Page 1

These servicing instructions are for use by qualified service personnel only. To reduce the risk of electric

nless you are

Since the Panel Module and the front Filter are made of glass, handling the broken Module and Filter

and the AC/DC Power supply have

The Panel Module should not be touched with bare hands in order to protect its surface from

It is recommended that you use clean soft gloves during the replacement work in order to protect not

No.

26LD9000TA

Caution

Be sure to read this manual before servicing. To ensure safety from fire, electric shock, injury, harmful

radiation and materials, various measures are provided in this LCD Television.

Be sure to read cautionary items described in the manual before servicing.

shock, do not perform any servicing other than that described in the operating instructions u

qualified to do so.

Service Warning

1.

carefully and with caution in order not to receive injury.

2. Replacement work should be started after the Panel Module

become sufficiently cool.

3. Special care should be taken when working near the display area in order not to damage its surface.

4.

blemishes and damage.

5.

only the display area of the Panel Module but also yourself.

1. Features ...................................... 3

Contents

8. Connection Diagram .............…28

32LD9000TA

2. Specifications............................... 4

3. Component names ......................6

4. Service points ..............................8

5. Adjustment...................................9

6. Troubleshooting......................... 15

7. Block Diagram ....................... …23

9. Wiring Diagram ......................... 29

10. Basic Diagram........................... 31

11. Printed wiring board diagram .... 33

12. Disassembly diagram................ 39

13. Replacement parts list............... 43

LCD Television

1

Page 2

abels are parts

that require attention. You must follow the

presented throughout this User Manual to

The Monitor uses special tubes and tapes

ls. Moreover,

connection it is possible to sustain severe

servicing.Be sure to check everything that

ohm meter to confirm that the

the impedance value is less than 4M ohm,

CAUTION FOR SAFETY

Please read this page before repair the monitor.

The following safety precautions are designed to help you stay safe and prevent accidents during the repair

work.

Please take note of these cautionary flags.

Warning

Caution

Also note these cautionary icons

This means "CAUTION"

This means "Potential to sustain injury or even death."

This means "Potential to sustain breakage or irreparable damage."

This means "MUST"

This means "POTENTIAL ELECTRIC

SHOCK"

This means "DO NOT"

WARNING

Follow instructions. Must use same types of wires and components.

The cabinet, chassis, and l

made from insulated materia

caution notes and safety instructions

prevent damage to them or injury to

yourself.

Prevent electric shock.

Exercise caution while working on the

device as the Monitor contains high

voltage parts and power supply.It is

possible to sustain severe injury or death

if you accidentally touch the wrong

parts.You must disconnect the power

supply while servicing, reassembling, or

change parts. If you touch a live

Perform safety check when done.

some materials are kept from making

contact with the PWB for the sake of

safety.Internal leads are kept from hot

parts or high voltage parts by means of

clamps or other measures. As such, you

must restored these parts to their original

conditions in order to prevent electric

shock or fire.

Every part (such as removed screws,

components, and wiring) must be

restored to their prior conditions after

injury or death.

Use recommended components.

Use only the recommended components

or componentst that structurally identical

to the originals. This is to ensure safety

and reliability. Pay special attention to

parts in the parts list and circuit diagrams

marked with . If you use

non-recommended components, then

electric shock or fire may result.

was repaired for damage or mistakes.

Also measure the insulated impedance

with a megimpedance value is more than 4M ohm.If

then electric shock or fire may result.

Do not try to check the HDCP code and

combination circuit.

Never remove the shield case protecting

the HDCP code and combination circuit.

2

Page 3

PRECAUTIONS

Cleaning the LCD panel of the television

Please make sure to unplug the power cord before cleaning the television.

● Wipe the panel with a lint-free and dry cloth in order to prevent damage to the panel surface.

● Do not use a chemical cloth or cleaner. Depending on the ingredients, it may cause discoloration and

damage the panel surface.

● Do not wipe with a hard cloth or rub hard. It may hurt the panel surface.

● In case of the greasy dirt such as fingerprint, wipe with a lint-free cloth moistened by a diluted neutral

detergent solution, and then wipe with a soft and dry cloth.

● Do not use a spray cleaner. It could cause malfunction.

Cleaning the monitor's cabinet of the television

● The following may cause crack, deformation, and paint peeling.

● Do not wipe the cabinet with benzene, thinner, and other chemical products.

● Do not spray volatile solutions such as insecticide over the cabinet.

● Do not leave the cabinet in prolonged contact with plastic or rubber materials.

● Do not use a chemical cloth, cleaner or wax. Depending on the ingredients, it may cause crack and

deformation.

● Use a lint-free cloth to clean the cabinet and control panel of the television. In case of the heavy dirt, wipe

with a soft cloth moistened by a diluted neutral detergent solution, and then wipe with a soft and dry cloth.

● Never use the following detergents. It could cause crack, discoloration, and scratch.

● Acid/ alkaline detergent, alcoholic detergent, abrasive cleaner, powder soap, OA cleaner, car wax, glass

cleaner, etc.

1. Features

● Large-screen and high-definition LCD panel.

● Improved Digital signal processor.

● Accept more digital input devices with HDMI terminals.

● Great diversity of connecting terminals to cover wide range of audio-visual equipments.

● Enjoy the image from PC with large, high-definition LCD screen.

● Easy-to-use On-Screen Display system operating with Remote control.

● Low power consumption with Power Saving feature.

3

Page 4

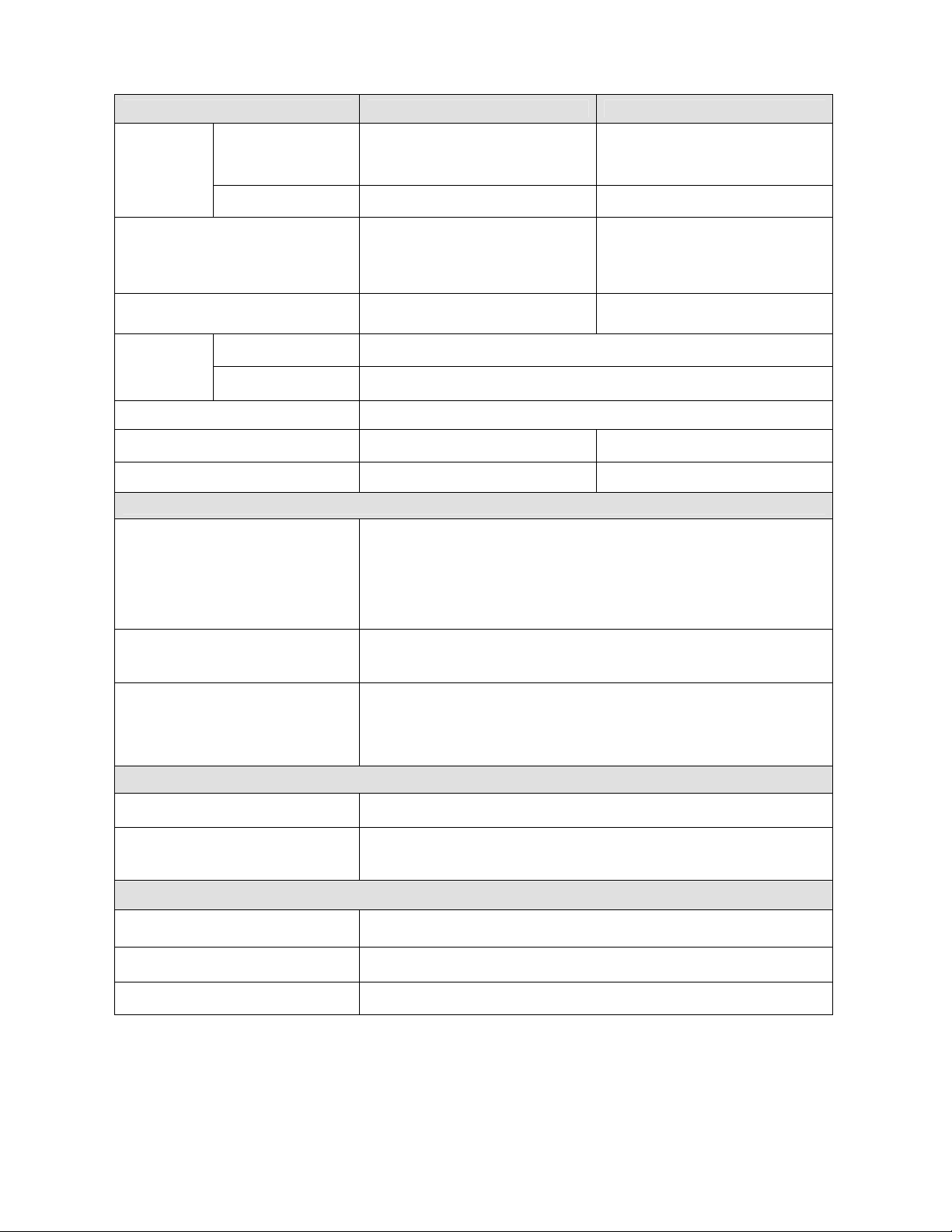

2. Specifications

SPECIFICATION 26LD9000TA 32LD9000TA

Panel

Approx. 26 inches

Display dimensions

Resolution 1366 (H) x 768 (V) pixels 1366 (H) x 768 (V) pixels

(576 (H) ×324 (V)mm,

diagonal 660.5mm)

Approx. 32inches

(698 (H) x 392 (V) mm,

diagonal 801mm)

including Stand:

Net dimensions

Net weight

Ambient

conditions

Power supply AC110 - 240V, 50/60Hz

Power consumption/at standby 125W/<1W 135W/<1W

Audio output Speaker total 14W 20W

(VIDEO input)

Input terminals

Input signals

Output signals

Temperature

Relative Humidity

664(W)x508(H)x262(D) mm

excluding Stand:

664(W)x471(H)x118.5(D) mm

including Stand:14kg

excluding Stand:12.5kg

Operating: 5°C to 35°C, Storage: 0°C to 40°C

Operating: 20% to 80%, Storage: 20% to 90% (non-condensing)

AV1.2: composite video input terminal (RCA)

S video input terminal

L/R audio input terminal (RCA)

AV3.4: component video input terminal (RCA)

L/R audio input terminal (RCA)

HDMI : HDMI input terminal

Composite video: PAL, SECAM, NTSC3.58, NTSC4.43, PAL60

Component video: 480i, 576i, 480p, 576p, 720p/50, 720p/60, 1080i/50,

1080i/60

OUTPUT (MONITOR): composite video monitor-output terminal (RCA)

OUTPUT (MONITOR): L/R audio monitor- output terminal (RCA)

OUTPUT (HEADPHONE): L/R audio monitor- output terminal (Mini-pin)

OUTPUT (SUB-WOOFER): Woofer output terminal

including Stand:

790(W)x585.5(H)x308.5(D) mm

excluding Stand:

790(W)x550(H)x120(D) mm

including Stand:19.2kg

excluding Stand:16.5kg

(RF input)

Input terminal / Receiving range ANT: 75Ω Unbalanced / 44~870MHz

PAL B, G, H / I / D, K

RF Video System

(RGB input)

Input terminals

Input signals 0.7 V, analog RGB (Recommended Signal)

Sync signals H/V separate, TTL level [2kΩ]

● The television takes at least 30 minutes to attain the status of optimal picture quality.

4

SECAM B, G / D, K / K1

NTSC-M

Analog RGB input terminal (D-sub 15-pin)

Audio input terminal (3.5mm Stereo Mini Jack)

Page 5

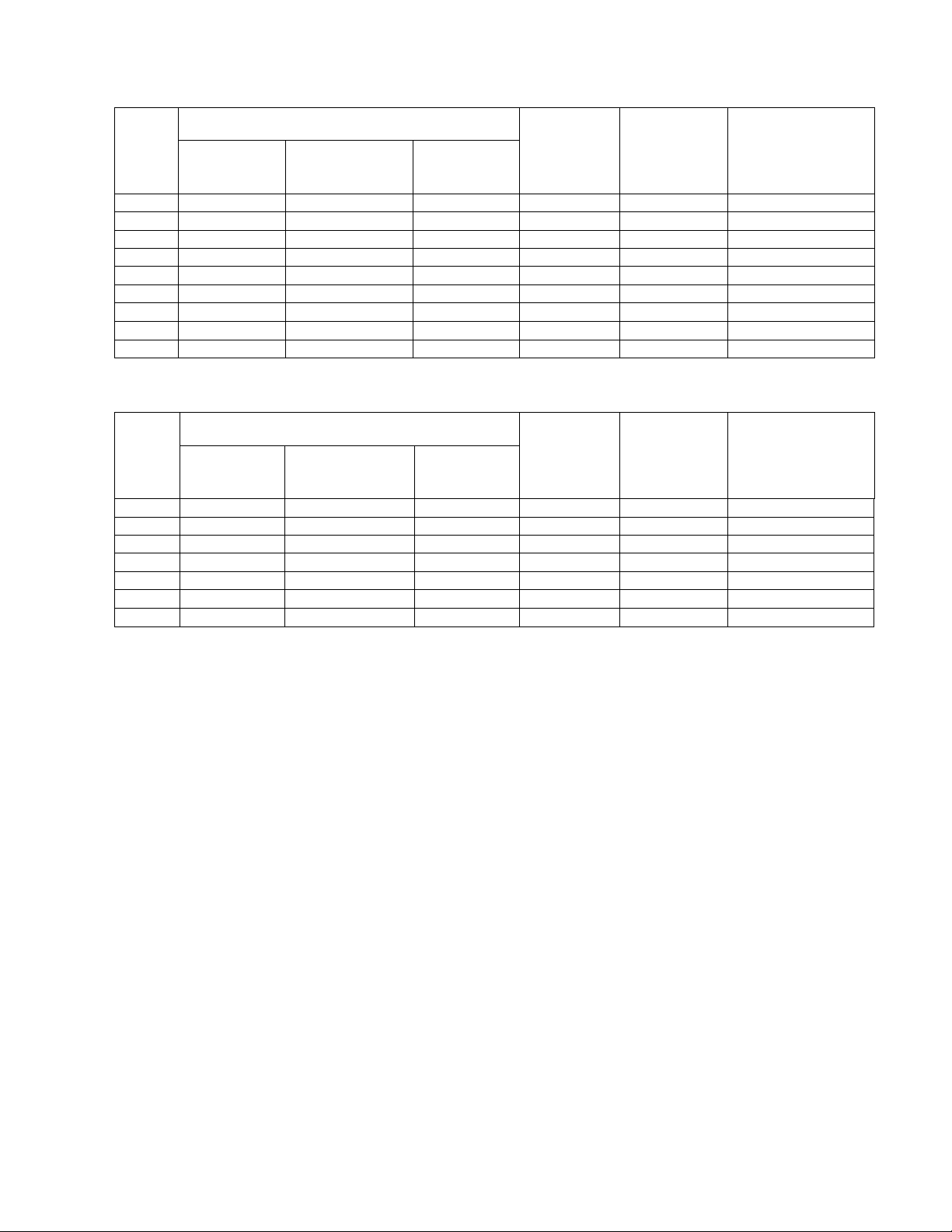

The Expression of input signal mode (format)

With HDMI INPUT

No.

Signal Name

Signal mode

Resolution

Vertical

frequency

Horizontal

frequency

(kHz)

Dot clock

frequency

(MHz)

Remarks

(Hz)

1 VGA 640x480 59.94 31.47 25.18

2 480i 720(1440)x480 60 15.75 27.00

3 480P 720x480P 60 31.5 27.00

4 576i 720(1440)x576 50 15.63 27.00

5 576P 720x576P 50 31.25 27.00

6 720P/60 1280x720 60 45 74.25

7 720P/50 1280x720 50 37.5 74.25

8 1080i/60 1920x1080 59.94 33.75 74.25

9 1080i/50 1920X1080 50 28.13 74.25

With RGB input

No.

Signal Name

Signal mode

Resolution

Vertical

frequency

Horizontal

frequency

(kHz)

Dot clock

frequency

(MHz)

Remarks

(Hz)

1 VGA 720 x 400 70.09 31.47 28.32

2 VGA 640 x 480 59.94 31.47 25.18

3 SVGA 800 x 600 56.25 35.16 36.0

4 SVGA 800 x 600 60.32 37.88 40.0

5 SVGA 800 x 600 72.19 48.08 50.0

6 XGA 1024 x 768 60.00 48.36 65.0

7 XGA 1024 x 768 70.07 56.48 75.0

The type of video board or connecting cable used may not allow for correct displays adjustment of

Horizontal Position, Vertical Position, Horizontal Clock and Clock Phase.

The television may fail to display an animation image correctly when a signal having a vertical frequency of

72Hz or higher is input to it.

The television differentiates the signal modes according to the horizontal and vertical frequencies and the

horizontal and vertical sync signal polarities. Note that different signals having all these elements alike may

be handled as the same signal.

Displaying images with more than 768 lines of vertical resolution a Full display (compressed display) can

result in the interpolation of stripes.

5

Page 6

3. Component names

1

2

3

7

5

4

6

2 1

43 2 1

4

[Main unit]

Front Panel

1. Cabinet

2. Panel

3. Indicating Lamp

4. Remote Control Receiver

5. Speaker

6. Desktop Stand

7. Main Power Switch (on the left side)

Rear Panel

1. Side Input

2. Power Cord Socket

3. Terminal Board (External Device Connection)

4. Control Panel (see below for details)

26LD9000TA 32LD9000TA

3

Control Panel

These buttons are located on the top.

5, 6

7

6

3, 4

2

1

1. Sub Power button

2. Menu button

3. Program UP/ button

4. Program DOWN/ button

5. Volume UP / button

6. Volume DOWN /button

7. Input button

Page 7

[Remote Control]

816

12

59 18

14

10 1

3

4

2

6

7

11

13

15

1. Power ON/OFF

2. [Color (Red, Green, Yellow, Blue)]

3. TV Select (TV)

Press this button to change input to TV.

4. Input Select (AV1/AV2/AV3/AV4/HDMI/RGB)

Press this button to change input mode.

5. Program Select

Press these buttons to select a TV program directly.

6. Freeze [Hold]

Press this button to change the picture to freeze

mode.

7. MENU

8. Cursor

9. Volume Up/Down

10. MUTE

11. [Index]

17

12. Picture Size

Press this button to change picture size.

13. Recall

19

20

21

22

Pressing this button shows the input signal status.

14. [TV Text]

Teletext mode can be changed each time pressed in

the following sequence. TV Teletext Mix mode

15. Return

You can use this to return to the previous menu.

16. OK

17. Picture Mode

Picture mode can be changed each time pressed in

the following sequence. Dynamic Natural Cinema

18. Channel Up/Down[P +/-]

19. CHI/II

This is exclusively for TV audio A2/NICAM mode.

20. [Reveal]

21. [Sub Title]

22. [Cancel]

NOTE

Some buttons are only for Teletext mode, and other buttons have different functions in Teletext mode from

the use of TV mode. Those buttons are indicated by

[ ]

.

7

Page 8

4. Service points

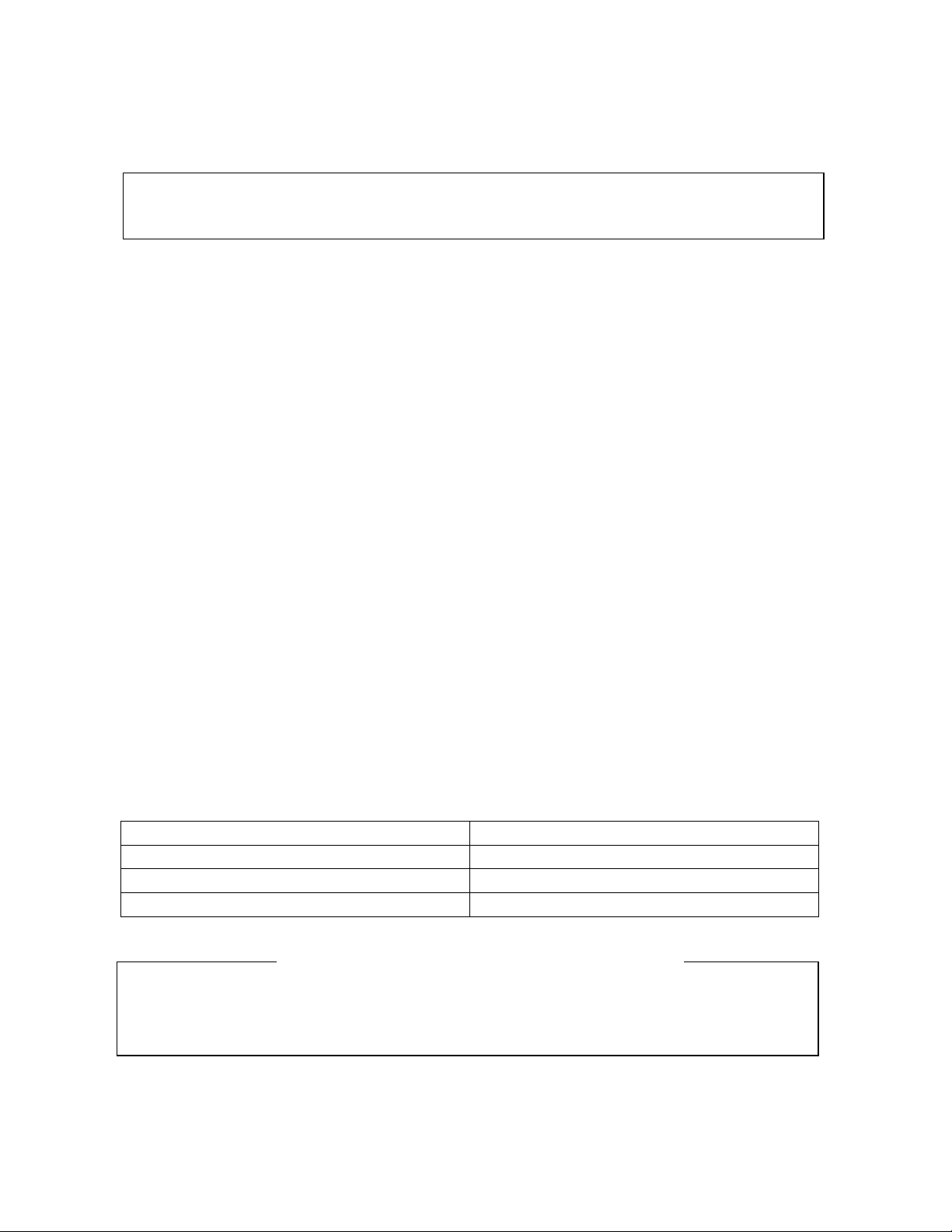

The PWB assembly which has used lead free

Lead-free solder

This product uses lead-free solder (unleaded) to help protect the environment. Please read these instructions

before attempting any soldering work.

Caution: Always wear safety glasses to prevent fumes or molten solder from getting into

the eyes. Lead-free solder can splatter at high temperatures (600℃).

Lead-free solder indicator

Printed circuit boards using lead-free solder are engraved with an "F."

Properties of lead-free solder

The melting point of lead-free solder is 40-50℃ higher than leaded solder.

Servicing solder

Solder with an alloy composition of Sn-3.0Ag-0.5Cu or Sn-0.7Cu is recommended. Although servicing with

leaded solder is possible, there are a few precautions that have to be taken. (Not taking these precautions may

cause the solder to not harden properly, and lead to consequent malfunctions.)

Precautions when using leaded solder

Remove all lead-free solder from soldered joints when replacing components.

If leaded solder should be added to existing lead free joints, mix in the leaded solder thoroughly after the

lead-free solder has been completely melted (do not apply the soldering iron without solder).

Servicing soldering iron

A soldering iron with a temperature setting capability (temperature control function) is recommended.

The melting point of lead-free solder is higher than leaded solder. Use a soldering iron that maintains a high

stable temperature (large heat capacity), and that allows temperature adjustment according to the part being

serviced, to avoid poor servicing performance.

Recommended soldering iron:

Soldering iron with temperature control function (temperature range: 320-450℃)

Recommended temperature range per part:

Part Soldering iron temperature

Mounting (chips) on mounted PCB 320ºC±30ºC

Mounting (chips) on empty PCB 380ºC±30ºC

Chassis, metallic shield, etc. 420ºC±30ºC

(1) IR PWB, SW PWB, KEY PWB, SIDE I/O PWB

(2) FORMATTER PWB

(3) POWER BOARD

8

Page 9

5. Adjustment

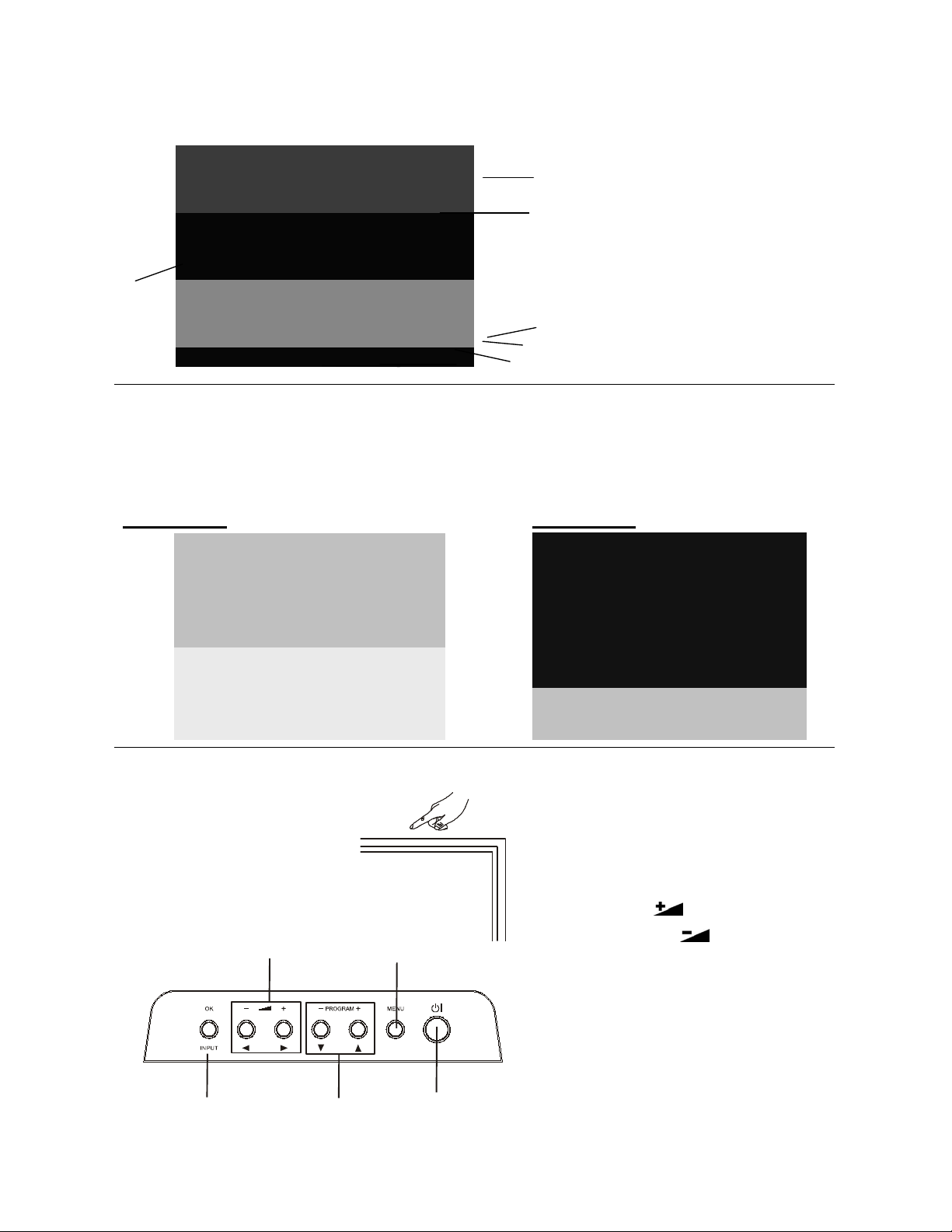

55 75 11 0

26LD9000TA/ 32LD9000TA VGA Color Temperature Adjustment Procedure

5.1 Preparation

1. Set the signal generator (ASTRO VG859A or equivalent) to RGB, 1024*768, 60HZ, Level:0.7V, all

white pattern..

2. Turn on the set and select RGB source,perform pre-heat run more than 30 min. with Full white

pattern.

3. Prepare Minolta CA210,and calibration before adjustment.

4. Press 「Menu」key , Press 「ok」 to select [Picture][Reset]「Reset」「ok」.

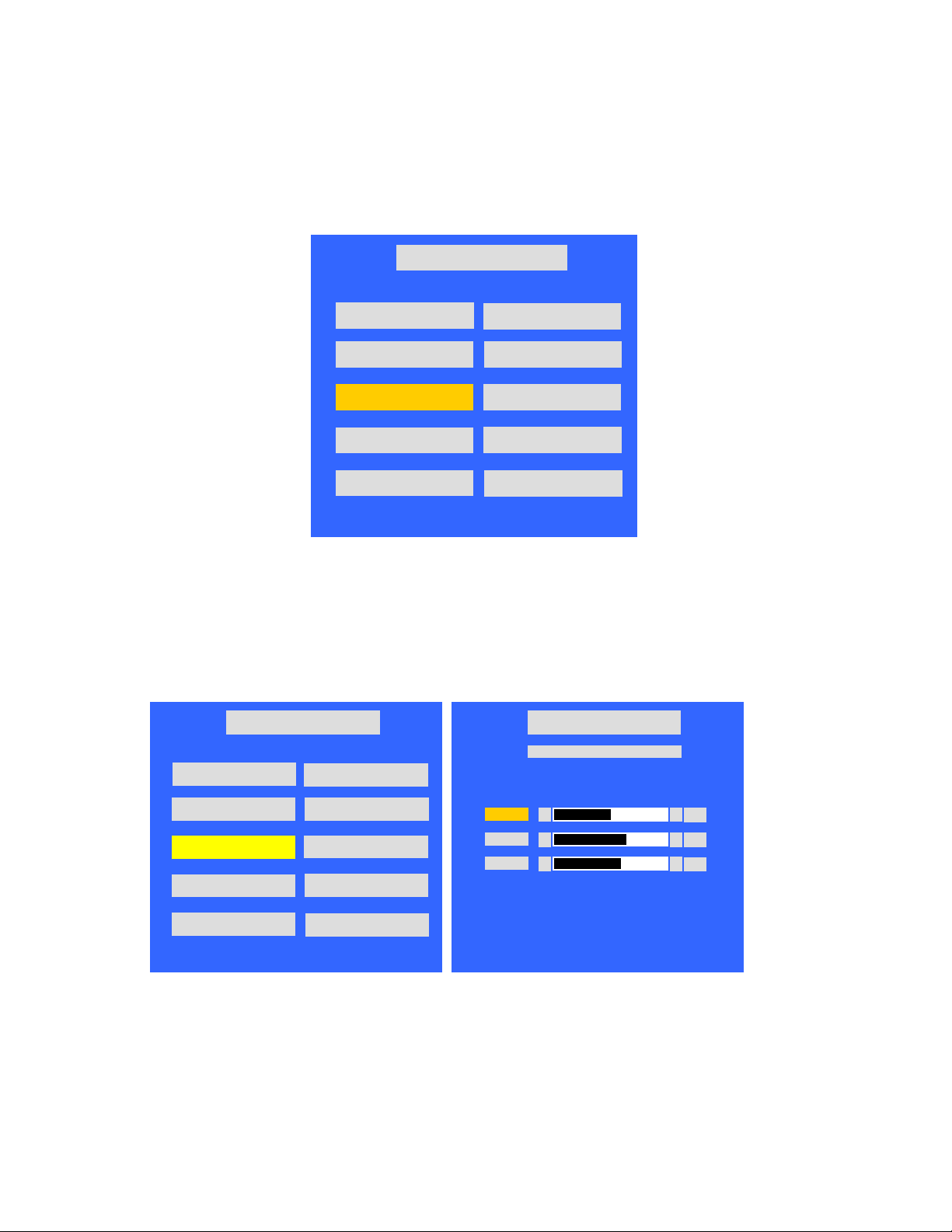

Picture

Picture Mode

Contrast

Brightness

Color

Sharpness

Tint

Color Temperature

Back Light

Reset

Select OK Set Return

5. Press [Menu] key exit OSD.

Dynmaic

Cool

High

Reset

50

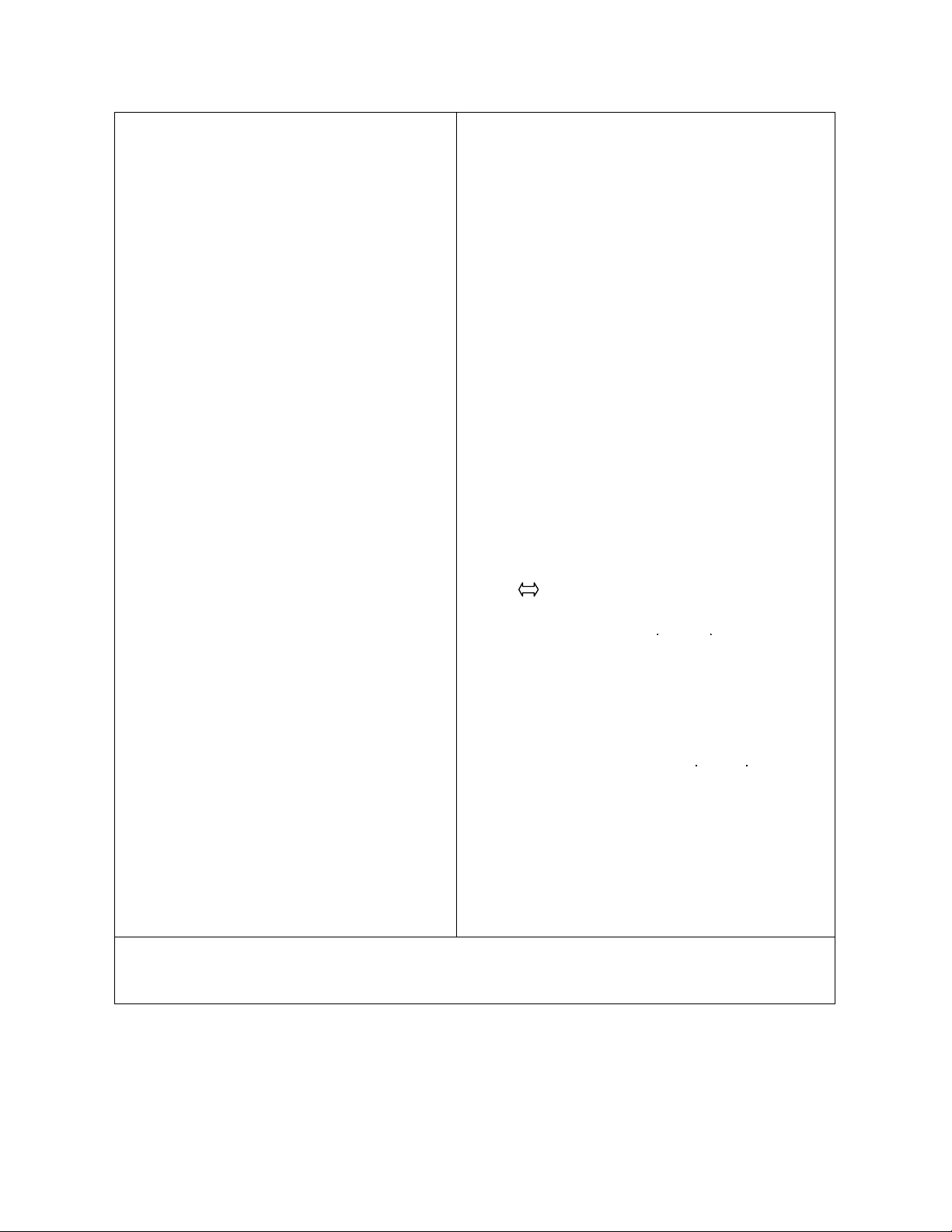

5.2 Entering into factory Mode:

In VGA mode, press “Red” key, next press “Green” key, next press “Return” key in remote control to

enter into factory mode.

Green

Factory Menu

NV CLEAR

Full Power

SourceCalibration

Reset Default

Aspect Ratio

Red

Return key

LH32CG v1.00 Oct 16.2006 21:40:50

WARM(6500K)

NORMAL(9300K)

COOL(15000K)

TimerClear

Shipping Mode

0 0 0 0 0 5 HOUR 58 MIN

9

Page 10

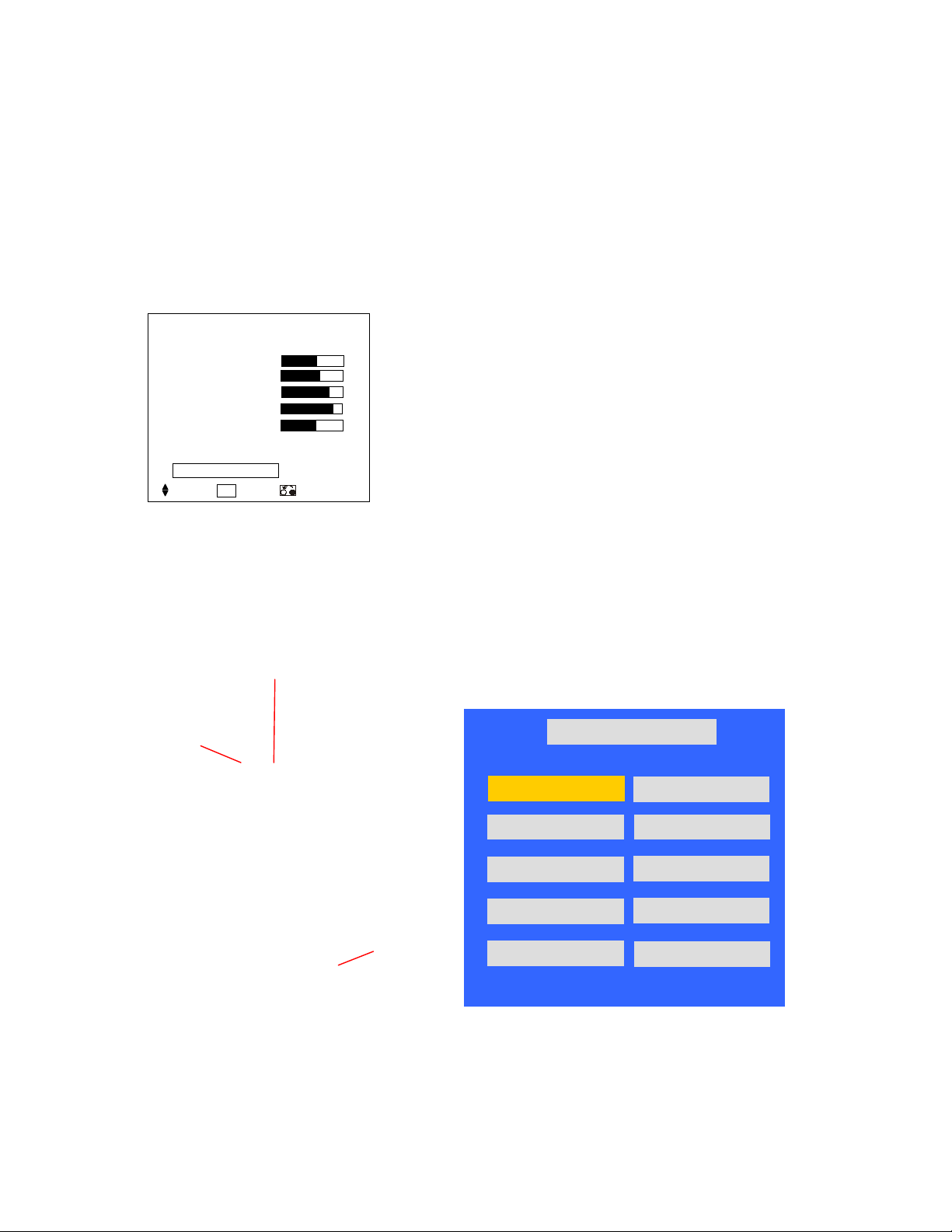

5.3 Source Calibration (RGB)

0 0 0 0 0 5

HOUR

58

MIN

0 0 0 0 0 5

HOUR

58

MIN

◄ ►

◄ ►

1. Set the signal generator to RGB, Color bar pattern (level: 0.7V, color order from left side: white,

yellow, cyan, green,magenta, red, bule, black, width ratio: 12.5% for each color),

2. Entering into factory Mode: Press up or down key of remote control to select “Source Calibration”,

Press 「OK」 key to enter the item.

Factory Menu

LH32CG v1.00 Oct 16.2006 21:40:50

WARM(6500K)

NORMAL(9300K)

COOL(15000K)

TimerClear

Shipping Mode

-> Source calibration performed automatically.

5.4 Color Temperature Adjustment

26LD9000TA

1. Set the signal generator to RGB, 1024*768, 60HZ, Level:0.56V(80%). Full white pattern.

2. Press up or down key of remote control to select “Cool”, Press 「OK」 key to enter the item.

R, G, B drive values are set for COOL, NORMAL, and WARM independently.

NV CLEAR

Full Power

SourceCalibration

Reset Default

Aspect Ratio

Factory Menu

LH26CG v1.00 Oct 16.2006 21:40:50

WARM(6500K)

NORMAL(9300K)

COOL(15000K)

TimerClear

Shipping Mode

NV CLEAR

Full Power

SourceCalibration

Reset Default

Aspect Ratio

Factory Menu

COOL(15000K)

Col or Temp eratu re

Red

Green

Blue

◄

130

►

145

140

For Red drive, keep initial value (130).

Change Green, or Blue drive as follows;

- Press “Up” or “Down” key to select the item “R”, “G”, or “B”, and press [OK] key to enter.

- Press “Left” or “Right” key to set the value.

- Press [OK] key to exit.

10

Page 11

3.Select 「Cool 15000」

(1) Cool:15000 K spec.:

x=0.266±0.001

y=0.270±0.001

(2) If the x and y value are larger than specification,

Decrease Green drive from default value.

Increase Blue drive from default value.

(3) If the x or y or both x and y value is/are smaller than specification.

Decrease Blue drive from default value

(4) According to a x and y value, please following adjustment of (4)-1 or (4)-2.

(4)-1 If x value is higher than spec

Increase Green drive from default value.

Increase Blue drive from default value.

(4)-2 If y value is higher than spec,

Decrease Green drive from default value

4.Select [Normal 9300]

Normal:9300 K spec.:

x=0.285±0.001

y=0.293±0.001

Adjust G drive (GREEN) or B drive (BLUE) to set x and y above.

5.Select [WARM]

(1) WARM:6500 K spec.:

x=0.314±0.001

y=0.327±0.001

Adjust G drive (GREEN) or B drive (BLUE) to set x and y above.

6. Exit Factory Mode:

After finish adjusting color temperature,press [MENU] to exit factory mode.

11

Page 12

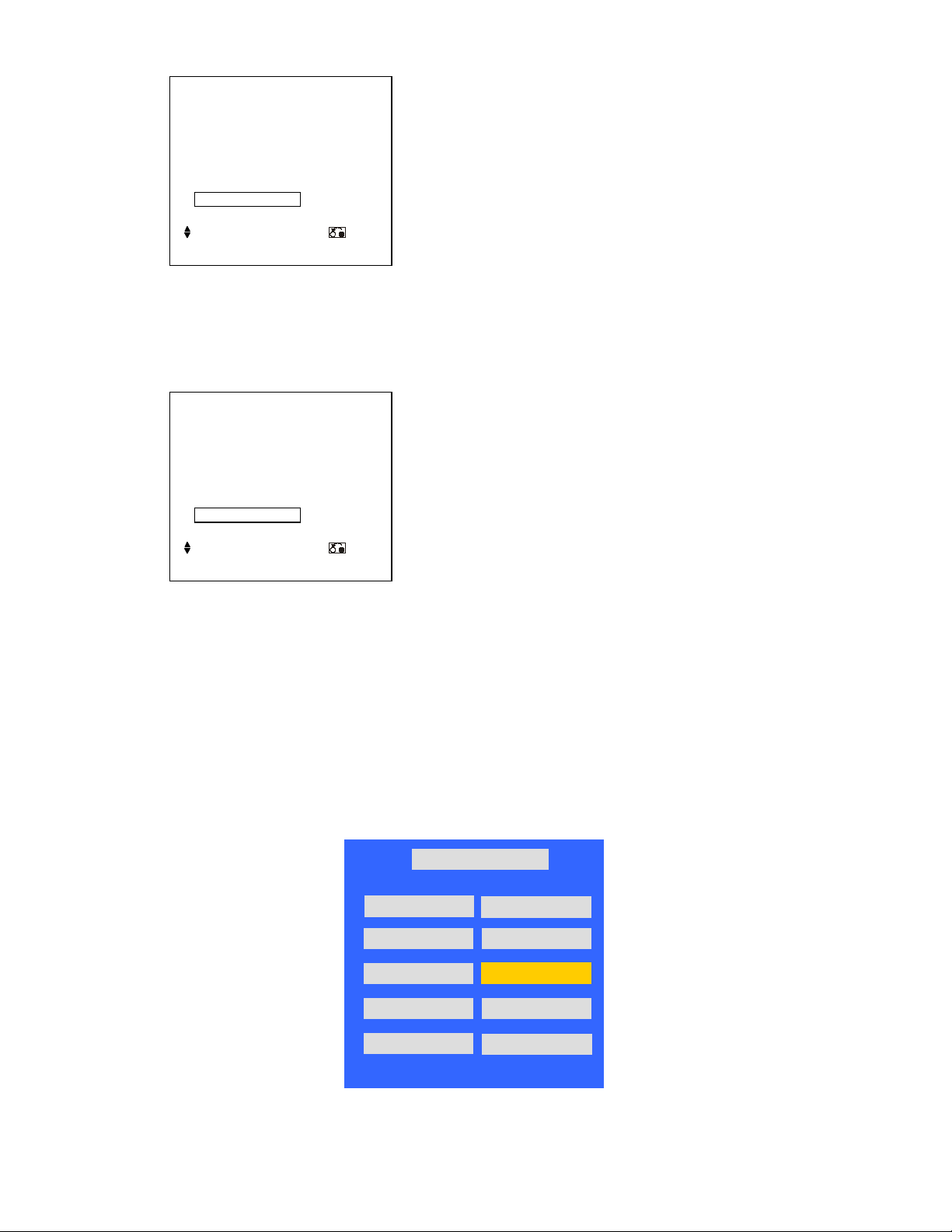

32LD9000TA

0 0 0 0 0 5

HOUR

58

MIN

1. Set the signal generator to RGB,

1024*768, 60HZ, Level:0.56V(80%

). Full white pattern.

2. Press up or down key of remote control to select “Cool”, Press 「OK」 key to enter the item.

R, G, B drive values are set for COOL, NORMAL, and WARM independently.

Factory Menu

LH32CG v1.00 Oct 16.2006 21:40:50

WARM(6500K)

NORMAL(9300K)

COOL(15000K)

TimerClear

Shipping Mode

NV CLEAR

Full Power

SourceCalibration

Reset Default

Aspect Ratio

Factory Menu

COOL(15000K)

Col or Temp eratu re

Red

Green

Blue

◄

◄

◄

►

140

►

125

►

127

For Red drive, keep initial value (140).

Change Green, or Blue drive as follows;

- Press “Up” or “Down” key to select the item “R”, “G”, or “B”, and press [OK] key to enter.

- Press “Left” or “Right” key to set the value.

- Press [OK] key to exit.

3.Select 「Cool 15000」

(1) Cool:15000 K spec.:

x=0.266±0.001

y=0.270±0.001

(2) If the x and y value are larger than specification,

Decrease Green drive from default value.

Increase Blue drive from default value.

(3) If the x or y or both x and y value is/are smaller than specification.

Decrease Blue drive from default value

(4) According to a x and y value, please following adjustment of (4)-1 or (4)-2.

(4)-1 If x value is higher than spec

Increase Green drive from default value.

Increase Blue drive from default value.

(4)-2 If y value is higher than spec,

Decrease Green drive from default value

4.Select [Normal 9300]

Normal:9300 K spec.:

12

Page 13

x=0.285±0.001

55 75 11 0

y=0.293±0.001

Adjust G drive (GREEN) or B drive (BLUE) to set x and y above.

5.Select [WARM]

(1) WARM:6500 K spec.:

x=0.314±0.001

y=0.327±0.001

Adjust G drive (GREEN) or B drive (BLUE) to set x and y above.

6. Exit Factory Mode:

After finish adjusting color temperature,press [MENU] to exit factory mode.

5.5 Color Temperature Check:

Press 「Menu」key , Press 「ok」 to select [Picture][Color Temp.][OK].

Picture

Picture Mode

Contrast

Brightness

Color

Sharpness

Tint

Color Temperature

Back Light

Reset

Select OK Set Return

Dynmaic

Cool

High

Reset

50

1. Select 「Cool」,check If the color temperature is in spec.

Color Temperature

Next/Prev ◄► Adjust Return

Cool:15000 K

x=0.266±0.005

y=0.270±0.005

Cool

13

Page 14

2. Select [Normal],check If the color temperature is in spec.

0 0 0 0 0

2 HOUR 50 MIN

Color Temperature

Next/Prev ◄► Adjust Return

Normal

Normal:9300K

x=0.285±0.005

y=0.293±0.005

3. Select [Warm],check If the color temperature is in spec.

Color Temperature

Warm

Next/Prev ◄► Adjust Return

Warm:6500 K

x=0.314±0.005

y=0.327±0.005

5.6 Source Calibration (Component only support AV3 port used)

1. Set the signal generator to Component, Color bar pattern (level: 0.7V, color order from left side:

white, yellow, cyan, green, magenta, red, bule, black, width ratio: 12.5% for each color)

2. Entering into factory Mode):Press up or down key of remote control to select “Comp

Calibration”, Press 「OK」 key to start adjusting..

LH32CG v1.02 Oct 31.2006 18:10:34 1

WARM(6500K)

NORMAL(9300K)

COOL(15000K)

Factory Menu

NV CLEAR

Full Power

Comp Calibration

TimerClear

Shipping Mode

-> Source calibration performed automatically.

14

Reset Default

Aspect Ratio

Page 15

5.7 Source Calibration (CVBS only support AV1 port used)

1. Set the signal generator to CVBS, Color bar pattern (level: 0.7V, color order from left side: white,

yellow, cyan, green, magenta, red, bule, black, width ratio: 12.5% for each color)

2. Entering into factory Mode:Press up or down key of remote control to select

“AV CVBS Calibration”, Press 「OK」 key to start adjusting..

LH32CG v1.02 Oct 31.2006 18:10:34 1

WARM(6500K)

NORMAL(9300K)

COOL(15000K)

TimerClear

Shipping Mode

0 0 0 0 0 2 HOUR 50 MIN

-> Source calibration performed automatically.

Factory Menu

NV CLEAR

Full Power

AV CVBS Calibration

Reset Default

Aspect Ratio

15

Page 16

6. Troubleshooting

The flow chart shown below will help you to troubleshoot your Televison set with it doesn’t display normally.

Each procedure offers a simple way to check for system errors. Before starting, ensure that there is a signal in

and that the Televison is turned on.

Power LED indicator

has no light

FIRMWARE MAIN/B

VTV-L3209 M/B

Check J12-pin 9

and FB77 =5V

(5V StandBy)

VTV-IR3209 IR/B

OK

PCBA IR/B

Check LED2-

pin 1=4V

NG

Change IR

board assembly

NG

Check J14 Pin 1= 0V

H

Change

R328

(0 Ω)

FIRMWARE MAIN/B

VTV-L3209 M/B

Check U38-pin 1

L

OK

5V

NG

Change Main

board assembly

Change power board

assembly

16

Page 17

TV has a video but no sound

VTV-IO3202 Side I/O

PCBA SIDE-IO/B

Press “ Mute” key

of remote control to

Cancel mute

function

Or adjust volume up

Check J4-pin4

= 4~5V

OK

NG

Change Side I/O

board

assembly

Check speaker unit

FIRMWARE MAIN/B

VTV-L3209 M/B

FIRMWARE MAIN/B

VTV-L3209 M/B

FIRMWARE MAIN/B

VTV-L3209 M/B

7Ω~8Ω

OK

Check J14-pin

8&9=22~23V

OK

Check U16-

pin44=4~5V

OK

Check U16-

pin45=0~0.2V

NG

NG

NG

NG

Change speaker

Change power board

assembly

Change Main board

assembly

Change Main board

assembly

OK

FIRMWARE MAIN/B

VTV-L3209 M/B

Check U32-pin3=5V

U31-pin3=8V

End

NG

Change Main board

assembly

17

Page 18

TV has a audio but no picture

FIRMWARE MAIN/B

VTV-L3209 M/B

FIRMWARE MAIN/B

VTV-L3209 M/B

FIRMWARE MAIN/B

VTV-L3209 M/B

Check J12-

pin6=5V

OK

Check J12-

pin7=1V~3.3V

OK

Check J13-

pin3=12V

OK

NG

NG

NG

Change Main board

assembly

Change Main board

assembly

Change Main board

assembly

Check backlight

Check backlight

CN1, CN4,

unit = 24V

PIN1=24V

NG

Change Power board

assembly

OK

Check LVDS

Check LVDS

cable connection

cable(308)

NG

Change panel assembly

End

18

Page 19

26LD9000TA Power Board

NG NG

OK

NG

OK NG

NG

OK OK

No O

utput Voltage +5VS, +12 V, +12V

audio, +24V

& SOUND

+5V

OK OK NG NG OK

OK

NG

+

12V

No Picture

PIN3

NO POWER

(Check PIN 2

of CNS3)

Check output

See No Pict ure

+5VS ?

OK

Check FUS E

(Check PIN 2

of CNS3)

(Check PIN2 o f

CNS3)

Open?

Open conn ector CNS3

or PIN2 lose wire

Check output

+5VS?

Under 5V

ZDS3,

CRS3,Q4,

IC7 etc

NO PICTURE

NG

STB

Over 5V

QS1,ZDS2

IC4,CRS3 ,

Q4,IC7 etc

(Check D-S,

G-S of Q3)

(Check D-S,

G-S of Q1, Q 2)

(Check D- S,

G-S of Q4 )

Check BD 1

open?

Check Q3

short?

Check Q1,Q2

short?

Check Q4

short?

See No Power

NG

BD1

Q3 etc

Q1,Q2,

IC1 etc

Q4

(Check

of CNS2)

(Check PIN3 of

CNS2)

+12Vaudio

Check CRS1

Short?

CRS1 etc

OK

See

No Picture

OK

See

No Picture

See No

Picture

cc

(Check PIN9 of

CNS2)

Check voltage

Pin 9 of CNS2

Under +12V

IC5,QS5,ICS4,RS34,

RS39,RS41,CRS1,

ZDS3,QS1,IC4 etc

Over

+12V NG

IC5,QS5,ICS4,RS34,

RS39,RS41,CRS1,

ZDS1,QS1,IC4 etc

See

No Picture

NG

Q1,Q2,CRS2,etc

(Check PIN1 of

CNS1)

+24Vinv

Check

Q1,Q2,CRS2,etc

See

(Check D-S, G-S

of Q1, Q2)

19

Page 20

(C

heck D-S, G-S

of

QS7) (Check PIN9

of

CNS2) (Check PIN1

of

CNS1)

(Check PIN9

of

CNS2) (Check PIN1

of

CNS1)

NG OK

NO

PICTURE

NG

C

heck

output

+24Vinv ?

NG OK

OK

NG

C

heck

output

C

heck

output

Panel

IC5

NG

OK

C

heck

output

IC5

Panel

Panel

NO

Output

+12Vcc, +24V

inv

+12Vcc ?

QS7,CRS4

,Q4,etc

NG

Open Connector CNS2

or PIN9 Lose wire

+12Vcc ?

NG

protect

Open connector

CNS1 and CNS4

+24Vinv ?

NG

protect

20

Page 21

32LD9000TA Power Board

QS6,IC

S7

Q3, etc

NG OK OK NG NG OK OK

NG OK

Check

output

5V

NG NG

& SOUND

+5V

See No

OK OK NG NG OK

OK

+24Vinv

See No P

ower

S

hort?

NG

+

12V

IC2,

ZDS2,QS5,

See

Under +12V

PIN3

NO POWER

(Check PIN2

of CNS3)

Check output

STB ?

(Check PIN2

of ICS7)

See

No Picture & Sound

(Check PIN2 of

CNS3)

FUSE Open?

voltage ICS7

Under 5V

etc

NO PICTURE

STB

Over 5V

ICS7 etc

NG

(Check D-S,

G-S of Q3)

(Check D-S,

G-S of Q1, Q2)

(Check D-S,

G-S of Q4)

check BD1

open?

check Q3

short?

check IC5,Q 1,Q2

short?

check Q4

short?

BD1

Q1, Q2,

IC5, etc

Q4, etc

(Check

of CNS2)

+22Vaudio

Check

DS7,CRS3

DS7,CRS3

,etc

OK

See

No Picture

OK

No Picture

Picture

cc

(Check PIN9 of

CNS2)

NG

Check voltage

Pin 8 of CNS2

QS7,CRS4,IC7,

ICS3,QS3,etc

Over

+12Vcc

ICS3, RS52, RS30,etc

See

No Picture

NG

QS1,QS2,CRS1

CRS2,etc

(Check PIN1 of

CNS1)

Check

QS1,QS2,CRS1,

CRS2,etc

See

No Picture

(Check D-S, G-S

of QS1, QS2)

21

Page 22

(Check PIN1 of

NO

PICTURE

OK NG OK NG OK

IC5 Protect

SW ON QS7

NG

NG

NO

Output

+12Vcc, +24Vinv

OK

OK

Panel NG

Open Connector

CNS1)

check output

+24Vinv ?

NG

(Check PIN9 of

CNS2)

QS7,CRS4,

Q4,etc

(Check D-S, G-S

of QS7)

check output

+12Vcc ?

QS7, Q4,

etc

Open Connector

CNS2

check output

+12Vcc ?

(Check PIN9 of

CNS2)

Q4

CNS1,CNS4

check output

+24Vinv ?

(Check PIN1 of

CNS1)

Panel NG

22

Page 23

7. Block Diagram

23

Page 24

26LD9000TA POWER BOARD

24

Page 25

25

Page 26

Power

Backlight

reset

OVP&OT

P

Ref. Voltage

ON/OFF

OC

P

32LD9000TA POWER BOARD

EMI filter

stage

Main power

stage

PFC stage

Standby power

26

stage

Power

ON/OFF

Page 27

27

Page 28

8. Connection Diagram

28

Page 29

9. Wiring Diagram

26LD9000TA

29

Page 30

32LD9000TA

30

Page 31

10. Basic Diagram

Power board

26LD9000TA

31

Page 32

32LD9000TA

32

Page 33

33

11. Printed Wiring Board Diagram

FIRMWARE Main/B

TOP SIDE

Page 34

34

BOTTOM SIDE

Page 35

POWER MODULE

26LD9000TA

35

Page 36

32LD9000TA

36

Page 37

PCBA KEY/B

TOP SIDE

BOTTOM SIDE

PCBA SIDE-IO/B

TOP SIDE

PCBA IR/B

26LD9000TA

TOP SIDE

BOTTOM SIDE

BOTTOM SIDE

37

Page 38

32LD9000TA

TOP SIDE

BOTTOM SIDE

38

Page 39

12. Disassembly Diagram

26LD9000TA

39

Page 40

40

Page 41

32LD9000TA

41

Page 42

42

Page 43

13. Replacement Parts List

26LD9000TA

ITEM PART NO DESCRIPTION SPEC

1 TE04821 PCBA IR/B VTV-IR3701 SLH37CG 1 1

2 TE04711 PCBA KEY/B VTV-K3209 SLH32CGA 1 1

3 TE04831 PCBA SWITCH/B VTV-SW3209 SLH26CG 1 1

4 TE04731 PCBA SIDE-IO/B VTV-IO3209 SLH32CG 1 1

5 TE04841 FIRMWARE MAIN/B VTV-L3209 SLH26CGA 1 1

6 TE04851 SPK SET 7W 4ohm 150x57x45 mm SLH26 1 1

7 TE04861 H-CON SET LH26 MB-SPK P&L 4P-2PX2 1 1

8 TE04862 H-CON SET LH26 MB J7 KEY PD J1 20P 1 1

9 TE04863 H-CON SET LH26 MB J11-F I/O J2 14P 1 1

10 TE04864 H-CON SET LH26 MB J26-IO J4 4P 1 1

11 TE04865 H-CON SET LH26 MB-POW 11P 1 1

12 TE04866 H-CON SET LH26 MB-POW 10P 1 1

13 TE04867 H-CON SET LH26 POW-INV 12P 1 1

14 TE04868 H-CON SET LH26 POW-INV 14P 1 1

15 TE04869 H-CON SET LH26 MB-LVDS 30P LPL 1 1

16 TE04871 WIRE SET W5.6X75X4.3D 1007#18 BLK 1 1

17 TE04881 POWER MODULE FSP164-4F01 POWER 1 1

18 TS08311 BACK COVER

19 TS08321 BEZEL ASSY Bezel + LED/IR Lens + Logo 1 1

20 TS08331 STAND ASSY Stand Assembly(add on cable clamp) 1 1

TJ05871

21

TJ05881

22 TE04891

23 TJ05891 EPE BAG LV26-K002 L820XW620 1 1

24 TJ05851 EPE SHEET(STAND) LV832H-K001 L800XW600MM 1 1

25 TE04801 POWER CORD SP60X1.8MXIS14H05/0.75BLK13AWP 0 1

26 HL02373 REMO CTRL SMK CLE-983 HITACH LH32CG 1 1

27 TJ05901 EPS BOTTOM LEFT LH26011 1 1

28 TJ05902 EPS TOP RIGHT LH2607 1 1

29 TJ05903 EPS TOP LEFT LH2608 1 1

30 TJ05904 EPS BOTTOM RIGHT LH2609 1 1

CARTON-26LD9000TA

CO

CARTON-26LD9000TA

NA

USER'S

MANUAL-26LD9000TA

With all labels without rating (Add on control

panel Ass'y,AC SW nob & decoration plate

of side IO)

C-LH26C-J88 FOR ASIA 1 0

C-LH26C-J88 FOR ASIA 0 1

U-LH26CGA-J88 E+TC+SC+R ASIA 1 1

26LD9000TA CO 26LD9000TA NA

USAGE

1 1

43

Page 44

32LD9000TA

ITEM PART NO DESCRIPTION SPEC

USAGE

32LD9000TA CO 32LD9000TA NA

1 TE04701 PCBA IR/B VTV-IR3209 SLH32CG 1 1

2 TE04711 PCBA KEY/B VTV-K3209 SLH32CGA 1 1

3 TE04721 PCBA SWITCH/B VTV-SW3209 SLH32CG 1 1

4 TE04731 PCBA SIDE-IO/B VTV-IO3209 S LH32CG 1 1

5 TE04741 FIRMWARE MAIN/B VTV-L3209 SLH32CGA 1 1

6 TE03922 INVERTER UNIT 6632L-0354A/0355A 1 1

7 TE04751 SPK SET 10W 8ohm 126.5X58X 1 1

8 TE04761 H-CON SET DV32 JOINT-POW 11P 1 1

9 TE04762 H-CON SET DV32 JOINT-POW 10P 1 1

10 TE04763 H-CON SET LV32CG MB-LVDS 30P 1 1

11 TE04764 H-CON SET LH32XG MB J26-IO J4 4P 1 1

12 TE04765 H-CON SET LH32 MB J7 KEY PD J1 20P 1 1

13 TE04766 H-CON SET LH32 MB J17 SPEAKE CABLE 1 1

14 TE04767 H-CON SET LH32 MB J11-F I/O J2 14P 1 1

15 TE04768 H-CON SET LH37/32 I NV -POW 14P-12P 1 1

16 TE04769 H-CON SET LH37/32 I NV -POW 12P 1 1

17 TE04771 NET SET W5.6X75X4.3D 144C/.12 TUBE 1 1

18 TE04781 POWER MODULE FSP207-5F05 5/12/24/24VAULG SW 1 1

19 TS08071 BACK COVER

20 TS08081 BEZEL ASSY Bezel + LED/I R Lens + Logo 1 1

21 TS08091 STAND ASSY Stand Assembly(add on cable clamp) 1 1

22

23 TE04791 USER'S MANUAL-32LD90 U-LH32CGA-J 88 S C FOR CHINA 1 1

24 TJ05841 EPE BAG LV32DA-K002 FOR MO 1 1

25 TE04801 POWER CORD SP60X1.8MXIS14H05/0.75BLK13AWP 0 1

26 HL02373 REMO CTRL SMK CLE-983 HITACH 1 1

27 TJ05861 EPS FORM BOTTOM RIGH LV320D EPS FORM BO 1 1

28 TJ05862 EPS FORM BOTTOM LEFT LV320E EPS FORM BO 1 1

29 TJ05863 EPS FORM TOP RIGHT LV320F EPS FORM TO 1 1

30 TJ05864 EPS FORM TOP LEFT LV320G EPS FORM TO 1 1

TJ05821 CARTON-32LD9000TA CO C-LH32CGA-J88 FOR ASIA 1 0

TJ05831 CARTON-32LD9000TA NA C-LH32C-J88 FOR ASIA 0 1

With all labels without rating (Add on control panel

Ass'y,AC SW nob & decoration plate of side IO)

1 1

44

Loading...

Loading...