialisation à devenir haute pour réinitialiser cet

appareil.

Commande de l’utilisateur

L’entrée par l’utilisateur s’effectue à l’aide de la télécommande à infrarouges (protocole RC5 de Philips) ; elle

est décodée à partir du récepteur I703 ou à partir de trois touches (sans matrice) locales de commande en

présence d’entrées actives basses, broches 18, 19 et 20 de I701. La DEL clignote chaque fois qu’une

touche est détectée ou lors de chaque réception d’une commande depuis la télécommande.

Réglage

La tension de commande du réglage du tuner est pilotée par la modulation à largeur d’impulsion de la

broche 1 de I701 et du circuit d’intégration qui se trouve autour de Q001. La tension minimale s’élève au

rapport maximal marque-espace (extrémité inférieure de chaque bande). La commutation de bande est

placée sous le contrôle des sorties actives basses des broches 14, 15 et 16 (haute, moyenne, basse) et des

transistors Q002 à Q004. Le contrôleur effectue des corrections de CAF en lisant les informations de

réglage, depuis I501, par le biais du bus I=B2C.

Etant donné que le tuner est piloté par la synthèse de tension, il n’y a pas de corrélation directe entre la

sortie du contrôleur et la fréquence de réglage.

Mémoire rémanente

La mémoire rémanente I702 détient les informations de configuration, les réglages d’utilisateurs, les

paramètres nécessaires pour les IC contrôlés I=B2C et les enregistrements de réglage de programmes. On

y accède par I=B2C.

Lors de l’installation d’un nouveau IC de mémoire, le microcontrôleur charge automatique les informations

implicites, ce qui prend quelques secondes lors de la mise sous tension. Un rechargement régulier des

données ou la corruption des réglages peut indiquer une défaillance de I702.

Commuation AV

Les entrées en provenance des broches 8 et 16 de péritel 1 font l’objet d’un échantillonnage par une

conversion analogique/numérique sur, respectivement, les broches 9 et 10 de I701. Les niveaux d’entrée

sont ajustés afin que le contrôleur puisse automatiquement passer sur AV1 lorsque la broche 8 est

30

Page 31

supérieure à 6 V et sur RVB lorsque la broche 16 est supérieure à 1 V. La constante de temps sur la broche

16 permet au contrôleur de ne pas détecter l’insertion de RVB en temps réel en utilisant la broche 16.

OSD/Télétexte

Les synchronisations de lignes et de champs dans le temps s’obtiennent à partir de V.sync sur la broche 37

et de l’entrée H.sync de la broche 36. Le télétexte (uniquement sur les postes équipés du télétexte) s’obtient

à partir de l’entrée CVBS de la broche 23. Les sorties RVB des broches 34, 33 et 32 sont, respectivement,

insérées dans la sortie TV après passage par une porte du signal OSD EN OUT de la broche 35. Le

contraste OSD/Télétexte est piloté par le niveau de référence de pointe sur la broche 31, qui est généré à

partir de la sortie PWM à modulation de largeur d’impulsion du microcontrôleur sur la broche 2 par le biais de

Q305.

Codes d’erreurs

Lorsque les conditions de défauts suivantes sont présentes, le téléviseur passe au mode de veille et la DEL

clignote.

Condition de défaut Nombre de clignotements

Erreurs multiples de TDA884X I=B2C 1

Tension excessive/protection contre les rayons X (OVP) 2

Echec de séquence de mise en route en ligne 3

Boucle instable de courant noir (BC) 4

Défaillance de scrutation verticale 5

Puissance continue de TDA884X lors de la réinitialisation 6

Des codes multiples d’erreurs peuvent apparaître ; exemples : deux clignotements rapides, une pause,

quatre clignotements rapides, etc. lorsque des erreurs portant sur la protection contre la surtension (OVP) et

sur la boucle BC de courant noir sont présentes.

Réglages

Pour effectuer des ajustements de services, y compris le réglage de la hauteur, de la largeur et, entre

autres, différentes options de configuration, il faut qu’un signal approprié soit programmé sur le téléviseur ;

l’idéal est une mire d’essai géométrique. Un signal de télétexte est recommandé pour régler le contraste

OSD sur un appareil équipé du télétexte.

Pour entrer dans le mode de service, placez une liaison de court-circuit entre les bornes 2 et 3 de P701.

Dans le mode de service, deux nombres hexadécimaux à deux chiffres apparaissent à gauche de l’écran ; le

nombre gauche correspond au numéro du paramètre de service et le nombre droit correspond à la valeur de

ce paramètre. Certains paramètres sont identifiés par un code à deux lettres et non pas par un nombre, voir

ci-après.

Par exemple : 0A 1F montre le paramètre dix (0A hex) à trente et un (1F = hex).

Dans ce mode de fonctionnement, certaines touches de la télécommande ont différentes fonctions ;

Les touches à flèches vers le haut et vers le bas et les touches de sélection locale s’utilisent pour choisir un

paramètre.