Page 1

HITACHI

Model

Modèle

Modelo

B13F

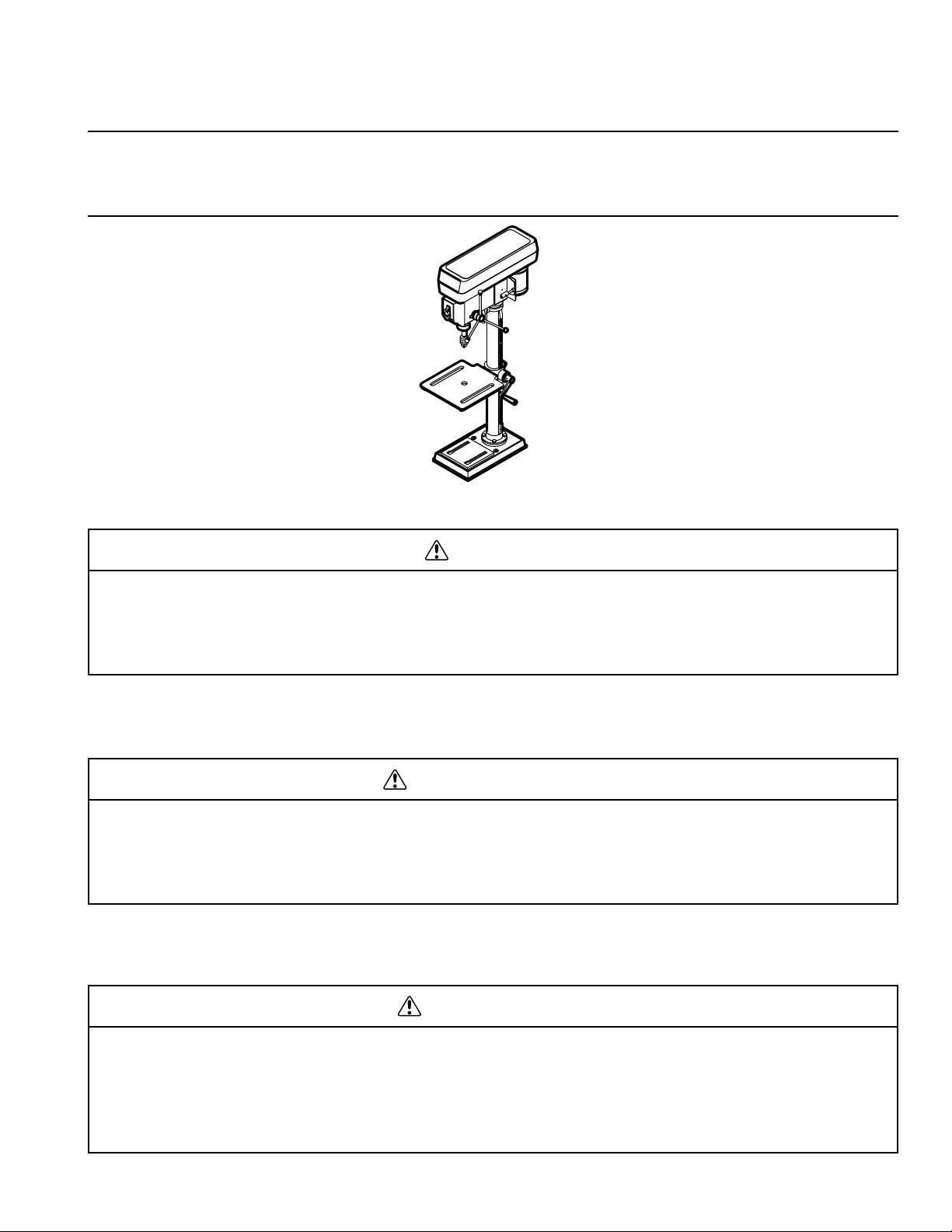

Bench Drill Press

Perceuse d’établi

Prensa Taladradora de Banco

INSTRUCTION MANUAL AND SAFETY INSTRUCTIONS

WARNING

Improper and unsafe use of this power tool can result in death or serious bodily injury!

This manual contains important information about product safety. Please read and understand

this manual before operating the power tool. Please keep this manual available for others

before they use the power tool.

Hitachi Koki

MANUEL D’INSTRUCTIONS ET CONSIGNES DE SÉCURITÉ

AVERTISSEMENT

L’utilisation inadéquate et non sécuritaire de cet outil électrique peut entraîner la mort ou des

blessures graves! Ce manuel contient des informations importantes sur la sécurité. Veuillez

lire et comprendre ce manuel avant d’utiliser l’outil électrique. Veuillez garder ce manuel

disponible pour les autres utilisateurs, avant qu’ils utilisent cet outil électrique.

MANUAL DE INSTRUCCIONES E INSTRUCCIONES DE SEGURIDAD

ADVERTENCIA

¡El uso inadecuado y no seguro de esta herramienta eléctrica puede ocasionar la muerte o

lesiones corporales graves! Este manual contiene información importante sobre la seguridad

del producto. Por favor lea y entienda este manual antes de usar la herramienta eléctrica.

Por favor mantenga disponible este manual para que otros puedan leerlo antes de usar la

herramienta eléctrica.

Page 2

SECTION Page

Product Specifications..........................................................3

Safety ...................................................................................4

Accessories and Attachments ..............................................7

Carton Contents ...................................................................7

Know Your Drill Press ...........................................................9

Glossary of Terms...............................................................10

SECTION Page

Assembly and Adjustments ................................................11

Operation............................................................................15

Maintenance.......................................................................18

Troubleshooting Guide........................................................19

Parts List.............................................................................55

TABLE OF CONTENTS

HITACHI AUTHORIZED SERVICE CENTERS

Service under this warranty is available from Hitachi Koki U.S.A., Ltd. at:

IN THE U.S.A.

3950 Steve Reynolds Blvd., Norcross, GA 30093

9409 Owensmouth Ave., Chatsworth, CA 91311

OR CALL: (800) 546-1666 for a service center nearest you.

IN CANADA

6395 Kestrel Road, Mississauga, ON L5T 1Z5

OR CALL: (800) 970-2299 for a service center nearest you.

English

SECTION Page

Spécifications du produit ....................................................20

Sécurité ..............................................................................21

Accessoires et équipements...............................................24

Contenu du carton..............................................................24

Connaître sa scie à ruban ..................................................26

Glossaire des termes .........................................................27

SECTION Page

Assemblage et ajustements ...............................................28

Fonctionnement..................................................................32

Entretien .............................................................................35

Guide de dépannage..........................................................36

Liste des pièces..................................................................55

TABLE DES MATIÈRES

CENTRES DE SERVICE AUTORISÉS D’HITACHI

Le service en vertu de cette garantie est disponible de Hitachi Koki U.S.A., Ltd,

aux emplacements suivants :

AUX É-U

3950 Steve Reynolds Blvd., Norcross, GA 30093

9409 Owensmouth Ave., Chatsworth, CA 91311

OU APPELER : (800) 546-1666 pour contacter un centre

de service le plus près de votre domicile.

AU CANADA

6395 Kestrel Road, Mississauga, ON L5T 1Z5

OU APPELER : (800) 970-2299 pour contacter un centre

de service le plus près de votre domicile.

Français

SECCION Página

Especificaciones del producto............................................37

Seguridad ...........................................................................38

Accesorios y aditamentos ..................................................41

Contenido de la caja...........................................................41

Conozca su sierra de banda...............................................43

Glosario de términos ..........................................................44

SECCION Página

Montaje y ajustes................................................................45

Operación...........................................................................49

Mantenimiento....................................................................52

Guía de identificación de problemas ..................................53

Lista de partes....................................................................55

CONTENIDO

CENTROS DE SERVICIO AUTORIZADO DE HITACHI

El servicio de mantenimiento y reparación bajo esta garantía está disponible a través de

Hitachi Koki U.S.A., Ltd. en:

EN EE.UU.

3950 Steve Reynolds Blvd., Norcross, GA 30093

9409 Owensmouth Ave., Chatsworth, CA 91311

O LLAME AL: (800) 546-1666 para averiguar cuál es el

centro de servicio más cercano a usted.

EN CANADA

6395 Kestrel Road, Mississauga, ON L5T 1Z5

O LLAME AL: (800) 970-2299 para averiguar cuál es el

centro de servicio más cercano a usted.

Español

– 2 –

Page 3

PRODUCT SPECIFICATIONS

MOTOR

Power Source...................115 V, 60 HZ, 3.5 AMPS.

Speeds.............................5 - 680~3000 RPM

(Revolutions Per Minute)

Horsepower......................1/3 HP (Continuous Duty)

Capacity

Chuck Size.......................1/2″

Spindle Travel...................2 1/2″

Throat ..............................5″

Table

Size..................................7 13/16″ x 7 13/16″

Tilt ....................................45° Right or Left

Dimensions

Base Size.........................8 1/16″ x 13 3/16″

Height ..............................28″

NET WEIGHT............................61 LB (27.5 kg)

To avoid electrical hazards, fire hazards, or damage to the

tool, use proper circuit protection.

Use a separate electrical circuit for your tools.

Your Drill Press is wired at the factory for 115V operation.

Connect to a 115V, 15 AMP branch circuit and use a 15 Amp

time delay fuse or circuit breaker. To avoid shock or fire,

replace power cord immediately if it is worn, cut or

damaged in any way.

WARNING

Some dust created by power sanding, sawing, grinding, drilling and other construction activities contains chemicals

known to the state of California to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals, work in a well-ventilated area and work with approved safety equipment such as dust masks that are

specially designed to filter out microscopic particles.

WARNING

SAVE THESE INSTRUCTIONS

– 3 –

English

Page 4

SAFETY

– 4 –

English

GENERAL SAFETY INSTRUCTIONS

BEFORE USING THE DRILL PRESS

Safety is a combination of common sense, staying alert and

knowing how to use this Drill Press.

To avoid mistakes that could cause serious injury, do not plug

the Drill Press in until you have read and understood the

following:

1. READ and become familiar with the entire Operator’s

Manual. LEARN the tool’s application, limitations and

possible hazards.

2. KEEP GUARDS IN PLACE and in working order.

3. REMOVE ADJUSTING KEYS AND WRENCHES.

Form a habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning ON.

4. KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

5. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t

use power tools in damp or wet locations, or expose

them to rain. Keep work area well lighted.

6. KEEP CHILDREN AWAY. All visitors should be kept

at a safe distance from work area.

7. MAKE WORKSHOP CHILDPROOF with padlocks,

master switches, or by removing starter keys.

8. DON’T FORCE THE TOOL. It will do the job better and

safer at the rate for which it was designed.

9. USE THE RIGHT TOOL. Do not force tool or attachment

to do a job for which it was not designed.

10. USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersized

cord will result in a drop in line voltage and in loss of

power that will cause the tool to overheat. The table on

page 6 shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt, use the

next heavier gauge. The smaller the gauge number, the

heavier the cord.

11. WEAR PROPER APPAREL. Do not wear loose clothing,

gloves, neckties, rings, bracelets, or other jewelry that

may get caught in moving parts. Non-slip footwear is

recommended. Wear protective hair covering to contain

long hair.

12. ALWAYS WEAR EYE PROTECTION. Any Drill Press

can throw foreign objects into the eyes that could cause

permanent eye damage. ALWAYS wear Safety Goggles

(not glasses) that comply with ANSI Safety Standard

Z87.1. Everyday eyeglasses have only impact-resistance

lenses. They ARE NOT safety glasses. Safety Goggles

are available at HITACHI.

NOTE: Glasses or goggles not in compliance with

ANSI Z87.1 could cause serious injury.

13. SECURE WORK. Use clamps or a vise to hold work

when practical. It’s safer than using your hand and it

frees both hands to operate tool.

14. DISCONNECT TOOLS before servicing; when changing

accessories such as blades, bits, cutters, and the like.

15. REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure switch is in OFF position before plugging in.

16. USE RECOMMENDED ACCESSORIES. Consult the

Operator’s Manual for recommended accessories. The

use of improper accessories may cause serious injury.

17. NEVER STAND ON TOOL. Serious injury could occur if

the tool is tipped or if the cutting tool is unintentionally

contacted.

18. CHECK FOR DAMAGED PARTS. Before further use of

the tool, a guard or other part that is damaged should

be carefully checked to determine that it will operate

properly and perform its intended function – check for

alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other conditions

that may affect its operation. A guard or other part that

is damaged should be properly repaired or replaced.

19. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWER “OFF”. Don’t leave tool until it comes to a

complete stop.

20. DON’T OVERREACH. Keep proper footing and balance

at all times.

21. MAINTAIN TOOLS WITH CARE. Keep tools sharp and

clean for best and safest performance. Follow instructions

for lubricating and changing accessories.

22. DO NOT use power tools in the presence of flammable

liquids or gases.

23. DO NOT OPERATE the tool if you are under the

influence of any drugs, alcohol or medication that could

affect your ability to use the tool properly.

24.

ALWAYS operate the Drill Press in a well-ventilated area

and provide for proper dust removal. Use dust collection

systems whenever possible. Dust generated from certain

materials can be hazardous to your health.

WARNING

Page 5

– 5 –

English

SPECIFIC SAFETY INSTRUCTIONS FOR

THE DRILL PRESS

For your own safety, do not try to use your drill press or plug

it in until it is completely assembled and installed according to

the instrucitons, and until you have read and understood this

intstruction manual.

1. THIS DRILL PRESS is intended for use in dry

conditions, indoor use only.

2. WEAR EYE PROTECTION. USE a face or dust mask

along with safety goggles if drilling operation is dusty.

USE ear protectors, especially during extended periods

of operation.

3. DO NOT wear gloves, neckties, or loose clothing.

4. DO NOT try to drill material too small to be securely held.

5. ALWAYS keep hands out of the path of a drill bit. Avoid

awkward hand positions where a sudden slip could

cause your hand to move into the drill bit.

6. DO NOT install or use any drill bit that exceeds 175mm

(7″) in length or extends 150mm (6″) below the chuck

jaws. They can suddenly bend outward or break.

7. DO NOT USE wire wheels, router bits, shaper cutters,

circle (fly) cutters, or rotary planers on this drill press.

8. WHEN cutting a large piece of material, make sure it is

fully supported at the table height.

9. DO NOT perform any operation freehand. ALWAYS hold

the workpiece firmly against the table so it will not rock or

twist. Use clamps or a vise for unstable workpieces.

10. MAKE SURE there are no nails or foreign objects in the

part of the workpiece to be drilled.

11. CLAMP THE WORKPIECE OR BRACE IT against the

left side of the column to prevent rotation. If it is too short

or the table is tilted, clamp it solidly to the table and use

the fence provided.

12. IF THE WORKPIECE overhangs the table such that it will

fall or tip if not held, clamp it to the table or provide

auxiliary support.

13. SECURE THE WORK. Use clamps or a vise to hold the

work when practical. It’s safer than using your hand and it

frees both hands to operate tool.

14. MAKE SURE all clamps and locks are firmly tightened

before drilling.

15. SECURELY LOCK THE HEAD and table support to the

column, and the table to the table support before

operating the drill press.

16. NEVER turn your drill press ON before clearing the table

of all objects (tools, scraps of wood, etc.).

17. BEFORE STARTING the operation, jog the motor switch

to make sure the frill bit does not wobble or vibrate.

18. LET THE SPINDLE REACH FULL SPEED before

starting to drill. If your drill press makes an unfamiliar

noise or if it vibrates excessively, stop immediately, turn

the drill press OFF and unplug. Do not restart the unit

until the problem is corrected.

19. DO NOT perform layout assembly or set up work on the

table while the drill press is in operation.

20. USE THE RECOMMENDED SPEED for any drill press

accessory and for different workpiece material. READ

THE INSTRUCTIONS that come with the accessory.

21. WHEN DRILLING large diameter holes, clamp the

workpiece firmly to the table. Otherwise, the bit may grab

and spin the workpiece at high speeds. DO NOT USE fly

cutters or multiple-part hold cutters, as they can come

apart or become unbalanced in use.

22. MAKE SURE the spindle has come to a complete stop

before touching the workpiece.

23. TO AVOID INJURY from accidental starting, always turn

the switch OFF and unplug the drill press before

installing or removing any accessory or attachment or

making any adjustment.

24. KEEP GUARDS IN PLACE and in working order.

25.

USE ONLY THE SELF-EJECTING TYPE CHUCK KEY

as provided with the drill press.

26. AVOID DIRECT EYE EXPOSURE when using the laser

guide.

27. ALWAYS ENSURE THE LASER BEAM IS AIMED AT A

SURFACE WITHOUT REFLECTIVE PROPERTIES.

Shiny reflective materials are not suitable for laser use.

WARNING

Page 6

ELECTRICAL REQUIREMENTS

POWER SUPPLY AND MOTOR SPECIFICATIONS

To avoid electrical hazards, fire hazards, or damage to the

tool, use proper circuit protection. Use a separate electrical

circuit for your tools. Your drill press is wired at the factory for

115V operation. Connect to a 115V, 15 Amp circuit and use a

15 Amp time delay fuse or circuit breaker. To avoid shock or

fire, if power cord is worn or cut, or damaged in any way,

have it replaced immediately.

GROUNDING INSTRUCTIONS

This tool must be grounded while in use to protect the

operator from electrical shock.

IN THE EVENT OF A MALFUNCTION OR BREAKDOWN,

grounding provides a path of least resistance for electric

current and reduces the risk of electric shock. This tool is

equipped with an electric cord that has an equipment-grounding

conductor and a grounding plug. The plug MUST be plugged

into a matching receptacle that is properly installed and

grounded in accordance with ALL local codes and ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not fit the

receptacle, have the proper receptacle installed by a qualified

electrician.

IMPROPER CONNECTION of the equipment-grounding

conductor can result in risk of electric shock. The conductor

with green insulation (with or without yellow stripes) is the

equipment-grounding conductor. If repair or replacement of

the electric cord or plug is necessary, DO NOT connect the

equipment-grounding conductor to a live terminal.

CHECK with a qualified electrician or service person if you

do not completely understand the grounding instructions,

or if you are not sure the tool is properly grounded.

USE ONLY 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept the

tool’s plug. Repair or replace damaged or worn cord

immediately.

Use a separate electrical circuit for your tools. This circuit

must not be less than #12 wire and should be protected with

a 15 Amp time delay fuse. Before connecting the motor to the

power line, make sure the switch is in the OFF position and

the electric current is rated the same as the current stamped

on the motor nameplate. Running at a lower voltage will

damage the motor.

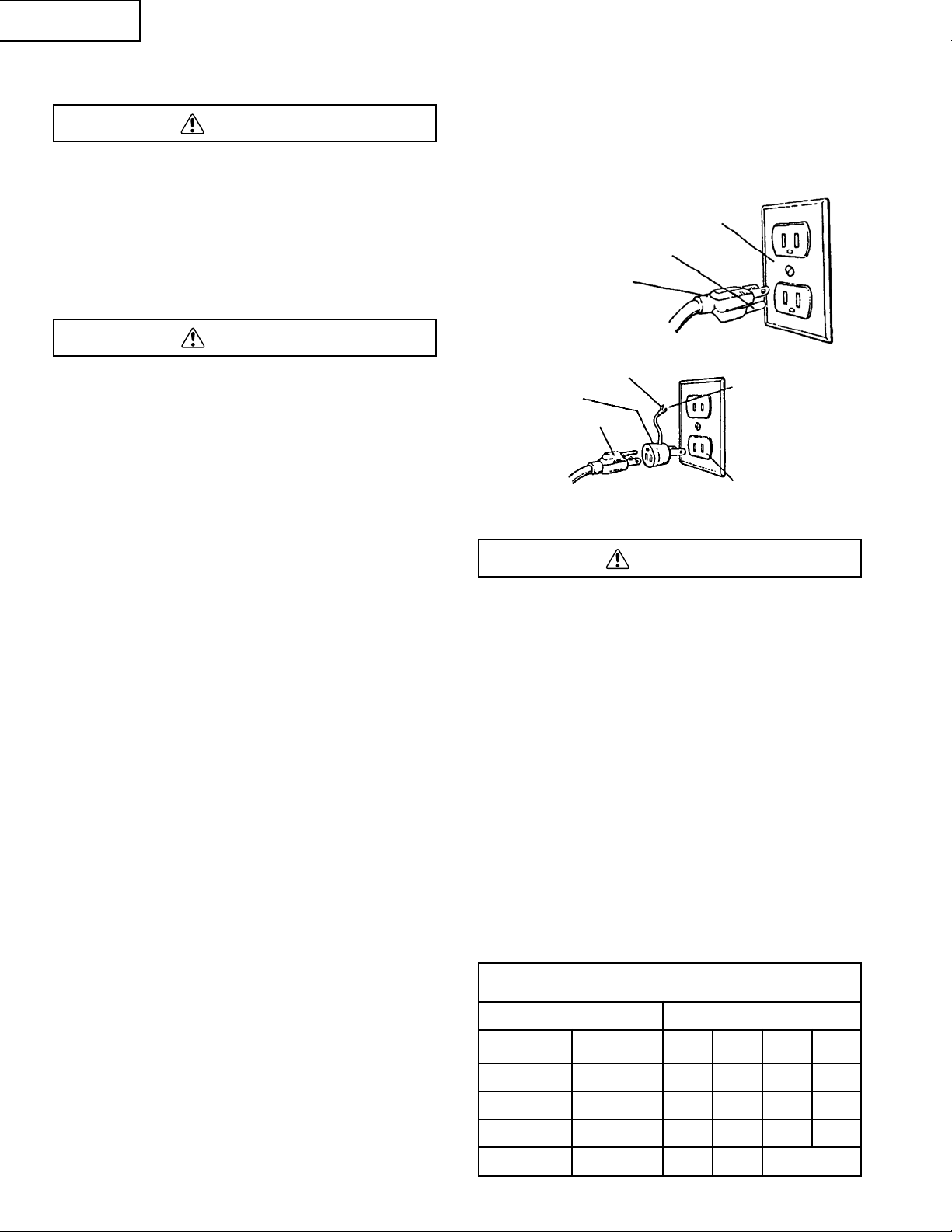

This tool is intended for use on a circuit that has a receptacle

like the one illustrated in Figure A showing a 3-prong

electrical plug and receptacle that has a grounding conductor.

If a properly grounded receptacle is not available, an adapter

(Figure B) can be used to temporarily connect this plug to

a 2-contact ungrounded receptacle. The adapter (Figure B)

has a rigid lug extending from it that MUST be connected

to a permanent earth ground, such as a properly grounded

receptacle box. THE TEMPORARY ADAPTER SHOULD

BE USED ONLY UNTIL A QUALIFIED ELECTRICIAN CAN

INSTALL A PROPERLY GROUNDED OUTLET. The

Canadian Electrical Code prohibits the use of adapters.

CAUTION: In all cases, make certain the receptacle is

properly grounded. If you are not sure, have a qualified

electrician check the receptacle.

This Drill Press is for indoor use only. Do not expose to rain

or use in damp locations.

GUIDELINES FOR EXTENSION CORDS

USE PROPER EXTENSION CORD. Make sure your extension

cord is in good condition. When using an extension cord,

be sure to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a drop in line

voltage, resulting in loss of power and cause overheating.

The table below shows the correct size to use depending on

cord length and nameplate ampere rating. If in doubt, use

the next heavier gauge. The smaller the gauge number

the heavier the cord.

Be sure your extension cord is properly wired and in good

condition. Always replace a damaged extension cord or have

it repaired by a qualified person before using it. Protect your

extension cords from sharp objects, excessive heat and

damp or wet areas.

MINIMUM GAUGE FOR EXTENSION CORDS (AWG)

(When using 120 Volt only)

Ampere Rating Total length in feet

More Than

Not

More Than

25′ 50′ 100′ 150′

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Applicable

WARNING

WARNING

WARNING

Properly Grounded

3-Prong Receptacle

Grounding Prong

3-Prong Plug

Grounding Lug

Adapter

3-Prong Plug

Make Sure This

is Connected to

a Known Ground

2-Prong Receptacle

Fig. A

Fig. B

– 6 –

English

Page 7

ACCESSORIES AND ATTACHMENTS

RECOMMENDED ACCESSORIES

To avoid injury:

• Use only accessories recommended for this Drill Press.

• Follow instructions that accompany accessories. Use of

improper accessories may cause hazards.

• Use only accessories designed for this Drill Press to

avoid injury from thrown broken parts or workpieces.

• Do not use any accessory unless you have completely

read the instruction or operator’s manual for that

accessory.

WARNING

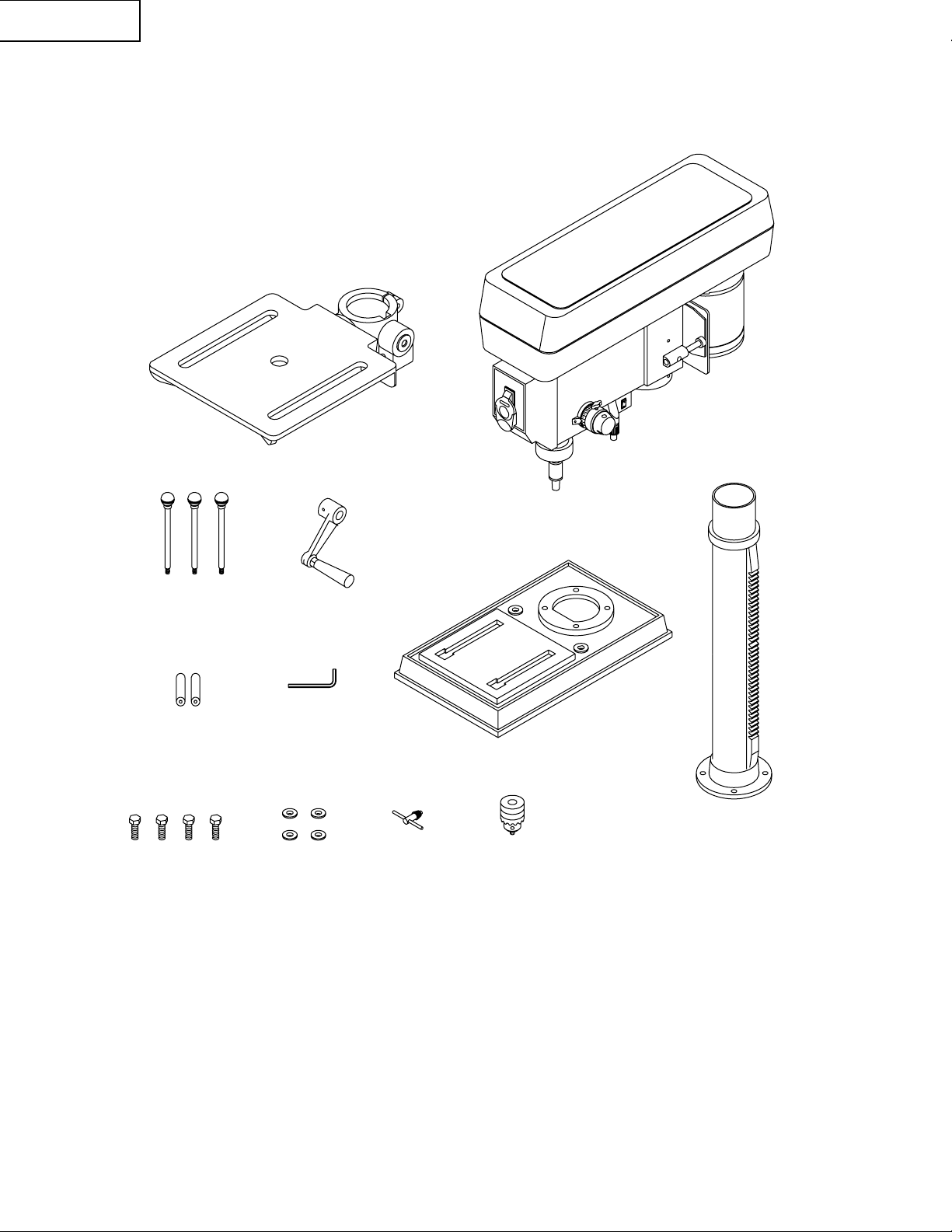

CARTON CONTENTS

– 7 –

English

UNPACKING AND CHECKING CONTENTS

Carefully unpack the Drill Press and all its parts, and compare

against the illustration following. Place the saw on a secure

surface and examine it carefully.

• To avoid injury from unexpected starting, do not plug

the power cord into a power source receptacle during

unpacking and assembly. This cord must remain

unplugged whenever you are assembling or adjusting

the drill press.

• If any part is missing or damaged, do not plug the drill

press in until the missing or damaged part is replaced,

and assembly is complete.

• To protect the drill press from moisture, a protective

coating has been applied to the machined surfaces.

Remove this coating with a soft cloth moistened with

kerosene or WD-40.

To avoid fire or toxic reaction, never use gasoline, naphtha,

acetone, lacquer thinner or similar highly volatile solvents to

clean the drill press.

TABLE OF LOOSE PARTS

ITEM DESCRIPTION QUANTITY

DRILL PRESS:

A. Head Assembly 1

B. Table 1

C. Base 1

D. Column Assembly 1

E. Feed Handle 3

F. Crank Handle 1

G. Batteries 2

LOOSE PARTS BAG:

H. Hex Bolts 4

I. Hex Wrench 1

J. Flat Washers 4

BOX:

K. Chuck Key 1

L. Chuck 1

WARNING

WARNING

Page 8

UNPACKING YOUR DRILL PRESS

B

A

C

D

E

F

G

I

H

J

K

L

– 8 –

English

Page 9

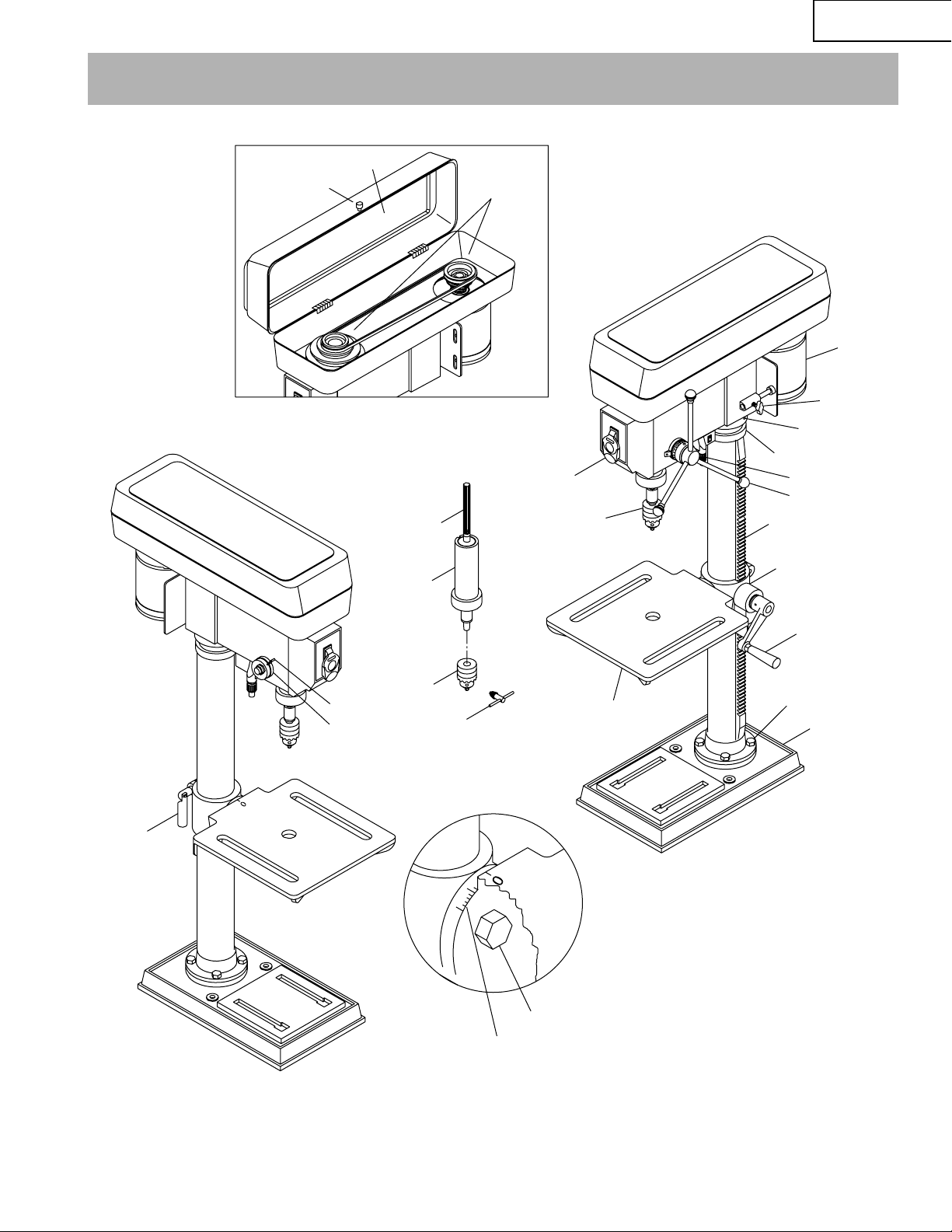

KNOW YOUR DRILL PRESS

Belt Guard Cover

Cover Knob

Table Support

Lock

Motor

Belt Pulleys

Spindle

Quill

Chuck

Chuck Key

Spring Cover

Feed Spring

Table Assembly

Belt Tension

Lock Knob

Head Locking

Set Screw

ON/OFF Switch

Chuck

Column Collar

Laser Guide

Feed Handles

Rack

Table Support

Table Crank

Column Support

Base

Bevel Scale

Table Bevel Lock

– 9 –

English

Page 10

GLOSSARY OF TERMS

– 10 –

English

DRILL PRESS TERMS

BASE GUIDES – Supports drill press. For additional stability,

holes are provided in base to bolt drill press to bench.

BACKUP MATERIAL – A piece of scrap wood placed

between the workpiece and table. The backup board prevents

wood in the workpiece from splintering when the drill passes

through the backside of the workpiece. It also prevents drilling

into the table top.

BELT GUARD ASSEMBLY – Covers the pulleys and belt

during operation of the drill press.

BELT TENSION – Refer to the Assembly Section, “Installing

and Tensioning Belt”.

BELT TENSION LOCK KNOBS – Tightening the knobs locks

the motor bracket support and the belt tension handle,

maintaining correct belt distance and tension.

BEVEL SCALE – Shows degree of table tilt for bevel

operations. The scale is mounted on the side of the table

bracket.

CHUCK – Holds a drill bit or other recommended accessory

to perform desired operations.

CHUCK KEY – A self-ejecting chuck key which will pop out

of the chuck when you let go of it. This action is designed to

help prevent throwing of the chuck key from the chuck when

the power is turned ON. Do not use any other key as a

substitute; order a new one if Damaged or Lost.

COLUMN – Connects the head, table, and base on a one

piece tube for easy alignment and movement.

COLUMN COLLAR – Holds the rack to the column. The rack

remains movable in the collar to permit table support

movements.

COLUMN SUPPORT – Supports the column, guides the rack

and provides mounting holes for the column to the base.

DEPTH SCALE STOP NUTS – Lock the spindle to a

selected depth.

DEPTH SCALE – Indicates depth of hole being drilled.

DRILL BIT – The cutting tool used in the drill press to make

holes in a workpiece.

DRILL ON/OFF SWITCH – Has a locking feature. This

feature is intended to help prevent unauthorized and possible

hazardous use by children and others. Insert the key into the

switch to turn the drill press on.

DRILLING SPEED – Changed by placing the belt in any of

the steps (grooves) in the pulleys. See the Spindle Speed

Chart inside belt guard or in the manual.

FEED HANDLE – Moves the chuck up or down. If necessary,

one or two of the handles may be removed whenever the

workpiece is of such unusual shape that it interferes with the

handles.

RACK – Combines with gear mechanism to provide easy

elevation of the table by the hand operated table crank.

RPM – Revolutions per minute. The number of turns

completed by a spinning object in one minute.

SPINDLE SPEED – The RPM of the spindle.

SPRING CAP – Adjusts the quill return spring tension.

TABLE SUPPORT LOCK – Tightening locks the table

support tot he column. Always have it locked in place while

operating the drill press.

TABLE – Provides a working surface to support the

workpiece.

TABLE ARM – Extends beyond the table support for

mounting and aligning the table.

TABLE BEVEL LOCK – Locks the table in any position from

0° to 45°.

TABLE CRANK – Elevates and lowers the table. Turn

clockwise to elevate the table. Support lock must be released

before operating the crank.

TABLE LOCK – Locks the table after it is rotated to various

positions.

TABLE SUPPORT – Rides on the column to support the

table arm and table.

WORKPIECE – Material being drilled.

Page 11

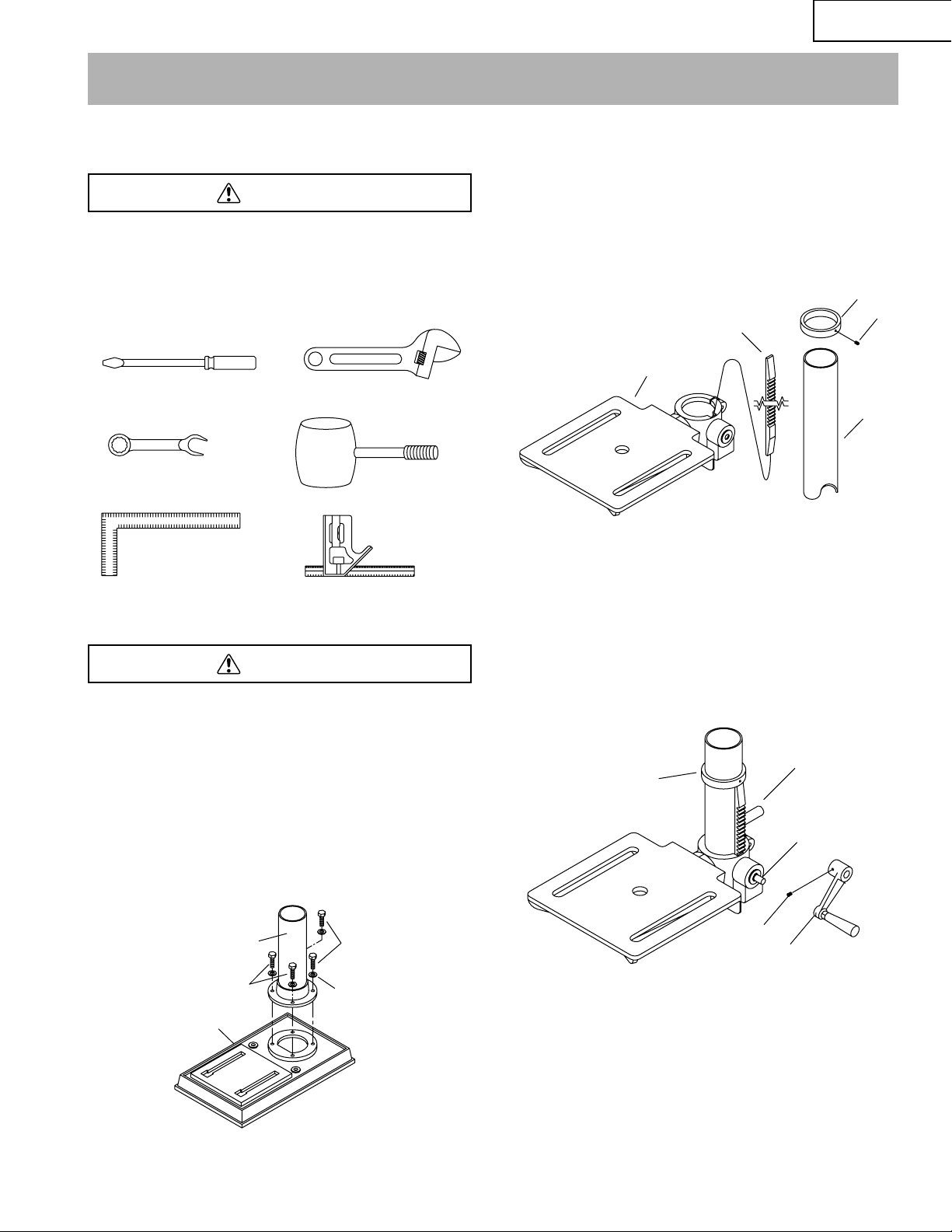

ESTIMATED ASSEMBLY TIME 20-40 MINUTES

ASSEMBLY INSTRUCTIONS

For your safety, never connect plug to power source

receptacle until all assembly and adjustment steps are

completed, and you have read and understood the safety

and operating instructions.

TOOLS NEEDED

The Drill Press is very heavy and MUST be assembled with

the help of 2 PEOPLE OR MORE, to safely assemble it.

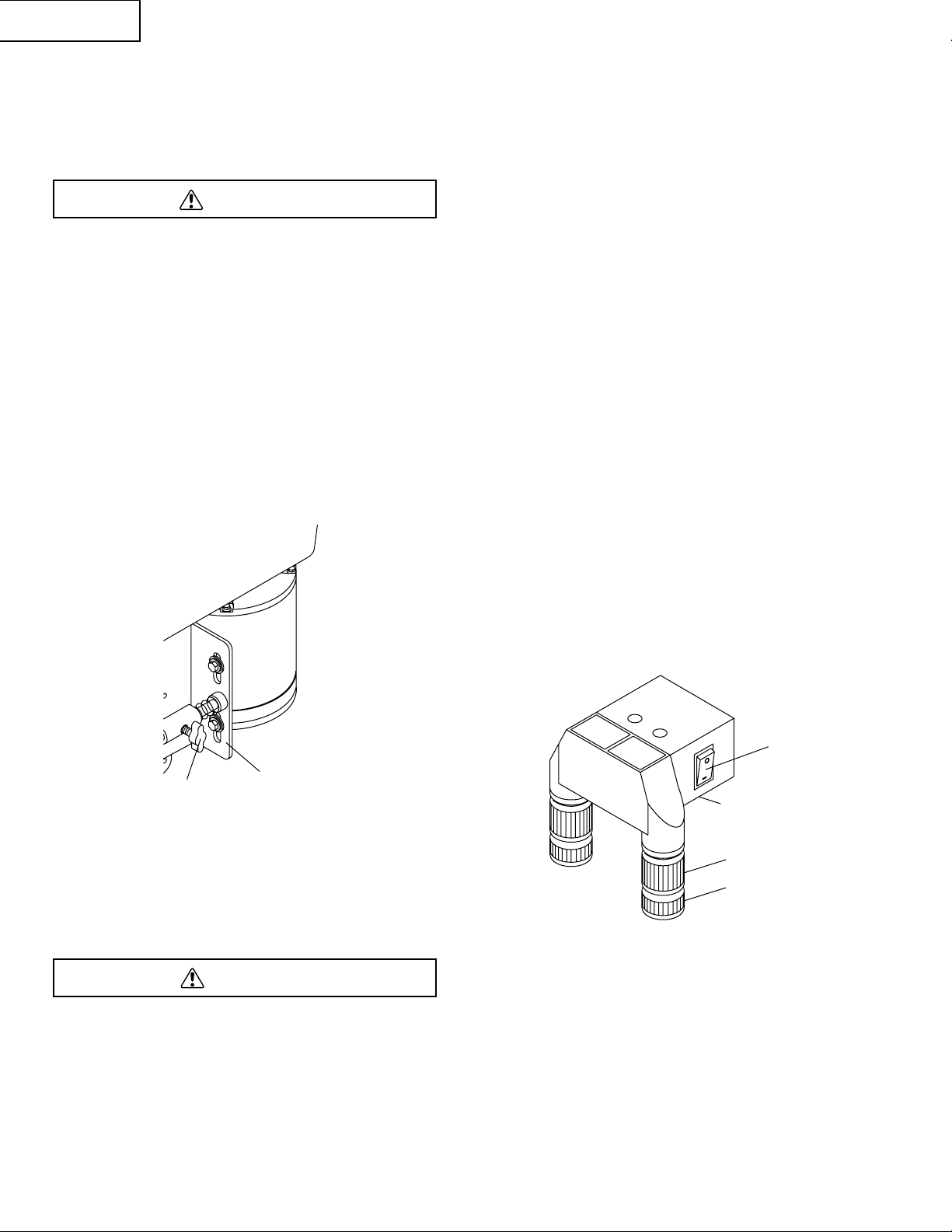

COLUMN SUPPORT TO BASE (Fig. A)

1. Position the base (1) on floor or bench.

2. Place the column (2) on the base, aligning the holes in

the column support with the holes in the base.

3. Locate the four long hex bolts (3) and washers (4) from

the loose parts bag.

4. Place a bolt in each hole through the column support and

the base. Tighten with an adjustable wrench.

INSTALLING THE TABLE (Fig. B and C)

1. Loosen set screw (1). Remove rack (2) and retaining ring

(3) from column (4).

2. Place rack inside table assembly bracket (5) with large,

unmachined portion of rack to the top. Slide rack into slot

in bracket so that teeth of reack engage pinion gear in

bracket.

3. Slide table assembly with rack over column. Place bottom

end of rack inside beveled edge of column flange.

4. (Fig. C) Slide rack retaining ring (3) over column with

beveled edge down. Position ring against top of rack so

that rack is in beveled edge of ring. Secure ring with set

screw (1).

5. Rotate table assembly around column. Adjust rack

retaining ring as necessary to prevent binding of rack.

6. Attach crank handle (6) to shaft (7), rotate to remove

slack, and shoulder crank handle against table bracket.

Secure handle with screw (8).

7. Tighten table bracket locking handle (9) to secure table

assembly.

WARNING

WARNING

ASSEMBLY AND ADJUSTMENTS

Slotted Screwdriver

Combination Wrench

Framing Square

8″ & 10″ Adjustable Wrench

Combination Square

Mallet

Fig. A

2

3

3

4

1

Fig. B

Fig. C

3

1

4

2

5

6

9

7

3

8

– 11 –

English

Page 12

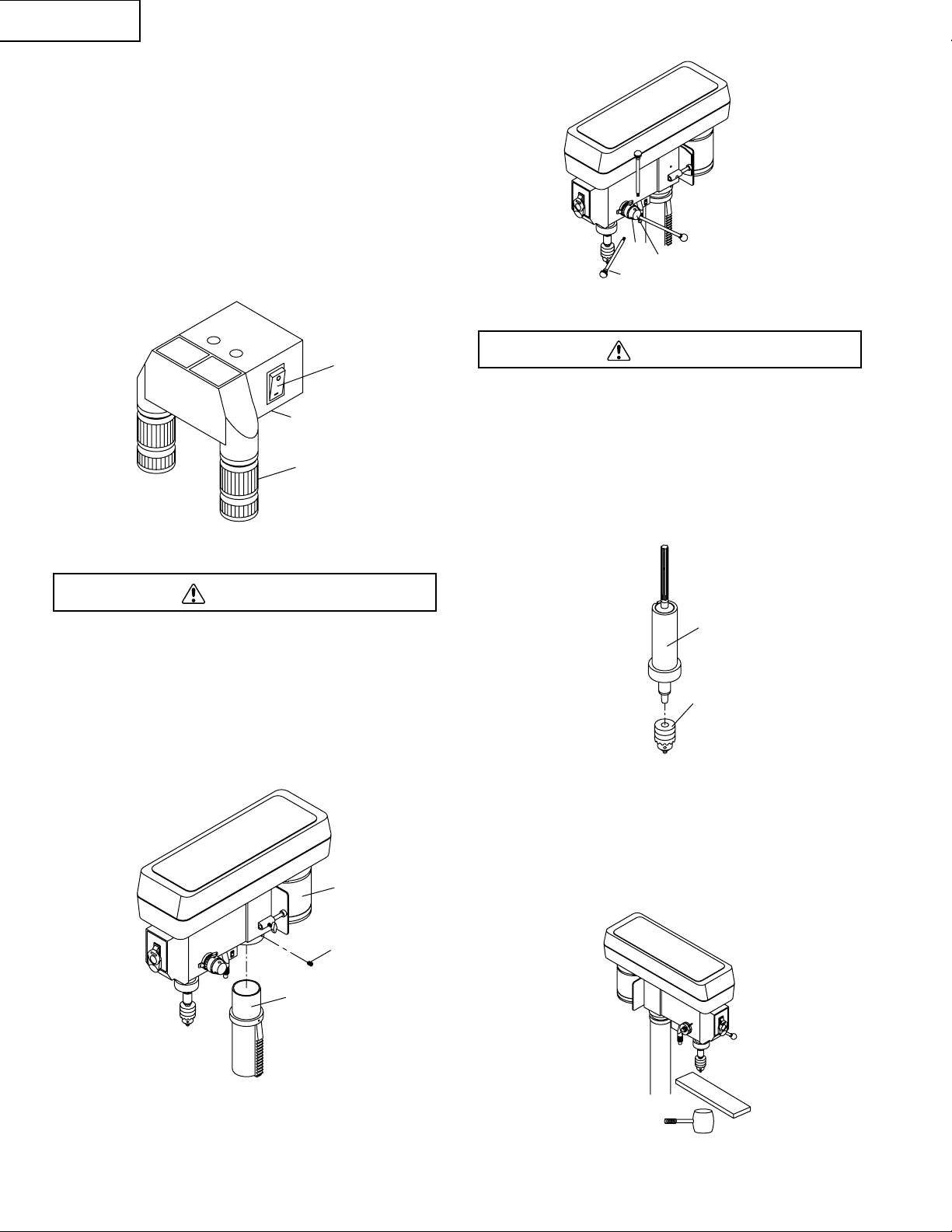

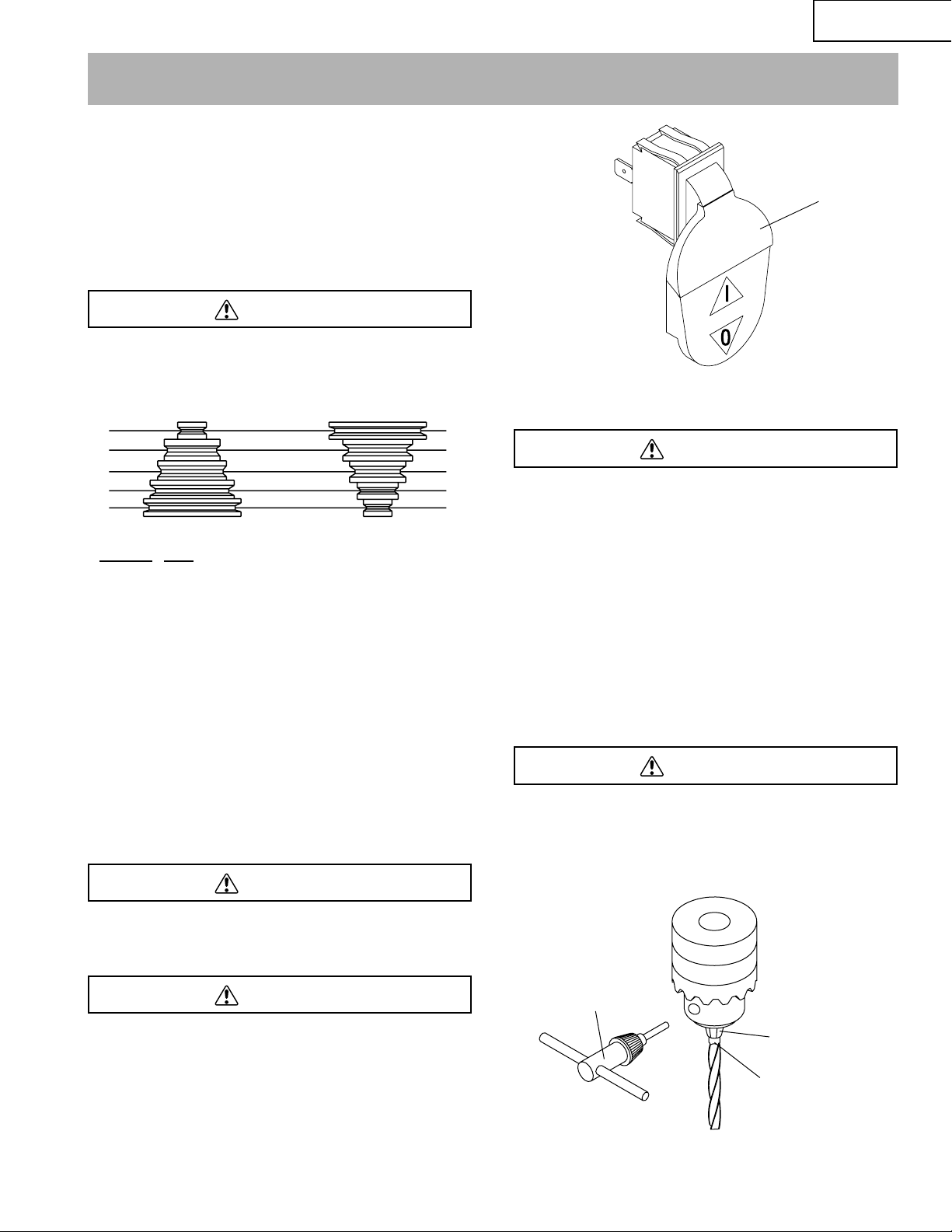

INSTALLING BATTERY FOR LASER GUIDE (Fig. C-1)

1. Open the cover (1) of battery compartment by sliding

cover towards switch.

2. Install 2 pieces of 1.5V batteries into the battery

compartment according to the polarity indicated on

compartment.

3. Close the cover

4. Turn on the switch (3) to check the LASER GUIDE

OPERATION.

NOTE: Replace the batteries with batteries that have a

reating of 1.5 volts (Number 4 sereis and AAA size or

equivalent). When replacing the batteries, the laser guide

should be thoroughly cleansed. Use a soft paintbrush or

similar device, to remove all sawdust and debris.

INSTALLING THE HEAD (Fig. D)

The Drill Press head is very heavy and MUST be lifted witht

he help of 2 PEOPLE OR MORE to safely assemble the Drill

Press head on the column.

1. Carefully lift the head (1) above the column (2) and slide

it onto the column. Make sure the head slides down over

the column as far as possible. Align the head with the

base.

2. Using the hex wrench, tighten the two head lock set

screws (3).

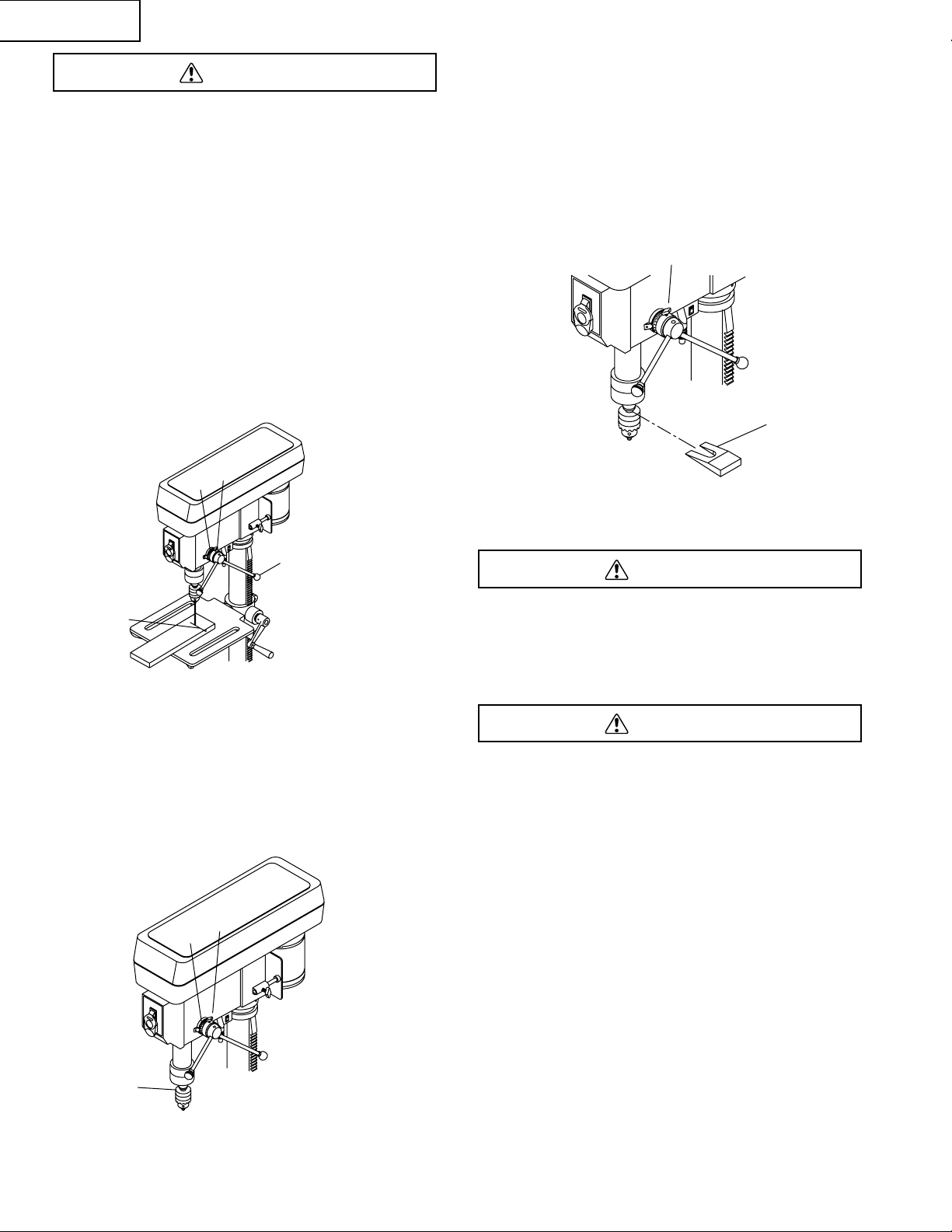

INSTALLING FEED HANDLES (Fig. E)

1. Locate the three feed handles in the loose parts bag.

2. Screw the feed handles (1) into the threaded holes (2) in

the hub (3). Tighten.

INSTALLING THE CHUCK (Fig. F and G)

Before any assembly of the chuck and arbor to the drill press

head, clean all mating surfaces with a non-petroleum based

product; such as alcohol or lacquer thinner. Any oil or grease

used in the packing of these parts must be removed,

otherwise the chuck may come loose during operation.

1. Open the jaws of the chuck (1) by rotating the chuck

sleeve clockwise. To prevent damage, make sure the

jaws are completely receded into the chuck.

2. Push the chuck (1) onto the spindle (2).

NOTE: Clean the spindle taper with a non-alcohol based

cleaner before inserting it into the chuck.

3. Using a rubber mallet, plastic-tipped hammer, or a block

of wood and a hammer, firmly tap the chuck upward into

position on the spindle shaft.

WARNING

WARNING

Fig. E

1

3

2

Fig. F

2

1

Fig. G

Fig. D

1

2

3

Fig. C-1

3

1

2

– 12 –

English

Page 13

DRILL PRESS ADJUSTMENTS

CAUTION: All the adjustments for the operation of the drill

press have been completed at the factory. Due to normal

wear and use, some occasional readjustments may be

necessary.

To prevent personal injury, always disconnect the plug from

the power source when making any adjustment.

TILTING THE TABLE (Fig. H)

NOTE: The bevel scale has been included to measure

approximate bevel angles. if precision is necessary, a square

or other measuring tool should be used to position the table.

To use the bevel scale (1):

1. Remove pin and nut (2). Tighten nut until pin slips out.

2. Loosen the large hex head bevel locking bolt (3).

To prevent injury, be sure to hold the table assembly, so it will

not swivel or tilt.

3. Tilt the table, aligning the desired angle measurement to

the zero line scribed on the table opposite the bevel

scale (1).

4. Tighten the bevel locking bolt (3).

5. To return the table to its original position, loosen the

bevel locking bolt (3). Realign the bevel scale (1) to the 0

scribed line on the table.

6. Back nut out several turns, reinsert pin and nut into table,

and tap into place with hammer.

7. Tighten the bevel locking bolt.

NOTE: The table has been removed from the illustration for

clarity.

To prevent personal injury, always disconnect the plug from

the power source when making any adjustment.

SPINDLE / QUILL (Fig. I)

Rotate the feed handles counterclockwise to lower spindle to

its lowest position. Hand support the spindle securely and

move it back and forth around the axis. If there is play, do the

following:

1. Loosen the lock nut (1).

2. Turn the screw (2) clockwise to eliminate the play, but

without obstructing the upward movement of the spindle.

3. Tighten the lock nut (1).

To prevent personal injury, always disconnect the plug from

the power source when making any adjustment.

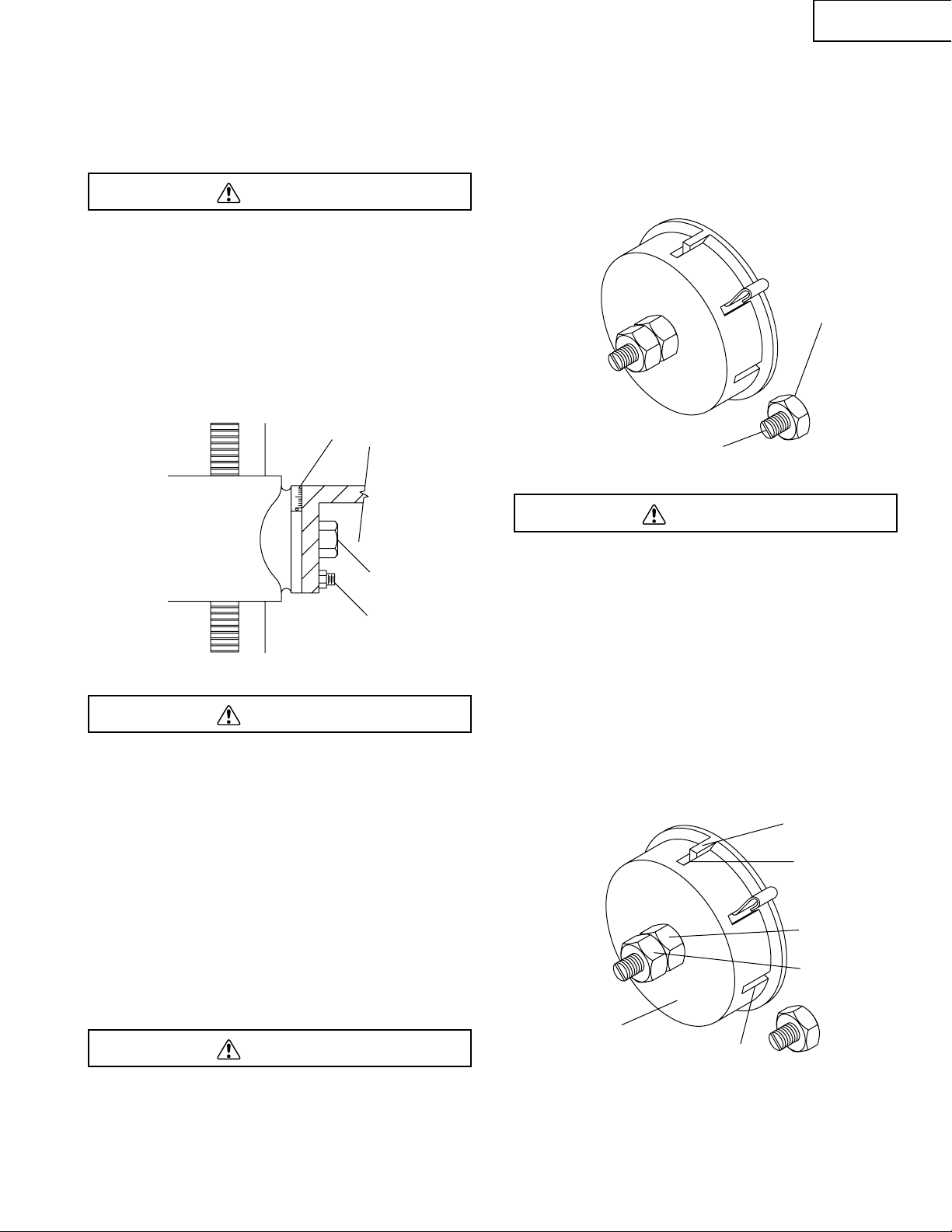

QUILL RETURN SPRING (Fig. J)

The quill return spring may need adjustment if the tension

causes the quill to return too rapidly or too slowly.

1. Lower the table for additional clearance.

2. Place a screwdriver in the lower front notch (1) of the

spring cap (2). Hold it in place while loosening and

removing only the outer jam nut (3).

3. With the screwdriver still engaged in the notch loosen the

inner nut (4) just until the notch (5) disengages from the

boss (6) on the drill press head.

CAUTION: DO NOT REMOVE THIS INNER NUT, because

the spring will forcibly unwind.

4. Carefully turn the spring cap (2) counterclockwise with

the screwdriver, engaging the next notch.

5. Lower the quill to the lowest position by rotating the feed

handle in a counterclockwise direction while holding the

spring cap (2) in position.

WARNING

WARNING

WARNING

WARNING

Fig. H

2

1

3

Fig. I

1

Fig. J

1

2

3

4

5

6

2

– 13 –

English

Page 14

6. If the quill moves up and down as easily as you desire,

tighten the inner nut (4) with the adjustable wrench. If too

loose, repeat steps 2 through 4 to tighten. If too tight,

reverse steps 3 and 4. DO NOT OVERTIGHTEN and

restrict quill movement.

7. Replace the jam nut (3) and tighten against the inner nut

(4) to prevent the inner nut from reversing.

To avoid injury from an accidental start, ALWAYS make sure

the switch is in the OFF position, the switch key is removed,

and the plug is not connected to the power source outlet

before making belt adjustments.

BELT TENSION (Fig. K)

1 To release the belt tension, turn the belt tension lock

knob (1) on the right side of the drill press head

counterclockwise.

2. To tighten the belts, push the motor mounting plate (2)

toward the rear (motor) end.

3. To loosen the belts, pull the motor mounting plate (2)

toward the front (switch) end.

4. Lock the belt tension lock knob (1) by turning clockwise.

NOTE: Belt tension is correct if the belt deflects

approximately 1/2 inch when pressed at its center.

THE LASER GUIDE

Your tool is equipped with our latest innovation, the Laser

Guide, a battery powered device using Class IIIa laser

beams. The laser beams will enable you to preview the drill

bit path on the workpiece to be drilled before you begin your

operation.

AVOID DIRECT EYE CONTACT

A Laser light is radiated when the laser guide is turned on.

Avoid direct eye contact. Always turn off the laser and unplug

the drill press from the power source before making any

adjustments.

• A laser pointer is not a toy and should not come into

hands of children. Misuse of this appliance can lead to

irreparable eye injuries.

• Any adjustments to increase the laser power is forbidden.

• When using the laser pointer, do not point the laser beam

towards people and / or reflecting surfaces. Even a laser

beam of lower intensity may cause eye damage.

Therefore, do not look directly into the laser beam.

• If the laser pointer is stored for more than three months

without use, please remove the batteries to avoid

damage from possibly leaking batteries.

• The laser pointer includes no user serviceable

components. Never open the housing for repair or

adjustments.

• On units equipped with the Laser-Guide attachment,

repairs shall only be carried out by the laser

manufacturer or authorized agent.

• Laser Warning label: Max output <5mW DIODE LASER:

630-660nm, Complies with 21CFR 1040.10 and 1040. 11.

ADUSTING THE LASER LINES (Fig. L)

How to check and adjust the Laser Beam Alignment:

Check the laser beam alignment to ensure the intersection of

the laser lines precisely at the spot where the drill bit meets

the workpiece. If it is not, the laser lines should be adjusted

using the laser adjustment knobs located on the opposite

sides of the head assembly.

1. Mark an “X” on a piece of scrap wood.

2. Insert a small drill bit into the chuck and align its tip to

the intersection of the lines of the “X”.

3. Secure the board to the table.

4. Turn on the laser (3) and verify the laser lines align with

the “X” on the workpiece.

5. If the laser lines do not align, loosen knobs (2) on each

side of the laser module and rotate the lasers (4) until the

lines meet in the center of the “X”. Retighten the knobs to

secure.

DANGER

WARNING

Fig. K

1

Fig. L

3

4

2

1

2

– 14 –

English

Page 15

BASIC DRILL PRESS OPERATIONS

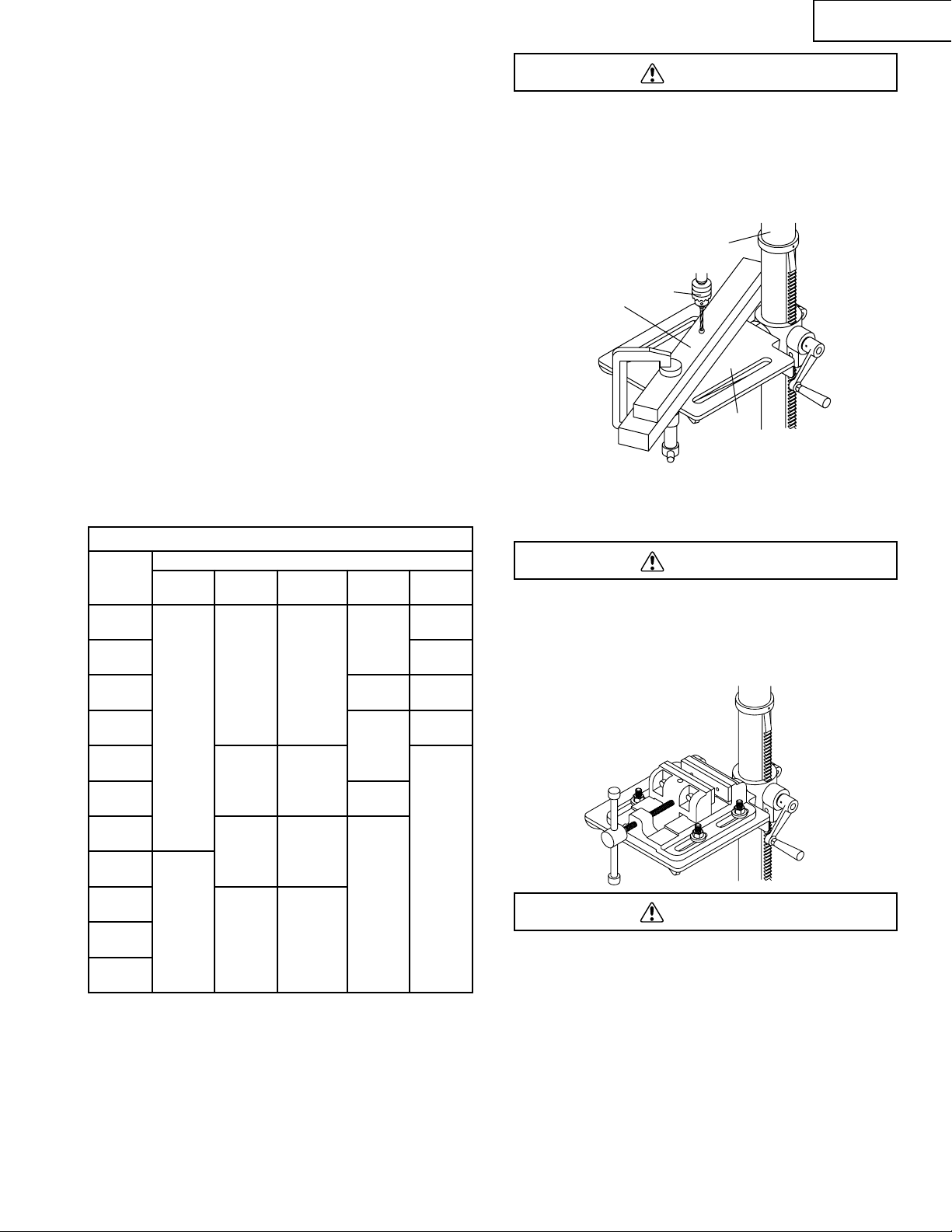

SPEEDS AND BELT PLACEMENT (Fig. M)

This drill press has 5 speeds, as listed below:

680 RPM; 1160 RPM; 1780 RPM;

2380 RPM; 3000 RPM

See the inside of the pulley guard for same chart as shown

in Figure M.

To avoid possible injury, keep the guard closed, in place, and

in proper working order while the tool is in operation.

ON/OFF SWITCH (Fig. N)

The keyed switch is intended to prevent unauthorized use of

the drill press.

1. To turn the drill press ON (I) insert the yellow key (1) into

the key slot in the center of the switch.

2. Push the key firmly into the slot, then push switch to the

ON position to start the drill press.

3. To turn the drill press OFF (O) push the switch to the

down position.

4. Remove the yellow switch key, when the drill press has

come to a complete stop, by gently pulling it outward.

Remove the switch key whenever the drill press is not in use.

Place it in a safe place and out of reach of children.

ALWAYS lock the switch OFF when the drill press is not in

use. Remove the key and keep it in a safe place. In the event

of power failure, blown fuse, or tripped circuit breaker, turn

the switch OFF and remove the key, preventing an accidental

startup when power comes on.

LASER ON / OFF SWITCH (Fig. L)

To turn the laser ON or OFF, press the rocker switch (3)

Laser is radiated when laser guide is turned on. Avoid direct

eye exposure. Always un-plug drill press from power source

before making any adjustment.

INSTALLING A DRILL BIT IN THE CHUCK (Fig. O)

1 With the switch “OFF” and the yellow switch key

removed, open the chuck jaws (1) using the chuck key

(2). Turn the chuck key counterclockwise to open the

chuck jaws (1).

2. Insert the drill bit (3) into the chuck far enough to obtain

maximum gripping by the jaws, but not far enough to

touch the spiral grooves (flutes) of the drill bit when the

jaws are tightened.

3. Make sure that the drill is centered in the chuck.

4. Turn the chuck key clockwise to tighten the jaws.

To avoid injury or accident by the chuck key ejecting forcibly

from the chuck when the power is turned ON, use only the

self-ejecting chuck key supplied with this drill press. ALWAYS

recheck and remove the chuck key before turning the power

ON.

WARNING

WARNING

DANGER

WARNING

WARNING

OPERATION

Fig. M - SPEED CHART

Fig. N

Fig. O

1

1

2

3

– 15 –

English

Spindle Motor

5

4

3

2

1

Belt

Location

5-5

4-4

3-3

2-2

1-1

RPM

3000

2380

1780

1160

680

5

4

3

2

1

Page 16

English

– 16 –

To prevent the workpiece or backup material from being torn

from your hands while drilling, you MUST position the

workpiece against the LEFT side of the column. If the

workpiece or backup material is not long enough to reach the

column, clamp them to the table. Failure to secure the

workpiece could result in personal injury.

DRILLING TO A SPECIFIC DEPTH (Fig. P)

1. Mark the depth (1) of the hole on the side of the

workpiece.

2. With the switch OFF, bring the drill bit down until the tip is

even with the mark.

3. Hold the feed handle (2) at this position.

4. Turn the depth scale ring (3) clockwise, until it is against

the depth stop.

5. Lock scale ring in place with depth knob (4).

6. The drill bit will stop after traveling the distance selected

on the depth scale.

LOCKING THE CHUCK AT THE DESIRED DEPTH (Fig. Q)

1. With the switch OFF, turn the feed handles until the

chuck (1) is at the desired depth. Hold the feed handles

at this position.

2. Turn the depth scale ring (3), clockwise, until it is against

the depth stop.

3. Lock scale ring in place with depth knob (2).

4. The chuck will now be held at this position when the feed

handles are released.

REMOVING CHUCK AND ARBOR (Fig. R)

1. With the switch OFF and the unit unplugged, adjust the

depth stop screw (10 to hold the drill at a depth of three

inches. (See instructions for “LOCKING CHUCK AT

DESIRED DEPTH“).

2. Insert a wedge (2) between chuck and quill.

3. Tap wedge (2) lightly with a plastic tipped hammer, until

the chuck falls away from the spindle.

NOTE: Place one hand below the chuck to catch it when it

falls out.

BASIC OPERATION ISTRUCTIONS

To get the best results and minimize the likelihood of personal

injury, follow these instructions for operating your drill press.

For your own safety, always observe the SAFETY

INSTRUCTIONS listed here and on pages 3, 4 & 5 of the

instruction manual.

YOUR PROTECTION

To avoid being pulled into the power tool, do not wear loose

clothing, gloves, neckties or jewelry. Always tie back long hair.

1. If any part of your drill press is missing, malfunctioning,

damaged or broken, stop operation immediately until that

part is properly repaired or replaced.

2. Never place your fingers in a position where they could

contact the drill bit or other cutting tool. The workpiece

may unexpectedly shift, or your hand could slip.

3. To avoid injury from parts thrown by the spring, follow

instructions exactly when adjusting the spring tension of

the quill.

4. To prevent the workpiece from being torn from your

hands, thrown, spun by the tool, or shattered, always

properly support your workpiece as follows:

a. Always position BACKUP MATERIAL (used beneath

workpiece) so that it contacts the left side of the

column, or use the fence provided and a clamp to

brace a small workpiece.

b. Whenever possible, position the WORKPIECE to

contact the left side of the column. If it is too short or

the table is tilted, use the fence provided or clamp it

solidly to the table, using the table slots.

c. When using a drill press vise, always fasten it to the

table.

WARNING

WARNING

WARNING

Fig. P

3

4

1

2

Fig. Q

3

1

2

Fig. R

1

2

Page 17

d. Never do any work freehand (hand-holding the

workpiece rather than supporting it on the table),

except when polishing.

e. Securely lock the head and support to the column, the

table arm to the support, and the table to the table

arm, before operating the drill press.

f. Never move the head or table while the tool is running.

g. Before starting an operation, jog the motor switch to

make sure the drill or other cutting tool does not

wobble or cause vibration.

h. If a workpiece overhangs the table so it will fall or tip if

not held, clamp it to the table or provide auxiliary

support.

i. Use fixtures for unusual operations to adequately hold,

guide, and position workpieces.

j. Use the SPINDLE SPEED recommended for the

specific operation and workpiece material. Check the

panel on the inside pulley cover or the chart below for

drilling speed information. For accessories, refer to the

instructions provided with each accessory.

5. Never climb on the drill press table, it could break or pull

the entire drill press down on you.

6. Turn the motor switch “OFF”, and put away the switch key

when leaving the drill press.

7. To avoid injury from thrown work or tool contact, do not

perform layout, assembly, or set up work on the table

while the cutting tool is rotating.

POSITIONING THE TABLE AND WORKPIECE (Fig. S and T)

1. Lock the table (1) to the column (2) at a position so the

tip of the drill bit (3) is just above the top of the workpiece

(4).

2. ALWAYS place BACK-UP MATERIAL (scrap wood) on

the table beneath the workpiece. This will prevent

splintering or heavy burring on the underside of the

workpiece. To keep the back-up material from spinning

out of control, it MUST contact the LEFT side of the

column.

To prevent the workpiece or back-up material from being torn

from your hands while drilling, you MUST position it against

the LEFT side of the column. If the workpiece or the back-up

material is not long enough to reach the column, use the

fence provided with the drill press to brace the workpiece.

Failure to do this could result in personal injury.

3. For small pieces that cannot be clamped to the table, use

a drill press vise (optional accessory)

The drill press vise MUST be clamped or bolted to the table

to avoid injury from a spinning workpiece, or damaged vise or

bit parts.

Remove the drill press fence when it interferes with other drill

press accessories.

To avoid injury from spinning work or tool breakage, always

clamp workpiece and back-up material securely to the table

before operating the drill press with the table tilted.

FEEDING

1. Pull down the feed handles with only enough effort to

allow the drill bit to cut.

2. Feeding too slowly might cause the drill bit to burn.

Feeding too rapidly might stop the motor, cause the belt

or drill to slip, or tear the workpiece loose and break the

drill bit.

3. When drilling metal, it may be necessary to lubricate the

drill bit tip with motor oil, to prevent burning.

WARNING

WARNING

WARNING

English

– 17 –

Fig. S

1

3

4

2

Fig. T

DRILLING SPEED TABLE (RPM )

Drill Bit

Diam.

(Inches)

Material

Wood

Aluminum

Plastic

Mild

Steel

Stainless

1/32

3000 3000 3000 3000 3000

1/16

1780

2380

1/8

1780

2380

1160

1160

3/16

1160

1160

680

680

1/4

1780

2380

1780

2380

5/16

680

680

3/8

1160

1160

1160

1160

7/16

1780

2380

1/2

680

680

680

680

9/16

5/8

Page 18

English

– 18 –

MAINTAINING YOUR DRILL PRESS

For our own safety, turn the switch OFF and remove the plug

from the power source outlet before maintaining or lubricating

your drill press.

Frequently blow out, using an air compressor or dust vacuum,

any dust that accumulates inside the motor. A coat of paste

wax applied to the table and column will help to keep the

surface clean & help avoid rust.

To avoid shock or fire hazard, if the power cord is worn

or cut on any way, have it replaced immediately.

LUBRICATION

All of the drill press ball bearings are packed with grease at

the factory. They require no further lubrication. Periodically

lubricate the gear and rack for the table elevation. Lower

spindle to maximum depth and oil moderately once every

three months.

BATTERIES

Check the laser batteries regularly to avoid deterioration.

Remove the batteries if you will not be using the laser for an

extended time.

WARNING

MAINTENANCE

Page 19

• To avoid injury from an accidental start, turn the switch OFF and remove the plug from the power source before making

any adjustments.

• All electrical or mechanical repairs should be done only by qualified service technicians. Contact Hitachi Authorized

Service Center.

GENERAL

English

– 19 –

TROUBLESHOOTING GUIDE

PROBABLE CAUSE

1. Incorrect belt tension.

2. Loose spindle pulley.

3. Loose motor pulley

1. Incorrect speed.

2. Chips not coming out of hole.

3. Dull drill bit.

1. Hand grain in wood or lengths of cutting

flutes and/or angles not equal.

2. Bent drill bit..

1. No backup material under workpiece.

1. Not supported or clamped properly.

1. Workpiece pinching drill bit, or excessive

feed pressure.

2. Improper belt tension.

1. Bent drill bit.

2. Worn bearings.

3. Drill bit not properly installed in chuck.

4. Chuck not properly installed.

1. Spring has improper tension.

1. Dirt, grease, or oil on the tapered inside

surface of chuck or on the spindle’s

tapered surface.

1. The batteries have become uncharged.

PROBLEM

Noisy operation

Drill bit burns.

Run out of drill bit point - drill

hole not round.

Wood splinters on underside.

Workpice torn loose from hand.

Drill bit binds in workpiece.

Excessive drill bit runout or

wobble.

Quill returns too slow or too

fast.

Chuck will not stay attached to

spindle. It falls off when trying

to install.

The LASER GUIDE will not

turn on.

REMEDY

1. Adjust tension. See DRILL PRESS

ADJUSTMENTS section, BELT TENSION.

2. Check tighteness of retaining nut on pulley, and

tighten if necessary

3. Tighten set screw in motor pulley.

1. Change speed. See BASIC DRILL PRESS

OPERATIONS section, SPEEDS AND BELT

PLACEMENT.

2. Retract drill frequently to clear chips.

3. Resharpen drill bit.

1. Resharpen drill bit correctly.

2. Replace drill bit.

1. Use backup material. See BASIC DRILL PRESS

OPERATIONS section.

1. Support workpiece or clamp it. See BASIC DRILL

PRESS OPERATIONS section.

1. Support workpiece or clamp it. See BASIC DRILL

PRESS OPERATIONS section.

2. Adjust tension. See DRILL PRESS

ADJUSTMENTS section, BELT TENSION.

1. Replace drill bit.

2. Replace bearings.

3. Install drill properly. See BASIC DRILL PRESS

OPERATIONS section, INSTALLING DRILL BIT.

4. Install chuck properly. See ASSEMBLY

INSTRUCTIONS section, INSTALLING THE

CHUCK.

1. Adjust spring tension. See ASSEMBLY

INSTRUCTIONS section, QUILL RETURN

SPRING.

1. Using a household detergent, clean the tapered

surface of the chuck and spindle to remove all dirt,

grease and oil. See ASSEMBLY INSTRUCTIONS

section, INSTALLING THE CHUCK.

1. See ASSEMBLY INSTRUCTIONS section,

INSTALLING BATTERY FOR LASER GUIDE.

WARNING

Page 20

Français

– 20 –

SPÉCIFICATIONS DU PRODUIT

MOTEUR

Source d’alimentation

électrique...........................115 V, 60 HZ, 3,5 A

Vitesse...............................5 - 680~3000 tr/min

(Révolutions par minute)

Puissance..........................2/3 CV (Service continu)

Capacité

Dimensions du mandrin.....1/2 po

Course de la broche ..........2 1/2 po

Gorge ................................5 po

Table

Dimensions........................7 13/16 po x 7 13/16 po

Inclinaison .........................45 à droite ou à gauche

Dimensions

Dimensions de la base ......8 1/16 po x 13 3/16 po

Hauter................................28 po

POIDS NET......................................27,5 kg (61 lb)

Afin d’éviter les risques d’origine électrique, les risques

d’incendie ou des dommages à l’outil, utiliser une protection

de circuit adéquate.

Utiliser un circuit électrique séparé pour vos outils.

Votre perceuse est câblée en usine pour fonctionner sur du

115 V. Brancher à un circuit de dérivation de 115 V, 15 A et

utiliser un fusible temporisé de 15 A ou un disjoncteur. Afin

d’éviter les risques de secousse électrique ou d’incendie,

remplacer immédiatement un cordon électrique usé, coupé

ou endommagé en quelque manière.

AVERTISSEMENT

Certaines poussières créées par le ponçage, le meulage et perçage électrique et par d’autres activités de construction

contiennent des produits chimiques reconnus par l'État de Californie pour causer le cancer, des anomalies congénitales

ou poser d’autres dangers pour la reproduction. Voici quelques exemples de ces produits chimiques :

• Le plomb dans les peintures à base de plomb

• La silice cristalline provenant des briques, du ciment et d’autres produits de maçonnerie

• L’arsenic et le chrome provenant du bois de construction traité chimiquement

Le risque encouru lors d’une exposition peut varier selon la fréquence d’exécution de ce type de travail. Afin de réduire votre

exposition à ces produits chimiques, travailler dans une aire bien ventilée et porter de l’équipement de sécurité approuvé

comme un masque protecteur contre la poussière spécialement conçu pour filtrer les particules microscopiques.

AVERTISSEMENT

CONSERVER CES INSTRUCTIONS

Page 21

Français

– 21 –

CONSIGNES DE SÉCURITÉ GÉNÉRALES

AVANT D’UTILISER CETTE PERCEUSE

La sécurité est une combinaison de bons sens, de présence

d’esprit et de connaissance de sa perceuse.

Afin d’éviter des erreurs susceptibles de provoquer des

blessures graves, ne pas brancher la perceuse avant d’avoir

lu et compris ce qui suit :

1. LIRE et se familiariser avec l’intégralité du manuel de

l’utilisateur. APPRENDRE à connaître les applications,

les limitations et les risques particuliers à l'outil.

2. GARDER LES PROTECTIONS EN PLACE et

fonctionnelles.

3. ENLEVER LES CLÉS DE RÉGLAGE ET LES CLÉS.

Prendre l’habitude de vérifier que les clés et les clés de

réglage sont enlevées de l'outil avant de le mettre en

marche.

4. MAINTENIR LA PROPRETÉ DE L’AIRE DE TRAVAIL. Les

endroits et établis encombrés prédisposent aux accidents.

5. NE PAS UTILISER DANS UN ENVIRONNEMENT

DANGEREUX. Ne pas utiliser des outils électriques dans

des endroits humides ou mouillés, ou les exposer à la pluie.

Garder l'aire de travail bien éclairée.

6. GARDER LES ENFANTS ÉLOIGNÉS. Maintenir les

visiteurs à une distance sécuritaire de l’aire de travail.

7. RENDRE L’ATELIER À L’ÉPREUVE DES ENFANTS avec

des cadenas, des commutateurs généraux ou en enlevant

les clés de mise en marche.

8. NE PAS FORCER L’OUTIL. Il fonctionnera mieux et de

façon plus sécuritaire à la vitesse pour laquelle il a été

conçu.

9. UTILISER L’OUTIL QUI CONVIENT. Ne pas forcer un outil

ou un accessoire à faire un travail pour lequel il n’a pas été

conçu.

10. UTILISER LA RALLONGE ÉLECTRIQUE QUI CONVIENT.

S’assurer que la rallonge électrique est en bon état.

Lorsqu’une rallonge électrique est utilisée, s’assurer que son

calibre est suffisant pour transporter le courant appelé par le

produit. Un cordon de calibre trop petit provoque une baisse

de tension et de puissance qui feront surchauffer l’outil. Le

tableau de la page 7 indique le rapport taille / longueur

correct de cordon à utiliser, de même que la plaque

signalétique et l’intensité nominale. En cas de doute, utiliser

un calibre plus gros. Plus le numéro de calibre est petit, plus

le cordon est lourd.

11. PORTER DES VÊTEMENTS APPROPRIÉS. Ne pas porter

de vêtements flottants, de gants, de cravate, de bagues, de

bracelets ni d’autres bijoux risquant d’être happés par les

pièces mobiles. Des chaussures à semelle antidérapante

sont recommandées. Porter un filet pour maintenir les

cheveux longs.

12. TOUJOURS PORTER UNE PROTECTION POUR LES

YEUX. Toute perceuse peut projeter des corps étrangers

dans les yeux et causer des blessures permanentes.

TOUJOURS porter des lunettes de sécurité (et non des

lunettes ordinaires) conformes à la norme ANSI Z87.1, car

les lunettes ordinaires ont seulement des lentilles qui

résistent aux chocs. Ce ne sont PAS des lunettes de

protection. Des lunettes de sécurité sont disponibles chez

Hitachi.

Remarque : Des lunettes ou des lunettes de sécurité non

conformes à la norme ANSI Z87.1 peuvent entraîner des

blessures graves.

13. FIXER SOLIDEMENT LA PIÈCE À TRAVAILLER. Utiliser

des pinces ou un étau pour maintenir la pièce en place

lorsque cela est possible. Cette pratique est plus sécuritaire

que l'utilisation des mains et libère ainsi les deux mains de

l’opérateur.

14. DÉBRANCHER LES OUTILS avant de les entretenir : lors

d’un changement d’accessoires, comme des lames, des

forets, des couteaux, etc.

15. RÉDUIRE LE RISQUE D’UN DÉMARRAGE INTEMPESTIF.

S’assurer que le commutateur est à la position d’« arrêt »

(OFF) avant de brancher le cordon électrique dans une prise

de courant.

16. UTILISER LES ACCESSOIRES RECOMMANDÉS.

Consulter le manuel de l’utilisateur pour connaître les

accessoires recommandés. L’utilisation d’outils inappropriés

risque de provoquer des blessures graves.

17. NE JAMAIS S’APPUYER SUR L’OUTIL. On peut subir des

blessures graves si l’outil se renverse ou si on vient

accidentellement en contact avec l’outil de coupe.

18. S’ASSURER QU’AUCUNE PIÈCE N’EST ENDOMMAGÉE.

Avant d’utiliser l’outil plus avant, une protection ou une autre

pièce endommagée doit être examinée minutieusement pour

déterminer si elle fonctionnera correctement et comme prévu

-- vérifier l'alignement des pièces mobiles, leur grippage, les

bris de pièces, leur installation et toute autre condition qui

pourrait affecter le fonctionnement de l’outil. Tout protecteur

ou toute autre pièce endommagée doit être réparé(e) ou

remplacé(e).

19. NE JAMAIS LAISSER L’OUTIL FONCTIONNER SANS

SURVEILLANCE. METTRE « HORS TENSION » (OFF). Ne

pas laisser l’outil tant qu’il n’est pas complètement arrêté.

20. NE PAS S’ÉTIRER POUR ATTEINDRE UN OBJET TROP

ÉLOIGNÉ. Conserver en tout temps un bon équilibre.

21. BIEN ENTRETENIR L’OUTIL. Garder les outils bien affûtés

et propres pour obtenir la performance la meilleure et la plus

sécuritaire. Suivre les instructions de lubrification et de

changement des accessoires.

22. NE PAS utiliser d’outils électriques en présence de liquides

ou de gaz inflammables.

23. NE PAS utiliser l’outil si vous êtes sous l’influence de

drogues, d’alcool ou de médicaments susceptibles de

réduire votre capacité d'utiliser correctement l'appareil.

24. Toujours utiliser la perceuse dans une aire bien ventilée et

fournir un système approprié d’évacuation de la sciure. Dans

la mesure du possible, utiliser un système de collecte de

sciure. La poussière produite par certains matériaux peut

présenter un risque pour votre santé.

AVERTISSEMENT

SÉCURITÉ

Page 22

CONSIGNES DE SÉCURITÉ SPÉCIFIQUES

À LA PERCEUSE D’ÉTABLI

Pour des questions de sécurité, ne pas tenter d’utiliser la

perceuse d’établi ni de la brancher avant qu’elle soit

complètement assemblée et installée conformément aux

instructions et que le manuel d’instructions ait été lu dans son

intégralité et bien compris.

1. CETTE PERCEUSE D’ÉTABLI doit être utilisée uniquement

à l’intérieur, dans une atmosphère sèche.

2. PORTER UNE PROTECTION POUR LES YEUX. UTILISER

UN écran facial ou un masque anti-poussière avec des

lunettes de sécurité si le perçage génère de la poussière.

UTILISER des protecteurs d’oreille, en particulier si le

perçage dure longtemps.

3. NE PAS porter de gants, de cravate ni de vêtements lâches.

4. NE PAS tenter de percer des pièces trop petites pour être

bridées de façon sécuritaire.

5. TOUJOURS éloigner les mains de la course du foret. Éviter

les positions de mains maladroites qui pourraient les faire

glisser subitement vers le foret.

6. NE PAS installer ni utiliser de foret de longueur supérieure à

7 po ou qui sorte de plus de 6 po des mâchoires du

mandrin. Il peut flamber soudainement vers l’extérieur ou

casser.

7. NE PAS UTILISER de meule en fils métalliques, de fraises,

d’outil pignon, de scie-cloche (coupe-joints) ni de rabot

tournant avec cette perceuse d’établi.

8. AVANT de percer une pièce de grandes dimensions,

s’assurer qu’elle est bien soutenue à la hauteur de la table.

9. NE JAMAIS travailler avec les mains libres. TOUJOURS

maintenir fermement la pièce contre la table pour éviter tout

mouvement. Utiliser des brides ou un étau pour les pièces

instables.

10. S’ASSURER qu’il n’y a ni clous ni corps étrangers dans la

partie à percer.

11. BRIDER OU CALER LA PIÈCE contre le côté gauche de la

colonne pour éviter qu’elle ne tourne. Si elle est trop petite

ou si la table est inclinée, utiliser le guide fourni et la brider

solidement sur la table.

12. SI UNE PIÈCE dépasse de la table et risque de tomber ou

de basculer si elle n’est pas maintenue, la brider à la table

ou fournir un support auxiliaire.

13. BRIDER FERMEMENT LA PIÈCE Utiliser des brides ou un

étau pour maintenir la pièce en place lorsque cela est

possible. Cette pratique est plus sécuritaire que mains et

libère ainsi les deux mains de l’opérateur.

14. S’ASSURER que toutes les brides et les dispositifs de

blocage sont serrés de façon sécuritaire avant de percer.

15. BLOQUER DE FAÇON SÉCURITAIRE LA TÊTE et le

support de table sur la colonne et la table sur son support

avant d’utiliser la perceuse.

16. NE JAMAIS mettre la perceuse en marche avant

d’avoirenlevé tous les objets se trouvant sur la table (outils,

éclats de bois, etc.)

17. AVANT D’UTILISER la perceuse, faire fonctionner

l’interrupteur du moteur par à-coups pour s’assurer que le

foret n’est pas désaxé ou ne vibre pas.

18. ATTENDRE QUE LA BROCHE ATTEIGNE LA PLEINE

VITESSE avant de commencer à percer. Si la perceuse fait

un bruit inhabituel, ou en cas de vibrations excessives,

arrêter le perçage immédiatement, couper le moteur et

débrancher la perceuse. Ne pas remettre la perceuse en

route avant d’avoir réglé le problème.

19. NE PAS effectuer de mise en place ou d’installation sur la

table lorsque l’outil fonctionne.

20. UTILISER LA VITESSE RECOMMANDÉE pour l’accessoire

utilisé et suivant le matériau de la pièce. LIRE LES

INSTRUCTIONS fournies avec l’accessoire.

21. LORS DU PERÇAGE de trous de grand diamètre, brider

fermement la pièce sur la table. Sinon, le foret risque

d’entraîner et de faire tourner la pièce à grande vitesse. NE

PAS UTILISER de coupe-joints ni d’autre appareil de coupe

de trous en plusieurs parties, car elles pourraient se

détacher ou devenir déséquilibrées pendant le perçage.

22. S’ASSURER que la broche est complètement arrêtée avant

de toucher la pièce.

23. POUR ÉVITER LES BLESSURES suite à une mise en

marche accidentelle, toujours placer l’interrupteur à la

position d’arrêt (OFF) avant d’installer ou d’enlever un

accessoire ou un équipement ou d’effectuer un quelconque

réglage.

24. GARDER LES PROTECTIONS EN PLACE et

fonctionnelles.

25. N’UTILISER QUE LA CLÉ DE MANDRIN AUTO-ÉJECTABLE

fournie avec la perceuse.

26.

ÉVITER LE CONTACT DIRECT AVEC LES YEUX lors de

l’utilisation du guide au laser.

27. TOUJOURS S’ASSURER QUE LES RAYONS LASER

SONT DIRIGÉS VERS UNE SURFACE NON l’utilisation des

RÉFLÉCHISSANTE. Le guide au laser ne doit pas être

utilisé avec des matériaux brillants.

AVERTISSEMENT

– 22 –

Français

Page 23

EXIGENCES ÉLECTRIQUES

ALIMENTATION ÉLECTRIQUE ET SPÉCIFICATIONS DU

MOTEUR

Afin d’éviter les risques d’origine électrique, les risques

d'incendie ou des dommages à l’outil, utiliser une protection de

circuit adéquate. Utiliser un circuit électrique séparé pour vos

outils. Votre scie est câblée en usine pour fonctionner sur du 120

V. Brancher à un circuit de 120 V, 15 A et utiliser un fusible

temporisé de 15 A ou un disjoncteur. Afin d’éviter une secousse

électrique ou un incendie, si le cordon d’alimentation est usé,

coupé ou endommagé, le faire remplacer immédiatement.

INSTRUCTIONS DE MISE À LA TERRE

Pour protéger l’opérateur contre les secousses électriques,

l’équipement doit être mis à la terre pendant qu’il est utilisé.

EN CAS DE DÉFECTUOSITÉ OU DE PANNE, la mise à la terre

offre au courant électrique un trajet de moindre résistance et

réduit les risques de secousses électriques. Cet outil est équipé

d’un cordon électrique muni qu’un conducteur de mise à la terre

et d’une fiche de mise à la terre. La fiche doit être branchée dans

une prise de courant correspondante, correctement installée et

mise à la terre conformément à tous les codes et règlements de

la municipalité.

NE PAS MODIFIER LA FICHE FOURNIE. Si la fiche n’est pas

adaptée à la prise de courant, faire installer une prise de courant

adéquate par un électricien qualifié.

Un MAUVAIS BRANCHEMENt du conducteur de mise à la terre

peut présenter un risque de secousses électriques. Le

conducteur à gaine verte (rayé jaune) est le conducteur de mise

à la terre pour l’équipement. Si le cordon ou la fiche électrique

doivent être réparés ou remplacés, ne pas brancher le

conducteur de mise à la terre sur une borne sous tension.

CONSULTER un électricien qualifié ou du personnel d’entretien

si vous ne comprenez pas complètement les instructions de mise

la terre ou si vous doutez de la mise à la terre correcte de l'outil.

UTILISER UNIQUEMENT un cordon prolongateur à 3

conducteurs muni d’une fiche à 3 broches d’un côté et d’une

prise à 3 trous de l’autre dont une de mise à la terre dans

laquelle on pourra brancher la fiche de l’outil. Réparer ou

remplacer immédiatement un cordon endommagé ou usé.

Utiliser un circuit électrique séparé pour vos outils. Ce circuit ne

doit pas être inférieur à un fil no 12 et doit être protégé avec un

fusible temporisé de 15 ampères. Avant de connecter le moteur à

une ligne d’alimentation électrique, s’assurer que l’interrupteur

est à la position d’arrêt (OFF) et que le courant a les mêmes

caractéristiques nominales que celles gravées sur la plaque

signalétique du moteur. Un moteur qui fonctionne à une tension

inférieure à celle pour laquelle il a été conçu subira des

dommages.

Cet outil est conçu pour être utilisé sur un circuit muni d’une

prise qui ressemble à celle illustrée dans la Figure A : une fiche

à 3 broches et une prise munie d'un conducteur de mise à la

terre. Si une prise adéquate n’est pas disponible, on pourra

utiliser un adaptateur (figure B) pour connecter temporairement

cette fiche à une prise à deux contacts sans mise à la terre.

L’adaptateur (Figure B) est muni d’une cosse rigide qui part de

celui-ci et doit être connectée à une prise de terre permanente,

comme une boîte de prise de courant correctement mise à la

terre. L’ADAPTATEUR TEMPORAIRE DOIT ÊTRE UTILISÉ

SEULEMENT TANT QU’UN ÉLECTRICIEN QUALIFIÉ N’A PAS

INSTALLÉ UNE PRISE CORRECTEMENT MISE À LA TERRE.

Le Code canadien de l’électricité interdit l’utilisation d’adaptateurs.

ATTENTION : Dans tous les cas, s’assurer que la prise est

correctement mise à la terre. Si vous avez des doutes, faites-la

vérifier par un électricien qualifié.

Cette perceuse d’établi est conçue pour être utilisée à l’intérieur

seulement. Ne pas exposer à la pluie ou laisser dans des

endroits humides.

DIRECTIVES POUR LES RALLONGES

ÉLECTRIQUES

UTILISER LA RALLONGE ÉLECTRIQUE QUI CONVIENT.

S’assurer que la rallonge électrique est en bon état. Lorsqu’une

rallonge électrique est utilisée, s’assurer que son calibre est

suffisant pour transporter le courant appelé par le produit. Une

rallonge de taille trop petite entraîne une surchauffe. Le tableau

ci-dessous indique le rapport taille / longueur correct de cordon à

utiliser, de même que la plaque signalétique et l’intensité

nominale. En cas de doute, utiliser un calibre plus gros. Plus le

numéro de calibre est petit, plus le cordon est lourd.

S’assurer que la rallonge électrique est correctement câblée

et en bon état. Toujours remplacer une rallonge endommagée ou

la faire réparer par du personnel qualifié avant de l’utiliser.

Protéger vos rallonges contre les objets acérés, une chaleur

excessive et des aires humides ou mouillées.

CALIBRE MINIMAL POUR CORDONS PROLONGATEURS

(AWG) (Avec du 120 V seulement)

Intensité nominale Longueur totale en pieds

Plus que

Au

maximum

25′ 50′ 100′ 150′

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12

Non

recommandé

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

– 23 –

Français

Prise à trois trous correctement

mise à la terre

Fiche de mise à la terre

Fiche à 3 broches

Cosse de mise à la terre

Fiche à 3 broches

S’assurer que cette

connexion est raccordée sur un dispositif de mise à la

terre connu

Prise à 2 bornes

Fig. A

Fig. B

Raccord réducteur

Page 24

DÉBALLAGE ET VÉRIFICATION DU

CONTENU

Déballer avec soin la perceuse et toutes ses pièces et les

comparer à l’illustration qui suit. Placer la scie sur une surface

solide et l’examiner minutieusement.

• Pour éviter les blessures provoquées par un démarrage

intempestif, ne pas brancher le cordon d'alimentation pendant

le déballage et l'assemblage. Ce cordon doit rester débranché

chaque fois que la perceuse est assemblée ou ajustée.

• Si une quelconque pièce est manquante ou endommagée, ne

pas brancher la perceuse tant que cette pièce n'est pas

remplacée et que l'assemblage ne soit complet.

• Afin de protéger la perceuse contre l’humidité, un revêtement

protecteur a été appliqué sur les surfaces usinées. Enlever ce

revêtement avec un chiffon légèrement imbibé de kérosène

ou de WD-40.

Pour éviter un incendie ou une réaction toxique, ne jamais utiliser

d’essence, de naphta, d’acétone, de diluant à peinture ou

d’autres solvants similaires très volatiles pour nettoyer la

perceuse.

TABLEAU DES PIÈCES DÉTACHÉES

ARTICLE DESCRIPTION QUANTITÉ

PERCEUSE :

A. Tête 1

B. Table 1

C. Socle 1

D. Colonne 1

E. Levier de manoeuvre 3

F. Manivelle 1

G. Piles 2

SAC DE PIÈCES DÉTACHÉES :

H Boulons hexagonaux 4

I Clé hexagonale 1

J Rondelles plates 4

BOÎTE :

K. Clé de mandrin 1

L Mandrin 1

AVERTISSEMENT

AVERTISSEMENT

ACCESSOIRES RECOMMANDÉS

Pour éviter des blessures :

• Utiliser uniquement des accessoires recommandés pour cette

perceuse.

• Suivre les instructions qui accompagnent les accessoires.

L’utilisation d’accessoires inappropriés peut poser des

risques.

• N’utiliser que des accessoires conçus pour cette perceuse

afin d'éviter des blessures provoquées par des pièces ou des

morceaux projetés.

• Ne pas utiliser d’accessoire avant d’avoir lu toutes les

instructions ou le manuel de l'utilisateur pour cet accessoire.

AVERTISSEMENT

– 24 –

Français

ACCESSOIRES ET ÉQUIPEMENTS

CONTENU DU CARTON

Page 25

– 25 –

Français

DÉBALLAGE DE LA PERCEUSE

B

A

C

D

E

F

G

I

H

J

K

L

Page 26

Français

– 26 –

CONNAÎTRE SA PERCEUSE

Couvercle de protecteur

de courroi

Bouton du

couvercle

Verrou de

support de table

Moteur

Poulies de

courroie

Broche

Arbre creux

Mandrin

Clé de mandrin

Couvercle

du ressort

Ressort de

positionnement

Ensemble table

Bouton de

verrouillage

de tension

de courroie

Vis de blocage

de la tête

Commutateur de

MARCHE/ARRÊT

Mandrin

Collier de colonne

Guide laser

Poignées de manœuvre

Crémaillère

Support de table

Manivelle de

la table

Support de colonne

Socle

Fausse équerre

Verrou d’inclinaison de table

Page 27

Français

– 27 –

SOCLE – Supporte la perceuse. Pour obtenir plus de stabilité, le

socle comprend des trous permettant de boulonner la perceuse

à l’établi.

MATÉRIAU DE SUPPORT – Une pièce de rebut en bois placée

entre la pièce à travailler et la table. Le panneau en bois évite au

bois de la pièce travaillée de voler en éclats lorsque le foret

débouche de la pièce. Il évite également de percer la surface de

la table.

PROTECTION DE COURROIE – Recouvre les poulies et la

courroie pendant le fonctionnement de la perceuse.

TENSION DE COURROIE – Se référer à la rubrique

« Assemblage », section « Installation et tension de la courroie ».

BOUTONS DE VERROUILLAGE DE TENSION DE

COURROIE – Un serrage des boutons verrouille le support du

moteur et la poignée de tension de courroie, afin de maintenir la

distance et la tension de courroie correctes.

FAUSSE ÉQUERRE – Indique le degré d’inclinaison de la table

pour les opérations de biseautage. L’équerre est installée sur le

côté du support de table.