Page 1

Instruction Manual

BT3562

BT3562-01

BT3563

BT3563-01

BATTERY HiTESTER

November 2010 Edition 1 BT3562A981-00 10-11H

Page 2

Page 3

Contents

Introduction.................................................................................1

7

10

11

12

A

p

pen

d

ixI

n

d

e

x

10

i

Contents

1

Verifying Pac ka g e Con te n ts............... ................ ................. .......1

Safety Informa tion ............. .. ... .. .. ................................................2

Operating Precautions 4

Chapter 1

Overview___________________________________ 7

1.1 Product Overview ................................................................7

1.2 Features ........................................................ ...................... 8

1.3 Names and Functions of Parts ............................................9

1.4 Menu Display Sequence (SHIFT

1.5 Measurement Flowchart ...................................................14

→ ENTER) .....................13

Chapter 2

Measurement Preparations___________________ 15

2.1 Preparation Flowchart .......................................................15

Connecting the power cord. ................................................15

Connect the test leads to the instrument. ............................15

Connect the EXT I/O connector and interface connector. ...15

Turn the power on............................................................... 15

Set measurement settings. .................................................15

Start measurement. .............................................................15

2

3

4

5

6

8

2.2 Connecting the Power Cord.............................................. 16

2.3 Connecting the Optional Test Leads................................. 17

2.4 Turning the Power On and Off ..........................................18

2.5 Selecting the Line Frequency ...........................................20

Chapter 3

Measurement ______________________________ 21

3.1 Pre-Operation Inspection ..................................................21

3.2 Basic Measurement Example ...........................................22

Preparations ........................................................................22

Instrument Settings............................................................. 23

Zero-Adjustment.................................................................. 24

Measurement ......................................................................25

3.3 Selecting Measurement Mode ..........................................26

3.4 Setting Measurement Range ............................................27

Resistance measurement range .........................................27

Voltage measurement range ...............................................28

Auto-Ranging ......................................................................29

9

Page 4

ii

Contents

3.5 Setting Sampling Rate ......................................................30

3.6 Zero-Adjust Function ........................................................31

Wiring Method for Zero-Adjustment ....................................31

Executing Zero-Adjustment ........................................ ..... ...31

3.7 Displaying Measurement Results .....................................34

Measurement Fault Detection ............................................ 35

Overflow Display .................................................................36

Chapter 4

Applied Measurement _______________________37

4.1 Comparator Function ........................................................38

Comparator Setting Example 1

(Upper and Lower Threshold Judgment) ............................39

Comparator Setting Example 2

(Reference Value and Tolerance Judgment) ......................43

Comparator Judgment Beeper Setting............................... 48

Comparator Execution Mode Setting ..................................48

Comparator Threshold Method Selection ................... ..... ...49

Upper and Lower Thresholds Setting

(by Reference Value and Tolerance) ..................................50

Configuring the Absolute Value Judgment Function

(Voltage) .............................................................................51

Enabling and Disabling the Comparator Function ..............52

Comparator Judgment Results ...........................................53

Switching Between Measurement Value and Comparator

Setting Displays ..................................................................54

4.2 Trigger Function ................................................................55

Trigger Source Settings ......................................................55

Trigger Delay Settings ........................................................56

4.3 Measurement Current Pulse Output Function ..................57

4.4 Averaging Function ...........................................................59

4.5 Statistical Calculation Functions .......................................60

4.6 Memory Function ..............................................................64

4.7 Key-Lock Function ............................................................66

4.8 Panel Save Function .........................................................67

4.9 Panel Load Function .........................................................68

4.10 Self-Calibration .................................................................69

4.11 Measurement Value Output Function ...............................70

4.12 Key Beeper Setting ...........................................................71

4.13 Reset Function ..................................................................72

Chapter 5

External Control (EXT I/O)__________________ __75

5.1 Overview........................................................................... 75

5.2 Signal Descriptions ...........................................................76

Page 5

Pinout ..................................................................................76

I

n

d

e

x

Input Signals .......................................................................77

Output Signals .....................................................................78

ERR Output .........................................................................79

Instrument Settings .............................................................80

iii

Contents

1

5.3 Timing Chart .....................................................................81

5.4 Internal Circuitry ................................................................83

5.5 External Control Q&A ........................................................86

Chapter 6

Printer (Optional) ___________________________ 87

6.1 Connecting the Printer ......................................................88

Connecting the 9670 PRINTER to the Instrument ..............89

Loading Recording Paper................................................... 90

Charging the Battery Pack...................................................91

Installing the Battery Pack in the Printer .............................91

6.2 Selecting the Interface ......................................................92

6.3 Setting of the 9670 Printer ................................................92

6.4 Printing .......................................................... .................... 93

Chapter 7

Analog Output _____________________________ 95

7.1 Connecting Analog Output ................................................95

2

3

4

5

6

7

7.2 Analog Output Specifications ............................................96

Chapter 8

RS-232C/GP-IB Interfaces ____________________ 97

8.1 Overview and Features .....................................................97

8.2 Specifications ............................................................ ........ 98

RS-232C Specifications ......................................................98

GP-IB Specifications (Model BT3562-01 only) ....................98

8.3 Selecting the Connections and Protocol ..........................99

Attaching the Connector...................................................... 99

Selecting the Interface...................................................... 101

8.4 Communication Methods ................................................102

Message Format ............................................ ...................102

Output Queue and Input Buffer .........................................106

Status Byte Register .........................................................107

Event Registers ...................... ..... ..... .... .............................109

Initialization Items ..............................................................112

Local Function ...................................................................112

8.5 Message List ...................................................................113

Standard Commands ..................................... .... ...............113

Device-Specific Commands ......................................... .... .114

8

9

10

10

11

12

Appendix

8.6 Message Reference ........................................................119

Page 6

iv

Contents

Standard Commands ........................................................120

Device-Specific Commands .............................................124

Measurement Value Formats ...........................................152

Command Compatibility with the Model 3560 AC

mΩ HiTESTER ..................................................................153

8.7 Basic Data Importing Methods ........................................158

8.8 Sample Programs ...........................................................159

To be prepared in Visual Basic 5.0/6.0 .............................159

To be prepared in Visual Basic 2005 ................................169

Creation Procedure(Visual Basic 2005) ...........................169

Sample Programs(Visual Basic 2005).............................. 171

Chapter 9

Specifications_____________________________173

9.1 Basic Specifications ........................................................173

9.2 Accuracy ......................................................................... 178

9.3 General Specifications ....................................................179

Chapter 10

Maintenance and Service ___________________181

10.1 Troubleshooting .............................................................. 181

10.2 Cleaning .................................................... ......................183

10.3 Error Display ...................................................................183

Appendix ________________________________ A 1

Appendix 1 Precautions for Making Custom Test Leads ...............A 1

Appendix 2 AC Four-terminal Method............................................A 4

Appendix 3 Measurement values when using four-terminal

measurement (Differences in measurement values

due to measurement leads used)................................A 5

Appendix 4 Synchronous Detection System ..................................A 6

Appendix 5 Configuration and Extension of the Test Leads ..........A 7

Appendix 6 Effect of Eddy Currents...............................................A 8

Appendix 7 Calibration Procedure..................................................A 9

Appendix 8 Zero Adjustment........................................................A 10

Appendix 9 Test Lead Options.....................................................A 15

Appendix 10Rack Mounting..........................................................A 16

Appendix 11Dimensional Diagram................................................A 18

Index _________________________________ Index i

Page 7

1

Confirm that these contents are provided. (One each)

Model BT3562/ Model BT3562-01

(GP-IB version) BATTER Y HiTESTE R

Model BT3563/ Model BT3563-01

(GP-IB version) BATTER Y HiTESTE R

Power Cord

Instruction Manual

Introduction

Introduction

Thank you for purchasing the HIOKI “Model BT3562, BT3562-01, BT3563, BT3563-01 BATTERY

HiTESTER.” To obtain maximum performance from the instrument, please read this manual first,

and keep it handy for future reference.

This manual uses the following conventions:

The Model BT3562, BT3562-01, BT3563, and BT3563-01 are referred to as "the instrument."

Unless otherwise note d, the Model BT3562 and BT35 62-01 are referred to collec tively as "Model BT3562,"

while the Model BT3563 and BT3563-01 are referred to collectively as "Model BT3563."

Verifying Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage occurred during

shipping. In particular, check the accessori es, panel swit ches, and con nectors. If damage is evide nt,

or if it fails to operate according to the specifications, contact your dealer or Hioki representative.

Use the original packing materials when transporting the instrument, if possible.

Options Model 9287-10 CLIP TYPE LEAD (70 VDC or less)

Model 9453 FOUR TERMINAL LEAD (60 VDC or less)

Model 9467 LARGE CLIP TYPE LEAD (50 VDC or less)

Model 9770 PIN TYPE LEAD (70 VDC or less)

Model 9771 PIN TYPE LEAD (70 VDC or less)

Model L2100 PIN TYPE LEAD (600 VDC or less)

Model 9454 ZERO ADJUSTMENT BOARD

Model 9637 RS-232C CABLE (9-pin to 9-pin/cross cable)

Model 9638 RS-232C CABLE (9-pin to 25-pin/cross cable)

Model 9151-02 GP-IB CONNECTOR CABLE (2 m)

Model 9670 PRINTER

(BL-80RS II, made by SANEI ELECTRIC INC.)

Model 9671 AC ADAPTER

(

for the 9670, BL-100W, made by SANEI ELECTRIC INC.)

Model 9672 BATTERY PACK

(for the 9670, UR-100 or UR-121, made by SANEI ELECTRIC INC. )

Model 9673 BATTERY CHARGER

(for the 9672, NC-LSC01, made by SANEI ELECTRIC INC.)

Model 9237 RECORDING PAPER

(80 mm x 25 m, 4 rolls, for the 9670)

Page 8

2

Safety Information

Safety Information

This instrument is desig ned to comply with IEC 61010 Safety Standards, and

has been thoroughly tested for safety prior to sh ipm ent . However, mishandling

during use could result in in ju ry or dea th, as wel l as damage to the inst ru men t.

Be certain that you understand the instruction s and prec autions in the manual

before use. We disclaim any responsibility for accidents or injuries not resulting

directly from instrument defects.

This manual contain s information and warnings essential for safe operation of

the instrument and for ma intainin g it in safe ope rating conditi on. Before using it,

be sure to carefully read the following safety precautions.

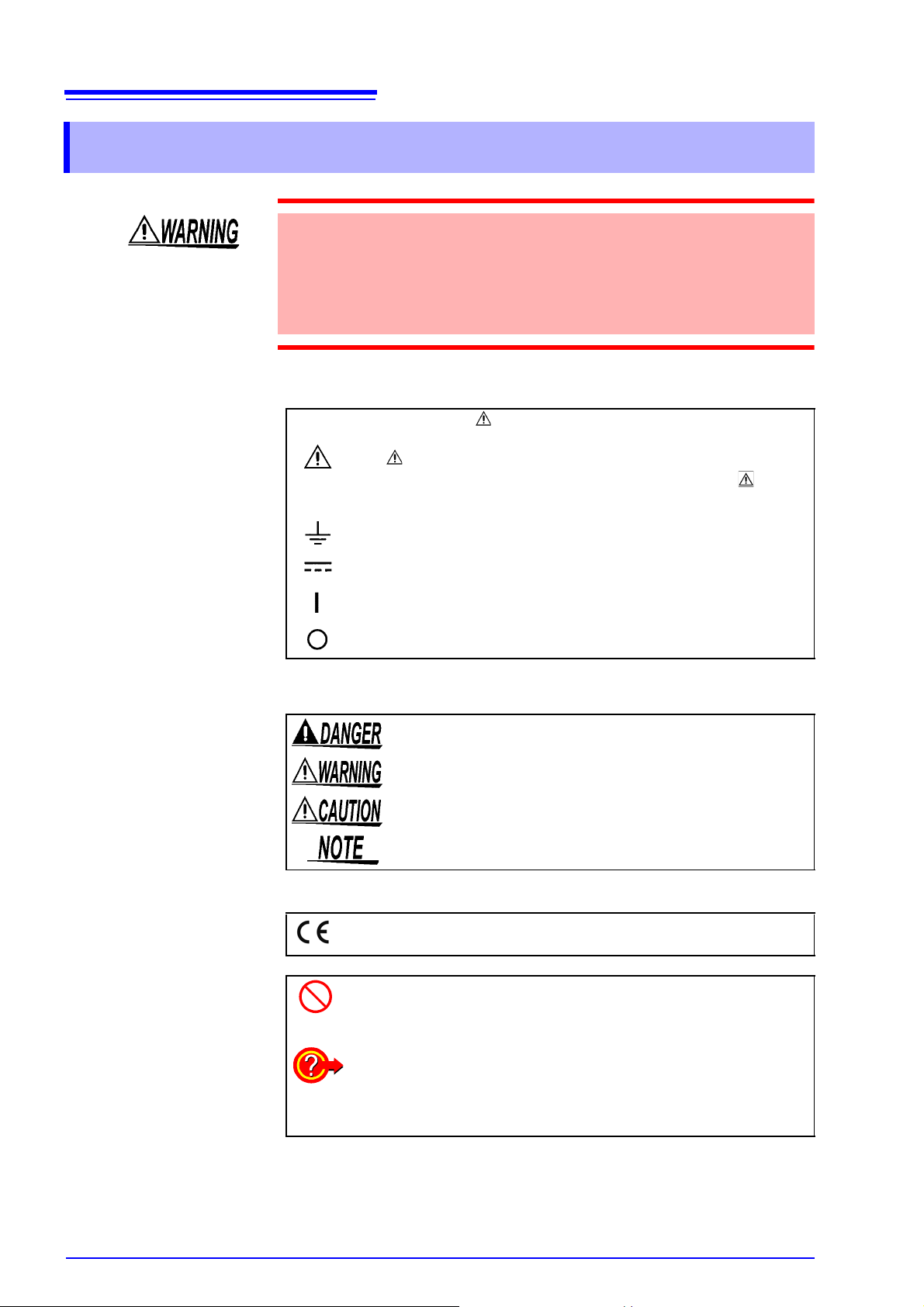

In the manual, the symbol indicates particularly important information

that the user should read before using the instrument.

The symbol printed on the instrument indicates that the user should

refer to a corresponding topic in the manual (marked with the symbol)

before using the relevant function.

The following symbols in this manual indicate the relative importance of cautions

and warnings.

Symbols for Various Standards

Other Symbols

Indicates a grounding terminal.

Indicates DC (Direct Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Indicates that incorrect operation presents an extreme hazard that

could result in serious injury or death to the user.

Indicates that incorrect oper ation prese nts a significant hazard that

could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of injury to

the user or damage to the instrument.

Indicates advisory items related to performance or correct operation of the instrument.

This symbol indicates that the product conforms to safety regulations set

out by the EC Directive.

Indicates a prohibited action.

(.p)

*

Indicates the location of reference information.

Indicates quick references for operation and remedies for troubleshooting.

Indicates that descriptive information is provided below.

Page 9

3

Safety Information

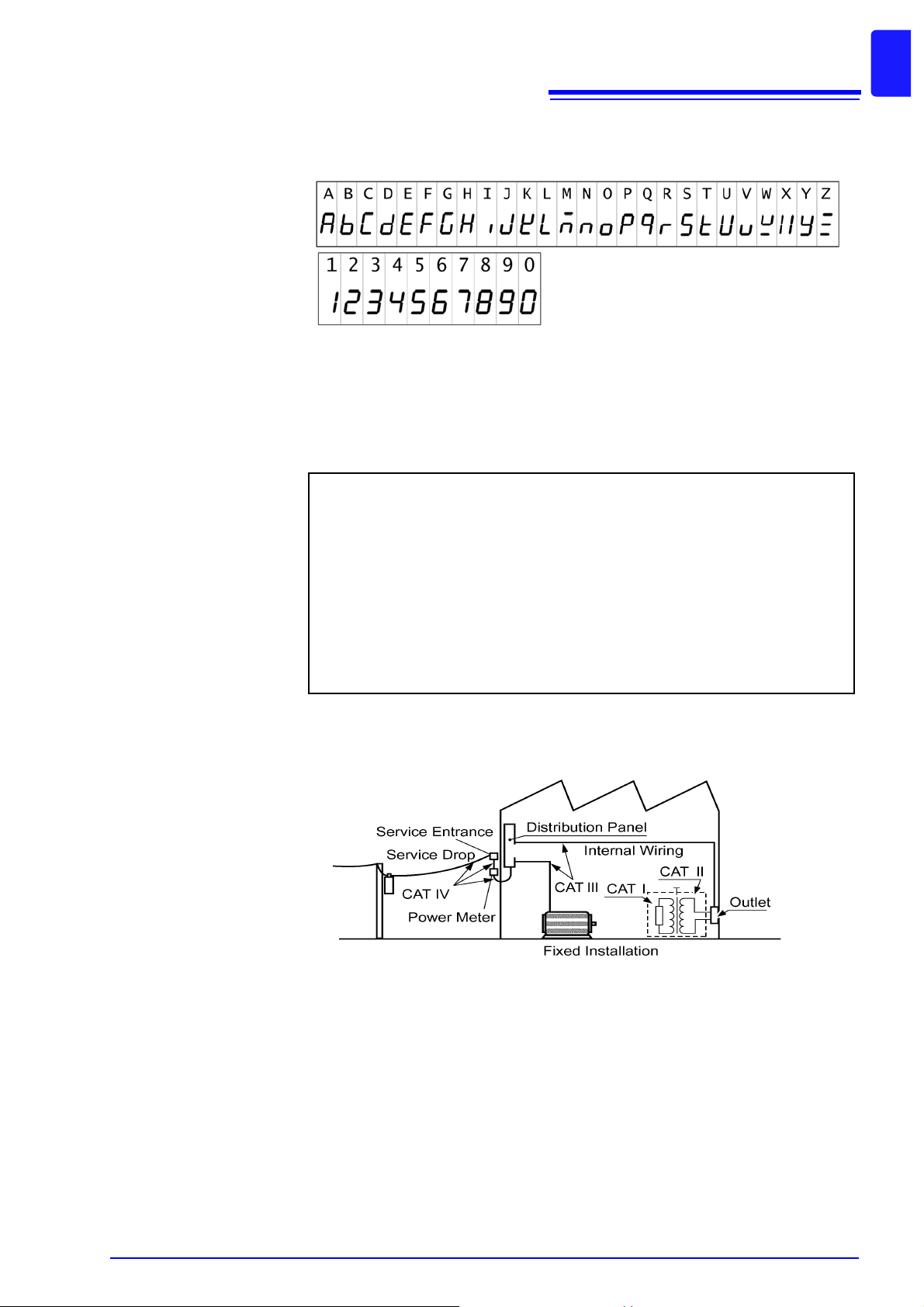

Screen display

The screen of this instrument displays characters in the following manner.

Measurement categories (Overvoltage categories)

This instrument complies with CAT I safety requirements.

To ensure safe operati on of measurement instruments, IEC 6 1010 establishes

safety standards for various electrical environments, categorized as CAT I to

CAT IV, and called measurement categories.

CAT I

CAT II

Secondary electrical circ uits connec ted to an AC ele ctrical o utlet throug h a

transformer or similar device.

Primary electrical circ uits in equi pment conne cted to an AC el ectrical outl et

by a power cord (portable tools, household appliances, etc.)

CAT II covers directly measuring electrical outlet receptacles.

Accuracy

CAT III

CAT IV

Using a measurement instrument in an environment designated wit h a highernumbered category th an that for which the in strument is rated c ould result in a

severe accident, and must be carefully avoided.

We define measurement tolerances in terms of f.s. (full scale), rdg. (reading) and

dgt. (digit) values, with the following meanings:

Primary electrical circuits of heavy equipment (fixed installations) connected directly to the distri but ion pa nel, an d feede rs from the dis tributi on pan el

to outlets.

The circuit from th e servi ce drop to the serv ice e ntranc e, and to t he po wer

meter and primary overcurrent protection device (distribution panel).

(maximum display value)

f.s.

The maximum displayable value. This is usually the name of the currently

selected range.

(reading or displayed value)

rdg.

The value currently being measured and indicated on the measuring instrument.

(resolution)

dgt.

The smallest displayable unit on a digital measuring instrument, i.e., the

input value that causes the digital display to show a "1" as the least-significant digit.

Page 10

4

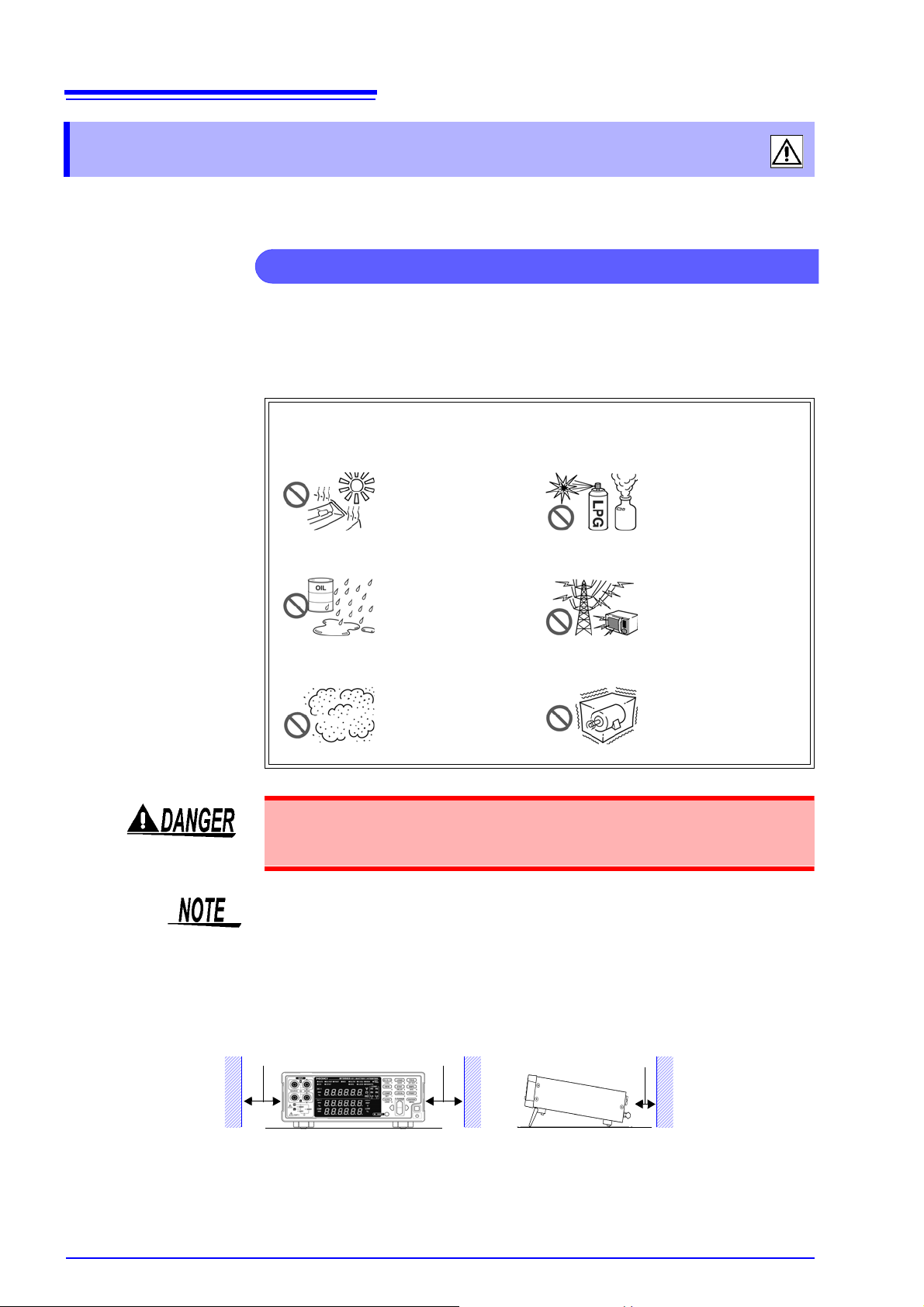

Instrument Install ation and Operating Environment

The instrument can be used with the stand. ( p.12)

It can also be rack-mounted. Appendix (

p.A16)

50 mm or more

10 mm or more

Rear

50 mm or more

Safety Information

Operating Precautions

Follow these precauti ons to ensure s afe opera tion and to obtai n the ful l bene fits

of the various functions.

Operating temperature and humidity:

0 to 40°C (32 ± 104°F), 80%RH or less (non-condensating)

Temperature and humidity range for guaranteed accuracy:

23 ± 5°C (73 ± 9°F), 80% RH or less (non-condensating)

Avoid the following locati ons that could cause an acc ident or damage to the

instrument.

Exposed to direct sunlight

Exposed to high temperature

In the presence of corrosive or explosiv e gases

To av oid electr ic shock, do n ot remov e the instrum ent's cas e. The inter nal components of the instrume nt carry high voltages a nd may become ve ry hot during

operation.

Avoid using near electrically noisy devices, as the noise may impinge upon the

test object and cause unreliable measurements.

Installation Precautions

• The instrument should be operated only with the bottom downwards.

• Do not place the instrument on an unstable or slanted surface.

Exposed to water, oil,

other chemicals, or

solvents

Exposed to high humidity or condensation

Exposed to high levels of particulate dust

Exposed to strong electromagnetic fields

Near electromagnetic

radiators

Subject to vibration

Page 11

5

Preliminary Checks

Measurement Precautions

Safety Information

Before using the instrument the first time, verify that it operates normally to

ensure that the no damage oc curred during stor age or shipping. If you fi nd any

damage, contact your dealer or Hioki representative.

Before using the instrument, make sure that the insulation on the power cord

and test leads is undamaged and that no bare conductors are improperly

exposed. Using the instrument in such conditions could cause an electric

shock, so contact your dealer or Hioki representative for replacements.

• To a void electri cal shock, be ca reful to avoid shorting l ive lines wit h the test

leads.

• To avoid inju ry or damage to the instr ument, do n ot attempt to measure AC

voltage and AC current, or DC voltage exceed ing

(BT3563).

• The maximum rated voltage betwee n input terminals and ground is

DC. Attempting to measure voltages exceeding 70 V (BT3562), 300 V

(BT3563) with respect to ground cou ld damage the instrum ent and result in

personal injury.

• Never connect a bat tery cell or module to a motor or other load while it is

being measured. Doing so may result in a surge voltage, which may damage

the instrument or cause injury.

± 60 V (BT3562), 300 V

± 70 V

• To prevent electrical shock, verify the ratings of the measurement leads

before measurement and exercise care not to measure voltages that exceed

those ratings.

• Do not touch the metallic tip of probes after measuring high-voltage batte ries. Doing so may resu lt in electr ical shock si nce inte rnal ins trume nt components could retain a charge unde r thos e c ond iti on s. (Int er nal di schar ge tim e:

Approx. 20 sec.)

• To av oi d sho rt-c irc ui t ac ciden ts, co nne ct the probe's banana term ina ls to t he

instrument before connecting the probes to the battery.

Page 12

6

Before Connecting and Powering On

Handling the Instru m en t

Handling the Test Leads and Cables

Safety Information

• Use only the specified test leads and cables. Using a non-specified cable may

result in incorrect measurements due to poor connection or other reasons.

• To ens ure cert ified mea suremen t accurac y, allow at least 30 minutes warmup. After warm-up, be sure to execute self-calibration.

See "4.10 Self-Calibration" ( p.69).

• The input circuit ry includes a protecti ve fuse. Measuremen t is not possible

when the fuse is blown.

• This instrument internally stores (backs up) all settings (except memory function and measurement values), such as measurement range, comparator

settings and etc., but only when no operation is performed for a certain time.

Therefore, to preserve settings, do not turn the power off for a short time

(about five seconds) after changing a setting. However, measurement settings made through the RS-232C or GP-IB interface and measurement settings loaded by LOAD

• Select an appropriate measurement range when measuring batteries. Using

a low range such as 3 mΩ to measure a button cell or other battery that has

high internal resistance may result in an open-terminal voltage (approx. 4

V), causing the battery to be charged.

signals of the EXT I/O connector are not memorized.

• Before turning the instrument on, make sure the supply voltage matches that

indicated on the i ts powe r con nec to r. Connection to an im pr op er su ppl y vo ltage may damage the instrument and present an electrical hazard.

• To avoid electrical accidents an d to maintain th e safety spec ifications of this

instrument, connect the power cord only to a 3-contact (two-conductor +

ground) outlet.

To suppress noise, the in strument needs to be set to matc h the frequency of

the power source. Before operating, set the instrument to the frequency of your

commercial power . If the supp ly freque ncy is not set prope rly, measur ements

will be unstable.

See "2.5 Selecting the Line Frequency" ( p.20).

Make sure the power is turned off before connecting or disconnecting the

power cord.

• To avoid damage to the instrument, protect it from physical shock when

transporting and handling. Be especially careful to avoid physical shock from

dropping.

• Do not apply heavy d ownward pres sure wit h the stand exte nded. The stand

could be damaged.

• T o avoid breaking the test leads and cables, do not bend or pull them.

• Avoid stepping on o r pin ching ca ble s, whi ch co uld dam age the cable insul a-

tion.

Page 13

7

1.1 Product Overview

1

Overview Chapter 1

1.1 Product Overview

The Model BT3562, BT3563 Battery Hitester measure battery internal resistance

using a four-terminal, 1-kHz AC method, while simultaneously measuring DC

voltage (electromoti ve force [emf]). The high-precision, fas t measurement performance and extensive interface capabilities make these models ideal for incorporating into battery testing production lines.

Chapter 1 Overview

Page 14

8

1.2 Features

1.2 Features

Simultaneously Measures Battery Internal Resistance and Voltage

The four-terminal AC method measures resistance and DC voltage simultaneously, so battery internal resistance and emf are measured and judged at

once.

High-Precision Measurements

The instrument provide s high-resolution resistance (0.1 μ

surements (10 μV). High precision (

measurements.

± 0.01% rdg.) ensures accurate voltage

Ω) and voltage mea-

High-Speed Meas urements

Simultaneous resis tance and voltage measur ements can be performed as fast

as once every 20 ms.

(Response time of approx. 10 ms + sampling time of approx. 8 ms)

High-voltage measurement

The Model BT3563 supports measurement of high-voltage batteries of up to 300

V (the Model BT3562 supports measurement of up to 60 V).

Comparator Functions

Resistance and volt age measur ement va lues ar e judged in three ca tegor ies (Hi,

IN and Lo), with results clearly di splayed. A compara tor judgment beeper a lso

provides distinc t sounds to indicate pass/fail judgm ents and to faci litate correct

recognition of judgment results.

Statistical Calc ulation Functions

Maximum, minimum and av erag e measurement values, standard dev ia tio n, pr ocess capability indices and other values can be automatically calculated for

applications such as production management. Calculation results can also be

applied as comparator setting values.

Measurement Value Memory Function

The instrument incl udes a Memory function and storage capacity for up to 400

pairs of measurement val ues. When making many sequential me asurements at

high speed and sendin g the me asur ed values to a PC a fter each measu remen t,

the time to switch te st objects can become unsatisfacto rily long. The Memory

function can avoid th e slow-down by sending stor ed measurements in batches

during idle times.

EXT I/O Interface

EXT I/O and RS-232C inter faces are equip ped as standard, supp orting transfer

rates up to 38,400 bps. Model BT3562-01 and BT3563 -01 also supports GP -IB

and analog output.

Printing Measurement Values and Statistical Results

Connect the optional Model 9670 Pr inter (option) to print measurement values

and statistical calculation results.

Page 15

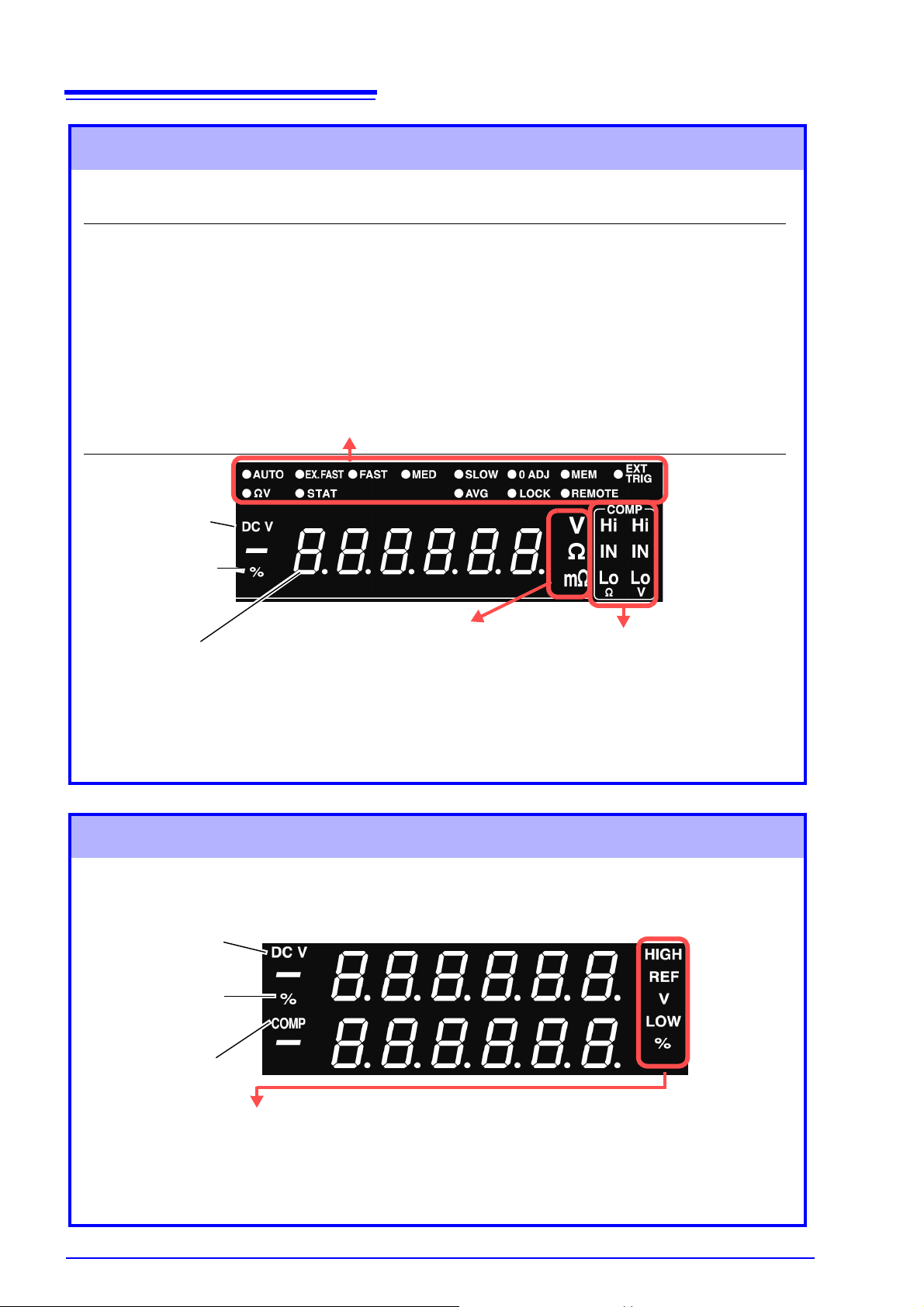

9

Front Panel

POWER Switch

Turns the instrument on and off (Standby).

Turns the power on and off (standby).

Off (standby) R On (cancel standby)

On (press and hold for 1 second) R Off (standby)

(The main power switch is located on the back of the

instrument.)

Input Terminals (INPUT)

Connect the optional test leads.

See

"2.3 Connecting the Optional T est Leads" ( p.17).

Operating Keys

( p.11)

Sub Display

( p.10)

SOURCE-H

SOURCE-L

SENSE-H

SENSE-L

Main Display

( p.10)

See

"2.4 T u rn ing the P ow e r O n an d Off" ( p.18)

1.3 Names and Functions of Parts

1.3 Names and Functions of Parts

1

Chapter 1 Overview

Page 16

10

Lit when measuring

voltage.

Indicates percentage

units during relative

value com parator operation.

Shows measured

value or setting item.

Main Display

(Upper row)

AUTO

Lit when measuring with Auto-Ranging.

EX.FAST, FAST, MED, SLOW

The selected Sampling Rate is lit.

0 ADJ

Lit when measuring in a range for

which Zero-Adjustment has been performed.

MEM

Lit when the Memory function is enabled.

EXT TRIG

Lit when the External Trigger function

is enabled.

(Lower row)

ΩV

Lit when the ΩV (Resistance and

Voltage measurement) mode is selected.

STAT

Lit when the Statistical Calcula tion

function is enabled.

AVG

Lit when measuring with the Averaging setting enabled.

LOCK

Lit when the keys are locked.

REMOTE

Lit during communications.

The current measu rement mode is indicated wh ile measuring, and the setti ng item is displayed while

making settings .

Shows Comparator Decision Result.

Hi

Indicates that the measured value is

above the upper threshold.

IN

Indicates that the m e as ure d value is between the upper an d l ower thresholds.

Lo

Indicates that the m eas ure d v al ue is below the lower threshold.

Units of displayed measuremen t

V

Unit of voltage

Ω

Unit of resistance (lit w hen the 3

Ω to 3000 Ω range is selected)

mΩ

Unit of resistance (lit w hen the 3

mΩ το 300 mΩ range is selected)

Indicates Voltage measurement mode

Indicates percentage

units during relative value

comparator operation

While measuring, indicates the Comparator

function is enabled.

HIGH, LOW Indicates that absolute value comparator operation is enabled

(while measuring), and also when setting.

REF, % Indicates that relative value comparator operation is enabled

(while measuring), and also when setting.

V Indicates voltage measurement units.

Upper and lower thresholds and other settings are displayed (when set).

Sub Display

1.3 Names and Functions of Parts

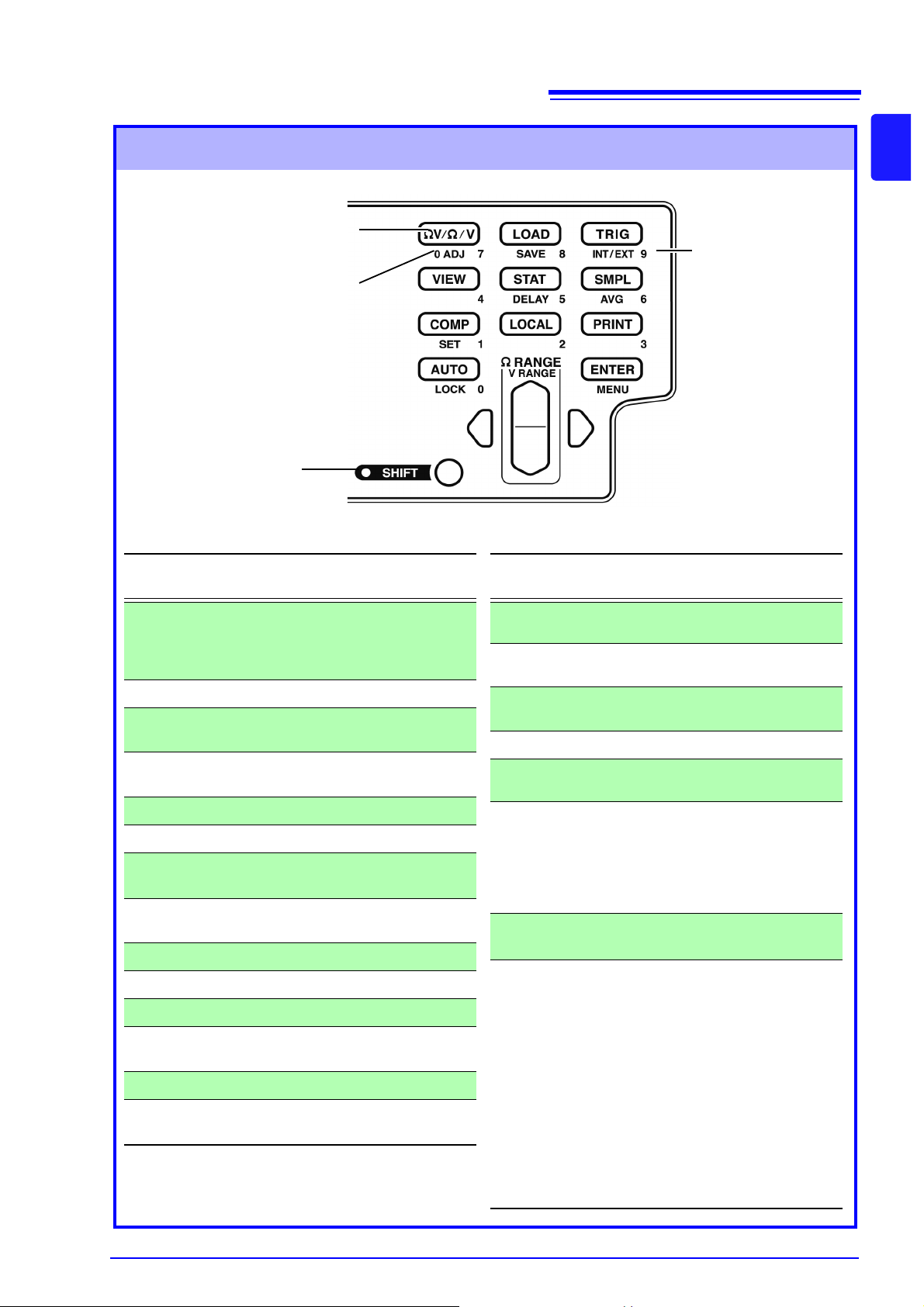

Page 17

Operating Keys

To use a function marked on a

key, just press the key.

To use a function printed under a key (blue letter), press

the SHIFT key first (and confirm the SHIFT lamp is lit),

and then the key.

SHIFT Lamp

Use as ten-keys to

enter numer ic al values.

(Numerical values

can be used with

the RANGE key.)

[ ]: Enabled after pressing the SHIFT key (SHIFT lamp lit ).

Operating

Key

Description

ΩV/ Ω/ V

Selects Measurement mode.

(Resistance and voltage measurement, Resistance measur ement or

Voltage measurement)

[0 ADJ]

Executes Zero-Adjustment.

LOAD

Loads a saved measurement configuration (Panel settings).

[SAVE]

Saves the current measurement configuration (Panel settings).

TRIG

Executes a Manual Trigger event.

[INT/EXT ]

Selects internal/external triggering.

VIEW

Switches the view mode of the ΩV

mode.

STAT

Displays and sets Statistical Calculation results.

[DELAY]

Sets the Trigger Delay.

SMPL

Selects the Sampling Rate.

[AVG]

Activates Averaging function settings.

COMP

Switches the Comparator function on

and off.

[SET]

Activates Comparator function setting.

LOCAL

Cancels remote control (RMT) and reenables key operations.

Operating

Key

Description

PRINT

Sends measurement values and statistical calculation results to the printer.

AUTO

Switches between Auto and Manual

range selection.

[LOCK]

Switches the Key-Lock function on and

off.

ENTER

Applies settings.

[MENU]

Selects various operating functions

and settings.

Ω RANGE

Up/Down:

Changes setting value or numerical

value, and sets the resistance measurement range.

Left/Right:

Moves the setting item or digit.

[V

RANGE]

Up/Down:

Sets voltage measurement range.

SHIFT

• Enables the functions of the operating keys marked in blue.

The lamp is lit when the SHIFT

state is active.

• Cancels settings in various setting

displays. (Returns to the Measurement display without applying settings.) However, this does not apply

to Menu display. However, from a

menu item display, changed settings are not canceled, but

accepted as the display returns to

measurement display (except after

Zero-Adjustment clear or resetting).

11

1.3 Names and Functions of Parts

1

Chapter 1 Overview

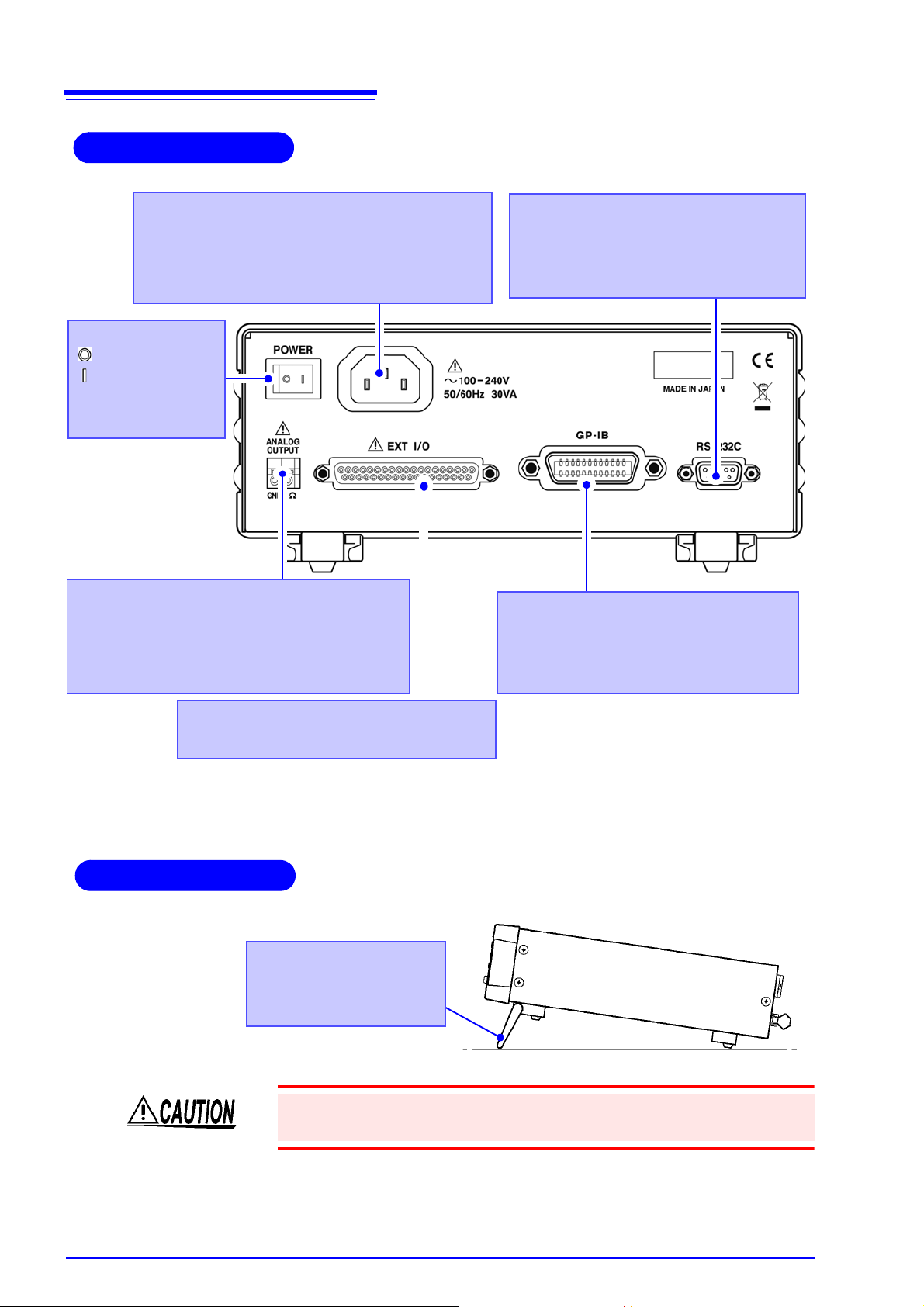

Page 18

12

EXT I/O Connector

Connect here to use the EXT I/O interface.

GP-IB Connector (Model BT3562-01,

BT3563-01 only)

Connect here to use the GP-IB interface.

See " Attaching the Connector" ( p.99).

Power Inlet

Connect the supplied power cord here.

See "2.2 Connecting the Power Cord" ( p.16).

RS-232C Connector

Connection for the printer or RS-232C

interface.

See

" Attaching the C onne ctor" ( p.99).

* The illustration shows the Model BT3563-01 Battery Hitester (GP-IB version).

See "Chapter 5 External Control (EXT I/O)" ( p.75 )

Rear Panel

Analog output connector

(Model BT3562-01, BT3563-01 only).

Connect when using analog output (of resistance measured values).

See "Chapter 8 RS-232C/GP-IB Inter fac es"

( p.97)

Main power switch

: Main power off

:Main power on

See "2.4 Turning the

Power On and Off"

( p.18)

Side View

Stand

Can be opened to tilt the

front panel upwards.

1.3 Names and Functions of Parts

Do not apply heavy downward pressure with the stand e xtended. The stand

could be damaged.

Page 19

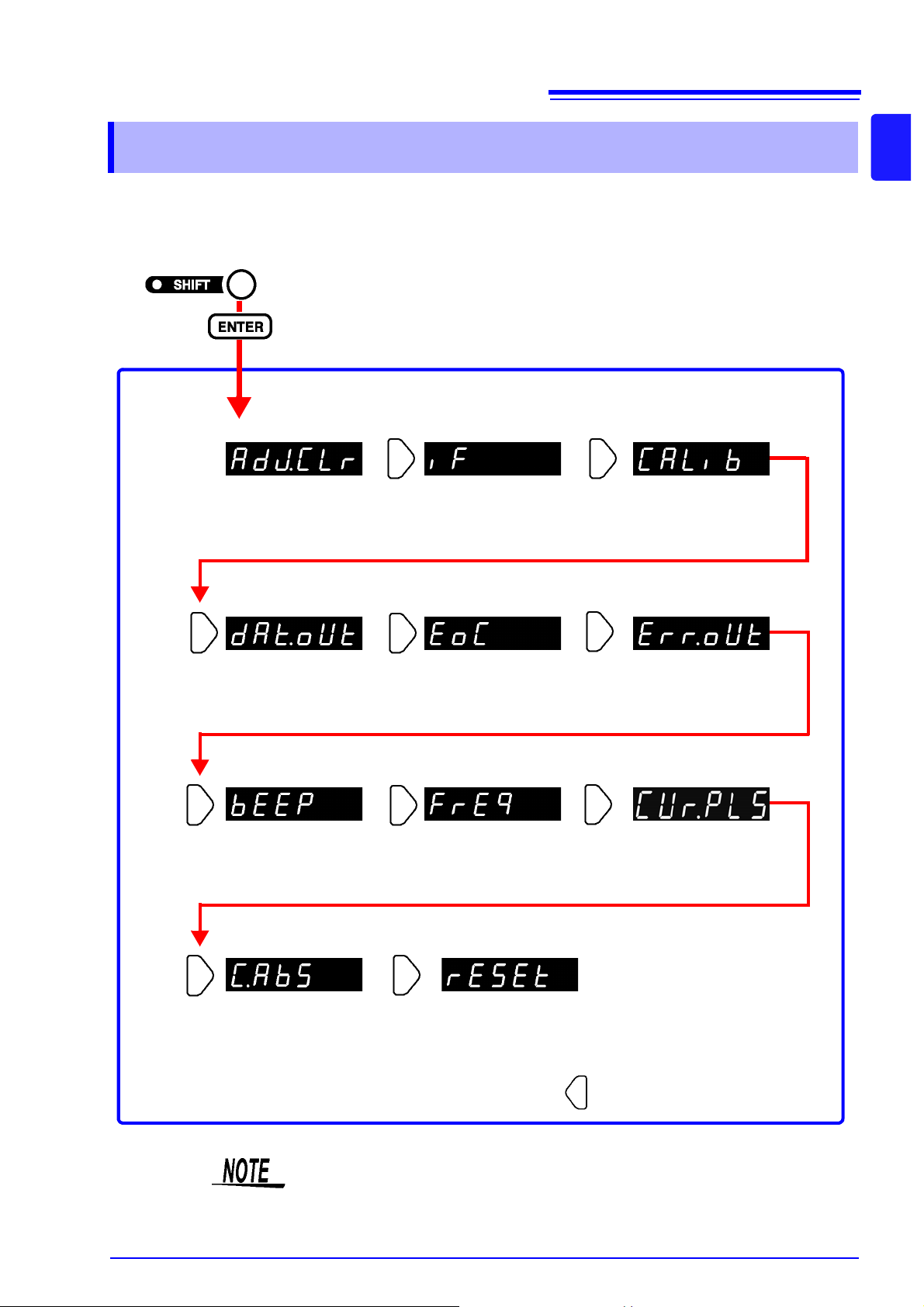

13

ERR Output Selection

display (

p.80)

Zero-Adjustment Clear

display (

p.31)

Interface Selection

display (

p.101)

Self-Calibration setting

display (

p.69)

Measurement Value Output

function setting display

( p.70)

Key Beeper setting

display (

p.71)

Line Frequency set-

ting display

(

p.20)

Measurement Current

Pulse Output

display(

p.57)

(SHIFT Lamp lit)

The Menu display appears.

(Main Display)

The up/down RANGE key change s the setting

shown on the Sub Display.

Pressing this key returns to the

previous item display.

EOM-signal setup dis-

play (

p.80)

Configuring the Absolute

Value Judgment display

( p.51)

Reset display

(

p.72)

1.4 Menu Display Sequence (SHIFT → ENTER)

1.4 Menu Display Sequence (SHIFT → ENTER)

Various auxiliary settings can be performed from the menu item displays.

1

Chapter 1 Overview

Settings on the menu item displays are applied and saved internally when

changed.

Page 20

14

Selecting the line frequency ( p.20)

Turning the power on ( p.18)

Connecting the test leads ( p.17)

Connecting the power cord ( p.16)

Selecting sampling rate ( p.30)

Selecting measurement range ( p.27)

Selecting measurement mode ( p.26)

Executing zero-adjustment

Short the test leads together ( p.31)

Measurement Preparations

Instrument’s Settings

Zero-Adjustment

Read the measured value ( p.34)

Connect the test leads to a test object.

Measurement Start

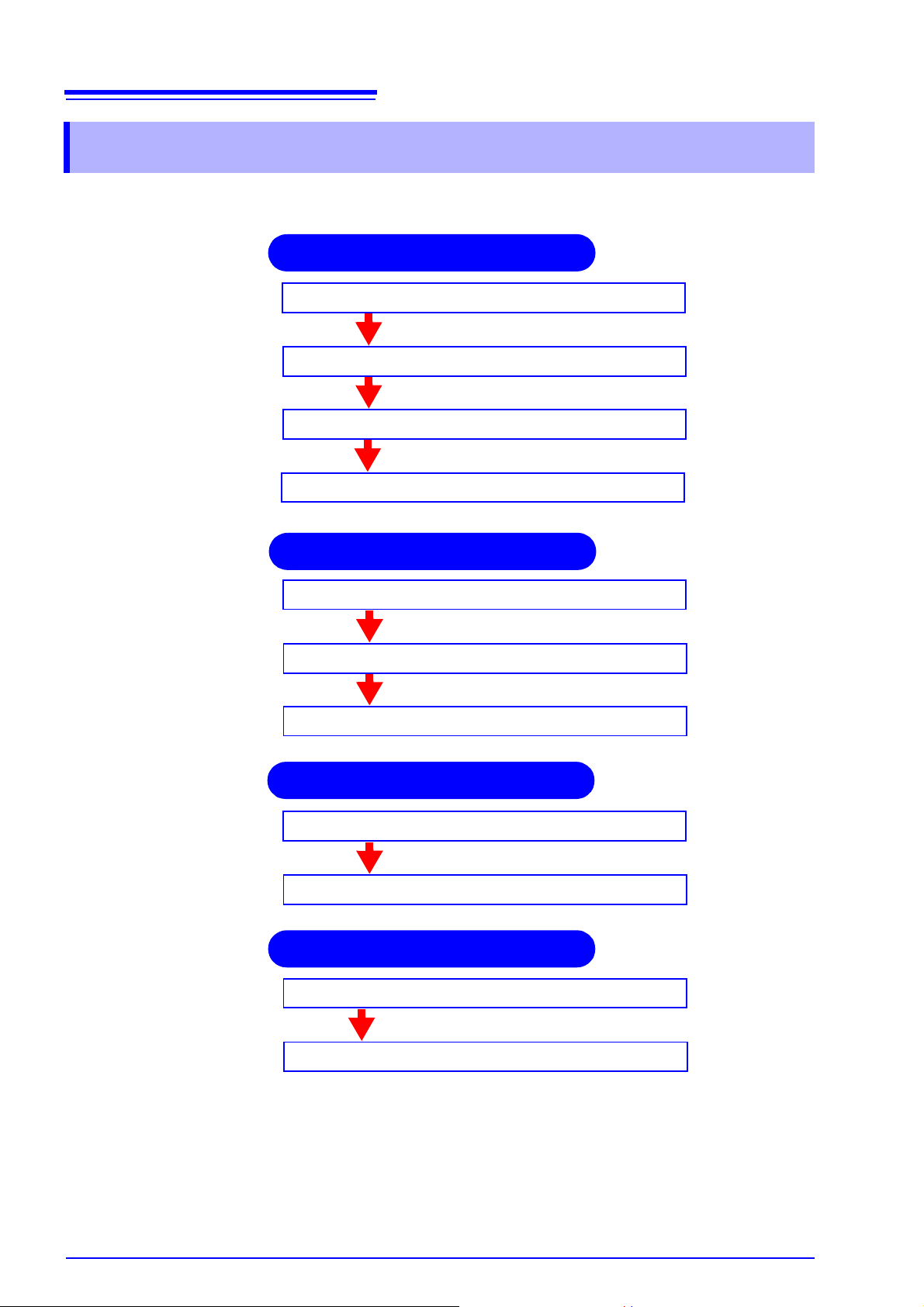

1.5 Measurement Flowchart

1.5 Measurement Flowchart

The basic measurement process flow is as follows:

For details about the fun ction s that can be appl ied to m easurem ent val ues suc h

as comparator, trigger and averaging functions, refer to "Chapter 4 Applied

Measurement" ( p.37).

Page 21

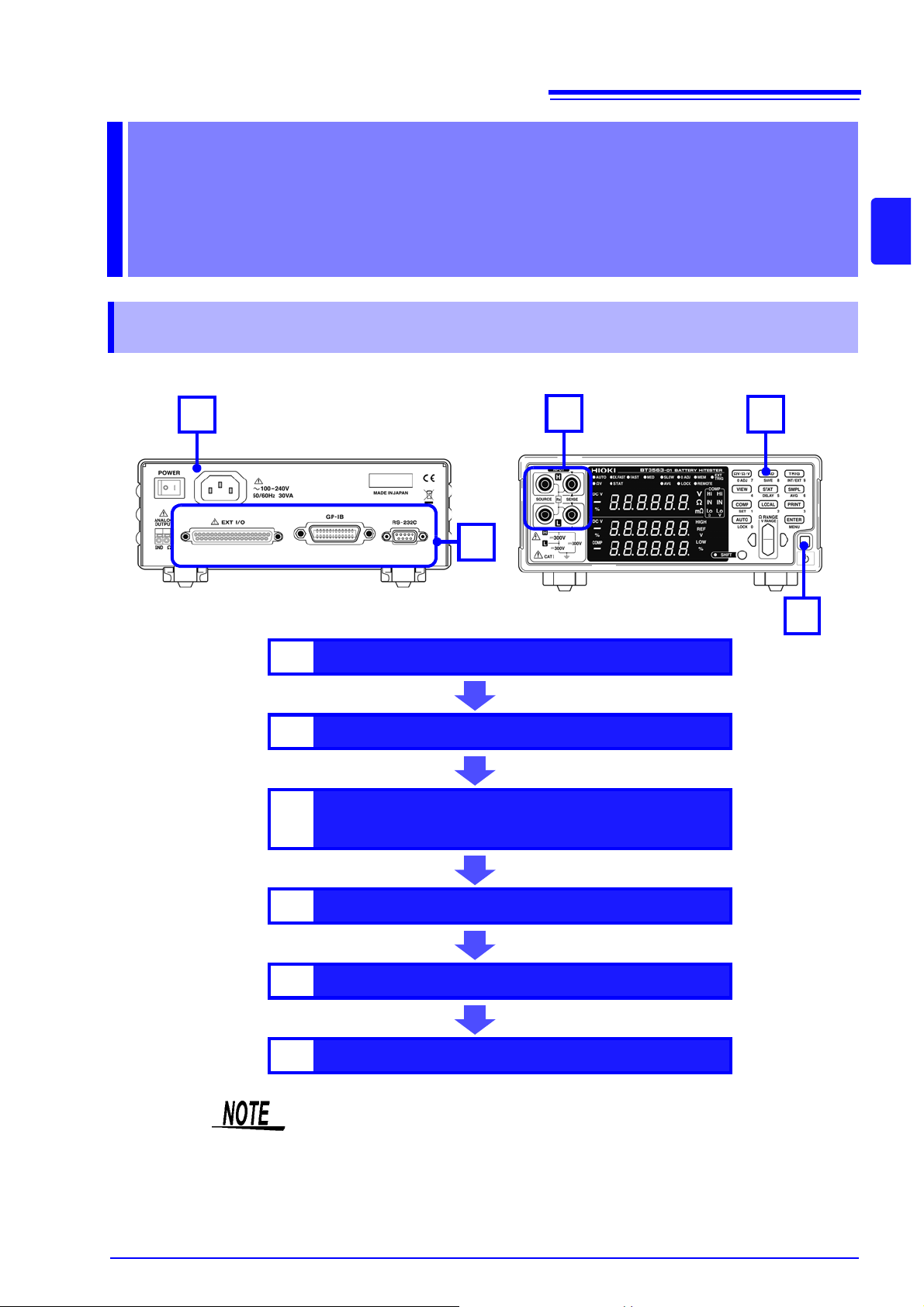

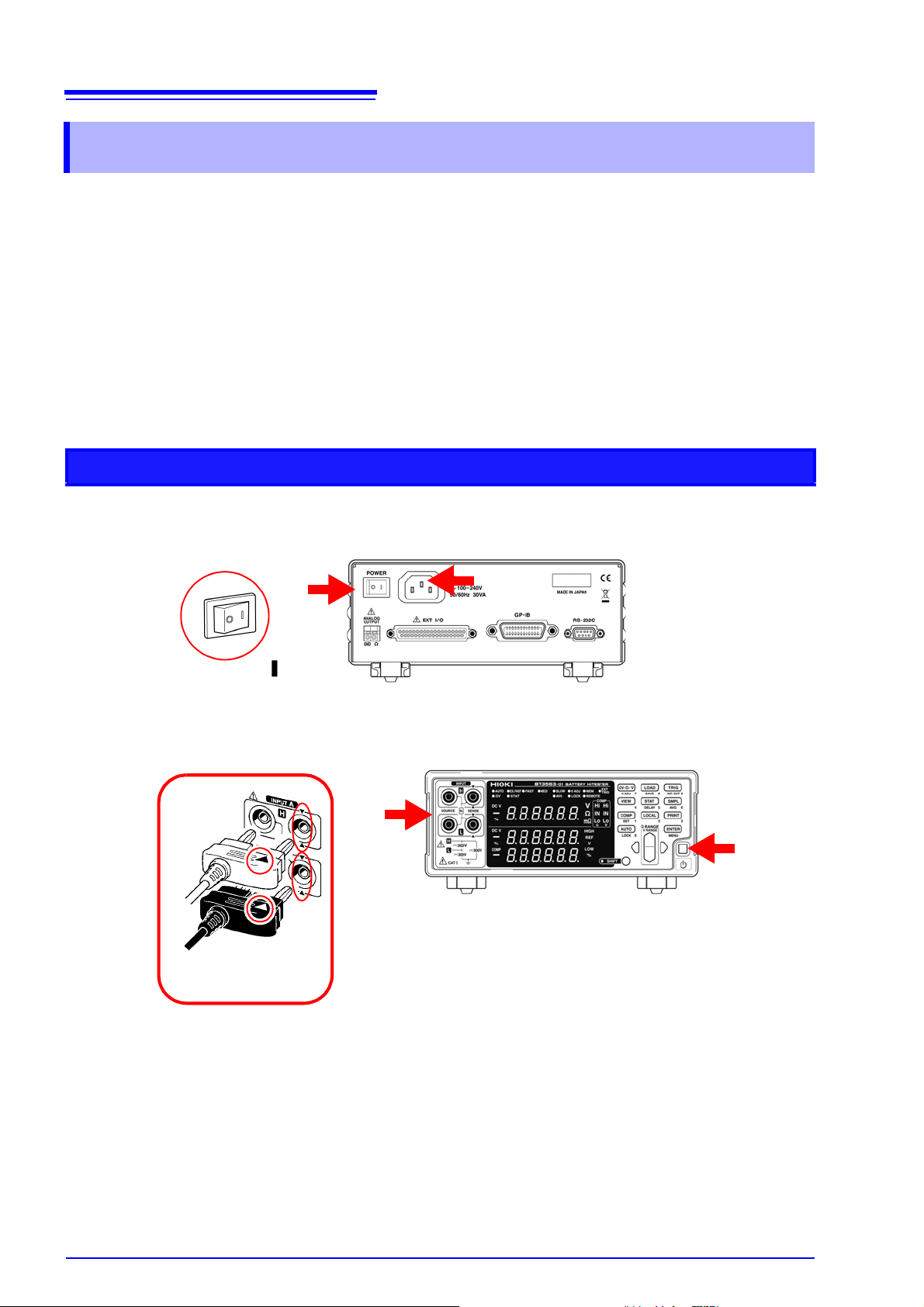

2.1 Preparation Flowchart

Rear Panel

2

1

4

( p.17)( p.16)

( p.18)

3

5

Front Panel

Measurement

Preparations Chapter 2

2.1 Pre paration Flowchart

This procedure de scr ib es inst ru me nt pr e par at ions such as making connect io n s and tu r ni ng po we r on.

15

2

Chapter 2 Measurement Preparations

1

2

3

4

5

6

Connecting the power cord.

Connect the test leads to the instrument.

Connect the EXT I/O connector and interface connector.

Turn the power on.

Set measurement settings.

Start measurement.

Verify that the instrument’ s line frequency is correctly set w hen using it for the

first time and after initialization following repair or recalibration.

See "2.5 Selecting the Line Frequency" ( p.20).

( p.16)

( p.17)

( p.99)

( p.18)

( p.21)

Page 22

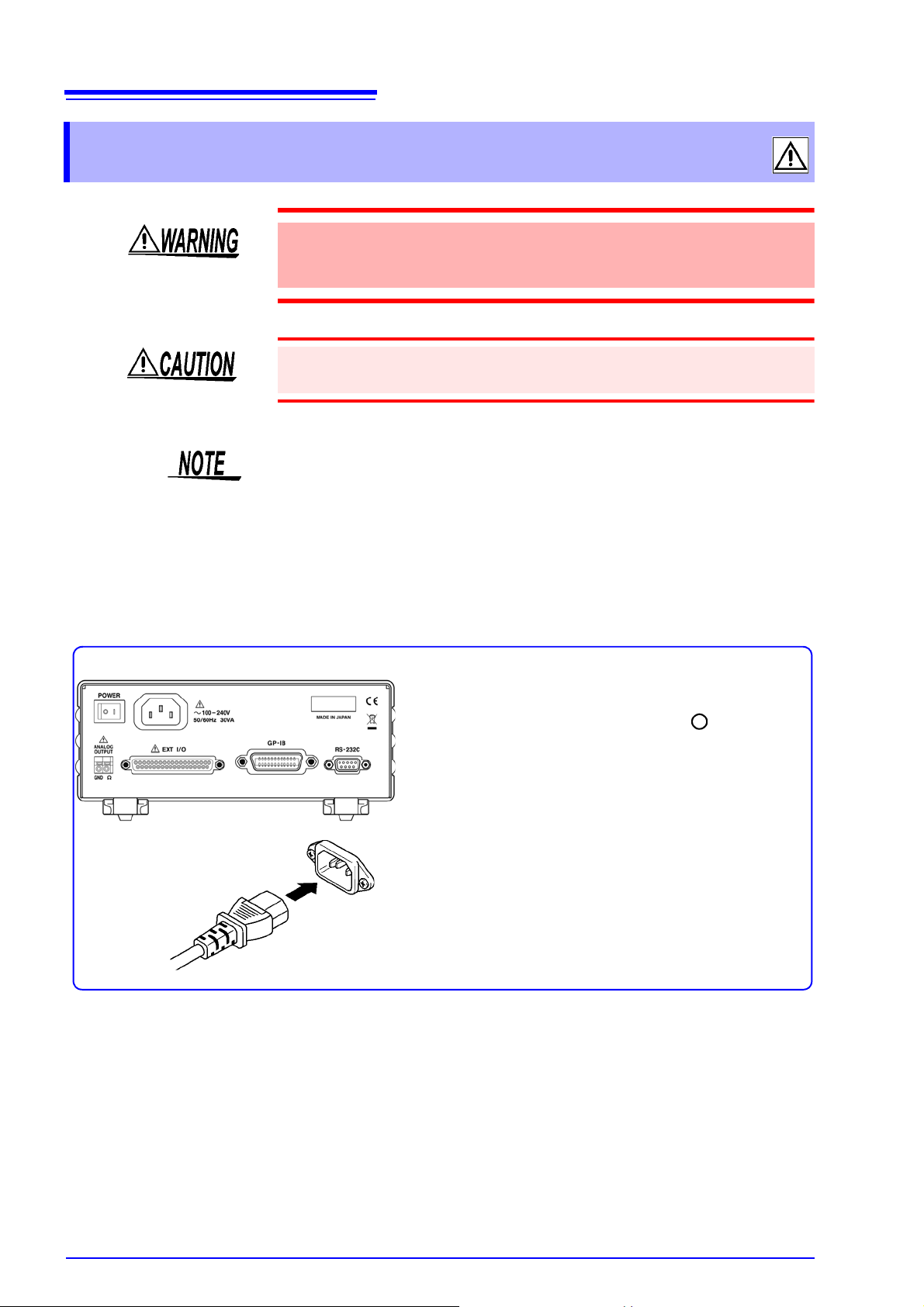

16

12

Rear Panel

1. Confirm that the instrument's Main power

switch (rear panel) is OFF(

).

2. Check that the power supply voltage ( 100

V to 240 V) is correct, and connect the

power cord to the power inlet socket on

the rear of the instrument.

3. Plug the power cord into the AC outlet.

2.2 Connecting the Power Cord

2.2 Connecting the Power Cord

To a void electrical accidents and t o maintain the safety speci fications of this

instrument, connect the power cord only to a 3-contact (two-conductor +

ground) outlet.

To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it from the power outlet.

To suppress noise, the instrument needs to be set to match the line frequency.

Before operating, set the instrument to the frequency of your commercial

power. If the supply frequency is not set properly, measurements will be unstable.

See "2.5 Selecting the Line Frequency" ( p.20).

Make sure the power is turned off before connecting or disconnecting the

power cord.

Page 23

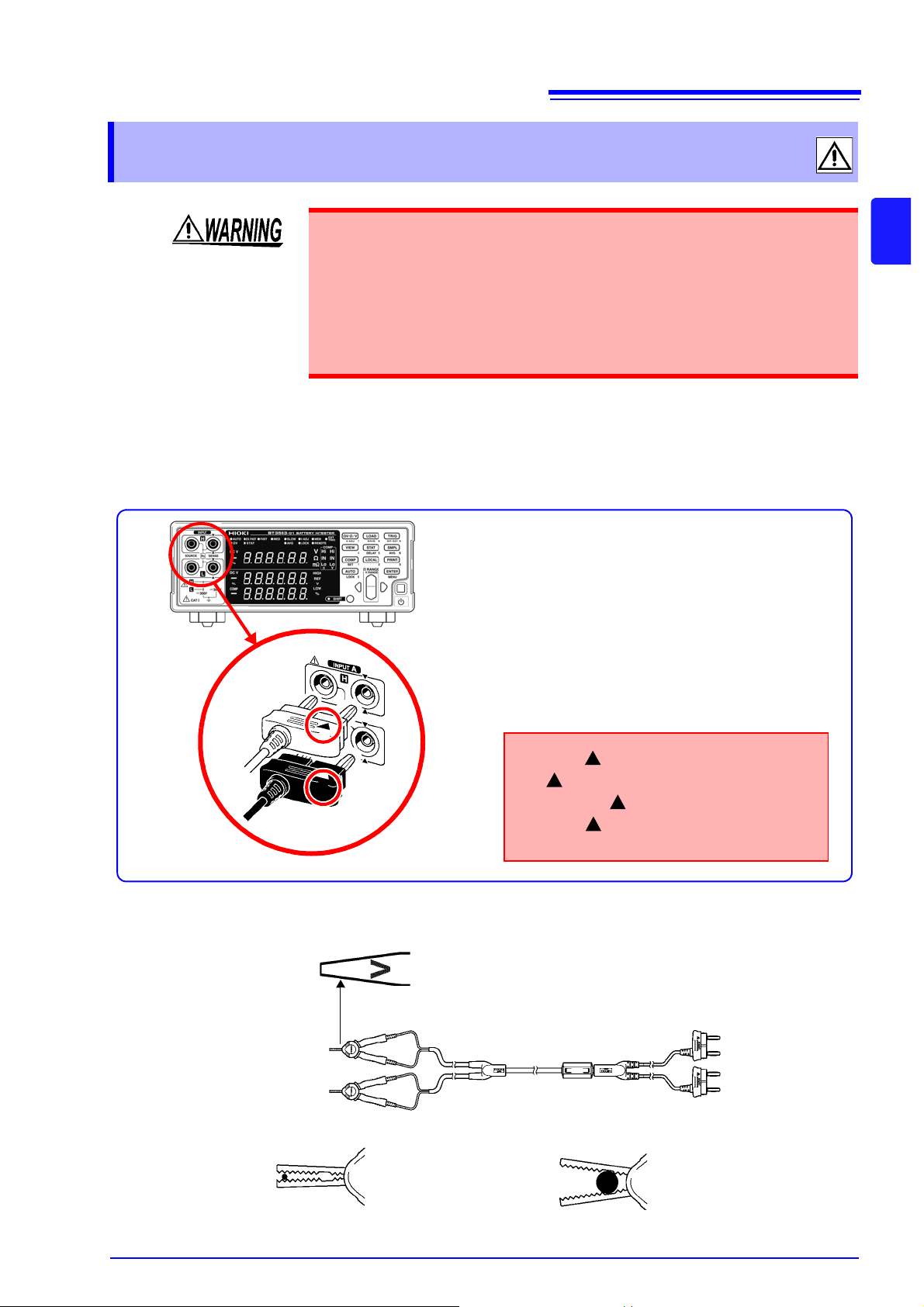

2.3 Connecting the Optional Test Leads

Plug the mark on the red lead into the

red marked jack on the instrument,

and plug the mark on the black lead int o

the black marked jack on the instrument.

Example: Optional model 9287-10 CLIP TYPE LEAD

Black Lead

Red Lead

1. Confirm that the instrument's Power

switch is OFF.

2. Verify that nothing is connected to the tips

of the four-terminal measurement leads.

3. Connect four-terminal test leads such as

the 9287-10 CLIP TYPE LEAD to INPUT

A.

SOURCE

SENSE

SENSE

SENSE

SOURCE

SOURCE

SOURCE

SENSE

Red

Black

Red

Black

The side with “V” mark is SENSE.

When clippi ng a t hi n li ne

(Clip the line at the tip,

serrated part of the

jaws.)

When clipping a thick line

(Clip the line at the

deep, non-serrated part

of the jaws.)

2.3 Connecting the Optional Test Leads

• To prevent an accident caused by short-ci rcuiting the bat tery, be sure to verify

that nothing is connected to the tips of the measurement leads before connecting the leads to or discon necting them from the instrument. ( Contact between

the banana terminals while the tips of the measurement leads are connected

to the battery will short-circuit the battery, possibly resulting in serious injury.)

• To prevent electrical shock, verify the ratings of the measurement leads before

measurement and ex ercise care not to measure voltages that exceed those

ratings.

Test leads are not included as standard accessor ies with the instrument, so the

appropriate options need to be purchased separately or constructed according to

the user’s application requirements. To constr uct custom test leads, ref er to "Pre-

cautions for Making Custom Test Leads"(

terminals on this instrument consist of four separate banana jacks.

See "Appendix 1 Precautions for Making Custom Test Leads"( p.A1).

p.A1). The resistance measurement

17

2

Chapter 2 Measurement Preparations

About Test Leads ______________________________________________

(Example: Model 9287-10 CLIP TYPE LEAD)

Page 24

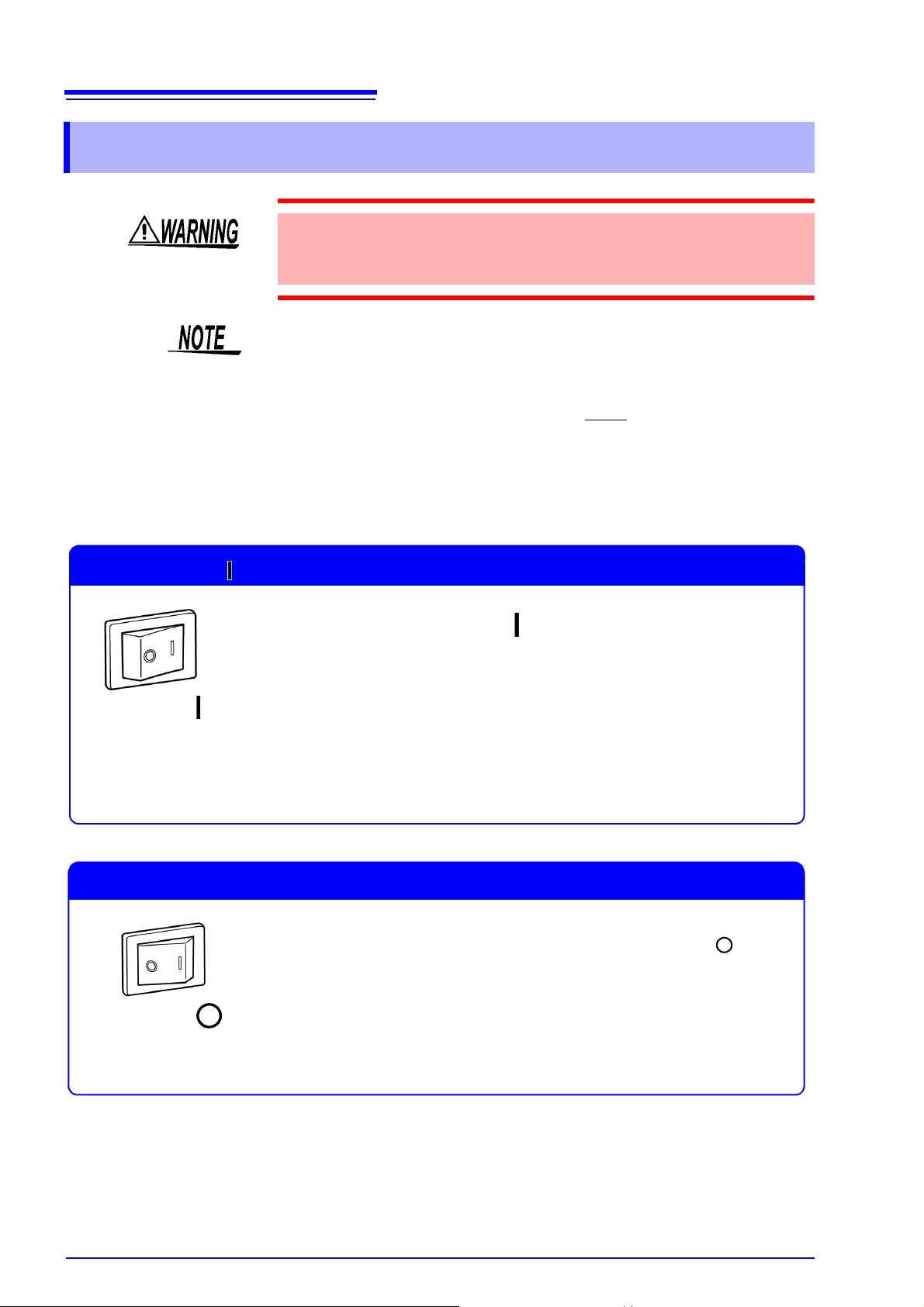

18

Turn on the main power switch on ( ) the rear of the instrument.

The instrument will st art up i n the standby state in which it was last

turned off. (The instrument ships in the standby state.)

Turning On ( ) the Main Power Switc h (Rear of In strument)

Power ON

Turn off the main power switch on the rear of the instrument.( ).

Turning the Power Off

Power OFF

2.4 Turning the Power On and Off

2.4 Turning the Power On and Off

Before turning the ins trument on, make su re the supply voltage m atches that

indicated on the its power co nnector. Connection to an improper supply voltage may damage the instrument and pres ent an electr ical haza rd .

• The measurement setting state is the same as when the power was previously turned off (backup).

To preserve changes to settings, wait a short time (about five seconds) after

changing a setting before turning power off.

• However, measurement settings made through the RS-232C or GP-IB interface and meas ur eme nt s etti ngs l oad ed by LO AD

nector are not memorized.

• Before starting to measure, allow 30 minutes for warm-up.

After warm-up, be sure to perform a self-calibration.

See "4.10 Self-Calibration" ( p.69).

signals of the EXT I/O con-

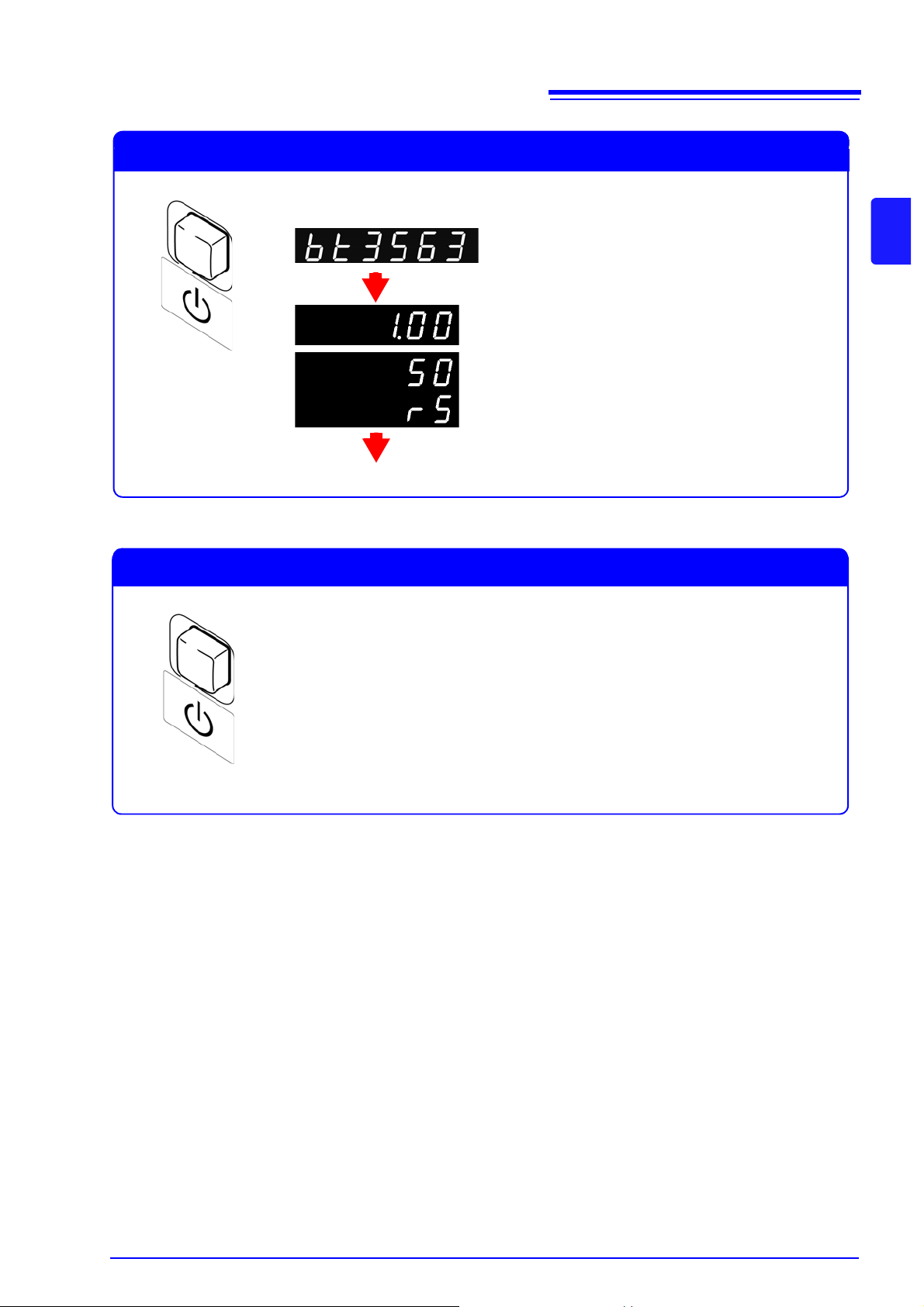

Page 25

19

Press the power switch on the front of the instrument while it is in the

standby state.

Cancelling the Standby State

(Main Display)

Software version

(Sub Display)

Line frequency

Interface

(Main Display)

Model name

The measurement display appears.

Press and hold the power switch on the front of the instrument for

approximately 1 second while it is in the operating state.

Placing the Instrument in the Standby State

2.4 Turning the Power On and Off

2

Chapter 2 Measurement Preparations

Page 26

20

(Main Display)

(Sub Display)

(Main Display)

(Sub Display)

(Main Display)

(Sub Display) flashing

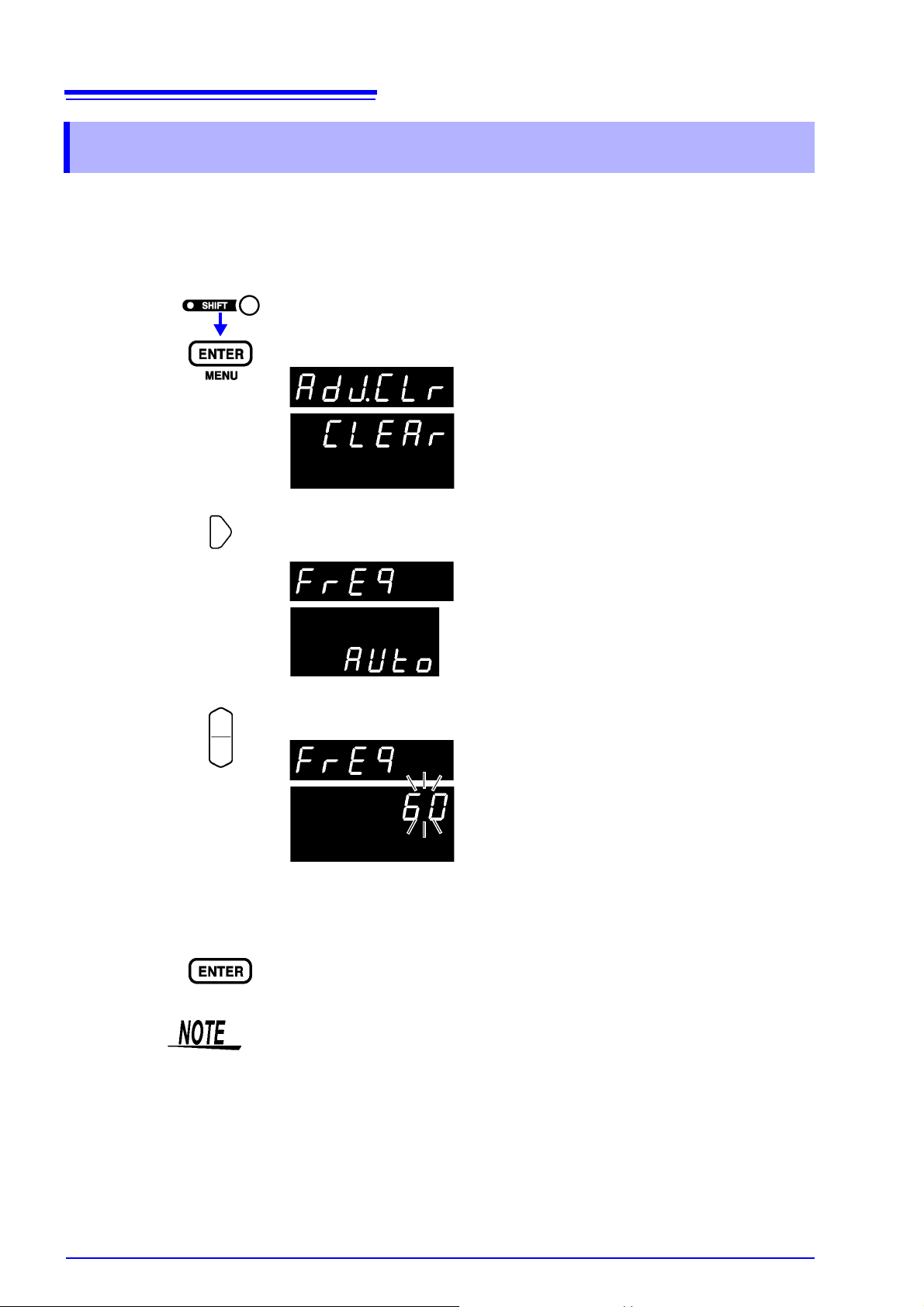

2.5 Selecting the Line Frequency

2.5 Selecting the Line Frequency

The instrument's power supply frequency must be set in order to eliminate noise.

Although the power sup ply frequency setting is co nfigured automatica lly ("AUTO") by defaul t, it can also be

set manually. Measured values will not stabilize if the power supply frequency is not set properly.

1

2

3

(The SHIFT indicator lights up.)

The Menu display appears.

Select the Line Frequency setting display.

See "1.4 Menu Display Sequence (SHIFT → ENTE R ) " ( p.13 ).

Select the frequency of the AC mains supply being used.

4

AUTO.... Automatic configuration of power supply frequency

50..........50 Hz

60..........60 Hz

Applies settings and returns to the Measurement displ ay.

• When set to aut omatic configuratio n (AUTO), a power supply frequency of

either 50 Hz or 60 Hz will b e automatically detected whenever the instr ument is turned on or reset.

• Changes in the p ower supply frequency occurrin g at other times w ill not be

detected.

• The power supply fr equen cy will be se t to eit her 50 Hz or 60 Hz, wh ichever

is closer.

Page 27

3.1 Pre-Operation Inspection

Before using the instrument for the first time, verify that it operates normally to ensure that no damage

occurred during storage or shipping. If you find any damage, contact your dealer or Hioki representative.

Measurement Chapter 3

Before starting measurement, please read Operating Precautions (Page 4) and

"Chapter 2 Measurement Preparations" ( p.15).

• To a void electri cal shock, be ca reful to avoid shorting l ive lines wit h the test

leads.

• To avoid inju ry or damage to the instr ument, do n ot attempt to measure AC

voltage and AC current, or DC voltage exceedi ng

(BT3563).

• The maximum rated voltage betwee n input terminals and ground is

DC (BT3562 (-01)),

ages exceeding 70 V with res pect to ground could damage the instrument

and result in personal injury.

± 300 V DC (BT3563 (-01)). Attempting to measure volt-

± 60 V (BT3562), ± 300 V

21

3

Chapter 3 Measurement

± 70 V

To prevent electrical shock, verify the ratings of the measurement leads before

measurement and ex ercise care not to measure voltages that exceed those

ratings.

3.1 Pre-Operation Inspection

Before using the i nstrument, p erform the f ollowing inspection to ensure th at it is

operating properly.

Check Point Check Contents

Instrument Chassis

(both front and rear panels)

Test Leads and Power

Cord

• No damage or cracks

• No internal circuitry is exposed

• Metal parts that should be insulated are not

exposed

Good Test Sample • Measures as good and displays the correct

measurement value

Bad Test Sample • Measures as bad and displays the correct

measurement value

If the inspection reveals a defect, stop using the instrument and contact your

dealer or Hioki representative.

Page 28

22

Required items: Lithium-ion battery (30 mΩ)

Test leads: Model 9770 PIN TYPE LEAD are used here.

Measurement

conditions:

Measurement mode.................. ΩV (Resistance and Voltage measurement)

Range....................................... 30 m

Ω, 6 V

Sampling rage .......................... SLOW

Zero adjustment........................ Enabled

3

1

Power ON

2

4

Black Lead

Red Lead

Example: Model 9770

3.2 Basic Measurement Example

3.2 Basic Measurement Example

The following example describes the measurement process.

Example: Measuring resistance and voltage of a 30 mΩ lithium-ion battery

Preparations

1

2

Connect the power cord.

See "2.2 Connecting the Power Cord" ( p.16).

Connect the test leads.

See "2.3 Connecting the Optional Test Leads" ( p.17).

3

4

Turn the main power switch on.

See "2.4 Turning the Power On and Off" ( p.18).

See "2.5 Selecting the Line Frequency" ( p.20).

Cancel the standby state.

See "2.4 Turning the Power On and Off" ( p.18).

Page 29

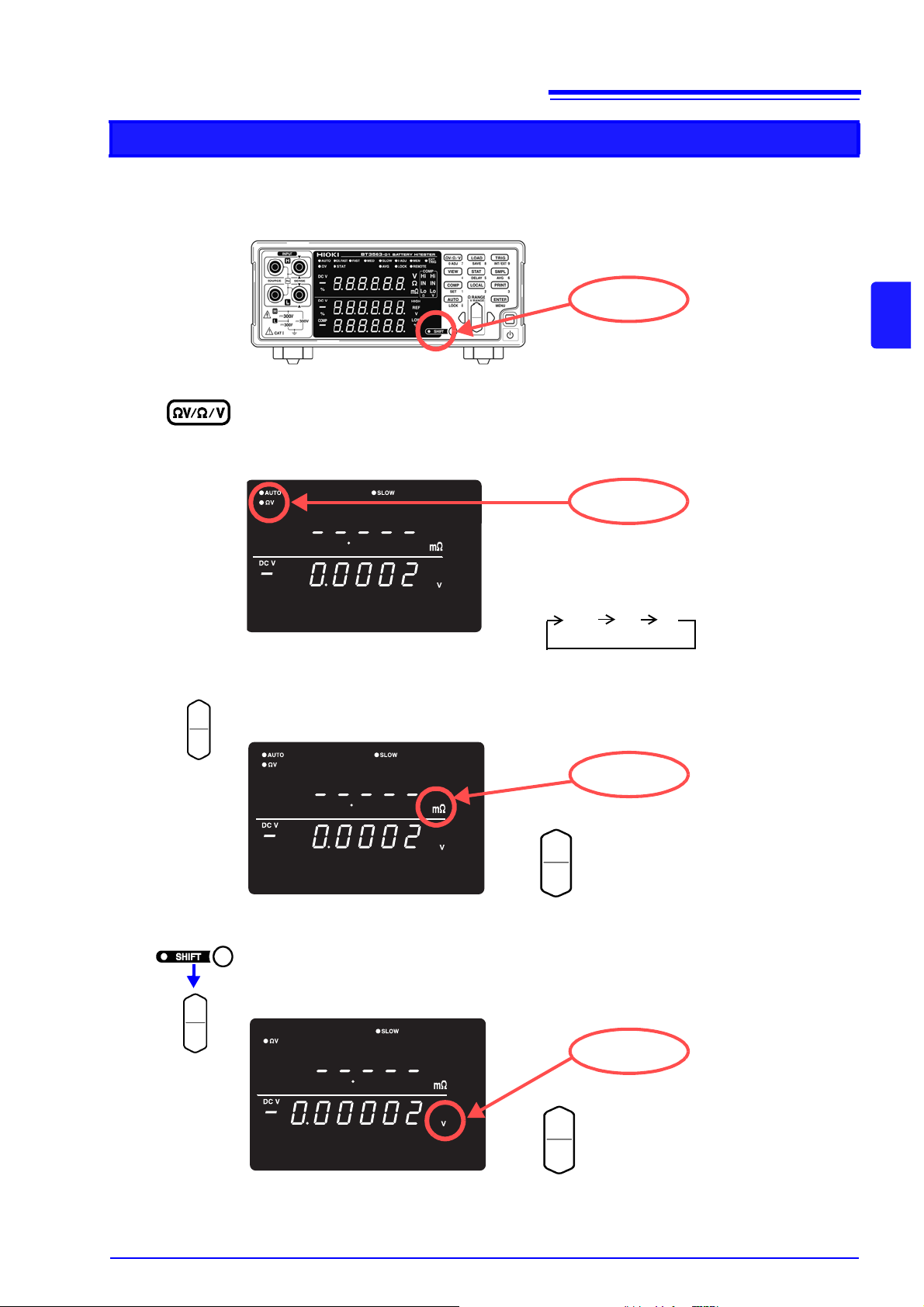

Instrument Settings

SHIFT not lit

The measurement mode changes each time

you press this key. Select Ω to measure only

resistance, or V to measure only voltage.

ΩV

Ω

V

ΩV lit

Increase the resistance measurement range.

Decrease the resistance measurement range.

mΩ lit

Increase the voltage measurement range.

Decrease the voltage measurement range.

V lit

23

3.2 Basic Measurement Example

5

6

Confirm the SHIFT lamp is not lit.

If this is lit, press the SHIFT key to turn it off.

3

Chapter 3 Measurement

Select the Resistance Measurement mode.

(Here, resistance and voltage measurement is selected.)

See "3.3 Selecting Measurement Mode" ( p.26).

7

8

Set the measurement range. (Here, 30 mΩ range is selected.)

See "3.4 Setting Measurement Range" ( p.27).

(SHIFT Lamp lit)

Set the voltage measurement range. (Here, the 6 V setting has been selected.)

See "Voltage measurement range" ( p.28)

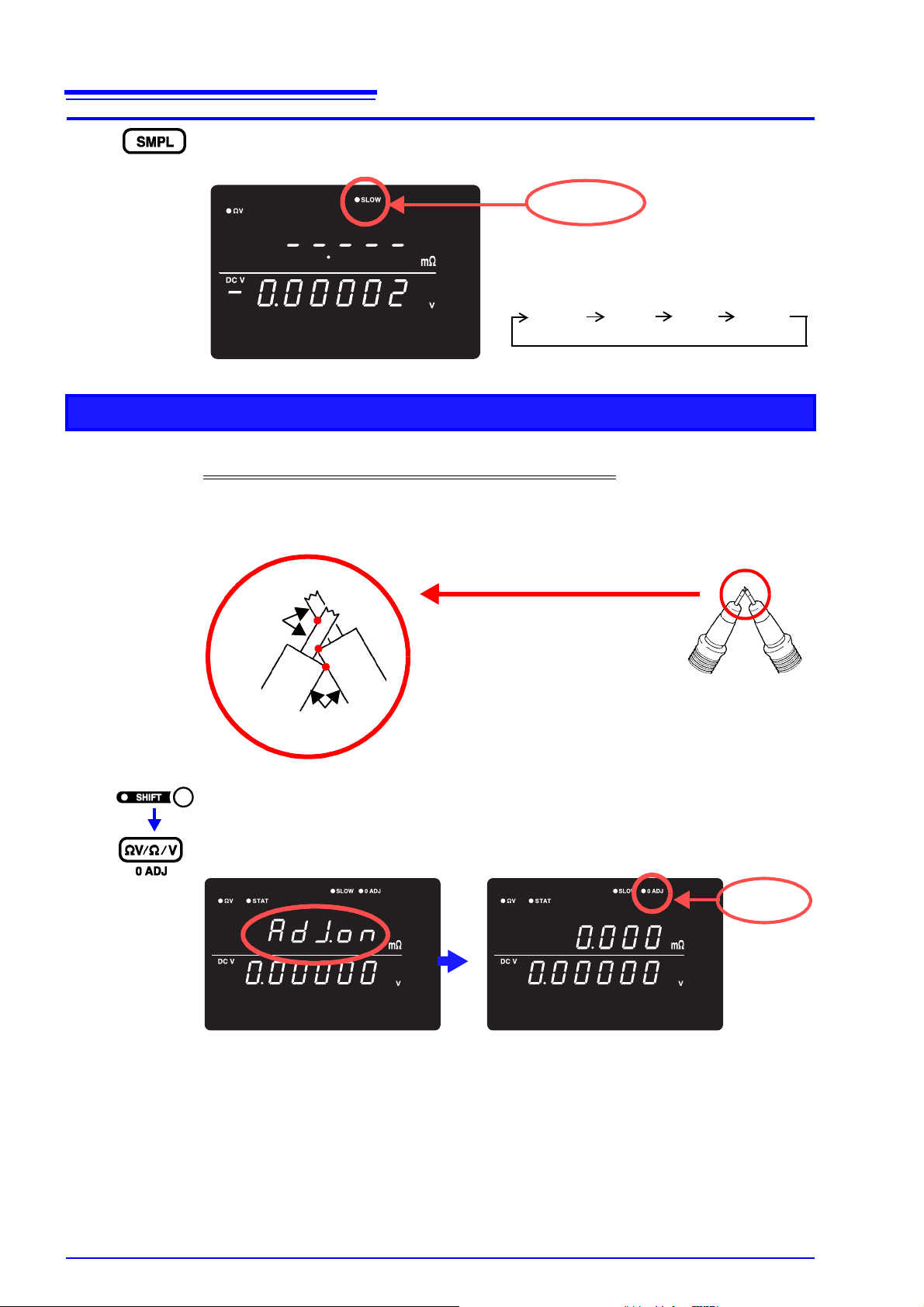

Page 30

24

The sampling rate changes each time you

press this key.

EX.FAST

FAST

SLOW

MED

SLOW lit

Bring the pins into contact at 3 points.

• Internal conductor and internal condu cto r

• Internal conductor and external cond uct or

• External conductor and external conductor

Model 9770

Internal

conductor

External

conductor

0ADJ lit

3.2 Basic Measurement Example

9

Set the sampling rate. (Here, SLOW is selected.)

See "3.5 Setting Sampling Rate" ( p.30).

Zero-Adjustment

10

Short the test leads together.

Proper Zero-Adjustment is not possible with incorrect wiring.

See "3.6 Zero-Adjust Function" ( p.31).

Example: Model 9770 Pin Type Lead

11

(The SHIFT indicator lights up.)

Execute Zero-Adjust.

After zero-adjustment, the display returns to the measurement mode.

“Err.02” appears if Zero-Adjustment fails. Verify that the test lead tips are properly shorted,

and try zero-adjustment again.

Page 31

Measurement

Measured Resistance

Measured Voltage

25

3.2 Basic Measurement Example

12

13

Connect the test leads to a battery.

Open-terminal voltages for the instrument are as follows:

3 m

Ω and 30 mΩ ranges: 25 V peak

300 m

Ω range: 7 V peak

3

Ω to 3000 Ω: 4 V peak

These voltages derive from the load associated with charging the 1.2 uF

capacitor inside the instr um ent.

• The open-terminal voltage for the 3 m

4 V approximately 500 ms after the terminal is placed in the open state.

• When building a measurem ent line usin g scanner s, use a relay with a dielectric strength that is greater than or equa l to the open-terminal voltage for the

range being used.

Read the measured resistance and voltage.

3

Chapter 3 Measurement

Ω, 30 mΩ, and 300 mΩ ranges peaks at

See "3.7 Displaying Measurement Results" ( p.34).

See "10.3 Error Display" ( p.183).

Please refer to "Before returning for repair." of "Measured value is unstable." (

p.182) as a measurement and attention.

Page 32

26

SHIFT not lit

ΩV mode

(Resistance and Voltage measurement) measurement)

Ω mode

(Resistance measuremen t)

V mode

(Voltage measurement)

“Ω” or “mΩ” lit

“ΩV” indicates the

ΩV mode is selected

3.3 Selecting Measurement Mode

3.3 Selecting Measurement Mode

Select the measurement mode from ΩV (both resistance and voltage measurement), Ω (resistance measurement only) or V (voltage measurement only).

1

2

Confirm the SHIFT lamp is not lit.

If this is lit, press the SHIFT key to turn it off.

Switches the displayed measurement mode.

Each key-press switches the measurement mode.

The fastest measur ements are provided by selecting the Ω or V mode when

measuring resistance or voltage, respectively.

See " Sampling Time" ( p.174).

Page 33

27

Ω lit

mΩ lit

When the 3 Ω range is selected

When the 300 m

Ω range is

selected

Increase the resistance measurement range.

Decrease the resistance measurement range.

3.4 Setting Measurement Range

3.4 Setting Measurement Range

This section descr ibes how to set the measure ment range for resistanc e or voltage me asureme nt. For resi stance measurement, yo u ca n sel ect fr om s even r ang es from 3 mΩ to 3000 Ω. For volta ge me as ureme nt, y ou

can select from two ranges fro m 6 V to 60 V (for the Model BT35 62[-01]) or thr ee ranges f rom 6 V to 300 V

(for the Model BT3563[- 01]). There is also an auto-ran ge function , which determi nes the optimal range automatically.

Resistance measurement range

3

Chapter 3 Measurement

1

2

Select the resistance measurement range.

The position of the decimal point and unit of measure ment on the dis play wil l

be switched according to the selected range.

Select the range to use.

Pressing the up or down keys while in auto-range mode will cancel auto-ranging,

leaving the current measurement range as the manually set range.

Page 34

28

V lit

V lit

When the 60 V range is selected

When the 6 V range is

selected

Increase the voltage measurement range.

Decrease the voltage measurement range.

3.4 Setting Measurement Range

Voltage measurement range

1

Select the range to use.

2

ΩV lit

Select the voltage measurement range.

The position of th e d ec im al poi nt and uni t o f m eas urem ent on the di sp lay w il l

be switched according to the selected range.

Page 35

Auto-Ranging

AUTO lit

29

3.4 Setting Measurement Range

When manual range selection is enabled, pressing this enables auto-ranging.

The most suitable measurement range is then selected automatically.

3

Chapter 3 Measurement

The auto-range setting (on/off) for the ΩV function applies to both resistance and

voltage measurement.

Switching from

Auto

-ranging back to

Manual

range selection

Press the AUTO key again. The range can now be changed manually.

• Depending on the state of the test object, auto -ranging ma y be unstable. In

this case, select the range manually, or increase the Delay time.

• Auto-ranging is not available when Comparator or Memory functions are

enabled (ON).

• Refer to "Specifications" ( p.173) for details about accuracy.

Resistance Measurement Mode

Range Displayed Values

Measured Current Open-Terminal Voltage

3 mΩ -0.1000 to 3.1000 mΩ 100 mA

30 mΩ -1.000 to 31.000 mΩ 100 mA

300 mΩ -10.00 to 310.00 mΩ 10 mA

3 Ω -0.1000 to 3.1000 Ω 1 mA

30 Ω -1.000 to 31.000 Ω 100 μA

300 Ω -10.00 to 310.00 Ω 10 μA

3000 Ω -100.0 to 3100.0 kΩ 10 μA

About 4 Vpeak.

6 V -6.00000 v to ±6.00000 V -- --

60 V -60.0000 v to ±60.0000 V -- --

*1

300 V

-300.000 v to ±300.000 V -- --

*1: BT3563 only

Page 36

30

EX.FAST FAST MEDIUM SLOW

3.5 Setting Sampling Rate

3.5 Setting Sampling Rate

The sampling rat e can be selec ted fr om EX .FAST , FAST, M ED IUM and SLOW.

Slower sampling rates generally provide greater measurement precision.

Selects the sampling rate

• Measurements are es pecially susceptible to interference from the environment when EX.FAST is selected, so countermeasures such as shielding or

twisting of test leads, ca bles and wiring ar ound the test objec t may be necessary.

See "Appendix 1 Precautions for Making Custom Test Leads" ( p.1)

• When SLOW sampli ng is selected, self-ca libration is execut ed during each

measurement. At other sampling rates, self-calibration is executed manually

or automatically every 30 minutes.

See "4.10 Self-Calibration" ( p.69).

• Refer to the specifications for details of sampling rates.

See " Sampling Time" ( p.174).

Page 37

3.6 Zero-Adjust Function

Connection

Connection

SENSE-H SENSE-L

SOURCE-H SOURCE-L

at zero adjustment at measurement

Execute zero adjustme nt before measuring to nullify any res idual offset voltage

from the instrument or measurement environment. Measurement accuracy specifications are applicable after zero adjustment. Zero adjustment can also be executed by the 0ADJ terminal of the EXT I/O connector.

See "5.2 Signal Descriptions" ( p.76).

31

3.6 Zero-Adjust Function

Wiring Method for Zero-Adjustment

Before executing zero adjustment, connect the test leads (probes) as follows:

1. Connect SENSE-H to SENSE-L.

2. Connect SOURCE-H to SOURCE-L.

3. Connect the joined SENSE and SOURCE leads together as shown below.

Executing Zero-Adjustment

1

Position the measurement leads in the actual measurement state.

Since the amount of zero adju stment var ies wi th the posi tion and st at e of t he mea-

surement leads (probes) (i.e., their length, shape, position, etc.), the measurement leads must be position ed in the actual measurement state before performing

zero adjustment.

3

Chapter 3 Measurement

These variations are particularly pronounced in the 3 mΩ and 30 mΩ ranges, so

be sure to position the leads in same state as will be used to perform actual measurement when using those configurations.

Page 38

32

Red

SOURCE

SOURCE

SOURCE

SENSE

SENSE

SENSE

Correct

Incorrect

Red

Black

Black

SOURCE

SENSE

Bring the "V" marks together at the

same position.

Model 9770 (Option)

Model 9453 (Option)

Perform zero adjustment with

the alligator clips and lead rods

placed as above.

Internal

conductor

External

conductor

Bring the pins into contact

at 3 points.

Model L2100 (Option)

Each sensor pin has a line affixed to its base.

When using the zero-adjust feature, align

these lines in the same direction.

Model 9454

ZERO ADJUSTMENT BOAR

Line

0ADJ lit

3.6 Zero-Adjust Function

2

Short the test leads together.

Proper zero adjustment is not possible with incorrect wiring.

Example: Model 9287-10 CLIP TYPE LEAD

3

(The SHIFT indicator lights up.)

Zero-adjust display appears.

After measurement, the mea sured value of the compensati on applied by the zero-adjust

function is displayed.

The range of zero adjustment is up to 1000 dgt.

Page 39

Clearing Zero-Adjustment

(Main Display)

(Sub Display) flashing

(Main Display)

33

3.6 Zero-Adjust Function

1

2

If Err02 is displayed

(The SHIFT indicator lights up.)

The Menu display appears.

The zero-adjust value is cleared. (0ADJ not lit)

Indicates that zero adjustment could not be executed, either because the

range to be adjusted exce eds

exists.

The zero adj us t fu nc ti o n i s canceled, so repe at t he op e r at io n a f ter co rr ecting

the cause of the error.

• Zero adjustment is limited to ± 1000 dgt. (all ranges)

• Perform zero adjustment for each range that will be used in measurement.

• When using the auto-range function, perform zero adjustment for all ranges.

• When using the

according to the resistance measurement range zero-adjust state.

• Zero-adjustment values are retained even when power is turned off.

• The 0ADJ terminal of the EXT I/O connector also executes zero adjustment.

See "5.2 Signal Descriptions" ( p.76).

• Zero adjustment is very difficult with the delicate probe tips of the Model

L2100 and 9771 Pin Type Leads. Refer to " Wiring Method for Z ero-Adjustment" ( p.31) to use other leads when executing zero adjustment.

ΩV function, the 0ADJ indicator lights up or turns off

± 1000 dgt, or a measurement fault c ondition

3

Chapter 3 Measurement

Page 40

34

Measured Voltage

Measured Resist anc e

Measured Resistance

Measured Voltage

3.7 Displaying Measurement Results

3.7 Displaying Measurement Results

In the ΩV mode , resistance measurements appear on the upper display, and

voltage measurements appear on the lower display.

In the

Ω mode, resistance measurements appear on the upper display.

In the V mode, voltage measurements appear on the upper display.

Page 41

Measurement Fault Detection

If a measurement does not execute properly, a measurement fault

“- - - - -” is indicated on the display.

In addition, a measurem ent fault signal (ERR) is outpu t at the EXT I/O connector.

See " ERR Output" ( p.79).

A measurement fault is displayed in the following cases.

• When a test lead is not connected to the test object

• When the resistance of the measured object is over-range

Example: Attempting to measure 30 Ω with the 300 mΩ range selected.

• When there is a break in a probe wire

• When the contact resistance is high due to probe wear, dirt, or other factors,

or when the wiring resistance is high (see chart below)

• If the circuit protection fuse is blown

See "10.1 Troubleshooting" ( p.181).

Levels at which a measurement fault is detected

A measurement fault will result when the resistance values (contact resistance +

wiring resistance + test object resistance) between the source H and L or the

sense H and L leads is greater than or equal to the values in the following table:

35

3.7 Displaying Measurement Results

3

Chapter 3 Measurement

Range SOURCE H-L SENSE H-L

3 mΩ 3 Ω 3 Ω

30 m

Ω 3 Ω 3 Ω

300 m

Ω 20 Ω 20 Ω

3

Ω 200 Ω 20 Ω

30

Ω 2 kΩ 200 Ω

300

Ω 6 kΩ 2 kΩ

3000

Ω 6 kΩ 20 kΩ

*Large contact resistance and/or wiring resistance values may increase the error

component in measur ed value s. (Accurac y is not guar anteed when the sum of

contact resistance and wiring resistance is greater than or equal to 20 Ω [for the

3 mΩ and 30 mΩ ranges, 2 Ω].)

*The instrument may be unable to detect measure ment faults when the mea-

surement lead capacitance is greater than or equal to 1 nF.

Page 42

36

3.7 Displaying Measurement Results

Overflow Display

Overflow is indicate d by “OF” or “-OF” on t he display , caused by one of the fo llowing:

Display Condition

OF

-OF

• The measured value exceeds the limit of the current

measurement range

• The test object impedance exceeds the input level.

• When the result of relative value calculation is larger

than +99.999%.

• The measured value is below the limit of the current

measurement range

• The test object impedance exceeds the input level (in

the negative direction).

• When the result of relativ e value calculation is smaller

than -99.999%.

Page 43

37

Applied

Measurement Chapter 4

This chapter describes advanced operations employing the Comparator, Statistical Calculation and Memory functions.

Judge measurement values

against specified thresholds

Measure when trigger events occur Trigger Function

Output averaged measurement val-

ues

Display the results of calculation ex-

pressions applied to measurement

values

Store measurement values Memory Function

Lock the keys Key-Lock Function

Save measurement configurations Panel Save Function

Load saved measurement configura-

tions

Increase measurement precision Self-Calibration

Output measurement values via the

RS-232C interface according to trigger input timing

Comparator Function

Averaging Function

Statistical Calculation Functions

Panel Load Function

Measurement Value

Output Function

( p.38)

4

( p.55)

Chapter 4 Applied Measurement

( p.59)

( p.60)

( p.64)

( p.66)

( p.67)

( p.68)

( p.69)

( p.70)

Enable/disable ke y- pres s beeps Key Beeper Setting

Re-initialize the instrument Reset Function

( p.71)

( p.72)

Page 44

38

4.1 Comparator Function

4.1 Comparator Function

The comparator functi on compares measur ed values to prese t upper and lower

thresholds, judges the measurements according to their relative levels within the

preset range, and indicates the results of the comparisons.

Comparator thresholds can be set either by specifying upper and lower thr esholds, or by specifying a reference value and tolerance.

Comparator results ca n be indicated by the Hi, IN and Lo LEDs, beeper sound

and signal output at the EXT I/O connector.

See "Chapter 5 External Control (EXT I/O)" ( p.75).

The comparator setting process flow is as follows:

Display the comparator settings

1

Set the comparator judgment beeper

2

Select the comparator execution mode

3

(Auto or Manual/External)

Select resistance measurement

(If you do not need to configure resistance settings,

4

proceed to step 7.)

Select the resistance comparison method.

5

(absolute or relative value) for the comparator

Specify the resistance upper and lower thresholds

6

(or reference value and tolerance).

Select voltage measurement

7

Select the voltage comparison method

8

(absolute or relative value) for the comparator

Specify the voltage upper and lower thresholds

9

(or reference value and tolerance)

Apply your comparator settings

10

Enable the Comparator function

11

Page 45

4.1 Comparator Function

Example:

Set the upper and low er thresh olds for r esist an ce and volt age in the ΩV mode (300

mΩ range), and indicate whether the measurement value exceeds the upper or

lower thresholds by sounding the beeper.

Resistance : Upper threshold value 150.00 mΩ, Lower threshold value 100.00 mΩ

Voltage : Upper threshold value 15.2000 V, Lower threshold value 15.0000 V

COMP not lit

ΩV lit

Increase the resistance measurement range.

Decrease the resistance measurement range.

mΩ lit

V lit

Increase the resistance measurement range.

Decrease the resistance measurement range.

Comparator Setting Example 1 (Upper and Lower Threshold Judgment)

This example describes the comparator setting method.

1

Confirm that the Comparator function is OFF.

First make sure the Comparator function is disabled. Settings cannot be changed while

the Comparator function is enabled. Press the COMP key, if necessary, to disable the

Comparator function.

39

4

Chapter 4 Applied Measurement

2

3

4

Select the ΩV measurement mode.

Select the Resistance measur ement range (f or this ex ample, th e 300 mΩ range).

Select the voltage measurement range (for this exampl e, the 60 V range).

Page 46

40

oFF flashing

HL flashing

A flashing

r flashing

4.1 Comparator Function

5

6

The Comparator setting display appears.

Set the comparator judgment beeper (for this example, select HL).

oFF........no beeps sound

HL..........beeps repeatedly (when measurements are Hi or Lo)

in ...........beeps continuously (when measurements are IN)

btH1.......beeps continuously while measurements are within the thresholds (IN), and

beeps repeatedly when measurements are Hi or Lo.

btH2.......beeps once when measurements move into the threshold range (IN), and beeps

repeatedly when measurements go Hi or Lo.

7

8

Press so that the indicated position blinks, and select the comparator execution

mode (for this example, Auto).

A............ Auto Comparator (default setting)

E............ Manual Comparator

Press so that the indicated position blinks, and select resistance.

r.............Resistance

u ............Voltage

Page 47

41

HIGH & LOW flashing

Or

ten-keys

For this example,

Upper Threshold: 150 m

Ω

Upper Threshold: 100 mΩ

Select a digit

Select numerical value

Select a digit to change by moving the blinking location, then select the new numerical value.

Using the RANGE keys: Using the ten-keys:

Press the numeric keys corresponding to the digits to

be entered.

u flashing

4.1 Comparator Function

9

10

Press so that the indicated position blinks, and select the comparison method for

the comparator (here, HIGH/LOW).

HIGH, LOW..... Compare by upper and lower thresholds (default setting)

REF, % ............ Compare by reference value and tolerance

Switch to the upper/lower threshold setting display, and specify the thresholds.

4

Chapter 4 Applied Measurement

To enter the current measurement as the setting value: AUTO key

(Press on a screen other than the upper/lower threshold setting display.)

To enter the result of statistical calculation as the setting value: STAT key

(Press on a screen other than the upper/lower threshold setting display.)

See " Upper and Lowe r Th resho lds Se tti ng (b y Ref eren ce Value and Tolerance)" ( p.50).

Press so that the indicated position blinks, and sel ect voltage.

11

r.............Resistance

u............Voltage

Page 48

42

HIGH & LOW flashing

Or

ten-keys

For this example,

Upper Threshold: 15.2 V

Upper Threshold: 15 V

COMP lit

Measured Resistance

Judgment Result

Measured Voltage

Upper Threshold Value < Measured Value

Lower Threshold Value ≤

Measured Value ≤ Upper Threshold Value

Measured Value < Lower Threshold Value

4.1 Comparator Function

12

13

14

Press so that the indicated position blinks, and select the comparison method for

the comparator (here, HIGH/LOW).

HIGH, LOW.....Compare by upper and lower thresholds (default setting)

REF, %.............Compare by reference value and tolerance

Switch to the upper/lower threshold setti ng display, and specify the thresholds.

Applies setting and returns to the Measurement display.

The comparator function is enabled.

15

To cancel the settings: SHIFT key

Connect a test object and judge the measured value.

In the ΩV mode, you can verify comparator settings by pressing the VIEW key.

See

" Switching Between Measurement Value and Comparator Setting Displays" ( p.54).

Page 49

4.1 Comparator Function

Example:

Set a referen ce valu e and to lerance in the ΩV mode (3 Ω range), and set the beeper

to sound while measured values are within tolerance.

Resistance : Reference value 1.5 Ω, Tolerance 5%

Voltage : Reference value 4.2 V, Tolerance 0.5%

COMP not lit

ΩV lit

Increase the resistance measurement range.

Decrease the resistance measurement range.

Ω lit

• The upper and lower thre sholds are saved as the displa yed counts (inde pendent of measurement mode and range). Therefore, changing the measurement mode or range resu lts in the same di splay c ounts represen ting different

absolute values.

Example:

To specify the lower threshold as 150 m

Switching to the 3

old to 1.5

• The instrument can also base judgments on the absolute value of voltage

measured values (to prevent Lo judgments when the positive and negative

terminals are connected backwards).

See "Configuring the Absolute Value Judgment Function (Voltage)" ( p.51)

Ω.

Ω range after making this setting changes the lower thresh-

Ω in the 300 mΩ range, enter “15000”.

Comparator Setting Example 2 (Reference Value and Tolerance Judgment)

This example describes the comparator setting method.

43

4

Chapter 4 Applied Measurement

1

2

3

Confirm that the Comparator function is OFF.

First make sure the Comparator function is disabled. Settings cannot be changed while

the Comparator function is enabled. Press the COMP key, if necessary, to disable the

Comparator function.

Select the ΩV measurement mode.

Select the measurement range (for this example, the 3 Ω range).

Page 50

44

V lit

oFF flashing

in flashing

A flashing

4.1 Comparator Function

4

5

6

Select the voltage measurement range (for this example, the 6 V range).

The Comparator setting display appears.

Set the comparator judgment beeper (for this example, select In).

7

oFF........no beeps sound

HL..........beeps repeatedly (when measurements are Hi or Lo)

in ...........beeps continuously (when measurements are IN)

btH1.......beeps continuously while measurements are within the thresholds (IN), and

beeps repeatedly when measurements are Hi or Lo.

btH2.......beeps once when measurements move into the threshold range (IN), and beeps

repeatedly when measurements go Hi or Lo.

Press so that the indicated position blinks, and select the comparator execution

mode (for this example, Auto).

A............ Auto Comparator (default setting)

E............ Manual Comparator

Page 51

45

r flashing

REF & % flashing

Or

ten-keys

For this example,

Reference value: 1.5

Ω

Tolerance: 5%

Select a digit

Select numerical value

Select a digit to change by moving the blinking location, then select the new numerical value.

Using the RANGE keys: Using the ten-keys:

Press the numeric keys corresponding to the digits to

be entered.

4.1 Comparator Function

8

9

Press so that the indicated position blinks, and select resistance.

r.............Resistance

u............Voltage

Press so that the indicated position blinks, and select the comparison method for

the comparator (here, REF/%).

4

Chapter 4 Applied Measurement

HIGH, LOW..... Compare by upper and lower thresholds (default setting)

REF, % ............ Compare by reference value and tolerance

10

Switch to the Ref/% threshold setting display, and specify the thresholds.

To enter the current measurement as the setting value: AUTO key

(Press on a screen other than the upper/lower threshold setting display.)

To enter the result of statistical calculation as the setting value: STAT key

(Press on a screen other than the upper/lower threshold setting display.)

See " Upper and Lowe r Th resho lds Se tti ng (b y Ref eren ce Value and Tolerance)" ( p.50).

Page 52

46

u flashing

REF & % flashing

Or

ten-keys

For this example,

Reference value: 4.2 V

Tolerance: 0.5%

COMP lit

4.1 Comparator Function

11

12

Press so that the indicated position blinks, and select voltage.

r.............Resistance

u ............Voltage

Press so that the indicated position blinks, and select the comparison method for

the comparator (here, REF/%).

HIGH, LOW.....Compare by upper and lower thresholds (default setting)

REF, %.............Compare by reference value and tolerance

13

14

Switch to the Ref/% threshold setting dis play, and specify the thresholds.

Applies setting and returns to the Measurement display.

The comparator function is enabled.

To cancel the settings: SHIFT key

Page 53

47

Voltage measurements are displayed as their relative percentage offset

from the reference value (%)

Resistance measure men ts ar e displa ye d as

their relative percentage offset from the reference value (%)

Judgment Result

Measured resistance - Reference value

=

Reference value

x 100

Relative

percentage

Upper Threshold Value of setting range < Measured value

Lower Threshold Value of setting range ≤ Measured value ≤ Upper

Threshold Value of setting range

Measured value < Lower Threshold Value of setting range

4.1 Comparator Function

15

Connect a test object and judge the measured value.

In the ΩV mode, you can verify comparator settings by pressing the VIEW key.

See

" Switching Between Measurement Value and Comparator Setting Displays" ( p.54).

4

Chapter 4 Applied Measurement

The instrument can als o base judgment s on the absolu te value of voltag e measured values (to prevent Lo judgments when the positive and negative terminals

are connected backwards).

See "Configuring the Absolute Value Judgment Function (Voltage)" ( p.51)